Pioneer CDJ-900 Service manual

2009

CDJ-900

For details, refer to "Important Check Points for good servicing".

MULTI PLAYER

CDJ-900

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

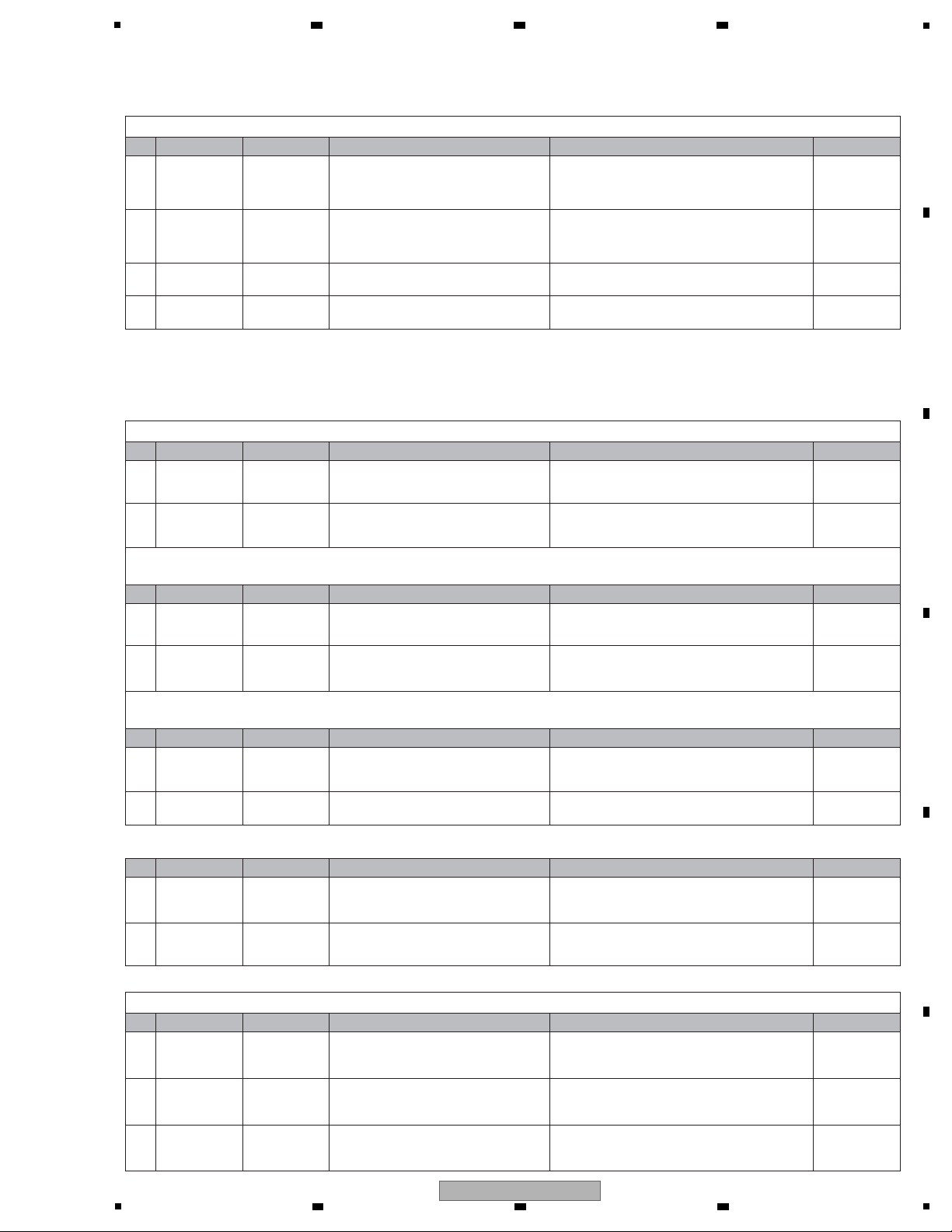

Model Type Power Requirement Remarks

CDJ-900 CUXJ AC 120 V

CDJ-900 SYXJ8 AC 220 V to 240 V

CDJ-900 FLXJ AC 110 V to 240 V

CDJ-900 KXJ5 AC 220 V to 240 V

CDJ-900 AXJ5 AC 220 V

ORDER NO.

RRV4000

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZE OCT.

2009 Printed in Japan

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S8902) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not in

LPS1 terminal side (when the mechanism is not clamped and

LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side.

( if LPS1 signal is low level ).

In the test mode ∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 5 of AN22022A

(IC7004) on the SRV Assy is connected to GND, or else the

terminals of Q7002 are shorted to each other (fault condition).

2. When the cover is opened, close viewing of the objective lens

with the naked eye will cause exposure to a Class 1 laser beam.

IMPORTANT

THIS PION EER APPARATUS CON TA IN S

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DON E BY A SPECIALLY

INSTRUCTED PERSON.

For CD Wave length (typ) : 790 nm

Operation output : 4 mW CW, Class 1

Maximum output : Class 1 (Under fault condition)

Laser Pickup specifications and Laser characteristics

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

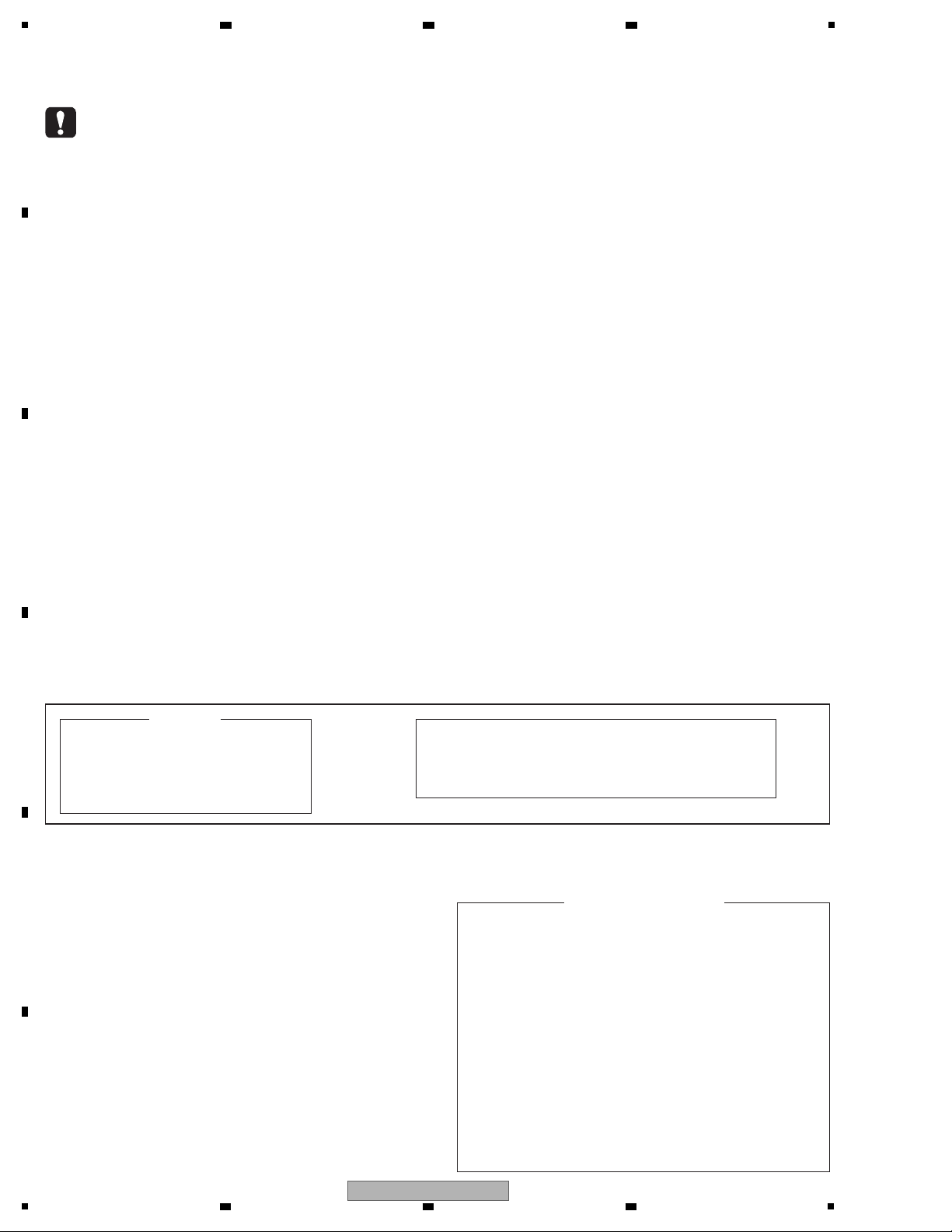

CDJ-900

LABEL CHECK

(Printed on the bottom plate)

CUXJ

(Printed on the bottom plate)

FLXJ

(Printed on the bottom plate)

SYXJ8

(Printed on the bottom plate)

KXJ5

(Printed on the bottom plate)

AXJ5

5

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

3

1

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

A

2 3 4

B

C

D

E

F

4

1

CDJ-900

2 3 4

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS ....................................................................................................................................................6

1.1 NOTES ON SOLDERING............................................................................................................................................... 6

1.2 NOTES ON FLASH ROM ...............................................................................................................................................6

1.3 NOTES ON PANEL CPU AND GUI CPU........................................................................................................................ 6

1.4 NOTES ON LINK CONNECTOR .................................................................................................................................... 7

1.5 REPAIR OF THE JACB ASSY........................................................................................................................................7

2. SPECIFICATIONS .................................................................................................................................................................8

2.1 SPECIFICATIONS .......................................................................................................................................................... 8

2.2 DISCS / FILES PLAYABLE.............................................................................................................................................9

2.3 PANEL FACILITIES....................................................................................................................................................... 11

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................14

3.1 CHECK POINTS AFTER SERVICING .........................................................................................................................14

3.2 PCB LOCATIONS ......................................................................................................................................................... 15

3.3 JIGS LIST .....................................................................................................................................................................17

4. BLOCK DIAGRAM ..............................................................................................................................................................18

4.1 OVERALL WIRING DIAGRAM .....................................................................................................................................18

4.2 SIGNAL BLOCK DIAGRAM.......................................................................................................................................... 20

4.3 POWER SUPPLY BLOCK DIAGRAM........................................................................................................................... 22

5. DIAGNOSIS ........................................................................................................................................................................ 24

5.1 POWER ON SEQUENCE.............................................................................................................................................24

5.2 TROUBLESHOOTING.................................................................................................................................................. 26

5.3 FAILURE JUDGEMENT OF THE PICKUP ASSY ........................................................................................................ 39

5.4 CONNECTION CHECK WITH THE PC........................................................................................................................ 40

6. SERVICE MODE................................................................................................................................................................. 41

6.1 OUTLINE OF THE SERVICE MODE............................................................................................................................41

6.2 ABOUT THE DEVICE OF CDJ-900..............................................................................................................................41

6.3 DETAILS ON SERVICE MODE .................................................................................................................................... 42

7. DISASSEMBLY ................................................................................................................................................................... 55

EACH SETTING AND ADJUSTMENT................................................................................................................................ 66

8.

8.1 JOG DIAL ROTATION LOAD ADJUSTMENT ............................................................................................................... 66

8.2 ITEMS FOR WHITCH USERS SETTING IS AVAILABLE............................................................................................. 67

8.3 UPDATING OF THE FIRMWARE AND RECOVERY.................................................................................................... 67

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................68

9.1 PACKING SECTION ..................................................................................................................................................... 68

9.2 EXTERIOR SECTION .................................................................................................................................................. 70

9.3 CONTROL PANEL SECTION ....................................................................................................................................... 72

9.4 JOG DIAL SECTION .................................................................................................................................................... 74

9.5 SLOTIN MECHA SECTION.......................................................................................................................................... 76

10. SCHEMATIC DIAGRAM .................................................................................................................................................... 78

10.1 SRV ASSY (1/2).......................................................................................................................................................... 78

10.2 SRV ASSY (2/2) and SLMB ASSY .............................................................................................................................80

10.3 MAIN ASSY (1/3)........................................................................................................................................................82

10.4 MAIN ASSY (2/3)........................................................................................................................................................88

10.5 MAIN ASSY (3/3) and USBA ASSY ........................................................................................................................... 94

10.6 JACB ASSY ................................................................................................................................................................ 96

10.7 DFLB and ENCB ASSYS............................................................................................................................................98

10.8 KSWB ASSY............................................................................................................................................................. 100

10.9 SLDB ASSY.................................................................................................................

10.10 BFLB

ASSY ............................................................................................................................................................104

10.11 MSWB ASSY ..........................................................................................................................................................106

10.12 JOGB ASSY ...........................................................................................................................................................107

10.13 JFLB ASSY............................................................................................................................................................. 108

10.14 POWER SUPPLY and ACIN ASSYS ...................................................................................................................... 110

10.15 WAVEFORMS.........................................................................................................................................................112

11. PCB CONNECTION DIAGRAM......................................................................................................................................116

11.1 SRV and SLMB ASSYS............................................................................................................................................ 116

11.2 MAIN ASSY ..............................................................................................................................................................120

11.3 USBA and JACKB ASSYS........................................................................................................................................ 124

11.4 DFLB and ENCB ASSYS..........................................................................................................................................126

11.5 KSWB and SLDB ASSYS......................................................................................................................................... 130

11.6 BFLB and MSWB ASSYS.........................................................................................................................................134

OGB and JFLB ASSYS...........................................................................................................................................136

11.7 J

11.8 POWER SUPPLY and ACIN ASSYS ........................................................................................................................138

12. PCB PARTS LIST ............................................................................................................................................................ 140

............................................. 102

A

B

C

D

E

F

CDJ-900

5

6 7 8

5

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

NEVER replace the FLASH ROM (IC114) on the MAIN Assy during servicing.

If the FLASH ROM is assumed to be defective, replace the whole MAIN Assy.

This FLASH ROM contains data that can only be written in at the factory.

An IEEE 802.3-based MAC address specific to this unit has been written.

After the PANEL CPU (IC8005) or GUI CPU (IC4002) is replaced, update its program.

The built-in PANEL CPU and GUI CPU contains a FLASH ROM and will not operate without a program.

For updating, proceed as follows:

1. Insert the USB flash memory device that contains the program.

2. While holding the USB STOP key pressed, turn on the unit.

Hold the USB STOP key pressed until the “Pioneer” logo disappears.

3. Updating starts.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

1.2 NOTES ON FLASH ROM

D

1.3 NOTES ON PANEL CPU AND GUI CPU

E

F

6

1

2 3 4

CDJ-900

5

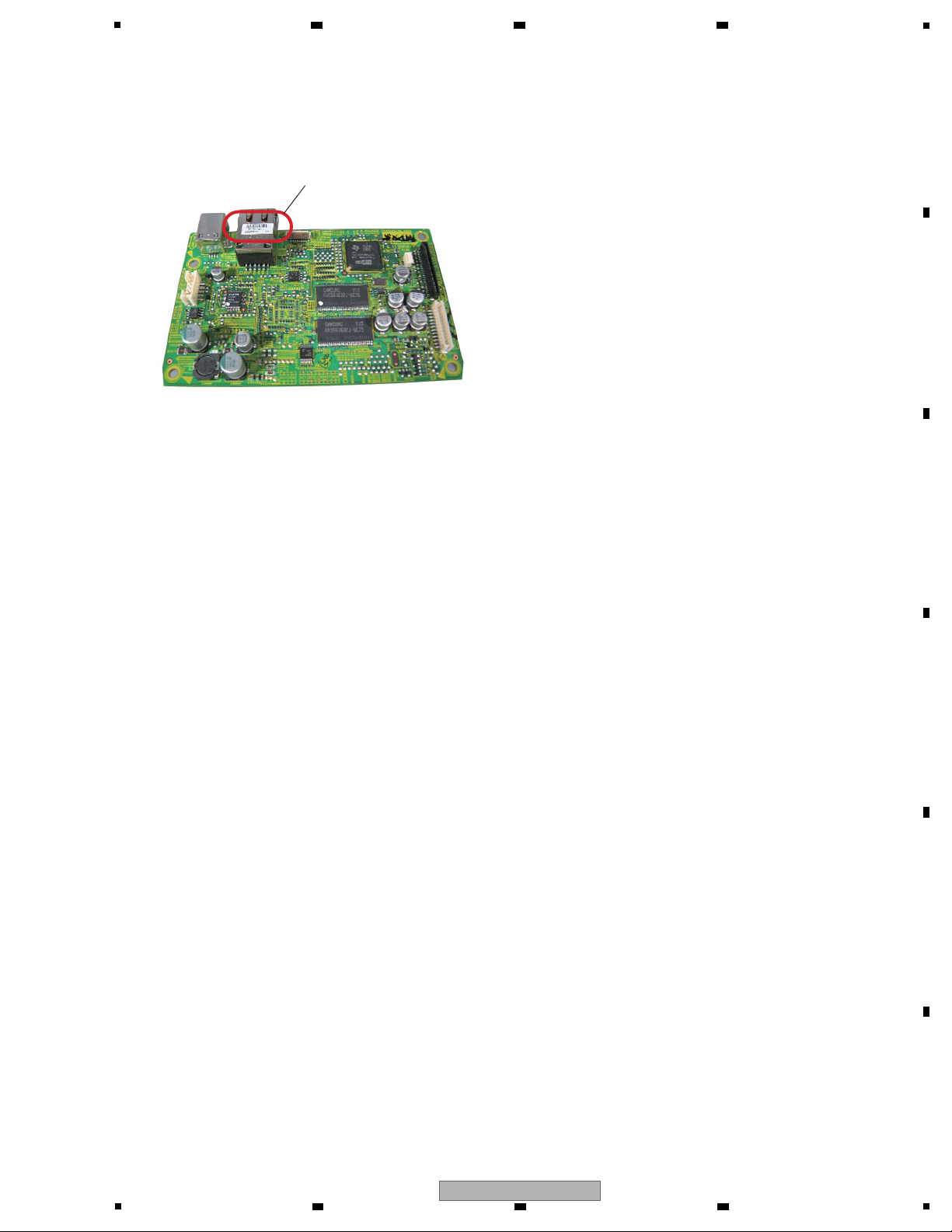

If the LINK connector (JA1301) is replaced during a repair of the MAIN Assy, detach the ID LABEL (AXW7015) from the old

connector then attach it to the new connector.

As an IEEE 802.3-based MAC address specific to this unit has been printed on the ID LABEL (AXW7015) be sure to attach it.

ID LABEL

MAIN Assy

When repairing the JACB Assy, note the following:

On part of the initial-lot JACB Assy, the DCN1186 (470 ohms, Part description No. 471) is mounted as the resistors

(R8820–8823, 8839–8844, 8855, and 8856). In such a case, mount a new DCN1186 during replacement. (See the section

10.6 JACB ASSY.)

This applies only to the initial-lot products for the destinations SYXJ8 and FLXJ.

For products for other destinations, replace with the DCN1185 (330 ohms, Part description No. 331), as described in the

circuit diagram.

6 7 8

1.4 NOTES ON LINK CONNECTOR

A

B

1.5 REPAIR OF THE JACB ASSY

C

D

E

F

CDJ-900

5

6 7 8

7

1

Power requirements.................................... AC 120 V, 60 Hz (CUXJ)

AC 220 V to 240 V, 50 Hz/60 Hz (SYXJ8, AXJ5)

AC 110 V to 240 V, 50 Hz/60 Hz (FLXJ)

AC 220 V, 60 Hz (KXJ5)

Power consumption................................................................... 26 W

Power consumption (standby).................................................. 0.4 W

Main unit weight....................................................................... 3.9 kg

External dimensions......305 mm (W) x 115.6 mm (H) x 385 mm (D)

Tolerable operating temperature...............................+5 °C to +35 °C

Tolerable operating humidity............. 5 % to 85 % (no condensation)

Analog audio output (AUDIO OUT L/ R)

Output terminal............................................................ RCA terminal

Output Level........................................................... 2.0 Vrms (1 kHz)

Frequency response.................................................. 4 Hz to 20 kHz

S/ N ratio.................................................................................115 dB

Total harmonic distortion...................................................... 0.003 %

Digital audio output (DIGITAL OUT)

Output terminal............................................................ RCA terminal

Output type................................................. Coaxial digital (S/ PDIF)

Output level............................................................... 0.5 Vp-p (75 Ω)

Output format................................................ 44.1 kHz, 24 bit/ 16 bit

USB downstream section (USB)

Port......................................................................................... Type A

Power supply...................................................... 5 V/ 500 mA or less

USB upstream section (USB)

Port......................................................................................... Type B

LAN (PRO DJ LINK)

Rating.............................................................................100Base-TX

Control output (CONTROL)

Port...................................................................................... Mini-jack

• The articles concerning free repairs, etc., indicated on the

warranty do not apply to the rekordbox music management

software. Before installing or using rekordbox, carefully read the

articles in Software end user license agreement.

• The specifications and design of this product are subject to

change without notice.

2. SPECIFICATIONS

2.1 SPECIFICATIONS

A

2 3 4

B

C

D

E

F

8

1

2 3 4

CDJ-900

5

2.2 DISCS / FILES PLAYABLE

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

9

1

A

B

2 3 4

C

D

E

F

10

1

2 3 4

CDJ-900

5

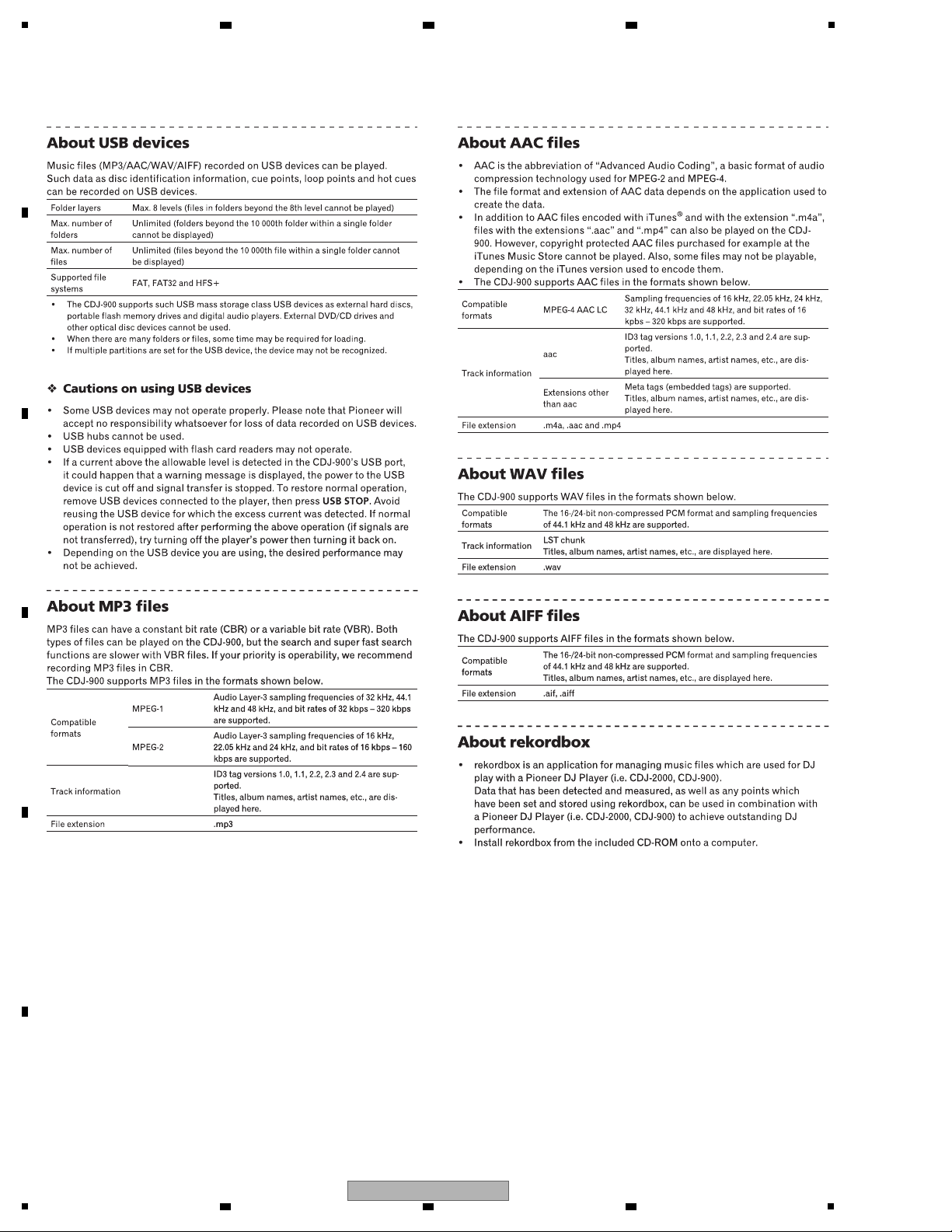

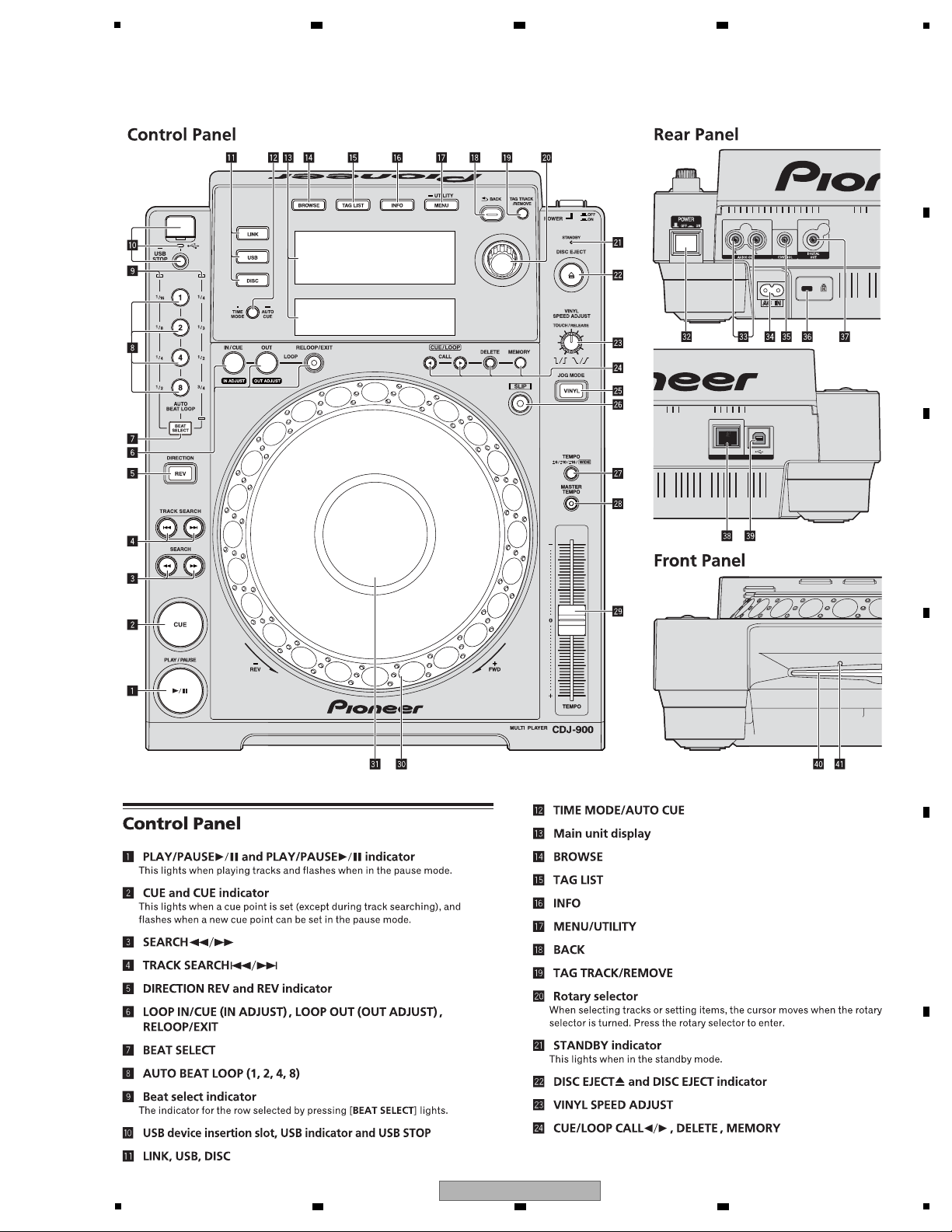

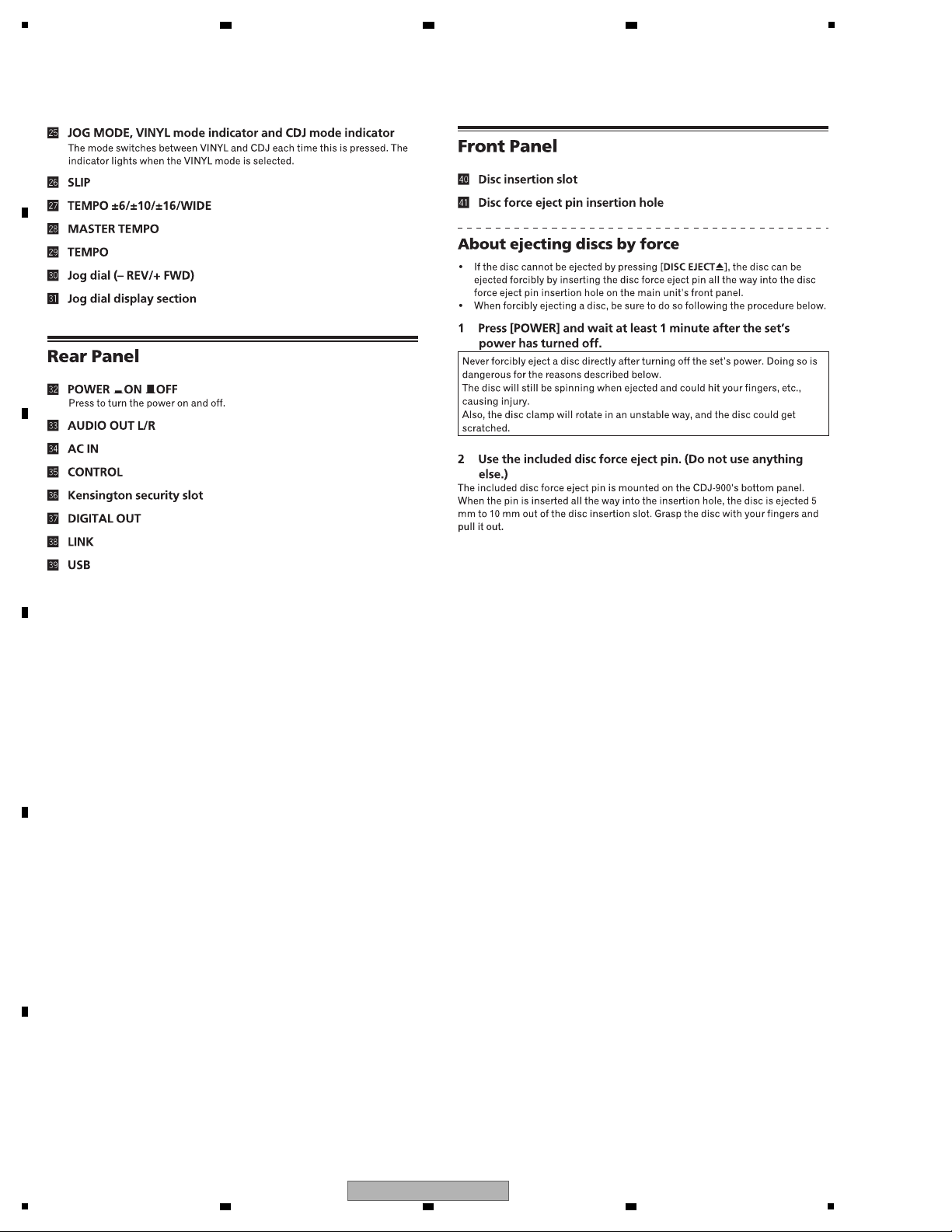

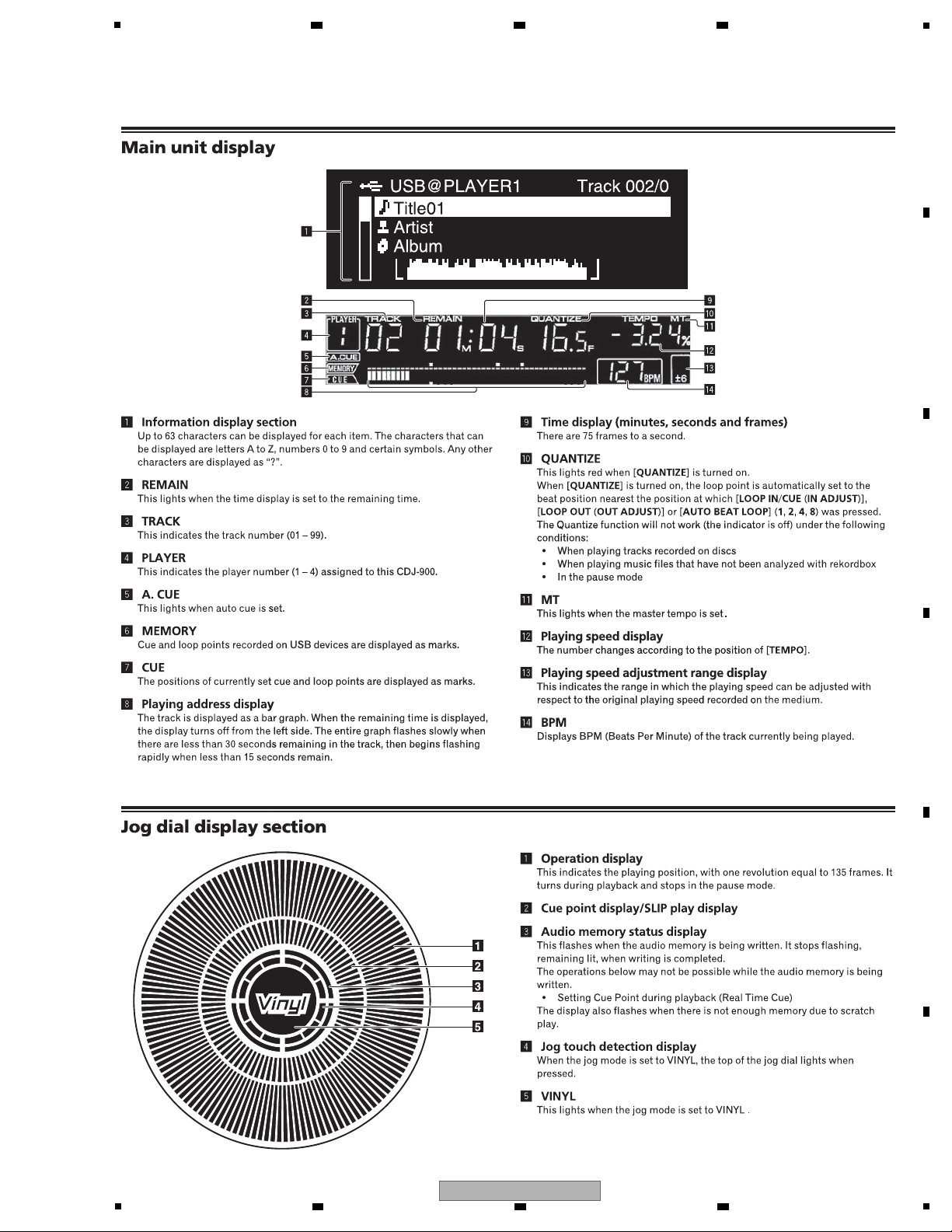

2.3 PANEL FACILITIES

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

11

1

A

B

2 3 4

C

D

E

F

12

1

2 3 4

CDJ-900

5

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

13

1

Items to be checked after servicing / CDJ

To keep the product quality after servicing, confirm recommended check points shown below.

No.

Procedures Check points

1

2

3

4

5

7

6

Confirm the firmware version on Test Mode.

The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Audio and operations must be normal.

Play back a CD. (track search) Audio, Search and operations must be normal.

Check the connection of each interface.

Play back data contained in the device connected to USB A. Audio, Search and operations must be normal.

USB B The device must be recognized by the PC.

LINK The PC must be linked.

Check output signals while the JOG dial or TEMPO slider is

being operated.

Audio and operations must be normal.

Check the appearance of the product.

No scratches or dirt on its appearance after receiving it for

service.

Check the keys on the unit.

Check whether a product can be operated properly by buttons

on the product.

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding video and audio.

Cleaning

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

NamePosition to be cleaned Part No. Remarks

Refer to “9.5 SLOTIN MECHA SECTION”.Cleaning liquidPickup lenses GEM1004

Cleaning paper GED-008

No. Procedures Check points

1

Confirm playback error rates at the innermost and outermost

tracks by using the following disc.

CD test disc (STD-905)

The error rates must be less than 3.0 × 10

-3

.

(This procedure can determine if the drive is degraded.)

Specific Items to be Checked

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

14

CDJ-900

1

2 3 4

5

1

B

SLMB ASSY

A

SRV ASSY

O

ACIN ASSY

C

MAIN

ASSY

E

JACB

ASSY

G

ENCB

ASSY

J

BFLB

ASSY

K

MSWB

ASSY

TM ASSY

SLOTIN MECHA ASSY

H

KSWB

ASSY

POWER

SUPPLY

ASSY

• Bottom view

• Bottom view

I

SLDB

ASSY

M

JFLB

ASSY

F

DFLB

ASSY

L

JOGB

ASSY

N

USBA

ASSY

D

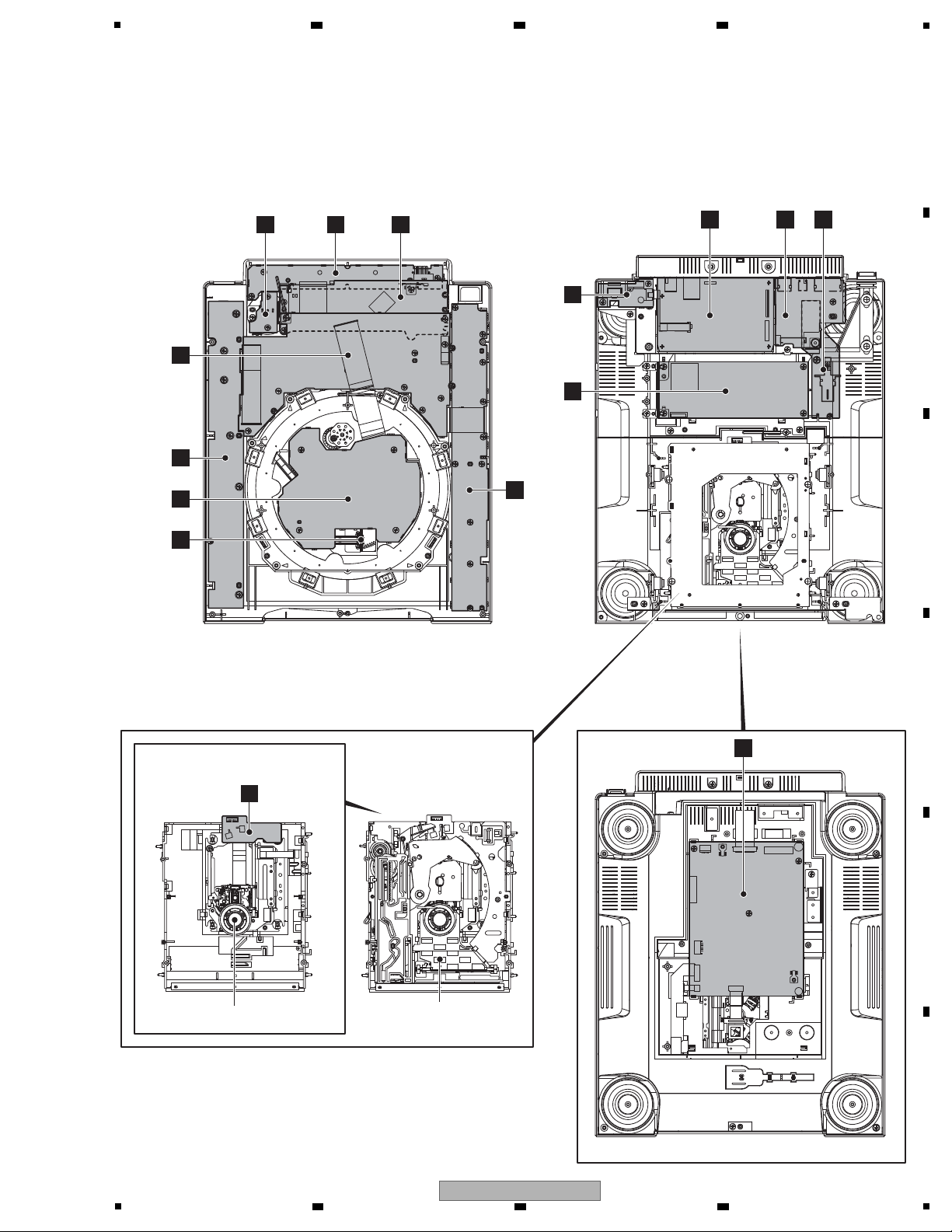

3.2 PCB LOCATIONS

6 7 8

A

B

C

D

5

CDJ-900

6 7 8

E

F

15

1

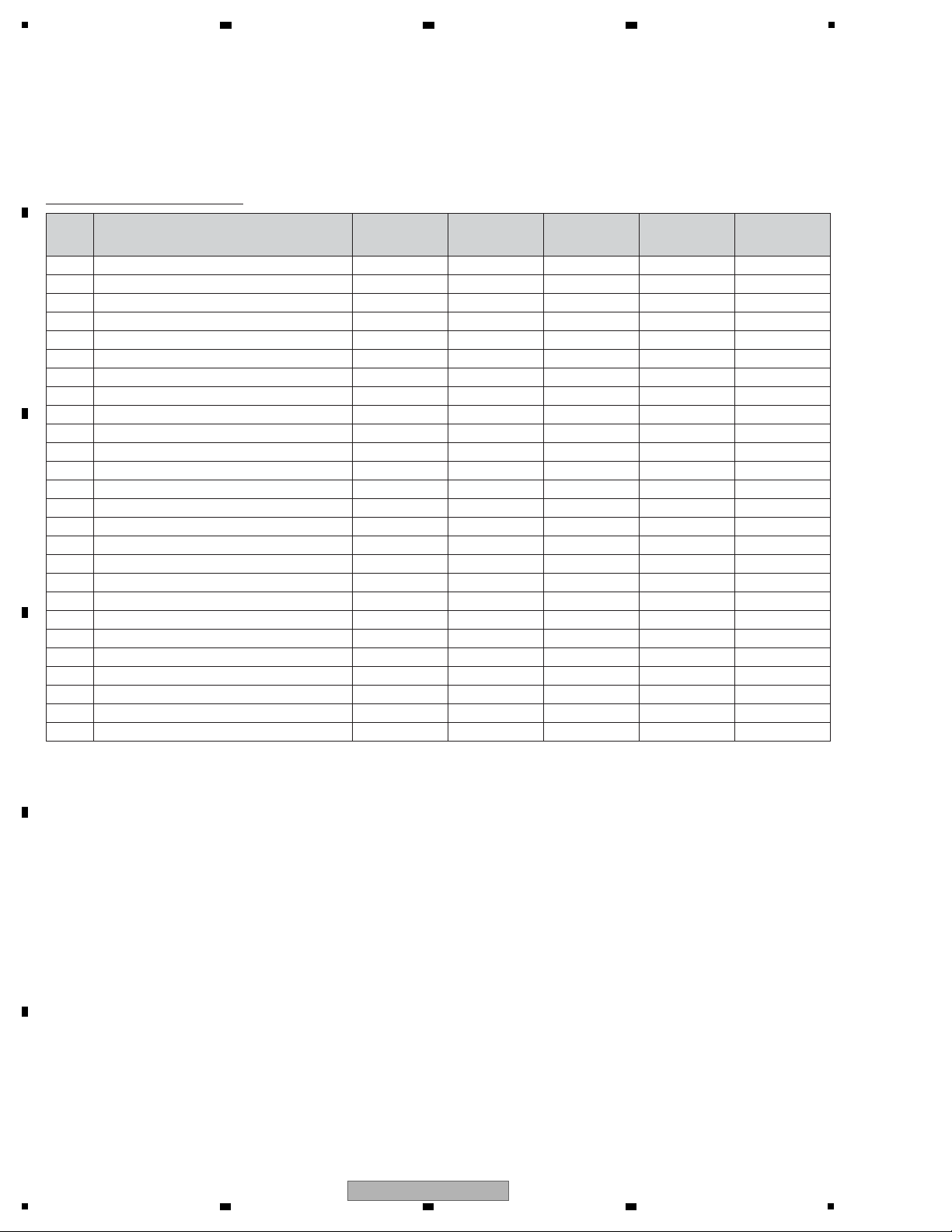

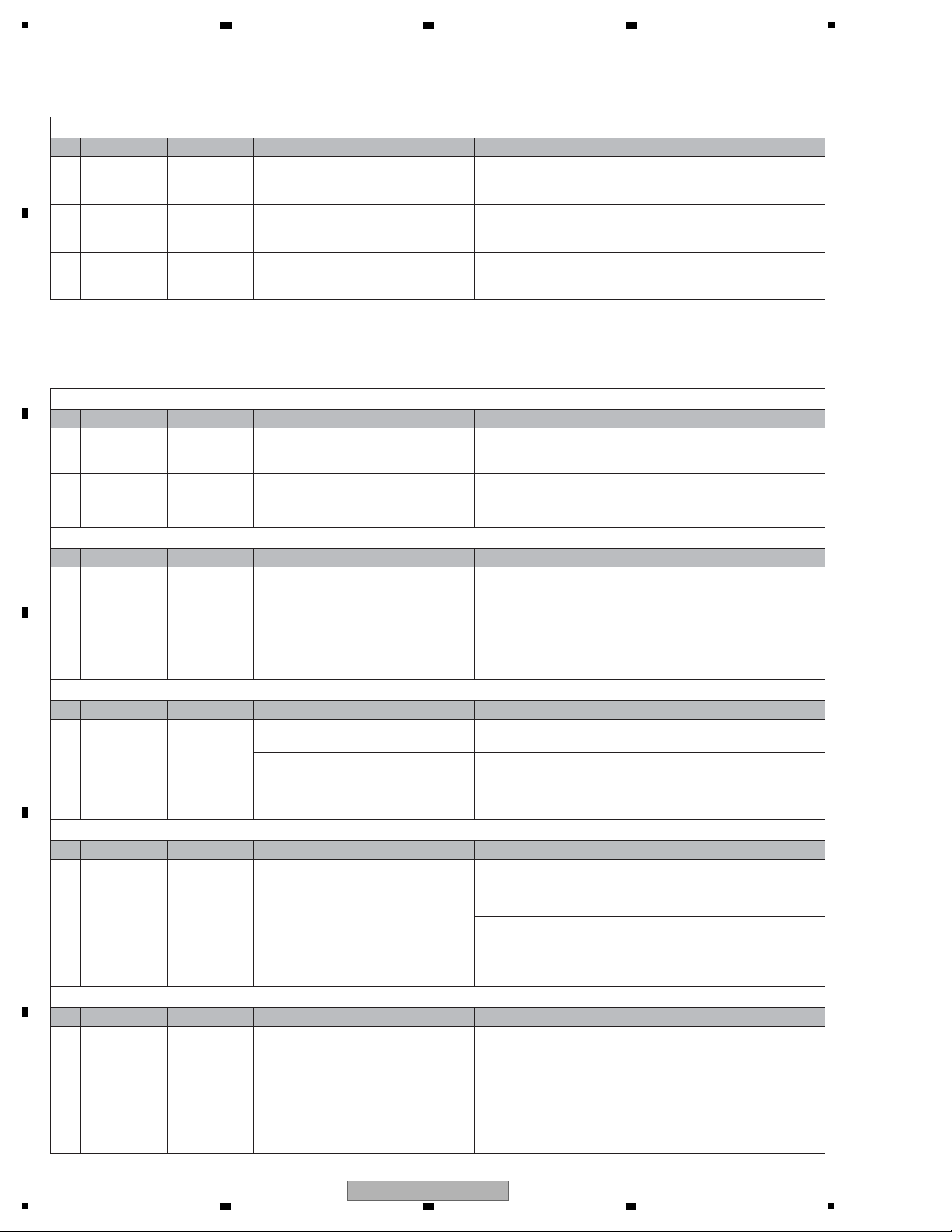

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Mark Symbol and Description

CDJ-900

/CUXJ

CDJ-900

/SYXJ8

CDJ-900

/FLXJ

CDJ-900

/KXJ5

CDJ-900

/AXJ5

NSP 1..DFLA ASSY DWM2361 DWM2361 DWM2361 DWM2361 DWM2361

2..KSWB ASSY DWS1416 DWS1416 DWS1416 DWS1416 DWS1416

NSP 1..JFLA ASSY DWM2362 DWM2356 DWM2356 DWM2356 DWM2356

1..MAIN ASSY DWX3019 DWX3019 DWX3019 DWX3019 DWX3019

1..SRV ASSY DWX3020 DWX3020 DWX3020 DWX3020 DWX3020

1..USBA ASSY DWX3044 DWX3044 DWX3044 DWX3044 DWX3044

2..ACIN ASSY DWR1461 DWR1462 DWR1462 DWR1462 DWR1462

2..MSWB ASSY DWS1415 DWS1415 DWS1415 DWS1415 DWS1415

2..JFLB ASSY DWX3024 DWX3024 DWX3024 DWX3024 DWX3024

2..BFLB ASSY DWX3025 DWX3025 DWX3025 DWX3025 DWX3025

2..JOGB ASSY DWX3026 DWX3026 DWX3026 DWX3026 DWX3026

2..SLDB ASSY DWS1417 DWS1417 DWS1417 DWS1417 DWS1417

2..SLMB ASSY DWS1418 DWS1418 DWS1418 DWS1418 DWS1418

2..DFLB ASSY DWX3021 DWX3021 DWX3021 DWX3021 DWX3021

2..ENCB ASSY DWX3022 DWX3022 DWX3022 DWX3022 DWX3022

2..JACB ASSY DWX3023 DWX3023 DWX3023 DWX3023 DWX3023

> 1..POWER SUPPLY ASSY DWR1463 DWR1463 DWR1463 DWR1463 DWR1463

NSP 1..SLOTIN MECHA ASSY DXA2121 DXA2121 DXA2121 DXA2121 DXA2121

1..TM ASSY 03-S VXX3125 VXX3125 VXX3125 VXX3125 VXX3125

A

2 3 4

B

C

D

E

F

16

CDJ-900

1

2 3 4

5

Lubricants and Glues List

Name Part No. Remarks

Dyfree GEM1036 Refer to “9.5 SLOTIN MECHA SECTION”.

Lubricating oil ZLB-HFD1600

Refer to “9.2 EXTERIOR SECTION”,

“9.4 JOG DIAL SECTION”.

Lubricating oil GYA1001

Refer to “9.4 JOG DIAL SECTION”,

“9.5 SLOTIN MECHA SECTION”.

3.3 JIGS LIST

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

17

1

N

POWER SUPPLY

ASSY (DWR1463)

SLOTIN MECHA ASSY

(DXA2121)

TM ASSY 03-S

(DXX3125)

D

SRV ASSY (DWX3020)

C

C C

1/3- 3/3

MAIN ASSY (DWX3019)

A

A A

1/2, 2/2

USBA ASSY

(DWX3044)

H

KS

(D

E

JACB ASSY

(DWX3023)

B

SLMB ASSY

(DWS1418)

G

E

(D

POWER CABLE

ADG7021: CUXJ

ADG1154: SYXJ8, FLXJ

ADG7097: FLXJ

XDG3054: KXJ5

ADG7079: AXJ5

O

-

Wh

-

The

The

-

ACIN ASSY

(DWR1461: CUXJ)

(DWR1462: SYXJ8, FLXJ, KXJ5, AXJ5)

CN 7005

JA1

CN 7301

CN 1

JA1101

JA8803

CN 7002

CN 8901

CN 7004

CN 2

JA8802

CN 7001

CN 7003

CN 7302

CN 1303

CN 2001

CN 3001

CN 501

CN 8801

JA8801

CN 8501

CN 8

CN 8001

CN 9201

JA9901

CN 9901

CN 8004

CN 1305

POWER CABLE

JA1301

XH-XH CABLE

FRTN

PD

TDRV

LD65

TRTN

FDRV

LD78

A

VRCOM

D

VR78

VR65

VREF1

H3-

GNDD

GNDA

INSIDE

7/x6

V+5D

H1-

RW/XR

H2+

F

H3+

H2-

C

GNDBGND

V+5A

EUP_CONT

GNDA

V+12

V+12

A1

V+12_EUP

H1+

A2

A3

E

GNDA

NC

VKN 1818-A

1

GNDD

2

ATA_CS1

3

ATA_CS0

4

GNDD

5

ATA_A2

6

ATA_A0

7

GNDD

8

ATA_A1

9

GNDD

10

ATA_IRQ

11

GNDD

12

ATA_DACLK

13

GNDD

14

ATA_RDY

15

GNDD

16

ATA_DIOR

17

GNDD

18

ATA_WR

19

GNDD

20

ATA_DREQ

21

GNDD

22

GNDD

23

ATA_D15

24

ATA_D0

25

ATA_D14

26

ATA_D1

27

ATA_D13

28

ATA_D2

29

ATA_D12

30

ATA_D3

31

ATA_D11

32

ATA_D4

33

ATA_D10

34

ATA_D5

35

ATA_D9

36

ATA_D6

37

ATA_D8

38

ATA_D7

39

GNDD

40

ATA_RESET

1

2

DKN1599-A

1

2

345

6

B2P3-VH

1

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

DKN1574-A

1

VBUS

2

D-

3

D+

4

GNDD

DKB1089-A

2 SPDIF

1GNDD

DKN1288-A

1

ST1-

2

ST1+

3

ST2-

4

ST2+

KM200NA5

1

2

3

4

5

AKM1291-A

1

LO-

2

LO+

3

GNDD

4

LPS1

5

LPS2

B6B-XH-A

12345

6

DSA1035-A

S1

1

2

VKB1243-A

2

CONT1

3

CONT1

1

CONT2

DKN1445-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

DKN1312-A

1

2

3

4

5

6

7

8

9

10

11

12

AKM1299-A

1

V+12_EUP

2

V+12

3

V+12

4

EUP_CONT

5

GNDD

6

V+3R3

7

V+3R3

8

GNDD

9

V+5

10

GNDD

11

V-11

12

GNDD

13

V+7R2

CKS5075-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

VKN 1430-A

1

ENV

2

FLCON_CNVSS

3

PNL_SCLK

4

FLCON_BUSY

5

PNL_RXD

6

CLK_REQ

7

PNL_BUSY

8

FLCON_RESET

9

PNL_TXD

10

PNL_CNVSS

11

GNDD

12

PNL_RESET

13

GNDD

14

GNDD

15

V+7R2

16

GNDD

17

V+12

18

V+12_EUP

19

V+12

20

GNDD

21

V+3R3

22

USB_SW

23

EUP_CONT

24

USB_LED

25

CPU_EUP_CONT

26

V+5

AKM1284-A

1

2

3

4

5

6

7

8

9

10

11

12

13

VKN 1938-A

1

V+10A

2

ROUT

3

GNDA

4

GNDA

5

LOUT

6

V-10A

7

V+REF2R5

8

MUTE

9

CONT110CONT2

11

GNDD

12

SPDIF

KM200NA12

1

2

3456789

101112

AKB7181-A

5

GNDD4GNDD

3

L_OUT

2

GNDD

1

R_OUT

KM200NA

KM20

9607S-20F

1

USB_LED

2

USB_SW

3

1KEY_SW42KEY_SW54KEY_SW

6

8KEY_SW

V+5

52492-2020

15

161718

19

20

DKB1087-A

1

V+5USB

2

D-

3

D+

4

DGND

KM200NA5L

123

4

GNDD

5

GNDD

VKN 1257-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

AKM1276-A

1

V+5USB

2

D-

3

D+

4

5

PH-PH CABLE

DKP3849L=90mm

ZWNN1007G28-9-06A

L=60mm (WHITE)

PH-PH CABLE

PF05PP-B17

L=175mm

LOADING MOTOR

LO-

03 TM.ASS'Y (VWT1225- /J)

SPINDLE MOTOR 04

(VXM1112-)

LIVE

NEUTRAL

DKP3822L=55mm

LIVE

NEUTRAL

USB CONNECTOR

(A TYPE)

USB CONNECTOR

(B TYPE)

VIOLET

ETHERNET

CONNECTOR

FFC

DDD1500SAME FACE

L=130mm

BLUE

LR

AUDIO OUT

CONTROL

DIGITAL OUT

04SD PICK UP ASS'Y R

(OWY8036- /XDP/5)

*STRIGHT TYPE

STEPPING

MOTOR

(VXM1113-)

DC MOTOR

(DXM1230-)

FFC

DDD1450SAME FACE

L=115mm

LO+

LO-

DKN1576-A

ZH-PH CABLE

DKP3838L=70mm

DDD1445-

FFC

L=320mm

REVERSE FACE

3

*RIGHT ANGLE

FRAME

GND

CHASSIS

GND

DE007VF0

L=75mm

DKP3831L=60mm

EARTH LEAD UNIT

ZWNN1007G28-8-06A

L=60mm (GRAY)

USB CABLE

DDA1040L=100mm

*RIGHT ANGLE

LO+

FPC

FFC

PH-PH CAB

PF04PP-Q1

L=175mm

FFC

DDD1501SAME FACE

L=90mm

2 3 4

4. BLOCK DIAGRAM

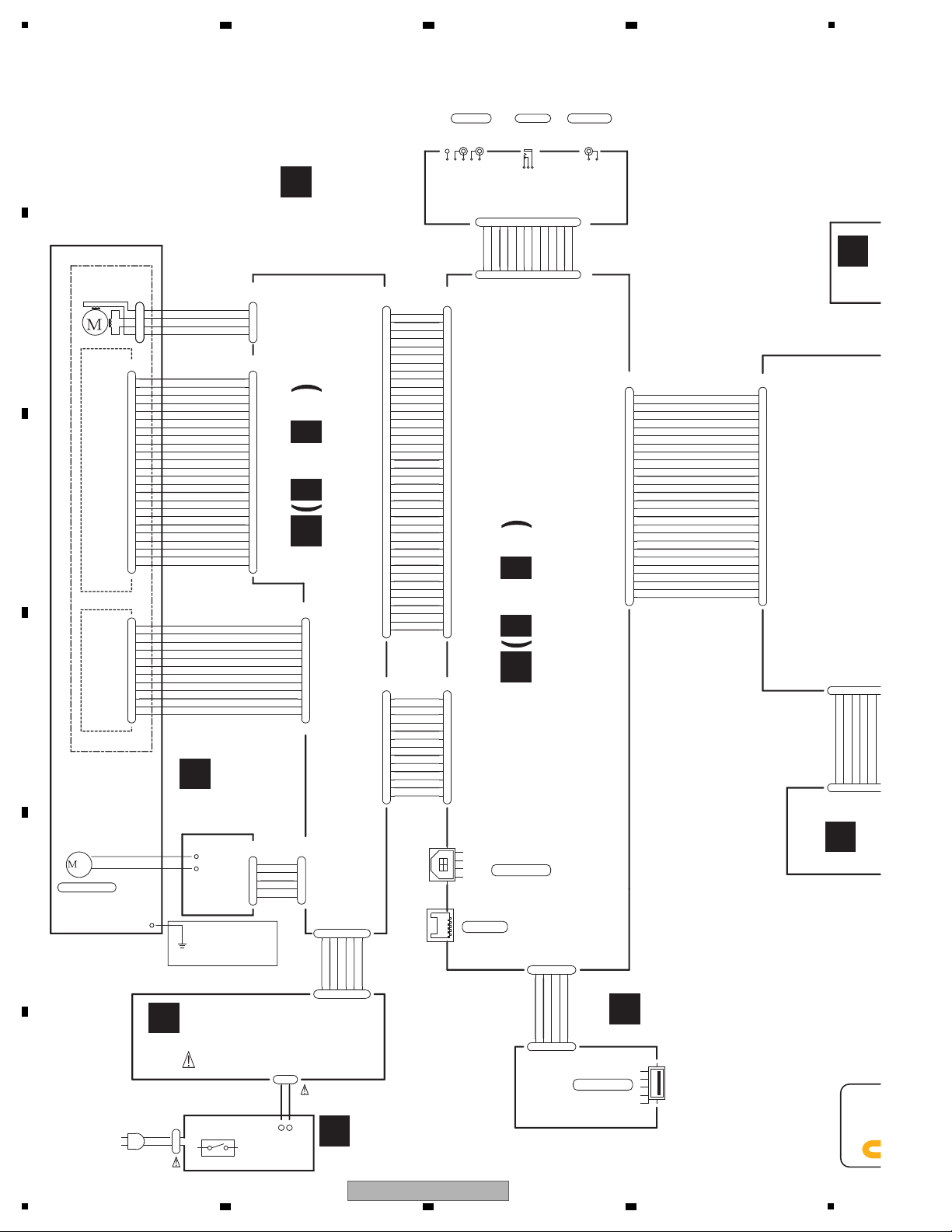

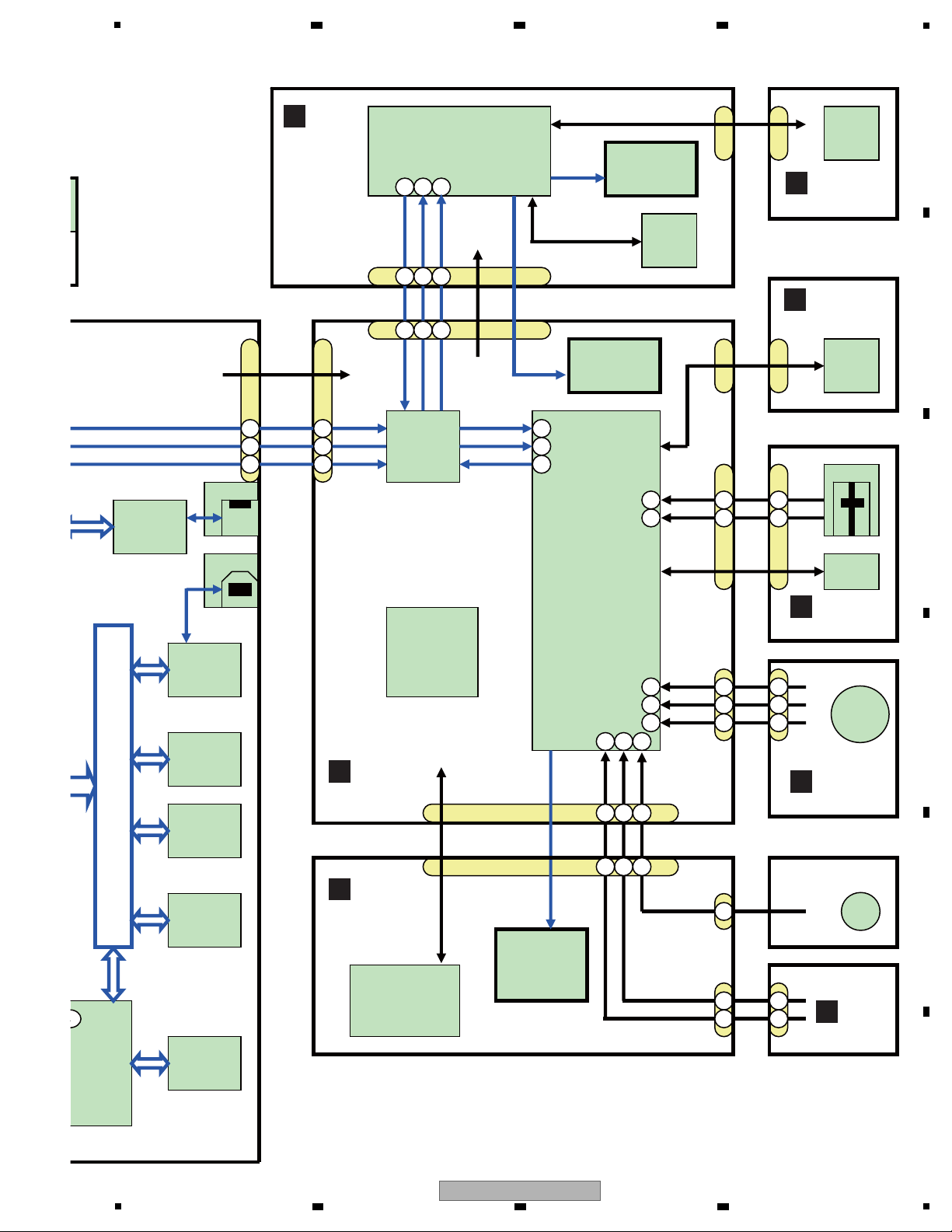

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

18

1

2 3 4

CDJ-900

F

DFLB ASSY

(DWX3021)

H

KSWB ASSY

(DWS1416)

M

JFLB ASSY

(DWX3024)

L

JOGB ASSY

(DWX3026)

I

SLDB ASSY

(DWS1417)

G

ENCB ASSY

(DWX3022)

K

MSWB ASSY

(DWS1415)

J

BFLB ASSY (DWX3025)

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

CN 9402

JH9401

CN 8501

CN 8005

JH9701

CN 4001

JH4001

CN 8002

CN 8001

CN 9201

CN 8003

CN 9403

CN 9501

CN 8701

CN 8006

CKS1072-A

1

JOG_SW

2

NC

3

GNDD

51048-0400

1

GNDD

2

V+3R3

3

JOG1

4

JOG2

KM200NA4L

1

2

3

4

KM200NA4L

1

GNDD

2

ENC_SW

3

ENC_2

4

ENC_1

51048-0700

1234567

XKP3022-A

123456789

10

GNDD

1112131415161718192021

22

51048-0700

1

V+122GNDD

3

KEY4

4

BROWS_LED

5

TAG_LIST-LED

6

INFO-LED7MENU-LED

XKP3022-A

1

CLK_REQ

2

FLCON_CNVSS

3

FLCON_BUSY

4

FLCON_SCLK

5

FLCONL_RXD

6

PNL_TXD2

7

FLCON_RESET

8

D_BK

9

D_LAT

10

N.C.(GNDD)

11

D_SDO

12

KEY3

13

KEY4

14

V+3R3

15

GNDD

16

V+7R2

17

GNDD

18

V+12

19

D_SCLK

20

GNDD

21

GNDD22V+54

9607S-20F

1

USB_LED

2

USB_SW

3

1KEY_SW42KEY_SW54KEY_SW

6

8KEY_SW

7

V+5

8

AS_IDCM1

9

AS_IDC4

10

AS_IDC3

11

AS_IDC2

12

AS_IDC1

13

AS_IDCM3

14

AS_IDCM2

15

SHIFT_SW

16

KEY2_B17CUE_SW

18

PLAY_SW

19

REV_SW

20

GNDD

52492-2020

123

45678

9

101112

131415

161718

19

20

52492-1920

1

JOG2

2

JOG1

3

JOG_SW

4

J_DSO

5

J_SCLK

6

J_LAT

7

J_BK

8

V+3R3

9

GNDD

10

V+7R2

11

GNDD

12

V+3313GNDD14V+1215GNDD16V+1217GNDD

18

GNDD

19

V+54

XKP3019-A

1

2

345

6

789

101112

13141516171819

52151-0410

1

2

3

4

52492-1320

1

2345678

9

10

11

12

13

52492-1320

1

GNDS2ADIN

3

ADCT

4

V+3R3E5MT_LED

6

V+12

7

VIN YL_LED

8

V+5

9

KEY0

10

GNDD

11

TCH/REL

12

EJECT_LED

13

EUP_LED

SHEET SW

(DSX1078-)

PH-PH CABLE

PF04PP-Q17

L=175mm

FFC

DDD1449REVERSE FACE

L=142mm

FFC

DDD1490SAME FACE

L=165mm

FFC

DDD1501SAME FACE

L=90mm

FFC

DDD1489REVERSE FACE

L=60mm

JUMPER WIRE

D20PYY0705E

L=50mm

JUMPER WIRE

D20PYY0405E

L=50mm

EARTH LEAD UNIT

L=70

DDF1032-A

5

6 7 8

A

B

C

D

E

CDJ-900

5

6 7 8

F

19

1

A

SRV ASSY

B

SLMB ASSY

O

ACIN ASSY

N

POWER

SUPPLY

ASSY

E

JACB ASSY

C

MAIN ASSY

D

USBA ASSY

USB High/Full Speed

CPU_TXD2

CPU_RXD2

CPU_SCK2

MII

LPS1,

LPS2

8bit

LO-,

LO+

16bit

16bit

16bit

JA8802

CONTROL OUT

32bit

JA8803

DIGITAL OUT SPDIF SPDIF_OUT

JA8801

32bit

R OUT ROUT

L OUT LOUT

ST1+/-,

ST2+/-

LOAD

FEDRV

TEDRV

TE

FE

RFENV

Q506

IC7004

FEP

SODC

IC7008

DRIVER

IC7002

IN SW

IC7006

FLASH

128kB

IC8801

04SD PICK UP ASS'Y R

(OWY8036- /XDP/5)

SPINDLE MOTOR 04

(VXM1112-)

M

STEPPING

MOTOR

(VXM1113-)

M

DC MOTOR

(DXM1230-)

CN7002

CN8901

CN7004

CN7001

CN7003

SLOT IN MECHA ASSY (DXM1230)

2

5

2

5

12 12

IC8802

57

57

IC8803

21

6

7

IC3003

DAC

8

11

IC501

DSP

I2S

SPI

A6

IC101

MAIN CPU

POWER SUPPLY

POWER SUPPLY

MAIN SYSTEM BUS

( CS0 : 16bit, CS1,3 : 32bit )

IC1304

ETHER

POW

14

18

29

89

111

109

112

67

120

119

46

5

4

175,

176

CN9901

CN1305

CN8801 CN501

CN1303

CN7005

CN7301

CN3CN2

CN7302 CN3001

JA9901

USB_A

(TOP)

ATAPI

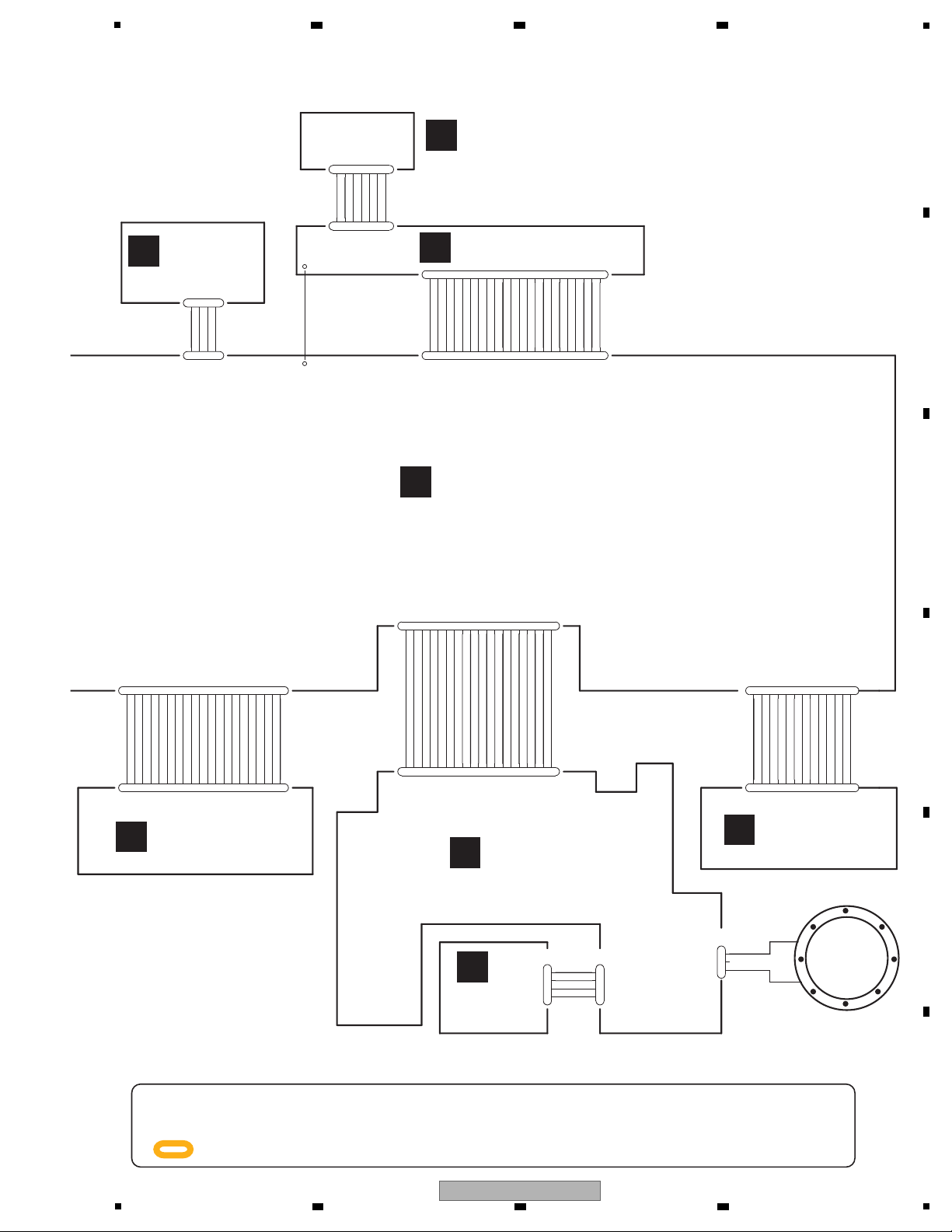

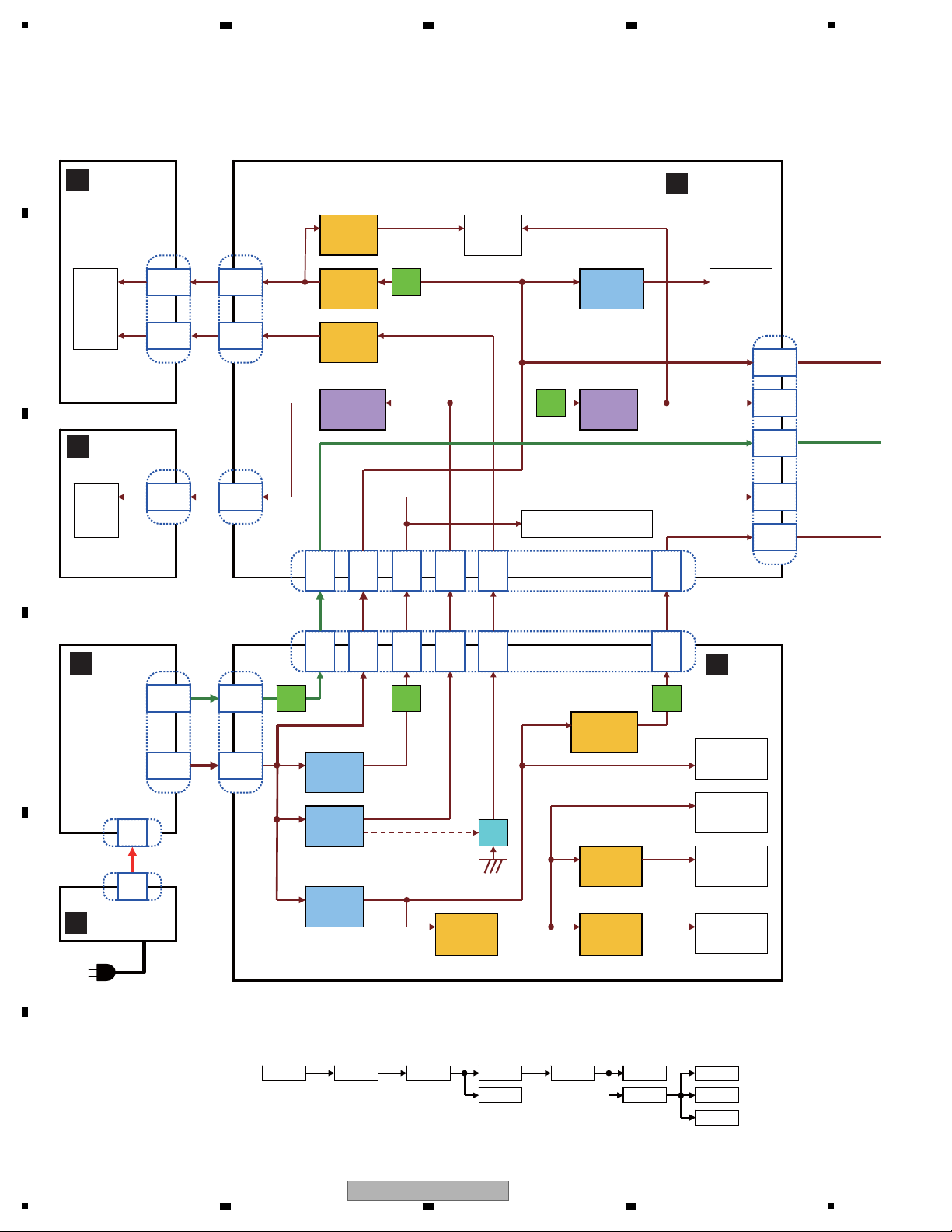

4.2 SIGNAL BLOCK DIAGRAM

A

B

C

D

2 3 4

E

F

20

1

2 3 4

CDJ-900

J

BFLB ASSY

K

MSWB ASSY

H

KSWB ASSY

I

SLDB ASSY

G

ENCB ASSY

L

JOGB ASSY

M

JFLB ASSY

F

DFLB ASSY

CPU_TXD2 ( PNL_TXD )

CPU_RXD2 ( PNL_RXD )

CPU_SCK2 ( PNL_SCLK )

MII

100/10Base-T

USB Full Speed

16bit

16bit

16bit JOG_SW

32bit

JOG1

JOG2

32bit

FLCON_SCLK

PNL_TXD2

FLCON_RXD

FLCON_RXD

PNL_TXD2

FLCON_SCLK

ENC_SW

ENC_2

ENC_1

JOG2

JOG1

JOG_SW

Serial

ADCT

ADIN

PNL_SCLK2

PNL_TXD2

PNL_RXD2

Serial

Serial

IC501

DSP

MAIN SYSTEM BUS

( CS0 : 16bit, CS1,3 : 32bit )

IC505

SDRAM

256MB

IC108

SDRAM

256MB

IC109

SDRAM

256MB

IC114

FLASH

4MB

IC1304

ETHER

IC1101

USB_B

Cntroller

POWER SUPPLY

IC8005

PANEL CPU

V8001

DATA FL

IC4002

GUI CPU

V4001

BROWSE FL

CN2001

CN7302

9

5

3

18

22

24

IC8002

IC8003

SW Buffer

33

32

31

313233

5 6 4

5 6 4

SW

LED

SW

LED

POWER

SUPPLY

IC8010

EUP

POWER

2

3

2

3

4

4

ROTARY

SEARCH

SW

LED

SLIDER

V9401

JOG FL

1

3

4

3

4

321

SHEET SW

(DSX1078-)

POWER SUPPLY

IC9401

POWER

(STEP-UP)

27V/33V/54V

90

91

25 27

6,26

92

SW

LED

2

1

2

3

2

3

CN9402

CN9501

JH9401

CN9403

CN8003

CN8005 CN8501

CN8701

CN8006

CN9201

CN8001

JH9701JH4001

CN4001

CN8002

JA1101

JA1301

LINK

(REAR)

USB_B

(REAR)

171819

5

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

21

1

O

ACIN ASSY

E

JACB ASSY

C

MAIN ASSY

A

SRV ASSY

D

USBA ASSY

N

POWER

SUPPLY

ASSY

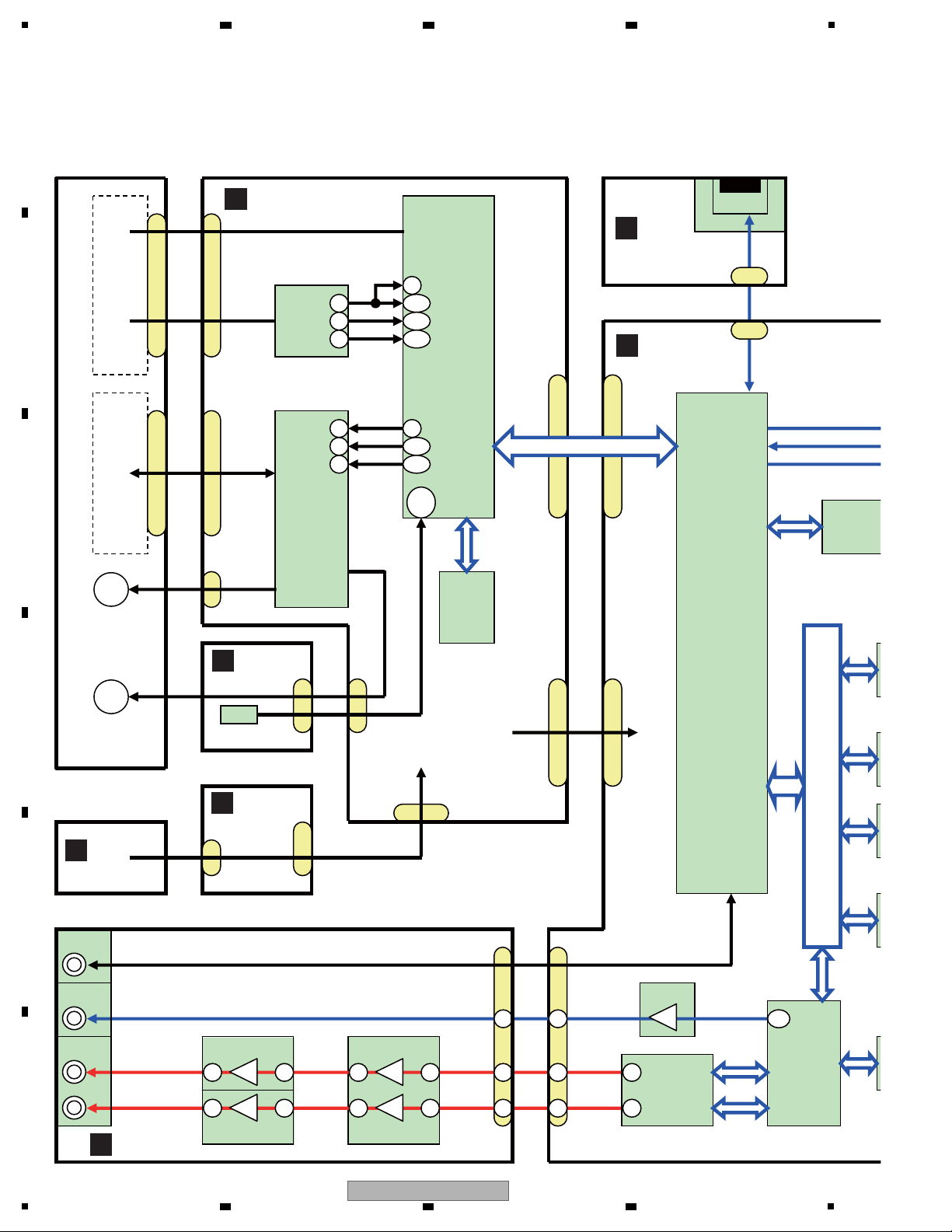

Power supply setup sequence

Show the power supply controlling the setup order by a circuit.

V+3R3

V+12_EUP

V+12

CN7301

CN2

V+5

V+5SW

V+12_EUP

V+7R2

V+12

V+7R2

V+12_EUP

V+5USB

V-11

V+5A

V+10A

V+3R3

V+1R2

V+5D

V+7R5

V+12

V+7R5

V+12

V+7R5

V+5

V+3D, V+3A

V+1R5D

V+5D, V+5A

V+3R3

V-11

AC

V+12_EUP

V+12

V+12_EUP

V+12

V+12_EUP

V+12

V+12_EUP

V+12

V+10A

for

Audio

AMP

V+12_EUP

for SODC

for

Spindle,Stepper

Loading,Actuator

Driver

for Driver, Flas h

SODC

V+12

V+5

V+3R3

V+5

V+3R3

V+5

for DAC

V+3R3

V+10A

V-11V-11

for

FEP, SODC

IC7301

D/D_CONV

12V -> 7.5V

SI-8005Q

IC7302

D/D_CONV

12V -> 5V

SI-8005Q

IC7303

D/D_CONV

12V -> 3.3V

SI-8005Q

IC7003

5V_REG

7.5V -> 5V

BA00DD0WHFP

IC7007

1.5V_REG

5V -> 1.5V

PQ1LAX95MSP

IC7005

3.3V_REG

5V -> 3.3V

MM1478DFBE

Q1303

Transistor

-11V -> -10V

2SD2662

Q1302

Transistor

12V -> 10V

2SB1698

Q1308

Transistor

10V -> 5V

2SB1698

IC3002

D/D_CONV

12V -> 1.235V

SI-8005Q

Q3001

FET_SW

5V

RTQ040P02

D7311

Schottky diode

7.5V -> 7.2V

RB060L-40

P2

0.5A

P7302

0.375A

P7307

1.25A

P7301

1.25A

P3

1.25A

V+12

V-10A

V+5D

Charge

Pump

-12V

GND

for

USB

Type A

IC1102

High-Side_SW

5V

BD2051AFJ

CN9901

CN1305

V+5USB

V+5USB

CN8801

CN501

V-10A

V-10A

CN2001

V+7R2

CN7302

V+7R2

CN3001

V+7R2

CN1

AC

V+12

V+5

V+3R3 V+7R5

V+7R2

V+27

V+54

V+33

V+12EUP

V+3R3E

V-11

12 34 56 7

for MAIN CPU, DSP, flashROM,

SDRAM, USB, Logic & ETHER

for MAIN CPU,

DSP

2 3 4

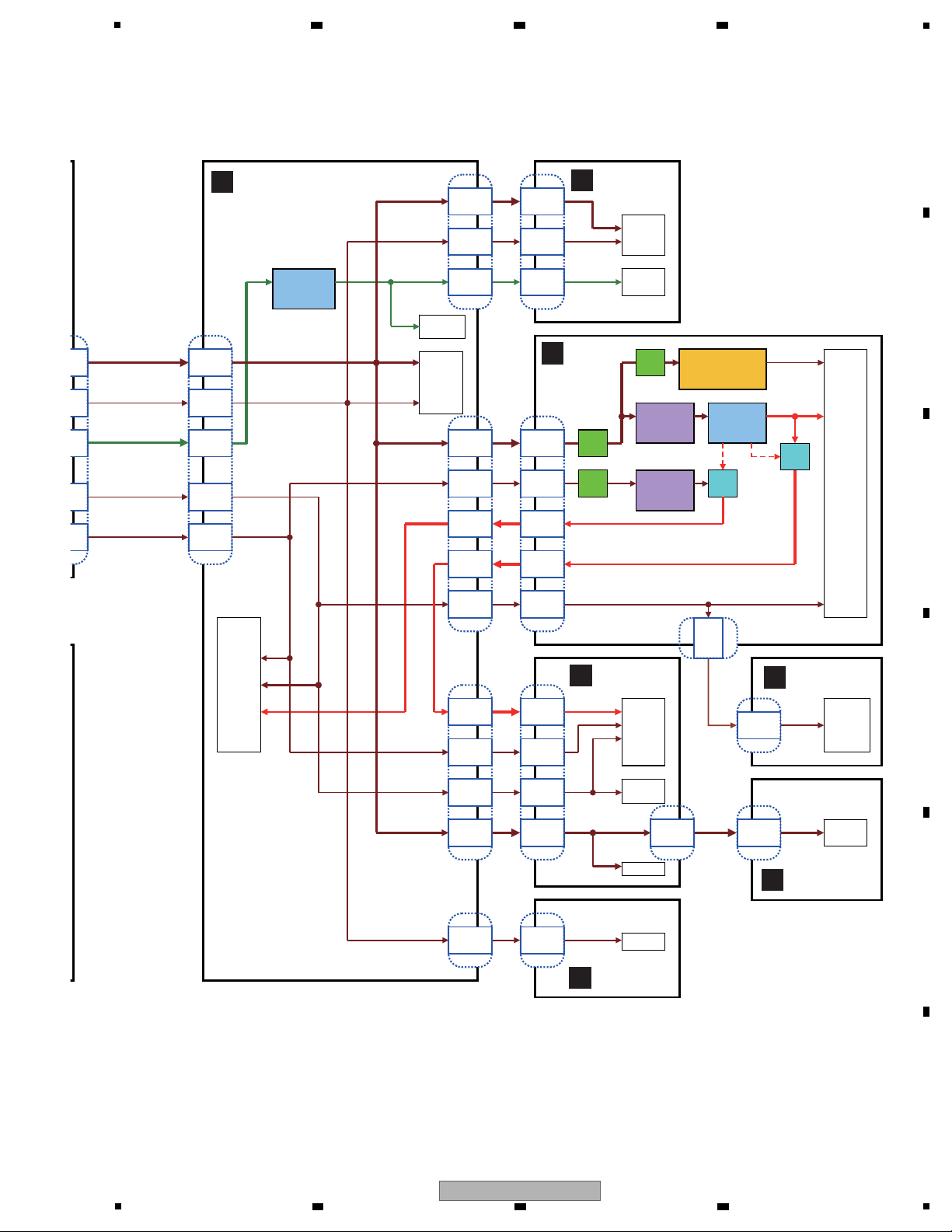

4.3 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

22

1

CDJ-900

2 3 4

5

L

JOGB ASSY

K

MSWB ASSY

M

JFLB ASSY

I

SLDB ASSY

J

BFLB ASSY

H

KSWB ASSY

F

DFLB ASSY

V+3R3E

V+5

V+12

V+3R3

V+7R2

V+54

V+5

V+12

V+12

V+3R3

V+3R3

V+54

V+7R2

V+3R3

V+5

V+3R3

V+12

V+7R2

V+3R3

V+33

V+5

V+7R2

V+12

V+12

V+12

V+5

V+3R3E

V+33

V+27

V+12

V+12_EUP

V+3R3

V+5

V+12 V+12

for LED

for

Slide Vol

V+54

V+54

V+7R2V+7R2

for

Data FL

V+54

V+54

V+5

V+5

for LED

V+33 V+33

V+7R2

V+7R2

V+3R3

V+3R3

IC8010

D/D_CONV

12V -> 3.3V

NJM2392M

IC9401

D/D_CONV

12V -> 27V

NJM2392M

Q9413

FET_SW

12V

RTQ040P02

Q9414

FET_SW

7.2V

RTQ040P02

P9405

0.5A

Charge

Pump

+27V

Charge

Pump

+27V

IC9402+T9401

Timer+Trans

12V -> AC2.7V

TLC555IP+DTT1232

P9401

0.5A

for

JOG FL

VFDP2R9

V+12

V+12

P9402

1.5A

for

PNL_uCON

for

Brows FL

for

GUI CPU

for LED

for

Jog Rotate

Detect

for LED

for LED

V+7R2R2

CN8006

CN8701

V+3R3E

CN8003

CN9403

V+3R3 V+3R3

CN8002 CN4001

V+12 V+12

CN8001

CN9201

V+5V+5

JH4001 JH9701

V+12V+12

CN9501

V+3R3

JH9401

V+3R3

V+3R3E

V+3R3

6 7 8

A

B

C

D

E

F

CDJ-900

5

6 7 8

23

1

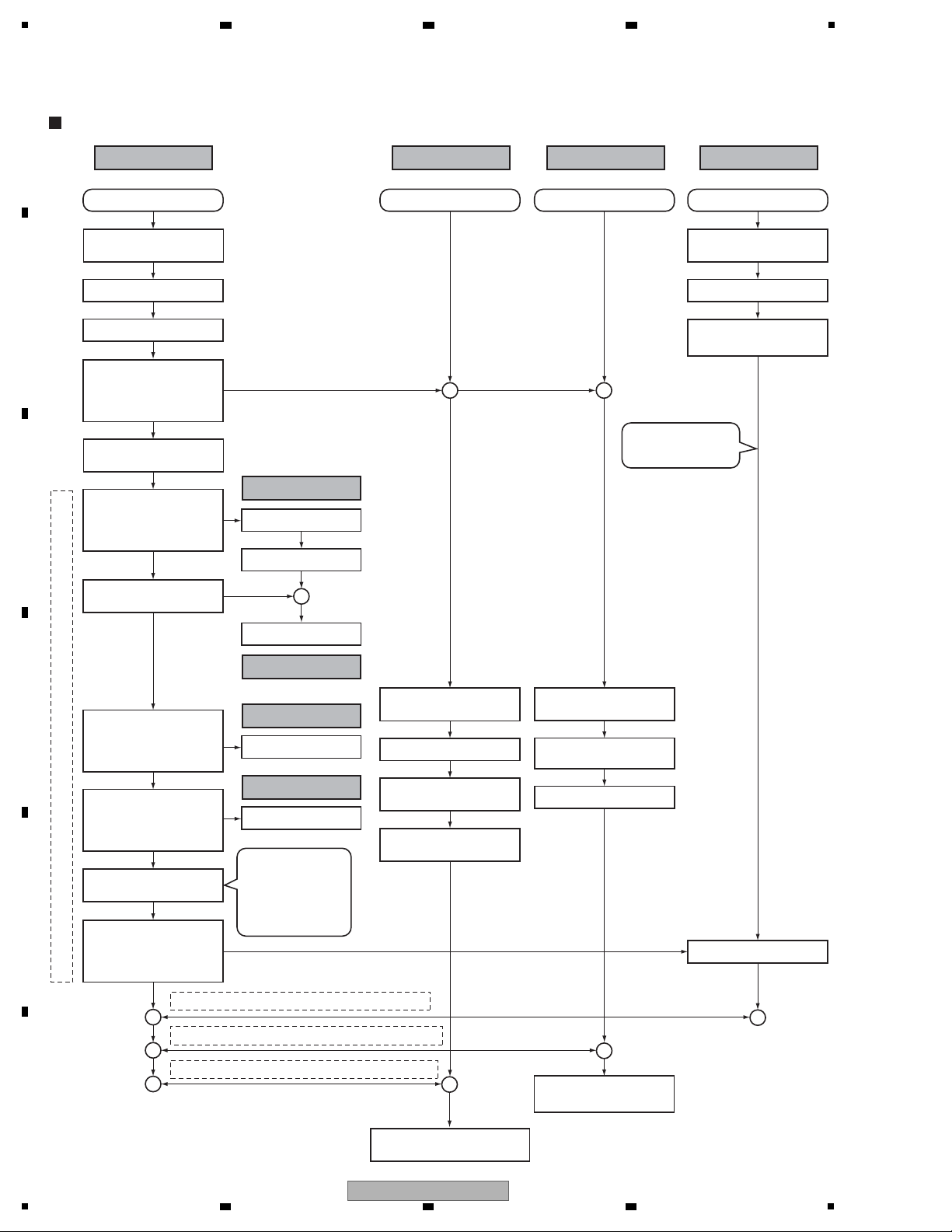

Main CPU

ETHER

DSP

DAC

USB_B CONTROLLER

GUI CPU

Power on Power on

Pin Y22 of Main CPU

(IC101) cancels reset at H.

Program transfer from

FLASH to SDRAM

Canceling DSP reset

from pin B18 of Main

CPU. Pin G2 of DSP

(IC501) becomes "H".

Canceling GUI CPU reset

from pin F3 of Main CPU.

Canceling PANEL CPU reset

from pin P1 of PANEL CPU.

Canceling ETHER reset

from pin A18 of Main

CPU. Pin 42 of ETHER

(IC1304) becomes "H".

Canceling USB_B CONTROLLER

reset from pin A17 of Main CPU.

Pin 46 of USB_B CONTROLLER

(IC1101) becomes "H".

Canceling ATAPI reset

from pin C10 of Main

CPU. Pin 173 of SODC

(IC7006) becomes "H".

Program transfer to

DSP

Initialization of the

built-in peripherals

Initialization of the SDRAM

Initialization of the SDRAM

Initialization of the DSP

Initialization of the USB_B

Initialization of the ETHER

Initialization of the DAC

Initialization of the peripheral device

Initialization of the Main CPU

Pin 12 of GUI CPU

(IC4002) cancels reset at H.

Initialization of the

Data and Browse FL

Display a Pioneer logo

on the Browse FL

Displays Browse FL and

Data FL.

LED initial lighting

Pin 12 of PANEL CPU

(IC8003) cancels reset at H.

Pin 45 of SODC (IC7006)

cancels reset at H.

Initialization of the GUI CPU

PANEL CPU

Power on

Initialization of the JOG_FL

Initialization of the

PA NEL CPU

SERVO

Power on

Initialization of the ATAPI

Display JOG FL.

LED initial lighting.

Communication between Main CPU and SERVO

Initialization of the SODC

Built-in peripherals

• USB_A

• ETH_MAC

• ATAPI

• SERIAL Bus

Communication between Main CPU and PANEL CPU

Communication between Main CPU and GUI CPU

Initialization of the

loading mechanism

The insertion of the

disk is possible.

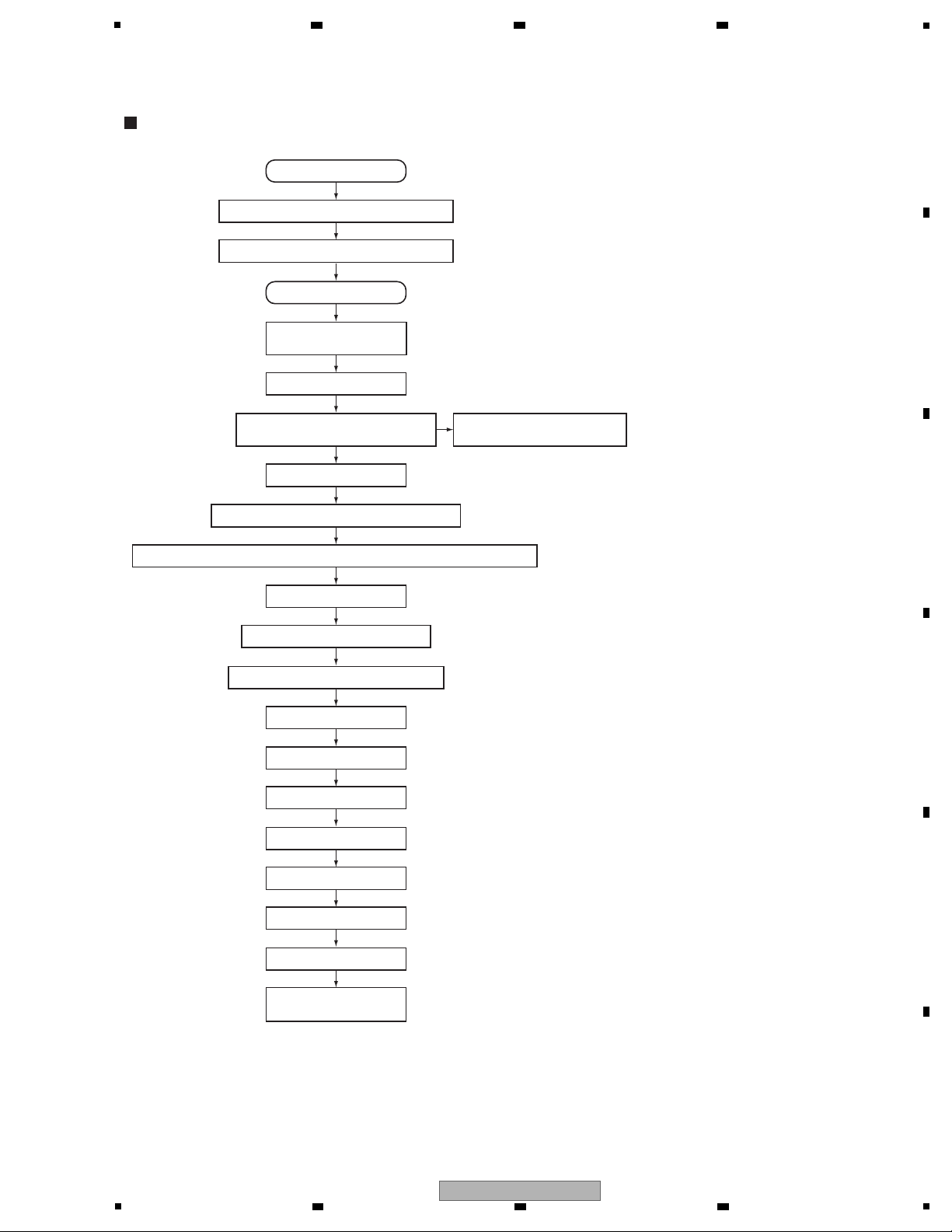

Power-on Sequence

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

A

2 3 4

B

C

D

E

F

24

1

2 3 4

CDJ-900

5

Power ON

Loading of a disc

Stepper moving to a

focusing position

Spin-up (CAV 2000 rpm)

Media distinction with the aid of reflectivity

Set a gain by media judgement result, and take in the S-shaped signal.

Offset canceling

TB adjustment

TEPP adjustment

T close

FB adjustment

FG adjustment

TOC read

CLV servo on

Searching for the

1st piece of music

LD OFF

Cancel the getting into of INSIDE SW

Initialization of the loading mechanism

Tu r n O N the LD on the CD side

to check for the presence of a disc.

Without a disc, an unloading

process starts.

Offset canceling for the 2nd time

LD ON for the 2nd time, and focusing

Set up Sequence of Servo Section

6 7 8

A

B

C

D

5

CDJ-900

6 7 8

E

F

25

1

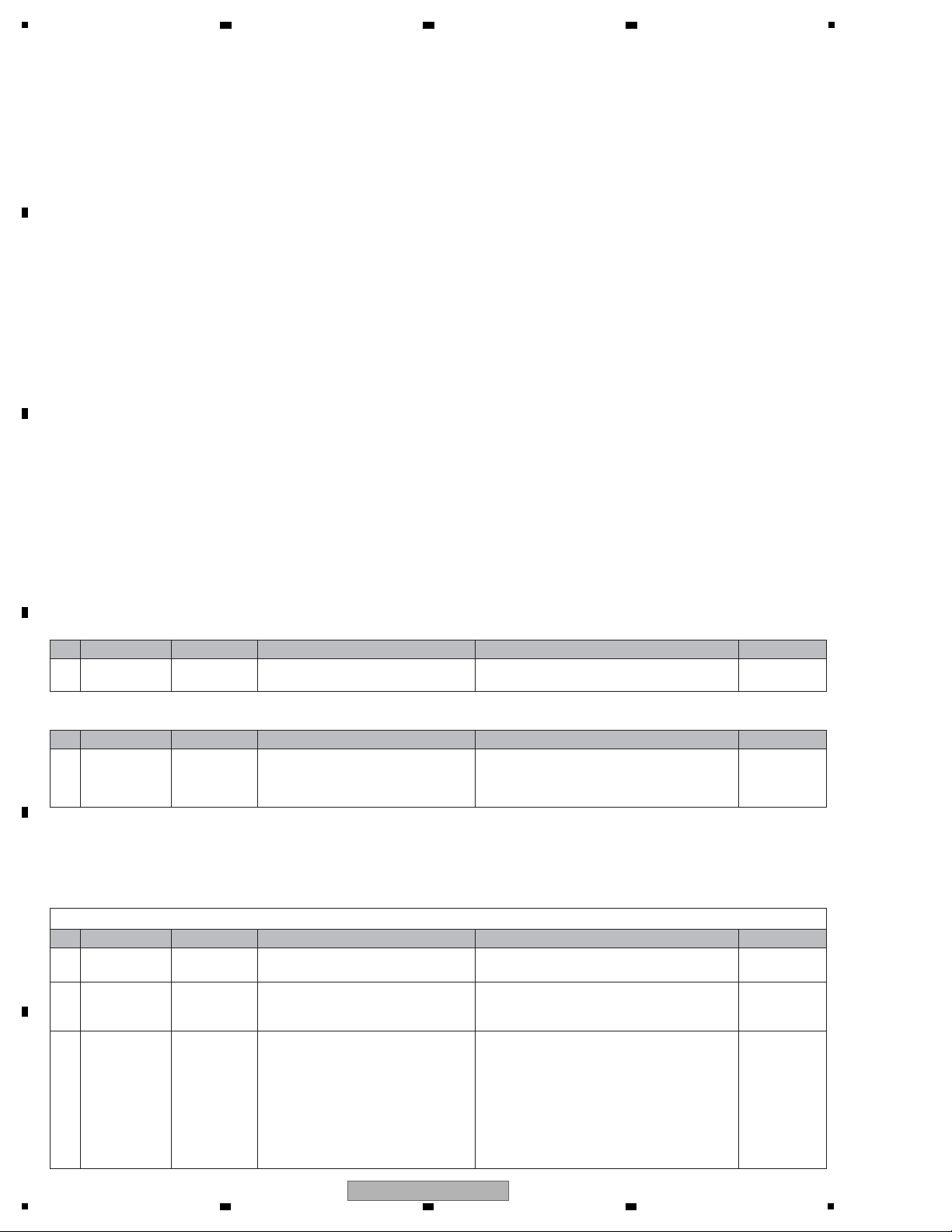

In this section, causes of failure, diagnostics points, and corrective measures can be searched for according to symptoms.

Before disassembling this unit, it is recommended to infer a failure point by performing a auto device check/alarm port and

referring to the error code.

Note: Alarm port is the Test port on the MAIN Assy.

(Location is referred to the Schematic diagram and PCB Connection diagram.)

For the relationship of each power-supply and signal system, see “4.3 POWER SUPPLY BLOCK DIAGRAM.”

If software of the product is updated before performing diagnostics, check that software updating has been performed properly

before proceeding to diagnostics.

If software updating has not been performed properly, update the software, following the instructions in [7] Firmware update of

“6.3 DETAILS ON SERVICE MODE.”

Contents

[0] Prior Confirmation

[1] Failure in Startup

[2] Display (DATA FL/BROWS FL/JOG FL/LED)

[3] Operations (SW/Volume/JOG)

[4] USB (Type A/Type B)

[5] LAN

[6] AUDIO OUT

[7] CONTROL

[8] DRIVE Assy

[9] EUP Mode

[10] SERVICE MODE

[11] Error Codes

The waveform numbers described in this section correspond to the “10.15 WAVEFORMS.”

[0] Prior Confirmation

[0-1] Checking in Service Mode

[0-2] Checking Cables

[1] Failure in Startup

[1-1] No power

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1—

Check the failure points in auto device

check / alarm port.

See the section describing locations of defects in

this manual.

6.SERVICE

MODE

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1 Cables

Disconnection,

breakage, or

loose connection

of cables

Check that all the cables are securely

connected.

Check that there is no breakage in the

cables.

Securely connect the cables. If a cable is broken,

replace it.

4.1 OVERALL

CONNECTION

DIAGRAM

4.3 POWER SUPPLY

BLOCK DIAGRAM

4.3 POWER SUPPLY

BLOCK DIAGRAM

Even after the unit is turned on, no indication is displayed nor can loading by the DRIVE Assy be performed.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective power

supply

SRV Assy Check V+12.

If V+12 is not checked, go to step 2.

If V+12 is checked, go to step 3.

2

Defective power

supply/Protector

breakage

SRV Assy

Check V+12EUP. Check also if the protector

(P7302) is broken.

If the protector is broken, replace the protector.

If the V+12EUP voltage is not output, the SW

power-supply IC may be defective. Replace it.

3 Signal errors SRV Assy Check the EUP_CONT signal.

If the signal is “L,” check the output from the SW

power-supply IC. If V+12 is not output, the SW powersupply IC may be defective. Replace it.

If the signal is “H,” check if the signal logics are the

same as those for normal status shown in the table in

the rightmost column. If either of the signal logics is

not the same, check the mounting status of the

IC8001 or IC8008 on the DFLB Assy, which corresponds to the wrong signal logic. If it is correctly

mounted, then it may be defective. Replace it.

Refe to “Signal

logic during

EUP mode.”

2 3 4

5.2 TROUBLESHOOTING

A

B

C

D

E

F

26

1

CDJ-900

2 3 4

5

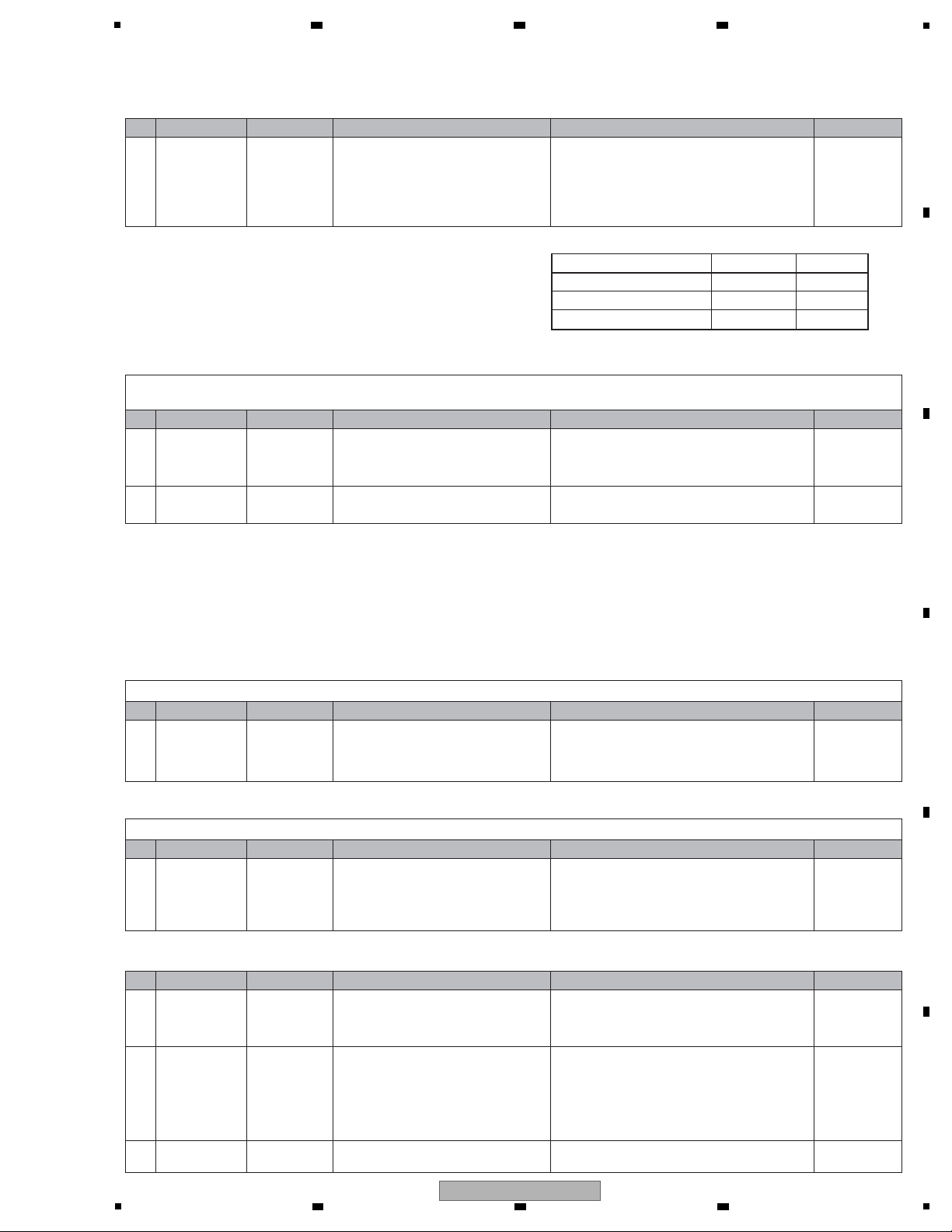

[2-3] The BROWS FL does not light.

[2] Display (DATA FL/BROWS FL/JOG FL/LED)

[2-1] Any of the DATA, BROWS, and JOG FLs are not lit.

[2-2] Neither the DATA nor BROWS FL is lit.

[1-2] Startup stops with the “Pioneer” logo displayed on the screen. (See *1.)

The DATA FL, BROWS FL and the LEDs (LINK, USB, DISC, BROWS, TAG LIST, INFO, MENU) are controlled by

the GUI CPU (IC4002).

The JOG FL and the other LEDs are controlled by the PANEL CPU (IC8005).

4.3 POWER SUPPLY

BLOCK DIAGRAM

4.3 POWER SUPPLY

BLOCK DIAGRAM

6.SERVICE

MODE

4

Defective power

supply/Protector

breakage

SRV Assy

Check V+7R2, V+5, V+3R3 and check

whether protector (P7302) does not break.

V+7R2 => P7310

V+3R3 => P7307

Refer to 4.3 POWER SUPPLY BLOCK

DIAGRAM.

If the protector is broken, replace the protector.

Check the mounting statuses of the regulator IC and

its peripheral parts for each power supply.

If they are properly mounted, then the parts may be

defective. Replace them.

If startup stops in such a status, the upstream and downstream communications between the MAIN CPU and PANEL CPU/GUI CPU

could not be established.

All types of driver power to be supplied are produced at the JFLB Assy.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Version upgrade

failed.

—

—

Version upgrade of the software for the

DRIVE unit may have failed.

If upgrading failed, startup stops with the “Pioneer”

logo displayed on the screen, and the LED for the

USB STOP key flashes repeatedly.

See “6. SERVICE MODE.”

6.SERVICE

MODE

2

—

MAIN Assy

Check a failure point at the status check

(alarm) port of the MAIN Assy.

If there is a point that has been judged as in failure,

see “6. SERVICE MODE” in this section.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective power

supply

BFLB Assy

Check the power-supply voltages

(V+3R3/V+7R2/V+54) of the FL.

If the presence of power is not confirmed, check the mounting

statuses of the regulator IC and its peripheral parts for each

power supply. If they are properly mounted, then the parts may

be defective. Replace them.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Breakage

of protectors

JFLB Assy/

SRV Assy

Check V+12 and check whether protectors

do not break.

JFLB Assy => P9402/P9405

SRV Assy => P7310

If the protector is broken, replace the protector.

4.3 POWER SUPPLY

BLOCK DIAGRAM

4.3 POWER SUPPLY

BLOCK DIAGRAM

Driver power to be supplied to the DATA and BROWS FLs is produced at the JFLB Assy.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective power

supply

JFLB Assy

Check supply voltages (V+33/V+54) of

the FL.

If the presence of power is confirmed, check the

connections to these FLs.

If the presence of power is not confirmed, check the

mounting statuses of the power circuit (IC9401) and

its peripheral parts. If there is any problem, correct it.

2 Signal errors BFLB Assy

Check the output signal and connection of

communication line of BROWS FL in the

BFLB Assy.

• B_SCLK

• B_BK

• B_LAT

• B_DSO

If no signal is output, the GUI CPU (IC4002) port

may be damaged. Replace it.

If soldering is improper, resolder it.

3

Defective parts

of FL

If the symptom persists after the above

corrections,

Replace the BROWS FL.

Normal mode EUP mode

EUP_CONT L H or open

PA NEL CPU(IC8005) pin28

H L

CPU_EUP_CONT X L

Reference: Signal logic during EUP mode

X : Not Concerned

10.10

BFLB ASSY

6 7 8

A

B

C

5

6 7 8

CDJ-900

D

E

F

27

1

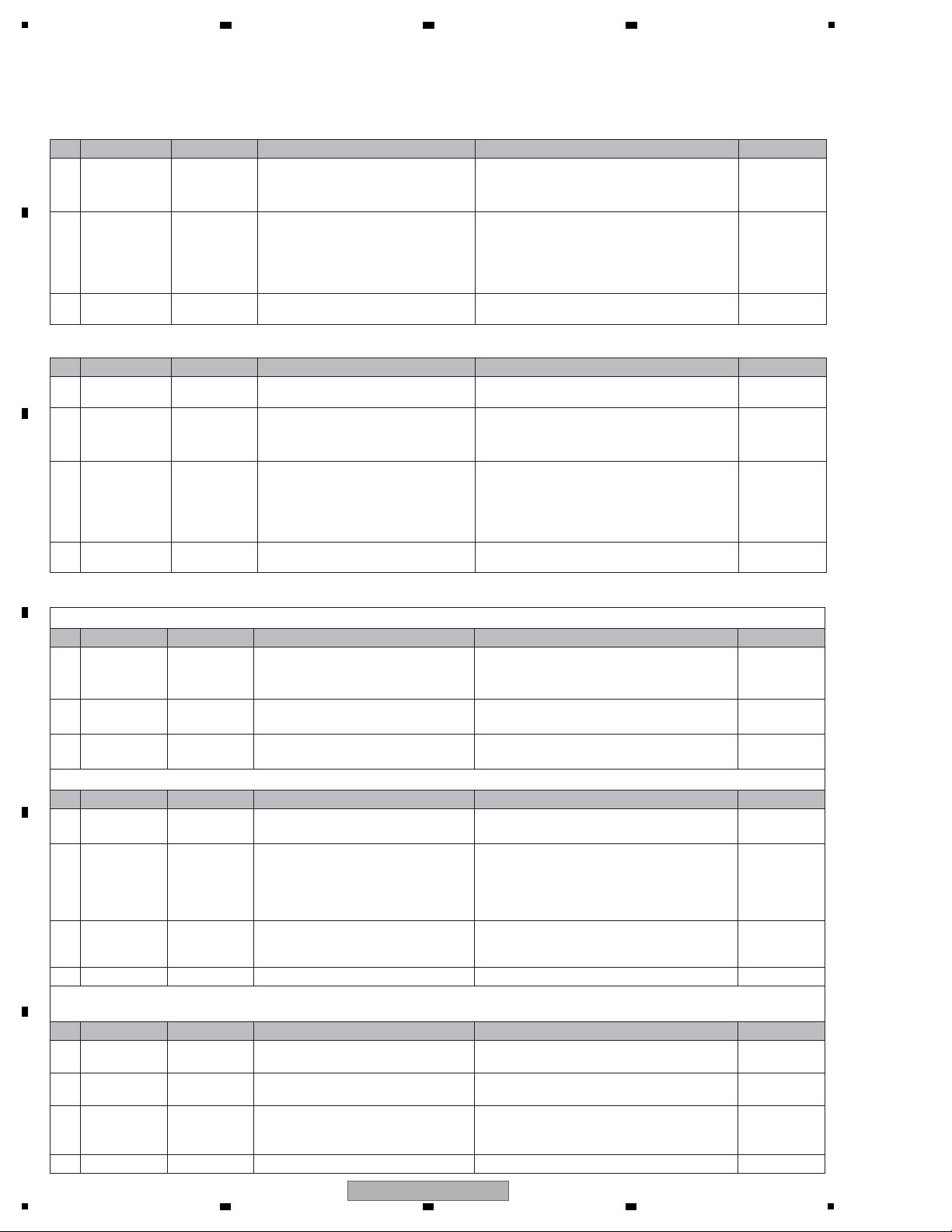

[2-6] The LED does not light.

[2-4] The DATA FL does not light.

[2-5] The JOG FL does not light.

10.7 DFLB and

ENCB ASSYS

10.10

BFLB ASSY

10.13

JFLB ASSY

10.10

BFLB ASSY

—

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective power

supply

DFLB Assy

Check the power-supply voltages (V+3R3/

V+7R2/V+33) of the FL.

If the presence of power is not confirmed, check the mounting

statuses of the regulator IC and its peripheral parts for each

power supply. If they are properly mounted, then the parts may

be defective. Replace them.

4.3 POWER SUPPLY

BLOCK DIAGRAM

2 Signal errors DFLB Assy

Check the waveforms and connection of the

FL communication line in the DFLB Assy.

• D_SCLK

• D_BK

• D_LAT

• D_DSO

If no signal is output, the GUI CPU (IC4002) port

may be damaged. Replace it.

If soldering is improper, resolder it.

3

Defective parts

of FL

If the symptom persists after the above

corrections,

Replace the DATA FL.

—

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

2

Defective power

supply

JFLB Assy

JFLB Assy

Check the power-supply voltages (V+3R3/

VFDP2R9_F1/VFDP2R9_F2/V+27) of

the FL.

If the presence of power is not confirmed, check the mounting

statuses of the regulator IC and its peripheral parts for each

power supply. If they are properly mounted, then the parts may

be defective. Replace them.

4.3 POWER SUPPLY

BLOCK DIAGRAM

3 Signal errors JFLB Assy

Check the connection of the FL communication line in the JFLB Assy.

• J_SCLK

• J_BK

• J_LAT

• J_DSO

If no signal is output, the GUI CPU (IC4002) port

may be damaged. Replace it.

If soldering is improper, resolder it.

4 Defective parts

of FL

If the symptom persists after the above

corrections,

Replace the JOG FL.

—

1

Breakage

of protectors

Check if the protector (P9401) is broken.

If the protector is broken, replace the protector.

LED (LINK, USB, DISC, BROWS, TAG LIST, INFO and MENU)

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1 Signal errors BFLB Assy

Check that the control signal for the LED

in question is output from the GUI CPU

(IC4002).

If no signal is output, the GUI CPU (IC4002) port

may be damaged. Replace it.

If soldering is improper, resolder it.

-

2

Defective parts

of LED

BFLB Assy

Check that the forward voltage (2.2 - 2.7 V)

is present at both ends of the LED.

If the forward voltage is not present, then the LED

itself is defective. Replace it.

-

3

Defective parts

of transistor

BFLB Assy

If the symptom persists after the above

corrections,

The transistor is defective. Replace it. -

LED (except for the USB STOP indicator) on KSWB Assy does not light.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Breakage

of protectors

MAIN Assy

Check if the protector (P3) is broken.

If the protector is broken, replace the protector. -

2- -

The LEDs (except for the USB STOP indicator) on the KSWB Assy are lit dynamically

in a matrix pattern.

Check if the unlit LED belongs to a certain

line/column group, referring to the circuit

diagrams.

If it does not belong to a group, then that LED may

be defective. Replace it.

If it belongs to a group, then the LED-drive signal for

that group is defective.

Go to [2].

10.8

KSWB ASSY

(Schematic

diagram)

3 Signal errors DFLB Assy

Check that the control signal for the LED

in question is output from the PANEL CPU

(IC8005).

If no signal is output, the PANEL CPU (IC8005)

port may be damaged. Replace it.

If soldering is improper, resolder it.

-

4- -

If the symptom persists after the above corrections,

The transistor is defective. Replace it. -

USB STOP indicator does not light.

This LED is controlled by the MAIN CPU (IC101).

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Breakage

of protectors

MAIN Assy Check if the protector (P3) is broken.

If the protector is broken, replace the protector.

-

2

Defective parts

of LED

BFLB Assy

Check that the forward voltage (2.2 - 2.7 V)

is present at both ends of the LED.

If the forward voltage is not present, then the LED

itself is defective. Replace it.

-

3

Defective

connection/

Signal errors

MAIN Assy/

DFLB Assy/

KSWB Assy

Check the connection of the LED control

signal.

If the signal is not output even if the connections are

properly made, the port on the MAIN CPU (IC101)

may be damaged. Replace it.

-

4- -

If the symptom persists after the above corrections,

The transistor is defective. Replace it. -

A

B

C

2 3 4

D

E

F

28

1

2 3 4

CDJ-900

10.7 DFLB and

ENCB ASSYS

Other LED does not light.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Breakage

of protectors

Related point

Check the drive voltage of the unlit LED.

For the 5-V-driven LEDs, check if the

protector (P3) is broken.

If the protector is broken, replace the protector. -

2 Signal errors -

Check that the signal for the LED in

question is output from the PANEL CPU

(IC8005).

When there is not output signal, check the connection of the PANEL CPU (IC8005). If the connection

is OK, the port may be damaged. Replace it.

-

3

Defective parts

of LED

-

Check that the forward voltage (2.2 - 2.7 V)

is present at both ends of the LED.

If the forward voltage is not present, then the LED

itself is defective. Replace it.

-

4

Defective parts

of transistor

-

If the symptom persists after the above

corrections,

The transistor is defective. Replace it. -

[3] Operations (Keys/variable controls/JOG)

As operations of all keys, variable controls, and JOG dial can be checked in Service mode.

[3-1] No key functions

The PLAY, CUE, AUTO BEAT LOOP, BEAT SELECT, REV, LOOP IN, LOOP OUT, or RELOOP key does not function.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Loose connection

/Defective SW

Related point

Check if there is loose connection on the

signal line from the PANEL CPU (IC8005)

up to the SW.

If there is no loose connection and if the signal does

not become L when the SW is pressed, that SW is

defective. Replace it.

-

2

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check the connection of the PANEL CPU (IC8005).

If the connection is OK, the port may be damaged.

Replace it.

-

Other keys (except for the USB STOP key) do not function.

The signals from other keys are analog and connected to multiple switches.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Loose connection

/Defective SW

Related point

Check if there is loose connection on the

signal line from the PANEL CPU (IC8005)

up to the SW.

If the SWs connected to the signal line function

properly and if the connections are properly made,

the SWs may be defective. Replace them.

-

2

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check the connection of the PANEL CPU (IC8005).

If the connection is OK, the port may be damaged.

Replace it.

-

The USB STOP key does not function.

The USB STOP key is controlled by the MAIN CPU.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Loose connection

/Defective SW

KSWB Assy/

MAIN Assy

Check if there is loose connection on the

signal line from the MAIN CPU (IC101)

up to the SW.

If there is no loose connection and if the signal does

not become L when the SW is pressed, that SW is

defective. Replace it.

-

2

Defective MAIN

CPU (IC101)

MAIN Assy

If the symptom persists after the above

corrections,

The MAIN CPU (IC101) is defective. Replace it. -

[3-2] Rotary selector not controllable

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective rotary

selector

ENCB Assy

Check if the signals from the ENC_1, ENC_2,

and ENC_SW signal lines are normal when

the rotary selector is turned or pressed.

If the signals are not normal, check the connections of

the signal lines. If the connections are properly made,

the encoder selector may be defective. Replace it.

2

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU(IC8005).

If the mounting is OK, the PANEL CPU is damaged.

Replace it.

-

[3-3] Variable controls not controllable

Tempo slider not controllable

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Loose

connection

SLDB Assy

/DFLB Assy

Check if there is loose connection on the

signal line from the PANEL CPU (IC8005)

to the tempo slider (VR8701).

If the connections of signal line are improper,

resolder it.

-

2

Defective tempo

slider

SLDB Assy

Check the waveforms of signal lines

(ADCT/ADIN) .

If the voltage of the signal line (ADIN) does not

change between 3.3 V and 0 V, the tempo slider

(VR8701) may be defective. Replace it.

-

3

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU(IC8005).

If the mounting is OK, the port may be damaged.

Replace it.

-

5

6 7 8

A

B

C

D

5

6 7 8

CDJ-900

E

F

29

1

VINYL SPEED ADJUST not controllable

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Loose

connection

SLDB Assy

/DFLB Assy

Check if there is loose connection on the

signal line from the PANEL CPU (IC8005)

to the SPEED ADJUST(VR8702).

If the connections of signal line are improper,

resolder it.

-

2 Defective VOL SLDB Assy

Check the waveforms of signal lines

(TCH/REL).

If the voltage of the signal line (TCH/REL) does not

change between 3.3 V and 0 V, the VINYL SPEED

ADJUST (VR8702) may be defective. Replace it.

-

3

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU(IC8005).

If the mounting is OK, the port may be damaged.

Replace it.

-

[3-4] Abnormalities regarding the JOG dial

After the JOG Assy is disassembled then reassembled, be sure to check that the load value for the JOG dial is within the

specified range.

Turning of the JOG dial is not detected

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective photo

interrupter

JOGB Assy/

JFLB Assy/

DFLB Assy

Check the waveforms of signal lines

(JOG1/JOG2).

If no waveform can be confirmed, the photo

interrupter (PC9501) may be defective. Replace it.

-

2

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC8005).

If the mounting is OK, the port may be damaged.

Replace it.

-

Pressing on the JOG dial cannot be detected.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective

SHEET SW

JFLB Assy

/DFLB Assy

Check the waveform of the signal on the

signal line (JOG_SW) when the JOG dial

is pressed.

If the signal on the signal line (JOG_SW) is not set to

L when the JOG dial is pressed, the SHEET SW

(DSX1078-A) may be defective. Replace it.

-

2

Defective PANEL

CPU (IC8005)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU(IC8005).

If the mounting is OK, the port may be damaged.

Replace it.

-

Noise is heard when the JOG dial is turned.

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Defective JFLB

Assy or gears

JOG Assy

Check if the JOG FL of the JFLB Assy

has been shifted upward from the holder.

The JOG FL may interfere with JOG A.

Replace the JFLB Assy.

-

There may be any scratches on the 3

gears or some foreign object between

the gears.

If there are any scratches, replace the scratched gear

with a new one. If there is any foreign object, remove

it then replace the gears with new ones.

Gears to be replaced: Load gear, Gear A, Gear B

-

The JOG dial turns too freely. (The load value for the JOG dial is outside the specified range.)

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Improper adjustment or assembly

of the JOG dial

JOG Assy

Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.1 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “How to Adjust” in “8.1 JOG

Dial Rotation Load Adjustment.”

8.1 JOG Dial

Rotation Load

Adjustment.

During the above adjustment, if the upper-limit adjustment position of the Adjust Plate is reached, oil may

have been spattered on the Adjust Plate.

Replace the washer, gear, and cam plate with new

ones, then reassemble.

-

Resistance to turning the JOG dial is too strong. (The load value for the JOG dial is outside the specified range.)

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1

Improper adjustment of the JOG

dial or defective

washer, gear, or

cam plate

JOG Assy

Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.1 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “How to Adjust” in “8.1 JOG

Dial Rotation Load Adjustment.”

8.1 JOG Dial

Rotation Load