Pioneer CDJ-400 Service manual

POWER

ON

OFF

CDJ-400

MULTI PLAYER

TIME

AUTO

MODE

CUE

TEXT

UTILITY

SOURCE SELECT

MODE

MODE

MEMORY PC

USB

SCRATCH

BUBBLE TRANS

JOG EFFECT

CD

DIGITAL

JET ROLL WAH

JOG BREAK

REALTIME CUE

IN

OUT RELOOP/EXIT BEAT LOOP

DIRECTION JOG MODE

TRACK SEARCH

SEARCH

BACK

SELECT PUSH

WAH

HOLD

LOOP DIVIDEOUT ADJUSTHOT LOOP

EJECT

MEMORY

DELETE

CUE/LOOP

CALL

LYNIVPOOLVER

TEMPO

±±±

10 16 WIDE

6

MASTER TEMPO

CUE

PLAY/PAUSE

REV FWD

0

TEMPO

CDJ-400

COMPACT DISC PLAYER

CDJ-400

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

CDJ-400 KUCXJ AC 120 V

CDJ-400 WYXJ5 AC 220 to 240 V

CDJ-400 TLFXJ AC 110 V to 240 V

ORDER NO.

RRV3679

For details, refer to "Important Check Points for good servicing".

PIONEER CORPORATION 4-1, Meguro 1-chome, Meguro-ku, Tokyo 153-8654, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION 2007

T-ZZR NOV. 2007 printed in Japan

1234

SAFETY INFORMATION

A

This service manual is intended for qualified service technicians ; it is not meant for the casual

do-it-yourselfer. Qualified technicians have the necessary test equipment and tools, and have been

trained to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

Health & Safety Code Section 25249.6 - Proposition 65

B

NOTICE

(FOR CANADIAN MODEL ONLY )

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

C

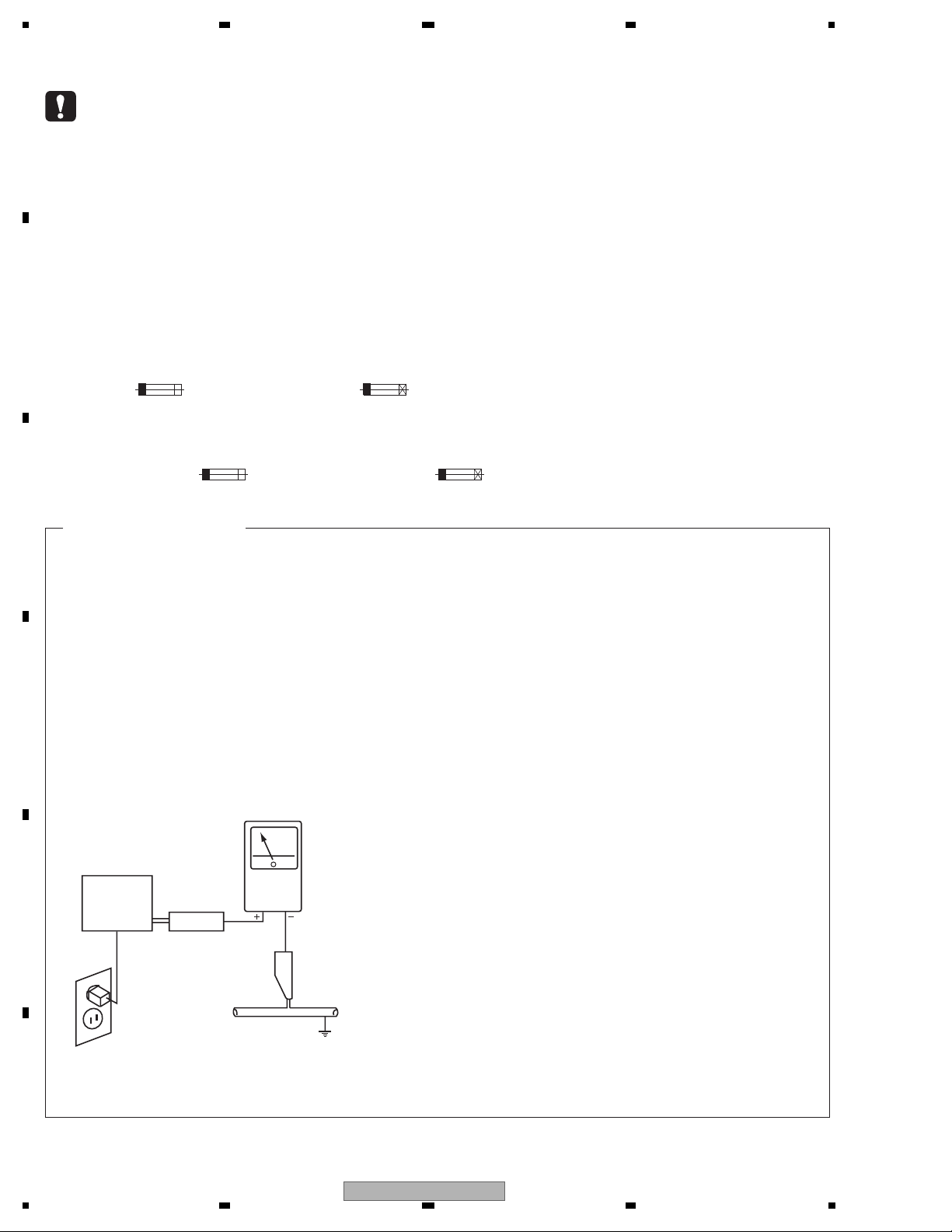

(FOR USA MODEL ONLY)

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

D

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

Reading should

Leakage

Device

E

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

current

tester

not be above

0.5 mA

Earth

ground

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Service Manual.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

AC Leakage Test

F

2

1234

CDJ-400

5678

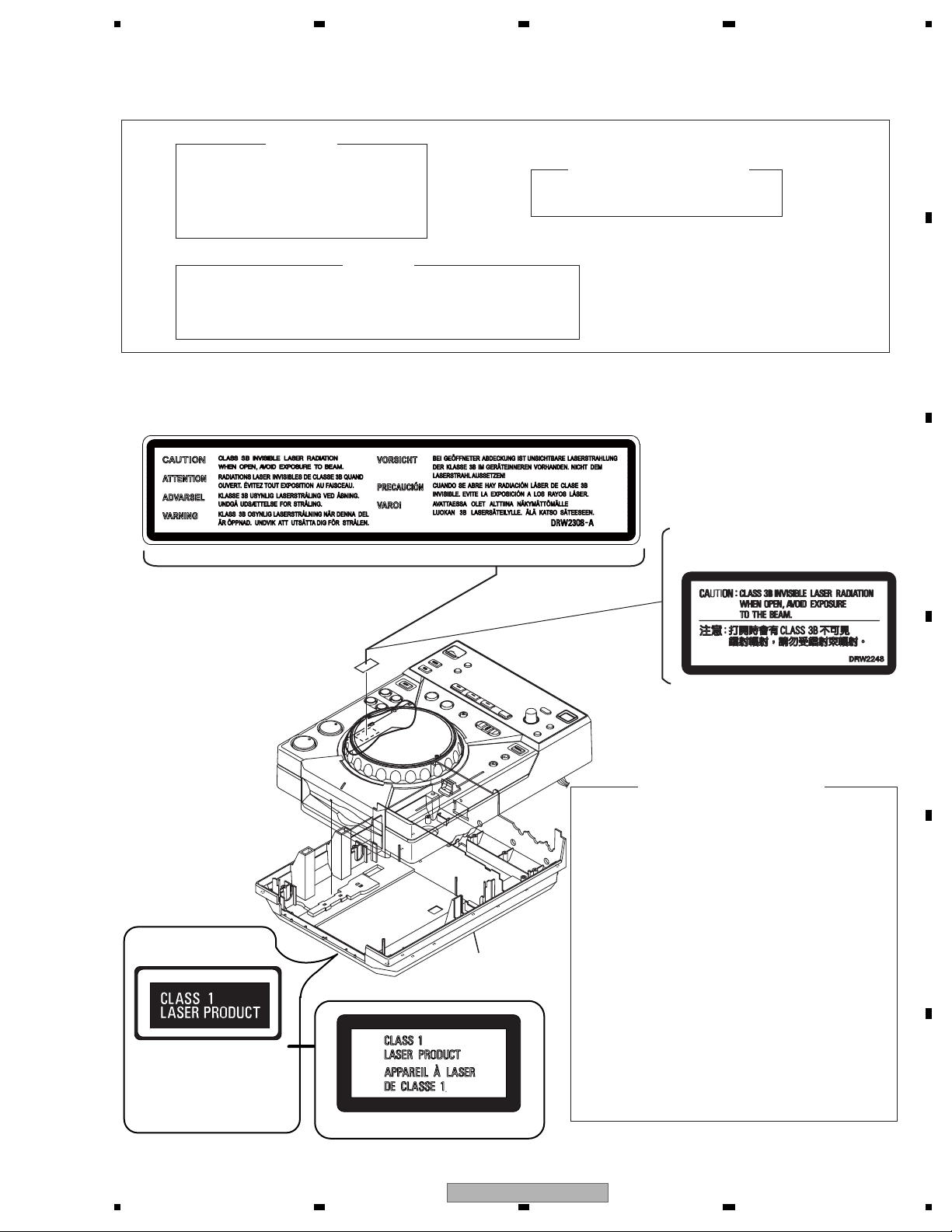

A

THIS PIONEER APPARATUS CONTA IN S

IMPORTANT

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DON E BY A SPECIALLY

INSTRUCTED PERSON.

The AEL(accessible emission level) of the laser power output is less then CLASS 1

but the laser component is capable of emitting radiation exceeding the limit for

CLASS 1.

A specially instructed person should do servicing operation of the apparatus.

LABEL CHECK

LASER DIODE CHARACTERISTICS

MAXIMUM OUTPUT POWER: 5 mW

WAVELENGTH: 780 – 785 nm

WARNING !

B

CDJ-400 WYXJ5 and KUCXJ : Types Only

C

for TLFXJ

(DRW2308)

for TLFXJ

Printed on the chassis

Chassis

for WYXJ5 and KUCXJ

Printed on the chassis

(DRW2248)

Additional Laser Caution

1. Laser Interlock Mechanism

The position of the switch (S1801) for detecting loading

completion is detected by the system microprocessor,

and the design prevents laser diode oscillation when

the switch is not in LPS1 terminal side (when the

mechanism is not clamped and LPS1 signal is

high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side. ( if LPS1 signal

is low level ).

In the test mode* the interlock mechanism will not

function. Laser diode oscillation will continue, if pin 41

of TC94A15FG (IC502) on the MAIN Assy is

connected to GND, or else the terminals of Q501 are

shorted to each other (fault condition).

2. When the cover is opened, close viewing of the

objective lens with the naked eye will cause exposure

to a Class 1 laser beam.

* : Refer to page 24.

D

E

F

CDJ-400

56

3

7

8

1234

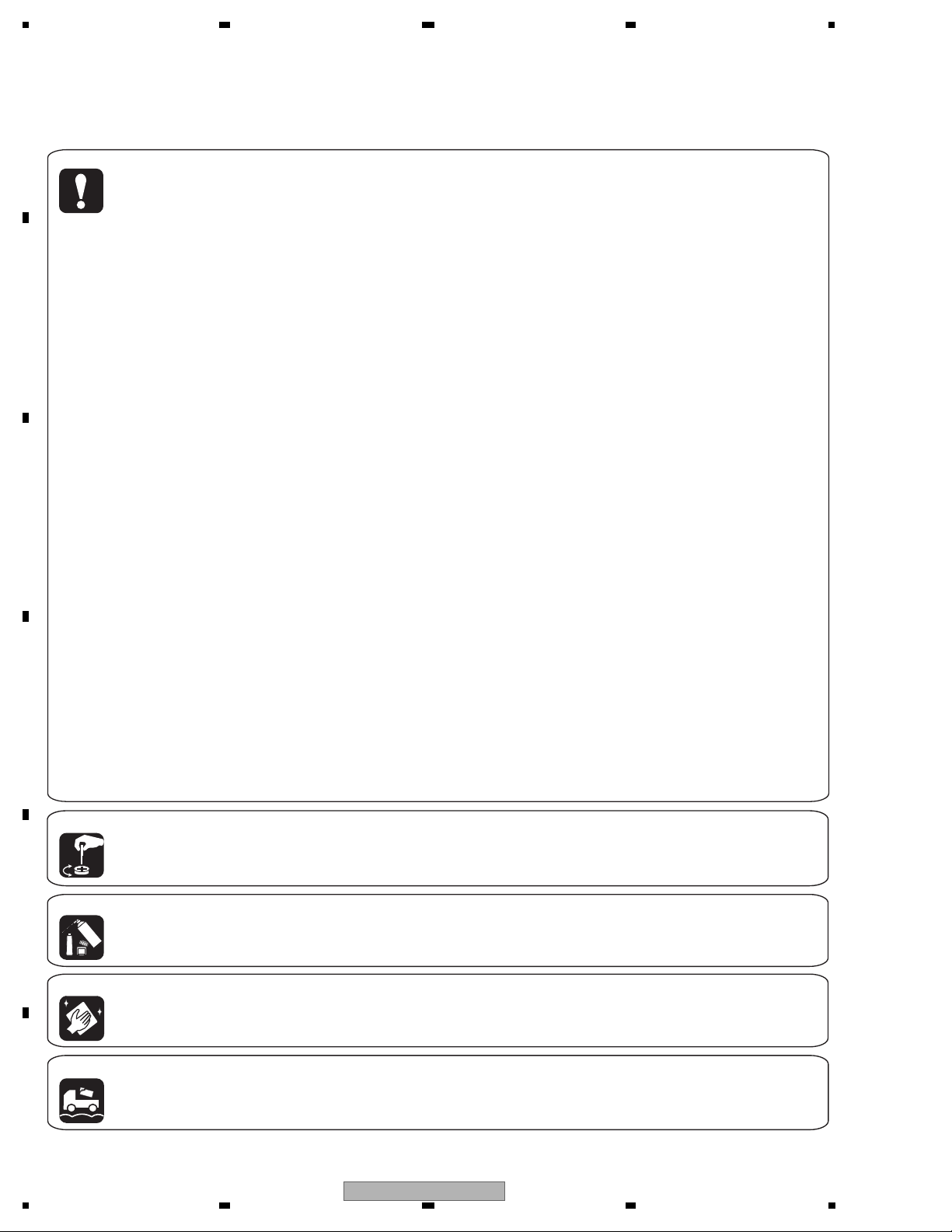

[Important Check Points for Good Servicing]

A

In this manual, procedures that must be performed during repairs are marked with the below symbol.

Please be sure to confirm and follow these procedures.

1. Product safety

Please conform to product regulations (such as safety and radiation regulations), and maintain a safe servicing environment by

following the safety instructions described in this manual.

1 Use specified parts for repair.

Use genuine parts. Be sure to use important parts for safety.

2 Do not perform modifications without proper instructions.

B

C

D

Please follow the specified safety methods when modification(addition/change of parts) is required due to interferences such as

radio/TV interference and foreign noise.

3 Make sure the soldering of repaired locations is properly performed.

When you solder while repairing, please be sure that there are no cold solder and other debris.

Soldering should be finished with the proper quantity. (Refer to the example)

4 Make sure the screws are tightly fastened.

Please be sure that all screws are fastened, and that there are no loose screws.

5 Make sure each connectors are correctly inserted.

Please be sure that all connectors are inserted, and that there are no imperfect insertion.

6 Make sure the wiring cables are set to their original state.

Please replace the wiring and cables to the original state after repairs.

In addition, be sure that there are no pinched wires, etc.

7 Make sure screws and soldering scraps do not remain inside the product.

Please check that neither solder debris nor screws remain inside the product.

8 There should be no semi-broken wires, scratches, melting, etc. on the coating of the power cord.

Damaged power cords may lead to fire accidents, so please be sure that there are no damages.

If you find a damaged power cord, please exchange it with a suitable one.

9 There should be no spark traces or similar marks on the power plug.

When spark traces or similar marks are found on the power supply plug, please check the connection and advise on secure

connections and suitable usage. Please exchange the power cord if necessary.

a Safe environment should be secured during servicing.

When you perform repairs, please pay attention to static electricity, furniture, household articles, etc. in order to prevent injuries.

Please pay attention to your surroundings and repair safely.

2. Adjustments

To keep the original performance of the products, optimum adjustments and confirmation of characteristics within specification.

Adjustments should be performed in accordance with the procedures/instructions described in this manual.

3. Lubricants, Glues, and Replacement parts

E

Use grease and adhesives that are equal to the specified substance.

Make sure the proper amount is applied.

4. Cleaning

For parts that require cleaning, such as optical pickups, tape deck heads, lenses and mirrors used in projection monitors, proper

cleaning should be performed to restore their performances.

5. Shipping mode and Shipping screws

To protect products from damages or failures during transit, the shipping mode should be set or the shipping screws should be

F

installed before shipment. Please be sure to follow this method especially if it is specified in this manual.

4

1234

CDJ-400

5678

CONTENTS

SAFETY INFORMATION .....................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................................................................6

1.1 NOTES ON SOLDERING...........................................................................................................................6

2. SPECIFICATIONS.............................................................................................................................................7

2.1 ACCESSORIES..........................................................................................................................................7

2.2 SPECIFICATIONS ......................................................................................................................................8

2.3 DISC USABLE WITH THIS UNIT ...............................................................................................................9

2.4 PANEL FACILITIES...................................................................................................................................11

3. BASIC ITEMS FOR SERVICE ........................................................................................................................14

3.1 CHECK POINTS AFTER SERVICING .....................................................................................................14

3.2 PCB LOCATIONS .....................................................................................................................................15

3.3 JIGS LIST .................................................................................................................................................16

4. BLOCK DIAGRAM ..........................................................................................................................................18

4.1 OVERALL WIRING DIAGRAM .................................................................................................................18

4.2 OVERALL BLOCK DIAGRAM ..................................................................................................................20

5. DIAGNOSIS ....................................................................................................................................................22

5.1 CHECKING THE PICKUP ASSY..............................................................................................................22

5.2 POWER ON SEQUENCE.........................................................................................................................23

6. SERVICE MODE.............................................................................................................................................24

6.1 OVERVIEW OF SERVICE MODE ............................................................................................................24

6.2 CHECK MODE OPERATION....................................................................................................................24

7. DISASSEMBLY ...............................................................................................................................................32

8. EACH SETTING AND ADJUSTMENT............................................................................................................39

9. EXPLODED VIEWS AND PARTS LIST ..........................................................................................................40

9.1 PACKING SECTION .................................................................................................................................40

9.2 EXTERIOR SECTION ..............................................................................................................................42

9.3 CONTROL PANEL SECTION...................................................................................................................44

9.4 JOG DIAL SECTION ................................................................................................................................46

9.5 SLOT-IN MECHANISM SECTION ............................................................................................................48

10. SCHEMATIC DIAGRAM................................................................................................................................50

10.1 MAIN ASSY (1/2)....................................................................................................................................50

10.2 MAIN ASSY (2/2)....................................................................................................................................52

10.3 CNCT and SLMB ASSYS.......................................................................................................................54

10.4 PNLB ASSY............................................................................................................................................56

10.5 JACB ASSY............................................................................................................................................58

10.6 REGB and ACIN ASSYS........................................................................................................................60

10.7 JOGB, TCHB and SW POWER SUPPLY ASSYS ..................................................................................62

10.8 VOLTAGES .............................................................................................................................................64

10.9 WAVEFORMS.........................................................................................................................................66

11. PCB CONNECTION DIAGRAM....................................................................................................................71

11.1 TCHB ASSY ...........................................................................................................................................71

11.2 MAIN, CNCT, SLMB and JACB ASSYS .................................................................................................72

11.3 PNLB ASSY............................................................................................................................................76

11.4 REGB ASSY.................................................................................................................

11.5 JOGB and ACIN ASSYS ........................................................................................................................82

12. PCB PARTS LIST..........................................................................................................................................84

..........................80

A

B

C

D

CDJ-400

56

E

F

5

7

8

1234

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 °C.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 °C in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

B

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

C

D

E

F

6

1234

CDJ-400

5678

2. SPECIFICATIONS

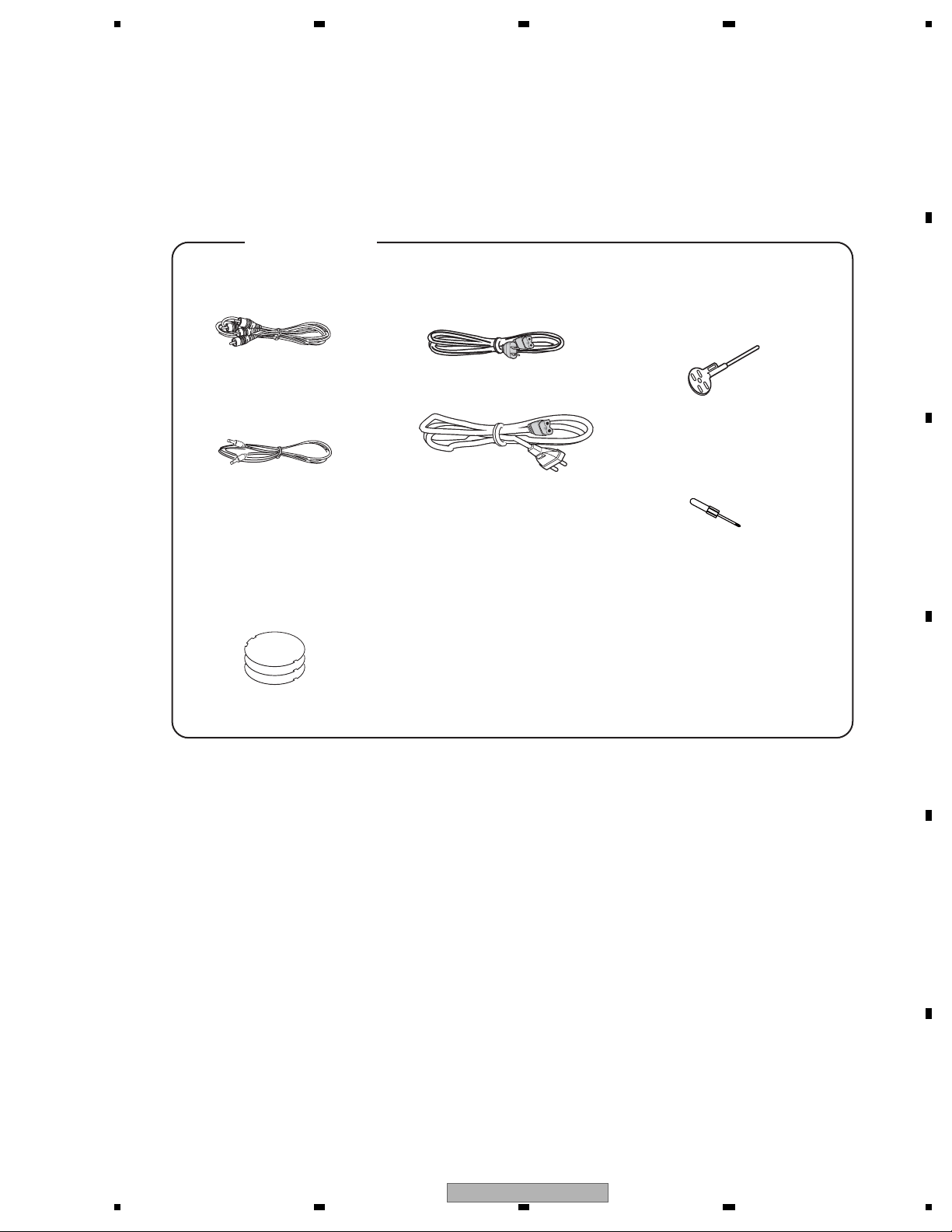

2.1 ACCESSORIES

Accessories

Audio Cable

(VDE1064) L=1.5m

Power Cord

(ADG7021 : KUCXJ)

(ADG7097 : TLFXJ)

Forced Fject Pin

(housed in a groove in

the bottom panel)

(DEX1008)

A

B

Control Cord

(ADE7108) L=1 m

• Jog sheets

( 1: DAH2599)

( 2: DAH2600)

( 3: DAH2601)

(ADG1154 : WYXJ5,TLFXJ)

(housed in a groove in

• Operating Instructions

(KUCXJ: DRB1450)

(WYXJ5: DRB1451)

(TLFXJ: DRB1452)

Screw driver

the bottom panel)

(DEX1022)

C

• Warranty Card

D

CDJ-400

56

E

F

7

7

8

1234

2.2 SPECIFICATIONS

A

• KUCXJ type

1. General

System............................ Compact disc digital audio system

Power requirements.................................... AC 120 V, 60 Hz

Power consumption...................................................... 17 W

Operating temperature.......... +5°C to +35°C (+41°F to +95°F)

Operating humidity............................................. 5 % to 85 %

(without condensation.)

Weight............................................................ 2.7 kg (5.8 lb)

Dimensions..................... 217.9 (W) x 107.5 (H) x 296.3 (D) mm

B

8.57 (W) x 4.23 (W) x 11.67 (D) in

2. Audio section

Frequency response........................................4 Hz to 20 kHz

Signal-to-noise ratio.......................... 115 dB or more (JEITA)

Distortion.................................................... .0.006 % (JEITA)

3. Accessories

• Operating instructions........................................................ 1

• Power cord........................................................................ 1

• Audio cable....................................................................... 1

• Control cable..................................................................... 1

C

• Forced eject pin (housed in a groove in the bottom panel)... 1

• Limited warranty................................................................ 1

• Screwdriver

• Jog sheets (for replacing) ............................................. 3

(housed in a groove in the bottom panel)

......... 1

• WYXJ5 type

1. General

System.......................... Compact disc digital audio system

Power requirements .................... AC 220 V to 240 V, 50/60 Hz

D

Power consumption ..................................................... 19 W

Operating temperature .................................. +5C to +35C

Operating humidity ............................................ 5 % to 85 %

(without condensation.)

Weight ....................................................................... 2.7 kg

Dimensions .................. 217.9 (W) x 107.5 (H) x 296.3 (D) mm

• TLFXJ type

1. General

System........................... Compact disc digital audio system

Power requirements .... AC 110 V to 240 V, 50/60 Hz

Power consumption ..................................................... 19 W

Operating temperature .................................. +5°C to +35°C

Operating humidity ........................................... 5 % to 85 %

(without condensation.)

Weight ........................................................................2.7 kg

Dimensions .............. 217.9 (W) x 107.5 (H) x 296.3 (D) mm

2. Audio section

Frequency response...................................... 4 Hz to 20 kHz

Signal-to-noise ratio ....................... 115 dB or more (JEITA)

Distortion ................................................... 0.006 % (JEITA)

3. Accessories

• Operating instructions ..................................................... 1

• Power cord ...................................................................... 1

• Audio cable ..................................................................... 1

• Control cable ................................................................... 1

• Forced eject pin (housed in a groove in the bottom panel)... 1

• Screwdriver

• Jog sheets (for replacing) ............................................. 3

NOTE:

Specifications and design are subject to possible modification

with-out notice.

(housed in a groove in the bottom panel)

......... 1

2. Audio section

Frequency response...................................... 4 Hz to 20 kHz

Signal-to-noise ratio ....................... 115 dB or more (JEITA)

Distortion ................................................... 0.006 % (JEITA)

E

3. Accessories

• Operating instructions ..................................................... 1

• Power cord ...................................................................... 1

• Audio cable ..................................................................... 1

• Control cable ................................................................... 1

• Forced eject pin (housed in a groove in the bottom panel)... 1

• Limited warranty................................................................ 1

• Screwdriver

• Jog sheets (for replacing) ............................................. 3

NOTE:

F

Specifications and design are subject to possible modification

with-out notice.

8

(housed in a groove in the bottom panel)

1234

......... 1

CDJ-400

5678

2.3 DISC USABLE WITH THIS UNIT

A

Types of discs playable on this unit

! The following marks and logos are displayed on disc la-

bels, packaging, or jackets.

Types and Logos of playable discs

CD CD-TEXT

(Note 1)

Note 1) Regarding TEXT display:

The number of characters that can be displayed is up to 48.

When a display exceeds eight characters in length, the display

will scroll. Only alpha-numerics and a limited number of

symbols can be displayed.

This player supports playback of CD-R/CD-RW discs recorded

in audio CD format or MP3.

* For details, consult the Operating Instructions for your re-

corder.

CD-R

(Note 2)

CD-RW

(Note 2)

Notes:

! Some CD-R/CD-RW discs recorded on standalone record-

ers or computer drives may not be playable back on this

player, due to a variety of reasons, including disc characteristics, scratches, dirt, player lens dirt or condensation, etc.

! Some discs recorded on computer drives may not be

playable on this player, depending on the recording application used, its settings, and operating environment. Be

sure to use the correct formatting for the discs used. For

details, consult the application author.

! This unit cannot play partially recorded CD-R or CD-RW

discs that have not been finalized.

! For detailed information regarding the handling of CD-R/

CD-RW discs, consult the handling precautions supplied

with each disc.

Regarding CD-R/RW discs

Due to the unique construction of CD-R/RW discs, leaving

them for extended periods of time in the pause (or cue

standby) mode at a single point may result in the discs’ becoming difficult to play at that place. The same symptom may

also occur if the loop function is used to play back a single

point on the disc excessively.

As a result, users are advised to construct backup archive

discs when playing discs containing important data.

About DualDisc playback

This product is designed to conform to standards for music

CDs. No warranty is made for operation or performance when

used with discs not conforming to such music CD standards.

B

C

D

Playing MP3 files

MP3 files may be found in two formats: Constant Bit Rate (CBR) and Variable Bit Rate (VBR). This component supports playback

and DJ play with both CBR and VBR type MP3 files, but in comparison with CBR files, files recorded in VBR format will experience

slower search and super-fast search speeds. As a result, when operating speed is most important, the use of the CBR recording

format is recommended for MP3 files.

MP3 files must follow the format requirements listed below.

MP3 format MPEG-1

MPEG-2

ID3 tag

File extension

56

Supports Audio Layer-3 sampling frequency 32 kHz, 44.1 kHz, 48 kHz,

Bit Rate 32 Kbps to 320 Kbps.

Supports Audio Layer-3 sampling frequency 16 kHz, 22.05 kHz, 24 kHz,

Bit Rate 16 Kbps (stereo) to 160 Kbps.

Supports ID3 Vers. 1.0/1.1/2.2/2.3/2.4. Displays title, album, artist.

Only alpha-numerics and a limited number of symbols can be

displayed.

.mp3, .MP3, .mP3, .Mp3

CDJ-400

7

8

E

F

9

1234

A

Playing Tracks from USB memory

By connecting a USB memory device to the CDJ-400, MP3 files on the USB memory can be played.

! The CDJ-400 may not support playback with all USB memory devices or provide sufficient electrical power. Additionally, note

that Pioneer is not responsible for any loss of data on a USB memory device that may occur as the result of connecting to the

CDJ-400.

! Reading from a USB memory device may take time if large quantities of data are involved.

! Erratic performance may result when a USB hub is used.

To disconnect a USB memory device

Use SOURCE SELECT to cancel the selection of the USB memory device, and then confirm that the USB memory device indicator

has gone out before removing the device.

B

USB Memory Device

Format

Folder hierarchy

Folder Max

File Max

Recording format

Maximum eight levels (cannot play files in folders exceeding 8th

hierarchy level)

10 000

20 000 (maximum 10 000 in single folder)

Devices conforming to USB mass storage class (USB MSC), including

external hard discs, portable flash memory devices, and digital audio

playback devices (supporting FAT16 and FAT32 format).

* No file sort function. Playback is in order recorded in memory.

* Longer startup times are required with increasing numbers of files.

C

About CD-ROM playback

MP3 files recorded on CD-ROM can be played back on this unit.

Disc format File extension

Folder layers

Maximum number of folders

Maximum number of files

Multi-session

D

CD-R recording method

* No file sort function. Playback is in order recorded in memory.

* Longer startup times are required with increasing numbers of files.

E

.mp3, .MP3, .mP3, .Mp3

Maximum eight layers; files in folders exceeding eight layers cannot

be played.

2 000

3 000

Does not support multi-session.

When the disc used is a multi-session disc, only the first session will

be played.

Record following the ISO9660 CD-ROM file system.

Supports only Disc At Once or Track At Once.

CDJ-400 does not support Packet Write recorded discs.

F

10

1234

CDJ-400

5678

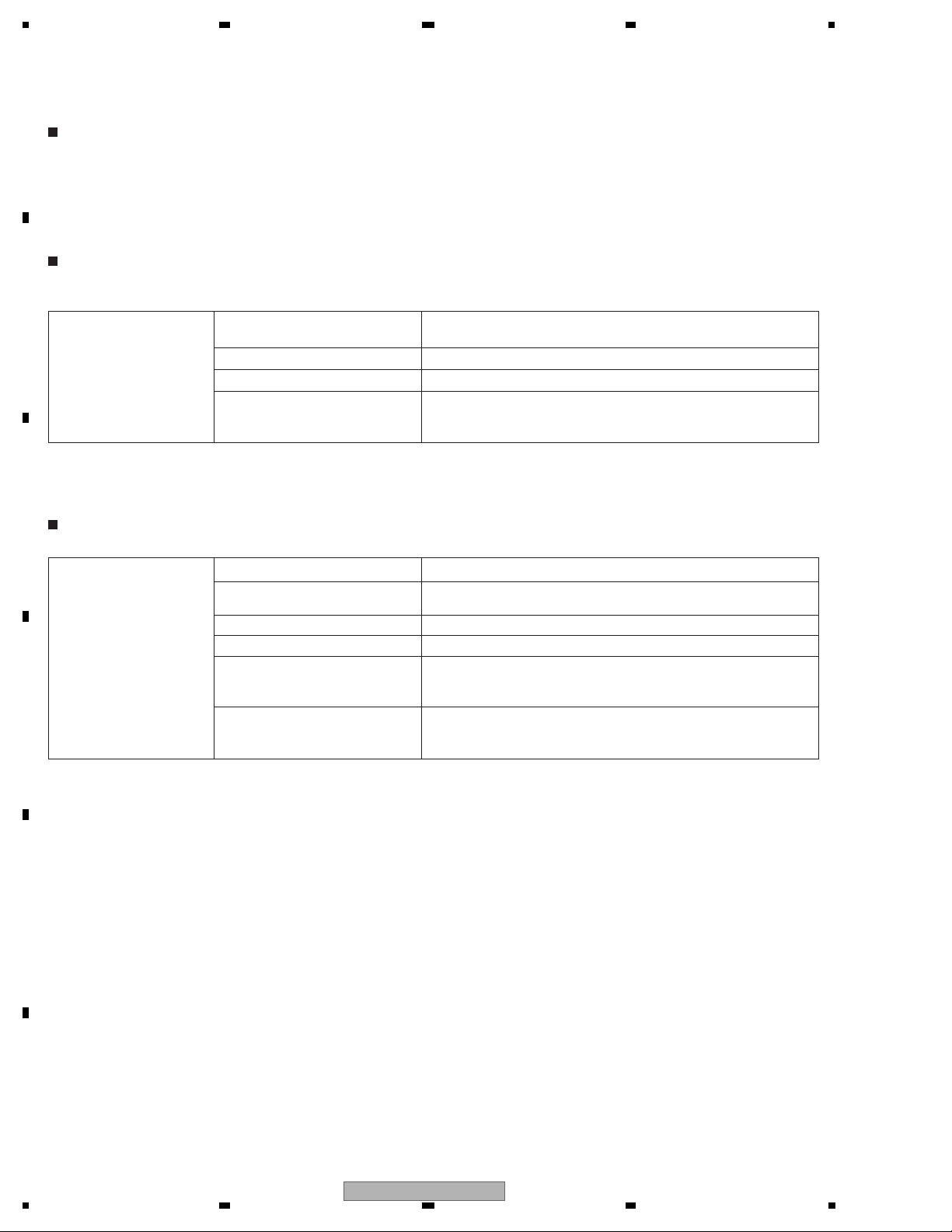

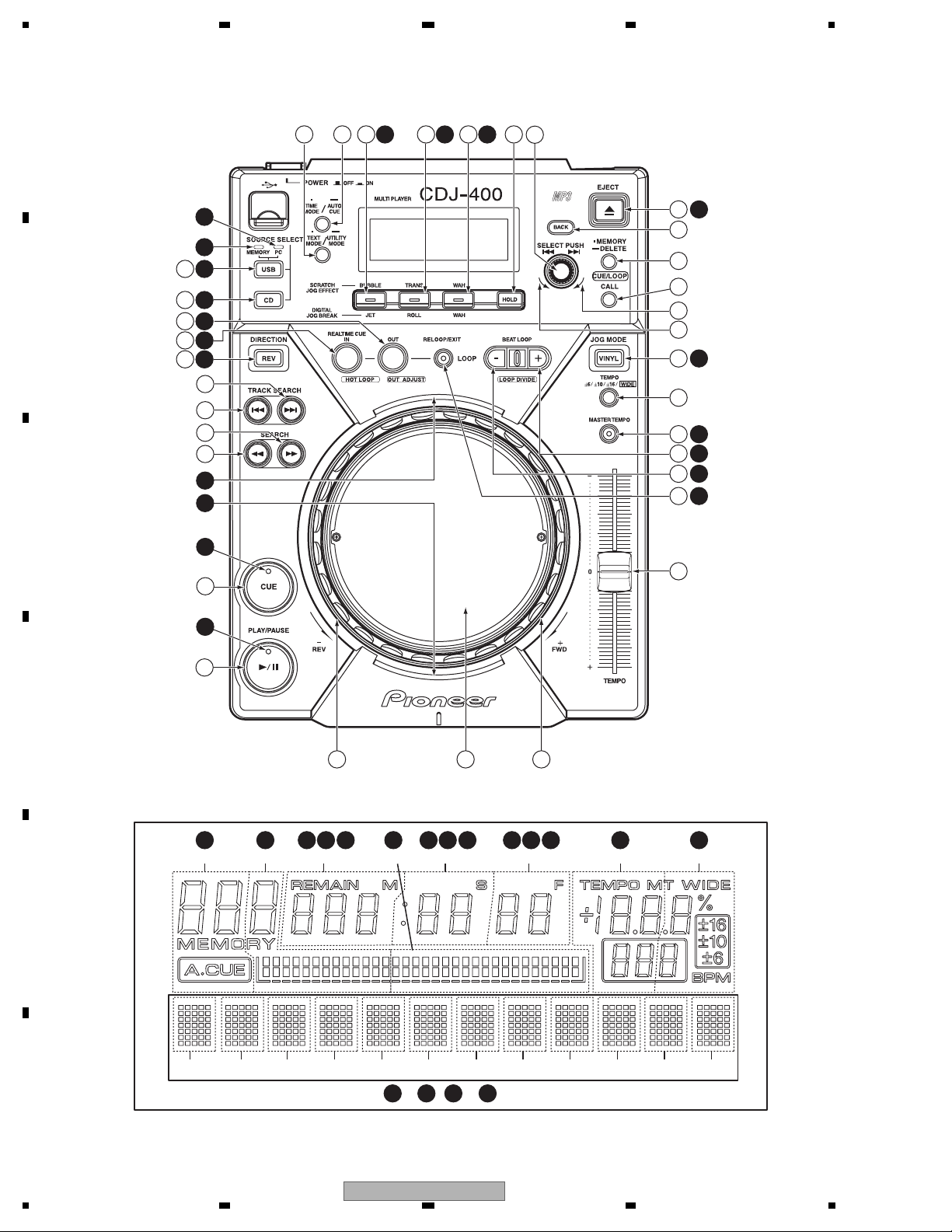

2.4 PANEL FACILITIES

PANEL FACILITIES

29

28

27

26

25

24

1 3 4

POWER

OFF

TIME

AUTO

MODE

CUE

TEXT

SOURCE SELECT

MEMORY PC

USB

DIRECTION JOG MODE

UTILITY

MODE

MODE

SCRATCH

JOG EFFECT

CD

DIGITAL

JOG BREAK

REALTIME CUE

IN OUT REL OOP/E XIT BEAT LOOP

23

TRACK SEARCH

22

21

23

SEARCH

20

19

18

CUE

PLAY/PAUSE

REV FWD

17

1. POWER switch (v OFF/w ON)

This switch is located on the rear panel of the unit. Switches

the unit’s power ON/OFF.

2. Display

3. Folder BACK button

Returns to the next higher level in the folder hierarchy when

using a CD-ROM or USB memory with a hierarchical folder

structure.

4. EJECT button

Ejects the disc.

5. CUE/LOOP button

! CUE/LOOP MEMORY/DELETE button

Use to record cue points and loop points.

! CUE/LOOP CALL buttons (c, d)

Use to call cue points and loop points recorded.

6. Rotary dial (SELECT PUSH o,p)

Use to select tracks in forward or reverse direction (track advance) and to select folders.

Press to confirm folder/track selections.

7. HOLD button

Preserves the effect of the Digital Jog Break and Scratch Jog

Effect.

8. JOG MODE VINYL button

VINYL mode: The button indicator lights. When the surface of

the jog dial is pressed during playback, play stops, and if the

jog dial is then rotated, sound is produced in accordance with

the degree of rotation.

CDJ mode: The above action does not occur when the jog dial

is pressed.

• The currently set jog mode is stored in memory even when

power is turned off.

2

ON

CDJ-400

MULTI PLAYER

BUBBLE TRANS

JET ROLL WAH

EJECT

BACK

MEMORY

SELECT PUSH

DELETE

WAH

HOLD

CUE/LOOP

CALL

5

6

7

LYNIVPOOLVER

LOOP DIVIDEOUT ADJUSTHOT LOOP

TEMPO

±± ±

6 10 16 WIDE

8

9

MASTER TEMPO

10

14

0

1213151630

11

TEMPO

9. TEMPO control range button (±6/±10/±16/WIDE)

Changes the variable range of the tempo control.

The tempo range will be saved in memory when the power

is turned off.

10. MASTER TEMPO button/indicator

Turns the Master Tempo function ON/OFF (lights when turned

ON).

11. TEMPO control slider

Controls the track’s tempo (playback speed).

12. Jog dial (–REV/+FWD)

A photograph or other graphic of your choice can be inserted

13. Jog indicator

• Indicator lights when disc is inserted during normal mode,

or if USB memory is selected during normal mode.

• The illumination pattern of the jog indicator can be

changed.

! Changing the jog indicator’s illumination pattern.

1. Hold the TEXT MODE/UTILITY MODE button depressed for

one second or more to enter utility setting mode.

Turn the rotary dial so that the display screen shows [JOG

ILLUMI], and then press to confirm the selection.

The display screen will show [PATTERN 1].

2. Turn the rotary dial to change the illumination pattern.

Patterns can be chosen from PATTERN 1 to PATTERN 6.

3. Press the rotary dial to confirm.

Utility setting mode will be canceled if no command is entered for 15 seconds. Pressing the BACK button will also

exit the setting mode.

14. Disc loading slot

Located in front panel.

15. Disc indicator

• When no disc is inserted, the indicator is turned off.

• When disc loading is completed, indicator turns on.

16. Forced ejection hole

Located in front panel of the unit.

17. PLAY/PAUSE button (f)

18. PLAY/PAUSE indicator (f)

Lights when playing, and flashes when in pause mode.

19. CUE button

Use to set and confirm cue point.

20. CUE indicator

Lights when cue point is set, and flashes when in pause mode.

21. SEARCH buttons (m, n)

Use to perform fast-forward and fast-reverse (with sound)

during playback mode.

22. TRACK SEARCH buttons (o, p)

Changes tracks in the forward/reverse direction.

23. Reverse button (DIRECTION REV)

When this button is pressed, its indicator lights and the unit is

set to reverse play.

A

B

C

D

E

F

CDJ-400

56

11

7

8

1234

A

24. LOOP buttons

! IN/REALTIME CUE/HOT LOOP button/indicator

Use to input loop-in point.

Use to set the current playback point as cue point. (REALTIME

CUE)

When pressed during loop play, returns playback to loop-in

point and begins replay. (HOT LOOP)

! OUT/OUT ADJUST button/indicator

Use to input loop-out point. (OUT )

When pressed during loop play, adjusts loop-out point. (OUT

ADJUST )

! RELOOP/EXIT button

B

After finishing loop play, the stored loop-in/out information

can be used to begin loop play again. (RELOOP )

When pressed during loop play, loop play stops and playback

returns to normal playback mode. (EXIT )

! BEAT LOOP/LOOP DIVIDE buttons/indicator

If pressed while playing or pausing a track, the loop-end will

be calculated based on the BPM (Beat Per Minute) of the track,

and loop-play will then start (BEAT LOOP).

Pressing the – button during loop-playback will divide the

playback loop, and pressing the + button will return the

playback loop to its original length (LOOP DIVIDE).

During loop-playback, the button’s indicator will light to

C

indicate that the LOOP DIVIDE button is enabled.

25. SCRATCH JOG EFFECT/DIGITAL JOG BREAK

buttons

The button’s function changes depending on the JOG mode.

• SCRATCH JOG EFFECT buttons

Turns on/off each of the effects BUBBLE, TRANS, and WAH

during VINYL mode.

• DIGITAL JOG BREAK buttons

Turns on/off each of the effects JET, ROLL, and WAH during

CDJ mode.

26. SOURCE SELECT buttons

• USB select button

Select when playing files from a connected USB memory device. Each time the button is pressed, the function alternates

between USB and PC.

• CD select button

Select when playing CDs or files on a CD-ROM.

27. USB port

Use to connect a USB memory device.

28. TEXT MODE/UTILITY MODE button

Changes the TEXT display

Hold the button depressed to enter utility setting mode.

29. TIME MODE/AUTO CUE button

Switches the display between the track’s elapsed time and remaining time.

Hold the button depressed to turn the auto cue function on/off.

1

D

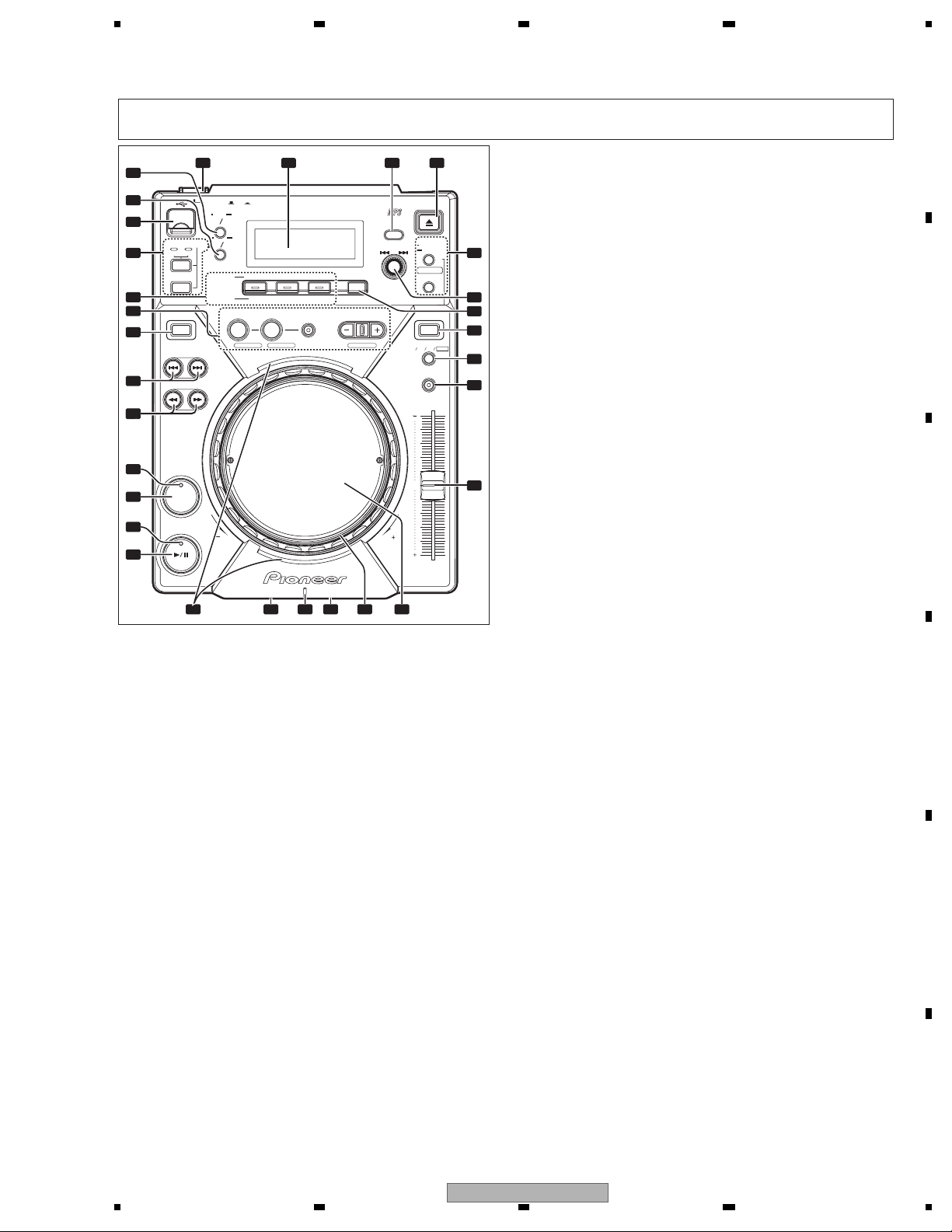

Rear Panel

E

1. USB port

Use to connect a computer.

2. AUDIO OUT L, R connectors

RCA-type analog audio output jacks.

3. CONTROL connector

When the accessory control cord is used to connect this connector to the corresponding CONTROL connector on a Pioneer DJ mixer, the DJ mixer can be used to control the CD

player for fader start play and back cue.

Also, by connecting this connector to the CONTROL connector on another Pioneer DJ CD player, automatic relay play can

F

be performed.

30. Jog touch indicators

During VINYL mode, lights when the top of the jog dial is

pressed.

3 4

2

5

6

4. DIGITAL OUT connector

RCA type coaxial digital output connectors used to connect a

DJ mixer or AV amplifier, CD player, etc., equipped with digital input connectors. The digital outputs here support all DJ

and other functions, but only audio data is output (without

subcodes; CD graphics are not supported).

5. AC inlet (AC IN)

Use the accessory power cord to connect this inlet to a standard AC power outlet.

6. POWER v OFF/w ON switch

12

CDJ-400

1234

5678

1 2 3 4 5 6 7 8

1214 13

11

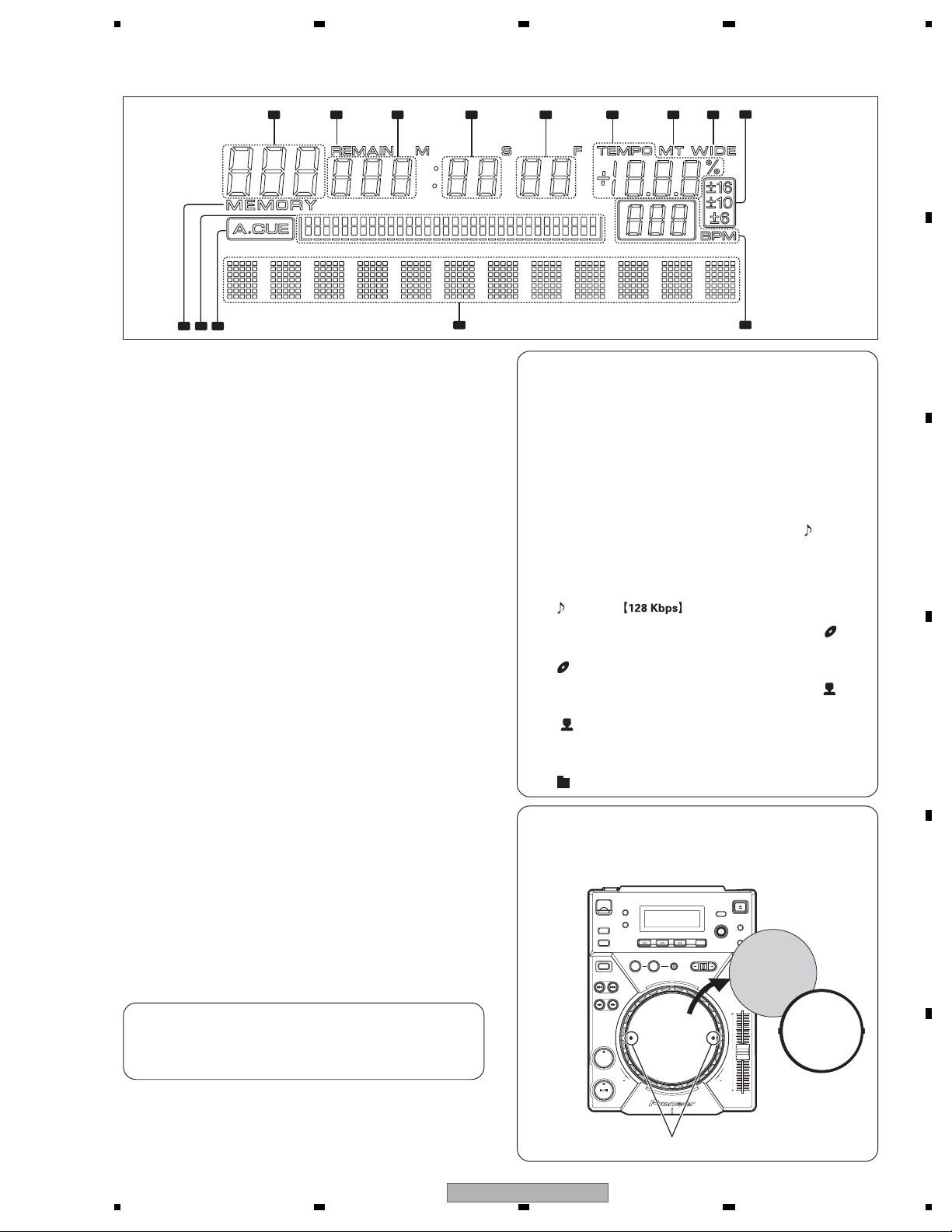

Display

1. Segment display x3

Displays folder number, track number, or alphanumeric data.

2. REMAIN

Lights when the track remaining time is displayed.

3. Segment display x3

Displays time (minutes) or alphanumeric data.

4. Segment display x2

Displays time (seconds) or alphanumeric data.

5. Segment display x2

Displays time (frame) or alphanumeric data.

6. TEMPO

Displays the change rate of tempo.

7. MT

Lights when Master Tempo function is ON.

8. WIDE

Lights when the TEMPO control range button is set to WIDE.

9. ±6, ±10, ±16

Lights to display tempo range.

10. BPM

Displays the BPM of the track displayed.

11. Dot matrix display (7x5) x12

Displays text.

12. A.CUE

Lights when Auto Cue function is turned on.

13. Playing address display

Displays the current playback position in a one-track full-scale

graph.

When displaying elapsed time, the graph lights from the left,

and when displaying the remaining time the graph light turns

off from the left.

When remaining time is less than 30 seconds, the graph

flashes slowly, and when remaining time is less than 15 seconds the graph flashes rapidly.

14. MEMORY

Lights when a cue/loop point is saved.

9

10

About TEXT display

Press the TEXT MODE button to switch the display between

track name/album name/artist name for CD-TEXT. During MP3

playback, the display shows ID3 tag track name (if no ID3 tag is

recorded, the display shows the file name) /ID3 tag album name/

ID3 tag artist name.

•

Each item can display up to 48 characters of text; text longer

than 10 characters is scrolled.

!

Text may include alphanumerics and some symbols.

!

If no text is available, the [NO TEXT] message will be displayed.

When a track name is selected in TEXT display, the [

be displayed followed by the track name (with MP3, the ID3 tag’s

title name or file name will be displayed).

Also, during MP3 play, the bit rate will be displayed following the

track name.

CDJ-400

When an album name is selected in TEXT display, the [ ] icon

will be displayed followed by the album name.

Pioneer

When an artist name is selected in TEXT display, the [

will be displayed followed by the artist’s name.

Pioneer PRO DJ

When folder search is performed with MP3, the folder name is

displayed during the search.

Pioneer DJ

] icon will

] icon

Removing the jog sheet

Using the furnished screwdriver, remove the two screws and the

jog plate. The inner jog sheet can then be replaced with another

supplied jog sheet or a graphic of your choice.

Jog sheet

REV

VYNIL

A

B

C

D

E

Time display

!

Press the TIME MODE button to alternate between elapsed

time (TIME) and the track’s remaining time (REMAIN).

!

The display mode is saved when the power is turned off.

56

CDJ-400

CUE

Jog plate

F

Screws

13

7

8

1234

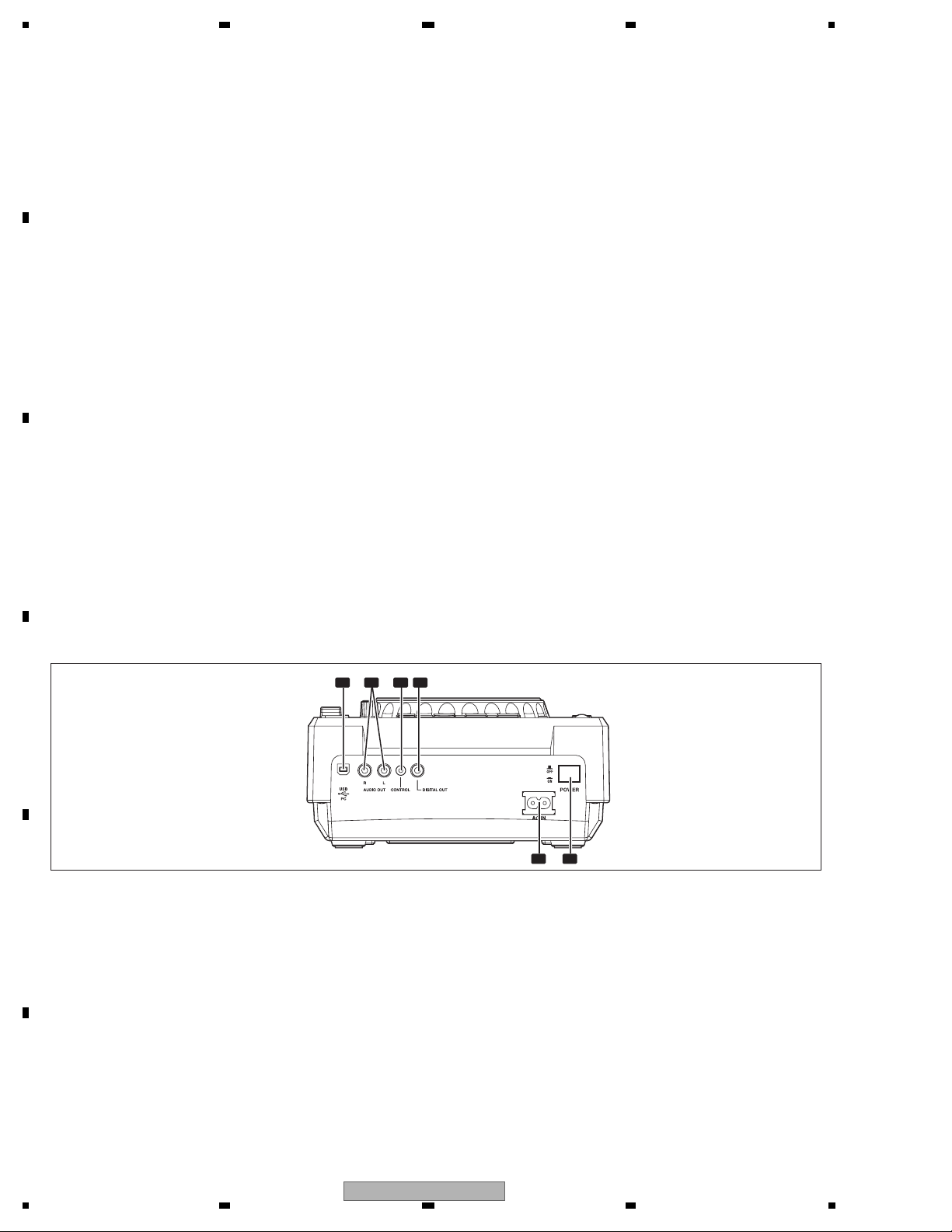

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

To ensure the quality of the product after repair, check the recommended items shown below:

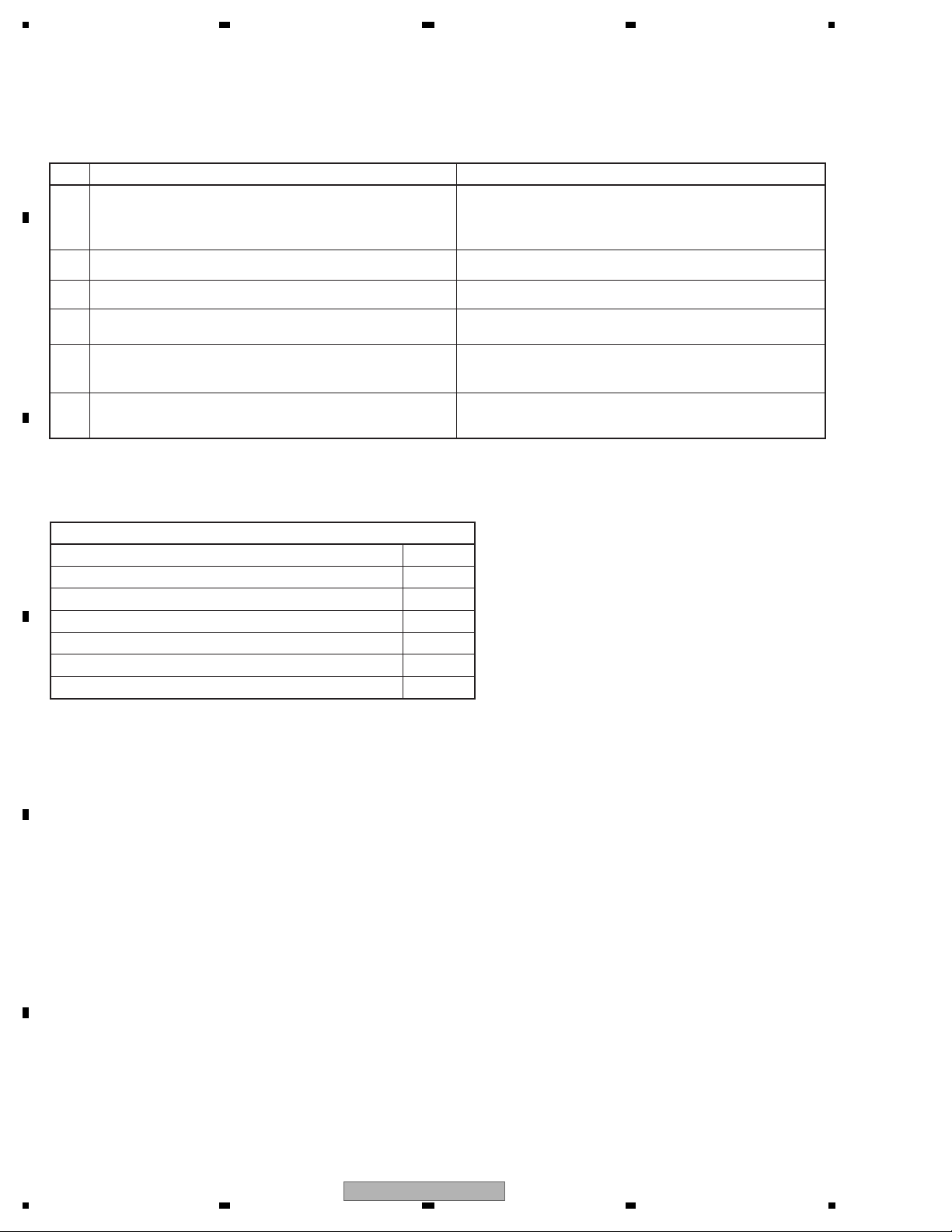

No. Procedures Item to be checked

Confirm whether the customer complain has been

solved. If the customer complain occurs with the

1

specific disc, use it for the operation check.

2

Chack the analog audio output.

3

Play back a CD. (track search)

B

4

Chack the digital audio output.

The symptoms in question must not be reproduced.

Audio and operations must be normal.

Audio and operations must be normal.

Audio and operations must be normal.

Audio and operations must be normal.

Check the outputs when it operated a JOG dial and a TEMPO

5

Vol..

6

Check the exterior section.

See the table below for the items to be checked regarding audio:

C

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

D

Audio and operations must be normal.

Check for any scratches or dirt that have been made or attached

on the exterior section after receiving the product for repair.

E

F

14

1234

CDJ-400

5678

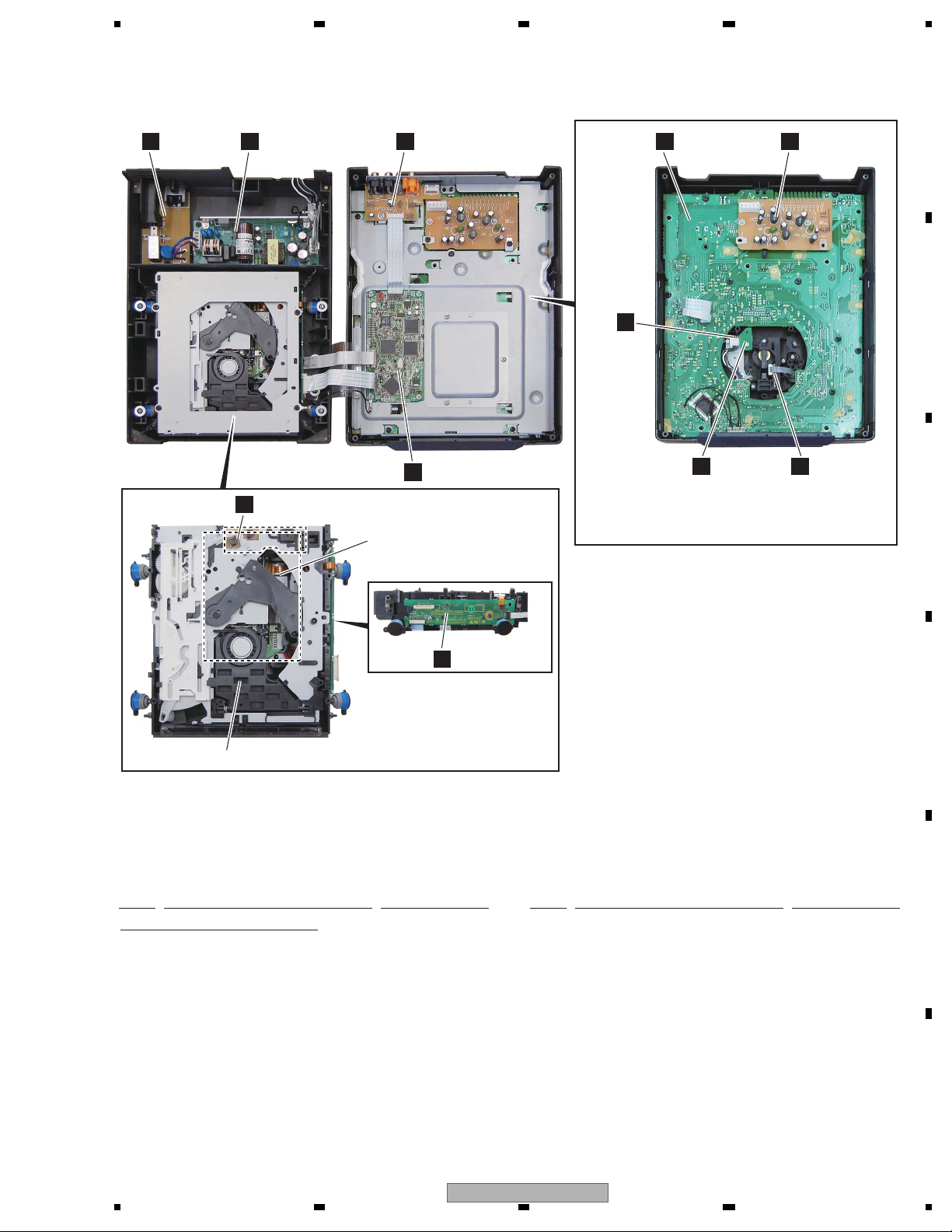

3.2 PCB LOCATIONS

ACIN ASSY

J

SW POWER SUPPLY

K

JACB ASSY

G

PNLB ASSY

F

REGB ASSY

I

A

SLMB ASSY

C

SLOT-IN MECHANISM ASSY

MAIN ASSY

A

03 TRAVERSE ASSY (Ro)

CNCT ASSY

B

JOGB

ASSY

D

STPB ASSYHTCHB ASSY

E

B

C

D

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Mark No. Description Part No.

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP MAIN ASSY DWG1652

NSP 1..PNLA ASSY (for KUCXJ) DWM2323

NSP 1..PNLA ASSY (for WYXJ5, TLFXJ) DWM2313

2..REGB ASSY DWR1442

2..SLMB ASSY DWS1404

2..PNLB ASSY DWX2756

2..JACB ASSY DWX2759

2..JOGB ASSY DWX2760

2..TCHB ASSY DWX2761

2..STPB ASSY DWX2792

> 2..ACIN ASSY (for KUCXJ) DWX2800

> 2..ACIN ASSY (for WYXJ5, TLFXJ) DWX2766

56

CNCT ASSY DWX2762

> SW POWER SUPPLY DWR1443

NSP SLOT-IN MECHANISM ASSY DXA2121

03 TRAVERSE ASSY (Ro) VXX3125

CDJ-400

7

E

F

15

8

1234

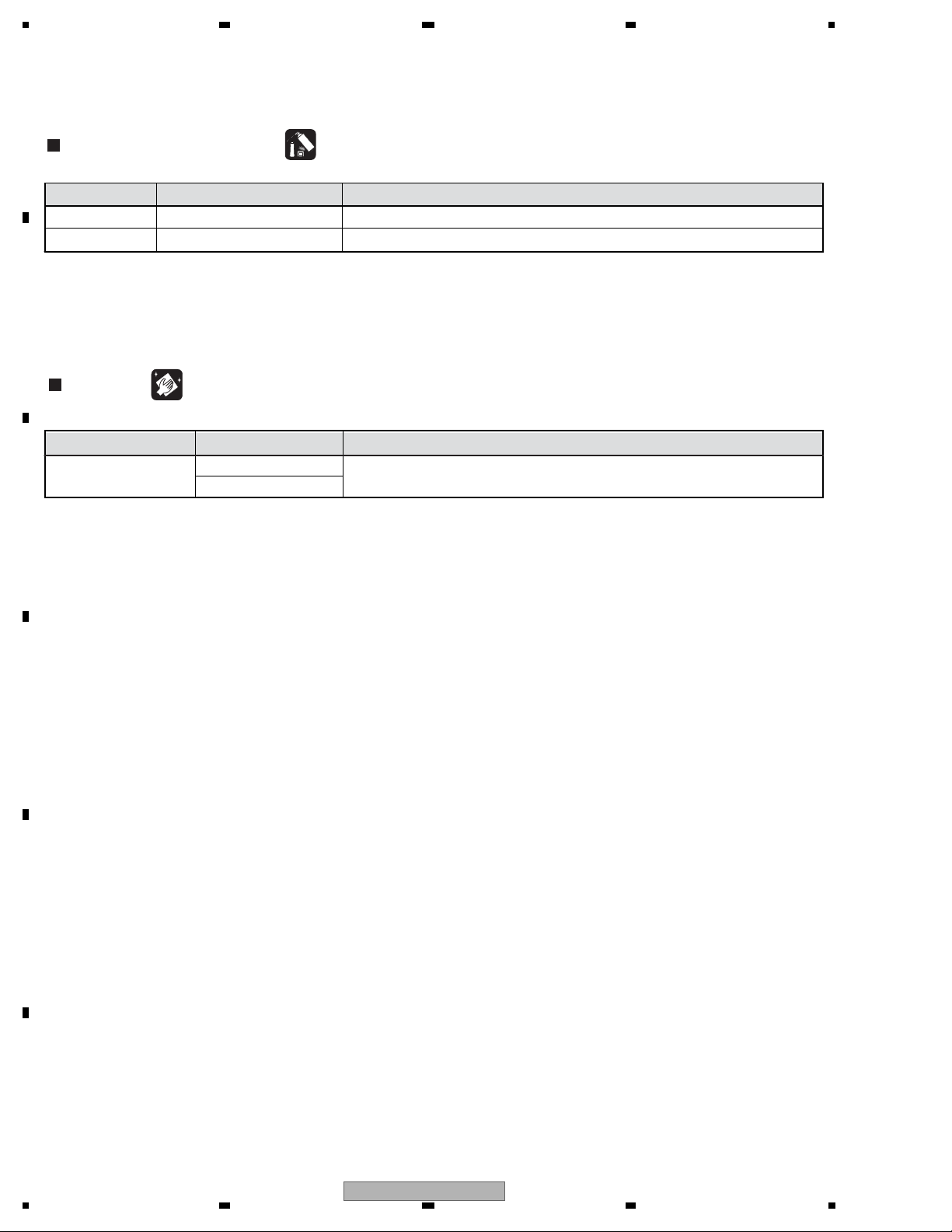

Name Lubricants and Glues No. Remark

Position to be cleaned Cleaning tools

Remark

3.3 JIGS LIST

A

Lubricants and Glues list

Name Lubricants and Glues No. Remark

Name Lubricants and Glues No. Remark

Dyefree GEM1036 (ZLX-ME413A) Refer to "9.5 SLOT-IN MECHANISM SECTION"

Grease GYA1001 (ZLB-PN397B) Refer to "9.4 JOG PANEL SECTION", "9.5 SLOT-IN MECHANISM SECTION"

B

Cleaning

• Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools:

Position to be cleaned Cleaning tools

Position to be cleaned Cleaning tools Remark

Pickup leneses Cleaning liquid : GEM1004

Cleaning paper : GED-008

C

Refer to "7. DISASSEMBLY SECTION" ,"9.5 SLOT-IN MECHANISM SECTION" .

Remark

D

E

F

16

CDJ-400

1234

5678

A

B

C

D

E

CDJ-400

56

F

17

7

8

1234

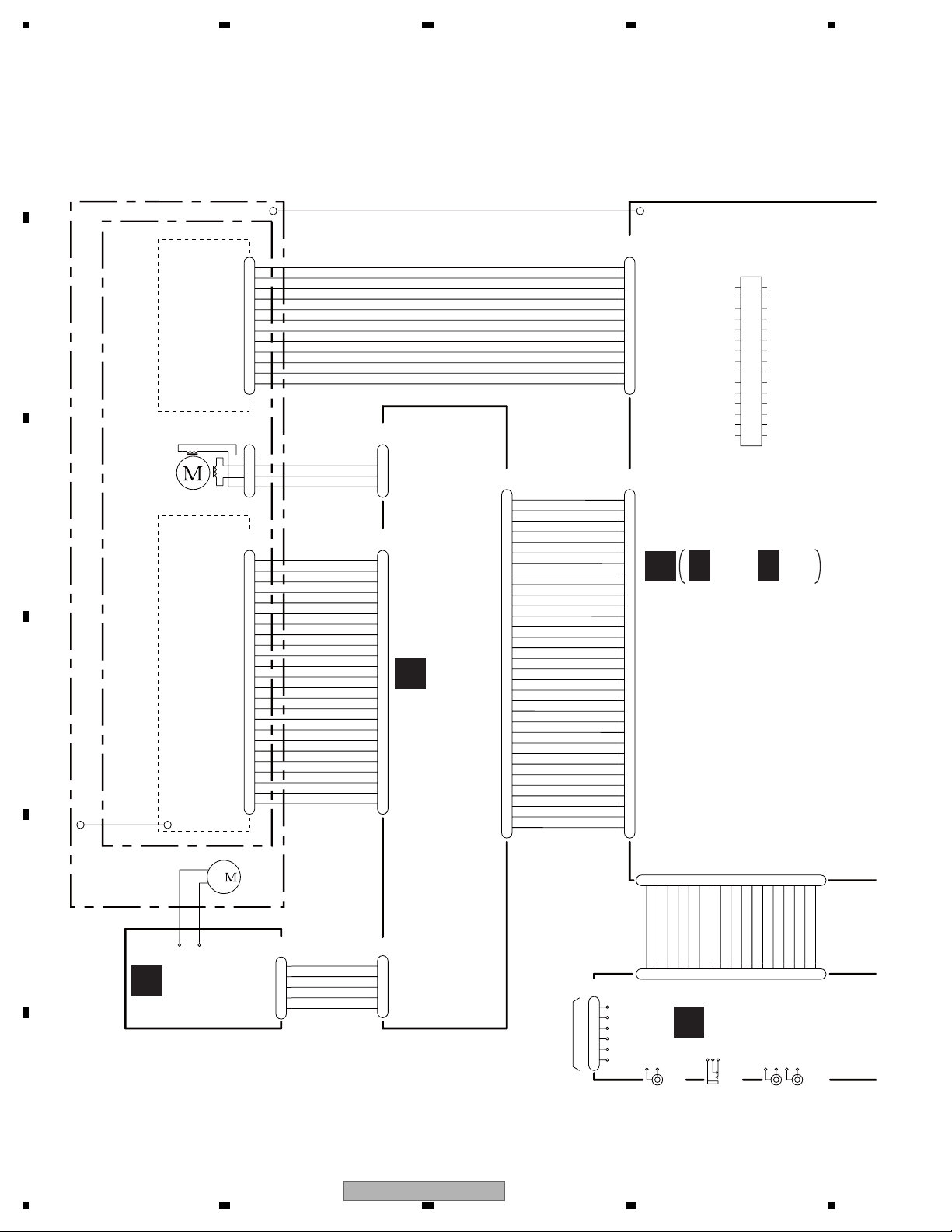

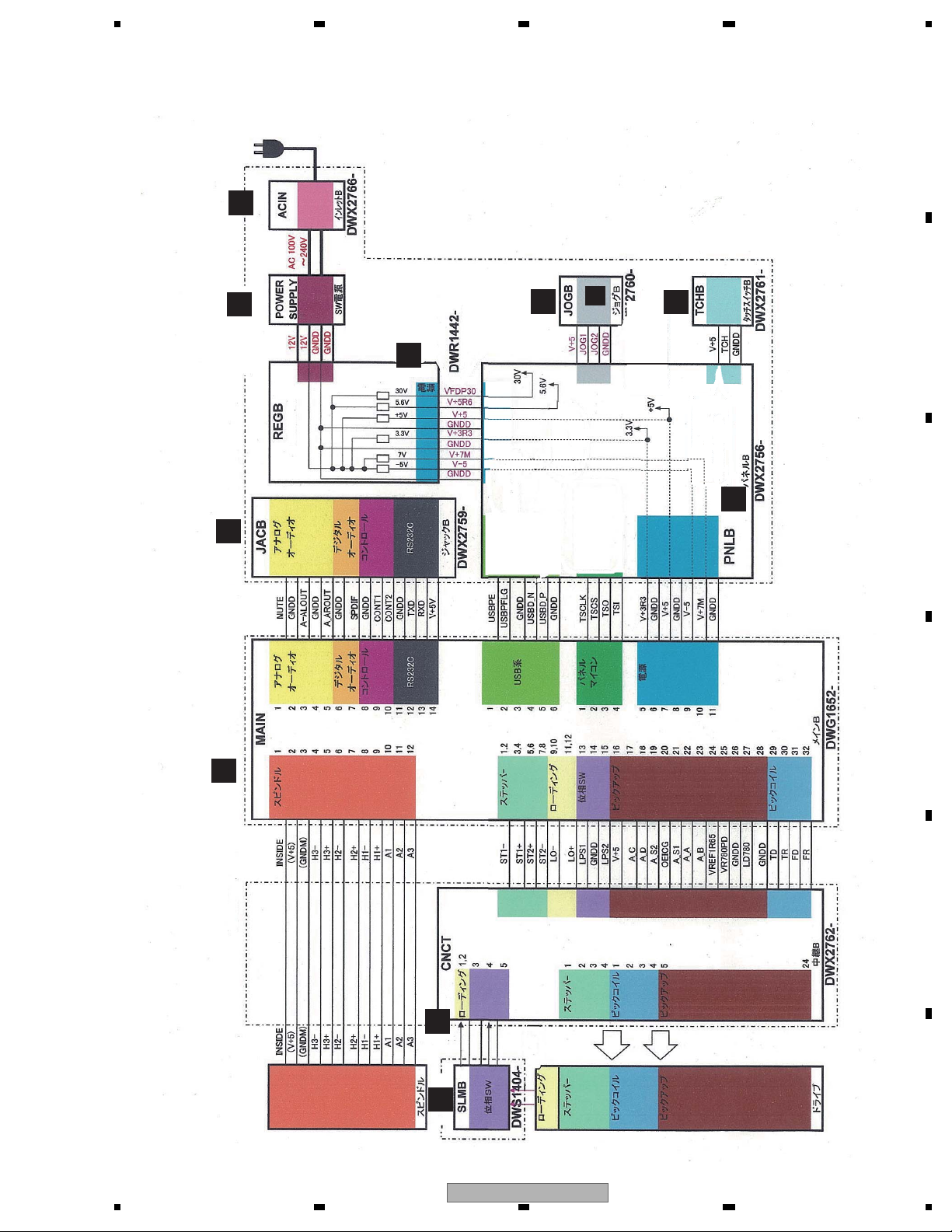

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

03TM.ASS'Y(RO) (VWT1225)

SLOTIN MECHA ASS'Y (DXA2121)

D

FRAME

GNDD

E

ZWNN1007G28-8-06A

L=60mm GRAY

F

STEPPING

MOTOR 04

(VXM1113)

DE010VE0

L=100mm

DC MOTOR

S(ROHS)

(DXM1230)

C

FRAME

GNDD

A3

1

A2

2

A1

3

H1+

4

H1-

5

H2+

6

H2-

7

H3+

8

H3-

9

GNDD

10

VCC

11

(VXM1112)

SPINDLE MOTOR 04

SW

12

1

2

3

4

CN1

OKN8002-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

(OWY8036/XDP/5)

04SD PICK UP ASS'Y R

18

19

20

21

22

23

24

FRAME

GNDD

LO-

LO+

ZWNN1007G28-9-06A

L=60mm WHITE

LO+

LO-

SLMB ASSY

(DWS1404)

CN1801

VKN1265-A

5

4

3

2

1

ST2-

ST2+

ST1+

ST1-

FR

FD

TR

TD

NC

GNDD

LD650

VR780PD

LD780

GNDD

VR780

VRCOM

VR650

VREF1R65A

A_B

A_A

A_S1

OEICG

A_S2

780/X650

A_D

A_C

V+5PA

GNDD

DDD1331-A

L=300mm

DDD1370-A

L=85mm

LO-

LO+

GNDD

LPS1

LPS2

CN2005

RKN1045-A

1

2

3

4

CN2002

DKN1445-A

1

2

3

4

5

6

7

8

9

10

11

12

B

13

14

CNCT ASSY

15

16

(DWX2762)

17

18

19

20

21

22

23

24

CN2003

DKN1402-A

1

2

3

4

5

DE010VE0

L=100mm

CN2001

DKN1447-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

FR

FD

TR

TD

GNDD

LD780

GNDD

VR780PD

VREF1R65

A_B

A_A

A_S1

OEICG

A_S2

A_D

A_C

V+5P

LPS2

GNDD

LPS1

LO-

LO-

LO+

LO+

ST1-

ST1-

ST1+

ST1+

ST2+

ST2+

ST2-

ST2-

DDD1371-A

L=110mm

CN1502

KM200NA6L

UPDATE CONNECTOR

(Only designer uses)

1

2

3

4

5

6

CN501

CKS4999-A

12

11

10

9

8

7

6

5

4

3

2

1

CN502

DKN1447-A

32

31

30

29

28

27

26

25

24

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

DDD1372-A

L=93mm

TXD

RXD

V+5

RMIN(NC)

FLWR(NC)

GNDD

FRAME

GNDD

A3

A2

A1

H1+

H1-

H2+

H2-

H3+

H3-

GNDD

V+5M

INSIDE

A

CN102

RKN1058-A

1

V+5DETD

1

CN101

TFM-115-32-S-D

GNDD

1

RSVD

3

GNDD

5

GNDD

7

XRST

9

V+3R3

11

GNDD

13

PST2

15

PST0

17

DT2

19

DT0

21

RSVD

23

GNDD

25

V+3R3

27

GNDD

29

NM

A 1/2, A 2/2

MAIN ASSY

(DWG1652)

3

4

6

7

8

2

RXD

SPDIF

VFDP5R6

151617

G

2

JA1503

DKB1089-A

DIGITAL OUT

9

5

TXD

10

MUTE

GNDD

GNDD

CONT1

CONT2

10

11

121314

JACB ASSY

(DWX2759)

2

3

1

JA1501

VKB1243-A

CONTROL

GNDD

2

TMSBKPT

4

TCKDS

6

RSVD

8

TDIDSI

10

TDODSO

12

PST3

14

PST1

16

DT3

18

DT1

20

GNDD

22

RSVD

24

PSTCLK

26

TA

28

GNDD

30

14

11

13

15

12

16

17

GNDD

GNDD

GNDD

USBB_N

USBB_P

A_ALOUT

A_AROUT

6

4

5

CN1501

VKN1248-A

321

L

R

234

1

JA1502

DKB1088-A

789

AUDIO OUT

18

CDJ-400

1234

5678

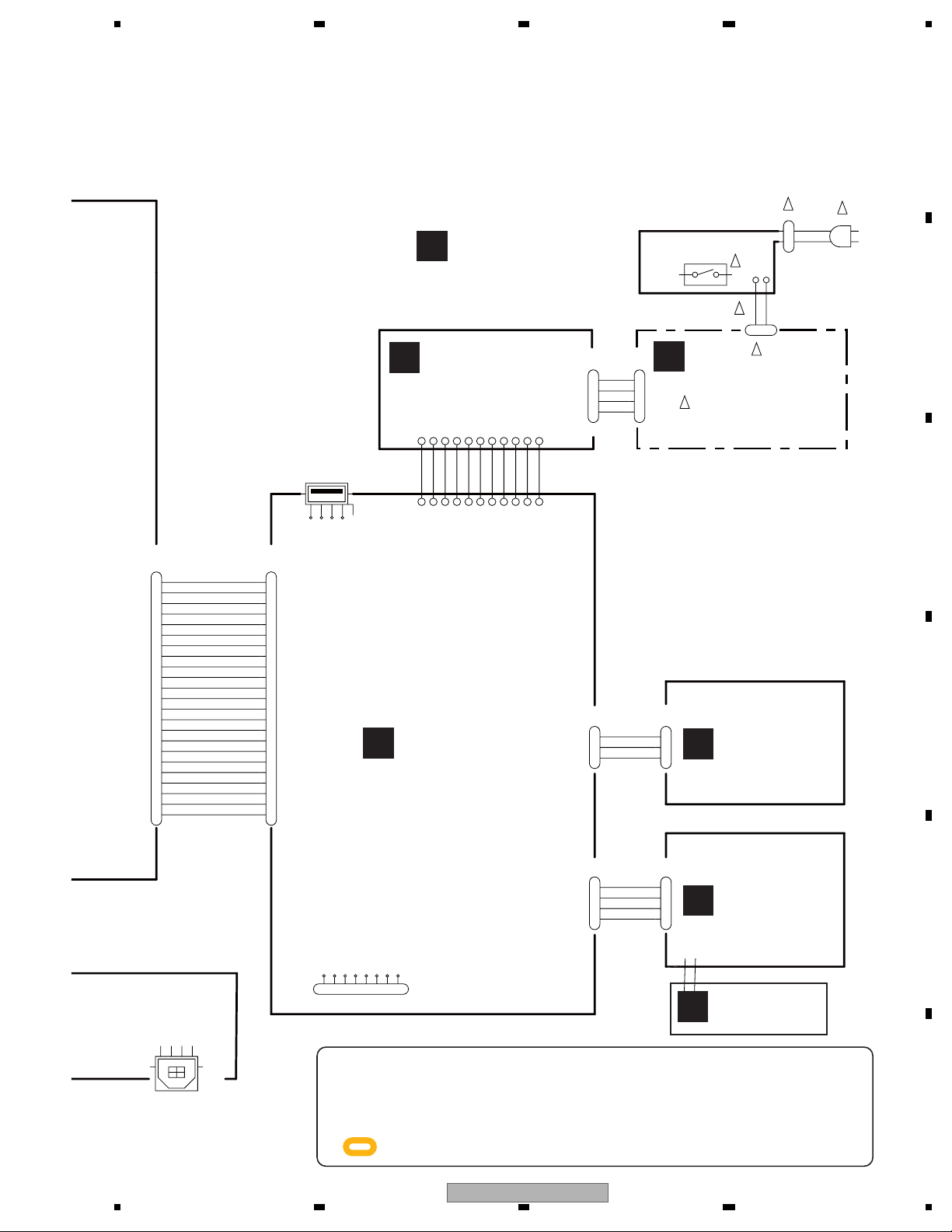

A

CN103

VKN1427-A

23

22

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

GNDD

USBA_P

USBA_N

GNDD

USBPFLG

TSCK

USBPE

TSI

GNDD

TSO

GNDD

TSCS

GNDD

V-5

GNDD

VFDP5R6

GNDD

V+3R3

V+3R3

GNDM

V+7M

GNDM

V+7M

DDD1374-A

L=61mm

CN1108

VKN1254-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

USB A Type

JA1101

DKB1087-A

RT1

1

2

USBA_N3USBA_P

ACIN ASSY

J

(DWX2800: KUCXJ

>

S1001

DSA1035-A

!

1

2

JA1001

!

!

LIVE

NEUTRAL

DWX2766: WYXJ5

DWX2766: TLFXJ)

CN1901

I

B4B-EH

REGB ASSY

(DWR1442)

J1917

J1903

J1916

J1907

J1924

J1901

V+7M

GNDD

J1922

JUMPER

GNDD

GNDD

V+3R3

VFDP30

JH1101

51048-0300

J1905

J1902

J1911

J1913

GNDD

RT2

4

RT3

F

GNDD

PNLB ASSY

(DWX2756)

GNDD

V-5

VFDP5R6

1

2

3

4

PF04EE-S22

L=225mm

1

2

3

P51

B4B-EH

GNDD

GNDD

V+12

V+12

D20PDY0310

L=100mm

K

1

2

SW POWER SUPPLY

3

!

4

CN1701

52151-0310

GNDD

1

TCH

2

V+5

E

3

!

VIOLET

BLUE

2

1

P1

B2P3-VH

!

(DWR1443)

TCHB ASSY

(DWX2761)

L=45mm

DKP3790-A

NEUTRALLIVE

B

C

D

CN1104

KM200NA4L

1

2

3

4

GNDD4BUSY

CNVSS2DISPRESET

VCC6SCLK7RXD

TXD

5

8

NM

1

234

FLASH UPDATE

1

3

CN1109

GNDD

V+5

JOG1

JOG2

PF04PG-B05

(BOARD IN)

L=50mm

CN1601

PF04PG-B05

1

2

3

4

JOGB ASSY

D

(DWX2760)

STPB ASSY

H

(DWX2792)

E

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS

RT1

USB

B Type

RT2

JA1504

DKN1237-A

LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety

factor of the part. Therefore, when replacing, be sure to use parts of identical

designation.

F

: The power supply is shown with the marked box.

CDJ-400

56

7

8

19

1234

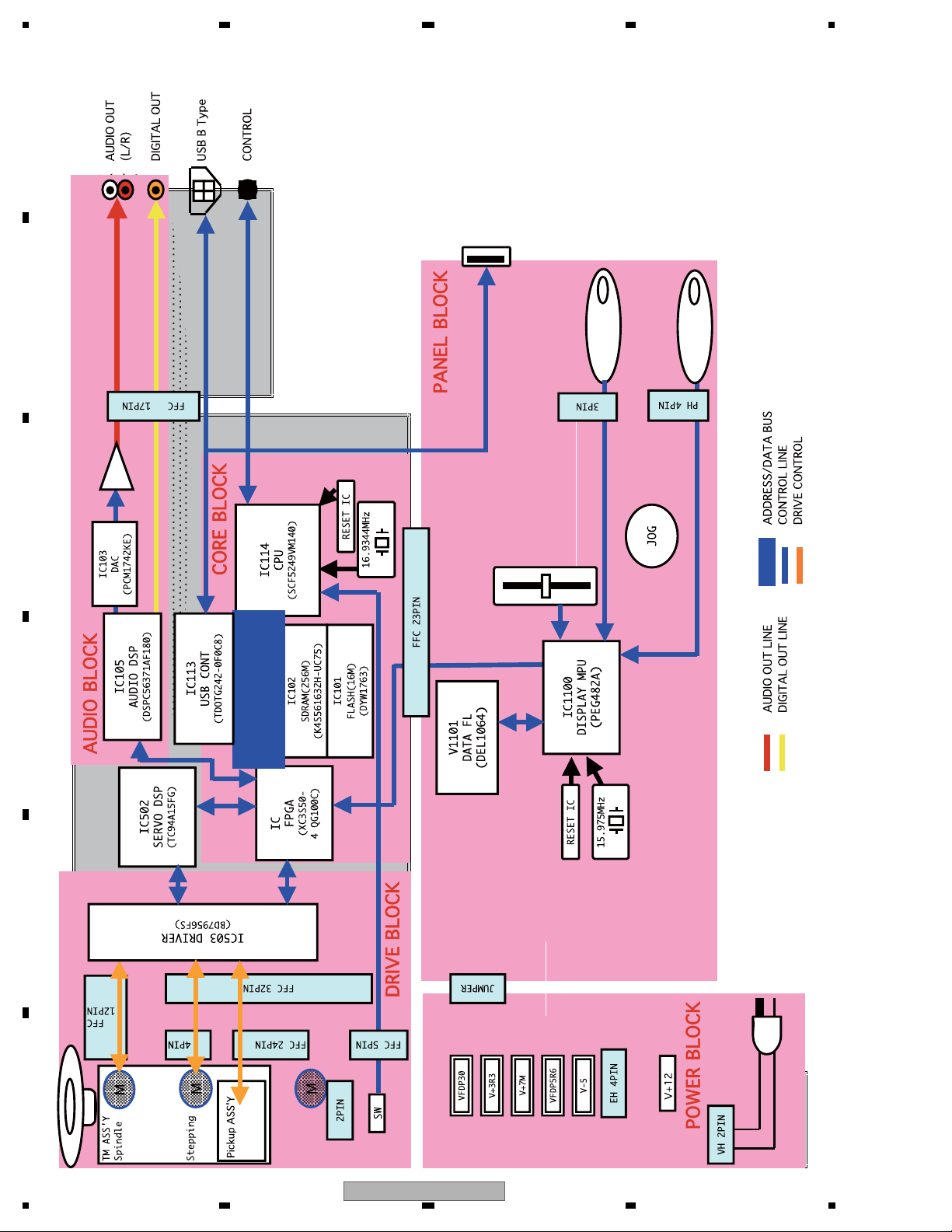

4.2 OVERALL BLOCK DIAGRAM

A

B

USB A Tayp

TCHB Sensor

JOG Sensor

C

D

106

V

E

F

20

1234

CDJ-400

5678

A

J

P1

K

P51CN102CN501

DWR1443

D

H

DWX

E

B

I

CN1901 JA1001

CN1104

CN1101

JACB ASSY

G

CN1502

MAIN ASSY

A

F

C

CN1108

CN103

D

CN502

E

CN2001

CN2005

CN2002

B

C

CDJ-400

56

F

21

7

8

1234

5. DIAGNOSIS

5.1 CHECKING THE PICKUP ASSY

A

SHORT OPEN

2

B

CNCT Assy

LD short-circuit

switch

equipment during measurement, if you

wish.

You may disconnect the measuring

equipment during measurement, if you

wish.

C

If the measurement result is beyond the

If the measurement result of the LD current is

80 mA or more, the LD is deteriorated.

Note: Check the mounting status of R502, R506,

R509 and R514 (22 ohms).

D

Connect a tester between the test lands LD3S and LD

1 Make sure that no CD is loaded.

2 Enter Service mode.

3

E

Typ. 70 mA

Max. 80 mA

Measure the voltage difference (DC value) between the

4 During Test Operation mode, press the TEMPO

button to turn the LD on.

5

6 Press the TEMPO button to turn the LD off.

Confirm that the voltage difference between test

lands LD3S and LD CHECK becomes 0 then

CHECK to check the voltage difference between them.

test lands LD3S and LD CHECK on the MAIN Assy.

specified value, the pickup is in failure.

disconnect the tester.

1 Make sure that no CD is loaded.

2 Remove the bottom plate and set the LD short-circuit

switch (S2002) to Short side. (see right figure.)

3 Disconnect the FFC cable that connects the CNCT

Assy and the MAIN Assy from the CN502 connector.

3.4 ± 0.5 Ω

If the measurement result is beyond the

specified value, the pickup is in failure.

4 Measure the conductor resistance of the terminal

assembly between Pins 31 and 32 of the FFC cable.

1 Make sure that no CD is loaded.

2 Remove the bottom plate and set the LD short-circuit

switch (S2002) to Short side. (see right figure.)

3 Disconnect the FFC cable that connects the CNCT

Assy and the MAIN Assy from the CN502 connector.

4.1 ± 0.6 Ω

If the measurement result is twice or more, or

50% or less of the reference value, the pickup

or the MAIN ASSY is defective.

1 Enter Service mode.

2 Load a pressed CD. (Standby)

3 Connect and set a digital oscilloscope so that the

p-p level at the test land (FE) can be measured.

4 During Test Operation mode, press the TIME, A,

then CUE buttons to send a command.

4 Measure the conductor resistance of the terminal

assembly between Pins 29 and 30 of the FFC cable.

Reference: 1.5 Vp-p

5 Measure the p-p level (S-shaped level) at the FF.

If the measurement result is twice or more, or

50% or less of the reference value, the pickup

or the MAIN ASSY is defective.

1 Enter Service mode.

2 Load a pressed CD. (Standby)

3 Connect and set a digital oscilloscope so that the

p-p level at the test land (TE) can be measured.

4 During Test Operation mode, press the buttons in the

following order to send a command: TIME, TEMPO,

Reference: 1.1 Vp-p

If the measurement result is twice or more, or

50% or less of the reference value, the pickup

or the MAIN ASSY is defective.

If the RFO level value is twice or less, or 50%

or less of the reference value, and the AGC RF

level is out of the range stipulated in the

RELOOP, then LOOPIN twice.

5 Measure the p-p level of waveform at the TE.

1 Play back a pressed CD.

2 Measure the p-p level of RF waveform at the RFO

test land on the MAIN Assy.

1 Play back a CD.

2 During playback, measure the p-p level of RF

waveform at the AGCRF test land on the MAIN Assy.

Reference: 1.2 Vp-p You may disconnect the measuring

1.2 Vp-p ± 10 %

specifications, the MAIN ASSY is defective.

Item Specifications Failure Judgment RemarksMeasurement Procedures

F

S-shaped level

Usually use a pressed CD, as the

measurement result depends on the disc

type.

Tracking Error (TE) level

Usually use a pressed CD, as the

measurement result depends on the disc

type.

RFO level

Usually use a pressed CD, as the

measurement result depends on the disc

type.

Auto Gain Control (AGC) RF level

The measurement result does not depend

on the disc type.

22

Laser Diode (LD) current

Focus coil resistance

Tracking coil resistance

CDJ-400

1234

5678

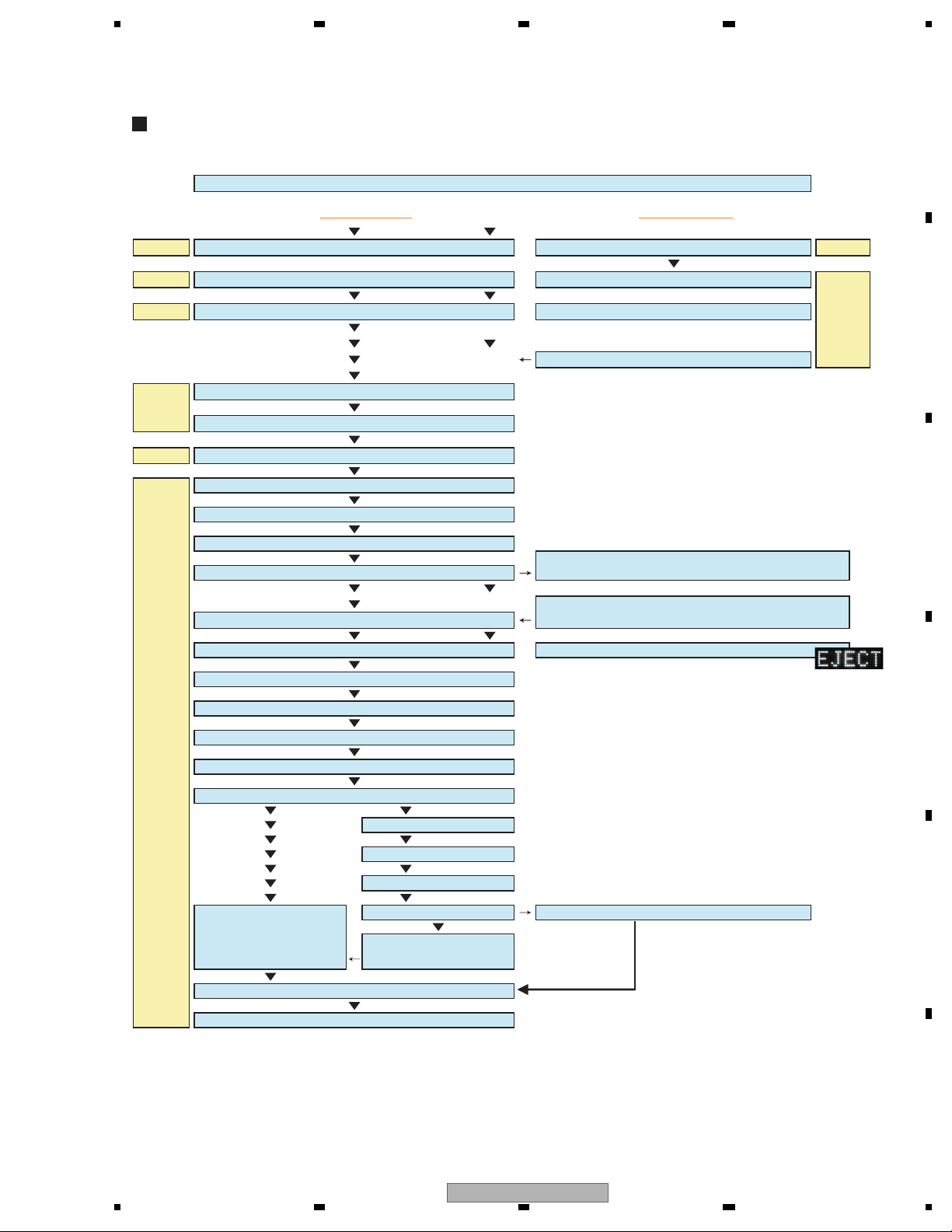

5.2 POWER ON SEQUENCE

POWER ON SEQUENCE

RESET ROOT

RESET IC

MPU

FPGA

DSP

ServoDSP

IC112 (Reset IC) RESET START

IC114(MPU) Reset receiving pin P12

IC106(FPGA)

IC105(DSP)

IC105(DSP) Program download

IC502 (Servo DSP) Reset receiving pin 90

Tracking and focus offset adjustment

Spindle kick & focus sweep & focus on

Reset

Reset

Inside SW check

Laser Diode ON

1

receiving pin 72

receiving pin 47

LD : Laser Diode

POWER ON

RESET ROOT

IC1101 (Reset IC) RESET START

IC1100(DISPLAY-MPU) Reset receiving pin 12

IC1100(DISPLAY-MPU) Indication 'POWER ON'

# 'POWERON' data is inside of DISPLAY-MPU.

IC1100(DISPLAY-MPU) Communication start to MPU

When a check fails one times,S-curve waveform is

measured in RF gain up.

2

RESET IC

DISPLAY

MPU

A

B

C

CD-DRIVE

CD-DRIVE

Focus OK check

Spindle acceleration 100msec

CLV servo ON

Wait for 300msec

Tracking balance adjustment (T open)

Tracking close

GFS check GFS : RF LOCK

Focus balance adjusutment

Focus gain adjusutment

Tracking gain adjusutment

TOC read RF gain adjusutment

The 1st time carries out TOC

position memory by stepper

accuracy after power on.

Search the first tune

Play (mute off)

If it is a program area, it

jump-backs to TOC area.

When S-curve waveform level is 0.88Vp-p or

less,focus on is carried out by OEIC and RG gain up.

When a check fails three times,display EJECT.

When TOC read is completion

D

E

CDJ-400

56

F

23

7

8

1234

6. SERVICE MODE

6.1 OVERVIEW OF SERVICE MODE

A

Two microcomputers are provided for this unit: One is for the Display section, and it controls key input, displays on the FL

display, and lighting of LEDs. The other is for the Player section, and it controls the drive of the player. Test modes are provided

for each microcomputer:

1 Display Check mode for the Display section

Mode for confirmation of key input and display functions

2 Mode for checking load on the JOG dial and Adjustment

Mode for measuring load on the JOG dial when turned

3 Version Check mode

B

Mode for checking the software version of each microcomputer

4 Updating mode

Mode for updating software of the microcomputer for the Player section (main microcomputer)

5 List of Error codes/Detail Display mode

Up to 16 error logs can be checked.

6 Operation Check mode for the Player section

This mode for operation check of the mechanism and servomechanism of the Player section consists of Player

Operation mode and Test Operation mode.

C

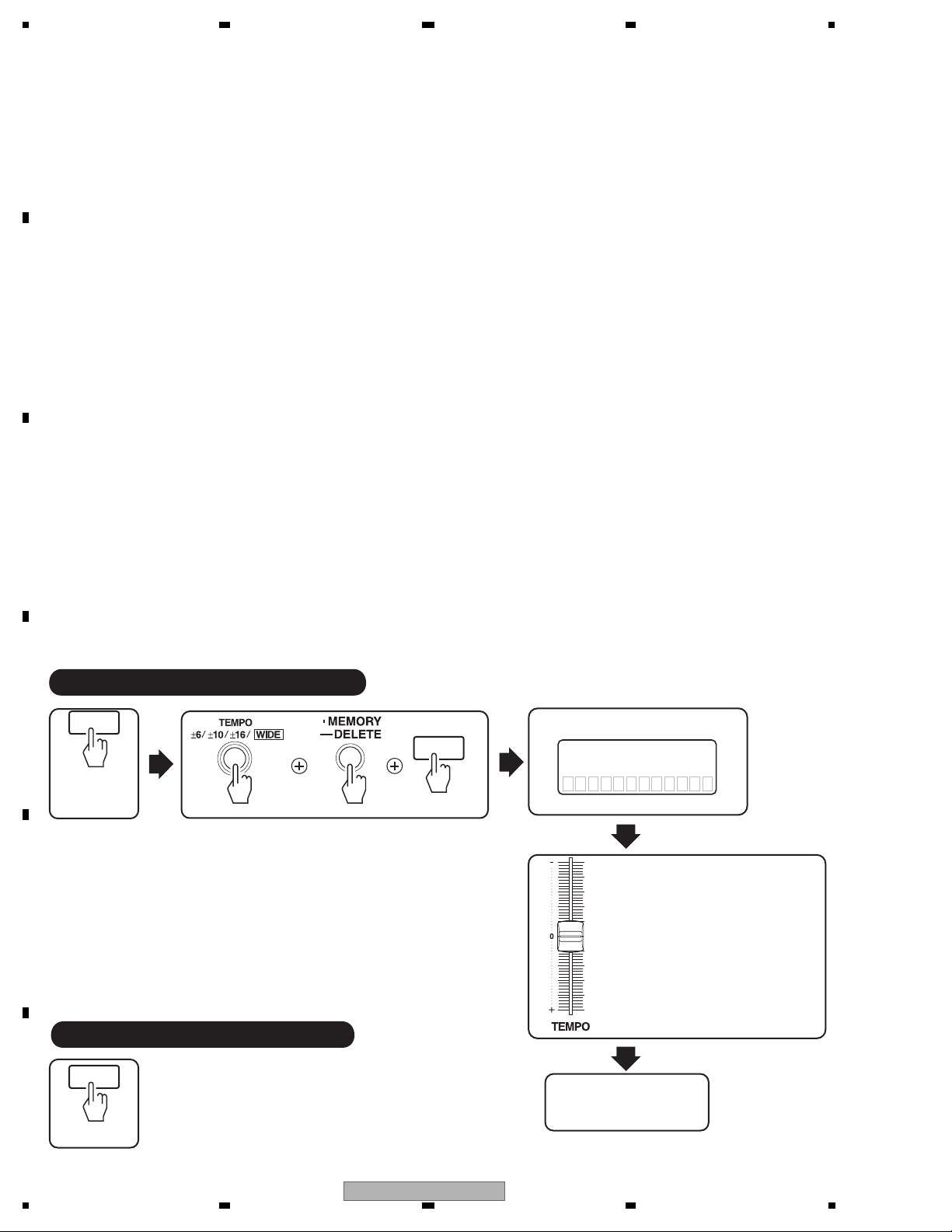

6.2 CHECK MODE OPERATION

6.2.1 Display Check mode for the Display section

In this mode, you can light up some LEDs and part of the Display section to check if the input of each key/variable control is

correctly reflected on the display. An LED or part of the display is lit while the corresponding key is held pressed.

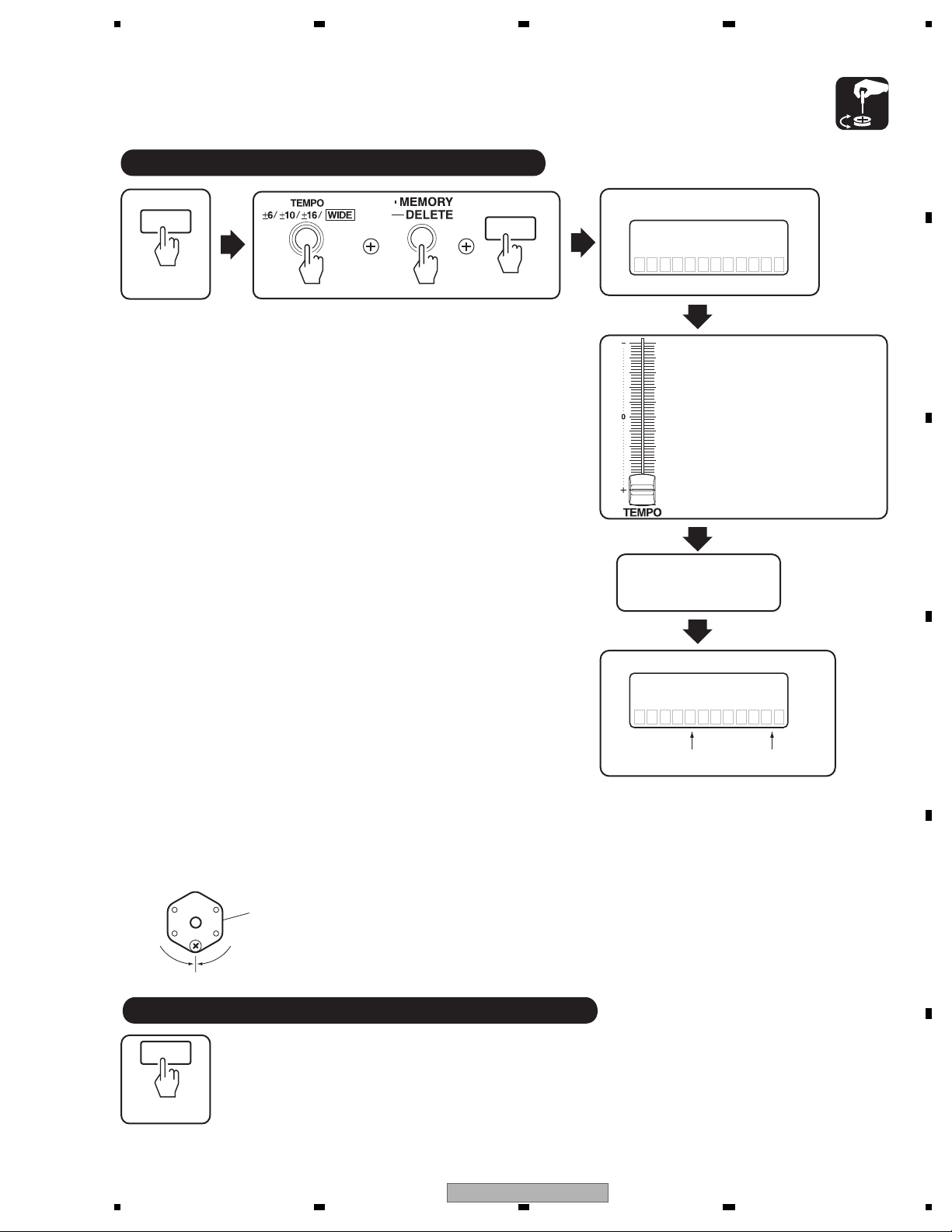

How to enter Display Check mode

D

E

POWER OFF

SERV I CEMO

POWER ON

FL Display

DE

If the TEMPO slider is located

anywhere other than the plus

(bottom) or positive (lowest)

maximum-value positions, the unit

enters Display Check mode for the

Display section.

How to exit Display Check mode

F

POWER OFF

24

1234

Display Check mode

for the Display section

In this mode, while a key is held pressed,

the corresponding FL display and LED are lit.

CDJ-400

5678

Key and Switch Name Dot FL Display Other FL Display LED Display

1 PLAY/PAUSE

2 CUE 2 CUE

3 SEARCH m 3 JOG touch indicator 1

4 SEARCH n 4 JOG touch indicator 2

5 TRACK SEARCH o

6 TRACK SEARCH p

7 DIRECTION REV 7 DIRECTION REVERSE

8 IN/REALTIME CUE 8 IN/REALTIME CUE

9 OUT/OUT ADJUST 9 OUT/OUT ADJUST

a RELOOP/EXIT a RELOOP/EXIT

b HOLD

c SOURCE SELECT CD c SOURCE SELECT CD

d SOURCE SELECT USB d SOURCE SELECT USB

e TEXT MODE e USB MEMORY

f TIME MODE/AUTO CUE f PC

g JET/BUBBLE g JET/BUBBLE

h ROLL/TRANS

i WAH i WAH

j MEMORY

k SELECT PUSH

l SELECT PUSH p

m SELECT PUSH o

n BACK

o EJECT o DISC IN INDICATOR

p CALL

q BEAT LOOP/LOOP DIVIDE – q BEET LOOP/LOOP DIVIDE

r BEAT LOOP/LOOP DIVIDE + r BEET LOOP/LOOP DIVIDE

s JOG MODE VINYL s JOG MODE VINYL

t TEMPO

u MASTER TEMPO u MASTER TEMPO

v TOUCH SENSOR (JOG dial)

w

During a JOG dial FWD direction rotation

x

During a JOG dial REV direction rotation

y TEMPO slider knob

2 CUE

3 REV <<

4 FWD >>

5 TRACK |<<

6 TRACK >>|

7 REVERSE

8 IN

9 OUT

a RELOOP

b HOLD

c CD

d USB

e TEXTMODE

f TIME/ACUE

g JET/BUBBLE

i WAH

j MEMORY

k PUSH

n

All the FL display light up

o EJECT

p CALL

q DIVIDE <?

r DIVIDE ?>

s JOG MODE

t TEMPO

u MASTER TEMPO

v TOUCH SW

w JOG>

x <JOG

y Bar display

g 13G section light up

h 14G section light up

i 15G section light up

l 14G light up 00 to FF

m 14G light up FF to 00

All the FL display light up

1 PLAY/PAUSE1 PLAY

h ROLL/TRANSh ROLL/TRANS

All the LED display light up

A

B

C

D

CDJ-400

56

E

F

25

7

8

1234

A

18

16

FL

display

17

17

18

11

20

24

23

19

24

13

15

14

13

14

15 16

25

12

12

B

9

9

8

8

7

7

21

22

2828

6

29

5

4

3

3

4

C

3030

2727

2626

1010

D

E

• FL Display

2

2

1

1

16

13GA

17 21 22

13GB1614GA

33

16

13GC

31

17 21 22

14GB

32

17 21 22

14GC

18

15GA

34

18

15GB

1G

F

26

1234

2G 3G 4G 5G 6G 7G 8G 9G 10G 11G 12G

1

20to23 34

to

,

CDJ-400

5678

6.2.2 Mode for checking load on the JOG dial and Adjustment

This mode is for objectively judging the load (light or heavy touch) on the JOG dial when it is turned, with a value.

Mode for Checking Load on the JOG Dial : ON

FL Display

POWER OFF

POWER ON

[Measuring procedure]

After entering this mode, rapidly turn the JOG dial, either clockwise or

counterclockwise. The figures will be displayed.

If, for example, "8.6: 115" is displayed, each figure means the following:

8.6 : Maximum speed (Normal speed is one rotation in 1.8 sec.)

115 : Time (in msec) required for decreasing the rotation speed

from 3 times to 1.5 times normal speed

To measure the time required for reducing the rotation speed, the

maximum speed must be 7.0 times normal speed or higher.

If measurements are consecutively performed several times, the mean

value of the results of up to four latest measurements will be displayed,

in order to minimize variation.

Standard value: 95 ± 25 msec

[Adjustment procedure]

1. Enter this mode.

2. Adjust the adjustment value of Adjust plate to "0".

3. Rapidly turn the JOG dial, either clockwise or counterclockwise.

4. The rotational speed (maximum speed) and time are displayed in

the dot FL display section.

• The time required so that the rotation may decrease from 3 times

normal speed to 1.5 times normal speed when maximum speed is

only 7 times normal speed or more is displayed.

• Moreover, the mean value of the measurement result at the

rotation decrease time is displayed since the second times.

• The thing that the mean value at the decrease of the rotation three

times in total time is in the standard value (95 ± 25 msec) is

confirmed. Perform the following procedure if coming off from the

standard value.

5. When the rotational speed is smaller than 70, the adjustment value

of the adjust plate is changed to "-1" and performs the procedure 3

and 4. (1)

When the rotational speed is larger than 120, the adjustment value

of the adjust plate is changed to "+1" and performs the procedure 3

and 4. (2)

SERV I CEMO

Place the TEMPO slider at the

positive maximum-value (lowest)

position then press any key once.

Mode for checking load

on the JOG dial

FL Display

:

0.0

Max. speed

The unit enters the mode for checking

load on the JOG dial, and the maximum

speed and the time required for transition

are displayed on the dot-matrix display.

DE

0

m

Time (msec)

A

B

C

D

-3

-2

+2

+1

-1

0

Adjust plate

(The installation position refers to the JOG Dial

of section "7. DISASSEMBLY".)

21

Mode for Checking Load on the JOG Dial : CANCEL

POWER OFF

CDJ-400

56

E

F

27

7

8

Loading...

Loading...