Philips TEA1207T-N1 Datasheet

DATA SH EET

Preliminary specification

Supersedes data of 1999 Jan 14

File under Integrated Circuits, IC03

1999 Oct 21

INTEGRATED CIRCUITS

TEA1207T

High efficiency DC/DC converter

1999 Oct 21 2

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1207T

FEATURES

• Fully integrated DC/DC converter circuit

• Up-or-down conversion

• Start-up from 1.85 V input voltage

• Adjustable output voltage

• High efficiency over large load range

• Power handling capability up to 0.85 A continuous

average current

• 275 kHz switching frequency

• Low quiescent power consumption

• Synchronizing with external clock

• True current limit for Li-ion battery compatibility

• Up to 100% duty cycle in down mode

• Undervoltage lockout

• Shut-down function

• 8-pin SO package.

APPLICATIONS

• Cellular and cordless phones, Personal Digital

Assistants (PDAs) and others

• Supply voltage source for low-voltage chip sets

• Portable computers

• Battery backup supplies

• Cameras.

GENERAL DESCRIPTION

The TEA1207T is a fully integrated DC/DC converter.

Efficient, compact and dynamic power conversion is

achieved using a novel digitally controlled concept like

Pulse Width Modulation (PWM) or Pulse Frequency

Modulation (PFM), integrated low R

DSon

CMOS power

switches with low parasitic capacitances, and fully

synchronous rectification.

The device operates at 275 kHz switching frequency

which enables the use of external components with

minimum size. Deadlock is prevented by an on-chip

undervoltage lockout circuit.

Efficient behaviour during short load peaks and

compatibility with Li-ion batteries is guaranteed by an

accurate current limiting function.

ORDERING INFORMATION

TYPE NUMBER

PACKAGE

NAME DESCRIPTION VERSION

TEA1207T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

1999 Oct 21 3

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1207T

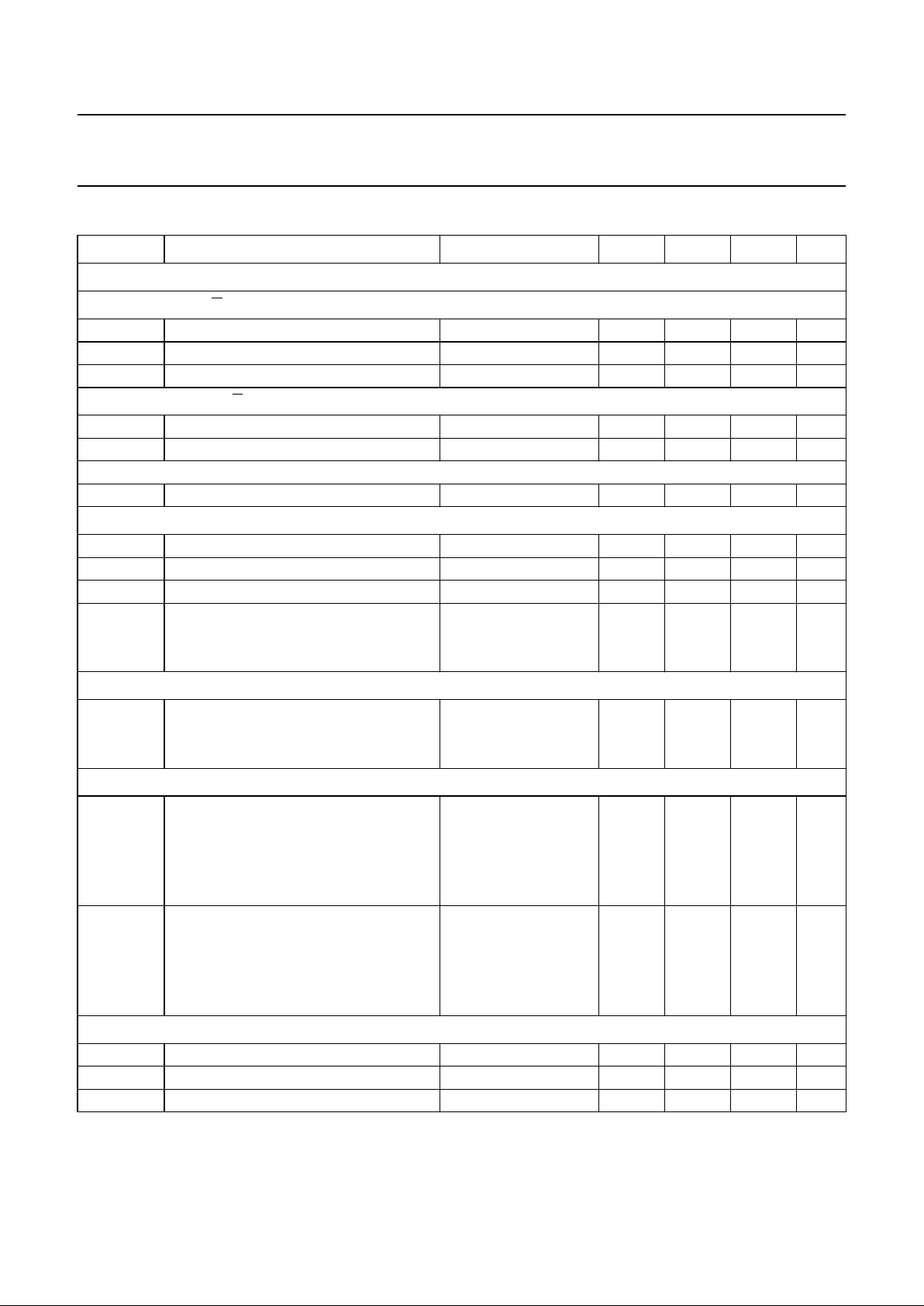

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Voltage levels

UPCONVERSION; pin U/D = LOW

V

I

input voltage V

I(start)

− 5.50 V

V

O

output voltage 2.80 − 5.50 V

V

I(start)

start-up input voltage IL< 125 mA 1.40 1.60 1.85 V

DOWNCONVERSION; pin U/D = HIGH

V

I

input voltage 2.80 − 5.50 V

V

O

output voltage 1.30 − 5.50 V

G

ENERAL

V

fb

feedback voltage 1.19 1.24 1.29 V

Current levels

I

q

quiescent current on pin 3 down mode; VI=3.6V526572µA

I

shdwn

current in shut-down state − 210µA

I

LX

maximum continuous current on pin 4 T

amb

=80°C −−0.60 A

∆I

lim

current limit deviation I

lim

= 0.5 to 5 A

up mode −17.5 − +17.5 %

down mode −17.5 − +17.5 %

Power MOSFETs

R

DSon

drain-to-source on-state resistance

N-type 0.10 0.20 0.30 Ω

P-type 0.10 0.22 0.35 Ω

Efficiency

η

1

efficiency upconversion VI= 3.6 V; VO= 4.6 V;

L1 = 10 µH

I

L

=1mA − 88 − %

I

L

= 200 mA − 95 − %

I

L

= 1 A; pulsed − 83 − %

η

2

efficiency downconversion VI= 3.6 V; VO= 2.0 V;

L1 = 10 µH

I

L

=1mA − 86 − %

I

L

= 200 mA − 93 − %

I

L

= 1 A; pulsed − 81 − %

Timing

f

sw

switching frequency PWM mode 220 275 330 kHz

f

sync

synchronization clock input frequency 4 6.5 20 MHz

t

res

response time from standby to P

0(max)

− 50 −µs

1999 Oct 21 4

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1207T

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsingthroughthepdfintheAcrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

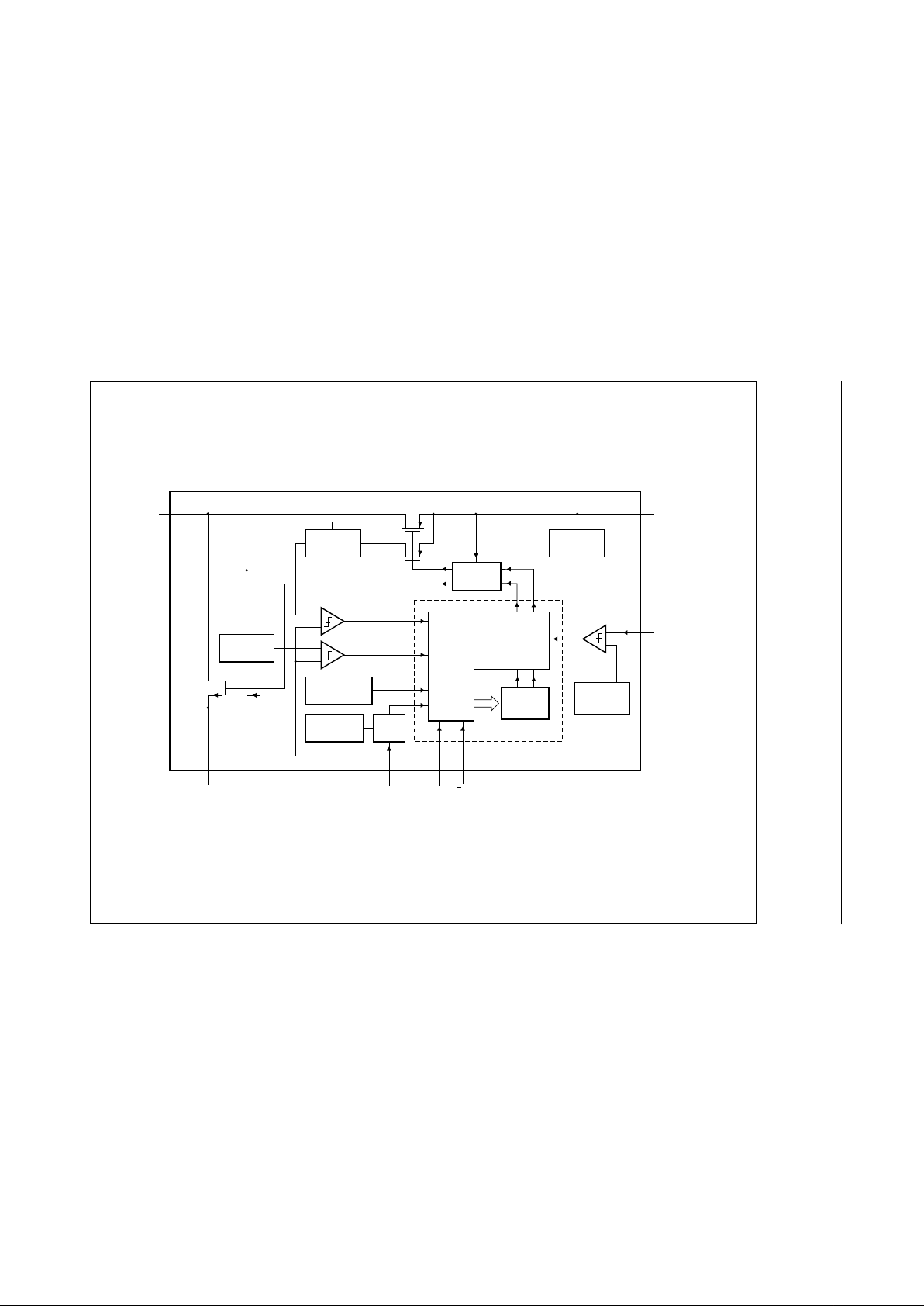

BLOCK DIAGRAM

a

ndbook, full pagewidth

MGR665

CONTROL LOGIC

AND

MODE GEARBOX

START-UP

CIRCUIT

I/V

CONVERTER

INTERNAL

SUPPLY

I/V

CONVERTER

TIME

COUNTER

BAND GAP

REFERENCE

13 MHz

OSCILLATOR

SYNC

GATE

TEMPERATURE

PROTECTION

DIGITAL CONTROLLER

sense FET

P-type POWER FET

sense

FET

SHDWN

GND

SYNC U/D

N-type

POWER

FET

LX

UPOUT/DNIN

FB

TEA1207T

5681

4

ILIM

2

3

7

CURRENT LIMIT

COMPARATORS

Fig.1 Block diagram.

1999 Oct 21 5

Philips Semiconductors Preliminary specification

High efficiency DC/DC converter TEA1207T

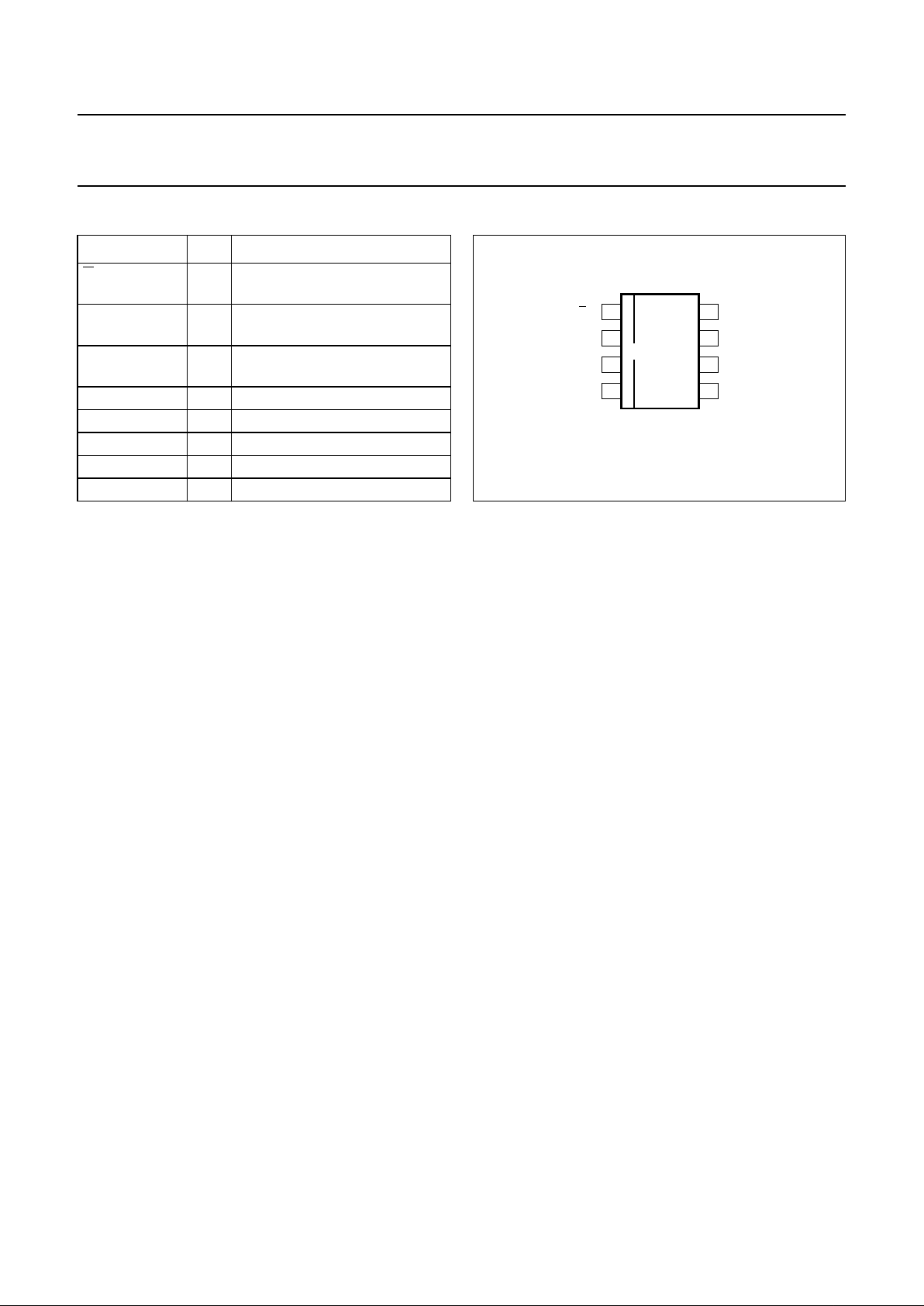

PINNING

SYMBOL PIN DESCRIPTION

U/D 1 up-or-down mode selection

input; active LOW for up mode

ILIM 2 current limiting resistor

connection

UPOUT/DNIN 3 output voltage in up mode;

input voltage in down mode

LX 4 inductor connection

SYNC 5 synchronization clock input

GND 6 ground

FB 7 feedback input

SHDWN 8 shut-down input

Fig.2 Pin configuration.

handbook, halfpage

MGR666

1

2

3

4

8

7

6

5

U/D SHDWN

ILIM FB

UPOUT/DNIN GND

LX SYNC

TEA1207T

FUNCTIONAL DESCRIPTION

Control mechanism

TheTEA1207T DC/DC converter is able to operate in PFM

(discontinuous conduction) or PWM (continuous

conduction) operating mode. All switching actions are

completely determined by a digital control circuit which

usesthe output voltage level as its control input. This novel

digital approach enables the use of a new pulse width and

frequency modulation scheme, which ensures optimum

power efficiency over the complete operating range of the

converter.

When high output power is requested, the device will

operate in PWM (continuous conduction) operating mode.

This results in minimum AC currents in the circuit

components and hence optimum efficiency, minimum

costs and low EMC. In this operating mode, the output

voltage is allowed to vary between two predefined voltage

levels. As long as the output voltage stays within this

so-called window, switching continues in a fixed pattern.

When the output voltage reaches one of the window

borders, the digital controller immediately reacts by

adjusting the pulse width and inserting a current step in

such a way that the output voltage stays withinthe window

with higher or lower current capability. This approach

enables very fast reaction to load variations. Figure 3

shows the converter’s response to a sudden load

increase. The upper trace shows the output voltage.

The ripple on top of the DC level is a result of the current

in the output capacitor, which changes in sign twice per

cycle, times the capacitor’s internal Equivalent Series

Resistance (ESR). After each ramp-down of the inductor

current, i.e. when the ESR effect increases the output

voltage, the converter determines what to do in the next

cycle. As soon as more load current is taken from the

output the output voltage starts to decay.

When the output voltage becomes lower than the low limit

of the window, a corrective action is taken by a ramp-up of

theinductor current during a much longer time. Asaresult,

the DC current level is increased and normal PWM control

can continue. The output voltage (including ESR effect) is

again within the predefined window. Figure 4 depicts the

spread of the output voltage window. The absolute value

ismostdependentonspread,whiletheactual window size

is not affected. For one specific device, the output voltage

will not vary more than 2% typically.

In low output power situations, the TEA1207T will switch

over to PFM (discontinuous conduction) operating mode.

In this mode, regulation information from earlier PWM

operating modes is used. This results in optimum inductor

peak current levels in the PFM mode, which are slightly

larger than the inductor ripple current in the PWM mode.

As a result, the transition between PFM and PWM mode is

optimum under all circumstances. In the PFM mode the

TEA1207Tregulates the output voltage to the high window

limit as shown in Fig.3.

Synchronous rectification

For optimum efficiency over the whole load range,

synchronous rectifiers inside the TEA1207T ensure that

during the whole second switching phase, all inductor

current will flow through the low-ohmic power MOSFETs.

Special circuitry is included whichdetects that the inductor

current reaches zero. Following this detection, the digital

controller switches off the power MOSFET and proceeds

regulation.

Loading...

Loading...