Page 1

NBP and CO2 Calibration Instructions

M3535A/M3536A HeartStart MRx

PHILIPS

Page 2

Notice

About This Edition

Edition 1

Printed in the USA

Publication number 453564067081.

The information in this document applies to the

HeartStart MRx, product version indicated below. This

information is subject to change without notice.

Philips shall not be liable for errors contained herein or

for incidental or consequential damages in connection

with the furnishing, performance, or use of this material.

Edition History

Pub. Number Ed. S/W Version Print Date

453564067081

1 9.00 and earlier Sept., 2007

Copyright

Copyright © 2007

Koninklijke Philips Electronics N.V.

All rights are reserved. Permission is granted to copy and

distribute this document for your organization’s internal

educational use. Reproduction and/or distribution

outside your organization in whole or in part is

prohibited without the prior written consent of the

copyright holder.

Windows Media Player® is a registered trademark of

Microsoft Corporation.

Use of supplies or accessories other than those

recommended by Philips may compromise product

performance.

Medical Device Directive

The HeartStart MRx complies with the requirements of

the Medical Device Directive 93/42/EEC and carries the

mark accordingly.

0123

Manufacturer:

Philips Medical Systems

3000 Minuteman Road

Andover, MA USA 01810-1099

(978) 687-1501

Authorized EU-representative:

Philips Medizin Systeme Böblingen GmbH

Hewlett Packard Str. 2

71034 Böblingen

Germany

U.S. FCC and Industry Canada Radio Compliance:

Contains FCC ID: PQC-WMTS-MODULE

Operation of this equipment requires the prior coordination with a

frequency coordinator designated by the FCC for the Wireless Medical

Telemetry Service. This device complies with Part 15 of the FCC rules

and RSS-210 of Industry Canada. Operation is subject to the

following conditions:

• This device may not cause harmful interference.

• This device must accept any interference received, including

interference that may cause undesired operation.

Any changes or modifications to this equipment not expressly

approved by Philips Medical Systems may cause harmful radio

frequency interference and void your authority to operate this

equipment.

Canada EMC: ICES-001

China: After-Sales Service: Beijing MEHECO-PHILIPS Medical

Equipment Service Center.

After-Sales Service Address: No. 208, 2nd District, Wang Jing Li Ze

Zhong Yuan, Chao Yang District, Beijing.

Postal code: 100102.

Telephone: 010-64392415.

Registration number: SFDA(I)20043211207.

Product Standard number: YZB/USA 52-21.

ii

Page 3

Conventions Used in This Manual

These upgrade instructions contain the following conventions:

WARNING Warning statements describe conditions or actions that can result in personal injury or loss of life.

CAUTION Caution statements describe conditions or actions that can result in damage to the equipment or loss of

data.

NOTE Notes contain additional information on usage.

TIP Tips provide hands-on insight into servicing this product.

Text represents messages that appear on the display

[Softkey] represents softkey labels that appear on the display above or below the button

to which they correspond.

On-line viewing only

* Hypertext represents hypertext links, which will display as blue; click on the blue link to go

to that destination, then click on the blue destination to return.

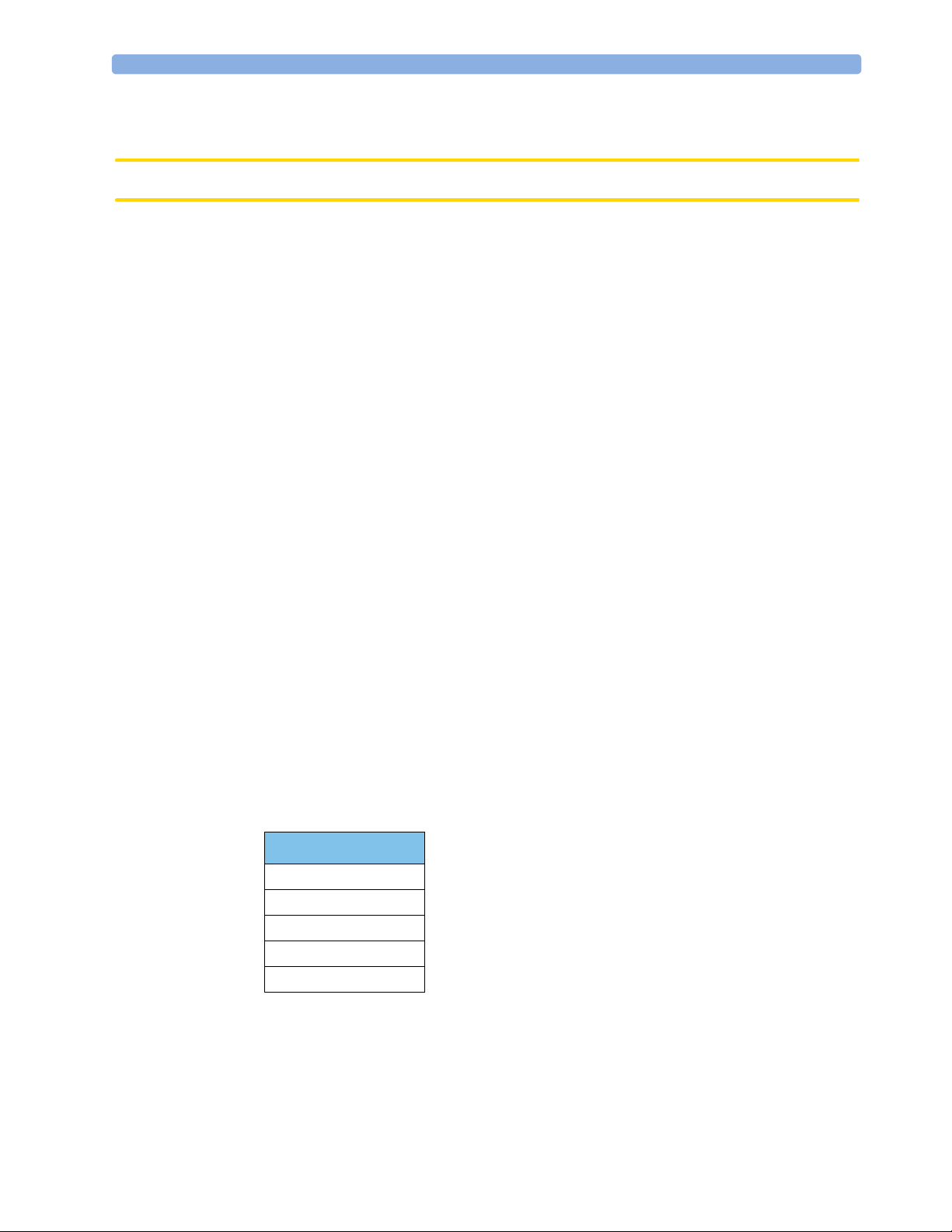

Abbreviations

Name Abbreviation

HeartStart MRx Monitor/Defibrillator monitor/defibrillator

device

Carbon dioxide CO

End-tidal carbon dioxide EtCO

Non-invasive Blood Pressure NBP

2

2

iii

Page 4

iv

Page 5

Introduction

Introduction

CAUTION These instructions are intended for users trained in the safe and proper HeartStart MRx operation.

HeartStart MRx NBP and EtCO2 calibration is part of the HeartStart MRx maintenance routine that

also includes operational checks, lithium ion battery maintenance, etc. described in HeartStart MRx

Instructions for Use. NBP and EtCO

not covered in the Instructions for Use.

This document covers the following calibration procedures:

• Yearly calibration (or every 10,000 cycles, whichever is sooner) of the Non-invasive Blood Pressure

(NBP) module

• Yearly calibration (or every 4000 hours, whichever is sooner) of the End-tidal Carbon Dioxide

(EtCO

Use these quick links to access the calibration procedures:

) module.

2

* NBP Module Calibration

calibration is the only HeartStart MRx maintenance procedure

2

* EtCO

Module Calibration

2

HeartStart MRx Calibration Overview

Consider reviewing the “HeartStart MRx Calibration” instructional video included in your calibration

kit before proceeding with the calibration. To watch the DVD on your PC, you may need to install the

latest version of Windows Media Player

http://www.microsoft.com/windows/windowsmedia/download/.

center

The video is also available online at

Perform calibration when prompted by the

Overdue

Fail/D (Versions B.05 and above) or Fail/NC (Versions prior to B.05).

Regardless of your configuration settings, millimeters of mercury are the unit of measure for pressure in

the HeartStart MRx calibration. Use the conversion formulae from Ta b le 1 if necessary:

Table 1 Units of Pressure Conversion

inops. If a calibration is overdue, then the HeartStart MRx Op. Check fails with the code

1 unit = __ mmHg

1 kPa = 7.5 mmHg

1 mb

1 psi

1 atm.

1 inHg = 25.4 mmHg 30 inHg = 30 × 25.4 mmHg = 762 mmHg

.75 mmHg

=

51.7 mmHg

=

760 mmHg

=

®

available for free download from Windows Media download

http://theonlinelearningcenter.com/schtml/mrx/calibration/.

CO2 Calibration Overdue and NBP Calibration

Example:

Accessing Service Mode

The calibration activities are accessed through the Service Mode. To access the Service Mode:

1 From the Main Menu select Other, then Service.

2 Enter the “27689” password when prompted by the device.

1

Page 6

NBP Module Calibration

This section describes how to calibrate the HeartStart MRx NBP module.

To calibrate the HeartStart MRx NBP module you need:

• the manometer and cuff assembly

• the plastic container to wrap the cuff around

Both the manometer / cuff assembly and plastic container are provided in the “NBP Calibration Kit,”

part # 453564063841.

NBP Calibration Setup

To prepare for NBP calibration:

1 Access the Service Mode Main menu as described in “Accessing Service Mode” on page 1.

2 From the Service Mode Main menu, select NBP.

The NBP Service screen is displayed (see Figure 1). You may hear a soft, high-pitch tone, this is

normal NBP pump operation.

Figure 1 NBP Service Screen

NBP Module Calibration

Service

Cycle Counter :

Last Calibration :

Pressure in Cuff :

- NBP

02 Jul 2007 10:52

50,010

30 Jun 2006 09:42

0

B

A

Replacement recommended

Calibration recommended

Main

Service

Calibrate

3 Check the Cycle Counter.

If the NBP module has executed more than 50,000 cycles, replacement is recommended.

Do not proceed with the calibration. Call for service.

2

Page 7

NBP Module Calibration

4

Connect the test cuff assembly to the NBP port and wrap the cuff around the container (see

Figure 2).

Do not overtighten the cuff. It should have space for about 500 mL of air. Leave room for two

fingers between the cuff and container before connecting the velcro.

Figure 2 NBP Calibration Setup

Container

Loosely fitted NBP cuff

Manometer

NBP Safety Features

The NBP module is equipped with the Timeout and Overpressure safety features that prevent injury to

the patient and damage to the device.

NBP Timeout

The NBP module times out when the pressure remains greater than 10 mmHg for 3 minutes. Do not

keep the cuff pressurized for more than 3 minutes during the calibration.

NBP Overpressure

The NBP module overpressure occurs when the cuff pressure reaches 300 mmHg. Do not raise the

pressure in the cuff to more than 280 mmHg during the calibration.

The safety features cause the valve to open and the pressure to drop. If a safety feature is triggered

during calibration, then reset the module:

1 Press the [Main Service] softkey

Pump

2 Access the NBP Service screen to restart the calibration.

3

Page 8

NBP Calibration Procedure

Complete the calibration process within three minutes to avoid the NBP module timeout.

To c al ib ra te :

1 Press the [Calibrate] softkey.

The message

2 Release all of the pressure in the cuff so that the manometer reads 0 mmHg.

3 Press the [Next] softkey.

The message Apply 250 mmHg. Select Next when ready is displayed.

4 Increase the pressure so that the manometer reads 250 mmHg.

Take time to allow the pressure in the unit to equalize and stabilize. One way to do this is to

pressurize the cuff to 255 or 260 mmHg and wait for 30 seconds, then gently adjust the pressure

with the pump and valve.

5 When the pressure is stable at 250 mmHg, press the [Next] softkey again.

6 Wait until the message Calibration complete. Please perform the accuracy and leakage

tests to check the results is displayed.

Apply 0 mmHg. Select Next when ready is displayed.

NBP Module Calibration

NOTE The message instructing you to perform the accuracy and leakage tests is for field service engineers

only. These tests do not need to be performed as part of calibration.

After several seconds the message clears, and the NBP Service screen is displayed.

7 Release the pressure in the cuff to avoid the safety timeout.

8 Run an operational check to update the calibration status.

See HeartStart MRx Instructions for Use for op.check guidance.

NBP Calibration Failure

If the error message Calibration failed. Check that the pressure applied is correct. Please

restart calibration appears at any moment during NBP calibration, then:

1 Recheck the manometer and cuff assembly connections.

2 Loosen the cuff. If less than ten pump compressions fill the cuff, then it is too tight.

3 Press the [Main Service] softkey.

4 Select NBP from the Service Main Menu.

5 Restart the NBP Calibration Procedure, making sure that the applied pressures are correct.

6 Call for service if you cannot successfully complete the calibration

4

Page 9

EtCO2 Module Calibration

EtCO2 Module Calibration

This section describes how to calibrate the HeartStart MRx EtCO2 (here called CO2) module.

To calibrate the HeartStart MRx CO

• Gas flow valve

• Modified Filterline set with T-shaped tubing assembly

• 5% calibration gas cylinder (15210-64010)

•A calculator

• A barometer to measure ambient pressure or other means of determining the ambient pressure.

Both the gas flow valve and Modified Filterline are provided in the “CO

# 453564063851. The CO

for troubleshooting only and not used in calibration.

CO2 Calibration Setup

Before performing calibration, the CO2 sensor must warm up for at least 20 minutes. Do not start

calibration until the CO

Warm Up the CO2 Sensor

To w ar m u p t he CO2 sensor:

1 Access the Service Mode Main menu as described in “Accessing Service Mode” on page 1.

2 Connect the Modified FilterLine from the kit to the HeartStart MRx CO

See Figure 3.

module you need:

2

Calibration Kit,” part

Calibration Kit also contains a flow tube and two air plugs that are used

2

sensor has been warmed up.

2

2

inlet marked .

2

Figure 3 CO

Modified FilterLine

Warm-Up Setup

2

!

5

Page 10

EtCO2 Module Calibration

3

From the Service Mode Main menu, select CO

.

2

After a few seconds delay, the CO2 Service screen is displayed, as shown in Figure 4.

Figure 4 CO

Service

CO2 Operating Hours :

Last Calibration :

Ambient Pressure :

Cell Pressure :

You may hear a soft, low-pitch tone, this is normal CO

the CO

pump activity is the difference between the Ambient and Cell pressures. Subtract the Cell

2

Service Screen

2

- CO2

02 Jul 2007 10:52

15,004 hours

30 Jun 2006 09:42

760 mmHg

733 mmHg

B

A

Replacement recommended

Calibration recommended

pump operation. Another indication of

2

pressure from the Ambient pressure and consult Ta bl e 2 to interpret the difference.

Table 2 Modified FilterLine Connection Checking and Troubleshooting

Ambient Pressure

Possible Cause Suggested Solution

– Cell Pressure

Bad connection 1 Reconnect the Modified FilterLine.

0

2 Go back to Main Service and reselect CO2.

Pump malfunction Call for service.

9 mmHg or less

Modified FilterLine

is broken

Replace the Modified FilterLine.

Pump malfunction Call for service.

10 - 30 mmHg The pump is operating normally, and the sensor is warming up.

31 mmHg or more Modified FilterLine

is blocked

Check that the Modified FilterLine is not kinked

and free of blockages. Replace if necessary.

3 When the pump starts working as expected, clock the warm-up time. You can use the

HeartStart MRx screen clock.

6

Page 11

EtCO2 Module Calibration

Prepare for the Calibration

Perform the following preparatory steps while the CO2 sensor is warming up:

1 Check the CO

If the CO

Operating Hours.

2

module has clocked more than 15,000 hours, replacement is recommended.

2

Do not proceed with the calibration. Call for service.

2 Obtain a reliable measurement of local atmospheric pressure by using a barometer or by getting the

local atmospheric pressure data from the Internet, local airport, or weather station located at the

same altitude as your lab.

3 Press the Menu Select button and select Ambient Pressure.

4 Using Up and Down buttons, adjust the HeartStart MRx’s Ambient Pressure setting to the

measurement obtained in Step 2.

5 Press the Menu Select button again to accept the adjusted Ambient Pressure value.

6 Calculate the expected CO

The expected CO

reading depends on both the gas concentration you are using (5.0%) and the

2

reading.

2

ambient pressure. Calculate as follows:

a.

Cal. Gas Concentration × ambient pressure = Expected CO2 value

For example:

[0.05] × [760 mmHg] = 38 mmHg

b. Calculate the allowable tolerance, which is ± 5% of the expected reading. Calculate as follows:

[±0.05] × Expected CO2 value = ± tolerance (mmHg)

For example:

[±0.05] × 38 = ± 1.9 (mmHg)

In this example, the displayed reading is expected to be 38 ± 1.9 mmHg.

c. Round to the nearest whole number because HeartStart MRx does not show fractions. The

expected CO

d. Save your calculations. You will compare the numbers with the actual CO

reading in our case should be between 36 and 40 mmHg.

2

sensor reading

2

during the calibration validation.

7 Fit the 5% CO

8 Watch the manometer on the valve.

gas cylinder with the valve. Screw the valve on tightly.

2

While the gas pressure does not have to be high for successful calibration, it should be present.

9 Connect the soft tubing at one end of the modified Filterline to the gas valve outlet, and leave the

other end open to atmosphere. See Figure 5.

7

Page 12

Figure 5 CO2 Calibration Setup

Do not touch

this regulator

EtCO2 Module Calibration

Gas flow valve

Modified FilterLine

CO2 Calibration Procedure

Make sure the CO2 sensor has been warmed up for at least 20 minutes before starting the calibration

steps.

To c al ib ra te th e C O

1 From the CO

The CO

2

2 Wait a few seconds until the softkeys become active. See Figure 6.

module:

2

Service menu, select Calibration Check.

2

Calibration screen is displayed.

Gas flow

regulator

Manometer

5% CO

calibration

2

gas cylinder

Figure 6 CO2 Calibration Screen

02 Jul 2007 10:52

Service

CO2 : 37 mmHg

Main

Service

- CO2

DoneCalibrate

B

A

8

Page 13

EtCO2 Module Calibration

3

Fully open the gas flow valve.

Turn the regulator on the side of the valve counterclockwise. Do not touch the regulator on the top

of the valve.

4 Allow the CO

value to stabilize.

2

5 Press the [Calibrate] softkey.

6 Use the Menu Select key to confirm that you are using the 5% CO

While it is recommended that you use the 5% gas, you can calibrate CO

CO

gas mix.

2

Figure 7 CO

Main

Service

Cal Gas Selection

2

Cancel

Done

Cal CO2

5 %

MENU

gas mix. See Figure 7.

2

module with 4% or 6%

2

7 Do not turn off gas or touch any buttons or tubing until completion.

CO2 calibration in progress message indicates that the calibration has started.

The

The

Calibration complete message indicates that the calibration is successful.

8 Turn off the gas.

9 Validate the calibration by checking the displayed CO

value against the expected value calculated

2

in the Prepare for the Calibration section.

The displayed value should match the expected value within the calculated allowable tolerance.

10 Press the [Done] softkey.

Note that even though the calibration is successful (the time of last calibration is updated), the

calibration status does not get updated until the op. check is completed. See Figure 8.

Figure 8 Successful CO

02 Jul 2007 10:52

Calibration

2

B

A

Calibration is successful, but the

Service

- CO2

Calibration recommended

message does not disappear until

CO2 Operating Hours :

Last Calibration :

Ambient Pressure :

Cell Pressure :

1504 hours

02 Jul 2007 10:50

760 mmHg

739 mmHg

Calibration recommended

the Op. Check is completed.

11 Run an Operational Check to update the calibration status.

See HeartStart MRx Instructions for Use for Op. Check guidance.

9

Page 14

CO2 Calibration Failure

If the error message Calibration failed. Please restart calibration appears at any moment during

CO

calibration, then:

2

1 Recheck the Modified FilterLine, gas cylinder, and valve connections.

EtCO2 Module Calibration

2 If the CO

See the War m Up th e C O

3 Restart the CO

4 If you cannot successfully complete the calibration, call for service.

module is off, restart the warm-up process and wait for 20 minutes.

2

Sensor section.

2

Calibration Procedure.

2

10

453564067081

Edition 1

September, 2007

*453564067081*

*1*

Loading...

Loading...