Philips TDVD1.1E AA Service Manual

Colour Television Chassis

TDVD1.1E

AA

CL 26532120_000.eps

061202

Contents Page

1. Technical Specifications, Connections

and Chassis Overview 2

2. Safety & Maintenance Instructions,

Warnings and Notes 4

3. Directions for Use 6

4. Mechanical Instructions 14

5. Service Modes, Error Codes and Faultfinding 15

6. Block Diagram, I2C Bus Interconnection Diagram

and Supply Voltage Diagram

Block Diagram 17

2

I

C-Bus Interconnection Diagram 18

Supply Voltage Diagram 19

7. Electrical Diagrams and PWB’s Diagram CBA

Main Panel: Tuner (Diagram A1) 20 26-27

Main Panel: Video Processor (Diagram A2) 20 26-27

Main Panel: SCART (Diagram A3) 21 26-27

Main Panel: EEPROM (Diagram A4) 21 26-27

Main Panel: Power Supply (Diagram A5) 22 26-27

Main Panel: Horizontal (Diagram A6) 23 26-27

Main Panel: u-Controller (Diagram A7) 21 26-27

Main Panel: Audio Amplifier (Diagram A8) 24 26-27

Main Panel: Vertical (Diagram A9) 24 26-27

Main Panel: Out (Diagram A10)25 26-27

Main Panel: Keyboard Panel (Diagram A11)25 26-27

CRT Panel (Diagram B) 28 28

RC Panel (Diagram C) 29 29

Front AV Module (Diagram D) 29 29

Line Out Panel (Diagram E) 30 30

8. Alignments 31

9. Circuit Description 34

Abbreviation List (Not Applicable yet) 34

IC Data Sheets 34

10 Spare Parts List 42

©

Copyright 2002 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by LM 0271 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12970

EN 2 TDVD1.1E1.

Technical Specifications, Connection Facilities, and Chassis Overview

1. Technical Specifications, Connection Facilities, and Chassis Overview

1.1 Technical Specifications

1.1.1 Reception

Tuning System : PLL

Colour Systems : PAL

: SECAM

:NTSC

Sound System : Mono

A/V Connections : SCART

: FRONT AV

Channel Selections : Air

: Cable

IF Frequency : B/G, D/K, L: 38.9 MHz

: L': 33.4 MHz

: I: 39.5 MHz

Aerial Input : 75 Ohm

1.1.2 DVD module

Disc formats : CD (R/RW)

:CVD

: (S) VCD

:DVCD

:DVD (+R/+RW)

Rotational speed : 4x CD

:2x DVD

Data transfer rate : 2760 kB/s for DVD

: 688 kB/s for VCD

Avg. access time : 250 ms typical

Data buffer capacity : 512 Kbytes

1.1.3 Miscellaneous

Audio Output (RMS) : 2 x 2.5 W

Mains Voltage : 220 - 240 V (± 10 %)

Mains Frequency : 50 / 60 Hz (± 5 %)

Power Consumption : 50 W

Standby Power Consumption : 4 W

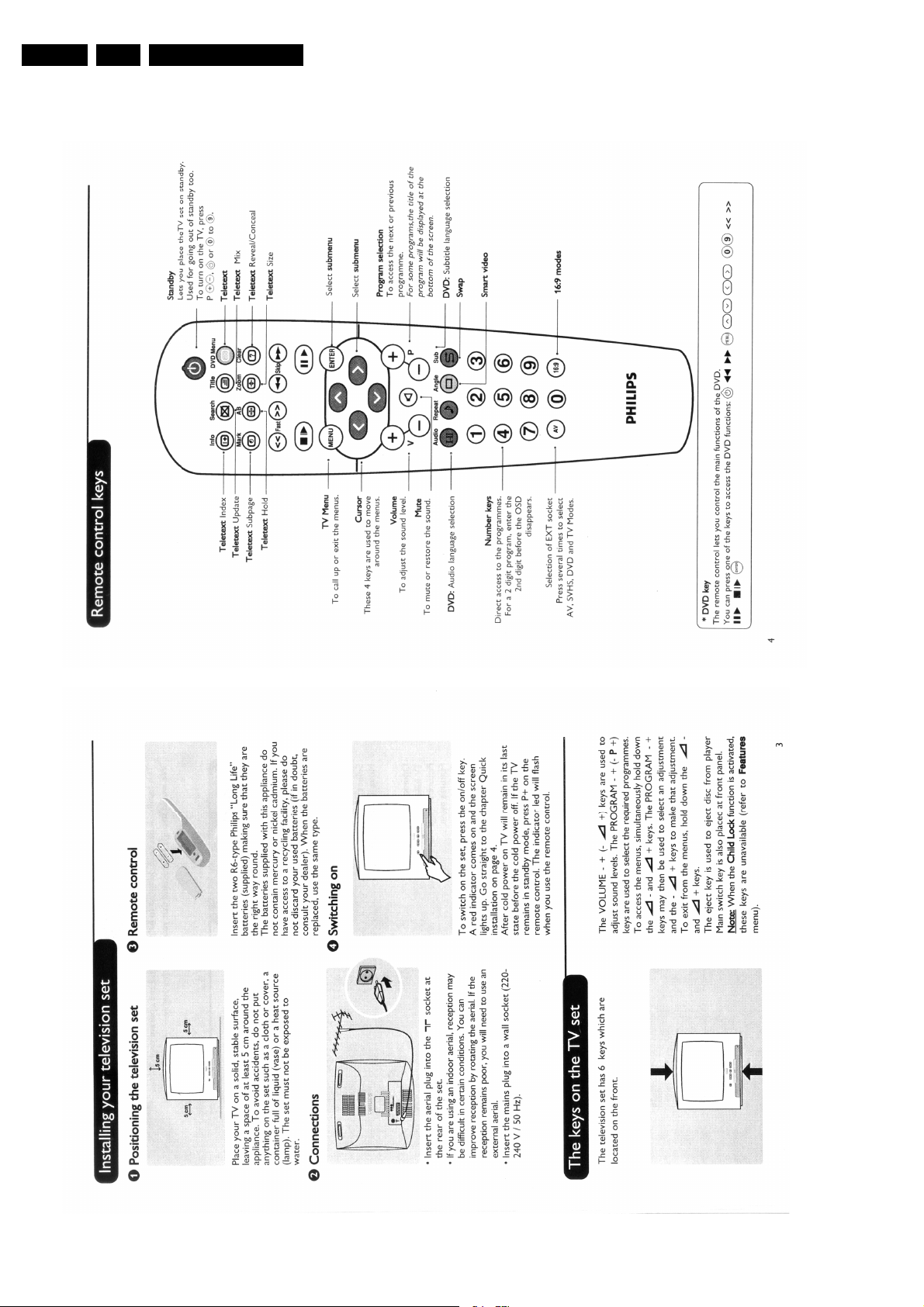

1.2 Connection/Control Facilities

1.2.1 TV Side Connections and Front Control

FRONT CONTROL

PHILIPS

- VOLUME + - PROGRAM +

SIDE I/O

VIDEO

AUDIO R

AUDIO L

CL 26532120_001.eps

IR

Receiver

081102

3.5

Cinch (Input)

1 - CVBS 1 Vpp / 75 Ω

2 - Audio - L 0.5 Vrms / 10 kΩ

3 - Audio - R 0.5 Vrms / 10 kΩ

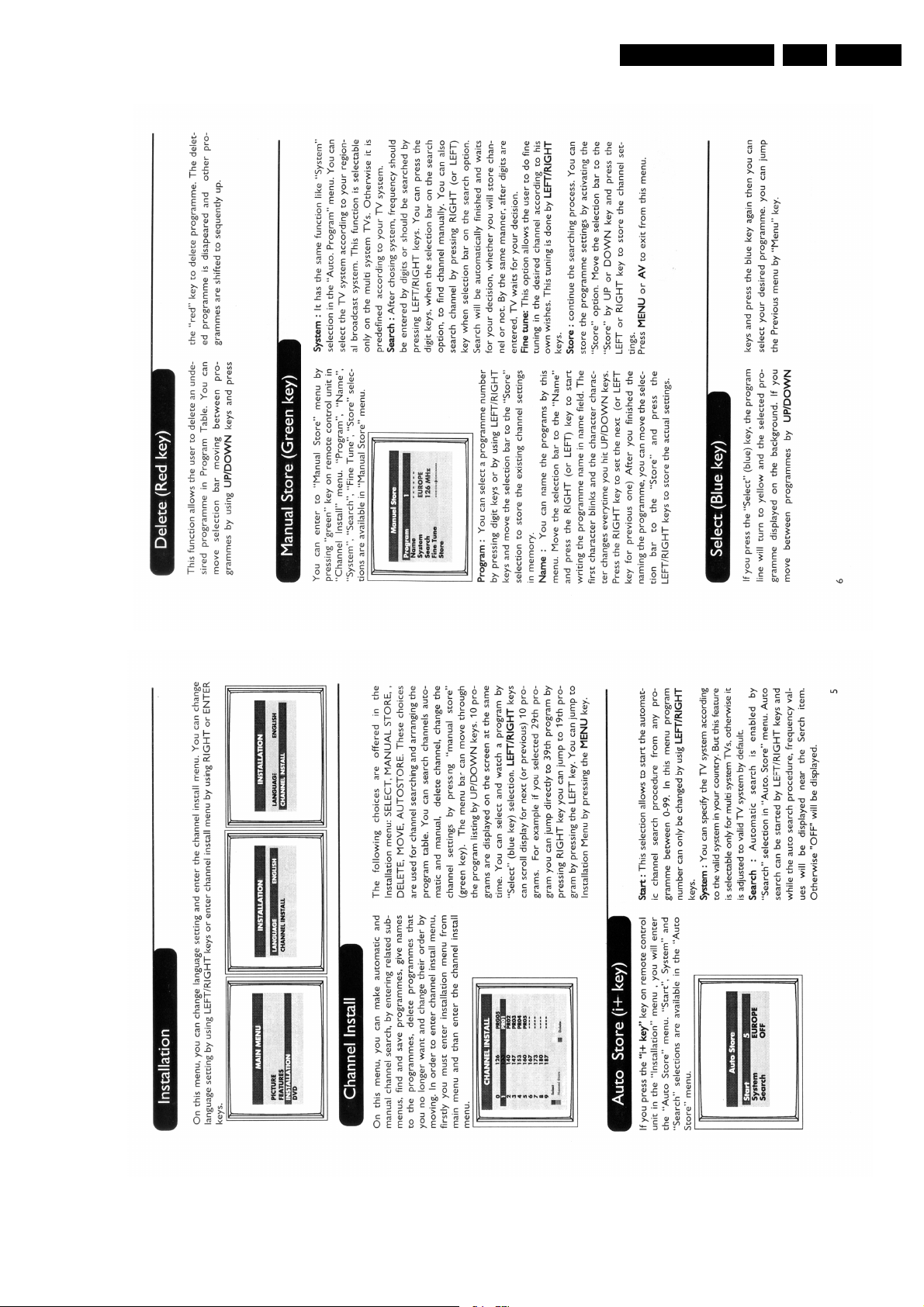

1.2.2 TV Rear Connections

REAR CONNECTIONS

PCMA/RA/L

EURO-AV

CL 26532120_002.eps

251002

Figure 1-2 Rear connections

Cinch (Output)

1 - Audio - L 0.5 Vrms / 1 kΩ

2 - Audio - R 0.5 Vrms / 1 kΩ

3 - S/PDIF (PCM)

Euro AV

121

CL96532137_056.eps

202

171199

Figure 1-3 SCART connector

1 - Audio - R 0.5 Vrms / 1 kOhm

2 - Audio - R 0.5 Vrms / 10 kOhm

3 - Audio - L 0.5 Vrms / 1 kOhm

4 - Audio Ground

5 - Blue Ground

6 - Audio - L 0.5 Vrms / 10 kOhm

7 - Blue 0.7 Vpp / 75 Ohm

8 - CVBS-status 0 - 1.3 V: INT

4.5 - 7 V: EXT 16:9

9.5 - 12 V: EXT 4:3

9 - Green Ground

10-

11-Green 0.7 Vpp / 75 Ohm

12-

13-Red Ground

14-CVBS status Ground

15-Red 0.7 Vpp / 75 Ohm

16-RGB status 0 - 0.4 V: INT

1 - 3 V: EXT / 75 Ohm

17-CVBS Ground

18-RGB status Ground

19-CVBS-o ut 1 Vpp / 75 Ohm

20-CVBS-in 1 Vpp / 75 Ohm

21-Shielding Ground

Figure 1-1 Side connections and Front control

Technical Specifications, Connection Facilities, and Chassis Overview

EN 3TDVD1.1E 1.

1.2.3 DVD Module Connections

DC Power Connector (CN401)

1 - Supply voltage + 12 V

2 - Ground

(analogue) A-GND

3 - Ground

(digital) D-GND

4 - Supply voltage + 5 V

A/V and DAIO Output (CN403)

1-ML n.c.

2-MC n.c.

3 - R/R (MD) Rear Right Audio

4 - AGND Audio Ground

5 - R/L (PCM2) Rear Left Audio

6 - CEN (PCM1) Centre Audio

7 - A-GND Audio Ground

8 - S/W (PCM0) Sub Woofer

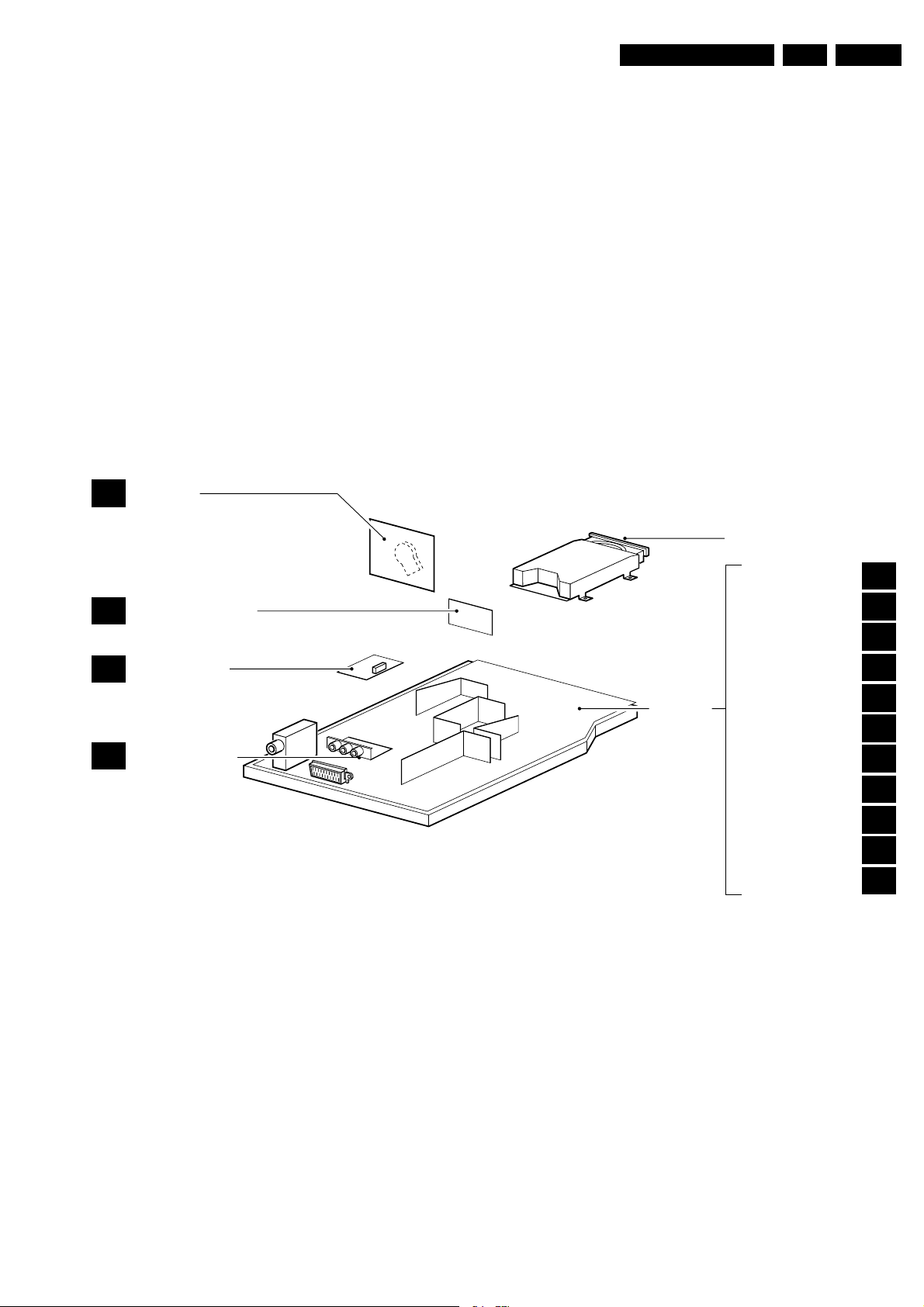

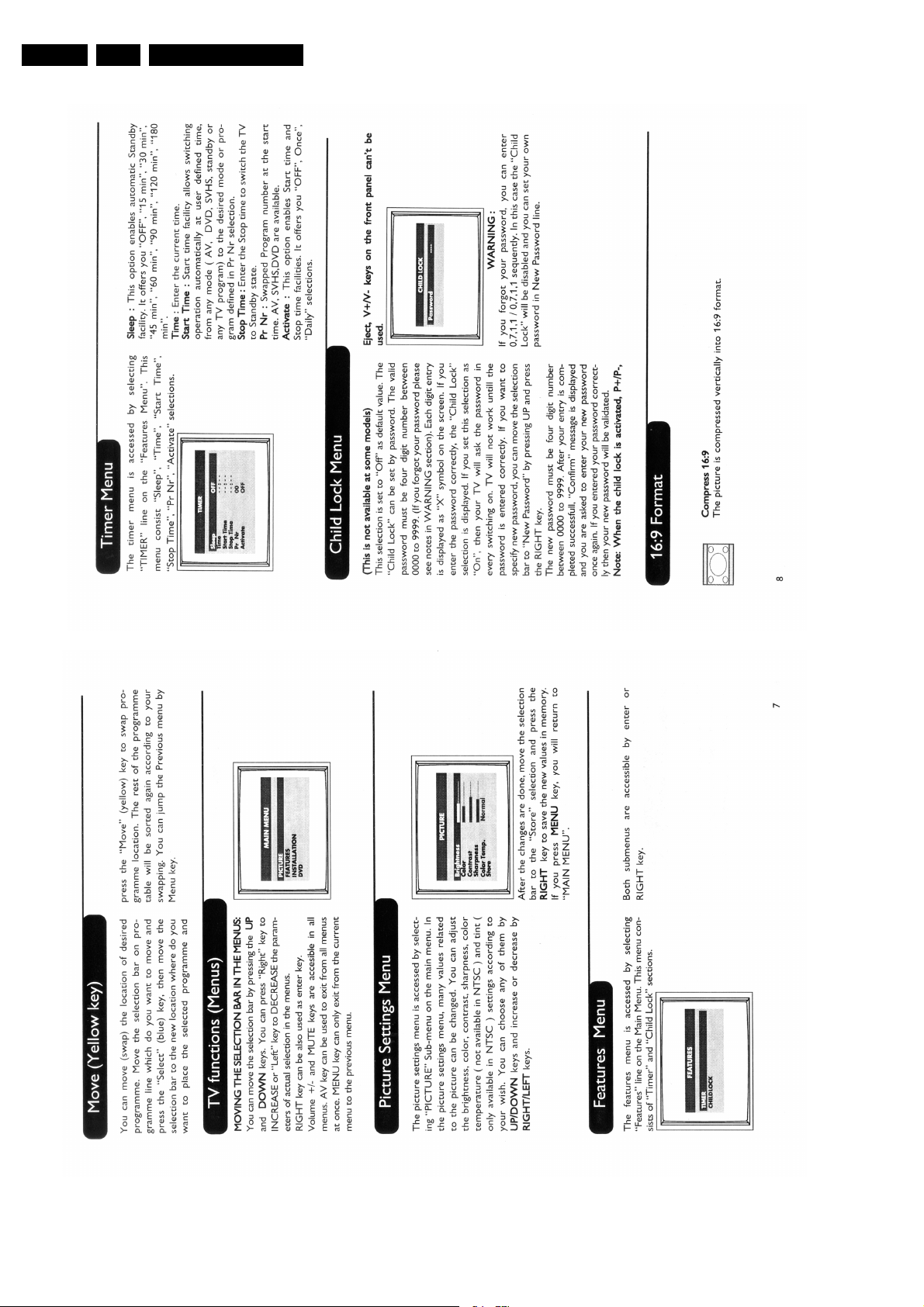

1.3 Chassis Overview

CRT PANEL

B

9 - F/R (SCK) Front Right Audio

10-A-GND Audio Ground

11-F/L (BCK) Front Left Audio

12-MUTE (LRCK) Mute for Audio

13-S/PDIF Digital Audio

14-D-GND Digital Ground

15-CVBS 1 Vpp / 75 Ohm

16-V-GND Video Ground

17-Y 1 Vpp / 75 Ohm

18-V-GND Video Ground

19-C 0.3 Vpp / 75 Ohm

20-V-GND Video Ground

21-G/Y 0.7 Vpp / 75 Ohm

22-B/Cb 0.7 Vpp / 75 Ohm

23-R/Cr 0.7 Vpp / 75 Ohm

24-V-GND Video Ground

25-VID_S/W Video switching

26-TV_S/W TV switching

DVD ENGINE

RC PANEL

C

FONT AV PANEL

D

LINE OUT PANEL

E

Figure 1-4 PWB location

MAIN

CHASSIS

PANEL

TUNER

VIDEO PROCESSOR

SCART

EEPROM

POWER SUPPLY

HORIZONTAL

µ-CONTROLLER

AUDIO AMPLIFIER

VERTICAL

AV INTERFACE CONN.

KEYBOARD

CL 26532120_003.eps

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

061202

EN 4 TDVD1.1E2.

Safety and Maintenance Instructions, Warnings, and Notes

2. Safety and Maintenance Instructions, Warnings, and Notes

2.1 S af et y In st ruc tions

Safety regulations require that during a repair:

• Due to the chassis concept, a part of the circuitry is 'hot'.

Therefore, connect the set to the mains via an isolation

transformer.

• Replace safety components, indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

• Wear safety goggles when you replace the CRT.

Safety regulations require that after a repair, you must return

the set in its original condition. Pay, in particular, attention to

the following points:

• General repair instruction: as a strict precaution, we advise

you to re-solder the solder connections through which the

horizontal deflection current is flowing. In particular this is

valid for the:

1. Pins of the line output transformer (LOT).

2. Fly-back capacitor(s).

3. S-correction capacitor(s).

4. Line output transistor.

5. Pins of the connector with wires to the deflection coil.

6. Other components through which the deflection current

flows.

Note: This re-soldering is advised to prevent bad connections

due to metal fatigue in solder connections, and is therefore only

necessary for television sets more than two years old.

• Route the wire trees and EHT cable correctly and secure

them with the mounted cable clamps.

• Check the insulation of the mains cord for external

damage.

• Check the strain relief of the mains cord for proper function,

to prevent the cord from touching the CRT, hot

components, or heat sinks.

• Check the electrical DC resistance between the mains plug

and the secondary side (only for sets that have an isolated

power supply). Do this as follows:

1. Unplug the mains cord and connect a wire between the

two pins of the mains plug.

2. Turn on the main power switch (keep the mains cord

unplugged!).

3. Measure the resistance value between the pins of the

mains plug and the metal shielding of the tuner or the

aerial connection of the set. The reading should be

between 4.5 MΩ and 12 MΩ.

4. Switch the TV 'off' and remove the wire between the

two pins of the mains plug.

• Check the cabinet for defects, to prevent the possibility of

the customer touching any internal parts.

,

Figure 2-1

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

2.2 Maintenance Instructions

We recommend a maintenance inspection carried out by

qualified service personnel. The interval depends on the usage

conditions:

• When a customer uses the set under normal

circumstances, for example in a living room, the

recommended interval is three to five years.

• When a customer uses the set in an environment with

higher dust, grease, or moisture levels, for example in a

kitchen, the recommended interval is one year.

• The maintenance inspection includes the following actions:

1. Perform the 'general repair instruction' noted above.

2. Clean the power supply and deflection circuitry on the

chassis.

3. Clean the picture tube panel and the neck of the picture

tube.

2.3 Warnings

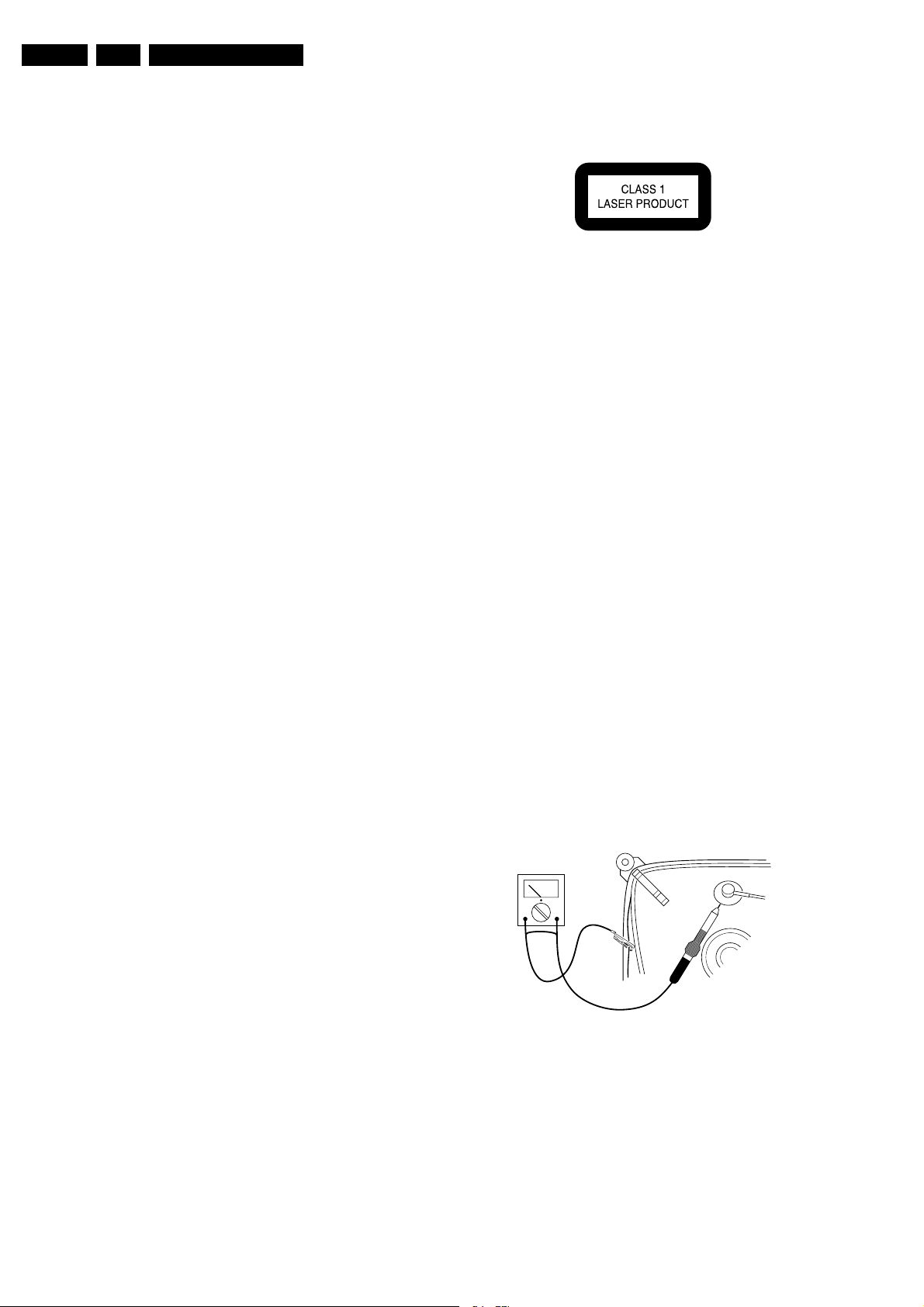

2.3.1 General

• In order to prevent damage to ICs and transistors, avoid all

high voltage flashovers. In order to prevent damage to the

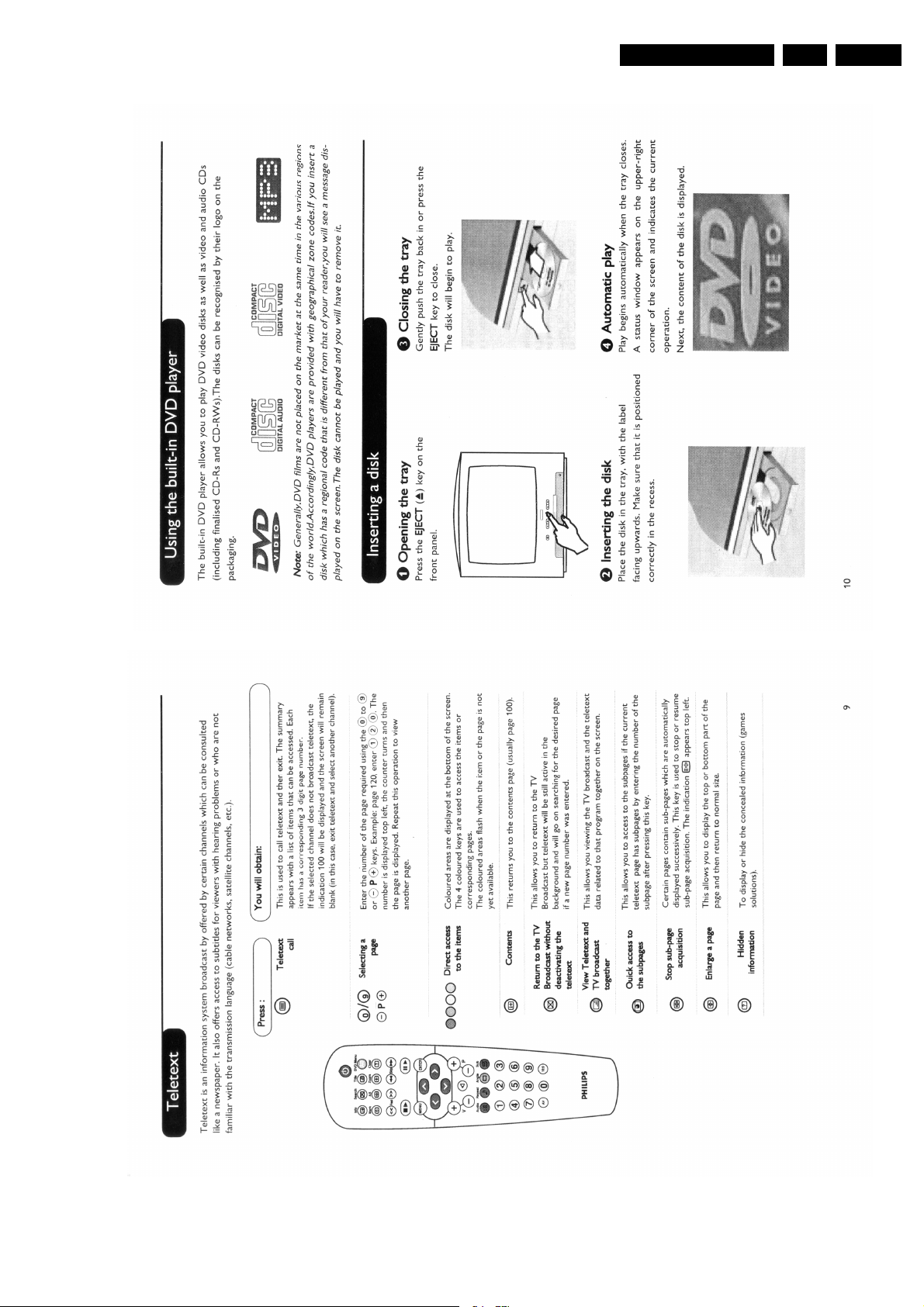

picture tube, use the method shown in Fig. 2-2, to

discharge the picture tube. Use a high voltage probe and a

multi-meter (position V

reading is 0 V (after approx. 30 s).

V

). Discharge until the meter

DC

2.1.1 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

CL96532156_040.eps

140501

Figure 2-2 Discharge picture tube

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol w). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are connected with the same

potential as the mass of the set by a wristband with

resistance. Keep components and tools also at this

potential. Available ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and ground cable)

4822 310 10671.

– Wristband tester 4822 344 13999.

Safety and Maintenance Instructions, Warnings, and Notes

• Together with the deflection unit and any multi-pole unit,

flat square picture tubes form an integrated unit. The

deflection and the multi-pole units are set optimally at the

factory. We do not recommend adjusting this unit during

repair.

• Be careful during measurements in the high voltage

section and on the picture tube.

• Never replace modules or other components while the unit

is 'on’.

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYO NNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

EN 5TDVD1.1E 2.

Figure 2-3

2.4 Notes

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (), or hot ground (), depending

on the tested area of circuitry.

• The voltages and waveforms shown in the diagrams are

indicative. Measure them in the Service Default Mode (see

chapter 5) with a colour bar signal and stereo sound (L: 3

kHz, R: 1 kHz unless stated otherwise) and picture carrier

at 475.25 MHz (PAL) or 61.25 MHz (NTSC, channel 3).

• Where necessary, measure the waveforms and voltages

with () and without () aerial signal. Measure the

voltages in the power supply section both in normal

operation () and in standby (). These values are

indicated by means of the appropriate symbols.

• The picture tube panel has printed spark gaps. Each spark

gap is connected between an electrode of the picture tube

and the Aquadag coating.

• The semiconductors indicated in the circuit diagram and in

the parts lists, are interchangeable per position with the

semiconductors in the unit, irrespective of the type

indication on these semiconductors.

EN 6 TDVD1.1E3.

3. Directions for Use

Directions for Use

Directions for Use

EN 7TDVD1.1E 3.

EN 8 TDVD1.1E3.

Directions for Use

Directions for Use

EN 9TDVD1.1E 3.

EN 10 TDVD1.1E3.

Directions for Use

Directions for Use

EN 11TDVD1.1E 3.

EN 12 TDVD1.1E3.

Directions for Use

Directions for Use

EN 13TDVD1.1E 3.

Personal Notes:

EN 14 TDVD1.1E4.

Mechanical instructions

4. Mechanical instructions

Index of this chapter:

1. Rear Cover Removal

2. Service Position Main Panel

3. DVD Module Removal

4. Side I/O Panel Removal

5. Rear I/O Panel Removal

6. Rear Cover Mounting

Note:

Figures can deviate slightly from the actual situation.

4.1 Rear Cover Removal

1. Remove all fixation screws (7x) of the rear cover.

2. Pull the rear cover a little backwards.

3. Disconnect the Rear I/O and Side I/O panel cables

4. Now pull the rear cover backwards to remove it.

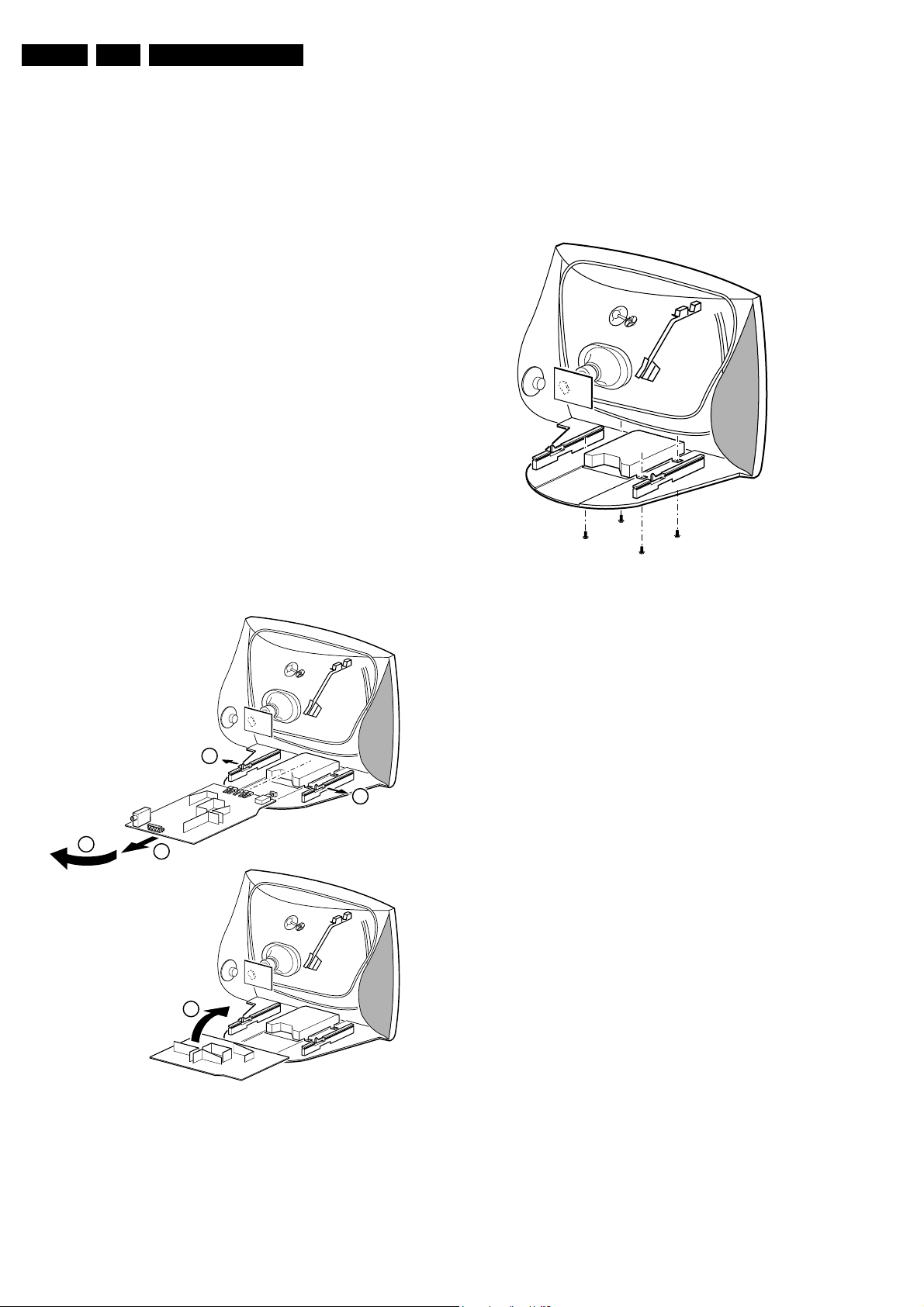

4.2 Service Position Main Panel

1. Disconnect all cables of the DVD module.

2. Remove the main panel, by pushing the two centre clips

outward [1]. At the same time, pull the panel away from the

CRT [2].

3. Turn the panel 90 degrees clockwise [3].

4. Flip the panel 90 degrees [4], with the components towards

the CRT.

4.3 DVD Module Removal

Remove the complete DVD module after unscrewing the four

fixation screws [1].

CL 26532120_026.eps

Figure 4-2 Disassemble DVD module

311002

4.4 Side I/O Panel Removal

A

Remove the side I/O panel after unscrewing the screw from the

outside of the rear cover.

4.5 Rear I/O Panel Removal

1

1

Remove the rear I/O panel after unscrewing the two screws

from the inside of the rear cover.

4.6 Rear Cover Mounting

3

2

B

To reassemble the set, perform all described processes in

reverse order.

Be sure that, before the rear cover is mounted:

• The mains cord is mounted correctly in its guiding bracket.

• All wires/cables are returned in their original position.

4

CL 26532120_027.eps

311002

Figure 4-1 Service position Main panel

Loading...

Loading...