Pioneer CDJ-800 Service Manual

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2002

CDJ-800

COMPACT DISC PLAYER

CDJ-800

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

CDJ-800 KUCXJ AC120V

CDJ-800 WYXJ AC220-240V

ORDER NO.

RRV2690

For details, refer to "Important symbols for good services" .

T-ZZR OCT. 2002 2002 printed in Japan

1234

-

d

y

u

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been traine

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and ma

void the warranty. If you are not qualified to perform the repair of this product properly and safely, yo

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to cause

cancer, birth defects or other reproductive harm.

B

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement par ts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

(FOR USA MODEL ONLY)

Health & Safety Code Section 25249.6 – Proposition 65

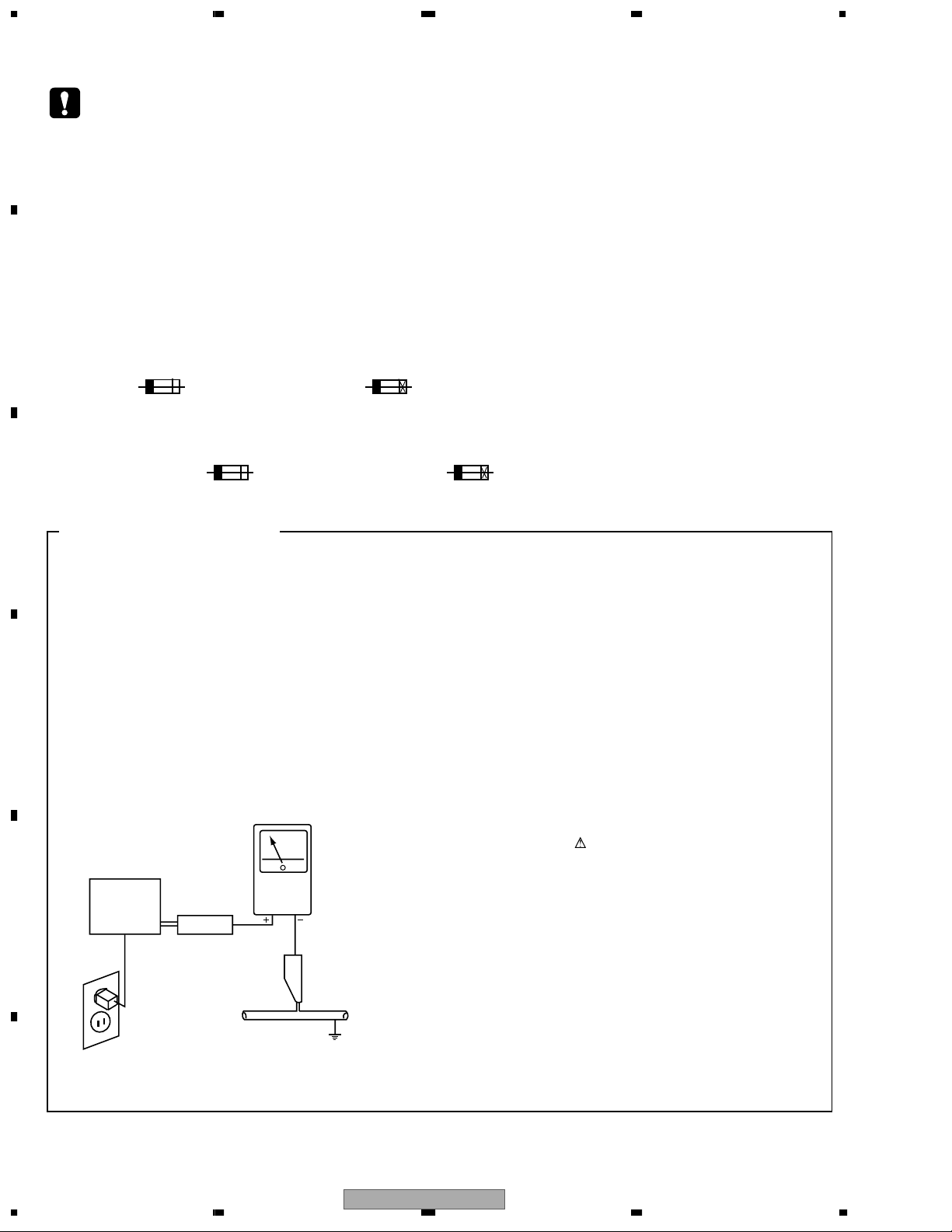

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground (water

pipe, conduit, etc.) by connecting a leakage current tester

D

E

such as Simpson Model 229-2 or equivalent between the

earth ground and all exposed metal parts of the appliance

(input/output terminals, screwheads, metal overlays, control

shaft, etc.). Plug the AC line cord of the appliance directly

into a 120V AC 60Hz outlet and turn the AC power switch

on. Any current measured must not exceed 0.5mA.

Reading should

not be above

0.5mA

Earth

ground

Device

under

test

Also test with

plug reversed

(Using AC adapter

plug as required)

Test all

exposed metal

surfaces

Leakage

current

tester

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are identified

by marking with a

in this Service Manual.

The use of a substitute replacement component which does

not have the same safety characteristics as the PIONEER

recommended replacement one, shown in the parts list in

this Service Manual, may create shock, fire, or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of, PIONEER

Service Manual may be obtained at a nominal charge from

PIONEER.

on the schematics and on the parts list

AC Leakage Test

F

2

1234

CDJ-800

5678

IMPORTANT

THIS PIONEER APPARATUS CONTAINS

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DONE BY A SPECIALLY

INSTRUCTED PERSON.

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 780 – 785 nm

WARNING !

The AEL(accessible emission level) of the laser power output is less then CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should servicing operation of the apparatus.

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S1901) for detecting loading

completion is detected by the system microprocessor, and

the design prevents laser diode oscillation when the switch

is not in LPS1 terminal side (when the mechanism is not

clamped and LPS1 signal is high level.) Thus, the interlock

will no longer function if the switch is deliberately set to LPS1

terminal side. ( if LPS1 signal is low level ).

In the test mode

∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 9 of TA2153FN

(IC118)on the MAIN ASSY is connected to GND,

or pin 10 of IC118 (LDON) is connected to low level

(ON), or else the terminals of Q110 are shorted to each

other (fault condition).

2. When the cover is opened, close viewing of the objective

lens with the naked eye will cause exposure to a Class 1

laser beam.

∗ : Refer to page 53.

CDJ-800 WYXJ : Types Only

Printed on the Bottom Plate

Bottom Plate

LABEL CHECK

A

B

C

D

E

F

56

CDJ-800

7

8

3

1234

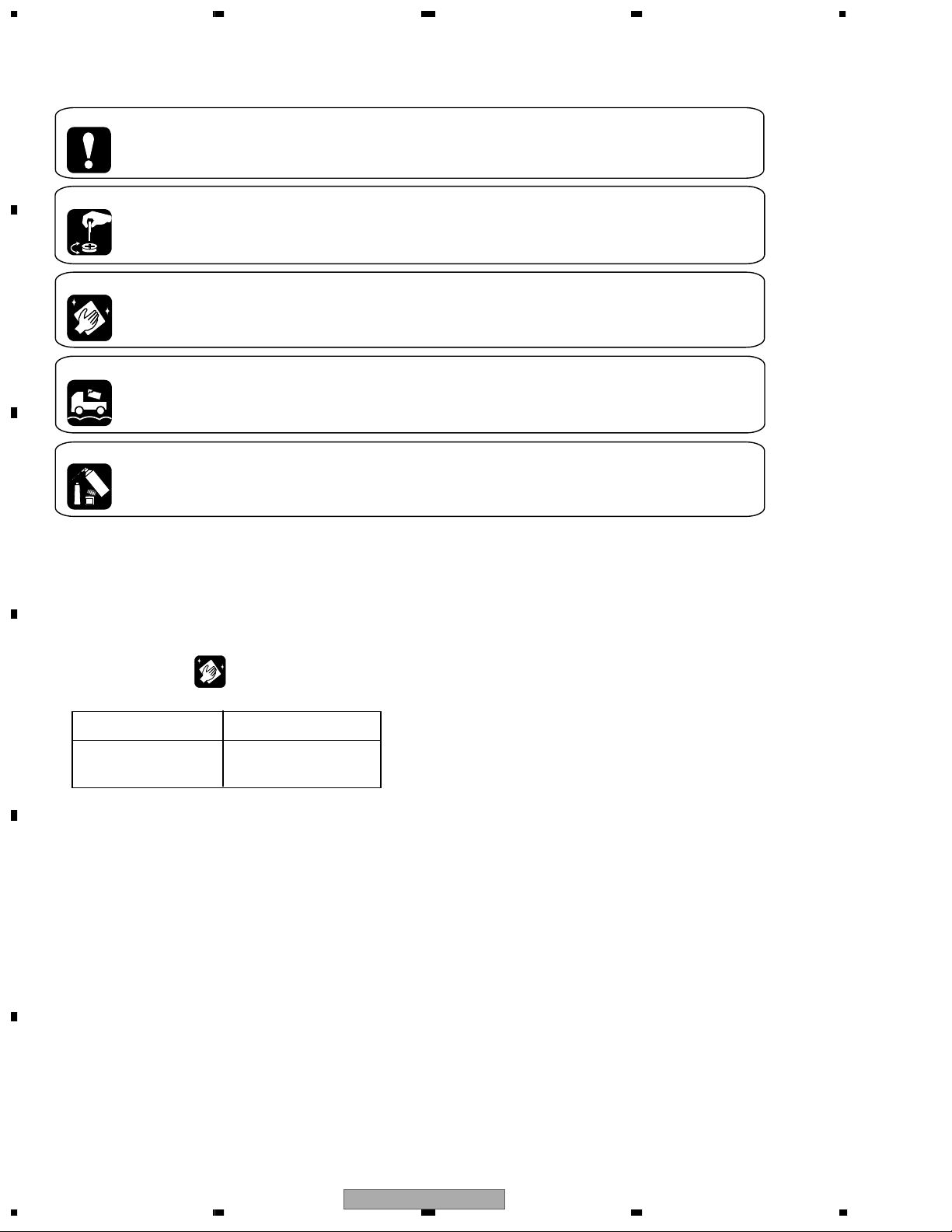

[ Important symbols for good services ]

In this manual, the symbols shown-below indicate that adjustments, settings or cleaning should be made securely.

A

When you find the procedures bearing any of the symbols, be sure to fulfill them:

1. Product safety

You should conform to the regulations governing the product (safety, radio and noise, and other regulations), and

should keep the safety during servicing by following the safety instructions described in this manual.

2. Adjustments

To keep the original performances of the product, optimum adjustments or specification confirmation is indispensable.

In accordance with the procedures or instructions described in this manual, adjustments should be performed.

3. Cleaning

B

For optical pickups, tape-deck heads, lenses and mirrors used in projection monitors, and other parts requiring cleaning,

proper cleaning should be performed to restore their performances.

4. Shipping mode and shipping screws

To protect the product from damages or failures that may be caused during transit, the shipping mode should be set or

the shipping screws should be installed before shipping out in accordance with this manual, if necessary.

5. Lubricants, glues, and replacement parts

Appropriately applying grease or glue can maintain the product performances. But improper lubrication or applying

glue may lead to failures or troubles in the product. By following the instructions in this manual, be sure to apply the

prescribed grease or glue to proper portions by the appropriate amount.For replacement parts or tools, the prescribed

C

ones should be used.

[ NOTES ON SERVICING ]

7 CLEARNING

D

E

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Pickup leneses Cleaning liquid : GEM1004

Cleaning paper : GED-008

F

4

1234

CDJ-800

5678

CONTENTS

SAFETY INFORMATION......................................................................................................................................2

1. SPECIFICATIONS.............................................................................................................................................6

2. EXPLODED VIEWS AND PARTS LIST.............................................................................................................8

2.1 PACKING ....................................................................................................................................................8

2.2 EXTERIOR SECTION ..............................................................................................................................10

2.3 CONTROL PANEL SECTION...................................................................................................................12

2.4 SLOT-IN MECHANISM SECTION ............................................................................................................14

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM ..........................................................................................16

3.1 BLOCK DIAGRAM....................................................................................................................................16

3.2 OVERALL WIRING DIAGRAM .................................................................................................................18

3.3 MAIN ASSY(1/2).......................................................................................................................................20

3.4 MAIN ASSY(2/2).......................................................................................................................................22

3.5 AC IN, TRNS, SECB and REGB ASSYS..................................................................................................24

3.6 MFLB, SLMB and KSWB ASSYS.............................................................................................................26

3.7 JFLB, SLDB and JOGB ASSYS ...............................................................................................................28

4. PCB CONNECTION DIAGRAM ......................................................................................................................35

4.1 MAIN ASSY ..............................................................................................................................................36

4.2 AC IN and TRNS ASSYS..........................................................................................................................38

4.3 SECB, REGB and SLMB ASSYS.............................................................................................................40

4.4 MFLB and KSWB ASSYS.........................................................................................................................42

4.5 SLDB, JOGB and JFLB ASSYS ...............................................................................................................46

5. PCB PARTS LIST............................................................................................................................................50

6. ADJUSTMENT ................................................................................................................................................54

7. GENERAL INFORMATION .............................................................................................................................55

7.1 DIAGNOSIS..............................................................................................................................................55

7.1.1 SERVICE MODE ...................................................................................................................................55

7.1.2 POWER ON SEQUENCE......................................................................................................................60

7.1.3 DISASSEMBLY......................................................................................................................................62

7.2 PARTS ......................................................................................................................................................65

7.2.1 IC ...........................................................................................................................................................65

7.2.2 DISPLAY................................................................................................................................................75

8. PANEL FACILITIES .........................................................................................................................................76

A

B

C

D

E

F

56

CDJ-800

7

8

5

1234

1. SPECIFICATIONS

A

1. General

System

Power requirements

Power requirements

Power consumption

Power consumption

Operating temperature

Operating humidity

(There should be no condensation of moisture.)

B

Weight

Dimensions

..............................

................................................

.............................................................

....................

12 - 5/8 (W) x 13 -17/32 (D) x 4 - 1/4 (H) in

Compact disc digital audio system

......................... (KUCXJ)AC 120 V, 60 Hz

...............(WYXJ)AC 220 -240V, 50/60 Hz

............................................ (KUCXJ)18 W

..............................................(WYXJ)21 W

......................................

305 (W)x 344.1 (D) x 108.5 (H) mm

+5

°C to +35°C

5% to 85%

3.9 kg (8.6 lb)

2. Audio section

Frequency response

Signal-to-noise ratio

Distortion

..............................................0.006% (JEITA)

.................................4 Hz to 20 kHz

...................115 dB or more (JEITA)

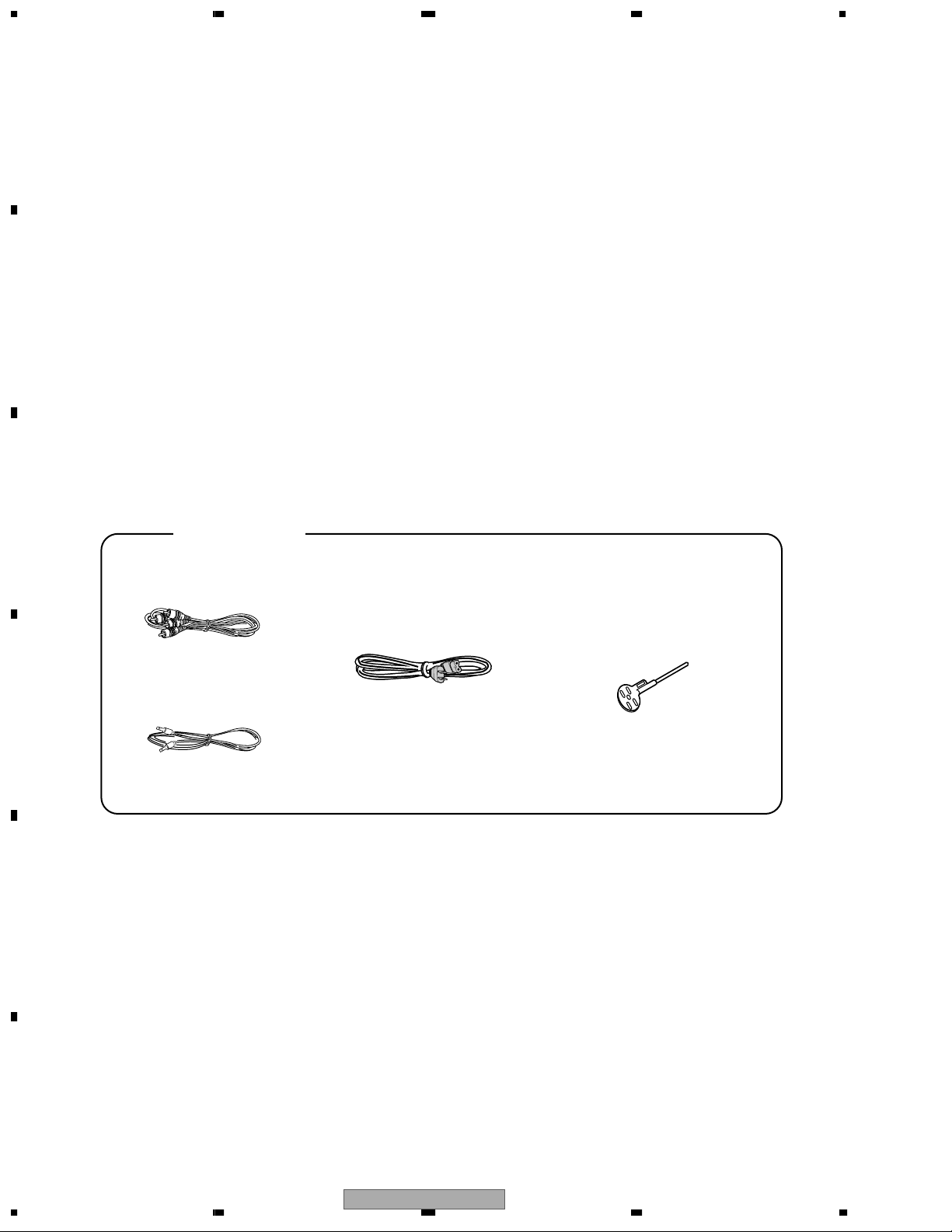

3. Accessories

÷ Operating instructions

÷ Power cord

÷ Audio cable

÷ Control cord.............................................................

÷ Forced eject pin

(housed in a groove in the bottom panel)

÷ Warranty(KUCXJ)

...............................................................

.............................................................

.............................................

.............................................

...................................................

1

1

1

1

1

1

NOTE:

Specifications and design are subject to possible

modification without notice.

C

Accessories

Audio Cable

(VDE1052) L=1.5m

Power Cord

(ADG1154 : WYXJ)

(ADG7021 : KUCXJ)

Forced Fject Pin

(housed in a groove in

the bottom panel)

(DEX1008)

Control Cord

D

E

F

(PDE-319) L=1 m

6

1234

CDJ-800

5678

A

B

C

D

E

56

CDJ-800

F

7

8

7

1234

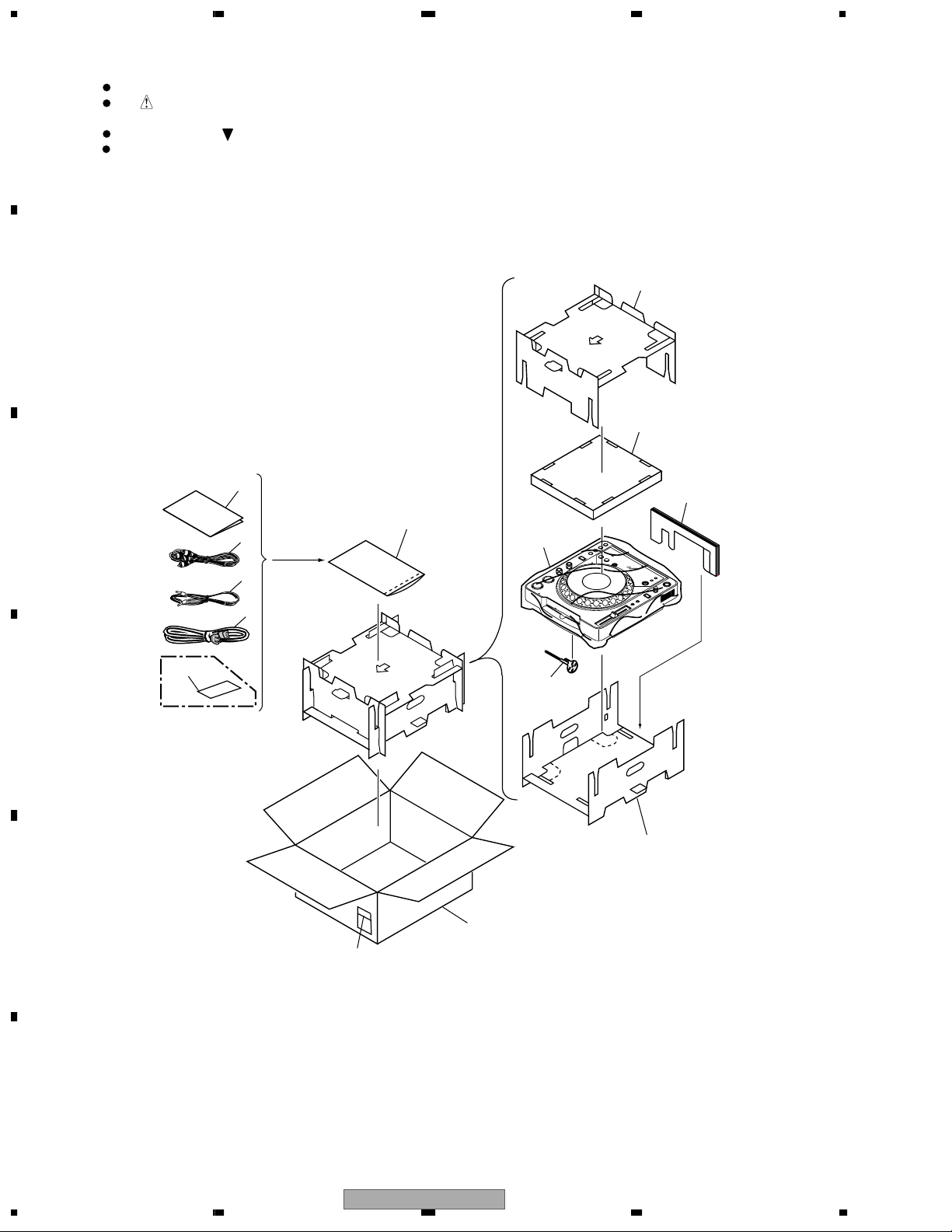

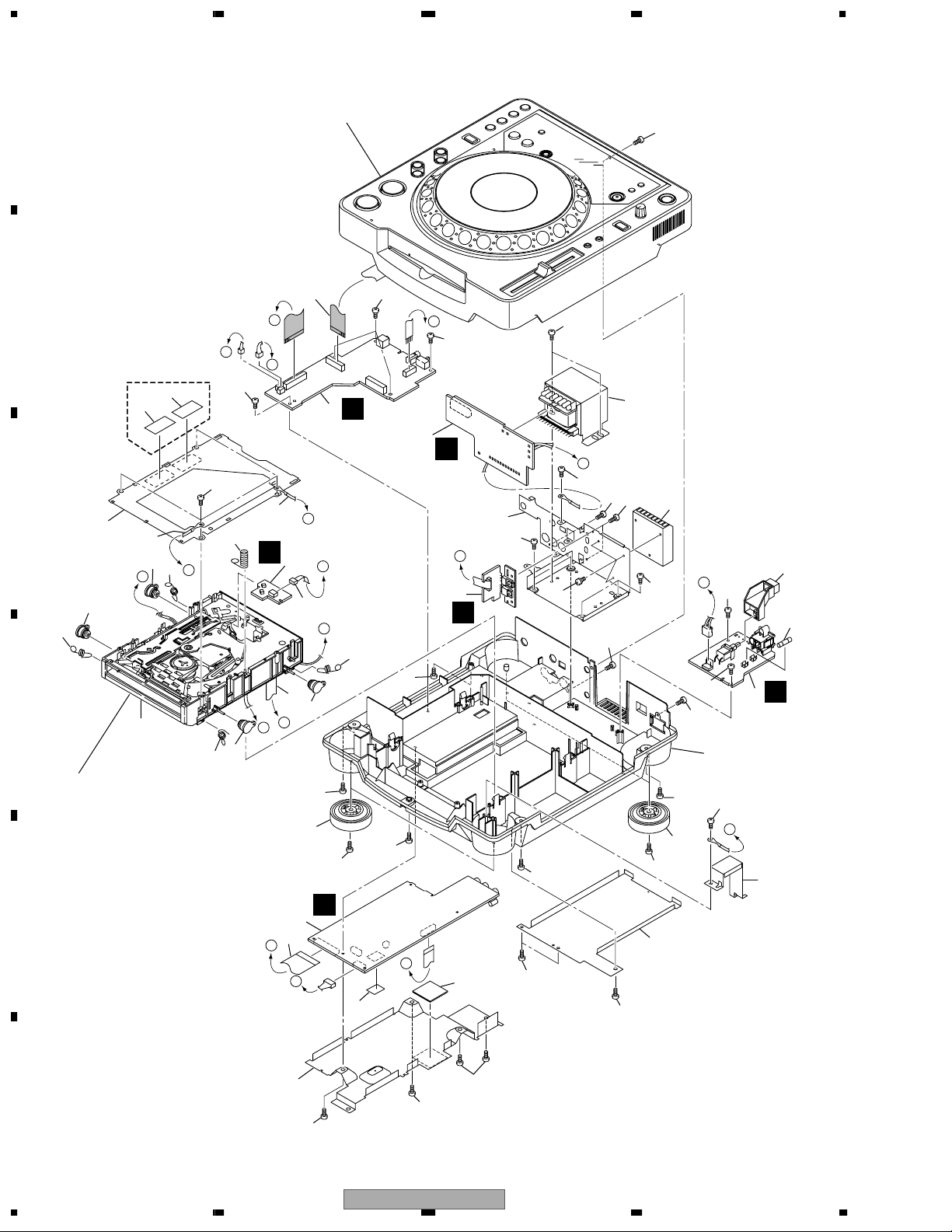

2. EXPLODED VIEWS AND PARTS LIST

NOTES:

A

2.1 PACKING

B

C

Parts marked by "NSP" are generally unavailable because they are not in our Master Spare Parts List.

The mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Screws adjacent to mark on product are used for disassembly.

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

6

7

4

5

3

9

8

2

1

13

10

D

E

KUCXJ type

only

11

12

14

F

8

1234

CDJ-800

>

>

5678

PACKING parts List

Mark

Mark No. Description Part No.

1 AC Power Cord See Contrast table(2)

2 Control Cord PDE-319

3 Audio Cord VDE1052

4 Operating Instructions See Contrast table(2)

5 Polyethylene Bag Z21-038

6 Pad B DHA1556

7 Pad C DHA1557

8 Pad D DHA1558

No. Description Part No.

9 Sheet RHX1006

10 Push Rod DEX1008

11 Pad A DHA1555

12 Packing Case See Contrast table(2)

NSP 13 Warranty Card See Contrast table(2)

NSP 14 Label VRW1629

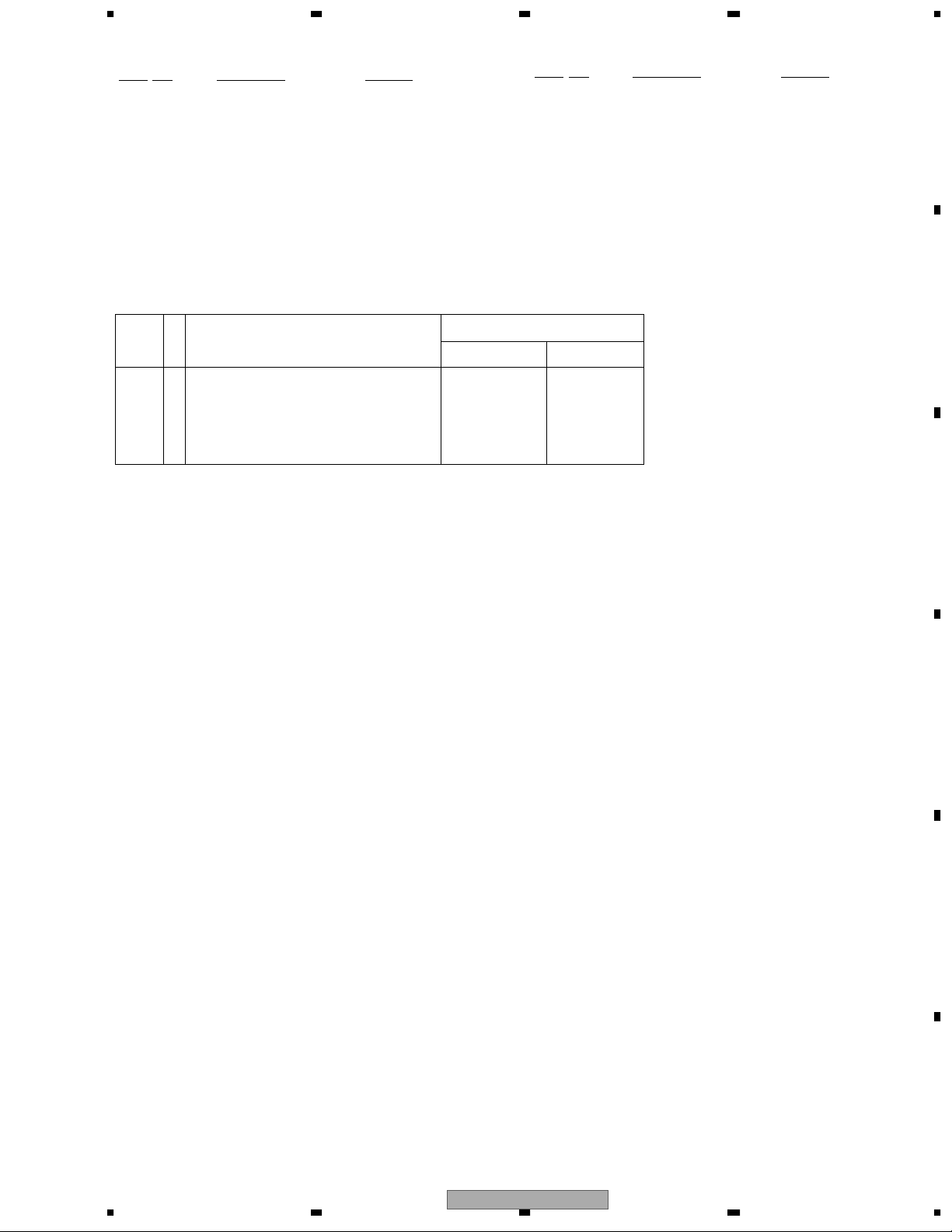

(2) CONTRAST TABLE

CDJ-800/KUCXJ and WYXJ types are constructed the same except for the following:

Mark No. Symbol and Description

1 AC Power Cord ADG7021 ADG1154

4 Operating Instructions (KUCXJ) DRB1333 Not used

4 Operating Instructions (WYXJ) Not used DRB1332

12 Packing Case DHG2291 DHG2290

NSP 13 Warranty Card ARY7043 Not used

Part No.

KUCXJ WYXJ

A

B

C

D

E

56

CDJ-800

F

7

8

9

1234

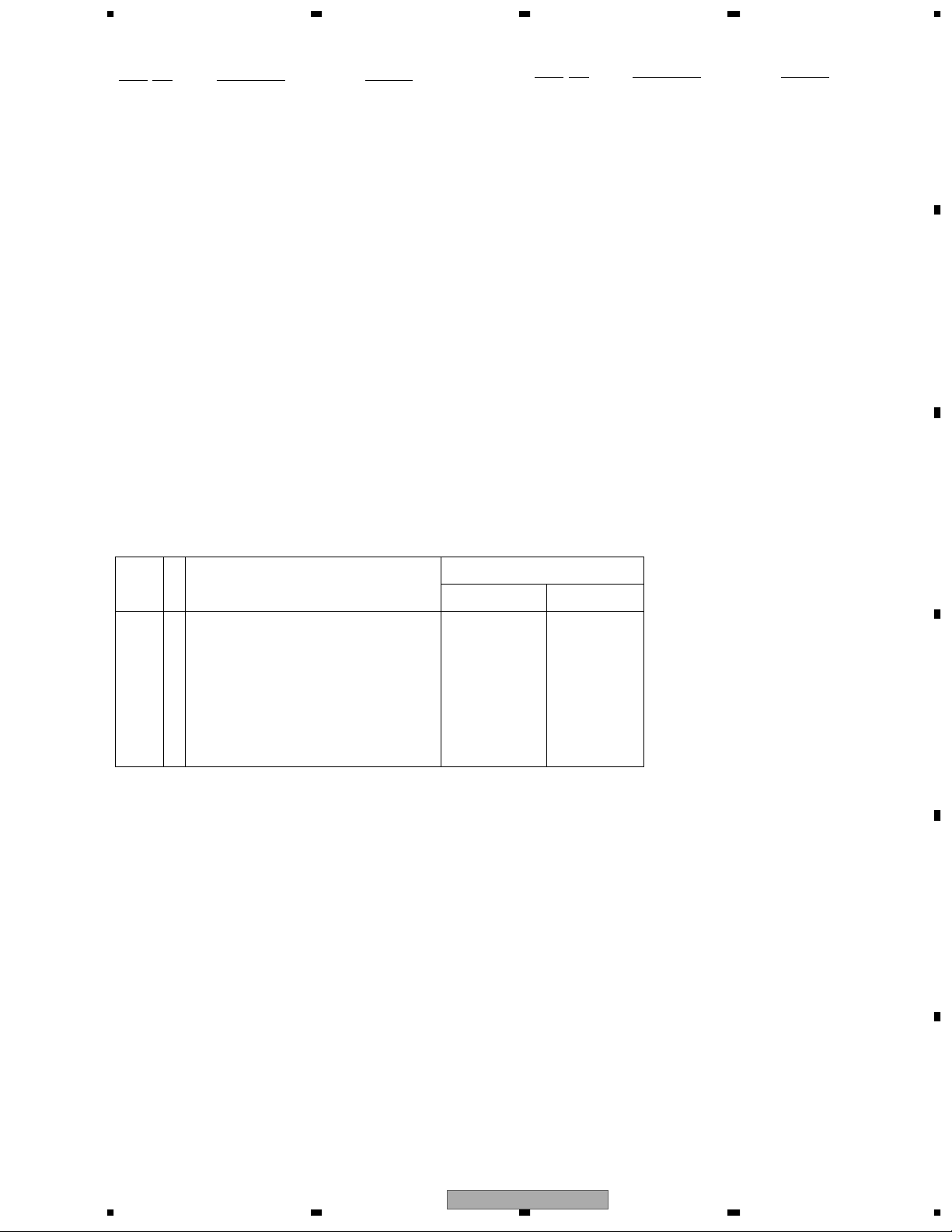

2.2 EXTERIOR SECTION

A

B

WYXJ type only

9

C

D

11

12

15

B

15

16

17

Refer to "2.4 SLOT-IN MECHANISM

SECTION".

16

Refer to "2.3 CONTROL PANEL SECTION".

7

D

B

A

16

33

13

15

33

G

H

10

4

D

E

6

A

14

E

16

18

15

C

33

19

35

8

I

33

33

33

32

F

32

3

C

30

33

F

5

E

33

36

37

G

32

33

33

32

31

33

35

29

19

33

33

33

28

G

33

27

B

2

26

33

I

25

20

23

A

1

24

C

H

21

33

33

22

33

33

32

CDJ-800

E

D

F

10

1234

>

>

>

>

>

5678

EXTERIOR SECTION parts List

Mark

Mark No. Description Part No.

1 MAIN Assy DWG1563

2 AC IN Assy See Contrast table(2)

3 TRNS Assy DWR1364

4 SECB Assy DWR1361

5 REGB Assy DWR1362

6 SLMB Assy DWS1322

7 19P F•F•C/60V DDD1222

8 Caution Label See Contrast table(2)

9 Caution Label HE See Contrast table(2)

10 Earth Lead Unit PDF1104

11 Mecha Plate DNH2339

NSP 12 Cord with Plug DE010VF0

13 Earth Spring DBH1398

14 Connector Assy PG03KK-E22

15 Damper CNV6011

16 Float Spring G5 DBH1494

NSP 17 Slot-in Mecha S4 Assy DXA1946

18 Lead Card 16P DDD1221

19 Insulator Assy DXA1945

No. Description Part No.

20 25P F•F•C/60V DDD1223

NSP 21 Silicon Rubber D5 L DEB1456

22 Bottom Cushion S4 DEC2506

23 Bottom Plate P DNH2531

24 Bottom Plate M DNH2546

25 Earth Plate DNH2532

NSP 26 Chassis See Contrast table(2)

27 FU11 Fuse See Contrast table(2)

28 Power Knob DAC2073

29 Heat Sink DNG1086

30 Trans Plate DNH2529

31 T21 Power Transformer See Contrast table(2)

32 Screw BBZ30P080FMC

33 Screw BPZ30P080FZK

34 . . . . . .

35 Screw IPZ30P100FMC

36 Screw PMA30P060FMC

37 Screw BBZ40P060FMC

(2) CONTRAST TABLE

CDJ-800/KUCXJ and WYXJ types are constructed the same except for the following:

Mark No. Symbol and Description

2 AC IN Assy DWR1366 DWR1363

8 Caution Label Not used VRW1094

9 Caution Label HE Not used PRW1233

NSP 26 Chassis DNK4060 DNK4059

27 FU11 Fuse (1.6A/125V) REK1077 Not used

27 FU11 Fuse (T800mA/L250V) Not used REK1021

31 T21 Power Transformer DTT1169 DTT1168

KUCXJ

Part No.

WYXJ

A

B

C

D

56

CDJ-800

E

F

7

8

11

1234

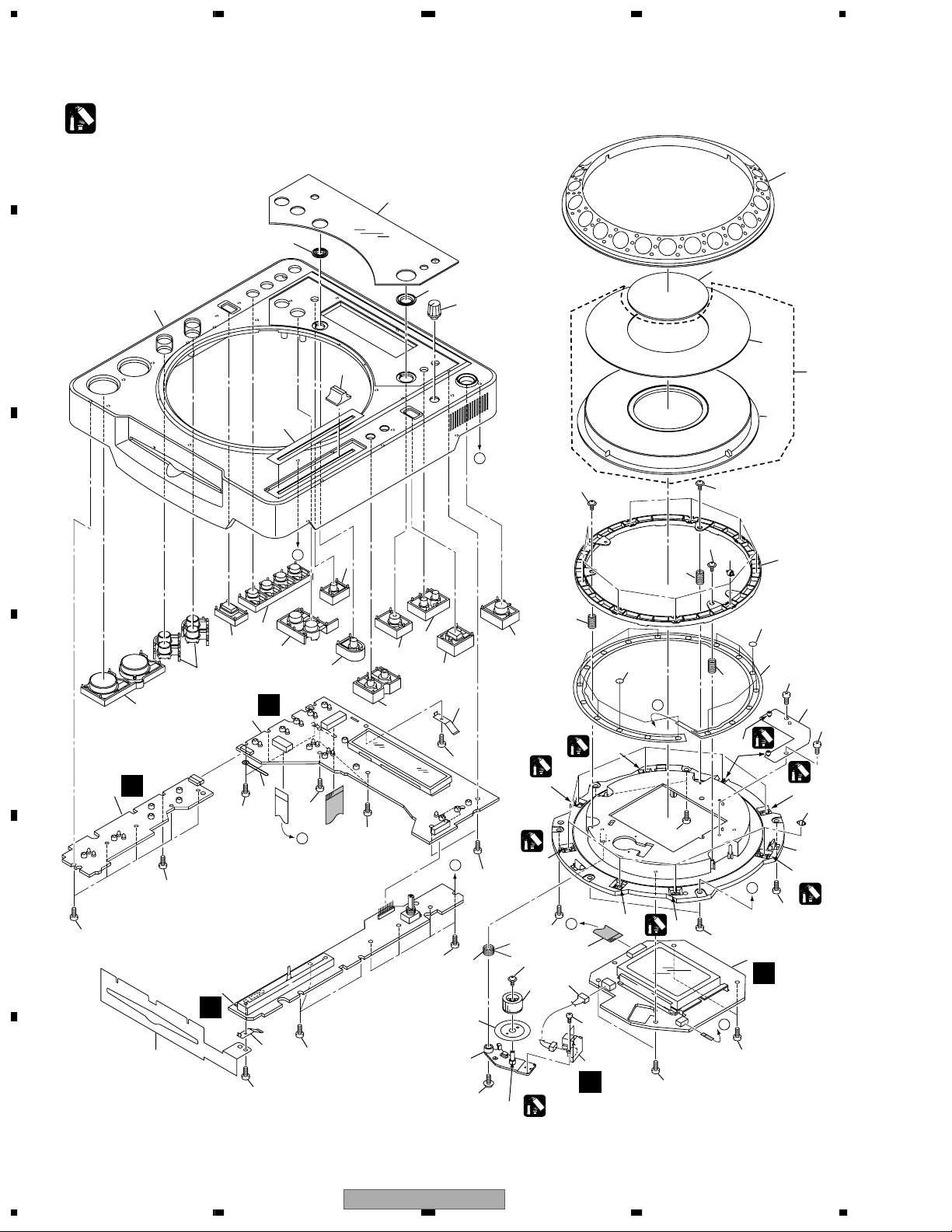

2.3 CONTROL PANEL SECTION

A

Lubricaing oil : ZLB-PN397B

1

*

7

B

8

11

26

6

27

9

10

29

28

24

B

49

C

A

17

49

35

34

1

*

1

*

1

*

41

46

C

39

44

*

47

5

K

15

14

13-1/2

D

E

46

12

2

H

46

4

46

16

18

F

1

45

46

C

46

J

23

25

46

F

46

19

20

21

46

22

13-2/2

23

46

B

46

40

42

43

48

1

*

35

D

46

1

*

46

49

49

1

46

30

31

35

*

32

34

36

46

37

46

1

1

*

31

38

1

*

A

46

3

I

D

46

12

1234

CDJ-800

5678

CONTROL PANEL SECTION parts List

Mark No. Description Part No.

1 MFLB Assy DWG1564

2 KSWB Assy DWS1321

3 JFLB Assy DWG1565

4 SLDB Assy DWS1323

5 JOGB Assy DWG1566

6 Display Panel DAH2139

7 RELOOP Guard DNK4057

8 Control Panel DNK4054

9 QR Guard DNK4058

10 Rotary Knob C DAA1143

A

11 Slide Knob DAC2067

12 PLAY Knob DAC2059

13 SET Knob (EJECT) DAC2060

14 REVERSE Knob DAC2068

15 AUTO BEAT LOOP Knob DAC2069

16 LOOP Knob DAC2066

17 TIME MODE Knob DAC2065

18 RELOOP Knob DAC2064

19 TEMPO Knob DAC2061

20 QUICK RETURN Knob DAC2070

21 CALL Knob DAC2062

22 VINYL Knob DAC2063

23 Earth Plate (CU) DBK1224

24 Slide Sheet 1C DAH1988

25 Vessel Sheet DEC2495

26 JOG B DNK4068

27 JOG Panel DAH2182

28 JOG Assy-S DXX2521

29 JOG Plate DAH2052

30 JOG A DNK4067

B

C

D

31 Roller A Assy DXB1773

32 SW Ring DNK4070

33 . . . . . .

34 SW Cushion HH48 DEC2523

35 SW Spring DBH1514

36 Sheet SW DSX1060

37 JOG Stay Assy DXB1774

38 JOG Holder DNK4069

39 13P F•F•C/60V DDD1220

40 Arm Spring DBH1503

41 D Gear DNK4066

42 ENC Plate DEC2498

43 Gear Arm DNK4065

44 Connector Assy PF04PP-B07

45 Cord Clamper RNH-184

46 Screw BPZ30P080FZK

47 Screw BPZ20P060FMC

48 Screw IPZ30P100FMC

49 Screw PBA1062

56

CDJ-800

E

F

7

8

13

1234

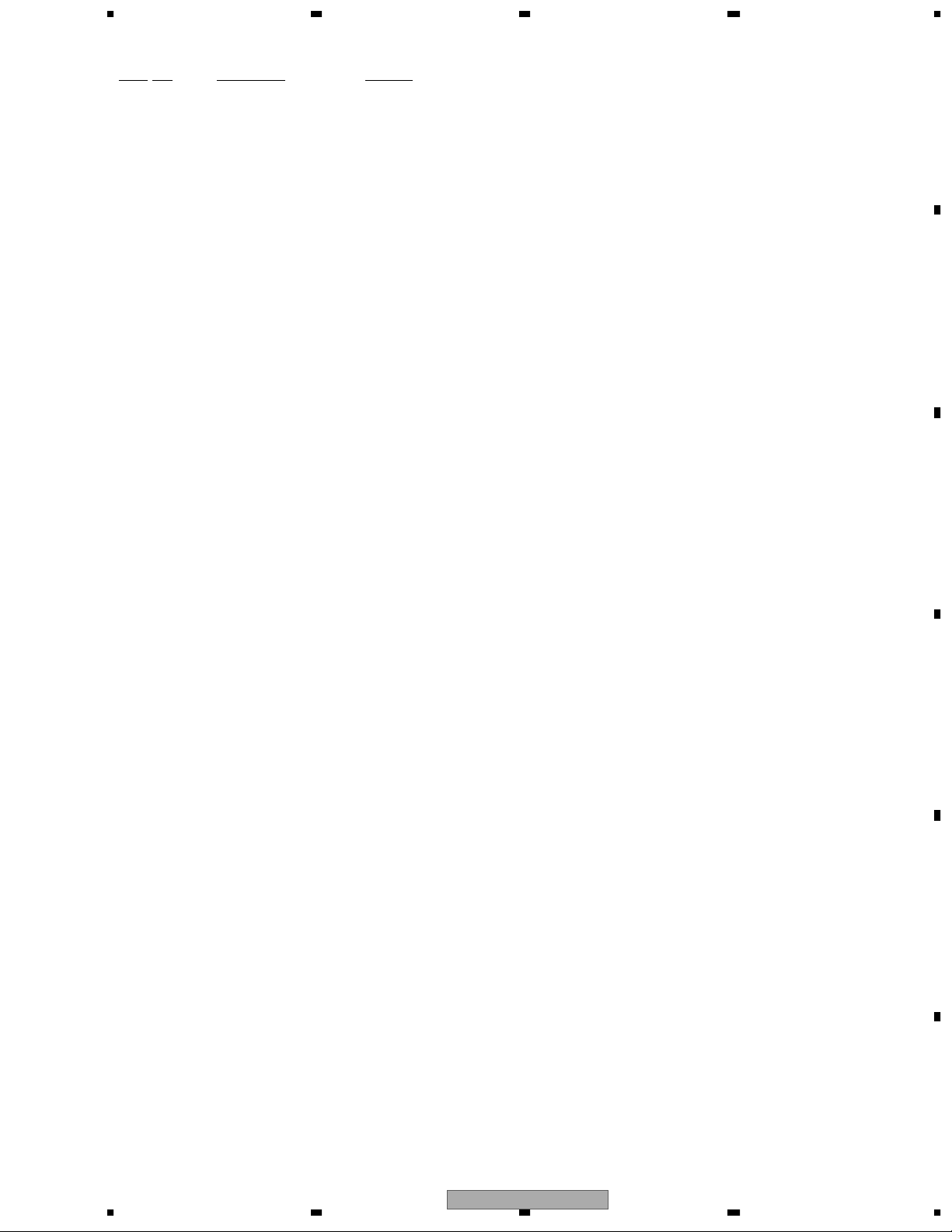

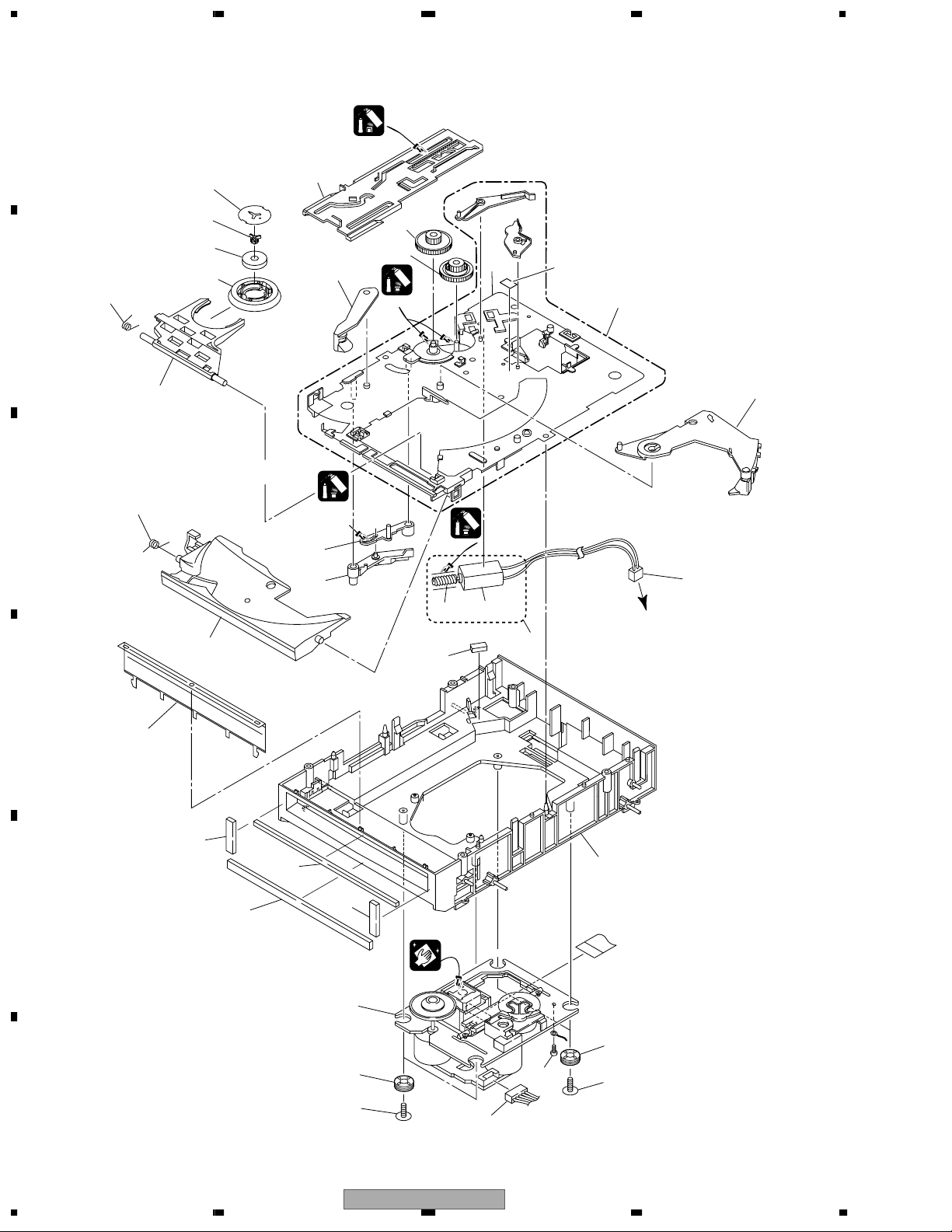

2.4 SLOT-IN MECHANISM SECTION

A

7

B

15

C

8

Paint grease the inner

surface of the wall.

11

13

32

10

Paint on side of axle.

23

Paint grease the inner

Paint grease the inner

surface of the wall.

surface of the wall.

Dyefree

Dyefree

(ZLX-ME413A)

(ZLX-ME413A)

18

Grease

(ZLB-PN397B)

12

(ZLB-PN397B)

22

21

Grease

Grease

(ZLB-PN397B)

33

Grease

(ZLB-PN397B)

9

16

17

1

14

19

20

24

To MAIN Assy

28

2

D

4

25

5

3

25

E

6

27

26

26

F

14

1234

30

29

CDJ-800

31

30

5678

SLOT-IN MECHANISM SECTION parts List

Mark No. Description Part No.

1 Connector Assy DKP3522

2 Spacer Por (T3) DEB1566

3 Float Base S4 Assy DXB1772

4 Front Sheet DED1132

5 Vessel Cushion A DEC2455

6 Vessel Cushion B DEC2456

7 Clamp Spring DBH1374

8 Guide Spring DBH1375

9 SW. Lever Spacer (Pet) DEC2420

10 Clamp Magnet DMG1009

A

11 Yoke S4 DNH2528

12 Loading Lever DNK3406

13 Main Cam DNK3407

14 Disc Guide DNK3478

15 Clamp Arm DNK3576

16 Loading Base Assy-S DEA1022

17 Eject Lever DNK3684

18 Lever AP DNK3835

19 Lever BP DNK3836

NSP 20 Worm Gear DNK3410

21 Loading Gear DNK3409

22 Drive Gear DNK3565

23 Clamper S4 DNK4072

NSP 24 DC Motor DXM1173

25 Vessel Cushion C DEC2457

26 Float Rubber S4 DEB1568

27 CD Mechanism DXA-DA114

28 DC Motor Assy-S DXX2510

29 Connector Assy (6P) PF06PP-B25

30 Screw DM DBA1104

B

C

D

31 Screw BBZ20P040FMC

32 Centering Guide DNK4073

NSP 33 Loading Base DNK3637

56

CDJ-800

E

F

7

8

15

1234

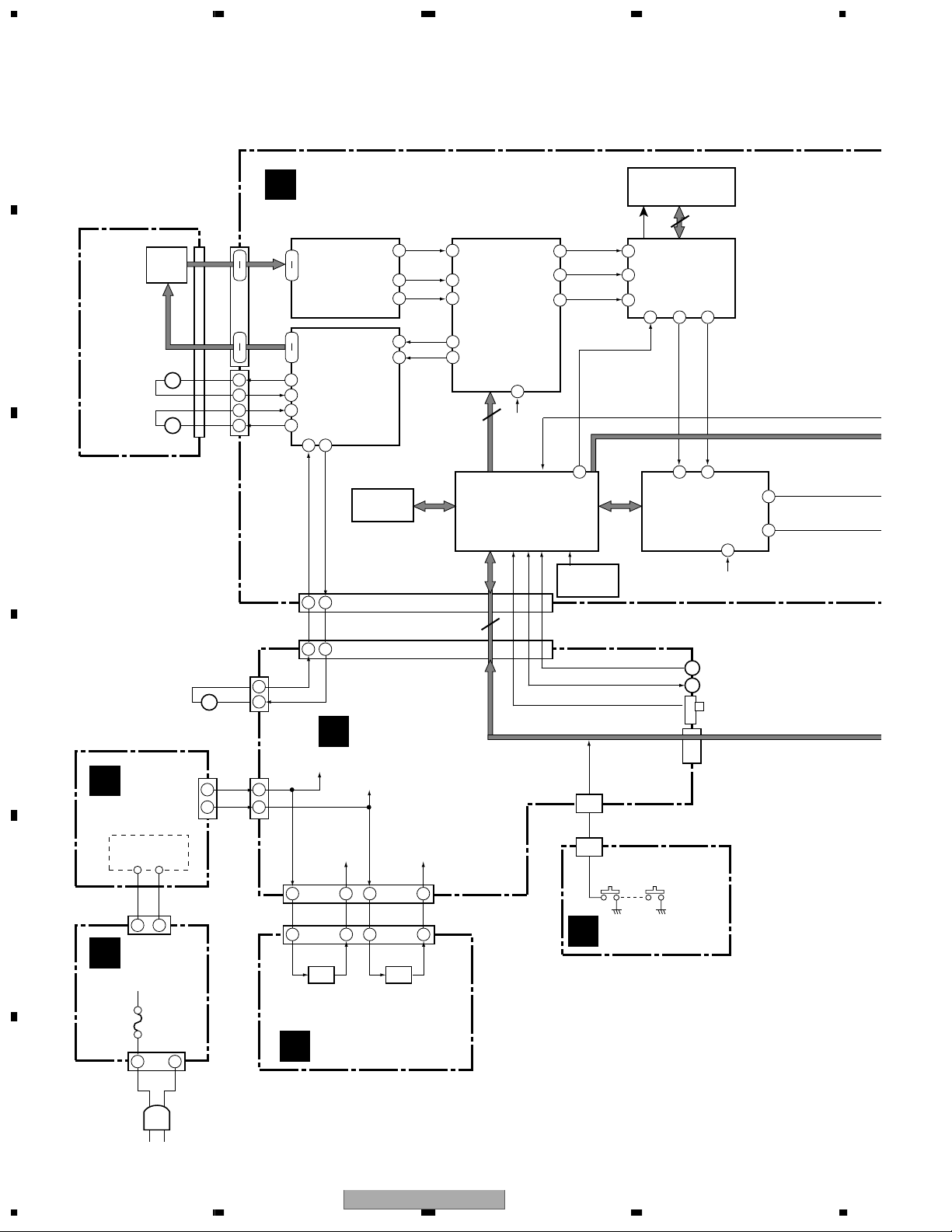

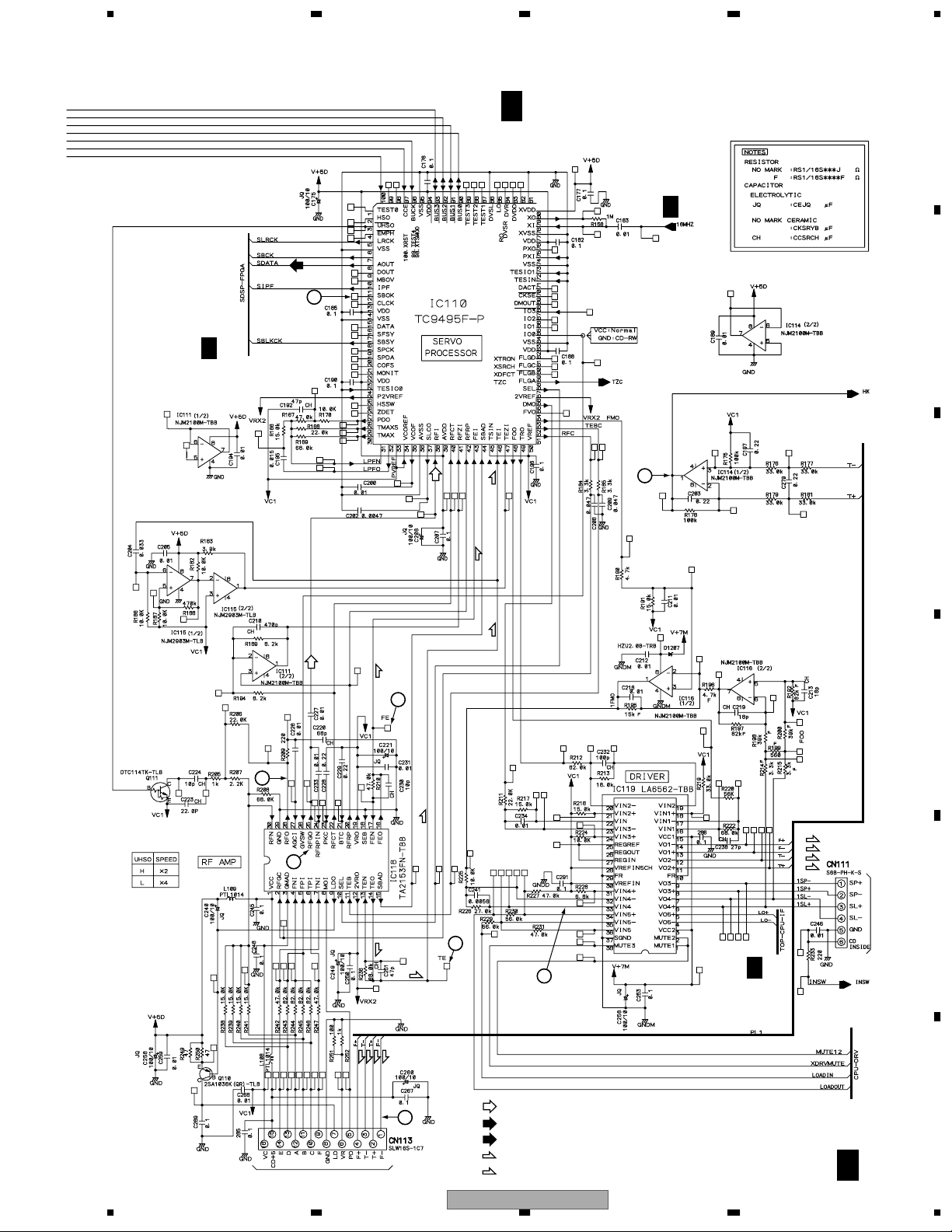

3. BLOCK DIAGRAM AND SCHEMATIC DIAGRAM

3.1 BLOCK DIAGRAM

A

MAIN ASSY

A

CD MECHANISM

PICKUP

ASSY

B

SLED

MOTOR

SPINDLE

MOTOR

+–

M

+–

M

C

LOADING

D

MOTOR

CN22

(11P)

C

TRNS ASSY

11

M

9

A-F

T+,TF+,F-

SL+

SL-

SP-

SP+

CN113

9

14

1

4

3

4

2 8

1 9

CN111

LO-

LO+

+–

V+7B

V+11B

(16P)

A-F

T+,TF+,F-

(6P)

2

1

11

9

CN122

(25P)

CN53

(25P)

CN54

CN51

(11P)

4

TA2153FN

7

RF AMP

11

14

6

BTL DRIVER

7

4

5

2 1

LO- LO+

24

25

D

V+7B

RFO

TEO

FEO

IC113

BR24C64F

EEPROM

25

14

17

18

19

IC118

IC119

LA6562

SECB ASSY

V+11B

Clock

Enable

RFI

38

TEI

46

FEI

43

FOO

48

TRO

49

Parallel data

BUS0

BUS1

BUS2

BUS3

Serial data in

data out

IC110

TC9495F

SERVO

PROCESSOR

78

16MHz

IC112

PD3442B8

SYSTEM CONTROL

MICROCOMPUTER

AOUT

8 83

LRCK

5 85

BCK

7 84

25MHz

61

IC122

M51957BFP

RESET IC

CN55

(3P)

IC109

K4S281632C-TC1H

SDRAM

LR Clock Audio

50MHz

88 67 60

25MHz 25MHz

BCK

Data

IC102

PDC101A

ASIC

O_SDATA

25MHz

11 55

IC117

XCA56367PV150

DSP

CONTROL

DATA IN/OUT

DIGITAL OUT MODE SW

NORMAL— DJ

CN56

(19P)

28

16MHz

SDOO

ADO

4

27

T21 PT

E

1 2

CN11

B

AC IN ASSY

AN11

LIVE

1 2

NEUTRAL

E

V+5D V+7A

1

1 3

IC91

BA05T

REG.

3

REGB ASSY

4 5

4 5

IC92

PQ15RW11

REG.

CN52

(6P)

J91

(6P)

CN1901

(3P)

LOADING PHASE SW

SLMB ASSY

G

F

AC IN

16

CDJ-800

1234

5678

A

B

CN110

ONLY DESIGNER USER

IC104

PE8001A

2 16

DAC

16MHz

MFLB ASSY

F

CN501

(19P)

PANEL KEY

PANEL KEY

KSWB ASSY

H

IC103 (1/2)

NJM4558MD

IC501

PD5848A

DISPLAY

MICROCOMPUTER

CN502

CN1502

(6P)

2

1

3

4MHz

Serial data

Latch clock

(6P)

CN500

(13P)

Serial data

CN600

(13P)

CN601

(4P)

AUDIO

L

OUT

DIGITAL

OUT

IC502

UPD16306B

FL DRIVER

IC601

UPD16306B

FL DRIVER

JFLB ASSY

I

V501

MAIN FL

V601

JOG FL

CN503

(11P)

CN1503

SHEET SW

CN602

(3P)

SLDB ASSY

J

(11P)

PANEL KEY

Slider

VR

C

D

E

CN1601

(4P)

JOGB ASSY

K

JOG ENCODER

CDJ-800

56

F

7

8

17

1234

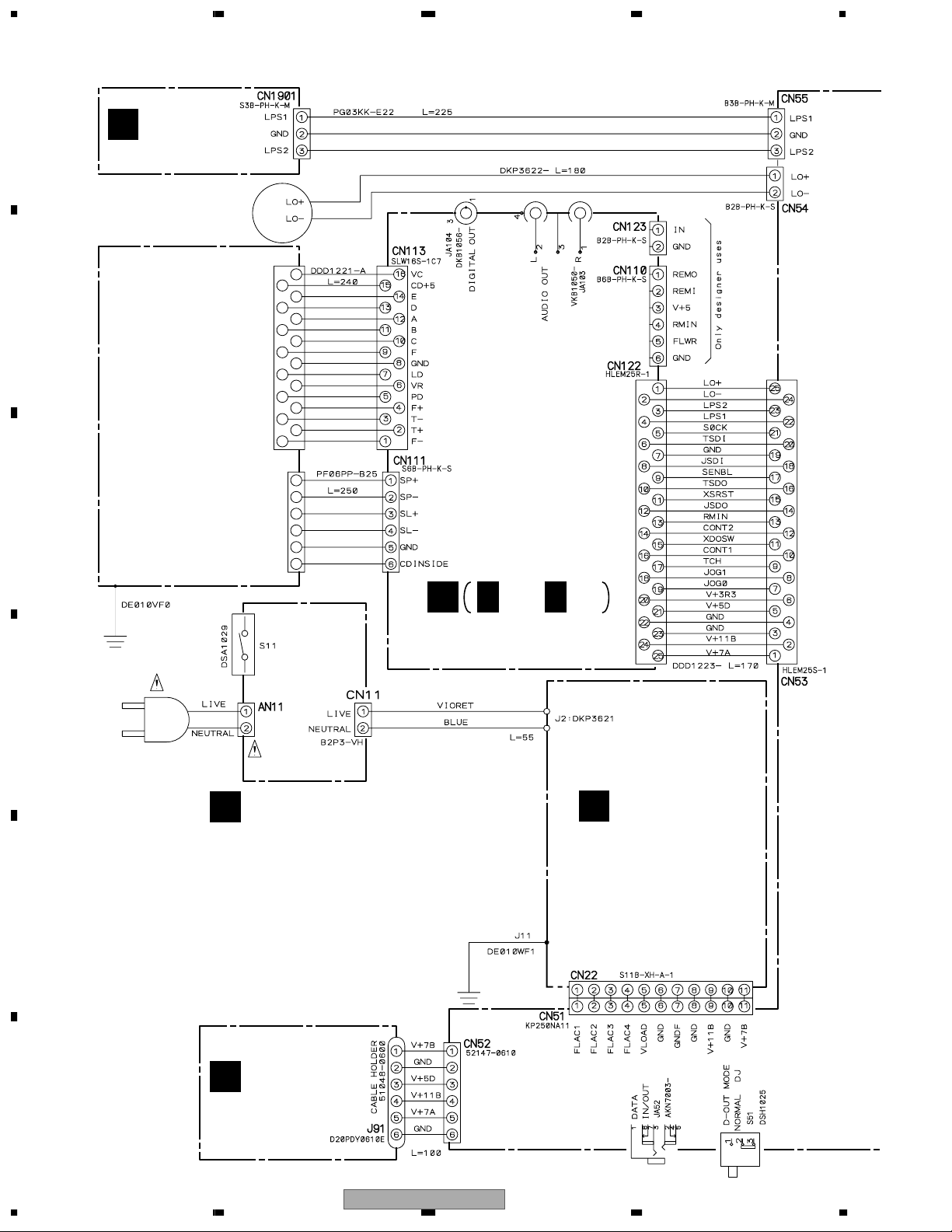

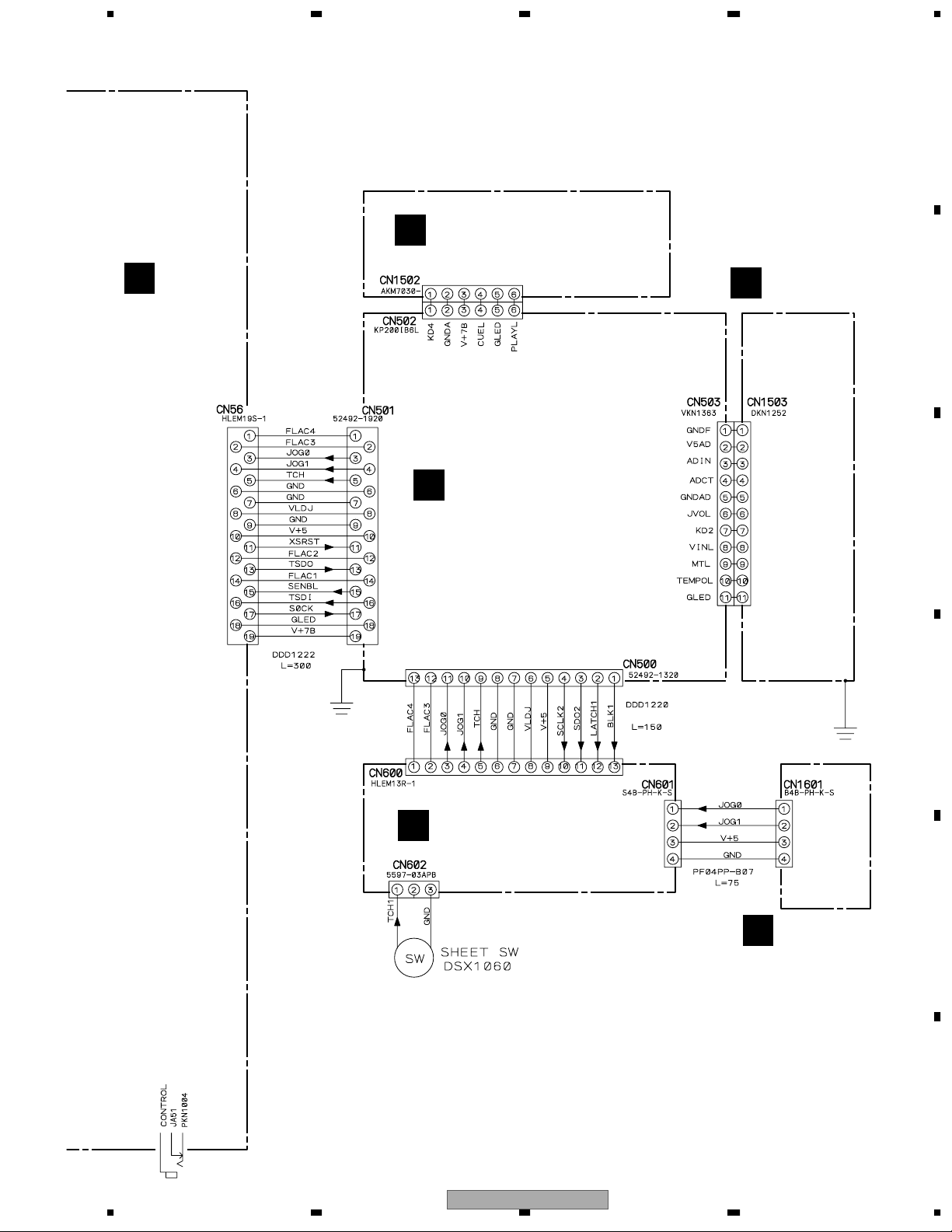

3.2 OVERALL WIRING DIAGRAM

A

SLMB ASSY

G

(DWS1322)

LOADING MOTOR

ASSY-S

DXX2510

B

CD MECHANISM

(DXA-DA114)

C

A

A 1/2- A 2/2

MAIN ASSY

(DWG1563)

AKP7032 (KUCXJ)

BKP1046 (WYXJ)

D

AC POWER CORD

(KUCXJ : ADG7021)

(WYXJ : ADG1154)

AC IN ASSY

B

(KUCXJ : DWR1366)

TRNS ASSY

C

(DWR1364)

(WYXJ : DWR1363)

E

REGB ASSY

E

(DWR1362)

F

18

1234

CDJ-800

5678

D

SECB ASSY

(DWR1361)

Note : When ordering service parts, be sure to refer to

"EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

KSWB ASSY (DWS1321)

H

MFLB ASSY (DWG1564)

F

SLDB ASSY

J

(DWS1323)

A

B

C

JFLB ASSY (DWG1565)

I

JOGB ASSY

K

(DWG1566)

D

E

F

56

CDJ-800

7

8

19

1234

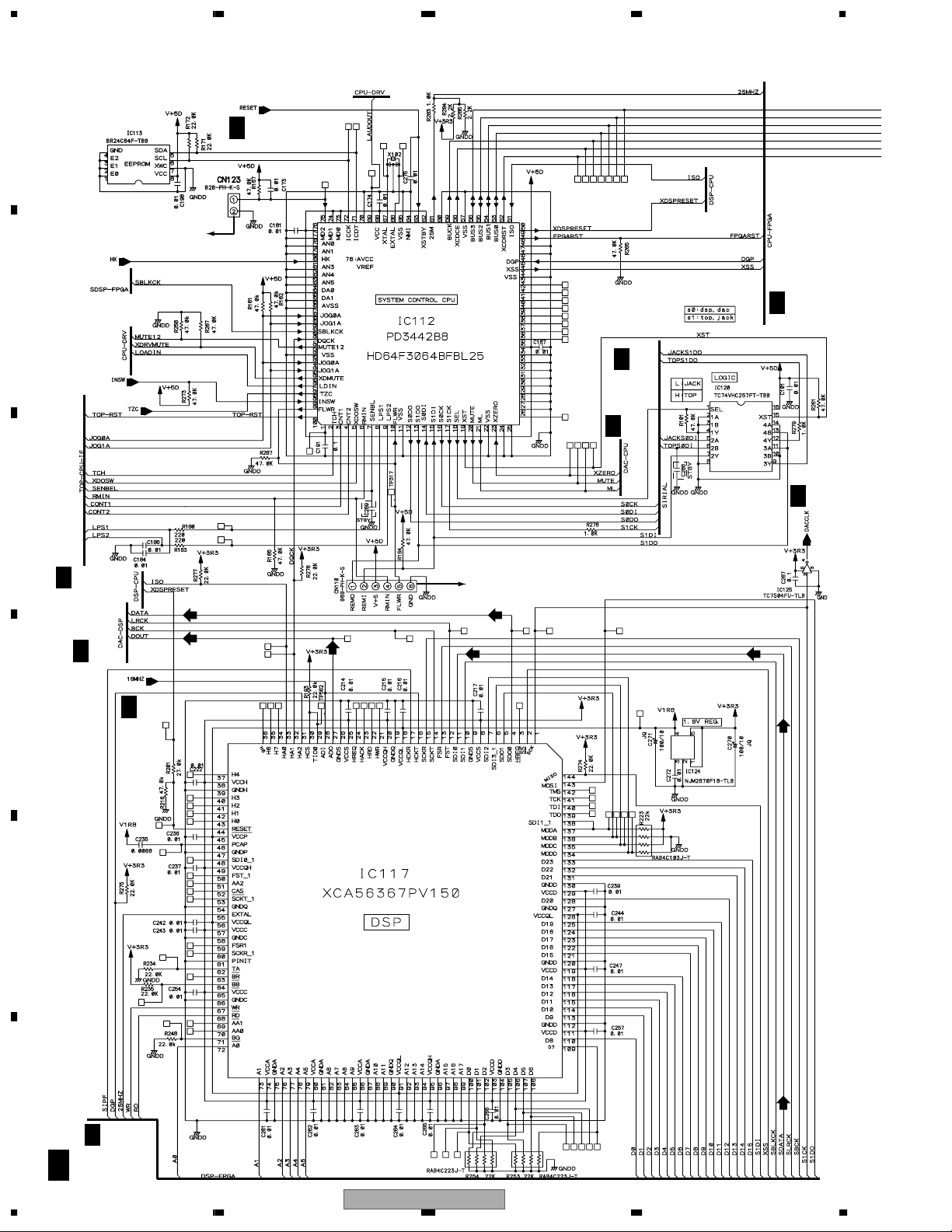

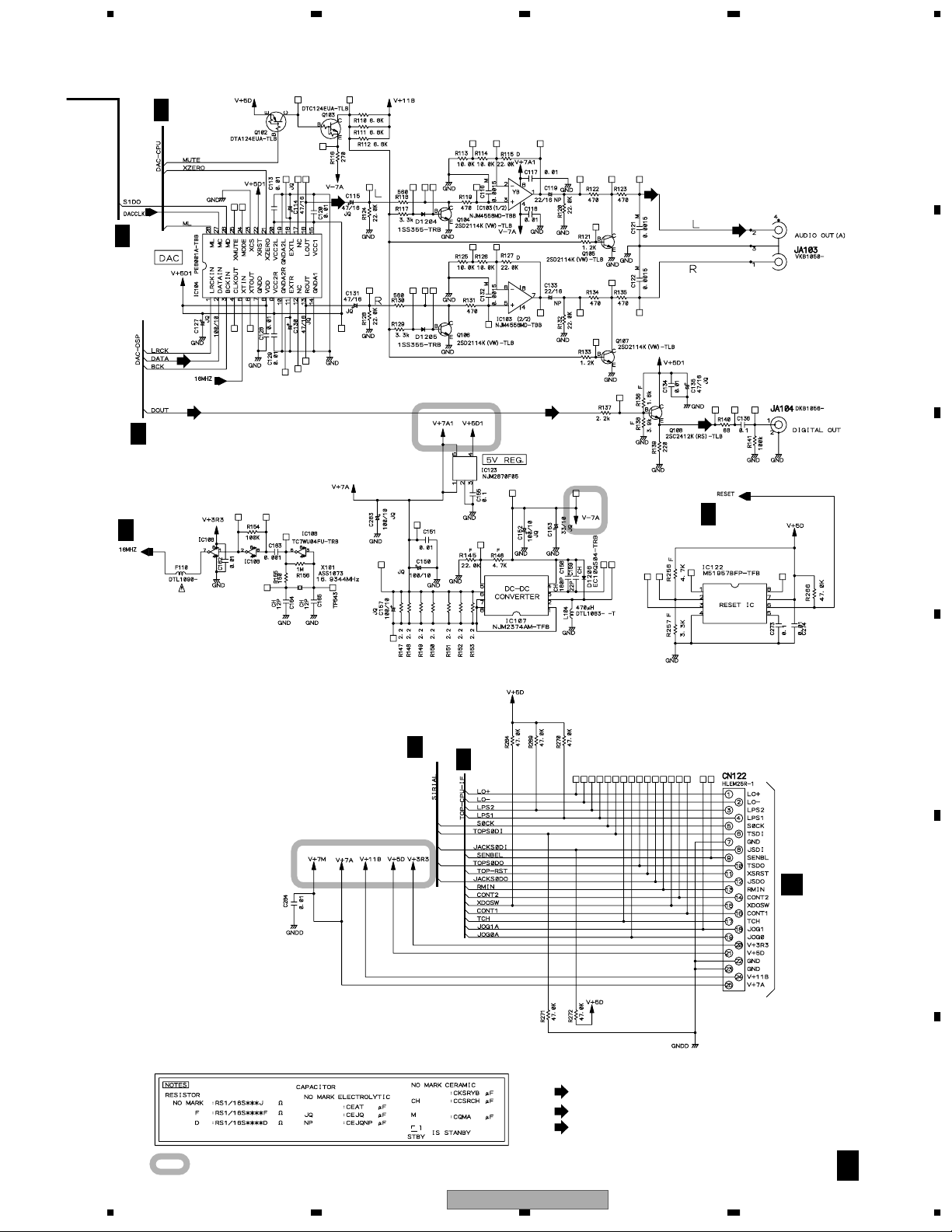

3.3 MAIN ASSY(1/2)

A

ONLY

DESIGNER

USER

A 2/2

DSS1139

B

A 2/2

A 2/2

A 2/2

A 2/2

C

A 2/2

(AD)

A 2/2

D

A 2/2

(D)

(D)

ONLY

DESIGNER

USER

(AD)

(AD)

(AD)

(AD)(AD)

E

F

A 1/2

20

A 2/2

CDJ-800

1234

5678

A 2/2

(AD)

A 1/2

MAIN ASSY

A

(DWG1563)

A 2/2

6

8

(RF)

B

C

(F)

(T) (T)

(RF)

1

2

(F)

3

D

(T)

(T)

4

(T)

7

A 2/2

(F)

(F)

(T)

(T)

E

TO CD MECHANISM

(F)

(T)

(T)

(F)

(RF)

: RF SIGNAL ROUTE

5

TO CD MECHANISM

(AD)

: AUDIO DATA SIGNAL ROUTE

(D)

: DIGITAL OUT SIGNAL ROUTE

(F)

: FOCUS SERVO SIGNAL ROUTE

(T)

: TRACKING SERVO SIGNAL ROUTE

CDJ-800

56

F

A 1/2

7

8

21

1234

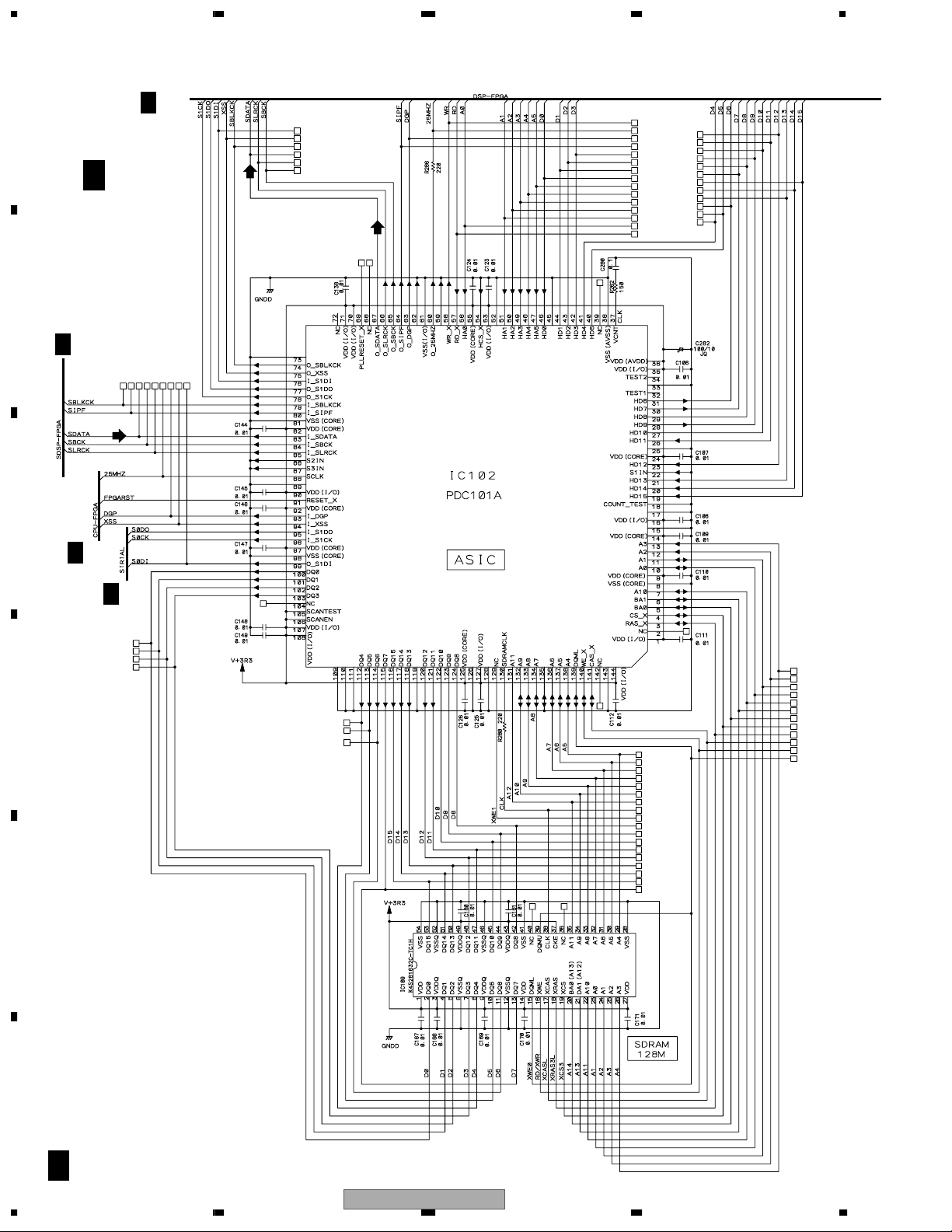

3.4 MAIN ASSY(2/2)

A

A 2/2

A 1/2

(AD)

MAIN ASSY

(DWG1563)

(AD)

B

GND

A 1/2

(AD)

C

GND

GND

GND

GND

GND

GND

GND

GND

GND

A 1/2

A 1/2

GND

GND

GND

D

E

GND

GND

GND

GND

GND

F

A 2/2

22

1234

CDJ-800

5678

A 1/2

A 1/2

A 1/2

A 1/2

(AD)

(D) (D)

(D)

A 1/2

A

B

C

A 1/2

A 1/2

: AUDIO SIGNAL ROUTE

(AD)

: AUDIO DATA SIGNAL ROUTE

(D)

: DIGITAL OUT SIGNAL ROUTE

: The power supply is shown with the marked box.

56

CDJ-800

D

CN53

D

E

F

A 2/2

7

8

23

1234

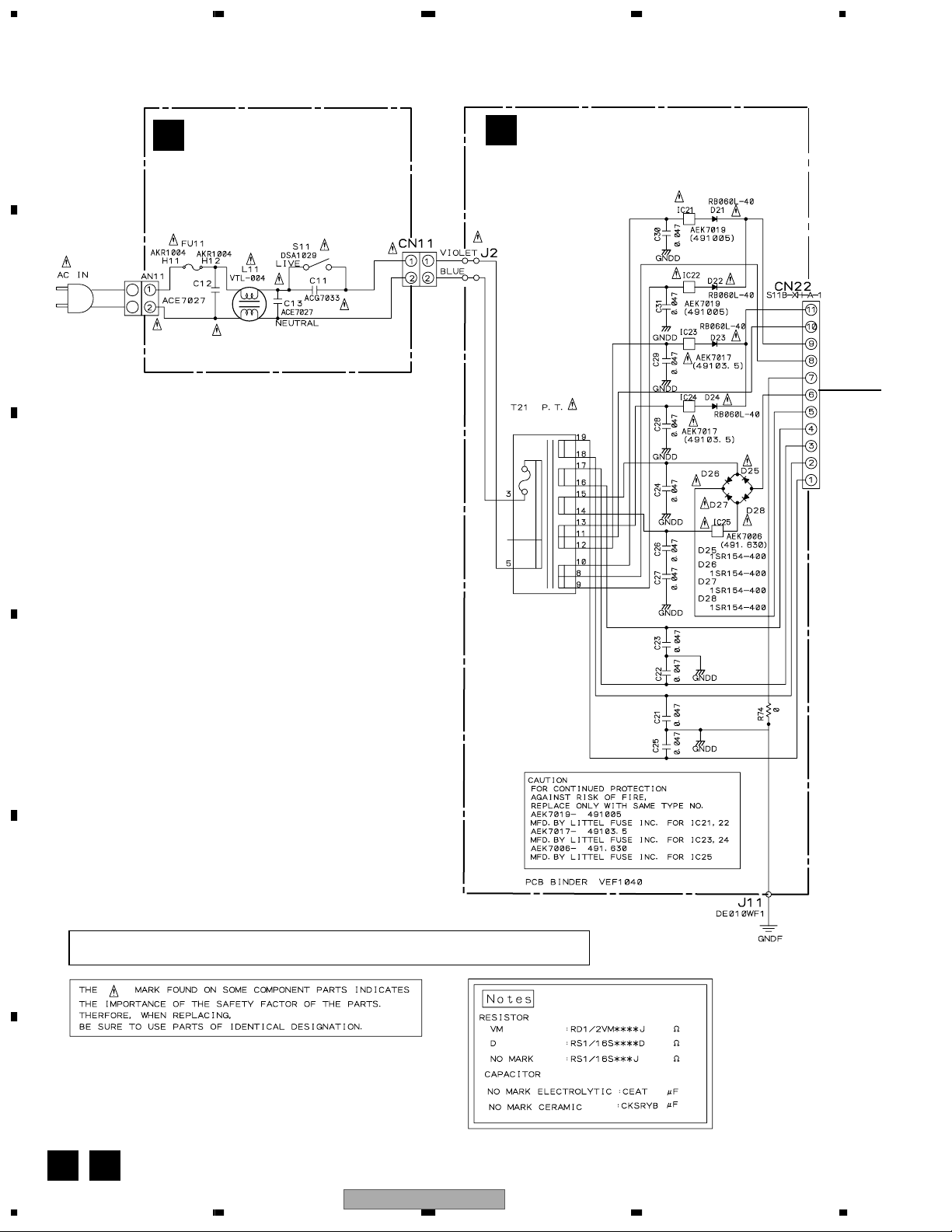

3.5 AC IN, TRNS, SECB and REGB ASSYS

A

AC IN ASSY

B

(KUCXJ : DWR1366)

(WYXJ : DWR1363)

FU11

KUCXJ: 1.6A/125V (REK1077)

WYXJ: T800mA/L250V (REK1021)

LIVE

TRNS ASSY (DWR1364)

C

B

C

D

NEUTRAL

AC POWER CORD

KUCXJ: ADG7021

WYXJ: ADG1154

KUCXJ: DTT1169

WYXJ: DTT1168

E

F

• NOTE FOR FUSE REPLACEMENT

CAUTION -

FOR CONTINUED PROTECTION AGAINST RISK OF FIRE.

REPLACE WITH SAME TYPE AND RATINGS ONLY.

B C

24

1234

CDJ-800

Loading...

Loading...