Philips HTS-7212, HTS-7202 Service Manual

1 - 1

Service

Service

BD Home Theater System

HTS7202/12 & HTS7212/12

Tfswjdf

Tfswjdf

Service

Service Manual

TABLE OF CONTENTS

Location Of PCB Boards............................................ 1-2

Versions Variation ...................................................... 1-2

Specifications ............................................................ 1-3

Measurement Setup .................................................. 1-6

Service Aids .............................................................. 1-7

ESD & Safety Instruction .......................................... 1-8

Lead-free Soldering Information ................................ 1-9

Setting Procedure & Repair Instructions ...................... 2

Disassembly Instructions & Service Positions .............. 3

Block & Wiring .............................................................. 4

Diagram Quick Strart Guide .......................................... 5

MAIN+MP3+IR+TUNE AUX IN Board .......................... 6

Power Board .................................................................. 7

BD Board........................................................................ 8

Touch Board .................................................................. 9

VFD Board .................................................................. 10

Mechanical Exploded View.......................................... 11

Revision List ................................................................ 12

Chapter

©

Copyright 2011 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in a retrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Published by RY_XYY1131 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

3139 785 35621

GB

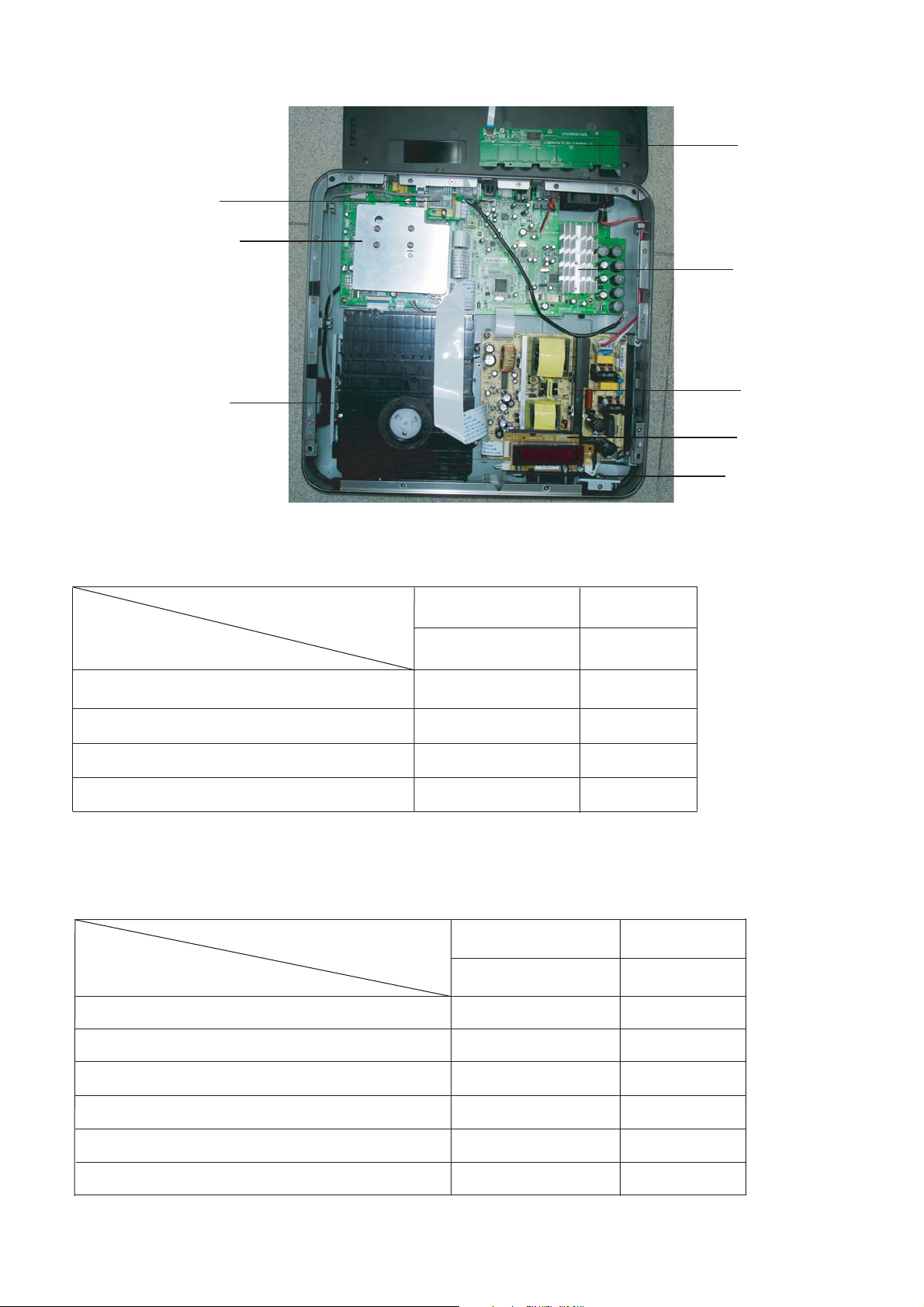

LOCATION OF PCB BOARDS

Tune AUX in

BD PCB

1 - 2

Touch PCB

Main PCB

MP3 PCB

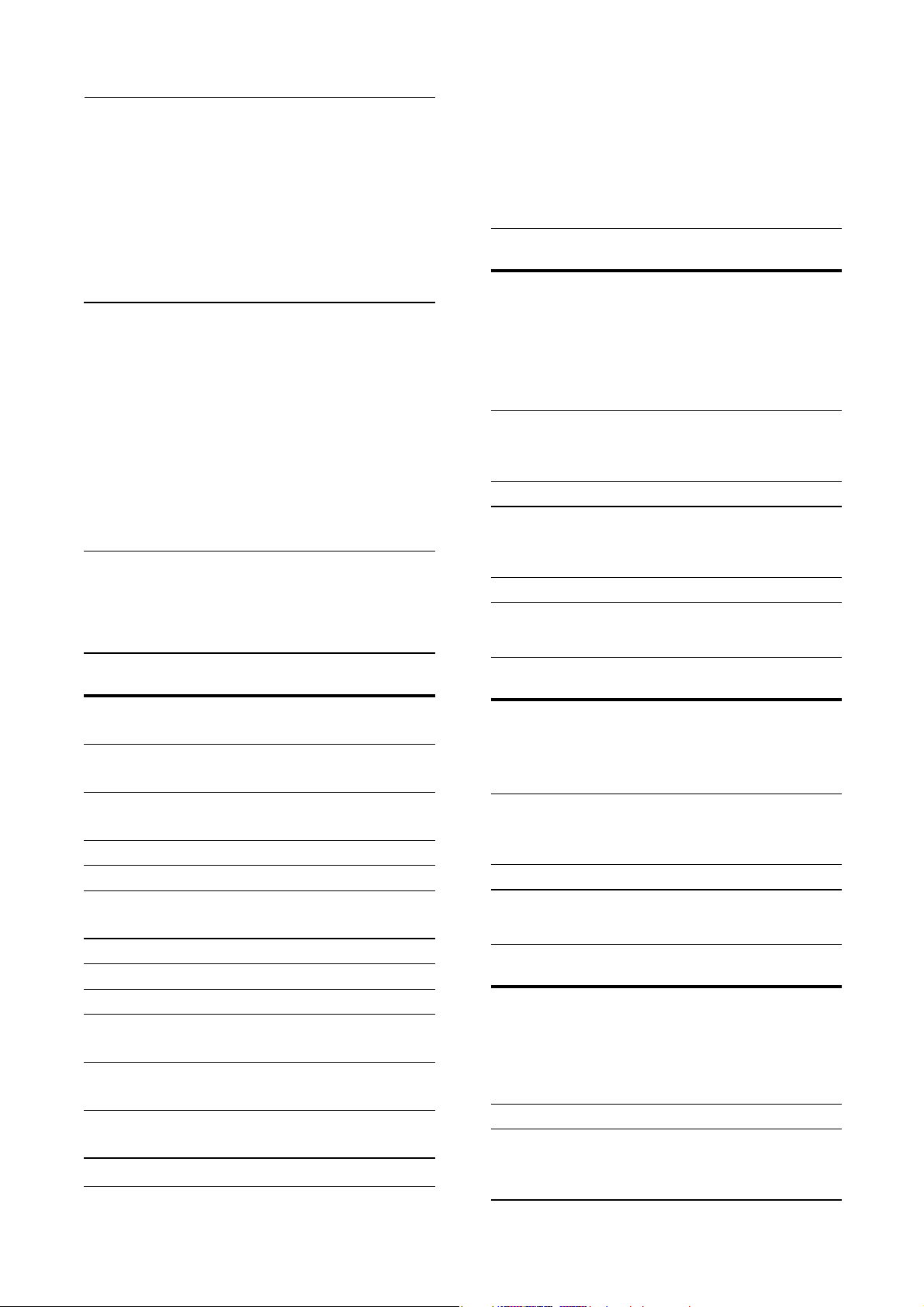

VERSION VARIATION:

Type/Versions

Features

Output Power - 440W/350W

Voltage (220~240V)

Ipod Dock

Music iLink

HTS7202

/12

x

x

x

x

Power PCB

VFD PCB

IR PCB

HTS7212

/12

x

x

x

x

SERVICE SCENARIO MATRIX:

Type/Versions

Board in used

MAIN+MP3+IR+TUNE AUX IN PCB Board

Power Board

VFD Board

BD Board

Touch Board

Ipod Dock Module

*Bd= Board Level Replacement

*C = Component Level Repair

HTS7202

/12

C

C

Bd

Bd

Bd

Bd

HTS7212

/12

C

C

Bd

Bd

Bd

Bd

SPECIFICATIONS

1 - 3

Media formats

AVCHD, BD, BD-R/ BD-RE, BD-Video,

•

DVD-Video, DVD+R/+RW, DVD-R/RW, DVD+R/-R DL, CD-R/CD-RW,

Audio CD, Video CD/SVCD, Picture files,

MP3 media, WMA media, DivX (Ultra)/

DivX Plus HD media, USB storage device

File formats

Audio: .aac, .mka, .mp3, .wma, .wav, .mp4,

•

.m4a

Video:

•

.avi,.divx,.mp4,.mkv,.asf,.wmv,

•

.mpg, .mpeg,

.rmvb,.rm(AvailableonlyinAsia

•

Pacific and China)

Picture: .jpg, .jpeg, .gif, .png

•

Audio formats

Your home theater sup por ts the fo llow ing

audio files.

theater allows you to play your video files

with:

•

Resolution: 1920 x 1080 pixels at

•

Frame rate: 6 ~ 30 frames per second.

.avi files in AVI container

Audio

codec

PCM,

AC-3,

Video codec Bit rate

DivX 3.11, DivX 4.x,

10Mbps max

DivX 5.x, DivX 6.x

DTS

core,

MP3,

WMA

MPEG 1, MPEG 2 20Mbps

(peak

40Mbps)

MPEG 4 ASP 10Mbps max

H.264/AVC

HP@4.1/4.0;

MP@3.2/3.1/3.0

20Mbps

(peak

40Mbps)

WMV9 20Mbps

.divx files in AVI container

Extension Container Audio

codec

Bit rate

.mp3 MP3 MP3 32kbps ~

320kbps

.wma ASF WMA 64kbps ~

160kbps

.aac AAC AAC,

192kbps

HE-AAC

.wav WAV PCM 1.4Mbps

.m4a MKV AAC 192kbps

.mka MKA PCM 27.648

Mbps

.mka MKA AC-3 640kbps

.mka MKA DTS core 1.54Mbps

.mka MKA MPEG 912kbps

.mka MKA MP3 32kbps ~

320kbps

.mka MKA WMA 64kbps ~

160kbps

.mka MKA AAC,

192kbps

HE-AAC

Video formats

If you have a high definition TV, your home

Audio

codec

PCM,

AC-3,

Video codec Bit rate

DivX 3.11, DivX 4.x,

10Mbps max

DivX 5.x, DivX 6.x

MP3,

WMA

MPEG 1, MPEG 2 20Mbps

(peak

40Mbps)

MPEG 4 ASP 10Mbps max

.mp4 or .m4v files in MP4 container

Audio

codec

AC-3,

MPEG,

Video codec Bit rate

MPEG 1, MPEG 2 20Mbps (peak

40Mbps)

MP3,

AAC,

HE-AAC

MPEG 4 ASP 10Mbps max

H.264/AVC

HP@4.1/4.0;

20Mbps (peak

40Mbps)

MP@3.2/3.1/3.0

.mkv files in MKV container

Audio codec Video codec Bit rate

1 - 4

Music iLink: 400 mV

•

PCM, AC-3,

DTS core,

MPEG,

MP3,

WMA,

AAC, HEAAC

.asf and .wmv files in ASF container

Audio

codec

PCM,

AC-3,

MP3,

WMA

.mpg and .mpeg files in PS container

Audio codec Video codec Bit rate

PCM,

DTS core,

MPEG, MP3

MPEG 1, MPEG220Mbps (peak

40Mbps)

MPEG 4 ASP 10Mbps max

H.264/AVC

HP@4.1/4.0;

MP@3.2/3.1/3.0

WMV9 20Mbps

Video codec Bit rate

MPEG 4 ASP 10Mbps max

H.264/AVC

HP@4.1/4.0;

MP@3.2/3.1/3.0

WMV9 20Mbps

MPEG 1,

MPEG 2

MPEG 1,

MPEG 2

20Mbps (peak

40Mbps)

20Mbps (peak

40Mbps)

20Mbps (peak

40Mbps)

20Mbps (peak

40Mbps)

Amplifier

Video

•

Signal system: PAL / NTSC

•

HDMI output: 480i/576i, 480p/576p,

720p, 1080i, 1080p, 1080p24

Audio

•

S/PDIF Digital audio input:

•

Coaxial: IEC 60958-3

•

Optical: TOSLINK

•

Sampling frequency:

•

MP3: 32 kHz, 44.1 kHz, 48 kHz

•

WMA: 44.1 kHz, 48 kHz

•

Constant bit rate:

•

MP3: 112 kbps - 320 kbps

•

WMA: 48 kbps - 192 kbps

Radio

•

Tuning r ang e:

•

Europe/China: FM 87.5-108 MHz (50

kHz)

•

Asia Pacific/Russia/Latin America: FM

87.5-108 MHz (50/100 kHz)

•

Signal-to-noise ratio: FM 55 dB

•

Frequency response: FM 60 kHz-12.5 kHz

/ ±3 dB

USB

•

Compatibility: Hi-Speed USB (2.0)

•

Class support: USB Mass Storage Class

(UMS)

•

File system: FAT16, FAT32, NTFS

•

Maximum memory support: < 160 GB

Total output power: 440W RMS (30%THD)ǃ

•

350W RMS (10%THD)

Frequency response: 20 Hz-20 kHz / ±3

•

dB

•

Signal-to-noise ratio: > 65 dB (CCIR) /

(A-weighted)

•

Input sensitivity:

•

AUX1, AUX2: 1100 mV

Main unit

•

Power supply:

•

Europe/China: 220-240 V~, 50 Hz

•

Latin America/Asia Pacific: 110-127

V/220-240 V~, 50-60 Hz

•

Russia/India: 220-240 V~, 50 Hz

•

Power consumption: 85 W

Standby power consumption: ≤ 0.5 W

•

Dimensions (WxHxD): 360 x 70 x 345

•

mm

Weight: 4.36 kg

•

1 - 5

Remote control batteries

•

2 x AAA-LR03-1.5V

Laser

Subwoofer

•

Total output power: 200W RMS (30%THD) ǃ

150W RMS (10%THD)

•

Impedance: 3 ohm

•

Speaker drivers: 165 mm (6.5”) woofer

•

Frequency response: 20 Hz-150 Hz

•

Dimensions (WxHxD): 196 x 395 x 342

(mm)

•

Weight: 5.29kg

•

Cable length: 3 m

Speakers

•

Total output power: 2 x 120W RMS (30%THD)ǃ

2 x 100W RMS (10%THD)

•

Speaker impedance: 5 ohm

•

Speaker drivers: 2 x 76.2 mm (3”) woofer

+ 1 x 25.4 mm (1”) tweeter

•

Frequency response: 150 Hz-20 kHz

•

Dimensions (WxHxD): 97 x 301 x 120

mm

•

Weight: 1.45 kg/each

•

Cable length: 3 m

•

Laser Type (Diode): InGaN/AIGaN (BD),

AIGaInP (DVD/CD)

•

Wave length: 405 +7nm/-7nm (BD), 655

+10nm/-10nm (DVD), 790 +10nm/-20nm

(CD)

•

Output power (Max. ratings): 20mW

(BD), 6mW (DVD), 7mW (CD)

Speci cations subject to change without

prior notice.

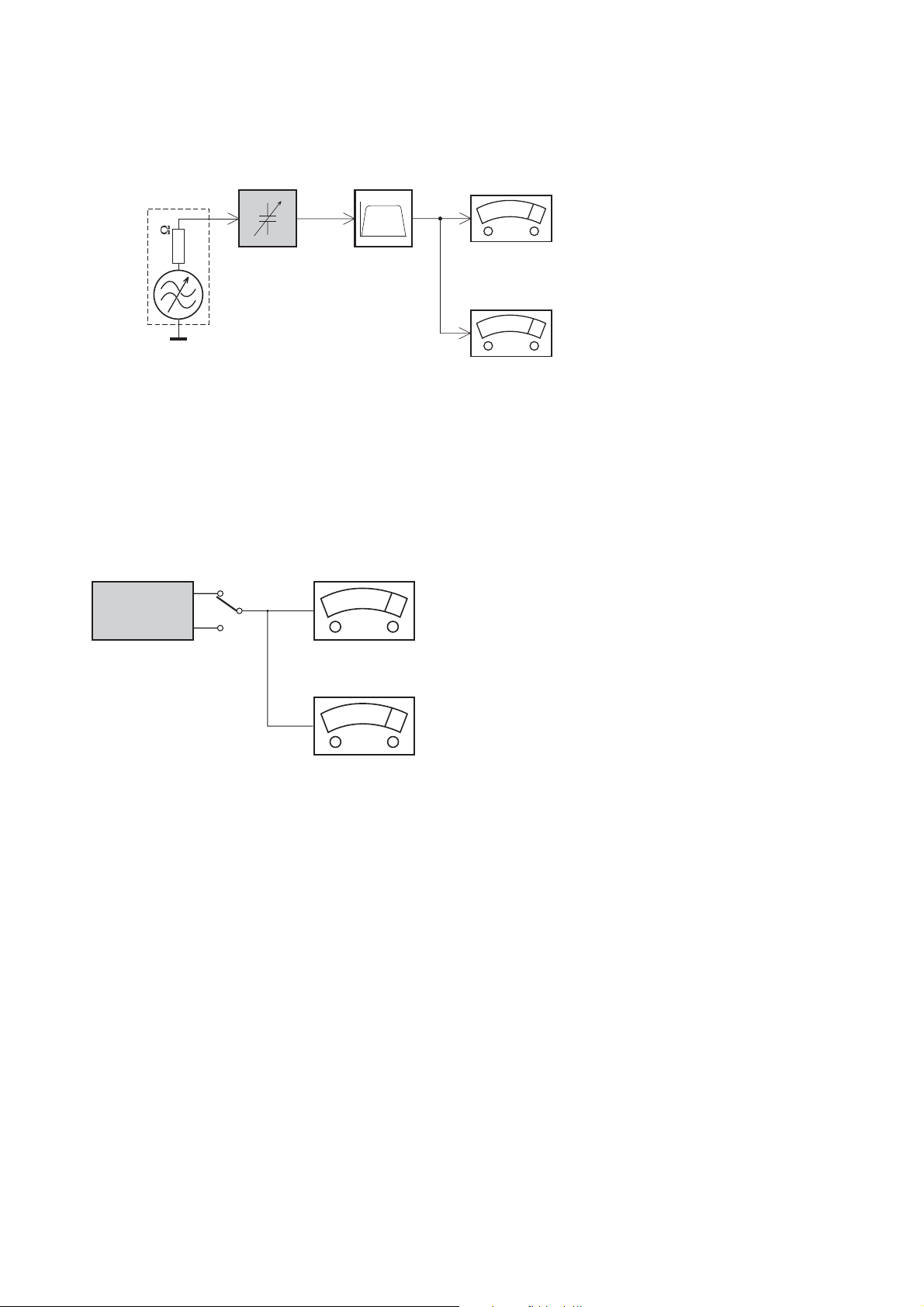

MEASUREMENT SETUP

Tuner FM

1 - 6

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

SBC429 4822 397 30184

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................4822 395 91019

Torx bit T10 150mm ...........................................4822 395 50456

Torx driver set T6-T20 .........................................4822 395 50145

Torx driver T10 extended .....................................4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ...........................4822 397 30096

SBC442 Audio Burn-in test disc 1kHz .................4822 397 30155

SBC429 Audio Signals disc .................................4822 397 30184

Dolby Pro-logic Test Disc ....................................4822 395 10216

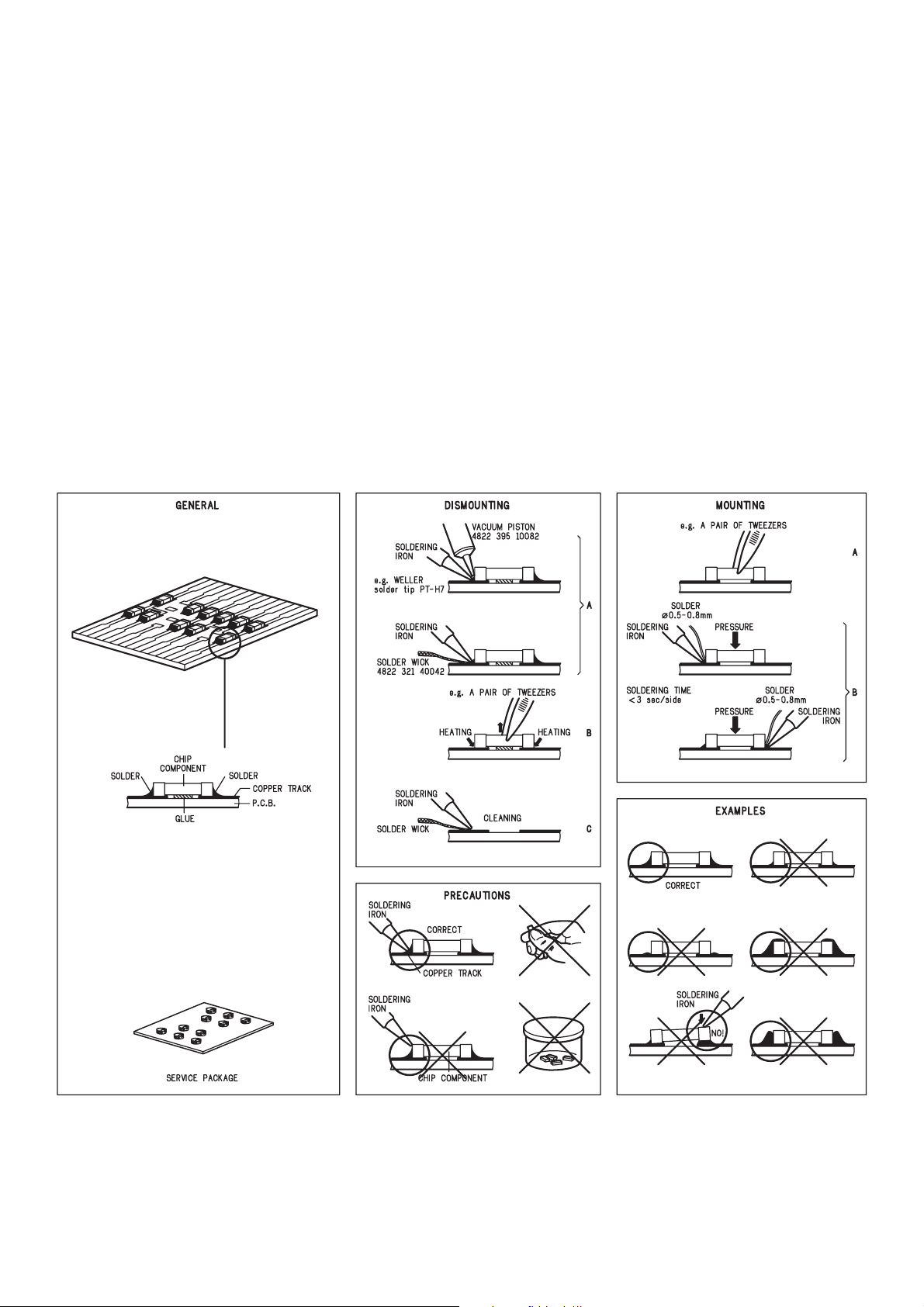

HANDLING CHIP COMPONENTS

1 - 7

GB

A

WARNING

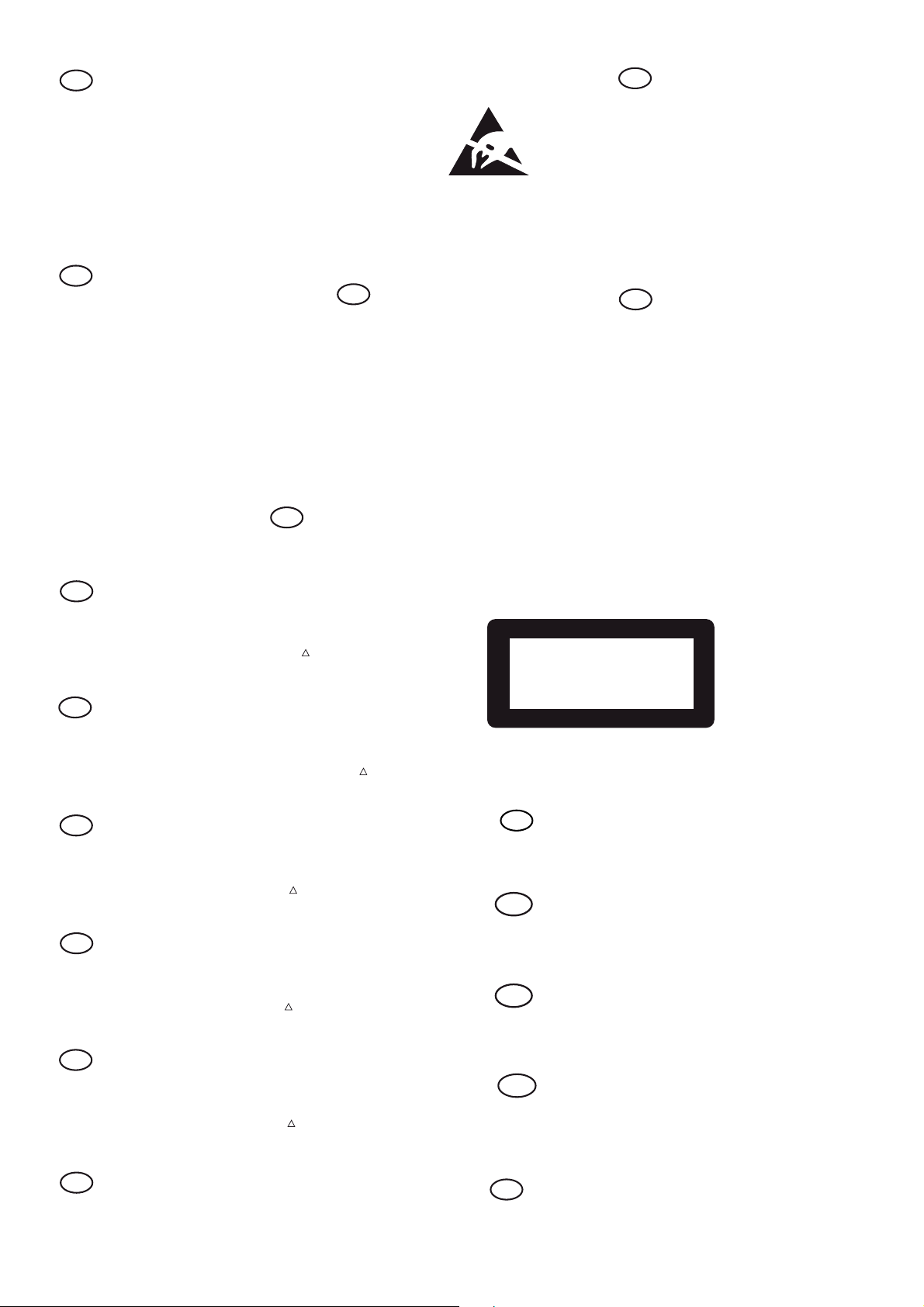

1 - 8

ESD

WAARSCHUWING

NL

ll ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

F

ATTENTION

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, estention cable and earth cable ....... 4822 310 10671

Wristband tester ................................................................. 4822 344 13999

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen

(ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

I

AVVERTIMENTO

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used.

Safety components are marked by the symbol

!

.

CLASS 1

LASER PRODUCT

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbol

!

.

3122 110 03420

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

.

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

.

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground

to assure no shock hazard exist, The leakage current must not

exceed 0.5mA.

GB

Warning !

Invisible laser radiation when open.

Avoid direct exposure to beam.

S

Varning !

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

Varoitus !

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK Advarse !

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

onemust treat allsets from 1 Jan 2005 onwards, according

next rules:

Important note: In fact also products of year 2004 must

be treated in this way as long as you avoid mixing solderalloys (leaded/ lead-free). So best to always use SAC305

and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste

is required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste

within workshops should be avoided because paste is

not easy to store and to handle.

• Use only adequate solder tools applicable for lead-

free solder alloy. The solder tool must be able

– To reach at least a solder-temperature of 400@C,

– To stabilize the adjusted temperature at the solder-

tip

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around

360@C – 380@C is reached and stabilized at the solder

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400@C otherwise

wear-out of tips will rise drastically and flux-fluid will

be destroyed. To avoid wear-out of tips switch off unused equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed solder alloy types (leaded and

lead-free).

If one cannot avoid or does not know whether product

is lead-free, clean carefully the solder-joint from old

solder alloy and re-solder with new solder alloy

(SAC305).

• Use only original spare-parts listed in the Service-

Manuals. Not listed standard-material (commodities)

has to be purchased at external companies.

• Special information for BGA-ICs:

– Always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for desoldering always use the lead-free temperature profile,

in case of doubt)

– Lead free BGA-ICs will be delivered in so-called ‘dry-

packaging’ (sealed pack including a silica gel pack) to

protect the IC against moisture. After opening,

1 - 9

dependent of MSL-level seen on indicator-label in the

bag, the BGA-IC possibly still has to be baked dry.

(MSL=Moisture Sensitivity Level). This will be

communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products

of 2004), containing leaded solder-alloy and

components, all needed spare-parts will be available

till the end of the service-period. For repair of such

sets nothing changes.

• On our website www.atyourservice.ce.Philips.com

you find more information to:

• BGA-de-/soldering (+ baking instructions)

• Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

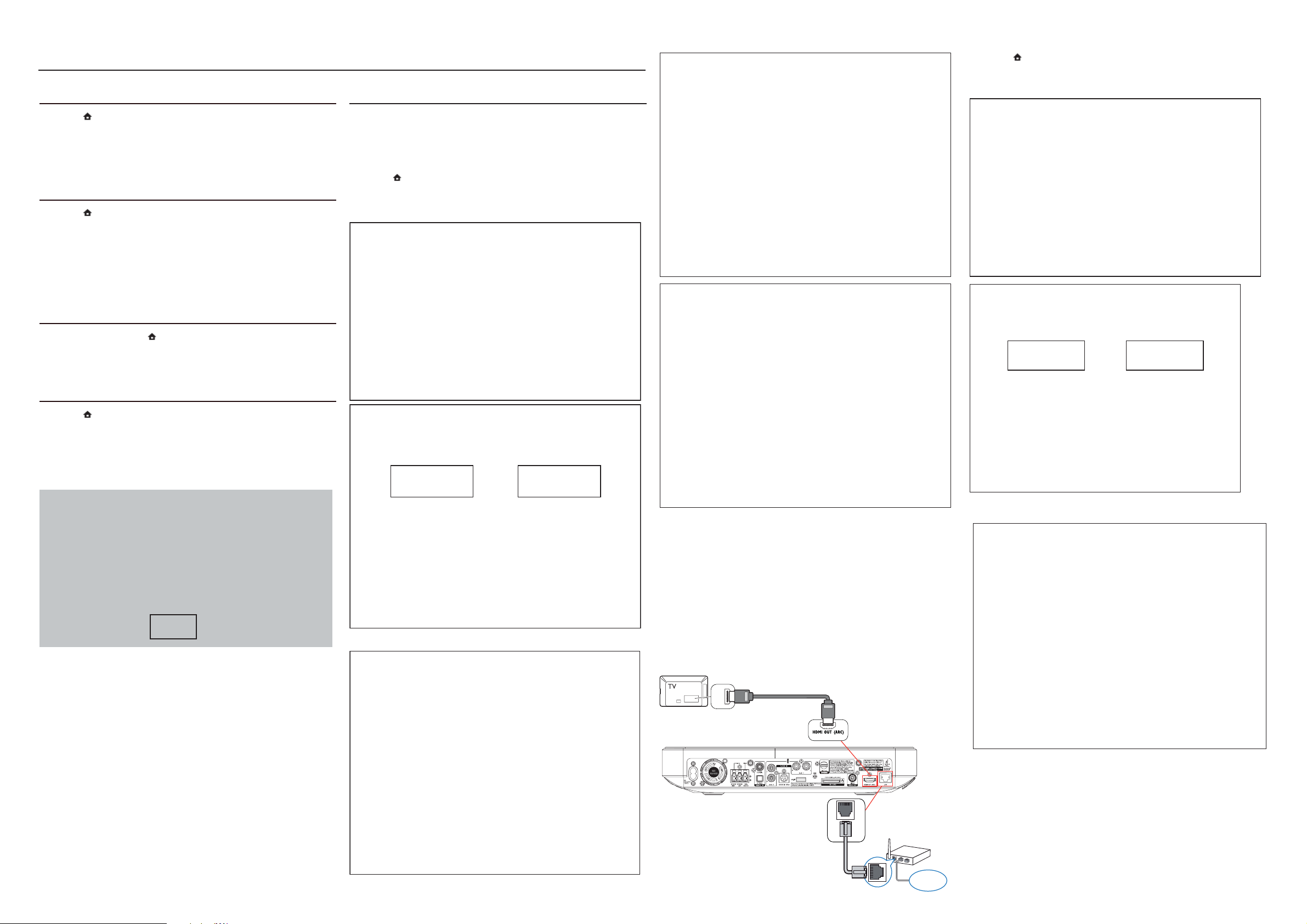

Software upgrade & Procedure to restore product setting

1)Restore factory setting

a) Press “ ” <Home> button on R/C.

b) Select <Setup>, then press “OK” button on R/C.

c) Select <Advanced>, then press < OK > button on R/C.

d) Select <Restore default settings>,then press <OK> to con rm.

2)Password change

a) Press “

” <Home> button on R/C.

b) Select <Setup>, then press “OK” button on R/C.

c) Select <Preference>, then press <OK> button on R/C.

d) Select <Change Password> <Confirm>, then press <OK> button

on R/C.

“0000” is default password supplied.

3)Trade mode

5) Upgrading new software

Method 1: Update software from a USB storage device

a) Create a folder named “UPG_ALL” in your USB storage device,

and Copy the latest upgrading software into the folder.

b) Connect the USB storage device to the home theater.

c) Press “

” <Home> button on R/C, and select <Setup>.

d) Select <Advanced> <Software Update> <USB>.

e) TV will show message as follow:

Now searching for upgrade software!

Please wait...!

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000025.0

Software BE Completed

Software FE Completed

Software MCU1: Not started

Software Dock: 2%

Software MCU3: Not started

Software upgrade will take 5 minutes

Do not switch off!

2 - 12 - 1

b) Press “

” <Home> button on R/C, and select <Setup>.

c) Select <Advance Setup> <Software Update> <Network>.

d) TV will show message as follow:

Now searching for upgrade software!

Please wait...!

Software updates for this player have been found. Do you want to

upgrade?

a) In open model,press “

” <Home> button on R/C.

b) Press “2” “5” “9” on R/C,VFD will display “TRA ON” or “TRA

OFF”.

4)Check software version

a) Press “

” <Home> button on R/C

b) Select <Setup>, then press <OK> button on R/C.

c) Select <Advanced> <Version Info.>,then press <OK> button on

R/C.

d) TV will show message as follow:

Model:HTS7202/12

Versions:

System SW:0.28.01

Subsystem SW:20-00-00-00

Ethernet MAC:00:25:D1:05:88:33

For more information,frequently asked questions and

software updates,please visit

philips.com/support

Close

e) Select <Close> on the version display screen and press <OK>

button to exit .

Software updates for this player have been found. Do you want to

upgrade?

Cancel

Start

f) Select <Start>, press <OK> button on R/C.

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000025.0

Software BE Completed

Software FE Completed

Software MCU1: 1%

Software Dock: Failed

Software MCU3:

g)The set will shut down automatically when the software upgrade

is completed.

Method 2: Update software from the internet

Note: To check for new updates, compare the current software

version of your home theater with the latest software version (if

available) on the Philips web site, and for BD-Live application and

software update, make sure that the network router has access to

the Internet and the firewall is disabled.

a) The “LAN” jack at the back panel of the set must be connect to

the network router via network cable and the set connect to TV,

Prepare the connection as shown follow:

/NI IMDH

CRA IMDH

Cancel

Start

e) Select <Start>, press <OK> button on R/C.

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000025.0

Software BE 80%

Software FE Completed

Software MCU1:

Software Dock:

Package version: 000025.0

Software BE 80%

Software FE Completed

Software MCU1:

Software Dock:

Software MCU3:

Software MCU3:

LAN

www

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000025.0

Software BE Completed

Software FE Completed

2 - 22 - 2

c) Assembly Blu-ray Loader to “J800”,”J900”,”J905” on the top of

BD Board as shown below.

Software MCU1: Not started

Software Dock: 2%

Software MCU3: Not started

Software upgrade will take 5 minutes

Do not switch off!

Package version: 000025.0

Software BE Completed

Software FE Completed

Software MCU1: 1%

Software Dock: Failed

Software MCU3:

f) The set will shut down automatically when the software upgrade

is completed.

K:16

K:11

K911

d) Remove soldered joint on the ESD protection points.

The ESD protection points

The ESD protection points

on the top of board

Top side view of OPU

on the top of board

Bottom side view of OPU

Note: The 2 ESD protection points on any one side must be

soldered if

o the Blu-ray Loader is OK and needs to be disconnected

from connector J800, J900 and J905 of the BD Board.

o the defective Blu-ray Loader is needed to be send back to

supplier for failure analysis and to support backcharging evidence.

CAUTION!

This information is confi dential and may not be

distributed.Only a qualifi ed service person should

reprogram the Region Code.

6)How to replace the defective Blu-ray Loader

a) Remove the defective Blu-ray Loader.

b) Remove the shield cover at the top of Blu-ray Loader as shown

below.

REPAIR INSTRUCTIONS

2 - 32 - 3

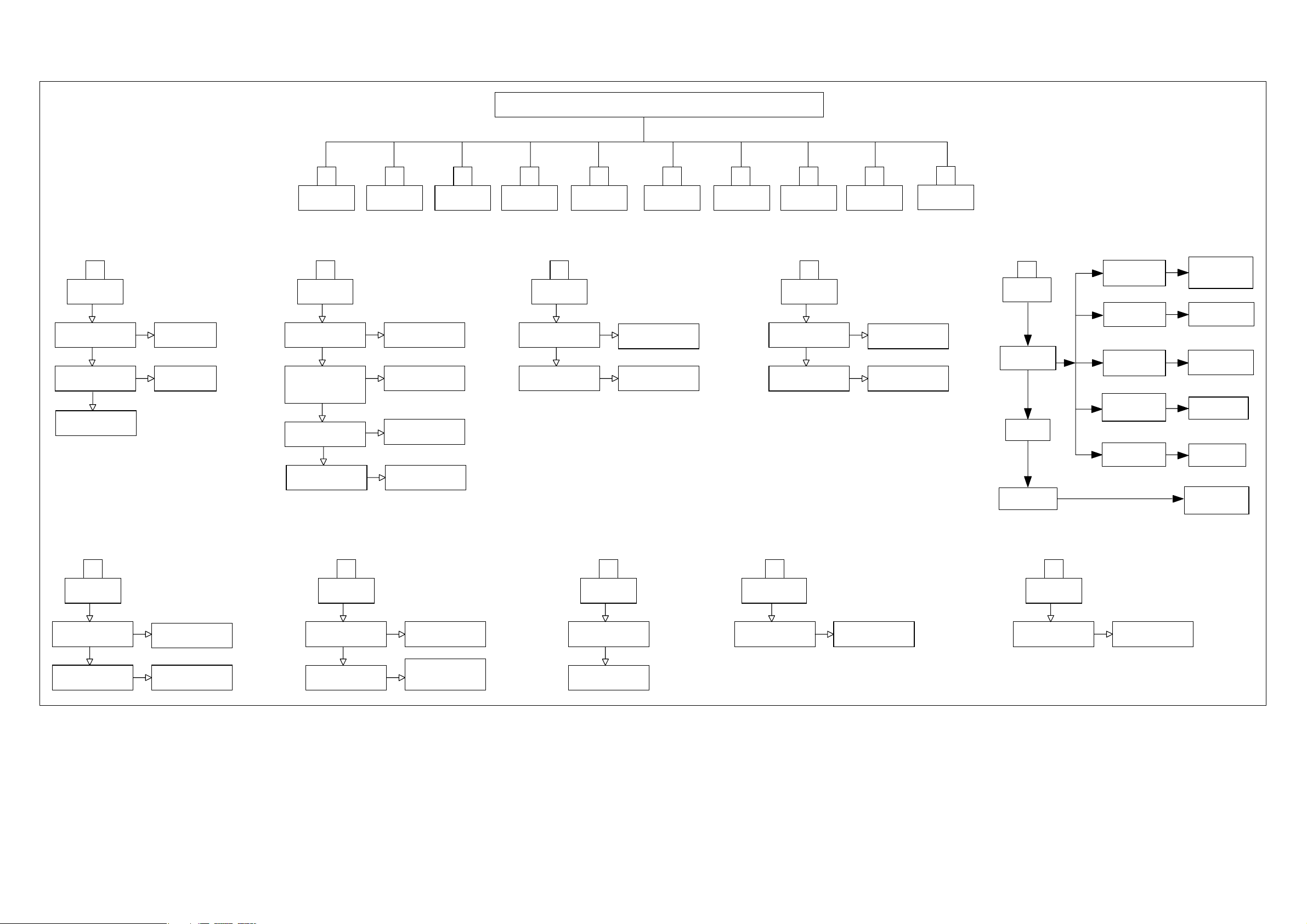

MAIN UNIT REPAIR CHART

A

All Functions

are not working

Check a ll system all cable

is loose or bad INT

NO

Panel st andby LED

whether li ght

YE S

Check MA IN PC B Q 106

and thei r conjoi nt part .

YE S

Check power boar d

NO

RE-i nsert and x

the cable

BK 3V3 out

AB D FG

All Functions

are not working

B

All Functions

are not sound

Check MAIN PC B CN 1007

whether at PIN1 -7 +31V

and at R5165 +12V .

YE S

Check MA IN PC B I C 5001

IC5004and thei r conjoi nt

part whether OK

YE S

Check MAIN PC B IC5006

PI N9.15.36.54

whether at +3.3 V

YE S

Ch eck MAIN PC B IC501

pin12.24.37/pin16.28.42

3.3V /1.8V whether OK

All Functions

are not sound

Check SW power and

NO

Check MAIN PC B IC5001

NO

IC5004 and their conjoint

Ch eck MAIN PC BQ 1007

NO

and their conj oint part

NO

L 502/L501 Wh ether OK.

conjoint pa rt

part whether OK

whether OK

Ch eck MAIN PC B

C

AUX1 In

is not sound

AUX2 In

is not sound

C

AUX1 In

is not sound

Check si gnal source

Whether output OK

YE S

Chec k MA IN PC B IC 304 Pi n

9/10 whether i nput ok .

E

MP3 In

is not sound

NO

NO

Tuner Function

is not sound

Check signal source and

their conjoint part whether

OK.

Check MAIN PC B

R 365/R364 a nd their

conjoint part Wh ether OK.

DISC Function

is not sound

H

USB Wire lines

are not function

D

AUX2 In

is not sound

Check si gnal source

Whether output OK

YE S

Check MA IN PC B IC 304 Pi n

7/8 whether input ok .

I

USB

is not function

Check signal source and

NO

their conjoint part whether

Check MAIN PC B

NO

R 308/R309 a nd their

conjoint part Wh ether OK.

OK.

J

Power Supply

is not working

J

Power Supply

is not working

YE S

Al l Voltage

No Output

YE S

Check F901

Bad Cause Damage

No

Check BK 3V 3 5V

Worki ng or Not

VCC Voltage

No Output

-27V Voltage

Worki ng or Not

No

No

12V Vo ltage

No Output

5V Vo ltage

No Output

BK 3V 3 Voltage

No Output

Check Q912 Q913 IC 905

No

Check Repair IC901 IC 903

Q909 IC904 IC906 And Its

And Its Conjoint Part

Check D919 Q907

And Its Conjoint Part

Check D923 Q901

And Its Conjoint Part

Check D922 Q906

And Its Conjoint Part

Check R978 IC906

And Its Conjoint Part

CONN CI RC UIT

E

MP3 In

is not sound

Check si gnal source

Whether output OK

YE S

Check MA IN PC B IC 304 Pi n

26/27 whether i nput ok .

Ch eck si gnal source and

NO

their conjoint part whether

Check MAIN PC B

NO

R 345/R346 a nd their

conjoint part Wh ether OK.

OK.

F

Tuner Function

is not sound

Check MAIN PC B

TU101P in7/8 output

whether OK.

YE S

Check MAIN PC B IC304

Pin23/24 whether IN OK.

Ch eck MAIN PC B TU301

NO

PI N5whether is 5V and

their conjoint part whether

Check MA IN PC B IC 304

Pin 23/24 their conjoint part

NO

OK.

whether OK.

G

DISC Function

is not sound

Check MAIN PC B CN 1006

cable and their co njoint

part whether OK.

YE S

Ch eck MAIN PC B IC501

and their conjoint part

whether OK.

H

USB Wire lines

are not function

Check USBW i re Li nes

cabl e and RB301

Wh ether OK

NO

RE-i nsert RB301 and x

the cable

I

USB

is not function

Check USB cabl e and

RB 1 5 Whether OK

RE-i nsert RB15 and x

NO

the cable

Loading...

Loading...