Page 1

Published by JH 661 TV Service Printed in the Netherlands Subject to modification EN 3122 785 16060

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

ret

rieval system or transmitted, in any form or by any means, electronic,

mecha

nical, photocopying, or otherwise without the prior permission of Philips.

Colour Television Chassis

TPF1.

3A LA

Page 2

2

TPF1.3A LA

1. Technical Specifications and Connections

1. Technical Specifications and Connections

Index of this chapter:

1.1 Technical Specifications

1.2 Connections

Note: Figures below can deviate slightly from the actual

situation, due to the different set executions.

1.1 Technical specifications

1.vision

Type NR. :A201SN02 (AUO)

Display area(mm) : 408(H) x 306(V) (20.1-inch diagonal)

Display mode : TN type, Normal white + SWV film

Number of Pixels : 800(H) x 600(V)

Pitch ( mm ) : 0.51(H) x 0.51(V)

Color pixel arrangement : RGB vertical stripes

Display mode : normally white TN

Number of color : 16.7M ( 8 bits)

Brightness (cd/m^2) : 450nit(typ.)

Viewing angle : -80

Response time : 16ms typ. (Tr+Tf)

Surface treatment : Hard Coating + AR

Electrical interface : TTL (1 port)

Total module power(W) : 35W(typ.)

Contrast ratio : Typical 500 : 1

Overall dimension (mm) : 448(W) x 347(H) x 23(D)(max.)

Module weight (g) : 3500

Backlight : 6 CCFL

2.Following table is the detail TV System list.

TV

system

M

N 4.5 BTSC-stereo+SAP PAL Argentina

B/G

L 6.5/5.85 AM-Mono/

I 6.0/6.552 FM-Mono/

D/K

Position of

sound carrier

(MHz)

4.5/4.724212 FM-Stereo(A2) NTSC Korea

4.5 FM-FM(EIA-J) NTSC Japan

4.5 BTSC-stereo+SAP NTSC USA

5.5/5.7421875 FM-stereo(A2) PAL Germany, Austria,

5.5/5.85 FM-Mono/

6.5/6.2578125 FM-Stereo

6.5/6.7421875 FM-Stereo

6.5/5.7421875 FM-Stereo

6.5/5.85 FM-Mono/

Sound system Color system Country

NICAM

NICAM

NICAM

(A2,D/K1)

(A2,D/K2)

(A2,D/K3)

NICAM(D/K,NICAM

)

3.Miscellaneous

Power supply

~80(H),-60~60(V)(Typ.)

Switzerland, Italy,

PAL Belgium, Spain,

SECAM-L France

PAL Great Britain, Hong

SECAM-East Slovak. Rep.

PAL None

SECAM-East Poland

PAL China, Hungary

Netherlands,

Denmark, Finland,

Norway, Sweden.

Kong, Ireland

1.2 Connections: please refer to the DFU for details

1.2.1 PC input connectors

Input ana

log D-sub connector pin assignment:

PIN No. SIGNAL

1Red

2 Green

3Blue

4GND

5GND

6RedGND

7 Green GND

8BlueGND

9 +5V (Supply from PC)

10 Sync GND

11 GND

12 Bi-directional data

13 H-sync

14 V-sync

15 Data clock

Sync polarity :

-Hori.sync positive/negative

-Vert.syncpositive/negative

1.PC Signal type

Analog Video: 0.7 Vp-p Linear , positive polarity

Sync : TTL level , separate , positive or negative polarity

2.TV signal type

RF signal : Aerial input

Video signal : S-video input

CVBS

YPbPr

3.Audio signal : S-video L/R ,YPbPr L/R audio input

PC line in

Power consumption : Operating 55 W (typical)

Power cord length : 1.8M

Power cord type : USA type

Power indicator : LED (On: Green ,Sleeping mode: Am ber )

Auto power saving : EPA

Operati ng

-Temperature C : 0°cto35°c

-Humidity : 20% ~ 80 %

-Altitude : 0-3658m

-Air pressure : 600-1100mBAR

Storage

-Temperature C : -20 to 60°

-Humidity : 95% max ( < 40

)

-Altitude : 0-12192m

-Air pressure : 300-1100mBAR

Note: Recommend at 0 to 35°C, Humidity less than 60 %

Page 3

2. Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

TPF1.3A LA

3

index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require that during a repair:

·

Connect the set to the AC Power via an isolation

transformer (> 800 VA).

·

Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

·

Route the wire trees correctly and fix them with the

mounted cable clamps.

·

Check the insulation of the AC Power lead for external

damage.

·

Check the strain relief of the AC Power cord for proper

function.

·

Check the electrical DC resistance between the AC Power

plug and the secondary side (only for sets which have a AC

·

Power isolated power supply):

1. Unplug the AC Power cord and connect a wire

between the two pins of the AC Power plug.

2. Set the AC Power switch to the "on" position (keep the

AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

AC Power plug and the metal shielding of the tuner or

the aerial connection on the set. The reading should be

between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the AC Power plug.

·

Check the cabinet for defects, to avoid touching of any

inner parts by the customer.

2.2 Warnings

·

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD ). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential.

·

Be careful during measurements in the high voltage

section.

·

Never replace modules or other components while the unit

is switched "on".

·

When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

1. Measure the voltages and waveforms with regard to the

chassis (= tuner) ground ( ), or hot ground ( ), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

2. Where necessary, measure the waveforms and voltages

with ( ) and without ( ) aerial signal. Measure the

voltages in the power supply section both in normal

operation ( ) and in stand-by ( ). These values are

indicated by means of the appropriate symbols.

3. The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

4. Manufactured under license from Dolby Laboratories.

"Dolby" and the "double-D symbol", are trademarks of

Dolby Laboratories.

2.3.2 Schematic Notes

1. All resistor values are in ohms and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

2. Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

3. All capacitor values are given in micro-farads (u= x10 ),

nano-farads (n= x10 ), or pico-farads (p= x10 ).

4. Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

5. An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

6. The correct component values are listed in the Electrical

Replacement Parts List. Therefore, always check this list

when there is any doubt.

-9

-12

-6

2.3.3 Rework on BGA (Ball Grid Array) Ics

General

Although (LF)BGA assembly yields are very high, there may still be

a requirement for component rework. By rework, we mean the

process of removing the component from the PWB and replacing it

with a new component. If an (LF)BGA is removed from a PWB, the

solder balls of the component are deformed drastically so the

removed (LF)BGA has to be discarded.

Device Removal

As is the case with any component that, it is essential when

removing an (LF)BGA, the board, tracks, solder lands, or

surrounding components are not damaged. To remove an(LF)BGA,

the board must be uniformly heated to a temperature close to the

reflow soldering temperature. A uniform temperature reduces the

chance of warping the PWB.To do this, we recommend that the

board is heated until it is certain that all the joints are molten.

Then carefully pull the component off the board with a vacuum

nozzle. For the appropriate temperature profiles, see the IC data

sheet.

Area Preparation

When the component has been removed, the vacant IC area must

be cleaned before replacing the (LF)BGA.Removing an IC often

leaves varying amounts of solder on the mounting lands. This

excessive solder can be removed with either a solder sucker or

solder wick. The remaining flux can be removed with a brush and

cleaning agent.After the board is properly cleaned and inspected,

apply flux on the solder lands and on the connection balls of

the (LF)BGA.

Note: Do not apply solder paste, as this has shown to result in

problems during re-soldering.

Device Replacement

The last step in the repair process is to solder the new component

on the board. Ideally, the (LF)BGA should be aligned under a

microscope or magnifying glass. If this is not possible, try to align

the (LF)BGA with any board markers. To reflow the solder, apply a

temperature profile according to the IC data sheet. So as not to

damage neighbouring components, it may be necessary to reduce

some temperatures and times.

More Information

For more information on how to handle BGA devices, visit this

URL: (needs subscription,

www.atyourservice.ce.philips.com

not available for all regions). After login, "select Magazine", then

go to "Workshop Information". Here you will find Information on

how to deal with BGA-ICs.

Page 4

4

TPF1.3A LA

2. Safety Instructions, Warnings and Notes

2.3.4 Lead Free Solder

Philips CE is going to produce lead-free sets (PBF) from

1.1.2005 onwards.

Lead-free sets will be indicated by the PHILIPS-lead-free logo

on the Printed Wiring Boards (PWB):

Fig 2-1 Lead-free logo

This sign normally has a diameter of 6 mm, but if there is less

space on a board also 3 mm is possible.

In case of doubt wether the board is lead-free or not (or with

mixed technologies), you can use the following method:

1. Always use the highest temperature to solder, when using

SAC305 (see also instructions below).

2. De-solder thoroughly (clean solder joints to avoid mix of

two alloys).

Caution

which is coupled to the 12NC. For an overview of these

profiles, visit the website

(needs subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Workshop information".

For additional questions please contact your local repairhelpdesk.

: For BGA-ICs, you must use the correct temperatureprofile,

www.atyourservice.ce.philips.com

2.3.5 Practical Service Precautions

1.

It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

2. While some may not be

Always respect voltages.

dangerous in themselves, they can cause unexpected

reactions - reactions that are best avoided. Before reaching

into a powered TV set, it is best to test the high voltage

insulation. It is easy to do, and is a good service precaution.

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

1. Use only lead-free soldering tin . If lead-free solder paste

is required,please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

2. Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able

-To reach at least a solder-tip temperature of 400 C.

-To stabilise the adjusted temperature at the solder-tip.

-To exchange solder-tips for different applications.

3. Adjust your solder tool so that a temperature around 360 C

- 380 C is reached and stabilised at the solder joint.

Heating time of the solder-joint should not exceed~4sec.

Avoid temperatures above 400 C, otherwise wear-out of

tips will rise drastically and flux-fluid will be destroyed. To

avoid wear-out of tips, switch "off" unused equipment or

reduce heat.

4. Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If not to avoid, clean carefully the

solder-joint from old tin and re-solder with new tin.

5. Use only original spare-parts listed in the Service-Manuals.

Not listed standard material (commodities) has to be

purchased at external companies.

6. Special information for lead-free BGA ICs: these ICs will be

delivered in so-called "dry-packaging" to protect the IC

against moisture. This packaging may only be opened

short before it is used (soldered). Otherwise the body of the

IC gets "wet" inside and during the heating time the

structure of the IC will be destroyed due to high (steam-)

pressure inside the body. If the packaging was opened

before usage, the IC has to be heated up for some hours

(around 90 C ) for drying (think of ESD-protection !).

Do not re-use BGAs at all!

7. For sets produced before 1.1.2005, containing leaded

soldering tin and components, all needed spare parts will

be available till the end of the service period. For the repair

of such sets nothing changes.

Page 5

3. Directions for Use

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

TPF1.3A LA

5

Page 6

6

TPF1.3A LA

4. Mechanical Instructions

Index of this chapter:

4.1 Assy/Panel Removal

4.2 Set Re-assembly

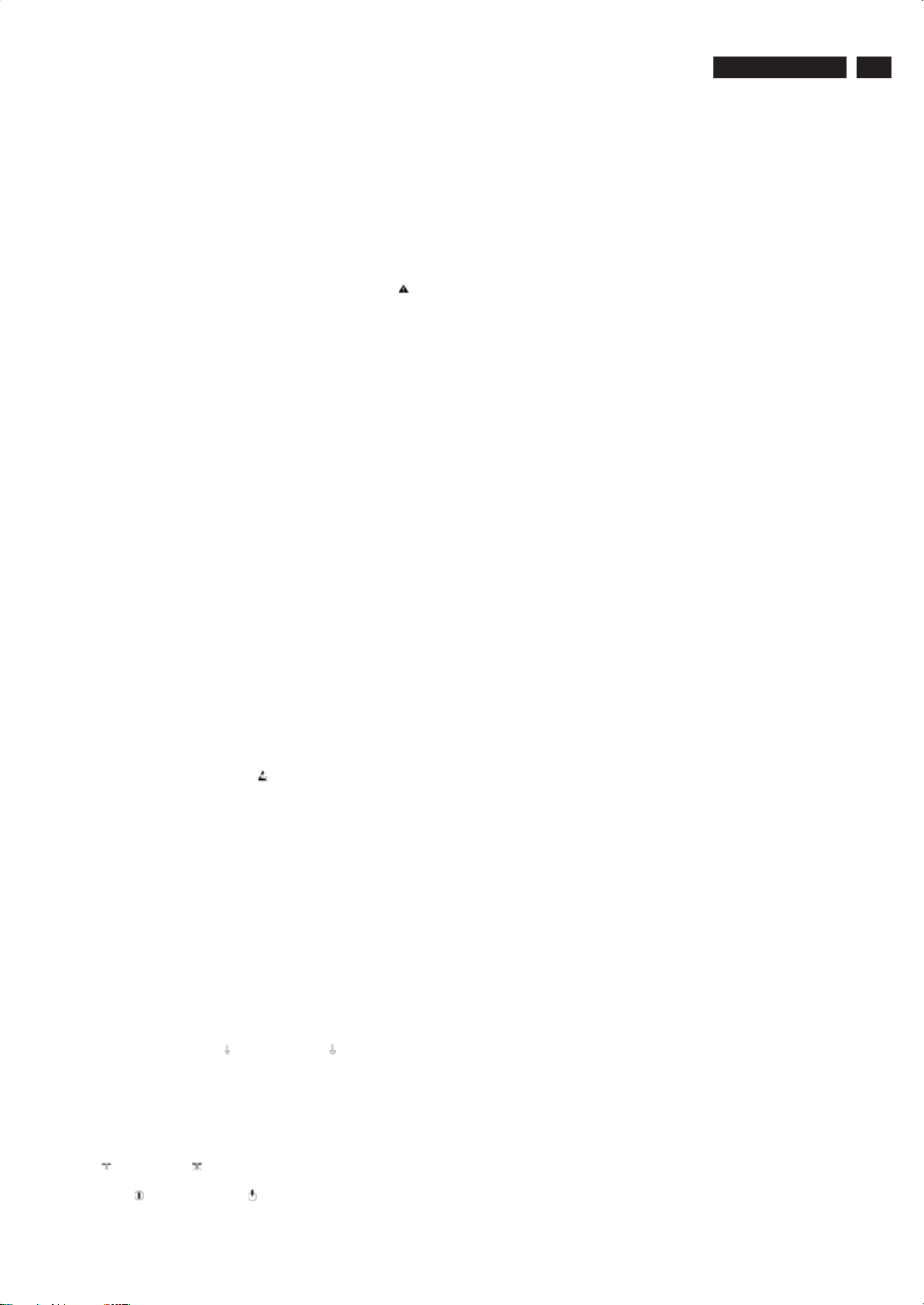

4.1 Assy/Panel Removal

Front view

Back view

4. Mechanical Instructions

Fig.6

Fig.7

Fig.1

Fig.2

Step 1. Remove the stand.

Remove the three screws as Fig.2,Fig.3

Fig.3

Step 2. Remove the Back cover as Fig.4~7.

Remove the 4 screws on the back cover as Fig.4

a.

b. Use thin "I" type screwdriver to push 2 clicks on bottom

side and use thin type screwdriver to open the bottom side as Fig.5

c.

Use thin "I" type screwdriver to push 2 clicks on top

side and use thin "I" type screwdriver to open the top side as Fig.6

d. Remove the back cover as Fig.7.

"I"

Step 3: Remove the shielding

a. Remove the 4 screws as Fig.8 Fig.9

b. Remove the shielding as Fig.10

Fig.8

Fig.9

Fig. 10

Fig.5

Fig.4

Step 4. Remove the YPbPr-IN,Scaler, KEY ,IR and inverter board.

a).Remove the 2 screws and disconnect the 10 cables as Fig. 10

to remove the YPbPr-IN board.

b).Remove the 4 screws and disconnect the connector as Fig.11

to remove the scaler board.

c).Remove the 2 screws and disconnect the connector as Fig.12

to remove the inverter board.

d).Remove the screw and disconnect the connector as Fig.13 to

remove the IR board.

Page 7

4. Mechanical Instructions

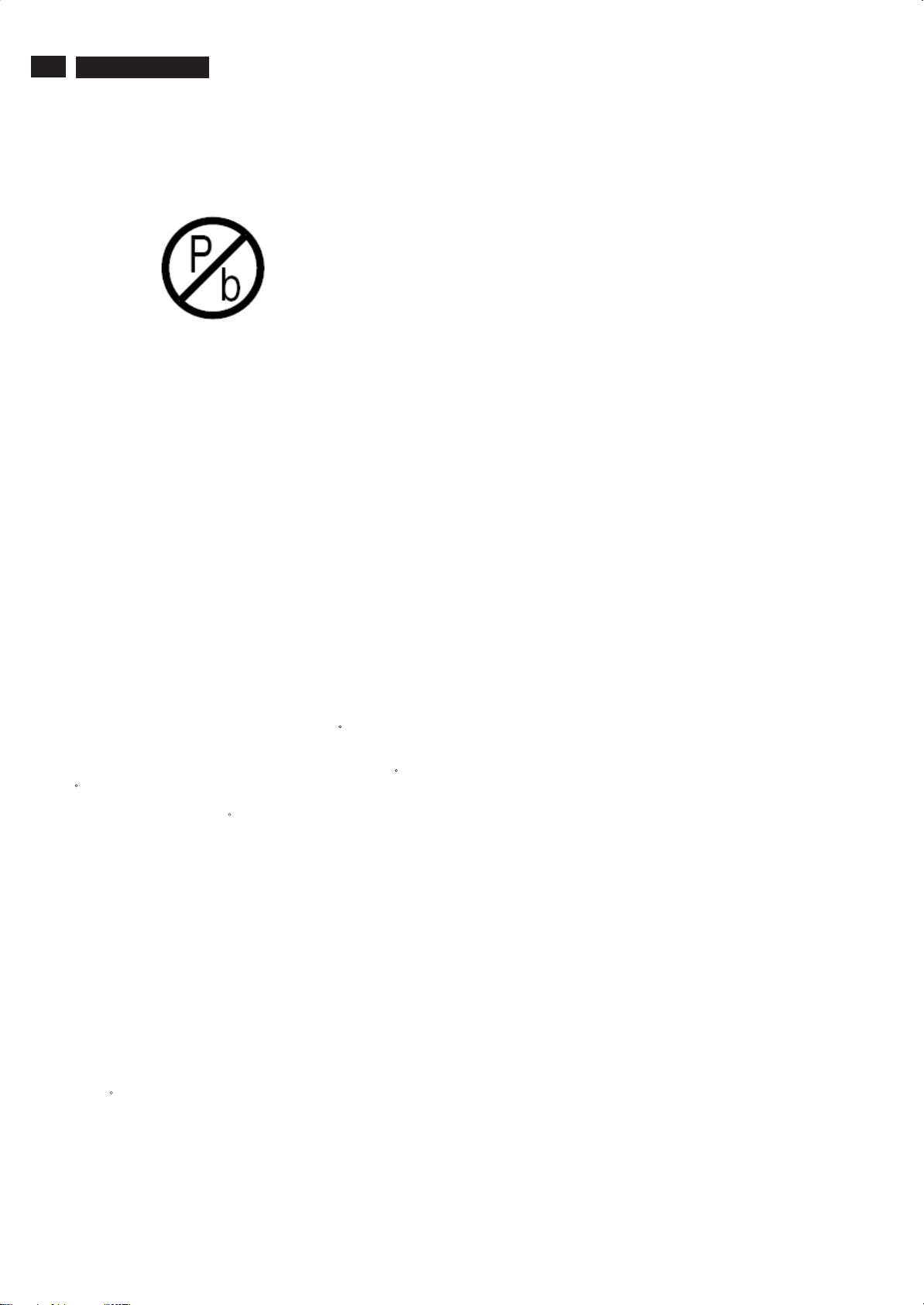

e). Remove the control board and open the click ,disconnect the

connector as Fig.14-Fig.15

TPF1.3A LA

7

Fig.11

Fig.12

Fig.15

Step 5. Remove the 4 screws as Fig.16 to remove the speaker

Fig. 16

Fig.17

Fig. 14

Fig. 13

Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

a. While re-assembling, make sure that all cables are placed

and connected in their original position.

b. Pay special attention not to damage the EMC foams at the

SSB shielding. Check that EMC foams are put correctly on

their places.

In warranty, it is not allowed to disassembly the LCD panel, even the

backlight unit defect.

Out of warranty, the replacment of backlight unit is a correct way

when the defect is cused by backlight (CCFL,Lamp).

Page 8

8

TPF1.3A LA

5. Aging and Factory Mode

5. Aging and Factory Mode

index of this chapter:

5.1 Access Aging Mode

5.2 Access Factory Mode

Top Control

-

Volume

Left

<B> <C> <D> <E> <F>

Right

+

Menu

-

Channel

+

UpDown

Front Control

Power SW

<A>

LED

RC sensor

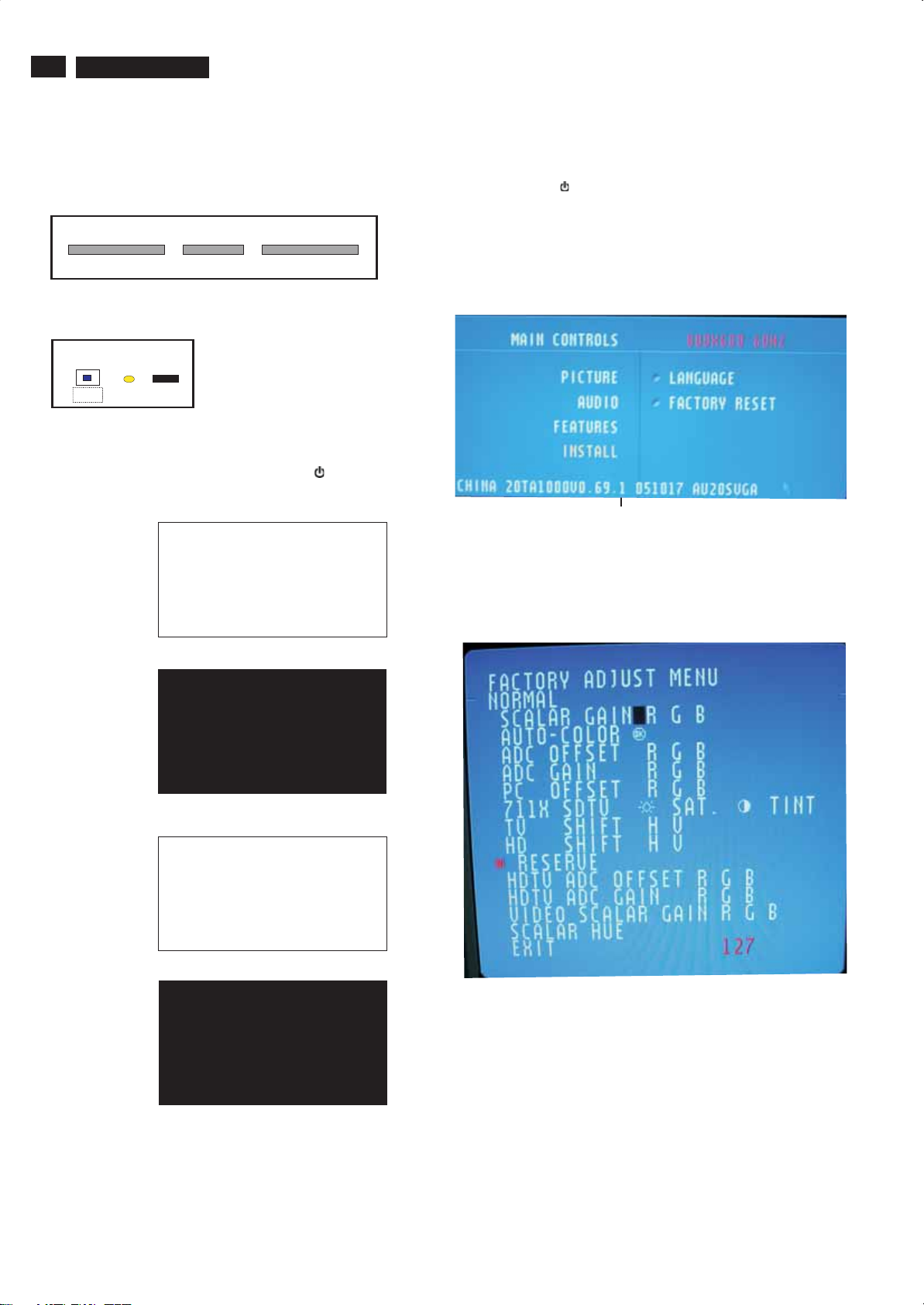

5.1 Access Aging Mode

Step 1 : D

Step 2 :

quickly push " + "and "-"ofVolume,and hold this two buttons

comes out " AGING screen"] => then release all buttons.

Bring up:

isconnect Interface Cable between Monitor and PC.

Turn off LCD monitor.Then press power " " button.Then

AGING...

untill

5.2 Access Factory Mode

1). Turn off monitor.

2).

Press power " " button.Then quickly push " + " and " - "of

Volume ,and hold this two buttons , then the screen comes out

"Waiting For Automatic Adjustment ",then the screen will be black

for one second untill comes out "Windows screen"] => then

release this two buttons.

3). Press "MENU" button, wait until the OSD menu with

Characters "CHINA MAGNAVOX32 V0.2.0 051012

CLAA320WA01" (below OSD menu) come on the Screen

of the monitor.

Factory Mode indicator

Factory Menu

Cursor can move on gray color area

Hot key function: at factory mode , press "MENU" button,then press

"+"and"-"ofChannel to the factory mode indicator ,then press

" + " of Volume .Press the " + " and "-"ofChannel to "exit " and

press "MENU" to exit factory adjust menu.

After 52 seconds,

bring up:

AGING...

After 60 seconds,

bring up:

AGING...

After 52 seconds,

bring up:

----------

---------repeatly

Connect Signal cable again=> go back to normal display

Page 9

10

TPF1.4A LA

6. Block Diagram

Index of this chapter:

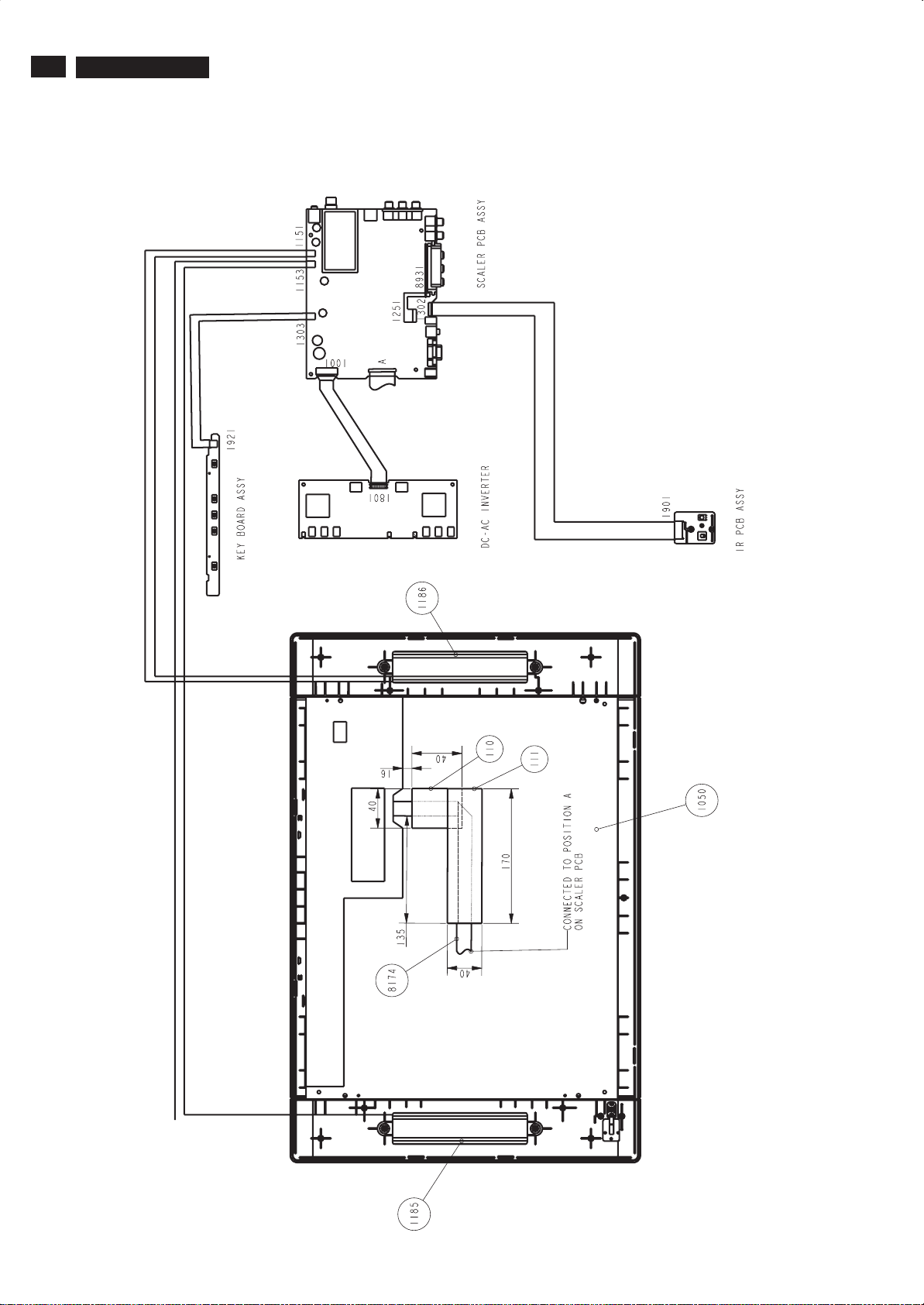

6.1

Wiring Diagram

6.2 Block Diagram

6.1 Wiring Diagram

6. Block Diagram

Page 10

10

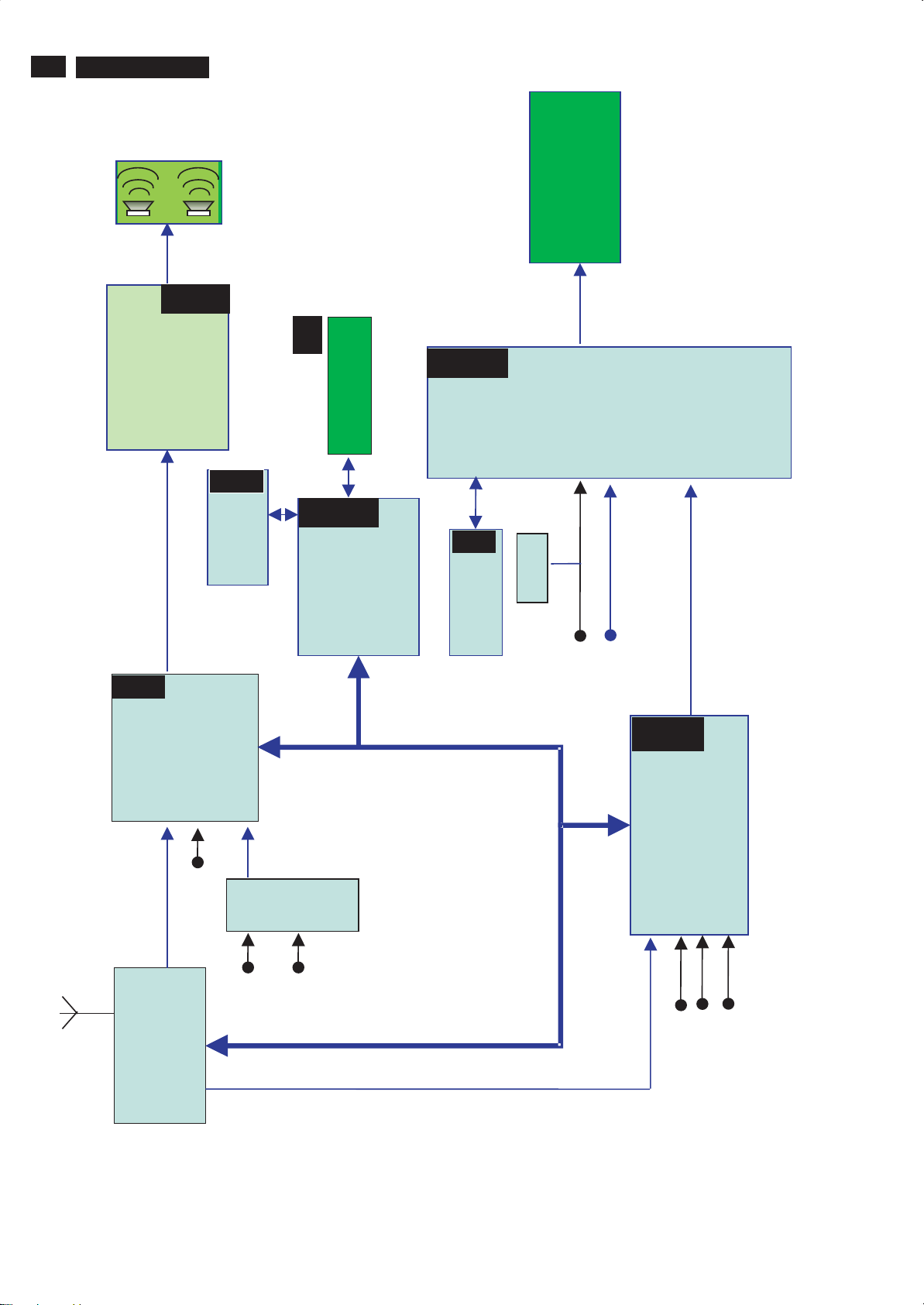

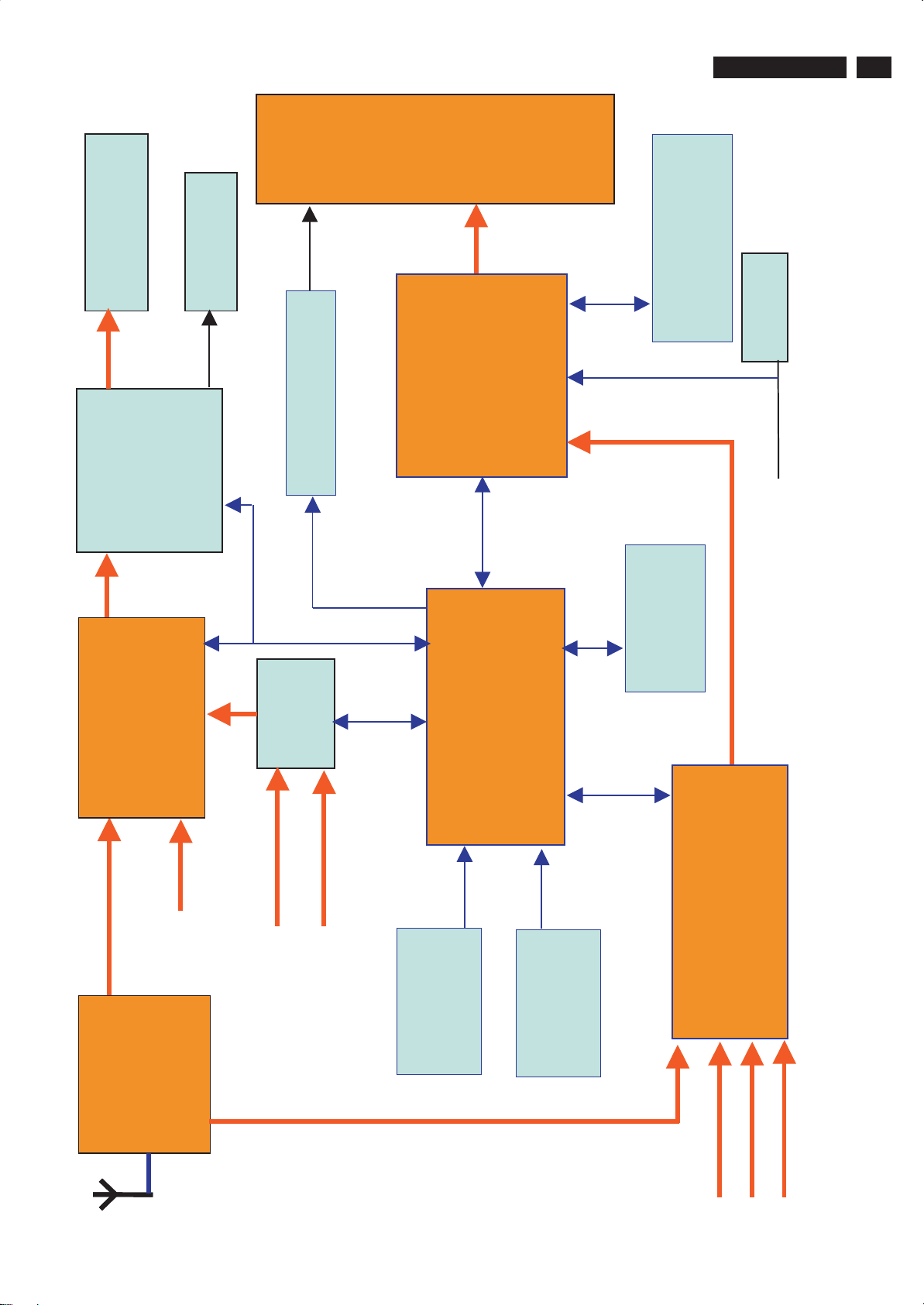

6.2 Main board block diagram

TPF1.3A LA

S-L

TPA3005D2

Audio AMP

S-G

K

6. Block Diagram

IR and key pad

Control Board

S-H

Panel

LVDS

SCALER

MST51502

MSP_OUT_L/R

S-K

IF

nd

2

EEPROM

MSP3415G

Sound decoder

PC audio

x8

4K

S-G

D

M

S-I

MCU

NT68F632

SDRAM

IIC

DDC

512Kx16x2

PC analog

...

VY[0… 7]

YPbPr (HD)

S-E

SAA7119E/V2

Video Decoder

X

audio

Tuner

video

SC -audio

S_Audio

Tuner CVBS

SVHC_YC

AV CVBS

YPbPr_RGB_SC

Page 11

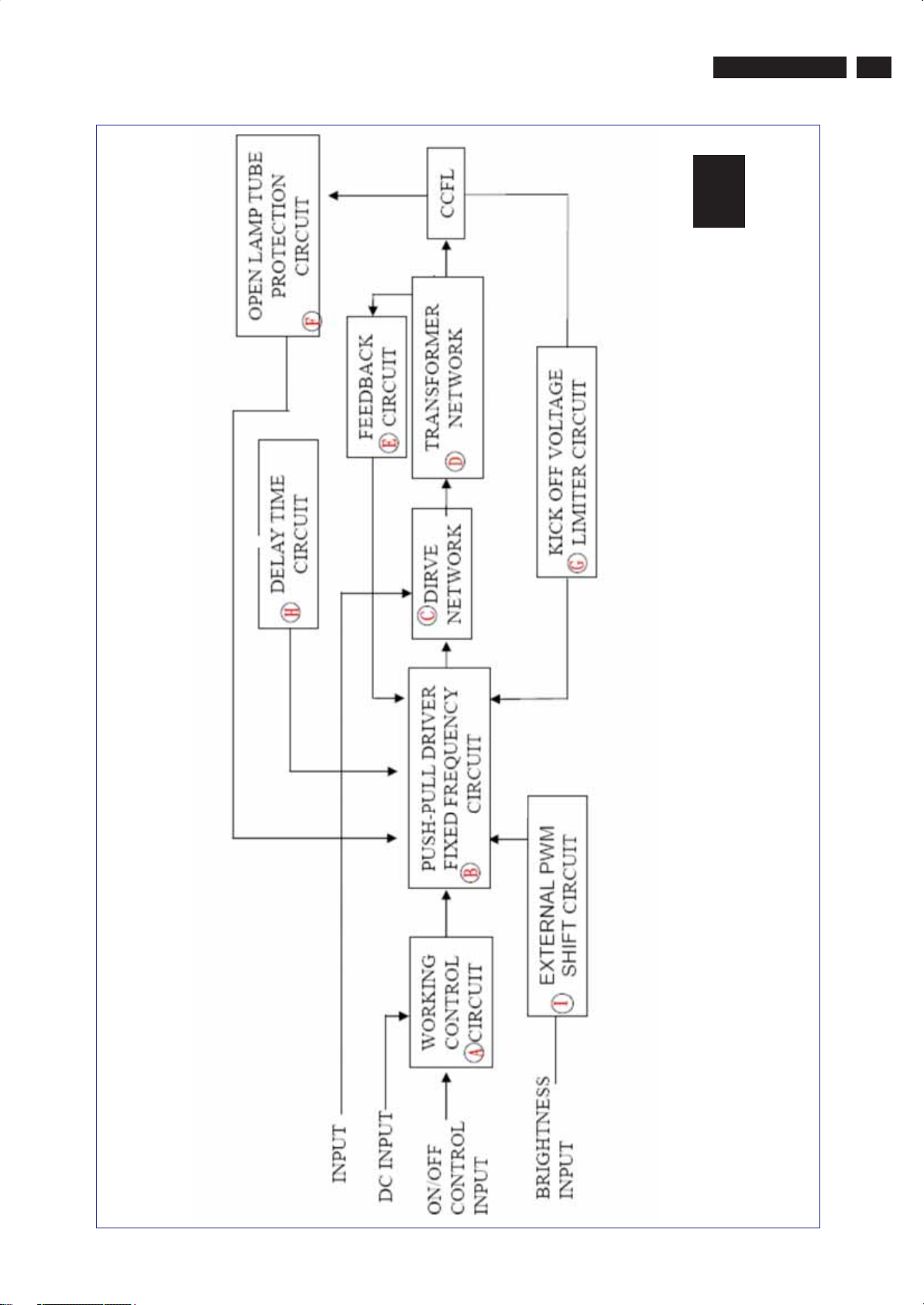

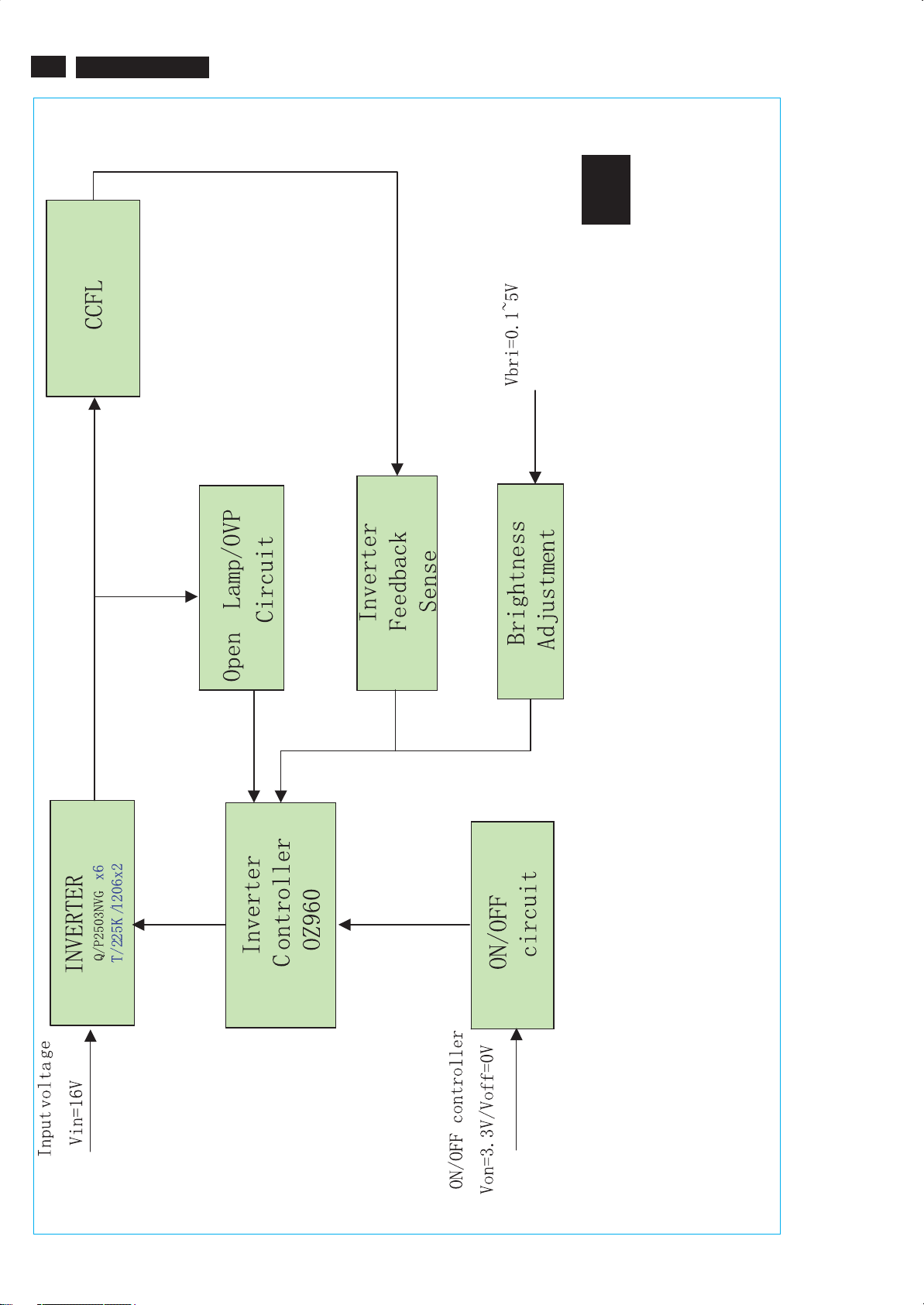

INVERTER BLOCK DIAGRAM

6. Block Diagram

P

TPF1.3A LA

11

12VDC

Page 12

12

TPF1.3A LA

INVERTER FUNCTION BLOCK DIAGRAM

6. Block Diagram

P

Page 13

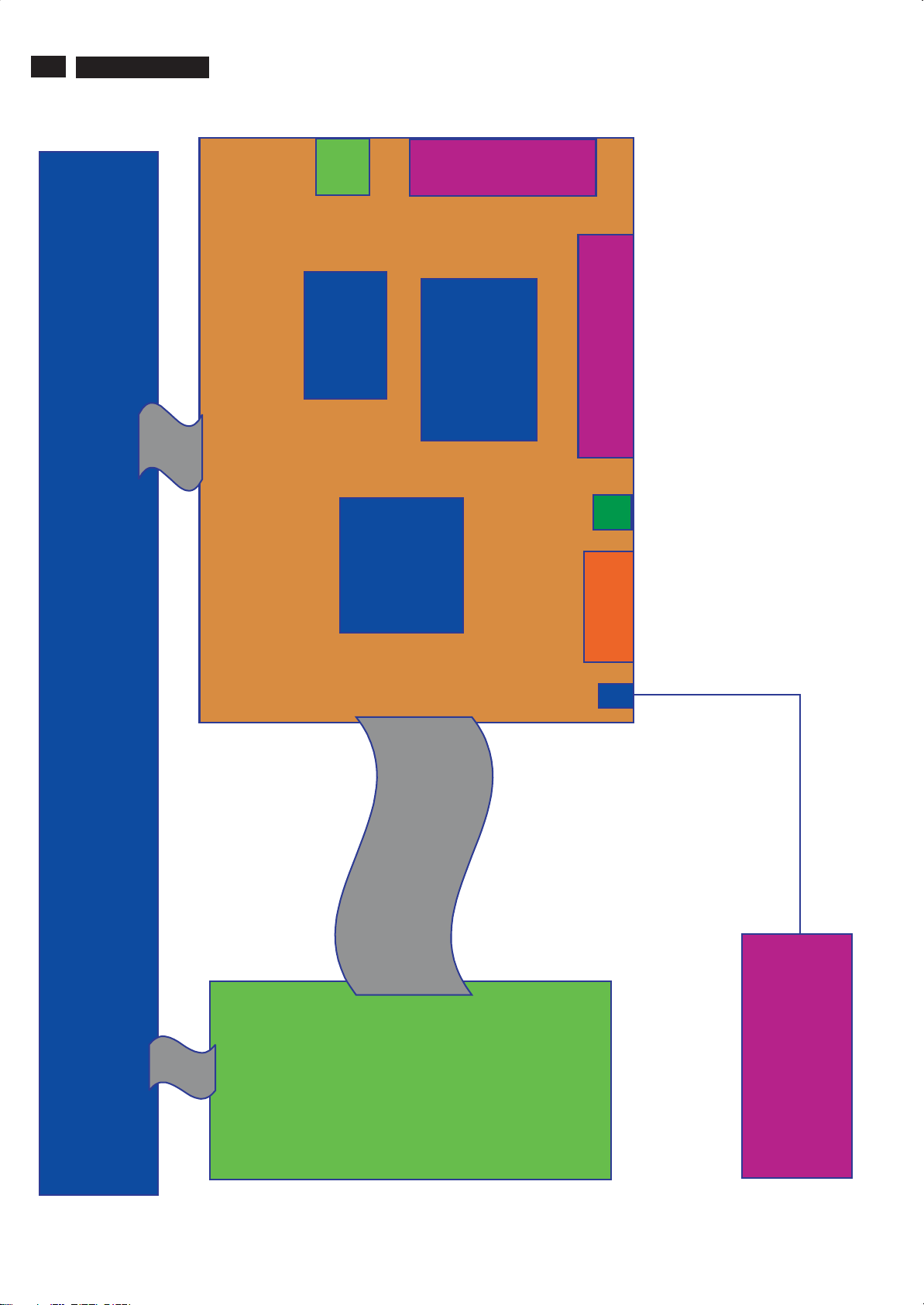

6. Block Diagram

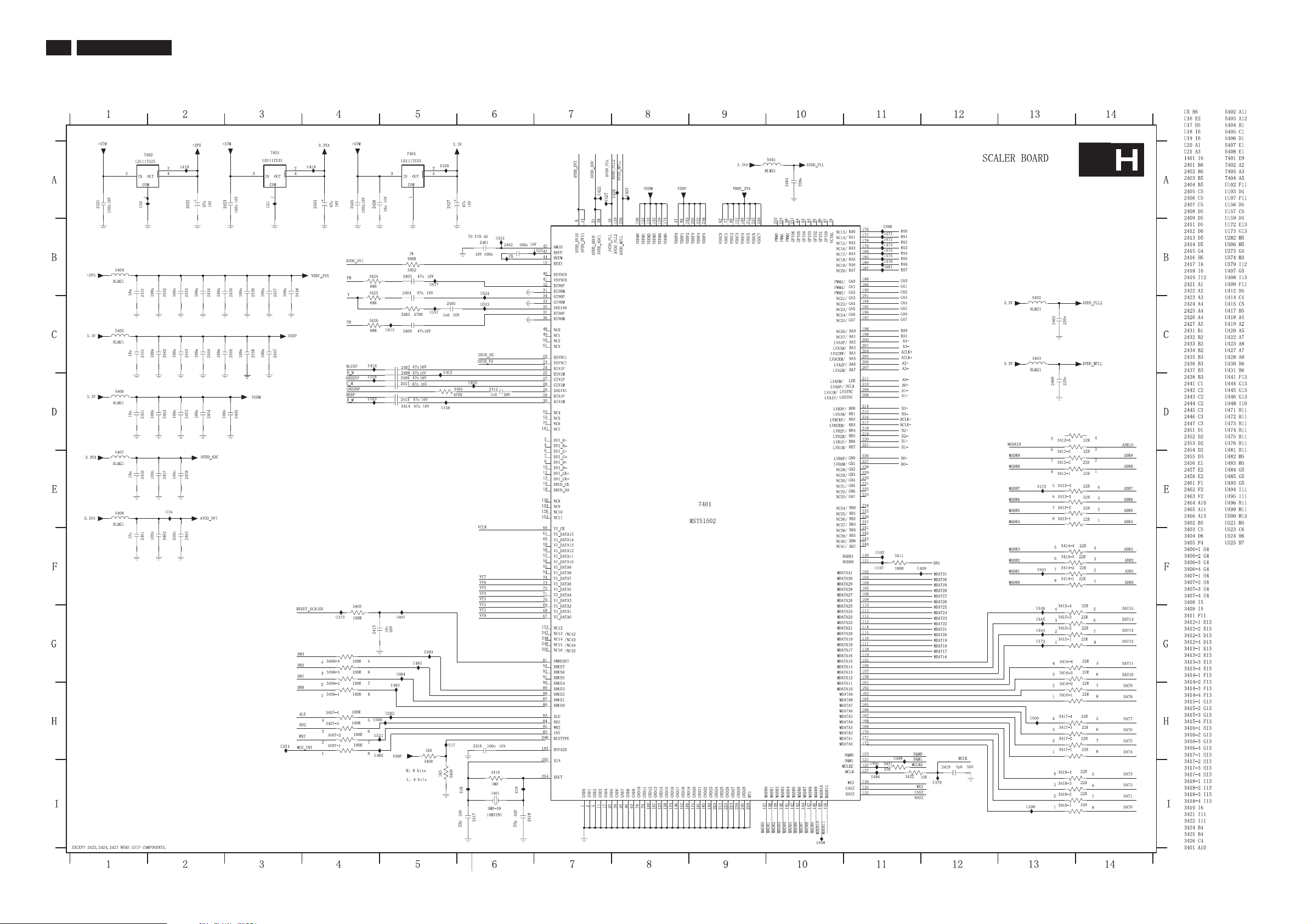

Scalar board

Panel

TPF1.3A LA

13

Speakers

AMP

Audio

Output

TPA3005

LVDS

1Mx16

SDRAMÁ 2

DDC

Scaler

MST51512

BL controller

PC Analog

24C32

Eeprom

Sound

Decoder

IF

nd

2

Tuner

MSP3415

PC audio

FQ1256/I

MUX

AV / S -Video audio

YPbPr(HD) audio

IR

OFF/ON

Tuner CVBS

MCU

NT68F632A(128KB)

Board

Control

SAA7119

Video Decoder

YPbPr(HD)

S-video

AV

Page 14

14

TPF1.4A LA

FFC

6. Block Diagram

S-Video

Sound

Decoder

AV L/R

Panel

Audio

Decoder

Scaler IC

YPbPr L/R

PC Audio

DSub

DC in

In

Inverter

Adapter

Page 15

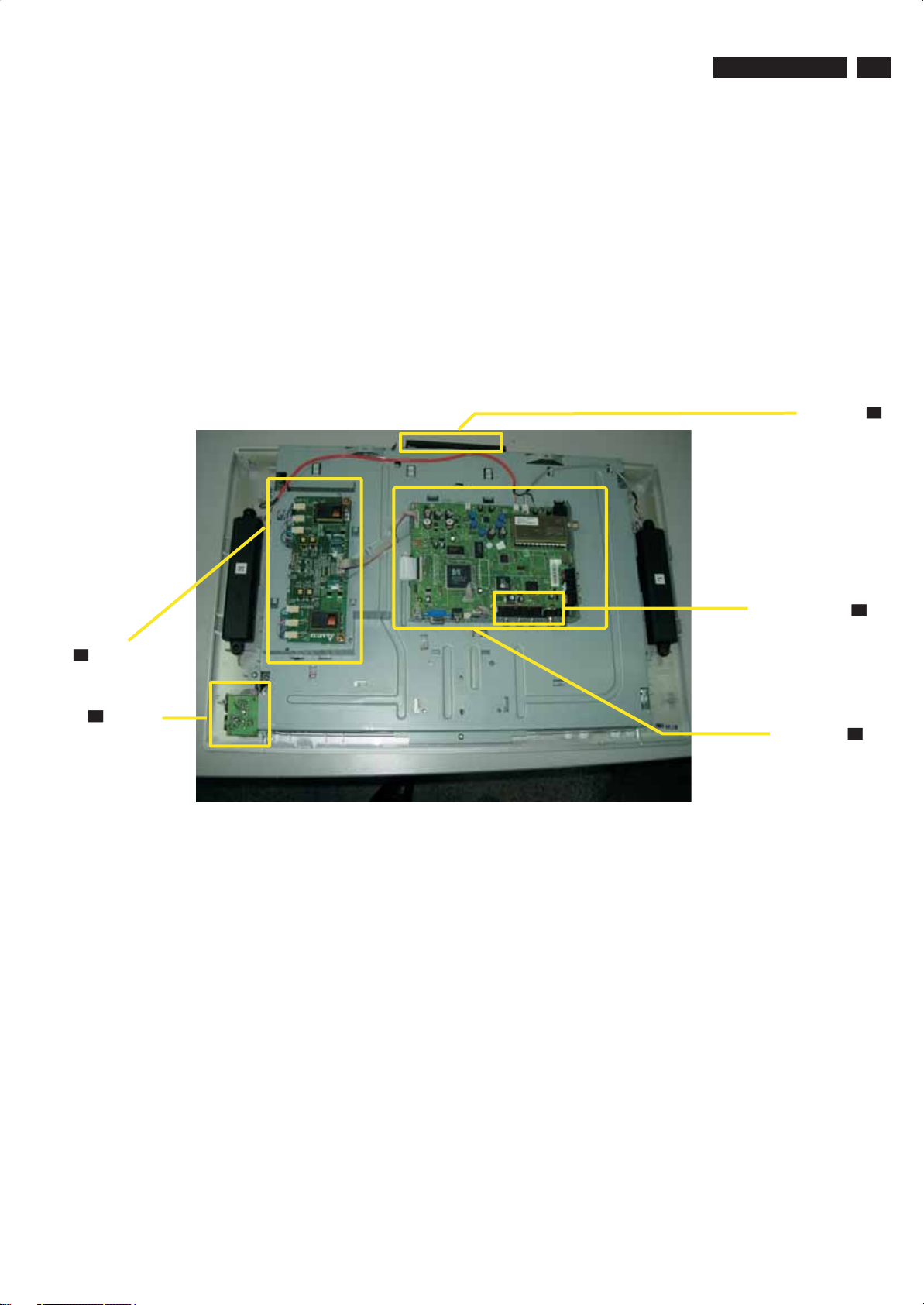

Index of this chapter:

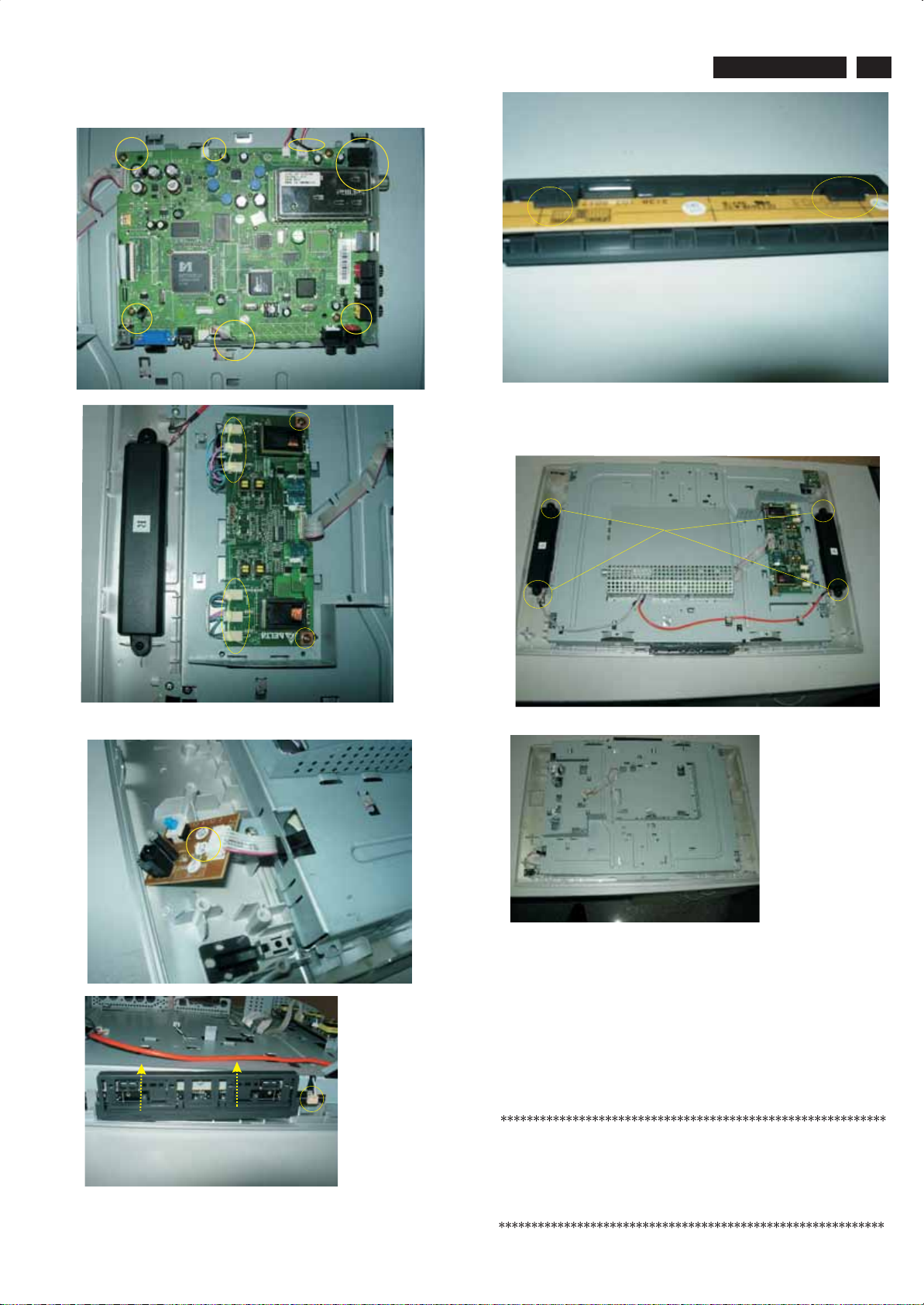

7.1 Chassis Overview

7.2 Exploded View

7.3 Scaler Schematic Diagram & Layouts

7.4 Power Schematic Diagram & Layouts

7.5 Key PCB Schematic Diagram & Layouts

7.6 IR PCB Schematic Diagram & Layouts

7.7 YPbPr-IN PCB Schematic Diagram & Layouts

7.1 Chassi Overview

7.Circuit Diagram & PWB Layouts

TPF1.3A LA

15

Innverter Board

P

I

IR Board

Key Board

YPbPr-IN Board

Scaler Board

K

Y

S

Page 16

16

TPF1.3A LA

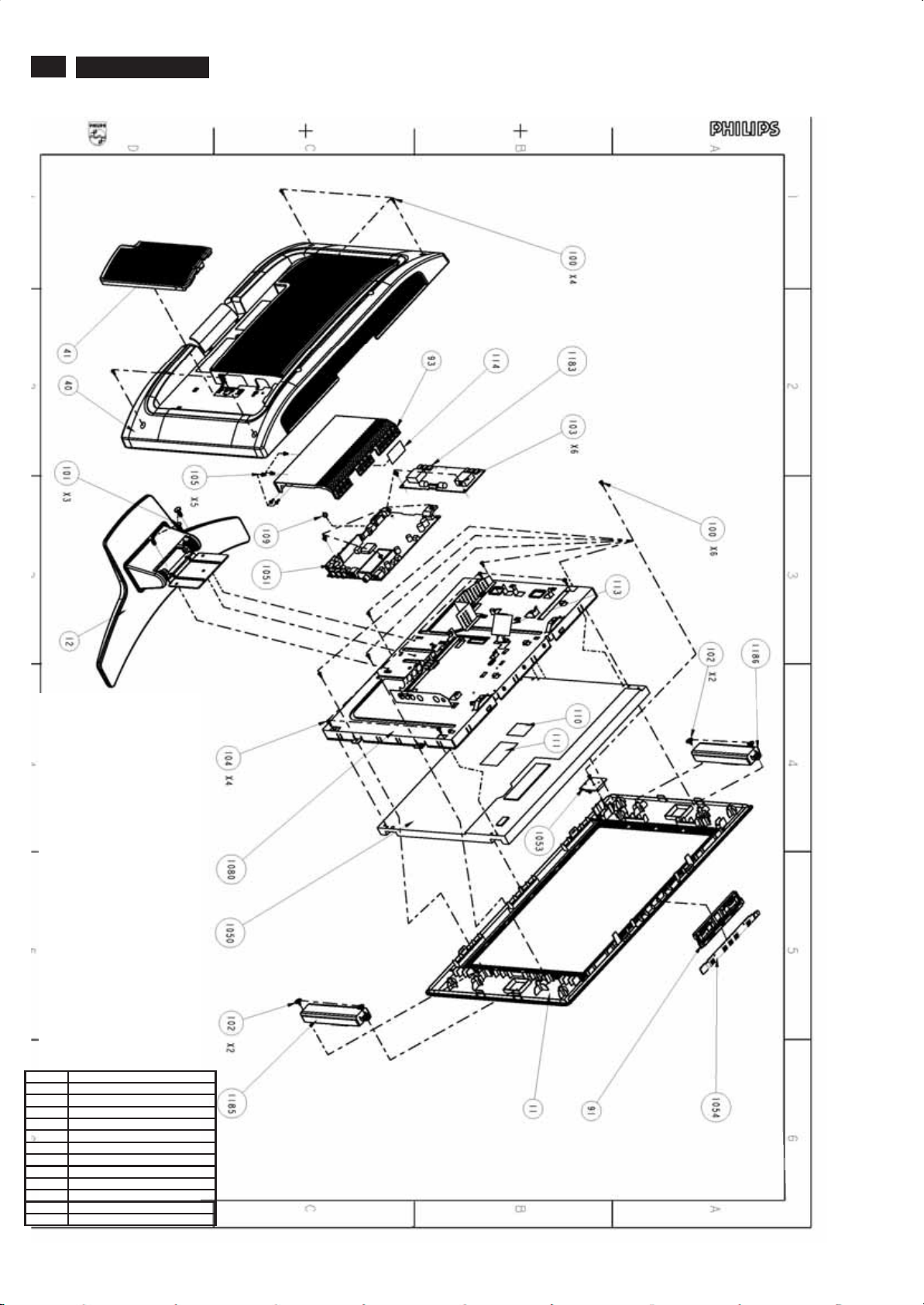

7.2 Exploded View

7. Circuit Diagrams and PWB Layouts

0011 BEZEL ASSY

0040 BACK COVER

0041 DOOR-CABLE

0091 CONTROL BUTTON

0093 SHIELD - SCALER

0109 NUT-AUDIO JACK

1050 TFT-LCD A201SN02V4 (AUOP) B

1051 SCALER ASSY(CHINA 20 AUO)

1053 KEY BOARD ASSY

1054 IR PCB ASSY

1183 PSU OPENFR INV BL6 (DAC-16T003

1185 LSP BOX 8R 3W - R (P 150CR)

1186 LSP BOX 8R 3W - R ( P150CL)

Page 17

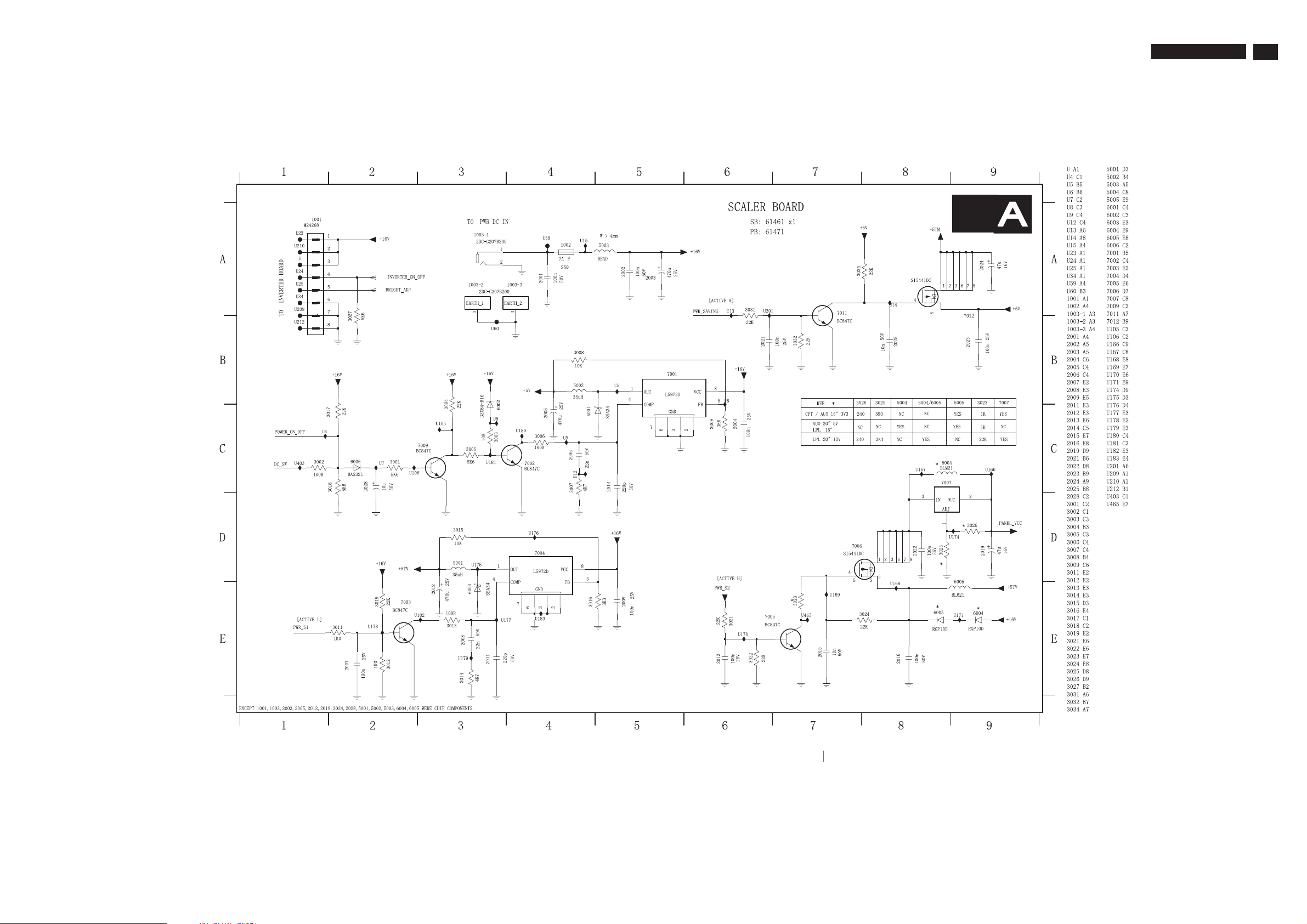

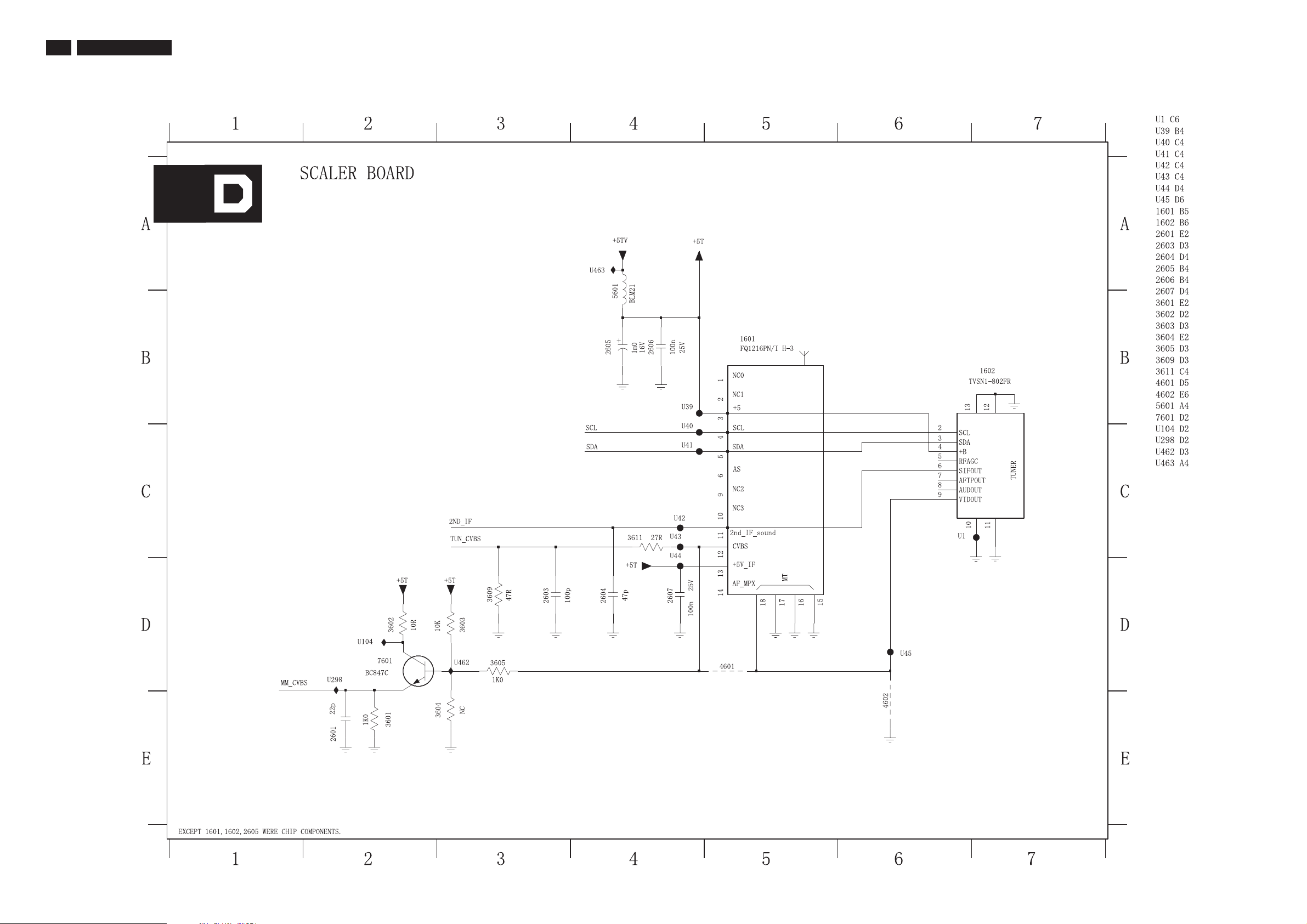

7.3.1 Scaler Schematic Diagram - power

7.Circuit Diagrams and PWB Layouts

S-

TPF 1.3A LA

17

Page 18

18

TPF 1.3A LA

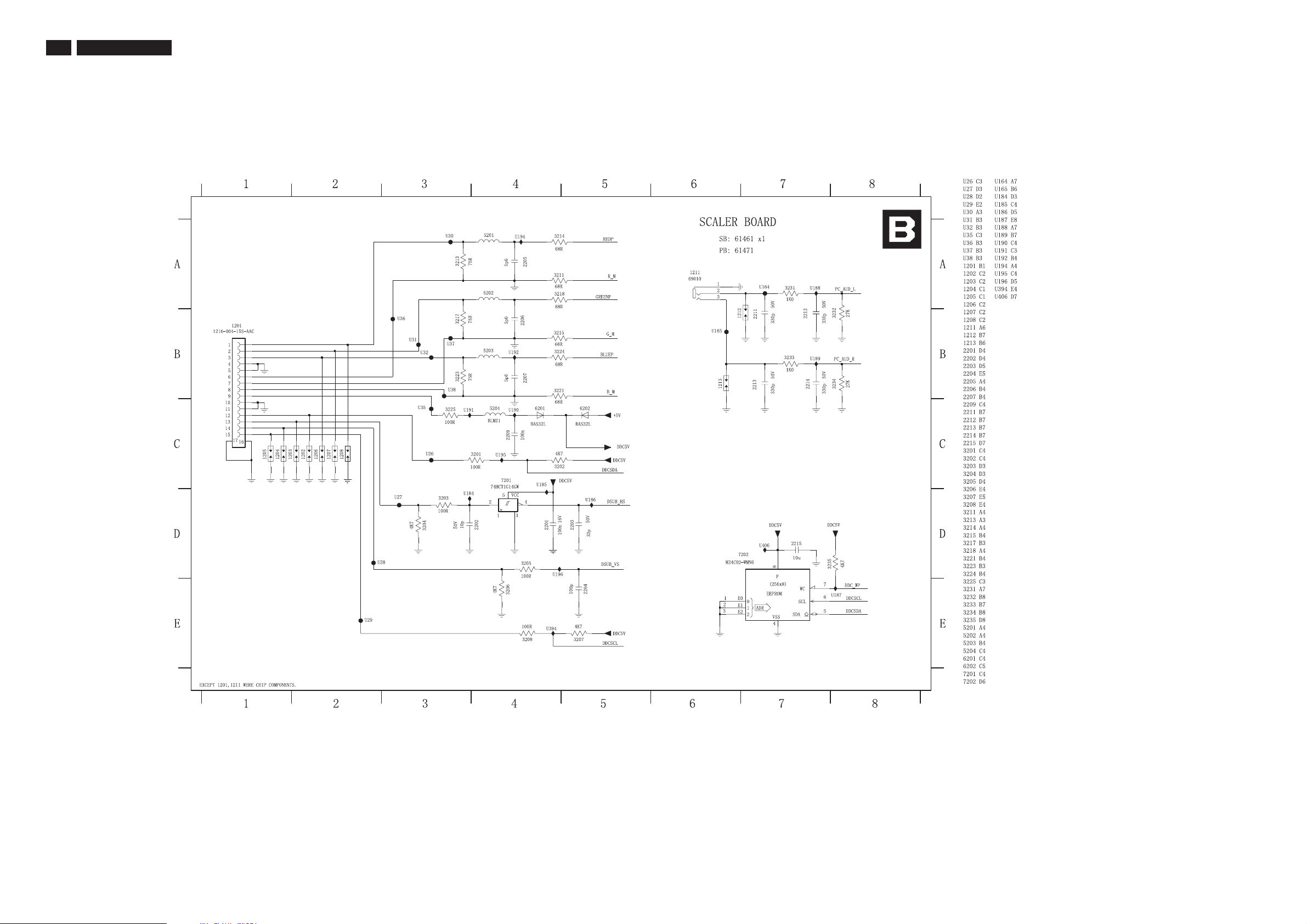

7.3.2 Scaler Schematic Diagram - PC IN

7. Circuit Diagrams and PWB Layouts

Page 19

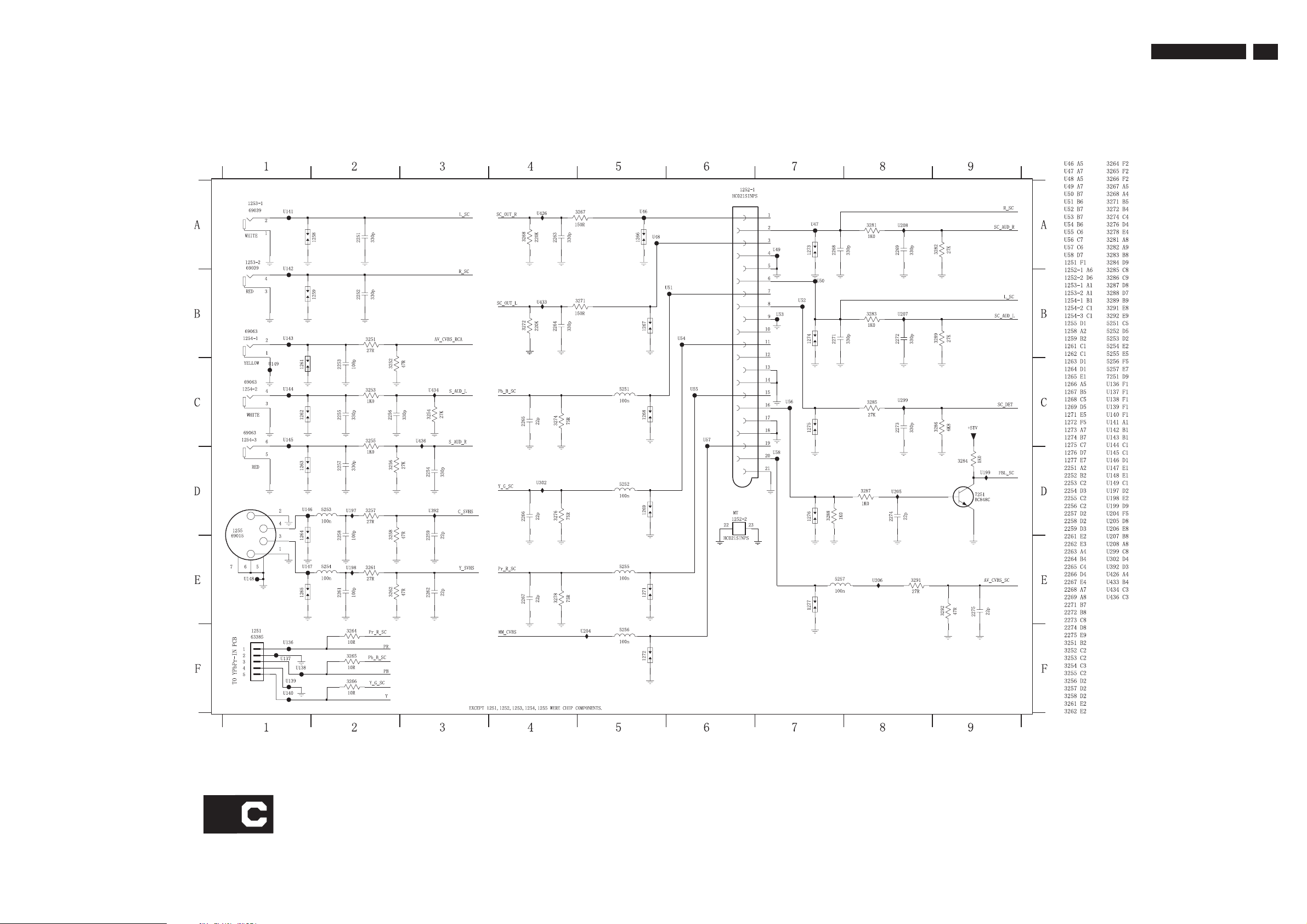

7.3.3 Scaler Schematic Diagram - SCART

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

19

S-

Page 20

20

7.3.4 Scaler Schematic Diagram - VIDEO IN

TPF 1.3A LA

S-

7. Circuit Diagrams and PWB Layouts

Page 21

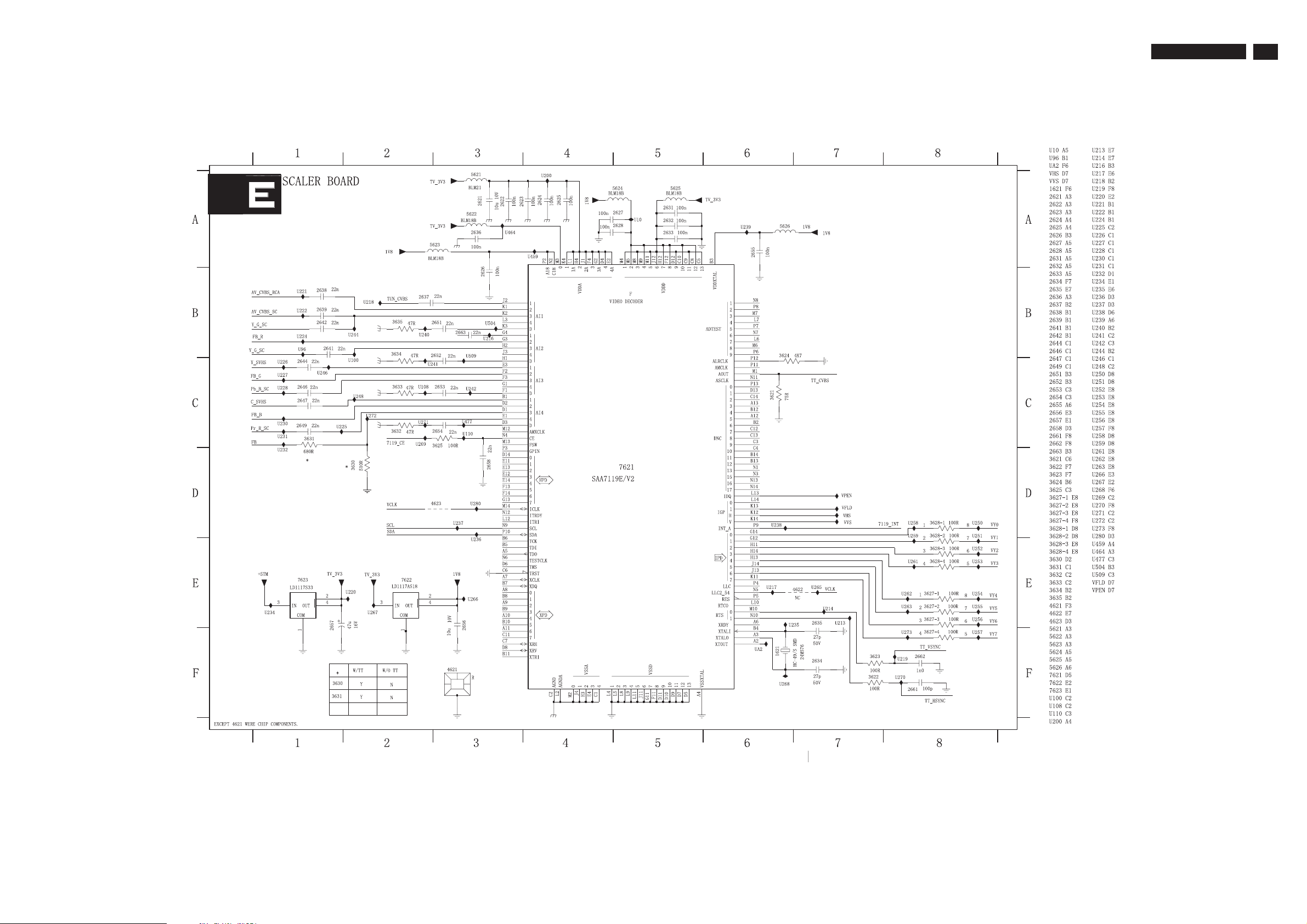

7.3.5 Scaler Schematic Diagram - VIDEO DECODER

S-

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

21

Page 22

22

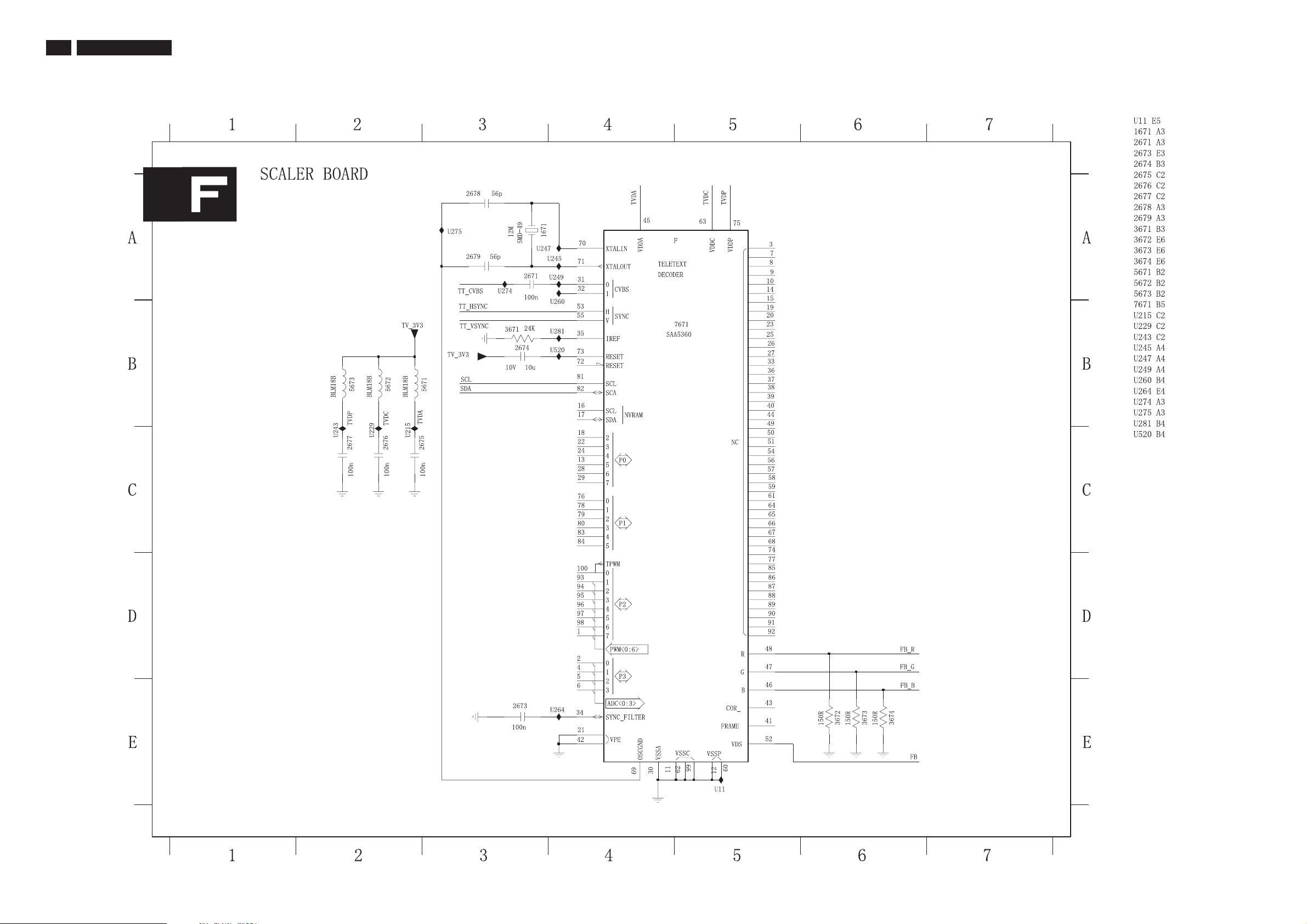

7.3.6 Scaler Schematic Diagram - T/T DECODER

TPF 1.3A LA

S-

7.Circuit Diagrams and PWB Layouts

Page 23

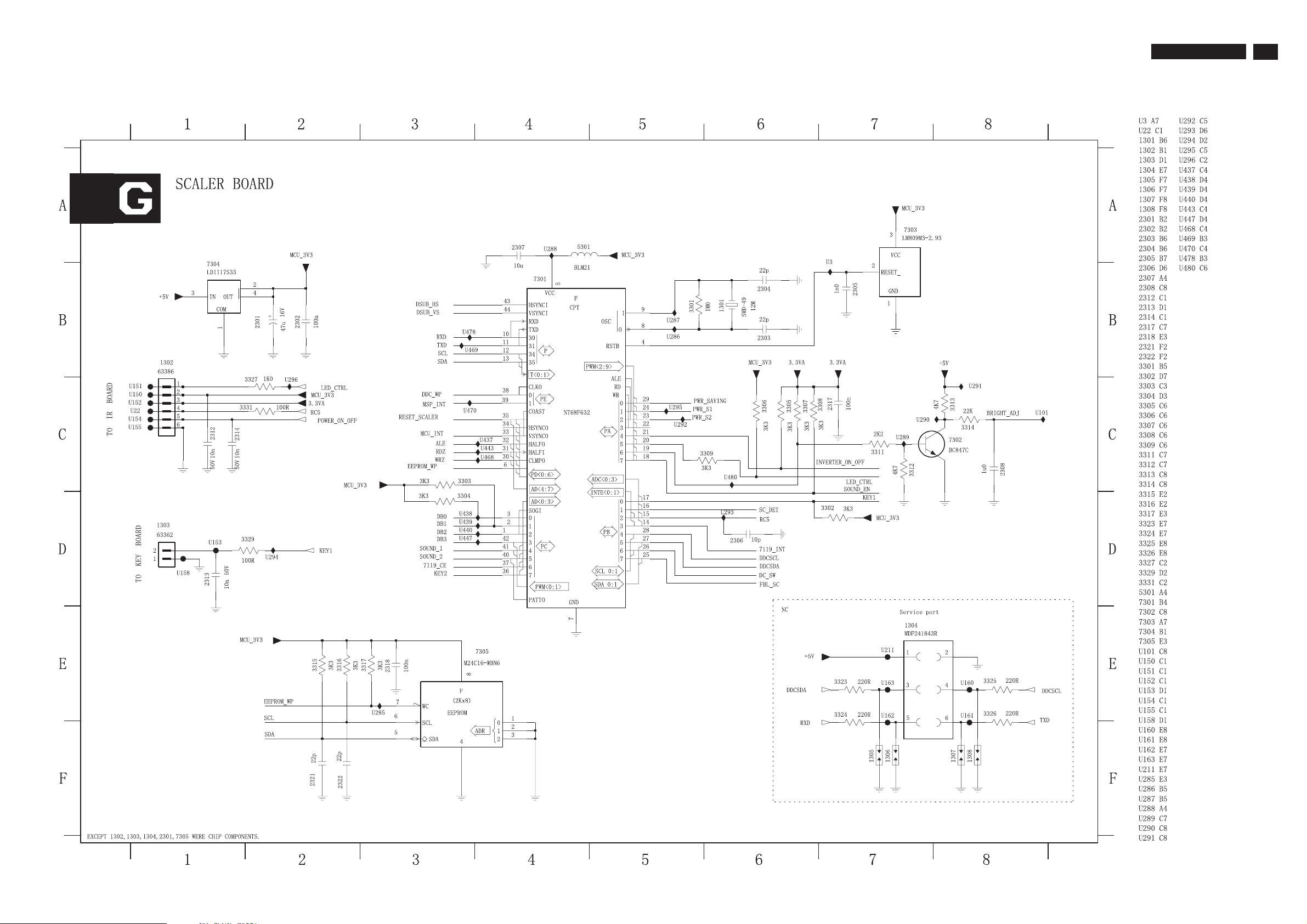

7.3.7 Scaler Schematic Diagram - MCU

S-

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

23

Page 24

24

7.3.8 Scaler Schematic Diagram - SCALER

TPF 1.3A LA

7. Circuit Diagrams and PWB Layouts

S-

Page 25

7.3.9 Scaler Schematic Diagram - SRAM

7. Circuit Diagrams and PWB Layouts

S-I

TPF 1.3A LA

25

Page 26

26

7.3.10 Scaler Schematic Diagram - Panel Interface

TPF 1.3A LA

7. Circuit Diagrams and PWB Layouts

S-J

Page 27

7.3.11 Scaler Schematic Diagram - SOUND DECODER

S-K

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

27

Page 28

28

7.3.12 Scaler Schematic Diagram - AUDIO

TPF 1.3A LA

S-L

7. Circuit Diagrams and PWB Layouts

Page 29

7.3.13 Scaler Board Layout-1

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

29

Page 30

30

TPF 1.3A LA

7.3.14 Scaler Board Layout-2

7. Circuit Diagrams and PWB Layouts

Page 31

7.4.1 Inverter Schematic Diagram

7. Circuit Diagrams and PWB Layouts

TPF 1.3A LA

31

Page 32

32

7.5 Key Board Schematic Diagram

TPF1.3A LA

K

7. Circuit Diagrams and PWB Layouts

Page 33

7.5 Key PCB Layout-1

7.Circuit Diagram & PWB Layouts

TPF1.3A LA

33

Page 34

34

7.5 Key PCB Layout-2

TPF1.3A LA

7. Circuit Diagrams and PWB Layouts

Page 35

7.6 IR PCB Schematic Diagram

I

7.Circuit Diagram & PWB Layouts

TPF1.3A LA

35

Page 36

36

TPF1.3A LA

7.6 IR PCB Layout-1

7. Circuit Diagrams and PWB Layouts

Page 37

7.6 IR PCB Layout-2

7.Circuit Diagram & PWB Layouts

TPF1.3A LA

37

Page 38

38

7.7 YPbPr-IN PCB Schematic Diagram

TPF1.3A LA

Y

7. Circuit Diagrams and PWB Layouts

Page 39

7.7 YPbPr-IN PCB Layout-1

Y

7.Circuit Diagram & PWB Layouts

TPF1.3A LA

39

Page 40

40

TPF1.3A LA

7.7 YPbPr-IN PCB Layout-2

7. Circuit Diagrams and PWB Layouts

Page 41

8. Alignments

TPF1.3A LA

41

8. Alignments

index of this chapter:

8.1 Electrical Instructions

8.2 DDC Instructions&Serial NO. Definition

8.3 DDC DATA

8.4 ISP Instructions

8.5 Display Adjustment

8.1 Electrical Instructions

1. General points

1.1 During the test and measuring, supply a distortion free AC mains

Voltage to the apparatus via an isolated transformer with low

internal resistance.

1.2 All measurements mentioned hereafter are carried out at a normal

mains voltage (90 - 132 VAC for USA version, 195 -264 VAC for

EUROPEAN version, or 90 - 264 VAC for the model with full range

power supply, unless otherwise stated.)

1.3 All voltages are to be measurement or applied with respect to

ground,unless otherwise stated.

Note: Don‘t use heat-sink as ground.

1.4 The test has to be done on a complete set including LCD panel

in a room with temperature of 25 +/- 5 degree C.

1.5 All values mentioned in these test instruction are only applicable

of a well aligned apparatus, with correct signal.

2.2 PC Input signal mode

PRE-LOAD VIDEO RESOLUTION

Mode 3, 6, 7 are preset modes that should pass QA inspection.

Mode 1, 2, 4, 5, 8 wil l r un aut o adjus tment o nly, and W/O QA

checking.

Dot rate (MHz) H.fr eq

(KHz)

1 25.175 31.469 IBM VGA 640 * 350 70.087

2 28.322 31.469 IBM VGA 720 * 400 70.087

3 25.175 31.469 IBM VGA 640 * 480 59.940

4 30.240 35.000 MACINTOSH 640 * 480 66.667

5 31.500 37.500 VESA 640 * 480 75.000

6 36.000 35.156 VESA 800 * 600 56.250

7 40.000 37.879 VESA 800 * 600 60.317

8 49.500 46.875 VESA 800 * 600 75.000

2.3 TV input signal Channel and pattern for China model (1)

Signal Distribution Table (PAL D)

Frequency Carriers

PRG CH

Video Sound

Mode Resolution V.freq (Hz)

TV System

Pattern

1.6 The letters symbols (B) and (S) placed behind the test instruction

denotes

(B): carried out 100% inspection at assembly line

(S): carried out test by sampling

1.7 The white balance (color temperature), has to be tested in subdued

Lighted room.

1.8 Repetitive power on/off cycle are allowed except it should be avoided

within 6 sec.

2. Input signal

---------------

2.1.1 PC Signal type

Analog Video : 0.7 Vp-p linear, positive polarity

Separate Sync. : TTL level, separate, positive or negative polarity

Audio signal : Mini-jack audio input

Input level: 500 mVrms (Speaker outpout 3W when Input level

> 630mVrms and Volume control at 100%)

TV Signal type

RF Signal : Aerial input, NTSC cable and antenna system.

Video signal : Cinch input, CVBS with NTSC and PAL system.

Level: 1.0Vp-p (0.7V video + 0.3V sync.)

S video input: Y/C signal, NTSC and PAL system.

Level: Y: 1.0Vp-p (0.7V video + 0.3V sync.)

C: +/- 0.3V.

Component input: Cinch G/B/R-> YPbPr cinch input.

Level: Y: 1.0Vp-p Pb/Pr: +/- 0.35V

Audio signal : Side cinch R/L for CVBS and S-video

Bottom cinch R/L for component input.

Input level: 500 mVrms (Speaker outpout 3W when Input level

> 630mVrms and Volume control at 100%)

C4 65.25MHz 71.75MHz

1

E7 184.25MHz 190.75MHz

2

E12 224.25MHz 230.75MHz

3

K21 471.25MHz 477.75MHz

4

G34 511.25MHz 517.75MHz

5

G62 547.25MHz 553.75MHz

6

M58 551.25MHz 557.75MHz

7

8

G47 615.25MHz 621.75MHz

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

PAL D

(CCIR)

Full Write

Circle

Pattern

Color Bar

Full Write

Circle

Pattern

Color Bar

Crosshatch

Color Bar

Table 1

Page 42

42

TPF1.3A LA

8. Alignments

3. TV mode display adjustment

3.1 White balance adjustment (B)

General set-up :

Equipment Requirements: Color analyzer.

Input requirements:

Input Signal Type : CVBS-PAL signal.

Frequency = 65.25 MHz (for China model).

Alignment method:

Initial Set-up : Set TV (7119) Brightness=120;

Contrast=70, Saturate=73,Tint=24 in

factory mode (can be fine tuned)

Set Smart picture as PERSONAL (Brightness=50,

Color=50, Contrast=50)

""

Apply 100IRE (100%) Full White pattern by TV pattern generator.

Alignment: Adjust the VIDEO SCALER GAIN R G B in Factory Mode

""

For NORMAL , COOL and WARM . (See Fig 1.)

[ Enter factory menu : press Volume - and Menu keys together

around six seconds]

Keep R=121 for the adjustment of NORMAL , COOL and WARM .

""

""""

""""

""

""

""

The 1931 CIE chromaticity (X, Y) co-ordinates shall be:

Picture Mode x y

Normal

Cool

Warm

0.287 ± 0.005 0.287 ± 0.005

0.275± 0.005 0.270± 0.005

0.315± 0.005 0.310± 0.005

Table 3.1: Readings with Minolta CA-110.

Gains NORMAL COOL WARM

R 127 119 128

G 118 109 111

B 114 112 91

4.3 Check the analog interface cable

Check the color poor & noise condition of 64-gray pattern.

5. HD mode display adjustment

5.1 White balance adjustment (B)

General set-up:

Equipment : Quantum Data Pattern Generator 801GD or 802G.

Apply 1080i, RGBW gray pattern.

FACTORY ADJUST MENU

NORMAL

SCALER GAIN R G B

AUTO-COLOR (OK)

ADC OFFSET R G B

ADC GAIN R G B

PC OFFSET R G B

7119 SDTV ? SAT TINT

TV SHIFT H V

HD SHIFT H V

RESERVE

HDTV ADC OFFSET R G B

HDTV ADC GAIN R G B

VIDEO SCALER GAIN R G B

SCALER HUE

EXIT Value

Fig-1

4.PC mode display adjustment

4.1 Display quality adjustment

Use timing mode as describe in 2.2, and use the POPO (pixel

on pixel off) pattern to adjust the clock until no stripe and

adjust the phase until clear picture.

(AUTO ADJUST hot key: press Volume- and Menu keys together

""

""

for 1 second.)

Check the 3 preset modes.

4.2 WHITE-D adjustment (B)

(Or FLUKE 54200, apply 576i, DIGITAL SCAN/DIGI_ADC1 pattern.)

Alig nment m ethod:

Initial Set-up: Set SA7119 as, Brightness=120;Saturation=70;

Contrast=73;Tint=24

Set Smart picture as Personal , Brightness=50,

""

Color=50, Contrast=50

Set AUTO-COLOR process.

Alignments: Make the VIDEO SCALER GAIN R G B same as TV mode.

Check chromaticity (X, Y) co-ordinates specification:

4.2.1 At factory mode apply 800x600/60Hz mode with 64 gray pattern.

Set main controls brightness control at 50% and contrast to 50% .

Select AUTO-COLOR function for ADC OFFSET and ADC GAIN

setup.

4.2.2 Set SCALER GAIN R G B

""

of NORMAL COOL and WARM

""

""

as:

Picture Mode x y

Personal/Normal

0.287 ± 0.015 0.287 ± 0.015

If out of specification, fine-tune HDTV ADC GAIN in factory mode

Page 43

8. Alignments

6. Preset EEPROM data

6.1 EEPROM data has to be preset data according following table.

Factory mode preset.

Function

SCALER GAIN

ADC Offset R/G/B

ADC Gain R/G/B

PC OFFset R/G/B

7119 brightness

PC Normal 127 118 114

PC Cool 119 109 112

PC Warm 128 111 91

120 (RF) 120(AV/SVHS/HD)

Preset value

127 127 127

127 127 127

127 127 127

TPF1.3A LA

HD(YPbPr) RICH NATURE SOFT MULTMEDIA PERSONAL

Brightness 48 40 30 46 50

Color 75 70 55 80 50

Contrast 60 57 57 67 50

Sharpness 79 58 58 87 50

Smart Sound

43

7119 Saturation

7119 contrast

7119 TINT

TV shift H

TV shift V

HD SHIFT H

HD SHIFT V

HD ADC OFFset R G B

HD ADC GAIN R G B

Video Scaler Gain

Scaler Hue

Factory mode:

6.2 Smart picture &Smart sound:

Regular

75 (RF) 70(AV/SVHS/HD)

75 (RF)

24 (RF) 24(AV/SVHS/HD)

73(AV/SVHS/HD)

NTSC PAL

146 162

914

##

##

127 127 127

127 127 127

127 127 127

50

Smart Sound : THEATRER

Sound volume :20

Incredible surround: OFF

AVL : OF F

6.2.1 Final TV mode out box setting.

RF channel: Channel 1

Format: 4:3

Language: Chinese

Smart picture: RICH(Cool)

Smart Picture

RF RICH NATURE SOFT MULTMEDIA PERSONAL

Brightness 43 40 39 50 50

Color 60 57 52 70 50

Contrast 60 50 45 56 50

Sharpness 41 33 29 50 50

AV/S-Video RICH NATURE SOFT MULTMEDIA PERSONAL

Brightness 40 38 35 45 50

Color 52 54 49 63 50

Contrast 60 52 45 60 50

Sharpness 75 58 50 70 50

Page 44

44

TPF1.3A LA

8. Alignments

8.2 DDC Instructions&Serial NO. Definition

General

DDC Data Re-programming

In case the DDC data memory IC or main EEPROM which storage all

factory settings were replaced due to a defect, the serial numbers have

to be re-programmed "Analog DDC IC, Digital DDC IC & EEPROM".

It is advised to re-soldered DDC IC and main EEPROM from the old

board onto the new board if circuit board have been replaced, in this case

the DDC data does not need to be re-programmed.

Additional information

Additional information about DDC (Display Data Channel) may be

obtained from Video Electronics Standards Association (VESA).

Extended Display Identification Data(EDID) information may be also

obtained from VESA.

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98 .

Y o Install the EDID_PORT_Tool under Win2000/XP . As

ou have t

Fig. 1 .

Note: The alignment box has already build-in a batteries socket for

using batteries (8~12V) as power source. Pull out the socket by

remove four screws at the rear of box. Please do not forget that

remove batteries after programming. The energy of batteries can

only drive circuits for a short period of time.

Pin assignment

A. 15-pin D-Sub Connector

PIN No. SIGNAL

1Red

2Green

3Blue

4GND

5GND

6RedGND

7GreenGND

8BlueGND

9 +5V (Supply from PC)

10 Sync GND

11 GND

12 Bi-directional data

13 H-sync

14 V-sync

15 Data clock

A. Cody the "UserPort.sys" to C:\WINNT\system32\drivers(win2000)

C:\WINDOWS\system32\drivers(winXP)

B. Running " io.exe" everytime, Before you start to programming

edid data .

3. EDID46.EXE program

4. A/D Alignment kits (12NC: 3138 106 10396):

inclusion : a. Alignment box x1 (Fig. 2)

Fig.1

b. Printer cable x1

c. (D-Sub) to (D-Sub) cable x1

Fig. 2

Page 45

8. Alignments

TPF1.3A LA

45

Configuration and procedure

There is no Hardware DDC (DDC IC) anymore. Main EEPROM stores

all factory settings and DDC data (EDID code) which is also called

Software DDC. The following section describes the connection and

procedure for Software DDC application. The main EEPROM can be reprogrammed by enabling '' factory memory data write'' function on the

DDC program (EDID46.EXE).

Initialize alignment box

In order to avoid that monitor entering power saving mode due

to sync will cut off by alignment box, it is necessary to initialize

alignment box before running programming software

(EDID46.EXE). Following steps show you the procedures and

connection.

Step 1: Supply 8-12V DC power source to the Alignment box by

plugging a DC power cord .

Step 2: Connecting printer cable and D-Sub cable of monitor as Fig. 4

PC

1= Power connector

2= D-SUB connector

3. At the submenu, type the letter of your computer's hard disk drive

followed by :EDID46 (for example, C:\EDID46, as shown in Fig. 6).

1

Fig. 6

4. Click OK button. The main menu appears (as shown in Fig. 7).

This is for initialize alignment box.

DC Power

8-12 V

----->

2

To printer port (LTP1)

Printer

Port

To

Monitor

To P C

----->

1

Fig. 4

Step 3: Installation of EDID46.EXE

Method 1: Start on DDC program

Start Microsoft Windows.

1. The Program"EDID46.EXE" in service manual cd-rom be copyed to C:\ .

2. Click , choose Run at start menu of Windows as shown

In Fig. 5.

Fig. 5

Fig. 7

Note 1: If the connection is improper, you will see the following error

message (as shown in Fig. 8) before entering the main menu.

Meanwhile, the (read EDID) function will be disable. At this

time, please make sure all cables are connected correctly and

fixedly, and the procedure has been performed properly.

Fig. 8

Note 2: During the loading, EDID46 will verify the EDID data which just

loaded from monitor before proceed any further function, once

the data structure of EDID can not be recognized, the following

error message will appear on the screen as below. Please

confirm following steps to avoid this message.

1. The data structure of EDID was incorrect.

2. DDC IC that you are trying to load data is empty.

3. Wrong communication channel has set at configuration setup

windows.

4. Cables loosed or poor contact of connection.

Fig. 9

Page 46

46

TPF1.3A LA

Re-programming Analog DDC IC

Step 1: After initialize alignment box, connecting all

cables and box as shown in Fig. 10.

PC

1= Power connector

2= D-SUB connector

8. Alignments

DC Power

8-12V

To printer port (LTP1)

To P C Video port (D-sub)

Printer

Port

To

Monitor

To P C

1

2

----->

----->

Step 2: Read DDC data from monitor

1. Click icon as shown in Fig. 11 from the tool bar to bring up

the Channels "Configuration Setup" windows as shown in Fig. 11.

=====>

Click this button

Fig. 11

2. Select the DDC2Bi as the communication channel.

As shown in Fig. 12.

Fig. 10

Fig. 13

Step 3: Modify DDC data (verify EDID version, week,

year)

Click (new function) icon from the tool bar, bring up

Step 1 of 9 as shown in Fig. 14 .

EDID46 DDC application provides the function selection and

text change (select & fill out) from Step 1 to Step 9.

Select and fill out,

If necessary.

Fig. 14

Step 4: Modify DDC data (Monitor Serial No.)

1. Click Next , bring up Fig. 15.

Fig. 12

3. Click OK button to confirm your selection.

4. Click icon (Read EDID function) to read DDC EDID data from

monitor. The EDID codes will display on screen as shown in Fig. 13.

Fig. 15

Page 47

2. Click Next , bring up Fig.16.

8. Alignments

5. Click Next , bring up Fig.19.

Fig. 16

TPF1.3A LA

47

Fig. 19

3. Click Next , bring up Fig.17.

4. Click Next , bring up Fig.18.

6. Click Next , bring up Fig. 20.

In this step, you can modify the SN as below.

Fig. 17

Fig. 20

7. Click Next , bring up Fig. 21.

Fig. 18

Fig. 21

Page 48

48

8. Click Next , bring up Fig. 22.

TPF1.3A LA

- Click Finish to exit the Step window.

- Serial number can be filled up at this moment (for example,

923418).

8. Alignments

4). Click (Write EDID) icon from the tool bar to write DDC data.wait

for 5 seconds ,DDC data will be finished Writing.

Step 6: Save DDC data

Sometimes, you may need to save DDC data as a text file

for using in other IC chip. To save DDC data, follow the

steps below:

1. Click (Save) icon (or click "file"-> "save as") from the tool

bar and give a file name as shown in Fig. 25.

The file type is EDID46 file (*.ddc) which can be open in

WordPad. By using WordPad, the texts of DDC data & table

(128 bytes, hex code) can be modified. If DDC TEXTS &

HEX Table ar completely correct, it can be saved as .ddc flie

to re-load it into DDC IC for DDC Data application.

Step 5: Write DDC data

1. Configuration should be as Fig. 23. And press OK.

Fig. 22

Fig. 23

20TA1000

20TA1000 analog

Fig. 25

2. Click Save.

Step 7: Exit DDC program

Pull down the File menu and select Exit as shown in Fig. 26.

2. Access Factory Mode

1). Turn off monitor.

2).

Press power " " button.Then quickly push"+"and"-"of

Volume ,and hold this two buttons , then the screen comes out

"Waiting For Automatic Adjustment ",then the screen will be black

for one second untill comes out "Windows screen"] => then

release this two buttons.

3). Press "MENU" button, wait u ntil the OSD menu appears

(See Fig.24).

Fig. 24

----------------->

Factory Mode

3) Push Menu to exit OSDmenu.""

Step 8: Turn off the monitor, exit the factory mode.

Fig. 26

Serial NO. definition

Indicator

Page 49

8. Alignments

TPF1.3A LA

49

8.3 DDC DATA

Display data channel : DDC2B

DDC DATA

Use a computer with DDC communication capability to read the

DDC2B display identification data from the monitor.

AUO panel:

**********************************************************************

EDID log file

**********************************************************************

Vendor/Product Identification

ID Manufacturer Name : PHL

ID Product Code : 4650 (HEX.)

ID Serial Number : 1010101 (HEX.)

Week of Manufacture : 39

Year of Manufacture : 2005

EDID Version, Revision

Version : 1

Revision : 3

Basic Display Parameters/Features

Video Input Definition : Analog Video Input

0.700V/0.300V (1.00Vpp)

without Blank-to-Black Setup

Separate Sync

without Composite Sync

without Sync on Green

no Serration required

Maximum H Image Size : 41

Maximum V Image Size : 31

Display Transfer Characteristic : 2.4

(gamma)

Monitor Descriptor #3

Monitor Name : PHL TA1000

Monitor Descriptor #4

Monitor Range Limits

Min. Vt rate Hz : 56

Max. Vt rate Hz : 62

Min. Horiz. rate kHz : 30

Max. Horiz. rate kHz : 40

Max. Supported Pixel : 40

No secondary GTF timing formula supported.

Extension Flag : 0

Check sum : AF (HEX.)

***********************************************************

EDID data (128 bytes)

***********************************************************

0: 00 1: ff 2: ff 3: ff 4: ff 5: ff 6: ff 7: 00

8: 41 9: 0c 10: 50 11: 46 12: 01 13: 01 14: 01 15: 01

16: 27 17: 0f 18: 01 19: 03 20: 08 21: 29 22: 1f 23: 8c

24: ee 25: fc 26: 60 27: a5 28: 55 29: 4a 30: 9c 31: 23

32: 10 33: 46 34: 4b 35: 23 36: 00 37: 00 38: 01 39: 01

40: 01 41: 01 42: 01 43: 01 44: 01 45: 01 46: 01 47: 01

48: 01 49: 01 50: 01 51: 01 52: 01 53: 01 54: 00 55: 00

56: 00 57: ff 58: 00 59: 0a 60: 20 61: 20 62: 20 63: 20

64: 20 65: 20 66: 20 67: 20 68: 20 69: 20 70: 20 71: 20

72: 00 73: 00 74: 00 75: ff 76: 00 77: 0a 78: 20 79: 20

80: 20 81: 20 82: 20 83: 20 84: 20 85: 20 86: 20 87: 20

88: 20 89: 20 90: 00 91: 00 92: 00 93: fc 94: 00 95: 50

96: 48 97: 4c 98: 20 99: 54 100: 41 101: 31 102: 30 103: 30

104: 30 105: 0a 106: 20 107: 20 108: 00 109: 00 110: 00 111: fd

112: 00 113: 38 114: 3e 115: 1e 116: 28 117: 04 118: 00 119: 0a

120: 20 121: 20 122: 20 123: 20 124: 20 125: 20 126: 00 127: af

Feature Support (DPMS) : Standby

Display Type : RGB color display

Standard Default Color Space : Primary color space

Preferred Timing Mode : Detailed timing block 1

Color Characteristics

Red X coordinate : 0.647

Red Y coordinate : 0.335

Green X coordinate : 0.292

Green Y coordinate : 0.609

Blue X coordinate : 0.138

Blue Y coordinate : 0.064

White X coordinate : 0.273

White Y coordinate : 0.293

Established Timings

Established Timings I : 640 x 480 @60Hz (IBM,VGA)

800 x 600 @56Hz (VESA)

800 x 600 @60Hz (VESA)

Established Timings II :

Manufacturer's timings :

Standard Timing Identification : Unused

Monitor Descriptor #1

Serial Number :

Suspend

Active Off

Monitor Descriptor #2

Serial Number :

Page 50

50

TPF1.3A LA

8.4 ISP Instructions

Configuration and procedure

"Easywriter " The software is provided by Novatek to upgrade the

firmware of CPU.

It is a windows-based program, which cannot be run in MS-DOS.

DDC2BI_ISP TOOL (3138 149 53161) is for the interface between

"Parallel Port of PC" and "15 pin-D-SUB connector of Monitor".

8. Alignments

System and equipment requirements

1. An i486 (or above) personal computer or compatible.

2. Microsoft operation system Windows 95/98/2000/XP.

3. ISP Software " Easywrite "

4. as shown in Fig. 1

DDC2BI_ISP TOOL (3138 106 10396)

D-SUB to monitor

Parallel Port to Print Port in PC

Fig. 1

5. Connect and Mains cord to Monitor as shown

in Fig. 2.

DDC2BI_ISP TOOL

Monitor (A)

PC

Ta1000 -Monitor (B)

D-Sub

Fig. 4

Step 5 :Copy the hex code to C:\Ta1000 as shown in Fig. 5 .

2oTA1000

Fig. 5

Update the firmware

1. Double click the Easywriter.exe icon in desktop then appears

window as shown in Fig.7 .

Connect to Mains

Connect to

Mains cord

Video cable

6. Install and setup the Easywriter program

Step 1 : Make a folder in your PC as shown in Fig. 3.

For example : C:\Ta1000

Step 2 : Copy ISP Software Easywriter into your folder

as shown in Fig.3.

Step 3 : Unzip Easywriter.zip into your folder as shown in Fig. 3.

Step 4 : Double click the EasywriterV2.09a_user.exe icon to install the

Application as Fig. 4.

To video card

Fig.2

.zip

cord at this moment.

ISP box

To printer port (LTP1)

------------------------------->

Fig. 3

Fig. 6

Fig. 7

2. Press the Load hex then select the hex as shown in Fig. 8.

Page 51

8. Alignments

Fig. 8

3 Press the AUTO to running program , the firmware be updated

as shown in Fig. 9~10.

TPF1.3A LA

If there is a warring message coming as shown in Fig 12. , you

have to check the AC power, Video cable, or Novatek MCU.

Fig. 12

5 Check the firmware version

51

Fig. 9

Fig. 10

4 Press the file --> exit to end program , as shown in Fig. 11.

1). Turn off monitor.

2).

Press power " " button.Then quickly push " + " and " - "of

Volume ,and hold this two buttons , then the screen comes out

"Waiting For Automatic Adjustment ",then the screen will be black

for one second untill comes out "Windows screen"] => then

release this two buttons.

3). Press "MENU" button, wait until the OSD menu come on the

Screen of the monitor,You will find, after upgrade, the version

have already been changed as shown in

Fig. 13 and Fig. 14.

Fig. 13

Factory Mode indicator

Fig. 11

Fig. 14

Factory Mode indicator

4) Turn off the monitor, exit the factory mode.

Page 52

52

TPF1.3A LA

8. Alignments

8.5 Display adjustment

Access Factory Mode

1). Select the source"PC" and turn off monitor.

2).

Press power ""button.Then quickly push " + " and"-"of

Volume ,and hold this two buttons , then the screen comes out

"Waiting For Automati

for one second untill comes out"Windowsscreen"] => then

release this two buttons.

3). Press "MENU" buttona nd bring upfactorymode indication as

shown in Fig.1

Use the CHNNEL- and CHNNEL+ to selectthe"

V0.88 051228AV20SVGA

c Adjustment ",then the screen will be black

Fig. 1

CHINA 20TA1000

" and then press the "VOL +" button

2.1 Aim the probe CA-A30 atthecenterofscreen asFig.4

2.2 Remove the lens protective coverofprobe CA-A30.

2.3 Set Measuring/viewing selector toMeasuring positionfor reset

analyzer. (Zero calibration) asFig.5

2.4 Turn onthecolour analyzer (CA-110).

2.5 Press 0-CAL buttonto start

reset analyzer. See Fig. 6

Measurement viewing selector

Fig.4

Cover (black)

Fig.5

O-CAL

Fig.6

Fig.2

PC mode WHITE-D adjustment (B)

1 Apply 800 X600/60Hz mode with 5 blockpattern as Fig 3. Set

main controls brightness control at 50% and contrast to 50% on

User mode. Set color setting atnatural color on User mode. Move

cursor to "AUTO-color" item onfactorymode, press "menu" key

toactivethisf

RGB automatically by it self.

2. Apply a 800*600 / 60Hz signal with full white pattern, set

brightness control at 50%, and contrast control at 50%.

R.G.B gain toreachspecial color temperature o n centerofscreen.

unction, then scalerwill adjust RGB and Color

Fig.3

Adjust the

2.6 Switch light probe to Viewing position.

2.7Move the Lens barrel forward or backwardto get clear image as

showninFig.7

2.8 Switch light probe toMeasuring position. It should be able to

indicate colour value ontheCA-110.

Clear image

Measurement/viewing selector

Fig.7

Readings with MinoltaCA-110.

2.9 Set Smartpicture asWARM , and COOL The SCALER GAIN

RGB=

.

Gains NORMAL COOL WARM

R127 119 128

G 118 109 111

B 114 112 91

Page 53

Index of this chapter

9.1 Trouble shooting

9.2 Circuit Description

9.3 IC Data Sheets

9.4 Repair Flow Chart

No Power

Check the TV power cord. Unplug the TV, wait 10

seconds, then reinsert the plug into the outlet and

push the POWER button again.

. Check that the outlet is not on a wall switch.

. Be sure the fuse is not blown on the AC power

strip, if one is being used.

No Pi ctu re

. Check antenna/cable connections. Are they properly

secured to the TV

. Try running the Auto Program feature to find all

available channels.

. Press the AV button on the remote to make

sure the correct signal source is selected.

. If using an accessory device, be sure that it is

functioning properly.

. If in PC Mode, a video signal MUST BE present or

the TV will turn off.

No Sound

. Check the VOLUME buttons.

. Check the MUTE button on the remote control.

.Ifyou

equipment, check the audio jack connections.

No AV Signal

. Check whether AV and S-Video sockets connected

simultaneously. If they are, disconnect the S-Video

socket. AV signal automatically overrides the S-Video

signal if both sockets are connected simultaneously.

S-VHS Color Becomes Faint

. Unplug socket for S-Video connection. Reconnect

the S-Video socket of the TV carefully to the VCR

socket.

TV Only Produces MONO Sound

. If using a cable box with RF only type connections,

the signal coming from the cable box will be

produced in MONO only.

. Check Sound control setting. Change setting to

Stereo.

re attempting to hook up auxiliary

Remo te Does Not Wo rk

. Check the batteries. Place lithium cell in the

remote. Be sure the (+) and (-) ends of the batteries

line up as marked inside the battery compartment.

. Clean the remote control and the remote control

sensor window on the TV.

. Check the TV power cord. Unplug the TV, wait 10

seconds,then reinsert the plug into the outlet and

push the POWER button again.

. Be sure the fuse is not blown on the AC power

strip, if one is being used.

. Check to be sure the TV outlet is not on a wall

switch.

. Be sure that the remote is in the correct operating

mode.

. Be sure the remote is pointed at the Remote

Sensor Window on the TV. See page 2 of the Quick

Use Guidefor details.

sANT75 plug?

9. Troubleshooting

TPF1.3A LA

TV Displays Wrong Channel or No Channels

Above 13

. Repeat channel selection.

. Add the desired channel numbers (using the

CHANNEL EDIT control) into the TV

. Run the Auto Program feature to find all available

channels.

s memory.

53

Page 54

54

TPF1.3A LA

9.Trouble Shooting

9.2Circuit Description

1. General Des cript ion

This LCD-TV-F1 support PC analog input up to 800X600 75Hz mode for SVGA panel, and support TV (RF), YC,

andCVBS. Also for Y Pb Pr signal input from SDTV to HDTV (480I, 480P, 720P, 1080i 60Hz and 576I, 576P, 720P,

1080I 50Hz).

This LCD - TV use MST51502as Scaler engine, which has embedded Analog D-sub, digital DVI decoder, scaling

input signal to panel OSD mapping and simple 3D de-interlacer. The extra SDRAM is to accomplish video frame rate

conversion and PIP function.

The external CPU can be used to back light control, RC, keypad input, IIC I/O communication and. TV tuning control,

sound control, and SAA7119A video decoder.

Video decoder SAA7119 is used for TV video processing and convert it with CCIR 601/16bits or 656/8bits digital

format and send to Scaler for de-interlace process, and also CC,V-chip data decode.

One audio decoder MSP3415G is used for TV sound processing, and output to post amplifier .

2. System block d iagram

Page 55

9. Troubleshooting

Circuit Description

3. Function description:

MM tuner is used to receive RF wave and output CVBS and 2nd IF signal. CVBS is to video decoder

(SAA7119) for color process, 2nd IF is to sound decoder (MSP3415) for audio process. The tuner control is via IIC ex.

channel tuning..

Stan dard TV input (Tuner, S-video, CVBS) is processed by SAA7119, But YPbPr, SDTV and HDTV(480i, 576i,

480p,576p,720p,1080i), is done by scaler MST51502LADC. But the signal is still link to SAA7119 if PIP (video in graph)

function is requested. Then all YPbPr signal processed by SAA7119 could be the PIP video source. (* May use down

sampling in HD0)

MV protect is decoded by scaler.

Vid eo dec od er SAA7119, is in charge of color decoding, could support PAL, NTSC and SECAM world wide

system. Compare to SAA7118, SAA7119 improve some picture quality, like V-chip CC I2C read-back, LTI, CTI, skin tone

correction(see task A), also the HD0 is supported.

Sou nd deco der MSP3415 is responsible to sound decode of tuner 2

sources input. Due to the input port limitation, a MUX is added for AV source select( PC audio in is sent to msp3415). If

the post audio amplifier is gain fixed type then the volume adjust will be on MSP3415.

Scal er MST51502L besides scaling function, PIP, 3D de-interlacer, color enhance are major feature.

Even de-interlacer is not so good but for static picture is enough to avoid image sticking.

The scaler structure limitation, the PIP source only from “video port”, 8 bits or 16 bits. The sub window /PIP size can

enlarge to half screen.

MCU, NT68F632AL, is 128K flash ROM inside. Power control, RC5 I/O, and key function all done by here, more detail

function will description in chapter 4.later.

nd

IF. It has one 2nd IF, one loudspeaker audio

TPF1.3A LA

55

All chip communication is by IIC (SDA/SCL), and ISP is via DDCIIC.

Page 56

56

TPF1.3A LA

9.Trouble Shooting

9.3 IC DATA SHEETS

9.3.1 IC DATA SHEETS - MST51502L (7401)

Page 57

IC Data Sheet

9. Troubleshooting

TPF1.3A LA

57

Page 58

58

TPF1.3A LA

IC DATA SHEETS

9.Trouble Shooting

Page 59

IC Data Sheet

9. Troubleshooting

TPF1.3A LA

59

Page 60

60

TPF1.3A LA

IC DATA SHEETS

9.Trouble Shooting

Page 61

IC Data Sheet

9. Troubleshooting

TPF1.3A LA

61

Page 62

62

TPF1.3A LA

9.3.2 IC DATA sheets - SAA7119 (7302)

Block Diagram & Pin Configuration

9.Trouble Shooting

Page 63

9.3.3 IC Data Sheet-MCU68F632(7301)

9. Troubleshooting

TPF1.3A LA

63

Page 64

64

TPF1.3A LA

IC DATA sheets

9.Trouble Shooting

Page 65

9. Troubleshooting

TPF1.3A LA

65

Page 66

66

TPF1.3A LA

9.Trouble Shooting

Page 67

9. Troubleshooting

TPF1.3A LA

67

Page 68

68

TPF1.3A LA

9.Trouble Shooting

Page 69

9. Troubleshooting

TPF1.3A LA

69

Page 70

70

TPF1.3A LA

9.3.4 IC DATA SHEET-TPA3005D2(7151)

9.Trouble Shooting

Page 71

9. Troubleshooting

TPF1.3A LA

71

Page 72

72

TPF1.3A LA

9.3.5 IC DATA SHEET-MSP3415G(7101)

9.Trouble Shooting

Page 73

Repair Flow Chart

TPF1.3A LA

73

1.No Work/LED is off

Check if

power switch

is normal

Yes

Check if AC

adaptor output

=16V

Yes

Check the inverter board

No

No

Replace power switch

Replace power adaptor

3.No picture/LED

is green

Check if working voltage

pin3=3.3Vof7303

3307=3.3V 3313=5V

1304 Pin1=5V

Check if clock source

1401,1301,1621

Yes

Check if scaler 7401

RGB,clk,H/V and

DE signal output

48 bits TTL

Yes

Check circuit around

No

each regulator and

eliminate short and

open situation

No

Replace 1401,13

Try to replace

CPUorCPU'Sflash Rom

No

CPU'S EEPROM

Painter

Painter's EEPROM

01,1621

2.No raster/picture

too dim

Check if 1001 on

scaler board

pin1,2,3=16V

pin 5=0~4.7V

Yes

Check if 1302 on

scaler board

pin3=3.3V

No

No

Check working

voltage, backlight

control signal and

brightness control

signal on scaler board

Check IR board

Check resistorsnetwork

Yes

Replace LVDS cable

No

Replace LCD panel

4.No D-Sub picture

Check if H/V

signals input to

schmitt trigger

7201

Yes

Check if schmitt

trigger 7201

output H/V signals

to JAGASM

No

No

No

Replace bad resistorsnetwork

Check input path

Replace 7201

Yes

Go to 3.No picture/LED is green

Page 74

74

TPF1.3A LA

5.no TV sound

Repair Flow Chart

8.LED and

function key poor

Check if tuner 1501

pin 10 output 2nd IF

signal

Yes

Chenck 7901

6. No earphone

sound

Check TPA3005D2

7151 5162=16V

Yes

Check TPA3005D2 7151

PIN 2=MSP-OUT-R

PIN 6=MSP-OUT-L

No

No

Eliminate short and open

situation

No

Replace 1501

Check circuit around

control board and

cable between

control board and

scaler board

Replace 7151

Yes

Replace phone Jack Board

7. No remote

function

Try another remote

control

No

Check IR receiver

Yes

Replace one good

remote control

Page 75

10. Spare Parts List - 1

TPF1.3A LA

75

Model type:20TA1000/93(AUO Panel)

Mechanical parts

0007 313815760961 BASE ASSY

0011 313815760891 BEZEL ASSY

0030 313815417671 BEZEL

0031 313815414921 LENS-IR

0032 313815414911 POWER BUTTON

0040 313815414961 BACK COVER

0051 313815136512 MAIN FRAME

0053 313815414981 GASKET( 20x20x30L)

0091 313815414931 CONTROL BUTTON

0093 313815136441 SHIELD - SCALER

0109 313815040511 NUT-AUDIO JACK

LCD Panel

1050 932222563682 TFT-LCD A201SN02V4 (AUOP) B

Packing

0129 313810650281 P.E. BAG (INSTR. BOOK)

0450 313815641771 CARTON

0451 313815641781 CUSHION-L

0452 313815641791 CUSHION-R

0453 313815640141 P.E. FOAM BAG(750 X 800)

0458 313815636362 P.E.BAG 275x320 mm

0506 313815641771 CARTON

0523 313815641771 CARTON

Accessory

0041 313815414971 DOOR-CABLE

0126 313815568821 RATING LABEL

0141 313815524141 QUICK SETUP GUIDE

0143 313912553585 CHINA GUARANTY CARD /93

0145 313815524151 USER'S MANUAL

0176 313810539241 PASS CARD LABEL

0289 313800992061 PROCESS BOX

0291 313815568831 LABEL

0292 313815568831 LABEL

PCB ASSY

1051 313815864011 SCALER ASSY(CHINA 20 AUO)

1052 313815860801 YPbPr-IN PCB ASSY

1053 313815860881 KEY BOARD ASSY

1054 313815860811 IR PCB ASSY

Miscellanea

0615 313811709211 HEX CODE OF F/W(NO MATL REQ)

1001 242202518821 CON V 8P M 2.00 63388 B

1002 242208611053 FUSE SM F 7A 125V UL R

1003 242202605309 SOC SUPP H 1P M DC 2.5MM L

4444 313810650010 CD ROM - SERVICE MANUAL

8161 313819874701 CBLE-266 6/360/6-266 AWG28

8174 313819874641 FFC 50/270/50 PITCH 0.5mm

8175 313819874671 CBLE-018 8/180/8-018 AWG28

8176 313819874651 CBLE-012 2/180/2-001 AWG28

PCB ASSY

1051 313815864011 SCALER ASSY(CHINA 20 AUO)

Various

1101 242254301364 RES XTL SM 18M432 16P SMD-49 R

1151 242202518888 CON H 2P M 2.50 69072 B

1152 313816877251 EARPHONE JACK

1153 242202518894 CON H 2P M 2.00 63362 B

1172 313818871651 MAINSCORD CCEE 10A 1M8 DET BK

1176 313923812901 PROD ASSY RC19335016/01B PKD

1177 313818876601 CON ACC ADP V 01P M 0.00/PAL B

1180 313815862162 MAIN FRAME+WIRE ASSY(AUO)

1183 313819876641 PSU OPENFR INVBL6 (DAC-16T003

1184 313819876631 PSU ADAPT 16V 60W (EADP-60FB B

1185 313819875451 LSP BOX 8R 3W - R (P150CR)

1186 313819875441 LSP BOX 8R 3W - R (P150CL)

1201 242202518053 SOC SUBD H 15P F BU 1216 B

1211 243803100429 SOC PHONE H 1P F 3.5 ST B

1251 242202518817 CON V 5P M 2.00 63385 B

1253 242202605451 SOC CINCH H 2P F 1L2 WHRD B

1254 242202605452 SOC CINCH H 3P F 1L3 YEWHRD B

1255 243803100431 SOC MDIN H 4P F 69015 B

1301 242254301501 RES XTL SM 11M059 20P HC49/S R

1302 242202518818 CON V 6P M 2.00 63386 B

1303 242202518894 CON H 2P M 2.00 63362 B

1305 243803100435 SOC IC V 8P F 2.54 DIL L

1401 243854300093 RES XTL SM 14M3181 18P SMD49 R

1501 313815862251 SDRAM ASSY (ISSI)

1553 242202518229 CON H 50P F 0.50 SM FPC 0.3 R

1601 313914723781 FRONTEND FQ1256/I H-5

1621 243854300089 RES XTL SM 24M576 16P HC49/S R

2001 223858619812 CER2 0603 Y5V 50V 100N P8020 R

2002 223858619812 CER2 0603 Y5V 50V 100N P8020 R

2003 202203100173 ELCAP EB 25V S 470U PM20 B

2004 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2005 202203100173 ELCAP EB 25V S 470U PM20 B

2006 223858015641 CER2 0805 X7R 50V 22N PM10 R

2007 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2008 223858015641 CER2 0805 X7R 50V 22N PM10 R

2009 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2011 223858015614 CER2 0805 X7R 50V 220P PM10 R

2012 202203100173 ELCAP EB 25V S 470U PM20 B

2013 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2014 223858015614 CER2 0805 X7R 50V 220P PM10 R

2016 223858619812 CER2 0603 Y5V 50V 100N P8020 R

2019 202203100367 ELCAP SK 16V S 47U PM20 B

2021 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2022 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2023 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2024 202203100367 ELCAP SK 16V S 47U PM20 B

2025 223858619805 CER2 0603 Y5V 50V 10N P8020 R

2026 223878619856 CER2 0603 Y5V 16V 330N P8020 R

2101 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2102 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2103 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2104 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2105 223886715159 CER1 0603 NP0 50V 15P PM5 R

2106 223886715479 CER1 0603 NP0 50V 47P PM5 R

2107 223878615649 CER2 0603 X7R 16V 100N PM10 R

2108 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2109 223824615654 CER2 0603 X7R 10V 220N PM10 R

2111 223878615649 CER2 0603 X7R 16V 100N PM10 R

2112 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2113 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2114 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2115 223858615632 CER2 0603 X7R 50V 4N7 PM10 R

2116 223858615632 CER2 0603 X7R 50V 4N7 PM10 R

2121 223886715159 CER1 0603 NP0 50V 15P PM5 R

2122 223886715159 CER1 0603 NP0 50V 15P PM5 R

2123 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2124 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2131 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2132 223878615649 CER2 0603 X7R 16V 100N PM10 R

2133 223878615649 CER2 0603 X7R 16V 100N PM10 R

2134 223878615649 CER2 0603 X7R 16V 100N PM10 R

2135 223878615649 CER2 0603 X7R 16V 100N PM10 R

2136 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2137 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2138 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2139 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2152 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2153 223891019854 CER2 0805 Y5V 25V 220N P8020 R

2154 223886715101 CER1 0603 NP0 50V 100P PM5 R

2155 223858119716 CER2 1206 Y5V 50V 470N PM20 R

2156 223886715101 CER1 0603 NP0 50V 100P PM5 R

2157 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2158 223891019854 CER2 0805 Y5V 25V 220N P8020 R

2161 223858615623 CER2 0603 X7R 50V 1N PM10 R

2162 223858615623 CER2 0603 X7R 50V 1N PM10 R

2163 223824619858 CER2 0603 Y5V 10V 470N P8020 R

2164 223824619858 CER2 0603 Y5V 10V 470N P8020 R

2165 223824619858 CER2 0603 Y5V 10V 470N P8020 R

2166 223824619858 CER2 0603 Y5V 10V 470N P8020 R

2167 223824619858 CER2 0603 Y5V 10V 470N P8020 R

2168 223891019854 CER2 0805 Y5V 25V 220N P8020 R

2169 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2172 223886715101 CER1 0603 NP0 50V 100P PM5 R

2173 223858119716 CER2 1206 Y5V 50V 470N PM20 R

2174 223886715101 CER1 0603 NP0 50V 100P PM5 R

2175 223891019854 CER2 0805 Y5V 25V 220N P8020 R

2176 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2177 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2178 202203100366 ELCAP SK 50V S 10U PM20 B

2179 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2181 223886115221 CER1 0805 NP0 50V 220P PM5 R

2182 223878615649 CER2 0603 X7R 16V 100N PM10 R

2183 202203100366 ELCAP SK 50V S 10U PM20 B

2184 202203100366 ELCAP SK 50V S 10U PM20 B

2185 202203100366 ELCAP SK 50V S 10U PM20 B

2186 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2187 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2191 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2192 202203100173 ELCAP EB 25V S 470U PM20 B

2193 202203100173 ELCAP EB 25V S 470U PM20 B

2194 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2195 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2201 223878615649 CER2 0603 X7R 16V 100N PM10 R

2202 223886715109 CER1 0603 NP0 50V 10P PM5 R

2203 223886715339 CER1 0603 NP0 50V 33P PM5 R

2204 223886715101 CER1 0603 NP0 50V 100P PM5 R

2205 223886715568 CER1 0603 NP0 50V 5P6 PM0P5 R

2206 223886715568 CER1 0603 NP0 50V 5P6 PM0P5 R

2207 223886715568 CER1 0603 NP0 50V 5P6 PM0P5 R

2209 223878615649 CER2 0603 X7R 16V 100N PM10 R

2211 223886715331 CER1 0603 NP0 50V 330P PM5 R

2212 223886715331 CER1 0603 NP0 50V 330P PM5 R

2213 223886715331 CER1 0603 NP0 50V 330P PM5 R

2214 223886715331 CER1 0603 NP0 50V 330P PM5 R

2215 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2251 223886715331 CER1 0603 NP0 50V 330P PM5 R

2252 223886715331 CER1 0603 NP0 50V 330P PM5 R

2253 223886715101 CER1 0603 NP0 50V 100P PM5 R

2254 223886715331 CER1 0603 NP0 50V 330P PM5 R

2255 223886715331 CER1 0603 NP0 50V 330P PM5 R

2256 223886715331 CER1 0603 NP0 50V 330P PM5 R

2257 223886715331 CER1 0603 NP0 50V 330P PM5 R

2258 223886715101 CER1 0603 NP0 50V 100P PM5 R

2259 223886715229 CER1 0603 NP0 50V 22P PM5 R

2261 223886715101 CER1 0603 NP0 50V 100P PM5 R

2262 223886715229 CER1 0603 NP0 50V 22P PM5 R

2269 223886715331 CER1 0603 NP0 50V 330P PM5 R

2272 223886715331 CER1 0603 NP0 50V 330P PM5 R

2301 202203100367 ELCAP SK 16V S 47U PM20 B

2302 223878615649 CER2 0603 X7R 16V 100N PM10 R

2303 223886715229 CER1 0603 NP0 50V 22P PM5 R

2304 223886715229 CER1 0603 NP0 50V 22P PM5 R

2305 223858615623 CER2 0603 X7R 50V 1N PM10 R

2306 223886715109 CER1 0603 NP0 50V 10P PM5 R

2307 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2308 223824619863 CER2 0603 Y5V 10V 1U P8020 R

2312 223858615636 CER2 0603 X7R 50V 10N PM10 R

2313 223858615636 CER2 0603 X7R 50V 10N PM10 R

2314 223858615636 CER2 0603 X7R 50V 10N PM10 R

2315 223858615636 CER2 0603 X7R 50V 10N PM10 R

2317 223878615649 CER2 0603 X7R 16V 100N PM10 R

2318 223878615649 CER2 0603 X7R 16V 100N PM10 R

2321 223886715229 CER1 0603 NP0 50V 22P PM5 R

2322 223886715229 CER1 0603 NP0 50V 22P PM5 R

2401 223878615649 CER2 0603 X7R 16V 100N PM10 R

2402 223878615649 CER2 0603 X7R 16V 100N PM10 R

2403 223878615645 CER2 0603 X7R 16V 47N PM10 R

2404 223878615645 CER2 0603 X7R 16V 47N PM10 R

2405 223858615623 CER2 0603 X7R 50V 1N PM10 R

2406 223878615645 CER2 0603 X7R 16V 47N PM10 R

2407 223878615645 CER2 0603 X7R 16V 47N PM10 R

2408 223878615645 CER2 0603 X7R 16V 47N PM10 R

2409 223878615645 CER2 0603 X7R 16V 47N PM10 R

2411 223878615645 CER2 0603 X7R 16V 47N PM10 R

2412 223858615623 CER2 0603 X7R 50V 1N PM10 R

2413 223878615645 CER2 0603 X7R 16V 47N PM10 R

2414 223878615645 CER2 0603 X7R 16V 47N PM10 R

2415 223858615636 CER2 0603 X7R 50V 10N PM10 R

2416 223878615649 CER2 0603 X7R 16V 100N PM10 R

2417 223886715229 CER1 0603 NP0 50V 22P PM5 R

2418 223886715229 CER1 0603 NP0 50V 22P PM5 R

2419 223886715568 CER1 0603 NP0 50V 5P6 PM0P5 R

2421 223878615649 CER2 0603 X7R 16V 100N PM10 R

2422 202203100367 ELCAP SK 16V S 47U PM20 B

2423 223878615649 CER2 0603 X7R 16V 100N PM10 R

2424 202203100367 ELCAP SK 16V S 47U PM20 B

2425 223878615649 CER2 0603 X7R 16V 100N PM10 R

2426 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2427 202203100367 ELCAP SK 16V S 47U PM20 B

2431 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2432 223878615649 CER2 0603 X7R 16V 100N PM10 R

2433 223878615649 CER2 0603 X7R 16V 100N PM10 R

2434 223878615649 CER2 0603 X7R 16V 100N PM10 R

2435 223878615649 CER2 0603 X7R 16V 100N PM10 R

2436 223878615649 CER2 0603 X7R 16V 100N PM10 R

2437 223878615649 CER2 0603 X7R 16V 100N PM10 R

2438 223878615649 CER2 0603 X7R 16V 100N PM10 R

2441 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2442 223878615649 CER2 0603 X7R 16V 100N PM10 R

2443 223878615649 CER2 0603 X7R 16V 100N PM10 R

2444 223878615649 CER2 0603 X7R 16V 100N PM10 R

2445 223878615649 CER2 0603 X7R 16V 100N PM10 R

2446 223878615649 CER2 0603 X7R 16V 100N PM10 R

2447 223878615649 CER2 0603 X7R 16V 100N PM10 R

2451 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2452 223878615649 CER2 0603 X7R 16V 100N PM10 R

2453 223878615649 CER2 0603 X7R 16V 100N PM10 R

2454 223878615649 CER2 0603 X7R 16V 100N PM10 R

2455 223878615649 CER2 0603 X7R 16V 100N PM10 R

2456 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2457 223878615649 CER2 0603 X7R 16V 100N PM10 R

2458 223878615649 CER2 0603 X7R 16V 100N PM10 R

2461 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2462 223878615649 CER2 0603 X7R 16V 100N PM10 R

2463 223878619854 CER2 0603 Y5V 16V 220N P8020 R

2464 223878619854 CER2 0603 Y5V 16V 220N P8020 R

2465 223878619854 CER2 0603 Y5V 16V 220N P8020 R

Page 76

76

TPF1.3A LA

10.Spare Parts List - 2

2466 223878619854 CER2 0603 Y5V 16V 220N P8020 R

2501 223878615649 CER2 0603 X7R 16V 100N PM10 R

2502 223878615649 CER2 0603 X7R 16V 100N PM10 R

2503 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2504 223878615649 CER2 0603 X7R 16V 100N PM10 R

2505 223878615649 CER2 0603 X7R 16V 100N PM10 R

2506 223878615649 CER2 0603 X7R 16V 100N PM10 R

2507 223878615649 CER2 0603 X7R 16V 100N PM10 R

2552 223886715108 CER1 0603 NP0 50V 1P PM0P25 R

2553 223886715109 CER1 0603 NP0 50V 10P PM5 R

2554 223858615623 CER2 0603 X7R 50V 1N PM10 R

2556 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2601 223886715229 CER1 0603 NP0 50V 22P PM5 R

2603 223886715101 CER1 0603 NP0 50V 100P PM5 R

2604 223886715479 CER1 0603 NP0 50V 47P PM5 R

2605 202203100074 ELCAP KM 16V S 1000U PM20 B

2606 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2607 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2621 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2622 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2623 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2624 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2625 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2626 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2627 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2628 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2631 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2632 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2633 223891619849 CER2 0603 Y5V 25V 100N P8020 R

2634 223886715279 CER1 0603 NP0 50V 27P PM5 R

2635 223886715279 CER1 0603 NP0 50V 27P PM5 R

2636 223878615649 CER2 0603 X7R 16V 100N PM10 R

2637 223878616641 CER2 0603 X7R 16V 22N PM10 R

2638 223878616641 CER2 0603 X7R 16V 22N PM10 R

2639 223878616641 CER2 0603 X7R 16V 22N PM10 R

2641 223878616641 CER2 0603 X7R 16V 22N PM10 R

2642 223878616641 CER2 0603 X7R 16V 22N PM10 R

2644 223878616641 CER2 0603 X7R 16V 22N PM10 R

2646 223878616641 CER2 0603 X7R 16V 22N PM10 R

2647 223878616641 CER2 0603 X7R 16V 22N PM10 R

2649 223878616641 CER2 0603 X7R 16V 22N PM10 R

2651 223878616641 CER2 0603 X7R 16V 22N PM10 R

2652 223878616641 CER2 0603 X7R 16V 22N PM10 R

2653 223878616641 CER2 0603 X7R 16V 22N PM10 R

2654 223878616641 CER2 0603 X7R 16V 22N PM10 R

2655 223878615649 CER2 0603 X7R 16V 100N PM10 R

2656 222224119876 CER2 1206 Y5V 10V 10U P8020 R

2657 202203100367 ELCAP SK 16V S 47U PM20 B

2658 223878616641 CER2 0603 X7R 16V 22N PM10 R