Page 1

INTEGRATED AMPLIFIER

A-30-K

A-30-S

A-20-K

A-20-S

A-20

ORDER NO.

RRV4297

A-30-K

A-10-K

A-10-S

THIS MANUAL IS APPLICABLE TO THE FOLLOWING MODEL(S) AND TYPE(S).

Model Type Power Requirement Remarks

A-30-K/-S PWSYXE8 AC 220 V to 230 V

A-20-K/-S PWSYXE8 AC 220 V to 230 V

A-20 CUXE AC 120 V

A-10-K/-S SYXE8 AC 220 V to 230 V

Page 2

1

1. SAFETY PRECAUTIONS

The following check should be performed for the

continued protection of the customer and service

technician.

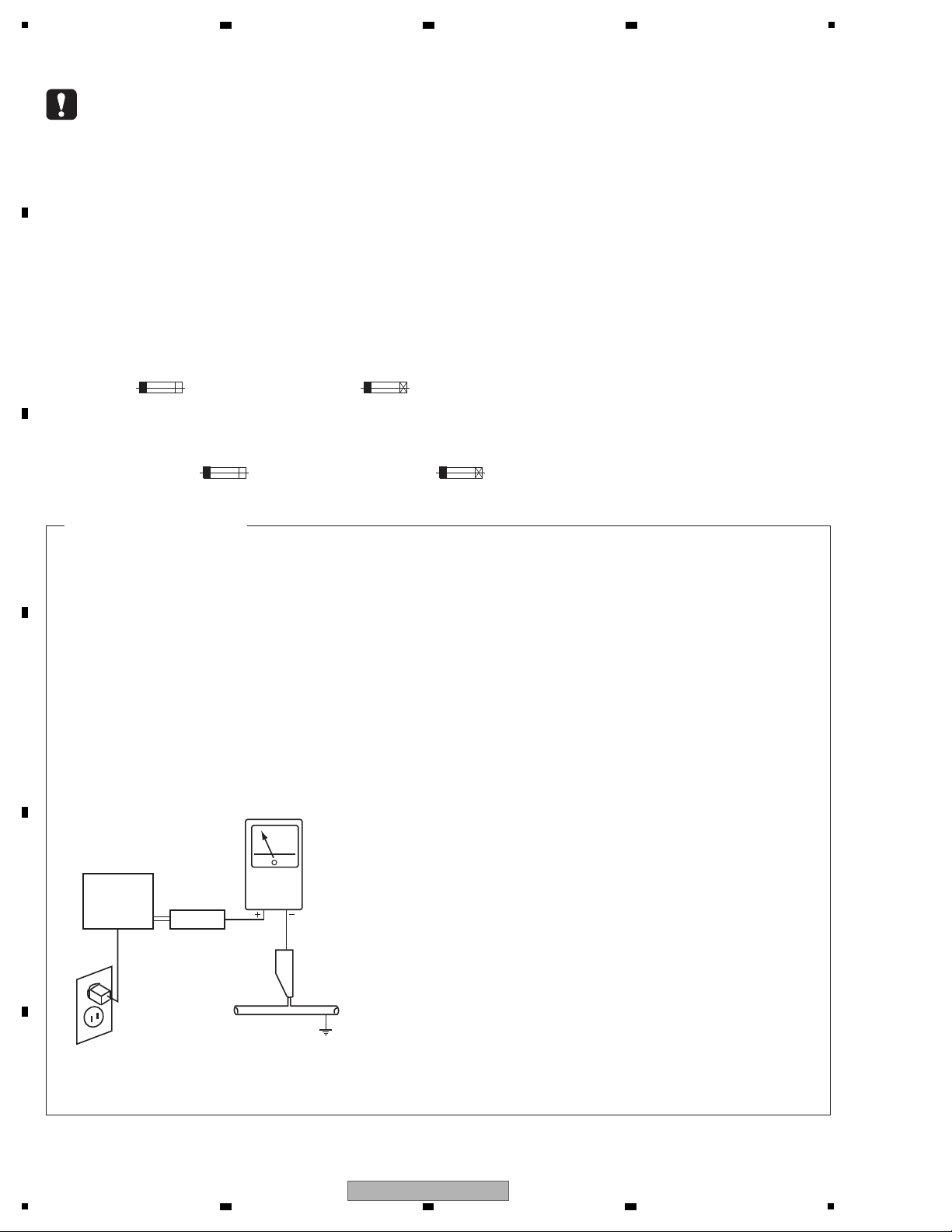

LEAKAGE CURRENT CHECK

Measure leakage current to a known earth ground

(water pipe, conduit, etc.) by connecting a leakage

current tester such as Simpson Model 229-2 or

equivalent between the earth ground and all exposed

metal parts of the appliance (input/output terminals,

screwheads, metal overlays, control shaft, etc.). Plug

the AC line cord of the appliance directly into a 120V

AC 60 Hz outlet and turn the AC power switch on. Any

current measured must not exceed 0.5 mA.

ANY MEASUREMENTS NOT WITHIN THE LIMITS

OUTLINED ABOVE ARE INDICATIVE OF A POTENTIAL

SHOCK HAZARD AND MUST BE CORRECTED BEFORE

RETURNING THE APPLIANCE TO THE CUSTOMER.

2. PRODUCT SAFETY NOTICE

Many electrical and mechanical parts in the appliance

have special safety related characteristics. These are

often not evident from visual inspection nor the protection

afforded by them necessarily can be obtained by using

replacement components rated for voltage, wattage, etc.

Replacement parts which have these special safety

characteristics are identified in this Service Manual.

Electrical components having such features are

identified by marking with a > on the schematics and on

the parts list in this Ser

vice Manua

l.

The use of a substitute replacement component which

does not have the same safety characteristics as the

PIONEER recommended replacement one, shown in the

parts list in this Service Manual, may create shock, fire,

or other hazards.

Product Safety is continuously under review and new

instructions are issued from time to time. For the latest

information, always consult the current PIONEER Service

Manual. A subscription to, or additional copies of,

PIONEER Service Manual may be obtained at a nominal

charge from PIONEER.

Leakage

current

tester

Reading should

not be above

0.5 mA

Device

under

test

Test all

exposed metal

surfaces

Also test with

plug reversed

(Using AC adapter

plug as required)

Earth

ground

AC Leakage T est

(FOR USA MODEL ONLY)

WARNING

This product contains lead in solder and certain electrical parts contain chemicals which are known to the state of California to

cause cancer, birth defects or other reproductive harm.

56 noitisoporP - 6.94252 noitceS edoC ytefaS & htlaeH

NOTICE

(FOR CANADIAN MODEL ONLY)

Fuse symbols (fast operating fuse) and/or (slow operating fuse) on PCB indicate that replacement parts must

be of identical designation.

REMARQUE

(POUR MODÈLE CANADIEN SEULEMENT)

Les symboles de fusible (fusible de type rapide) et/ou (fusible de type lent) sur CCI indiquent que les pièces

de remplacement doivent avoir la même désignation.

This service manual is intended for qualified service technicians ; it is not meant for the casual do-it-

yourselfer. Qualified technicians have the necessary test equipment and tools, and have been trained

to properly and safely repair complex products such as those covered by this manual.

Improperly performed repairs can adversely affect the safety and reliability of the product and may

void the warranty. If you are not qualified to perform the repair of this product properly and safely, you

should not risk trying to do so and refer the repair to a qualified service technician.

2 3 4

SAFETY INFORMATION

A

B

C

D

E

F

2

1

2 3 4

A-30-K

Page 3

5

6 7 8

CONTENTS

SAFETY INFORMATION..........................................................................................................................................................2

1. SERVICE PRECAUTIONS................................................................................... ..... ...... ..... .................................................4

1.1 NOTES ON SOLDERING...............................................................................................................................................4

2. SPECIFICATIONS........................................................ ...... ...... ..... ........................................................................................5

2.1 ACCESSORIES..............................................................................................................................................................5

2.2 SPECIFICATIONS..........................................................................................................................................................5

3. BASIC ITEMS FOR SERVICE ..............................................................................................................................................6

3.1 CHECK POINTS AFTER SERVICING ...........................................................................................................................6

3.2 PCB LOCATIONS...........................................................................................................................................................7

3.3 JIGS LIST.......................................................................................................................................................................7

4. BLOCK DIAGRAM .................................................. ..... ...... ...... ..... ........................................................................................8

4.1 OVERALL CONNECTION DIAGRAM.............................................................................................................................8

4.2 BLOCK DIAGRAM........................................................................................................................................................10

5. DIAGNOSIS ................................................ ...... ...... ..... ............................................. ..........................................................12

5.1 TROUBLESHOOTING..................................................................................................................................................12

5.2 PROTECTION CIRCUIT DESCRIPTION .....................................................................................................................15

5.3 IC INFORMATION........................................................................................................................................................17

6. SERVICE MODE.......................................................... ...... ...... ..... ...... ..... ...........................................................................21

7. DISASSEMBLY ........................................... ...... ...... ..... ...... ...... ...........................................................................................22

8. EACH SETTING AND ADJUSTMENT..................................................... ...... ...... ..... ...... ....................................................29

8.1 HOW TO CHECK THE FIRMWARE VERSION............................................................................................................29

8.2 FARMWARE UPDATING..............................................................................................................................................29

8.3 HOW TO ADJUST THE IDLE CURRENT ....................................................................................................................31

9. EXPLODED VIEWS AND PARTS LIST...............................................................................................................................32

9.1 PACKING SECTION.....................................................................................................................................................32

9.2 EXTERIOR SECTION (A-30/A-20)...............................................................................................................................34

9.3 EXTERIOR SECTION (A-10).......................................................................................................................................38

10. SCHEMATIC DIAGRAM....................................................................................................................................................40

10.1 MAIN ASSY................................................................................................................................................................40

10.2 FRONT ASSY and SECOND POWER SW ASSY (A-30/A-20)..................................................................................42

10.3 MASTER VOLUME ASSY, TONE ASSY and HEADPHONE ASSY ...........................................................................44

11. PCB CONNECTION DIAGRAM........................................................................................................................................46

11.1 MAIN ASSY................................................................................................................................................................46

11.2 FRONT ASSY.............................................................................................................................................................50

11.3 MASTER VOLUME ASSY..........................................................................................................................................52

11.4 TONE ASSY...............................................................................................................................................................53

11.5 HEADPHONE ASSY and SECOND POWER SW ASSY (A-30/A-20)........................................................................54

12. PCB PARTS LIST..............................................................................................................................................................55

A

B

C

D

E

F

A-30-K

5

6 7 8

3

Page 4

1

• For environmental protection, lead-free solder is used on the printed circuit boards mounted in this unit.

Be sure to use lead-free solder and a soldering iron that can meet specifications for use with lead-free solders for repairs

accompanied by reworking of soldering.

• Compared with conventional eutectic solders, lead-free solders have higher melting points, by approximately 40 ºC.

Therefore, for lead-free soldering, the tip temperature of a soldering iron must be set to around 373 ºC in general, although

the temperature depends on the heat capacity of the PC board on which reworking is required and the weight of the tip of

the soldering iron.

Do NOT use a soldering iron whose tip temperature cannot be controlled.

Compared with eutectic solders, lead-free solders have higher bond strengths but slower wetting times and higher melting

temperatures (hard to melt/easy to harden).

The following lead-free solders are available as service parts:

• Parts numbers of lead-free solder:

GYP1006 1.0 in dia.

GYP1007 0.6 in dia.

GYP1008 0.3 in dia.

2 3 4

1. SERVICE PRECAUTIONS

1.1 NOTES ON SOLDERING

A

B

C

D

E

F

4

1

2 3 4

A-30-K

Page 5

5

Remote control unit (A-30-K/-S : CARTA30)

(A-20-K/-S,A-20 : CARTA20)

AAA/R03 dry cell battery x 2 (A-30-K/-S, A-20-K/-S, A-20)

AC Power cord (A-30-K/-S : CJA2B054Z)

(A-20-K/-S, A-10-K/-S : CJA2B020Z)

Warranty card (A-30-K/-S, A-20-K/-S, A-10-K/-S : CQE1A541Z)

Operating instructions (A-30-K/-S, A-20-K/-S, A-10-K/-S : CQX1A1640Y)

(A-20 : CQX1A1644Z)

Amplifier section

Power output specification is for when power supply is 230 V.

(A-30-K/-S, A-20-K/-S, A-10-K/-S)

Power output specification is for when power supply is 120 V.

(A-20)

•Continuous power output (both

channels driven at 20 Hz to 20 kHz)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .70 W + 70 W

A-20, A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . .50 W + 50 W

(THD 0.1 %, 4 Ω)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .40 W+40 W

A-20, A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . .30 W+30 W

(THD 0.05 %, 8 Ω)

Audio section

•Input (Sensitivity/Impedance)

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 200 mV/50 kΩ

POWER AMP DIRECT (A-30 only). . . . . . . . . . . . .1 V/10 kΩ

PHONO (MM). . . . . . . . . . . . . . . . . . . . . . . . . 2.8 mV/50 kΩ

•Output (Level/Impedance)

RECORDER OUT . . . . . . . . . . . . . . . . . . . . . 200 mV/2.2 kΩ

PHONES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 250 mV/32 Ω

•Frequency response

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5 Hz to 100 kHz dB*

PHONO (MM). . . . . . . . . . . . . . . .20 Hz to 20 kHz ±0.5 dB*

* Measured with DIRECT button switched on.

•Tone control

(When VOLUME is set to

-

30 dB)

Bass. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 10 dB (100 Hz)

Treble. . . . . . . . . . . . . . . . . . . . . . . . . . . . .± 10 dB (10 kHz)

•Signal-to-Noise Ratio (IHF SHORTED,

A-NETWORK)

SACD/CD, NETWORK, TUNER, AUX, RECORDER

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 105 dB*

PHONO (MM, 2.8 mV input) . . . . . . . . . . . . . . . . . . .77 dB*

* Measured with DIRECT button switched on.

•Speaker load impedance

A, B . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Ω to 16 Ω

A+B. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8 Ω to 32 Ω

Bi-wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4 Ω to 16 Ω

Miscellaneous

Power requirements

. . . . . . . . . . . . . . . . . . . . . . . . . . AC 220 V to 230 V, 50 Hz

(A-30-K/-S, A-20-K/-S, A-10-K/-S)

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . AC 120 V, 60 Hz

(A-20)

Power consumption

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175 W

A-20/A-10. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135 W

In standby . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.3 W

Dimensions

. . . . . . . . . . . . . . .435 mm (W) x 128 mm (H) x 360 mm (D)

Weight (without package)

A-30 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.9 kg

A-20 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7.2 kg

A-10 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6.7 kg

Note

•Specifications and the design are subject to

possible modifications without notice, due to

improvements.

•Corporation and product names mentioned herein

are trademarks or registered trademarks of the

respective corporations.

2. SPECIFICATIONS

2.1 ACCESSORIES

6 7 8

A

2.2 SPECIFICATIONS

B

C

D

5

A-30-K

6 7 8

E

F

5

Page 6

1

Item to be checked regarding audio

Distortion

Noise

Volume too low

Volume too high

Volume fluctuating

Sound interrupted

To keep the product quality after servicing, confirm recommended check points shown below.

See the table below for the items to be checked regarding audio.

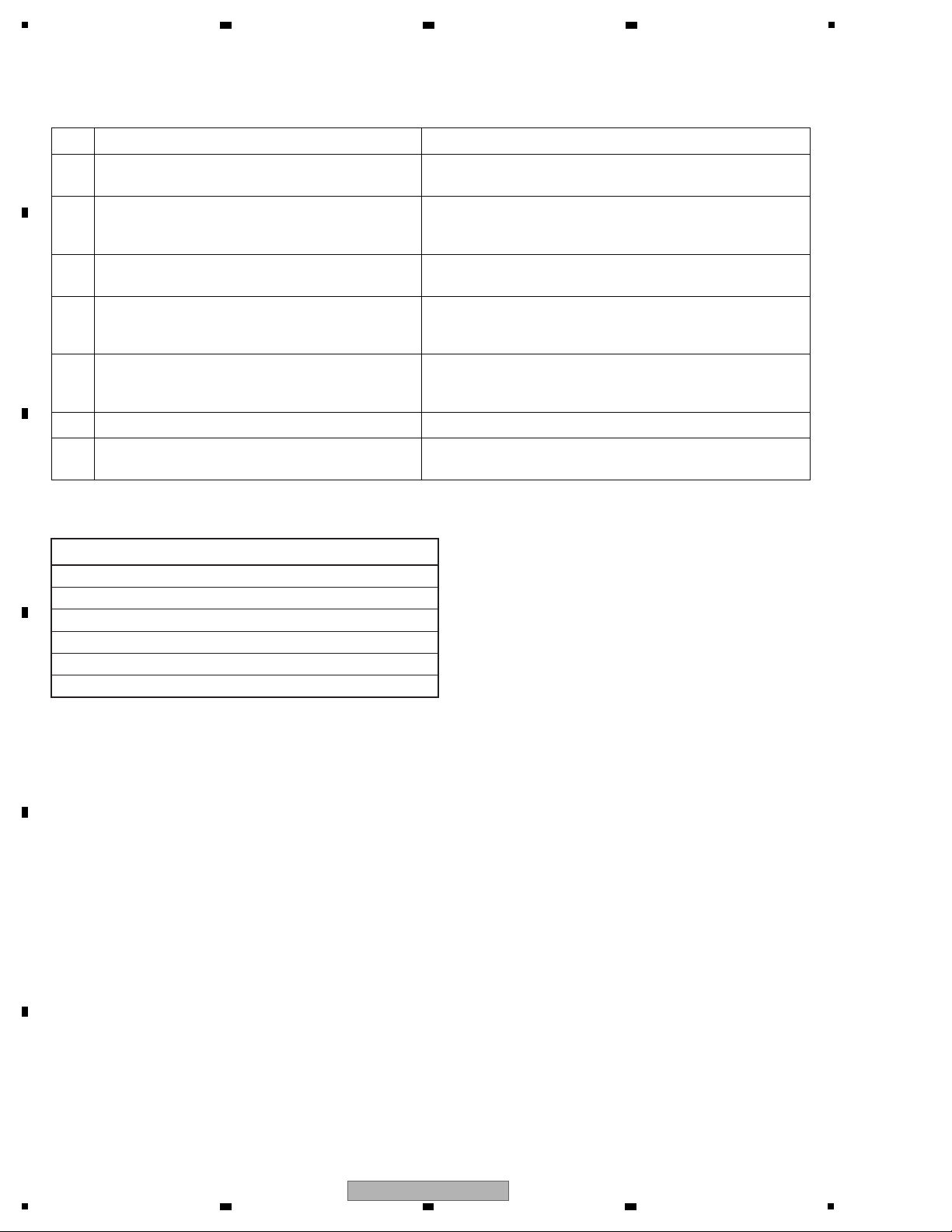

No. Procedures Check points

1

Check the symptom pointed out by a customer The pointed content should not reoccur

Sound and operation should not be defective

2

Check each input and main VOL (check the

operation of selector)

The sound is output by selecting an analog-connected input

with a selector and the sound volume should change by

rotating main VOL knob

3

Check the tone control, balance, and function The sound quality or right and left balances should change

by rotating each V OL knob

4

Check LOUDNESS and DIRECT functions The sound quality should change by setting LOUDNESS

function to ON. LOUDNESS function should be disabled by

setting DIRECT function to ON.

5

Check POWER AMP DIRECT terminal (only A-30)

(connected from pre-out terminal of AV AMP to

POWER AMP DIRECT terminal)

The sound volume should change by adjusting the sound

volume of connected AV AMP. The sound volum e shoul d not

be changed by the main VOL on the main unit.

6 Check SPEAKER A/B and headphone terminal There should not be defect in sound such as noise

7

Check the external package Check scratch or taint is not generated after accept ing the

repair

2 3 4

3. BASIC ITEMS FOR SERVICE

3.1 CHECK POINTS AFTER SERVICING

A

B

C

D

E

F

6

1

2 3 4

A-30-K

Page 7

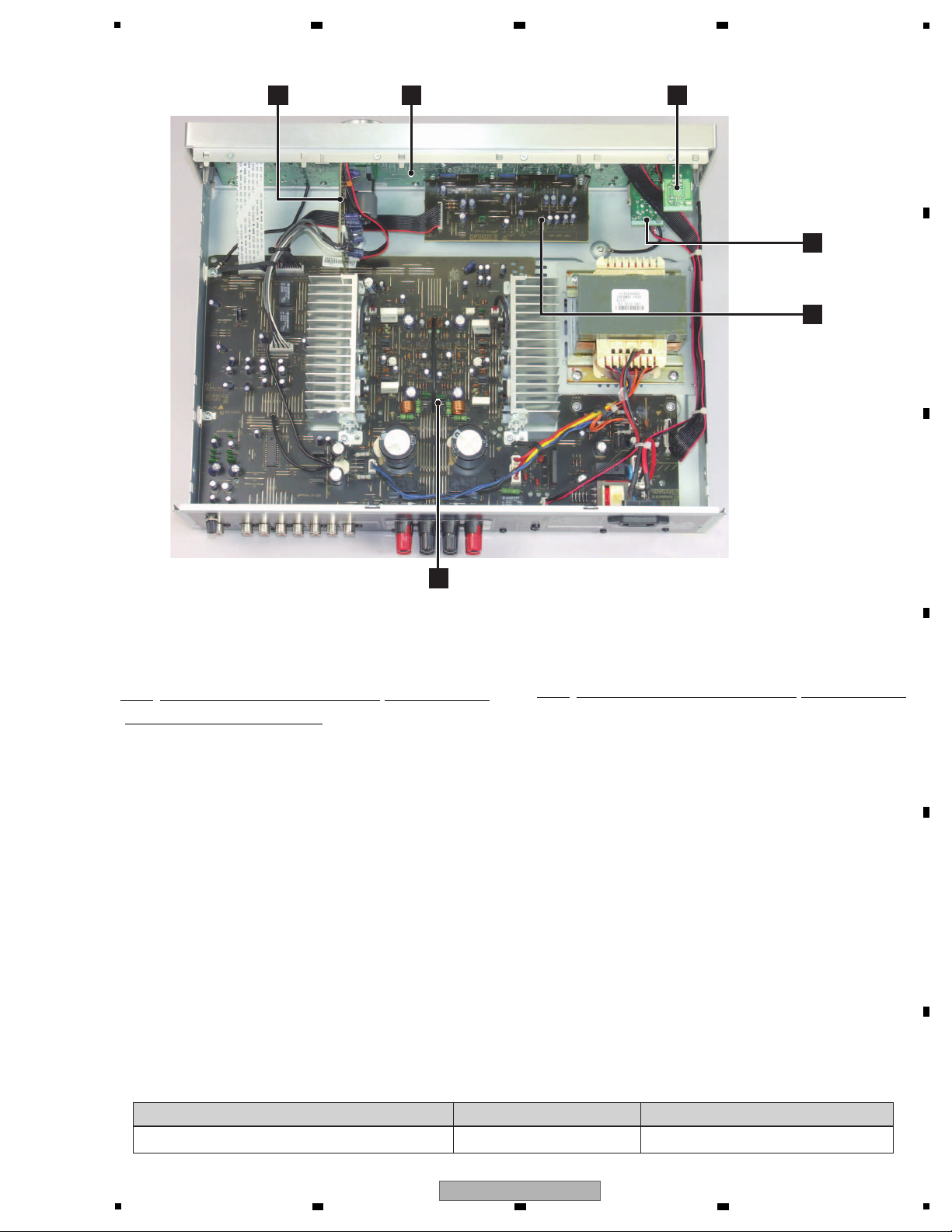

5

SECOND POWER SW ASSY

MAIN ASSY

A

MASTER VOLUME ASSY

C F

HEADPHONE ASSY

E

TONE ASSY

D

FRONT ASSY

B

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

Name Jig No. Remarks

UPDATE JIG GGF1675 Farmware Update

3.2 PCB LOCATIONS

6 7 8

A

B

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP 1..MAIN ASSY (A-30-K/-S) COP12421B

2..MAIN ASSY AZW7487

NSP 1..MAIN ASSY (A-20-K/-S) COP12421D

2..MAIN ASSY AZW7489

NSP 1..MAIN ASSY (A-20) COP12421E

2..MAIN ASSY AZW7490

NSP 1..MAIN ASSY (A-10-K/-S) COP12421F

2..MAIN ASSY AZW7491

NSP 1..FRONT ASSY (A-30-K/-S) COP12422B

2..FRONT ASSY AZW7482

2..MASTER VOLUME ASSY AZW7476

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

Mark No. Description Part No.

NSP 1..FRONT ASSY (A-20-K/-S) COP12422C

2..FRONT ASSY AZW7483

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

NSP 1..FRONT ASSY (A-20) COP12422G

2..FRONT ASSY AZW7484

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

NSP 1..FRONT ASSY (A-10-K/-S) COP12422D

2..FRONT ASSY AZW7485

2..MASTER V OLU ME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

C

D

E

3.3 JIGS LIST

5

6 7 8

A-30-K

F

7

Page 8

1

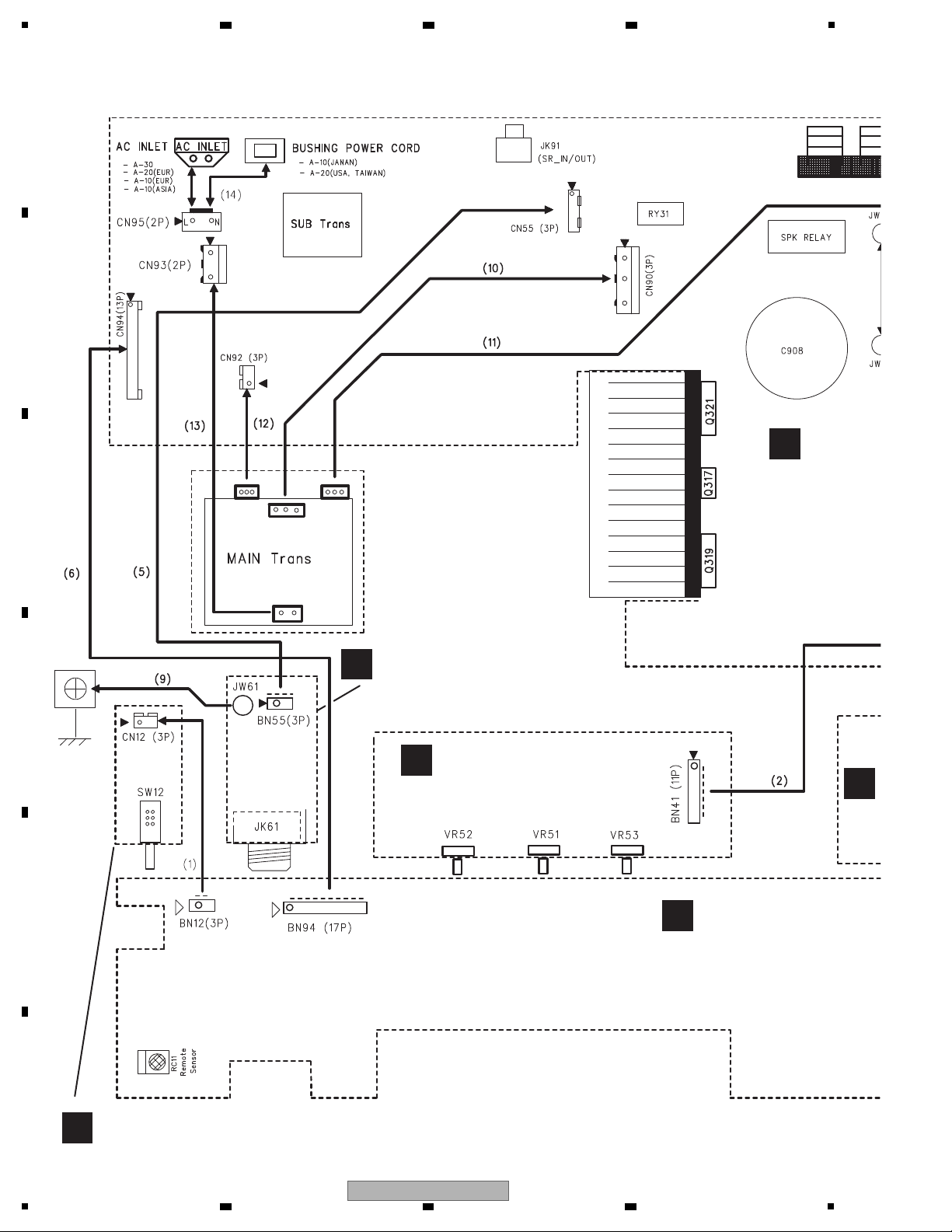

MAIN AS

(A-30-K/

(A-20-K/

(A-20

(A-10-K/

A

FRONT ASSY

(A-30-K/-S : AZW748

(A-20-K/-S : AZW748

(A-20 : AZW748

(A-10-K/-S : AZW748

B

SECOND POWER SW ASSY

(A-30-K/-S, A-20-K/-S, A-20 : AZW7478)

F

C

TONE ASSY

(AZW7477)

D

HEADPHONE ASSY

(AZW7479)

E

2 3 4

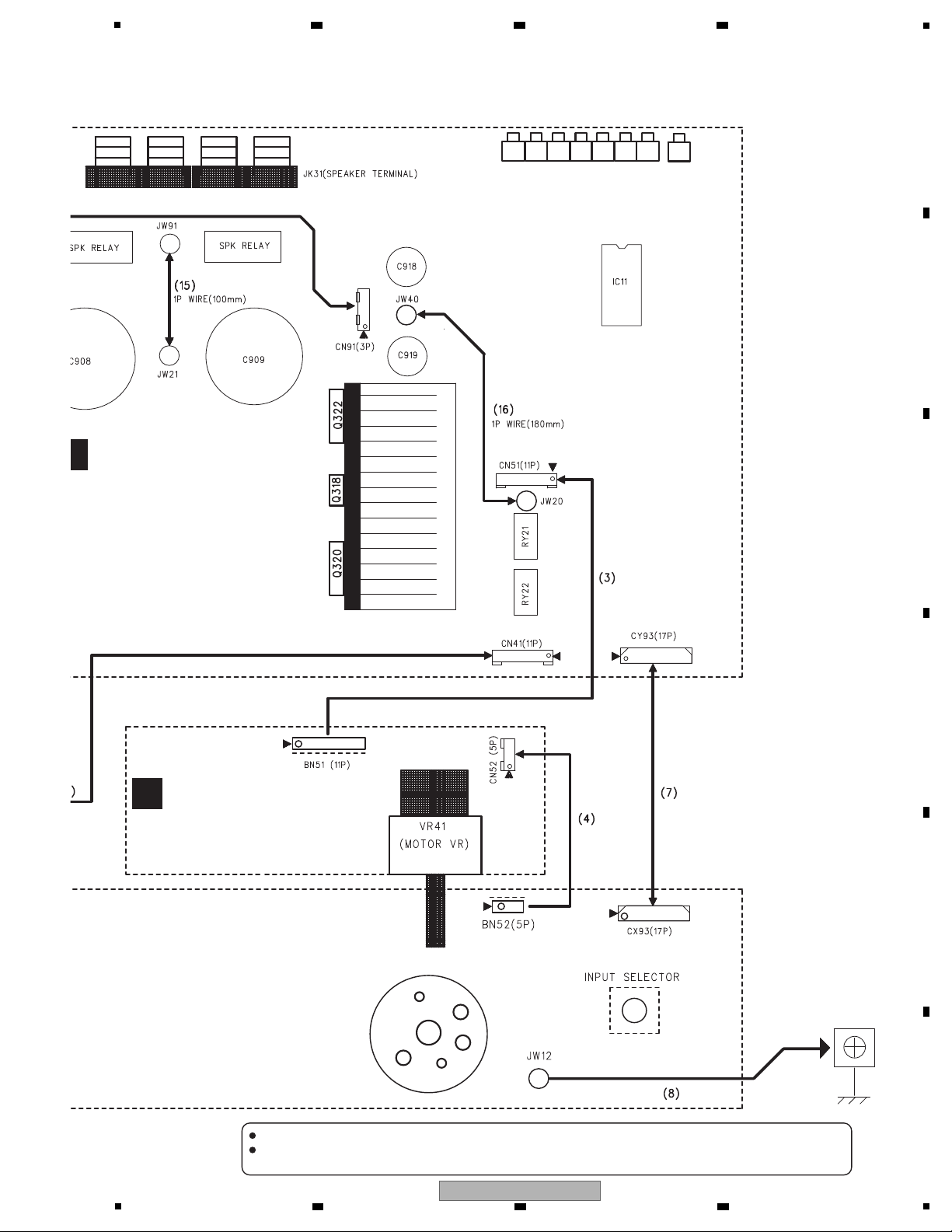

4. BLOCK DIAGRAM

4.1 OVERALL CONNECTION DIAGRAM

A

B

C

D

E

F

8

1

2 3 4

A-30-K

Page 9

5

MAIN ASSY

(A-30-K/-S : AZW7487)

(A-20-K/-S : AZW7489)

(A-20 : AZW7490)

(A-10-K/-S : AZW7491)

S : AZW7482)

S : AZW7483)

: AZW7484)

S : AZW7485)

MASTER VOLUME ASSY

(A-30-K/-S : AZW7476)

(A-20-K/-S, A-20,

A-10-K/-S : AZW7481)

C

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

6 7 8

A

B

C

D

E

5

6 7 8

A-30-K

F

9

Page 10

1

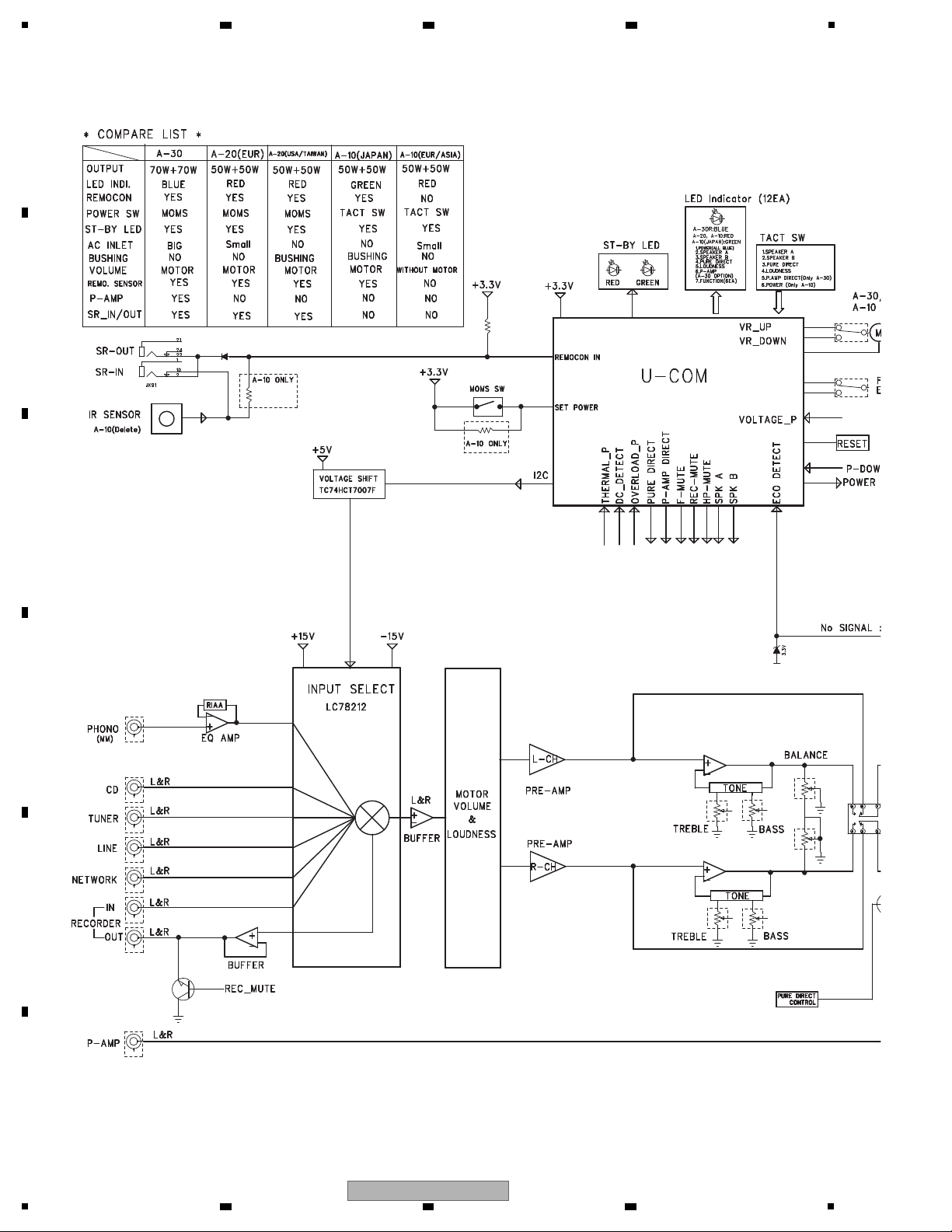

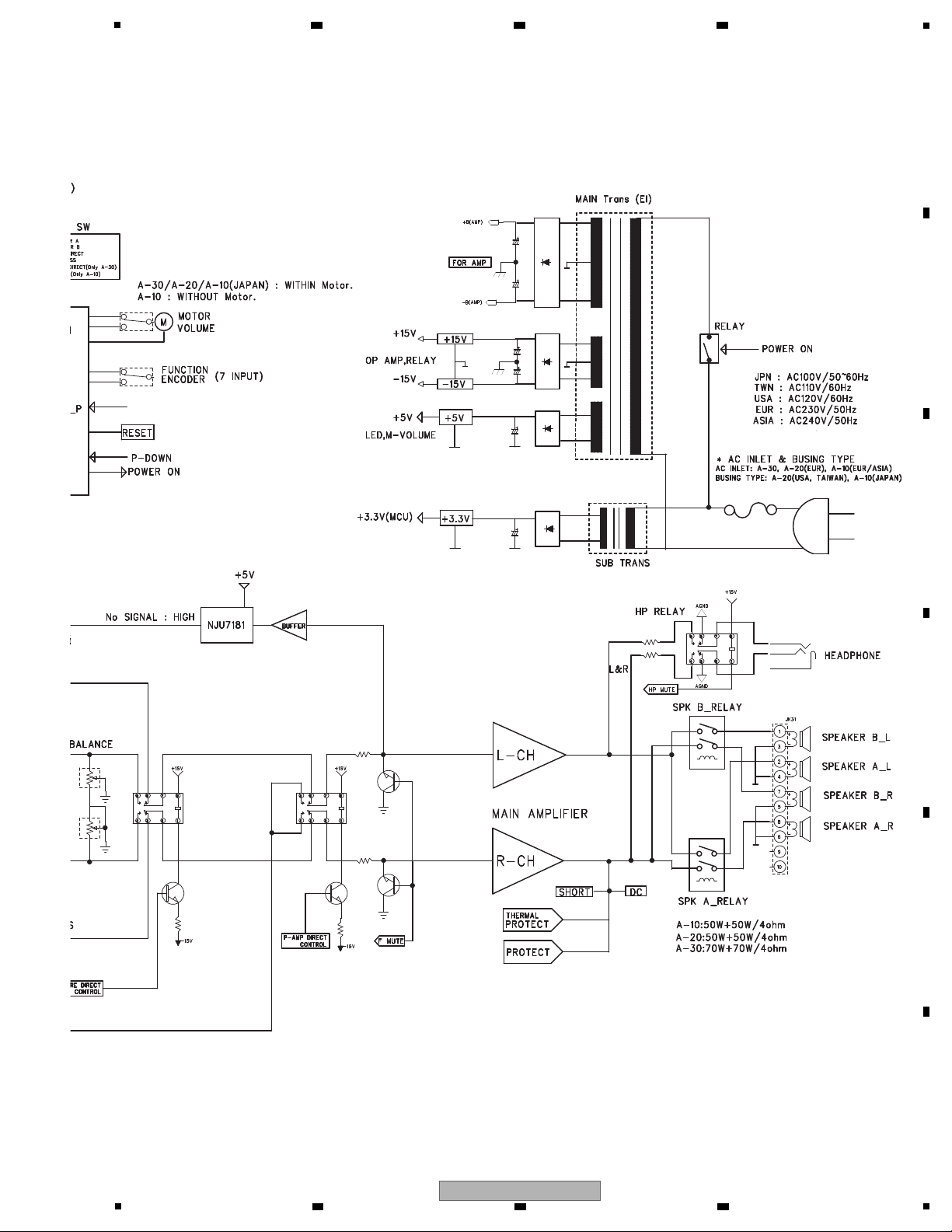

4.2 BLOCK DIAGRAM

A

B

2 3 4

C

D

E

F

10

1

2 3 4

A-30-K

Page 11

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

11

Page 12

1

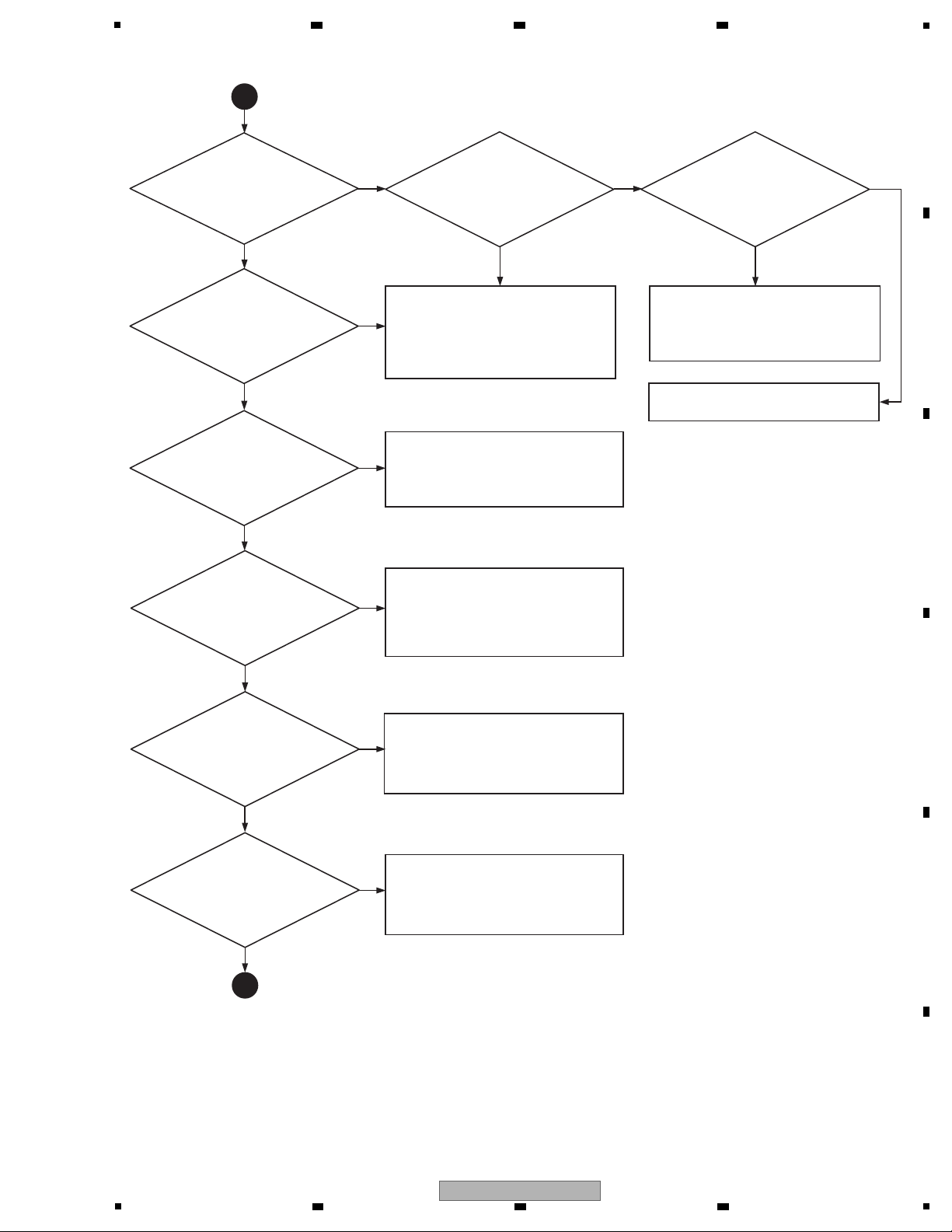

Is the Power supply

turned ON ?

A

No

No

Yes

Yes

No No No

Yes Yes

Yes

Yes

Yes

Yes

No

No

No

[Status of product]

Insert AC Power cord

Main unit POWER SW: ON (A-30/A-20)

POWER ON operation by remote control Unit

Select SPEAKER-A

INPUT : SACD/CD

Is the standby LED blinking ?

No sound

The protection circuit is operating

Is the voltage of ST_+3.3V

(CN94: 4, 5 pins) +3.3V ?

Is the voltage of IC91: 2 pin

approximately 5V ?

Is there AC waveform on

D913 anode side ?

IC91 failure

D913 failure

D914 failure

Is BACK UP line set to "H" ?

(CN94: 7 pin)

Q903, D917 failure

F901 failure

T901 failure

Is voltage of IC11: 1 pin +3.3V ?

IC12 failure

Is there

a waveform of Remote

Controller signal at IC11: 59 pin

(REMOTE IN) when POWER key

on the Remote Control

Unit pressed ?

IC11 failure

RC11 failure

Connection failure between BN94

and CN94(A-30/A-20)

(For the type, refer to the 5.2 PROTECTION CIRCUIT DESCRIPTION)

No sound

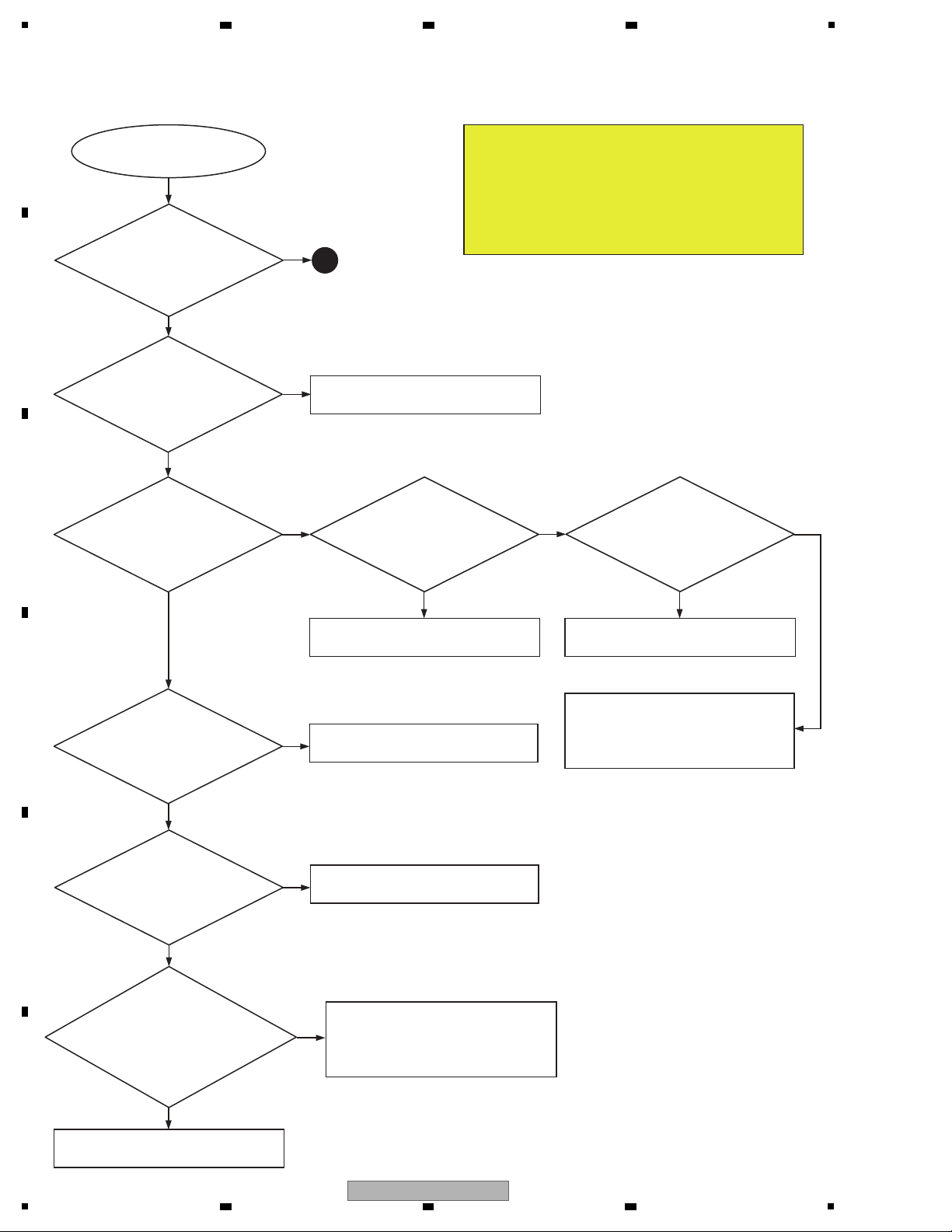

5. DIAGNOSIS

5.1 TROUBLESHOOTING

A

2 3 4

B

C

D

E

F

12

1

2 3 4

A-30-K

Page 13

A

No

No

No

No

No

No No No

B

Yes

Yes

Yes

Yes

Yes

Yes

Yes Yes

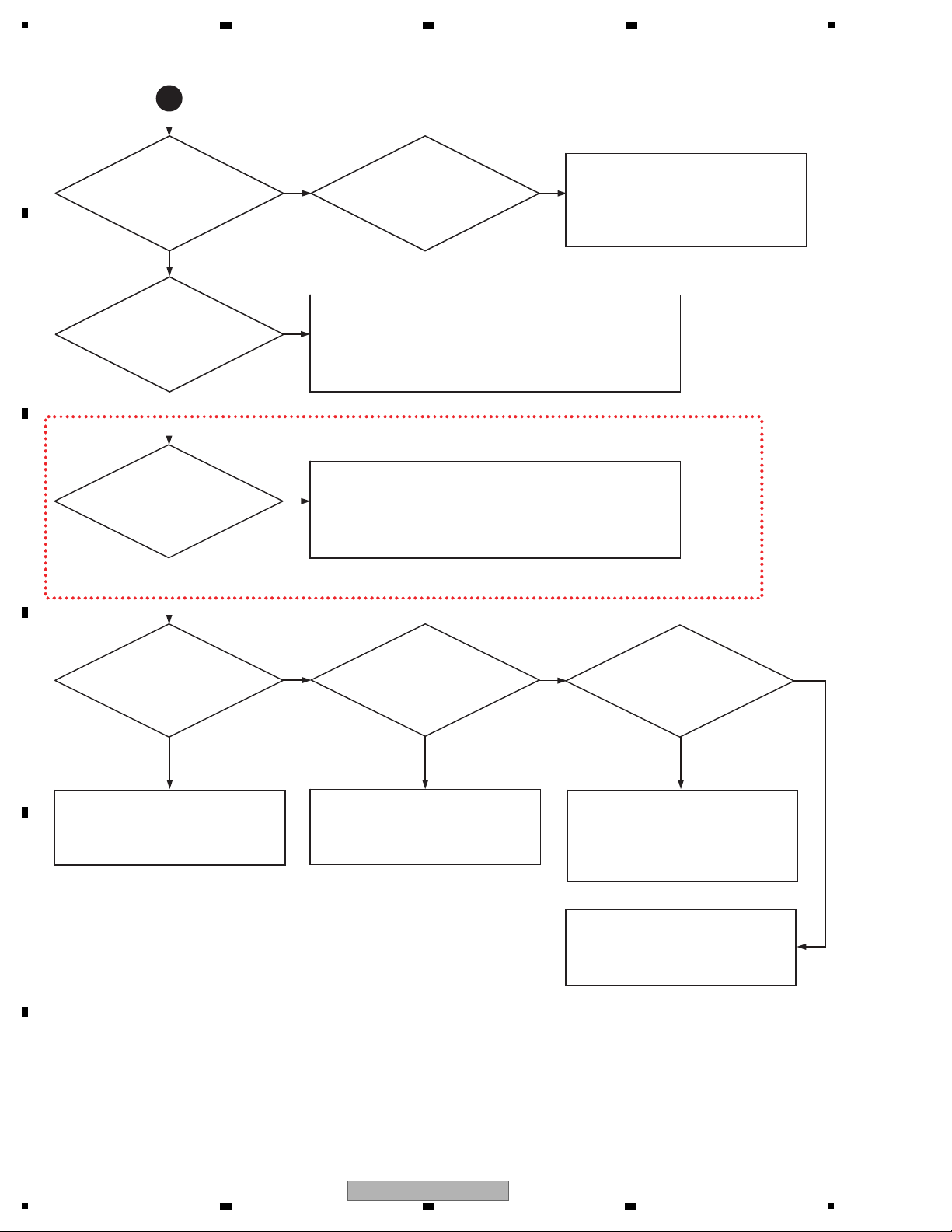

Does the protection

relay "click" and is it turned ON

after the power supply

is turned ON ?

Is IC11: 50 pin

(SPEAKER A) set to "H" ?

Is SPEAKER A LED

lighting ?

Is there output at

HP terminal ?

Relay power supply resistance

(R392, R394) failure

RY33 failure

Connection failure between

CY93 and CX93

S103 failure

IC11 failure

IC11 failure

Is there output at

REC OUT terminal ?

IC21 failure, communication failure

Connection failure between

CY93 and CX93

Solder failure of input pin jack

Is there a signal at

BN51:1, 9 pins ?

IC23 failure

Solder failure of IC23 I/O coupling

electrolysis capacitor

Connection failure between

CN51 and BN51

Is there a signal at

BN51:3, 7 pins ?

IC41 failure

Solder failure of IC41 I/O coupling

electrolysis capacitor

Check IC42 power supply (±7.5V)

Is there a signal at

BN51:3, 7 pins ?

IC41 failure

Solder failure of IC41 I/O coupling

electrolysis capacitor

Check IC42 power supply (±7.5V)

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

13

Page 14

1

A-30 ONLY

B

Yes

Yes

No

Yes

No

No

No

No

Yes

Yes Yes Yes

No

Isn't the

symptom changed by

DIRECT ON/OFF ?

Only DIRECT OFF

is not output

Solder failure of R503, R514

Connection failure between

CN41 and BN41

IC51, IC52 failure

Is there

a signal at J208 and

J209 (RY21 output) ?

PURE DIRECT control signal circuit

failure (Q203, Q204, R259, R261)

Connection failure between CY93 and CX93

RY21 failure

Is there

a signal at J215

(RY22 output) ?

P_AMP DIRECT control signal circuit

failure (Q205, Q206, R260, R262)

Connection failure between CY93 and CX93

RY22 failure

Is there a

signal at power amplifier

input (R301, R302) ?

Isn't F_MUTE

set to "H" ?

(Isn't the sound

muted ?)

Is ±15V of

MUTE circuit properly

supplied ?

Solder failure of R301,

R302, C301, C302

Reset MUTE

Solder failure of IC11:

44 pin

F_MUTE control signal

circuit failure (Q207-Q212)

Connection failure

between CY93 and CX93

D250 failure

Solder failure of R275

A

2 3 4

B

C

D

E

F

14

1

2 3 4

A-30-K

Page 15

5

1. PROTECTION operation

Purpose of PROTECTION operation

Protection of operation due to failure of product

Protection of operation due to wrong use by a user

e.g.) Rare short of speaker connection is generated, or product is installed by

blocking the heat release hole

1.1 DC DETECT

After DC DETECT is detected, MUTE ON & PROTECTION RELAY OFF are carried out.

If DC DETECT is detected for 3 seconds or more continuously, it is evaluated as "1.1.1 AMP failure" shown below.

If DC DETECT is detected for less than 3 seconds, it is evaluated as 1.1.2 SIGNAL CLIP" shown below.

1.1.1 AMP failure

If DC DETECT is detected for 3 seconds or more continuously, it is evaluated as "AMP failure" and

the power is turned OFF.

If the power supply is automatically turned OFF after AMP failure is detected, all key operations are prohibited

(power ON is prohibited).

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

1.1.2 SIGNAL CLIP

If DC DETECT is detected for less than 3 seconds, it is evaluated as "SIGNAL CLIP".

If the detection of DC DETECT is reset within 3 seconds, MUTE OFF & PROTECTION RELAY ON

are carried out.

NOTE) If the detection of DC DETECT is reset within 3 seconds and DC detection functions immediately,

PROTECTION RELAY OFF/ON is repeated, however, there is no problem.

1.2 OVER LOAD

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

After OVER LOAD is detected, the key operation is not prohibited (the power supply can be turned ON).

NOTE) If a short of speaker cable may be generated, the connection is made again and the power supply

cannot be turned ON by a user, so a complaint is generated.

If AMP is broken actually, DC detection operates, so there is no problem.

1.3 Temperature PROTECTION

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

After temperature PROTECTION is detected, the key operation is not prohibited (the power supply

can be turned ON).

NOTE) After the detection, if the temperature is still high even by turning ON the power supply,

the temperature PROTECTION is detected again and the power supply is turned OFF.

1.4 Power PROTECTION

MUTE ON & PROTECTION RELAY OFF are carried out immediately after the detection and the power is

turned OFF.

If the power supply is automatically turned OFF after the power PROTECTION is detected, all key operations are

prohibited (power ON is prohibited).

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

2. Keeping the prohibition of power ON after 1.1.1 AMP failure is detected and 1.4 power

PROTECTION is detected

If the power supply is automatically turned OFF after AMP failure is detected and power PROTECTION is detected,

all key operations are prohibited (power ON is prohibited).

The power ON prohibition status is kept even if the backup is carried out and the power cord is disconnected and

inserted.

For turn ON the power supply again, refer to "3. How to reset the prohibition of power ON" shown below.

5.2 PROTECTION CIRCUIT DESCRIPTION

6 7 8

A

B

C

5

6 7 8

A-30-K

D

E

F

15

Page 16

1

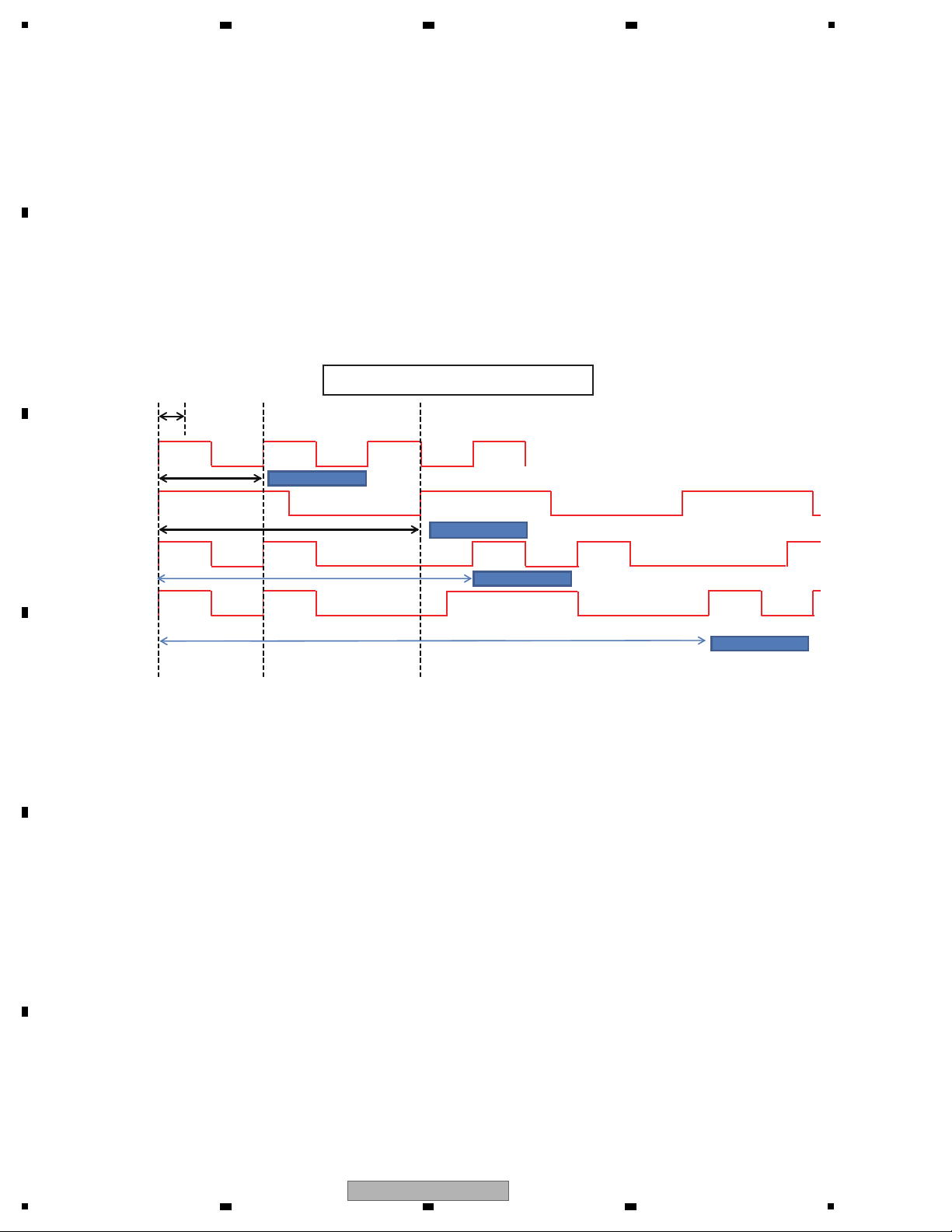

200ms

On

Temperature

Protection

Off

AMP Overload

Protection

1CYCLE : 1.4S

DC DETECT

(DC Balance)

Power

Protection

1TIME : 800mS

1TIME : 2.4S

1TIME: 4.2S

1TIME : 2S

Protect LED display specifications

3. How to reset the prohibition of power ON

Press Front Key [ DIRECT ] + [ SPEAKER B ] at the same time for 2 seconds or more continuously.

The key prohibition mode after 1.1.1 AMP failure is detected and 1.4. power PROTECTION is detected is released and

the power supply is turned ON.

4. STANDBY LED display after PROTECTION is detected

Each PROTECTION operations above are identified by blinking timing of STANDBY LED.

The blinking of LED is continued until the power supply is turned ON again.

For the blinking specification of LED, refer to "Protect LED display specifications" shown below.

A

B

2 3 4

C

D

E

F

16

1

2 3 4

A-30-K

Page 17

5

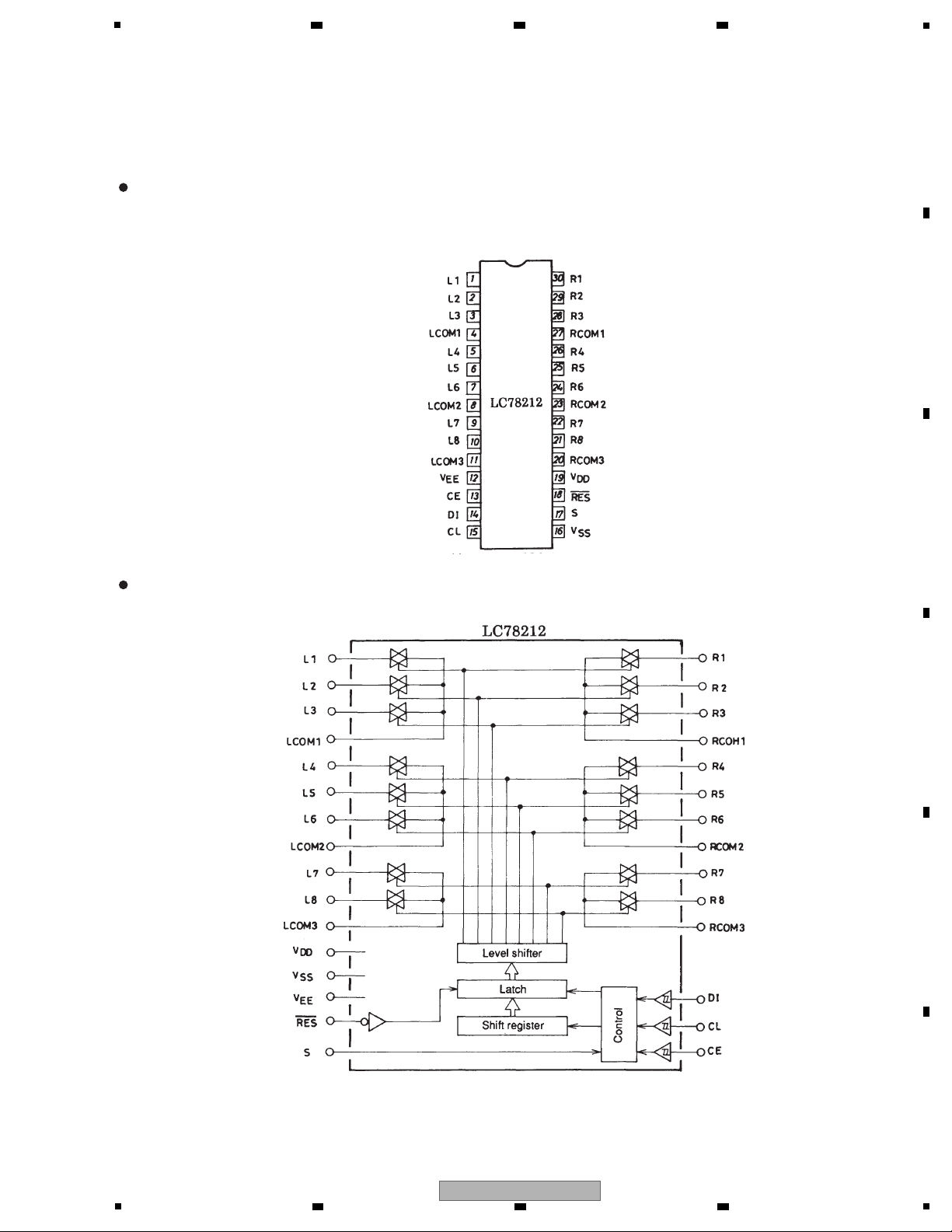

1/1

HVILC78212

(Analog Function Switch)

(Top View)

Pin Layout

Block Diagram

5.3 IC INFORMATION

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

17

Page 18

1

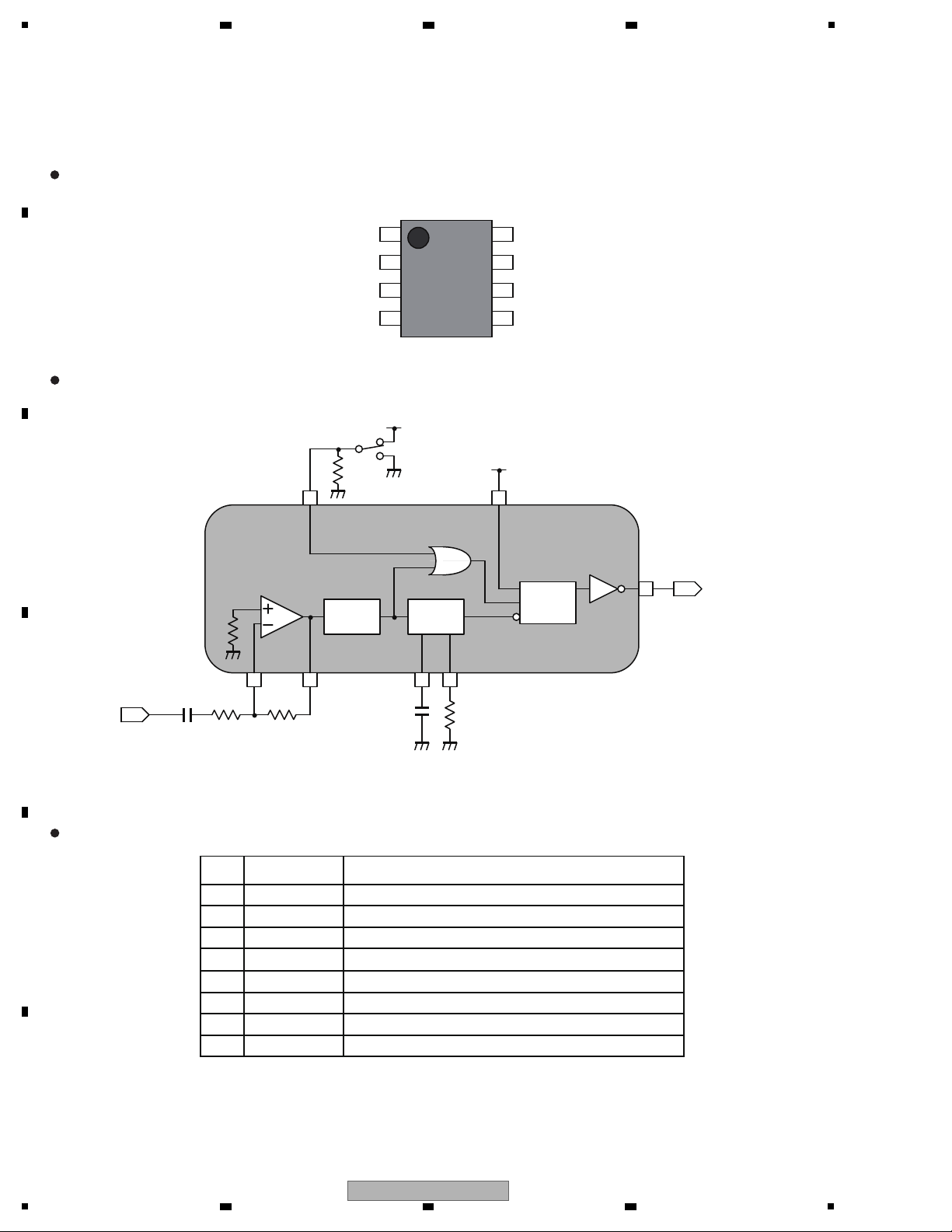

1/1

CVINJU7181RB1

(Signal Level Sensor System)

(TVSP8)

Level

Detector

Delay

Latch

CLR

D

L

IN

OUT

V

+

V

+

ON

OFF

External Trigger

18

54

Pin Layout

Block Diagram

Pin Function

(Top View)

1 IN AC Input

2 AMP_OUT Amplifier Output

3 TRIN External Trigger Input

4 GND Ground

5 CAP_D Capacitor connection terminal for delay time setting

6 RES_D Resister connection terminal for delay time setting

7 OUT DC Output

8 V

+

Power Supply Voltage

FunctionPin NameNo.

A

2 3 4

B

C

D

E

F

18

1

A-30-K

2 3 4

Page 19

1/3

CVIANAM1656A

(Micro Controller)

V

REF-

AIN10/PF0

AIN7/PB7

AIN6/PB6

[I2C_SDA] AIN5/PB5

[I2C_SCL] AIN4/PB4

[TIM1_ETR] AIN3/PB3

[TIM1_CH3N] AIN2/PB2

[TIM1_CH2N] AIN1/PB1

[TIM1_CH1N] AIN0/PB0

AIN8/PE7

AIN9/PE6

AIN11/PF3

V

REF+

V

DDA

V

SSA

6463 6261 6059 5857565554 5352 5150 49

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

171819 202122 2324 2930 31322526 2728

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

V

SS

VCAP

V

DD

V

DDIO_1

[TIM3_CH1] TIM2_CH3/PA3

UART1_RX/ (HS) PA4

UART1_TX/ (HS) PA5

UART1_CK/ (HS) PA6

AIN15/PF7

AIN14/PF6

AIN13/PF5

AIN12/PF4

NRST

OSCIN/PA1

OSCOUT/PA2

V

SSIO_1

PG1/CAN_RX

PG0/CAN_TX

PC7 (HS)/SPI_MISO

PC6 (HS)/SPI_MOSI

V

DDIO_2

V

SSIO_2

PC5 (HS)/SPI_SCK

PC4 (HS)/TIM1_CH4

PC3 (HS)/TIM1_CH3

PC2 (HS)/TIM1_CH2

PC1 (HS)/TIM1_CH1

PE5/SPI_NSS

PI0

PG4

PG3

PG2

PD3 (HS)/TIM2_CH2[ADC_ETR]

PD2 (HS)/TIM3_CH1[TIM2_CH3]

PD1 (HS)/SWIM

PD0 (HS)/TIM3_CH2 [TIM1_BKIN] [CLK_CCO]

PE0 (HS)/CLK_CCO

PE1 (T)/I2C_SCL

PE2 (T)/I2C_SDA

PE3/TIM1_BKIN

PE4

PG7

PG6

PG5

PD7/TLI [TIM1_CH4]

PD6/UART3_RX

PD5/UART3_TX

PD4 (HS)/TIM2_CH1 [BEEP]

Pin Layout

1. (HS) high sink capability.

2. (T) True open drain (P-buffer and protection diode to VDD not implemented).

3. [ ] alternate function remapping option (If the same alternate function is shown twice, it indicates an exclusive choice not a

duplication of the function).

4. CAN_RX and CAN_TX is available on STM8S208xx devices only.

5

6 7 8

A

B

C

D

E

5

6 7 8

A-30-K

F

19

Page 20

A

2/3

CVIANAM1656A

(Micro Controller)

Block Diagram

XTAL 1-24 MHz

RC int. 16 MHz

RC int. 128 kHz

STM8 core

Debug/SWIM

I

2

C

SPI

UART1

UART3

AWU timer

Reset block

Reset

POR

BOR

Clock controller

Detector

Clock to peripherals and core

10 Mbit/s

LIN master

16 channels

Address and data bus

Window WDG

Up to 128 Kbytes

Up to 2 Kbytes

Up to 6 Kbytes

Boot ROM

ADC2

beCAN

Reset

400 Kbit/s

1 Mbit/s

Master/slave

Single wire

autosynchro

debug interf.

SPI emul.

high density program

Flash

data EEPROM

RAM

16-bit general purpose

16-bit advanced control

timer (TIM1)

timers (TIM2, TIM3)

8-bit basic timer

(TIM4)

Beeper

1/2/4 kHz

beep

Independent WDG

4 CAPCOM

channels

Up to

5 CAPCOM

channels

Up to

+ 3 complementary

outputs

B

1

2 3 4

C

D

E

F

20

A-30-K

1

2 3 4

Page 21

5

6 7 8

3/3

CVIANAM1656A

Pin Function

(Micro Controller)

Pins Pin Name TYPE

1 NRST I/O

2 PA1/OSCIN I/O OSC_IN GPIO O L L - OSC_IN

3 PA2/OSCOUT I/O OSC_OUT GPIO O L L - OSC_OUT

4 Vssio_1 S

5 Vss S

6 Vcap S

7 Vdd S

8 Vddio_1 S

9 PA3/TIM2_CH3 I/O PA3 TIM2_CH3 I - - H SEC_POWER

10 PA4/UART1_Rx I/O PA4 UART1 I/O - L - UPDATE_TX

11 PA5/UART1_Tx I/O PA5 UART1 O H L L UPDATE_RX

12 PA6/UART1_Clk I/O PA6 UART1 I - - H ECO_DETECT

13 PF7/AN15 I/O PF7 ADC O L L L STBY_LED

14 PF6/AN14 I/O PF6 ADC O L L H LOUDNESS_LED

15 PF5/AN13 I/O PF5 ADC O L L H SPEAKER_B_LED

16 PF4/AN12 I/O PF4 ADC O L L H SPEAKER_A_LED

17 PF3/AN11 I/O PF3 ADC O L L H P_AMP_DIRECT

18 Vref+ S

19 Vdda S

20 Vssa S

21 Vref- S

22 PF0/AN10 I/O PF0 ADC O L L H P_AMP LED

23 PB7/AN7 I/O PB7 ADC O L L H PHONO_LED

24 PB6/AN6 I/O PB6 ADC I - - H MODEL_OPT

25 PB5/AN5 I/O PB5 ADC O L L H TUNER_LED

26 PB4/AN4 I/O PB4 ADC O L L H RECORDER_LED

27 PB3/AN3 I/O PB3 ADC O L L H AUX_LED

28 PB2/AN2 I/O PB2 ADC O L L H NETWORK_LED

29 PB1/AN1 I/O PB1 ADC O - - - KEY_IN#2

30 PB0/AN0 I/O PB0 ADC O - - - KEY_IN#1

31 PE7/AN8 I/O PE7 ADC O L L H CD_LED

32 PE6/AN9 I/O PE6 ADC O L L H VR_DOWN

33 PE5/SPI_NSS I/O PE5 SPI O L L H FUNC_CE

34 PC1/TIM1_CH1 I/O PC1 TIM1_CH1 O L L H VR_UP

35 PC2/TIM1_CH2 I/O PC2 TIM1_CH2 I - - L THERMAL_P

36 PC3 I/O PC3

37 PC4/TIM1_CH4 I/O PC4 TIM1_CH4 I - - L OVERLOAD_P

38 PC5/SPI_SCK I/O PC5 SPI O L L H/L FUNC_CLK

39 Vssio_2 S

40 Vddio_2 S

41 PC6/SPI_MOSI I/O PC6 SPI O L L H/L FUNC_DATA

42 PC7/SPI_MISO I/O PC7 SPI I - - L VOLTAGE_P

43 PG0/CAN_Tx I/O PG0 O H H(OD) H REC_MUTE

44 PG1/CAN_Rx I/O PG1 O H H(OD) H F_MUTE

45 PG2 I/O PG2 O L L H P_ON_RELAY

46 PG3 I/O PG3

47 PG4 I/O PG4 O L L H PURE_DIRECT

48 PI0 I/O PI0 O L L 49 PG5 I/O PG5 O L L H SPEAKER_B

50 PG6 I/O PG6 O L L H SPEAKER_A

51 PG7 I/O PG7 O L L H PURE_DIRECT_LED

52 PE4 I/O PE4 I - - H/L FUNCTION_EN1

53 PE3/TIM1_BKIN I/O PE3 TIM1_BKIN I - - H/L FUNCTION_EN2

54 PE2/I2C_SDA I/O PE2 I2C I - - L UPDATE_SEL

55 PE1/I2C_SCL I/O PE1 I2C O L L 56 PE0/CLK_CCO I/O PE0 CLK_CCO O L L H POWER_LED

57 PD0/TIM3_CH2 I/O PD0 TIM3_CH2 O L L H APD_LED

58 PD1/SWIM I/O DEBUG GPIO O

59 PD2/TIM3_CH1 I/O PD2 TIM3_CH1 I - - H/L REMOTE_IN

60 PD3/TIM2_CH2 I/O PD3 TIM2_CH2 O L L H DIMMER

61 PD4/TIM2_CH1 I/O PD4 TIM2_CH1 O L L 62 PD5/UART3_Tx I/O PD5 UART3 O L L 63 PD6/UART3_Rx I/O PD6 UART3 O L L L HP_MUTE

64 PD7/TLI I/O PD7 TLI O - - L BACK_UP

Main

Function

(After reset)

Default

Alternate

functions

USE

I - - L DC_DETECT

O L L H LOUDNESS

- - - NRST

- - - VSSIO_1

- - - VSS

- - - VCAP

- - - VDD

- - - VDDIO1

- - -

- - -

- - -

- - -

Status

init stby Act.Lvl

Pin Description

Debug Jig

A

B

C

D

E

6. SERVICE MODE

There is no information to be shown in this chapter.

5

6 7 8

A-30-K

F

21

Page 22

1

1

1

1

3

4

1

2

2

2

2

2

Top Cabinet

Note 1 : Even if the unit shown in the photos and illustrations in this manual may differ from your product, the procedures

described here are common.

Note 2 : As for the assembling, please perform assembling following to the opposite procedures of How to Disassemble.

If any notes are existed, please follow those instructions.

Note 3 : Before starting the diagnosis, wait for several seconds until the electricity of the unit is discharged.

While spreading

Top Cabinet

Rear Panel

Insert nails

While spreading

[1] Top Cabinet

(1) Remove the four screws.

(

A-30-K, A-20-K, A-20, A-10-K: )

CTB4+6FFZRP

(

A-30- S, A-20-S, A-10-S:

)

CTB4+6FFCP

(2) Remove the five screws.

(BBZ30P060FTB)

(3) Insert nails between the Top Cabinet and

Rear Panel and pull the Top Cabinet

backward horizontally.

(4) Take out Top Cabinet upward while spreading

Rear Side Piece.

2 3 4

7. DISASSEMBLY

A

B

C

D

E

F

22

1

2 3 4

A-30-K

Page 23

1

2

3

3

2

HEADPHONE ASSY

MAIN ASSY

Bottom Chassis

CN94

CN55

Ground Cable from the HEADPHONE ASSY

[2] Diagnosis

[3] Front Section

(1) Remove the screw. (CTW3+6JR)

(2) Cut the two Clampers. (CHR301)

(3) Disconnect the two connectors.

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

23

Page 24

1

5

4

MAIN ASSY

Wire Clamper

4

4

CN51

CN41

CY93

Front Section

Ground Cable

from the FRONT ASSY

6

6

6

6

6

6

7

7

(4) Disconnect the three connectors.

(5) Remove the screw. (CTW3+6JR)

(6) Remove the six screws.

(

A-30-K, A-20-K, A-20, A-10-K: )

BBZ30P080FTB

(

A-30- S, A-20-S, A-10-S:

)

CTB3+8JFC

(7) Unhook the two hooks and remove the Front

Section.

• Bottom view

A

2 3 4

B

C

D

E

F

24

1

A-30-K

2 3 4

Page 25

5

D901

CN91

3 times twist

Hemelon T ape

1

1

2

3

2

5

4

Front

Pow er Transformer

Heat Sink

Heat Sink

Secondary Side Cable of

Power Transformer

Secondary Side Cable of

Power Transformer

Secondary Side Cable of

Power Transformer

Fixing with

Clamper

Fixing with

Clamper

Fixing with Clamper

Fixing with Clamper

Fixing with Wire Clamper

Detached

Extra

length

Extra

length

Detached

Detached

Cable from the

HEADPHONE ASSY

Detached

Notes on assembling

(1) Secondary Side Cable of the Power

Transformer (∗)

Fix the cable from the position near the

Power Transformer with a Clamper (x1)

and Wire Clampers (x2) and release the

extra length to the opposite direction of the

Power Transfo rmer.

(2) Secondary Side Cable of the Power

Transformer (∗)

Release it not to touch with the Heat Sink.

(3) Secondary Side Cable of the Power

Transformer (∗) connect to CN91

After checking it is not twisted, twist it three

times.

(4) Cable from the HEADPHONE ASSY

Release it not to touc h with th e Sec ondary

Side Cable of Power Transformer.

(5) Secondary Side Cable of the Power

Transformer (∗)

Release it not to touch with the D901.

∗ Power Transformer

(

A-30-K, A-30-S: CL T5U050ZE

)

A-20-K, A-20-S,

A-10-K, A-10-S: CLT5R043ZE

A-20: CLT5R043ZU

[1] Styling of cables

When you attach each unit, make styling, connection of cables and other parts as shown in the photo.

6 7 8

A

B

C

D

E

5

A-30-K

6 7 8

F

25

Page 26

1

6

7

8

Cable of Temperature Sensor

Cable of Temperature Sensor

MASTER VOLUME ASSY

FRONT ASSY

Q319

Q320

9

9

Front

Front

Cable from the

MASTER VOLUME ASSY

Cable from

the TONE ASSY

Heat Sink

Heat Sink (Left)

Wire Clamper

Detached

Bottom Chassis

Detached

Detached

Heat Sink (Right)

Hemelon T ape

(6) Cable from the MASTER VOLUME ASSY

Fix it with the Cable from the TONE ASSY,

using the Clamper. Release it not to touch

with the Heat Sink.

(7) Cable from the MASTER VOLUME ASSY

Fix it with the Wire Clamper and release it

not to touch with the Heat Sink.

(8) Wrap the protr usion at the lower p art of lef t

front side of the Bottom Chassis with Hemelon

Tape to prevent short with the FRONT ASSY.

(9) Cable of right and left Temperature Sensors

Release it not to touch with the transistor

(Q319, Q3 20).

A

2 3 4

B

C

D

E

F

26

A-30-K

1

2 3 4

Page 27

5

Attach two pieces

90°

MASTER VOLUME ASSY

[3] Where to attach the sound quality improvement tape

Acetate Tape or Double Side Tape is att ac he d to so me pa rts in this mo d el to im pr ove soun d q ual ity. When the following

compone nts are replaced, be su re to attach design ated the Acetate Tape and Double Side Tape again to the d esignated

location. C oncer ning the Ac etate Tape, if it is diffi cult to reu se the Tape, order a new Tape and attach it . (You can use other

Acetate Tape than that designated by cutting it to a designated size.)

The Double Side Tape cannot be reused easily. When the knob is removed, attach a new Tape.

(1) Panel section

Attach two pieces of Acetate Tape

(Part No.: CHS1A217, 10 mm x 15 mm) to a

flat surface around the Volume Knob as

shown in the photo.

Be sure to attach the Tape to a flat surface.

(2) MASTER VOLUME ASSY

Attach a piece of Acetate Tape

(Part No.: CHS1A217, 10 mm x 15 mm) to

the specified position on the lateral side of

the Electric Volume as shown in the photo.

Attach a piece

Insulator

[2] Direction of Insulator

Align the mark at under surface of the Insulator

with the direction of photo.

(

A-30-K, A-20-K, A-20, A-10-K: )

CKL1A204

(

A-30- S, A-20-S, A-10-S:

)

CKL1A204H65

6 7 8

A

B

C

D

E

5

6 7 8

A-30-K

F

27

Page 28

1

FRONT ASSY (SIDE B)

Hole for the Volume Shaft

Acetate T ape:

CHS1A218

Top Cushion:

CHG1A530

Top Cabinet

Top

Attach two pieces

Double Side Tape: C4FA051

Double Side Tape: C4FA051

Each axis of BASS, TREBLE and BALANCE in TONE ASSY

INPUT SELECTOR part

(3) FRONT ASSY

Attach two pieces of Acetate Tape

(Part No.: CHS1A217, 10 mm x 15 mm) to

the pattern surface of the FRONT ASSY as

shown in the photo.

The Acetate Tape comes between the

Electric Volume and the FRONT ASSY, but

fix them directly with screws from the

FRONT ASSY.

(4) Top Cabinet

Attach four pieces of Acetate Tape

(Part No.: CHS1A218, 5 mm x 25 mm) to the

front side of the reverse surface at the same

location as that of the Top Cushion.

(5) FRONT ASSY (INPUT SELECTOR),

TONE ASSY

(Carry ou t the oper ation s hown bel ow when

Volume part or Encoder part of each ASSY is

replaced too)

Attach a piece of Double Side Tape

(Part No.: C4FA051, 5 mm x 5 mm) to flat

surface at the tip of each axis at Volume

part and axis at Encoder part.

A

B

2 3 4

C

D

E

F

28

1

2 3 4

A-30-K

Page 29

5

SPK A SPK B LOUD CD NET A PHONO TUNER AUX REC

No USE

0 0

1 1 1

2 2

3 3

4 4

5 5

6 6

7

<e.g.> Ver.3.6.0

3 6 0

Minor2

PURE D

Major Version

Minor1

1. In STANDBY status, press Front Key [ DIRECT ] + [ SPEAKERS A ] at the same time (5 seconds).

At this time, the version can be checked with the indicator.

If the power supply is turned ON in this status, the product is reset to the factory-shipping status.

[Connection Diagram]

PC

RS-232C

straight cable

7P to 7P FFC

SW102

(UPDATE SW)

(GGF1675 update jig)

(A-30 rear panel)

[Necessary T ool]

Firmware

PC with a serial port (for PC without a serial port, a commercially-available USB serial conversion cable is also available)

RS-232C cable (9-pin to 9-pin, straight cable)

RS-232C update jig: GGF1675 (use included FFC (7P to 7P))

(The mark is the contact surface of the FFC.)

6 7 8

8. EACH SETTING AND ADJUSTMENT

8.1 HOW TO CHECK THE FIRMWARE VERSION

A

B

8.2 FARMWARE UPDATING

C

D

E

A-30-K

5

6 7 8

F

29

Page 30

1

LED display at update

6. If "Updating completed" is displayed, quit the update application and

disconnect the power cord.

7. Disconnect UPDATE JIG.

ClickClick

* If the update cannot be executed because of "Connection Error" * If the update cannot be executed because of "Connection Error"

message, connect RS-232C cable a

gain and carry out the operation message, connect RS-232C cable again and carry out the operation

from the beginning.from the beginning.

[Update Procedure]

1. Connect UPDATE JIG (GGF1675) to A-30/20/10 and PC when the power cord is disconnected.

MAIN ASSY CN95 UPDATE JIG CN101

PC (RS-232C connector) UPDATE JIG JK101

2. Set SW102 (UPDATE SW) of UPDATE JIG to UPDATE MODE side and connect the power cord.

(At this time, the front LED enters in Update Mode (Waiting) status)

3. Prepare update application and update file.

It is necessary to store 3 files in the same folder of PC.

a. PioneerAxxUpdate.ini : Update Information File

b. UpdateAppPioneerA30_1v2.exe : Windows Update Application File

c. PIONEER_A-30SOFT_REL.BIN : Update Binary File

4. Double-click UpdateAppPioneerA30_1v2.exe and start up the update application.

5. Select the serial port you connected and click "START UPDATE" button.

(At this time

, the front LED enters in Update Mode (Updating) status)

Update Mode

On

Standby LED

Off

Power LED

Update Mode

Standby LED

Power LED

128 Byte Writing Time

500mS

( Updating )

( Waiting )

A

2 3 4

B

C

D

E

F

30

1

A-30-K

2 3 4

Page 31

5

CN31 adjustment VR31

CN32 adjustment VR32

CN31

CN32

VR31

VR32

Multi-meter

1. Turn ON the power supply of the product.

2. Set INPUT SELECTOR to SACD/CD and set VOL to MIN, and wait for 3 minutes.

3. Connect a multi-meter to CN31 and CN32 of MAIN ASSY.

4. Adjust VR31 and VR32 so that DC LEVEL becomes 8 ± 2 mV.

[Adjustment Procedure]

[Adjustment Condition]

Idle current needs to be adjusted when the following components are replaced:

1. MAIN ASSY (Adjust the idle current for both channels)

2. Components within the red frame (excluding the capacitors)

The circuit diagram below is for Lch, but it is only necessary to adjust the idle current only for the channel in

which the components are replaced.

L ch R ch

6 7 8

8.3 HOW TO ADJUST THE IDLE CURRENT

A

B

C

D

E

A-30-K

5

6 7 8

F

31

Page 32

1

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

Screws adjacent to b mark on product are used for disassembly.

-

For the applying amount of lubricants or glue, follow the instructions in this manual.

(In the case of no amount instructions, apply as you think it appropriate.)

Except A-20/CUXE

Except A-10-K/SYXE8,

A-10-S/SYXE8

Except

A-20/CUXE

Tape

Tape

2 3 4

9. EXPLODED VIEWS AND PARTS LIST

A

9.1 PACKING SECTION

B

C

D

E

F

32

1

2 3 4

A-30-K

Page 33

5

(1) PACKING SECTION PARTS LIST

6 7 8

Mark No. Description Part N o.

1 Warranty Card SY See Contrast table (2)

2 Remote Control Unit See Contrast table (2)

> 3 AC Power Cord See Contrast table (2)

4 Polyethylene Bag CPB1A013W

5 Packing Case See Contrast table (2)

6 Packing Pad (L) CPS1A914

7 Packing Pad (R) CPS1A915

8 Speaker Caution En CQE1A539Z

9 Operating Instructions See Contrast table (2)

NSP 10 Serial Label S VRW2017

NSP 11 AAA/R03 Dry Cell Battery x 2 • • • • •

12 Polyethylene Bag (Accessary) See Contrast table (2)

13 Polyethylene Bag (Manual) CPB1A197Z

(2) CONTRAST TABLE

A-30-K/PWSYXE8, A-30-S/PWSYXE8, A-20 -K/PWSYXE8, A-20-S/PW SYXE8, A-20/CUXE, A-10-K/SYXE8 and A-10-S/SYXE8

are constructed the same except for the following:

Mark No. Symbol and Description

1 Warranty Card SY CQE1A541Z CQE1A541Z CQE1A541Z CQE1A541Z Not used CQE1A541Z CQE1A541Z

2 Remote Control Unit CARTA30 CARTA30 CARTA20 CARTA20 CARTA20 Not used Not used

3 AC Power Cord CJA2B054Z CJA2B054Z CJA2B108ZV CJA2B108ZV Not used CJA2B108ZV CJA2B108ZV

>

5Packing Case CPG1A961Z CPG1A961W CPG1A961Y CPG1A961U CPG1A961T CPG1A961X CPG1A961R

9 Operating Instructions CQX1A1640Y CQX1A1640Y CQX1A1640Y CQX1A1640Y CQX1A1644Z CQX1A1640Y CQX1A1640Y

A-30-K/

PWSYXE8

A-30-S/

PWSYXE8

A-20-K/

PWSYXE8

A-20-S/

PWSYXE8

A-20/

CUXE

A-10-K/

SYXE8

A-10-S/

SYXE8

A

B

C

12 Polyethylene Bag (Accessary) CPB1A008Z CPB1A008Z CPB1A008Z CPB1A008Z Not used CPB1A008Z CPB1A008Z

D

E

F

A-30-K

5

6 7 8

33

Page 34

1

A

∗1

∗1

∗1

A

B

A

B

C

D

E

E

F

F

G

H

G

A

D

E

E

B

C

D

E

F

B

H

C

A

A´

A´

B

B´

B´

C

F

C

D

F

D

∗1 : Cut from the Sub Panel.

CONTACT SIDE

NON-CONTACT

SIDE

A-20-K/PWSYXE8,

A-20-S/PWSYXE8 only A-20/CUXE only

2 3 4

9.2 EXTERIOR SECTION (A-30/A-20)

A

B

C

D

E

F

34

1

A-30-K

2 3 4

Page 35

5

6 7 8

(1) EXTERIOR SECTION (A-30/A-20) PARTS LIST

Mark No. Description Part N o.

1 MAIN ASSY See Contrast table (2)

2 FRONT ASSY See Contrast ta ble (2)

3 MASTER VOLUME ASSY See Contrast table (2)

4 TONE ASSY AZW7477

5 HEADPHONE ASSY AZW7479

Mark

No. Description Part No.

36 Heat Sink Bracket CMD1A800

37 Trans Bracket CMD1A801

> 38 AC Power Cord (CU) See Contrast table (2)

39 Screw BBZ30P060FTB

40 Special Screw CHD3A012R

A

6 SECOUND POWER SW ASSY AZW7478

7Power Knob See Contrast table (2)

8Function Knob See Contrast table (2)

9 Balance Knob See Contrast table (2)

10 Volume Knob See Contrast table (2)

11 Input Knob See Contrast table (2)

12 IR Window See Contrast table (2)

13 Power Indicator CGL1A296

14 Standby Indicator CGL1A297

15 Funkcion Indicator CGL1A298

16 Sub Panel See Contrast table (2)

17 PCB Holder CHE170

18 Foot Cushion CHG1A528

19 Top Cushion CHG1A530

20 Main Cushion CHG1A531

21 PEF Cushion CHG1A532

22 Wire Clamper CHK1A009

23 Clamper CHR301

NSP 24 Serial Label S VRW2017

25 Cover Sheet CHS1A154

26 AC Inlet See Contrast table (2)

27 Top Cabinet See Contra

28

anel See Contrast table (2)

Rear P

29 Insulator See Contrast table (2)

30 AL Panel See Contrast table (2)

st table (2)

41 Screw See Contrast table (2)

42 Screw CTB3+8JR

43 Screw BBZ30P100FTB

44 Screw See Contrast table (2)

45 AC Cord Bushing See Contrast table (2)

46 Screw See Contrast table (2)

47 Screw CTW3+6JR

48 EOL Item Screw CTW3+8JR

49 Screw CTW3+12JR

50 Trans Screw CHDR1A023R

51 Screw BSZ30P060FTB

52 Screw See Contrast table (2)

53 Special Screw CHD4A012R

54 Screw CTB3+6JR

55 17P FFC Cable

CWC4F4A17B150B10

> 56 Fuse (250V) See Contrast table (2)

57 Ground Washer CNW1A035

58 • • • • •

59 • • • • •

60 • • • • •

61 • • • • •

62 Power TR CVT2SD2390P43M

63 Power TR CVT2SB1560P43M

64 Bias TR HVTKTC3114A

65 Posistor ASSY CRTDHTS100070W2

B

C

D

> 31 Power Transformer See Contrast table (2)

32 Ground Terminal CMA1A006

33 Speaker Sheet CMZ1A139Z

34 Pioneer Badge (AL) See Contrast table (2)

35 AC Inlet Wire (SY) See Contrast table (2)

5

6 7 8

A-30-K

66 Acetate Tape (5 x 25) CHS1A218

67 Acetate Tape (10 x 15) CHS1A217

68 Double Side T ape C4FA051

69 Knob Spring CUS2A169

70 Hemelon Tape CHS1A032

E

F

35

Page 36

1

2 3 4

(2) CONTRAST TABLE

A-30-K/PWSYXE8, A-30-S/PWSYXE8, A-20-K/PWSYXE8 , A-20-S/PWSYXE8 and A-20/CUXE are constructed the same except

for the following:

Mark No. Symbol and Description

A

1 MAIN ASSY AZW7487 AZW7487 AZW7489 AZW7489 AZW7490

2 FRONT ASSY AZW7482 AZW7482 AZW7483 AZW7483 AZW7484

3 MASTER VOLUME ASSY AZW7476 AZW7476 AZW7481 AZW7481 AZW7481

7 Power Knob CBT1A1162 CBT1A1162C81 CBT1A1162 CBT1A1162C81 CBT1A1162

8Funktion Kn o b CBT1A1163 CBT1A1163MQG69 CBT1A1163 C BT1A1163MQG69 CBT1A1163

9 Balance Knob CGK1A164ZA CGK1A164YA CBN1A260 CBN1A260MQG69 CBN1A260

10 Volume Knob CGK1A165ZA CGK1A165YA CBN1A262 CBN1A262MQG69 CBN1A262

11 Input Knob CGK2A164ZA CGK2A164YA CBN1A261 CBN1A261MQG69 CBN1A261

12 IR Window CGL1A295Z CGL1A295 CGL1A295Z CGL1A295 CGL1A295Z

16 Sub Panel CGW1A517 CGW1A517MQG69 CGW1A517 CGW1A517MQG69 CGW1A517

B

26 AC Inlet CJJ8A006ZW CJJ8A006ZW CJJ8A018Z CJJ8A018Z Not used

27 Top Cabinet CKC2A214B62 CKC2A214G70 CKC2A214B62 CKC2A214G70 CKC2A214B62

28 Rear Panel CKF1A452Z CKF1A452R CKF2A452X CKF2A452Q CKF4A452W

29 Insulator CKL1A204 CKL1A204H65 CKL1A204 CKL1A204H65 CKL1A204

30 AL Panel CKM1A243ZC79 CKM1A243YC80 CKM2A243XC79 CKM2A243WC80 CKM2A243VC79

31 Power Transformer CLT5U050ZE CLT5U050ZE CLT5R043ZE CLT5R043ZE CLT5R043ZU

>

34 Pioneer Badge (AL) BAM1004 VAM1124 BAM1004 VAM1124 PAN1376

35 AC Inlet Wire (SY) Not used Not used CWZA10CN96A CWZA10CN96A Not used

38 Power Cord (CU) Not used Not used Not used Not used CJA523FBYA

>

41 Screw BBZ30P080FTB CTB3+8JFC BBZ30P080FTB CTB3+8JFC BBZ30P080FTB

A-30-K/

PWSYXE8

A-30-S/

PWSYXE8

A-20-K/

PWSYXE8

A-20-S/

PWSYXE8

A-20/

CUXE

C

D

E

44 Screw CTB4+6FFZRP CTB4+6FFCP CTB4+6FFZRP CTB4+6FFCP CTB4+6FFZRP

45 AC Cord Bushing Not used Not used Not used Not used CHR1A028

46 Screw CTS3+8JFZR CTS3+8JR CTB3+8JFZR CTB3+8JFZR CTB3+8JFZR

52 Screw CBZ30P080FTB CBZ30P080FTB CTB3+8JFZR CTB3+8JFZR Not used

56 Fuse (250V) CBA2C2000TLEC CBA2C2000TLEC CBA2C2000TLEC CBA2C2000TLEC CBA2C3150TLEC

>

F

36

1

2 3 4

A-30-K

Page 37

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

37

Page 38

1

A

D

F

B´

C

A

B

A

B

D

E

E

F

G

B

C

D

E

G

F

A

A´

B

B´

C

C

C

A´

E

D

A

B

E

F

D

CONTACT SIDE

NON-CONTACT

SIDE

9.3 EXTERIOR SECTION (A-10)

A

B

2 3 4

C

D

E

F

38

1

2 3 4

A-30-K

Page 39

5

6 7 8

(1) EXTERIOR SECTION (A-10) PARTS LIST

Mark No. Description Part N o.

1 MAIN ASSY AZW7491

2 FRONT ASSY AZW7485

3 MASTER VOLUME ASSY AZW7481

4 TONE ASSY AZW7477

5 HEADPHONE ASSY AZW7479

Mark

No. Description Part No.

36 • • • • •

37 Screw BBZ30P060FTB

38 Special Screw CHD3A012R

39 Screw See Contrast table (2)

40 Screw CTB3+8JR

A

6Power Knob See Contrast table (2)

7Function Knob See Contrast table (2)

8 Balance Knob See Contrast table (2)

9Volume Knob See Contrast table (2)

10 Input Knob See Contrast table (2)

11 AC Inlet Wire (SY) CWZA10CN96A

12 Power Indicator CGL1A296

13 Standby Indicator CGL1A297

14 Function Indicator CGL1A298

15 PCB Holder CHE170

16 Foot Cushion CHG1A528

17 Top Cushion CHG1A530

18 Main Cushion CHG1A531

19 PEF Cushion CHG1A532

20 Wire Clamper CHK1A009

21 Clamper CHR301

NSP 22 Serial Label S VRW2017

23 Cover Sheet CHS1A154

24 • • • • •

25 AC Inlet (Screw Type) CJJ8A018Z

26 Top Cabinet See Contrast table (2)

27 Rear Panel See Contrast table (2)

28 Insulator See Contrast table (2)

29 Front Panel See Contrast table (2)

> 30 Power Tran

Ground Terminal CMA1A006

31

sf

ormer (74 x 53) SY CLT5R043ZE

32 Speaker Sheet CMZ1A139Z

33 Pioneer Badge See Contrast table (2)

34 • • • • •

35 Heat Sink Bracket CM D1A 800

41 Screw BBZ30P100FTB

42 Screw See Contrast table (2)

43 Screw CTB3+8JFZR

44 Screw CTW3+6JR

45 EOL Item Screw CTW3+8JR

46 Screw CTW3+12JR

47 Trans Screw CHDR1A023R

48 Screw BSZ30P060FTB

49 Special Screw CHD4A012R

50 • • • • •

51 17P FFC Cable

CWC4F4A17B150B10

> 52 Fuse (250V 2A) CBA2C2000TLEC

53 • • • • •

54 • • • • •

55 • • • • •

56 • • • • •

57 Power TR CVT2SD2390P43M

58 Power TR CVT2SB1560P43M

59 Bias TR HVTKTC3114A

60 Posistor ASSY CRTDHTS100070W2

61 Acetate Tape (5 x 25) CHS1A218

62 Acetate Tape (10 x 15) CHS1A217

63 Double Side T ape C4FA051

64 Knob Spring CUS2A169

65 Hemelon Tape CHS1A032

B

C

D

(2) CONTRAST TABLE

A-10-K/SYXE8 and A-10-S/SYXE8 are constructed the same except for the following:

Mark No. Symbol and Description

6 Power Knob CBT1A1162 CBT1A1162C81

7Function Kn o b CBT1A1163 CBT1A1163MQG69

8 Balance Knob CBN1A260 CBN1A260MQG69

9Volume Knob CBN1A262 C BN1A262MQG69

10 Input Knob CBN1A261 CBN1A261MQG69

26 Top Cabinet CKC2A214B62 CKC2A214G70

27 Rear Panel CKF3A452U CKF3A452P

28 Insulator CKL1A204 CKL1A204H65

29 Front Panel CGW2A518H10Z CGW2A518MQG69Y

33 Pioneer Badge AAM7016 VAM1129

39 Screw BBZ30P080FTB CTB3+8JFC

42 Screw CTB4+6FFZRP CTB4+6FFCP

A-10-K/

SYXE8

A-30-K

5

6 7 8

A-10-S/

SYXE8

E

F

39

Page 40

1

A

CN41

D

BN41

CN51

C

BN51

JK11

JK12

JK13

JK14

JK15

CY93

CN95

B

CX93

B

BN94

CN94

C

2 3 4

10. SCHEMATIC DIAGRAM

10.1 MAIN ASSY

A

B

C

D

E

F

40

1

2 3 4

A-30-K

Page 41

5

A

JK91

CN96

CN93

CN92

CN91

CN90

CN55

JK31

E

BN55

MAIN ASSY

(A-30-K/-S : AZW7487)

(A-20-K/-S : AZW7489)

(A-20 : AZW7490)

(A-10-K/-S : AZW7491)

A

Therefore, when replacing, be sure to use parts of identical designation.

When ordering service parts, be sure to refer to "EXPLODED VIEWS and PARTS LIST" or "PCB PARTS LIST".

The > mark found on some component parts indicates the importance of the safety factor of the part.

ACH7378

6 7 8

A

B

C

D

E

F

5

6 7 8

A-30-K

41

Page 42

1

XB

A

CN94

A

CY93

BN94

CX93

2 3 4

10.2 FRONT ASSY and SECOND POWER SW ASSY (A-30/A-20)

A

B

C

D

E

F

42

A-30-K

1

2 3 4

Page 43

5

FB

C

CN52

FRONT ASSY

(A-30-K/-S : AZW7482)

(A-20-K/-S : AZW7483)

(A-20 : AZW7484)

(A-10-K/-S : AZW7485)

B

SECOND POWER SW ASSY

(A-30-K/-S, A-20-K/-S, A-20 : AZW7478)

F

BN52

CN12

BN12

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

43

Page 44

1

C

MASTER VOLUME ASSY

(A-30-K/-S : AZW7476)

(A-20-K/-S, A-20, A-10-K/-S : AZW7481)

C

BN51

CN52

A

CN51

B

BN52

2 3 4

10.3 MASTER VOLUME ASSY, TONE ASSY and HEADPHONE ASSY

A

B

C

D

E

F

44

1

2 3 4

A-30-K

Page 45

ED

TONE ASSY

(AZW7477)

D

HEADPHONE ASSY

(AZW7479)

E

A

CN41

BN55

A

CN55

BN41

5

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

45

Page 46

1

A

BN94

CN94

B

AC IN

CN96

CN93

CN92 CN90 CN91

TRANSFORMER

BN55

CN55

E

SIDE A

MAIN ASSY

A

NOTE FOR PCB DIAGRAMS :

1. The parts mounted on this PCB include all

necessary parts for se veral destinations.

For further information for respective

destinations, be sure to check with the

schematic diagram.

CapacitorConnector

P.C. Bo ard Chip Part

SIDE A

SIDE B

2. Vie w point of PCB diagrams.

2 3 4

11. PCB CONNECTION DIAGRAM

11.1 MAIN ASSY

A

B

C

D

E

F

46

1

A-30-K

2 3 4

Page 47

5

A

BN51

CN51

C

BN41

CN41

D

CX93

CY93

B

SIDE A

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

47

Page 48

A

A

CN91

CN51

CN41CY93

SIDE B

MAIN ASSY

A

B

1

2 3 4

C

D

E

F

48

1

A-30-K

2 3 4

Page 49

5

A

CN94

CN93

CN92

CN90

CN55

CN96

SIDE B

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

49

Page 50

1

B

CN12

BN12

F

CN94

BN94

A

BN94

BN12

SIDE B

SIDE A

FRONT ASSY

B

FRONT ASSY

B

11.2 FRONT ASSY

A

2 3 4

B

C

D

E

F

50

A-30-K

1

2 3 4

Page 51

5

B

CN52

BN52

C

CY93

CX93

BN52 CX93

A

SIDE B

SIDE A

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

51

Page 52

1

C C

CN51

BN51

BN51

A

BN52

CN52

CN52

B

SIDE B

SIDE B

SIDE A

SIDE A

MASTER VOLUME ASSY

C

MASTER VOLUME ASSY

C

11.3 MASTER VOLUME ASSY

A

2 3 4

B

C

D

E

F

52

1

2 3 4

A-30-K

Page 53

5

D D

CN41

BN41

BN41

A

SIDE B SIDE B

SIDE A

SIDE A

TONE ASSY

D

TONE ASSY

D

11.4 TONE ASSY

6 7 8

A

B

C

D

E

F

A-30-K

5

6 7 8

53

Page 54

1

E F FE

CN55

BN55

A

BN12

CN12

BN55

CN12

B

SIDE B

SIDE B

SIDE A

SIDE A

HEADPHONE ASSY

E

SECOND POWER SW ASSY

F

HEADPHONE ASSY

E

SECOND POWER SW ASSY

F

2 3 4

11.5 HEADPHONE ASSY and SECOND POWER SW ASSY (A-30/A-20)

A

B

C

D

E

F

54

1

2 3 4

A-30-K

Page 55

5

5 6 2 1

1 R 0

R 5 0

5 6 1

4 7 3

NOTES: - Parts marked by “NSP” are generally unavailable because they are not in our Master Spare Parts List.

-

The > mark found on some component parts indicates the importance of the safety factor of the part.

Therefore, when replacing, be sure to use parts of identical designation.

-

When ordering resistors, first convert resistance values into code form as shown in the following examples.

Ex.1 When there are 2 effective digits (any digit apart from 0), such as 560 ohm and 47 k ohm (tolerance is shown by J = 5%,

and K = 10%).

560 Ω → 56 × 101 → 561

...................................................................

RD1/4PU J

47 kΩ → 47 × 10

3

→ 473

...................................................................

RD1/4PU J

0.5 Ω → R50

.................................................................................................

RN2H K

1 Ω → 1R0

.................................................................................................

RS1P K

Ex.2 When there are 3 effective digits (such as in high precision metal film resistors).

5.62 kΩ → 562 × 101 → 5621

.................................................................

RN1/4PC F

12. PCB PARTS LIST

6 7 8

A

[Wiring number reading substitute list]

SCHEMATIC

DIAGRAM, PCB

JK11 JA11 CJJ4N034Z MAIN

JK12 JA12 CJJ4P028Z MAIN

JK13 JA13 CJJ4P028Z MAIN

JK14 JA14 CJJ4P028Z MAIN

JK15 JA15 CJJ4N034Z MAIN

JK31 JA31 CJJ5Q006Z MAIN

JK91 JA91 HJJ1D002Z MAIN

RC11 IC1011 CRVKSM601TE5CA FRONT

BN12 J12 CWB1B00308047 FRONT

BN52 J52 CWB1B00515047 FRONT

BN94 J94 CWB1B01335047 FRONT

SW11 S11 CSR2A056Z FRONT

BN51 J51 CWB1C0112004W001 MASTER VOLUME

BN41 J41 CWB1B01120047 T ONE

BN55 J55 CWB4B00340047 HEADPHONE

JK61 JA61 CJJ2E020Z HEADPHONE

SW12 S12 CSH2B024Z SECOND POWER SW

Mark No. Description Part No.

LIST OF ASSEMBLIES

NSP 1..MAIN ASSY (A-30-K/-S) COP12421B

2..MAIN ASSY AZW7487

NSP 1..MAIN ASSY (A-20-K/-S) COP12421D

2..MAIN ASSY AZW7489

NSP 1..MAIN ASSY (A-20) COP12421E

2..MAIN ASSY AZW7490

NSP 1..MAIN ASSY (A-10-K/-S) COP12421F

2..MAIN ASSY AZW7491

NSP 1..FRONT ASSY (A-30-K/-S) COP12422B

2..FRONT ASSY AZW7482

2..MASTER VOLUME ASSY AZW7476

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

Parts List Parts No. Name of Assembly

Mark No. Description Part No.

NSP 1..FRONT ASSY (A-20) COP12422G

2..FRONT ASSY AZW7484

2..MASTER VOLUME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

NSP 1..FRONT ASSY (A-10-K/-S) COP12422D

2..FRONT ASSY AZW7485

2..MASTER VOLUME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

B

C

D

E

NSP 1..FRONT ASSY (A-20-K/-S) COP12422C

2..FRONT ASSY AZW7483

2..MASTER VOLUME ASSY AZW7481

2..TONE ASSY AZW7477

2..HEADPHONE ASSY AZW7479

2..SECOND POWER SW ASSY AZW7478

5

6 7 8

A-30-K

F

55

Page 56

1

CAUTIONS

The parts number of Q317, Q318 (BIAS Transistor), Q319, Q320,

Q321, Q322 (Power Transistor) and TH31, TH32 (Posistor) are

indicated in [9.2 EXTERIOR SECTION (A-30/A-20)] and

[9.3 EXTERIOR SECTION (A-10)] of [9. EXPLODED VIEWS

AND PARTS LIST]

2 3 4

A MAIN ASSY

AZW7487, AZW7489, AZW7490 and AZW7491 are constructed the same except for the following:

A

Symbol and

Mark

Description

JA15 CJJ4N034Z Not used Not used Not used

RY22 CSL4B022ZE Not used Not used Not used

RY32 CSL4B023ZE CSL4B024ZE CSL4B024ZE CSL4B024ZE

RY33 CSL4B023ZE CSL4B024ZE CSL4B024ZE CSL4B024ZE

T901 CLT5I010ZE CLT5I010ZE CLT5I010ZU CLT5I010ZE

C908 ACH7378 CCET50 VPLP822NCP CCET50VPLP822NCP CCET50VPLP822NCP

C909 ACH7378 CCET50 VPLP822NCP CCET50VPLP822NCP CCET50VPLP822NCP

AZW7487AZW7489

AZW7490 AZW7491

B FRONT ASSY

B

AZW7482, AZW7483, AZW7484 and AZW7485 are constructed the same except for the following:

Symbol and

Mark

Description

D109 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D110 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D111 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D112 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D114 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D115 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D116 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D117 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

C

D118 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D119 CVDGY34MD22B51CMCACL CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ CVDGY34SU05R41BJDABJ

D120 CVDGY34MD22B51CMCACL Not used Not used Not used

S101 Not used Not used Not used CST1A023ZT

S106 CST1A023ZT Not used Not used Not used

AZW7482AZW7483AZW7484AZW7485

PCB PARTS LIST FOR A-30-K/-S UNLESS OTHERWISE NOTED

Mark No. Description Part No.

MAIN ASSY

A

D

SEMICONDUCTORS

IC 20 HVINJM2068MDTE1

IC 21 HVILC78212

IC 22,23,26 CVIAZ4580MTR-E1

IC 24 CVINJU7181RB1

IC 25 HVITC74HCT7007F

IC 91 CVINJU7223F33

IC 93,94 CVILM7815FTL

IC 95 CVIISP278R05FTL

Q 301-306,311,312 CVTKSC1845FTA

Q 307-310 CVTKSA992FTA

E

Q 313,314 HVTKTA1360Y

Q 315,316 HVTKTC3423Y

Q 323,324 HVTKTC3198YT

D 901 HVDGBJ806

D 902-905,908,909 CVD1N4003ST

D 906,907,918 CVDRB521S-30

D 912-917 CVD1N4003ST

MISCELLANEOUS

L 301,302 COIL , SPEAKER(0.5UH) CLEY0R5KAK

F

JA 11,15 JACK , IN/OUT CJJ4N034Z

JA 12-14 JACK , IN/OUT CJJ4P028Z

JA 31 TERMINAL , SPEAKER CJJ5Q006Z

JA 91 JACK , STEREO(2P 3.5PIE) HJJ1D002Z

56

1

2 3 4

A-30-K

Mark No. Description Part No.

VR 31,32 RES , SEMI FIXED (220 OHM) CVN12A221B03T

RY 21,22 RELAY , BC3-24H , DC24V , 2C2P CSL4B022ZE

RY 31 RELAY , BC3-24H , DC24V , 2C2P CSL4B022ZE

RY 32,33 RELAY , HL3-2A-24 , DC24V , 2C2P CSL4B023ZE

RY 91 RELAY,G5PA-1,DC6V,1C1P CSL1E002ZE

T 901 TRANS , SUB RCD-M37EUR CLT5I010ZE

RESISTORS

R 347-350 CRG1SANJ3R3RT

R 351-354 CRG1SANJ180RT

R 355,356,369,370 CRF5EKR22H

R 371,372,375,376 CRG1ANJ100H

R 933,934 CRQ1AJR47H

CAPACITORS

C 278 CCEA1EH102ECP

C 918,919 CCEA1EH222ECP

C 927,933,937,950 CCEA1CH102ECP

C 938 CCEA0JH102T

C 947,948 KCKDKS472ME

Page 57

5

6 7 8

Mark No. Description Part No.

FRONT ASSY

B

SEMICONDUCTORS

IC 11 CVIANAM1656A

IC 12 CVIML61C282PR

IC 1011 CRVKSM601TE5CA

D105

D 106 CVDBLBUF4V5K1AV

D 107,109-112

D 114-120

MISCELLANEOUS

J 12 ROCKING TYPE WIRE ASSY CWB1B00308047

(3P, 80MM, 2.0MM)

J 52 ROCKING TYPE WIRE ASSY CWB1B00515047

(5P, 150MM, 2.0MM)

J 94 ROCKING TYPE WIRE ASSY CWB1B01335047

(13P, 350MM, 2.0MM)

S 11 VR, ENCODER CSR2A056Z

S 102-106 SW , TACT CST1A023ZT

MASTER VOLUME ASSY

C

SEMICONDUCTORS

IC 41 CVIAZ4580MTR-E1

IC 42 CVIBU4052BCF

CVDGY34MU22Y16BJTAA4

CVDGY34MD22B51CMCACL

CVDGY34MD22B51CMCACL

Mark No. Description Part No.

HEADPHONE ASSY

E

MISCELLANEOUS

J 55 ROCKING TYPE WIRE ASSY CWB4B00340047

(3P, 400MM, 2.0MM)

JA 61 JACK, PHONES(6.35MM,GOLD) CJJ2E020Z

RESISTORS

R 601,602 CRD25TJ470T

SECOND POWER SW ASSY(A-30/A-20)

F

MISCELLANEOUS

S 12 SW, PUSH (FOR DC , 2C2P) CSH2B024Z

A

B

C

MISCELLANEOUS

J 51 ROCKING TYPE SHIELD WIRE ASSY CWB1C0112004W001

(11P, 200MM, 2.0MM)

VR 41 VOLUME , MOTOR CVV9Y13B503Z

RESISTORS

R 403 CRD25TJ100T

CAPACITORS

C 440 CCEA0JH102TC

TONE ASSY

D

SEMICONDUCTORS

IC 51,52 CVIAZ4580MTR-E1

MISCELLANEOUS

J 41 ROCKING TYPE WIRE ASSY CWB1B01120047001

(11P, 200MM, 2.0MM)

VR 51,52 RES, VARIABLE(ANGLE) CVV3W01B103Z

VR 53 RES, VARIABLE(ANGLE) CVV3W02M203Z

RESISTORS

R 503,514 CRD25TJ100T

D

E

F

A-30-K

5

6 7 8

57

Loading...

Loading...