Page 1

Series 50 Fetal Monitors

Series 50 A (M1351A)

Series 50 IP-2 (M1353A)

SERVICE AND INSTALLATION GUIDE

M1353-9000J

Printed in Germany April 2002

Page 2

Notice

Philips makes no warranty of any kind with regard to this material, including, but

not limited to, the implied warranties of merchantability and fitness for a particular

purpose. Philips Medical Systems shall not be liable for errors contained herein or for

incidental or consequential dam age s in co nn ect ion w ith the fu rni shi ng, pe rforman ce

or use of this material.

This document contains proprietary information that is protected by copyright. All

rights are reserved. No part of this document may be photocopied, reproduced or

translated to another language without prior written consent of Philips Medical

Systems.

The information contained in this document is subject to change without notice.

Philips assumes no responsibility for the use or reliability of its software on

equipment that is not fu rnished by Philips.

Purchase of this instrument confers no express or implied license under any Nellcor

patent or copyright to use this instrument with any fetal oximetry sensor that is not

manufactured or licensed by Nellcor.

Dinamap is a trademark of General Electric.

Press-Mate is a trademark of the COLIN Corporation.

Federal Law (US) restricts this device to sale by or on the order of a physician.

Caution

Failure on the part of the responsi ble individual hospital or institution

employing the use of this equipment to implement a satisfactory

maintenance schedule may cause und u e equipment failure and possible

health hazards.

Page 3

Printing History

New editions are complete revisions of the manual. Update packages, which are issued

between editions, contain additional and replacement page s to be add ed t o t he manual . Th e

dates on the title page ch a nge only when a new edition or a new update is published.

Edition 1: June 1992

Edition 2: A ugust 1993

Edition 3: February 1995

Edition 4: March 1997

Edition 5: February 1998

Edition 6: May 2000

Edition 7: Apri l 2002

2002 Philips Medizinsysteme Böblingen GmbH

All rights are reserved. Reproduction in wh ole or in part is prohibited without the prior

written consent of the copyright holder.

Page 4

Page 5

Contents

1. General Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Who Should Read This Guide. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

What to do Next. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Repair Strategy . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1

Conventions and Symbols Used in this Guide . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .2

Initial Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Claims for Damage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Repacking . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .3

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .4

Major Keys and Parts at a Glance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Monitor Control and Display Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

M1351A Single Ultrasound Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

M1351A Dual Ultrasound Twins Model. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .7

M1353A Model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .8

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .9

Series 50 A (M1351A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Series 50 IP-2 (M1353A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Documentation. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

Options. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

2. Technical Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Power Requirements . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

Weight and Dimensions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .13

Displays . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Inputs . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .14

Recorder. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

Self-Test Facilities . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Combined Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .16

Modem Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Remote Event Marker (15249A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Transducers and Cables. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .17

Brown Toco Transducer (M1355A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Blue Toco Transducer (M1355A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Brown Ultrasound Transducer (M1356A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

1

Blue

Ultrasound Transducer (M1356A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

DECG Transducer (M1357A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

MECG Transducer (M1359A). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

DECG/MECG Patient Module (M1364A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .18

IUP Quartz Transducer (1290C option J05) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

IUP Pressure Transducer (CPJ840J5) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

3. Installing the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fitting the Monitor to a Surface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .21

Contents v

Page 6

Fitting the Monitor to the Angle Mount. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Fitting the Monitor to a Wall . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Wall Mount Dimensions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22

Fitting the Paper Take-Up Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .23

Cart-mounted Paper Tray . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Carts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .24

Fitting the Barcode Reader Holder . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

4. Configuring the Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .25

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 25

Configuring the Monitor Using Pushbuttons . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Examples: How to Change the Time Format and IUP Format using Pushbuttons. . . . . . . . . . . . . . . . . . . . 28

Configuring the Monitor Using Barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 29

Configuring the Monitor Using a PC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .29

Installing the Service Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 30

Connecting the PC to the Monitor. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Loading the Service Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Using the Service Program . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Error Log Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

5. Setting Time, Date, and Paper Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .47

Time and Date . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 47

Paper Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .48

6. Theory of Operation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

System Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .49

Booting and Self Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .50

Front End Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .52

M1351A (M1353-66501 and M1353-66511) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

M1353A (M1353-66512) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Frontend Board for M1353A (M1350-66517) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Power Supply Board (M1353-66502) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 55

CPU Board (M1353-66503 and M1353-66513) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

CPU Board M1353-66503. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

CPU Board M1353-66513. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 56

Display Board (M1350-66520) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 58

Recorder Interface Board (M1353-66510) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 59

Interface Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .60

Combined Interface Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Modem Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 63

7. Tests and Error Messages. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .65

Service Philosophy. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Overview of the Service Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Performance Assurance Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Self Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 65

Quick Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 66

Parameter Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Operator Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 69

Permanent Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

FSpO2. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 70

8. Troubleshooting Flowcharts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

vi Contents

Page 7

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .71

Error 500: General Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .72

Error 501, 511, 512, 516, 517: Front End Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

Error 502: Power Supply. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Error 503 and 513: CPU Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .78

Error 510: Recorder Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .79

Error 531: Combined Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .80

Error 532: Modem Interface Board. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .81

Error 70: Modem Not Responding . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .82

Error 77: Modem Transmission Failure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .83

Error 601: Paper Feed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .84

Error 610: No Loudspeaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .85

Error 611: Loudspeaker. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .86

Ultrasound Parameter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .87

DECG Parameter Test. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .88

MECG Parameter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .89

Toco Parameter Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .90

Maternal NIBP with the Dinamap 1846/8100 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .91

Maternal NIBP with the COLIN Model BP-8800 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .92

Fetal Pulse Oximetry with Nellcor N-400 or Compatible Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .93

Paper Sensing Test . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .94

9. Preventive Maintenance,

Care and Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 95

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Cleaning the Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .95

Regular Maintenance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .96

Mechanical Inspection. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Recorder Maintenance. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 96

Accessory Testing. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .97

Testing Toco Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 97

Testing Ultrasound Transducers . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .98

Testing Patient Modules (M1364A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

IUP. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 99

Safety Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

Safety Test Procedures. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .100

When to Perform Safety Tests. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .102

Test and Inspection Matrix . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 103

Safety Tests . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 104

10. Peripherals . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 107

Fitting the Combined Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .107

Connecting Peripheral Devices. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .108

RS232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .109

Barcode Reader . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 110

NIBP Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .111

Maternal Measurements on the FHR Trace. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .112

FSpO2 Monitor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 113

Telemetry System . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .115

80235A (OBMS), M1370A (ODIS), and OB TraceVue . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .117

11. Replacing Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Contents vii

Page 8

Ordering Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 119

Safety Test Requirements. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .119

Service Tools . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Lists of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 120

Monitor Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 122

Recorder Parts . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 125

Monitor Housing Color. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

Toco Transducer (Blue, M1355A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 127

Ultrasound Transducer (Blue, M1356A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 128

DECG Transducer (M1357A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 129

MECG Transducer (M1359A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Toco Transducer (Brown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 131

Ultrasound Transducer (Brown) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .133

Patient Module (M1364A) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .135

Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 135

Fuses. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .136

Batteries . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .137

Top Cover. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .138

Front End Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .139

Power Supply Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 140

CPU Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 141

Combined Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .142

Modem Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 142

Chassis . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 143

On/Off Switch . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 144

Recorder Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 145

Display Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .146

Switch Board . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .147

Loudspeaker . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 148

Transformer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 149

Drawer Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .150

Thermal Printhead . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 151

Recorder Sensing Assembly . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .153

Stepper Motor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .154

A. Modem Interface Module. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Introduction . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Fitting the Modem Interface Module . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 155

Connecting Peripheral Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .156

Barcode Reader Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 157

RS232 Serial Interface . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 158

Entering, Storing, and Transmitting Data. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .159

Setting the Receiver Phone Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Setting the Patient Phone Number. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Setting the Patient ID . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 160

Clearing Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Starting Storage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 161

Displaying Memory . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Stopping the Storage or Transmission of Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

Transmitting Data . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 162

PCMCIA Card Modem. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 163

Modem Compatibility . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

viii Contents

Page 9

Modem Initialization . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .164

Using the Modem Setup Barcodes. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 164

List of Parts. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 65

Troubleshooting and Error Messages . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .165

Telephone Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .166

Modem Setup Barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

Service Barcodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .168

B. Safety and Environment. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Safety Information . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1 71

Protective Earth . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .171

Patient Safety. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 171

Environment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1 72

Spillage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

Electromagnetic Compatibility. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

EMC Testing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .173

System Characteristics. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173

Avoiding Interference . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 174

C. Upgrade Key . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 175

Introduction. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Upgrade Procedure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .175

Contents ix

Page 10

x Contents

Page 11

Introduction

1

General Information

This guide tells you how to install, service, and repair an Series 50A (M1351A) and an

Series 50 IP/IP-2 (M1353A) fetal monitor. Throughout this book, the M1353A is referred

to as the IP-2. This also covers the IP, unless stated otherwise. It describes the system

hardware and software, and tells you how to test the system and diagnose operating and

service problems.

It gives instructions for both the Series 50 A and the Series 50 IP/IP-2 monitors. The

features available on the monitor you are installing or serv icing depend on which options

have been purchased. If your monitor does not have a described parameter, you can skip

that part of the instruction and move on to the next point.

Who Should Read This Guide

What to do Next

Repair Strategy

The manual is for anyone who services an d repairs Series 50 A (M1351A) and Series

50 IP/IP-2 (M1353A) fetal monitors. You must understand English and be familiar with

current conventional technical terms.

Famil iarize your self with the conte nts of this guide be fore attemp ting to install or service the

monitor.

Reading operating error messages and the error lo g helps you to d etermine wheth er a fault is

a hardware or software problem. Faults may be repaired by replacing a board when possible,

or exchanging the monitor. Repair or replacement of components on the boards should not

be attempted.

After any repairs you must carry out the following tests:

l

Performance test, by running the Self Test (see page 65).

l

Quick Test (see page 66).

l

Parameter Test (see page 68).

You must also perform the appropriate safety tests (see the section “Safety Testing” on

page 100).

A series of preventive maintenance tasks and performance assurance tests must be carried

out regularly to ensure the proper functioning of the monitor: these are described in

“Regular Maintenance” on page 96.

Chapter 1 General Information 1

Page 12

Conventions and Symbols Used in this Guide

Conventions and Symbols Used in this Guide

This guide uses the following conventions for notes, cautions, and warnings:

Warning

A warning alerts you to a potential serious outcome, adverse event or safety

hazard. Failure to observe a warning may result in death or serious injury to

the user or patient.

Caution

A caution alerts you to situations where special care is necessary for the safe

and effective use of the product. Failure to observe a caution may result in

minor or moderate personal injury or damage to the product or other

property, and possibly in a remote risk of more serious injury.

Note— A note calls your attention to an importan t p o int in th e text.

On your monitor, this sign indicates that there is detailed

information in this book which you must read before

proceeding with your task

Equipotential Terminal

This symbol is used to identify terminals which are connected together, bringing various

parts of an equipment or system to the same potential, not necessarily being earth potential

(the value of potenti a ls of earth may be indicated adjacent to the symbol).

Protective Earth Terminal

This symbol identifies the terminal for connection to an external protective earth.

2 Chapter 1 General Information

Page 13

Initial Inspection

Initial Inspection

The monitor and any supporting options ordered are supplied packed in protective

shipping cartons. Before unpacking, visually check the packaging and ensure that there are

no signs of mishandling or damage.

Claims for Damage

If the shipping cartons show signs of having been mishandled, contact the carrier and

arrange for his agent to make an inspection.

If any of the equipment supplied is damaged, you should contact both the carrier and your

local Philips Medical Service Organization. Ar rangements will then be made for repair or

replacement, as appropriate.

Repacking Y ou are advised to retain the original packing carton and material. Y ou will find it useful if it

becomes necessary to return a piece of equipment to Philips for service. If you need to

repack the equipment but cannot locate the original packing materials, Philips can advise

you on alternatives.

Chapter 1 General Information 3

Page 14

Overview

Overview

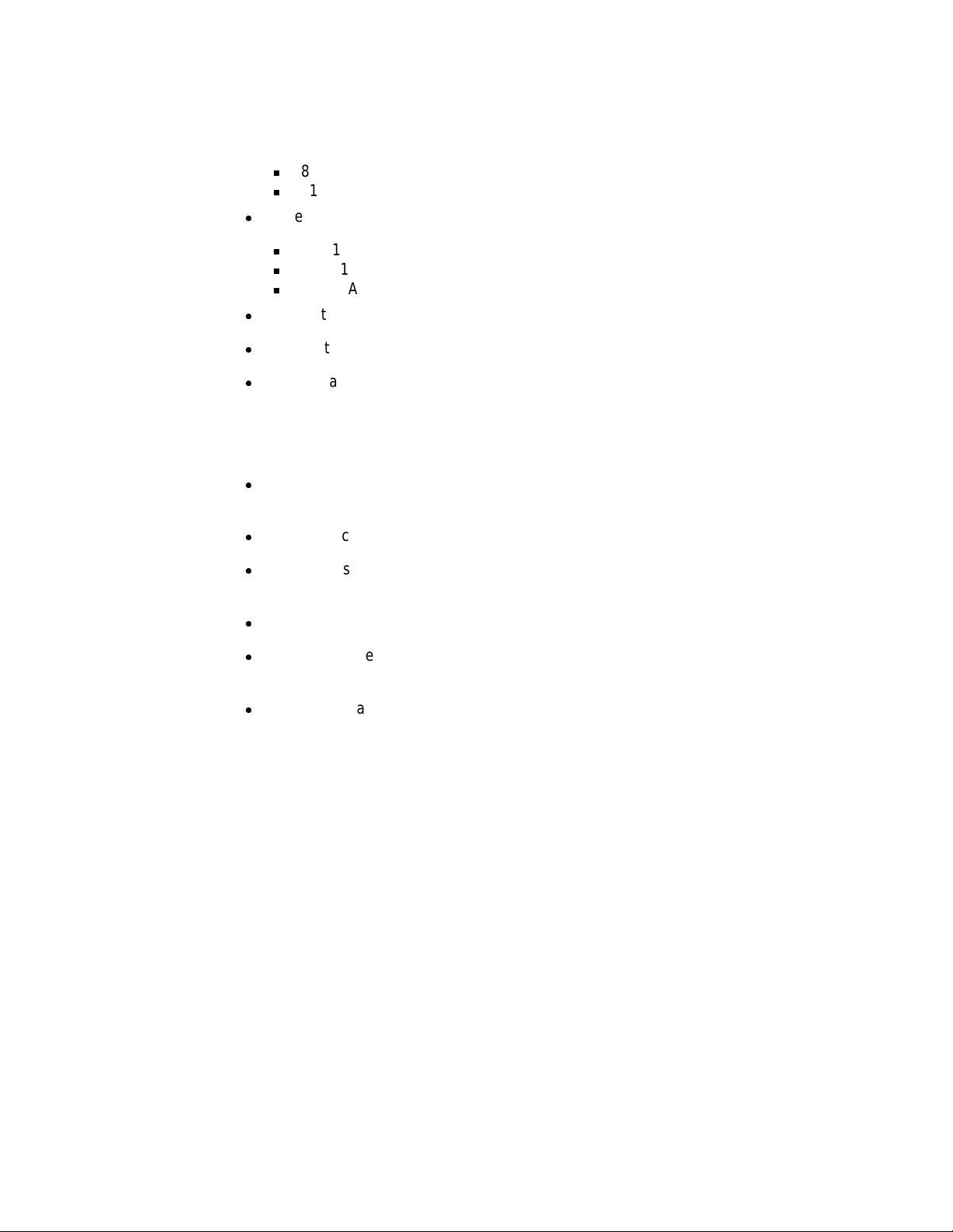

This guide describes three different Series 50 Fe tal Monitor models:

l

M1351A Single Ultrasound model (with US and Toco channels).

l

M1351A Dual Ultrasound Twins model (with US1, Toco and US2 channels).

l

M1353A model (with US1, Toco and US2/ECG channels).

The M1351A single and double ultrasound model is for external monitoring of FHR an d

uterine activity in the a nte nata l peri o d fr om ea rl y ge st ati on (appr o x im a te ly 20 to 25 w ee ks)

to term. The M1353A is for monitoring FHR, including twins, maternal heart rate and

uterine activity. FHR and uterine activity can be monitored externally in the antenatal

period from early gestation to term, and in ternally th roug hout labor and delive ry. The basic

capabilities of the three models are summarized in the table below.

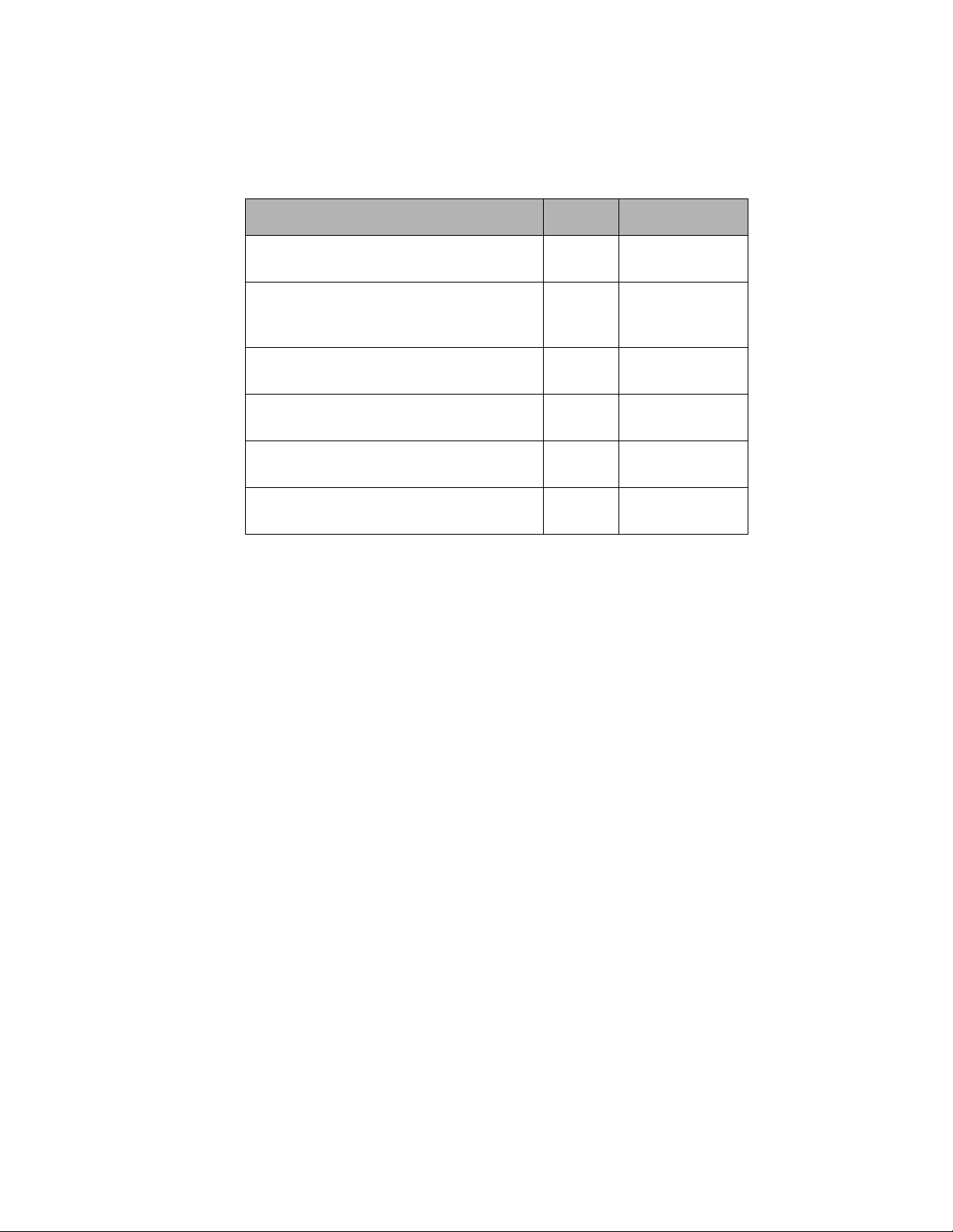

Table 1-1 Fetal Monitor Parameters

Parameter

M1351A

Single

M1351A

Twin

M1353A

Monitor FHR us ing ultrasound Yes Yes Yes

Monitor twin FHRs using ultras ound No Yes Yes

Monitor twins using DECG a nd ultrasound No No Yes

Monitor FHR using DECG No No Yes

Monitor uterine activity using Toco ext Yes Yes Yes

Monitor IUP No No Yes

Monitor maternal heart rate No No Yes

Detect fetal movements

1

Yes Yes Yes

Mark events Yes Yes Yes

Record nurs in g not e s

1

Transmission of fetal trace information

Fetal trace memory

1

1

Yes Yes Yes

Yes Yes Yes

Yes Yes Yes

Interfacing to fetal pulse oximetry Yes Yes Yes

1. May be ordered as an option for all models

4 Chapter 1 General Information

Page 15

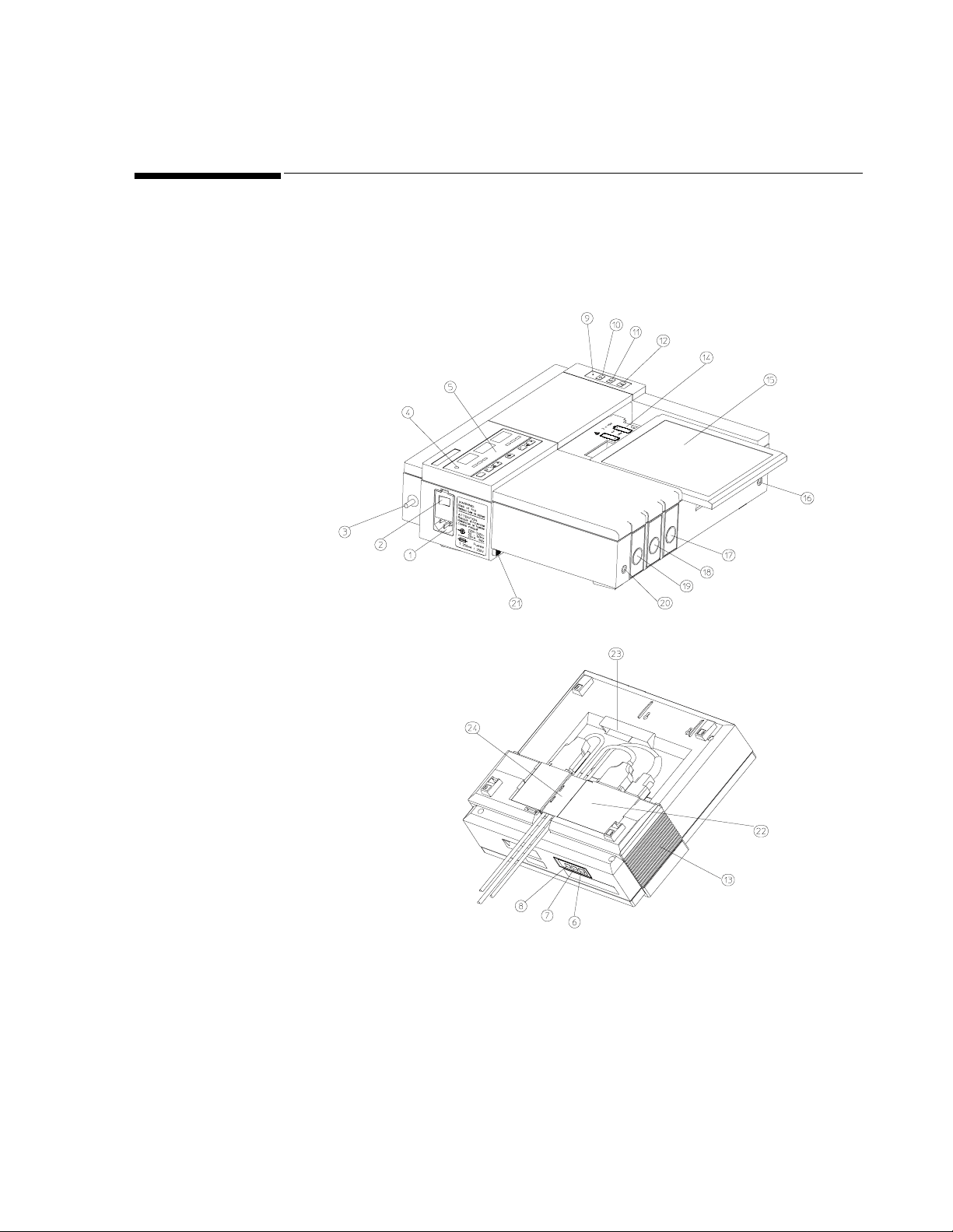

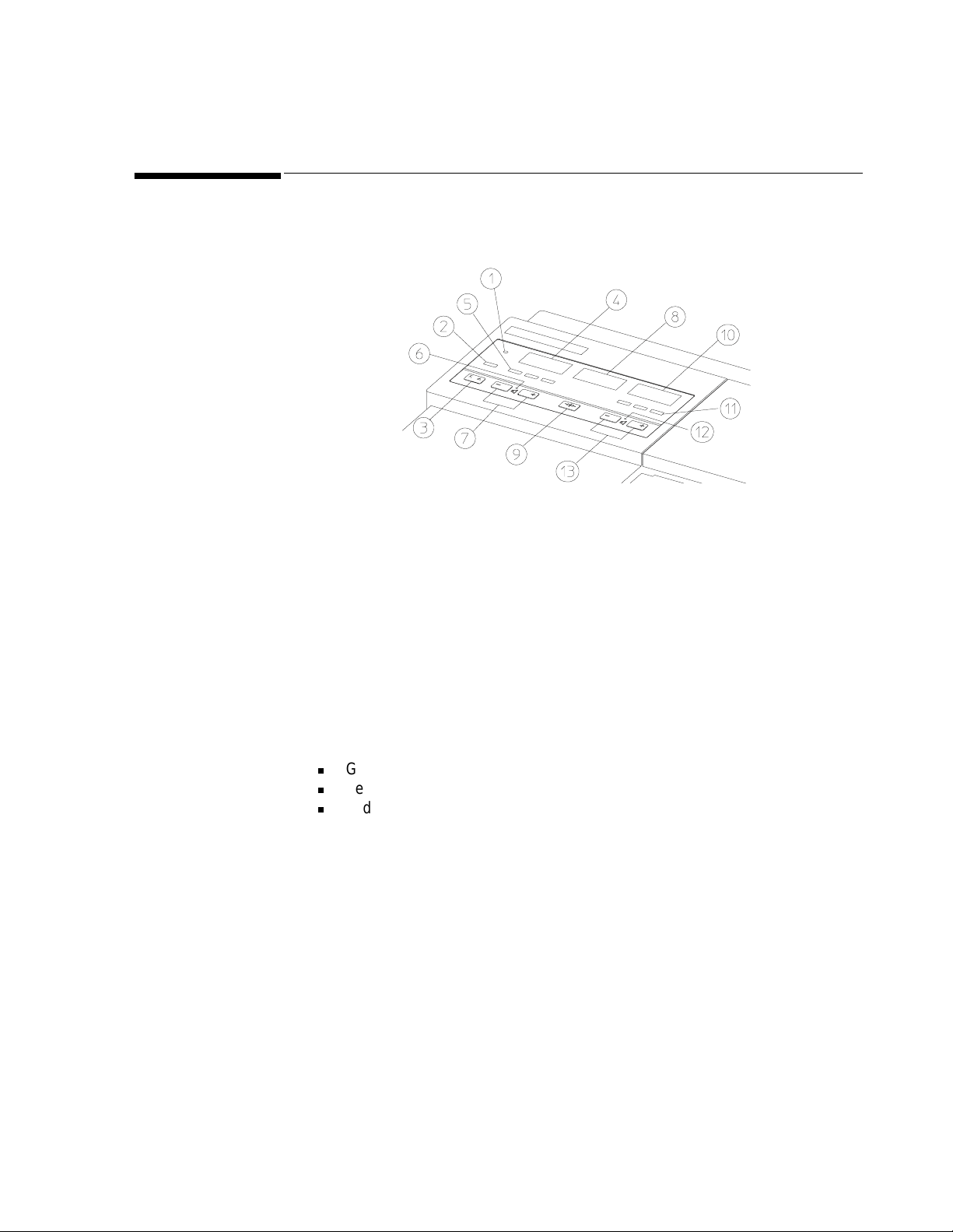

Major Keys and Parts at a Glance

Major Keys an d Parts at a Glance

Figure 1-1 General Layout of the Series 50 A and Series 50 IP-2 Fetal

Monitors

Chapter 1 General Information 5

Page 16

Major Keys and Parts at a Glance

10. Recorder on/off key

11. Event marker key (Alert acknowledge key)

12. Paper advance key

13. Loudspeaker

14. Battery compartment

15. Paper table

16. Service socket

17. Series 50A: US2 Socket (not present on Single Ultrasound mode l)

18. Toco socket

19. Series 50A: Single Ultrasound M odel: US Socket

20. Socket for remote event marker

21. Lock-release button

22. Combi ne d interface module

23. Integrated carrying handle

24. Cable clamp

1. Mains socket

2. Monitor on/off switch

3. Equipotential grounding point

4. Monitor on/off light

5. Display panel

6. Time and date key

7. Paper speed key

8. Test key

9. Recorder on/off light

Series 50 IP-2: US2/ECG Socket

Double Ultrasound Model: US1 socket

Series 50 IP-2:US1 socket

6 Chapter 1 General Information

Page 17

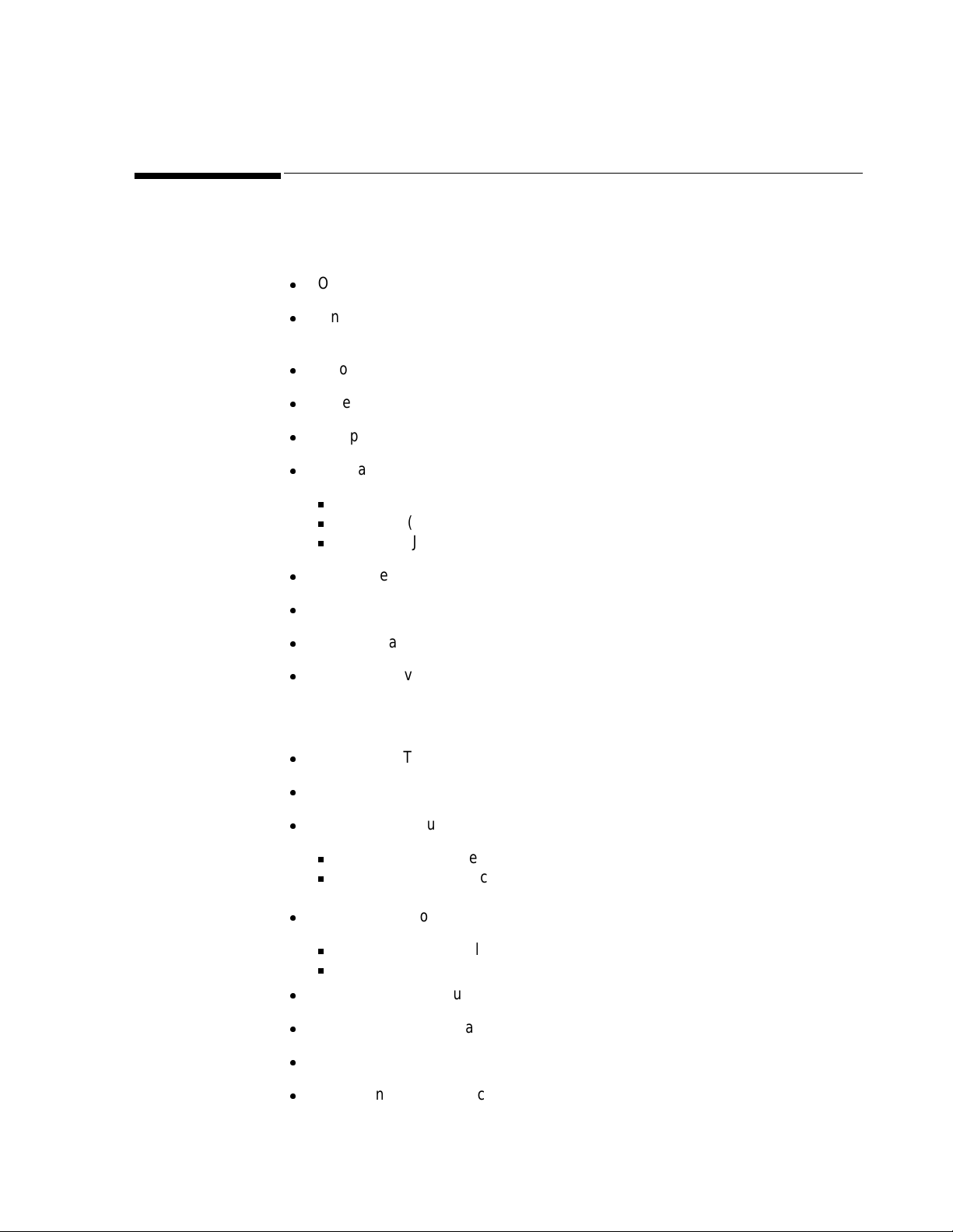

Monitor Control and Display Panel

Monitor Control and Display Panel

M1351A Single Ultrasound Model

M1351A Dual Ultrasound Twins Model

Figure 1-2 Layout of the Monitor Control and Display Panel

1. Monitor On/Off Light.

2. Telemetry Indicator. On when the Fetal Tele me try Rece iv er is con ne cte d a nd

switched on.

3. Function Key. Used to switch FMP and Fetal Alerting on and off.

4. US Display. Shows the FHR detected by the US transducer.

5. US Signal Quality Indicator. Indicates the quality of the signal detected by the US

transducer:

n

Green (optimum).

n

Yellow (fair to potentially poor).

n

Red (unacceptable).

6. US Speaker Light. On when you are hearing the US heartbeat.

7. US Volume Keys. Sets the volume and selects the US heartbeat.

8. Toco Display. Shows uterine activity.

9. Toco Baseline Key. Zeroes the Toco display and trace to 20 units.

1. Monitor On/Off Light.

2. Telemetry Indicator. On when the Fetal Tele me try Rece iv er is con ne cte d a nd

switched on.

3. Function Key. Used to switch Twins Offset, FMP, and Fetal Alerting on and off.

4. US1 Display. Shows the FHR detected by the US1 transducer.

Chapter 1 General Information 7

Page 18

Monitor Control and Display Panel

5. US1 Signal Quality In dicator. Indicates the quality of the signal detected by th e US1

transducer.

6. US1 Speaker Light. On when you are hearin g the US1 heartbeat.

7. US1 Volume Keys. Sets the volume and selects the US1 heartbeat.

8. Toco Display. Shows uterine activity.

9. Toco Baseline Key. Zeroes the Toco display and trace to 20 units.

10. US2 Display. Shows the FHR detected by the US2 transducer.

11. US2 Signal Quality Indicator. Indicates the quality of the signal detected by the US2

transducer.

12. US2 Speaker Light. On when you are hearing the US2 heartbeat.

13. US2 Volume Keys. Sets the volume and selects the US2 heartbeat.

M1353A Model 1. Monitor On/Off Light.

2. Telemetry Indicator. On when the Fetal Tele me try Rece iv er is con ne cte d a nd

switched on.

3. Function Key. Used to switch Twins Offset, Logic, FMP, and Fetal Alerting on and

off.

4. US Display. Shows the FHR detected by the US transducer.

5. US1 Signal Quality In dicator. Indicates the quality of t he signal detected by the US1

transducer:

6. US1 Speaker Light. On when you are hearin g the US1 heartbeat.

7. US1 Volume Keys. Sets the volume and selects the US1 heartbeat.

8. Toco Display. Shows uterine activity.

9. Toco Baseline Key. Zeroes the Toco display and trace to 20 units (when monitoring

externally) or 0 units (when monitoring internally).

10. US2/ECG Display. Shows the FHR detected by the ECG transducer.

11. US2/ECG Signal Quality Indicator. Indicates the quality of the signal detected by the

ECG transducer.

12. US2/ECG Speaker Light. On when you are hearing the ECG heartbeat.

13. US2/ECG Volume Keys. Sets the volume and selects the ECG heartbeat.

8 Chapter 1 General Information

Page 19

Accessories

Accessories

Series 50 A (M1351A)

The following accessories are supplied as standard with the Monitor:

l

One external Toco transducer (M1355-60011).

l

One ultrasound transducer (M1356-60011) (or two with the Dual Ultrasound

Model).

l

Two reusable transducer belts (M1562A) (or three with Dual Ultrasound Model).

l

Three transducer knob adapters (M1356-43201).

l

One power cord.

l

One pack of paper:

n

M1910A (USA/Canada)

n

M1911A (Europe)

n

M1913A (Japan)

l

One bottle of gel: 40483A (Acquasonic gel)

l

One User’s Guide.

l

One Installation and Servi ce Guide

l

One remote event marker (15249A).

Series 50 IP-2

The following accessories are supplied as standard with the Monitor:

(M1353A)

l

One external Toco transducer (M1355-60011).

l

One ultrasound transducer (M1356-60011).

l

One patient module M1364A with cables:

n

One DECG legplate adapter cable (M1362B)

n

One MECG adapter cable (M1363A)

l

Five spiral electrodes:

n

15133D Single spiral (USA).

n

15133E Double spiral (Europe).

l

Three reusable transducer belts.

l

Three transducer knob adapters (M1356-43201).

l

One power cord.

l

Equipotential grounding cable:

Chapter 1 General Information 9

Page 20

Accessories

n

8120-2961 (USA).

n

8120-4808 (Europe).

l

One pack of paper:

n

M1910A (USA/Canada)

n

M1911A (Europe)

n

M1913A (Japan)

l

One bottle of gel: 40483A (Acquasonic gel)

l

One Instructions for Use.

l

One Installation and Service Guide.

Documentation The following documentation is available for the Series 50 A and Series 50 IP-2 fetal

monitors. Unless otherwise specified localized versions are available.

l

Technical Data Sheets: Contain features and benefits, technical specifications,

accessories, ordering, upgrading and re-ordering information.

l

Service Documentation: All service documentation is in English.

l

Instructions for Use: Detailed operating information, care and cleaning, and safety

requirements.

l

Video Tapes: 30-minute VHS video tapes demonstratin g the Monitor.

l

Barcode Booklets: Labels and cards, and instructions on how to customize sheets of

nursing notes.

l

Digital Interface Protocol Specifications: Written as a programmer’s guide, describing

the data exchange between the Series 50 Fetal Monitors and an Information

Management System such as OB

TraceVue. English only.

10 Chapter 1 General Information

Page 21

Accessories

Options The following accessories can also be supplied when the appropriate option is ordered.

Accessories Option Model

Barcode Reader, including a reader and barcode booklet. This

H15 Series 50 A and Series 50 IP

requires Option J10 or J15.

Combined Interface Module for telemetry and obstetrical

J10

1

Series 50 A and Series 50 IP

surveillance systems (e.g. Philips OB TraceVue) and barcode

reader

Combined Interface Module for telemetry and obstetrical

J13

1

Series 50 A and Series 50 IP

surveillance systems (e.g. Philips OB TraceVue), includes an

interface cable M1350-61609.

• for Dinamap 1846 or

• COLIN Press-Mate/Nippon Colin Listmini Model BP-

8800 NIBP Monitor

Combined Interface Module for telemetry and obstetrical

J14

1

Series 50 A and Series 50 IP

surveillance systems (e.g. Philips OB TraceVue), includes an

interface cable M1353-61614

• for Nellcor Ox iFirst™ Fetal Oxygen Saturation Monitor

(N-400)

Modem Interface Module allows the transmission of fetal

J15

1

Series 50 A

trace data from a Series 50 A to a receiver (e.g., an OB

TraceVue system)

Fetal Movem ent Prof il e C02 Series 50 A a nd Series 50 IP

IUP Pressure Transducer (CPJ840J5) C07 Series 50 IP

Disposable IUP Catheter. This includes 1 x box M1333A

C08

2

Series 50 IP

(containing 10 catheters) disposable intraute rine sensor-tip

pressure catheters a nd M1334A reusable connector cable

1. Options J10, J13, J14 and J15 cannot be fitted at the same time

2. Not available in all countries.

Chapter 1 General Information 11

Page 22

Accessories

Accessories Option Model

Service an d In stallation Guide 0B3 Series 50 A and

Series 50 IP

Installation and Operating Guide Video

• VHS

• VHS

⁄ NTSC

⁄ PAL

0B5 Series 50 A and

Series 50 IP

Wall mounting kit 1AB Series 50 A and

Series 50 IP

Paper take-up tray

1

1AC Series 50 A and

Series 50 IP

Angled mounting kit 1AD Series 50 A and

Series 50 IP

Mobile cart 2AE Series 50 A and

Series 50 IP

1. Not compatible with the wall mounting kit.

12 Chapter 1 General Information

Page 23

Monitor

2

Technical Specifications

Power Requirements

The monitor is set for the corr ect voltage at the fact ory. Before you connect power, however,

ensure that the voltage label shows the correct setting for your country.

Operating Voltage: 100V - 120V∼ or 220V - 240V (±10%).

Line Frequency: 50 to 60Hz ±5%.

Power Consumption: 25VA max.

Battery Type: 2 x 1.5V (AA si ze ). Li f et im e > 1 y ear.

Environment The monitor should be used in an environment which is reasonably free from vibration,

dust, corrosive or explosive gases, extremes of temperature, humidity, etc. It operates within

specifications at ambient temperatures between 0 and 55°C. Ambient temperatures which

exceed these limits can affect the accuracy of the monitor and cause damage to the

components and circuits. Allo w at least 5cm (2i n) cle ara nce ar ou nd the monitor for proper

air circulation.

Operating Temp: 0 to +55°C (32°F to 131°F).

Storage Temp: -40 to +75°C (-40°F to 167°F), excludes transducers: -40 to

Relative Humidity: 5 to 95%.

+60°C (-40°F to +140°F)

Weight and

Height: 115mm (4.5in).

Dimensions

Width: 340mm (13.4in).

Depth: 308mm (12.1in).

Weight: 5.74kg (12.6lb) (without transducers).

Chapter 2 Technical Specifications 13

Page 24

Monitor

Displays

Numerical Display M1351A Single

Ultrasound Model: One heart rate display (orange) an d one uterine activity display

(green).

M1351A Dual

Ultrasound Twins Model:Two heart rate displays and one uterine activit y display.

M1353A Model: Two heart rate displays and one uterine activit y display.

Type: 7-segment LEDs (10mm).

FHR Range: 50 to 240 bpm.

Uterine Activity Range: -99 to +127 relative units.

Instrument Display Telemetry Mode is displayed if Option J10 is fitted and an or M13 10A or 80240A Fetal

Telemetry System is connected and switched on.

M1351A Single

Ultrasound Model: One signal quality indicator.

M1351A Dual

Ultrasound Twins Model:Two signal quality indicators.

M1353A Model: Two signal quality indicators.

Inputs M1351A Single

Ultrasound Model US socket accepts the M1356A ultrasound transducer. Toco

M1351A Dual

Ultrasound Twins Model US1 and US2 sockets accept M1356A ultrasound transducers.

M1353A Model US1 socket accepts the M1356A ultrasound transducer. To co

socket accepts the M1355A Toco transducer. Socket for the

Remote Event Mar k er (15 24 9A ), a nd another for servicing . T he

monitor automatically selects the correct operating mode.

Toco socket accepts the M1355A Toco transducer. Socket for the

Remote Event Mar k er (15 24 9A ), a nd another for servicing . T he

monitor automatically selects the correct operating mode.

socket accepts the M1355A external Toco or the M1350A/

8040A compatible internal Toco transducer. US2/ECG socket

accepts either the M1356A ultrasound tran sducer, or the

M1364A DECG/MECG patient module or the M1357A

DECG or the M1359A MECG transducer. There is a socket for

the remote event marker (15249A), and another for servicing.

The monitor automatically selects the correct operating mode.

14 Chapter 2 Technical Specificati ons

Page 25

Ultrasound Mode System: Pulsed Doppler oscillation.

Frequency: 998.4 kHz.

Repetition Rate: 3.2 kHz.

Ultrasound Intensity: 1.5mW/cm² average for each of the seven active surfaces.

Monitor

DECG and MECG

Mode

External Labor Signal Range: 0 to 127 units.

See Specifications for Transducers and Cables on page 17.

Offset Compensation: ±200 units.

Internal Labor Signal Range: -99 to +127 mmHg.

Patient Leakage Current:

≤10 µA

rms

.

Sensitivity: 40 µV/V/mmHg (M1348A).

5 µV/V/mmHg (M1334A and CPJ840J5).

Recorder Mechanism: 3-channel, high-resolution (8 dots/mm) thermal array recorder

with paper-end detection.

Paper Speeds: 1, 2 or 3 cm/min.

Recording Time Per Pack

of Paper: 1 cm/min (25 h).

2 cm/min (12 h 30 min).

3 cm/min (8 h 20 min).

Paper Advance Speed: 24 cm/min (with automatic stop at the paper-end mark).

Annotation: Time of day, date, and paper speed are printed automatically

every ten minutes. Monitoring mode is printed with every

alteration of parameter.

Paper: Fanfold paper with numbered pages.

FHR Scale: USA: 30 to 240 bpm @ 30 bpm/cm.

Other countries: 50 to 210 bpm @ 20 bpm /c m.

Labor Scale: 0 to 100 units @ 25 units/cm.

Chapter 2 Technical Specifications 15

Page 26

Monitor

Self-Test Facilities

Combined Interface Module

Modem Interface Module

Self-test fac il it ie s incl ud e:

System test: With no transducers connecte d (incl ude s a display and recorder

test).

Parameter test: With the appropriate transducer connected, the monitoring

mode (ultrasound or uterine activity) is tested.

Telemetry: M1310A Fetal Telemetry System.

System: M1383A/B/C OB TraceVue.

Either

Barcode Reader: SmartWand.

or

Maternal NIBP Monitor: Dinamap

COLIN Press-Mate

or

Nellcor OxiFirst

compatible.

Modem: Interface socket for an Philips-approved PCMCIA card modem.

Fetal T race Memory: Local fetal trace storage.

Barcode Reader: Smart Wand.

1846/8100.

/Nippon Colin Listm in i Model BP-8800.

Fetal Oxygen Saturation Monitor (N-400) or

Remote Event Marker (15249A)

RS232 Serial Interface: For internal use only.

Length: 2.8m/9ft 2in.

Weight: 75g/2.65oz.

16 Chapter 2 Technical Specificati ons

Page 27

Transducers and Cables

Transducers can be stored at temperat ure s between -40 and +60°C.

Transducers and Cables

Brown Toco Transducer (M1355A)

Blue1 Toco

Transducer

(M1355A)

Brown Ultrasound Transducer (M1356A)

Blue1 Ultrasound Transducer (M1356A)

System: Passive Straingauge.

Dynamic Range: 0 to 12N (overload protected).

Weight: 180g/6.3oz.

Cable Length: 2.5m/8ft 2in.

System: Passive Straingauge.

Dynamic Range: 0 to 12N (overload protected).

Weight: 180g/6.3oz.

Cable Length: 2.5m/8ft 2in or 0.7m/2ft 3in.

System: Pulsed Doppler.

Oscillator Frequency: 998.4kHz.

Weight: 185g/6.5oz.

Cable Length: + 2.5m/8ft 2in.

Size: 75mm/2.95in di ameter.

System: Pulsed Doppler.

Oscillator Frequency: 998.4kHz.

Weight: 185g/6.5oz.

Cable Length: 2.5m/8ft 2in or 0.7m/2ft 3in.

Size: 75mm/2.95in di ameter.

1. Indicates transducer is waterproof.

Chapter 2 Technical Specifications 17

Page 28

Transducers and Cables

DECG Transducer (M1357A)

MECG Transducer (M1359A)

Input Impedance: >10MΩ (differential, dc to 50/60Hz).

CMRR: >110dB (with patient cable, 51.5kΩ/0.047µF imbalance at line

frequency).

Noise: <4µV

(referred to input with 25kΩ).

p

Contact Potential

Tolerance: ±400mV.

Input Voltage Range: 20µV

Patient Leakage Current: <10µA

to 3mVp.

p

@ 120V/60Hz.

rms

Patient Auxiliary Current:<0.1µA (dc).

Dielectric Strength: 1500V

(spark-gap protected).

rms

Weight: 185g/6.5oz.

Cable Length: 2.5m/8ft 2in or 0.7m/2ft 3in.

Input Impedance: >10MΩ (differential, dc to 50/60Hz).

CMRR: >90dB (with patient cable, 51.5kΩ/0.047µF imbalance at lin e

frequency).

Noise: <4µV

(referred to input with 25kΩ).

p

Contact Potential

Tolerance: ±400mV.

DECG/MECG Patient Module (M1364A)

Input Voltage Range: 80µV

Patient Leakage Current: <10µA

to 4mVp.

p

@ 120V/60Hz.

rms

Patient Auxiliary Current:<0.1µA (dc).

Dielectric Strength: 1500V

(spark-gap protected).

rms

Weight: 175g/6.2oz.

Cable Length: 2.5m/8ft 2in.

The patient module has a 7-pin ECG connector into which you can plug either DECG

cable (M1362A or B) or MECG cable (M1363A).

Overall length: 2706mm (+30, -100mm)

Length of free cable: 2618mm (+30, -100mm)

Weight: 120 grams

Size: 88x42x30mm

Socket: DECG or MECG connection

18 Chapter 2 Technical Specificati ons

Page 29

Transducers and Cables

DECG Cable

(M1362A)

DECG Adaptor

Cable (M1362B)

MECG Cable

(M1363A)

M1364A With DECG

Cable M1362A

Cable weight: 22 grams

Cable Length: 666mm +/- 30mm

Cable weight: 35 grams (approx.)

Cable Length: 77cm (approx.)

Cable weight: 16 grams

Cable Length: 606mm +/-30mm

Patient Leakage Current: 120V at 60Hz, 10µA rms

Patient Auxiliary Current: < 0.1µA (dc)

Dielectric strength: 1500Vrms spark gap protected

Input Impedance: > 10MΩ

CMRR: with patient cable, 51.5kΩ/0.047µF imbalance at line frequency > 110dB

Noise: (referred to input with 25kΩ) < 4µVp

Contact Potential Difference: ±500mV

Input Voltage Range: 20µVp to 3mVp

M1364A With

MECG Cable

M1363A

IUP Quartz Transducer (1290C option J05)

Patient Leakage Current: 120V at 60Hz, 10µA rms

Patient Auxiliary Current: < 0.1µA (dc)

Dielectric strength: 1500Vrms spark gap protected

Input Impedance: > 10MΩ

CMRR: with patient cable, 51.5kΩ/0.047µF imbalance at line frequency > 80dB

Noise: (referred to input with 25kΩ) < 4µVp

Contact Potential Difference: ±500mV

Input Voltage Range: 80µVp to 4mVp

Dynamic Range: -50 to 300mmHg.

Sensitivity: 5µV/V/mmHg.

Non-linearity: Whichever is greater: ±1% of the reading or ±1mmHg.

Vo lum e Displacem en t: 0.2mm³/100mmHg.

Weight: 180g/6.3oz.

Cable Length: 3m/9ft 10in.

Length: 66mm/2.6in.

Chapter 2 Technical Specifications 19

Page 30

Transducers and Cables

Width: 37mm/1.5in.

Height: 21.7mm/0.9in.

Operating Temp: 15 to 40°C.

IUP Pressure Transducer (CPJ840J5)

Pressure range: -20 to + 300 mm Hg

Max. overpressure: 10,000 mm Hg

Sensitivity:

Resonance frequency: 300 Hz typical (transducer and dome)

Max. electrical excitation: 15 V DC or AC

Bridge resistance: 1000 Ohms (input and output)

Non-linearity and hysteresis: max. 0.5% of full scale

Zero balance: max. 0.15 mm Hg/°C

Operating temperature range: +10 to +50°C

Storage temperature range: -20 to +70°C

Isolation resistance: min. 1000 MOhms

Leakage current: max.1.5mA at 250V, 50 Hz

Weight: 24 grams (without cable)

Connector: Equipment specified

5µV/V/mmHg

20 Chapter 2 Technical Specificati ons

Page 31

Fitting the Monitor to a Su rface

The monitor can be mounted on (but not fixed to) an existing surface.

Fitting the Monitor to the Angle Mount

To fit the monitor to the angle mount:

1. Holding the monitor at a slight angle, put the front feet into the holes (A).

2. Lower the monitor till the back feet “click” into the holes (B). Make sure that all four

feet are located firmly in place.

3

Installing the Monitor

Figure 3-1 Fitting the Monitor to the Angle Mount

To remove the monitor from the angle mount hold the monitor in both hands, press both

lock-release butto ns (C) sim ul ta ne ous ly an d r em ove the monitor from the angle mo un t.

The lock mechanism may break if it is not fully released!

Chapter 3 Installing the Monitor 21

Page 32

Fitting the Monitor to a Wall

Fitting the Monitor to a Wall

Before you can fit the monitor to the wall, you must first secure the mounting plate to the

wall. For details of how to fit this plate to the wall, refer to the instructions supplied with it.

To fit the monitor to the plate:

1. Holding the monitor at a slight angle, put the front feet into the holes (A).

2. Push the monitor upright till the back feet “click” into the holes (B).

Wall Mount Dimensions

Figure 3-2 Fitting the Monitor to the Wall Mount

To remove th e monitor from the plate:

1. Hold the monitor in both hands

2. Press both lock-release buttons (C) simultaneously and lift the monitor away from the

plate.

Figure 3-3 Removing the Monitor from the Wall Mount

The wall mount is a metal plate that measures:

Width: 314mm (12.36 inches).

Height: 268 mm (10.55 inches).

Depth: 26 mm (1.03 inches).

22 Chapter 3 Installing the Mo nitor

Page 33

Fitting the Paper Take-Up Tray

To fit the paper take-up tray to the monitor:

1. Slide the tray between the guides (A) until the pins locate in the holes (B).

2. Pull the tray forward to lock it in place.

Fitting the Paper Take-Up Tray

Cart-mounted Paper Tray

Figure 3-4 Fitting the Paper Take-Up Tray to the Monitor

To fit the paper take-up tray (Option 1AB) to the mounting plate:

1. Holding the tray at a slight angle, put the top edge in the slot on the plate.

2. Swing the tray down into place.

Figure 3-5 Fitting the Paper Take-Up Tray to the Wall Mount

Attach the paper tray befor e installi ng the monito r on the a ngle mo unt. S lide the paper tray

into position so that the small hole in the attaching edge at the rear of the paper tray hooks

over the mounting projection in the angle mount itself. This secures the paper tray to the

angle mount.

Chapter 3 Installing the Monitor 23

Page 34

Carts

Carts

You can mount the Series 50 A and the S eri es 50 IP-2 fetal moni tors on the CL, CM o r CX

carts. Cleaning instructions for the carts and safety details are provided in the Carts

Equipment Note delivered with your cart.

Table 3-1 Carts: Specific ations

Specifications

Width (mm) 514 614 614

Depth (mm) 625 625 625

Height (mm) 805 989 1117

Weight ( kg) 24.2 50.6 63.4

Carts

CL (M1323A) CM (M1324A) CX (M1325A)

Table 3-2 Carts Replacement Parts

Replacement

Parts

Wheels M1324-42100 ✘✔✔

Drawers M1324-68500 ✘✔✔

CAM Mounting

Arm Kit

Mounting Kit IUP

Pole

Infusion Pole

Mount

Mounting Rail Kit 5061-8365 ✔✔✔

Part numbers

M1323-42075 ✔✘✘

M1323-68450 ✔✘✘

5061-8340 ✔✔✔

80310-68701 ✔✔✔

5061-8364 ✔✔✔

Fitting the Barcode Reader Holder

To fit the Barcode Reader holder (HBCS-2998) to the monitor or cart:

Cart CL

(M1323A)

Cart CM

(M1324A)

Cart CX

(M1325A)

1. Using ethanol, clean the surface of the monitor or cart thoroughly.

2. Peel off the backing from the adhesive strip and press the holder firmly into place.

Before using the holder, allow 24 hours for the adhesive to set.

24 Chapter 3 Installing the Mo nitor

Page 35

Introduction

4

Configuring the Monitor

This chapter describes how to confi gure the moni tor incl uding ti me and date format, paper

speed, and IUP scale. You can configure the monitor using any of the following methods:

l

Pushbuttons

l

Barcode Reader

l

PC

The tasks you can carry out are summarized in Table 4-1. To find out how to set the current

time, date, and paper speed, see Chapter5, “Setting Time, Date, and Paper Speed.”

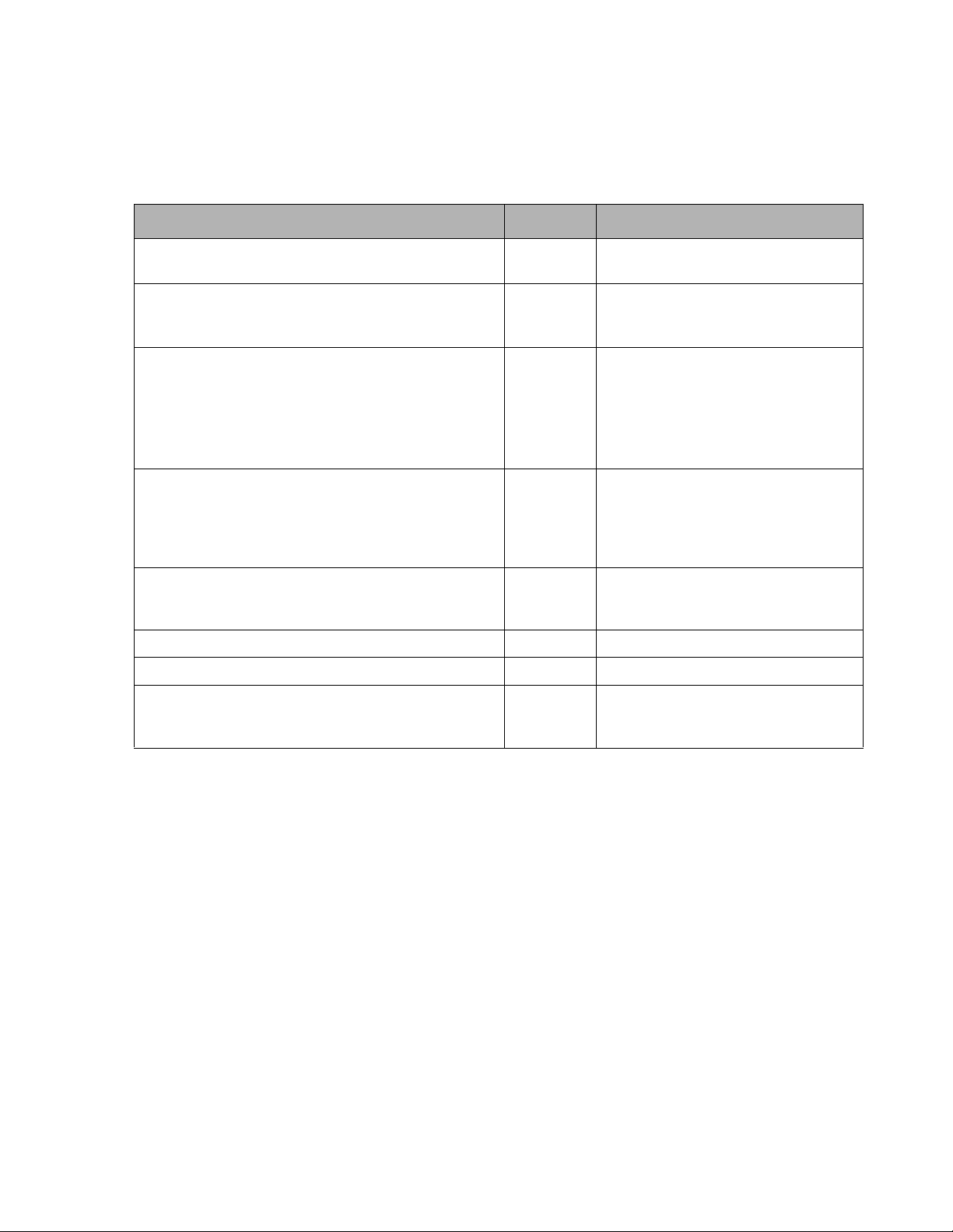

Table 4-1Configuration Tasks

Barcode

Reader

✗✓

✗✗

✗✗

✗✓

✗

PC

✗

Task Buttons

Configure the time format ✓✓✓

Configure the date format ✓✓✓

Configure the IUP format ✓✓✓

Configure the paper format ✓✓✓

Configure the recorder print offset ✓✗✓

Configure the recorder heat adjust ✓✗✓

Configure the language op tion ✓✗✗

Marker for alert acknowledgement at Marker button ✓✗✗

Configure note tra nsmission on/off ✓✗✗

Configure interface setting ✓✗✗

Read the options installed ✗✗✓

Run the cyclic test

Run the permanent test

Read the error log ✗✗✓

Print the error log

Clear the error log

Write the serial number and set the options ✓✗✓

Enable fetal pulse oximetry interface ✓

1.

✗

2.

✓

2.

✓

2.

✓

Enable maternal blood pressure interface ✓✗✗

Enable NST timer, paper out alert ✓

1. However you can run the Permanent Test, which is similar. See page 70 for details.

2. See “Printing the Error Log” on page 38 for details

Chapter 4 Configuring the Monitor 25

✗

✗

Page 36

Configuring the Monitor Using Pushbuttons

Configuring the Monitor Using Pushbuttons

You can use the pushbuttons to set such settings as, time format, date format, IUP scale,

paper format, recorder scale offset, recorder heat, and language options.

To change a setting:

1. Disconnect all transducers from the monitor and disconnect or switch off Telemetry.

2. While pressing , press

The display shows C01 in the US1/US display and 0 or 1 in the Toco display.

3. Scroll through the menu by pressing the or key until you arrive at the

menu item you want to cha nge . Th e m en u i tem s a nd the ir setti ngs a re sho wn in T a bl e

4-2.

4. Press the key to change the setting (

5. Press

Test to store the new settings, or wait about 15 seconds without making any

keystrokes.

Test.

0 or 1).

26 Chapter 4 Configuring the Monit or

Page 37

Configuring the Monitor Using Pushbuttons

Table 4-2Configuration Options

Menu Setting Options Default

C01 Time Format 0=AM/PM

1=24-hour

C02 Date Format 0=Month/Day/Year

1=Day.Month.Year

C03 IUP Format 0=mmHg

1=kPa

C04 Paper Format 0=US (30-240)

1=Europe (50-210)

C05

Recorder P rint Of fset

1.

0 to 11

0=right 1=left

C06 Recorder Heat Adjust 0 to 11

0=minimum 11=maximum

C07 Language Option 1=International

2=French

10=Japanese

13=Chinese sim plified

C08 System Alert ac knowledge at Marker

button

0=off

1=on

C09 Note Output to System 0=off

1=on (Roman 8).

C10

Combined Interface Module Settings

2

0=Barcode Reader

1=Dinamap 1846/8100 NIBP Monitor

2=COLIN Model BP-8800 NIBP Monitor

3=Nellcor OxiFirst FSpO

C11 External Toco gain 0=100% External Toco gain

1=50%

Monitor (N-400)

2

0

0

0

0

0

11

1

0

1

0

0

C12 NST Timer,

Paper-Out-Alert

3.

C15 Remote Patient Data after phone

transmission

A01

A02

A03

1. To find the correct setting, connect a resting Toco transducer (one that is not under any load) to the monitor and th en change the

setting until the trace is recordin g 2 0 units on the pa per. Because of the 15-second time-out feature, and the delay between changing the setting and seeing the change on the paper, you may have to repeat this procedure to set the offset.

2. The interface to an NIBP monitor is only available on the Combined Interface Module with the label M1353-66531,E.

3. The NST auto recorder off option switches the recorder off automatically (advancing the paper to the next perforation) once the

NST time set has passed.

4. See -38 for more information on these menu items.

Print Error Log

Clear Error Log

Start Permanent Test

4.

4.

4.

See Table 4-3 4

0=Clear remote patient data

1=Keep remote patient data

0

Chapter 4 Configuring the Monitor 27

Page 38

Configuring the Monitor Using Pushbuttons

Table 4-3 NST Timer Paper-Out-Alert

Examples: How to Change the Time Format and IUP Format using Pushbuttons

Options NST Timer

0

1

2

3

4

5

Note— After you put paper into the recorde r, let it run for a few pages (use the

advance key) to allow the paper to align itself correctly to the right side.

Example 1:

To change the time format from AM/PM format to 24-hour format, do the following:

1. Disconnect all transducers from the monitor and disconnect or switch off Telemetry.

2. While pressing , press

3. Press the key to change the setting to

✗✗✗

✓✗✗

✓✗✗

✗✗✓

✓✗✓

✓✓✓

NST automatic

recorder off

Test.

Paper-Out-Alert

1.

4. Press

Example 2:

To change the IUP format from mmHg to kPa, do the following:

Disconnect all transducers from the monitor and disconnect or switch off Telemetry.

While pressing , press

Press repeatedly until

Press the key to change the setting to

Press

28 Chapter 4 Configuring the Monit or

Test to store the new settings.

Test.

C03 is displayed.

1.

Test to store the new settings.

Page 39

Configuring the Monitor Using Barcodes

The time format, date format, IUP scale and paper format can be set using barcodes. To

select a setting using a barcode, read the required barcode from the separate Feature Setting

Sheet provided with the Barcode Reader Kit.

To config ure the Modem Interface Module using a Barcode Reader, refer to “Using the

Modem Setup Barcodes” on page 164.

Configuring the Mo ni tor Using a PC

The service program (M1360-68875) allows you to carry out various extended

configuration and service functions on the monitor. Contact your Philips Sales Office for

details.

The Software Program is supplied in a kit which contains:

l

3.5 inch disk containing the software.

Configuring the Monitor Using Barcodes

l

Cable adapter for connecting to a PC.

The program can be run on an industry-standard PC. To use the program with a Vectra,

you must replace the adapter on the end of the cable with the one provided, and copy the

software onto a disk.

Figure 4-1 Cable for an Industry Standard compatible PC

Chapter 4 Configuring the Monitor 29

Page 40

Configuring the Monitor Using a PC

Installing the Service Program

Before you install the program, ensure that the serial port COM1 is set up as follows:

Transmission Rate 9600 BPS

Parity None

Word length (bits) 8

Stop-bits 1

This is done by giving the mode command (

mode com1:96,N,8,1) at the DOS

prompt. Refer to your MS-DOS Manual for details.

To install the program:

1. Switch on the PC.

2. Create a directory for the program files. For example, to create a directory called

service, at the DOS prompt type in:

md service

and press Enter.

3. Insert the program disk into drive A.

4. At the DOS prompt type

A: and press Enter.

5. At the A: prompt, type:

copy pegserv.exe c:\service

and press Enter. Where service is the directory you created to contain the

program files.

The program is copied to

c:\service

Make sure that the serial interface configuration on the PC is set up as follows:

Datacom-Configuration

Parameter Serial

Transmission Rate (BPS)9600

Word Length (bits) 8

Stop-Bits 1

Parity None

%ON /%OFF Pacing Off

CTS Line Regard

DSR Line Regard

DCD Line Ignore

Power to Interface Off

30 Chapter 4 Configuring the Monit or

Page 41

Connecting the PC to the Monitor

Configuring the Monitor Using a PC

Figure 4-2 Service Socket

Connect the cable from the COM1 port of the PC to the service socket (1).

Loading the Service Program

Using the Service Program

1. Switch on both the monitor and the PC.

2. Load the program by doing one of the following:

n

If the program files are contained in a directory, change to that directory and

enter:

pegserv

n

If you want to load the program from drive A: (or another drive)

i. Insert the program disk into drive A:

ii. Chang e to driv e A: and enter:

pegserv

n

If you are using Windows 98/ NT: Start the service program by double-clicking

on the pegserv icon o r on the filename pegserv-exe

3. The program is now loaded and ready for use.

When the program has been loaded onto your PC, the main menu is displayed. (If the

menu is not displayed, an error message is displayed along the bottom of the screen.)

Chapter 4 Configuring the Monitor 31

Page 42

Configuring the Monitor Using a PC

Main Menu

To select an item from the menu, move the cursor to the item you require and press Enter.

Series 50 Fetal Monitor Configuration and Service Software Rev A.nn.nn

Main Menu

Configuration Settings

Recorder Adjustmen ts

Service Menu

Exit

MESSAGE:

Select with >cursor keys< or >E, S, D, X< then press <ENTER> to execute!!

Configuring the

Monitor

Use the , , , keys on the keypad, or the

E, S, D or X keys to move the cursor.

While the service program is working , messages maybe displayed along the bottom of the

screen. For example:

Reading Recorder Adjustments from the Monitor.

Reading Serial Number from the Monitor.

Clearing the Error Log.

Series 50 Fetal Monitor Configuration and Service Software Rev A.nn.nn