Pioneer CDJ-2000NXS Service manual

2012

CDJ-2000NXS

MULTI PLAYER

CDJ-2000NXS

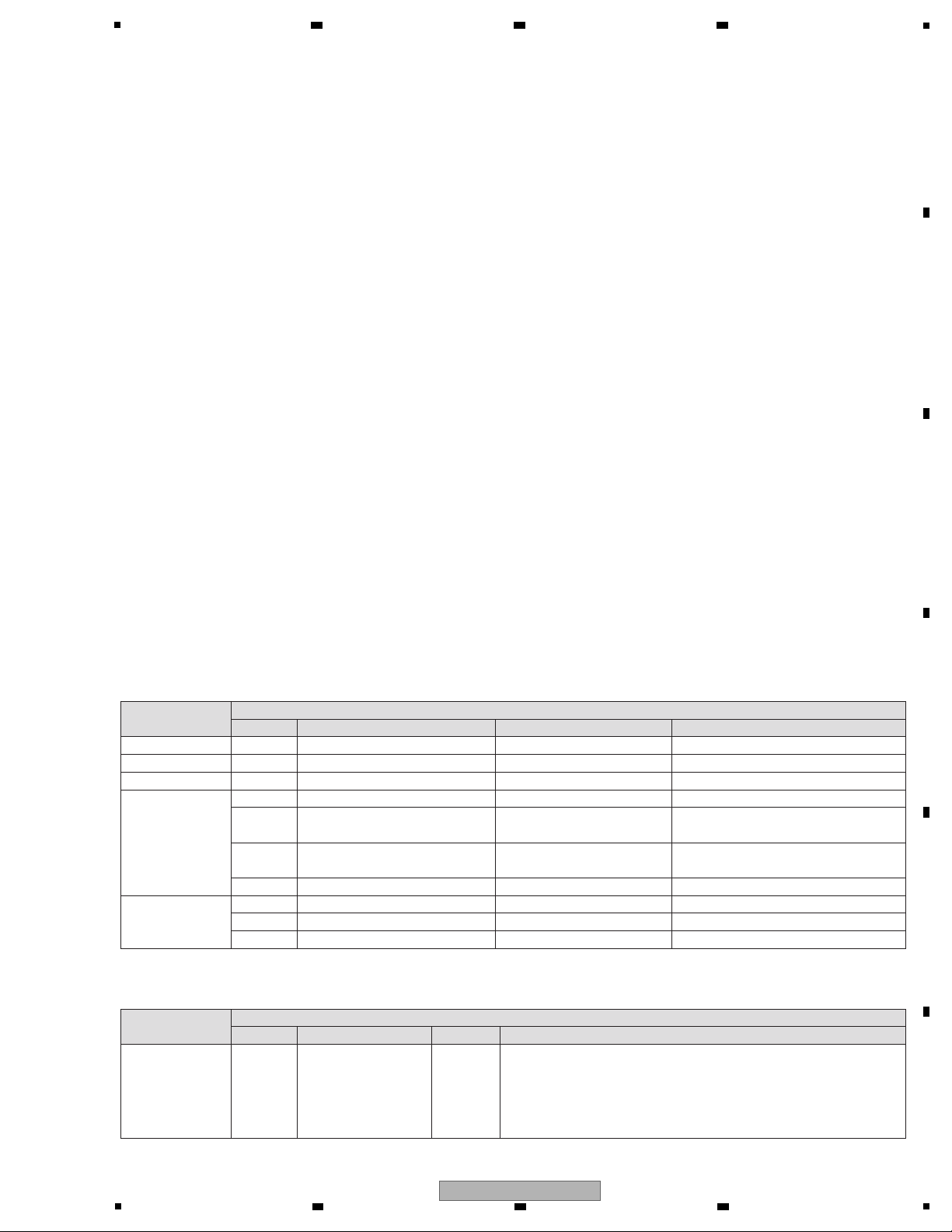

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

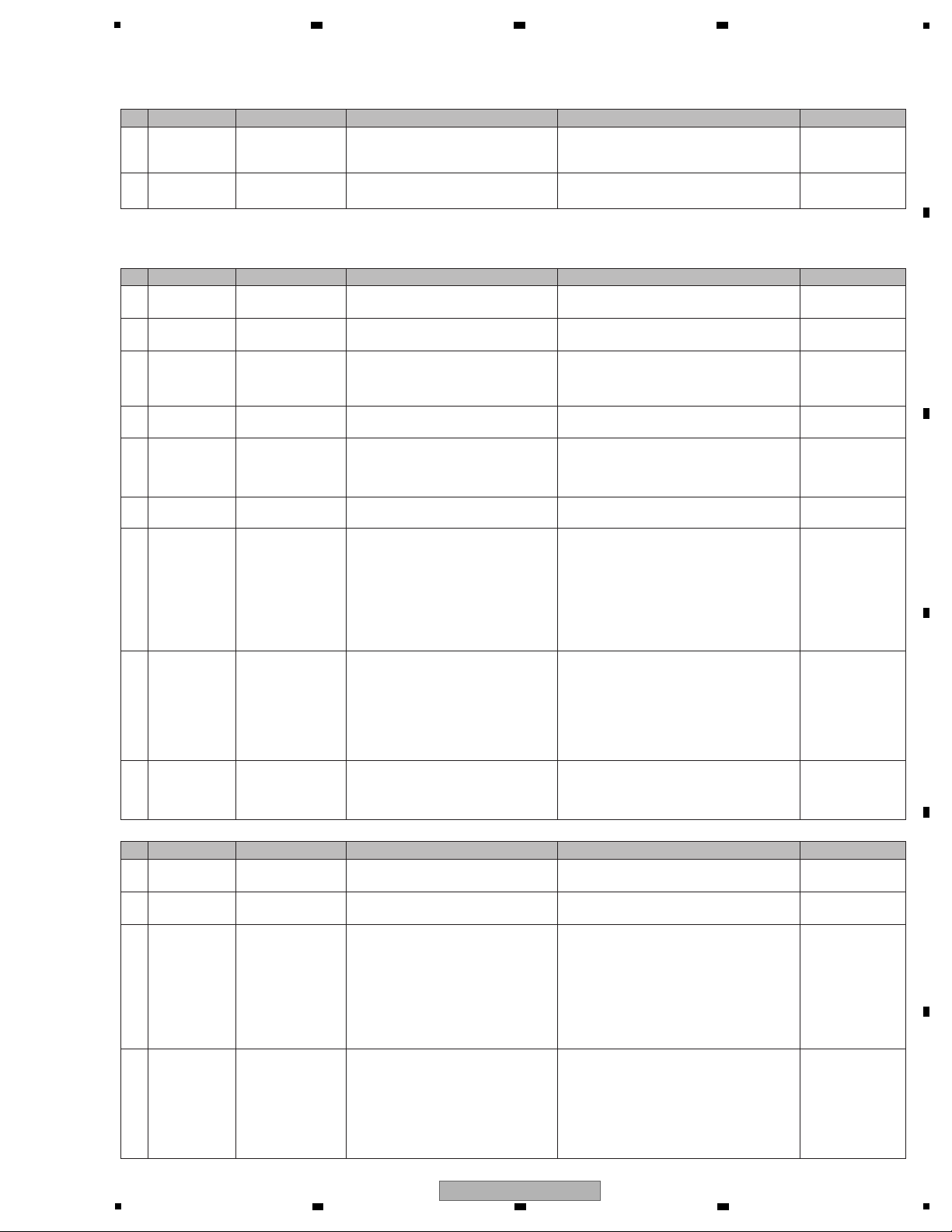

Model Type Power Requirement Remarks

CDJ-2000NXS UXJCB AC 120 V

CDJ-2000NXS SYXJ8 AC 220 V to 240 V

CDJ-2000NXS FLXJ AC 110 V to 240 V

CDJ-2000NXS AXJ5 AC 220 V to 240 V

CDJ-2000NXS KXJ5 AC 220 V

ORDER NO.

RRV4356

PIONEER CORPORATION 1-1, Shin-ogura, Saiwai-ku, Kawasaki-shi, Kanagawa 212-0031, Japan

PIONEER ELECTRONICS (USA) INC. P.O. Box 1760, Long Beach, CA 90801-1760, U.S.A.

PIONEER EUROPE NV Haven 1087, Keetberglaan 1, 9120 Melsele, Belgium

PIONEER ELECTRONICS ASIACENTRE PTE. LTD. 253 Alexandra Road, #04-01, Singapore 159936

PIONEER CORPORATION

K-MZV SEPT.

2012 Printed in Japan

1

WARNING

This product may contain a chemical known to the State of California to cause cancer, or birth defects or other reproductive

harm.

Health & Safety Code Section 25249.6 - Proposition 65

This service manual is intended for qualified service technicians; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

This product contains mercury. Disposal of this material may be regulated due to environmental

considerations. For disposal or recycling information, please contact your local authorities or the

Electronics Industries Alliance: www.eiae.org.

The backlighting lamp of LCD in this equipment contains mercury. Disposal of this material may be

regulated due to environmental considerations according to Local, State or Federal Laws.

For disposal or recycling information, please contact your local authorities or the Electronics Industries

Alliance: www.eiae.org

IMPORTANT

THIS PION EER APPARATUS CON TA IN S

LASER OF CLASS 1.

SERVICING OPERATION OF THE APPARATUS

SHOULD BE DON E BY A SPECIALLY

INSTRUCTED PERSON.

Additional Laser Caution

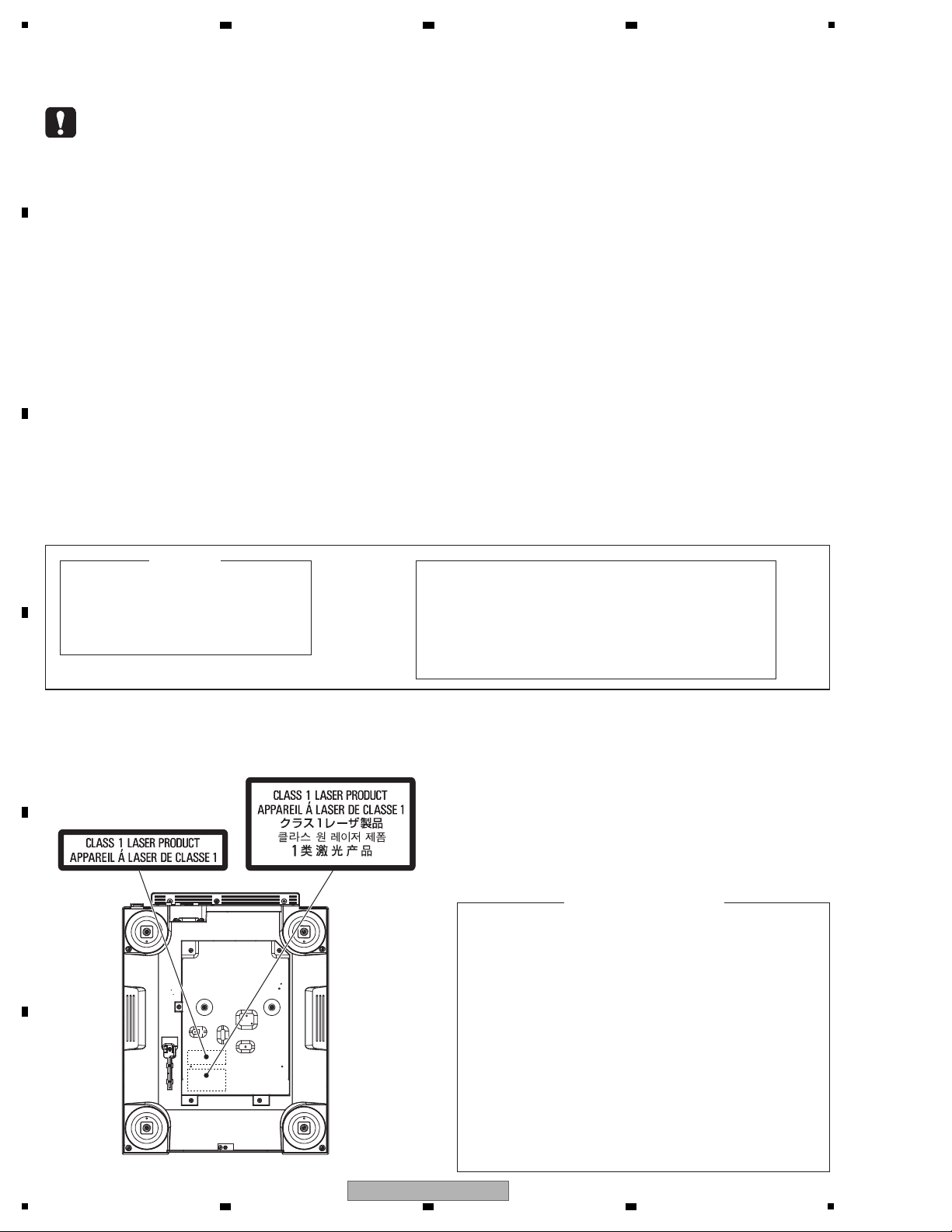

1. Laser Interlock Mechanism

The position of the switch (S9002) for detecting loading

completion is detected by the system microprocessor, and the

design prevents laser diode oscillation when the switch is not in

LPS1 terminal side (when the mechanism is not clamped and

LPS1 signal is high level.)

Thus, the interlock will no longer function if the switch is

deliberately set to LPS1 terminal side.

( if LPS1 signal is low level ).

In the test mode ∗ the interlock mechanism will not function.

Laser diode oscillation will continue, if pin 5 (pin 3) of

AN22022A (IC7002) on the SRVB Assy is connected to GND,

or else the terminals of Q7002 (Q7001) are shorted to each

other (fault condition).

2. When the cover is opened, close viewing of the objective lens

with the naked eye will cause exposure to a Class 1 laser beam.

For DVD Wave length (typ) : 655 nm

Operation output : 3 mW CW, Class 1

Maximum output : Class 1 (Under fault condition)

For CD Wave length (typ) : 790 nm

Operation output : 4.5 mW CW, Class 1

Maximum output : Class 1 (Under fault condition)

Laser Pickup specifications and Laser characteristics

LABEL CHECK

Bottom view

for UXJCB and FLXJ

(Printed on the plate)

for SYXJ8, AXJ5 and KXJ5

(Printed on the plate)

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

CDJ-2000NXS

2 3 4

5

6 7 8

CONTENTS

SAFETY INFORMATION.......................................................................................................................................................... 2

1. SERVICE PRECAUTIONS ....................................................................................................................................................5

1.1 NOTES ON SOLDERING............................................................................................................................................... 5

1.2 NOTES ON REPLACING PARTS ................................................................................................................................... 5

1.3 SERVICE NOTICE.......................................................................................................................................................... 6

2. SPECIFICATIONS .................................................................................................................................................................7

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................7

3.1 JIGS LIST .......................................................................................................................................................................7

3.2 CHECK POINTS AFTER SERVICING ........................................................................................................................... 8

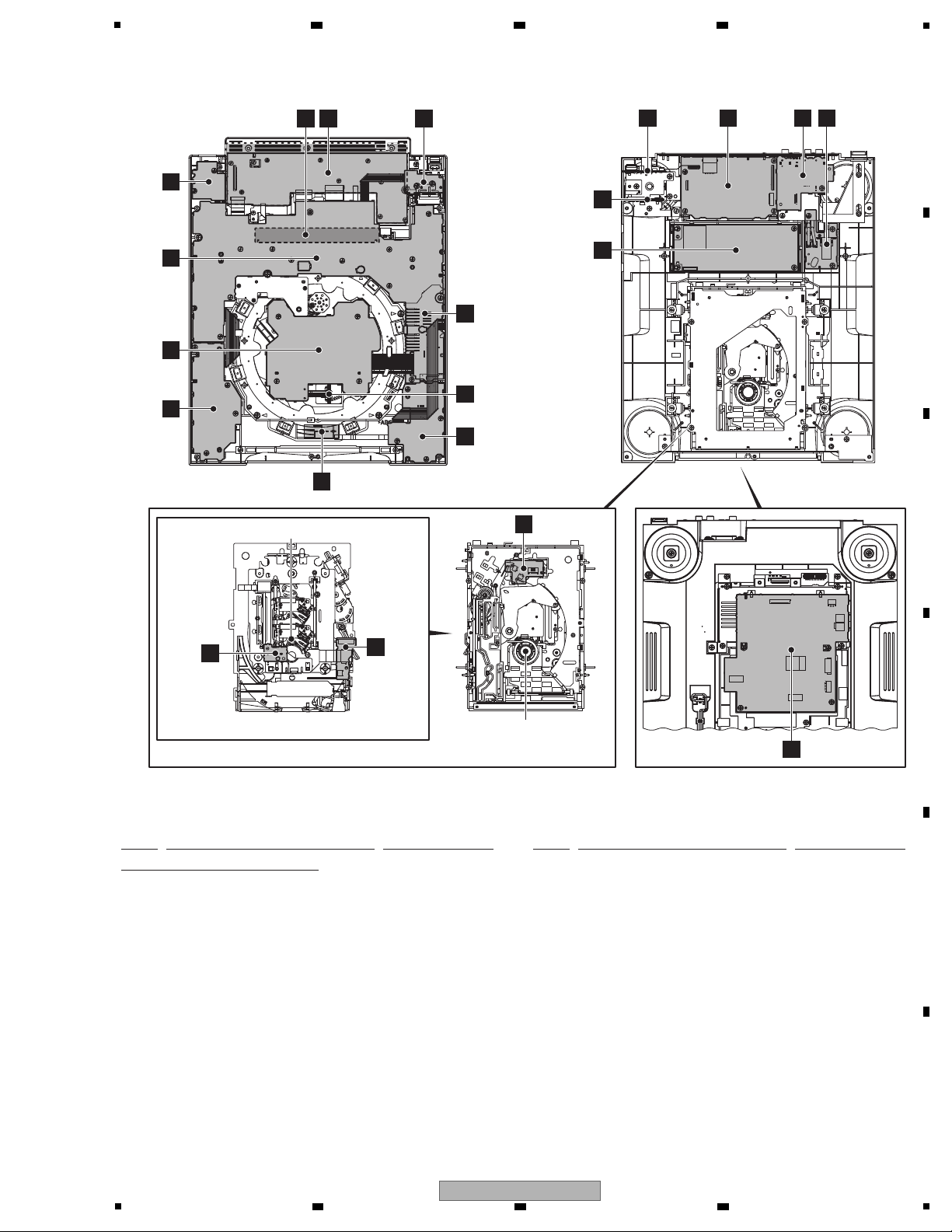

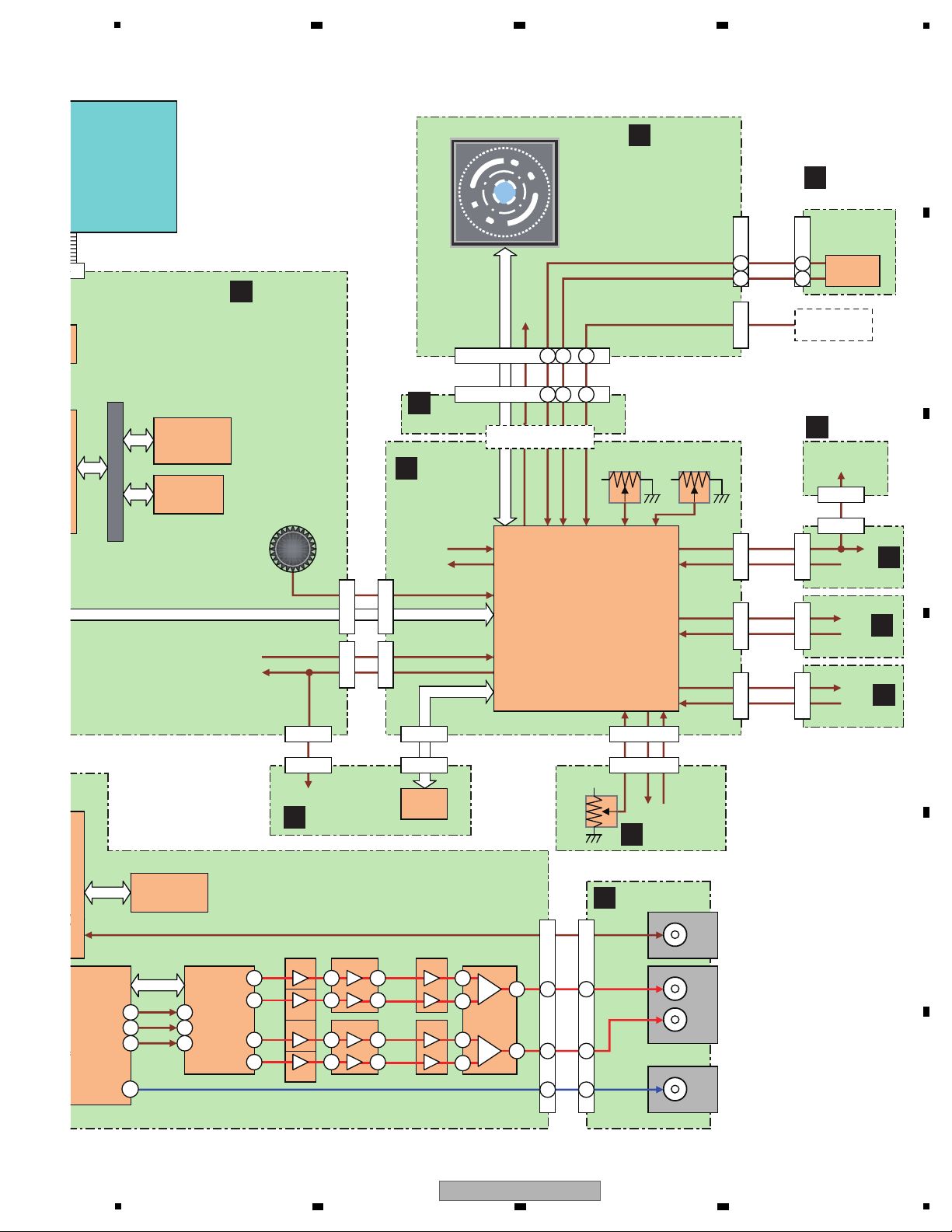

3.3 PCB LOCATIONS ........................................................................................................................................................... 9

4. BLOCK DIAGRAM ..............................................................................................................................................................10

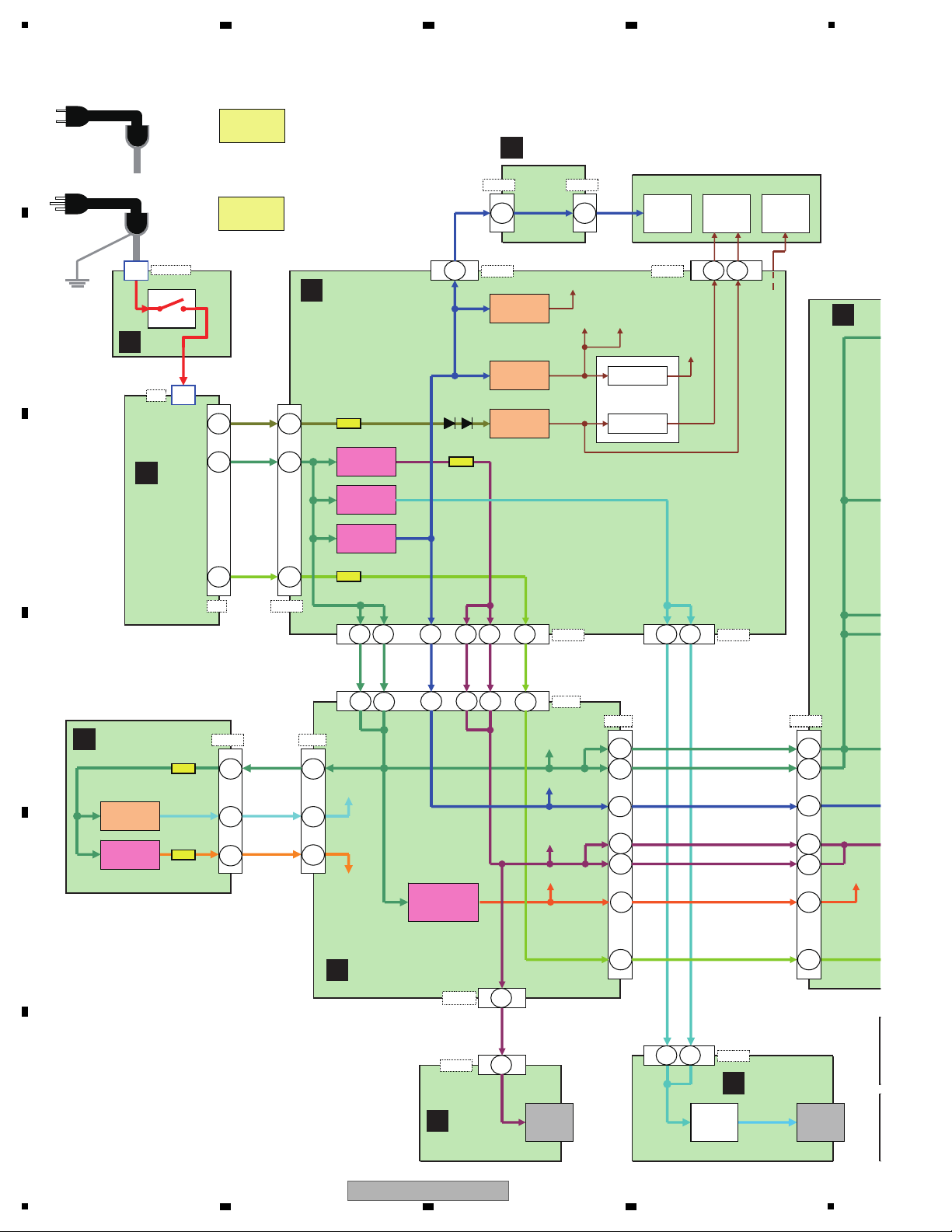

4.1 OVERALL WIRING DIAGRAM .....................................................................................................................................10

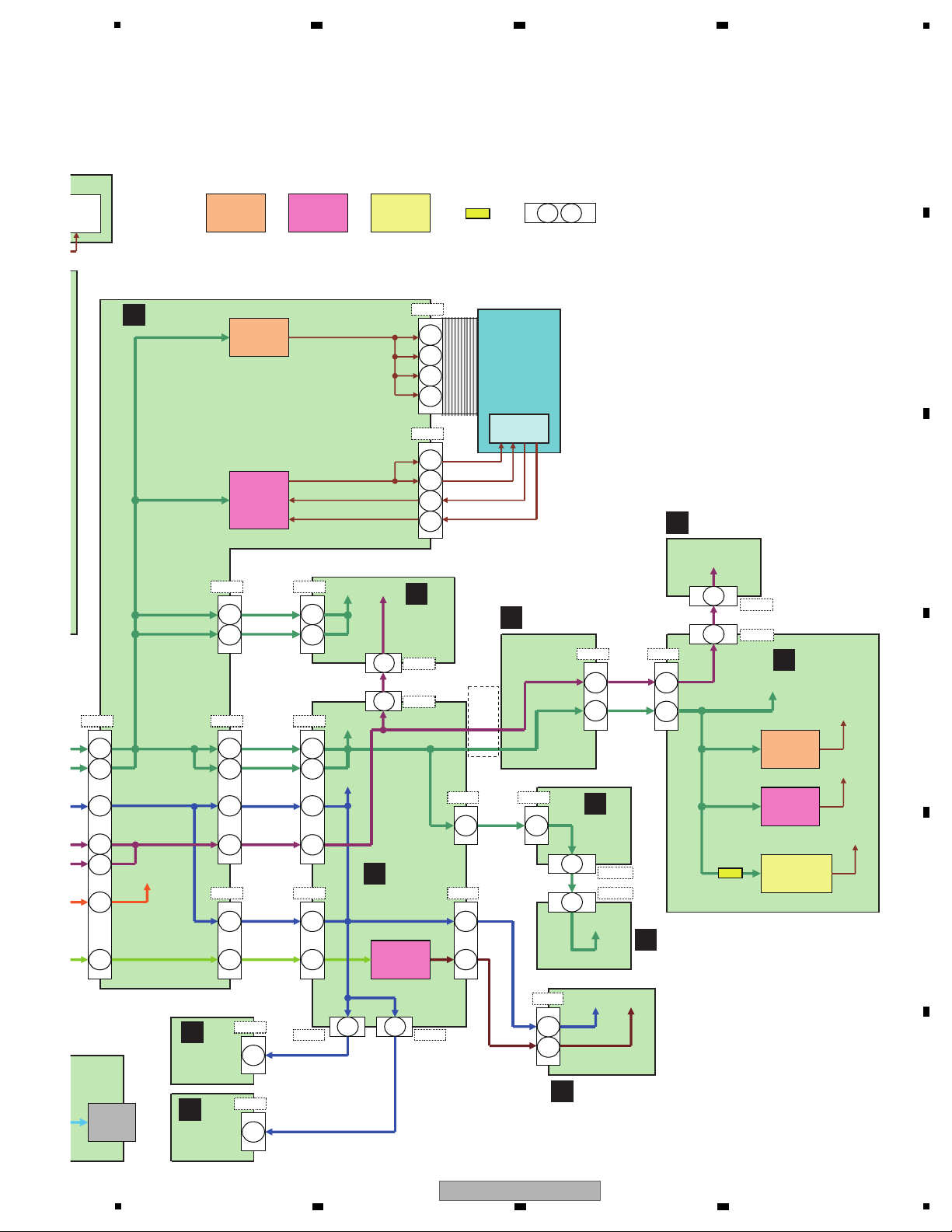

4.2 SIGNAL BLOCK DIAGRAM.......................................................................................................................................... 12

4.3 POWER SUPPLY BLOCK DIAGRAM........................................................................................................................... 14

5. DIAGNOSIS ........................................................................................................................................................................ 16

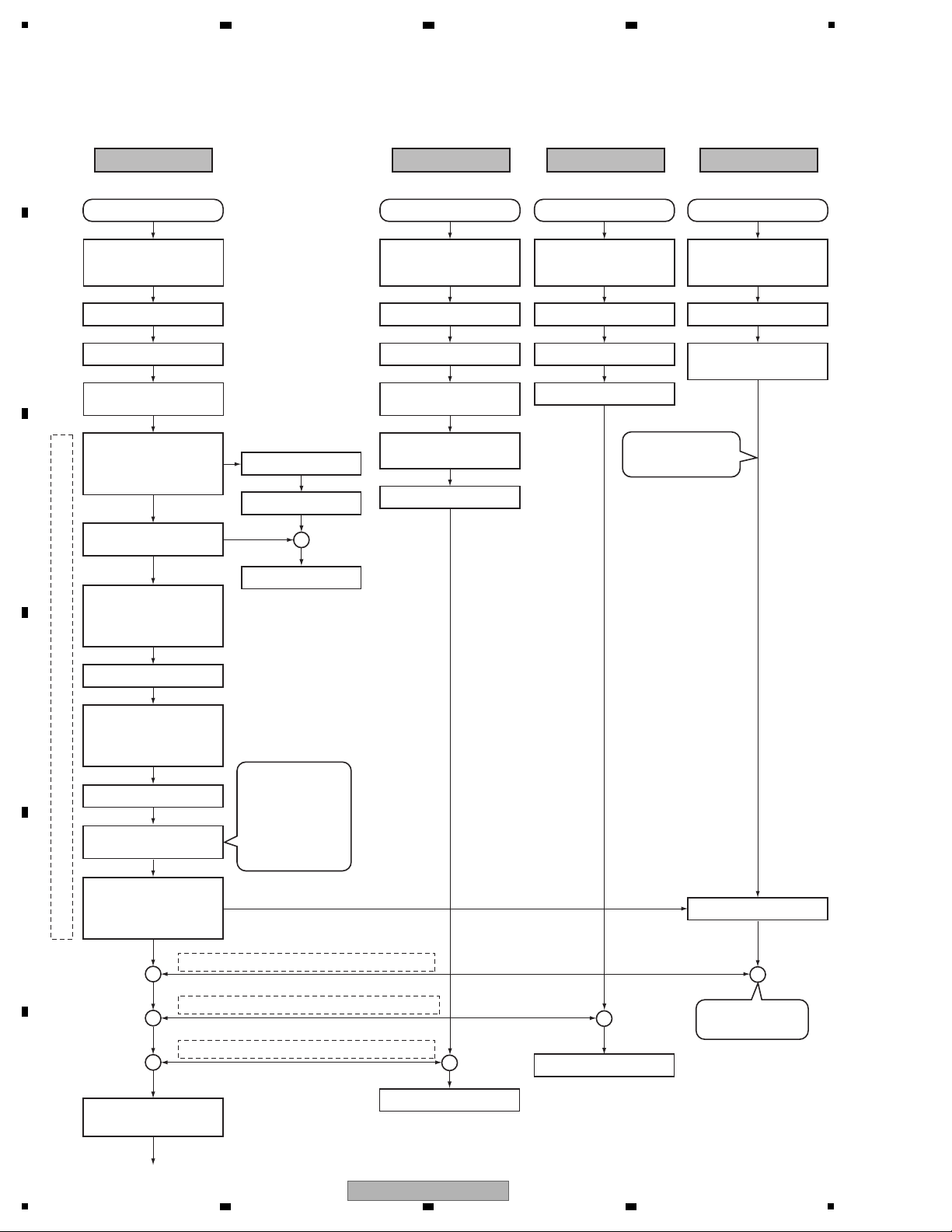

5.1 POWER ON SEQUENCE.............................................................................................................................................16

5.2 FAILURE JUDGEMENT OF THE PICKUP ASSY ........................................................................................................ 17

5.3 TROUBLESHOOTING.................................................................................................................................................. 18

5.4 OPERATIONAL WAVEFORMS .................................................................................................................................... 31

5.5 SETUP SEQUENCE..................................................................................................................................................... 32

5.6 CONNECTION CONFIRMATION WITH THE PC......................................................................................................... 33

6. SERVICE MODE................................................................................................................................................................. 34

6.1 SERVICE MODE .......................................................................................................................................................... 34

6.2 ABOUT THE DEVICE................................................................................................................................................... 51

7. DISASSEMBLY ................................................................................................................................................................... 52

8. EACH SETTING AND ADJUSTMENT................................................................................................................................ 67

8.1 NECESSARY ITEMS TO BE NOTED........................................................................................................................... 67

8.2 FIRMWARE UPDATE / RECOVERY.............................................................................................................................67

8.3 JOG DIAL ROTATION LOAD ADJUSTMENT ............................................................................................................... 68

8.4 TEMPO ZERO POINT ADJUSTMENT.........................................................................................................................69

8.5 ITEMS FOR WHICH

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................72

9.1 PACKING SECTION ..................................................................................................................................................... 72

9.2 EXTERIOR SECTION .................................................................................................................................................. 74

9.3 CONTROL PANEL SECTION ....................................................................................................................................... 76

9.4 JOG DIAL SECTION .................................................................................................................................................... 78

9.5 DISPLAY SECTION ...................................................................................................................................................... 80

9.6 SLOT IN MECHA SECTION.........................................................................................................................................82

9.7 TM ASSY-S ................................................................................................................................................................... 84

10. SCHEMATIC DIAGRAM .................................................................................................................................................... 86

10.1 SRVB ASSY (1/2) ....................................................................................................................................................... 86

10.2 SRVB ASSY (2/2), SPCN, INSW and SLMB ASSYS................................................................................................. 88

10.3 MAIN ASSY (1/5)........................................................................................................................................................90

10.4 MAIN ASSY (2/5)........................................................................................................................................................92

10.5 MAIN ASSY (3/5)........................................................................................................................................................94

10.6 MAIN ASSY (4/5)........................................................................................................................................................96

10.7 MAIN ASSY (5/5)........................................................................................................................................................98

10.8 JACB ASSY .............................................................................................................................................................. 100

10.9 SDCB ASSY .............................................................................................................................................................102

10.10 USBB ASSY ...........................................................................................................................................................104

10.11 TFTB ASSY (1/2)....................................................................................................................................................106

10.12 TFTB ASSY (2/2)....................................................................................................................................................108

10.13 PNLB ASS

Y............................................................................................................................................................110

10.14 JFLB ASSY............................................................................................................................................................. 112

10.15 CDCB and SDSW ASSYS......................................................................................................................................114

10.16 SLDB and EUPB ASSYS........................................................................................................................................115

10.17 CNCT and KSWB ASSYS ......................................................................................................................................116

10.18 JOGB and INDB ASSYS ........................................................................................................................................ 117

10.19 POWER SUPPLY and ACIN ASSYS ...................................................................................................................... 118

10.20 WAVEFORMS.........................................................................................................................................................120

USER SETTINGS ARE AVAILABLE........................................................................................... 70

A

B

C

D

E

F

CDJ-2000NXS

5

6 7 8

3

1

2 3 4

11. PCB CONNECTION DIAGRAM ......................................................................................................................................122

11.1 SRVB ASSY..............................................................................................................................................................122

A

11.2 SPCN, INSW and SLMB ASSYS..............................................................................................................................127

11.3 MAIN ASSY...............................................................................................................................................................128

11.4 JACB, SDCB and USBB ASSYS ..............................................................................................................................132

11.5 TFTB ASSY...............................................................................................................................................................134

11.6 PNLB ASSY ..............................................................................................................................................................138

11.7 JFLB, CDCB and SDSW ASSYS..............................................................................................................................142

11.8 SLDB, EUPB and CNCT ASSYS ..............................................................................................................................146

11.9 KSWB, JOGB and INDB ASSYS ..............................................................................................................................148

11.10 POWER SUPPLY and ACIN ASSYS.......................................................................................................................150

12. PCB PARTS LIST ............................................................................................................................................................152

B

C

D

E

F

4

1

2 3 4

CDJ-2000NXS

5

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

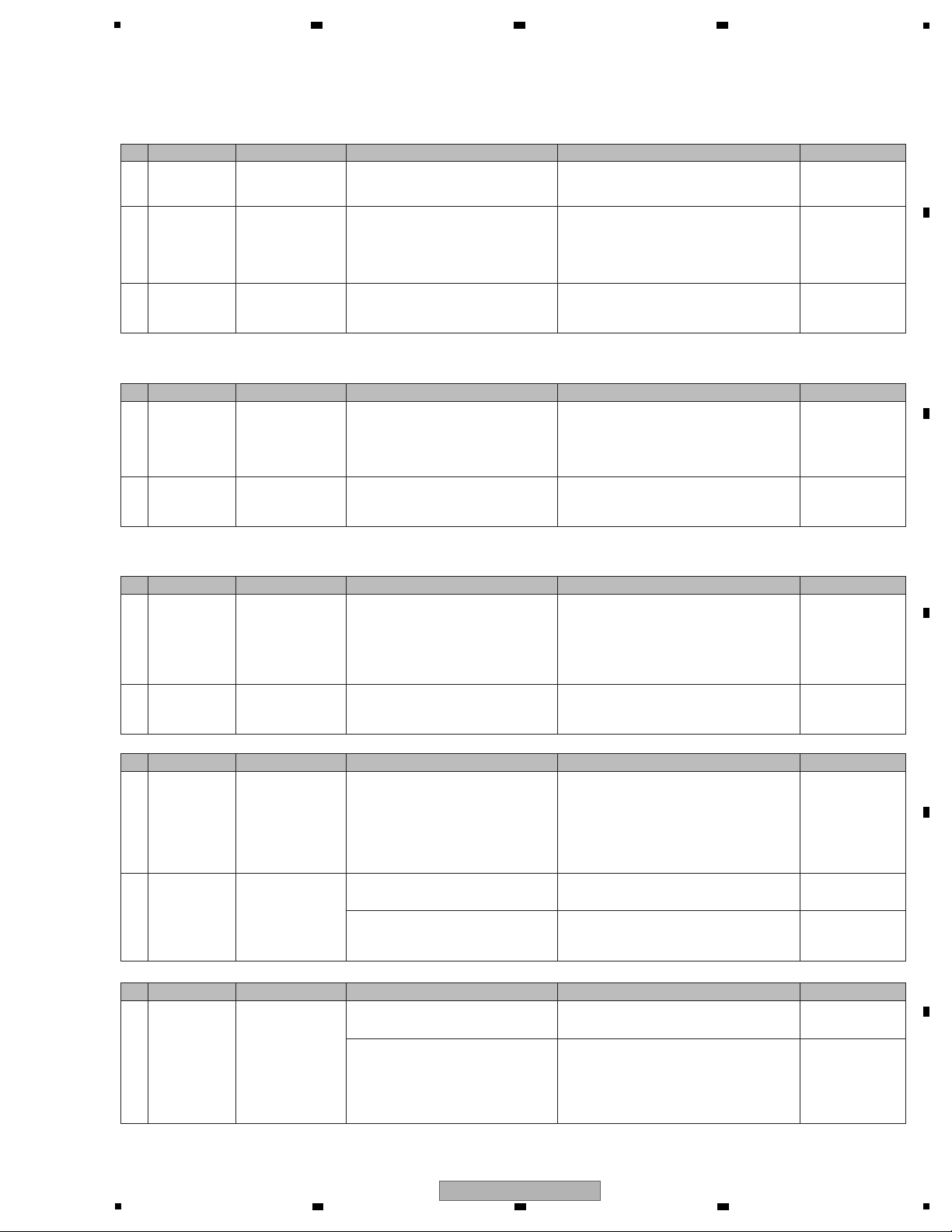

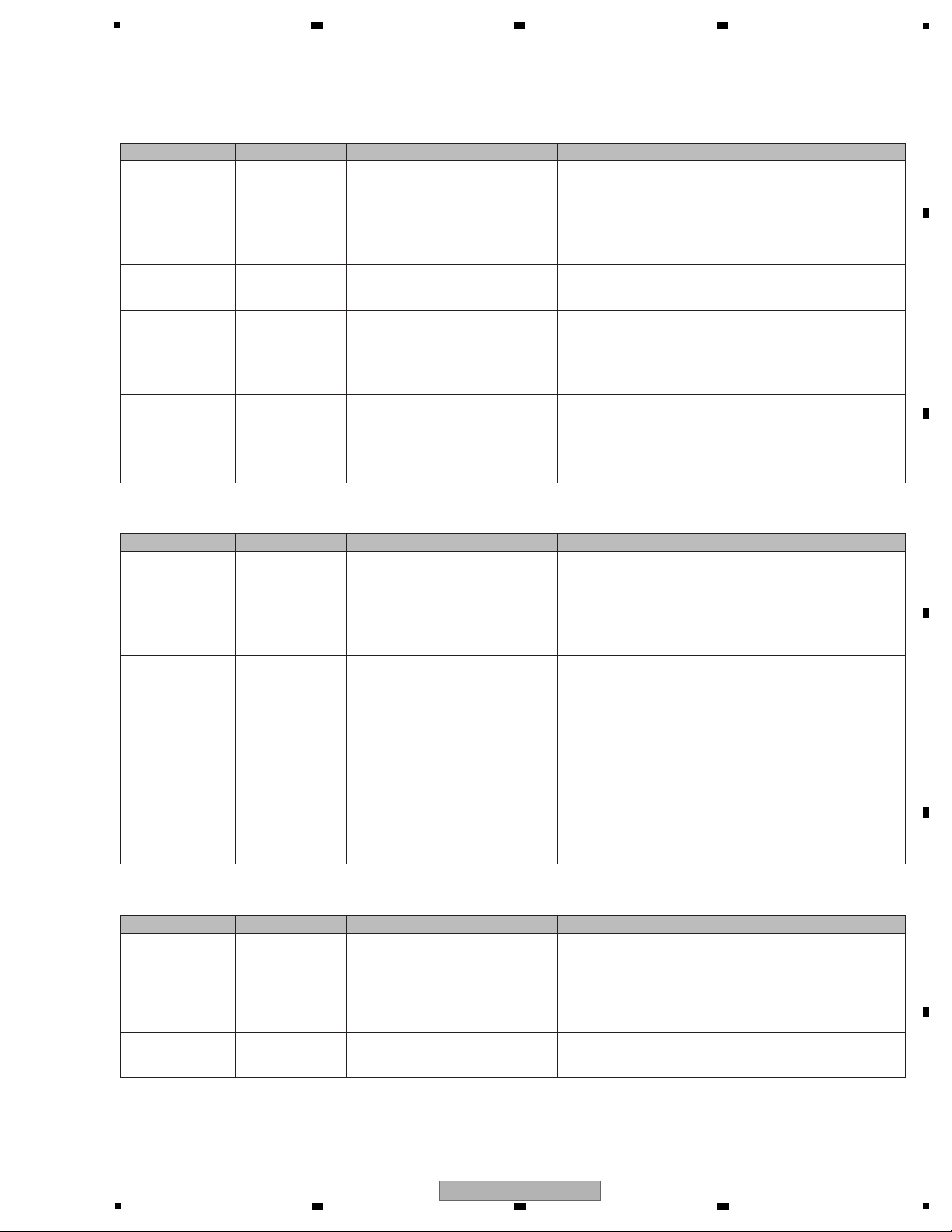

The part listed below is difficult to replace as a discrete component part.

When the part listed in the table is defective, replace whole Assy.

Assy Name

CDCB Assy

CDC SENSOR AD7147ACPZ500RL7

IC with heat-pad

IC5001

SRVB Assy 12V→USB5V DC/DC converter BD9328EFJ

IC with heat-pad

IC7301

12V→3.3V DC/DC converter BD9328EFJ

IC with heat-pad

IC7302

12V→5V DC/DC converter BD9328EFJ

IC with heat-pad

IC7305

TFTB Assy BACK LIGHT CONTROL TK61222CQ6

IC with heat-pad

IC4018

USBB Assy USB CURRENT LIMIT IC TPS2557DRB

IC with heat-pad

IC6301

12V→1.2V DC/DC converter BD9328EFJ IC with heat-padIC705

MAIN Assy

CPU R5S77641N300BG

BGA package

IC10

Authentication Coprocessor 337S3959-TBB USON package

(UltraSmallOutlineNon-lead)

IC14

DSP D810K013BZKB400

D810K013CZKB400

BGA packageIC301

Parts that is Difficult to Replace

Ref No. Function Part No. Remarks

The part listed below is difficult to replace as a discrete component part.

The replaceing method see remarks.

Assy Name

JFLB Assy

JOG FL DEL1058

As the JOG FL is integrated with the FL Holder (DNF1735) with the aid of two

pieces of double-back tape (Z12-016), first remove the integrated JOG FL and

FL Holder, attach a new JOG FL and an FL Holder, using two pieces of

double-back tape, then mount them together. (Note: As the integrated JOG FL

and FL Holder are exactly the same parts as those for the CDJ-2000, you can

handle them in the same manner as with the CDJ-2000.)

V9201

Parts that is Difficult to Replace

Ref No. Function Part No. Remarks

6 7 8

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

1.2 NOTES ON REPLACING PARTS

5

6 7 8

CDJ-2000NXS

C

D

E

F

5

1

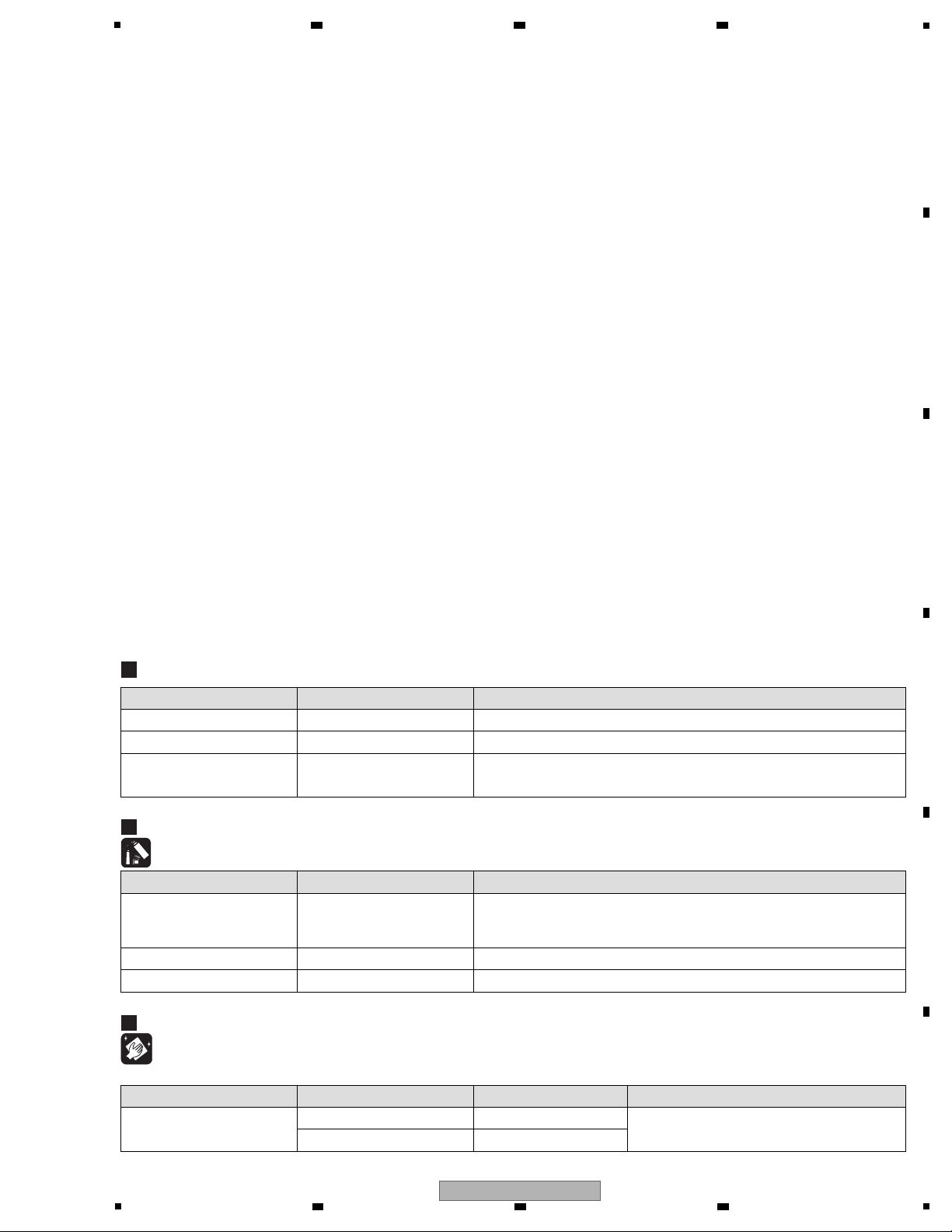

About the PNLB and CNCT Assys

The PNLB Assy and CNCT Assy are wired with jumper leads. The PNLB Assy (Part No. DWX3338) is supplied as a service

part with the CNCT Assy connected. The CNCT Assy is not supplied individually as a service part.

About the Flash ROM (IC3) in the MAIN Assy

Replacement of the Flash ROM (IC3: DYW1814) in the MAIN Assy is not possible during service, because writing of

the MAC address on the production line is required.

Therefore, the Flash ROM (IC3) is not supplied as a service part. If the Flash ROM is defective, replace the whole MAIN Assy.

About work required after replacement of the Traverse Mechanism Assy (09SD)

After replacement of the traverse mechanism Assy (09SD), reset the LD lighting time to zero.

How to Reset: See "7 Drive LD life reset" in "[3] Indication of various information" in "6.1 SERVICE MODE."

About transfer of the accumulated LD lighting time data after replacement of the MAIN Assy

This unit is equipped with self-diagnostic functions for the drives in Service mode. The service-life check for the laser

diode (for CDs/DVDs) among the self-diagnostic functions uses the accumulated lighting time for judgment. If it is

7,000 hours or less, the laser diode is judged as OK. The accumulated lighting time of the LD is stored in the Flash ROM

(IC3: DYW1814) in the MAIN Assy. Therefore, after replacement of the MAIN Assy, the accumulated lighting time of the

LD is cleared and proper judgment will not be possible after that. To avoid such a situation, when replacement of the

MAIN Assy is required, transfer the LD accumulated lighting time data.

Before replacement, confirm the drive LD lighting time in Service mode and take note of the time value. After replacement

is finished, enter Service mode then change the drive LD lighting time value to what you noted.

For details on how to confirm and change the LD lighting time, see "8 Drive LD life manual input" in "[3] Indication of

various information" in "6.1 SERVICE MODE."

About the self-diagnostic functions for the drives

This unit has self-diagnostic functions for the drives in Service mode. Use the self-diagnostic functions to check the drives if

the problem symptom pointed out by the customer is a malfunction related to the drives or if a drive-related error is logged in

the error history.

For details on the self-diagnostic functions for the drives, see "[5] Drive Self-Diagnosis" and "[6] Contents of Drive

Self-Diagnosis" in "6.1 SERVICE MODE."

About the iPod cable supplied with this unit

An iPod cable is supplied with this unit. Be sure to use the iPod cable supplied with this unit to connect an iPad with this unit in

order to determine the cause of a charging problem with an iPad. Do not use the standard cable supplied with iPhones for this

purpose, because it does not meet the specifications required for iPads (a voltage drop may result, because it is thin).

The iPod cable supplied with this unit has been registered as service jig.

About backup of the UTILITY settings

As this unit is provided with user-settable UTILITY settings (such as the Play mode setting,) it is recommended that you back

up the settings before starting repair. The settings can be stored for backup in a USB memory device or an SD card.

For details on how to back up and restore data, see "g How to Back Up and Restore the Settings" in "8.5 ITEMS

FOR WHICH USER SETTINGS ARE AVAILABLE ."

2 3 4

1.3 SERVICE NOTICE

A

B

C

D

E

F

6

1

2 3 4

CDJ-2000NXS

5

Power consumption..................................................................37 W

Power consumption (standby) ................................................0.4 W

Main unit weight...................................................................... 4.7 kg

External dimensions .......320 mm (W) × 106.5 mm (H) × 405.7 mm (D)

Tolerable operating temperature.............................. +5 °C to +35 °C

Tolerable operating humidity............5 % to 85 % (no condensation)

Analog audio output (AUDIO OUT L/R)

Output terminals ..........................................................RCA terminal

Digital audio output (DIGITAL OUT)

Output terminals ..........................................................RCA terminal

Output type..................................................Coaxial digital (S/PDIF)

USB downstream section (USB)

Port........................................................................................ Type A

Power supply..........................................................5 V/2.1 A or less

USB upstream section (USB)

Port........................................................................................ Type B

LAN (PRO DJ LINK)

Rating ........................................................................... 100Base-TX

Control output (CONTROL)

Port..................................................................................... Mini-jack

SD memory card section

File system ....Conforming to “SD Specifications Part 2 File System

Specification Version 2.00”

Max. memory capacity............................................................32 GB

Main display

Display type.............. Active matrix TFT liquid crystal display (LCD)

Screen size................................................................. 6.1-inch, wide

Supported languages ................................................. 18 languages

• The specifications and design of this product are subject to

change without notice.

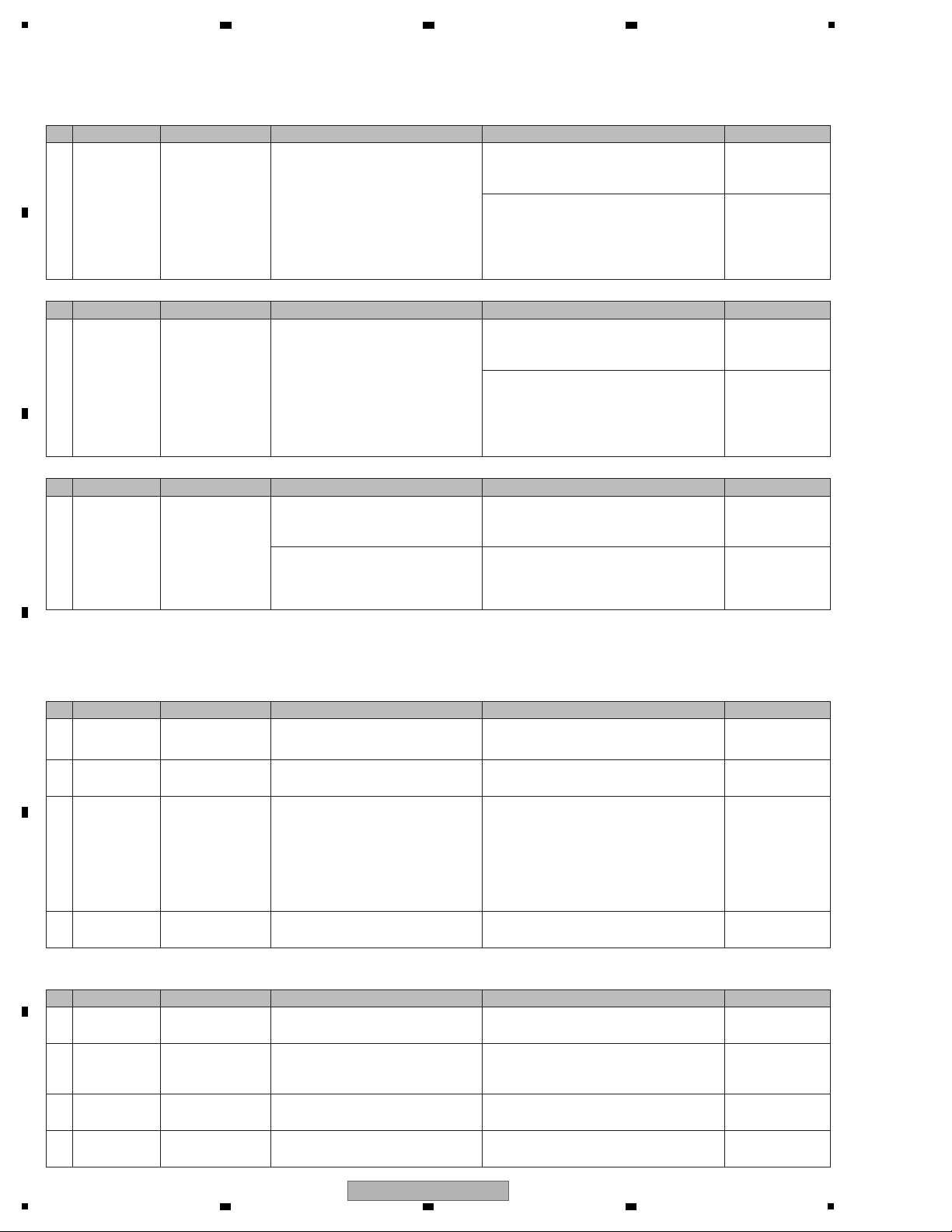

Cleaning

Name Part No. Remarks

Cleaning paper GED-008

Cleaning liquied GEM1004 Refer to "9.7 TM ASSY-S".

Position to be cleaned

Pickup lens

Before shipping out the product, be sure to clean the following positions by using the prescribed cleaning tools.

Name Part No. Remarks

Lubricating oil GYA1001 Refer to “9.3 CONTROL PANEL SECTION”,

“9.4 JOG DIAL SECTION”, “9.6 SLOTIN MECHA

SECTION”, “9.7 TM ASSY-S”.

Dyfree GEM1036 Refer to “9.6 SLOTIN MECHA SECTION”.

Lubricating oil GEM1034 Refer to “9.4 JOG DIAL SECTION”.

Lubricants and Glues List

Jigs List

Jig Name Part No. Purpose of use / Remarks

CD test disc STD-905 Drive self-diagnosis

DVD test disc GGV1035 (DVDT-001) Drive self-diagnosis

iPod cable GGP1201

For use in determining a cause of charging problem for an iPad

DDE1142 (accessory for the CDJ-2000NXS) registered as a special tool

2. SPECIFICATIONS

6 7 8

A

B

3. BASIC ITEMS FOR SERVICE

3.1 JIGS LIST

C

D

E

CDJ-2000NXS

5

6 7 8

F

7

1

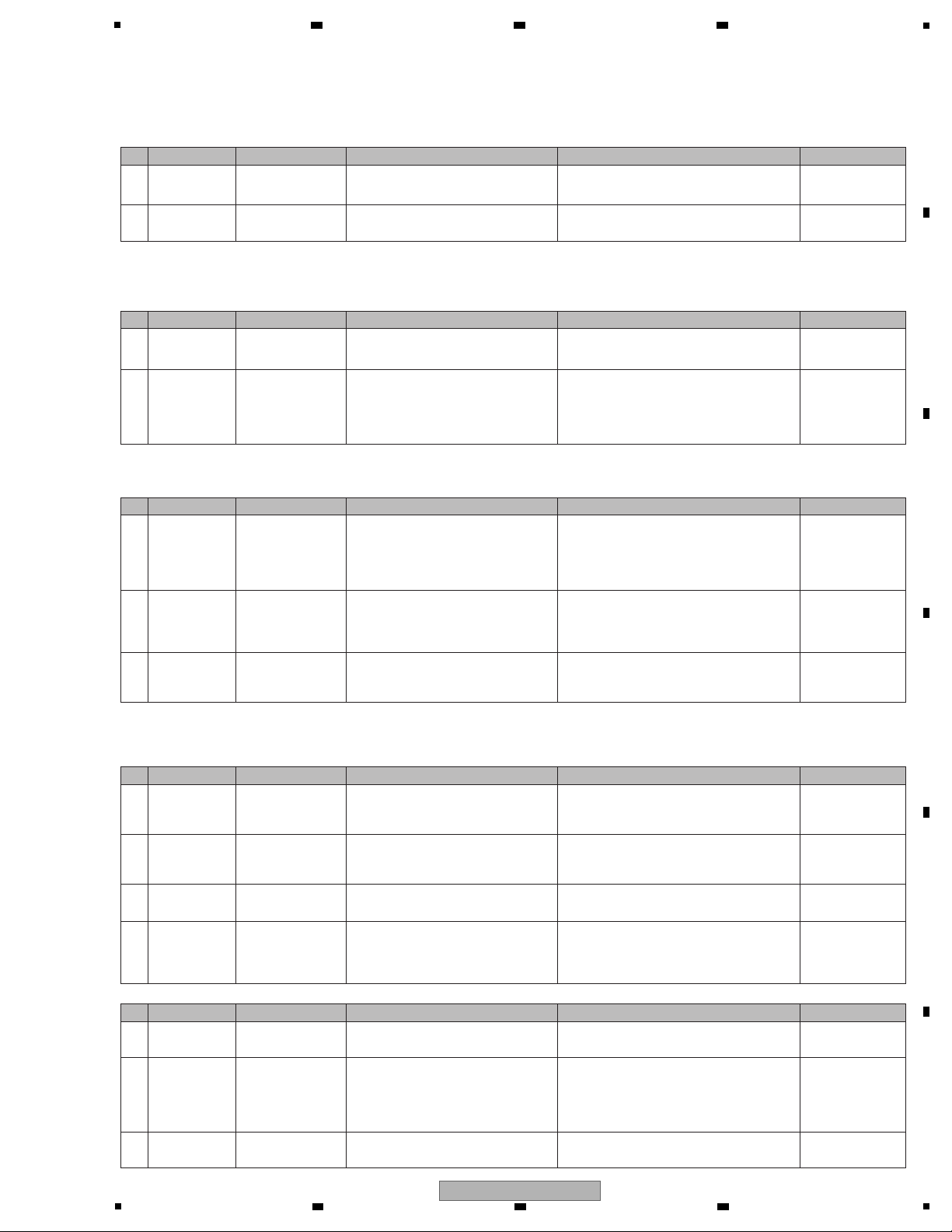

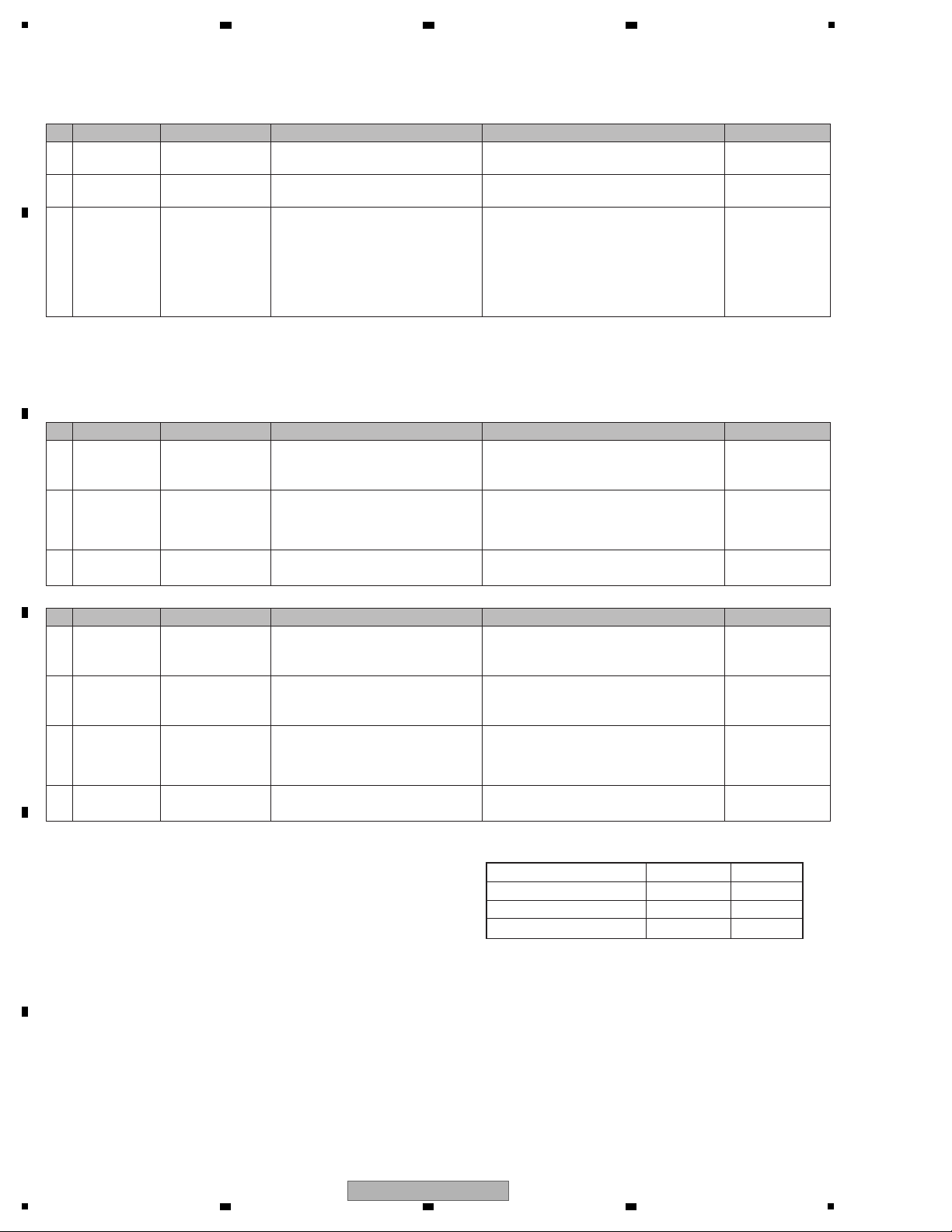

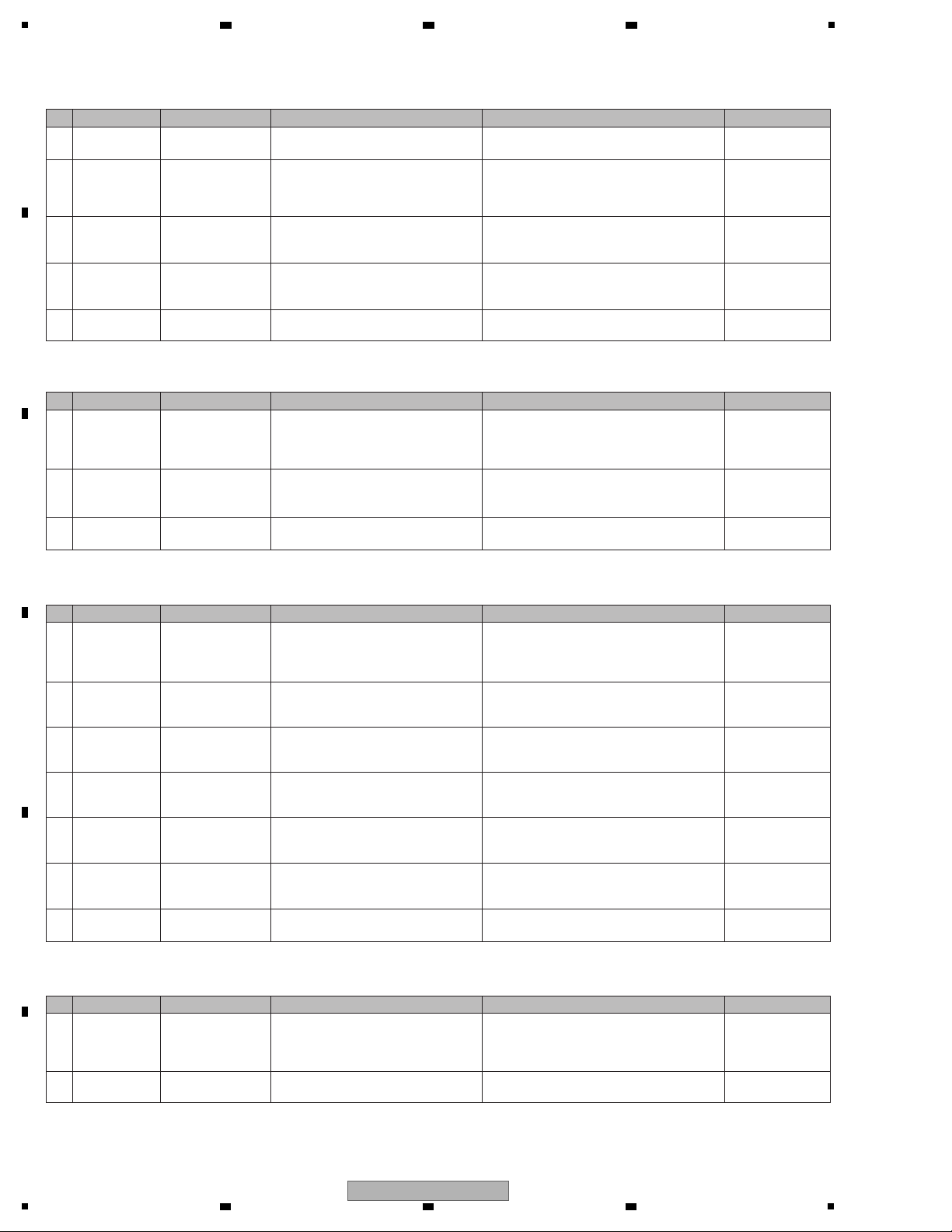

No. Check pointsProcedure

1

Confirm the firmware version on Service Mode.

The version of the firmware must be latest.

Update firmware to the latest one, if it is not the latest.

2

Confirm whether the customer complain has been solved.

If the customer complain occurs with the specific disc, use it for

the operation check.

The customer complain must not be reappeared.

Audio and operations must be normal.

Playback data contained in the device connected to USB A.

Audio, Search and operations must be normal.

USB B

The PC must be linked.

Playback data contained in an SD card.

Audio, Search and operations must be normal.

LINK

The PC must be linked.

3 Playback a disc. (track search) Audio, Search and operations must be normal.

5 Check output signals while the JOG dial or TEMPO slider is

being operated.

Audio and operations must be normal.

6 Check the keys on the unit. Check whether a product can be operated properly by buttons

on the product.

7 Check the LCD display.

Check that there is no dirt or dust trapped inside the LCD display.

4 Check the connection of each interface.

Items to be checked after servicing

No. Check pointsProcedure

1

Confirm playback error rates at the innermost and outermost

tracks by using the following disc.

DVD test disc (GGV1025)

The error rates must be less than 5.0e-4.

(This procedure can determine if the drive is degraded.)

Specific Items to be Checked

To keep the product quality after servicing, confirm recommended check points shown below.

8

Check the appearance of the product.

No scratches or dirt on its appearance after receiving it for service.

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

See the table below for the items to be checked regarding audio.

2 3 4

3.2 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

8

1

2 3 4

CDJ-2000NXS

5

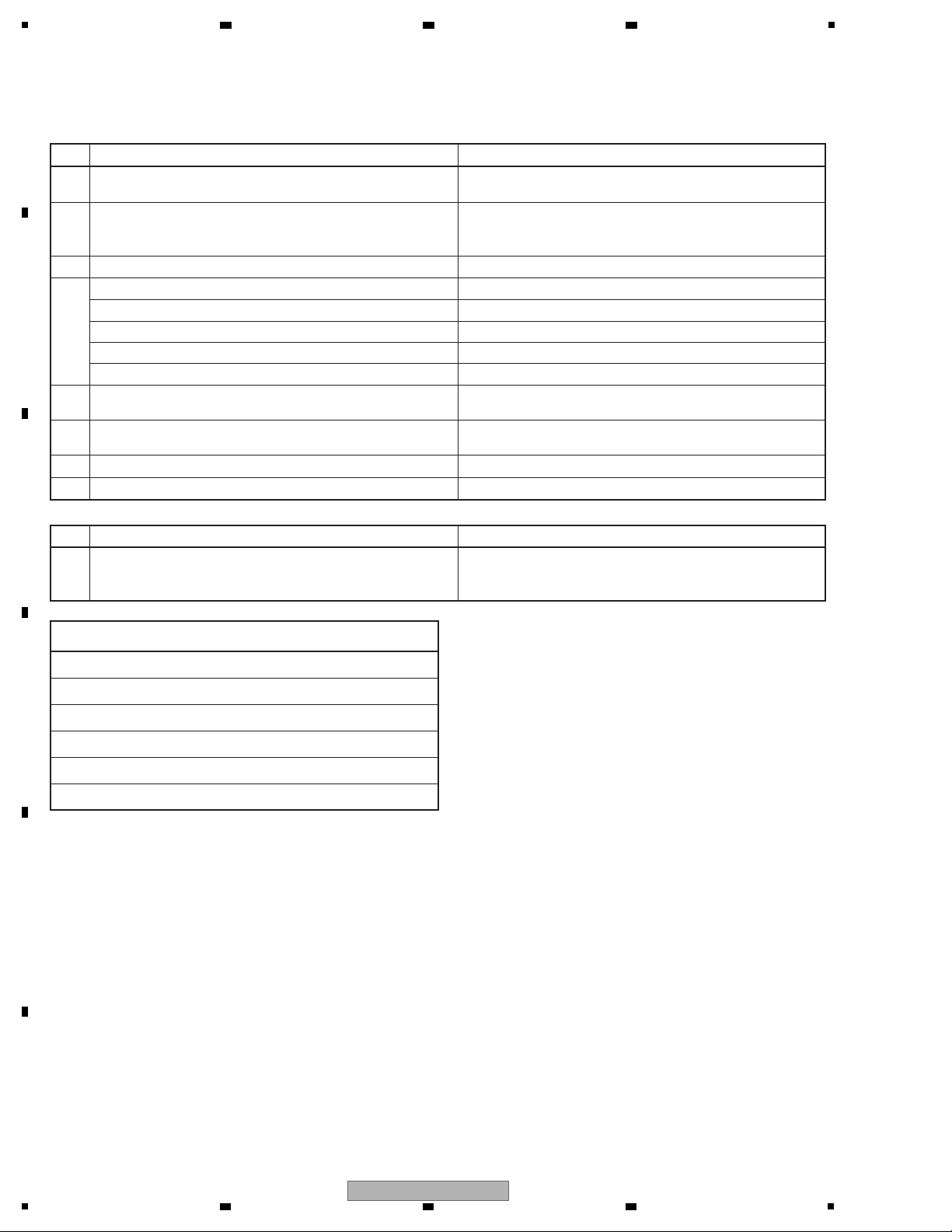

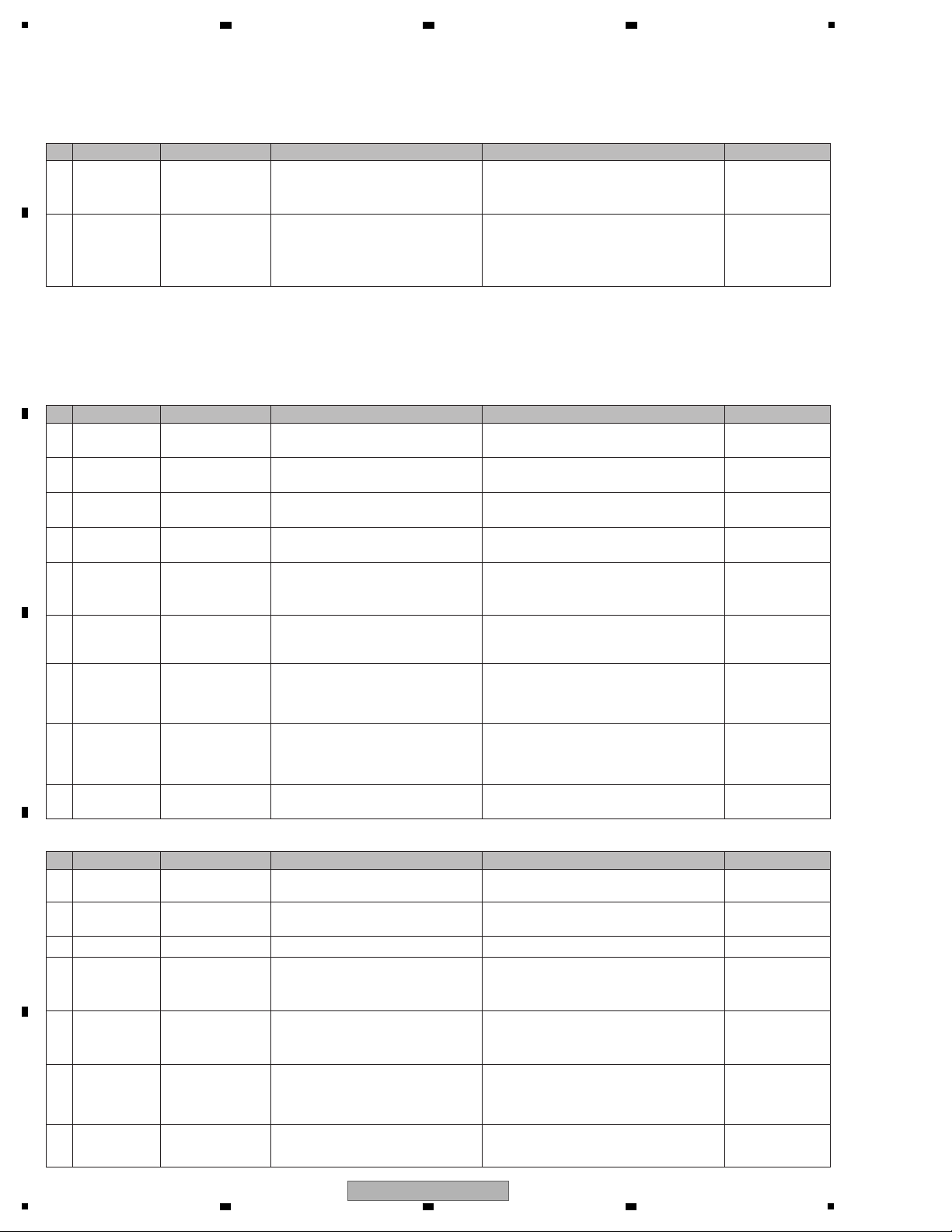

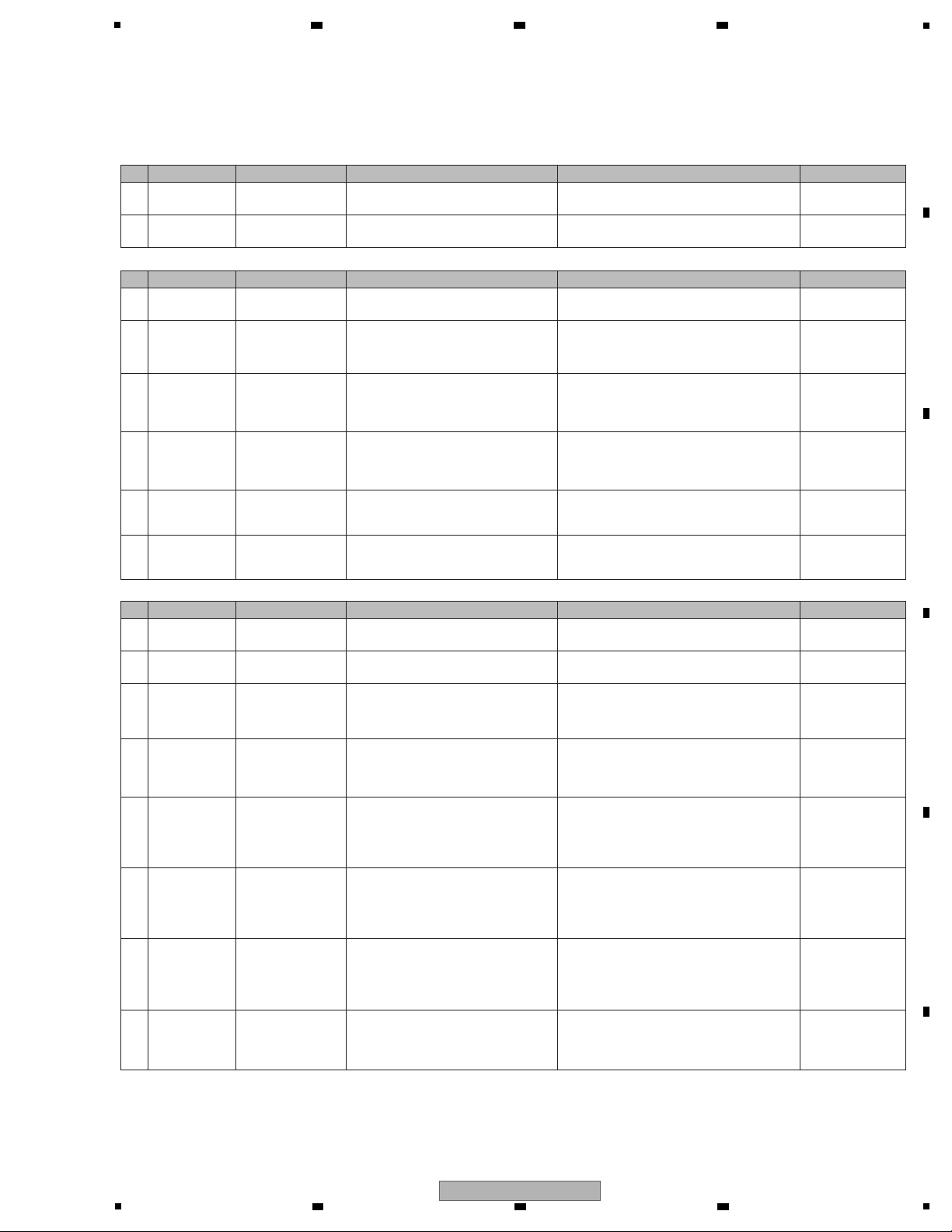

F

JACB

ASSY

D

SLMB ASSY

TM ASSY 09SD-S

A

SRVB ASSY

S

INDB ASSY

E

MAIN

ASSY

U

ACIN ASSY

H

USBB ASSY

I

TFTB ASSYMSDSW ASSY

L

CDCB ASSY

Q

KSWB ASSY

B

SPCN

ASSY

P

CNCT ASSY

R

JOGB ASSY

T

POWER SUPPLY

ASSY

G

SDCB ASSY

SLOTIN MECHA

G11 ASSY

• Bottom view

• Bottom view

• Bottom view

O

EUPB

ASSY

N

SLDB

ASSY

C

INSW

ASSY

J

PNLB

ASSY

K

JFLB

ASSY

1..MAIN ASSY DWX3312

NSP 1..TFTA ASSY DWM2458

2..TFTB ASSY DWX3331

2..CDCB ASSY DWX3332

2..SDCB ASSY DWX3333

NSP 1..SRVA ASSY DWM2459

2..SRVB ASSY DWX3334

2..INSW ASSY DWX3335

2..SPCN ASSY DWX3336

2..INDB ASSY DWX3337

NSP 1..PNLA ASSY DWM2460

2..PNLB ASSY DWX3338

2..KSWB ASSY DWX3339

2..SDSW ASSY DWX3340

2..EUPB ASSY DWX3341

2..SLDB ASSY DWX3342

NSP 2..CNCT ASSY DWX3343

NSP 1..JFLA ASSY DWM2461

2..SLMB ASSY DWX3345

2..ACIN ASSY DWX3346

2..JFLB ASSY DWX3348

2..JOGB ASSY DWX3349

2..JACB ASSY DWX3350

1..USBB ASSY DWX3395

> 1..POWER SUPPLY ASSY DWR1463

NSP SLOTIN MECHA G11 ASSY DXA2163

TM ASSY 09SD -S DXX2697

Mark No. Description Part No. Mark No. Description Part No.

LIST OF ASSEMBLIES

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

3.3 PCB LOCATIONS

6 7 8

A

B

C

5

CDJ-2000NXS

6 7 8

D

E

F

9

1

!

!

!

!!

V+3R3

SD_DET

SD_CMD

SD_DATA3

SD_DATA1

SD_DATA2

SD_DATA0

SD_CLK

SD_WP

GNDD

GNDD

A_S2

V+5A

7/x6

A_C

A_D

A_S1

GNDD

A_A

VR65

VR78

A_B

VRCOM

RF

LD78

F+

T-

LD65

T+

PD

F-

GNDSD

INSW

GNDSD

GNDD

STBY_CTRL_IN

NC

GNDD

V+12_EUP

CPU_EUP_CONT

EUP_CONT

USB_STOP

USB_LED

PNL_CNVSS

PNL_SCK

PNL_BUSY

PNL_TXD

PNL_RXD

PNL_RST

V+12

V+12

V+5

V+3R3

V+3R3

V+1R2

TFT_DATA0

TFT_DATA1

TFT_TFS1

TFT_TSCLK1

TFT_RSCLK1

TFT_RST

GNDD

TFT_PF1

GNDD

GNDD

TFT_DATA3

TFT_RFS1

GNDD

USB_DP_A

USB_DN_A

GNDD

GNDD

VBUS_B

USB_DN_B

USB_DP_B

GNDD

GNDD

HSSW_PWREN

HSSW_PWRFL

GNDD

VREF1

V+12_SWITCHED_IN

V+12_SWITCHED_IN

V+12_STBY10mA

RKP1751-A

1

2

B6B-XH-A

1

2

345

6

AKM1283-A

1

2

3

4

5

6

7

8

9

10

11

12

KM200NA3

V+5_USB_D

1

V+5_USB_D

2

GNDD

3

KM200NA5L

1

2

3

4

5

DKN1288-A

ST1+

1

ST1-

2

ST2+

3

ST2-

4

1

2

3

4

52151-0510

1

2

3

4

5

52147-0510

1

2

3

4

5

AKM1291-A

LO-

1

LO+

2

GNDSD

3

LPS1

4

LPS2

5

VKN 1414-A

1

2

3

4

5

6

7

8

9

10

NM

V+3.3V

1

BF_EMU#

2

GNDD

3

BF_TMS

4

BF_TCK

5

BF_TRST#

6

BF_TDI

7

BF_TDO

8

GNDD

9

GNDD

10

CKS5561-B

NC

1

CATHODE2

2

CATHODE1

3

NC

4

NC

5

ANODE2

6

ANODE1

7

NC

8

NC

9

NC

10

VKN 1414-A

1

2

3

4

5

6

7

8

9

10

AKM1298-A

V+12_EUP

1

V+12

2

V+12

3

XEUP_CONT

4

GNDD

5

GNDD

6

V+5

7

GNDD

8

V+3R3

9

V+3R3

10

GNDD

11

GNDD

12

DKN1205-A

1

2

3

4

5

6

7

8

9

10

11

12

DKN1312-A

NC

1

W

2

V

3

U

4

HB

5

HW-

6

HW+

7

HV-

8

HV+

9

HU-

10

HU+

11

V+5

12

VKN 1417-A

123456789

101112

13

VKN 1273-A

123456789

101112

13

DKN1313-A

V+5

1

HU+

2

HU-

3

HV+

4

HV-

5

HW+

6

HW-

7

HB

8

U

9

V

10

W

11

GNDSD

12

INSW

13

DKN1313-A

1

2

3

4

5

6

7

8

9

10

11

12

13

VKN 1273-A

123456789

101112

13

RKN1054-A

V-12

1

GNDD

2

V+12

3

GNDD

4

SPDIF

5

CONT2

6

V+5_DAC

7

CONT1

8

MUTE

9

A_LOUT

10

GNDA

11

A_ROUT

12

GNDA

13

DKN1445-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

241

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

NM

V+3R3_CPU

1

V+3R3_CPU

2

GNDD

3

GNDD

4

NC

5

CPU_TRST

6

CPU_TDI

7

CPU_TMS

8

CPU_TCK

9

CPU_TDO

10

CPU_MPMD

11

CPU_AUDSYNC

12

CPU_AUDATA3

13

CPU_AUDATA1

14

CPU_AUDATA0

15

CPU_EMU_BRK

16

CPU_RST

17

GNDD

18

DSP_TMS

19

DSP_TDI

20

DSP_TDO

21

DSP_TCK

22

DSP_EMU0

23

DSP_TRST

24

VKN 1433-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

VKN 1433-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

CKS5660-A

GND

1

GND

2

GND

3

NC

4

VCC

5

VCC

6

VCC

7

VCC

8

NC

9

TEST3

10

TEST2

11

TEST1

12

VSYNC

13

HSYNC

14

GND

15

SHUT

16

GND

17

R5

18

R4

19

R3

20

R2

21

R1

22

R0

23

GND

24

G5

25

G4

26

G3

27

G2

28

G1

29

G0

30

GND

31

B5

32

B4

33

B3

34

B2

35

B1

36

B0

37

GND

38

DCLK

39

GND

40

VKN 2050-A

ATA_RST

1

GNDD

2

ATA_D7

3

ATA_D8

4

ATA_D6

5

ATA_D9

6

ATA_D5

7

ATA_D10

8

ATA_D4

9

ATA_D11

10

ATA_D3

11

ATA_D12

12

ATA_D2

13

ATA_D13

14

ATA_D1

15

ATA_D14

16

ATA_D0

17

ATA_D15

18

GNDD

19

GNDD

20

ATA_DREQ

21

GNDD

22

ATA_WR

23

GNDD

24

ATA_DIOR

25

GNDD

26

ATA_RDY

27

GNDD

28

ATA_DACK

29

GNDD

30

ATA_INT

31

GNDD

32

ATA_A1

33

GNDD

34

ATA_A0

35

ATA_A2

36

GNDD

37

ATA_CA0

38

ATA_CS1

39

GNDD

40

FH12-40S-0.5SH(55)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

VKN 181 8-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

1

SD

2

SD

3

GN

4

VD

5

SD

6

GN

7

SD

8

SD

10

SD

9

SD

B2P3-VH

1

2

VKN 1940-A

1

2

VKN 1940-A

1

2

AKM1289-A

1

2

3

DKN1599-A

1

2

345

6

DKB1113-A

2

1

RKN1004-A

231

DKB1102-A

432

1

DKB1106-A

1

2

3

4

RT1

RT2

DKN1646-A

1

2

3

4

RT1

RT2

DSA1037-A

S9101

12

ZWNN1007G28-9-07A

L=70mm

WHITE SINGLE WIRE

LO+

ZWNN1007G28-8 -07A

L=70mm

GRAY SINGLE WIRE

LOADING MOTOR

LO-

DKP3822-A

L=55mm

LIVE

NEUTRAL

PURPLE

BLUE

LR

AUDIO OUT

CONTROL OUT

DIGITAL OUT

FOR DEBUG (BF)

09SD PICK UP ASSY

STEPPING

MOTOR SK

DC MOTOR

TM ASSY 09SD-S (DXX2697)

SPINDLE MOTOR G11

USB CONNECTOR

(A TYPE)

ETHERNET

CONNECTOR

TFT-LCD MODULE (CWX3970-)

LO+

LO-

DKN1650-A

FOR DEBUG (DSP&CPU)

DDD1481

L=258mm

DDD1480

L=78mm

FFC(SAME FACE)

D20PDY0

DDD1484

L=78mm

DDD1479

L=68mm

DKP3845

L=50mm

CONNECTOR ASSY

DKP3844

L=90mm

PF05PP-C25

L=250mm

DDD1460

L=98mm

DKP3769

L=180mm

DDD1452

L=78mm

*RIGHT ANGLE

*RIGHT ANGLE

FRAME

GND

CHASSIS

GND

DE007VE0

L=70mm

DDD1541

L=58mm

FFC(SAME FACE)

GOLD PLATING

FFC(SAME FACE)

FFC(SAME FACE)

CONNECTOR ASSY

CONNECTOR ASSY

EARTH LEAD UNIT

CONNECTOR ASSY

FFC(SAME FACE)

FFC(SAME FACE)

Vertical

Horizontal

Vertical

USB CONNECTOR

(B TYPE)

*VERTICAL

Vertical

Horizontal

Vertical

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Vertical

Vertical

Vertical

Horizontal

Horizontal

Vertical

FFC(REVERSE)

DDD1606

L=67mm

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

Horizontal

JP9101

Vertical

DKP3935

DKP3934

DKP3939

L=167mm

CRIMP

CONNECTOR

CONNECTOR ASSY

FFC

SAME FACE

DESTINATION

/SYXJ8

/FLXJ

/AXJ5

/KXJ5

/UXJCB

DKP3935DKP3935-

DKP3935DKP3935DKP3934-

AC INLET AC POWER CORD

XDG3061ADG7076-(Taiwan)

ADG7105ADG7115DDG1108-

XDG3061-

CN 9101

CN 2

CN 705

CN 6302

CN 9001

CN 7004

CN8601

CN8651

CN 7003

CN 5102

CN 4001

CN 4014

CN 702

CN 7301

CN8055

CN 6102

CN 703

CN 9401

CN 7009CN 6101

CN 6301

CN 501

CN 7001

CN 1

CN 502

CN 704 CN4002

CN 4013

CN 701

CN 7005

CN 1

CN 6001

CN 6103

CN 7303

CN 7302

JA9403

JA9401

JA9402

JA6301

JA6302

JA702

EARTH

NEUTRAL(Blue) 98+/-3mm

LIVE(Brown) 112+/-3mm

EARTH

(Green&Yellow Stripe)

63+/-3mm

CHASSIS

NEUTRAL

LIVE

NEUTRAL

LIVE

LIVE

NEUTRAL

NEUTRAL

LIVE(Brown) 114+/-3mm

NEUTRAL(Blue) 100+/-3mm

LIVE

NEUTRAL

LIVE

AC POWER CORD AC INLET

Backlight Module

F

JACB ASSY

(DWX3350)

O

EUPB ASSY

(DWX3341)

TFTB ASSY (DWX33

I

I I

1/2, 2/2

E

E E

1/5- 5/5

MAIN ASSY (DWX3312)

SRVB ASSY (DWX3334)

A

A A

1/2, 2/2

SLOTIN MECHA G11 ASSY

D

C

SLMB ASSY

(DWX3345)

INSW ASSY

(DWX3335)

B

SPCN ASSY

(DWX3336)

T

POWER SUPPLY

ASSY (DWR1463)

!

U

ACIN ASSY

(DWX3346)

H

USBB ASSY

(DWX3395)

M

SDSW ASSY

(DWX3340)

G

SD

(D

2 3 4

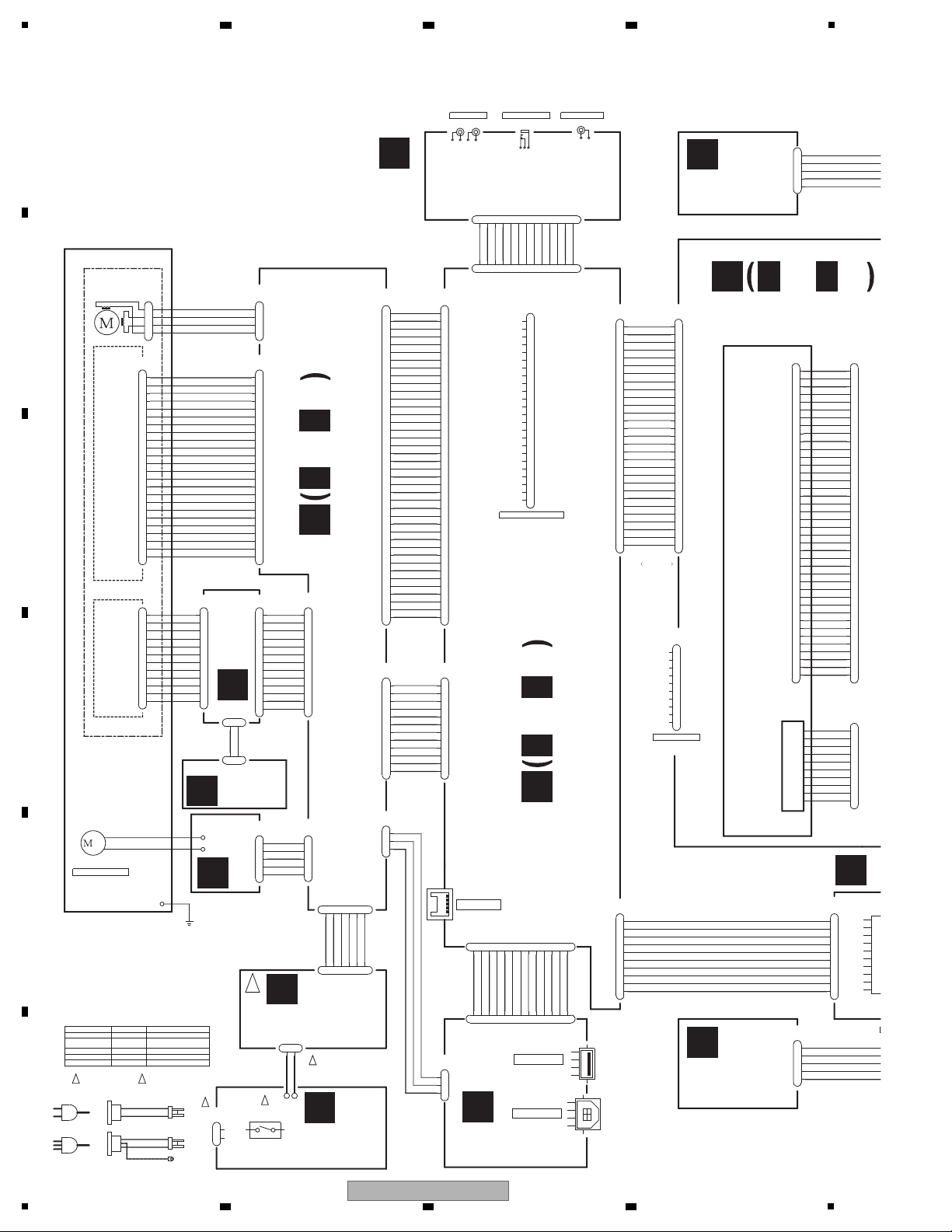

4. BLOCK DIAGRAM

4.1 OVERALL WIRING DIAGRAM

A

B

C

D

E

F

10

1

2 3 4

CDJ-2000NXS

5

V+3R3

JOG1

JOG2

GNDD

V+12

GNDD

V+3R3

JOGILM_R

JOGILM_W

J_LAT

J_DSO

J_BK

J_SCLK

JOG2

JOG1

JOG_SW

KEY3_B

TRSTL

GNDD

ADCT

ADIN

V+3R3E

GNDS

V+5

USB_LED

USB_LED

USB_STOP

USB_STOP

SD_SW

SD_SW

EUPL

EJECTL

KEY4_B

V+5

V+5

GNDD

GNDD

PRPRL

S_SDL

INFOL

S_LINKL

BRWSL

S_USBL

MENUL

KEY2

V+3R3

USB_STOP

V+5

KEY1

GNDD

USB_LED

GNDD

V+12

V+12

V+12EUP

GNDD

GNDD

V+5

PNL_BUSY

ENC_2

PNL_SCK

ENC_1

PNL_TXD

PNL_RST

PNL_RXD

PNL_CNVSS

CPU_EUP_CONT

ENC_SW

EUP_CON

ENCL

JOG2

JOG1

V+3R3

J_DSO

J_BK

J_LAT

JOG_SW

J_SCLK

GNDD

JOGILM_R

JOGILM_W

V+12

V+3R3

GNDD

CDC_INT

CDC_DSO

CDC_DSI

CDC_SCLK

CDC_CS

S_DISKL

R_BOXL

QUANTIZEL

KEY0

NEEDLEL

V+12

GNDD

GNDD

D_INDIL

V+12

V+12

GND_LED

NEEDLEL

GNDD

V+5

D_INDL

D_INDL

D_INDL

PLAY

PLAY

PLAY

CUE

CUE

CUE

PLAYL

PLAYL

PLAYL

CUEL

CUEL

CUEL

GNDD

GNDD

GNDD

V+12

V+12

V+12

CKS1072-A

JOG_SW

1

NC

2

GNDD

3

VKN 1409-A

1

2

3

4

RKN1045-A

1

2

3

4

52151-0410

1

2

3

4

VKN 1264-A

1

2

3

4

VKN 1409-A

1

2

3

4

52151-0510

1

2

3

4

5

1

2

3

4

5

VKN 1267-A

1234567

VKN 1411-A

1234567

52147-0710

1234567

VKN 1414-A

1

2

3

4

5

6

7

8

9

10

CKS5561-B

NC

1

CATHODE2

2

CATHODE1

3

NC

4

NC

5

ANODE2

6

ANODE1

7

NC

8

NC

9

NC

10

52147-1210

1

2345678

9

101112

VKN 1276-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VKN 1420-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

VKN 1426-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

VKN 1282-A

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

CKS5660-A

GND

1

GND

2

GND

3

NC

4

VCC

5

VCC

6

VCC

7

VCC

8

NC

9

TEST3

10

TEST2

11

TEST1

12

VSYNC

13

HSYNC

14

GND

15

SHUT

16

GND

17

R5

18

R4

19

R3

20

R2

21

R1

22

R0

23

GND

24

G5

25

G4

26

G3

27

G2

28

G1

29

G0

30

GND

31

B5

32

B4

33

B3

34

B2

35

B1

36

B0

37

GND

38

DCLK

39

GND

40

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

CKS5956-A

1

SD_DATA3

2

SD_CMD

3

GND

4

VDD

5

SD_CL

6

GND2

7

SD_DATA0

8

SD_DATA1

10

SD_DET

9

SD_DATA2

12

SD_W

11

TER

51048-0400

123

4

51048-0500

12345

51048-0500

1

2

3

4

5

51048-0700

1234567

51048-0800

1

2

3

4

5

6

7

8

51048-0800

1

2

3

4

5

6

7

8

51048-1200

123456789

101112

SD CARD CONNECTOR

SHEET SW

(DSX1078-)

DDD1609

L=60mm

D20PDY0505E

L=50mm

D20PDY0510E

L=100mm

D20PDD0810E

L=100mm

PARALLEL JUMPER

DDD1611

L=210mm

D20PYY0405E

L=50mm

JUMPER

L=22.5mm

D20PDY1210E

L=100mm

DDD1483

L=68mm

DDD1485

L=108mm

DDD1541

L=58mm

FFC(SAME FACE)

GOLD PLATING

PARALLEL JUMPER

PARALLEL JUMPER

PARALLEL JUMPER

PARALLEL JUMPER

FFC(SAME FACE)

FFC(SAME FACE)

FFC(SAME FACE)

PARALLEL JUMPER

Horizontal

Horizontal

Vertical

Horizontal

Vertical

Horizontal

Vertical

Vertical

DDD1607

L=115mm

FFC(SAME FACE)

JP8002

JP8001

JP8003

JP8004

Horizontal

Horizontal

DDD1608

L=75mm

FFC(SAME FACE)

JP9203

JP9202

Horizontal

Vertical

Horizontal

Vertical

CN 9203

CN 4015

CN 6201

CN 9301

CN8501

CN 5002

CN8601

CN8003

CN 5001

CN8502

CN 5102

CN 4014

CN8801

CN8002CN 4007

CN 4012

CN8001

CN 4013

CN 5101

JH9202

JH8001

JH8002

JH8004

JH8701

JH8003

JH9201

Backlight Module

I

1/2, 2/2

G

SDCB ASSY

(DWX3333)

J

PNLB ASSY

(DWX3338)

P

CNCT ASSY (DWX3343)

Q

KSWB ASSY

(DWX3339)

K

JFLB ASSY

(DWX3348)

S

INDB ASSY

(DWX3337)

R

JOGB ASSY

(DWX3349)

L

CDCB ASSY

(DWX3332)

N

SLDB ASSY

(DWX3342)

-

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

: The power supply is shown with the marked box.

6 7 8

A

5

CDJ-2000NXS

6 7 8

B

C

D

E

F

11

1

CPU : MAIN->TFT

CLK: 6MHz

CPU : MAIN->PANEL

CPU : TFT->MAIN

CLK: 1MHz

ATAPI

Serial (SSI0 only) (SSI1 : no use)

PICKUP ASSY

Control

S/PDIF

LRCLK

DATA

BCLK

JA702

LAN

Connector

IC301

DSP

CLK:16.9344MHz

Core CLK:389.4912MHz

IC10

MAIN CPU

CLK:26.965MHz

Core CLK:323.58MHz

TFT-LCD MODULE

Host I/F

16

16

MAIN System Bus

K3

T3

K4

D8

16

JA6301

USB-A Jack

CN5101

SD Card

Connector

CN704

IC7006

SODC

CLK:16.934MHz

IC7004

128kB

FLASH

8

112109111

IC7002

FEP

15 19 29

175

176

IC7001

6ch

Servo Driver

119 120

62

46 5 4

RFENV

FE

TE

TEDRV

FEDRV

LOAD

CN701

CN7005

OEIC

CN7001

MM

CN 9001

CN 7003

4

5

4

5

LOADING

MOTOR

MM

CN6101

CN6103

CN7009

CN6001

1

1

1

13

CN7004

STEPPING

MOTOR SK

TRAVERSE MECHANISM

SLOTIN MECHA ASSY

CN6102

CN2

CN7302

POWER

CN4002

LPS2

IC4001

TFT CPU

CLK:24.576MHz

Core CLK:393.216MHz

16

TFT S

y

stem Bus

16

16

CN4013

Se

6

INSW

IC1

Authent

IC

SPINDLE

MOTOR

JA6302

USB-B Jack

IC302

32MB

SDRAM

Bus CLK

129.8304MHz

IC3

4MB

FLASH

16

IC1

32MB

SDRAM

Bus CLK

107.86MHz

16 16

IC12

32MB

SDRAM

Bus CLK

107.86MHz

IC13

32MB

SDRAM

Bus CLK

107.86MHz

16

16

CS1

CS2 CS0

CS3

CN6301

CN703

CN5102

CN702

U-HPI

32M

Bus C

2M

I2C

IC701

USB-B IC

CLK:48MHz

IC704

Ether PHY

CLK:25MHz

MII , MDC

CD

LPS1

Universa

Host-Port

Interface

IC4018

Backlight

Power

IC2

32MB

SDRAM

Bus CLK

107.86MHz

T

POWER SUPPLY

ASSY

A

SRVB ASSY

E

MAIN ASSY

G

SDCB ASSY

H

USBB ASSY

D

SLMB

ASSY

C

INSW

ASSY

B

SPCN

ASSY

RGB 5bit

Sync.

SDHC I/F (CLK: 27 MHz)

USB Full/High Speed I/F

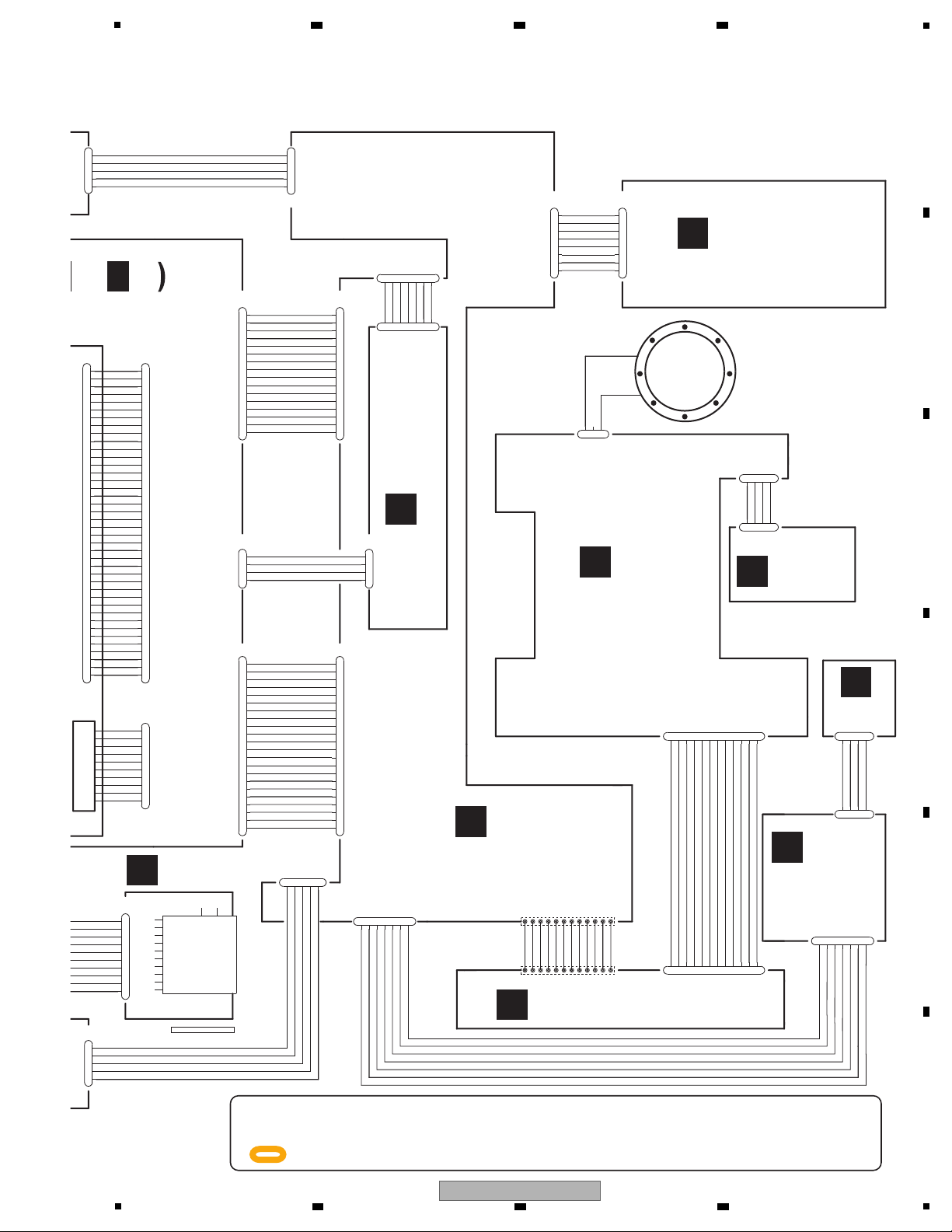

4.2 SIGNAL BLOCK DIAGRAM

A

B

C

2 3 4

D

E

F

12

1

2 3 4

CDJ-2000NXS

5

OPAMP

OPAMP

FET AMP

Q504

Control

JA9402

Analog out

JA9403

Digital out

JA9401

Control out

Lch

Rch

S/PDIF (Digital Audio) (fs=44.1kHz const.)

LRCLK

DATA

BCLK

CN501

IC505

DAC

CLK:16.9344MHz

IC301

DSP

MODULE

K3

T3

K4 1

2

3

D8

IC503

IC502

IC504

12

10

5

1

7

Analog Audio

CN9401

4

2

9

16

TFT S

y

stem Bus

16

16

LED

KEY

Serial (Syncronus)

LED KEY

LED

KEY

TCH

JOG2

JOG1

LED

KEY

IC5001

CDC IC

JH8003

JH8701

JH8002

CN8651

PC9301

Encorder

JH9202

CN9301

4

3 3

4

Serial (Syncronus)

VR8001

TOUCH / BRAKE

VR8002

RELEASE / START

VR8701

TEMPO SLIDER

CN4007

CN8002

S4028

Rotary Search

IC14

Authentication

IC

U-HPI

Vinyl

IC4005

32MB SDRAM

Bus CLK : 98.304MHz

IC4004

2MB FLASH

I2C

CN8001

CN4012

CN5002

CN4015

LED

LED

KEY

JH8001

CN8601

JH8004

CN8502

LED

CN8501

CN6201

CN8003

CN5001

Serial

LED

CN9203

SHEET SW

JUMPER

CN8801

JH9201

511

12

51112

LED

KEY

IC8003

PANEL CPU

(Within FLASH)

CLK:15.975MHz

Q503

Q505

Q506

FET AMP

Q518

Q517

5

2

3

6

1

6

1

7

7

2

2

6

R

L

Digital Audio

Control

16

17

12

13

JOG FL

Universal

Host-Port

Interface

t

J

PNLB ASSY

I

TFTB ASSY

K

JFLB ASSY

S

INDB ASSY

R

JOGB ASSY

Q

KSWB ASSY

P

CNCT ASSY

O

EUPB ASSY

L

CDCB ASSY

M

SDSW ASSY

N SLDB ASSY

F

JACB ASSY

6 7 8

A

B

C

D

5

CDJ-2000NXS

6 7 8

E

F

13

1

Spindle

Traverse Mecha ASSY

Power Cable AC Inlet ASSY

Motor

EARTH

LIVE/NEAUTRAL

PickUp

Others

IC7002

132

7

9 10

AC

IC7301

12V -> 5.14V

IC7302

12V -> 3.34V

6

4

5

6

4

5

V+12_EUP

CN7302

V+12

V+12S

P

1210

11

6

4 3

CN705

CN7301

V+12_EUP

V+3R3

1

7

3

13

7

11

CN501CN9401

IC705

12V -> 1.265V

13

15

17

18

1

14

16

CN702

CN704 CN4002

IC7010

12V -> 5V

IC9401

12V -> -12V

V+1R2

V+12_EUP

IC7005

5V -> 1.5V

IC7003

5V -> 3.3V

3.3V -> 1.65V

5V -> 2.2V

V+5A

V+3

A

V+3D

VREF1

VHALF

V+5

V+1R5D

P7003

P7302

P7001

P

P9401

P

P9402

P

V+12S

V+5_DAC

V+12

CN1

CN2

S9101

AC CN9101

Chassis

IC7305

12V -> 5.10V

P

V+3R3

V+12_EUP

V+5

V+12

V+3R3

V+12

CN7303

1

2

CN7001

V+3A

CN7009

1

13

CN6101

12

V+5

V+5

V+5_DAC

IC9403

12V -> 5V

V-12

V-12

V+5

V+3R3

V+3R3

V+12

V+12

10

1

CN6302

1

2

CN5101

SD Card

Connector

V+3R3

V+5_USB_D

V+5_USB_D

V+5_USB_D

V+5_USB_D

V+5_USB_D

V+5_USB

CN5102

CN6102

V+5A

V+5

V+3R3

V+12

V+1R2

IC6301

Current

Detect

JA6301

USB-A

Connector

V+5

V+1R2

17

15

13

12

29

16

14

3

4

For

/UXJCB

Power Cable AC Inlet ASSY

LIVE/NEAUTRAL

For

/SYXJ8, /AXJ5

/FLXJ , KXJ5

U

ACIN ASSY

A

SRVB ASSY

B

SPCN ASSY

T

POWER

SUPPLY

ASSY

E

MAIN ASSY

F

JACB ASSY

G

SDCB ASSY

I

TFT

H

USBB ASSY

2 3 4

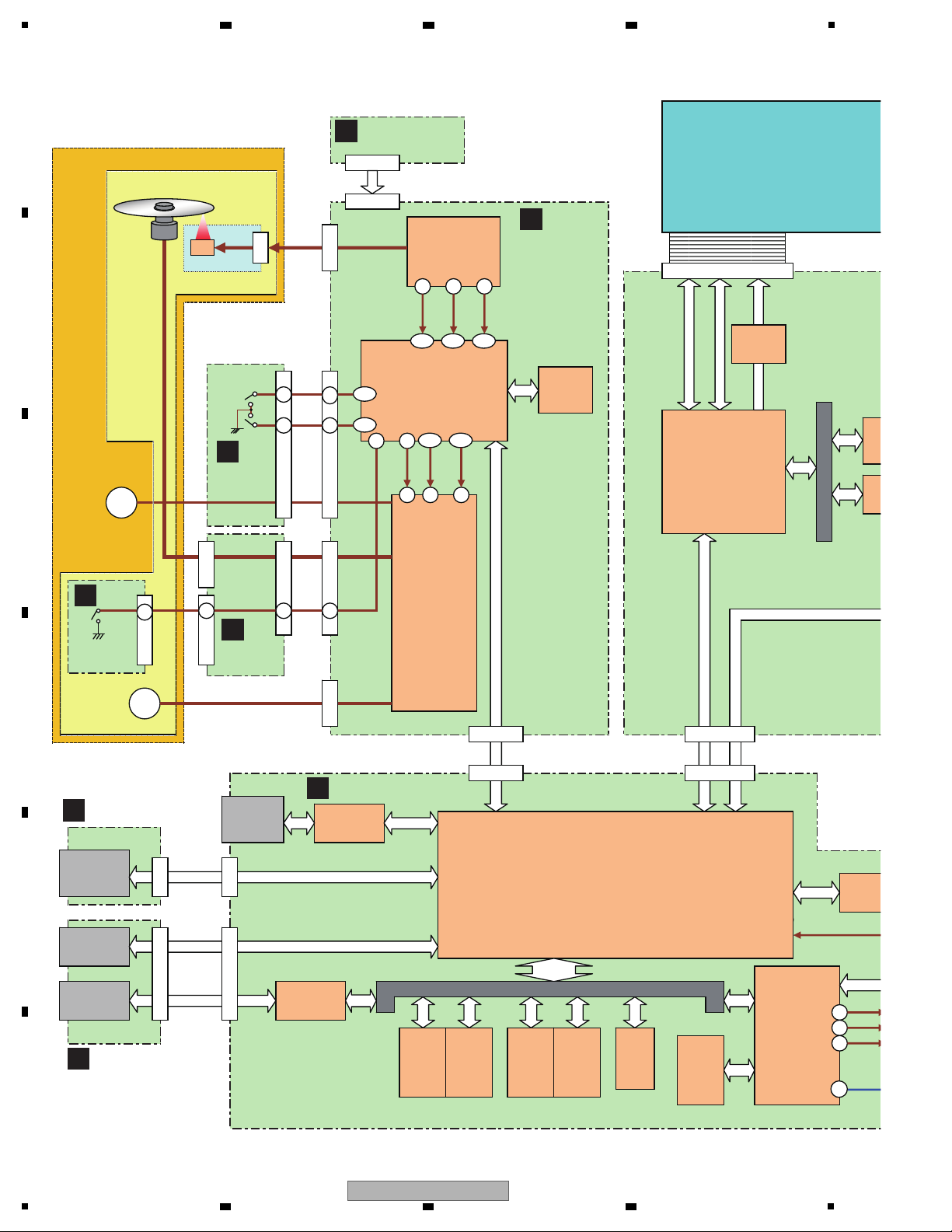

4.3 POWER SUPPLY BLOCK DIAGRAM

A

B

C

D

E

F

14

1

2 3 4

CDJ-2000NXS

CN4002

CN4007

CN8003

8

1

2

2

JH9202

CN9301

IC8002

12V -> 3.3V

IC9203

12V -> 27V

IC9204

12V -> 3.3V

IC9202

12V -> AC2.7V

V+5

7

8

6

5

V+3R3FL

V+27

VFDP2R7

V+3R4_LCD

7

6

IC4018

12V -> 15.6V

IC4019

12V -> 3.4V

CN4014

CN4013

3

2

JA6301

USB-A

Connector

V+1R2

ANODE1,2

CATHODE1

CATHODE2

V+5

V+12

CN4012

CN8001

CN8002

V+12_EUP

V+3R3

V+5

V+12

V+12

V+5

8

1

7

JH8003

17

15

13

12

29

16

14

17

19

21

20

3

1

17

19

21

20

1

3

CN4015

3

4

CN5002

2

1

V+5

CN5001

7

V+12

V+3R3

JH8701

V+3R3EV+5

V+3R3E

V+5

CN8502

V+12

V+12

V+3R3

V+12

V+3R3

P

P9201

V+12

4

CN8501

1

CN6201

JH8004

7

7

1

10

1

10

JH9201CN8801

1

CN8601

5

CN8651

JH8001

1

JH8002

5

DCDC

Converter

Regulator

Notes

DCAC

Converter

P

Protector

1 5

Connector&Pin No.

V+12

V+12

V+3R3

V+12

Jumper

Backlight

O

EUPB

ASSY

I

TFTB ASSY

J

PNLB ASSY

R

JOGB ASSY

P

CNCT ASSY

L

CDCB

ASSY

M

SDSW

ASSY

N

SLDB ASSY

Q

KSWB

ASSY

S

INDB ASSY

K

JFLB ASSY

TFT LCD

5

6 7 8

A

B

5

C

D

E

CDJ-2000NXS

6 7 8

F

15

1

Power on Power on

Pin Y22 of Main CPU

(IC101) cancels reset

at H.

Program transfer from

FLASH to SDRAM

Canceling DSP reset

from pin B18 of Main

CPU. Pin G2 of DSP

(IC501) becomes "H".

Canceling ETH_PHY reset

from pin A18 of Main

CPU. Pin 42 of ETH_PHY

(IC1304) becomes "H".

Canceling USB_B reset

from pin A17 of Main

CPU. Pin 46 of USB_B

(IC1101) becomes "H".

Canceling ATAPI reset

from pin C10 of Main

CPU. Pin 173 of SODC

(IC7006) becomes "H".

Program transfer to

DSP

Register setting of ETH_PHY

Register setting of USB_B

Initialization of the

built-in peripherals

Initialization of the SDRAM

Initialization of the SDRAM

Initialization of the DSP

Initialization of the DAC

Initialization of the peripheral device

Initialization of the Main CPU

Pin 13 of TFT CPU

(IC4001) cancels reset

at H.

Program transfer from

FLASH to SDRAM

Pin 12 of PNL CPU

(IC8003) cancels reset

at H.

Pin 45 of SODC

(IC7006) cancels reset

at H.

Initialization of the SDRAM

Initialization of the TFT CPU

Display an opening screen

Initialization of the

peripheral device

Power on

Initialization of the JOG_FL

Initialization of the PNL CPU

Initialization of the CDC

Power on

Initialization of the

loading mechanism

Initialization of the ATAPI

LED initial lighting

Device select screen

Canceling reset

Apple

authentication

chip

Communication between Main CPU and SRVO

Initialization of the SODC

The insertion of the

disk is possible.

The insertion of the

disk is possible.

Built-in peripherals

• USB_A

• ETH_MAC

• SD

• ATAPI

• SERIAL

• SSI

Communication between Main CPU and PNL CPU

Communication between Main CPU and TFT CPU

MAIN CPU TFT CPU PANEL CPU SRVO

2 3 4

5. DIAGNOSIS

5.1 POWER ON SEQUENCE

A

B

C

D

E

F

16

1

2 3 4

CDJ-2000NXS

5

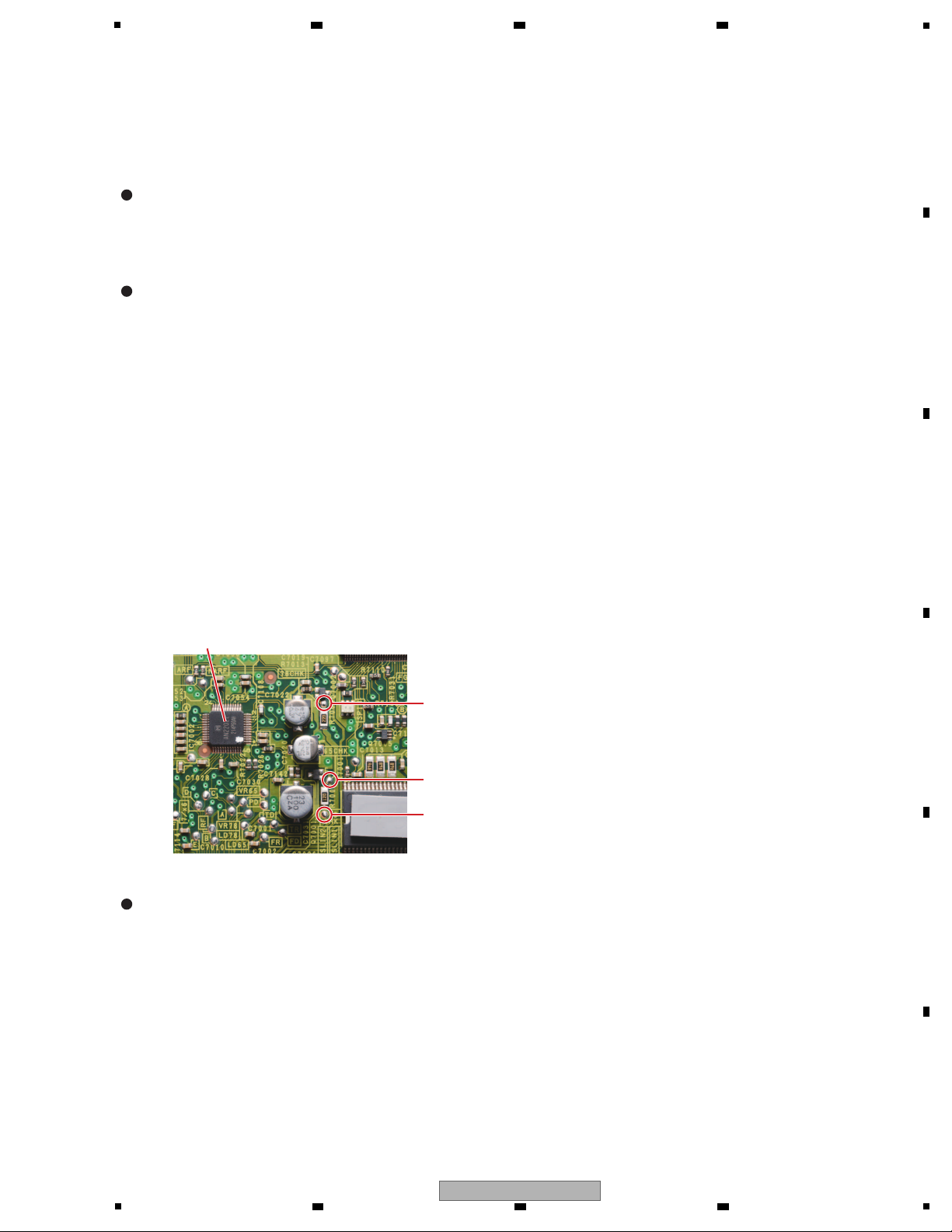

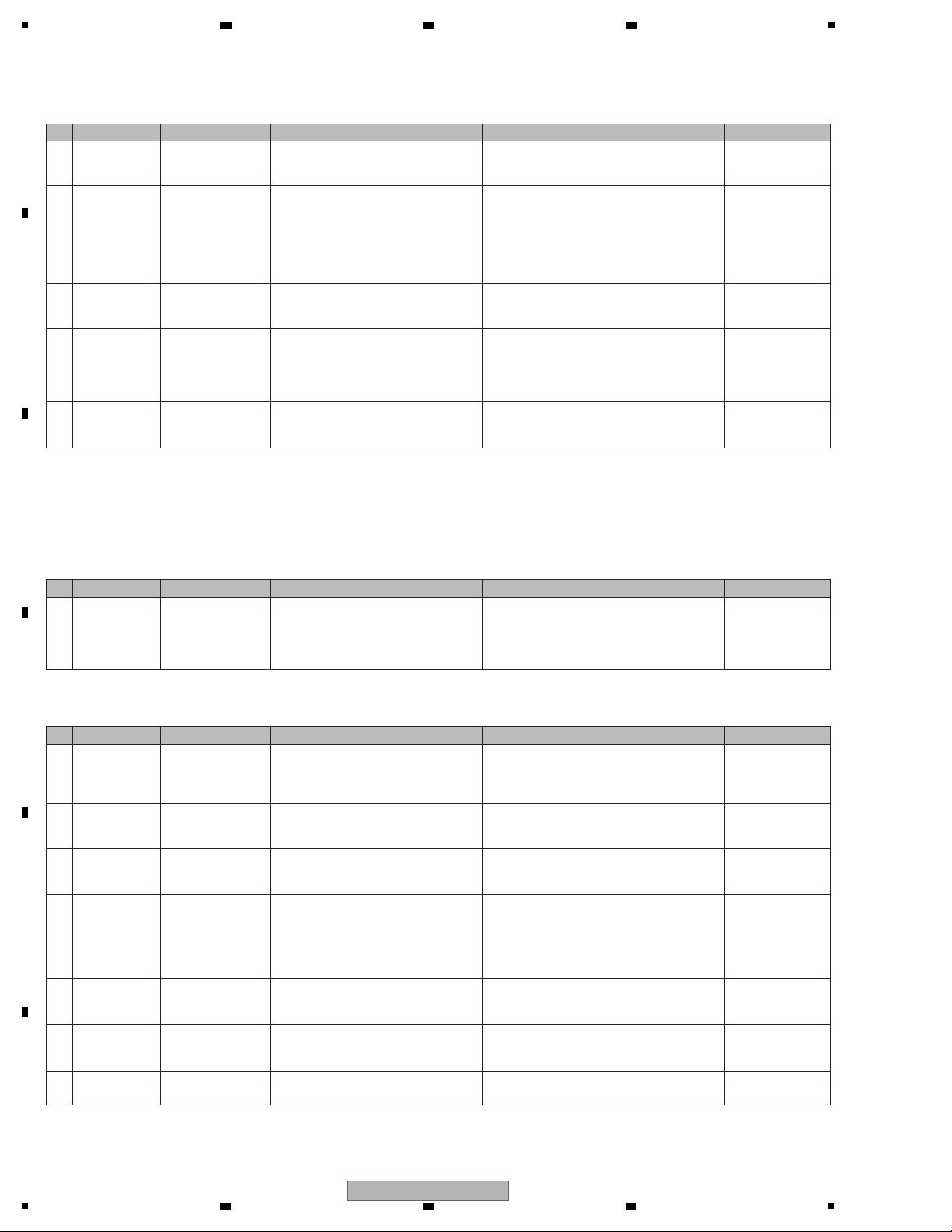

Measure the voltage at the probe pad on the SRVB Assy (see the photo below), using a tester.

∗ To check lighting of each LD, follow the procedure indicated in "[7] Checking the servo operations of the drive unit" in

"6.1 SERVICE MODE."

∗ Note that the LD may be degraded if the probes of a tester are applied to or pulled away from the probe pad with the LD ON.

Check method

Directly measure the resistance value of the actuator, using a tester.

* Before measuring, short-circuit the LD short-circuit pads.

Note that the LD may be degraded if connection/disconnection of CN7001 is performed with the LD short-circuit pads open.

• Focus side

Disconnect* the FFC connected to the CN7001 then measure the resistance value between FFC pins 23 and 24.

• Tracking side

Disconnect* the FFC connected to the CN7001 then measure the resistance value between FFC pins 21 and 22.

Check method

1. With the LD OFF, apply the probes of a tester to the reference probe pad (LDCHK) and 78CHK (CD side) or 65CHK

(DVD side).

2. With the probes kept applied to the above-mentioned pads, turn the LD ON to measure the voltage between them.

3. After measurement, turn the LD OFF (ALL OFF) then pull the probes away.

4. Calculate the current value by dividing the measured voltage value by the resistance value mentioned below.

(For CDs: R7008 = 22 ohms, For DVDs: R7007 = 12 ohms)

Procedures

If the calculated current value exceeds the maximum value, the LD has been degraded

Failure judgment:

A value out of the range of the specifications is judged as failure.

Failure judgment:

78CHK

65CHK

IC7002

Fig.1 SRVB Assy

LDCHK

LD power after passing through the objective lens [mW]

SPEC: DVD 0.180 ± 0.03

CD 0.210 ± 0.03

Check method: Measure the LD power, using an optical power meter.

Failure judgment: A value out of the range of the specifications is judged as failure.

Actuator resistance value [ohms]

Specifications on the focus side: 3.7 ±0.55

Specifications on the tracking side: 4.3 ±0.65

LD current [mA]

SPEC: DVD TYP50 MAX70

CD TYP65 MAX75

This unit has self-diagnostic functions for the drives.

For drive-related malfunctions, first perform the self-diagnostics to check the drives in Service mode. If the results indicate any

problem with the drives, check the following items:

6 7 8

5.2 FAILURE JUDGEMENT OF THE PICKUP ASSY

A

B

C

D

E

5

6 7 8

CDJ-2000NXS

F

17

1

1 ————— ————— Check for the location of a defect in

Service mode.

See the section describing locations of defects in

this manual.

6.1 SERVICE MODE

In this section, causes of failure, diagnostics points, and corrective measures can be searched for according to symptoms.

Before disassembling this unit, it is recommended to infer a failure point by performing a status check and referring to the error

code.

For the relationship of each power-supply and signal system, see “4. BLOCK DIAGRAM,” and “10. SCHEMATIC DIAGRAM.”

If software of the product is updated before performing diagnostics, check that software updating has been performed properly

before proceeding to diagnostics.

If software updating has not been performed properly, update the software, following the instructions in [9] Firmware update of

“6.1 SERVICE MODE.”

Contents

[0] Prior Confirmation

[1] Failure in Startup

[2] Display (JOG FL/LED)

[3] Operations (SW/Volume/JOG/CDC/Rotary Encoder)

[4] USB (Type A/Type B), SD Card

[5] LAN

[6] ATAPI DRIVE

[7] AUDIO OUT

[8] CONTROL

[9] DRIVE Assy

[10] EUP Mode

[11] SERVICE MODE

[12] Error Codes

[0] Prior Confirmation

[0-1] Checking in Service Mode

1 Disconnection,

breakage, or

loose connection

of cables

Cables Check that all the cables are securely

connected.

Check that there is no breakage in the

cables.

Securely connect the cables. If a cable is broken,

replace it.

4.1 OVERALL

WIRING DIAGRAM

10. SCHEMATIC

DIAGRAM

[0-3] Checking Cables

1 ————— Alarm port on

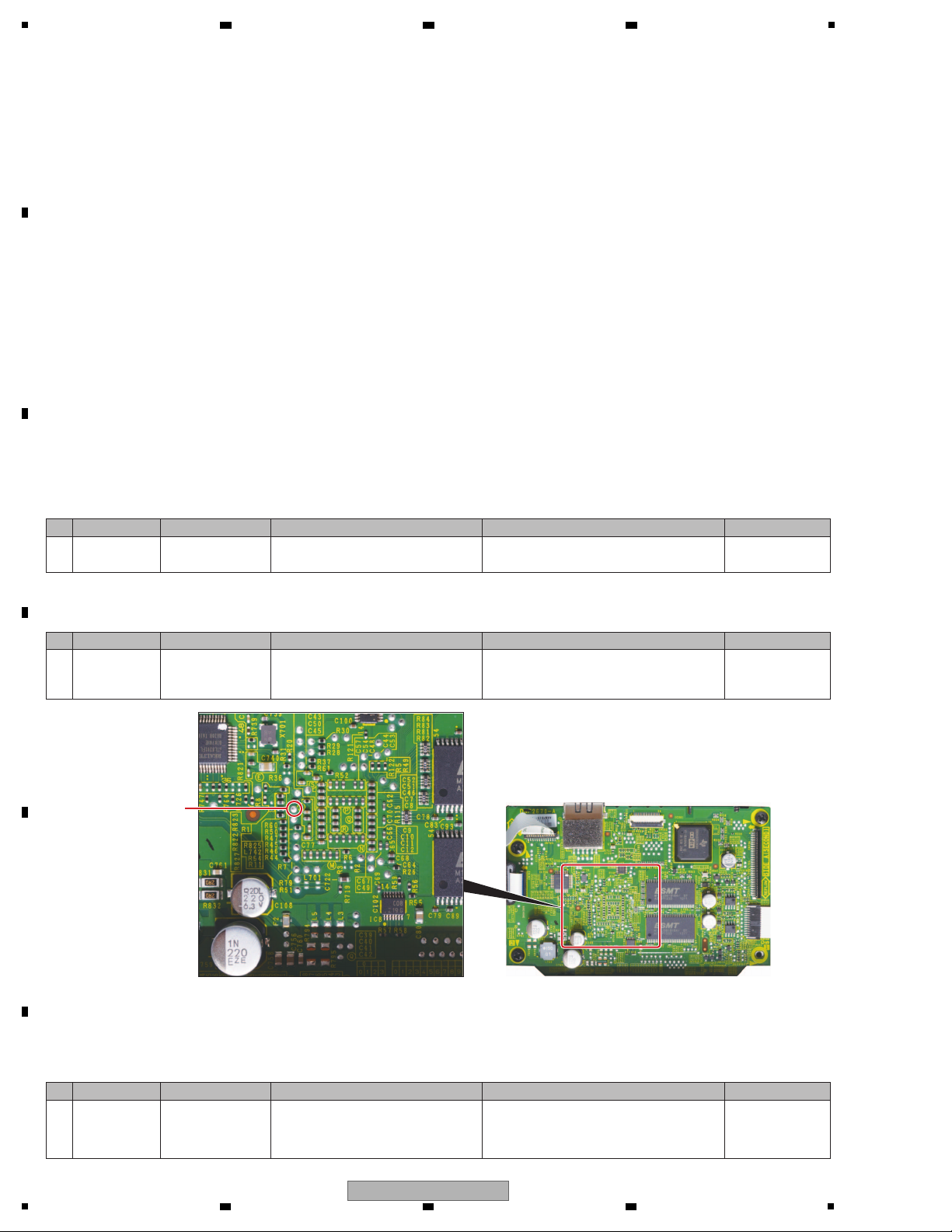

the MAIN Assy

(Fig. 1)

Check the output waveforms from the

alarm port.

If an output waveform is judged to be improper,

see the section describing locations of defects in

this manual.

6.1 SERVICE MODE

_[8] Outputs of the

Alarm Port

[0-2] Checking the Alarm Port

If “[0-1] Checking in Service Mode” is performed, this check is not required.

Fig. 1

MAIN Assy

Alarm port

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

2 3 4

5.3 TROUBLESHOOTING

A

B

C

D

E

F

18

1

2 3 4

CDJ-2000NXS

5

[1] Failure in Startup

[1-1] No power

[2] Display (JOG FL/LED)

[2-1] The JOG FL does not light.

The JOG FL and the LEDs are controlled by the PANEL CPU (IC8005).

[1-2] Indications on the LCD

Check the indications on the LCD.

Nothing is displayed on the LCD. (Black screen)

Indications on the LCD are in white screen.

1 The SW power

does not function

properly.

SRVB Assy Check V+12_EUP. If V+12_EUP (CN7301 pin_1) is not output, the

SW power is defective. Replace it.

—————

2 The SW power

does not function

properly.

PNLB Assy Check V+3R3_PNL.

The regulator IC (IC8002) may be loosely connected

with its peripheral devices or a part may be defective.

Correct loose connection. If the symptom persists,

replace the defective part.

—————

4 Various power

supply ICs do

not function

properly.

SRVB Assy,

MAIN Assy

Check each power-supply IC.

The regulator IC and its peripheral devices for each

power supply may be loosely connected or a part

may be defective. Correct loose connection.

If the symptom persists, replace the defective part.

—————

3 The EUP control

unit does not

function properly.

SRVB Assy Check the EUP_CONT signal. If the signal is L, check the output of the SW

power. If V+12 (CN7301 pin_2) is not output,

the SW power is defective. Replace it.

If the signal is H, see [10] EUP Mode.

—————

1

Power supply for

the backlight is

not input properly.

TFTB Assy

Check the connection on the V+12T line and

check the mounting status of the peripheral

parts of the backlight power circuit.

The V+12T line may be loosely connected or the

backlight power circuit may be defective.

Correct loose connection.

If the symptom persists, replace the defective part.

10.11, 10.12

TFTB ASSY

1

Power is not

supplied properly.

JFLB Assy Check the power-supply voltages (V+3R3,

VFDP2R7_F1, VFDP2R7_F2, and V+27)

of the FL.

Each power-supply may be loosely connected or

may be defective. Correct loose connection. If the

symptom persists, replace the defective part.

—————

3

Defective JOG FL

————— If the symptom persists after the above

corrections,

Replace the JOG FL. —————

2 Defective

control signal

JFLB Assy Check that the FL control line is properly

connected in the JFLB ASSY.

• J_SCLK

• J_BK

• J_LAT

• J_DSO

Check the connection and correct loose

connection.

As the JOG FL is controlled by the PANEL CPU,

if no signal is output, check the PANEL CPU.

—————

Startup stops with the “Pioneer” logo displayed.

1

Communication

between the MAIN

CPU and TFT CPU

could not be

established.

TFTB Assy,

MAIN Assy

Check the serial communication cable

connection between the MAIN CPU and

TFT CPU.

Diagnose the TFT CPU and its peripherals,

referring to [12-5] E-7023: GUI CPU ERROR.

—————

1

The TFT CPU

does not function

properly.

TFTB Assy Check the power supply and signals

around the TFT CPU.

• V+3R3T_BF, V+1R2_BF

• RESET_TFT

• BUSCLK (Approx. 98 MHz)

Diagnose the TFT CPU and its peripherals,

referring to [12-5] E-7023: GUI CPU ERROR.

—————

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

6 7 8

A

B

C

D

E

5

6 7 8

CDJ-2000NXS

F

19

1

[2-2] An LED does not light.

1 Defective SW PNLB Assy Check if there is loose connection on the

signal line from the PANEL CPU (IC8003)

up to the SW.

If there is no loose connection and if the signal

does not become L when the SW is pressed,

that SW is defective. Replace it.

—————

2 Defective PANEL

CPU

PNLB Assy If the symptom persists after the above

corrections.

Check the connection of the PANEL CPU

(IC8003). If the connection is OK, the port may

be damaged. Replace it.

—————

2 Defective PANEL

CPU

PNLB Assy If the symptom persists after the above

corrections.

Check the connection of the PANEL CPU

(IC8003). If the connection is OK, the port may

be damaged. Replace it.

—————

2 Defective PANEL

CPU

PNLB Assy If the symptom persists after the above

corrections.

Check the connection of the PANEL CPU

(IC8003). If the connection is OK, the port may

be damaged. Replace it.

—————

1 Defective SW PNLB Assy Check if there is loose connection on the

signal line from the PANEL CPU (IC8003)

up to the SW.

If other SWs connected to the same port on the

PA NEL CPU (IC8003) function properly and if

connection is properly made, replace the SW.

—————

2 Defective

MAIN CPU

MAIN Assy If the symptom persists after the above

corrections.

The MAIN CPU (IC10) is defective.

Replace the MAIN Assy.

—————

1 Defective SW SDSW Assy,

MAIN Assy

Check if there is loose connection on the

signal line from the MAIN CPU (IC10)

up to the SW.

If there is no loose connection and if the signal

does not become L when the SW is pressed,

that SW is defective. Replace it.

—————

1 Defective

Tempo slider

SLDB Assy,

PNLB Assy

Check the waveform of signals on the

signal line (ADCT, ADIN).

If the voltage on the signal line (ADIN) fluctuates

within the range of 0–3.3 V, with 1.65 V at the

center, go to Step 2. If it does not, the Tempo

slider (VR8701) is defective. Replace it.

—————

2 Defective PANEL

CPU

PNLB Assy If the symptom persists after the above

corrections.

Check the connection of the PANEL CPU

(IC8003). If the connection is OK, the port may

be damaged. Replace it.

—————

1 Defective VOL PNLB Assy Check the connections of and waveforms

of signals on the signal lines (TCH/BRK)

and (RELS/ST).

If the voltage on the signal line (TCH/BRK and

RELS/ST) fluctuates within the range of 0–3.3 V,

go to Step 3. If it does not, the TOUCH/BRAKE

(VR8001) and RELEASE/START (VR8002) are

loosely connected or defective. Connect them

properly or replace them.

—————

1 Defective LEDs LED in question

Check that soldering at the LED in question

is properly made. If it is OK, check that the

forward voltage (2.2 - 2.7 V) is present at

both ends of the LED.

Correct any defective soldering.

If the forward voltage is present, then the LED

itself is defective. Replace it.

—————

2 Defective drive

circuit

Transistor in

question

Check that the control signal for the LED in

question is output from the PANEL CPU (IC8003).

If the LED does not light even if the control signal is

output properly, then the transistor is defective. Replace it.

—————

3 Defective PANEL

CPU

PNLB Assy If the symptom persists after the above

corrections.

Check the connection between the PANEL CPU

(IC8003) and the LED in question. If the connection

is OK, the port may be damaged. Replace it.

—————

[3] Operations (Keys/variable controls/JOG)

[3-1] No key functions.

[3-2] Variable controls not controllable

As operations of all keys, variable controls, and JOG dial can be checked in Service mode, it is recommended to check operations of

those controls in Service mode before proceeding to the subsequent checks. (For details, refer to 6. SERVICE MODE.)

The PLAY, CUE, AUTO BEAT LOOP, BEAT SELECT, REV, LOOP IN, LOOP OUT, or RELOOP key does not function (direct input).

Other keys (except for the USB STOP key) do not function. (Because of A/D input, multiple SWs are connected to the same port on the PANEL CPU.

The USB STOP key does not function. (The signal from the USB STOP key is input to the MAIN CPU.)

Tempo slider not controllable

TOUCH/BRAKE and RELEASE/START not controllable

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

No. Cause Diagnostics Point Item to be Checked Corrective Action Reference

A

2 3 4

B

C

D

E

F

20

1

2 3 4

CDJ-2000NXS

5

[3-3] The NEEDLE SEARCH does not work.

1

Loose connections

in the communication

line

CDCB Assy Check the connections of the peripheral

circuits of the CDC (IC5001).

The communication line may be loosely

connected. Correct it if it is.

—————

2 Defective CDC PNLB Assy

Check that the signal from Pin 5 of CN8003

changes when the NEEDLE SEARCH pad