Page 1

WORKSHOP MANUAL

633234

X9 Evolution 500

Page 2

WORKSHOP

MANUAL

X9 Evolution 500

The descriptions and illustrations given in this publication are not binding. While the basic specifications

as described and illustrated in this manual remain unchanged, PIAGGIO-GILERA reserves the right, at

any time and without being required to update this publication beforehand, to make any changes to

components, parts or accessories, which it considers necessary to improve the product or which are

required for manufacturing or construction reasons.

Not all versions shown in this publication are available in all countries. The availability of single versions

should be checked at the official Piaggio sales network.

"© Copyright 2005 - PIAGGIO & C. S.p.A. Pontedera. All rights reserved. Reproduction of this publication

in whole or in part is prohibited."

PIAGGIO & C. S.p.A. - Q.C.S./After sales V.le Rinaldo Piaggio, 23 - 56025 PONTEDERA (Pi)

www.piaggio.com

Page 3

WORKSHOP MANUAL

X9 Evolution 500

This workshop manual has been drawn up by Piaggio & C. Spa to be used by the workshops of PiaggioGilera dealers. This manual is addressed to Piaggio service mechanics who are supposed to have a

basic knowledge of mechanics principles and of vehicle fixing techniques and procedures. Any important

changes made to the vehicles or to specific fixing operations will be promptly reported by updates to this

manual. Nevertheless, no fixing work can be satisfactory if the necessary equipment and tools are

unavailable. It is therefore advisable to read the sections of this manual relating to specific tools, along

with the specific tool catalogue. Important information in this manual is marked as follows.

N.B. Provides key information to make the procedure easier to understand and carry out.

CAUTION Refers to specific procedures to carry out for preventing damages to the vehicle.

WARNING Refers to specific procedures to carry out to prevent injuries to the repairer.

Personal safety Failure to completely observe these instructions will result in serious risk of personal

injury.

Safeguarding the environment Sections marked with this symbol indicate the correct use of the vehicle

to prevent damaging the environment.

Vehicle intactness The incomplete or non-observance of these regulations leads to the risk of serious

damage to the vehicle and sometimes even the invalidity of the guarantee.

Page 4

Page 5

INDEX OF TOPICS

CHARACTERISTICS CHAR

TOOLING TOOL

MAINTENANCE MAIN

TROUBLESHOOTING TROUBL

ELECTRICAL SYSTEM ELE SYS

ENGINE FROM VEHICLE ENG VE

ENGINE ENG

INJECTION INJEC

SUSPENSIONS SUSP

BRAKING SYSTEM BRAK SYS

COOLING SYSTEM COOL SYS

CHASSIS CHAS

PRE-DELIVERY PRE DE

TIME TIME

Page 6

INDEX OF TOPICS

CHARACTERISTICS CHAR

Page 7

X9 Evolution 500 Characteristics

This section describes the general specifications of the vehicle.

Rules

This section describes general safety rules for any maintenance operations performed on the vehicle.

Safety rules

•

Should it be necessary to keep the engine running while servicing, make sure that the area

or room is well ventilated, and use special exhaust fans, if required. never let the engine run

in an enclosed area. Exhaust fumes are toxic.

•

The battery electrolyte contains sulphuric acid. Protect your eyes, clothes and skin. Sulphuric acid is highly corrosive; in the event of contact with your eyes or skin, rinse thoroughly

with abundant water and seek immediate medical attention.

•

The battery produces hydrogen, a gas that can be highly explosive. Do not smoke and avoid

sparks or flames near the battery, especially when charging it.

•

Fuel is highly flammable, and in some conditions it can be explosive. Do not smoke in the

working area, and avoid open flames or sparks.

•

Clean the brake pads in a well ventilated environment, directing the compressed air jet so

as to not inhale the dust produced by the wear of the friction material. Even though the latter

contains no asbestos, dust inhalation is harmful.

Maintenance rules

•

Use original PIAGGIO spare parts and lubricants recommended by the Manufacturer. Nonoriginal or non-conforming spares may damage the vehicle.

•

Use only the special tools designed for this scooter.

•

Always use new gaskets, sealing rings and split pins upon reassembly.

•

After removal, clean the components using non-flammable or low fire-point solvent. Lubricate all the work surfaces except the tapered couplings before refitting.

•

After reassembly, check that all components have been installed properly and that they are

in good working order.

•

For removal, overhaul and reassembly operations use only tools provided with metric measures. Metric bolts, nuts and screws are not interchangeable with coupling members with

English measurement. Using unsuitable coupling members and tools may damage the

scooter.

•

Should any interventions to the scooter electrical system be required, check that the electrical connections - especially earth and battery connections - have been implemented

properly.

CHAR - 7

Page 8

Characteristics X9 Evolution 500

Vehicle identification

VEHICLE IDENTIFICATION

Specification Desc./Quantity

Chassis prefix ZAPM 27000 ÷ 4000001

Engine prefix M271M ÷ 1001

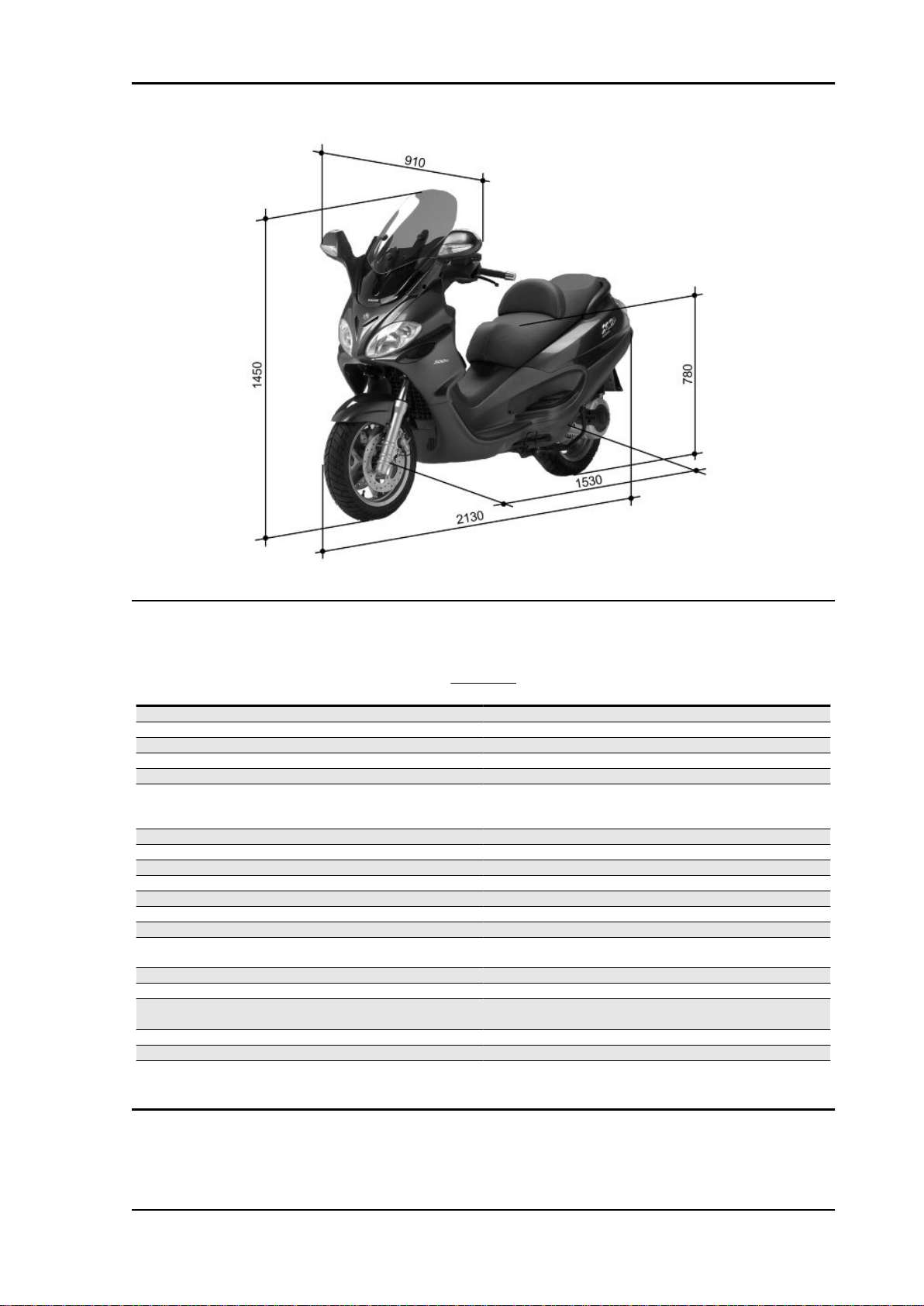

Dimensions and mass

Specification

Total dry weight 206 Kg

Width (at the mirrors) 910 mm

Wheel base 2130 mm

Length 1530 mm

Height (at the saddle) 780 mm

Height at the windscreen (high position) 1450 mm

CHAR - 8

WEIGHT AND DIMENSIONS

Desc./Quantity

Page 9

X9 Evolution 500 Characteristics

Engine

CO % value (measured at the intake manifold) 1 - 1.5%

ENGINE

Specification

Engine Single-cylinder, four-stroke

Bore 92 mm

Stroke 69 mm

Cubic capacity 460 cm³

Compression ratio 10.5: 1

Timing system Single overhead camshaft with integrated tone wheel, control

from flywheel side chain, 4 valves and automatic start-up valve

Valve clearance: intake 0.15 mm (when cold)

Valve clearance: discharge 0.15 mm (when cold)

Valve clearance adjustment By threaded adjuster on the rockers

Engine idle speed 1500 ± 50 rpm

Air filter Dry paper filter.

Starting system Electric starter system with freewheel.

Lubrication By trochoidal pump (inside the crankcase), pressure adjust-

Lubrication pressure 4 bar

Minimum allowed (at 100° C) 0.8 bar

Fuel supply Electronic injection system with electric fuel pump, Ø 38 mm

Max. power (at crankshaft) 29.5 kW at 7500 rpm

Max. torque (at crankshaft) 43 Nm at 5500 rpm

Cooling system Fluid circulation through a motor-driven pump, 3-way thermo-

Desc./Quantity

lifting device.

ment by-pass and oil filter.

throttle body and single injector.

stat and electric fan.

CHAR - 9

Page 10

Characteristics X9 Evolution 500

Transmission

TRANSMISSIONS

Specification Desc./Quantity

Transmission With automatic expandable pulley variator with torque server,

V belt, automatic clutch, gear reduction unit and transmission

housing with forced air circulation cooling.

Capacities

CAPACITIES

Specification Desc./Quantity

Cooling system approx. 1.8 l

Fuel tank (including reserve ~ 2.5 l) ~ 14,5 l

Rear hub ~ 250 cc

Engine oil (empty) 1.7 lt.

Engine oil (at oil and filter change) 1.5 lt.

Electrical system

ELECTRICAL COMPONENTS

Specification

1 Ignition type Inductive, high efficiency, integrated with injection, vari-

able advance and separate HV coil.

2 Spark advance (before TDC) Variable, controlled by the injection controller

3 Spark plug CHAMPION RG6YC; NGK CR7EKB

4 Battery 12V-14Ah

5 Fuses n.1 70A_n.1 30A_n.2 15A_n.3 10A_n.4 7,5A_n.2 5A_n.

6 Generator in three-phase alternating current

Desc./Quantity

1 3A

Frame and suspensions

FRAME AND SUSPENSIONS

Specification

Type Welded structure consisting of steel pipes with asymmetrical

trestle structure, front crosspieces and union members made

Front suspension Hydraulic telescopic fork with dual effect, Ø 40 mm stems and

back pin with couplongs for dual brake calipers.

Front fork stroke 104 mm

Rear suspension Engine based on oscillating fork pivoted to the chassis by 2-

freedom degree oscillating arm and pair of dual effect hydraulic

shock absorbers with 4-position preload adjustment

Rear suspension range 76.6 mm (minimum spring preload)

Desc./Quantity

of sheet steel.

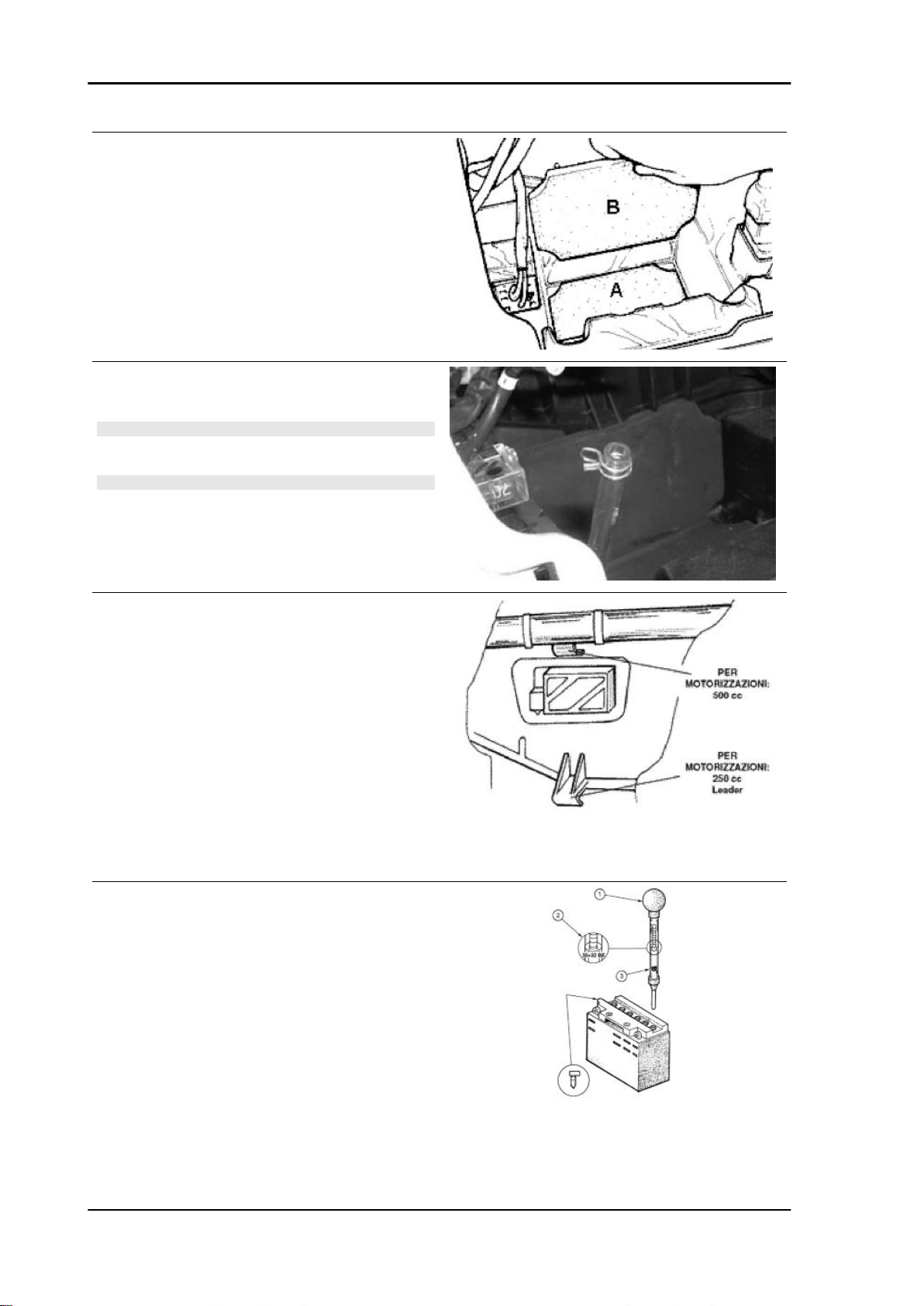

X9 Evolution 125-250-500:

Please take note that, starting from chassis serial number ZAPM2300003509521, the front small chassis fixing system has changed in order to improve its locking to the chassis. Therefore we have

introduced:

• N°2 screws drawing 432142

• N°2 4x11x0 external teeth spring washers drawing 012533

• N°2 nuts drawing 968224

CHAR - 10

Page 11

X9 Evolution 500 Characteristics

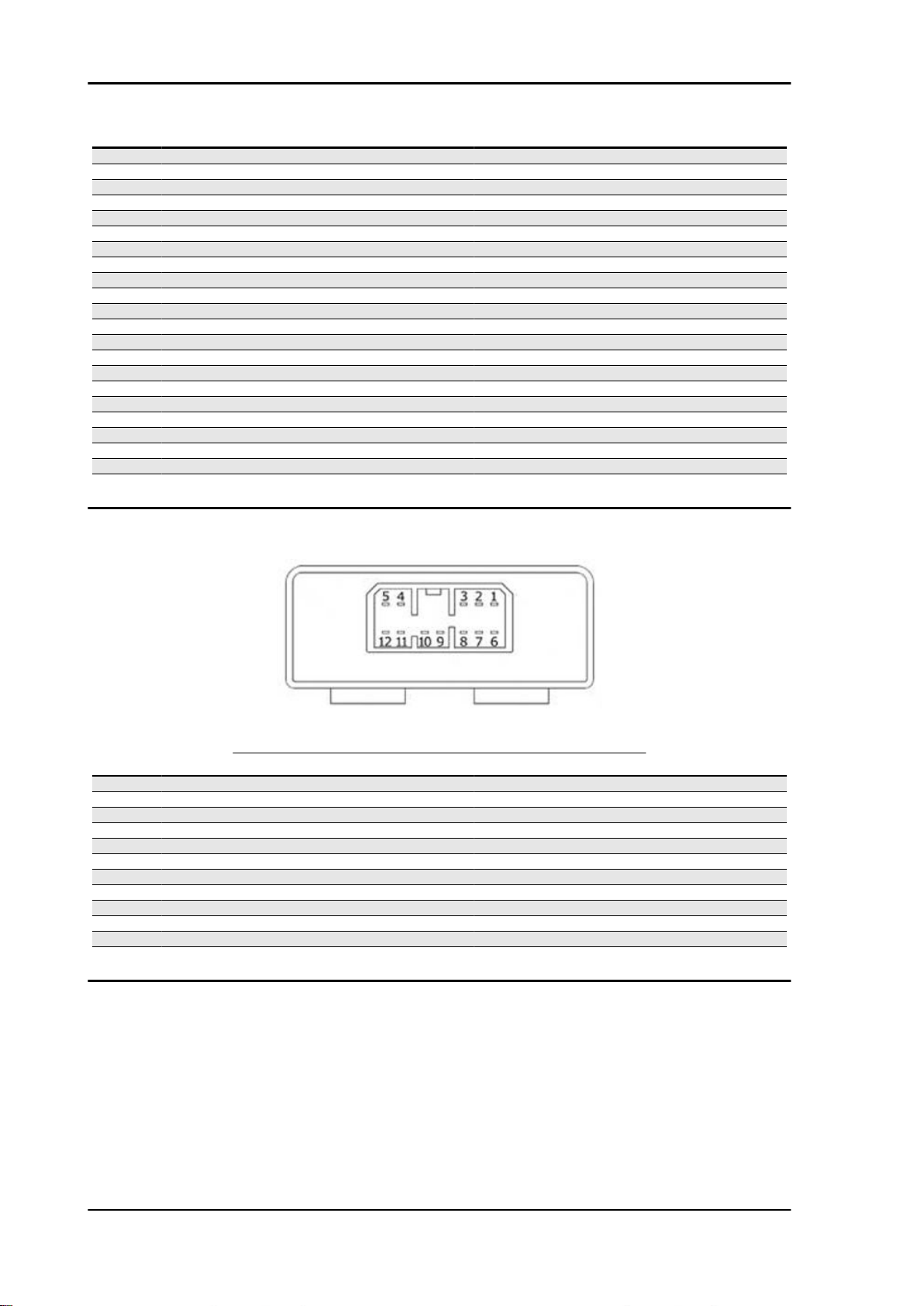

Front fork

This is to inform you that, starting from frame no. ZAPM2700004008122, the front fork has been replaced to improve comfort. The new suspension differs from the previous one for a different stiffness

of the springs and a higher quantity of oil: from 268 cc to 273 cc ± 2 cc of Selenia Fork 7.5 W

Brakes

Specification

Combined With dual disc brake, Ø 260 front LH with 2 piston floating cal-

Wheels and tyres

Specification

Light alloy rims (Front): 3,50x14"

Light alloy rims (rear): 4,50x14"

Tyre pressure (when cold): front 2,2 bar

Tyre pressure (when cold): rear 2,4 bar (2,6 bar with passenger or optional trunk on)

Front Tyre Michelin Gold Standard 120/70-14' M/C reinforced TL 55 S

Manufacturer / Model / Size Pirelli GTS 23 120/70_14'M/C TL 55 S

Rear Tyre Michelin Gold Standard 150/70-14' M/C TL 66 S

Manufacturer / Model / Size Pirelli GTS 24 150/70_14' M/C TL 66 S

CAUTION

BRAKES

Desc./Quantity

Front Disc brake Ø 260 (vehicle RH side), with hydraulic command

activated from handlebars with right-hand lever and 2 piston

floating caliper.

iper and Ø 240 rear, with 2 opposed piston floating caliper.

Hydraulic command activated from handlebars with left-hand

lever. The system is interlocked with a pressure distribution

valve.

WHEELS AND TYRES

Desc./Quantity

IT IS MANDATORY TO ADOPT EXCLUSIVELY "S" CLASS TYRES, WHICH GUARANTEE CORRECT VEHICLE PERFORMANCE AT THE DIFFERENT SCOOTER SPEEDS. USING ANY OTHER

TYRE MAY RESULT IN VEHICLE INSTABILITY. IT IS ADVISABLE TO USE TYRE TYPES RECOMMENDED BY PIAGGIO.

CHAR - 11

Page 12

Characteristics X9 Evolution 500

Tightening Torques

STEERING UNIT

Name Torque in Nm

Steering wheel upper ring nut 36 ÷ 39

Steering wheel lower ring nut 10 ÷ 13 then loosen by 90° (see "Steering wheel ring nut lock-

Handlebar fixing screw (*) 43 ÷ 47

STEERING WHEEL LOCKING RING NUT

1) Apply to the lower ring nut a setting torque of 20±25 Nm then loosen it.

2) Tighten the ring nut again at a torque of 10±13 Nm.

3) Loosen the lower ring nut by 90°.

4) Insert the spacer.

5) Lock the upper ring nut at a torque of 36 ± 39 Nm

CHASSIS UNIT

Name Torque in Nm

Oscillating arm pin right nut - Engine 100 ÷ 120

Oscillating arm pin left nut - Engine 56 ÷ 70

Oscillating arm-chassis pin 14 ÷ 17

Oscillating arm-chassis pin lock nut 40 ÷ 50

Oscillating arm pin right nut - Chassis 66 ÷ 73

Side stand support fixing bolt 33 ÷ 41

Bolt fixing the centre stand to the frame 25 ÷ 30

Hydraulic actuator fixing screw to chassis 20 ÷ 25

Side stand screw 35 ÷ 40

Side stand switch screw 5 ÷ 7

Side stand nut 40 ÷ 45

Oscillating arm damper bar nut 33 ÷ 41

Damper pad support plate nut 33 ÷ 41

ing")

FRONT SUSPENSION

Name

Fork leg tightening clamp screw 20 ÷ 25

Front wheel axle 45 ÷ 50

Wheel axle tightening clamp screw 6 ÷ 7

Front mudguard fixing screw 5 ÷ 6,5

Pumping fixing screw to fork leg 45 ÷ 50

Torque in Nm

FRONT BRAKE

Name

Screw for fixing the caliper support to the fork 42 ÷ 62

Brake fluid pump-hose fitting 16 ÷ 20

Brake fluid pipe-calliper fitting 16 ÷ 20

Disc tightening screw (°) 5 ÷ 6

Oil drainage screw 12 ÷ 16

Torque in Nm

REAR SUSPENSION

Name

Right and left shock absorber support fixing 20 ÷ 25

Shock absorbers fixing to chassis 33 ÷ 41

Shock absorbers fixing to lower supports 33 ÷ 41

Rear wheel axle 104 ÷ 126

Rear wheel rim screws 33 ÷ 37

Silencer support arm fixing to engine 33 ÷ 42

Torque in Nm

CHAR - 12

Page 13

X9 Evolution 500 Characteristics

COMBINED BRAKE

Name Torque in Nm

Oil pipe union on combined brake pump 16 ÷ 20

Combined brake pipe union on front calipers 16 ÷ 20

Combined brake pipe union on rear calipers 16 ÷ 20

Front brake caliper pipe union on combined braking device 20 ÷ 25

Rear brake caliper pipe union on combined braking device 20 ÷ 25

Brake caliper fixing screw to supports 20 ÷ 25

Rear disc tightening screw (°) 14 ÷ 17

Oil bleed screw 12 - 16

Rear brake caliper fastening screw to engine 20 ÷ 25

Rear brake piping support fixing screw to engine 5 ÷ 6,5

Rear brake piping support fixing screw to chassis 9 ÷ 11

SILENCER

Name Torque in Nm

Manifold fixing screw to silencer 16 ÷ 18

Silencer support bracket fixing screw to engine 33 ÷ 41

Silencer heat guard fixing screw 3 ÷ 4

Exhaust gas inlet screw 22 ÷ 26

ENGINE UNIT

Name Torque in Nm

Clutch locking nut 65 ÷ 75

Driven pulley shaft support fixing screw 23 ÷ 26

Belt anti-flapping roller fixing screw 17 ÷ 20

Driving pulley nut (°) 160 ÷ 175

Flywheel nut (°) 115 ÷ 125

Driven pulley nut 92 ÷ 100

Half-crankcase union screw 11 ÷ 13

Head cover screws 11 ÷ 13

Head nuts (°) (§) (*) 38 ÷ 42

Cylinder stud bolts 44 ÷ 46

Camshaft bell screw (#) 30 ÷ 35

Camshaft plate fixing screw (#) 4 ÷ 6

Valve clearance adjustment lock nut 6 ÷ 8

Water pump impeller 4 ÷ 6

Starter motor fastening screw 11 ÷ 13

Ignition spark plug 12 ÷ 14

Hub oil drainage cap 15 ÷ 17

Rear hub cap screw 24 ÷ 27

Transmission cover screw 11 ÷ 13

Oil pump head screw 8 ÷ 10

Engine oil drainage cap 24 ÷ 30

Water pump cover screw 3 ÷ 4

Screw fixing the oil pump to the crankcase 5 ÷ 6

Stator fastening screw 8 ÷ 10

Screw fixing the start-up free wheel to the flywheel (#) 13 ÷ 15

Flywheel cover screw 11 ÷ 13

Head intake manifold screw 11 ÷ 13

Screw fixing the throttle body to the manifold 11 ÷ 13

Chain tightener sliding block screw (#) 10 ÷ 14

Timing chain tensioner central screw 5 - 6

Timing chain tensioner support screw 11 ÷ 13

Counter-rotating shaft fixing nut (#) 25 ÷ 29

Screw fixing the silencer to the support arm 20 ÷ 25

Exhaust manifold - cylinder nuts 27 ÷ 33

Screw fixing the rear brake caliper support bracket to the en-

gine

Driving shaft timing cap 3,5 ÷ 4,5

Head water outlet cover screw 3 ÷ 4

Calibrated dowel 5 ÷ 7

Oil cap with level bar 1,5 ÷ 2,5

Oil filter 12 ÷ 16

Oil filter engagement union 18 ÷ 22

20 ÷ 25

CHAR - 13

Page 14

Characteristics X9 Evolution 500

Name Torque in Nm

Oil vent pipe fixing 3 ÷ 4

Minimum oil pressure sensor 12 ÷ 14

Fairlead bracket fixing 3 ÷ 4

Head/Cylinder/Crankcase fixing 10 ÷ 12

Revolution timing sensor fixing screw 3 ÷ 4

Coolant temperature sensor 10 ÷ 12

Pressure reducer counterweight retainer 7 ÷ 8.5

Counter shaft gear fixing on driving shaft (#) 10 ÷ 12

Thermostat cover 1,5 ÷ 2

Start-up rim counter shaft plate fixing 3 ÷ 4

Injector support fixing (#) 3 ÷ 4

Head lubrication control jet 5 - 7

(°)Lubricate parts before fitting.

(^) Apply LOCTITE for surfaces type 510.

(#) Apply thread-holding LOCTITE medium type 242.

(§) 1st locking: 20 N·m crossed, locking at torque 38 - 42 N·m crossed, crossed loosening.

(*) 2nd tightening: 20 N·m crossed, locking at torque 38 - 42 N·m crossed.

N.B.

LUBRICATE THE THREADS.

NOTICE OF TECHNICAL SERVICING

For correct tightening, the expansion tank cap locking torque has been standardised to 2.5 Nm

Please take note that we have normalized to 17 - 20 Nm the temperature sensor locking torque, in order

to guarantee a correct locking

This is to inform you that the tightening torque for

screws with dwg. no. 842502 has been increased

from 8-10 Nm to 14-16 Nm, to prevent the exhaust

pipe from coming loose.

Overhaul data

This section provides the main information for scooter servicing.

Assembly clearances

CHAR - 14

Page 15

X9 Evolution 500 Characteristics

Cylinder - piston assy.

(Values in mm)

HEIGHT AT WHICH THE DIAMETER SHOULD BE MEASURED

Specification Desc./Quantity

A: 10 mm

B: 43 mm

CATEGORIES OF COUPLING

Name

Cylinder Piston A 91.990 - 91.997 91.954 - 91.961 0.029 - 0.043

Cylinder Piston B 91.997 - 92.004 91.961 - 91.968 0.029 - 0.043

Cylinder Piston C 92.004 - 92.011 91.968 - 91.975 0.029 - 0.043

Cylinder Piston D 92.011 - 92.018 91.975 - 91.982 0.029 - 0.043

N.B.

THE PISTON MUST BE INSTALLED WITH THE ARROW FACING TOWARDS THE EXHAUST SIDE,

THE PISTON RINGS MUST BE INSTALLED WITH THE WORD «TOP» OR THE STAMPED MARK

FACING UPWARDS.

Initials Cylinder Piston Play on fitting

Piston rings

* Fit rings «2» and «3» with the word «TOP» facing upwards.

** Position the openings in the rings as shown here.

*** Value «A» of sealing ring inside the cylinder

**** Ring opening

CHAR - 15

Page 16

Characteristics X9 Evolution 500

SEALING RINGS

Name Initials Cylinder Piston Play on fitting

1st Compression ring A 0.15 ÷ 0.35 0.5 </>

Middle piston ring A 0.25 ÷ 0.50 0.65 </>

Oil scraper ring A 0.25 ÷ 0.50 0.65 </>

Crankcase - crankshaft - connecting rod

Characteristic

Drive shaft / crankcase axial clearance:

0.1 - 0.5 mm (when cold)

AXIAL CLEARANCE BETWEEN CRANKSHAFT AND CONNECTING ROD

Name

Transmission-side

shoulder

Transmission-side half-

shaft

Connecting rod 22 0.10-0.15 C D= 0.20 - 0.40

Flywheel-side shoulder 13 ± 0.025 F D= 0.20 - 0.40

Flywheel-side half-shaft 19.6 +0.050 E D= 0.20 - 0.40

Complete drive shaft 63.5+0.1-0.05 G D= 0.20 - 0.40

CHAR - 16

Description Dimensions Initials Quantity

0.8 ± 0.025 A D= 0.20 - 0.40

19.6 + 0.050 B D= 0.20 - 0.40

Page 17

X9 Evolution 500 Characteristics

Diameter of crankshaft bearings.

Measure the capacity on both axes x-y.

CRANKSHAFT

Specification Desc./Quantity

Cat. 1 Standard diameter: 40.010 ÷ 40.016

Cat. 2 Standard diameter: 40.016 ÷ 40.022

Crankshaft alignment

Specific tooling

020335Y Magnetic support for dial gauge

MAX. ADMISSIBLE DISPLACEMENT

Specification

A = 0.15 mm

B = 0.010 mm

C = 0.010 mm

D = 0.10 mm

Crankcase / countershaft coupling

Besides considering it should match the crankshaft, the crankcase is chosen according to the centre

to centre distance between the seat of the crankshaft and that of the contra-rotating shaft.

Both the centre to centre distance and the pair of gears driving the contra-rotating shaft are divided into

two types (A and B) to be matched (A with A and B with B).

This selection is useful to keep the difference between the working distance of the gears and their

Desc./Quantity

distance without clearance at a given value in order to avoid abnormal noise.

TYPE A

Specification

Centre to centre distance of the gears without clearance 76.937 ÷ 76.867

Centre to centre distance on the crankcase 77.022 ÷ 76.992

Desc./Quantity

TYPE B

Specification

Centre to centre distance of the gears without clearance 76.907 ÷ 76.837

Desc./Quantity

CHAR - 17

Page 18

Characteristics X9 Evolution 500

Specification Desc./Quantity

Centre to centre distance on the crankcase 76.992 ÷ 76.962

The gears with centre to centre distance without clearance between 76.867 and 76.907 are considered

universal and can be fitted to either crankcase type.

Either the pair of gears or the crankcase is identified with the letter referring to the type (on the crankcase, this mark is found at the cylinder mouth, flywheel side).

Slot packing system

Shimming system for limiting the compression ratio Rc = 10.5 : 1

DISTANCE "A" IS A PROJECTION OR RECESS VALUE OF THE PISTON TOP FROM THE CYLINDER PLANE.

DISTANCE "A" ALLOWS THE THICKNESS OF THE GASKET TO BE DETERMINED THAT HAS TO

BE FITTED TO THE CYLINDER HEAD IN ORDER TO RESTORE THE COMPRESSION RATIO. THE

BASE GASKET MUST BE THICKER, THE MORE THE PLANE FORMED BY THE PISTON TOP

PROTRUDES FROM THE PLANE FORMED BY THE CYLINDER HEAD. ON THE OTHER HAND,

THE MORE THE PISTON TOP IS RECESSED INTO THE CYLINDER TOP PLANE, THE SMALLER

THE GASKET THICKNESS.

BASE GASKET THICKNESS

Name

«A» MEASURE TAKEN - 0.185 - - 0.10 0.4 ± 0.05

«A» MEASURE TAKEN - 0.10 - + 0.10 0.6 ± 0.05

«A» MEASURE TAKEN + 0.10 ÷ + 0.185 0.8 ± 0.05

N.B.

VALUES INDICATED WITH «-» REFER TO PISTON CROWN RECESSES WITH RESPECT TO THE

CYLINDER PLANE.

CHAR - 18

Measure A Thickness

Page 19

X9 Evolution 500 Characteristics

Products

PRODOTTI

Product Description Specifications

AGIP ROTRA 80W-90 Rear hub oil SAE 80W/90 Oil that exceeds the re-

AGIP FILTER OIL Oil for air filter sponge Mineral oil with specific additives for in-

AGIP CITY HI TEC 4T Engine oil SAE 5W-40, API SL, ACEA A3, JASO MA

AGIP BRAKE 4 Brake fluid FMVSS DOT 4 Synthetic fluid

SPECIAL AGIP PERMANENT fluid coolant Monoethylene glycol-based antifreeze

AUTOSOL METAL POLISH Muffler cleaning paste special product for cleaning and polishing

AGIP GP 330 Grease for brake levers, throttle White calcium complex soap-based

AGIP CITY TEC 2T Mixer oil synthetic oil for 2-stroke engines: JASO

ARNICA 46 Electro-hydraulic centre-stand Highly viscous oil for hydraulic controls

quirements of API GL3 specifications

creased adhesiveness

Synthetic oil

fluid, CUNA NC 956-16

stainless steel muffler

spray grease with NLGI 2; ISO-L-XBCIB2

FC, ISO-L-EGD

CHAR - 19

Page 20

INDEX OF TOPICS

TOOLING TOOL

Page 21

X9 Evolution 500 Tooling

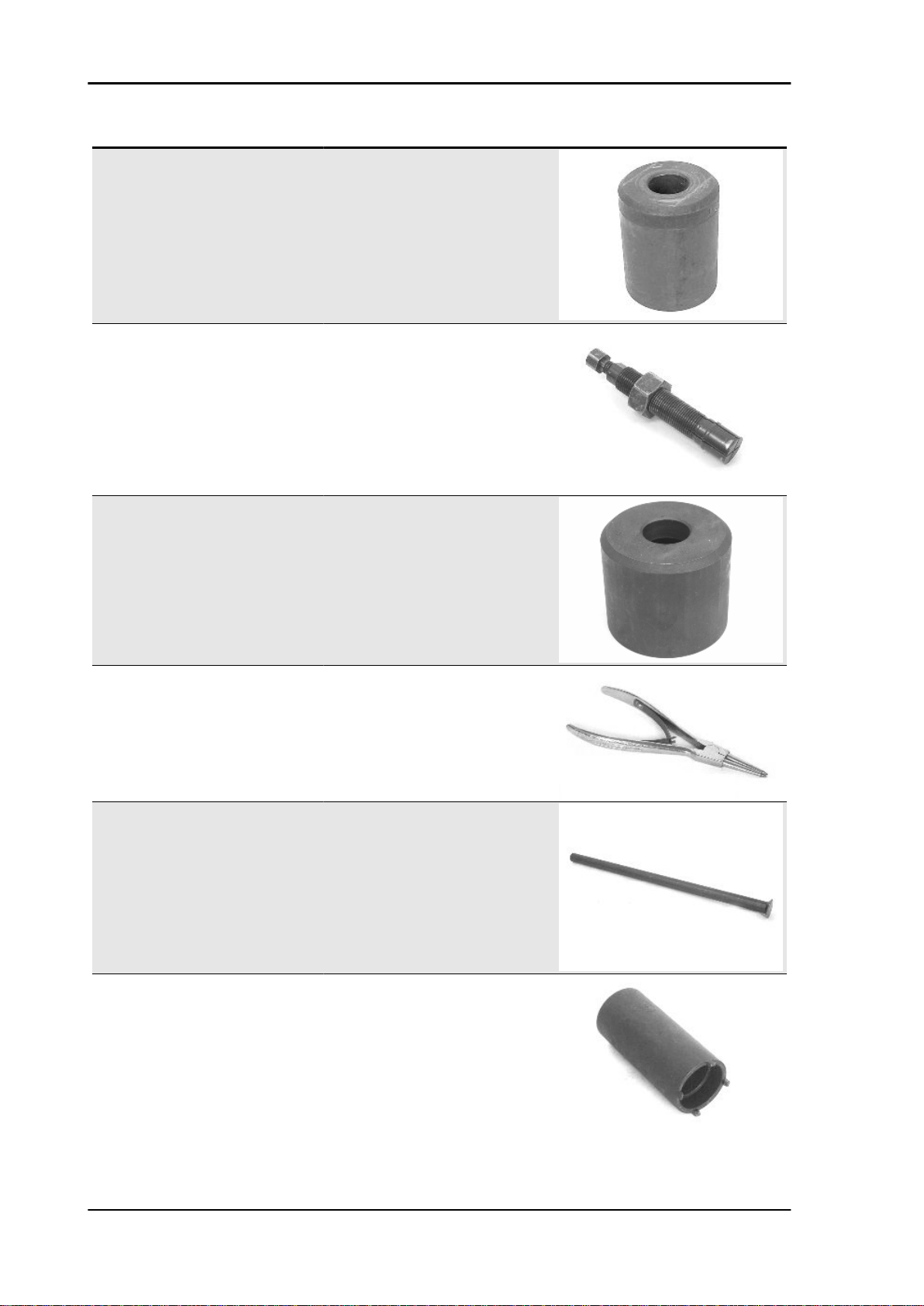

SPECIFIC TOOLING

Stores code Description

001330Y Tool for fitting steering seats

001467Y002 Driver for OD 73 mm bearing

001467Y006 Pliers to extract 20 mm bearings

001467Y007 Driver for OD 54-mm bearings

001467Y008 Pliers to extract 17 mm ø bearings

001467Y017 Driver for OD 36 mm bearings

TOOL - 21

Page 22

Tooling X9 Evolution 500

Stores code Description

001467Y031 Bell

001467Y034 Pliers to extract ø 15-mm bearings

001467Y035 Belle for OD 47-mm bearings

002465Y Pliers for circlips

020004Y Punch for removing fifth wheels from

020055Y Wrench for steering tube ring nut

headstock

TOOL - 22

Page 23

X9 Evolution 500 Tooling

Stores code Description

020074Y Support base for checking crankshaft

020150Y Air heater support

020151Y Air heater

alignment

020193Y Oil pressure gauge

020306Y Punch for assembling valve seal rings

020329Y MityVac vacuum-operated pump

TOOL - 23

Page 24

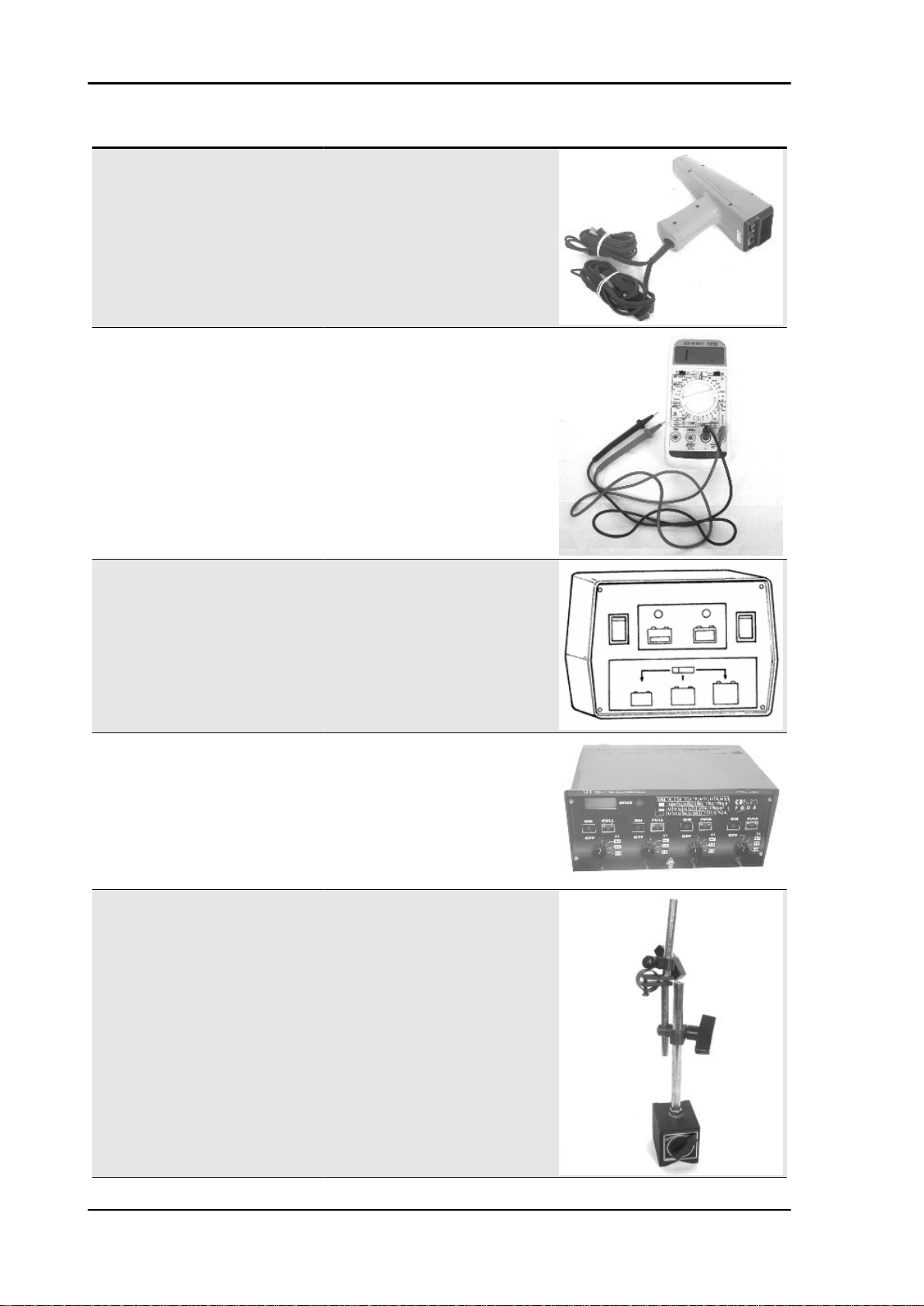

Tooling X9 Evolution 500

Stores code Description

020330Y Stroboscopic light to check timing

020331Y Digital multimeter

020333Y Single battery charger

020334Y Multiple battery charger

020335Y Magnetic support for dial gauge

TOOL - 24

020358Y 37x40-mm adaptor

Page 25

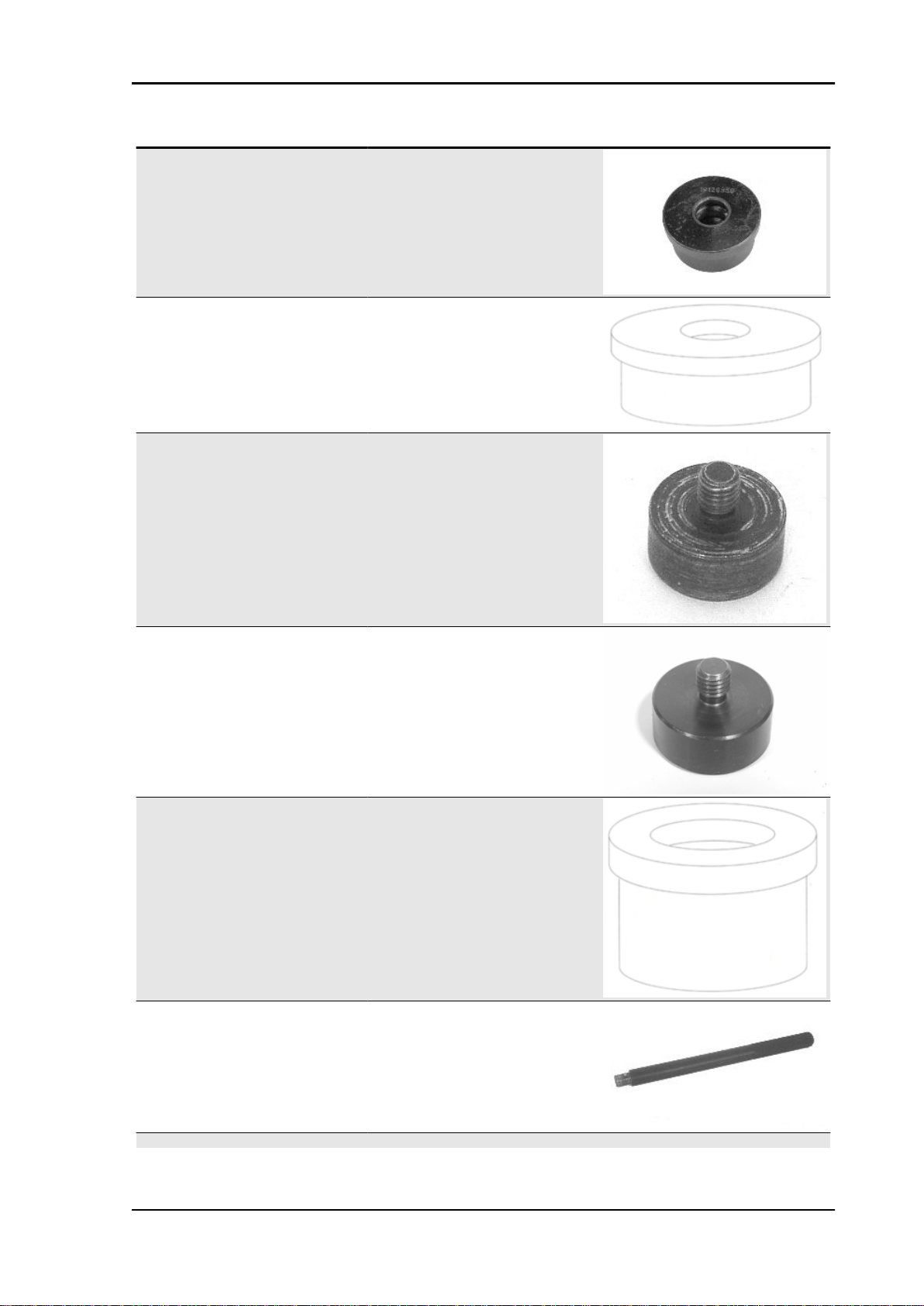

X9 Evolution 500 Tooling

Stores code Description

020359Y 42x47-mm adaptor

020360Y Adaptor 52 x 55 mm

020363Y 20 mm guide

020364Y 25-mm guide

020375Y Adaptor 28 x 30 mm

020376Y Adaptor handle

020382Y012 bush (valve removing tool)

TOOL - 25

Page 26

Tooling X9 Evolution 500

Stores code Description

020412Y 15 mm guide

020431Y Valve oil seal extractor

020434Y Oil pressure control fitting

020439Y 17 mm guide

020444Y Tool for fitting/ removing the driven pulley

clutch

TOOL - 26

Page 27

X9 Evolution 500 Tooling

Stores code Description

020444Y009 46x55 Wrench

020456Y Ø 24 mm adaptor

020458Y Puller for lower bearing on steering tube

020459Y Punch for fitting bearing on steering tube

020460Y Scooter diagnosis and tester

TOOL - 27

Page 28

Tooling X9 Evolution 500

Stores code Description

020467Y Flywheel extractor

020468Y Piston fitting band

020469Y Reprogramming kit for scooter diagnosis

020470Y Pin retainers installation tool

020471Y Pin for countershaft timing

tester

TOOL - 28

Page 29

X9 Evolution 500 Tooling

Stores code Description

020472Y Flywheel lock wrench

020474Y Driving pulley lock wrench

020475Y Piston position checking tool

020476Y Stud bolt set

020477Y Adaptor 37 mm

020478Y Punch for driven pulley roller casing

TOOL - 29

Page 30

Tooling X9 Evolution 500

Stores code Description

020479Y Countershaft lock wrench

020480Y Petrol pressure check set

020481Y Control unit interface wiring

020482Y Engine support

020483Y 30 mm guide

020512Y Piston fitting fork

TOOL - 30

Page 31

X9 Evolution 500 Tooling

Stores code Description

020527Y Engine support base

020565Y Flywheel lock calliper spanner

020604Y011 Fitting adapter

494929Y Exhaust fumes analyser

TOOL - 31

Page 32

INDEX OF TOPICS

MAINTENANCE MAIN

Page 33

X9 Evolution 500 Maintenance

Maintenance chart

Adequate maintenance is fundamental to ensuring long-lasting, optimum operation and performance

of your vehicle.

To this end, a series of checks and maintenance operations (at the owner's expense) have been suggested, which are included in the summary table on the following page. Any minor faults should be

reported without delay to an Authorised Service Centre or Dealer without waiting until the next

scheduled service to solve it.

All scheduled maintenance services must be carried out at the specified intervals, even if the stated

mileage has not yet been reached. Punctual scooter servicing is essential to ensure your warranty

remains valid. For any further information concerning Warranty procedures and "Scheduled Maintenance", please refer to the "Warranty Booklet".

EVERY 2 YEARS

60'

Action

Coolant - change

Brake fluid - change

EVERY 3,000 KM

Action

Engine oil - level check/ top-up

Brake pads - check condition and wear

AFTER 1,000 KM OR 4 MONTHS

90'

Action

Engine oil - replacement

Hub oil - change

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Steering - adjustment

Brake control levers - greasing

Brake fluid level - check

Safety locks - check

Electrical system and battery - check

Vehicle and brake test - road test

MAIN - 33

Page 34

Maintenance X9 Evolution 500

AFTER 6,000 KM OR 12 MONTHS

80'

Action

Engine oil - replacement

Hub oil - level check

Spark plug / electrode gap - check

Air filter - cleaning

Engine oil - change

Valve clearance - check

Base vent - check

Variable speed rollers - replacement

Driving belt - checking

Coolant level - check

Brake fluid level - check

Electrical system and battery - check

Tyre inflation and wear - Check

Vehicle and brake test - road test

AFTER 12,000 KM OR 24 MONTHS AND 60,000 KM

205'

Action

Engine oil - replacement

Hub oil - level check

Spark plug/electrode gap - replacement

Air filter - clean

Engine oil - change

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Variable speed rollers - replacement

Roller support sliding blocks - check/change

Driving belt - replacement

Coolant level - check

Steering - adjustment

Brake control levers - greasing

Transmission elements - lubrication

Brake fluid level - check

Safety locks - check

Suspensions - check

Electrical system and battery - check

Headlight - adjustment

Tyre pressure and wear - check

Vehicle and brake test - road test

150'

Engine oil - replacement

Hub oil - level check

Spark plug / electrode gap - check

Air filter - change

Engine oil - change

Valve clearance - check

Base vent - check

Variable speed rollers - replacement

Driving belt - checking

Coolant level - check

Radiator - external cleaning/ check

Brake fluid level - check

Electrical system and battery - check

Tyre inflation and wear - Check

Vehicle and brake test - road test

MAIN - 34

AFTER 18,000 KM AND AFTER 54,000 KM

Action

Page 35

X9 Evolution 500 Maintenance

AFTER 24,000 KM

255'

Action

Engine oil - replacement

Hub oil - change

Spark plug / electrode gap - replacement

Air filter - clean

Engine oil - change

Fuel filter - check

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Variable speed rollers - replacement

Roller support sliding blocks - check/change

Driven pulley bushing - check / grease

Driving belt - replacement

Coolant level - check

Steering - adjustment

Brake control levers - greasing

Transmission elements - lubrication

Brake fluid level - check

Safety locks - check

Suspensions - check

Electrical system and battery - check

Headlight - adjustment

Tyre inflation and wear - Check

Vehicle and brake test - road test

AFTER 30,000 KM, 42,000 KM AND 66,000 KM

80'

Engine oil - replacement

Hub oil - level check

Spark plug / electrode gap - check

Air filter - cleaning

Engine oil - change

Base vent - check

Variable speed rollers - replacement

Driving belt - checking

Coolant level - check

Brake fluid level - check

Electrical system and battery - check

Tyre inflation and wear - Check

Vehicle and brake test - road test

365'

Engine oil - replacement

Hub oil - level check

Spark plug/electrode gap - replacement

Air filter - change

Engine oil - change

Valve clearance - check

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Variable speed rollers - replacement

Roller support sliding blocks - check/change

Driving belt - replacement

Coolant level - check

Radiator - external cleaning/ check

Steering - adjustment

Action

AFTER 36,000 KM

Action

MAIN - 35

Page 36

Maintenance X9 Evolution 500

Action

Brake control levers - greasing

Brake fluid hoses - replacement

Transmission elements - lubrication

Brake fluid level - check

Safety locks - check

Suspensions - check

Electrical system and battery - check

Headlight - adjustment

Tyre inflation and wear - Check

Vehicle and brake test - road test

AFTER 48,000 KM

255'

Action

Engine oil - replacement

Hub oil - change

Spark plug / electrode gap - replacement

Air filter - clean

Engine oil - change

Fuel filter - replacement

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Variable speed rollers - replacement

Roller support sliding blocks - check/change

Driven pulley bushing - check / grease

Driving belt - replacement

Coolant level - check

Steering - adjustment

Brake control levers - greasing

Transmission elements - lubrication

Brake fluid level - check

Safety locks - check

Suspensions - check

Electrical system and battery - check

Headlight - adjustment

Tyre inflation and wear - Check

Vehicle and brake test - road test

405'

Engine oil - replacement

Hub oil - change

Spark plug / electrode gap - check / replacement

Air filter - change

Engine oil - change

Fuel filter - check

Valve clearance - check

Carburetion - check/adjust

Seals/injection system hoses - visual check

Base vent - check

Variable speed rollers - replacement

Roller support sliding blocks - check/change

Driven pulley bushing - check / grease

Driving belt - replacement

Coolant level - check

Radiator - external cleaning/ check

Steering - adjustment

Brake control levers - greasing

Brake fluid hoses - replacement

Brake fluid level - check

Safety locks - check

Suspensions - check

MAIN - 36

AFTER 72,000 KM

Action

Page 37

X9 Evolution 500 Maintenance

Action

Electrical system and battery - check

Headlight - adjustment

Tyre inflation and wear - Check

Vehicle and brake test - road test

Transmission elements - lubrication

Spark plug

Check and replacement

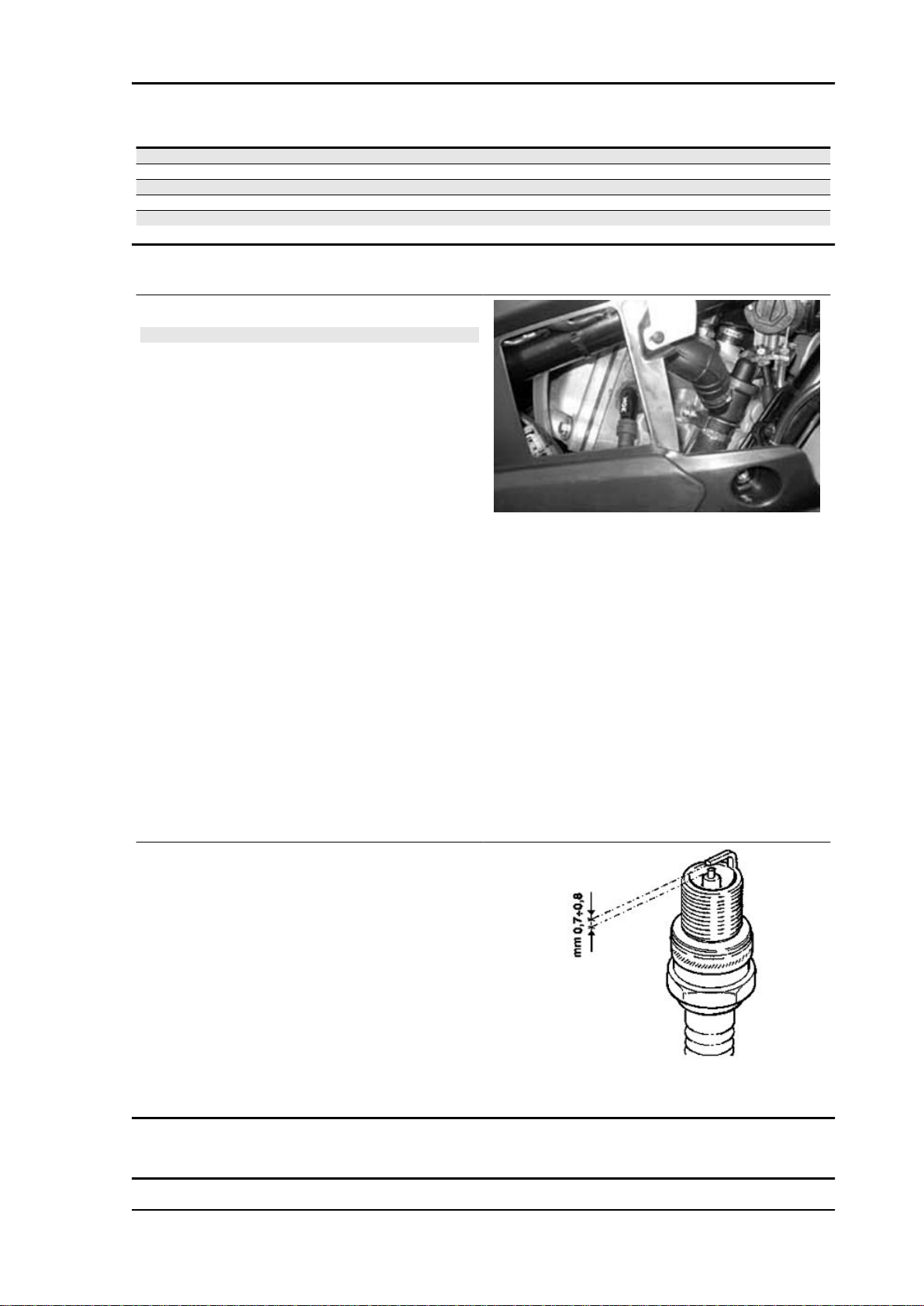

CAUTION

THE SPARK PLUG MUST BE REMOVED WITH COLD EN-

GINE. THE SPARK PLUG SHOULD BE CHECKED EVERY

6,000 KM AND REPLACED EVERY 12,000 KM. THE USE OF

NON-CONFORMING IGNITION CONTROL UNITS AND

SPARK PLUGS OTHER THAN THOSE PRESCRIBED CAN

SERIOUSLY DAMAGE THE ENGINE.

Characteristic

Recommended spark plugs:

CHAMPION RG6YC - NGK CR 7 EKB

- Position the scooter on centre stand.

- Open the door on the left side and remove the relevant screw lifting from the lower part in the specific

groove.

- Disconnect the shielded spark plug cap

- Unscrew the spark plug.

- Check the conditions of the spark plug, make sure the insulation is intact, that the electrodes are not

excessively worn or grimy, the conditions of the washer, and measure the distance between the electrodes using the appropriate feeler gauge.

Characteristic

Electrode gap

0.7-0.8 mm

Adjust the gap if necessary, carefully bending the

earth electrode. In the event of irregularity, replace

the spark plug with a recommended type.

- Fit the spark plug with the correct inclination and

manually screw it all the way down, then use the

special spanner to tighten it.

Locking torques (N*m)

Spark plug 12 ÷ 14

- Insert the cap onto the spark plug and proceed with the reassembly operations.

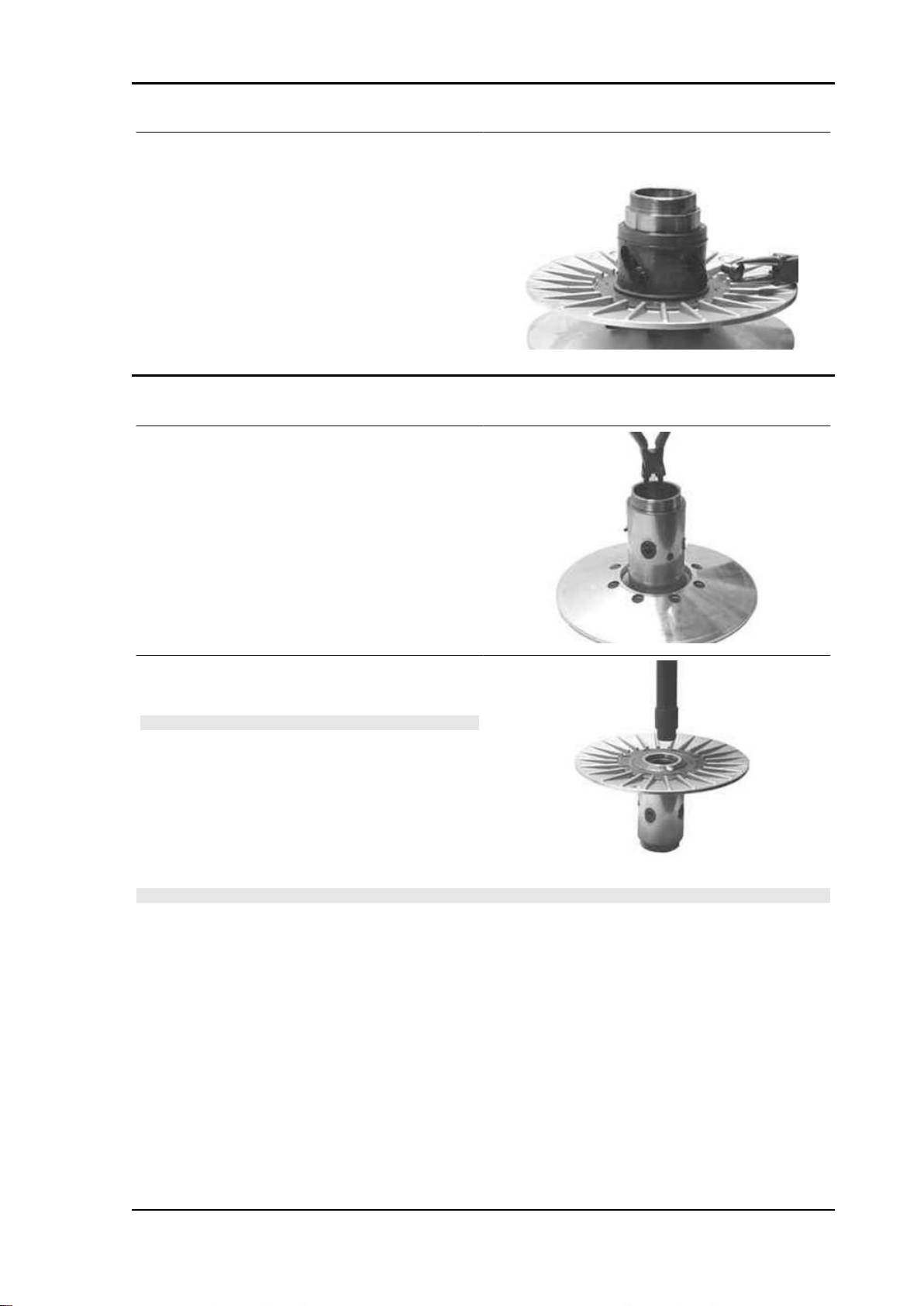

Hub oil

MAIN - 37

Page 38

Maintenance X9 Evolution 500

Check

- Take the vehicle to a flat ground and rest it on the

central stand.

- Unscrew the oil bar «A», dry it with a clean cloth

and reinsert it, screwing it in thoroughly;

- Pull out the bar and check that the oil level is between the MAX and MIX levels indicated on the

bar (see figure); if the level is below the MIN value,

restore the proper amount of oil in the hub.

- Screw the oil bar back on, checking that it is tightly in place.

N.B.

THE NOTCHES ON THE HUB OIL LEVEL BAR, WITH THE

EXCEPTION OF THOSE INDICATING THE MAX AND MIN

LEVEL, REFER TO SOME OF THE MANUFACTURER'S

OTHER MODELS AND HAVE NO SPECIFIC FUNCTION AS

FAR AS REGARDS THIS VEHICLE.

Replacement

- Prepare a suitable container.

- Remove the oil drainage cap «B» and let the oil

drain out completely.

- Tighten the drainage cap again and fill the hub

with oil.

Recommended products

AGIP ROTRA 80W-90 rear oil hub

SAE 80W/90 Oil that exceeds the requirements of

API GL3 specifications

Characteristic

Rear hub oil

250 cc

MAIN - 38

Page 39

X9 Evolution 500 Maintenance

Air filter

- Raise the saddle.

- Remove the piston ring and the battery cover.

- Loosen the 4 mounting screws shown in the figure.

- Loosen the mounting screw located under the intake manifold.

- Replace the air filter and reassemble the various

components, reversing the removal procedure.

MAIN - 39

Page 40

Maintenance X9 Evolution 500

- An inspection and possible cleaning (with compressed air) of the air filter is scheduled every 6000

km in any case.

- The air jet must be directed from the inside to the

outside of the filter (i.e. opposite the direction of

the air flow during normal operation of the engine).

- Any deposits of condensate out of the engine oil

caused by blow-by can be removed via the pipe

shown in the figure.

N.B.

FAILURE TO OBSERVE THE RULES REGARDING CLEANING OF THE FILTER ELEMENT CAN

LEAD TO IMPROPER LUBRICATION OF THE ELEMENT. POOR LUBRICATION AFFECTS THE

FILTERING CAPACITY. EXCESSIVE LUBRICATION AS WITH A SOILED FILTER CAUSES AN

EXCESSIVELY RICH FUEL/AIR MIXTURE.

CAUTION

WHEN TRAVELLING ON DUSTY ROADS, THE AIR FILTER MUST BE CLEANED MORE OFTEN

THAN SHOWN IN THE SCHEDULED MAINTENANCE CHART.

WARNING

DO NOT RUN THE ENGINE IF THE AIR FILTER IS NOT IN PLACE THIS WILL RESULT IN EXCESSIVE WEAR TO ALL THE PARTS OF THE COOLING SYSTEM.

Engine oil

In 4T engines, the engine oil is used to lubricate the distribution elements, the bench bearings and the

thermal group. An insufficient quantity of oil can cause serious damage to the engine.

In all 4T engines, the deterioration of the oil characteristics, or a certain consumption should be considered normal, especially if during the run-in period. Consumption levels in particular can be influenced

by the conditions of use (e.g.: oil consumption increases when driving at "full throttle".

Check

This operation must be carried out with the engine

cold and following the procedure below:

1) Rest the vehicle on the central stand and on a flat ground.

2) Unscrew the cap/dipstick "A", dry it with a clean cloth and reinsert it, screwing it thoroughly.

3) Remove the cap/dipstick again and check that the level is between the max. and min levels; top-up,

if required.

Topping up from the MIN to MAX. level requires around 1700 cc.

If the check is carried out after the vehicle has been used, and therefore with a hot engine, the level

line will be lower; in order to carry out a correct check it is necessary to wait at least 10 minutes after

the engine has been stopped, so as to get the correct level.

MAIN - 40

Page 41

X9 Evolution 500 Maintenance

Oil top up

The oil should be topped up after having checked the level and in any case by adding oil without ever

exceeding the MAX. level.

The restoration level between the MIN and MAX levels implies a quantity of oil of approx. 400 cc.

Engine oil filter

CAUTION

DO NOT DISPOSE OF OIL IN THE ENVIRONMENT. OIL, GASKET AND FILTER SHOULD BE DISPOSED OF ACCORDING TO THE REGULATIONS IN FORCE.

WARNING

AVOID TOUCHING PARTS OF THE ENGINE WHEN HOT, AS THIS MAY CAUSE BURNS.

- Remove the muffler.

- Remove the filler plug.

- Remove and clean the mesh pre-filter of the drain

cap with compressed air.

- Use a belt spanner for filters to remove cartridge

filter "C".

- Make sure the pre-filter and drain cap O-rings are

in good condition.

- Lubricate them and refit the mesh filter and oil

drain cap by tightening to the prescribed torque.

- Refit a new cartridge filter making sure to lubricate the O-ring before fitting, then screw until it

comes into contact with the seal and further tighten

to the prescribed torque.

- Refit the muffler.

- Add recommended engine oil.

MAIN - 41

Page 42

Maintenance X9 Evolution 500

- Start the engine and let it run for a few minutes and then turn it off.

After 5 minutes check the level and top up, if necessary, never exceed the MAX. level.

N.B.

IF THE OIL IS CHANGED WITHOUT CHANGING THE CARTRIDGE FILTER (1ST COUPON) ADD

AROUND 1500 CC OF OIL INSTEAD OF 1700 CC SINCE PART OF THE LUBRICATION CIRCUIT

IS FILLED.

Characteristic

Engine oil:

1700 cm³

Locking torques (N*m)

Engine oil drainage plug 24 ÷ 30 Engine oil filter 12 - 16

Oil pressure warning light

The vehicle is equipped with a warning light on the

instrument panel that lights up when the key is

turned to the «ON» position. However, this light

should switch off once the engine has been started.

If the light turns on during braking, at idling

speed or while turning a corner, it is necessary

to check the oil level and the lubrication system.

Checking the ignition timing

- Using a TORX wrench, remove the timing check

cap located on the flywheel cover.

- Remove the transmission cover to access the

driving pulley fastening nut that allows the driving

shaft rotation.

- Remove the head cover as described in the Thermal unit and timing system chapter.

- Turn the driving shaft to make the reference located on the magnet support collimate with that on

the flywheel cover (TDC).

- Make sure that the reference on the wheel speed

sensor is aligned with that obtained on the head.

If the reference is located opposed to the index

MAIN - 42

Page 43

X9 Evolution 500 Maintenance

obtained on the head, make the driving shaft perform a further revolution.

- Check that the two references match perfectly; if

not, remove the timing belt and install it again.

See also

Cylinder assy. and timing system

Checking the valve clearance

- To check the clearance in the valves collimate

the references between the cam shaft control pulley and head.

- Use a feeler to make sure the clearance between

the valve and register screw correspond to the indicated values. If the clearance does not correspond, adjust it by loosening the lock nut using a

screwdriver on the set screw as shown in the figure.

Characteristic

Valve clearance: intake

0.15 mm (when cold)

Valve clearance: discharge

0.15 mm (when cold)

Cooling system

Engine cooling fluid level check

The fluid level inspection should be carried out every 6,000 km when the motor is cold, following the

methods indicated below:

- Rest the vehicle on the central stand and on a flat

ground.

- Remove the expansion tank cap and top up, if the

fluid level is near to or below the MIN level into the

MAIN - 43

Page 44

Maintenance X9 Evolution 500

expansion tank. The fluid level should always be

between the «MIN» and «MAX» level.

- To have an indication of the fluid level, refer to a

notch made in a cylindrical insert, coaxial to the

filler and visible inside it once you remove the

loading cap.

The top side of the notch indicates the MAX level

while the lower one indicates the MIN level.

The cooling fluid consists of a mixture of 50%

demineralised water and ethylene glycol and corrosion inhibitors based anti-freeze solution.

WARNING

TO CHECK THE PRESENCE OF AIR IN THE CIRCUIT, PRO-

CEED AS DESCRIBED IN THE «COOLING» CHAPTER

CAUTION

DO NOT EXCEED THE MAX. LEVEL WHEN FILLING SO AS

TO AVOID THE COOLANT ESCAPING FROM THE EXPANSION TANK WHEN THE vehicle IS IN USE.

Characteristic

Cooling system

approx. 1.8 l

See also

Cooling system

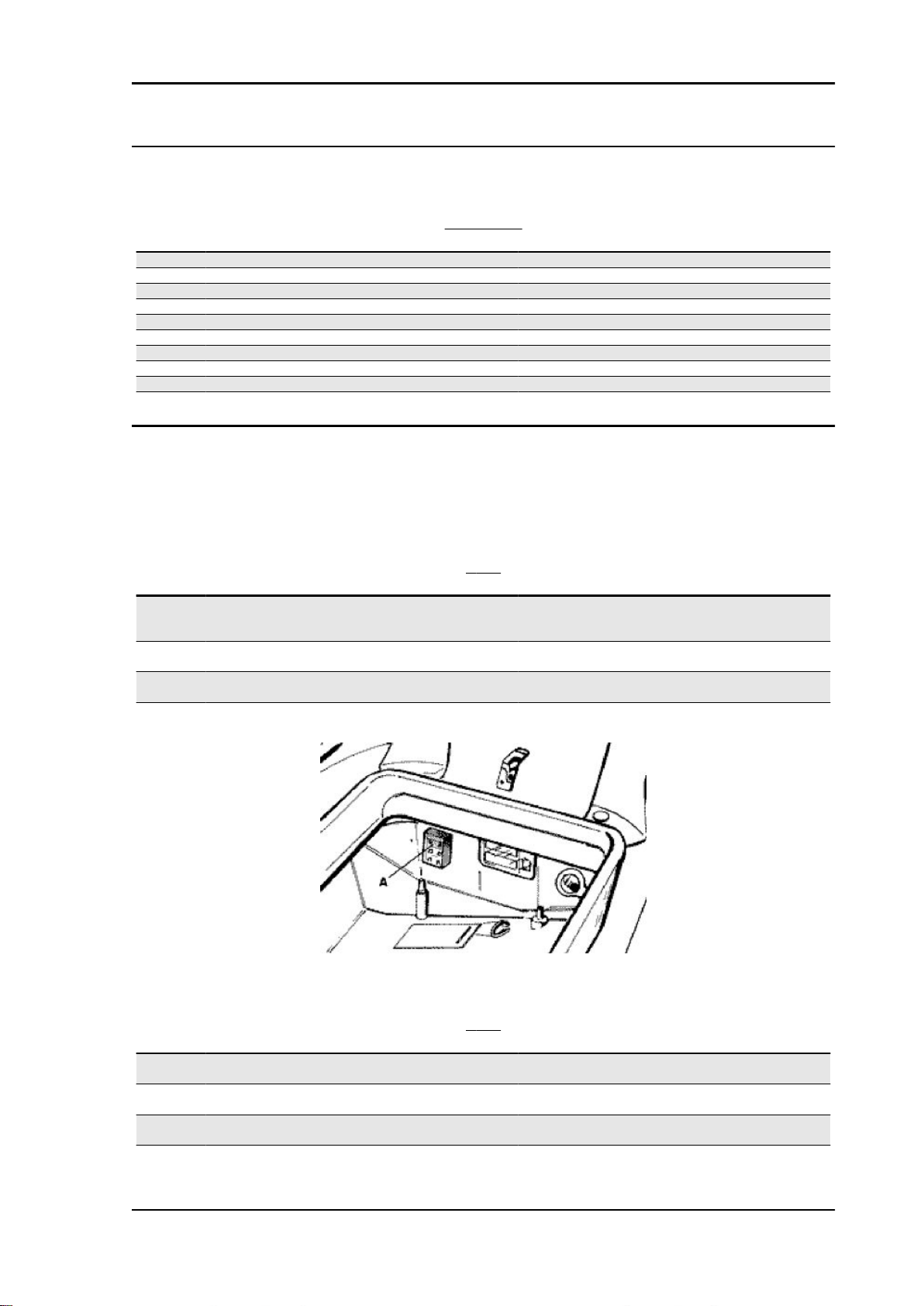

Level check

The front and rear brake fluid tanks can be accessed removing the cover located on the right

side of the handlebar cover and the display PICS

on the left side.

To check the level proceed as follows:

- rest the vehicle on the central stand with the handlebars in a central position;

- remove cover «A» loosening the fixing screw

«B» and check the front brake fluid level;

- remove screws «C» fixing the display PICS and

check the combined brake fluid level;

The level will go down to a certain extent due to

lining wear.

MAIN - 44

Page 45

X9 Evolution 500 Maintenance

Braking system

Level check

- Rest the scooter on a flat ground and on the central stand.

- Remove the brake pump cover as shown in the

figure.

- Check the brake fluid level by the special indicator located on the pump, as shown in the figure.

N.B.

THE LEVEL TENDS TO DROP AS THE BRAKE PADS GET WORN, A MINIMUM LEVEL SHOULD

NOT BE REACHED. IF THE LEVEL IS TOO LOW, CHECK AND FIX THE SYSTEM SEALS, IF RE-

MAIN - 45

Page 46

Maintenance X9 Evolution 500

QUIRED. TOP UP THE PUMP TANK, IF REQUIRED, CONSIDERING THAT THE "MAX." LEVEL

MUST ONLY BE OBTAINED WITH NEW PADS.

Top-up

To top up the fluid proceed as follows:

Remove the right cover and/or the PICS display,

then remove the tank cap loosening the relevant

two screws, remove the intermediate rubber membrane and restore the level using the prescribed

fluid without exceeding the max level.

CAUTION

ONLY USE DOT 4-CLASSIFIED BRAKE FLUID.

Recommended products

AGIP BRAKE 4 Brake fluid

FMVSS DOT 4 Synthetic fluid

In normal weather conditions, the fluid should be

replaced every 20,000 km or in any case every 2

years.

Never use braking fluid from containers that have

already been opened, or partially used.

CAUTION

THE BRAKE FLUID IS HYGROSCOPIC, THAT IS, IT AB-

SORBS MOISTURE FROM THE SURROUNDING AIR. IF

THE LEVEL OF HUMIDITY IN THE BRAKE FLUID EXCEEDS

A GIVEN VALUE, BRAKING EFFICIENCY WILL BE REDUCED.

CAUTION

AVOID CONTACT OF THE BRAKE FLUID WITH YOUR

EYES, SKIN, AND CLOTHING. IN CASE OF ACCIDENTAL

CONTACT, WASH WITH WATER.

WARNING

BRAKE CIRCUIT FLUID IS VERY CORROSIVE; DO NOT

LET IT COME INTO CONTACT WITH PAINTED PARTS.

N.B.

SEE THE BRAKING SYSTEM CHAPTER WITH REGARD TO

THE CHANGING OF BRAKE FLUID AND THE BLEEDING

OF AIR FROM THE CIRCUITS.

Headlight adjustment

- Place the vehicle in use conditions, with no load, with tyres inflated at the prescribed pressure on flat

ground at 10 m from a white screen placed in dim light, making sure that the vehicle's axle is perpendicular to the screen.

- Trace a horizontal line on the screen at 70 - 73 cm above ground level.

MAIN - 46

Page 47

X9 Evolution 500 Maintenance

- Turn the headlight on, switch on the dipped beam

and check that the horizontal limit line between the

dark zone and the illuminated zone does not fall

above the horizontal line traced on the screen.

- Adjust the screw located under the front shield to

change the headlight inclination and the light beam

height.

Checking the end compression pressure

- With the engine cold remove the sparkplug cap.

- Remove the sparkplug.

- Fit a compression testing pressure gauge in the sparkplug seat with a 10 mm sparkplug fitting tightened

to the correct torque.

- With the switch on "ON" wait a few seconds and then disconnect the rpm-timing sensor to disable

operation of the injector and sparkplug.

- Run the engine using the starter motor and with the throttle body fully open, until the reading on the

pressure gauge is stable.

- If the pressure is greater than XX - XX, remove the device and reassemble the vehicle.

- If pressure values lower than those indicated are measured, check the engine rpm used for the test;

if under 450 rpm, check the starter system.

When the compression end pressure is under the norm, remove the fitting from the pressure gauge and

pour a few cc of oil in the combustion chamber, rotate the engine (preferably by hand) to lubricate the

cylinder.

Repeat the pressure test:

if the new values are still low check the valve seals.

Higher pressure values of a new engine indicate poor sealing of the parts.

Locking torques (N*m)

Spark plug 12 ÷ 14

MAIN - 47

Page 48

Maintenance X9 Evolution 500

MAIN - 48

Page 49

INDEX OF TOPICS

TROUBLESHOOTING TROUBL

Page 50

Troubleshooting X9 Evolution 500

Transmission and brakes

Clutch grabbing or performing inadequately

IRREGULAR CLUTCH PERFORMANCE OR SLIPPAGE

Possible Cause Operation

Faulty clutch Check that there is no grease on the masses. Check that the

clutch mass contact surface with the casing is mainly in the

centre with equivalent characteristics on the three masses.

Check that the clutch casing is not scored or worn in an anom-

alous way

Insufficient braking

INSUFFICIENT BRAKING

Possible Cause Operation

Inefficient braking system Check the pad wear (1.5 min). Check that the brake discs are

Fluid leakage in hydraulic braking system Failing elastic fittings, plunger or brake pump seals, replace

not worn, scored or warped. Check the correct level of fluid in

the pumps and change brake fluid if necessary. Check there is

no air in the circuits; if necessary, bleed the air. Check that the

front brake calliper moves in axis with the disc.

Brakes overheating

Possible Cause

Rubber gaskets swollen or stuck Replace gaskets.

Compensation holes on the pump clogged Clean carefully and blast with compressed air

Brake disc slack or distorted Check the brake disc screws are locked; use a dial gauge and

Defective piston sliding Check calliper and replace any damaged part.

Braking vibrations or noise

VIBRATIONS OR NOISE WHEN BRAKING

Possible Cause

Brake disc slack or distorted Check the brake disc screws are locked; use a dial gauge and

Electrical system

BRAKES OVERHEATING

Operation

a wheel mounted on the vehicle to measure the axial shift of

the disc.

Operation

a wheel mounted on the vehicle to measure the axial shift of

the disc.

TROUBL - 50

Page 51

X9 Evolution 500 Troubleshooting

Battery

BATTERY

Possible Cause Operation

Battery This is the device in the system that requires the most frequent

Turn signal lights malfunction

TURN INDICATOR NOT WORKING

Possible Cause Operation

Electronic ignition device failure With the key switch set to "ON" jump the contacts 1 (Blue -

attention and the most thorough maintenance. If the vehicle is

not used for some time (1 month or more) the battery needs to

be recharged periodically. The battery runs down completely in

the course of 3 months. If the battery is fitted on a motorcycle,

be careful not to invert the connections, keeping in mind that

the black ground wire is connected to the negative terminal

while the red wire is connected to the terminal marked+.

Black) and 5 (Red/Blue) on the control unit connector. If by

operating the turn indicator control the lights are not steadily

on, replace the control unit; otherwise, check the cable harness

and the switch.

Steering and suspensions

Controls

STEERING CONTROLS AND SUSPENSIONS

Possible Cause

Torque not conforming Check the tightening of the top and bottom ring nuts. If irregu-

Steering hardening Check the tightening of the top and bottom ring nuts. If irregu-

Malfunctions in the suspension system If the front suspension is noisy, check: the efficiency of the front

Seal fault or breakage Replace the shock absorber Check the condition of wear of the

Operation

larities in turning the steering continue even after making the

above adjustments, check the seats on which the ball bearings

rotate: replace them if they are recessed or if the balls are flat-

tened.

larities in turning the steering continue even after making the

above adjustments, check the seats on which the ball bearings

rotate: replace them if they are recessed or if the balls are flat-

tened.

shock absorbers; the condition of the ball bearings and relevant

lock-nuts, the limit switch rubber buffers and the movement

bushings. In conclusion, check the tightening torque of the

wheel hub, the brake calliper, the shock absorber disk in the

attachment to the hub and the steering tube.

steering covers and the adjustments.

Heavy steering

Torque not conforming Check the tightening of the top and bottom ring nuts.

Possible Cause

STEERING HARDENING

Operation

If irregularities continue in turning the steering even after mak-

ing the above adjustments, check the seats in which the ball

bearings rotate: replace if they are recessed.

TROUBL - 51

Page 52

Troubleshooting X9 Evolution 500

Excessive steering play

EXCESSIVE STEERING CLEARANCE

Possible Cause Operation

EXCESSIVE STEERING CLEARANCE Check the tightening of the top and bottom ring nuts.

If irregularities continue in turning the steering even after mak-

ing the above adjustments, check the seats in which the ball

bearings rotate: replace if they are recessed.

Noisy suspension

NOISY SUSPENSION

Possible Cause Operation

NOISY SUSPENSION If the front suspension is noisy, check: the efficiency of the front

shock absorbers; the condition of the ball bearings and relevant

lock-nuts, the limit switch rubber buffers and the movement

bushings.

Suspension oil leakage

Possible Cause

Oil leakage from suspension Service the pumping members and check the sleeves and

OIL LEAKAGE FROM SUSPENSION

Operation

sealing rings are in good conditions. Replace the damaged

parts

TROUBL - 52

Page 53

INDEX OF TOPICS

ELECTRICAL SYSTEM ELE SYS

Page 54

Electrical system X9 Evolution 500

ELECTRICAL SYSTEM

Specification

1 Outside temperature sensor

2 Rear brake stop button

3 Light switch with flash

4 Indicators switch

5 Horn button

6 Emergency flashing button

7 Front fuse holder box

8 Fuse no.3 7,5A

9 Horn

10 Fuse 15A

11 Side stand switch

12 Intercom connectors

13 Voltage regulator

14 Electric side stand control unit

15 Engine stop remote control switch 30A

16 Remote electronic controller switch 30A

17 No. 2 side stand pump remote control switches

18 Fuse 70A

19 Fuse holder box with side stand pump base

20 LH taillight with sidelights bulb and flashing light bulb

21 Fuse 7,5A

22 Fuse 10A

23 Fuse 5A

24 Fuse 3A

25 No. 2 rear fuse holder boxes for control unit

26 Anti-tilting sensor

27 Saddle opening actuator

28 Intercom control unit

Desc./Quantity

ELE SYS - 54

Page 55

X9 Evolution 500 Electrical system

Specification Desc./Quantity

29 Front left-hand direction indicator with bulb

30 Analogue instrument unit (5 bulbs)

31 Radio display

32 Digital instrument unit with no. 11 LED indicators

33 Front headlight

34 Front right-hand direction indicator with bulb

35 Diode unit

36 Diode 6A

37 Diode 1A

38 Main remote control switch 30A

39 Socket 12V

40 Helmet compartment glass bowl with lamp

41 Rear brake light with no. 5 bulbs

42 Number plate light with bulb

43 RH taillight with sidelights bulb and flashing light bulb

44 Start-up remote control switch

45 Battery 12V-14Ah

46 Helmet compartment light button

47 Starter motor

48 No. 3 7.5A fuses

49 Fuse holder box

50 Fuse 15A

51 HV coil

52 Connector cap

53 Saddle opening button

54 Fuel level indicator with pump

55 Immobilizer aerial

56 Key switch

57 Anti-theft alarm fitting

58 Electric fan

59 Electric fan remote control switch 30A

60 Fitting for accessories

61 Side stand button

62 Start up button

63 Reset button

64 Actuators control unit

65 Engine stop switch

66 Decoder

67 Front brake stop button

68 Wheel rpm sensor

69 Injection ECU

70 Side stand pump motor

71 End of stroke button

72 Enable button

73 No. 2 buttons with clamp

74 Fuel injector

75 Throttle potentiometer

76 Idle adjustment motor

77 Engine rpm sensor

78 Engine rpm sensor

79 Engine water temperature sensor

80 Stuck relay indicator

81 Engine oil pressure sensor

82 Magneto flywheel

WIRING COLOUR CHART:

B = White - Bl = Blue - G = Yellow - Mr = Brown - N = Black - BV = White - Green - GN = Yellow - Black

- G = Grey - Rs Pink - R = Red - Vi = Purple - V = Green - VN = Green - Black - BN = White - Black -

BBl = White - Blue - GV = Yellow - Green - Ar = Orange - Az = Light blue - GrBl = Grey - Blue - GrN

= Grey - Black.

CAUTION

ELE SYS - 55

Page 56

Electrical system X9 Evolution 500

SHOULD ANY INTERVENTIONS TO THE ELECTRIC SYSTEM BE REQUIRED, MAKE SURE THAT

THE LEADS TO THE ELECTRONIC IGNITION DEVICE ARE PROPERLY CONNECTED ACCORDING TO POLARITY AND TO THE LEAD COLOURS.

Components arrangement

COMPONENTS LOCATION

Specification

1 Side stand switch

2 Voltage regulator

3 Side stand control unit

4 Electronic control unit remote control switch

5 Engine stop remote control switch

6 Service remote control switch

7 Fuse holder box (n.3 7.5A, n.1 15A)

8 No. 2 start-up remote control switches

9 Magneto flywheel 373W

10 No. 2 buttons for side stand

11 Side stand pump motor

12 Pump unit with level indicator

13 Starter motor

14 Helmet compartment lighting button

15 Helmet compartment glass bowl

16 Socket 12V

17 No. 2 rear fuse holder boxes for control unit (n.1 3A, n.1

5A, n.1 10A, n.1 3A)

18 (Diode holder box (n. 2 6A and 2A diodes)

19 Fuse holder box (n.2 7.5A, n.1 15A and 5A)

20 Fuse holder box with base for stand pump remote control

switch (n.1 70A)

21 Digital instrument unit (11 indicators and led)

22 Analogue instrument unit (5 bulbs)

23 Headlight with n. 2 position bulbs and n.2 high/low beam

bulbs 55W

24 Front LH direction indicator with 10W bulb

25 Rear brake stop button

Desc./Quantity

ELE SYS - 56

Page 57

X9 Evolution 500 Electrical system

Specification Desc./Quantity

26 Light switch with flash

27 Indicators switch

28 Horn button

29 Emergency flashing button

30 Reset button

31 Horn

32 LH taillight with sidelights bulb 5W and flashing light bulb

33 Rear tail light with 5 2.3W bulbs

34 Number plate light bulb 12V-5W

35 Rh taillight with sidelights bulb 5W and flashing light bulb

36 Battery 12V-14Ah

37 Front brake stop button

38 Engine stop switch

39 Wheel rpm sensor

40 Front RH direction indicator with 10W bulb

41 Main remote control switch

42 Light switch

43 Start up button

44 Side stand button

45 Key switch

46 Radio display

47 Electric fan remote control

48 30A fuse with start-up remote control switch

49 Radio/intercom/handsfree control unit

50 No. 2 pump remote control switches

51 Stuck relay indicator

52 No. 2 headlight remote control switches

10W

10W

Conceptual diagrams

Ignition

ELE SYS - 57

Page 58

Electrical system X9 Evolution 500

IGNITION SECTION

Specification Desc./Quantity

1 Anti-theft alarm fitting

2 Side stand switch

3 Engine stop switch

4 Voltage regulator

5 Battery 12V - 4Ah

6 Start up button

7 Diode 6A

8 Starter motor

9 Fuse no. 13 30 A

10 Remote starter switch

11 Main remote control switch

12 Diode 2 A

13 Key switch contacts

14 Two brake light buttons

15 Digital instrument unit

16 Engine stop remote control switch

17 Electronic control unit remote control switch

18 Immobilizer aerial

19 Decoder

20 HV coil

21 Start-up/injection electronic control unit

22 Fuse no. 2 10 A

23 Fuse no. 3 3A

24 Fuse no. 10 7,5A

Headlights and automatic starter section

HEADLIGHTS AND AUTOMATIC STARTER SECTION

Specification

1 Anti-theft alarm fitting

2 Bulb for upper beams 12V - 55W

3 Bulb for lowerbeams 12V - 55W

ELE SYS - 58

Desc./Quantity

Page 59

X9 Evolution 500 Electrical system

Specification Desc./Quantity

4 Light switch

5 Side stand switch

6 Engine stop switch

7 Voltage regulator

8 Roof lamp for box helmet illumination with lamp

9 Helmet compartment lighting button

10 Battery 12V - 14 Ah

11 Fuse no. 13 30 A

12 Main remote control switch

13 Diode 2 A

14 Key switch contacts

15 No. 2 bulbs for front sidelight 12V-3W

16 License plate light bulb 12V - 5W

17 Two (2) taillight bulbs 12V - 5W

18 Digital instrument unit

19 4 Turn indicator bulbs 12V-10W

20 Indicators switch

21 Emergency flashing light button (4 direction indicators)

22 Engine stop remote control switch

23 Connettore per predisposizione accessori

24 Start-up/injection electronic control unit

25 Fuse no. 5 15 A

26 Fuse no. 8 7,5 A

27 Fuse no. 4 5 A

28 Fuse no. 12 7,5 A

29 Fuse no. 11 7,5 A

30 Fuse no. 9 15 A

Battery recharge and starting

BATTERY RECHARGE AND START-UP SECTION

Specification

1 Side stand switch

2 Engine stop switch

3 Magneto flywheel

Desc./Quantity

ELE SYS - 59

Page 60

Electrical system X9 Evolution 500

Specification Desc./Quantity

4 Voltage regulator

5 Battery 12V - 4Ah

6 Start up button

7 Diode 6A

8 Starter motor

9 Fuse no. 13 30 A

10 Remote starter switch

11 Main remote control switch

12 Diode 2 A

13 Key switch contacts

14 Two brake light buttons

15 No. 5 bulbs for brake light 12V-2,3W

16 Digital instrument unit

17 Control unit power supply remote control switch (engine

18 Start-up/injection electronic control unit

19 Fuse no. 4 5 A

20 Fuse no. 10 7,5A

stop)

Level indicators and enable signals section

LEVEL INDICATORS AND ENABLE SIGNALS SECTION

Specification

1 Anti-theft alarm fitting

2 Side stand switch

3 Engine stop switch

4 Saddle opener actuator

5 Saddle opening button

6 Voltage regulator

7 Key switch contacts

8 Roof lamp for box helmet illumination with lamp

9 Helmet compartment lighting button

10 Battery 12V - 4Ah

11 Fuse no. 13 30 A

12 Main remote control switch

ELE SYS - 60

Desc./Quantity

Page 61

X9 Evolution 500 Electrical system

Specification Desc./Quantity

13 Diode 2 A

14 Key switch contacts

15 Engine warning indicator

16 Engine not enable indicator

17 Low fuel warning light

18 High-beam warning light

19 Wheel RPM sensor

20 Outside temperature sensor

21 Digital instrument unit

22 Fuel level sender

23 Control unit power supply remote control switch (engine

24 Electronic control unit components remote control switch

25 Saddle opener receiver

26 Pump remote control switches

27 Side stand pump motor

28 Stuck relay indicator

29 Side stand out enable button

30 Side stand in enable button

31 Electro-hydraulic side stand actuation button

32 Side stand control unit

33 Tilting sensor

34 Air temperature sensor

35 Engine rpm sensor

36 Double wire screened cable

37 Fuel injector

38 Idle adjustment motor

39 Fuel pump

40 Engine temperature sensor

41 Diagnostics socket connector

42 Throttle potentiometer

43 Start-up/injection electronic control unit

44 Fuse no. 5 15A

45 Fuse no. 6 10A

46 Fuse no. 14 70A

47 Fuse no. 2 10A

48 Fuse no. 1 5A

49 Fuse no. 4 5 A

50 Fuse no. 12 7,5 A

stop)

Checks and inspections

Battery recharge circuit

The recharge system is provided with a three phase alternator with permanent flywheel.

The alternator is directly connected to the voltage regulator.

This, in its turn, is connected directly to the ground and the battery positive terminal passing through

the 30A protective fuse.

This system therefore requires no connection to the key switch.

The three- phase generator provides good recharge power and at low revs, a good compromise is

achieved between generated power and idle stability.

Stator check

Stator winding check-up

WARNING

THIS CHECK-UP CAN BE MADE WITH THE STATOR PROPERLY INSTALLED.

ELE SYS - 61

Page 62

Electrical system X9 Evolution 500

1) Remove the door in the saddle compartment.

2) Disconnect the connector between the stator and regulator with the three yellow wires.

3) Measure the resistance between each of the yellow terminals and the other two.

Electric characteristic

Resistance:

0.2 - 1 Ω

4) Check that there is insulation between the each yellow cable and the ground.

5) If values are incorrect, replace the stator.

Recharge system voltage check

Look for any leakage

1) Check that the battery does not show signs of leaking fluid before checking the output voltage.

2) Turn the ignition key to OFF and connect the multimeter leads between the battery negative pole (-)

and the Black cable.

3) With the multimeter leads connected, disconnect the Black cable from the battery negative pole (-).

4) With the ignition key always at OFF, the reading indicated by the ammeter must be ≤ 0.5 mA.

Maximum current output check.

- With engine off and panel set to "ON" turn on the lights and let the battery voltage set to 12V.

- Connect ammeter pliers to the 2 recharge positive poles in output from the regulator.

- Keep the lights on and start the engine, bring it to normal speed and read the values on the ammeter.

With an efficient battery a value must be detected: > 20A

Check the charging current

WARNING

BEFORE CARRYING OUT THE CHECK, MAKE SURE THAT THE BATTERY IS IN GOOD WORKING ORDER.

1) Place the vehicle on its centre stand

2) With the battery correctly connected to the circuit, place the tester terminals between the battery

terminals..

3) Start the engine, ensure that the lights are all out, increase the engine speed and at the same time

measure the voltage.

Electric characteristic

Voltage ranging between 14.0 and 15.0V at 5000 rpm.

VOLTAGE REGULATOR/RECTIFIER

Specification

Type Non-adjustable three-phase transistor

Voltage 14 ÷ 15V at 5000 rpm with lights off

ELE SYS - 62

Desc./Quantity

Page 63

X9 Evolution 500 Electrical system

Lights list

LIGHTS LIST

Specification Desc./Quantity

1 Dipped beam light N° 1, 12V-55W, halogen

2 Upper beam light N° 1, 12V-55W, halogen

3 Front position lights N° 2, 12V-3W, all glass

4 Front direction indicator lights N° 2, 12V-10W, spherical

5 Rear position lights N° 2, 12V-5W, spherical

6 Stop lights N° 5, 12V-2,3W, spherical

7 Rear turn indicator bulbs Two, 12V-10W, spherical

8 Instrument panel lights N° 5, 12V-2W, all glass

9 Helmet compartment light N° 1, 12V-5W, cylindrical

10 Number plate lights N° 1, 12V-5W, cylindrical

Fuses

The electric system is equipped with:

1. four fuses «A» into the under saddle compartment.

FUSE

Specification

1 N.1 Capacity: 15 A

Protected Circuits : Socket 12V for users- Under sad-

2 N.1 Capacity: 10 A

Protected Circuits : Saddle opening by button

3 N.1 Capacity: 10 A

Protected Circuits : PICS device

4 N.1 Capacity: 7,5 A

Protected Circuits : Dipped and high beam bulb

Desc./Quantity

dle compartment light

2. five fuses «B» next to the battery, on the left side.

FUSE

Specification

1 N.1 Capacity: 70 A

Protected Circuits : Electro-hydraulic stand

2 N.1 Capacity: 5 A

Protected Circuits : Electro-hydraulic stand

3 N.1 Capacity: 10 A

Protected Circuits : Fuel pump - Injector - H.V. coil

4 N.1 Capacity: 3 A

Protected circuits: Immobilizer (Decoder and EMS en-

Desc./Quantity

gine management control unit)

ELE SYS - 63

Page 64

Electrical system X9 Evolution 500

Specification Desc./Quantity

5 N.1 Capacity: 5 A

Protected circuits: Diagnostic outlet - Decoder and

control unit enable signal

3. four fuses «C» into the trunk on the left side.

FUSE

Specification Desc./Quantity

1 N.1 Capacity: 15 A

2 N.1 Capacity: 7,5 A

3 N.1 Capacity: 7,5 A

4 N.1 Capacity: 7,5 A

Protected circuits: Horn - High beam bulb - Accesso-

ries

Protected circuits: Start-up enable signal - Brake light

lamp

Protected circuits: Front and rear position light - Num-

ber plate light

Protected circuits: PICS - Saddle opening by remote

control

4. a 30A fuse (main fuse), located next to the battery on the right side and on the start-up remote

control switch; a spare fuse is provided below it.

ELE SYS - 64

Page 65

X9 Evolution 500 Electrical system

Dashboard

Vehicle X9 is provided with an instrument panel

divided into 2 sections: the analogue section is

fixed into the cap while the digital section is integral

to the handlebar.

The analogue section includes:

- Tachometer with dual scale (MPH/KMH) controlled by the fifth wheel by the digital section;

- RPM counter controlled by the signal sent by the

injection control unit;

- Fuel level indicator controlled by a resistive sensor (into the tank)

- Cooling fluid temperature indicator controlled by

a resistive sensor (on the head)

These instruments are electrical and managed by

stepping motors.

The digital section has the following indications:

- Fuel reserve: amber coloured;

- Position and dipped beam lights: green coloured;

- Upper or passing beams: blue coloured;

- Left direction indicator: green coloured;

- Right direction indicator: green coloured;

- Emergency lights (four direction indicators): red

coloured;

- Engine disabled: red coloured;

- ABS system failure (optional): red coloured;

- Oil pressure: red coloured;

- Injection warning: amber coloured;

- ALARM (electro-hydraulic stand): red coloured.

The fuel reserve, direction indicators and emergency flashing functions are activated by the instrument

electronics. For example, the fuel reserve indicator light only turns on when the reserve indication coming from the engine lasts at least 13.5 seconds. This prevents the intermitting turning on of the reserve

light indicator.

- The intermitting function is built in the instrument electronics: this allows operating the emergency

lights with switch in position "OFF" and control switch off. The control switch is only active when the

instrument panel is on.

ELE SYS - 65

Page 66

Electrical system X9 Evolution 500

To ensure safety while riding, the "direction indicators control" function is connected to the odometer.

If the indicator is left on, it automatically stops after 1 kilometre travelled.

- The "engine disabled" indicator is activated by the side stand switch and by the emergency switch on

the right side of the handlebar.

- The LCD display gives a 5 digit indication for the total kilometres covered by the vehicle. It can be

expressed in kilometres or in miles: of course, this indication cannot be reset. To select the indication,

press "Trip" and "M" at the same time, then tirn the key switch to "ON"; keep these 2 buttons

pressed for more than 3" to display "SET" on the display, then the display switches from miles

to kilometres, or vice versa.

The instrument panel digital section is completed

by a liquid crystal display and 4 control buttons.

The display has 3 icons:

- Oil

- Service

- Belt

- The "Oil" icon warns the user of the need of replacing the engine oil.

- The "Service" icon warns the user of the need of servicing the vehicle.

- The "Belt" icon warns the user of the need of replacing the driving belt.

After servicing by the authorised workshop, the icon message must be reset by the "Reset" button

located in the front side of the vehicle under the headlight upper cover. The "Reset" button allows

resetting the kilometres covered and, in the case of "OIL" and "BELT" and "SERVICE", also the year

count. This count remains active even if the battery is disconnected for a short time.

To reset one of the icons, press the "Reset" button for less than a second, then on the icon

before that to be reset press "Reset" for at least 3" so as to display:

- The selectionj of the desired icon through the relevant solid light.

- The flashing of this light confirms the reset.

- For example, to reset the "Service" icon, go to "Oil" and press the "Reset" button for at least 3". To

reset "Oil", repeat the above procedure going to "Belt".

This procedure must be repeated since the selection of the icon and its reset are operations to be made

at the same time (it is not possible to view the desired function and reset by two different button pressures since in this way the next icon would be reset).

Data check function

The date must be adjusted upon the vehicle delivery to the customer. This is because the clock starts

counting the year for the «Service» function. If the clock has already been started, reset the functions

ELE SYS - 66

Page 67

X9 Evolution 500 Electrical system

«Oil», «Service» and «Belt». The calendar is programmed from 2000 to 2050, to adjust the date and

time use the two buttons «Clock» and «Set».

To guarantee the vehicle safety, every time the key switch is set to «ON», all of the digital indications

are checked.

The digital section also has a functional check of the 4 analogue instruments and of the flashing light

control. To start this check, keep buttons «Clock» and «Set» pressed and set the key switch to

«ON». Within 4 seconds, the software version is displayed, the instruments indicate the scale bottom

and the direction indicators turn on.

At the end of the above procedure, there is the normal check of the indicator lights.

pics

PICS SECTION

Specification

1 Display pics

2 Intercom Controller

3 Intercom connectors

4 Battery 12V - 4Ah

5 Fuse no. 13 30 A

6 Key switch contacts

7 Fuse no. 7 10A

8 Fuse no. 12 7,5 A

Desc./Quantity

ELE SYS - 67

Page 68

Electrical system X9 Evolution 500

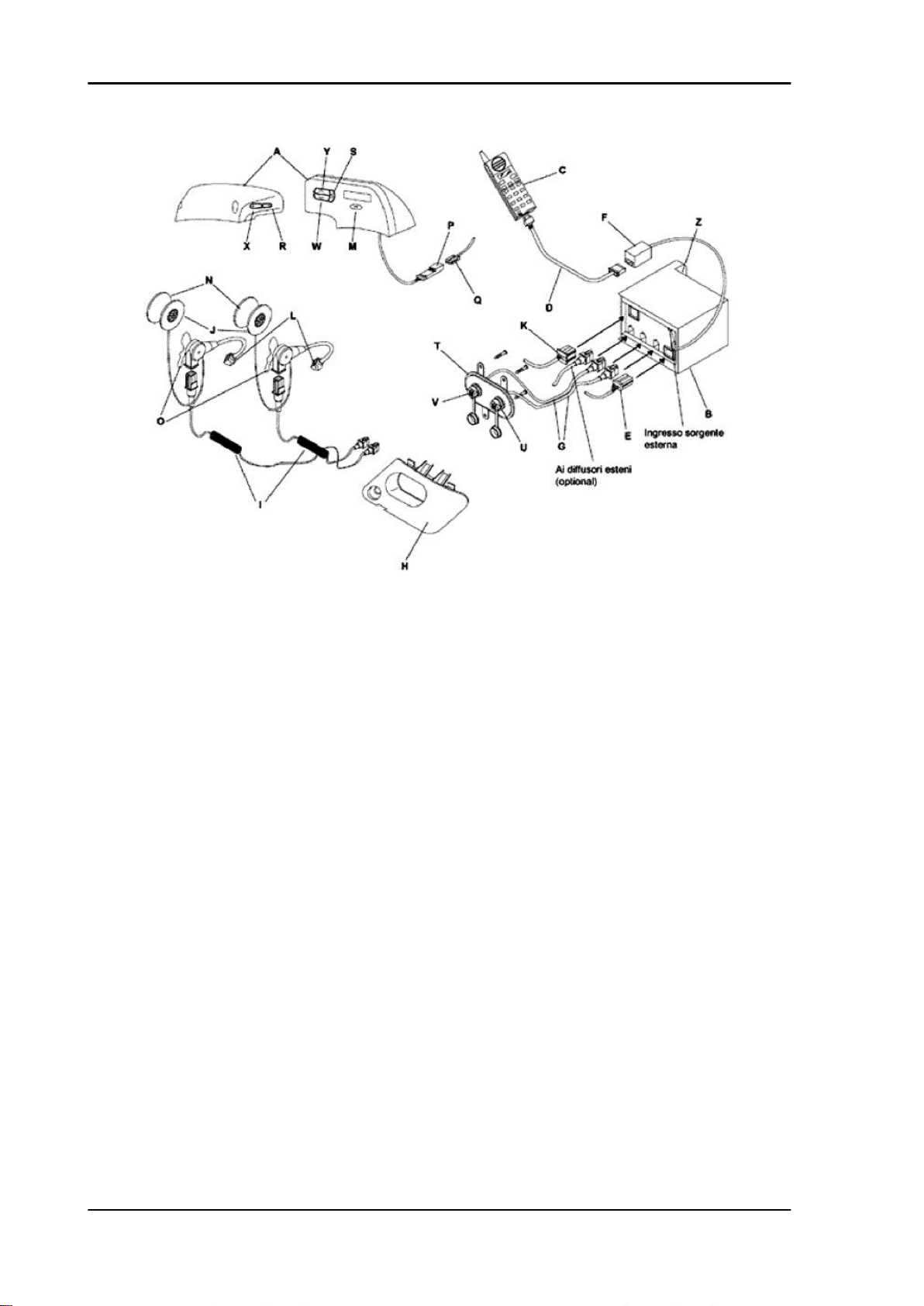

Captions

A = Satellite

D = Mobile phone cable

F = Telephone connector

H = Spark plug inspection port

J = Loudspeaker

L = Microphone

O = Headset clip

R = Volume button-

U = Passenger connection

X = Volume button +

B = Control unit

E = Control unit power supply connector

K = Vehicle control unit connector

M = MODE button