Page 1

Service

Service

17" Auto Scan Colour Monitor

Se rvi ce

Chassis:V30

MODEL : V30 107T50/00

Horizontal frequencies

30-71KHz

TABLE OF CONTENTS

Description Page

Important Safety Notice-------------------------------- 2

Technical data ------------------------------------------- 3

Installation------------------------------------------------ 4

On-screen Display (OSD)--------------------------5 ~ 8

OSD Lock/Unlock, Burn In, Service mode-----9 ~ 12

Wiring Diagram ---------------------------------------- 14

Mechanical Instructions -------------------------- 15,16

Warning and Notes ---------------------------------- --17

Electrical Instructions---------------------------- 18~20

DDC Instructions ----------------------------------21~28

Block Diagram------------------------------------------ 29

Circuitry schematic diagrams(Main) ----------30~ 33

Description Page

Circuitry schematic diagrams(Audio) --------34~ 36

Circuitry schematic diagrams(Key ) ---------- 37, 38

Exploded View -----------------------------------------39

Recommend Parts List -------------------------------40

Spare Parts List------------------------------------41,42

General Product Specification ----------------43~72

Repair Flow Chart-------------------------------- 73~80

Light Fram for Windows------------------------- 81~84

Repair Tips --------------------------------------------- 85

Safety Test Requirements----------------------------86

General Troubleshooting Guide ------------- 87~109

SAFETY NOTICE

ANY PERSON ATTEMPTING TO SERVICE THIS CHASSIS MUST FAMILIARIZE HIMSELF WITH THE CHASSIS

AND BE AWARE OF THE NECESSARY SAFETY PRECAUTIONS TO BE USED WHEN SERVICING ELECTRONIC

EQUIPMENT CONTAINING HIGH VOLTAGES.

CAUTION: USE A SEPARATE ISOLATION TRANSFORMER FOR THIS UNIT WHEN SERVICING.

REFER TO BACK COVER FOR IMPORTANT SAFETY GUIDELINES

Published by BCU Monitors Printed in Taiwan Copyright reserved Subject to modification Mar. 14 , 2003 GB

S

3138 106 10264

Page 2

2

107T5107T5

Go to cover page

Important Safety Notice

Proper service and repair is important to the safe, reliable

operation of all PHILIPS Consumer Electronics Company**

Equipment. The service procedures recommended by

PHILIPS and described in this service manual are effective

methods of performing service operations. Some of these

service operations require the use of tools specially designed

for the purpose. The special tools should be used when and

as recommended.

It is important to note that this manual contains various

CAUTIONS and NOTICES which should be carefully read in

order to minimize the risk of personal injury to service

personnel. The possibility exists that improper service

methods may damage the equipment. It is also important to

understand that these CAUTIONS and NOTICES ARE NOT

EXHAUSTIVE. PHILIPS could not possibly know, evaluate

and advise the service trade of all conceivable ways in which

service might be done or of the possible hazardous

consequences of each way. Consequently, PHILIPS has not

undertaken any such broad evaluation. Accordingly, a

servicer who uses a service procedure or tool which is not

recommended by PHILIPS must first satisfy himself

thoroughly that neither his safety nor the safe operation of the

equipment will be jeopardized by the service method selected.

FOR PRODUCTS CONTAINING LASER :

DANGER-

CAUTION-

CAUTION-

TO ENSURE THE CONTINUED RELIABILITY OF THIS

PRODUCT, USE ONLY ORIGINAL MANUFACTURER'S

REPLACEMENT PARTS, WHICH ARE LISTED WITH THEIR

PART NUMBERS IN THE PARTS LIST SECTION OF THIS

SERVICE MANUAL.

Invisible laser radiation when open.

AVOID DIRECT EXPOSURE TO BEAM.

Use of controls or adjustments or

performance of procedures other than

those specified herein may result in

hazardous radiation exposure.

The use of optical instruments with this

product will increase eye hazard.

* * Hereafter throughout this manual, PHILIPS Consumer

Electronics Company will be referred to as PHILIPS.

WARNING

Critical components having special safety characteristics are

identified with a by the Ref. No. in the parts list and

enclosed within a broken line*

(where several critical components are grouped in one area)

along with the safety symbol on the schematics or

exploded views.

Use of substitute replacement parts which do not have the

same specified safety characteristics may create shock, fire,

or other hazards.

Under no circumstances should the original design be

modified or altered without written permission from Philips.

Philips assumes no liability, express or implied, arising out of

any unauthorized modification of design.

Servicer assumes all liability.

* Bro ken Lin e

Page 3

Technical Data

107T5

Go to cover page

9

3

Technical Specification*

Dimensions : 17 inch

Pitch : 0.25

Deflection angle : 90 degrees

Glass : dark

Light transmission : 50%(CPT), 52.8%(LG), 52.6%(SDI),

Surface : AGARAS

Implosion protection : CRT is provided with P-mini-rim-band.

Black matrix : Yes

Phosphor : P22

EHT : 25 KV (Ib=0)

CRT source : CPT, LG, SDI

Scanning

Horizontal scanning : 30 - 71 KHz

Vertical scanning : 50 - 160 Hz

Input signals

Video : Analog level

Sync. : Separate sync. with TTL level

Polarity : Positive or negative

Signal input level

Video : 0.7 Vp-p 75 ohms

Sync : TTL level

Impedance

Video : Terminated with 75 ohms

Sync : Terminated with 4.7K ohms pull down resistors

Video amplifiers

Dot Rate : 108 Mhz

Operating limits

Temperature : 0C to 40C

Humidity : 10 to 90% (W/O condensation)

Air pressure : 700 ~ 1100 mbar

Pin No.

1

2

3

4

5

6

7

8

Assignment

Red video input

Green video input

Blue video input

Gnd

For self-test

Red video ground

Green video ground

Blue video ground

Pin No.

9

10

11

12

13

14

15

Assignment

+5V DDC

Gnd

Gnd

Bidirectional Data

H.Sync /H

V.Sync(VCLK for DDC)

Data clock line(SCL)

Data Storage

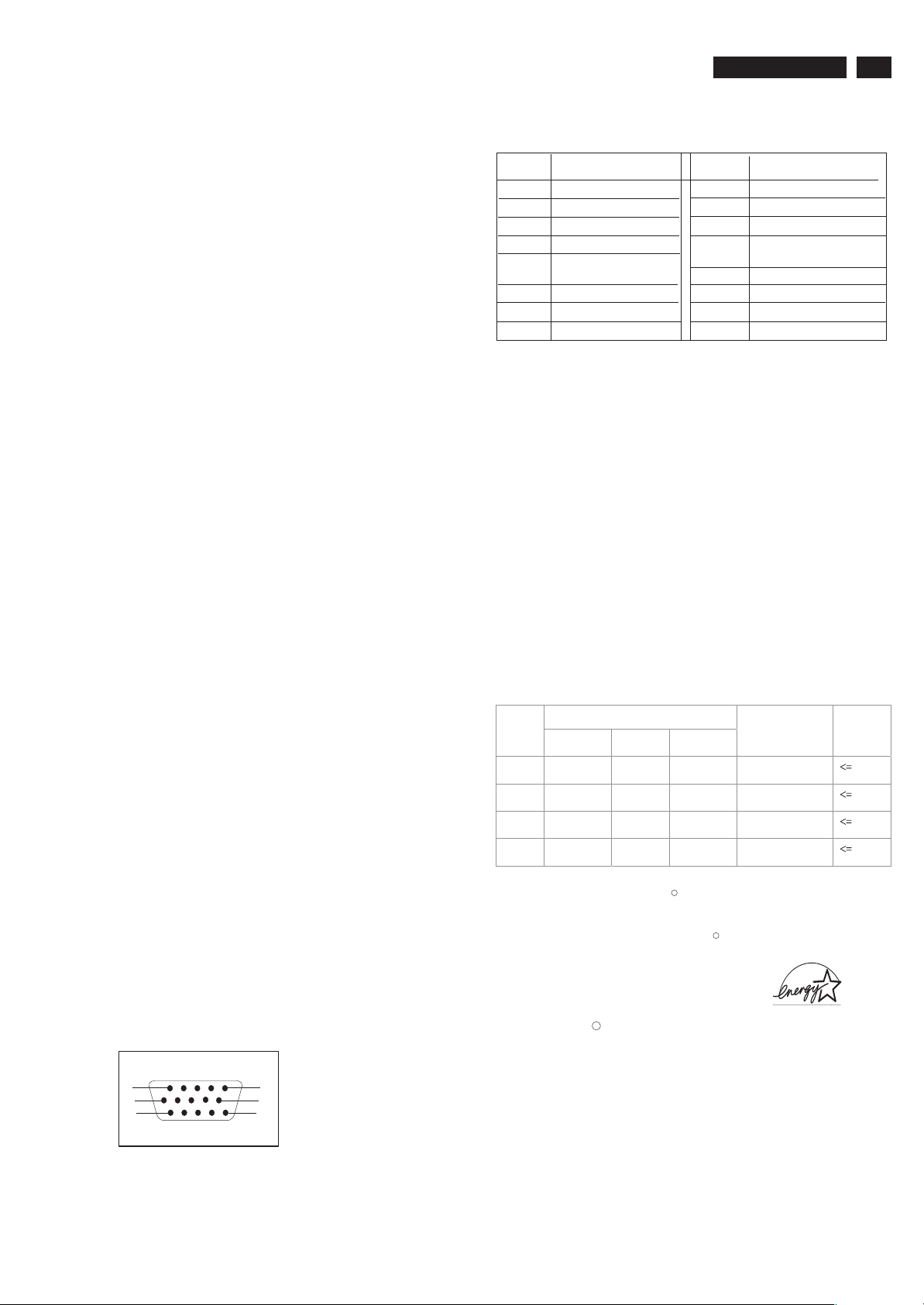

Factory preset modes:

This monitor has 8 factory-preset modes as indicated in the

Factory preset modes : 8

Resolution H. freq. V. freq. H. V.

1. 720 x 400 31.5 KHz 70Hz (VGA) - +

2. 640 x 480 31.47 KHz 60Hz (VGA) - -

3. 640 x 480 43.3 KHz 85Hz (VESA) - -

4. 800 x 600 46.9 KHz 75Hz (VESA) + +

5. 800 x 600 53.674KHz 85Hz (VESA) + +

6. 1024 x 768 60.0 KHz 75Hz (VESA) + +

7. 1024 x 768 68.7 KHz 85Hz (VESA) + +

8. 1280 x 1024 64.0 KHz 60Hz (VESA) + +

Automatic Power Saving

:The 15-pin D-sub connector(male) of the signal cable

Non-operating limits (storage)

Carton box

White color adjustment

Based on the 1931 CIE chromatic diagram (x,y) coordinates

For 9300 K X = 0.283 0.015 Y = 0.297 0.015

For 6500 K X = 0.313 0.015 Y = 0.329 0.015

For sRGB X = 0.313 0.015 Y = 0.329 0.015

Temperature : -25C to 65C

Humidity : 5 to 95 % (W/O condensation)

Altitude : 300 to 1100 mbar

A-1 Size (with pedestal)

496(W)416(H)556(D)

A-2 Carton paper : double wall AB flute corrugate

Bursting : 19.3 kgf/cm min

Compression : 600 kgf min

of white display on screen center should be:

board, color brown

2

Pin assignment :

1

6

11

5

10

15

Signal

H-Sync V-Sync Video

On Active Active Active Mandatory 75w

Off Inactive Active Blanked Mandatory 2w

Off Active Inactive Blanked Mandatory 2w

Off Inactive Inactive Blanked Mandatory 2w

This monitor is ENERGY STAR compliant.

this product meets the ENERGY STAR guidelines for energy

Efficiency

ENERGY STAR is a U.S. registered mark. AS AN ENERGY STAR

PARTNER, DELL Computer Corporation HAS DETERMINED THAT

THIS PRODUCT MEETS THE ENERGY STAR GUIDELINES FOR

ENERGY EFFICIENCY.

R

R

R

Compliance

Requirement

Power

Page 4

4

Go to cover page

9

107T5

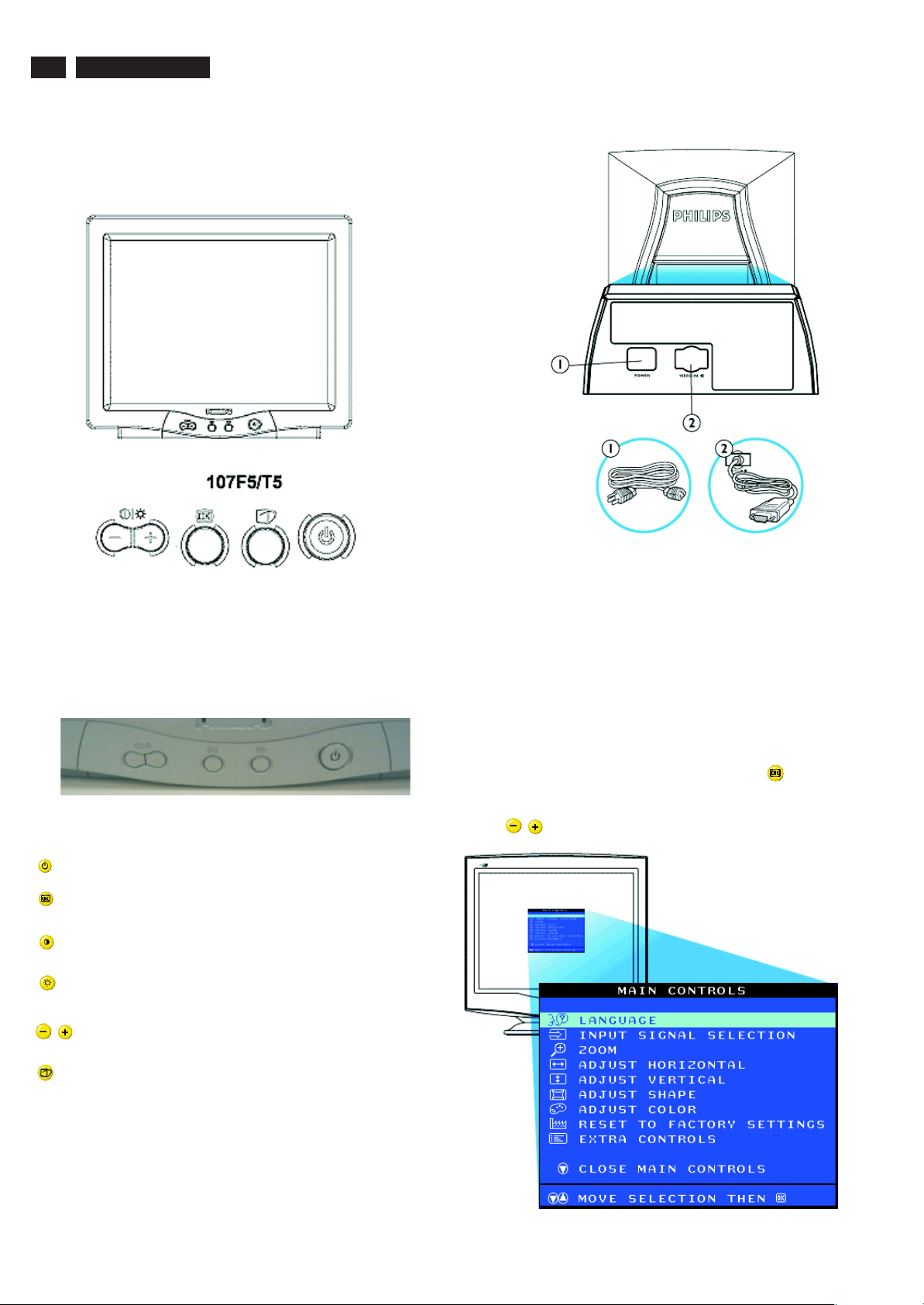

Front control & OSD

Front View

Rear view

Front control

Power button switches your monitor on.

OK button which when pressed will take you to the OSD

controls

Contrast hotkey. When the "-" button is pressed,

the adjustment controls for the CONTRAST will show up.

Brightness hotkey. When the "+" button is pressed,

the adjustment controls for BRIGHTNESS will show up.

"-" and "+" buttons, are used for adjusting the OSD of your

Monitor.

1. Power in - attach power cable here.

2. Video In - this is a cable which is already attached to your monitor.

Connect the other end of the cable to your PC.

Description of the On Screen Display

What is the On-Screen Display?

This is a feature in all Philips monitors which allows an end-user to

adjust screen performance of monitors directly though an on-screen

instruction window. The user interface provides user-friendliness and

ease-of-use when operating the monitor.

Basic and simple instruction on the control keys.

On the front controls of your monitor, once you press the button, the

On Screen Display (OSD) Main Controls window will pop up and you

can now start making adjustments to your monitor's various features.

Use the the keys to make your adjustments within.

LightFrame hotkey. When the button is pressed, the adjustment

controls for LightFrame will show up.

Page 5

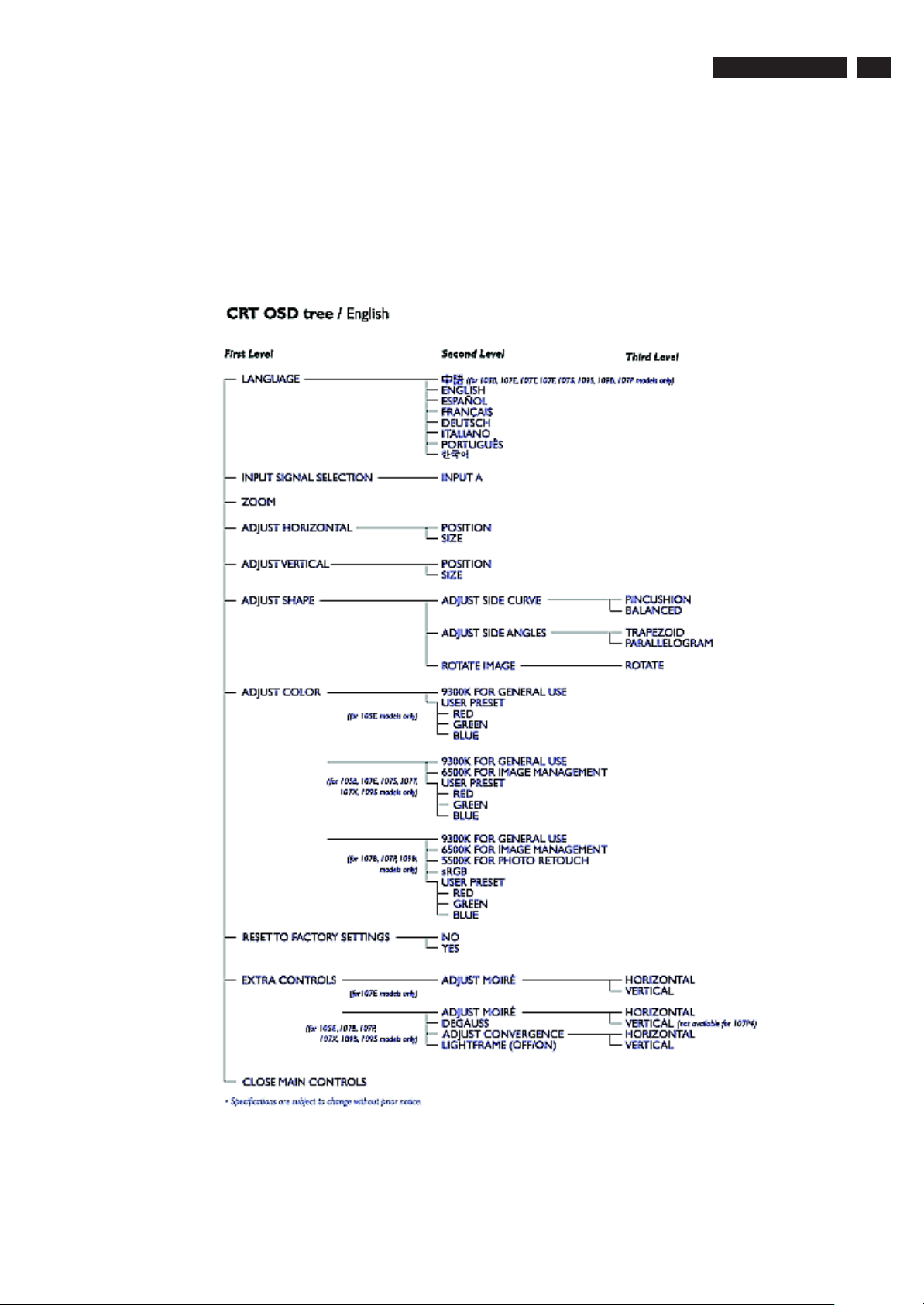

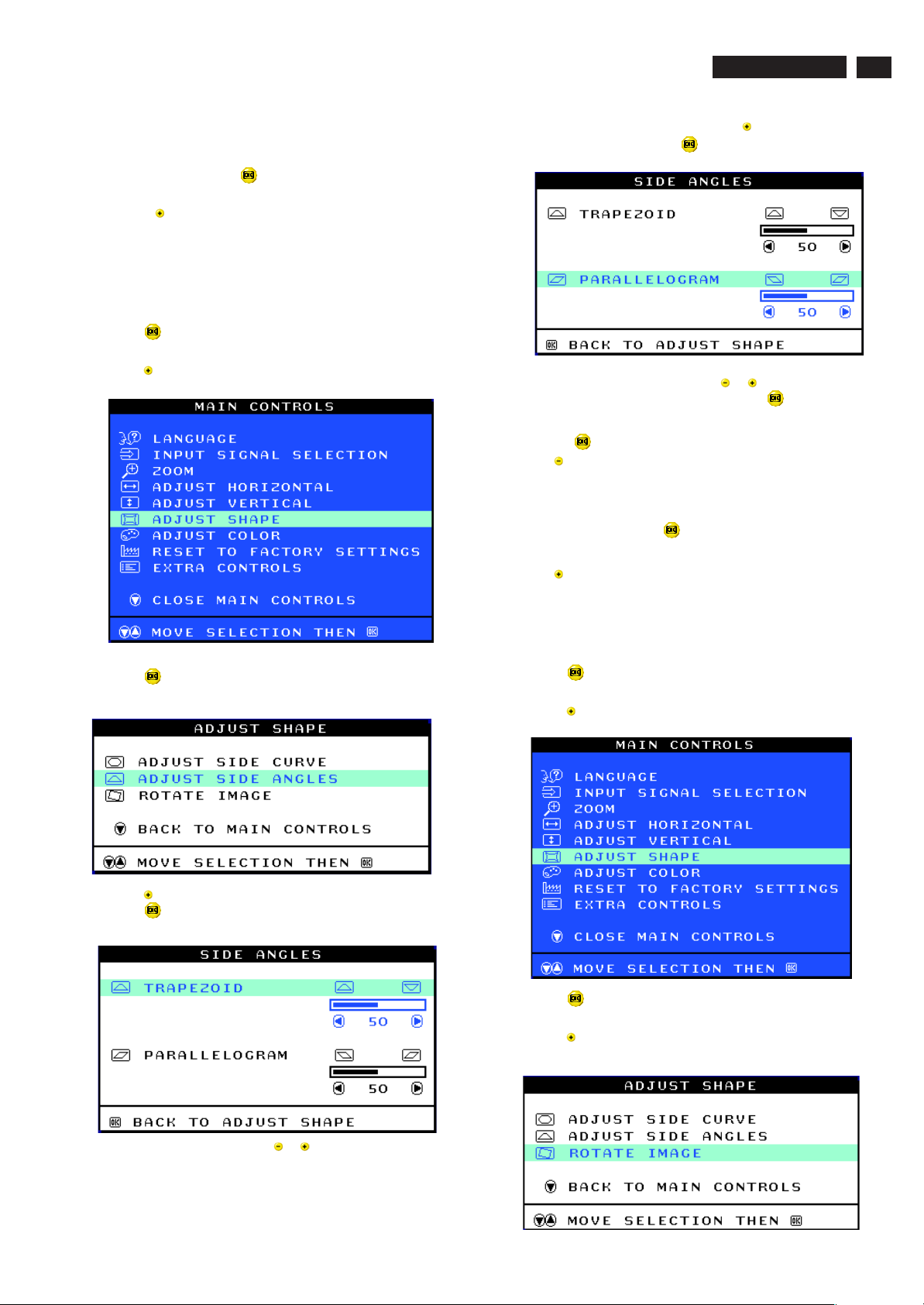

OSD menu tree

The OSD Tree

Below is an overall view of the structure of the On-Screen

Display. You can use this as reference when you want to

later on work your way around the different adjustments.

107T5

Go to cover page

9

5

Page 6

6

Go to cover page

9

107T5

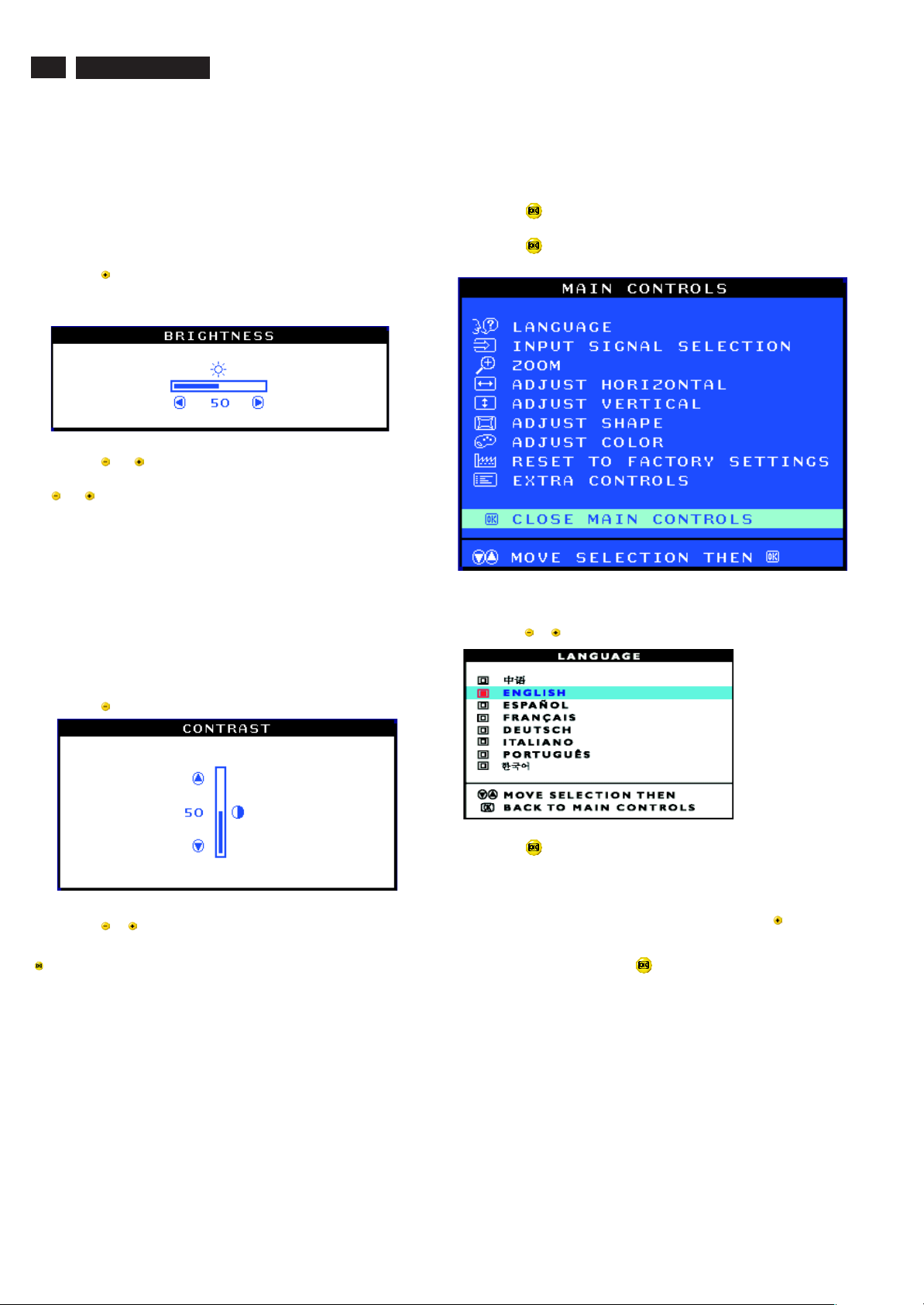

OSD Adjustments

The OSD Controls

BRIGHTNESS

To adjust your screen's brightness, follow the steps below. Brightness is

the overall intensity of the light coming from the screen. A 50%

brightness is recommended.

1) Press the button on the monitor. The BRIGHTNESS window

appears.

2) Press the or button to adjust the brightness.

3) When the brightness is adjusted to the level desired, stop pressing

the or button and after three seconds the BRIGHTNESS window

will disappear with the new adjustment saved.

Smart Help

continue to the CONTRAST window, follow the steps under CONTRAST.

After the BRIGHTNESS window has disappeared, to

LANGUAGE

The ON SCREEN DISPLAY shows its settings in one of eight languages.

The default is English, but you can select French, Spanish, German,

Italian, Simplify-Chinese, Korea, Brazilian or Portuguese.

1) Press the button on the monitor. The MAIN CONTROLS window

appears. LANGUAGE should be highlighted.

2) Press the button again. The LANGUAGE window appears.

CONTRAST

To adjust your screen's contrast, follow the steps bellow. Contrast is the

difference between the light and dark areas on the screen. A 100%

contrast is recommended.

1) Press the button on the monitor. The CONTRAST window appears.

2) Press the or button to adjust the contrast.

3) When the contrast is adjusted to the level desired, stop pressing the

Button and after three seconds the CONTRAST window will

disappear with the new adjustment saved.

Smart Help

continue to the MAIN CONTROLS, follow the steps under LANGUAGE

After the CONTRAST window has disappeared, to

3) Press the or button until the desired language is highlighted.

4) Press the button to confirm your selection and return to MAIN

CONTROLS window. CLOSE MAIN CONTROLS will be highlighted...

Smart Help

...tocontinue to INPUT SIGNAL SELECTION, press the button until

INPUT SIGNAL SELECTION is highlighted. Next, follow steps3-5

under INPUT SIGNAL SELECTION.

...toexit completely, press the button

After returning to MAIN CONTROLS...

Page 7

OSD Adjustments (Continued)

107T5

Go to cover page

9

7

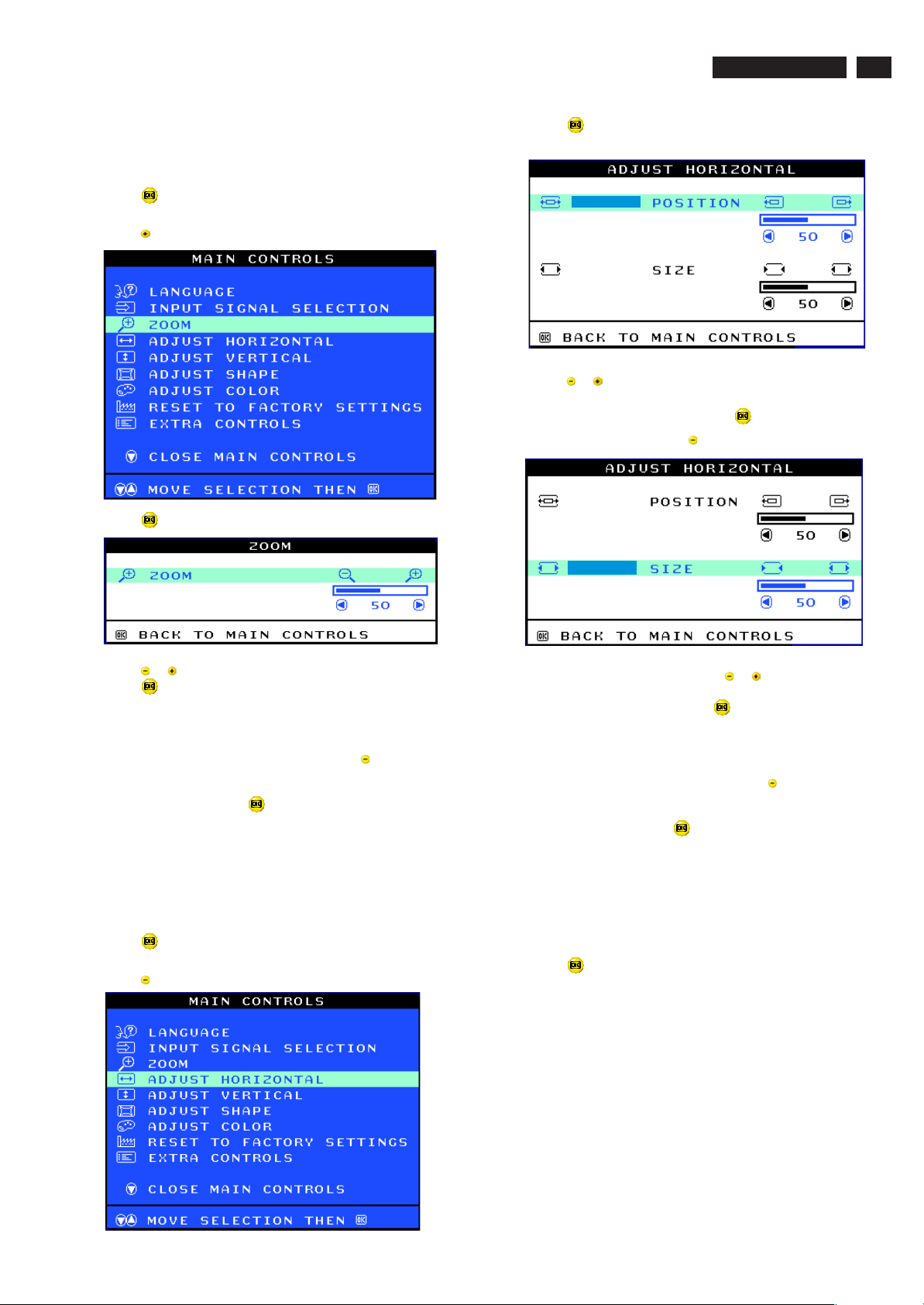

ZOOM

ZOOM increases or decreases the size of the images on your screen.

To adjust the ZOOM follow the steps below.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until ZOOM is highlighted.

3) Press the button. The ZOOM window appears.

3) Press the button. The ADJUST HORIZONTAL window appears.

ADJUST POSITION should be highlighted.

4) Press the or button to move the image to the left or right.

5) When the position is adjusted, press the button to return to MAIN

CONTROLS window, or press the to highlight ADJUST SIZE.

4) Press the or button to adjust ZOOM.

5) Press the button to confirm your selection and return to the MAIN

CONTROLS window. CLOSE MAIN CONTROLS will be highlighted.

Smart Help

...tocontinue to ADJUST HORIZONTAL, press the button until

ADJUST HORIZONTAL is highlighted. Next, follow steps3-7under

ADJUST HORIZONTAL.

...toexit completely, press the button

ADJUST HORIZONTAL

ADJUST POSITION under ADJUST HORIZONTAL shifts the image on

your screen either to the left or right. Use this feature if your image does

not appear centered. ADJUST SIZE under ADJUST HORIZONTAL

expands or controls the image on your screen, pushing it out toward the

left and right sides or pulling it in toward the center.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until ADJUST HORIZONTAL is highlighted.

After returning to MAIN CONTROLS...

6) To adjust the horizontal size, press the or button.

7) When the size is adjusted, press the button to return to MAIN

CONTROLS window. CLOSE MAIN CONTROLS will be highlighted.

Smart Help

...tocontinue to ADJUST VERTICAL, press the button until ADJUST

VERTICAL is highlighted. Next, start with step 3 under ADJUST

VERTICAL and follow the directions.

...toexit completely, press the button

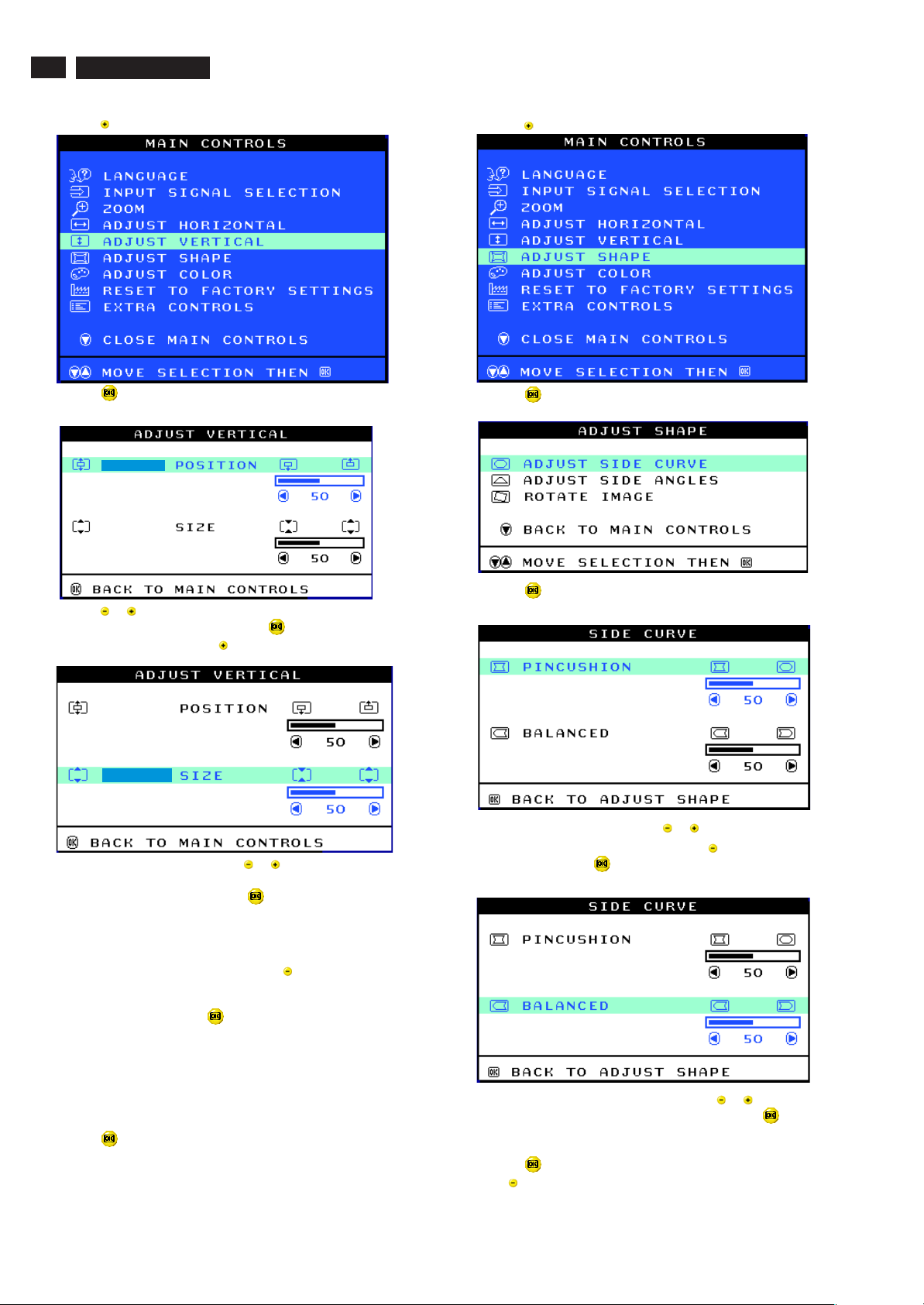

ADJUST VERTICAL

ADJUST POSITION under ADJUST VERTICAL shifts the image on

your screen either up or down. Use this feature if your image does not

appear centered. ADJUST SIZE under ADJUST VERTICAL expands or

controls the image on your screen, pushing it out toward the top or

bottom or pulling it in toward the center.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

After returning to MAIN CONTROLS...

Page 8

8

Go to cover page

9

107T5

OSD Adjustments (Continued)

2) Press the button until ADJUST VERTICAL is highlighted.

3) Press the button. The ADJUST VERTICAL window appears.

ADJUST POSITION should be highlighted.

2) Press the button until ADJUST SHAPE is highlighted.

3) Press the button. The ADJUST SHAPE window appears.

ADJUST SIDE CURVE should be highlighted.

4) Press the or button to move the image up or down.

5) When the position is adjusted, press the button to return to MAIN

CONTROLS window, or press the button to highlight ADJUST SIZE.

6) To adjust the vertical size, press the or button.

7) When the size is adjusted, press the button to return to MAIN

CONTROLS window. CLOSE MAIN CONTROLS will be highlighted.

Smart Help

...tocontinue to ADJUST SHAPE, press the button until ADJUST

SHAPE is highlighted. Next, start with step 3 under ADJUST SHAPE

and follow the directions.

...toexit completely, press the button

ADJUST SHAPE

ADJUST SIDE CURVE

ADJUST SIDE CURVE under ADJUST SHAPE allows you to adjust two

of the five preset options. These two options are PINCUSHION and

BALANCED pincushion. Note: use these features only when the picture

is not square.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

After returning to MAIN CONTROLS...

4) Press the button. The SIDE CURVE window appears.

PINCUSHION should be highlighted.

5) To adjust the pincushion, press the or button.

6) When the pincushion is adjusted, press the button to highlight

BALANCED or press the button to return to the ADJUST SHAPE

window.

7) To adjust the balanced pincushion, press the or button.

8) When the balanced pincushion is adjusted, press the button to

return to the ADJUST SHAPE window. BACK TO MAIN WINDOWS will

be highlighted.

9) Press the button to return to the MAIN CONTROLS window, or

press the button until ADJUST SIDE ANGLES is highlighted.

Page 9

OSD Adjustments (Continued)

107T5

Go to cover page

9

9

Smart Help After returning to MAIN CONTROLS...

...to continue to ADJUST SIDE ANGLES, start with step 5 under

ADJUST SIDE ANGLES and follow the directions.

...to exit completely, press the button twice.

...to adjust only the BALANCED pincushion, follow steps1-4above,

then press the button, and follow steps7-9.

ADJUST SIDE ANGLES

ADJUST SIDE ANGLES under ADJUST SHAPE allows you to adjust

two of the five preset options. These two options are TRAPEZOID and

PARALLELOGRAM. Note: use these features only when the picture is

not square.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until ADJUST SHAPE is highlighted.

3) Press the button. The ADJUST SHAPE window appears.

ADJUST SIDE CURVE should be highlighted.

7) When the trapezoid is adjusted, press the button to highlight

PARALLELOGRAM or press the button to return to the ADJUST

SHAPE window.

8) To adjust the parallelogram, press the or button.

9) When the parallelogram is adjusted, press the button to return to

the ADJUST SHAPE window. BACK TO MAIN WINDOWS will be

highlighted.

10) Press the button to return to the MAIN CONTROLS window, or

press the button until ROTATE IMAGE is highlighted.

Smart Help

...to continue to ROTATE IMAGE, start with step 5 under ROTATE

IMAGE and follow the directions.

...to exit completely, press the button twice.

...to adjust only the PARALLELOGRAM, follow steps1-4above, then

press the button, and follow steps 7 -9

ROTATE IMAGE

ROTATE IMAGE under ADJUST SHAPE allows you to adjust one of

the five preset options. These two options are PINCUSHION and

BALANCED pincushion. Note: use this feature only when the picture is

not square.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until ADJUST SHAPE is highlighted.

After returning to MAIN CONTROLS...

4) Press the button to highlight ADJUST SIDE ANGLES.

5) Press the button. The SIDE ANGLES window appears.

TRAPEZOID should be highlighted.

6) To adjust the trapezoid, press the or button.

3) Press the button. The ADJUST SHAPE window appears.

ADJUST SIDE CURVE should be highlighted.

4) Press the arrow until ROTATE IMAGE is highlighted.

Page 10

10

Go to cover page

9

107T5

OSD Adjustments (Continued)

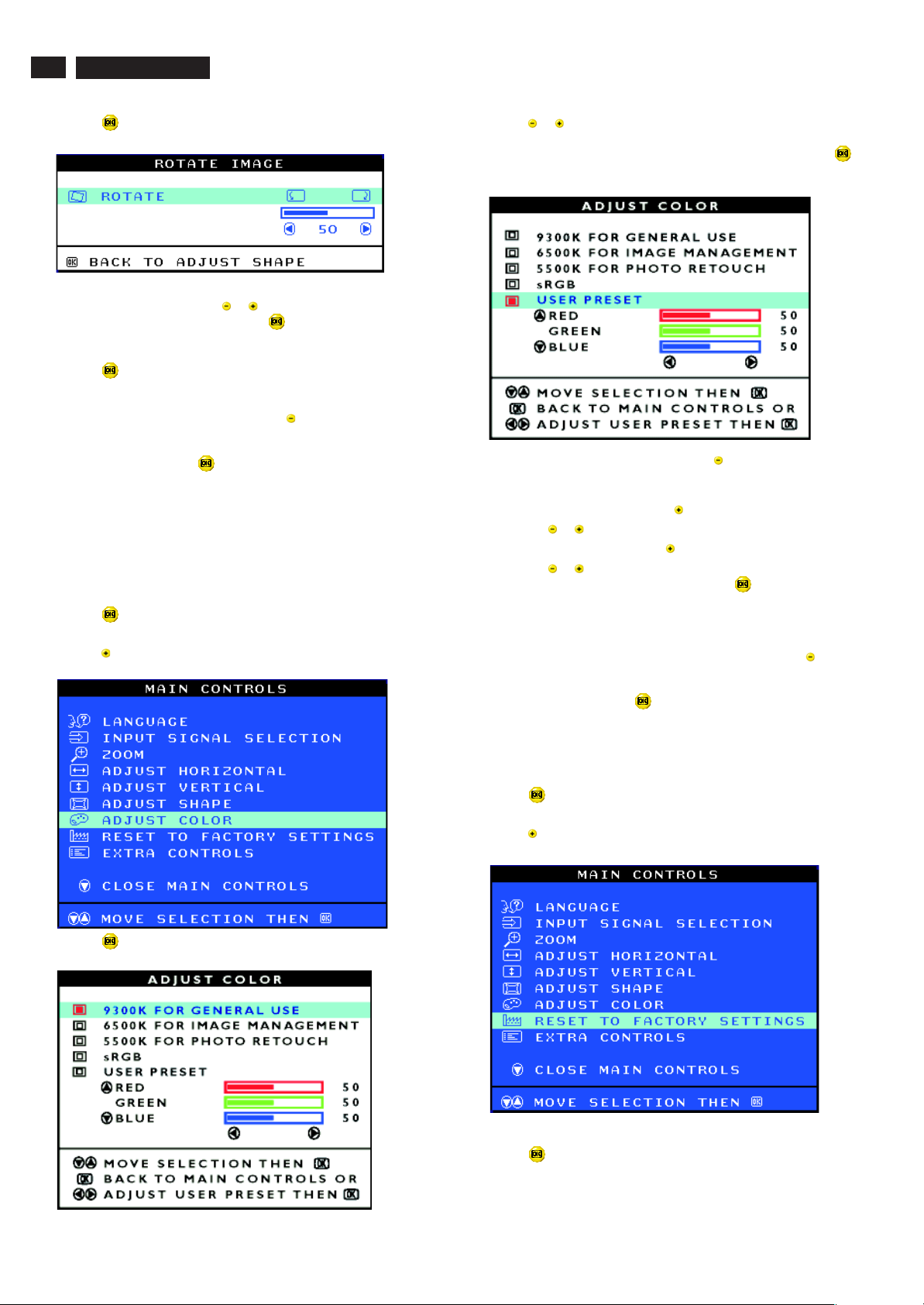

5) Press the button. The ROTATE IMAGE window appears. ROTATE

should be highlighted.

6) To adjust the rotation, press the or button.

7) When the rotation is adjusted, press the button to return to the

ADJUST SHAPE window. BACK TO MAIN CONTROLS should be

highlighted.

8) Press the button to return to MAIN CONTROLS.

Smart Help

...tocontinue to ADJUST COLOR, press the button until ADJUST

COLOR is highlighted. Next, start with step 3 under ADJUST COLOR

and follow the directions.

...to exit completely, press the button twice.

ADJUST COLOR

Your monitor has two preset options you can choose from. The first

option is for GENERAL USE, which is fine for most applications. The

second option is for GAMES, which is for playing computer games.

When you select one of these options, the monitor automatically adjusts

itself to that option. There is also a third option, USER PRESET, which

allows you to adjust the colors on your screen to a setting you desire.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until ADJUST COLOR is highlighted.

After returning to MAIN CONTROLS...

4) Press the or button to highlight 9300K for GENERAL USE,

6500K for GAMES, or USER PRESET.

5) Once you have highlighted GENERAL USE or GAMES, press the

button to confirm you selection and return to the MAIN CONTROLS

window. CLOSE MAIN CONTROLS will be highlighted.

6a) If USER PRESET is highlighted, press the button to highlight RED.

Next, press the LEFT CURSOR or RIGHT CURSOR button to adjust the

color red.

6b) When finished with RED, press the button to highlight GREEN.

Next, press the or button to adjust the color green.

6c) When finished GREEN, press the button to highlight BLUE.

Next, press the or button to adjust the color blue.

6d) When all adjustments are complete, press the button to confirm

your adjustments and return to the MAIN CONTROLS window. CLOSE

MAIN CONTROLS will be highlighted.

Smart Help

...tocontinue to RESET TO FACTORY SETTINGS, press the button

until RESET TO FACTORY SETTINGS is highlighted. Next, start with

step 3 under RESET TO FACTORY SETTINGS.

...toexit completely, press the button.

After returning to MAIN CONTROLS. . .

3) Press the button. The ADJUST COLOR window appears.

RESET TO FACTORY SETTINGS

RESET TO FACTORY SETTINGS returns everything in all the windows

to factory presets.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until RESET TO FACTORY SETTINGS is

highlighted.

3) Press the button. The RESET TO FACTORY SETTINGS window

appears.

Page 11

OSD Adjustments (Continued)

107T5

Go to cover page

9

11

4) Press the or button to select YES or NO. NO is the default. YES

returns all settings to their original factory adjustments.

5) Press the button to confirm your selection and return to the MAIN

CONTROLS window. CLOSE MAIN CONTROLS will be highlighted.

Smart Help

...tocontinue to EXTRA CONTROLS, press the button until EXTRA

CONTROLS is highlighted. Next, start with step 3 under EXTRA

CONTROLS.

...toexit completely, press the button.

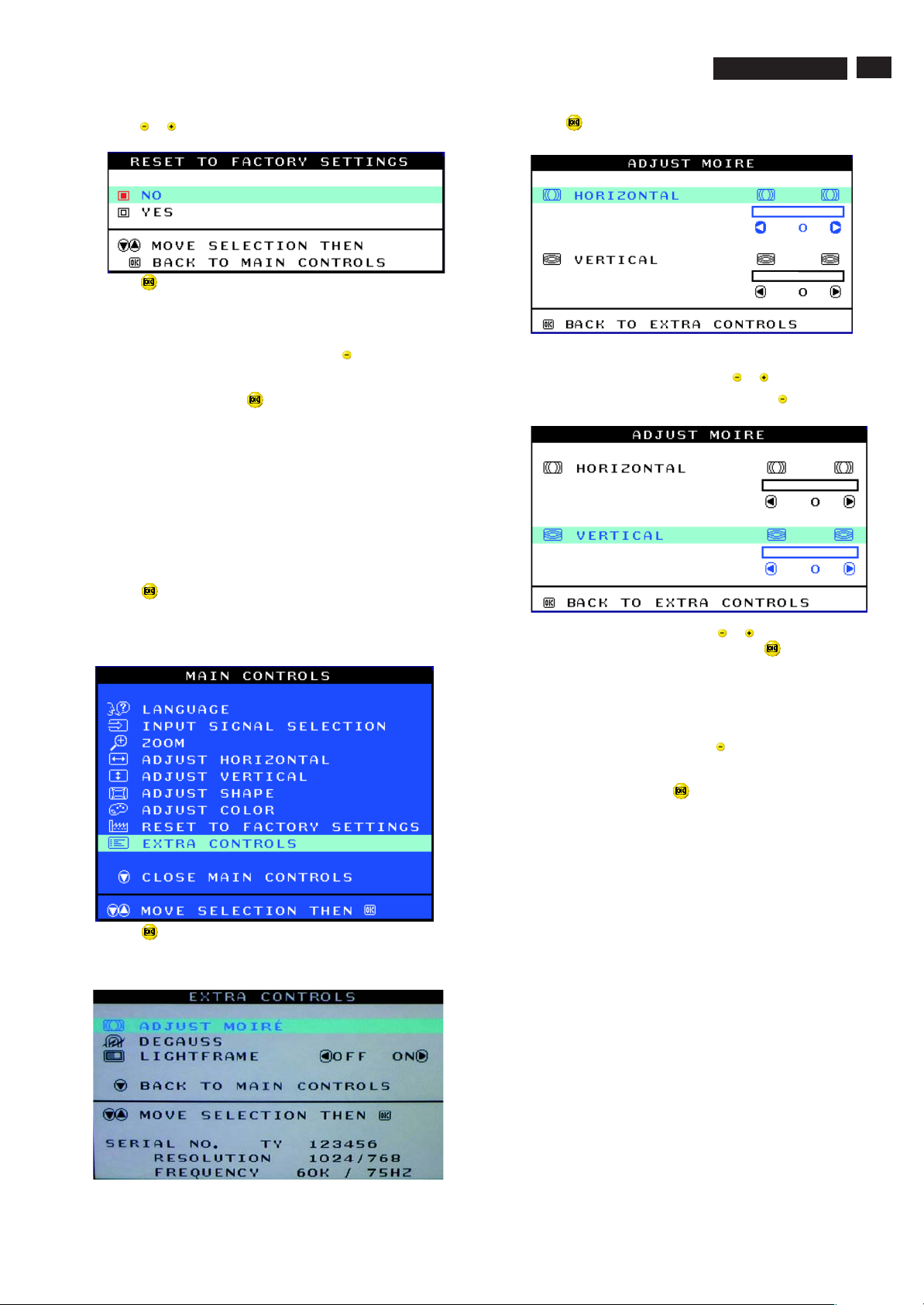

EXTRA CONTROLS

ADJUST MOIRE

EXTRA CONTROLS is a set of three features, including ADJUST

MOIRE. Moire is a fringe pattern arising from the interference between

two superimposed line patterns. To adjust your moire, follow the steps

below. Note: Use only if necessary. By activating ADJUST MOIRE,

sharpness can be affected.

After returning to MAIN CONTROLS...

4) Press the button. The ADJUST MOIRE window appears.

HORIZONTAL will be highlighted.

5) To adjust the horizontal moire, press the or button.

6) When the horizontal moire is adjusted, press the button to highlight

VERTICAL.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the DOWN CURSOR button until EXTRA CONTROLS is

highlighted.

3) Press the button. The EXTRA CONTROLS window appears. will

be highlighted.ADJUST MOIRE will

7) To adjust the vertical moire, press the or button.

8) When the vertical moire is adjusted, press the button to return to

the EXTRA CONTROLS window. BACK TO MAIN CONTROLS will be

highlighted.

Smart Help After returning to MAIN CONTROLS...

...tocontinue to DEGAUSS, press the button until is

highlighted. Next, start with step 3 under EXTRA CONTROLS,

DEGAUSS.

...toexit completely, press the button.

DEGAUSS

Page 12

12

Go to cover page

9

107T5

OSD Adjustments (Continued), Troubleshooting

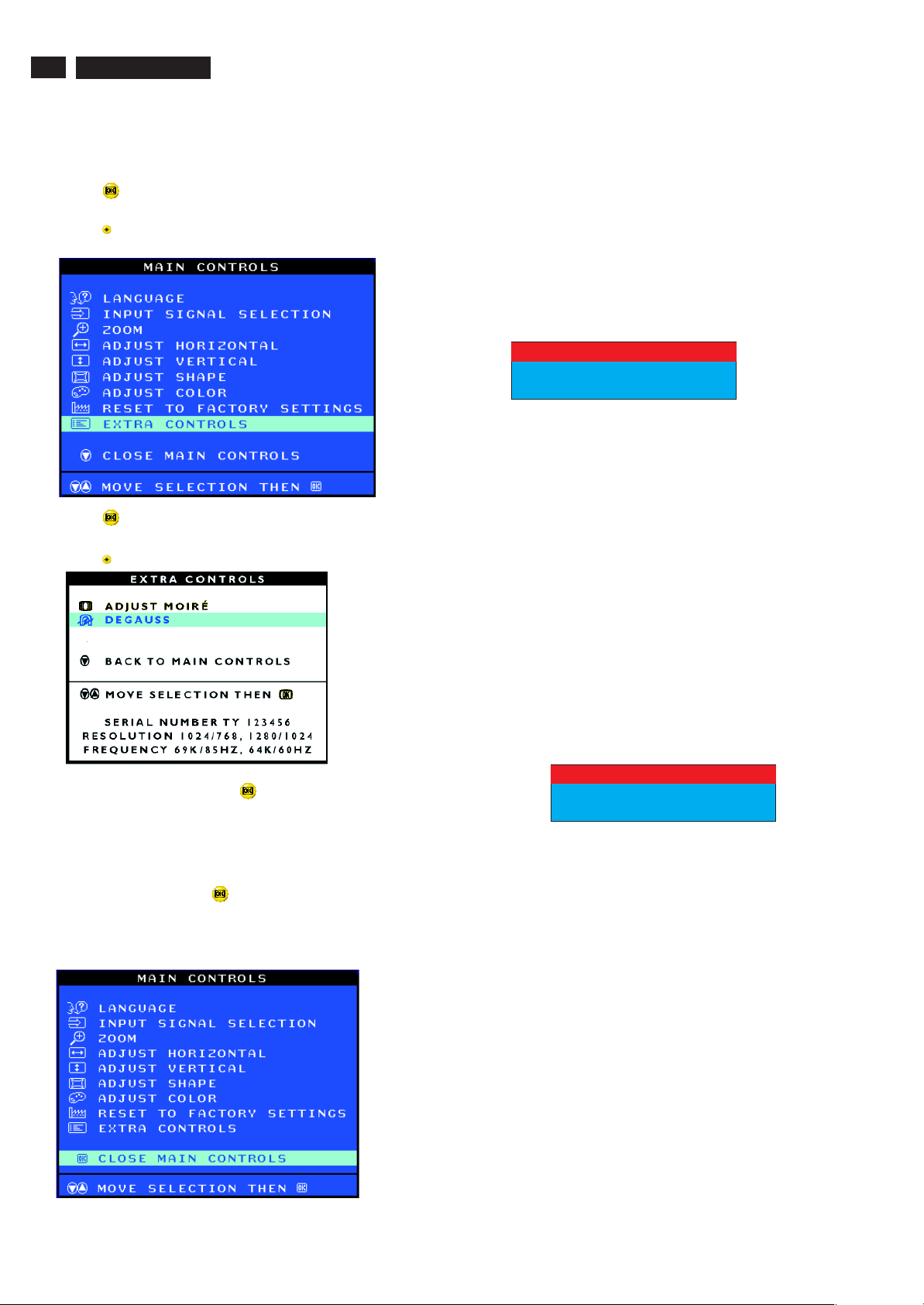

DEGAUSS

EXTRA CONTROLS is a set of three features, including DEGAUSS.

Degaussing removes electromagnetic build up that may distort the color

on your screen.

1) Press the button on the monitor. The MAIN CONTROLS window

appears.

2) Press the button until EXTRA CONTROLS is highlighted.

3) Press the button. The EXTRA CONTROLS window appears.

ADJUST MOIRE will be highlighted.

4) Press the button until DEGAUSS is highlighted.

Monitor Specific Troubleshooting

Self-Test Feature Check (STFC)

Your monitor provides a self-test feature that allows you to check

whether your monitor is functioning properly. If your monitor and

computer are properly connected but the monitor screen remains

dark, run the monitor self-test by performing the following steps:

1. Turn off both your computer and the monitor.

2. Unplug the video cable from the back of the computer.

3. Turn on the monitor.

If the monitor is functioning properly, you will see a OSD

message as shown in the following illustration:

ATTENTION

CHECK SIGNAL CABLE

This box also appears during normal system operation if the

video cable becomes disconnected or damaged. This box

will remain on for one minute, go off five seconds, then on for

one minute, and will repeat cycle.

1. Turn off your monitor and reconnect the video cable;

then turn on both your computer and the monitor.

2. While in self-test mode, the LED remains green and the

pattern remains on and stationary.

If your monitor screen still remains dark after you use the

previous procedure, check your video controller and computer

system; your monitor is functioning properly.

5) To degauss your screen, press the button. Your screen will be

degaussed, then the MAIN CONTROLS window will reappear. CLOSE

MAIN CONTROLS will be highlighted.

Smart Help After returning to MAIN CONTROLS...

...toexit completely, press the button.

CLOSE MAIN CONTROLS

NO SIGNAL INPUT

If there is something wrong with the input signal, a message

appears on the screen although the power indicator LED is

still on. The message may indicate that the monitor is NO

SIGNAL INPUT or that you need to check the signal cable.

ATTENTION

NO SIGNAL INPUT

Page 13

Lock/Unlock, Factory Mode, Burn In, Service Mode

107T5

Go to cover page

9

13

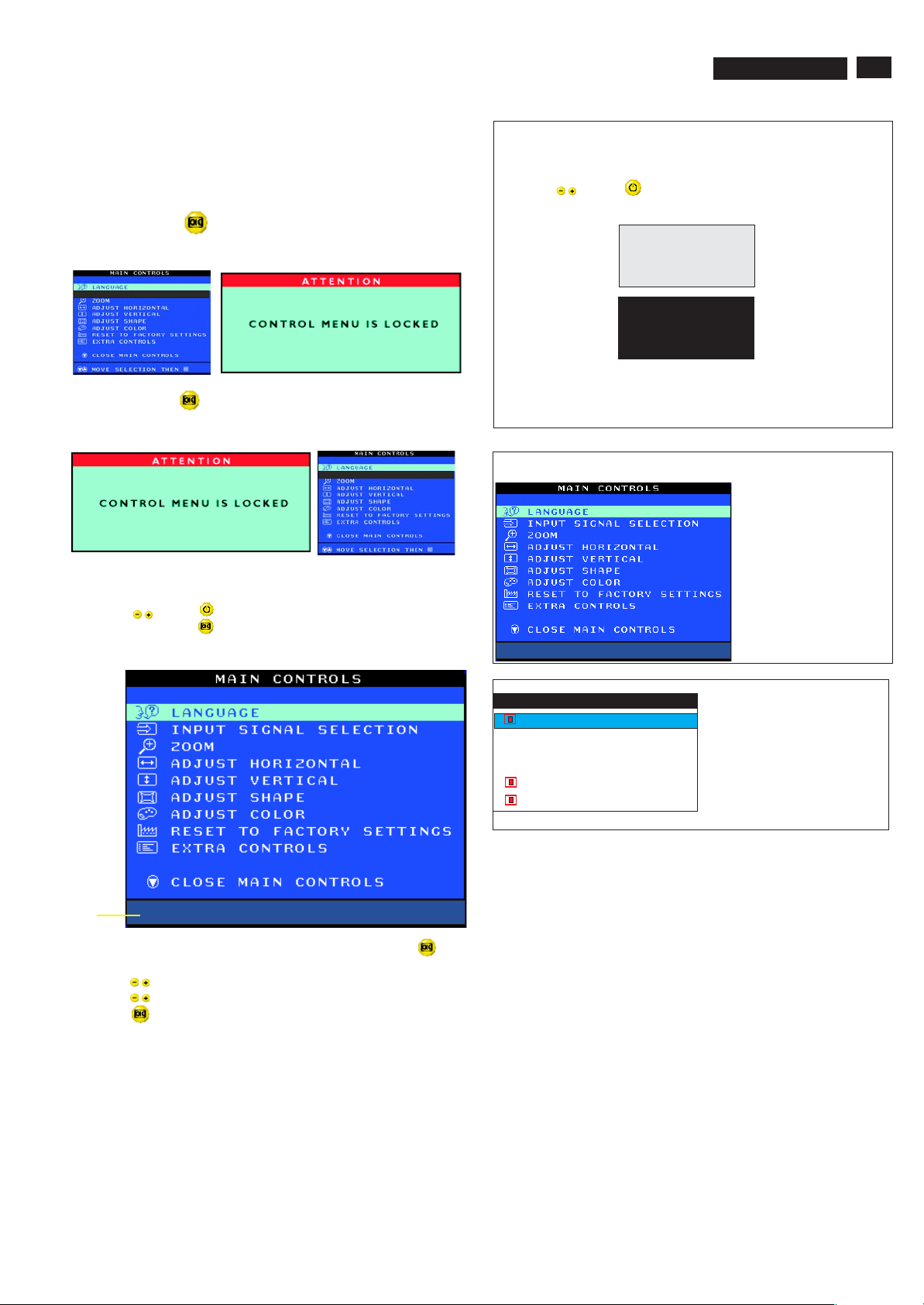

OSD Lock

OSD lock is a feature which disables the OSD controls. It can be used

when the monitor is set up for demonstration purposes or when

adjustment of the OSD is not desirable.

Switch on OSD lock feature:

Press and hold the button continuously for 15 seconds.

Release the button when the message

"CONTROL MENU IS LOCKED" appears.

Switch off OSD lock feature:

Press and hold the button continuously for 15 seconds or until the

message window "CONTROL MENU IS LOCKED" disappears, and

"MAIN CONTROLS" appears.

To access factory mode

1. Turn off monitor (don't turn off PC)

2. Press '" " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V30 107T5 V0.48 20021218 (below OSD menu)" come on the

screen of monitor.

To access BURN IN mode

First of all, monitor displays an image.

1. Disconnect the video cable (interface cable).

2. Turn off monitor

3. Press '" " and " " simultaneously on the front control

panel,then the BURN IN mode comes on the screen of monitor

as below.

50 seconds around

5 seconds around

repeatly

4.

Reconnect the video cable, then return to normal image.

SERVICE MODE (Indication-Factory mode)

02060

MODEL SELECT

V30 107T5 V0.48 20021218

------------------------>

02060: stands for

1. using 10 hours already.

2. turn on/off 10 times.

3. using several hours

+ turn on/off monitor.

Factory

Mode

Indicator

3. If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

4. Using " " : to select OSD menu.

5. Using " " : to increase or decrease the setting.

6. Using " " to access/confirm the selection.

To leave factory mode

7. After alignment of factory mode, turn off monitor (if you do not turn

off monitor, the OSD menu is always at the factory mode), then

turn on monitor again (at this moment, the OSD menu goes back

to user mode).

MODEL SELECT

V30 107T5 V0.48 20021218

Default setting of MODEL SELECT (Do not change it.)

MODEL SELECT

107T5

107B5

RESERVE

RESERVE

RESERVE

SWDDC

LF 3

Page 14

14

Go to cover page

107T5

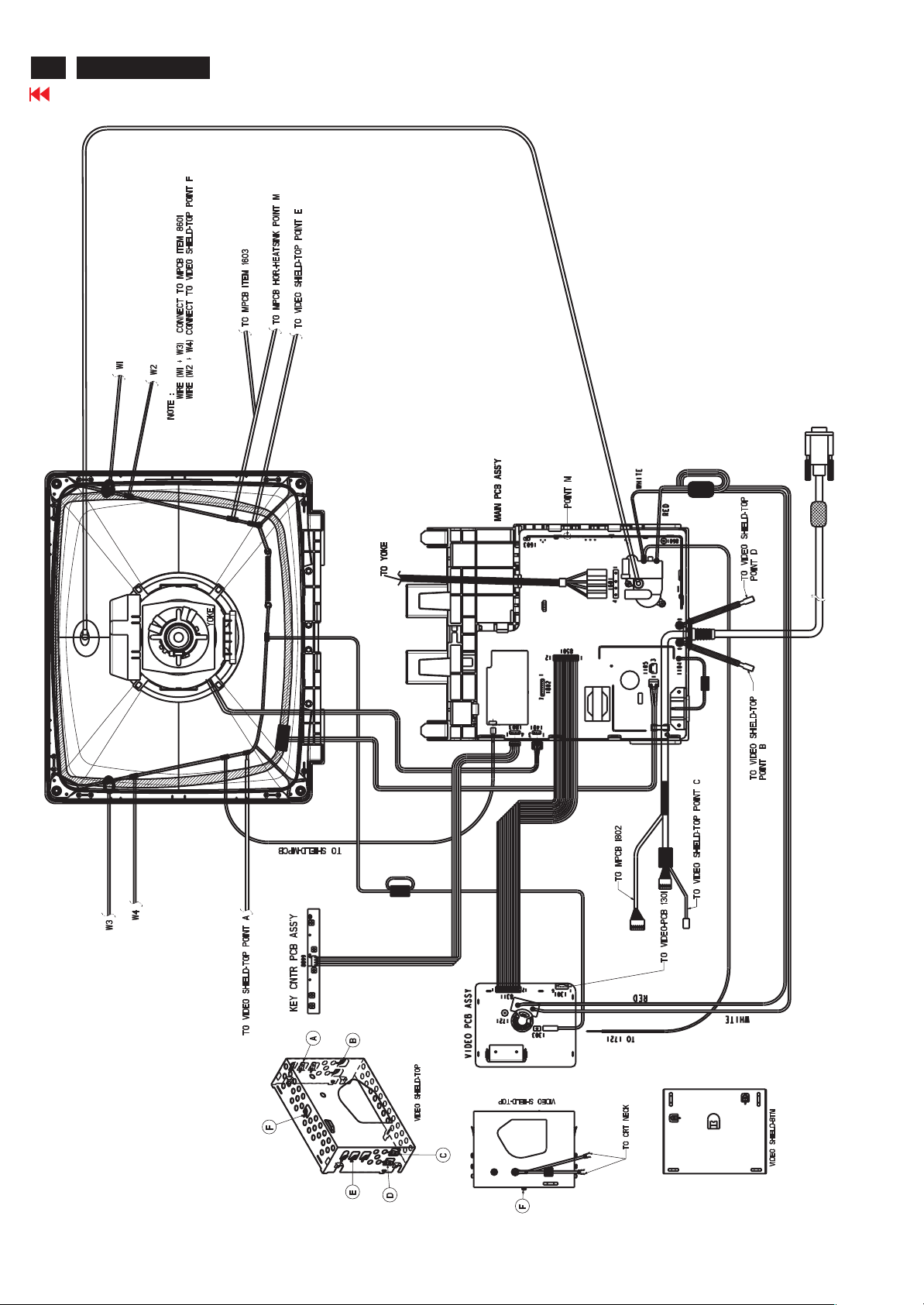

Wiring Diagram

Page 15

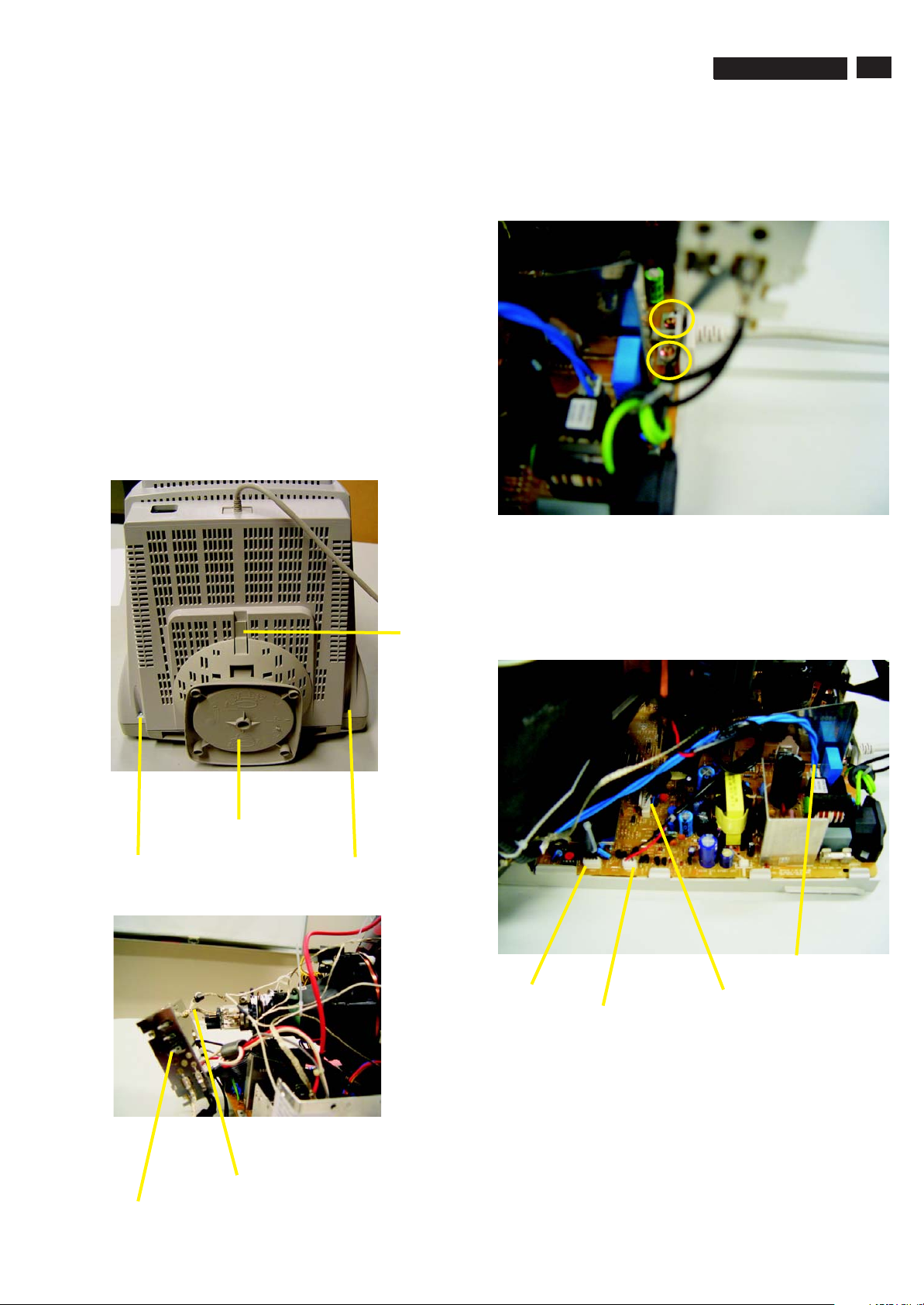

Mechanical Instructions

0. General

To be able to perform measurements and repairs on the "circuit

boards", these unit should placed in the service position first.

1.Remove the rear cover in Fig. 1.

-Remove 2 screws as shown

-Remove back cover as shown

-Remove pedestal as shown

2. Video panel

- Disconnect the wire between metal shield of Video panel and

CRT neck as shown in Fig. 2.

- Disconnect the CRT ground from Video panel.

- Remove screw grounding and grounding wire in Fig. 3.

3.Main board connector in Fig. 4

-Disconnect york wire

-Disconnect rotation connector

-Disconnect control board connector

-Remove Screw for fixed I/F cable

-Remove signal connector

-Remove degaussing wire connector

107T5

9

Go to cover page

15

Screw

Pedestal ass'y

Fig. 1

Screw

Clip

Control connector

Rotation connector

===============>

screw - grounding

Fig. 3

Degaussing wire connector

Signal connector

Video Panel

Fig. 4

CRT grouding wirel

Fig. 2

Page 16

16

107T5

Mechanical Instructions

Go to cover page

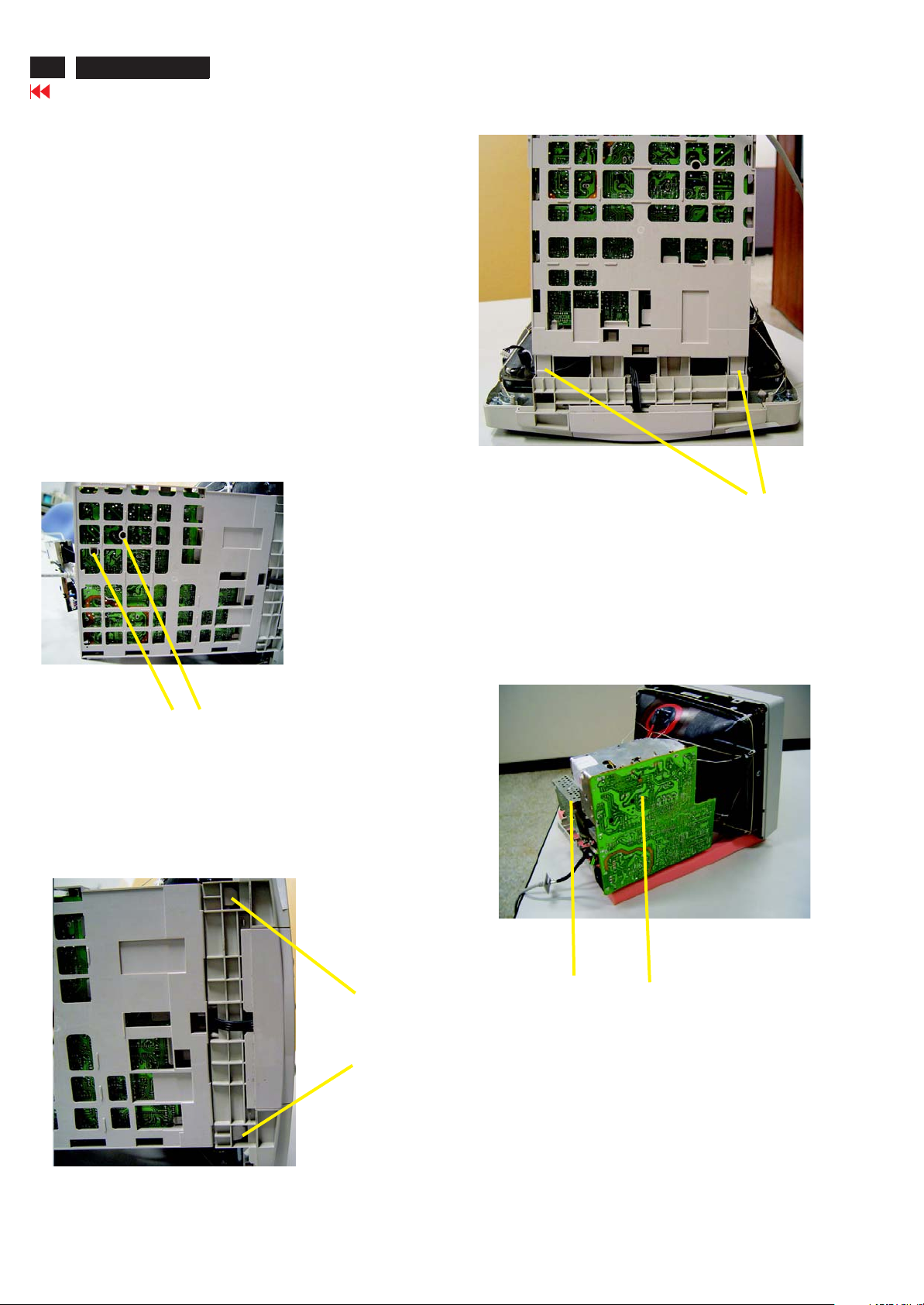

4. Main panel with Bottom Tray

-Remove 2 screws for disconnect the Bottom tray as Fig. 5.

-Pull the bottom tray from fig. 6

to fig. 7.

5. SERVICE POSITION

Reconnect connectors, some wires and panels (chassis),

service position can be available for DC/AC measurement

as shown in Fig. 8.

on press right and left side clip

Screw

Fig. 5

Fig. 7

=======>

Pull-up

Fig. 6

Press CLIP

Video panel

Fig. 8 SERVICE POSITION

Main panel

Page 17

Warning and Notes

107T5

Go to cover page

17

Warnings

1

. Safety regulations require that the unit should be returned

in its original condition and that components identical to

the original components are used. The safety components

are indicated by the symbol .

2

. In order to prevent damage to ICs and transistors, all

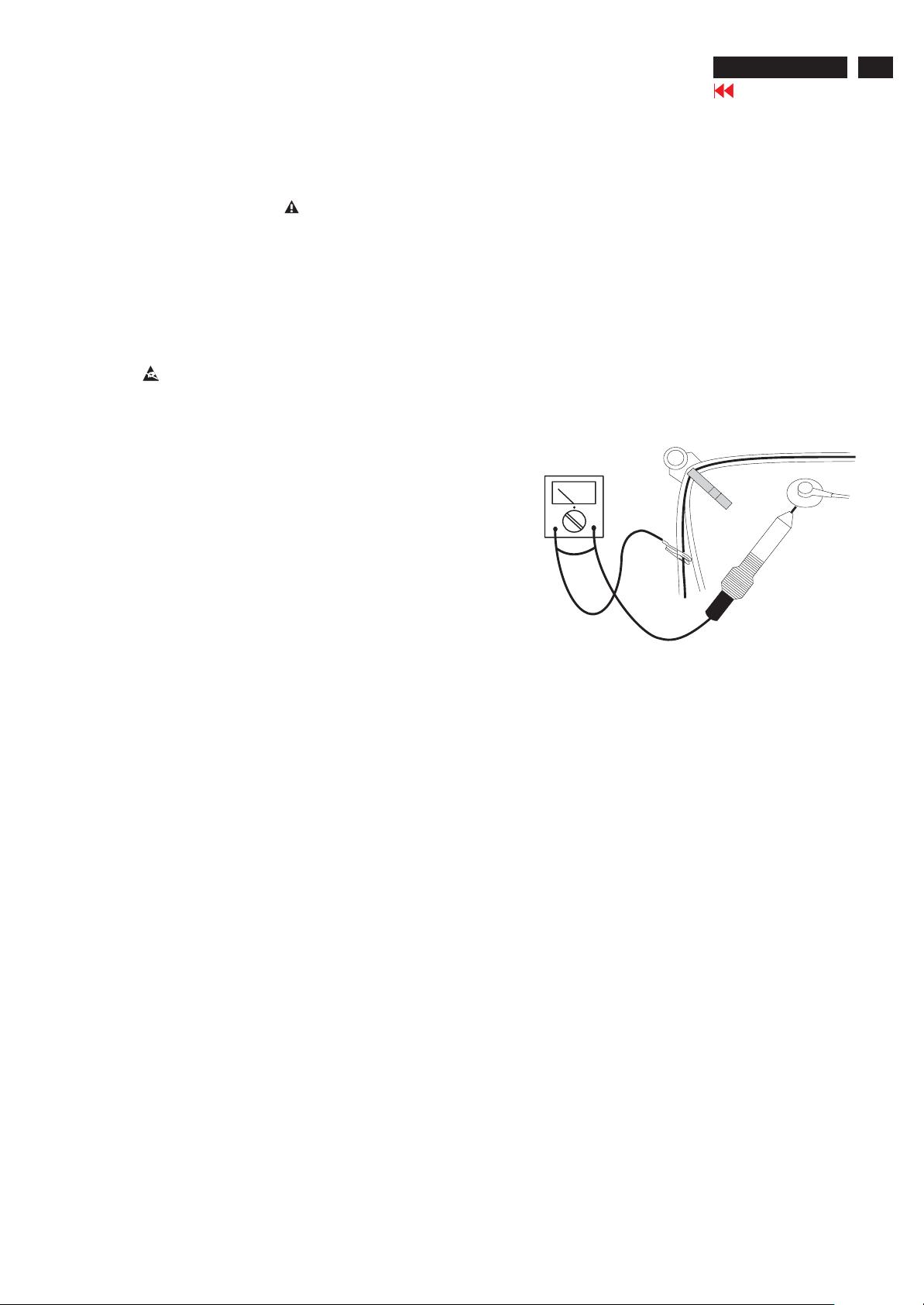

high-voltage flash-overs must be avoided. In order to

prevent damage to the picture tube, the method shown

in Fig. 1 should be used to discharge the picture tube.

Use a high-voltage probe and a multimeter (position DC-V).

Discharge until the meter reading is (after approximately

30 seconds).

.

3 ESD

All ICs and many other semiconductors are sensitive to

electrostatic discharges (ESD). Careless handling during

repair can drastically shorten their life. Make sure that

during repair you are connected by a pulse band with

resistance to the same potential as the ground of the unit.

Keep components and tools also at this same potential.

. When repairing a unit, always connect it to the AC Power

4

voltage via an isolating transformer.

. Be careful when taking measurements in the high-voltage

5

section and on the picture tube panel.

0V

Notes

1.

The direct voltages and waveforms are average voltages.

They have been measured using the Service test software

and under the following conditions :

- Mode : 640 * 480 (31.5kHz / 60Hz)

- Signal pattern : grey scale

- Adjust brightness and contrast control for the

mechanical mid-position (click position)

2.

The picture tube panel has printed spark gaps.

Each spark gap is connected between an electrode of the

picture tube and the Aquadag coating.

The semiconductors indicated in the circuit diagram(s)

3.

and in the parts lists are completely interchangeable per

position with the semiconductors in the unit, irrespective

of the type indication on these semiconductors.

V

. It is recommended that saferty goggles be worn when

6

replacing the picture tube.

. When making adjustments,use plastic rather than metal tools.

7

This will prevent any short-circuit or the danger of a

circuit becoming unstable.

. Never replace modules or other components while the

8

unit is switched on.

. Together with the defleciton unit, the picture tube is used

9

as an integrated unit. Adjustment of this unit during repair

is not recommended.

After repair, the wiring should be fastened in place with

10.

the cable clamps.

All units that are returned for service or repair must pass

11.

the original manufactures safety tests.

Fig.1

Page 18

18

X

107T5

Go to cover page

Electrical Instructions

1. General point

==========

1.1 During alignment and measurement supply a distortion

free AC-mains voltage to the apparatus via an isolating

transformer with a low internal resistance.

1.2 All voltages have to be measured or applied with respect

to ground, unless otherwise stated. Note: Not all heatsinks

are grounded, avoid using heatsinks as ground.

1.3 The term "Linear RGB" is meant the 0.7 Vpp video with

separate SYNC ( TTL Level ). Reference factory preset

mode timings (format of pattern generator CHROMA-2135)

are shown in TABLE 1 to TABLE 8. Preload timing

TABLE 9 to TABLE 22.

1.4 Any external voltage source should have low internal

impedance.

1.5 The alignment has to be done in room temperature 25 5C.

1.6 Digit control buttons for

OSD MENU :

LANGUAGE

ZOOM

ADJUST HORIZONTAL

ADJUST VERTICAL

ADJUST SHAPE

ADJUST COLOR

- 3colour temperatures (9300K, 6500K, SRGB)

- 1 user preset independent RGB adjustment

RESET TO FACTORY SETTING

EXTRA CONTROLS

- ADJUST MOIR

- HORIZONTAL

- VERTICAL

- DEGAUSSING

- POSITION

- SIZE

- POSITION

- SIZE

- ADJUST SIDE CURVE

- PINCUSHION

- BALANCE

- ADJUST SIDE ANGLES

- TRAPEZOID

- PARALLELOGRAM

- ROTATE IMAGE

4.2 During all alignments, supply a distortion free AC mains

voltage to the monitor set via an isolating transformer with

low internal impedance.

4.3 All measurements are carried out at nominal mains voltage,

unless otherwise stated.

4.4 Align in pre-warmed condition, at least 30 minutes warm-up

with nominal light output.

4.5 Purity, geometry and subsequent alignments should be

carried out in a magnetic cage with correct magnetic field.

Northern Hemisphere:H=0, V= 450mG,Z=0

Southern Hemisphere:H=0, V=-500mG,Z=0

Equatorial Support :H=0,V= 0mG,Z=0

4.6 All voltages are to be measured or applied with respect to

ground , unless otherwise stated.Attention : Not all

heatsinks are GND, avoid using heatsinks as ground.

4.7 The white balance and purity has to be adjusted in dully

lighted room.

4.8 All alignments have to be done in a room with a temperature

Of 25 10 C.

4. Alignment of Vg2, cut-off point, white tracking

================================ =

5.1 EEPROM data has to be pre-set according to software

approval sheets, sheet-139,

sheet-140: (loaded beforehand with average values of

mode pre-set data and mode pre-set selection bytes.) The

following table is for reference only.Optimum values should

be determined by Factory(ME) for every production batch.

In factory, alignments are done via I C on the I/F cable

DDC bus , but the set can also be manually aligned.

Enter factory mode by pressing both Up and Down

keys while power-on. Select factory.

====

2

MODEL SELECT

CLOSE MAIN CONTROLS

2. Pre warm-up

========

2.1 Align in pre-warmed condition at least 30 minutes during

Manufacturing.

3. Main chassis alignment

==================

3.1 Power supply adjustment :

All supply voltages were fixed and adjustment is

unnecessary. (Check the voltages on Chassis line)

3.2 Apply a VGA 31.5KHz/480 lines cross-hatch signal.

3.2.1 Adjust BPLUS of factory setting to obtain the

anode voltage 25.0KV+/-1KVat zero beam current

3.3 Monitor the following auxiliary voltages.

+5 source across 7153 Pin out and GND +5V 0.15 VDC

+6 source across C2154 +6.2V 0.2 VDC

+12 source across C2155 +12.6V 0.4 VDC

-12 source across C2156 -12.5V 0.4 VDC

+82 source across C2153 +82.0V 1.5 VDC

+190 source across C2152(+toGnd) +190.5V 3.0 VDC

-96 source across C2630 -96V 6.0 VDC

4. General conditions for aging and alignment

================================

4.1 Aging/burn-in:Use low mains AC supply (90Vac) for monitor

first power on test.Pre-adjust the Focus till cross hatch

pattern can be clearly visible then enter the agingmode.

(Press both Up and Down keys, and then switch-on the

monitor with signal cable disconnected.)

==

.

Page 19

Electrical Instructions

107T5

Go to cover page

19

X

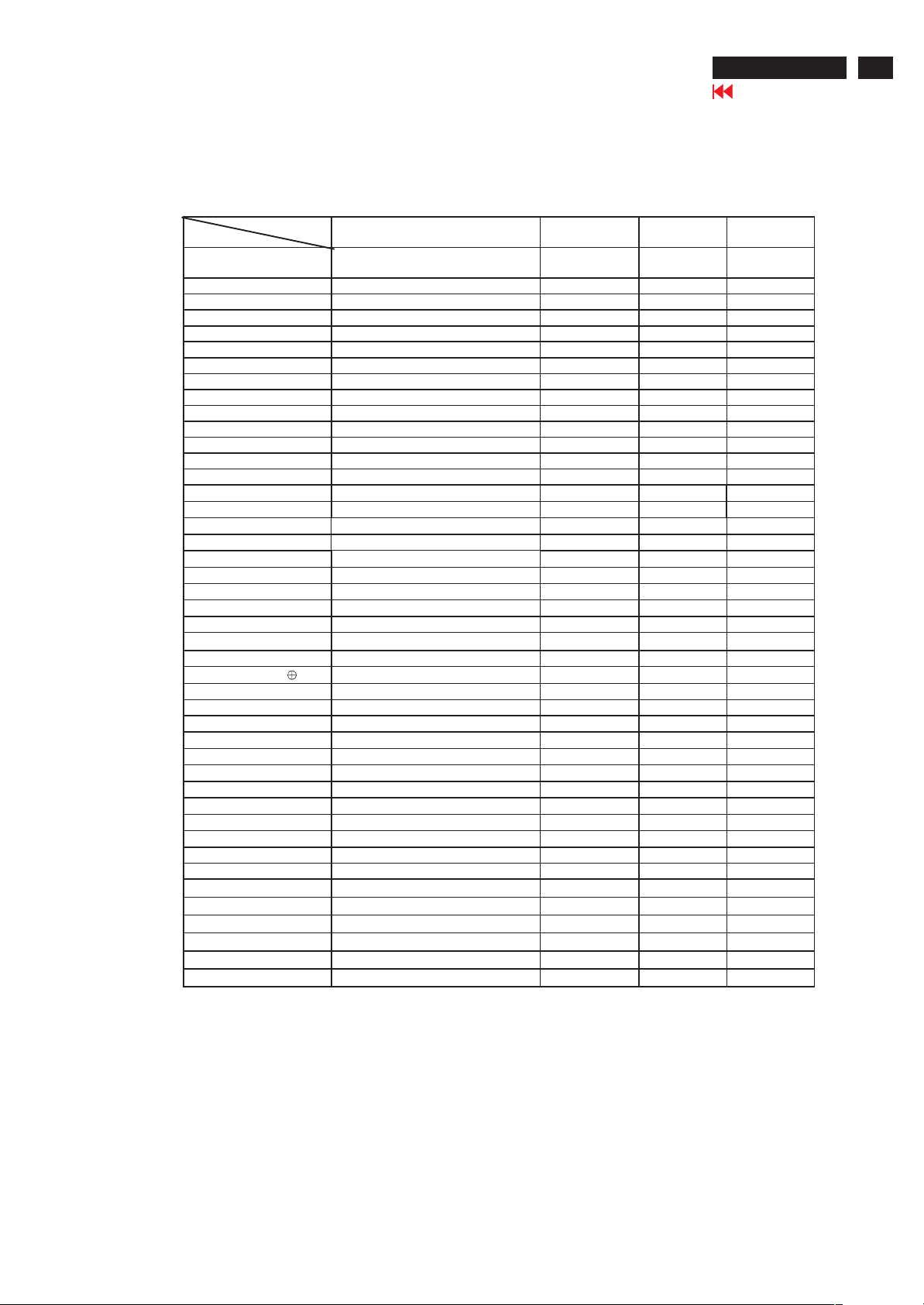

Item

CRT

9300/6500/sRGB

Bias

9300/6500/sRGB Gain Nominal Gain setting

sRGB contrast sRGB contrast

sRGB bright sRGB brightness

Corner -T, B Fh < 36KHz

Corner -T, B 36KHz <Fh < 52KHz

Corner -T, B 52KHZ < Fh <65KHz

Corner -T, B Fh > 65KHz

Pin Correction -T, B Top/Bottom pin correction

Pin Correction -S, W S/W shape pin correction

V-offset V-raster centering

V-gain V size control range for user

Sub-contrast 9300 peak light output adjust

Sub-brightness Brightness control range limit

Linearity -H

Linearity -H

Linearity -H

Linearity -H

Linearity -H

Linearity -H

Linearity -H

Linearity -H

Linearity -H Fh >66.00 KHz

Linearity -V Vertical S -correction

Range-UserH H size control range for user

Range-Sub Zoom control range for user

B+ Adjusted for Anode voltage

ABL 9300 full white light o/p adjust

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V

EHT comp -H, V Fh >66.00 KHz

V-Linbal Vertical top/bottom linearity

V-Focus Vertical focus amplitude

OSD Contrast OSD Contrast

LF-Brigh LightFrame Brightness

LF-Sharp LightFrame Sharpness

Moiré setting -H All modes

Moiré setting -V All modes

Condition/Description CPT DAC

Nominal Cut -off setting

Fh < 33.00KHz

33.00KHz < Fh < 36.00KHz

36.00KHz < Fh < 40.00KHz

40.00KHz < Fh < 45.00KHz

45.00KHz < Fh < 52.00KHz

52.00KHz < Fh < 55.00KHz

55.00KHz < Fh < 60.50KHz

60.50KHz < Fh < 66.00KHz

Fh < 33.00KHz

33.00KHz < Fh < 36.00KHz

36.00KHz < Fh < 40.00KHz

40.00KHz < Fh < 45.00KHz

45.00KHz < Fh < 52.00KHz

52.00KHz < Fh < 55.00KHz

55.00KHz < Fh < 60.50KHz

60.50KHz < Fh < 66.00KHz

value

127 127 127

185 185 185

255 255 255

127 127 127

134, 122 134, 126 136, 124

134, 122 130, 126 130, 124

140, 122 126, 126 130, 124

140, 120 126, 126 128, 124

120, 126 122, 122 120, 120

130, 144 136, 130 130, 144

65 60 90

180 180 200

220 220 220

160 160 160

170 175 180

140 140 165

125 130 150

105 115 115

90 95 90

80 90 85

70 80 80

65 75 70

60 60 60

50 50 50

75 75 75

55 55 55

89 89 89

110 120 135

132, 114 132, 116 132, 114

124, 114 130, 114 124, 114

122, 116 126, 116 122, 114

120, 116 124, 116 120, 116

114, 116 118, 118 114, 116

112, 116 118, 118 112, 116

112, 116 116, 118 112, 116

112, 118 114, 118 112, 118

114, 118 114, 118 114, 118

140 140 140

100 100 180

255 255 255

333

333

000

000

LG

DAC value

SDI

DAC value

Page 20

20

X

107T5

Go to cover page

Electrical Instructions

5.2 External degaussing Remove ferromagnetic measuring

equipment, Iron tablet, etc., in the neighbourhood of the

apparatus within half a meter. Position the set in E-W

direction and degauss well via external degaussing coil.

Slowly increase the distance between the picture tube and

Degaussing coil, keeping the coil in parallel with the

Screen of CRT. When the distance is more than 2m, turn

of f The degaussing current.

5.3 Adjustment mode: 68.7KHz/85Hz with correctly adjusted

video size 306x230mm. Use color-analyzer

(Minolta CA-100) to adjust cut-off and white balance.

Before alignment, set initial data as item 5.1 and

brightness set to 50%.

White alignment measurement equipment set-ups:

Setup A: 100x100mm white block , 0.7Vpp input video

signal, contrast at 0%, 9300 mode Calibrate CA100, Low

9300 RGB=100 x=0.283, y=0.297, Y=0.10FL 0.05FL

Setup B: 100x100mm white block , 0.7Vpp input video

signal, contrast at 100%, 9300 mode Calibrate Ca100,

High 9300 RGB=100 x=0.283, y=0.297, Y=41FL 1FL

Setup C: 100x100mm white block , 0.7Vpp input video

signal, contrast at 0%, 6500 mode Calibrate CA100, Low

6500 RGB=100 x=0.313, y=0.329, Y=0.10FL 0.05FL

Setup D: 100x100cm white block , 0.7Vpp input video signal,

contrast at 100%, 6500 mode Calibrate CA100, High 6500

RGB=100 x=0.313, y=0.329, Y=36FL 1FL

Setup E: 100x100mm white block , 0.7Vpp input video signal,

contrast at 0%, sRGB mode Calibrate CA100, Low sRGB

RGB=100 x=0.313, y=0.329, Y=0.10FL 0.05FL

Setup F: 100x100cm white block , 0.7Vpp input video signal,

contrast at 100%, sRGB mode Calibrate CA100, High

sRGB RGB=100 x=0.313, y=0.329, Y=36FL 1FL

Setup G: Full white (306x230mm), 0.7Vpp input video signal,

contrast at 100% , 9300 mode Calibrate CA100, High 9300

RGB=100 x=0.313, y=0.329, Y=30FL 1FL

Adjustment procedure:

5.3.1 Setup A, manually rotate Vg2 pot-meter on LOT until

brightness reaches 100 scale.

5.3.2 Setup A, adjust RGB cut-off (I C) for all colors at 100 7

scale, 9300 mode. (x=0.283, y=0.297, Y=0.10 0.05FL)

5.3.3 Setup B, adjust RGB gain (I C) for all colors at 100 2 scale,

2

2

9300 mode. (x=0.283, y=0.297, Y=41 0.5 FL)

5.3.4 Repeat 5.3.2, 5.3.3 (RGB cut-off and gain) to get both low

and high 9300 scales at 100. (0.10FL 0.05FL for low

scale; 41FL 1FL for high scale. x/y tolerance 0.005)

5.3.5 Setup C, adjust RGB cut-off (I C) for all colors at 100 7

scale, 6500 mode. (x=0.313, y=0.329, Y=0.10FL 0.05FL)

5.3.6 Setup D, adjust RGB gain (I C) for all colors at 100 2

2

2

scale, 6500 mode. (X=0.313, y=0.329, Y=36FL 1FL)

5.3.7 Repeat 5.3.5, 5.3.6 (RGB cut-off and gain) to get both low

and high 6500 scales at 100. (0.10FL 0.05FL for low scale;

36FL 1FL for high scale. x/y tolerance 0.005)

4.3.8 Setup E, adjust RGB cut-off (I C) for all colors at 100 7

2

scale, sRGB mode.

(x=0.313, y=0.329, Y=0.10FL 0.05FL)(same values as

6500 mode)

4.3.9 Setup F, adjust RGB gain (I C) for all colors at 100 2 scale,

2

sRGB mode.

(x=0.313, y=0.329, Y=36FL 1FL)(same values as 6500

mode)

5.3.10 sRGB brightness at 50%. Adjust sRGB contrast (I C) to get

2

Y=23FL 1FL for full white pattern.

(0.10FL 0.05FL for low scale, 23FL 1FL for high scale.

x/y tolerance 0.005)

5.4 Setup G, adjust ABL (I C) for 30FL 0.5FL, 9300 mode.

2

The above alignment method may be changed, as long as

the final results are the same.

(The above method has least amount of adjustment and

iteration steps.)

6. Adjustment of the picture geometry

=========================

6.1 Alignment of primary geometry

6.1.1 Apply Timing 7 (64KHz/60Hz, 1280x1024) with black video

signal, set V-position at 50%, set H and V-size for visible

raster edges at all sides.

(RGB cut-off can be increased temporarily to make raster

visible. After adjustment, restore RGB cut-off to original

values.) Slide switch 1603 for centered raster in horizontal

Direction. Adjust V-offset (I C) for centered raster in

2

vertical direction.

Apply Timing 8 (68.7kHz / 85Hz) with crosshatch signal and

start geometry alignment.

6.1.2 Adjust the Horizontal Size to 306mm.

6.1.3 Adjust the Horizontal Position for centered video.

6.1.4 Adjust the Vertical Size to 230 mm.

6.1.5 Adjust Vertical Position for centered video

6.1.6 Adjust picture tilt for correct TOP/BOTTOM lines.

(Picture tube should be mounted without tilt w.r.t. cabinet)

6.1.7 Adjust pincushion to get optimum vertical line.

6.1.8 Adjust trapezoid to get optimum vertical line.

6.1.9 Adjust balanced pincushion to get optimum vertical line.

6.1.10 Adjust the parallelogram to get optimum vertical line.

6.1.11 If needed, adjust the top / bottom corner control to get

optimum corner geometry.

Top and bottom corner only affect top and bottom 60mm of

the vertical lines.

(6.1.7, 6.1.8, 6.1.9 and 6.1.10 may need to be readjusted.)

6.1.12 Store the adjusted result and exit OSD.

(The values for pincushion, trapezoid, balance pincushion

and parallelogram can be copied to the other pre-set

modes to shorten alignment time.)

6.2 Other pre-set mode geometry adjustment

Use following procedure for all pre-set modes (except

68.7kHz/85Hz) (Timing Table1-8)

6.2.1 Adjust the Horizontal Size to 306mm.

6.2.2 Adjust the Horizontal Position to center position.

6.2.3 Adjust the Vertical Size to 230 mm.

6.2.4 Adjust the Vertical Position for correctly centred vertical

video.

6.2.5 Adjust pincushion to get optimum vertical line.

6.2.6 Adjust trapezoid to get optimum vertical line.

6.2.7 Adjust balanced pincushion to get optimum vertical line.

6.2.8 Adjust the parallelogram to get optimum vertical line.

(6.2.5, 6.2.6, 6.2.7 and 6.2.8 may need some iteration.)

6.2.9 Store the set result and exit OSD.

6.3 Other pre-load modes can be visible inside the bezel.

7 Focus adjustment

=============

With full white pattern display at timing 68Khz /85Hz

1024x768, set brightness at 50% and adjust contrast to 25

FL at the center of the screen.

8

and adjust H and V focus pot-meters which are located at

flyback transformer, until H- and V-line focus is optimal over

the entire screen.

8 Adjustment of Moir

================

Apply full white pattern and adjust contrast till luminance

around 15FL. 1/3 area with minor moiré can be acceptable.

If needed, use moir cancellation function and adjust the

H- moir or V-moir to cancel the moiré defect, then save

at factory.

9 Loading DDC code

=================

The DDC HEX data (refer to sheet-190) should be written

into the DDC by EEPROM writer or equivalent method.

10 Default settings

==============

The finished product should have the following default

Settings: Contrast: 100%, Brightness: 50%, Color: 9300,

Language: English(Chinese),

Power Save: On (Remark : Every mode is independent for

eset to factory setting.))

TIMING FOR V30 GS4 107T5 71K MODEL

REFERENCE PATTERN GENERATOR : CHROMA 2135

* According to VESA version 1.0 release 0.6p

Page 21

DDC Instructions

Video Card

107T5

Go to cover page

21

X

1. General

DDC Data Re-programming

In case the main EEPROM with which store all factory

settings were replaced because a defect,repaired monitor the serial

numbers have to be re-programmed.

It is advised to re-soldered the main EEPROM from

the old board onto the new board if circuit board have been replaced, in

this case the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

DDC EDID structure

For the monitor : Standard Version 3.0

Structure Version 1.2

Software DDC

with Software DDC

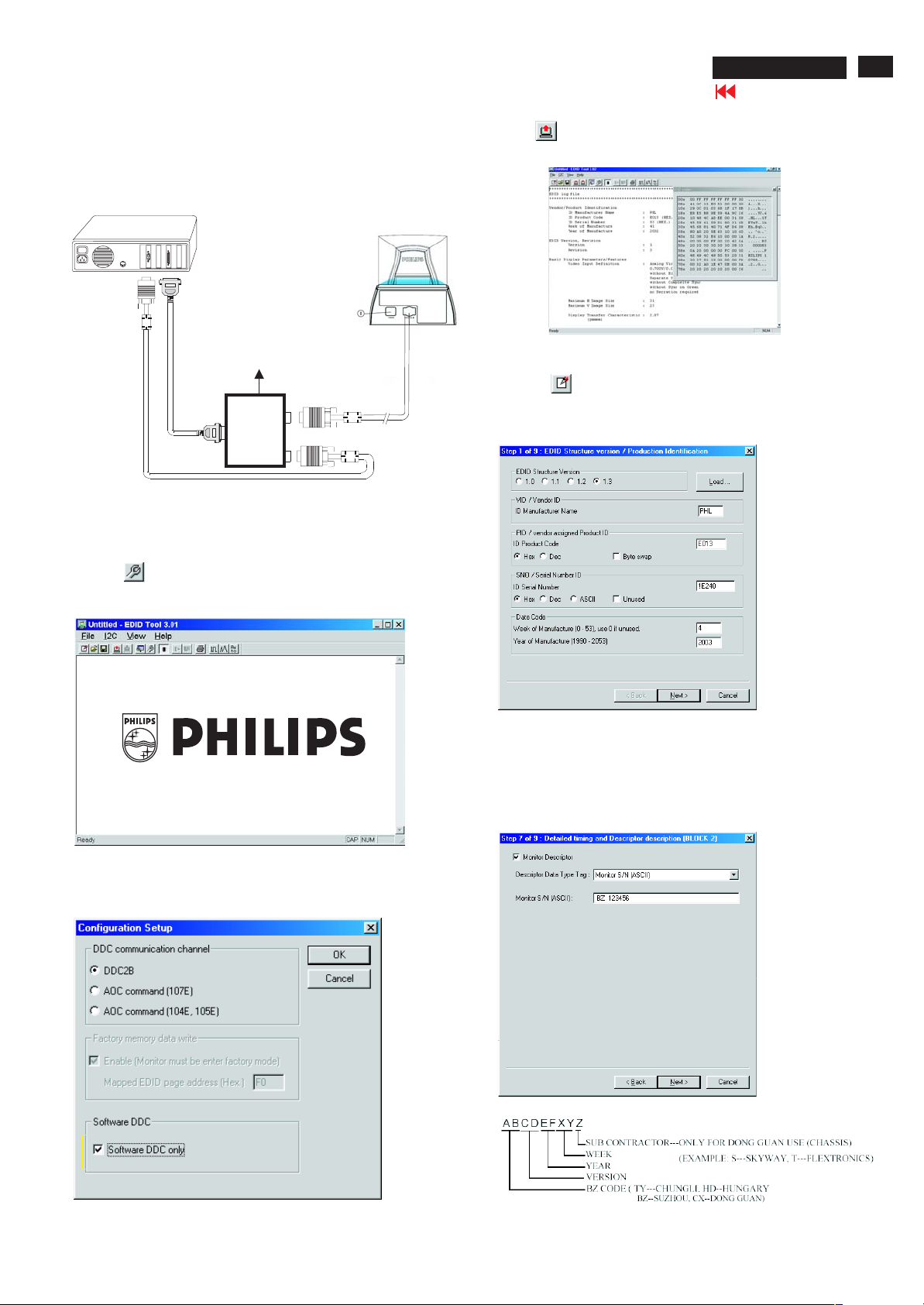

2. System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98.

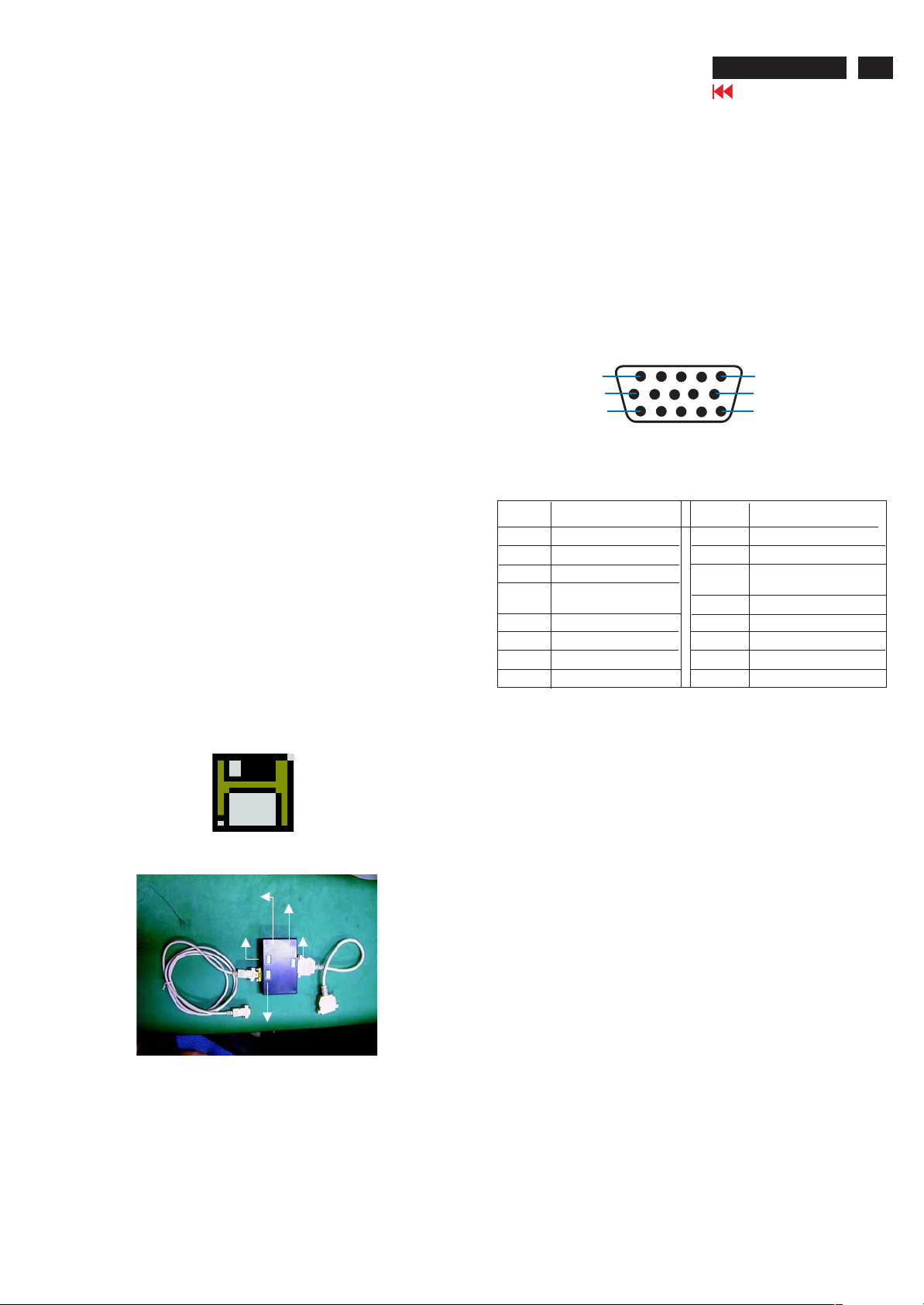

3. EDID301.EXE program (3138 106 10103) shown as Fig. 1

4. Software DDC Alignment kits (4822 310 11184) shown as Fig. 2.

The kit contents: a. Alignment box x1

Note: The EDID301.EXE (Release Version 1.58, 20000818)is a

windows-based program, which cannot be run in MS-DOS.

b. Printer cable x1

c. D-Sub cable x1

3. Pin assignment

A. 15-pin D-Sub Connector

The 15-pin D-sub connector (male) of the signal cable

on the 3rd row for DDC feature :

1

10

Not connected - no.pin

Sync. Ground

Ground

Bi-directional data(SDA)

H.Sync

V.Sync(VCLK)

Data clock line(SCL)

Pin No.

1

2

3

4

5

6

7

8

6

11

Assignment

Red video input

Green video input

Blue video input

Ground

for selftest(PC ground)

Red video ground

Green video ground

Blue video ground

Pin No.

9

10

11

12

13

14

15

5

15

Assignment

Figure 1

Diskette with EDID301.EXE

DC 8V~12V

To Monitor

Fig. 2 Alignment Kits

EDID301.EXE

Ver:1.58

Video Card

Power indicator

To Printer

Page 22

22

X

107T5

Go to cover page

DDC Instructions

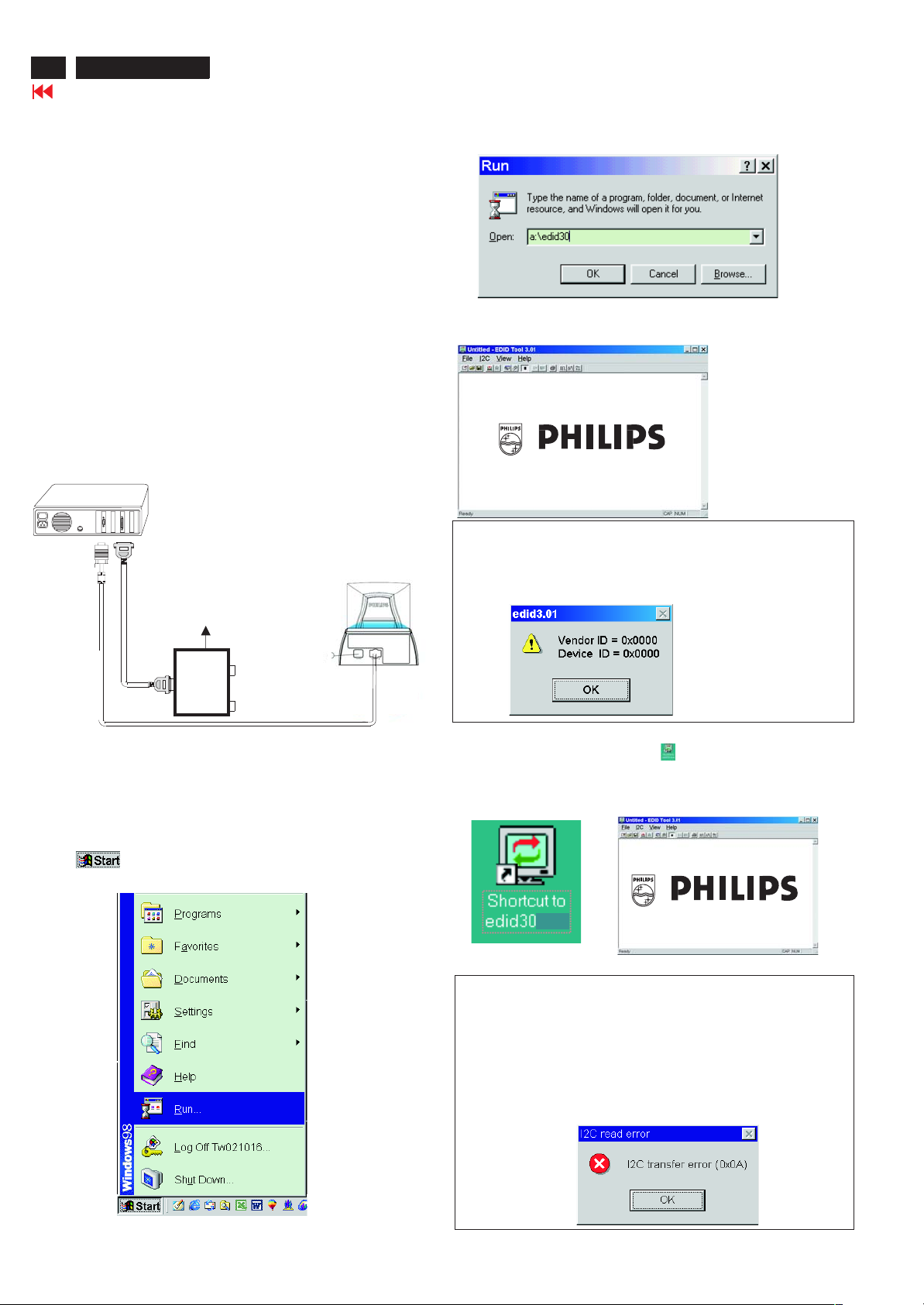

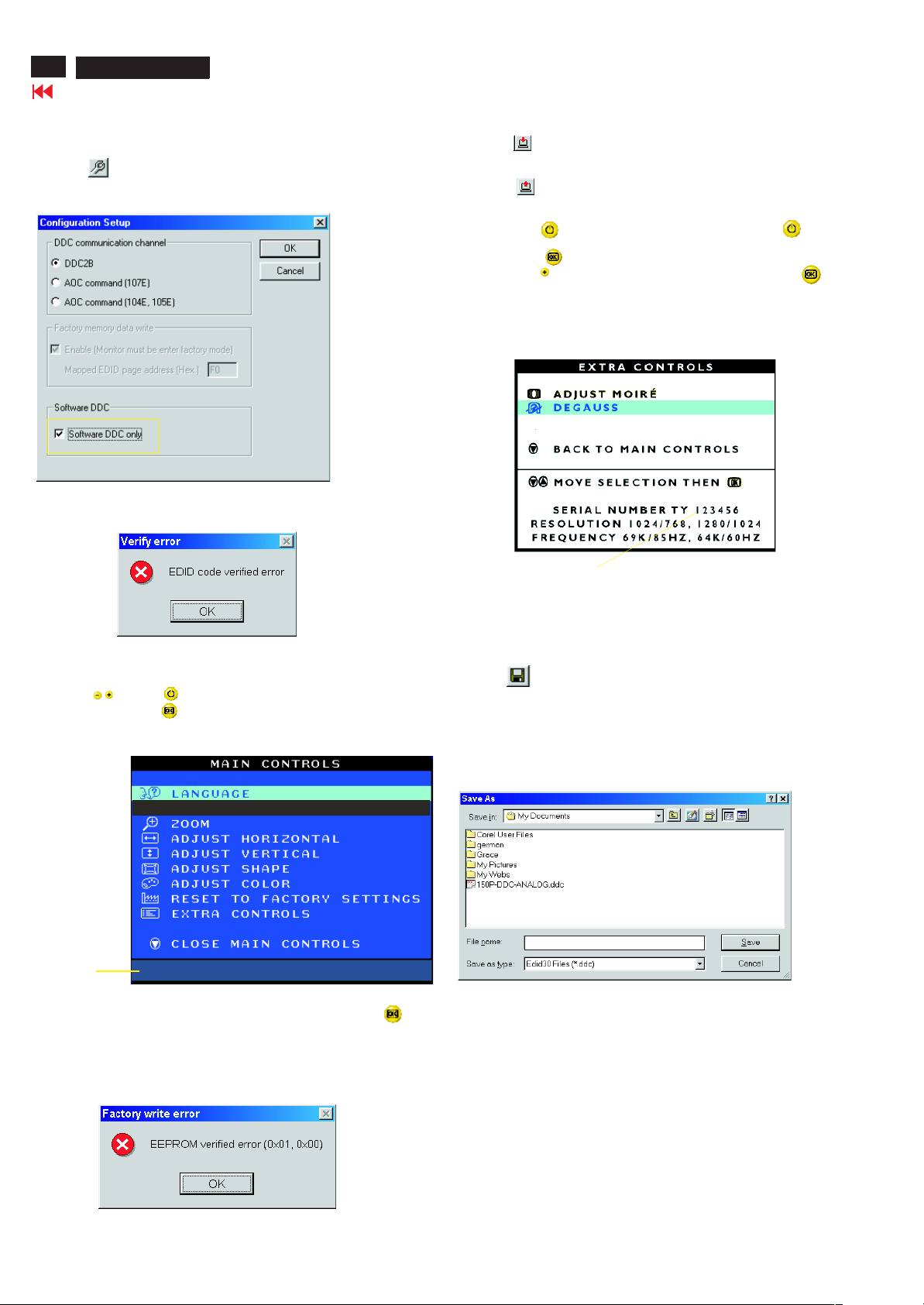

4. Configuration and procedure

There is no Hardware DDC (DDC IC) anymore. Main EEPROM stores

all factory settings and DDC data (EDID code) which is so called

Software DDC. The following section describes the connection and

procedure for Software DDC application. The main EEPROM can be reprobrammed by enabling "factory memory data write" function on the

DDC program (EDID301.EXE).

*** INITIALIZE ALIGNMENT BOX ***

In order to avoid that monitor entering power saving mode due to

sync will cut off by alignment box, it is necessary to initialize

alignment box before re-programming DDC Data. Following steps

show you the procedures and connection.

Step 1

: Supply 8~12V DC power source to the Alignment box by

plugging a DC power cord or using batteries.

: Connecting printer cable and video cable of monitor as

Step 2

shown in Fig.3.

PC

Fig. 3

Rear view of the monitor

DC Power

8~12 V

~

~

3. At the submenu, type the letter of your computer's floppy disk drive

followed by :EDID301 (for example, A:\EDID301, as shown in Fig. 5).

Fig. 5

4. Click button. The main menu appears (as shown in Fig. 6).OK

This is for initialize alignment box.

Fig. 6

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 7) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this time,

please make sure all cables are connected correctly and fixedly,

and the procedure has been performed properly.

To video card

Step 3: Installation of EDID301.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. Insert the disk containing EDID301.EXE program into floppy disk

drive.

2. Click , choose Run at start menu of Windows 95/98 as

shown in Fig. 4.

To printer port (LTP1)

Printer

Port

To

Monitor

To PC

Video cable

Fig. 4

Fig. 7

Method 2: After create a shortcut of EDID301.EXE

: Double click EDID301 icon (as shown in Fig. 8) which is

on the screen of Windows Wallpaper.

Bring up main menu of EDID301 as shown in Fig. 9.

This is for initialize alignment box.

1

Fig. 8

Note 2: During the loading, EDID301 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Fig. 9

Page 23

DDC Instructions

107T5

Go to cover page

23

X

Re-programming EEPROM (Software DDC)

Step 1: After initialize alignment box, connecting all cables and

box as shown in Fig. 10

PC

Rear view of the monitor

Fig. 10

DC Power

8~12 V

~

~

To video card

Step 2: Read DDC data from monitor

1-1 Click the left key of Mouse, or hit any key on the keyboard,

then the characters disappear from the screen.

1-2 Click icon as shown if Fig. 11 from the tool bar to bring up

the "Configuration Setup" windows as shown in Fig. 12.

To printer port (LTP1)

Printer

Port

To

Monitor

To PC

Video cable

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 13

Step 3: Modify DDC data (verify EDID version, week, year)

1. Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID301 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Fig. 14

2. Select the DDC2B as the communication channel.

Select " " & fill out " " for Mapped EDID page address

Enable F0

as shown in Fig. 12.

Fig. 11

Fig. 12

Step 4: Modify DDC data (Monitor Serial No.)

1. Click till the Step 7 of 9 window appears as shown in Fig. 15.

2. Fill out the new Serial No. (for example, TY 503960, TY 123456).

3. Click till the last step window appears, then click to exit

Next

Next Finish

the Step window.

Fig. 15

3. Click OK button to confirm your selection.

Page 24

24

X

107T5

Go to cover page

DDC Instructions

Step 5: **Configuration Setup & Enter Factory Mode **

for "write EDID data"

1. Click icon from the tool bar to bring up the Configuration Setup

windows again. Then, select "Software DDC only" as shown in

Fig. 16. Click "OK".

Fig. 16

If you do not select "Software DDC only", when you execute

"write EDID", it will bring up an error message as below.

Step 6: Write DDC data

1. Click (Write EDID) icon from the tool bar to write DDC data.

Bring up "Writing 0%~100%, ready" a progressing bar on the left

down corner.

2. Click (Read EDID) to confirm it.

Step 7: Confirm Serial Number in User Mode

1. Press the button to turn off the monitor. Press the button

again to turn on the monitor.

2. Press the button to bring up the OSD Main Menu.

3. Press the button to select Extra Controls, press the

button to confirm your selection.

4. Confirm the Serial Number "123456" is updated

as shown in Fig. 18.

To access factory mode

1. Turn off monitor (don't turn off PC)

2. Press " " and " " simultaneously on the front control

panel,then press " ",wait till the OSD menu with characters

V30 10T5 P V2.01 20030110 (below OSD menu)" come on the

screen of monitor.

Fig. 17

MODEL SELECT

Factory

Mode

Indicator

If OSD menu disappears on the screen of monitor, press " "

again (anytime), then the OSD menu comes on the screen again.

V30 107T5 P V.2.01 20030110

Fig. 18

Step 8: Save DDC data

Sometimes, you may need to save DDC data as a text file for using

in other IC chip. To save DDC data, follow the steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool bar

and give a file name as shown in Fig. 19.

The file type is EDID301 file (*.ddc) which can be open in WordPad.

By using WordPad, the texts of DDC data & table (128 bytes, hex

code) can be modified. If DDC TEXTS & HEX Table are completely

correct, it can be saved as .ddc flie to re-load it into EEPROM for

DDC Data application.

Fig. 19

107T5 V30

2. Click .Save

If you do not access "Factory mode", when you execute

"write EDID", it will bring up an error message as below.

Page 25

DDC Instructions

107T5

Go to cover page

25

X

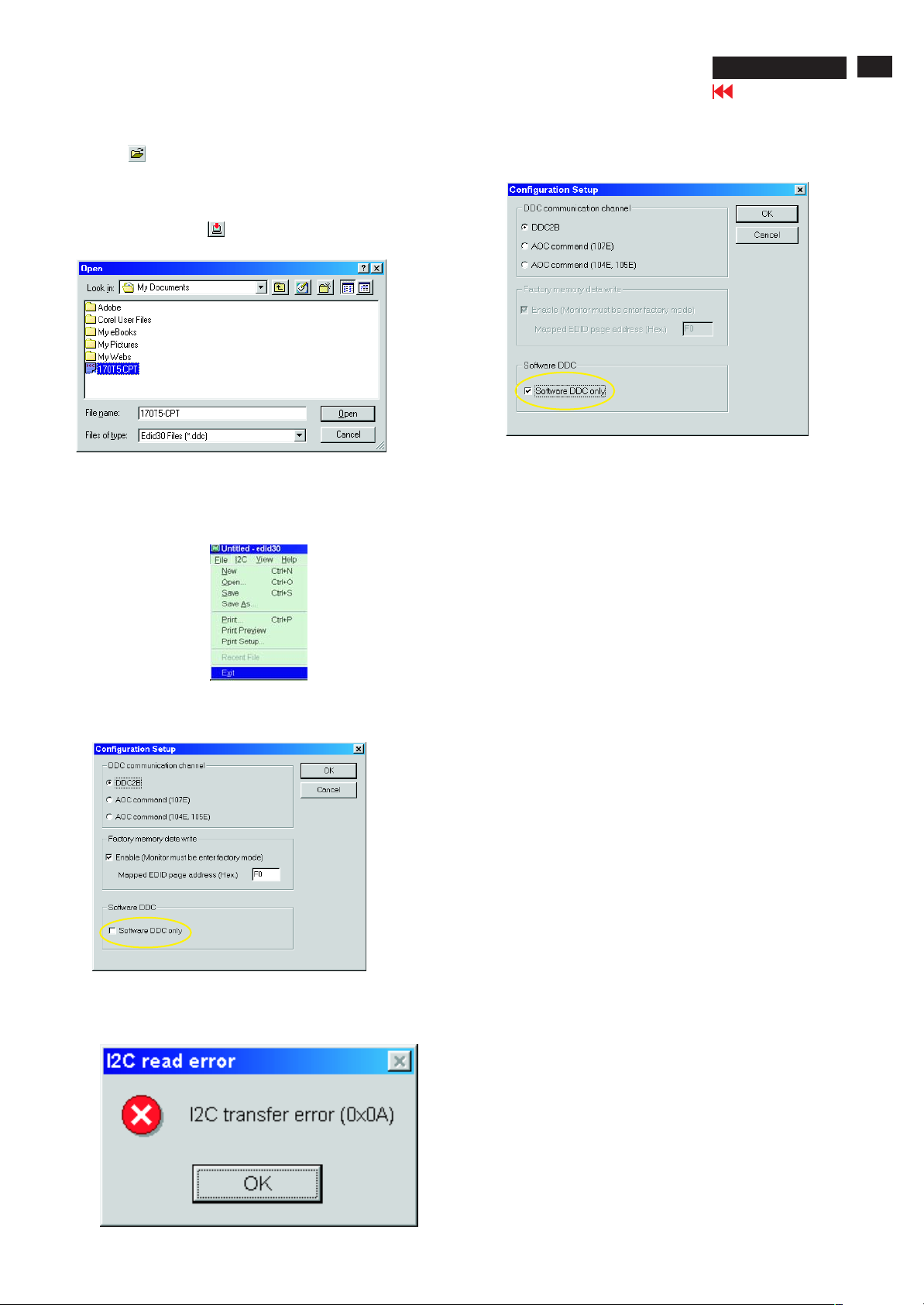

Step 9: Load DDC data

1. Click from the tool bar.

2. Select the file you want to open as shown in Fig. 20.

3. Click .

4. Access "Factory Mode" and enable "Software DDC only" as shown

5. Write EDID (click ).

Step 10: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 21.

(EDID Tool 3.01)

Open

in Fig. 17 & Fig. 16.

Fig. 20

Note2:InFactory Mode: Read/Write DDC data

Before Read/Write EDID code, please confirm that the

Software DDC only was enabled

as shown in Fig. 23.

Fig. 23

Fig. 21

Note1 : In User Mode: Read DDC data only

Before read EDID code, please confirm that the

DDC only was disabled

If you do not disable "Software DDC only", when you execute

"read EDID", it will bring up an error message as below.

as shown in Fig. 22.

Software

Fig. 22

Page 26

26

X

107T5

Go to cover page

Hex Data of DDC2B

**********************************************************************

EDID log file for CPT tube

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : E013 (HEX.)

ID Serial Number : 1E240 (HEX.)

Week of Manufacture : 4

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

without Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 31

Maximum V Image Size : 23

Display Transfer Characteristic : 2.86

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Color Characteristics

Red X coordinate : 0.631

Red Y coordinate : 0.329

Green X coordinate : 0.276

Green Y coordinate : 0.6

Blue X coordinate : 0.143

Blue Y coordinate : 0.057

White X coordinate : 0.283

White Y coordinate : 0.297

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

Manufacturer's timings :

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #5

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #6

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #8

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Detailed Timing #1

Pixel Clock (MHz) : 25.18

H Active (pixels) : 640

H Blanking (pixels) : 160

V Active (lines) : 350

V Blanking (lines) : 99

H Sync Offset (F Porch) (pixels) : 16

H Sync Pulse Width (pixels : 96

V Sync Offset (F Porch) (lines) : 37

V Sync Pulse Width (lines) : 2

H Image Size (mm) : 306

V Image Size (mm) : 230

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Negative Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : BZ 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 107T5

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 50

Max. Vt rate Hz : 160

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 71

Max. Supported Pixel : 110

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 7D (HEX.)

**********************************************************************

EDID data (128 bytes)

*********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 13 11: e0 12: 40 13: e2 14: 01 15: 00

16: 04 17: 0d 18: 01 19: 03 20: 68 21: 1f 22: 17 23: ba

24: e8 25: 9e 26: a8 27: a1 28: 54 29: 46 30: 99 31: 24

32: 0e 33: 48 34: 4c 35: ad 36: ee 37: 00 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 81 45: 80 46: 31 47: 68

48: 45 49: 68 50: 81 51: 40 52: 71 53: 4f 54: d6 55: 09

56: 80 57: a0 58: 20 59: 5e 60: 63 61: 10 62: 10 63: 60

64: 52 65: 08 66: 32 67: e6 68: 10 69: 00 70: 00 71: 1a

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 42 79: 5a

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 30 105: 37 106: 54 107: 35 108: 00 109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e 116: 47 117: 0b 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 74

Page 27

Hex Data of DDC2B

107T5

Go to cover page

27

X

**********************************************************************

EDID log file for LG tube

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : E013 (HEX.)

ID Serial Number : 1E240 (HEX.)

Week of Manufacture : 4

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

without Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 31

Maximum V Image Size : 23

Display Transfer Characteristic : 2.83

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Color Characteristics

Red X coordinate : 0.636

Red Y coordinate : 0.327

Green X coordinate : 0.278

Green Y coordinate : 0.6

Blue X coordinate : 0.145

Blue Y coordinate : 0.064

White X coordinate : 0.283

White Y coordinate : 0.297

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

Manufacturer's timings :

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #5

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #6

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #8

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Detailed Timing #1

Pixel Clock (MHz) : 25.18

H Active (pixels) : 640

H Blanking (pixels) : 160

V Active (lines) : 350

V Blanking (lines) : 99

H Sync Offset (F Porch) (pixels) : 16

H Sync Pulse Width (pixels) : 96

V Sync Offset (F Porch) (lines) : 37

V Sync Pulse Width (lines) : 2

H Image Size (mm) : 306

V Image Size (mm) : 230

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Negative Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : BZ 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 107T5

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 50

Max. Vt rate Hz : 160

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 71

Max. Supported Pixel : 110

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : 9B (HEX.)

**********************************************************************

EDID data (128 bytes) for LG tube

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 13 11: e0 12: 40 13: e2 14: 01 15: 00

16: 04 17: 0d 18: 01 19: 03 20: 68 21: 1f 22: 17 23: b7

24: e8 25: f6 26: 28 27: a2 28: 53 29: 47 30: 99 31: 25

32: 10 33: 48 34: 4c 35: ad 36: ee 37: 00 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 81 45: 80 46: 31 47: 68

48: 45 49: 68 50: 81 51: 40 52: 71 53: 4f 54: d6 55: 09

56: 80 57: a0 58: 20 59: 5e 60: 63 61: 10 62: 10 63: 60

64: 52 65: 08 66: 32 67: e6 68: 10 69: 00 70: 00 71: 1a

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 42 79: 5a

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 30 105: 37 106: 54 107: 35 108: 00 109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e 116: 47 117: 0b 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: 9b

Page 28

28

X

107T5

Go to cover page

Hex Data of DDC2B

**********************************************************************

EDID log file for SDI tube

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : E013 (HEX.)

ID Serial Number : 1E240 (HEX.)

Week of Manufacture : 4

Year of Manufacture : 2003

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.000V (0.70Vpp)

without Blank-to-Black Setup

Separate Sync

without Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 31

Maximum V Image Size : 23

Display Transfer Characteristic : 2.9

(gamma)

Feature Support (DPMS) : Standby

Suspend

Active Off

Display Type : RGB color display

Color Characteristics

Red X coordinate : 0.645

Red Y coordinate : 0.316

Green X coordinate : 0.265

Green Y coordinate : 0.606

Blue X coordinate : 0.143

Blue Y coordinate : 0.058

White X coordinate : 0.283

White Y coordinate : 0.297

Established Timings

Established Timings I : 720 x 400 @70Hz (IBM,VGA)

640 x 480 @60Hz (IBM,VGA)

640 x 480 @72Hz (VESA)

640 x 480 @75Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II : 800 x 600 @72Hz (VESA)

800 x 600 @75Hz (VESA)

832 x 624 @75Hz (Apple,Mac II)

1024 x 768 @60Hz (VESA)

1024 x 768 @70Hz (VESA)

1024 x 768 @75Hz (VESA)

Manufacturer's timings :

Standard Timing Identification #1

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #2

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #3

Horizontal active pixels : 1024

Aspect Ratio : 4:3

Refresh Rate : 85

Standard Timing Identification #4

Horizontal active pixels : 1280

Aspect Ratio : 5:4

Refresh Rate : 60

Standard Timing Identification #5

Horizontal active pixels : 640

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #6

Horizontal active pixels : 800

Aspect Ratio : 4:3

Refresh Rate : 100

Standard Timing Identification #7

Horizontal active pixels : 1280

Aspect Ratio : 4:3

Refresh Rate : 60

Standard Timing Identification #8

Horizontal active pixels : 1152

Aspect Ratio : 4:3

Refresh Rate : 75

Detailed Timing #1

Pixel Clock (MHz) : 25.18

H Active (pixels) : 640

H Blanking (pixels) : 160

V Active (lines) : 350

V Blanking (lines) : 99

H Sync Offset (F Porch) (pixels) : 16

H Sync Pulse Width (pixels) : 96

V Sync Offset (F Porch) (lines) : 37

V Sync Pulse Width (lines) : 2

H Image Size (mm) : 306

V Image Size (mm) : 230

H Border (pixels) : 0

V Border (lines) : 0

Flags : Non-interlaced

: Normal Display, No stereo

: Digital Separate sync.

: Negative Vertical Sync.

: Positive Horizontal Sync.

Monitor Descriptor #2

Serial Number : BZ 123456

Monitor Descriptor #3

Monitor Name : PHILIPS 107T5

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 50

Max. Vt rate Hz : 160

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 71

Max. Supported Pixel : 110

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : F1 (HEX.)

**********************************************************************

EDID data (128 bytes) for SDI tube

**********************************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 13 11: e0 12: 40 13: e2 14: 01 15: 00

16: 04 17: 0d 18: 01 19: 03 20: 68 21: 1f 22: 17 23: be

24: e8 25: 0d 26: b8 27: a5 28: 51 29: 43 30: 9b 31: 24

32: 0e 33: 48 34: 4c 35: ad 36: ee 37: 00 38: 31 39: 59

40: 45 41: 59 42: 61 43: 59 44: 81 45: 80 46: 31 47: 68

48: 45 49: 68 50: 81 51: 40 52: 71 53: 4f 54: d6 55: 09

56: 80 57: a0 58: 20 59: 5e 60: 63 61: 10 62: 10 63: 60

64: 52 65: 08 66: 32 67: e6 68: 10 69: 00 70: 00 71: 1a

72: 00 73: 00 74: 00 75: ff 76: 00 77: 20 78: 42 79: 5a

80: 20 81: 20 82: 31 83: 32 84: 33 85: 34 86: 35 87: 36

88: 0a 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 49 98: 4c 99: 49 100: 50 101: 53 102: 20 103: 31

104: 30 105: 37 106: 54 107: 35 108: 00 109: 00 110: 00 111: fd

112: 00 113: 32 114: a0 115: 1e 116: 47 117: 0b 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: f1

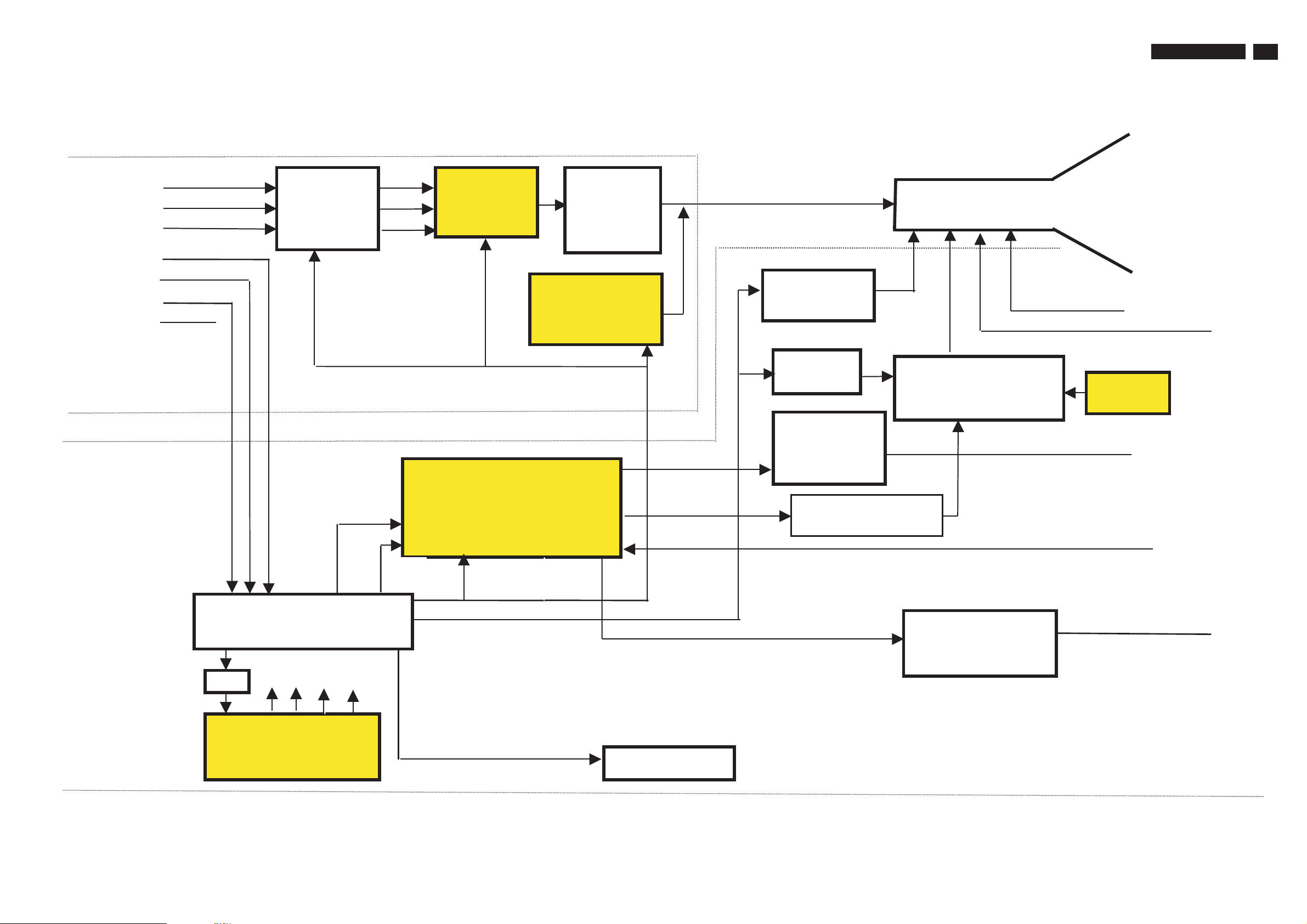

Page 29

Function Block of V30 107T5

107T5

Go to cover page

9

29

R

G

B

H

SDA

SCL

V

Self-

test

KEY

CONTROL

&

LED

LIGHT

FRAME IC

TDA4823

I2C

H

PREAMP

with OSD

NT6812

I2C

DC

RESTORATION

VIDEO

OUTPUT

STAGE

LM2480

VIDEO

HORIZONTZL & VERTICAL

SYNC PROCESSOR

& B+ CONTROLLER

TDA 9112A

V

I2C control

STV9556

R/G/B

ROTATION

BC516+BC517

S-CAP

SWITCH

BUCK

CONVERTER

MTP5P25

H-Driver

BSN254A

EHT Compensation

G1, G2

FOCUS

H-OUTPUT/

FOCUS

BU2527AF/DM32F5

/TIP122

CRT

EHT

LOT

CF2091

EEPROM

M24C04

-BN6

AC

INPUT

MICRO-PROCESSOR

MCU WT62P2

OFF

DC

O/P

SWITCH MODE

POWER SUPPLY

TEA1507

DEGAUSSING

VERTICAL

OUTPUT STAGE

TDA8172

MIC I/P

MAIN

BOARD

(30-71KHz)

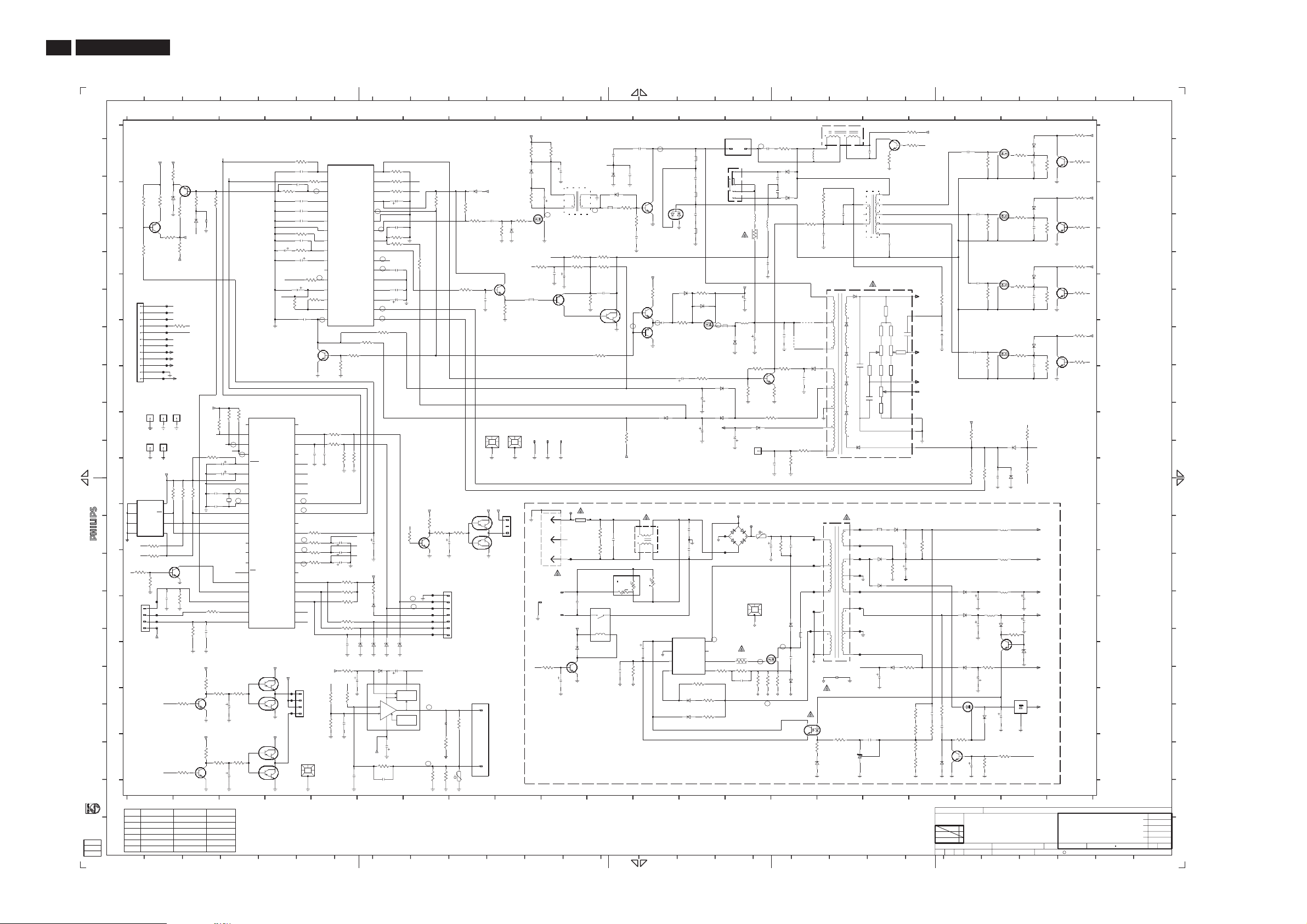

Page 30

30

Go to cover page

9

107T5

Schematic Diagram of Main board

Allrights reserved. Reproduction inwhole or inparts

isprohibited without the writtenconsent of thecopyright

owner.

Allerechten voorbehouden. Verveelvuldiging,geheel of

gedeeltelijk,is niet toegestaan danmet schriftelijke

toestemmingvan de auteursrechthebbende.

123

A

B

C

D

123

MAIN PCB

SB: 57251x1

PB: 57271

A

[R]

B

[R]

C

+6

+6

3K3

3501

6502

[R]

3519

3518

BZX79-C2V4

3502

[R]

7503

3527

[R]

100K

3526

-100

E

D

F

E

G

H

F

I

G

F1

12

SDA

F2

11

SCL

F3

10

VE

F4

3511

9

1

F5

1K5

8

F6

7

Hflb

F7

6

VS

F8

5

+6

F9

4

TO VIDEOBOARD 831

8501

42061

+12

F10

3

+83

F11

2

F12

1

G1

8811

8813

8812

1

1

1

8815

8814

1

1

J

M24C16-BN6

1

E0

2

E1

E23SCL

4

VSS

SCL

SDA

3823

47K

1803

JFE63173

1

2

3

4

TOCTRLBD8899

+5

7802

4K7

3804