Page 1

PMCtendo AC

Motors

Operating Manual – Item No. 21 894-02

Page 2

All rights to this documentation are reserved by Pilz GmbH & Co. KG. Copies may be made

for internal purposes.

Suggestions and comments for improving this documentation will be gratefully received.

The names of products, goods and technologies used in this documentation are registered

trademarks of the respective companies. Automation Workbench

®

PNOZ

, Primo®, PSS®, SafetyBUS p® are registered trademarks of Pilz GmbH & Co. KG.

®

, Pilz®, PIT®, PMI®,

Page 3

Contents

Introduction 1-1

Validity of documentation 1-2

Overview of documentation 1-3

Definition of symbols 1-4

Overview 2-1

View of servo motor 2-1

Features 2-1

Type label 2-2

Order references 2-4

Safety 3-1

Intended use 3-1

Safety guidelines 3-1

Use of qualified personnel 3-2

EMCD 3-2

Warranty and liability 3-2

Disposal 3-2

Function Description 4-1

Structure 4-1

Servo amplifier 4-1

Motor feedback system 4-2

Operating mode 4-2

Overload protection 4-2

Holding brake 4-3

Motor shaft and bearings 4-3

Transport and Storage 5-1

Transport 5-1

Storage 5-1

1Operating Manual: PMCtendo AC

Page 4

Contents

Installation 6-1

Preparing for installation 6-1

Mounting location 6-1

Mounting position 6-1

Motor 6-2

Carrying out the installation 6-2

Wiring 7-1

General requirements 7-1

Cabling 7-1

Cable cross sections 7-1

Earthing, shielding and EMC 7-2

Pin assignment and connection 7-3

Motor feedback connections 7-3

Resolver 7-3

Hiperface encoder 7-5

Connections for supply voltage, thermal switch and holding brake 7-6

General 7-6

Terminal box on servo motors AC1 and AC2 7-6

Terminal box on servo motors AC3 and AC4 7-8

Round connector for servo motors AC1 and AC2 7-9

Round connector for servo motors AC3 and AC4 7-10

Connecting the supply voltage 7-11

Connecting the holding brake 7-12

Commissioning 8-1

General requirements 8-1

Check installation and wiring 8-2

Commissioning the drive unit 8-3

Troubleshooting guidelines 8-4

Maintenance and Repair 9-1

General guidelines for maintenance and repair 9-1

Maintenance intervals 9-2

Changing the servo motor 9-3

2 Operating Manual: PMCtendo AC

Page 5

Glossary 10-1

Appendix 11-1

Changes in the documentation 11-1

Changes in Version 21 894-01 11-1

Changes in Version 21 894-02 11-1

Technical Details 12-1

General technical details 12-1

Derating 12-3

Derating diagram: Installation height 12-3

Derating diagram: Ambient temperature 12-4

Derating diagram: Operating time 12-5

Type-specific technical details 12-6

Key to the designations used in the table header 12-6

Servo motors PMCtendo AC1 12-8

Performance data: PMCtendo AC1 12-8

Mechanical data: PMCtendo AC1 12-11

Dimensions: PMCtendo AC1 12-14

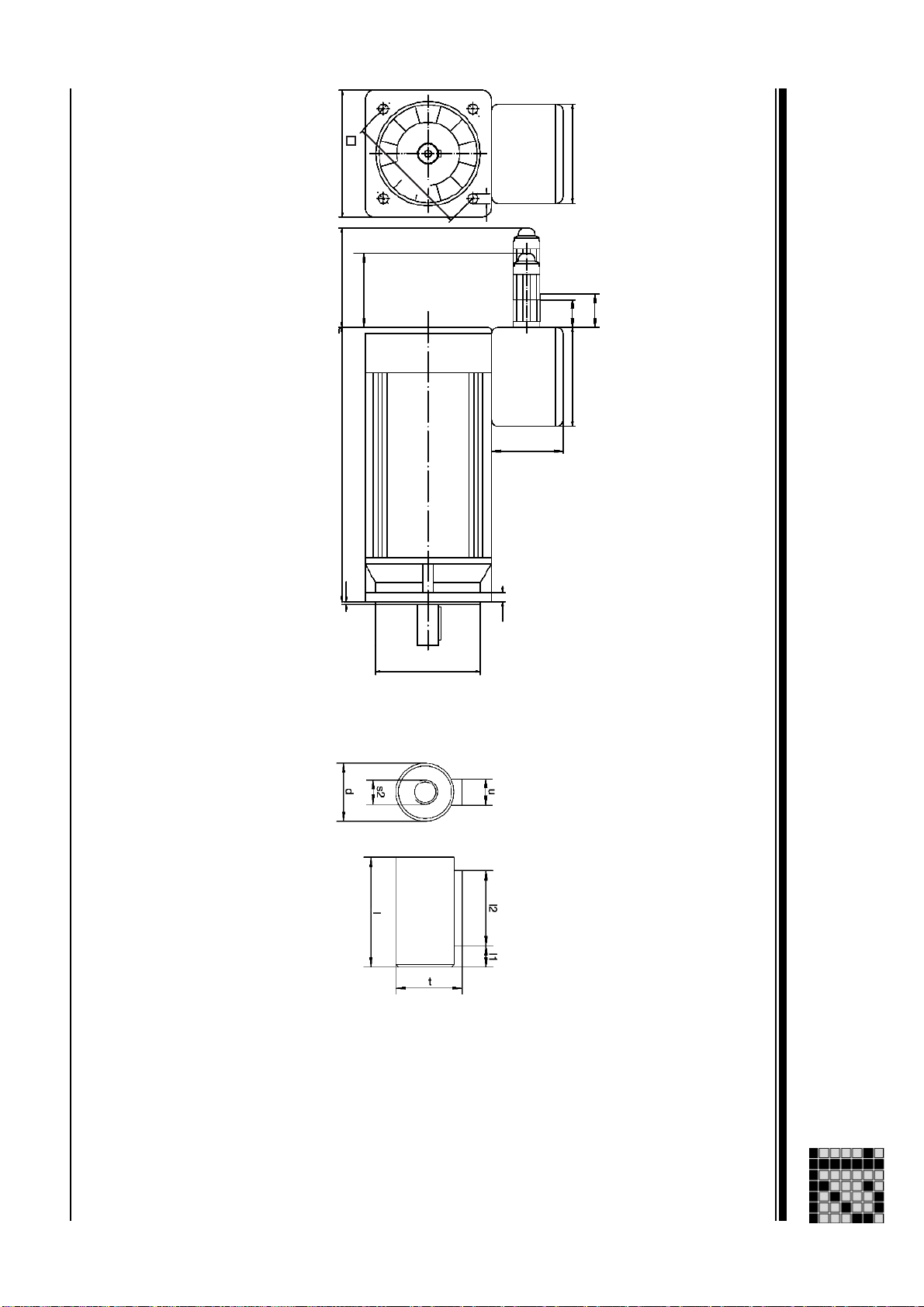

Dimensioned drawing: PMCtendo AC1 12-16

Servo motors PMCtendo AC2 12-17

Performance data: PMCtendo AC2 12-17

Mechanical data: PMCtendo AC2 12-20

Dimensions: PMCtendo AC2 12-25

Dimensioned drawing: PMCtendo AC2 12-27

Servo motors PMCtendo AC3 12-29

Performance data: PMCtendo AC3 12-29

Mechanical data: PMCtendo AC3 12-30

Dimensions: PMCtendo AC3 12-32

Dimensioned drawing: PMCtendo AC3 12-33

Servo motors PMCtendo AC4 12-34

Performance data: PMCtendo AC4 12-34

Mechanical data: PMCtendo AC4 12-35

Dimensions: PMCtendo AC4 12-36

Dimensioned drawing: PMCtendo AC4 12-37

3Operating Manual: PMCtendo AC

Page 6

Page 7

Introduction

This operating manual describes the 3-phase synchronous servo motors PMCtendo AC.

The servo motors PMCtendo AC are divided into the following series:

• PMCtendo AC1

Servo motors for universal use, for large power ratings

• PMCtendo AC2

Servo motors for universal use

• PMCtendo AC3

Servo motors with low moment of inertia, dynamic version

• PMCtendo AC4

Compact servo motors, highly dynamic version

Please also refer to the operating manual for the servo amplifier you are using.

This operating manual is intended for instruction and should be retained for future

reference.

Operating Manual: PMCtendo AC 1-1

Page 8

Introduction

Validity of documentation

This documentation is valid for

• PMCtendo AC1 from Version 1.0

• PMCtendo AC2 from Version 1.0

• PMCtendo AC3 from Version 1.0

• PMCtendo AC4 from Version 1.0

It is valid until new documentation is published. The latest documentation is always

enclosed with the unit.

Operating Manual: PMCtendo AC1-2

Page 9

Overview of documentation

1 Introduction

The introduction is designed to familiarise you with the contents, structure and

specific order of this operating manual.

2 Overview

This chapter provides information on the most important features of the

servo motors PMCtendo AC.

3 Safety

This chapter must be read as it contains important information on safety regulations

and intended use.

4 Function Description

This chapter describes the servo motors PMCtendo AC and their components.

5 Transport, Unpacking, Storage

This chapter describes the procedures required when handling the servo motors.

6 Installation

This chapter explains how to install the servo motors PMCtendo AC.

7 Wiring

This chapter contains information and requirements for the electrical installation and

the servo motor connection.

8 Commissioning

This chapter describes the different requirements and options during

commissioning.

9 Maintenance and Repair

This chapter contains information and requirements for maintaining and repairing a

servo motor.

10 Glossary

This section explains the most important specialist terms that are used.

11 Appendix

12 Technical Details

Operating Manual: PMCtendo AC 1-3

Page 10

Introduction

Definition of symbols

Information in this manual that is of particular importance can be identified as follows:

DANGER!

This warning must be heeded! It warns of a hazardous situation that poses an

immediate threat of serious injury and death and indicates preventive measures that

can be taken.

WARNING!

This warning must be heeded! It warns of a hazardous situation which could lead to

serious injury or death and indicates preventive measures that can be taken.

CAUTION!

This refers to a hazard that can lead to a less serious or minor injury plus material

damage, and also provides information on preventive measures that can be taken.

NOTICE

This describes a situation in which the unit(s) could be damaged and also provides

information on preventive measures that can be taken.

INFORMATION

This gives advice on applications and provides information on special features, as well

as highlighting areas within the text that are of particular importance.

Operating Manual: PMCtendo AC1-4

Page 11

Overview

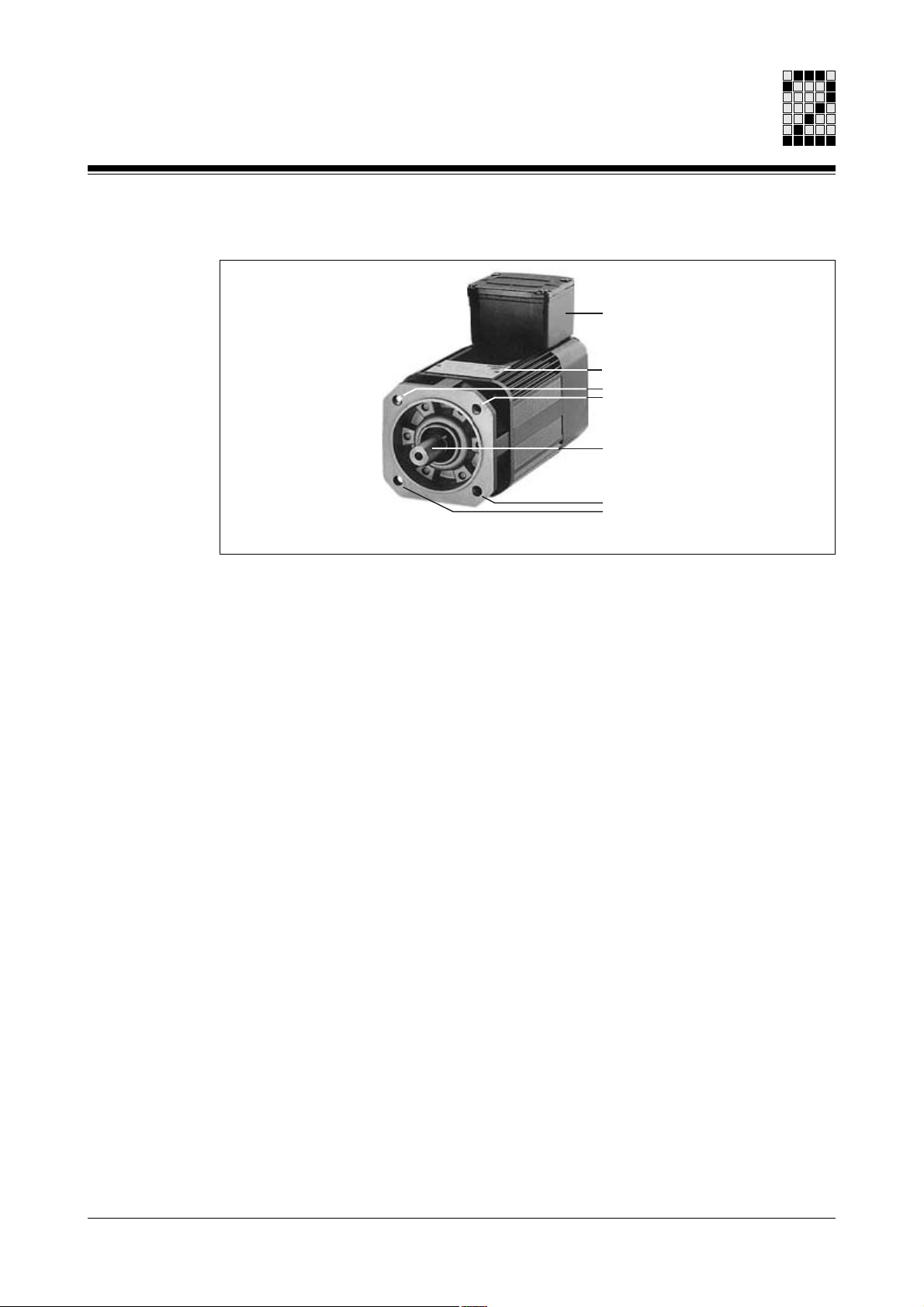

View of servo motor

Fig. 2-1: Servo motor PMCtendo AC (example)

Terminal box

(example)

Type label

Mounting holes

Motor shaft

(drive end)

Mounting holes

Features

The servo motors PMCtendo AC are particularly suitable for

• Printing and packaging machines

• Minor axes on machine tools

• Woodworking machines

• Lift drives and travelling drives

• Robotics and palletising systems

• Applications with high requirements for dynamics and controllability

The servo motors PMCtendo AC have the following features:

• 3-phase synchronous motors with permanently energised rotor (rare earth permanent

magnet)

• Sinusoidal electromotive force (EMF)

The 3 lines are connected internally in star configuration

• Motor feedback system, either

- 2-pole resolver

- Hiperface single-turn for SinCos encoder

- Hiperface multi-turn for SinCos encoder

• Drive shaft, either

- With feather key groove

- Without feather key groove, smooth shaft

• Overload protection through motor temperature monitoring

- Thermal switch (N/C contact) in the motor winding

2-1Operating Manual: PMCtendo AC

Page 12

Overview

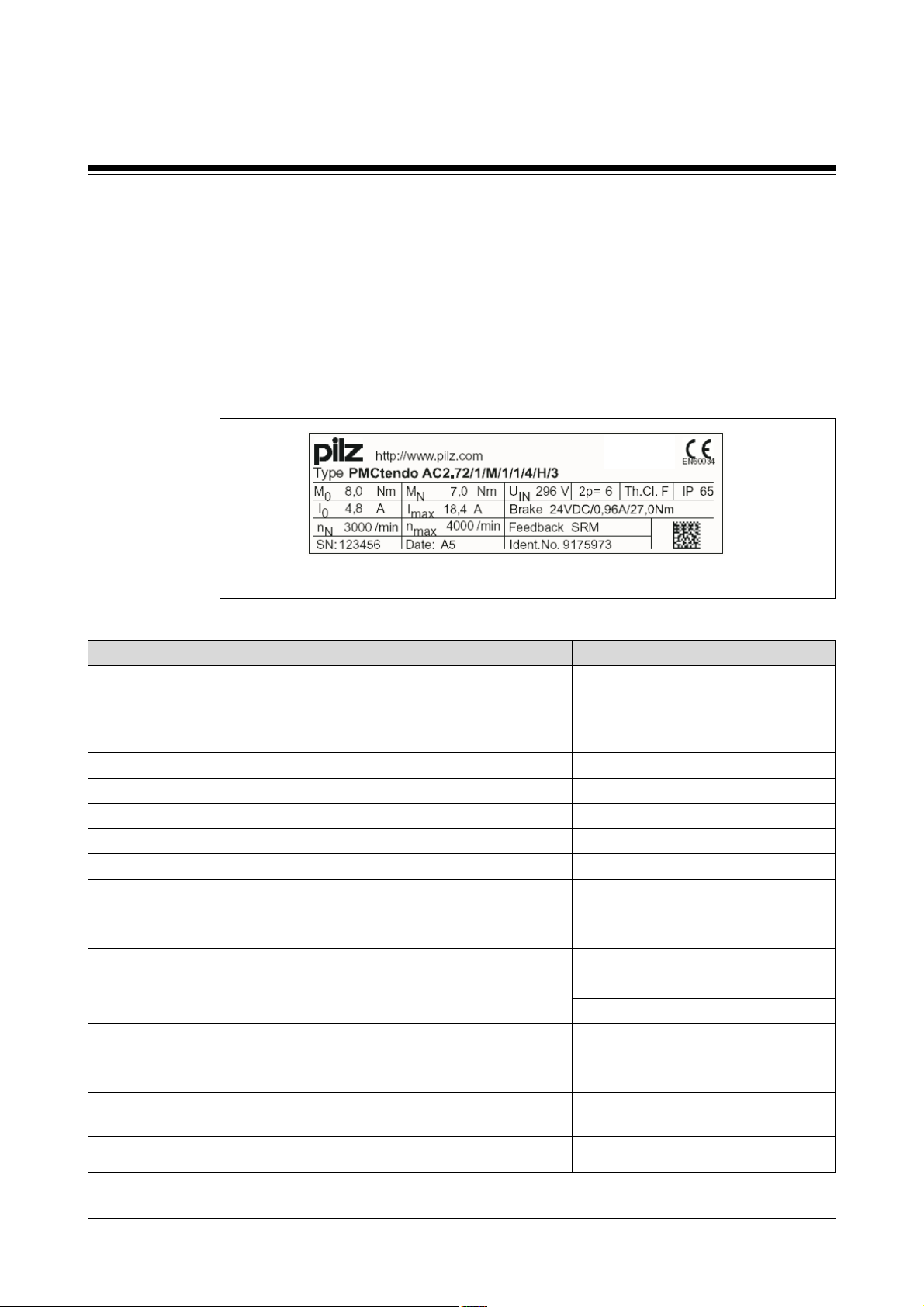

Type label

• Holding brake (optional)

- Backlash-free permanent magnet holding brake for safe standstill of the axis when

the supply to the servo motor is switched off

• Type B5

The type label contains all the key data for a servo motor.

Fig. 2-2: Type label for a servo motor PMCtendo AC (example)

Description

Type

M

0

I

0

n

N

SN

M

N

I

max

n

max

Date

U

IN

2p

Th.Cl.

IP

Brake

Feedback

Ident.No.

Key

Type of servo motor and servo motor's

order reference

(see section entitled “Order references”)

Constant standstill torque

Constant standstill current

Rated speed

Serial number

Rated torque

Peak current

Maximum speed

Code for the date of manufacture

(see table: “Code for the date of manufacture”)

Regenerated voltage

Number of motor poles

Heat class

Protection type

Data for holding brake

(see chapter entitled “Technical Details”)

Encoder type

(see table: “Encoder types”)

Material number

Information in the example

PMCtendo AC

2.72/1/M/1/1/4/H/3

8.0 Nm

4.8 A

3000/min

123456

7.0 Nm

18.4 A

4000/min

A5

296 V

6 (3 pairs of poles)

F

65

24 VDC/0.96A/27.0Nm

SRM

9175973

2-2 Operating Manual: PMCtendo AC

Page 13

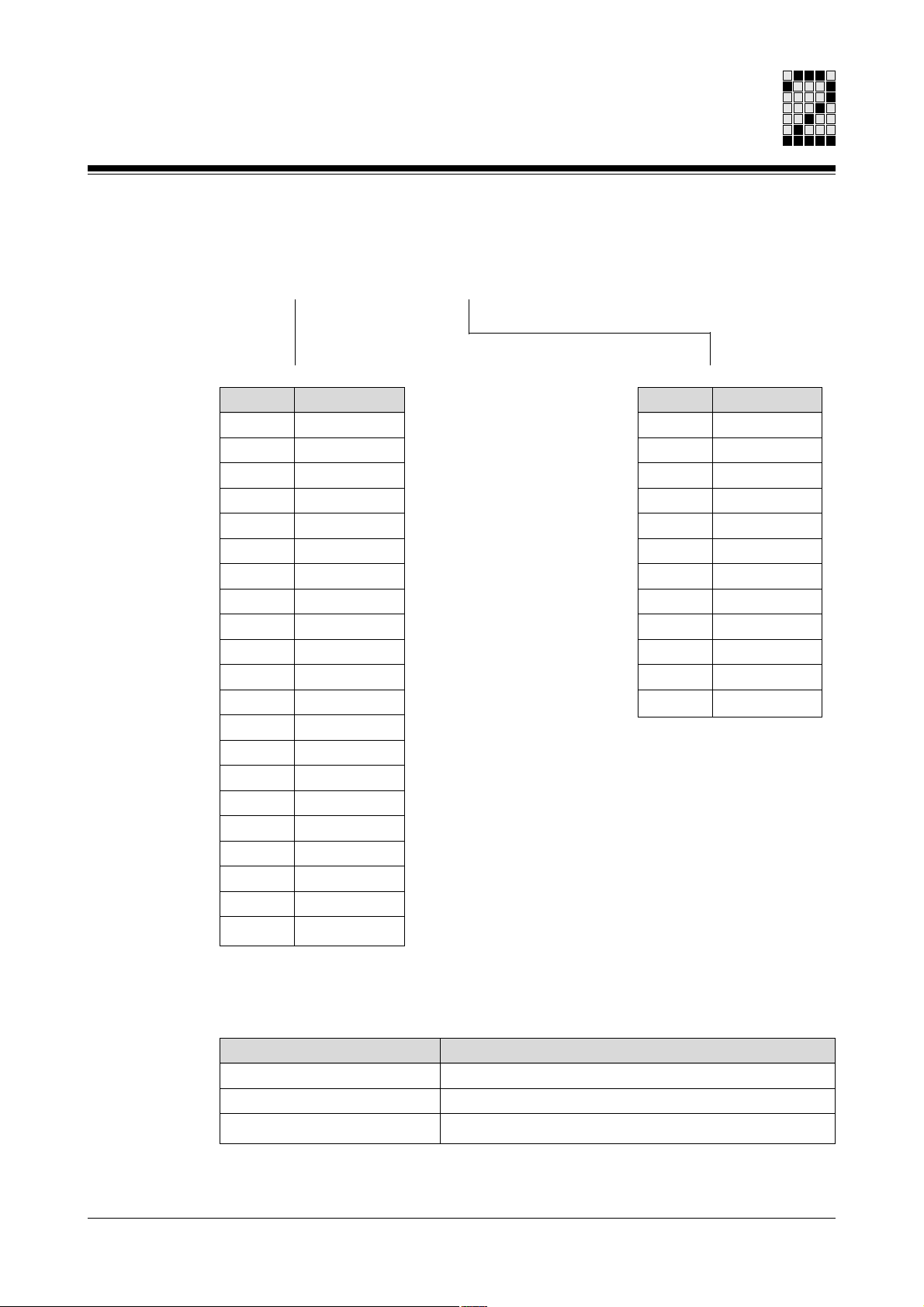

Code for the data of manufacture

The 2-digit code on the type label is structured as follows:

<Code for the year> <Code for the month>

Code

A

B

C

D

E

F

H

J

K

L

M

N

P

R

S

T

U

V

W

X

A

Year

2000

2001

2002

2003

2004

2005

2006

2007

2008

2009

2010

2011

2012

2013

2014

2015

2016

2017

2018

2019

2020

Code

1

2

3

4

5

6

7

8

9

O

N

D

Month

January

February

March

April

May

June

July

August

September

October

November

December

Encoder types

The type label distinguishes between the following encoder types:

Description

Res2

SRS

SRM

Encoder type

2-pole resolver

Encoder system for Hiperface single-turn

Encoder system for Hiperface multi-turn

2-3Operating Manual: PMCtendo AC

Page 14

Overview

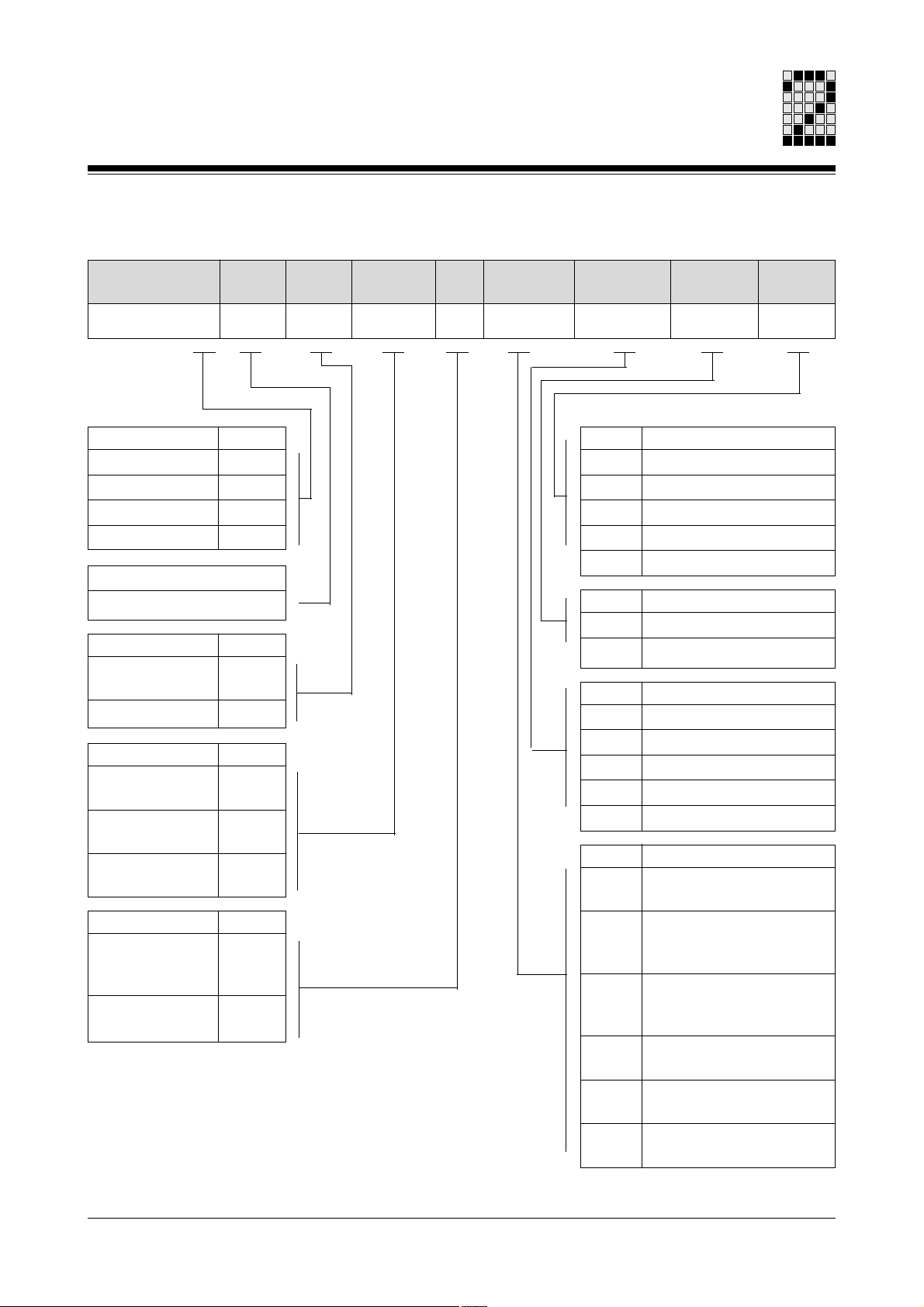

Order references

Type

Motor

size

Brake Feedback Type Con-

nection

PMCtendo AC...

Series

PMCtendo AC1

PMCtendo AC2

PMCtendo AC3

PMCtendo AC4

Code

1

2

3

4

Code for motor size

21 ... AB

Brake

Without brake

With brake

Feedback

2-pole resolver

Code

0

1

Code

5

(standard)

Hiperface

L

single-turn

Hiperface

M

multi-turn

Type

B5, shaft end with

Code

1

feather key

(standard)

B5, shaft end

2

without feather key

[1] Connection direction: see section entitled “Definition of motor ends”

Connection

direction

Code

1

2

3

4

6

Code

M

H

Code

1

2

4

5

6

Code

1

Speed

1200 min

2000 min

3000 min

4000 min

6000 min

Voltage

230 V

400 V

Connection direction [1]

To right

To left

Upwards

To B-end

To A-end

Connection

Connector for motor and

feedback on housing

2

Terminal box with cable

for motor and connector

for feedback

3

Terminal box with

connector for motor and

feedback

4

Cable for motor and

feedback

6

Angled connector for

motor and feedback

7

Angled swivel connector

for motor and feedback

Voltage Speed

-1

-1

-1

-1

-1

2-4 Operating Manual: PMCtendo AC

Page 15

Safety

Intended use

The servo motors are designed for incorporation into a machine or for assembly with

other components to form a plant or machine. They must be operated in conjunction

with servo amplifiers with speed, torque or position control.

The servo motors may not be operated directly on the mains. The servo motors must be

operated via a suitable servo amplifier which has been set with the correct parameters

(e.g. PMCtendo DD, PMCprimo Drive from Pilz).

The thermal switch incorporated into the motor winding must be monitored and

evaluated.

The following is deemed improper use:

• Any component, technical or electrical modification

• Use outside the areas described in this manual

• Use outside the documented technical details (see chapter entitled “Technical

Details”).

Safety guidelines

Failure to keep to these guidelines will render all warranty and liability claims invalid:

• All health and safety / accident prevention regulations for the particular area of

• The unit must not be put into service until it can be guaranteed that the plant or

application must be observed.

machine into which the servo motor has been incorporated meets the requirements of

the EU Directive 98/37/EC (Machinery Directive) as a whole.

3-1Operating Manual: PMCtendo AC

Page 16

Safety

Use of qualified personnel

Assembly, installation, commissioning, operation, maintenance and decommissioning

may only be undertaken by qualified personnel. Qualified personnel are people who,

because they are:

• Qualified electrical engineers

• And/or have received training from qualified electrical engineers,

are suitably experienced to operate devices, systems, plant and machinery in

accordance with the general standards and guidelines for safety technology.

EMCD

The servo motors are designed for use in an industrial environment. Interference may

occur if used in a domestic environment in conjunction with servo amplifiers.

Warranty and liability

Disposal

All claims to warranty and liability will be rendered invalid if:

• The servo motor is used contrary to the purpose for which it was intended

• Damage can be attributed to not having followed the guidelines in the manual

• Operating personnel are not suitably qualified

• Any type of modification has been made.

The servo motor must be disposed of properly when it reaches the end of its service life.

3-2 Operating Manual: PMCtendo AC

Page 17

Function Description

Structure

PMCtendo AC servo motors are 3-phase, brushless synchronous motors with

permanently energised rotor. The rotor contains rare earth permanent magnets made of

neodymium iron boron. The rare earth magnetic material is a major factor in enabling

these servo motors to be operated with high dynamics.

The 3-phase, stator winding is designed for sinusoidal commutation and enables a high

efficiency factor, while at the same time having optimum true running characteristics.

PMCtendo AC servo motors are totally enclosed, self-cooled motors and correspond to

type IC410 (in accordance with IEC 60034-6).

Servo amplifier

A suitable servo amplifier is required for commutation (e.g. PMCtendo DD, PMCprimo

Drive from Pilz). Commutation occurs electronically within the servo amplifier.

The servo motor and servo amplifier should always be regarded as one cohesive

system. The most important selection criteria are:

• Constant standstill torque M0 [Nm]

• Constant standstill current I0 [A]

• Rated speed nN [min-1]

• Mass moment of inertia of motor and load J [kgcm²]

• Effective torque (calculated) M

• Regenerative energy in braking mode

rms

[Nm]

When selecting the servo amplifier, please consider both the static and the dynamic

load (acceleration/braking).

Operating Manual: PMCtendo AC 4-1

Page 18

Function Description

Motor feedback system

PMCtendo AC servo motors may be equipped with one of the following motor feedback

systems:

• Resolver (2-pole)

The resolver determines the absolute position of the rotor to the stator within a

revolution and signals this information to the servo amplifier. This feeds sinusoidal

currents to the winding on the servo amplifier, depending on the rotor position.

• Hiperface-compatible feedback system for SinCos encoder

A Hiperface-compatible feedback system operates with differential signals in

accordance with the RS 485 specification.

The absolute position of the rotor to the stator is determined on power up and is

signalled to the counter in the servo amplifier via the parameter channel. The counter

then continues to count incrementally, based on this absolute value. For this purpose

the analogue sine/cosine voltage is transmitted via the process data channel and is

converted within the servo amplifier.

- Hiperface single-turn for SinCos encoder

With the Hiperface single-turn, only one shaft revolution is triggered. One shaft

resolution is transmitted in 32 768 steps.

- Hiperface multi-turn for SinCos encoder

With the Hiperface multi-turn, several shaft revolutions are triggered. A maximum of

4096 revolutions can be transmitted, each in 32 768 steps.

Operating mode

PMCtendo AC servo motors are designed for continuous duty. This corresponds to

operating mode S1 (in accordance with DIN EN 60 034-1).

Overload protection

PMCtendo AC servo motors have overload protection, which protects the stator winding

from damage in the case of constant overload. The motor temperature is monitored via a

thermal switch in the stator winding. The contact on the thermal switch is opened when

the winding temperature is exceeded. The switch does not protect against temporary

high overload.

The thermal switch incorporated into the motor winding must be monitored and

evaluated by the servo amplifier.

4-2 Operating Manual: PMCtendo AC

Page 19

Holding brake

As an option, the PMCtendo AC servo motors may be supplied with a built-in holding

brake, for backlash-free holding of the axis at standstill or when the supply to the plant or

machine is switched off. The permanent magnet brake blocks the rotor when the supply

voltage is switched off. Once the brake is released, the rotor can move without residual

torque.

INFORMATION

Only use the holding brake when the axes are at standstill!

It may not be used for dynamic braking mode. Make sure you read the holding brake

information provided in the chapters entitled “Wiring” and “Technical Details”.

The holding brake does not guarantee personal protection!

Personal protection can only be achieved by using a second brake and through

additional higher level design measures (e.g. guard).

Motor shaft and bearings

PMCtendo AC servo motors are available with two different types of shaft end (drive

end):

• Shaft end with feather key groove

Rotor balancing is performed using a half feather key. These shaft ends are suitable

for low loads. Under continuous duty with varying torques or strong reverse mode, the

feather key may become unseated. If this is the case the true running quality is

reduced; there is backlash. Increasing deformation can break the feather key and

damage the drive shaft.

• Smooth shaft end

With a frictional connection, torque transfer must only be achieved through surface

pressure. This guarantees a safe, backlash-free force transfer.

• Bearings

The bearings are lubricated with maintenance-free grease which is resistant to high

temperatures.

Operating Manual: PMCtendo AC 4-3

Page 20

Function Description

Notes

4-4 Operating Manual: PMCtendo AC

Page 21

Transport and Storage

Transport

The servo motors must be transported in such a way that no damage can occur.

INFORMATION

Be sure to avoid any impact, jerky movements or heavy vibration during transportation.

Storage

If a servo motor is not to be put into service immediately upon delivery, make absolutely

sure that it is stored correctly.

The servo motors should only be stored in an enclosed room that is dry, dust free and

ventilated. Please refer to the information provided under “Technical Details”.

Do not remove anti-corrosion coatings on the shaft ends, flange surfaces, etc. While in

storage, these should be inspected at defined intervals and any damage made good.

The storage site should not be liable to vibration. When servo motors are kept in storage

we recommend that the rotor is rotated at defined intervals to prevent corrosion on the

bearings.

If the servo motor has been in storage for more than 3 months, rotate the servo motor in

both directions at low speed (< 100 min-1) to ensure that the lubricant on the bearings is

distributed equally.

Operating Manual: PMCtendo AC 5-1

Page 22

Transport and Storage

Notes

5-2 Operating Manual: PMCtendo AC

Page 23

Installation

Preparing for installation

Secure the installation site in accordance with the regulations (barrier, warning signs

etc.). Installation may only be carried out by qualified personnel.

Mounting location

Please note the following when selecting the location:

• The mounting location must be free from conductive and aggressive materials.

• The unit may only be mounted on a flat, vibration-free and warp-resistant substructure.

• It is essential to comply with the ambient temperature (see chapter entitled “Technical

Details”).

Ensure there is sufficient heat dissipation; if necessary, additional ventilation should

be provided for the servo motor.

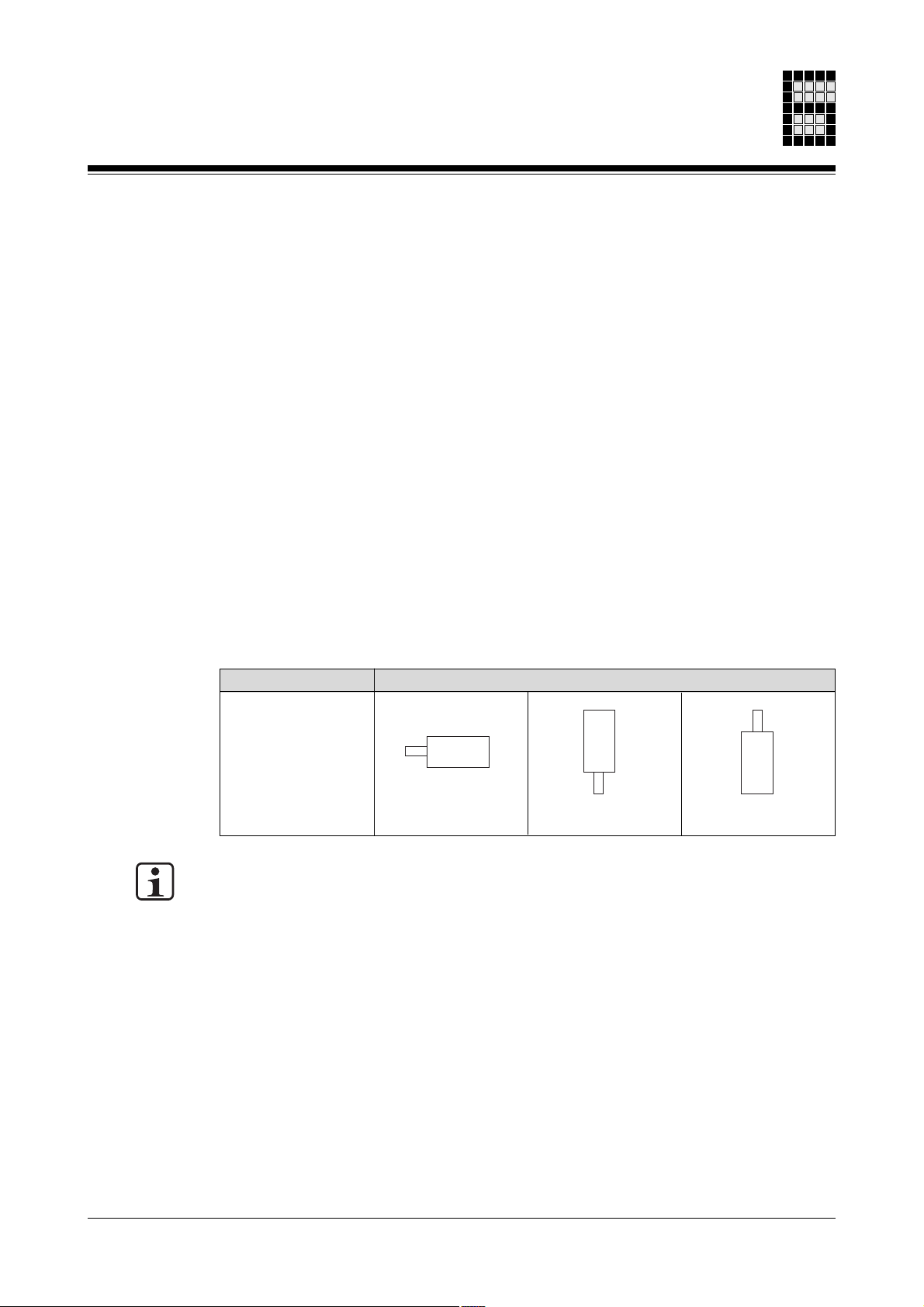

Mounting position

Permitted mounting positions:

Design

Permitted mounting positions

B5

IM B5

IM V1

IM V3

INFORMATION

• The mounting position IM V3 (DIN EN 60034-7) is not recommended in conjunction

with gear units!

• With the mounting position IM V3 (DIN EN 60034-7), ensure that liquids cannot

penetrate into the bearings, whether during installation or during operation.

Operating Manual: PMCtendo AC 6-1

Page 24

Installation

Motor

• Check the servo motor for any transport damage. Never install a servo motor that

shows clear signs of damage!

• Ensure that any anti-corrosion agents and/or contamination on the shaft end (drive

end) are thoroughly removed. This can be done using a standard solvent. Make sure

that the solvent cannot come into contact with the gaskets and/or bearings, otherwise

materials may be damaged!

Carrying out the installation

WARNING!

Electric shock

Contact with live parts will result in serious injury.

The motor should always be installed with the supply voltage switched off. Switch off

the supply voltages to all connected devices!

Hazardous values may still be present up to 5 minutes after the voltage is switched off,

due to residual charges in the servo amplifier’s capacitors.

When the shaft is rotating (externally driven, running down) the motor acts as a

generator. This means that hazardous voltages will be present at the connection

terminals.

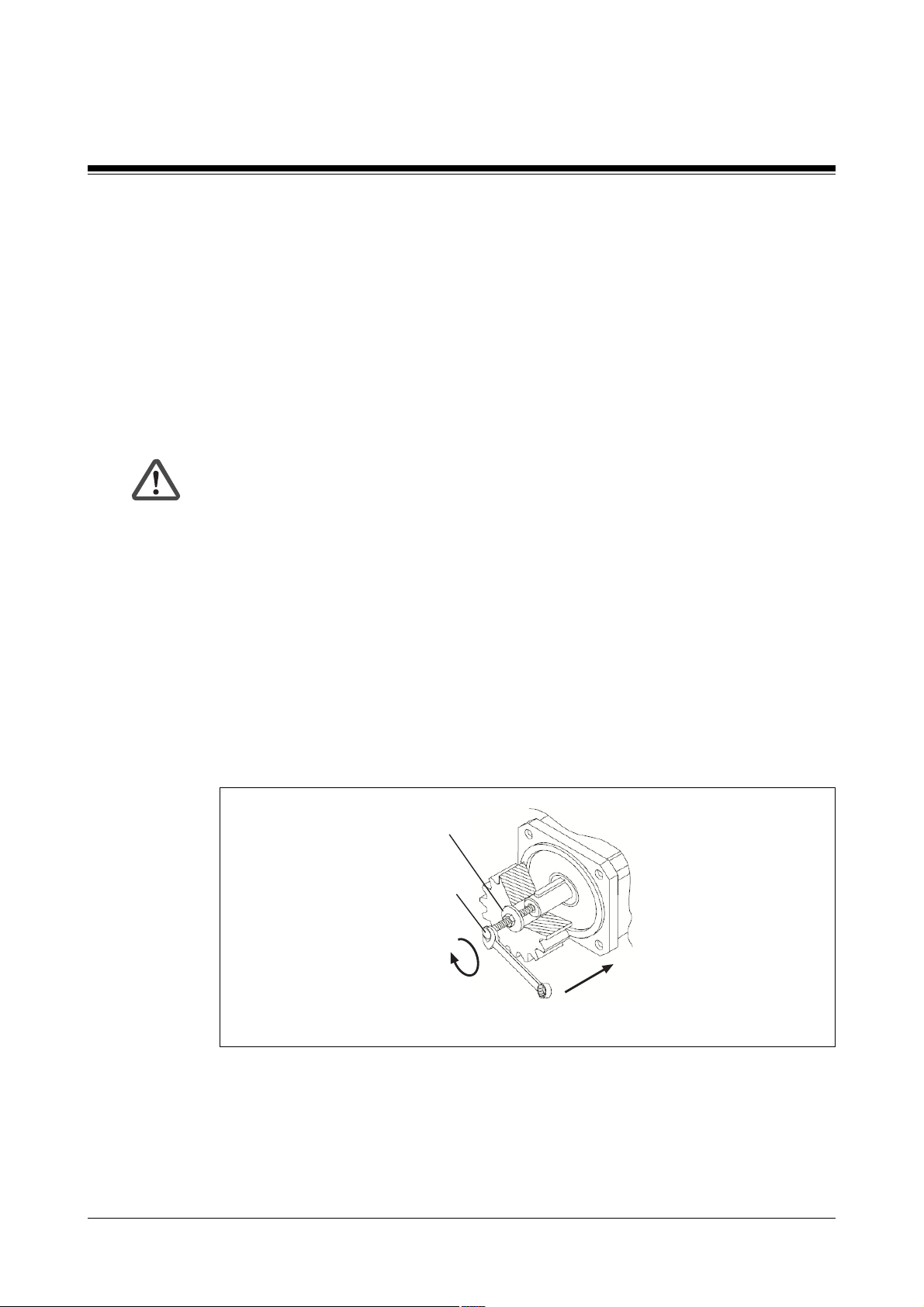

If possible, only use backlash-free, frictionally engaged chucks or clutches.

Use the tightening thread provided in the motor shaft to tighten the clutches, gears or

belt pulleys and, if possible, warm up the drive elements. Do not use excessive force as

this will damage bearings, feedback and the motor shaft.

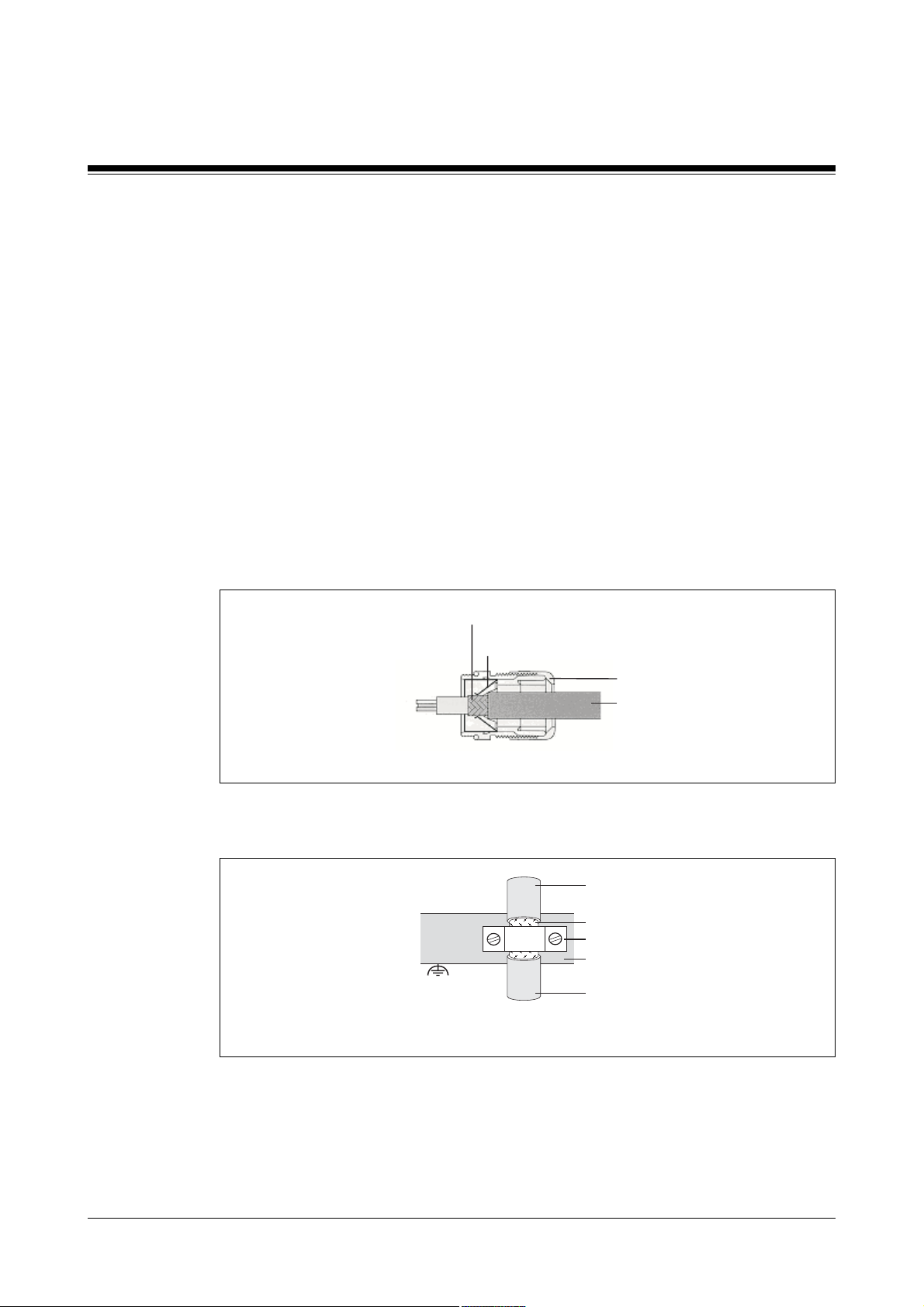

Spacing washer

Tightening thread

Fig. 6-1: Tightening thread in the motor shaft

Please note:

• Align the clutch correctly

Misalignment can cause undue vibration and can damage the ball bearings and

clutch!

6-2 Operating Manual: PMCtendo AC

Page 25

• Mechanical overdefinition of the motor shaft bearing should be avoided

A rigid clutch and/or an external additional bearing (e.g. in the gear unit) can cause

excess mechanical stress on the motor shaft.

• Do not fasten or attach temperature-sensitive components to the motor

CAUTION!

Burns

Contact with the motor surface during operation will result in injury.

During operation, the surface temperature of the servo motor can exceed 65 °C!

Safety measures should be put in place to protect against contact during operation,

whether accidental or intentional.

Operating Manual: PMCtendo AC 6-3

Page 26

Installation

Notes

6-4 Operating Manual: PMCtendo AC

Page 27

Wiring

General requirements

Secure the site in accordance with the regulations (barrier, warning signs etc.). Wiring

may only be carried out by qualified personnel.

• Please refer to the information and specifications stated in the operating manual of the

servo amplifier you are using.

CAUTION!

Uncontrolled movements of the servo motor will result in injury

Incorrect wiring of the servo motor and/or motor feedback can trigger uncontrolled

movements and result in material and/or personal injury.

• If necessary, consider the trailing capability of the cables you are using.

Cabling

It is possible to differentiate between cables according to their function. The following

groups exist:

• Group 1: Data and supply lines for DC voltages below 60 V and AC voltages

below 25 V

• Group 2: Data and supply lines for DC voltages from 60 V to 400 V and AC voltages

from 25 V to 400 V.

• Group 3: Supply lines above 400 V

Cabling inside buildings:

• The cable groups listed above should be laid separately.

• Cables of the same group can be laid within the same cable duct.

• Cables from group 1 and group 2 should be laid in separate groups or in cable ducts

• Cables from group 1 and group 3 should be laid in separate groups or in cable ducts

• Data lines and control lines should be laid as close as possible to an earthed surface.

Cable cross sections

Please refer to the information stated in the operating manual of the servo amplifier you

are using. The cable cross sections you select should depend on the current supplied by

the servo amplifier.

which are at least 10 cm apart.

which are at least 50 cm apart.

Operating Manual: PMCtendo AC 7-1

Page 28

Wiring

Earthing, shielding and EMC

• On the servo motors, the connection to PE is established via the supply voltage cable

(see section entitled “Connections for supply voltage, thermal switch and holding

brake”).

• If necessary, use a toroidal core for the supply voltage cable, or a motor throttle close

to the servo amplifier. Please refer to the information stated in the operating manual

of the servo amplifier you are using.

• You will need shielded cable for data and control lines.

- Earth the cable shield connection on both sides (e.g. on a bus bar).

- If you are using longer cables and there is the possibility of transient currents, these

can be prevented by using equipotential bonding cables. If you are unable to use

equipotential bonding cables, connect the shield at one end.

• Shields should be connected over a wide surface area (low impedance), using

metallised connector housings or EMC-compliant cable screw connections. Use the

EMC cable screw connection supplied with the unit.

Cable shield

EMC contact surface

Housing

Cable

Fig. 7-1: EMC screw connection

• An appropriate connection material (e.g. shielded terminals) should be used to

connect the cable shield to the earth bar or bus bar.

Cable

Cable shield

Shielded terminal

Earth bar or

bus bar

Cable

Fig. 7-2: Earthing the cable shield (example)

7-2 Operating Manual: PMCtendo AC

Page 29

Pin assignment and connection

The sections below describe all the connections on a PMCtendo AC servo motor plus

their layout. The connections that your servo motor actually has at its disposal will

depend on the code stated in the order reference (see section entitled “Overview”).

INFORMATION

Only used shielded cable. Pre-assembled cable in various lengths and cross sections is

available from Pilz.

Motor feedback connections

Resolver

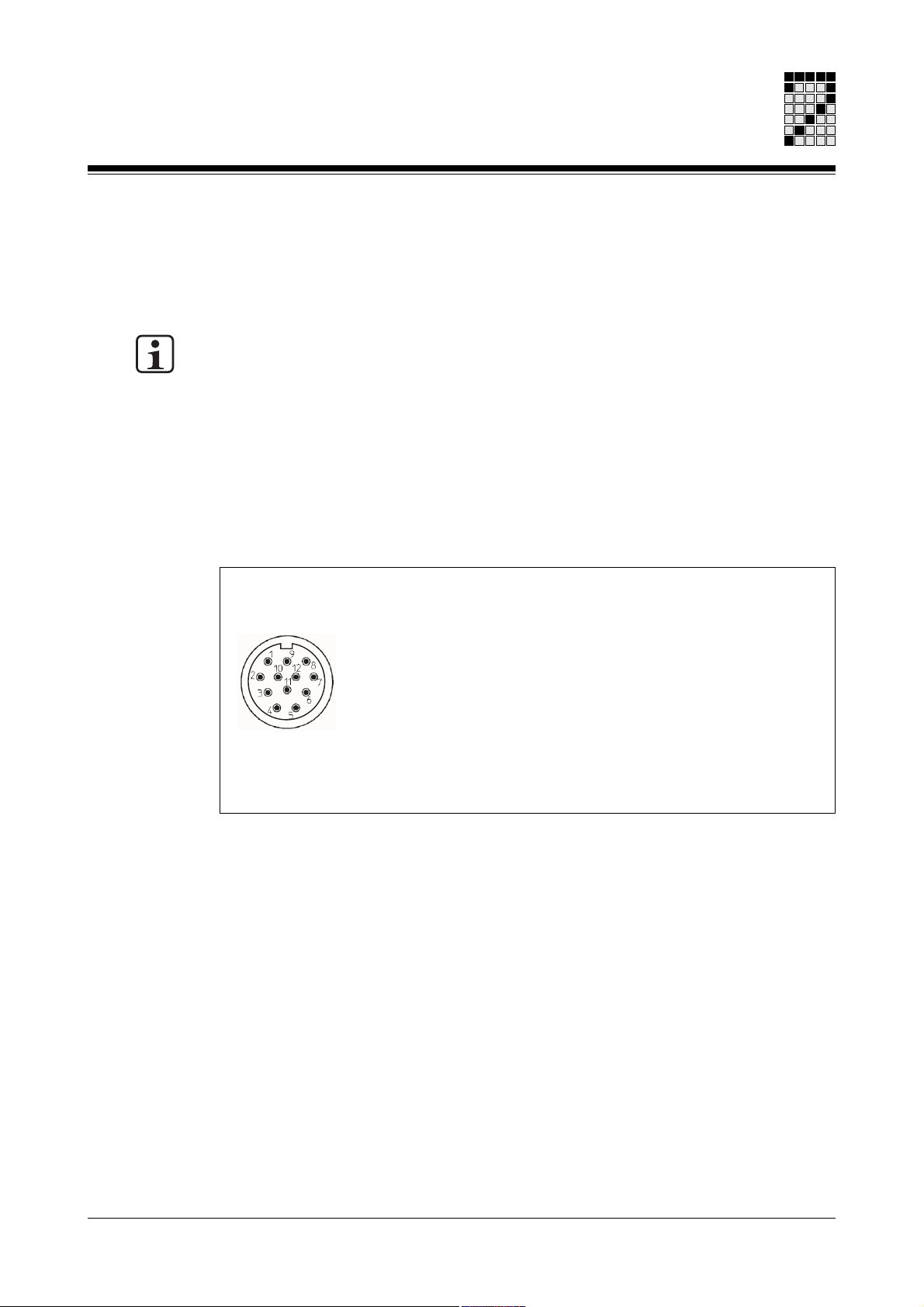

To connect the resolver (see Fig. 7-3) to the servo amplifier you will need a cable with a

layout as shown in Fig. 7-4.

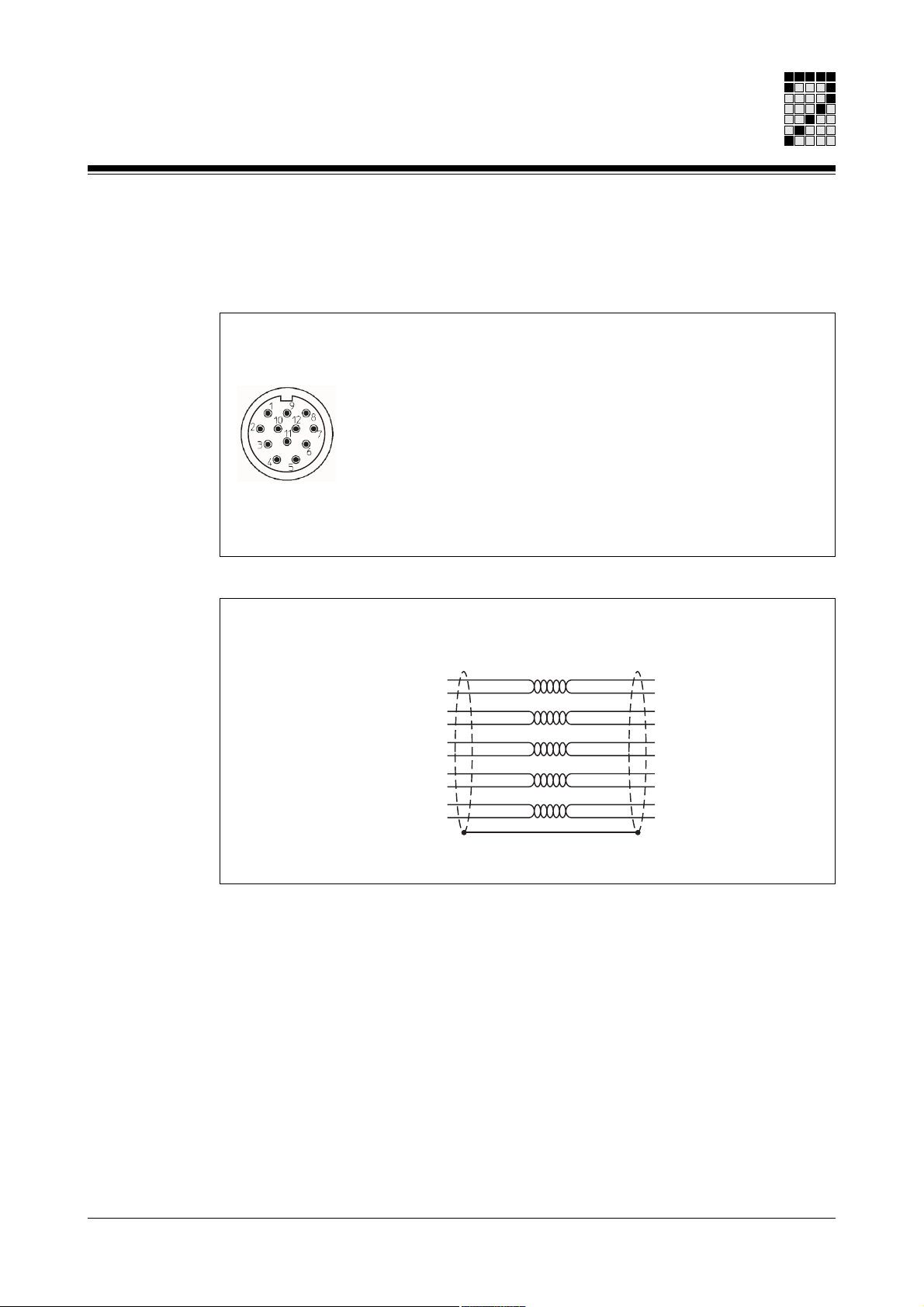

Round connector

12-pin, male

1: S1 (Cos1)

2: S2 (Sin1)

3: S4 (Sin2)

4: n.c.

5: n.c.

6: S3 (Cos2)

7: R1 (Ref1)

8: Internal shield

9: Thermal switch

10: Thermal switch

11: R2 (Ref2)

12: n.c.

Fig. 7-3: Pin assignment of the round resolver connector

n.c. = not connected

Operating Manual: PMCtendo AC 7-3

Page 30

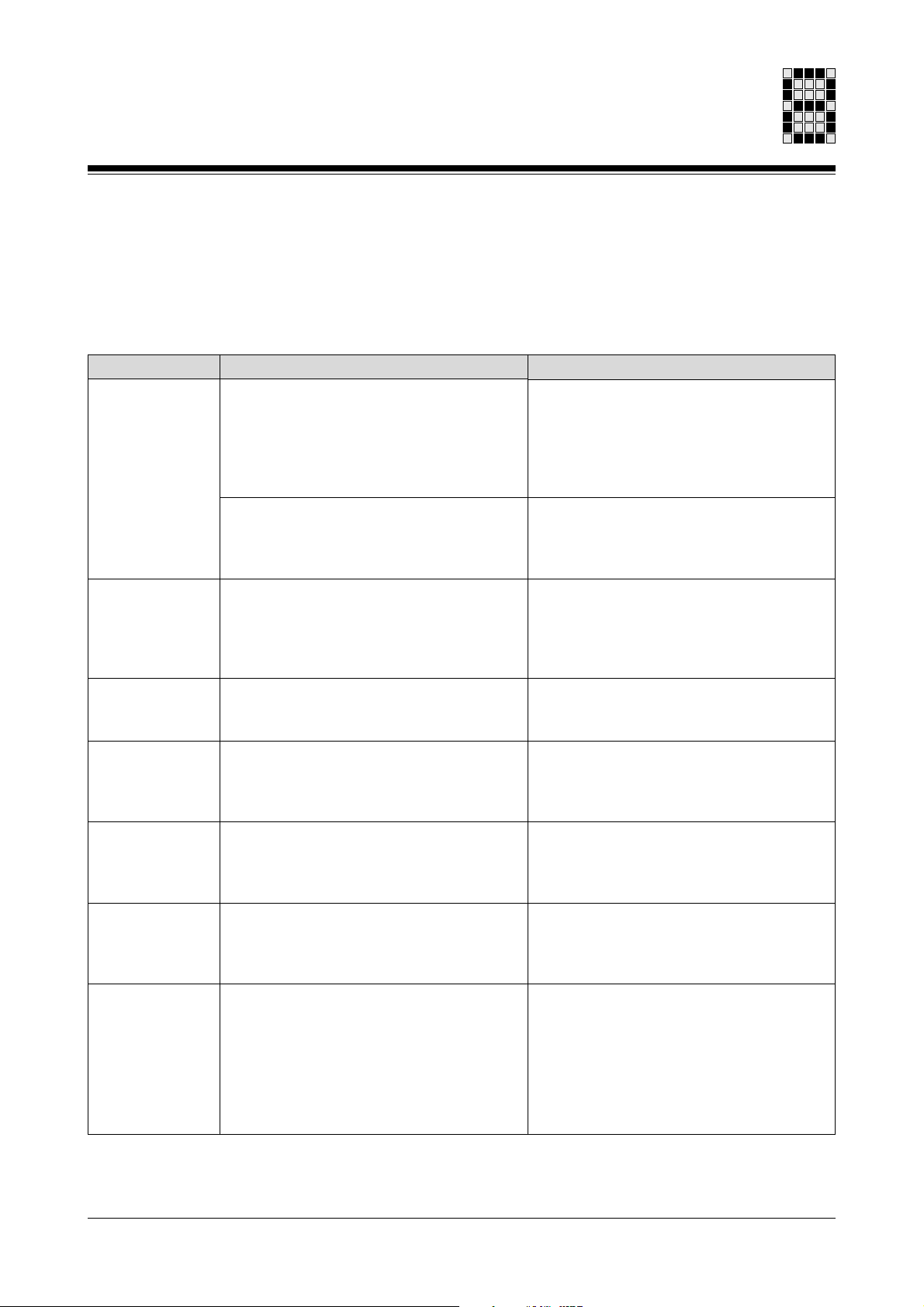

Wiring

Resolver (servo motor)

12-pin round connector, female

11

10

2

3

1

6

7

9

8

S2 (Sin1)

S4 (Sin2)

S1 (Cos1)

S3 (Cos2)

R1 (Ref1)

R2 (Ref2)

Thermal switch

Thermal switch

Shield

Fig. 7-4: Connection cable for resolver

Shield

S2 (Sin1)

S4 (Sin2)

S1 (Cos1)

S3 (Cos2)

R1 (Ref1)

R2 (Ref2)

Thermal switch

Thermal switch

Shield

Cable features:

• Round connector type:

- M23 connector (e.g. made by Intercontec), 12-pin

• Cable cross section and cable runs:

- Depend on the requirements of the servo amplifier you are using

Servo amplifier

7-4 Operating Manual: PMCtendo AC

Page 31

Hiperface encoder

To connect the Hiperface rotary encoder (see Fig. 7-5) to the servo amplifier you will

need a cable with a layout as shown in Fig. 7-6.

Round connector

12-pin, male

1: Us (7 ... 12 V)

2: GND

3: REFSIN

4: REFCOS

5: Data + (RS485)

6: Data - (RS485)

7: + SIN

8: + COS

9: n.c.

10: n.c.

11: Thermal switch

12: Thermal switch

n.c. = not connected

Fig. 7-5 Pin assignment of the round Hiperface connector

Hiperface rotary encoder (servo motor)

12-pin round connector, female

11

12

1

2

7

3

8

4

5

6

Shield

Us (7 ... 12 V)

GND

+ SIN

REFSIN

+ COS

REFCOS

Data + (RS485)

Data - (RS485)

Thermal switch

Thermal switch

Fig. 7-6: Connection cable for Hiperface rotary encoder

Cable features:

• Round connector type:

- M23 connector (e.g. made by Intercontec), 12-pin

• Cable cross section and cable runs:

- Depend on the requirements of the servo amplifier you are using

Servo amplifier

Us (7 ... 12 V)

GND

+ SIN

REFSIN

+ COS

REFCOS

Data + (RS485)

Data - (RS485)

Thermal switch

Thermal switch

Operating Manual: PMCtendo AC 7-5

Page 32

Wiring

Connections for supply voltage, thermal switch and holding brake

General

If you are using a cable that incorporates the wires for the holding brake, the wires for

the holding brake must be shielded.

Terminal box on servo motors AC1 and AC2

To supply the voltage to the servo motor (see Fig. 7-7) via the servo amplifier you will

need a cable with a layout as shown in Fig. 7-8.

INFORMATION

The thermal switch is dual wired. It is carried in the motor feedback cable (see sections

entitled “Resolver” and “Hiperface rotary encoder”), as well as the supply voltage cable.

Connection terminals

Supply voltage for servo motor:

U: Phase U

V: Phase V

W: Phase W

Thermal switch:

BR: Thermal switch

BR2: Thermal switch

PE: Earth connector

Holding brake (optional):

Red: + 24 VDC

Blue: 0 V

Fig. 7-7: Pin assignment within the terminal box (servo motors AC1 and AC2)

7-6 Operating Manual: PMCtendo AC

Page 33

Connection cable (servo motor) Servo amplifier

PE

BR

BR2

1

3

4

Shield

Phase U

Phase W

Phase V

Earth conductor

Thermal switch

Thermal switch

Holding brake

+ 24 VDC

0 VDC

Fig. 7-8: Connection cable for the terminal box (servo motors AC1 and AC2)

Phase U

Phase W

Phase V

Earth conductor

Thermal switch

Thermal switch

Holding brake

+ 24 VDC

[1] Depends on the servo amplifier you are using

Cable features:

• Cable cross section: max. 14 mm

- Wires for supply voltage: max. 3 x 2.5 mm

- Wire for earth conductor PE: max. 1 x 2.5 mm

- Wires for thermal switch: max. 2 x 1 mm

- Wires for holding brake: max. 2 x 1 mm

2

2

2

2

• Cable runs:

- Depend on the requirements of the servo amplifier you are using

[1]

0 VDC

Operating Manual: PMCtendo AC 7-7

Page 34

Wiring

Terminal box on servo motors AC3 and AC4

To supply the voltage to the servo motor (see Fig. 7-9) via the servo amplifier you will

need a cable with a layout as shown in Fig. 7-10.

INFORMATION

Please note that the thermal switch connection is only available via the motor feedback

cable (see sections entitled “Resolver” and “Hiperface rotary encoder”).

Connection terminals Supply voltage for servo motor:

U: Phase U

V: Phase V

W: Phase W

Thermal switch:

BR: Not connected

BR2: Not connected

PE: Earth conductor

Holding brake (optional):

Red: + 24 VDC

Blue: 0 V

Fig. 7-9: Pin assignment within the terminal box (servo motors AC3 and AC4)

Connection cable (servo motor) Servo amplifier

PE

1

3

4

Shield

Phase U

Phase W

Phase V

Earth conductor

Holding brake

+ 24 VDC

0 VDC

Phase U

Phase W

Phase V

Earth conductor

Holding brake

+ 24 VDC

0 VDC

Fig. 7-10: Connection cable for the terminal box (servo motors AC3 and AC4)

Cable features:

• Cable cross section: max. 14 mm

- Wires for supply voltage: max. 3 x 2.5 mm

- Wire for earth conductor PE: max. 1 x 2.5 mm

- Wires for holding brake: max. 2 x 1 mm

2

2

2

• Cable runs:

- Depend on the requirements of the servo amplifier you are using

7-8 Operating Manual: PMCtendo AC

Page 35

Round connector for servo motors AC1 and AC2

Round connectors are used when I0 < 20 A. To connect the servo motor (see Fig. 7-11)

to the servo amplifier you will need a cable with a layout as shown in Fig. 7-12.

INFORMATION

The thermal switch is dual wired. It is carried in the motor feedback cable (see sections

entitled “Resolver” and “Hiperface rotary encoder”), as well as the supply voltage cable.

Round connector

8-pin, male

Supply voltage

Servo motor:

1: Phase U

Holding brake:

A: + 24 VDC

B: 0 VDC

3: Phase W

4: Phase V

Thermal switch:

C: Thermal switch

PE: Earth conductor

Fig. 7-11: Pin assignment of the round connector (servo motors AC1 and AC2)

D: Thermal switch

Connection cable (servo motor)

8-pin round connector, female

PE

1

3

4

C

D

A

B

Shield

Phase U

Phase W

Phase V

Earth conductor

Thermal switch

Thermal switch

Holding brake

+ 24 VDC

0 VDC

Servo amplifier

Phase U

Phase W

Phase V

Earth conductor

Thermal switch

Thermal switch

Holding brake

+ 24 V DC

0 V DC

[1]

Fig. 7-12: Connection cable for the round connector (servo motors AC1 and AC2)

[1] Depends on the servo amplifier you are using

Cable features:

• Round connector type:

- Connector with 28 mm diameter (e.g. made by Intercontec), 8-pin

• Cable cross section:

- Wires for supply voltage: max. 3 x 2.5 mm

- Wire for earth conductor PE: max. 1 x 2.5 mm

Operating Manual: PMCtendo AC 7-9

2

2

Page 36

Wiring

- Wires for thermal switch: max. 2 x 1 mm

- Wires for holding brake: max. 2 x 1 mm

• Cable runs:

- Depend on the requirements of the servo amplifier you are using

Round connector for servo motors AC3 and AC4

Round connectors are used when I0 < 20 A. To connect the servo motor (see Fig. 7-13)

to the servo amplifier you will need a cable with a layout as shown in Fig. 7-14.

INFORMATION

Please note that the thermal switch connection is only available via the motor feedback

cable (see sections entitled “Resolver” and “Hiperface rotary encoder”).

Round connector

8-pin, male

Supply voltage

Servo motor:

1: Phase U

3: Phase W

4: Phase V

PE: Earth conductor

2

2

Holding brake:

A: + 24 VDC

B: 0 VDC

Thermal switch:

C: Not connected

D: Not connected

Fig. 7-13: Pin assignment of the round connector (servo motors AC3 and AC4)

Connection cable (servo motor)

8-pin round connector, female

Phase U

Phase W

Phase V

Earth conductor

Holding brake

+ 24 VDC

0 VDC

Fig. 7-14: Connection cable for the round connector (servo motors AC3 and AC4)

PE

1

3

4

A

B

Shield

Phase U

Phase W

Phase V

Earth conductor

Holding brake

+ 24 VDC

Cable features:

• Round connector type:

- Connector with 28 mm diameter (e.g. made by Intercontec), 8-pin

Servo amplifier

0 VDC

7-10 Operating Manual: PMCtendo AC

Page 37

• Cable cross section:

- Wires for supply voltage: max. 3 x 2.5 mm

- Wire for earth conductor PE: max. 1 x 2.5 mm

- Wires for thermal switch: max. 2 x 1 mm

- Wires for holding brake: max. 2 x 1 mm

• Cable runs:

- Depend on the requirements of the servo amplifier you are using

Connecting the supply voltage

Never remove or attach the connections while voltage is applied.

WARNING!

Electric shock

Contact with live parts will result in serious injury.

Switch off the supply voltages to all connected devices!

Hazardous values may still be present up to 5 minutes after the voltage is switched off,

due to residual charges in the servo amplifier’s capacitors. When the shaft is rotating

(externally driven, running down) the motor acts as a generator. This means that

hazardous voltages will be present at the connection terminals.

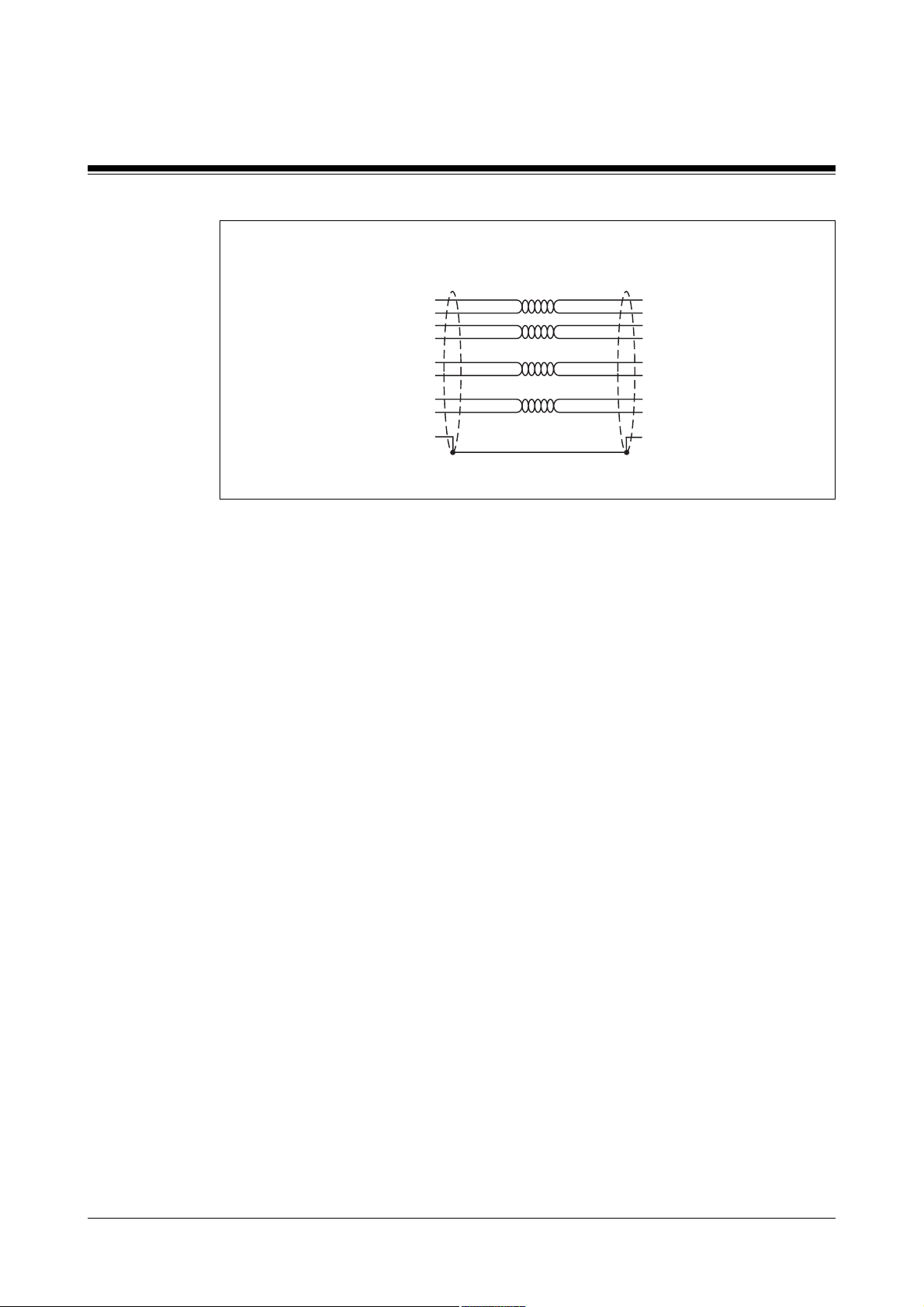

The direction of rotation of the servo motor is determined by the phase sequence of the

supply voltage. The servo motor is designed so that the motor shaft rotates to the right

when it is connected as shown in Fig. 7-15.

Any change to the direction of rotation must be made via the servo amplifier. Servo

amplifiers can change the direction of rotation of the servo motor by changing the phase

sequence electronically.

2

2

2

2

L1 L2 L3

Servo amplifier

L1

L2

L3

Direction

of rotation

A-end

View direction

Fig. 7-15: “Clockwise” direction of rotation, viewed from the drive end (principle)

Operating Manual: PMCtendo AC 7-11

(drive end)

U

V

W

right

Servo motor

U

V

W

B-end

Page 38

Wiring

Connecting the holding brake

The holding brake can be controlled directly by the servo amplifier. In this case, the

braking action is suppressed within the servo amplifier. No additional wiring is required

within the braking circuit. Servo amplifiers from Pilz are fitted with a brake control as

standard.

If the holding brake is not controlled by the servo amplifier, the brake circuit must be

fitted with a suppression device through additional wiring (e.g. varistor).

Suppression device

(e.g. varistor)

Power supply

+24 VDC

0 VDC

Fig. 7-16: Suppression device within the holding brake circuit (principle)

+24 VDC

M

0 VDC

If the operation of the holding brake is to include personal safety, an extra N/O contact is

required for the holding brake within the brake circuit, as well as the additional

suppression device (e.g. varistor). Control of this N/O contact must be safety-related.

External safety-related control

of N/O contact

Power supply

Servoregler

Fig. 7-17: Safety-related control of the holding brake circuit (principle)

+24 VDC

0 VDC

+24 VDC

M

0 VDC

INFORMATION

The holding brake is operated with DC voltage (24 VDC). When you connect it, make

sure that the polarity is correct.

7-12 Operating Manual: PMCtendo AC

Page 39

Commissioning

General requirements

Secure the site in accordance with the regulations (barrier, warning signs etc.).

Commissioning may only be carried out by qualified personnel.

• Please refer to the information and specifications stated in the operating manual of the

servo amplifier you are using.

• During commissioning, make sure that no personal injury and/or material damage can

occur, even if the drive moves unintentionally.

CAUTION!

Uncontrolled movements of the servo motor will result in injury

Incorrect wiring of the servo motor and/or motor feedback can trigger uncontrolled

movements and result in material and/or personal injury.

Operating Manual: PMCtendo AC 8-1

Page 40

Commissioning

Check installation and wiring

Installation

Check the installation and orientation of

the servo motor.

- - -

Check the drive elements (clutch, gear unit,

belt pulley) to ensure that they are firmly

seated and set up correctly.

Check that the motor surface is protected

against contact during operation, whether

accidental or intentional.

Check that the rotor of the servo motor can

rotate freely.

WARNING!

Risk of life-threatening injury when operating the

servo motor

Servo motors with feather key must not be operated

unless the drive pulley is fully installed! Make sure

that the drive connection between the shaft and the

machine has been fully installed.

CAUTION!

Burns

During operation, the surface temperature of the

servo motor can exceed 65 °C!

INFORMATION

If a holding brake is present, this must first be

released (see “Holding brake”).

Check the polarity!

8-2 Operating Manual: PMCtendo AC

Page 41

Wiring

Check that the units are earthed correctly.

Check that all live parts are safely

protected against contact during operation,

whether accidental or intentional.

WARNING!

Electric shock

Life-threatening voltages are present at the supply

voltage connections.

Check the wiring and the connections to

the servo motor, brake and servo amplifier.

Check the direction of rotation of the servo

motor.

Holding brake

Check the function of the holding brake.

Then carry out all the other checks required specifically for your plant.

Commissioning the drive unit

CAUTION!

Uncontrolled movements of the servo motor will result

in injury

Incorrect wiring of the servo motor and/or motor

feedback can trigger uncontrolled movements and

result in material and/or personal injury.

Activate the servo motor via the servo amplifier.

Apply the 24 V control voltage:

The holding brake must release.

Check the polarity!

Do not commission the drive unit (servo motor and servo amplifier) until you have

performed all the checks.

When commissioning, please note the following:

• Make sure that you follow the commissioning instructions for the servo amplifier you

are using.

• With multi-axis systems, each drive unit should be commissioned separately.

Operating Manual: PMCtendo AC 8-3

Page 42

Commissioning

Troubleshooting guidelines

The table below only lists the errors that directly affect the servo motor. You should also

refer to the error messages for the servo amplifier you are using. Multi-axis systems with

higher level position control systems may also have additional error causes.

Fault

Motor does not

rotate

Motor spins

(positive

feedback)

Motor vibrates

Error message

Output stage

error

Error message

Feedback

Error message

Motor

temperature

Potential error cause

• Servo amplifier has not been enabled

• Set point cable is broken

• Motor phases transposed

(incorrect phase sequence)

• Brake has not been released

• Drive is mechanically blocked

• Torque is too low

• Incorrect feedback offset

• Motor phases transposed

(cyclically transposed, correct phase

sequence)

• Shield on the feedback line

is broken

• Invalid control parameters

• Motor cable has a short

circuit or earth fault

• Motor has a short

circuit or earth fault

• Feedback connector is not inserted

correctly

• Feedback line is broken,

crushed or similar

• Thermal switch has energised

• Connection to the thermal switch

is broken

Remedy

• Apply the enable signal

from the servo amplifier

• Check the set point cable

• Connect the motor phases correctly

• Check the brake control

• Check the mechanics

Lift the current limitation in the servo

amplifier

or

Use a larger motor or servo amplifier

• Check feedback offset and

set the parameters correctly

• Change the direction of rotation

in the servo amplifier

• Connect the motor phases correctly

• Change the feedback line

• Adjust the controller

• Swap the cable

• Swap the motor

• Check the plug-in connection

• Check the wiring

Wait for the motor to cool down, then:

• Check the connector and cable

• Possibly use a new cable

Holding brake

doesn’t catch

8-4 Operating Manual: PMCtendo AC

• Required holding torque is too

high

• Holding brake is defective

• Motor shaft axially overloaded

• Check the specification of the

holding brake

• Swap the motor

• Check the axial load and

reduce if necessary,

also swap the motor because the

bearings are damaged

Page 43

Maintenance and Repair

General guidelines for maintenance and repair

Before starting maintenance or repair work, please note the following:

• Maintenance and repair work may only be carried out by qualified personnel.

• Make sure that the plant or machine is isolated in accordance with the regulations.

• The plant or machine should be safeguarded against inadvertent reconnection.

• Check that the voltage is disconnected.

WARNING!

Electric shock

Control and power connections may carry voltage, as residual charges in the servo

amplifier’s capacitors may still show hazardous values up to 5 minutes after the

voltage is switched off.

• A servo motor may only be repaired by Pilz GmbH & Co. KG. If the servo motor is

opened without authorisation and handled improperly the warranty will be rendered

invalid.

Operating Manual: PMCtendo AC 9-1

Page 44

Maintenance and Repair

Maintenance intervals

If suitably installed, the servo motors are largely maintenance free. As operating

conditions can vary greatly, maintenance intervals must be adapted to suit the local

conditions (e.g. pollution degree, switch on frequency, load).

Maintenance interval

Regularly

Every 500 operating hours,

or

min. once per year

Every 2500 operating hours,

or

min. once per year

After 20000 operating hours

(under rated conditions)

What to do?

Clean the servo motor

Check the electrical and mechanical

connections and retighten if

necessary

Check that the servo motor is

running quietly and, if necessary,

check the installation; if necessary,

change the servo motor

Check the noise level of the ball

bearings and, if there is any

deterioration, check the installation;

if necessary, send in the servo motor

to have the ball bearings changed

Check the noise level of the ball

bearings and, if necessary, send in

the servo motor to have the ball

bearings changed

Send in the servo motor to have the

ball bearings changed

What to consider?

Cleaning intervals should depend on

the local pollution degree

• Let the motor cool down

• Do not use solvents

• Select a cleaning method that’s

appropriate for the servo motor’s

protection type, otherwise the

ingress of liquid could damage the

motor.

- - -

See section entitled “Changing the

servo motor”

The ball bearings may only be

exchanged by Pilz GmbH & Co. KG!

(refer also to the section entitled

“Changing the servo motor”)

9-2 Operating Manual: PMCtendo AC

Page 45

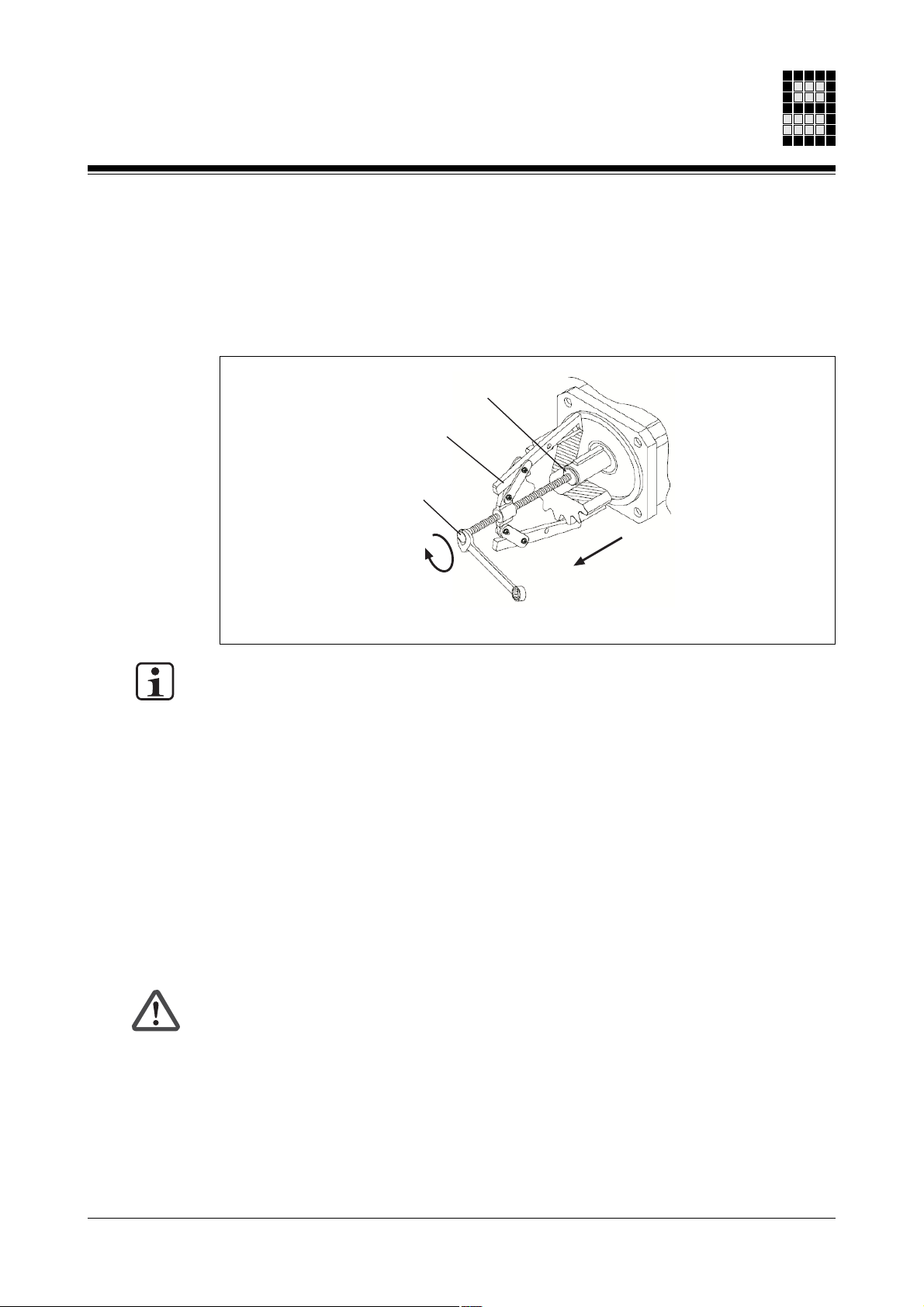

Changing the servo motor

When uninstalling you must use the tightening thread provided in the motor shaft and, if

possible, warm up the drive elements. Do not use excessive force as this will damage

bearings, feedback and the motor shaft. Use a suitable extraction tool.

Fig. 9-1: Tightening thread in the motor shaft

INFORMATION

You must read the information in the section entitled “General guidelines for

maintenance and installation” before changing the servo motor.

Spacing washer

Extraction tool

Tightening thread

Please note the following when changing the motor:

• If servo motors have been in storage for longer than 2 years, the holding brake must

be resurfaced before the servo motor is used.

- Only resurface the holding brake while the servo motor is uninstalled!

- With the holding brake in a closed condition, turn the servo motor by hand for

approx. 50 revolutions.

The holding brake is now ready for operation.

• Please refer to the information in the chapter entitled “Installation”, under “Installing

the servo motor”.

• On servo axes with indirect position measuring via the encoder, the reference to the

machine coordinate system is lost.

CAUTION!

Injury due to unintended axis movements!

Once the unit has been exchanged, restore the reference to the machine coordinate

system.

Operating Manual: PMCtendo AC 9-3

Page 46

Maintenance and Repair

Notes

9-4 Operating Manual: PMCtendo AC

Page 47

Glossary

C

Constant standstill current Current (sinusoidal effective value) that is required to generate constant

standstill torque M0 when speed n = 0

Abbreviation: I

0

Unit: A

Constant standstill torque Torque that can be applied for an unlimited time when speed n = 0

Abbreviation: M

0

Unit: Nm

M

Mass moment of inertia Mass moment of inertia of the servo motor (with/without holding brake)

1 kgcm2 = 1 x 10-4 kgm

2

Abbreviation: J

Unit: kgm

2

P

Peak current Short-term maximum permitted current (sinusoidal effective value), at

which the servo motor is undamaged

Abbreviation: I

max

Unit: A

Peak torque Torque produced at peak current I

Abbreviation: M

max

max

Unit: Nm

Operating Manual: PMCtendo AC 10-1

Page 48

Glossary

R

Rated current Current (sinusoidal effective value) consumed by the servo motor when

subject to rated speed nN and rated torque M

N

Abbreviation: I

N

Unit: A

Rated power Mechanical output at the servo motor shaft when it is subject to rated

torque MN at rated speed n

Abbreviation: P

N

N

Unit: W

Rated speed Speed at which the rated torque MN can be achieved as a minimum, at

rated voltage U

Abbreviation: n

Unit: min

Rated torque Torque that can be applied for an unlimited time at rated speed n

Abbreviation: M

N

N

-1

N

N

Unit: Nm

Rated voltage Output voltage (sinusoidal effective value) of servo amplifier

Abbreviation: U

N

Unit: V

T

Thermal time constant When there is a load change, the period after which 63 % of the

corresponding temperature change is achieved

After 5 x tth the temperature change is complete.

Abbreviation: T

th

Unit: min

Torque constant Factor for the relationship between current and torque.

When Kt = 1Nm/A, the servo motor generates torque of 1Nm at 1 A

current (sinusoidal effective value)

Abbreviation: K

T

Unit: Nm/A

10-2 Operating Manual: PMCtendo AC

Page 49

Appendix

Changes in the documentation

Changes in Version 21 894-01:

Old

page

- - -

Changes in Version 21 894-02:

Old

page

12-8 to

12-37

New

page

- - -

New

page

12-8 to

12-37

Change

The operating manual was completely revised

Change

Technical details updated

Operating Manual: PMCtendo AC 11-1

Page 50

Appendix

Notes

11-2 Operating Manual: PMCtendo AC

Page 51

Technical Details

General technical details

Electrical data

Supply voltage

Type M

Type H

Current consumption

Current form

Insulation material class

(IEC 60085)

Environmental data

Protection type (IEC 60034-5)

without shaft seal

with shaft seal motor size 21 ... 25

with shaft seal

Mounting position

(IEC 60034-7)

Ambient temperature

(IEC 60034-1)

Storage temperature

(IEC 60034-1)

Cooling

(IEC 60034-6)

Condensation

Installation height

Shaft end

Option with feather key groove

Balancing (DIN ISO 8821)

Feather key groove assembly

Option without feather key groove

Fit

(IEC 60072-1)

Flange

Design

(IEC 60034-7)

Fit

(DIN 42948)

Accuracy

(DIN 42955)

230 V

400 V

see section entitled “Performance data”

Sinusoidal

H

Performance measurement to F

IP44

IP44

IP65

IM B5, IM V1, IM V3

+5 ... +40 °C

-15 ... +40 °C

Self-cooling IC410

Not permitted

≤≤

≤ 1000 m above sea level

≤≤

With feather key

With half feather key

DIN 6885-1

Smooth shaft

k6

IM B5

j6

Increased

Operating Manual: PMCtendo AC 12-1

Page 52

Technical Details

Mechanical data

Weight

Dimensions

The names of products, goods and technologies used in this manual are trademarks of the respective companies.

See section entitled “Mechanical data”

See section entitled “Dimensions”

12-2 Operating Manual: PMCtendo AC

Page 53

Derating

When dimensioning the drive you should take into account the factor K

calculated from the factors K

The factor K

can be used to calculate the permitted torque:

total

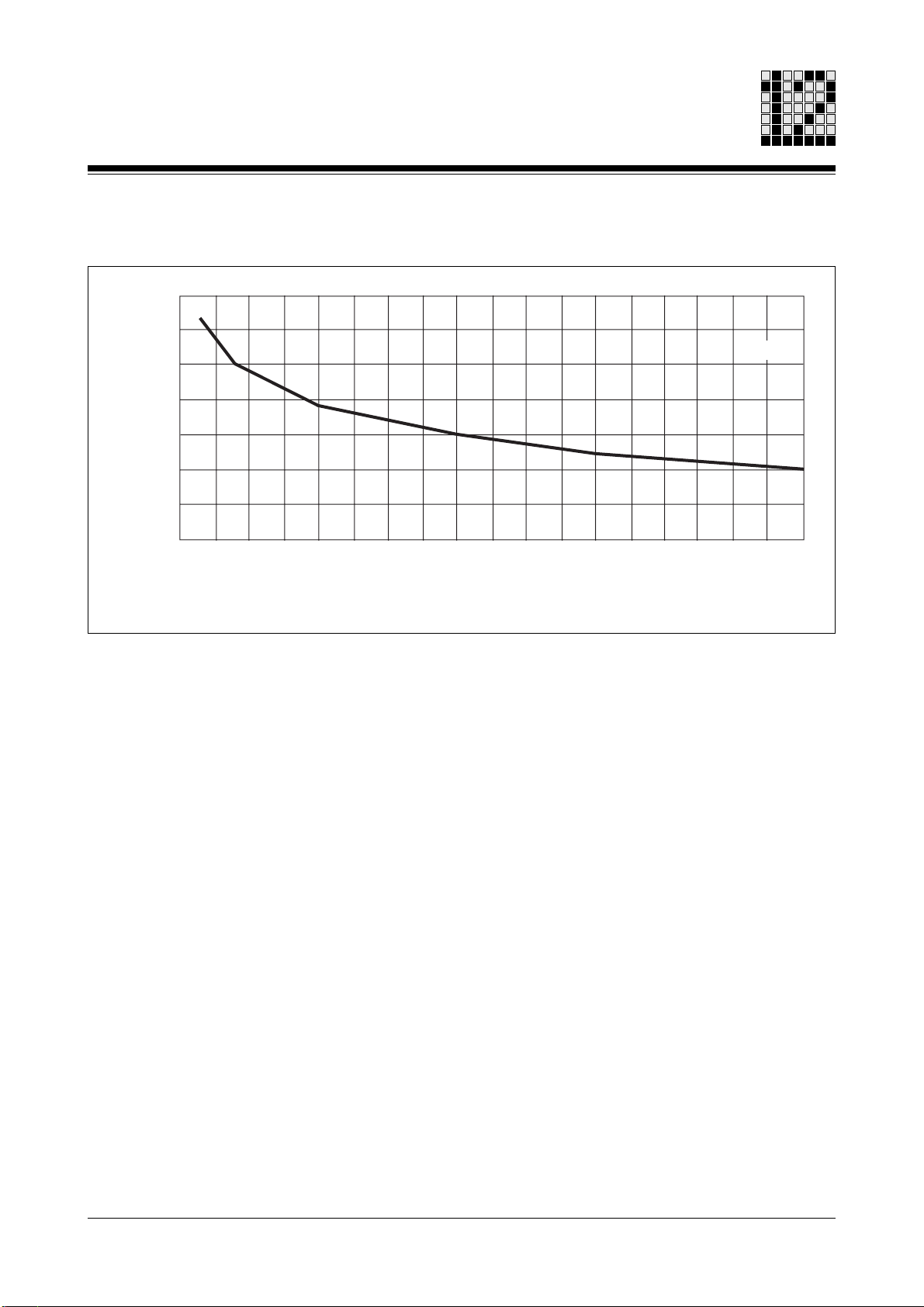

Derating diagram: Installation height

120

100

[%]

N

80

60

40

, K

total

temp

= K

and K

height

height

K

Permitted torque = K

:

duty

* K

* K

temp

* Rated torque M

total

duty

. It is

total

N

K

height

Rated torque M

20

0

500 1000 1500 2000 2500 3000 3500

Installation height [m above sea level]

Fig. 12-1: Permitted torque in relation to installation height

Example:

Installation height = 2000 m above sea level

According to the diagram (Fig. 12-1), at this installation height the permitted torque is

approx. 90 % of the rated torque MN.

This gives the following for factor K

K

= 0.9.

height

height

:

Operating Manual: PMCtendo AC 12-3

Page 54

Technical Details

Derating diagram: Ambient temperature

140

120

100

[%]

N

80

60

40

Rated torque M

20

0

-20 -10 0 10 20 30 40

Ambient temperature [°C]

K

temp

50 60

Fig. 12-2: Permitted torque in relation to ambient temperature

Example:

Ambient temperature = 50 °C

According to the diagram (Fig. 12-2), at this ambient temperature the permitted torque is

approx. 90 % of the rated torque MN.

This gives the following for factor K

K

= 0.9.

temp

temp

:

12-4 Operating Manual: PMCtendo AC

Page 55

Derating diagram: Operating time

350

300

250

[%]

N

200

150

100

Rated torque M

50

K

duty

0

20 30 40 50 60 70 80

Operating time [%]

Fig. 12-3: Permitted torque in relation to operating time

Example:

Operating time = 70 %

According to the diagram (Fig. 12-3), at this operating time the permitted torque is

approx. 125 % of the rated torque MN.

This gives the following for factor K

K

= 1.25.

duty

duty

90 100

:

Operating Manual: PMCtendo AC 12-5

Page 56

Technical Details

Type-specific technical details

Key to the designations used in the table header

The table below contains the key to the designations used in the table header for the

performance data (see section entitled “Performance data”).

Designation

used in the

table header

Msize

UN [V]

Mmax [Nm]

nN [min-1]

M0 [Nm]

I0 [A]

IN [A]

Imax [A]

nmax [min-1]

2p

Uin [V]

Tth [min]

KE [Vs]

KT [Nm/A]

R20 [Ohm]

L [mH]

Unit

- - V

Nm

min-1

Nm

A

A

A

min-1

- - V

min

Vs

Nm/A

Ohm

mH

Key

Motor size

Ratedvoltage

Peak torque

Rated speed

Constant standstill torque

Constant standstill current

Rated current

Peak current

Peak speed

Number of poles

Regenerated voltage

Thermal time constant

Voltage constant

Torque constant

Winding resistance phase/phase

Winding inductance

Table 12-1: Key for performance data

12-6 Operating Manual: PMCtendo AC

Page 57

The table below contains the key to the designations used in the table header for the

mechanical data (see section entitled “Mechanical data”).

Designation

Unit

Key

used in the

table header

Msize

BR

BrValues

J [ kgcm²]

L [mm]

MFB

mNet

Fan

Table 12-2: Key for mechanical data

- - -

- - -

- - kgcm²

mm

- - kg

- - -

Motor size

Brake

Brake connection values

Mass moment of inertia

Overall motor length

Motor feedback

Net weight

Separate ventilation

The table below contains the key to the designations used in the table header for the

dimensions (see section entitled “Dimensions”).

Designation

Unit

Key

used in the

table header

Msize

a1 [mm]

a2 [mm]

b1 [mm]

c1 [mm]

d [mm]

e1 [mm]

f1 [mm]

l [mm]

l1 [mm]

l2 [mm]

s1 [mm]

s2 [mm]

t [mm]

u [mm]

- - mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

mm

Motor size

Motor flange

Motor flange

Centre diameter

Flange strength

Shaft diameter information

Pitch circle diameter

Pitch circle collar

Wavelength

Feather key spacing

Feather key length

Screw hole

Shaft centering thread

Shaft diameter with feather key

Feather key width

Table 12-3: Key for dimensions

Operating Manual: PMCtendo AC 12-7

Page 58

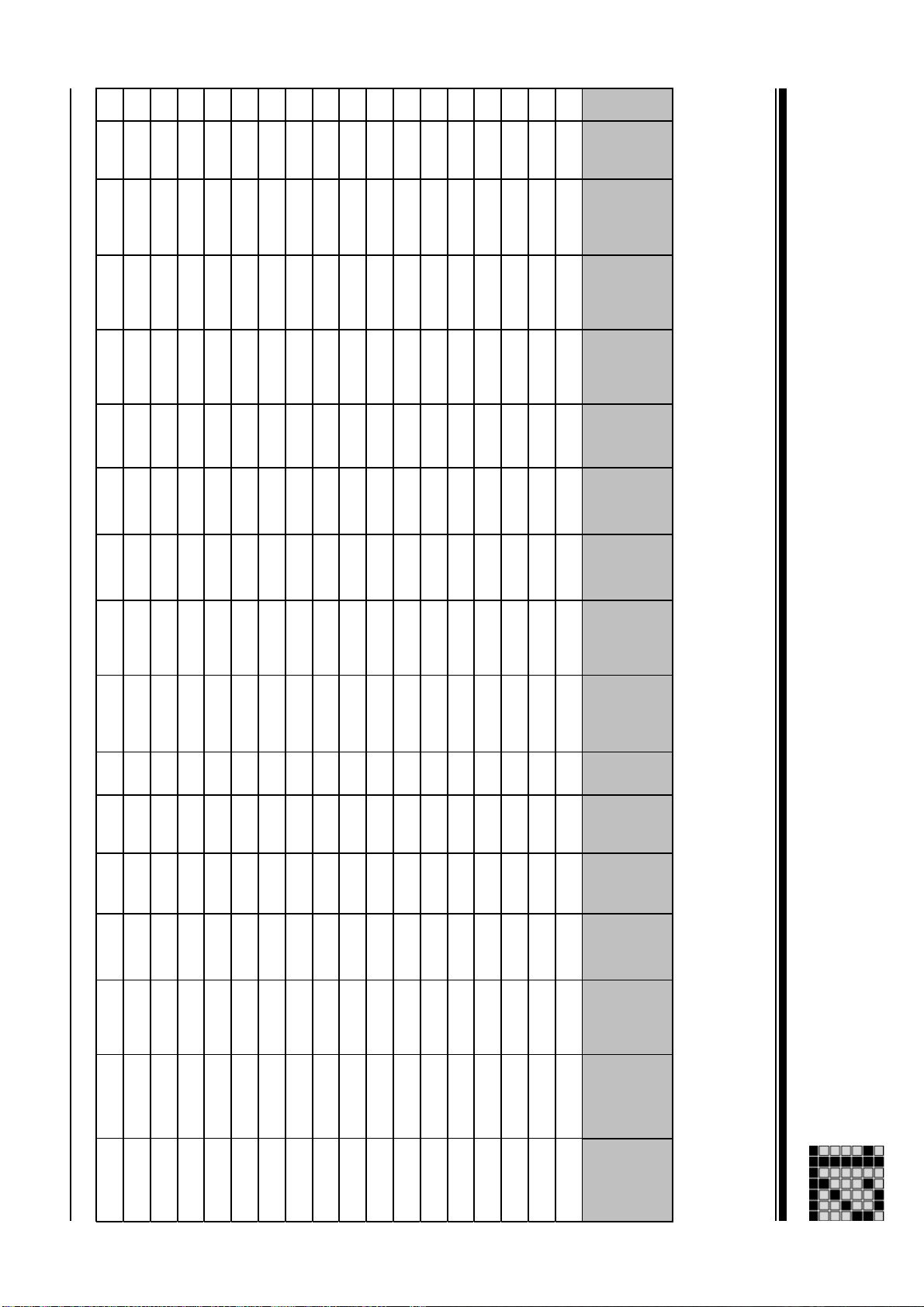

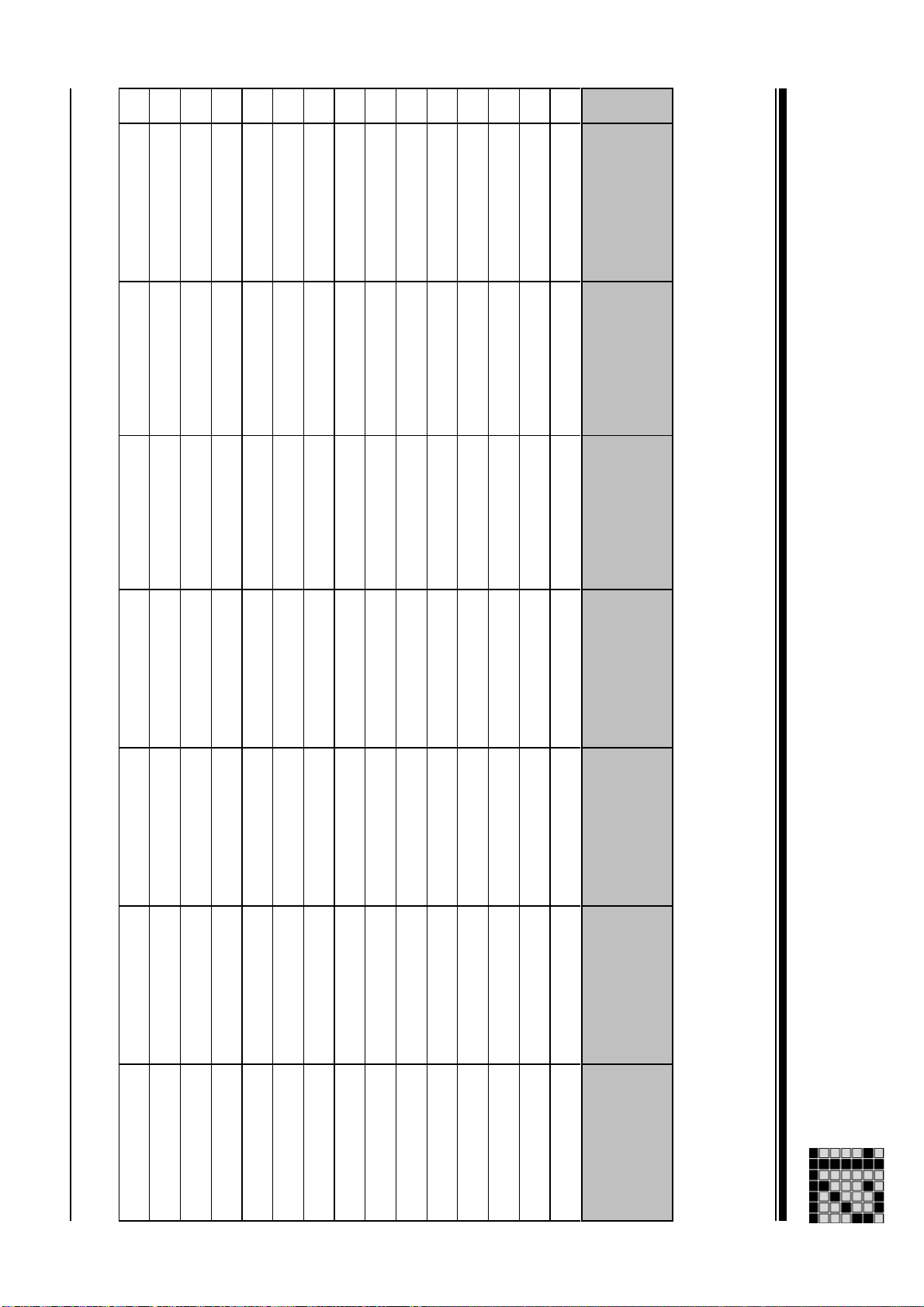

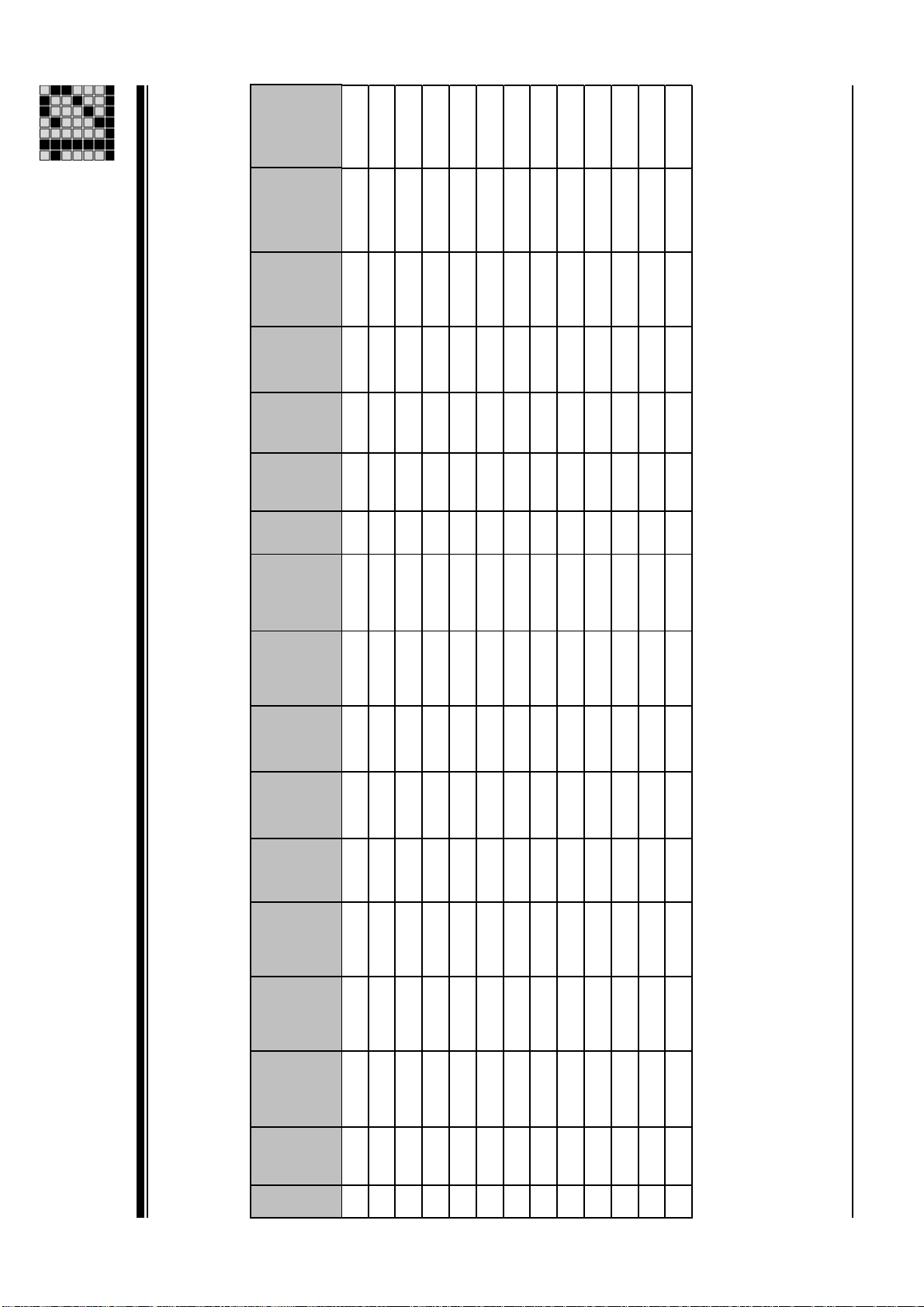

Performance data

Operating Manual: PMCtendo AC 1

61 400 V 2,00 Nm 1,80 Nm 8,80 Nm 1,20 A

61 400 V 2,00 Nm 1,70 Nm 8,80 Nm 1,60 A

61 400 V 2,00 Nm 1,50 Nm 8,80 Nm 2,50 A

54 400 V 2,80 Nm 1,90 Nm 6,60 Nm 3,90 A

53 400 V 1,90 Nm 1,60 Nm 4,80 Nm 1,30 A

53 400 V 1,90 Nm 1,60 Nm 4,80 Nm 1,30 A

53 400 V 1,90 Nm 1,50 Nm 4,80 Nm 1,70 A

53 230 V 1,90 Nm 1,60 Nm 4,80 Nm 2,30 A

52 400 V 1,30 Nm 1,00 Nm 3,30 Nm 1,20 A

52 400 V 1,30 Nm 1,00 Nm 3,30 Nm 0,90 A

52 230 V 1,30 Nm 1,00 Nm 3,30 Nm 1,50 A

52 230 V 1,30 Nm 0,90 Nm 3,30 Nm 3,10 A

51 400 V 0,60 Nm 0,50 Nm 1,70 Nm 0,40 A

25 400 V 0,70 Nm 0,65 Nm 2,20 Nm 0,89 A

24 400 V 0,50 Nm 0,45 Nm 1,63 Nm 0,64 A

24 230 V 0,50 Nm 0,39 Nm 1,63 Nm 2,22 A

22 400 V 0,25 Nm 0,22 Nm 0,81 Nm 0,32 A

21 400 V 0,13 Nm 0,11 Nm 0,41 Nm 0,17 A

Performance data: PMCtendo AC1

Msize

Technical Details

UN [V]

M0 [Nm]

MN [Nm]

Mmax [Nm]

I0 [A]

1,10 A 5,40 A

3000 rpm 6000 rpm 6 296 V 20 min 0,94 V 1,63 Nm 35,60 Ohm 122,00 mH

1,80 A 10,80 A

1,40 A 7,20 A

6000 rpm 6000 rpm 6 296 V 20 min 0,47 V 0,82 Nm 8,80 Ohm 30,00 mH

4000 rpm 6000 rpm 6 296 V 20 min 0,71 V 1,22 Nm 20,10 Ohm 68,00 mH

1,10 A 3,30 A

2,60 A 9,10 A

3000 rpm 6000 rpm 4 264 V 76 min 0,84 V 1,45 Nm 27,80 Ohm 121,70 mH

6000 rpm 6000 rpm 4 263 V 95 min 0,42 V 0,73 Nm 4,41 Ohm 18,40 mH

1,10 A 3,30 A

3000 rpm 6000 rpm 4 263 V 76 min 0,84 V 1,45 Nm 27,80 Ohm 121,70 mH

1,90 A 5,70 A

1,40 A 4,40 A

3000 rpm 6000 rpm 4 152 V 76 min 0,48 V 0,84 Nm 9,46 Ohm 40,90 mH

4000 rpm 6000 rpm 4 263 V 76 min 0,63 V 1,09 Nm 15,90 Ohm 68,90 mH

0,90 A 3,00 A

4000 rpm 6000 rpm 4 263 V 45 min 0,63 V 1,09 Nm 29,80 Ohm 105,80 mH

0,68 A 2,30 A

3000 rpm 6000 rpm 4 263 V 45 min 0,84 V 1,45 Nm 52,70 Ohm 187,20 mH

2,10 A 7,90 A

1,20 A 3,90 A

6000 rpm 6000 rpm 4 152 V 45 min 0,24 V 0,42 Nm 4,60 Ohm 16,40 mH

3000 rpm 6000 rpm 4 152 V 45 min 0,48 V 0,84 Nm 17,80 Ohm 64,00 mH

0,30 A 1,20 A

3000 rpm 6000 rpm 4 263 V 50 min 0,84 V 1,45 Nm 160,00 Ohm 446,00 mH

0,57 A 2,10 A

0,83 A 2,80 A

3000 rpm 6000 rpm 4 142 V 40 min 0,45 V 0,78 Nm 59,00 Ohm 130,00 mH

3000 rpm 6000 rpm 4 142 V 43 min 0,45 V 0,78 Nm 45,00 Ohm 97,00 mH

0,28 A 1,00 A

1,73 A 7,23 A

3000 rpm 6000 rpm 4 142 V 35 min 0,45 V 0,78 Nm 180,00 Ohm 284,00 mH

6000 rpm 6000 rpm 4 82 V 40 min 0,13 V 0,23 Nm 5,00 Ohm 11,00 mH

0,14 A 0,52 A

3000 rpm 6000 rpm 4 142 V 32 min 0,45 V 0,78 Nm 536,00 Ohm 635,00 mH

IN [A]

Imax [A]

nN [min-1]

nmax [min-1]

2p

Uin [V]

Tth [min]

KE [Vs]

KT [Nm/A]

R20 [Ohm]

L [mH]

2 - 8

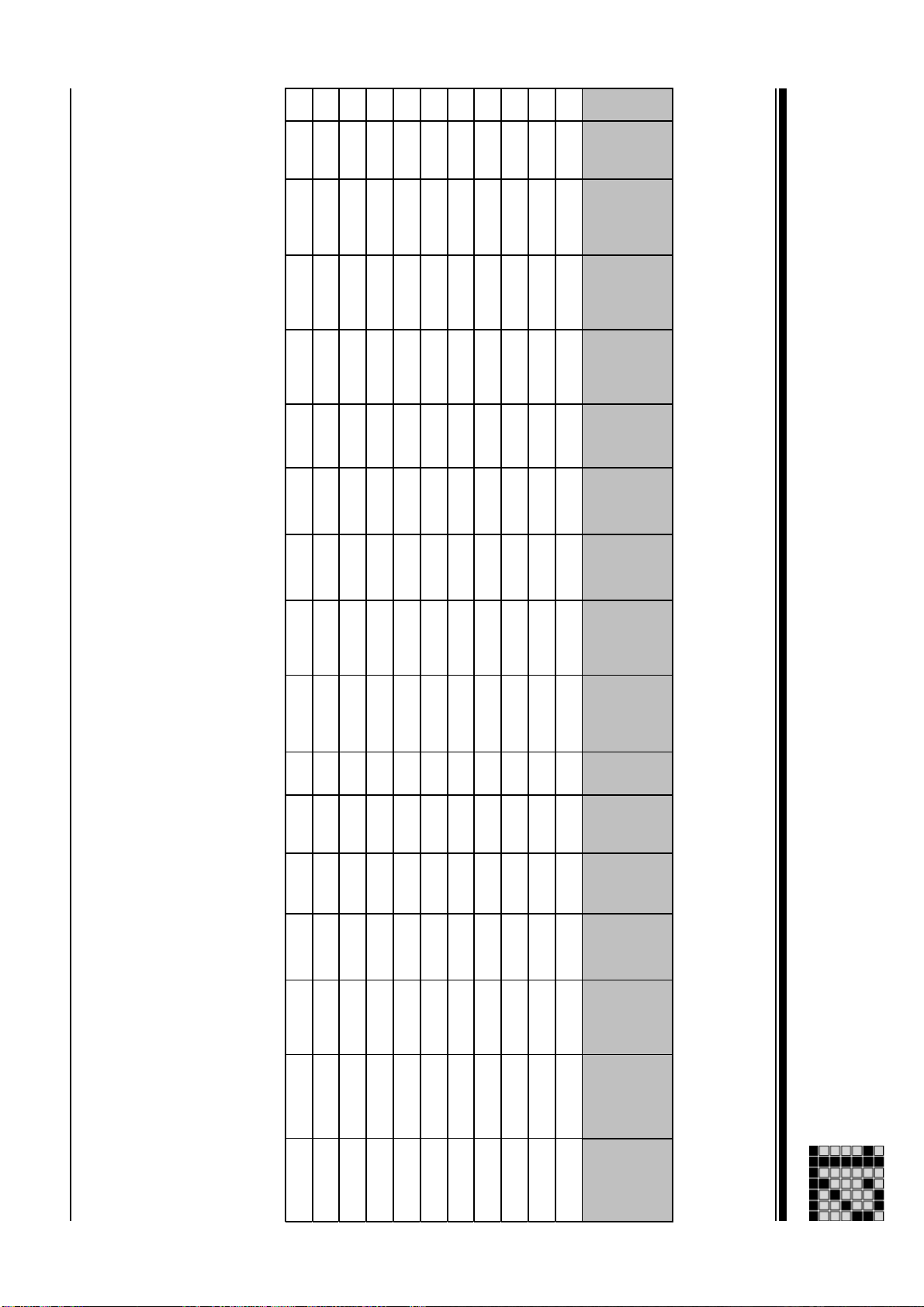

Page 59

L [mH]

R20 [Ohm]

KT [Nm/A]

KE [Vs]

Tth [min]

Uin [V]

2p

2 - 9

nmax [min-1]

nN [min-1]

Imax [A]

IN [A]

I0 [A]

Mmax [Nm]

MN [Nm]

3000 rpm 4000 rpm 6 171 V 25 min 0,54 V 0,94 Nm 3,50 Ohm 16,00 mH

4000 rpm 4000 rpm 6 296 V 25 min 0,71 V 1,22 Nm 5,70 Ohm 25,00 mH

3,70 A 18,10 A

2,70 A 14,00 A

4000 rpm 6000 rpm 6 296 V 25 min 0,71 V 1,22 Nm 5,70 Ohm 25,00 mH

3000 rpm 4000 rpm 6 296 V 25 min 0,94 V 1,63 Nm 11,10 Ohm 48,70 mH

2,70 A 14,00 A

2,10 A 10,50 A

2000 rpm 4000 rpm 6 296 V 25 min 1,14 V 2,45 Nm 24,80 Ohm 108,40 mH

1,50 A 7,00 A

4000 rpm 6000 rpm 6 296 V 30 min 0,71 V 1,22 Nm 3,00 Ohm 15,80 mH

3000 rpm 4000 rpm 6 296 V 30 min 0,94 V 1,63 Nm 5,50 Ohm 28,50 mH

4,10 A 20,00 A

3,30 A 15,00 A

3000 rpm 4000 rpm 6 297 V 30 min 0,94 V 1,63 Nm 5,50 Ohm 28,50 mH

3000 rpm 4000 rpm 6 298 V 30 min 0,94 V 1,63 Nm 5,50 Ohm 28,50 mH

3,30 A 15,00 A

3,30 A 15,00 A

4000 rpm 6000 rpm 6 171 V 30 min 0,41 V 0,71 Nm 0,68 Ohm 4,10 mH

4000 rpm 6000 rpm 6 296 V 30 min 0,71 V 1,22 Nm 2,00 Ohm 11,90 mH

9,30 A 46,80 A

5,40 A 27,10 A

3000 rpm 4000 rpm 6 296 V 30 min 0,94 V 1,63 Nm 3,70 Ohm 22,50 mH

6000 rpm 6000 rpm 6 296 V 35 min 0,47 V 0,82 Nm 0,68 Ohm 4,23 mH

4,40 A 20,30 A

9,40 A 49,70 A

3000 rpm 4000 rpm 6 171 V 45 min 0,54 V 0,94 Nm 0,76 Ohm 5,41 mH

4000 rpm 4000 rpm 6 296 V 45 min 0,71 V 1,22 Nm 1,20 Ohm 7,70 mH

8,30 A 39,20 A

11,10 A 50,90 A

3000 rpm 4000 rpm 6 296 V 45 min 0,94 V 1,63 Nm 2,30 Ohm 15,10 mH

3000 rpm 4000 rpm 6 171 V 45 min 0,54 V 0,94 Nm 0,42 Ohm 3,59 mH

6,40 A 29,40 A

15,00 A 63,70 A

4000 rpm 4000 rpm 6 296 V 45 min 0,71 V 1,22 Nm 0,86 Ohm 7,00 mH

8,60 A 49,00 A

M0 [Nm]

UN [V]

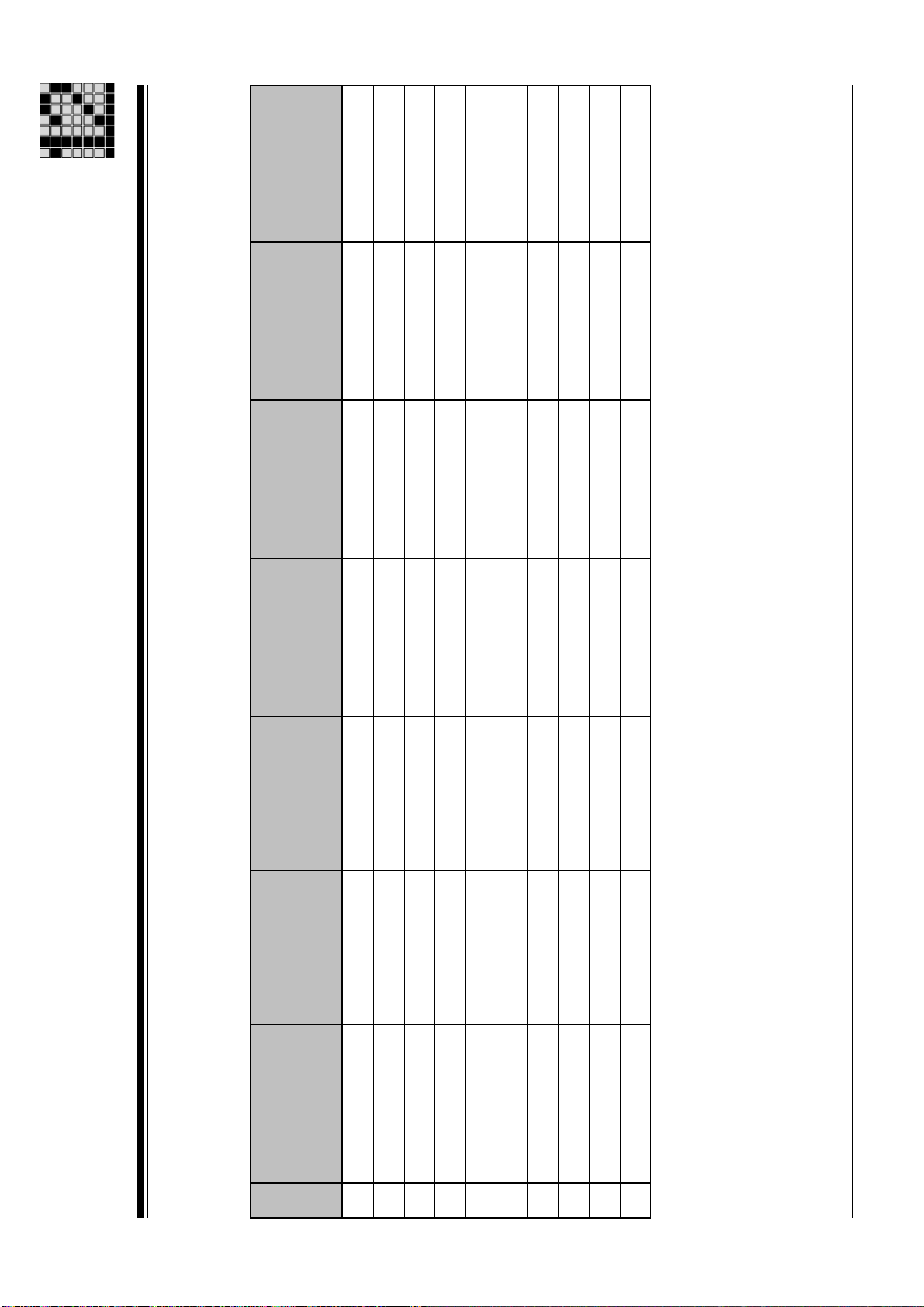

Performance data: PMCtendo AC1

Msize

Technical Details

Performance data

62 230 V 4,00 Nm 3,50 Nm 17,10 Nm 4,20 A

62 400 V 4,00 Nm 3,30 Nm 17,10 Nm 3,30 A

62 400 V 4,00 Nm 3,30 Nm 17,10 Nm 3,30 A

62 400 V 4,00 Nm 3,50 Nm 17,10 Nm 2,50 A

62 400 V 4,00 Nm 3,60 Nm 17,10 Nm 1,60 A

63 400 V 6,00 Nm 5,00 Nm 24,40 Nm 4,90 A

63 400 V 6,00 Nm 5,30 Nm 24,40 Nm 3,70 A

63 400 V 6,00 Nm 5,30 Nm 24,40 Nm 3,70 A

63 400 V 6,00 Nm 5,30 Nm 24,40 Nm 3,70 A

64 230 V 8,00 Nm 6,60 Nm 33,10 Nm 11,30 A

64 400 V 8,00 Nm 6,60 Nm 33,10 Nm 6,50 A

64 400 V 8,00 Nm 7,10 Nm 33,10 Nm 4,90 A

65 400 V 10,00 Nm 7,70 Nm 40,50 Nm 12,30 A

73 230 V 11,70 Nm 10,50 Nm 48,00 Nm 12,20 A

73 400 V 11,70 Nm 10,10 Nm 48,00 Nm 9,60 A

73 400 V 11,70 Nm 10,50 Nm 48,00 Nm 7,20 A

74 230 V 15,60 Nm 14,10 Nm 60,00 Nm 16,60 A

74 400 V 15,60 Nm 13,50 Nm 60,00 Nm 9,60 A

Operating Manual: PMCtendo AC 1

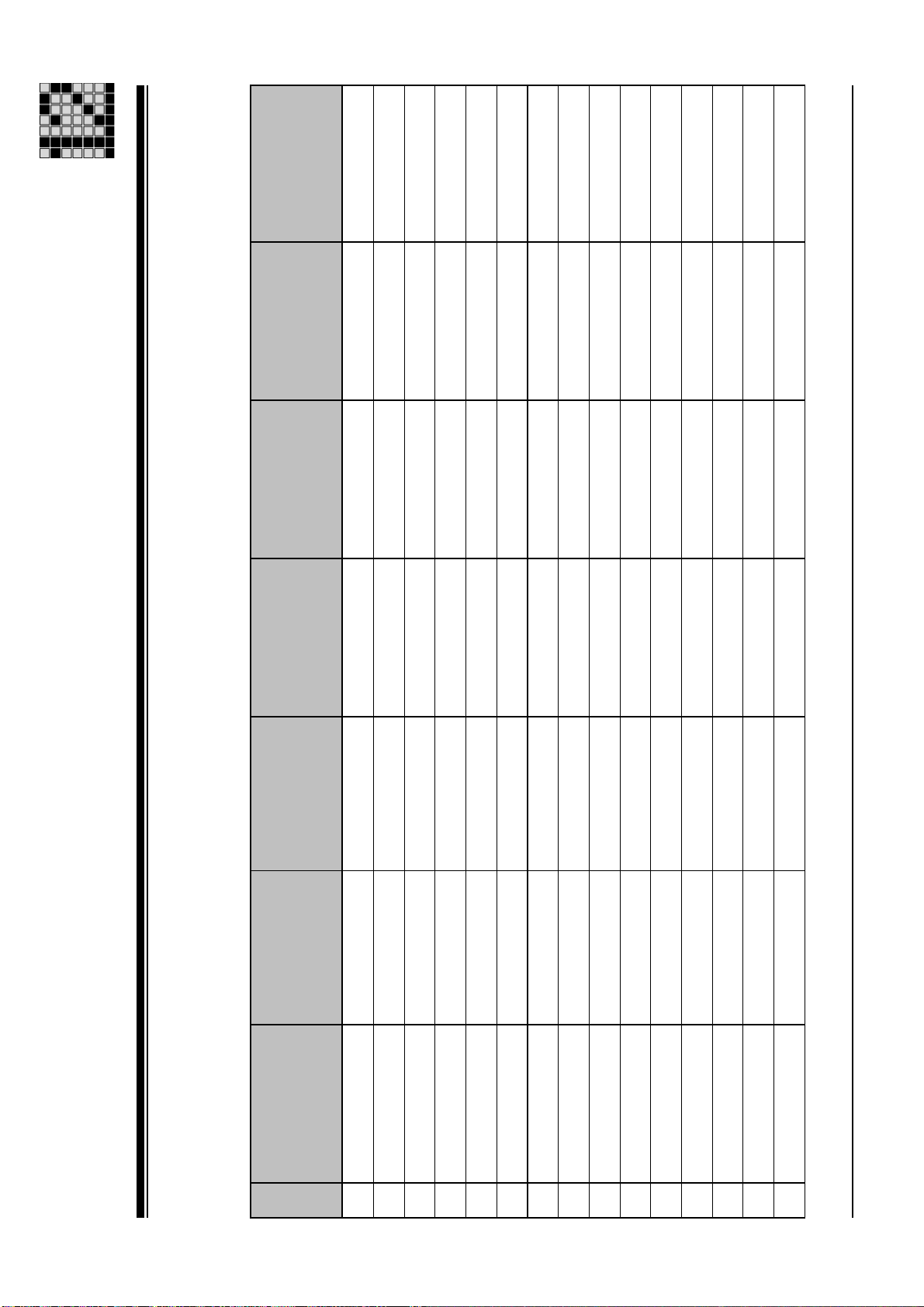

Page 60

Performance data

Operating Manual: PMCtendo AC 1

A7 400 V 43,00 Nm 39,10 Nm 139,00 Nm 17,60 A

A9 400 V 54,00 Nm 49,10 Nm 163,00 Nm 22,00 A

A4 400 V 24,00 Nm 21,80 Nm 89,00 Nm 9,80 A

A5 400 V 30,00 Nm 26,20 Nm 99,00 Nm 18,40 A

A2 400 V 12,00 Nm 10,10 Nm 41,00 Nm 12,80 A

A4 400 V 24,00 Nm 20,90 Nm 89,00 Nm 14,70 A

76 400 V 23,40 Nm 20,10 Nm 92,00 Nm 19,10 A

76 400 V 23,40 Nm 21,10 Nm 92,00 Nm 14,30 A

74 400 V 15,60 Nm 14,10 Nm 60,00 Nm 9,60 A

75 230 V 19,50 Nm 17,60 Nm 80,00 Nm 20,70 A

74 400 V 15,60 Nm 14,10 Nm 60,00 Nm 12,70 A

Performance data: PMCtendo AC1

Msize

Technical Details

UN [V]

M0 [Nm]

MN [Nm]

Mmax [Nm]

I0 [A]

16,00 A 56,70 A

20,00 A 66,50 A

2000 rpm 3000 rpm 6 296 V 65 min 1,41 V 2,45 Nm 0,55 Ohm 7,60 mH

2000 rpm 4000 rpm 6 296 V 70 min 1,41 V 2,45 Nm 0,39 Ohm 5,90 mH

16,00 A 60,60 A

8,90 A 36,30 A

2000 rpm 3000 rpm 6 296 V 55 min 1,41 V 2,45 Nm 1,10 Ohm 13,60 mH

3000 rpm 4000 rpm 6 296 V 60 min 0,94 V 1,63 Nm 0,37 Ohm 5,30 mH

10,70 A 43,60 A

12,80 A 54,50 A

3000 rpm 4000 rpm 6 296 V 50 min 0,94 V 1,63 Nm 1,70 Ohm 20,50 mH

3000 rpm 4000 rpm 6 296 V 55 min 0,94 V 1,63 Nm 0,55 Ohm 6,80 mH

16,40 A 75,20 A

12,90 A 56,40 A

4000 rpm 4000 rpm 6 296 V 55 min 0,71 V 1,22 Nm 0,35 Ohm 2,90 mH

3000 rpm 4000 rpm 6 296 V 55 min 0,94 V 1,63 Nm 0,64 Ohm 5,40 mH

18,70 A 84,90 A

8,60 A 36,80 A

3000 rpm 4000 rpm 6 296 V 45 min 0,94 V 1,63 Nm 1,61 Ohm 13,00 mH

3000 rpm 4000 rpm 6 171 V 50 min 0,54 V 0,94 Nm 0,32 Ohm 2,84 mH

11,00 A 36,80 A

3000 rpm 4000 rpm 6 296 V 45 min 0,94 V 1,63 Nm 1,61 Ohm 13,00 mH

IN [A]

Imax [A]

nN [min-1]

nmax [min-1]

2p

Uin [V]

Tth [min]

KE [Vs]

KT [Nm/A]

R20 [Ohm]

L [mH]

2 - 10

Page 61

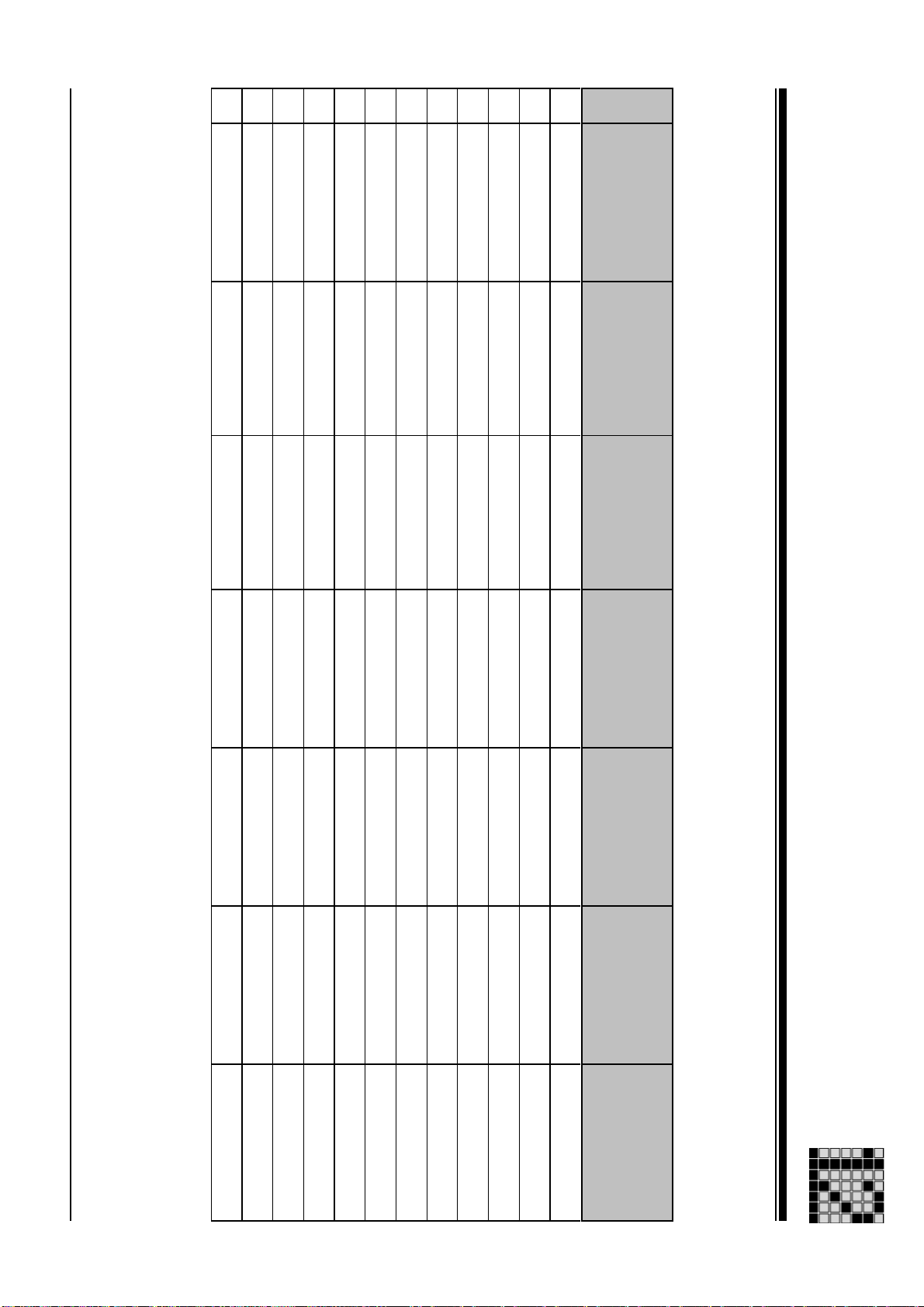

Fan

mNet

MFB

11

2 -

L [mm]

J [ kgcm²]

BrValues

no 0,21 kgcm² 149 mm Resolver 2-pole 1.650 g no

no 0,16 kgcm² 129 mm Resolver 2-pole 1.350 g no

no 0,32 kgcm² 189 mm Resolver 2-pole 2.250 g no

no 0,32 kgcm² 190 mm Resolver 2-pole 2.250 g no

no 0,38 kgcm² 209 mm Resolver 2-pole 2.550 g no

24VDC/0,51A/3,5Nm 1,40 kgcm² 238 mm Resolver 2-pole 5.200 g no

no 0,73 kgcm² 185 mm Resolver 2-pole 3.700 g no

24VDC/0,51A/3,5Nm 2,22 kgcm² 263 mm Hiperface single-turn 6.200 g no

24VDC/0,51A/3,5Nm 2,22 kgcm² 263 mm Resolver 2-pole 6.200 g no

no 1,40 kgcm² 210 mm Resolver 2-pole 4.600 g no

24VDC/0,71A/9,5Nm 6,85 kgcm² 229 mm Resolver 2-pole 7.800 g no

no 1,84 kgcm² 235 mm Hiperface multi-turn 5.600 g no

no 1,84 kgcm² 235 mm Hiperface single-turn 5.600 g no

no 1,84 kgcm² 235 mm Resolver 2-pole 5.600 g no

no 2,28 kgcm² 260 mm Resolver 2-pole 6.500 g no

BR

Msize

Technical Details

Mechanical data: PMCtendo AC1

Mechanical data

21

22

24

24

25

51

52 yes

52

53 yes

53 yes

53

53

53

54

61 yes

Operating Manual: PMCtendo AC 1

Page 62

Operating Manual: PMCtendo AC 1

74

74 yes

74

73 yes

73

65

64

64

64 yes

63

63

62

63 yes

61

62 yes

Msize

Mechanical data

Mechanical data: PMCtendo AC1

Technical Details

BR

no 31,53 kgcm² 284 mm Resolver 2-pole 16.400 g no

no 31,53 kgcm² 330 mm

no 23,60 kgcm² 259 mm Resolver 2-pole 14.100 g no

24VDC/0,96A/27,0Nm 41,03 kgcm² 314 mm Resolver 2-pole 18.300 g no

no 11,20 kgcm² 274 mm Resolver 2-pole 10.100 g no

no 11,20 kgcm² 338 mm Ext. encoder mount-ready 10.100 g no

no 13,65 kgcm² 331 mm Hiperface multi-turn 12.000 g no

24VDC/0,96A/27,0Nm 33,10 kgcm² 289 mm Resolver 2-pole 16.100 g no

24VDC/0,71A/9,5Nm 14,80 kgcm² 305 mm Resolver 2-pole 12.200 g no

no 8,55 kgcm² 249 mm Resolver 2-pole 9.000 g no

no 8,55 kgcm² 313 mm Ext. encoder mount-ready 9.000 g no

no 5,81 kgcm² 224 mm Resolver 2-pole 7.100 g no

24VDC/0,71A/9,5Nm 12,15 kgcm² 280 mm Resolver 2-pole 10.800 g no

24VDC/0,71A/9,5Nm 9,41 kgcm² 255 mm Resolver 2-pole 9.300 g no

no 3,25 kgcm² 199 mm Resolver 2-pole 6.000 g no

BrValues

J [ kgcm²]

L [mm]

2 12

Ext. encoder mount-ready 16.400 g no

MFB

mNet

Fan

Page 63

Fan

mNet

MFB

13

2 -

L [mm]

J [ kgcm²]

BrValues

no 38,44 kgcm² 309 mm Resolver 2-pole 18.600 g no

no 45,35 kgcm² 334 mm Resolver 2-pole 20.800 g no

no 6,80 kgcm² 276 mm Resolver 2-pole 26.000 g no

no 136,00 kgcm² 301 mm Resolver 2-pole 26.000 g no

no 136,00 kgcm² 328 mm Hiperface multi-turn 26.000 g no

331,80 kgcm² 490 mm Resolver 2-pole 52.600 g no

24VDC/0,90A/48,0Nm 269,80 kgcm² 376 mm Resolver 2-pole 44.600 g no

no 136,00 kgcm² 328 mm Hiperface single-turn 26.000 g no

no 170,00 kgcm² 353 mm Hiperface single-turn 30.000 g no

no 170,00 kgcm² 353 mm Resolver 2-pole 30.000 g no

BR

Msize

Technical Details

Mechanical data: PMCtendo AC1

Mechanical data

75

76

A2

A4

A4

A4

A5

A5

A7 yes

A9 yes

Operating Manual: PMCtendo AC 1

Page 64

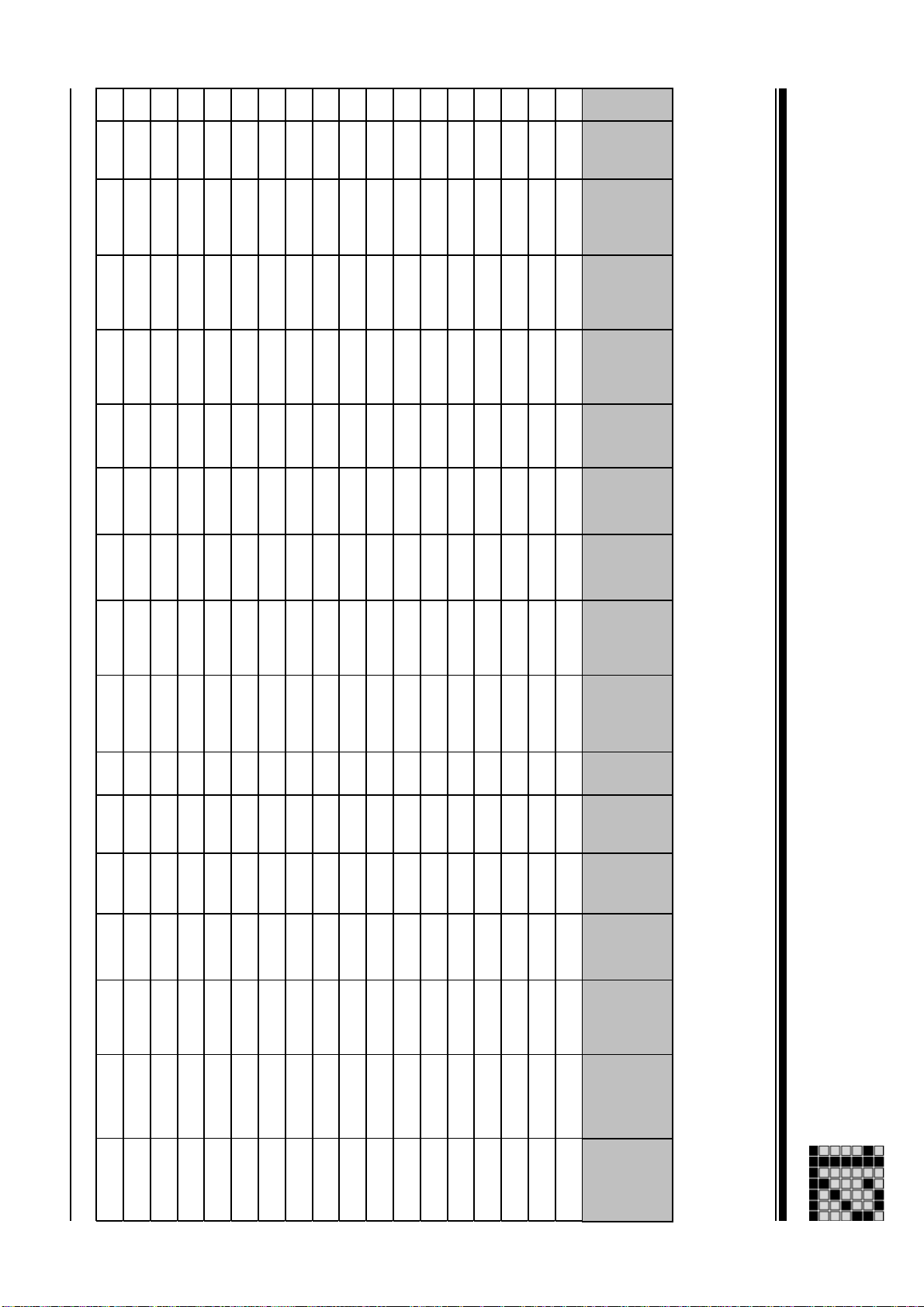

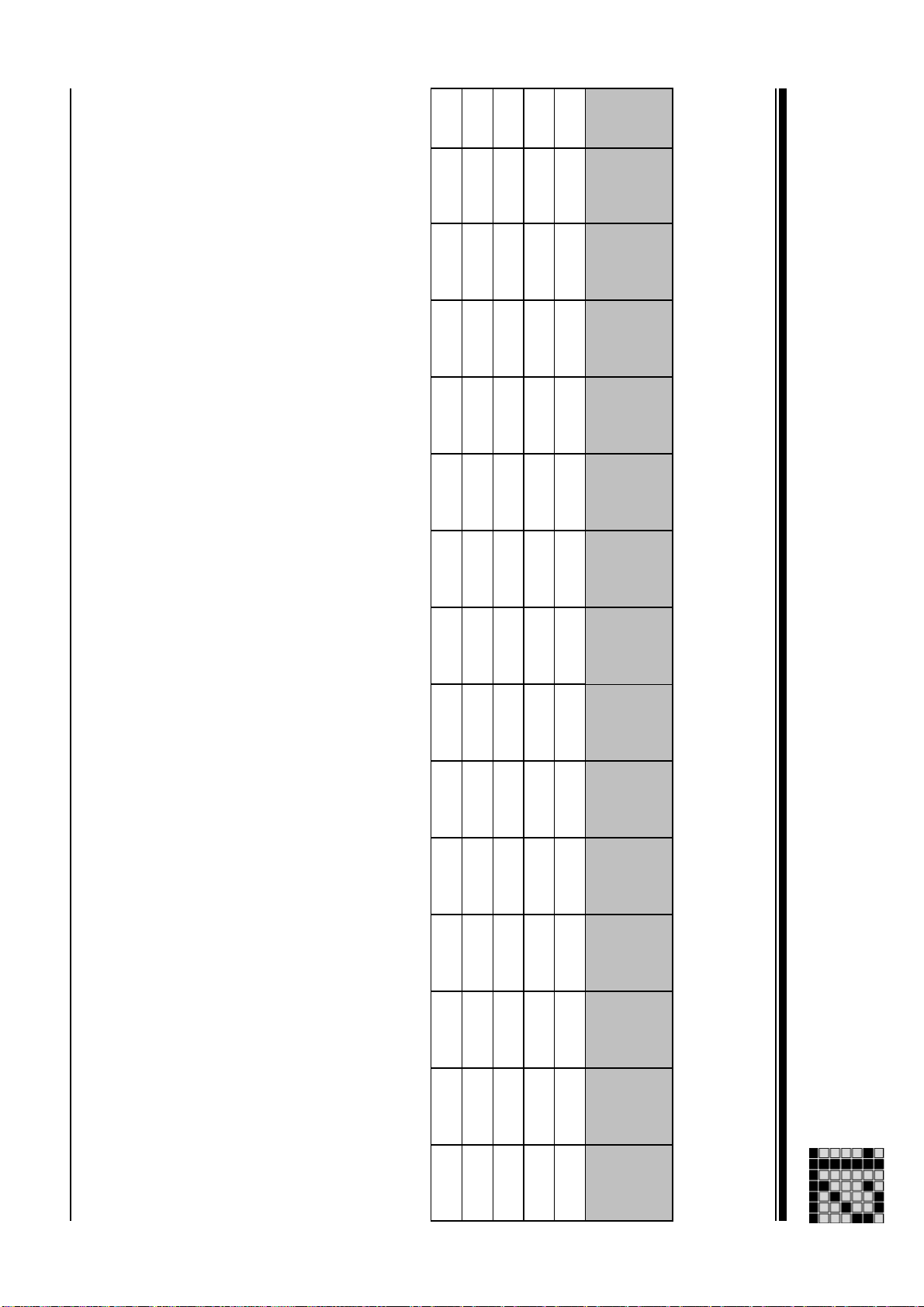

Dimensions

Operating Manual: PMCtendo AC 1

22 9 mm58 mm 40 mm 8 mm 63 mm 2,5 mm 20 mm 2,5 mm 15 mm 5,5 mm 10,5 mm 3 mm

24 9 mm58 mm 40 mm 8 mm 63 mm 2,5 mm 20 mm 2,5 mm 15 mm 5,5 mm 10,5 mm 3 mm

25 9 mm58 mm 40 mm 8 mm 63 mm 2,5 mm 20 mm 2,5 mm 15 mm 5,5 mm 10,5 mm 3 mm

51 14 mm92 mm 80 mm 11 mm 100 mm 3,0 mm 30 mm 5,0 mm 20 mm 6,6 mm M5 x 10 16,0 mm 5 mm

52 14 mm92 mm 80 mm 11 mm 100 mm 3,0 mm 30 mm 5,0 mm 20 mm 6,6 mm M5 x 10 16,0 mm 5 mm

53 14 mm92 mm 80 mm 11 mm 100 mm 3,0 mm 30 mm 5,0 mm 20 mm 6,6 mm M5 x 10 16,0 mm 5 mm

54 14 mm92 mm 80 mm 11 mm 100 mm 3,0 mm 30 mm 5,0 mm 20 mm 6,6 mm M5 x 10 16,0 mm 5 mm

61 19 mm115 mm 95 mm 8 mm 115 mm 3,0 mm 40 mm 5,0 mm 30 mm 9,0 mm M6 x 20 21,0 mm 6 mm

62 19 mm115 mm 95 mm 8 mm 115 mm 3,0 mm 40 mm 5,0 mm 30 mm 9,0 mm M6 x 20 21,0 mm 6 mm

63 19 mm115 mm 95 mm 8 mm 115 mm 3,0 mm 40 mm 5,0 mm 30 mm 9,0 mm M6 x 20 21,0 mm 6 mm

64 19 mm115 mm 95 mm 8 mm 115 mm 3,0 mm 40 mm 5,0 mm 30 mm 9,0 mm M6 x 20 21,0 mm 6 mm

65 19 mm115 mm 95 mm 8 mm 115 mm 3,0 mm 40 mm 5,0 mm 30 mm 9,0 mm M6 x 20 21,0 mm 6 mm

73 24 mm142 mm 130 mm 12 mm 165 mm 3,5 mm 50 mm 5,0 mm 40 mm 12,0 mm M8 x 20 27,0 mm 8 mm

74 24 mm142 mm 130 mm 12 mm 165 mm 3,5 mm 50 mm 5,0 mm 40 mm 12,0 mm M8 x 20 27,0 mm 8 mm

21 9 mm58 mm 40 mm 8 mm 63 mm 2,5 mm 20 mm 2,5 mm 15 mm 5,5 mm 10,5 mm 3 mm

Dimensions: PMCtendo AC1

Msize

a1 [mm]

a2 [mm]

b1 [mm]

c1 [mm]

d [mm]

Technical Details

e1 [mm]

f1 [mm]

l [mm]

l1 [mm]

l2 [mm]

s1 [mm]

s2 [mm]

t [mm]

u [mm]

2 - 14

Page 65

u [mm]

t [mm]

s2 [mm]

s1 [mm]

l2 [mm]

l1 [mm]

2 - 15

l [mm]

f1 [mm]

e1 [mm]

d [mm]

c1 [mm]

b1 [mm]

a2 [mm]

a1 [mm]

Technical Details

Dimensions

Msize

Dimensions: PMCtendo AC1

75 24 mm142 mm 130 mm 12 mm 165 mm 3,5 mm 50 mm 5,0 mm 40 mm 12,0 mm M8 x 20 27,0 mm 8 mm

76 24 mm142 mm 130 mm 12 mm 165 mm 3,5 mm 50 mm 5,0 mm 40 mm 12,0 mm M8 x 20 27,0 mm 8 mm

A2 32 mm190 mm 180 mm 16 mm 215 mm 4,0 mm 58 mm 6,5 mm 45 mm 13,0 mm M12 x 20 35,5 mm 10 mm

A4 32 mm190 mm 180 mm 16 mm 215 mm 4,0 mm 58 mm 6,5 mm 45 mm 13,0 mm M12 x 20 35,5 mm 10 mm

A5 32 mm190 mm 180 mm 16 mm 215 mm 4,0 mm 58 mm 6,5 mm 45 mm 13,0 mm M12 x 20 35,5 mm 10 mm

A7 32 mm190 mm 180 mm 16 mm 215 mm 4,0 mm 58 mm 6,5 mm 45 mm 13,0 mm M12 x 20 35,5 mm 10 mm

A9 32 mm190 mm 180 mm 16 mm 215 mm 4,0 mm 58 mm 6,5 mm 45 mm 13,0 mm M12 x 20 35,5 mm 10 mm

Operating Manual: PMCtendo AC 1

Page 66

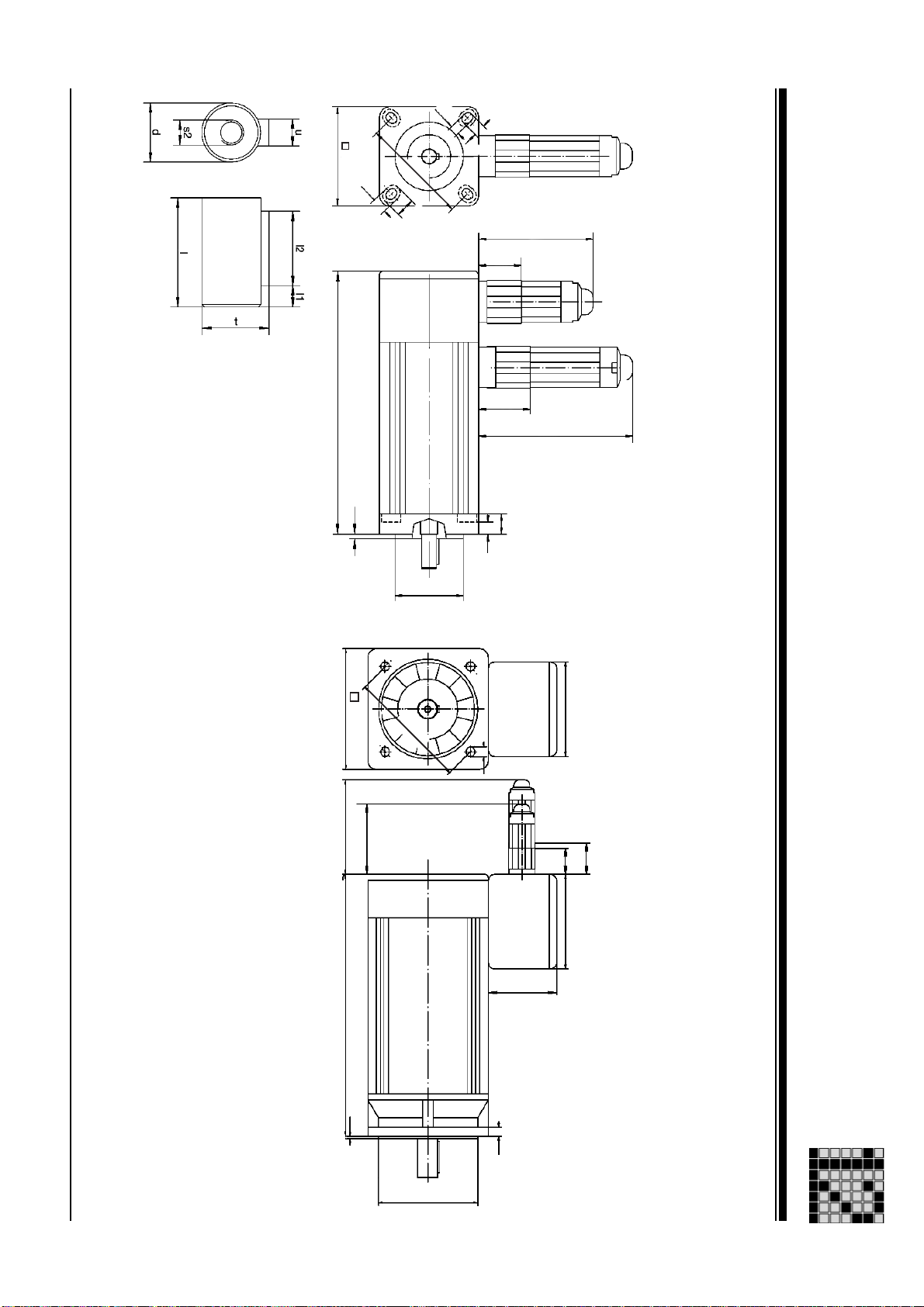

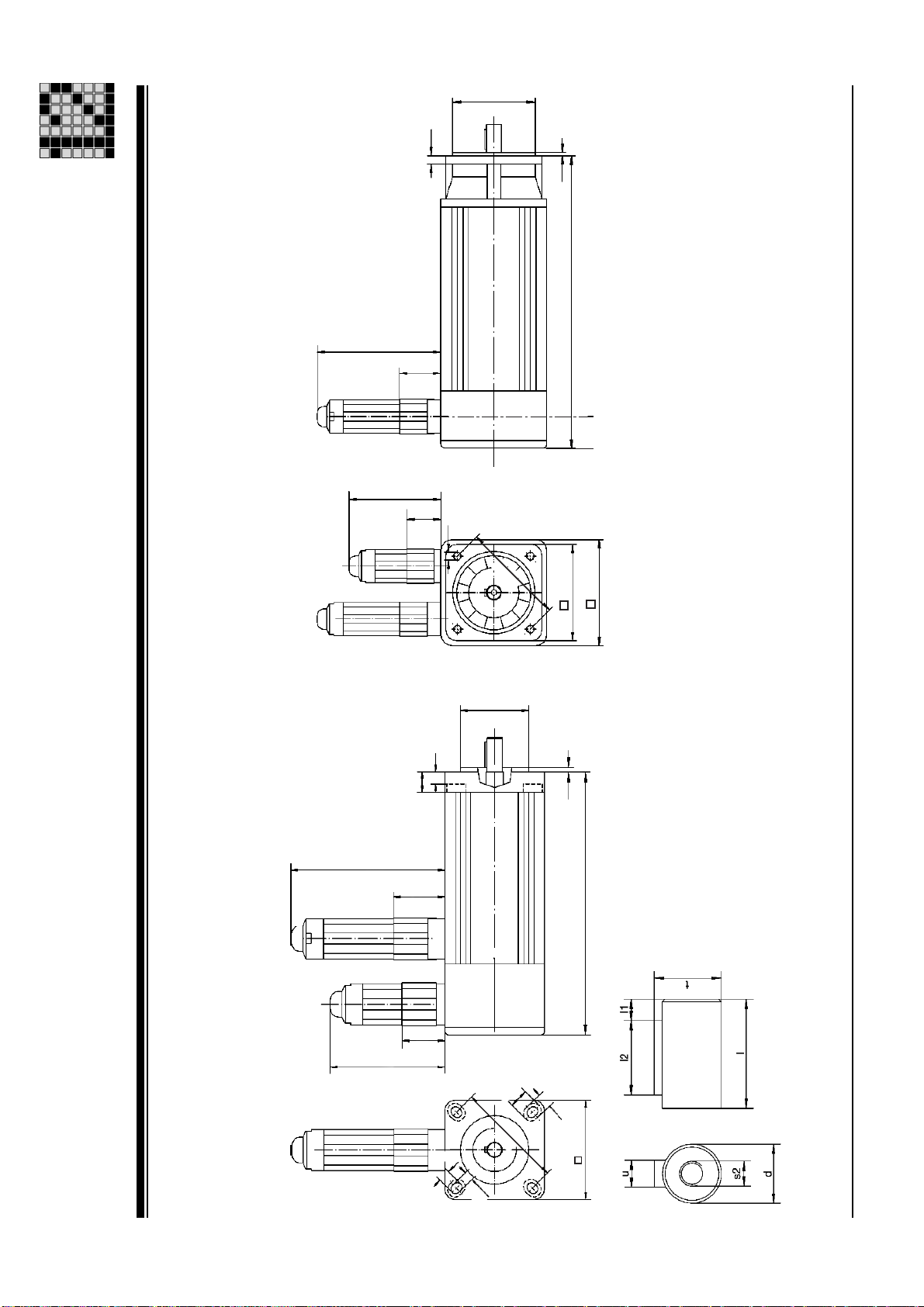

Dimensioned drawing: PMCtendo AC1

Operating Manual: PMCtendo AC 1

5,5

Msize: 2x Msize: 5x ... Ax

Dimensioned drawing

Technical Details

a1

L

Æ

10

f1

e1

11,5

b1

Æ

70

24

34

90

12

c1

a1

90

L

f1

70

Æ

e1

s1

91

34

24 84

67

c1

2 16

b1

Æ

Page 67

L [mH]

R20 [Ohm]

KT [Nm/A]

KE [Vs]

Tth [min]

Uin [V]

2p

2 - 17

nmax [min-1]

nN [min-1]

Imax [A]

IN [A]

I0 [A]

Mmax [Nm]

MN [Nm]

6000 rpm 6000 rpm 4 263 V 32 min 0,42 V 0,73 Nm 203,00 Ohm 172,00 mH