Page 1

Operating Manual PSSu E S RS232(- T)

Operating Manual PSSu E S RS232(-T)

PSSu E S RS232(-T)

Decentralised system PSSuniversal I/O

Operating Manual — No. 1001378-EN-03

Page 2

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

Page 3

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.1.2 Terminology: System environment A and B 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Module structure 2-1

2.1.1 Module features 2-1

2.2 Front view 2-2

Chapter 3 Safety

3.1 Intended use 3-1

3.2 Safety regulations 3-3

3.2.1 Use of qualified personnel 3-3

3.2.2 Warranty and liability 3-3

3.2.3 Disposal 3-3

Chapter 4 Function description

4.1 Module features 4-1

4.1.1 Function description 4-1

4.1.2 Integrated protection mechanisms 4-2

4.2 Data exchange 4-3

4.3 Configuration 4-4

4.3.1 Interface parameters 4-4

4.3.2 Receive buffer threshold 4-4

Chapter 5 Installation

5.1 General installation guidelines 5-1

5.1.1 Dimensions 5-1

5.2 Installing the base module 5-3

5.3 Inserting and removing an electronic

module

5.3.1 Inserting an electronic module 5-4

5.3.2 Removing an electronic module 5-5

5.3.3 Changing an electronic module during

operation

5-4

5-5

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Page 4

Contents

Chapter 6 Wiring

6.1 General wiring guidelines 6-1

6.1.1 Mechanical connection of the base

6.2 Terminal configuration 6-4

6.3 Connecting the module 6-6

Chapter 7 Operation

7.1 Messages 7-1

7.2 Display elements 7-2

7.2.1 Display element for operational readiness 7-2

7.2.2 Display element for module error 7-2

7.2.3 Display elements for data transmission 7-3

6-1

modules

Chapter 8 Technical details

8.1 Technical details 8-1

8.2 Order reference 8-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 5

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-][BA Einf Gültigkeit_(T)

This documentation is valid for the products PSSu E S RS232 and

Einf Einleitung

Bestimm_Verwend_ Zusatz-(T)

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

PSSu E S RS232-T. It is valid until new documentation is published.

This operating manual explains the function and operation, describes

the installation and provides guidelines on how to connect the product .

The module PSSu E S RS232-T is suitable for use where there are increased environmental requirements (see Technical Details).

This documentation is intended for instruction and should be retained

for future reference.

1.1.2 Terminology: System environment A and B

Terminology: System environment A and B1-][BA Einf Begriffsdefinition Sys A + B

The PSSu system can be used in two different system environments.

The module's application area is described in the chapter "Intended

Use" of the manual.

The distinction is made between

PSSu in system environment A

PSSu in system environment B

The distinction is based on the application area of the PSSu system.

PSSu in system environment A may be used in the

Decentralised system PSSu I/O with SafetyBUS p

Decentralised system PSSu I/O with ST fieldbuses such as CANopen,

DeviceNet

Not in the automation system PSS 4000

PSSu in system environment B may be used in the

Automation system PSS 4000, e.g. with the

– Decentralised system PSSu I/O with SafetyNET p

– Control system PSSu PLC

– Control system PSSu multi

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

Page 6

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-][BA Einf Übersicht E-Modul

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on safety

and intended use.

4 Function Description

This chapter describes the product's individual components.

5 Installation

This chapter explains how to install the product.

6 Wiring

This chapter describes the product's wiring.

7 Operation

This chapter explains the display elements and advises on what to do if

a fault occurs.

8 Technical Details

This chapter contains the product's technical details and order reference.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 7

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

Page 8

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 9

2 Overview

2.1 Module structure

22000OverviewOverview2-2.1Module structure2100Module structure2-][BA Übersicht Aufbau

A module consists of

Electronic module and

Base module with

The base modules are the carrier units for the electronic modules and

are used to connect the field wiring. The electronic modules are inserted

on to the base modules and determine the module's function.

Details of the base modules that can be used are available in the chapter

entitled “Intended Use”.

– Screw terminals or

– Cage clamp terminals

2.1.1 Module features

Module features2-Geraetemerkmale_Modul_Zusatz BA Einleitung_alt

][Merkmale_Ein_Aus RS232 Ser

][Merkmale_LED ST Ser

][Merkmale_Zusatz ST-Module Sys A + B

][Geraetemerkmal_T

The module has the following features:

Serial interface: RS 232

Communication channels: 2 (Tx/Rx, full duplex)

Configurable transmission rates

Receive buffer: 1023 Byte

Send buffer: 127 Byte

Max. number per system: 6

LEDs for:

– Operational readiness

– Module error

– Data transmission

For standard applications in system environment A and B

Coated version of the module:

PSSu E S RS232-T: for increased environmental requirements

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

Page 10

2 Overview

2111

2212

2313

2414

9

8

7

5

6

10

11

A

B

1

3

4

2

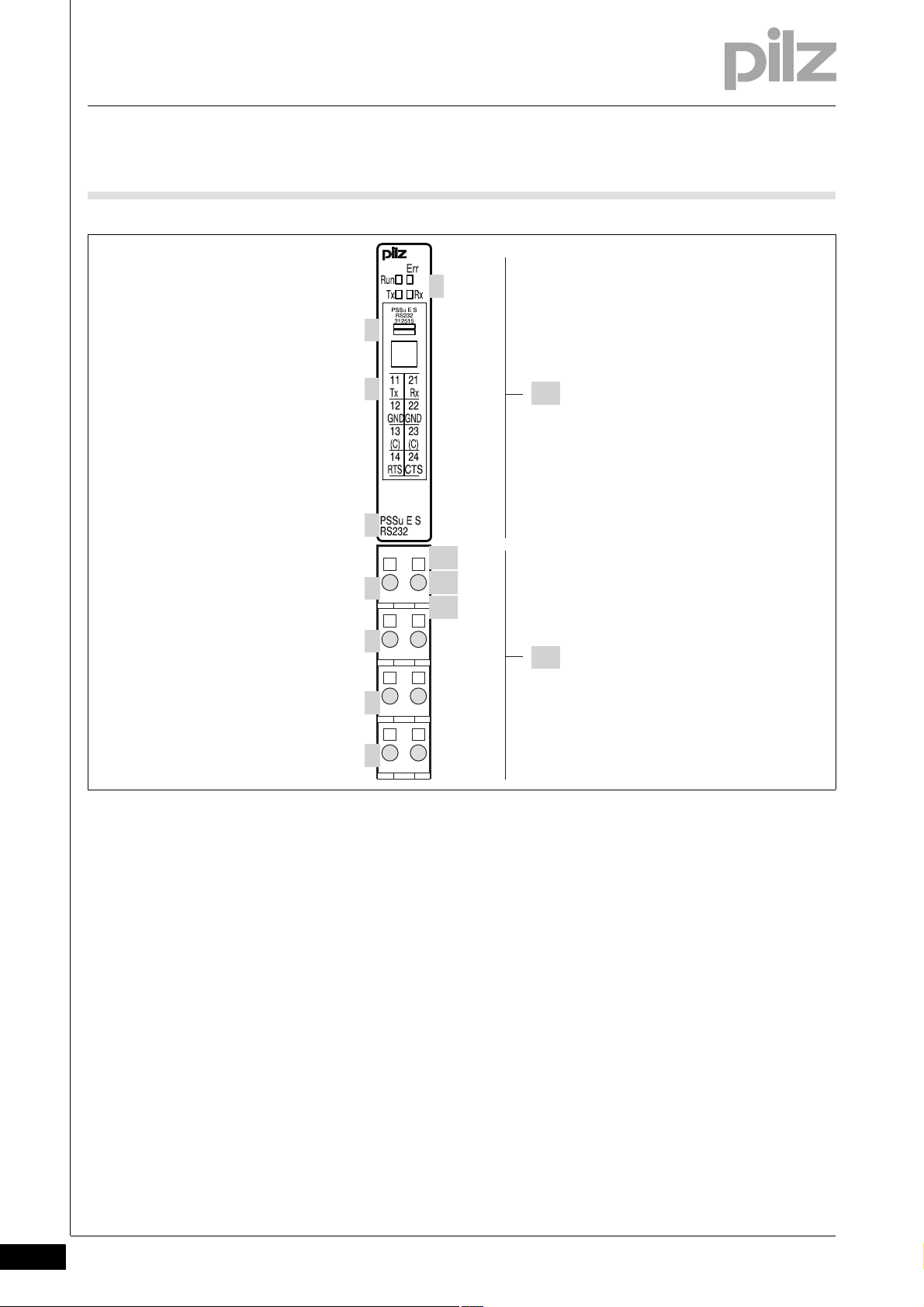

2.2 Front view

2.2Front view2200Front view2-BA_Fron tansicht

][BA_Frontansicht Legende Diag-T

2-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Key:

A: Electronic module

PSSu E S RS232

PSSu E S RS232-T

B: Base module

1: LED for module diagnostics

2: Labelling strip with:

– Name of electronic module

– Order number

– Serial number

– Hardware version number

–2D code

3: Labelling strip for the terminal configuration on the base module

4: Name of electronic module

5: Connection level 1

6: Connection level 2

7: Connection level 3

8: Connection level 4

Page 11

2 Overview

2.2 Front view

9: Square mounting holes (connection levels 1, 2, 3 and 4)

– With screw to loosen/tighten the screw terminal on base modules

with screw terminals

– With mechanism to operate the cage clamp on base modules with

cage clamp terminals

10: Round connection holes (connection levels 1, 2, 3 and 4) for con-

necting the signal lines

11: Mounting slot for colour marker to label the connection level (con-

nection levels 1, 2, 3 and 4)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

Page 12

2 Overview

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 13

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-][Gerätebe schreibung ST-Mo dule Sys A + B

][Gertebeschreibung ST Ser

Bestimm_Verwend_ Zusatz-(T)

Bestimmung/Gertebeschreibung_Ausschluss

The module may be used for standard applications in system environment A and B.

The module provides a serial interface, which is intended for communication in non-safety-related applications.

The module PSSu E S RS232-T is suitable for use where there are increased environmental requirements (see Technical Details).

Intended use includes making the electrical installation EMC-compliant.

Please refer to the guidelines stated in the "PSSuniversal Installation

Manual". The module is designed for use in an industrial environment. It

is not suitable for use in a domestic environment, as this can lead to interference.

Bestimm_Verwend_Info_PSSu_ab_1.8.1_PAS4000_ab_1.1.1

Bestimm_Verwend_B asismodule

Bestimm_Basismodule Ser

Bestimm_Verwend_B asismodule-T

The following is deemed improper use in particular:

Any component, technical or electrical modification to the module

Use of the module outside the areas described in this manual

Use of the module outside the technical details (see chapter entitled

"Technical Details")

INFORMATION

The module is supported by

PSSuniversal Configurator and PSSuniversal Assistant from

Version 1.8.1

PAS4000 from Version 1.1.1

– We recommend that you always use the latest version

(download from www.pilz.de).

The PSSu E S RS232 module may be used in conjunction with the following base modules:

PSSu BP 1/8S

PSSu BP 1/8C

PSSu BP 1/12S

PSSu BP 1/12C

PSSu BP-C 1/8S

PSSu BP-C 1/8C

PSSu BP-C 1/12S

PSSu BP-C 1/12C

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

Page 14

3 Safety

3.1 Intended use

Bestimm_Basismodule Ser-T

The module PSSu E S RS232-T may be used in conjunction with the following base modules:

PSSu BP 1/8S-T

PSSu BP 1/8C-T

PSSu BP 1/12S-T

PSSu BP 1/12C-T

PSSu BP-C 1/8S-T

PSSu BP-C 1/8C-T

PSSu BP-C 1/12S-T

PSSu BP-C 1/12C-T

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 15

3 Safety

3.2 Safety regulations

3.2Safety regulations3200Safety regulation s3-

3.2.1 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge required to test, assess and operate the work equipment, devices,

systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

3.2.2 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

3.2.3 Disposal

Disposal3-Si ch Entsorgung

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

Page 16

3 Safety

3-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 17

4 Function description

Ext. device

with serial

interface

RS232

Control

system

Electronic module

PSSu E S RS232(-T)

Head

module

Bus system/

Network

Module

bus

PSSu I/O

Ext. device

with serial

interface

RS232

Electronic module

PSSu E S RS232(-T)

Head

module

with

control

system

Module

bus

4.1 Module features

44000Function descriptionFunction description4-4.1Module features4100Module features4-

4.1.1 Function description

Function description4-][Funktionsbeschreibung BA Einleitung Ser

][Funktionsbeschreibung Module Supply

][Funktionsbeschreibung_Peri Ser

][Funktionsbeschreibung Datenaustausch Ser

][Funktionsdiagramm ST RS232 Ser

The module enables communication via a serial interface.

Module supply

The module supply provides the module with voltage.

Periphery supply

The periphery supply provides the serial interface with voltage.

Signal processing

In each cycle, a max. of 8 Bytes of data can be transferred in both di-

rections between control system and module. The data to be transferred is stored temporarily in a send and receive buffer.

Two additional status bytes and control bytes are available in the

process image for data exchange between control system and module.

All the configuration data is stored in the head module and is assigned

to the module on restart. This way the configuration data is retained

even if you change the module.

Schematic representation of signal processing with decentralised system PSSu I/O:

][Funktionsdiagramm ST RS232 Ser 2

Schematic representation of signal processing with the PSSu PLC/

PSSu multi control system:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-1

Page 18

4 Function description

4.1 Module features

4.1.2 Integrated protection mechanisms

Integrated protection mechanisms4-][Schutzmechanismen E/A-Module

When the PSSu E F PS1(-T) is used to supply the system, the module

][Schutzmechanismen ST-Module

supply is buffered for 20 ms if the supply voltage is interrupted.

The module detects the following errors:

Start-up error

Configuration error

ST communication error

Bus termination error

4-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 19

4 Function description

4.2 Data exchange

4.2Data exchange4200Data exchange4-][Funktionsbeschreibung_Zusatz Ser

A function block is required for data exchange between the bus subscribers.

INFORMATION

The necessary function block is available from technical support

(telephone: +49 711 3409-444).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

4-3

Page 20

4 Function description

4.3 Configuration

4.3Configuration4300Configuration4-][Funktionsbeschreibung_BA_Konfig Einf Ser

The module has the following configuration options:

Interface parameter

Threshold receive buffer

4.3.1 Interface parameters

Interface parameters4-][Funktionsbeschreibung_BA_Konfig Schnitt RS232 Ser

The following interface parameters can be configured:

Transmission rate

Block size (data bits and parity)

Number of stop bits

Continuous sending

Xon/Xoff when sending

Xon/Xoff when receiving

RTS and CTS activated

4.3.2 Receive buffer threshold

Receive buffer threshold 4-][Funktionsbeschrei bung_BA_Konfig Schwell Ser

The number of Bytes in a receive buffer of the module is defined with this

value, from which the status bit "Receive buffer full" is set (default value:

512).

4-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 21

5 Installation

12,6 mm

76 mm

52,1 mm8,1 mm

67,7 mm

12,6 mm

56,1 mm 71,8 mm

0,8 mm

128,9 mm

72,6 mm

(2.051")(0.319")

(0.496")

(2.858")

(0.496")

(2.99")

(2.209") (2.827")

(0.031")

(5.075")

(2.665")

5.1 General installation guidelines

55000InstallationInstallation5-5.1General installation guidelines5100General installation guidelines5-][Montage BA E-Modul Allgemein

Montage_EMV ESD

5.1.1 Dimensions

Dimensions5-][Abmessungen 1xR + 1xRL

Please also refer to the PSSuniversal Installation Manual.

CAUTION!

Damage due to electrostatic discharge!

Electrostatic discharge can damage components. Ensure

against discharge before touching the product, e.g. by touching

an earthed, conductive surface or by wearing an earthed armband.

Base modules with four connection levels:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-1

Page 22

5 Installation

12,6 mm

76 mm

52,1 mm8,1 mm

67,7 mm

82,0 mm 71,8 mm

0,8 mm

72,6 mm

(2.051")(0.319")

(2.858")

(0.496")

(2.99")

(3.228") (2.827")

(0.031")

(2.665")

12,6 mm

(0.496")

154,6 mm

(6.087")

5.1 General installation guidelines

Base modules with six connection levels:

5-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 23

5 Installation

[2]

[1]

[3]

5.2 Installing the base module

5.2Installing the base module5200Installing the base module5-][Montage Basismodul

Prerequisite:

The head module must be installed.

If the head module does not have an integrated power supply, a sup-

ply voltage module must be installed to the right of the head module.

Please note:

For mechanical reasons it is not possible to mix base modules with

screw terminals and base modules with cage clamp terminals.

All contacts should be protected from contamination.

The mechanics of the base modules are designed for 50 plug in/out

cycles.

Procedure:

We recommend that you wire up the base modules before inserting

the electronic modules.

Slot the groove on the base module on to the mounting rail from be-

low [1].

Push the base module back [2] until you hear it lock into position.

On the mounting rail, slide the base module to the left until you hear

the two lateral mounting hooks on the adjacent module lock into position [3].

Schematic representation:

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-3

Page 24

5 Installation

[2]

[1]

[1]

5.3 Inserting and removing an electronic module

5.3Inserting and removing an electronic module5300Inserting and removing an electronic module5-][Elektronikmodul stecken und ziehen

Please note:

Only insert on to base modules that are already installed.

Preferably these base modules should be ready wired.

Electronic modules with outputs may only be inserted and removed

when the load is switched off. Unforeseeable error reactions may be

triggered if modules are inserted and removed under load.

When an electronic module is plugged into a base module for the first

time, one part of the coding element remains on the electronic module, while its counterpart is fixed on to the base module. This is how

the base module is coded.

The mechanics of the electronic modules are designed for 50 plug in/

out cycles.

5.3.1 Inserting an electronic module

Inserting an electronic module5-][Elektronikmodul stecken

Procedure:

The electronic module must audibly lock into position [1].

Mark the electronic module using the labelling strips [2].

Schematic representation:

5-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 25

5 Installation

[1]

[2]

[1]

5.3 Inserting and removing an electronic module

5.3.2 Removing an electronic module

Removing an electronic module5-][Elektronikmodul ziehen

Procedure:

Press the locking mechanisms [1] together simultaneously.

Pull out the electronic module [2].

Schematic representation:

5.3.3 Changing an electronic module during operation

Changing an electronic module during operation5-][Montage BA Hot Swapping ST

It is possible to change an electronic module during operation. However,

changing an electronic module during operation may cause an ST communication error. The configuration data is retained when a module is

changed.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5-5

Page 26

5 Installation

5-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 27

6 Wiring

DIN 5264-A

6.1 General wiring guidelines

66000WiringWiring6-6.1General wiring gu idelines6100Gene ral wiring guideline s6-][Verdrahtung BA Einleitung

][Verdrahtung ST analog

Safe electrical isolation must be ensured for the voltage supply to the

sensors and actuators. Failure to do so could result in electric shock.

Please note:

We recommend that you use shielded signal lines.

On base modules with C-rail:

– Connect the shield to the terminals on the C-rail.

– Connect the C-rail with low impedance to the functional earth.

On base modules without C-rail:

– Connect the shield as shown in the terminal configuration section.

The module connects the shield to the mounting rail.

– Connect the mounting rail to the functional earth via an earthing

terminal.

In environments with strong EMC interference, base modules without

a C-rail provide better protection if the shield is connected.

][Verdrahtung Zusatz mit C

Use copper wiring.

The terminal configuration as stated on the front plate applies for base

modules with C-rail. The terminal configuration as stated in the technical documentation applies for all other base modules.

6.1.1 Mechanical connection of the base modules

Mechanical connection of the base modules6-][Modulverdrahtung mech

Procedure:

Use a flat blade screwdriver (DIN 5264-A)!

Strip the wire back 8 mm.

If necessary, label the connection level with a colour marker [3].

Base module with screw terminals:

– Use a screwdriver to loosen the screw on the screw terminal [1]

– Insert the stripped cable into the round fixing hole [2], as far as it

will go.

– Tighten up the screw on the screw terminal.

– Check that the cable is firmly seated.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-1

Page 28

6 Wiring

2111

[1]

[3]

[2]

[4]

[5]

[6]

6.1 General wiring guidelines

Base module with cage clamp terminals:

– Insert the screwdriver [4] into the square hole [1].

– Insert the stripped cable into the round fixing hole [2], as far as it

will go [5].

– Pull out the screwdriver [6].

– Check that the cable is firmly seated.

][Modulverdrahtung el Sys A + B

Please note:

The minimum cable cross section for field connection terminals on the

2

base modules is 0.14 mm

The maximum cable cross section for field connection terminals is:

– Digital inputs: 1.5 mm

– Digital outputs: 2.0 mm

– Inputs/outputs on the counter modules: 1.5 mm

– Analogue inputs/outputs: 1.5 mm

– Communication cables: 1.5 mm

– Test pulse outputs: 1.5 mm

– Power supply: 2.5 mm

– Functional earth: 2.5 mm

(AWG26)

2

(AWG16)

2

(AWG14)

2

(AWG16)

2

(AWG12)

2

(AWG12)

2

(AWG16)

2

(AWG16)

2

(AWG16)

6-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 29

6 Wiring

6.1 General wiring guidelines

On base modules with screw terminals:

– If you use a multi-strand cable to connect the I/Os, it is recom-

mended that you use ferrules conforming to Parts 1 and 2 of

DIN 46228, 0.14 ... 1.5 mm

sential. To crimp the ferrules you can use crimp pliers (crimp form

A or C) conforming to EN 60947-1, such as the PZ 1.5 or PZ 6.5

from Weidmüller, for example.

– Maximum torque setting: 0.8 Nm

Use copper wiring.

2

, Form A or C, although this is not es-

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

6-3

Page 30

6 Wiring

2111

2212

2313

2414

2111

2212

2313

2414

6.2 Terminal configuration

6.2Terminal configuration6200Terminal configuration6-][Klemmenbe legung RS232 Ser

Base module Terminal configuration

Screw terminals:

PSSu BP 1/8S

PSSu BP 1/8S-T

Cage clamp terminals:

PSSu BP 1/8C

PSSu BP 1/8C-T

Screw terminals:

PSSu BP-C 1/8S

PSSu BP-C 1/8S-T

Without C-rail:

11: Output Tx (send data)

21: Input Rx (receive data)

12-22: GND

(12-22 linked within the base module)

13-23: Shield connection

(13-23 linked within the base module)

14: Output RTS

24: Input CTS

With C-rail:

11: Output Tx (send data)

Cage clamp terminals:

PSSu BP-C 1/8C

PSSu BP-C 1/8C-T

21: Input Rx (receive data)

12-22: GND

(12-22 linked within the base module)

13-23: C-rail supply,

shield connection

(13-23 linked within the base module)

14: Output RTS

24: Input CTS

6-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 31

6 Wiring

2111

2212

2313

2414

2616

2515

2111

2212

2313

2414

2616

2515

6.2 Terminal configuration

Base module Terminal configuration

Screw terminals:

PSSu BP 1/12S

PSSu BP 1/12S-T

Cage clamp terminals:

PSSu BP 1/12C

PSSu BP 1/12C-T

Without C-rail:

11: Output Tx (send data)

21: Input Rx (receive data)

12-22: GND

(12-22-15-25 linked within the base

module)

13-23: Cable shield

(13-23-16-26 linked within the base

module)

14: Output RTS

24: Input CTS

15-25: GND

(12-22-15-25 linked within the base

module)

16-26: Cable shield

(13-23-16-26 linked within the base

module)

Screw terminals:

PSSu BP-C 1/12S

PSSu BP-C 1/12S-T

Cage clamp terminals:

PSSu BP-C 1/12C

PSSu BP-C 1/12C-T

With C-rail:

11: Output Tx (send data)

21: Input Rx (receive data)

12-22: GND

(12-22 linked within the base module)

13-23: C-rail supply,

shield connection

(13-23 linked within the base module)

14: Output RTS

24: Input CTS

15-25: GND

(12-22-15-25 linked within the base

module)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

16-26: C-rail supply,

cable shield

(13-23-16-26 linked within the base

module)

6-5

Page 32

6 Wiring

2111

2212

2313

2414

Tx

Tx

Rx

GND

GND

GND

Rx

RTS

CTS

2111

2212

2313

2414

Tx

Tx

Rx

GND

GND

GND

Rx

RTS

CTS

C

C

2111

2212

2313

2414

Tx

Tx

Rx

GND

GND

GND

Rx

RTS

CTS

RTS

CTS

2111

2212

2313

2414

Tx

Tx

Rx

GND

GND

GND

Rx

RTS

CTS

RTS

CTS

C C

6.3 Connecting the module

6.3Connecting the module6300Connecting the module6-][Anschluss RS232 Ser

Input and output circuit Without C-rail With C-rail

With hardware handshake

With hardware handshake

6-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 33

7 Operation

7.1 Messages

77000OperationOperation7-7.1Messages71 00Messages7-][BA_Betrieb Störung LED "Err" Sys A + B

A module error is displayed via the "Err" LED (see section entitled "Display elements"), signalled to the head module and then entered in the

head module's

Error stack, with PSSu in system environment A

][BA_Betrieb Fehler Ser

Errors Statement Remedy

Start-up error Error as the PSSu system starts up Change faulty module.

Configuration error Wrong module type selected or invalid

ST communication error Error during ST communication Change faulty module

Bus termination error There is no terminating plate or there is

Diagnostic log, with PSSu in system environment B.

The module can detect the following errors:

Adjust the configured hardware regis-

module configuration

a bad contact with the module bus.

try to the actual hardware registry so

that they match, or correct the module

configuration.

Install a terminating plate with integrated end bracket or insert the base

modules together correctly.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-1

Page 34

7 Operation

Err

11I021

I1

Err

7.2 Display elements

7.2Display elements7200Display elements7-Anzeige Legende 2x

Key:

LED on

LED off

7.2.1 Display element for operational readiness

Display element for operational readiness7-][BA_Anzeige LED Run ST Se r

The module has an LED to display operational readiness ("Run" LED).

LED Key

Description Colour Status

Run - - - Module not

7.2.2 Display element for module error

Display element for module error7-][BA_Anzeige LED Err ST

The module has an LED for displaying module errors (“Err” LED).

LED Key

Description Colour Status

Err - - - No fault

ready for operation

Green Module ready

for operation

Red Module is faulty

7-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 35

7 Operation

7.2 Display elements

7.2.3 Display elements for data transmission

Display elements for data transmission7-][BA_Anze ige LED Tx/Rx ST Se r

The module has the LEDs Tx and Rx to display data transmission (LEDs

"Tx" and "Rx").

LED Key

Descrip-

tion

Tx - - - No data

Colour Status Signal Terminal

Green Send

11

transfer

data

Rx - - - No data

transfer

Green Receive

data

21

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-3

Page 36

7 Operation

7-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 37

8 Technical details

8.1 Technical details

88000Technical detailsTechnical details8-8.1Technical details8100Technical details8-][Technische Daten PSSu seriell(-T)

Technical details

Application range Standard

Module's device code 0720h

Number of ST input bits 64

Number of ST output bits 64

Number of ST status bits 16

Number of ST control bits 16

Support in system environment A

from ST firmware version for other head modules 17

from ST firmware version PSSu H S PN 1

Support in system environment B

from head module ST firmware version 1.0.0

Electrical data

Internal supply voltage (module supply)

Supply voltage range of module supply 4.8 - 5.4 V

Module's current consumption 125 mA

Module's power consumption 0.63 W

Periphery's supply voltage (periphery supply)

Voltage range 16.8 - 30.0 V

Module's current consumption 20 mA

Module's power consumption 0.48 W

Max. power dissipation of the module 1.20 W

Serial interface

Number of RS232 interfaces 1

Transmission rate (configurable) 1.2 kBit/s, 19.2 kBit/s, 2.4 kBit/s, 300 Bit/s, 4.8 kBit/s,

600 Bit/s, 9.6 kBit/s

Max. cable run 15 m

Size of receive buffer 1,023 Byte

Size of send buffer 127 Byte

Potential isolation between interface and Module Supply yes

Potential isolation between interface and Periphery Supply yes

Environmental data

Climatic suitability EN 60068-2-14, EN 60068-2-1, EN 60068-2-2,

EN 60068-2-30, EN 60068-2-78

Ambient temperature in accordance withEN 60068-2-14 0 - 60 °C

-40 - 70 °C coated version (-T)

Storage temperature in accordance with EN 60068-2-1/-2 -25 - 70 °C

-40 - 70 °C coated version (-T)

Climatic suitability in accordance with EN 60068-2-30,

EN 60068-2-78

Condensation no

Max. operating height above sea level 2000 m

EMC EN 61000-4-2, EN 61000-4-3, EN 61000-4-4,

Vibration to EN 60068-2-6

Frequency 10 - 150 Hz

Max. acceleration 1g

93 % r. h. at 40 °C

yes coated version (-T)

5000 m coated version (-T)

EN 61000-4-5, EN 61000-4-6, EN 61131-2

10 - 1,000 Hz coated version (-T)

5g coated version (-T)

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-1

Page 38

8 Technical details

8.1 Technical details

Environmental data

Shock stress

EN 60068-2-27 15g

11 ms

EN 60068-2-29 10g

25g coated version (-T)

16 ms

6 ms coated version (-T)

Protection type in accordance with EN 60529

Mounting (e.g. cabinet) IP54

Housing IP20

Terminals IP20

Airgap creepage in accordance with EN 60664-1,

EN 61131-2

Overvoltage category II

Pollution degree 2

Mechanical data

Housing material

Front PC

Bottom PC

Coding PA

Dimensions

Height 76.0 mm

Width 12.6 mm

Depth 60.2 mm

Weight 36 g

37 g coated version (-T)

Mechanical coding

Type K

Colour dark grey

Technische Daten_Satz No rmen

The standards current on 2009-03 apply.

8-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 39

8 Technical details

8.2 Order reference

8.2Order reference8200Order reference8-Bestel ldaten E-Module

Order reference

Description Order no.

PSSu E S RS232

(Electronic module)

PSSu E S RS232-T

(Electronic module, coated version)

Bestelldaten Basism odule

Base modules Order no.

PSSu BP 1/8S

(Base module without C-rail with screw terminals)

PSSu BP 1/8S-T

(Base module without C-rail with screw terminals, coated

version)

PSSu BP 1/8C

(Base module without C-rail with cage clamp terminals)

PSSu BP 1/8C-T

(Base module without C-rail with cage clamp terminals,

coated version)

PSSu BP 1/12S

(Base module without C-rail with screw terminals)

PSSu BP 1/12S-T

(Base module without C-rail with screw terminals, coated

version)

PSSu BP 1/12C

(Base module without C-rail with cage clamp terminals)

PSSu BP 1/12C-T

(Base module without C-rail with cage clamp terminals,

coated version)

PSSu BP-C 1/8S

(Base module with C-rail with screw terminals)

PSSu BP-C 1/8S-T

(Base module with C-rail with screw terminals, coated version)

PSSu BP-C 1/8C

(Base module with C-rail with cage clamp terminals)

PSSu BP-C 1/8C-T

(Base module with C-rail with cage clamp terminals, coated version)

PSSu BP-C 1/12S

(Base module with C-rail with screw terminals)

PSSu BP-C 1/12S-T

(Base module with C-rail with screw terminals, coated version)

PSSu BP-C 1/12C

(Base module with C-rail with cage clamp terminals)

PSSu BP-C 1/12C-T

(Base module with C-rail with cage clamp terminals, coated version)

312 515

314 515

312 600

314 600

312 601

314 601

312 618

314 618

312 619

314 619

312 610

314 610

312 611

314 611

312 620

314 620

312 621

314 621

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

8-3

Page 40

8 Technical details

8-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Page 41

...

1001378-EN-03, 2011-04 Printed in Germany

© Pilz GmbH & Co. KG, 2011

+49 711 3409-444

support@pilz.com

Pilz GmbH & Co. KG

Felix-Wankel-Straße 2

73760 Ostfildern, Germany

Telephone: +49 711 3409-0

Telefax: +49 711 3409-133

E-Mail: pilz.gmbh@pilz.de

Internet: www.pilz.com

Technical support

In many countries we are

represented by our subsidiaries

and sales partners.

Please refer to our homepage

for further details or contact our

headquarters.

InduraNET p

®

, Pilz

®

, PIT

®

, PMCprotego

®

, PMI

®

, PNOZ

®

, Primo

®

, PSEN

®

, PSS

®

, PVIS

®

, SafetyBUS p

®

, SafetyEYE

®

, SafetyNET p

®

, the spirit of safety

®

are registered and protected trademarks

of Pilz GmbH & Co. KG in some countries. We would point out that product features may vary from the details stated in this document, depending on the status at the time of publication and the scope

of the equipment. We accept no responsibility for the validity, accuracy and entirety of the text and graphics presented in this information. Please contact our Technical Support if you have any questions.

Contact address

Loading...

Loading...