Page 1

Service Manual

Service

Service

AV System

Service

Service

Service

1. For repair information on the SD4.00SA DVD Module, refer to Service Manual

"DVD Module SD-4.00SA_CH - 3122 785 12480".

2. For repair information on the Subwoofer SW7100SA/00, refer to Service

Manual "SW7100SA/00 - 3139 785 30480".

LX7100SA/22

TABLE OF CONTENTS

Page

Location of pc boards & Version variations................1-2

Technical Specifications .............................................1-3

Measurement setup ....................................................1-4

Service Aids, Safety Instruction, etc...........................1-5

Reprogramming of DVD version matrix ..................... 1-7

Setting the TV system default .................................... 1-8

Disassembly Instructions & Service positions .............. 2

Service Test Programs .................................................. 3

Set Block diagram ......................................................4-1

Set Wiring diagram .....................................................5-1

Key & Control Boards ....................................................6

ECO6 Tuner Board : Systems Cenelec..................... 7B

Supply & Main Boards ...................................................8

Power Amplifier Board ................................................... 9

AVC Board ...................................................................10

Set Mechanical Exploded view & parts list ................. 11

Revision List ................................................................ 12

COMPACT

DIGITAL AUDIO

CLASS 1

©

Copyright 2003 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by BB 0333 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

LASER PRODUCT

3139 785 30431

GB

Page 2

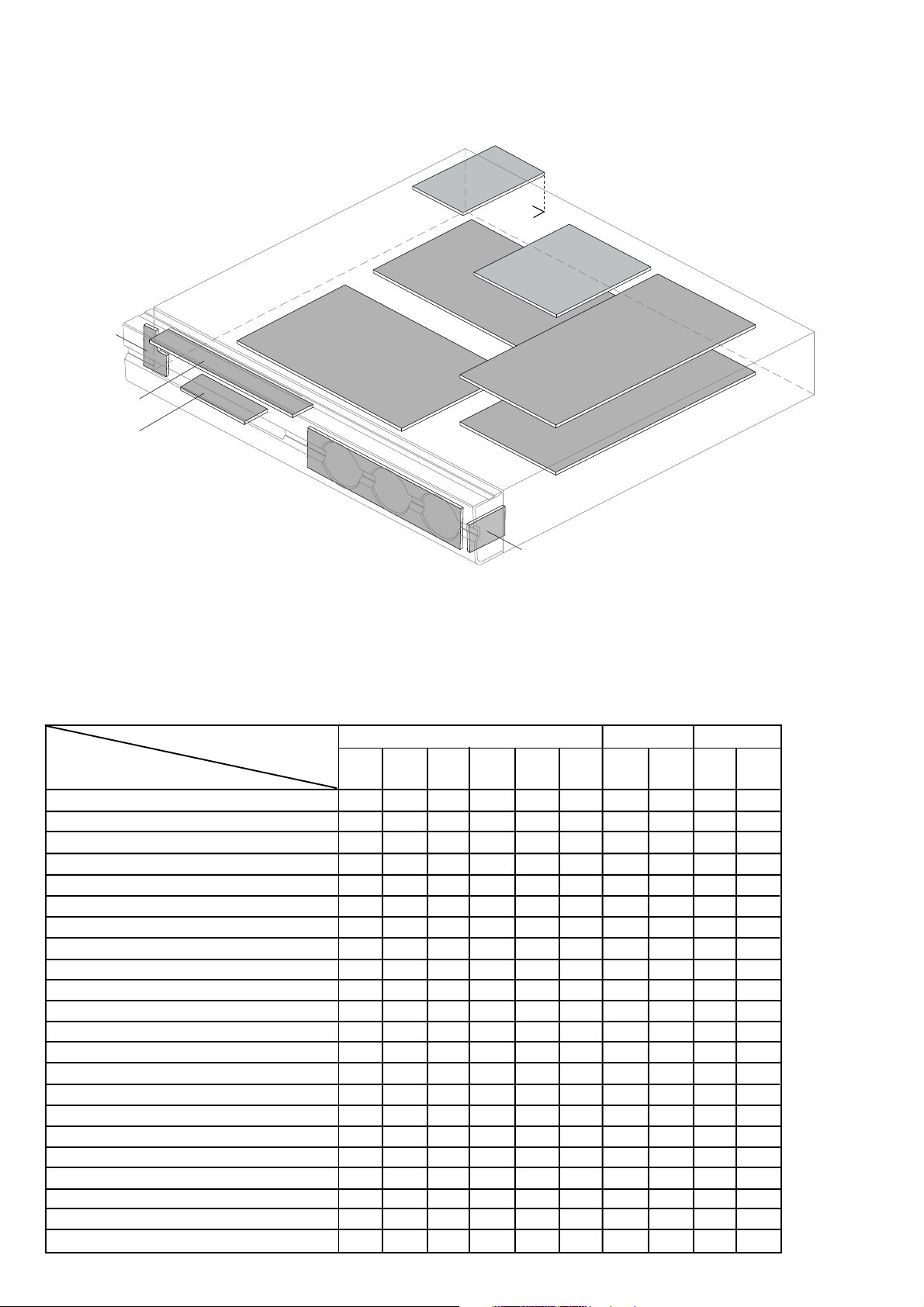

LOCATION OF PRINTED CIRCUIT BOARDS

1-2

TUNER

BOARD

POWER ON/OFF

BOARD

TOP KEY BOARD

SACD LED BOARD

VERSION VARIATIONS:

Type /Versions: LX7100SA

Features &

Board in used:

Aux in / TV in / Line out x

Digital in / Digital out x

Center out x

Subwoofer out (Woofer Line out) x

Video out (CVBS / S-Video) x

Scart out x

YUV out

RDS x

Dolby Digital, DTS, Dolby ProLogic x

Surround x

Karaoke Features

Voltage Selector

ECO Power Standby (Clock Display Off) x

ECO6 Tuner Board - Systems Non-Cenelec

ECO6 Tuner Board - Systems Cenelec x

Progressive Scan (P-Scan)

Subwoofer SW7100SA/00 x

AVC BOARD

DVD BOARD

VOLUME & IR BOARD

/22

MAIN BOARD

SUPPLY BOARD

BOARD

POWER AMPLIFIER

HEADPHONE

BOARD

Page 3

SPECIFICATIONS

1-3

GENERAL:

Mains voltage : 110-127V/220-240V Switchable for /21

120V for /37

220-230V for /22

Mains frequency : 50/60Hz

Power consumption : < 0.5W at ECO Power Standby

: < 20W at Standby (DEMO mode off)

: 160W at Active

Clock accuracy : < 4 seconds per day

Dimension centre unit : 390 x 73 x 360mm

TUNER:

FM

Tuning range : 87.5-108MHz

Grid : 50kHz

100kHz for /37

IF frequency : 10.7MHz ± 25kHz

Aerial input : 75 ohm coaxial

Sensitivity at 26dB S/N : < 7uV

Selectivity at 600kHz bandwidth : > 25dB

Image rejection : > 25dB

Distortion at RF=1mV, dev. 75kHz : < 3%

-3dB Limiting point : < 8uV

Crosstalk at RF=1mV, dev. 40kHz : > 18dB

MW

Tuning range : 531-1602kHz

530-1700kHz for /21/37

Grid : 9kHz

10kHz for /21/37

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : < 4.0mV/M

Selectivity at 18kHz bandwidth : > 18dB

IF rejection : > 45dB

Image rejection : > 28dB

Distortion at RF=50mV, M=80% : < 5%

AUDIO INPUTS / OUTPUTS:

Input sensitivity

Aux in (at 1kHz) : 880mV ± 3dB

TV in (at 1kHz) : 350mV ± 3dB

Output sensitivity

Line out (Left/Right) : 0.6V ± 2dB at 100 kohm

Center out (Vol. Max.) : 500mV ± 2dB at 47 kohm

Subwoofer out (Vol. Max.) : 0.76V ± 2dB at 47 kohm

Headphone output at 32 ohm : 660mV ± 2dB (Vol. Max.)

VIDEO OUTPUTS:

All output terminals to be terminated with 75 ohm.

CVBS Out

CVBS Level : 1Vpp ± 0.1V

Luminance S/N : >=45dB (unweighted)

S-Video Out

Y Level : 1Vpp ± 0.1V

Y S/N : >=48dB (unweighted)

C Level (burst) : 286mVpp +1/-4dB

RGB / YUV Out

Amplitude : 0.7Vpp ± 0.1V

S/N : >=50dB (unweighted)

DIGITAL INPUT / OUTPUT:

To be terminated with 75 ohm.

Digital in : IEC 60958

Digital out : SPDIF Coaxial

AMPLIFIER:

Output power (6 ohm, 1kHz, 10% THD)

L & R, Center, Surround : 40W RMS / channel

Amplifier Frequency Response (-3dB) : 250Hz-32kHz

SURROUND : Multichannel, Stereo, 3D Sound

SOUND : JAZZ, ROCK, DIGITAL, CLASSIC

[DRAMA, ACTION, SCI-FI, CONCERT]

[.....] Sound effect available when playing a DVD/VCD disc.

Page 4

MEASUREMENT SETUP

Tuner FM

1-4

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette Fe SBC420 4822 397 30071

LF Generator

e.g. PM5110

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 5

SERVICE AIDS

1-5

Service Tools:

Universal Torx driver holder .................................. 4822 395 91019

Torx bit T10 150mm ............................................. 4822 395 50456

Torx driver set T6 - T20 ......................................... 4822 395 50145

Torx driver T10 extended ...................................... 4822 395 50423

Cassette:

SBC419 Test cassette CrO2 ................................. 4822 397 30069

SBC420 Test cassette Fe ..................................... 4822 397 30071

MTT150 Dolby level 200nWb/M ............................ 4822 397 30271

Compact Disc:

SBC426/426A Test disc 5 + 5A ............................ 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz ................. 4822 397 30155

SBC429 Audio Signals disc .................................. 4822 397 30184

Dolby Pro-logic Test Disc ...................................... 4822 395 10216

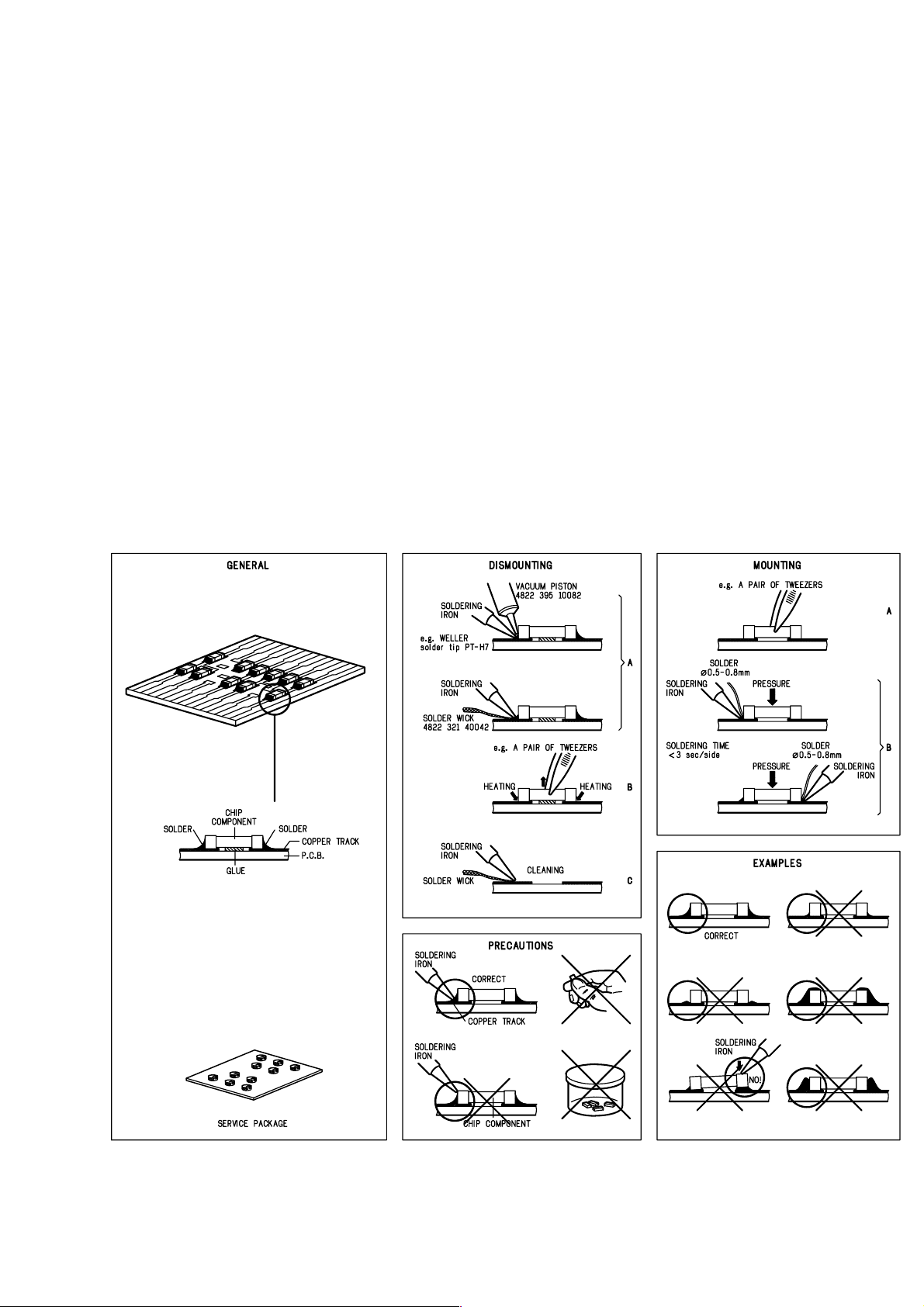

HANDLING CHIP COMPONENTS

ESD Equipment:

Anti-static table mat - large 1200x650x1.25mm ... 4822 466 10953

Anti-static table mat - small 600x650x1.25mm ..... 4822 466 10958

Anti-static wristband .............................................. 4822 395 10223

Connector box (1MΩ) ............................................ 4822 320 11307

Extension cable

(to connect wristband to conn. box) .................. 4822 320 11305

Connecting cable

(to connect table mat to conn. box) .................. 4822 320 11306

Earth cable (to connect product to mat or box) .... 4822 320 11308

Complete kit ESD3

(combining all above products) ......................... 4822 320 10671

Wristband tester .................................................... 4822 344 13999

Page 6

1-6

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

F

WARNING

ATTENTION

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

WAARSCHUWING

I

AVVERTIMENTO

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

!

Safety components are marked by the symbol

.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

!

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

!

Sicherheitsbauteile sind durch das Symbol

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

CLASS 1

LASER PRODUCT

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

S

Warning !

Varning !

Varoitus !

Advarse !

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground to

assure no shock hazard exist. The leakage current must not exceed

0.5mA.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 7

1-7

Caution:

This information is confidential and may not be distributed. Only a qualified service person should

do the reprogramming.

After replacement/repair, the customer settings and also the region code may be lost.

Reprogramming will put the set back in the state in which it has left the factory, i.e. with the default settings

and the allowed region code.

Reprogramming will be done by way of the Remote Control.

Complete version matrix to be enter is

'PLAY 159 XXX XXX XX PLAY'

.

Do the following steps with the Remote Control:

1) Ensure no disc is loaded in the tray.

2) Set the Remote Control to

DISC

source.

3) Press

<PLAY>

followed by numerical keys

<1> <5> <9>

Remark: Top left hand corner of the TV screen will display "

X"

for all these 4 keys that you have pressed.

4) Press now the following numerical keys (8 digits version matrix):

Remark: Nothing will be displayed on the TV screen for all these 8 digits that you have pressed.

for LX7100SA/22 :

<2> <2> <2> <0> <3> <0> <0> <8>

5) Press

<PLAY>

again.

Caution: Wait for about 3 seconds for the set to reset to the required setting.

The TV screen will turn blue follow by a loud sound at the speaker output.

6) Disconnect mains to ensure proper reset.

How to check the version matrix and the software version number of the set:

1) Power up the set and select

DISC

source.

2) Press

<SYSTEM MENU>

on the Remote Control to enter the User Preference Manual (UPM),

follow by pressing the following key:

-

<Cursor Down>

key 4 times

-

<Cursor Right>

key 1 time

-

<Cursor Down>

key 4 times

3) Message "(C)PHILIPS 01- 02 5580 W.WW.WW ...... PXXXXXXXX Y.YY.Y" will be displayed

on the TV screen:

W.WW.WW - indicate the BEA software version number

PXXXXXXXX - indicate the version matrix programmed

Y.YY.Y - indicate the FEA (servo) software version number

4) Press

<SYSTEM MENU>

on the Remote control to exit.

Reprogramming of DVD version matrix

Page 8

Setting the TV system default

1-8

1) Press

2) From the User Preference Manual on the TV screen, select

<SYSTEM MENU>

accordingly as shown in the table below:

on the Remote Control to enter the User Preference Manual (UPM).

Version Region TV system default

/21R Region 3 AUTO

/21S Region 4 NTSC

/22 , /22S Region 2 PAL

/30S Region 4 AUTO

/33S Region 3 AUTO

/37S Region 1 NTSC

3) Press

<SYSTEM MENU>

on the Remote control to exit.

TV SYSTEM

to change the TV system default

Page 9

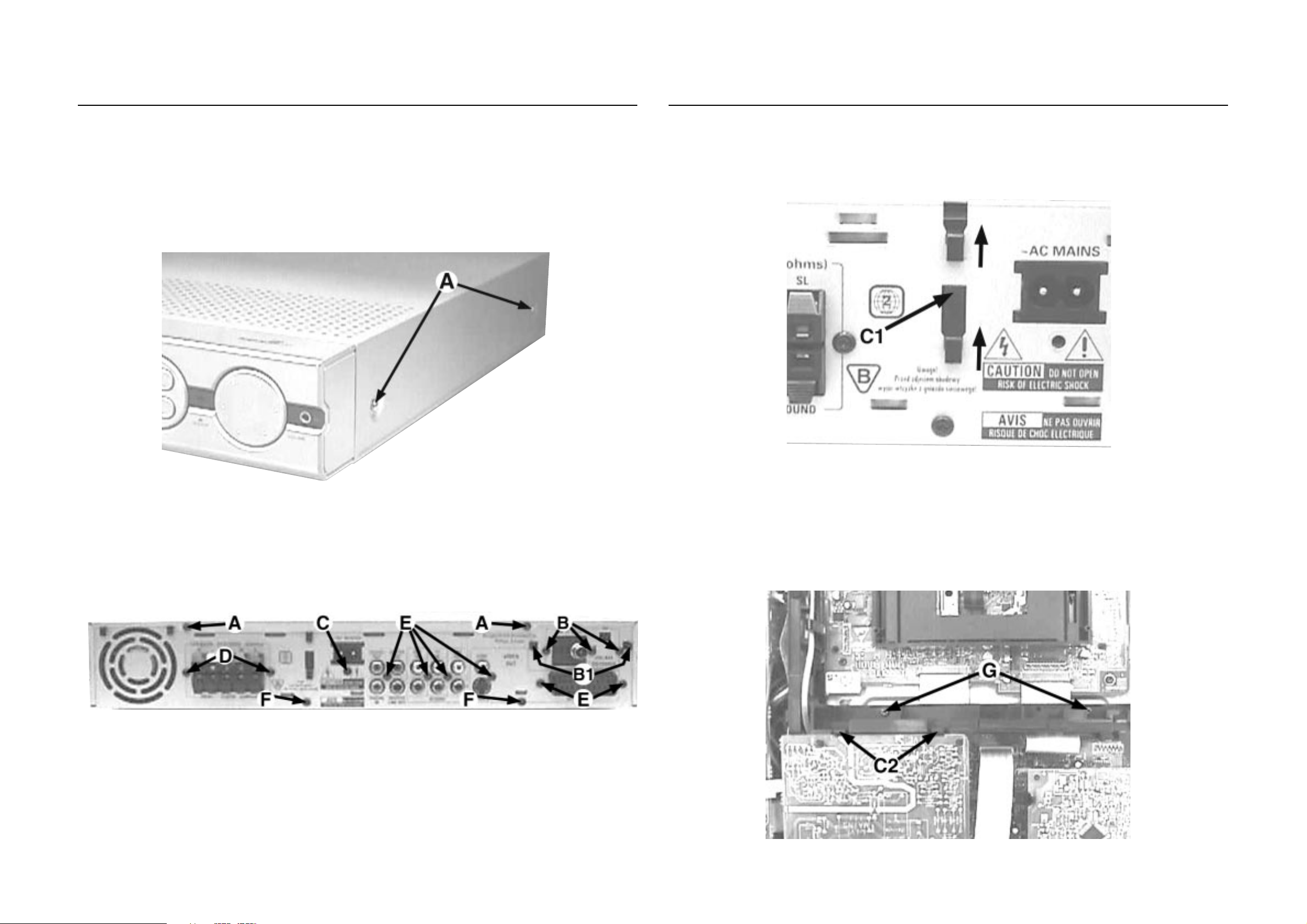

DISMANTLING INSTRUCTIONS

2-1 2-1

Dismantling of the Tuner Board and Main Board and AVC Board

1) Loosen 6 screws A to remove the Cover Top (pos 260).

- 2 screws each on the left & right side (see Figure 1)

- 2 screws on the rear (see Figure 2)

- See Service position A

2) Remove 3 screws B and uncatch 2 catches B1 (see Figure

2) to loosen the Tuner Board (pos 1101).

Dismantling of the Tuner Board and Main Board and AVC Board

3) Remove the Bracket PCB Mains (pos 259) by pressing

the catch C1 inward and slide it up in the direction as

shown in Figure 3.

4) Remove 1 screw C (see Figure 2) and uncatch 2 catches

C2 (see Figure 4) to loosen the Main Board (pos 1104-B).

- See Service position B

Figure 1

Figure 2

5) Remove 2 screws G (see Figure 4) to loosen the Bracket

AV PCB (pos 255).

Figure 3

6) Remove 6 screws E and 2 screws F (see Figure 2) to

loosen the Plate Rear (pos 251) and AVC Board (pos

1102).

- See Service position D

Figure 4

Page 10

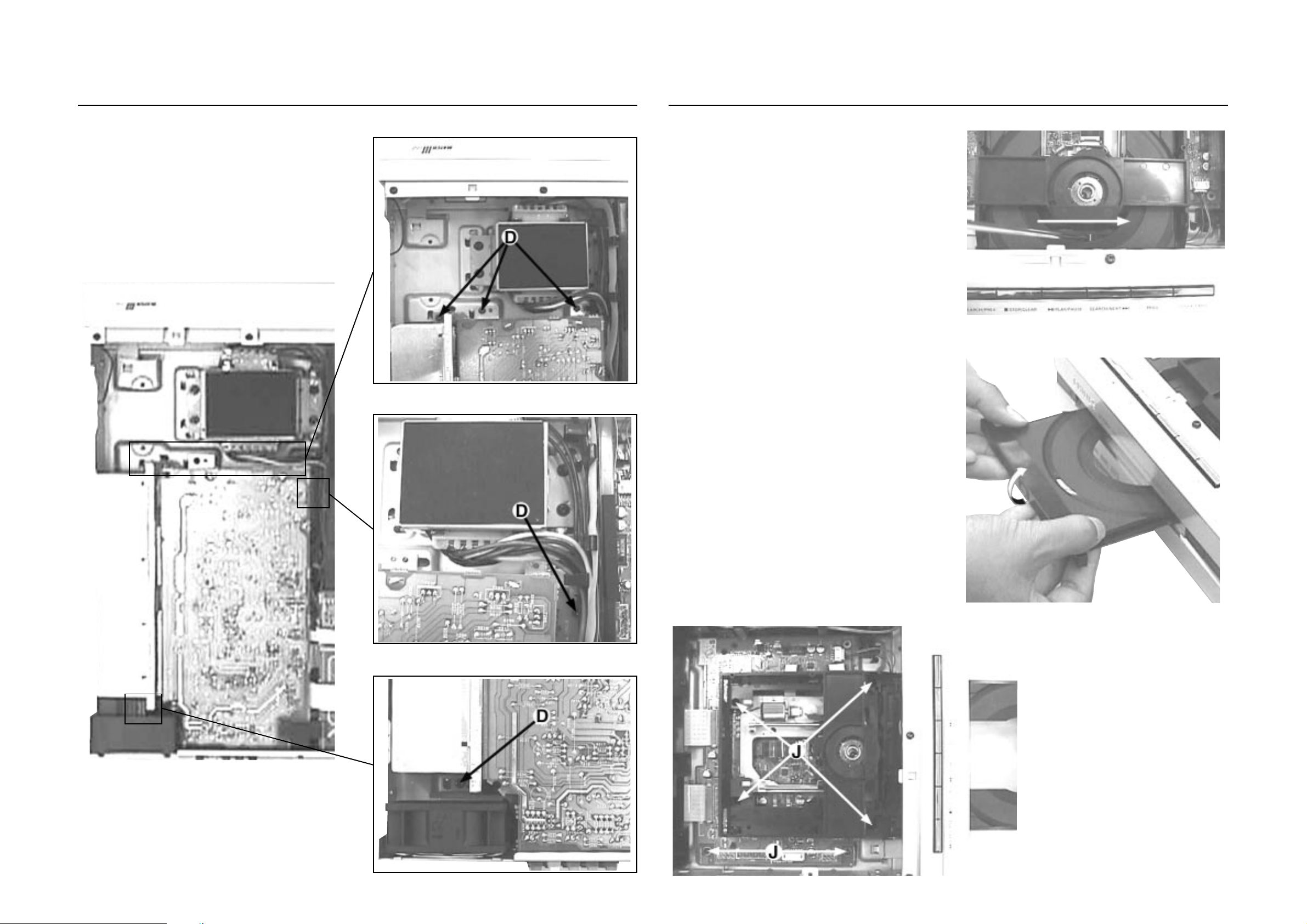

DISMANTLING INSTRUCTIONS

2-2

2-2

Dismantling of the Supply Board and Power Amplifier Board

1) Remove 7 screws D to loosen the Supply Board (pos

1104-A) and Power Amplifier Board (pos 1103-1001).

- 2 screws on the Plate Rear (see Figure 2)

- 5 screws on the Plate Bottom (see Figure 5, 6, 7 & 8)

- See Service position C

Dismantling of the DVD Module

1) Use a Flat Head screw driver to give a push in the

direction as shown in Figure 9 to unlock the DVD Tray

before sliding it out.

Figure 9

2) Slide out the DVD Tray and remove the Cover Tray DVD

(pos 105) as shown in Figure 10.

Figure 6

Figure 5

3) Slide out the DVD Tray fully and remove 6 screws J (see

Figure 11) to loosen the DVD Module (pos 1109).

- See Service position E

Figure 10

Figure 7

Figure 11

Figure 8

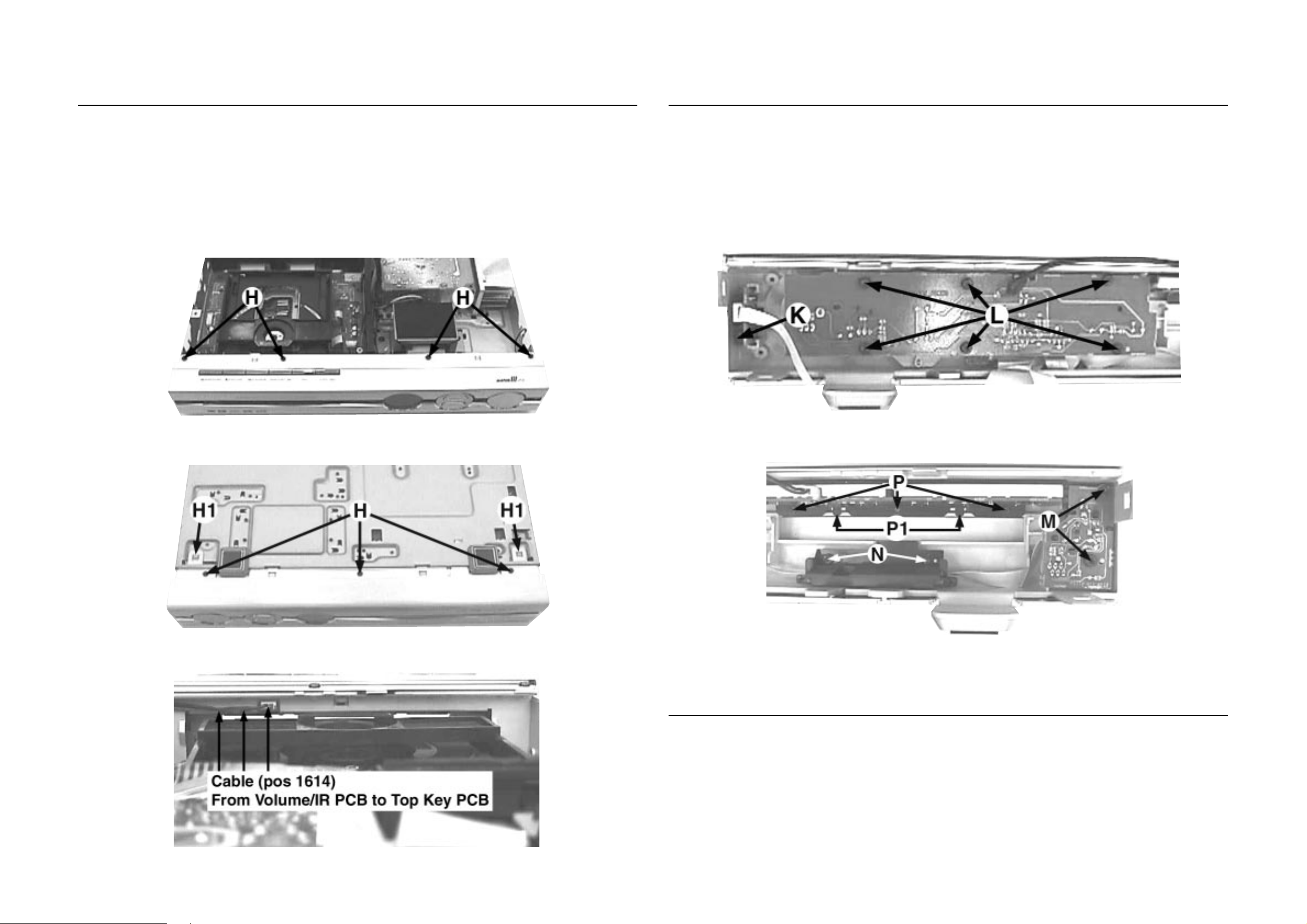

Page 11

DISMANTLING INSTRUCTIONS

2-3 2-3

Dismantling of the Front Panel Assembly

1) Remove 7 screws H (see Figure 12 and Figure 13) and

uncatch 2 catches H1 (see Figure 13) to loosen the Front

Panel Assembly from the set.

- 4 screws on top of the Front Panel Assembly

- 3 screws and 2 catches H1 at the bottom of the Front

Panel Assembly

- See Service position F

2) Make sure to unplug the cable (if obstructed) before

separate the Front Panel Assembly from the set (see

Figure 14).

Dismantling of the Key & Control Boards

1) Remove 1 screw K (see Figure 15) to loosen the

Headphone Board (pos 1105-D).

2) Remove 6 screws L (see Figure 15) to loosen the

Volume & IR Board (pos 1105-C).

3) Remove 2 screws M (see Figure 16) to loosen the Power

On/Off Board (pos 1105-A).

4) Remove 2 screws N (see Figure 16) to loosen the

Bracket LED SACD (pos 109) and SACD LED Board

(pos 1105-B).

5) Remove 3 screws P (for LX8000SA 2 screws only) and

uncatch 2 catches P1 (see Figure 16) to loosen the Top

Key Board (pos 1105-E).

Figure 12

Figure 13

Figure 15

Figure 16

Repair Hints

Figure 14

1) During repair it is possible to disconnect the ECO6 Tuner

Board completely unless the fault is suspected to be in

that area. This will not affect the performance of the rest

of the set.

2) The flex cables are very fragile, care should be taken not

to damage them during repair. After repair, be very sure

that the flex cables are inserted properly into the flex

sockets before encasing, otherwise faults may occurs.

Page 12

DISMANTLING INSTRUCTIONS

2-4 2-4

Service position A

Service position B

Service position D

Use a insulation sheet to

prevent any damaged or

short-circuit of the boards.

Service position E

Service position C

Use a insulation sheet to

prevent any damaged or

short-circuit of the boards.

Service position F

Page 13

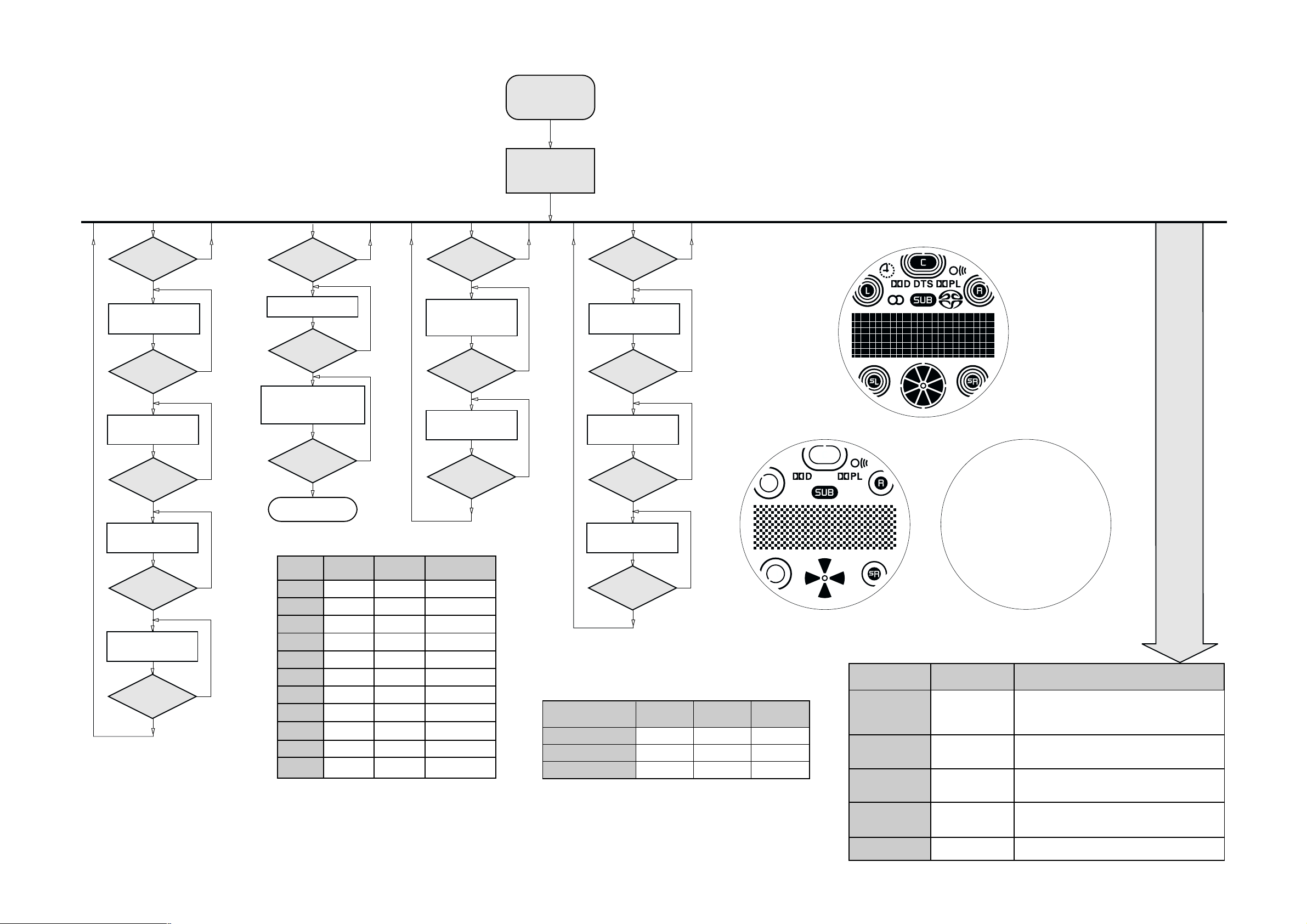

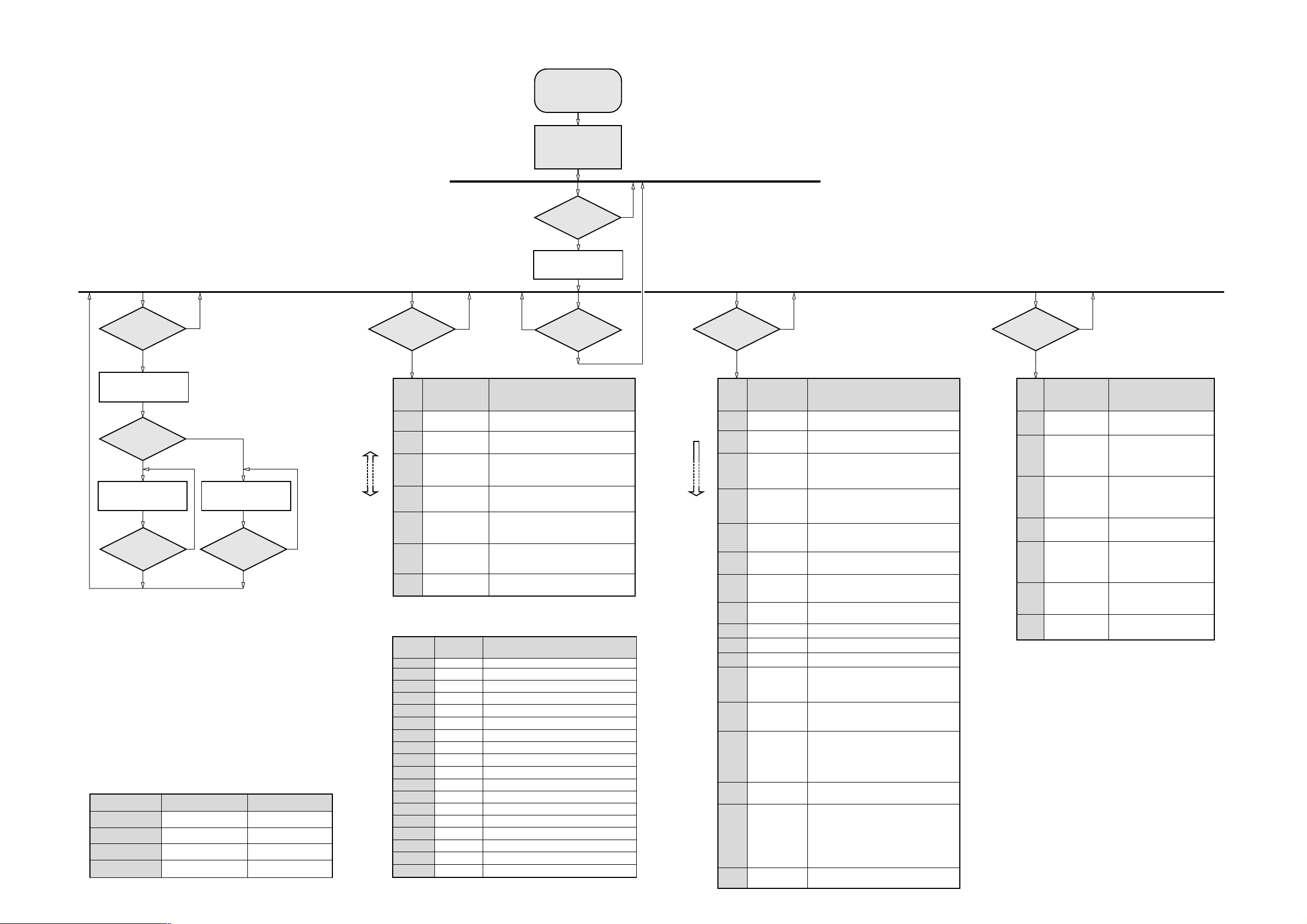

3-1

3-1

SERVICE TEST PROGRAM

ADC

TEST

SOURCE

Button pressed?

Y

Display shows

"ADC1 Value"

(Input Line - Key0)

SOURCE

Button pressed?

Y

Display shows

"ADC2 Value"

(Input Line - Key1)

SOURCE

Button pressed?

Y

N

N

N

TUNER

TEST

PROG

Button pressed?

Y

Display Tuner Version

"ccc"

PROG

Button pressed?

Y

Service frequencies are

copied to the RAM (see Table 1)

Tuner works normally except:

PROGRAM button

Disconnect

Mains cord ?

Y

Service Mode left

To start service test program

QUARTZ

TEST

N

N

N

CLOCK/TIMER

Button pressed?

Y

Display shows

32K

Output on Quartz-Test-Pin

pin 19 of uP = 2048Hz

CLOCK/TIMER

Button pressed?

Y

Display shows

12M

Output on Quartz-Test-Pin

pin 19 of uP = 2,929.6875Hz

9

Button pressed?

Y

N

& SOURCE

hold T

depressed while

plugging in the mains cord

Display shows the

ROM version

"S-Vyy"

(Main menu)

N

N

S refers to Service Mode

V refers to Version

yy refers to Software version number of the uProcessor

(counting up from 01 to 99)

DISPLAY

TEST

BII

Button pressed?

Y

Display shows Figure 1

and switch all LEDs on

(see Table 2 - Pattern 1)

BII

Button pressed?

Y

Display shows Figure 2

and switch alternate LEDs on

(see Table 2 - Pattern 2)

BII

Button pressed?

Y

N

N

N

Figure 1

Display shows

"ADC3 Value"

(Input Line - AmNTC)

SOURCE

Button pressed?

Y

Display shows

"ADC4 Value"

(Input Line - Option)

9

Button pressed?

Y

ADC Test is used for checking the ADC inputs

to the microprocessor.

The display shows an ADC value between 0

and 255 for an input signal between 0 and 5V.

Note :

If the ADC value on the NTC line is below 69,

the set will go to standby mode because the

temperature is too high.

N

N

PRESET

1

2

3

4

5

6

7

8

9

10

11

Europe

"EUR"

87.5MHz

108MHz

531kHz

1602kHz

558kHz

1494kHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

98MHz

USA

"USA"

87.5MHz

108MHz

530kHz

1700kHz

560kHz

1500kHz

98MHz

87.5MHz

87.5MHz

87.5MHz

87.5MHz

Oversea

"OSE"

87.5MHz

108MHz

531/530kHz*

1602/1700kHz*

558/560kHz*

1494/1500kHz*

87.5/98MHz*

87.5MHz

87.5MHz

87.5MHz

98/87.5MHz*

Table 1

Note: * Depending on the selected grid frequency (9 or 10kHz).

By holding the "SOURCE" and "PROG" buttons depressed

while switching on the Mains supply, the tuning grid frequency

is toggled between 9kHz and 10kHz for the Oversea (/21)

version.

Display shows Figure 3

and switch all LEDs off

(see Table 2 - Pattern 3)

Button pressed?

LEDs

SACD

STANDBY / ECO POWER

LCD BACKLIGHT

Pattern 1

ON

GREEN

ON

Table 2

N

Figure 2 Figure 3

Various

other Tests

ACTION

"PASS" is displayed if the uProcessor read back

the test pattern correctly, otherwise "FAIL" will be

displayed.

Load default data. Display shows "NEW" for 1 second.

Caution!

All presets from the customer will be lost!!

Pressing this button will toggle between the status

"AUTO STANDBY ON" and "AUTO STANDBY OFF".

Pattern 2

OFF

RED

ON

Pattern 3

OFF

OFF

ON

TEST

EEPROM TEST A test pattern will be sent to the EEPROM.

Activated with

T

9 to Exit

EEPROM FORMAT

TEST

AUTO STANDBY

TOGGLE

S

CENTER -

(RC)

The status will scroll once across the Display.

ROTARY

ENCODER TEST

Rotary Volume

Knob

Display shows value for 2 seconds.

Values increases or decreases in steps of 1 until

9

Y

0 (Volume Min.) or 40 (Volume Max.) is reached.

LEAVE SERVICE

TEST PROGRAM

Disconnect

mains cord

LX7000SA & LX8000SA_Service Test Program_dd wk0232

Page 14

3-2 3-2

SERVICE TEST PROGRAM

DVD IIC

COMMUNICATION

TEST

MUTE (RC)

Button pressed?

Y

Send request for

DVD Software Version

via IIC ports

Software Version

Received?

Y

Display shows

"DVD/www/xx.yy.zz"

9 (RC)

Button pressed?

Y

DVD IIC Communication Test is used to test the IIC communication port

between the DVD module and the microprocessor of the set.

www : refer to BEA Software version.

BEA = Back End Application (DVD Application Software).

xx.yy.zz : refer to Basic Engine Software version.

Basic Engine = part of the DVD module controlling the servo.

ERROR CODE (Faulty Modules)

ERROR CODE

00

01

10

11

N

N

Display shows

N

Button pressed?

BASIC ENGINE PART

OK

OK

Faulty

Faulty

Table 3

"FAIL"

9 (RC)

Y

STI + PERIPHERALS

N

OK

Faulty

OK

Faulty

Remote Control (RC) must be in DVD source

before start of any DVD Service Test.

DVD VERSION

MATRIX INFO

N

DISPLAY

SLASH ’###’

REGION ’#’

MULANG ’US/AP’

or

MULANG ’US/EU’

ASLANG ’#’

MULTI-CH ’YES’

or

MULTI-CH ’NO’

SMARTPIC ’YES’

or

SMARTPIC ’NO’

Choose step

by pressing

S

(RC)

T

(RC)

"DIM" (RC)

Button pressed?

Y

STEP

1

2

3

4

5

6

DVD Version Matrix Info is used to read the version matrix information

that are stored/defined in the DVD module software.

ERROR CODE (Nucleaus)

ERROR

CODE

0601

1101

1102

1103

1104

1201

1202

1203

1204

1301

1302

1303

1304

1601

5401

5402

5403

5403

NUCLEUS

NUMBER

6

11

-

-

-

12

-

-

-

13

-

-

16

54

-

-

-

To start service test program

& SOURCE

hold T

depressed while

plugging in the mains cord

Display shows the

ROM version

"S-Vyy"

(Main menu)

DVD SERVICE

TEST

DISC (RC)

Button pressed?

Y

Display shows

"DVD SERVICE"

N

9 (RC)

Button pressed?

Y

INFORMATION

Slash version number

Region code setting (Number 1 - 6)

Menu language table :

US/AP (USA-Asian Pacific language table)

US/EU (USA-Europe language table)

Audio/Subtitle language table

(Number 1 - 4)

Available of multichannel decording

Available of smart picture

Press 9 (RC) to exit

ERROR

DESCRIPTION

Calculated Checksum of FLASH is not correct

I2C bus busy before start

NVRAM access time-out

No NVRAM acknowledge

NVRAM reply time-out

I2C bus busy

Error sending I2C command to Slave

Slave controller not responding

Slave response is not correct

Parity error receiving data from Basic Engine

Parity error sending data to Basic Engine

No communication with Basic Engine

Comunication time-out with Basic Engine

The SDRAM is faulty

I2C bus busy

Error sending I2C command to Scart Switch IC

Scart switch IC not responding

Scart switch IC response is not correct

Table 4

N

S refers to Service Mode

V refers to Version

yy refers to Software version number of the uProcessor

(counting up from 01 to 99)

DVD PLAYER

TEST

N

DISPLAY

BAR

PICTURE

PINK

NOISE

SCART

LOOP DVD

SCART

LOOP EXT

SINE

SOUND

ENG"xx.yy.zz"

TRAY

SLEDGE

MOTOR

FOCUS

RADIAL

GROOVES

TRAY

LO"wwxxyyzz"

ERROR

"BITS xx"

"aa-bbb

cccc"

Go to next

step

by pressing

T

(RC)

"VOL +" (RC)

Button pressed?

Y

STEP

1**

2**

3A**

3B**

4**

5

6

7

8**

9**

10**

11

12

13

14

15

ACTION

Output of a test picture on all available video

output devices.

Output of noise on all channels available.

Output of internally generated pink noise on all

channels available, test picture (internally

generated Colour Bar) on screen.

Press

S

(RC) to go to Step 3B.

Output of internally generated pink noise on all

channels available, test picture (external signal)

on screen.

Press

T

(RC) to return to Step 3A.

Sine sound output on all channels available.

The sound can be stopped by pressing the

"STOP"(RC) button.

Returns the Software Version of the basic

engine.

The user can move the tray in and out by

pressing "PLAY"(RC) or "RESUME"(RC) button.

User can insert or remove a disc.

The user can move the sledge in and out by

pressing "PLAY"(RC) or "RESUME"(RC) button.

The disc motor starts to run.

Focus Test.

Radial Test.

The laser spot jumps to another position.

Press "PLAY"(RC) to jump to the next position.

Press "RESUME"(RC) to jump to the previous

jump position.

The user can move the tray in and out by

pressing "PLAY"(RC) or "RESUME"(RC) button.

User can insert or remove a disc.

Reads out info from the error log (8 hex digits).

Up to 16 errors can be stored in a buffer.

The elements can be selected by pressing the

"PLAY"(RC) or "RESUME"(RC) button.

If the error log does not contain any fault codes,

"LO-00000000" will be displayed.

Shows all error bits. Selects the error bit by

pressing "PLAY"(RC) or "RESUME"(RC) button.

Runs the Dealer Test infinitely. The information

returned from the module will be displayed.

The loop number indicates the number of times

the loop test has been performed.

aa - Error Code Faulty Modules (see Table 3)

bbb - Loop Number

cccc - Error Code Nucleaus (see Table 4)

Disconnect mains cord to exit the Service Test

Program.

DVD DEALER

TEST

"VOL -" (RC)

Button pressed?

N

Y (Execute all the tests below without interaction)

STEP

1

2

3

4

5

6

DISPLAY

CHECKSUM

FLASH

S2B

ECHO

IIC

NVRAM

NVRAM

WRITE

SDRAM

WRITE

ALL TEST FAIL

or

ALL TEST PASS

ACTION

Check the correctness of the

checksum of the flash.

S2B Echo Mode.

(This test is executed very fast

and hence user will not be able

to see this display message)

Check the correctness of the

IIC bus to the NVRAM.

(This test need about 3 minutes

to perform)

Check writing to the NVRAM.

Check writing to the SDRAM.

(This test is executed very fast

and hence user will not be able

to see this display message)

Result of all the tests.

Disconnect mains cord to exit

the Service Test Program.

DVD Dealer Test is used to check the flash RAM, the SDRAM,

the DRAM, the NVRAM and the I2C communication.

When all the tests are passed, display shows "ALL TEST PASS".

If at least one of the test fails, display shows "ALL TEST FAIL".

DVD Player Test is used to start several DVD specific tests.

At the end of the test, an error code "aa-bbb cccc" (see Step15) will be

shown that indicates which module(s) failed.

** User has to give a confirmation by triggering one of the following:

- If the test is OK, press "PLAY"(RC) button then follow by T (RC)

button to go to the next step.

- If the test is not OK, press "RESUME"(RC) button then follow by

T (RC) button to go to the next step.

Note : By pressing only the T (RC) button to go to the next step without

triggering a confirmation, the test will be assume as OK by default.

Equipment required to run the DVD Player Test:

- television set

- 6 audio speakers

- an external video source

LX7000SA & LX8000SA_Service Test Program_dd wk0232

Page 15

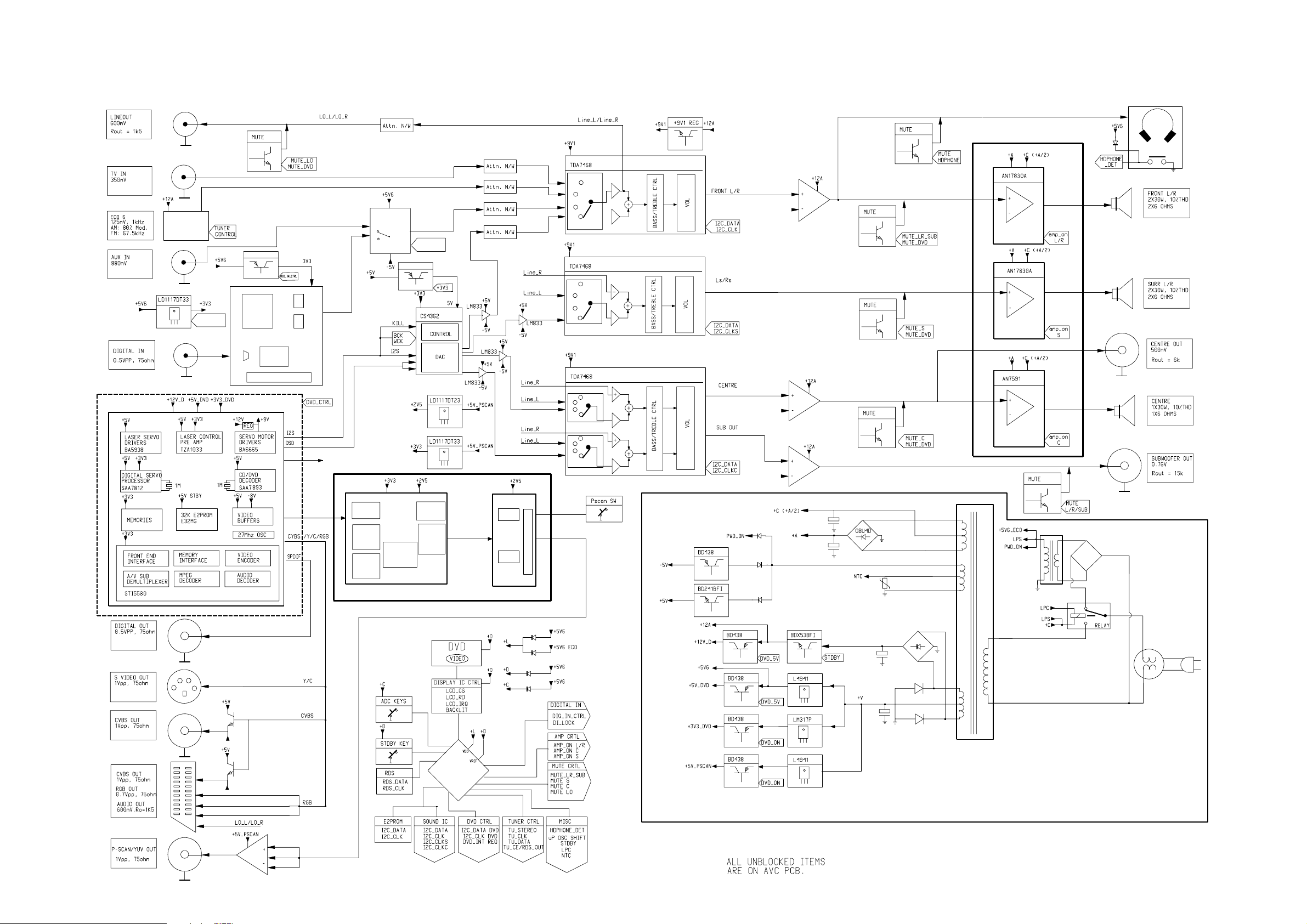

SET BLOCK DIAGRAM

FM-95.00

DIG_IN_CTRL

BC369 & LD1117

UDA1351TS

L3-BUS

INTERFACE

IEC958

DECODER

4-1

HEF4053BT

DIG_IN_CTRL

BC369

DAC

DAC

4-1

L/R

POWER AMP

SURROUND

POWER AMP

DVD

CLK & TIMING CIRCUIT

YUV

MUTE_DVD

*

FLI2200

PLL / CLK

GENERATOR

INPUT

SIGNAL

FORMATTER

CONTROL

INTERFACE

& REGISTERS

DEINTERLACER

CORE

SYNC

GENERATOR

OUTPUT

SIGNAL

FORMATTER

ADV7300

STD

DEF

HIGH

DEF

P-SCAN / YUV

OVERSAMPLING

CENTRE

POWER AMP

MAINS TRAFO

*

LPS COIL

SUPPLY

-5V

*

-5V

*

3X

TMP88CU74F

Not in all versions

*

3139 119 34790_Block Diagram (Sheet 130)_dd wk0240

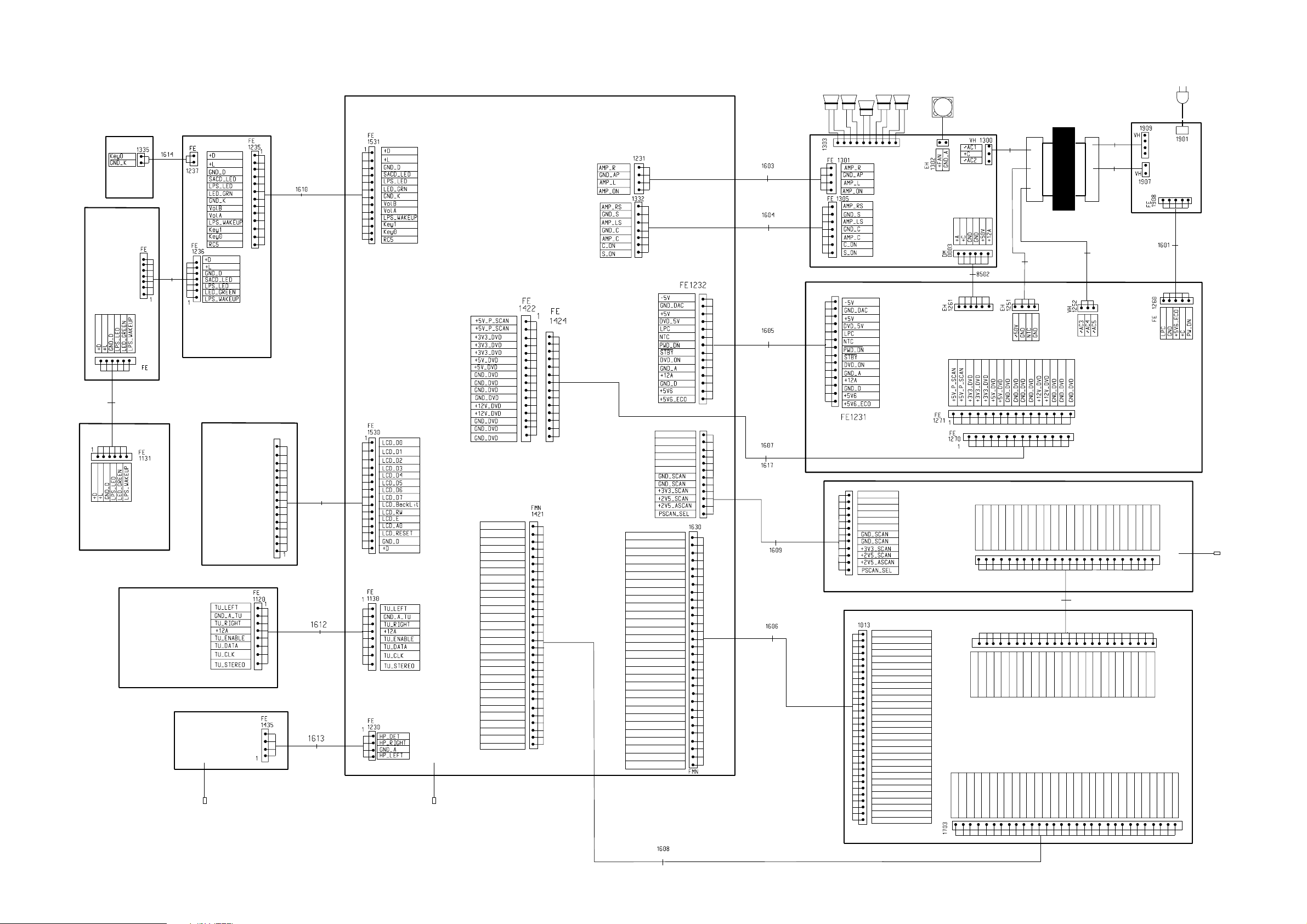

Page 16

SET WIRING DIAGRAM

5-1

5-1

TOP

KEY

SACD

LED

1

1616

side

1

180mm

2P

1580

1615

7P

120mm

FOLD

side

1581

side

6P 100mm AD FOLD

1

side

AD

side

VOLUME / IR

13P 340mm AD FOLD

side

AVC

L

SL

C

SRR

FAN

0385

TRAFO

1

4P 140mm BD

1

1

7P 140mm BD

1

AMPLIFIER

1

1

180mm

280mm

340mm

340mm

180mm

6P 120mm

1

1

1

***

MAIN

**

side

**

**

1

5P 140mm BD

1

*

1

1

14P 120mm AD FOLD

SUPPLY

1

side

LCD

DISPLAY

POWER

ON / OFF

TUNER

SIDE

HEADPHONE

1820 100mm 1601 100mm

3139 119 34790_Wiring Diagram (Sheet 132)_dd wk0232

BD 15P

380mm

8P 100mm AD

4P 480mm BD

FOLD

I2C_CLK_DVD

I2C_DATA_DVD

SCART1

SCART0

B_REF

B_U

G_REF

G_Y

R_REF

R_V

Y_REF

Y

C_REF

C

CVBS_REF

CVBS

+3V3

+3V3

+5V

+12V

+12V

MUTE_DVD

GND

PCMSCLK(NC)

PCMDATA0(NC)

GND

PCMCLK (NC)

PCMLRCLK(NC)

GND

SPDIF

FOR SET WITH PROGRESSIVE SCAN ONLY

:

*

FOR SET WITH LOW STANDBY

:

**

FOR /21 ONLY

:

***

FE 1423

GND

Y

GND

Pb/Cb

GND

Pr/Cr

1

GND

384FS

GND

DSD_LFE

GND

DSD_CENTRE

GND

DSD_Rs

GND

DSD_Ls

GND

DSD_R

GND

DSD_L

GND

WORD_CLK/SEL_DSD

GND

BIT_CLK/DSD_CLK

GND

256FS

GND

SCL-DAC

SDA-DAC

GND

DSD_PCM8 (NC)

GND

DSD_PCM9(NC)

INT_REQ

DAC_RST

CLK_SEL

30P 100mm BD 1MMP

*

*

16P 260mm AD FOLD

14P 260mm AD FOLD

Side FE 1002

1

1

*

12P 120mm AD

1

30P 100mm BD 1MMP

*

GND

Y

GND

Pb/Cb

GND

Pr/Cr

1

GND

384FS

GND

DSD_LFE

GND

DSD_CENTRE

GND

DSD_Rs

GND

DSD_Ls

GND

DSD_R

GND

DSD_L

GND

WORD_CLK/SEL_DSD

GND

BIT_CLK/DSD_CLK

GND

256FS

GND

SCL-DAC

SDA-DAC

GND

DSD_PCM8 (NC)

GND

DSD_PCM9

P50/GPIO2(NC)

GPIO3

GPIO1(NC)

*

PSCAN

*

C

SDA

SCL

GND

1

Side FMN 1000

1

VSYNC

SCL

SDA

GND

VSYNC

HSYNC

HSYN

*

GND

GND

GND

27MHZ CLK

GND

27MHZ CLK

YC0

1602

*

1704

YC0

GND

GND

YC1

YC1

GND

GND

YC2

GND

YC2

24P 120mm BD 1MM FD

FFC 1MM

YC3

GND

YC3

YC5

+3V3

YC4

+5V

+3.3V

YC5

+3V3

YC4

+5V

DVD SD4-00-SA-CH

GND

I2C_DATA_DVD

I2C_CLK_DVD

1

SCART1

SCART0

B_REF

B_U

G_REF

G_Y

R_REF

R_V

Y_REF

+3V3

C

C_REF

CVBS

CVBS_REF

Y

+3V3

MUTE

+12V

+12V

+5V

+3.3V

GND

YC6

GND

YC6

PCMDATA0(NC)

PCMSCLK(NC)

YC7

YC7

GND

GND

GND

PCMLRCLK

PCMCLK (NC)

GND

SPDIF

1618 70mm

Page 17

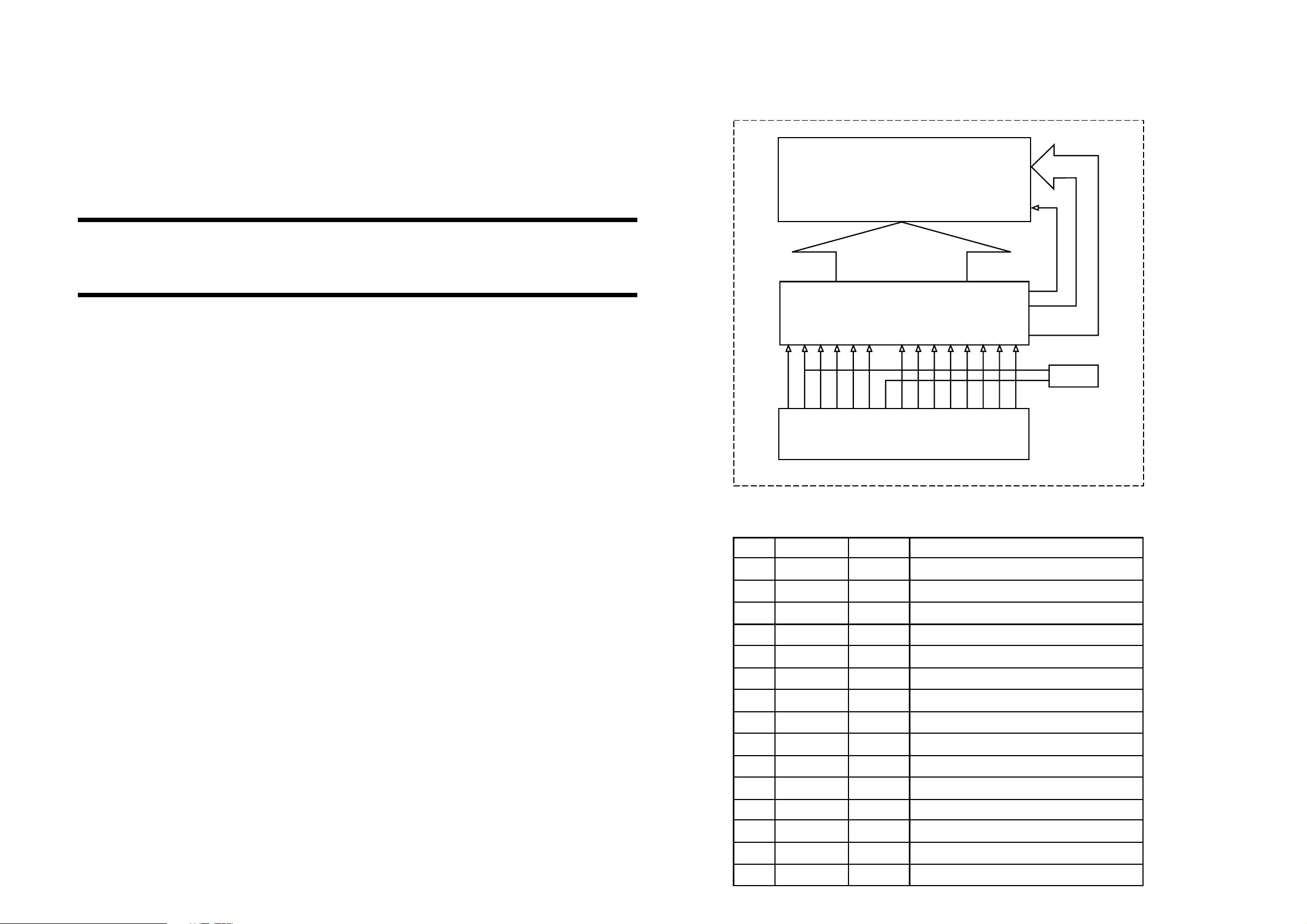

6-1

LCD MODULE

BLOCK DIAGRAM

6-1

LCD PANEL

48 * 15 DOTS with 38 ICONS

C0

C14

.

.

.

.

.

.

.

.

.

KEY & CONTROL BOARDS

TABLE OF CONTENTS

LCD Module - Block diagram .......................................... 6-1

LCD Module - Interface Pin Function .............................. 6-1

Top Key Part - Layout & Circuit diagram ......................... 6-2

SACD LED Part - Layout & Circuit diagram .................... 6-3

Volume & IR Part - Component & Chip layout ................ 6-4

Volume & IR Part - Circuit diagram ................................. 6-5

Headphone Part - Layout & Circuit diagram ................... 6-6

Power ON/OFF Part - Layout & Circuit diagram ............. 6-6

Electrical parts list............................................................ 6-7

S0 S49

.....

.....

.

.

.

.....

.

.....

.

.

.

.....

.

.....

.

.

...

.

.

IC AX6120

5

6

7

8

9

10

11

12

13

14

15

E

VDD

VSS

A0

RESET

LED+

D7

D5RWD4D3D2D1D0

D6

INTERFACE

INTERFACE PIN FUNCTION

NO SYMBOL I/O FUNCTION

1. DB0 I/O Data Bus

2. DB1 I/O Data Bus

C15

C15

C14

.

.

.

.

.

.

.

.

.

C0

LED

1

2

3

4

3. DB2 I/O Data Bus

4. DB3 I/O Data Bus

5. DB4 I/O Data Bus

6. DB5 I/O Data Bus

7. DB6 I/O Data Bus

8. DB7 I/O Data Bus

9. LED+ P Power Supply for LED

10. RW I Read/Write Execution Control

11. E I Read/Write Start Signal

12. A0 I Register Select input

13. RESET I Reset Input Pin

14. VSS (LED-) P GND

15. VDD P Power Supply for Logic

Page 18

6-26-2

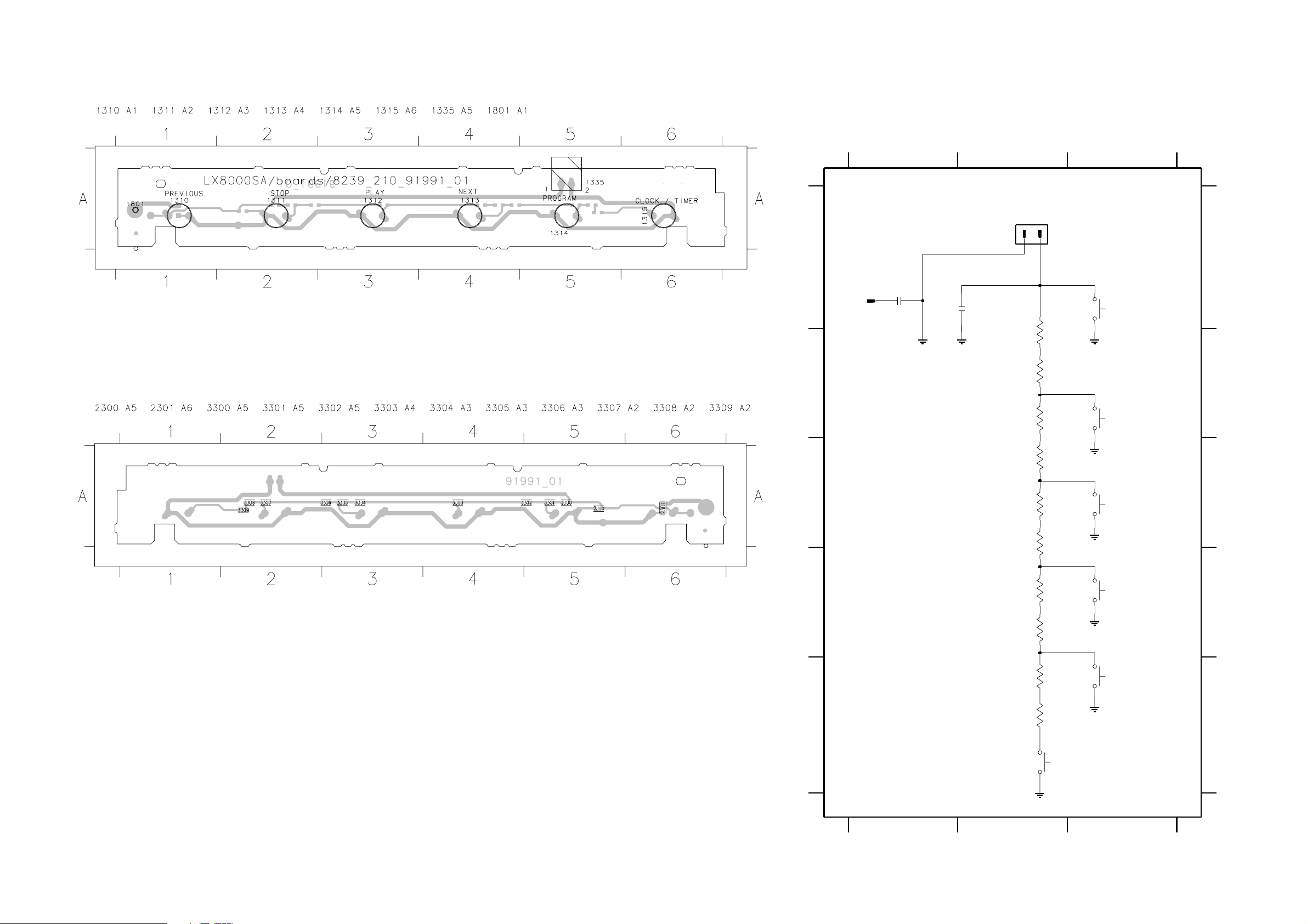

TOP KEY BOARD - CIRCUIT DIAGRAMTOP KEY BOARD - COMPONENT LAYOUT

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

TOP KEY BOARD - CHIP LAYOUT

3139 113 3481 pt1 dd wk0227

1310 A3

1311 B3

1312 C3

A

B

1313 D3

1314 E3

1315 E2

TOP KEY

RT-01T

1

1801

1335 A2

1801 A1

2300 A1

2301 A1

3300 B2

3301 B2

3302 B2

3303 C2

3304 C2

3305 C2

3306 D2

3307 D2

123

From VOLUME / IR

EH-S

1335

1

2

# 2301

100n

GND_K

2300

33p

GND_K

150R

220R

270R

3300

3302

A

1310

1311

3308 E2

3309 E2

PREV

GND_K

STOP

A

B

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3139 113 3481 pt1 dd wk0227

C

D

E

Note :

Some values may varies, see respective

parts list for correct value.

# : Provision

390R

560R

820R

1K2

1K8

2K7

4K7

1315

3303

3304

3306 3305

3307 3301

3308

3309

Clock/ Timer

1313 1312

1314

GND_K

PLAY

GND_K

NEXT

GND_K

Program

GND_K

C

D

E

3139 118 55940...8239_210_91991_01...for 3481 pt1 dd wk0227

123

GND_K

Page 19

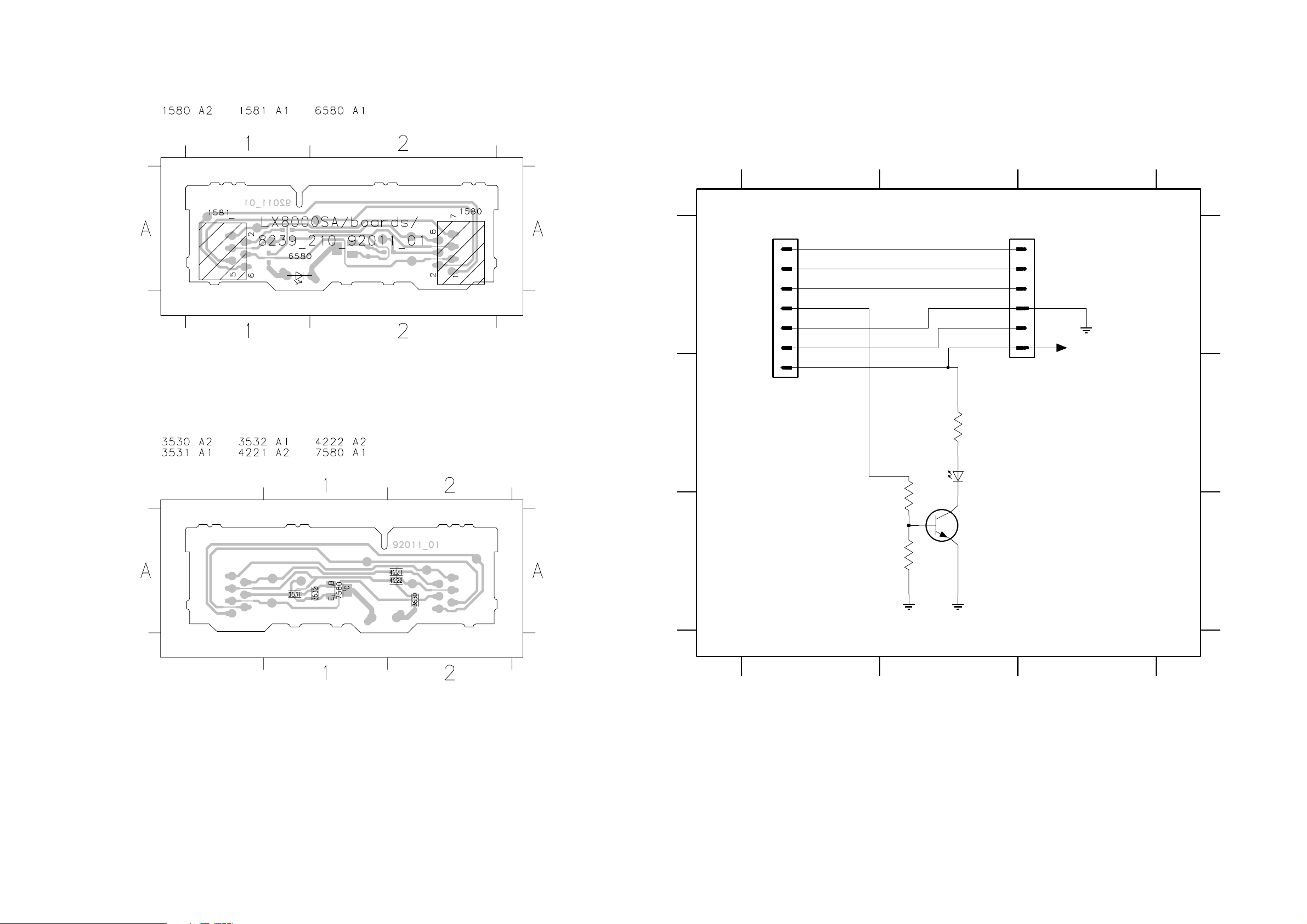

6-3 6-3

SACD LED BOARD - CIRCUIT DIAGRAMSACD LED BOARD - COMPONENT LAYOUT

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram and respective parts list.

SACD LED BOARD - CHIP LAYOUT

3139 113 3481 pt1 dd wk0227

1580 A1 1581 B3 3530 B2

FE-ST-VK-N

1580

1

2

A

3

4

5

From VOLUME / IR

6

7

B

3531 C2 3532 C2

6580 B2 7580 C2

123

SACD LED

LPS_WAKEUP

1581

6

5

4

3

+D

2

1

To POWER ON/OFF

GND_D

SCAD_LED

LED_GRN

3530

LPS_LED

GND_D

+L

+D

FE-ST-VK-N

150R

A

B

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram and respective parts list.

3139 113 3481 pt1 dd wk0227

C

Note : Some values may varies, see respective

parts list for correct value.

123

6580

10K

3531

7580

BC847B

10K

3532

GND_D GND_D

1CHTDK3

C

3139 118 55940...8239_210_92011_01...for 3481 pt1 dd wk0227

Page 20

VOLUME & IR BOARD - COMPONENT LAYOUT

6-46-4

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

VOLUME & IR BOARD - CHIP LAYOUT

3139 113 3481 pt1 dd wk0227

This assembly drawing shows a summary of all possible versions. For components used in a specific version see schematic diagram and respective parts list.

3139 113 3481 pt1 dd wk0227

Page 21

VOLUME & IR BOARD - CIRCUIT DIAGRAM

6-5 6-5

1235 A1 1236 A3 1237 C4 1242 C6

12345678

FE-ST-VK-N

1235

1

2

3

4

5

6

7

8

9

10

11

12

13

To AVC PCB

A

B

+D

+L

GND_D

SACD_LED

LPS_LED

LPS_GRN

GND_K

VolB

VolA

LPS_WAKEUP

Key 1

Key 0

RC5

GND_K

1243 C7 1244 D3 1245 C7 1246 C8 2211 D4 2212 D4 2214 B7 2215 A7 2216 A6 2217 C6 3213 C4 3214 C4 3215 C6 3216 A8 3217 A6 3218 B7 3220 C7 3221 C7

FE-ST-VK-N

1236

7

6

5

4

3

2

To SACD LED

1

+D

GND_D

GND_K

1

2

EH-S

1237

+D

TO TOP KEY

+D

3217

100R

GND_D

RC5

47u

2216

GND_D

GND_D

2n2

2215

47n

2214

3218

1K

3216

10K

VS2

OUT1

GND3

GND_D

3222 C7 3223 C8 3224 C8

9

VOLUME & IR

TSOP2236

DEM

CTRL

CIRCUIT

BAND

PASS

AGC

INP

PIN

7210 A9

A

7210

B

C

D

3222

390R220R

1245

3223

560R

Surround

3224

820R

1246

Sound

GND_KGND_K

3139 118 55940...8239_210_92001_01...for 3481 pt1 dd wk0227

C

D

VolA

VolB

1244

EVE

MT15MT2

4

13

2

GND_D

10K

2211

GND_D

3213

10n

10K

2212

GND_D

3214

10n

2217

GND_K

3215

150R

33p

1242

Source

GND_K GND_K

3220

1243

3221

270R

Open_Close

Note : Some values may varies, see respective parts list for correct value.

12345678 9

Page 22

6-6

6-6

HEADPHONE BOARD - COMPONENT

LAYOUT

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram

and respective parts list.

3139 113 3481 pt1 dd wk0227

HEADPHONE BOARD - CHIP LAYOUT

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram

and respective parts list.

3139 113 3481 pt1 dd wk0227

POWER ON/OFF BOARD - COMPONENT

LAYOUT

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram

and respective parts list.

3139 113 3481 pt1 dd wk0227

POWER ON/OFF BOARD - CHIP LAYOUT

This assembly drawing shows a summary of all possible versions.

For components used in a specific version see schematic diagram

and respective parts list.

3139 113 3481 pt1 dd wk0227

HEADPHONE BOARD - CIRCUIT DIAGRAM

1400 A3

1435 A1

1820 A3

2401 A3

2402 A3

2403 A3

2404 A3

3409 B3

123

HEADPHONE

A

A_HP

FE-ST-VK-N

1435

1

2

HP_L

HP_R

3

4

HP_DETECT

B

Note : Some values may varies, see respective

parts list for correct value.

123

5401 A2

5402 A2

5402

2u2

5401

2u2

5403 A3

A_HP

2401

22n

2402

22n

5403

2u2

2403

100n

22n

2404

1

A_HP

RT-01T

1820

1400

HSJ1063

1

3

2

4

5

6

22R

3409

3139 118 55940...8239_210_91871_01...for 3481 pt1 dd wk0227

A

B

POWER ON/OFF BOARD - CIRCUIT DIAGRAM

1105 C2

1131 B1

3100 A2

3101 A3

3102 A4

3103 B3

3104 C3

3105 B4

3106 C4

6101 B3

6102 B4

7100 B3

1234

POWER ON-OFF

A

10K

3100

FE-BT-VK-NA

1131

From SACD LED

B

GND_D

1

2

3

4

5

+D

6

+L

LPS_LED

LED_GRN

LPS_WAKEUP

LPS_Key

22K

3103

1105

C

GND_D

Note : Some values may varies, see respective

parts list for correct value.

1

234

7101 B4

3104

3102

3101

330R

6101

LTL-1CHPE

7100

BC847B

10K

GND_DGND_D

3139 118 55940...8239_210_91881_01...for 3481 pt1 dd wk0227

220R

6102

LTL-1CHGE

BC847B

7101

GND_D GND_D

3106

A

B

22K

3105

10K

C

Page 23

ELECTRICAL PARTS LIST - KEY & CONTROL BOARDS

MISCELLANEOUS

1105 4822 276 13775 Tact Switch

1131 4822 267 10731 Flex Connector 6P

1235 4822 267 10756 Flex Connector 13P

1236 4822 267 10956 Flex Connector 7P

1242 4822 276 13775 Tact Switch

1243 4822 276 13775 Tact Switch

1244 2422 129 16836 Rotary Encoder 12P

1245 4822 276 13775 Tact Switch

1246 4822 276 13775 Tact Switch

1310 4822 276 13775 Tact Switch

1311 4822 276 13775 Tact Switch

1312 4822 276 13775 Tact Switch

1313 4822 276 13775 Tact Switch

1314 4822 276 13775 Tact Switch

1315 4822 276 13775 Tact Switch

1400 2422 026 05332 Headphone Socket

1435 4822 265 11183 Flex Connector 4P

1580 4822 267 10956 Flex Connector 7P

1581 4822 265 11207 Flex Connector 6P

CAPACITORS

2211 5322 126 11583 10nF 10% 50V

2212 5322 126 11583 10nF 10% 50V

2214 2238 786 11554 2,2nF 5% 16V

2215 3198 017 34730 47nF 16V

2216 4822 124 81286 47uF 20% 16V

2217 2222 867 15339 33pF 5% 50V

2300 2222 867 15339 33pF 5% 50V

2401 3198 017 42230 22nF 50V

2402 3198 017 42230 22nF 50V

2403 2238 586 59812 100nF +80/-20% 50V

2404 3198 017 42230 22nF 50V

RESISTORS

3100 4822 051 30103 10k 5% 0,062W

3101 4822 051 30331 330R 5% 0,062W

3102 4822 051 30221 220R 5% 0,062W

3103 4822 051 30223 22k 5% 0,062W

3104 4822 051 30103 10k 5% 0,062W

3105 4822 051 30223 22k 5% 0,062W

3106 4822 051 30103 10k 5% 0,062W

3213 4822 051 30103 10k 5% 0,062W

3214 4822 051 30103 10k 5% 0,062W

3215 4822 051 30151 150R 5% 0,062W

3216 4822 051 30103 10k 5% 0,062W

3217 4822 051 30101 100R 5% 0,062W

3218 4822 051 30102 1k 5% 0,062W

3220 4822 051 30221 220R 5% 0,062W

3221 4822 051 30271 270R 5% 0,062W

3222 4822 051 30391 390R 5% 0,062W

3223 4822 051 30561 560R 5% 0,062W

6-7

3224 4822 117 12968 820R 5% 0,62W

3300 4822 051 30151 150R 5% 0,062W

3301 4822 051 30221 220R 5% 0,062W

3302 4822 051 30271 270R 5% 0,062W

3303 4822 051 30391 390R 5% 0,062W

3304 4822 051 30561 560R 5% 0,062W

3305 4822 117 12968 820R 5% 0,62W

3306 4822 117 11817 1k2 1% 1/16W

3307 4822 117 12903 1k8 1% 0,063W

3308 4822 051 30272 2k7 5% 0,062W

3309 4822 051 30472 4k7 5% 0,062W

3409 4822 117 12139 22R 5% 0,062W

3530 4822 051 30151 150R 5% 0,062W

3531 4822 051 30103 10k 5% 0,062W

3532 4822 051 30103 10k 5% 0,062W

4201 4822 051 30008 0R Jumper 0603

4202 4822 051 30008 0R Jumper 0603

4203 4822 051 30008 0R Jumper 0603

4204 4822 051 30008 0R Jumper 0603

4205 4822 051 30008 0R Jumper 0603

4206 4822 051 30008 0R Jumper 0603

4207 4822 051 30008 0R Jumper 0603

4208 4822 051 30008 0R Jumper 0603

4209 4822 051 30008 0R Jumper 0603

4210 4822 051 30008 0R Jumper 0603

4211 4822 051 30008 0R Jumper 0603

4212 4822 051 30008 0R Jumper 0603

4213 4822 051 30008 0R Jumper 0603

4214 4822 051 30008 0R Jumper 0603

4215 4822 051 30008 0R Jumper 0603

4216 4822 051 30008 0R Jumper 0603

4217 4822 051 30008 0R Jumper 0603

4218 4822 051 30008 0R Jumper 0603

4219 4822 051 30008 0R Jumper 0603

4220 4822 051 30008 0R Jumper 0603

4221 4822 051 30008 0R Jumper 0603

4222 4822 051 30008 0R Jumper 0603

COILS & FILTERS

5401 4822 157 10586 Coil 2,2uH 10%

5402 4822 157 10586 Coil 2,2uH 10%

5403 4822 157 10586 Coil 2,2uH 10%

DIODES

6101 4822 130 82978 LED VS LTL-1CHPE

6102 4822 130 10791 LED VS LTL-1CHGE

6580 9322 185 23676 LED VS LTL-1CHTDK3

TRANSISTORS & INTEGRATED CIRCUITS

7100 5322 130 60159 BC847B

7101 5322 130 60159 BC847B

Page 24

ELECTRICAL PARTS LIST - KEY & CONTROL BOARDS

TRANSISTORS & INTEGRATED CIRCUITS

7210 9322 155 82667 IR Receiver TSOP2236ZC1

7580 5322 130 60159 BC847B

Note : Only the parts mentioned in this list are normal

service spare parts.

6-8

Page 25

7B-17B-1

1

AM

Mixer

AM

Osc.

AM IF

IF1

IF2

FM

Det.

AM

Det.

37 33

RADIO IC

TEA 5762

TUNER BOARD

ECO 6

Systems Cenelec

1018 11

143915

24

right

AM/FM

right

left

left

stereo

VCO

4140 36 193244 25

Stereo

Decoder

AFC

AFC +

AFC -

4

4

AGC

Pre-

scaler

Multi-

plexer

Charge

pump

Stabilizer

CONTROL

Reference

Oscillator

292827

clock

data

enable

P1

P0

31

30

programmable

output ports

V

Loop

V

Loop

V

Loop

2

6

5 FM Osc.

C

D

450kHz450kHz450kHz

20

75kHz

V

Stab

AV

Stab

BV

Stab

B

V

Stab

A V

Stab

B

10,7 MHz 10,7 MHz

35 9

Vdd Vcc1

723

V

Stab

A

V

Stab

B

38

34

22

Vcc2

8

ECO6 Systems Cenelec, 140499

V

Loop

+FM

AM-RF

AM-Osc.

FM-IF 1 FM-IF 2

LF filter

MPX

buffer ampl.

RDS

(MPX)

5

RDS

(MPX)

stereo

clock

data

enable

Version

3

1120

AM-IF 1 AM-IF 2

AM-AFC

1

8

AM

Frontend

2

AM-FRAME AERIAL

B

1103

1101

(1102)

A

FM

AM/FM

Discriminator

10,7 MHz

Vdd

+FM

Vcc1

Vcc

Vcc2

MW/LW

AM-RF,

AM-Osc.

1

Ant.

Osc.

out

GND

234 6 5

8

7

V

CC

V

varicap

MIXER

FM FRONTEND

IF

out

ECO6 Tuner Board

version:

SYSTEMS CENELEC

TABLE OF CONTENTS

Blockdiagram ..................................................................7B-1

Schematic Diagram.........................................................7B-2

Component Layout..........................................................7B-3

Adjustment table .............................................................7B-3

Electrical Partslist............................................................7B-4

BLOCK DIAGRAM

Page 26

7B-2 7B-2

MIXER

varicap

FM FRONTEND

GND

PRE-

SCALER

MULTI-

PLEXER

VSTABA

AM-IF

MONO/

XTAL

AGC

CONTROL

OSC

AM DET

AM

OSC

AGC

VCC2

AGC

PUMP

AM

MIXER

DECODER

CHARGE

FM

IF1

FRONTEND

AM

VSTABB

DET

FM

CONTROL

FILTER

AM

IF

AM

DET

STEREO

STEREO

FM

IF2

RIPPLE

AGC

STABILIZER

AFC

VDD

CTRL

AGC

A

B

C

D

E

F

G

H

I

234567891011121314

123456

31576120

MW=HIGH

FM 75 OHM

PROGRAMMABLE

OUTPUT PORTS

FM-IF2

LW

VERSION DETECTION

FM-IF1

7

I

7 8 9 1011121314

A

B

C

D

E

F

G

H

from

kHz

3170

BUFFER AMPLIFIER

VCC

1

1

2

LEGEND

* ... only assembled in FM/AM-version SMD jumper

MW=HIGH

BIRDY FILTER

/00 /02 FM/MW

/00 /02 FM/MW/LW

2169

/ SYSTEMS-CENELEC

STEREO

3

450kHz

AM-IF2

3156

RIGHT

MW

LW only

450kHz

DISCRIMINATOR

AM-AFC

AM-IF1

8

/01 FM/MW

6105

6

LW only

LW =HIGH

VERSION PROGRAMMING COMPONENTS

marked components not for LW version

MW/LW-RF

VCO

RDS only

MPX

to/from

GND

from 7101/39

LEFT

/17 FM/AM

to 1120

HN1V02H

VERSION

/14 FM-OIRT/MW

450kHz

LW=HIGH

TUNER BOARD ECO6

pin 5

54

LW ... for LW version only

MW

ENABLE/MPX

LW

component mounted

7111

AM-OSCILLATOR

CLOCK

DATA

AM FRAME AERIAL

p ...for provision only

USA ... for USA version only

2166

1n

T117

4

IF-OUT

7

910

8

OSC.

OUT

V

5

VCC

6

150K

3169

1110

FE450

ANT

1

23

T110

3168

T115

T109

3161

22K

120R

2130

22n

3142

100K

22u

2162

2137

220n

2123

390p

6

78

T106

T121

5103

1

2

3

4

T140

T118

T114

BC337-40

7105

T113

7124

100u

2129

68K

3151

BC847C

220p

2146

HN1V02H

6105-1

1

2

7

2K2

3128

2190

100n

0R

4102

*

3159

470R

YKD31-

0432

1

2

470R

3160

2149

33p

1102

1103

XH-S

1

2

22

VCC2

9 VCO

23

VDD

38

VSTABA

VSTABB

34

29

WRITE-EN

25

470n

2131

IF-GND

14

LEFT

12

LPF

24

11

MPX-IN

13

MUTE

43

NC

30P0

31P1

16

PILOT

4 RF-GND1

42

RF-GND2

15

RIGHT

1 RIPPLE

7 VCC1

40

AM-MIXOUT

6 AM-OSC

2 AM-RF

39

AM|FM

27

CLOCK

28

DATA

26DIG-GND

21

FIELDSTR-IND

18

FM-DEMOD

3 FM-GND

37

FM-IF1-IN

35

FM-IF2

33FM-IF2-IN

5 FM-OSC

8

I-TUNE

17

TEA5762

7101

10

AF-OUT

20

AFC+

19

AFC-

44

AGC

32AM-AFC

41

AM-IF1-IN

36

AM-IF2

2107

1u

56K

3141

BAS216

6106

22K

3134

7110

BC857B

6

7

8

2u2

2138

1120

FE-BT-VK-N

1

2

3

4

5

1

2

34

6

78

5111

22K

3143

470R

3158

2143

220n

T124

330R

3154

T123

T125

T111

3190

120R 120R

3191

BAS216

6120

1K

3144

100K

3156

2144

1u

47K

3171

3194

2K2

2132

470n

1132

C-PAD

2118

2p2

220R

3105

2161

100n

p

2141

100n

T105

3157

100K

2119

10p

2K2

3145

2120

18p

22p

LW

1

2

3

2124

10n

*

YKD21

1101

USA

T126

7122

BC847C

2109

10p

T116

2

34

6

78

1u

2133

5114

7P

1

3

6

22K

3137

22R

3146

HN1V02H

6105-2

5

2122

3n3

2159

33p

10u

2128

10K

3150

47R

3132

BC857C

7103

3172

5K6

2167

12p

DT-381

5121

75

T142

2147

220p

T104

BC857B

7109

2K2

3108

4K7

3123

T122

T120

T127

7112

BC547C

2134

22n

USA

22n

USA

C-PAD

1131

T141

2106

11p

20p_LW

0R

4104

*

0R

41xx

2165

100n

1130

C-PAD

10K

3180

2150

100n

BZX284-C11

6107

T102

2127

220n

2169

2n2

100K

3170

1I3

O

2125

560p

5109

2

G

470R

3152

2108

100p

3125

10K

3153

470R

330R

3193

T103

120R

3167

100R

3195

78

33K

3176

8

5122

1

2

34

6

5123

1

2

34

6

7

5110

G

2

I1O

3

5115

123

46

7

8

2

34

6

78

5119

1

2135

100n

2163

LW

7104

BC337-40

2145

220p

150R

3155

220n

2136

6

78

T112

T107

*

5102

7KL

1

2

34

5

3109

4K7

4101

0R

7111

BC847C

1

2

34

6

7

8

330R

3192

2n2

2148

5112

7P

470n

2164

ECO6 Sys-Cenelec, 010517

2140

82p

VCC1

VCC1

2139

15p

MPX

+FM

P0

P1

VDD

VDD

VCC2

VCC2

VCC1

MPX

P01

P1

P0

P01

P0

VDD VDD

AM/FM

+FM

AM/FM

P0

1101 A2

1102 B1

1103 E2

1110 B2

1120 E14

1130 A2

1131 C2

1132 F13

2102 B1

2105 A2

2106 E3

2107 E4

2108 G3

2109 G3

2118 H6

2119 H6

2120 H6

2122 I6

2123 H6

2124 H6

2125 H6

2127 E7

2128 B8

2129 C7

2130 F11

2131 F8

2132 F8

2133 F8

2134 I8

2135 I9

2136 H14

2137 H13

2138 F9

2139 G9

2140 G9

2141 F10

2143 G12

2144 G11

2145 E11

2146 E12

2147 E12

2148 E12

2149 H7

2150 A10

2159 D5

2161 C11

2162 H12

2163 D11

2164 G10

2165 C7

2166 E11

2167 E11

2169 G8

2180 C4

2190 C3

2191 C3

3105 D5

3108 D2

3109 G4

3123 H3

3125 H2

3128 H3

3130 I9

3131 I9

3132 G4

3134 H6

3135 E7

3137 H7

3141 E7

3142 E6

3143 G7

3144 G8

3145 F8

3146 G13

3150 H12

3151 H12

3152 G14

3153 G13

3154 F13

3155 G12

3156 C12

3157 D12

3158 E13

3159 D13

3160 D13

3161 D13

3167 F12

3168 F11

3169 E11

3170 D12

3171 G12

3172 G12

3176 H7

3180 I3

3190 B6

3191 B7

3192 B6

3193 B4

3194 C4

3195 C3

4101 E2

4102 F3

4104 H5

5102 E3

5103 F2

5109 B9

5110 B10

5111 A9

5112 A11

5114 B11

5115 E7

5118 G9

5119 G9

5121 E11

5122 H5

5123 G5

6105-1 E4

6105-2 G6

6106 D4

6107 G13

6120 C13

7101 C8

7103 H8

7104 D2

7105 F4

7109 H3

7110 H12

7111 C13

7112 G12

7122 H4

7124 H7

T102 B2

T103 B2

T104 B6

T105 E2

T106 E2

T107 C3

T109 D5

T110 D5

T111 E5

T112 F7

T113 A9

T114 B11

T116 F10

T117 F13

T118 G11

T120 F13

T121 F13

T122 E13

T123 E13

T124 G14

T125 F14

T126 F13

T127 F13

T140 F11

T141 F10

T142 F10

p

p

p

2191

100u

2102

100n

2105

USA

100n

5118

1nH

15n

15n

3131

820R

3130

820R

1K

3135

2180

10n

8.3V

7.5V

7.2V

9V

11V

8.2V

0.1V

1.2V

1.6-8V

5

1

A

3

2

D

C

4

...V MW mode

...V LW mode

voltages measured while

set is tuned to a strong transmitter

0.7V

0.7V

1.3V

0.7V

0V

7.4V

0V

7.5V

0.7V

0V

mono 4.8V

0V

0V

stereo 0.4V

7.5V

7.5V

1.4V

1.6-8V

0.1V

0V

0V

2V

0.2V

1.4V

1.4V

0.4V

0.7V

1.4V

1.4V

1.1V

0.7V

1.4V

0.6V

0.6V

0.8V

0.15V

...V FM mode stereo

EVM

V

B

8V

6.7V

8.3V

0.7V

0V

0V

0V

0.1V

0V

11V

2V

1.1V

1.1V

1V

1V

8.2V

7.8V

1.2V

0V

8.9V

12Vtyp

8.2V

mono 4.8V

stereo 0.2V

1.4V

0V

0V

0V

0V

0.1V

0V

0.7V

0.1V

0V

0.2V

(10-14V)

9.6V

12V

8.9V

8.2V

7.5V

8.3V

8.2V

0.8V

1.2V

0.7V

1.3V

1V

8.2V

7.8V

1-8V

0V

5V

0V

152kHz, 50mV

pp

stereo stereomono

Signal path

FM

AF - left/right

AM

MPX (Audio Frequency)

Page 27

7B-37B-3

98MHz

Waverange Input frequency Input Tuned to Adjust Output Scope/Voltmeter

VARICAP ALIGNMENT

FM - VCO

FM RF (channel separation)

AM IF

AM RF

3)

108MHz

87.5MHz

check

check

8V ±1.2V

1.6V ±0.5V

8V ±0.2V

6.9V ±0.2V

1.1V ±0.4V

152kHz ±1kHz

1)

98MHz 3142

198kHz198kHz 5103

5111

FM

87.5 - 108MHz

(50kHz grid)

1602kHz

531kHz

5123

check

MW

531 - 1602kHz

(9kHz grid)

8V ±0.2V

1.1V ±0.4V

279kHz

153kHz

5122

check

LW

153 - 279kHz

(3kHz grid)

FM

FM

LW

558kHz558kHz

1494kHz

5102

1494kHz 2106

MW

MW

98MHz, 1mV

continuous wave

98MHz, 1mV

90% Left + 9% pilot

mod=1kHz

IF coil

inside

FM

frontend

1110

1

3

5

5

A

FM - IF

0mV ±3mV5119

FM

10.7MHz, 45mV

continuous wave

2D

right channel min.

4A

0mV ±2mV5114

2

C

Repeat

C

5112

1)

If sensitivity of frequency counter is too low adjust to max. channel separation

(input signal: stereo left 90% + 9%, adjust output on right channel to minimum)

2)

RC network serves for damping the IF-filter while adjusting the other one.

3)

For AM RF adjustments the original frame antenna has to be used!

TUNER ADJUSTMENT TABLE

( ECO6 Cenelec FM/MW - and FM/MW/LW - versions with AM-frame aerial )

max.

symmetric

f

o

max.

symmetric

f

o

ECO6 Sys Cenelec, 190599

B

∆f = ±30kHz

V

RF

as low as

possible

MW has to be aligned before LW.

3-band

2-band

Note: The FM-frontend unit has already been adjusted by the factory

and needs therefore no further adjustments for service purposes.

2141

shortcircuit

to block AFC

21

IC 7101

see

remark

2)

220R

100nF

36

IC 7101

220R

100nF

40

IC 7101

450kHz

connect pin 6 of

IC 7101 (AM Osc.)

with 3.3kΩ to Vcc

AM AFC

MW

continuous wave

VRF = 2mV

∆f = ±10kHz

V

RF

= 0.5mV

(as low as

possible)

Use Service Testprogram. By selecting the TUNER TEST test frequencies will be stored as preset frequencies automatically.

AM FRAME AERIAL

FM 75Ω

FM FRONTEND

Birdy Filter

ECO6 Sys-Cenelec, layout stage .6, 160501

1101 B5

1102 B5

1103 C5

1110 B4

1120 A4

1130 A5

1131 C5

1132 A4

2106 B4

2107 B3

2128 A3

2129 B3

2133 C1

2138 B1

2144 B1

2162 A4

2191 B4

3142 C2

5102 C4

5103 C4

5109 B3

5110 A2

5111 A3

5112 A2

5114 A2

5115 C2

5119 B2

5121 B2

5122 C3

5123 C3

7104 C4

7105 C5

7112 B1

9101 A2

9102 B2

9103 A1

9104 B1

9105 B1

9106 B1

9107 B4

9108 B3

9109 C2

9110 A4

9111 A3

TUNER BOARD ECO6

Systems - Cenelec

/ componentside view

B

A

These assembly drawings show a summary of all possible versions.

For components used in a specific version see schematic diagram respectively partslist.

ECO6 Sys-Cenelec, layout stage .6, 160501

41..

in schematic diagram)

(not all items shown

SMD jumper

EB

C

A

K

TUNER BOARD ECO6

Systems - Cenelec

/ copperside view

2102 B1

2105 B1

2108 C1

2109 C1

2118 C3

2119 C3

2120 C3

2122 C3

2123 C3

2124 C3

2125 C3

2127 C4

2130 B3

2131 C4

2132 C4

2134 C5

2135 C5

2136 A3

2137 A3

2139 B4

2140 B4

2141 B5

2143 B5

2145 B5

2146 B5

2147 A5

2148 B4

2149 C4

2150 B3

2159 B3

2161 A4

2163 A4

2164 B4

2165 B3

2166 B5

2167 B4

2169 A3

2180 B2

2190 B2

3105 B3

3108 C2

3109 C1

3123 A5

3125 A5

3128 C2

3130 C4

3131 C4

3132 B3

3134 C3

3135 C4

3137 C4

3141 B3

3143 C5

3144 A5

3145 C4

3146 B5

3150 B3

3151 A2

3152 A3

3153 A3

3154 B5

3155 B5

3156 A4

3157 A4

3158 A3

3159 A3

3160 A3

3161 A4

3167 A5

3168 C5

3169 B4

3170 A4

3171 B5

3172 B5

3176 C4

3180 A5

3190 B2

3191 A3

3192 A2

3193 B2

3194 B2

3195 B2

4101 C2

4102 C2

4104 C3

4105 B2

4106 B3

4107 C4

5118 C4

6105 B2

6106 B2

6107 B5

6120 A4

7101 B4

7103 C5

7109 A5

7110 B2

7111 A4

7122 C3

7124 C3

1

1

8

2

7

8

5118

2180

3135

4

D

A

C

1 25

3

V

dd

Vcc2

Vcc1

+FM

Page 28

Electrical Partslist

ECO6

SYSTEMS-CENELEC

MISCELLANEOUS

–––––––––––––––––––––––––––––––––––––––––––––––––––––

1101 2422 015 19376 SOCKET CLICKFIT 2P USA only

1102 4822 267 10283 SOCKET COAX, IEC 75Ω not USA

1103 4822 265 31184 JST CONNECTOR, 2 POLE

1110 2422 542 90071 FM FRONTEND

1120 4822 265 11515 FFC SOCKET, 8P

CAPACITORS

–––––––––––––––––––––––––––––––––––––––––––––––––––––

2102© 4822 126 13838 100nF 10% 50V not USA

2105© 4822 126 13838 100nF 10% 50V USA only

2106 2020 800 00204 TRIMCAP. 4,2 - 20pF, N750 LW only

2106 2020 800 00191 TRIMCAP. 3 - 11pF, N450 FM/AM only

2107 4822 121 51319 1µF 20% 50V

2108© 5322 122 32531 100pF 5% 50V LW only

2109© 5322 122 32448 10pF 5% 50V LW only

2120© 4822 126 13689 18pF 1% 63V FM/AM only

2120© 5322 122 32658 22pF 5% 50V LW only

2122© 4822 122 33891 3,3nF 10% 63V LW only

2123© 2020 552 93494 390pF 1% 50V LW only

2124© 4822 122 33177 10nF 20% 50V FM/AM only

2125© 2020 552 96199 560pF 1% 50V

2127© 4822 126 14076 220nF 20% 25V

2128 4822 124 40248 10µF 20% 63V

2129 4822 124 41584 100µF 20% 10V

2130© 5322 122 32654 22nF 10% 63V

2131© 4822 126 13482 470nF 20% 16V

2132© 4822 126 13482 470nF 20% 16V

2133 4822 124 21913 1µF 20% 63V

2134© 3198 017 31530 15nF 10% 50V not USA

2134© 5322 122 32654 22nF 10% 63V USA only

2135© 3198 017 31530 15nF 10% 50V not USA

2135© 3198 017 32230 22nF 10% 25V USA only

2136© 4822 126 14076 220nF 20% 25V

2137© 4822 126 14076 220nF 20% 25V

2138 4822 124 22652 2,2µF 20% 50V

2139© 4822 126 14236 15pF 5% 50V

2140© 4822 126 13695 82pF 1% 63V

2141© 4822 126 13838 100nF 10% 50V

2143© 4822 126 14076 220nF 20% 25V

2144 4822 124 21913 1µF 20% 63V

2145© 4822 122 33575 220pF 5% 50V

2146© 4822 122 33575 220pF 5% 50V

2147© 4822 122 33575 220pF 5% 50V

2148© 4822 122 33127 2,2nF 10% 63V

2149© 5322 122 32659 33pF 5% 50V RDS only

2150© 4822 126 13838 100nF 10% 50V

2159© 5322 122 31151 22µF 20% 50V

2163© 4822 126 13838 100nF 10% 50V LW only

2164© 4822 126 13482 470nF 20% 16V

2165© 4822 126 13838 100nF 10% 50V

2166© 5322 122 31647 1nF 10% 63V

2167© 4822 122 33926 12pF 5% 50V

2169© 4822 122 33127 2,2nF 10% 63V RDS only

2180© 3198 017 31030 10nF 10% 50V

2190© 4822 126 13838 100nF 10% 50V

2191 4822 124 40178 100µF 20% 10V

RESISTORS

–––––––––––––––––––––––––––––––––––––––––––––––––––––

3105© 4822 117 11503 220Ω 5% 0,1W

3108© 4822 117 11449 2,2kΩ 1% 0,1W LW only

3109© 4822 051 20472 4,7kΩ 5% 0,1W LW only

3123© 4822 051 20472 4,7kΩ 5% 0,1W LW only

3125© 4822 117 10833 10kΩ 1% 0,1W LW only

RESISTORS

–––––––––––––––––––––––––––––––––––––––––––––––––––––

3128© 4822 117 11449 2,2kΩ 1% 0,1W LW only

3130© 3198 021 38210 820Ω 5% 0,06W

3131© 3198 021 38210 820Ω 5% 0,06W

3132© 4822 051 20479 47Ω 5% 0,1W

3134© 4822 051 20223 22kΩ 5% 0,1W

3135© 3198 021 31020 1kΩ 5% 0,06W

3137© 4822 051 20223 22kΩ 5% 0,1W LW only

3141© 4822 117 11148 56kΩ 1% 0,1W

3142 4822 100 12159 TRIMPOT. 100kΩ

3143© 4822 051 20223 22kΩ 5% 0,1W RDS only

3144© 4822 051 10102 1kΩ 2% 0,25W RDS only

3145© 4822 117 11449 2,2kΩ 1% 0,1W

3146© 4822 051 20229 22Ω 5% 0,1W

3150© 4822 117 10833 10kΩ 1% 0,1W

3151© 4822 051 20683 68kΩ 5% 0,1W

3152© 4822 051 20471 470Ω 5% 0,1W

3153© 4822 051 20471 470Ω 5% 0,1W

3154© 4822 117 13577 330Ω 1% 0,1W

3155© 4822 117 10353 150Ω 5% 0,1W

3156© 4822 117 10837 100kΩ 1% 0,1W

3157© 4822 117 10837 100kΩ 1% 0,1W

3158© 4822 051 20471 470Ω 5% 0,1W

3159© 4822 051 20471 470Ω 5% 0,1W

3160© 4822 051 20471 470Ω 5% 0,1W

3161© 4822 051 20223 22kΩ 5% 0,1W

3167© 4822 051 20121 120Ω 5% 0,1W

3168© 4822 051 20121 120Ω 5% 0,1W

3169© 4822 051 20154 150kΩ 5% 0,1W

3170© 4822 117 10837 100kΩ 1% 0,1W

3171© 4822 117 10834 47kΩ 1% 0,1W

3172© 4822 051 20562 5,6kΩ 5% 0,1W

3176© 4822 051 20333 33kΩ 5% 0,1W RDS only

3180© 4822 117 10833 10kΩ 1% 0,1W LW only

3190© 4822 051 20121 120Ω 5% 0,1W

3191© 4822 051 20121 120Ω 5% 0,1W

3192© 4822 117 13577 330Ω 1% 0,1W

3193© 4822 117 13577 330Ω 1% 0,1W

3194© 4822 117 11449 2,2kΩ 1% 0,1W

3195© 4822 051 20101 100Ω 5% 0,1W

4101© 4822 051 20008 CHIP JUMPER 0805 FM/AM only

4102© 4822 051 20008 CHIP JUMPER 0805 FM/AM only

4104© 4822 051 20008 CHIP JUMPER 0805 FM/AM only

4105© 4822 051 20008 CHIP JUMPER 0805

4106© 4822 051 20008 CHIP JUMPER 0805

4107© 4822 051 20008 CHIP JUMPER 0805

COILS

–––––––––––––––––––––––––––––––––––––––––––––––––––––

5102 4822 157 71634 RF-COIL MW

5103 2422 549 44107 RF-COIL LW LW only

5109 4822 157 71639 FM-IF FILTER 10,7MHz

5110 4822 242 70665 FM-IF FILTER 10,7MHz

5111 2422 549 44023 AM-IF FILTER 450kHz

5112 4822 157 70302 AM-IF FILTER 450kHz

5114 4822 157 70302 AM-IF FILTER 450kHz

5115 4822 157 71636 ANTI BIRDY FILTER

5118© 2422 535 95881 100nH