Philips lm3915 DATASHEETS

LM3915

Dot/Bar Display Driver

LM3915 Dot/Bar Display Driver

February 2001

General Description

The LM3915 is a monolithic integrated circuit that senses

analog voltage levels and drives ten LEDs, LCDs or vacuum

fluorescent displays, providing a logarithmic 3 dB/step analog display.Onepinchanges the display from a bar graph to

a moving dot display. LED current drive is regulated and

programmable, eliminating the need for current limiting resistors. The whole display system can operate from a single

supply as low as 3V or as high as 25V.

The IC contains an adjustable voltage reference and an

accurate ten-step voltage divider. The high-impedance input

buffer accepts signals down to ground and up to within 1.5V

of the positive supply.Further, it needs no protection against

inputs of

parators referenced to the precision divider. Accuracy is

typically better than 1 dB.

The LM3915’s 3 dB/step display is suited for signals with

wide dynamic range, such as audio level, power, light intensity or vibration. Audio applications include average or peak

level indicators, power meters and RF signal strength

meters. Replacing conventional meters with an LED bar

graph results in a faster responding, more rugged display

with high visibility that retains the easeofinterpretation of an

analog display.

The LM3915 is extremely easy to apply. A 1.2V full-scale

meter requires only one resistor in addition to the ten LEDs.

One more resistor programs the full-scale anywhere from

1.2V to 12V independent of supply voltage. LED brightness

is easily controlled with a single pot.

±

35V. The input buffer drives 10 individual com-

The LM3915 is very versatile. The outputs can drive LCDs,

vacuum fluorescents and incandescent bulbs as well as

LEDs of any color. Multiple devices can be cascaded for a

dot or bar mode display with a range of 60 or 90 dB.

LM3915s can also be cascaded with LM3914s for a linear/

log display or with LM3916s for an extended-range VU

meter.

Features

n 3 dB/step, 30 dB range

n Drives LEDs, LCDs, or vacuum fluorescents

n Bar or dot display mode externally selectable by user

n Expandable to displays of 90 dB

n Internal voltage reference from 1.2V to 12V

n Operates with single supply of 3V to 25V

n Inputs operate down to ground

n Output current programmable from 1 mA to 30 mA

n Input withstands

n Outputs are current regulated, open collectors

n Directly drives TTL or CMOS

n The internal 10-step divider is floating and can be

referenced to a wide range of voltages

The LM3915 is rated for operation from 0˚C to +70˚C. The

LM3915N-1 is available in an 18-lead molded DIP package.

±

35V without damage or false outputs

© 2001 National Semiconductor Corporation DS005104 www.national.com

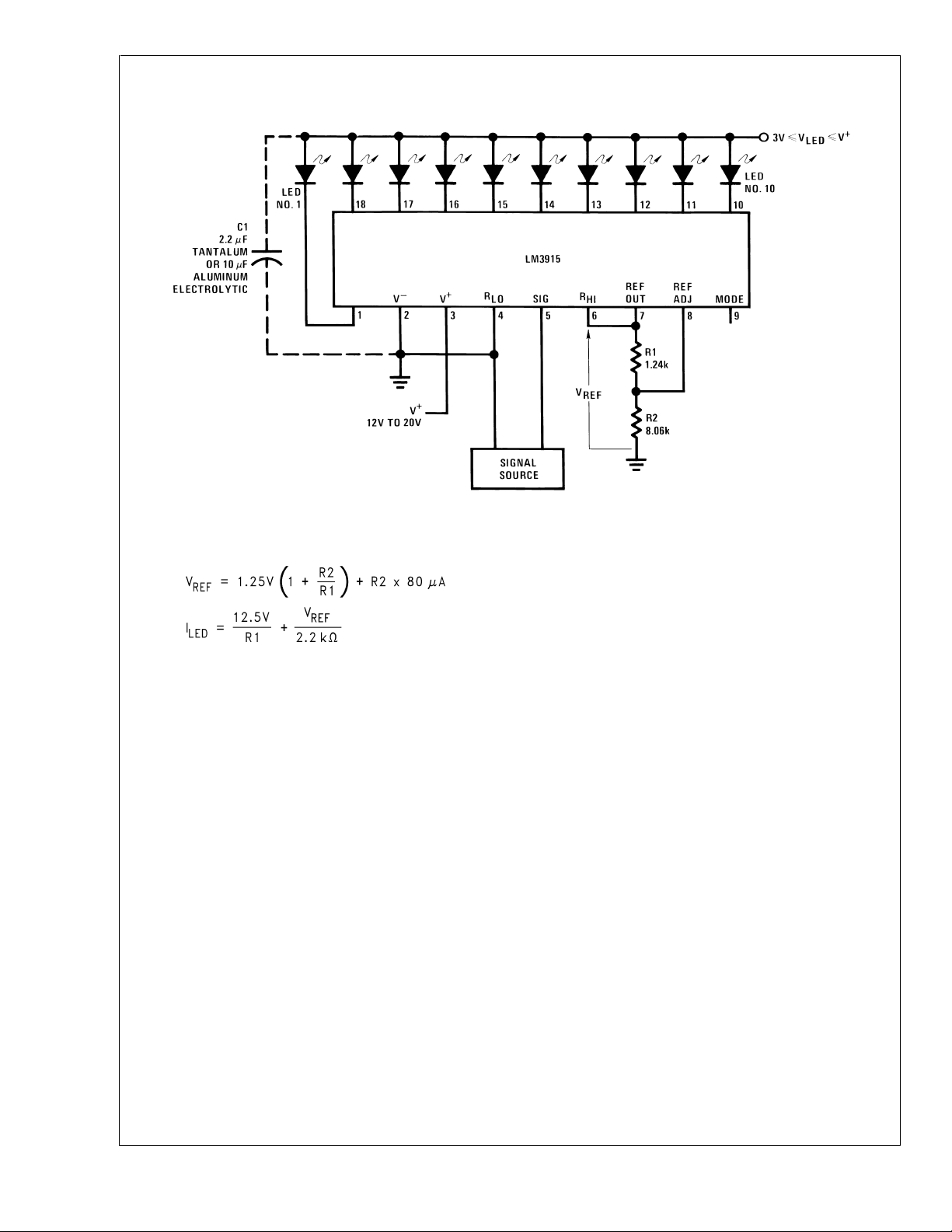

Typical Applications

LM3915

Notes: Capacitor C1 is required if leads to the LED supply are 6" or longer.

Circuit as shown is wired for dot mode. For bar mode, connect pin 9 to pin 3. V

dissipation.

0V to 10V Log Display

must be kept below 7V or dropping resistor should be used to limit IC power

LED

DS005104-1

www.national.com 2

LM3915

Absolute Maximum Ratings (Note 1)

If Military/Aerospace specified devices are required,

please contact the National Semiconductor Sales Office/

Distributors for availability and specifications.

Power Dissipation (Note 6)

Molded DIP(N) 1365 mW

Supply Voltage 25V

Voltage on Output Drivers 25V

Input Signal Overvoltage (Note 4)

±

Divider Voltage −100 mV to V

Reference Load Current 10 mA

Storage Temperature Range −55˚C to +150˚C

Lead Temperature

(Soldering, 10 sec.) 260˚C

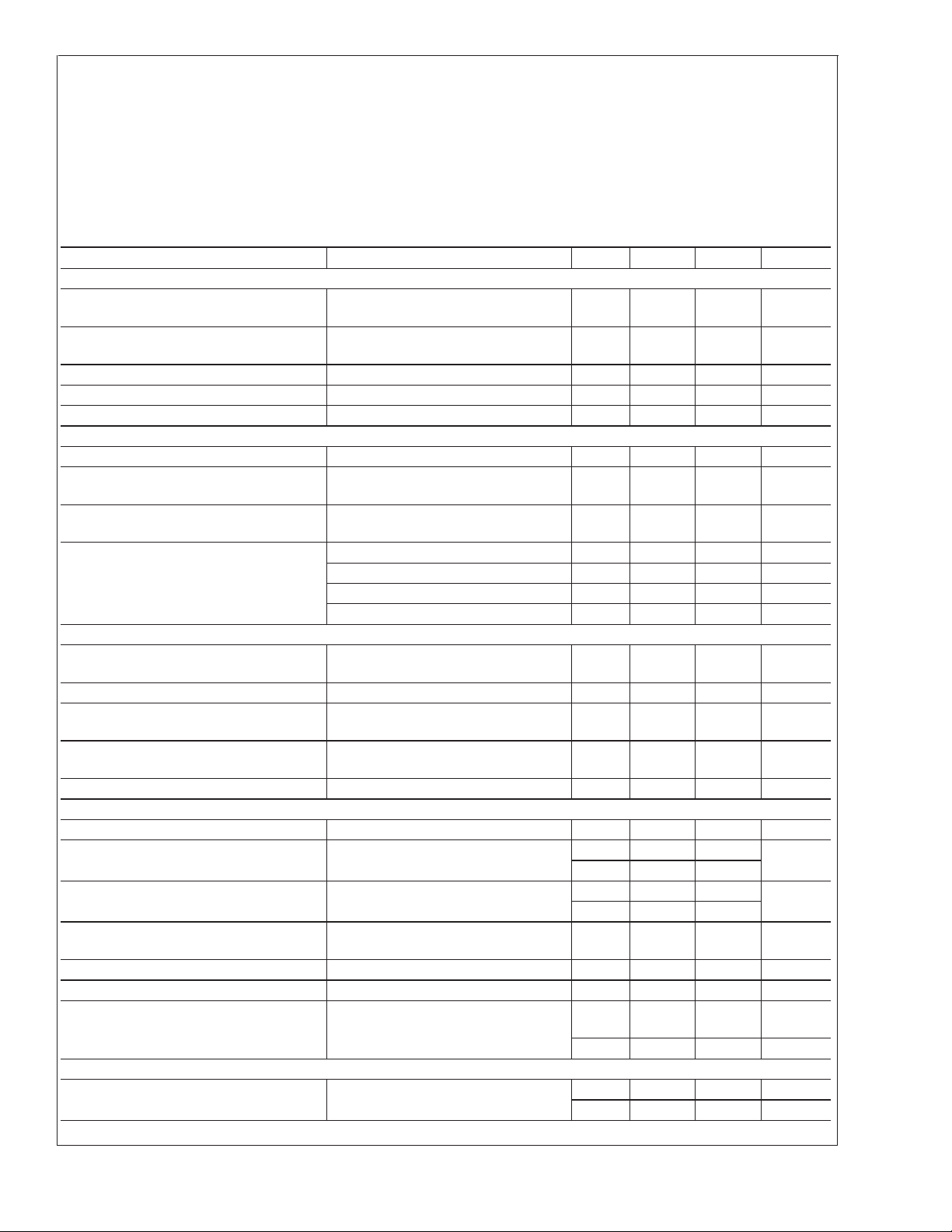

Electrical Characteristics (Notes 2, 4)

Parameter Conditions (Note 2) Min Typ Max Units

COMPARATOR

Offset Voltage, Buffer and First

Comparator

Offset Voltage, Buffer and Any Other

Comparator

Gain (∆I

/∆VIN)I

LED

Input Bias Current (at Pin 5) 0V ≤ V

Input Signal Overvoltage No Change in Display −35 35 V

VOLTAGE-DIVIDER

Divider Resistance Total, Pin 6 to 4 16 28 36 kΩ

Relative Accuracy (Input Change

Between Any Two Threshold Points)

Absolute Accuracy at Each Threshold

Point

VOLTAGE REFERENCE

Output Voltage 0.1 mA ≤ I

Line Regulation 3V ≤ V

Load Regulation 0.1 mA ≤ I

Output Voltage Change with

Temperature

Adjust Pin Current 75 120 µA

OUTPUT DRIVERS

LED Current V

LED Current Difference (Between

Largest and Smallest LED Currents)

LED Current Regulation 2V ≤ V

Dropout Voltage I

Saturation Voltage I

Output Leakage, Each Collector (Bar Mode) (Note 5) 0.1 10 µA

Output Leakage

Pins 10–18

Pin 1 60 150 450 µA

SUPPLY CURRENT

Standby Supply Current

(All Outputs Off)

0V ≤ V

=1mA

I

LED

0V ≤ V

=1mA

I

LED

L(REF)

(Note 3)

RLO=VRHI

RLO=VRHI

= 2 mA, I

≤ (V+− 1.5V) 25 100 nA

IN

≤ 12V,

≤ 12V,

= 10 mA 3 8 mA/mV

LED

310mV

315mV

2.0 3.0 4.0 dB

(Note 3)

V

= −3, −6 dB −0.5 +0.5 dB

IN

V

= −9 dB −0.5 +0.65 dB

IN

V

= −12, −15, −18 dB −0.5 +1.0 dB

IN

V

= −21, −24, −27 dB −0.5 +1.5 dB

IH

≤ 4 mA,

+

=V

V

+

=V

V

0˚C ≤ T

+

=V

V

+

=V

V

LED

V

LED

=20mA

I

LED

LED(ON)

∆I

LED

= 2.0 mA, I

LED

L(REF)

=5V

LED

+

≤ 18V 0.01 0.03 %/V

≤ 4 mA,

L(REF)

=5V

LED

≤ +70˚C, I

A

=5V

LED

= 5V, I

LED

= 5V, I

LED

= 5V, I

LED

≤ 17V, I

LED

= 20 mA,@V

=2mA

20 mA

= 1 mA,

L(REF)

= 1 mA 7 10 13 mA

L(REF)

=2mA

LED

= 5V,

LED

=2mA

= 0.4 mA 0.15 0.4 V

L(REF)

1.2 1.28 1.34 V

0.4 2 %

1%

0.12 0.4

1.2 3

0.1 0.25

13

1.5 V

(Dot Mode) (Note 5)

0.1 10 µA

+

V

= +5V, I

+

= +20V, I

V

L(REF)

L(REF)

= 0.2 mA

= 1.0 mA

2.4 4.2 mA

6.1 9.2 mA

mA

mA

35V

+

www.national.com3

Electrical Characteristics (Notes 2, 4) (Continued)

Note 1: Absolute Maximum Ratings indicate limits beyond which damage to the device may occur. Operating Ratings indicate conditions for which the device is

LM3915

functional, but do not guarantee specific performance limits. Electrical Characteristics state DC and AC electrical specifications under particular test conditions which

guarantee specific performance limits. This assumes that the device is within the Operating Ratings. Specifications are not guaranteed for parameters where no limit

is given, however, the typical value is a good indication of device performance.

Note 2: Unless otherwise stated, all specifications apply with the following conditions:

3V

≤ V+≤ 20 V

DC

3V

≤ V

LED

RHI

≤ V

≤ 12 V

DC

−0.015V ≤ V

Note 3: Accuracyis measured referred to 0 dB = + 10.000 V

comparator offset voltage may add significant error. See table for threshold voltages.

Note 4: Pin 5 input current must be limited to

Note 5: Bar mode results when pin 9 is within 20 mV of V

disabled if pin 9 is pulled 0.9V or more below V

Note 6: Themaximum junction temperature of the LM3915 is 100˚C. Devices must be derated for operation at elevated temperatures. Junction to ambient thermal

resistance is 55˚C/W for the molded DIP (N package).

DC

+

−0.015V ≤ V

V

REF,VRHI,VRLO

0V ≤ VIN≤ V+− 1.5V

DC

≤ 12 V

RLO

≤ (V+− 1.5V) For higher power dissipations, pulse testing is used.

±

3 mA. The addition of a 39k resistor in series with pin 5 allows±100V signals without damage.

.

LED

TA= 25˚C, I

DC

at pin 5, with + 10.000 VDCat pin 6, and 0.000 VDCat pin 4. At lower full scale voltages, buffer and

DC

+

. Dot mode results when pin 9 is pulled at least 200 mV below V+. LED#10 (pin 10 output current) is

= 0.2 mA, pin 9 connected to pin 3 (bar mode).

L(REF)

Threshold Voltage (Note 3)

Output dB Min Typ Max Output dB Min Typ Max

1 −27 0.422 0.447 0.531 6 −12 2.372 2.512 2.819

2 −24 0.596 0.631 0.750 7 −9 3.350 3.548 3.825

3 −21 0.841 0.891 1.059 8 −6 4.732 5.012 5.309

4 −18 1.189 1.259 1.413 9 −3 6.683 7.079 7.498

5 −15 1.679 1.778 1.995 10 0 9.985 10 10.015

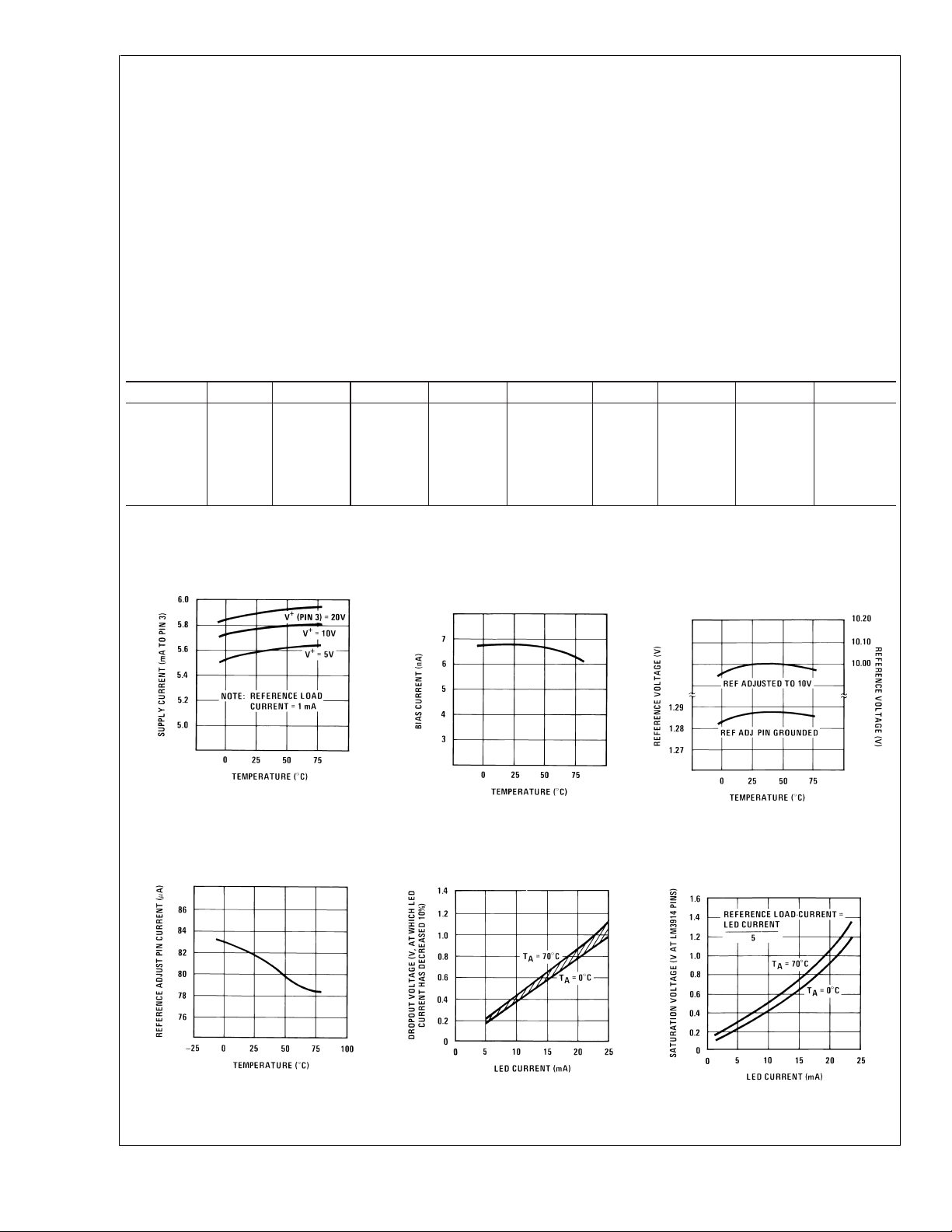

Typical Performance Characteristics

Supply Current vs Temperature

DS005104-34

Reference Adjust Pin

Current vs Temperature

Operating Input Bias Current vs

Temperature

LED Current-Regulation

Dropout

DS005104-35

Reference Voltage vs

Temperature

DS005104-36

LED Driver Saturation

Voltage

DS005104-37

www.national.com 4

DS005104-38

DS005104-39

Typical Performance Characteristics (Continued)

LM3915

Input Current Beyond

Signal Range (Pin 5)

Total Divider Resistance

vs Temperature

DS005104-40

LED Current vs

Reference Loading

Common-Mode Limits

DS005104-41

LED Driver Current

Regulation

DS005104-42

Output Characteristics

DS005104-43

DS005104-44

DS005104-45

www.national.com5

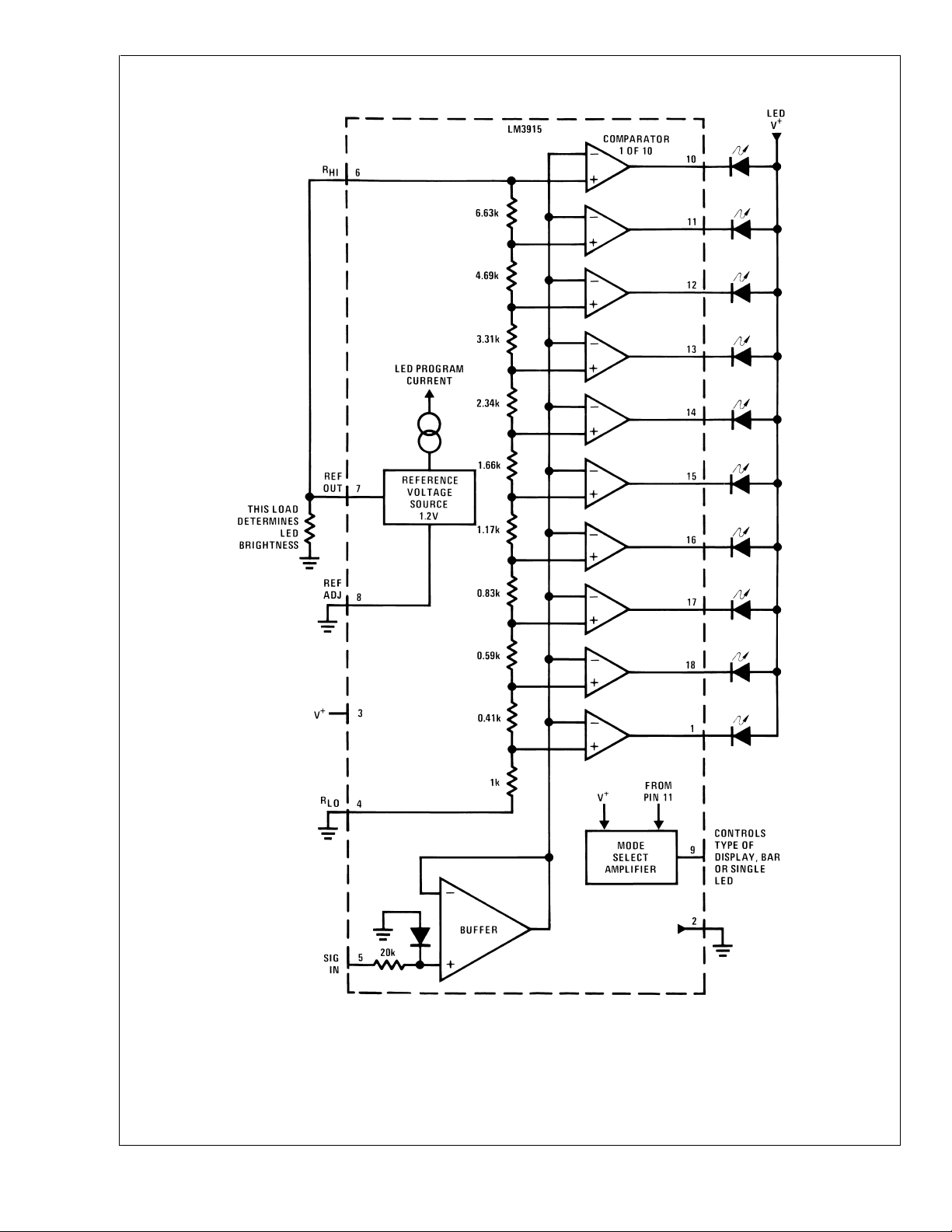

Block Diagram (Showing Simplest Application)

LM3915

www.national.com 6

DS005104-4

LM3915

Functional Description

The simplified LM3915 block diagram is included to give the

general idea of the circuit’s operation. A high input impedance buffer operates with signals from ground to 12V, and is

protected against reverse and overvoltage signals. The signal is then applied to a series of 10 comparators; each of

which is biased to a different comparison level by the resistor

string.

In the example illustrated, the resistor string is connected to

the internal 1.25V reference voltage. In this case, for each

3 dB that the input signal increases, a comparator will switch

on another indicating LED. This resistor divider can be connected between any 2 voltages, providing that they are at

least 1.5V below V

INTERNAL VOLTAGE REFERENCE

The reference is designed to be adjustable and develops a

nominal 1.25V between the REF OUT (pin 7) and REF ADJ

(pin 8) terminals. The reference voltage is impressed across

program resistor R1 and, since the voltage is constant, a

constant current I

R2 giving an output voltage of:

Since the 120 µA current (max) from the adjust terminal

represents an error term, the reference was designed to

minimize changes of this current with V

For correct operation, reference load current should be between 80 µA and 5 mA. Load capacitance should be less

than 0.05 µF.

CURRENT PROGRAMMING

A feature not completely illustrated by the block diagram is

the LED brightness control. The current drawn out of the

reference voltage pin (pin 7) determines LED current. Approximately 10 times this current will be drawn through each

lighted LED, and this current will be relatively constant despite supply voltage and temperature changes. Current

drawn by the internal 10-resistor divider, as well as by the

external current and voltage-setting divider should be included in calculating LED drive current. The ability to modulate LED brightness with time, or in proportion to input voltage and other signals can lead to a number of novel displays

or ways of indicating input overvoltages, alarms, etc.

The LM3915 outputs are current-limited NPN transistors as

shown below. An internal feedback loop regulates the transistor drive. Output current is held at about 10 times the

reference load current, independent of output voltage and

processing variables, as long as the transistor is not saturated.

+

and no lower than V−.

then flows through the output set resistor

1

DS005104-5

+

and load changes.

LM3915 Output Circuit

DS005104-6

Outputs may be run in saturation with no adverse effects,

making it possible to directly drive logic. The effective saturation resistance of the output transistors, equal to R

plus

E

the transistors’ collector resistance, is about 50Ω. It’s also

possible to drive LEDs from rectified AC with no filtering. To

avoid oscillations, the LED supply should be bypassed with a

2.2 µF tantalum or 10 µF aluminum electrolytic capacitor.

MODE PIN USE

Pin 9, the Mode Select input, permits chaining of multiple

LM3915s, and controls bar or dot mode operation. The

following tabulation shows the basic ways of using this input.

Other more complex uses will be illustrated in the applications.

Bar Graph Display: Wire Mode Select (pin 9)

+

3(V

pin).

directly

to pin

Dot Display, Single LM3915 Driver: Leave the Mode Select

pin open circuit.

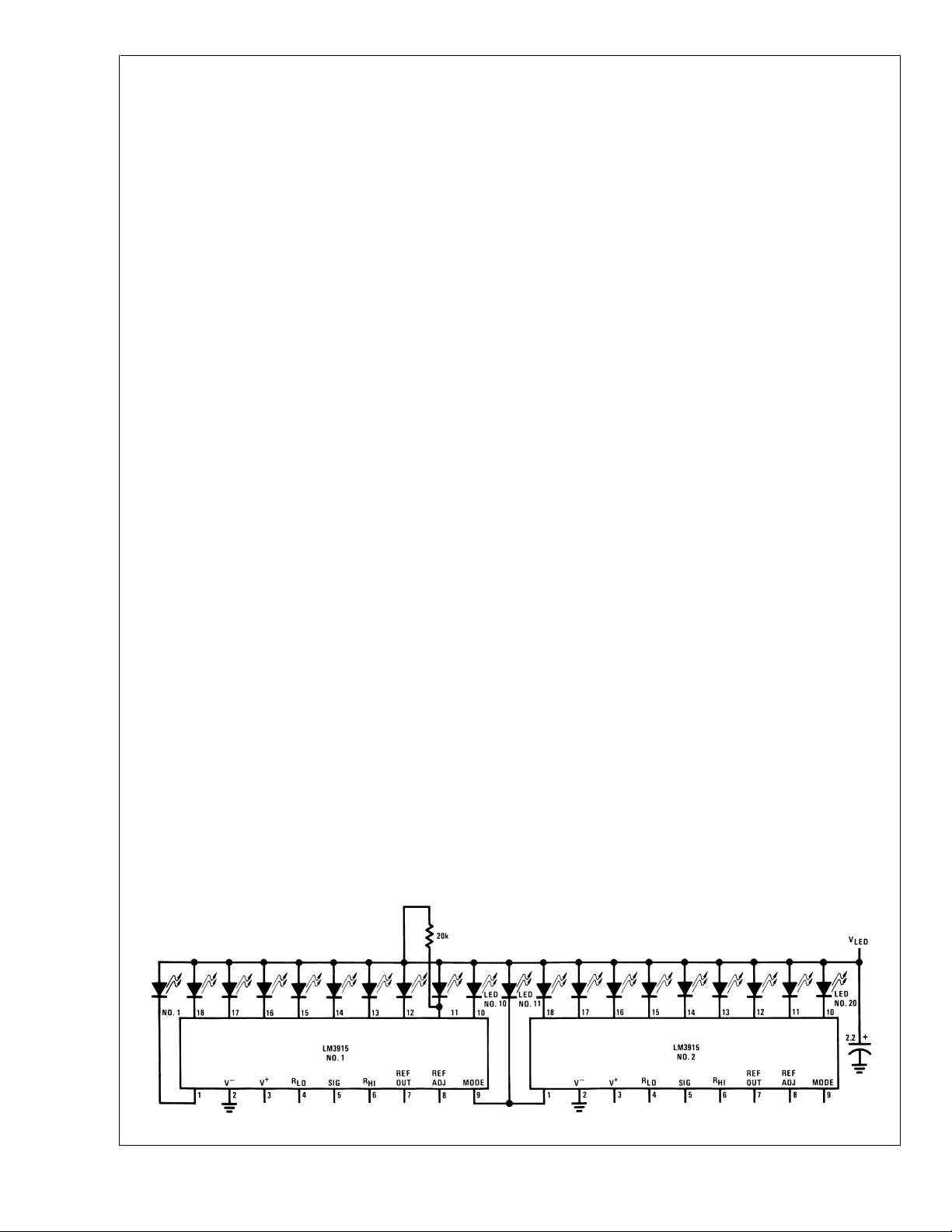

Dot Display, 20 or More LEDs: Connect pin 9 of the

first

driver in the series (i.e., the one with the lowest input voltage

comparison points) to pin 1 of the next higher LM3915 driver.

Continue connecting pin 9 of lower input drivers to pin 1 of

higher input drivers for 30 or more LED displays. The last

LM3915 driver in the chain will have pin 9 left open. All

previous drivers should have a 20k resistor in parallel with

#

LED

9 (pin 11 to V

LED

).

Mode Pin Functional Description

This pin actually performs two functions. Refer to the simplified block diagram below.

Block Diagram of Mode Pin Function

DS005104-7

*

High for bar

www.national.com7

Mode Pin Functional Description

(Continued)

LM3915

DOT OR BAR MODE SELECTION

The voltage at pin 9 is sensed by comparator C1, nominally

referenced to (V

pin 9 is above this level; otherwise it’s in dot mode. The

comparator is designed so that pin 9 can be left open circuit

for dot mode.

Taking into account comparator gain and variation in the

100 mV reference level, pin 9 should be no more than 20 mV

below V

+

open circuit) for dot mode. In most applications, pin 9 is

either open (dot mode) or tied to V

pin 9 should be connected directly to pin 3. Large currents

drawn from the power supply (LED current, for example)

should not share this path so that large IR drops are avoided.

DOT MODE CARRY

In order for the display to make sense when multiple

LM3915s are cascaded in dot mode, special circuitry has

been included to shut off LED

#

LED

1 of the second device comes on. The connection for

cascading in dot mode has already been described and is

depicted below.

As long as the input signal voltage is below the threshold of

the second LM3915, LED

sees effectively an open circuit so the chip is in dot mode.As

soon as the input voltage reaches the threshold of LED

pin 9 of LM3915

below V

referenced 600 mV below V

low, which shuts off output transistor Q2, extinguishing LED

#

10.

V

is sensed via the 20k resistor connected to pin 11. The

LED

very small current (less than 100 µA) that is diverted from

#

LED

9 does not noticeably affect its intensity.

An auxiliary current source at pin 1 keeps at least 100 µA

flowing through LED

enough to extinguish the LED. This ensures that pin 9 of

LM3915

any

higher LED is illuminated. While 100 µA does not normally produce significant LED illumination, it may be noticeable when using high-efficiency LEDs in a dark environment.

If this is bothersome, the simple cure is to shunt LED

with a 10k resistor. The 1V IR drop is more than the 900 mV

worst case required to hold off LED

that LED

+

− 100 mV). The chip is in bar mode when

for bar mode and more than 200 mV below V+(or

+

(bar mode). In bar mode,

#

10 of the first device when

#

11is off. Pin 9 of LM3915#1 thus

#

1 is pulled an LED drop (1.5V or more)

. This condition is sensed by comparator C2,

LED

#

11 even if the input voltage rises high

#

1 is held low enough to force LED#10 off when

#

11 does not conduct significantly.

. This forces the output of C2

LED

#

10 yet small enough

OTHER DEVICE CHARACTERISTICS

The LM3915 is relatively low-powered itself, and since any

number of LEDs can be powered from about 3V, it is a very

efficient display driver. Typical standby supply current (all

LEDs OFF) is 1.6 mA. However, any reference loading adds

4 times that current drain to the V

+

(pin 3) supply input. For

example, an LM3916 witha1mAreference pin load (1.3k)

would supply almost 10 mA to every LED while drawing only

10 mA from its V

+

pin supply. At full-scale, the IC is typically

drawing less than 10% of the current supplied to the display.

The display driver does not have built-in hysteresis so that

the display does not jump instantly from one LED to the next.

Under rapidly changing signal conditions, this cuts down

high frequency noise and often an annoying flicker.An “overlap” is built in so that at no time are all segments completely

off in the dot mode. Generally 1 LED fades in while the other

fades out over a mV or more of range. The change may be

much more rapid between LED

#

1ofa

second

device “chained” to the first.

#

10 of one device and LED

Application Hints

The most difficult problem occurs when large LED currents

are being drawn, especially in bar graph mode. These currents flowing out of the ground pin cause voltage drops in

external wiring, and thus errors and oscillations. Bringing the

return wires from signal sources, reference ground and bottom of the resistor string to a single point very near pin 2 is

#

11,

#

11

the best solution.

Long wires from V

to LED anode common can cause

LED

oscillations. Depending on the severity of the problem

0.05 µF to 2.2 µF decoupling capacitors from LED anode

common to pin 2 will damp the circuit. If LED anode line

wiring is inaccessible, often similar decoupling from pin 1 to

pin 2 will be sufficient.

If LED turn ON seems slow (bar mode) or several LEDs light

(dot mode), oscillation or excessive noise is usually the

problem. In cases where proper wiring and bypassing fail to

stop oscillations, V

+

voltage at pin 3 is usually below suggested limits. Expanded scale meter applications may have

one or both ends of the internal voltage divider terminated at

relatively high value resistors. These high-impedance ends

should be bypassed to pin 2 with at least a 0.001 µF capacitor, or up to 0.1 µF in noisy environments.

Cascading LM3915s in Dot Mode

www.national.com 8

DS005104-8

Loading...

Loading...