Philips PCA82C250, PCA82C250U Datasheet

INTEGRATED CIRCUITS

DATA SH EET

PCA82C250

CAN controller interface

Product specification

Supersedes data of 1997 Oct 21

File under Integrated Circuits, IC18

2000 Jan 13

Philips Semiconductors Product specification

CAN controller interface PCA82C250

FEATURES

• Fully compatible with the

“ISO 11898”

standard

APPLICATIONS

• High-speed applications (up to 1 Mbaud) in cars.

• High speed (up to 1 Mbaud)

• Bus lines protected against transients in an automotive

environment

• Slope control to reduce Radio Frequency Interference

(RFI)

• Differential receiver with wide common-mode range for

GENERAL DESCRIPTION

The PCA82C250 is the interface between the CAN

protocol controller and the physical bus. The device

provides differential transmit capability to the bus and

differential receive capability to the CAN controller.

high immunity against ElectroMagnetic Interference

(EMI)

• Thermally protected

• Short-circuit proof to battery and ground

• Low-current standby mode

• An unpowered node does not disturb the bus lines

• At least 110 nodes can be connected.

QUICK REFERENCE DATA

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

I

1/t

V

V

t

T

CC

CC

bit

CAN

diff

PD

amb

supply voltage 4.5 5.5 V

supply current standby mode − 170 µA

maximum transmission speed non-return-to-zero 1 − Mbaud

CANH, CANL input/output voltage −8 +18 V

differential bus voltage 1.5 3.0 V

propagation delay high-speed mode − 50 ns

ambient temperature −40 +125 °C

ORDERING INFORMATION

TYPE

NUMBER

NAME DESCRIPTION CODE

PACKAGE

PCA82C250 DIP8 plastic dual in-line package; 8 leads (300 mil) SOT97-1

PCA82C250T SO8 plastic small outline package; 8 leads; body width 3.9 mm SOT96-1

PCA82C250U − bare die; 2790 × 1780 × 380 µm −

2000 Jan 13 2

Philips Semiconductors Product specification

CAN controller interface PCA82C250

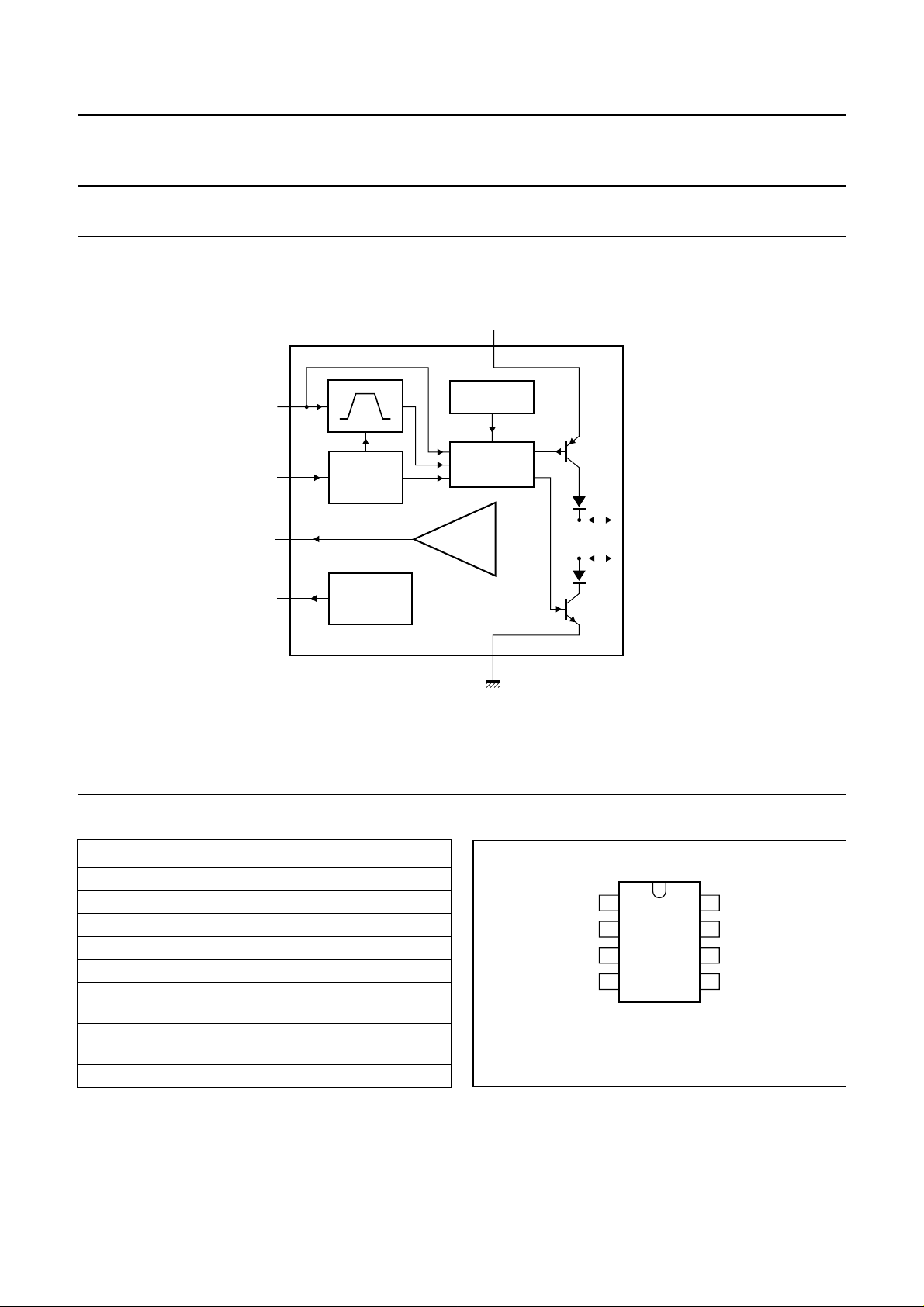

BLOCK DIAGRAM

handbook, full pagewidth

TXD

RXD

V

ref

Rs

1

8

4

5

SLOPE/

STANDBY

REFERENCE

VOLTAGE

V

CC

3

PROTECTION

DRIVER

HS

RECEIVER

PCA82C250

2

GND

Fig.1 Block diagram.

MKA669

7

CANH

6

CANL

PINNING

SYMBOL PIN DESCRIPTION

TXD 1 transmit data input

GND 2 ground

V

CC

3 supply voltage

RXD 4 receive data output

V

ref

5 reference voltage output

CANL 6 LOW-level CAN voltage

input/output

CANH 7 HIGH-level CAN voltage

input/output

Rs 8 slope resistor input

2000 Jan 13 3

handbook, halfpage

TXD

1

2

PCA82C250

3

V

CC

4

RXD

MKA670

Fig.2 Pin configuration.

8

7

6

5

Rs

CANHGND

CANL

V

ref

Philips Semiconductors Product specification

CAN controller interface PCA82C250

FUNCTIONAL DESCRIPTION

The PCA82C250 is the interface between the CAN

protocol controller and the physical bus. It is primarily

intended for high-speed applications (up to 1 Mbaud) in

cars. Thedevice provides differential transmit capability to

the bus and differential receive capability to the CAN

controller. It is fully compatible with the

“ISO 11898”

standard.

A current limiting circuit protects the transmitter output

stage againstshort-circuit to positive and negative battery

voltage. Although the power dissipation is increased

during this fault condition, this feature will prevent

destruction of the transmitter output stage.

If the junction temperature exceeds a value of

approximately 160 °C, the limiting current of both

transmitter outputs is decreased. Because the transmitter

is responsible for the major part of the power dissipation,

this will result in a reduced powerdissipation and hence a

lowerchip temperature.All otherparts of theIC willremain

in operation.The thermal protection is particularly needed

when a bus line is short-circuited.

The CANH and CANL lines are also protected against

electrical transients which may occur in an automotive

environment.

Pin 8 (Rs) allows three different modes of operation to be

selected: high-speed, slope control or standby.

For high-speed operation, the transmitter output

transistors are simply switched on and off as fast as

possible. In this mode, no measures are taken to limit the

rise and fall slope. Use of a shielded cable is

recommended to avoid RFI problems. The high-speed

mode is selected by connecting pin 8 to ground.

For lower speeds or shorter bus length, an unshielded

twisted pair or a parallel pair of wires can be used for the

bus. To reduce RFI, the rise and fall slope should be

limited. The rise and fall slope can be programmed with a

resistor connected from pin 8 to ground. The slope is

proportional to the current output at pin 8.

If a HIGH level is applied to pin 8, the circuit enters a low

current standby mode. In this mode, the transmitter is

switched off and the receiver is switched to a low current.

If dominant bits are detected (differential bus voltage

>0.9 V), RXD will be switched to a LOW level.

The microcontroller should react to this condition by

switching the transceiver back to normal operation (via

pin 8). Because the receiver is slow in standby mode, the

first message will be lost.

Table 1 Truth table of the CAN transceiver

SUPPLY TXD CANH CANL BUS STATE RXD

4.5 to 5.5 V 0 HIGH LOW dominant 0

4.5 to 5.5 V 1 (or floating) floating floating recessive 1

<2 V (not powered) X

2V<VCC< 4.5 V >0.75V

2V<VCC< 4.5 V X

(1)

(1)

CC

floating floating recessive X

floating floating recessive X

floating if

VRs> 0.75V

CC

floating if

VRs> 0.75V

recessive X

CC

Note

1. X = don’t care.

Table 2 Pin Rs summary

CONDITION FORCED AT PIN Rs MODE RESULTING VOLTAGE OR CURRENT AT PIN Rs

V

> 0.75V

Rs

−10 µA<I

VRs< 0.3V

CC

< −200 µA slope control 0.4VCC<VRs< 0.6V

Rs

CC

standby IRs< 10 µA

CC

high-speed IRs< −500 µA

(1)

(1)

(1)

2000 Jan 13 4

Philips Semiconductors Product specification

CAN controller interface PCA82C250

LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134); all voltages are referenced to pin 2;

positive input current.

SYMBOL PARAMETER CONDITIONS MIN. MAX. UNIT

V

CC

V

n

V

6, 7

V

trt

T

stg

T

amb

T

vj

V

esd

Notes

1. In accordance with

Tvj=T

amb+Pd×Rth(vj-a)

the allowable combinations of power dissipation (Pd) and ambient temperature (T

2. Classification A: human body model; C = 100 pF; R = 1500 Ω; V = ±2000 V.

3. Classification B: machine model; C = 200 pF; R = 25 Ω; V = ±200 V.

supply voltage −0.3 +9.0 V

DC voltage at pins 1, 4, 5 and 8 −0.3 VCC+ 0.3 V

DC voltage at pins 6 and 7 0 V < VCC< 5.5 V;

−8.0 +18.0 V

no time limit

transient voltage at pins 6 and 7 see Fig.8 −150 +100 V

storage temperature −55 +150 °C

ambient temperature −40 +125 °C

virtual junction temperature note 1 −40 +150 °C

electrostatic discharge voltage note 2 −2000 +2000 V

note 3 −200 +200 V

“IEC 60747-1”

, where R

. An alternative definition of virtual junction temperature is:

is a fixed value to be used for the calculation of Tvj. The rating for Tvj limits

th(j-a)

).

amb

THERMAL CHARACTERISTICS

SYMBOL PARAMETER CONDITIONS VALUE UNIT

R

th(j-a)

thermal resistance from junction to ambient in free air

PCA82C250 100 K/W

PCA82C250T 160 K/W

QUALITY SPECIFICATION

According to

“SNW-FQ-611 part E”

.

2000 Jan 13 5

Philips Semiconductors Product specification

CAN controller interface PCA82C250

CHARACTERISTICS

VCC= 4.5 to 5.5 V; T

to ground (pin 2); positive input current; all parameters are guaranteed over the ambient temperature range by design,

but only 100% tested at +25 °C.

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

Supply

I

3

supply current dominant; V1=1V −−70 mA

DC bus transmitter

V

V

I

IH

I

IL

V

I

LO

V

V

∆V

IH

IL

6,7

7

6

6, 7

HIGH-level input voltage output recessive 0.7V

LOW-level input voltage output dominant −0.3 − 0.3V

HIGH-level input current V1=4V −200 − +30 µA

LOW-level input current V1=1V −100 −−600 µA

recessive bus voltage V1= 4 V; no load 2.0 − 3.0 V

off-state output leakage current −2V<(V6,V7)<7V −2 − +1 mA

CANH output voltage V1= 1 V 2.75 − 4.5 V

CANL output voltage V1= 1 V 0.5 − 2.25 V

difference between output

voltage at pins 6 and 7

I

I

sc7

sc6

short-circuit CANH current V7= −5 V; VCC≤ 5V −−−105 mA

short-circuit CANL current V6=18V −−160 mA

DC bus receiver: V1= 4 V; pins 6 and 7 externally driven; −2V<(V6,V7) < 7 V; unless otherwise specified

= −40 to +125 °C; RL=60Ω; I8> −10 µA; unless otherwise specified; all voltages referenced

amb

recessive; V

=4V;

1

−−14 mA

R8=47kΩ

recessive; V

=4V;

1

−−18 mA

V8=1V

standby; T

amb

<90°C;

− 100 170 µA

note 1

− VCC+ 0.3 V

CC

CC

−5V<(V

)<18V −5 − +12 mA

6,V7

V1= 1 V 1.5 − 3.0 V

V

=1V; RL=45Ω;

1

1.5 −−V

VCC≥ 4.9 V

= 4 V; no load −500 − +50 mV

V

1

V

= −5 V; VCC= 5.5 V −−−120 mA

7

V

V

diff(r)

differential input voltage

(recessive)

−7V<(V

6,V7

not standby mode

V

diff(d)

differential input voltage

(dominant)

−7V<(V

6,V7

not standby mode

V

diff(hys)

V

OH

differential input hysteresis see Fig.5 − 150 − mV

HIGH-level output voltage

I4= −100 µA 0.8V

(pin 4)

V

OL

R

i

LOW-level output voltage (pin 4) I4=1mA 0 − 0.2V

=10mA 0 − 1.5 V

I

4

CANH, CANL input resistance 5 − 25 kΩ

2000 Jan 13 6

)<12V;

)<12V;

−1.0 − +0.5 V

−1.0 − +0.4 V

0.9 − 5.0 V

1.0 − 5.0 V

− V

CC

CC

CC

V

V

Loading...

Loading...