Page 1

THIS MANUAL IS APPLICABLE TO THE

FOLLOWING MODEL(S) AND TYPE(S).

Type

KU/CA AC120V

MY AC220-230V

Model

CDR-850

Power Requirement Remarks

FOR U.S. MODELS

NECESSARY INFORMATION FOR DHHS

RULES MARKED ON THE REAR BASE AND ON

THE TOP OF CD MECHANISM AS BELOW.

DANGER – LASER RADIA TION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

Page 2

CDR-850

1. SAFETY INFORMATION

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 – Proposition 65

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

(FOR USA MODEL ONLY)

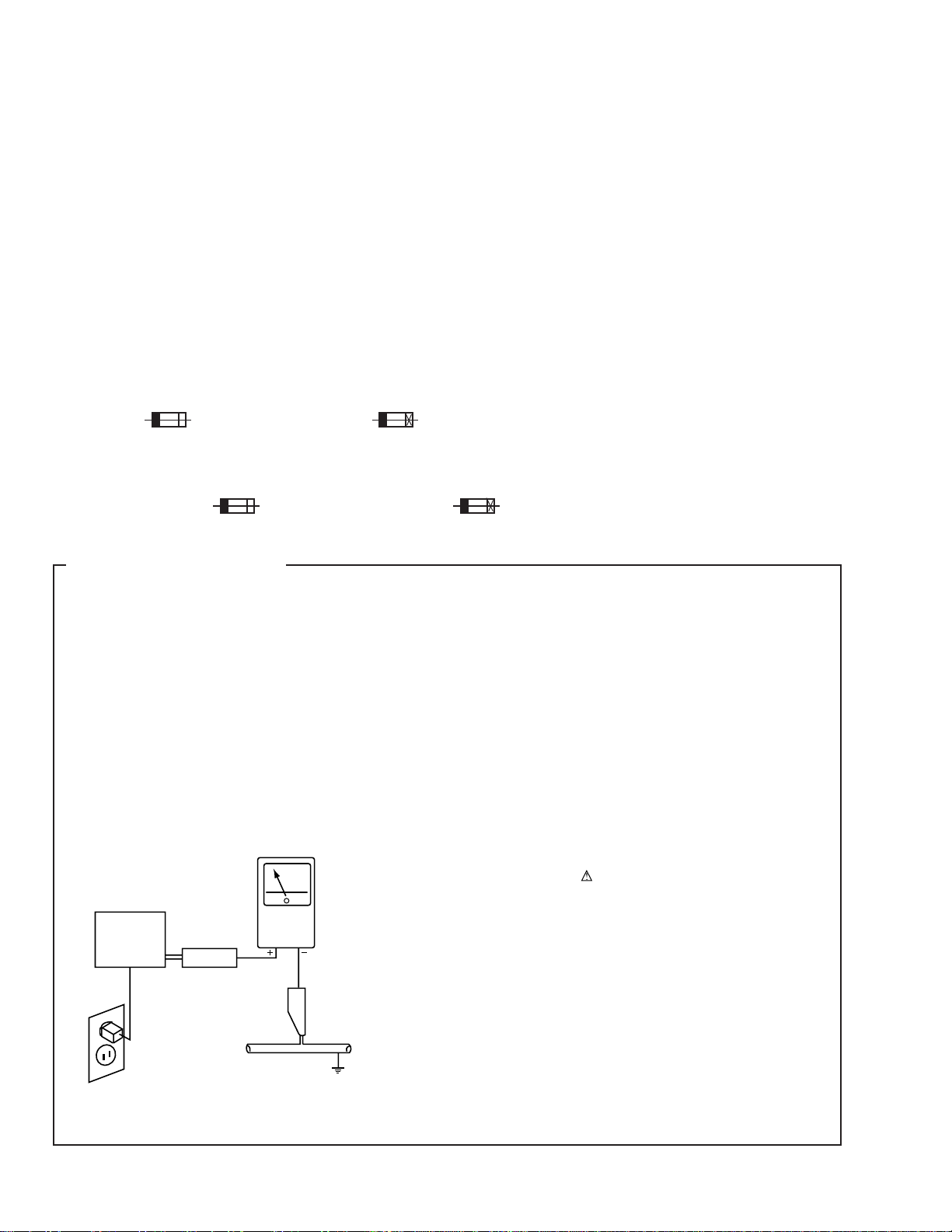

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Leakage

current

tester

Test all

exposed metal

surfaces

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

2

Page 3

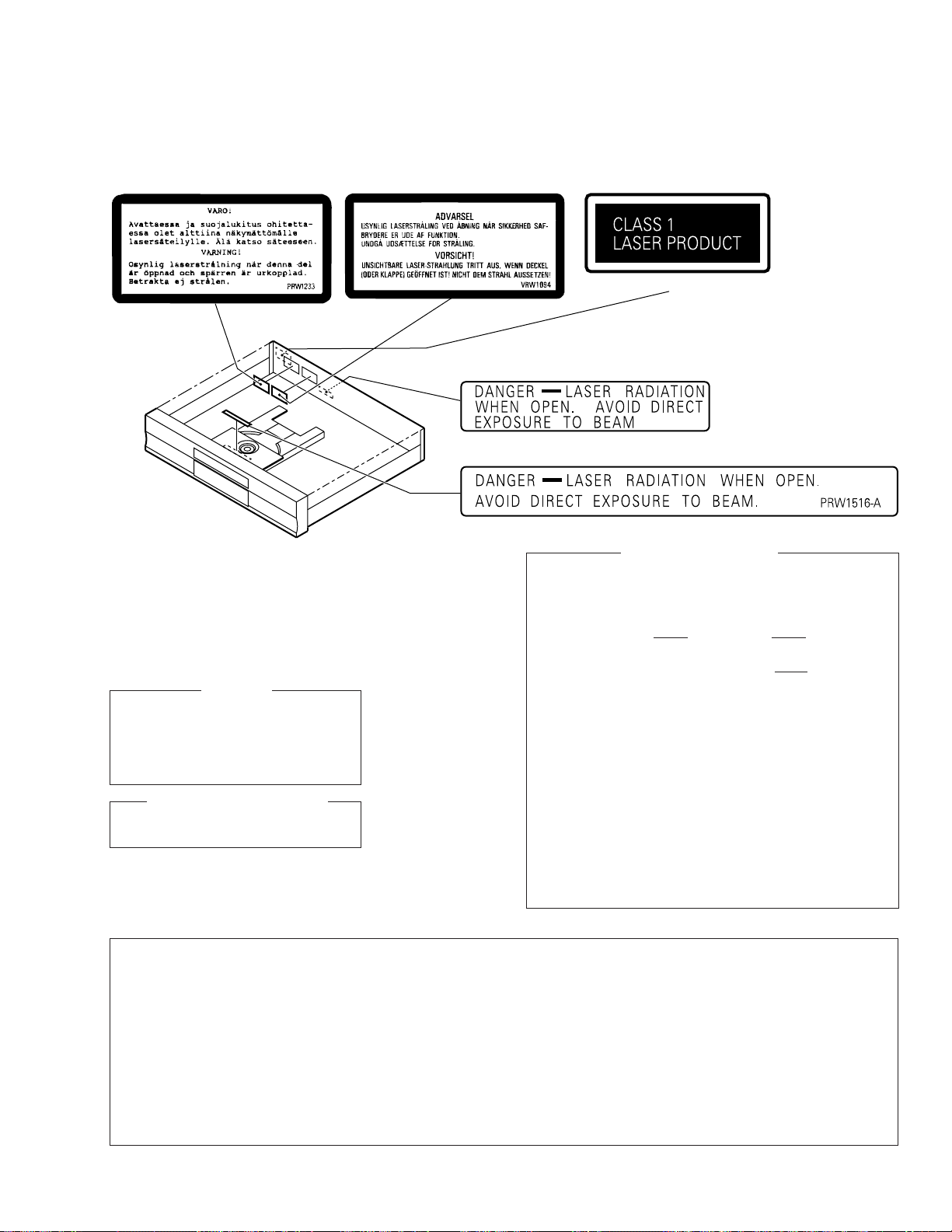

LABEL CHECK

KU/CA type

Printed on Rear Panel

Printed on Rear Panel

MY Type

MY Type MY Type

CDR-850

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS ΙΙΙ b.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 23 mW

WAVELENGTH: 778 – 787 nm

IMPORTANT

CONTENTS

1. SAFETY INFORMATION

2. EXPLODED VIEWS AND PARTS LIST

3. SCHEMATIC DIAGRAM

4. PCB CONNECTION DIAGRAM

5. PCB PARTS LIST

6. ADJUSTMENT

...............................................

....................................................

......................................

................

.....................................

..........................

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S601) for detecting loading

state is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch

(S601) is not on CLMP terminal side (CLMP signal is OFF

or high level.). Thus, the interlock will no longer function if

the switch (S601) is deliberately set to CLMP terminal side

(low level).

The interlock also does not function in the test mode ∗.

Laser diode oscillation will continue, if pin 1 of M51593FP

(IC101) on the PRE-AMP BOARD ASSY mounted on the

pickup assembly is connected to GND, or pin 19 is

connected to low level (ON), or else the terminals of Q101

are shorted to each other (fault condition).

2. When the cover is opened with the servo mechanism

block removed and turned over, close viewing of the

objective lens with the naked eye will cause exposure to a

Class 1 laser beam.

∗ Refer to page 53.

2

7. GENERAL INFORMATION

4

7.1 PARTS

10

7.1.1 IC

34

7.1.2 DISPLAY

48

7.2 BLOCK DIAGRAM

53

7.3 DIAGNOSIS

.........................................................

...........................................................

................................................

................................................

................................

......................................

8. PANEL FACILITIES AND SPECIFICATIONS

....

59

59

59

74

76

78

83

3

Page 4

CDR-850

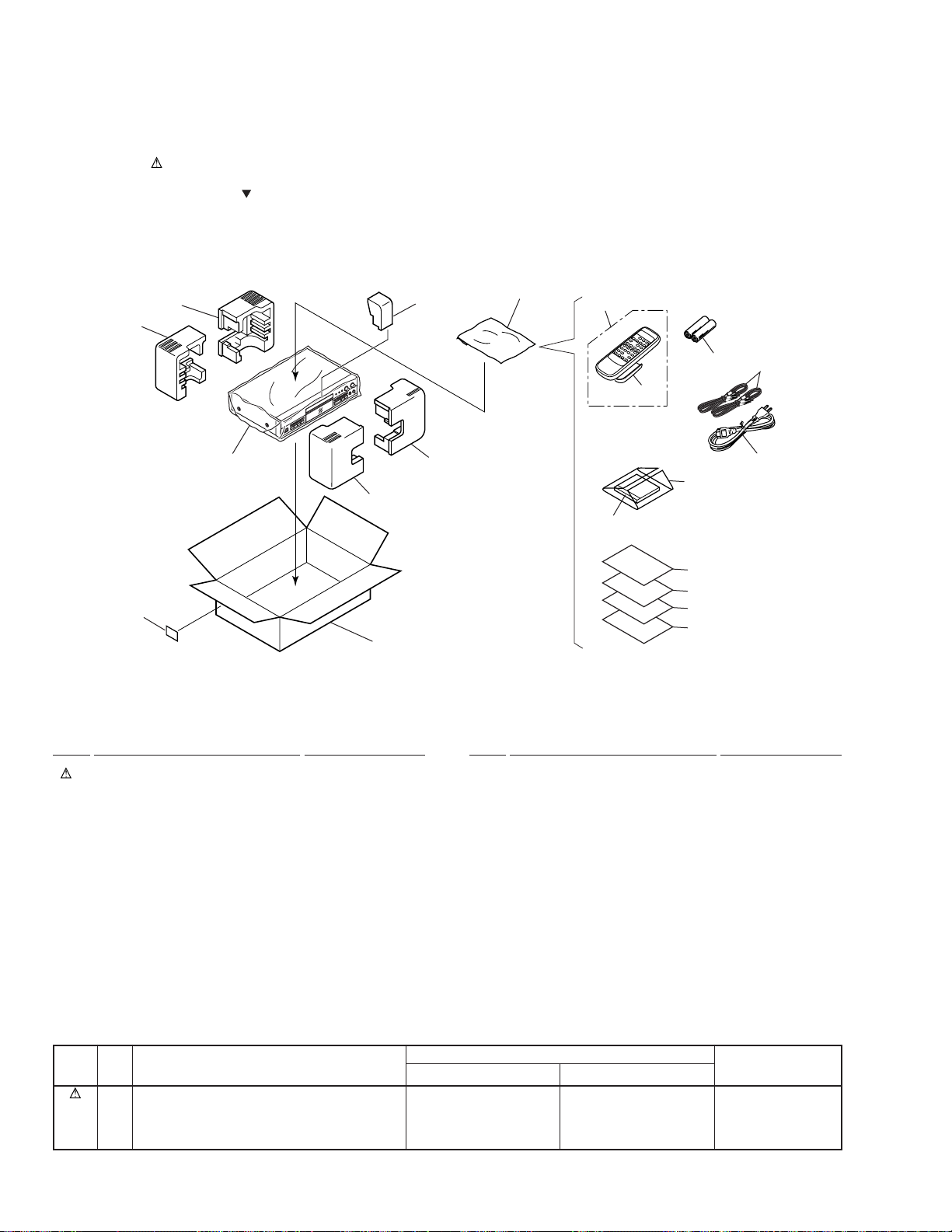

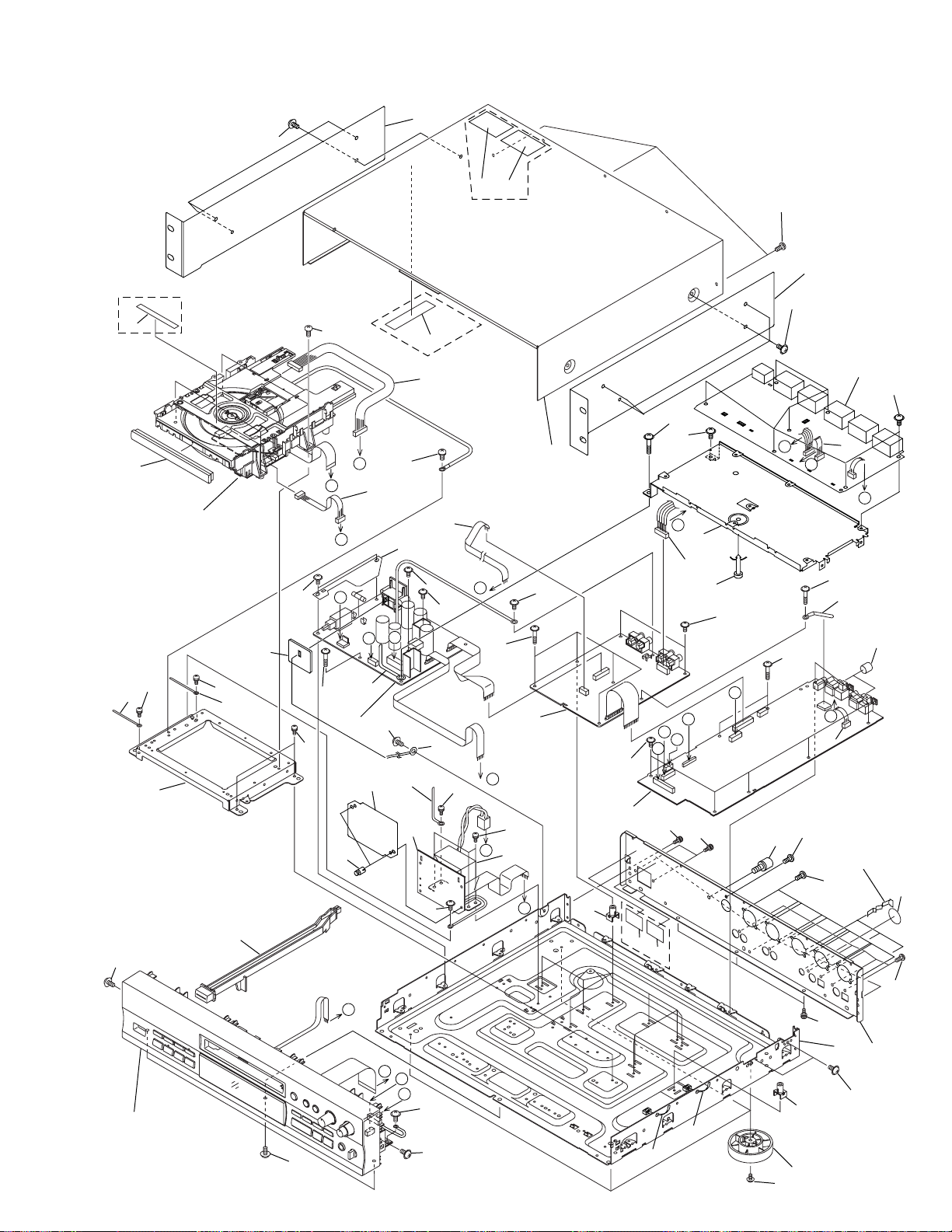

2. EXPLODED VIEWS AND PARTS LIST

NOTES:• Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

2.1 PACKING

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on the product are used for disassembly.

•

12 (2/3)

12 (1/3)

13

2

(1) PACKING PARTS LIST

11 (1/2)

10

12 (3/3)

11 (2/2)

9

6

8

3

7

1

17

14

5

15

16

4

Mark No. Description Part No.

1 AC Power Cord See Contrast table (2)

2 Bar Code Label MY See Contrast table (2)

3 Audio Cable (L=1.2m) PDE1003

4 Operating Instructions PRE1282

(English/French/Spanish)

5 Caution PRM1045

6 Remote Control Unit PWW1122

(R-800)

7 Battery Cover PZN1010

NSP 8 Dry Cell Battery (R03,AAA) VEM-022

9 Polyethylene Bag RHL1024

10 Packing Case PHG2365

Mark No. Description Part No.

11 Protector (F) PHA1341

12 Protector (R) PHA1342

13 Seat RHX1006

NSP 14 CDR Disc PEX1007

NSP 15 Registration Card See Contrast table (2)

NSP 16 Brochure PEX1009

17 Polystylene cover PHL1067

(2) CONTRAST TABLE

CDR-850/MY and KU/CA are constructed the same except for the following :

Mark No. Symbol and Description

1 AC Power Cord DDG1072 DDG1028

2 Bar Code Label MY PRW1531 Not used

2 Bar Code Label KU Not used PRW1530

NSP 15

Registration Card PEX1010 PEX1008

4

CDR-850/MY CDR-850/KU/CA

Part No.

Remarks

Page 5

CDR-850

2.2 EXTERIOR SECTION

52

KU/CA

Type only

40

28

Refer to "2.4 LOADING

MECHANISM ASSY".

No Supplied

23

33

18

33

23

Part

11

31

C

B

D

34

33

59

14

3

45

42

39

KU/CA

Type only

8

12

I

7

5

60

10

E

48

12

J

50

14

4

12

H

11

25

24

D

KU/CA

43

Type only

56

11

15

K

47

20

12

34

2

A

24

9

J

11

1

13

49

11

C

I

B

F

11

51

53

46

52

41

11

K

34

A

IC308

19

6

G

L

34

14

22

L

26

57

Accessories for

the INPUT ASSY

58

36

30

Refer to "2.3 FRONT

PANEL SECTION".

27

55

37

MY

38

Type only

29

E

F

H

G

30

35

30

35

11

13

21

55

16

17

30

5

Page 6

CDR-850

(1) EXTERIOR SECTION PARTS LIST

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 SERVO DIGITAL Assy See Contrast table (2)

2 AUDIO Assy See Contrast table (2)

3 POWER Assy See Contrast table (2)

NSP 4 TRANS Assy PWZ3752

5 Jumper Wire (J) D20PYY0335E

6 Connector Assy (8P) PDE1303

7 Connector Assy PG05KK-E10

8 Connector Assy PG09KK-E35

9 Power Transformer See Contrast table (2)

10 Fuse (FU1) See Contrast table (2)

11 Screw (Steel) ABA1011

12 Screw (Steel) ABA1207

NSP 13 PCB Mould AMR1525

NSP 14 Cord Stopper DNF1128

15 Bonnet PYY1267

NSP 16 Under Base PNA2484

17 Rear Base See Contrast table (2)

NSP 18 Mecha Base PNB1591

19 Terminal Screw AKE-031

20 Connector Assy (8P) PDE1304

21 Insulator AMR7198

NSP 22 Cap VEC1810

23 Cord Clamper RNH-184

24 Screw RBA1132

NSP 25 Lead Wire Unit PDF1195

26 Connector Assy PF03PP-C16

27 Power Button PAC1918

28 Tray Panel PNW2902

29 Screw BBZ30P080FCC

30 Screw IBZ30P060FCC

31 Screw BBZ30P100FCC

32 • • • • •

33 Screw PBA1112

34 Screw IBZ30P180FCC

35 Binder PEC-107

36 Black Label PRW1470

37 Caution Label HE See Contrast table (2)

38 Caution Label See Contrast table (2)

39 65 Label See Contrast table (2)

NSP 40 Laser Caution Label See Contrast table (2)

41 INPUT Assy See Contrast table (2)

42 FCC Label See Contrast table (2)

43 DOC Label See Contrast table (2)

44 • • • • •

45 Rack Angle L PNB1604

46 Rack Angle R PNB1605

NSP 47 I/O Angle PNB1607

NSP 48 Transformer Cover PNM1338

NSP 49 Card Spacer QEC1012

50 Screw RBA1128

51 Screw BBZ40P080FCC

52 Screw BBZ40P140FZK

53 Screw IBP30P090FCC

54 • • • • •

55 Screw IBZ30P080FZK

56 Screw IBZ30P200FMC

57 Screw PMZ26P040FMC

58 Screw PMZ30P060FCC

59 Rivet RBM-003

60 Fuse Cover PNM1343

(2) CONTRAST TABLE

CDR-850/MY and KU/CA are constructed the same except for the following :

Mark No. Symbol and Description

NSP 1 SERVO DIGITAL Assy PWM2219 PWM2220

2 AUDIO Assy PWZ3933 PWZ3934

3 POWER Assy PWZ3937 PWZ3938

9 Power Transformer PTT1346 PTT1355

10 Fuse (FU1 : T500mA) AEK1051 Not used

10 Fuse (FU1 : 1A) Not used REK1075

17 Rear Base PNA2488 PNA2482

37 Caution Label HE PRW1233 Not used

38 Caution Label VRW1094 Not used

39 65 Label Not used ARW7050

NSP 40 Laser Caution Label Not used PRW1516

41 INPUT Assy PWZ3929 PWZ3930

42 FCC Label Not used VRW1725

43 DOC Label Not used VRW1726

CDR-850/MY CDR-850/KU/CA

6

Part No.

Remarks

Page 7

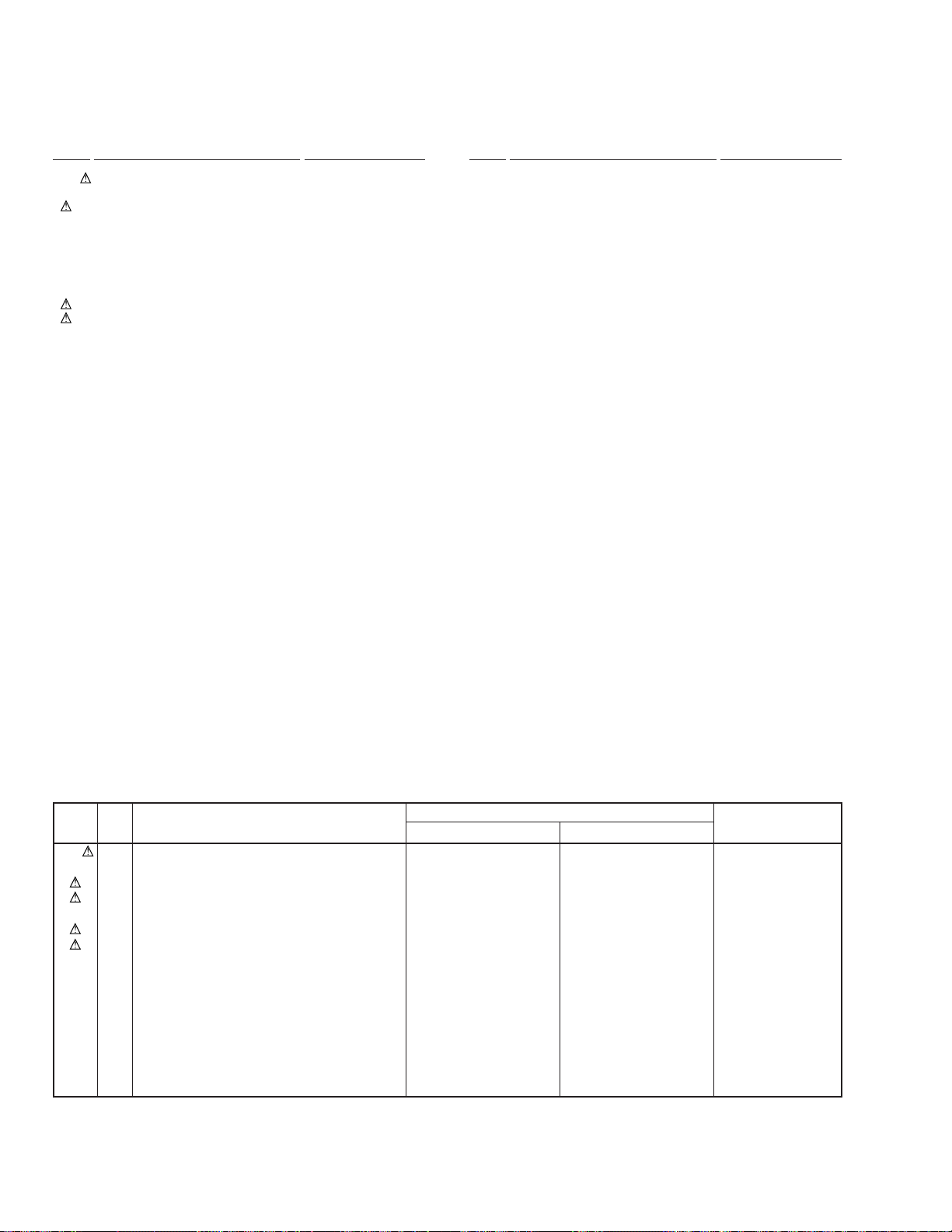

2.3 FRONT PANEL SECTION

CDR-850

23

16

12

8

23

7

17

15

13

14

Accessories for the

VR ASSY.

1

19

20

11

A

21

23

26

6

4

10

9

18

22

A

5

2

23

3

FRONT PANEL SECTION PARTS LIST

•

Mark No. Description Part No. Mark No. Description Part No.

NSP 2 HEADPHONE Assy PWZ3715

1 FUNCTION Assy PYY1266

NSP 3 VR Assy PWZ3719

4 22P F•F•C/60V PDD1190

5 Screw With Washer ABA1005

6 HP Knob H PAC1944

7 Mode Button H PAC1945

8 Manual Button H(L) PAC1946

9 REC Button H PAC1948

10 Cord Clamper RNH-184

11 Manual Button H(R) PAC1947

12 VOL Knob Assy PXA1621

13 REC Knob H L PAC1942

14 REC Knob H R PAC1943

15 FL Sheet PAM1762

16 Display Window H PAM1794

17 LED Lens PNW2745

18 REC Ring PNW2795

19 Lens PNW2796

20 Sub Panel PNW2797

21 Front Panel H PNW2903

22 Play Button H PAC1950

23 Screw PPZ30P100FMC

24 • • • • •

25 • • • • •

26 IC (EEPROM) PYY1250

7

Page 8

CDR-850

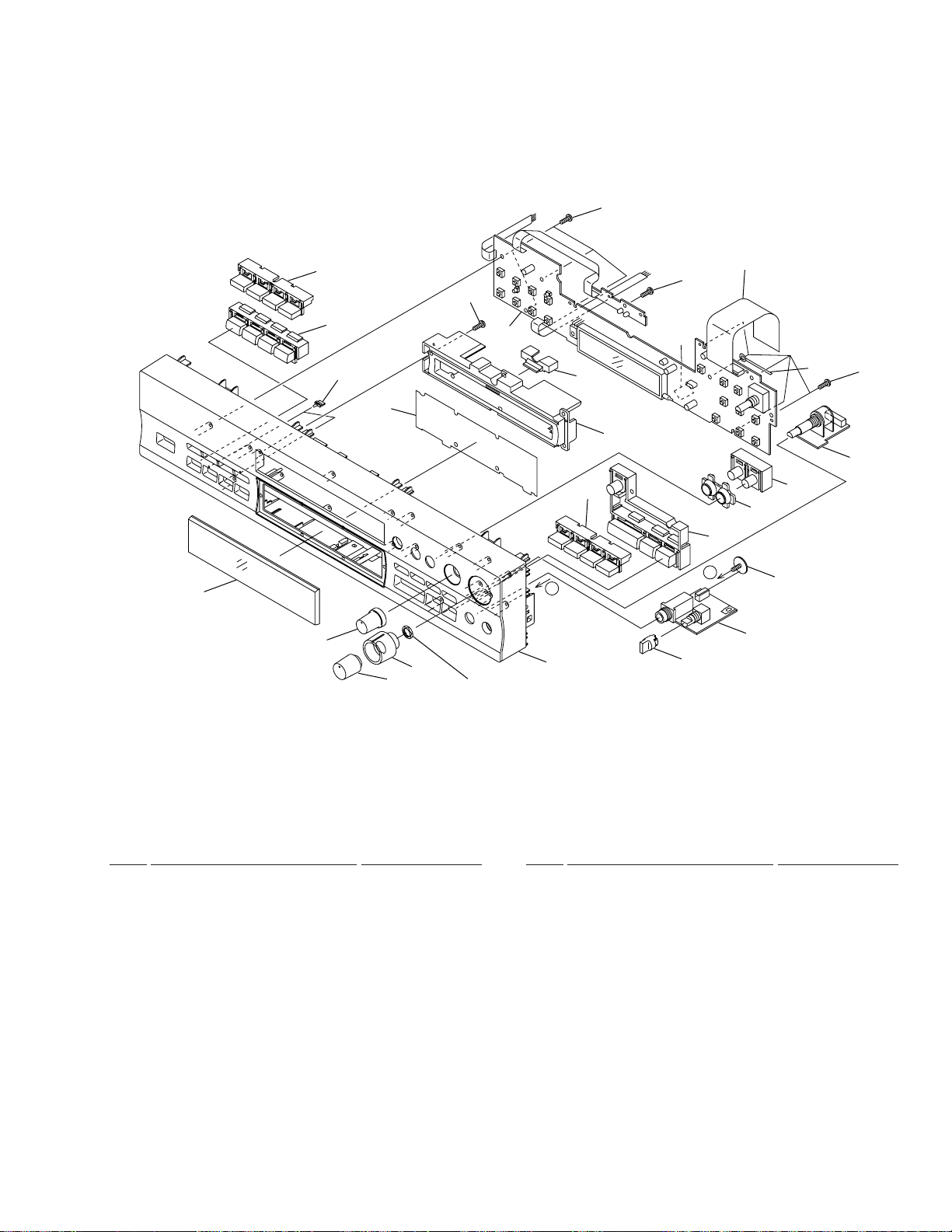

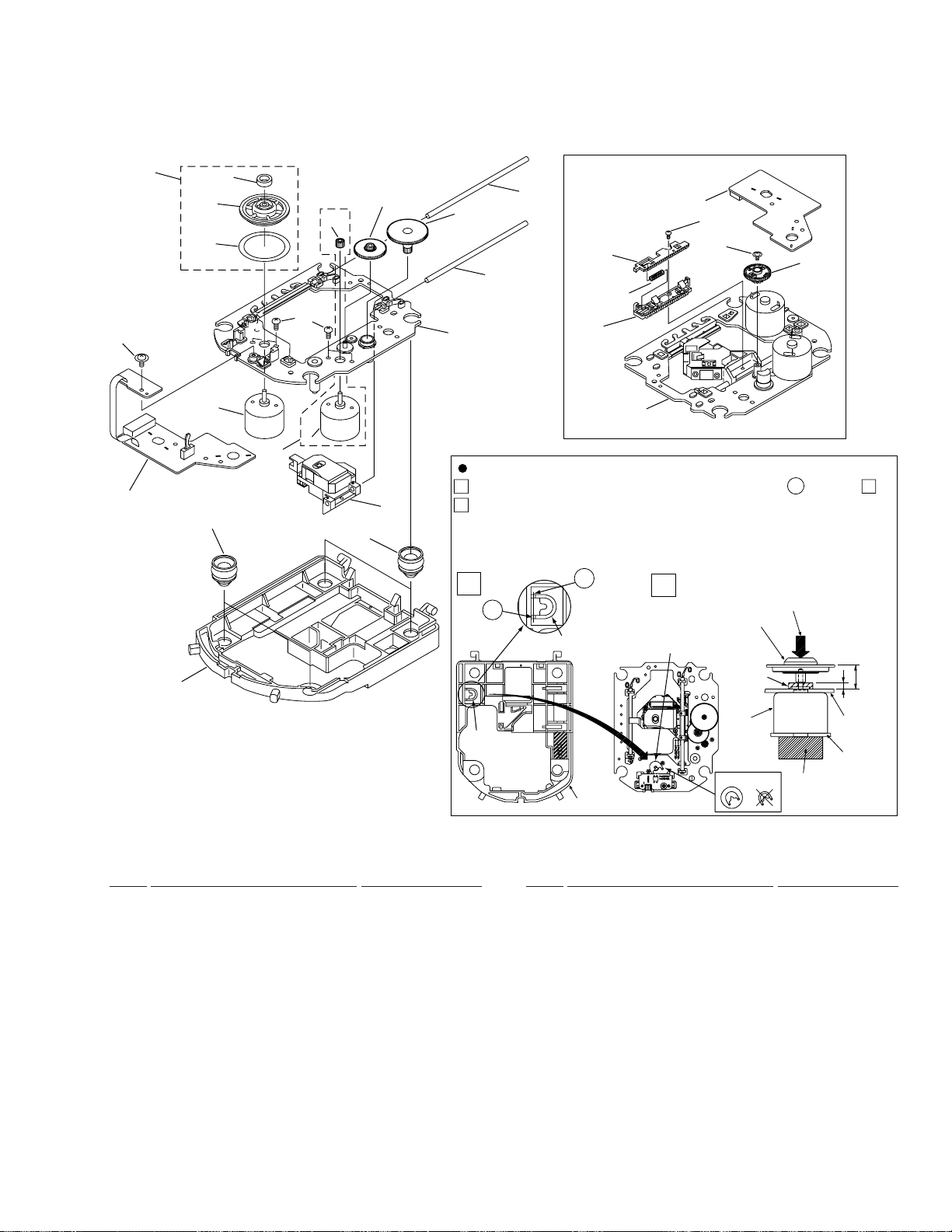

2.4 LOADING MECHANISM ASSY

• Bottom View

20

9

26

24

23

30

26

27

A

13

12

Loading Base

25

7

21

6

4

3

28

A

15

14

19

1

29

22

5

2

31

5

18

11

16

17

8

LOADING MECHANISM ASSY PARTS LIST

•

10

Mark No. Description Part No. Mark No. Description Part No.

NSP 2 Earth Lead Unit PDF1088

1 32P F•F•C/30V PDD1187

3 Connector Assy PG02KK-E35

4 DC Motor PXM1027

5 Screw DBA1006

6 Motor Pulley PNW1634

7 Screw VBA1055

8 Tray Stopper Spring VBH1277

9 Rubber Belt VEB1260

10 Loading Base VNL1730

11 Tray VNL1731

12 Gear Pulley VNL1733

13 Loading Gear VNL1734

14 Drive Gear VNL1735

15 Drive Cam VNL1736

NSP 18 CD-RW SERVO MECH Assy PXA1609

NSP 22 Loading Mechanism Assy PXA1608

NSP 27 LOADING A Assy PWZ3727

NSP 28 LOADING B Assy PWZ3728

16 Lock Plate VNL1820

17 Tray Stopper VNL1739

19 Screw BBZ26P040FMC

20 Screw IPZ20P080FMC

21 Loading Motor Assy VXX2505

23 Clamper Plate VNE2068

24 Bridge VNE2069

25 Clamper VNL1738

26 Screw IPZ26P060FMC

29 Tray Holder PNM1341

30 Spacer PNM1334

31 Stopper DNH2076

8

Page 9

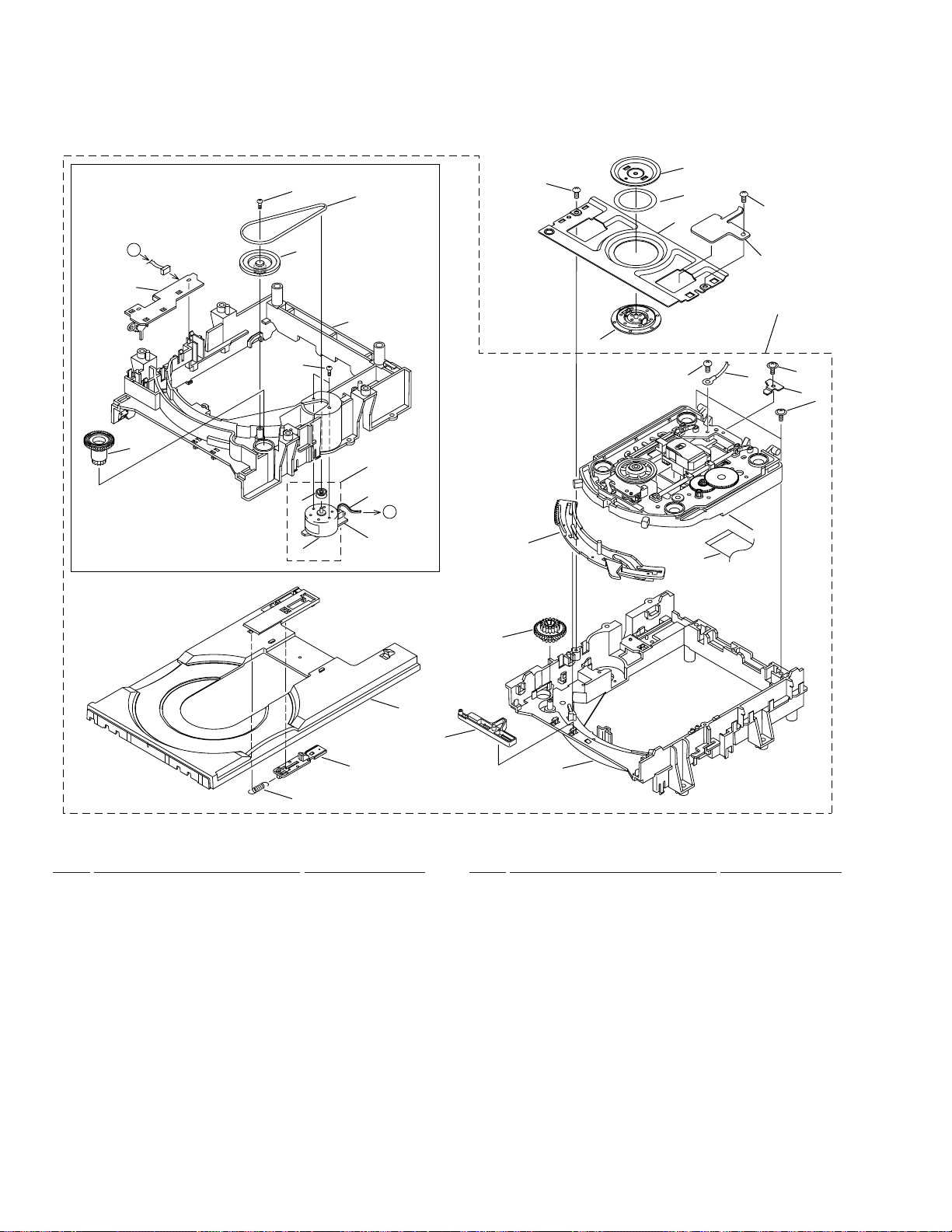

2.5 SERVO MECHANISM ASSY

CDR-850

22

25

15

20

10

9

7

23

2

3

26

11

16

19

18

• Bottom View

SERVO MECH ASSY

14

6

13

Carriage Base S

24

22

12

How to Install the Disc Table

1

1

4

21

5

Use nippers or other tool to cut the two sections marked A in figure

2

While supporting the spindle motor shaft with the stopper, put spacer on

top of the carriage base, and stick the disc table on top (takes about 9kg

pressure). Take off the spacer.

1

A

A

Spacer

2

Spacer setting

Position

(Pressure of about 9kg)

Disc table Assy

1

.

8

SERVO MECHANISM ASSY PARTS LIST

•

Spacer

Servo Base

Spacer

Spindle

motor

OK NG

Stopper

Mark No. Description Part No. Mark No. Description Part No.

NSP 1 SERVO MECH Assy PWZ3758

2 D.C.mortor Assy PEA1235

NSP 3 DC Motor PXM1042

4 Float Rubber A AEB7063

5 Float Rubber B AEB7066

NSP 6 Rack Spring DBH1285

NSP 7 Mirror Sheet PNM1325

8 Servo Base PNW2853

9 Pinion Gear PNW2854

10 Gear A PNW2855

11 Gear B PNW2856

12 Gear C PNW2857

13 Rack PNW2858

14 Rack Stopper PNW2859

NSP 15 Disc Table PNW2860

NSP 20 Magnet VYM1024

16 Carriage Base S PNW2874

17 • • • • •

18 Guide Bar VLL1488

19 Sub Guide Bar VLL1489

21 CD-R Pickup PEA1351

22 Screw IPZ20P060FMC

23 Screw PMZ20P030FMC

24 Screw JGZ17P030FMC

25 Disc Table Assy PEA1349

26 Carriage Motor Assy PEA1350

11mm

2.8mm

Carriage

Base

PCB

9

Page 10

1

23

4

CDR-850

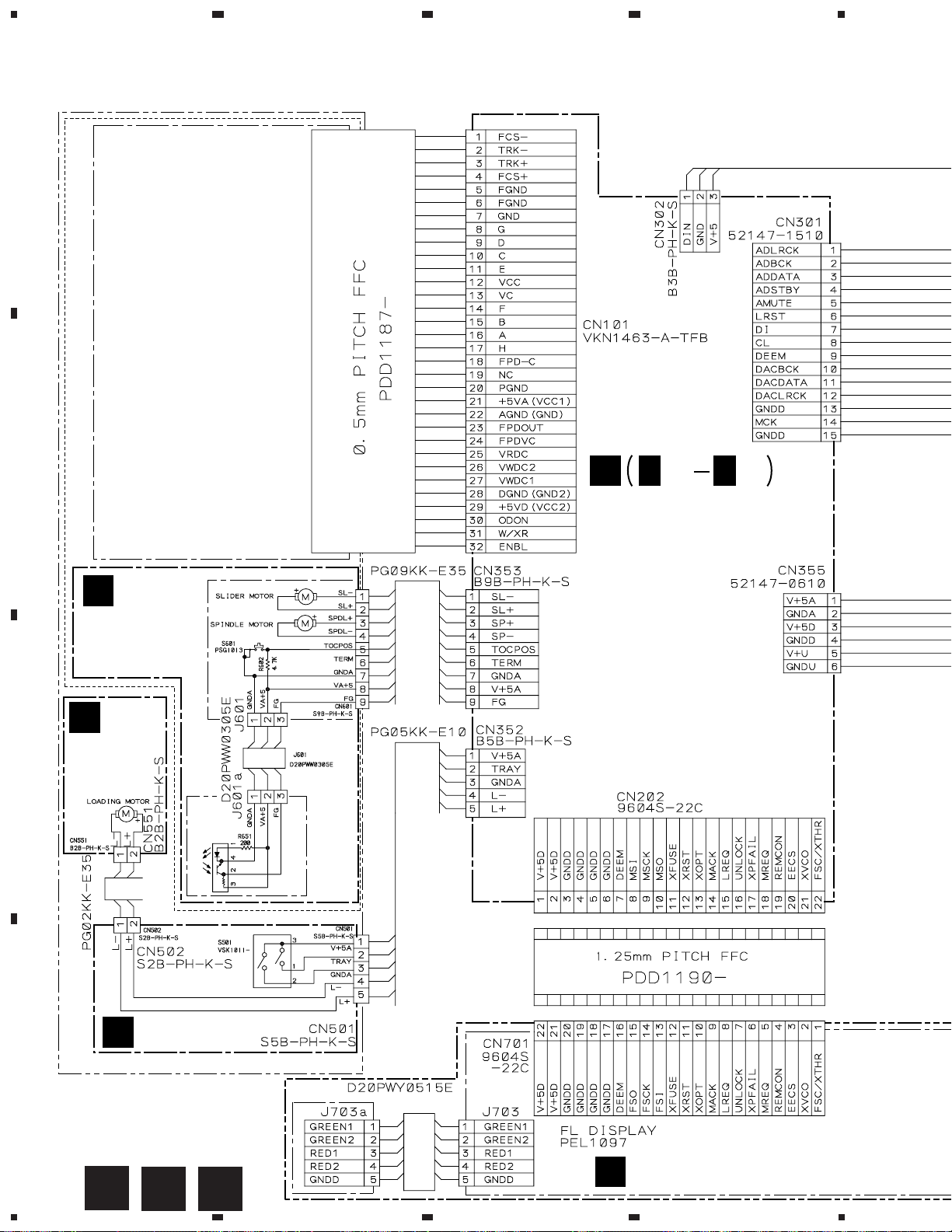

3. SCHEMATIC DIAGRAM

3.1 OVERALL CONNECTIONS, LOADING A, B, and SERVO MECH ASSEMBLIES

A

CD-R PICUP ASSY

PEA1351

B

C

SERVO

MECH ASSY

(PWZ3758)

PEA1350

PEA1235

D

SERVO DIGITAL ASSY

(PWM2219 : MY)

(PWM2220 : KU/CA)

D

1/6

D

6/6

B

LOADING B

C

ASSY

(PWZ3728)

VXX2505

PC651

NJL5803K–F1

LOADING A ASSY

A

(PWZ3727)

D

LOADING MECH ASSY (PXA1608)

10

A

B C

1234

FUNCTION ASSY

J

(PWZ3699)

Page 11

5

678

CDR-850

Note : When ordering service parts, be sure to refer to "EXPLODED VIEWS and P AR TS LIST" or "PCB PARTS LIST".

F

HEADPHONE

ASSY

E

E

AUDIO ASSY

(PWZ3933: MY)

(PWZ3934: KU/CA)

1/2,

E

2/2

(PWZ3715)

A

B

H

TRANS ASSY

I

(PWZ3752)

POWER ASSY

(PWZ3937: MY)

(PWZ3938: KU/CA)

POWER TRANSFORMER

AC POWER CORD

DDG1072 : MY TYPE

DDG1028 : KU/CA TYPE

K

INPUT ASSY

(PWZ3929: MY)

(PWZ3930: KU/CA)

VR ASSY

G

(PWZ3719)

C

D

11

5

6

7

8

Page 12

1

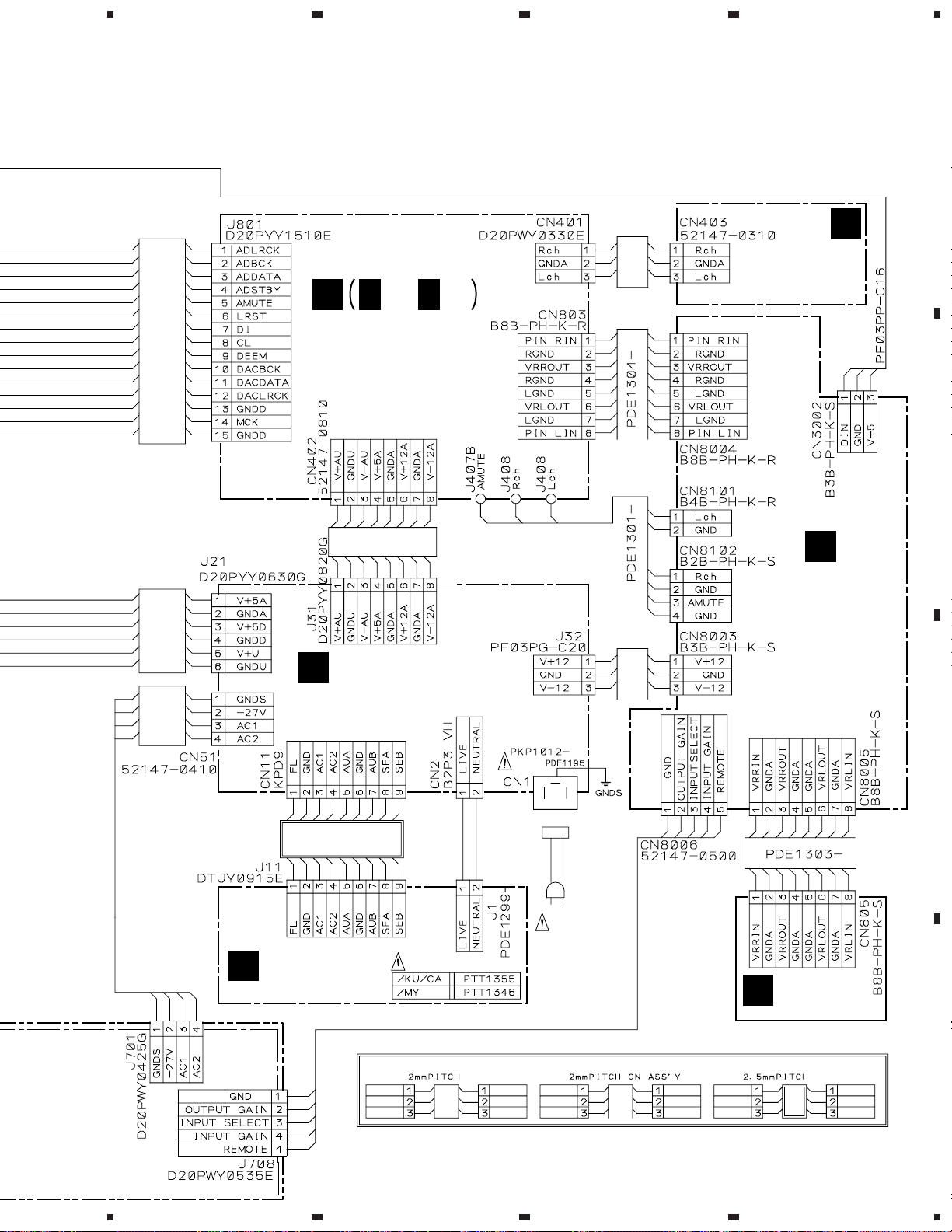

CDR-850

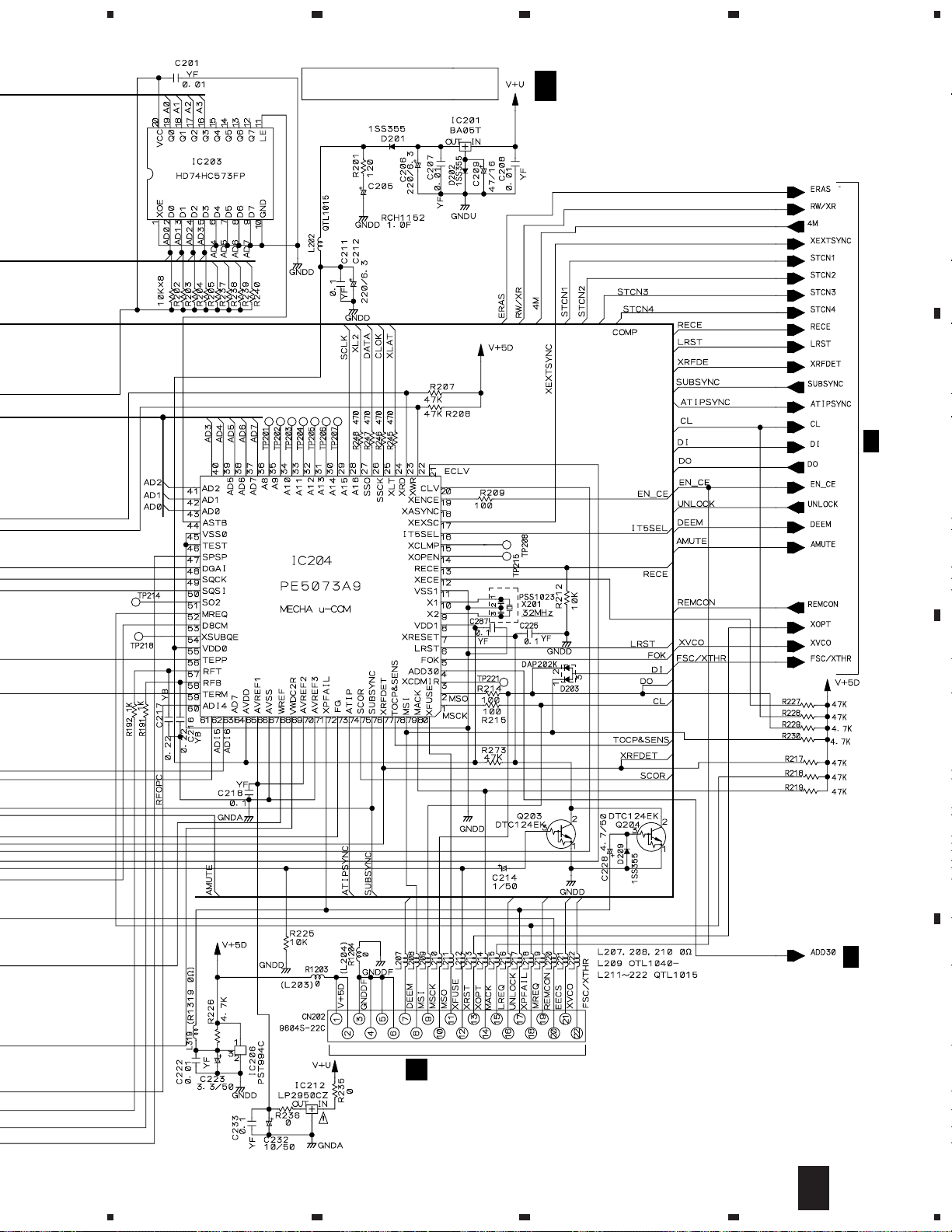

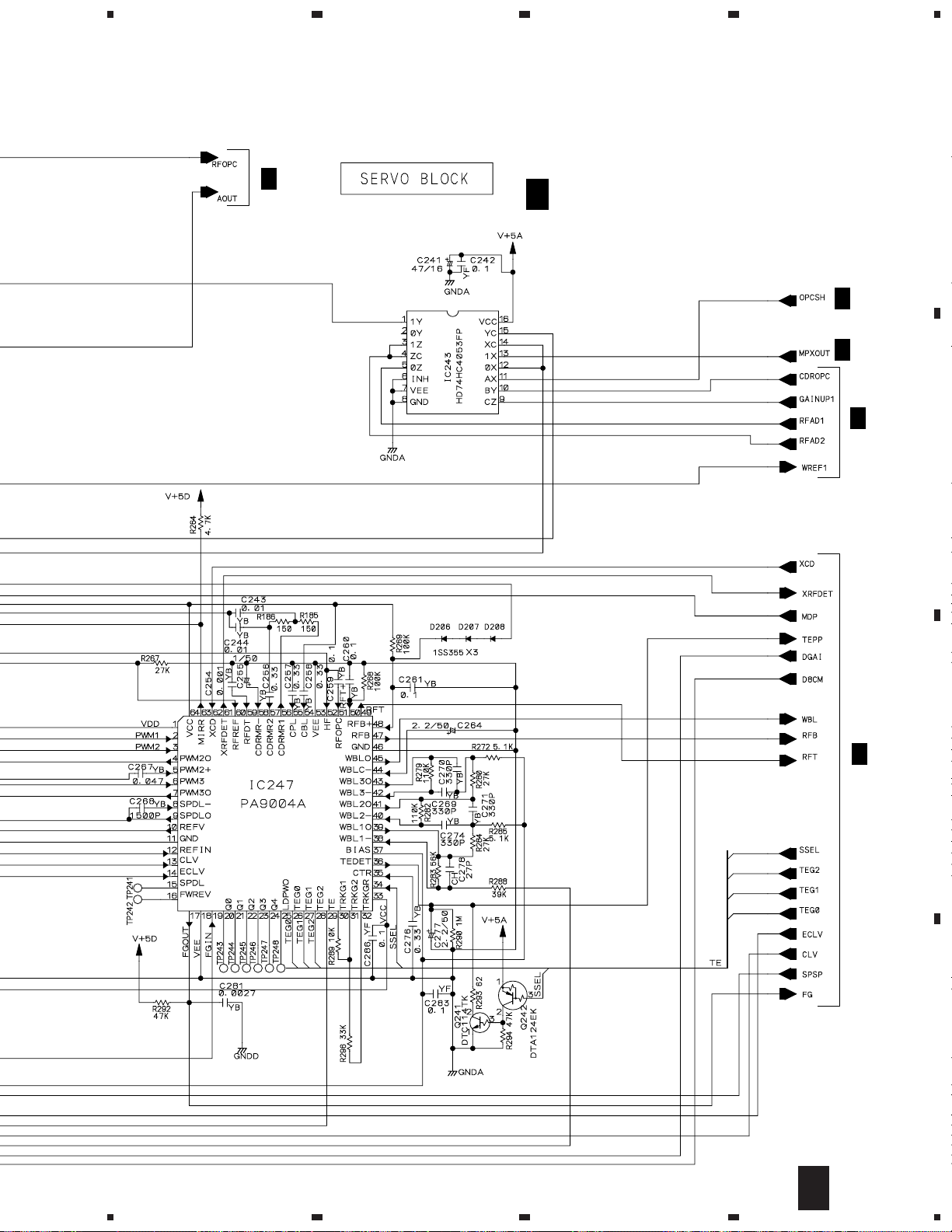

3.2 SERVO DIGITAL ASSY(1/6)

A

2/6

D

B

23

5/6

D

4

4/6

D

2/6

D

ATIP DECODER

C

3/6

D

D

12

1/6

D

1234

Page 13

5

678

CDR-850

8BIT LATCH

MECH.CONTROL MICOM BLOCK

D

SERVO DIGITAL ASSY(1/6)

1/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

MECH. CONTROL MICOM BLOCK

D

A

4/6

B

C

6/6

D

CN701

J

1/6

D

5

6

7

8

13

D

Page 14

1

23

CDR-850

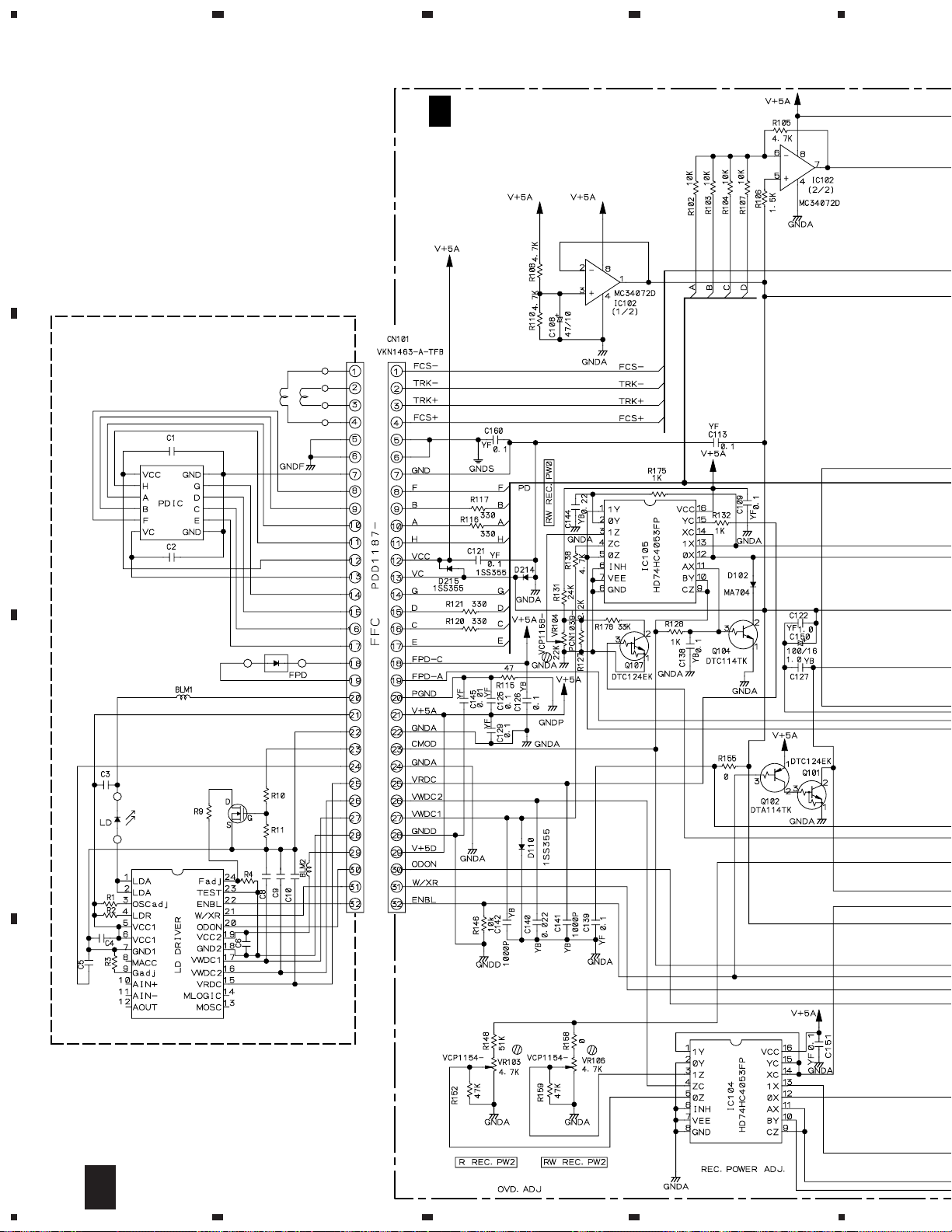

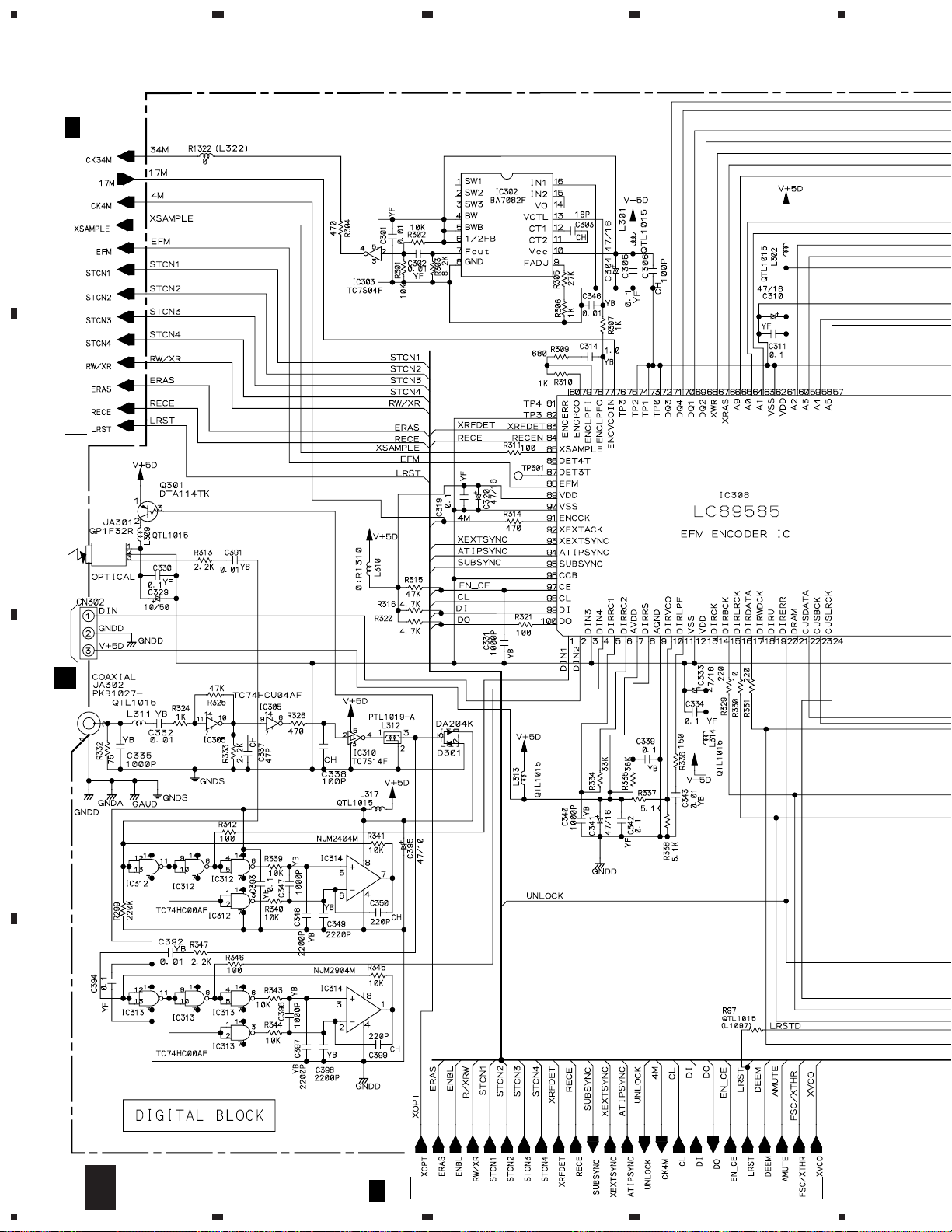

3.3 SERVO DIGITAL(2/6) and PICKUP ASSEMBLIES

4

D

A

CD-R PICUP ASSY

PEA1351

B

SERVO DIGITAL ASSY(2/6)

2/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

RF PROCESSOR BLOCK

C

D

14

2/6

D

1234

Page 15

5

678

CDR-850

A

3/6

D

5/6

D

B

MY TYPE

ONLY

D

4/6

D

D

D

3/6

1/6

6/6

C

D

2/6

D

5

6

7

8

15

Page 16

1

CDR-850

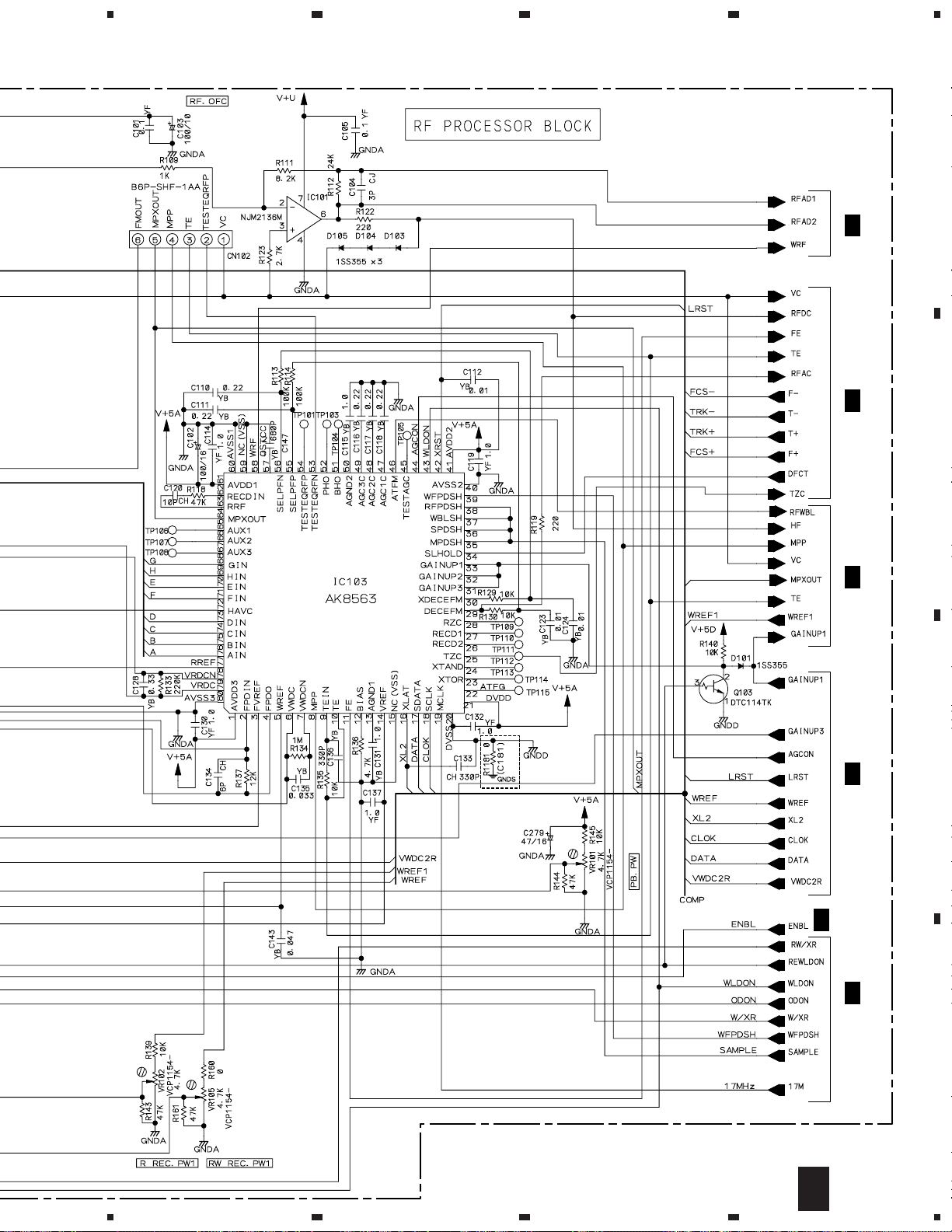

3.4 SERVO DIGITAL ASSY(3/6)

A

2/6

D

1/6

D

B

23

4

5/6

D

C

2/6

D

D

16

3/6

D

1234

Page 17

5

678

CDR-850

A

1/6

D

D

SERVO DIGITAL ASSY(3/6)

3/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

SERVO BLOCK

D

D

6/6

1/6

D

2/6

B

CDR SERVO AMP

5

1/6

D

3/6

D

6

7

8

17

C

D

Page 18

1

CDR-850

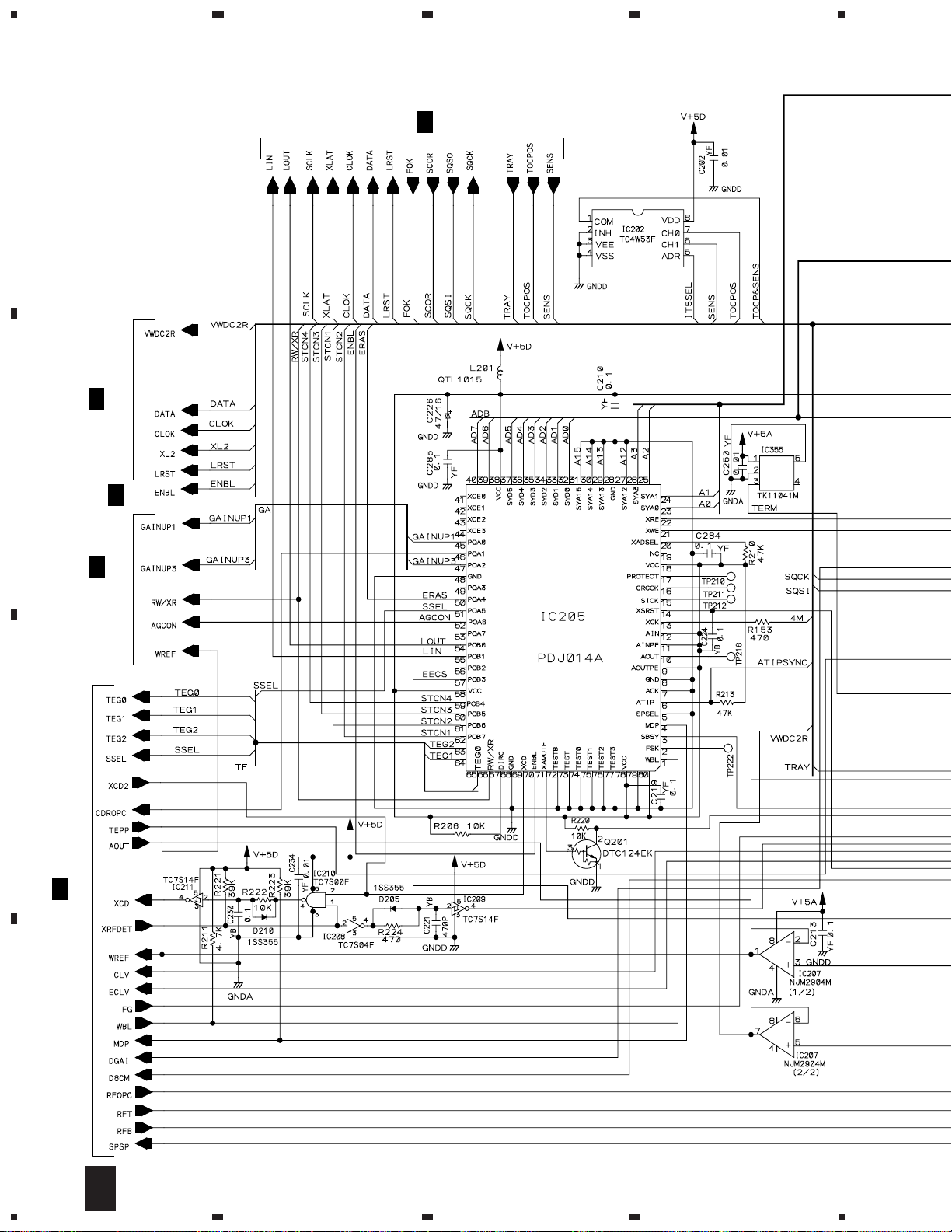

3.5 SERVO DIGITAL ASSY(4/6)

6/6

D

A

B

23

4

INPUT

CN3002

K

C

INPUT

D

1/6

18

4/6

D

1234

D

Page 19

5

678

CDR-850

A

D

SERVO DIGITAL ASSY(4/6)

4/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

DIGITAL BLOCK

OUTPUT

OUTPUT

B

C

1/2

E

J801

D

5/6

D

5

6

7

D

4/6

8

19

Page 20

1

CDR-850

3.6 SERVO DIGITAL ASSY(5/6)

3/6

D

A

B

23

4

CN501

A

CN601

C

C

D

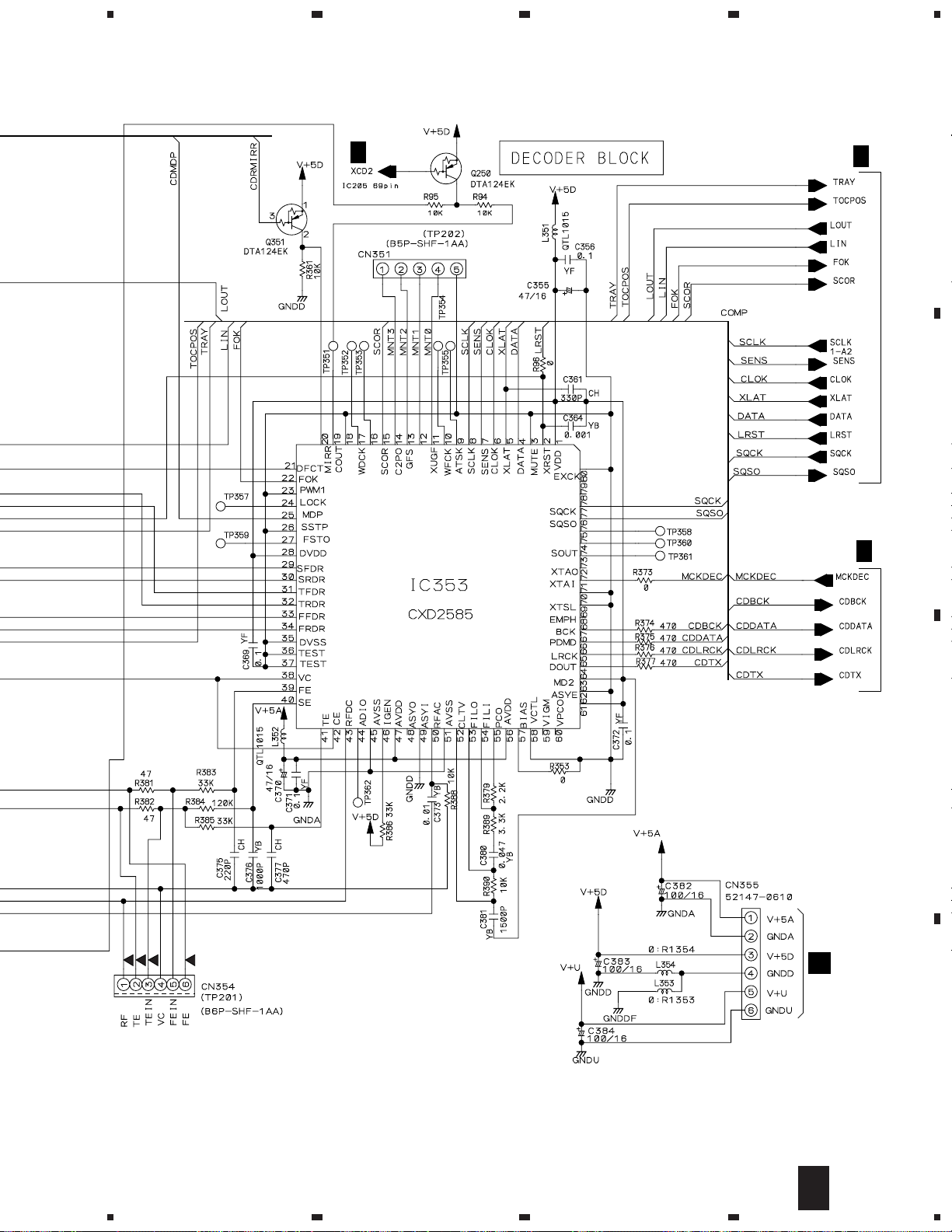

SERVO DIGITAL ASSY(5/6)

5/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

DECODER BLOCK

D

2/6

D

20

5/6

D

1234

Page 21

5

6

678

CDR-850

1/6

D

D

1/6

A

B

H

J21

D

4/

C

D

5/6

D

5

6

7

8

21

Page 22

1

23

CDR-850

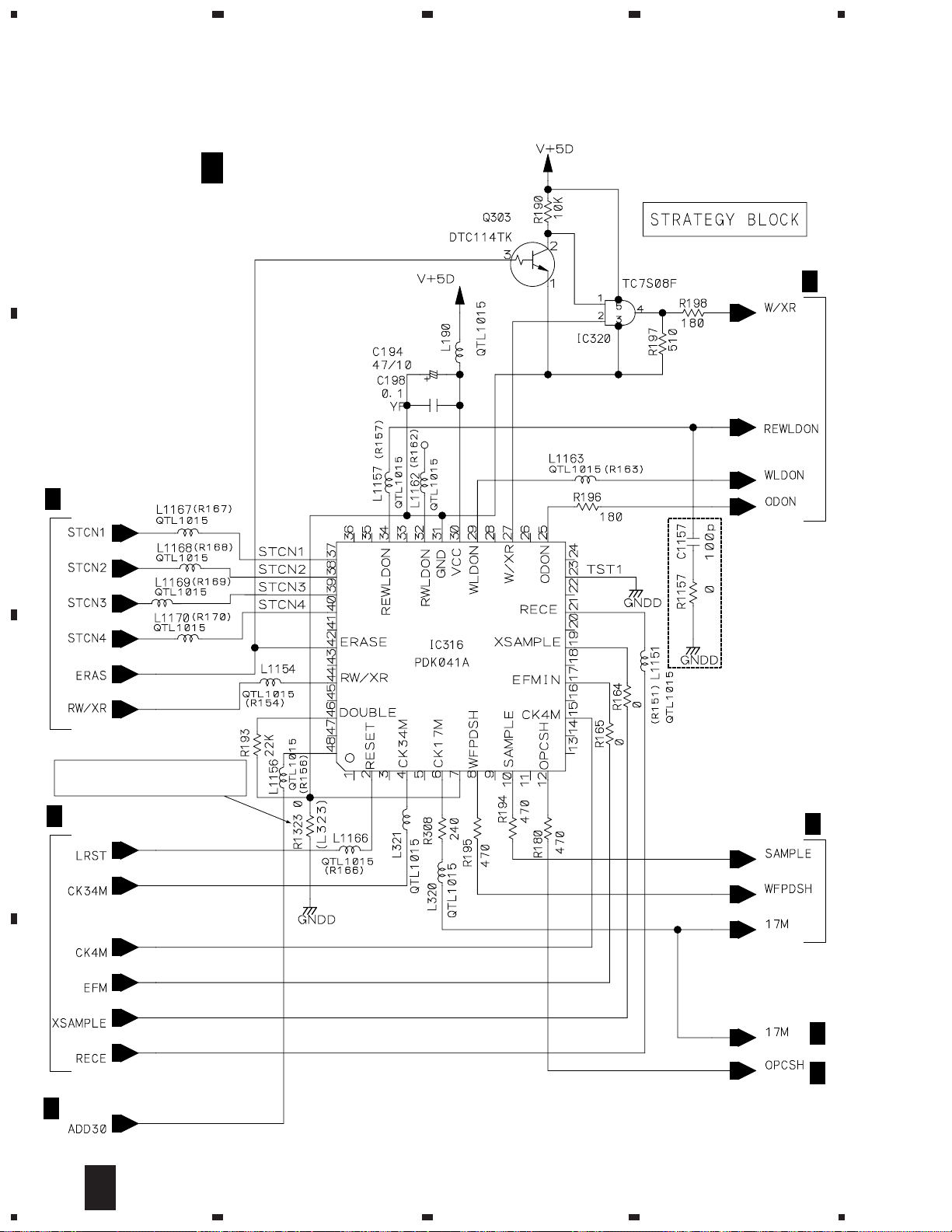

3.7 SERVO DIGITAL ASSY(6/6)

4

A

D

B

4/6

D

SERVO DIGITAL ASSY(6/6)

6/6

(PWM2219 : MY)

(PWM2220 : KU/CA)

•

STRATEGY BLOCK

KU/CA TYPE

ONLY

D

2/6

C

D

R1323 : 0 (MY TYPE)

L323 : QTL1015 (KU/CA TYPE)

4/6

D

1/6

D

22

6/6

D

1234

D

D

D

2/6

4/6

3/6

Page 23

CDR-850

23

Page 24

1

23

CDR-850

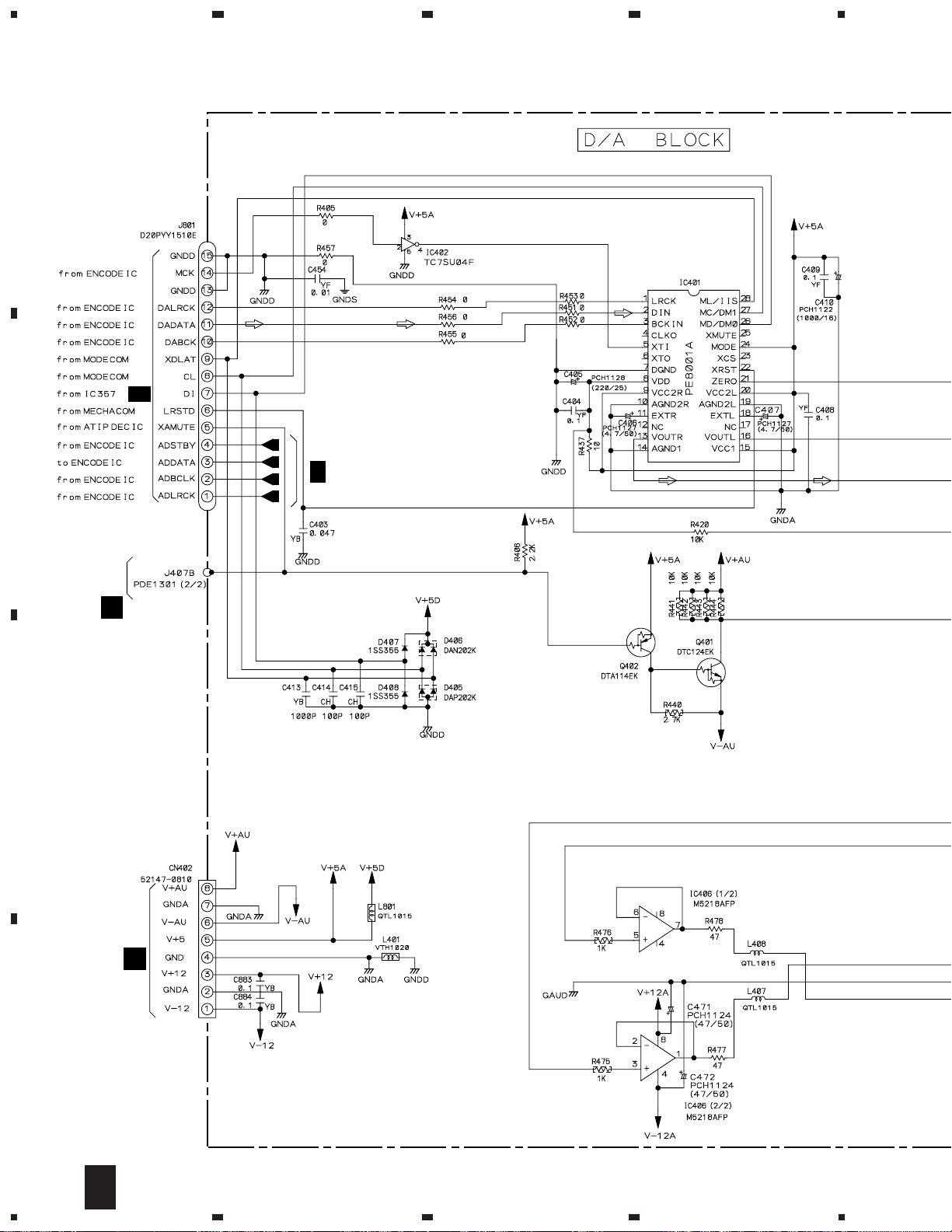

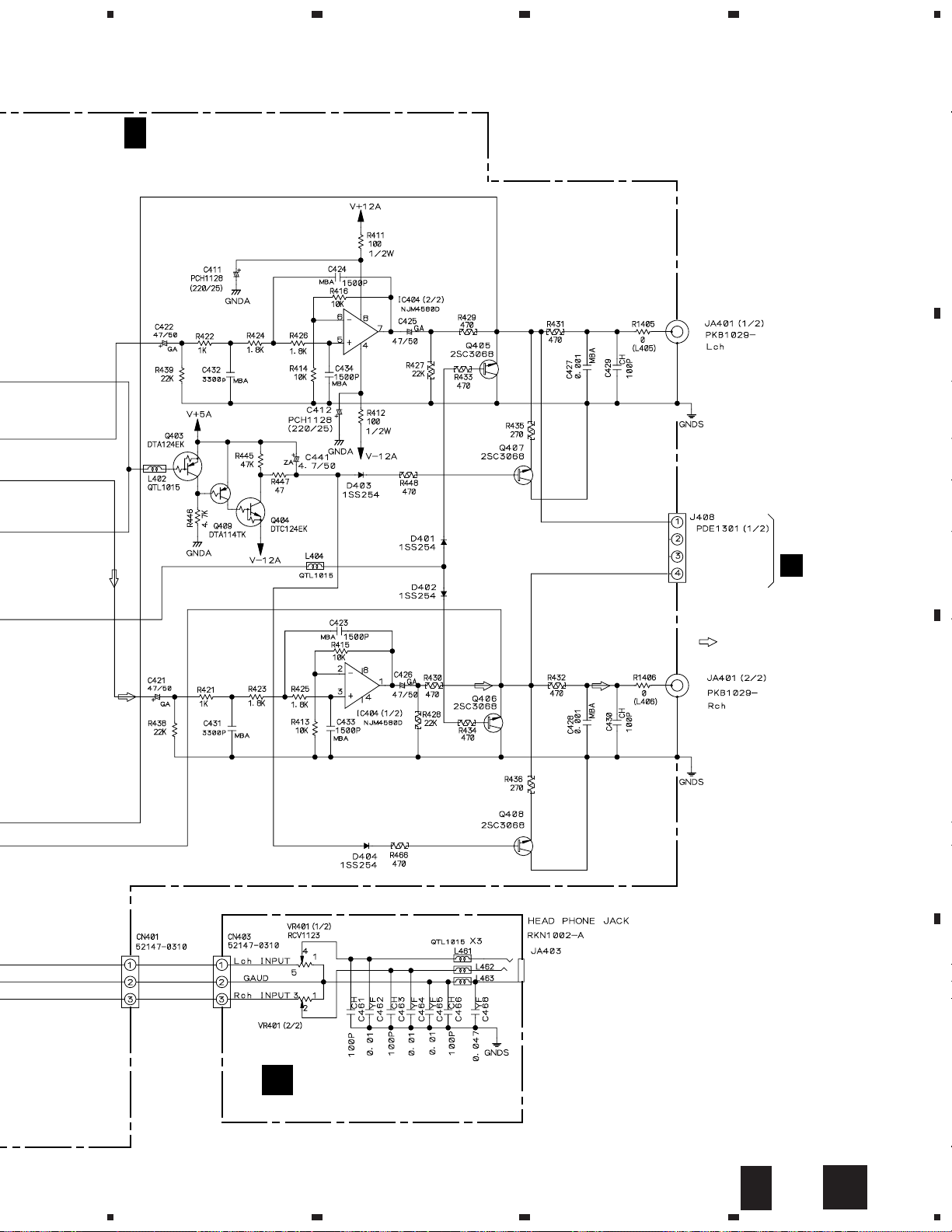

3.8 AUDIO(1/2) and HEADPHONE ASSEMBLIES

A

CN301

4/6

D

4

D/A CONVERTER

B

CN8101

E

2/2

K

C

J31

H

D

24

1/2

E

1234

Page 25

5

678

CDR-850

E

AUDIO ASSY(1/2)

1/2

(PWZ3933 : MY)

(PWZ3934 : KU/CA)

• D/A BLOCK

CN8101,

CN8102

K

A

B

HEADPHONE ASSY

F

(PWZ3715)

: AUDIO SIGNAL

ROUTE

C

D

1/2

E

5

6

7

F

8

25

Page 26

1

23

CDR-850

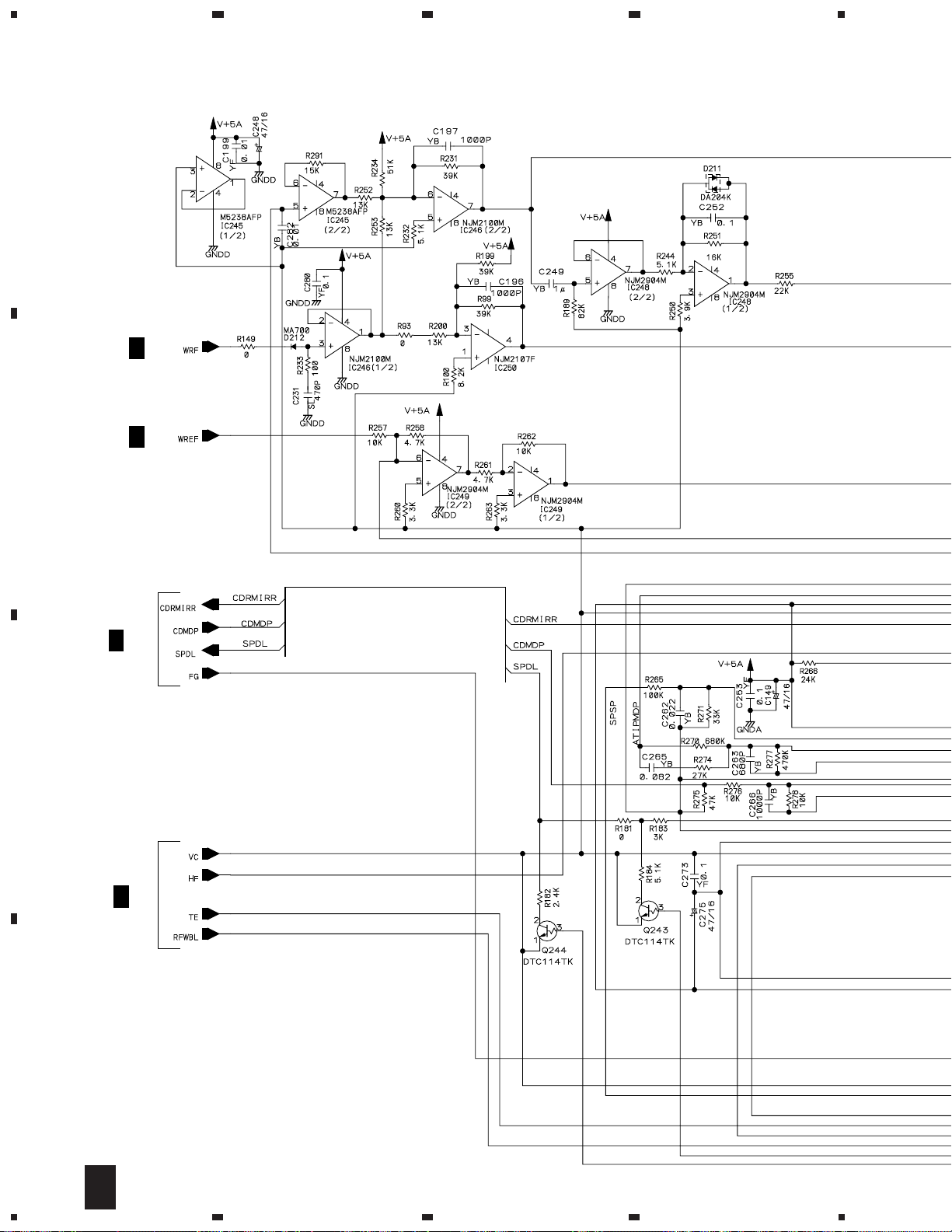

3.9 AUDIO(2/2) and VR ASSEMBLIES

A

4

B

C

CN8004

K

VR ASSY

G

(PWZ3719)

CN8005

K

D

26

2/2

E

1234

G

Page 27

5

678

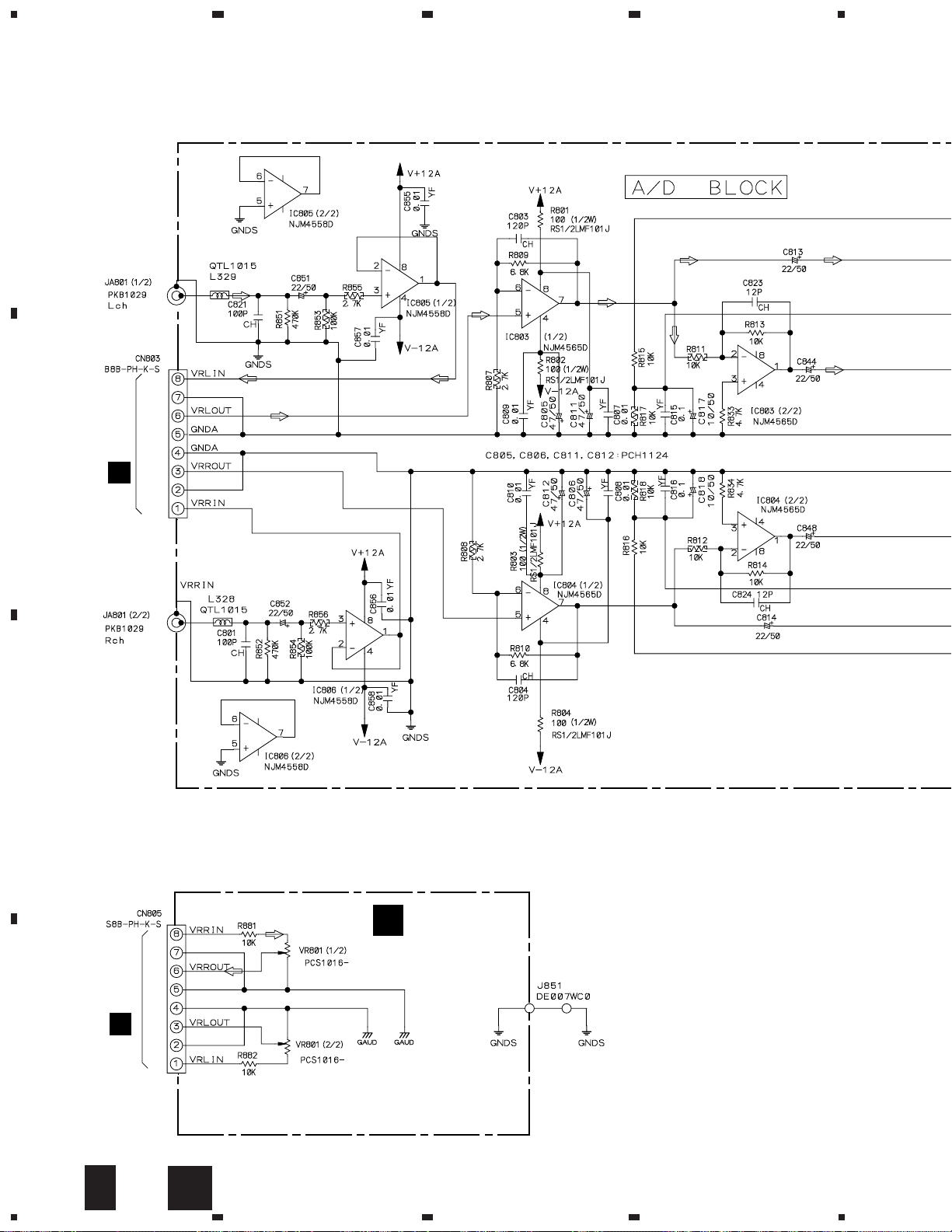

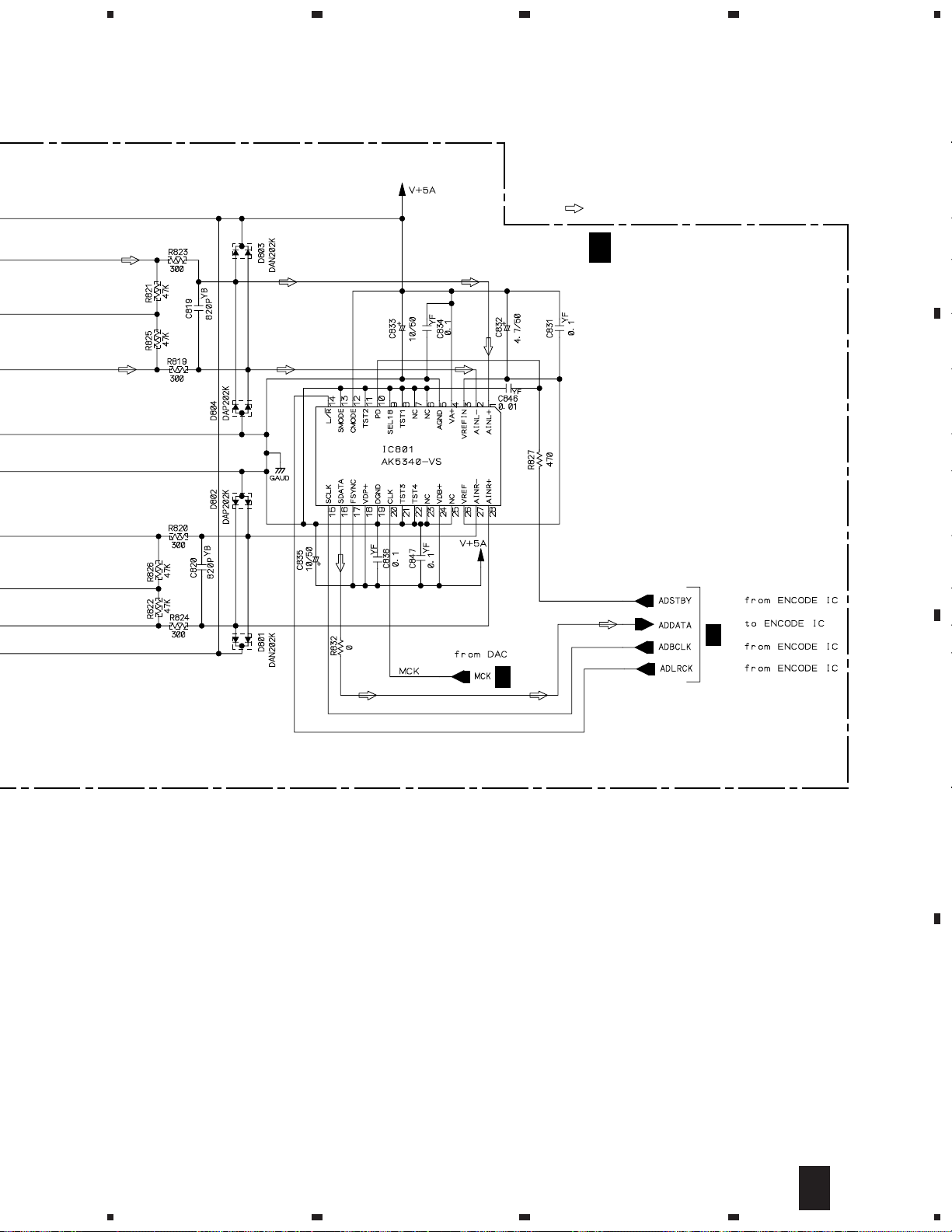

CDR-850

A

: AUDIO SIGNAL ROUTE

A/D CONVERTER

E

1/2

E

AUDIO ASSY(2/2)

2/2

(PWZ3933 : MY)

(PWZ3934 : KU/CA)

•

A/D BLOCK

1/2

E

B

C

D

2/2

E

5

6

7

8

27

Page 28

1

23

CDR-850

3.10 POWER and TRANS ASSEMBLIES

A

AC POWER

CORD

(10000p/250)

B

1P AC INLET

• NOTE FOR FUSE REPLACEMENT

(10000p/250)

(10000p/250)

4

POWER TRANSFORMER

C901

C902

C903

C904

C905

C906

C

C909

C907

C908

TRANS ASSY

I

(PWZ3752)

D

28

H

I

1234

Page 29

5

678

CDR-850

A

POWER ASSY

H

(PWZ3937 : MY)

(PWZ3938 : KU/CA)

J701

J

B

CAUTION : FOR CONTINUED PROTECTION AGAINST

RISK OF FIRE. REPLACE ONLY WITH

SAME TYPE NO. ICP-N15, MFD BY ROHM

CO., LTD. FOR IC22,IC23,IC25.

1/2

E

CN402

CN8003

K

5/6

D

CN355

C

D

H

5

6

7

8

29

Page 30

1

CDR-850

3.11 FUNCTION ASSY

23

4

A

REMOTE

RECEIVER

UNIT

FL HOLDER

J

FUNCTION ASSY

FUNCTION ASSY

S702 : PLAY 3

S703 : PAUSE 8

B

GNDS

H

CN51

V–27

AC2

AC1

S704 : STOP 7

S705 : TRACK SEARCH 4 1

S706 : TRACK SEARCH ¡ ¢

S707 : OPEN/CLOSE

S708 : TIME/MARGIN

S709 : RECORD

S710 : DIGITAL SYNCHRO

S711 : REC MUTE

S712 : SKIP ID SET

S713 : SKIP ID CLEAR

S714 : SKIP PLAY

S715 : MENU

S716 : TRACK No. AUTO/MANUAL

S717 : TRACK No. WRITE

S718 : FINALIZE

S719 : ERASE

(PWZ3699)

C

S712–S719 : VSG1009

D

CN8006

K

30

J

1234

Page 31

5

678

CDR-850

A

CN202

1/6

D

B

R710–R715 :

ACN7081

MODE CONTROLLER

SYSTEM

RESET

Q701–Q704 :

DTA114EK

C

D

J

5

6

7

8

31

Page 32

1

CDR-850

3.12 INPUT ASSY

A

B

23

4

CN805

G

CN803

2/2

E

J32

H

J708

J8006

J

K

C

D

32

K

1234

Page 33

K

J8006

5

678

CDR-850

K

INPUT ASSY

(PWZ3929 : MY)

(PWZ3930 : KU/CA)

A

B

1/2

E

J407,

J408

E

J408

1/2

C

4/6

D

CN302

D

K

5

6

7

8

33

Page 34

CDR-850

4. PCB CONNECTION DIAGRAM

NOTE FOR PCB DIAGRAMS :

1. Part numbers in PCB diagrams match those in the schematic

diagrams.

2. A comparison between the main parts of PCB and schematic

diagrams is shown below.

Symbol In PCB

Diagrams

BCE

BCE

D

Symbol In Schematic

Diagrams

BCEBCE

BCE

DGGSS

BCE

DGS

Part Name

Transistor

Transistor

with resistor

Field effect

transistor

Resistor array

3. The parts mounted on this PCB include all necessary parts for

several destinations.

For further information for respective destinations, be sure to

check with the schematic diagram.

4. View point of PCB diagrams.

Connector

Capacitor

SIDE A

P.C.Board

Chip Part

SIDE B

3-terminal

regulator

34

Page 35

1

234

4.1 LOADING A, LOADING B and SERVO MECH ASSEMBLIES

CDR-850

A

SIDE A

A

LOADING A ASSY

D

CN352

B

LOADING

B ASSY

SIDE B

B

M

(PNP1447-B)

D

CN353

C

SERVO MECH

ASSY

C

M

M

D

(PNP1447-B)

BA

1

2

3

C

4

35

Page 36

1

1

C

C

CDR-850

4.2 SERVO DIGITAL ASSY

A

C

CN601

23

A

CN501

PICKUP

ASSY

D

SERVO DIGITAL

ASSY

4

H

J2

B

J

CN701

C

VR101 VR107

VR108

VR103

IC351 Q107

IC352

VR104

VR106

VR102

VR105

Q102 IC243

Q101Q106 IC103 IC101

IC355

Q250IC206

IC248

IC249

IC247

IC245

IC212

IC250

IC213

Q243

Q244

IC211 IC209

I

I

SIDE A

D

36

D

1234

Page 37

H

0

J21

E

5

J801

678

CDR-850

A

K

CN3002

B

C

VR301

IC201 IC302 IC310IC309

IC205 IC204 IC303 IC202 IC314 Q301IC316

9

IC353 IC301 IC308 IC311 IC318

Q203

5

6

7

(PNP1445-G)

D

8

D

37

Page 38

A

B

1

CDR-850

23

D

SERVO DIGITAL ASSY

4

C

(PNP1445-G)

IC305 Q302 IC354 Q351

IC312 Q204 IC207 IC203

Q201IC313 IC320 Q303

SIDE B

D

38

D

1234

Page 39

5

678

CDR-850

A

B

IC246 IC105Q242

IC210 IC208

5

Q241

Q103

6

Q104 Q105Q201 IC102 IC104

C

D

D

7

8

39

Page 40

1

23

CDR-850

4.3 AUDIO, HEADPHONE and VR ASSEMBLIES

CN8101

K

CN8102

A

Q407

Q408

Q406

Q405

IC803

IC804

IC404

B

4

G

VR ASSY

(PNP1456-D)

K

CN8005

K

CN8004

H

J31

D

CN301

C

IC451

(PNP1463-B)

E

AUDIO ASSY

K

CN8101

D

SIDE A

40

E

F

1234

G

HEADPHONE

F

ASSY

(PNP1456-D)

Page 41

G

VR ASSY

(PNP1456-D)

1

234

CDR-850

E

AUDIO ASSY

A

Q404

Q409

Q403

IC406

B

HEADPHONE

F

ASSY

IC401

IC801

Q401

IC402

Q402

C

(PNP1463-B)

(PNP1456-D)

1

D

SIDE B

FE

2

3

G

4

41

Page 42

1

23

CDR-850

4.4 POWER and TRANS ASSEMBLIES

4

AC POWER CORD

H

A

LIVENEUTRAL

B

POWER ASSY

K

CN8003

E

CN402

IC37

IC33

IC36

IC32

IC31

IC35

D

CN355

IC25

IC21

IC23

IC24

(PNP1463-B)

J

C

J701

SIDE A

D

I

42

H

I

1234

POWER

TRANSFORMER

TRANS ASSY

(PNP1456-D)

Page 43

1

234

CDR-850

H POWER ASSY

A

B

SIDE B

(PNP1463-B)

C

I TRANS ASSY

D

(PNP1456-D)

43

H

1

2

3

I

4

Page 44

1

CDR-850

4.5 FUNCTION ASSY

J

A

B

23

FUNCTION ASSY

4

D

SIDE A

IC705

J

FUNCTION ASSY

C

CN202

Q705 IC702

D

IC701

44

SIDE B

J

1234

Page 45

5

678

CDR-850

H

CN51

A

B

K

(PNP1456-D)

CN8006

C

D

IC704

Q701 Q704Q706

J

5

6

7

8

45

Page 46

1

CDR-850

4.6 INPUT ASSY

A

23

K INPUT ASSY

4

IC3001

Q408

D CN302

G CN805

B

Q8009

Q8010

E CN803

J J708

H J32

C

D

Q8101

Q8102

J407,

E

J408

E J408

SIDE A

46

K

1234

(PNP1463-B)

Page 47

1

234

CDR-850

K

INPUT ASSY

A

Q8002

Q8004

Q8007

Q8003

Q8006

Q8005

IC8001

IC8003

Q8202

Q8201

IC8101

IC8103

IC8105

Q8103

B

C

IC8102

IC8104

IC8106

Q8104

Q3705

Q3706

Q3707

Q3708

Q3701

Q3702

Q3703

Q3704

(PNP1463-B)

1

2

3

SIDE B

K

4

47

D

Page 48

CDR-850

Mark No. Description Part No.

Mark No. Description Part No.

5. PCB PARTS LIST

NOTES:•Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

•

Therefore, when replacing, be sure to use parts of identical designation.

When ordering resistors, first convert resistance values into code form as shown in the following examples.

•

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47k ohm (tolerance is shown by J=5%,

and K=10%).

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

560 Ω→56 × 10

47k Ω→47 × 103→ 473 ........................................................ RD1/4PU 4 7 3 J

0.5 Ω→R50 .....................................................................................RN2H

1 Ω→1R0 .....................................................................................RS1P

5.62k Ω→ 562 × 10

LIST OF WHOLE PCB ASSEMBLIES

Mark Symbol and Description

NSP SERVO MECH ASSY PWX1569 PWX1569

NSP LOADING A ASSY PWZ3727 PWZ3727

NSP LOADING B ASSY PWZ3728 PWZ3728

NSP SERVO MECH ASSY PWZ3758 PWZ3758

NSP

SERVO DIGITAL ASSY PWM2219 PWM2220

1

→ 561 ........................................................ RD1/4PU 5 6 1 J

R 5 0

1 R 0

1

→ 5621 ...................................................... RN1/4PC 5 6 2 1 F

Part No.

MY Type KU/CA Type

K

K

Remarks

NSP

NSP

Mark No. Description Part No. Mark No. Description Part No.

A

SWITCH

OTHERS

B

OTHERS

C

SEMICONDUCTORS

POWER AUDIO I/O ASSY PWX1600 PWX1601

INPUT ASSY PWZ3929 PWZ3930

AUDIO ASSY PWZ3933 PWZ3934

POWER ASSY PWZ3937 PWZ3938

FUNCTION ASSY PWX1595 PWX1595

NSP FUNCTION ASSY PWZ3699 PWZ3699

NSP HEADPHONE ASSY PWZ3715 PWZ3715

NSP VR ASSY PWZ3719 PWZ3719

NSP TRANS ASSY PWZ3752 PWZ3752

LOADING A ASSY

S501 VSK1011

CN502 KR CONNECTOR S2B-PH-K-S

CN501 KR CONNECTOR S5B-PH-K-S

SWITCHES AND RELAYS

S601 PSG1013

RESISTORS

All Resistors RD1/4PU J

OTHERS

J601 3P JUMPER WIRE D20PWW0305E

CN601 KR CONNECTOR S9B-PH-K-S

LOADING B ASSY

SERVO DIGITAL ASSY

D

CN551 KR CONNECTOR B2B-PH-K-S

SERVO MECH ASSY

PC651 NJL5803K-F1

(1) CONTRAST TABLE

PWM2220 and PWM2219 are constructed the same except

for the following :

Mark Symbol and Description

L323 Not used QTL1015

C1157 Not used

R1157 Not used RS1/10S0R0J

R1181,R1323 RS1/10S0R0J Not used

PWM2219 PWM2220

Part No.

CCSQCH101J50

Remarks

48

Page 49

CDR-850

Mark No. Description Part No.

(2) PARTS LIST FOR PWM2219

SEMICONDUCTORS

IC311 AD1893JST

IC103 AK8563

IC201 BA05T

IC351 BA5912AFP-Y

IC352 BA5932FP

IC302 BA7082F

IC353 CXD2585Q

IC104, IC105, IC243, IC318 HD74HC4053FP

IC203 HD74HC573FP

IC308 LC89585

IC301 LH64256CK-70

IC212 LP2950CZ-5.0(NS)

IC245 M5238AFP

IC102 MC34072D

IC246 NJM2100M

IC250 NJM2107F

IC101 NJM2136M

IC207, IC248, IC249, IC314 NJM2904M

IC247 PA9004A

IC309 PCX1021

IC205 PDJ014A

IC316 PDK041A

IC204 PE5073A9

IC206 PST994C

IC202 TC4W53F

IC312, IC313 TC74HC00AF

IC305 TC74HCU04AF

IC210 TC7S00F

IC208, IC303 TC7S04F

IC320 TC7S08F

IC209, IC211, IC310 TC7S14F

IC355 TK11041M-1

Q302 DTA114EK

Q102, Q301 DTA114TK

Q242, Q351 DTA124EK

Q250 DTA124TK

Q103, Q104, Q241, Q243, Q244 DTC114TK

Q303 DTC114TK

Q101, Q107, Q201, Q203, Q204 DTC124EK

D101, D103–D105, D110 1SS355

D201, D202, D205–D210 1SS355

D214, D215 1SS355

D211, D301 DA204K

D302 DAN202K

D203 DAP202K

D102, D212 MA704

COILS AND FILTERS

L209 OTL1040

L308 PULSE TRANS. PTL1003

L315 CHOKE COIL PTL1017

L312 EMI FILTER PTL1019

L1097, L1098, L1151, L1154 QTL1015

L1156, L1157, L1162, L1163 QTL1015

L1166–L1171, L190, L201, L202 QTL1015

L211–L222, L301–L304, L307 QTL1015

L309 CHIP SOLID INDUCTOR QTL1015

L311 CHIP SOLID INDUCTOR QTL1015

Mark No. Description Part No.

L313, L314, L317, L318 QTL1015

L320, L321, L351, L352 QTL1015

CAPACITORS

C120 CCSQCH100D50

C306, C316, C325, C326, C338 CCSQCH101J50

C303 CCSQCH160J50

C350, C375, C399 CCSQCH221J50

C203, C204, C278 CCSQCH270J50

C133, C361 CCSQCH331J50

C337 CCSQCH470J50

C231, C377 CCSQCH471J50

C134 CCSQCH6R0D50

C1188 CCSQCH681J50

C1395 CCSQCH820J50

C104 CCSQCJ3R0C50

C328 CCSQSL561J50

C232, C307, C318, C329 CEAT100M50

C103 CEAT101M10

C102, C150, C382–C384, C386 CEAT101M16

C390 CEAT101M16

C214, C255 CEAT1R0M50

C206, C212 CEAT221M6R3

C264, C277 CEAT2R2M50

C323 CEAT330M25

C223 CEAT3R3M50

C108, C194, C395 CEAT470M10

C149, C209, C226, C241, C248 CEAT470M16

C275, C279, C295, C304, C310 CEAT470M16

C320, C321, C333, C341, C344 CEAT470M16

C355, C370, C385 CEAT470M16

C228 CEAT4R7M50

C9327 CKCYF473Z50

C141, C142, C196, C197, C254 CKSQYB102K50

C266, C331, C335, C340, C347 CKSQYB102K50

C351, C364, C376, C396 CKSQYB102K50

C112, C123, C124, C222, C1350 CKSQYB103K50

C243, C244, C282, C296–C299 CKSQYB103K50

C315, C322, C332, C343, C346 CKSQYB103K50

C365–C368, C373, C391, C392 CKSQYB103K50

C126, C138, C224, C230, C252 CKSQYB104K25

C259–C261, C327, C339 CKSQYB104K25

C115, C127, C131, C249, C312 CKSQYB105K10

C314 CKSQYB105K10

C268, C381 CKSQYB152K50

C348, C349, C397, C398 CKSQYB222K50

C140, C262 CKSQYB223K50

C110, C111, C116–C118, C144 CKSQYB224K16

C216, C217 CKSQYB224K16

C281 CKSQYB272K50

C136, C269–C271, C274 CKSQYB331K50

C135 CKSQYB333K50

C128, C256–C258, C276 CKSQYB334K16

C221, C288, C354, C358, C359 CKSQYB471K50

C267, C380 CKSQYB473K25

C143 CKSQYB473K50

C147, C263, C357, C362, C363 CKSQYB681K50

C352, C353 CKSQYB682K50

C265 CKSQYB823K25

49

Page 50

CDR-850

Mark No. Description Part No.

C145, C199, C201, C202 CKSQYF103Z50

C207, C208, C234, C240, C250 CKSQYF103Z50

C301, C302 CKSQYF103Z50

C101, C105, C109, C113, C121 CKSQYF104Z25

C125, C129, C139, C151, C160 CKSQYF104Z25

C198, C210, C211, C213 CKSQYF104Z25

C218, C219, C225, C233, C242 CKSQYF104Z25

C253, C273, C280, C283–C287 CKSQYF104Z25

C294, C305, C308, C309, C311 CKSQYF104Z25

C313, C317, C319, C324, C330 CKSQYF104Z25

C334, C342, C345, C356, C369 CKSQYF104Z25

C371, C372, C388, C393, C394 CKSQYF104Z25

C114, C119, C122, C130, C132 CKSQYF105Z16

C137 CKSQYF105Z16

C205 RCH1152

RESISTORS

R127 (2.2kΩ) PCN1039

VR101–VR103, VR105, VR106 VCP1154

(4.7kΩ)

VR104 (22k Ω) VCP1158

Other Resistors RS1/10S J

OTHERS

CN355 6P JUMPER CONNECTOR 52147-0610

CN301 15P JUMPER CONNECTOR 52147-1510

CN202 22P FFC CONNECTOR 9604S-22C

CN302 KR CONNECTOR B3B-PH-K-S

CN352 KR CONNECTOR B5B-PH-K-S

CN351 5P TOP POST B5P-SHF-1AA

CN102, CN354 6P TOP POST B6P-SHF-1AA

JA301 OPTICAL RECEIVE MODULE GP1F32R

JA303 OPTICAL SEND MODULE GP1F32T

JA302 1P JACK (ORANGE) PKB1027

JA304 1P JACK (ORANGE) PKB1028

JA305 REMOTE CONTROL JACK PKN1004

PCB BINDER VEF1040

CN101 32P FFC CONNECTOR VKN1463

KN302, KN303 VNF1084

EARTH METAL FITTING

Mark No. Description Part No.

Q403 DTA124EK

Q401, Q404 DTC124EK

D401–D404 1SS133

D407, D408 1SS355

D406, D801, D803 DAN202K

D405, D802, D804 DAP202K

COILS AND FILTERS

L328, L329, L402, L404 QTL1015

L407, L408 QTL1015

CHIP SOLID INDUCTOR

L401 FERRITE BEAD VTH1020

CAPACITORS

C414, C415, C429, C430, C801 CCSQCH101J50

C821 CCSQCH101J50

C823, C824 CCSQCH120J50

C803, C804 CCSQCH121J50

C817, C818 CEAT100M50

C813, C814, C844, C848 CEAT220M50

C851, C852 CEAT220M50

C441 CEAT4R7M50

C421, C422, C425, C426 CEGA470M50

C413 CKSQYB102K50

C403 CKSQYB473K50

C819, C820 CKSQYB821K50

C454, C807–C810, C846 CKSQYF103Z50

C855–C858 CKSQYF103Z50

C815, C816, C831, C834, C836 CKSQYF104Z25

C847, C883, C884 CKSQYF104Z25

C404, C408, C409 CKSQYF104Z50

C427, C428 CQMBA102J50

C423, C424, C433, C434 CQMBA152J50

C431, C432 CQMBA332J50

C471, C472, C805, C806 PCH1124

C811, C812, C833, C835 PCH1124

(47µF/50V)

C406, C407, C832 (4.7µF/50V) PCH1127

C405, C410–C412 (220µF/25V) PCH1128

X301 XTAL RESONATOR PSS1008

X201 CERAMIC RESONATOR PSS1023

AUDIO ASSY

E

(16.9344MHz)

(32MHz)

Although PWZ3934 and PWZ3933 are different in part

number, they consist of the same components.

PARTS LIST FOR PWZ3933

SEMICONDUCTORS

IC801 AK5340-VS

IC406 M5218AFP

IC805, IC806 NJM4558MD

IC803, IC804 NJM4565D-D

IC404 NJM4580D

IC401 PE8001A

IC402 TC7SU04F

Q405–Q408 2SC3068

Q402 DTA114EK

Q409 DTA114TK

50

RESISTORS

R475, R476 RD1/4PU102J

R441–R444, R811, R812 RD1/4PU103J

R817, R818 RD1/4PU103J

R427, R428 RD1/4PU223J

R435, R436 RD1/4PU271J

R440, R807, R808 RD1/4PU272J

R819, R820, R823, R824 RD1/4PU301J

R429–R434, R448, R466 RD1/4PU471J

R821, R822, R825, R826 RD1/4PU473J

R411, R412 RDR1/2PM101J

R413–R416 RN1/10SE1002D

R853, R854 RN1/10SE1003D

R855, R856 RN1/10SE3302D

R801–R804 RS1/2LMF101J

Other Resistors RS1/10S J

OTHERS

CN401 3P JUMPER CONNECTOR 52147-0310

CN402 8P JUMPER CONNECTOR 52147-0810

J801 JUMPER WIRE 15P D20PYY1510E

J810 6P CONNECTOR ASSY PDE1301

JA401, JA801 2P JACK PKB1029

Page 51

CDR-850

Mark No. Description Part No.

KN111, KN112, KN114 VNF1084

HEADPHONE ASSY

F

PCB BINDER VEF1040

EARTH METAL FITTING

COILS AND FILTERS

L461–L463 CHIP SOLID INDUCTOR QTL1015

CAPACITORS

C461, C463, C466 CCSQCH101J50

C469 CGCYX104K25

C462, C464, C465 CKSQYF103Z50

RESISTOR

VR401 (500Ω-Bx2) RCV1123

OTHERS

CN403 3P JUMPER CONNECTOR 52147-0310

403 HEADPHONE JACK AKN-045

KN401 EARTH METAL FITTING VNF1084

VR ASSY

G

RESISTORS

VR801 (50KΩ-Ax2) PCS1016

Other Resistors RS1/10S J

Mark No. Description Part No.

C12 CKSQYF104Z50

C15, C24 CKSQYF473Z50

C32, C33 CQMA223J50

C55, C56 CQMA273J50

C42 (1000µF/16V) PCH1122

C52 (100µF/50V) PCH1126

C34, C35 (4.7µF/50V) PCH1127

C54 (220µF/25V) PCH1128

C23, C25 (470 µF/50V) PCH1129

C36, C40 (3300µF/35V) PCH1137

C37, C41 (2200 µF/35V) PCH1138

RESISTORS

R38 RFA1/4PL8R2J

R21 RS1/10S822J

Other Resistors RD1/4PU J

OTHERS

6P CABLE HOLDER 51048-0600

8P CABLE HOLDER 51048-0800

CN51 4P JUMPER CONNECTOR 52147-0410

H1, H2 FUSE CLIP AKR1003

CN2 2P-VH CONNECTOR B2P3-VH

J21 JUMPER WIRE 6P D20PYY0630G

J31 JUMPER WIRE 8P D20PYY0820G

CN11 9P JUMPER CONNECTOR KPD9

J2 EARTH LEAD UNIT PDF1168

CN1 AC INLET PKP1012

POWER ASSY

H

Although PWZ3938 and PWZ3937 are different in part

number, they consist of the same components.

PARTS LIST FOR PWZ3937

SEMICONDUCTORS

IC21, IC24 BA05T

IC31 BA12T

IC22, IC23, IC25 ICP-N15

IC33 NJM7805FA

IC32 NJM79M12FA

D31–D34 10DF2FA9

D52 11ES2

D54 MTZJ18B

D11 S2VB20F

COILS AND FILTERS

L1 FILTER VTL1008

L11, L23 FERRITE BEAD VTH1020

SWITCHES AND RELAYS

S1 RSA1001

CAPACITORS

C1–C3 (10000pF/AC250V) ACG7020

C21 CEAT103M16

C11, C13 CFTLA123J50

C31 CKSQYF102Z50

C16, C17 CKSQYF103Z50

HEAT SINK PNS1043

KN12, KN13 EARTH METAL FITTING VNF1084

TRANS ASSY

I

PCB BINDER VEF1040

SEMICONDUCTORS

IC1 AEK7017

CAPACITORS

C901–C909 CKSQYF104Z50

OTHERS

J11 PARALLEL CORD DTUY0915E

J1 CONNECTOR ASSY 2P PDE1299

J3 EARTH LEAD UNIT PDF1176

FUNCTION ASSY

J

9P CABLE HOLDER 51052-0900

SEMICONDUCTORS

IC704 BU2092F

IC701 PE5056B9

IC702 S-806E

Q705 2SC2412K

Q701–Q704 DTA114EK

Q706 DTC124TKA

D709 1SS355

D707, D708 GL3ED8

D705, D706 SLP9118C51H

COILS AND FILTERS

L701 CHIP SOLID INDUCTOR QTL1015

51

Page 52

CDR-850

Mark No. Description Part No.

SWITCHES AND RELAYS

S720 PSB1008

S702–S719 VSG1009

CAPACITORS

C701 CCSQCH101J50

C743 CCSQCH470J50

C705, C739 CEAT101M16

C711, C712 CEAT470M16

C702 CKSQYF103Z50

C706, C708–C710 CKSQYF104Z25

RESISTORS

R710–R715 ACN7081

R731 DCN1094

Other Resistors RS1/10S J

OTHERS

CN701 22P FFC CONNECTOR 9604S-22C

J701 JUMPER WIRE 4P D20PWY0425G

J703 JUMPER WIRE 5P D20PWY0515E

J709 JUMPER WIRE 5P D20PYY0555G

V701 FL INDICATOR TUBE PEL1097

X701 CERAMIC RESONATOR VSS1014

INPUT ASSY

K

5P CABLE HOLDER 51048-0500

REMOTE RECEIVER UNIT GP1U27X

(4.19MHz)

Although PWZ3930 and PWZ3929 are different in part

number, they consist of the same components.

PARTS LIST FOR PWZ3929

SEMICONDUCTORS

IC8001–IC8004, IC8101–IC8106 NJM4558MD

IC3001 SN75157P

Q3701–Q3708 2SA1037K

Q8009, Q8010, Q8101, Q8102 2SC3068

Q8001–Q8005, Q8103, Q8104 2SD2114K

Q8006, Q8201 DTA124TK

Q8202 DTC124EK

Q8007 DTC124TKA

D8001–D8006, D8101–D8104 1SS355

D3701–D3708 DA204K

COILS AND FILTERS

L3002, L3011–L3013, L3704–L3712 QTL1015

L8001–L8004 QTL1015

L8021–L8025, L8027, L8029, L8030 QTL1015

L8101–L8106, L8109–L8112 QTL1015

L8009 QTL1015

Mark No. Description Part No.

CAPACITORS

C8111–C8114 CCSQCH101J50

C3006 CCSQCH331J50

C3002, C3003, C8101–C8104 CCSQCH470J50

C8123, C8124, C8127, C8128 CCSQCH470J50

C8011, C8012 CEAT101M25

C8105–C8108 CEYANP101M25

C8003–C8006 CEYANP220M25

C3005, C3712–C3719 CKSQYF103Z50

C3720 CKSQYF104Z25

C3001, C3708, C8022, C8023 CKSQYF104Z50

C8119–C8122 CKSQYF104Z50

C8020, C8021 PCH1122

C8007–C8010 PCH1124

C3004, C3709, C8115–C8118 PCH1128

RESISTORS

R8089, R8090, R8105, R8106 RN1/10SE1002D

R8113, R8114, R8119, R8120 RN1/10SE1002D

R8123, R8124 RN1/10SE1002D

R8011–R8014 RN1/10SE1003D

R8157, R8158, R8167, R8168 RN1/10SE1201D

R8117, R8118 RN1/10SE1202D

R8007, R8008, R8107, R8108 RN1/10SE2701D

R8149–R8152, R8159–R8162 RN1/10SE3000D

R8169–R8172 RN1/10SE3000D

R8017–R8020, R8109, R8110 RN1/10SE3602D

R8005, R8006, R8009, R8010 RN1/10SE3901D

R8101, R8102 RN1/10SE4700D

R8103, R8104, R8125–R8140 RN1/10SE4702D

R8153–R8156 RN1/10SE4702D

R8015, R8016, R8021–R8026 RN1/10SE5601D

R8115, R8116, R8121, R8122 RN1/10SE5601D

Other Resistors RS1/10S J

OTHERS

3P CABLE HOLDER 51048-0300

CN8006 5P JUMPER CONNECTOR 52147-0510

CN8102 CONNECTOR POST B2B-PH-K-S

CN3002,CN8003 CONNECTOR POST B3B-PH-K-S

CN8101 CONNECTOR POST B4B-PH-K-R

J8005, J8006 3P JUMPER WIRE D20PYY0310G

JA3001,JA8001,JA8002 CONNECTORPKP1011

JA8101,JA8102 CONNECTOR PKP1013

CN3702 DIN SOCKET 8P RKN1030

PCB BINDER VEF1040

L8201–L8205, L8231 QTL1015

SWITCHES AND RELAYS

RY8001,RY8002,RY8101,RY8102 RSR1029

RY8003,RY8004 VSR1006

52

Page 53

6. ADJUSTMENT

g

CDR-850

6.1 DISCS TO BE USED

1. When adjusting the servo system adjustment

CD : Test disc for adjustment (STD-903 or equivalent)

6.2 MEASURING INSTRUMENTS

(1) Laser Power Meter

Following power meter manufactured by Advantest Corporation

TQ8210 + TQ82017,

TQ8215 + TQ82021,

TQ8215 + TQ82010 + TQ82017,

Following power meter manufactured by Leader Corporation

LE8010,

or equivalent.

(2) Oscilloscope

(3) CD Jitter Meter

6.3 TEST MODE

6.3.1 Test Mode

For adjustment, set the unit to Test mode. To enter Test mode, turn

on the unit with the Test Mode Short-Circuit pattern on the

FUNCTION Assy. In Test mode, all the displays (FL, LEDs) on

the unit should be lit. If not, turn the power off and repeat the same

steps again.

6.3.2 Operations in Test Mode

In Test mode, the following adjustment functions are assigned to

the buttons, as explained below.

¶ (RECORD) and

SET button

Set

CLEAR button

Reset the adjusted

values

Fig.2 During adjustment of LD power (Input selector: AES/EBU)

SET button

Set

LED for confirmation of

LD emission

ERASE button

Switching CD, CD-R

and CD-RW

4 1,

¡ ¢

buttons

Sled move

¶

(RECORD)

button

– key

• (REC MUTE)

buttons

LD emitting

7 (STOP) button

LD not emitting

•

(REC MUTE)

button

+ key

DIGITAL

SYNCHRO

button

Average

FUNCTION ASSY

SIDE B

Fi

. 1 Enter the Test mode

Short-circuit

AUTO/MANUAL

button

Adjustment mode

switch

FINALIZE button

Focus in

Fig.3 During adjustment of servo system (Input selector: optical)

ERASEbutton

Mode switch

3 (PLAY) button

Spindle kick

7 (STOP) button

Stop

8 (PAUSE) button

Tracking close

6.3.3 How to Playback a Disc in Test Mode

In test mode, since the servos operate independently, playing back a

disc requires that you operate the keys in the correct order to close

the servos.

Here is the key operation sequence for playing back a disc in test

mode.

FINALIZE Lights up the laser diode and closes the focus servo.

‘

PLAY 3 Starts the spindle motor and closes the spindle

servo.

‘

PAUSE 8 Close the tracking servo.

‘

Wait at least 2 – 3 seconds between each of these operations.

53

Page 54

CDR-850

6.4 ADJUSTMENT 1 (LASER DIODE POWER ADJUSTMENT)

SERVO DIGITAL ASSY

CN354

1

6

CN102

6

VR105

RW REC.

1

VR102

R REC. PW1

VR101

PB. PW

VR106

RW REC.

PW2

VR104

RW REC.PW0

Fig. 4 Adjustment points

The following adjustments 1 through 3 must be done with the Input

Selector set to the AES/EBU position (LD power adjustment mode).

PW1

VR103

R REC.PW2

Playback CD-R recording

Note 1 : Attach the remote sensor of the laser power meter to a point angled away

Note 2 : When adjusting with VR101 to VR106, first turn them completely counter-

Note 3 : Set the wavelength of laser power meter to 780 nm.

CD-R overdrive

CD-R record

power

Playback power

CD-RW recording

CD-RW erase

power

Fig.5 Output power of the laser diode

about 10 degrees against the pickup lens and where the maximum power

is detected, so that there will be no light reflected onto the pickup.

clockwise and then adjust clockwise, so that the value to be reached is not

exceeded.

CD-RW record power

CD-RW bias

power

AES/EBU

DANGER – LASER RADIA TION WHEN OPEN.

6.4.1 Playback Power Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

(1) Check that "CD" is displayed on the FL display. If "CD-R" or "CD-RW" is displayed, press the ERASE button repeatedly until "CD" is

displayed.

(2) Press the RECORD button. The LED for confirmation of LD emission will light in green.

(3) Press the REC MUTE button. The LED for confirmation of LD emission will light in orange. The LD is emitting in this status.

(4) Turn VR101 clockwise until the adjustment value to be reached is obtained.

(5) Press the STOP button to shut off the LD.

Pickup objective lens

VR101 (PB. PW)

0.60 mW ± 0.05 mW

AVOID DIRECT EXPOSURE TO BEAM.

54

Page 55

6.4.2 CD-R Record Power Adjustment

CDR-850

DANGER – LASER RADIA TION WHEN OPEN.

AVOID DIRECT EXPOSURE TO BEAM.

Test Point

Adjustment Point

Adjustment Value

Pickup objective lens

VR102 (R REC. PW1), VR103 (R REC. PW2)

VR102 : 4.60 mW ± 0.1 mW

VR103 : Addition of 0.1 mW ± 0.01 mW to the adjustment value of VR102

[Procedure]

(1) Turn VR102 and VR103 completely counterclockwise to set their power output to minimum.

(2) Press the ERASE button once so that "CD-R" appears on the FL display.

If the indication is "CD" or "CD-RW," press the ERASE button repeatedly until "CD-R" is displayed on the FL display.

(3) Press the RECORD button. The LED for confirmation of LD emission will light in green.

(4) Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this status.

Adjustment of CD-R record power

(5) Turn VR102 clockwise until the adjusted value is 4.60 mW ± 0.1 mW.

Adjustment of CD-R overdrive power

(6) Turn VR103 clockwise until the adjusted value becomes adjustment value at Step 5 above + (0.1 mW ± 0.01 mW).

(7) Press the STOP button to shut off the LD.

DANGER – LASER RADIA TION WHEN OPEN.

6.4.3 CD-RW Record Power Adjustment

AVOID DIRECT EXPOSURE TO BEAM.

Test Point

Adjustment Point

Adjustment Value

Pickup objective lens

VR104 (RW REC. PW0), VR106 (RW REC. PW2), VR105 (RW REC. PW1)

VR104 : 0.40 mW ± 0.05 mW * Serial No. 1-19 (MY Type), 1-27 (KU/CA Type)

VR106 : 2.0 mW ± 0.1 mW * VR106 : 2.4 mW ± 0.1 mW

VR105 : 5.7 mW ± 0.1 mW * VR105 : 5.9 mW ± 0.1 mW

[Procedure]

(1) Turn VR104, VR105 and VR106 completely counterclockwise to set their power output to minimum.

(2) Press the ERASE button twice so that "CD-RW" appears on the FL display.

If the indication is "CD" or "CD-R," press the ERASE button repeatedly until "CD-RW" appears on the FL display.

(3) Press the RECORD button. The LED for confirmation of LD emission will light in green.

(4) Press the REC MUTE button. The LED for confirmation of LD emission will light in red. The LD is emitting in this status.

(5) Turn VR104 clockwise until the adjusted value is 0.40 mW ± 0.05 mW.

Adjustment of CD-RW record power

(6) Turn VR106 clockwise until the adjusted value is 2.0 mW ± 0.1 mW. * Serial No. 1-19 (MY Type), 1-27 (KU/CA Type) 2.4 mW ± 0.1 mW

Adjustment of CD-RW erase power

(7) Turn VR105 clockwise until the adjusted value is 5.7 mW ± 0.1 mW. * Serial No. 1-19 (MY Type), 1-27 (KU/CA Type) 5.9 mW ± 0.1 mW

(8) Press the STOP button to shut off the LD.

* CD-RW Record power adjustment value is different according to

the part number used for IC316.

IC316 PDK033A PDK041A

VR106 2.4 mW 2.0 mW

VR105 5.9 mW 5.7 mW

Serial No.

1-19 (MY Type) 20- (MY Type)

1-27 (KU/CA Type) 28- (KU/CA Type)

55

Page 56

CDR-850

6.5 ADJUSTMENT 2 (SERVO SYSTEM ADJUSTMENT)

SERVO DIGITAL ASSY

For servo adjustment, set the INPUT SELECTOR to OPTICAL.

OPT

CN354 (TP201)

Use the RECORD and REC MUTE buttons to make the adjustments.

To register an adjustment, press the (SKIP ID) SET button.

To reset the adjusted values to the initial settings, press and hold the

(SKIP ID) CLEAR button for 4 seconds.

6

CN354

1 : RF

2 : TE

3 : TEIN

4 : VC

5 : FEIN

6 : FE

1

CN102

6

1

CN102

1 : VC

2 : TESTEQRFP

3 : TE

4 : MPP

5 : MPXOUT

6 : FMOUT

Fig. 6 Adjustment points

6.5.1 Focus Offset Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

(1) Press the AUTO/MANUAL button until "01 F4" appears on the FL display.

(2) Adjust with the RECORD and REC MUTE buttons until the value for Pin 6 of CN354 is 0 mV ± 10 mV.

(3) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET button, "?" on the FL display will disappear.

FE

VC

CN354 - pin 6 (FE)

RECORD button and REC MUTE button

0 mV ± 10 mV

10 : 1

10:1 probe

Oscilloscope

56

Page 57

6.5.2 M-S Mix Ratio Adjustment

CDR-850

Test Point

Adjustment Point

Adjustment Value

CN102 - pin 3 (TE) and pin 4 (MPP)

RECORD button and REC MUTE button

Adjust until the value of the output signals from pin 3 (TE) and pin 4 (MPP) of CN102 are the same,

or the differential output of these signals is minimal.

[Procedure]

(1) Press the AUTO/MANUAL button so that "02 F3" appears on the FL display.

(2) Press the FINALIZE button for focus-in.

(3) Press the PLAY button for CAV-servo spindle kick (the status where the spindle rotates with the focus servo on and tracking servo off).

(4) Adjust with the RECORD and REC MUTE buttons until the value to be reached is obtained.

(5) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET button, "?" on the FL display will disappear.

(6) Press the STOP button to stop the unit.

Note: For adjustment, use the following circuits.

TE

MPP

VC

39kΩ

39kΩ

0.001µF

0.001µF

10 : 1

10 : 1

10:1 probe

CH1

CH2

Oscilloscope

Note: Adjustment must be done around mid-radius on a disc.

6.5.3 Tracking Offset Adjustment

Test Point

Adjustment Point

Adjustment Value

[Procedure]

(1) Press the AUTO/MANUAL button so that "03 F6" appears on the FL display.

(2) Adjust with the RECORD and REC MUTE buttons until the above adjustment value to be reached is obtained.

(3) Press the SET button to register the adjustment.

Once the adjustment is registered with the SET button, "?" on the FL display will disappear.

TE

VC

Note: Perform the adjustment in Stop mode.

This adjustment is possible with the low-pass filter used in adjustment 5 above attached.

CN354 - pin 2 (TE) or CN102-pin 3 (TE)

RECORD button and REC MUTE button

0 mV ± 10 mV

10 : 1

10:1 probe

Oscilloscope

57

Page 58

CDR-850

6.5.4 Focus Bias Adjustment

Test Point

Adjustment Point

Adjustment Value

CN354 - pin 1 (RF)

DIGITAL SYNCHRO button, RECORD button and REC MUTE button

Adjust until RF jitter is minimal or that the eye pattern of the RF waveform is most open.

[Procedure]

(1) Press the DIGITAL SYNCHRO button in Stop mode.

Note: Make sure the unit is in Stop mode.

(2) Check that "48" appears on the FL display.

(3) Press the AUTO/MANUAL button so that "04 34" appears on the FL display.

(4) Press the FINALIZE button for focus-in.

(5) Press the PLAY button for CAV-servo spindle kick.

(6) Press the PAUSE button to close the tracking servo, then set the unit to Playback mode.

(7) Adjust with the RECORD and REC MUTE buttons until the above adjustment value to be reached is obtained.

Press the SET button to register the adjustment. Once the adjustment is registered with the SET button, "?" on the FL display will

disappear.

(8) Press the STOP button to stop the unit.

RF

VC

10 : 1

10:1 probe

Jitter Meter

or

Oscilloscope

Note: Adjustment must be done around mid-radius on a disc.

58

Page 59

CDR-850

7. GENERAL INFORMATION

7.1 PARTS

7.1.1 IC

• The information shown in the list is basic information and may not correspond exactly to that shown in the schematic diagrams.

List of IC

•

NJM2136M, MC34072D, AK8563, BA7082F, AD1893JST, BA5912AFP-Y, BA5932FP, CXD2585Q,

TK11041M-1, S-806E, PE8001A, PE5056A, PE5073A, PDJ014A

NJM2136M (SERVO DIGITAL ASSY : IC101)

• Operational Amplifier

Block Diagram

•

BAL

–INPUT

+INPUT

V–

1

2

3

4

8

BAL

7

V+

6

OUTPUT

5

NC

MC34072D (SERVO DIGITAL ASSY : IC102)

• Operational Amplifier

Pin Assignment

•

Output 1

Input 1

Input 1

V

EE

Block Diagram

•

1

2

3

4

8

V

7

Output 2

6

Input 2

5

Input 2

CC

V

CC

Inputs

Q1 Q3

Bias

–

+

Q2

Base

Current

Cancellation

R1

Q8 Q9

D1

R3

Q4 Q5 Q6 Q7 Q17

R2

C1

Q10 Q11

Q14

Q13

Q12

R4

R5

C2

D2

R6 R7

D3

Q16

Q15

Q18

Output

R8

Q19

Current

Limit

VEE/GND

59

Page 60

CDR-850

AK8563 (SERVO DIGITAL ASSY : IC103)

• RF Processor IC

Pin Assignment (Top view)

•

AVSS160NC(VSS)59WRF58OSTCC57SLLPFN56SLLPFP55TESTEQRFP

AVDD1 61

RECDIN 62

RRF 63

MPXOUT 64

AUX1 65

AUX2 66

AUX3 67

GIN 68

HIN 69

EIN 70

FIN 71

HAVC 72

DIN 73

CIN 74

BIN 75

AIN 76

RREF 77

VRDCN 78

VRDC 79

AVSS3 80 DVDD21

54

53

TESTEQRFN

PHO52BHO51AGND250AGC3C49AGC2C48AGC1C47ATFM46TESTAGC

45

AGCON44WLDON43XRST42AVDD2

41

AVSS240

WFPDSH39

RFPDSH38

WBLSH37

SPDSH36

MPDSH35

SLHOLD34

GAINUP133

GAINUP232

GAINUP331

XDECEFM30

DECEFM29

RZC28

RECD127

RECD226

TZC25

XTAND24

XTOR23

ATFG22

60

1

AVDD3

2

FPDIN

3

FVREF

4

FPDO

5

WREF

6

VWDC

7

8

VWDCN

9TE10FE11

MPP

TEIN

12

13

BIAS

14

VREF

AGND1

15

16

NC(VSS)

17

XLAT

18

SCLK

SDATA

19

MCLK

20

DVSS

Page 61

Block Diagram

•

CDR-850

HAVC

MPDSH

AIN

BIN

CIN

DIN

SPDSH

EIN

FIN

GIN

HIN

WBLSH

GAINUP1

WRF

58

72

35

76

75

74

73

36

70

71

68

69

37

33

SH

MATRIX

SRFO

SPPO

SADBC

RFOM

SLHOLD56SLLPFN55SLLPFP62RECDIN

DECEFM

XDECEFM63RRF28RZC27RECD126RECD257OSTCC53TESTEQRFN

34

29

30

RFO

FEO

MPP

ADO

BCO

WRF

RF_EQUALIZER

TESTEQRF

RRF

TESTEQRFP11FE10TE

MPP

54

8

FOCUS &

TRACK

ATIP

RRF

FE

TE

ATFM

VRDC

VWDC

P/H & B/H

MPX

TEIN

9

25

TZC

24

XTAND

23

XTOR

44

AGCON

32

GAINUP2

31

GAINUP3

46

ATFM

22

ATFG

47

AGC1C

48

AGC2C

49

AGC3C

52

PH0

51

BH0

65

AUX1

66

AUX2

67

AUX3

64

MPXOUT

WLDON

RFPDSH

WFPDSH

FPDO

FPDIN

FVREF

80

1

AVDD3

VREF

20

21

DVDD

AVSS3

15

DVSS

NC(VSS)

59

NC(VSS)

17

SDATA

18

REGVREF

16

42

SCLK

XLAT

XRST

43

38

39

4

2

3

78

79

VRDCN

APC

77

RREF

VRDC

7

6

VWDC

VWDCN

5

WREF

14

VREF

13

12

BIAS

AGND150AGND2

61

19

45

MCLK

TESTAGC

41

60

AVSS1

AVDD1

40

AVSS2

AVDD2

61

Page 62

CDR-850

Pin Function

•

.oNemaNniPO/InoitcnuF.oNemaNniPO/InoitcnuF

13DDVAI nipylppusrewopevitisopgolanA142DDVAI nipylppusrewopevitisopgolanA

2NIDPFI nipnoitcennocedoidrotinomresaL24TSRXI retsigerehtezilaitinI:"L"teserretsigeR

3FERVFI CPAroftupniegatlovecnerefeR34NODLWI

40DPFO/I

5FERWI CPAetirWroftupniegatlovgnittesrewoP54CGATSETOniptseT

6CDWVO etirWroftuptuolortnocrevirdresaL64MFTAO tuptuolangiselbboW

7NCDWVI etirWrof)–(.pmalortnocrevirdresaL74C1CGAO

8PPMO tuptuolangisllup-hsupniaM84C2CGAO

9NIETI ssecorplangisgnikcartroftupnI94C3CGAO

01ETO tuptuolangisrorregnikcarT052DNGAO egatlovecnereferlanretnirofnipgnilpuoceD

11EFO tuptuolangisrorresucoF150HBO langisFRRfotuptuolevel-mottoB

21SAIBO k7.4=SAIBR.rotsisersaibatcennoC Ω 250HPO langisFRRfotuptuolevel-kaeP

311DNGAO egatlovecnereferlanretnirofnipgnilpuoceD35NFRQETSETOniptseT

41FERVO/I

51)SSV(CN − SSVottcennoC55PFPLLSI ecilsotuarof)+(tupniFPL

61TALXI gnittesretsigerroftupnihctaL65NFPLLSI ecilsotuarof)–(tupniFPL

71ATADSI gnittesretsigerroftupniataD75CCTSOO

81KLCSI gnittesretsigerroftupnikcolC85FRWO tuptuolangisFRetirW

91KLCMI )zHM4475.43(tupnikcolcniaM95)SSV(CN − SSVottcennoC

02SSVDI nipdnuorglatigiD061SSVAO nipdnuorggolanA

12DDVDI nipylppusrewopevitisoplatigiD161DDVAI nipylppusrewopevitisopgolanA

22GFTAO

32ROTXO tuptuonoitcetededutilpmagnikcarT36FRRO tuptuolangisFRdaeR

42DNATXO tuptuonoitcetedrorregnikcarT46TUOXPMO rotinomlangisroftuptuorexelpitluM

52CZTO tuptuolangisnoitcetedssorc-orezgnikcarT561XUAI rotinomlangisrof)1(tupniyrailixuA

622DCERO

721DCERO

82CZRO tuptuolangisnoitcetedssorc-orezFR86NIGI tupni)G(langismaebediS

92MFECEDO )noisrevni(decilsretfatuptuoMFE96NIHI tupni)H(langismaebediS

03MFECEDXO )esahp-evitisop(decilsretfatuptuoMFE07NIEI tupni)E(langismaebediS

133PUNIAGI

232PUNIAGI 27CVAHI slangismaebedisdnaniamfotupniegatlovretneC

331PUNIAGI 37NIDI tupni)D(langismaebniaM

43DLOHLSI dloH:"H"tupnilangisdlohlevelecilS47NICI tupni)C(langismaebniaM

53HSDPMI

63HSDPSI

73HSLBWI

83HSDPFRI

93HSDPFWI

042SSVAI nipdnuorggolanA083SSVAI nipdnuorggolanA

)noisrevnoc

tupniegatlovrotinomresaL

tupniegatlovecnerefeR

2langisnoitcetedkcolbgnidroceR

1langisnoitcetedkcolbgnidroceR

tupnilortnocgnihctiwsBd81+dna0

Bd0:"L",Bd81+:"H"

maeb-niamroftupnieslupelpmaS

dloH:"L",elpmaS:"H"

maeb-edisroftupnieslupelpmaS

dloH:"L",elpmaS:"H"

dloH:"L",elpmaS:"H"

CPAdaeRroftupnieslupelpmaS

dloH:"L",elpmaS:"H"

CPAetirWroftupnieslupelpmaS

dloH:"L",elpmaS:"H"

V/Irofrotsiseratcennoc(tuptuorotinomresaL

/))2nip(NIDPFdnanipsihtneewtebnoisrevnoc

44NOCGAI

/egatlovecnereferlanretnirofnipgnilpuoceD

kcolbgnidrocernU:"L",kcolbgnidroceR:"H"

kcolbgnidrocernU:"L",kcolbgnidroceR:"H"

langiselbboWroftupnieslupelpmaS

45PFRQETSETOniptseT

atadyranibehtretfalangiselbboW(tuptuoGFPITA

26NIDCERI noitcetedkcolbgnidrocerroftupniFR

662XUAI rotinomlangisrof)2(tupniyrailixuA

763XUAI rotinomlangisrof)3(tupniyrailixuA

17NIFI tupni)F(langismaebediS

57NIBI tupni)B(langismaebniaM

67NIAI tupni)A(langismaebniaM

77FERRI CPAdaeRroftupniegatlovgnittesrewoP

87NCDRVI daeRrof)–(.pmalortnocrevirdresaL

97CDRVO daeRroftuptuolortnocrevirdresaL

tupnilortnocDLetirW

NODL:"H",orezoteulav-tesCPAetirWteS:"L"

tupnielbaneCGAelbboW

teserCGA:"L",NOCGA:"H"

esnopserCGArofnipnoitcennocroticapaclanretxE

gnittesdeeps

rezilauqefognittescfrofnipnoitcennocroticapaC

rellecnac-tesffotuptuo

62

Page 63

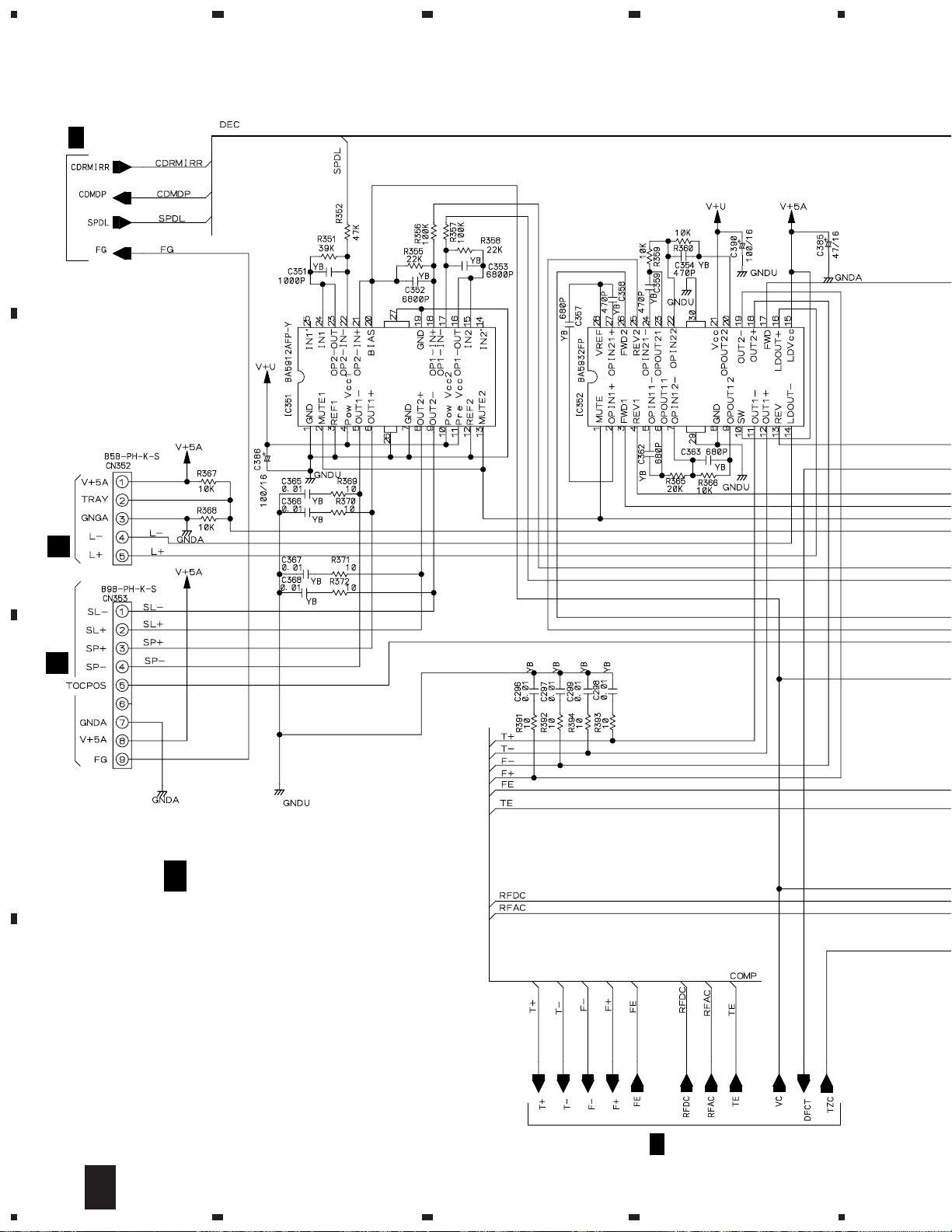

BA7082F (SERVO DIGITAL ASSY : IC302)

• VCO IC

Block Diagram

•

IN1

16

IN2

15

VO

14

VCTL

13

CT1

12

CT2

11

VCC

10

CDR-850

F

ADJ

9

VCO

SW

Pin Function

•

1

SW1

2

SW2

3

SW3

BW

4

5

BWB

6

1/2FB

7

FOUT

.oNemaNniPO/InoitcnuF.oNemaNniPO/InoitcnuF

11WS

22WS01CCV

33WS112TC

O

tnemtsujda

4WB

5BWB31LTCVI

I

tnemtsujda

tuptuoneporotcelloC

ytilibisneslortnocroftuptuokcolbcigoL

ytilibisneslortnocroftupnikcolbcigoL

9JDAF

211TC

−

−

−

nipCCV

ytilibisneslortnocroftupnikcolbcigoL

6BF2/1I

reilpitlumedycneuqerf2/1dnatnemtsujda

ycneuqerf2/1:L,hguorht:Hhctiws

410VO tnemtsujdaytilibisnesroftuptuo.pmA

tuptuoreilpitlumed

7TUOFO niptuptuoOCV512NI

8DNG

−

nipDNG611NI

I

1/2

8

GND

niptsujdA0f

noitallicsoOCVrofnipnoitcennocroticapaC

-trohsrofesu,yllamroNniplortnocOCV

.)41nip(OVhtiwtiucric

tnemtsujdaytilibisnesroftupni.pmA

tupnignitrevnI:2NItupniesahp-evitisop:1NI

AD1893JST (SERVO DIGITAL ASSY : IC311)

• Sample Rate Converter IC

Block Diagram

•

NC43DATA_I42XTAL_I41NC40XTAL_O39NC38SETSLW

44

1

NC

BCLK_I

WCLK_I

LR_I

NC

VDO

GND

NC

BKPOL_I

MODE0_I

NC

2

3

4

5

6

7

8

9

10

11

12

NC

SERIAL IN

FIFO COEF ROM

13

14

15NC16

RESET

MODE1_I

SERIAL OUT

ACCUM

MULT

CLOCK

TRACKING

17NC18

GND

37NC36

19NC20

MUTE_I

PWRDWN

BCLK_O34NC

35

21

22

NC

MUTE_O

MODE1_O

33

NC

32

WCLK_O

31

LR_O

30

DATA_O

29

NC

28

VDO

27

GND

26

NC

25

BKPOL_O

24

MODE0_O

23

NC

63

Page 64

CDR-850

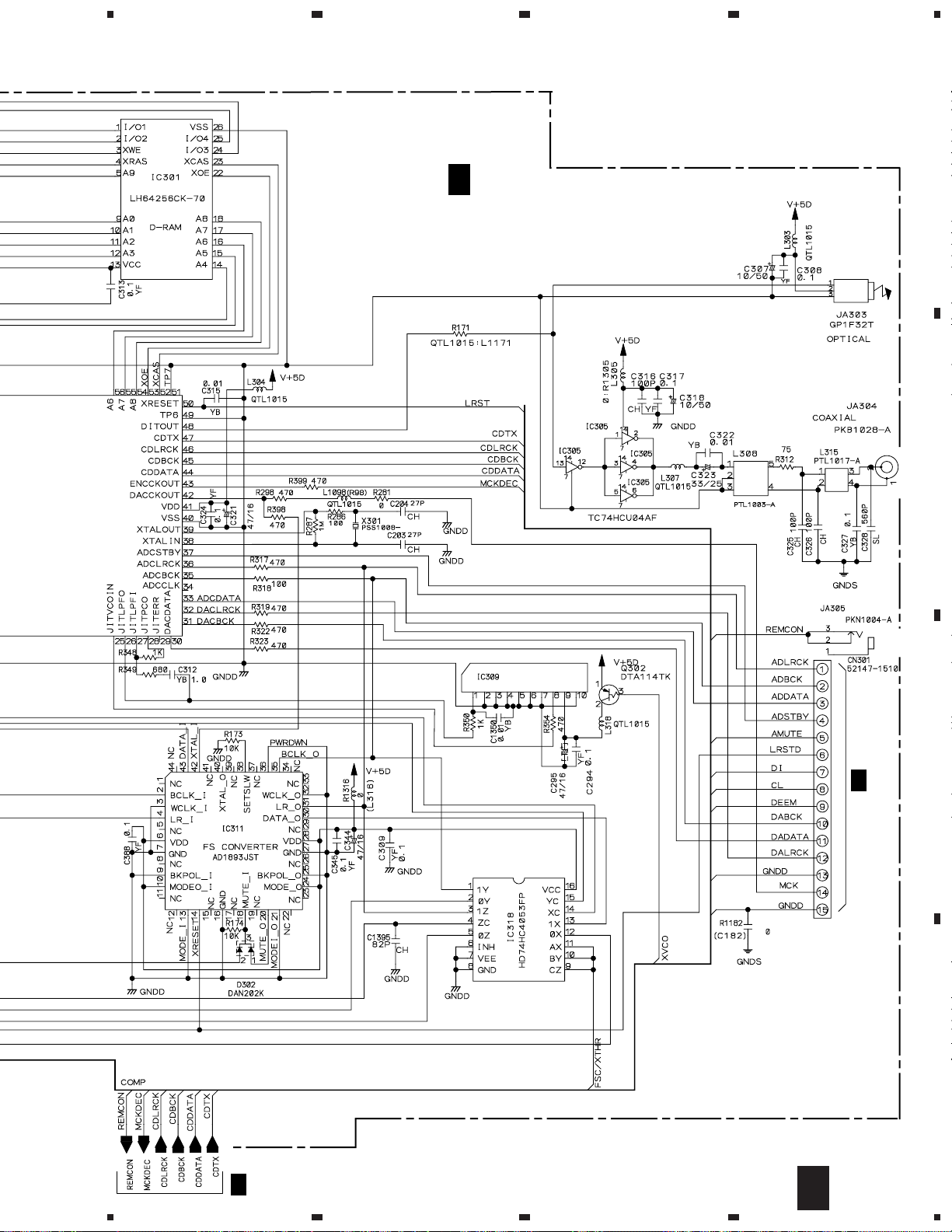

BA5912AFP-Y (SERVO DIGITAL ASSY : IC351)

• Driver IC

Block Diagram

•

IN1'24IN123OP2-OUT22OP2-IN–21OP2-IN+20BIAS

25

10kΩ

10kΩ

LEVEL

SHIFT

Vref1 Vref1 Vref2 Vref2

REF1

1

MUTE

GND

SWITCH

CH1

2

MUTE1

10kΩ

10kΩ 10kΩ

3

4

5

6

REF1

OUT1–

Pow Vcc1

T.S.D.

10kΩ 10kΩ

10kΩ 10kΩ

7

OUT1+

GND18OP1-IN+17OP1-IN–16OP1-OUT15IN214IN2'

19

LEVEL

SHIFT

SWITCH

11

Pre Vcc

Pow Vcc2

GND

8

OUT2+

10kΩ

9

OUT2–

10

REF2

12

10kΩ

10kΩ

CH2

MUTE

REF2

13

MUTE2

Pin Function

•

.oNemaNniPnoitcnuF.oNemaNniPnoitcnuF

1DNGDNGthgiarts-buS41'2NItnemtsujdaniagrofniptupni2HC

21ETUMnipetum1HC512NItupnidexifniag2HC

31FERnipgnihctiwsferV1HC61TUO-1POtuptuo1.pmaPO

41ccVwoP)1HC(ccVwoP71–NI-1POtupni–1.pmaPO

5–1TUOtuptuoevitagen1HC81+NI-1POtupni+1.pmaPO

6+1TUOtuptuoevitisop1HC91DNGDNGthgiarts-buS

7DNGDNGthgiarts-buS02SAIBtupnisaiB

8+2TUOtuptuoevitisop2HC12+NI-2POtupni+2.pmaPO

9–2TUOtuptuoevitagen2HC22–NI-2POtupni–2.pmaPO

012ccVwoP)2HC(ccVwoP32TUO-2POtuptuo2.pmaPO

11ccVerPccVerP421NItupnidexifniag1HC

212FERnipgnihctiwsferV2HC52'1NItnemtsujdaniagrofniptupni1HC

312ETUMnipetum2HC

64

Page 65

BA5932FP (SERVO DIGITAL ASSY : IC352)

• Driver IC

Block Diagram

•

CDR-850

VREF27OPIN21+26FWD225REV224OPIN21–23OPOUT2122OPIN22

28

4

REV1

10kΩ

10kΩ

10kΩ

10kΩ

5

OPIN11–

6

OPOUT11

7

OPIN12–

10kΩ 10kΩ

2

OPIN11+

10kΩ 10kΩ

3

FWD1

Driver⋅Mute

1

MUTE

Pin Function

•

.oNemaNniPnoitcnuF.oNemaNniPnoitcnuF

1ETUMnipetuM51ccVDLnoitcesegdirbHtuptuodnagnidaolrofccV

2+11NIPOtupnignitrevni-non.pmaPO61+TUODLtuptuoevitisopgnidaoL

31DWFtupnidrawroF71DWFtupnidrawrofgnidaoL

41VERtupniesreveR81+2TUOtuptuorevirD

5–11NIPOtupnignitrevni.pmaPO91–2TUOtuptuorevirD

611TUOPOtuptuo.pmaPO0222TUOPOtuptuo.pmaPO

7–21NIPOtupnignitrevni.pmaPO12ccVnoitceserpgnidaoldnarevirdsexaowtrofccV

8DNGDNGthgiarts-buS2222NIPOtupnignitrevni.pmaPO

921TUOPOtuptuo.pmaPO3212TUOPOtuptuo.pmaPO

01WStupnihctiwsgolanA42–12NIPOtupnignitrevni.pmaPO

11–1TUOtuptuorevirD522VERtupniesreveR

21+1TUOtuptuorevirD622DWFtupnidrawroF

31VERtupniesrevergnidaoL72+12NIPOtupnignitrevni-non.pmaPO

41–TUODLtuptuoevitagengnidaoL82FERVtuptuoegatlovecnerefeR

VCC20OPOUT2219OUT2–18OUT2+17FWD16LDOUT+15LDVCC

21

Vcc

Vcc

8

GND

× 1

10kΩ

10kΩ

9SW10

OPOUT12

TSO

Analog⋅Switch

× 1

× 1

11

OUT1–

× 1

12

OUT1+

LOADING

Vcc

FWD OUT

LOADING

REV OUT

13

14

REV

LDOUT–

65

Page 66

CDR-850

CXD2585Q (SERVO DIGITAL ASSY : IC353)

• Digital Signal Processor IC

Pin Assignment (Top view)

•

1

DD

FILI

PCO

AV

BIAS

VCTL

V16M

VPCO

53

54

55

56

57

58

59

60

FILO

52

1

SS

AV

CLTV

51

50

ASYI

RFAC

49

ASYO

48

0

0

SS

DD

TE

RFDC

ADIO

AV

IGEN

AV

41

42CE43

44

45

46

47

DVDD2

ASYE

MD2

DOUT

LRCK

PCMD

BCK

EMPH

XTSL

DVSS2

XTAI

XTAO

SOUT

SOCK

XOLT

SQSO

SQCK

SCSY

SBSO

EXCK

61

62

63

64

65

66

67

68

69

70

71

72

73

74

75

76

77

78

79

80

1

2

3

4

5

6

7

8

10

11

12

13

14

15

16

17

18

19

0

DD

DV

XRST

MUTE

XLAT

DATA

CLOK

SENS

SCLK9ATSK

WFCK

XPCK

XUGF

GFS

C2PO

SCOR

C4M

0

SS

DV

WDCK

20

MIRR

COUT

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

SE

FE

VC

TES1

TEST

DVSS1

FRDR

FFDR

TRDR

TFDR

SRDR

SFDR

DVDD1

FSTO

SSTP

MDP

LOCK

PWMI

FOK

DFCT

66

Page 67

Block Diagram

•

FSTO

C4M

RFAC

ASYI

ASYO

ASYE

BIAS

CDR-850

XTAI72XTAO60VPCO

XTSL58VCTL

V16M

71

69

59

27

16

50

49

48

62

57

Clock

Generator

Asymmetry

Corrector

XUGF13GFS68EMPH

11

10

EFM

Demodulator

WFCK

Corrector

Error

32k

RAM

WDCK14C2PO65LRCK

17

D/A

Interface

PCMD66BCK

3

67

MUTE

37

36

2

TES1

TEST

XRST

XPCK

FILO

FILI

PCO

CLTV

MDP

LOCK

PWMI

SENS

DATA

XLAT

CLOK

SCOR

SBSO

EXCK

SCSY

SQSO

SQCK

RFDC

CE

TE

SE

FE

VC

IGEN

12

53

54

55

52

25

24

23

7

4

5

6

15

79

80

78

76

77

Digital