Page 1

DVD Micro theatre

MCD715

all versions

TABLE OF CONTENTS

Service Aids ..................................................................................1-1

Info. about lead-free soldering.......................................................1-1

Service Instruction ........................................................................1-1

CD Playability Check .............................................................2-1..2-3

Disassembly digram ...............................................................3-1..3-3

Software version check and upgrading .........................................4-1

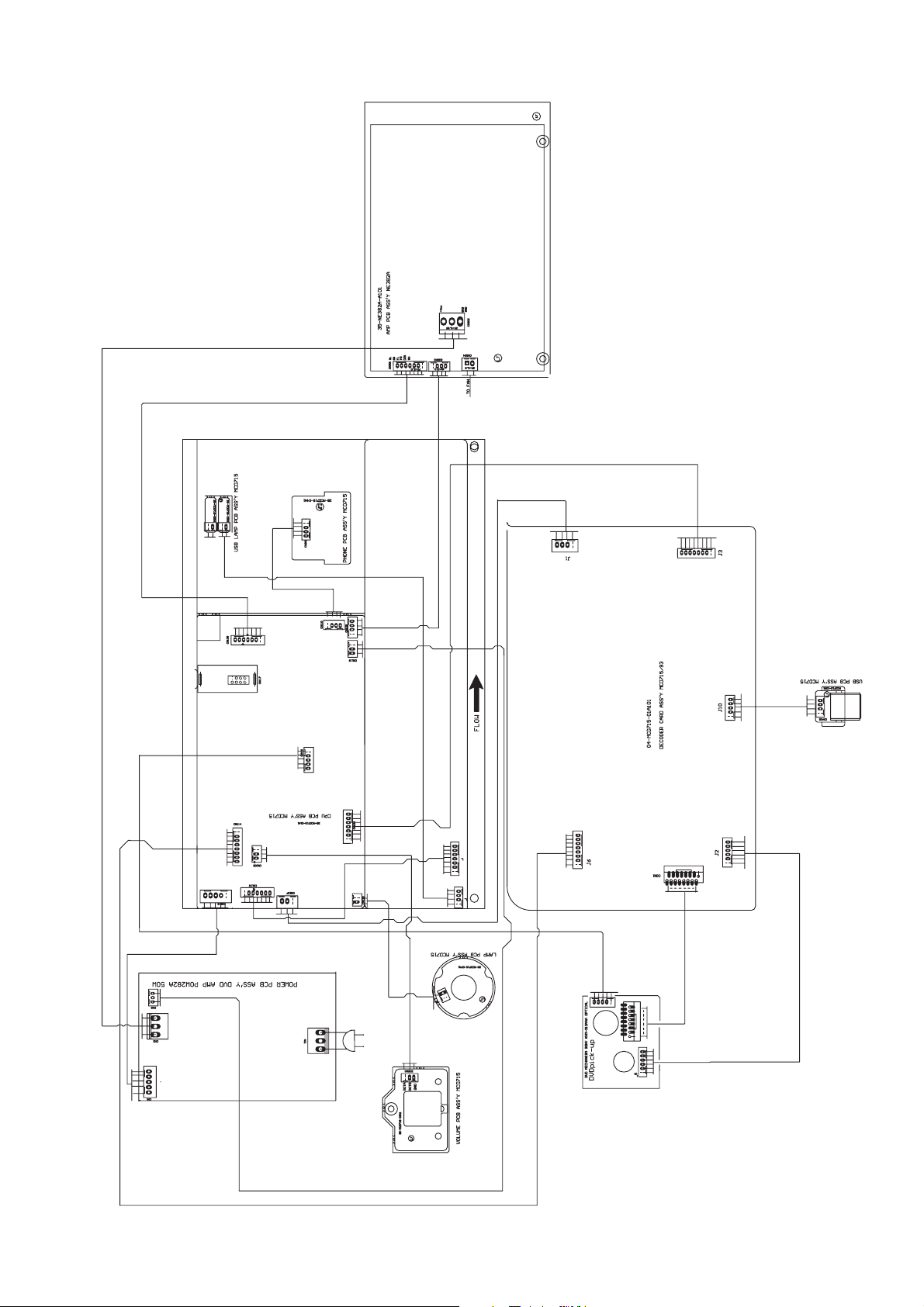

Block diagram................................................................................5-1

Wiring diagram .............................................................................6-1

Tuner Board

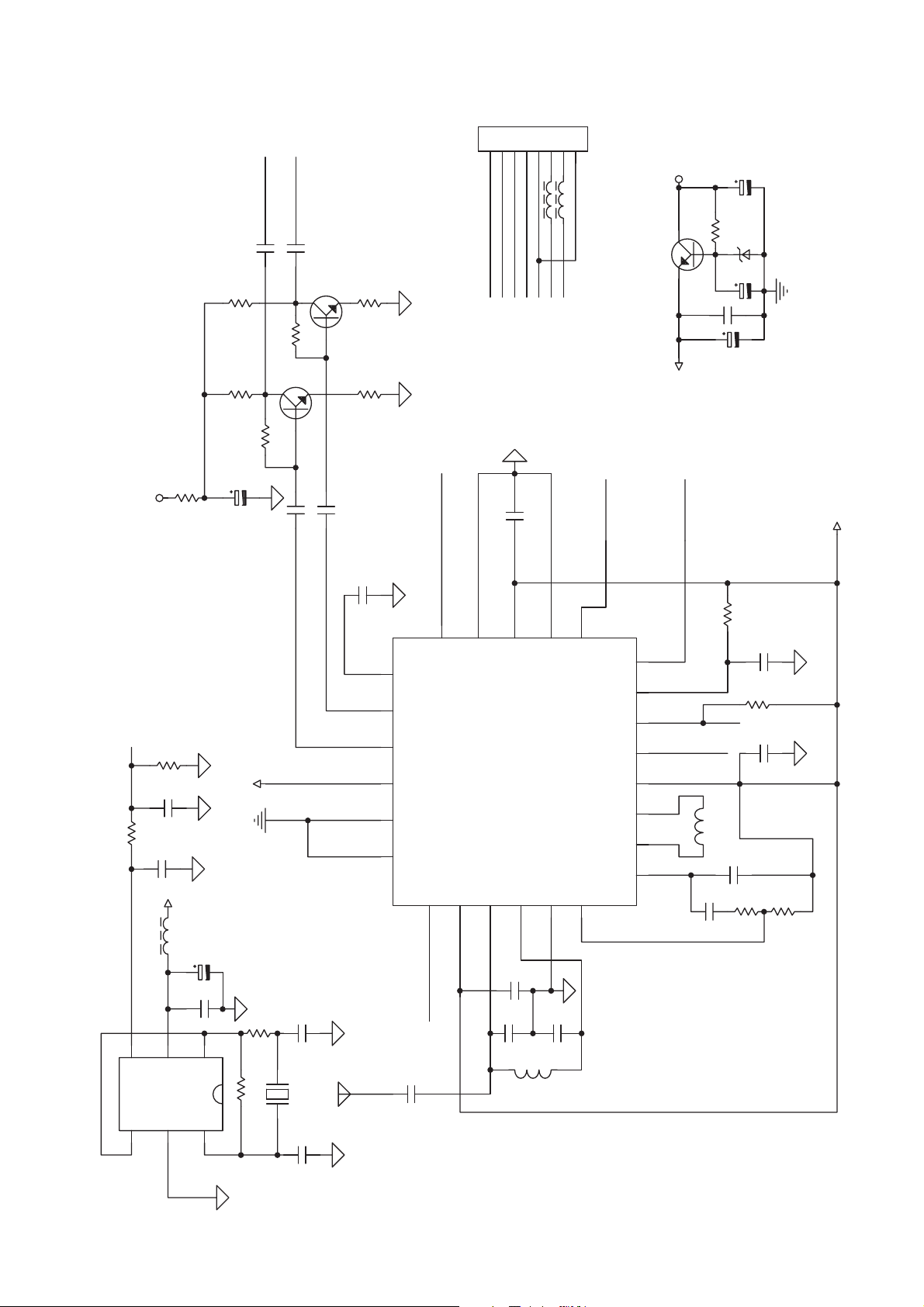

circuit diagram ..........................................................................7-1

layout diagram..........................................................................7-2

VFD Board

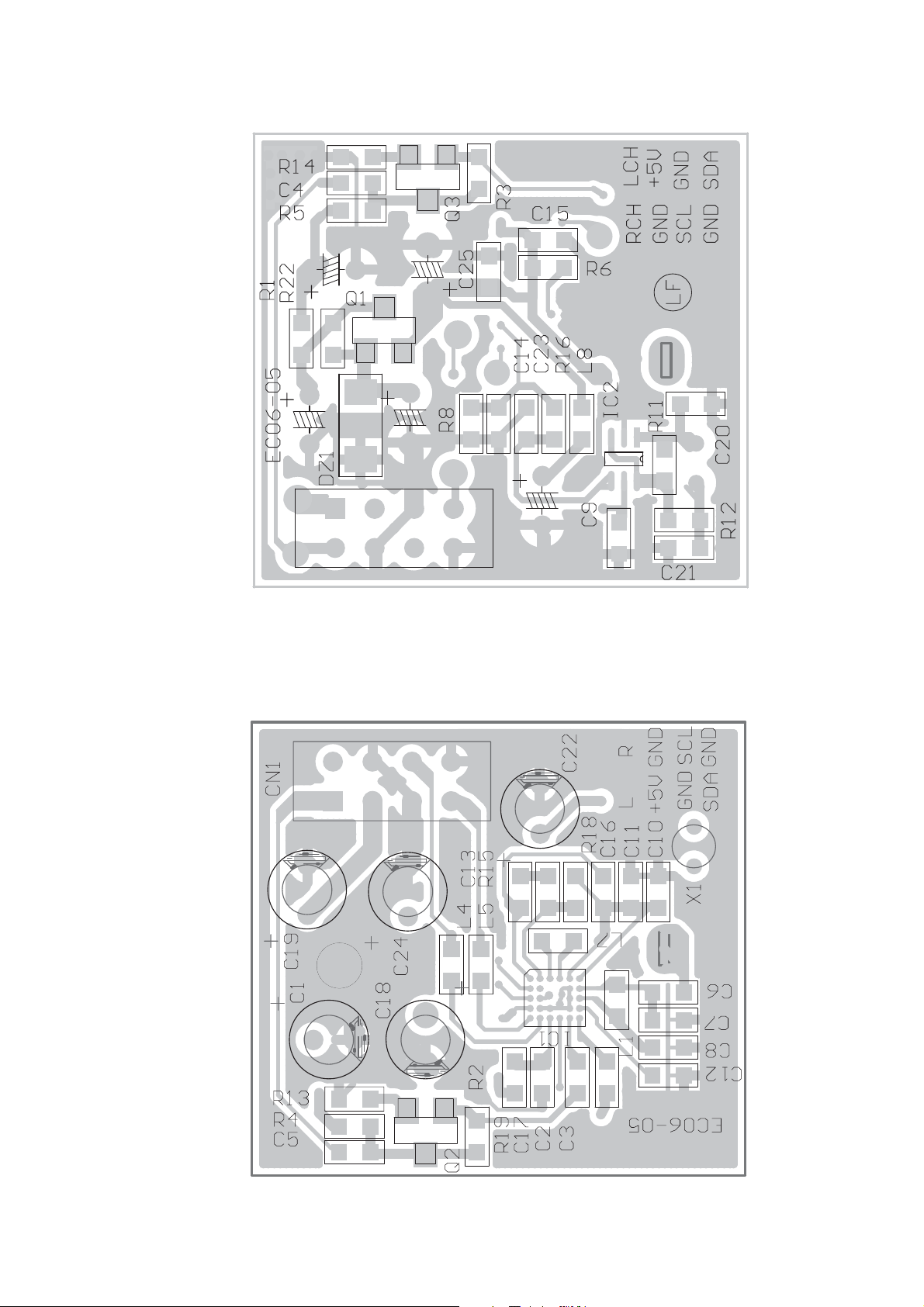

circuit diagram ..........................................................................8-1

layout diagram..........................................................................8-2

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval

system or transmitted, in any form or by any means, electronic, mechanical, photocopying,

or otherwise without the prior permission of Philips.

CPU Board

circuit diagram. .........................................................................9-1

layout diagram ..................................................................9-2...9-3

AMP Board

circuit diagram ........................................................................10-1

layout diagram ..............................................................10-2..10-3

MPEG Board

circuit diagram. .............................................................. 11-1..11-6

layout diagram ........................................................................11-7

Power Board

circuit diagram. .............................................................. 12-1..12-2

layout diagram ........................................................................12-3

Exploded view diagram ...............................................................13-1

Service partslist ...........................................................................14-1

Commercial partslist

Published by LX 0736 Service Audio Subject to modification

Version 1.1

3141 785 32111

Page 2

SERVICE AIDS

1-1

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

WARNING

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

ESD

CLASS 1

LASER PRODUCT

Lead free

Page 3

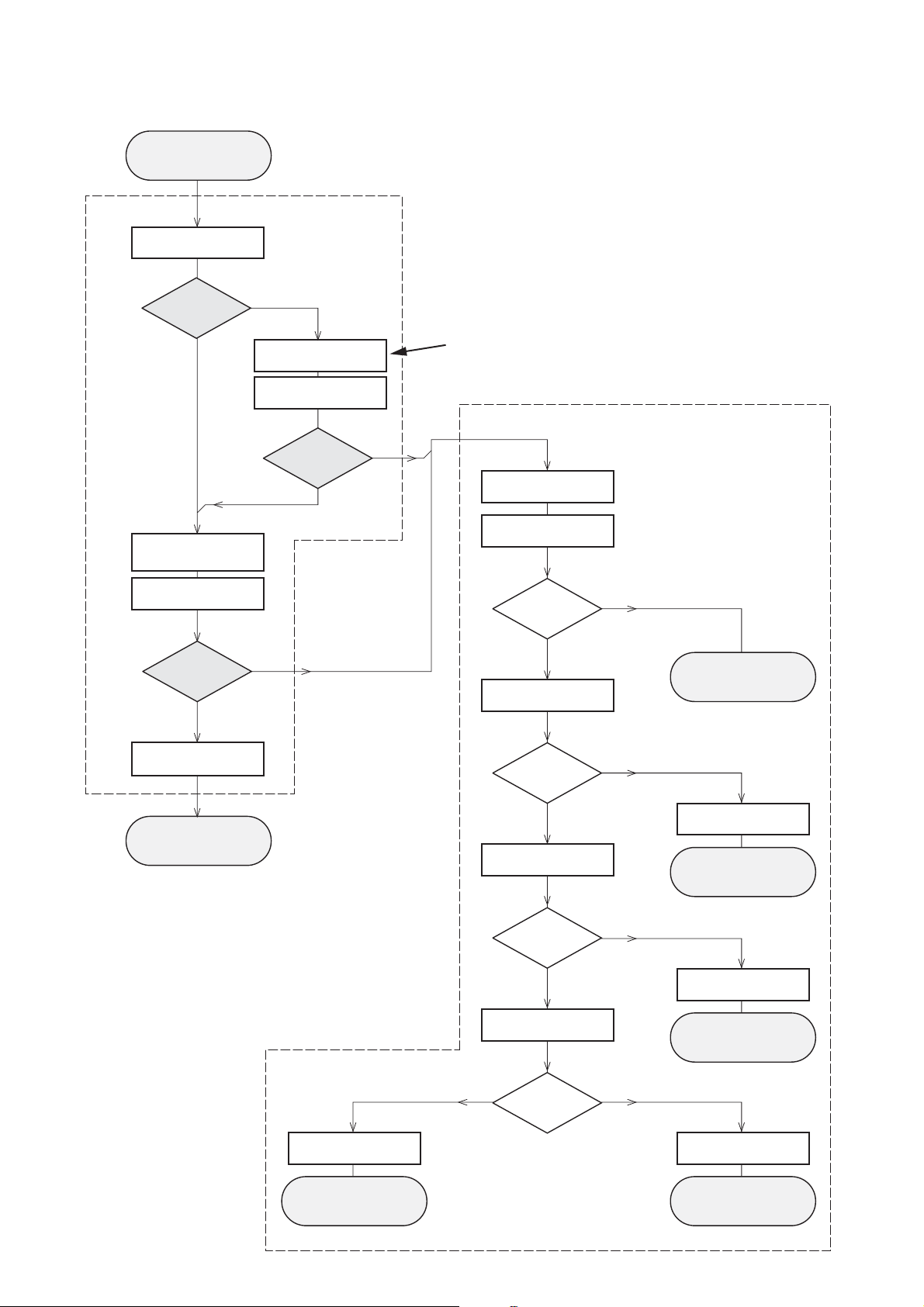

CD PLAYABILITY CHECK

Customer complaint

"CD related problem"

check playability

2 -1

Set remains closed!

1

playability

ok ?

Y

Play a CD

for at least 10 minutes

check playability

playability

ok ?

Y

add Info for customer

"SET OK"

return set

N

"fast" lens cleaning

check playability

playability

N

2

ok ?

3

For flap loaders (= access to CD drive possible)

cleaning method

4 is recommended

Standard repair procedure

N

Y

clean the lens

check playability

playability

ok ?

check "EYE-Pattern"

EYE-Pattern

ok ?

check Laser current

4

Y

N

5

N

Y

return set

replace CD Drive

6

return set

1 - 7

For description - see following pages

replace Signal Processor

return set

Laser current

ok ?

Y

check CD Drive offsets

Y

CD Drive offsets

ok ?

N

replace CD Drive

7

return set

N

replace CD Drive

return set

Page 4

CD PLAYABILITY CHECK

2-2

1

PLAYABILITY CHECK

For sets which are compatible with CD-RW discs

use CD-RW Printed Audio Disc ....................7104 099 96611

TR 3 (Fingerprint)

TR 8 (600μ Black dot) maximum at 01:00

• playback of these two tracks without audible disturbance

playing time for: Fingerprint t10seconds

Black dot from 00:50 to 01:10

• jump forward/backward (search) within a reasonable time

For all other sets

use CD-DA SBC 444A..................................4822 397 30245

TR 14 (600μ Black dot) maximum at 01:15

TR 19 (Fingerprint)

TR 10 (1000μ wedge)

• playback of all these tracks without audible disturbance

playing time for: 1000μ wedge t10seconds

Fingerprint t10seconds

Black dot from 01:05 to 01:25

• jump forward/backward (search) within a reasonable time

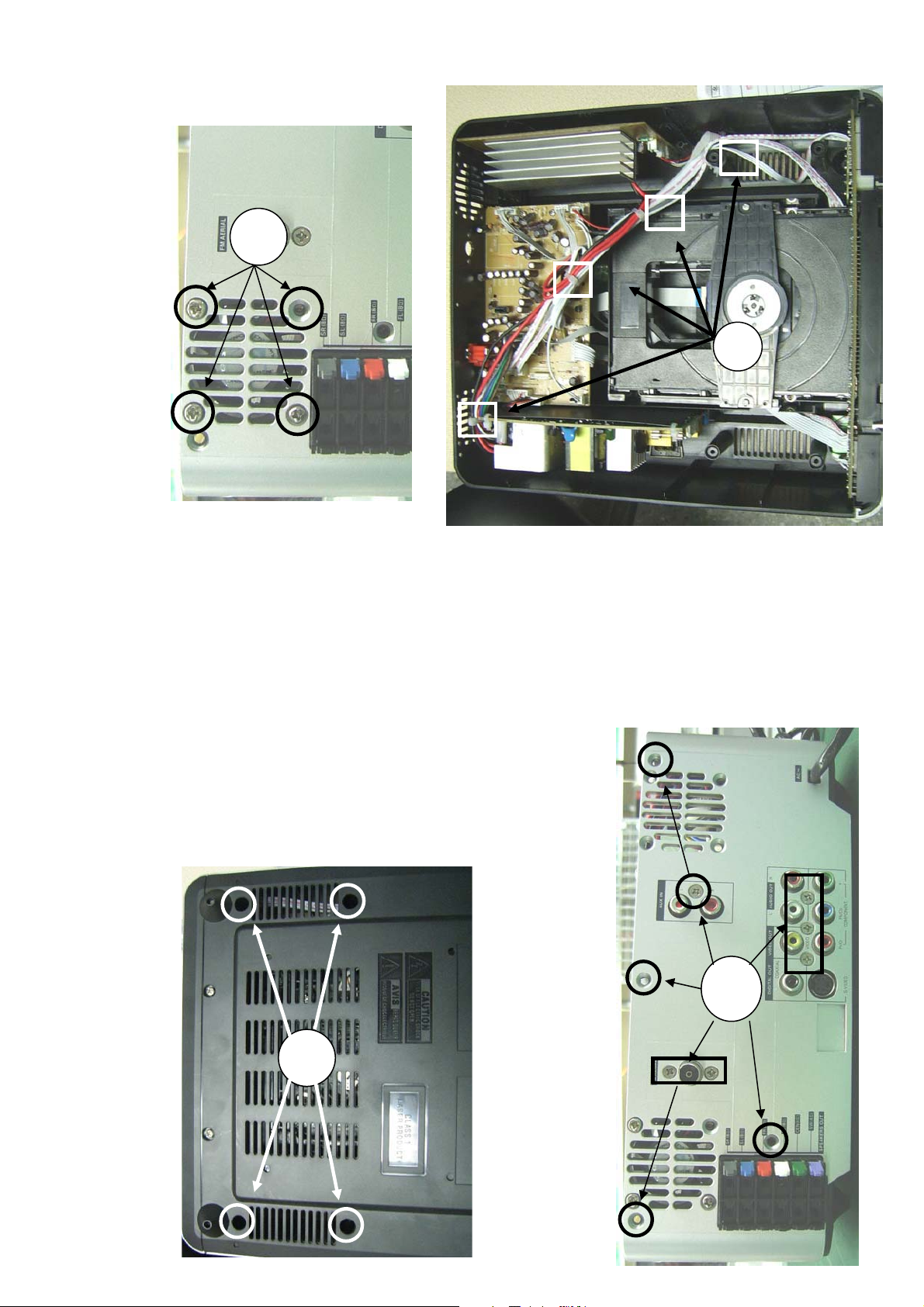

4

LIQUID LENS CLEANING

Before touching the lens it is advised to clean the

surface of the lens by blowing clean air over it.

This to avoid that little particles make scratches on

the lens.

Because the material of the lens is synthetic and coated

with a special anti-reflectivity layer, cleaning must be done

with a non-aggressive cleaning fluid. It is advised to use

“Cleaning Solvent B4-No2”, available with codenumber

4822 389 10026.

The actuator is a very precise mechanical component and

may not be damaged in order to guarantee its full function.

Clean the lens gently (don’t press too hard) with a soft and

clean cotton bud moistened with the special lens cleaner.

The direction of cleaning must be in the way as indicated in

the picture below.

2

CUSTOMER INFORMATION

It is proposed to add an addendum sheet to the set which

informs the customer that the set has been checked

carefully - but no fault was found.

The problem was obviously caused by a scratched, dirty or

copy-protected CD. In case problems remain, the customer

is requested to contact the workshop directly.

The lens cleaning (method 3) should be mentioned in the

addendum sheet.

The final wording in national language as well as the printing

is under responsibility of the Regional Service Organizations.

3

FAST LENS CLEANING (dry brush)

Use lens cleaning CD

SBC AC300 ...........................................9082 100 00043

Insert the lens cleaning CD, press PLAY and follow the

voice guide´s instructions on the CD.

Page 5

11

D4

CD PLAYABILITY CHECK

2-3

5

EYE-PATTERN SIGNAL – JITTER MEASUREMENT

Measure the signal on the input of the Signal processor

using an analog oscilloscope. Please find the exact

measuring point in your Service Manual.

EYE-PATTERN

800mVpp

TB = 0.5Ps/div

HF-Amplifier

+5V_HF

3920

100R

1K5

3902

220u

2885

2,4V

7876

6 (A-D)

2881

560p

3901

560R

BC847B

1,8V

2882

2883

470n

1,2V

82p

3907

820R

3908

3903

2K2

3K3

0,65V

2884

7877

BC847B

3904

470R

3906

3K3

470n

See below examples of the signal. Amplitude should read at

least 700mVpp using SBC444A.

VrefCD10

3905

2,6V

680R

2813

4n7

+3.3V

7878

BC847B

D3

D2

D1

3898

220R

3893

470R

3896

100R

47n

2818

4u7

2817

3n3

2814

3897

HFIN

28152816

LDON

to 3826,3827

3899

CD_DA: 0V / CD_RW: 3V

2K7

+3.3V

3895

2887

10

D3

9

D2

8

D1

VREF GE

7

VRIN

6

IREF

27K

5

VDDA1

47n

4

VSSA1

3

ISLICE

33K

2

HFIN

100p

1

HFREF

22n

ON

LD

64

3909

3923

10K

Sanyo

DA12T3

6

CD DRIVE – LASER CURRENT MEASUREMENT

The laser current can be measured as a voltage drop on a

resistor. The resistor is marked in every Service Manual.

The value depends on the type of CD drive.

typical value most probably defect

VAMxxxx : 150-230mV t350mV

MCDxx : 170-230mV t300mV

DA1x : 210-250mV t350mV

DA2x : 175-200mV t250mV

Use SBC444A (CD-DA) for measurement.

Laser power control

U >250mV

->Laser damaged !

+5V_HF

LASER DIODE

3817

47R

3820

4R7

470n

2876

47R

47R

3819

3818

3,9V

2V

47n

2869

3,3V

7879

BC807-40

2877

3821

47u

3822

100n

2878

1R

10K

3823

+5V

2841

100n

4,6V

7811-A

LM358D

1

3V

1K

0,17V

3

8

2880

2

4

0,17V

2879

33p

1n

good

bad

If the oscilloscope shows a signal like the ‘bad’ one, and/or

the amplitude decreases within 1 minute - the CD drive has

to be replaced.

7

CD DRIVE – OFFSET MEASUREMENT

The photodiodes of the CD-drive may have an offset. These

offsets have to be compensated by the signal processor.

High offsets can lead to poor playability of some CDs

(skipping tracks).

To measure the offset values, start the Service Test

Program - section “Focus Test” without a CD.

The offsets can be measured with a DC Millivoltmeter

directly on the connector (see drawing below). Pin

numbering varies from drive to drive.

The values from diode A-D should read 0±10mV.

Diodes E and F are less critical.

CD Drive

Sanyo DA12T3

1800

VREF

VCC

E

E

B

A

C

D

F

D

A

B

C

F

GND

If one of the offsets is higher than ±10mV the CD drive has

to be replaced. Otherwise replace the Signal Processor.

16

15

14

13

12

11

10

9

8

VrefCD10

+5V_HF

E

D

A

B

C

F

E

D

A

B

C

F

Page 6

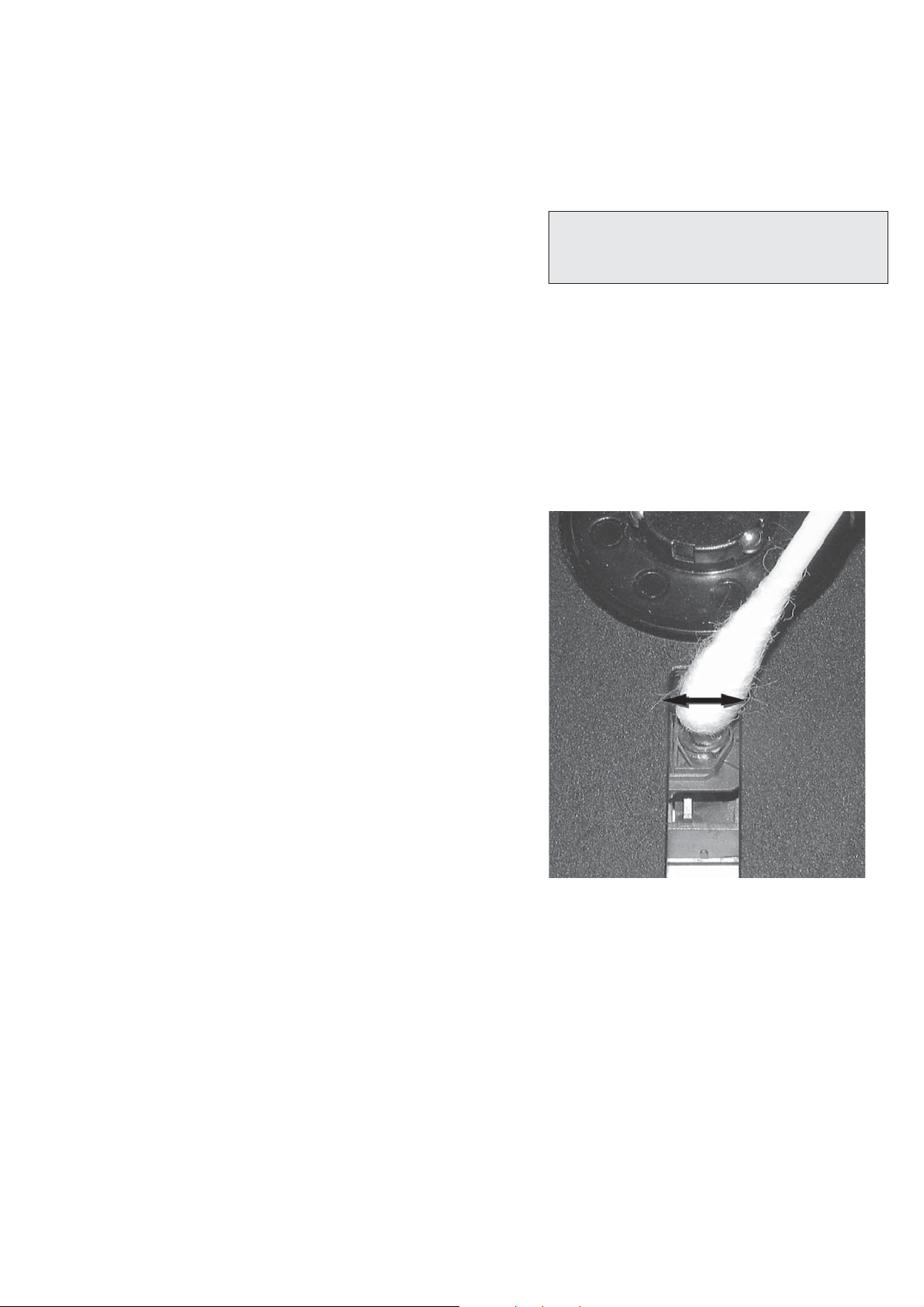

Page:56

C

D

3 - 1

B

A1

A. Remove bottom cover C. Loosen screws h15FM(4PCS),and then remove the fan

Disassembly diagram

A1. Loosen screws h3$4PCS)

B. Loosen screws h10FA(10PCS),and D.Cut off 4PCS wire tic

then remove top cover and rear shuck

Page 7

Page:57

H

I

I. Loosen screws h10BA(2PCS), remove bezel panel

F

3 - 2

G

E

E. Loosen screws h6PT(3PCS), remove CPU board HǃLoosen screws h6PT(4PCS), remove decode card

F. Loosen screws h8BA(1PC), remove AMP board

Disassembly diagram

G. Loosen screws h10PWA(4PCS), remove mechanism core

Page 8

Page:58

L

J

3 - 3

K

J. Loosen screws 2.h8BA(8PCS), remove VFD board

Disassembly diagram

. Loosen screws 2.h8BA(3PCS), remove volume card L. Loosen screws 2.h8BA(4PCS), remove USB, earphone socket

K

Page 9

4 - 1 4 - 1

SOFTWARE VERSION CHECK AND UPGRADING

Page 10

TDA8947J

TDA8947J

PT2322

9228

24C02

PT2323

TUNER

BLOCK

IC:TEA5760

AUX R

AUX R IN

AUX L

AUX L IN

RED

ROUT

VIDEO

V-OUT

S-VIDEO

S-V OUT

COAXIAL

OPTICAL

GREEN

GR OUT

BLUE

BOUT

MEPG2

BLOCK

MECHANISM

DVD

STBY&MUTE

CONTROL

VFD

PT16311

REM

1

GND

2

Vcc

3

REM-SENSOR

+5V

+5V

+5V

+22V

GND

DVD +12V

AC

POWER BLOCK

STANDBY

+5V

DVD ON/OFF

TUNER POWER

TUNER IN

DVD MR

DVD ML

D-FL

D-FR

SL

SR

CEN

SW

SW

CEN

SL

SR

FL

FR

FL

FR

SW

CEN

SL

SR

CPU

SDA

SCL

FR

FL

SLSRCEN

SW

KEY

CONTROL

FR

SR

CEN

SW

SL

FL

STANDBY

MUTE

SUR-MUTE

MUTE

SUR-MUTE

FM

AUX L IN

AUX R IN

TL072

+12V

-12V

+12V

-12V

SW

5 - 1

5 - 1

SET BLOCK DIAGRAM

Page 11

6 - 1

6 - 1

SET WIRING DIAGRAM

Page 12

7 - 1

1234567

CN1

LOUT

ROUT

224

224

C5

C4

Q3

9014

R14

224

1K

R13

1K

INTX

C12

104

R5

4.7K

R3

1M

Q2

R2

1M

C2

9014

224

C3

R4

4.7K

R1

47

+5V

C1

22uF

LOUT

ROUT

+5V

C15

SGND

SGND

103

600R

L4

SCL

600R

L5

SDA

8

8P

223

C18

330

47uF/6.3V

C19

DZ1

3.6V

C24

22uF

Q1

+5V

R22

8050

C25

47uF

3.0V

SDA

SCL

3.0V

7 - 1

CLOCK

R16

4

10K

R8

C14

C23

5

68k

10pF

100pF

3.0V

L8

10uH

C22

6

22uF

C9

104

B2

IC1

TMUTE

VAFR

VAFL

AGND

FREQIN

C1

INTX

MPXOUT

TIFcentre

VCC

A6

D6

E6

E5

MPX

E4

B5

D5

D2

DGND

C10

B6

RFIN1

D1

103

VDD

RFIN2

C6

D3

DGND

RFGND

C5

E1

DATA

LOOPSW

A2

TEA5760UK

CLOCK

VREFDIG

BUSEN

SWPORT

VccVCO

LO2

LO1

CPOUT

R19

10R

C17

103

E2

E3

C2

B1

R6

BUS_ENABLE

SW1

4.7K

C11

103

A5

A4

L7

C13

39nH

104

C16

103

R18

100K

R15

10K

A3

A1

CLOCK

C21

R12

1M

39pF

C7

27pF

C8

47pF

74HC2G04

IC2

2Y

2A

3

2

VCC

GND

1Y

R11

10M

X1

1A

1

CIRCUIT DIAGRAM - TUNER BOARD

32.768K

C20

12pF

RFIN

C6

100pF

L1

120nH

Page 13

7 - 2

7 - 2

LAYOUT DIAGRAM - TUNER BOARD

Page 14

8 - 18 - 1

123

CN202

ROTA

3

MCD715-08A1

A

ENCODER

R229

0.5/0.5

C200

VFD200

NE-1300CD-3.G

123

1

2

CN501

1

2

2P/2.0

123

4

CN401

4P/2.0

VOL BLOCK

MCD715-07A1

ROTB

VGND

2

1

B

G

ENCODER800

R228

0.5/0.5W

C201

104

104

VF2

36

VF2

35

S16

34

S15

33

S14

32

S13

31

S12

30

S11

29

S10

28

S9

27

G12

26

G11

25

G10

24

G9

23

G8

22

G7

21

NC

20

NC

19

NC

18

NC

17

G6

16

G5

15

G4

14

G3

13

G2

12

G1

11

S8

10

S7

9

S6

8

S5

7

S4

6

S3

5

S2

4

S1

3

VF1

2

VF1

1

LED703

LED

R702

220

LED702

LED

R701

220

LED701

LED

R700

220

SW206

SW205

PROGRAM

SW202

SW201

OPEN

K1

K2

K1

K2

VF1-1

VF2-1

K4

-28V

3

2

1

CN001

3P

S16

S15

S14

S13

S12

S11

S10

S9

G12

G11

G10

G9

G8

G7

104P

G6

G5

C203

G4

G3

G2

G1

S8

S7

S6

S5

S4

S3

S2

S1

K3

S11

S12

26

25

S13

S13

27

S14

S14

28

S15

S12/KS12

S15

S16

G12

G11

G10

G9

G8

G7

G6

G5

G4

G3

G2

G1

S11/KS11

29

S16

30

S17/G12

31

S18/G11

32

Vdd

33

VEE

34

S19/G10

35

S20/G9

36

G8

37

G7

38

G6

39

G540G4

41

K3

KS2

4148

SW209

D207 4148

D206 4148

D205

S2

S3 KS3

S1

S10

24

19

23

20

S6/KS6

S4/KS418S5/KS5

S7/KS721S8/KS822S9/KS9

S10/KS10

IC203

uPD16311

G3

G2

Vdd45LED546LED4(BBE)47LED3(POWER)48LED2(FANCT)

G1

43

44

42

USB LED

LED3

LED4

R208

4.7K

K4

SW200

D209

17

S3/KS3

49

LED2

SW207

PLAY

SW203

PRERET+

KS2

KS3

4148

S1S2S3S4S5S6S7S8S9

15

16

S1/KS1

S2/KS2

Vss

LED1(7507RST)

51

50

47K

R254

K3

STANDBY

NES

+5V

LED

LED501

㓓㡆

PRE

PRERET-

K4K3K2

R501

SW208

SW204

K4

K1

MCD715-05A1

1K

DSC

SOURCE

KS2

KS3

R258 33K

R257 33K

R256 33K

33K

R255

14

Vdd

KEY4

13

KEY3

12

KEY2

KEY1

STB

CLK

IC

DIN

DOUT

SW4

SW3

SW2

SW1

OSC

DS-STB1

11

10

9

8

7

6

5

4

3

2

1

DS-CLK

DS-DAT

52

C217

104P

+5V

LED200

ECO-POWER

R207

0

UGND

3

5

4

2

1

MCD715-10A1

D-

D+

vbus

GND

GND

J1001

USB HOST

+5V

R232

10K

R259

4K7

R231

10K

USB BLOCK

D201

L201

+5V

ECO-power

4

CN201

RO-H

LO-H

MU-H

5

2

1

4

3

L

R

MCD715-02A1

DZ200

6.2V/1W

R210

R211

10K

R204

100

R205

VF2-1

VF1-1

6

7

B200

1

3

2

C234

473M

Q208

8050

1K

R226

C232

470/16V

4001

D204

4148

200UH

R224

X

47uF

C205

COM4

GND-H

9

678

11

10

J201

PHONE3.5

15

100

-28V

C235

220U/35V

D208

FR104

10

9

BZ1

4

5

C233

8050

Q209

R227

1K

104

R203

100

4

3

2

1

CN208

TO-USB

R206

USB LED

+5V

104

C202

0

CIRCUIT DIAGRAM - VFD BOARD

+5V

REM

DS-STB1

DS-DAT

REM

+5V

ECO-POWER

GND

DS-CLK

CN?

7P

12345

6

7

C204

GND

47

47uF

104

R260

C219

3

2

Vcc

REM1GND

S200

REMOTE

MCD715-02A1

Page 15

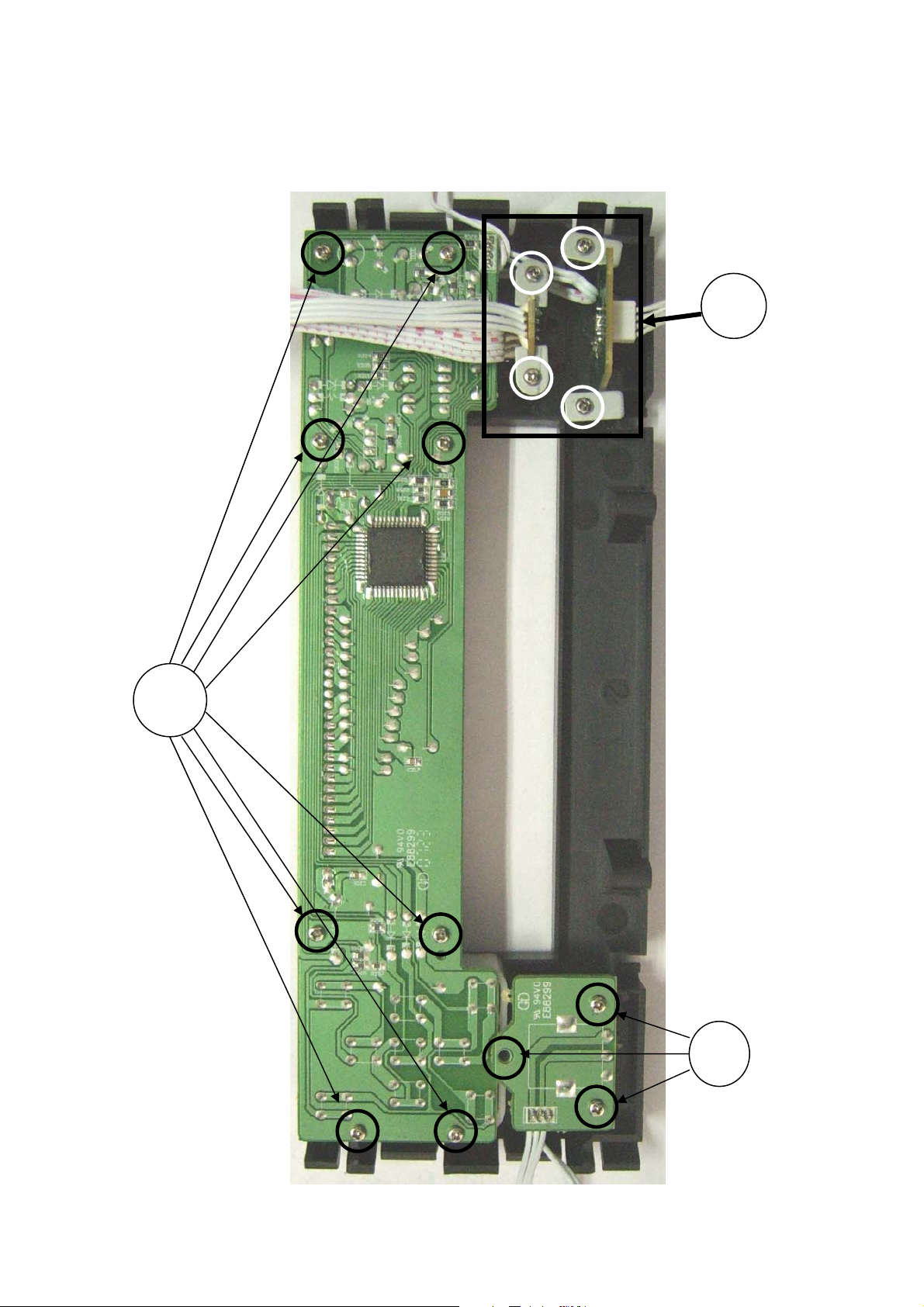

8 - 2 8 - 2

LAYOUT DIAGRAM - VFD BOARD

Page 16

L1

1

L2

2

L3

3

L4

4

FL-IN

5

FR-IN

6

CEN-IN

7

SW-IN

8

SL-IN

9

SR-IN

10

MIXO

11

VCC

12

REF

13

GND14SDA

15

SCL

16

SR-OUT

17

SL-OUT

18

SW-OUT

19

CEN-OUT

20

FR-OUT

21

FL-OUT

22

LPF-O

23

LPF-I

24

R4

25

R3

26

R2

27

R1

28

IC104

PT2323

R1090

270

R1089

270

R1088

270

R1087

270

R1086

270

R1085

270

C1076

683J

C1079

223J

R1055

24K

R1054

24K

C1029

4.7uF/50V

C10304.7uF/50V

C1031

4.7uF/50V

C1022

4.7uF/50V

C1021 4.7uF/50V

C1020

4.7uF/50V

C10194.7uF/50V

C10184.7uF/ 50V

C10174.7uF/ 50V

C10164.7uF/ 50V

C10154.7uF/ 50V

C10144.7uF/ 50V

C1040

10uF/25V

C1051

100uF/16V

C1053

104P

R1047

100

R1082

20K

R1081

20K

C1028

4.7uF/50V

C1027

4.7uF/50V

C1026

4.7uF/50V

C1025

4.7uF/50V

C1024

4.7uF/50V

C1023

4.7uF/50V

1

2

3

4

5

6

7

8

9

CN113

9P/2.0

D-MUTE

AGND

FLIN

FRIN

AGND

SR

SL

SW

CEN

+12V

R1063

1K

R1064

1K

D1001

4148

MUTE

AUX1-L

AUX1-R

SCL

SDA

R1061

6.8K

R1062

6.8K

R1040

100K

R1041

100K

C1089

473(M)

C1090

473(M)

C1085

10uF/16V

C1091

473(M)

C1088

473(M)

RCMID2_FR

1

RCMID1_RF2CTRE_FR3IN_FR4IN_SR5IN_SUB

6

VREF

7

GND

8

IN_CT9IN_SL10IN_FL11CTRE_FL12RCMID1_FL

13

RCMID3_FL

14

RCBAS1_FL

15

RCBAS2_FL

16

OUT_FL17OUT_SL

18

OUT_CT

19

VCC

20

OUT_SUB

21

OUT_SR22OUT_FR

23

SCL

24

SDA

25

GND

26

RCBAS2_FR27RCBAS1_FR

28

IC105

PT2322

C1102

104M

C1101

104M

C1083

103M

C1082

103M

C1080

103M

C1081

103M

R1076

3.3K

R1093

6.2K

R1092

6.2K

R1075

3.3K

R1083

20K

R1084

20K

C1086

222M

C1084

10uF/16V

C1087

222M

C1052

100uF/16V

C1056

104P

R1098

100

C1092

473(M)

C1094

104

C1093

104

SDA

SCL

FL-IN

SR-IN

+12V

C1058

4.7uF

C1057

4.7uF

CEN-IN

SW-IN

SL-IN

FR-IN

R1056 1.5K

R1057 1.5K

R1058 1.5K

R1059 1.5K

R1060 1.5K

1

3

2

J1000

RCA-2P

1

2

3

4

5

6

7

CN109

8P

TUN-L

TUN-R

IOP-L

IOP-R

AGND

123

45678

CN114

8P/2.0

+12V

REC-R

REC-L

AGND

S12V

MIC R

C1049

102

C1050

100uF/16V

R103947K

C1039

2.2uF/25V

MIC L

Q109

8050

Vcc

1

REF

2

GND

3

DGND

4

CLK

5

VCO

6

CC1

7

CC0

8

L1IN

16

L1OUT

15

L2OUT

14

L2IN

13

OUT2

12

IN2

11

IN1

10

OUT1

9

IC108

PT2399

C1012

4.7uF/50V

R1024

15K

R1014

10K

R1013

10K

R1035

22K

R1033

18K

R1010

220

R1026

15K

R1027

1K

R1034

22K

R1019

220K

C1013

4.7uF/50V

C1011

47uF/25V

R1025

15K

R1015

10K

R1016

10K

C1006

1uF/50V

D1000

4148

C1034

220uF/16V

C1010

47uF/25V

C1041

561

C1042

561

C1044

683(M)

C1045

683(M)

C1033

332

C1047

104(M)

C1046

104(M)

DZ101

5V6

MIC

R1018

6K8

R1020

5K6

+12V

R1029

1K

R1043

100

R1037

1M

R1036

47K

Q110

8050

R1046

2.2K

C1032

332

C1037

10uF/25V

C1043

103

R1021

5K6

MIC ONLY

Q108

9014

R1091

270

R1065

4.7K

R1066

4.7K

C1003

102

R1079

47K

R1008

1M

+12V

R1071

8.2K

R1017

10K

C1069

154P

R1073

3.3K

+Vs

8

OUT2

7

IN2-

6

IN2+

5

OUT1

1

IN1-

2

IN1+

3

-Vs

4

IC107

TL072

C1071

683P

C1070

334M

R1072

240K

R1070

8.2K

C1072

224P

C1055

104p

C1054

104p

R1074

3.3K

C1065

220uf

C1066

220uf

SER-IN

123

CN118

3P/2.0

R1049

100

C1064

220uF

DGND

+5V

DGND

S12V

TUN-L

TUN-R

+5V

AGND

SCL

AGND

SDA

C1075

100uF/16V

R1068

10K

R1069

10K

1

2

CN116

3P/2.5

12345

678

CN117

8P/1.0

1

2

3

4

5

CN115

5P/2.5

S12V

DGND

MUTE-O

R1053

100

R1050

100

R1051

100

C1100

330P

C1098

330P

C1097

330P

C1099

330P

123

CN107

3P/2.5

HP-MUTE

+12V

AGND

123

4

CN110

4P

R1096

150

H-OUT L

H-OUT R

R1094

1K

R1095 1K

D1003

4148

DZ102

5.1V

OUT1

1

MUTE

2

IN1

3

GND

4

IN2

5

BIAS6OUT27VDD

8

IC106

PT2309

C1096

47uF

C1095

47uF

R1097

10K

C1068

220uF

C1067

220uF

C1063 2.2uF

C1062

2.2uF

R1042

100K

D1002

4148

Q112

8050

R1067

4.7K

R1080

47K

FL-IN

FR-IN

MUTE-O

IOP-L

IOP-R

FR

FL

MIC-R

MIC-L

C1077

2.2uF

C1078

2.2uF

MUTE

1

2

3

4

CN108

4P

AGND

+12V

S-MUTE

MIC-MUTE

+12V

MIC IN

DGND

GND

C1073

10uf

X101

32.768

R1131

10K

C1109

15P

SDA

SCL

A5V

X102

4.19MHz

C1120

30P

C1121

30P

X103

32.768KHz

C1123

30P

C1124

30P

C1107

47UF/10V

C1125

104P

R1134

22K

D1006

4148

C1108

10UF/10V

SCL

SDA

MUTE

M-DOWN

36

M-UP

35

LED

34

DVD-STB

17

DVD-CLK

16

MUTE

30

PLL-DA

21

SUR-MUTE

29

RDS-SDA

19

ST/TUNED

27

SDA

26

SCL

25

TUN-ON

24

PLL-CE

23

PLL-CL

22

TEST

9

Vss

6

XT-OUT

7

XT-IN

8

M-CLOSE

32

DVD-DI

15

DVD-DO

14

DVD-ON

13

RESET

12

X-OUT

11

X-IN

10

RDS-Q

20

RDS-SCL

18

M-OPEN

33

Vdd

5

CLOSE-SW

4

DVD-TMS

3

OPEN-SW

1

ROT-A

41

KEY

2

ROT-B

42

REMTOE40DS-CLK

39

DS-DAT38DS-STB1

37

STANDBY

31

4052-A

28

M+

43

M-

44

IC101

2SC9228

STANDBY

A0

1

A1

2

A2

3

GND

4

SDA

5

SCL

6

TEST

7

Vdd

8

IC103

24C08

1

2

34567

CN104

7P/2.0

D1004

IN60

REM

R1124

68K

R1125

4.7K

DS-STB1

DS-DAT

DS-CLK

REM

ROT-A

ROT-B

R1109

10K

R1108

10K

R1110 10K

R1112 10K

C1118

103P

C1119

103P

+5V

D1005

4148

DGND

DVD IR

DVD STB

DVD CLK

DVD DATA

L101

100UH

R1128

100

DVD-ON

DVD-TMS

IPOD-TX

R1119

1K

R1120

1K

R1115

470

R1116

470

R1114

10K

R1113

10K

Q104

8050

Q103

8050

12345

CN101

5P/2.0

M-CLOSE

M-OPEN

Q102

8550

Q101

8550

OPEN-SW

CLOSE-SW

M-CLOSE

M-OPEN

OPEN-SW

CLOSE-SW

LED

M1+

M1-

DGND

+5V

C1103

220UF/16V

R1117

2.2K

R1118

2.2K

C1104

470P

C1105

470P

A5V

S-MUTE

ECO-POEWR

ROT-A

ROT-B

DGND

R1122

10K

USB-ON

+5V

Q105

8050

R1129

22K

D1007

4148

R1130

47K

C1106

220UF/16V

LED

+5V

DGND

USB-ON

DOCKCTL

IPOD-DET

1

2

3

CN105

5P/2.0

Ctrl

IPOD-TX

DOCKCTL

IPOD-DET

R1123

0

R1099

100

R1100

100

R1101

100

R1102

100

R1103

100

R1104

100

C1112

330P

C1113

330P

C1114

330P

C1115

330P

C1116

330P

C1117

330P

R1126

100

R1127

100

C1110

330P

C1111

330P

R1105

100

R1106

100

R1107

100

DVD-ON

12345

6

CN103

6P/2.0

+12V

oscI

1

oscO2Int3Vss

4

SDA

5

SCL

6

Clk

7

Vdd

8

IC102

PCF8563

A5V

123

456

7

CN119

7P/2.0

DS-STB1

DS-DAT

DS-CLK

REM

DGND

+5V

ECO-POEWR

STANDBY

DVD-ON

123

4

CN111

4P/2.0

DGND

MIC-L/R

AGND

+12V

1

2

3

4

CN102

4P/2.0

MIC-R

MIC-L

AGND

+12V

123

4

CN106

4P/2.0

R1135

47K

R1136

47K

MIC-L

MIC-R

1

2

CN120

2P/2.0

C1126

2.2UF

C1127

2.2UF

REC-R

REC-L

1

2

3

4

CN112

4P/2.0

MUTE

+12V

-12V

R1137

100 1/4W

V21SNAF

9 - 1

9 - 1

CIRCUIT DIAGARM - CPU BOARD

Page 17

9 - 2

9 - 2

LAYOUT DIAGARM - CPU BOARD

Page 18

9 - 3

9 - 3

LAYOUT DIAGRAM - CPU BOARD

Page 19

10 - 1

000

000

R342

R341

CENOUT-

Vcc

CENOUT+

C310

LOUT-

ROUT+

SWOUT-

Vcc

C325

1000uF/25V

C308

104

R327

10K

12V

DZ300

15K

Q301

8050

R325

1.5K

IC300

R323

8050

Q300

R321

270

C322

ROUT

1

IN1+8IN3+

223

223

C318

R309

2.2K

R317

FRIN

OUT1+

2.2K

6

C319

47K

R316

FLIN

1000uF

LOUT

4

OUT2-

IN2+

C312

C311

9

C320

1000uF

C321

14

1uF

102

OUT3-

IN4+12CIV

102

1K

R318

SWIN

C309

104

17

16

3

OUT3+

13

C316

22u/25V

R310

R308

2

GND215VCC2

11

47K

333

C328

SVR

D301

7

4148

R331

GND1

TDA8947J

MODE2

SGND

MODE1

5

10

C332

2.2uF

C329

100u/25V

4.7K

R332

4.7K

Q304

8050

R311

47K

R319

1K

R330

4.7K

C326

10uF/16

VCC1

47K

15K

R324

Q302

R322

R328

8050

10K

12V

DZ301

R326

1.5K

Q303

8050

270

SWOUT+

SLO-

SRO+

1

IN1+

IC301

8

474

C333

R315

R314

4.7K

R335

SRIN

OUT1+

47K

474

C334

4.7K

R334

17

3

15

2

OUT3-

102

10K

R329

CENIN

OUT3+

IN4+12CIV

16

VCC1

GND2

GND1

VCC2

SVR

SGND

MODE1

7

11

C317

10

22u/25V

D304

4148

R338

000

4.7K

R336

102

47K

Q305

8050

C313

R320

1K

13

R313

4

14

OUT2-

IN2+

IN3+

6

9

C335

474

C315

47K

C314

102

SLIN

D302

D300

4148

MUTE

5

R333

MUTE

AGND AGND

104

000

000

L300

2

1

2P/2.5

C336

47/16V

ONLY FAN

+12V

R343

0.47/0.25

J300 000

CN304

FAN

R340

R339

TDA8947J

MODE2

C331

100u/25V

C330

100u/25V

4.7K

R337

R312

47K

4.7K

C327

10uF/16

D303

4148

4148

SUR-MUTE

10 - 1

CIRCUIT DIAGRAM - AMP BOARD

CENOUT+

CENOUT-

SLO-

SRO+

SWOUT+

SWOUT-

LOUT

ROUT

R305

R304

R303

R301

R300

R306

R307

2.2R

R302

2.2R

2.2R

2.2R

2.2R

2.2R

2.2R

C307

104

2.2

C306

104

C305

C304

C303

C302

C301

C300

104

104

104

104

7P/2.0

CN301

104

104

CN300

WP12-2

56789

432

1

SWOUT-

SWOUT+

CENOUT+

10

11

12

PGND

PGND

LOUT-

ROUT+

PGND

CENOUT-

PGND

CENIN

SLIN

SWIN

FLIN

FRIN

AGND

SRIN

234

567

Vcc

PGND

2

3

1

CN302

MUTE

SUR-MUTE

+12V

DGND

1

3P/3.95

123

4

CN303

4P/2.0

SROUT+

SLOUT-

SRO+

1000uF

C324

SLO-

C323

1000uF

Page 20

10 - 2

10 - 2

LAYOUT DIAGRAM - AMP BOARD

Page 21

10 - 310 - 3

LAYOUT DIAGRAM - AMP BOARD

Page 22

Standby 5

URST# 2

Y5

Y4

Y2

Y1

VCC

+12V

L3

U1 MP9141

100uH_1.7A

C1 0.01uF

45

123

BS

VIN

VSW

COMP

EN

SYNC

678

GNDFB

+

D1

SK34/SMD

CB2

R5

CB1

0.1uF

CE2

220uF/16V

0.1uF

10K

Standby

URST#

1 2

CB4

R8

750/NC

0.1uF

R9

390/NC

V18

L4 FB/NC

CB69

CB68

CB67

CB66

R2

3.3K

R1

27K

VCC

R3 150K

11 - 1 11 - 1

+12V

VCC

L2

L1

FB/DIP/3.5*4.7

P5V

P+12V

Standby

123

4

CIRCUIT DIAGRAM - MPEG BOARD

PART 1

J1

C2

0.022uF

C3

100pF

R4

300K

Standby

CE1

220uF/16V

+

FB/DIP/3.5*4.7/NC

CON2.54-4

R6

15K

89L_3V3

L5

V33

2

OUTIN

GND

1

U2 1117-ADJ/NC

3

+2.5v

CB5

0.1uF

RFV33

CE6

47uF/16v

+

CB3

0.1uF

CE3

220uF/16v

+

FB

DV33

L7 FB

CB6

0.1uF

RESET Circuit

+

L6

FB

CE5

220uF/16v

DV33

R170

URST#

CB70

0.1uF

R171 1K

CB70 must closer to PIN43 of

1389L

10k

Q27

3904

1 3

2

R172

1k

R173

10k

+

CE49

10uF/16v

D13

1 2

1N4148

Page 23

11 - 211 - 2

89L_3V3

V18

DQ[0..15]

APLLVDD3

47uH/0805

L9

L8 47uH/0805

ADACVDD

RFVDD3

L11

89L_3V3

89L_3V3

CB7 0.1uF

RFV18-1

V18

DQ[0..15] 4

MA[0..11] 4

DQM[0..1] 4

BA[0..1] 4

RAS# 4

CAS# 4

WE# 4

SF_DI 4

SF_CK 4

SF_CS 4

L12 FB

3DDVCAD 3DDVCAD

L10 FB

MA[0..11]

CE7

+

CB12

CB11

CB10

CB9

C5

FB

CB8 0.1uF

RFV18-2V18

L13 FB

DQM[0..1]

thrice resonance

10uF/16V

0.1uF

0.1uF

0.1uF

0.1uF

4.7uF

BA[0..1]

R10 100K

crystal need add

DCLK 4

CAS#

RAS#

DCLK

XOXI

Y3

L14 2.7uH/NC

SERVO RF DeCAP.

J2

6

SP-A

DV33

WE#

CKE

C8

27MHz

C7

C6

1000pF/NC

5

LIMIT

R11 10K

SP+

CKE 4

DRAM I/F

22pF

22pF

RFV33

4

SL-

L15

V1P4

V20

123

SL+

SF_CK

AADVDD

+

CB14

+

CB13

SF_CS

SF_DI

CE10

+

C9

47uH/0805

CE9

47uF/16V

0.1uF

CE8

47uF/16V

0.1uF

CON2.0-6

SF_DO 4

SF_DO

S-FLASH

+

CE12220uF/16V

220uF/16V

6800pF

OP-

R12 10K

SP-

ALF 5

ALF

CE11 100uF/16V

+

CB15 0.1uF

RF Reference

DV33

1

CB17 0.1uF

ALS

R13

ALS 5

CB16 0.1uF

ARS 5

ARS

2

D3

ARF 5

AR 5

ARF

ALARASPDIF

C11 10uF/10V

C10 4.7uF

RFO

C12 10uF/10V

ADVCM

BAT54C

3

CB18

0.1uF

1/0805

R14 NC

SP+

AL 5

ASPDIF 6

C13 1500pF

C15

C14

1uF

CB19 0.1uF

OPO

R16 10K

R15 0

SP-A

220pF

MDI2

R17 0

MDI1

R18

V_G/Y

V_B/U

V_R/V

OP-

FS

AR

AVCM

AL

2K

ALS

ALF

V_CVBS 6

V_R/V

V_CVBS

AUDIO I/F

89L_3V3

V_CVBS

DACVDD3

DACVDD3

OUT3

ADVCM

IO_USB

AADVDD

APLLVDD3

ARF

ARS

ADACVDD

RFV18-1

1389_OP+

1389_OP+OPO

FGOPO

R19 0

R20 0/NC

V_B/U 6

V_G/Y 6

V_R/V 6

V_B/U

V_G/Y

97

98

99

100

101

G

102

B

103

R

104

105

106

107

108

109

110

111

112

113

114

115

116

117

118

119

120

121

122

123

124

125

126

127

128

129

U3

+5VS

STBY 3

STBY

VIDEO I/F

CB20 0.1uF

VREF1

96

FS

DACVSSC

CVBS

DACVDDB

DACVDDA

AADVSS

AADVDD

APLLVDD

APLLCAP

ADACVSS2

ADACVSS1

ARF / GPIO

ARS / GPIO

AR / GPIO0

AVCM

AL / GPIO1

ALS / GPIO

ALF / GPIO

ADACVDD1

ADACVDD2

AVDD18

AGND18

RFIP

PAD_GND

1

R23 0

R22 10K

Q1

R21 4.7K

TRIN 3

TROUT 3

TRIN

TROUT

ASPDIF

DACVDD3

TRIN

949093

95

VREF

GPIO13

DACVDDC

ADVCM / GPIO20

RFIN / OPOUT

RFG / OPINP

RFH / OPINN

RFC

RFB

RFA

4

3

2

R25 0

R26 0

R27 0

BECDF

A

IOA

R24 10K

2

2N3904

T- 3

T+ 3

F- 3

F-T-F+

T+

V18

GPIO11

TRCLOSE

TxD

RxD

92

91

898884

GPIO9

GPIO11

GPIO10

DVDD18

SPDIF / GPIO12

AKIN2 / GPIO19 / Audio_Mute

AKIN1 / GPIO21 / Audio_Mute

RFD

RFE

RFF

AVDD18

AVDD33

5

789

6

R29 0

R28 0

XI

RFVDD3

RFV18-2

1 3

F+ 3

SL- 3

SL+ 3

SP- 3

SP+ 3

FOSO 3

TRSO 3

FMSO 3

DMSO 3

SL+

SL-

SP-

SP+

TRSO

FOSO

FMSO

DMSO

MA1

MA2

BA1

MA10

CKE

MA0

MA3

81

87

80

86

82

BA1

RA3

RA2

RA1

RA0

RA10

GPIO8

DVDD33V14

GPIO7 / CKE

LQFP 128

MT1389L/K

XTALI

XTALO

AGND

V20

REXT

MDI1

MDI2

LDO1

101112

16171819202122

13

15

14

MDI2

MDI1

V20

V1P4

R34 0

LDO1

R31 15K

XO

89L_3V3

VCC

L17

FB

CE13

+

+5VS

L16

FB

CB21

R30 4.7K

2

Q3

2N3904

R33

1 3

1 3

R32

2

Q2

2N3904

SONY313

798583

DVSS18

Desktop

LDO2

R35 0

LDO2

V1P4

BA0

78

AVDD33

L18 FB

100uF/16V

0.1uF

100

100

V1P4 3

SERVO I/F

CAS#

RAS#

WE#

77

76

75

BA0

RAS#

CAS#

RWE#

V1.0

AVDD33

DMO

FMO

TRAY_OPEN

DMO

STBY

FMO

CB22

0.1uF

C16

4.7uF

CON1

USB_DP 6

USB_DP

USB_DM

MA4

MA6

MA7

MA8

MA9

MA5

72

68

73

74

71

RA9

RA8

RA4

RA5

RA6

RA7

TRAY_CLOSE

TRO

FOO

FG / GPIO2

USB_DP

USB_DM

25

26272829303132

23

24

USB_DM

IOA

TRO

USB_DP

USB_V33

FOO

FG

C19

10uF/10V

0.1uF

CB23

89L_3V3

Very Important to

reduce Noise

C18 NC

C17 NC

LD-DVD

MDI1

AVCC1

22

26

21

25

23

24

URST# 1

USB_DM 6

URST#

USB I/F

DCLK

MA11

DQM1

65

66

676970

RA11

RCLK

DQM1

DVDD33

USB_V33

USB_GND

PAD_VRT

USB_V18

USB_V18

CB24

0.1uF

C20 NC

R36 5.1K

C21

10uF/10V

L19 FB

L20 FB

V18

CB25 0.1uF

LD-CDEV20FA

AVCC1

16

17

13

14

181920

15

URST

MT1389L

LQFP128/SMD/1389L

RD8

64

RD9

63

RD10

62

RD11

61

DVSS33

60

RD12

59

RD13

58

RD14

57

RD15

56

DQM0

55

DVDD18

54

RD7

53

RD6

52

RD5

51

DVDD33

50

RD4

49

RD3

48

RD2

47

RD1

46

RD0

45

IR

44

PRST#

43

ICE

42

UP1_7 / SDA

41

UP1_6 / SCL

40

SF_CK

39

SF_DI

38

SF_DO

37

SF_CS_

36

GPIO6

35

GPIO4

34

GPIO3 / INT#

33

LDO2

R37

L22

10uH/SMD

L21

10uH/SMD

B

9

12

10

11

TOP

TRCLOSE 3

TROPEN 3

OUT1 4

OUT2 4

TRCLOSE

TROPEN

OUT1

OUT2

CE14

100uF/16V

+

Q5

0

Q4

2

8550/DIP

C22

NC

IOA

C

RFODF+

T-

5

6

7

4

8

2N3906

CE15

T+

3

R38 10K

2

+

1 3

2

DQ8

DQ9

DQ10

DQ11

DQ12

DQ13

DQ14

DQ15

DQM0

DQ7

DQ6

DQ5

89L_3V3 V18

DQ4

DQ3

DQ2

DQ1

DQ0

IR

URST#

ICE

UP1_7

UP1_6

SF_CK

SF_DI

SF_DO

SF_CS

TROPEN

LIMIT

TROUT

RFV33

1 3

47uF/16V

R39 4.7

R40 4.7

F-

1

HEADER 24 SMD0.5 TOP

TP1

13

R41 10K

Q6

2

CE16

+

CE17

+

2N3906

47uF/16V

2

13

DV33

100uF/16V

R42

Q7

8550/DIP

0

J3

OUT3

R47 1K

R46 1K

R45 1K

R44 1K

LDO1

FOO

R43 27K

FOSO

9

TRO

R48 27K

TRSO

OUT2

FMO

R49 15K

FMSO

OUT1

DMO

R50 10K

DMSO

678

IO_USB

VSDA

R51 0

UP1_7

C25

CB26

C24

C23

CON2.0-9

1

5

234

VSTB

VSCK

REM

C32

100pF

C31

100pF

C30

100pF

IR/VFD

R52 0

R53 0

R54 10

C29

100pF

C28

100pF/NC

C27

100pF/NC

C26

100pF/NC

GPIO11

IR

UP1_6

J4

CON2.0-4

123

4

RxD

TxD

DV33

RS-232

CB32

0.1uF

CB31

V1889L_3V3

0.1uF

CB30

0.1uF

CB29

0.1uF

Chip Decap.

CB28

0.1uF

CB27

0.1uF

V1P4

0.015uF

0.1uF

330pF

330pF

CIRCUIT DIAGRAM - MPEG BOARD

PART 2

Page 24

TRIN 2

STBY 2

TROPEN 2

TRCLOSE 2

T+ 2

SL- 2

T- 2

SL+ 2

F+ 2

F- 2

SP- 2

TROUT 2

SP+ 2

V1P4 2

DMSO 2

FMSO 2

FOSO 2

TRSO 2

TROPENF-TROUT

STBY

TRIN

TRCLOSE

+2.5V

T+

F+

D5

D4

SL-

SL+

VCC

12

1

2

MO_VCC

SP+

SP-

FOSO

IN4001/DIP

IN4001/DIP

D6

12

TRSO

DMSO

IN4001/DIP

V1P4T-FMSO

V18

Q8

23

1

DMSO

SERVO I/F

CB35

+

8550/DIP

R58

4.7K

R60

IN4001/DIP

VCC

0.1uF

CE19

100uF/16V

10K

D7

12

8550/DIP

23

1

TR_B2

L23

V33

Q9

V18=(R58/R60+1)*1.25

FB

CB37

MO_VCC

R62

+

CE20

15K

0.1uF

100uF/16V

CE21

+

CB39

CB38

REGO2

100uF/16V

0.1uF

0.1uF

R64

9.1K

11 - 3 11 - 3

CIRCUIT DIAGRAM - MPEG BOARD

PART 3

L24 FB

FOSOSTBY

29

30

G1G2

TROPEN

6

7

5

REV

FWD

VINLD

GND

24

22

23

FMSO

R57 10K

REGO2

4

3

VINSL+

REGO1

TRB2

NC

25

26

TRSO

TR_B2

1

2

TRB1

REGO2

VINTK

BIAS

27

28

V1P4

CB33

VINFC

MUTE

AM5888

HSOP28/SMD

CB34

R59

0.1uF

0.1uF

10K

DV33

VCC

J5

1

LOAD-

LOAD+

CB36 0.1uF

234

TROUT

R61 10K

5

TRIN

R63 10K

CON2.0-5

+F-T

SP-

LOAD+

SP+

LOAD-F-TRCLOSE

91012

14

13

11

8

VCC

VOSL-

VOFC-

VOTR-

VOSL+

VOFC+

VOTR+

VOLD+

VOLD-

VOTK-

VOTK+

U4

15

VCTL

VCC2

NC

17

21

19

20

18

16

T+

SL+

SL-

R55 10K

R56 10K

MO_VCC

Page 25

DQ[0..15] 2

MA[0..11] 2

DQM[0..1] 2

BA[0..1] 2

DCLK 2

RAS# 2

CAS# 2

WE# 2

CKE 2

SF_CK 2

SF_DI 2

SF_CS 2

SF_DO 2

CVBS_EN 6

16:9B 6

16:9A 6

RGB_SWITCH 6

OUT2 2

AUDIO_MUTE 5

OUT1 2

11 - 411 - 4

DQ[0..15]

MA[0..11]

DQM[0..1]

DQ1

DQ0

DQ2

BA[0..1]

DQ4

DQ3

DCLK

SD33DV33

DQ5

RAS#

DQ6

CAS#

SD33

L25 FB

DQ7

WE#

DQ8

CKE

DQ9

CB42

CB41

CB40

CE23

+

CE22

+

DQ10

DRAM I/F

0.1uF

0.1uF

0.1uF

100uF/16V

47uF/16V

DQ12

DQ13

DQ11

DQ14

SF_CK

SF_CS

DQ15

SF_DI

SF_DO

SD33

S-FLASH

SD33

SD33

CVBS_EN

CB47

0.1uF

CB46

0.1uF

CB45

0.1uF

CB44

0.1uF

CB43

0.1uF

I/O

16:9A

16:9B

RGB_SWITCH

SCART

DV33

AUDIO_MUTE

OUT1

OUT2

OUT1

16:9A

CVBS_EN

16:9B

RGB_SWITCH

2

569121516192010

Q0Q1Q2Q3Q4Q5Q6

VCC

D0D1D2D3D4D5D6D7OC

U6

347

8

131417

MA4

MA0

MA3

MA5

MA6

MA1

MA2

DV33

NOR

2TUO7AM

AUDIO_MUTE

Q7

1

18

5

VCC

U8

ABGND Y

213

GND

G

74LCX373

11

4

SN74AHC1G02

2

4

DQ0

A0A1A2

U5

23

242526

MA0

MA1

SDRAM

CIRCUIT DIAGRAM - MPEG BOARD

PART 4

DQ1

MA2

5

798

DQ2

MA3

104611

DQ3

DQ4

DQ5

A3

A4A5A6A7A8

29

3031323334

MA4

MA6

MA5

DCS#

R65 10K

DQ6

MA7

50

51

DQ13

BA1/A12

21

DBA1

53

DQ14

DQ15

CLK

38

SDCLK

CKE

37

SDCKE

SDCLK

DBA0

R67 0

R66 33

BA0

DCLK

1

VCC

CS

19

DCS#

DBA1

R68 0

BA1

14

VCC

RAS

DCAS#

DRAS#

VCC

CAS

161718

DWE#

RN1 0x4

3627

VCCQ

WE

DRAS#

234

1

RAS#

43

VCCQ

DQML

39

15

DQM0

DQM1

DWE#

DCAS#

5 6

WE#

CAS#

49

VCCQ

VCCQ

DQMH

SDCKE

7 8

CKE

12

52

VSSQ

VSSQ

VSSQ

VSSQ

VSS

NC

NC

VSS

VSS

ESMT M12L64164A

41

40

36

54

28

R169 10K

DV33

DRAM EXTENSION GPO

DV33

R69 10K

DV33

SF_CK

8

7

6

VDD

HOLD#

CE#SOWP#

U7

123

SF_DO

SF_CS

R70 10K

S-FLASH

DV33

CB48

SF_DI

SCK

4 5

VSS SI

DRAS#

SDCKE

0.1uF

EN25B80

8M bit

DV33

R72 10K/NC

SF_CS

R71 10K

45

48

13

42

44

47

DQ8

DQ9

DQ7

DQ10

DQ11

DQ12

A11

A10/AP

A9

BA0/A13

22

20

35

DBA0

MA11

MA8

MA10

MA9

Page 26

AL 2

AR 2

ALS 2

ALF 2

ALARALS

ARS

ALFMLMRFLFR

ARS 2

ARF 2

ML 6

MR 6

FL 6

FR 6

Standby 1

AUDIO_MUTE 4

ARF

Standby

AUDIO_MUTE

AUDIO I/F

11 - 5 11 - 5

R74

ML

L26 FB

10K

+

CE24 10uF/16V

C33 120pF

C34

R76

Q10

2

A_MUTE

100pF

47K

2N3904

A_MUTE

Q14

2N3906

1 3

CE27

100uF/16V

+

D10

Q11

2N3904

1 3

2

R91

10K

1N4148/SMD

D9

R82

1M

CE28

10uF/16V

1K/0805

Q12

2N3906

1 3

2

R87

43K

1 2

MR

L27 FB

C37

100pF

47K

R86

Q13

2N3904

2

R89

R85 10K

A_MUTE

+

C36 120pF

R83

D8

1N4148/SMD

1 2

+12V_OUT

FL

1 3

R80

100

1K

R77

+

CE26

10uF/16V

1

U9A

C4558

+

-

8 4

3

2

2

R90

10K

1N4148/SMD

DV33

CE29

+

1 3

1K

R94

CE31

1 2

R95

10uF/16V

FR

100

+

10uF/16V

7

-

6

R96

D11

+

5

10K

R97

33

10K

4.3V/SMD

U9B

C4558

8 4

AUDIO_MUTE

MUTE_Circuit

CB50

0.1uF

+12A

CB49

0.1uF

VREF

NC

C39 120pF

R102

CE33

SL

100

+

10uF/16V

1

-

2

J6

1

2

345

+12V_OUT

R105

100

CE35

+

+12A

R104

10K

+

VREF

CE34

U10A

C4558

+

8 4

3

100uF/16V

R106

10K

220uF/16V

SUBFRSLFLCENSRA_MUTE

678

C41 120pF

CON2.0-8

R110

100

CE37

10uF/16V

-

Standby

R115

20K

R116

Q16

C43 120pF

2N3904

10K

R119

100

CE39

10uF/16V

-

SUB

+

1

U11A

C4558

+

8 4

3

2

C45 120pF

R124

CE41

CEN

100

+

10uF/16V

7

-

6

CB54

0.1uF

U11B

C4558

+12A

+

8 4

5

VREF

CB53

0.1uF

+12V

+12V_OUT

SR

+

7

U10B

C4558

+

8 4

5

6

R113

100K

Q15

AO3407

+12A

VREF

CB52

CB51

0.1uF

0.1uF

10K

R112

R79

5.1K

C35

CE25

2200pF

R78

10K

+

10uF/16V

R81

100K

AL

R73 33K

R75

0/NC

CIRCUIT DIAGRAM - MPEG BOARD

PART 5

R93

5.1K

R84 33K

R92

R88

0/NC

+

CE30

AR

10K

C38

10uF/16V

2200pF

R101

5.1K

R99 33K

R98

100K

CE32

R100

+

10uF/16V

C40

2200pF

10K

R103

100K

ALS

R109

5.1K

C42

CE36

2200pF

R108

10K

+

10uF/16V

R111

100K

ARS

R107 33K

R118

5.1K

C44

CE38

R117

+

10uF/16V

2200pF

10K

R120

100k

ARF

R114 33K

R123

5.1K

C46

CE40

2200pF

R122

10K

+

10uF/16V

R125

100K

ALF

R121 33K

Page 27

SC

SY

11 - 611 - 6

CVBS_EN

+5VV

7

4

ML 5

FR 5

MR 5

ASPDIF 2

FL 5

USB_DP 2

V_G/Y 2

V_CVBS 2

V_R/V 2

CVBS_EN 4

V_CVBS

V_B/U

V_R/V

16:9

R127

+12V

+5VV

L28 FB

VCC

CB55

0.1uF

R126

3.3K

V_B/U 2

V_G/Y

R128

680

DV33

CB56

0.1uF

Q17

CE42

L29

VIDEO I/F

R129

75

4.7K

R133

DV33

1K

R131

4.7K

CE43

220uF/16V

+

G/Y

2N3904

1 3

2

R132

+

C48

22uF/16V

C47

1.8uH/SMD

USB_DP

2.2K

R134

2.2K

USB_DM 2

USB_DM

Q19

2

R136

16:9B

Q18

2

R135

16:9A

75 1%

47pF

47pF

2N3904

2N3904

RGB_SWITCH 4

16:9B 4

16:9A 4

P1

J7

R147

CON2.0-3

4.7K/NC

123

CVBS_IN

CTR_IPOD

CE45

U12

C51

220uF/16v

NJM2244

10uF/0805

R148 0

CVBS

+

7

OUT

IN-1

1

CVBS_IN

+5VV

DASW-10

2

SW1

IN-2

3

R1490

CVBS1

4

5

C52

SW2

IN-3

FB

10uF/0805

R151

CB60

R150

6 8

L31

R152

8

9

G/YMLB/U

MR

C54

47pF

100/NC

R155

C53

0.1uF

VCC GND

C55

4.7uF/16V/0805

R154

100/NC

R153

100/NC

75/NC

75/NC

0.1uF

3.3K

CE46

L32

Q23

2

2N3904

+

6

R/V

1 3

R157

C57

22uF/16V

C56

1.8uH/SMD

5

+5VV

R158

75 1%

2.2K

47pF

47pF

MR

ML

ASPDIFFLFR

USB

1 3

1 3

DV33

2.2K

+5VV

AUDIO I/F

RGB/CVBS#

Q20

2N3906

1 3

R137 33

16:9B

16:9A

RGB_SWITCH

SCART

CVBS_EN

0/NC

R146

CB58

0.1uF

2

VCC

R140

2.2K

4.7K

R139

RGB_SWITCH

B/U

CB57

0.1uF

+5VV

Q21

2N3904

1 3

R143

75 1%

2

R138

R142

2.2K

3.3K

+

C50

47pF

CE44

22uF/16V

L30

1.8uH/SMD

C49

47pF

R144 0/NC

CVBS1 CVBS

+12V

SC

CB59

0.1uF

Q22

2N3904

1 3

R145

75 1%

2

1013111214

1

3

CVBS

CB61

0.1uF

GG

CY

2

15

16

COXIAL

R/V

COXIAL

C58

0.1uF

C59

330pF

R161

100

R159

100

SY

Q24

2N3904

1 3

R160

75 1%

2

J8

CON2.0-3

+5VV

123

SPDIF

R162 33

ASPDIF

VCC

C60

J9

123456789

CB63

0.1uF

CE47

47uF/16v

+

R163

22

27pF/NC

0.1uF

CB62

R164

3.3K

CE48

1.8uH/SMD

L33

CVBS_ST

Q25

2

+

R/V

2N3904

G/YFLFR

CVBS_ST

1 3

22uF/16V

B/U

2

R166

C62

C61

10

RGB/CVBS#

16:9

D12

DIODE SMD BAV99

R167

75 1%

2.2K

47pF

47pF

CON2.0-10

+5VV

3

1

J10

CON2.0-4

3

4

2

1

CB65

0.1uF

USB_DP

PWR2

PWR2

USB_DM

F1

500mA/NC

L34 FB/1206

VCC

Only for MT1389L

CVBS1

CB64

0.1uF

Q26

2N3904

+5VV

1 3

R168

75 1%

2

R130

V_G/Y

160 1%

CIRCUIT DIAGRAM - MPEG BOARD

PART 6

V_B/U

R165

V_CVBS

R141

160 1%

V_R/V

R156

160 1%

160 1%

Page 28

11 - 7 11 - 7

LAYOUT DIAGRAM - MPEG BOARD

Page 29

12-1

R97 4.7R 1W

+1 2 V

S

F2

ZD2

R41

6.2V 1/2W

100R 1206

6

-24 V

D9

8

F1

R42 10K 1206

R47

100R 1206

7

FR104

CE15

CE11

CE7

47uF/50V

47uF/50V

47uF/50V

GND

+1 2V

4800U5

L3 DR6*8

D12

UF5404

11

12

0R 1206

R55

CE10

1000uF/16V

CE6

1000uF/16V

+5 V

10uH

R48

D10

1N5819

9

R61

CE18

CE17

4.7K 1206

220uF/16V

470uF/10V

CE12

470uF/10V

GND

STB

1K 1206

R62

2222

T5

T6

2222

4.7K 1206

R46

NC

R45

R43

470R 1206

NC

R44

10

C

11

C

D11

FR104

4.7K 1206

R51

U4-B

PC817

Z11

CE16

47uF/50V

R36

47K 0805

C12

104/50V 0805

PC817

IC3

TL431

102/400V

Y5

U3-B

15V 1/2W

R36

ZD4

LL4148

R39

100K 1206

4.7K 1206

1K 1206

R40

Port

H

TR1

MOS2

4

472/1KV

3

C5

13003

IC1

TP218

12-1

R16

100R 1206

Z4

C6

101/1KV

LL4148

C8

103/50V

0R 1206

R27

U4-A

PC817

D8

FR104

10R 1206

R30

B

N

R23

220R 1206

ZD1

16V 1/2W

CE3

22uF/50V

5

1

2

L

FR157

R14

120K 1W

510K 1206

R7

A

68uF/400V

68uF/400V

D6

510K 1206

R11

CE2

CE1

1N5408

D1 D2

D4 D3

0.22uF/275V

X3

L21

471/250V

471/250V

510K 1206

R15

510K 1206

X2

X1

0.22uF/275V

510K 1206

R19

0.22uF/275V

8D13

Y2

R2

510K 1206

RT1

c

F1

T3.15AL/250V

Y3

L1

R1

0R 1206

R12

22uF/50V

CE4

Power Board -- Circuit Diagram 1

Page 30

12-2

DR8*10

L11

V-12V

R31

2K 1206

+VCC

1000uF/16V

CE21

1000uF/16V

DR8*10

L3

V+12V

R67

CE13

47uF/50V

27K 1206

R70

27K 1206

27K 1206

27K 1206

47uF/50V

10uH

L4

CE8

BC1

BC2

102/50V

27K 1206

R32

R80

27K 1206

2K 1206

R31

104/50V 0805

104/50V

R99

U2

330R 0805

OPTO-B

C14

104/50V 0805

2.7K 0805

R78

R79

820K 0805

IC2

TL431

R71

R69

C14

GND

R72

27K 1206

CE22

CE23

47uF/50

S

CE19

47uF/50V

12-2

D15

TR2

A

FR104

D14

FR104

C4

101/1KV

ZD6

C104/50V 1206

104/50V 0805

ZD3

16V 1/2W

ER1602

8

1

2

68K 2W

R10

C4

103/1KV

R21

R22

R63

910

0R 1206

10R 1206

10R 1206

11 12

7

FR157

D5

C10

MOS4

R31

2K 1206

MOS1

LL4148

Z1

78

100R 1206

R6

6

3.9K 1206

R8

10N60

1K 1206

R5

UC3843S

4

C3

101/50V 0805

C2

3

101/50V 0805

5

2

1

R28

R19 LL4148

R18 3.9K

Z8

LL4148

R13

0R 1206

C15

BL1

R64

R3

0.22R 2W

R9

10K 1206

R17

U2-A

PC817

104/50V 0805

103/50V

10K 1206

C11

Y7 222/400V

Y6 102/400V

Power Board -- Circuit Diagram 2

47uF/50V

CE5

D7

FR104

B

Page 31

12-3 12-3

Power Board -- Layout Diagram

Page 32

EXPLODED VIEW DIAGRAM

112

13 - 1

13 - 1

125

1226

(1227)

116

1141

1123

114

121

1231

119

1222

Page 33

14 - 1

SERVICE PARTSLIST

111 996510008405 CPU PCB ASSY MCD715

112 996510007817 VFD DISPLAY PCBASSY MCD710

113 996510008406 AMP PCB ASSY NE382A

114 996510007819 TUNER BOARD PCB ASSY ECO6-05

1141 996510007820 HEADPHONE PCB ASSY MCD710

115 996510007821 LAMP PCB ASSY MCD710

116 996510007822 USB PCB ASSY MCD710

117 996510007823 USB LAMP PCB ASSY MCD710

118 996510007824 VOLUME PCB ASSY MCD710

119 996510008407 DECODER PCB ASSY MCD715/93

120 996510008408 MCU PARTSASSY MCD715/93

121 996500042540 DISC ASS’Y MCD708

125 996510040712 POWER PCB ASSY DVD AMP POW282A 50W

1221 996510007826 MCD710 CABINET FRONT HIPS BK

1222 996510008409 MCD715 CAB BOTTOM 5.1CH HIPS

1223 996510007828 MCD710 PLASTIC CAB FRONT HIPS

1224 996510007829 MCD710 CENTER BUTTON BRACKET

1225 996510007830 MCD710 BUTTON BRACKET

1226 996510007831 MCD710 STANDBY BUTTON BRACKET

1227 996510007832 MCD710 STANDBY BUTTON

1228 996510007833 MCD710 FUNCTION -BUTTON

1229 996510007869 MCD710 BEARING KNOB

1230 996510007870 MCD710 KNOB

1231 996510007871 MCD710 VOLUME KNOB

1232 996510007834 MCD710 BIG LENS PMMA

1233 996510007836 MCD710 FUNTION-KNOB OPEN/CLOSE

1234 996510007837 MCD710 FUNTION-BUTTON(STOP)

1235 996510008410 MCD908 DVD DOOR ABST920

1236 996510008411 RUBBER FOOT 4X7.8

1237 996510008412 AC LINE CORD 1.95M CQ-5332-00

1238 996510008413 MINI FAN RDM4010S DC12V/0.07A

1239 994000005519 FLAT FLEX CABLE 24PX200X0.5XA

ACCESSORIES

1241 994000005078 AUDIO SINGLE WIRE W/RCA 1.5M

1242 996510008414 26WIRE 1.5m Fm ANT. WIRE

1243 996510008445 SPEAKER CASING PARTSASSY (L)

1244 996510008446 SPEAEKR CASING PARTSASSY(R)

1245 996510008447 SURROUND CASING PARTS(L)ASSY

1246 996510008415 SURROUND CASING PARTS(R)ASSY

1247 996510008416 CENTER PARTS ASSY

1248 996510008417 WOOFER SPEAKER BOX ASSY

1249 996510008418 REMOTE CONTROL ASSY PRC501-17

Note: Only these parts mentioned in the list are

normal service parts.

Page 34

Page:40

BOM NO. DESCRIPTION Q'TY UNIT USAGE

09-MCD715-01A101 DVD MAIN UNIT PARTS ASS'Y MCD715/93 1 SET

07-MCD715-01A101 CPU PCB ASS'Y MCD715 1 SET

13000068 CHIP RESISTOR 1K 1/4W J (1206) 2 PCS R1119,1120

13000116 CHIP RESISTOR 3.3K 1/4W J (1206) 2 PCS R1074,1073

13000127 CHIP RESISTOR 47K 1/16W J (0805) 5 PCS R1079,1080,1130,1135,1136

13000178 CARBON FILM RESISTOR 100 1/8W J-52 4 PCS R1047,1049,1100,1098

13000180 CARBON FILM RESISTOR 100 1/4W J-52 1 PCS R1137

13000245 CARBON FILM RESISTOR 150 1/8W J-52 1 PCS R1096

13000280 CARBON FILM RESISTOR 20K 1/8W J-52 2 PCS R1081,1082

13000321 CARBON FILM RESISTOR 24K 1/8W J-52 1 PCS R1054

13000058 CHIP RESISTOR 0 1/16W J (0805) 1 PCS R1123

13000085 CHIP RESISTOR 1.5K 1/16W J (0805) 5 PCS R1056-1060

13000065 CHIP RESISTOR 100 1/16W J (0805) 14 PCS R1053,1051,1050,1099,1126,1127,R1101-1107

13000074 CHIP RESISTOR100K 1/16W J (0805) 3 PCS R1042,1041,1040

13000070 CHIP RESISTOR 10K 1/16W J (0805) 12 PCS R1017,1108,1109,1113,1114,1122,R1097,1131,1112,1110,1068,1069

13000067 CHIP RESISTOR 1K 1/16W J (0805) 4 PCS R1095,1094,1063,1064

13000077 CHIP RESISTOR 1M 1/16W J (0805) 1 PCS R1008

13000101 CHIP RESISTOR 2.2K 1/16W J (0805) 3 PCS R1117,1118,1091

13000094 CHIP RESISTOR 20K 1/16W J (0805) 2 PCS R1084,1083

13000103 CHIP RESISTOR 22K 1/16W J (0805) 2 PCS R1134,1129

13000106 CHIP RESISTOR 24K 1/16W J (0805) 1 PCS R1055

13000108 CHIP RESISTOR 270 1/16W J (0805) 6 PCS R1085-1090

13000115 CHIP RESISTOR 3.3K 1/16W J (0805) 2 PCS R1076,1075

13000124 CHIP RESISTOR 4.7K 1/16W J (0805) 3 PCS R1067,1065,1125

13000122 CHIP RESISTOR 470 1/16W J (0805) 2 PCS R1115,1116

13000140 CHIP RESISTOR 8.2K 1/16W J (0805) 2 PCS R1071,1070

13000137 CHIP RESISTOR 68K 1/16W J (0805) 1 PCS R1124

13000134 CHIP RESISTOR 6.2K 1/16W J (0805) 2 PCS R1093,1092

13000107 CHIP RESISTOR 240K 1/16W J (0805) 1 PCS R1072

13000136 CHIP RESISTOR 6.8K 1/16W J (0805) 2 PCS R1062,1061

14000199 ELECTROLYTIC CAP.100u 16V L-5 5X11 3 PCS C1052,1051,1075

14000234 ELECTROLYTIC CAP.2.2u 50V L-5 5X11 2 PCS C1063,1062

14000306 ELECTROLYTIC CAP.4.7u 50V L-5 5X11 18 PCS C1014-1031

14000313 ELECTROLYTIC CAP.47u 10V L-5 5X11 3 PCS C1096,1095,1107

14000386 CHIP CAP.104P 50V M (0805) Y5V 9 PCS C1094,1093,1102,1101,1056,1053,C1055,1054,1125

14000420 CHIP CAP.330P 50V K (0805) X7R 12 PCS C1110-1117,1097-1100

14000160 NONINDUCTIVE CAP.473P 100V K-5 5 PCS C1092,1091,1090,1089,1088

14000515 ELECTROLYTIC CAP.10u 16V M-5 5X11 3 PCS C1073,1085,1084

14000375 CHIP CAP.102P 50V K (0805) X7R 1 PCS C1003

14000379 CHIP CAP.103P 50V K (0805) X7R 6 PCS C1080-1083,1118,1119

14000437 CHIP CAP.473P 50V M (0805) Y5V 1 PCS C1072

Page 35

Page:41

BOM NO. DESCRIPTION Q'TY UNIT USAGE

14000410 CHIP CAP.223P 50V M(0805) Y5V 1 PCS C1079

14000395 CHIP CAP.15p 50V J(0805) NPO 1 PCS C1109

14000407 CHIP CAP.222P 50V K (0805) X7R 2 PCS C1087,1086

14000768 ELECTROLYTIC CAP.10u 25V L-5 4X5 1 PCS C1040

14000435 CHIP CAP.470P 50V K (0805) X7R 2 PCS C1104,1105

14000446 CHIP CAP.683P 50V M (0805) Y5V 2 PCS C1076,1071

14000415 CHIP CAP.30p 50V J(0805) NPO 4 PCS C1120,1121,1123,1124

14001003 ELECTROLYTIC CAP. 220u 16V L-5 6.3X5 7 PCS C1064-1068,1103,1106

14000684 CHIP CAP.154P 50V M (0805) Y5V 1 PCS C1069

14000848 CHIP CAP.334P 16V M (0805) Y5V 1 PCS C1070

14001088 ELECTROLYTIC CAP.10u 10V M4X5 1 PCS C1108

15000010 AXAIL FIXED INDUCTOR 100u 1 PCS L101

16000018 DIODE 4148-52 6 PCS D1001-1003,1005-1007

16000068 ZENER DIODE 5.1V 1/2W-52 1 PCS DZ102

16000115 DIODE IN60 L26 1 PCS D1004

17000004 CHIP TRANSISTOR 8050(SOT-23) 1 PCS Q112

17000025 TRANSISTOR 8050C-5 3 PCS Q103,104,105

17000030 TRANSISTOR 8550C-5 2 PCS Q101,102

17000034 TRANSISTOR 9014C-5 1 PCS Q108

19000075 IC PT2309-S(L) SOP 1 PCS IC106

19000081 IC PT2322 SOP 1 PCS IC105

19000083 IC PT2323 SOP 1 PCS IC104

19000253 IC TL072 SOP 1 PCS IC107

19000383 IC PCF8563/AMI8563 SOP8 1 PCS IC102

19000071 IC AT24C02-PC27(2.7V) SOP PACKING 1 PCS IC103

22000018 CERAMIC CRYSTAL OSCILLATOR 4.19mHz 1 PCS X102

22000021 CRYSTAL OSCILLATOR 32.768KHz ĭ3XH8±10PPM 1 PCS X101

24000070 RCA SOCKET 2p AV2-8.4-13 RED WHITE 1 PCS J1000

25000009 PINS CONNECTOR 2.0/2P 1 PCS CN120

25000012 PINS CONNECTOR 2.5/2P 1 PCS CN116

25000014 PINS CONNECTOR 2.0/3P 2 PCS CN118,105

25000016 PINS CONNECTOR 2.5/3P 1 PCS CN107

25000025 PINS CONNECTOR 2.0/4P 2 PCS CN110,108

25000034 PINS CONNECTOR 2.0/5 1 PCS CN101

25000038 PINS CONNECTOR 2.5/5P 1 PCS CN115

25000040 PINS CONNECTOR 2.0/6P 1 PCS CN103

25000044 PINS CONNECTOR 2.0/7P 3 PCS CN104,119,109

25000053 PINS CONNECTOR 2.0/9P 1 PCS CN113

35-MCD715-01A1 CPU PCB 35-MCD715-01A1 1 PCS

42000135 BARE WIRE ĭ0.6X40mm (375m=1kG) 16 PCS JP101-116

07-MCD710-02A101 VFD DISPLAY PCB ASS'Y MCD710 1 SET

Page 36

Page:42

1 PCS B200

ƸTRANSFORMER EE13 5V

BOM NO. DESCRIPTION Q'TY UNIT USAGE

11000402

13000060 CHIP RESISTOR 0 1/4W J (1206) 2 PCS R206,207

13000065 CHIP RESISTOR 100 1/16W J (0805) 3 PCS R203,204,205

13000067 CHIP RESISTOR 1K 1/16W J (0805) 2 PCS R226,227

13000070 CHIP RESISTOR 10K 1/16W J (0805) 2 PCS R211,231

13000071 CHIP RESISTOR 10K 1/4W J (1206) 1 PCS R232

13000117 CHIP RESISTOR 33K 1/16W J (0805) 4 PCS R255,256,257,258

13000121 CHIP RESISTOR 47 1/4W J(1206) 1 PCS R260

13000124 CHIP RESISTOR 4.7K 1/16W J (0805) 1 PCS R259

13000160 CARBON FILM RESISTOR 0.5 1/4W J-52 1 PCS R229

13000238 CARBON FILM RESISTOR 15 1/4W J-52 1 PCS R210

13000731 CHIP RESISTOR 47K 1/4W J(1206) 1 PCS R254

13000317 CARBON FILM RESISTOR 2.2 1/2W J-52 1 PCS R228

14000158 MYLAR CAP. 473J 100V K 1 PCS C234

14000326 ELECTROLYTIC CAP.47u 16V L-5 5X7 2 PCS C205,219

14000386 CHIP CAP.104P 50V M (0805) Y5V 4 PCS C204,203,217,233

14000562 ELECTROLYTIC CAP.470u 16V L-5 8X11.5/12 1 PCS C232

14000636 CHIP CAP.104P 50V M (1206) Y5V 1 PCS C202

14001004 ELECTROLYTI CAP.220u 35V L-5 8X11.5 1 PCS C235

15000210 INDUCTOR 200U 6X5 1 PCS L201

16000018 DIODE 4148-52 5 PCS D204-207,209,

16000098 ZENER DIODE 6.2V 1W 1 PCS DZ200

16000104 RECTIFIER DIODE 4001-52 1 PCS D201

16000316 DIODE FR104 1 PCS D208

17000025 TRANSISTOR 8050C-5 2 PCS Q208,209

19000295 IC PT6311/SC16311/CD16311 1 PCS IC203

21000001 REMOTE CONTROL SENSOR IR SENSOR SMALL 1 PCS S200

23000034 LIGHT TOUCH SWITCH 6X6X5 130g 5 PCS SW200,201,204,205,208

23000036 LIGHT TOUCH SWITCH 6X6X5 250g 5 PCS SW202,203,206,207,209

29000271 VFD DISPLAY NE-705D-3.GB 1 PCS VFD200