Page 1

PROFIBUS-DP-Slave

Software

Programmable control systems PSS

®

Operating Manual – Item No. 19 419-06

Page 2

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

The names of products, goods and technologies used in this documentation are registered

®

trademarks of the respective companies. Automation Workbench

PNOZ

®

, Primo®, PSS®, SafetyBUS p® are registered trademarks of Pilz GmbH & Co. KG.

, Pilz®, PIT®, PMI®,

Page 3

Contents

Introduction 1-1

Overview of manual 1-1

Terminology 1-2

Definition of symbols 1-3

Overview 2-1

Software package 2-1

Functions 2-2

Range 2-2

Intended Use 3-1

Standard function block SB 230 3-2

Setting Parameters 4-1

Diagnostics 4-2

Internal system diagnostics 4-2

External diagnostics 4-3

Device-related diagnostics 4-3

Configuring input and output data 4-6

Setting data blocks 4-11

Examples 4-13

Commissioning 5-1

Configuration 5-1

Commissioning sequence 5-1

PROFIBUS-DP-Slave Operating Manual 1

Page 4

Contents

Standard Function Blocks 6-1

SB 230 6-1

Appendix 7-1

Example 7-1

Changes in the documentation 7-6

2

PROFIBUS-DP-Slave Operating Manual

Page 5

Introduction

This manual describes the communications software for the:

• PSS(1) DP-S module

and

• PSS SB 3006 DP-S compact programmable safety system.

Separate manuals are available for using the respective programmable

control systems PSS:

• PROFIBUS-DP-Slave Hardware Manual

• PSS SB 3006 DP-S Shortform

• PSS SB 3006 DP-S Installation Manual

To fully understand this manual you will need to be conversant with the

information found in the general documentation for the programmable

control systems PSS (System Manual, Installation Manual for the modular

PSS and the Programming Manual).

Familiarity with general documentation on PROFIBUS (EN 50170 Volume

2 in the current version) is also required in order to understand busspecific processes, configurations and terminology. Familiarity with a

network configuration tool is also required.

This manual is intended for instruction and should be retained for future

reference.

Overview of manual

1 Introduction

The introduction is designed to familiarise you with the contents,

structure and specific order of this manual.

2 Overview

This chapter provides information on the most important features of

the software package and briefly outlines the application area.

3 Intended use

You must read this chapter, as it contains important information on

safety regulations and intended use.

1-1PROFIBUS-DP-Slave Operating Manual

Page 6

Introduction

4 Setting parameters

5 Commissioning

6 Standard function blocks

7 Appendix

Terminology

This chapter describes the parameters, diagnostics and the

configuration of input and output data.

This chapter describes the commissioning procedure.

This chapter provides information on the parameters and

management of standard function block SB 230.

The example is designed to provide support when linking standard

function block SB 230 into a user program.

• The term "safety system", "system" or "PSS" will be used in this manual

to refer to the programmable control systems PSS. If the description is

only valid for a particular device, the specific product name will be used

(e.g. PSS SB 3006 DP-S, PSS(1) DP-S).

• In this manual, data transfer is always regarded as viewed from the PSS:

input data / receive data is sent from a PROFIBUS subscriber to the

PSS. Output data / send data is sent from the PSS to a PROFIBUS

subscriber.

1-2 PROFIBUS-DP-Slave Operating Manual

Page 7

Definition of symbols

Information in this manual that is of particular importance can be identified

as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation which

poses an immediate threat of serious injury and death, and indicates

preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation that

could lead to serious injury and death, and indicates preventive

measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus

material damage, and also provides information on preventive measures

that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also

provides information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special

features, as well as highlighting areas within the text that are of particular

importance.

1-3PROFIBUS-DP-Slave Operating Manual

Page 8

Introduction

Notes

1-4 PROFIBUS-DP-Slave Operating Manual

Page 9

Overview

This software package connects the PSS(1) DP-S module or compact

programmable safety system PSS SB 3006 DP-S to PROFIBUS-DP. The

PSS connection is in accordance with PROFIBUS specification EN 50170

Volume 2.

Software package

Data exchange via PROFIBUS is a Master-Slave communication. The

maximum length of data to be exchanged is defined in the master data file

(see file PILZ2500.GSD on the disk supplied). Parameters must be set for

the Slave prior to communication. For example, parameters describe

configuration data, the length of input/output data, station address, etc.

Data cannot be exchanged until the Master has received the parameter

data record.

The setting of parameters on the PROFIBUS-DP-Slave is supported by

standard function blocks. All the required parameters are entered in one

data block.

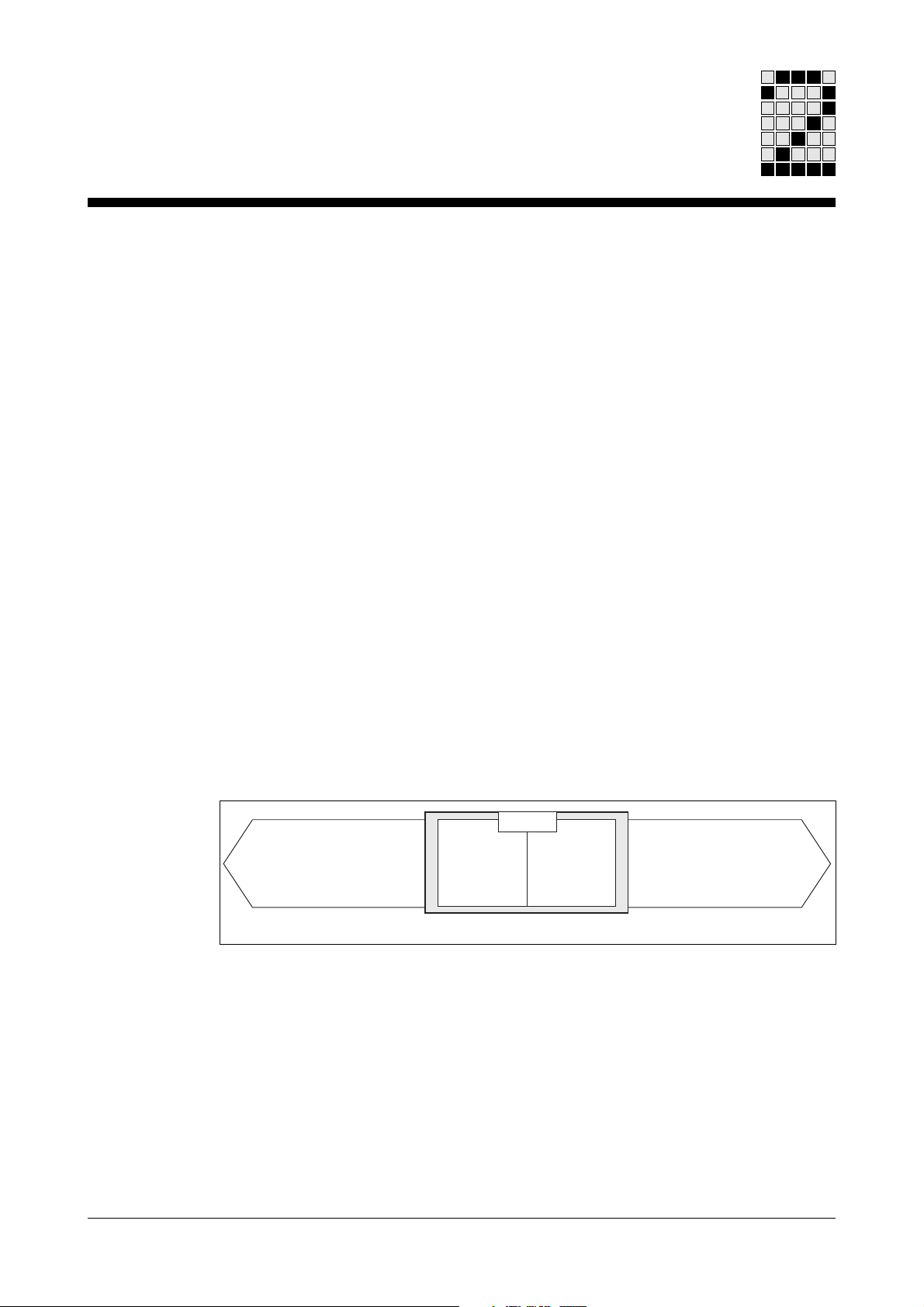

The programmable control systems PSS have been designed for use in

plant and machinery safety circuits. They consist of a failsafe (FS) section

and a standard (ST) section.

Control and monitoring of

Steuerung von

safety-related

sicherheitsgerichteten

tasks

Aufgaben

e.g.: E-STOP circuits etc.

z. B.: NOT-AUS usw.

Fig. 2-1: Structure of the PSS

Fail-safe-

Failsafe

Section

Teil

PSS

Standard-

Standard

Teil

Section

Steuerung und

Control of

Regelung von

non-safety-related

nicht sicherheitsgerichteten

tasks

Aufgaben

e.g.: diagnostics etc.

z. B.: Diagnose usw.

This software package is designed for use in the standard section of a

programmable control system PSS.

PROFIBUS-DP-Slave Operating Manual 2-1

Page 10

Overview

Functions

Range

The PROFIBUS-DP-Slave supports the following functions:

• Internal system diagnostics

• Device-related diagnostics

• Transfer of max. 488 bytes of user data

INFORMATION

In this manual, data transfer is always regarded as viewed from the PSS:

Input data is sent from the Master to the PSS, output data is sent from the

PSS to the Master.

The software package consists of:

• one disk and

• one operating manual: PROFIBUS-DP-Slave Software

The disk contains:

• Standard function blocks SB 230, SB 231, SB 232

• Master data files:

PILZ2500.GSD (German)

PILZ2500.GSE (English)

PILZ2500.GSF (French)

• One sample program

2-2 PROFIBUS-DP-S -Slave Operating Manual

Page 11

Intended Use

This software package is designed to connect a programmable control

system PSS to PROFIBUS-DP. It is essential to use a suitable module or

compact safety system.

This software package is intended for use with the following programmable

control systems PSS:

• PSS DP-S module when using a module rack from the PSS 3000 series.

• PSS1 DP-S module when using a module rack from the PSS 3100

series.

• PSS SB 3006 DP-S programmable safety system as a compact device.

The safety systems are passive subscribers (Slaves) on PROFIBUS-DP.

The meet standard EN 50170 Volume 2, PROFIBUS.

Disregard of the information in this manual and use of the software

package outside the specifications described here will be deemed as

improper application.

INFORMATION

This software package is exclusively for use in non-safety-related

applications. It must be used in the standard section of the PSS.

Conditions for operation:

• The module must be installed in accordance with the PROFIBUS DPSlave Hardware Manual and the relevant “Installation Manual” for the

programmable safety system.

• You must be familiar with and adhere to standard EN 50170 Volume 2,

PROFIBUS.

PROFIBUS-DP-Slave Operating Manual 3-1

Page 12

Intended Use

Standard function block SB 230

SB 230 may be used with the following functions and parameters:

• PROFIBUS-DP connection

• To trigger a slave reset

• To trigger static diagnostics

• Permitted data lengths:

Input data: 0 ... 108 words (set via parameters)

Output data: 0 ... 108 words (set via parameters)

Diagnostic data: 4 ... 35 words (set via parameters)

Configuration data: 1 ... 244 bytes (set via parameters)

Please note that the overall data length may be a max. of 1472 Bytes.

Information on calculating the data length can be found in the section

entitled "Setting data blocks".

INFORMATION

SB 230 must be called up in the user program as part of each cycle.

3-2 PROFIBUS-DP-Slave Operating Manual

Page 13

Setting Parameters

Setting Parameters

Before operating the PSS(1) DP-S and PSS SB 3006 DP-S, a number of

parameters must be established and then entered in a data block. You can

use any free data block or amend the data block supplied (DB 050).

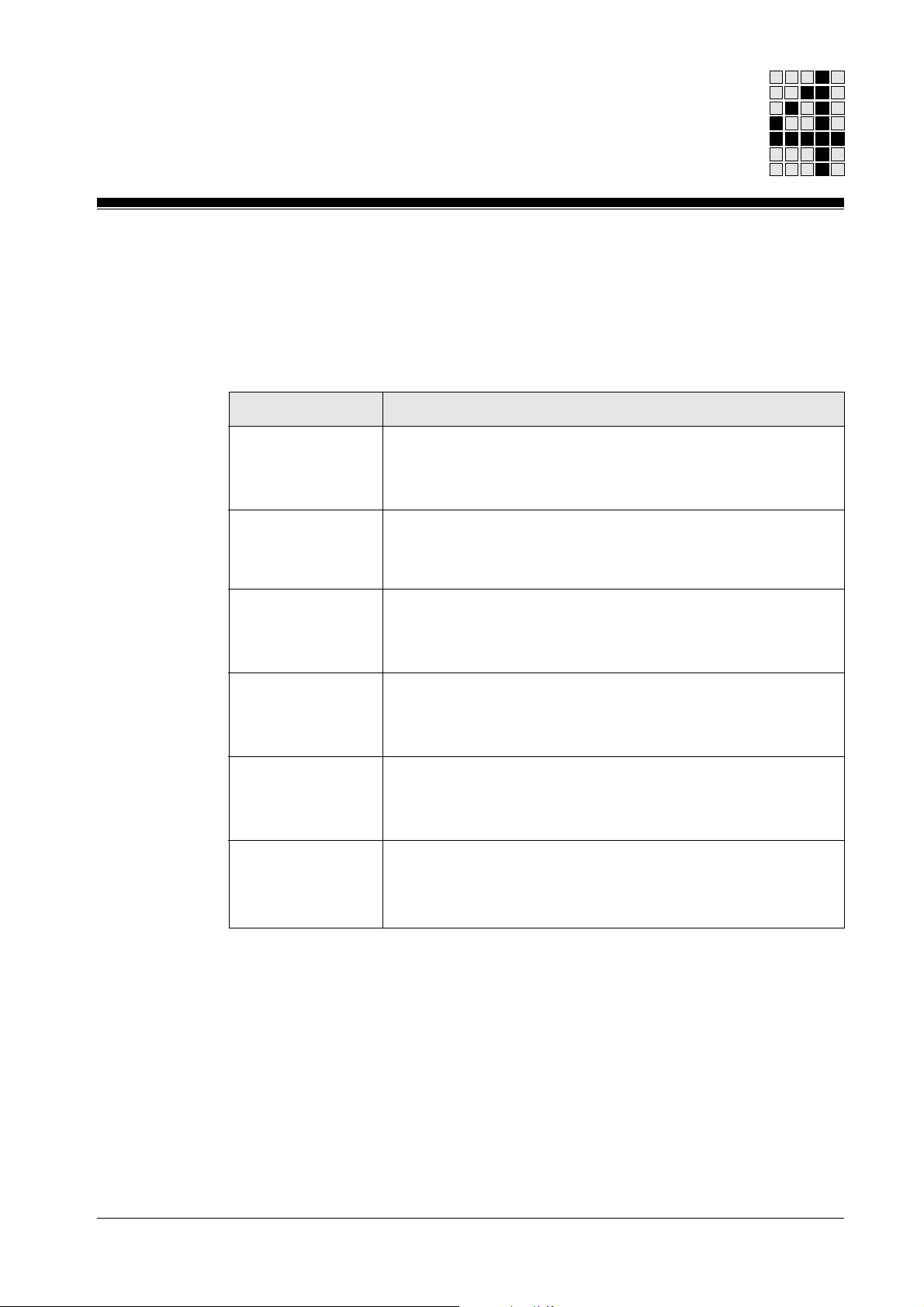

Data block configuration:

Data word Contents

DW 0000

... Input data from the Master to the PSS

DW 0127

DW 0128

... Output data from the PSS to the Master

DW 0255

DW 0256

... Diagnostic data

DW 0383

DW 0384

... Configuration data

DW 0511

DW 0512

... Reserved

DW 0767

DW 0768

... Control and status information

DW 1023

PROFIBUS-DP-Slave Operating Manual 4-1

Page 14

Setting Parameters

Diagnostics

The diagnostics function provides information about the PSS / Slave to the

Master. The standard divides diagnostic information into two areas:

• Internal system diagnostic data

• External diagnostic data

- device-specific diagnostic data

- user-specific diagnostic data

Internal system and device-specific diagnostic data is transferred

automatically. If the PSS(1) DP-S or PSS SB 3006 DP-S receives a

diagnostic message, it will inform the Master that it is present. The Slave

cannot send the diagnostic data until the Master requests it. During

transmission, I/O data traffic (transfer of usable data) is interrupted.

It is also possible to transfer user-specific messages (diagnostic data).

The time of transfer for user-specific messages can be set individually.

The user establishes the event which will trigger the transfer of diagnostic

data.

Application example: a machine's operating status is to be transmitted

constantly (e.g. 10 Bytes). If a certain temperature is exceeded, additional

data will be required (e.g. 40 Bytes). The 10 Bytes for operating status will

be transferred within the usable data; the 40 Bytes of additional data will

be transferred in diagnostics mode. This means that in normal operation,

only small amounts of data are transferred and the communication speed

will be high. In exceptional cases (when the temperature is exceeded),

larger amounts of data must be transferred and the communication speed

will be reduced.

Internal system diagnostics

Standard function block SB 230 prepares data for internal system

diagnostics:

Byte 1 Bit 6: Prm_Fault

Byte 1 Bit 3: Ext_Diag

Byte 1 Bit 1: Station_Not_Ready

4-2 PROFIBUS-DP-Slave Operating Manual

Page 15

Setting Parameters

Byte 2 Bit 1: Stat_Diag

Byte 2 Bit 0: Prm_Req

Byte 3 Bit 7: Ext_Diag_Overflow

Byte 5-6: ID-number 2500H (ID-number assigned through PROFIBUS

User Organisation)

INFORMATION

For details of what the parameters mean, please refer to the PROFIBUS

standard EN 50170 Volume 2.

External diagnostics

On the PSS(1) DP-S and PSS SB 3006 DP-S, external diagnostics are

limited to device-related diagnostics. ID and channel-related diagnostics

are only sensible if more than 61 Bytes of user-specific diagnostic data are

to be transferred. These diagnostic types are not described in this manual.

Please refer to EN 50170 and note also that these applications may not be

possible with all Master-Slave configurations.

Device-related diagnostics

Device-related diagnostics automatically detect whether the PSS is in a

RUN or STOP condition. A maximum of 61 Bytes of memory is available

for additional user-specific messages.

Device-related diagnostics without user-specific messages:

Only 2 data bytes are required for this type of diagnostics: one data byte

for the coding and one for the contents. The two data bytes correspond to

Bytes 7 and 8.

Enter the following values in the data block:

.

.

.

DL DR

DW 0259 Byte 8 Byte 7

...

DW 0812 KF 04

.

.

.

PROFIBUS-DP-Slave Operating Manual 4-3

Page 16

Setting Parameters

Contents of data word DW 0259 DR: Header byte 7:

Bit No. 7 6543210

00000010

Code for Block length in Bytes including

Device-related diagnostics Header byte: 2 Bytes

INFORMATION

In the case of device-related diagnostics without user-specific messages,

DW 0259 DR will always contain 02.

The PSS(1) DP-S or PSS SB 3006 DP-S registers in DW 0259 DL:

Header byte 8:

Bit No. 7 6543210

xxxxxxx 0/1

0: ST section of PSS in RUN mode

Not used 1: ST section of PSS in STOP mode

The PSS(1) DP-S or PSS SB 3006 DP-S uses a hardware signal to detect

whether the PSS standard section is in a RUN or STOP condition.

INFORMATION

This type of diagnostics is only possible if the slave has been fully

initialised by the PSS and has been recognised by the Master.

The length of the diagnostic data must be entered in DW 0812. Diagnostic

data has a length of at least 4 words:

3 words of internal diagnostic data in DW 0256, 0257 and 0258

+ 1 word in DW 0259 (as described).

4-4 PROFIBUS-DP-Slave Operating Manual

Page 17

Setting Parameters

Device-related diagnostics with user-specific messages:

Device-related diagnostics can be extended by a maximum of 61 Bytes

with user-specific messages. These messages are entered in the data

block from DW 0260.

Enter the following values in the data block:

.

. DL DR

.

DW 0259 Byte 8 Byte 7

DW 0260

... User-specific messages

DW 0383

.

.

.

DW 0812 KF Length of diagnostic data

.

.

.

Contents of data word DW 0259 DR: Header byte 7:

MSB LSB

Bit No. 7 6 5 43210

00xxxxxx

Code for Length of user messages:

device-related diagnostics 2 ... 63 relates to 2 ... 63 Bytes

If the length entered in DW 0259 is greater than 2, the user messages will

follow on from DW 0260 (Byte 9). If the length entered is less than 2,

device-specific diagnostics will not be possible.

Contents of data word DW 0259 DL: Byte 8:

In DW 0259 DL the PSS(1) DP-S or PSS SB 3006 DP-S registers whether

the PSS standard section is in a RUN or STOP condition (see page 4-4).

The length of the diagnostic data must be entered in DW 0812. This is

composed of:

3 words of internal diagnostic data (DW 0256+DW 0257+DW 0258)

+ 1 word of device-specific diagnostic data (DW 0259)

+ x words user-specific data.

PROFIBUS-DP-Slave Operating Manual 4-5

Page 18

Setting Parameters

Configuring input and output data

The length of the input and output data plus data consistency are all

established through the configuration. Data consistency can refer to a

single word or to the whole data length. The maximum data length of the

input or output data is 122 words (244 Bytes). The configuration of the

Master, PSS(1) DP-S or PSS SB 3006 DP-S must match (see also

Chapter 6, page 6-4).

INFORMATION

The PSS(1) DP-S or PSS SB 3006 DP-S transfers all data word by word.

As the PSS CPU always accesses the Slave word by word, byte structures

are not supported.

There are two ways of configuring the PSS(1) DP-S or PSS SB 3006

DP-S: either through a simple ID-format which establishes the length,

consistency and direction of communication, or by means of a special ID

which allows for additional data through a separate length byte. The

configuration is undertaken in an “ID-Byte”.

Simple ID-Format

The simple ID-format is suitable for transmissions of up to a maximum of

16 words. With larger transmissions you will either need to use several IDbytes in succession or the special ID-format.

Enter the following parameters in the data block:

• When only output or input data is being transferred, or when input and

output data of the same length is to be transferred simultaneously:

.

.

.

DW 0384

.

.

.

DW 0813 Length of the configuration data in Bytes

• When input and output data of different lengths is to be transferred

simultaneously:

.

.DLDR

.

DW 0384 Input ID-Byte Output ID-Byte

.

.

.

DW 0813 Length of the configuration data in Bytes

DL DR

00 ID-Byte

4-6 PROFIBUS-DP-Slave Operating Manual

Page 19

Setting Parameters

Contents of ID-Byte:

Bit No. 7 6 5 43210

x1xxxxxx

Length of data: 0000 ... 1111

corresponds to 1 ... 16 words

Input / Output

00 = Special ID-format

01 = PSS output data

10 = PSS input data

11 = PSS input and output data

Data structure: 1: Word, 0: Byte

We recommend you set Bit 6 = 1 (Word)

Consistency: 0: for one word, 1: for the whole data length

The length of the configuration data must be entered in bytes in DW 0813.

The length is 1, if only one byte is used, or two if both bytes of data word

DW 0384 are used.

Examples: Consistency always over the whole data length

DW 0384

1 word output 1101 0000

16 words output 1101 1111

1 word input 1110 0000

16 words input 1110 1111

Input and output, 1 word each 1111 0000

Input and output, 12 words each1111 1011

1 word output and 1101 0000

2 words input 1110 0001

D0

B

B

B

B

B

B

B

B

DF

E0

EF

F0

FB

D0

E0

H

H

H

H

H

H

H

H

00 D0

00 DF

00 E0

00 EF

00 F0

00 FB

E0 D0

15 words output and 1101 1110

16 words input 1110 1111

PROFIBUS-DP-Slave Operating Manual 4-7

DE

B

B

EF

H

H

EF DE

Page 20

Setting Parameters

Special ID-Format

The ID-format occupies a maximum of three data words. Enter the

following values in the data block:

• When only output or input data is to be transferred:

.

.DLDR

.

DW 0384 Length-Byte ID-Byte

.

.

.

DW 0813 KF 2 ;Length of the configuration data in Bytes

.

.

.

• When input and output data is to be transferred simultaneously:

.

.DLDR

.

DW 0384 Length-Byte E ID-Byte

.

.

.

DW 0813 KF 3 ;Length of the configuration data in Bytes

.

.

.

• When more than 64 Bytes of input and output data are to be transferred

simultaneously. Data must be transferred consecutively: first the 64

Bytes and then the remaining Bytes:

.

.DLDR

.

DW 0384 Length-Byte E ID-Byte

.

.

.

DW 0813 KF 6 ;Length of the configuration data in Bytes

.

.

.

00 Length-Byte A

ID-Byte Length-Byte A

Length-Byte A Length-Byte E

4-8 PROFIBUS-DP-Slave Operating Manual

Page 21

Setting Parameters

ID-Byte:

Bit No. 7 6 5 43210

xx00xxxx

00 = Reserved

01 = 1 length byte for PSS output data follows

10 = 1 length byte for PSS input data follows

11 = 1 length byte for PSS input data and one length byte for

Length of manufacturer-specific data

ID-code

PSS output data follow

INFORMATION

Manufacturer-specific data is not pre-assigned by Pilz. Users may enter

their own data - please refer to the standard.

If no data is to be entered, enter the value 0 in Bits 0 ... 3 .

Length-Byte:

Bit No. 7 6 5 43210

x1xxxxxx

Length of data: 000000 ... 111111 corresponds to

1 ... 64 words

Data structure: 1: Word, 0: Byte

We recommend you set Bit 6 = 1 (Word)

Consistency: 0: for one word, 1: for the whole data length

INFORMATION

The amount of configuration data must be entered in Bytes in DW 0813.

PROFIBUS-DP-Slave Operating Manual 4-9

Page 22

Setting Parameters

Examples: Consistency always over the whole data length

1 word output 0100 0000

1100 0000

DL DR

40

B

B

C0

H

H

CO 40

16 words output 0100 0000

1100 1111

1 word input 1000 0000

1100 0000

64 words input 1000 0000

1111 1111

Input and o/p, 2 words each 1100 0000

1100 0001

1100 0001

Input and o/p, 16 words each 1100 0000

1100 1111

1100 1111

Input and o/p, 64 words each 1100 0000

1111 1111

1111 1111

40

B

B

B

B

B

B

B

B

B

B

B

B

B

B

B

CF

80

C0

80

FF

C0

C1

C1

C0

CF

CF

C0

FF

FF

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

CF 40

C0 80

FF 80

C1 C0

00 C1

CF C0

00 CF

FF C0

00 FF

2 words input and 1100 0000

3 words output 1100 0001

1100 0010

16 words input and 1100 0000

4 words output 1100 1111

1100 0011

4-10 PROFIBUS-DP-Slave Operating Manual

C0

B

B

B

B

B

B

C1

C2

C0

CF

C3

H

H

H

H

H

H

C1 C0

00 C2

CF C0

00 C3

Page 23

Setting Parameters

122 words input and 2 words output

1st ID-Byte for input data

Length-Byte for input data (64 words)

2nd ID-Byte for output data

Length-Byte for output data C1 40

3rd ID-Byte for input data

Length-Byte for input data (58 words)

Setting data blocks

1000 0000

1111 1111

0100 0000

1100 0001

1000 0000

1111 1001

80

B

B

B

B

B

B

FF

40

C1

80

F9

H

H

H

H

H

H

FF 80

F9 80

Enter the values in a data block, as shown overleaf. In addition to

diagnostic and configuration data, the following data words must be

written:

• The first 128 data words are reserved for input data and the next 128 for

output data.

• Enter the maximum length of the diagnostic data in data word DW 0783.

This value means that a memory area is reserved for the diagnostic data

during initialisation. The value max_diag_len is stated in bytes and must

be at least equal to the length in words of the diagnostic data in data

word DW 0812.

INFORMATION

DW 0812 should be entered in words and DW 0783 in bytes!

• “F5” should always be entered in data word DW 0795.

• The station address should be entered in data word DW 0800. This

address must be identical to the address set on the front plate.

• In data word DW 0801, enter the transmission sequence for the I/O-data

and the user-specific diagnostic data:

0: (default; Motorola) The PSS sends the left data byte to the

Master first, followed by the right data byte.

1: (Intel) the PSS transmits the right data byte first, followed by the

left data byte.

PROFIBUS-DP-Slave Operating Manual 4-11

Page 24

Setting Parameters

• Enter the length of the input data in data word DW 0810 and the length of

the output data in data word DW 0811.

• Always enter “0” in data words DW 0814 and DW 0815.

Data block configuration:

NOTICE

Only edit data words and output data that are shaded grey.

Data words 256, 257, 512 ... 782, 784 ... 794, 796 ... 799, 802 ... 809 and

816 ... 1023 cannot be amended!

Data word Type Contents

DW 0000...DW 0127 Input data Master --> PSS

DW 0128...DW 0255 Output data PSS --> Master

DW 0256 Reserved for internal diagnostic data

DW 0257 Reserved for internal diagnostic data

DW 0258 KH ID number: 2500 hex

DW 0259 KH Device-specific diagnostic data [Byte]

DW 0260...DW 0383 KH User-specific diagnostic data

DW 0384...DW 0511 KH Configuration data

DW 0512...DW 0782 Reserved

DW 0783 KF max_diag_len [Byte] (>2 x DW 0812)

DW 0784...DW 0794 Reserved

DW 0795 KH Only F5 hex is permitted

DW 0796...DW 0799 Reserved

DW 0800 KF Slave address 0 ... 126

DW 0801 KF Transmission sequence of Bytes 0 or 1

DW 0802...DW 0809 Reserved

DW 0810 KF Length of input data 0 - 122 [Words]

DW 0811 KF Length of output data 0 - 122 [Words]

DW 0812 KF Length of diagnostic data 4 - 35 [Words]

1 Byte Header (DR 0259)

+ 1 Byte Pilz diagnostics (DL 0259)

+ x Byte user diagnostics (DR 0260ff)

Equals coding switch on the module

3 words internal diagnostics (DW 0256 ...

DW 0258)

x words device-specific diagnostics

(= DW 0259 / 2)

4-12 PROFIBUS-DP-Slave Operating Manual

Page 25

Setting Parameters

Data word Type Contents

DW 0813 KF Amount of configuration data 1- 244 [Byte]

DW 0814 KF Only 0 is permitted

DW 0815 KF Only 0 is permitted

DW 0816...DW 1023 Reserved

NOTICE

The data length may be a maximum of 1472 Bytes. The maximum data

length is calculated as follows:

3 x length of the input data

+ 3 x length of the output data

+ 2 x length of the diagnostic data

+ 4 x length of the configuration data

+ 120 Byte

(DW 0384ff)

Examples

Example 1:

12 words input and output: configuration byte FBH ;

Length of configuration data: 1 Byte

Diagnostics: 3 words of internal diagnostic data

1 word of device-related diagnostic data

Data word Contents Description

DW 0000 - DW 0011 ... Input data

DW 0128 - DW 0139 ... Output data

DW 0258 KH 2500 ID-number

DW 0259 KH 0002 Device-related diagnostics

DW 0384 KH 00FB Configuration data

DW 0783 KF 10 max_diag_len [Byte]

DW 0795 KH F5 Pre-assigned

DW 0800 KF 1 Slave address [0-126]

DW 0801 KF 0 Transmission sequence

DW 0810 KF 12 Length of input data in words

DW 0811 KF 12 Length of output data in words

DW 0812 KF 4 Length of diagnostic data in words

DW 0813 KF 1 Amount of configuration data in bytes

DW 0814 KF 0 Pre-assigned

DW 0815 KF 0 Pre-assigned

PROFIBUS-DP-Slave Operating Manual 4-13

Page 26

Setting Parameters

Example 2:

64 words output, special configuration byte: 40, Length byte: FF

Diagnostics: 3 words of internal diagnostic data

1 word of device-related diagnostic data

Data word Contents Description

DW 0128 - DW 0191 ... Output data

DW 0258 KH 2500 ID-Number

DW 0259 KH 0002 Device-related diagnostics

DW 0384 KH FF40 Configuration data

DW 0783 KF 10 max_diag_len [Byte]

DW 0795 KH F5 Pre-assigned

DW 0801 KF 0 Transmission sequence

DW 0800 KF 1 Slave address [0-126]

DW 0810 KF 0 Length of input data in words

DW 0811 KF 64 Length of output data in words

DW 0812 KF 4 Length of diagnostic data in words

DW 0813 KF 2 Amount of configuration data in bytes

DW 0814 KF 0 Pre-assigned

DW 0815 KF 0 Pre-assigned

4-14 PROFIBUS-DP-Slave Operating Manual

Page 27

Setting Parameters

Example 3:

2 words input and 1 word output,

Special configuration byte: C0,

Length byte input: C1

Length byte output: C0

Diagnostics: 3 words of internal diagnostic data

Data word Contents Description

DW 0000 - DW0001 ... Input data

DW 0128 ... Output data

DW 0258 KH 2500 ID-Number

DW 0259 KH 0002 Device-related diagnostics

DW 0384 KH C1C0 Configuration data

DW 0385 KH 00C0

DW 0783 KF 10 max_diag_len [Byte]

DW 0795 KH F5 Pre-assigned

DW 0800 KF 1 Slave address [0-126]

DW 0801 KF 0 Transmission sequence

DW 0810 KF 2 Length of input data in words

DW 0811 KF 1 Length of output data in words

DW 0812 KF 4 Length of diagnostic data in words

DW 0813 KF 3 Amount of configuration data in bytes

DW 0814 KF 0 Pre-assigned

DW 0815 KF 0 Pre-assigned

1 word of device-related diagnostic data

PROFIBUS-DP-Slave Operating Manual 4-15

Page 28

Setting Parameters

Example 4 :

100 words input and output

Configuration byte: C0

Length byte input (64 words): FF

Length byte output (64 words): FF

Configuration byte: C0

Length byte input (36 words): E3

Length byte output (36 words): E3

Diagnostics: 3 words of internal diagnostic data

Data word Contents Description

DW 0000 - DW 0099 ... Input data

DW 0128 - DW 0227 ... Output data

DW 0258 KH 2500 ID-number

DW 0259 KH 0052 Device-related diagnostics

DW 0384 KH FFC0 Configuration data

DW 0385 KH C0FF

DW 0386 KH E3E3

DW 0783 KF 58 max_diag_len [Byte]

DW 0795 KH F5 Pre-assigned

DW 0800 KF 1 Slave address [0-126]

DW 0801 KF 0 Transmission sequence

DW 0810 KF 100 Length of input data in words

DW 0811 KF 100 Length of output data in words

DW 0812 KF 29 Length of diagnostic data in words

DW 0813 KF 6 Amount of configuration data in bytes

DW 0814 KF 0 Pre-assigned

DW 0815 KF 0 Pre-assigned

1 word of device-related diagnostic data

50 bytes of user-specific diagnostic data

4-16 PROFIBUS-DP-Slave Operating Manual

Page 29

Setting Parameters

Example 5:

2 words input and 1 word output

Configuration byte: C0

Length byte input: C1

Length byte output: C0

Diagnostics: 3 words of internal diagnostic data

Data word Contents Description

DW 0000 - DW 0001 ... Input data

DW 0128 ... Output data

DW 0258 KH 2500 ID-number

DW 0259 KH 0004 Device-related diagnostics

DW 0260 KH xxxx User-specific diagnostic data

1 word of device-related diagnostic data

2 bytes of user-specific diagnostic data

DW 0384 KH C1C0 Configuration data

DW 0385 KH 00C0

DW 0783 KF 10 max_diag_len [Byte]

DW 0795 KH F5 Pre-assigned

DW 0800 KF 1 Slave address [0-126]

DW 0801 KF 0 Transmission sequence

DW 0810 KF 2 Length of input data in words

DW 0811 KF 1 Length of output data in words

DW 0812 KF 5 Length of diagnostic data in words

DW 0813 KF 3 Amount of configuration data in bytes

DW 0814 KF 0 Pre-assigned

DW 0815 KF 0 Pre-assigned

PROFIBUS-DP-Slave Operating Manual 4-17

Page 30

Setting Parameters

Notes

4-18 PROFIBUS-DP-Slave Operating Manual

Page 31

Commissioning

Configuration

Before commissioning, the following values need to be established:

• The number of inputs and outputs in words

• The amount of diagnostic data in words

• Station address (see PROFIBUS-DP-Slave Hardware Manual or PSS SB

3006 DP-S Shortform).

The Master can be configured using the configuration data and the data

from the unit's master data file.

Commissioning Sequence

Requirement

The module must have been installed in accordance with the instructions

provided in the PROFIBUS-DP-Slave Hardware Manual or PSS SB 3006

DP-S Shortform. Master and Slave must be ready for operation.

• Create a cold-start organisation block, OB 020, and state the necessary

parameters in a data block; enter the slave module under hardware

registry in DB 004; an example for OB 020 can be found in the Appendix.

• Establish the parameters for standard function block SB 230 (see

Chapter 6 for further details).

• SB 230 must be called up in each PSS cycle.

• Transfer the following blocks to the PSS:

- OB 001 and OB 020

- SB 230, SB 231 and SB 232

- DB 4, DB 5 and the data block containing the parameters

- any additional blocks required by the user.

• After configuration, output parameter

230 can no longer register an error. It should display:

Any other value indicates an error. For further information please refer to

Chapter 6, “Standard Function Blocks”.

ERR

on standard function block SB

ERR

= KH 2000.

PROFIBUS-DP-Slave Operating Manual 5-1

Page 32

Commissioning

Notes

5-2 PROFIBUS-DP-Slave Operating Manual

Page 33

Standard Function Blocks

SB 230

Function

• Communication between the PSS and PROFIBUS-DP-Slave

• Trigger a Slave reset

• Trigger static diagnostics

Block Header

SB230

DP-SLAVE

W- BASE ERR -W

B- DB

B- MODE

W: Word, B: Byte

Parameters

• Input parameters

- BASE: Module's start address (Offset)

The module occupies 1024 words after the start address.

These words may not be accessed.

- MODE: = 01: Static diagnostics

= 02: Reset:

All other values: Data exchange (Data_exchange):

- DB: Data block

• Output parameters

ERR: Error message (see table below)

ERR (hex) Key Cause/Remedy

0001 DP_SL_ERR_DPS2_LENGTH Total length calculated for diagnostic,

parameter, input and output data is too

high; reduce the data length!

0002 DP_SL_ERR_DPS2_INIT Hardware initialisation error;

Change PSS(1) DP-S module or

PSS SB 3006 DP-S

PROFIBUS-DP-Slave Operating Manual 6-1

Page 34

Standard Function Blocks

ERR (hex) Key Cause/Remedy

0003 DP_SL_ERR_SSA_IND Master attempting to change slave

address; reconfigure Master

0004 DP_SL_ERR_DIAG_LEN Diagnostic data length is incorrect;

Change data length

0005 DP_SL_ERR_CFG_LEN Configuration data length is incorrect;

Change length

0006 DP_SL_ERR_PRM_LEN Parameter data length is incorrect;

Change length

0007 DP_SL_ERR_IO_LEN Data length is incorrect (inputs or outputs);

Change length

0008 DP_SL_ERR_DP_WD_TIMEOUT Master monitoring has elapsed;

0009 DP_SL_ERR_WRONG_ADRESS Invalid station address has been set;

Set a valid address (0 - 126) on the switch

and in the data block

000A DP_SL_ERR_IDENT_NR_P Incorrect ID-number in data block;

Correct ID-number: 2500 hex.

000B DP_SL_ERR_WRONG_DB_NR Invalid DB number; select a valid DB

000C DP_SL_ERR_IO_NULL_PTR Input and output data length equal zero;

check the configuration data

1000 DP_SL_ERR_SLAVE_NOT_ Slave does not respond or is busy;

READY Reset the module

1001 DP_SL_ERR_WRONG_SLAVE_ Undefined slave condition; reset or

STATE restart module

1002 DP_SL_ERR_DIAG_DATA_ Access to DPR denied; reset or restart

AREA_NOT_READY module

1003 DP_SL_ERR_CFG_DATA_ Access to DPR denied; reset or restart

AREA_NOT_READY module

00FA DP_SL_ERR_DPRAM_TIMEOUT PSS not enabling the DPR or DPR

is defective; reset or restart module

00FB DP_SL_ERR_SET_PRM Parameter data on Master and Slave do

not match; check the configuration data

00FC DP_SL_ERR_MASTER_NOT_ Master not available, bus interrupted

READY when starting the slave

6-2 PROFIBUS-DP-Slave Operating Manual

Page 35

Standard Function Blocks

ERR (hex) Key Cause/Remedy

00FD DP_SL_ERR_CHK_CFG Configuration data on Master and Slave

do not match; check the configuration

data on the Slave and the Master. See

“Copying the Slave configuration from the

Master configuration”, page 6-4

00FE DP_SL_ERR_BUS_FAULT No communication between Master and

Slave, e.g. incorrect slave ID-number

on the Master, Bus interrupted during

data exchange, Master switched off;

Establish cause and rectify

00FF DP_SL_ERR_FATAL Hardware error; change PSS(1) DP-S

module or PSS SB 3006 DP-S

2000 DP_SL_NO_ERROR No error detected

2001 DP_SL_ERR_SLAVE_NOT_ Slave does not respond or is busy;

READY Reset the module

2002 DP_SL_ERR_DIAG_DATA_ PSS not enabling the DPR or DPR

AREA_NOT_READY is defective; Change PSS(1) DP-S module

or PSS 3006 DP-S.

2003 DP_SL_ERR_ IN_DATA_ PSS not enabling the DPR or DPR

AREA_NOT_READY is defective; Change PSS(1) DP-S module

or PSS 3006 DP-S.

2004 DP_SL_ERR_ OUT_DATA_ PSS not enabling the DPR or DPR

AREA_NOT_READY is defective; Change PSS(1) DP-S module

or PSS 3006 DP-S.

2005 DP_SL_RESET_MODE A reset has been triggered.

2006 DP_SL_ERR_ILLEGAL_MODE Invalid mode has been set

2007 DP_SL_ERR_ILLEGAL_ Undefined slave condition; reset or restart

SLAVE_STATE the module.

INFORMATION

Standard function blocks SB 231 and SB 232 must also be transmitted to

the controller in addition to SB 230. However, parameters do not need to

be set for them, nor do they need to be called up.

NOTICE

The flag range MW 059.00 ... MW 063.16 is reserved for temporary flags.

This range may not be used for global parameters, nor for SB input or

output parameters, otherwise the flags used in the SB will be overwritten.

PROFIBUS-DP-Slave Operating Manual 6-3

Page 36

Standard Function Blocks

Copying the Slave configuration from the Master configuration

The configuration data for the Slave is located in the data block from

DW 0384 (see Chapter 4, “Setting Parameters”), while the configuration

data for the Master is entered from DW 0830. The length of the

configuration data is entered in DR of DW 0830. This is followed by the

data.

Compare the values on the Master and the Slave and ensure they match.

The following table provides information on the entries.

NOTICE

The addresses of the data block in which the Master writes the

configuration data can be found in the “DP Master” column. The data block

addresses for the Slave configuration data can be found in the “PSS (DP

Slave)” column. The Slave's configuration data must be checked and, if

necessary, adjusted to that of the DP Master.

Configuration

Amount of configuration data

[Bytes]

1st configuration data byte

2nd configuration data byte

3rd configuration data byte

4th configuration data byte

5th configuration data byte

6th configuration data byte

...

Sum total of input data

[Words]

Sum total of output data

[Words]

DP

Master

DR 0830

DL 0830

DR 0831

DL 0831

DR 0832

DL 0832

DR 0833

...

PSS

(DP Slave)

DW 0813

DR 0384

DL 0384

DR 0385

DL 0385

DR 0386

DL 0386

...

DW 0810

DW 0811

Contents

Type

KH

KH

KH

KH

KH

KH

KH

...

KF

KF

Value

06

C0

CD

CF

C0

41

40

...

16

17

Example

Input

data

[Words]

14

2

...

16

Output

data

[Words]

16

1

...

17

6-4 PROFIBUS-DP-Slave Operating Manual

Page 37

Appendix

Example

Data block DB 050 is selected for setting the parameters. The data block

is configured in OB 020. The configuration corresponds to Example 5 in

Chapter 4. SB 230 is called up in OB 001.

OB 020 Cold start ST

:A DB 004 ;Registered hardware on standard section

:L KH B220 ;Enter the code of the module (B220)

:T DW 0027 ;on slot 7

:

:A DB 005 ;Start address for Slave module

:L KH 0000 ;Start address (Offset) is 0

:T DW 0007 ;Slave module on slot 7

:

:L KH 0000 ;Reset the used flag

:T MB 000.00 ;in OB 001

:T MW 030.00 ;

:T MW 010.00 ;

:

:A DB 050 ;Data block for setting the parameters

;(input parameter “DB” from SB 230)

:L KH 2500 ;ID-Number

:T DW 0258 ;

:

:L KH 0004 ;Length of the diagnostic data [Bytes]

:T DW 0259 ;

:

:L KH C1C0 ;Configuration data

:T DW 0384 ;

:L KH 00C0 ;

:T DW 0385 ;

:L KF 0010 ;Reserved

:T DW 0783 ;

:L KH 00F5 ;Reserved

:T DW 0795 ;

:

:L KF 0001 ;Station address [0-126]

:T DW 0800 ;

PROFIBUS-DP-Slave Operating Manual 7-1

Page 38

Appendix

:L KF 0000 ;Reserved

:T DW 0801 ;

:L KF 000002 ;Length of input data [Words]

:T DW 0810 ;

:L KF 000001 ;Length of output data [Words]

:T DW 0811 :

:L KF 000005 ;Length of diagnostic data [Words]

:T DW 0812 ;

:L KF 000003 ;Amount of configuration data [Bytes]

:T DW 0813 ;

:

:L KF 000000 ;Reserved

:T DW 0814 ;

:L KF 000000 ;Reserved

:T DW 0815

7-2 PROFIBUS-DP-Slave Operating Manual

Page 39

Appendix

OB 001

Comment: Segment 00

************************************************************************************

* Sample program *********************************************************

************************************************************************************

**

* 2 Words input data *

* 1 Word output data *

* 1 Word diagnostic data *

**

* Key to inputs / outputs: *

* E 02.00 triggers a module reset *

* E 02.01 Slave goes to a static diagnostic condition *

**

* Cyclical data transfer : *

* PSS -> Master(output data): *

* AW 0.0 -> DW 0128 -> Master *

**

* PSS <- Master(input data): *

* EW 1.0 <- DW 0000 <- Master *

* EW 1.16 <- DW 0001 <- Master *

**

* If an error occurs in the FS Section of the PSS (M113.01 = 1), *

* the slave module will go to a static diagnostic condition. *

* In the example, the value KH FFFF is sent to the Master as diagnostic *

* data. *

*************************************************************************************

:L E 02.00

:SPB = reset

:L E 02.01

:SPB = stat.diag

:L KF 000000

:T MB 000.00

:SPA = start

reset: Segment 01

:L KB 002

:T MB 000.00

:SPA = start

PROFIBUS-DP-Slave Operating Manual 7-3

Page 40

Appendix

stat.diag: Segment 02

start: Segment 03

no_err: Segment 05

:L KB 001

:T MB 000.00

:A DB 050

:L DW 0000

:T EW 01.00

:L DW 0001

:T EW 01.16

:

:L AW 00.00

:T DW 0128

:

:LN M 113.01 .FS_no_ERR/ERR status FS, 0 = no error, 1 = err

:SPB = no_err

:L KH FFFF

:T DW 0260

:L KH 0000

:L KB 001

:T MB 000.00

:

**********************************************************************************

* Input parameters: *

* -Base: Module's XW-Offset *

* -Mode: KB001 -stat.Diagnostics *

* KB002 -Module reset *

* KB000 -Data-Exchange *

* -DB: Data block KB 011-KB 127 or -KB 255 *

(from operating system version 9) *

**

* Output parameters: *

* -Fehl: Error evaluation *

* KH 2000: No errors *

* see chapter entitled “Standard function blocks” *

**********************************************************************************

7-4 PROFIBUS-DP-Slave Operating Manual

Page 41

Appendix

Display ERR : Segment 06

:

:CAL SB 230

SB230

DP-Slave

KF 00000 -W- BASE

MB 000.00 -B- MODE ERR -W - MW 030.00

KB 050 -B- DB

**********************************************************************************

*FB 100 ************************************************************************

**********************************************************************************

* Input parameters: *

* -Disp: 1 = Errors output to the display *

* 0 = Errors not output to the display *

**

* -ERR: Flag word which is output to the display *

**

* M 010.00 internal flag *

**

**********************************************************************************

:

: CAL FB 100

FB100

Display

E 02.03 -X- DISP

MW 030.00 -W- ERR

end: Segment xx

:BE

PROFIBUS-DP-Slave Operating Manual 7-5

Page 42

Appendix

Changes in the documentation

Changes from Version II to Version III

Master data file was amended.

Changes from Version III to Version IV

The manual is also now valid for the PSS SB 3006 DP-S. Editorially the

manual has been completely revised. The division of chapters has been

amended.

The master data file has been removed from the manual completely (Appendix).

Old New Change

page page

5-2 6-2 Error 00FD: Note added

5-3 6-3 Section: “Copying the Slave configuration from the

Master configuration”

Changes from Version IV to Version V

Old New Change

page page

- 6-2 New: ERR 000C, 00FB, 00FC

- 6-3 New: ERR 2006

Changes in Version 19 419-06

Old New Change

page page

3-2 3-2 Section "Standard function block SB 230" was amended,

note added

4-13 4-13 Section "NOTICE" was amended

7-6 PROFIBUS-DP-Slave Operating Manual

Page 43

...

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our Homepage

for further details or contact our

headquarters.

Pilz GmbH & Co. KG

Sichere Automation

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

www

www.pilz.com

Technical support

+49 711 3409-444

19 419-06, 2007-04 Printed in Germany

Loading...

Loading...