INTEGRATED CIRCUITS

DATA SH EET

OM5193H

Disk drive spindle and VCM with

servo controller

Product specification

File under Integrated Circuits, IC11

1998 Nov 02

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

CONTENTS

1 FEATURES

1.1 Servo control

1.2 Motor control

1.2.1 Spindle motor driver

1.2.2 Voice coil motor driver

1.3 Miscellaneous items

2 APPLICATIONS

3 GENERAL DESCRIPTION

3.1 Overview

3.2 Servo controller

3.3 Spindle and voice coil motor

3.4 Safety functions

4 QUICK REFERENCE DATA

5 ORDERING INFORMATION

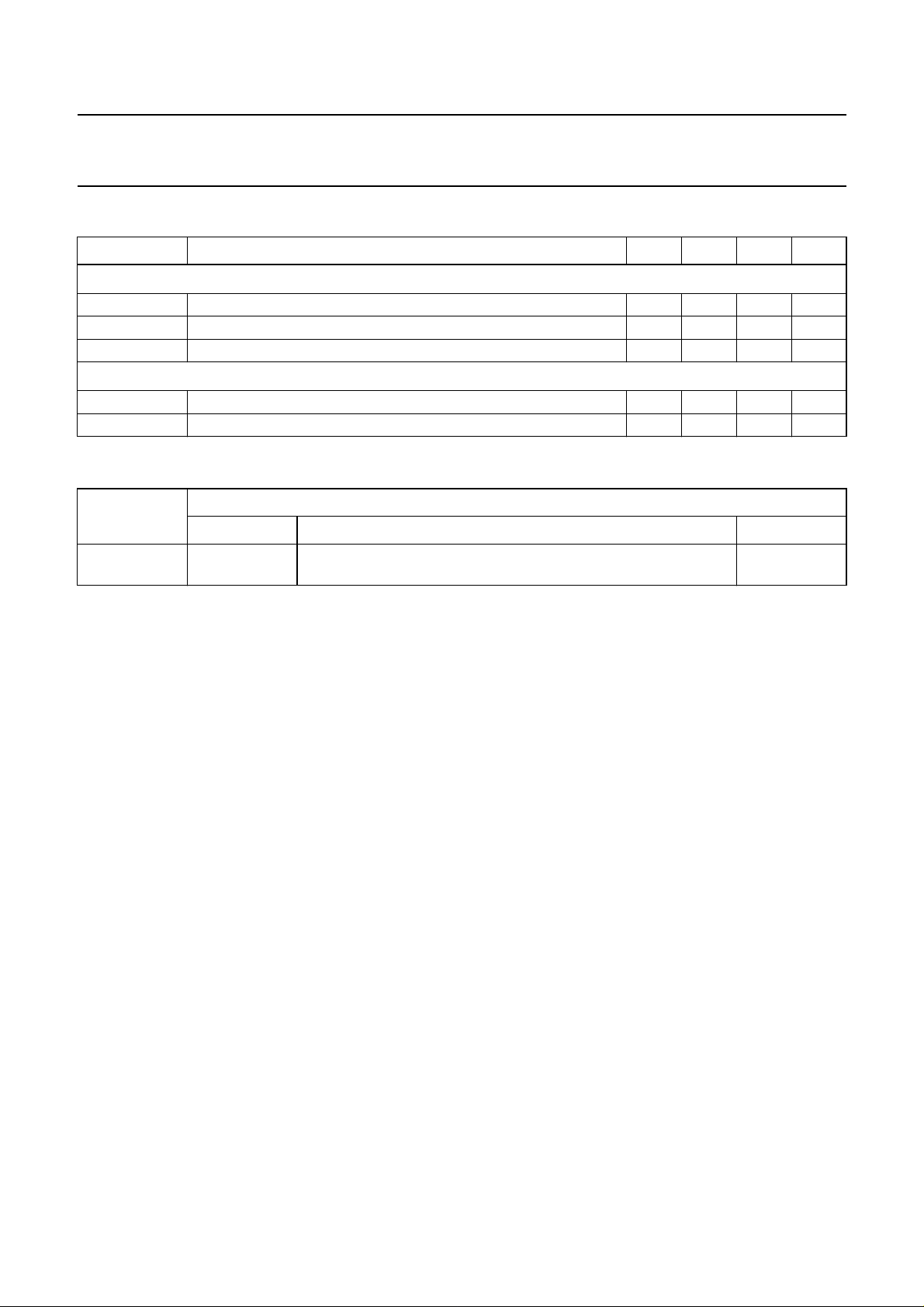

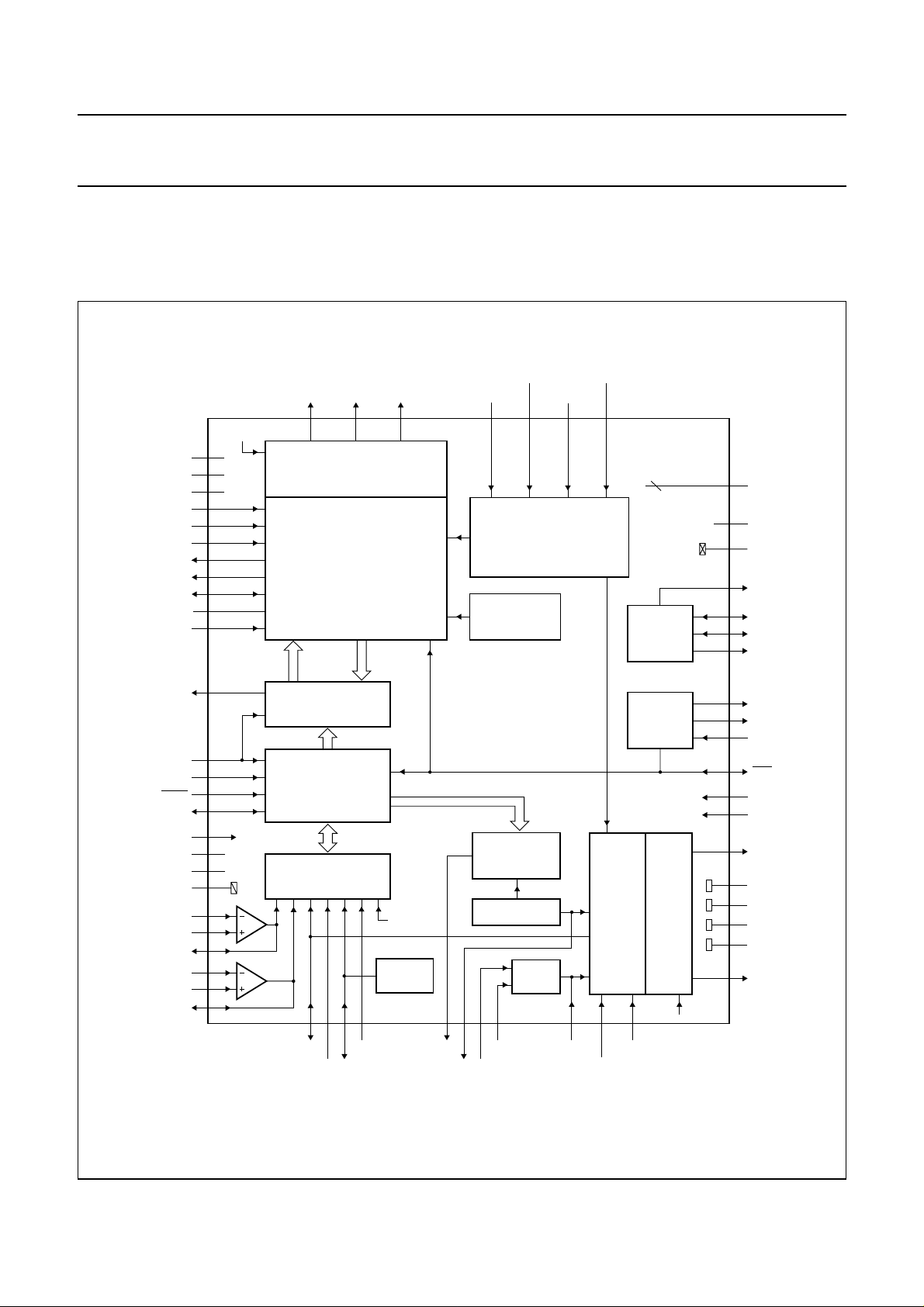

6 BLOCK DIAGRAMS

7 PINNING

8 FUNCTIONAL DESCRIPTION

8.1 Serial interface

8.2 Commutation and sleep mode

8.3 Commutation control

8.3.1 Blanks, Watchdog and Start-up delays

8.3.2 Comdelim delay

8.4 10-bit ADC with 7 analog inputs

8.4.1 Input channels

8.4.2 Input ranges

8.4.3 Conversion modes

8.4.4 Programming register#0

8.4.5 Converter clock frequency values

8.5 10-bit VCM DAC

8.6 Reference voltage

8.7 Stand-alone op-amps

8.8 Analog switch

8.9 Charge pump voltage

8.10 Spindle driver

8.11 VCM driver

8.12 Park the VCM

8.13 Precharge the VCM

8.14 Brake the motor

8.15 Power-on reset

8.16 Thermal monitor and shutdown

8.17 Power supply isolation

8.17.1 External isolation diode

8.17.2 External power FET

8.18 Thermal behaviour

OM5193H

9 LIMITING VALUES

10 HANDLING

11 THERMAL CHARACTERISTICS

12 CHARACTERISTICS

13 APPLICATION INFORMATION

14 PACKAGE OUTLINE

15 SOLDERING

15.1 Introduction

15.2 Reflow soldering

15.3 Wave soldering

15.4 Repairing soldered joints

16 DEFINITIONS

17 LIFE SUPPORT APPLICATIONS

1998 Nov 02 2

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

1 FEATURES

1.1 Servo control

• 10-bit VCM Digital-to-Analog Converter (DAC)

• 7-channel 10-bit Analog-to-Digital Converter (ADC)

• Programmable spindle commutation control logic

• 3-wire serial interface

• Two stand-alone operational amplifiers (op-amps) with

outputs connected to the ADC

• Analog multiplexer with two inputs used to select VCM

seek mode or track-following mode.

1.2 Motor control

1.2.1 S

• 3-phase output motor driver

• 1.9 A maximum available start-up current

• Total R

• Back ElectroMotive Force (BEMF) processing for

sensorless motor commutation

• Linear current control

• External current sense resistor

• External current control loop compensation

• Adjustable slew rate control

• Short-circuit brake

• Adjustable brake-after-park delay time.

1.2.2 V

• 1.5 A maximum current capability

• Total R

• Linear class AB output with low cross-over distortion

delay

• Precision current control loop with external current

sense resistor

• Programmable seek and track-following mode with

adjustable current loop gain

• External current control loop compensation

• Precharge during brake mode

• 20 kHz current control loop bandwidth

• Parking function

• Adjustable park voltage with limiter.

PINDLE MOTOR DRIVER

= 0.6 Ω (typical) at 25 °C

ds(on)

OICE COIL MOTOR DRIVER

= 0.8 Ω (typical) at 25 °C

ds(on)

OM5193H

1.3 Miscellaneous items

• Precision low voltage 5 and 12 V power monitor with

hysteresis

• Precision internal voltage reference for servo and power

control circuits

• Thermal sense circuit with over-temperature shutdown

sensor

• Internal charge pump voltage generator

• Automatic brake-after-park at power-down, thermal

shutdown or sleep mode

• Sleep mode: low power consumption mode.

2 APPLICATIONS

• 12 V hard disk drive products.

3 GENERAL DESCRIPTION

3.1 Overview

The OM5193H is a combination of a voice coil motor and

a spindle motor driver with embedded servo controller

designed for use in disk drives. Configuration and control

registers are set via a 3-wire serial port running up to

30 MHz to interface commonly to a microcontroller or a

digital signal processor.

The device operates at 5 and 12 V power supplies and

integrates safety functions such as power stages

overvoltage protection, power and temperature monitor,

over-temperature shutdown and dynamic

brake-after-park.

The device is contained in a QFP80 package with 18 pins

connected to the leadframe thus providing low thermal

resistance.

3.2 Servo controller

The servo controller includes the following circuits:

• 3-wire serial interface

• Spindle commutation logic

• A 10-bit ADC with 7 inputs selected by an internal

multiplexer

• A 10-bit VCM DAC with 1.5, 2.5 and 3.5 V voltage

references

• Two low-offset stand-alone op-amps

• Analog multiplexer with 2 inputs.

1998 Nov 02 3

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

The serial interface is used:

• To adjust the timing parameters for proper spindle

commutation sequence

• To accurately adjust head positioning via the 10-bit VCM

DAC

• To set VCM seek or track-following mode via the

low-impedance switch

• To select and process analog signals via a 7-channel

multiplexer connected to the 10-bit ADC.

The spindle commutation logic circuit ensures proper

spindle start-up (no reverse rotation) and commutation

sequence for the spindle driver by processing BEMF

sensing circuit output signals.

The two stand-alone op-amps, with the inputs connected

to the read channel IC, provide servo track signals

processed by the microcontroller to perform accurate

track-following mode.

3.3 Spindle and voice coil motor

OM5193H

3.4 Safety functions

The OM5193H is protected against transient voltage

spikes that are generated by the inductive loads of spindle

and VCM.

Power supplies and temperature are monitored in order to

guarantee data reliability and self-protection of the device

in case of power loss or temperatures beyond maximum

rating.

Park and brake functions secure heads and disk media in

case of power-down or high temperature failure. This

function is also activated by the sleep mode.

An internal temperature monitor is available to monitor the

chip temperature and thus prevents over-temperature

shutdown. Internally connected to the ADC channel 4, it

can be used by the microcontroller as an early

‘temperature-too-high’ warning during a long VCM seek

sequence.

The OM5193H drives a 3-phase brushless, sensorless DC

spindle motor and a voice coil motor.

Spindle and voice coil motor power stages with low R

and high current capability are suitable for mid-end and

low-end 12 V disk drives. Power stages are designed in

such a way that external Schottky diodes are not needed.

Spindle current is sensed by an external resistor and

monitored by the external signal SPCC (SPindle Current

Control). Spindle speed is regulated by the microcontroller

via the ZCROSS signal (Zero CROSSing detection

frequency output). BEMF comparators provide the digital

zero crossing signals. These are processed by the

commutation logic circuit to properly switch-on and

switch-off spindle power drivers thus ensuring the rotation

of the motor.

The control of the heads positioning is accomplished by

the internal 10-bit VCM DAC. Seek and track-following

VCM current loop gain is set by external resistors. VCM

zero current is referenced to the 2.5 V internal voltage

reference.

An internal precharge of the actuator (magnetic latch)

during brake mode guarantees total control of the current

when VCM starts running without current spikes.

ds(on)

1998 Nov 02 4

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

4 QUICK REFERENCE DATA

SYMBOL PARAMETER MIN. TYP. MAX. UNIT

Supply voltage

V

DDA1

V

DDD

V

DDA2

Drivers

I

SPOUT

I

VCMRUN

5 ORDERING INFORMATION

TYPE

NUMBER

OM5193H QFP80 plastic quad flat package; 80 leads (lead length 1.95 mm);

5 V analog supply voltage 4.5 5.0 5.5 V

5 V digital supply voltage 4.5 5.0 5.5 V

12 V analog supply voltage 10.8 12.0 13.2 V

spindle start-up current −−1.9 A

VCM current −−1.5 A

PACKAGE

NAME DESCRIPTION VERSION

SOT318-2

body 14 × 20 × 2.8 mm

1998 Nov 02 5

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

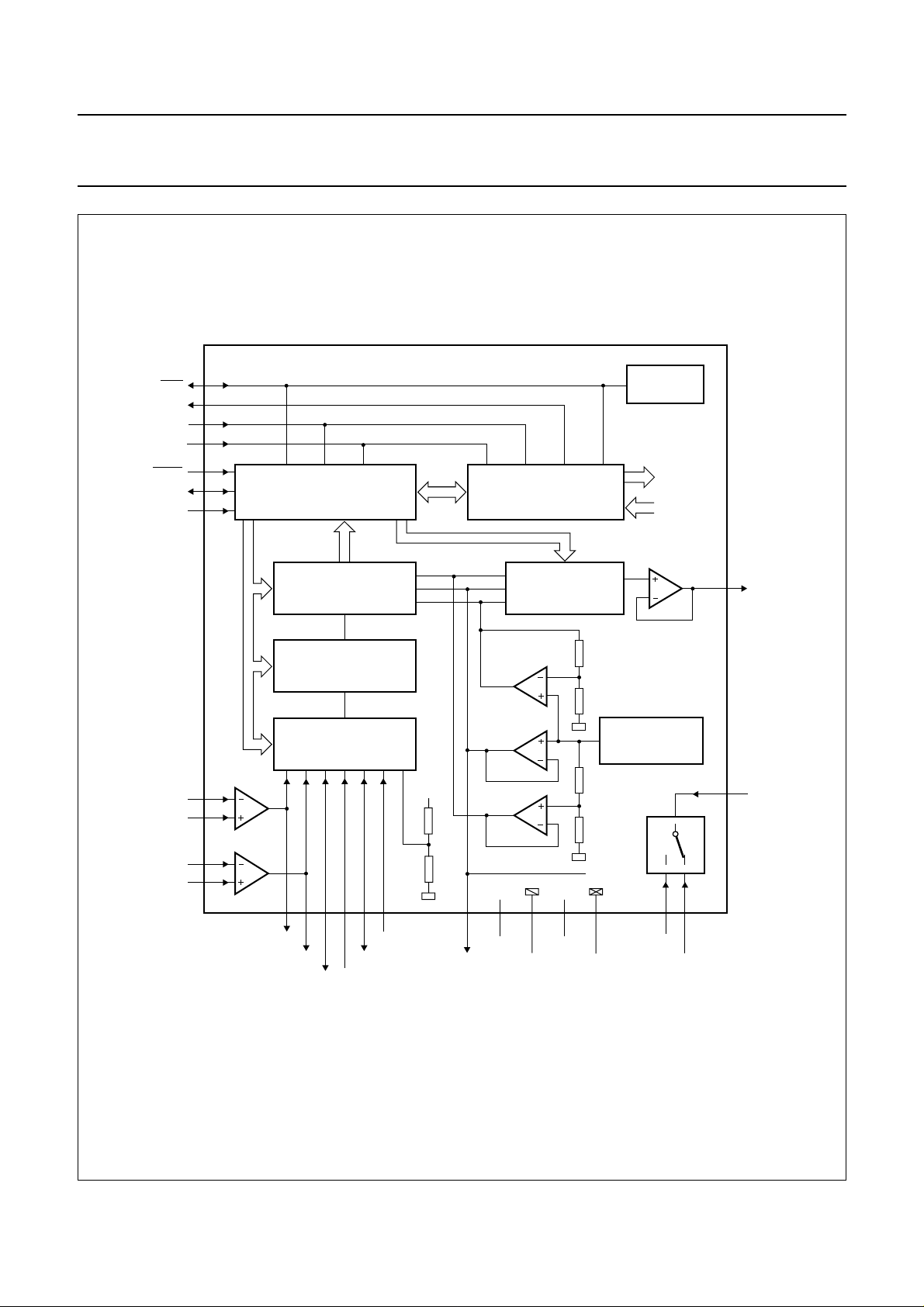

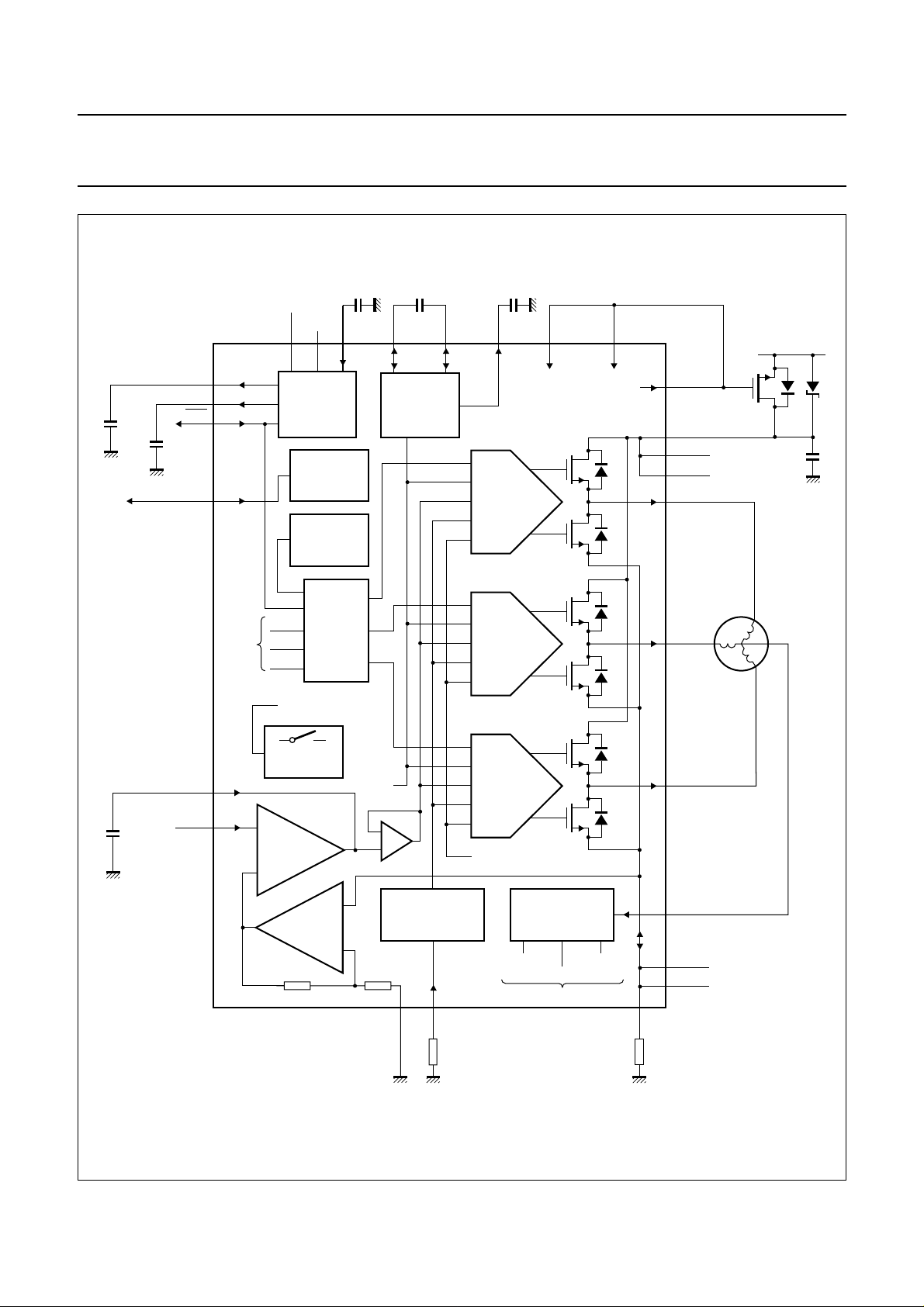

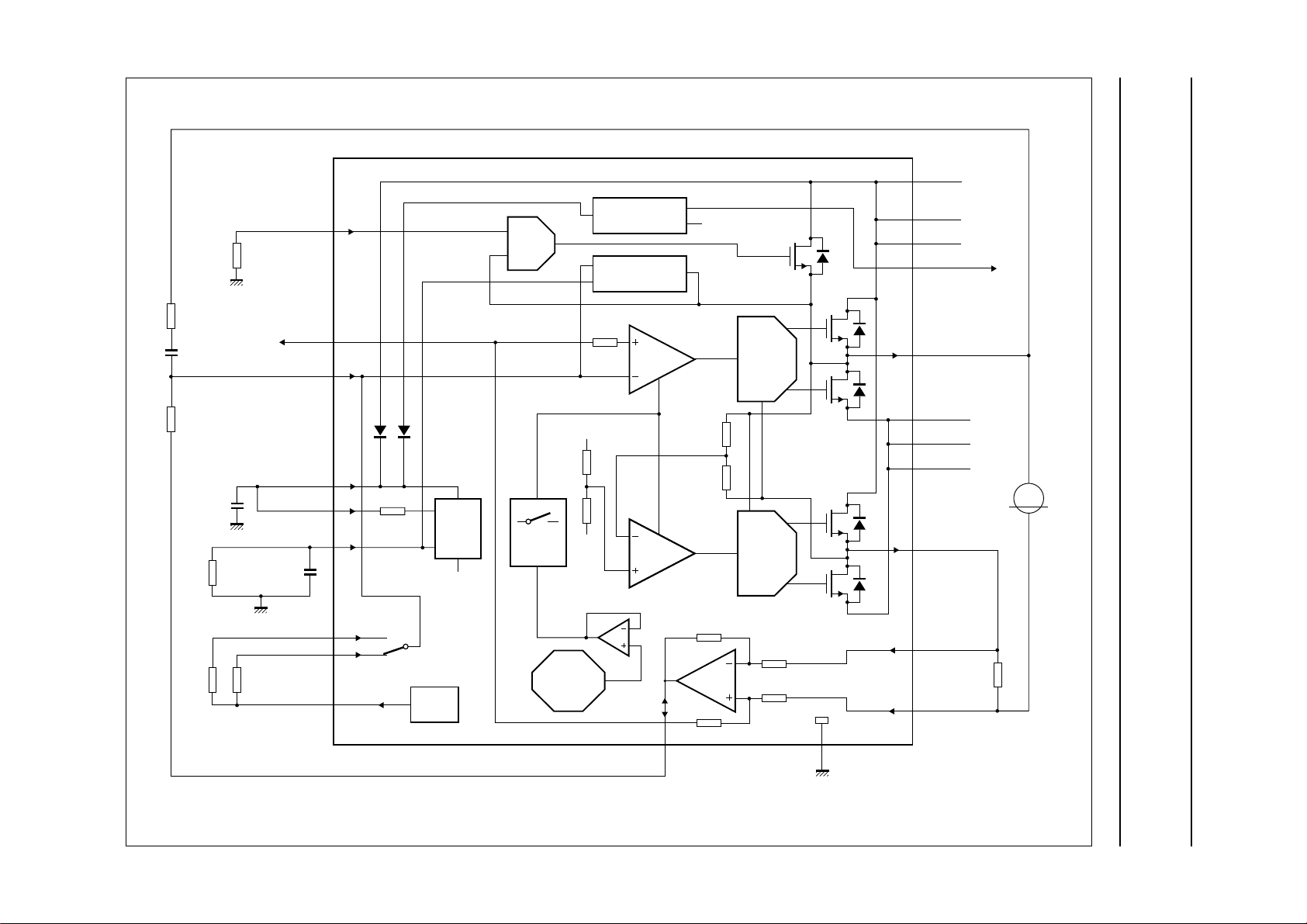

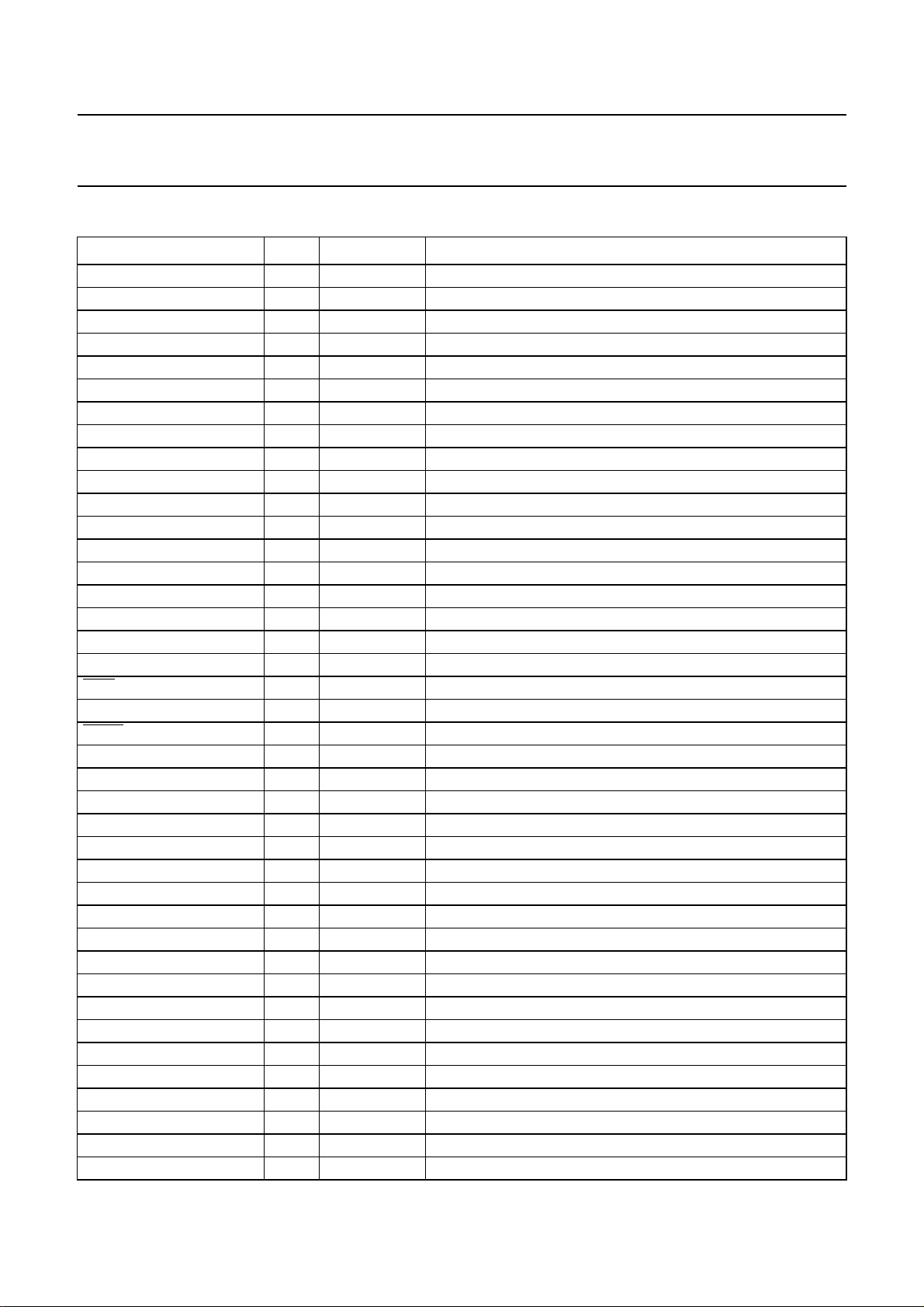

6 BLOCK DIAGRAMS

Figures 1, 2, 3 and 4 provide block diagrams of the OM5193H servo and motor control (top level diagram, servo

controller, spindle motor driver and voice coil motor driver).

handbook, full pagewidth

CLAMP1

CLAMP2

CLAMP3

SLEW

SPCCOUT

SPCC

MOTSENSE3

MOTSENSE2

MOTSENSE1/

SPSENSEH

GNDS/SPSENSEL

ZCROSS

CLOCK

SCLOCK

SDEN

SDATA

SCANTEST

V

DDA1

V

DDA2

AGND

INTINN

INTIN

ADC[0]/INTOUT

PESAMPN

PESAMP

ADC[1]/DIFOUT

CT

10

55

56

12

14

13

73

76

2

11

9

25

24

23

21

22

26

44

15

39

37

38

28

35

36

29

CLAMP

A2

A1

MOTA

72

SPINDLE

CONTROL

COMA

COMB

COMC

COMMUTATION

LOGIC

SERIAL

INTERFACE

7-CHANNEL

10-BIT ADC

0 1 2 3 4 5 6

30 31 32 33 34 40 42 41 43 53 52

ADC[2]/SOUT

ADC[3]

MOTB

74

POWER

STAGE

ACROSS

BCROSS

CCROSS

THERMAL

MONITOR

ADC[5]

ADC[4]/TEMP

BRAKEDELAY

MOTC

BRAKEPOWER

3 48 50 49 51

PARK AND BRAKE

THERMAL

SHUTDOWN

OM5193H

10-BIT

VCM DAC

0.5V

DDA1

DACOUT

REF2V5

BANDGAP

VCM

SWITCH

SEEKSELECT

TRACKFWSELECT

PARKVOLT

BRAKEADJH

VCMIN

VCMSENSEL

VCM

CONTROL

VCMSENSEH

1, 4 to 7,

58 to 61, 64 to 67,

70, 75, 78 to 80

18

CHARGE

PUMP

POWER-ON

RESET

POWER

STAGE

CLAMP

20

27

16

17

18

46

47

45

19

57

77

69

71

68

63

54

62

MGM972

8

HEATSINK

V

DDD

DGND

SWITCHGATE

BSTCP1

BSTCP2

CAPY

CHK5

CHK12

CPOR

POR

PWRBIAS1

PWRBIAS2

NIVCM

GNDVCM1

GNDVCM2

GNDVCM3

GNDV

IVCM

Fig.1 Block diagram, top level.

1998 Nov 02 6

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

handbook, full pagewidth

POR

ZCROSS

CLOCK

SCANTEST

SDEN

SDATA

SCLOCK

19

25

24

26

21

22

23

SERIAL INTERFACE COMMUTATION LOGIC

10-BIT ADC

10-BIT VCM DAC

POWER-ON

RESET

COMA

COMB

COMC

ACROSS

BCROSS

CCROSS

OM5193H

34

DACOUT

INTINN

INTIN

PESAMPN

PESAMP

37

A2

38

35

A1

36

ADC[0]/INTOUT

ADC[1]/DIFOUT

ADC[2]/SOUT

RANGE

ADAPTER

INPUT

MULTIPLEXER

30 31 32 33

29

28

ADC[5]

ADC[4]/TEMP

ADC[3]

V

DDA1

V

ref3V5

V

ref2V5

V

ref1V5

V

ref2V5

40 39

V

REF2V5

44

DDA1

AGND DGND

V

20

DDD

OM5193H

2.5 V BANDGAP

VCM switch

for VCM

27

SEEKSELECT

TRACKFWSELECT

VCMIN

414342

MGM973

Fig.2 Block diagram, servo controller.

1998 Nov 02 7

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

handbook, full pagewidth

C

CHK5

C

CHK12

POR

V

DDA1

46CHK5

47CHK12

19

32ADC[4]/TEMP

POWER-ON

C

CPOR

V

DDA2

CPOR BSTCP1 BSTCP2 CAPY PWRBIAS1 PWRBIAS2

44 15 45 16

RESET

THERMAL

MONITOR

THERMAL

SHUTDOWN

C

CAPX

CHARGE

PUMP

C

CAPY

17 18 7757

OM5193H

PREDRIVER

8

SWITCH GATE

10

CLAMP1

55

CLAMP2

56

CLAMP3

72

MOTA

OM5193H

V

DDA2POWER

C

SPCCOUT

SPCCOUT

SPCC

from

commu-

tation

logic

14

13

COMA

COMB

COMC

V

(from VCM)

ref

SPINDLE

SWITCH

CONTROL

AMPLIFIER

SENSE

AMPLIFIER

GNDS/SPSENSEL

DECODER

V

CAPY

SLOPE

CURRENT

CONTROL

1211

SLEW

R

SLEW

PREDRIVER

PREDRIVER

I

(from VCM)

brake

COMPARATOR

ACROSS

to commutation logic

BEMF

BCROSS

MOTSENSE1/

CCROSS

SPSENSEH

74

MOTB

3

MOTC

9

CT

MOTSENSE2

76

MOTSENSE3

73

2

R

SPSENSE

MGM974

Fig.3 Block diagram, spindle motor driver.

1998 Nov 02 8

This text is here in white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here in

a

_white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader.This text is here inThis text is here in

white to force landscape pages to be rotated correctly when browsing through the pdf in the Acrobat reader. white to force landscape pages to be ...

1998 Nov 02 9

VCMIN

51

PARK

40

43

48

49

BRAKE

50

AFTER

PARK

I

brake

(to spindle)

SWITCH

V

(to spindle)

ref

R

VCMCOMPRC

C

VCMCOMPRC

R

FEEDBACK

C

BRAKEP

R

R

PARKVOLT

BRAKEPOWER

BRAKEDELAY

BRAKED

C

BRAKED

PARKVOLT

REF2V5

BRAKEADJH

ndbook, full pagewidth

POWER-DOWN

PRECHARGE

12 V

GND

ERROR

ERROR

ERROR

master

slave

V

CAPY

PRE

DRIVER

PRE

DRIVER

OM5193H

10

CLAMP1

55

CLAMP2

56

CLAMP3

8

SWITCHGATE

62

IVCM

71

GNDVCM1

68

GNDVCM2

63

GNDVCM3

69

NIVCM

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

M

TRACKFWSELECT

R

VCMTRACKFW

SEEKSELECT

R

VCMSEEK

DACOUT

42

41

34

VCM switch

BANDGAP

VCM

DAC

Fig.4 Block diagram, voice coil motor driver.

SENSE

30

ADC[2]/SOUT GNDV

54

53

VCMSENSEL

R

52

VCMSENSEH

VCMSENSE

MGM975

OM5193H

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

7 PINNING

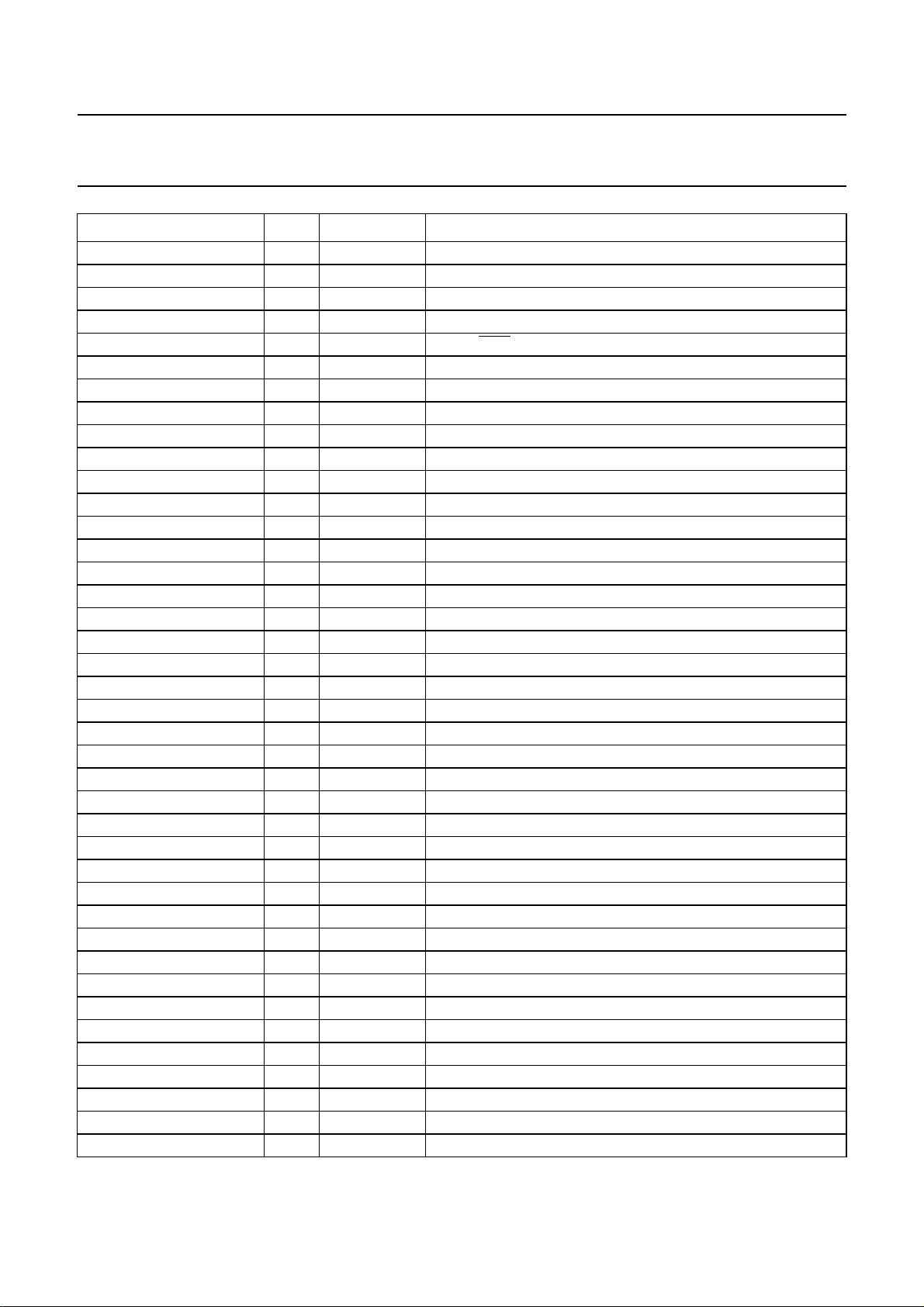

SYMBOL PIN I/O DESCRIPTION

HEATSINK 1 − dissipation pin; internally connected to the leadframe

MOTSENSE1/SPSENSEH 2 analog I/O sense line of the spindle/spindle sense amplifier input

MOTC 3 analog output spindle motor power output

HEATSINK 4 − dissipation pin; internally connected to the leadframe

HEATSINK 5 − dissipation pin; internally connected to the leadframe

HEATSINK 6 − dissipation pin; internally connected to the leadframe

HEATSINK 7 − dissipation pin; internally connected to the leadframe

SWITCHGATE 8 analog output isolation FET driver

CT 9 analog input centre tap of the spindle

CLAMP1 10 supply power stage supply voltage

GNDS/SPSENSEL 11 ground spindle ground connection/spindle sense amplifier ground

SLEW 12 analog input spindle motor slope control

SPCC 13 analog input spindle current control

SPCCOUT 14 analog input compensation point of the spindle current control loop

V

DDA2

BSTCP1 16 analog I/O booster capacitor 1

BSTCP2 17 analog I/O booster capacitor 2

CAPY 18 analog output DC-to-DC converter output (19 V)

POR 19 digital I/O power-on reset signal; active LOW

V

DDD

SDEN 21 digital input serial interface data enable; active LOW

SDATA 22 digital I/O serial interface data line

SCLOCK 23 digital input serial interface clock line

CLOCK 24 digital input clock input

ZCROSS 25 digital output zero crossing detection signal

SCANTEST 26 digital input scantest mode control; at LOW-level in normal conditions

DGND 27 ground servo digital ground

ADC[0]/INTOUT 28 analog I/O ADC channel 0 input/output of the A2 amplifier

ADC[1]/DIFOUT 29 analog I/O ADC channel 1 input/output of the A1 amplifier

ADC[2]/SOUT 30 analog I/O ADC channel 2 input/VCM sense amplifier output

ADC[3] 31 analog input ADC channel 3 input

ADC[4]/TEMP 32 analog I/O ADC channel 4 input/temperature monitor, thermal shutdown

ADC[5] 33 analog input ADC channel 5 input

DACOUT 34 analog output 10-bit VCM DAC output

PESAMPN 35 analog input inverting input of the A1 amplifier.

PESAMP 36 analog input non-inverting input of the A1 amplifier

INTINN 37 analog input inverting input of the A2 amplifier

INTIN 38 analog input non-inverting input of the A2 amplifier

AGND 39 ground servo analog ground

REF2V5 40 analog output 2.5 V bandgap reference voltage

15 supply 12 V analog supply voltage

20 supply 5 V digital supply voltage

1998 Nov 02 10

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

SYMBOL PIN I/O DESCRIPTION

SEEKSELECT 41 analog input input for the seek mode

TRACKFWSELECT 42 analog input input for the track-following mode

VCMIN 43 analog input VCM control input

V

DDA1

CPOR 45 analog input set the

CHK5 46 analog output set the V

CHK12 47 analog output set the V

BRAKEPOWER 48 analog input brake power capacitor

BRAKEADJH 49 analog input adjust current consumption during park mode

BRAKEDELAY 50 analog input set the brake-after-park delay time

PARKVOLT 51 analog input set the park voltage

VCMSENSEH 52 analog input positive input of the VCM sense amplifier

VCMSENSEL 53 analog input negative input of the VCM sense amplifier

GNDV 54 ground VCM ground connection

CLAMP2 55 supply power stage supply voltage

CLAMP3 56 supply power stage supply voltage

PWRBIAS1 57 analog input power stages isolation bias; externally connected to the clamp

HEATSINK 58 − dissipation pin; internally connected to the leadframe

HEATSINK 59 − dissipation pin; internally connected to the leadframe

HEATSINK 60 − dissipation pin; internally connected to the leadframe

HEATSINK 61 − dissipation pin; internally connected to the leadframe

IVCM 62 analog output inverted output of the VCM (master stage)

GNDVCM3 63 ground VCM power stage ground

HEATSINK 64 − dissipation pin; internally connected to the leadframe

HEATSINK 65 − dissipation pin; internally connected to the leadframe

HEATSINK 66 − dissipation pin; internally connected to the leadframe

HEATSINK 67 − dissipation pin; internally connected to the leadframe

GNDVCM2 68 ground VCM power stage ground

NIVCM 69 analog output non-inverted VCM output (slave stage)

HEATSINK 70 − dissipation pin; internally connected to the leadframe

GNDVCM1 71 ground VCM power stage ground

MOTA 72 analog output spindle motor power output

MOTSENSE3 73 analog output sense line of the spindle

MOTB 74 analog output spindle motor power output

HEATSINK 75 − dissipation pin; internally connected to the leadframe

MOTSENSE2 76 analog output sense line of the spindle

PWRBIAS2 77 analog input power stages isolation bias; externally connected to the clamp

HEATSINK 78 − dissipation pin; internally connected to the leadframe

HEATSINK 79 − dissipation pin; internally connected to the leadframe

HEATSINK 80 − dissipation pin; internally connected to the leadframe

44 supply 5 V analog supply voltage

POR delay time

POR threshold

DDA1

POR threshold

DDA2

1998 Nov 02 11

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

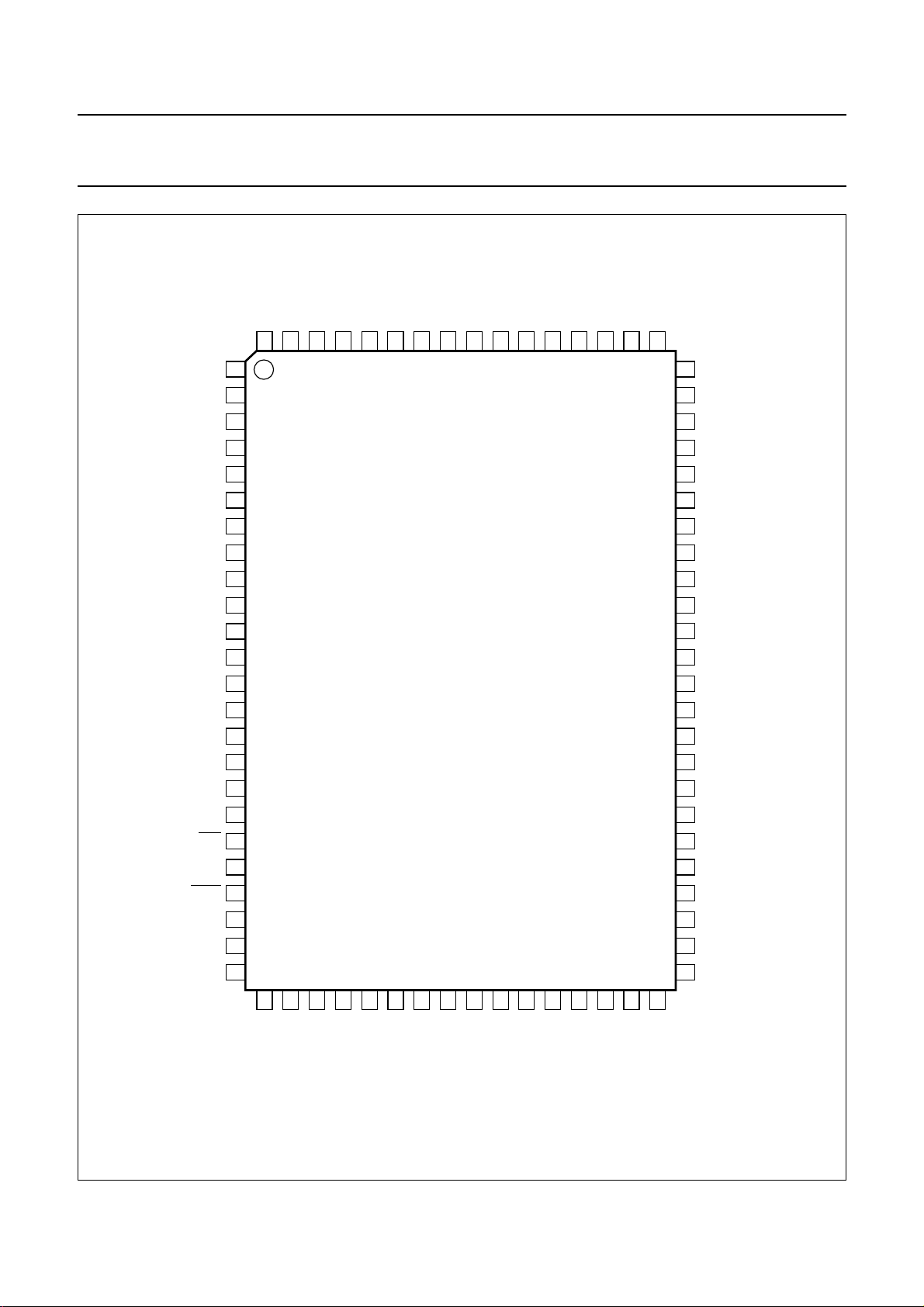

handbook, full pagewidth

PWRBIAS2

HEATSINK

78

77

HEATSINK

MOTSENSE1/

SPSENSEH

MOTC

HEATSINK

HEATSINK

HEATSINK

HEATSINK

SWITCHGATE

CT

CLAMP1

GNDS/SPSENSEL

SLEW

SPCC

SPCCOUT

V

DDA2

BSTCP1

BSTCP2

CAPY

POR

V

DDD

SDEN

SDATA

SCLOCK

CLOCK

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

1

2

3

4

5

6

7

8

9

HEATSINK

HEATSINK

80

79

MOTSENSE2

HEATSINK

MOTB

76

75

74

MOTSENSE3

73

OM5193H

MOTA

72

GNDVCM1

HEATSINK

71

70

NIVCM

69

GNDVCM2

HEATSINK

68

67

HEATSINK

HEATSINK

66

65

OM5193H

HEATSINK

64

GNDVCM3

63

IVCM

62

HEATSINK

61

HEATSINK

60

HEATSINK

59

HEATSINK

58

PWRBIAS1

57

CLAMP3

56

CLAMP2

55

GNDV

54

VCMSENSEL

53

VCMSENSEH

52

PARKVOLT

51

BRAKEDELAY

50

BRAKEADJH

49

BRAKEPOWER

48

CHK12

47

CHK5

46

CPOR

45

V

44

DDA1

VCMIN

43

TRACKFWSELECT

42

SEEKSELECT

41

25

26

27

28

29

30

31

32

ZCROSS

SCANTEST

DGND

ADC[0]/INTOUT

ADC[1]/DIFOUT

ADC[3]

ADC[2]/SOUT

ADC[4]/TEMP

Fig.5 Pin configuration.

1998 Nov 02 12

33

ADC[5]

34

35

DACOUT

PESAMPN

36

37

INTINN

PESAMP

38

INTIN

39

AGND

40

MGM976

REF2V5

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

8 FUNCTIONAL DESCRIPTION

8.1 Serial interface

The serial interface is a 3-wire bidirectional port for writing

and reading data to and from the internal registers of the

OM5193H. Each read or write will be composed of 16 bits.

For data transfer

presented at the SDATA pin, and a serial clock is applied

to the SCLOCK pin. After the SDEN pin goes LOW, the

first 16 pulses applied to the SCLOCK pin shift the data

presented at the SDATA pin into an internal shift register

on the rising edge of each clock pulse. An internal counter

prevents more than 16 bits from being shifted into the

register. The data in the shift register is latched when

SDEN goes HIGH. If less than 16 clock pulses are

provided before SDEN goes HIGH, the data transfer is

aborted.

All transfers are shifted into the serial port with the MSB

first. The first 4 bits of the transfer contain address and

instruction information. The MSB is the R/W bit which

SDEN is brought LOW, serial data is

OM5193H

determines if the transfer is a read (logic 1) or a

write (logic 0).

The remaining 3 bits determine the internal register to be

accessed. The other 12 bits contain the programming

data. In the read mode (R/

the register contents of the selected address. In the write

mode (R/W = 0), the OM5193H loads the selected register

with the data presented on the SDATA pin. During sleep

mode, the serial port remains active and register

programmed data is retained.

SCLOCK is driven by the microcontroller. When the

microcontroller drives the SDATA line, the data is valid on

the rising edge of SCLOCK. When the OM5193H is driving

the SDATA line (in read mode after the R/W bit and 3 bits)

the data is valid on the falling edge of SCLOCK.

SDEN marks the end of the serial transfer. When the

SDEN pin goes HIGH, the shift register data is latched into

the addressed register of the OM5193H.

W = 1), the OM5193H outputs

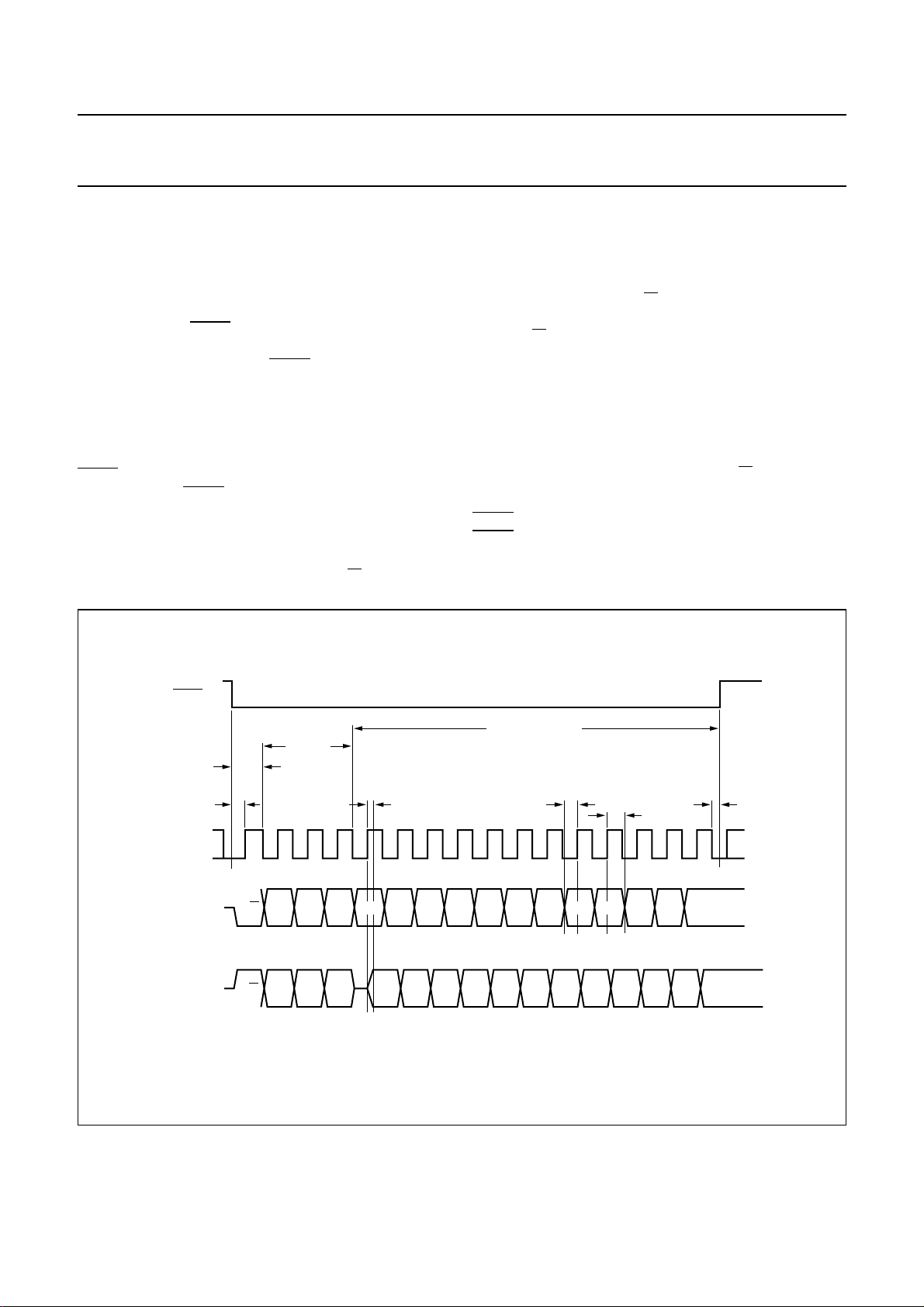

handbook, full pagewidth

SDEN

SCLOCK

SDATA

Write to the OM5193H

SDATA

Write to, then read from the OM5193H

send/receive data

address

direction

325476981110 1312 14 1615 1

t

st

R/W

R/W

A1A2 D11A0 D9D10 D7D8 D5D6 D3D4 D2 D0D1

write registers read back data

A1A2 D11A0 D9D10 D7D8 D5D6 D3D4 D2 D0D1

t

ren

t

su

t

hd

t

ex

MGM977

Fig.6 Serial port timing information.

1998 Nov 02 13

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

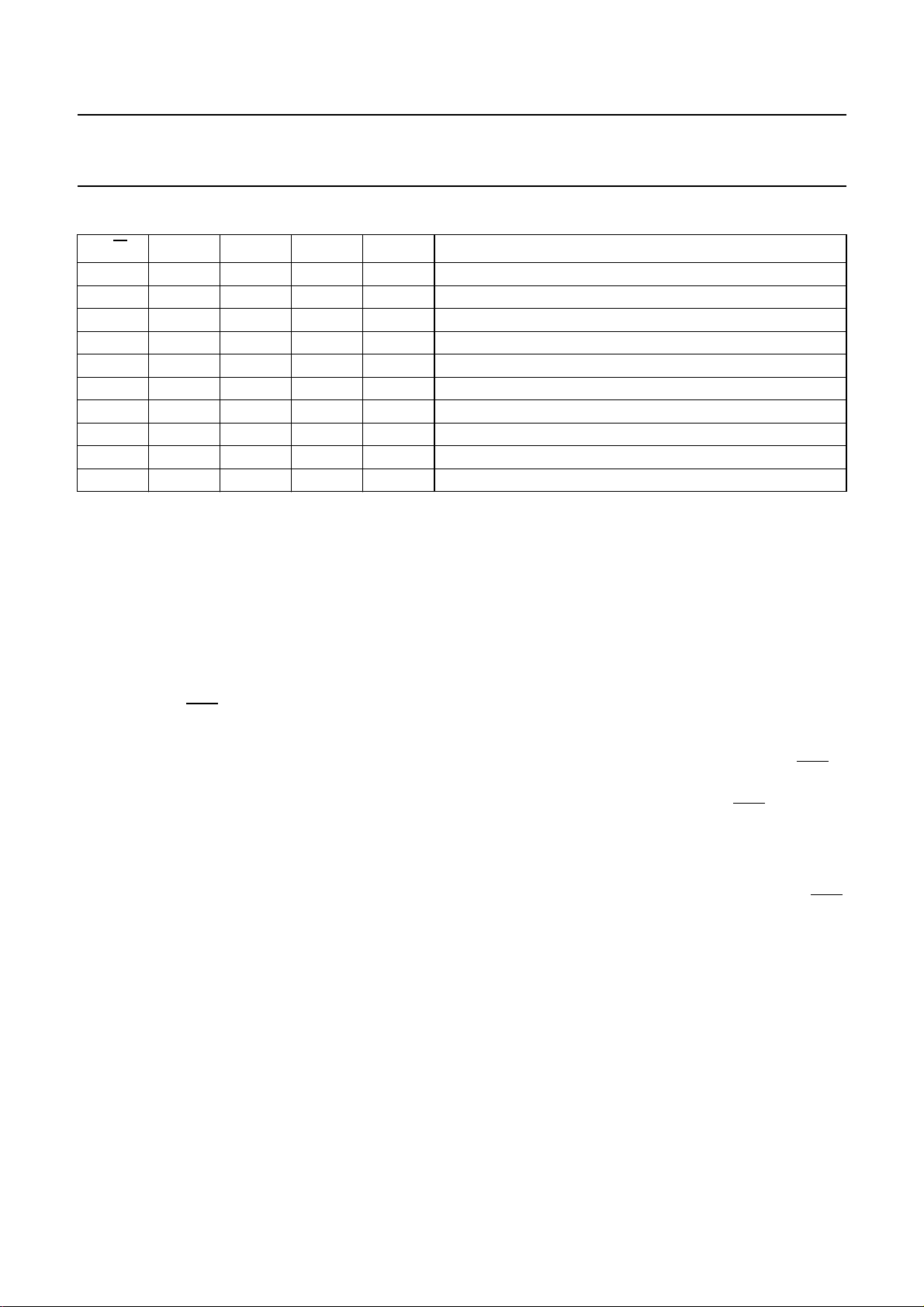

Table 1 Timing information for the serial interface

SYMBOL PARAMETER MIN. MAX. UNIT

f

clk

t

st

t

su

t

hd

t

rd

t

ren

t

rhd

t

rsu

t

exW

t

exR

T

bpa

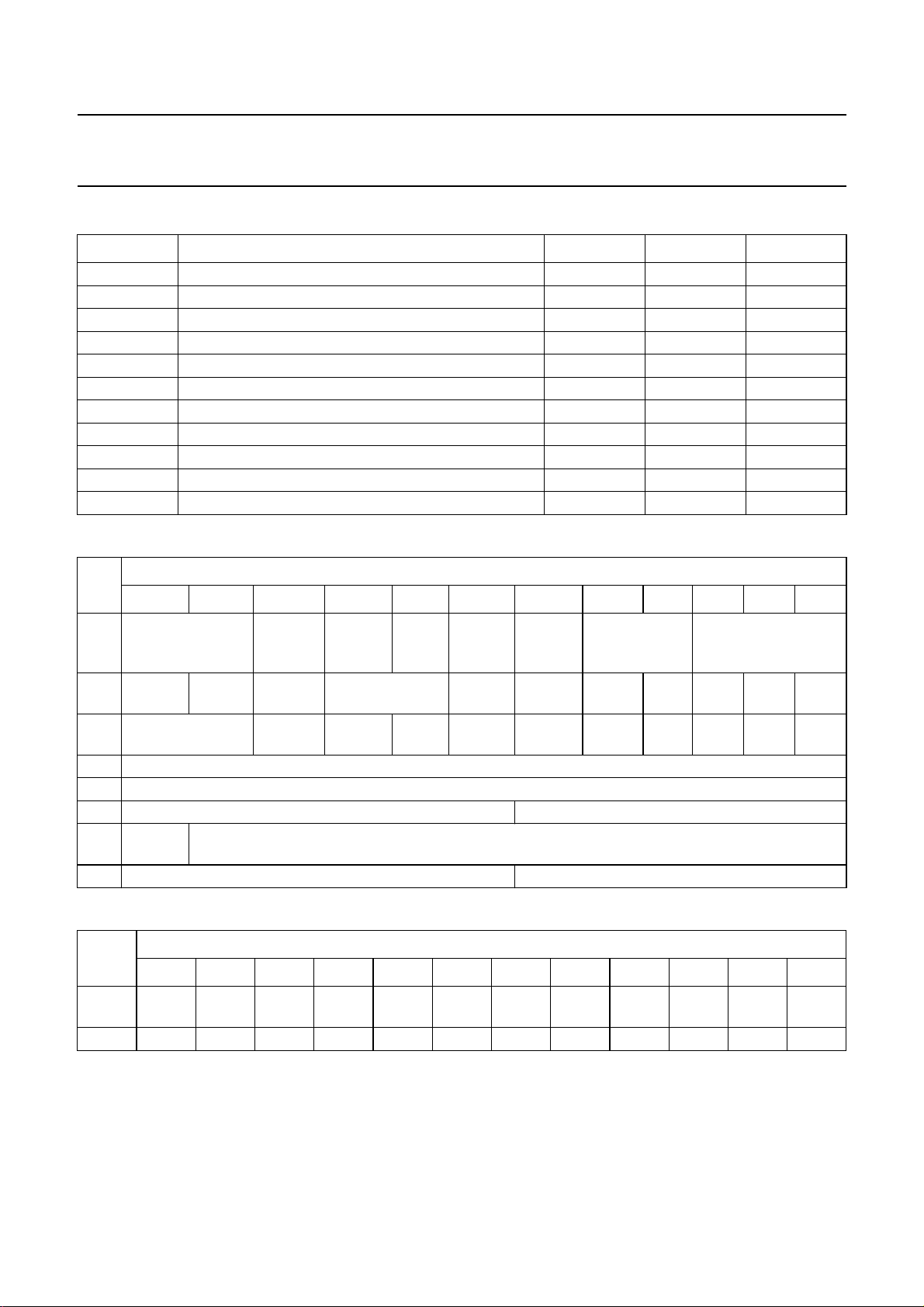

Table 2 Writeable registers of the serial interface

REG

0 not used

1 reverse

break

2 not used

3 not used

4 not used

5 Watchdog Blank 1

6 high

Clock_N

7 Start-up Blank 2

clock frequency − 30 MHz

chip select to first active clock edge

1

⁄2T

clk

− ns

data to clock set-up time 12 − ns

clock to data hold time 12 − ns

time data line is driven after 5th negative clock − 5ns

time from positive clock for data line to be driven 0 − ns

receive data hold time 0 − ns

receive data set-up time 12 − ns

last active clock to chip select; inactive on write 0 − ns

last active clock to chip select; inactive on read 10 − ns

time between successive serial port accesses 5 − clock cycles

BITS

11 10 9 8 7 6 5 4 3210

auto

Conv.

select

range

Select

test

Mode_N

not used ADC MUX address

not used sleep_N spindiv manual

DAC

(7)

DAC

(6)

DAC

(5)

DAC

(4)

run/

comC comB comA

stop

DAC

(3)

DAC

(2)

DAC

(1)

not

used

opamp

Select_N

seek/

trackfw

DAC

(9)

increm.

Channel

DAC

(8)

Comdelim

DAC

(0)

Table 3 Readable registers of the serial interface

BITS

REG

11109876543210

0 ADC

status

ADC

(9)

ADC

(8)

ADC

(7)

ADC

(6)

ADC

(5)

ADC

(4)

ADC

(3)

ADC

(2)

ADC

(1)

1 Ccross Bcross Across

1998 Nov 02 14

ADC

(0)

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

Table 4 Address of registers

R/W A2 A1 A0 REG. DESCRIPTION

00000ADC channel and programmable options

10000ADC status and value

00011commutation, sleep, and VCM switch controls

10011commutation state in manual mode

0010210-bit DAC

00113not used

01004not used

01015Blank 1 and Watchdog delays

01106commutation delay limit (11 bits), internal clock divider factor

01117Start-up and Blank 2 delays

8.2 Commutation and sleep mode

Spindle control and sleep mode are controlled by writing or

reading on register#1.

• Register#1 (0, 1 and 2) control the spindle

commutations in manual mode when run/stop, manual

and sleep bits are correctly set. The commutation

sequence is described in Section “Spindle driver” (see

also Table 16 and Fig.12).

• Register#1 (3) is the run/stop bit. After the power is

turned on and POR is HIGH, the motor will not start

spinning until register#1 (3) has been set to logic 1.

The motor stops spinning when this bit is set to logic 0.

• Register#1 (4) is the manual commutation mode bit.

When this bit is set to logic 1 and register#1 (3) set to

logic 1, the commutation logic in the OM5193H will be

disabled so that the spindle will not automatically go to

the next commutation.

When register#1 (3 and 4) are set to logic 1, the

microcontroller is expected to generate the different

commutation states for the motor. The OM5193H will

still provide the coil status which will be available by

reading register#1. The different waveforms are shown

in Section “Spindle driver” (see also Fig.12). Note that

depending on the coil status acquisition moment,

transient states (due to the flyback pulses) can be read.

When register#1 (4) is set to logic 0, the manual mode

is disabled and the OM5193H will automatically

commutate the motor each time a zero crossing is

detected. The time between the zero crossing and the

next commutation is half the time between the two

preceding zero crossings. This is explained in the

detailed description in Section “Commutation control”.

• Register#1 (5) is the spindiv bit. This bit together with

register#6 (11) enables the selection of a divider factor

for both converter clock and spindle clock. Clock

configurations are described in Section “Commutation

control” (see also Table 6).

• Register#1 (6) is the sleep mode bit. When it is set to

logic 0, the OM5193H will enter the low power mode.

Then the commutation control generates (101) output

codes on commutation signals to set spindle and VCM

head into sleep mode. This causes the OM5193H to go

into the brake-after-park mode. The only operating

circuits are the power monitor, the voltage reference

generator, the VCM precharge circuit and the serial

interface. The OM5193H is in sleep mode when

LOW.

When the power is first turned on, the POR signal goes

HIGH after the POR delay. The OM5193H is then

automatically set in sleep mode and thus in low power

consumption mode. The VCM DAC output is in

high-impedance mode, the spindle is in the brake mode

and the VCM is in the precharge mode. Only after POR

is HIGH and register#1 (6) is set to logic 1, OM5193H is

ready to be functional. When register#1 (6) goes HIGH,

the VCM DAC outputs the 2.5 V reference voltage.

• Register#1 (11) is dedicated to brake the spindle motor

without going in ‘brake-after-park’ mode.

The commutation sequence is shifted in order to

efficiently brake the motor. This brake, called reverse

brake, is activated when register#1 (11) bit is set to

logic 1. Note that there is no action on the VCM input

signal when the reverse brake is used. When this bit is

set to logic 0, the spindle motor starts again with normal

spindle commutations.

POR is

1998 Nov 02 15

Philips Semiconductors Product specification

Disk drive spindle and VCM with

OM5193H

servo controller

Reading register#1 will read the state of the 3 coils coming

from the spindle control block (ACROSS, BCROSS and

CCROSS). The 3 input lines will be in bits 0, 1, and 2.

The different waveforms are shown in Section “Spindle

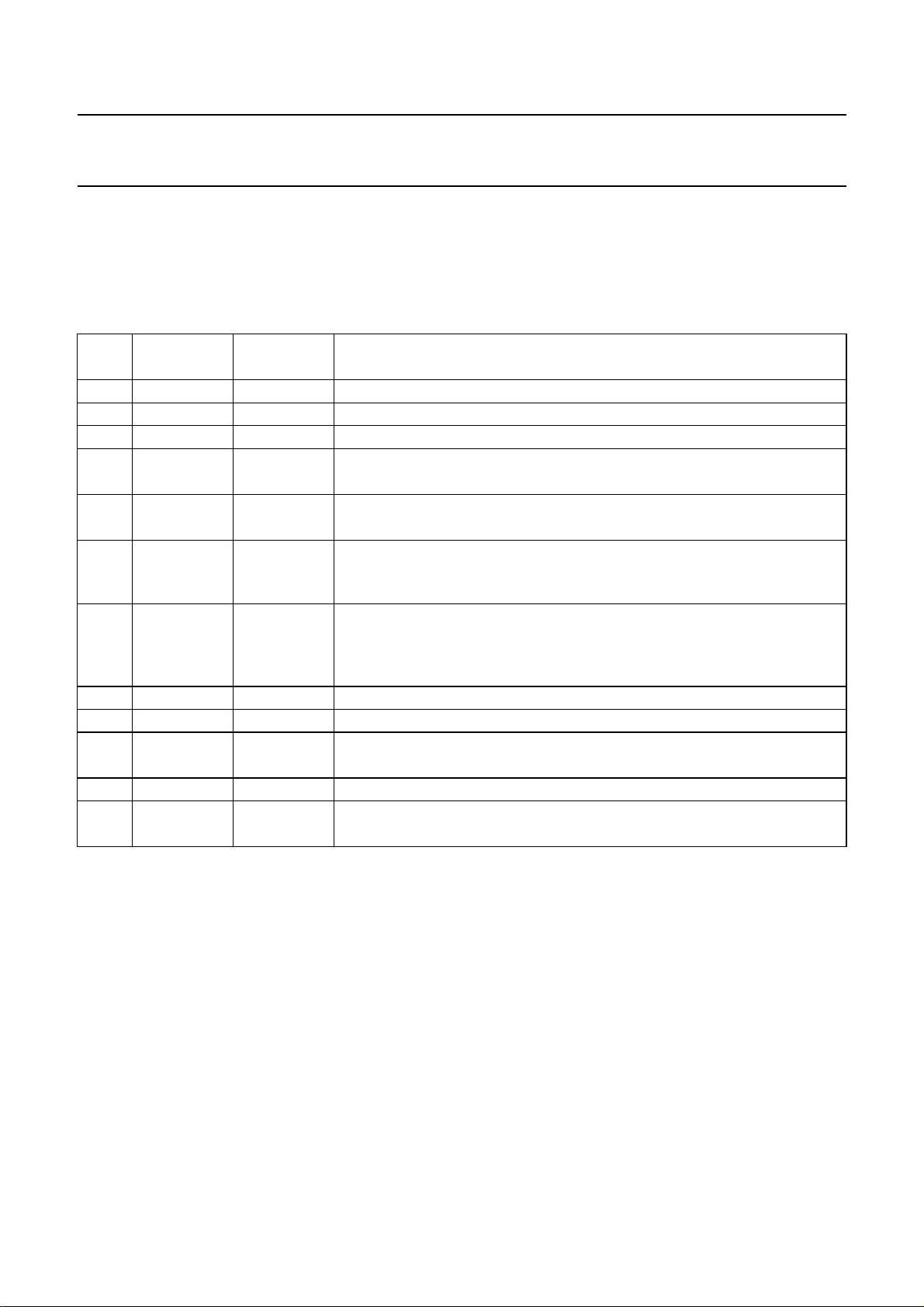

Table 5 Writing register#1

BIT

0 0 comA drives COMA when in manual commutation

1 0 comB drives COMB when in manual commutation

2 0 comC drives COMC when in manual commutation

3 0 run/stop 0 = motor to brake-after-park mode

4 0 manual 0 = automatic commutation mode with run/stop = 1

5 0 spindiv 0 = the internal spindle clock frequency is controlled by register#6 (11)

6 0 sleep_N 0 = sleep mode: low power mode, serial interface active, power stages in

70− not used

80− not used

9 1 seek/trackfw 0 = VCMIN connected to SEEKSELECT

10 1 − not used

11 0 reverse break 1 = active brake control

DEFAULT

VALUE

NAME DESCRIPTION

1 = motor spinning; VCM active

1 = manual commutation mode with run/stop = 1

(bit highClock_N)

1 = an additional divider by 4 is added on the internal spindle clock

brake-after-park mode

1 = fully functional mode: sleep_N has higher priority than run/stop if both are

active

1 = VCMIN connected to TRACKFWSELECT

0 = normal commutations as defined by bits above

driver” (see also Fig.12). Note that depending on the coil

status acquisition moment, transient states (due to the

flyback pulses) can be read.

8.3 Commutation control

The commutation logic block generates the six different

states to rotate the spindle motor. The spindle driver block

provides the BEMF zero crossing information.

The commutation block interprets the zero crossing

information and determines the commutation delay time

and the next coil state. The commutation block must take

into account the following situations:

• Start-up

• No start

• Reverse rotating

• Run

• Manual commutation.

1998 Nov 02 16

The commutation logic keeps the motor spinning by

commutating the motor after each detected zero crossing.

It measures the time between two successive BEMF zero

crossings and then determines the next commutation.

The delay (commutation delay) between a zero crossing

and the next commutation is half the time between the two

preceding zero crossings. The commutation delay

(Comdelim) can be limited to guarantee a faster lock after

the motor has gone out of lock. A maximum commutation

delay can be set via the serial port. The time is a function

of both the external clock frequency, the individual register

prescalers and the time programmed into the registers.

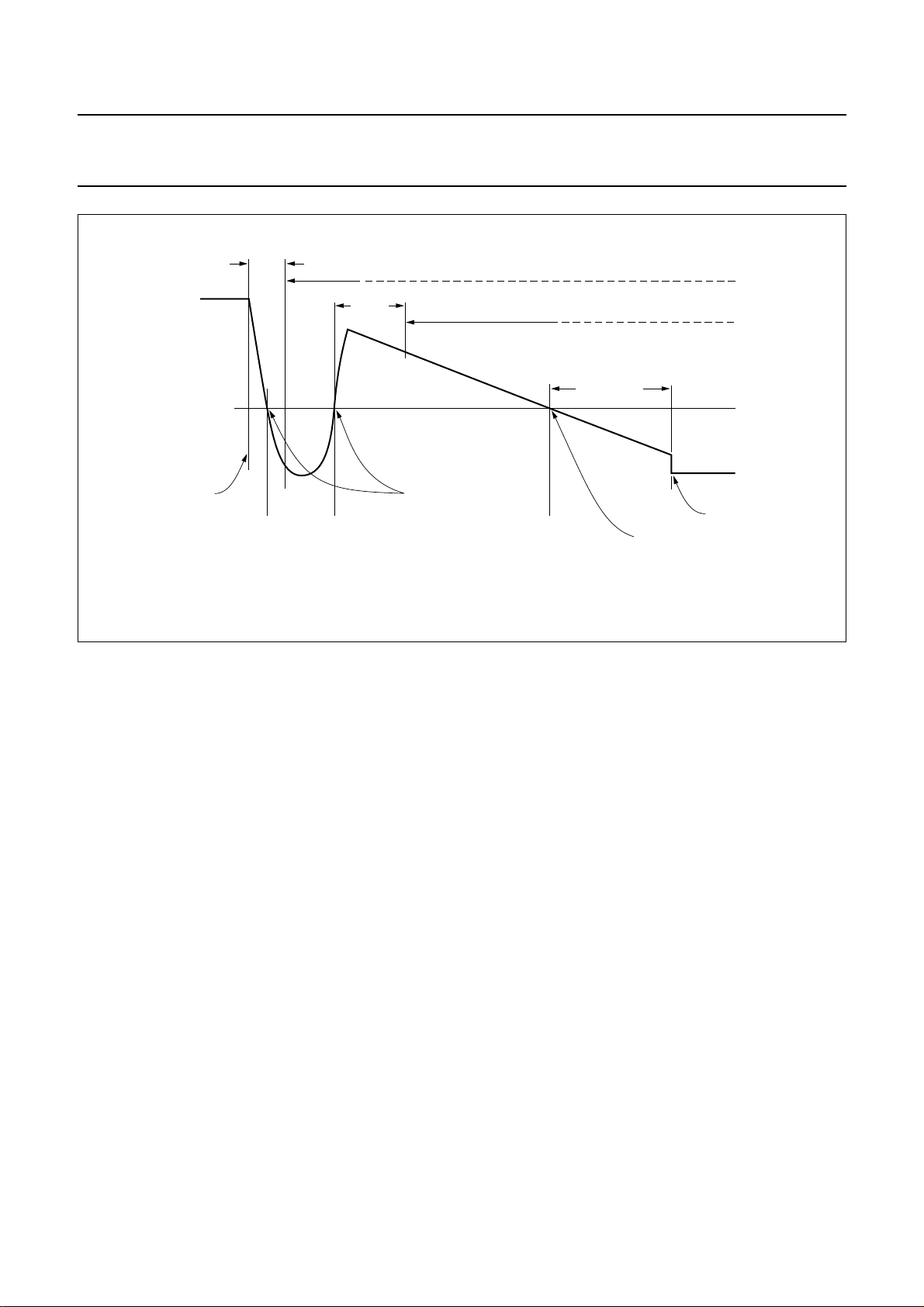

Figure 7 shows a typical motor commutation timing

diagram.

Philips Semiconductors Product specification

Disk drive spindle and VCM with

servo controller

handbook, full pagewidth

Blank 1

centre tap

commutation

Zc

1

flyback pulse

Watchdog

Zc

2

Blank 2

Start-up

false zero crossings

Zc

3

Commutation

delay

OM5193H

commutation

true zero crossing

MGM978

Fig.7 A typical motor commutation diagram.

• Blank 1

After a commutation occurs, the leading edge of the

flyback pulse has a zero crossing (Zc1). Blank 1 timer is

used to ignore this zero crossing by masking it while the

timer initialized at Blank 1 value is counting. The state

associated to Blank 1 down-counter will end when the

counter reaches the zero value.

• Blank 2

The Blank 2 timer starts counting as soon as the second

zero crossing occurs (Zc2). After the second flyback

pulse zero crossing, all extra zero crossings are ignored

during the Blank 2 time. This allows the ringing of the

coil voltage without causing a commutation advance.

The state associated to Blank 2 down-counter will end

when the counter reaches the zero value.

• Watchdog

The Watchdog timer makes sure the motor is running in

forward direction. If the motor is rotating in reverse

direction, the BEMF voltage is inverted and the second

crossing of the flyback pulse (Zc2) will not occur until the

true BEMF zero crossing is detected. Therefore, if the

Watchdog timer expires before a zero crossing occurs,

the motor is assumed to be rotating backwards.

The commutation is advanced by one step to correct

this condition. The Watchdog time must be set to a value

that is greater than the flyback pulse duration, measured

when the spindle motor stands still.

The state associated to the Watchdog timer will start

when the one associated to Blank 1 timer is finished and

will end when Zc2 occurs or when the Watchdog counter

expires.

• Start-up

If the motor is not spinning, the BEMF zero crossings will

not occur. The Start-up timer detects this if it expires

before the true zero crossing (Zc3) has occurred. It will

advance the commutation by one step if this happens.

The state associated to Start-up timer will start when the

one associated to Blank 2 timer is finished and will end

when Zc3 occurs or when Start-up expires.

• Comdelim

The timer associated to Comdelim value allows to

control the maximum commutation delay (between zero

crossing and next commutation). When the true zero

crossing is detected (Zc3), the timer will count until it

expires and then will commutate the motor to the next

step. This commutation delay time is equal to half the

measured value between 2 zero crossings.

The Comdelim value should be set to the maximum

allowable delay value. If ∆Zc

is lower than the

meas

programmed Comdelim value, the next timer value will

be ∆Zc

divided by 2. If ∆Zc

meas

is higher than the

meas

programmed Comdelim value, the next timer value will

be the programmed Comdelim value divided by 2.

1998 Nov 02 17

Loading...

Loading...