Page 1

MX4000/6000 Dual and

MX4000

System Installation Instructions

4550 193 80401

Revision D

This document and the information contained in it is proprietary and confidential information of Philips Healthcare ("Philips") and may not be reproduced,

copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written permission of the Philips Legal Department.

Use of this document and the information contained in it is strictly reserved for current Philips personnel and Philips customers who have a current and

valid license from Philips for use by the customer’s designated in-house service employee on equipment located at the customer’s designated site. Use

of this document by unauthorized persons is strictly prohibited. Report violation of these requirements to the Philips Legal Department. This document

must be returned to Philips when the user is no longer licensed and in any event upon Philips’ first written request.

© 2010 Philips Healthcare

Page 2

Philips Healthcare

„ 2010 KONINKLIJKE PHILIPS ELECTRONICS N. V. ALL RIGHTS RESERVED.

Warranty Disclaimer

PHILIPS PROVIDES THIS DOCUMENT WITHOUT WARRANTY OF ANY KIND, EITHER IMPLIED OR EXPRESSED,

INCLUDING, BUT NOT LIMITED TO, THE IMPLIED WARRANTIES OF MERCHANTABILITY AND FITNESS FOR A

PARTICULAR PURPOSE.

Limitation of Liability

OR CHANGES IN THE PRODUCT(S) OR PROGRAM(S) DESCRIBED IN THIS DOCUMENT AT ANY TIME.

Password Notice

Page 3

Symbol Descriptions

Attention symbol Radiation warning symbol

Laser warning symbol Biohazard warning symbol

Magnetism warning symbol Projectile warning symbol

Electrical warning symbol Do not touch

Page 4

Revision History

ECO # Revision Date Comments

New Release

Removed Gantry Rotation Locking Pin Release Procedure

H3000384 A November 2006

H3000423 B January 2007

H3000753 C July 2007

Updated “Cable Connection Overview” on page 48

Updated “Connecting the UPS (Option)” on page 67

Updated “Service license Key” on page 96

Updated:

“Connecting the Computer Rack” on page 59

“Connecting the UPS (Option)” on page 67

Added: “Record X-ray Exposure Times” on page 113

Changes to “Packing List” on page 4 and “Shipping Case Contents” on page 5

Isolation Transformer now called “Unpacking & Transporting System Units” on page 7

Changes in “Transport Specifications” on page 8

Added section “Changing the Warning Labels” on page 73

Changes in “Power Filter Box or Isolation Transformer” on page 27 options

Page 5

ECO # Revision Date Comments

“ Shipping Case Contents” on page 5

Modified “Connecting the CT-Box” on page 57

Modified “Connecting the CT-Box Interface Board” on page 66

Deleted “Connecting the Network switch”

Modified “Record X-ray Exposure Times” on page 113

Modified “Dell Service Tag Transfer” on page 116

Modified “ Leveling the Gantry” on page 90

Modified “Positioning the Gantry” on page 29

Modified “Connecting the Patient Table” on page 56

Modified “Connecting the Computer Rack” on page 59

Added “Setting the Console Power Management for UPS Option” on page 132

Modified “Packing List” on page 4

Modified “Unpacking the Patient Table” on page 18

Modified “Positioning the Patient Table” on page 30

Modified “Power Filter Box or Isolation Transformer” on page 27

Modified “Preface” on page 111

Added “Power Filter Box (ROW - Out of China Configuration)” on page 124

Updated “Power Supply Troubleshooting” on page 135

This document was prepared by the CT BU Haifa Service Innovation Department.

For any additions, corrections, or suggestions, contact:

CT BU Haifa Customer Support Department

Email: helpdesk.ct.haifa@philips.com

Page 6

Safety Information

To the User of This Manual

The user of this manual is directed to read and carefully review the instructions, warnings and cautions contained herein prior to beginning installation or service activities.

While you may have previously installed or serviced equipment similar to that described in this manual, changes in design, manufacture or procedure may have occurred

which significantly affect the present installation or service.

Installation and Environment

Except for installations requiring certification by the manufacturer per federal standards, see that a radiation protection survey is made by a qualified expert in accordance

with NCRP 102, section 7, as revised or replaced in the future. Perform a survey after every change in equipment, workload, or operating conditions which might

significantly increase the probability of persons receiving more than the maximum permissible dose equivalent.

Diagnostic Imaging Systems - Mechanical-electrical Warning

All of the moveable assemblies and parts of this equipment should be operated with care and routinely inspected in accordance with the manufacturer’s recommendations

contained in the equipment manuals.

Only properly trained and qualified personnel should be permitted access to any internal parts. Live electrical terminals are deadly; be sure line disconnects are opened and

other appropriate precautions are taken before opening access doors, removing enclosure panels, or attaching accessories.

Do not under any circumstances, remove the flexible high tension cables from the x-ray tube housing or high tension generator and/or the access covers from the generator

until the main and auxiliary power supplies have been disconnected. Failure to comply with the above may result in serious or fatal bodily injuries to the operator or those

in the area.

The equipment must be grounded to an earth ground by a separate conductor. The neutral side of the line is not to be considered the earth ground. On equipment

provided with a line cord, the equipment must be connected to properly grounded, three-pin receptacle. Do not use a three-to-two pin adapter.

Diagnostic Imaging Systems - Radiation Warning

X-ray and Gamma-rays are dangerous to both operator and others in the vicinity unless established safe exposure procedures are strictly observed.

The useful and scattered beams can produce serious or fatal bodily injuries to any persons in the surrounding area if used by an unskilled operator. Adequate precautions

must always be taken to avoid exposure to the useful beam, as well as to leakage radiation from within the source housing or to scattered radiation resulting from the

passage of radiation through matter.

Those authorized to operate, participate in or supervise the operation of the equipment must be thoroughly familiar and comply completely with the current established

safe exposure factors and procedures described in publications, such as: Subchapter J of Title 21 of the Code of Federal Regulations, "Diagnostic X-ray Systems and Their

Major Components", and the national council on radiation protection (NCRP) no. 102, "Medical X-ray And Gamma-ray Protection For Energies Up To 10 Mevequipment Design and Use", as revised or replaced in the future.

Those responsible for planning of x-ray and gamma-ray equipment installations must be thoroughly familiar and comply completely with NCRP no. 49, "Structural

Shielding Design and Evaluation For Medical Of X-rays and Gamma-rays of Energies Up to 10 Mev", as revised and replaced in the future. Failure to observe these

warnings may cause serious or fatal bodily injuries to the operator or those in the area.

Add additional safety information as needed

Page 7

Contents

Introduction 1

How this Manual is Organized .................................................................................................................................................. 1

Safety........................................................................................................................................................................................ 1

Implementation Order and Time Table ..................................................................................................................................... 2

Pre-installation .................................................................................................................................................................... 2

Implementation ................................................................................................................................................................... 3

Packing List............................................................................................................................................................................... 4

Shipping Case Contents ........................................................................................................................................................... 5

Unpacking & Transporting System Units 7

Gantry ....................................................................................................................................................................................... 8

Delivery Method Instructions............................................................................................................................................... 8

Transport Specifications ..................................................................................................................................................... 8

Unloading the Gantry .......................................................................................................................................................... 9

Forklift Specifications .................................................................................................................................................... 9

Unpacking the Gantry ......................................................................................................................................................... 10

Releasing the Gantry from the Pallet .................................................................................................................................. 11

Attaching the Transport Dollies........................................................................................................................................... 12

Transporting the Gantry ...................................................................................................................................................... 14

Transporting Guidelines................................................................................................................................................ 14

Transporting the Gantry through Doors and Hallways .................................................................................................. 15

Transporting the Gantry through Minimum Width Clearance........................................................................................ 16

The Patient Table...................................................................................................................................................................... 18

Unpacking the Patient Table............................................................................................................................................... 18

Workspace and Accessories..................................................................................................................................................... 26

Power Filter Box or Isolation Transformer ................................................................................................................................ 27

Positioning System Components 28

Checking the Rotating Frame ................................................................................................................................................... 28

Positioning the Gantry............................................................................................................................................................... 29

Removing the Base Covers ................................................................................................................................................ 29

Positioning the Patient Table .................................................................................................................................................... 30

Positioning the Connection Piece ............................................................................................................................................. 33

Positioning the Operating Console ........................................................................................................................................... 34

Operator’s Table ................................................................................................................................................................. 35

Assembly Steps ............................................................................................................................................................ 36

Computer Rack ................................................................................................................................................................... 39

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover i

Page 8

Contents

Changing Computer Rack Door Orientation ................................................................................................................. 39

Installing the System 47

Cable Connection Overview ..................................................................................................................................................... 48

Routing the System Cables ................................................................................................................................................ 49

Routing the External System Cables .................................................................................................................................. 49

Installing the Power Distributor (Power Supply Devices and/or Power Protector).................................................................... 50

Connecting the Gantry.............................................................................................................................................................. 51

Routing the Signal and Power Cables ................................................................................................................................ 51

Connecting the Gantry Right Column ................................................................................................................................. 53

Input Power Connection................................................................................................................................................ 53

Door Interlock and X-ray Lamp ON Connections.......................................................................................................... 54

Connecting the Gantry Left Column.................................................................................................................................... 55

Connecting the Patient Table.................................................................................................................................................... 56

Connecting the Operating Station............................................................................................................................................. 57

Connecting the Operating Table ......................................................................................................................................... 57

Connecting the CT-Box................................................................................................................................................. 57

Connecting the Monitor................................................................................................................................................. 58

Connecting the Computer Rack.......................................................................................................................................... 59

Connecting Power to the Computer Rack..................................................................................................................... 62

Connecting Power Cables to the Multi-outlet................................................................................................................ 63

Connecting the UPS (Option) ............................................................................................................................................. 67

Tools ............................................................................................................................................................................. 67

UPS Package Contents ................................................................................................................................................ 68

Installing the UPS.......................................................................................................................................................... 69

Final Steps .................................................................................................................................................................... 72

Changing the Warning Labels................................................................................................................................................... 73

Pre-start-up Procedures 76

System Power Up ..................................................................................................................................................................... 77

Verifying Output Power Voltage.......................................................................................................................................... 77

Opening the Gantry Front and Rear Covers............................................................................................................................. 80

Checking the Protective (GND) Covers .................................................................................................................................... 83

Gantry GND Check ............................................................................................................................................................. 84

Gantry Stationary .......................................................................................................................................................... 84

Gantry Rotor Frame ...................................................................................................................................................... 85

Computer Rack ................................................................................................................................................................... 86

Patient Table....................................................................................................................................................................... 87

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover ii

Page 9

Contents

Ensuring Air-conditioning Readiness ........................................................................................................................................ 87

Checking Manual Rotation and Tilt ........................................................................................................................................... 88

System Leveling and Anchoring 89

Inserting the Anchor Bolts......................................................................................................................................................... 89

Gantry ....................................................................................................................................................................................... 90

Leveling the Gantry............................................................................................................................................................. 90

Adding Shims ................................................................................................................................................................ 92

Final Anchoring of the Gantry ............................................................................................................................................. 92

Removing the Transport Dollies.......................................................................................................................................... 92

Patient Table............................................................................................................................................................................. 93

Leveling the Patient Table .................................................................................................................................................. 93

Verifying and/or Installing the License Keys 94

Option License Key................................................................................................................................................................... 94

Service license Key................................................................................................................................................................... 96

Setting Hospital Name and License Key Expiration.................................................................................................................. 96

Setting Hospital Name ........................................................................................................................................................ 96

License Key Expiration ....................................................................................................................................................... 97

First Time System Operation 98

Closing Duct Covers ................................................................................................................................................................. 99

Closing Gantry Covers.............................................................................................................................................................. 99

Gantry Base Covers............................................................................................................................................................ 99

Gantry Rear Cover.............................................................................................................................................................. 100

Gantry Front Cover ............................................................................................................................................................. 101

Gantry Side Covers............................................................................................................................................................. 102

Gantry Right Column Cover .......................................................................................................................................... 102

Gantry Left Column Cover ............................................................................................................................................ 102

Position the Connection Piece Cover ....................................................................................................................................... 103

Ensuring Safety Measures........................................................................................................................................................ 104

Checking the Emergency Shutdown Buttons...................................................................................................................... 105

Checking the Door Contact Switch ..................................................................................................................................... 105

Checking the Gantry Fans .................................................................................................................................................. 105

Checking Movement from the Gantry Panel ....................................................................................................................... 105

Checking Movement from the CT-Box................................................................................................................................ 107

Checking Reconstruction and Image Display ........................................................................................................................... 107

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover iii

Page 10

Contents

Final Patient Table Alignment and Anchoring........................................................................................................................... 107

Final Patient Table Checks ....................................................................................................................................................... 108

Checking Gantry and Patient Table Collision ..................................................................................................................... 108

Gantry Tilt Angle Graph ................................................................................................................................................ 109

Closing Patient Table Covers ............................................................................................................................................. 110

Acceptance Test 111

Preface...................................................................................................................................................................................... 111

Gantry Balance Check.............................................................................................................................................................. 112

Record X-ray Exposure Times.................................................................................................................................................. 113

Network Installation and Configuration 114

Setting the Date and Time Properties 114

Performing Backup 115

Dell Service Tag Transfer 116

Delivery and Installation Report 117

Appendix A: Using the Floor Template to Drill Gantry Anchor Holes 118

Positioning the Floor Template ................................................................................................................................................. 119

Drilling the Gantry and Patient Table Anchor Holes ................................................................................................................. 121

Installing the Concrete Floor Anchors....................................................................................................................................... 122

Recommendation for Subfloor Construction for Installation Floor ...................................................................................... 122

Appendix B: Installing the Power Filter Box or Isolation Transformer 123

Power Filter Box (ROW - Out of China Configuration).............................................................................................................. 124

Procedure to install Power Filter Box.................................................................................................................................. 125

HuaRan Isolation Transformer (China only) ............................................................................................................................. 127

Teal Isolation Transformer (ROW Optional - Out of China Configuration)................................................................................ 128

Appendix C: Selecting System Language 129

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover iv

Page 11

Contents

Appendix D: Modifying the Lateral Laser Position 130

Appendix E: Modifying the Image Rotation Angle 131

Appendix F: Setting the Console Power Management for UPS Option 132

Appendix G: Power Supply Troubleshooting 135

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover v

Page 12

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Introduction

This manual defines the installation procedures applied to the MX 4000/6000 Dual and MX 4000 CT system. Ensure

that all steps described in the Pre-installation Manual are completed before system installation.

Only certified Philips CT Engineers and authorized distributors shall install the MX 4000/6000 Dual and MX 4000 CT

scanner.

Prior to the start of the installation, a Philips Service Engineer, together with the Hospital’s facility representative and

local Philips Project Manager are required to inspect the site. Individual site layout and environmental specifications are

reflected in the final site planning drawings. All materials needed for installation are included with the scanner.

How this Manual is Organized

This installation manual is organized in the order of procedures necessary to install the MX 4000/6000 Dual and MX

4000 CT scanner. This manual complies with Philips Medical Systems service documentation format. Its landscape

format is intended for easy viewing on the Field Service Engineer’s computer. In addition to the bookmarks displayed in

Acrobat Reader, the user can take advantage of the Table of Contents in the beginning of the manual. These

navigation tools enable the FSE to find the necessary information quickly.

Introduction

Safety

WARNING PRIOR TO INSTALLATION READ AND UNDERSTAND ALL GUIDELINES IN THE

SAFETY MANUAL.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 1

Page 13

Implementation Order and Time Table

Pre-installation

Make sure that all pre-installation procedures have been performed and that the site is ready for delivery of the system.

For all detailed information pertaining to Room requirements and system Planning Data, refer to the on-line PRD

(Planning Reference Data), section 728 on TechNet as follows:

1 Log on to at:

http://incenter.medical.philips.com/Default.aspx?tabid=43&PTLLObjId=356730.

NOTE InCenter requires log in with User ID (your email— firstname.lastname@philips.com) and password

(IST password).

2 Under Tools and Resources (right side of the screen), click Planning Reference Data.

3 On the Homepage PRD, click Current Products | 728 Computed Tomograph | Commercial Catalogue |

MX 4000/6000.

Site preparation includes (partial list):

• Planning room layout

• Environmental conditions

• Power requirements

• Safety protection requirements

• Drilling anchor holes

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 2

Page 14

Implementation

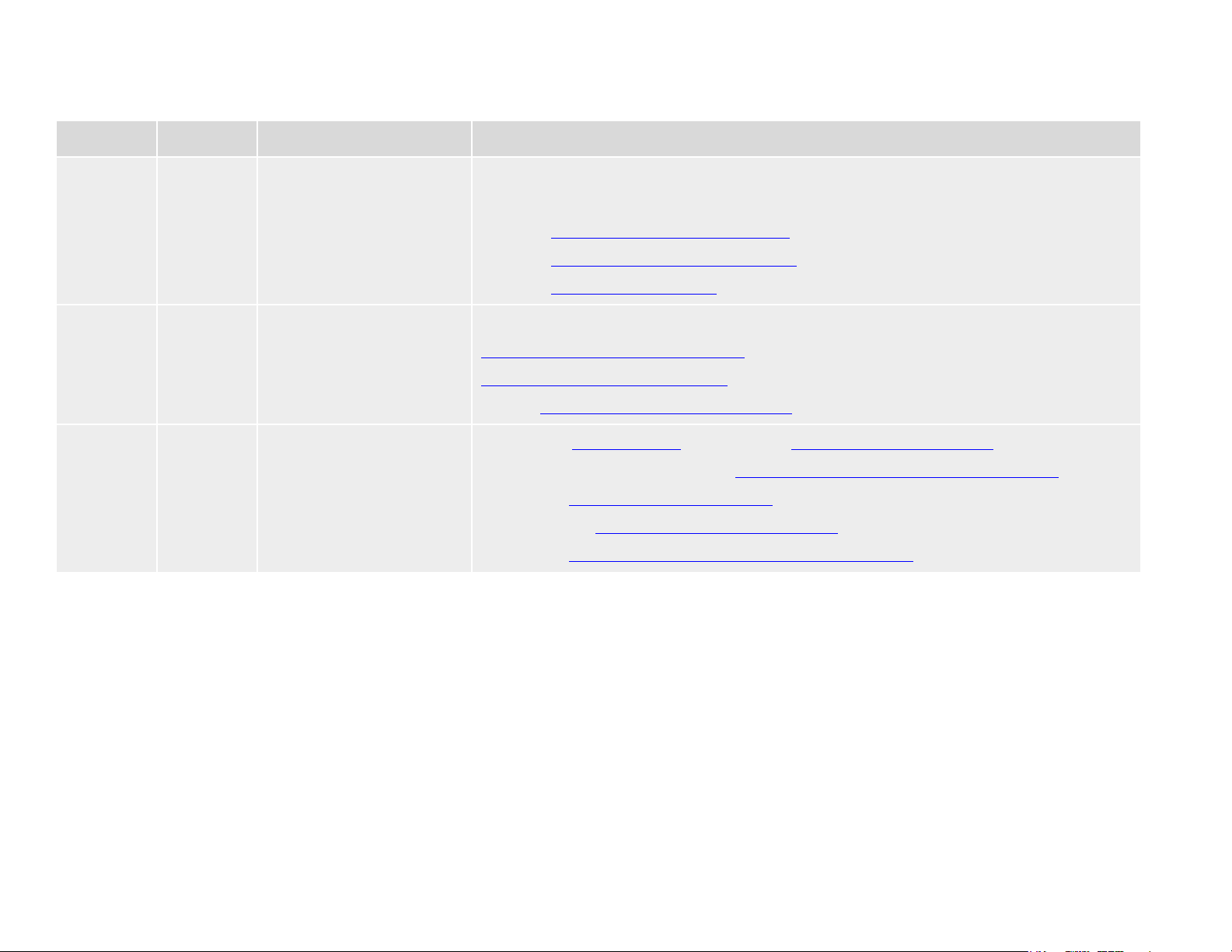

It is most important to perform the pre-installation and installation tasks in the order shown in Tab le 1. Estimated time for

each installation operation is included. The total estimated time (not including pre-installation tasks) is three days.

Number Activity Estimated Time

1 Completing site preparation and Site Inspection checklist Pre-installation

2 Unpacking and positioning units 2

3 Anchoring units 2

4 Connecting system components 2

5 Preparing the system for operation Half a day

6 System first time operation and functional checks Half a day

7 Preparing system for clinical operation 1 day

*Some times estimates assume two people and/or no seismic requirements for installation of the system.

Table 1: Implementation Order

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 3

Page 15

Packing List

Table 2 lists the shipping cases that are included in a delivery of the MX 4000/6000 Dual and MX 4000 system. For

shipping case contents, refer to Shipping Case Contents.

Table 2: Component Weights and Sizes

Component

Item #

1 Gantry

2 Patient Table

3 Accessories

Huaran Isolation Transformer

4

(Optional China only)

37 kVA Teal Isolation Transformer

6

(Optional)

Dimensions (L x W x H in mm)

Dimensions (L x W x H in inches)

Net Package Net Package

2210 x 850 x 1890

87 x 33.5 x 74.4

2440 (max) x 575 x 1100 (max)

96 x 22.6 x 43.3

600 x 450 x850

23.6 x 17.7 x 33.5

2370 x 1030 x 2320

93 x 40.6 x 91.3

2570 x 970 x 1220

101 x 38.2 x 48

1220 x 1160 x 870

47.2 x 45.7 x 34.3

700 x 640 x 1200

27.6 x 25.2 x 47.2

516x552x712

20.3x21.7x28

Weight in kg

Weight in lb

1700

3748

350

772

240

529

2000

4409

450

992

260

573

260

573

274

604

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 4

Page 16

Shipping Case Contents

Item #1 Gantry - Contents Qty

Gantry 1

Item #2 Patient Table - Contents Qty

Patient Table 1

Patient Table Cushion 1

Connection Piece ASSY 1

Gantry Mylar 2

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 5

Page 17

NOTE Tools listed below are shipped with the system. These tools do not replace the standard FSE tool kit

(prerequisite for system installation and maintenance).

Item #4 Accessories - Contents Qty Item #4 Accessories - Contents Qty

Work desk 1 System Phantom for Image Quality checks 1

Computer Rack (without Host Computer) 1 7” Water phantom 1

Host Computer 1 10” Water phantom 1

19” LCD Monitor 1 14” Water phantom 1

CT Box 1 Step phantom 1

Rack PE cable (W417) 1 Grease Gun (with 2 plugs) 1

Line power cable (W403) 1 Manual Box 1

Gantry power supply cable (W101) 1 Quality certification 1

Network cable (W119) 1 Testing report 1

CT BOX cable 1 (W124) 1 Installation Template 1

CT BOX cable 2 (W125) 1 Shims A 10

Head holder (with one head strap) 1 Shims B 4

Coronary chin pad 1 Caps for screw hole 21

Neck pad 1 16x200 drill bit 1

Head holder Cushion 1 18x200 Drill bit 1

Knee pad 1 Patient Table Anchoring Bolts - M12x110 5

Extended board to cradle (optional) 1 Gantry Anchoring Bolts - M14x123 5

Water phantom support 1 Operator table box 1

FSE toolbox 1

Warning Label Assy 1

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 6

Page 18

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Left Right

Person

Unpacking & Transporting System Units

Careful unpacking and transporting of the system units will help to prevent damage to the equipment and make

installation easier.

This chapter provides instructions to unpack and transport the following units, in the order listed:

Gantry

The Patient Table

Workspace and Accessories

Power Filter Box or Isolation Transformer

Refer to Section Shipping Case Contents when unpacking to verify that you have received all system components

listed. In the event that any component is missing, contact CT Customer Support immediately for further instructions.

If a unit shows external or internal damage, contact the transportation company and file a damage claim under ICC

regulations. In addition, contact the CT Customer Support immediately for further instructions.

Unpacking & Transporting System Units

NOTE Left and right references in this manual are from the point of view of a person standing at the open end

of the Patient Table, facing the Gantry as shown in Figure 1.

Figure 1:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 7

Page 19

Gantry

Delivery Method Instructions

To prevent damage to the system, transport the system on site only as described in this chapter.

CAUTION Transport the entire system in its original packaging.

CAUTION The truck used to transfer the system must have shock absorbers.

Transport Specifications

During transportation, the environment must meet the following conditions:

Temperature in °C (°F) -30°C ~ +55°C (-22°F ~ 131°F)

Gradient Temperature in °C (°F) /hour 5°C (-41°F)

Humidity in% (non-condensing) 10%—90%, non-condensing

Atmosphere pressure: 50Kpa~106Kpa

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 8

Page 20

Unloading the Gantry

Unload the Gantry from truck by forklift with extension arm and then place it on the aisle that leads to the scanning room

on the same level.

Forklift Specifications

The forklift must be a minimum load of 3000 kg and able to balance a load that is 2.4 M long with center of gravity at

midpoint when lowering the crate from the truck and transporting it.

Fork specifications:

max.184 mm wide by 57 mm high

minimum 1524 mm length

Both forks must spread 610 mm apart (center to center)

Dolly wheels must be obtained locally from the SSD or Regional Office.

CAUTION If there is an incline exceeding 5° or if there are steps on the aisle, the Gantry must be

unloaded with its packing box onto the aisle or steps.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 9

Page 21

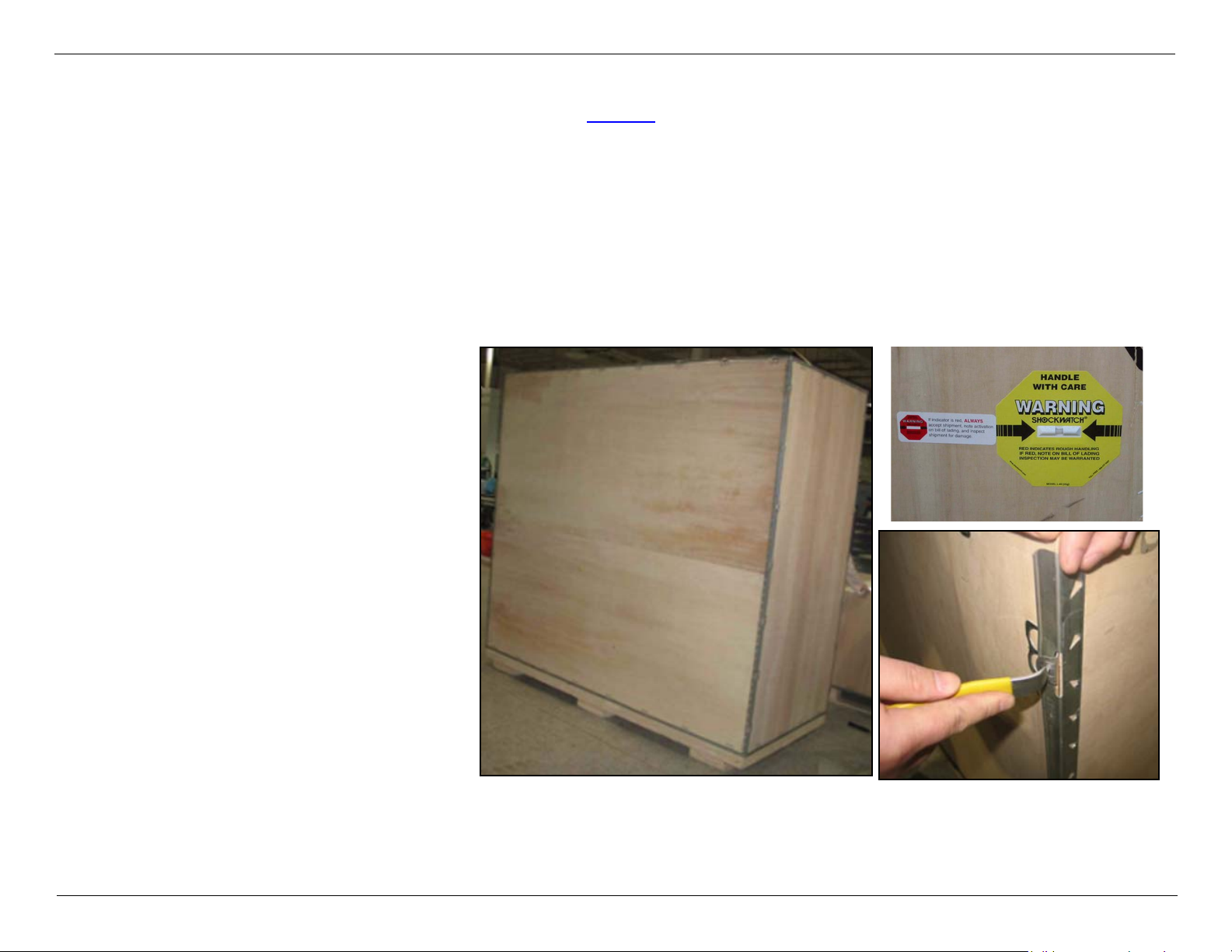

Unpacking the Gantry

The Gantry is delivered in a packing crate (see Figure 2) equipped with a Shockwatch device that will indicate if the

crate has sustained a shock above tolerance level while in transit.

Before opening the crate, observe the Shockwatch device. If damage is indicated, contact the SSD or local service

support.

WARNING Take all necessary safety precautions when opening the gantry crate. Use safety

equipment such as gloves, reinforced shoes, etc.

NOTE The unpacking tool can be ordered prior to installation, and is found in the shipped-with package.

Unpack as follows:

1 Release the clamps that

secure the packing crate top

and carefully remove it.

2 Release the clamps from all

four sides and lower them

carefully.

3 Remove the anti-static

wrapping covering the

Gantry.

Figure 2:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 10

Page 22

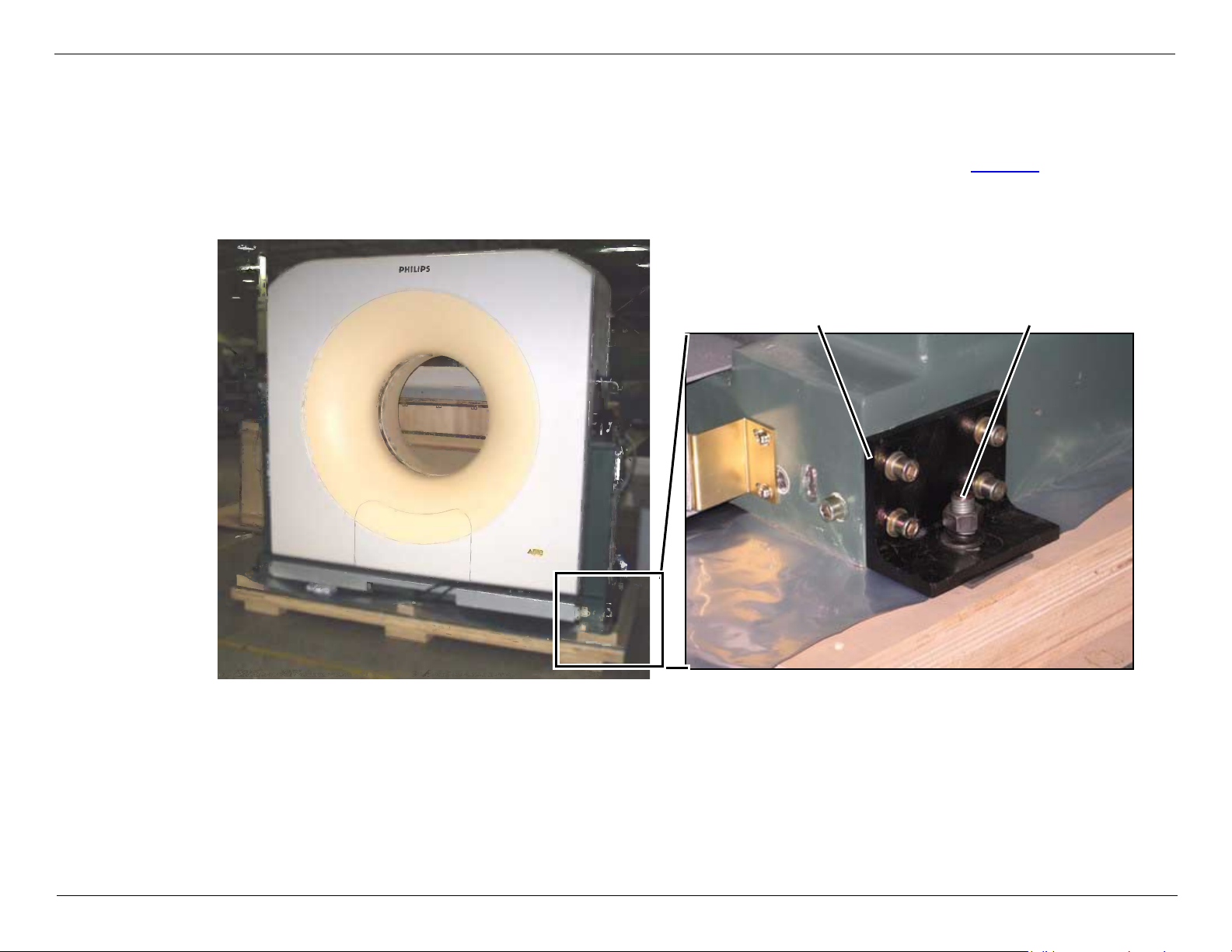

Releasing the Gantry from the Pallet

Gantry secure screwShipping bracket

1 Remove the Gantry side covers.

2 There are two bolts on each side of the Gantry that secure the shipping brackets to the pallet. Release all nuts and

washers and push the bolts down so that the Gantry is now released from the pallet (see Figure 3).

3 Use a 23mm crescent wrench or open wrench to release the four screws that secure the shipping bracket to the

Gantry.

Figure 3:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 11

Page 23

MX4000/6000 Dual and MX4000 Single System Installation Instructions

NOTE

Securing bolt Transportation adapter

NOTE Verify that the transportation adapter is installed, before you install the Gantry dollies

Unpacking & Transporting System Units

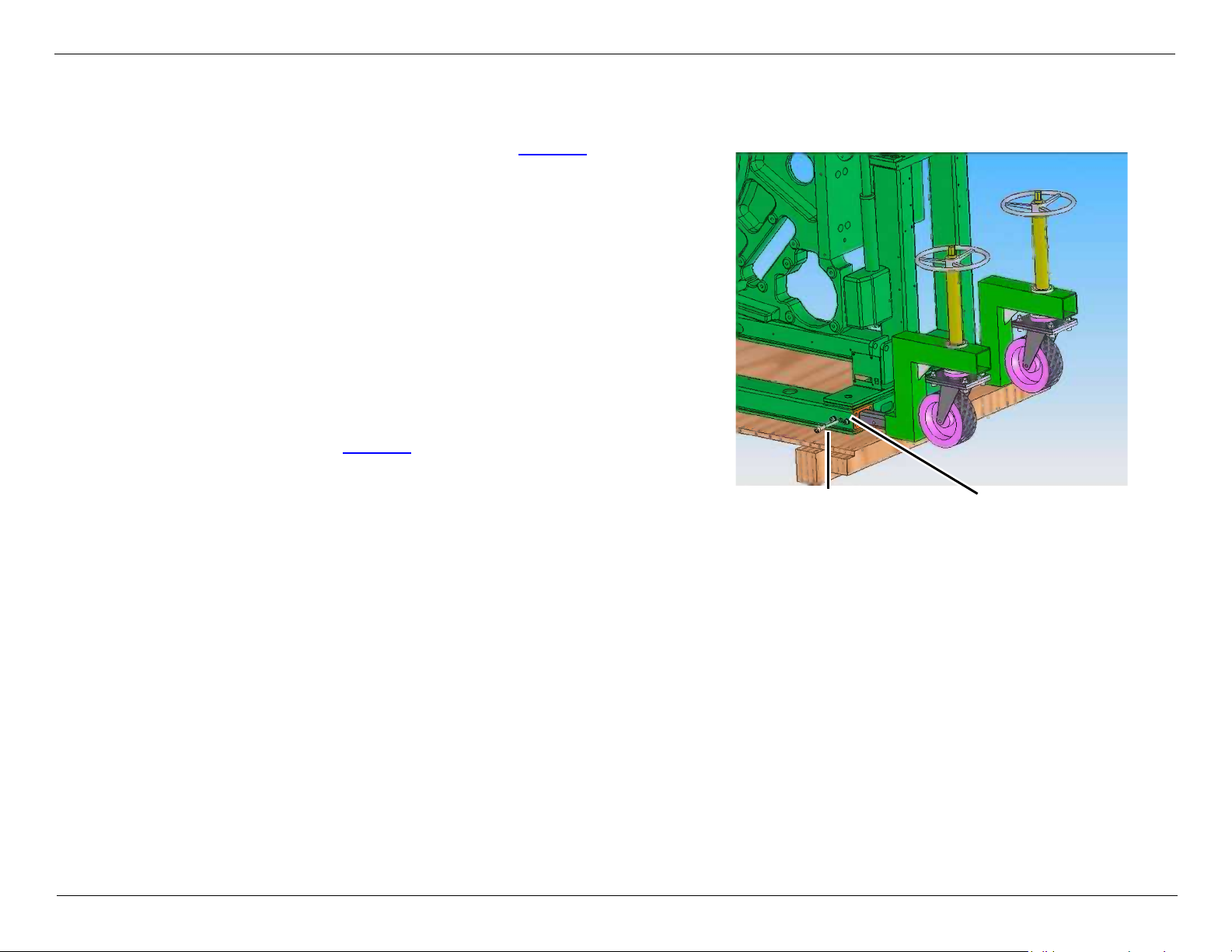

1 Attach all four transport dollies (see Figure 4

sides of the Gantry and fasten with the securing bolt.

If you have difficulty inserting the security bolt, loosen

the two adjacent screws to allow freer movement.

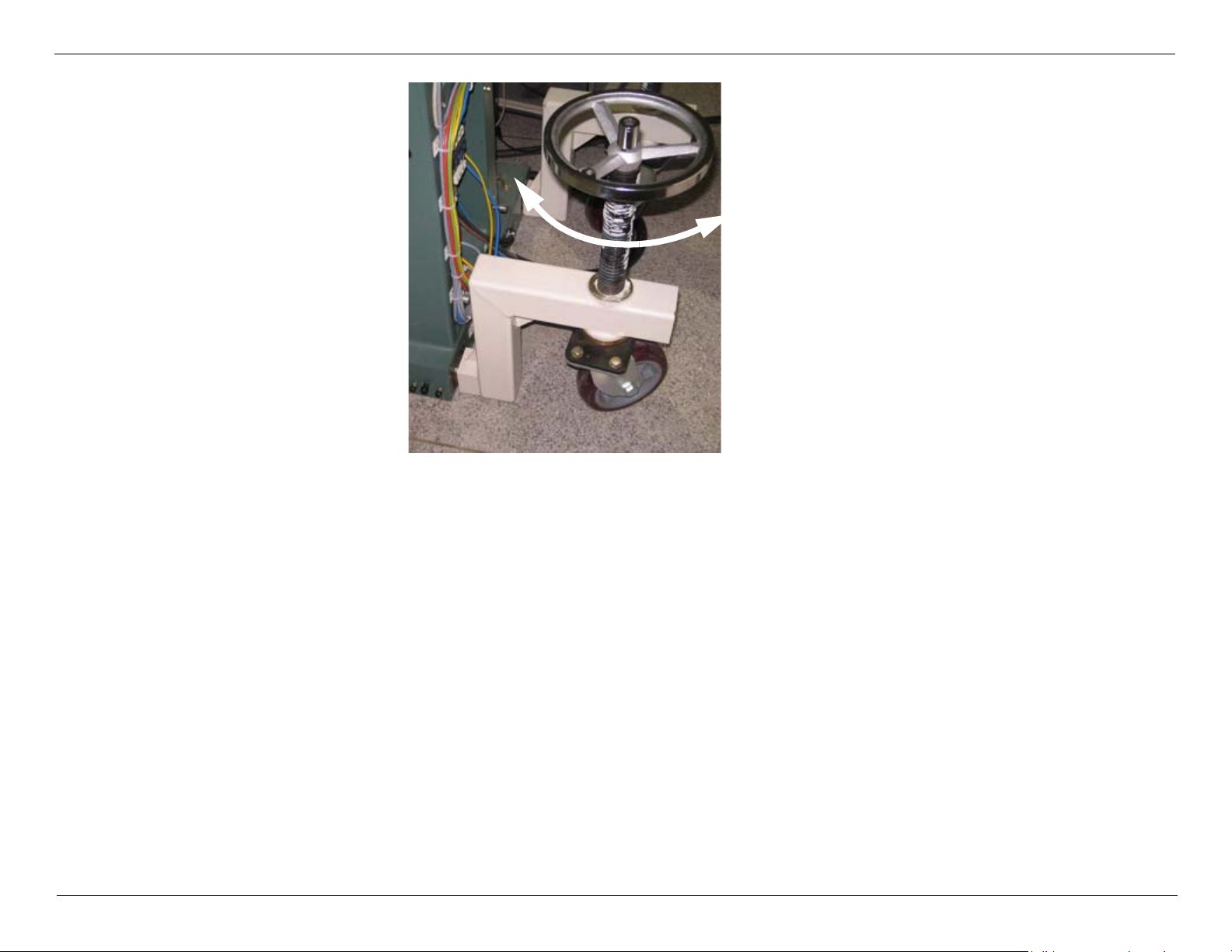

2 Rotate the hand wheels of the transport devices

clockwise to lower the rollers to the floor.

3 Continue rotating each of the hand wheels clockwise to

raise the Gantry with the transport dollies until it clears

the pallet (see Figure 5).

) to both

Figure 4: Securing Dollies

WARNING Rotate the hand wheels of all four dollies alternately so that the gantry remains

straight and does not lean.

WARNING crush hazard. minimize the clearance between the Gantry base and the floor

when transporting the Gantry. this will prevent excess stress on the jack screws

and to reduce the possibility of tipping the Gantry. failure to comply may result

in serious injury or death to service personnel.

4 Remove the pallet.

5 Rotate each of the hand wheels counter-clockwise until the Gantry base is clear of the floor by approximately

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 12

15 mm. The Gantry is prepared for transport. Push on its solid surfaces in the lower half of the Gantry.

Page 24

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Turn hand wheel:

• Clockwise - raise Gantry

• Counter-clockwise -

lower Gantry

Unpacking & Transporting System Units

Figure 5:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 13

Page 25

Transport the Gantry as follows:

— Ensure that the floor load for the transport path as well as the installation rooms has been approved by a

structural engineer prior to the installation. Installation floors must be laid out to support a load of min. 400 kg/

plate. During transport of the Gantry, higher loads can occur at individual points (3-point load, e.g., if the floor is

not level). Cover the transport path with sheet metal to distribute the floor load.

— Use the rollers of the transport dollies to move the Gantry to the installation location.

— Turn the rollers of the transport dollies in the direction that the Gantry is to be moved.

— To avoid damage, do not move the transport dollies over obstructions.

— Do not transport the Gantry over uneven flooring. Hard bumps against the Gantry can damage its more sensitive

parts (e.g. ball bearings).

— To minimize the danger of tilting, do not raise the Gantry more than 15 mm above the floor.

— The transport path must be smooth and level due to the required minimal floor clearance of the Gantry.

NOTE

NOTE

Appendix A: Using the Floor Template to Drill Gantry Anchor Holes or

refer to the PRD documents for necessary information.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 14

Page 26

Transporting the Gantry through Doors and Hallways

Door Height Requirements

The Gantry will fit through a standard 2000 mm door height with dolly assembly provided by Philips.

NOTE The casters have hard plastic wheels. Tiled floors should be protected with 6 mm thick tempered

masonite panels or an equivalent hard material.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 15

Page 27

Transporting the Gantry through Minimum Width Clearance

In some cases where passageways are too narrow to allow the Gantry to move, it may be necessary to remove the

Gantry covers.

Removing the Gantry Front Cover

Removing the Gantry Front Cover

WARNING This procedure requires two people. Do not attempt to remove the Gantry

cover by yourself.

1 Release the two screws on each side of the Gantry located at the lower edge of the front cover (see Figure 6).

2 Carefully open the front cover. Remove the mylar ring and set it aside.

NOTE By following this procedure, you will save time when aligning the front cover during replacement.

The Gantry Front Cover is supported by two gas struts, one on each side (see Figure 7).

Figure 6:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 16

Figure 7:

Gas Struts

Page 28

Remove the front cover as follows:

NOTE There should be no need for any further adjustment if cover

removal was performed according to the procedure.

A

B

1 Prop up the cover using a support (for example, wooden brace).

2 Release the nut securing the Gantry Front Cover Gas strut at point A

(see Figure 8).

3 Release the nut securing the cover hinge on top at point B.

4 Carefully lower the cover and set it aside.

Replace the front cover, after you have transported the Gantry to its final

position.

Figure 8:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 17

Page 29

The Patient Table

Unpacking the Patient Table

The Patient Table is delivered in a packing crate (see Figure 9); unpack as follows:

1. Release the clamps that secure the packing crate top and carefully remove it.

NOTE Keep the Top Cover, it will be used as a ramp to lower the Patient Table to the floor.

2. Release the clamps from all four sides and remove them carefully.

WARNING Take all necessary safety precautions when opening the crate. Use safety

equipment such as gloves, reinforced shoes, etc.

Figure 9: Patient Table Unpacking

3. Put the Top Cover of Patient Table Package in front of the Patient Table (see Figure 10

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 18

).

Page 30

4. Remove the anti-static wrapping.

Figure 10: Position the Package Top Cover

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 19

Page 31

5. Cut the straps which secure the Connection Piece and remove it from the package.

Mylar Box

Connection Piece

Bottom Cover

NOTE The Patient table connection piece is packaged with the patient table (see Figure 11).

6. Cut off the Straps which secure the Mylar box and bottom cover, and remove the Mylar box from Patient Table (see

Figure 11).

7. Release the 2 screws which secure the Bottom Cover to the Patient table, then remove the Bottom Cover.

8. While the Patient Table is still on the shipping pallet, release the strap that secures the Patient Table Connection

Piece and carefully remove it.

Figure 11: Bottom Cover Removal

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 20

Page 32

9. Release the four nuts (two on each sides) that secure

Front Metal Plate

the Patient Table to the pallet (see Figure 12) and

push them down, to enable removal of the Patient

Table.

10. Remove the Metal plate from the Patient Table front

bottom (see Figure 13).

Figure 12: Shipping bolts

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 21

Figure 13: Remove the metal plate

Page 33

11. Assemble the transport wheels to the Patient Table.

NOTE The secure screws (Screw (B)) for transport dollies are assembled in their original locations (see Figure 17

on page 23).

a. Remove the secure screws (see Figure 14), then install the screws without washer and spring washer(see

Figure 15), keep these items for later use.

Figure 15: Reinstall

Figure 14: Remove washers

b. Use the handles to move the Patient Table transport wheels to the minimum height.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 22

Page 34

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Hole (A)

Screw (B)

Unpacking & Transporting System Units

CAUTION Make sure not to raise the pedestals too much, so that they do not release from the Patient

Table Transport Wheels.

c. Join the transportation wheels to the Patient Table: Line up the hole (A) with the screw (B) in Patient Table Base

(see Figure 16), screw out the screw (B) till its head aligns with the outer surface of the hole (A) (see Figure 17).

Figure 16: Transport Wheel

Figure 17: Transport Wheel

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 23

Page 35

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Figure 18: Secure the Transport Wheel

Unpacking & Transporting System Units

Figure 19:

d. Repeat this same procedure for both ends of the Patient Table.

e. Close the Patient Table pedestals.

NOTE If you encounter resistance when turning the dolly screw, lubricate the screw with grease to enable easy

rotation.

12. Align the wheels with the ramp (see Figure 20), and raise the Patient Table with the dollies.

13. Position the top cover of the packing crate so that it serves as a ramp for unloading the Patient table and carefully

roll the Patient Table off the pallet (see Figure 20).

14. Transport the Patient Table to the CT scanner room.

15. Do not remove the transport dollies yet.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 24

Page 36

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Unpacking & Transporting System Units

Figure 20: Transport the Patient Table

WARNING CRUSH HAZARD: Minimize the clearance between the Patient Table and the

floor when transporting. This will prevent the possibility of Patient Table

rollover. Failure to comply may result in serious injury to service personnel.

CAUTION When moving the Patient Table into the scan room, pay attention on the anchor bolts.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 25

Page 37

Workspace and Accessories

The follow components packaged in accessories crate

Console table

Computer rack

System accessories (cables, phantoms, tools etc.)

UPS option (China only)

System Mylar

Anchor kit

Unpack the Accessories crate as follows:

1 Release the clamps that secure the packing crate top and carefully remove it (see Figure 21).

2 Remove all cartons inside the crate(see Figure 22).

Figure 21:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 26

Figure 22:

Page 38

Power Filter Box or Isolation Transformer

Philips supplies Power Filter Box for PRODUCT FAMILY (for out of China).

Philips supplies two types of Isolation Transformers for the PRODUCT FAMILY:

HuaRun Isolation Transformer (for China only): Optional

Teal Isolation Transformer (for sites world-wide): Optional

Refer to the OEM/manufacturer’s documents for additional information.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 27

Page 39

Positioning System Components

This section includes the following procedures:

Positioning the Gantry

Positioning the Patient Table

Positioning the Connection Piece

Positioning the Operating Console

Checking the Rotating Frame

WARNING ENSURE THAT THERE IS NO POWER TO THE SYSTEM.

WARNING POINT OF INJURY! USE EXTREME CAUTION WHEN MOVING THE ROTATING

FRAME BY HAND. THERE ARE MANY SHARP PROTRUSIONS AND CLOSE

CLEARANCES ON THE ROTATING FRAME THAT MAY CAUSE INJURY TO

PERSONNEL.

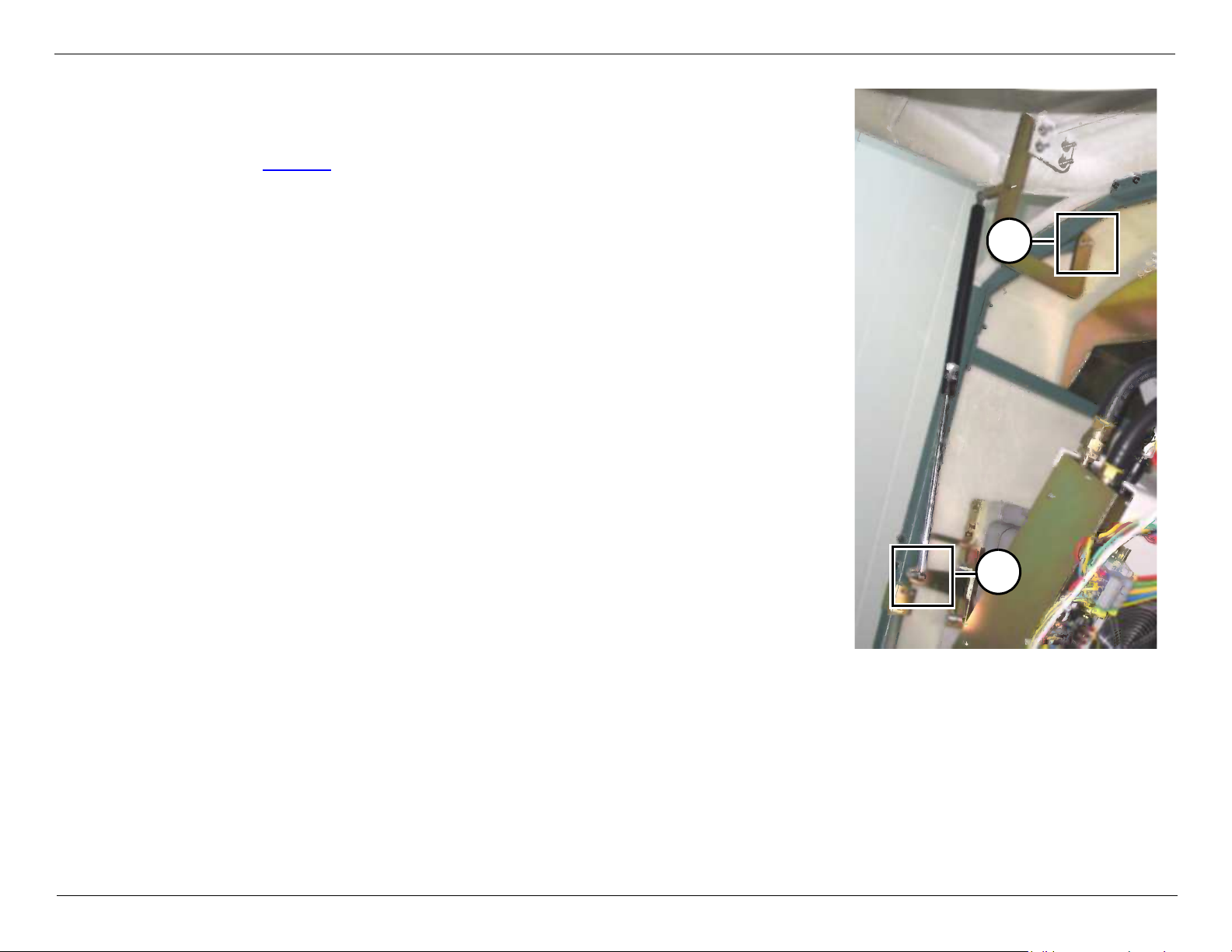

1 Remove the Gantry Tilt restraints as follows:

a On the Gantry Left Column, release the two Allen screws that secure the red Tilt restraint to the Gantry frame (see

Figure 23) with a 12mm Allen wrench.

b Release the Allen screw that secures the red bracket to the tilt mechanism.

c Store the red bracket and screws for further use.

d Repeat the procedure on the Gantry Right Column (see Figure 24).

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 28

Page 40

2 Slowly move the rotating frame two or three turns clockwise (CW) by hand.

3 Listen closely for any noises indicating friction between components or loose parts, etc. during the manual rotation.

4 Check that all components on the rotating frame are tightly secured.

5 Secure any loose cables or components if necessary.

Positioning the Gantry

Position the Gantry according to the marked alignment points indicated on the mylar template as described in

Appendix A: Using the Floor Template to Drill Gantry Anchor Holes. If you have not yet drilled the holes for the anchors

using the Mylar, drill them now.

Removing the Base Covers

To access the holes for anchoring in the Gantry frame it is necessary to remove the base panels from both the front and

rear of the Gantry as follows:

1 Supply 220V to the input of power supply G102.

Figure 23: Figure 24:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 29

Page 41

WARNING PAY MORE ATTENTION, NOW THE GANTRY IS WITH VOLTAGE.

Screw Base Panel

2 Tilt the gantry manual,loosen the screws in the base covers and then remove the covers.

3 Release the screws at both ends of the base panel (see

Figure 25).

4 Remove the base panel.

5 Remove the 220V from G102.

6 Connect the G102.

7 Lower the Gantry as much as possible without it

touching the floor.

8 Use marked Gantry alignment points (A1–A4) indicated

on the mylar template and move the Gantry so that the

anchor holes in the floor and that Gantry approximately

match on both sides.

Figure 25:

Positioning the Patient Table

NOTE The Gantry

1 Raise the Patient Table about 50mm so that the Patient Table is higher than the anchor bolts , and roll the Patient

Table on its transport dollies (see Figure 26 on page 31) over the anchor bolt.

2 When the Patient Table is positioned over the anchor bolts, lower the Patient Table front and rear synchronously to

the floor over the template (see Figure 27).

3 Put the insulation cover on the anchor bolt, and screw the nuts on the bolts (do not tighten) (see Figure 27).

4 Do not remove the transport dollies; they may be required for final levelling.

NOTE

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 30

Page 42

Figure 26: Transporting the Patient Table

Insultation

Cover

Figure 27: Patient Table Alignment

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 31

Page 43

5 Hold the bar, and release the screws to remove the

Screw Screw

Put the service

bracket in here

service bracket on both sides (see Figure 28).

Figure 29).

Figure 28: Service Bracket

6 Put both of the service brackets in the Patient Table.

Figure 29: Service Bracket installed

They will be required for repair and replacement or

maintenance procedures in the future.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 32

Page 44

Positioning the Connection Piece

To Gantry

To Patient Table

Step1: Secure to Patient Table

Once the Patient Table and Gantry are in place, install the Connection Piece between the Gantry and the Patient Table.

Note the direction of the Connection Piece indicated in Figure 30.

NOTE There is no mechanical assembly between the Connection Piece and the Gantry.

1 Secure the Connection Piece to the Patient Table using the secure screws of the Transport wheels.

Figure 30:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 33

Page 45

Positioning the Operating Console

CT-Box

Mouse

Monitor

Keyboard

Computer Rack

For positioning the Operating Console (Table and Computer Rack), refer to the system layout drawings in the PRD.

Figure 31 shows the Operating Console fully assembled.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 34

Figure 31: Operating Console

Page 46

Operator’s Table

Cover Board

Keel Board

Lateral Boards

The Operator’s Table is packed in a carton box (see Figure 32). The parts included are (see Figure 33):

Lateral Boards (Left and Right Side Panels)

Keel Board 1 unit

Cover Board 1 unit

Connector Bar 11 units

Round Fastener 11 units

Figure 32:

Figure 33:

Assembled Operator’s Table

NOTE There are two holes in the cover board for routing of monitor, keyboard, mouse, and CT Box cables.

Select the hole for routing according to the operator’s position while viewing the Gantry room.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 35

Page 47

1 Transport the Operator’s Table to the Control Room.

2 Unpack the Table carefully.

3 Assembly the Table on a flat padded surface, making sure not to scratch the surface of the parts (use the packing

carton as a surface for assembly).

There are two holes on the desk surface. The Operator can select one of them to locate the emergency switch,

depending on the angle that allow the operator the best view of the scanning room. The other hole is used for the

monitor, keyboard, mouse and microphone cables.

Assembly Steps

NOTE Two people are required for table assembly.

1 Insert the connector bars and round fasteners into the

respective holes in the four boards. Make sure that the

end with triangle arrow on the round fastener points to

the lateral hole on the board end (see detail in

Figure 34).

Figure 34: Connector bar and round fastener

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 36

Page 48

2 Erect a lateral board first, and connect it with the keel board:

a Insert the two connecting bars into the holes on the lateral side (see Figure 35).

b Insert the round fasteners in the keel board.

c Join the keel board and the lateral board. Tighten the round fasteners on the keel board clockwise with a large

screwdriver (see Figure 36).

Figure 35: Figure 36:

3 Connect the second lateral board in the same manner as in Step 2 (see Figure 37).

Figure 37:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 37

Page 49

4 Insert connector bars into all holes in the underside of the cover board.

5 Mount the installed lateral and keel board assembly on the upturned cover board. Tighten the round fasteners on

the lateral and keel boards to finish the assembly. Ensure that the connection between boards is tight and firm.

Figure 38:

6 Turn over the table.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 38

Page 50

Computer Rack

Release screw

Unpack the Computer Rack and roll it on its wheels to the Control Room.

NOTE Verify that the front wheels are unlocked to enable free movement.

The front wheels on the Computer Rack have levers that lock the wheels. These will be engaged later after completing

cable connections to the Computer Rack.

Changing Computer Rack Door Orientation

The Computer Rack is supplied with left-hand door orientation. This section describes the procedure of changing the

orientation of the Computer Rack door to right-hand orientation if called for by the site layout.

Removing the Computer Rack Front Door

1 Use a Phillips screw driver to release the GND wire

screw on the Rack (see Figure 39).

Figure 39:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 39

Page 51

2 Remove the plastic hinge lock to release the upper hinge (see Detail A in Figure 40).

Detail A Detail B

Hinge Lock

Bolt

3 Slide down the bolt that locks the hinge into the Computer Rack (see Detail B in Figure 40) and release the door

(see Figure 41).

Figure 40:

Figure 41:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 40

Page 52

Installing the Door on the Right-hand Side

1 Turn the door over so the top hinge is now on the bottom.

2 Insert the hinge into the hole (see Figure 42) at the bottom right-hand side of the Computer Rack.

3 Straighten the door and slide up the bolt that locks the hinge into hole at the top right-hand side of the Computer

Rack (see Figure 43).

Figure 42:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 41

Figure 43:

Page 53

4 Connect the GND wire to the Computer Rack (see Figure 44).

5 Slide the plastic hinge lock up to secure the upper hinge (see Figure 45).

Figure 44:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 42

Figure 45:

Page 54

Reversing the Door Handle Direction

This procedure has two main steps:

1 Reversing the Handle Lock

2 Revering the Lock Bolt

Reversing the Handle Lock

1 Use a Philips screwdriver to remove the cover on the handle lock (see Figure 46).

2 Detach the handle lock from the door (see Figure 47).

Figure 46: Figure 47:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 43

Page 55

3 Assembly the handle lock on the door in the reverse direction (see Figure 48).

4 Secure the handle lock cover with the two Philips screws (see Figure 49).

Figure 48: Figure 49:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 44

Page 56

Revering the Lock Bolt

BoltWasher

1 Use a Philips screwdriver to release the screw that secures the bolt. (see Figure 50).

2 There are two components for the lock bolt, a bolt and a washer (see Figure 51):

a Rotate the washer clockwise by 90°.

b Rotate the bolt clockwise by 180°.

Figure 50: Figure 51:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 45

Page 57

3 Tighten the screw that secures the lock bolt (see Figure 52).

Figure 53 shows the Computer Rack with right-hand door orientation.

Figure 52: Figure 53:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 46

Page 58

MX4000/6000 Dual and MX4000 Single System Installation Instructions

Installing the System

This section contains instructions for the electrical connections to the main system components:

Cable Connection Overview

Installing the Power Distributor (Power Supply Devices and/or Power Protector)

Connecting the Gantry

Connecting the Patient Table

Connecting the Operating Station

Included also are layout diagrams and tables that define routing of mains and protective conductors, and system

cables.

Installing the System

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 47

Page 59

Cable Connection Overview

Workspace

Computer Rack

X1-6108

X-ray ON Lamp

Door Interlock

Switched

P/S

CT Box

Interface

CAN

Emergency

LAN

P.C.

Dell T3500

Monitor

Keyboard

Mouse

CT-Box

GND

X2-6108

X110

UPS

(China

only)

Bracket

220VAC

Hospital

Net

(DI COM)

Isolation

Transformer

(Export only)

Right Left

380VAC

X101

Power

Cont.

PCB

CAN

Eme rge ncy

CAN

Emergency

On-site

Power In

GANTRY

OPERATORS CONSOLE

Pow er

B-Code

Inte rc om

Intercom

LAN

Figure 54:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 48

Page 60

Routing the System Cables

From To Cable

Gantry Left Column

Connector X110 Computer Rack Network Switch W119 LAN

Connector X1-6018 CT-Box interface board (X2-6017) W124

Connector X2-6018 CT-Box interface board (X3-6017) W125

Gantry Right Column

X-ray ON Signal (x118) On-site X-ray ON lamp indicator X-ray ON Signal

On-site Door Switch (x118) On-site Door Switch X101 On-site Door Switch

Gantry Center

Gantry

Figure 4 - 1:

Patient Table Connector X3077

Patient Table Connector X3073

Patient Table Connector X30718

Patient Table Connector X301 W108 230VAC Power In

Patient Table GND

W123

Connection Piece

Foot Switch Connector X30712

Computer Rack

CT Box Interface Board (X401) CT-Box W402

Host Computer Keyboard, Mouse, Monitor

Routing the External System Cables

The following table lists the cable routed to external destinations.

Table 4 - 1:

From To Cable

Isolation Transforme/Power Filter Box

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 49

Page 61

Table 4 - 1:

From To Cable

Isolation Transformer/Power

Filter Box output

Gantry Right Column X101 W 301 380VAC

Computer Rack 220VAC

Installing the Power Distributor (Power Supply Devices and/or Power Protector)

Refer to Appendix B: Installing the Power Filter Box or Isolation Transformer for installation instructions for both China

only and out of China configurations.

NOTE The Philips Service Engineer is only authorized to connect the power cable to the Gantry Right

Column.

WARNING DO NOT TURN ON POWER TO THE SYSTEM AT THIS TIME.

WARNING ENSURE ALL ELECTRICAL CONNECTIONS ARE TIGHT. LOOSE CONNECTIONS

ARE THE MOST COMMON FAILURE POINT IN THIS AND ALL WIRING SYSTEMS.

NOTE Only a licensed electrician authorized by the customer may perform line power device installation. The

Philips FSE is not authorized to install line power devices.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 50

Page 62

Connecting the Gantry

P

o

w

e

r

S

i

g

n

a

l

his section describes the following procedures:

Routing the Signal and Power Cables

Connecting the Gantry Right Column

Connecting the Gantry Left Column

Routing the Signal and Power Cables

Signal and Power cable routing is performed from the rear of the Gantry as shown in Figure 5.

Figure 5:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 51

Page 63

Route the power and signal cables as follows:

Cable

conduit

1 Pass the power and signal cables through the Gantry rear (see Figure 5).

2 Route the power cable to the left and to the Gantry Right Column. Secure the cable with cable ties from inside the

Gantry (see Figure 7).

3 Pass the power cable through the right column conduit and connect the cables as instructed in section Connecting

the Gantry Right Column.

4 Route the signal cable to the right and to the Gantry Left Column. Secure the cable with cable ties from inside the

Gantry.

5 Pass the signal cable through the left column conduit (see Figure 6 and Figure 7) and connect the cables as

instructed in section Connecting the Gantry Left Column.

Figure 6: Figure 7:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 52

Page 64

Connecting the Gantry Right Column

L1 L2 L3 N

GND

Connections on the Gantry Right Column are as follows:

Input Power Connection

Door Interlock and X-ray Lamp ON Connections

Input Power Connection

WARNING ENSURE THAT ALL BREAKERS ON THE GANTRY RIGHT COLUMN ARE IN OFF

POSITION, AND THE MAIN TRANSFORMER ON/OFF SWITCH IS OFF.

1 Connect input power to Terminal X101 as shown in Figure 8.

Figure 8:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 53

Page 65

Door Interlock and X-ray Lamp ON Connections

NOTE Door interlock cables and X-ray lamp indicator connectors must be performed by the hospital

authorized electrician.

Connect the door interlock and X-ray ON lamp cables to the contacts as shown in Figure 9.

Figure 9: Door Interlock and X-ray ON Lamp Connection

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 54

Page 66

Connecting the Gantry Left Column

Figure 5: Gantry Left Column Connections

W124 W125 W119

WARNING REMOVE ALL INCOMING POWER AT THE WALL BOX. FAILURE TO COMPLY

CAN RESULT IN SERIOUS INJURY OR DEATH TO SERVICE PERSONNEL.

On the Gantry Left Column, connect the following (see Figure 5):

Figure 4 - 1:

From To Cable

Connector X1-6018 Computer Rack for CT-Box W124

Connector X2-6018

Connector X110

Computer Rack—CAN comm. to

W125

CT-Box

Computer Rack for communication

W119 LAN

with Host Computer

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 55

Page 67

Connecting the Patient Table

Power X301

GND

Speaker X321

X311

X2

X15

X14

X10

Connect the Patient Table cables as follows:

1 Remove the front Patient Table Transport Wheel.

2 Route the two cables from the Gantry.

3 Connect the cables to the Patient Table (facing the Gantry) as shown in Figure 6 and Ta bl e 5 on page 57.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 56

Figure 6: Patient Table Connection Piece

Page 68

From Patient Table Connector Cable

Gantry cable W103 X301 Patient Table Interface X301 W103 220V

Gantry cable W103 PE Patient Table Interface GND W103

Gantry X311 Patient Table Interface X311 W103 24V

Gantry cable W109 X321 Patient Table Speaker Interface X321 W109

Foot Switch Patient Table Motion Control Board X10 Foot Switch

Gantry X2-2082 Patient Table Motion Control Board X2 Network cable

Gantry cable W109 X14-2082 Patient Table Motion Control Board X14 W109

Gantry cable W109 X15-2082 Patient Table Motion Control Board X15 W109

Connecting the Operating Station

Table 5:

Connecting the Operating Table

Connecting the CT-Box

Route cable W402 from the CT-Box Interface Board (Computer Rack) and connect it to the CT-Box as shown in

Figure 7.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 57

Page 69

Connecting the Monitor

Assemble the monitor according to the steps illustrated below.

Figure 7:

Figure 8: Assemble Monitor to Base, connect VGA Figure 9: Rotate the Monitor to expose the connection panel

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 58

Page 70

Figure 10: Connect the VGA cable to the Host Computer Figure 11: Connect the Power Cable to the Monitor and the

Connecting the Computer Rack

Figure 12 shows the Computer Rack with its two variations:

with UPS option

without UPS option

NOTE The Out of China Configuration includes a protective metal plate to prevent operator’s access to the

electrical components.

Multi-outlet

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 59

Page 71

Host ComputerSwitch

New Computer Rack with

Dell 490 and UPS Option

Out of China Rack

UPS Panel

Cover

Figure 12:

1 Unpack the Host computer and insert it into the Computer Rack.

2 For system with UPS—Unpack the UPS and insert it into the Computer Rack.

NOTE For installation of the DELL 670 on new Computer Rack (with slot), refer to the Workspace Repair and

Replacement manual to remove the slot out from the Computer Rack.

Figure 13 shows the rear view of the Computer Rack.

Open the rear cover of the Computer Rack and remove it to enable access to the internal components.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 60

Page 72

Figure 13: Rear of Computer Rack

Cable outlet

Power Inlet

Multi-outlet

(In China)

Host

Computer

UPS (option)

Switch Power

CT-Box Interface

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 61

Page 73

Cables routed to the Computer Rack are:

NOTE Figure 14 shows the cables with the rear

cover mounted. Make sure to route all cables

through the cable inlet openings in the rear

cover and in the Computer Rack.

Power Supply

W403

Mouse

Keyboard

CT-Box

Monitor Display

Monitor Power

Gantry CAN

Gantry Emergency

Gantry LAN

Hospital LAN

Power and GND from Isolation transformer/Power Filter

Box

Figure 14:

Connecting Power to the Computer Rack

Connect the 220VAC Power Cable from the Isolation Transformer/Power Filter Box to the Computer Rack.

WARNING Make sure that there is no power to the system at this time!

NOTE Power to the components in the Computer Rack can be provided as follows (see Figure 54):

• with a UPS (option) - the power supply cable from the Multi-Outlet connects to the UPS power input. The

output of UPS is then connected to the monitor and Host computer. The Switched Power Supply receives

power directly from the multi-outlet.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 62

Page 74

• without a UPS - the power supply enters the Computer Rack through a Power-In connector to the Multi-

Power Supply to PC

Computer

Power Supply

to Monitor

Power Supply to

switch power

(+5,±12V)

Power Supply to PC

Computer

Power Supply

to Monitor

Power Supply to switch

power (+5,±12V)

outlet. The components on the Rack and Console Table are connected and receive a direct power supply from

the Multi-Outlet.

Connecting Power Cables to the Multi-outlet

Verify the PC computer and the LCD monitor power cables are connected to the multi-outlet (see Figure 16).

NOTE If you have a UPS, refer to the section Connecting the UPS (Option) for correct cable connections of

the 220V AC Power Cables.

Figure 15: Multi Outlet Out of China

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 63

Figure 16: Multi Outlet for China

Page 75

Computer Connections

Table 6:

Description

Keyboard

Mouse

USB*

Hospital LAN

Gantry LAN

LCD display

Power IN cable (not shown)

Audio OUT (center jack)

Gantry LAN

Audio OUT

LCD Monitor

Power IN

Hospital LAN

Fiber Cable Port

Micphone

Mouse

Keyboard

Connect the following cables to the PC Computer according to Tab le 6 (see Figure 17).

* Mouse and KB with a USB connector can be used. If so, connect them to the USB ports.

NOTE The system adapts to 110-220V.

NOTE After power-up, verify correct LAN connection via LED indicators on LAN jack.

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 64

Figure 17: PC Computer Rear Panel

Page 76

Verifying Connection to the Switch Power

220VAC IN +12VDC +5VDC

Verify the following pre-installed connections (see

Figure 18):

— Power supply cable from the multi-outlet to the

220VAC connectors on the left side of the Switch

Power

— Cable W406 for CT-Box Interface Board to the

+12, +5VDC connectors

— Power cable +12VDC for the Hub to the +12VDC

connector (+V and COM)

Figure 18:

CSIP Level 0 © 2010 Koninklijke Philips Electronics N.V All Rights Reserved Refer to Front Cover 65

Page 77