2010

CDJ-850

For details, refer to "Important Check Points for good servicing".

MULTI PLAYER

CDJ-850

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

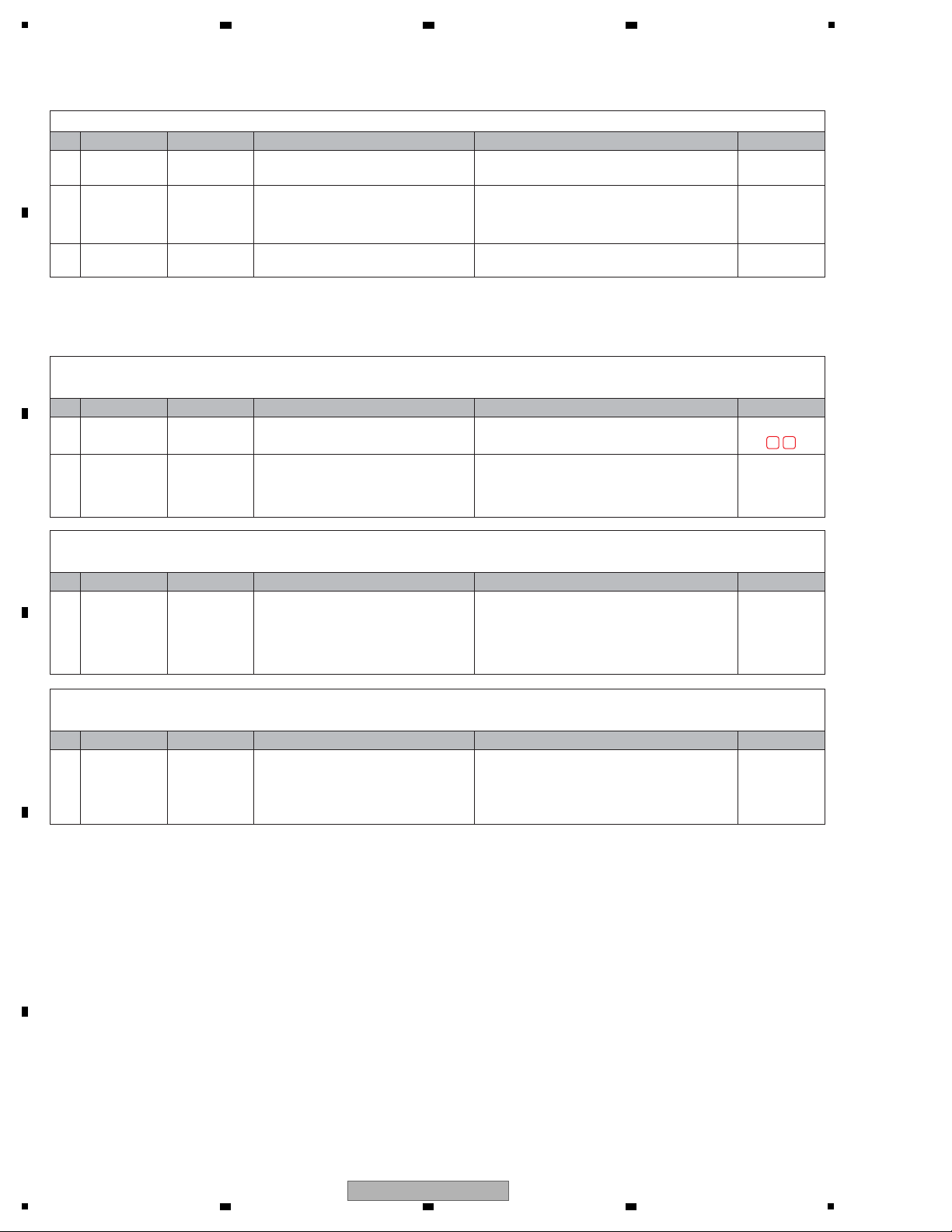

Model Type Power Requirement Remarks

CDJ-850 SYXJ8 AC 220 V to 240 V

CDJ-850 CUXJ AC 120 V

CDJ-850 FLXJ AC 110 V to 240 V

CDJ-850 KXJ5 AC 220 V

CDJ-850 AXJ5 AC 220 V to 240 V

ORDER NO.

RRV4128

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-IZV JULY

2010 Printed in Japan

1

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S1702) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not in

LPS1 terminal side (when the mechanism is not clamped and

LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side.

( if LPS1 signal is low level ).

In the Service mode the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 41 of TC94A15FG

(IC201) on the MAIN Assy is connected to GND, or else the

terminals of Q201 are shorted to each other (fault condition).

2. When the cover is opened, close viewing of the objective lens

with the naked eye will cause exposure to a Class 1 laser beam.

IMPORTANT

THIS PION EER APPARATUS CON TA IN S

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DON E BY A SPECIALLY

INSTRUCTED PERSON.

For CD Wave length (typ) : 790 nm

Operation output : 4 mW CW, Class 1

Maximum output : Class 1 (Under fault condition)

Laser Pickup specifications and Laser characteristics

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians ; it is not meant for the casual do-ityourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

CAUTION

This product is a class 1 laser product classified

under the Safety of laser products, IEC 60825-1:2007.

CLASS 1 LASER PRODUCT

D58-5-2-2a_A1_En

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

CDJ-850

LABEL CHECK

(Printed on the chassis)

(Printed on the chassis) (Printed on the chassis)

(Printed on the chassis) (Printed on the chassis)

SYXJ8

KXJ5 AXJ5

CUXJ FLXJ

5

6 7 8

A

B

C

D

E

5

CDJ-850

6 7 8

F

3

1

[Important Check Points for Good Servicing]

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

3. Lubricants, Glues, and Replacement parts

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

A

2 3 4

B

C

D

E

F

4

1

CDJ-850

2 3 4

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS ....................................................................................................................................................6

1.1 NOTES ON SOLDERING............................................................................................................................................... 6

1.2 ABOUT POWER SUPPLY MONITORING...................................................................................................................... 6

2. SPECIFICATIONS .................................................................................................................................................................7

2.1 SPECIFICATIONS .......................................................................................................................................................... 7

2.2 USABLE DISCS AND USB DEVICES............................................................................................................................ 8

2.3 PANEL FACILITIES....................................................................................................................................................... 10

3. BASIC ITEMS FOR SERVICE ............................................................................................................................................13

3.1 CHECK POINTS AFTER SERVICING .........................................................................................................................13

3.2 JIGS LIST .....................................................................................................................................................................13

3.3 PCB LOCATIONS ......................................................................................................................................................... 14

4. BLOCK DIAGRAM ..............................................................................................................................................................16

4.1 OVERALL WIRING DIAGRAM .....................................................................................................................................16

4.2 SIGNAL BLOCK DIAGRAM.......................................................................................................................................... 18

4.3 POWER SUPPLY BLOCK DIAGRAM........................................................................................................................... 20

5. DIAGNOSIS ........................................................................................................................................................................ 22

5.1 POWER ON SEQUENCE.............................................................................................................................................22

5.2 TROUBLESHOOTING.................................................................................................................................................. 23

5.3 DIAGNOSIS OF THE PICKUP ASSY........................................................................................................................... 32

5.4 CONNECTION CHECK WITH THE PC........................................................................................................................ 33

5.5 ABOUT POWER SUPPLY MONITORING.................................................................................................................... 34

5.6 ABOUT THE PROTECTORS........................................................................................................................................ 34

6. SERVICE MODE................................................................................................................................................................. 35

6.1 SERVICE MODE ................................................................................................................

6.2 ABOUT THE DEVICE OF CDJ-850..............................................................................................................................35

6.3 DETAILS ON SERVICE MODE .................................................................................................................................... 36

7. DISASSEMBLY ................................................................................................................................................................... 42

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 52

8.1 NECESSARY ITEMS TO BE NOTED...........................................................................................................................52

8.2 USER SETABLE ITEMS ............................................................................................................................................... 52

8.3 UPDATING OF THE FIRMWARE ................................................................................................................................. 53

8.4 JOG DIAL ROTATION LOAD ADJUSTMENT ............................................................................................................... 55

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................56

9.1 PACKING SECTION ..................................................................................................................................................... 56

9.2 EXTERIOR SECION.....................................................................................................................................................58

9.3 CONTROL PANEL SECTION ....................................................................................................................................... 60

9.4 JOG DIAL SECTION .................................................................................................................................................... 62

9.5 SLOTIN MECHA SECTION.......................................................................................................................................... 64

10. SCHEMATIC DIAGRAM .................................................................................................................................................... 66

10.1 CNCT, SLMB and JINT ASSYS .................................................................................................................................. 66

10.2 MAIN ASSY (1/4)........................................................................................................................................................68

10.3 MAIN ASSY (2/4)........................................................................................................................................................70

10.4 MAIN ASSY (3/4)........................................................................................................................................................72

10.5 MAIN ASSY (4/4)........................................................................................................................................................74

10.6 CMPX (1/2) and USBA ASSYS .................................................................................................................................. 76

10.7 CMPX ASSY (2/2) ......................................................................................................................................................78

10.8 DFLB ASSY .....................................................................................................................

SW1 and KSW2 ASSYS .......................................................................................................................................... 82

10.9 K

10.10 JFLB and JOGB ASSYS...........................................................................................................................................84

10.11 SLD1, PSWB and SLD2 ASSYS ..............................................................................................................................86

10.12 POWER SUPPLY and ACIN ASSYS ........................................................................................................................ 88

10.13 VOLTAGES ............................................................................................................................................................... 90

10.14 WAVEFORMS...........................................................................................................................................................91

10.15 EACH SIGNAL LEVEL.............................................................................................................................................. 93

11. PCB CONNECTION DIAGRAM........................................................................................................................................94

11.1 CNCT, SLMB and JINT ASSYS .................................................................................................................................. 94

11.2 MAIN ASSY ................................................................................................................................................................ 98

11.3 CMPX and USBA ASSYS.........................................................................................................................................102

11.4 DFLB ASSY .............................................................................................................................................................. 106

SW1 and KSW2 ASSYS ........................................................................................................................................ 110

11.5 K

11.6 JFLB and JOGB ASSYS...........................................................................................................................................112

11.7 SLD1, PSWB and SLD2 ASSYS ..............................................................................................................................114

11.8 POWER SUPPLY and ACIN ASSYS ........................................................................................................................116

12. PCB PARTS LIST ............................................................................................................................................................ 118

.......................................... 35

........................................... 80

A

B

C

D

E

F

CDJ-850

5

6 7 8

5

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

This unit always monitors for power failure and will shut itself off immediately after an error is detected. If an error is generated,

the STANDBY LED will flash after the unit shuts itself off. After the unit shuts itself off because of an error, unplug the AC power

cord and wait 1 minute before turning the unit ON by pressing the STANDBY/ON key.

Repair the unit, according to “5.5 ABOUT POWER SUPPLY MONITORING.”

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

1.2 ABOUT POWER SUPPLY MONITORING

D

E

F

6

1

2 3 4

CDJ-850

5

Power requirements........ AC 220 V to 240 V, 50 Hz/ 60 Hz (SYXJ8)

AC 120 V, 60 Hz (CUXJ)

AC 110 V to 240 V, 50 Hz/ 60 Hz (FLXJ)

AC 220 V, 60 Hz (KXJ5)

AC 220 V to 240 V, 50 Hz/ 60 Hz (AXJ5)

Power consumption................................................................... 21 W

Power consumption (standby).................................................. 0.4 W

Main unit weight....................................................................... 2.3 kg

Max. dimensions........ 305 mm (W) × 105.5 mm (H) × 364.4 mm (D)

(12 in. (W) × 4.2 in. (H) × 14.3 in. (D))

Tolerable operating temperature.............................. +5 °C to +35 °C

(+41 °F to +95 °F)

Tolerable operating humidity.............5 % to 85 % (no condensation)

Analog audio output (AUDIO OUT L/ R)

Output terminal.............................................................RCA terminal

Output Level........................................................... 2.0 Vrms (1 kHz)

Frequency response.................................................. 4 Hz to 20 kHz

S/ N ratio.................................................................................115 dB

Total harmonic distortion.......................................................0.003 %

USB downstream section (USB)

Port..........................................................................................Type A

Power supply.......................................................5 V/ 500 mA or less

USB upstream section (USB)

Port..........................................................................................Type B

Control output (CONTROL)

Port...................................................................................... Mini-jack

• The specifications and design of this product are subject to

change without notice.

2. SPECIFICATIONS

2.1 SPECIFICATIONS

6 7 8

A

B

C

D

E

F

CDJ-850

5

6 7 8

7

1

2 3 4

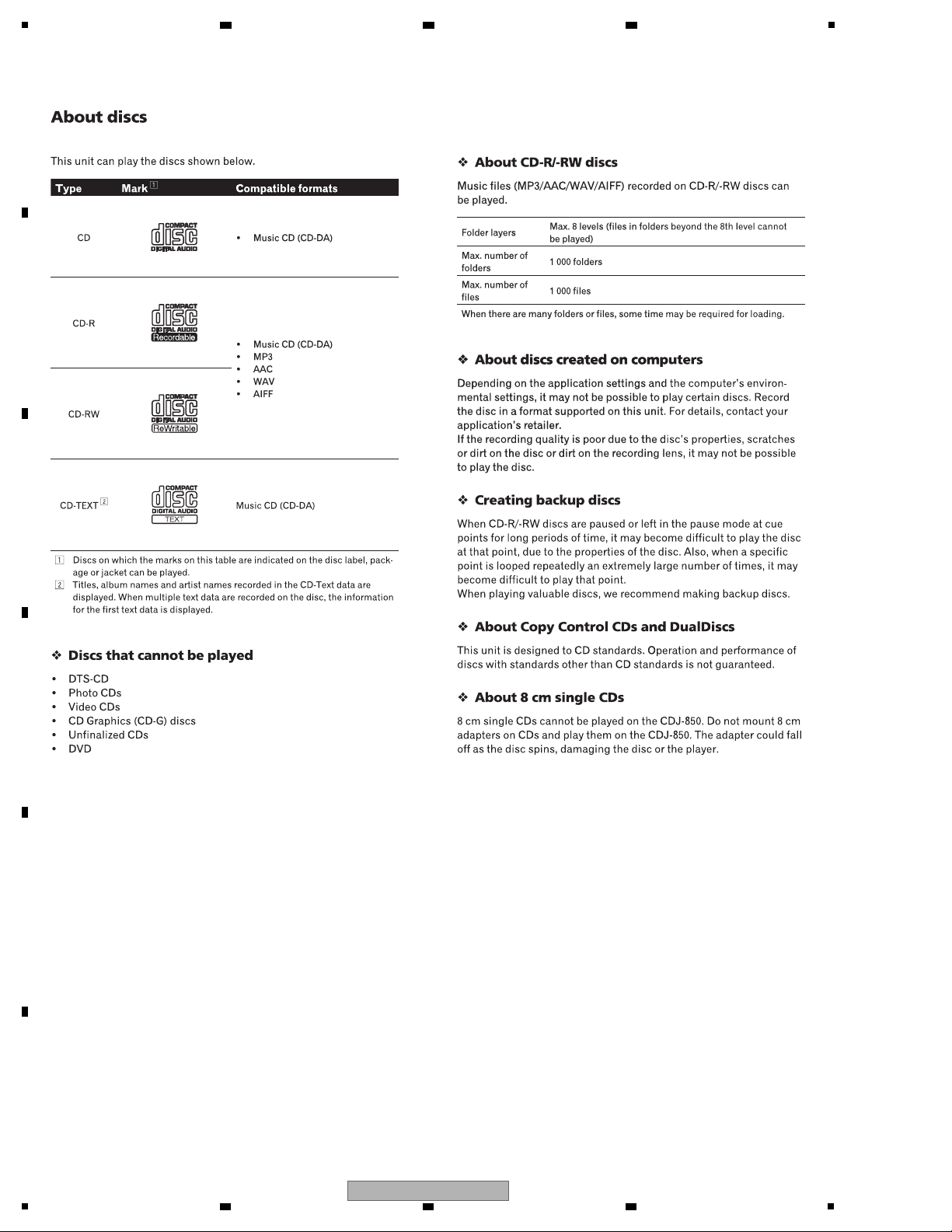

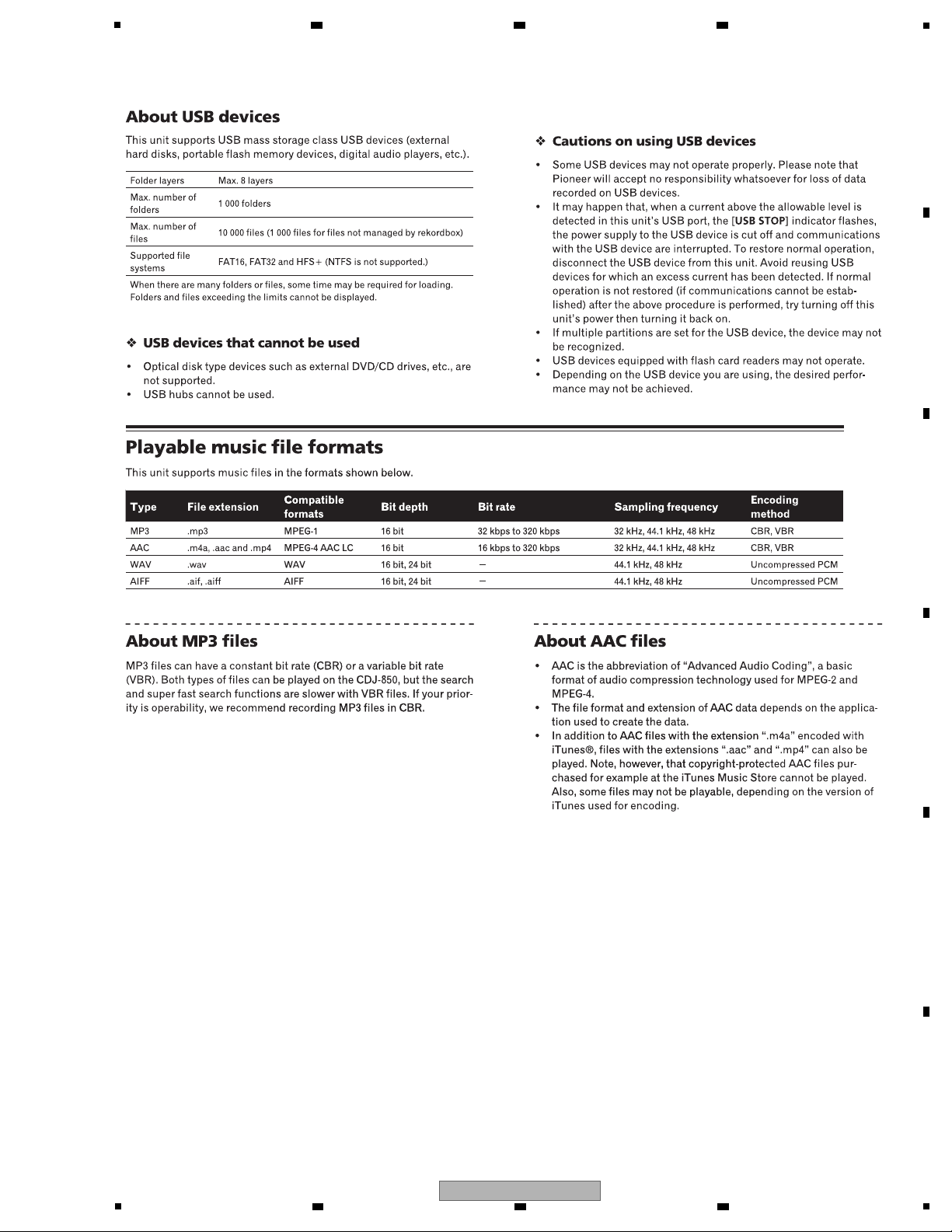

2.2 USABLE DISCS AND USB DEVICES

A

B

C

D

E

F

8

1

2 3 4

CDJ-850

5

6 7 8

A

B

C

D

E

F

CDJ-850

5

6 7 8

9

1

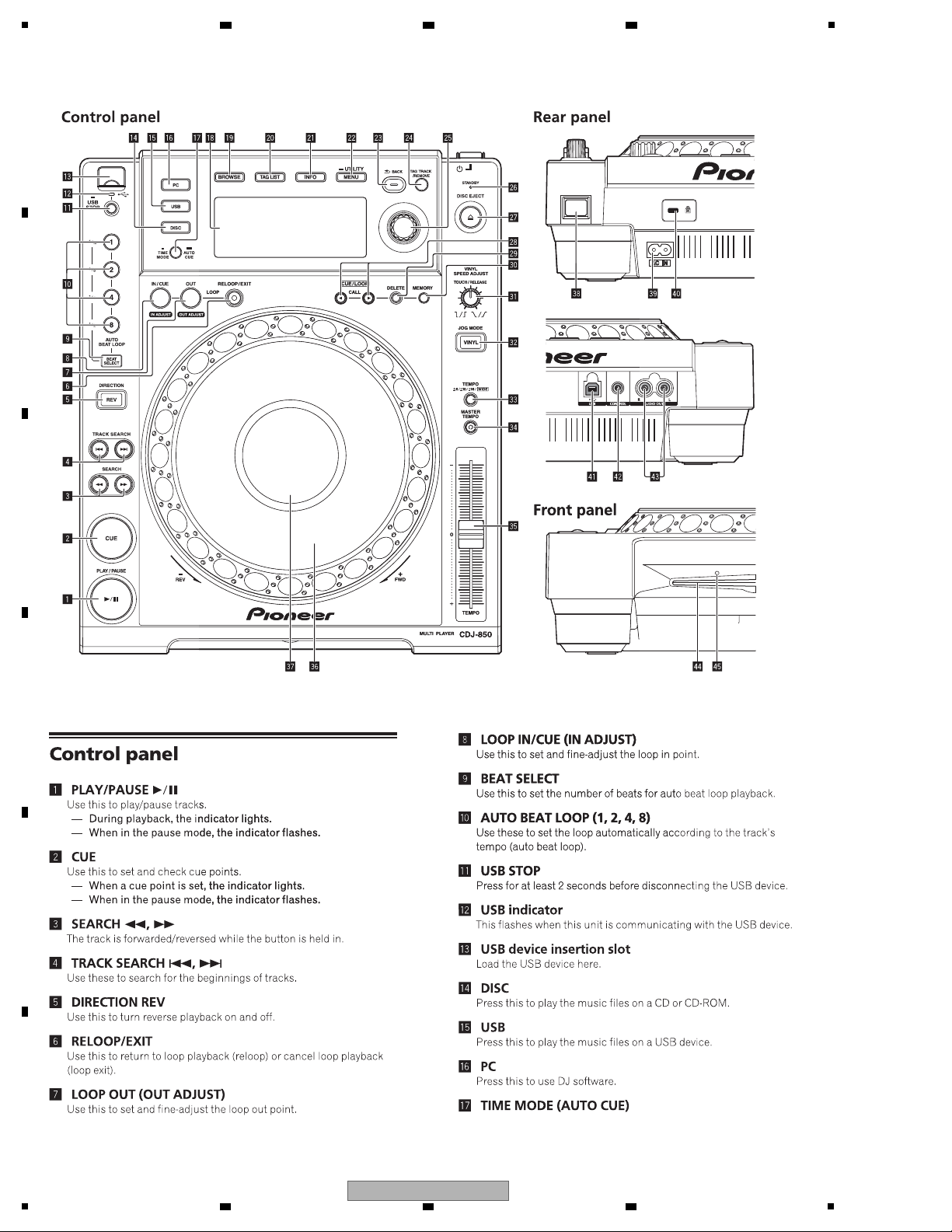

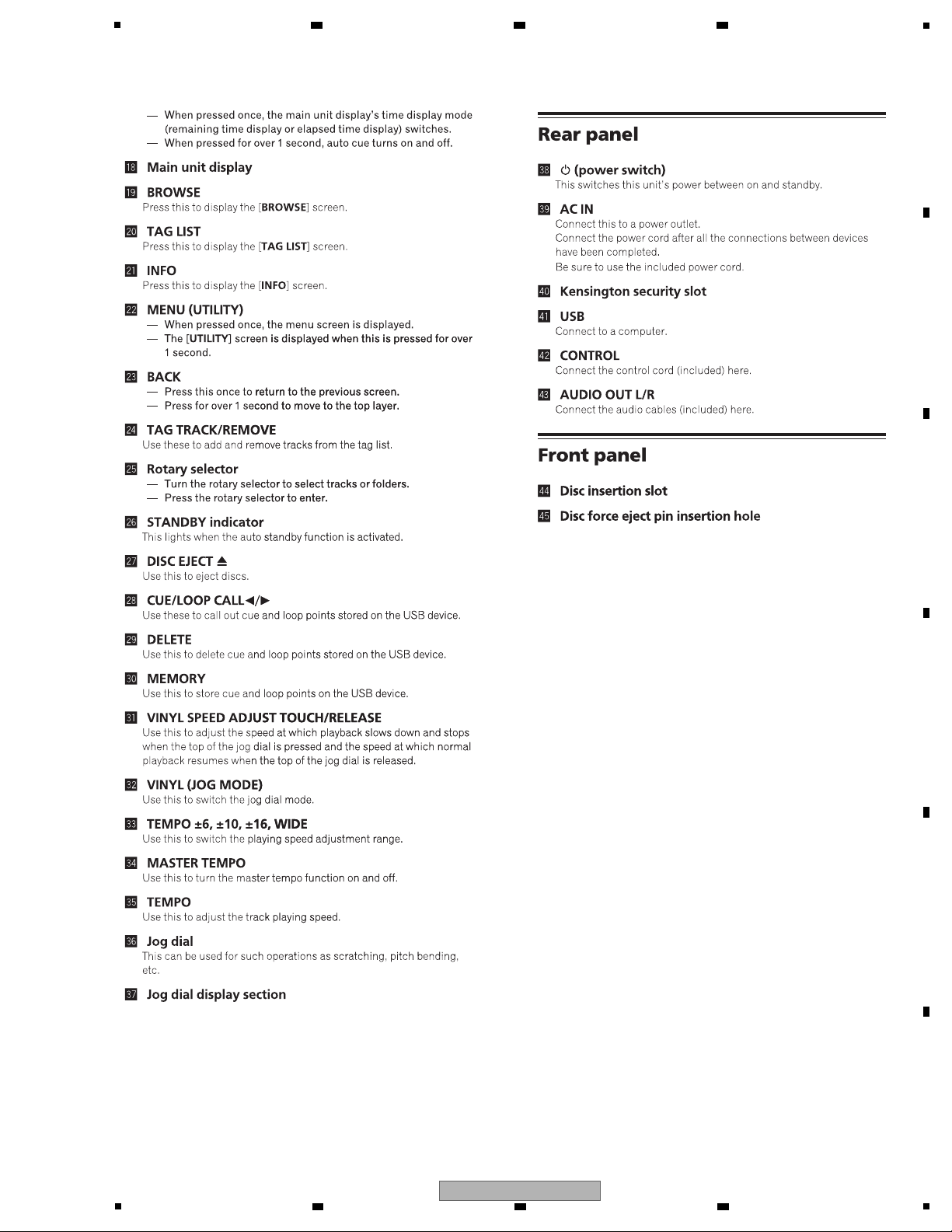

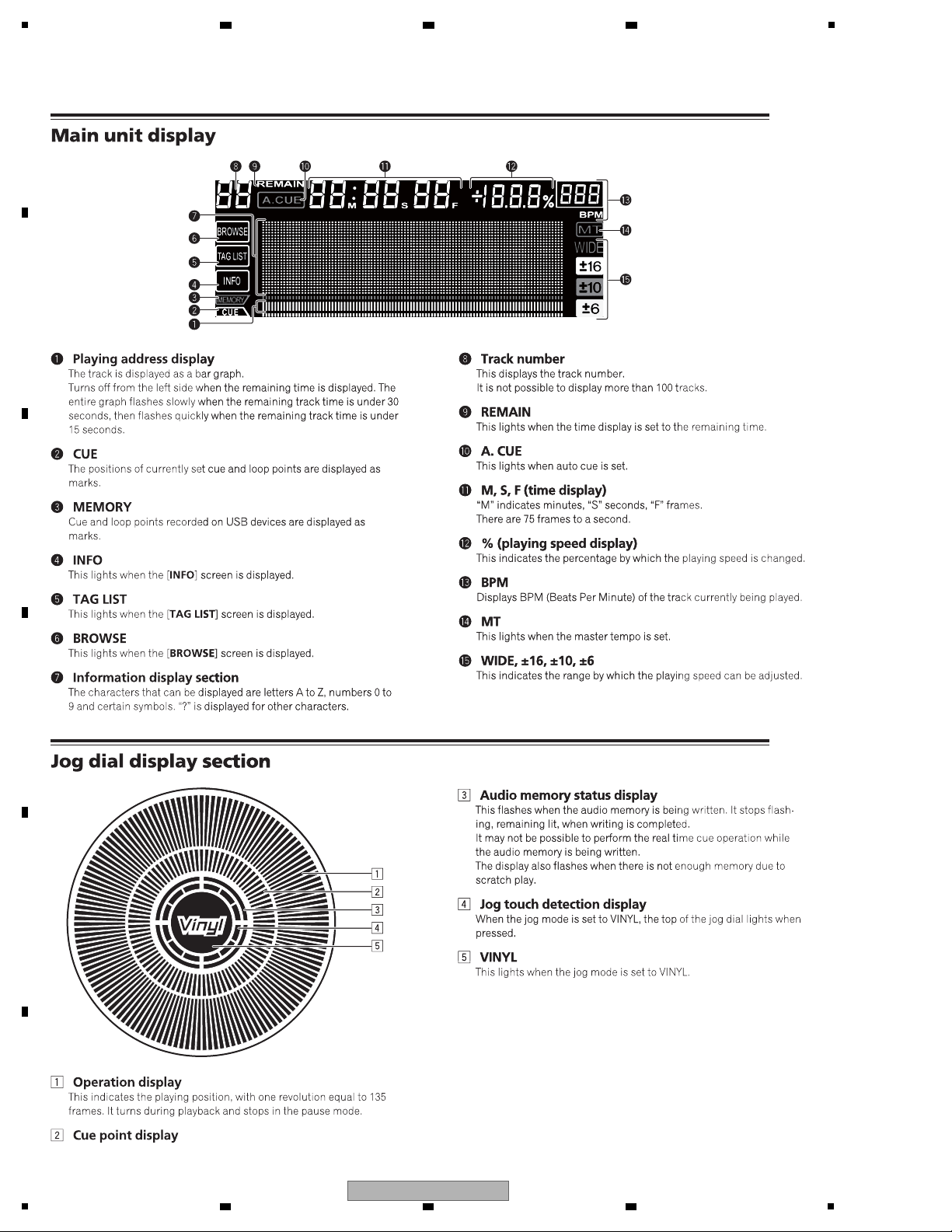

2.3 PANEL FACILITIES

A

B

2 3 4

C

D

E

F

10

1

2 3 4

CDJ-850

5

6 7 8

A

B

C

D

E

F

CDJ-850

5

6 7 8

11

1

A

B

2 3 4

C

D

E

F

12

1

2 3 4

CDJ-850

5

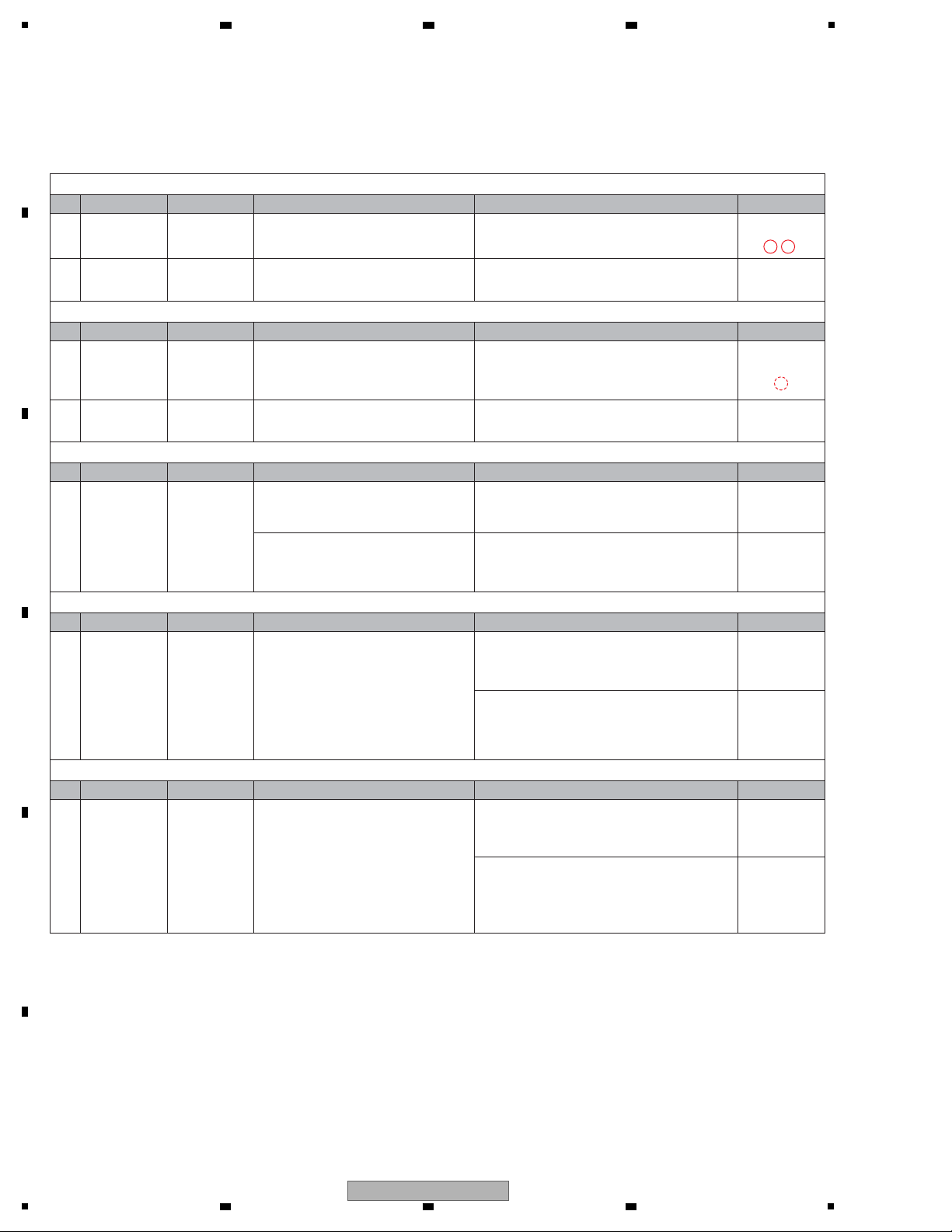

Items to be checked after servicing / CDJ

To keep the product quality after servicing, confirm recommended check points shown below.

No.

Procedures Check points

1

3

4

5

6

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Audio and operations must be normal.

Play back a CD. (track search) Audio, Search and operations must be normal.

2 Check output analog audio. Audio and operations must be normal.

Check the connection of each interface.

Play back data contained in the device connected to USB A. Audio, Search and operations must be normal.

USB B The device must be recognized by the PC.

Check output signals while the JOG dial or TEMPO slider is

being operated.

Audio and operations must be normal.

Check the appearance of the product.

No scratches or dirt on its appearance after receiving it for

service.

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding video and audio.

Cleaning

Name Part No. Remarks

Cleaning paper GED-008

Cleaning liquied GEM1004 Refer to

"9.5 SLOTIN MECHA SECTION".

Position to be cleaned

Pickup lenses

Jigs List

Jig Name Part No. Purpose of use / Remarks

CD test disc STD-905 CD playback diagnosis

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

Lubricants and Glues List

Name Part No. Remarks

Lubricating oil ZLB-HFD1600 Refer to “9.4 JOG DIAL SECTION”.

Dyfree GEM1036 Refer to “9.5 SLOTIN MECHA SECTION”.

Lubricating oil GYA1001

Refer to “9.4 JOG DIAL SECTION”,

“9.5 SLOTIN MECHA SECTION”.

6 7 8

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

3.2 JIGS LIST

5

6 7 8

CDJ-850

C

D

E

F

13

1

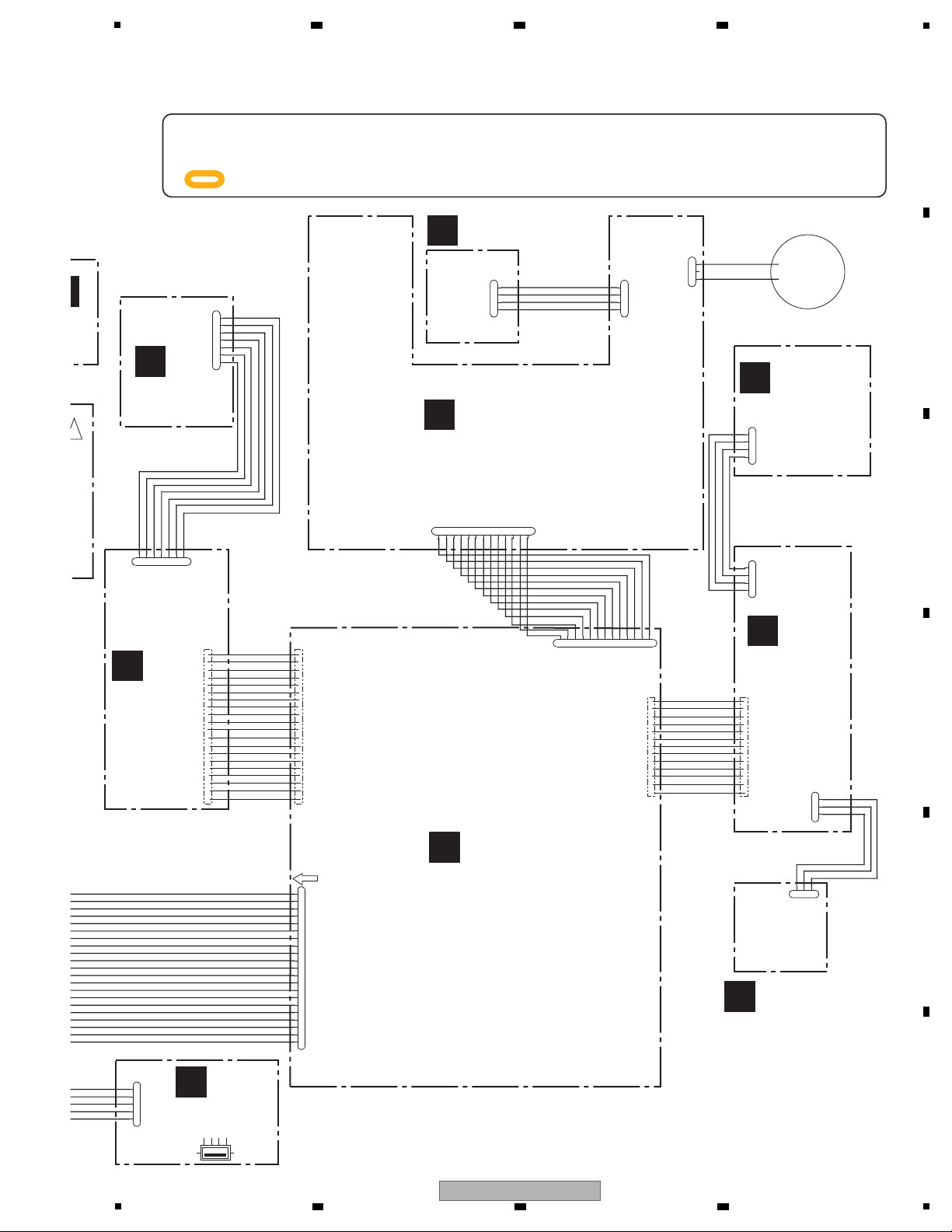

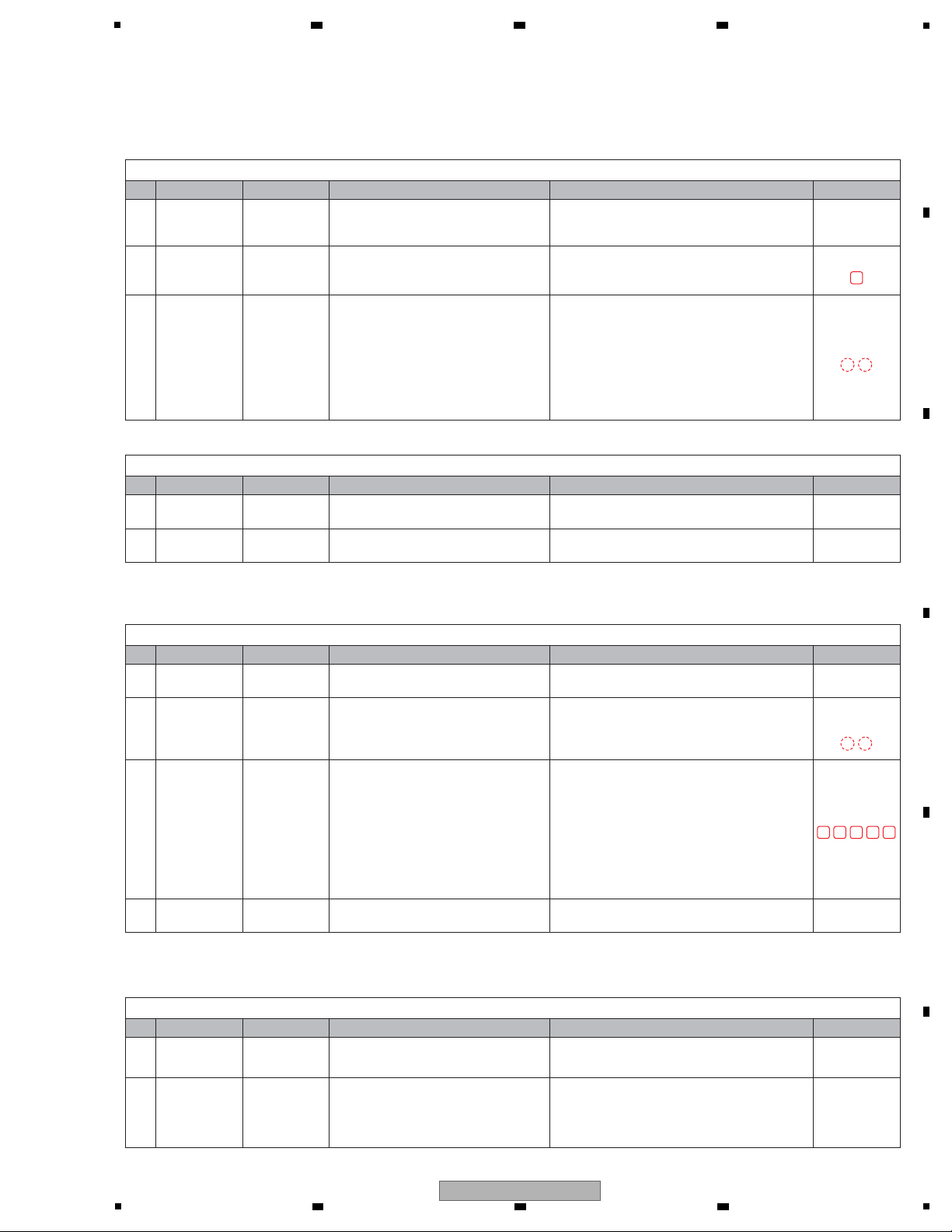

1..MAIN ASSY DWX3174

NSP 1..SUB1 ASSY (SYXJ8, FLXJ, KXJ5, AXJ5) DWM2399

NSP 1..SUB1 ASSY (CUXJ) DWM2405

NSP 2..KSW1 ASSY DWS1422

NSP 2..SLD1 ASSY DWS1423

2..PSWB ASSY DWS1424

2..SLMB ASSY DWS1425

2..KSW2 ASSY DWS1426

2..SLD2 ASSY DWS1427

2..DFLB ASSY DWX3152 ∗

2..JFLB ASSY DWX3154

2..JOGB ASSY DWX3155

2..ACIN ASSY (SYXJ8, FLXJ, KXJ5, AXJ5) DWX3158

2..ACIN ASSY (CUXJ) DWX3173

NSP 1..SUB2 ASSY DWM2400

2..CNCT ASSY DWX3151

2..CMPX ASSY DWX3153

2..USBA ASSY DWX3156

2..JINT ASSY DWX3157

> 1..POWER SUPPLY ASSY DWR1463

NSP 1..SLOTIN MECHA ASSY DXA2206

1..TM ASSY-S (VTM091) DXX2616

E

CMPX ASSY

G

DFLB ASSY

H

KSW1 ASSY

F

USBA ASSY

O

POWER SUPPLY ASSY

I

KSW2 ASSY

K

JOGB ASSY

B

SLMB ASSY

P

ACIN ASSY

• Bottom view

A

CNCT

ASSY

TM ASSY-S

(VTM091)

C

JINT

ASSY

J

JFLB

ASSY

L

SLD1

ASSY

N

SLD2

ASSY

M

PSWB

ASSY

D

MAIN

ASSY

SLOTIN MECHA ASSY

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

∗

The service part of DFLB Assy (DWX3152) is supplied with KSW1 Assy (DWS1422) and SLD1 Assy (DWS1423).

(There assemblies are connected with the jumper wires.)

3.3 PCB LOCATIONS

A

2 3 4

B

C

D

E

F

14

1

2 3 4

CDJ-850

5

6 7 8

A

B

C

D

E

F

CDJ-850

5

6 7 8

15

1

ADG7022 (For CUXJ)

ADG7097, ADG1154 (For FLXJ)

XDG3054 (For KXJ5)

ADG1154 (For SYXJ8)

ADG7079 (For AXJ5)

ACIN ASSY

(DWX3173: CUXJ)

(DWX3158: OTHERS)

P

DKP3891: CUXJ

DKP3889: OTHERS

I

H

KSW2

(DWS

KSW1 A

(DWS1

B

C

SLMB ASSY

(DWS1425)

O

POWER SUPPLY

ASSY

(DWR1463)

JINT ASSY

(DWX3157)

A

CNCT ASSY

(DWX3151)

CMPX ASSY

(DWX3153)

E

E E

1/2, 2/2

MAIN ASSY

(DWX3174)

D

D D

1/4- 4/4

!

!

AKM1299-A

CN401

1

V+7R6_M2GNDM

3

GNDD4GNDD5GNDD

6

V+7R6_D7V+7R6_D

8

GNDD

9

V+12

10

GNDD

11

V-10_A

12

GNDA

13

V+10_A

B6B-XH-A

1

GNDM

2

GNDD

3

PWR_XON

4

V+12

5

V+12

6

V+12_EUP

B2P3-VH

1

LIVE(PURPLE)

2

NEUTRAL(BLUE)

1V+6R6

2GNDD

3CUE_LED

4CUE_SW

5PLAY_LED

1

ST1-

2

ST1+

3

ST2+

4

ST2-

1

FR

2

FD

3

TR

4

TD

5

NC

6

GNDS

7

LD650

8

PD

9

LD780

10

GNDS

11

VR780

12

VRCOM

13

VR650

14

A

15

B

16

VRF

17

SW1_DVD/CD

18

C

19

D

20

E

21

Vcc

22

VREF

23

F

24

GNDS

DKN1445-A

CN2302

GNDS

1

V+5P

2

F

3

VREF

4

E

5

D

6

C

7

GNDS

8

GNDS

9

B

10

A

11

GNDS

12

GNDS

13

VR780PD

14

GNDS

15

GNDS

16

GNDS

17

GNDS

18

LD780

19

GNDS

20

TD

21

TR

22

FD

23

FR

24

DKN1312-A

CN2301

1

INSW

2

W

3

V

4

U

5

HB

6

W-

7

W+

8

V-

9

V+

10

U-

11

U+

12

VCC

CN2304

DKN1288-A

ST1-

1

ST1+

2

ST2+

3

ST2-

4

DKN1445-A

CN2501

FR

1

FD

2

TR

3

TD

4

NC

5

GNDS

6

LD650

7

PD

8

LD780

9

GNDS

10

VR780

11

VRCOM

12

VR650

13

A

14

B

15

VRF

16

SW1_DVD/CD

17

C

18

D

19

E

20

Vcc

21

VREF

22

F

23

GNDS

24

DKN1445-A

CN2502

1

GNDS

2

V+5P

3

F

4

VREF

5

E

6

D

7

C

8

GNDS

9

GNDS

10

B

11

A

12

GNDS

13

GNDS

14

VR780PD

15

GNDS

16

GNDS

17

GNDS

18

GNDS

19

LD780

20

GNDS

21

TD

22

TR

23

FD

24

FR

CN1701

VKN 1265-A

LPS21

LPS12

GNDD3

LO+4

LO-5

RKN1058-A

CN403

1

GNDD

2

GNDD

3

VBUS_B

4

GNDD

5

USB_D_P

6

USB_D_N

7

GNDD

8

CONT2

9

GNDD

10

CONT1

11

GNDD

12

GNDD

13

GNDA

14

LOUT

15

GNDA

16

ROUT

17

GNDA

RKN1068-A

CN402

1

USBA_D_P

2

USBA_D_N

3

GNDD

4

USB_CODETFLG

5

GNDD

6

USB_VBUSON

7

GNDD

8

PWR_ON

9

GNDD

10

VDET

11

GNDD

12

MAIN_XMUTE

13

GNDD

14

MAIN_XRST

15

TSI

16

MAIN_XBUSY

17

TSO

18

PNL_XBUSY

19

GNDD

20

TSCK

21

GNDD

22

V+5R6

23

V+5R6

24

GNDD

25

GNDD

26

V+12_EUP

27

GNDD

KM200NA13

CN2004

1

V+7R6_M

2

GNDM

3

GNDD

4

GNDD

5

GNDD

6

V+7R6_D

7

V+7R6_D

8

GNDD

9

V+12

10

GNDD

11

V-10_A

12

GNDA

13

V+10_A

B6B-XH-A

CN2001

1

GNDM

2GNDD

3PWR_XON

4V+12

5V+12

6V+12_EUP

VKN1252-A

CN2003

1

TSO

2

PNL_XBUSY

3

TSI

4

GNDD

5

TSCK

6

GNDD

7

PNL_CNVSS

8

GNDD

9

PNL_XRST

10

MAIN_XBUSY

11

USB_STOP

12

MAIN_XRST

13

PWR_ON

14

PNL_XMUTE

15

VDET

16

GNDD

17

V+12

18

V+12

19

GNDD

20

V+12_EUP

21

GNDD

VKN 1258-A

CN2002

CN1

CN2

1

GNDD

2

V+12_EUP

3

GNDD

4

GNDD

5

V+5R6

6

V+5R6

7

GNDD

8

TSCK

9

GNDD

10 PNL_XBUSY

11 TSO

12

MAIN_XBUSY

13 TSI

14

MAIN_XRST

15

GNDD

16

MAIN_XMUTE

17

GNDD

18

VDET

19

GNDD

20 PWR_ON

21

GNDD

22

USB_VBUSON

23

GNDD

24 USB_CODETFLG

25

GNDD

26 USBA_D_N

27 USBA_D_P

VKN1248-A

CN2006

1

GNDA

2

ROUT

3

GNDA

4

LOUT

5

GNDA

6

GNDD

7

GNDD

8

CONT1

9

GNDD

10

CONT2

11

GNDD

12

USB_D_N

13

USB_D_P

14

GNDD

15

VBUS_B

16

GNDD

17

GNDD

CN2005

52147-0510

1

V+5_USB

2

USBA_D_N

3

USBA_D_P

4

GNDD

5

GNDD

51048-0500

JH2201

1

V+5_USB

2

USBA_D_N

3

USBA_D_P

4

GNDD

5

GNDD

JA2401

1

2

DKN1407-A

CN2305

1

INSW

2

W

3

W

4

V

5

V

6

U

7

U

8

GNDD

9

HW-

10

HW+

11

HV-

12

HV+

13

HU-

14

HU+

15

V+5M

16

GNDD

17

FR

18

FD

19

TR

20

TD

21

GNDS

22

LD780

23

GNDS

24

PD

25

A_A

26

A_B

27

A_C

28

A_D

29

A_S1

30

VREF

31

A_S2

32

V+5P

33

GNDS

34

GNDS

35

GNDS

36

LPS1

37

LPS2

38

GNDS

39

LO-

40

LO-

41

LO+

42

LO+

43

ST2+

44

ST2+

45

ST2-

46

ST2-

47

ST1+

48

ST1+

49

ST1-

50

ST1-

DKN1404-A

CN201

1

ST1-

2

ST1-

3

ST1+

4

ST1+

5

ST2-

6

ST2-

7

ST2+

8

ST2+

9

LO+

10

LO+

11

LO-

12

LO-

13

GNDS

14

LPS2

15

LPS1

16

GNDS

17

GNDS

18

GNDS

19

V+5P

20

A_S2

21

VREF

22

A_S1

23

A_D

24

A_C

25

A_B

26

A_A

27

PD

28

GNDS

29

LD780

30

GNDS

31

TD

32

TR

33

FD

34

FR

35

GNDD

36

V+5M

37

HU+

38

HU-

39

HV+

40

HV-

41

HW+

42

HW-

43

GNDD

44

U

45

U

46

V

47

V

48

W

49

W

50

INSW

CN2303

VKN 1374-A

1

LPS2

2

LPS1

3

GNDD

4

LO+

5

LO-

1

INSW

2

W

3

V

4

U

5

HB

6

W-

7

W+

8

V-

9

V+

10

U-

11

U+

12

VCC

NEUTRAL

LIVE

SPINDLE MOTOR

09SD PICK UP ASSY

DDD1527Pitch=1.0mm

Length=180mm

Same Face

FFC

DDD1491Pitch=0.5mm

Length=175mm

Reverse Face FFC

ZWNN1007G28-9-06A

Length=60mm

White Single Wire

ZWNN1007G28-8-06A

Length=60mm

Gray Single Wire

LO-

LO-

LO+

LO+

LOADING MOTOR

ASSY-S

(DXX2615)

Pitch=1.0mm

Reverce Face

FFC

DDD1536-(Gold)

Pitch=0.5mm

Length=66mm

Reverse Face FFC

PF13PP-S07

Pitch=2.0mm

Length=75mm

Connector Ass'y

DDD1524Pitch=1.0mm

Length=70mm

Same Face

FFC

DDD1523Pitch=1.0mm

Length=70mm

Same Face

FFC

D20PDY07

Pitch=2.0m

Length=20

Parallel Ju

DDD1522Pitch=1.0mm

Length=170mm

Same Face

FFC

D20PDY0510E

Pitch=2.0mm

Length=100mm

Parallel Jumper

Wire

DE010VE0

Length=100mm

Earth Lead Cable

Horizontal

Contact Side Down

Vertical

Horizontal

AC POWER CORD

Vertical

Contact Side

Vertical

Contact Side

Vertical

Vertical

VH

Soldered

DKP3869Pitch=2.5mm

Length=100mm

Connector Assy

DKP3870Pitch=3.96mm

Length=100mm

Connector Ass'y

US

Pitch=1.0mm

Same Face

FPC

STEPPING

MOTOR

Horizontal

Contact Side Up

Vertical

Contact Side

Horizontal

Contact Side Up

Horizontal

Contact Side Down

Horizontal

Contact Side Down

Horizontal

Contact Side Down

Horizontal

Contact Side Down

Horizontal

Contact Side Down

Horizontal

Contact Side Up

Horizontal

Contact Side Up

Boardin

Vertical

Vertical

Vertical

Verti

Vertical

Contact Side

Soldered

DDD1535Pitch=0.5mm

Length=80mm

Reverse Face FFC

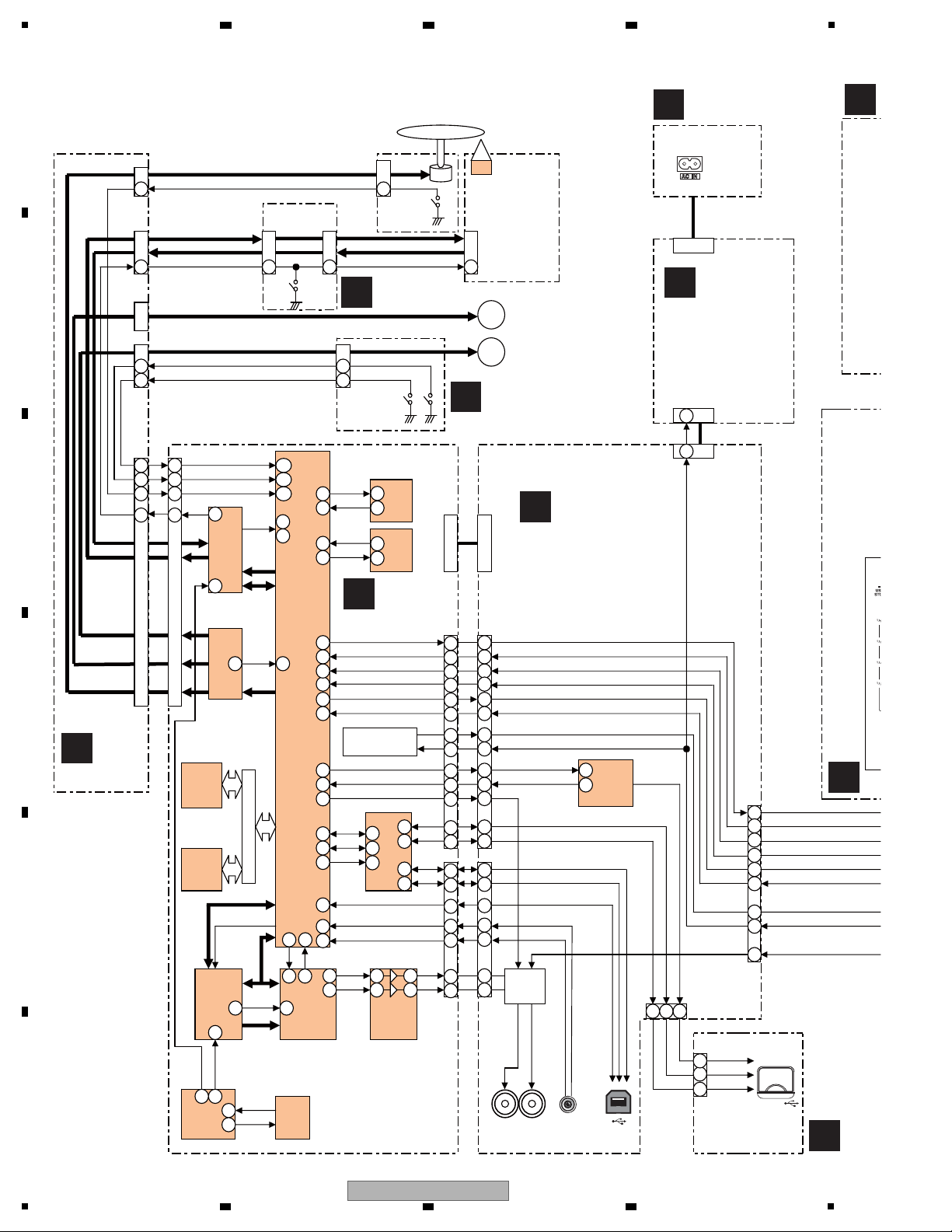

SLOTIN MECHA ASSY

(DXA2206)

TM ASSY-S (DXX2616)

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

16

1

B

C

D

E

F

2 3 4

2 3 4

CDJ-850

5

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

G

DFLB ASSY

(DWX3152)

I

H

KSW2 ASSY

(DWS1426)

F

USBA ASSY

(DWX3156)

K

JOGB ASSY

(DWX3155)

N

SLD2 ASSY

(DWS1427)

L

SLD1 ASSY

(DWS1423)

KSW1 ASSY

(DWS1422)

J

JFLB ASSY

(DWX3154)

LY

M

PSWB ASSY

(DWS1424)

!

CN1801

CKS1072-A

1JOG_SW

2N C

3G NDD

52147-0710

CN1401

1

V+6R6

2

GNDD

3

CUE_LED

4

CUE_SW

5

PLAY_LED

6

PLAY_SW

7

KEY2_B

VKN 1273-A

CN1002

1V +12

2GNDD

3V +38

4GNDD

5JOG1

6JOG2

7JOG_SW

8J_DSO

9J_BK

10J_SCLK

11J_LAT

12GNDD

13V+3R3_SW

CN1901

52151-0410

1

JOG2

2

JOG1

3

V+3R3_SW

4

GNDD

CN1601

52147-0310

1PWR_SW

2GN DD

3GN DD

CN1501

52147-0410

1

ADCT

2

ADIN

3

GNDA

4

V+3R3_EUP

DKB1106-1

JA2201

1

234

RT1

RT2

51048-0700

JH1201

1V+6R6

2GNDD

3CUE_LED

4CUE_SW

5PLAY_LED

6PLAY_SW

7KEY2_B

51048-0400

JH1801

1

JOG2

2

JOG1

3

V+3R3_SW

4

GNDD

51048-0400

JH1301

1 ADCT

2 ADIN

3GNDA

4 V+3R3_EUP

51048-0300

JH1302

1

PWR_SW

2

GNDD

3

GNDD

51048-0500

JH2201

1

V+5_USB

2

USBA_D_N

3

USBA_D_P

4

GNDD

5

GNDD

VKN 1252-A

CN1001

1

GNDD

2

V+12_EUP

3

GNDD

4

V+12

5

V+12

6

GNDD

7

VDET

8

PNL_XMUTE

9

PWR_ON

10

MAIN_XRST

11

USB_STOP

12

MAIN_XBUSY

13

PNL_XRST

14

GNDD

15

PNL_CNVSS

16

GNDD

17

TSCK

18

GNDD

19

TSI

20

PNL_BUSY

21

TSO

VKN 1244-A

CN1802

1

V+3R3_SW2GNDD

3 J_LAT

4

J_SCLK

5

J_BK

6

J_DSO7JOG_SW

8 JOG2

9 JOG1

10

GNDD

11

V+38

12

GNDD

13

V+12

D20PDY0720E

Pitch=2.0mm

Length=200mm

Parallel Jumper Wire

D20PDY0410E

Pitch=2.0mm

Length=100mm

Parallel Jumper Wire

D20PDY0310E

Pitch=2.0mm

Length=100mm

Parallel Jumper Wire

D20PYY0405E

Pitch=2.0mm

Length=50mm

Parallel Jumper Wire

DDD1522Pitch=1.0mm

Length=170mm

Same Face

FFC

ngth=100mm

re

DDD1521Pitch=1.0mm

Length=120mm

Same Face

FFC

Jumper Wire

Horizontal

ADIN

PWR_SW

MT_LED

ADCT

EJECT_LED

TCH/REL

KEY0

VIN YL_LED

ADIN

PWR_SW

MT_LED

ADCT

EJECT_LED

TCH/REL

VIN YL_LED

KEY0

EUP_LED

EUP_LED

GNDD

GNDD

V+6R6

V+6R6

V+3R3_EUP

V+3R3_EUP

GNDA

GNDA

SHIFT_SW

1KEY_SW

USB_ACT_LED

REV_SW

8KEY_LED

1KEY_LED

4KEY_SW

4KEY_LED

REV_LED

USB_STOP

8KEY_SW

2KEY_SW

2KEY_LED

PLAY_LED

PLAY_SW

GNDD

CUE_LED

V+6R6

CUE_SW

KEY2_B

4KEY_LED

USB_STOP

8KEY_SW

2KEY_SW

2KEY_LED

KEY2_B

PLAY_LED

SHIFT_SW

CUE_LED

GNDD

PLAY_SW

REV_LED

CUE_SW

1KEY_SW

USB_ACT_LED

REV_SW

8KEY_LED

V+6R6

1KEY_LED

4KEY_SW

Vertical

Contact Side Up

Horizontal

Contact Side Up

Horizontal

Contact Side Up

Jumper Wire

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Vertical

Contact Side

SHEET SW

(DSX1078)

6 7 8

A

B

C

D

5

6 7 8

CDJ-850

E

F

17

1

IC105

Buffer

PICKUP ASSY

JA2002

CONTROL

IC101

32M

FLASH ROM

IC302

DAC

IC301

DSP

IC103

MAIN CPU

CLK: 33 MHz

CORE CLK:

200 MHz

IC102

256M

SDRAM

IC303

OP AMP

7

1

JH2201

IC201

SERVO

DSP

IC204

DRIVER

OEIC

M

LOADING

MOTOR

M

STEPPING

MOTOR

12

15

1

2

3

5

10

13

14

PNL_XMUTE

3 2

CN2005

13

18

24

8

10

12

14

16

20

22

USB_CODETFLG

USB_VBUSON

PNL_XBUSY

TSO

MAIN_XBUSY

TSI

MAIN_XRST

MAIN_XMUTE

VDET

PWR_ON

TSCK

26

27

VBUS_B

3

3

CN1701

CN2301

CN2302

CN2303

CN2304

7

8

16

System Bus (Bus CLK:66MHz)

IC107

USB SW

X102

X-tal

48MHz

X101

X-tal

33MHz

JA2001

USB Type B

CONNECTOR

JA2003

AUDIO OUT

JA2003

USB Type A

CONNECTOR

K

1

SPINDLE

MOTOR

1

INSW

LD780

SHORT

SW

9

LD780

1

2

1

2

LPS2

LPS1

15

14

50

LPS1

LPS2

INSIDE

29

DP

DM

15

10

4

20

18

17

16

14

12

8

6

2

1

5

14

16

10

8

6

3

3

2

MUTE

CIRCUIT

VBUS

1

1

IC2003

USB OVER

CURRENT

PROTECT

POWER DETECT

CIRCUIT

13

4

2

8

10

12

15

CONT2

CONT1

USBB_D_N

USBB_D_P

USBA_D_N

USBA_D_P

USBA_D_N

USBA_D_P

V+5_USB

V+5_USB

3

5

16

16

36

37

1

22

CN2501CN2502

135

134

136 94

93 1

3

3

1

56

55

USB_X2

USB_X1

XTAL

EXTAL

LOUT

ROUT

66

70

64

48

75

59

88

71

USB_CDETFLG

MUTE

87

4

5

USB_ABSEL

LDO

ST1+,ST1-,ST2+,ST2-

LO+,LO-

W,V,U,HB,W-,W+,V-,V+,U-,U+

ST1+,ST1-,

ST2+,ST2-

LO+,LO-

W,V,U,HB,W-,W+,

V-,V+,U-,U+

VR780PD,

A,B,C,D,E,F

ALO

ARO

FR,FD,TR,TD

FR,FD,TR,TD

X103

X-tal

16.9344

MHz

5

6

210

CLK11M

USB

Full Speed

I/F

SCIF

DACBCLK,

DACBCLK,

DACBCLK

DRVMUTE1,

DRVMUTE2,

PWMLO,

PWMSL1IN,

PWMSL2IN

SPDLFG

TCOUNT,

ADC

DSPCS,DSPRST,PLAY

ZERO

45

73

43 181

161 185

102

100

101

208

113

160

3

5

10

1

7

2

6

149

150

15 11

41

73

16

DACCS

AUDIO_SCK,

AUDIO_SI,

AUDIO_SO

BCK,

LRCK,

DATA_L,

DATA_R

SRVSCLK,

SRVLRCK,

SRVSDATA

SRVBCLK,SRVBUS0-3,

SRVSBSY,SRVCCE,

SRVRST

11

JA2401

CN2001

CN2004

CN401

CN2002

CN402

CN2305

CN201

CN403

CN2006

CONT2

CONT1

LOUT

ROUT

PWR_XON

CN2003

JH120

CN140

119

P

ACIN ASSY

I

H

KS

E

CMPX ASSY

B

SLMB ASSY

A

CNCT ASSY

D

MAIN ASSY

C

JINT ASSY

F

USBA

O

POWER SUPPLY

ASSY

VR780PD,A,B,C,D,E,F

CLK_S_16M

CLK_A_16M

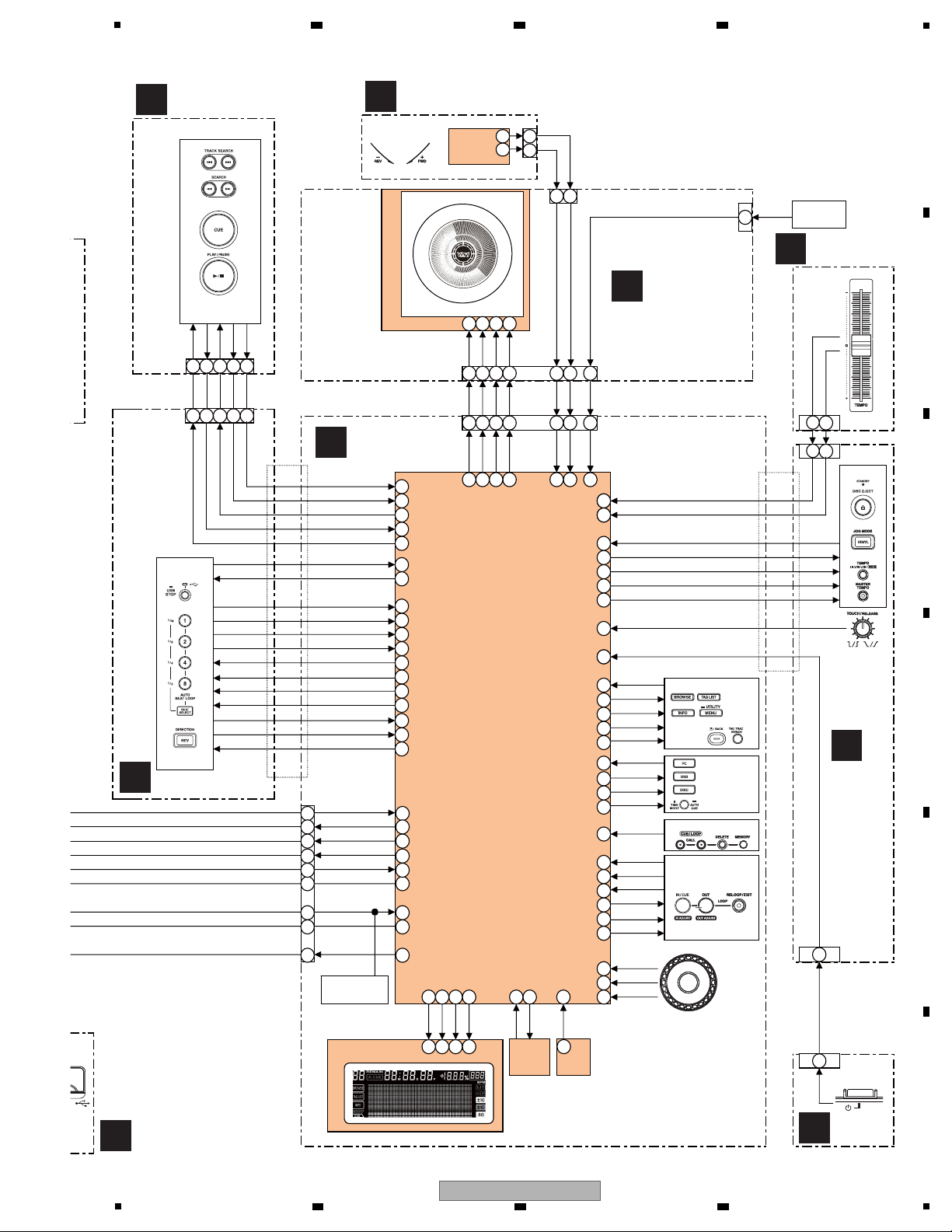

4.2 SIGNAL BLOCK DIAGRAM

A

2 3 4

B

C

D

E

F

18

2 3 4

1

CDJ-850

IC1007

PANEL CPU

CLK: 15.975 MHz

JOG2

JOG1

PWR_SW

CN1601

PC1901

ENCODER

4

3

2

1

VR8701

TEMPO SLIDER

98

6

4

JOG_SW

JH1801

1

1

1

1

1

2

ADIN

ADCT

3 5 7

ADIN

ADCT

PLAY_SW

7

64

KEY2_B

PLAY_LED

CUE_SW

CUE_LED

3 5

76

4

3 5

VDET

PNL_XMUTE

PNL_XBUSY

TSI

TSCK

MAIN_XBUSY

MAIN_XRST

PWR_ON

TSO

X1001

X-tal

15.975 MHz

VR1301

TOUCH/RELEASE

PWR_SW

90

2

1

5

68

10

11

9 7

2625242321 28 27

ENC_2

ENC_1

ENC_SW

5

4

3

S1018

KEY,LED

83

60

58

61

59

CUE_LED

CUE_SW

PLAY_LED

PLAY_SW

KEY2

TCH/REL

88

KEY,LED

EUP_LED1

EJECT_LED

KEY0

VINYL_LED

MT_LED

TCH/REL

92

93

87

94

95

EUP_LED

EJECT_LED

KEY0

VINYL_LED

MT_LED

3937

38

323133

35

30

XOUT

XIN

LOOPIN_SW

56

63

65

66

67

68

4KEY_LED

8KEY_LED

REV_LED

SHIFT_SW

REV_SW

69

70

1KEY_LED

2KEY_LED

71

72

4KEY_SW

8KEY_SW

73

2KEY_SW

74

57

USB_STOP

1KEY_SW

75

USB_ACT_LED

KEY,LED

1

2

KEY,LED

IN_LED

55

54

53

52

51

76

82

LOOPOUT_SW

OUT_LED

RELOOP_LED

RELOOP_SW

DISC_LED

UTILITY_LED

80

79

78

77

PLAYLIST_LED

BROWSE_LED

PC_LED

USB_LED

81

84

INFO_LED

85

86

KEY4

KEY1

KEY3

1

DATA FL

JOG FL

24252726

40

32

34

31

33

42

44

45

43

10

7

21

20

19

17

12

9

8

JUMPER

JUMPER

IC1004

RESET IC

1215

4

13

PNL_XRST

1

2

POWER DETECT

CIRCUIT

KEY,LED

KEY,LED

KEY,LED

SHEET SW

CN1001

JH1201

CN1401

CN1901

CN1802

CN1002

JOG_SW

JOG1

JOG2

JOG_SW

JOG1

JOG2

J_DSO

J_BK

J_SCLK

J_LAT

J_DSO

J_BK

J_SCLK

J_LAT

D_BK

D_LAT

D_SCLK

D_DSO

ROTARY SW

JH1302

PWR_SW

JH1301

CN1501

CN1801

I

KSW2 ASSY

H

KSW1 ASSY

K

JOGB ASSY

J

JFLB ASSY

G

DFLB ASSY

N

SLD2 ASSY

L

SLD1

ASSY

M

PSWB ASSY

F

USBA ASSY

V1801

5

V100

6 7 8

A

B

C

D

E

F

CDJ-850

5

6 7 8

19

1

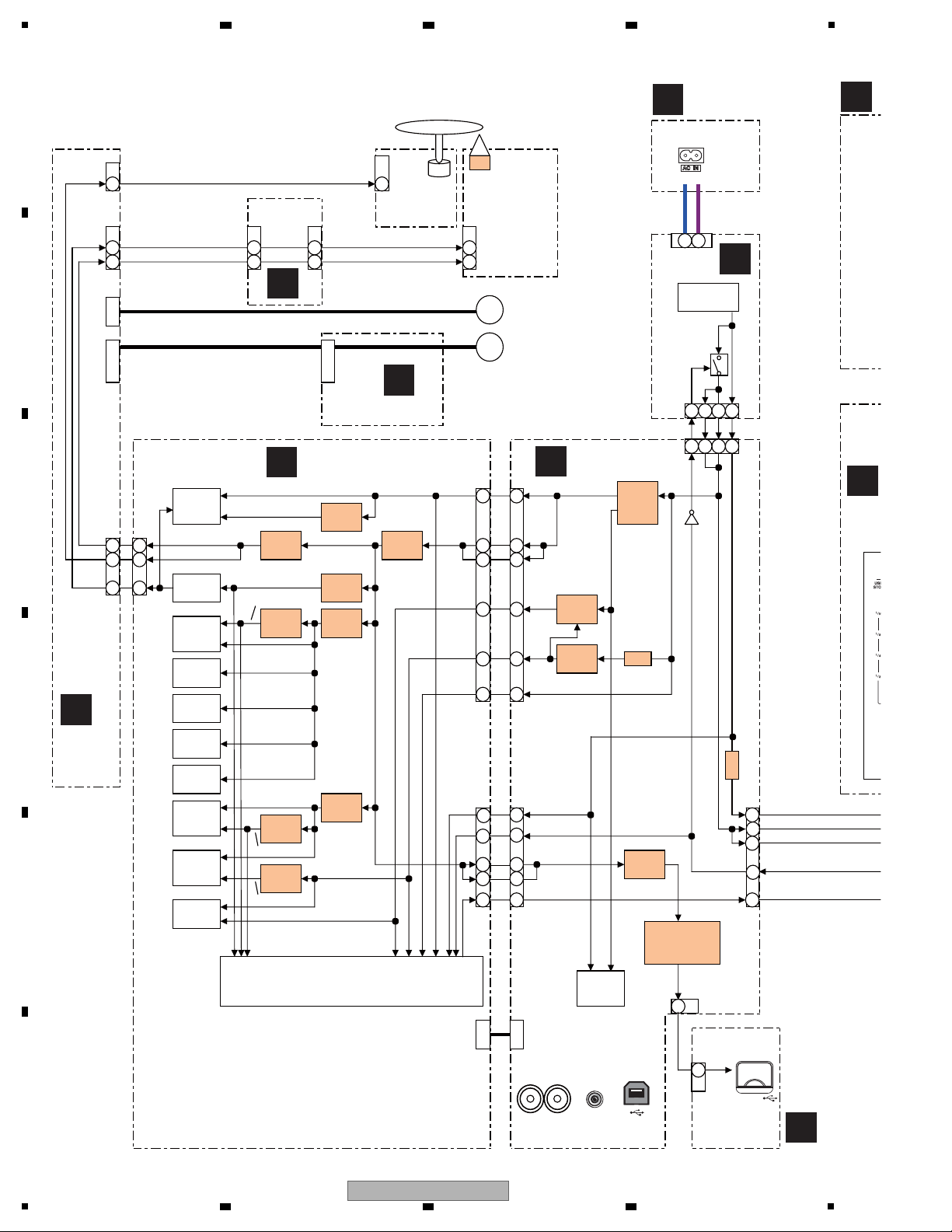

A

CNCT ASSY

P

ACIN ASSY

I

K

H

KSW

E

CMPX ASSY

B

SLMB ASSY

D

MAIN ASSY

C

JINT

ASSY

F

USBA AS

O

POWER

SUPPLY

ASSY

IC105

Buffa

JA2002

CONTROL

IC101

32M

FLASH ROM

IC302

DAC

IC301

DSP

IC103

MAIN CPU

IC102

256M

SDRAM

IC303

OP AMP

JH2201

IC201

SERVO DSP

IC204

DRIVER

OEIC

M

LOADING

MOTOR

M

STEPPING

MOTOR

V+

18

CN2003

CN2005

20

PWR_ON

3

3

CN1701

CN2301

CN2302

CN2303

CN2304

IC107

USB SW

JA2001

USB Type B

CONNECTOR

JA2003

AUDIO OUT

JA2003

USB Type A

CONNECTOR

12

SPINDLE

MOTOR

12

2 2 21

21

8

MUTE

CIRCUIT

1

1

IC2003

USB OVER CURRENT

PROTECT (1A)

POWER DETECT CIRCUIT

V+5_USB

32

CN2501CN2502

17

20

13

PW

2

26

V+12_EUP

622

523

V+5R6

11

V+7R6_M

V+7R6_D

V+12

V+10_A

V-10_A

13

7

7

1

9

5 6

65

V+1

IC2001

DCDC

12V→7.6V

12V→-11V

Q2028

REGULATOR

12V→10V

Q2028

REGULATOR

-11V→-10V

66

VCC

22

4

V+5P

VREF

VCC

VREF

V+5P

VREF

V+5M

19

30

21

15 36

IC409

DCDC

7.6V→5.6V

IC401

REGULATOR

5.6V→3.3V

IC402

REGULATOR

5.6V→3.3V

IC405

REGULATOR

5.6V→5V

IC206

REGULATOR

7.6V→5.6V

IC404

REGULATOR

3.3V→1.2V

IC408

REGULATOR

5.6V→3.3V

IC403

REGULATOR

3.3V→1.25V

IC406

REGULATOR

10V→5V

13

11

15

VD

ACDC

18

10

IC2002

REGULATOR

5.6V→5V

1

9

12

4

4

224

PICKUP ASSY

V+7R6_M

V+7R6_D

V+12

V+10_A

V-10_A

V+10_A

V-10_A

VREF1R65

V+5P

V+5M

V+

V-11_A

P2003

PROTECTOR

(0.5A)

P2004

(0.375A)

VDET

VDET

V+7R6

V+5R6

V+3R3

V+3R3_S

V+5R6_M

V+1R2

V+3R3_A

V+1R25

V+5_A

CN2305

CN201

CN403

CN2006

V+5_USB

V-11_A

V+12_EUP

CN2002

CN402

CN401

CN2004

CN2001

PWR_XON

V+12

V+12_EUP

JA2401

CN140

JH120

PROTECTOR

2 3 4

4.3 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

20

1

2 3 4

CDJ-850

5

I

KSW2 ASSY

H

KSW1 ASSY

K

JOGB ASSY

J

JFLB ASSY

G

DFLB ASSY

N

SLD2 ASSY

L

SLD1

ASSY

M

PSWB ASSY

F

USBA ASSY

IC1007

PANEL CPU

CN1601

PC1901

ENCODER

VR8701

TEMPO SLIDER

JH1801

1

4

1

1

V+3R3_EUP

1

1

CN1001

V+12

VR1301

TOUCH/RELEASE

S1018

ROTARY SW

LED

LED

LED

4

LED

DATA FL

JOG FL

23

4

JUMPER

JUMPER

IC1004

RESET IC

POWER DETECT CIRCUIT

LED

LED

LED

V+3R3_SW

3

1

38

1

13 11

V+27

IC1802

DCAC

12V→AC2.7V

IC1803

DCDC

12V→27V

VFDP2R7_F1

V+6R6

V+3R3_EUP

V+6R6

5

2

IC1006

DCDC

12V→6.6V

IC1006

DCDC

12V→3.3V

Q1018

FET SW

V+3R3_EUP

V+3R3_EUP

V+3R3_SW

9

PWR_ON

V+12_EUP

VDET

7

131 3

1

34

35

2

3

V+12

V+12_EUP

V+12

V+6R6

V+3R3_SW

V+6R6

V+27_SW

V+3R3_SW

V+38

V+3R3_EUP

PWR_SW

PWR_SWPWR_SW

V+38

PWR_ON

3

3

V+6R6

CN1401

JH1201

V+6R6

V+38

V+3R3_SW

V+6R6_FL

V1001

VDET

CN1002

CN1802

V1801

V+38

V+3R3_SW

V+12

CN1901

CN1801

SHEET SW

CN1501

JH1301

JH1302

VDET

PWR_ON

6 7 8

A

B

C

D

CDJ-850

5

6 7 8

E

F

21

1

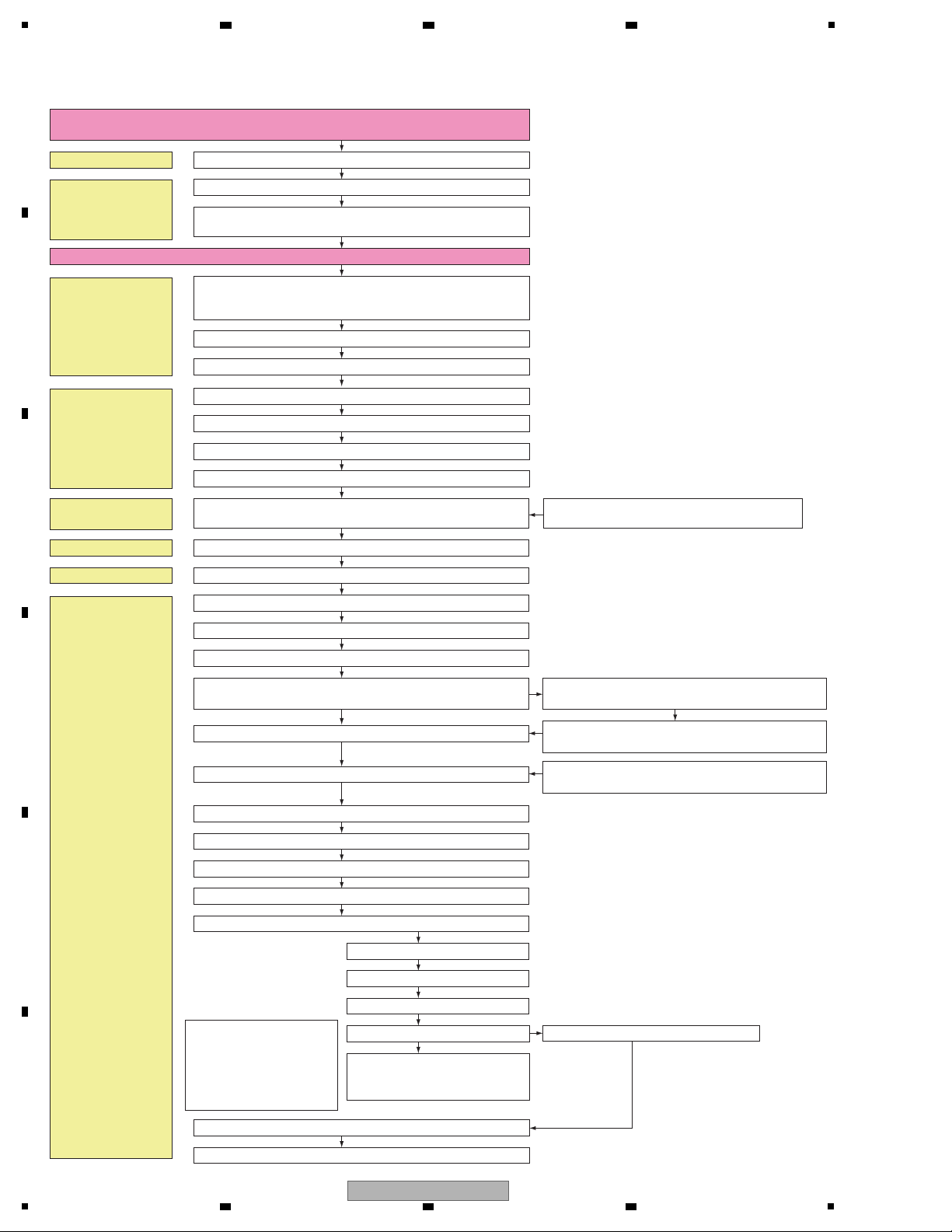

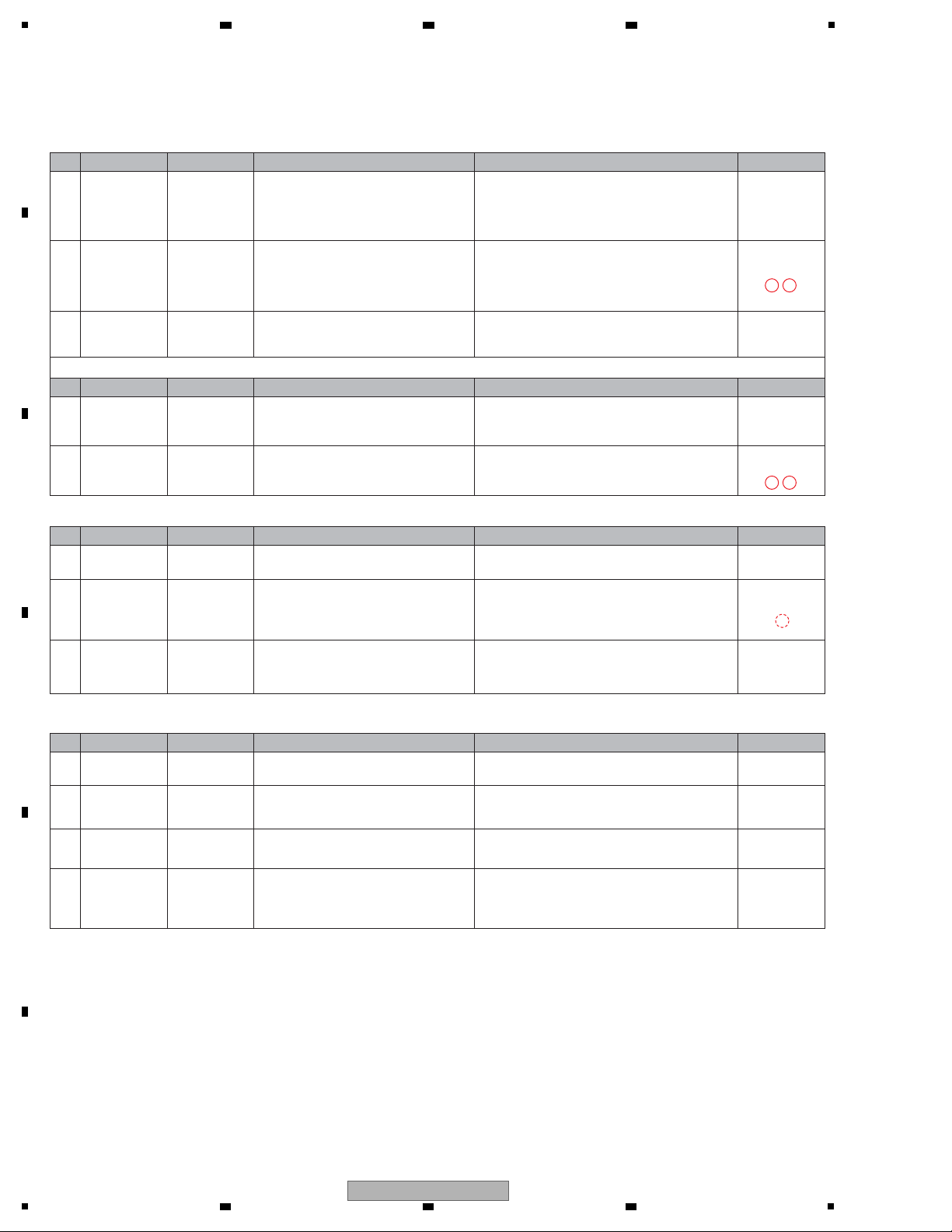

If the level of the S-shaped waveform is 0.88 Vp-p or less,

focusing is turned ON with RF gain increased.

If checking fails three times, “EJECT” will be

displayed on the FL display.

The first track is searched for.

After TOC reading is completed

Waiting 300 ms

Tracking balance adjustment (Tracking open)

Tracking close

GFS (RF lock) check

Main CPU (IC103)

Panel CPU (IC1007)

Adjustment of tracking and focus offset

Spindle kick, focus sweep, and focus ON

Checking if focus is OK

Audio DSP (IC301)

Servo DSP (IC201)

CD drive

Playback (Muting OFF)

Focus gain adjustment

AC IN (Plugging of the AC power cord)

Power supply (V+12_EUP, V+3R3R_EUP) to the Panel CPU starts.

Reset IC (IC1004)

TOC reading

Depending on the accuracy

of the stepper, the TOC

position memory will be

located after the unit is

turned ON.

Tracking gain adjustment

RF gain adjustment

If the pickup is reading the

program area, it will jump

to the TOC area.

The program is downloaded to IC301 (Audio DSP).

IC103 (Pin 158): The Reset signal is sent to the Audio DSP (IC301).

IC301 (Pin 47): Receives the Reset signal.

IC1007 (Pin 12): Receives the Reset signal.

IC1004 (Pin 4): The Reset signal is sent to the Panel CPU (IC1007).

POWER ON (Turn on the POWER switch.)

Main CPU

(IC103)

STANDBY mode is entered.

*FL display: Unlit.

Panel CPU

(IC1007)

Panel CPU

(IC1007)

IC1007 (Pin 45): Power supply to the Main CPU (IC103) starts.

IC1007 (Pin 40): The Reset signal is sent to the Main CPU (IC103).

IC103 (Pin 69): The Reset signal is sent to the Servo DSP (IC201).

If communication fails, “E–8709” will be

displayed on the FL display.

STANDBY mode is shifted to POWER_ON mode.

“POWER ON” is displayed on the FL display.

Focus balance adjustment

IC103 (Pin 59): Receives the Reset signal.

Communication between the Main CPU (IC103) and

Panel CPU (IC1007) starts.

IC201 (Pin 90): Receives the Reset signal.

Checking the inside SW

LD (Laser Diode) ON

Acceleration of spindle (200 ms)

CLV servo ON

If the first check fails, measure the level of the S-shaped

waveform while the pickup lens is descending.

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

A

2 3 4

B

C

D

E

F

22

1

CDJ-850

2 3 4

5

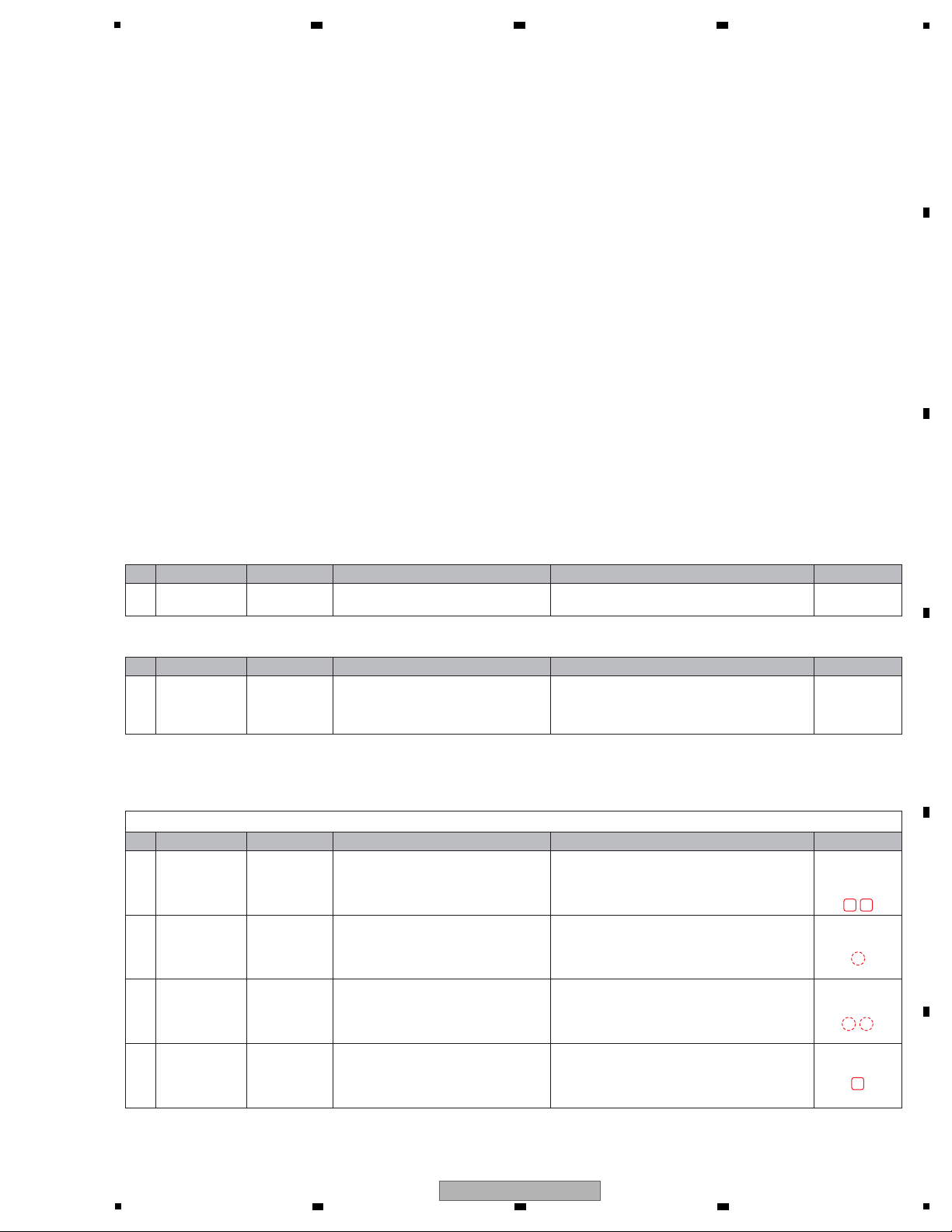

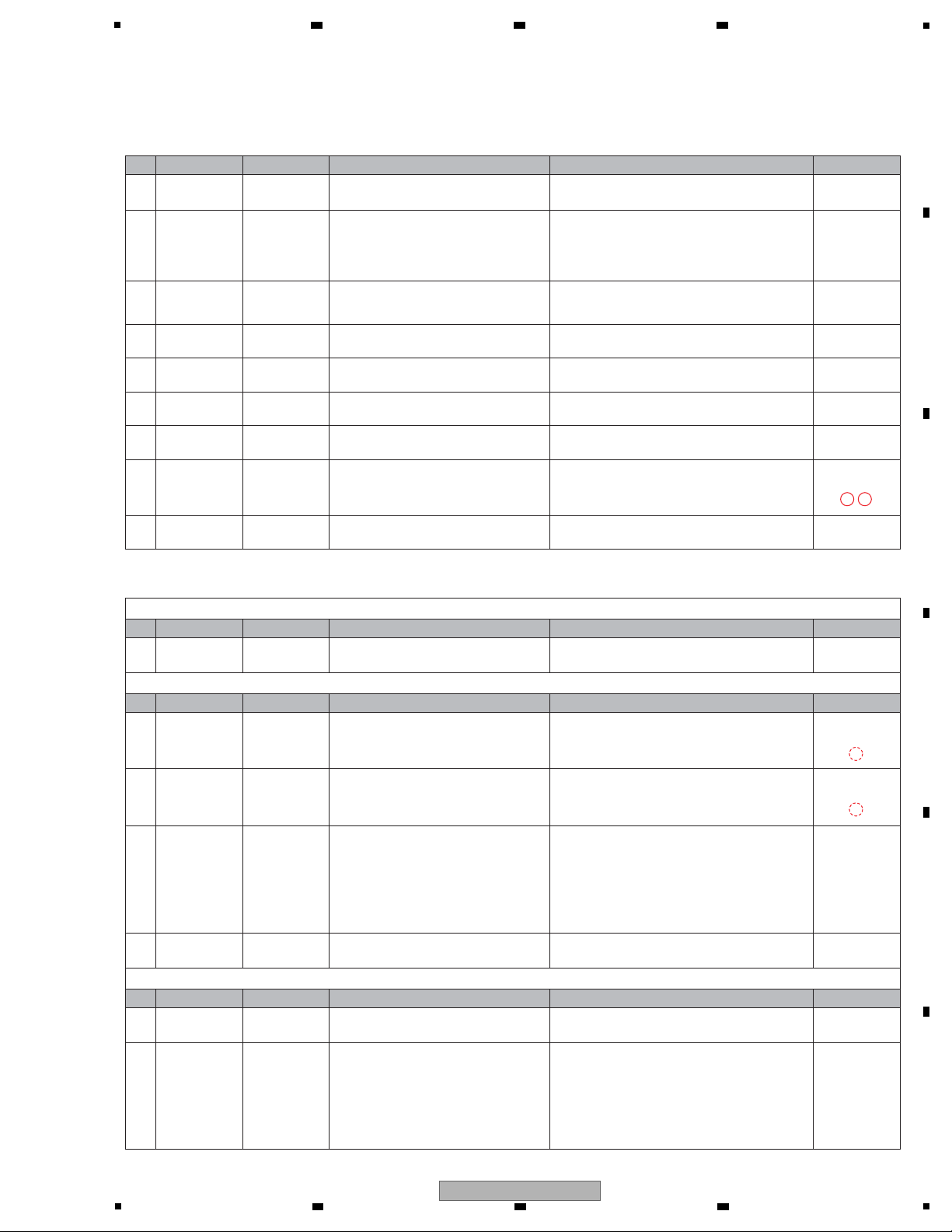

In this section, causes of failure, diagnostics points, and corrective measures can be searched for according to symptoms.

Before disassembling this unit, it is recommended to infer a failure point by referring to the error code.

For the relationship of each power-supply and signal system, see “4.3 POWER SUPPLY BLOCK DIAGRAM.”

If software of the product is updated before performing diagnostics, check that software updating has been performed properly

before proceeding to diagnostics.

If software updating has not been performed properly, update the software, following the instructions in “8.3 UPDATING OF

THE FIRMWARE.”

Contents

[0] Prior Confirmation

[1] Failure in Startup

[2] Display (DATA FL/JOG FL/LED)

[3] Operations (SW/Volume/JOG)

[4] USB (USB-Type A), PC (USB-Type B)

[5] AUDIO OUT

[6] CONTROL

[7] DRIVE Assy

[8] SERVICE MODE

[9] Error Codes

[10] Basic Operation Check of CPU/DSP

The waveform numbers described in this section correspond to the “10.14 WAVEFORMS.”

[0] Prior Confirmation

[0-1] Checking in Service Mode

[0-2] Checking Cables

[1] Failure in Startup

[1-1] No power

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

1 — Check the failure points.

See the section describing locations of defects in

this manual.

6. SERVICE

MODE

1 Cables

Service mode

Disconnection,

breakage, or

loose connection

of cables

Check that all the cables are securely

connected.

Check that there is no breakage in the

cables.

Securely connect the cables. If a cable is broken,

replace it.

4.1 OVERALL

CONNECTION

DIAGRAM

4.3 POWER SUPPLY

BLOCK DIAGRAM

10.13 VOLTAGES

Plug the AC power cord in and even if turn the power on, the product does not startup.

1

Standby power

failure

CMPX Assy

DFLB Assy

POWER

SUPPLY Assy

Check the voltages of V+12_EUP and

V+3R3_EUP.

If the V+12_EUP voltage is not output, the POWER

SUPPLY Assy may be defective.

If the V+12_EUP voltage is output, the DFLB Assy

may be defective.

10.15 EACH

SIGNAL LEVEL

2

Path failure of

the power switch

DFLB Assy

SLD1 Assy

PSWB Assy

Check if there is loose connection on the

signal line from the Power switch (S1601)

to PANEL CPU (IC1007).

If the connection up to the Power switch is properly

made and if the PWR_SW signal is not set to "L"

when the Power switch is pressed, the Power switch

may be defective.

10.15 EACH

SIGNAL LEVEL

3

Path failure of

the power on

DFLB Assy

CMPX Assy

Check the level of PWR_ON (IC1007-pin

45) and PWR_XON (CN2001-pin 3) signals.

If the PWR_ON is "L", PANEL CPU(IC1007) may be

defective.

If the PWR_XON is "H", poor connection or Q2021

may be defective.

10.13 VOLTAGES

4 Power failure

CMPX Assy

POWER

SUPPLY Assy

Check the V+12 voltage of CN2001-pins

4 and 5.

If the voltage is not output, POWER SUPPLY Assy

may be defective.

2

1 18

B J

A

6 7 8

5.2 TROUBLESHOOTING

A

B

C

D

E

F

CDJ-850

5

6 7 8

23

1

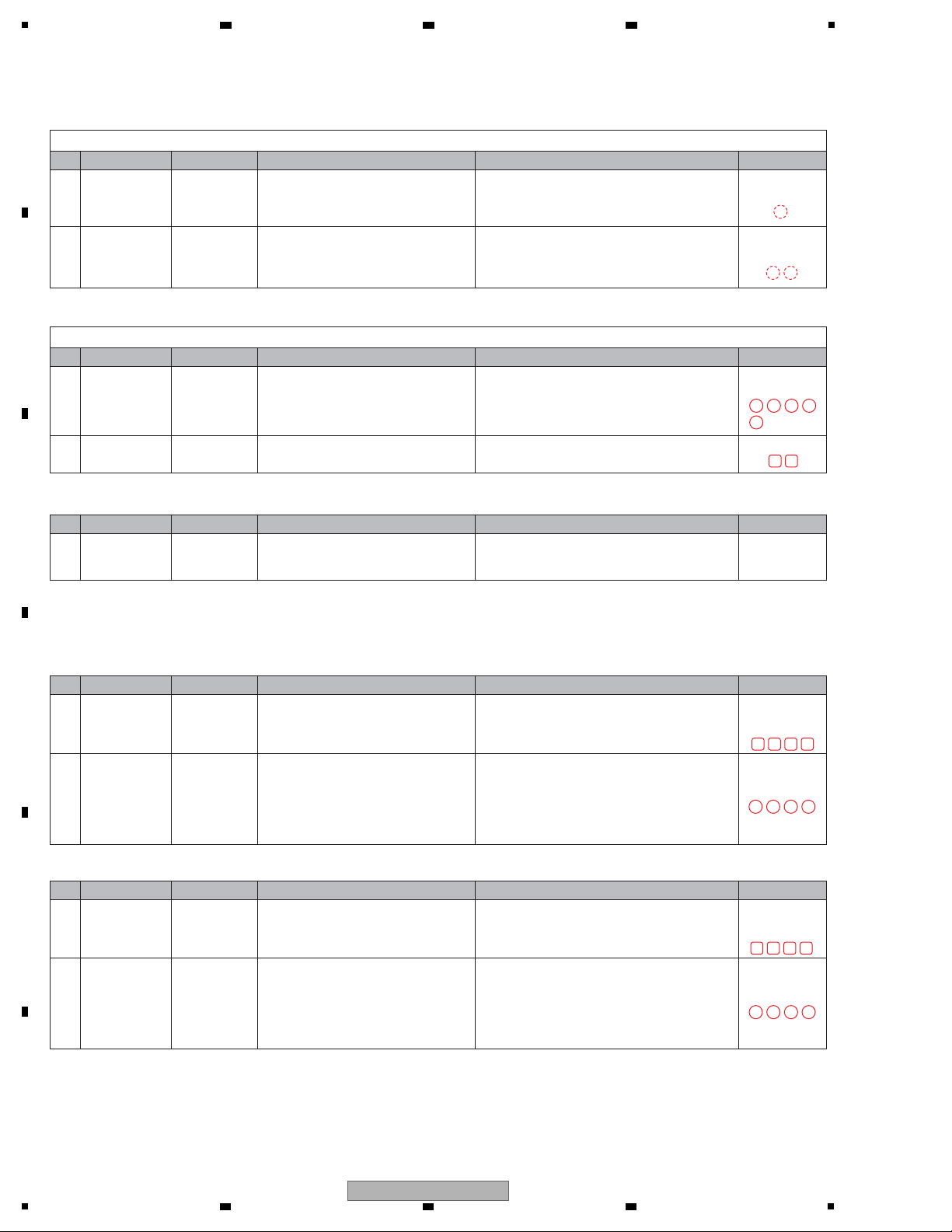

[1-2] Mode shift error in Standby mode

[2-1] The DATA FL does not light.

[2-2] The JOG FL does not light.

[2] Display (DATA FL/JOG FL/LED)

[1-3] “E-8709” is displayed on the DATA FL display after startup.

[1-4] The Standby LED flashes in red.

Shifting to the STANDBY mode cannot be performed even if turn the power off.

1

Path failure of

the power switch

DFLB Assy

SLD1 Assy

PSWB Assy

Check if there is loose connection on the

signal line from the Power switch (S1601)

to PANEL CPU (IC1007).

If the connection up to the Power switch is properly

made and if the PWR_SW signal is not set to "H"

when the Power switch is turned off, the Power switch

may be defective.

2

Path failure of

the power on

DFLB Assy

CMPX Assy

Check the level of PWR_ON (IC1007-pin

45) and PWR_XON (CN2001-pin 3) signals.

If the PWR_ON is "H", PANEL CPU(IC1007) may be

defective.

If the PWR_XON is "L", poor connection or Q2021

may be defective.

10.14

WAVEFORMS

1 Power failure DFLB Assy

Check the power-supply voltages

(V+6R6,F±, V+38, V+3R3_SW) of the FL.

If the presence of power is not confirmed, check the

mounting statuses of the regulator IC and its

peripheral parts for each power supply. If they are

properly mounted, then the parts may be defective.

4.3 POWER SUPPLY

BLOCK DIAGRAM

10.13 VOLTAGES

2 Signal errors DFLB Assy

Check the waveforms and connection of

communication line of FL in the DFLB Assy.

• D_SCLK

• D_SO

• D_LAT

• D_BK

If no signal is output, the PANEL CPU (IC1007) may

be defective.

If output signal is no problem, DATA FL (V1001) may

be defective.

10.14

WAVEFORMS

1 Power failure JFLB Assy

Check the power-supply voltages

(VFDP2R7_F1, VFDP2R7_F2, V+27,

V+3R3_SW) of the FL.

If the presence of power is not confirmed, check the

mounting statuses of the regulator IC and its

peripheral parts for each power supply. If they are

properly mounted, then the parts may be defective.

4.3 POWER SUPPLY

BLOCK DIAGRAM

10.13 VOLTAGES

2 Signal errors JFLB Assy

Check the waveforms and connection of

communication line of FL in the JFLB Assy.

• J_SCLK

• J_SO

• J_LAT

• J_BK

If no signal is output, the PANEL CPU (IC1007) may

be defective.

If output signal is no problem, JOG FL (V1801) may

be defective.

10.13 VOLTAGES

5.5 ABOUT POWER

SUPPLY MONITORING

10.13 VOLTAGES

10.14

WAVEFORMS

Communication between the Main CPU and Panel CPU has not been established.

1

Communication

failure between

the microcomputer

DFLB Assy

MAIN Assy

Check the TSCK, TSI, PNL_BUSY, TSO and

MAIN_BUSY waveforms.

If no signal is output, the possible causes are poor

connection, failure in the PANEL CPU (IC1007) or

MAIN CPU (IC103), and startup failure of the

MAIN CPU caused by defective FLASH ROM

(IC101) or SDRAM (IC102).

1

A voltage error

was generated.

— Check the level of the VDET signal.

If the signal level is "L", a voltage error was

generated.

2 Power failure MAIN Assy

Check the V+3R3 and V+1R2 power

voltages.

If power is not output, a part of the power supply

section may be defective.

10.15 EACH

SIGNAL LEVEL

10.15 EACH

SIGNAL LEVEL

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

20 21 23 19

24 25 22 19

9 10

B J

A

849 7 10

1 4 3 2

1 4 3 2

A

2 3 4

B

C

D

E

F

24

CDJ-850

1

2 3 4

5

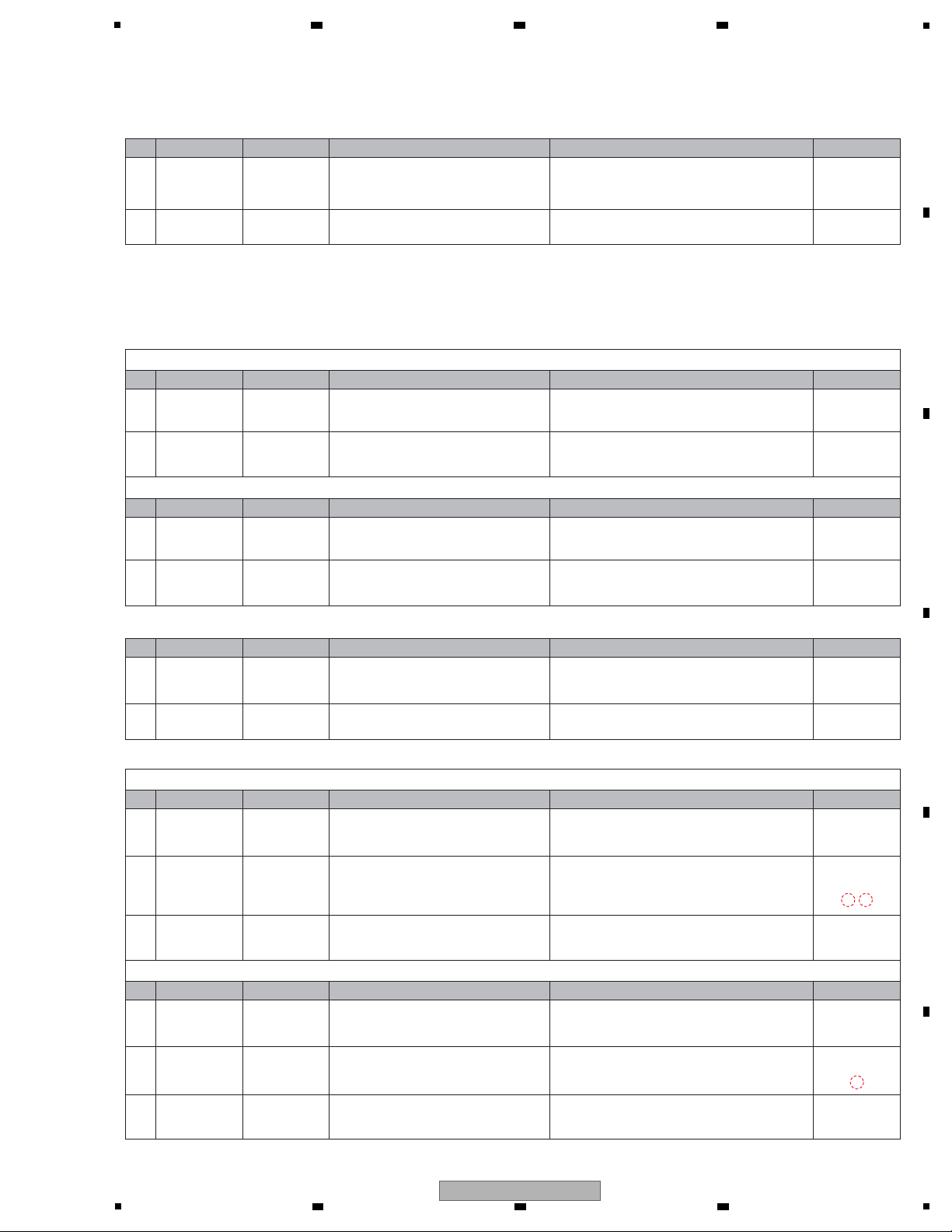

[2-3] The LED does not light.

—

[3] Operations (Keys/variable controls/JOG)

As operations of all keys, variable controls, and JOG dial can be checked in Service mode.

[3-1] No key functions

PLAY, CUE, AUTO BEAT LOOP 1-4, BEAT SELECT, REV, LOOP IN/OUT, RELOOP, or USB STOP key does not function.

1

Loose connection

/Defective SW

Related point

Check if there is loose connection on the

signal line from the PANEL CPU (IC1007)

up to the SW.

If there is no loose connection and if the signal does

not become "L" when the SW is pressed, that SW is

defective.

2

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

The signals from other keys are analog and connected to multiple switches.

1

Loose connection

/Defective SW

Related point

Check if there is loose connection on the

signal line from the PANEL CPU (IC1007)

up to the SW.

If the SWs connected to the signal line function

properly and if the connections are properly made,

the SWs may be defective.

2

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

[3-2] Rotary selector not controllable

1

Defective rotary

selector

DFLB Assy

Check if the signals from the RENC_1, RENC

_2, and RENC_SW signal lines are normal

when the rotary selector is turned or pressed.

If the signals are not normal, check the connections of

the signal lines. If the connections are properly made,

the Rotary selector (S1018) may be defective. Replace it.

2

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

[3-3] Variable controls not controllable

Tempo slider not controllable

1

Loose

connection

DFLB Assy

SLD1 Assy

SLD2 Assy

Check if there is loose connection on the

signal line from the PANEL CPU (IC1007)

to the tempo slider (VR1501).

If the connections of signal line are improper,

resolder it.

2

Defective tempo

slider

DFLB Assy

SLD2 Assy

Check the ADCT and ADIN signals level.

If the voltage of the ADCT signal (IC1007-pin 1) is not

1.65 V, or the voltage of the ADIN signal (IC1007-pin 2)

does not change between 3.3 V and 0 V, the Tempo

slider (VR1501) may be defective.

3

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

1 Signal errors DFLB Assy

Check that the control signal for the LED

is output from the PANEL CPU (IC1007).

If no signal is output, check a mounting state of

PA NEL CPU(IC1007). If the mounting is OK, the

IC1007 may be defective.

[10] Basic operation

check of CPU/DSP

[10] Basic operation

check of CPU/DSP

—

—

[10] Basic operation

check of CPU/DSP

[10] Basic operation

check of CPU/DSP

[10] Basic operation

check of CPU/DSP

2 Defective parts DFLB Assy

Check that the voltage (2.2 V) is present

at both ends of the LED.

If the voltage is abnormal, the LED, transistor or

peripheral resistors may be defective.

10.15 EACH

SIGNAL LEVEL

10.15 EACH

SIGNAL LEVEL

10.15 EACH

SIGNAL LEVEL

VINYL SPEED ADJUST not controllable

1

Loose

connection

DFLB Assy

SLD1 Assy

Check if there is loose connection on the

signal line from the PANEL CPU (IC1007) to

the VINYL SPEED ADJUST VR (VR1301).

If the connections of signal line are improper,

resolder it.

2

Defective

variable

controls

DFLB Assy

SLD1 Assy

Check the TCH/REL signal level.

If the voltage of the TCH/REL signal line (IC1007-pin 88)

does not change between 3.3 V and 0 V, the VINYL

SPEED ADJUST VR (VR1301) may be defective.

3

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

—

[10] Basic operation

check of CPU/DSP

10.15 EACH

SIGNAL LEVEL

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

E

C D

6 7 8

A

B

C

D

E

5

6 7 8

CDJ-850

F

25

1

—

—

—

[10] Basic operation

check of CPU/DSP

[3-4] Abnormalities regarding the JOG dial

After the JOG Assy is disassembled then reassembled, be sure to check that the load value for the JOG dial is within the

specified range. (Refer to the "8.4 JOG DIAL ROTATION LOAD ADJUSTMENT".)

Turning of the JOG dial is not detected

1

Defective part of

photo interrupter

DFLB Assy

JFLB Assy

JOGB Assy

Check the waveforms of signal lines.

JOG1_C (IC1007-pin 26)

JOG2_C (IC1007-pin 25)

If no waveform can be confirmed, the photo

interrupter (PC1901) may be defective.

10.14

WAVEFORMS

2

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

Pressing on the JOG dial cannot be detected.

1

Defective part

DFLB Assy

JFLB Assy

Check the level of JOG_SW signal (IC1007

-pin 27) when the JOG dial is pressed.

If the JOG_SW signal (IC1007-pin 27) is not set to

"L" when the JOG dial is pressed and it is not set to

"H" when the JOG dial is not pressed, the SHEET

SW(DSX1078) may be defective.

2

Defective PANEL

CPU (IC1007)

DFLB Assy

If the symptom persists after the above

corrections,

Check a mounting state of PANEL CPU (IC1007).

If the mounting is OK, the IC1007 may be defective.

Noise is heard when the JOG dial is turned.

1

Defective

attachment of

the JOG FL.

Defective gear

or JOG DIAL B.

JFLB Assy

JOGB Assy

Check if the JOG FL of the JFLB Assy has been

shifted upward from the holder.

Also check the JOGB Assy is attached normally.

The JOG FL may interfere with JOG A.

There may be any scratches on the 3

gears or some foreign object between

the gears.

If there are any scratches, replace the scratched gear

with a new one. If there is any foreign object, remove

it then replace the gears with new ones.

Gears to be replaced: Load gear, Gear A, Gear B

The JOG dial turns too freely. (The load value for the JOG dial is outside the specified range.)

1

Improper adjustment or assembly

of the JOG dial

JOG Assy

Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.4 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “Load adjustment method” in

“8.4 JOG Dial Rotation Load Adjustment.”

8.4 JOG Dial

Rotation Load

Adjustment.

8.4 JOG Dial

Rotation Load

Adjustment.

During the above adjustment, if the upper-limit adjustment position of the Adjust Plate is reached, oil may

have been spattered on the Cam Plate.

Replace the washer, load gear, and cam plate with

new ones, then reassemble.

Resistance to turning the JOG dial is too strong. (The load value for the JOG dial is outside the specified range.)

1

Improper adjustment of the JOG

dial or defective

washer, gear, or

cam plate

JOG Assy

Check that the load value for the JOG dial

is within the specified range, referring to

“Measuring method” in “8.4 JOG Dial

Rotation Load Adjustment.”

If it is outside the specified range, adjust the position

of the Adjust Plate to change the load value for the

JOG dial, referring to “Load adjustment method” in

“8.4 JOG Dial Rotation Load Adjustment.”

8.4 JOG Dial

Rotation Load

Adjustment.

8.4 JOG Dial

Rotation Load

Adjustment.

During the above adjustment, if the lower-limit adjustment position of the

Adjust

Plate is reached, shavings

from the worn-out washer may have increased the

friction. Replace the washer, load gear, and cam plate

with new ones, then reassemble.

10.15 EACH

SIGNAL LEVEL

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

No. Cause

Diagnostics Point

Item to be Checked Corrective Action Reference

F

5 6

A

2 3 4

B

C

D

E

F

26

1

2 3 4

CDJ-850

5

[5] AUDIO OUT

The analog audio signal is not output.

Improper fader operation after fader start.

3 Power failure MAIN Assy

Check the voltages for audio (V+10_A,

V-AUDIO(V-10_A), V+5_A, V+3R3_A,

V+1R25).

Check also if the protector (P2003) is

broken.

• If the V+10_A voltage level is abnormal, Q2028

and its peripheral parts may be defective.

• If the V-AUDIO(V-10_A) voltage level is abnormal,

Q2031 and its peripheral parts may be defective.

• If the V-5_A voltage level is abnormal, IC406

and its peripheral parts may be defective.

• If the V+3R3_A voltage level is abnormal, IC402

and its peripheral parts may be defective.