Philips TDA5147K Datasheet

INTEGRATED CIRCUITS

DATA SH EET

TDA5147K

12 V Voice Coil Motor (VCM) driver

and spindle motor drive

combination chip

Product specification

File under Integrated Circuits, IC11

1996 Jul 26

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

FEATURES

Spindle motor driver

• Internal 1 A peak current power drivers

• Low R

drivers

• Induction sense start-up option

• External current sense resistor

• Soft switching on both upper and lower drivers

• Programmable linear or PWM spindle mode

• Provide spindle active dynamic braking mode.

Voice coil motor driver

• 0.8 Amp VCM power driver

• Maximum of 1 V drop across the power driver at 0.8 A

• External current sense resistor, with sense amplifier

• External current control loop compensation

• 15 kHz (typ.) VCM current control loop bandwidth

• Three mode operation: enable VCM, retract, and

disable.

Power monitor and retract circuit

• +5 and +12 V power monitor threshold accuracy ±2%

• Hysteresis on both power monitor comparators

• Precision internal voltage generator ±2%

• Buffered reference voltage output pin

1 Ω max total for high, low and isolation

ds(on)

TDA5147K

• Retract circuit operates down to 2 V

• Internal thermal sense circuitry with an over temperature

shut down option

• Internal boost voltage generator

• Sleep mode.

APPLICATIONS

• Hard disk drive for PC products.

GENERAL DESCRIPTION

The TDA5147K is an ASIC combination chip that includes

the following functions; spindle motor drive, voice coil

motor drive, retract, and power-on. The circuit is contained

in a 52-pin PLCC package.

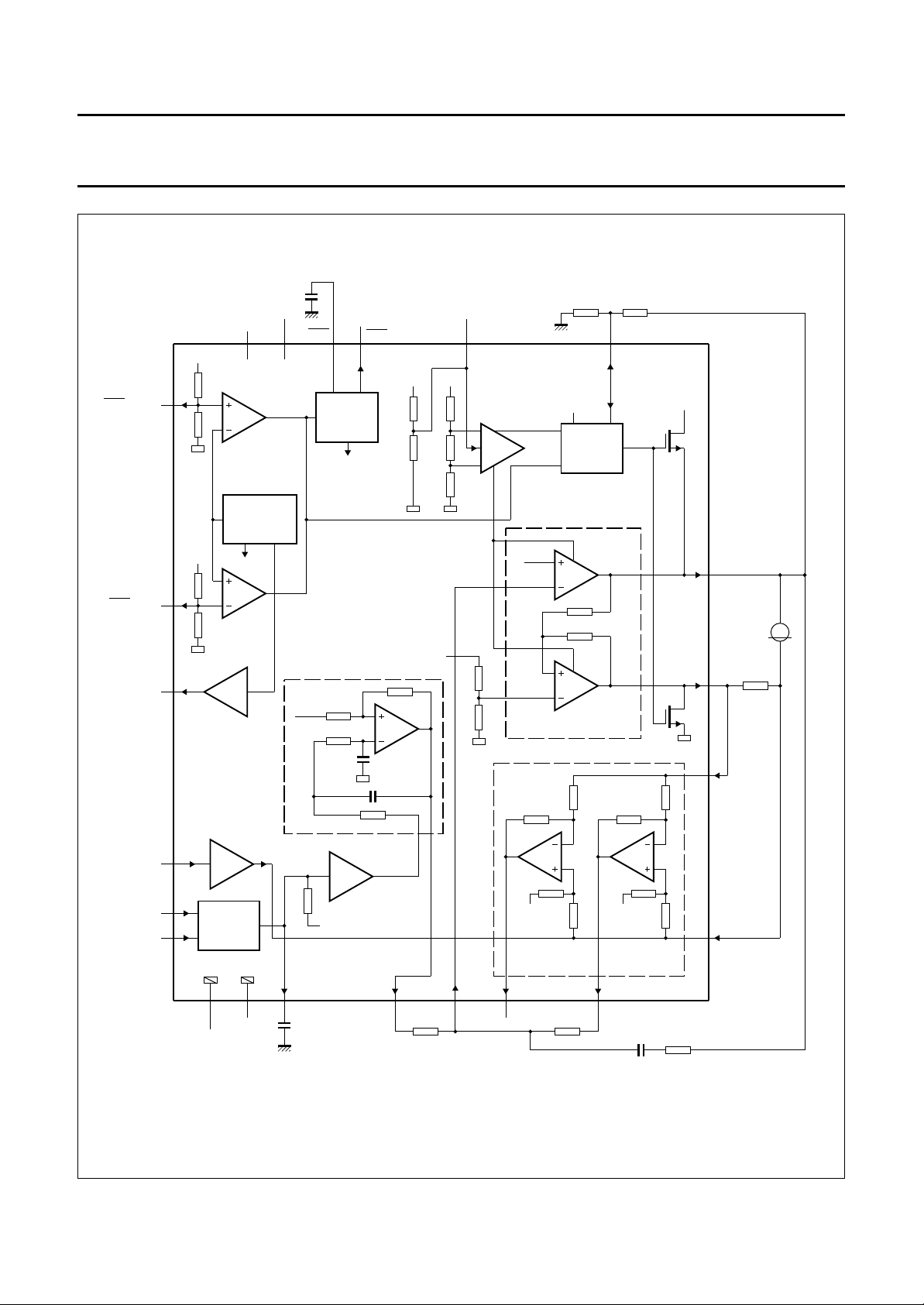

The TDA5147K (see Fig.1) is controlled by a custom

digital ASIC. The custom ASIC provides the necessary

commutation sequences for the spindle drivers via the

SCNTL1, SCNTL2 and SCNTL3 inputs. Spindle speed is

monitored by comparator outputs SENU, SENV and

SENWIS. Motor speed control is accomplished by a PWM

signal (input at the SIPWM pin).

Control of the VCM circuits is via the V

input signals. These two inputs provide control of the coil

current. The V

output signal can be used to monitor

ISENSE2

the voice coil current.

IPWMH

and V

IPWML

QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Supply voltage

V

V

CCA1

CCA2

analog supply voltage 1 4.5 5.0 5.5 V

analog supply voltage 2 10.8 12.0 13.2 V

Drivers

I

spin(max)

I

VCM(max)

maximum spindle current − 1 − A

maximum voice coil motor current − 0.8 − A

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION VERSION

PACKAGE

TDA5147K PLCC52 plastic leaded chip carrier; 52 leads SOT238-2

1996 Jul 26 2

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

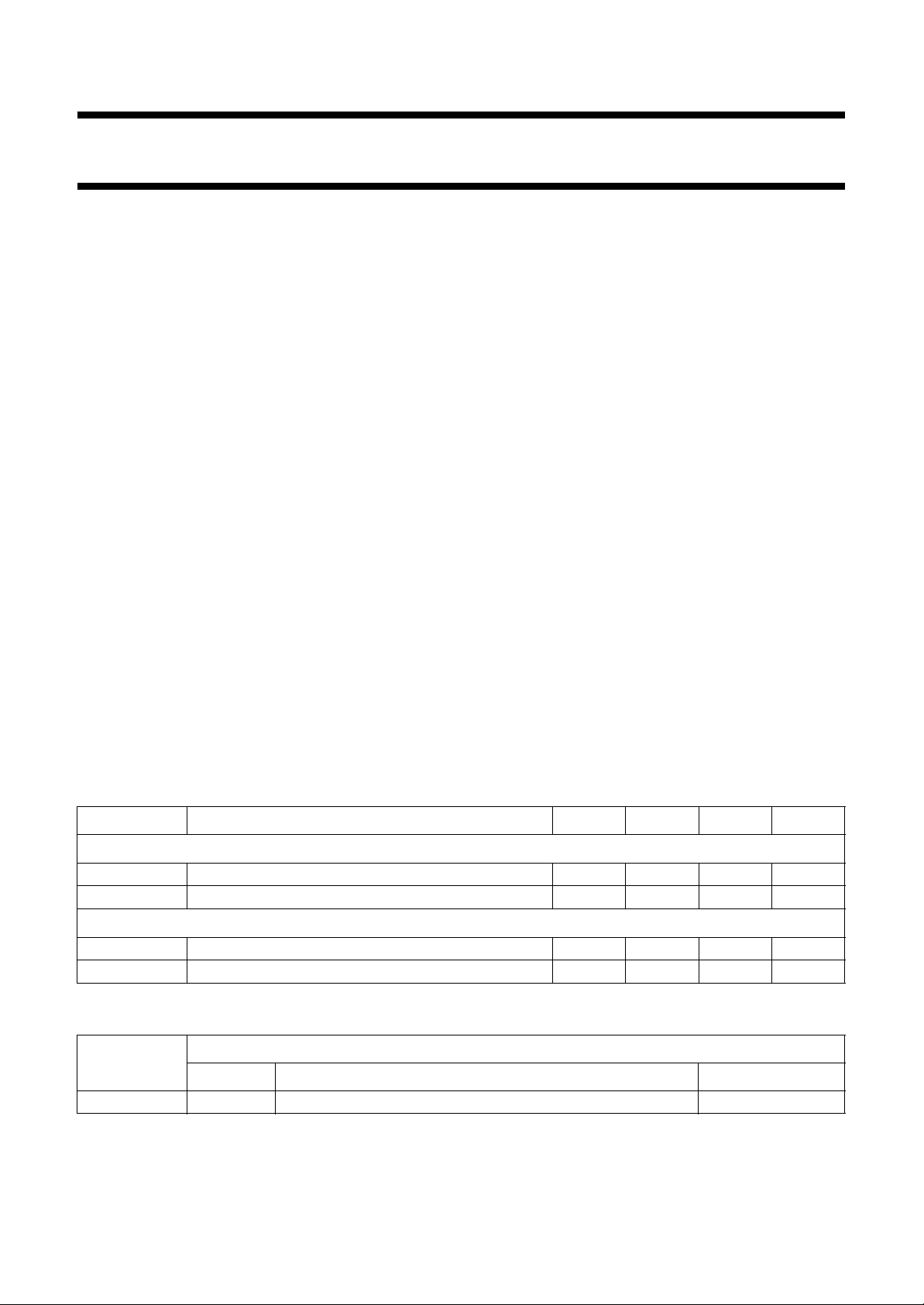

BLOCK DIAGRAMS

handbook, full pagewidth

POR

V

PCNTL

V

IPWMH

V

IPWML

V

DIGITAL

CIRCUIT

ISENS2

SCNTL1 to 3

SENU, SENV, SENWIS

SIPWM

TDA5147K

POWER-ON RESET

PARK

VOICE COIL

MOTOR DRIVE

SPINDLE

TDA5147K

ACTUATORS

MBH018

Overview

No external power drivers; dynamic braking for non-power down situations; 1 A spindle current; 0.8A VCM power driver; full-wave spindle mode,

POR monitors for both 5 and 12 V supplies; auto-park in the event of power-down.

Fig.1 System block diagram.

1996 Jul 26 3

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

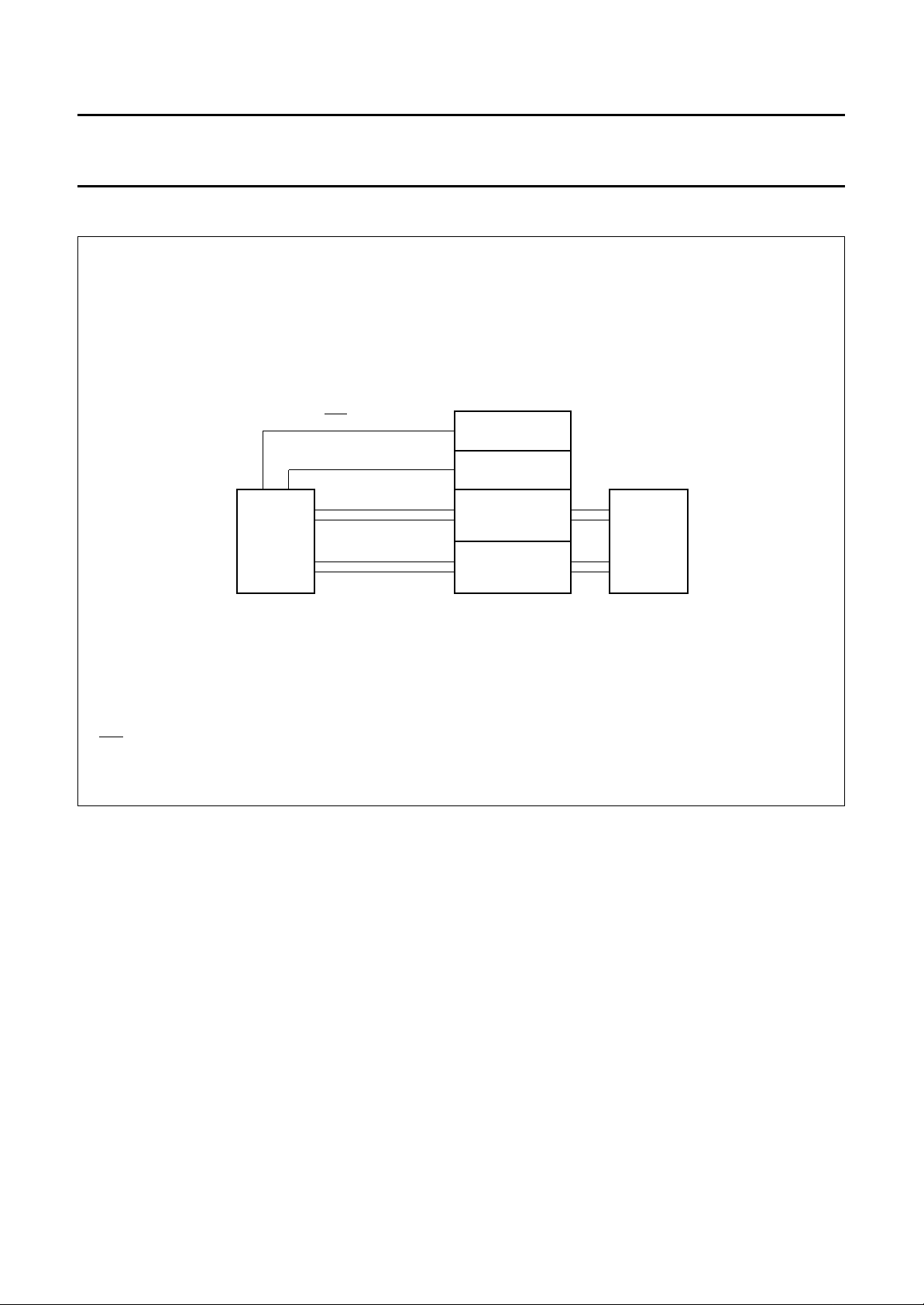

handbook, full pagewidth

BSTFLT

SCNTL2

SCNTL3

20

10SCNTL1

11

14

3SMODE1

V

23SCOMP

DECODER

V

CCA1

25 21

UPPER

BOOSTER

LOGIC

CCA1

BSTCP2BSTCP1

U.H

U.H

V.H

V.L

W.H

W.L

brake

disable

M

COMP

PWM/LIN

V

CCS

to the VCM

output stages

l

comp

THERMAL

SWITCH

I

set

I

sense

control

amplifier

SPWMTC

15

PWM/LIN

PWM

U.H

U.L

V.H

V.L

W.H

W.L

DRIVER

DRIVER

DRIVER

DRIVER

DRIVER

DRIVER

disable

disable

brake

disable

disable

brake

disable

disable

brake

from POR block

V

CCS

TDA5147K

19

SHPWR3

51

SHPWR2

24

SDRVU

29

SHPWR1

C

clamp

12

SDRVV

2

SDRVW

I

13

V

I

sense

CCS

set

COMP

34

PGND150V

TDA5147K

I

COMP

CCA2

SISENL 32

SISENH 31

R

s

30SIPWM

26SPWMFLT

PWM

DECODER

FILTER

AMP

V

ref

Fig.2 Block diagram of spindle motor drivers.

1996 Jul 26 4

SISINK1, SISINK2

COMP

COMP

COMP

M

multiplexer

9

SISINK227SISINK145PGND2

SDRVU

SDRVV

SDRUW

16

18

17

MBH024

8

SDRVN

SENV

SENU

SENWIS

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

handbook, full pagewidth

V

CCS

V

POR12

ADJ

V

6

V

CCA2

CCAI

CCV

UNDER

VOLTAGE

GENERATOR

V

ref

C

1339

POR

4

PWM

DETECTOR

to spindle

section

POR

5

V

V

DD

DD

disable

V

PCNTL

35

park

autopark

V

ref(o)

SHPWR

PARK

CICUITRY

POWER

RET

22

ADJ

SDRU

TDA5147K

36

V

CMN

POR5

V

IPWML

V

IPWMH

V

V

ADJ

ref(o)

ref(i)

7

37

38

46

47

PWM

DECODER

AGND1

5228

AGND2

V

ref(o)

48

V

FLTINP

TDA5147K

V

ref(o)

V

CCA2

V

FLTOUT

3349

V

CMINP

POWER

POWER AMPLIFIERS

SENSE

V

ref(o)

41 44

V

ISEN2

SENSE

V

ref(o)

V

ISEN1

42VCMP

43

V

ISENL

40VISENH

M

R

s

MBH023

Fig.3 Block diagram of voice coil motor driver.

1996 Jul 26 5

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

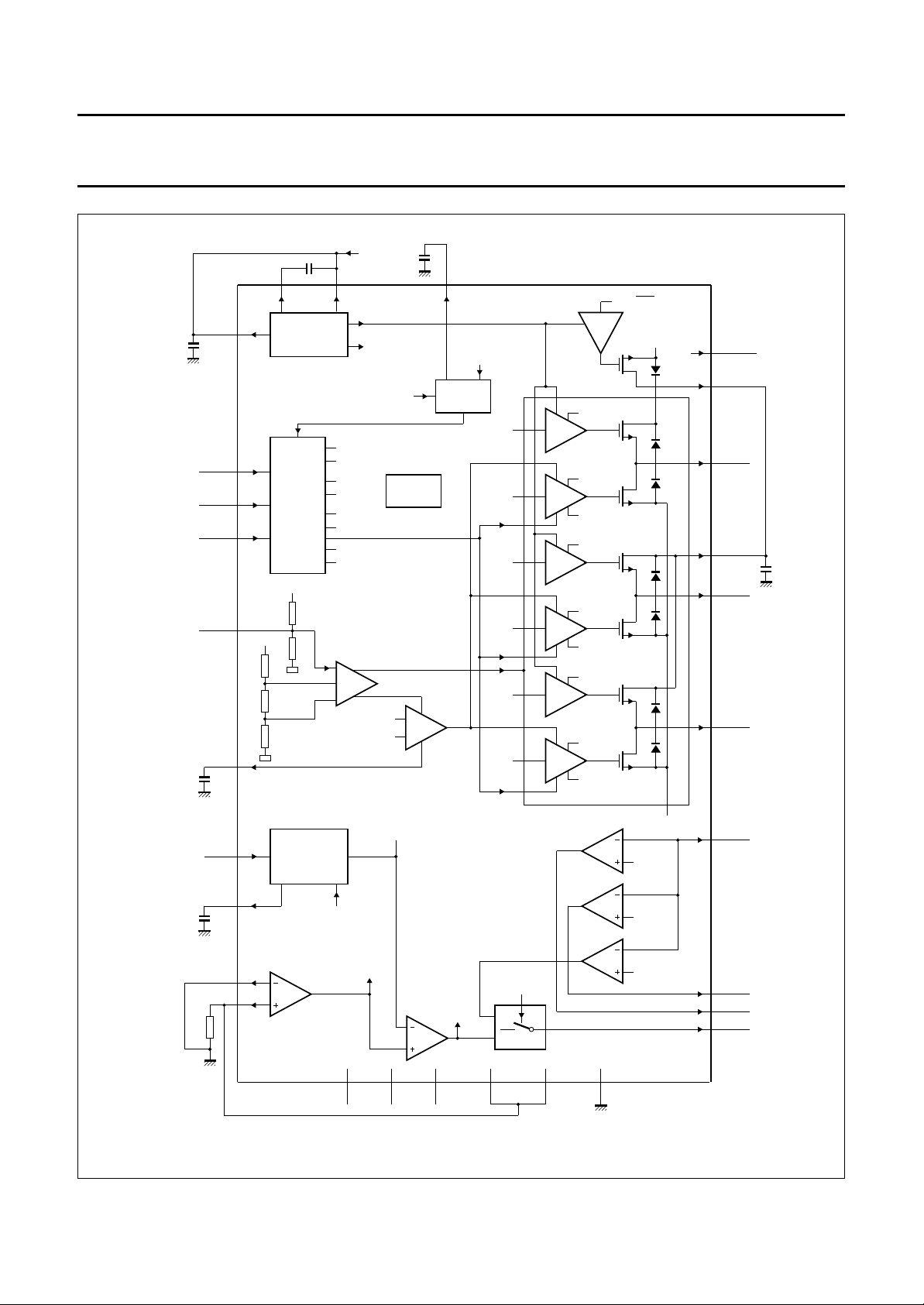

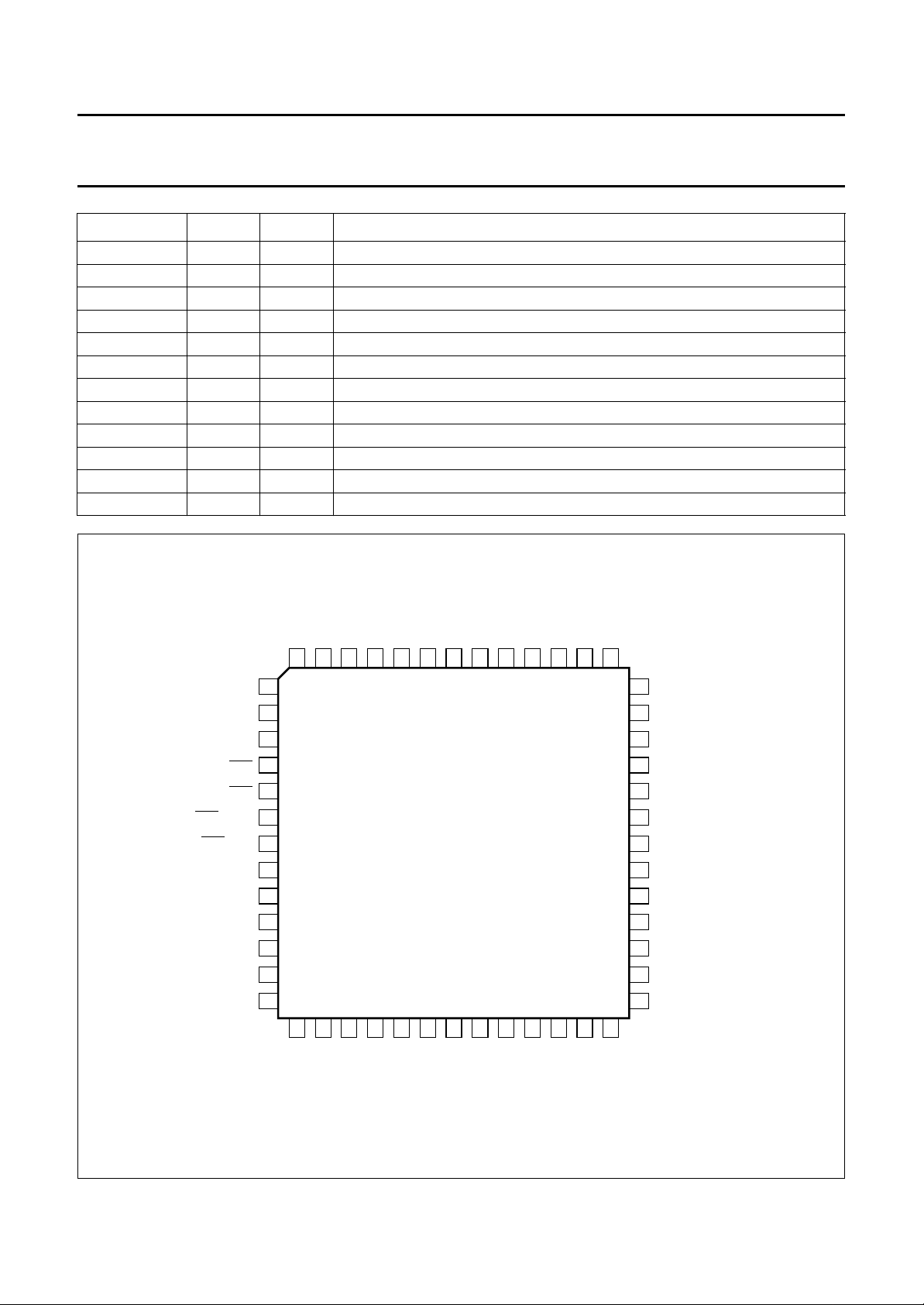

PINNING

SYMBOL PIN I/O DESCRIPTION

V

CCA1

SDRVW 2 O phase 3 output for spindle motor

SMODE1 3 I 3-state level input for spindle mode

C

POR

POR 5 O power-on reset digital output (active LOW)

POR12

POR5

ADJ

ADJ

SENWIS 8 O digital output of back EMF sense 3/inductive sense

SISINK2 9 − connection 2 to the sense resistor

SCNTL1 10 I digital input 1 for spindle decoder

SCNTL2 11 I digital input 2 for spindle decoder

SDRVV 12 O phase 2 output for spindle motor

V

CCS

SCNTL3 14 I digital input 3 for spindle decoder

SPWMTC 15 O capacitor for spindle low side PWM time off

SDRVN 16 O centre TAP connection to spindle motor

SENU 17 O digital output of back EMF sense 1

SENV 18 O digital output of back EMF sense 2

SHPWR3 19 O capacitor 3 for PARK supply voltage

BSTFLT 20 O booster filter output

BSTCP2 21 O booster capacitor 2 output

RET

ADJ

SCOMP 23 O control amplifier pole adjustment

SDRVU 24 O phase 1 output for spindle motor

BSTCP1 25 O booster capacitor 1 output

SPWMFLT 26 O capacitor for spindle PWM filter

SISINK1 27 − connection 1 to the sense resistor

AGND1 28 − analog ground 1

SHPWR1 29 O capacitor 1 for PARK supply voltage

SIPWM 30 I digital PWM input for spindle current

SISENH 31 O sense resistor for spindle current

SISENL 32 O isolated ground connection for spindle sense amplifier

V

CMINP

PGND1 34 − power ground of VCM driver

V

PCNTL

V

CMN

V

ref(o)

V

ref(i)

V

CCV

V

ISENH

1 − analog supply voltage 1 (+5 V)

4 I/O power-on reset delay capacitor

6 O adjustment of POR threshold (for +12 V)

7 O adjustment of POR threshold (for +5 V)

13 − power supply of spindle motor drivers (+12 V)

22 I/O retract voltage adjustment pin

33 I closed loop voltage compensation of VCM

35 I PARK enable 3-state voltage level input

36 O negative output voltage of H-bridge

37 O reference voltage output for external ADC

38 I reference voltage input for the 2nd sense amplifier

39 − power supply of VCM driver (+12 V)

40 I positive input voltage of sense resistor amplifier

TDA5147K

1996 Jul 26 6

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

SYMBOL PIN I/O DESCRIPTION

V

ISENS2

V

CMP

V

ISENL

V

ISENS1

PGND2 45 − power ground 2 of voice coil motor driver

V

IPWML

V

IPWMH

V

FLTINP

V

FLTOUT

V

CCA2

SHPWR2 51 O capacitor for PARK supply voltage

AGND2 52 − analog ground 2

41 O voltage output 2 of sense resistor amplifier

42 O positive output voltage of H-bridge

43 I negative input voltage of sense resistor amplifier

44 O voltage output 1 of sense resistor amplifier

46 I PWM input voltage (LSB)

47 I PWM input voltage (MSB)

48 O voice coil motor PWM filter capacitor

49 O PWM filter output voltage

50 − analog supply voltage 2 (+12 V)

TDA5147K

handbook, full pagewidth

V

SDRVW

SMODE1

POR12

POR5

SENWIS

SISINK2

SCNTL1

SCNTL2

SDRVV

CCA1

C

POR

POR

ADJ

ADJ

V

CCS

CCA2VFLTOUTVFLTINPVIPWMHVIPWMLVISENS1

V

SHPWR2

AGND2

52

51

50

49

48

47

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

SCNTL3

SDRVN

SPWMTC

17

SENU

TDA5147K

18

19

SENV

SHPWR3

PGND2

46

45

20

21

BSTFLT

BSTCP2

44

22

ADJ

RET

ISENLVCMP

V

43

23

SCOMP

42

41

24

25

SDRVU

BSTCP1

ISENS2VISENH

V

40

39

38

37

36

35

34

33

32

31

30

29

28

27

26

MBH017

SPWMFLT

V

CCV

V

ref(i)

V

ref(o)

V

CMN

V

PCNTL

PGND1

V

CMINP

SISENL

SISENH

SIPWM

SHPWR1

AGND1

SISINK1

Fig.4 Pinning configuration.

1996 Jul 26 7

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

FUNCTIONAL DESCRIPTION

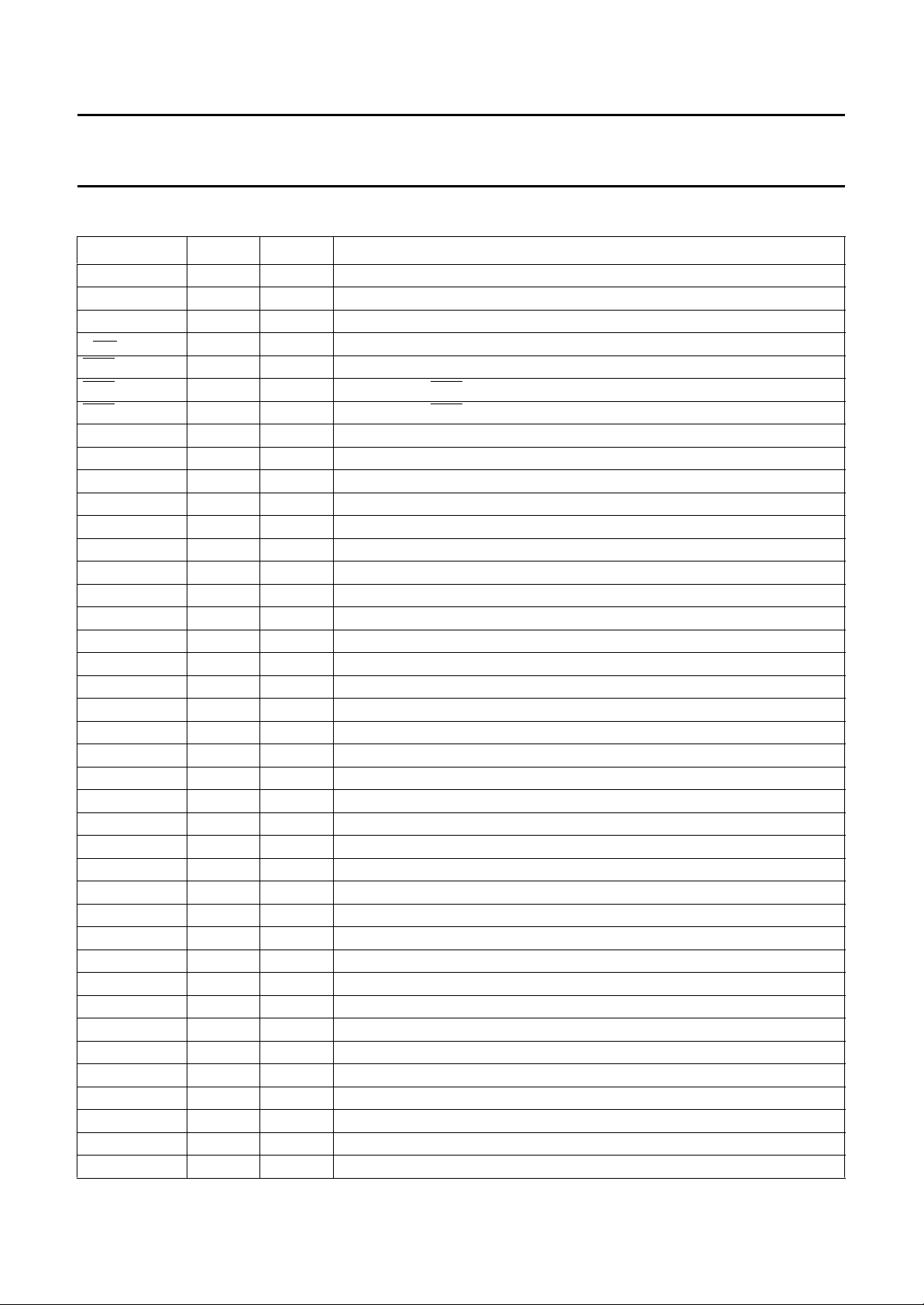

Spindle drivers

The spindle section contains both the low and high side

drivers (configured as H bridges) for a three-phase DC

brushless motor. Back EMF (BEMF) sensing of the

commutation rate needs to be output to an external digital

ASIC circuit. This digital circuit also provides the input

commutation control. Consequently, all speed control,

start-up routine and commutation control will be generated

by the digital circuit.

The SIPWM signal from the digital circuit is used to control

the spindle current. This PWM signal is internally filtered.

The output of this filter is duty factor dependent only. The

filter characteristics is that of a 1-pole low-pass filter, with

the pole location being controlled by the external capacitor

connected to pin SPWMFLT.

Dynamic braking is possible only during non power-down

situations and must be initiated by the digital circuit.

SMODE1

TDA5147K

to obtain high start-up torque. The purpose of the PWM

mode is to drive the low drivers into saturation (saturation

reduces the power dissipation in the TDA5147K during

start-up).

When the spindle current reaches the programmed set

current (SIPWM) value, a one-shot is fired. The output of

the one-shot remains high for the programmed off-time

) set by the capacitor/resistor network at the SPWMTC

(t

off

pin. The one-shot is not retriggerable for approximately

10% of the off-time, this gives a minimum of (10% t

time-on. During the off-time, the lower spindle output

drivers are switched off. The on-time of the drivers is not

fixed but is determined by the charging time of the coil

current to reach the program set current.

The turn-off time is calculated by the equation:

t

=R×C

off

Where R = 68 kΩ and C = 220 pF, t

ln(2)

= 10.4 µs.

off

The minimum on-time can be calculated by the equation:

CV

t

=

--------

on

I

)

off

A 3-state level mode line (SMODE1) has been included to

allow for;

1. An induction sensing algorithm in pre-start-up (V

2. PWM control during start-up (0.5V

CCA1

).

CCA1

3. Linear control (0 V).

S

ENSING MODE

The induction sensing mode is used for two purposes.

Firstly one of the BEMF sensor outputs (SENWIS) will be

shared with the voltage comparator that is used for the

induction sensing function. Prior to start-up each phase

can be excited for a short period of time. The current from

each coil can be monitored via the multiplexed output

(SENWIS). By comparing the rise times of each phase the

rotor position can be determined.

Secondly, in situations where the spindle motor requires

more current to spin-up, this mode is used with the

exception that the output SENWIS is ignored. Since, in the

induction sense mode, the output drivers are operated in

saturation mode, the motor current is limited only by the

power supply. This condition of induction sense mode can

be used to overcome the head friction and must be used

only when needed.

PWM M

ODE

INEAR MODE

L

The linear mode is used when the motor is near to its

).

intended speed. It can also be used at start-up, but higher

power dissipation will occur. In the linear mode the linear

drivers are controlled by a sensing amplifier. A Miller

network is used to obtain soft switching on the lower

drivers. This prevents large voltage spikes on the motor

coils when the lower drivers are switching. The high drivers

are switched into the linear (resistive) region.

The transconductance gain of the low driver current to filter

voltage can be calculated as follows:

G

m

I

coil

--------------------------- V

SPWMFLT

V

1

SISENH

------

--------------------------- -

R

V

s

SPWMFLT

==

1

-----R

s

For a 100% duty factor at SIPWM, the nominal voltage at

SPWMFLT = 1.74 V. The calculated coil current for a

100% duty factor (sense resistors R

1

1

I

coil

-----------

0.33

1.74 1.05 A=××=

-- 5

= 0.33 Ω) is:

s

Referencing to the duty factor, the coil current is:

I

coil

-----R

1.74

0% duty

××

--------------------100

1

1

-- 5

s

1

0.348()

-----R

s

1

A/V===

-- 5

0% duty

×== =

--------------------100

The PWM mode is normally used during the start-up

phase. Maximum drive voltage is applied to the low drivers

1996 Jul 26 8

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

TDA5147K

spindle motor drive combination chip

The duty factor is arranged so that at 100%, the voltage SPWMFLT = 1.74 V and at a 5% duty factor SPWMFLT = 0 V.

This is to ensure that at 0% duty factor the current will be zero (allowances for circuit tolerances).

The input decoder is driven by three lines which define the windings to be energized. The input decoder must then

translate these lines to six lines to drive the six output drivers. The truth table is given in Table 1.

Table 1 Input decoder truth table

(1)

CONDITION SCNTL1 SCNTL2 SCNTL3 SDRVU

SDRVV

Disable LOW LOW LOW X X X

Dynamic brake HIGH HIGH HIGH HIGH HIGH HIGH

State 1 HIGH HIGH LOW LOW X HIGH

State 2 HIGH LOW LOW X LOW HIGH

State 3 HIGH LOW HIGH HIGH LOW X

State 4 LOW LOW HIGH HIGH X LOW

State 5 LOW HIGH HIGH X HIGH LOW

State 6 LOW HIGH LOW LOW HIGH X

Under voltage −−−XXX

Note

1. X = 3-state.

(1)

SDRVW

(1)

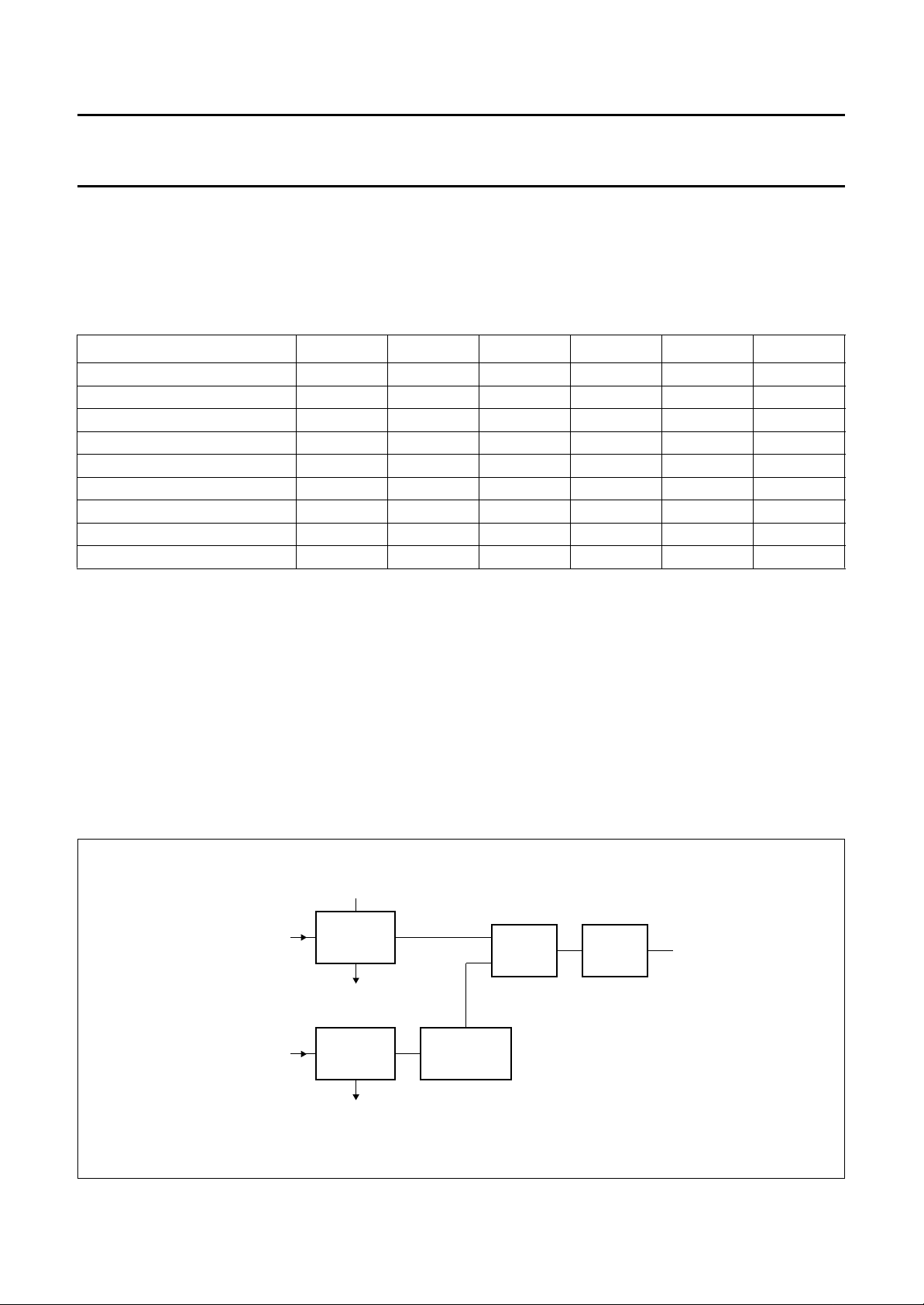

VCM driver

The VCM driver is a linear, class AB, H-bridge type power

driver with all power devices internal to the chip. In addition

to the power stage a sense resistor enables VCM current

to be measured and brought out to a separate ADC via the

V

pin. The reference voltage for the V

ISENS2

ISENS2

output

is provided externally. The current level to the VCM is

controlled via two PWM signals that are generated by the

digital circuit. The input voltage at pin 47 (V

handbook, full pagewidth

PWM (MSD)

PWM (LSB)

LEVEL

CONVERTOR

LEVEL

CONVERTOR

V

IPWMH

ref

)

ATTENUATION

represents a weighting of 32 times more than the input

voltage at pin 46 (V

equal to 32 × duty factor (V

), thus the current command is

IPWML

IPWML+VIPWMH

). These PWM

signals are filtered by an internal 3rd-order low-pass filter

(Butterworth filter). The bandwidth of this low-pass filter is

nominally 40 kHz (less than 2 degrees lag at 500 Hz), but

the real pole may be adjustable by an external capacitor.

The analog output of the filter depends on the duty factor

of the PWM signal and not on the logic level.

32 : 1

SUM

UNITY

GAIN

LOW-PASS

MBH019

analog

output

Fig.5 Block diagram of the PWM filter.

1996 Jul 26 9

Philips Semiconductors Product specification

12 V Voice Coil Motor (VCM) driver and

spindle motor drive combination chip

PARK ENABLE

A 3-state-level mode line (V

will:

1. Enable VCM drivers; V

2. Disable VCM drivers; 0.5V

3. PARK (soft retract the actuator); 0 V.

Enable VCM drivers

When the enable signal is HIGH, the VCM drivers are

controlled by the two PWM inputs. The two digital signals

convert the duty factor to a voltage level at V

100% duty factor the V

above V

. At a 0% duty factor the V

ref(o)

FLTINP

approximately −1 V below V

voltage level is equal to V

ref(o)

voltage is amplified, filtered and output at V

voltage at V

V

voltage, in conjunction with the sense resistor

FLTOUT

varies between ±2 V about V

FLTOUT

amplifier, drives the two VCM drivers as illustrated in Fig.8.

The transconductance equation that governs the voltage

to I

I

coil

R2

------- R1

is:

coil

–

1

Amps per Volt

×××=

-----R

s

==

from V

FLTINP

G

---------------------------------------------

m

V

1

2

-----------gain

FLTINPVref o()

In a typical application:

I

--------------------------------------------V

coil

–

FLTINPVref o()

2

-- 4

6.6 kΩ

×

-----------------10 kΩ

The transconductance is variable by selecting external

resistors R2/R1 and sense resistors R

Disable VCM drivers

With the PARK enable signal at 0.5V the VCM drivers are

disabled while the rest of the circuits remain enabled.

A sleep mode is initiated when the spindle and VCM are

disabled (this places the TDA5147K in its lowest power

setting).

) has been included that

PCNTL

(normal).

CCA1

.

CCA1

. At a

FLTOUT

voltage is approximately 1 V

voltage is

FLTINP

. At a 50% duty factor, the

ref(o)

(typical 4 V). The V

I

-----------------------------------------------------V

coil

FLTOUTVref o()

–()

1

× 1 Amp per Volt==

-----------

0.33

s

FLTOUT

FLTINP

. The

ref(o)

. The

TDA5147K

CTUATOR PARK

A

Retracting the actuator can be accomplished by driving

V

LOW in conjunction with either the spindle is

PCNTL

turning or a brake voltage has been applied. An adjustable

retract voltage of 1.2 V (max.) is applied between the V

and V

outputs. The retract circuit obtains its retract

CMP

current from the spindle SDRVU phase. If the SDRVU

phase is zero there will be no retract voltage.

The retract voltage is determined by two external resistors.

One end is tied to V

common point is tied to pin 22 (RET

and the other to ground. The

CMN

); see Fig.1 for

ADJ

additional information.

The calculation of V

V

RETRACT

Where 0.65 is V

0.65

BE

RETRACT

×=

at 25 °C ∆VBE/∆T=−2 mV/°C; 50 kΩ

is as follows:

1R2+

-----------------

R1

+

--------------- 50 kΩ

R2

can vary by ±30%

It should be noted that R2 has to be less than 10 kΩ.

Power-on reset

The power-on reset circuit monitors the voltage levels of

both the +5 V and the +12 V supply voltages as shown

in Fig.6. The

POR (active LOW) logic line is set HIGH

following a supply voltage rise above a specified voltage

threshold plus a hysteresis, and delayed by a time, tC that

is controlled by an external capacitor. This

POR signal

should remain HIGH until either the +5 or +12 V supplies

drop below the voltage threshold, at which point the

line should be asserted LOW.

The tC timing is set by the following equation:

CV

×

=

t

C

Where V

th

-----------------I

= 2.5 V and I is 12 µA (typ.).

th

A negative going pulse width of 5 µs on either the

+5 or +12 V rail will provide a full output pulse. If another

trigger pulse occurs before the output is completed a new

output pulse will be originated. This implies the power-on

reset circuit is a retriggerable one-shot with a maximum

trigger pulse of 5 µs (see Fig.7).

CMN

POR

1996 Jul 26 10

Loading...

Loading...