Pilz PX 30, PX 120 Operating Manual

Artisan Technology Group is your source for quality

new and certied-used/pre-owned equipment

• FAST SHIPPING AND

DELIVERY

• TENS OF THOUSANDS OF

IN-STOCK ITEMS

• EQUIPMENT DEMOS

• HUNDREDS OF

MANUFACTURERS

SUPPORTED

• LEASING/MONTHLY

RENTALS

• ITAR CERTIFIED

SECURE ASSET SOLUTIONS

SERVICE CENTER REPAIRS

Experienced engineers and technicians on staff

at our full-service, in-house repair center

WE BUY USED EQUIPMENT

Sell your excess, underutilized, and idle used equipment

We also offer credit for buy-backs and trade-ins

www.artisantg.com/WeBuyEquipment

REMOTE INSPECTION

Remotely inspect equipment before purchasing with

our interactive website at www.instraview.com

LOOKING FOR MORE INFORMATION?

Visit us on the web at www.artisantg.com for more

information on price quotations, drivers, technical

specications, manuals, and documentation

Contact us: (888) 88-SOURCE | sales@artisantg.com | www.artisantg.com

SM

View

Instra

Displays and Operator Terminals

PX 30 and PX 120

Operating Manual

Item No. 17 940

Pilz GmbH & Co.

Felix-Wankel-Straße 2, 73760 Ostfildern, Deutschland

Telefon (07 11) 34 09-0, Telefax (07 11) 34 09-1 33

AUS

BR

DK

A

B

L

CH

D

E

...

www

MEX

J

IRL

I

GB

FIN

F

NL

P

PRC

ROK

S

SGP

USA

Pilz GmbH & Co.

Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone +49 (7 11) 34 09-0, Telefax +49 (7 11) 34 09-133

Pilz Ges.m.b.H.

Modecenterstraße 14

1030 Wien

Austria

Telephone (01) 7 98 6263-0

Telefax (01) 7 9862 64

E-Mail: pilz@pilz.at

Pilz Australia

Industrial Automation LP.

9/475 Blackburn Road

Mt. Waverley, Melbourne VIC 3149

Australia

Telephone (03) 95 44 6300

Telefax (03) 95 4463 11

E-Mail: safety@pilz.com.au

Pilz Belgium

BC Building

lndustriezone lII

lndustrielaan 4

9320 Erembodegem

Belgium

Telephone (0 53) 8366 70

Telefax (0 53) 8389 58

E-Mail: info@pilz.be

Pilz do Brasil Sistemas Eletrônicos

Industriais Ltda.

Rua Ártico, 123 - Jd. do Mar

09726-300

São Bernardo do Campo - SP

Brazil

Telephone (11) 43 37-12 41

Telefax (11) 43 37-1242

E-Mail: pilz@pilzbr.com.br

Pilz lndustrieelektronik GmbH

Gewerbepark Hintermättli

Postfach 6

5506 Mägenwil

Switzerland

Telephone (0 62) 8 8979 30

Telefax (0 62) 889 79 40

E-Mail: pilz@pilz.ch

Headquarters:

Pilz GmbH & Co.

Felix-Wankel-Straße 2

73760 Ostfildern

Germany

Telephone (07 11) 34 09-0

Telefax (07 11) 3409-1 33

E-Mail: pilz.gmbh@pilz.de

Pilz Skandinavien KS

Ellegaardvej 25 L

6400 Sonderborg

Denmark

Telephone 74 4363 32

Telefax 74 4363 42

E-Mail: pilz@pilz.dk

Pilz lndustrieelektronik S.L.

Edificio Tilma

Avda. Sant Julià 1

08400 Granollers

Spain

Telephone (93) 8 49 7433

Telefax (93) 8 4975 44

E-Mail: central@pilzspain.com

Pilz France Electronic

1, rue Jacob Mayer

BP 12

67037 Strasbourg Cedex

France

Telephone 03 8810 40 00

Telefax 03

8810 80 00

E-Mail: siege@pilz-france.fr

Pilz Skandinavien KS

Pakilantie 61

00660 Helsinki

Finland

Telephone (09) 27 09 3700

Telefax (09) 27 0937 09

E-Mail: pilz.sk@kolumbus.fi

Pilz Automation Technology

Willow House, Medlicott Close

Oakley Hay Business Park

Corby

Northants NN18 9NF

United Kingdom

Telephone (0 15 36) 46 0766

Telefax (0 15 36) 4608 66

E-Mail: sales@pilz.co.uk

Pilz ltalia Srl

Via Meda 2/A

22060 Novedrate (CO)

Italy

Telephone (0

31) 78 9511

Telefax (0 31) 7895 55

E-Mail: info@pilz.it

Pilz Ireland Industrial Automation

Cork Business and Technology Park

Model Farm Road

Cork

Ireland

Telephone (0 21) 4 3465 35

Telefax (0 21) 480 4994

E-Mail: sales@pilz.ie

Pilz Japan Co., Ltd.

Three One Building 701

3-20-5 Shin-Yokohama

Kohoku-ku

Yokohama 222-0033

Japan

Telephone (0 45) 4 71-2281

Telefax (0 45) 471-22 83

E-Mail: pilz@pilz.co.jp

Pilz de Mexico S. de R.L. de C.V.

Av. San Ignacio 1079

Col. Jardines de San Ignacio

C.P. 45000

Guadalajara, Jalisco

Mexico

Telephone (0 13) 1 2216 81

Telefax (0 13) 647 8185

E-Mail: pilz_msolis@infosel.net.mx

Pilz Nederland

Postbus 186

4130 ED Vianen

Netherlands

Telephone (03 47) 3204 77

Telefax (03 47) 3204 85

E-Mail: info@pilz.nl

Pilz Industrieelektronik S.L.

Apartado 2028

2706-909 Colares

Portugal

Telephone (21) 9 2891 09

Telefax (21) 9 2891 13

E-Mail: pilz@esoterica.pt

Pilz China Representative Office

Flat F9/F Huijing Building

134 Siyou Xin Malu

Dongshan District

Guangzhou 510600

China

Telephone (0 20) 8737 16 18

Telefax (0 20) 8737 3555

E-Mail:

pilzchn@public.guangzhou.gd.cn

Pilz Korea Liaison Office

102-1402 Ilsung apt

767, Kyomun-Dong, Kuri-Si

Kyungki-Do 417-715

Korea

Telephone (31) 5 5412 80

Telefax (31) 5 5412 80

E-Mail: pilzkr@hotmail.com

Pilz Skandinavien KS

Energigatan 10 B

43437 Kungsbacka

Sweden

Telephone (03 00) 1 3990

Telefax (03 00) 307 40

E-Mail: pilz@tripnet.se

Pilz Industrial Automation Pte Ltd.

61, Kaki Bukit Ave 1, #05-01

Shun Li Industrial Park

Singapore 417943

Singapore

Telephone 8 4444 40

Telefax 8 4444 41

E-Mail: sales@pilz.com.sg

Pilz LP

7150 Commerce Boulevard

Canton

Michigan 48187

USA

Telephone (7 34) 354-02 72

Telefax (7 34) 354-33 55

E-Mail: info@pilzusa.com

In many countries we are represented by sales partners. Please refer to our

Homepage for further details or contact our headquarters.

Internet enquiries and orders: www.pilz.com

www.pilz.com

17 940-01/02 Printed in Germany

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

All rights reserved by Pilz GmbH & Co. Copying permitted for internal use only.

In the interest of continual technical advancement we reserve the right to amend

technical details without prior notice. No responsibility accepted for errors or omissions.

We are grateful for any feedback on the contents of this manual.

The names of products, goods and technologies are trademarks of the companies

concerned.

III, 01/02

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

1

Safety Regulations 1.1

General Safety Regulations 1-1

Unit-Specific Safety Regulations 1-1

System Description PX 30 and PX 120 2-1

Operation 2-1

Features 2-3

Flash-EPROM Memory 2-3

Dimmer Function 2-4

Hardware 2-4

PLC Connections 2-5

Driving the Display 3-1

Handshake Function 3-1

Operating Modes in Display Mode 3-2

Parallel Drive through a PLC's I/O-Level

Display Mode 3-3

Coding 3-3

Text Display with 24 Inputs (PX 120) 3-5

Text Display with 16 Inputs

(PX 30 or PX 120 in 16-Input Mode) 3-12

Parallel Drive through a PLC's I/O-Level

Monitor Mode 3-20

Function and Layout of Inputs 3-20

Serial Drive

Display Mode 3-22

Data Communication Protocol 3-22

PX 30/PX 120 Response 3-23

Operating Modes 3-23

Examples for Serial Drive in Display Mode 3-26

Contents

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2

PX 30 and PX 120 Operating Manual

Contents

Contents

Serial Drive

Monitor Mode 3-31

Communication Protocol 3-31

Communication Protocol for individual data 3-31

Communication Protocol for packaged data 3-32

Text in Display Mode 4-1

Text Memory 4-1

Creating Text 4-1

Character Set 4-1

Control Characters (ESCAPE Sequences) 4-1

Layout 4-2

Clear Display 4-2

Scrolling Background Text 4-3

Variables in Display Mode 5-1

Basics 5-1

Variable Layout 5-1

Text Characters within Variables 5-2

Overlapping Variables 5-2

Left / Right Justification 5-2

Leading Zeros 5-2

Inserting a Cursor or Question Mark 5-3

Variables in Background Text 5-3

Configuration 6-1

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

3

Appendix 7-1

Technical Details 7-1

Connector Pin Assignment (V24) 7-1

Dimensions 7-2

PX 30 Text Display 7-2

PX 120 Text Display 7-2

Control Codes 7-3

System Messages 7-4

Error Codes 7-4

Error Messages 7-5

Procedure after Power-up 7-5

Networking Capabilities 7-6

Character Sets 7-7

IBM Character Set 7-7

Cyrillic Character Set 7-8

V24 Connection Cable - Pin Layout 7-9

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

4

PX 30 and PX 120 Operating Manual

Contents

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-1

PX 30 and PX 120 Operating Manual

Safety Regulations

General Safety Regulations

• Electrical connections must be made by a qualified electrical engineer

who is familiar with the operating manual and the valid regulations for

safety in the workplace. VDE and local regulations must be observed, in

particular with regard to safety.

• It is important to keep within the permitted operating temperature range.

• Do not open the unit, otherwise all warranty becomes void. Units

requiring repair must be returned to Pilz.

• The correct function of the unit is guaranteed only for the operating

modes specified in the operating manual. Incorrect connections may

damage or destroy the unit or machinery.

Unit-Specific Safety Regulations

You must comply with the following safety regulations in order to ensure

the correct operation of your unit:

• When selecting where to install your display, please remember to keep

as large a distance as possible between the unit and any

electromagnetic fields. This is especially important when frequency

converters are nearby. We also recommend you use a bulkhead to

separate the display from any source of interference.

• Inductive components built into the surrounding area (eg. contactor, relay

and solenoid valve coils), must be wired with an RC-network, especially if

they are fed from the same source.

• Data and power lines should be installed separately to avoid capacitive

and inductive transmission (recommended minimum distance = 10 cm/

3.94")!

• To avoid the build-up of heat, a distance of 10 cm/3.94" should be main-

tained all round the unit.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual1-2

Safety Regulations

• Interference voltages accessing the unit via supply and signal lines, and

electrostatic voltages passed on through contact, are diverted to the

earth point (spade terminal on the rear of the unit).

Connect the earth point ( ) to the earth conductor PE using as short a

copper conductor as possible (> 6 mm2 csa).

• The earth conductor should be connected to the terminal marked on

the supply voltage connector (1.5 mm2 diameter).

• Before applying voltage always check that the voltage information given

on the unit matches your supply.

• Shielded, twisted pair cable must be used for connections to the inter-

faces.

• Always use metallic or metallised synthetic connectors with the connec-

tion cable.

• We recommend that the shielded connection on the network cable

between two subscribers is connected on both sides. This will require

sufficient potential equalisation between the earth conductor potentials at

each subscriber. The most effective method of screening is to connect

the braided screening to a potential equalisation rail over a wide surface

area. Both the unscreened wires at the cable ends and the shielded

connections should be kept as short as possible.

Please note: On the display system, the cable screening is connected

directly (galvanically) to the housing.

If the potential equalisation is insufficient, the screening on the

connection and/or programming cable may only be connected on one

side of the connector housing.

Please note: The screening on the programming cable supplied by Pilz

is connected on one side (PX-side) of the connector housing.

• Please ensure that the mounting screws on the connector are firmly

attached.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

1-3

PX 30 and PX 120 Operating Manual

• The power supply for the text display must be designed for a peak

switching current of 15 x IN.

• Connections / units must not be removed or modifed during operation.

Always ensure that the supply is switched off.

• Do not change the text memory while power is applied to the unit.

Before installation you should also check the safety requirements laid

down by the PLC manufacturer.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual1-4

Safety Regulations

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

2-1

Operation

The PX 30 and PX 120 can be driven in parallel through a PLC's I/O-level or in serial

through the V24 interface of a PLC or PC.

The PX 30 has 16 inputs and the PX 120 has 24 inputs available for parallel drive, plus

one output.

The PX 120 can be configured to use just 16 inputs (instead of 24) for communicating data

and commands. The configuration of "16-input mode" is explained in the chapter entitled

"Configuration" from page 6-1 onwards.

Both units (PX 30 and PX 120) can be operated as either a:

• Text Display or

• Text Monitor.

You can select the mode (display or monitor mode) in which the display unit will operate

via input E15 on the PX 30 and input E23 on the PX 120:

• E15 or E23 high = monitor mode

• E15 or E23 low = display mode

In display mode, the PLC selects the text stored in the memory through its text number,

and variable values sent from the PLC are inserted in the displayed text.

In monitor mode, texts are sent from the PLC as characters from the IBM character set

(extended ASCII character set). Control commands such as cursor positioning and the

allocation of attributes, etc. must be sent as part of the message.

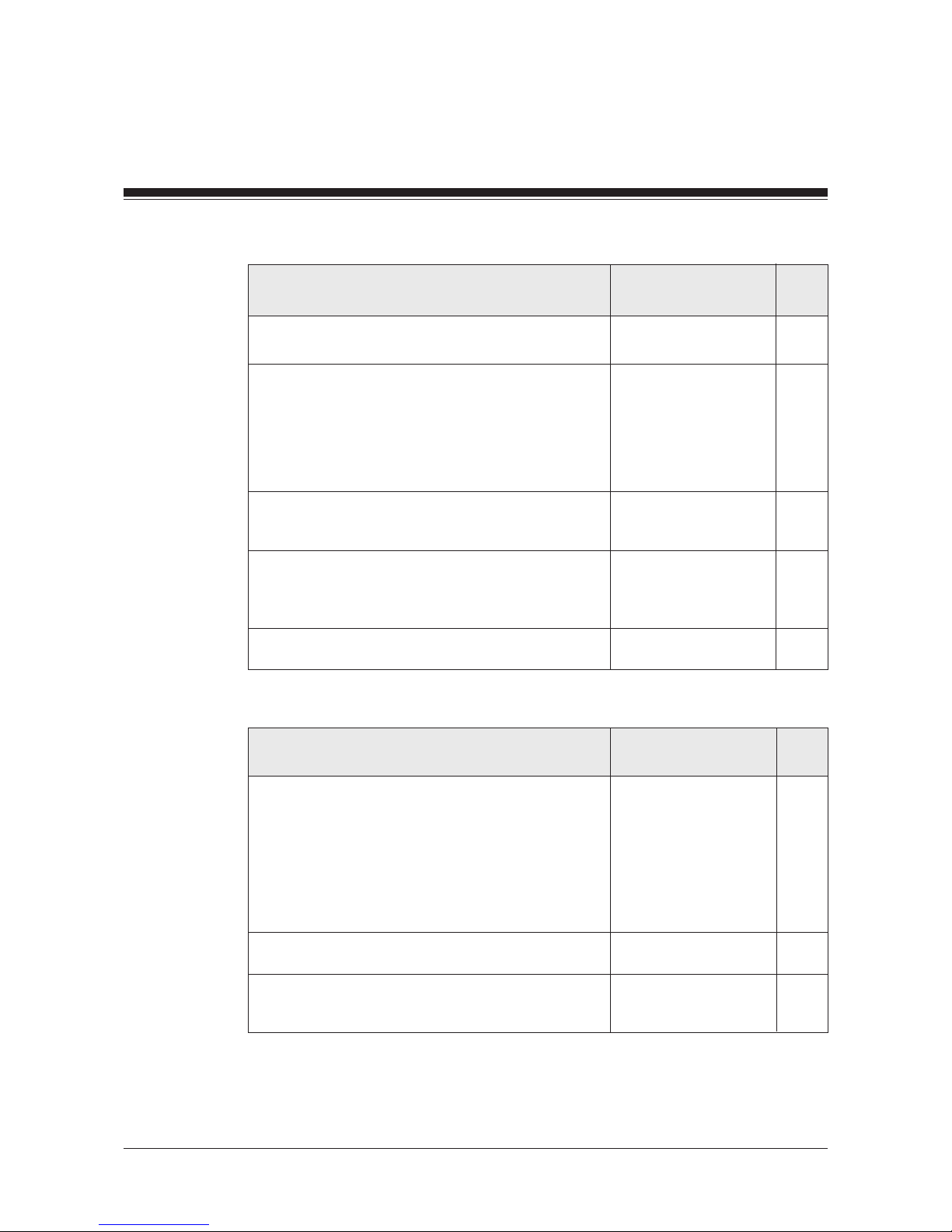

The features of the two different display modes are described in the table below. The two

right-hand columns tell you where you can find additional information on the individual

features.

Operating in Display Mode

Feature Refer to Chapter / From

Section Page

Both parallel and serial drive is possible:

- parallel drive via 24 inputs (PX120) Parallel drive via a 3-5

PLC's I/O level display mode:

Text display with

24 inputs

- parallel drive via 16 inputs (PX 30 or PX 120 in Text display with 3-12

16-input mode) 16 inputs

- serial drive Serial drive 3-22

display mode

System Description PX 30 and PX 120

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-2

System Description PX 30 and PX 120

PX 30 and PX 120 Operating Manual

Operating in Display Mode (Ctd.)

Feature Refer to Chapter / From

Section Page

Texts stored in the text memory are selected (Text in general:) Text 4-1

and displayed in display mode

Variables (eg. true and set values) can be inserted (Variables in general:) 5-1

into the text. These variables are selected Variables in display

via their number and can be displayed with certainmode

attributes (eg. flashing, right justification).

Control characters and text masks edited in the text

enable you to allocate attributes and position the

cursor.

Additional display functions (eg. scrolling and Driving the Display 3-1

segment test) are available via control commands

from the PLC.

Configuration instructions stored in the text memory Configuration 6-1

enable the display to adapt to certain user

requirements (eg. scroll function, coding and the

number of inputs used).

Several displays can be networked through a Appendix / Networking 7-6

V24 - RS 485 interface adapter. Capabilities

Operating in Monitor Mode

Feature Refer to Chapter / From

Section Page

Both parallel and serial drive is possible:

- parallel drive via 24 inputs (PX 120) Parallel drive via a 3-20

- parallel drive via 16 inputs (PX 30 or PX 120 in PLC's I/O level -

16-input mode monitor mode

- serial drive Serial drive 3-31

monitor mode

PLC sends texts as IBM/ASCII characters.

These are displayed at the cursor position.

Additional display functions (eg. scrolling and

segment test) are available via control commands

from the PLC.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

2-3

Features

The following features have been incorporated into the units:

• IBM character set

• Flash-EPROM as text memory, programmable within the PX-unit.

• Either parallel (via I/O-level) or serial (via V24) drive

• Optimum speed

• Shallow modular depth

• Automatic brightness control on the display (dimmer function)

• Extended scrolling options

• Networkable

• Status display

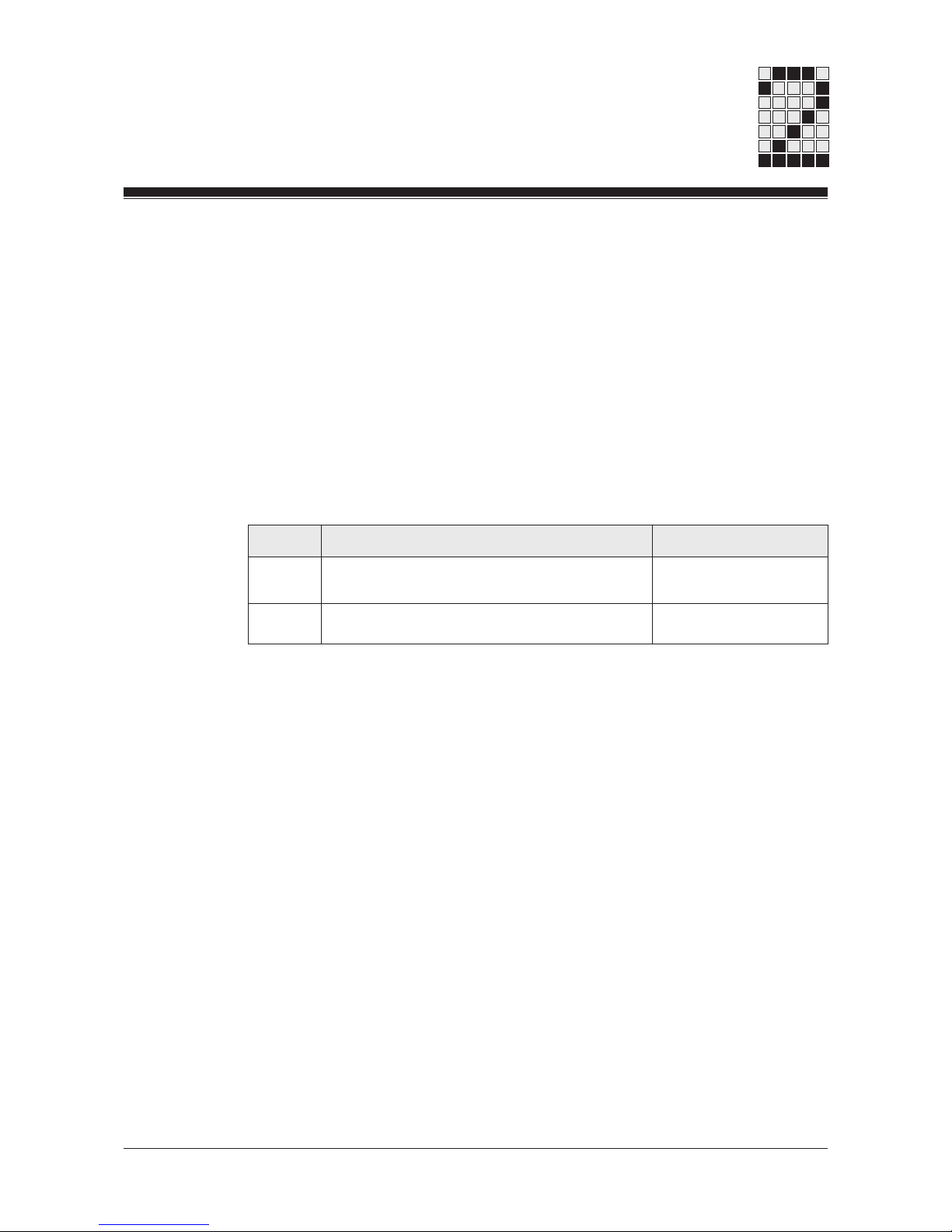

The main difference between the PX 30 and PX 120 is their display format and the

number of inputs they have available:

Unit Display Format Number of PX Inputs

PX 30 2 lines of 20 characters; 5 mm character height; 16

5 x 7 dot matrix

PX 120 2 lines of 40 characters; 9 mm character height; 24

5 x 12 dot matrix

Data transmission varies depending on the number of inputs. These differences are

explained in Chapter 2.

Flash-EPROM Memory

Flash-EPROMs are used as text memory. These are currently the quickest memory chips

available for text displays. Just like EEPROM-chips, they are programmed and cleared

electrically. Flash-EPROMs can be programmed directly inside the PX-unit, combining

the data security of an EPROM with the flexibility of a RAM. The ability of the EEPROM to

clear byte by byte is not availabe on the Flash-EPROM, but this facility is not required on

text displays.

The simplest way to create text is to use an IBM-compatible PC with ADIT DOS (version

4.0 and above). This software has been specially designed for organising data transmission on these PX-units. Texts, attributes for text and variables (eg. flashing representation) and text masks for variables are all edited through dialogue.

The Flash-EPROM is programmed directly inside the PX-unit. When the text display is

ready for operation, (ie. 24 V is supplied), just connect it up to a PC through its serial

interface and the text memory can be programmed quite simply using the ADIT DOS Text

Editor (under MS DOS).

The programming of the Flash-EPROM in the PX-unit via the serial interface (V24) is not

described in this manual. For further details please refer to the ADIT DOS Manual.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-4

System Description PX 30 and PX 120

PX 30 and PX 120 Operating Manual

Dimmer Function

A sensor judges the brightness at the front of the unit and adapts the brightness of the

display accordingly.

This dimmer function is activated by setting a jumper (1) on the rear of the unit (below the

Flash-EPROM).

The jumper is not inserted ex-works, so the dimmer is switched off. In this case the

display will operate at a constant maximum brightness.

When the dimmer is activated (jumper inserted), optimum standard brightness is achieved

as follows:

Adjust the dimmer setting (2) with a screwdriver until maximum brightness is achieved

under typical light conditions.

Start from the right stopper and turn anti-clockwise until the display begins to darken.

Then carefully turn it clockwise again until it lightens.

Hardware

Both units have:

• Fluorescent Display; 2 lines

• 24 V inputs (16 inputs on the PX 30, 24 inputs on the PX 120)

• One 24 V output (handshake output "HS")

• Serial Interface (V24, 9-pin)

• Automatic brightness control (dimmer function)

• 32 KByte Flash-EPROM cartridge; 64 KByte available as an option

• Ability to program the Flash-EPROM inside the unit.

MEMORY

DISPLAY

RS 232

(2) (1)

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

2-5

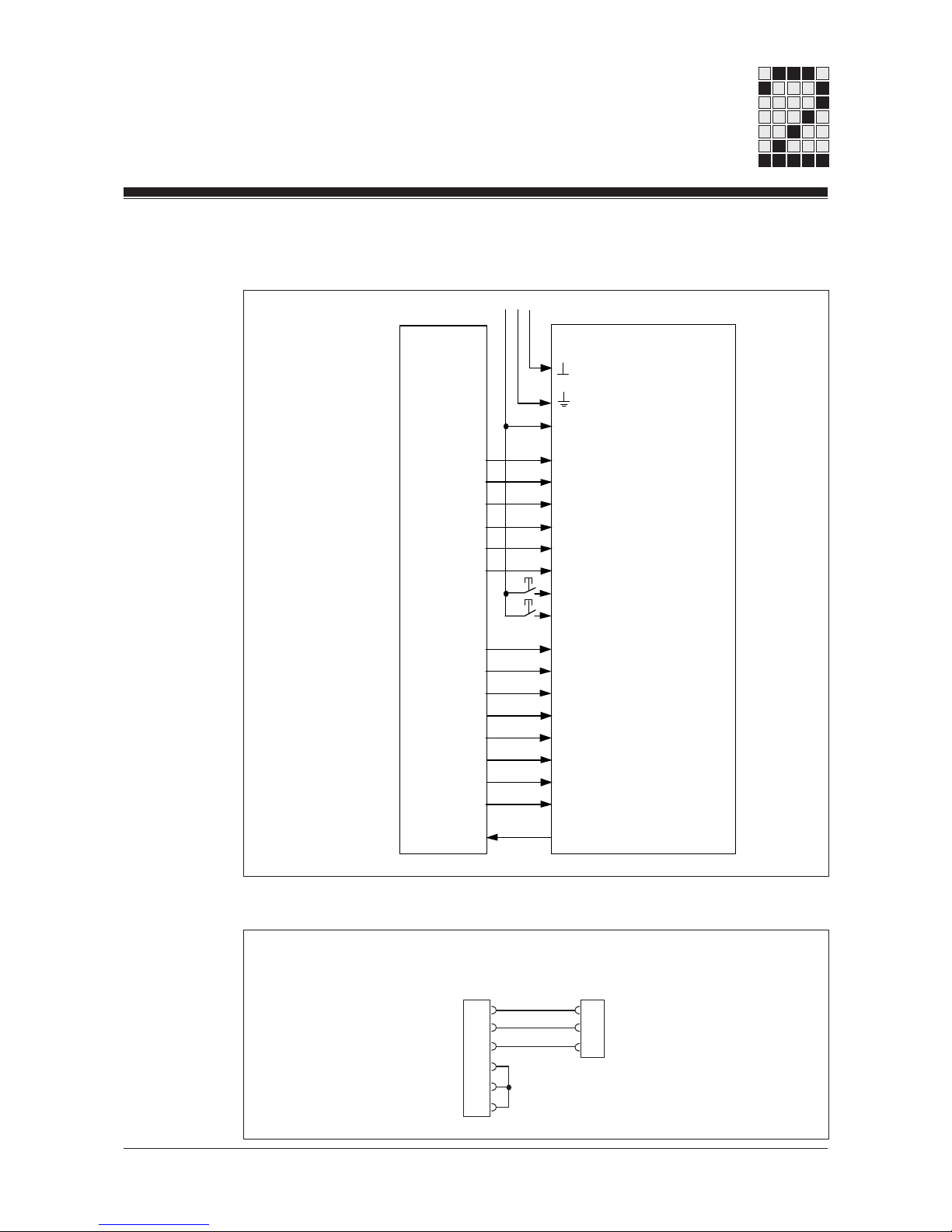

PLC PX 30 / PX 120

Parallel drive via the I/O-level:

Serial drive via the V24 Interface:

HS HANDSHAKE

E 7/E 15

E 6/E 14

E 5/E 13

E 4/E 12

E 3/E 11

E 2/E 10

E 1/E 9

E 0/E 8

E 15/E 23 Display Mode

E 14/E 22 Enable

E 13/E 21 Operating Mode

E 12/E 20 Special Mode

E 11/E 19 End of Cycle

E 10/E 18 Start of Cycle

E 9/E 17 Scroll Up

E 8/E 16 Scroll Down

+24 V=

PLC Connections

O/P x.h

O/P x.g

O/P x.f

O/P x.e

O/P x.d

O/P x.c

O/P x.b

O/P x.a

O/P y.h

O/P y.g

O/P y.f

O/P y.e

O/P y.d

O/P y.c

O/P y.b

O/P y.a

I/P v.w

2

3

5

6

7

8

3

2

5

RxD

TxD

Ground

RxD

TxD

Ground

P9/P10/PSS (Master):

9-pin SUB-D

connector

PX30/PX120 (Slave):

9-pin SUB-D

connector

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

2-6

System Description PX 30 and PX 120

PX 30 and PX 120 Operating Manual

Notes

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

3-1

Handshake Function

Important: The handshake function can only be applied when driving the display through

a PLC's I/O-level in parallel mode!

When the display is driven in parallel (in display and monitor mode), data communication

occurs in the handshake algorithm, which serves the handshake output HS. Its status

signalizes:

• High-level: Display is ready to receive

• Low-level: Display is not ready to receive

Data and commands received by the PX are validated with an enable signal (positive-

going pulse edge at E22 on the PX 120 and E14 on the PX 30).

Exception: Scroll inputs E16/E17 (PX 120) and E8/E9 (PX 30) operate without an enable

signal. They merely require a positive-going pulse edge at the relevant input.

The diagram overleaf illustrates the handshake function.

Driving the Display

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-2

Driving the Display

PX 30 and PX 120 Operating Manual

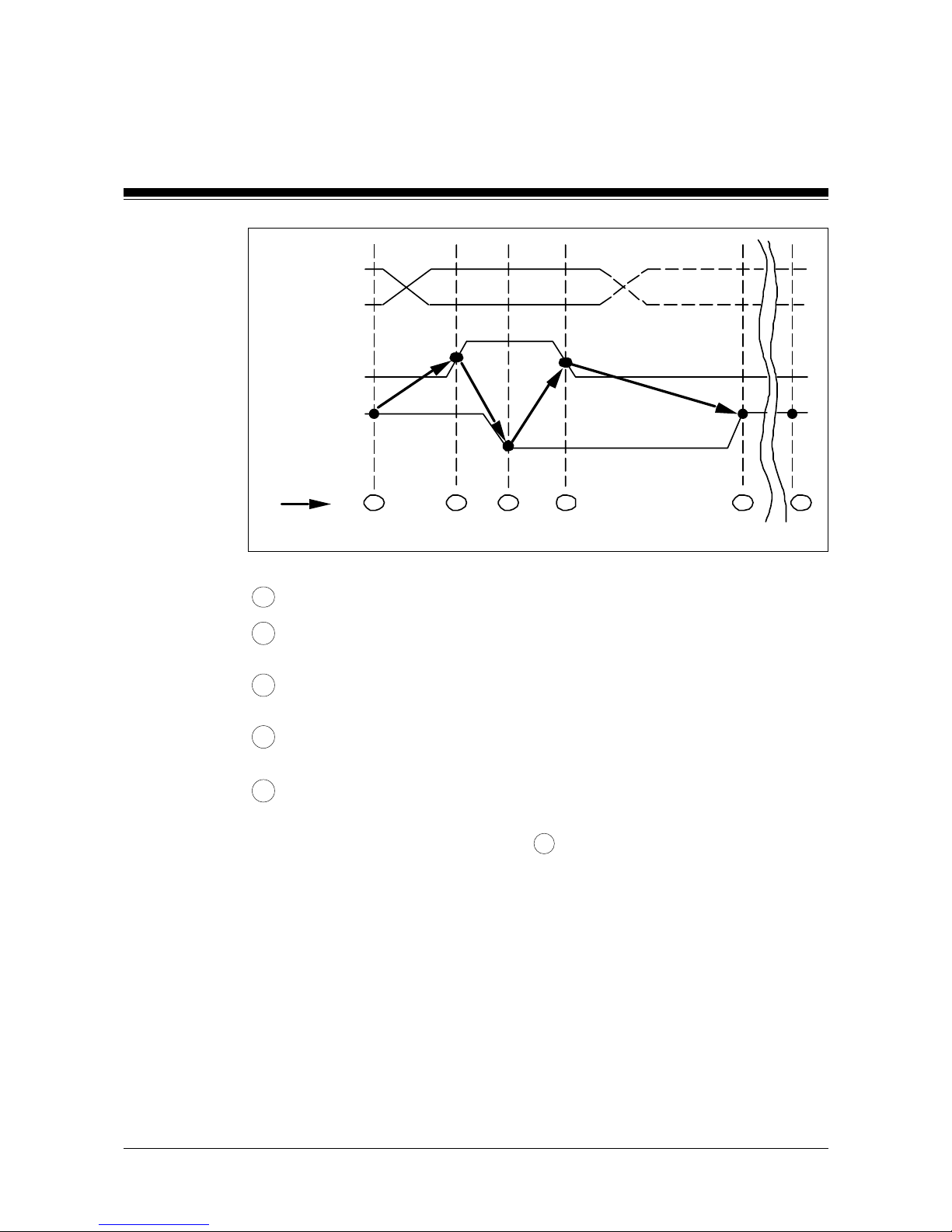

Data

Input E22

(PX 30: E14)

HS-Output

...........................................

1 enable

disable

0

1

0

1234 5

1

t

1 HS-output = 1: New data can be supplied.

2 Input E22 (PX 30: E14) may be set from 0 to 1 no earlier than the time at

which the data arrives (enable signal).

3 As a result of the positive-going pulse edge at E22 (PX 30: E14), new data is

read in from the PX-unit and the HS-output is automatically set at 0.

4 Only then is E22 (PX 30: E14) returned to 0. Only at this point can new data

be supplied.

5 As a result of the negative-going pulse edge at E22 (PX 30: E14), the HS-

output automatically returns to 1, but only once the data is processed

by the PX-unit. A Logic 1 signal at the HS-output signals that the unit is

ready to receive new data (see 1 ).

Operating Modes in Display Mode

The following operating modes are supported when the PX is in display mode, with both

parallel and serial drive:

• Text mode

• Variable mode

• Special mode

In text mode, texts are selected and displayed by means of their text number, which can

be either binary or BCD-coded.

Variable mode is used for the selection, evaluation and insertion of variables. Variable

transmission may be binary, BCD or ASCII-coded.

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

3-3

For further details of codes and their features, please refer below to the section entitled

"Coding".

In special mode, the following special functions are supported:

• Segment test

• Output of version number

• Automatic display of the text memory contents

• Clear display

• Status display

Parallel Drive through a PLC's I/O-level

Display Mode

Coding

For parallel drive of the PX 30 and PX 120 in display mode, two base settings can be

configured for data coding:

• Binary-coding (default)

• BCD-coding

The required coding method (binary or BCD) is set in the $M-configuration instruction (see

section entitled "Configuration" on page 6-1) and is then used for communicating text

numbers (text selection in text mode).

If no $M-configuration instruction is present, both the PX 30 and PX 120 will operate in

binary code in display mode (default setting).

In variable mode when binary coding has been configured, or the default setting is unchanged, variable values can be transmitted in three ways:

• Binary-coded

• BCD-coded or

• ASCll-coded

If BCD-coding has been configured, variable values can be transmitted in two ways:

• BCD-coded or

• ASCll-coded

The variable code is selected in the 1st cycle of each new variable transmission.

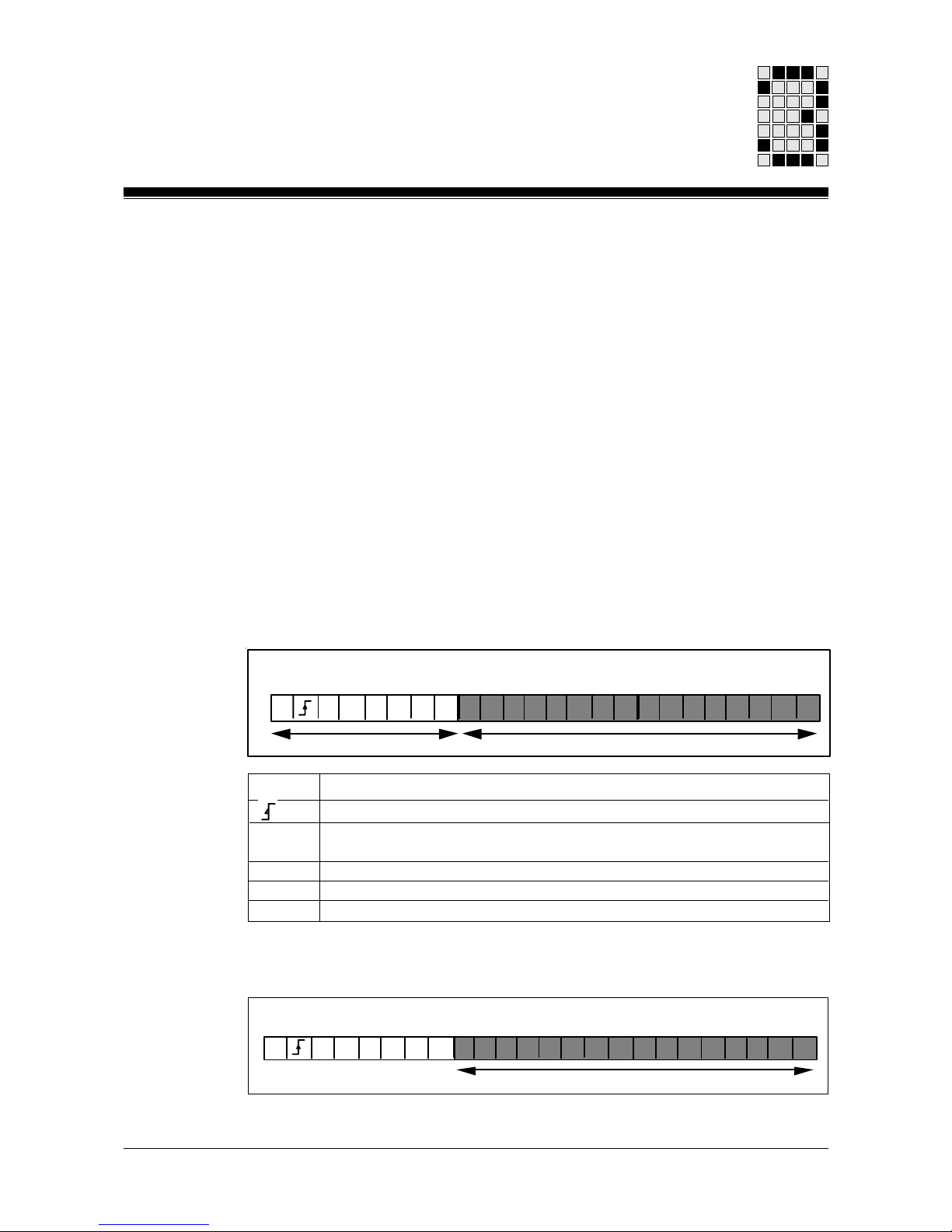

The diagram overleaf shows the function and layout of inputs E0 - E7 in the 1st cycle of

each variable transmission (ID-Byte).

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

3-4

Driving the Display

PX 30 and PX 120 Operating Manual

A = 1 Display ASCll-coded variables

A = 0 Display binary or BCD-coded variables

? = 1 "?" flashes alternately with the lowest

value digit of the variable value

? = 0 "?" not inserted

_ = 1 "_" flashes alternately with the lowest

value digit of the variable value

_ = 0 "_" not inserted

N = 1 A negative prefix "-" is placed before

the variable value

N = 0 Display without negative prefix

C = 1 BCD-coding

C = 0 Binary-coding

If E3 = 0, binary coding is selected, if E3 = 1, BCD-coding is selected.

If BCD-coding is selected, the maximum number of BCD-digits per cycle will be transmit-

ted in parallel operation. The maximum number is 4 BCD-digits in 24-input mode and 2

BCD-digits in 16-input mode, provided the $M-configuration instruction has not been used

to reduce the number of digits which can be transmitted in parallel operation in BCDmode (see page 6-1).

Important: Input E3 has no function when BCD-coding is configured.

Please note:

• The configuration for the number of inputs used on the PX 120 (24 or 16-input-mode) is

described in the section entitled "Configuration" from page 6-1 onwards.

• If input E4 is latched, a negative prefix can be placed before a BCD-digit.

Binary mode operates with signed integers.

• The conversion of a positive binary integer into a negative binary integer of the same

value (taking into account the prefix coding in the highest value bit) is carried out as

follows:

7

0

A ?

_

N C

n n n

123456

Input

Variable Number

0 ... 7, binary coded

n n n

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

PX 30 and PX 120 Operating Manual

3-5

1. Positive binary integer

2. Complementing (negation) of binary value

3. Add "1"

Example: "-21" as a signed 8-bit binary figure

1. "+21": 00010101

2. 11101010

3. + 00000001

4. 11101011 (on PX-unit): "-21"

Important: You will need to be in variable mode to use input E3 to switch between binary

and BCD-coding. Even in this case, binary coding will need to have been configured, or

the $M-configuration instruction will need to have been omitted!

Text Display with 24 Inputs (PX 120)

Note: The PX 120 can be configured to use just 16 inputs (see page 6-1), making it fully

compatible with the PX 30. The function and layout of inputs in 16-input mode is described from page 3-12 onwards.

Function and Layout of Inputs (general)

E23 = 0 Display Mode

Enable signal (positive-going pulse edge)

B/S Operating Mode/Special Mode: 0/0 = Text Mode; 0/1: Special Mode;

1/0 = Variable Mode; (1/1 = reserved)

e End of data transmission: 1 = last cycle

a Start of data transmission: 1 = first cycle

s Scroll inputs (E17 up; E16 down)

Text Mode

Binary Coding

The text number is interpreted as a signed 16-bit integer. Text numbers from 0 ... 9999

are accepted.

23 22 21 20 19 18 15

00

11

Text Number

w w w w w w w w w w w w w w w w

70

0

7

0

Input

23 22 21 20 19 18 17 16 15

Seass

Control Inputs Data Inputs

B0

23 22 21 20 19 18 15

23 22 21 20 19 18 17 16 15

Artisan Technology Group - Quality Instrumentation ... Guaranteed | (888) 88-SOURCE | www.artisantg.com

Loading...

Loading...