Page 1

查询OM6206供应商

INTEGRATED CIRCUITS

DATA SH EET

OM6206

65 × 102 pixels matrix LCD driver

Product specification

File under Integrated Circuits, IC17

2001 Nov 14

Page 2

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

CONTENTS

1 FEATURES

2 APPLICATIONS

3 GENERAL DESCRIPTION

4 ORDERING INFORMATION

5 BLOCK DIAGRAM

6 PINNING

6.1 Pin functions

6.1.1 R0 to R64: row driver outputs

6.1.2 C0 to C101: column driver outputs

6.1.3 V

6.1.4 V

6.1.5 V

6.1.6 V

6.1.7 V

and V

SS1

, V

DD1

: LCD supply voltage

LCDIN

LCDOUT

LCDSENSE

: ground supply rails

SS2

and V

DD2

DD3

: voltage multiplier output

: voltage multiplier regulation input

: supply voltage rails

6.1.8 T1 to T5: test pins

6.1.9 SDIN: serial data line

6.1.10 SCLK: serial clock line

6.1.11 D/C: mode select

6.1.12 SCE: chip enable

6.1.13 OSC: oscillator

6.1.14 RES: reset

7 FUNCTIONAL DESCRIPTION

7.1 Oscillator

7.2 Address counter

7.3 Display data RAM (DDRAM)

7.4 Timing generator

7.5 Display address counter

7.6 LCD row and column drivers

7.7 Addressing

7.7.1 Data structure

8 INSTRUCTIONS

8.1 Initialization

8.2 Reset function

8.3 Function set

8.3.1 PD

8.3.2 V

8.3.3 H

8.4 Display control

8.4.1 D and E

8.5 Set Y-address of RAM

8.6 Set X-address of RAM

8.7 Set high-voltage generator stages

8.8 Bias system

8.9 Temperature control

8.10 Set VOP value

9 LIMITING VALUES

10 HANDLING

11 DC CHARACTERISTICS

12 AC CHARACTERISTICS

13 APPLICATION INFORMATION

13.1 Programming example for the OM6206

13.2 Application diagrams

13.3 Application for COG

13.4 Chip information

14 BONDING PAD INFORMATION

15 DEVICE PROTECTION CIRCUITS

16 TRAY INFORMATION

17 DATA SHEET STATUS

18 DEFINITIONS

19 DISCLAIMERS

2001 Nov 14 2

Page 3

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

1 FEATURES

• Single-chip LCD controller and driver

• 65 row and 102 column outputs

• Display data RAM 65 × 102 bits

• On-chip:

– Configurable 5 (4, 3 and 2) × voltage multiplier

generating V

(external V

LCD

also possible)

LCD

– Generation of intermediate LCD bias voltages

– Oscillator requires no external components

(external clock also possible).

• External reset input pin RES

• Serial interface maximum 4.0 Mbits/s

• CMOS compatible inputs

• Multiplex rate of 1 : 65

• Logic supply voltage range from 2.5 to 5.5 V

(V

to VSS)

DD1

• High-voltage generator supply voltage range from

2.5 to 4.5 V (V

DD2

and V

DD3

to VSS)

• Display supply voltage range from 4.5 to 9.0 V

(V

to VSS)

LCD

• Low power consumption, suitable for battery operated

systems

• Temperature compensation of V

LCD

• Temperature range from −40 to +85 °C

• Slim chip layout, suited for Chip-On-Glass (COG)

applications.

2 APPLICATIONS

• Telecom equipment.

3 GENERAL DESCRIPTION

The OM6206 is a low-power CMOS LCD controller and

driver, designed to drive a graphic display of 65 rows and

102 columns. All necessary functions for the display are

provided in a single chip, including on-chip generation of

LCD supply and bias voltages, resulting in a minimum of

external components and low power consumption.

TheOM6206interfacesto microcontrollersvia aserial bus

interface.

4 ORDERING INFORMATION

PACKAGE

TYPE NUMBER

NAME DESCRIPTION VERSION

OM6206U/Z − chip with bumps in tray −

2001 Nov 14 3

Page 4

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

5 BLOCK DIAGRAM

handbook, full pagewidth

V

LCDIN

V

LCDSENSE

V

LCDOUT

T1

T2

T3

T4

T5

V

SS1VSS2

214 to

217,

221,

222

224 to 229

237

230 to 236

218

198

223

220

219

V

DD1VDD2

200 to

213

174 to

179

BIAS

VOLTAGE

GENERATOR

HIGH

VOLTAGE

GENERATOR

181 to

193

V

DD3

REGISTER

C0 to C101

180

COLUMN DRIVERS

DATA LATCHES

DISPLAY DATA RAM

(DDRAM)

65 × 102

ADDRESS COUNTER

DATA

I/O BUFFER

37 to 138

OM6206

R0 to R64

2 to 15, 18 to 36,

139 to 156,

159 to 172

ROW DRIVERS

SHIFT REGISTER

RESET

OSCILLATOR

TIMING

GENERATOR

DISPLAY

ADDRESS

COUNTER

199

1

RES

OSC

195 194 196 197

SDIN SCLK

Fig.1 Block diagram.

2001 Nov 14 4

D/C

SCE

MGT859

Page 5

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

6 PINNING

SYMBOL PAD DESCRIPTION

R0 to R18 18 to 36 LCD row driver outputs

R19 to R32 2 to 15 LCD row driver outputs

R33 to R50 156 to 139 LCD row driver outputs

R51 to R64 159 to 172 LCD row driver outputs

C0 to C101 37 to 138 LCD column driver outputs

V

SS1

214 to 217,

ground supply 1

221 and 222

V

SS2

V

DD1

V

DD2

V

DD3

V

LCDIN

V

LCDOUT

V

LCDSENSE

200 to 213 ground supply 2

174 to 179 supply voltage 1

181 to 193 supply voltage 2

180 supply voltage 3

224 to 229 LCD supply voltage (V

230 to 236 voltage multiplier output

(V

)

LCD

237 voltage multiplier

regulation input (V

LCD

)

LCD

T1 218 test 1 input

T2 198 test 2 output

T3 223 test 3 input/output

T4 220 test 4 input

T5 219 test 5 input

SCLK 194 serial clock input

SDIN 195 serial data input

D/

C 196 dataor commandselection

input

SCE 197 chip enable (active LOW)

OSC 199 oscillator signal input

RES 1 external reset input (active

LOW)

6.1 Pin functions

6.1.1 R0 TO R64: ROW DRIVER OUTPUTS

These pins output the row signals.

6.1.2 C0 TO C101: COLUMN DRIVER OUTPUTS

These pins output the column signals.

6.1.3 V

The supply rails V

SS1

AND V

SS1

: GROUND SUPPLY RAILS

SS2

and V

must be connected

SS2

together.

6.1.4 V

V

and V

DD2

DD1,VDD2

DD3

AND V

: SUPPLY VOLTAGE RAILS

DD3

are the supply voltage for the internal

voltagegenerator. Bothhave thesame voltageand should

be connected together outside the chip. V

supply voltage for the rest of the chip. V

connected together with V

DD2

and V

DD1

can be

DD1

but in this case

DD3

care must be taken to respect the supply voltage range

(see Chapter 11).

If the internal voltage generator is not used the pins

V

DD2

and V

must be connected to pin V

DD3

DD1

connected to the supply voltage.

)

6.1.5 V

: LCD SUPPLY VOLTAGE

LCDIN

Positive supply voltage for the liquid crystal display. An

external LCD supply voltage can be supplied using

pin V

. In this case, V

LCDIN

has to be left open and

LCDOUT

the internal voltage generator has to be programmed to

zero. If the OM6206 is in Power-down mode, the external

LCD supply voltage has to be switched off.

6.1.6 V

: VOLTAGE MULTIPLIER OUTPUT

LCDOUT

Positive supply voltage for the liquid crystal display. If the

internal voltage generator is used, the two supply rails

V

LCDIN

and V

must be connected together. If an

LCDOUT

external supply is used this pin must be left open.

6.1.7 V

V

LCDSENSE

LCDSENSE

INPUT

is the input of the internal voltage multiplier

: VOLTAGE MULTIPLIER REGULATION

regulation.

If the internal voltage generator is used then V

must be connected to V

voltage is used then V

LCDSENSE

. If an external supply

LCDOUT

can be left open or

connected to ground.

6.1.8 T1 TO T5: TEST PINS

T1, T3, T4 and T5 must be connected to VSS, T2 must be

left open. Not accessible to user.

is used as

or

LCDSENSE

2001 Nov 14 5

Page 6

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

6.1.9 SDIN: SERIAL DATA LINE

Input for the data line.

6.1.10 SCLK: SERIAL CLOCK LINE

Input for the clock signal: up to 4.0 Mbits/s.

6.1.11 D/C: MODE SELECT

Input to select either command or address data input.

6.1.12 SCE: CHIP ENABLE

The enable pin allows data to be clocked in. Signal is

active LOW.

6.1.13 OSC: OSCILLATOR

When the on-chip oscillator is used this input must be

connected to VDD. An external clock signal, if used, is

connected to this input. If theoscillator and external clock

are both inhibited by connecting pin OSC to VSS, the

display is not clocked and may be left in a DC state. To

avoid this the chip should always be put into

Power-down mode before stopping the clock.

6.1.14 RES: RESET

This signal will reset the device and must be applied to

properly initialize the chip. Signal is active LOW.

7 FUNCTIONAL DESCRIPTION

7.1 Oscillator

The on-chip oscillator provides the clock signal for the

display system.No external componentsare required and

the OSC input must be connected to VDD. An external

clock signal, if used, is connected to this input.

7.2 Address counter

The address counter assigns addresses to the display

data RAM for writing. The X-address X6to X0 and the

Y-address Y3to Y0 are set separately. After a write

operation, the address counter is automatically

incremented by 1 according to bit V (see Section 7.7).

7.3 Display Data RAM (DDRAM)

The OM6206 contains a 65 × 102 bits static RAM which

stores the display data. The RAM is divided into

eight banks of 102 bytes (8 × 8 × 102 bits) and one bank

of 102 bits (1 × 102 bits). During RAM access, data is

transferred to the RAM via the serial interface. There is a

direct correspondence between X-address and column

output number.

7.4 Timing generator

The timing generator produces the various signals

required to drive the internal circuitry. Internal chip

operation is not affected by operations on the data bus.

7.5 Display address counter

The display is generated by continuously shifting rows of

RAM data to the dot matrix LCD via the column outputs.

The display status (all dots on/off and normal/inverse

video) is set by bits E and D in the command ‘Display

control’ (see Table 2).

7.6 LCD row and column drivers

The OM6206 contains 65 rows and 102 column drivers,

which connect the appropriate LCD bias voltages in

sequence to the displayin accordance with the data tobe

displayed. Figure 2 shows typical waveforms. Unused

outputs should be left unconnected.

2001 Nov 14 6

Page 7

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

ROW0

R0(t)

ROW1

R1(t)

COL0

C0(t)

COL1

C1(t)

V

LCD

V3 − V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

LCD

2

3

4

5

SS

frame n frame n + 1

V

state1

V

state2

(t)

(t)

V

− V

LCD

V

state1

V

state2

V

(t) = C1(t) to R0(t).

state1

V

(t) = C1(t) to R1(t).

state2

(t)

(t)

0 V

V3 − V

V

LCD

V3 − V

V

LCD

0 V

V3 − V

2

SS

− V

2

2

2

012345678... ... 64 012345678... ... 64

Fig.2 Typical LCD driver waveforms.

2001 Nov 14 7

V4 − V

0 V

VSS − V

V4 − V

− V

LCD

V4 − V

0 V

VSS − V

V4 − V

− V

LCD

MGT860

5

5

LCD

5

5

LCD

Page 8

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

DDRAM

bank 0

top of LCD

bank 1

bank 2

bank 3

bank 7

bank 8

LCD

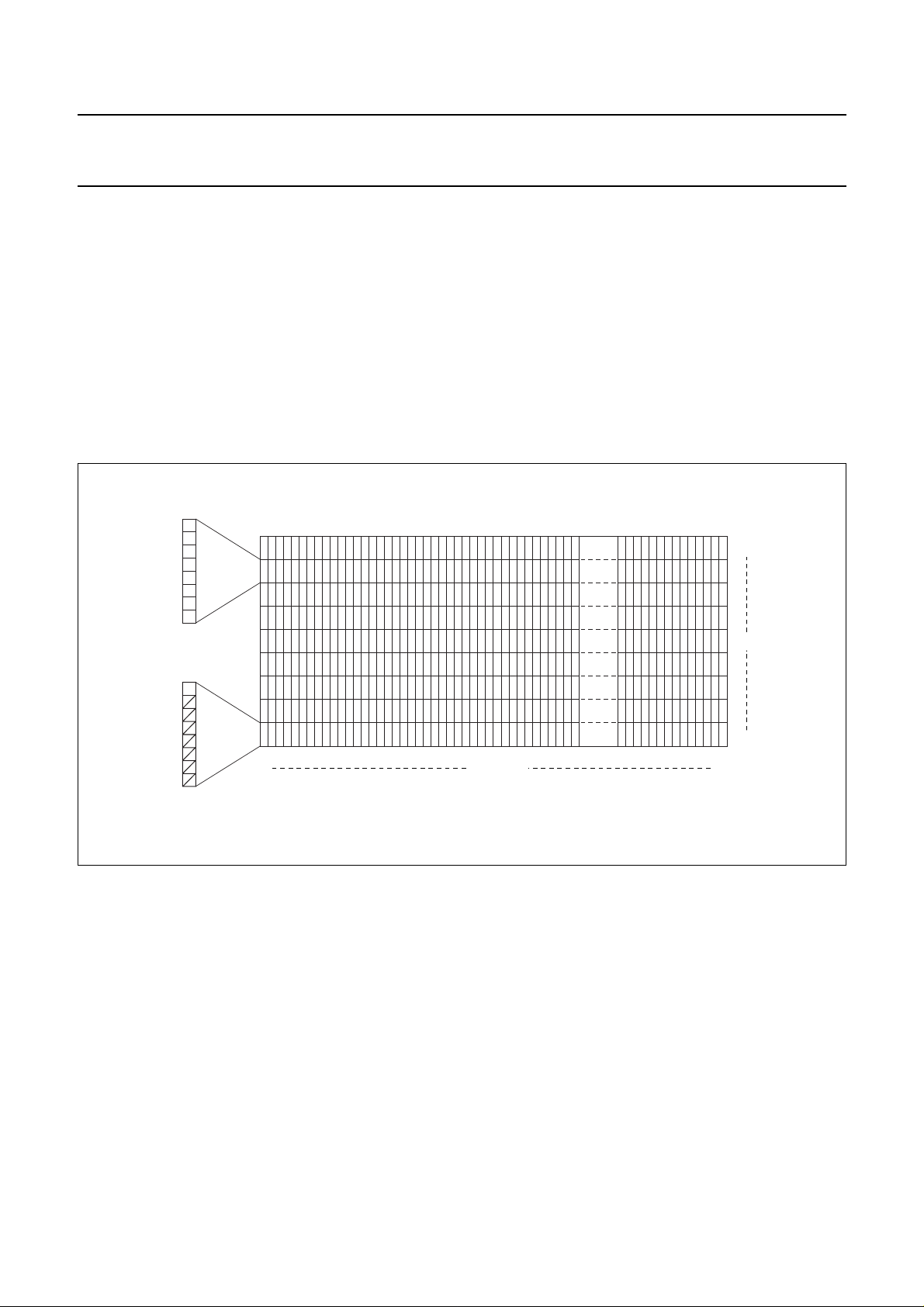

Fig.3 DDRAM to display mapping.

2001 Nov 14 8

MGT861

Page 9

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

7.7 Addressing

Data is downloaded in bytes into the RAM matrix of

OM6206 as indicated in Figs.3, 4, 5 and 6.

The display RAM has a matrix of 65 × 102 bits. The

columns are addressed by the address pointer. The

address ranges are: X from 0 to 101 (1100101)

and Y from 0 to 8(1000). Addressesoutside theseranges

are not allowed.

In vertical addressing mode (bit V = 1) the Y-address

increments after each byte (see Fig.6).

7.7.1 DATA STRUCTURE

handbook, full pagewidth

LSB

MSB

After the last Y-address (Y = 8) Y wraps

around to 0 and X increments to addressthe next column.

In horizontal addressing mode (bit V = 0) the X-address

increments after each byte (see Fig.5). After the last

X-address (X = 101) X wraps around to 0 and

Y increments to address the next row.

After the very last address (X = 101, Y = 8) the address

pointers wrap around to address X = 0, Y = 0.

0

Y-address

LSB

MSB

0 101X-address

Fig.4 RAM format, addressing.

8

MGT862

2001 Nov 14 9

Page 10

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

handbook, full pagewidth

handbook, full pagewidth

09

110

2

3

4

5

6

7

8 917

0 101X-address

0

Y-address

8

MGT 863

Fig.5 Sequence of writing data bytes into RAM with vertical addressing (V = 1).

012

102 103 104

204 205 206

306 307 308

408 409 410

510 511 512

612 613 614

714 715 716

816 817 818 917

0 101X-address

0

Y-address

8

MGT864

Fig.6 Sequence of writing data bytes into RAM with horizontal addressing (V = 0).

8 INSTRUCTIONS

The instruction format is divided into two modes:

• If D/C (mode select) is set LOW, the current byte is

interpreted as command byte (see Table 1).

• If D/C is set HIGH, the following bytes are stored in the

display data RAM. After every data byte the address

counter is incremented automatically.

Thelevel ofthe D/C signalis readduringthe lastbit ofdata

byte.

2001 Nov 14 10

Every instruction canbe sent in anyorder to the OM6206.

The MSBof a byte istransmitted first (seeFig.7). Figure 8

shows one possible command stream, used to set up the

LCD driver.

The serialinterface isinitialized whenSCE isHIGH. In this

state SCLK clock pulses have no effect and no power is

consumedby the serialinterface. Anegative edgeon SCE

enablesthe serialinterfaceand indicatesthe startofa data

transmission.

Page 11

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

handbook, halfpage

MSB (DB7) LSB (DB0)

Fig.7 General format of data stream.

handbook, full pagewidth

bias systemfunction set (H = 1)

Fig.8 Serial data stream, example.

Figures 9 and 10 show the serial bus protocol:

• When SCE is HIGH, SCLK clock signals are ignored.

During the HIGH time of SCE, the serial interface is

initialized (see Fig.11)

• SDIN is sampled at the positive edge of SCLK

• D/C indicates, whether the byte is a command

(D/C = LOW) or RAM data(D/C = HIGH); it is read with

the eighth SCLK pulse

datadata

MGT865

set V

OP

temperature control

X-addressY-addressdisplay controlfunction set (H = 0)

MGT866

• If SCE stays LOW after the last bit of a

command/data byte, theserial interface expects bit 7of

the next byte at the next positive edge of SCLK (see

Fig.11)

• A reset pulse with RES interrupts the transmission.

No data are written into the RAM. The registers are

cleared. If SCE is LOW after the positive edge of RES,

the serial interface is ready to receive bit 7 of a

command/data byte (see Fig.11).

handbook, full pagewidth

SCE

D/C

SCLK

SDIN

DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Fig.9 Serial bus protocol for transmission of one byte.

2001 Nov 14 11

MGT867

Page 12

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

handbook, full pagewidth

SCE

D/C

SCLK

SDIN DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DB7DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Fig.10 Serial bus protocol for transmission of several bytes.

handbook, full pagewidth

SCE

D/C

RES

SCLK

SDIN DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0 DB7DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Fig.11 Serial bus reset function (SCE).

DB6 DB5

MGT868

DB6 DB5

MGT869

handbook, full pagewidth

SCE

RES

D/C

SCLK

SDIN DB7 DB6 DB5 DB4 DB3 DB7DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

Fig.12 Serial bus interrupt function (RES).

2001 Nov 14 12

DB6 DB5 DB4

MGT870

Page 13

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

Table 1 Instruction set

INSTRUCTION DESCRIPTION

PIN COMMAND BYTE

C DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

D/

(H=0or1)

NOP no operation LOW 00000000

Function set power down control; entry

LOW00100PDVH

mode; extended instruction set

control (H)

D

D

D

D

D

D

Write data writes data to display RAM HIGH D

7

6

5

4

3

2

D

1

0

(H=0)

Reserved do not use LOW 000001XX

Display control sets display configuration LOW 00001D0E

Set HIGHor LOW

V

programming range select LOW 0001000PRS

LCD

program range

V

OP

Set Y-address of

RAM

Set X-address of

RAM

sets Y-address of RAM;

0 ≤ Y ≤ 8

sets X-address of RAM;

0 ≤ X ≤ 101

LOW0100Y

LOW 1 X

X

6

X

5

3

X

4

3

Y

2

X

2

Y

1

X

1

Y

0

X

0

(H=1)

Reserved do not use LOW 00000001

do not use LOW 0000001X

Temperature

control

HVgen stages multiplication of high-voltage

set Temperature Coefficient

(TCx)

LOW000001TC

LOW000010S

1TC0

1

S

0

generator voltage (Sx)

Bias system set Bias System (BSx) LOW00010BS

2BS1

BS

0

Reserved do not use (reserved for test) LOW 0 1 XXXXXX

Set V

OP

write V

to register LOW 1 V

OPx

OP6VOP5VOP4VOP3VOP2VOP1VOP0

Table 2 Explanations for symbols in Table 1

BIT BIT VALUE DESCRIPTION RESET STATE

PD 0 chip is active 1

1 chip is in Power-down mode

V 0 horizontal addressing 0

1 vertical addressing

H 0 use basic instruction set 0

1 use extended instruction set

D and E 00 display blank 00

10 normal mode

01 all display segments on

11 inverse video mode

PRS 0 V

1V

programming range LOW 0

LCD

programming range HIGH

LCD

2001 Nov 14 13

Page 14

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

BIT BIT VALUE DESCRIPTION RESET STATE

TC1and TC

S

and S

BS

V

1

OP6

to BS

2

to V

0

OP0

0

0

00 V

01 V

10 V

11 V

temperature coefficient 0 00

LCD

temperature coefficient 1

LCD

temperature coefficient 2

LCD

temperature coefficient 3

LCD

00 2× voltage multiplier 00

01 3× voltage multiplier

10 4× voltage multiplier

11 5× voltage multiplier

− bias system 000

− V

programming 0000000

LCD

8.1 Initialization

Immediately following power-on, all internal registers as

well asthe RAMcontent are undefined.A RESpulse must

be applied.

Reset isaccomplished byapplying an externalreset pulse

(active LOW) at pin RES. When reset occurs within the

specified time, all internal registers are reset however the

RAM isstill undefined. Thestate afterreset is describedin

Section 8.2.

RES input must be ≤0.3VDDwhen VDD reaches V

(or higher) within a maximal time t

after VDD going

VHRL

DD(min)

HIGH (see Fig.16).

8.2 Reset function

After reset the LCD driver has the following state:

• Power-down mode (PD = 1)

• Horizontal addressing (V = 0)

• Normal instruction set (H = 0)

• Display blank (E andD=0)

• Address counter X6to X0= 0, Y3to Y0=0

• Temperature control (TC1and TC0=0)

• Bias system (BS2to BS0=0)

• V

is equal to 0 V and the high-voltage generator is

LCD

switched off (V

OP6

to V

= 0 and PRS = 0)

OP0

• After power-on, RAM data are undefined, the reset

signal does not change the content of the RAM

• All LCD outputs at VSS (display off).

8.3 Function set

8.3.1 PD

When PD = 1 the chip is in Power-down mode:

• All LCD outputs at VSS (display off)

• Bias generator and V

generator off; V

LCD

LCD

can be

disconnected

• Oscillator off (external clock possible)

• Serial bus: command, function etc.

• RAM contents not cleared; RAM data can be written

• V

discharged to VSS in Power-down mode.

LCD

8.3.2 V

When V = 0, the horizontal addressing is selected. The

data is written into the DDRAM as shown in Fig.6.

When V = 1, the vertical addressing is selected. Thedata

is written into the DDRAM as shown in Fig.5.

8.3.3 H

When H = 0 the commands ‘display control’, ‘set

Y-address’, ‘set X-address’ and ‘set the PRS bit’(LOW or

HIGH range of the high-voltage generator) can be

performed; when H = 1 the others can be executed. The

commands ‘write data’ and ‘function set’can be executed

in both cases.

8.4 Display control

8.4.1 D AND E

The bits D and E select the display mode (see Table 2).

2001 Nov 14 14

Page 15

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

8.5 Set Y-address of RAM

Y3to Y0 define the Y-address vector address of the display RAM.

Table 3 X/Y-address range

Y

3

Y

2

Y

1

Y

0

00000 0to101

00011 0to101

00102 0to101

00113 0to101

01004 0to101

01015 0to101

01106 0to101

01117 0to101

10008; note 2 0 to 101

BANK

(1)

ALLOWED X-RANGE

Notes

1. Display RAM.

2. Only the MSB is accessed.

8.6 Set X-address of RAM

The X-address points to the columns. The range of X is

0 to 101 (65H).

8.7 Set high-voltage generator stages

TheOM6206 incorporatesa softwareconfigurable voltage

multiplier. After reset (RES) the voltagemultiplier is set to

2 × V

. Other voltage multiplier factors are set via the

DD2

command ‘HVgen stages’ (see Tables 1 and 2).

Table 4 Programming the required bias system

BS

2

BS

1

BS

0

0007 1:100

0016 1:80

0105 1:65 or 1:65

0114 1:48

1003 1:40 or 1:34

1012 1:24

1101 1:18 or 1:16

1110 1:10 or 1:9 or 1:8

8.8 Bias system

The bias voltage levels are set in the ratio of

R-R-nR-R-R giving a bias system. Different

1

------------ n4+

multiplex rates require different factors n (see Table 4).

This is programmed by BS

to BS0. For multiplex rate

2

1 : 65 the optimum bias value n is given by:

n653–5.062 5===

resulting in a

1

/9bias system.

n RECOMMENDED MULTIPLEX RATE

(1)

2001 Nov 14 15

Page 16

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

Table 5 LCD bias voltage

SYMBOL BIAS VOLTAGES BIAS VOLTAGE FOR1⁄9 BIAS

V1 V

LCD

V2

V3

V4

V5

V6 V

SS

8.9 Temperature control

n3+

------------ n4+

n2+

------------ n4+

2

------------ n4+

1

------------ n4+

V

V

LCD

SS

8

⁄9× V

7

⁄9× V

2

⁄9× V

1

⁄9× V

LCD

LCD

LCD

LCD

Due to the temperature dependency of the liquid crystals viscosity the LCD controlling voltage V

must be increased

LCD

with lower temperature to maintain optimal contrast. There are four temperature coefficients available in the OM6206

(see Fig.13). The coefficients are selected by the two bits TC1and TC0. Table 6 shows the typical values of the

temperature coefficients. The coefficients are proportional to the programmed V

(1) TC0.

(2) TC1.

(3) TC2.

(4) TC3.

handbook, halfpage

V

LCD

(V)

T

cut

MGT871

at reference temperature.

LCD

(1)

(2)

(3)

(4)

T (°C)

Fig.13 Temperature coefficients behaviour.

2001 Nov 14 16

Page 17

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

8.10 Set VOP value

The operation voltage V

can be set by software. The

LCD

generated voltage is dependent on the programmed

voltage at reference temperature (T

), the programmed

cut

Temperature Coefficient (TC) and the operating

temperature (T).

The voltage at reference temperature can be calculated

as:

abV

V

LCD Tcut()

×+=

OP

The voltage at operating temperature can be calculated

as:

V

LCD(T)

V

LCD(Tcut)

TT

–()TC×+=

cut

Two overlapping V

command ‘set HIGH or LOW program range VOP’.

For the LOW range (bit PRS = 0) component a = a1 and

for the HIGH range (bit PRS = 1) component a = a2. The

steps in both ranges are equal to b.

It should be noted that the charge pump is turned off if

bits V

OP6

to V

OP0

Fig.14).

(2)

For multiplexer rate 1 : 65 the optimum operation voltage

of the liquid can be calculated as:

165+

---------------------------------------

21

×

(3)

V

LCD

ranges are selectable via the

LCD

and bit PRS are all set to zero (see

× 6.85 Vth×==

V

1

–

----------

th

65

The parameters are explained in Table 6.

Themaximum voltagethat canbegenerated isdepending

on the V

voltage and the display load current.

DD2

where V

material used.

is the threshold voltage of the liquid crystal

th

Table 6 Typical values for parameters for the high-voltage generator programming

SYMBOL VALUE UNIT

a

1

a

2

2.94 (PRS = 0) V

6.75 (PRS = 1) V

b 0.03 V

T

cut

27

(4)

°

C

Table 7 Temperature coefficients

BIT

NAME

TC

1

TC

0

TC0 0 0 −0.00 × 10−3× V

TC1 0 1 −0.76 × 10

TC2 1 0 −1.05 × 10

TC3 1 1 −2.10 × 10

−3

−3

−3

× V

× V

× V

LCD(Tcut)

LCD(Tcut)

LCD(Tcut)

LCD(Tcut)

VALUE UNIT

V/°C

V/°C

V/°C

V/°C

2001 Nov 14 17

Page 18

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

handbook, full pagewidth

V

LCD

(V)

b

a

2

a1 + b

a

1

charge pump off

00

01 02

V

to V

OP6

to be programmed (00H to 7FH), programming ranges LOW and HIGH.

OP0

As theprogramming range forthe internally generatedV

03 04 05 06

LOW (PRS = 0) HIGH (PRS = 1)

. . . 5F 6F 7F 00 01 02 03 04 05 06 . . . 5F 6F 7F

Fig.14 VOP programming at T = T

allows valuesabove the maximumallowed V

LCD

cut

.

MGT878

(9.0 V) the

LCD

user has toensure while setting the VOPvalue and selectingthe Temperature Coefficient (TC), that under allconditions

and including all tolerances the V

remains below 9.0 V.

LCD

9 LIMITING VALUES

In accordance with the Absolute Maximum Rating System (IEC 60134); notes 1 and 2.

SYMBOL PARAMETER MIN. MAX. UNIT

V

V

V

V

I

I

P

DD1

DD2,

LCD

i

SS

, I

I

tot

, V

DD3

O

supply voltage 1 −0.5 +6.5 V

supply voltages 2 and 3 −0.5 +4.5 V

supply voltage LCD −0.5 +9.0 V

all input voltages −0.5 VDD+ 0.5 V

ground supply current −50 +50 mA

DC input or output current −10 +10 mA

total power dissipation − 300 mW

P/out power dissipation per output − 30 mW

T

stg

storage temperature −65 +150 °C

Notes

1. Stresses above those listed under limiting values may cause permanent damage to the device.

2. Parameters are valid over operating temperature range unless otherwise specified. All voltages are with respect to

VSS unless otherwise specified.

2001 Nov 14 18

Page 19

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

10 HANDLING

Inputs and outputs are protected against electrostatic discharge in normal handling. However, to be totally safe, it is

desirable to take normal precautions appropriate to handling MOS devices (see

11 DC CHARACTERISTICS

VDD= 2.5 to 5.5 V; VSS=0V; V

= 4.5 to 9.0 V; T

LCD

= −40 to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

V

V

V

DD1

DD2

DD3

supply voltage 1 2.5 − 5.5 V

,

supply voltages 2 and 3 LCD voltage internally

generated (voltage generator

enabled)

V

LCDIN

input supply voltage LCD LCD voltage externally supplied

(voltage generator disabled)

V

LCDOUT

output supply voltage LCD LCD voltage internally

generated (voltage generator

enabled); note 1

I

DD(tot)

total supply current normal mode; VDD= 2.8 V;

V

= 7.6 V; no serial clock;

LCD

T

=25°C; no display load;

amb

4 × charge pump; note 2

Power-down mode;with internal

I

LCDIN

supply current from

external V

LCD

or external V

VDD= 2.8 V; V

serial clock; T

LCD

LCD

amb

; note 3

= 7.6 V; no

=25°C; no

display load; notes 2 and 4

Logic

V

IL

V

IH

I

L

LOW-level input voltage V

HIGH-level input voltage 0.7VDD− V

leakage current VI=VDDor V

SS

Column and row outputs

R

col

output resistance of

V

= 7.6 V − 12 20 kΩ

LCD

columns C0 to C101

R

row

output resistance of

V

= 7.6 V − 12 20 kΩ

LCD

rows R0 to R64

V

col

bias tolerance voltage of

columns C0 to C101

V

row

bias tolerance voltage of

rows R0 to R64

LCD supply voltage generator

∆V

LCD

tolerance of internally

generated V

LCD

VDD= 2.8 V; V

serial clock; T

LCD

amb

=25°C;

= 7.6 V; no

display load is 10 µA; notes 5

and 6

TC0 V

temperature

LCD

note 7 − 0 × 10−3V

coefficient 0

“Handling MOS devices”

).

2.5 − 4.5 V

4.5 − 9.0 V

4.5 − 9.0 V

− 200 300 µA

− 1.5 −µA

− 30 −µA

SS

− 0.3VDDV

DD

V

−1 − +1 µA

−100 0 +100 mV

−100 0 +100 mV

−300 0 +300 mV

LCD

− V/°C

2001 Nov 14 19

Page 20

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

TC1 V

TC2 V

TC3 V

Notes

1. Themaximum possibleV

2. Internal clock.

3. During Power-down mode, all static currents are switched off.

4. If external V

5. Tolerancedepends on thetemperature; typicalnull at T

temperate range limit; maximum tolerance is proportional to V

6. For TC1 to TC3.

7. VDD= 2.8 V; no serial clock; T

temperature

LCD

note 7 −−0.76 × 10−3V

coefficient 1

temperature

LCD

note 7 −−1.05 × 10−3V

coefficient 2

temperature

LCD

note 7 −−2.10 × 10−3V

coefficient 3

voltage thatmay begenerated isdependent onvoltage, temperatureand (display)load.

LCD

, the display load current is not transmitted to IDD.

LCD

= −20 to +70 °C; display load = 10 µA.

amb

− V/°C

LCD

− V/°C

LCD

− V/°C

LCD

=27°C; maximumtolerance valuesare measured atthe

amb

.

LCD

12 AC CHARACTERISTICS

VDD= 2.5 to 5.5 V; VSS=0V; V

= 4.5 to 9.0 V; T

LCD

= −40 to +85 °C; unless otherwise specified.

amb

SYMBOL PARAMETER CONDITIONS MIN. TYP. MAX. UNIT

f

osc

f

ext

f

frame

t

VHRL

t

RW

oscillator frequency VDD= 2.8 V; T

= −20 to +70 °C223867kHz

amb

external clock frequency 20 38 67 kHz

frame frequency f

VDDHIGH to RES LOW time see Fig.16 0

osc

or f

= 38 kHz; note 1 − 73 − Hz

ext

(2)

− 1 µs

RES LOW pulse width see Fig.16 100 −−ns

Serial bus timing characteristics; see Fig.15

f

SCLK

t

CYC

t

PWH1

t

PWL1

t

S2

t

H2

t

PWH2

t

H5

t

S3

t

H3

t

S4

t

H4

clock frequency VDD= 3.0 V ±10%; note 3 0 − 4 MHz

SCLK clock cycle time 250 −−ns

SCLK pulse width HIGH 100 −−ns

SCLK pulse width LOW 100 −−ns

SCE setup time 60 −−ns

SCE hold time 100 −−ns

SCE HIGH time 100 −−ns

SCE start hold time note 4 100 −−ns

D/C setup time 100 −−ns

D/C hold time 100 −−ns

SDIN setup time 100 −−ns

SDIN hold time 100 −−ns

Notes

f

1.

f

frame

ext

=

--------- 520

2001 Nov 14 20

Page 21

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

2. RES may be LOW before VDD goes HIGH.

3. All signal timing is based on 20% to 80% of VDD and a maximum rise and fall time of 10 ns.

4. tH5is the time from the previous SCLK positive edge(irrespective of the state of SCE) to the negative edge of SCE.

handbook, full pagewidth

SCE

D/C

SCLK

SDIN

t

S2

t

t

S4

t

S3

PWL1

t

H3

t

PWH1

t

H4

Fig.15 Serial interface timing.

t

H2

(tH5)

t

CYC

t

S2

t

PWH2

t

H5

MGT872

handbook, full pagewidth

V

DD

RES

V

DD

RES

t

RW

t

VHRL

t

RW

Fig.16 Reset timing.

2001 Nov 14 21

t

RW

t

RW

MGT873

Page 22

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

13 APPLICATION INFORMATION

13.1 Programming example for the OM6206

Table 8 Programming example

STEP

DISPLAY OPERATION

D/C DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

SERIAL BUS BYTE

1 start

SCE is going LOW

2 000100001 function set:

PD = 0 and V = 0; select

extended instruction set

(H=1)

3 010010000 set V

: VOP is set to

OP

a +16 × b [V]

4 000100000 function set:

PD = 0 and V = 0; select

normal instruction set

(H=0)

5 000001100 display control: set

normal mode

(D=1andE=0)

6 100011111 data write: Yand X are

initialized to 0 by default,

so they are not set here

MGT144

7 100000101 data write

MGT145

8 100000111 data write

MGT146

9 100000000 data write

MGT146

10100011111 data write

MGT148

11100000100 data write

MGT149

2001 Nov 14 22

Page 23

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

STEP

C DB7 DB6 DB5 DB4 DB3 DB2 DB1 DB0

D/

DISPLAY OPERATION

12100011111 data write

SERIAL BUS BYTE

MGT151

13000001101 display control: set

inverse video mode

(D=1andE=1)

MGT152

14010000000 set X-address of RAM:

set address to ‘0000000’

MGT152

15100000000 data write

MGT874

13.2 Application diagrams

handbook, full pagewidth

(1) 6 if external oscillator is used.

Fig.17 Application diagram: internal charge pump is used and a single supply VDD.

LCD

(65 × 102 pixels)

102 column drivers33 row drivers 32 row drivers

OM6206

DD2

DD3VDD1

V

V

(1)

5

C

I/O

V

DD

VDD

SS1VSS2VLCDSENSE

V

C

VLCD

V

SS

LCDOUTVLCDIN

V

MGT875

2001 Nov 14 23

Page 24

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

handbook, full pagewidth

LCD

(65 × 102 pixels)

102 column drivers33 row drivers 32 row drivers

OM6206

DD2

DD3VDD1

V

V

(1)

5

I/O

V

DD2

V

DD1

C

C

VDD2

VDD1

SS1VSS2VLCDSENSE

V

C

V

SS

VLCD

LCDOUTVLCDIN

V

MGT876

(1) 6 if external oscillator is used.

Fig.18 Application diagram: internal charge pump is used and two separate supplies V

handbook, full pagewidth

LCD

(65 × 102 pixels)

102 column drivers33 row drivers 32 row drivers

DD1

and V

DD2

.

OM6206

DD2

DD3VDD1

V

V

(1)

5

C

I/O

V

DD

VDD

SS1VSS2VLCDSENSE

V

V

SS

V

LCDOUTVLCDIN

V

LCDIN

MGT877

(1) 6 if external oscillator is used.

Fig.19 Application diagram: external supply V

2001 Nov 14 24

LCDIN

is used.

Page 25

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

The required minimumvalue for the externalcapacitors in

an application with the OM6206 are:

• C

• C

VLCD

VDD

> 100 µF

, C

VDD1

and C

VDD2

>1µF

Higher capacitor values are recommended for ripple

reduction.

13.3 Application for COG

The pinning of the OM6206 is optimized for single plane

wiring e.g.for Chip-On-Glass (COG)display modules with

display size of 65 × 102 pixels.

14 BONDING PAD INFORMATION

COORDINATES

(1)

SYMBOL PAD

xy

RES_B 1 −3870 +935

row32 2 −4270 +935

row31 3 −4340 +935

row30 4 −4410 +935

row29 5 −4480 +935

row28 6 −4550 +935

row27 7 −4620 +935

row26 8 −4690 +935

row25 9 −4760 +935

row24 10 −4830 +935

row23 11 −4900 +935

row22 12 −4970 +935

row21 13 −5040 +935

row20 14 −5110 +935

row19 15 −5180 +935

dummy pad 16 −5320 +935

dummy pad 17 −5355 −935

row0 18 −5005 −935

row1 19 −4935 −935

row2 20 −4865 −935

row3 21 −4795 −935

row4 22 −4725 −935

row5 23 −4655 −935

row6 24 −4585 −935

row7 25 −4515 −935

row8 26 −4445 −935

row9 27 −4375 −935

To reduce the sensitivity of a reset to ESD/EMC

disturbances for a chip-on-glass application, it is strongly

recommended to implement on the glass (indium track

resistance) a series input resistance in the reset line

(recommended minimum value of 8 kΩ).

13.4 Chip information

TheOM6206 ismanufactured inn-well CMOStechnology.

The substrate is on VSS potential.

COORDINATES

(1)

SYMBOL PAD

xy

row10 28 −4305 −935

row11 29 −4235 −935

row12 30 −4165 −935

row13 31 −4095 −935

row14 32 −4025 −935

row15 33 −3955 −935

row16 34 −3885 −935

row17 35 −3815 −935

row18 36 −3745 −935

col0 37 −3605 −935

col1 38 −3535 −935

col2 39 −3465 −935

col3 40 −3395 −935

col4 41 −3325 −935

col5 42 −3255 −935

col6 43 −3185 −935

col7 44 −3115 −935

col8 45 −3045 −935

col9 46 −2975 −935

col10 47 −2905 −935

col11 48 −2835 −935

col12 49 −2765 −935

col13 50 −2695 −935

col14 51 −2625 −935

col15 52 −2555 −935

col16 53 −2485 −935

col17 54 −2415 −935

col18 55 −2345 −935

2001 Nov 14 25

Page 26

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

SYMBOL PAD

COORDINATES

xy

col19 56 −2275 −935

col20 57 −2205 −935

col21 58 −2135 −935

col22 59 −2065 −935

col23 60 −1995 −935

col24 61 −1925 −935

col25 62 −1785 −935

col26 63 −1715 −935

col27 64 −1645 −935

col28 65 −1575 −935

col29 66 −1505 −935

col30 67 −1435 −935

col31 68 −1365 −935

col32 69 −1295 −935

col33 70 −1225 −935

col34 71 −1155 −935

col35 72 −1085 −935

col36 73 −1015 −935

col37 74 −945 −935

col38 75 −875 −935

col39 76 −805 −935

col40 77 −735 −935

col41 78 −665 −935

col42 79 −595 −935

col43 80 −525 −935

col44 81 −455 −935

col45 82 −385 −935

col46 83 −315 −935

col47 84 −245 −935

col48 85 −175 −935

col49 86 −105 −935

col50 87 +35 −935

col51 88 +105 −935

col52 89 +175 −935

col53 90 +245 −935

col54 91 +315 −935

col55 92 +385 −935

col56 93 +455 −935

col57 94 +525 −935

(1)

SYMBOL PAD

COORDINATES

xy

col58 95 +595 −935

col59 96 +665 −935

col60 97 +735 −935

col61 98 +805 −935

col62 99 +875 −935

col63 100 +945 −935

col64 101 +1015 −935

col65 102 +1085 −935

col66 103 +1155 −935

col67 104 +1225 −935

col68 105 +1295 −935

col69 106 +1365 −935

col70 107 +1435 −935

col71 108 +1505 −935

col72 109 +1575 −935

col73 110 +1645 −935

col74 111 +1715 −935

col75 112 +1785 −935

col76 113 +1925 −935

col77 114 +1995 −935

col78 115 +2065 −935

col79 116 +2135 −935

col80 117 +2205 −935

col81 118 +2275 −935

col82 119 +2345 −935

col83 120 +2415 −935

col84 121 +2485 −935

col85 122 +2555 −935

col86 123 +2625 −935

col87 124 +2695 −935

col88 125 +2765 −935

col89 126 +2835 −935

col90 127 +2905 −935

col91 128 +2975 −935

col92 129 +3045 −935

col93 130 +3115 −935

col94 131 +3185 −935

col95 132 +3255 −935

col96 133 +3325 −935

(1)

2001 Nov 14 26

Page 27

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

COORDINATES

(1)

SYMBOL PAD

xy

col97 134 +3395 −935

col98 135 +3465 −935

col99 136 +3535 −935

col100 137 +3605 −935

col101 138 +3675 −935

row50 139 +3815 −935

row49 140 +3885 −935

row48 141 +3955 −935

row47 142 +4025 −935

row46 143 +4095 −935

row45 144 +4165 −935

row44 145 +4235 −935

row43 146 +4305 −935

row42 147 +4375 −935

row41 148 +4445 −935

row40 149 +4515 −935

row39 150 +4585 −935

row38 151 +4655 −935

row37 152 +4725 −935

row36 153 +4795 −935

row35 154 +4865 −935

row34 155 +4935 −935

row33 156 +5005 −935

dummy pad 157 +5355 −935

dummy pad 158 +5320 +935

row51 159 +5180 +935

row52 160 +5110 +935

row53 161 +5040 +935

row54 162 +4970 +935

row55 163 +4900 +935

row56 164 +4830 +935

row57 165 +4760 +935

row58 166 +4690 +935

row59 167 +4620 +935

row60 168 +4550 +935

row61 169 +4480 +935

row62 170 +4410 +935

row63 171 +4340 +935

row64 172 +4270 +935

COORDINATES

(1)

SYMBOL PAD

xy

dummy pad 173 +4050 +935

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

V

DD1

DD1

DD1

DD1

DD1

DD1

DD3

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

DD2

174 +3890 +935

175 +3810 +935

176 +3730 +935

177 +3650 +935

178 +3570 +935

179 +3490 +935

180 +3250 +935

181 +3090 +935

182 +3010 +935

183 +2930 +935

184 +2850 +935

185 +2770 +935

186 +2690 +935

187 +2610 +935

188 +2530 +935

189 +2450 +935

190 +2370 +935

191 +2290 +935

192 +2210 +935

193 +2130 +935

SCLK 194 +1890 +935

SDIN 195 +1650 +935

DC_B 196 +1410 +935

SCE_B 197 +1170 +935

T2 198 +930 +935

OSC 199 +690 +935

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

V

SS2

200 +530 +935

201 +450 +935

202 +370 +935

203 +290 +935

204 +210 +935

205 +130 +935

206 +50 +935

207 −30 +935

208 −110 +935

209 −190 +935

210 −270 +935

211 −350 +935

2001 Nov 14 27

Page 28

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

COORDINATES

(1)

SYMBOL PAD

xy

V

SS2

V

SS2

V

SS1

V

SS1

V

SS1

V

SS1

212 −430 +935

213 −510 +935

214 −670 +935

215 −750 +935

216 −830 +935

217 −910 +935

T1 218 −1150 +935

T5 219 −1630 +935

T4 220 −2030 +935

V

SS1

V

SS1

221 −2110 +935

222 −2190 +935

T3 223 −2270 +935

V

LCDIN

V

LCDIN

V

LCDIN

V

LCDIN

V

LCDIN

V

LCDIN

V

LCDOUT

V

LCDOUT

V

LCDOUT

V

LCDOUT

V

LCDOUT

V

LCDOUT

V

LCDOUT

V

LCDSENSE

224 −2510 +935

225 −2590 +935

226 −2670 +935

227 −2750 +935

228 −2830 +935

229 −2910 +935

230 −3070 +935

231 −3150 +935

232 −3230 +935

233 −3310 +935

234 −3390 +935

235 −3470 +935

236 −3550 +935

237 −3630 +935

Alignment marks

Circle 1 −5185 −910

Circle 2 +5185 −910

Circle 3 +4160 +910

Circle 4 −4160 +910

Table 9 Bonding pad dimensions

NAME DIMENSION

Pad pitch 70 µm

Pad size, aluminium 62 × 100 µm

Bump dimensions 50 × 90 × 17.5 (±5) µm

Wafer thickness (including

maximum 430 µm

bumps)

Wafer thickness (without

typical 380 µm

bumps)

Note

1. Allx/y coordinates(in µm) arereferencedto thecentre

of the chip (see Fig.20).

2001 Nov 14 28

Page 29

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

ndbook, full pagewidth

.

.

.

.

.

.

DD1

V

DD2

V

SS2

SS1

dummy bump

R51

R64

dummy bump

DD3

V

SCLK

SDIN

D/C

SCE

T2

OSC

V

V

(1)

y

alignment mark

x

0,0

(1)

alignment mark

OM6206

R33

.

.

.

.

.

.

R50

C101

.

.

.

.

.

.

C76

C75

.

.

.

.

.

.

C50

C49

.

.

.

MGT887

dummy bumpdummy bump

10.94 mm

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

_white to force landscape pages to be rotated correctly when browsing through the pdf in theAcrobat reader.This text is here inThis text is here in

white to forcelandscape pages to berotated correctly when browsing throughthe pdf in the Acrobatreader. white to forcelandscape pages to be ...

2001 Nov 14 29

T1

T5

T4

SS1

V

T3

LCDIN

V

LCDOUT

V

LCDSENSE

V

RES

row 32

.

.

.

.

.

.

row 19

dummy bump

.

.

.

C25

C24

.

.

.

.

.

.

pad 237

pad 1

(1)

alignment mark

(1)

mm

2.14

C0

R18

.

.

.

.

.

.

R0

alignment mark

Fig.20 Bonding pad locations.

(1) The alignment marks are circles with a diameter of 100 µm.

Page 30

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

15 DEVICE PROTECTION CIRCUITS

SYMBOL PAD INTERNAL CIRCUIT

V

DD1

174 to 179

MGT879

V

SS1

V

DD2

V

DD3

V

SS1

V

SS2

V

LCDIN

V

LCDSENSE

V

LCDOUT

181 to 193

180

214 to 217, 221, 222

200 to 213

224 to 229

237

230 to 236

page

MGT879

MGT883

MGT879

MGT880

V

V

SS1

V

V

SS1

V

V

SS2

SS1

SS1

SS2

T2 198

T3 223

2001 Nov 14 30

MGT882

V

V

DD1

SS1

Page 31

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

SYMBOL PAD INTERNAL CIRCUIT

SDIN 195

SCLK 194

SCE 197

D/

C 196

OSC 199

RES 1

T1 217

T4 218

T5 220

R0 to R64 2 to 15,18 to 36,139 to 156,

159 to 172

C0 to C101 37 to 138

alfpage

MGT884

1 per block

V

V

DD1

SS1

V

LCDIN

MGT881

V

SS1

2001 Nov 14 31

Page 32

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

16 TRAY INFORMATION

handbook, full pagewidth

x

y

H

F

G

A

E

C

D

B

MGT885

Fig.21 Tray details.

handbook, halfpage

OM6206

MGT886

The orientation of the IC in a pocket is indicated by the position of the IC type name on the die surface with respect to the chamfer on the upper left

corner of the tray. Refer to the bonding pad location diagram for the orientating and position of the type name on the die surface.

Fig.22 Tray alignment.

2001 Nov 14 32

Page 33

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

Table 10 Tray dimensions

DIMENSIONS DESCRIPTION VALUE

A pocket pitch; in the x direction 13.77 mm

B pocket pitch; in the y direction 4.45 mm

C pocket width; in the x direction 11.04mm

D pocket width; in the y direction 2.24mm

E tray width; in the x direction 50.8 mm

F tray width; in the y direction 50.8 mm

G distance from cut corner to pocket centre 11.63 mm

H distance from cut corner to pocket centre 5.41 mm

x number of pockets in the x direction 3

y number of pockets in the y direction 10

2001 Nov 14 33

Page 34

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

17 DATA SHEET STATUS

PRODUCT

DATA SHEET STATUS

Objective data Development This data sheet contains data from the objective specification for product

Preliminary data Qualification This data sheet contains data from the preliminary specification.

Product data Production This data sheet contains data from the product specification. Philips

(1)

STATUS

(2)

development. Philips Semiconductors reserves the right to change the

specification in any manner without notice.

Supplementary data will be published at a later date. Philips

Semiconductors reserves the right to change the specification without

notice, in order to improve the design and supply the best possible

product.

Semiconductors reserves the right to make changes at any time in order

to improve the design, manufacturing and supply. Changes will be

communicated according to the Customer Product/Process Change

Notification (CPCN) procedure SNW-SQ-650A.

DEFINITIONS

Notes

1. Please consult the most recently issued data sheet before initiating or completing a design.

2. The product status of the device(s) described in this data sheet may have changed since this data sheet was

published. The latest information is available on the Internet at URL http://www.semiconductors.philips.com.

18 DEFINITIONS

Short-form specification The data in a short-form

specification is extracted from a full data sheet with the

same type number and title. For detailed information see

the relevant data sheet or data handbook.

Limiting valuesdefinition Limitingvalues givenare in

accordance with the Absolute Maximum Rating System

(IEC 60134). Stress above one or more of the limiting

values may cause permanent damage to the device.

These are stress ratings only and operation of the device

atthese orat anyotherconditions abovethose givenin the

Characteristics sectionsof the specification isnot implied.

Exposure to limiting values for extended periods may

affect device reliability.

Application information Applications that are

described herein for any of these products are for

illustrative purposes only. Philips Semiconductors make

norepresentation orwarrantythat suchapplications willbe

suitable for the specified use without further testing or

modification.

19 DISCLAIMERS

Life support applications These products are not

designed for use in life support appliances, devices, or

systems where malfunction of these products can

reasonably beexpected toresult inpersonal injury.Philips

Semiconductorscustomers usingorselling theseproducts

for use in such applications do so at their own risk and

agree to fully indemnify Philips Semiconductors for any

damages resulting from such application.

Right to make changes Philips Semiconductors

reserves the right to make changes, without notice, in the

products, including circuits, standard cells, and/or

software, described or contained herein in order to

improve design and/or performance. Philips

Semiconductors assumes no responsibility or liability for

theuse ofany oftheseproducts, conveysnolicence ortitle

under any patent, copyright, or mask work right to these

products,and makesno representationsor warrantiesthat

these products are free from patent, copyright, or mask

work right infringement, unless otherwise specified.

Bare die All die are tested and are guaranteed to

comply with all data sheet limits up to the point of wafer

sawing for a period of ninety (90) days from the date of

Philips' delivery. If there are data sheet limits not

guaranteed, these will be separately indicated in the data

sheet. There are no post packing tests performed on

individual die or wafer. Philips Semiconductors has no

control of third party procedures in the sawing, handling,

packing or assembly of the die. Accordingly, Philips

Semiconductors assumes no liability for device

functionality or performance of the die or systems after

third party sawing, handling, packing or assembly of the

die. It is the responsibility of the customer to test and

qualify their application in which the die is used.

2001 Nov 14 34

Page 35

Philips Semiconductors Product specification

65 × 102 pixels matrix LCD driver OM6206

NOTES

2001 Nov 14 35

Page 36

Philips Semiconductors – a w orldwide compan y

Contact information

For additional information please visit http://www.semiconductors.philips.com. Fax: +31 40 27 24825

For sales offices addresses send e-mail to: sales.addresses@www.semiconductors.philips.com.

© Koninklijke Philips Electronics N.V. 2001

All rights are reserved. Reproduction in whole or in part is prohibited without the prior written consent of the copyright owner.

The information presented in this document doesnot formpart of any quotation or contract, isbelieved to be accurate and reliable and may bechanged

without notice. No liability will be accepted by the publisher for any consequence of its use. Publication thereof does not convey nor imply any license

under patent- or other industrial or intellectual property rights.

Printed in The Netherlands 403506/01/pp36 Date of release: 2001 Nov 14 Document order number: 9397 750 07746

SCA73

Loading...

Loading...