Safe monitoring relays

Standstill

PSWZ X1P

Standstill monitor for safe standstill

monitoring

Approvals

PSWZ X1P

Unit features

` Positive-guided relay outputs:

– 2 safety contacts (N/O), instanta-

neous

– 1 auxiliary contact (N/C), instan-

taneous

` LED indicator for:

– Supply voltage

– Standstill on channel 1/2

–Switch status

– Fault signal if simultaneity time is

exceeded

` Semiconductor outputs signal:

– Error

–Switch status

` Semiconductor input for reset func-

tion

` Measuring inputs for single or

three-phase motors

` Measuring voltage selectable

` Feedback loop

` Plug-in connection terminals (either

cage clamp terminal or screw terminal)

` See order reference for unit types

Unit description

The unit is used for safe standstill

monitoring. It is designed for use on

` Standstill monitoring on plants with

dangerous machine parts or tools

(EN 1088 clause 7.4),

` Safety circuits in accordance with

EN 60204-1 and IEC 60204-1.

Standstill is only detected on powerfree measuring circuits. Residual voltages, induced voltages or drives within the position control will prevent safe

standstill detection!

Safety features

` Relays K1 and K2 are interlocked in

such a way that the unit cannot be

switched back on in the case of

contact welding or an open circuit.

` The unit monitors the measuring

circuits for open circuit. If an open

circuit occurs between the unit and

the motor or on the motor itself, the

unit immediately switches off.

` The standstill monitor prevents the

plant from being enabled in the fol-

lowing cases

– Power supply failure

– Component failure

– Measuring circuits are open cir-

cuit

– Coil defect/open circuit

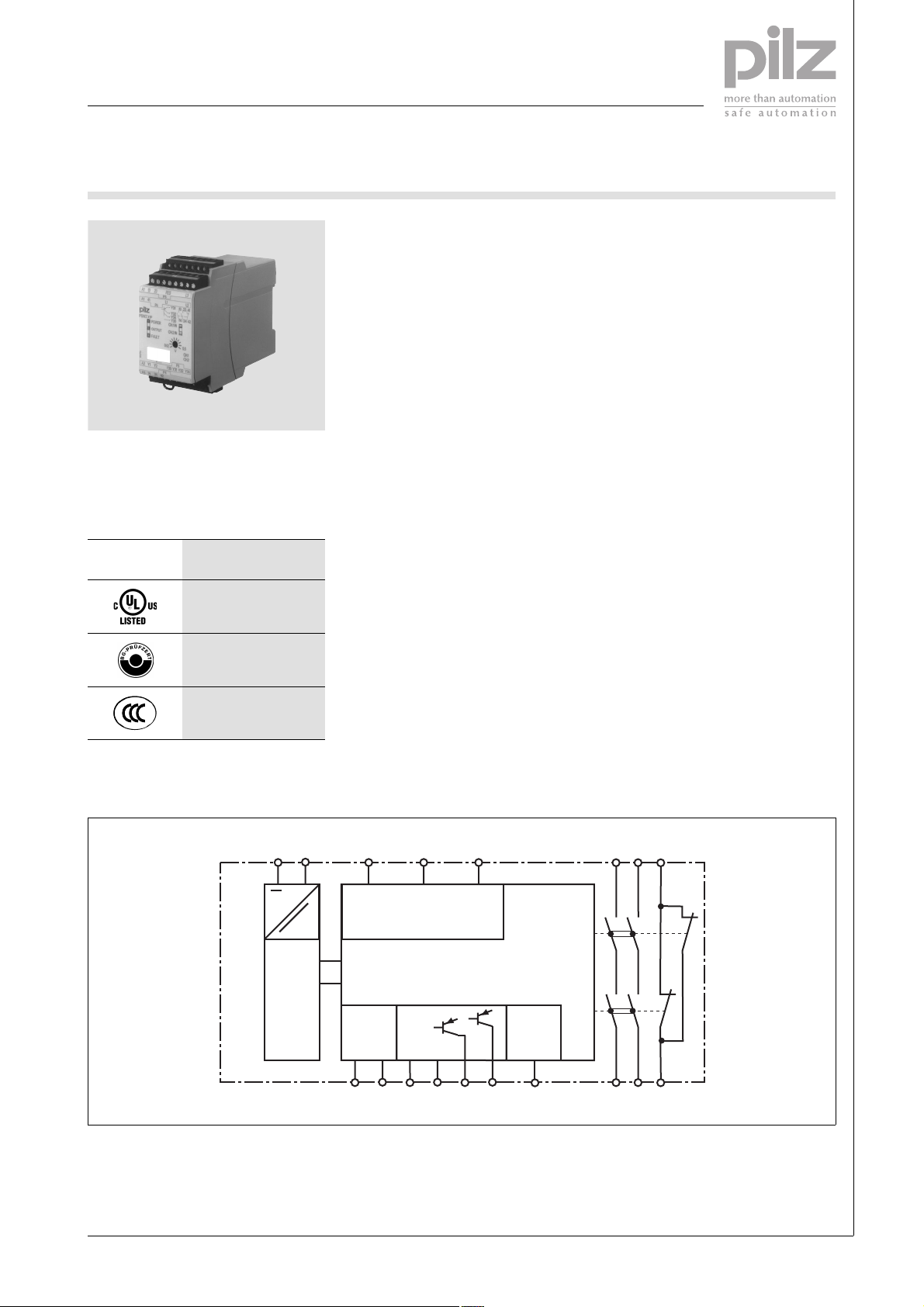

Block diagram

A1 A2

~

Power

=

L1

Feed-

back

L2 L3

Input

0 V 24 V

Y30 Y31 Y32 Y35Y1 Y2

Reset

RESET

K1

K2

23 41

13

14 24 42

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10

Safe monitoring relays

Standstill

PSWZ X1P

Function description

The device uses two separate measuring channels to measure the regenerated voltage, induced from the motor

during the rundown period or during

start-up. If the voltage falls below the

set response value (standstill threshold), the standstill monitor enables the

monitored plant. If the voltage exceeds the set release value, the standstill monitor disables the monitored

plant.

To reactivate, the voltage at both

channels must fall below the response

value U

within the time tg (simultane-

on

ity monitoring). To do this the feedback loop Y1-Y2 must be closed. If the

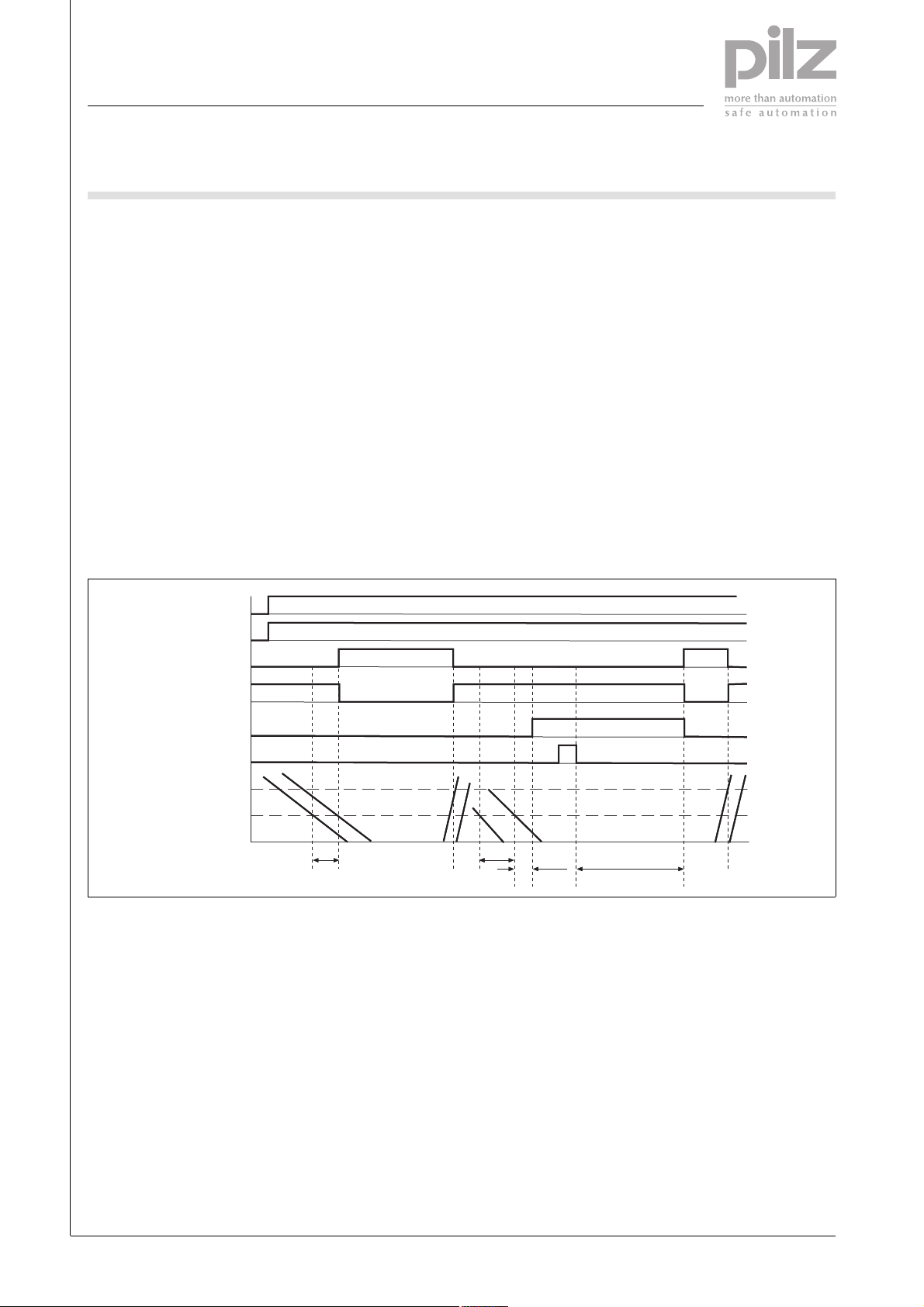

Timing diagram

POWER

POWER

Feedback

Feedback

Output safe

Output safe

simultaneity requirement is exceeded,

the standstill monitor does not enable

the monitored plant. The unit can be

reactivated by switching 24 VDC on

and off at the RESET input.

The response value U

can be set

on

jointly for both channels in order to suit

the motor that is to be monitored. The

release value U

(hysteresis) corre-

off

sponds to twice the response value.

When used with frequency converters,

the PSWZ X1P cannot detect standstill

until the controller inhibit has been

switched off.

After the supply voltage is switched

on, the unit performs a self test. The

unit simulates a situation in which the

release value is exceeded and the

measuring circuit has an open circuit.

The correct function of the output relay

and feedback loop is also tested. The

test takes ca. 1.5 s.

Operating modes:

` Single-channel operation:

– One measuring circuit affects

both channels

– No redundancy (failsafe) in the

measuring circuits

` Dual-channel operation:

– Two redundant (identical) meas-

uring circuits affect channel 1

and 2

– Monitoring of voltages in the

measuring circuit (failsafe in the

event of a short circuit)

Output aux

Output aux

Semi Y35

Semi Y35

RESET

RESET

UL1/UL2

UL1/UL2

U

U

off

off

U

U

on

on

Key

` POWER: Supply voltage

` UL1/UL2: Input circuitL1, L2, L3

` Feedback: Feedback loop Y1-Y2

` Output safe: Safety contacts 13-14,

23-24

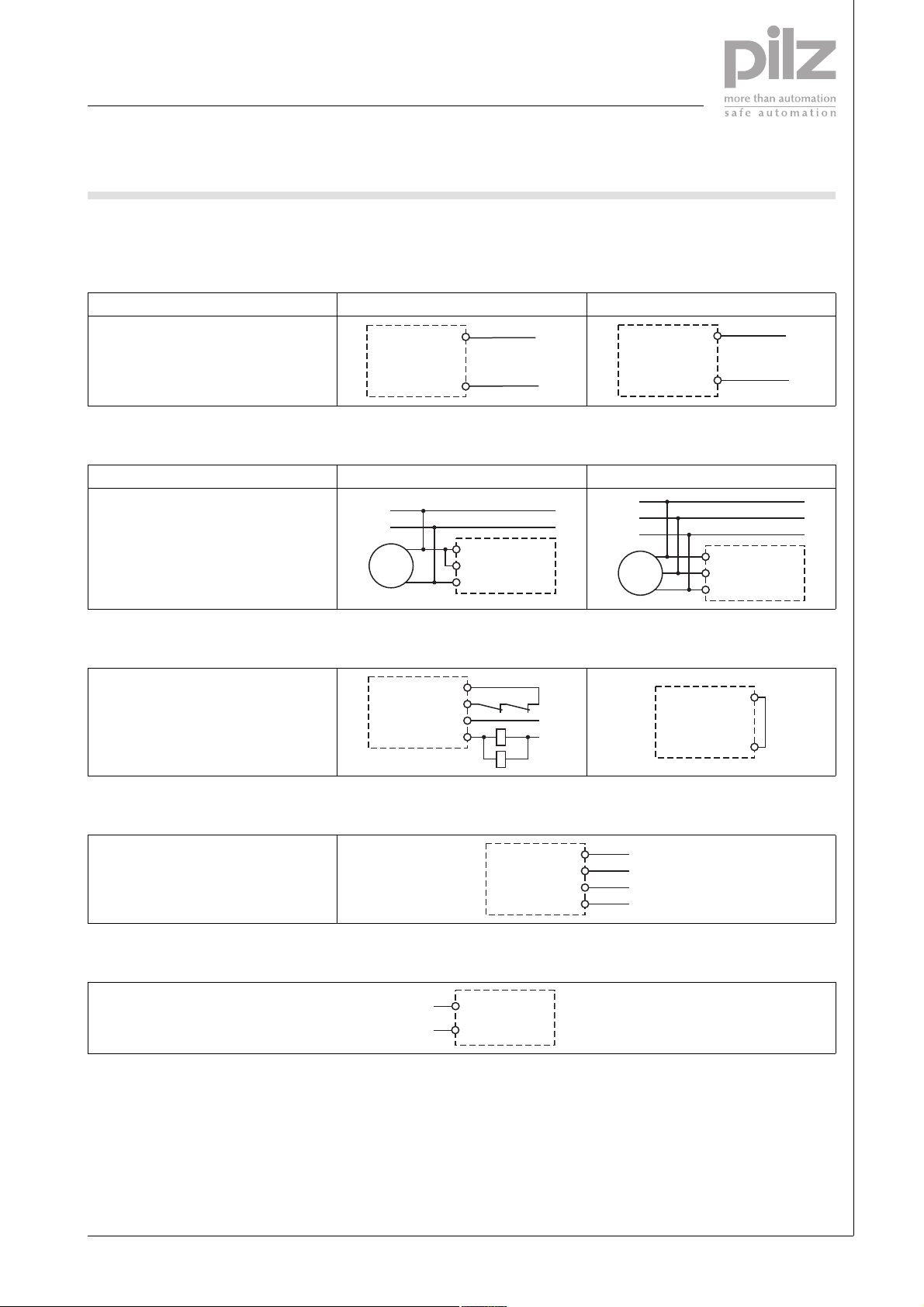

Wiring

Please note:

` Information given in the “Technical

details” must be followed.

` Outputs 13-14, 23-24 are safety

contacts, output 41-42 is an auxiliary contact (e.g. for display).

` To prevent contact welding, a fuse

should be connected before the

t < tg

t < tg

t > tg

t > tg

` Output aux: Auxiliary contact 41-42

` Semi Y35: Semiconductor output

for fault signal

` RESET: Reset input RESET

: Response value

` U

on

output contacts (see technical details).

` Use copper wire that can withstand

60/75 °C.

` When used with converters: Use

screened cable for the wiring between the standstill monitor and the

50 ms

50 ms

1,5 s

1,5 s

` U

: Release value

off

` tg: Simultaneity

motor. Connect the cable screening

on the motor.

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-2

Safe monitoring relays

Standstill

PSWZ X1P

Preparing for operation

` Supply voltage

Supply voltage AC DC

A1

A2

L1

N

` Input circuit

Input circuit Single-phase motor Three-phase motor

L1

N

M

~

L1

L2

L3

L1

L2

L3

M

~

` Feedback loop

Contacts from external contactors or link

Y1

Y2

13 (23)

14 (24)

K5

K6

K5

K6

L1

N

A1

A2

L+

L-

L1

L2

L3

Y1

Y2

` Semiconductor output

Y32: Semiconductor output for switch status

Y35: Semiconductor output for fault signal

Y31

Y32

Y35

Y30

` Semiconductor input

SPS Output

0 V

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

RESET

Y30

24 V DC

SPS Input

SPS Input

0 V

NSG-D-2-336-2006-10

Safe monitoring relays

Standstill

PSWZ X1P

Terminal configuration

Installation

` The safety relay should be installed

in a control cabinet with a protection type of at least IP54.

` Use the notch on the rear of the unit

to attach it to a DIN rail.

` Ensure the unit is mounted securely

on a vertical DIN rail (35 mm) by using a fixing element (e.g. retaining

bracket or an end angle).

Dimensions

* with cage clamp terminals

94 (3.70")

* 101 (3.98")

121 (4.76")

45

(1.77")

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-4

Safe monitoring relays

Standstill

PSWZ X1P

Notice

Service life graph

This data sheet is only intended for use

during configuration. For installation

and operation, please refer to the op-

10

AC15: 230 V

erating instructions supplied with the

unit.

1

D Nennbetriebstrom (A)

GB Nominal operating current (A)

F Courant coupé (A)

0.1

E Corriente nominal de servicio (A)

I Corrente di esercizio nominale (A)

NL Nominale bedrijfsstroom (A)

10 100 1000 10000

D Schaltspielzahl x 10

GB Cycles x 10

F Nombre de manvres x 10

Technical details

Electrical data

Supply voltage

Supply voltage U

AC/DC 24 - 240 V

B

Voltage tolerance -15 %/+10 %

Power consumption at U

Power consumption at U

AC 5.0 VA

B

DC 3.0 W

B

Frequency range AC 50 - 60 Hz

Residual ripple DC 160 %

Voltage and current at

Feedback loop DC: 24.0 V 35.0 mA

Number of output contacts

Safety contacts (S) instantaneous: 2

Auxiliary contacts (N/C): 1

Category of output contacts in accordance with EN 954-1

Safety contacts (S) instantaneous: 4

Utilisation category in accordance with EN 60947-4-1

Safety contacts: AC1 at 240 V I

Safety contacts: DC1 at 24 V I

Auxiliary contacts: AC1 at 240 V I

Auxiliary contacts: DC1 at 24 V I

: 0.01 A , I

min

P

max

: 0.01 A , I

min

P

max

: 0.01 A , I

min

P

max

: 0.01 A , I

min

P

max

Utilisation category in accordance with EN 60947-5-1

Safety contacts: AC15 at 230 V I

Safety contacts: DC13 at 24 V (6 cycles/min) I

Auxiliary contacts: AC15 at 230 V I

Auxiliary contacts: DC13 at 24 V (6 cycles/min) I

max

max

max

max

Contact material AgCuNi + 0.2 µm Au

DC13: 24 V

3

3

max

: 1500 VA

max

: 150 W

max

: 1500 VA

max

: 150 W

: 3.0 A

: 4.0 A

: 3.0 A

: 4.0 A

: 6.0 A

: 6.0 A

: 6.0 A

: 6.0 A

DC1: 24 V

AC1: 230 V

E Número de ciclos x 10

I Numero dei cicli di commutazione x 10

3

NL Aantal schakelingen x 10

3

3

3

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10

Safe monitoring relays

Standstill

PSWZ X1P

Electrical data

External contact fuse protection (IK = 1 kA) to EN 60947-5-1

Blow-out fuse, quick

Safety contacts: 6 A

Auxiliary contacts: 6 A

Blow-out fuse, slow

Safety contacts: 4 A

Auxiliary contacts: 4 A

Circuit breaker 24 VAC/DC, characteristic B/C

Safety contacts: 4 A

Auxiliary contacts: 4 A

Semiconductor outputs (short circuit proof) 24.0 V DC, 50 mA

External supply voltage 24.0 V DC

Voltage tolerance -20 %/+20 %

Semiconductor input

High 15 VDC

Low 5VDC

Input current 20 mA

Measuring circuit

Input voltage L1-L3, L1-L2, L2-L3 0 – 690 VAC/DC

Input voltage in accordance with UL 0 – 600 VAC

Frequency range 0 – 3000 Hz

Input impedance 1300 kOhm

Switching threshold per channel

Response value U

Release value U

Max. inrush current: 10 A, max. 20 ms

Times

Switch-on delay at motor standstill

Max. 1,500 ms

After power on max. 2,200 ms

Delay-on de-energisation after motor on max. 170 ms

Recovery time at max. switching frequency 1/s

after power failure 2200 ms

Simultaneity, channel 1 and 2 7 s

Supply interruption before de-energisation 20 ms

Environmental data

EMC EN 60947-5-1, EN 61000-6-2, EN 61000-6-4

Vibration to EN 60068-2-6

Frequency 10 - 55 Hz

Amplitude 0.35 mm

Climatic suitability EN 60068-2-78

Airgap creepage EN 60947-1

Ambient temperature -10 - 55 °C

Storage temperature -40 - 85 °C

Protection type

Mounting (e.g. cabinet) IP54

Housing IP40

Terminals IP20

Mechanical data

Housing material

Housing PPO UL 94 V0

Front ABS UL 94 V0

on

off

7,5 – 500 mV Order no.: 777951, 787951

20 - 500 mV Order no.: 777949, 787949

120 - 3000 mV Order no.: 777950, 787950

2 x Uon

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

-6

Safe monitoring relays

Standstill

PSWZ X1P

Mechanical data

Max. cross section of external conductors with screw terminals

1 core flexible 0.25 - 2.50 mm² , 24 - 14 AWG Order no.: 777949, 777950,

777951

2 core, same cross section, flexible:

with crimp connectors, without insulating sleeve 0.25 - 1.00 mm² , 24 - 16 AWG Order no.: 777949, 777950,

without crimp connectors or with TWIN crimp connectors 0.50 - 1.50 mm² , 24 - 16 AWG Order no.: 777949, 777950,

Torque setting with screw terminals 0.60 Nm Order no.: 777949, 777950, 777951

Max. cross section of external conductors with cage clamp terminals/spring-loaded terminals: Flexible without crimp connectors

Cage clamp terminals/spring-loaded terminals: Terminal points

per connection

Stripping length 8 mm Order no.: 787949, 787950, 787951

Dimensions

Height 101.0 mm Order no.: 787949, 787950, 787951

Width 45.0 mm

Depth 121.0 mm

Weight 315 g Order no.: 787949, 787950, 787951

777951

777951

0.20 - 1.50 mm² , 24 - 16 AWG Order no.: 787949, 787950,

787951

2 Order no.: 787949, 787950, 787951

94.0 mm Order no.: 777949, 777950, 777951

320 g Order no.: 777949, 777950, 777951

The standards current on 03/05 apply.

Order reference

Type Features Terminals Order no.

PSWZ X1P C 24 - 240 VAC/DC 0,02 - 0.5 V Cage clamp terminals 787 949

PSWZ X1P 24 - 240 VAC/DC 0,02 - 0.5 V Screw terminals 777 949

PSWZ X1P C 24 - 240 VAC/DC 0,12 - 3 V Cage clamp terminals 787 950

PSWZ X1P 24 - 240 VAC/DC 0,12 - 3 V Screw terminals 777 950

PSWZ X1P C 24 - 240 VAC/DC 0,0075 – 0,5 V Cage clamp terminals 787 951

PSWZ X1P 24 - 240 VAC/DC 0,0075 – 0,5 V Screw terminals 777 951

Pilz GmbH & Co. KG, Sichere Automation, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

NSG-D-2-336-2006-10

Loading...

Loading...