Philips Semiconductors Product specification

Digital servo processor (DSIC2) TDA1301T

FEATURES

The DSIC2 realizes the following servo functions:

• Diode signal preprocessing

• Focus servo loop

• Radial servo loop

• Sledge motor servo loop

• Three-line serial interface via the microcontroller

The other features include:

• Full digital signal processing

• Low power consumption, down to 30 mW

• Low voltage supply 3 to 5.5 V

• Integrated analog-to-digital converters and digital servo

loop filters

• Double speed possible

• Easy application

– Single supply voltage

– Small number of external components; only

6 decoupling capacitors

– Flexible system oscillator circuitry

– Usable for single/double Foucault and astigmatic

focus

– Full automatic radial error signal initialization offset

control and level initialization for track position

indicator

– No external adjustments required; no component

ageing

– Wide range of adjustable servo characteristics

– Simple 3-line serial command interface

– 28-pin SO package

– Great flexibility towards different CD mechanisms

– Full and transparent application information

• High robustness/shock insensitivity

– Sophisticated track-loss (TL) detection mechanism

– Fast focus restart procedure

– Extended radial error signal

– Adjustable radial shock detector

– Defect drop-out detector

• Fully automatic jump procedure for radial servo

• Automatic focus start-up procedure and built-in FOK

(Focus OK)

• Fast radial jump or access procedure

• Self-operational servo-control without continuous

communication via the microcontroller

• Direct communication to photodiode optics; no external

preprocessing.

GENERAL DESCRIPTION

The TDA1301T is a fully digital servo processor which has

been designed to provide all servo functions, except the

spindle motor control, in two-stage three-spot compact

disc systems. The device offers a high degree of

integration, combined with the low additional cost of

external components. The servo characteristics have a

wide range of adjustment via a three-line serial interface.

This offers an enormous flexibility with respect to

applications for different CD mechanisms. The circuit is

optimized for low-power low-voltage applications.

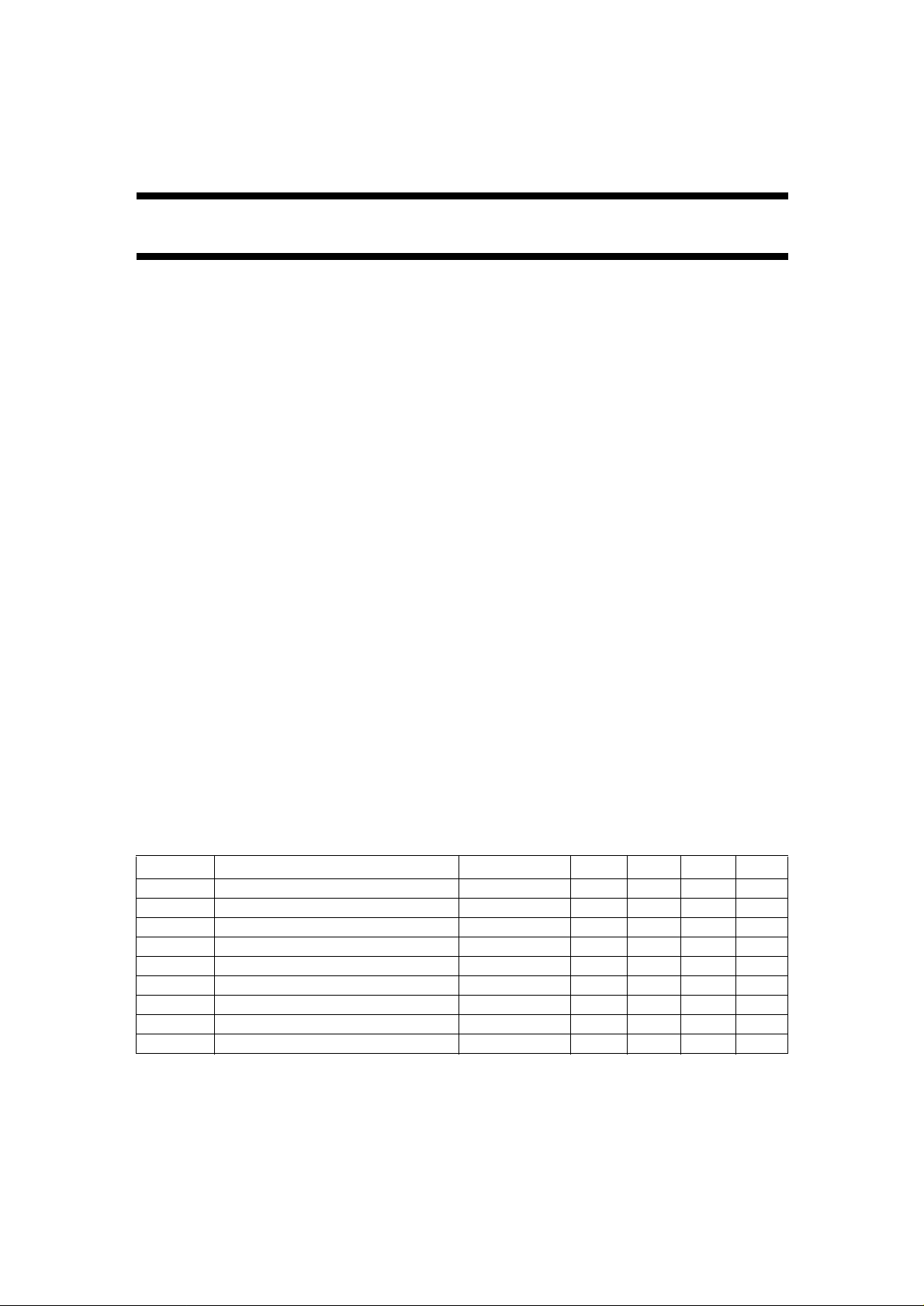

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

DDD

V

DDA

I

DDD

I

DDA

I

DDD(q)

I

i(cd)

I

i(sd)

P

tot

T

amb

digital supply voltage 3.0 − 5.5 V

analog supply voltage 3.0 − 5.5 V

digital supply current − 5 − mA

analog supply current − 5 − mA

digital quiescent supply current − − 10 µA

central diode input currents (D1 to D4) note 1 − − 15.8 µA

satellite diode input currents (R1 and R2) note 1 − − 7.9 µA

total power dissipation − 50 − mW

operating ambient temperature −40 − +85 °C

Note

1. f

= 4.2336 MHz; VRL = 0 V; VRH = 2.5 V (externally applied).

sys

March 1994 2

Philips Semiconductors Product specification

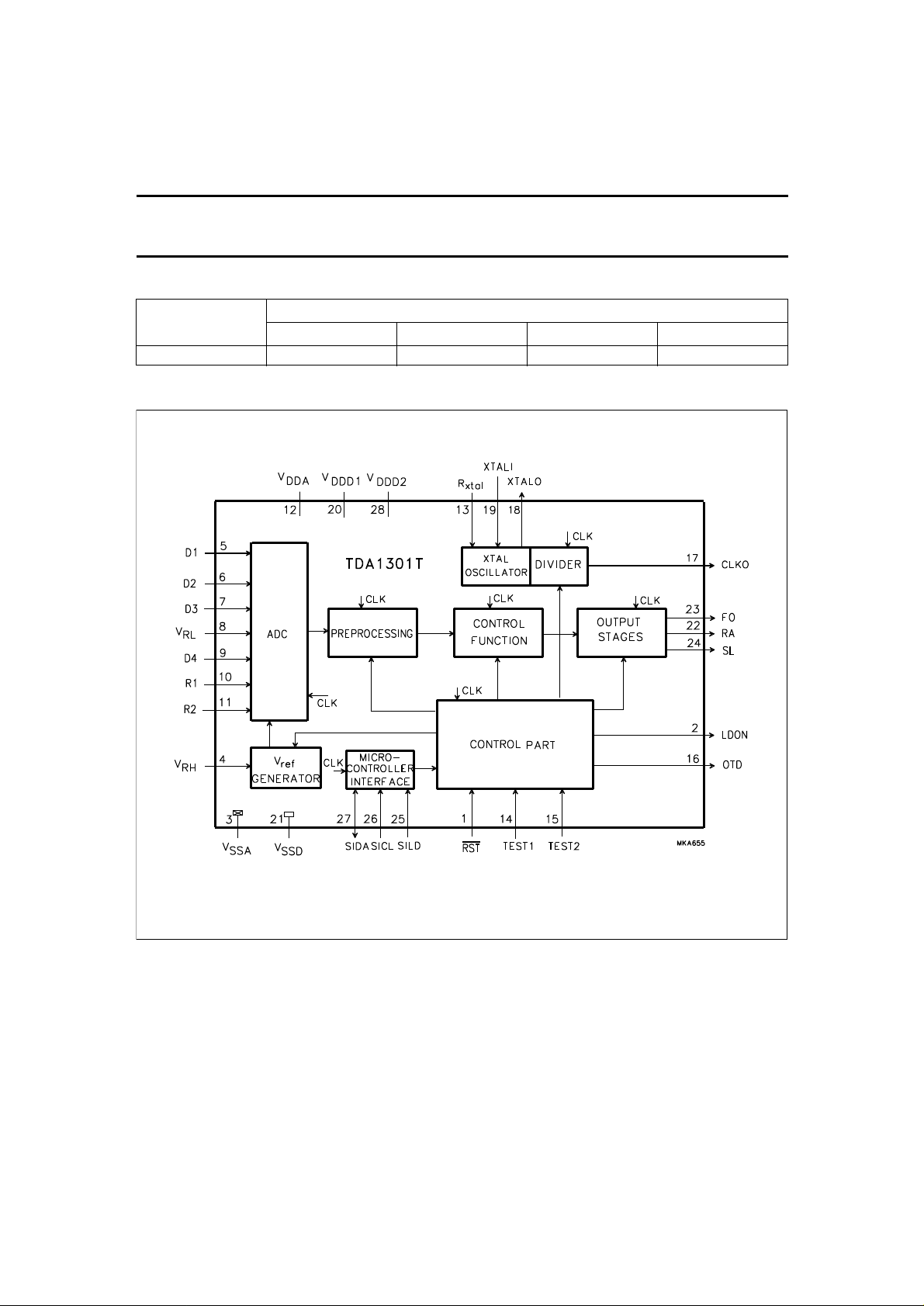

Fig.1 Block diagram.

Digital servo processor (DSIC2) TDA1301T

ORDERING INFORMATION

EXTENDED TYPE

NUMBER

TDA1301T 28 SO28L plastic SOT136A

BLOCK DIAGRAM

PINS PIN POSITION MATERIAL CODE

PACKAGE

March 1994 3

Philips Semiconductors Product specification

Fig.2 Pin configuration.

Digital servo processor (DSIC2) TDA1301T

PINNING

SYMBOL PIN DESCRIPTION

RST 1 reset input (active LOW)

LDON 2 laser drive on output

V

SSA

V

RH

D1 5 unipolar current input

D2 6 unipolar current input

D3 7 unipolar current input

V

RL

D4 9 unipolar current input

R1 10 unipolar current input

R2 11 unipolar current input

V

DDA

XTAL

TEST1 14 test input 1

TEST2 15 test input 2

OTD 16 off-track detector output

CLKO 17 clock output

XTALO 18 oscillator output

XTALI 19 oscillator input

V

DDD1

V

SSD

RA 22 radial actuator output

FO 23 focus actuator output

SL 24 sledge output

SILD 25 serial interface load input

SICL 26 serial interface clock input

SIDA 27 serial interface data input/output

V

DDD2

3 analog ground

4 reference input for reference voltage

generator

(central diode signal input)

(central diode signal input)

(central diode signal input)

8 reference input for ADC

(central diode signal input)

(satellite diode signal input)

(satellite diode signal input)

12 analog supply voltage

13 oscillator reference input

ref

20 digital power supply 1

21 digital ground

28 digital power supply 2

March 1994 4

Philips Semiconductors Product specification

–

]

]

4–

D3 D4+

----------------------

–=

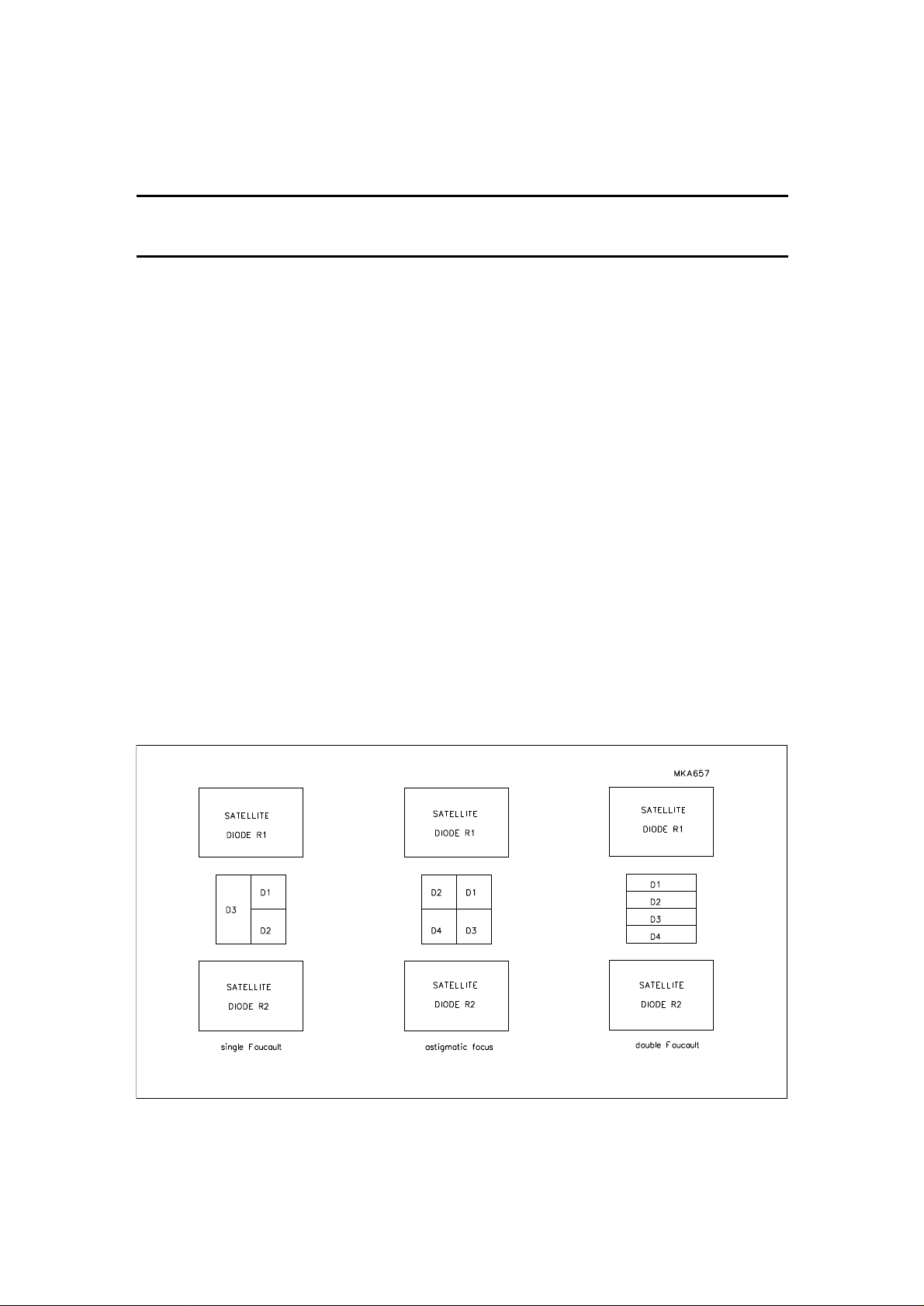

Fig.3 Diode configuration.

Digital servo processor (DSIC2) TDA1301T

FUNCTIONAL DESCRIPTION

Three spots front-end

The photo detector in a two-stage three-spots compact

disc system normally contains six discrete elements. Four

of these elements (in the event of single Foucault: three

elements) carry the central aperture (CA) signal while the

other two elements (satellite signals) carry the radial

tracking information. Besides the HF signal, which is finally

applied to both of the audio channels, the central aperture

also contains information for the focus servo loop. To

enable the HF signal to be processed, the frequency

contents of the central aperture signal must be divided into

an HF data part and an LF servo part. The HF signal is

processed outside the DSIC2 by the TDA1302 or a

discrete amplifier-equalizer. The necessary crossover

point, to extract the LF servo part, is compensated for in

the amplifier.

Diode signal processing

The analog signals from the photo detectors are converted

into a digital representation using analog-to-digital

converters. The ADCs are designed to convert unipolar

currents into a digital code. The dynamic range of the input

currents is adjustable within a given range and is

dependent on the ADC input reference voltages V

and

RL

VRH. The maximum current for the central diodes signals

is given in equation (1).

I

i max( )fsysVRHVRL

( ) 1.5 106–×××= µA[

(1)

The maximum current for the satellite signals is given in

equation (2).

I

i max( )fsysVRHVRL

V

is generated internally. There are four different levels

RH

–( ) 0.75 106–×××= µA[

(2)

(1.0, 1.5, 2.0 and 2.5 V) which can be selected under

software control. In the application VRL is connected to

V

. It is also possible to drive VRH with an external

SSA

voltage source but in this situation the internal voltage

source has to be switched off (software controlled).

Signal conditioning

The digital codes retrieved from the ADCs are applied to

logic circuitry to obtain the various control signals. The

signals from the central aperture detectors are processed

so that the normalized focus error signal (FE) given in

equation (3) is realized:

FE

n

D1 D2–

---------------------D1 D2+

D3 D

(3)

Where the detector set-up is assumed to be as illustrated

in Fig.3.

March 1994 5

Philips Semiconductors Product specification

( )

R1 R2+( ) Sum_gain×–

[]sin=

Digital servo processor (DSIC2) TDA1301T

In the event of single Foucault focusing method, the DSIC2

signal conditioning can be switched under software control

so that the signal processing conforms to that given in

equation (4).

FEn2

×=

---------------------D1 D2+

(4)

D1 D2–

The FEn thus obtained is further processed by a

proportional integral and differential filter section (PID).

A focus OK flag (FOK) is generated by means of the

central aperture signal and an adjustable reference level.

This signal is used to provide extra protection for the

Track-Loss (TL) generation, the focus start-up procedure

and the drop-out detection. The radial or tracking error

signal is generated by the satellite detector signals R1 and

R2. The radial error signal (RE) can be formulated as per

equation (5).

RE

=

s

R1 R2–( ) RE_gain×

R1 R2+( ) RE_offset×

+

(5)

Where the index ‘s’ indicates the automatic scaling

operation which is performed on the radial error signal.

This scaling is necessary to avoid non-optimum dynamic

range usage in the digital representation and, also, to

reduce radial bandwidth spread. The radial error signal will

also be released from offset during disc start-up. The four

signals from the central aperture detectors, together with

the satellite detector signals, generate a track position

signal (TPI) which can be formulated as per equation (6).

TPI D1 D2 D3 D4+ + +

(6)

Where the weighting factor Sum_gain is generated

internally in the DSIC2 during initialization.

Focus control

The following focus servo functions are incorporated in the

DSIC2 digital controller.

OCUS START-UP

F

Five initially loaded coefficients influence the start-up

behaviour of the focus controller. The automatically

generated triangular voltage can be influenced by

3 parameters, for the height (ramp_heigth) and DC-offset

(ramp_offset) of the triangle and its steepness (ramp_inc).

To protect against false focus point detections two

parameters are available. One is an absolute level on the

CA signal (CA_start) and the other is an absolute level on

the FEn signal (FE_start). When the CA_start level is

reached, the FOK signal becomes true. If the FOK signal

is true when the level on the FEn signal is reached the

focus PID is enabled and switches on when the next zero

crossing is detected in the FEn signal.

FOCUS POSITION CONTROL LOOP

The focus control loop contains a digital PID controller

which has 5 parameters available to the user. These

coefficients influence the integrating (foc_int), proportional

(foc_prop) and differentiating (foc_pole_lead) action of this

PID and the digital low-pass filter (foc_pole_noise) which

follows the PID. The fifth coefficient (foc_gain) influences

the loop gain.

D

ROP-OUT DETECTION

This detector can be influenced by one parameter

(CA_drop). The FOK signal will become false and the

integrator of the PID will hold if the CA signal drops below

the programmed absolute CA level. When the FOK signal

becomes false it is assumed, initially, to be caused by a

black dot.

FOCUS LOSS DETECTION AND FAST RESTART

Whenever FOK is false for longer than approximately

3 ms, it is assumed that the focus point is lost. A fast

restart procedure is initiated which is capable of restarting

the focus loop within 200 to 300 ms depending on the

programmed coefficients set by the microcontroller.

FOCUS LOOP GAIN SWITCHING

The gain of the focus control loop (foc_gain) can be

multiplied by a factor of 2 or divided by a factor of 2 during

normal operation. The integrator value of the PID is

corrected accordingly. The differentiating (foc_pole_lead)

action of the PID can be switched at the same time as the

gain switching is performed.

Radial control

The following radial servo functions are incorporated in

the DSIC2 digital controller.

LEVEL INITIALIZATION

During start-up an automatic adjustment procedure is

activated to set the values of the radial error gain

(RE_gain), offset (RE_offset) and satellite sum signal gain

(Sum_gain) for TPI level generation. The initialization

procedure runs in a radial open-loop situation and is

≤300 ms. This start-up time period may coincide with the

last part of the turn table motor start-up time period.

March 1994 6

Loading...

Loading...