Page 1

24

tcpO2/tcpCO2 Module Section

This chapter provides information on transcutaneous monitoring of

oxygen (tcpO

information on preparing the transducer for use, and applying the

transducer to the patient. This chapter includes the following sections:

• Introduction to the tcpO2/tcpCO2 Parameter Module . . . . . . . . 24-2

• Activating the Transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-7

• Preparing the transducer. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-8

• Troubleshooting- Calibration Failure . . . . . . . . . . . . . . . . . . . . . 24-16

• tcpO2/tcpCO2 Alarms and INOP Messages. . . . . . . . . . . . . . . . . 24-21

• Parameter Settings Transfer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-24

• Accessories and Ordering . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-25

• Performance Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-26

• Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24-29

) and of carbon dioxide (tcpCO2). It also provides

2

tcpO2/tcpCO2 Module Section 24-1

Page 2

Introduction to the tcpO2/tcpCO2 Parameter Module

Introduction to the tcpO2/tcpCO2 Parameter Module

What does it

Measure?

How the

tcpO2/

tcpCO2

Measureme

nt Works

Correlation

of

Transcut ane

ous with

Arterial

Blood Gas

Values

Section

tcpO2/tcpCO2 Module

The tcpO2/tcpCO2 module measures the partial pressure of the oxygen

and carbon dioxide that diffuses transcutaneously (through the skin).

The oxygen measurement is valid for an infant patient who is not under

gas anesthesia. These partial pressures provide a measure of the oxygen

and carbon dioxide levels in the blood.

The tcpO2/tcpCO2 transducer heats the skin. This has the effect of

increasing local blood perfusion so that oxygen and carbon dioxide can

diffuse to the skin surface more easily.

The transducer contains an electrolyte solution which is held in place by

two gas-permeable membranes. The oxygen and carbon dioxide that

diffuses out of the skin passes through these membranes into the

electrolyte solution where electrochemical reactions take place. These

reactions generate electrical signals which are representative of the

amounts of oxygen and carbon dioxide present. The electrical signals

are measured by the module to enable the tcpO

displayed as numerics on the standard display.

Transcutaneous measurements are not capable of replacing arterial

blood gas monitoring. However, transcutaneous monitoring can be used

to reduce the frequency of arterial sampling.

Transcutaneous values are representative of the carbon dioxide and

oxygen levels in the blood. The values at tissue level will not be the

same as those measured arterially because of the transcutaneous nature

of the measurement. However, provided that the transducer is properly

handled by following the procedures described in this chapter, the

transcutaneous values will correlate with (track closely) the arterial

values. For example, a drop in transcutaneous values will usually

indicate that arterial values have dropped as well.

/tcpCO2 values to be

2

Note that transcutaneous values will not always correlate with blood

samples taken from the capillary blood of the heel (heelsticks or

astrups).

24-2 tcpO2/tcpCO2 Module Section

Page 3

Introduction to the tcpO2/tcpCO2 Parameter Module

For information on “Correlation of transcutaneous with arterial blood gas

values”, see references 5, 6 and 7 in Appendix on Analog Output)

Setting up

the Module

Transducer

Temperature

The optimum application period for the transducer at one site on a patient

is dependent on the transducer temperature and on the sensitivity of the

patient's skin. Before calibrating the transducer, (see the section

Calibrating the tcpO2/tcpCO2 Transducer in this chapter) you should

adjust the transducer temperature and also set the Site Timer.

WarningWarning

The temperature should be selected according to the patient’s age,

weight and physical condition.

Available temperatures for the transducer are 37.0°C, 41.0°C, 41.5°C,

42.0°C, 42.5°C, 43.0°C, 43.5°C, 44.0°C, 44.5°C and 45.0°C. Usually, a higher

transducer temperature results in both a better correlation and also a

shorter time delay between a change in arterial blood gas and its

detection by the transducer. However higher temperatures also increase

the risk of skin burns. A temperature between 42° and 44°C is preferred

by most physicians.

Note—The tcpO

/ tcpCO2 module is equipped with a temperature limiter

2

which prevents the sensor temperature from exceeding 46ºC. If the

temperature limiter fails, the following INOP message is displayed on the

monitor:

• tc EQUIP MALF.

Site Timer The Site Timer helps you to guard against the risk of skin burn by

ensuring that the transducer is used at one site for no longer than a

predefined period. The transducer can be set to operate for any of the

following time periods: 0.5, 1, 1.5, 2, 2.5, 3, 4, 5, 6, 7 or 8 hours. The

selection is visible in the task window next to “Site Time##, and the

time remaining before the Site Timer expires appears next to “Time

Left:”.

Site time settings should be adapted to the patient's skin sensitivity.

tcpO2/tcpCO2 Module Section 24-3

Section

tcpO2/tcpCO2 Module

Page 4

Introduction to the tcpO2/tcpCO2 Parameter Module

After the selected period of time has expired, an INOP message

“tcCHANGE SITE” is displayed and the INOP tone is sounded. The

Monitor can be configured either to switch off the transducer heating

when the Site Time has expired, or to continue monitoring. This should

be set as required by your hospital's policy, either by your biomedical

engineering department or by the Philips Service Engineer.

Correction for

tcpCO

Section

Values

2

If the choice

Off is available along with the above site times, you can

choose to disable the Site Timer so that no “CHANGE SITE” reminder is

displayed and the transducer monitors (and heats) indefinitely.

Availability of this choice will depend on your hospital's policy and can

be set by your biomedical engineering department or the Philips Service

Engineer.

Transcutaneous pCO

values tend to be higher than arterial values (due

2

to the metabolic processes of the skin and the effect of heating on the

blood under the transducer). This effect can be compensated for by

selecting the Severinghaus correction in a special Configuration Mode

on the monitor. (This has been selected if “corr.” appears under the

value for tcpCO

in the Task Window - consult your biomedical

2

engineering department or the Philips Service Engineer if you wish to

add or remove this correction.)

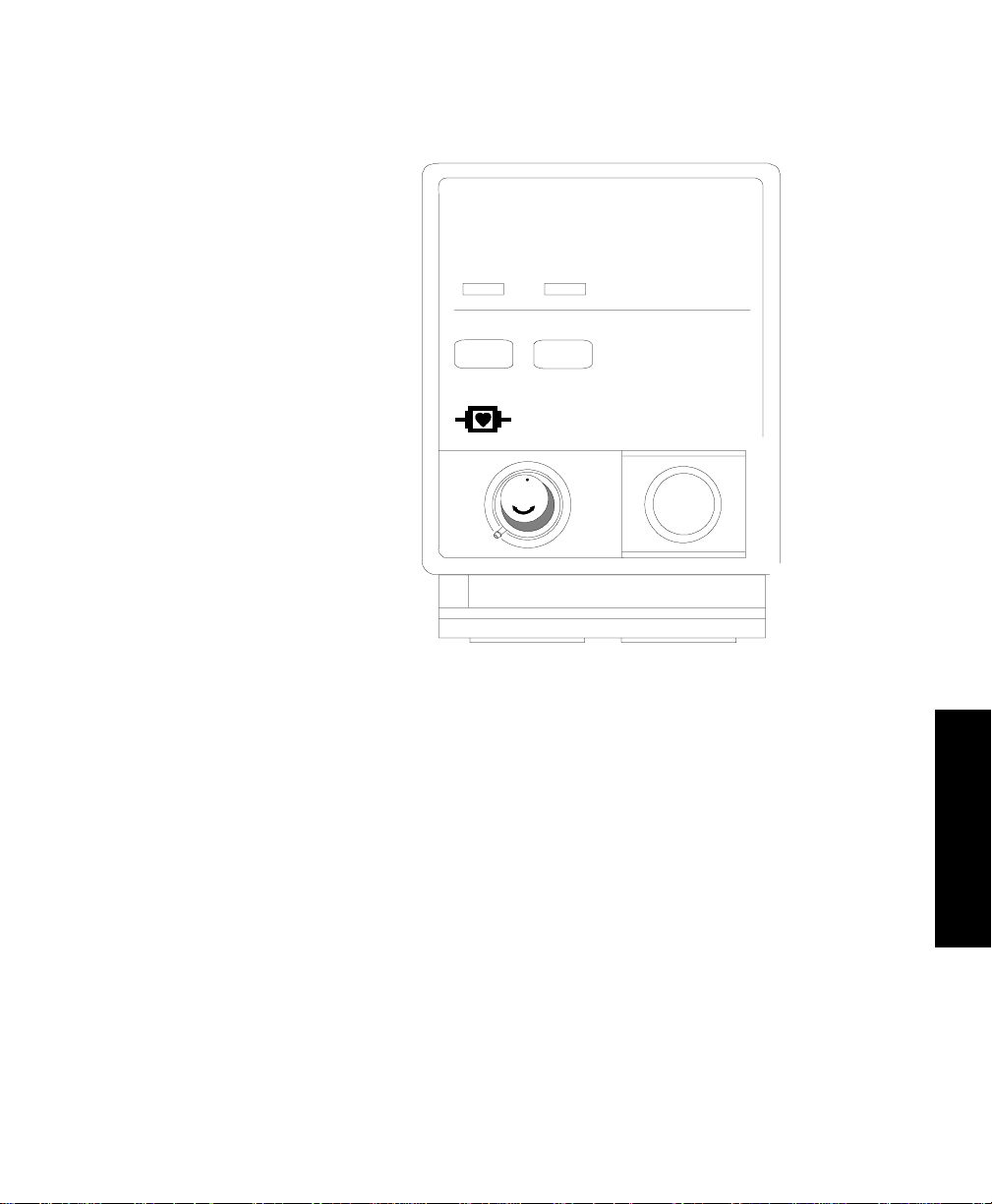

• The front of the module has two keys:

– The key for parameter setup. A light will appear

O2/CO2

above the key when you are in setup.

tcpO2/tcpCO2 Module

24-4 tcpO2/tcpCO2 Module Section

Page 5

Introduction to the tcpO2/tcpCO2 Parameter Module

– The CAL key to start calibration procedures.

tcpO2 /tcpCO

M1018A

O2 /CO

2

CAL

2

T

80 x 70

The tcpO

Note—The “T” on the front of the module indicates that this module

transfers parameter settings from one monitor to another.

/tcpCO2 Module

2

Symbols to

Indicate Key

Functions

As detailed in the table below, some versions of this module now use

symbols, instead of words, to indicate the function of some keys. If the

monitor’s Reference Manual tells you, for example, to select the CAL key,

you should press the key marked with the corresponding “calibration”

symbol.

The design change also means that you will now find the module’s

product number on the rear of the module’s housing, not on the front.

Although the new modules do not show the letter “T” on the housing, all

modules retain their capability to transfer parameter settings from one

monitor to another.

tcpO2/tcpCO2 Module Section 24-5

Section

tcpO2/tcpCO2 Module

Page 6

Introduction to the tcpO2/tcpCO2 Parameter Module

Symbol Name Function Which Modules?

Cal calibrate SvO

Mainstream CO

(M1021A), tcpO2/tcpCO2 (M1018A)

2

(M1016A)

2

Section

tcpO2/tcpCO2 Module

24-6 tcpO2/tcpCO2 Module Section

Page 7

Activating the Transducer

Follow the 24 hour activation procedure if:

• the electrolyte in your transducer has dried out (this occurs when

the transducer has been out of use for a long period),

• or you are about to use a new transducer (new transducers are

shipped dry).

Activate by following the Remembraning the Transducer procedure, then

leave the transducer in a safe place for 24 hours, unplugged from the

module and with the cap on. Remembrane the transducer again just

before carrying out the calibration procedure.

Activating the Transducer

tcpO2/tcpCO2 Module Section 24-7

Section

tcpO2/tcpCO2 Module

Page 8

Preparing the transducer

Preparing the transducer

There are three steps to preparing a transducer for application to a

patient.

First, remembrane the transducer.

Then, calibrate the transducer (first checking the module settings

- Site Time, Transducer Temp and Alarm Limits).

Finally, prepare a site and apply the transducer to your patient.

The procedure for carrying out these steps is described in the following

three sections. Each section gives guidelines on when you should carry

out each step. Follow the procedures carefully to ensure best results.

Section

tcpO2/tcpCO2 Module

1. Remembrane the

tcpO2/

tcpCO2

Transducer

With normal use, the membranes will last approximately 1 week before

a change is required. Change the membrane on the transducer if:

• you are about to use a new transducer,

• the transducer is to be used with a new patient,

• the membranes of the transducer are damaged (scratched or

wrinkled),

• the transducer has been used for 5 days continuously,

• the transducer has been in storage for up to 28 days,

• you have a transducer which must be remembraned after

activating for 24 hours (see previous page, Activating the

Transducer), or

• calibration has failed twice.

1. Check that you have the Philips tc Accessory Kit containing an Oring remover, absorbent paper, electrolyte solution and membrane

replacers.

24-8 tcpO2/tcpCO2 Module Section

Page 9

Preparing the transducer

2. Unscrew the protection cap from the transducer, then hook the Oring remover under both O-rings to remove them.

tcpO2/tcpCO2 Module Section 24-9

Section

tcpO2/tcpCO2 Module

Page 10

Preparing the transducer

3. Remove both of the clear plastic membranes using your fingers.

4. Clean the transducer head with absorbent paper. Make sure you

clean the groove in the head and also the rim around the head to

remove any old electrolyte - all of the old electrolyte must be

removed to ensure a successful calibration and reliable

measurements.

Section

tcpO2/tcpCO2 Module

24-10 tcpO2/tcpCO2 Module Section

Page 11

Preparing the transducer

5. Apply electrolyte solution to the transducer head (approximately

two drops). Break any air bubbles in the electrolyte using the nozzle

of the solution container.

6. Press the transducer head downwards into an unused membrane

replacer until the replacer retracts as far as it can and a click is

heard. Discard the used replacer.

7. Remove any surplus electrolyte solution on the outside of the

membranes with a soft tissue.

8. Examine the transducer carefully to ensure that the new

membranes are secured by two O-rings on the transducer. If any air

bubbles are visible under the membranes, repeat this procedure - air

bubbles will cause incorrect readings.

tcpO2/tcpCO2 Module Section 24-11

Section

tcpO2/tcpCO2 Module

Page 12

Preparing the transducer

Provided that you do not need to activate the transducer for 24 hours

(see the section Activating the Transducer on page 20-7), the

transducer is now ready to be calibrated and can be placed in the

calibration chamber on the front of the module - see the next section.

2.

Calibrating

the tcpO2/

tcpCO2

System

Section

Module Setup

Calibration of your tcpO

• you have just fitted a new membrane,

• you have just changed the transducer operating temperature, or,

• the INOP message tc CAL REQUIRD appears on the screen.

Note—To maintain accuracy, the tcpO

calibrated regularly, even if the CMS, V24 or V26 monitor does not

prompt you to do so.

-->

tcpO2/tcpCO2

/tcpCO2 system is required if:

2

/tcpCO2 transducer should be

2

tcpO2/tcpCO2 Module

24-12 tcpO2/tcpCO2 Module Section

Calibration of your tcpO

/tcpCO2 system is recommended if:

2

• the accuracy of the measurement is in doubt,

• you are about to start a new monitoring period, or

• you are about to change the measurement site, or

• at least six hours have elapsed since the last calibration

Page 13

Preparing the transducer

1. Check that you have a tcpO2/tcpCO2 module (inserted at the

extreme left position in the rack for best accessibility) and a Philips

Calibration Unit (15210B). The Calibration Unit must have a gas

cylinder inserted in the rear and a pressure indicator reading that is

above the out-of-gas zone (black on 15210B and red on Radiometer

TCC3 Calibration Unit).

2. Check that the transducer is plugged into the module and that the

transducer is inserted into the calibration chamber on the front of

the module (swing the flap back and insert the transducer, then

swing the flap over the transducer).

V24 Monitor with 15210B Calibration Unit

tcpO2/tcpCO2 Module Section 24-13

Section

tcpO2/tcpCO2 Module

Page 14

Preparing the transducer

.

.

V24 Monitor with Radiometer TCC3 Calibration Unit

Section

tcpO2/tcpCO2 Module

24-14 tcpO2/tcpCO2 Module Section

3. Press , followed by to bring up

the tcpO

screen by pressing on the front of the module.)

Module Setup

/tcpCO2 Setup Task Window. (You can also reach this

2

tcpO2/tcpCO2

O2/CO2

4. Check the module settings as displayed on the screen - Transducer

Temp., Site Time and Alarm Limits. You can change any of these

values by pressing the appropriate softkeys (see the CMS, V24 or

V26).

5. Fit the gas tubing from the Calibration Unit into the inlet on the

side of the calibration chamber (the other end of the tubing must

be fitted into the Calibration Unit).

6. If you are using a 15210B Calibration Unit, turn the timer control

dial on the Calibration Unit clockwise as far as you can and press

Start Calibr

on the Monitor. If you are using a Radiometer

TCC3 Calibration Unit, press the button with the green arrow on

the front of the calibration unit once, then press

Start Calibr

on the monitor.(You can also start the calibration by pressing the

CAL key on the front of the module until the light above the key

Page 15

Preparing the transducer

.

comes on and a tone sounds. In addition, a calibration can be

restarted by pressing .)

Start Calibr

7. Wait for “...tcpO

“...tcpO

/tcpCO2 calibration complete” in the task window (the

2

/tcpCO2 calibration running” to be replaced by

2

calibration process generally takes 3 to 10 minutes but may take up

to 20 minutes). For 15210B Calibration Units: If the timer control

dial has not reached the start position when “...tcpO

/tcpCO2

2

calibration complete” is displayed, you can save gas by turning the

dial counter-clockwise to the start position. For Radiometer TCC3

Calibration Units: If the green light on the front of the Calibration

Unit is still flashing when “...tcpO

/tcpCO2 calibration complete” is

2

displayed, you can save gas by pressing the button with the green

arrow again.

When calibration is complete, the transducer is ready to be applied to a

patient - see the next section. The Site Timer will start when you remove

the transducer from the calibration chamber.

Apply the transducer to your patient as soon as possible after the

“...calibration complete” message appears on the screen. If you wait

longer than 30 minutes, the heat supply to the transducer is automatically

switched off in order to prevent the electrolyte from drying out. This

means that a new calibration will be required.

Section

tcpO2/tcpCO2 Module

tcpO2/tcpCO2 Module Section 24-15

Page 16

Preparing the transducer

Trouble-

shooting-

Calibration

Failure

If the calibration is unsuccessful, the message “...tcpO

/tcpCO2

2

transducer or Cal Unit malf” is displayed in the task window. In

addition, the CAL FAILED INOP message for tc, tcpO

or tcpCO2

2

appears in the upper left corner of the screen. Perform each of the

following steps in the order specified until calibration is successful:

1. Check the Calibration Unit, then recalibrate, remembering to turn

on the gas supply on the Calibration Unit. (If the pressure

indicator reading is in the out of gas zone, there is insufficient gas

in the cylinder. The gas tubing must be firmly connected to the

Calibration Unit and to the calibration chamber on the module.)

2. If Step 1 is unsuccessful, check whether you need to activate the

transducer (necessary if the electrolyte has dried out or if you

have a new transducer, see page 24-6). Then remembrane the

transducer ensuring that you:

a. remove the old membranes, and

b. clean the transducer head thoroughly.

Then calibrate a second time.

3. If Step 2 is unsuccessful, calibrate again. (A second calibration

may be required in order to stabilize the electrochemical system

in the transducer.)

Section

tcpO2/tcpCO2 Module

24-16 tcpO2/tcpCO2 Module Section

4. Only if the above steps are unsuccessful (you have activated and

remembraned the transducer and calibration has still failed twice),

replace the transducer.

Page 17

Preparing the transducer

3. Applying

the

Transducer

to the

Patient

To apply the transducer to your patient, use the following procedure:

1. Check that you have the Philips Fixation Kit containing a box of

fixation rings and contact fluid.

2. Select a measuring site and clean the skin with alcohol solution. (To

optimize the measurement, select a site with high capillary density

and blood flow, thin epidermis and no cardiovascular disorders.

Most physicians use the abdomen, chest and back.)

3. Take a fixation ring from the box and peel off the protection film

to reveal the sticky surface.

4. Apply the fixation ring to clean and dry skin by pressing the ring

onto the site with a finger, first in the center and then around the

outside to ensure a good seal. (A good seal between the fixation ring

and the skin is essential for good results.)

tcpO2/tcpCO2 Module Section 24-17

Section

tcpO2/tcpCO2 Module

Page 18

Preparing the transducer

5. Place 3 to 5 drops of contact fluid in the center of the ring.

6. Remove the transducer from the chamber (the Site Timer on the

screen will start) and align the arrow on the transducer either with

or opposite the tab on the ring.

7. Turn the transducer a quarter-turn clockwise to fasten it to the

ring.

Section

tcpO2/tcpCO2 Module

24-18 tcpO2/tcpCO2 Module Section

8. Wait 10 to 20 minutes for readings to stabilize. (The tcpO

tcpCO

numerics are displayed on the standard display.)

2

and

2

Page 19

Preparing the transducer

r

Restarting the

Site Timer

• The Site Timer is automatically restarted after the transducer has

been calibrated and removed from the calibration chamber

(calibration is recommended whenever the site is changed).

• You can restart the Site Timer up to 2 hours after the time period

has expired. (After this 2 hour period a calibration is required.)

Press to enter the Site Timer task window. Confirm

Site Time

your required time.

When changing the application site after a measuring period, some users

leave the fixation rings in position. This allows the transducer to be

quickly moved from site to site.

Note— During the initial 3 minutes of use, tcpO

/tcpCO2 alarms are

2

suspended to eliminate false alarms. During this period, the

“STABILIZING” INOP message is displayed for tc, tcpO

or tcpCO2. After

2

the transducer has been attached to the skin, the instrument reading will

slowly assume a steady value. The reading will stabilize as soon as the

measurement site is warmed up and local hyperemization is completed;

usually 10 to 20 minutes for the tcpO

tcpCO

The tcpO

.

2

/tcpCO2 Setup Task Window indicates the amount of remaining

2

reading and 3 to 7 minutes for

2

time before the Site Timer expires. At the end of the site time the INOP

message “CHANGE SITE” is displayed and the INOP tone is sounded. The

Monitor will switch off the transducer heating or will continue

monitoring, depending on how the Monitor has been configured.

WarningWarning

• Prolonged continuous monitoring may increase the risk of

undesirable changes in skin characteristics, such as

irritation, reddening, blistering or burns. If the Site Timer is

Section

Off (disabled) or automatic heating switch-off has been

disabled, the transducer will heat indefinitely while on a

patient. Ensure that the site is changed in accordance with

tcpO2/tcpCO2 Module

standard medical procedures in your hospital.

• Always unscrew the transducer from the fixation ring before

removing the fixation ring from the skin.

• When defibrillating a patient, it is important to either:

tcpO2/tcpCO2 Module Section 24-19

Page 20

Preparing the transducer

– remove the transducer before defibrillating, or

– remembrane and calibrate the transducer after

defibrillating

Caution

• All specified transducers (but not membranes) are protected

against the effects of the discharge of a defibrillator.

• To avoid transducer damage, remove it from the patient during

high frequency surgical procedures.

Section

tcpO2/tcpCO2 Module

24-20 tcpO2/tcpCO2 Module Section

Page 21

tcpO2/tcpCO2 Alarms and INOP Messages

tcpO2/tcpCO2 Alarms and INOP Messages

The tcpO2/tcpCO2 alarm messages are rated in order of severity:

** Yellow

INOP message

Alarm tone = a single tone repeated every second

INOP tone = a single beep repeated every 2 seconds.

Physiological Alarms

Alarm Message Condition Visual Indication

tcpO2 90>80 tcpO

above high alarm limit tcpO2 numeric blinks.

2

Yellow alarm lamp.

tcpO2 40<50 tcpO

below low alarm limit tcpO2 numeric blinks.

2

Yellow alarm lamp.

tcpCO2 60>50 tcpCO

above high alarm limit tcpCO2 numeric blinks.

2

Yellow alarm lamp.

tcpCO2 20<30 tcpCO

below low alarm limit tcpCO2 numeric blinks.

2

Yellow alarm lamp.

Audible

Indication

Alarm tone

Alarm tone

Alarm tone

Alarm tone

Section

tcpO2/tcpCO2 Module

tcpO2/tcpCO2 Module Section 24-21

Page 22

tcpO2/tcpCO2 Alarms and INOP Messages

Technical

Alarms

INOP messages appear when the monitor cannot measure or process

signals properly or when the measuring site is to be changed. For

transcutaneous gas measurements all INOP messages except CHANGE

SITE and CHECK TIME relate to equipment-related problems but you

must check the patient's condition first. If the INOP message is

accompanied by an audible alarm, it can be silenced with the

Silence/Reset

key.

INOP Messages

INOP Message Condition Visual Indication

tc UN-PLUGGED Parameter switched on and

unplugged from rack. Silencing

tcpO

/tcpCO2

2

numerics display -?-.

the alarm switches the

parameter off.

tc EQUIP MALF Malfunction in the transducer or

module.

tcpO

/tcpCO2

2

numerics display -?-.

Prompt message

appears in task

window.

tc NO TRANSDUC No transducer is connected to

the tcpO

/tcpCO2 module.

2

tcpO

/tcpCO2

2

numerics display -?-.

Silencing the alarm switches the

parameter off.

Audible

Indication

INOP tone

INOP tone

INOP tone

tc CHANGE SITE Site Timer has timed out tcpO

Section

tcpO2/tcpCO2 Module

24-22 tcpO2/tcpCO2 Module Section

/tcpCO2

2

numerics may

display -?- depending

on configuration.

Prompt message

appears in task

window.

INOP tone

Page 23

tcpO2/tcpCO2 Alarms and INOP Messages

INOP Message Condition Visual Indication

tc CAL FAILED

1

Calibration failed due to out of

range or unstable signal during

calibration.

tcpO2/tcpCO2

numerics display -?-.

Prompt message

appears in task

window.

tc CAL REQUIRD Calibration is required before

applying the transducer to the

patient

2

tcpO2/tcpCO2

numerics display -?-.

Prompt message

appears in task

window.

tc CAL RUNNING The tcpO

running.

/tcpCO2 calibration is

2

Numerics display -?-.

Prompt message

appears in task

window.

tc STABILIZING The transducer has not yet

reached the selected

temperature and/or skin

hyperemization is not yet

complete.

tcpO

/tcpCO2

2

numeric is displayed

with ? to indicate

that values are

unstable.

Audible

Indication

INOP tone

INOP tone

None

None

tc CHECK TIME Site Timer due to time out (15

minutes or less)

1

See “Troubleshooting - Calibration Failure” earlier in this chapter or the

CMS, V24 or V26 User’s Guide.

2

Possible module or transducer malfunction if calibration in progress.

None None

Section

tcpO2/tcpCO2 Module

tcpO2/tcpCO2 Module Section 24-23

Page 24

Parameter Settings Transfer

Parameter Settings Transfer

The following parameter settings can be transferred with tcpO2/tcpCO2

modules. For more information on Parameter Settings Transfer, refer to

“Parameter Settings Transfer,” Chapter 3.

Setting Name Meaning

tcpO2/tcpCO2 Module

Section

Alarm limits tcpO

and tcpCO2 high and low alarm limits

2

Site Time setting Period transducer will be active at one site

Transducer temperature Temperature to which transducer is heated

Recalibration of the tcpO

/tcpCO2 system is required if the module has

2

been transferred.

24-24 tcpO2/tcpCO2 Module Section

Page 25

Accessories and Ordering

Accessories and Ordering

You can order parts and accessories from Philips supplies at

www.medical.philips.com or consult your local Philips representative for

details.

Warning Reuse: Never reuse disposable transducers, sensors, accessories

and so forth that are intended for single use, or single patient use

only.

Philips’ approval: Use only Philips-approved accessories.

Packaging: Do not use a sterilized accessory if its packaging is

damaged.

This symbol indicates that the specified transducer (but not

its membranes) is designed to have special protection

against electric shocks (particularly regarding allowable

leakage currents), and is defibrillator proof.

Description Part No.

12x tc Accessory Kit (O-ring remover, absorbent paper, electrolyte solution, replacement membrane)

tc Application Kit (4x25 disposable fixation rings, 4x20ml contact fluid)

Calibration gas - 6 gas bottles 15210-60010

Calibration gas - 6 gas bottles (Europe and Japan only) 15210-64010

Replacement tubing (5 tubes) M2205A

tcpO2/CO2 transducer M1918A

Calibration unit 15210B

Radiometer TCC3 calibration unit (available from Radiometer) n/a

tcpO2/tcpCO2 Module Section 24-25

15209-60010

15209-60020

Section

tcpO2/tcpCO2 Module

Loading...

Loading...