Pilz D72-000-0-0-2-208-480VAC User Manual

Operating Manual PMCpro tego D.48, PMCprot ego D.72

Operating Manual PMCprotego D.48, PMCprotego D.72

PMCprotego D.48, PMCprotego D.72

Servo amplifiers

Operating Manual — No. 1001735-EN-01

This document is a translation of the original document.

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

Pilz®, PIT®, PMI®, PNOZ®, Primo®, PSEN®, PSS®, PVIS®, SafetyBUS p®, SafetyEYE®,

SafetyNET p®, the spirit of safety® are registered and protected trademarks of

Pilz GmbH & Co. KG in some countries.

SD means Secure Digital.

Preface

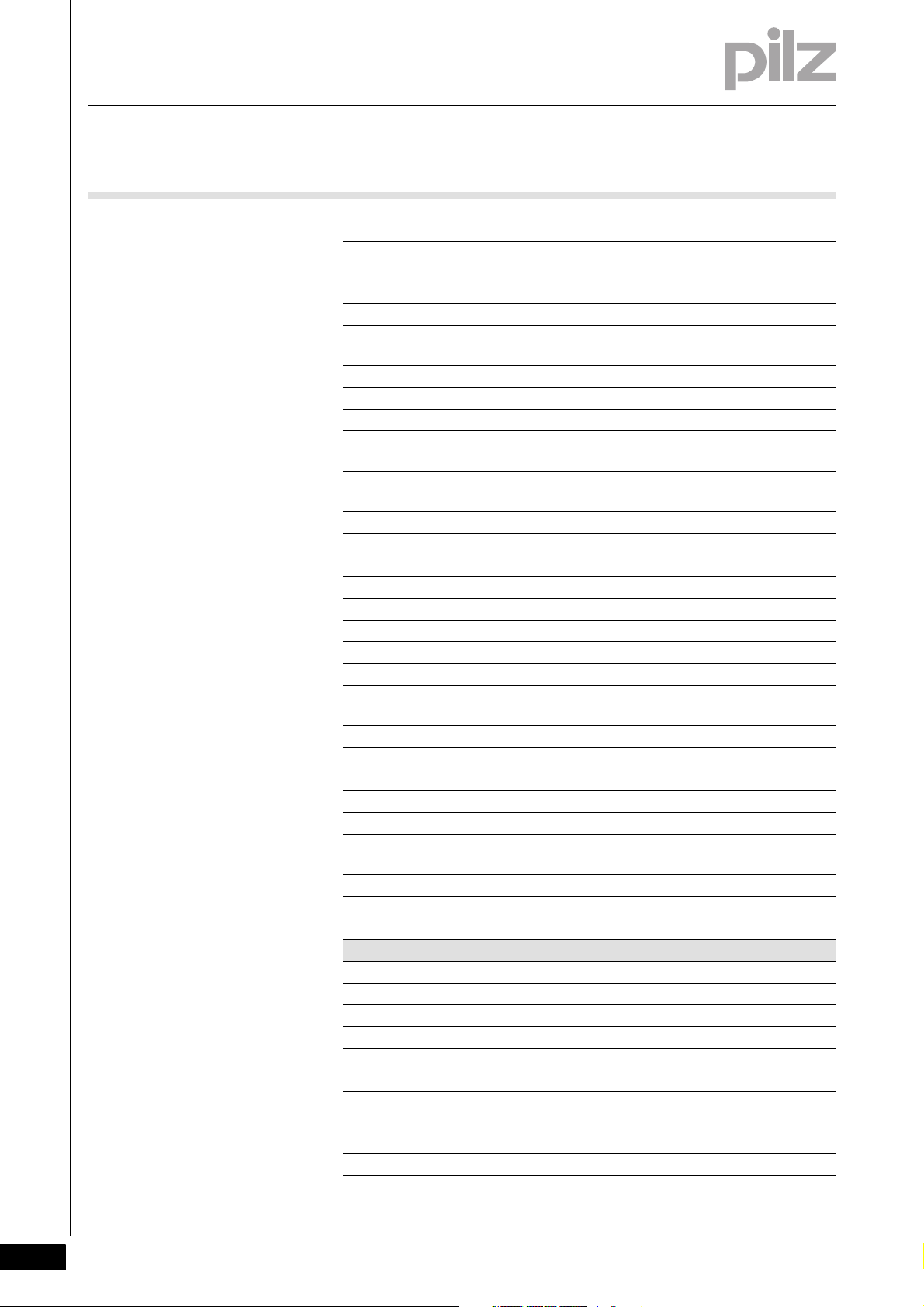

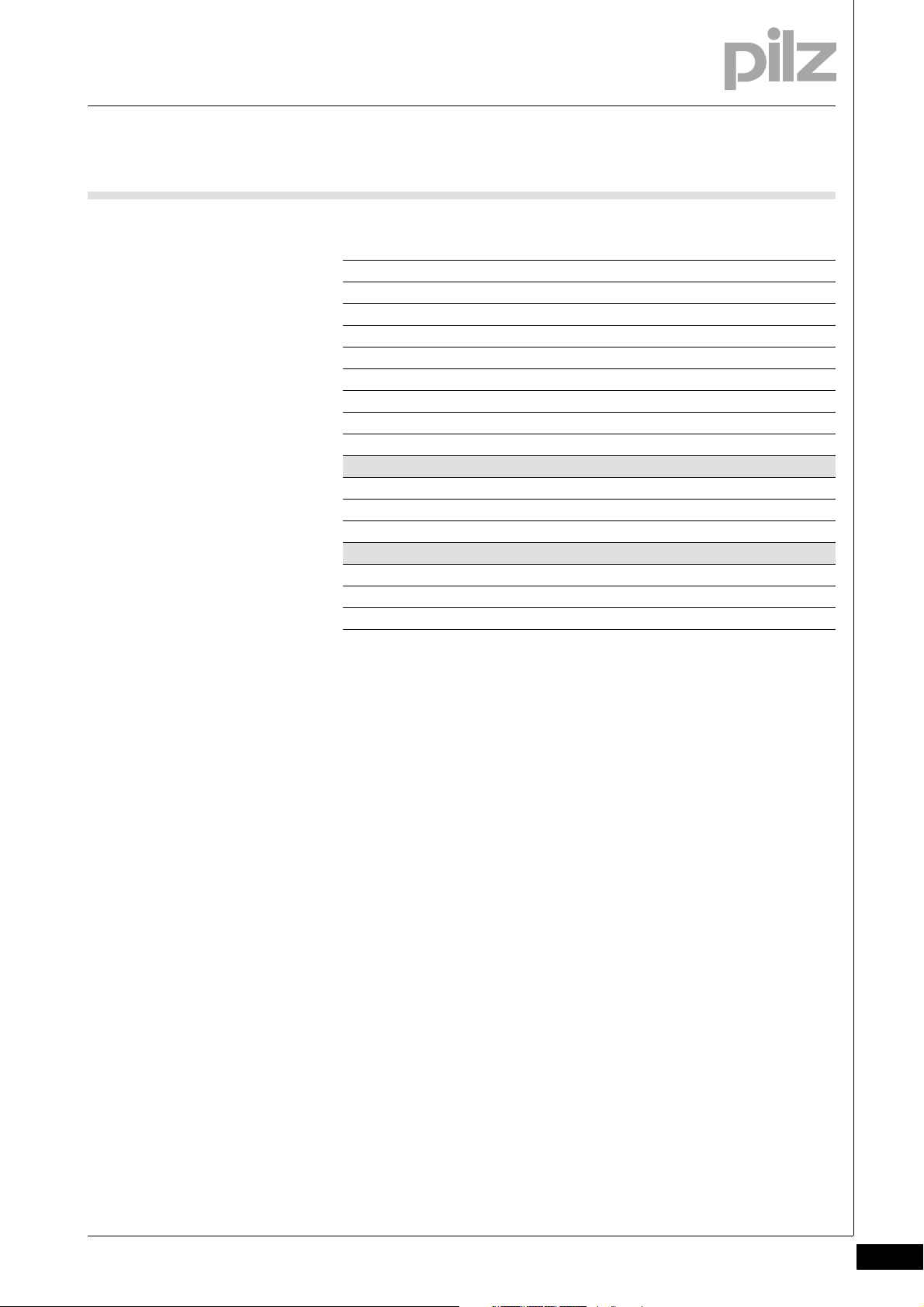

Contents

Contents

Contents Page

Chapter 1 Introduction

1.1 Validity of documentation 1-1

1.1.1 Retaining the documentation 1-1

1.2 Overview of documentation 1-2

1.3 Definition of symbols 1-3

Chapter 2 Overview

2.1 Unit structure 2-1

2.1.1 Unit features 2-1

2.1.1.1 Power element 2-1

2.1.1.2 Control element 2-2

2.2 Front view 2-5

2.3 Plan view 2-6

2.4 Scope of delivery 2-7

2.5 Type code 2-8

2.6 Type label 2-9

Chapter 3 Safety

3.1 Intended use 3-1

3.1.1 Hazard analysis 3-1

3.1.2 Electrical data 3-1

3.1.3 Ambient conditions 3-2

3.1.4 Guidelines for UL approval 3-2

3.1.5 Safety function STO 3-3

3.1.6 Use of qualified personnel 3-4

3.1.7 Warranty and liability 3-5

3.1.8 Disposal 3-5

3.2 Safety during operation 3-6

3.3 Standards 3-7

3.4 Stop and E-STOP functions 3-9

3.4.1 Stop functions 3-9

3.4.2 E-STOP functions 3-10

Chapter 4 Function Description

4.1 Overview 4-1

4.2 Power element 4-3

4.2.1 Mains voltage 4-3

4.2.2 Motor connection 4-6

4.2.3 Motor holding brake 4-6

4.2.4 Brake resistor 4-9

4.2.5 Intermediate circuit 4-10

4.3 Control element 4-11

4.3.1 Supply voltage 24 VDC 4-11

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1

Contents

4.3.2 Digital inputs and outputs 4-11

4.3.2.1 Overview 4-11

4.3.2.2 Digital inputs 4-12

4.3.2.3 Digital outputs 4-15

4.3.3 Safety function STO 4-16

4.3.3.1 Safety information 4-17

4.3.3.2 Signal states 4-17

4.3.3.3 Safety function STO without a safety card 4-19

4.3.3.4 Safety function STO with safety card 4-21

4.3.3.5 Reaction time 4-21

4.3.3.6 Connection example for STO, single-channel

4.3.3.7 Connection example for STO, dual-channel

4.3.4 Analogue inputs 4-23

4.3.5 Encoder systems 4-25

4.3.5.1 Overview 4-25

4.3.5.2 Resolver 4-28

4.3.5.3 SinCos encoder 4-28

4.3.5.4 Incremental encoders 4-31

4.3.5.5 Absolute encoder with SSI interface 4-31

4.3.6 Electronic gearing 4-32

4.3.6.1 Stepper motor control systems (pulse/direction)

4.3.6.2 Master-Slave mode 4-34

4.3.7 Encoder emulation 4-35

4.3.8 Communications interfaces 4-38

4.3.8.1 RS 232 interface 4-38

4.3.8.2 CANopen interface 4-38

4.3.8.3 Ethernet interface (in development) 4-39

4.3.9 SD card 4-39

4.3.10 Tools 4-40

4.4 Expansion cards 4-41

4.4.1 Expansion card PMCprotego S1, PMCprotego S2

4.4.2 Expansion card I/O-14/08 4-41

4.4.3 Expansion card PosI/O, PosI/O-AO 4-43

4.4.3.1 Electronic gearing, Master-Slave mode 4-44

4.4.3.2 Encoder emulation 4-45

4.4.3.3 Analogue inputs 4-48

4.4.3.4 Analogue outputs 4-48

4.4.4 Expansion card with PROFIBUS-DP interface

4.4.5 Expansion card for SERCOS interface 4-49

4.4.6 Expansion card with DeviceNet interface 4-51

4.5 Switch on/switch off behaviour 4-54

4-22

4-22

4-33

4-41

4-49

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

2

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Contents

4.5.1 Normal mode 4-55

4.5.2 Fault condition 4-57

4.6 Implementation of stop categories 4-59

4.6.1 Stop Category 0 4-59

4.6.2 Stop Category 1 4-61

4.6.3 Stop Category 2 4-63

Chapter 5 Installation

5.1 General requirements 5-1

5.2 Dimensions 5-2

5.3 Installing the servo amplifier 5-3

5.4 Installing the shielding plate 5-4

5.5 Installing the expansion cards 5-5

5.5.1 Expansion cards for slot 1 5-5

5.5.2 Expansion cards for slot 2 5-6

5.5.3 Expansion cards for slot 3 5-7

Chapter 6 Wiring

6.1 Connector description 6-1

6.2 Block diagram 6-2

6.3 Notes on wiring 6-5

6.3.1 Contact protection 6-6

6.3.1.1 Leakage current 6-6

6.3.1.2 Residual current devices FI 6-7

6.3.1.3 Isolating transformer 6-8

6.3.2 Connection cables 6-8

6.4 Wiring procedure 6-10

6.5 EMC-compliant wiring 6-11

6.5.1 Earthing 6-11

6.5.2 Shielding 6-11

6.5.2.1 Shield connection on the front plate 6-12

6.5.3 Filters 6-13

6.5.4 Chokes 6-14

6.6 Power element 6-15

6.6.1 Mains voltage 6-15

6.6.2 Motor 6-16

6.6.3 Motor holding brake 6-17

6.6.4 External brake resistor 6-18

6.6.5 Intermediate circuit 6-19

6.7 Control element 6-22

6.7.1 Supply voltage 24 VDC 6-22

6.7.2 Digital inputs 6-23

6.7.3 Digital outputs 6-25

6.7.4 Analogue inputs 6-27

6.7.5 Encoder systems 6-28

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3

Contents

6.7.5.1 Resolver 6-28

6.7.5.2 SinCos encoder with HIPERFACE interface

6.7.5.3 SinCos encoder with EnDat 2.1 interface 6-31

6.7.5.4 SinCos encoder with EnDat 2.2 interface 6-32

6.7.5.5 SinCos encoder with BISS interface, analogue

6.7.5.6 SinCos encoder with BISS interface, digital 6-35

6.7.5.7 SinCos encoder with SSI interface 6-37

6.7.5.8 SinCos encoder without data track 6-38

6.7.5.9 Incremental encoder ROD (AquadB) 5 V,

350 kHz

6.7.5.10 Incremental encoder ROD (AquadB) 5 V,

1.5 MHz

6.7.5.11 Absolute encoder with SSI interface 6-44

6.7.5.12 Electronic gearing, Master-Slave mode 6-45

6.7.5.13 Encoder emulation 6-47

6.7.6 Communications interfaces 6-49

6.7.6.1 RS 232 interface 6-49

6.7.6.2 CANopen interface 6-51

6.7.6.3 Ethernet interface (in development) 6-52

6.8 Expansion cards 6-54

6.8.1 Expansion card PMCprotego S1, PMCprotego S2

6.8.2 Expansion card I/O-14/08 6-54

6.8.3 Expansion card PosI/O, PosI/O-AIO 6-56

6.8.3.1 Electronic gearing 6-57

6.8.3.2 Encoder emulation 6-59

6.8.3.3 Analogue inputs and outputs 6-61

6.8.4 Expansion card with PROFIBUS-DP interface

6.8.5 Expansion card for SERCOS interface 6-63

6.8.6 Expansion card with DeviceNet interface 6-64

6-29

6-34

6-40

6-42

6-54

6-62

Chapter 7 Commissioning

7.1 Safety guidelines 7-1

7.2 Commissioning the servo amplifier 7-3

7.2.1 Gather the project data 7-3

7.2.2 Wire components 7-3

7.2.3 Preparing for commissioning 7-5

7.2.4 Connect 24 VDC supply voltage 7-5

7.2.5 Establish communication PMCprotego <-

7.2.6 Set parameters for the servo amplifier 7-6

7.2.7 Perform the first test run 7-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

4

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

7-6

> PC

Contents

7.3 Download firmware from SD card to servo

amplifier

7.4 LEDs and keys 7-10

7.4.1 Key functions 7-10

7.4.2 Standard menu 7-10

7.4.3 Advanced menu 7-11

7.5 Messages/errors 7-13

7.5.1 Status messages 7-13

7.5.2 Error messages 7-13

7.5.3 Warnings 7-14

Chapter 8 Technical Details

8.1 PMCprotego D.48 8-1

8.2 PMCprotego D.72 8-4

Chapter 9 Appendix

9.1 Glossary 9-1

9.2 Abbreviations 9-2

9.3 Index 9-4

7-9

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

5

Contents

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

6

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1 Introduction

1.1 Validity of documentation

11000IntroductionIntroduction1-1.1Validity of docume ntation1100Validity of documenta tion1-BA_Einfhrung

This documentation is valid for the products PMCprotego D.48 and

BA_Einfuehrung_2

][Einfhrung_Dokumente_b eachten

PMCprotego D.72. It is valid until new documentation is published.

This operating manual explains the product's function and operation,

describes the installation and provides guidelines on how to connect the

PMCprotego D.

Please also refer to the following documents from the motion control

range:

The online help for the PDrive commissioning software describes how

to set the parameters for the servo amplifier.

The "PMCprimo CAN Networking" manual contains guidelines for

networking multiple PMCprimo control systems and additional CANopen devices.

All these manuals can be found on the supplied CD-ROM: "Motion Control Documentation".

You will need to be conversant with the information in these documents

in order to fully understand this manual.

BA_Einfhrung_D.48 und D.72

This operating manual is valid for the following products:

PMCprotego D.48 from Version 1.0

PMCprotego D.72 from Version 1.0

1.1.1 Retaining the documentation

Retaining the documentation1-Einf Aufbewahren

This documentation is intended for instruction and should be retained

for future reference.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-1

1 Introduction

1.2 Overview of documentation

1.2Overview of documentation1200Overview of documentation1-][Einfuehrung_Uebersicht_1

1 Introduction

The introduction is designed to familiarise you with the contents, structure and specific order of this manual.

2 Overview

This chapter provides information on the product's most important features.

3 Safety

This chapter must be read as it contains important information on intended use.

4 Function Description

This chapter describes the product's individual components.

5 Installation

This chapter explains how to install the product.

6 Wiring

This chapter describes the product's wiring.

7 Commissioning

This chapter describes how to commission the product.

8 Technical Details

9 Appendix

This chapter contains a glossary, a list of the abbreviations used and the

index.

1-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1 Introduction

1.3 Definition of symbols

1.3Definition of symbols1300Definition of symbols1-Einfhrung Zeichen

Information that is particularly important is identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation

that poses an immediate threat of serious injury and death and

indicates preventive measures that can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation

that could lead to serious injury and death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor

injury plus material damage, and also provides information on

preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged

and also provides information on preventive measures that can

be taken. It also highlights areas within the text that are of particular importance.

INFORMATION

This gives advice on applications and provides information on

special features.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

1-3

1 Introduction

1-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2 Overview

2.1 Unit structure

22000OverviewOverview2-2.1Unit structure2100Unit structure2-

2.1.1 Unit features

Unit features2-][Ueber_Geraeteaufbau_protego_D_48_72

The PMCprotego D is a compact servo amplifier consisting of:

A power element

A control element with

– Inputs and outputs

– Sequence control

– Control loops for current, speed and position

– Interfaces for communication with the periphery

Unit types:

Continuous output currents:

– PMCprotego D.48: 48 A

– PMCprotego D.72: 72 A

2.1.1.1 Power element

Power element2-Ueber_Merkmale_Leistungsteil_protego_D_48_und_72

][Ueber_Merkmale_Entstoerfilter

The servo amplifier's power element has the following features:

Connection to earthed three-phase supplies, rated voltage range

208V – 480V

TN network and TT network with earthed star point, max. 42 kA sym-

metrical rated current, connection to other networks only with isolating transformer

B6 rectifier bridge integrated directly on the three-phase, earthed net-

work, mains filter and start-up circuit

Fuse protection (e.g. blow-out fuse) through user

All shield connections directly on the servo amplifier

Max. intermediate circuit voltage in generator mode: 260 – 900 VDC,

can be connected in parallel

Brake chopper, brake power distributed over several amplifiers on the

same intermediate circuit

No internal brake resistor, external brake resistor available on re-

quest.

Inverted rectifier with isolated current measurement and IGBT transis-

tors

Connection of synchronous servo motors, linear motors, asynchro-

nous motors

Integrated noise suppression filters in accordance with EN 61800-3

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-1

2 Overview

2.1 Unit structure

2.1.1.2 Control element

Control element 2-Uebersicht

][Ueber_Merkmale_Versorg_24_VDC

Ueber_Merkmale_Versorg_24_VDC_Zusatz

][Ueber_Merkmale_Entstoerfilter

Ueber_Merkmale_Geber_protego_D

Ueber_Merkmale_Ein_Aus_protego_D

][Ueber_Merkmale_dig_Regelung_protego_D

The servo amplifier's control element has the following features:

Supply voltage

Supply voltage 24 VDC

Controller supply isolated from fan and brake, fused internally

Separate supply voltage for control element, external motor holding

brake and digital outputs

Integrated noise suppression filters in accordance with EN 61800-3

Encoder systems

Integrated evaluation of the following encoder systems

Resolver

Incremental encoder

SinCos encoder

®

– with HIPERFACE

interface

– with EnDat interface 2.1 and 2.2

– with BISS interface

Inputs and outputs

2 analogue voltage inputs

– Differential input

– Signal range: ±10 V, referenced to earth

– Resolution (with sign bit) 16 Bit

4 digital inputs

– 2 of these digital inputs are suitable for fast signals

2 digital inputs or outputs (switchable signal direction)

24 V pulse and direction

All digital signals are free to be linked

2-2

Digital control

Digital control loop

Digital speed regulator

Digital position controller

Pulse/direction interface for connecting a servo motor to a stepper

motor controller

][Ueber_Merkmale_Parametrierung

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2 Overview

2.1 Unit structure

][Ueber_Merkmale_Bedienung_protego_D

][Ueber_Merkmale_integrierte_Sicherheit

Ueber_Merkmale_Schnittst ellen_protego_D

Parameter setting

Via the serial interface, using the PDrive commissioning software

Via the CAN interface, using the motion control system PMCprimo C

together with the commissioning software PDrive and CoDeSys (development environment in accordance with IEC 61131-3)

Operation and display

Servo amplifier operated via two keys

Three-digit LED display for status and messages

Integrated safety

Device safety

– Safe electrical isolation between mains voltage/motor connection

and control element, in accordance with EN 61800-5-1

– Soft start, overvoltage detection, short circuit protection, phase

failure monitoring

– Temperature monitoring of servo amplifier and motor (when using

Pilz motors with ready-made cables)

Protection of personnel and plant

– Safety function STO – Safe torque off

Single-channel without feedback: Up to PL d (Cat. 2) of

EN ISO 13849-1 and SIL CL 2 of EN/IEC 62061

Dual-channel with feedback: Up to PL e (Cat. 4) of EN ISO 138491 and SIL CL 3 of EN/IEC 62061

– Slot for safety card: Safety functions for safe operation of drive

axes in accordance with DIN IEC 61800-5-2, up to PL e (Cat. 4) of

EN ISO 13849-1 and SIL CL 3 of EN/IEC 62061

Communications interfaces

CANopen interface for

– Connection to CAN bus systems

– Parameters for several drives can be set via a servo amplifier's se-

rial interface

RS 232 interface for parameter setting with the PDrive commissioning

software

2 Ethernet interfaces (in development)

][Ueber_Merkmale_SD_protego_D

SD card

Read/write device for SD card, for reading and writing parameters

and firmware

Ueber_Merkmale_Erweiterungen_protego_D

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-3

2 Overview

2.1 Unit structure

Expansion cards

3 slots for expansion cards

Expansion cards for slot 1:

– I/O-14/08

– PROFIBUS

– DeviceNet

–SERCOS

Expansion cards for slot 2:

– PosI/O

– PosI/O-AIO

INFORMATION

Only one expansion card can be installed, in slot 1 or slot 2.

Example: If a PROFIBUS expansion card is installed in slot 1,

another expansion card may not be inserted in slot 2.

Expansion cards for slot 3:

– PMCprotego S1, PMCprotego S2

– PosI/O

– Pos//O-AIO

2-4

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2 Overview

1

2

3

4

5

6

7

9

8

10

11

12

13

14

15

16

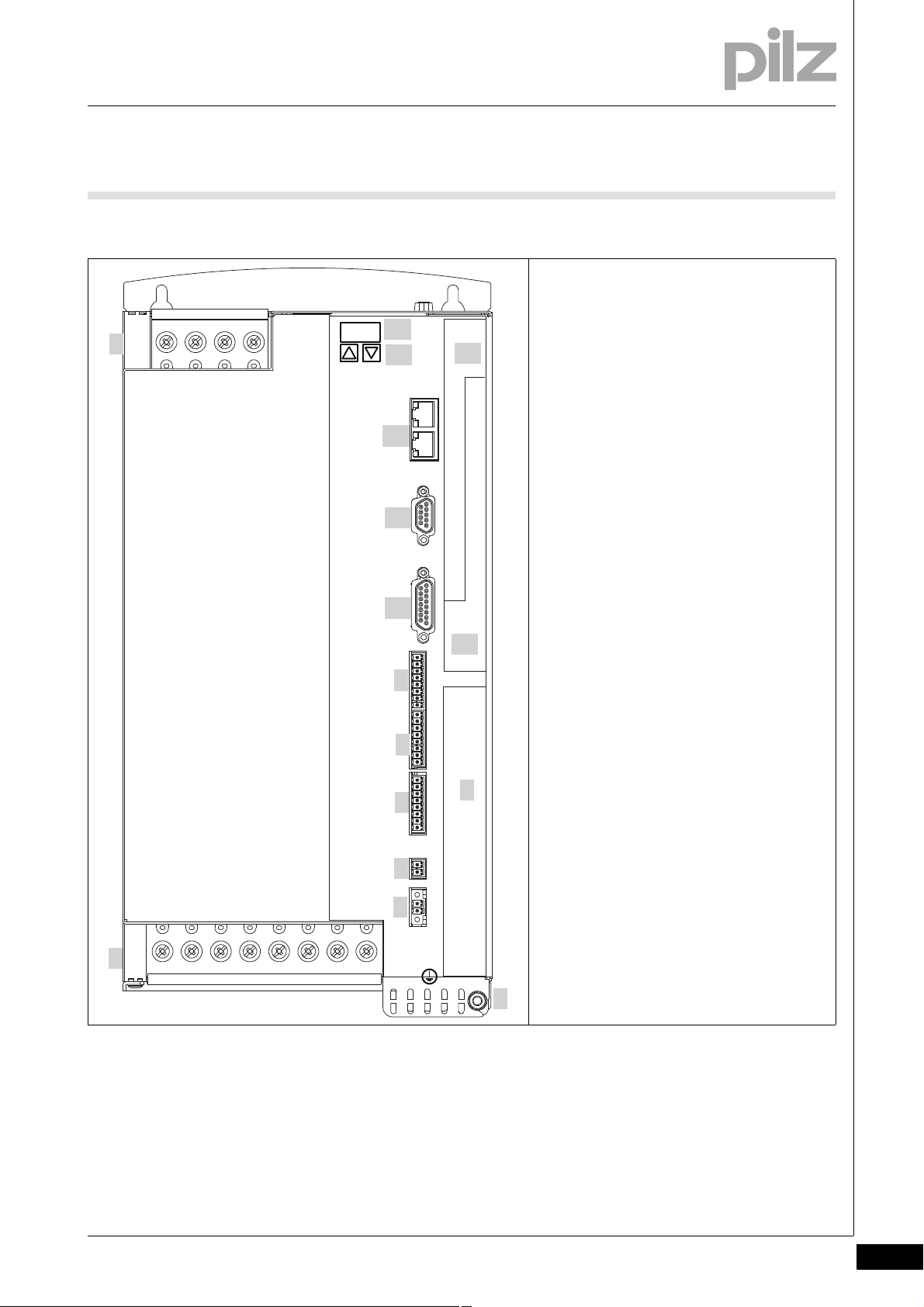

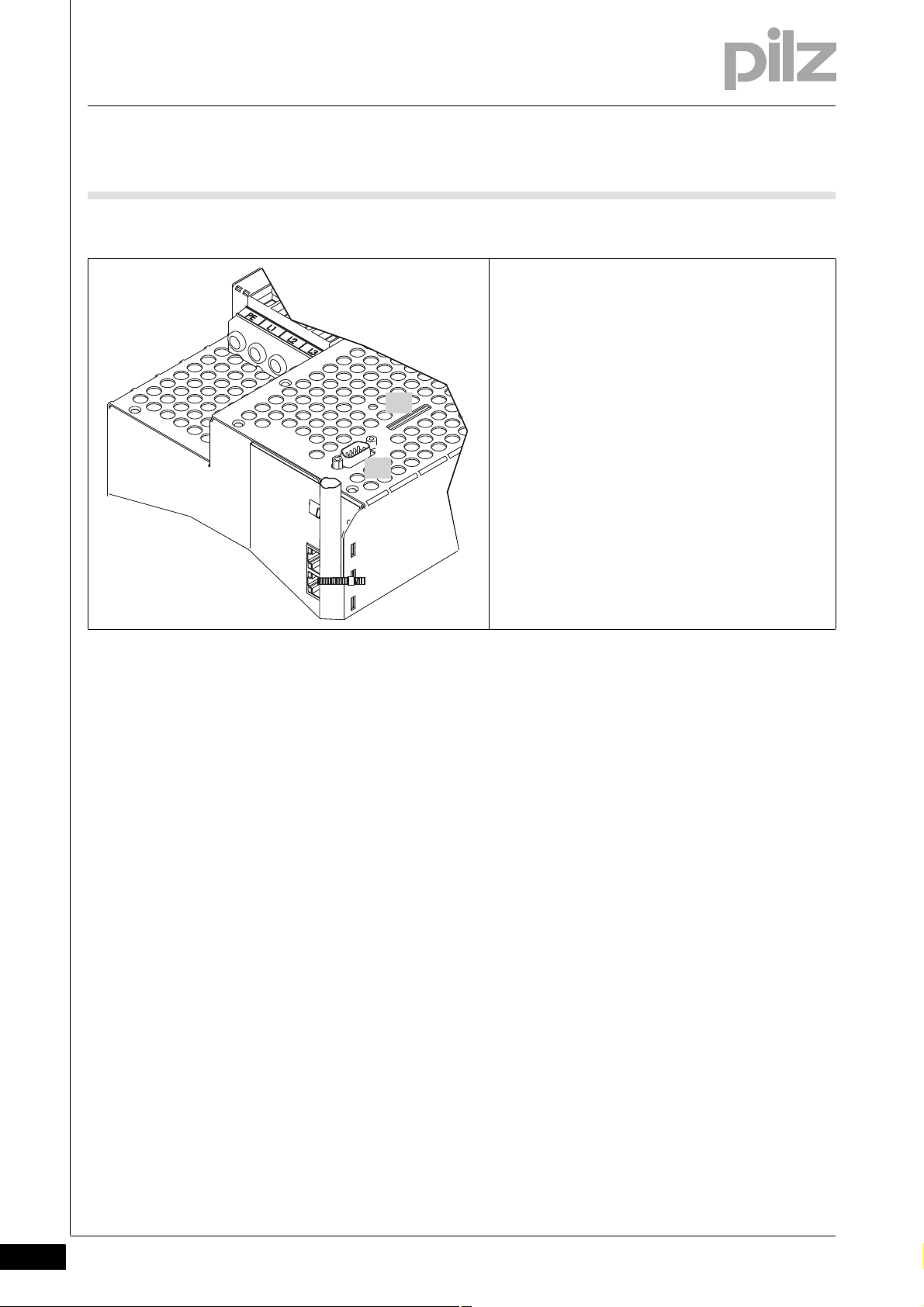

2.2 Front view

2.2Front view2200Front view2-Uebersicht_Front

Front view of PMCprotego D

Legend:

1: Mains voltage, power element

2: External brake resistor, connection for motor,

intermediate circuit

3: Connection for earth conductor PE

4: Connection for motor holding brake

5: Supply voltage for motor holding brake

6: Supply voltage 24 VDC and safety function

STO

7: Expansion cards slot 3

8: Enable signal, 4 digital inputs, 2 digital inputs

or outputs (parameters can be set)

9: 2 analogue inputs, relay output for operational readiness

10: Expansion cards slot 2

11: Connection for incremental encoder, sine/

cosine encoder, pulse/direction 24 V

12: Connection for resolver

13: Ethernet interface

14: Expansion cards slot 1

15: Buttons

16: LED display for messages

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-5

2 Overview

18

17

2.3 Plan view

2.3Plan view2300Plan view2-Uebersicht_Drauf

Plan view of the PMCprotego D

Legend:

17: RS 232 interface for commissioning and parameter

setting or CANopen controller

18: Read/write device for SD card

2-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2 Overview

2.4 Scope of delivery

2.4Scope of delivery2400Scope of delivery2-Uebersich t_Lieferumfang

This is what you receive when you order a servo amplifier from the PMCprotego series:

Servo amplifier PMCprotego D

Mating connectors X3A, X3B, X4, X9A, X9B

Operating manual on CD-ROM

Ueber_Zubehoer_D48_72

Order reference: Accessories

INFORMATION

The D-Sub mating connectors are not supplied with the unit!

They are available as accessories.

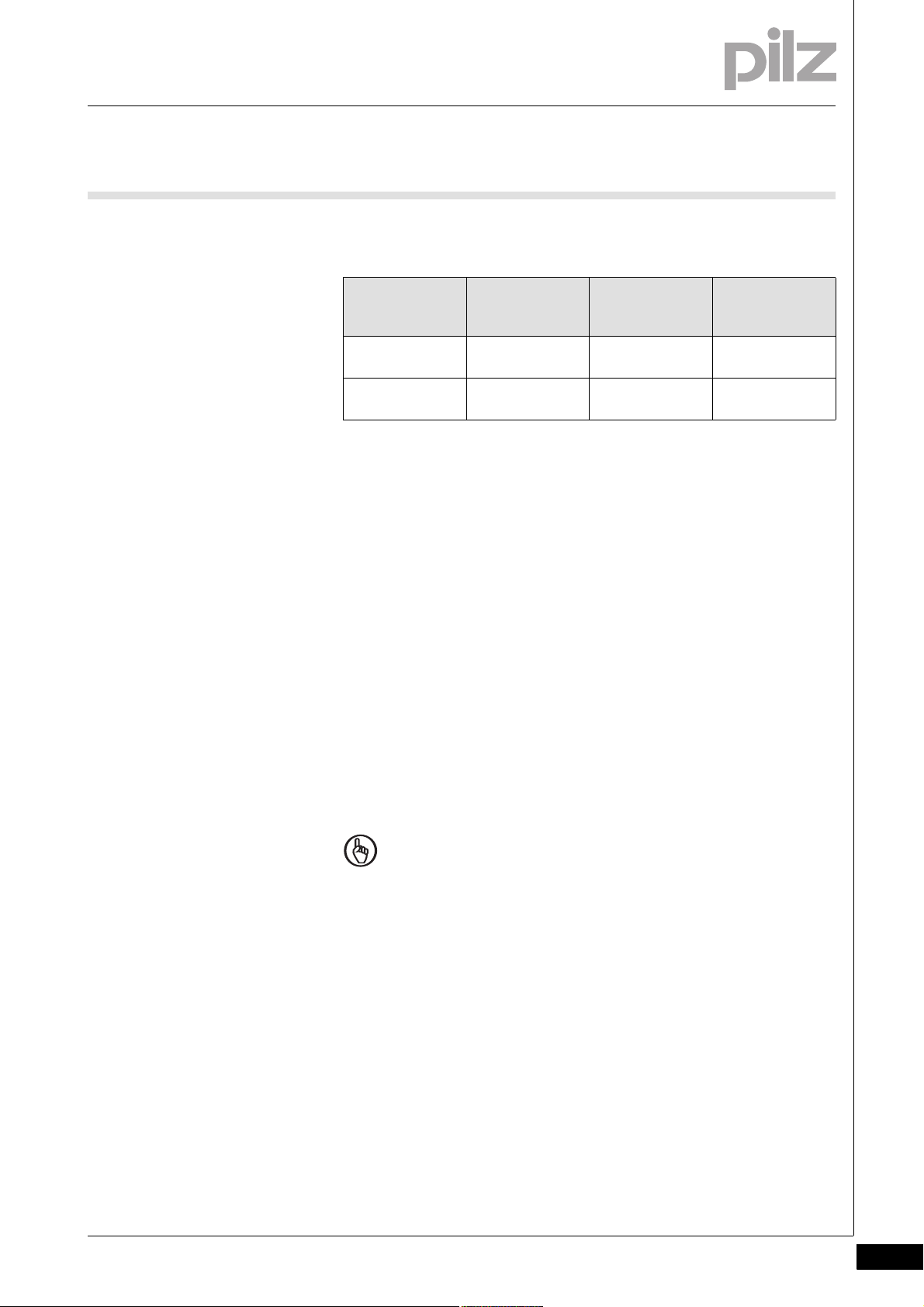

Product type Features Order no.

PMCprotego D.CAN-Adapter 4872A

Fieldbus junction box 8176470

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-7

2 Overview

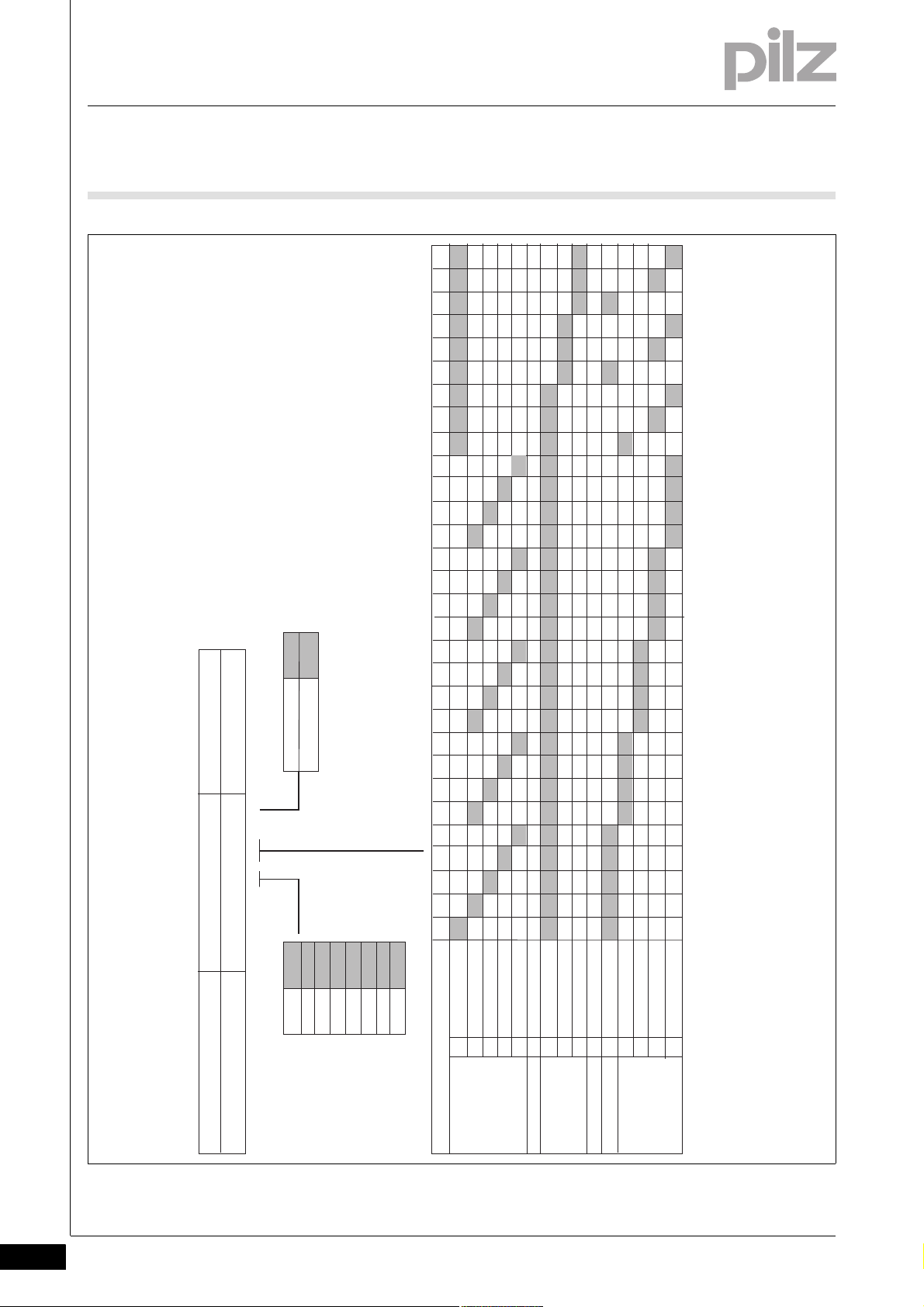

Always state when ordering

Type

Mains voltage

Order number

PMCprotego D. _ _ / _ _ _ / 0 / _ 208 - 480 V AC

Hardware options

Slot 1

Slot 2

Slot 3

01234

012

012

A

B

Without

I/O 14/08

PROFIBUS

SERCOS II

DeviceNet

Without

PosI/O 2)PosI/O-AIO

3)

Without

PosI/O 2)PosI/O-AIO

3)

PMCprotego S1

PMCprotego S2

000

100

200 300 400 101 201 301 401 202102

Current

1.5 A

3 A

6 A

12 A

24 A

48 A

72 A

Size

010306

12 1)24 1)48

72

302

402

10A

20A

30A 40A

10B

20B 30B 40B 001 00A 00B 010 012 01B 020 02A

02B

Options

I

peak

= 3x

1)

Value

P

1) Peak output current is increased

2) Without analogue outputs

3) With analogue inputs/outputs

2.5 Type code

2.5Type code2500Type code2-Uebersicht_Typenschluessel

2-8

Fig. 2-1: Type code

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2 Overview

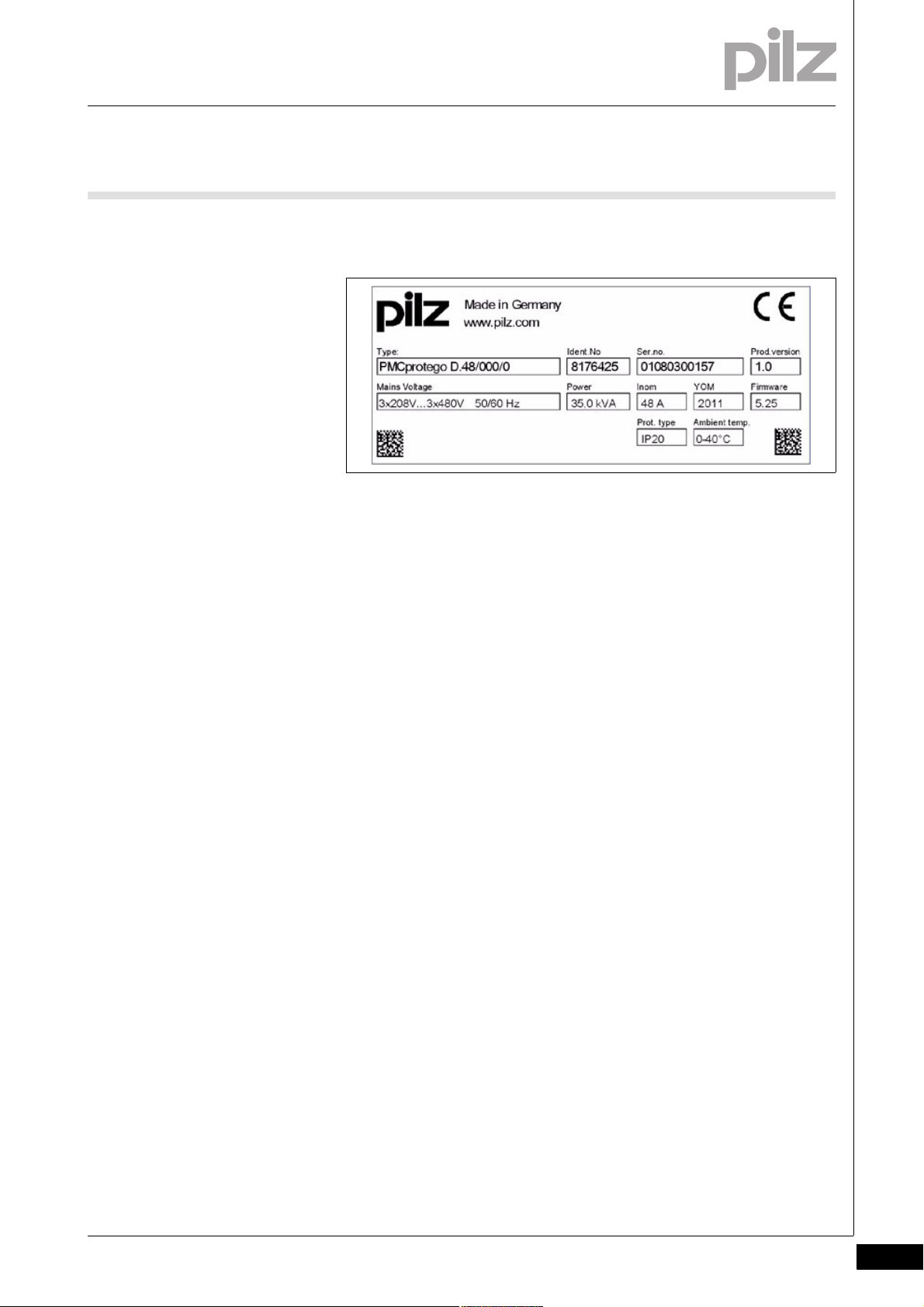

2.6 Type label

2.6Type label2600Type label2-Type nschild

The type label is situated on the side of the servo amplifier.

Fig. 2-2: Type label

Key:

Type: Type code

Ident. No.: Order number

Ser. No.: Serial number

Prod.version: Product version

Firmware: Firmware version

Mains Voltage: Mains voltage

Power: Power

Inorm: Continuous output current

YOM: Year of manufacture

Prot. type: Protection type

Ambient temp: Ambient temperature

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

2-9

2 Overview

2-10

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3 Safety

3.1 Intended use

33000SafetySafety3-3.1Intended use3100Intended use3-][Sicherheit_Bestimmung_protego_D

][Sicherheit_Bestimmung_Ausschluss

The servo amplifiers PMCprotego D are designed to drive suitable

brushless, synchronous servo motors and asynchronous motors with

closed loop speed, torque and/or position control.

The following is deemed improper use:

Any component, technical or electrical modification to the servo am-

plifier

Use of the servo amplifier outside the areas described in this manual

Use of the servo amplifier outside the documented technical details

(see chapter entitled “Technical Details”)

Intended use includes making the installation and wiring EMC-compliant. Please refer to the guidelines stated in this manual.

3.1.1 Hazard analysis

Hazard analysis3-][Sicherheit_Bestimmung_Gefahrenanalyse

3.1.2 Electrical data

Electrical data3-][Sicherheit_Bestimmung_elektrisch_protego_D

][Funktion_Netzspannung_Drossel

The machine manufacturer must produce a hazard analysis for the machine. He must take appropriate measures to ensure that unexpected

movements do not lead to hazardous situations for either people or

equipment.

Please note the electrical requirements stated in the chapters entitled

“Technical Details”, “Wiring” and “Function Description”.

INFORMATION

A 3L line choke with u

= 2% must be used in the event of a

k

mains voltage imbalance of > 3%. Install the line choke on the

mounting plate in a way that is EMC-compliant.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-1

3 Safety

3.1 Intended use

3.1.3 Ambient conditions

Ambient conditions3-][Sicherheit_Bestimmung_Umgebung

][EMV_Wohnumgebung

Please note the following conditions for using the servo amplifier:

Operation of the servo amplifier is forbidden in the following condi-

tions:

– Potentially explosive areas

– Environments containing corrosive and/or conductive acids, alka-

line solutions, oils, fumes or dusts

– Where there is a direct connection to unearthed or asymmetrically

earthed mains supplies with U

> 240 V. See chapter entitled “Wir-

N

ing”, section on “Mains voltage”.

–On ships and offshore installations

The servo amplifier may only be operated in an enclosed control cab-

inet in compliance with the ambient conditions defined under “Technical details”. Ventilation or cooling may be required to maintain the

control cabinet temperature below 40 °C.

3.1.4 Guidelines for UL approval

Guidelines for UL approval3-][Sicherheit_Bestimmung_UL_D_48_72

Please note the following guidelines for UL approval:

Only use copper wiring that can withstand temperatures of 60°/75°C.

Clamping torque for power connection terminals:

X0: 8-2 AWG, TQ Lb In. 40

X8: 8-2 AWG, TQ Lb In. 40

Only use the servo amplifier in max. pollution degree 2 environments.

The servo amplifier can be used on supply networks that are able to

provide no mor e than 42 kA sy mmetrical at a maximum voltage of 480

VAC.

WARNING!

In a residential environment this product may cause high-frequency noise, so that suppression measures may be required.

3-2

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3 Safety

3.1 Intended use

Power supply protection:

Unit Fuse class Nominal data Max. fuse rating

and short circuit

rating

PMCprotego

D.48

PMCprotego

D.72

Only for use with fixed earthed Y-power supply or similar.

RK5, CC, J, T 600 VAC 60 A / 200 kA

RK5, CC, J, T 600 VAC 80 A / 200 kA

3.1.5 Safety function STO

Safety function STO3-][Sicherheit_Bestimmung_STO

The safety function "safe torque off" (Safe Torque Off, STO) activates

the pulse disabler on the servo amplifier and removes the power to the

motor. It meets the requirements in accordance with EN 61800-5-2.

The inputs STO1-ENABLE and STO2-ENABLE meet the following requirements:

With single-channel activation without feedback, in accordance with

EN ISO 13849-1: PL d (Cat. 2) and EN/IEC 62061: SIL CL 2.

With dual-channel activation with feedback, in accordance with

EN ISO 13849-1: PL e (Cat. 4) and EN/IEC 62061: SIL CL 3.

NOTICE

With dual-channel activation of the inputs STO1-ENABLE and

STO2-ENABLE, the safe pulse disabler must be tested periodically to ensure it switches safely. See section 4.3.3, entitled

"Safety function STO".

The safety card PMCprotego S1 or PMCprotego S2 can also be used to

trigger the safety function STO.

The STO1-ENABLE input on the servo amplifier has no function if the

servo amplifier contains a safety card. In this case, the safety card activates the safe pulse disabler on the servo amplifier in order to shut down

the power element.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-3

3 Safety

3.1 Intended use

][Sicherheit_Bestimmung_Gefahr

The safety function "safe torque off" corresponds to a category 0 stop

(uncontrolled stop) in accordance with EN 60204-1.

The safety function STO may not be used when the drive is to be

stopped for the following reasons:

Cleaning, maintenance and repair work, or long interruptions in oper-

ation: Remove the voltage and secure the entire plant (main switch).

E-STOP: Switch off the mains contactor (E-STOP pushbutton).

DANGER!

Risk from rotating motor after STO has been triggered!

The safety function STO switches the motor to torque-free. On

motors without a safe holding brake, moving parts present a

threat to life.

Use an additional mechanical measure to block the drives safely

(e.g. with the motor holding brake), particularly with suspended

loads.

Sicherheit_Gefahr_Haltebremse

3.1.6 Use of qualified personnel

Use of qualified personnel3-Sich Qualif. Personal

The products may only be assembled, installed, programmed, commissioned, operated, maintained and decommissioned by competent persons.

DANGER!

Risk from non-safety-related activation of the motor holding

brake!

Activation of a holding brake via output BR+/BR- of the servo

amplifier is not safety-related. Depending on the application,

hazardous motor movements may cause serious injury or death.

A motor holding brake activated by the servo amplifier alone is

not suitable for personal protection.

Block the drive through an additional mechanical holding brake,

which is activated safely (e.g. with the safety card PMCprotego

S1).

3-4

A competent person is someone who, because of their training, experience and current professional activity, has the specialist knowledge

required to test, assess and operate the work equipment, devices, systems, plant and machinery in accordance with the general standards

and guidelines for safety technology.

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3 Safety

3.1 Intended use

3.1.7 Warranty and liability

Warranty and liability3-Sich Gewhrleistung

It is the company's responsibility only to employ personnel who:

Are familiar with the basic regulations concerning health and safety /

accident prevention

Have read and understood the safety guidelines given in this descrip-

tion

Have a good knowledge of the generic and specialist standards ap-

plicable to the specific application.

All claims to warranty and liability will be rendered invalid if:

The product was used contrary to the purpose for which it is intended

Damage can be attributed to not having followed the guidelines in the

manual

Operating personnel are not suitably qualified

Any type of modification has been made (e.g. exchanging compo-

nents on the PCB boards, soldering work etc.).

3.1.8 Disposal

Disposal3-Si ch Entsorgung

In safety-related applications, please comply with the mission time t

M

in the safety-related characteristic data.

When decommissioning, please comply with local regulations regard-

ing the disposal of electronic devices (e.g. Electrical and Electronic

Equipment Act).

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-5

3 Safety

3.2 Safety during operation

3.2Safety during operation3200Safety during operation3-][Sicherheit_Bestimmung_Betrieb_1

DANGER!

While the units are in operation there is a risk of death or serious injury

and material damage.

Do not open or touch the units during operation.

Keep all covers and cabinet doors closed during operation.

When the units are switched on, they should only be touched during

commissioning by qualified staff.

During operation the servo amplifiers may contain live, uninsulated

components, depending on their protection type.

Control and power connections may still carry voltage, even when the

motor is not rotating.

Surfaces on the servo amplifiers may become hot during operation.

][Sicherheit_Bestimmung_Betrieb_D48_D72

Temperatures may reach more than 80° C.

DANGER!

In unfavourable conditions arcing may occur, causing potential injury to

persons and damage to electrical contacts.

For this reason, never unplug the electrical connections on the servo

amplifier while voltage is applied.

After disconnecting the servo amplifier from the mains voltages, wait

at least eight minutes before touching any parts that carry voltage

(e.g. contacts) or loosening the connections.

After the mains voltages have been switched off, capacitors continue

to carry hazardous voltages for up to 10 min.

To be safe, measure the voltage in the intermediate circuit and wait

until the voltage has dropped below 40 VDC.

3-6

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3 Safety

3.3 Standards

3.3Standards3300Standards3-][Sicherheit_Normen

Servo amplifiers are components designed for incorporation into electrical plant or machinery within the industrial sector. The servo amplifier

may not be used for its intended purpose until it has been established

that the plant or machinery complies with the provisions of the following

directives:

EU Machinery Directive (2006/42/EC)

EU EMC Directive (2004/108/EC)

EU Low Voltage Directive (2006/95/EC)

Standards for compliance with the EU Machinery Directive (2006/

42/EC)

EN 60204-1:2007 (Safety and electrical equipment of machines)

EN 12100:2009 (Safety of machinery)

The machine manufacturer must produce a hazard analysis for the machine and take appropriate measures to ensure that unexpected movements do not cause injury to people or damage to equipment.

Standards for compliance with the EU Low Voltage Directive (2006/

95/EC)

EN 60204-1:2007 (Safety and electrical equipment of machines)

EN 60439-1:2005 (Low voltage switchgear and controlgear assem-

blies)

EN 61800-5-1:2007 (Adjustable speed electrical power drive systems

- Safety requirements)

Standards for compliance with the EU EMC Directive (2004/108/EC)

EN 61000-6-1/2:2006 (Immunity for residential, commercial and light-

industrial environments)

EN 61000-6-3/4:2007 (Emission standard for residential, commercial

and light-industrial environments)

EN 61800-3:2004 (Adjustable speed electrical power drive systems -

EMC requirements)

It is the manufacturer's responsibility to comply with the limit values for

the plant or machinery as required by EMC legislation. This documentation contains tips on how to make your installation EMC-compliant (such

as shielding, earthing, how to manage the connectors and lay the cables).

UL conformity

UL 508C

UL 508C describes the fulfilment by design of minimum requirements

for electrically operated power conversion equipment, such as fre-

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

3-7

3 Safety

3.3 Standards

quency converters and servo amplifiers, which are intended to eliminate the risk of these devices causing a fire.

UL 840

UL 840 describes the fulfilment by design of clearance and creepage

distances on electrical equipment and printed circuit boards.

Functional safety standards

EN 61800-5-2:2007 (Adjustable speed electrical power drive systems

– Safety requirements – Functional)

EN ISO 13849-1:2008 (Safety of machinery – Safety-related parts of

control systems)

EN 61508-1:1998 (Functional safety of electrical/electronic/program-

mable electronic safety-related systems – General requirements)

EN 61508-2: 2000 (Functional safety of electrical/electronic/program-

mable electronic safety-related systems – Requirements)

EN 61508-3:1998 (Functional safety of electrical/electronic/program-

mable electronic safety-related systems – Software requirements)

EN 61508-4:1998 (Functional safety of electrical/electronic/program-

mable electronic safety-related systems – Definitions and abbreviations)

IEC 62061:2005 (Safety of machinery - Functional safety of safety-re-

lated electrical, electronic and programmable electronic control systems)

The machine or plant manufacturer must check to see whether any additional standards or EU directives are applicable for his plant or machinery.

3-8

Pilz GmbH & Co. KG, Felix-Wankel-Straße 2, 73760 Ostfildern, Germany

Telephone: +49 711 3409-0, Telefax: +49 711 3409-133, E-Mail: pilz.gmbh@pilz.de

Loading...

Loading...