Page 1

ISP1301

Universal Serial Bus On-The-Go transceiver

Rev. 01 — 14 April 2004 Product data

1. General description

The ISP1301 is a Universal Serial Bus (USB) On-The-Go (OTG) transceiver device

that isfully compliant with

Supplement to the USB Specification Rev. 1.0a

receive serial data at both full-speed (12 Mbit/s) and low-speed (1.5 Mbit/s) data

rates.

It is ideal for use in portable electronics devices, such as mobile phones, digital still

cameras, digital video cameras, Personal Digital Assistants (PDAs) and digital audio

players. It allows USB Application Specific Integrated Circuits (ASICs),

Programmable Logic Devices (PLDs) and any system chip set (with the USB host or

device function built-in but without the USB physical layer)to interface to the physical

layer of the USB.

The ISP1301 can interface to devices with digital I/O voltages in the range of

1.65 V to 3.6 V.

UniversalSerial Bus Specification Rev. 2.0

. The ISP1301 can transmit and

and

On-The-Go

2. Features

The ISP1301 is available in HVQFN24 package.

■ Fully complies with:

◆

Universal Serial Bus Specification Rev. 2.0

◆

On-The-Go Supplement to the USB 2.0 Specification Rev. 1.0a

◆

On-The-Go Transceiver Specification (CEA–2011) Rev. 1.0

■ Can transmit and receive serial data at both full-speed (12 Mbit/s) and low-speed

(1.5 Mbit/s) data rates

■ Ideal for system ASICs or chip sets with built-in USB OTG dual-role core

■ Supports mini USB analog car kit interface

■ Supports various serial data interface protocols; transparent general-purpose

buffer mode allows you to control the direction of data transfer

■ Supports data line and V

■ Contains Host Negotiation Protocol (HNP) command and status registers

■ Supports serial I2C-bus™ interface for OTG status and command controls

■ 2.7 V to 4.5 V power supply input range for the ISP1301

■ Built-in charge pump regulator outputs 5 V at current greater than 8 mA

■ Supports external charge pump

■ Supports wide range interfacing I/O voltage (V

control logics

pulsing session request

BUS

DD_LGC

= 1.65 V to 3.6 V) for digital

Page 2

Philips Semiconductors

ISP1301

USB OTG transceiver

3. Applications

4. Abbreviations

■ 8 kV built-in electrostatic discharge (ESD) protection on the DP, DM, V

lines

■ Full industrial grade operation from −40 °Cto+85°C

■ Available in a small HVQFN24 (4 × 4mm2) halogen-free and lead-free package.

■ Mobile phone

■ Digital camera

■ Personal digital assistant

■ Digital video recorder.

ASIC — Application-Specific Integrated Circuit

ATX — Analog USB transceiver

HNP — Host Negotiation Protocol

ESD — ElectroStatic Discharge

I2C-bus — Inter IC-bus

IC — Integrated Circuit

OTG — On-The-Go

PDA — Personal Digital Assistant

SE0 — Single-Ended zero

SOF — Start-of-Frame

SRP — Session Request Protocol

USB — Universal Serial Bus

USB-IF — USB Implementers Forum.

BUS

and ID

5. Ordering information

Table 1: Ordering information

Type

number

ISP1301BS HVQFN24 plastic thermal enhanced very thin quad flat package;

9397 750 11355

Product data Rev. 01 — 14 April 2004 2 of 46

Package

Name Description Version

SOT616-1

no leads; 24 terminals; body 4 × 4 × 0.85 mm

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 3

Philips Semiconductors

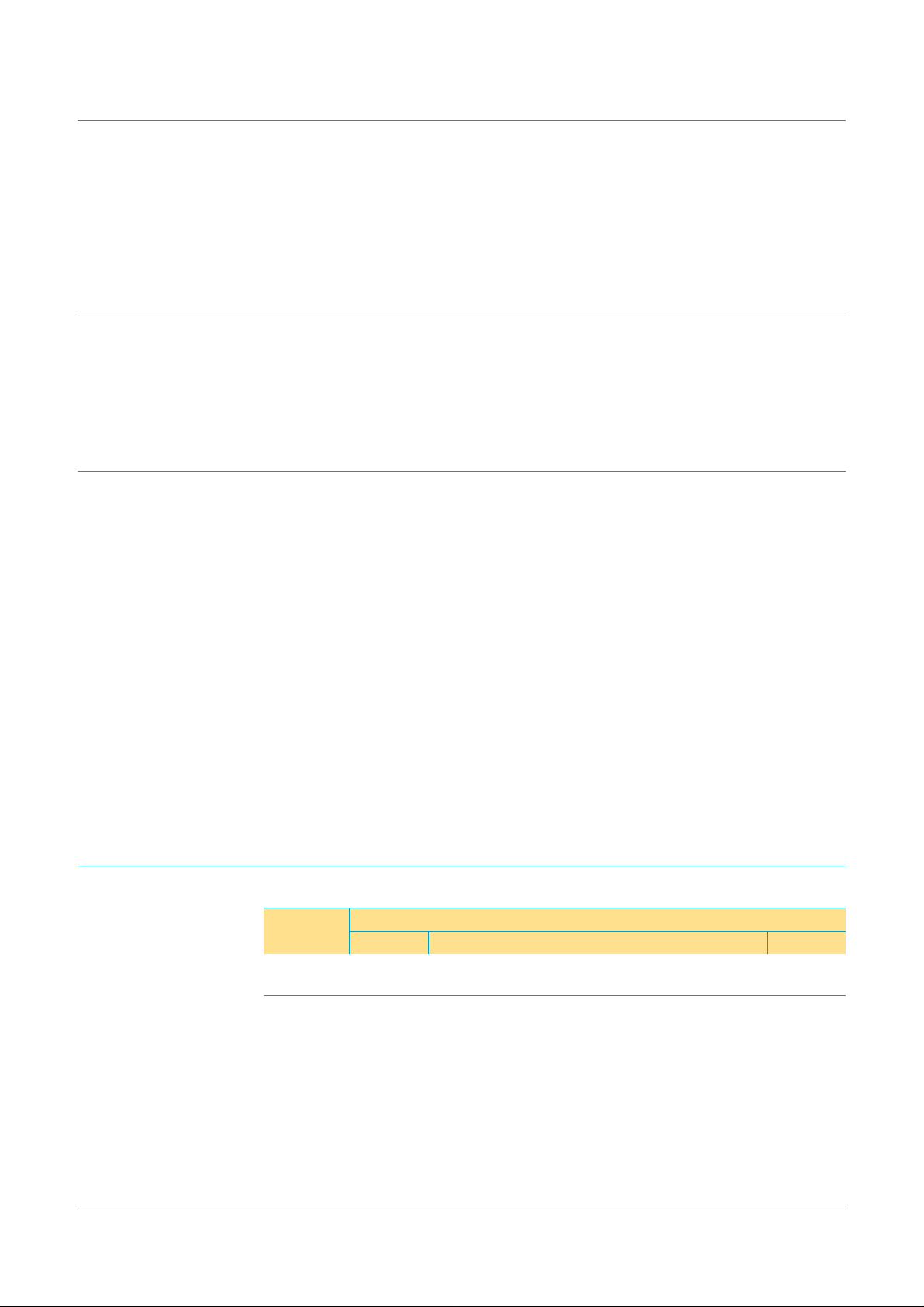

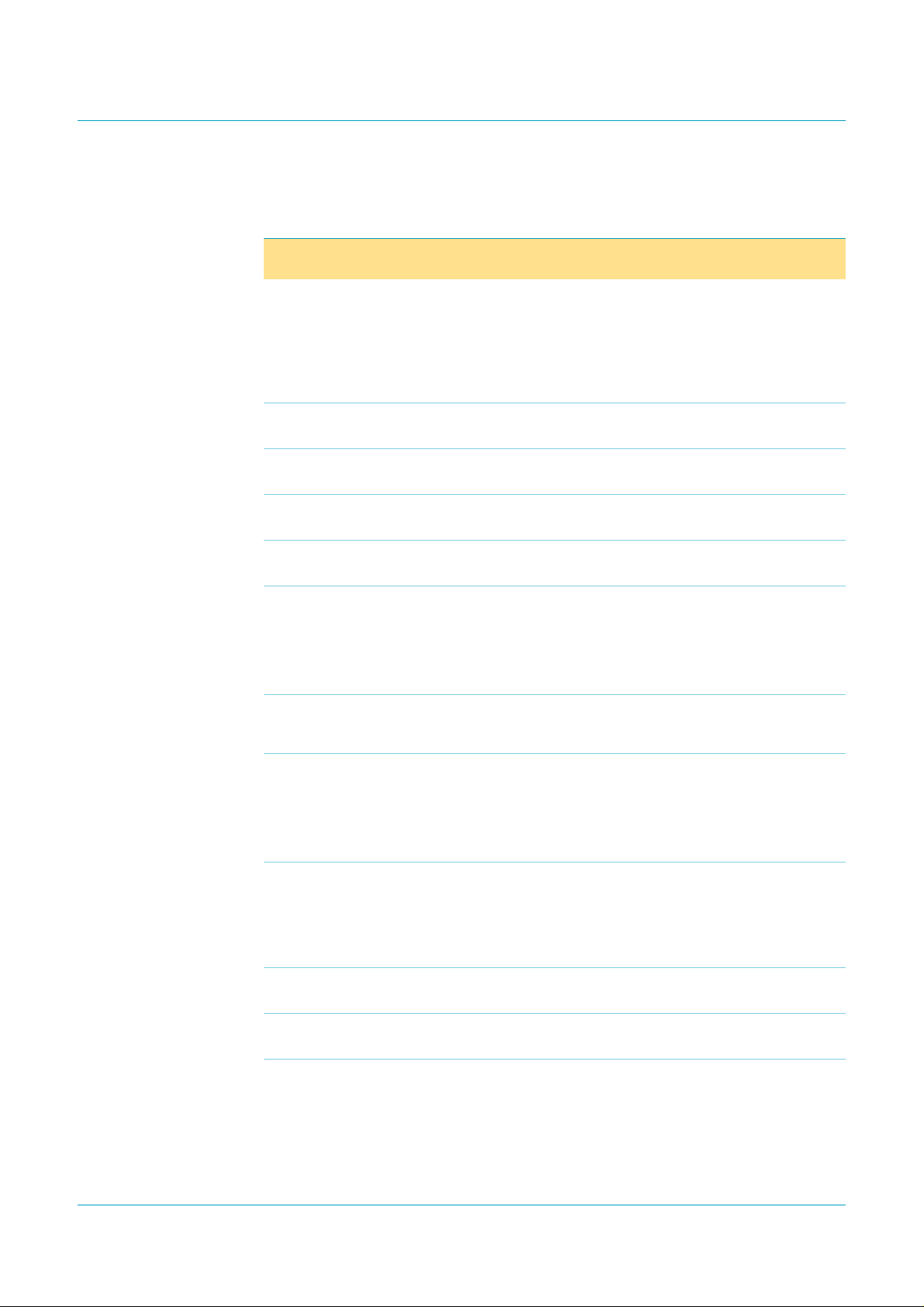

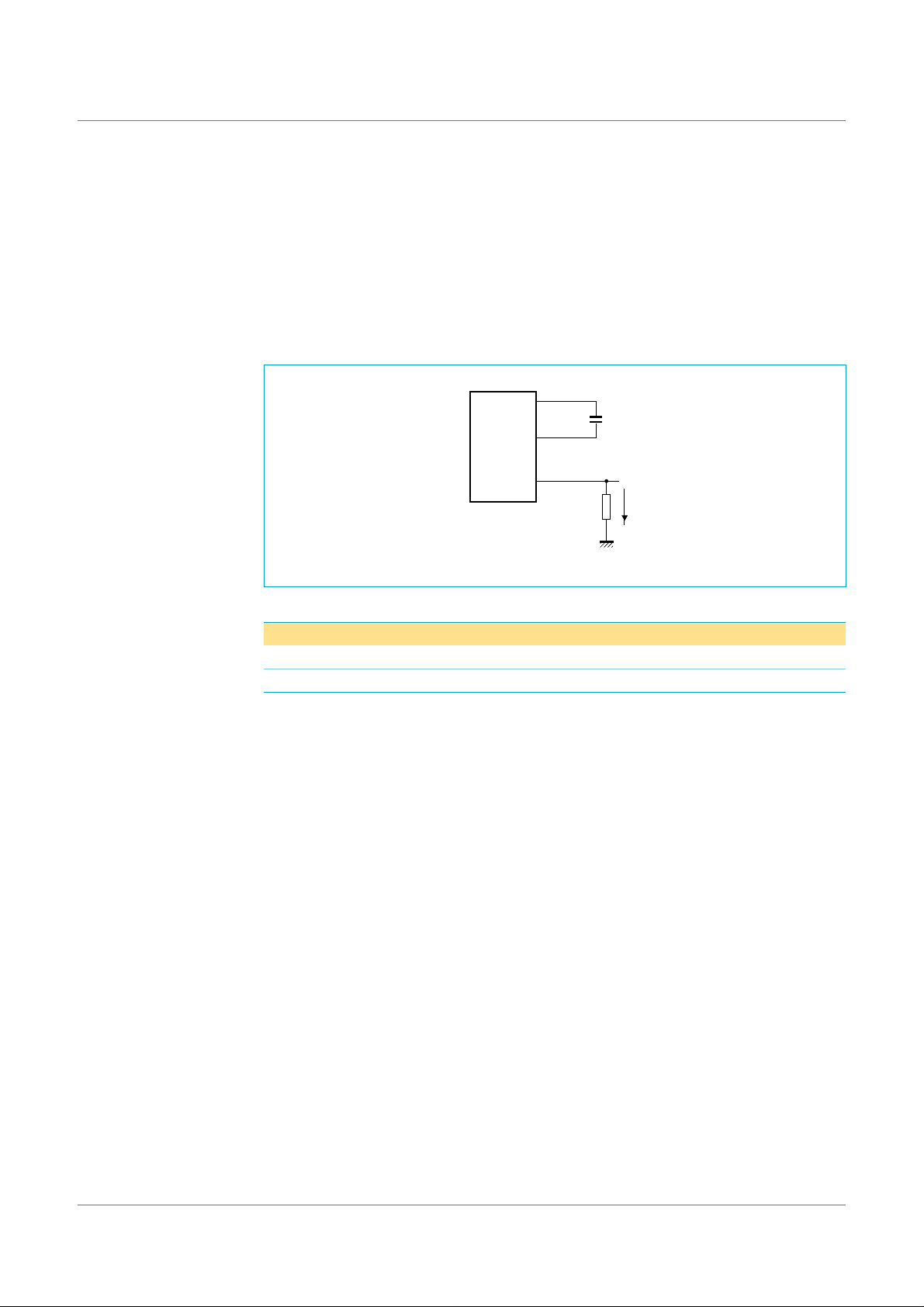

6. Block diagram

ISP1301

USB OTG transceiver

SCL

SDA

ADR/PSW

INT_N

OE_N/INT_N

DAT/VP

SE0/VM

RCV

VP

VM

SPEED

SUSPEND

V

DD_LGC

24

V

REG(3V3)

720

3.3 V DC-DC

REGULATOR

V

BAT

C2 C1

22 21

V

BUS

CHARGE PUMP

23

19

CGND

V

BUS

ISP1301

V

3

2

1

5

SERIAL

CONTROLLER

9

14

13

12

11

10

6

8

LEVEL

SHIFTER

CARKIT

INTERRUPT

DETECTOR

BUS

COMPARATORS

ID DETECTOR

PULL-UP AND

PULL-DOWN

RESISTORS

18

ID

RESET_N

Fig 1. Block diagram.

4

exposed die pad

DGND AGND

TRANSCEIVER

17

USB

15

16

004aaa195

DM

DP

9397 750 11355

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data Rev. 01 — 14 April 2004 3 of 46

Page 4

Philips Semiconductors

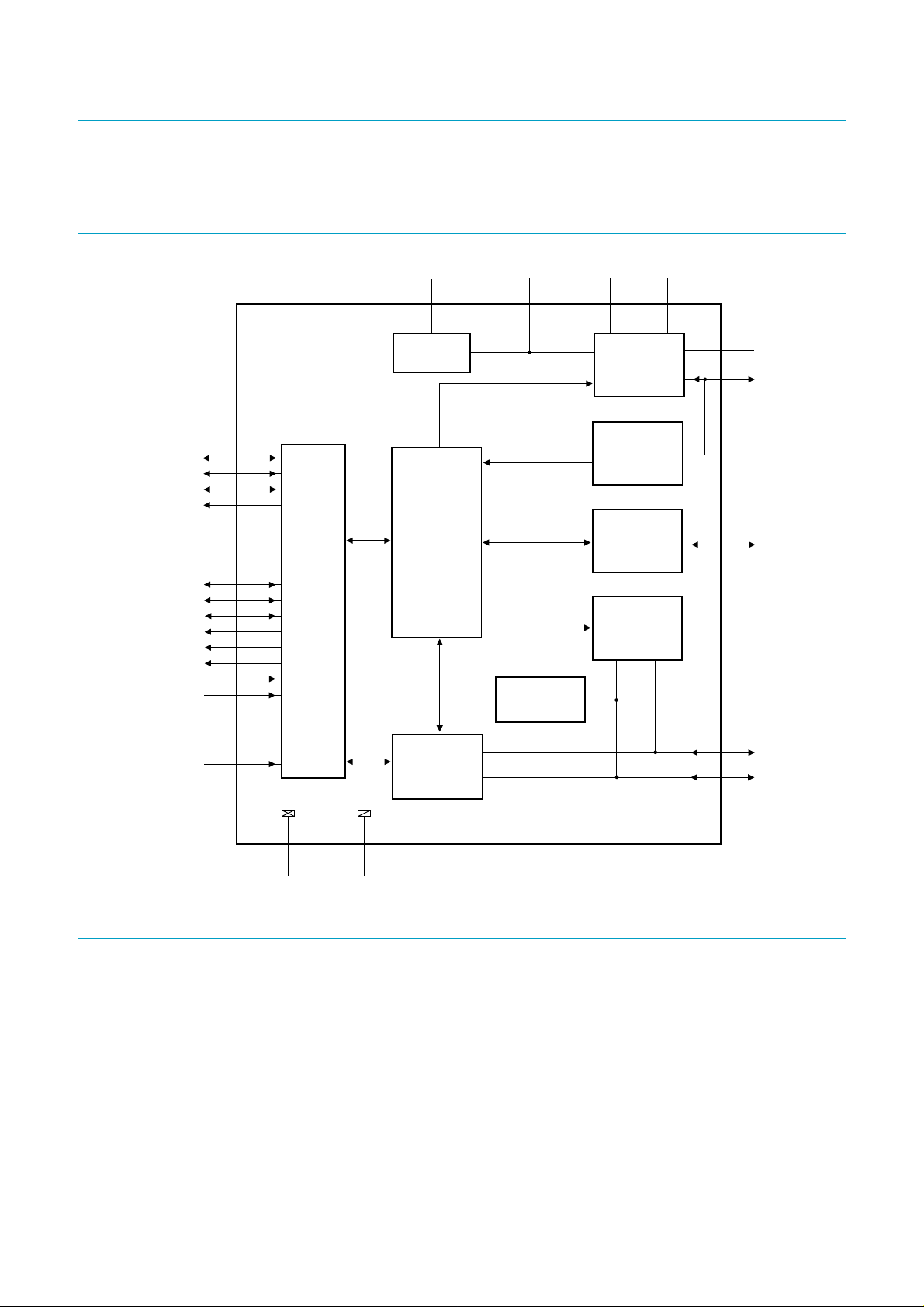

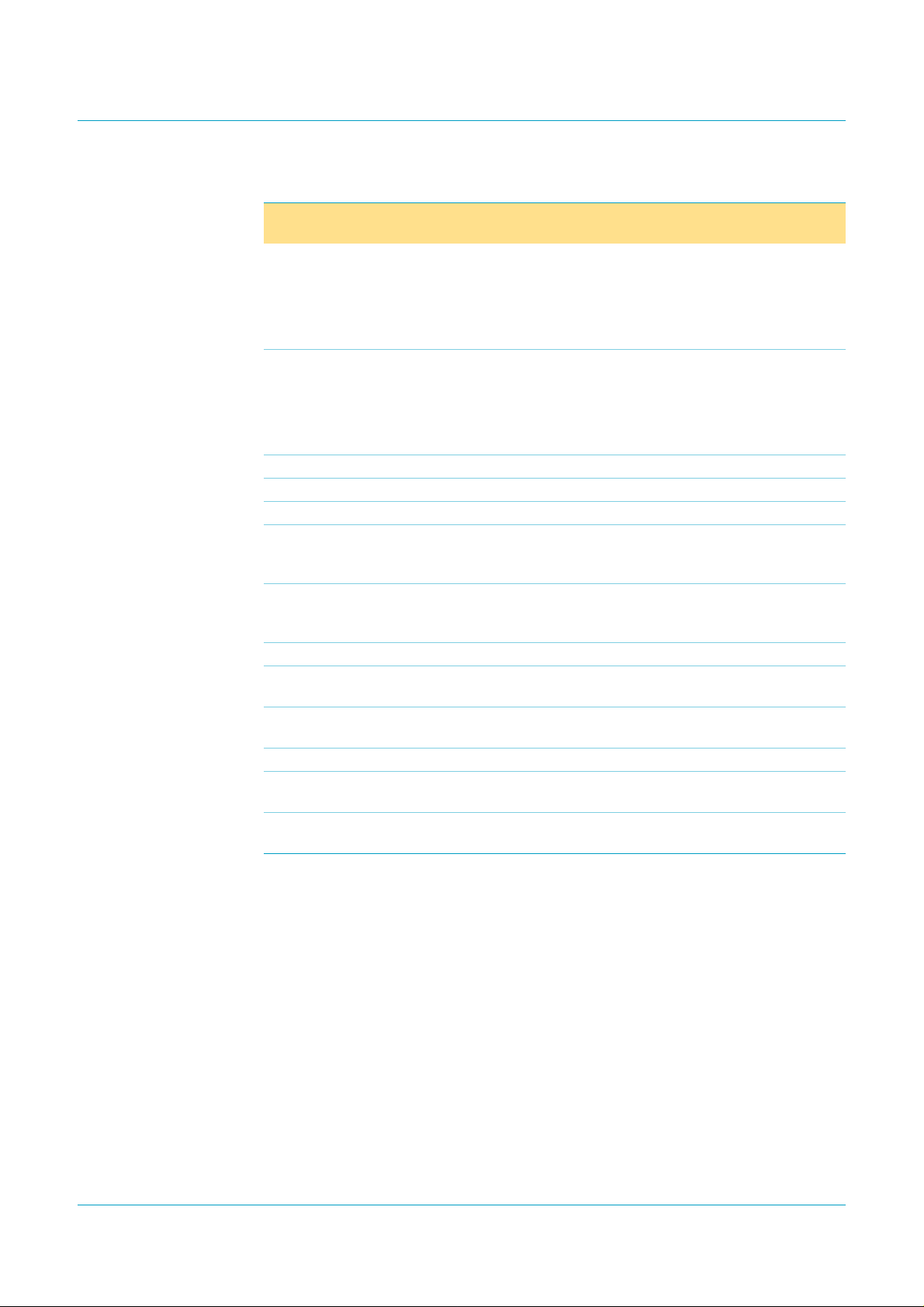

7. Pinning information

7.1 Pinning

ISP1301

USB OTG transceiver

DD_LGC

ADR/PSW

SDA

SCL

RESET_N

INT_N

SPEED

1

2

3

4

5

6

V

24

7

REG(3V3)

V

CGND

23

ISP1301BS

8

SUSPEND

C2

22 21 20

9 10 11

OE_N/INT_N

Fig 2. Pin configuration HVQFN24 (top view).

REG(3V3)

SUSPEND

SPEED

V

7

6

OE_N/INT_N

8

91011

C1

VM

VM

BAT

V

VP

VP

BUS

V

19

ID

18

AGND

17

16

DP

DM

15

DAT/VP

14

13

SE0/VM

12

004aaa542

RCV

RCV

12

SE0/VM

13

INT_N

RESET_N

SCL

SDA

ADR/PSW

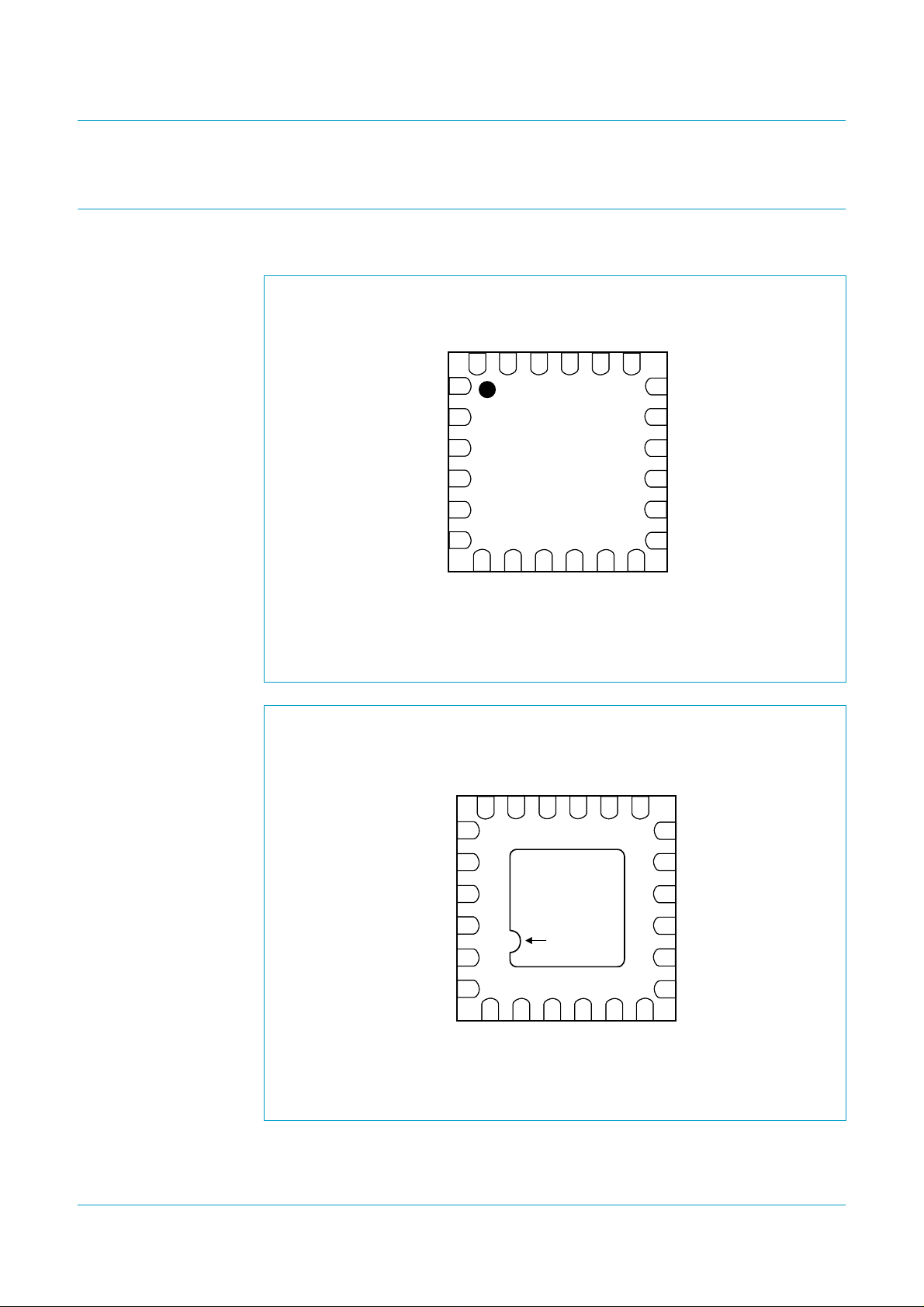

Bottom view

5

4

3

2

1

24

DD_LGC

V

DGND

(exposed die pad)

ISP1301BS

terminal 1

23

22 21 20

C2

CGND

C1

BAT

V

DAT/VP

14

15

DM

DP

16

AGND

17

18

ID

19

004aaa196

BUS

V

Fig 3. Pin configuration HVQFN24 (bottom view).

9397 750 11355

Product data Rev. 01 — 14 April 2004 4 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 5

Philips Semiconductors

7.2 Pin description

ISP1301

USB OTG transceiver

Table 2: Pin description

Symbol

ADR/PSW 1 I/O high-Z ADR input — sets the least-significant I

SDA 2 I/OD high-Z serial I

SCL 3 I/OD high-Z serial I

RESET_N 4 I - asynchronous reset; active LOW

INT_N 5 OD high-Z interrupt output; active LOW

SPEED 6 I - speed selection input for the ATX;effectivewhen

[2]

Pin Type

[1]

[3]

Reset

value

Description

2

C-bus

address bit of the ISP1301; latched-on reset

(including power-on reset)

PSW output — enables or disables the external

charge pump after reset

bidirectional; push-pull input; three-state output

2

C-bus data input and output

bidirectional; push-pull input; open-drain output

2

C-bus clock input and output

bidirectional; push-pull input; open-drain output

push-pull input

open-drain output

bit SPD_SUSP_CTRL = 0:

• LOW: low-speed

• HIGH: full-speed.

push-pull input

V

REG(3V3)

SUSPEND 8 I - suspend selection input for ATX; effective when

7 P - output of the internal voltage regulator; an

external decoupling capacitor of 0.1 µF is

required

bit SPD_SUSP_CTRL = 0:

• LOW: normal operating

• HIGH: suspend.

push-pull input

OE_N/

INT_N

VM 10 O - single-ended DM receiver output

VP 11 O - single-ended DP receiver output

RCV 12 O 0 differential receiver output; reflects the

9 I/O high-Z OE_N input — enable driving DP and DM when

in the USB mode

INT_N output — interrupt (push pull) when

suspended and bit OE_INT_EN = 1

bidirectional; push-pull input; three-state output

push-pull output

push-pull output

differential value of DP and DM

push-pull output

9397 750 11355

Product data Rev. 01 — 14 April 2004 5 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 6

Philips Semiconductors

Table 2: Pin description

Symbol

SE0/VM 13 I/O -

DAT/VP 14 I/O -

DM 15 AI/O - USB data minus pin (D−)

DP 16 AI/O - USB data plus pin (D+)

AGND 17 P - analog ground

ID 18 AI/O - identification detector input and output;

V

BUS

V

BAT

C1 21 AI/O - charge pump capacitor pin 1; typically use a

C2 22 AI/O - charge pump capacitor pin 2; typically use a

CGND 23 P - ground for the charge pump

V

DD_LGC

DGND exposed

ISP1301

USB OTG transceiver

[1]

…continued

[2]

Pin Type

19 AI/O - V

20 P - supply voltage (2.7 V to 4.5 V)

24 P - supply voltage for the interface logic signals

die pad

[3]

Reset

Description

value

[4]

SE0 (input and output) — SE0 function in

DAT_SE0 USB mode

VM (input and output) — VM function in

VP_VM USB mode

bidirectional; push-pull input; three-state output

[4]

DAT (input and output) — DAT function in

DAT_SE0 USB mode

VP (input and output) — VP function in VP_VM

USB mode

bidirectional; push-pull input; three-state output

connected to the ID pin of the USB mini

receptacle

line input and output of the USB interface;

BUS

place an external decoupling capacitor of 0.1 µF

close to this pin

100 nF capacitor between pins C1 and C2

100 nF capacitor between pins C1 and C2

(1.65 V to 3.6 V)

P - digital ground

[1] A detailed description of these pins can be found in Section 8.9.

[2] Symbol names ending with underscore N (for example, NAME_N) indicate active LOW signals.

[3] I = input; O = output; I/O = digital input/output; OD = open-drain output; AI/O = analog input/output;

P = power or ground pin.

[4] High-Z when pin OE_N/INT_N is LOW. Driven LOW when pin OE_N/INT_N is HIGH.

9397 750 11355

Product data Rev. 01 — 14 April 2004 6 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 7

Philips Semiconductors

8. Functional description

8.1 Serial controller

The serial controller includes the following functions:

2

• I

C-bus slave interface

• Interrupt generator

• Mode Control registers

• OTG registers

• Interrupt related registers

• Device identification registers.

The serial controller acts as an I2C-bus slave, and uses the SCL and SDA pins to

communicate with the OTG controller.

For more details on serial controller, see Section 11.

ISP1301

USB OTG transceiver

8.2 V

charge pump

BUS

The charge pump supplies current to the V

following modes:

• Output 5 V at current greater than 8 mA

• Pull-up V

• Pull-down V

before initiating SRP.

8.3 V

8.3.1 V

8.3.2 Session valid comparator

comparators

BUS

V

comparators provide indications regarding the voltage level on V

BUS

valid comparator

BUS

This comparator is used by an A-device to determine whether or not the voltage on

V

is at a valid level for operation. The minimum threshold for the V

BUS

comparator is 4.4 V. Any voltage on V

fault. During power up, it is expected that the comparator output will be ignored.

The session valid comparator is a TTL-level input that determines when V

enough for a session to start. Both the A-device and the B-device use this comparator

to detect when a session is being started. The A-device also uses this comparator to

indicate when a session is completed. The session valid threshold of the ISP1301 is

between 0.8 Vand 2.0 V.

to 3.3 V through a resistor (R

BUS

to ground through a resistor (R

BUS

line. It can operate in any of the

BUS

VBUS(PU)

below this threshold is considered to be a

BUS

) for initiating V

VBUS(PD)

) for discharging V

pulsing SRP

BUS

.

BUS

valid

BUS

BUS

BUS

is high

8.3.3 Session end comparator

The session end comparator determines when V

is below the B-device session

BUS

end threshold of 0.2 V to 0.8 V.

9397 750 11355

Product data Rev. 01 — 14 April 2004 7 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 8

Philips Semiconductors

8.4 ID detector

In either the active or suspended power mode, the ID detector senses the condition of

the ID line and differentiates between the following three conditions:

• Pin ID is floating; bit ID_FLOAT = 1

• Pin ID is shorted to ground; bit ID_GND = 1

• Pin ID is connected to ground through resistor R

The ID detector also has a switch that can be used to ground pin ID. This switch is

controlled by bit ID_PULLDOWN in the serial controller.

8.5 Pull-up and pull-down resistors

The pull-up and pull-down resistors include the following switchable resistors:

• Pin DP pull-up

• Pin DP pull-down

• Pin DM pull-up

• Pin DM pull-down.

ID_GND = 0.

ISP1301

USB OTG transceiver

; bit ID_FLOAT = 0 and bit

ACC_ID

The pull-up resistor is a context variable as described in the

document. The variable pull-up resistor hardware is implemented to meet the USB

ECN_27% specification.

ECN_27%_Resistor

8.6 USB transceiver (ATX)

The behavior of the USB transceiver depends on the operation mode of the ISP1301:

• In the USB mode, the USB transceiver block performs USB full-speed or

low-speed transceiver functions. This includes differential driver, differential

receiver and single-ended receivers.

• In the transparent general purpose buffer mode or the UART mode, the USB

transceiverblockfunctions as a level shifter between the pins DAT/VP and SE0/VM

and the pins DP and DM.

8.7 3.3 V DC-DC regulator

The built-in 3.3 V DC-DC regulator conditions the supply voltage (V

ISP1301:

• V

• V

The output of the regulator can be monitored on the V

= 3.6 V to 4.5 V: the regulator will output 3.3 V ± 10 %

BAT

< 3.6 V: the regulator will be bypassed.

BAT

REG(3V3)

pin.

) for use in the

BAT

8.8 Car kit interrupt detector

The car kit interrupt detector is a comparator that detects when the DP line is below

the car kit interrupt threshold V

detector is enabled in the audio mode only (bit AUDIO_EN = 1).

9397 750 11355

Product data Rev. 01 — 14 April 2004 8 of 46

PH_CR_INT

(0.4 V to 0.6 V). The car kit interrupt

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 9

Philips Semiconductors

8.9 Detailed description of pins

8.9.1 ADR/PSW

The ADR/PSW pin has two functions. On reset (including power-on reset), the level

on this pin is latched as ADR_REG, which represents the least significant bit (LSB) of

the I2C address of the ISP1301. If bit ADR_REG = 0, the I2C-bus address for the

ISP1301 is 0101100 (0x2C); if bit ADR_REG = 1, the I2C-bus address for the

ISP1301 is 0101101 (0x2D).

After reset, the ADR/PSW pin can be programmed as an output. If in the Mode

Control 2 register bit PSW_OE = 1, then the ADR/PSW output will be enabled. The

logic level will be determined by bit ADR_REG. If bit ADR_REG = 0, then the

ADR/PSW pin will drive HIGH. If bit ADR_REG = 1, then the ADR/PSW pin will drive

LOW.

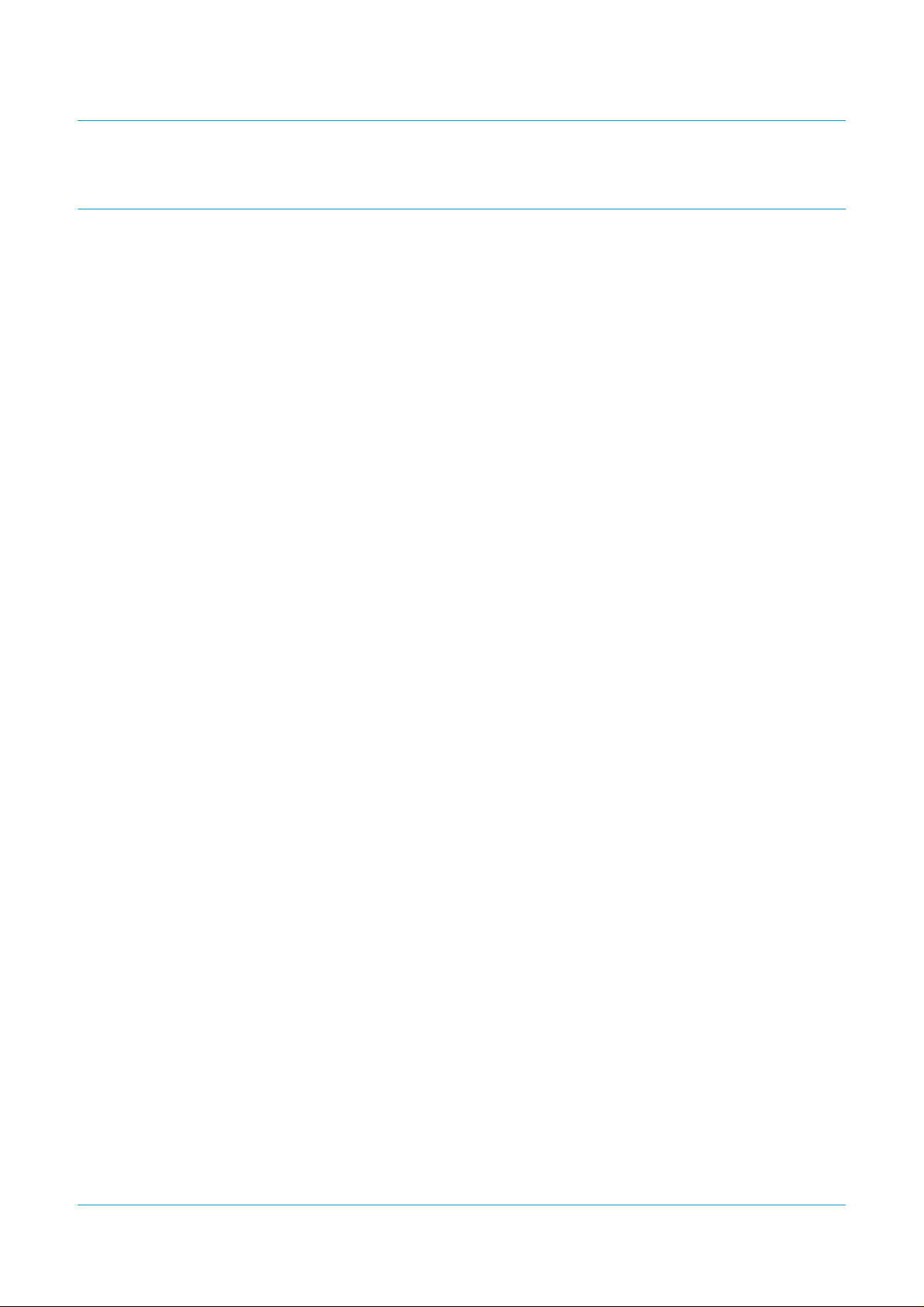

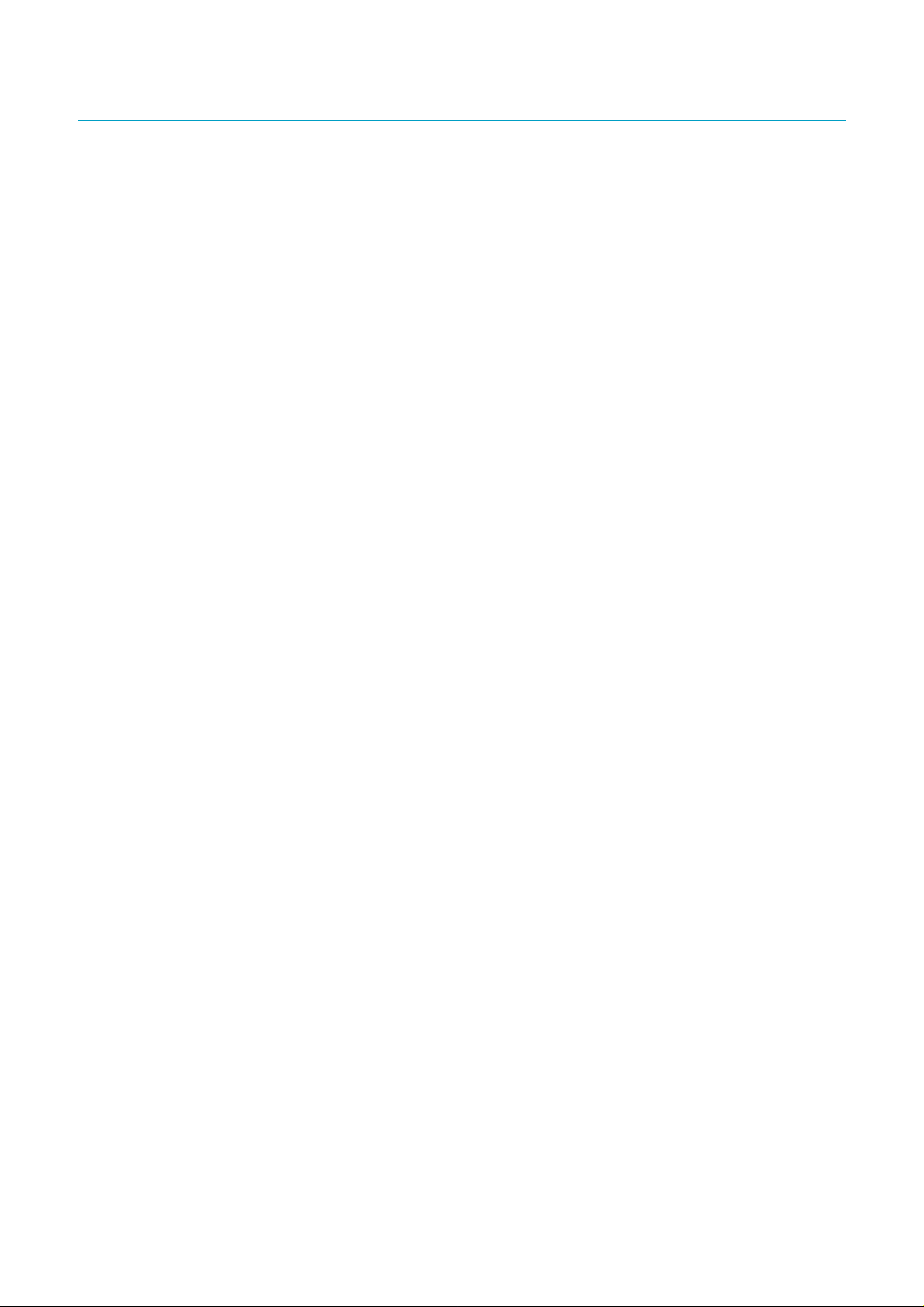

The ADR/PSW pin can be used to turn on or off the external charge pump. The

ISP1301 built-in charge pump supports V

more current support (for example, 50 mA), an external charge pump may be

needed. In this case, the ADR/PSW pin can act as a power switch for the external

charge pump. Figure 4 shows an example of using external charge pump.

ISP1301

USB OTG transceiver

current at 8 mA. If the application needs

BUS

ISP1301

Fig 4. Using external charge pump.

8.9.2 SCL and SDA

The SCL (serial clock) and SDA (serial data) signals implement a two-wire serial

I2C-bus.

8.9.3 RESET_N

Active LOW asynchronous reset for all digital logic. Either connect this pin to V

for power-on reset or apply a minimum of 10 µs LOW pulse for hardware reset.

ADR/PSW

V

BUS

+3.3 V

100 kΩ

V

BAT

V

CHARGE PUMP

ON/OFF

V

IN

OUT

4.7 µF

V

BUS

ID

DM

DP

GND

004aaa437

DD_LGC

8.9.4 INT_N

The INT_N (interrupt) pin is asserted while an interrupt condition exists. It is

deasserted when the Interrupt Latch register is cleared. The INT_N pin is open-drain,

and, therefore, can be connected using a wired-AND with other interrupt signals.

9397 750 11355

Product data Rev. 01 — 14 April 2004 9 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 10

Philips Semiconductors

8.9.5 OE_N/INT_N

Pin OE_N/INT_N is normally an input to the ISP1301.

When bit TRANSP_EN = 0 and bit UART_EN = 0, the OE_N/INT_N pin controls the

direction of DAT/VP, SE0/VM, DP and DM as indicated in Table 4.

When suspended (either pin SUSPEND = HIGH or bit SUSPEND_REG = 1) and bit

OE_INT_EN = 1, pin OE_N/INT_N becomes a push-pull output (active LOW) to

indicate the interrupt condition.

8.9.6 SE0/VM, DAT/VP, RCV, VM and VP

The ISP1301 transmits USB data on the USB line under the following conditions:

• Bit TRANSP_EN = 0

• Bit UART_EN = 0

• Pin OE_N/INT_N = LOW.

Table 10 shows the operation of the SE0/VM and DAT/VP pins during the transmit

operation. The RCV pin is not used during transmit.

ISP1301

USB OTG transceiver

The ISP1301 receives USB data from the USB line under the following conditions:

• Bit TRANSP_EN = 0

• Bit UART_EN = 0

• Pin OE_N/INT_N = HIGH.

Table 12 shows the operation of the SE0/VM, DAT/VP and RCV pins during the

receive operation.

The VP and VM pins are single-ended receiver outputs of the DP and DM pins,

respectively.

8.9.7 DP and DM

The DP (data plus) and DM (data minus) pins implement the USB data signals. When

in the transparent general-purpose buffer mode, the ISP1301 operates as a level

shifter between the (DAT/VP, SE0/VM) and (DP, DM) pins.

8.9.8 ID

The ID (identification) pin is connected to the ID pin on the USB mini receptacle. An

internal pull-up resistor (to V

ID_PULLDOWN is set, the ID pin will be shorted to ground.

8.9.9 V

BUS

This pin acts as an input to the V

REG(3V3)

BUS

) is connected to this pin. When bit

comparator or an output from the charge pump.

When the VBUS_DRV bit of the OTG Control register is asserted, the ISP1301 tries

to drive V

least 8 mA.

9397 750 11355

Product data Rev. 01 — 14 April 2004 10 of 46

to a voltage of 4.4 V to 5.25 V with an output current capability of at

BUS

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 11

Philips Semiconductors

ISP1301

USB OTG transceiver

8.9.10 V

BAT

This pin is an input and supplies power to the ISP1301. The ISP1301 operates when

V

is between 2.7 V and 4.5 V.

BAT

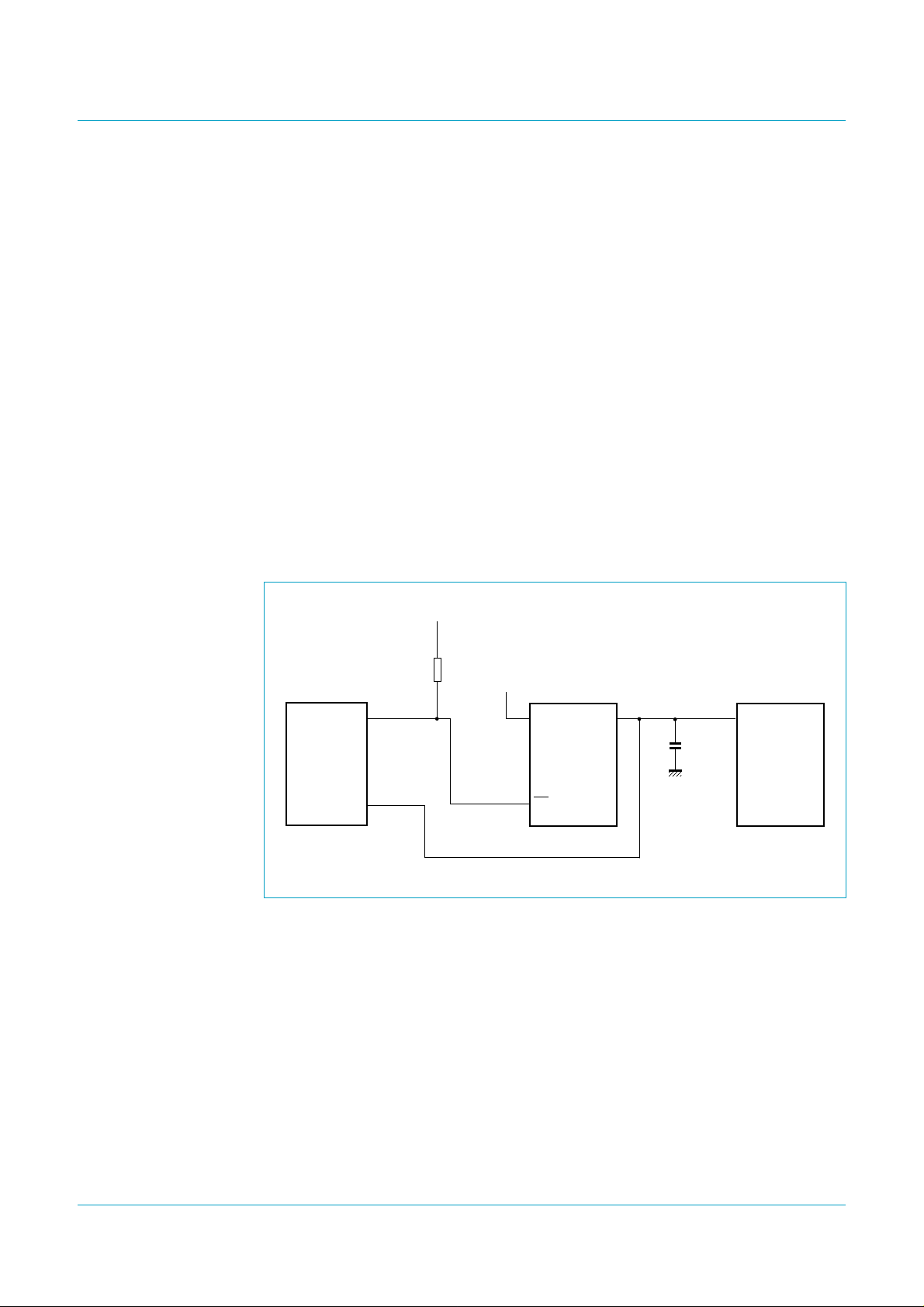

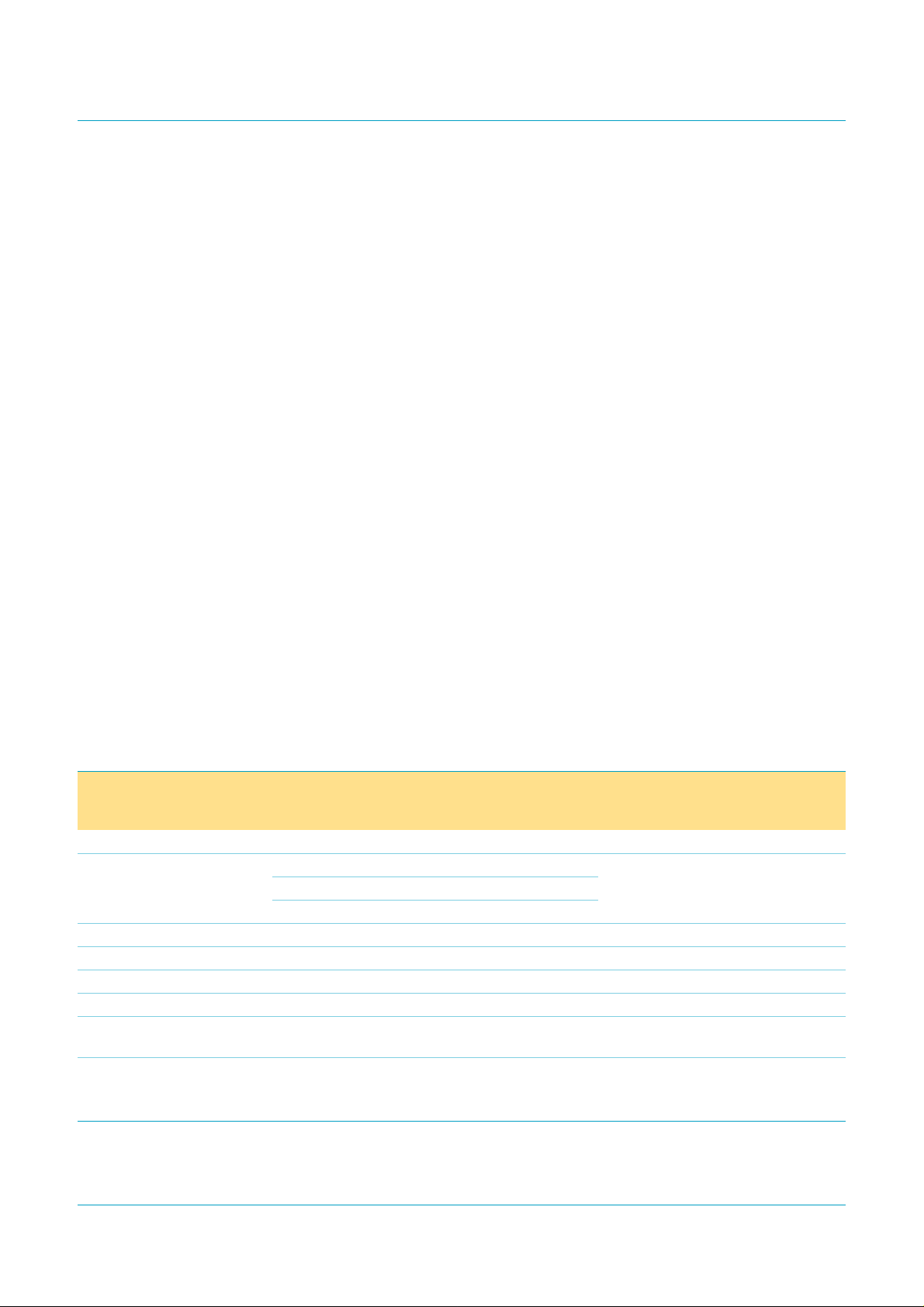

8.9.11 C1 and C2

The C1 and C2 pins are for connecting the flying capacitor of the charge pump. The

output current capacity of the charge pump depends on the value of the capacitor.

For maximum efficiency, place capacitors as close as possible to the pins.

Fig 5. Charge pump capacitor.

Table 3: Recommended charge pump capacitor value

C

ext

47 nF 8 mA

100 nF 18 mA

ISP1301

004aaa278

C1

C2

V

BUS

IL (max)

C

ext

I

L

[1]

[2]

8.9.12 V

[1] For output voltage V

[2] For V

DD_LGC

= 3.0 V to 4.5 V.

BAT

> 4.7 V (bit VBUS_VLD = 1).

BUS

This pin is an input and sets logic thresholds. It also powers the pads of the following

logic pins:

• ADR/PSW

• DAT/VP, SE0/VM and RCV

• VM and VP

• INT_N

• OE_N/INT_N

• RESET_N

• SPEED

• SUSPEND

• SCL and SDA.

8.9.13 AGND, CGND and DGND

AGND, CGND and DGND are ground pins for analog, charge pump and digital

circuits, respectively. These pins can be connected separately or together depending

on the system performance requirements.

9397 750 11355

Product data Rev. 01 — 14 April 2004 11 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 12

Philips Semiconductors

9. Modes of operation

There are four types of modes in the ISP1301:

• Power modes

• Direct I

• USB modes

• Transparent modes.

9.1 Power modes

The power modes of the ISP1301 are as follows:

• Active power mode: power is on.

• USB suspend mode: to reduce power consumption, the USB differential receiver is

powered down.

• Global power-down mode: set bit GLOBAL_PWR_DN = 1 of the Mode Control 2

register; the differential transmitter and receiver, clock generator, charge pump,

and all biasing circuits are turned off to reduce power consumption to the minimum

possible; for details on waking up the clock, see Section 12.

2

C-bus mode

ISP1301

USB OTG transceiver

9.2 Direct I2C-bus mode

In the direct I2C-bus mode, an external I2C-bus master (OTG controller) directly

communicates with the serial controller through the SCL and SDA lines. The serial

controller has a built-in I2C-bus slave function.

In this mode, an external I2C-bus master can access the internal registers of the

device (Status, Control, Interrupt, and so on) through the I2C-bus interface.

The supported I2C-bus bit rate is 100 kbit/s (maximum).

The ISP1301 is in the direct I2C-bus mode when either bit TRANSP_EN bit = 0 or pin

OE_N/INT_N is deasserted.

9.3 USB modes

The four USB modes of the ISP1301 are:

• VP_VM unidirectional mode

• VP_VM bidirectional mode

• DAT_SE0 unidirectional mode

• DAT_SE0 bidirectional mode.

In the VP_VM USB mode, the DAT/VP pin is used for the VP function, the SE0/VM

pin is used for the VM function, and the RCV pin is used for the RCV function.

In the DAT_SE0 USB mode, the DAT/VP pin is used forthe DAT function, the SE0/VM

pin is used for the SE0 function, and the RCV pin is not used.

In the unidirectional mode, the DAT/VP and SE0/VM pins are always inputs. In the

bidirectional mode, the direction of these signals depends on the OE_N/INT_N input.

9397 750 11355

Product data Rev. 01 — 14 April 2004 12 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 13

Philips Semiconductors

Table 6 specifies the functionality of the device during the four USB modes.

The ISP1301 is in the USB mode when both the TRANSP_EN and UART_EN bits

are cleared.

9.4 Transparent modes

9.4.1 Transparent general-purpose buffer mode

In the transparent general-purpose buffer mode, the DAT/VP and SE0/VM pins are

connected to the DP and DM pins, respectively. Using bits TRANSP_BDIR1 and

TRANSP_BDIR0 of the Mode Control 2 register as specified in Table 8, you can

control the direction of data transfer. The ISP1301 is in the transparent

general-purpose buffer mode if bit TRANSP_EN = 1 and bit DAT_SE0 = 1.

9.4.2 Transparent UART mode

When in the transparent UART mode, the ATX behaves as two logic level translator

between the following pins:

ISP1301

USB OTG transceiver

• For TxD signal: from SE0/VM (V

• For RxD signal: from DP (+3.3 V level) to DAT/VP (V

level) to DM (+3.3 V level)

DD_LGC

DD_LGC

level).

In the UART mode, the OTG controller is allowed to connect a UART to the DAT/VP

and SE0/VM pins of the ISP1301.

The UART mode is entered by setting the UART_EN bit in the Mode Control 1

register. The UART mode is equivalent to one of the transparent general purpose

buffer mode (bit TRANSP_BDIR1 = 1, bit TRANSP_BDIR0 = 0).

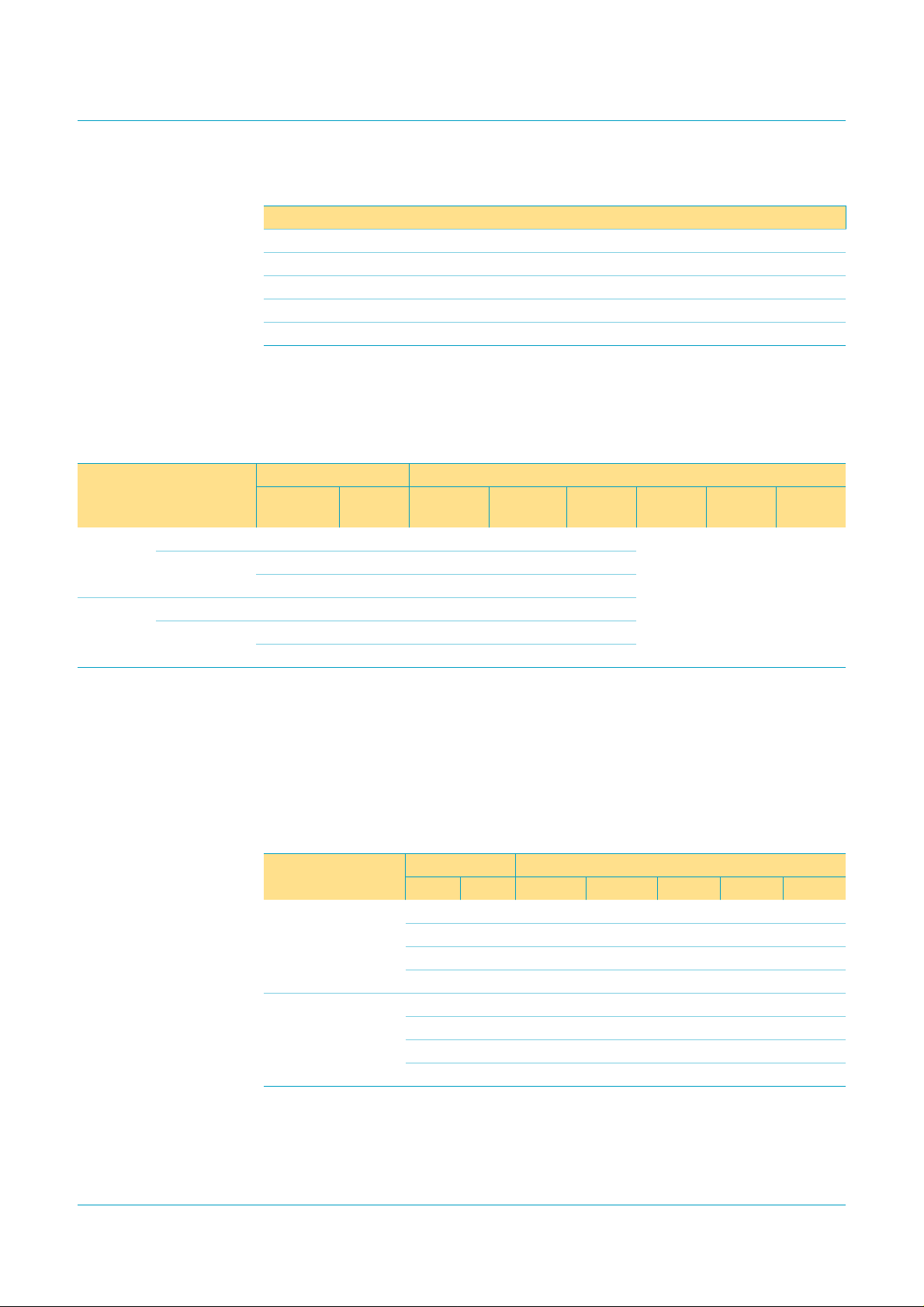

9.4.3 Summary tables

Table 4: Device operating modes

Mode USB

suspend

condition

Direct I

Direct I

USB modes

USB suspend mode 1 X X 0 0 see Table 5 and Table 7

USB functional mode 0 X X 0 0 ATX is fully functional; seeTable 6

Transparent modes

Transparent general-purpose

buffer mode

Transparent UART mode X X X X 1 DAT/VP <= DP (RxD signal of UART)

2

C-bus mode

2

C-bus mode X X X 0 X

X X HIGH 1 X

X1X1X

X 1 X 1 0 ATX is not functional; see Table 8

Bit

DAT

[1]

_SE0

Pin

OE_N/

INT_N

Bit

TRANSP

_EN

Bit

UART

_ EN

Description

SE0/VM => DM (TxD signal of UART);

ATX is not functional

[1] Conditions:

a) bit SPD_SUSP_CTRL = 0 and pin SUSPEND = HIGH, or

b) bit SPD_SUSP_CTRL = 1 and bit SUSPEND_REG = 0.

9397 750 11355

Product data Rev. 01 — 14 April 2004 13 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 14

Philips Semiconductors

Table 5: USB suspend mode: I/O

Pin Function

DP as output can be driven if pin OE_N/INT_N is active LOW, otherwise high-Z

DM as output can be driven if pin OE_N/INT_N is active LOW, otherwise high-Z

V

BUS

SCL connected to SCL I/O of the I

SDA connected to SDA I/O of the I

[1] In the USB suspend mode, the ISP1301 can drive the DP and DM lines, if the OE_N/INT_N input

ISP1301

USB OTG transceiver

[1]

[1]

can be driven depending on bit VBUS_DRV

2

C-bus slave

2

C-bus slave

(when the OE_INT_EN bit is not set) is LOW. In such a case, these outputs are driven as in the USB

functional modes, but with the full-speed characteristics, irrespective of the value of the SPEED input

pin or the SPEED_REG bit.

Table 6: USB functional modes: I/O values

[1]

USB mode Bit Pin

DAT_SE0 BI_DI OE_N/

DAT/VP SE0/VM VP VM RCV

INT_N

VP_VM unidirectional 0 0 X TxD+

bidirectional 0 1 LOW TxD+

0 1 HIGH RxD+

DAT_SE0 unidirectional 1 0 X TxD

bidirectional 1 1 LOW TxD

1 1 HIGH RxD

[1] Some of the modes and signals are provided to achieve backward compatibility with IP cores.

[2] TxD+ and TxD− are single-ended inputs for driving the DP and DM outputs, respectively, in the single-ended mode.

[3] RxD+ and RxD− are the outputs of the single-ended receivers connected to DP and DM, respectively.

[4] TxD is the input for driving DP and DM in the DAT_SE0 mode.

[5] FSE0 is for forcing an SE0 on the DP and DM lines in the DAT_SE0 mode.

[6] RxD is the output of the differential receiver.

[7] RSE0 is an output indicating that an SE0 has been received on the DP and DM lines.

[2]

[2]

[3]

[4]

[4]

[6]

TxD−

TxD−

RxD−

FSE0

FSE0

RSE0

[2]

[2]

[3]

[5]

[5]

[7]

RxD+

[3]

RxD−

Table 7: USB suspend mode: I/O values

USB suspend mode Input pin Output pin

DP DM DAT/VP SE0/VM VP VM RCV

DAT_SE0

(bit DAT_SE0 = 1)

LOW LOW LOW HIGH LOW LOW LOW

HIGH LOW HIGH LOW HIGH LOW LOW

LOW HIGH LOW LOW LOW HIGH LOW

HIGH HIGH HIGH LOW HIGH HIGH LOW

VP_VM

(bit DAT_SE0 = 0)

LOW LOW LOW LOW LOW LOW LOW

HIGH LOW HIGH LOW HIGH LOW LOW

LOW HIGH LOW HIGH LOW HIGH LOW

HIGH HIGH HIGH HIGH HIGH HIGH LOW

[3]

RxD

[3]

9397 750 11355

Product data Rev. 01 — 14 April 2004 14 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 15

Philips Semiconductors

Table 8: Transparent general-purpose buffer mode

Bit

TRANSP_BDIR[1:0]

00 DAT/VP => DP SE0/VM => DM

01 DAT/VP => DP SE0/VM <= DM

10 DAT/VP <= DP SE0/VM => DM

11 DAT/VP <= DP SE0/VM <= DM

10. USB transceiver

10.1 Differential driver

The operation of the driver is described in Table 9. The register bits and the pins used

in the column heading are described in Section 11.1 and Section 8.9, respectively.

Table 9: Transceiver driver operation setting

Suspend

0 0 LOW 0 output value from DAT/VP to DP and

0 0 LOW 1 output value from DAT/VP to DP and DM

1 0 LOW X output value from DAT/VP to DP and DM

X X HIGH X high-Z

X 1 X X high-Z

[1]

Bit

TRANSP_

EN

Direction of the data flow

Pin

OE_N/

INT_N

Bit

DAT_SE0

ISP1301

USB OTG transceiver

Differential driver

SE0/VM to DM

if SE0/VM is 0; otherwise, drive both DP

and DM LOW

[1] Can be controlled by using either the SUSPEND pin or the SUSPEND_REG bit.

Table 10: USB functional mode: transmit operation

USB mode Input pin Output pin

DAT/VP SE0/VM DP DM

DAT_SE0 LOW LOW LOW HIGH

HIGH LOW HIGH LOW

LOW HIGH LOW LOW

HIGH HIGH LOW LOW

VP_VM LOW LOW LOW LOW

HIGH LOW HIGH LOW

LOW HIGH LOW HIGH

HIGH HIGH HIGH HIGH

10.2 Differential receiver

Table 11 describes the operation of the differential receiver. The register bits and the

pins used in the column heading are described in Section 11.1 and Section 8.9,

respectively.

9397 750 11355

Product data Rev. 01 — 14 April 2004 15 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 16

Philips Semiconductors

The detailed behavior of the receive transceiver operation is given in Table 12.

Table 11: Differential receiver operation settings

Suspend

1X X X0

X X LOW X 0

X1 X X0

0 0 HIGH 1 output differential value from DP

0 0 HIGH 0 output differential value from DP

[1] Can be controlled by using either the SUSPEND pin or the SUSPEND_REG bit.

Table 12: USB functional mode: receive operation

USB mode Suspend

DAT_SE0 0 LOW LOW RCV HIGH last value of RCV

DAT_SE0 0 HIGH LOW HIGH LOW HIGH

DAT_SE0 0 LOW HIGH LOW LOW LOW

DAT_SE0 0 HIGH HIGH RCV LOW last value of RCV

DAT_SE0 1 LOW LOW LOW HIGH LOW

DAT_SE0 1 HIGH LOW HIGH LOW LOW

DAT_SE0 1 LOW HIGH LOW LOW LOW

DAT_SE0 1 HIGH HIGH HIGH LOW LOW

VP_VM 0 LOW LOW LOW LOW last value of RCV

VP_VM 0 HIGH LOW HIGH LOW HIGH

VP_VM 0 LOW HIGH LOW HIGH LOW

VP_VM 0 HIGH HIGH HIGH HIGH last value of RCV

VP_VM 1 LOW LOW LOW LOW LOW

VP_VM 1 HIGH LOW HIGH LOW LOW

VP_VM 1 LOW HIGH LOW HIGH LOW

VP_VM 1 HIGH HIGH HIGH HIGH LOW

[1]

Bit

TRANSP_EN

Pin

OE_N/INT_N

[1]

Input pin Output pin

DP DM DAT/VP SE0/VM RCV

Bit

DAT_SE0

Differential receiver

and DM to DAT/VP and RCV

and DM to RCV

ISP1301

USB OTG transceiver

[1] Can be controlled by using either the SUSPEND pin or the SUSPEND_REG bit.

9397 750 11355

Product data Rev. 01 — 14 April 2004 16 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 17

Philips Semiconductors

ISP1301

USB OTG transceiver

11. Serial controller

11.1 Register map

Table 13 provides an overview of the serial controller registers.

Table 13: Serial controller registers

Register Width

(bits)

Vendor ID 16 R 00–01H device identification registers Section 11.1.1 on page 17

Product ID 16 R 02–03H

Version ID 16 R 14–15H

Mode Control 1 8 R/S/C Set — 04H

Mode Control 2 8 R/S/C Set — 12H

OTG Control 8 R/S/C Set — 06H

OTG Status 8 R 10H

Interrupt Source 8 R 08H interrupt related registers Section 11.1.4 on page 20

Interrupt Latch 8 R/S/C Set — 0AH

Interrupt Enable Low 8 R/S/C Set — 0CH

Interrupt Enable High 8 R/S/C Set — 0EH

Access

[1]

Memory address Functionality Reference

mode control registers Section 11.1.2 on page 18

Clear — 05H

Clear — 13H

OTG registers Section11.1.3 on page 19

Clear — 07H

Clear — 0BH

Clear — 0DH

Clear — 0FH

[1] The R/S/C access type represents a field that can be read, set or cleared (set to 0). A register can be read from either of the indicated

addresses—set or clear. Writing logic 1 to the set address causes the associated bit to be set. Writing logic 1 to the clear address

causes the associated bit to be cleared. Writing logic 0 to an address has no effect.

11.1.1 Device identification registers

Vendor ID register (Read: 00H–01H): Table 14 provides the bit allocation of the

Vendor ID register.

Table 14: Vendor ID register: bit description

Bit Symbol Access Value Description

15 to 0 VENDORID

[15:0]

R 04CCH Philips Semiconductors’ Vendor ID

Product ID register (Read: 02H–03H): The bit allocation of this register is given in

Table 15.

Table 15: Product ID register: bit description

Bit Symbol Access Value Description

15 to 0 PRODUCTID

[15:0]

9397 750 11355

Product data Rev. 01 — 14 April 2004 17 of 46

R 1301H Product ID of the ISP1301

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 18

Philips Semiconductors

ISP1301

USB OTG transceiver

Version ID register (Read: 14H–15H): Table 16 shows the bit allocation of this

register.

Table 16: Version ID register: bit description

Bit Symbol Access Value Description

15 to 0 VERSIONID

[15:0]

R 0210H Version number of the ISP1301

11.1.2 Mode control registers

Mode Control 1 register (Set/Clear: 04H/05H): The bit allocation of the Mode

Control 1 register is given in Table 17.

Table 17: Mode Control 1 register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol - UART_EN OE_INT_

EN

Reset -0000000

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

BDIS_

ACON_EN

TRANSP_ENDAT_SE0 SUSPEND

_REG

SPEED_

REG

Table 18: Mode Control 1 register: bit description

Bit Symbol Description

7 - reserved

6 UART_EN When set, the ATX is in the transparent UART mode.

5 OE_INT_EN When set and when in the suspend mode, pin OE_N/INT_N

becomes an output and is asserted when an interrupt occurs.

4 BDIS_ACON_EN Enables the A-device to connect if the B-device disconnect is

detected; see Section 11.3

3 TRANSP_EN When set, the ATX is in the transparent mode.

2 DAT_SE0 0 — VP_VM mode

1 — DAT_SE0 mode; see Table 6 and Table 7

1 SUSPEND_REG Sets the ISP1301 in the suspend mode, if bit

SPD_SUSP_CTRL = 1.

0 — active-power mode

1 — USB suspend mode

0 SPEED_REG Sets the rise time and the fall time of the transmit driver in

USB modes, if bit SPD_SUSP_CTRL = 1.

0 — USB low-speed mode

1 — USB full-speed mode

Mode Control 2 register (Set/Clear: 12H/13H): For the bit allocation of this register,

see Table 19.

9397 750 11355

Product data Rev. 01 — 14 April 2004 18 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 19

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 19: Mode Control 2 register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol EN2V7 PSW_OE AUDIO_EN TRANSP_

BDIR1

Reset 0000010 0

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

Table 20: Mode Control 2 register: bit description

Bit Symbol Description

7 EN2V7 0 — V

1 — V

6 PSW_OE 0 — ADR/PSW pin acts as an input

1 — ADR/PSW pin is driven

5 AUDIO_EN 0 — SE receiver is enabled; cr_int detector is disabled

1 — SE receiver is turned off (pin VP = LOW,pinVM = LOW);

cr_int detector is enabled

4 to 3 TRANSP_BDIR[1:0] controls the direction of data transfer in the transparent

general-purpose buffer mode; see Table 8

2 BI_DI 0 — direction of DAT/VP and SE0/VM are fixed (transmit only)

1 — direction of DAT/VP and SE0/VM are controlled by

pin OE_N/INT_N; see Table 6

1 SPD_SUSP_CTRL control of speed and suspend in USB modes:

TRANSP_

BDIR0

= 3.0 V to 4.5 V

BAT

= 2.7 V to 4.5 V

BAT

BI_DI SPD_SUSP

_CTRL

GLOBAL_

PWR_DN

0 — controlled by pins SPEED and SUSPEND

1 — controlled by bit SPEED_REG and bit SUSPEND_REG

of the Mode Control 1 register

0 GLOBAL_PWR_DN 0 — normal operation

1 — sets the ISP1301 to the power down mode

2

Activities on the I

chip; see Section 12

C-bus or any OTG event can wake up the

11.1.3 OTG registers

OTG Control register (Set/Clear: 06H/07H): Table 21 provides the bit allocation of

the OTG Control register.

Table 21: OTG Control register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol VBUS_

CHRG

Reset 00001100

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

VBUS_

DISCHRG

VBUS_

DRV

ID_PULL

DOWN

DM_PULL

DOWN

DP_PULL

DOWN

DM_PULLUPDP_PULL

UP

9397 750 11355

Product data Rev. 01 — 14 April 2004 19 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 20

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 22: OTG Control register: bit description

Bit Symbol Description

7 VBUS_CHRG charge V

6 VBUS_DISCHRG discharge V

5 VBUS_DRV drive V

4 ID_PULLDOWN connect the ID pin to ground

3 DM_PULLDOWN connect DM pull-down resistor to ground

2 DP_PULLDOWN connect DP pull-down resistor to ground

1 DM_PULLUP connect DM pull-up resistor to 3.3 V

0 DP_PULLUP connect DP pull-up resistor to 3.3 V

through a resistor to 3.3 V

BUS

through a resistor to ground

BUS

to 5 V through the charge pump

BUS

OTG Status register (Read: 10H): Table 23 shows the bit allocation of the OTG

Status register.

Table 23: OTG Status register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol B_SESS_

VLD

Reset 00000000

Access RRRRRRRR

B_SESS_

END

reserved

Table 24: OTG Status register: bit description

Bit Symbol Description

7 B_SESS_VLD set when the V

threshold (2.0 V to 4.0 V)

6 B_SESS_END set when the V

threshold (0.2 V to 0.8 V)

5 to 0 - reserved

voltage is above the B-device session valid

BUS

voltage is below the B-device session end

BUS

11.1.4 Interrupt related registers

Interrupt Source register (Read: 08H): This register indicates the current state of

the signals that can generate an interrupt. The bit allocation of the Interrupt Source

register is given in Table 25.

Table 25: Interrupt Source register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol CR_INT BDIS_

ACON

Reset 00000000

Access RRRRRRRR

ID_FLOAT DM_HI ID_GND DP_HI SESS_VLD VBUS_VLD

9397 750 11355

Product data Rev. 01 — 14 April 2004 20 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 21

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 26: Interrupt Source register: bit description

Bit Symbol Description

7 CR_INT DP pin is above the car kit interrupt threshold (0.4 V to 0.6 V)

6 BDIS_ACON set when bit BDIS_ACON_EN is set, and the ISP1301 asserts bit

DP_PULLUP after detecting the B-device disconnect

5 ID_FLOAT ID pin is floating

4 DM_HI DM pin is HIGH

3 ID_GND ID pin is connected to ground

2 DP_HI DP pin is HIGH

1 SESS_VLD session valid comparator; threshold = 0.8 V to 2.0 V

0 VBUS_VLD A-device V

valid comparator; threshold > 4.4 V

BUS

Interrupt Latch register (Set/Clear: 0AH/0BH): This register indicates the source

that generated the interrupt. The bit allocation of the Interrupt Latch register is given

in Table 27.

Table 27: Interrupt Latch register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol CR_INT BDIS_

ACON

Reset 00000000

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

ID_FLOAT DM_HI ID_GND DP_HI SESS_VLD VBUS_VLD

Table 28: Interrupt Latch register: bit description

Bit Symbol Description

7 CR_INT interrupt for CR_INT status change

6 BDIS_ACON interrupt for BDIS_ACON status change

5 ID_FLOAT interrupt for ID_FLOAT status change

4 DM_HI interrupt for DM_HI status change

3 ID_GND interrupt for ID_GND status change

2 DP_HI interrupt for DP_HI status change

1 SESS_VLD interrupt for SESS_VLD status change

0 VBUS_VLD interrupt for VBUS_VLD status change

Interrupt Enable Low register (Set/Clear: 0CH/0DH): This register enables

interrupts on transition from true to false. For the bit allocation of this register, see

Table 29.

Table 29: Interrupt Enable Low register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol CR_INT BDIS_

ACON

Reset 00000000

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

ID_FLOAT DM_HI ID_GND DP_HI SESS_VLD VBUS_VLD

9397 750 11355

Product data Rev. 01 — 14 April 2004 21 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 22

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 30: Interrupt Enable Low register: bit description

Bit Symbol Description

7 CR_INT interrupt enable for CR_INT status change from 1 to 0

6 BDIS_ACON interrupt enable for BDIS_ACON status change from 1 to 0

5 ID_FLOAT interrupt enable for ID_FLOAT status change from 1 to 0

4 DM_HI interrupt enable for DM_HI status change from 1 to 0

3 ID_GND interrupt enable for ID_GND status change from 1 to 0

2 DP_HI interrupt enable for DP_HI status change from 1 to 0

1 SESS_VLD interrupt enable for SESS_VLD status change from 1 to 0

0 VBUS_VLD interrupt enable for VBUS_VLD status change from 1 to 0

Interrupt Enable High register (Set/Clear: 0EH/0FH): The Interrupt Enable High

register enables interrupts on transition from FALSE to TRUE. Table 31 provides the

bit allocation of this register.

Table 31: Interrupt Enable High register: bit allocation

Bit 7 6 5 4 3 2 1 0

Symbol CR_INT BDIS_

ACON

Reset 00000000

Access R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C R/S/C

ID_FLOAT DM_HI ID_GND DP_HI SESS_VLD VBUS_VLD

Table 32: Interrupt Enable High register: bit description

Bit Symbol Description

7 CR_INT interrupt enable for CR_INT status change from 0 to 1

6 BDIS_ACON interrupt enable for BDIS_ACON status change from 0 to 1

5 ID_FLOAT interrupt enable for ID_FLOAT status change from 0 to 1

4 DM_HI interrupt enable for DM_HI status change from 0 to 1

3 ID_GND interrupt enable for ID_GND status change from 0 to 1

2 DP_HI interrupt enable for DP_HI status change from 0 to 1

1 SESS_VLD interrupt enable for SESS_VLD status change from 0 to 1

0 VBUS_VLD interrupt enable for VBUS_VLD status change from 0 to 1

11.2 Interrupts

Table 26 indicates the signals that can generate interrupts. Any of the signals given in

Table 26 can generate an interrupt when the signal becomes either LOW or HIGH.

After an interrupt has been generated, the OTG controller should be able to read the

status of each signal and the bit that indicates whether or not that signal generated

the interrupt.

A bit in the Interrupt Latch register is set when any of these occurs:

• Writing logic 1 to its set address causes the corresponding bit to be set

• The corresponding bit in the Interrupt Enable High register is set, and the

associated signal changes from LOW to HIGH

• The corresponding bit in the Interrupt Enable Low register is set, and the

associated signal changes from HIGH to LOW.

9397 750 11355

Product data Rev. 01 — 14 April 2004 22 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 23

Philips Semiconductors

The Interrupt Latch register bit is cleared by writing logic 1 to its clear address.

11.3 Autoconnect

The Host Negotiation Protocol (HNP) in the OTG supplement specifies the following

sequence of events to transfer the role of the host from the A-device to the B-device:

1. The A-device puts the bus in the suspend state

2. The B-device simulates a disconnect by deasserting its DP pull-up

3. The A-device detects SE0 on the bus, and asserts its DP pull-up

4. The B-device detects that the DP line is HIGH, and takes the role of the host.

The OTG supplement specifies that the time between the B-device deasserting its DP

pull-up and the A-device asserting its pull-up must be less than 3 ms. For an A-device

with a slow interrupt response time, 3 ms maynot be enough time to write an I2C-bus

command to the ISP1301 to assert the DP pull-up. An alternative method is for the

A-device transceiver to automatically assert the DP pull-up after detecting an SE0

from the B-device.

ISP1301

USB OTG transceiver

The sequence of events is as follows:

After finishing data transfers between the A-device and the B-device and before

suspending the bus, the A-device sends SOFs. The B-device receives these SOFs,

and does not transmit any packet back to the A-device.During this time, the A-device

sets the BDIS_ACON_EN bit in the ISP1301. This enables the ISP1301 to look for

SE0 whenever the A-device is not transmitting (that is, whenever the OE_N/INT_N

pin of the ISP1301 is not asserted). After the BDIS_ACON_ENbit is set, the A-device

stops transmitting SOFs and allows the bus to go to the idle state. If the B-device

disconnects, the bus goes to SE0, and the ISP1301 logic automatically turns on the

A-device pull-up.

9397 750 11355

Product data Rev. 01 — 14 April 2004 23 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 24

Philips Semiconductors

12. Clock wake up scheme

This section explains the ISP1301 clock stop timing, events triggering the clock to

wake up, and the timing of the clock wake up.

12.1 Power down event

The clock is stopped when the GLOBAL_PWR_DN bit is set. It takes approximately

8 ms for the clock to stop from the time the power down condition is detected. The

clock always stops at its falling edge. The waveform is given in Figure 6.

SCL

GLOBAL_PWR_DN

CLOCK

ISP1301

USB OTG transceiver

Fig 6. Clock stopped using the GLOBAL_PWR_DN bit.

12.2 Clock wake up events

The clock wakes up when any of the following events occur on the ISP1301 pins:

• SCL goes LOW

• V

goes above the session valid threshold (0.8 V to 2.0 V), provided the

BUS

SESS_VLD bit in the Interrupt Enable High register is set.

• ID changes when mini-A plug is inserted, provided the ID_FLOAT bit in the

Interrupt Enable Low register is set.

• ID changes when mini-A plug is removed, provided the ID_FLOAT bit in the

Interrupt Enable High register is set.

• DP goes HIGH, provided the DP_HI bit in the Interrupt Enable High register is set.

• DM goes HIGH, provided the DM_HI bit in the Interrupt Enable High register is set.

The event triggers the clock to start and a stable clock is guaranteed after about six

clock periods, which is approximately 8 µs. The startup analog clock time is 10 µs.

Therefore, the total estimated start time after a triggered event is about 20 µs. The

clock will always start at its rising edge.

8 ms

004aaa217

Waveforms of the clock wake up because of different events are given in Figure 7,

Figure 8, Figure 9, Figure 10 and Figure 11.

SCL

CLOCK

Fig 7. Clock wake up using SCL.

9397 750 11355

Product data Rev. 01 — 14 April 2004 24 of 46

20 µs

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

004aaa218

Page 25

Philips Semiconductors

SESS_VLD

CLOCK

20 µs

ISP1301

USB OTG transceiver

004aaa219

Fig 8. Clock wake up by V

ID_FLOAT

CLOCK

BUS

.

Fig 9. Clock wake up by ID change (1).

ID_FLOAT

CLOCK

Fig 10. Clock wake up by ID change (2).

DP_HI

or DM_HI

CLOCK

20 µs

20 µs

20 µs

004aaa220

004aaa221

004aaa434

Fig 11. Clock wake up by data line SRP.

When an event is triggered and the clock is started, it will remain active for 8 ms. If

the GLOBAL_PWR_DN bit is not cleared within this 8 ms period, the clock will stop. If

the clock wakes up because of any event other than SCL going LOW, an interrupt will

be generated once the clock is active.

9397 750 11355

Product data Rev. 01 — 14 April 2004 25 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 26

Philips Semiconductors

13. I2C-bus protocol

ISP1301

USB OTG transceiver

For detailed information, refer to

The I2C-bus specification; version 2.1

13.1 I2C-bus byte transfer format

Table 33: I2C-bus byte transfer format

S Byte 1 A Byte 2 A Byte 3 A … A P

8 bits 8 bits 8 bits …

[1] S = Start; A = Acknowledge; P = Stop.

13.2 I2C-bus device address

Table 34: Device address byte 1

Bit 7 6 5 4 3 2 1 0

Name A6 A5 A4 A3 A2 A1 A0 R/W

Value 0 1 0 1 1 0 X X

Table 35: Bit description

Bit Symbol Description

7 to 1 A[6:0] Device address: The device address of the ISP1301 is: 0101 10 (A0).

The value of A0 (LSB) is loaded from pin ADR/PSW during reset

(including power-on reset). If pin ADR/PSW = HIGH, bit A0 = 1;

otherwise bit A0 = 0.

0 R/W Read/write command.

.

[1]

device address -

0 — write

1 — read.

13.3 Write format

A write operation can be performed as:

• One-byte write to the specified register address

• Multi-byte write to N consecutive registers, starting from the specified start

address. N defines the number of registers to write. If N = 1, only the start register

is written.

13.3.1 One-byte write

Figure 12 illustrates the byte sequence.

Table 36: Transfer format description for one-byte write

Byte Description

S master starts with a START condition

Device select master transmits device address and write command bit R/W = 0

ACK slave generates an acknowledgment

Register address K master transmits address of register K

9397 750 11355

Product data Rev. 01 — 14 April 2004 26 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 27

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 36: Transfer format description for one-byte write

Byte Description

ACK slave generates an acknowledgment

Write data K master writes data to register K

ACK slave generates an acknowledgment

P master generates a STOP condition

13.3.2 Multiple-byte write

Figure 12 illustrates the byte sequence.

Table 37: Transfer format description for multiple-byte write

Byte Description

S master starts with a START condition

Device select master transmits device address and write command bit R/W = 0

ACK slave generates an acknowledgment

Register address K master transmits address of register K. This is the start address for

ACK slave generates an acknowledgment

Write data K master writes data to register K

ACK slave generates an acknowledgment

Write data K + 1 master writes data to register K + 1

ACK slave generates an acknowledgment

::

Write data

K+N− 1

ACK slave generates an acknowledgment

P master generates a STOP condition

…continued

writing multiple data bytes to consecutive registers. After a byte is

written, the register address is automatically incremented by 1.

Remark: If the master writes to a non existent register, the slave must

send a 'not ACK' and also must not increment the index address.

master writes data to register K + N − 1. When the incremented

address K + N − 1 becomes > 255, the register address rolls over to 0.

Therefore, it is possible that some registers may be overwritten, if the

transfer is not stopped before the rollover.

9397 750 11355

Product data Rev. 01 — 14 April 2004 27 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 28

Philips Semiconductors

ISP1301

USB OTG transceiver

ACK

S

S

DEVICE SELECT

device select

WR

register address K

One-byte write

ACK

S

S

DEVICE SELECT

DEVICE SELECTwrite data K + 2

device select

WR

ACK

register address K

write data K + 3

Fig 12. Writing data to the ISP1301 registers.

13.4 Read format

A read operation can be performed in two ways:

ACK

ACK

ACK

.... maximum, rollover to 0

Multiple-byte write

write data K

write data K

ACK

ACK

ACK

P

write data K + 1

write data K + N - 1

ACK

ACK

P

004aaa213

• Current address read: to read the register at the current address.

– Single register read.

• Random address read: to read N registers starting at a specified address.

N defines the number of registers to be read. If N = 1, only the start register is

read.

– Single register read

– Multiple register read.

13.4.1 Current address read

Figure 13 illustrates the byte sequence.

Table 38: Transfer format description for current address read

Byte Description

S master starts with a START condition

Device select master transmits device address and read command bit R/W = 1

ACK slave generates an acknowledgment

Read data K slave transmits and master reads data from register K. If the start

address is not specified, the read operation starts from where the index

register is pointing to because of a previous read or write operation.

No ACK master terminates the read operation by generating a No Acknowledge

P master generates a stop condition

9397 750 11355

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data Rev. 01 — 14 April 2004 28 of 46

Page 29

Philips Semiconductors

ISP1301

USB OTG transceiver

S

S

Fig 13. Current address read.

13.4.2 Random address read

Single read: Figure 14 illustrates the byte sequence.

Table 39: Transfer format description for single-byte read

SDA line Description

S master starts with a START condition

Device select master transmits device address and writes command bit R/W = 0

ACK slave generates an acknowledgment

Register address K master transmits (start) address of register K to be read from

ACK slave generates an acknowledgment

Device select master transmits device address and read command bit R/W = 1

ACK slave generates an acknowledgment

Read data K slave transmits and master reads data from register K

No ACK master terminates the read operation by generating a No Acknowledge

P master generates a STOP condition

DEVICE SELECT

device select

ACK

RD

Current address read

read data K

No ACK

P

004aaa215

Multiple read: Figure 14 illustrates the byte sequence.

Table 40: Transfer format description for multiple-byte read

SDA line Description

S master starts with a START condition

Device select master transmits device address and write command bit R/W = 0

ACK slave generates an acknowledgment

Register address K master transmits (start) address of register K to be read from

ACK slave generates an acknowledgment

Device select master transmits device address and read command bit R/W = 1

ACK slave generates an acknowledgment

Read data K slave transmits and master reads data from register K. After a byte is

read, the address is automatically incremented by 1.

ACK slave generates an acknowledgment

Read data K + 1 slave transmits and master reads data from register K + 1

ACK slave generates an acknowledgment

::

Read data

K+N− 1

No ACK master terminates the read operation by generating a No Acknowledge

P master generates a STOP condition

slave transmits and master reads data register K + N − 1. This is the

last register to read. After incrementing, the address rolls over to 0.

Here, N represents the number of addresses available in the slave.

9397 750 11355

Product data Rev. 01 — 14 April 2004 29 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 30

Philips Semiconductors

ISP1301

USB OTG transceiver

ACK

device select

S

S

DEVICE SELECT

S

S

DEVICE SELECTread data K + 1

DEVICE SELECT

device select

WR

ACK

WR

ACK

Fig 14. Random address read.

ACK

register address K

Random address single read

ACK

register address K

ACK

read data K + 2

.... maximum, rollover to 0

Random access multiple read

S

S

DEVICE SELECT

S

S

device select

device select

DEVICE SELECT

ACK

RD

ACK

RD

ACK

read data K

read data K

write data K + N - 1

No ACK

P

ACK

No ACK

P

004aaa214

9397 750 11355

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data Rev. 01 — 14 April 2004 30 of 46

Page 31

Philips Semiconductors

ISP1301

USB OTG transceiver

14. Limiting values

Table 41: Absolute maximum ratings

In accordance with the Absolute Maximum Rating System (IEC 60134).

Symbol Parameter Conditions Min Max Unit

V

BAT

V

DD_LGC

V

I

I

lu

V

esd

T

stg

[1] Equivalent to discharging a 100 pF capacitor through a 1.5 kΩ resistor (Human Body Model). A 4.7 µF capacitor is needed from

V

REG(3V3)

supply voltage −0.5 +5.5 V

I/O supply voltage −0.5 +4.6 V

input voltage VI=−1.8 V to +5.4 V −0.5 V

DD_LGC

+ 0.5 V

latch-up current - 100 mA

electrostatic discharge voltage ILI<1µA

[1]

pins DP, DM, ID,

, AGND, CGND

V

BUS

−8+8 kV

and DGND

all other pins −2+2 kV

storage temperature −60 +125 °C

and V

to ground.

BUS

15. Recommended operating conditions

Table 42: Recommended operating conditions

Symbol Parameter Conditions Min Typ Max Unit

V

BAT

V

DD_LGC

V

I

V

I(AI/O)

V

O(OD)

T

amb

[1] V

DD_LGC

supply voltage 2.7 - 4.5 V

I/O supply voltage

input voltage 0 - V

input voltage on analog I/O pins DP

[1]

1.65 - 3.6 V

DD_LGC

0 - 3.6 V

and DM

open-drain output pull-up voltage on

0 - 3.6 V

pins SCL, SDA and INT_N

ambient temperature −40 - +85 °C

should be less than or equal to V

BAT

.

V

9397 750 11355

Product data Rev. 01 — 14 April 2004 31 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 32

Philips Semiconductors

ISP1301

USB OTG transceiver

16. Static characteristics

Table 43: Static characteristics: supply pins

V

=

2.7 V to 4.5 V; V

BAT

Symbol Parameter Conditions Min Typ Max Unit

Charge pump disabled

V

REG(3V3)

I

BAT

I

DD_LGC

I

BAT(idle)

regulated supply voltage output V

operating supply current transmitting and receiving at

operating I/O supply current transmitting and receiving at

supply current during full-speed

idle and SE0

I

DD_LGC(static)

I

BAT(pd)

static I/O supply current idle, SE0 or suspend - - 20 µA

power down mode supply current bit GLOBAL_PWR_DN = 1

Charge pump enabled

I

BAT(cp)

operating supply current for the

charge pump

DD_LGC

=

1.65 V to 3.6 V; T

=−40°

amb

BAT

V

BAT

12 Mbit/s; C

C to +85°C; unless otherwise specified.

= 3.0 V to 4.5 V

[1]

3.0 - 3.6 V

= 2.7 V to 3.0 V 2.7 - 3.0 V

[2]

- 48mA

= 50 pF on

L

pins DP and DM

[2]

- 12mA

12 Mbit/s

idle: VDP> 2.7 V, VDM< 0.3 V;

SE0: V

I

LOAD

I

LOAD

< 0.3 V, VDM< 0.3 V

DP

= 8 mA; ATX is idle - - 20 mA

= 0 mA; ATX is idle - - 300 µA

[3]

- - 300 µA

[3]

--20µA

[1] In the suspend mode, the minimum voltage is 2.7V.

[2] Maximum value characterized only, not tested in production.

[3] Excluding any load current to the 1.5 kΩ and 15 kΩ pull-up and pull-down resistors (200 µA typical).

Table 44: Static characteristics: digital pins

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; T

amb

=−40°

C to +85°C; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Input levels

V

IL

V

IH

LOW-level input voltage - - 0.3V

HIGH-level input voltage 0.6V

DD_LGC

-- V

DD_LGC

V

Output levels

V

OL

V

OH

LOW-level output voltage IOL= 2 mA - - 0.4 V

= 100 µA - - 0.15 V

I

OL

HIGH-level output voltage IOH= 2mA

= 100 µAV

I

OH

[1]

V

− 0.4 - - V

DD_LGC

− 0.15 - - V

DD_LGC

Leakage current

I

LI

input leakage current −1-+1µA

Open-drain outputs

I

OZ

OFF-state output current −5-+5µA

Capacitance

C

IN

input capacitance pin to GND - - 10 pF

[1] Not applicable for open-drain outputs.

9397 750 11355

Product data Rev. 01 — 14 April 2004 32 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 33

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 45: Static characteristics: analog I/O pins DP and DM

V

=

2.7 V to 4.5 V; V

BAT

Symbol Parameter Conditions Min Typ Max Unit

Input levels

V

DI

V

CM

differential input sensitivity |V

differential common mode

voltage

V

IL

V

IH

LOW-level input voltage - - 0.8 V

HIGH-level input voltage 2.0 - - V

Output levels

V

OL

V

OH

LOW-level output voltage RLof 1.5 kΩ to +3.6 V - - 0.3 V

HIGH-level output voltage RLof 15 kΩ to GND

Leakage current

I

LZ

OFF-state leakage current −1- +1µA

Capacitance

C

IN

transceiver capacitance pin to GND - - 10 pF

Resistance

R

PD

pull-down resistor on pins

DP and DM

R

PU_DP

R

PU_DM

Z

DRV

Z

INP

pull-up resistor on pin DP bus idle 900 - 1575 Ω

pull-up resistor on pin DM bus idle 900 - 1575 Ω

driver output impedance steady-state drive

input impedance 10 - - MΩ

Termination

V

TERM

termination voltage for the

upstream port pull-up

resistor (R

DD_LGC

)

PU

=

1.65 V to 3.6 V; T

=−40°

C to +85°C; unless otherwise specified.

| 0.2 - - V

I(DM)

I(DP)

amb

− V

includes VDI range 0.8 - 2.5 V

= 3.0 V to 4.5 V 2.8 - 3.6 V

V

BAT

= 2.7 V to 3.0 V 2.6 - 3.0 V

V

BAT

14.25 - 24.8 kΩ

bus driven 1425 - 3090 Ω

bus driven 1425 - 3090 Ω

[1]

34 - 44 Ω

3.0 - 3.6 V

[1] Includes external series resistors of 33 Ω±1 % each on DP and DM.

Table 46: Static characteristics: analog I/O pin ID

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; T

amb

=−40°

C to +85°C; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Resistance

R

PU_ID

R

PD_ID

9397 750 11355

Product data Rev. 01 — 14 April 2004 33 of 46

pull-up resistor on pin ID to

V

REG(3V3)

impedance to GND bit ID_PULLDOWN = 1- - 10Ω

77 - 130 kΩ

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 34

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 46: Static characteristics: analog I/O pin ID

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; T

…continued

=−40°

amb

C to +85°C; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

R

A_ID

A-device ID impedance to

bit ID_GND = 1 - - 1 kΩ

GND

R

B_ID

B-device ID impedance to

bit ID_FLOAT = 1 800 - - kΩ

GND

R

ACC_ID

Accessory device ID

impedance to GND

bit ID_GND = 0;

bit ID_FLOAT = 0

20 - 200 kΩ

Table 47: Static characteristics: charge pump

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; T

amb

=−40°

C to +85°C; unless otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Current

I

LOAD

maximum load current C

= 100 nF; V

ext

= 4.7 V - - 8.0 mA

BUS

Voltage

V

BUS

regulated V

BUS

output

I

LOAD

= 8 mA; C

= 100 nF 4.65 5 5.25 V

ext

voltage

V

BUS(LEAK)

V

th(VBUSVLD)

V

th(SESSEND)

V

leakage voltage charge pump disabled - - 0.2 V

BUS

V

valid threshold 4.4 - 4.65 V

BUS

V

session end

BUS

0.2 - 0.8 V

comparator threshold

V

hys(SESSEND)VBUS

session end

- 150 - mV

comparator hysteresis

V

th(SESSVLD)

V

session valid

BUS

0.8 - 2.0 V

comparator threshold

V

hys(SESSVLD)VBUS

session valid

- 200 - mV

comparator hysteresis

V

th(BSESSVLD)VBUS

session valid

for the B-device 2.0 - 4.0 V

comparator threshold

V

hys(BSESSVLD)VBUS

session valid

for the B-device - 200 - mV

comparator hysteresis

E efficiency when loaded I

LOAD

= 8 mA; V

= 3V - 75 - %

BAT

Resistance

R

VBUS(PU)

pull-up resistor connect to V

BUS

REG(3V3)

when

460 - 1000 Ω

V

VBUS_CHRG = 1

R

VBUS(PD)

V

pull-down resistor connect to GND when

BUS

660 - 1200 Ω

VBUS_DISCHRG = 1

R

VBUS(IDLE_A)VBUS

idle impedance for

ID pin connected to GND 40 - 100 kΩ

A-device

9397 750 11355

Product data Rev. 01 — 14 April 2004 34 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 35

Philips Semiconductors

ISP1301

USB OTG transceiver

17. Dynamic characteristics

Table 48: Dynamic characteristics: reset and clock

V

=

2.7 V to 4.5 V; V

BAT

Symbol Parameter Conditions Min Typ Max Unit

Reset

t

W(RESET_N)

pulse width on input RESET_N 10 - - µs

Internal clock

f

clk

clock frequency bit GLOBAL_PWR_DN = 0 700 1000 1300 kHz

Table 49: Dynamic characteristics: digital I/O pins

V

=

2.7 V to 4.5 V; V

BAT

otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

t

TOI

bus turnaround time

(OE_N/INT_N to DAT/VP and

SE0/VM)

t

TIO

bus turnaround time

(OE_N/INT_N to DAT/VP and

SE0/VM)

DD_LGC

DD_LGC

=

1.65 V to 3.6 V; T

=

1.65 V to 3.6 V; C

=−40°

amb

L

=

C to +85°C; unless otherwise specified.

50 pF; R

PU

output-to-input; see

Figure 19

input-to-output; see

Figure 19

=

1.5 kΩ on DP to V

; T

=−40°

TERM

amb

Cto+85°C; unless

0- 5ns

0- 5ns

Table 50: Dynamic characteristics: analog I/O pins DP and DM

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; C

=

L

50 pF; R

=

1.5 kΩon DP to V

PU

TERM;Tamb

=−40°

C to +85°C; unless

otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

Driver characteristics

t

FR

rise time CL= 50 pF to 125 pF;

4 - 20 ns

10%to90% of

− VOL|; see Figure 15

|V

OH

t

FF

fall time CL= 50 pF to 125 pF;

4 - 20 ns

90%to10% of

− VOL|; see Figure 15

|V

OH

FRFM differential rise/fall time

V

CRS

matching (t

output signal crossover voltage excludingthefirsttransition

FR/tFF

)

excludingthefirsttransition

from idle state

90 - 111.1 %

[1]

1.3 - 2.0 V

from idle state; see

Figure 16

Driver timing

t

PLH(drv)

t

PHL(drv)

t

PHZ

t

PLZ

t

PZH

driver propagation delay

(DAT/VP, SE0/VM to DP, DM)

driver propagation delay

(DAT/VP, SE0/VM to DP, DM)

driver disable delay

(OE_N/INT_N to DP, DM)

driver disable delay

(OE_N/INT_N to DP, DM)

driver enable delay

(OE_N/INT_N to DP, DM)

LOW-to-HIGH; see

Figure 16 and Figure 20

HIGH-to-LOW; see

Figure 16 and Figure 20

HIGH-to-OFF; see

Figure 17 and Figure 21

LOW-to-OFF; see

Figure 17 and Figure 21

OFF-to-HIGH; see

Figure 17 and Figure 21

- - 18 ns

- - 18 ns

- - 15 ns

- - 15 ns

- - 15 ns

9397 750 11355

Product data Rev. 01 — 14 April 2004 35 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 36

Philips Semiconductors

ISP1301

USB OTG transceiver

Table 50: Dynamic characteristics: analog I/O pins DP and DM

V

=

2.7 V to 4.5 V; V

BAT

DD_LGC

=

1.65 V to 3.6 V; C

=

L

50 pF; R

…continued

=

1.5 kΩon DP to V

PU

TERM;Tamb

=−40°

C to +85°C; unless

otherwise specified.

Symbol Parameter Conditions Min Typ Max Unit

t

PZL

driver enable delay

(OE_N/INT_N to DP, DM)

OFF-to-LOW; see

Figure 17 and Figure 21

- - 15 ns

Receiver timing

Differential receiver

t

PLH(rcv)

t

PHL(rcv)

propagation delay (DP, DM to

RCV)

propagation delay (DP, DM to

RCV)

LOW-to-HIGH; see

Figure 18 and Figure 22

HIGH-to-LOW; see

Figure 18 and Figure 22

- - 15 ns

- - 15 ns

Single-ended receiver

t

PLH(se)

propagation delay (DP, DM to

VP and DAT/VP, VM and

LOW-to-HIGH; see

Figure 18 and Figure 22

- - 18 ns

SE0/VM)

t

PHL(se)

propagation delay (DP, DM to

VP and DAT/VP, VM and

HIGH-to-LOW; see

Figure 18 and Figure 22

- - 18 ns

SE0/VM)

[1] Characterized only; not tested. Limits guaranteed by design.

1.8 V

logic input

tFR, t

V

OH

V

OL

LR

90 %

10 %

90 %

tFF, t

10 %

LF

MGS963

0 V

V

OH

V

OL

differential

data lines

0.9 V

t

PLH(drv)

V

CRS

0.9 V

t

PHL(drv)

V

CRS

MGS964

Fig 15. Rise and fall times. Fig 16. Timing of DAT/VP and SE0/VM to DP and DM.

1.8 V

logic input

0 V

V

OH

differential

data lines

V

OL

0.9 V

t

PZH

t

V

PZL

CRS

0.9 V

t

PHZ

t

PLZ

V

−0.3 V

OH

V

+0.3 V

OL

MGS966

2.0 V

differential

data lines

0.8 V

V

OH

logic output

V

OL

V

CRS

t

PLH(rcv)

t

PLH(se)

0.9 V

V

CRS

t

PHL(rcv)

t

PHL(se)

0.9 V

MGS965

Fig 17. Timing of OE_N/INT_N to DP and DM. Fig 18. Timing of DP and DM to RCV, VP or DAT/VP and

VM or SE0/VM.

9397 750 11355

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data Rev. 01 — 14 April 2004 36 of 46

Page 37

Philips Semiconductors

ISP1301

USB OTG transceiver

OE_N/INT_N

t

TOI

DAT/VP

SE0/VM

output

Fig 19. SIE interface bus turnaround timing.

V

TERM

V

REG(3V3)

D.U.T.

004aaa448

1.5 kΩ

DP or DM

33 Ω

Load capacitance CL= 50 pF (minimum or maximum timing).

Fig 20. Load on pins DP and DM.

input

test point

t

TIO

output

004aaa439

C

15 kΩ

L

test point

V = 0 V for t

V = V

REG(3V3)

PZH

and t

for t

PZL

PHZ

and t

.

D.U.T.

PLZ

33 Ω

.

500 Ω

50 pF

V

MBL142

Fig 21. Load on pins DP and DM for enable and disable times.

test point

D.U.T.

25 pF

MGS968

Fig 22. Load on pins VM, SE0/VM, VP, DAT/VP and RCV.

9397 750 11355

Product data Rev. 01 — 14 April 2004 37 of 46

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Page 38

Philips Semiconductors

Table 51: Characteristics of I/O stages of I2C-bus lines (SDA, SCL)

Symbol Parameter Standard mode Unit

f

SCL

t

HD;STA

t

LOW

t

HIGH

t

SU;STA

t

SU;DAT

t

HD:DAT

t

r

t

f

t

SU;STO

t

BUF

ISP1301

USB OTG transceiver

Min Max

SCL clock frequency - 100 kHz

hold time for the START condition 4.0 - µs

LOW period of the SCL clock 4.7 - µs

HIGH period of the SCL clock 4.0 - µs

set-up time for the START condition 4.7 - µs

data set-up time 250 - ns

data hold time 0 - µs

rise time of SDA and SCL signals - 1000 ns

fall time of SDA and SCL signals - 300 ns

set-up time for the STOP condition 4.0 - µs

bus free time between a STOP and START

condition

4.7 - µs

SDA

HIGH

t

f

t

SU;STA

Sr

SCL

t

HD;DAT

t

SU;DAT

t

t

f

t

LOW

t

HD;STA

S

t

r

Fig 23. Definition of timing for standard-mode devices on the I2C-bus.

t

HD;STA

t

SP

t

SU;STO

t

t

r

BUF

P

S

004aaa216

9397 750 11355

© Koninklijke Philips Electronics N.V. 2004. All rights reserved.

Product data Rev. 01 — 14 April 2004 38 of 46