Page 1

PMCtendo SZ

Pilz Motion Control

OperatingManual1002405EN03

Page 2

Preface

Thisdocumentisatranslationoftheoriginaldocument.

AllrightstothisdocumentationarereservedbyPilzGmbH&Co.KG.Copiesmaybemade

forinternalpurposes.Suggestionsandcommentsforimprovingthisdocumentationwillbe

gratefullyreceived.

Pilz®,PIT®,PMI®,PNOZ®,Primo®,PSEN®,PSS®,PVIS®,SafetyBUSp®,

SafetyEYE®,SafetyNETp®,thespiritofsafety®areregisteredandprotectedtrademarks

ofPilzGmbH&Co.KGinsomecountries.

SDmeansSecureDigital

Page 3

Table of contents

Table of contents

1 Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.1 Purpose of the manual. . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.2 Further support . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

1.3 Modifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2 Notes on Safety . . . . . . . . . . . . . . . . . . . . . . . . . .

2.1 Warranty and liability . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.2 Component part of the product . . . . . . . . . . . . . . . . . . . . . . .

2.3 Operation in accordance with its intended use . . . . . . . . . . .

2.4 Qualified personnel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.5 Working on the machine . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.6 Disposal . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.7 Directives and norms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

2.8 Presentation of notes on safety . . . . . . . . . . . . . . . . . . . . . . .

3 Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6

6

6

6

7

7

7

7

8

8

8

8

9

11

3.1 PMCtendo SZ servo motors. . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.1 Type label . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.1.2 Order reference. . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.2 Drive controller. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.3 Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.4 Dynamic performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.5 Operating mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.6 Thermal winding protection . . . . . . . . . . . . . . . . . . . . . . . . . .

3.7 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8 Holding brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

3.8.1 Motor holding brake . . . . . . . . . . . . . . . . . . . . . . . .

3.8.2 Brake test and grinding . . . . . . . . . . . . . . . . . . . . . .

3.9 Motor shaft and bearings . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4 Transportation and storage. . . . . . . . . . . . . . . . .

11

12

13

14

14

14

14

15

15

15

15

16

16

17

Operating Manual PMCtendo SZ

1002405-EN-03

3

Page 4

Table of contents

4.1 Transportation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

4.2 Storage. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5 Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.1 Installation Location . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

5.2 Install motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6 Electrical installation . . . . . . . . . . . . . . . . . . . . . .

6.1 General information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.1 Wiring . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.1.2 Earthing, shielding and EMC. . . . . . . . . . . . . . . . . .

6.1.3 Selecting the cables . . . . . . . . . . . . . . . . . . . . . . . .

6.1.4 speedtec® and springtec® plug connector . . . . . . .

6.2 Servo motor and motor brake . . . . . . . . . . . . . . . . . . . . . . . .

6.2.1 Power cable . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.2.2 Assignment: Motor and power cable . . . . . . . . . . . .

17

17

18

18

19

21

21

21

22

23

23

26

26

28

6.3 Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.4 External fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

6.5 Water cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7 Commissioning . . . . . . . . . . . . . . . . . . . . . . . . . .

7.1 Check installation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.2 Check connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

7.3 Put into operation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8 Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.1 Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.2 In the event of disruptions . . . . . . . . . . . . . . . . . . . . . . . . . . .

8.3 Replace motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9 Technical data. . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.1 Ambient conditions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.2 Device Features. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

30

31

31

32

32

33

34

36

36

37

38

39

39

39

Operating Manual PMCtendo SZ

1002405-EN-03

9.3 Electrical Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4 Cooling. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

40

40

4

Page 5

Table of contents

9.4.1 Convection cooling . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.2 External fan . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.4.3 Water cooling . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.5 Feedback . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.6 Holding brake. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.7 Thermal winding protection . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8 Derating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.1 Installation altitude . . . . . . . . . . . . . . . . . . . . . . . . .

9.8.2 Ambient temperature. . . . . . . . . . . . . . . . . . . . . . . .

9.9 Type-specific data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9.1 Inertia . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9.2 Weight . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

9.9.3 Permitted shaft load . . . . . . . . . . . . . . . . . . . . . . . .

9.9.4 Voltage limit curves . . . . . . . . . . . . . . . . . . . . . . . . .

40

40

41

42

43

46

47

47

48

49

62

63

64

70

9.9.5 Key safety-related indicators. . . . . . . . . . . . . . . . . .

10 Glossary . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

79

80

Operating Manual PMCtendo SZ

1002405-EN-03

5

Page 6

1 Introduction

1Introduction

1.1 Purpose of the manual

This operating manual describes the servo motors PMCtendo SZ. It includes information

about, transport, storage, installation, connection, commissioning, service and disposal.

Please also refer to the documentation for the servo amplifier.

1.2 Further support

If you have any queries that are not covered in this document, you can find more information at www.pilz.com

1.3 Modifications

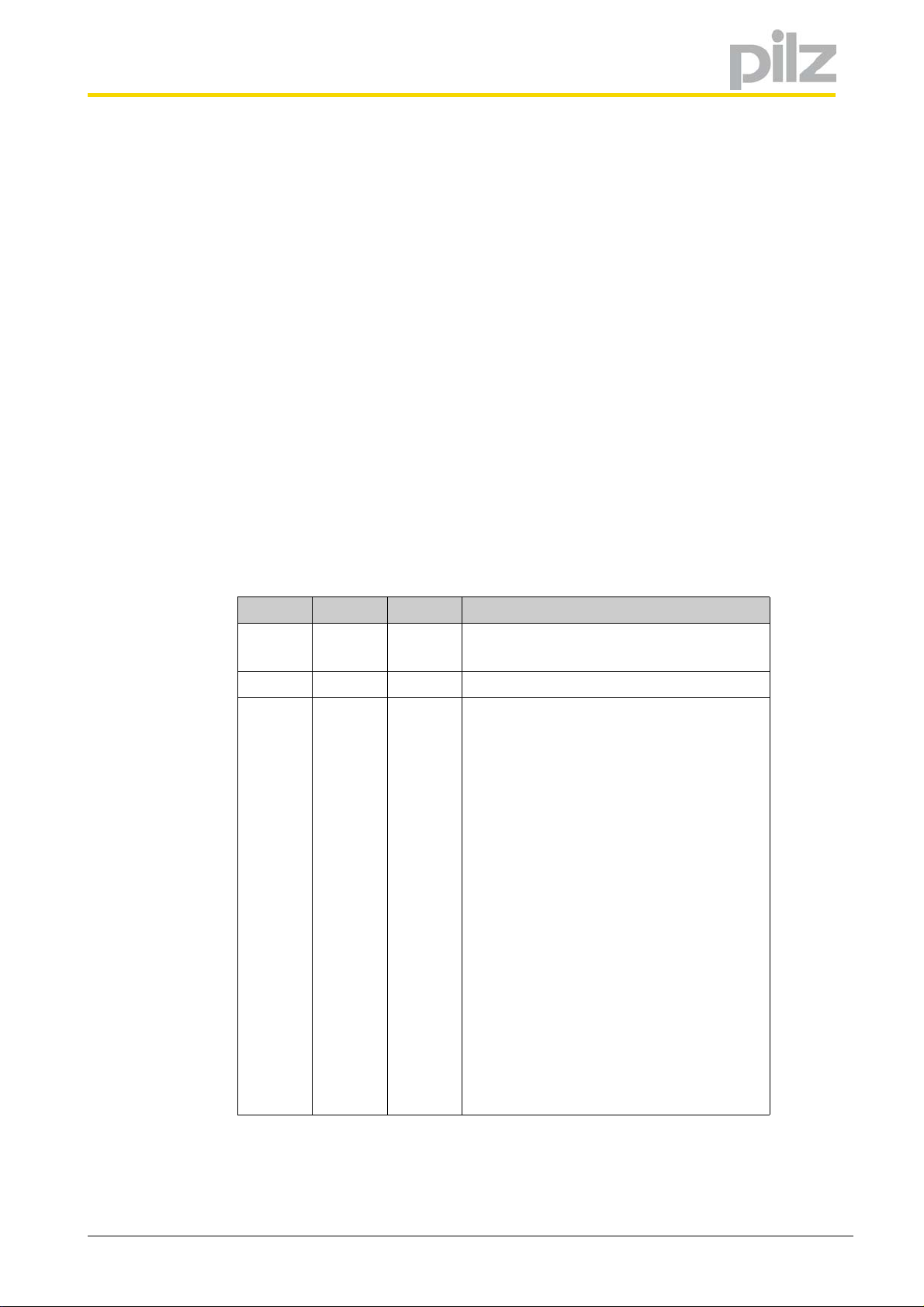

No. Versi on Date Change

1002504 01 0

1002504 02 09/2012 Update: Feedback system

1002504 03 03/2014 • Additions:

First edition

7/2012

Motor types SZ3x and SZ8x

Type keys

Directives and standards

springtec® plug connector

Type-specific data

Characteristic safety values

• Updates:

Rating plate

Power cable

Feedback connection

External fan

Thermal winding protection

Electrical installation

Brake data, brake moment of inertia values

Number of motor poles

Formula symbols

Operating Manual PMCtendo SZ

1002405-EN-03

6

Page 7

2 Notes on Safety

2 Notes on Safety

2.1 Warranty and liability

The devices can represent a source of danger. Therefore observe

• the safety guidelines, technical rules and regulations given in the following sections

•and points.

Warranty and liability claims will be void if

• the product has not been used for its intended purpose,

• the damage is attributable to a failure to observe the operation instruction,

• the operating personnel has not been properly trained, or

• modifications of any kind have been made.

2.2 Component part of the product

The technical documentation is a component part of a product.

• Since the technical documentation contains important information, always keep it

handy in the vicinity of the device until the machine is disposed of.

• If the product is sold, disposed of, or rented out, always include the technical documentation with the product.

2.3 Operation in accordance with its intended use

The servo motors are intended for installation in machines or systems or for assembly

with other components in a machine They must be operated in conjunction with suitable

and correctly configured servo amplifiers (e.g. PMCtendo DD4, PMCtendo DD5 or

PMCprotego D).

The thermal motor protection integrated in the motor winding must be monitored and

evaluated.

The following is deemed improper use:

• direct connection to the mains power supply,

• any component, technical or electrical modification,

• use outside the areas described in this manual,

• use outside the documented technical details.

Operating Manual PMCtendo SZ

1002405-EN-03

7

Page 8

2 Notes on Safety

2.4 Qualified personnel

Devices may cause residual risks. For this reason, all work on the devices as well as operation and disposal must only be performed by qualified personnel who are aware of the

possible dangers.

Qualified personnel are persons who have acquired the authorisation to perform these

activities by

• Training from specialists and/or

• Instruction from specialists

In addition, they must have

• read,

• understood and

• observed the applicable regulations, legal provisions, rules and standards and existing technical documentation including the safety information contained in it.

2.5 Working on the machine

Apply the 5 safety rules in the order stated before working on the machine:

1. Activate. Make sure the auxiliary circuits are activated.

2. Secure against unintentional restart.

3. Make sure no voltage is present.

4. Ground and short-circuit.

5. Cover or enclose adjacent live parts.

2.6 Disposal

Please comply with the latest national and regional regulations! Dispose of the individual

parts separately depending on their nature and currently valid regulations such as, for

example:

• Electronic scrap (PCBs)

• Plastic

• Sheet metal

• Copper

•Aluminum

2.7 Directives and norms

The servo motors meet the following guidelines and norms

• Directive 2006/95/EC (Low Voltage Directive)

• Directive 2004/108/EC (Directive on Electromagnetic Compatibility)

• DIN EN 60204-1 version 2007

• DIN EN 60034-1 version 2011

Operating Manual PMCtendo SZ

1002405-EN-03

8

Page 9

2 Notes on Safety

• DIN EN 60034-5 version 2007

• DIN EN 60034-6 version 1996

• DIN EN 60034-9 version 2008

• DIN EN 60034-14 version 2008

• UL and CSA approval

All motors are supplied with certifications as "Recognized Component Class 155 (F)

motor insulation system".

UL approval is registered with Underwriters Laboratories USA under UL File Number

E182088 (N), Classes OBJY2 and OBJY8, Component-Systems, Electrical Insulation. UL certification is needed mainly for the use of motors and geared motors on

the US market. But, also in many countries UL approval is considered a special mark

of quality.

2.8 Presentation of notes on safety

IMPORTANT

IMPORTANT

This means that material damage may occur

if the safety precautions stated are not observed.

NOTICE!

CAUTION

This means that a minor injury may occur.

if the safety precautions stated are not observed.

WARNING!

Warning

means that there may be a serious danger of death

if the stated precautionary measures are not taken.

Operating Manual PMCtendo SZ

1002405-EN-03

9

Page 10

2 Notes on Safety

DANGER!

Danger

means that serious danger of death exists

if the stated precautionary measures are not taken.

INFO

refers to important information about the product or serves to emphasize a

section in the documentation to which the reader should pay special attention.

Operating Manual PMCtendo SZ

1002405-EN-03

10

Page 11

3 Description

3 Description

3.1 PMCtendo SZ servo motors

The PMCtendo SZ synchronous servo motors have a very short design achieved thanks

to an optimized winding technology. This feature makes it possible to manufacture the

stator windings with the highest possible copper fill factor. With this technology and further optimizations in the mechanical parts it has been possible to shorten the length of

the motor by almost half without reducing the power output.

Operating Manual PMCtendo SZ

1002405-EN-03

11

Page 12

3 Description

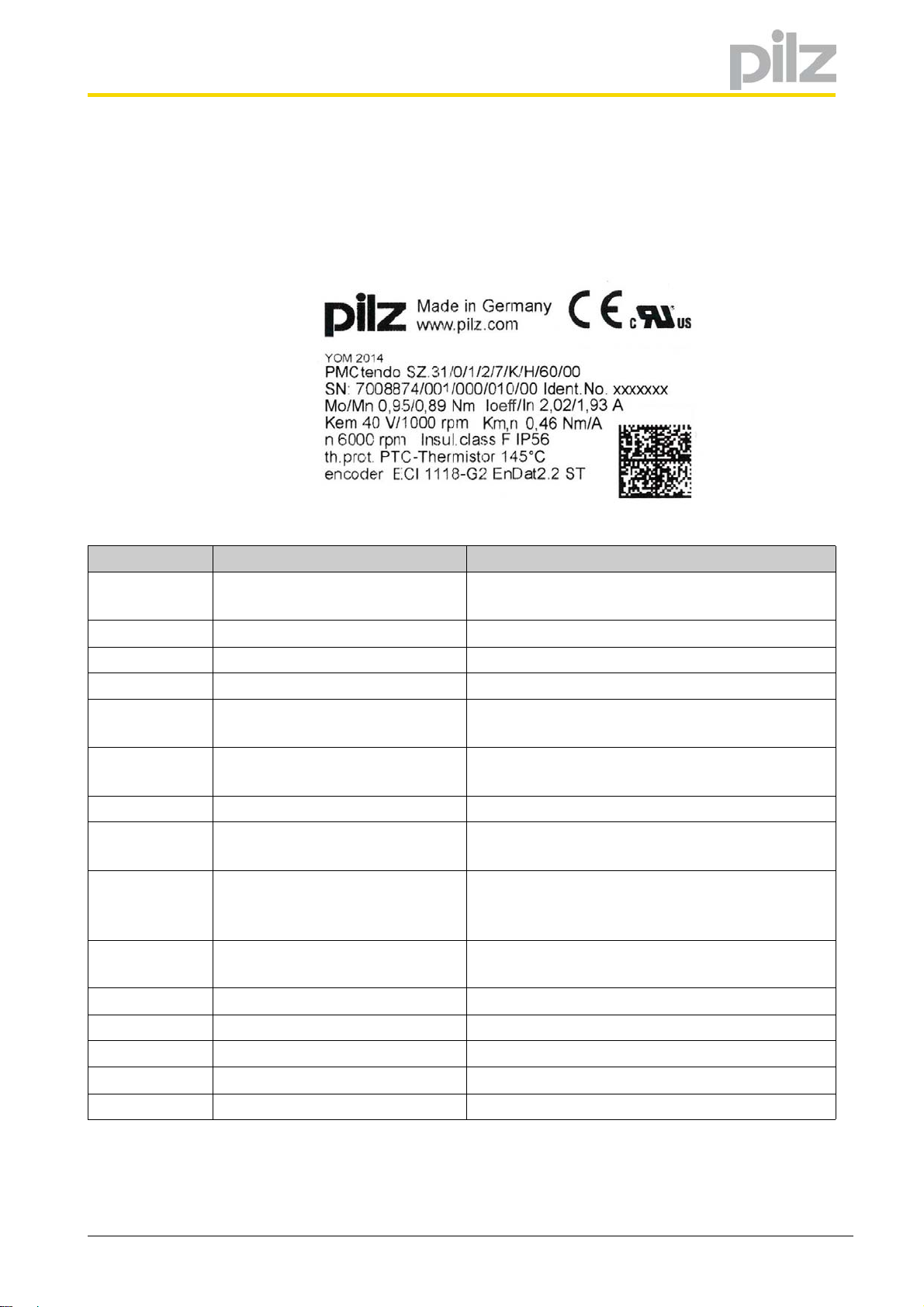

3.1.1 Type label

Description Value in example Meaning

Year of

YOM 2014 Year of manufacturing 2014

Manufacturing

Type PMCtendo SZ.31/0/1/2/7/K/H/60/00 Order references

SN 7008874/001/000/010/00 Serial number

Ident.No. xxxxxxx Identification number

M

0,95 Nm Standstill torque: Constant standstill torque for

0

250 min

M

0,89 Nm Rated torque; highest constant torque of the motor for

N

a rated speed n

I

2,02 A Standstill current: I

0eff

I

1,93 A Rated current: Constant current at MN ± 5 % and

N

n

K

40 V/1000 rpm EMC voltage stability: Peak value of the chained, in-

E M

± 5 %

N

-1

± 5 %

± 5 %

N

is the current flowing at M0

0eff

duced voltage for an operating voltage (∆T = 100 K)

when idle running as generator

K

1,35 Nm/A Torque constant: Constant in the entire functional

M ,N

range of a motor

n 6000 rpm Rated speed n

N

Insul.-class F Thermal class acc. to EN 60034/VDE 0530

IP 56 Protection class

th.prot. PTC thermistor 145 °C Thermal winding protection by PTC drilling

encoder ECI 1118-G2 EnDat 2.2 ST Feedback system

Operating Manual PMCtendo SZ

1002405-EN-03

12

Page 13

3 Description

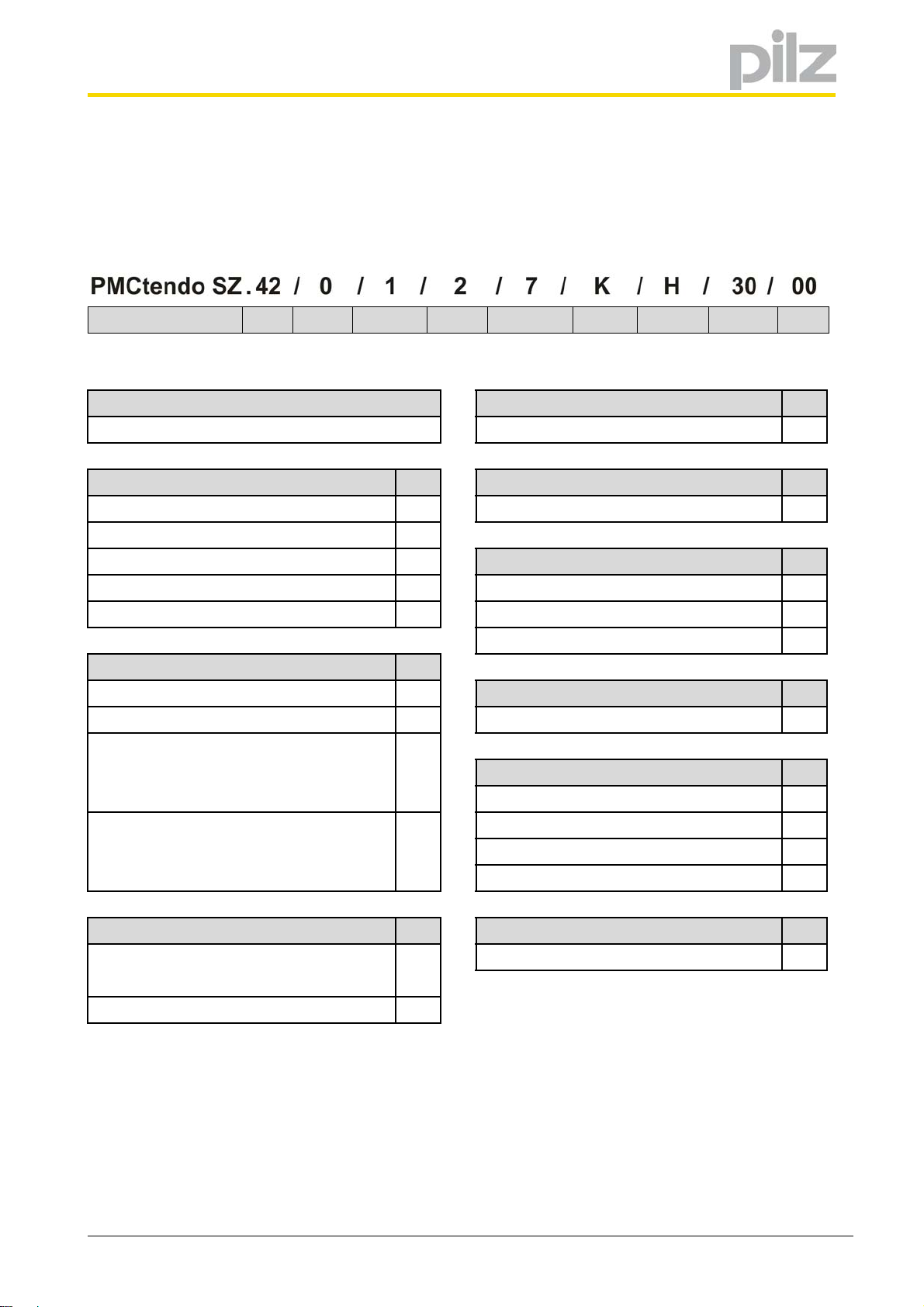

3.1.2 Order reference

1 2 3 4 5 6 7 8 9 10

Product name Size Brake Feedback Design Connection Cooling Voltage Speed Option

1 Product name 5 Design Code

PMCtendo SZ B5, smooth shaft 2

2 Size Code 6 Connection Code

PMCtendo SZ3x 3x Feedback 7

PMCtendo SZ4x 4x

PMCtendo SZ5x 5x

PMCtendo SZ7x 7x Convection K

PMCtendo SZ8x 8x External fan (not applicable for SZ.3x) F

3 Brake and dynamic design Code

Without brake and dynamic design 0

With brake and dynamic design 1 400 V (UZK = 540 V) H

Without brake, with increased mass moment 2

of inertia

(not applicable for SZ.3x, SZ.51, SZ.71) 2000 min

With brake, with increased mass moment 3 3000 min

of inertia 4500 min

(not applicable for SZ.3x, SZ.51, SZ.71) 6000 min

4 Feedback Code 10 Option Code

Single-turn EnDat® 2.2 ECI1118-G2 1 Standard 00

inductive

Multi-turn EnDat® 2.2 EQN1135 optical 2

7 Cooling Code

Water cooling (not applicable for SZ.3x) W

8 Voltage Code

9 Speed a) Code

-1

20

-1

30

-1

45

-1

60

a) See section Type-specific data

Operating Manual PMCtendo SZ

1002405-EN-03

13

Page 14

3 Description

3.2 Drive controller

The servo motors must be operated in conjunction with a servo amplifier with speed,

torque or position control, e.g. PMCtendo DD4, PMCtendo DD5 or PMCprotego D.

Servo motors, cables and servo amplifiers should always be regarded as one cohesive

system. The most important selection criteria are:

• Constant standstill torque M

• Constant standstill current I

• Rated speed n

• Mass moment of inertia of motor and load J [kgcm

• Effective torque (calculated) M

• Regenerative energy in braking mode

• Overload capacity

•EMC

[min-1]

N

[Nm]

0

0 eff

[A]

eff

[Nm]

2

]

When selecting the servo amplifier, please consider both the static and the dynamic load

(acceleration/ braking).

3.3 Feedback

PMCtendo SZ motors may be fitted with the following feedback systems:

• Single-turn EnDat

• Multi-turn EnDat

Single-turn feedback systems provide an absolute position within one revolution while

multi-turn feedback systems specify an absolute position over a number of revolutions.

®

2.2 ECI1118-G2 inductive,

®

2.2 EQN1135 optical.

3.4 Dynamic performance

The PMCtendo SZ motors are designed as standard for applications with high dynamic

performance, i.e. they have the lowest possible mass moment of inertia. As an option the

servo motors can be supplied with an increased mass moment of inertia in order to optimize the inertia ratio between motor and load.

3.5 Operating mode

The servo motors are designed for continuous operation. This corresponds to operating

mode S1 (in accordance with DIN EN 60 034-1).

Operating Manual PMCtendo SZ

1002405-EN-03

14

Page 15

3 Description

3.6 Thermal winding protection

The servo motors have a thermal winding protection, which protects the stator winding

from damage in the case of constant overload.

The PMCtendo SZ motors are fitted with PTC drilling as standard. If the motor temperature reaches a critical level, the ohmic resistance of the PTC resistors increases abruptly

and this indicates motor overload.

INFO

Each thermal winding protection must be monitored and evaluated by the

servo amplifier or an external triggering device.

3.7 Cooling

As standard the servo motors are dimensioned for convection cooling.

In order to increase the continuous torque output or continuous power output, the servo

motors can be fitted as an option with external fan systems (IP44). External fan systems

can be retrofitted.

In applications requiring a higher protection class than IP44 or a lower noise level, the

servo motors can be water-cooled in the A-side flange.

3.8 Holding brake

WARNING!

Danger to life!

The motor brake is not a safety brake!

Check whether additional safety measures must be taken, e. g. when remaining un-

der suspended loads.

3.8.1 Motor holding brake

The servo motors may be supplied with a built-in permanent magnet brake for backlashfree holding of the motor shaft. This blocks the rotor when the supply voltage is switched

off. The brake has electromechanical ventilation: The applied voltage generates a magnetic field that counteracts the permanent magnetic field and neutralises its influence.

Operating Manual PMCtendo SZ

1002405-EN-03

15

Page 16

3 Description

As the servo motors can be quickly and actively braked by appropriate setpoint settings

at the servo amplifier, the built-in brakes function as a holding brake. Additional brakes

must be provided for braking when the motor is turning, e.g. for an emergency stop.

3.8.2 Brake test and grinding

If a brake does not perform any friction work over an extended period of time, its friction

factor may change due to accumulations of flash rust or vapors resulting from high motor

temperatures. It is also possible that a slight material distortion may be noted as the result of major temperature fluctuations.

To ensure the functional safety of brakes, including the case of gravity-loaded vertical axes, the brakes must be subjected to brake tests at regular intervals.

Testing brakes

Load the brake with 1.3 times the load torque. Make certain that the suspended load of

a vertical axis is already exerting torque on the motor when it is at a standstill.

Regrind the brake

If the tested braking torque differs from the required value, a brake can be reground.

To do this, run the motor at maximum 20 rpm.

Release and close the brake once per second so that the motor is required to work

against the closed brake for about 0.7 seconds.

Repeat these steps in the reverse direction of rotation after about 20 cycles. If the nominal holding torque of the brake is still not correct after this regrinding, repeat the entire

process. If the nominal holding torque of the brake has still not been reestablished after

grinding five times, check for other factors that could be responsible for the deviating

nominal holding torque of the brake, for example if the wear limit has been reached.

Depending on the relevant servo inverter types, the grinding routine can also be automated. For further details see the corresponding documentation.

3.9 Motor shaft and bearings

The servo motors have a smooth shaft end (DIN 6885) on the drive side. With a friction

connection, torque transfer must be achieved through surface pressure. This guarantees

a safe, backlash-free force transfer.

The bearings are designed as ball bearings with permanent lubrication and non-contact

seals.

Operating Manual PMCtendo SZ

1002405-EN-03

16

Page 17

4 Transportation and storage

4 Transportation and storage

4.1 Transportation

Secure the shafts and bearings of the servo motor against impact when transporting. Use

eye bolts (if provided) and suitable slings when transporting the servo motor. Only lift the

servo motor at the eye bolts without additional attachments. Never transport the servo

motor on the fan guards or the angular flange sockets.

4.2 Storage

Store the servo motors in enclosed, dry spaces. Storage on the fan guards is not permitted.

If the servo motors are protected from all harmful environmental influences, brief storage

in open-air spaces with roofing is permitted.

Make sure that no condensation forms during storage, e.g. because of extreme temperature fluctuations with a high level of humidity.

Protect the motor shaft from corrosion when storing over an extended period. Note that

the insulation resistance of the winding must be checked after storing over an extended

period.

Operating Manual PMCtendo SZ

1002405-EN-03

17

Page 18

5 Installation

5Installation

WARNING!

Electric shock hazard!

Risk of serious injury from contact with live parts!

Observe the 5 safety rules (see chapter 2.5 Working on the machine).

Disconnect the motor from the power supply before carrying out work!

Ensure that the motor shaft is at a standstill before carrying out work! A rotating rotor

can generate high voltages at the terminals.

Switch off the power supplies to all connected devices and devices to be connected.

Note that dangerously high voltages can still occur at the servo amplifier even 10

minutes after switching off the power supply due to the residual charge of the DC link

capacitors.

Cover all open electrical connections, e.g with protective caps.

Cordon off the installation area according to the safety regulations, e.g. with barriers,

warning signs.

WARNING!

Burns!

The surface temperature of the servo motor can exceed 65 °C during operation!

Safety measures should be put in place to protect against contact during operation,

whether accidental or intentional.

5.1 Installation Location

The following preconditions apply for the installation location:

• The installation location must be free from aggressive substances and electrically

conductive atmospheres.

• The substructure must be level, vibration-free and torsionally rigid.

• Ensure adequate heat dissipation. Ensure compliance with the admissible ambient

temperature. If necessary, cool the servo motor additionally, e.g. using an external

fan.

• Observe the minimum clearance to the air intake of an external fan.

Operating Manual PMCtendo SZ

1002405-EN-03

18

Page 19

5 Installation

Motor External fan Minimum distance x

SZ.4x FL4 20

SZ.5x FL5 20

SZ.7x FL7 30

SZ.8x FL8 30

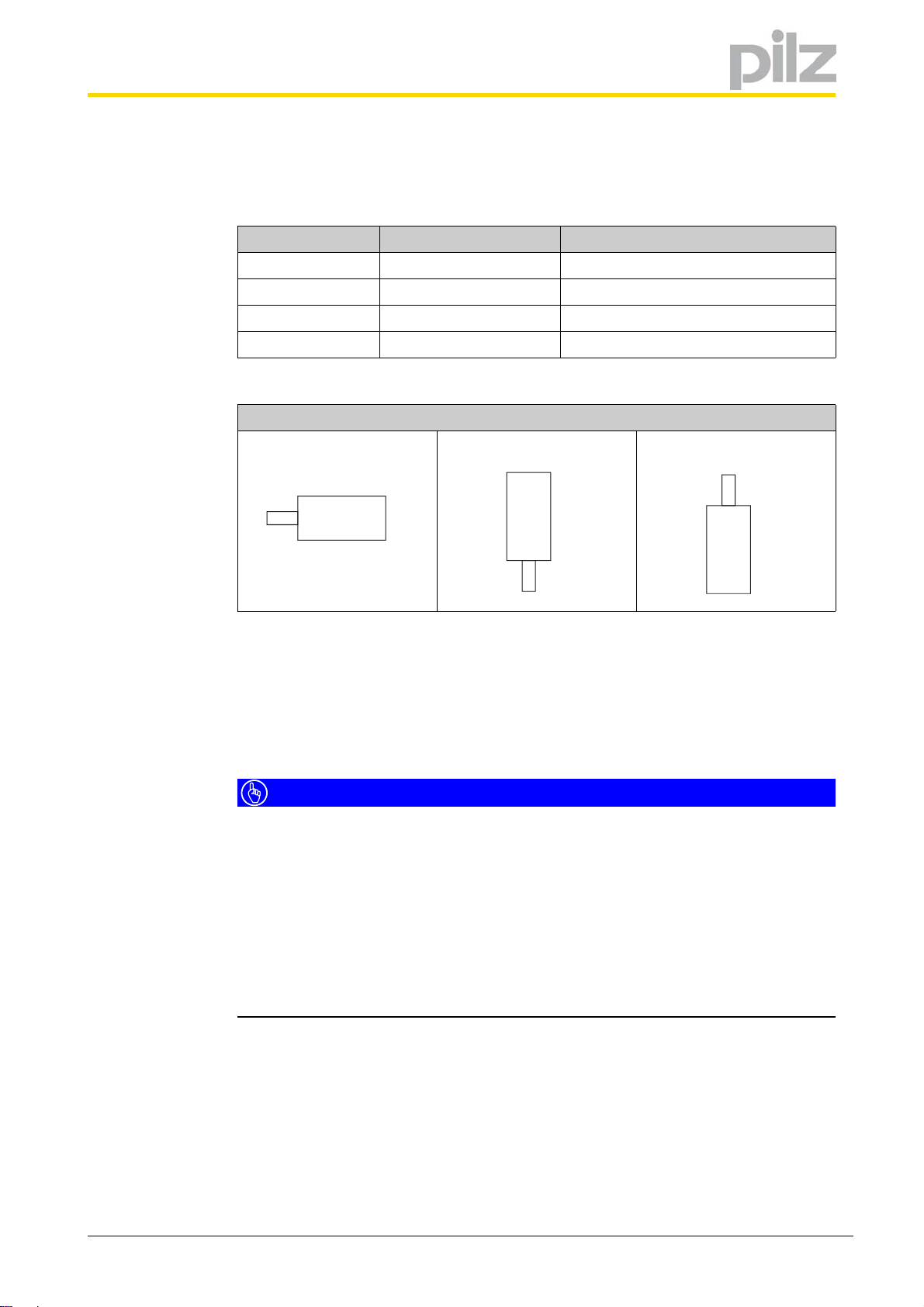

The following installation positions are admissible:

Admissible installation positions

IM B5 IM V1 IM V3

Particularly in installation position IM V3, ensure that no liquids from attachments can run

into the motor bearings.

Fmin

[mm]

5.2 Install motor

IMPORTANT

Material damage!

Impact and other forces can cause damage to the bearings, feedback system and motor

shaft.

Do not hit the motor shaft or motor housing with a hammer or other tools.

Do not apply any pressure, impact or high acceleration to the motor.

Use backlash-free, frictionally engaged chucks or clutches.

Always use the tightening thread provided in the motor shaft to fit or remove clutches,

gears or belt pulleys. Use suitable tools!

Operating Manual PMCtendo SZ

1002405-EN-03

19

Page 20

5 Installation

Material damage!

Solvent damages the sealing lips of the shaft seal rings.

Make sure that solvent can not come into contact with the sealing lips of the shaft

Prepare the motor for installation

• Check the motor for transport damage. Never install a servo motor that shows clear

• Check the insulation resistance of the winding of the motor after storage.

• Thoroughly remove anti-corrosion agents and/or contamination on the motor shaft.

• If possible, warm up the drive elements, e.g. belt pulley

• Make sure that the paintwork of the servo motors is not damaged.

IMPORTANT

seal rings.

signs of damage!

This can be done using a standard solvent. Make sure that the solvent can not come

into contact with the sealing lips of the shaft seal rings, otherwise materials may be

damaged.

Install motor

• Align the clutch correctly. Misalignment can cause undue vibration and can damage

the ball bearings and clutch!

• Mechanical overdefinition of the motor shaft bearing should be avoided. A rigid clutch

and/or an external additional bearing (e.g. in the gear unit) can cause excess mechanical stress on the motor shaft.

• Prevent temperature-sensitive components coming into contact with the motor.

During operation, the surface temperature of the servo motor can exceed 65 °C!

• When removing the eye bolts after installation, permanently close the threaded hole

according to the protection class of the motor.

Operating Manual PMCtendo SZ

1002405-EN-03

20

Page 21

6 Electrical installation

6 Electrical installation

WARNING!

Electric shock hazard!

Risk of serious injury from contact with live parts!

Observe the 5 safety rules (see chapter 2.5 Working on the machine).

Disconnect the motor from the power supply before carrying out work!

Ensure that the motor shaft is at a standstill before carrying out work! A rotating rotor

can generate high voltages at the terminals.

Switch off the power supplies to all connected devices and devices to be connected.

Note that dangerously high voltages can still occur at the servo amplifier even 10

minutes after switching off the power supply due to the residual charge of the DC link

capacitors.

Cover all open electrical connections, e.g with protective caps.

Cordon off the installation area according to the safety regulations, e.g. with barriers,

warning signs.

WARNING!

Uncontrolled movements of the servo motor can result in injury!

Incorrect wiring of the servo motor and/or feedback unit can trigger uncontrolled movements and result in material damage and/or personal injury.

All work must be carried out by specialists.

Observe the specifications in this operating manual and in the documentation of the

servo amplifier used.

Observe the applicable regulations.

6.1 General information

6.1.1 Wiring

Observe the regulations applicable for your machine or system when installing the electrical equipment, e.g. DIN IEC 60364 or DIN EN 50110.

Operating Manual PMCtendo SZ

1002405-EN-03

21

Page 22

6 Electrical installation

6.1.2 Earthing, shielding and EMC

Note the following points:

• On the servo motors, the connection to PE is established via the supply voltage cable

(see section 6.2 Servo motor and motor brake). For an additional earth in accordance

with DIN EN 60204-1, the motors have an earth connection attached and indicated

on the exterior.

• If necessary, use a toroidal core for the supply voltage cable, or a motor throttle close

to the servo amplifier. Please refer to the information stated in the operating manual

of the servo amplifier you are using.

• You will need shielded cable for data and control lines.

– Earth the inner and outer cable shield connections on both sides (e.g. on a bus

bar).

• You will need shielded cable for data and control lines.

– Earth the outer cable shield connection on both sides (e.g. on a bus bar).

– Earth the inner cable shield on the side of the servo amplifier (e.g. on a bus bar).

– If you are using longer cables and there is the possibility of transient currents,

these can be prevented by using equipotential bonding cables.

• Shields should be connected over a wide surface area (low impedance), using metallised connector housings or EMC-compliant cable screw connections.

• An appropriate connection material should be used to connect the cable shield to the

earth bar or bus bar (e.g. shielded terminals, see Fig. 6-1: ).

Fig. 6-1: Cable shield connection using a shielded terminal on the earth bar (reproduced

with permission from icotek GmbH, www.icotek.de)

Operating Manual PMCtendo SZ

1002405-EN-03

22

Page 23

6 Electrical installation

6.1.3 Selecting the cables

Note that motor, cables and servo amplifier each have electrical properties which influence one another. If not properly balanced, this can lead to inadmissibly high voltage

peaks at motor and servo amplifier.

Please note also the following points:

• Select the lead cross-sections according to the admissible continuous open-circuit

current of the motor. Observe also the documentation on the servo amplifier.

• If necessary, pay attention also to the trailability and torsional strength of the leads.

• The leads are connected to the servo motor by plug connectors. Cables are available

as accessories.

• For the choice of the cable cross-sections, see chapter 6.2 Servo motor and motor

brake.

• When using a motor brake, pay attention to the drop in the supply voltage on the lead.

• Observe the statutory regulations on EMC.

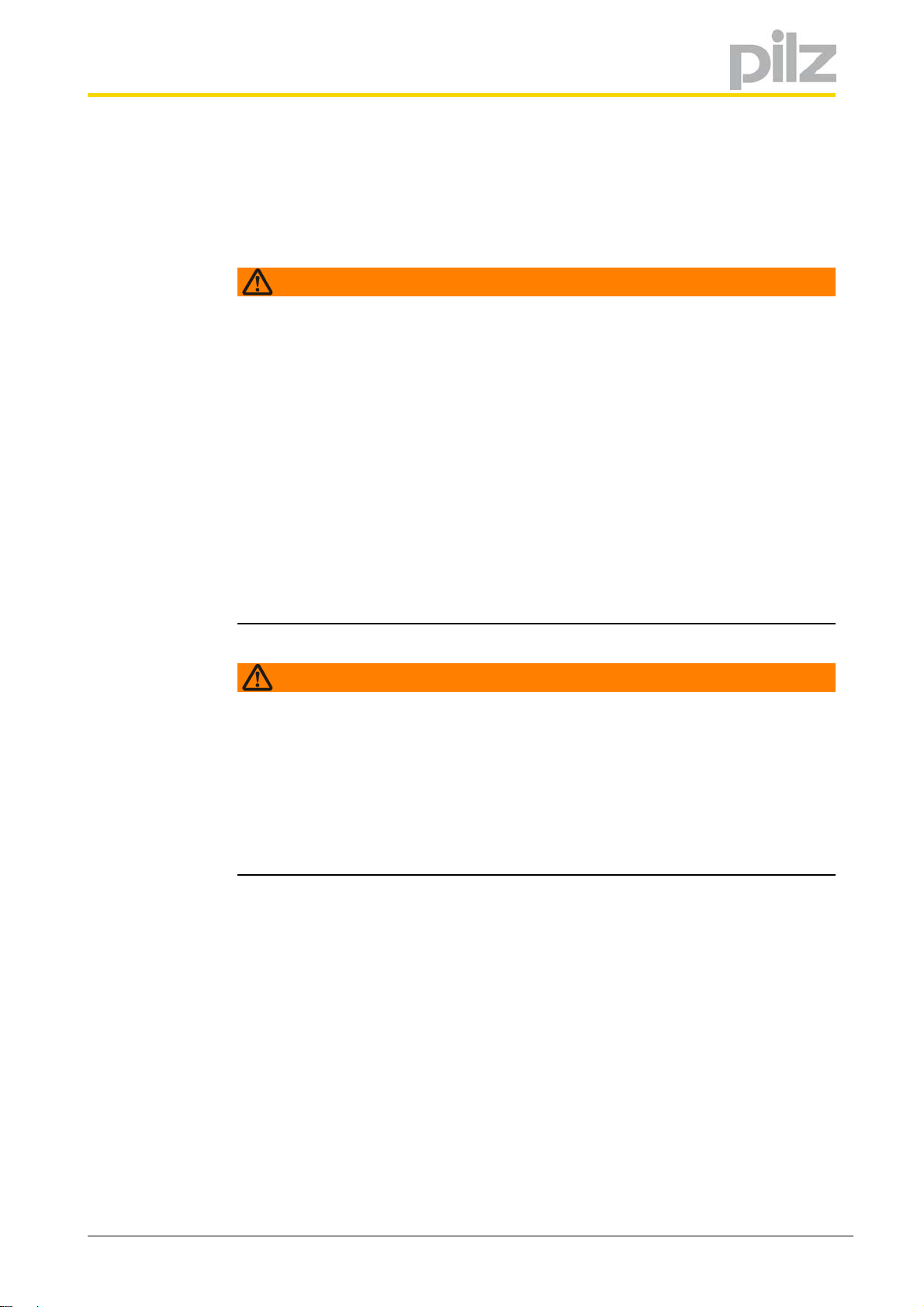

6.1.4 speedtec® and springtec® plug connector

The servo motors are fitted with speedtec angular flange sockets. A cable with a speed-

®

tec

plug connector is connected as follows.

Requirement: You have removed the protection caps from the angular flange sockets.

Connect the cable to the speedtec

1 Align the union nut so that the arrow faces the union nut and angular sock-

et:

®

plug connector

Operating Manual PMCtendo SZ

1002405-EN-03

23

Page 24

6 Electrical installation

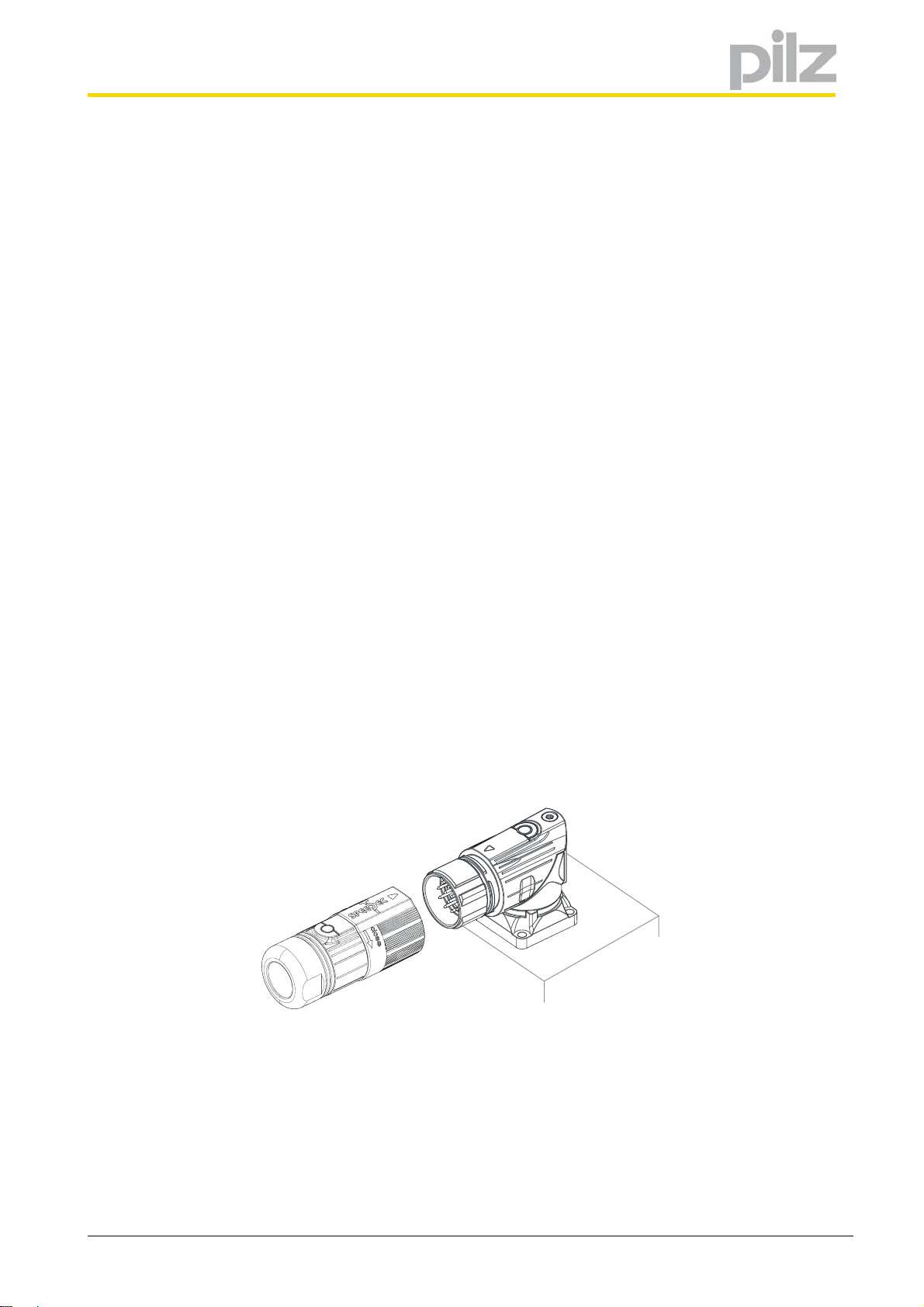

2 Attach the union nut evenly on the angular socket:

3 Turn the screw cap of the union nut in the direction of "close" up to the limit

stop:

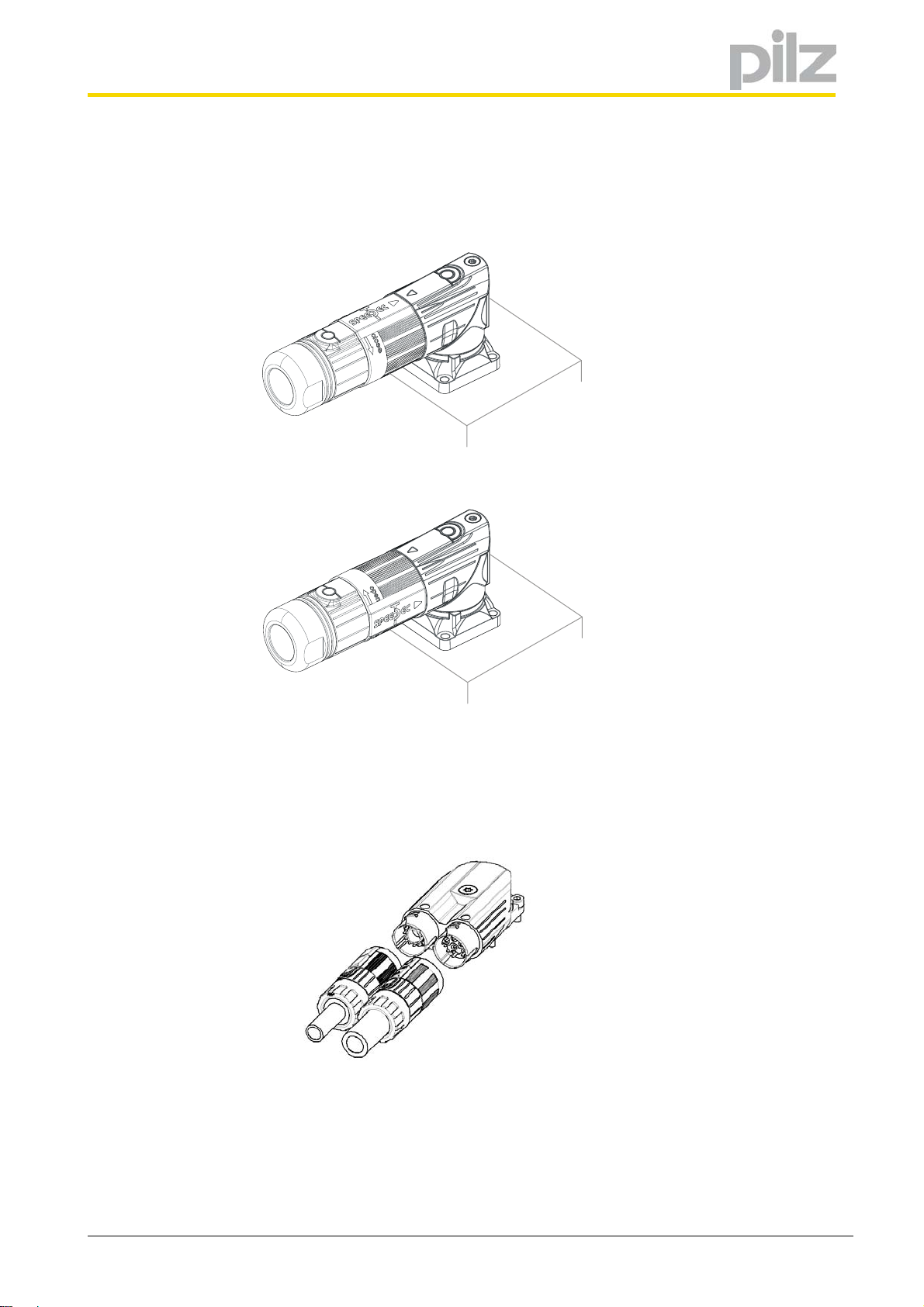

Connect the cable with springtec® plug connector

1 Align the respective union nuts of the green encoder plug and the orange

power connector so that the points on the union nuts and the angle connection socket are facing each other:

Operating Manual PMCtendo SZ

1002405-EN-03

24

Page 25

6 Electrical installation

2 Connect the union nuts directly onto the angle connection socket:

Operating Manual PMCtendo SZ

1002405-EN-03

25

Page 26

6 Electrical installation

6.2 Servo motor and motor brake

6.2.1 Power cable

PMCtendo SZ servo motors will be connected to the drive controllers via the following

power cables (the colour specifications apply to the connection strands and are only relevant for the motor wiring).

Power cable – connector size con.15

Angular flange socket – motor Pin Signal Colour

A1U1 BK

B 1V1 BU

C1W1 RD

1

2

3 1BR+ (brake + 24 V

4 1BR– (brake 0 V) BK

PE GNYE

Housing Shield

Power cable – connector size con.23

Angular flange socket – motor Pin Signal Colour

A 1BR+ (brake + 24 V

B 1BR– (brake 0 V) BK

C

D

11U1 BK

31W1 RD

4 1V1 BU

PE GNYE

)RD

DC

)RD

DC

Operating Manual PMCtendo SZ

1002405-EN-03

Housing Shield

26

Page 27

6 Electrical installation

Power cable – connector sizes con.40, con.58

Angular flange socket – motor Pin Signal Colour

U1U1 BK

V1V1 BU

W1W1 RD

+ 1BR+ (brake + 24 VDC) RD

– 1BR– (brake 0 V) BK

1

2

PE GNYE

Housing Shield

Operating Manual PMCtendo SZ

1002405-EN-03

27

Page 28

6 Electrical installation

6.2.2 Assignment: Motor and power cable

Assignment of connector size and minimum cross-section of power cores.

INFO

Note that the following assignment of the connector size to the minimum

cross-section ø

PMCtendo SZ – convection-cooled (PMCtendo SZ.xx/.../K/...)

nN = 2000 min-1 nN = 3000 min-1 nN = 4500 min-1 nN = 6000 min-1

Motor

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

SZ.31 — — con.15 1,0 — — con.15 1,0

refers to a maximum cable length of 100 m.

min

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

[mm2]

min

SZ.32 — — con.15 1,0 — — con.15 1,0

SZ.33 — — con.15 1,0 — — con.15 1,0

SZ.41 — — con.15 1,5 — — con.23 1,5

SZ.42 — — con.23 1,5 — — con.23 1,5

SZ.44 — — con.23 1,5 — — con.23 1,5

SZ.51 — — con.23 1,5 — — con.23 1,5

SZ.52 — — con.23 1,5 — — con.23 1,5

SZ.53 — — con.23 1,5 — — con.23 1,5

SZ.55 — — con.23 1,5 con.23 1,5 — —

SZ.71 — — con.23 1,5 — — con.23 1,5

SZ.72 — — con.23 1,5 — — con.23 2,5

SZ.73 — — con.23 1,5 con.23 2,5 — —

SZ.75 — — con.40 2,5 con.40 4,0 — —

SZ.82 — — con.40 4,0 con.40 6,0 — —

SZ.83——con.406,0————

SZ.85con.4010,0——————

Operating Manual PMCtendo SZ

1002405-EN-03

28

Page 29

6 Electrical installation

PMCtendo SZ – externally ventilated (PMCtendo SZ.xx/.../F/...)

nN = 2000 min-1 nN = 3000 min-1 nN = 4500 min-1 nN = 6000 min-1

Motor

SZ.41 — — con.23 1,5 — — con.23 1,5

SZ.42 — — con.23 1,5 — — con.23 1,5

SZ.44 — — con.23 1,5 — — con.23 1,5

SZ.51 — — con.23 1,5 — — con.23 1,5

SZ.52 — — con.23 1,5 — — con.23 1,5

SZ.53 — — con.23 1,5 — — con.23 2,5

SZ.55 — — con.23 1,5 con.23 2,5 — —

SZ.71 — — con.23 1,5 — — con.23 1,5

SZ.72 — — con.23 1,5 — — con.23 4,0

SZ.73 — — con.23 2,5 con.23 4,0 — —

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

[mm2]

min

SZ.75 — — con.40 4,0 con.40 6,0 — —

SZ.82 — — con.40 6,0 con.40 10,0 — —

SZ.83——con.4010,0————

SZ.85con.5816,0——————

PMCtendo SZ – water-cooled (PMCtendo SZ.xx/.../W/...)

nN = 2000 min-1 nN = 3000 min-1 nN = 4500 min-1 nN = 6000 min-1

Motor

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

Connec-

tor size

ø

min

[mm2]

SZ.41 — — con.23 1,5 — — con.23 1,5

SZ.42 — — con.23 1,5 — — con.23 1,5

SZ.44 — — con.23 1,5 — — con.23 1,5

SZ.51 — — con.23 1,5 — — con.23 1,5

SZ.52 — — con.23 1,5 — — con.23 1,5

SZ.53 — — con.23 1,5 — — con.23 2,5

SZ.55 — — con.23 1,5 con.23 2,5 — —

SZ.71 — — con.23 1,5 — — con.23 1,5

SZ.72 — — con.23 1,5 — — con.23 4,0

SZ.73 — — con.23 2,5 con.23 4,0 — —

SZ.75 — — con.40 4,0 con.40 6,0 — —

SZ.82 — — con.40 6,0 con.40 10,0 — —

SZ.83——con.4010,0————

SZ.85con.5816,0——————

Operating Manual PMCtendo SZ

1002405-EN-03

29

Page 30

6 Electrical installation

6.3 Feedback

PMCtendo SZ servo motors will be connected to the feedback systems single-turn/multiturn EnDat® 2.2 optical/inductive via the following feedback cables (the colour specifications apply to the connection strands and are only relevant for the motor wiring).

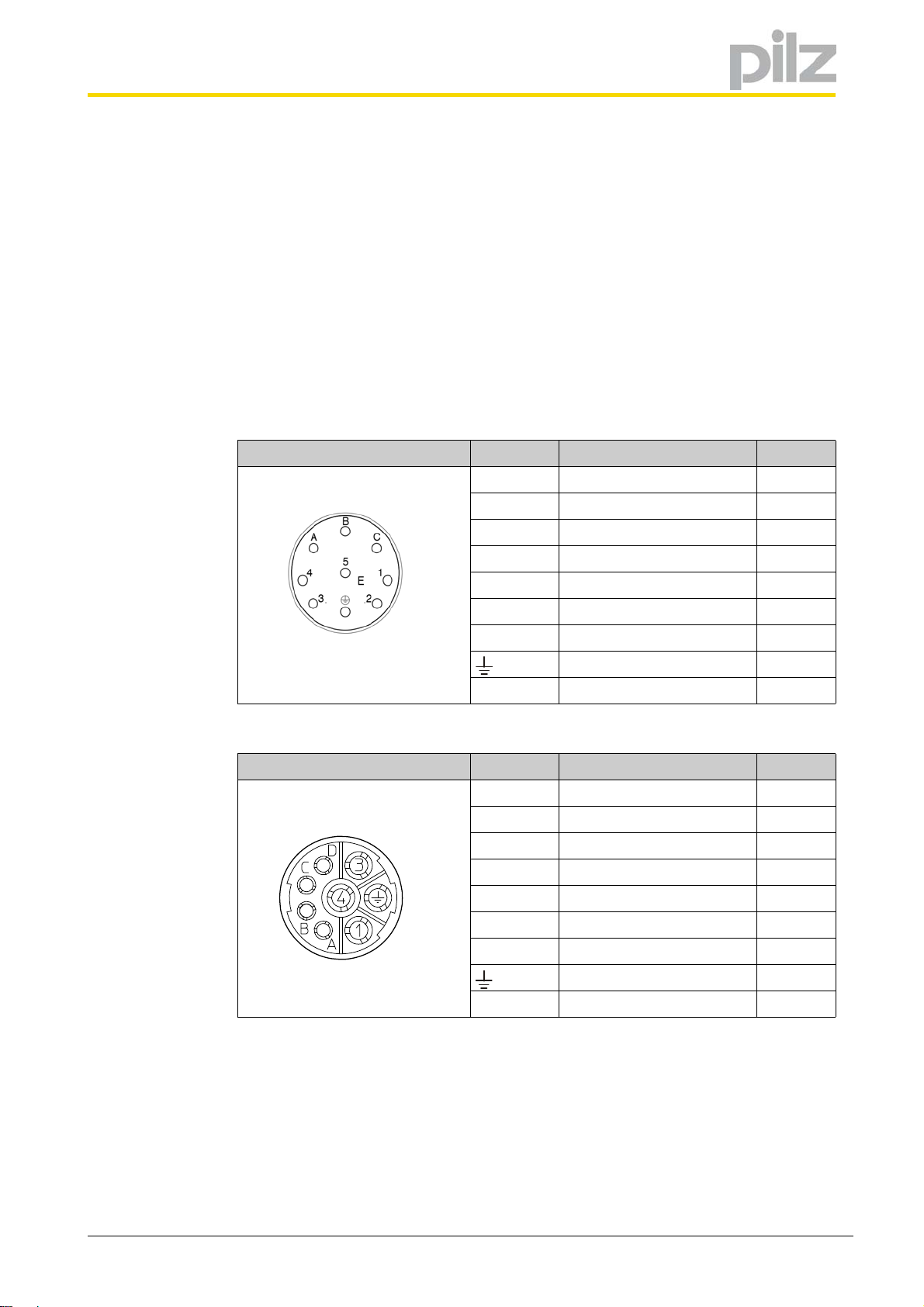

Feedback cable – plug connector con.15

Angular flanged socket - motor Pin Signal Colour

1CLOCKVT

2

3

4PTC– WH

5 DATA/ PK

6DATA GY

7

8CLOCK/YE

9

10 0 V WHGN

11 PTC+ BK

12 0 V BNGN

Housing Shield

Feedback cable – plug connector con.23

Angular flanged socket - motor Pin Signal Colour

1CLOCKVT

2

3

4PTC– WH

5 DATA/ PK

6DATA GY

7

Operating Manual PMCtendo SZ

1002405-EN-03

8CLOCK/YE

9

10 0 V WHGN

11 PTC+ BK

12 Up BNGN

Housing Shield

30

Page 31

6 Electrical installation

A

A

1

2

3

6.4 External fan

The following plug connection for connecting the external fan is included with delivery.

Pin Signal

1L1

2N

3—

PE

6.5 Water cooling

Connect the water cooling to the hose connectors G1/8" (fittings). Connection is possible

on the connector side or opposite.

Observe the specifications for the cooling circuit, see section 9.4.3 Water cooling.

Operating Manual PMCtendo SZ

1002405-EN-03

31

Page 32

7 Commissioning

7 Commissioning

7.1 Check installation

WARNING!

Electric shock hazard!

Risk of serious injury from contact with live parts!

Observe the 5 safety rules (see chapter 2.5 Working on the machine).

Disconnect the motor from the power supply before carrying out work!

Ensure that the motor shaft is at a standstill before carrying out work! A rotating rotor

can generate high voltages at the terminals.

Switch off the power supplies to all connected devices and devices to be connected.

Note that dangerously high voltages can still occur at the servo amplifier even 10

minutes after switching off the power supply due to the residual charge of the DC link

capacitors.

Cover all open electrical connections, e.g with protective caps.

Cordon off the installation area according to the safety regulations, e.g. with barriers,

warning signs.

Installation

Check the installation and alignment of the servo motor.

Check the drive elements (clutch, gears, belt pulley)

for secure mechanical fitting and correct setting.

Check whether the motor surface is protected against

contact, whether accidental or intentional.

Check that contact with temperature-sensitive parts on

the motor has been prevented.

Check that the rotor of the servo motor can turn freely. If a motor brake is provided, this must be ventilated be-

—

—

Note:

Risk of burns or fire!

The surface temperature of the servo motor can exceed 65 °C during operation!

fore the test. Observe the polarity of the connections

when doing this!

Operating Manual PMCtendo SZ

1002405-EN-03

32

Page 33

7 Commissioning

7.2 Check connection

WARNING!

Electric shock hazard!

Risk of serious injury from contact with live parts!

Observe the 5 safety rules (see chapter 2.5 Working on the machine).

Disconnect the motor from the power supply before carrying out work!

Ensure that the motor shaft is at a standstill before carrying out work! A rotating rotor

can generate high voltages at the terminals.

Switch off the power supplies to all connected devices and devices to be connected.

Note that dangerously high voltages can still occur at the servo amplifier even 10

minutes after switching off the power supply due to the residual charge of the DC link

capacitors.

Cover all open electrical connections, e.g with protective caps.

Cordon off the installation area according to the safety regulations, e.g. with barriers,

warning signs.

WARNING!

Risk of injury from moving parts!

Make sure that

no persons are at risk due to start-up.

all protective and safety equipment is properly installed, even during commissioning

and test operation.

components attached to the drive are adequately protected against centrifugal forces

(e.g. feather keys, clutch elements, etc.).

Connection

Check that the earth has been properly connected.

Check that all live parts are safely protected against

contact, whether accidental or intentional.

Check the wiring and the connections of the servo motor, feedback, servo amplifier and, if provided, external

fan and motor brake.

Check the direction of rotation of the servo motor. Control the servo motor using the servo amplifier.

—

Please refer to the documentation for the servo amplifier.

Check the function of the motor brake. Apply the control voltage to the motor brake (ensure

correct polarity): The motor brake must release.

Operating Manual PMCtendo SZ

1002405-EN-03

33

Page 34

7 Commissioning

7.3 Put into operation

WARNING!

Uncontrolled movements of the servo motor can result in injury!

Incorrect wiring of the servo motor and/or feedback unit can trigger uncontrolled movements and result in material damage and/or personal injury.

All work must be carried out by specialists.

Observe the specifications in this operating manual and in the documentation of the

servo amplifier used.

Observe the applicable regulations.

Carry out commissioning only when the following preconditions are satisfied:

• The tests in chapters 7.1 Check installation and 7.2 Check connection have been

carried out.

• All other specific and necessary tests for your system have been carried out.

Note during commissioning:

• Be sure to following the instructions for commissioning of the servo amplifier used.

• On multi-axis systems, commission each drive individually.

Tips on troubleshooting

The following table lists typical faults that can affect the servo motor during commissioning. Further sources of faults can be:

• The servo amplifier

• A higher-level controller

• Integration of the motor into a multi-axis system

Take care therefore to also observe the respective documentation!

Operating Manual PMCtendo SZ

1002405-EN-03

34

Page 35

7 Commissioning

Fault Possible cause of fault Measure

Motor shaft not

rotating

Servo amplifier not enabled • Connect enable signal for the servo

amplifier

Reference value cable interrupted • Check reference value cable

Motor phases incorrectly connected (rotary field incorrect)

Motor brake not released • Check brake controller

Drive is blocked mechanically • Check mechanical parts

Torque too low • Check current limit in the servo ampli-

• Connect motor phases correctly

• Check voltage supply to the motor

brake

fier

• Install stronger motor or servo amplifier

Motor shaft rotates

uncontrolled (positive

feedback)

Motor oscillates Screen of feedback cable interrupted • Reconnect screen of feedback cable

Output stage fault

signalled (at servo

amplifier)

Feedback fault

signalled (at servo

amplifier)

Motor temperature

fault signalled (at servo amplifier)

Motor brake does not

engage

Wrong feedback offset • Check feedback offset and correct, if

necessary

Motor phases incorrectly connected (reversed cycle, rotary field correct)

Control parameters incorrect • Correct control parameters in servo

Motor cable has short-circuit or earth fault • Replace cable

Motor has short-circuit or earth fault • Replace motor

Feedback plug is not correctly connected • Check plug connectors

Feedback cable is interrupted, pinched,

etc.

Connection to motor thermal protection interrupted

Motor thermal protection has tripped • Check thermal situation at installation

Demanded holding torque too high • Check dimensioning of the motor

• Reverse direction of rotation in servo

amplifier

• Connect motor phases correctly

interrupted

• Replace cable, if necessary

amplifier

• Inspect cable

• Check plug connectors

• Check leads

location

• Use external fan, if necessary

brake

Motor brake defective • Replace motor

Motor shaft with axial overload • Check axial load and reduce, if neces-

Operating Manual PMCtendo SZ

1002405-EN-03

sary; also replace motor because the

bearings are damaged

35

Page 36

8 Service

8 Service

Electric shock hazard!

Risk of serious injury from contact with live parts!

Observe the 5 safety rules (see chapter 2.5 Working on the machine).

Disconnect the motor from the power supply before carrying out work!

Ensure that the motor shaft is at a standstill before carrying out work! A rotating rotor

can generate high voltages at the terminals.

Switch off the power supplies to all connected devices and devices to be connected.

Note that dangerously high voltages can still occur at the servo amplifier even 10

minutes after switching off the power supply due to the residual charge of the DC link

capacitors.

WARNING!

Cover all open electrical connections, e.g with protective caps.

Cordon off the installation area according to the safety regulations, e.g. with barriers,

warning signs.

INFO

Note that repairs must only be carried out by Pilz GmbH & Co. KG. If the servo motor is opened without authorisation and handled improperly, the warranty will be rendered invalid.

8.1 Maintenance

If properly installed, the servo motors are more or less maintenance-free. As the operating conditions can differ widely, the maintenance intervals must be adapted to the conditions at the operating site (e.g. degree of soiling, cyclic duration factor, load).

Maintenance interval What is to be done? What has to be observed?

At regular intervals Clean servo motor Adapt the cleaning intervals to the de-

gree of soiling on site. Note that the original paintwork must be retained at all

costs:

• Allow the motor to cool down

• Do not use solvents

• Select the cleaning method according to the protection class of the servo motor

Operating Manual PMCtendo SZ

1002405-EN-03

36

Page 37

8 Service

Maintenance interval What is to be done? What has to be observed?

Every 500 operating

hours or

at least every 3 months

Check electrical and mechanical connections and retighten, if necessary

Check the smoothness of running of the

servo motor and check the installation;

replace the servo motor, if necessary

Check the ball bearings for noises; in the

event of a deterioration, send in the servo

motor for replacement of the ball bearings, if necessary

8.2 In the event of disruptions

—

See 8.3 Replace motor

Note that the ball bearings may only be

replaced by Pilz GmbH & Co. KG!

Increase the awareness of all persons who work on the machine or motor (machine operators, machine users, service personnel, etc.) for changes to normal operation. The following features indicate that the function of the machine has been affected. These

include:

• higher power consumption, temperatures or degree of vibration

• unusual noises or odours

• (frequent) response from monitoring equipment

In this case, stop the machine and inform a responsible qualified person immediately.

Check which safety measures for remaining in the transport area of a motor, e.g. in the

machine/system, particularly under a suspended load, have to be taken.

Operating Manual PMCtendo SZ

1002405-EN-03

37

Page 38

8 Service

8.3 Replace motor

IMPORTANT

Material damage!

Impact and other forces can cause damage to the bearings, feedback system and motor

shaft.

Do not hit the motor shaft or motor housing with a hammer or other tools.

Do not apply any pressure, impact or high acceleration to the motor.

Use backlash-free, frictionally engaged chucks or clutches.

Always use the tightening thread provided in the motor shaft to fit or remove clutches,

gears or belt pulleys. Use suitable tools!

Please note the following when changing the motor:

• If servo motors with a motor brake have been in storage for longer than 2 years, the

motor brake must be resurfaced before the servo motor is used.

• Check the insulation resistance of the winding of the motor after storing over an extended period.

• Please refer to the information in 5 Installation.

• Once the unit has been exchanged, restore the reference to the machine coordinate

system.

Operating Manual PMCtendo SZ

1002405-EN-03

38

Page 39

9 Technical data

9 Technical data

9.1 Ambient conditions

Ambient conditions Standard Optional

Protection class IP56 IP66

Transport/

storage ambient conditions

Ambient temperature during operation -15°C to +40°C —

Thermal class F

-30°C to +85°C —

—

(Limit temperature 155°C, warming ∆T = 100 K in accordance

with DIN EN 60034/VDE 0530)

Cooling IC 410 Convection cooling • IC 416 Convection cooling by

external fan (IP 44)

• Water cooling in A-side

flange

Installation height ≤ 1000 m above sea level —

Vibration level A according to DIN 60034-14:

2008-03

Maximum vibrating load for quasi-sinusoidal movements up to 1 kHz

5 g

Note that built-in brakes can no

longer fully establish their holding torque due to vibration loads

B according to DIN 60034-14:

2008-03

—

9.2 Device Features

Device features Standard

Model IM B5, IM V1, IM V3

Surface Matt black in accordance with RAL 9005

Bearings Ball bearings with permanent lubrication and non-contact seal

Service life > 20 000 h

Seal Radial shaft seal rings A-side

Shaft end Smooth shaft, diameter quality k6

True running accuracy tolerance N in accordance with DIN 42955

Coaxiality tolerance N in accordance with DIN 42955

Axial run-out N in accordance with DIN 42955

Noise level Limit values in accordance with EN 60034-9

Operating Manual PMCtendo SZ

1002405-EN-03

39

Page 40

9 Technical data

9.3 Electrical Data

standard

Servo amplifier DC link connection 540 V

Winding Three-phase, single-tooth design;

Star configuration, center is not led out

Current consumption See section 9.9 Type-specific data

Current waveform Sinusoidal

Protection class I (protective grounding)

Insulation class F as per EN 60034/VDE 0530

9.4 Cooling

9.4.1 Convection cooling

Standard Optional

PMCtendo SZ IC 410 Convection cooling • IC 416 Convection cooling by

external fan (IP 44)

• Water cooling in A-side

flange

9.4.2 External fan

FL4 FL5 FL7 FL8

Motor SZ.4x SZ.5x SZ.7x SZ.8x

U

230 V, -10% to +6%, 50/60 Hz 230 V, ±10 %,

N

50/60 Hz

I

[A] 0.07 0.1 0.1 0.2

N

P

[W] 10141426

N

Q

[m3/h] 59 160 160 420

N

G [dBA] 41 45 45 54

m [kg] 1.4 1.9 2.9 5.0

x

[mm] 20 20 30 30

F min

Protection class IP 44

Maximum ambient temperature 60°C

Operating Manual PMCtendo SZ

1002405-EN-03

40

Page 41

9 Technical data

9.4.3 Water cooling

Mechanical connection

Inlet and outlet

Ambient temperature during operation +5°C to +40°C

Storage ambient temperature -30°C to +85°C, the coolant must be drained for temperatures be-

Coolant temperature at inlet +10°C to +35°C, max. 5 K smaller than ambient temperature

Winding excess temperature 100 K

Cooling circuit type Closed with heat exchanger,

Maximum operating pressure 3.5 bar

Coolant Clear, aerosol-free and free of dirt (provide particle filter if neces-

pH value 6,5–7,5

Hardness 8–14 dH°

Salt content Desalinated and demineralised, NaCl < 100 ppm

Corrosion protection Add anti-corrosion additive, max. proportion 25 %,

Minimum coolant flow rate SZ.4: 4.5 l/min

Nominal coolant flow rate SZ.4: 6 l/min

Installation height ≤ 1000 m above sea level, no derating possible

Hose connector G1/8" (fittings)

On connector side or opposite

low 3°C

pressure control valve in supply line,

do not use any nonferrous metals

sary)

anti-corrosion agent must act neutrally against aluminium and cast

iron

SZ.5: 4.5 l/min

SZ.7: 5 l/min

SZ.8: 5 l/min

SZ.5: 6 l/min

SZ.7: 7.5 l/min

SZ.8: 7.5 l/min

Operating Manual PMCtendo SZ

1002405-EN-03

41

Page 42

9 Technical data

9.5 Feedback

EnDat® 2.2 ECI1118-G2 single-turn inductive (type PMCtendo SZ.xx/x/1)

Protocol EnDat® 2.2

Resolution per revolution 262 144 (18 bit)

Operating voltage range 3,6–14 V

Power consumption 3.6 V: ≤ 520 mW

EnDat® 2.2 EQN1135 multi-turn optical (type PMCtendo SZ.xx/x/2)

Protocol EnDat® 2.2

Resolution per revolution 8 388 608 (23 bit)

Revolutions 4096

Operating voltage range 3,6–14 V

Power consumption 3.6 V: ≤ 700 mW

DC

14 V: ≤ 600 mW

DC

14 V: ≤ 800 mW

Operating Manual PMCtendo SZ

1002405-EN-03

42

Page 43

Operating Manual PMCtendo SZ

1002405-EN-03

9 Technical data

9.6 Holding brake

Motor UN M

V Nm Nm A kJ kJ — 10-4kgm2 ms ms

SZ.31 24 ± 5 % 2.5 2.4 0.51 180 6.0 48000 0.752 20 25

SZ.32 24 ± 5 % 4 3.8 0.75 180 8.5 38000 0.952 26 44

SZ.33 24 ± 5 % 4 3.8 0.75 180 8.5 30000 1.17 26 44

SZ.41 24 ± 5 % 4 3.8 0.75 180 8.5 16000 2.24 26 44

SZ.42 24 ± 5 % 8 7 0.75 300 8.5 13500 4.39 20 40

SZ.44 24 ± 5 % 8 7 0.75 300 8.5 8500 7.09 20 40

SZ.51 24 ± 5 % 8 7 0.75 300 8.5 8700 6.94 20 40

SZ.52 24 ± 5 % 8 7 0.75 300 8.5 5200 11.5 20 40

SZ.53 24 ± 5 % 15 12 1 550 11 5900 18.6 30 60

SZ.55 24 ± 5 % 15 12 1 550 11 4000 27.8 30 60

SZ.71 24 ± 5 % 15 12 1 550 11 5400 20.5 30 60

SZ.72 24 ± 5 % 15 12 1 550 11 3600 30.9 30 60

SZ.73 24 ± 5 % 32 28 1.1 1400 25 5200 54.6 25 100

SZ.75 24 ± 5 % 32 28 1.1 1400 25 3500 79.4 25 100

SZ.82 24 ± 5 % 65 35 1.7 2250 45 6000 149 50 200

SZ.83 24 ± 5 % 65 35 1.7 2250 45 4500 200 50 200

Bstat

M

IN W

Bdyn

B,Rlim

W

B,Rmax/h

N

B,NOT

J

t1 t2

B,NOT

43

SZ.85 24 ± 5 % 115 70 2.1 6500 65 7000 376 65 190

Page 44

9 Technical data

S

1

W

BRmax h

W

B

------------------------------ -=

W

BR B

J

tot

n2

182 4

------------------- -

M

B

MBM

L

----------------------

=

J

tot

2J

MotorJBremse

+=

Diagram for switching behaviour

Formulas for further calculations

Number of permissible stops if conditions deviate.

S

W

J

1

B,R/B

tot

Maximum permissible number of stops if conditions deviate

Friction work per braking:

Total mass moment of inertia [kgm2]

Note section 9.9.1 Inertia.

J

motor

J

brake

n Speed [min

Mass moment of inertia – motor

Mass moment of inertia – brake

-1

]

M

B

M

L

Operating Manual PMCtendo SZ

1002405-EN-03

Braking torque [Nm]

Load torque [Nm]

44

Page 45

9 Technical data

t

dec

266 t1

nJ

tot

955 M

B

-------------------------+=

Stop time

t

dec

Stop time [ms]

Operating Manual PMCtendo SZ

1002405-EN-03

45

Page 46

9 Technical data

9.7 Thermal winding protection

Technical data for PTC drilling

max. operating voltage 7.5 VDC

Cold resistance R

Nominal response temperature

(NRT)

Resistance for NRT R

Thermal class F

25°C

≥ 3990 Ω

145°C

≤ 750 Ω

145°C ± 5 K

(Limit temperature 155°C, warming ∆T =

100 K in accordance with DIN EN 60034/

VDE 0530)

Thermal response time < 5 s

Characteristic line of the individual PTC resistor

Operating Manual PMCtendo SZ

1002405-EN-03

46

Page 47

9 Technical data

D

total

DhD

T

=

M

zul

D

totalMN

=

9.8 Derating

When dimensioning the drive, observe the derating for:

• An installation altitude above 1000 m (factor D

• An ambient temperature other than 40°C (factor D

The total derating is calculated as follows:

)

h

)

T

The admissible torque M

9.8.1 Installation altitude

can be calculated from D

perm.

total

:

Operating Manual PMCtendo SZ

1002405-EN-03

Example

The drive is to be installed at an altitude of 1500 m above sea level.

According to the diagram, the admissible torque is approx. 95% of the rated torque M

at this altitude. Hence D

= 0.95.

h

N

47

Page 48

9 Technical data

9.8.2 Ambient temperature

IMPORTANT

Motor damage caused by exceeding the admissible ambient temperatures for servo motors with external fan!

Note that servo motors with external fan have to be operated at ambient temperatures

up to max. +60°C.

IMPORTANT

Motor damage caused operating outside the admissible ambient temperature

range for water-cooled servo motors!

Note that water-cooled servo motors have to be operated at ambient temperatures from

+5°C to +40°C.

Example

The drive should be operated at an ambient temperature of 50°C. According to the diagram, the admissible torque is approx. 91% of the rated torque M

perature. We thus have a factor D

Operating Manual PMCtendo SZ

1002405-EN-03

= 0.91.

T

at this ambient tem-

N

48

Page 49

9 Technical data

9.9 Type-specific data

IMPORTANT

Overheating!

Repainting the motor changes the thermal properties. The motor can not be operated

with the nominal data.

Retain the paint of the motor (matt black in accordance with RAL 9005).

The technical data apply to energy-optimized servo amplifier settings and were determined under the following thermal mounting conditions:

• Mounting of motor with steel bracket on baseplate.

• Minimum mounting surface area between motor and steel bracket, and between

steel bracket and baseplate according to the following table:

Motor Mounting area

between motor flange and

steel bracket

S B H [mm] [m2]

SZ.3x 20 210 285 0,03

SZ.4x 20 210 285 0,03

SZ.5x 25 210 285 0,03

SZ.7x 25 285 285 0,03

SZ.8x 25 285 285 0,03

Ensure that comparable thermal mounting conditions exist in your system!

PMCtendo SZ motors – number of motor poles

Motor Number of poles – PZ [1]

SZ.3x 10

SZ.4x 14

SZ.5x 14

SZ.7x 14

SZ.8x 16

between steel bracket and

baseplate

Operating Manual PMCtendo SZ

1002405-EN-03

49

Page 50

Operating Manual PMCtendo SZ

1002405-EN-03

9 Technical data

PMCtendo SZ motors IC410, convection-cooled (SZ.xx/.../K/...)

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I

M,N

KM0 MR n

0eff

max

M

max

I

max

R

U-V

L

U-V

Tel

1000

SZ.31 40 6000 0,89 1,93 0,461 0,56 0,95 2,02 0,49 0,04 8000 2,8 12,7 11,7 39,8 3,4

SZ.31 40 3000 0,93 1,99 0,467 0,29 0,95 2,02 0,49 0,04 8000 2,8 12,7 11,7 39,8 3,4

SZ.32 42 6000 1,5 3,18 0,472 0,94 1,68 3,48 0,494 0,04 8000 5 17,8 4,5 18,7 4,16

SZ.32 86 3000 1,59 1,6 0,994 0,5 1,68 1,67 1,03 0,04 8000 5 8,55 17,8 75 4,21

SZ.33 55 6000 1,96 3,17 0,618 1,2 2,25 3,55 0,645 0,04 8000 7 16,9 4,9 21,1 4,31

SZ.33 109 3000 2,07 1,63 1,27 0,65 2,19 1,71 1,304 0,04 8000 7 8,25 13,1 68,7 5,24

SZ.41 47 6000 2,3 4,56 0,504 1,4 2,8 5,36 0,53 0,04 8000 8,5 33 1,94 11,52 5,94

SZ.41 96 3000 2,8 2,74 1,022 0,88 3 2,88 1,056 0,04 6500 8,5 16,5 6,7 37,7 5,63

SZ.42 60 6000 3,5 5,65 0,619 2,2 4,9 7,43 0,665 0,04 6500 16 43,5 1,2 8,88 7,4

SZ.42 94 3000 4,7 4,4 1,068 1,5 5,2 4,8 1,092 0,04 6500 16 26,5 3 21,8 7,26

SZ.44 78 6000 5,8 7,18 0,808 3,6 8,4 9,78 0,863 0,04 6500 29 51 0,89 7,07 7,94

SZ.44 116 3000 6,9 5,8 1,19 2,2 8,6 6,6 1,309 0,04 6500 29 35 1,85 15 8,11

SZ.51 68 6000 3,4 4,77 0,71 2,1 4,4 5,8 0,769 0,06 6500 16 31 2,1 12,1 5,76

SZ.51 97 3000 4,3 3,74 1,15 1,4 4,7 4 1,19 0,06 6500 16 22 3,8 23,5 6,18

SZ.52 72 6000 5,2 7,35 0,707 3,3 7,8 9,8 0,802 0,06 6500 31 59 0,76 5,6 7,37

SZ.52 121 3000 7,4 5,46 1,355 2,3 8 5,76 1,399 0,06 6500 31 33 2,32 16,8 7,24

50

SZ.53 84 6000 6,2 7,64 0,812 3,9 10,6 11,6 0,921 0,06 6500 43 63,5 0,62 5 8,06

SZ.53 119 3000 9,7 6,9 1,406 3,1 11,1 7,67 1,455 0,06 6500 43 41 1,25 10 8

SZ.55 103 4500 9,5 8,94 1,063 4,5 15,3 13,4 1,148 0,06 6500 67 73 0,5 4,47 8,94

SZ.55 141 3000 13,5 8,8 1,534 4,2 16 10 1,606 0,06 6500 67 52 0,93 8,33 8,96

SZ.71 76 6000 5,2 6,68 0,778 3,3 7,9 9,38 0,868 0,24 6500 20 31 0,87 8,13 9,34

SZ.71 95 3000 7,4 7,2 1,028 2,3 8,3 8 1,068 0,24 6500 20 25 1,3 12,83 9,87

SZ.72 82 6000 7,2 8,96 0,804 4,5 14,3 16,5 0,879 0,24 6500 41 60,5 0,34 3,9 11,47

SZ.72 133 3000 12 8,2 1,463 3,8 14,4 9,6 1,525 0,24 6500 41 36 1 11,73 11,73

Page 51

Operating Manual PMCtendo SZ

1002405-EN-03

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I

M,N

KM0 MR n

0eff

max

M

max

I

max

R

U-V

L

U-V

Tel

9 Technical data

1000

SZ.73 99 4500 12,1 11,5 1,052 5,7 20 17,8 1,137 0,24 6500 65 78 0,36 4,42 12,28

SZ.73 122 3000 16,5 11,4 1,447 5,2 20,8 14 1,503 0,24 6500 65 62 0,52 6,8 13,08

SZ.75 106 4500 16,4 14,8 1,111 7,7 30 25,2 1,2 0,24 6500 104 114 0,22 2,76 12,55

SZ.75 140 3000 21,3 14,2 1,5 6,7 30,2 19,5 1,561 0,24 6500 104 87 0,33 4,8 14,55

SZ.82 90 4500 10,5 11,2 0,938 5,0 34,5 33,3 1,045 0,3 5000 100 135 0,13 1,9 26,6

SZ.82 136 3000 22,3 13,9 1,604 7,0 37,1 22,3 1,677 0,3 5000 100 84 0,3 5 26,6

SZ.83 131 3000 26,6 17,7 1,503 8,4 48,2 31,1 1,559 0,3 5000 145 124 0,18 2,79 32,7

SZ.85 142 2000 43,7 25,9 1,687 9,2 66,1 37,9 1,752 0,3 5000 205 155 0,13 2,22 45,8

51

Page 52

Operating Manual PMCtendo SZ

1002405-EN-03

9 Technical data

PMCtendo SZ motors IC416, externally ventilated (SZ.xx/.../F/...)

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I0 KM0 MR n

M,N

max

M

max

I

max

R

U-V

L

U-V

Tel

1000

SZ.41 47 6000 2,9 5,62 0,516 1,8 3,5 6,83 0,518 0,04 6500 8,5 33 1,94 11,52 5,94

SZ.41 96 3000 3,4 3,4 1 1,1 3,7 3,6 1,039 0,04 6500 8,5 16,5 6,7 37,7 5,63

SZ.42 60 6000 5,1 7,88 0,647 3,2 6,4 9,34 0,69 0,04 6500 16 43,5 1,2 8,88 7,4

SZ.42 94 3000 5,9 5,5 1,073 1,9 6,3 5,8 1,093 0,04 6500 16 26,5 3 21,8 7,26

SZ.44 78 6000 8 9,98 0,802 5 10,5 12 0,878 0,04 6500 29 51 0,89 7,07 7,94

SZ.44 116 3000 10,2 8,2 1,244 3,2 11,2 8,7 1,292 0,04 6500 29 35 1,85 15 8,11

SZ.51 68 6000 4,5 6,7 0,67 2,8 5,7 7,5 0,768 0,06 6500 16 31 2,1 12,1 5,76

SZ.51 97 3000 5,4 4,7 1,15 1,7 5,8 5 1,172 0,06 6500 16 22 3,8 23,5 6,18

SZ.52 72 6000 8,2 11,4 0,721 5,2 10,5 13,4 0,788 0,06 6500 31 59 0,76 5,6 7,37

SZ.52 121 3000 10,3 7,8 1,321 3,2 11,2 8,16 1,38 0,06 6500 31 33 2,32 16,8 7,24

SZ.53 84 6000 10,4 13,5 0,772 6,5 14,8 15,9 1,068 0,06 6500 43 63,5 0,62 5 8,06

SZ.53 119 3000 14,4 10,9 1,32 4,5 15,9 11,8 1,353 0,06 6500 43 41 1,25 10 8

SZ.55 103 4500 16,4 16,4 0,999 7,7 22 19,4 1,138 0,06 6500 67 73 0,5 4,47 8,94

SZ.55 141 3000 20,2 13,7 1,475 6,4 23,4 14,7 1,596 0,06 6500 67 52 0,93 8,33 8,96

SZ.71 76 6000 7,5 10,6 0,71 4,7 10,2 12,4 0,842 0,24 6500 20 31 0,87 8,13 9,34

SZ.71 95 3000 9,7 9,5 1,021 3,1 10,5 10 1,074 0,24 6500 20 25 1,3 12,83 9,87

52

SZ.72 82 6000 12,5 16,7 0,749 7,9 19,3 22,1 0,886 0,24 6500 41 60,5 0,34 3,9 11,47

SZ.72 133 3000 16,6 11,8 1,407 5,2 19,3 12,9 1,515 0,24 6500 41 36 1 11,73 11,73

SZ.73 99 4500 19,8 20,3 0,975 9,3 27,2 24,2 1,134 0,24 6500 65 78 0,36 4,42 12,28

SZ.73 122 3000 24 18,2 1,319 7,5 28 20 1,412 0,24 6500 65 62 0,52 6,8 13,08

SZ.75 106 4500 27,7 25,4 1,091 13 39,4 32,8 1,209 0,24 6500 104 114 0,22 2,76 12,55

SZ.75 140 3000 33,8 22,9 1,476 11 41,8 26,5 1,586 0,24 6500 104 87 0,33 4,8 14,55

SZ.82 90 4500 30,6 30,5 1,003 14 47,4 45,1 1,058 0,3 5000 100 135 0,13 1,9 14,6

SZ.82 136 3000 34,3 26,5 1,294 11 47,9 28,9 1,668 0,3 5000 100 84 0,3 5 16,66

Page 53

Operating Manual PMCtendo SZ

1002405-EN-03

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I0 KM0 MR n

M,N

max

M

max

I

max

R

U-V

L

U-V

Tel

9 Technical data

1000

SZ.83 131 3000 49 35,9 1,365 15 66,7 42,3 1,584 0,3 4500 145 124 0,18 2,79 15,5

SZ.85 142 2000 77,2 45,2 1,708 16 94 53,9 1,749 0,3 4000 205 155 0,13 2,22 17,08

53

Page 54

Operating Manual PMCtendo SZ

1002405-EN-03

9 Technical data

PMCtendo SZ motors, water-cooled (SZ.xx/.../W/...)

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I

M,N

KM0 MR n

0eff

max

M

max

I

max

R

U-V

L

U-V

Tel

1000

SZ.41 47 6000 2,55 5,2 0,49 1,6 3,35 6,95 0,488 0,04 6500 8,5 33 1,94 11,52 5,94

SZ.41 96 3000 3,3 3,7 0,892 1 3,55 3,9 0,921 0,04 6500 8,5 16,5 6,7 37,7 5,63

SZ.42 60 6000 5 8 0,625 3,1 6,45 9,7 0,669 0,04 6500 16 43,5 1,2 8,88 7,4

SZ.42 94 3000 5,85 5,5 1,064 1,8 6,35 6 1,065 0,04 6500 16 26,5 3 21,8 7,26

SZ.44 78 6000 7,7 10,5 0,733 4,8 10,6 12,3 0,865 0,04 6500 29 51 0,89 7,07 7,94

SZ.44 116 3000 10,4 8,3 1,253 3,3 11,3 8,9 1,274 0,04 6500 29 35 1,85 15 8,11

SZ.51 68 6000 4,3 6,4 0,672 2,7 5,55 7,25 0,774 0,06 6500 16 31 2,1 12,1 5,76

SZ.51 97 3000 5,4 4,75 1,137 1,7 5,65 4,85 1,177 0,06 6500 16 22 3,8 23,5 6,18

SZ.52 72 6000 8,1 11,2 0,723 5,1 10,3 12,9 0,803 0,06 6500 31 59 0,76 5,6 7,37

SZ.52 121 3000 10,2 7,7 1,325 3,2 11 7,85 1,409 0,06 6500 31 33 2,32 16,8 7,24

SZ.53 84 6000 9,95 12,6 0,79 6,3 14,2 15,2 0,938 0,06 6500 43 63,5 0,62 5 8,06

SZ.53 119 3000 13,5 10,2 1,324 4,2 15,2 11,3 1,35 0,06 6500 43 41 1,25 10 8

SZ.55 103 4500 14,2 13 1,093 6,7 20,2 17,2 1,178 0,06 6500 67 73 0,5 4,47 8,94

SZ.55 141 3000 17,9 11,4 1,566 5,6 21,5 13,1 1,655 0,06 6500 67 52 0,93 8,33 8,96

SZ.71 76 6000 7 10,2 0,686 4,4 10,4 12,7 0,834 0,24 6500 20 31 0,87 8,13 9,34

SZ.71 95 3000 10,2 9,95 1,025 3,2 10,4 10 1,064 0,24 6500 20 25 1,3 12,83 9,87

54

SZ.72 82 6000 12 17,5 0,686 7,5 19,3 22,5 0,856 0,24 6500 41 60,5 0,34 3,9 11,47

SZ.72 133 3000 17,1 12,2 1,402 5,4 19,3 13,1 1,47 0,24 6500 41 36 1 11,73 11,73

SZ.73 99 4500 19,1 18,1 1,055 9 26,7 23,7 1,139 0,24 6500 65 78 0,36 4,42 12,28

SZ.73 122 3000 22,5 17 1,319 7,1 27,5 19,6 1,415 0,24 6500 65 62 0,52 6,8 13,08

SZ.75 106 4500 24,1 22 1,096 11 37,2 31,6 1,185 0,24 6500 104 114 0,22 2,76 12,55

SZ.75 140 3000 30,3 20,5 1,478 9,5 39,4 25,4 1,561 0,24 6500 104 87 0,33 4,8 14,55

SZ.82 90 4500 30,7 30,3 1,013 15 46,9 44,6 1,058 0,3 5000 100 135 0,13 1,9 14,6

SZ.82 136 3000 32,2 26,6 1,21 10 48,9 29,6 1,662 0,3 5000 100 84 0,3 5 16,66

Page 55

Operating Manual PMCtendo SZ

1002405-EN-03

Motor KEM nN MN IN K

Vmin/

min-1 Nm A Nm/A kW Nm A Nm/A Nm min-1 Nm A Ω mH ms

PN M0 I

M,N

KM0 MR n

0eff

max

M

max

I

max

R

U-V

L

U-V

Tel

9 Technical data

1000

SZ.83 131 3000 46,7 34,1 1,37 15 65,7 41,7 1,583 0,3 4500 145 124 0,18 2,79 15,5

SZ.85 142 2000 72,1 42,1 1,713 15 90,1 51,9 1,742 0,3 4000 205 155 0,13 2,22 17,08

55

Page 56

9 Technical data

Dimensioned drawing SZ motors IC410, convection cooled (SZ.xx/.../K/...)

Without brake

With brake

1 With feedback system EnDat® optical

Operating Manual PMCtendo SZ

1002405-EN-03

56

Page 57

9 Technical data

Motor øb1 øe1 ød l ±a c f1 ±g p1 p2 q0 q1 øs1 øs2 w1 x z0

SZ.31 60j6 75 14k6 30 72 7 3 72 45 19 116 156 6 M5 56 21 80,5

SZ.32 60j6 75 14k6 30 72 7 3 72 45 19 138 178 6 M5 56 21 102,5

SZ.33 60j6 75 14k6 30 72 7 3 72 45 19 160 200 6 M5 56 21 124,5

SZ.41 95j6 115 14k6 30 98 9,5 3,5 98 40 32 118,5 167 9 M5 91 22 76,5

SZ.42 95j6 115 19k6 40 98 9,5 3,5 98 40 32 143,5 192 9 M5 91 22 101,5

SZ.44 95j6 115 19k6 40 98 9,5 3,5 98 40 32 193,5 242 9 M5 91 22 151,5

SZ.51 110j6 130 19k6 40 115 10 3,5 115 40 36 109 163,5 9 M6 100 22 74,5

SZ.52 110j6 130 19k6 40 115 10 3,5 115 40 36 134 188,5 9 M6 100 22 99,5

SZ.53 110j6 130 24k6 50 115 10 3,5 115 40 36 159 213,5 9 M6 100 22 124,5

SZ.55 110j6 130 24k6 50 115 10 3,5 115 40 36 209 263,5 9 M6 100 22 174,5

SZ.71 130j6 165 24k6 50 145 10 3,5 145 40 42 121 180 11 M8 115 22 83

SZ.72 130j6 165 24k6 50 145 10 3,5 145 40 42 146 205 11 M8 115 22 108

SZ.73 130j6 165 24k6 50 145 10 3,5 145 40 42 171 230 11 M8 115 22 133

SZ.75 130j6 165 32k6 58 145 10 3,5 145 71 42 226 285 11 M12 134 22 184

SZ.82 180j6 215 32k6 58 190 15 3,5 190 71 60 222 299 13,5 M12 157 22 168

SZ.83 180j6 215 38k6 80 190 15 3,5 190 71 60 263 340 13,5 M12 157 22 209

SZ.85 180j6 215 38k6 80 190 15 3,5 190 71 60 345 422 13,5 M12 157 22 291

CAD data can be found on the Internet at www.pilz.com or are available on request.

Operating Manual PMCtendo SZ

1002405-EN-03

57

Page 58

9 Technical data

Dimensioned drawing SZ motors IC416, with external fan (SZ.xx/.../F/...)

Without brake

With brake

Operating Manual PMCtendo SZ

1002405-EN-03

58

Page 59

9 Technical data

Motor øb1 øe1 ød l ±a c f1 ±g1 p1 p2 q3 q4 øs1 øs2 w1 w2 z0 z5

SZ.41 95j6 115 14k6 30 98 9,5 3,5 118 40 32 175 224 9 M5 91 111 76,5 25

SZ.42 95j6 115 19k6 40 98 9,5 3,5 118 40 32 200 249 9 M5 91 111 101,5 25

SZ.44 95j6 115 19k6 40 98 9,5 3,5 118 40 32 250 299 9 M5 91 111 151,5 25

SZ.51 110j6 130 19k6 40 115 10 3,5 135 40 36 179 234 9 M6 100 120 74,5 25

SZ.52 110j6 130 19k6 40 115 10 3,5 135 40 36 204 259 9 M6 100 120 99,5 25

SZ.53 110j6 130 24k6 50 115 10 3,5 135 40 36 229 284 9 M6 100 120 124,5 25

SZ.55 110j6 130 24k6 50 115 10 3,5 135 40 36 279 334 9 M6 100 120 174,5 25

SZ.71 130j6 165 24k6 50 145 10 3,5 165 40 42 213 272 11 M8 115 134 83,0 40

SZ.72 130j6 165 24k6 50 145 10 3,5 165 40 42 238 297 11 M8 115 134 108,0 40

SZ.73 130j6 165 24k6 50 145 10 3,5 165 40 42 263 322 11 M8 115 134 133,0 40

SZ.75 130j6 165 32k6 58 145 10 3,5 165 71 42 318 377 11 M12 134 134 184,0 40

SZ.82 180j6 215 32k6 58 190 15 3,5 215 71 60 322 399 13,5 M12 156,5 134 184,0 40

SZ.83 180j6 215 38k6 80 190 15 3,5 215 71 60 363 440 13,5 M12 156,5 134 184,0 40

SZ.85 180j6 215 38k6 80 190 15 3,5 215 65 60 445 522 13,5 M12 178 134 184,0 40

CAD data can be found on the Internet at www.pilz.com or are available on request.

Operating Manual PMCtendo SZ

1002405-EN-03

59

Page 60

9 Technical data

Dimensioned drawing SZ motors, water cooled (SZ.xx/.../W/...)

SZ.4, SZ.7, SZ.8

SZ.5

Further dimensions, see dimensioned drawing SZ motors IC410, convection-cooled.

Operating Manual PMCtendo SZ

1002405-EN-03

60

Page 61

9 Technical data

Motor w3 z7

SZ.41 49 12,5

SZ.42 49 12,5

SZ.44 49 12,5

SZ.51 70,5 10,5

SZ.52 70,5 10,5

SZ.53 70,5 10,5

SZ.55 70,5 10,5

SZ.71 72,5 10,5

SZ.72 72,5 10,5

SZ.73 72,5 10,5

SZ.75 72,5 10,5

SZ.82 95 15

SZ.83 95 15

SZ.85 95 15

CAD data can be found on the Internet at www.pilz.com or are available on request.

Operating Manual PMCtendo SZ

1002405-EN-03

61

Page 62

9 Technical data

9.9.1 Inertia

INFO

Note that servo motors are not delivered with increased mass moment of inertia in the standard configuration. It is only available optionally (see section

3.4 Dynamic performance).

Motor J

SZ.31 0,19 —

SZ.33 0,4 —

SZ.41 0,93 0,2 0,192

SZ.42 1,63 0,4

SZ.44 2,98 0,8

SZ.51 2,9 —

SZ.52 5,2 1,1

SZ.53 7,58 2

SZ.55 12,2 4,1

SZ.71 8,5 —

SZ.72 13,7 4,4

SZ.73 21,6 6,3

SZ.75 34 13,6

motor

∆J motors with

increased mass moment of

inertia

10-4kgm

∆J motors with

motor brake (= J

2

0,186SZ.32 0,29 —

0,566

0,571

1,721

1,743

5,68

brake

)

SZ.82 58 14,9

SZ.83 83,5 22,3

SZ.85 133 37,2 55,46

Operating Manual PMCtendo SZ

1002405-EN-03

16,46

62

Page 63

Operating Manual PMCtendo SZ

1002405-EN-03

9 Technical data

9.9.2 Weight

Motor ... with convection

cooling (IC 410)

m m m ∆m ∆m

SZ.311,5———

SZ.332,6———

SZ.41 4 5,4 4 0,08 0,76

SZ.42 5,1 6,5 5,1 0,15

SZ.44 7,2 8,6 7,2 0,31

SZ.51 5 7 5 —

SZ.52 6,5 8,5 6,5 0,22

SZ.53 8 10 8 0,43

SZ.55 10,9 12,9 10,9 0,87