Page 1

*

Philips A1 and A3 Patient Monitors

A1 Models: M3921A

M3922A

M3923A

M3924A

A3 Models: M3926A

M3927A

M3928A

M3929A

Service Guide

*M3921-9000C

Part Number M3921-9000C

Printed in the U.S.A. February 2002

First Edition

Page 2

About this Manual

Proprietary Information

This document contains proprietary information, which is protected by copyright. All Rights

Reserved. Reproduction, adaptation, or translation without prior written permission is

prohibited, except as allowed under the copyright laws.

Philips Medical Systems

3000 Minuteman Road

Andover, MA 01810-1085

(978) 687-1501

Publication number

M3921-9000C

Printed in USA

Warranty

The information contained in this document is subject to change without notice.

Philips Medical Systems makes no warranty of any kind with regard to this material,

including, but not limited to, the implied warranties or merchantability and fitness for Philips

Medical Systems shall not be liable for errors contained herein or for incidental or

consequential damages in connection with the furnishing, performance, or use of this material.

Copyright

Printing History

Copyright © 2002 Philips Electronics North America Corporation

New editions of this document incorporate all material updated since the previous edition.

Update packages may be issued between editions and contain replacement and additional

pages to be merged by a revision date at the bottom of the page. Pages that are rearranged due

to changes on a previous page are not considered revised.

The documentation printing date and part number indicate its current edition. The printing

date changes when a new edition is printed. (Minor corrections and updates that are

incorporated at reprint do not cause the date to change.) The document part number changes

when extensive technical changes are incorporated.

This edition, M3921-9000C combines both A1 and A3 Service Guides into one book.

There is no M3921-9000B book.

First Edition............................................................... February 2002

ii

Page 3

Philips Software License Terms

ATTENTION: USE OF THE SOFTWARE IS SUBJECT TO THE PHILIPS SOFTWARE LICENSE

TERMS SET FORTH BELOW. USING THE SOFTWARE INDICATES YOUR

ACCEPTANCE OF THESE LICENSE TERMS. IF YOU DO NOT ACCEPT THESE

LICENSE TERMS, YOU MAY RETURN THE SOFTWARE FOR A FULL REFUND. IF

THE SOFTWARE IS BUNDLED WITH ANOTHER PRODUCT, YOU MAY RETURN

THE ENTIRE UNUSED PRODUCT FOR A FULL REFUND.

PHILIPS SOFTWARE LICENSE TERMS

The following License Terms govern your use of the accompanying Software unless you have

a separate signed agreement with Philips Medical Systems.

License Grant. Philips Medical Systems grants you a license to Use one copy of the

Software. "Use" means storing, loading, installing, executing or displaying the Software. You

may not modify the Software or disable any licensing or control features of the Software. If

the Software is licensed for "concurrent use", you may not allow more than the maximum

number of authorized users to Use the Software concurrently.

About this Manual

Ownership. The Software is owned and copyrighted by Philips or its third party suppliers.

Your license confers no title to, or ownership in, the Software and is not a sale of any rights in

the Software. Philips’ third party suppliers may protect their rights in the event of any

violation of these License Terms.

Copies and Adaptations. You may only make copies or adaptations of the Software for

archival purposes or when copying or adaptation is an essential step in the authorized Use of

the Software. You must reproduce all copyright notices in the original Software on all copies

or adaptations. You may not copy the Software onto any public network.

No Disassembly or Decryption. You may not disassemble or decompile the Software unless

Philips prior written consent is obtained. In some jurisdictions, Philips consent may not be

required for limited disassembly or decompilation. Upon request, you will provide Philips

with reasonably detailed information regarding any disassembly or decompilation. You may

not decrypt the Software unless decryption is a necessary part of the operation of the

Software.

Transfer. Your license will automatically terminate upon any transfer of the Software. Upon

transfer, you must deliver the Software, including any copies and related documentation, to

the transferee. The transferee must accept these License Terms as a condition to the transfer.

Termination. Philips Medical Systems may terminate your license upon notice for failure to

comply with any of these License Terms. Upon termination, you must immediately destroy

the Software, together with all copies, adaptations and merged portions in any form.

Export Requirements. You may not export or re-export the Software or any copy or

adaptation in violation of any applicable laws or regulations.

U.S. Government Restricted Rights. The Software and any accompanying documentation

have been developed entirely at private expense. They are delivered and licensed as

iii

Page 4

About this Manual

"commercial computer software" as defined in DFARS 252.227-7013 (Oct. 1988), DFARS

252.211-7015 (May 1991) or DFARS 252.227-7014 (Jun. 1995), as a "commercial item" as

defined in FAR 2.101(a), or as "Restricted computer software" as defined in FAR 52.227-19

(Jun. 1987)(or any equivalent agency regulation or contract clause), whichever is applicable.

You have only those rights provided for such Software and any accompanying documentation

by the applicable FAR or DFARS clause or the Philips standard software agreement for the

product involved.

iv

Page 5

Text Conventions

The following conventions for Notes, Cautions, and Warnings are used in this manual.

NOTE

A Note calls attention to an important point in the text.

A Caution calls attention to a condition or possible situation that could damage or destroy the

product or the user’s work.

A Warning calls attention to a condition or possible situation that could cause injury to

the user and/or patient.

About this Manual

Caution

WarningWarning

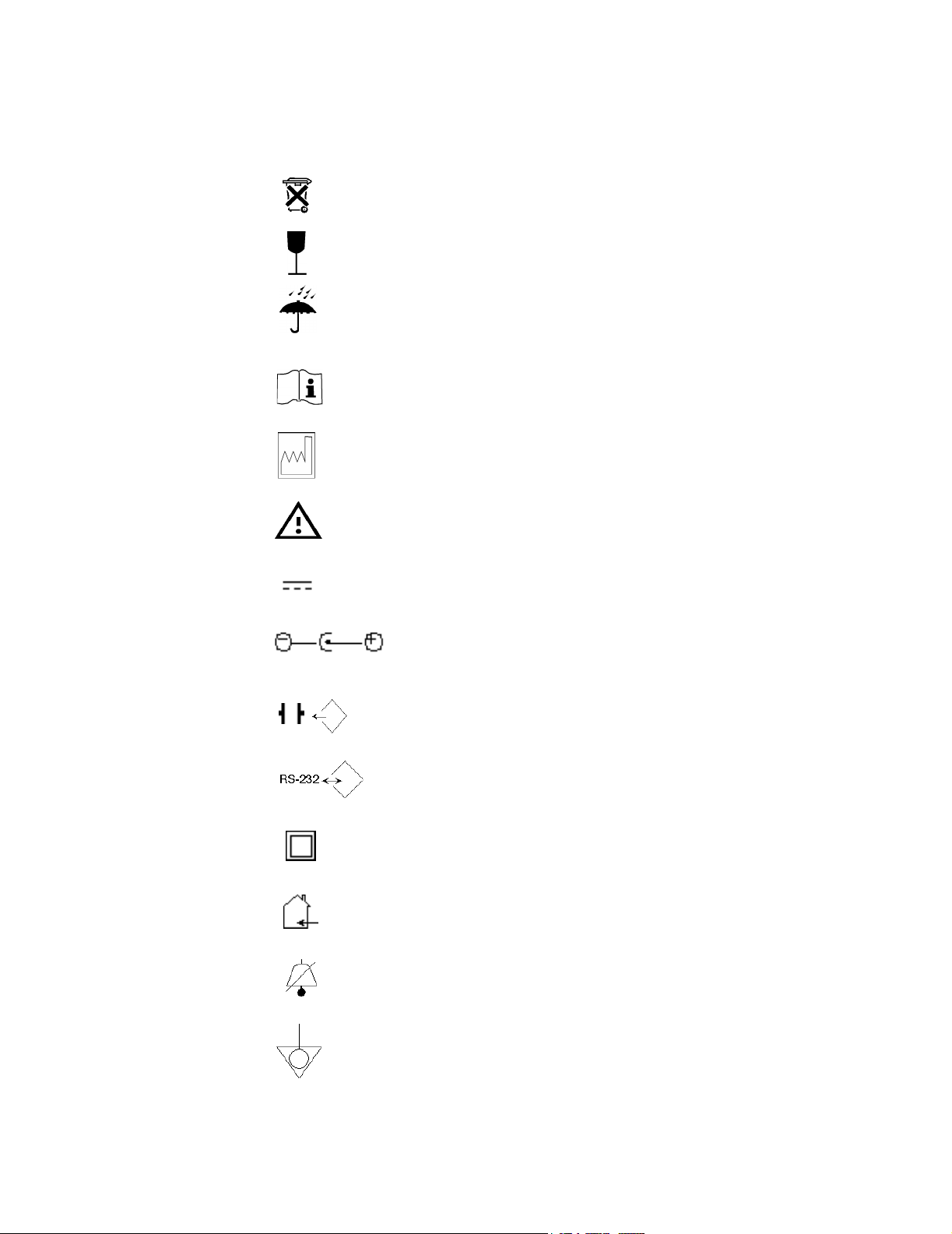

Explanation of Symbols

Symbols on products and packaging mean the following:

Battery Gauge icon

Defibrillator-proof type CF equipment

On/Standby button.

Alarm Limits icon.

Adjust Screen Contrast to display (monochrome) or invert the video to (color).

Adjust Heart Rate Tone volume.

Initiate NiBP measurement

v

Page 6

About this Manual

T

Temperature

NiBP

ECG

SpO

2

SpO

2

Located on recorder. Produces a 20 Second Snapshot

Located on recorder. Produces a Continuous Print

Signal (ECG) Input

Signal (ECG) Output

Data input/output

Alternating Current

Direct Current

Temperature

Humidity

Altitude or atmospheric pressure

vi

Page 7

About this Manual

Contains parts that may not be put into normal waste disposal but must be recycled or

dealt wi disposed as chemical waste

Fragile, handle with care

Keep dry

Consult instructions for use

Date of manufacture

Refer to User’s Guide

DC Lines

DC Input

Defib Sync.

RS-232 I/O

Class II Equipment

Power supply if for indoor use only

Silence Alarm

Equipotential Ground

vii

Page 8

About this Manual

Recorder’s front-panel charging LED

Recorder’s front-panel communication LED

Ground Wire

viii

Page 9

Contents

1. Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Manual Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Patient Monitor Description . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Introduction to External Recorder (M3925A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Related Documents . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2. Routine Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Periodic Safety And Functional Checks . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Battery . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Environmental Protection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

3. Performance Verification. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 7

Test And Inspection Matrix. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Equipment Needed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Performance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Charge . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Battery Performance Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Power-On Self-Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Hardware and Software Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

SpO

2

Operation with an ECG Simulator . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Operation with a Respiration Simulator (A3 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

Verification of Pneumatic System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Operation with a Temperature Simulator (A1 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Operation with a Temperature Simulator (A3 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

General Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Serial Interface Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Printer Verification (For A1 Optional Printer M3925A) . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Ground Integrity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Electrical Leakage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

4. Power-up Defaults Menu And Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Power-up Defaults Menu . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 37

Diagnostic Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 40

System Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 41

System A/D Values . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

NIBP Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 43

Restoring Factory Settings. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Contents ix

Page 10

5. Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

How To Use This Section . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Who Should Perform Repairs. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Replacement Level Supported . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Obtaining Replacement Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Troubleshooting Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Power . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 50

Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Generating an Error Log Printout (A1 only) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 53

Serviceable Hardware Error Codes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Other Error Codes (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 57

Buttons/Wheels (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Display/Audible Tones (All Monitors) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Operational Performance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

6. Disassembly Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

How To Use This Chapter . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Disassembly Procedures (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Closed Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Separation of Front and Rear Case Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Front Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

Rear Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 75

Main PCB Disassembly Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 77

Disassembly Procedures (A3) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Closed Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 79

Separation of Front and Rear Case Assemblies . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 80

Front Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Rear Case Disassembly Procedures . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 85

7. Spare Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Small Parts Kit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 91

Top Level Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 92

Front Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Rear Case Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Main PCB Assembly (A1) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Power Supply, Cables, and Miscellaneous Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 109

Exchange Unit Part Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 112

8. Packing For Shipment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

General Instructions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Repacking In Original Carton . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Repacking In A Different Carton. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

x Contents

Page 11

9. RS-232 Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 115

Cable Connections . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .116

Nurse Call . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 116

10. Training Program. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Levels of Involvement . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Preventative Maintenance Only . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 117

Phone Support or Service . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

Training Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Essential Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Optional Materials . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 118

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Support Strategies. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Unit exchange . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Bench repair . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .120

Theory of Operation and System Architecture . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

General . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .121

System Overview - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Block Diagram - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 121

Block Diagram - A1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

System Overview - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Block Diagram - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 123

Block Diagram - A3 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 124

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .129

Disassembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Monitor Applications and Algorithms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Reference Documents and Other Sources . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 132

Preventative Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 133

Index

Contents xi

Page 12

xii Contents

Page 13

Manual Overview

1

Introduction

This manual contains information for servicing the A1 and A3 patient

monitors, subsequently referred to as the monitor throughout this manual.

Only where there are differences in service procedures for the two monitor

types is each monitor referred to specifically as A1 and A3. Only qualified

service personnel should service this product. Before servicing the monitor,

read the User Guide carefully for a thorough understanding of operation.

Introduction 1

Page 14

Patient Monitor Description

Patient Monitor Description

The purpose and function of the patient monitor is to monitor: ECG; heart

rate; noninvasive blood pressure (systolic, diastolic, and mean arterial

pressures); functional arterial oxygen saturation; respiration rate (A3 only);

and temperature for adult and pediatric patients in all hospital areas and

hospital-type facilities. It can be used during hospital transport and in mobile,

land-based environments, such as ambulances.

The physical and operational characteristics of the monitor are described in

the User Guide.

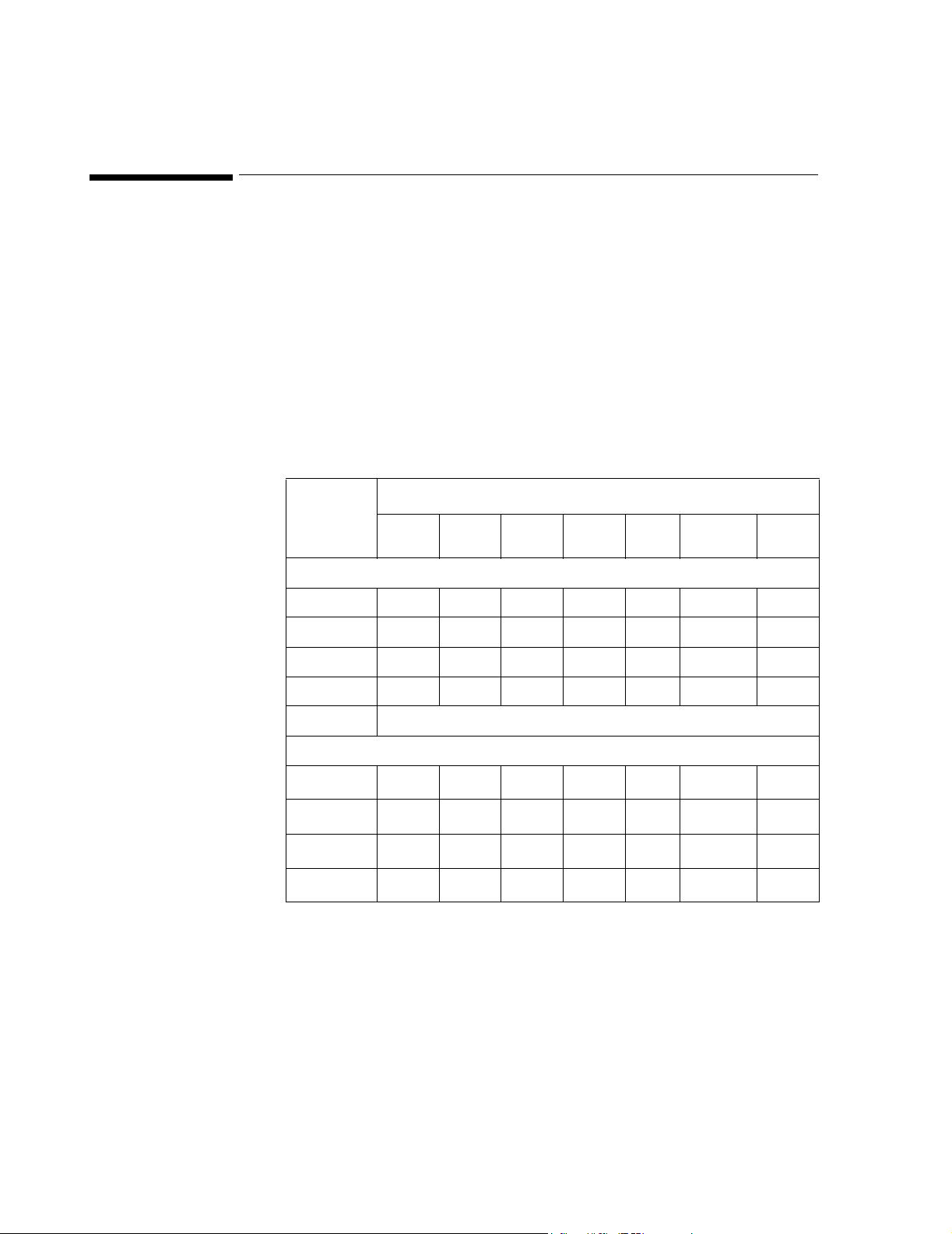

The measurement parameters and features for each model are indicated

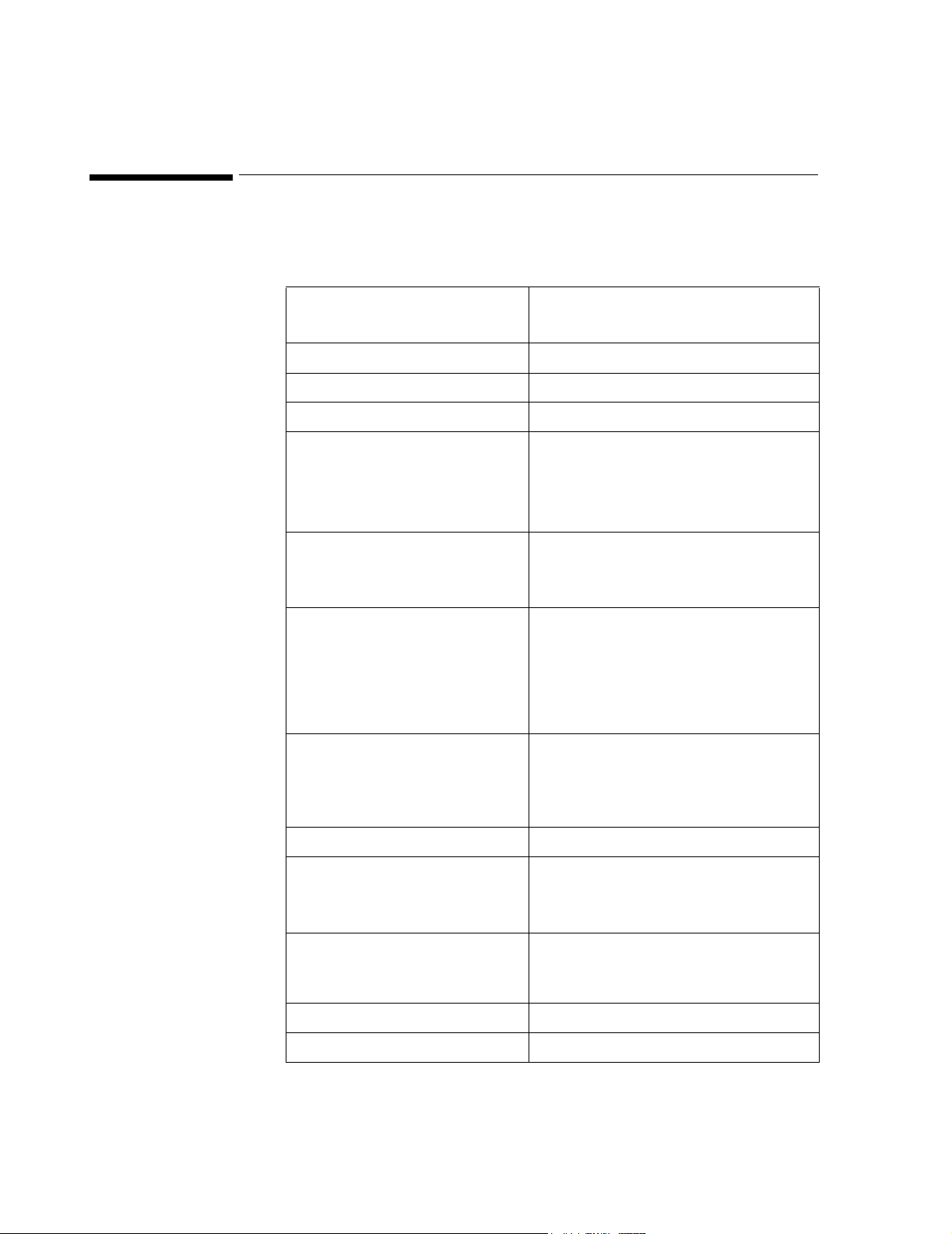

below.

Model

NIBP SpO

M3921A Yes Yes No No No No Mono

M3922A Yes Yes Yes No No No Mono

M3923A Yes Yes No Yes No No Mono

M3924A Yes Yes Yes Yes No No Mono

M3925A Optional Standalone Recorder for A1

M3926A Yes Yes Yes Yes Yes

M3927A Yes Yes Yes Yes Yes

M3928A Yes Yes Yes Yes Yes

M3929A Yes Yes Yes Yes Yes

Measurement Parameters and Features

Temp ECG Resp Integral

2

A1 Monitor

A3 Monitor

Recorder

No

Yes

No

Yes

Color/

Mono

Mono

Mono

Color

Color

2 Introduction

Page 15

Introduction to External Recorder (M3925A)

The recorder is an optional, standalone printer designed for use with the A1

patient monitor. The recorder communicates with the monitor using a nullmodem cable connected between each device’s RS-232 connector.

The recorder contains an internal battery, which, when fully charged, will

operate the recorder for 3 hours (typical, at 25°C, producing fifteen 20-second

printouts per hour). The recorder can be connected to AC power using an

external power supply. The recorder uses the same type of power supply as

the A1 monitor, the PS-120V or PS-240V.

The recorder does not have an On/Off switch. The recorder can sense when it

has an established communication link with the monitor. At that time, the

green LINKED indicator on the front panel lights, indicating that the recorder

is ready for operation. See the recorder’s User Guide for more information

regarding its operation.

Introduction to External Recorder (M3925A)

Related Documents

To perform test and troubleshooting procedures and to understand the

principles of operation and circuit analysis sections of this manual, you must

know how to operate the monitor. Refer to the User Guide to understand the

various sensors, ECG lead, blood pressure cuffs, and temperature probes that

work with the monitor. Refer also to the user guide and individual directions

for use that accompany these accessories.

Introduction 3

Page 16

Related Documents

4 Introduction

Page 17

Routine Maintenance

Cleaning

Warning Do not immerse the monitor or its accessories in liquid or

clean with caustic or abrasive cleaners. Do not spray or

pour any liquid on the monitor or its accessories.

To clean the monitor, dampen a cloth with a commercial, nonabrasive cleaner

and wipe the exterior surfaces lightly. Do not allow any liquids to come in

contact with the power connector or switches. Do not allow any liquids to

penetrate connectors or openings in the instrument. For cables, sensors and

cuffs, follow the cleaning instructions in the directions for use that accompany

these accessories.

2

Periodic Safety And Functional Checks

The monitor requires cleaning, battery maintenance and NiBP performance

and verification check every two years. The following performance

verification tests may be used following repair or during routine maintenance

(if required by your local institution).

1. Inspect the exterior of the monitor for damage.

2. Inspect labels for legibility. If the labels are not legible, contact Philips’

Response Center or your local Philips representative.

3. Verify that the NiBP performs properly as described in “Verification of

Pneumatic System” on page 21.

Battery

If the monitor has not been used for a long period of time, the battery will

need charging. To charge the battery, connect the monitor to an AC outlet, or

external DC supply in the case of the A3, as described in “Battery Charge” on

page 13 or the “Setup and Use” chapter of the User Guide.

Note Storing the monitor for a long period without charging the battery

can degrade the battery capacity. A complete battery recharge

requires 8 hours.

Chapter 2 - Routine Maintenance 5

Page 18

Environmental Protection

The battery can be recharged while the monitor is in use, in

which case, the battery requires 14 hours to be recharged.

The battery can require a full discharge/charge cycle to restore

normal capacity.

If the monitor operates1 for less than one hour on battery power before the

low battery alarm occurs, the battery should be conditioned.

If the same symptom persists even after the battery is conditioned and

indicating a full charge, the battery should be replaced.

Refer to Chapter 6, “Disassembly Guide”.

Environmental Protection

Follow local governing ordinances and recycling plans regarding disposal or

recycling batteries and other device components.

1. See “Battery Performance Test” on page 14 for typical battery operating times

and conditions.

6 Chapter 2 - Routine Maintenance

Page 19

Introduction

3

Performance Verification

This section discusses the tests used to verify performance following repairs

or during routine maintenance. All tests can be performed without removing

the covers of the monitor.

If the monitor fails to perform as specified in any test, repairs must correct the

problem before the monitor is returned to the user.

Performance Verification 7

Page 20

Test And Inspection Matrix

Test And Inspection Matrix

The following test map shows which tests are required in which situations.

Table 1 Test Map

Service Event (When

Performing…)

Installation Visual and Power On Tests

Repairs

A. Unit Exchange Visual and Power On Tests

B. Unit Opened Power On Test

C. NBP Pump replaced Power On Test

D. SpO

E. Front End Connectors replaced Power On Test

Module replaced Power On Test

2

Test Blocks Required (…Complete

these Tests)

Basic Pneumatic Leakage Test (BPL)

Ground Integrity Test

Leakage Current Test

NBP Tests:

Pneumatic Leakage and Inflation Rate

BPL Test

Tests:

SpO

2

Dynamic Operating Range and

LED Excitation

BPL Test

Performance test for the parameter that had

the connector replaced.

F. Power Supply replaced (A3 only) Power On, BPL, and Safety tests

G. Component level repair on any

PC board

H. Main PC board replaced Power On Test

All software upgrades Power On

Preventative maintenance Power On and NBP Performance Tests

8 Performance Verification

Power On Test

All Performance Tests

All Safety Tests

All Performance tests except Battery

Charge Test and Battery Performance Test

Page 21

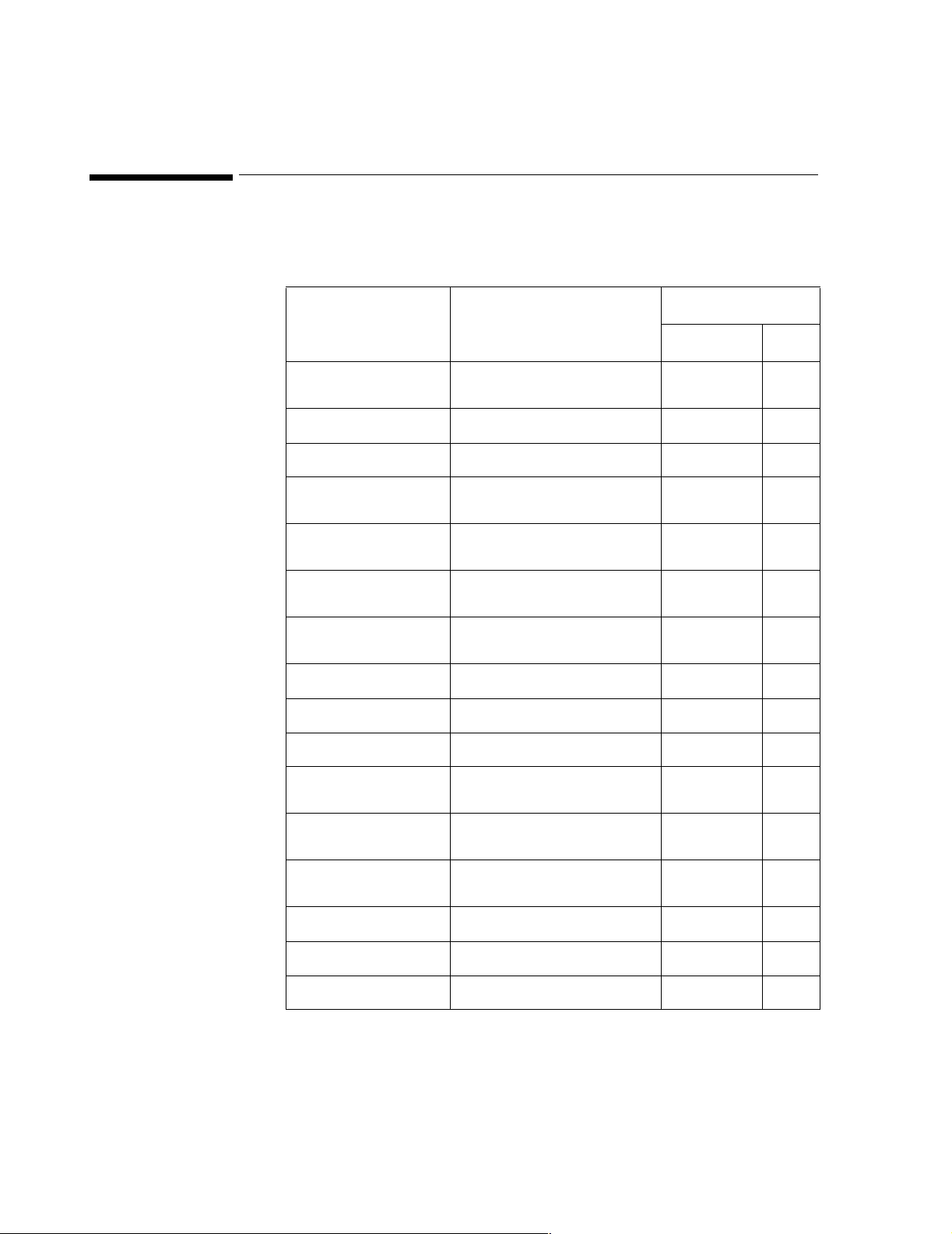

Table 2 Test and Inspection Reporting

Test And Inspection Matrix

1

Test

Visual: Inspect exterior

of monitor for damage

Power-On Self-Test Displays Normal Monitoring

Basic Pneumatic

Leakage Test (NBP

test)

NiBP Accuracy Test 250 mmHg; ±5 mmHg

NiBP Leakage Test After 1 Minute at 250 mmHg,

NiBP Inflation Rate

Test

NiBP Overpressure

Test

Expected Results

No Visual Damage V:P or V:F

Screen Configuration and emits

tones

After 1 minute at approximately

250 mmHg, pressure drops no

more than 6 mmHg.

pressure drops no more than

6 mmHg

Monitor Reports NiBP = 280

mmHg in <6 seconds

Overpressure Deflation is

activated at a value between

280 mmHg to 330 mmHg

What to Record

PO:P or PO:F

BPL: Px6

Where x6 =Pressure

Drop in mmHg

PN:P/X1…X4 (or X5

PN:F/X1…X4 (or X5

Record Pressure in

mmHg = X1

Record Pressure

Drop in mmHg = X2

Record Time to

280 mmHg in

Seconds = X3

Record value in

mmHg at which

Overpressure

Deflation occurs =X4

2

3

)

3

)

NiBP Deflation Rate

Test (A3 only)

Safety Performance

Tests

Monitor reports NiBP >10

mmHg and <190 mmHg

All Safety Performance Tests

are in range of Table 5 to

Table 12

Record value in

mmHg on monitor at

1 min = X5

S:P or S:F

1. Details of the tests are included later in this chapter.

2. When authorized Philips Medical Systems personnel service the instrument. The results are reported back to Philips. The collected data form a

database to be used in product development. It is not necessary for hospital personnel to report these results.

3. In the case of the NiBP Deflation Rate Test, applicable to the A3 only.

Performance Verification 9

Page 22

Equipment Needed

Equipment Needed

The following table lists the equipment required for performance verification.

Table 3 Required Test Equipment

Required For

Equipment Description A1 A3

Digital multimeter

(DMM)

Sensor extension cable M4787A

Finger clip sensor M4789A

Oxisensor® II adhesive

sensor

ECG cable M3913A M3923A and

ECG electrodes Standard M3923A and

ECG leads M3914A (IEC) or M3915A

NiBP tubing M3918A

NiBP cuff 40401C

Pulse oximeter tester Nellcor Puritan Bennett SRC-2

ECG simulator Dynatech Nevada medSim

Fluke Model 87 or equivalent

D-25

(AAMI)

300 or equivalent

··

··

··

··

M3924A only

M3924A only

M3923A and

M3924A only

··

··

··

··

·

·

·

NiBP simulator Bio-Tek BP Pump or

equivalent

Temperature simulator medSim 300 or equivalent M3922A and

Respiration simulator medSim 300 or equivalent

Safety analyzer Bio-Tek 601 Pro or equivalent

Stopwatch Manual or electronic

10 Performance Verification

··

·

M3924A only

-·

··

··

Page 23

Performance Tests

Battery Charge

Performance Tests

The battery charge and battery performance test should be performed before

monitor repairs whenever the battery is suspected as being a source of the

problems. All other tests can be used following repairs or during routine

maintenance (if required by your local institution). Before performing the

battery performance test, ensure that the battery is fully charged. (See

“Battery Charge” below).

This section is written using factory-set power-up defaults. If your institution

has pre configured custom defaults, those values display.

To fully charge the battery:

1. Connect the monitor to an AC power source using the proper power cord. For

the A1, use the PS-120V or PS-240V external power supply and power cord.

2. • For the A1, verify that the EXTERNAL POWER indicator is

lit.

• For the A3, verify that the

BATTERY CHARGING/AC SOURCE

indicator is lit.

3. Charge the battery for at least 8 hours.

The battery can require a complete discharge/charge cycle to restore its normal

capacity, depending on its previous usage.

4. To check for a full charge, perform the procedure described in “Battery

Performance Test” on page 12.

Performance Verification 11

Page 24

Battery Performance Test

Battery Performance Test

The the A1 and A3 mono monitors are specified to typically operate on

battery power for a minimum of 4 hours, at 25°C, with no printing, and one

NiBP measurement every 15 minutes. The A3 color monitor is specified to

typically operate on battery power for a minimum of 3 hours, at 25°C, with no

printing, and one NiBP measurement every 15 minutes. Before performing

this test, ensure that the battery is fully charged (see “Battery Charge”).

1. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the monitor

via the M4787A sensor cable.

2. Connect the NiBP simulator to the monitor via the M3918A tubing.

3. Set the SRC-2 switches as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

4. Set the NiBP simulator to simulate a pressure setting of 120/80 mmHg and heart

rate of 80 bpm.

5. Ensure that the monitor is not connected to AC power.

6. With the monitor turned off, press the ON/STANDBY button and verify

that the battery icon appears at the bottom of the display after the power-on selftest is completed. The boxes in the battery icon should all be filled, indicating

that the battery is charged.

7. Verify that the monitor is responding to the SpO

audible alarm is sounding. Use the wheel to select the SpO

permanently silence the SpO

8. Use the wheel to select the NiBP Menu and set the Automatic Measurement

Interval to 15 minutes. Exit the menu and press the front panel NiBP button

to manually start the first NiBP measurement. Subsequent NiBP

measurements are taken automatically every 15 minutes.

audible alarm.

2

simulator signal and that the

2

Menu and

2

12 Performance Verification

Page 25

Power-On Self-Test

Power-On Self-Test

9. The A1 and A3 mono monitors must operate for at least 4 hours before they

automatically power down due to low battery condition. The A3 color monitor

must operate for at least 3 hours before the monitor automatically powers down

due to low battery condition.

10. Verify that the low battery alarm occurs 15-30 minutes before the battery fully

discharges.

11. Allow the monitor to operate until it automatically powers down due to low

battery condition. Verify that the audible alarm sounds when the monitor

automatically shuts down. Press the Alarm Silence button to terminate this

audible alarm.

12. If monitor passes this test, immediately recharge the battery. (See “Battery

Charge” on page 11).

1. Connect the monitor to an AC power source. For the A1, use the PS-120V or

PS-240V power supply and power cord. For the A3, use the proper power cord

supplied.

2. • For the A1, verify that the EXTERNAL POWER indicator is

lit.

• For the A3, verify that the

BATTERY CHARGING/AC SOURCE

indicator is lit.

3. Do not connect any input cables to the monitor.

4. Observe the monitor front panel. With the monitor off, press the ON/

STANDBY button . The monitor must perform the following sequence:

a. The A1 emits a beep.

The A3 emits three consecutively higher pitched beeps.

b. A few seconds later, the display backlight illuminates, but the display is

blank.

c. The version numbers of the boot and operational software display in the

lower left corner of the display.

d. A beep signals the end of the power-on self-test. Power-on self-test takes

approximately 10 seconds to complete.

e. Upon successful completion of the power-on self-test, the display is in

normal monitoring screen configuration. No vital-sign numeric values or

waveforms are displayed.

Performance Verification 13

Page 26

Hardware and Software Tests

Hardware and Software Tests

Hardware and software testing includes the following tests applicable to the

indicated models in the series:

SpO2 Testing A1, A3 - all models

Operation with an ECG Simulator A1 - M3923A, M3924A

Operation with a Respiration Simulator A3 - all models

Verification of Pneumatic System A1, A3 - all models

Operation with a Temperature Simulator A1 - M3922A, M3924A

Test Applies to Model(s)

A3 - all models

A3 - all models

SpO

Testing

2

Alarms and Alarm

Silence

General Operation A1, A3 - all models

SpO2 testing includes the following tests:

n Alarms and Alarm Silence

n Heart Rate Tone Volume Control

n Dynamic Operating Range

n LED Excitation Test

1. Connect the SRC-2 pulse oximeter tester to the M4787A sensor cable and

connect the cable to the monitor.

2. Set SRC-2 as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION OFF

RCAL/MODE RCAL 63/LOCAL

3. Press the ON/STANDBY button to turn the monitor on.

4. After the normal power-up sequence, verify that the SpO

14 Performance Verification

% display initially

2

Page 27

Hardware and Software Tests

indicates zero or is blank. The pulse bar can occasionally indicate a step change

as the monitor is in the pulse search mode.

5. Move the modulation switch on the SRC-2 to LOW.

6. Verify the following monitor reaction:

a. The pulse bar begins to track the artificial pulse signal from the SRC-2.

b. Initially, zero is displayed in the SpO

frame, or it is blank.

2

c. After about 10 to 20 seconds, the monitor displays saturation and heart rate

as specified by the tester. Verify that the values are within the following

tolerances:

Oxygen Saturation Range 79% to 83%

Heart Rate Range 35 to 41 bpm

d. The audible alarm sounds and both the SpO2% and HEART RATE displays

flash, indicating both parameters have violated the default alarm limits.

e. The heart rate tone is heard. For this test, the user should set the heart rate

tone source to SpO

7. Press the ALARM SILENCE button on the front panel of the monitor.

The audible alarm is temporarily silenced.

8. Verify the following:

a. The audible alarm remains silenced.

b. The slashed bell icon appears in each numeric frame on the display.

c. The SpO

% and HEART RATE displays continue flashing.

2

from the Heart Rate Menu.

2

d. The heart rate tone remains audible.

e. The audible alarm returns in approximately 60 seconds.

Heart Rate Tone

Volume Control

1. Connect the SRC-2 pulse oximeter tester to the M4787A sensor cable and

connect the cable to the monitor.

2. Set SRC-2 as follows:

POSITION

SWITCH

A1 A3

RATE 38 38

LIGHT LOW LOW

MODULATION LOW OFF

RCAL/MODE RCAL 63/LOCAL RCAL 63/LOCAL

Performance Verification 15

Page 28

Hardware and Software Tests

3. Power on the monitor and verify that the SpO2 and heart rate values are

correctly displayed.

4. Press the ALARM SILENCE button on the front panel of the monitor

to temporarily silence the audible alarm.

5. Verify that the heart rate tone source, found in the Heart Rate Menu, is set to

SpO

.

2

6. Press the Heart Rate Tone VOLUME button on the front panel of the

monitor. Within 3 seconds of having pressed the button, rotate the wheel

clockwise and verify that the beeping heart rate tone sound level increases.

7. Rotate the wheel counterclockwise and verify that the beeping heart rate tone

decreases until it is no longer audible. Rotate the wheel clockwise to return the

beep volume to a comfortable level.

3 seconds after the last button-press or rotation of the wheel, function of the

wheel reverts to moving the highlight on the display screen.

Dynamic Operating

Range

The following test sequence verifies proper monitor operation over a range of

input signals.

1. Connect the pulse oximeter tester to the monitor and turn the monitor on.

2. Place the SRC-2 pulse oximeter tester in the RCAL 63/LOCAL mode.

3. Set the SRC-2 as indicated in below. Verify that the monitor readings are within

the indicated tolerances. Allow the monitor several seconds to stabilize the

readings.

Table 4 SRC 2 Settings and Monitor Indications

SRC-2 Settings Monitor Indications

RATE LIGHT MODULATION SpO2 Pulse Rate

38 HIGH2 LOW

112 HIGH1 HIGH

201 LOW LOW

201 LOW HIGH 79-83* 195-207*

An * indicates values that produce an alarm. Press the ALARM SILENCE

button to temporarily silence the audible alarm.

For the pulse rate setting of 201 bpm, the pulse rate tolerance of 195 to 207 bpm

is greater than the ±3 bpm accuracy specification of the monitor, due to the

performance characteristics of the SRC-2 tester.

79-83* 35-41*

79-83* 109-115

79-83* 195-207*

4. Turn the monitor off.

LED Excitation Test

16 Performance Verification

This procedure uses normal system components to test circuit operation. A

Page 29

Hardware and Software Tests

Nellcor Puritan Bennett Oxisensor II adhesive sensor, model D-25, is used to

examine LED intensity control. The red LED is used to verify intensity

modulation caused by the LED intensity control circuit.

1. Connect a M4787A sensor extension cable to the monitor.

2. Connect a D-25 sensor to the sensor extension cable.

3. Press the ON/STANDBY button to turn the monitor on.

4. Leave the sensor open with the LED and photo detector visible.

5. After the monitor completes its normal power-up sequence, verify that the

sensor LED is brightly lit.

6. Slowly move the sensor LED in proximity to the photo detector element of the

sensor. Verify, as the LED approaches the optical sensor, that the LED intensity

decreases.

7. Open the sensor and notice that the LED intensity increases.

8. Repeat step 6 and the intensity again decreases. This variation is an indication

that the micro-processor is in proper control of LED intensity.

9. Turn the monitor off.

Operation with an ECG Simulator

1. With the monitor off, connect the ECG leads to the appropriate jacks on the

ECG tester.

2. Connect the leads to the ECG cable.

3. Connect the cable to the ECG input port on the monitor.

4. Set the ECG simulator as follows:

Heart rate: 30 bpm

Amplitude: 1 millivolt

Lead select: II

Wave Type: Normal sinus rhythm

Patient Type: Adult mode

Note

The accuracy of the monitor’s ECG measurements is ±5 bpm. In

the procedure below, add the tolerance of the simulator to the

acceptable range of readings.

5. Press On/Standby button to turn monitor on.

Performance Verification 17

Page 30

Hardware and Software Tests

6. After normal power-up sequence, verify the following monitor reactions:

a. After at least five heartbeats, the monitor displays a heart rate of 30 ±5 bpm.

b. The audible alarm sounds and the

indicating heart rate is below the default lower alarm limit.

7. Press the ALARM SILENCE button. Verify that the audible alarm is

silenced.

8. Increase the heart rate setting on the ECG simulator to 240 bpm.

9. After at least five heartbeats, verify that the monitor displays a heart rate of 240

±5 bpm.

10. Verify that the audible alarm sounds and the

indicating that the heart rate is above the default upper alarm limit.

11. Press ALARM SILENCE button to silence alarm.

12. Decrease the heart rate setting on ECG simulator to 120 bpm.

13. After at least five heartbeats, verify that the monitor displays a heart rate of 120

±5 bpm.

14. Disconnect the LL lead from ECG simulator.

15. Verify that the

displayed in

sounds.

16. Reconnect the LL lead to ECG simulator. Verify that the

message no longer appears and audible alarm is silenced.

17. Repeat steps 14 through 16 for LA and RA leads.

18. Turn the monitor off.

Leads Off alarm message appears, three dashes are

HEART RATE display, and the low priority audible alarm

HEART RATE display flashes,

HEART RATE display flashes,

Leads Off alarm

Operation with a Respiration Simulator (A3 only)

1. With the monitor off, connect the ECG leads to the appropriate jacks on the

respiration simulator.

2. Connect the ECG leads to the ECG cable.

3. Connect the cable to the ECG input port on the monitor.

Note

The accuracy of A3 measurements is ±3 breaths per minute. In

the procedure below, add the tolerance of the simulator to the

acceptable range of readings.

4. Set the simulator for a respiration rate of 120 breaths per minute.

5. Press the ON/STANDBY button to turn the monitor on.

18 Performance Verification

Page 31

Hardware and Software Tests

6. After the normal power-up sequence, verify the following monitor reactions:

a. The monitor displays a respiration rate of 120 ±3 breaths per minute.

b. The audible alarm sounds and

indicating respiration rate is above default upper alarm limit.

7. Press the ALARM SILENCE button . Verify that the alarm is silenced.

8. Decrease the respiration rate setting on the respiration simulator to 20 breaths

per minute.

9. Verify that the monitor displays a respiration rate of 20 ±3 breaths per minute.

Verification of Pneumatic System

The following tests, from “Basic Pneumatic Leakage Test” on page 19

through “Over-Pressure” on page 23, verify the functionality of the pneumatic

system of the monitor. All these tests, with the exception of the Basic

Pneumatic Leakage Test, require the use of an appropriate NiBP simulator.

Although the tests were designed to use the Bio-Tek BP Pump noninvasive

blood pressure simulator, any equivalent NiBP simulator with the same

internal test volume can be used. The internal test volume of the Bio-Tek

simulator is 250 ml.

The monitor must be placed in Diagnostic Mode, with the NiBP Test screen

active for each of the NiBP tests. For a detailed explanation of the Diagnostic

Mode, refer to Chapter 4, “Power-up Defaults Menu And Diagnostic Mode”.

RESPIRATION RATE display flashes,

Basic Pneumatic

Leakage Test

The purpose of this test is to verify the integrity of the NiBP Pneumatic

System after the monitor has been opened. This covers all external and

internal tubing and tubing connections. No simulator is required for this test.

In cases where the performance of the NiBP is in question or could have been

compromised during repair the complete set of NiBP performance tests

described in this service manual should be used (see test map, page 8, for

guidance).

1. Attach an NiBP cuff (adult model 40401C is recommended) and the NiBP

adapter cable to the monitor NiBP connector.

2. Wrap the cuff around itself and place on a table for the test, DO NOT place the

cuff on your arm.

Performance Verification 19

Page 32

Hardware and Software Tests

3. Power on the monitor and enter the NiBP test screen.

a. Use the wheel to select Set up menu (screwdriver icon on bottom

of screen.)

b. Select the Power up defaults menu.

c. Use the wheel to select password 2-1-5.

Note

d. Select

e. Select NBP test.

4. Press the Heart Rate Tone VOLUME button to close valves.

5. Press NBP start/stop switch, hold until the monitor screen shows 250 mmHg.

6. Wait 15-20 seconds to allow the value to stabilize.

7. Note the value on the screen, start 1-minute timer.

8. After 1 minute note the value on the screen, if the difference is less than or equal

to 6 mmHg the test has passed.

9. Press and hold the Heart Rate Tone VOLUME button until the screen

shows the pressure has released and the value is 0 mmHg.

10. Turn the monitor off.

Enter Diagnostic Mode = yes.

If the test fails, ensure the integrity of the cuff and adapter tubing,

then test again. If the test fails again, verify the integrity of all the

pneumatic system tubing inside the monitor. If the test still does

not pass, see test map, page 8.

Each of the tests mentioned below must be performed to verify pneumatic

system functionality. These tests can be performed individually (in any order)

or sequentially. Prior to performing any of these tests, perform the following

setup procedure. If these tests are performed in sequence, this procedure

needs to be performed once prior to the first test.

1. Turn on the Bio-Tek simulator and press the MODE button to place the

simulator in test mode. The simulator screen indicates

Pressure Gauge.

and

2. Connect the simulator tubing to the NiBP connector on the monitor.

3. Follow the procedure described in Chapter 4 to place the monitor in Diagnostic

Mode with the NiBP Test screen active.

Pressure Transducer

Accuracy

20 Performance Verification

The pressure transducer accuracy test verifies the pressure accuracy of the

monitor’s pressure transducer.

Internal Cuff

Page 33

Hardware and Software Tests

1. Confirm that the Bio-Tek simulator is in test mode. The simulator should display

Pressure Gauge.

2. Confirm that the simulator is set up for the internal cuff.

3. Confirm that the NiBP Test screen is active on the monitor.

• On the A1, press, then release, the Heart Rate Tone VOLUME button

to verify that the valve is closed.

• On the A3, press the ALARM SILENCE button to ensure that

both valves are closed.

4. Perform an offset adjustment so that the simulator and monitor both display a

pressure of 0 mmHg by doing the following:

a. Press the CONTRAST button on the monitor.

b. Press the ZERO button on the simulator.

5. Press the SELECT button on the simulator until the simulator displays

Pressure Source Set Test Pressure.

6. Use the UP/DOWN buttons on the simulator to adjust for a pressure of 250

mmHg.

7. Press the START PUMP button on the simulator. The simulator begins to

pressurize. The current pressure in mmHg is displayed on both the simulator and

the monitor displays.

8. Allow 15-20 seconds for the pressure to stabilize.

The pressure displayed on the monitor and the simulator should be within 5

mmHg of one another to complete the test successfully.

9. Press the STOP PUMP button on the simulator to stop the test.

10. Press and hold the Heart Rate Tone VOLUME button until the monitor

displays a pressure of 0 mmHg.

Additional NiBP tests can be performed at this time. If no further NiBP tests

are to be conducted, turn the monitor off. Normal monitoring operation

returns the next time the monitor is turned on.

Performance Verification 21

Page 34

Hardware and Software Tests

Pneumatic Leakage The pneumatic leakage test verifies the integrity of the pneumatic system.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should display

Pressure Gauge.

2. Confirm that the simulator is set up for the internal cuff.

3. Ensure that the NiBP Test screen is active on the monitor.

4. Press the Heart Rate Tone VOLUME button on the monitor.

• On the A1, this verifies that the valve is closed.

• On the A3, this verifies that both the valves are closed.

5. Perform an offset adjustment so that the simulator and monitor both display a

pressure of 0 mmHg by doing the following:

a. Press the CONTRAST button on the monitor.

b. Press the ZERO button on the simulator.

6. Press the NiBP button on the monitor to activate the pump.

7. Hold the NiBP button until the monitor displays a pressure of

approximately 250 mmHg.

8. Allow 15-20 seconds for the pressure to stabilize.

9. Record the pressure displayed on the monitor.

10. Start a 1 minute timer.

11. After 1 minute, again record the pressure displayed.

The test is successfully completed if the pressure has dropped by 6 mmHg, or

less, during the 1 minute period.

12. Press and hold the Heart Rate Tone VOLUME button until the monitor

displays a pressure of 0 mmHg.

Additional NiBP tests can be performed at this time. If no further NiBP tests

are to be conducted, turn the monitor off. Normal monitoring operation

returns the next time the monitor is turned on.

22 Performance Verification

Page 35

Hardware and Software Tests

Inflation Rate The inflation rate test verifies the inflation rate of the monitor.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should display

Pressure Gauge.

2. Confirm that the simulator is set up for the internal cuff.

3. Ensure that the NiBP Test screen is active on the monitor.

4. Press the Heart Rate Tone VOLUME button on the monitor.

• On the A1, this verifies that the valve is closed.

• On the A3, this verifies that both the valves are closed.

5. Perform an offset adjustment so that the simulator and monitor both display a

pressure of 0 mmHg by doing the following:

a. Press the CONTRAST button on the monitor.

b. Press the ZERO button on the simulator.

1. Press the NiBP button on the monitor to activate the pump, and

simultaneously start the timer.

2. Hold the NiBP button until the monitor displays a pressure of 280

mmHg, then stop the timer.

The test is successfully completed if the inflation time is between 1 and 6

seconds.

3. Press and hold the Heart Rate Tone VOLUME button until the monitor

displays a pressure of 0 mmHg.

Additional NiBP tests can be performed at this time. If no further NiBP tests

are to be conducted, turn the monitor off. Normal monitoring operation

returns the next time the monitor is turned on.

Over-Pressure The over-pressure test verifies the functionality of the over-pressure relief

system of the monitor.

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should display

Pressure Gauge.

2. Confirm that the simulator is set up for the internal cuff.

3. Ensure that the NiBP Test screen is active on the monitor.

4. Press the Heart Rate Tone VOLUME button on the monitor.

• On the A1, this verifies that the valve is closed.

• On the A3, this verifies that both the valves are closed.

5. Perform an offset adjustment so that the simulator and monitor both display a

Performance Verification 23

Page 36

Hardware and Software Tests

pressure of 0 mmHg by doing the following:

a. Press the CONTRAST button on the monitor.

b. Press the ZERO button on the simulator.

6. Press the NiBP button on the monitor to activate the pump.

7. Hold the NiBP button until the monitor displays a pressure of

approximately 250 mmHg.

8. Press the SELECT button on the simulator until the simulator displays

Overpressure Test.

9. Press the START TEST button on the simulator. The simulator pressurizes the

system until the monitor’s overpressure relief system activates, including the

warning display screen. The simulator displays the pressure value that caused

the monitor’s overpressure relief system to activate. The test is successfully

completed if the simulator displays a pressure reading of 280 mmHg to 330

mmHg.

10. Press and hold the Heart Rate Tone VOLUME button to ensure that the

monitor displays a pressure of 0 mmHg.

Additional NiBP tests can be performed at this time. If no further NiBP tests

are to be conducted, turn the monitor off. Normal monitoring operation

returns the next time the monitor is turned on.

Deflation Rate The deflation rate test verifies the deflation rate of the A3 monitor. (There is

no deflation rate test for the A1).

1. Ensure that the Bio-Tek simulator is in test mode. The simulator should display

Pressure Gauge.

2. Confirm that the simulator is set up for the internal cuff.

3. Ensure that the NiBP Test screen is active on the monitor.

4. Press the Heart Rate Tone VOLUME button on the monitor. This verifies

that both the valves are closed.

5. Perform an offset adjustment so that the simulator and monitor both display a

pressure of 0 mmHg by doing the following:

a. Press the CONTRAST button on the monitor.

b. Press the ZERO button on the simulator.

6. Press the NiBP button on the monitor to activate the pump.

24 Performance Verification

Page 37

Hardware and Software Tests

7. Hold the NiBP button until the monitor displays a pressure of

approximately 250 mmHg.

8. Start 1 minute timer, and simultaneously press and hold the ALARM SILENCE

button on the monitor.

This causes the pneumatic system to deflate at a rate of 3 mmHg/s ±1.5 mmHg/

s.

9. After 1 minute, record the pressure displayed on the monitor. The test has been

successfully completed if the monitor displays a pressure reading of 10 mmHg

to 190 mmHg.

10. Press and hold Heart Rate Tone VOLUME button until monitor displays

a pressure of 0 mmHg.

Additional NIBP tests can be performed at this time. If no further NiBP tests

are to be conducted, turn the monitor off. Normal monitoring operation

returns the next time the monitor is turned on.

Operation with a Temperature Simulator (A1 only)

1. Remove the probe from its holder.

2. Insert the calibration key in the temperature input port T on the A1.

3. Press the ON/STANDBY button to turn the monitor on. After the normal

power-up sequence, verify that the temperature reads 36.3 ± 0.1°C (or 97.3 ±

0.2°F).

4. Turn the monitor off.

Operation with a Temperature Simulator (A3 only)

1. With monitor off, connect the temperature cable (supplied with the temperature

simulator) to the appropriate connector on temperature simulator.

2. Connect the temperature cable to the temperature input port on the A3.

3. Set the temperature simulator as follows:

Temperature: 37°C (98.6°F)

Probe Type: YSI 400 Series

Note

The accuracy of A3 temperature measurements is ±0.1°C

(±0.2°F). In the procedure below, add the tolerance of the

simulator to the acceptable range of readings.

Performance Verification 25

Page 38

General Operation

General Operation

Serial Interface Test

4. Press the ON/STANDBY button to turn monitor on.

5. After normal power-up sequence, verify temperature reads 37°C ±0.1°C (98.6°F

±0.2°F if Fahrenheit is selected as temperature units.)

6. Turn the monitor off.

The following tests provide an overall performance check of the system:

• Serial Interface Test

• Printer Verification (for optional printer - A1 only)

Note Perform only if nurse call signal is used.

Perform the following procedure to test the serial port voltages. The test is

qualitative and only verifies that the serial interface port is powered correctly,

and that the Nurse Call signal is operational. The serial connector is a male

DB-9 located on the monitor’s real panel, identified with the RS-232 symbol

.

1. Turn the monitor on.

2. Set up the DMM with the function set to

3. Connect the DMM negative lead to connector pin 5 (GND), or the shell of the

RS-232 connector.

4. Referring to the following table, connect the DMM positive lead to each pin in

turn, and verify the voltage values listed. Voltage for pin 9 is that listed for the

VDC at a range of 10 volts.

no alarm condition.

26 Performance Verification

Page 39

General Operation

Table 5 Serial Interface Voltages

Measurement (V)

Pin Signal Direction

Min. Typical Max.

1 not used 0.4 0.0 0.4

2 RXD<<< input –0.4 0.0 0.4

3 TXD>>> output –0.5 –9.0 –15.0

4 DTR>>> output –5.0 –9.0 –15.0

5 GND –0.4 0.0 0.4

6 DSR<<< input –0.4 0.0 0.4

7 RTS>>> output –5.0 –9.0 –15.0

8 CTS<<< input –0.4 0.0 0.4

9 Alarm Out>>>

(no alarm)

9 Alarm Out>>>

(alarm underway)

output –5.0 –9.0 –15.0

output 5.0 9.0 15.0

5. Connect the Nellcor Puritan Bennett SRC-2 pulse oximeter tester to the monitor

via the M4787A sensor extension cable.

6. Set the SRC-2 switches as follows:

SWITCH POSITION

RATE 38

LIGHT LOW

MODULATION LOW

RCAL/MODE RCAL 63/LOCAL

7. Verify that the monitor is responding to the SpO

simulator signal and the

2

audible alarm is sounding. If desired, press the ALARM SILENCE button

to temporarily silence the audible alarm.

8. Connect the DMM positive lead to pin 9 and verify the voltage value listed in

Table 5. Voltage for pin 9 is that listed for the

alarm underway

condition.

Performance Verification 27

Page 40

General Operation

Printer Verification (For A1 Optional Printer M3925A)

Printer verification consists of connecting the printer to the monitor and the

monitor to a human subject for a qualitative test.

1. Connect the output of the appropriate power supply, PS-240V or PS-120V, to

the labeled connector on the rear of the printer. When the

printer’s external power supply is connected, the printer front-panel charging

LED is lit.

2. Connect the serial cable between the labeled connectors on the

rear panels of the monitor and the printer.

3. The printer front panel communication LED is lit when the RS-232

communications link is completed.

4. Rotate the monitor wheel to highlight the setup icon . Press the wheel

and ensure Communications Selection is

Printer.

5. Connect a M4787A sensor extension cable to the monitor. Connect an oxygen

transducer to the sensor extension cable. Attach it to the subject as described in

the sensor directions for use.

6. Press the ON/STANDBY button to turn the monitor on and verify that

the monitor is operating.

7. The monitor should stabilize on the subject’s physiological signal in about 15 to

30 seconds. Verify that the saturation and heart rate is reasonable for the subject.

8. Press the printer CONTINUOUS button . Verify that the printout contains

vital signs across the top of the paper, and that a SpO

waveform, with grid

2

marks, occupies the center portion of the paper. To terminate the printout, press

the CONTINUOUS button again.

9. Disconnect the sensor and shut off the monitor.

28 Performance Verification

Page 41

Safety Tests

Ground Integrity

Safety Tests

Philips safety tests meet the standards of, and are performed in accordance

with IEC 601-1, Clause 19 (EN60601-1, Second Edition, 1988; Amendment

1, 1991-11, Amendment 2, 1995-03).

The A1 patient monitor is a Class II device. It is double insulated and does not

require a protective earth (ground) wire. The A3 patient monitor is a Class I

device. It requires a protective earth (ground) wire. Test requirements differ

for Class I and Class II devices. Be aware of the differences and use the

appropriate test procedure for the monitor in use.

There are two categories of safety tests:

n Ground Integrity

n Electrical Leakage

Table 6 Ground Integrity

Test or “Inspection” to Perform Expected Test Results

Protective Earth

See “Safety Test Diagram - Protective

Earth” on page 30

With mains cable:

Maximum impedance = x <= 100 mOhms

Performance Verification 29

Page 42

Safety Tests

Safety Test Diagram - Protective Earth

Test or Inspection to Perform

Measures impedance of Protective Earth (PE) terminal to all exposed metal parts of

IUT, which are for safety reasons connected to the Protective Earth (PE). Max. 100

mOhm. Test current 25 Amps applied for 5 to 10 seconds. We recommend to flex

the main cable during the test in order to identify potential bad contact or damage of

the earth wire. Safety test according to EN60601-1 (Clause 18). Report largest

value.

Note The A1 does not require an isolated Earth Ground terminal,

neither is one installed. No Protective Ground Continuity check is

required.

30 Performance Verification

Page 43

Electrical Leakage

Safety Tests

The following tests verify the electrical leakage of the monitor:

n Earth Leakage Current (A3 only)

n Enclosure Leakage Current

n Patient Leakage Current

n Patient Source Current, with Mains Voltage on the Applied Part

Perform all leakage tests any time the unit is opened.

Earth Leakage Current

(A3 only)

This test is in compliance with IEC 601-1 (Earth Leakage Current). In

locations where mains voltage is 100-120 volts, the applied voltage is 132

volts. In locations where mains voltage is 220-240 volts, the applied voltage is

264 volts. The applied AC frequency should be the same as the local mains

(50 or 60 Hz).

All measurements shall be made with the power switch in both

ON and OFF

positions.

1. Connect the monitor AC plug to the electrical safety analyzer as recommended

by the analyzer operating instructions.

2. Perform test as recommended by analyzer operating instructions.

Earth leakage current is measured under various conditions of the AC mains

and protective earth conductor. For each condition, the measured leakage

current must not exceed that indicated below

Table 7 Earth Leakage Current Values (A3 Only).

Tes t

Condition

Normal

1

S.F.C

Open

Supply

Polarity Allowable Leakage Current

Normal 300 µA

Reversed 300 µA

Normal 1000 µA

Reversed

1000 µA

1. S.F.C = Single Fault Condition

Enclosure Leakage

Current

This test is compliance with EN60601-1 (Enclosure Leakage Current). Test at

110% of the nominal line voltage.

1. Connect the A3’s AC mains power cord to the analyzer as recommended by the

analyzer operating instructions.

2. Using the appropriate test cable, connect the analyzer to the snap nearest to the

handle fixing screw as shown in the following photograph.

Performance Verification 31

Page 44

Safety Tests

C

onnect analyzer

test cable to the

snap as arrowed

(or alternatively,

to the handle

fixing screw)

NOTE: do NOT use this

snap on the rear of the

case, or any of the

other screws on the rear

of the monitor

3. Turn the monitor on.

4. Perform the test as recommended by the analyzer operating instructions.

The analyzer leakage current indication must not exceed the values listed

below.

32 Performance Verification

Page 45

Safety Tests

Table 8 Enclosure Leakage Current

EN60601-1 (1990 + A1, A2, A11, A12, A13) and UL2601 (2nd Ed. 1997) US Deviations

Test Condition Polarity Allowable Leakage Current

Patient Leakage

Current

Normal

1

S.F.C

Open Supply

(A1 Only)

1

Open

S.F.C

Protective Earth

(A3 Only)

Normal 100 µA

Reversed 100 µA

Normal 150 µA

Reversed 150 µA

Normal 300 µA

Reversed

300 µA

1. S.F.C = Single Fault Condition

This test measures patient leakage current in accordance with EN60601-1,

Clause 19, for Class I, type CF equipment. Patient leakage current in this test

is measured from any individual patient connection to earth (power ground).

This test requires a sample patient cable for each device parameter. These

must be configured as recommended by the safety analyzer operating

instructions.

1. Configure the electrical safety analyzer as recommended by the analyzer

operating instructions.

2. • A1 - Connect the appropriate external power supply input power cord

to the analyzer as recommended by the analyzer operating instructions.

Connect the external power supply output cord to the monitor.

• A3 - Connect the monitor’s AC mains power cord to the analyzer as

recommended by analyzer operating instructions.

3. Connect the ECG test cable between the ECG connector on the monitor

and the appropriate input connector on the analyzer.

4. Turn the monitor on.

5. Perform the test as recommended by the analyzer operating instructions.

Patient leakage current is measured under various conditions of the AC mains

and protective earth conductor. For each condition, the measured leakage current

must not exceed that indicated below.

6. Repeat the test for SpO

and temperature patient connections, using appropriate

2

test cables.

Performance Verification 33

Page 46

Safety Tests

Table 9 Patient Leakage Current Values

Test Condition Polarity

Allowable Leakage

Current (Max.)

Typ e CF

Normal

S.F.C.

S.F.C.

1

(Open Supply)

(A1 Only)

1

(Open Earth/Ground)

(A3 Only)

Normal 10 µA

Reversed 10 µA

Normal 50 µA

Reversed 50 µA

Normal 50 µA

Reversed 50 µA

1. S.F.C. = Single Fault Condition

Patient Leakage

Current, with Mains

Voltage on the Applied

Part

This test measures patient leakage current in accordance with EN60601-1,

Clause 19, for Class I, type CF equipment. In this test, 110% of mains voltage

is applied between each patient connection and earth (power ground). Patient

leakage current is then measured from any individual patient connection to

earth.

Warning AC mains voltage is present on the applied part terminals

during this test. Exercise caution to avoid electrical shock

hazard.

Table 10 Safety Tests - Patient Leakage Current, with Mains

Voltage on the Applied Part

Test or “Inspection” to Perform Expected Test Results

Patient Leakage Current - AC

See “Safety Test Diagram - Patient

Leakage Current - AC” on page 35

34 Performance Verification

Maximum leakage current = x

<= 50 mA @ 250V (IEC601-1 or UL2601-1)

Test at 110% of the nominal line voltage.

Page 47

Safety Test Diagram - Patient Leakage Current - AC

Test or Inspection to Perform

Safety Tests

Measures patient leakage current from Applied Part to earth caused by external

mains voltage on Applied Part with switch S5 open and closed. Each polarity

combination possible is tested using S2 and S6.

Safety test according to EN60601-1 (Clause 19.4.h). Report largest value.

Performance Verification 35

Page 48

Safety Tests

36 Performance Verification

Page 49

Power-up Defaults Menu And Diagnostic

Mode

Introduction

This section discusses use of the Power-up Defaults Menu to configure

power-on default settings, and the Diagnostic Mode to obtain service-related

information about the monitor.

Power-up Defaults Menu

The purpose of the Power-up Defaults Menu is to allow the authorized user to

create a power-up default for each setting in the monitor. Power-up defaults

are the settings in effect each time the monitor is powered on. Once the

Power-up Defaults Menu is entered, physiological monitoring is terminated.

The screen layouts do not display any information associated with normal

monitoring operation.

4

Note

Use the following procedure to configure the power-up default settings for the

monitor:

1. Set the monitor to normal monitoring mode.

2. Adjust each accessible setting on the monitor as desired.

Use the techniques described in the User Guide. Such settings

include alarm limits, choice of display type for the graphic

frames, and ECG lead select.

3. Use the wheel to invoke the Set-up Menu (choose the screwdriver icon

found along the bottom of the display).

4. Select menu item

selected, a pop-up box will appear with the text

Passcode.

5. Use the wheel to enter the passcode,

Enter Power-Up Defaults Menu. Once

Enter 3-Digit

2 1 5.

Note

Power-up Defaults Menu And Diagnostic Mode 37

This passcode is set at the factory and cannot be changed.

6. The Power-up Defaults Menu is now present. The available menu items are

explained below. Make changes to these menu items as desired.

Page 50

Power-up Defaults Menu

Menu Item* Choices** Explanation

Accept Current

Settings as Power-Up

Defaults?

Adult/Neonatal Mode

(A3 only)

Alarm Silence Period 30 s, 60 s,

Permanent Audible

Alarm Silent

Yes

No

90 s, 120 s

Make Available

Deny Access

If Yes is chosen, the current monitor

settings become the power-up defaults.

Neonatal mode is not available at this time;

thus, when this item is selected, the

following pop-up message will appear:

Selection not available.

Time is indicated in seconds. Pressing the

front-panel Alarm Silence button

temporarily silences audible alarms for the

time indicated in the Silence Period menu

item. Alarm state(s) in effect at the end of

the pre-set interval cause the audible alarm

to sound. Pressing the Alarm Silence

button a second time (while the silence

interval is still in effect) ends the interval

immediately. Silencing audible alarms

does not affect visual alarm indications.

If Make Available is chosen, the

caregiver may permanently silence the

audible alarm for a particular parameter via

the Alarm/Limits Menu. Some institutions

may wish to prevent audible alarms from

being permanently silenced. If so, Deny

Access should be selected.

Alarm Suspend Make Available

Deny Access

Auto-Set Limits Make Available

Deny Access

SpotCheck Mode

(A1 only)

Deny Access

Make Available

If Make Available is chosen, the