查询TEA1207UK供应商

INTEGRATED CIRCUITS

DATA SH EET

TEA1207UK

High efficiency DC/DC converter

Chip Scale package

Product specification 2002 Jul 03

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

FEATURES

• Fully integrated DC/DC converter circuit

• Up-or-down conversion

• Start-up from 1.85 V input voltage

• Adjustable output voltage

• High efficiency over large load range

• Power handling capability up to 0.85 A continuous

average current

• 275 kHz switching frequency

• Low quiescent power consumption

• Synchronizing with external clock

• True current limit for Li-ion battery compatibility

• Up to 100% duty cycle in down mode

• Undervoltage lockout

• Shut-down function

• 2 × 2 mm footprint chip scale package.

TEA1207UK

GENERAL DESCRIPTION

The TEA1207UK is a fully integrated DC/DC converter.

Efficient, compact and dynamic power conversion is

achievedusinganoveldigitallycontrolledconceptsuchas

Pulse Width Modulation (PWM) or Pulse Frequency

Modulation (PFM), integrated low R

switches with low parasitic capacitances, and fully

synchronous rectification.

The device operates at a 275 kHz switching frequency

which enables the use of external components with

minimum size. Deadlock is prevented by an on-chip

undervoltage lockout circuit.

Efficient behaviour during short load peaks and

compatibility with Li-ion batteries is guaranteed by an

accurate current limiting function.

CMOS power

DSon

APPLICATIONS

• Cellular and cordless phones, Personal Digital

Assistants (PDAs) and others

• Supply voltage source for low-voltage chip sets

• Portable computers

• Battery backup supplies

• Cameras.

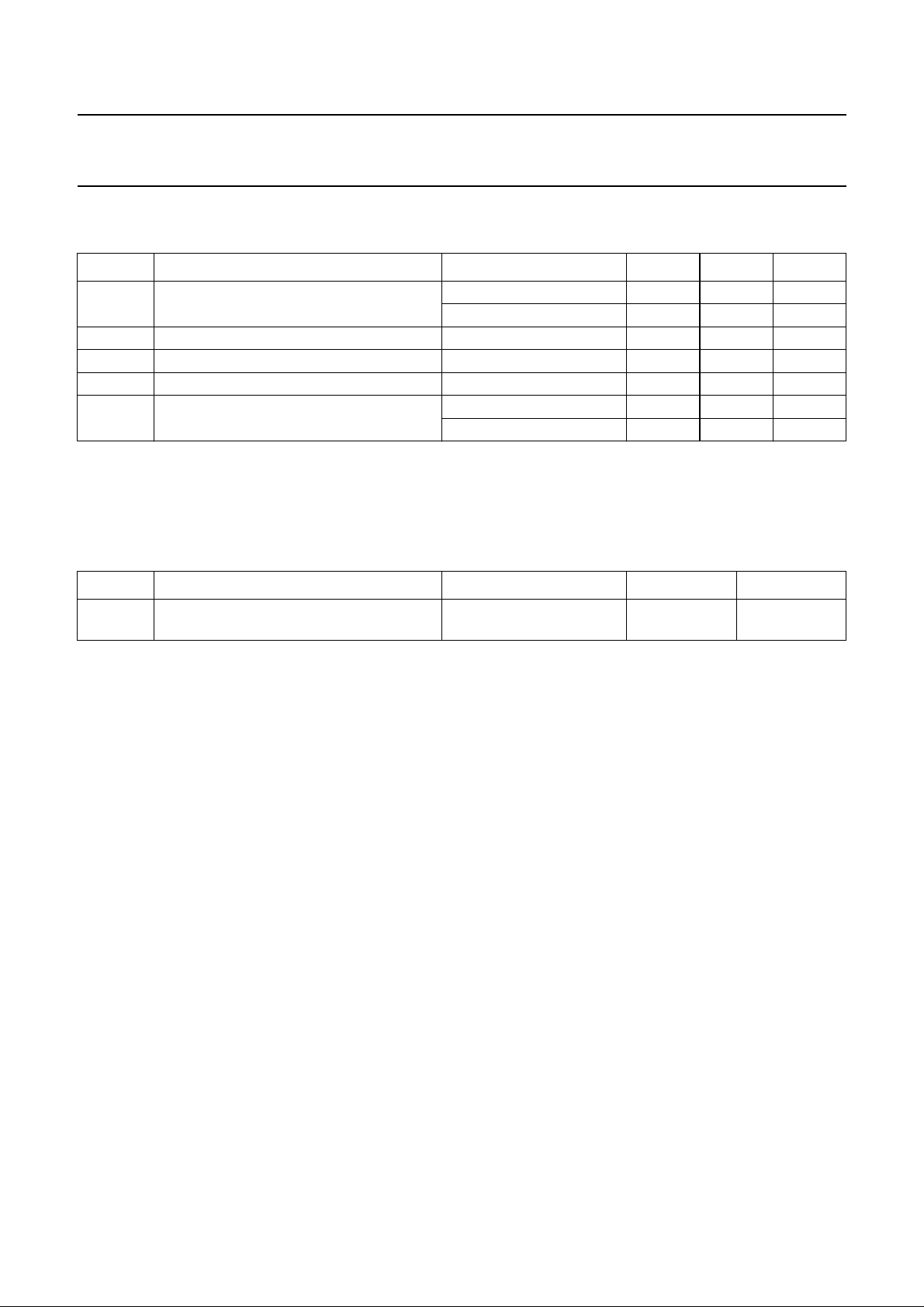

ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

TEA1207UK LFBGA8 plastic low profile fine-pitch ball grid array package;

8 balls; body 2 × 2 × 0.46 mm

−

2002 Jul 03 2

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Voltage levels

UPCONVERSION; BALL U/D=LOW

V

I

V

O

V

I(start)

input voltage V

output voltage 2.80 − 5.50 V

start-up input voltage IL< 125 mA 1.40 1.60 1.85 V

DOWNCONVERSION; BALL U/D = HIGH

V

I

V

O

input voltage 2.80 − 5.50 V

output voltage 1.30 − 5.50 V

GENERAL

V

fb

feedback voltage 1.19 1.24 1.29 V

Current levels

I

q

I

shdwn

I

LX

quiescent current on ball A1 down mode; VI=3.6V 526572µA

current in shut-down state − 210µA

maximum continuous current on

ball A2

∆I

lim

current limiting deviation I

Power MOSFETs

R

DSon

drain-to-source on-state resistance

N-type 0.10 0.20 0.30 Ω

P-type 0.10 0.22 0.35 Ω

Efficiency

η1 efficiency upconversion V

η2 efficiency downconversion V

Timing

f

sw

f

sync

t

res

switching frequency PWM mode 220 275 330 kHz

synchronization clock input frequency 4 6.5 20 MHz

response time from standby to P

T

=60°C −−0.85 A

amb

= 0.5 to 5 A

lim

up mode −17.5 − +17.5 %

down mode −17.5 − +17.5 %

= 3.6 V; VO= 4.6 V;

I

L1 = 10 µH

I

=1mA − 88 − %

L

I

= 200 mA − 95 − %

L

= 1 A; pulsed − 83 − %

I

L

= 3.6 V; VO= 2.0 V;

I

L1 = 10 µH

I

=1mA − 86 − %

L

I

= 200 mA − 93 − %

L

= 1 A; pulsed − 81 − %

I

L

o(max)

− 50 −µs

− 5.50 V

I(start)

2002 Jul 03 3

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

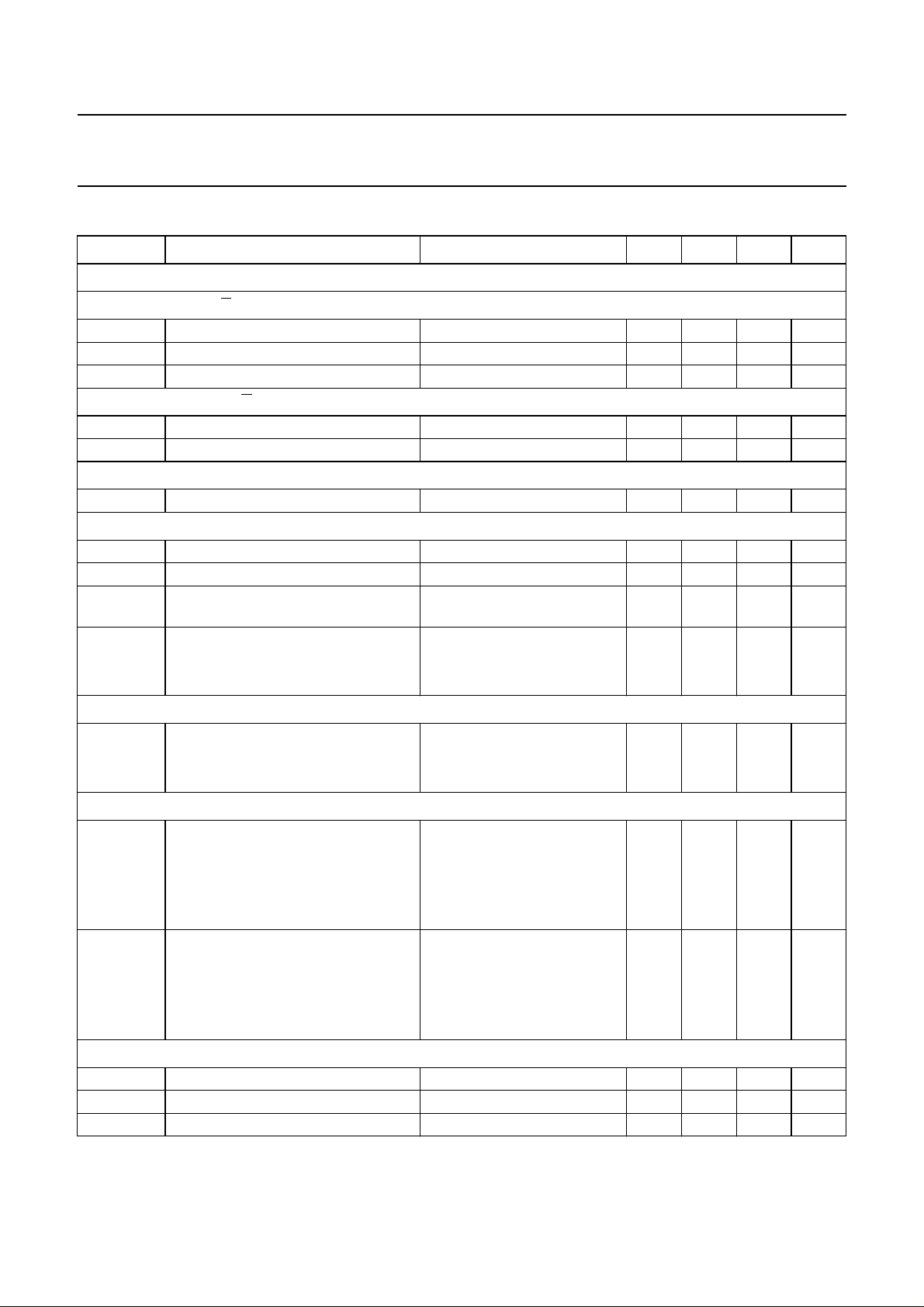

BLOCK DIAGRAM

UPOUT/DNIN

A1

SUPPLY

INTERNAL

TEA1207UK

B2

FB

BAND GAP

REFERENCE

TIME

COUNTER

TEA1207UK

MGU402

book, full pagewidth

P-type POWER FET

A2

sense FET

I/V

CONVERTER

C1

CIRCUIT

START-UP

AND

MODE GEARBOX

CONTROL LOGIC

CURRENT LIMIT

COMPARATORS

I/V

CONVERTER

N-type

PROTECTION

TEMPERATURE

FET

POWER

FET

sense

DIGITAL CONTROLLER

GATE

SYNC

13 MHz

OSCILLATOR

B1A3 C3 C2

SHDWN

SYNC U/D

GND

Fig.1 Block diagram.

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

2002 Jul 03 4

LX

ILIM

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

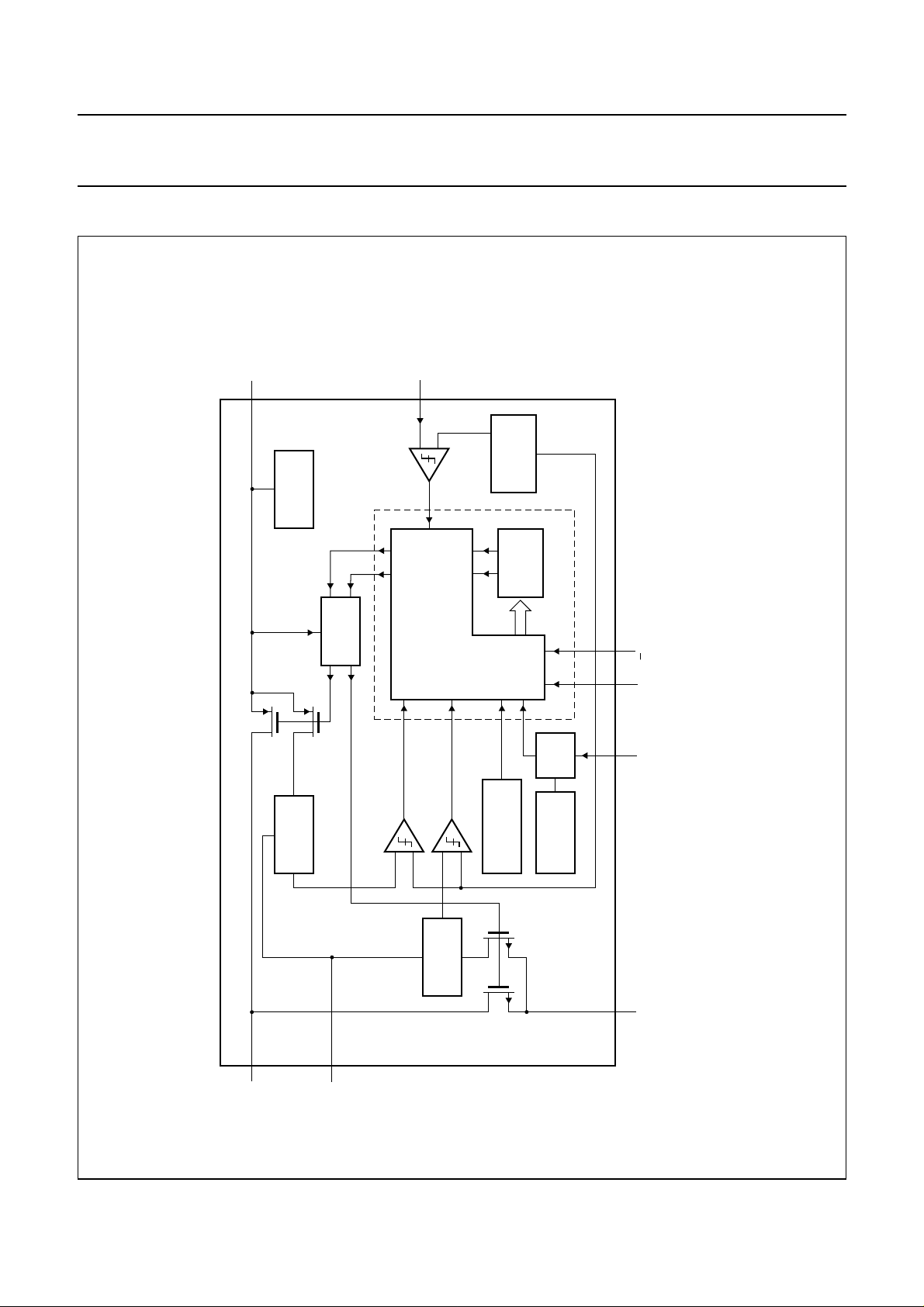

PINNING

SYMBOL BALL DESCRIPTION

UPOUT/DNIN A1 output voltage in up mode;

input voltage in down mode

LX A2 inductor connection

GND A3 ground

SYNC B1 synchronization clock input

FB B2 feedback input

ILIM C1 current limiting resistor

connection

U/D C2 up-or-down mode selection

input; active LOW for up mode

SHDWN C3 shut-down input

handbook, halfpage

C2 C3C1

B2B1

A2 A3

A1

MGU399

TEA1207UK

When high output power is requested, the device will

operate in the PWM mode. This results in minimum AC

currents in the circuit components and hence optimum

efficiency, minimum cost and low EMC. In this operating

mode, the output voltage is allowed to vary between two

predefined voltage levels. As long as the output voltage

stays within this so-called window, switching continues in

a fixed pattern. When the output voltage reaches one of

the window borders, the digital controller immediately

reacts by adjusting the pulse width and inserting a current

step in such a way that the output voltage stays within the

window with higher or lower current capability. This

approach enables very fast reaction to load variations.

Figure 3 shows the converter’s response to a sudden load

increase. The upper trace shows the output voltage. The

ripple on top of the DC level is a result of the current in the

output capacitor, which changes in sign twice per cycle,

times the capacitor’s internal Equivalent Series

Resistance (ESR). After each ramp-down of the inductor

current, i.e. when the ESR effect increases the output

voltage, the converter determines what to do in the next

cycle. As soon as more load current is taken from the

output the output voltage starts to decay.

When the output voltage becomes lower than the low limit

of the window, a corrective action is taken by a ramp-up of

theinductorcurrent during a much longer time. As a result,

the DC current level is increased and normal PWM control

can continue. The output voltage (including ESR effect) is

again within the predefined window. Figure 4 shows the

spread of the output voltage window. The absolute value

ismostdependentonspread,whiletheactualwindowsize

is not affected. For one specific device, the output voltage

will not vary more than 2% typical.

Fig.2 Ball configuration (bottom view).

FUNCTIONAL DESCRIPTION

Control mechanism

The TEA1207UK is able to operate in PFM (discontinuous

conduction) or PWM (continuous conduction) operating

mode. All switching actions are completely determined by

a digital control circuit which uses the output voltage level

asitscontrolinput. This novel digital approach enables the

use of a new pulse width and frequency modulation

scheme,whichensuresoptimumpowerefficiencyoverthe

complete operating range of the converter.

2002 Jul 03 5

In low output power situations, the TEA1207UK will switch

over to PFM mode. In this mode, regulation information

from earlier PWM operating modes is used. This results in

optimum inductor peak current levels in the PFM mode,

which are slightly larger than the inductor ripple current in

the PWM mode. As a result, the transition between PFM

andPWMmodeisoptimumunderallcircumstances. In the

PFM mode the TEA1207UK regulates the output voltage

to the high window limit shown in Fig.3.

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

Synchronous rectification

For optimum efficiency over the whole load range,

synchronous rectifiers within the TEA1207UK ensure that

during the whole second switching phase, all inductor

current will flow through the low-ohmic power MOSFETs.

Special circuitry is included which detects when the

inductorcurrentreaches zero. Following this detection, the

digital controller switches off the power MOSFET and

proceeds with regulation.

Start-up

Start-up from low input voltage in boost mode is realized

by an independent start-up oscillator, which starts

switching the N-type power MOSFET as soon as the

voltage at ball UPOUT/DNIN is sufficiently high. The

switch actions of the start-up oscillator will increase the

output voltage. As soon as the output voltage is high

enough for normal regulation, the digital control system

takes over the control of the power MOSFETs.

Undervoltage lockout

As a result of too high load or disconnection of the input

power source, the output voltage can drop so low that

normal regulation cannot be guaranteed. In this event, the

device switches back to start-up mode. If the output

voltage drops down even further, switching is stopped

completely.

Shut-down

When the shut-down input is made HIGH, the converter

disables both power switches and the power consumption

is reduced to a few microamperes.

Power switches

The power switches in the IC are one N-type and one

P-type power MOSFET, having a typical drain-to-source

resistance of 0.20 and 0.22 Ω respectively. The maximum

average current in the power switches is 0.60 A at

T

=80°C.

amb

TEA1207UK

Current limiters

If the current in one of the power switches exceeds its limit

in the PWM mode, the current ramp is stopped

immediately, and the next switching phase is entered.

Current limiting is required to enable optimum use of

energy in Li-ion batteries, and to keep power conversion

efficientduring temporary high loads. Furthermore,current

limiting protects the IC against overload conditions,

inductor saturation, etc. The current limiting level is set by

an external resistor.

External synchronization

If an external high frequency clock is applied to the

synchronization clock input, the switching frequency in

PWM mode will be exactly that frequency divided by 22.

In PFM mode, the switching frequency is always lower.

The quiescent current of the device increases when

external clock pulses are applied. If no external

synchronization is necessary, the synchronization clock

input must be connected to ground.

Behaviour when the input voltage exceeds the

specified range

In general, an input voltage exceeding the specified range

isnot recommended since instability may occur. There are

two exceptions:

• Upconversion: at an input voltage higher than the target

output voltage, but up to 6 V, the converter will stop

switchingandtheinternal P-type power MOSFET will be

conducting. The output voltage will equal the input

voltage minus some resistive voltage drop. The current

limiting function is not active.

• Downconversion: when the input voltage is lower than

the target output voltage, but higher than 2.8 V, the

P-type power MOSFET will stay conducting resulting in

an output voltage being equal to the input voltage minus

some resistive voltage drop. The current limiting

function remains active.

Temperature protection

When the device operates in the PWM mode, and the die

temperature gets too high (typically 175 °C), the converter

stops operating. It resumes operation when the die

temperature falls below 175 °C again. As a result, low

frequent cycling between the on and off state will occur.

It shouldbenotedthat in the event of a device temperature

around the cut-off limit, the application will differ strongly

from the maximum specification.

2002 Jul 03 6

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

handbook, full pagewidth

load increase

V

o

I

L

start corrective action

time

time

TEA1207UK

high window limit

low window limit

MGK925

handbook, full pagewidth

V

out, typ

V

h

2%

V

l

typical situation

Fig.3 Response to load increase.

maximum positive spread of V

V

h

2%

V

+4%

l

−4%

maximum negative spread of V

fb

V

h

2%

V

l

upper specification limit

lower specification limit

fb

MGR667

Fig.4 Spread of location of output voltage window.

2002 Jul 03 7

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134).

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

n

T

j

T

amb

T

stg

V

es

Notes

1. Class 3; equivalent to discharging a 100 pF capacitor through a 1500 resistor.

2. Class 2; equivalent to discharging a 200 pF capacitor through a 10 Ω resistor and a 0.75 µH inductor.

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

voltage on any ball shut-down mode −0.2 +6.5 V

operating mode −0.2 +5.9 V

junction temperature −25 +150 °C

ambient temperature −40 +80 °C

storage temperature −40 +125 °C

electrostatic handling voltage human body model; note 1 −4000 +4000 V

machine model; note 2 −300 +300 V

thermal resistance from junction to

Printed-Circuit Board (PCB)

in free air; note 1 145 K/W

Note

1. The thermal resistance is highly dependent on printed-circuit board type and metal routing. The value given is valid

for a single metal layer printed-circuit board.

QUALITY SPECIFICATION

In accordance with

“SNW-FQ-611 part E”

.

2002 Jul 03 8

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

CHARACTERISTICS

T

= −40 to +80 °C; all voltages are measured with respect to ground; positive currents flow into theIC; unless

amb

otherwise specified.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Voltage levels

PCONVERSION; BALL U/D=LOW

U

V

i

V

o

V

i(start)

V

i(uvlo)

OWNCONVERSION; BALL U/D = HIGH

D

V

i

V

o

input voltage V

output voltage 2.80 − 5.50 V

start-up input voltage IL< 125 mA 1.40 1.60 1.85 V

undervoltage lockout input voltage note 1 1.50 2.10 2.50 V

input voltage note 2 2.80 − 5.50 V

output voltage 1.30 − 5.50 V

GENERAL

V

∆V

fb

wdw

feedback input voltage 1.19 1.24 1.29 V

output voltage window PWM mode 1.5 2.0 3.0 %

Current levels

I

q

I

shdwn

I

LX

quiescent current on ball A1 down mode;

current in shut-down mode − 210µA

maximum continuous current on

ball A2

∆I

lim

current limit deviation I

Power MOSFETs

R

DSon

drain-to-source on-state resistance

N-type 0.10 0.20 0.30 Ω

P-type 0.10 0.22 0.35 Ω

Efficiency

η1 efficiency upconversion V

I(start)

52 65 72 µA

V3= 3.0 V; note 3

T

=60°C −−0.85 A

amb

T

=80°C −−0.60 A

amb

= 0.5 to 5.0 A;

lim

note 4

up mode −17.5 − +17.5 %

down mode −17.5 − +17.5 %

= 3.6 V; VO= 4.6 V;

I

L1 = 10 µH; note 5

I

=1mA − 88 − %

L

I

=10mA − 93 − %

L

I

=50mA − 93 − %

L

I

= 100 mA − 94 − %

L

= 200 mA − 95 − %

I

L

= 500 mA − 92 − %

I

L

I

= 1 A; pulsed − 83 − %

L

− 5.50 V

2002 Jul 03 9

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

η2 efficiency downconversion VI= 3.6 V; VO= 2.0 V;

L1 = 10 µH; note 5

I

=1mA − 86 − %

L

I

=10mA − 91 − %

L

I

=50mA − 92 − %

L

I

= 100 mA − 92 − %

L

= 200 mA − 93 − %

I

L

I

= 500 mA − 89 − %

L

I

= 1 A; pulsed − 81 − %

L

Timing

f

sw

f

sync

t

res

Temperature

T

amb

T

co(max)

Digital levels

V

lL

V

IH

Notes

1. Theundervoltagelockoutvoltage shows wide specification limits since it decreases at increasing temperature. When

the temperature increases, the minimum supply voltage of the digital control part of the IC decreases and therefore

the correct operation of this function is guaranteed over the whole temperature range.

2. When Vi is lower than the target output voltage but higher than 2.8 V, the P-type power MOSFET will remain

conducting (100% duty cycle), resulting in Vo following Vi.

3. V3 is the voltage on ball A1 (UPOUT/DNIN).

4. The current limit is defined by the external resistor R

current limit increases in proportion to the programmed current limiting level.

5. The specified efficiency is valid when using an output capacitor having an ESR of 0.10 Ω and a 10 µH small size

inductor (Coilcraft DT1608C-103).

6. If the applied HIGH-level voltage is less than V3to 1 V, the quiescent current (lq) of the device will increase.

switching frequency PWM mode 220 275 330 kHz

synchronization clock input frequency 4 6.5 20 MHz

response time from standby to P

o(max)

− 50 −µs

ambient temperature −40 +25 +80 °C

maximum internal cut-off temperature 150 175 200 °C

LOW-level input voltage on balls B1,

0 − 0.4 V

C2 and C3

HIGH-level input voltage note 6

on ball C2 V

on balls B1 and C3 0.55V

(see Section “Current limiting resistors”). Accuracy of the

lim

− 0.4 − V3+ 0.3 V

3

− V3+ 0.3 V

3

2002 Jul 03 10

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

APPLICATION INFORMATION

handbook, full pagewidth

L1

V

I

C1

LX

A2

C2 B1 C3 C1

TEA1207UK

A3

GNDU/D SYNC SHDWN ILIM

D1

UPOUT/DNIN

A1

FB

B2

R

lim

R1

R2

C2

MGU400

TEA1207UK

V

O

handbook, full pagewidth

V

I

Fig.5 Complete application diagram for upconversion.

UPOUT/DNIN

C1

A1

TEA1207UK

C1C2 B1 A3 C3

R

lim

GNDU/D SYNC SHDWNILIM

A2

B2

LX

FB

D1

L1

R1

R2

MGU401

C2

V

O

Fig.6 Complete application diagram for downconversion.

2002 Jul 03 11

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

External component selection

INDUCTOR L1

The performance of the TEA1207UK is not very sensitive

to inductance value. Best efficiency performance over a

wide load current range is achieved by using e.g.

TDK SLF7032-6R8M1R6, having an inductance of 6.8 µH

and a saturation current level of 1.6 A. In case the

maximum output current is lower, other inductors are also

suitable such as the small sized Coilcraft DT1608 range.

INPUT CAPACITOR C1

The value of capacitor C1 strongly depends on the type of

input source. In general, a 100 µF tantalum capacitor will

do, or a 10 µF ceramic capacitor featuring very low series

resistance (ESR value).

OUTPUT CAPACITOR C2

The value and type of capacitor C2 depend on the

maximum output current and the ripple voltage which is

allowed in the application. Low-ESR tantalum capacitors

show good results. The most important specification of

capacitor C2 is its ESR, which mainly determines the

output voltage ripple.

DIODE D1

The Schottky diode is only used for a short time during

takeover from N-type power MOSFET and P-type power

MOSFET and vice versa. Therefore, a medium-power

diode such as Philips PRLL5819 is sufficient.

FEEDBACK RESISTORS R1 AND R2

TEA1207UK

• Use1%accurate SMD type resistors only. In case larger

body resistors are used, the capacitance on ball B2

(feedback input) will be too large, causing inaccurate

operation.

• Resistors R1 and R2 should have a maximum value of

57 kΩ when connected in parallel. A higher value will

result in inaccurate operation.

Under these conditions, the output voltage can be

R1

calculated by the formula:

URRENT LIMITING RESISTORS

C

V

O

The maximum instantaneous current is set by the external

resistors R

The connection of resistor R

. The preferred type is SMD, 1% accurate.

lim

differs per mode:

lim

• At upconversion (up mode): resistor R

connected between ball C1 (ILIM) and ball A1

(UPOUT/DNIN). The current limiting level is defined by:

238

=

I

--------- -

lim

R

lim

• At downconversion (down mode): resistor R

connected between ball C1 (ILIM) and ball A3 (GND).

The current limiting level is defined by:

The average inductor current during limited current

operation also depends on the inductance value, input

voltage, output voltage and resistive losses in all

components in the power path. Ensure that I

saturation current of the inductor.

1.24 1

×=

+

------- R2

must be

lim

I

lim

lim<Isat

must be

lim

270

=

--------- R

lim

The output voltage is determined by the resistors

R1 and R2. The following conditions apply:

2002 Jul 03 12

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

PACKAGE OUTLINE

LFBGA8: plastic low profile fine-pitch ball grid array package; 8 balls; body 2.0 x 2.0 x 0.46 mm

B

D

ball A1

index area

A

E

A

2

A

A

1

detail X

TEA1207

eZ

C

B

A

213

DIMENSIONS (mm are the original dimensions)

A

UNIT

mm

OUTLINE

VERSION

TEA1207

max.

0.70

A

1bA2

0.28

0.20

D

0.48

0.44

2.05

1.95

2.05

1.95

0.38

0.26

IEC JEDEC JEITA

b

E

0.5

∅ w

M

D

Z

E

e

0 1 2 mm

scale

ye

w

0.63

0.05v0.1

REFERENCES

0.03

0.38

A

v

A

Z

Z

D

E

0.63

0.38

y

X

EUROPEAN

PROJECTION

MSD746

ISSUE DATE

2002 Jul 03 13

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

SOLDERING

Introduction to soldering surface mount packages

Thistextgivesa very brief insight to a complex technology.

A more in-depth account of soldering ICs can be found in

our

“Data Handbook IC26; Integrated Circuit Packages”

(document order number 9398 652 90011).

There is no soldering method that is ideal for all surface

mount IC packages. Wave soldering can still be used for

certainsurfacemount ICs, but it is not suitableforfinepitch

SMDs. In these situations reflow soldering is

recommended.

Reflow soldering

Reflow soldering requires solder paste (a suspension of

fine solder particles, flux and binding agent) to be applied

totheprinted-circuitboardbyscreenprinting,stencillingor

pressure-syringe dispensing before package placement.

Several methods exist for reflowing; for example,

convection or convection/infrared heating in a conveyor

type oven. Throughput times (preheating, soldering and

cooling) vary between 100 and 200 seconds depending

on heating method.

Typical reflow peak temperatures range from

215 to 250 °C. The top-surface temperature of the

packages should preferable be kept below 220 °C for

thick/large packages, and below 235 °C for small/thin

packages.

Wave soldering

Conventional single wave soldering is not recommended

forsurfacemount devices (SMDs) or printed-circuit boards

with a high component density, as solder bridging and

non-wetting can present major problems.

To overcome these problems the double-wave soldering

method was specifically developed.

TEA1207UK

If wave soldering is used the following conditions must be

observed for optimal results:

• Use a double-wave soldering method comprising a

turbulent wave with high upward pressure followed by a

smooth laminar wave.

• For packages with leads on two sides and a pitch (e):

– larger than or equal to 1.27 mm, the footprint

longitudinal axis is preferred to be parallel to the

transport direction of the printed-circuit board;

– smaller than 1.27 mm, the footprint longitudinal axis

must be parallel to the transport direction of the

printed-circuit board.

The footprint must incorporate solder thieves at the

downstream end.

• Forpackageswith leads on four sides, the footprintmust

be placed at a 45° angle to the transport direction of the

printed-circuit board. The footprint must incorporate

solder thieves downstream and at the side corners.

During placement and before soldering, the package must

be fixed with a droplet of adhesive. The adhesive can be

applied by screen printing, pin transfer or syringe

dispensing. The package can be soldered after the

adhesive is cured.

Typical dwell time is 4 seconds at 250 °C.

A mildly-activated flux will eliminate the need for removal

of corrosive residues in most applications.

Manual soldering

Fix the component by first soldering two

diagonally-opposite end leads. Use a low voltage (24 V or

less) soldering iron applied to the flat part of the lead.

Contact time must be limited to 10 seconds at up to

300 °C.

When using a dedicated tool, all other leads can be

soldered in one operation within 2 to 5 seconds between

270 and 320 °C.

2002 Jul 03 14

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

Suitability of surface mount IC packages for wave and reflow soldering methods

PACKAGE

BGA, LBGA, LFBGA, SQFP, TFBGA, VFBGA not suitable suitable

HBCC, HBGA, HLQFP, HSQFP, HSOP, HTQFP, HTSSOP, HVQFN,

HVSON, SMS

(4)

PLCC

LQFP, QFP, TQFP not recommended

SSOP, TSSOP, VSO not recommended

Notes

1. FormoredetailedinformationontheBGApackagesrefertothe

2. All surface mount (SMD) packages are moisture sensitive. Depending upon the moisture content, the maximum

3. These packages are not suitable for wave soldering. On versions with the heatsink on the bottom side, the solder

4. If wave soldering is considered, then the package must be placed at a 45° angle to the solder wave direction.

5. Wave soldering is suitable for LQFP, TQFP and QFP packages with a pitch (e) larger than 0.8 mm; it is definitely not

6. Wave soldering is suitable for SSOP and TSSOP packages with a pitch (e) equal to or larger than 0.65 mm; it is

, SO, SOJ suitable suitable

from your Philips Semiconductors sales office.

temperature (with respect to time) and body size of the package, there is a risk that internal or external package

cracks may occur due to vaporization of the moisture in them (the so called popcorn effect). For details, refer to the

Drypack information in the

cannot penetrate between the printed-circuit board and the heatsink. On versions with the heatsink on the top side,

the solder might be deposited on the heatsink surface.

The package footprint must incorporate solder thieves downstream and at the side corners.

suitable for packages with a pitch (e) equal to or smaller than 0.65 mm.

definitely not suitable for packages with a pitch (e) equal to or smaller than 0.5 mm.

“Data Handbook IC26; Integrated Circuit Packages; Section: Packing Methods”

(1)

not suitable

“(LF)BGAApplicationNote

SOLDERING METHOD

WAVE REFLOW

(3)

suitable

(4)(5)

suitable

(6)

suitable

”(AN01026);orderacopy

(2)

.

2002 Jul 03 15

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

TEA1207UK

Scale package

DATA SHEET STATUS

PRODUCT

DATA SHEET STATUS

Objective specification Development This data sheet contains data from the objective specification for product

Preliminary specification Qualification This data sheet contains data from the preliminary specification.

Product specification Production This data sheet contains data from the product specification. Philips

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

(1)

STATUS

(2)

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change

Notification (CPCN) procedure SNW-SQ-650A.

DEFINITIONS

DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting values definition Limiting values given are in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

attheseoratany other conditions above those given in the

Characteristics sections of the specification is not implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentation or warranty that such applicationswillbe

suitable for the specified use without further testing or

modification.

DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably be expected to result in personal injury. Philips

Semiconductorscustomers using or selling theseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes, without notice, in the

products, including circuits, standard cells, and/or

software, described or contained herein in order to

improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for

theuseof any of these products, conveys nolicenceortitle

under any patent, copyright, or mask work right to these

products,andmakesnorepresentationsorwarrantiesthat

these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

2002 Jul 03 16

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

NOTES

TEA1207UK

2002 Jul 03 17

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

NOTES

TEA1207UK

2002 Jul 03 18

Philips Semiconductors Product specification

High efficiency DC/DC converter Chip

Scale package

NOTES

TEA1207UK

2002 Jul 03 19

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2002

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document does not form part of any quotation or contract, is believed to be accurate and reliable and may be changed

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 403502/02/pp20 Date of release: 2002 Jul 03 Document order number: 9397 750 08491

SCA74

Loading...

Loading...