Page 1

Colour Television Chassis

TPS1.2A

LA

I_17620_000.eps

260308

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 10

6. Block Diagrams, Test Point Overview, and

Waveforms

Wiring Diagram 13

Block Diagram Scaler Board 14

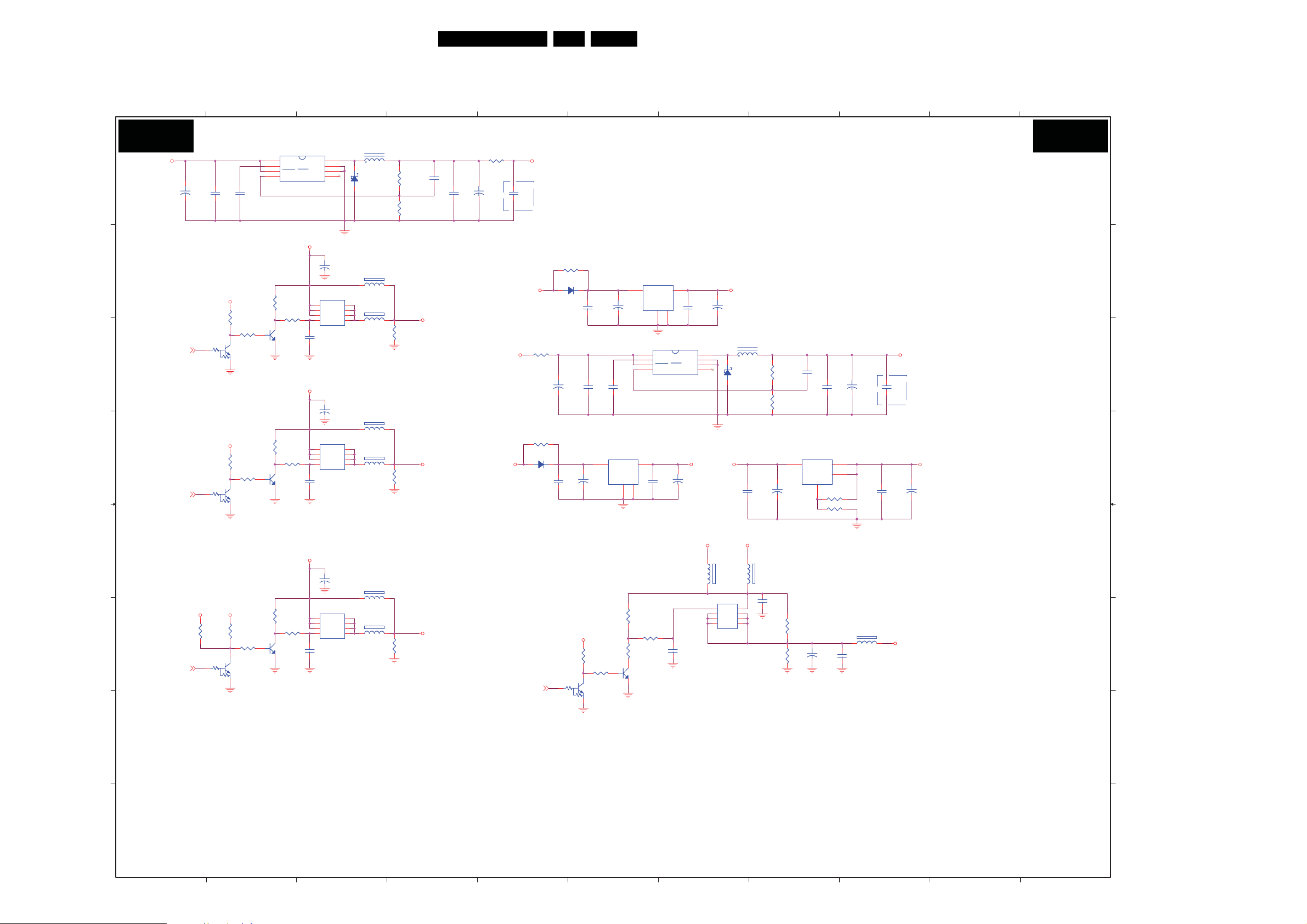

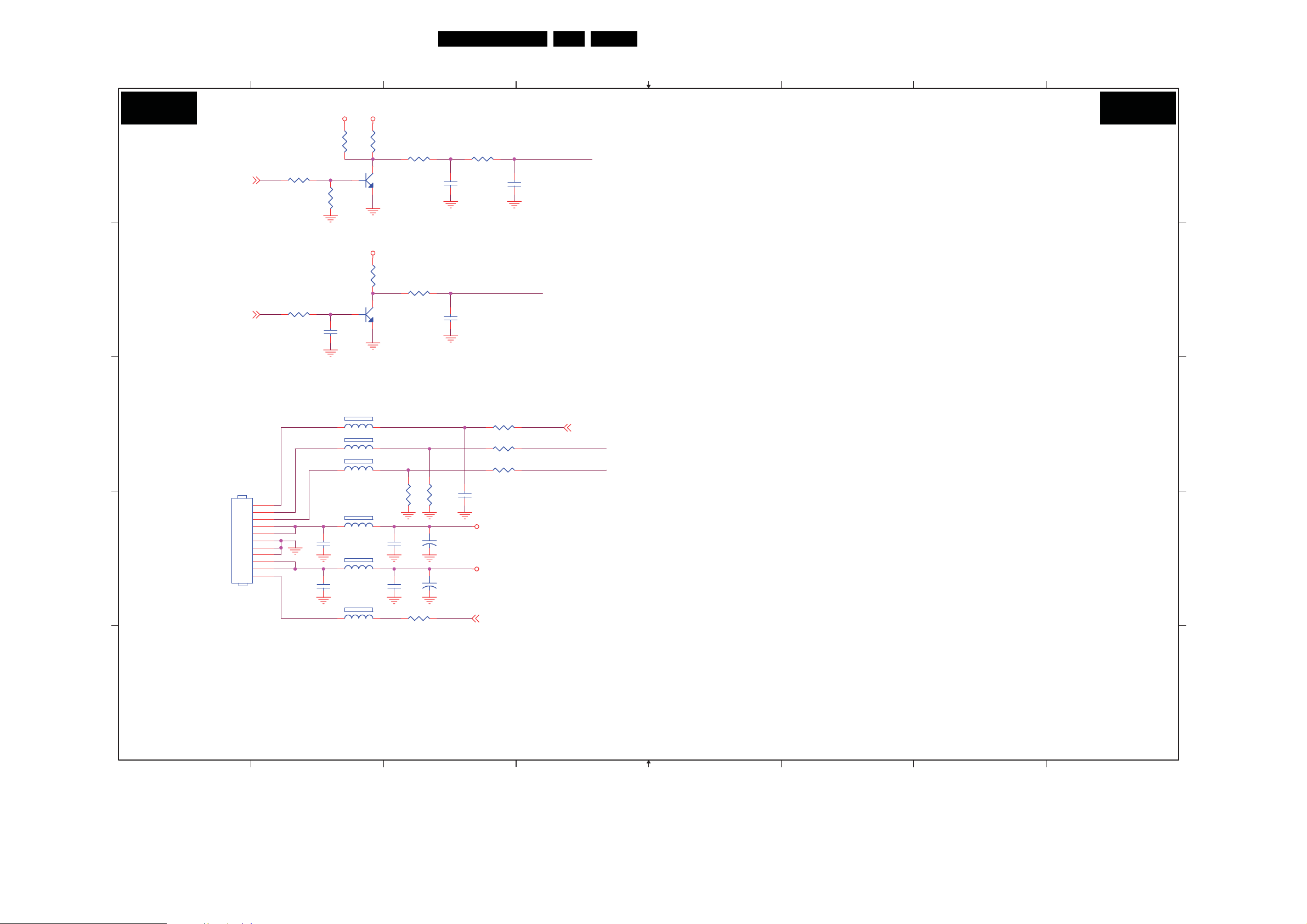

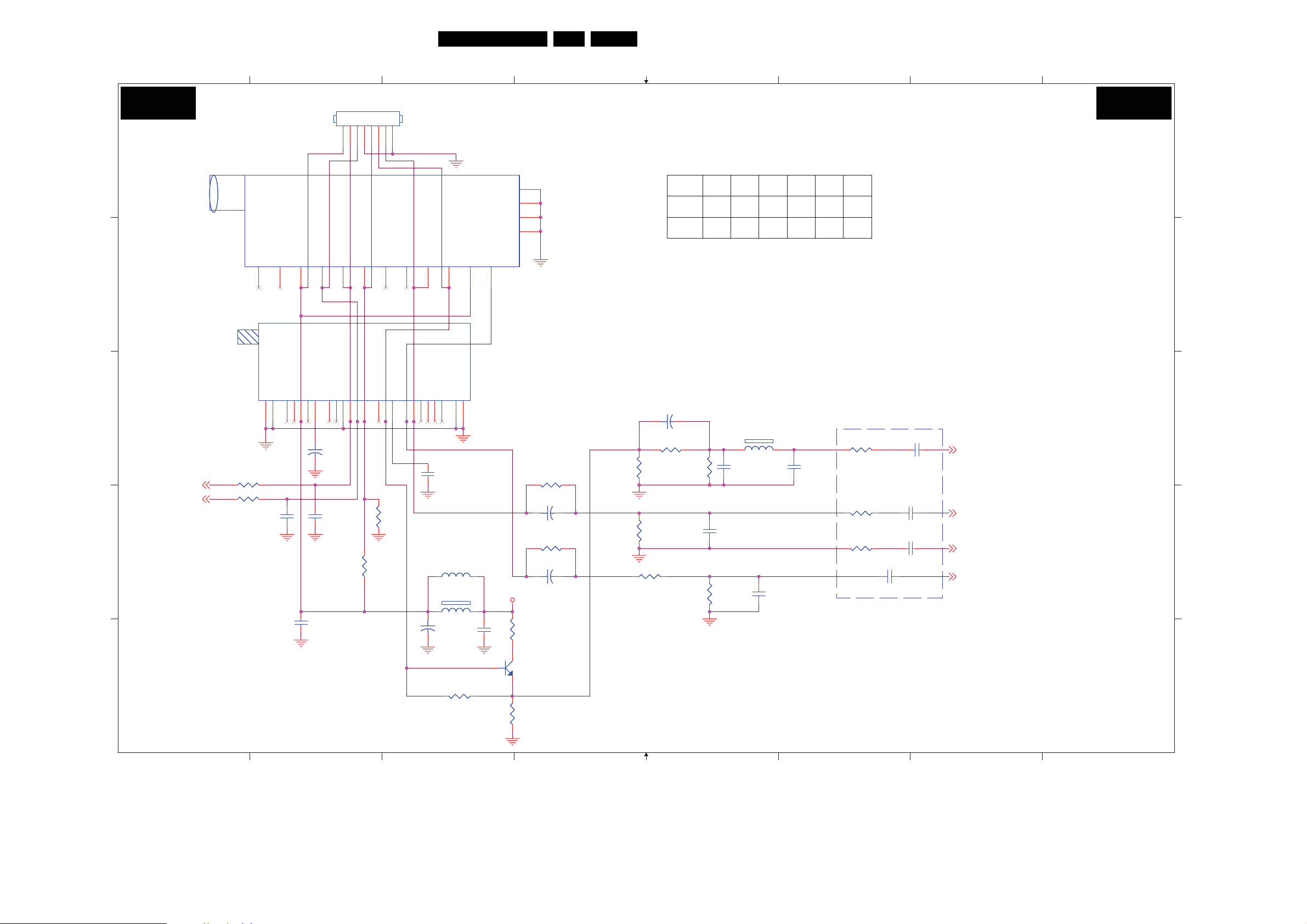

7. Circuit Diagrams and PWB Layouts Diagram PWB

Scaler Board: DC-DC Power (SB01) 15 33-34

Scaler Board: PS & Inverter I/F

Scaler Board: Tuner (SB03) 17 33-34

Scaler Board: Video Input 1 (SB04) 18 33-34

Scaler Board: Video Input 2 (Side AV) (SB05) 19 33-34

Scaler Board: D-Sub Input (SB06) 20 33-34

Scaler Board: HDMI Input 1

Scaler Board: HDMI Input 2 (n.c.) (SB08) 22 33-34

WT6702F (Standby MCU)

Scaler Board: Scaler MST98980CLD (SB09) 24 33-34

Scaler Board: Flash ROM & Memory (SB10) 25 33-34

Scaler Board: KEY, IR BD & Compair I/F

Scaler Board: ITV I/F

Scaler Board: Panel I/F

Scaler Board: Audio I/F

Scaler Board: Audio Amplifier (SB15) 30 33-34

Scaler Board: Audio Out (n.c.) (SB16) 31 33-34

Scaler Board: USB (n.c.) (SB17) 32 33-34

Keyboard Control Panel (KB01) 35 36

IR & LED Panel (IB01) 37 38

Power Board: Adapter (PB01) 39 42-43

Power Board: Inverter (PB02) 40 42-43

Power Board: Jumper

©

Copyright 2008 Koninklijke Philips Electronics N.V.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

(SB02) 16 33-34

(SB07) 21 33-34

(SB08) 23 33-34

(SB11) 26 33-34

(SB12) 27 33-34

(SB13) 28 33-34

(SB14) 29 33-34

(PB03) 41 42-43

8. Alignments 45

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 47

Abbreviation List 48

IC Data Sheets 50

10. Spare Parts List & CTN Overview 56

11. Revision List 56

Published by CS 0866 BU TV Consumer Care Printed in the Netherlands Subject to modification EN 3122 785 17591

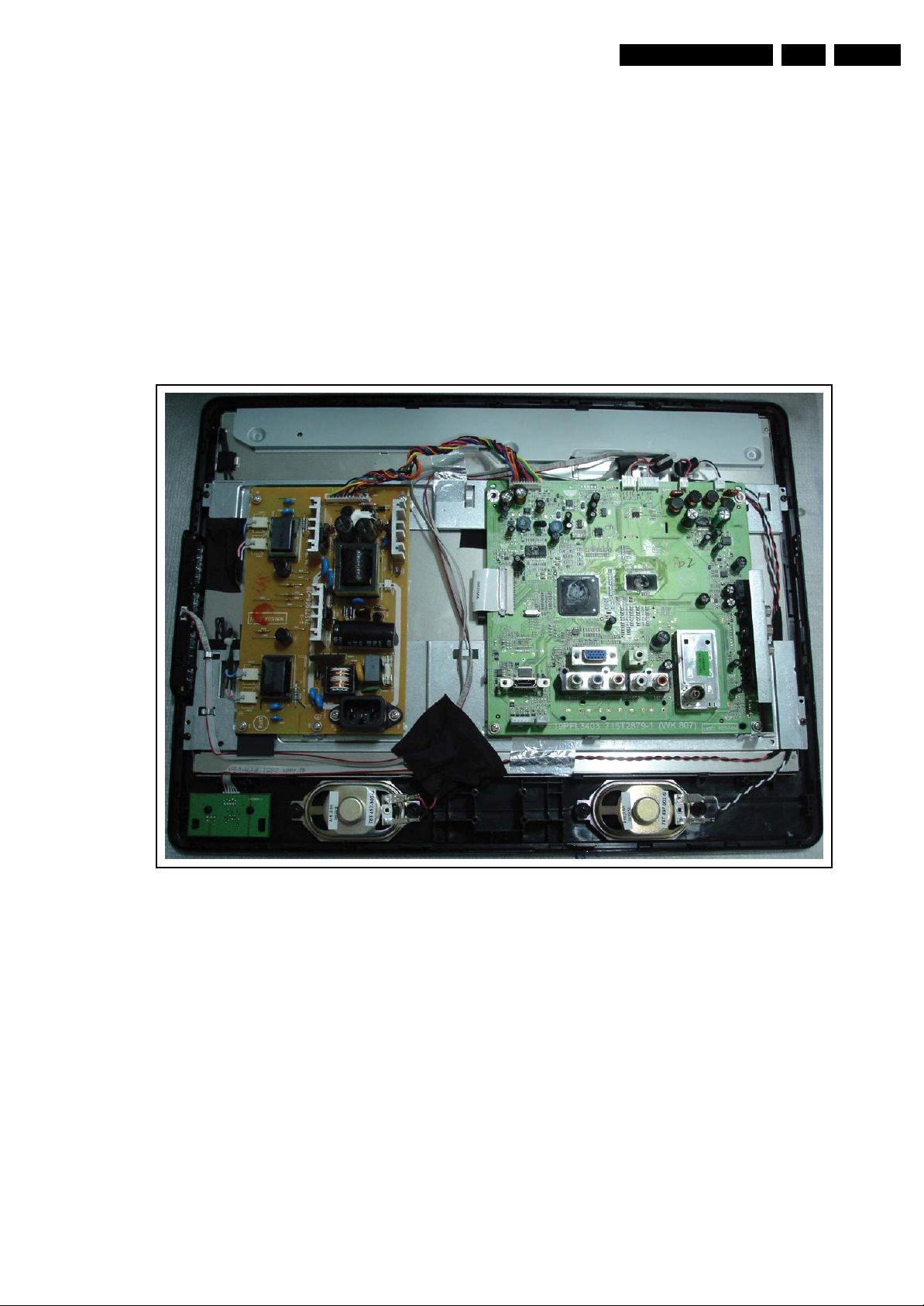

Page 2

EN 2 TPS1.2A LA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Figures can deviate due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : LCD

Screen Size : 19"

Display area (mm) : 408.24(H)x255.15(V)

Number of Pixel : 1440 (H) x 900 (V)

Pitch (mm) : 0.2835 x 0.2835

Colour pixel arrangement : RGB vertical stripe

Display operating mode : TN Mode, Normally

White

Colour depth : 16.7M colours (RGB

6-bits + HiFRC)

Brightness (cd/m^2) : 300 (typ.)

Viewing angle (typ.) : R/L 170, U/D 160

Surface treatment : Anti-glare type,

Hardness 3H

Electrical interface : Dual Channel LVDS

Response Time (ms) : 5 (typ.)

Contrast ratio : 1000:1 (typ.)

Backlight : 4 CCFL

Support Video Formats : 720 x 400@ 70 Hz

: 640 x 480@ 60 Hz

: 640 x 480@ 67 Hz

: 800 x 600@ 60 Hz

: 1024 x 768@ 60 Hz

: 1280 x 960@ 60 Hz

: 1440 x 900@ 60 Hz

1.1.2 Sound

Sound systems : Mono, Stereo,

Incredible Surround

Maximum power : 2 x 3W

1.1.3 Miscellaneous

Power supply

AC line voltage range : 90~264V

AC line frequency range : 50~60Hz

Power consumption : 50W

Horizontal scan

Horizontal : 30~81kHz

Vertical : 56~76 Hz

Box dimension (LxWxH, mm) : 562 x 486 x 186

Product dimension (HxWxD, mm) : 392 x 468 x 166

Gross weight : 6.0kg

Net weight : 4.8kg

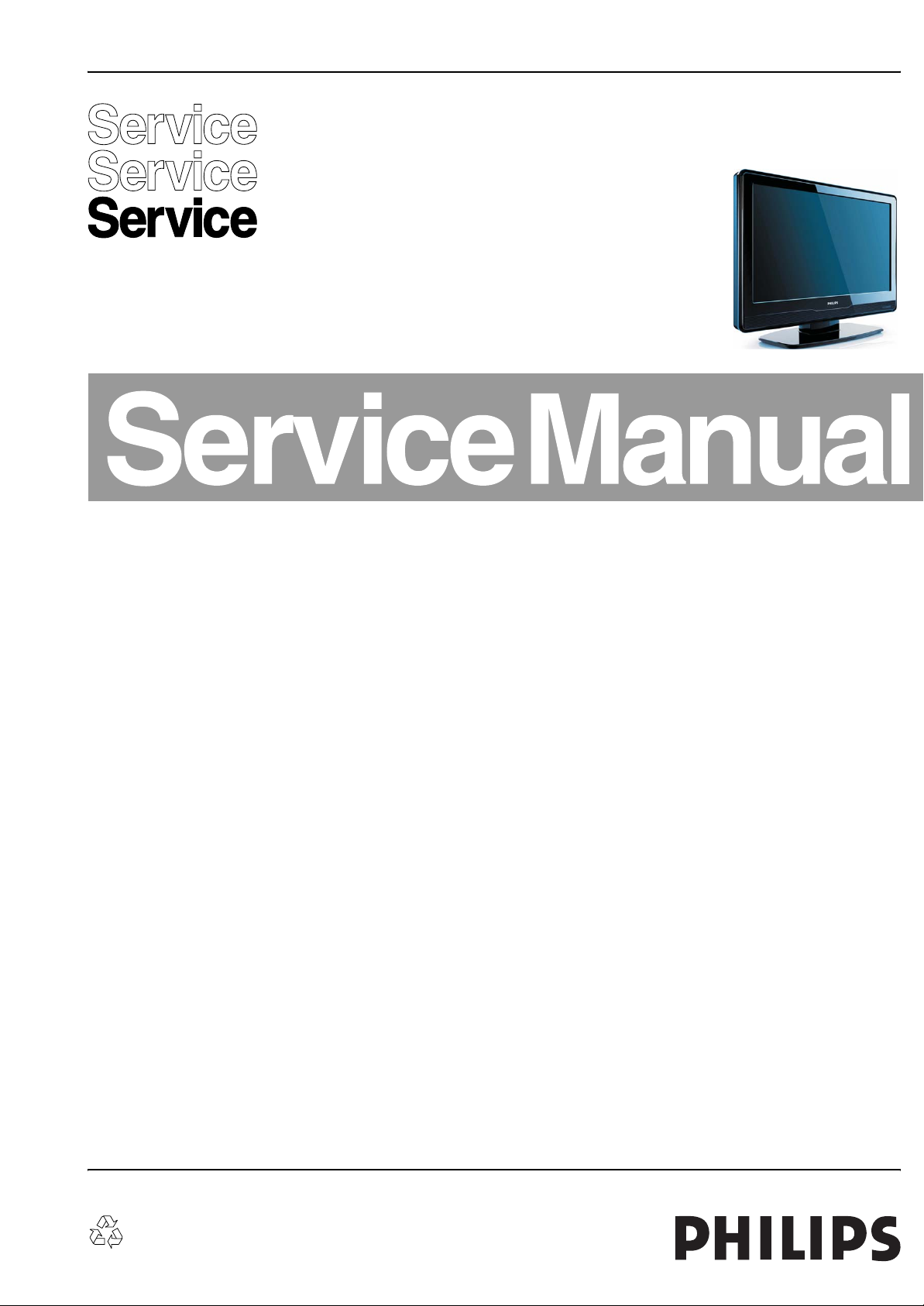

1.2 Connection Overview

1.2.1 Rear and Side Connections

1

HDMI

YPbPr LR

PC IN

VGA AUDIO IN

CVI

2

3

75 Ω

4

Figure 1-1 Rear and Side I/O

HDMI

PC IN

VGA AUDIO IN

CVI

YPbPr LR

5

6

L-AUDIO-RVIDEO IN

75 Ω

SIDE AV

7

8

S-VIDEO

I_17590_051.eps

300508

Page 3

Technical Specifications, Connections, and Chassis Overview

EN 3TPS1.2A LA 1.

1.2.2 Rear Connections

Note: The following connector colour abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

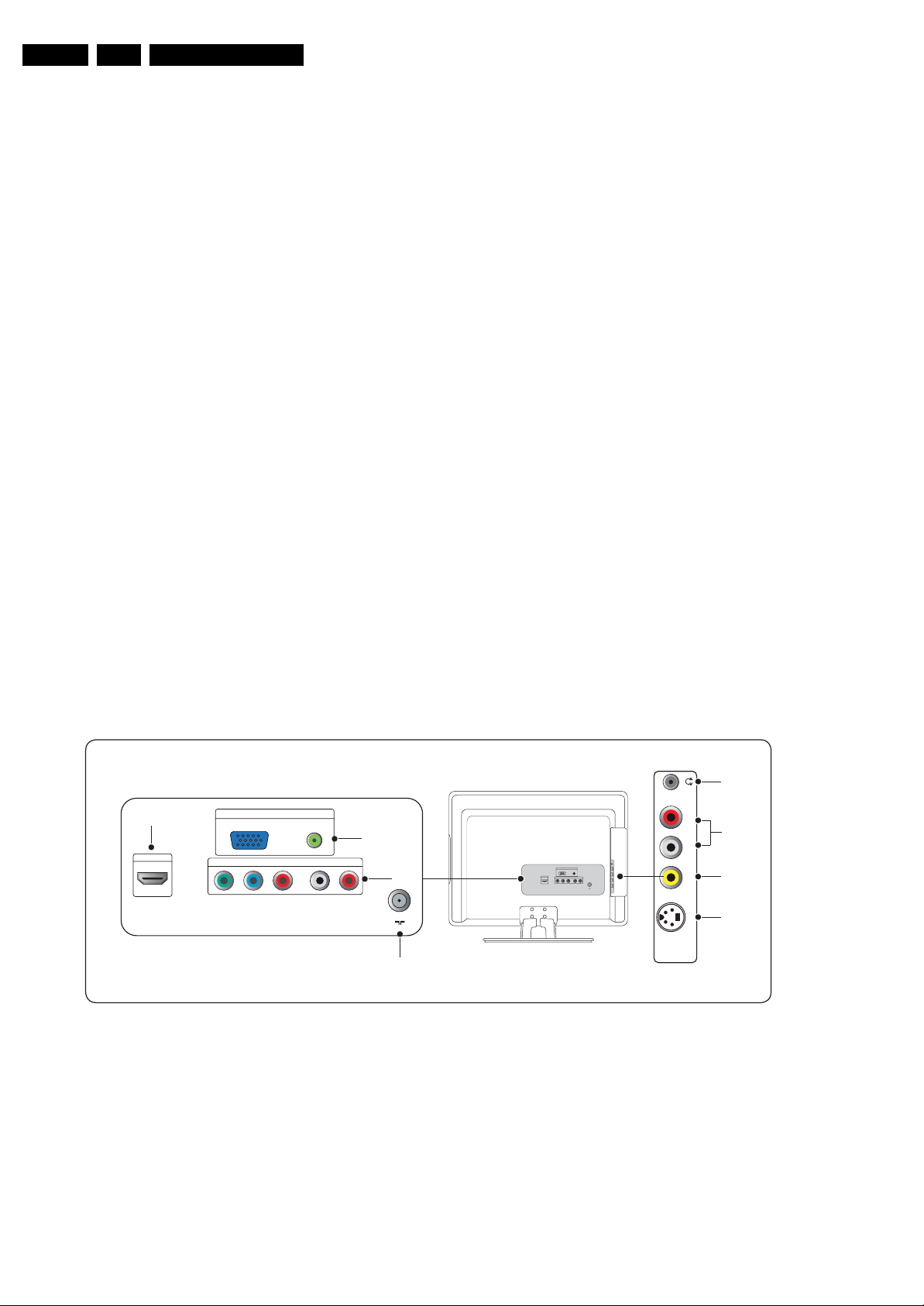

1. HDMI: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-2 HDMI (type A) connector

1 -D2+ Data channel j

2 -Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5 -Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8 -Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - CEC

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

4. Aerial - In

- - IEC-type (EU) Coax, 75 ohm D

5. Side AV: Audio Head phone- Out

Bk - Head phone 32 - 600 ohm / 10 mW rt

6. Side AV: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

7. Side AV: Video CVBS - In

Ye - Video CVBS 1 V

/ 75 ohm jq

PP

8. Side AV: Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 -Video Y 1 V

4 -Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

2. PC In: Video RGB - In

1

6

11

5

10

15

E_06532_002.eps

050404

Figure 1-3 VGA Connector

1 -Video Red 0.7 V

2 -Video Green 0.7 V

3 -Video Blue 0.7 V

4-n.c.

/ 75 ohm j

PP

/ 75 ohm j

PP

/ 75 ohm j

PP

5 -Ground Gnd H

6 -Ground Red Gnd H

7 -Ground Green Gnd H

8 -Ground Blue Gnd H

9-+5V

10 - Ground Sync Gnd H

+5 V j

DC

11 - n.c.

12 - DDC_SDA DDC data j

13 - H-sync 0 - 5 V j

14 - V-sync 0 - 5 V j

15 - DDC_SCL DDC clock j

2. PC In: Audio - In

Bk - Audio L 0.5 V

Bk - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

3. CVI: Video YPbPr - In, Audio - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Page 4

EN 4 TPS1.2A LA1.

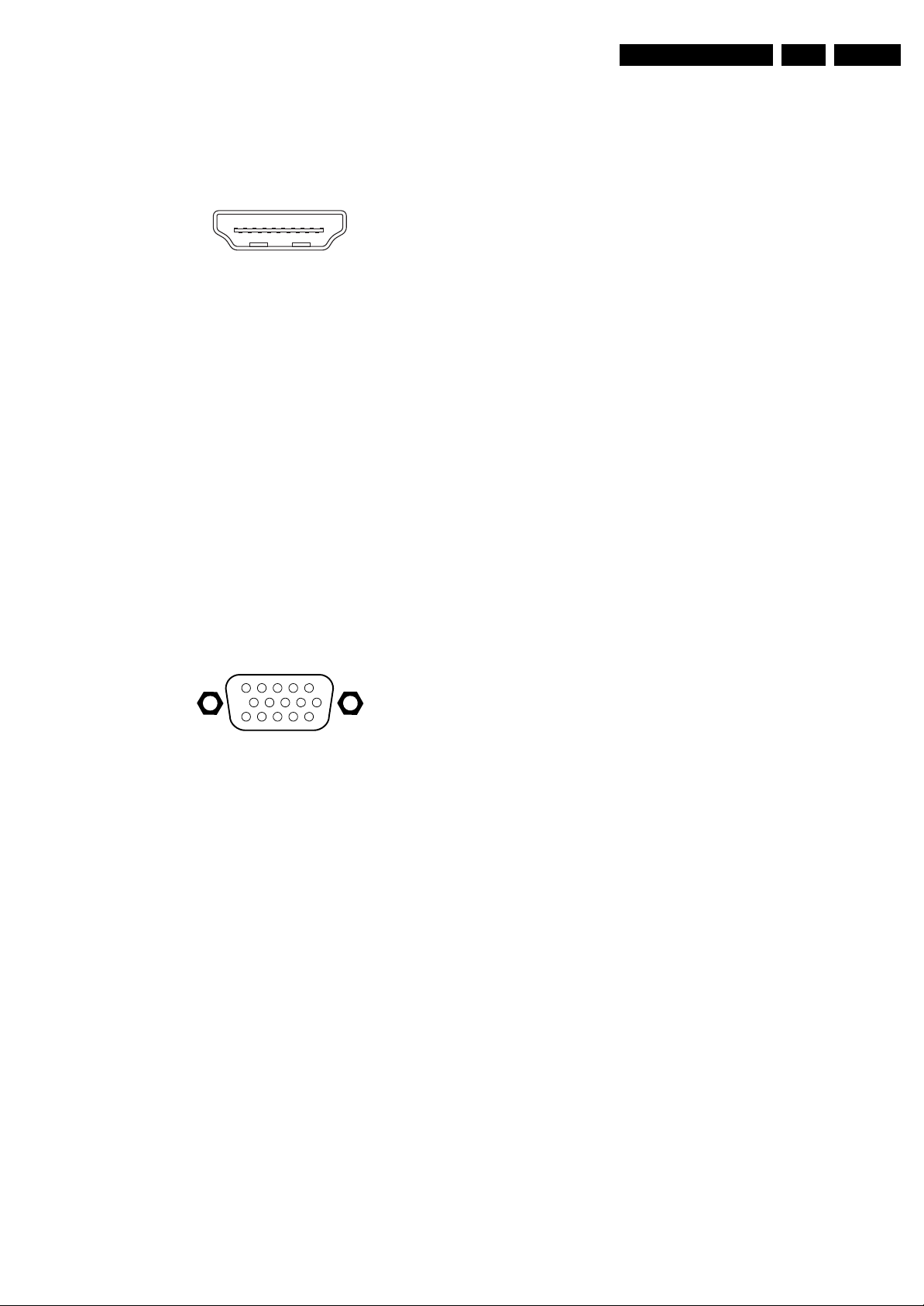

1.3 Chassis Overview

Technical Specifications, Connections, and Chassis Overview

Figure 1-4 Chassis Overview

I_17590_007.eps

260508

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5TPS1.2A LA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the “on” position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ.

4. Switch “off” the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched “on”.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a colour bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kΩ).

• Resistor values with no multiplier may be indicated with

either an “E” or an “R” (e.g. 220E or 220R indicates 220 Ω).

• All capacitor values are given in micro-farads (μ=× 10

nano-farads (n =× 10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An “asterisk” (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

“Magazine”, chapter “Repair downloads”.

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

-9

), or pico-farads (p =× 10

-12

-6

),

).

Page 6

EN 6 TPS1.2A LA3.

2.3.5 Alternative BOM identification

Note: on the European Service website, “Alternative BOM” is

referred to as “Design variant”.

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production centre (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

Directions for Use

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

MADE IN BELGIUM

220-240V 50/60Hz

~

VHF+S+H+UHF

S

128W

BJ3.0E LA

E_06532_024.eps

260308

Figure 2-1 Serial number (example)

2.3.6 Board Level Repair (BLR) or Component Level Repair (CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

2.3.7 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

Page 7

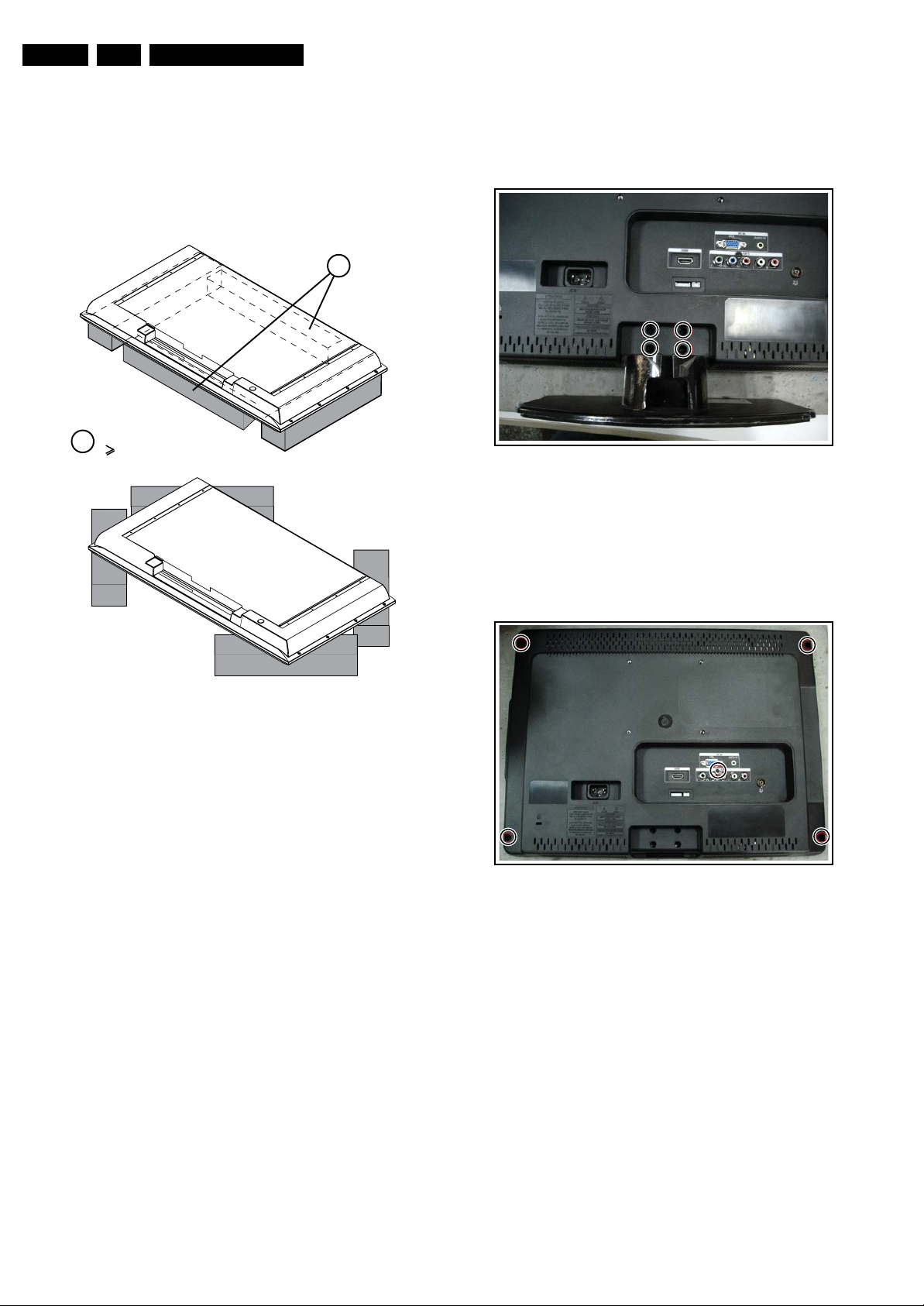

4. Mechanical Instructions

Index of this chapter:

1. Cable Dressing

2. Service Positions

3. Assy/Panel Removal

4. Re-assembly

Notes:

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Follow the disassembly instructions in the described order.

4.1 Cable Dressing

Mechanical Instructions

EN 7TPS1.2A LA 4.

Figure 4-1 Cable dressing

I_17590_008.eps

260508

Page 8

EN 8 TPS1.2A LA4.

Mechanical Instructions

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging (see figure “Rear cover”).

• Foam bars (created for Service).

4.2.1 Foam Bars

Required for sets

1

42"

4.3 Assy/Panel Removal

4.3.1 Base

Remove the marked screws to remove the base.

1

I_17591_003.eps

240608

Figure 4-3 Remove Base

4.3.2 Rear Cover

E_06532_018.eps

171106

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42” and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

1. Remove the marked screws, which secure the rear cover.

2. Lift the rear cover from the cabinet. Make sure that wires

and flat foils are not damaged during cover removal.

I_17591_004.eps

240608

Figure 4-4 Remove rear cover

Page 9

Mechanical Instructions

EN 9TPS1.2A LA 4.

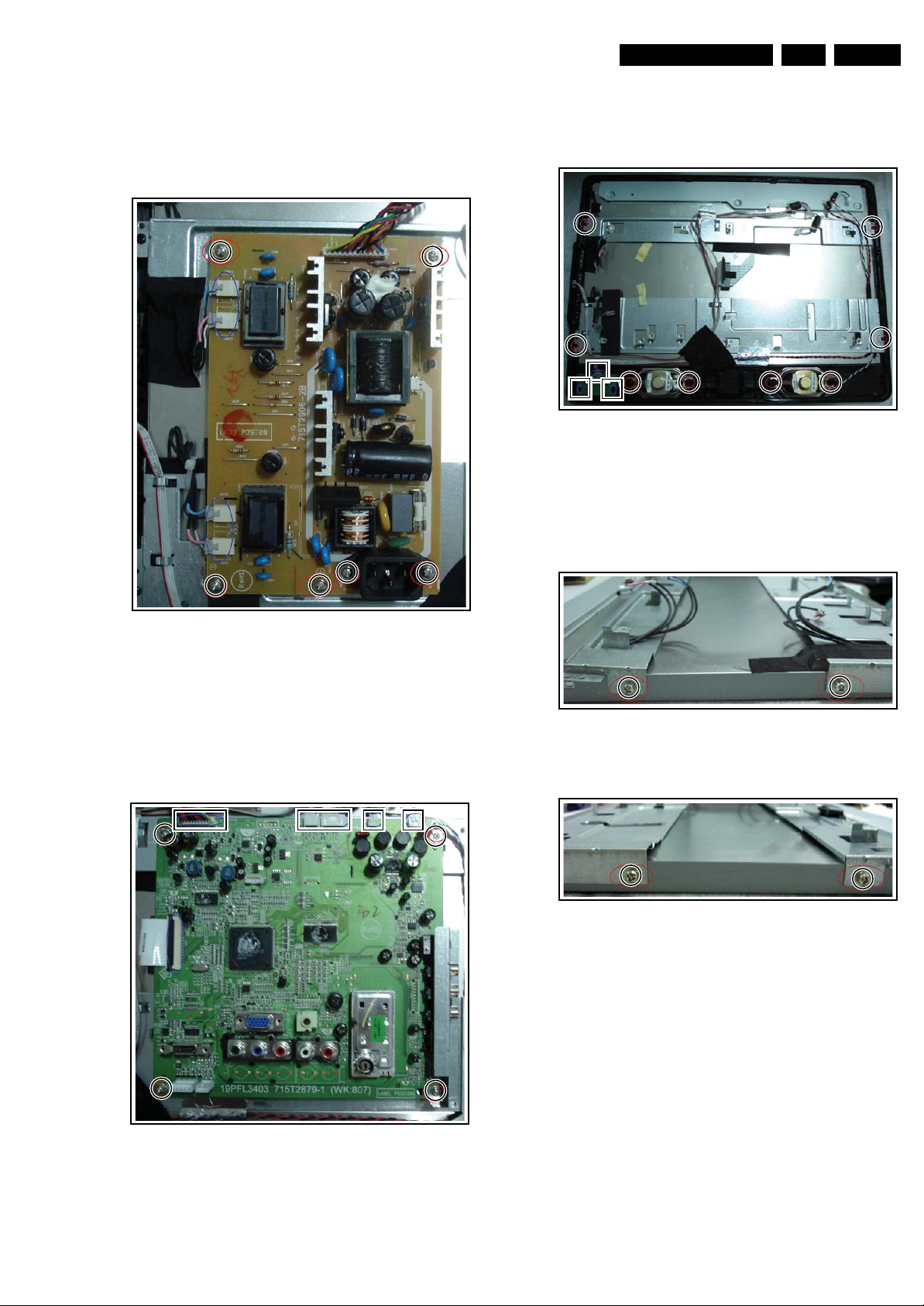

4.3.3 Power Board

1. Refer to next figure.

2. Unplug the marked connectors.

3. Remove the marked screws to remove the Power board.

When defective, replace the whole unit.

4.3.5 Bezel

1. Refer to next figures.

2. Remove the marked screws to remove the bezel.

Figure 4-7 Bezel

4.3.6 Bracket

1. Refer to next two figures.

2. Remove the marked screws to remove the brackets.

I_17590_013.eps

260508

Figure 4-5 Power Board

4.3.4 Scaler Board

1. Refer to next figure.

2. Unplug the marked connectors.

3. Remove the marked screws to remove the Scaler board.

When defective, replace the whole unit.

I_17590_011.eps

260508

Figure 4-8 Bracket 1/2

Figure 4-9 Bracket 2/2

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

I_17590_014.eps

260508

I_17590_015.eps

260508

Figure 4-6 Scaler Board

I_17590_012.eps

260508

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure “Cable

dressing”.

Page 10

EN 10 TPS1.2A LA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Mode

5.3 Service Tools

5.4 Tips and Tricks

5.1 Test Points

This chassis is not equipped with test points in the service

printing.

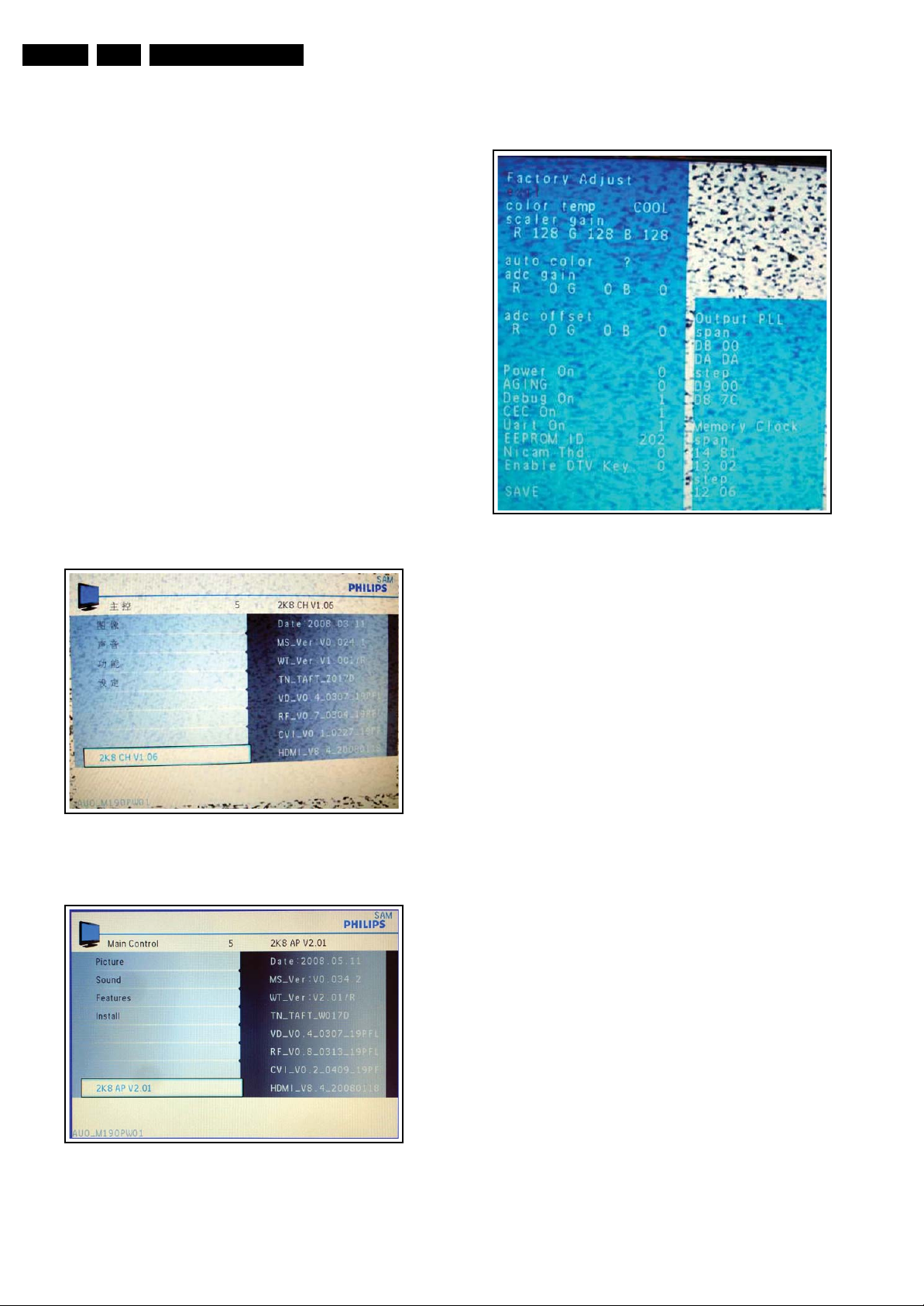

5.2 Service Mode

5.2.1 Factory Mode

How to Enter

To enter the Factory mode, please use the following method:

• Press the remote control codes ”062596” + ”STATUS/

EXIT”. Then select “2K8 CH V1 06” in the menu and press

“OK” in order to enter the factory mode.

Caution: This function is meant for development and

service personnel only, not for end customers.

After entering the factory mode, the following screen is visible.

You can now select one of them and press OK.

Figure 5-3 Factory mode menu 2

I_17590_017.eps

260508

I_17590_016.eps

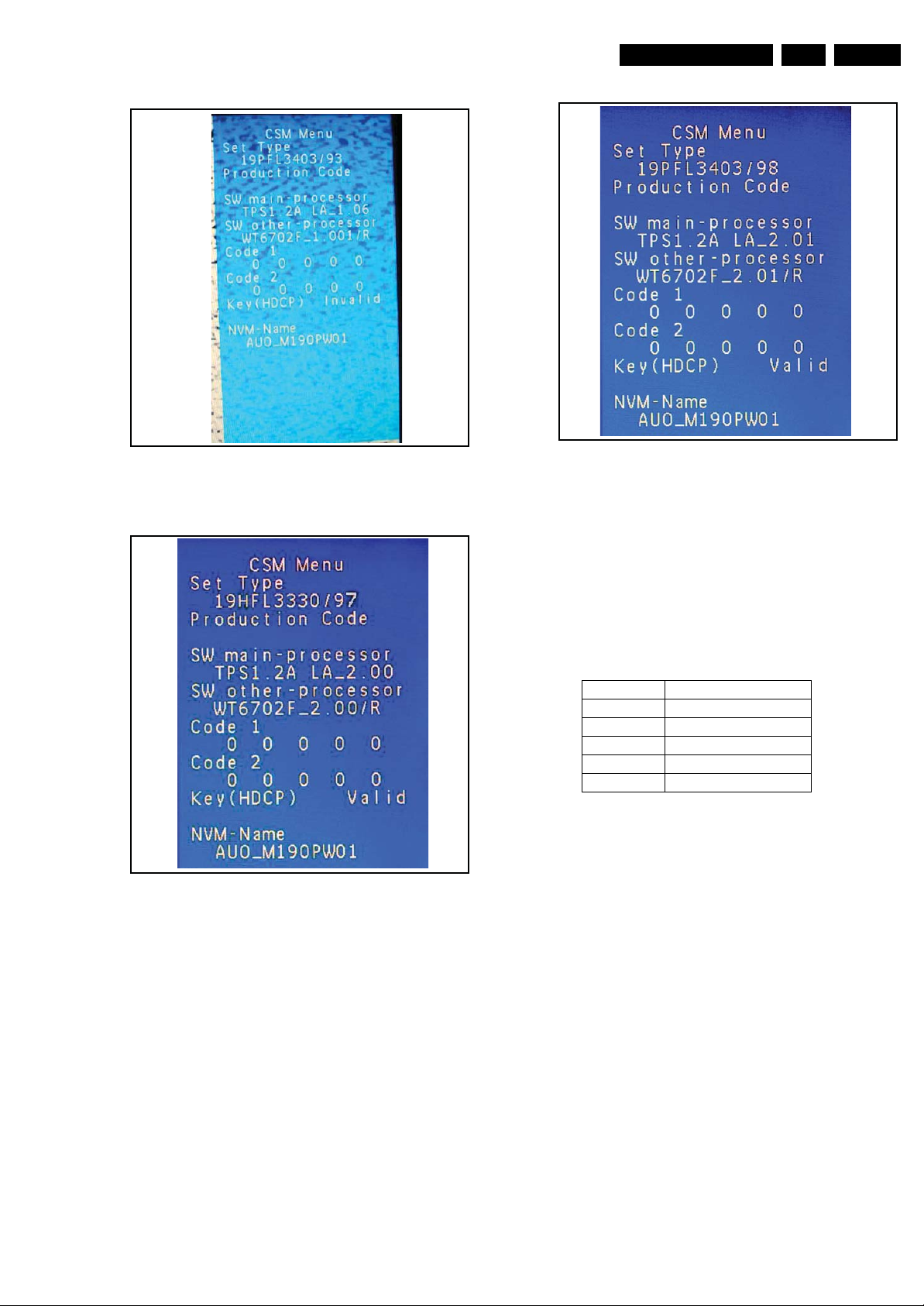

Figure 5-1 Factory mode menu 1 (19PFL3403/93)

260508

How to EXIT

Choose ‘EXIT”, then press “MENU” button on the remote

control.

5.2.2 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Help desk. The service

technician can then ask the customer to activate the CSM in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer. The

CSM is read only mode; therefore, modifications in this mode

are not possible.

How to Activate CSM

Key in the codes ”123654” via the standard RC transmitter to

enter the Customer Service Mode.

How to Navigate

By mean of the “CURSOR-DOWN/UP” knob on the RCtransmitter on the screen.

I_17591_005.eps

240608

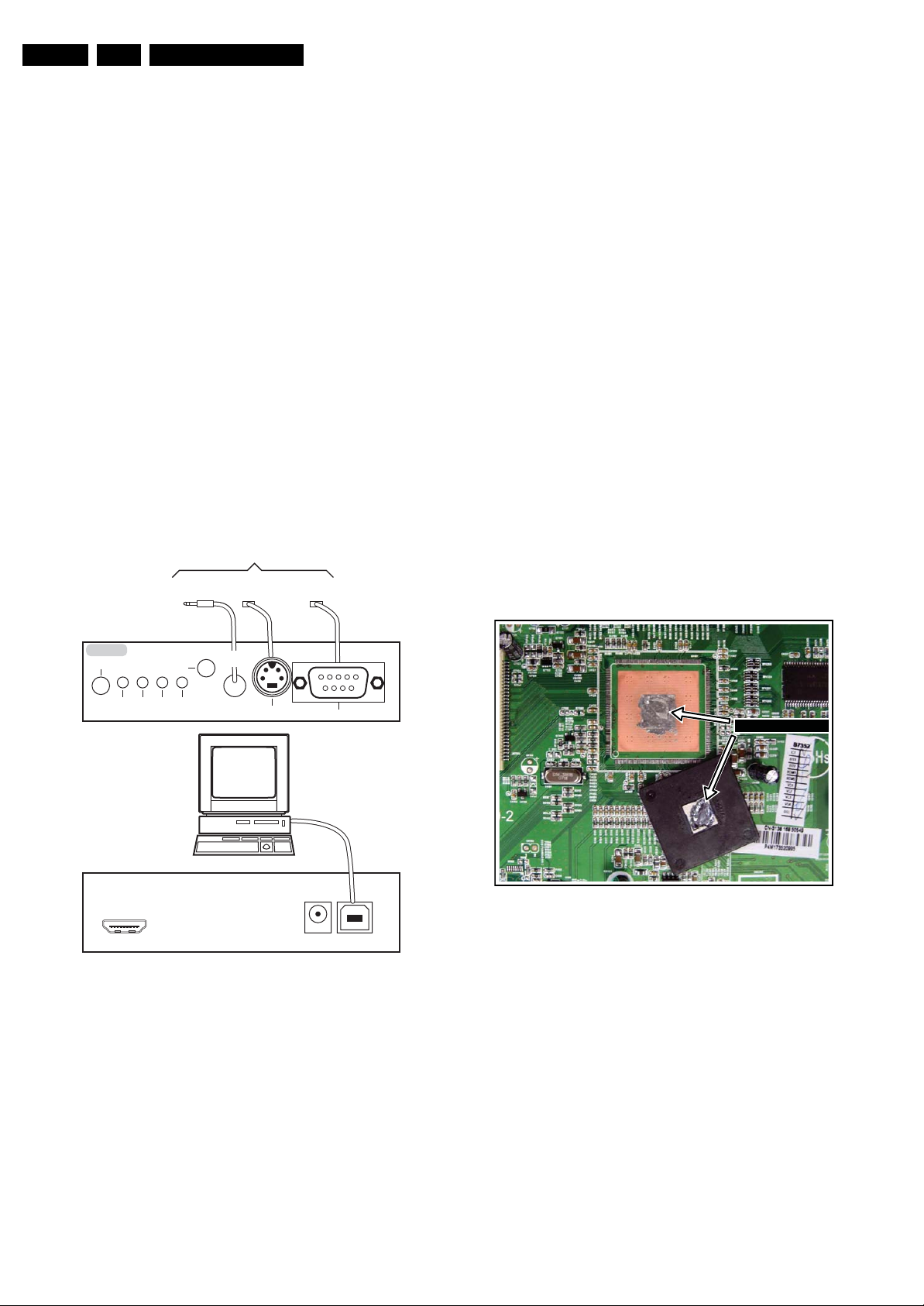

Figure 5-2 Factory mode menu 1 (19PFL3403/987& 19HFL3330/97)

Page 11

Contents of CSM

Service Modes, Error Codes, and Fault Finding

EN 11TPS1.2A LA 5.

Figure 5-4 CSM Menu (19PFL3403/93)

Figure 5-5 CSM Menu (19HFL3330/97)

I_17590_018.eps

260508

I_17591_006.eps

240608

I_17591_007.eps

240608

Figure 5-6 CSM Menu (19PFL3403/98)

Menu Explanation

1. Set Type: Type number and region.

2. Production code: Product serial no.

3. SW main-processor: SW-naming of Mstar/Trident.

4. SW other-processor: SW-naming of MCU.

5. Code 1: Logging I2C error codes in NVM/EEPROM (5 last

logged errors).

6. Code 2: Logging I2C error codes in NVM/EEPROM (5 first

logged errors).

For the error codes, please refer to the table below.

Error Code Error Code Type

0x01 Audio decoder error

0x02 I2C bus error

0x03 Tuner error

0x04 NVRAM error

0x05 Scaler chip error

7. Key (HDCP): Indicates if the HDCP-key is valid.

8. NVM-Naming: Indicates the used LCD panel type and

region (NVM content and main SW depend on the used

LCD panel).

How to exit

Press ”MENU” on the RC-transmitter.

Page 12

EN 12 TPS1.2A LA5.

Service Modes, Error Codes, and Fault Finding

5.3 Service Tools

5.3.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. And offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software upgrade possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

a USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

How to Connect

This is described in the ComPair chassis fault finding database.

TO

UART SERVICE

CONNECTOR

2

C or UART commands

TO TV

TO

I2C SERVICE

CONNECTOR

TO

UART SERVICE

CONNECTOR

5.3.2 LVDS Tool

Support of the LVDS Tool has been discontinued.

5.4 Tips and Tricks

Below find some repair tips and tricks.

5.4.1 Soft Reset

When a consumer has forgotten his lock code, you can set the

TV back in Virgin mode by keying in the code”978450” via the

standard RC transmitter. The NVM is not erased.

The standard unlock code will then be “0711”.

5.4.2 Hard Reset (erase NVRAM)

A hard reset is executed by together pressing the “P+” and “V+”

buttons on the TV, while unplugging and replugging the mains

cord.

Note: By using this hard reset mode, the TV will be brought

back in Virgin mode, but also all TV settings will be erased!

TV must completely be re-aligned via the “Factory” mode.

5.4.3 Removal of Morning Star Microprocessor

The Morning Star uP is fitted with a so-called E-pad (see photo

below). This is an extra surface for cooling and grounding. This

E-pad is soldered to the PWB.

To remove/place this IC on the PWB, use dedicated

equipment.

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

RC out

Multi

function

2

C

I

RS232 /UART

PC

ComPair II Developed by Philips Brugge

Optional power

HDMI

2

C only

I

5V DC

E_06532_036.eps

150208

Figure 5-7 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

Soldered E-Pad

I_17620_046.eps

Figure 5-8 E-pad (photo from TPS1.0 chassis)

280308

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• For SW see Philips service website.

• ComPair UART interface cable: 3122 785 90630.

Note: If you encounter any problems, contact your local

support desk.

Page 13

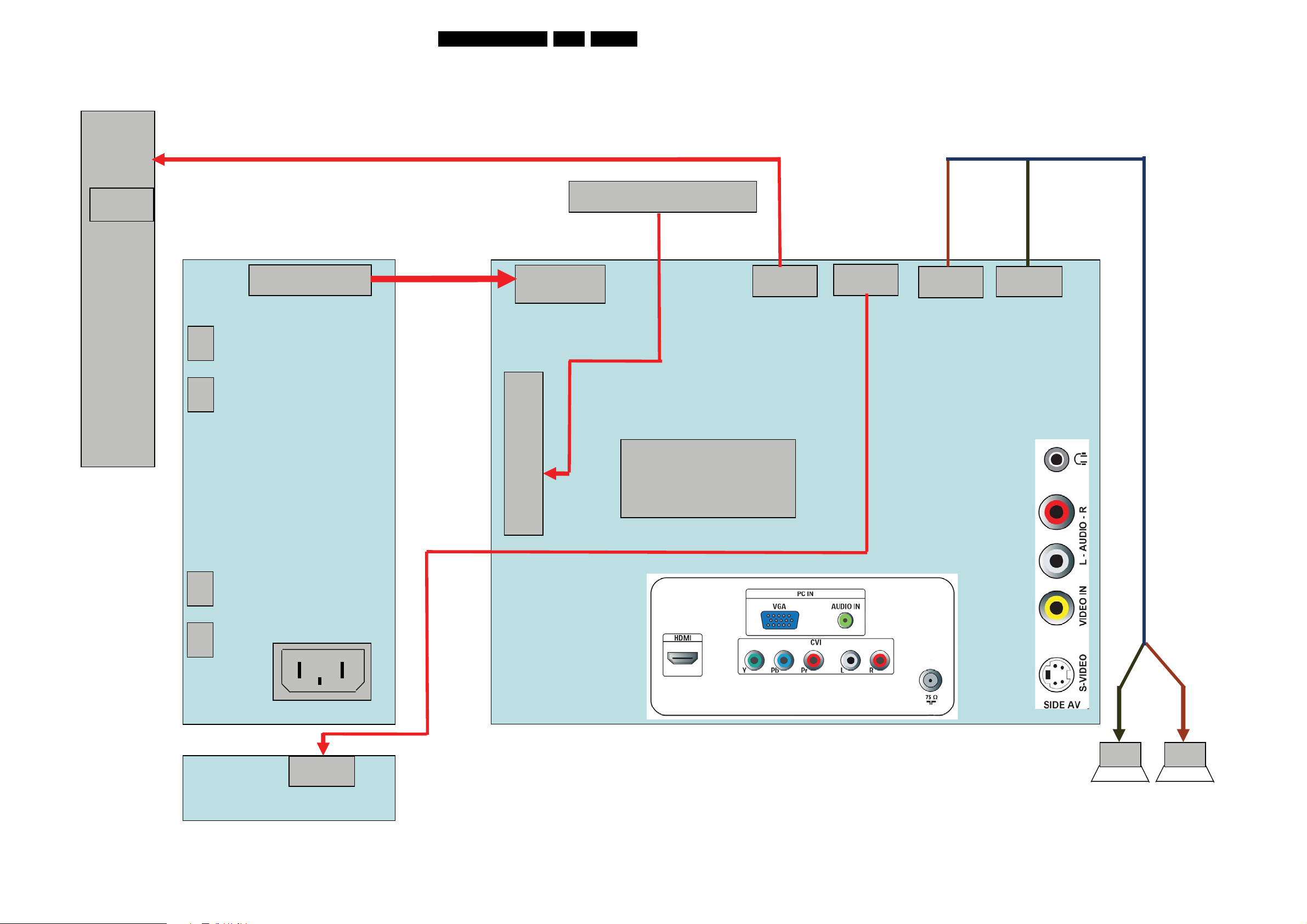

Block Diagrams, Test Point Overview, and Waveforms

6. Block Diagrams, Test Point Overview, and Waveforms

Wiring Diagram

13TPS1.2A LA 6.

Key

Board

4 Pin

CN0101

095T8013 2X912

4

095T8014 4X912

095T8013 2X911

Panel

1

CN7302

12 Pin

1

CN902

CN825

CN824

Power Board

12

11

CN7502

11 Pin

CN7201

30

30 Pin

1

089T179E30C921

MST98980CLD-LF

FFC Cable

U4201

4 Pin

4

CN7301

1

7 Pin

7

2 Pin 2Pin

1

2121

CN6101

CN6102

HEADPHONE

CN823

CN821

IR Board

AC IN

CN901

1

5 Pin

CN0201

1

AUDIO R/L

095T8014 7X909

VIDEO

S-VIDEO

5

Speaker R/L

I_17591_001.eps

230608

Page 14

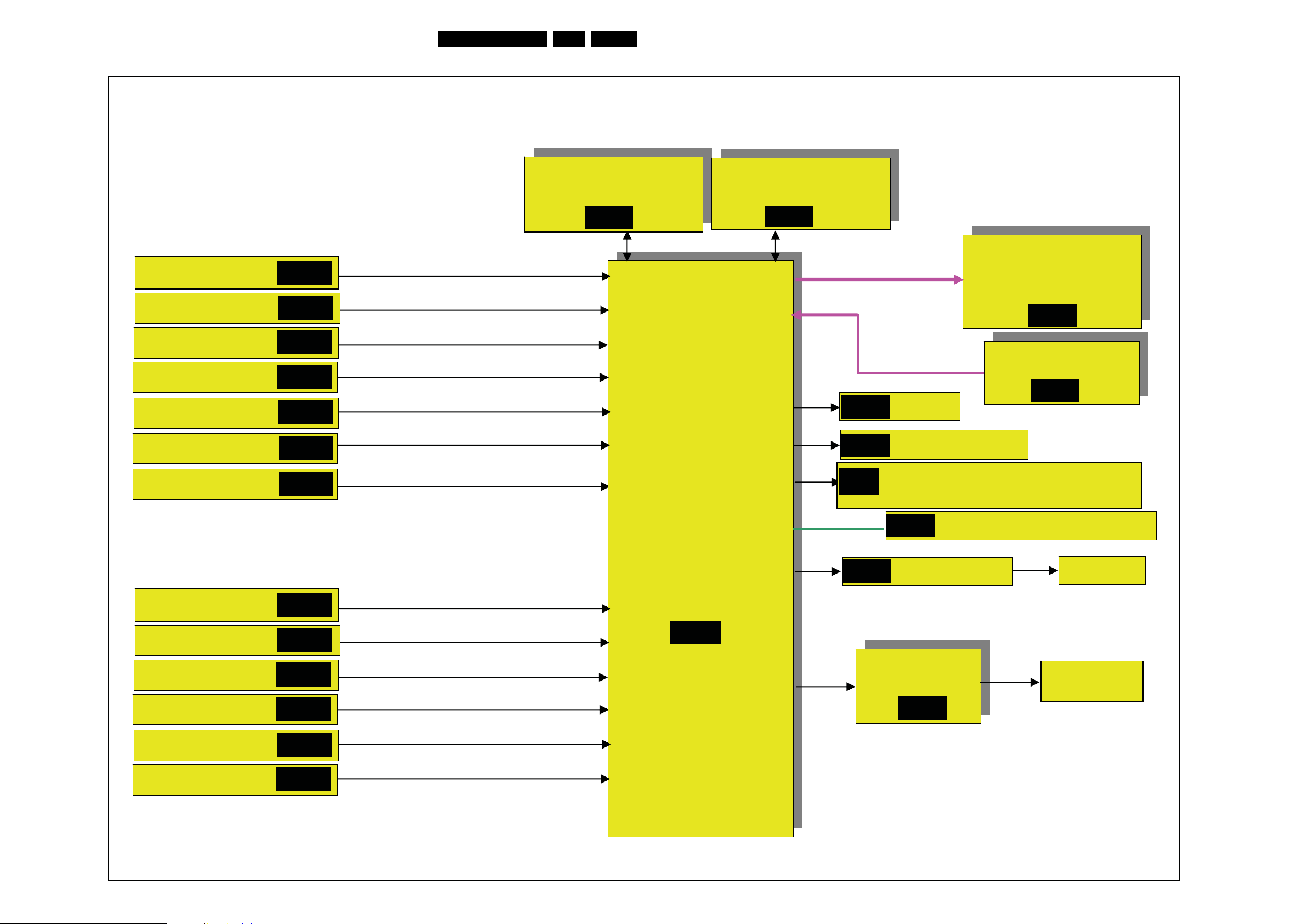

Block Diagrams, Test Point Overview, and Waveforms

Block Diagram Scaler Board

PHILIPS 19W Block Diagram

14TPS1.2A LA 6.

Video Block

Tuner PACK

CVI

S_VIDEO

VGA

HDMI

MAIN_AV_CVBS

SIDE _AV_CVBS

SB-03

SB-04

SB-05

SB-06

SB-07

SB-04

SB-05

Tuner_CVBS

YPbPr

Y/C

PC(R,G,B&H,V)

WT6702F_S240

(Sub MCU)

SB-09

MST98980CLD

MST98980CLD

HY57V641620FTP-6-C

(SDRAM)

SB-11

SB-12

SB-12

SB-11

2

I

C BUS

LVDS to panel

M190PW01 V000

CTOC AUO

SB-14

Inverter Power

SB-02

KEY/IR

IR Receiver LED

Flash /93 :MX25L4005AM2C-12G

/98:MX25L8005M2I-15G

SB-10 EEPROM M24C32-WMN6TP

Audio Block

Tuner_SIF

CVI L/R

MAIN AV

PC AUDIO

HDMI

SIDE AV

SB-03

SB-04

SB-04

SB-15

SB-07

SB-05

TV

TV

CONTROLLER

CONTROLLER

SB-10

SB-16

EARPHONE AMP

TDA7491LP13TR

SB-16

Headphone

speakers

I_17591_002.eps

230608

Page 15

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

15TPS1.2A LA 7.

Scaler Board: DC-DC Power

1

2

3

4

5

6

7

8

9

10

11

DC-DC POWER

SB01

A

B B

C C

D

E

F F

+

+

5V_PWR_SWSB09

5V_PWR_SW1SB10

+5V_STBY

12V_PWR_SWSB9,10

C7101

C7101

47uF 25V

47uF 25V

2

2

R7127

R7127

47K(NC)

47K(NC)

2

C7102

C7102

0.1uF

0.1uF

+5V_STBY

1 3

+5V_SW

1 3

+5V_SW

1 3

C7103

C7103

0.1uF

0.1uF

R7123

R7123

47K

47K

R71241KR7124

1K

Q7101

Q7101

MUN2211T

MUN2211T

R7125

R7125

47K

47K

R71261KR7126

1K

Q7103

Q7103

MUN2211T

MUN2211T

R7136

R7136

47K(NC)

47K(NC)

R7128

R7128

1K(NC)

1K(NC)

Q7105

Q7105

MUN2211T(NC)

MUN2211T(NC)

R7102

R7102

56K

56K

2

R7105

R7105

56K

56K

2

R7108

R7108

56K(NC)

56K(NC)

2

U7101

U7101

AIC1550POTR

AIC1550POTR

1

VIN

2

BP

3

SHDN

4

FB

R7103

R7103

3

Q7109

Q7109

BC847C

BC847C

1

R7106

R7106

3

Q7110

Q7110

BC847C

BC847C

1

R7109

R7109

100K(NC)

100K(NC)

3

Q7111

Q7111

BC847C(NC)

BC847C(NC)

1

56K

56K

100K

100K

MODE/

MODE/

SYNC

+5V_STBY

+5V_STBY

+12V_STBY

8

LX

7

GND

6

5

RT

+

+

C7107

C7107

100UF 25V

100UF 25V

Q7102

Q7102

1

S

2

S

3

S

4

G

SI4835BDY

SI4835BDY

C7106

C7106

100N 50V

100N 50V

+

+

C7110

C7110

100UF 25V

100UF 25V

Q7104

Q7104

1

S

2

S

3

S

4

G

SI4835BDY

SI4835BDY

C7109

C7109

220N 25V

220N 25V

+

+

C7113

C7113

100UF 25V(NC)

100UF 25V(NC)

Q7106

Q7106

1

S

2

S

3

S

4

G

SI4835BDY(NC)

SI4835BDY(NC)

C7112

C7112

220N 25V(NC)

220N 25V(NC)

D

D

D

D

D

D

D

D

D

D

D

D

ZD7102

ZD7102

SSA34-E3(NC)

SSA34-E3(NC)

1 2

1 2

8

7

6

1 2

5

1 2

8

7

6

1

5

1

8

7

6

5

1 2

L7102

L7102

6.8uH

6.8uH

FB7101

FB7101

120R(NC)

120R(NC)

FB7102

FB7102

120R

120R

FB7103

FB7103

120R(NC)

120R(NC)

FB7104

FB7104

120R

120R

FB7105

FB7105

120R(NC)

120R(NC)

FB7106

FB7106

120R(NC)

120R(NC)

R7101

R7101

0R05

C7137

C7137

4.7UF

4.7UF

0R05

+

+

C7138

C7138

47UF 25V

47UF 25V

+5V_SW1

+5V_SW

R7134

R7134

560K 1%

560K 1%

R7135

R7135

162K 1%

162K 1%

R7104

R7104

10K

10K

2

R7107

R7107

10K

10K

2

R7110

R7110

10K(NC)

10K(NC)

+5V_SW

+5V_SW1

+12V_SW

C7104

C7104

33P

33P

+3V3_STBY+5V_STBY

C7139

C7139

0.1uF

0.1uF

R7111

R7111

0R(NC)

0R(NC)

D7102

D7102

+5V_SW +3V3_SW

R7132

R7132

0R05

0R05

R7114

R7114

0R(NC)

0R(NC)

D7103

D7103

1

K

A

S1D-E3

S1D-E3

SB10

PANEL_PWR

2

A1K

S1D-E3

S1D-E3

C7114

C7114

100N

100N

+

+

C7118

C7118

C7119

C7119

47uF 25V

47uF 25V

0.1uF

0.1uF

U7104

U7104

AME8815AEGT330Z

+

+

C7126

C7126

10uF 50V

10uF 50V

R7129

R7129

47K

47K

Q7107

Q7107

MUN2211T

MUN2211T

1 3

AME8815AEGT330Z

1

R71301KR7130

1K

2

C7125

C7125

0.1uF

0.1uF

+5V_SW

2

U7102

U7102

AME8815AEGT330Z

AME8815AEGT330Z

1

+

+

C7115

C7115

10UF/50V

10UF/50V

C7120

C7120

0.1uF

0.1uF

3

VOUT

VIN

GND

TH

2

4

R7121

R7121

56K

56K

R7133

R7133

0R05

0R05

3

Q7112

Q7112

2

BC847C

BC847C

1

VIN

U7103

U7103

AIC1550POTR

AIC1550POTR

1

VIN

2

BP

3

SHDN

4

FB

R7122

R7122

75K

75K

VOUT

GND

2

C7127

C7127

0.1uF

0.1uF

TH

4

3

MODE/

MODE/

GND

SYNC

+

+

C7128

C7128

100uF 10V

100uF 10V

C7133

C7133

0.1u 25V

0.1u 25V

C7116

C7116

100N

100N

LX

RT

+3V3

+12V_STBY

8

7

6

5

+5V_SW1

12

4

3

2

1

FB7107

FB7107

120R(NC)

120R(NC)

Q7108

Q7108

SI5441DC

SI5441DC

+

+

C7117

C7117

100uF 10V

100uF 10V

ZD7101

ZD7101

SSA34-E3(NC)

SSA34-E3(NC)

1 2

S

G

D

D

D

D

D

D

L7101

L7101

15uH

15uH

+5V_STBY

12

5

6

7

8

C7129

C7129

0.1uF(NC)

0.1uF(NC)

FB7108

FB7108

120R

120R

C7134

C7134

0.1uF

0.1uF

R7112

R7112

560K 1%

560K 1%

R7113

R7113

820K 1%

820K 1%

+

+

C7130

C7130

10uF 50V(NC)

10uF 50V(NC)

C7121

C7121

68P

68P

U7105

U7105

AME1117ACGTZ(NC)

AME1117ACGTZ(NC)

3

VIN

VOUT

1

R7137

R7137

0R05(NC)

0R05(NC)

+

+

C7135

C7135

R7131

R7131

10uF 50V

10uF 50V

10K

10K

C7122

C7122

4.7UF

4.7UF

2

4

TH

ADJ

R7115

R7115

100R 1%(NC)

100R 1%(NC)

R7116

R7116

110R 1%(NC)

110R 1%(NC)

+

+

C7123

C7123

100UF/25V

100UF/25V

FB7109

FB7109

1 2

120R

120R

C7136

C7136

0.1uF

0.1uF

C7124

C7124

0.1uF

0.1uF

C7131

C7131

0.1uF(NC)

0.1uF(NC)

PANEL_VCC

+1V2

+2V6

+

+

C7132

C7132

100uF 10V(NC)

100uF 10V(NC)

SB01

A

D

E

C7101 A1

C7102 A2

C7103 A2

C7104 A4

C7106 C3

C7107 B3

C7109 D3

C7110 C3

C7112 F3

C7113 E3

C7114 B6

C7115 B6

C7116 B7

C7117 B7

C7118 C5

C7119 C6

C7120 C6

C7121 C8

C7122 C8

C7123 C9

C7124 C9

C7125 D5

C7126 D6

C7127 D6

C7128 D7

C7129 D7

C7130 D8

C7131 D9

C7132 D9

C7133 F7

C7134 E8

C7135 F8

C7136 F8

C7137 A4

C7138 A4

C7139 A5

D7102 B5

D7103 D5

FB7101 B3

FB7102 B3

FB7103 D3

FB7104 D3

FB7105 E3

FB7106 F3

FB7107 E7

FB7108 E7

FB7109 F9

L7101 C7

L7102 A3

Q7101 C2

Q7102 B3

Q7103 D2

Q7104 D3

Q7105 F2

Q7106 F3

Q7107 F5

Q7108 F7

Q7109 C2

Q7110 D2

Q7111 F2

Q7112 F6

R7101 A5

R7102 B2

R7103 B2

R7104 C3

R7105 D2

R7106 D2

R7107 D3

R7108 F2

R7109 F2

R7110 F3

R7111 B5

R7112 C8

R7113 C8

R7114 D5

R7115 D8

R7116 D8

R7121 F6

R7122 F6

R7123 B2

R7124 C2

R7125 D2

R7126 D2

R7127 F1

R7128 F2

R7129 F6

R7130 F6

R7131 F8

R7132 C5

R7133 F6

R7134 A4

R7135 A4

R7136 F2

R7137 F8

U7101 A2

U7102 B6

U7103 C6

U7104 D6

U7105 D8

ZD7101 C7

ZD7102 A3

G G

H H

I_17590_021.eps

1

2

3

4

5

6

7

8

9

10

260508

11

Page 16

Circuit Diagrams and PWB Layouts

16TPS1.2A LA 7.

Scaler Board: PS & Inverter I/F

1

PS & INVERTER I/F

SB02 SB02

A A

R7205

BL_ADJSB10

B

BL_ENSB10

R7205

R7209

R7209

2

R7201

R7201

4K7(NC)

4K7(NC)

10K

10K

10K

10K

+3V3

2

R7215

R7215

4K7

4K7

2

C7203

C7203

1U(NC)

1U(NC)

+5V_SW1

R7202

R7202

4K7

4K7

3

Q7201

Q7201

BC847C

BC847C

1

+5V_SW1

R7206

R7206

10K

10K

3

Q7202

Q7202

BC847C

BC847C

1

R7203

R7203

R7208

R7208

0R05

0R05

100R

100R

3

R7204

R7204

C7201

C7201

1U(NC)

1U(NC)

INVERTER_ON_OFF

C7204

C7204

0.1uF

0.1uF

10R

10R

C7202

C7202

0.1uF(NC)

0.1uF(NC)

BRIGHT_ADJ

4

5

6

7

8

CN7201 C1

C7201 A3

C7202 A3

C7203 B2

C7204 B3

C7205 C3

C7206 D2

C7207 D3

C7208 D3

C7209 D2

C7210 D3

C7211 D3

FB7201 C2

FB7202 C2

FB7203 C2

FB7204 D2

FB7205 D2

FB7206 D2

Q7201 A2

Q7202 B2

R7201 A2

R7202 A2

R7203 A3

R7204 A3

R7205 A2

R7206 B2

R7208 B3

R7209 B2

B

R7210 C3

R7211 C3

R7212 C3

R7213 C3

R7214 C3

R7215 A2

R7216 D3

R7210

C C

For PS

CN7201

CN7201

1

2

3

4

5

6

7

8

D D

63391 11P 2.0MM

63391 11P 2.0MM

E

9

10

11

1 2

FB7201

FB7201

1 2

FB7202

FB7202

1

FB7203

FB7203

FB7204

FB7204

1

120R

120R

C7206

C7206

0.1uF

0.1uF

FB7205

FB7205

1

120R

120R

C7209

C7209

0.1uF

0.1uF

FB7206

FB7206

1 2

120R

120R

120R

120R

120R

120R

120R

120R

2

R7214

R7214

0R(NC)

0R(NC)

2

2

C7207

C7207

0.1uF

0.1uF

C7210

C7210

0.1uF

0.1uF

R7216

R7216

R7212

R7212

47K

47K

C7208

C7208

+

+

470uF 25V

470uF 25V

C7211

C7211

+

+

470uF 25V

470uF 25V

47R

47R

R7210

R7211

R7211

R7213

R7213

C7205

C7205

0.1uF

0.1uF

+5V_STBY

+12V_STBY

STANDBY SB09

47R

47R

47R

47R

47R

47R

PANEL_ID SB10

INVERTER_ON_OFF

BRIGHT_ADJ

E

I_17590_022.eps

1

2

3

4

5

6

7

8

260508

Page 17

Circuit Diagrams and PWB Layouts

17TPS1.2A LA 7.

Scaler Board: Tuner

1

2

3

4

5

6

7

8

TUNER

SB03 SB03

1234567

A A

ANT IN

ANT IN

+5V3SCL4SDA

N.C.

N.C.

2

1

B B

TH121TH2

NC1NC2+B3NC4AGC5TP(TU)6NC7GND8SDA9SCL10AS11NC12VIDEO OUT13AFT14AUDIO OUT15SIF OUT16NC17NC18NC19NC

100P

100P

47R

47R

47R

47R

C1103

C1103

22

C1102

C1102

0.1uF

0.1uF

+

+

C1101

C1101

2U2 50V

2U2 50V

C1104

C1104

100P

100P

C C

R1101

I2C_SDASB09,10,13

I2C_SCLSB09,10,13

D D

E

R1101

R1102

R1102

AS_TU

6

5

R1104

R1104

0R(NC)

0R(NC)

CN1101

CN1101

63388 8P 2.0MM(NC)

63388 8P 2.0MM(NC)

8

AS_IF102ND IF SOUND

NC

9

R11030RR1103

0R

CVBS

11

12

20

C1105

C1105

330N 16V

330N 16V

L1101

L1101

22uH(NC)

22uH(NC)

FB1101

FB1101

1 2

120R

120R

+

+

C1106

C1106

1000uF 16V

1000uF 16V

R11050RR1105

NC

NC

+5V,IF

13

TU1101

TU1101

TH323TH4

TUNER TAFT-Z017D

TUNER TAFT-Z017D

24

2

0R

TU1102

TU1102

AF O/P

14

+5V_SW1

C1107

C1107

0.1uF

0.1uF

TH1

TH2

TH3

TH4

3

1

15

16

17

18

R1116

R1116

C1109

C1109

+

+

10uF 50V

10uF 50V

R1117

R1117

C1110

C1110

+

+

10uF 50V(NC)

10uF 50V(NC)

R1106

R1106

10K(NC)

10K(NC)

Q1101

Q1101

BC847C(NC)

BC847C(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

TV_CVBS

R1108

R1108

75R 1%

75R 1%

TV_SIF

Mono

R1115

R1115

C1108

C1108

470uF 10V

470uF 10V

R1118

R1118

75R 1%(NC)

75R 1%(NC)

R1110

R1110

2K2(NC)

2K2(NC)

10K(NC)

10K(NC)

TU1101

TU1102

+

+

0R(NC)

0R(NC)

100K(NC)

100K(NC)

R1114

R1114

R1113

R1113

C1101

Ye s

NC

C1114

C1114

22P

22P

C1105

Ye s

NC

1 2

FB110230RFB110230R

C1111

C1111

330P(NC)

330P(NC)

C1118

C1118

100P(NC)

100P(NC)

C1108

Ye s

NC

C1109

Ye s

NC

C1112

C1112

330P(NC)

330P(NC)

R1116

NC

Ye s

R1118

NC

Ye s

R1109

R1109

R11110RR1111

R11120RR1112

47R

47R

0R

0R

C1117

C1117

C1113

C1113

C1115

C1115

C1116

C1116

0.1uF(NC)

0.1uF(NC)

47N

47N

0.1uF

0.1uF

0.1uF

0.1uF

TUNER_CVBS SB10

SIFP0 SB10

SIFM0 SB10

AUMONO SB10

E

CN1101 A2

C1101 C2

C1102 D2

C1103 D2

C1104 D2

C1105 C3

C1106 D3

C1107 D3

C1108 C5

C1109 D4

C1110 D4

C1111 C5

C1112 C6

C1113 C6

C1114 D5

C1115 D6

C1116 D6

C1117 D6

C1118 D5

FB1101 D3

FB1102 C5

L1101 D3

Q1101 E3

R1101 C1

R1102 C1

R1103 D2

R1104 D2

R1105 E3

R1106 D3

R1107 E3

R1108 C4

R1109 C6

R1110 D4

R1111 D6

R1112 D6

R1113 D5

R1114 C5

R1115 D4

R1116 C4

R1117 D4

R1118 C5

TU1101 B1

TU1102 A1

R1107

R1107

10K(NC)

10K(NC)

I_17590_023.eps

1

2

3

4

5

6

7

8

260508

Page 18

Circuit Diagrams and PWB Layouts

18TPS1.2A LA 7.

Scaler Board: Video Input 1

1

SB04 SB04

A

VIDEO INPUT 1

2

3

4

5

6

7

8

9

10

11

For MM/DVB-T Module IN

CN1201

CN1201

B

63387 7P 2.0MM(NC)

C C

D D

63387 7P 2.0MM(NC)

1

2

3

4

5

6

7

CN1202

CN1202

RCA JACK 1x3V GBR

RCA JACK 1x3V GBR

2

1

4

3

6

5

R_PR2

G_Y2

B_PB2

75R 1%(NC)

75R 1%(NC)

AV_AU_INL

AV_AU_INR

PR1

Y1

PB1

75R 1%

75R 1%

R1201

R1201

R1208

R1208

1

FB1201

FB1201

1

FB1204

FB1204

30R(NC)

30R(NC)

C1201

C1201

10P(NC)

10P(NC)

C1208

C1208

10P(NC)

10P(NC)

2

R1202

R1202

75R 1%(NC)

75R 1%(NC)

2

30R

30R

R1209

R1209

75R 1%

75R 1%

1

FB1202

FB1202

C1202

C1202

10P(NC)

10P(NC)

1 2

FB1205

FB1205

C1209

C1209

10P(NC)

10P(NC)

30R(NC)

30R(NC)

75R 1%(NC)

75R 1%(NC)

2

R1203

R1203

30R

30R

R1210

R1210

75R 1%

75R 1%

1 2

FB1203

30R(NC)

FB1203

30R(NC)

C1203

C1203

10P(NC)

10P(NC)

1 2

FB1206

FB1206

C1210

C1210

10P(NC)

10P(NC)

30R

30R

R1204

R1204

R1205

R1205

R1206

R1206

R1207

R1207

R1211

R1211

R1212

R1212

R1213

R1213

R1214

R1214

47R(NC)

47R(NC)

47R(NC)

47R(NC)

47R(NC)

47R(NC)

470R(NC)

470R(NC)

47R

47R

47R

47R

47R

47R

470R

470R

C1204 47N(NC)C1204 47N(NC)

C1205 47N(NC)C1205 47N(NC)

C1206 47N(NC)C1206 47N(NC)

C1207 1N(NC)C1207 1N(NC)

C1211

C1211

C1212 47NC1212 47N

C1213 47NC1213 47N

C12141NC1214

47N

47N

1N

PR2+

Y2+

PB2+

SOY2

PR1+

Y1+

PB1+

SOY1

PR2+ SB10

Y2+ SB10

PB2+ SB10

SOY2 SB10

PR1+ SB10

Y1+ SB10

PB1+ SB10

SOY1 SB10

CN1201 A1

CN1202 C1

CN1203 D1

C1201 B2

C1202 B3

C1203 B4

A

C1204 A5

C1205 B5

C1206 B5

C1207 B5

C1208 C2

C1209 C3

C1210 C4

C1211 C5

C1212 C5

C1213 C5

C1214 C5

C1218 D5

B

C1219 D6

C1220 D7

C1222 D2

C1223 D3

C1224 D4

D1205 D5

D1206 D6

D1207 D6

D1208 D7

FB1201 A2

FB1202 A3

FB1203 B4

FB1204 C2

FB1205 C3

FB1206 C4

FB1207 D2

R1201 B2

R1202 B3

R1203 B3

R1204 A4

R1205 B4

R1206 B4

R1207 B4

R1208 C2

R1209 C3

R1210 C3

R1211 C4

R1212 C4

R1213 C4

R1214 C4

R1216 D2

R1217 D3

E E

+3V3_ESD

CN1203

CN1203

RCA JACK 1x3V YWR(NC)

F F

G G

H H

RCA JACK 1x3V YWR(NC)

1

2

1

4

3

6

5

MAIN_AV_CVBS

75R 1%(NC)

75R 1%(NC)

AV_AU_INL

AV_AU_INR

2

R1216

R1216

1 2

FB1207

FB1207

30R(NC)

30R(NC)

C1222

C1222

330P(NC)

330P(NC)

AV_AU_INL SB15

AV_AU_INR SB15

3

R1217

R1217

C1223

C1223

330P(NC)

330P(NC)

47R(NC)

47R(NC)

4

C1224 47N(NC)C1224 47N(NC)

5

AV_CVBS1 SB10

6

D1205

D1205

PR1

3

BAV99(NC)

BAV99(NC)

D1208

9

D1208

3

BAV99(NC)

BAV99(NC)

2

C1220

C1220

0.1uF(NC)

0.1uF(NC)

1

I_17590_024.eps

10

260508

11

D1206

2

C1218

C1218

0.1uF(NC)

0.1uF(NC)

1

7

D1206

Y1 PB1

3

BAV99(NC)

BAV99(NC)

BAS32L(NC)

BAS32L(NC)

8

D1207

D1207

2

C1219

C1219

0.1uF(NC)

0.1uF(NC)

1

2

K

A

1

Page 19

Circuit Diagrams and PWB Layouts

19TPS1.2A LA 7.

Scaler Board: Video Input 2 (Side AV)

SIDE_SV_Y0

11

SIDE_SV_C0

SIDE_AV_CVBS

2

SIDE_AU_INL

SIDE_AU_INR

R1301

R1301

75R 1%

75R 1%

R1303

R1303

75R 1%

75R 1%

R1305

R1305

75R 1%

75R 1%

1 2

FB1301

FB1301

C1301

C1301

330P(NC)

330P(NC)

1 2

FB1302

FB1302

C1304

C1304

330P(NC)

330P(NC)

1 2

FB1303

FB1303

C1307

C1307

330P(NC)

330P(NC)

SIDE_AU_INL SB15

SIDE_AU_INR SB15

1

SB05

A

B

C C

VIDEO INPUT 2 (SIDE AV)

CN1301A

CN1301A

SJACK+RCA1X3H

SJACK+RCA1X3H

12

7 8

CY

CY

9 10

GG

GG

13

CN1301B

CN1301B

SJACK+RCA1X3H

SJACK+RCA1X3H

2

1

4

3

6

5

30R

30R

30R

30R

30R

30R

3

R1302

R1302

C1302

C1302

330P(NC)

330P(NC)

R1304

R1304

C1305

C1305

330P(NC)

330P(NC)

R1306

R1306

C1308

C1308

330P(NC)

330P(NC)

47R

47R

47R

47R

47R

47R

C1303

C1303

C1306 47NC1306 47N

C1309

C1309

47N

47N

47N

47N

4

SV_Y0 SB10

SV_C0 SB10

AV_CVBS0 SB10

5

CN1302

CN1302

1

2

3

4

5

6

7

8

9

10

63390 10P 2.0MM(NC)

63390 10P 2.0MM(NC)

CN1303

CN1303

2SJ1508-001111

2SJ1508-001111

HP_DET_IN

5

4

3

2

7

8

1

R1307

R1307

SIDE_AV_CVBS

SIDE_SV_C0

SIDE_SV_Y0

SIDE_AU_INL

SIDE_AU_INR

HPL

HPR

C1311

C1311

6N8

6N8

100R

100R

HPL SB16

HPR SB16

1 2

FB1304

FB1304

1 2

FB1305

FB1305

C1312

C1312

6N8

6N8

6

C1310

C1310

100P(NC)

100P(NC)

120R

120R

120R

120R

HP_DET SB10

HP_DET_IN

HPR

HPL

7

8

SB05

N1301A A1

N1301B C1

CN1302 B5

CN1303 C5

C1301 B2

C1302 B3

C1303 B4

C1304 B2

C1305 B3

C1306 B4

A

C1307 C2

C1308 C3

C1309 C4

C1310 B6

C1311 C5

C1312 C6

FB1301 B3

FB1302 B3

FB1303 C3

FB1304 C6

FB1305 C6

R1301 B2

R1302 B3

R1303 B2

R1304 B3

R1305 C2

R1306 C3

R1

B

307 A6

D D

E

I_17590_025.eps

1

2

3

4

5

6

7

8

260508

E

Page 20

Circuit Diagrams and PWB Layouts

Scaler Board: D-Sub Input

1

20TPS1.2A LA 7.

2

3

4

5

6

7

8

SB06

3

VGA5V

2

VGA_5V

C1403

C1403

33P(NC)

33P(NC)

DDCSCL

R1401

R1401

2K7

2K7

R1402

R1402

10R

10R

DDCSDA

HS

VS

R1403

R1403

2K7

2K7

R1404

R1404

10R

10R

R1405

R1405

10K

10K

DDC_DSUB_WP SB07

R1406

R1406

22K(NC)

22K(NC)

ISP_SDA SB12

ISP_SCL SB12

1716

11

12

13

14

15

+3V3_STBY

R1430

R1430

10K

10K

+3V3_ESD

D1402

D1402

R G

3

BAV99(NC)

BAV99(NC)

6

1

7

2

8

3

9

4

10

5

1 2

FB1401

120R

FB1401

120R

2

1

VGA5 V

C1410

C1410

0.1uF(NC)

0.1uF(NC)

R

G

B

R1423

R1423

75R 1%

75R 1%

D1403

D1403

3

BAV99(NC)

BAV99(NC)

FB1402

FB1402

R1424

R1424

75R 1%

75R 1%

2

C1411

C1411

0.1uF(NC)

0.1uF(NC)

1

1 2

FB1403

FB1403

1 2

FB1404

FB1404

R1425

R1425

75R 1%

75R 1%

30R

30R

1 2

B

30R

30R

30R

30R

D1404

D1404

3

BAV99(NC)

BAV99(NC)

R1426

R1426

R1427

R1427

R1428

R1428

R1429

R1429

2

C1412

C1412

0.1uF(NC)

0.1uF(NC)

1

47R

47R

C1406 47NC1406 47N

47R

47R

C1407 47NC1407 47N

47R

47R

C1408 47NC1408 47N

47R

47R

C1409 47NC1409 47N

+5V_SW+5V_STBY

A A

B

CN1402

CN1402

C

63132 2P 2.54mm(NC)

63132 2P 2.54mm(NC)

1

2

+3V3_STBY

R1407

R1407

10K(NC)

10K(NC)

2

3

1

Q1401 BC847C(NC)Q1401 BC847C(NC)

R1408

R1408

10K(NC)

10K(NC)

11

S1

10

S2

9

S3

6

E

PWR_ON_OFF SB09,10,12

R1409

R1409

16

14

1Z

VCC

12

1Y0

13

1Y1

2

2Y0

1

2Y1

5

3Y0

3

3Y1

U1402

2Z153Z4GND8VEE

U1402

74LV4053PW(NC)

74LV4053PW(NC)

7

R1410

R1410

VGA_5V

R1411

R1411

R1412

R1412

R1413

R1413

R1414

R1414

47R(NC)

47R(NC)

C1404

C1404

0.1uF(NC)

0.1uF(NC)

47R(NC)

47R(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

0R(NC)

R1431

R1431

0R05

0R05

U1401

U1401

1

A0

2

A1

3

A2

GND4SDA

M24C02-WMN6TP

M24C02-WMN6TP

R14170RR1417

R14150RR1415

0R

0R

R14180RR1418

R14160RR1416

0R

0R

R1432

R1432

0R05(NC)

0R05(NC)

1

C1401

C1401

0.1uF

0.1uF

8

VCC

7

WP

6

SCL

5

C1402

C1402

33P(NC)

33P(NC)

ISP2_SDA SB10

ISP1_SDA SB09

ISP2_SCL SB10

ISP1_SCL SB09

D1401

D1401

BAT54C

BAT54C

SB06

CN1401 C4 CN1402 C1

C1401 A3 C1402 B3

C1403 B4 C1404 C2

C1405 D5 C1406 C8

C1407 C8 C1408 C8

C1409 C8 C1410 B6

C1411 B6 C1412 B7

D1401 A3 D1402 B5

D1403 B6 D1404 B7

FB1401 C5 FB1402 C6

FB1403 C7 FB1404 C7

Q1401 B1 R1401 B4

R1402 B4 R1403 B4

R1404 B4 R1405 B4

R1406 B4 R1407 B1

R1408 C1 R1409 C2

R1410 C2 R1411 C2

R1412 C2 R1413 C2

R1414 C2 R1415 C3

R1416 C3 R1417 C3

R1418 C3 R1419 D4

R1420 D4 R1421 D4

R1422 D4 R1423 C6

R1424 C6 R1425 C7

R1426 C7 R1427 C7

R1428 C7 R1429 C7

R1430 A6 R1431 A3

R1432 A3 U1401 B3

U1402 C1 ZD1401 D4

ZD1402 D4 ZD1403 D3

ZD1404 D4 ZD1405 D5

RIN+SB10

GIN+

BIN+

SOG

SB10

SB10

SB10

D-SUB INPUT

B

C

C1405

C1405

0.1uF

CN1401

CN1401

DSUB15-FEM

DSUB15-FEM

ZD1401

BZX84-C5V6

BZX84-C5V6

ZD1401

R1419

R1419

2K2

2K2

D

ZD1403

ZD1403

1 3

E E

1

2

3

ZD1402

ZD1402

1 3

BZX84-C5V6

BZX84-C5V6

ZD1404

ZD1404

1 3

4

1 3

BZX84-C5V6

BZX84-C5V6

BZX84-C5V6

BZX84-C5V6

R1421

R1421

R1422

R1422

R1420

R1420

2K2

2K2

100R

100R

100R

100R

HS_RGB SB09,10

VS_RGB SB09,10

ZD1405

ZD1405

5

0.1uF

1 3

BZX84-C5V6

BZX84-C5V6

I_17590_026.eps

6

7

8

260508

D

Page 21

Circuit Diagrams and PWB Layouts

21TPS1.2A LA 7.

Scaler Board: HDMI Input 1

1

2

HDMI INPUT 1

SB07

A A

B

HD_5V_A

C

D

C1505

C1505

0.1uF

0.1uF

CN1501

CN1501

20

TH1

21

TH2

22

TH3

23

TH4

24

TH5

CON-HDMI-V-19P

CON-HDMI-V-19P

U1501A

U1501A

TMDS_D2+_4

TMDS_D2+_35

1

5V

TMDS_D2-_33

TMDS_D1+_7

TMDS_D1+_32

TMDS_D1-_30

TMDS_D0+_10

TMDS_D0+_29

TMDS_D0-_12

TMDS_D0-_27

TMDS_CK+_13

TMDS_CK+_26

TMDS_CK-_15

TMDS_CK-_24

2

3.3V

38

NC

37

TMDS_BYP

CM2021-02TR

CM2021-02TR

D2+

D2 Shield

D2-

D1+

D1 Shield

D1-

D0+

D0 Shield

D0-

CK+

CK Shield

CK-

CE Remote

DDC CLK

DDC DATA

GND

+5V

HP DET

TMDS_D2-_6

TMDS_D1-_9

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

GND

GND

NC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

4

35

6

33

7

32

9

30

10

29

12

27

13

26

15

24

5

34

8

31

11

28

14

25

3

36

1RX2+

1RX21RX1+

1RX11RX0+

1RX01RXC+

1RXC-

DDC_1CLK_IN

DDC_1DAT_IN

HPD_1IN

1RX2+

1RX2-

1RX1+

1RX1-

1RX0+

1RX0-

1RXC+

1RXC-

CEC_1IN

R15041KR1504

SB07

SB06

R1502

R1502

R1503

R1503

1K

DDC_HDMI_WP

DDC_DSUB_WP

100R

100R

100R

100R

R1505

R1505

R1506

R1506

R1507

R1507

R1508

R1508

R1509

R1509

R1510

R1510

R1511

R1511

R1512

R1512

1

FB1501

FB1501

SB10

3

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2R2

2

120R

120R

ZD1501

ZD1501

DDC_HDMI_WP

HPD1

1 3

D1502

D1502

BAT54C

BAT54C

BZX84-C5V6

BZX84-C5V6

R_1TX2+ SB10

R_1TX2- SB10

G_1TX1+ SB10

G_1TX1- SB10

B_1TX0+ SB10

B_1TX0- SB10

TXCLK1+ SB10

TXCLK1- SB10

DDC_HDMI_WP

HD5V_A

C1501

C1501

0.1uF

0.1uF

2

3

1

R1518

R1518

2

4K7

4K7

+3V3_SW

2

3

Q1504

Q1504

BC847C

BC847C

3

Q1501

Q1501

BC847C

BC847C

1

R1514

R1514

4K7

4K7

C1503

C1503

22P(NC)

22P(NC)

R1527

R1527

47K

47K

R1519

R1519

47K

47K

4

+5V_SW

R1515

R1515

4K7

4K7

C1504

C1504

22P(NC)

22P(NC)

1

DDC_WP SB10

HD_5V_A

R1520

R1520

4K7

4K7

HD_5V_A

R1516

R1516

10K

10K

R1517

R1517

22K(NC)

22K(NC)

R1521

R1521

4K7

4K7

R1523

R1523

R1522

R1522

1

CECSB08

D1501

D1501

BAT54C

BAT54C

3

22R

22R

22R

22R

5

HD5V_A

2

R1513

R1513

100R(NC)

100R(NC)

C1502

C1502

0.1uF

0.1uF

U1502

8

7

6

5

U1502

VCC

WP

SCL

SDA

M24C02-WMN6TP

M24C02-WMN6TP

+5V_STBY

R1525

0R(NC)

R1525

0R(NC)

R1524

R1524

U1501B

U1501B

16

CEC_IN

17

SCL_IN

18

SDA_I N

HPDET_IN19HPDET_OUT

CM2021-02TR

CM2021-02TR

SCL_HD1 SB10

SDA_HD1 SB10

A0

A1

A2

GND

Q1502

Q1502

2N7002

2N7002

1

2

3

4

R1526

R1526

0R(NC)

0R(NC)

+5V_STBY

CEC_OUT

SCL_OUT

SDA_OUT

Q1503

Q1503

2N7002

2N7002

0R(NC)

0R(NC)

23

22

21

20

6

CEC_HDMI SB09,10

CEC_1IN

DDC_1CLK_IN

DDC_1DAT_IN

HPD_1IN

7

8

SB07

B

C

D

CN1501 A1

C1501 B3

C1502 A5

C1503 B4

C1504 B4

C1505 D1

D1501 A5

D1502 C3

FB1501 B3

Q1501 D4

Q1502 C5

Q1503 C5

Q1504 C4

R1502 B3

R1503 B3

R1504 B2

R1505 A3

R1506 A3

R1507 A3

R1508 A3

R1509 A3

R1510 A3

R1511 A3

R1512 A3

R1513 A5

R1514 A4

R1515 A4

R1516 A4

R1517 B4

R1518 D3

R1519 C4

R1520 C4

R1521 C4

R1522 D4

R1523 D4

R1524 C5

R1525 C5

R1526 C5

R1527 B4

U1501A B1

U1501B D5

U1502 A5

ZD1501 B3

E E

I_17590_027.eps

1

2

3

4

5

6

7

8

260508

Page 22

Circuit Diagrams and PWB Layouts

22TPS1.2A LA 7.

Scaler Board: HDMI Input 2 (n.c.)

1

2

3

4

5

6

7

8

HDMI INPUT 2 (n.c.)

SB08

A

CN1601

CN1601

2RX2+

1

D2+

D2-

D1+

D1-

D0+

D0-

CK+

CK-

NC

GND

+5V

HP DET

GND

GND

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

4

35

6

33

7

32

9

30

10

29

12

27

13

26

15

24

5

34

8

31

11

28

14

25

3

36

2RX22RX1+

2RX12RX0+

2RX02RXC+

2RXC-

DDC_2CLK_IN

DDC_2DAT_IN

HPD_2IN

2RX2+

2RX2-

2RX1+

2RX1-

2RX0+

2RX0-

2RXC+

2RXC-

CEC_2IN

R1604

R1604

R1603

R1603

D2 Shield

D1 Shield

D0 Shield

CK Shield

CE Remote

20

TH1

DDC CLK

DDC DATA

TH2

TH3

TH4

TH5

CON-HDMI-V-19P(NC)

CON-HDMI-V-19P(NC)

U1601A

U1601A

TMDS_D2+_4

TMDS_D2+_35

TMDS_D2-_6

5V

TMDS_D2-_33

TMDS_D1+_7

TMDS_D1+_32

TMDS_D1-_9

TMDS_D1-_30

TMDS_D0+_10

TMDS_D0+_29

TMDS_D0-_12

TMDS_D0-_27

TMDS_CK+_13

TMDS_CK+_26

TMDS_CK-_15

TMDS_CK-_24

3.3V

TMDS_GND

TMDS_GND

TMDS_GND

NC

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_GND

TMDS_BYP

CM2021-02TR(NC)

CM2021-02TR(NC)

HD_5V_B

C1605

C1605

0.1uF(NC)

0.1uF(NC)

21

22

23

24

1

2

38

37

B B

C C

D

R1602

R1602

1K(NC)

1K(NC)

R1605

R1605

R1606

R1606

R1607

R1607

R1608

R1608

R1609

R1609

R1610

R1610

R1611

R1611

R1612

R1612

100R(NC)

100R(NC)

100R(NC)

100R(NC)

1

FB1601

FB1601

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

2R2(NC)

120R(NC)

120R(NC)

SB10

SB07

2

HPD2

R_2TX2+ SB10

R_2TX2- SB10

G_2TX1+ SB10

G_2TX1- SB10

B_2TX0+ SB10

B_2TX0- SB10

TXCLK2+ SB10

TXCLK2- SB10

DDC_HDMI_WP

ZD1601

ZD1601

1 3

BZX84-C5V6(NC)

BZX84-C5V6(NC)

HD5V_B

C1601

C1601

0.1uF(NC)

0.1uF(NC)

R1618

R1618

4K7(NC)

4K7(NC)

R1614

R1614

4K7(NC)

4K7(NC)

C1603

C1603

22P(NC)

22P(NC)

R1619

R1619

47K(NC)

47K(NC)

3

Q1601

Q1601

2

BC847C(NC)

BC847C(NC)

1

+5V_SW

R1615

R1615

4K7(NC)

4K7(NC)

C1604

C1604

22P(NC)

22P(NC)

HD_5V_B

R1620

R1620

4K7(NC)

4K7(NC)

1

HD_5V_B

R1616

R1616

10K(NC)

10K(NC)

R1617

R1617

22K(NC)

22K(NC)

R1621

R1621

4K7(NC)

4K7(NC)

R1623

R1623

R1622

R1622

D1601

D1601

BAT54C(NC)

BAT54C(NC)

3

100R(NC)

100R(NC)

8

7

6

5

CECSB07

22R(NC)

22R(NC)

22R(NC)

22R(NC)

HD5V_B

2

R1613

R1613

C1602

C1602

0.1uF(NC)

0.1uF(NC)

U1602

U1602

VCC

WP

SCL

SDA

M24C02-WMN6TP(NC)

M24C02-WMN6TP(NC)

A0

A1

A2

GND

R1624

R1624

U1601B

U1601B

16

CEC_IN

17

SCL_IN

18

SDA_I N

HPDET_IN19HPDET_OUT

CM2021-02TR(NC)

CM2021-02TR(NC)

SCL_HD2 SB10

SDA_HD2 SB10

1

2

3

4

0R(NC)

0R(NC)

CEC_OUT

SCL_OUT

SDA_OUT

23

22

21

20

CEC_2IN

DDC_2CLK_IN

DDC_2DAT_IN

HPD_2IN

SB08

A

D

CN1601 A1

C1601 B4

C1602 B5

C1603 B4

C1604 B4

C1605 D1

D1601 A5

FB1601 B3

Q1601 C4

R1602 B3

R1603 B3

R1604 B3

R1605 A3

R1606 A3

R1607 A3

R1608 A3

R1609 A3

R1610 B3

R1611 B3

R1612 B3

R1613 A5

R1614 B4

R1615 B4

R1616 B5

R1617 B5

R1618 C4

R1619 C4

R1620 C4

R1621 C5

R1622 C5

R1623 C5

R1624 C5

U1601A C1

U1601B C5

U1602 B5

ZD1601 B3

E E

I_17590_028.eps

1

2

3

4

5

6

7

8

260508

Page 23

Circuit Diagrams and PWB Layouts

23TPS1.2A LA 7.

WT6702F (Standby MCU)

1

2

3

4

5

6

7

8

WT6702F (STANDBY MCU)

SB09

10K

10K

10K(NC)

10K(NC)

R4127

R4127

R4126

R4126

+3V3_STBY

10K

10K

R4128

R4128

+3V3_STBY

A

33K

33K

6K8

33K

33K

R4131

R4131

R4132

R4132

33K

33K

33K(NC)

33K(NC)

R4124

R4124

R4123

R4123

+3V3_STBY

6K8

R4133

R4133

10K(NC)

10K(NC)

R4125

R4125

10K

10K

33K

33K

R4130

R4130

R4129

R4129

KEY1SB10,12

STA ND B YSB02

5V_PWR_SW

SB01

SB10

SB06,10

SB10,13

SB06,12

RC_IR_3V3

CEC_IRQ

VS_RGB

HS_RGBSB06,10

12V_PWR_SWSB01,10

LED2_STBY

ISP1_SCLSB06,12

ISP1_SDA

I2C_SCLSB03,10,13

I2C_SDASB03,10,13

TXD1SB10,13

RXD1

C4105

C4105

22P

22P

C4106

C4106

100P

100P

10K

10K

R4121

R4121

10K

10K

R4122

R4122

SB10,12

B

SB10,12

C C

FB4101

FB4101

1 2

120R

120R

RESET

R4120

R4120

R4119

R4119

R4118

R4118

R4117

R4117

R4116

R4116

HD_CEC

R4115

R4115

R4114

R4114

R4113

R4113

R4112

R4112

R4111

R4111

R4110

R4110

R4109

R4109

R4108

R4108

R4107

R4107

R4106

R4106

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R

33R(NC)

33R(NC)

33R

33R

22R

22R

22R

22R

33R

33R

33R

33R

+3V3_STBY

R4141

R4141

0R05

0R05

C4101

C4101

10U 10V

10U 10V

4

22

21

20

19

12

11

10

9

8

7

18

17

16

15

14

13

1

A

K

2

D4101

D4101

LS4148(NC)

LS4148(NC)

C4102

C4102

0.1uF

0.1uF

U4101

U4101

NPST

GPIOA0/AD0

GPIOA1/AD1

GPIOA2/AD2

GPIOA3/AD3/IR

GPIOB2/IRQ0

GPIOB3/IRQ1

GPIOB4/VIN

GPIOB5/HIN

GPIOB6/IRQ2/TXD

GPIOB7/IRQ3/RXD

GPIOA4/SCL3

GPIOA5/SDA3

GPIOA6/SCL1

GPIOA7/SDA1

GPIOB0/SCL2

GPIOB1/SDA2

WT6702F_S240

WT6702F_S240

23

VDD

VSS

3

24

32KOSCO

VDD_RTC

32KOSCI

GPIOC1/PWM1

GPIOC0/PWM0

1

2

5

6

R4102

R4102

R4103

R4103

OSCO

OSCI

33R

33R

33R

33R

+3V3_STBY

33K

33K

R4104

R4104

+3V3_SW

OSCO

OSCI

PWR_ON_OFF SB06,10,12

RST_MSPH SB10

33K

33K

R4105

R4105

R4136

R4136

100R(NC)

100R(NC)

R4101

R4101

33R

33R

C4103

C4103

22P

22P

U4102

U4102

1

GND

2

RESET

AP1701FWL(NC)

AP1701FWL(NC)

R4137

R4137

100K(NC)

100K(NC)

1 2

X1401

X1401

32.768KHz

32.768KHz

3

Vcc

+3V3_STBY

+3V3_STBY

C4108

C4108

0.1uF(NC)

0.1uF(NC)

C4104

C4104

22P

22P

SB09

A

B

C4101 A3

C4102 A3

C4103 A6

C4104 A6

C4105 B2

C4106 B2

C4107 D4

C4108 C6

C4109 D5

D4101 C3

FB4101 A3

R4101 A5

R4102 B4

R4103 B4

R4104 B5

R4105 B5

R4106 B3

R4107 B3

R4108 B3

R4109 B3

R4110 B3

R4111 B3

R4112 B3

R4113 B3

R4114 B3

R4115 B3

R4116 B3

R4117 B3

R4118 B3

R4119 A3

R4120 A3

R4121 C2

R4122 C2

R4123 C2

R4124 C2

R4125 C2

R4126 C2

R4127 C2

R4128 C2

R4129 A2

R4130 A2

R4131 A2

R4132 A2

R4133 A2

R4134 C3

R4135 D3

R4136 C5

R4137 C5

R4138 D5

R4139 D6

R4140 D3

R4141 C3

U4101 A3

U4102 C6

X1401 A6

R4140

SB07,10

D D

E E

1

CEC_HDMI

2

CEC_HDMI

R4140

100R

100R

3

R4134 27KR4134 27K

R4135

R4135

0R05

0R05

HD_CEC

C4107

C4107

100P 50V(NC)

100P 50V(NC)

4

RESET

R4138

R4138

5

100R

100R

R4139 10KR4139 10K

+

+

C4109

C4109

4U7 50V

4U7 50V

I_17590_029.eps

6

7

8

260508

Page 24

Circuit Diagrams and PWB Layouts

24TPS1.2A LA 7.

Scaler Board: Scaler MST98980CLD

175

PWM0/MCUCFG0

248

HWRESET

PWM1/MCUCFG1

176

AVDD_AU

AVDD _SIF

70

AVDD_AU

PWM3/MCUCFG3

PWM2/MCUCFG2

192

191

R4205

R4205

C4237

C4237

0.1uF

0.1uF

63

5

100R

100R

RST_MSPH SB09

VDDP

VDDC

AVDDA

101

149

185

193

AVDD_33

SCK

58

168

AVDD_33

SDI

169

R4236

R4236

15K(NC)

15K(NC)

SCZ

VDDC

SDO

170

240

165

VDDP99VDDP

VDDC

VDDC

VDDC

VDDC

MST98980CLD-LF

MST98980CLD-LF

GND

GND

GND

3

11

17

40

SPI_DO SB11

SPI_CZ SB11

SPI_DI SB11

SPI_CK SB11

RC_IR_3V3 SB09,12

VDDP

GND

183

61

SB18

194

GND

66

14

39

254

AVDD_33

AVDD_33

AVDD_SIF

IRIN

167

182

+3V3_SW

R4235

R4235

100R

100R

VDDP

GND

207

VDDP

GND

100

221

235

VDDP

VDDP

U4201

U4201

GND

GND

GND

105

113

134

DRV_USB

AVDD_MemPLL

VDDM

108

114

119

VDDM

VDDM

GND

GND

166

184

148

6

135

147