Page 1

Published by KC-TE 0519 AV Systems Printed in the Netherlands Subject to modification EN 3139 785 31550

HTS3300MKII/05/12/51/98/55

DVD Receiver

CLASS 1

LASER PRODUCT

1 Technical Specifications and Connection

Facilities 2

2 Measurements Setup, Service Aid &

Lead Free Requirements 4

3 Dismantling Instructions & Service Positions 10

4 Service Test Program 12

5 FTD Display Pin Connection 14

6 Block Diagram 15

Wiring Diagram 16

7 Circuit Diagram and PWB Layout 17

Front: Display 17

Front: Display (Top view) 18

Front: Display (Bottom view) 19

Mono Board: Circuit Diagram (Part 1) 20

Mono Board: Circuit Diagram (Part 2) 21

Mono Board: Circuit Diagram (Part 3) 22

Mono Board: Circuit Diagram (Part 4) 23

Mono Board: Circuit Diagram (Part 5) 24

Layout: Mono Board (Top View) 25

Layout: Mono Board (Bottom View) 26

Front: Standby 27

PSU Circuit Diagram 28

©

Copyright 2005 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in

a retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Version 1.0

Contents PageContents Page

8 Overview - Modulator, Input/Output and

Headphone/Line Output Connectors 30

TAS5086-5142V6REF 30

Power Output Stage (SE) 31

Power Output Stage (BTL) 32

Power Supplies 33

9 Exploded View & Spare Parts List 35

Exploded View of the set 35

Spare Part List 36

Page 2

EN 2

3139 785 315501.

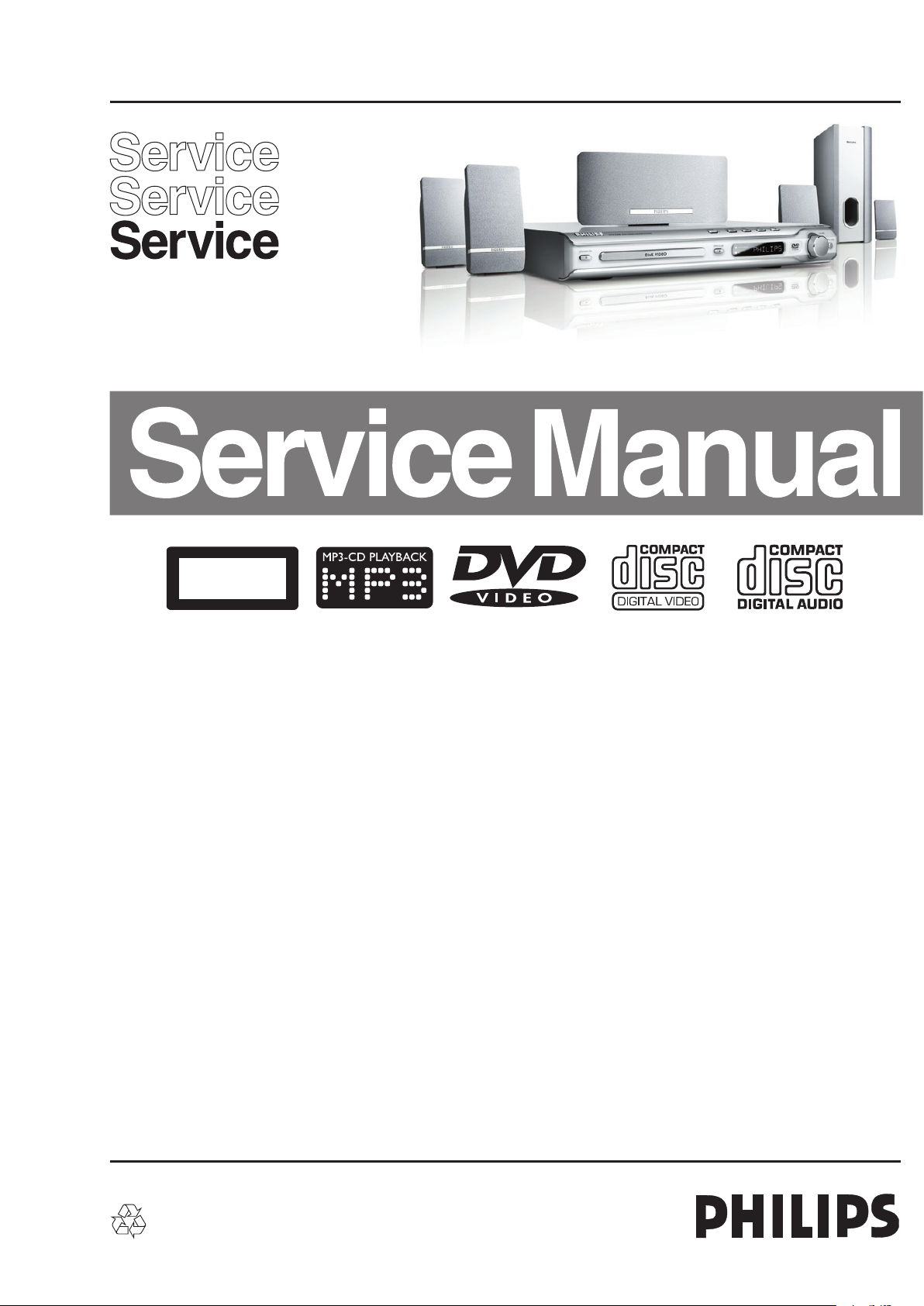

LOCATION OF PC BOARDS

Technical Specifi cations and Connection Facilities

VERSION VARIATIONS:

Type /Versions:

Features &

Progressive Scan

Line-Out

TV-In

Aux-In

Y/Pb/Pr (YUV) Component Video Output

Coax

CVBS

S-Video Output

SCART

/98

x

x

x

x

x

HTS3300MK2

/55

/51 /12 /05

x

x

x

x

x

xxx

x

x

xx

x

x

Page 3

Technical Specifi cations and Connection Facilities

1. Specifi cations

3139 785 31550

1.

EN 3

1.1 General:

Mains voltage : 230V for /05, /12, /51

120V/230V for /55

/98

Mains frequency : 50/60Hz for /98, /55,

50Hz for /12, /05,

/51

Power consumption : 70W

< 0.5W Eco standby

power

< 70W at 1/8 P

(For main unit)

rated

Dimension main unit : 360 x 54 x 324mm

1.2 Tuner

FM

Tuning range : 87.5-108MHz

Grid : 50kHz for /12, /05, /51

100kHz for /98, /55

IF frequency : 10.7MHz ± 25kHz

Aerial input : 75Ω coaxial

Sensitivity at 26dB S/N : < 7μV

Selectivity at 600kHz bandwidth : > 25dB

IF rejection : > 60dB

Image rejection : > 25dB

Distortion at RF=1mV, dev. 75kHz : < 3%

-3dB Limiting point : 8μV

Crosstalk at RF=1mV, dev. 67.5kHz : > 28dB

Crosstalk at RF=1mV, dev. 40kHz : > 18dB

1.3 AMPLIFIER:

Output power

Front : 100W RMS / channel

Rear : 75W RMS / channel

Center : 100W RMS

Subwoofer : 150W RMS

Frequency response ±0.5dB : 20Hz-20kHz

Hum (Volume Minimum) : 200nW

Residual noise (Volume Minimum) : 40nW

Input sensitivity

Aux In : 1V ± 3dB at 22kΩ

Scart In : 0.5V ± 3dB at 22kΩ

Output sensitivity

Line Out (Left/Right) : 1V ± 2dB at 10kΩ

Scart Out (Left/Right) : 1V ± 2dB at 10kΩ

1.4 COMPACT DISC/VCD/DVD:

Video Decoding : MPEG-1/MPEG-2/

MPEG-4/DivX 3.11,

4.x & 5.x

Video DAC : 12 Bits

Signal System : PAL / NTSC

Video Format : 4:3 / 16:9

CVBS Out

CVBS level : 1.0 ± 0.1V

Luminance S/N : >= 60dB

1)

p-p

MW

Tuning range : 531-1602kHz for /12,

/05, /51, /98, /93, /55

530-1700kHz for /98,

/55

Grid : 9kHz for /12, /05, /51,

/98, /55

10kHz for /98, /55

IF frequency : 450kHz ± 1kHz

Aerial input : Frame aerial

Sensitivity at 26dB S/N : < 4.0mV/M

Selectivity at 18kHz bandwidth : > 20dB

IF rejection : > 45dB

Image rejection : > 28dB

Distortion at RF=50mV, m=80% : < 5%

S-Video Out

Y level : 1.0 ± 0.1V

1)

p-p

Y S/N : >= 60dB

C level (burst) : 286mV pp +1/-4 dB

RGB/YUV Out

Amplitude : 0.7 ± 0.1V

S/N : >= 60dB

1)

Output terminals to be terminated with 75Ω

1)

p-p

Page 4

EN 4

3139 785 315502.

Measurements Setup, Service Aid & Lead Free Requirements

2. Measurements Setup, Service Aid & Lead Free Requirements

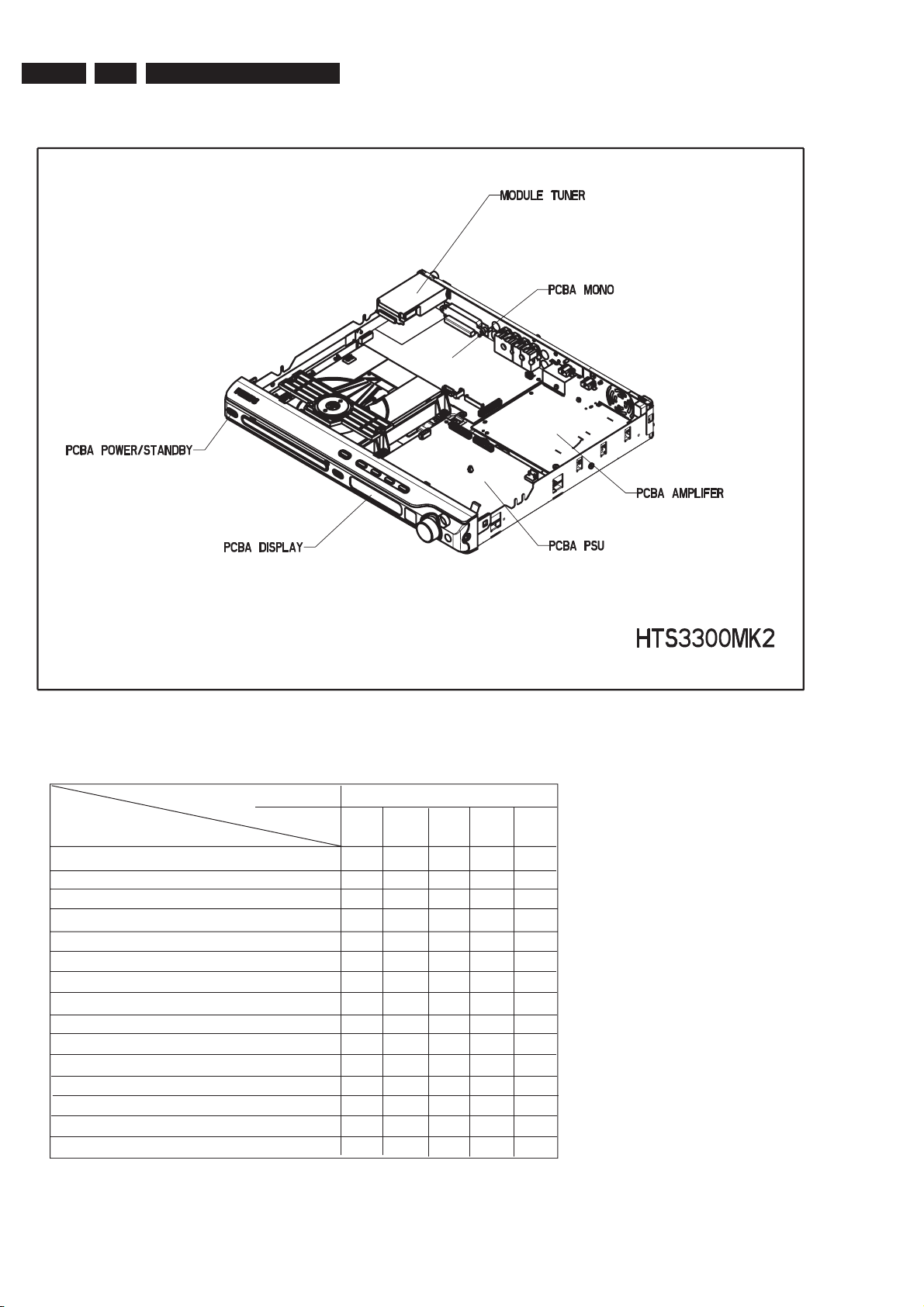

MEASUREMENT SETUP

Tuner FM

Bandpass

LF Voltmeter

e.g. PM2534

RF Generator

e.g. PM5326

DUT

250Hz-15kHz

e.g. 7122 707 48001

Ri=50Ω

S/N and distortion meter

e.g. Sound Technology ST1700B

Use a bandpass filter to eliminate hum (50Hz, 100Hz) and disturbance from the pilottone (19kHz, 38kHz).

Tuner AM (MW,LW)

RF Generator

e.g. PM5326

Ri=50Ω

DUT

Frame aerial

e.g. 7122 707 89001

Bandpass

250Hz-15kHz

e.g. 7122 707 48001

LF Voltmeter

e.g. PM2534

S/N and distortion meter

e.g. Sound Technology ST1700B

To avoid atmospheric interference all AM-measurements have to be carried out in a Faraday´s cage.

Use a bandpass filter (or at least a high pass filter with 250Hz) to eliminate hum (50Hz, 100Hz).

CD

Use Audio Signal Disc

(replaces test disc 3)

DUT

L

R

SBC429 4822 397 30184

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Recorder

Use Universal Test Cassette CrO2 SBC419 4822 397 30069

or Universal Test Cassette

LF Generator

e.g. PM5110

Fe SBC420 4822 397 30071

DUT

L

R

S/N and distortion meter

e.g. Sound Technology ST1700B

LEVEL METER

e.g. Sennheiser UPM550

with FF-filter

Page 5

Measurements Setup, Service Aid & Lead Free Requirements

SERVICE AIDS

Service Tools:

Universal Torx driver holder .................................. 4822 395 91019

Torx bit T10 150mm ............................................. 4822 395 50456

Torx driver set T6 - T20 ......................................... 4822 395 50145

Torx driver T10 extended ...................................... 4822 395 50423

Compact Disc:

SBC426/426A Test disc 5 + 5A ............................ 4822 397 30096

SBC442 Audio Burn-in Test disc 1kHz ................. 4822 397 30155

SBC429 Audio Signals disc .................................. 4822 397 30184

Dolby Pro-logic Test Disc ...................................... 4822 395 10216

3139 785 31550

2.

EN 5

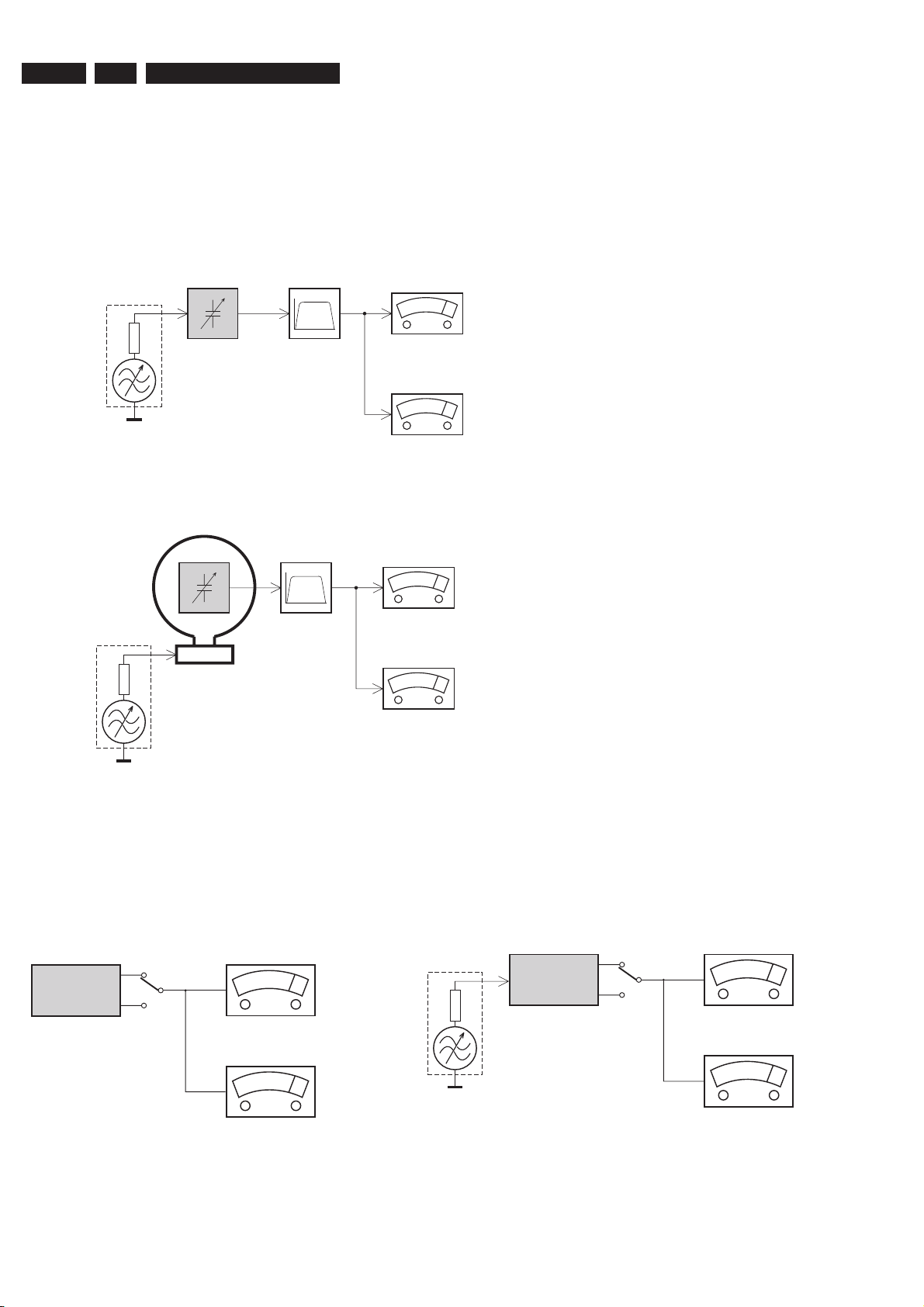

HANDLING CHIP COMPONENTS

Page 6

EN 6

3139 785 315502.

Measurements Setup, Service Aid & Lead Free Requirements

GB

All ICs and many other semi-conductors are

susceptible to electrostatic discharges (ESD).

Careless handling during repair can reduce life

drastically.

When repairing, make sure that you are

connected with the same potential as the mass

of the set via a wrist wrap with resistance.

Keep components and tools also at this

potential.

Tous les IC et beaucoup d’autres

semi-conducteurs sont sensibles aux

décharges statiques (ESD).

Leur longévité pourrait être considérablement

écourtée par le fait qu’aucune précaution n’est

prise à leur manipulation.

Lors de réparations, s’assurer de bien être relié

au même potentiel que la masse de l’appareil et

enfiler le bracelet serti d’une résistance de

sécurité.

Veiller à ce que les composants ainsi que les

outils que l’on utilise soient également à ce

potentiel.

F

WARNING

ATTENTION

GB

Complete Kit ESD3 (small tablemat, wristband,

connection box, extention cable and earth cable) ...........4822 310 10671

Wristband tester ....................................................................4822 344 13999

ESD

D

WARNUNG

Alle ICs und viele andere Halbleiter sind

empfindlich gegenüber elektrostatischen

Entladungen (ESD).

Unsorgfältige Behandlung im Reparaturfall kan

die Lebensdauer drastisch reduzieren.

Veranlassen Sie, dass Sie im Reparaturfall über

ein Pulsarmband mit Widerstand verbunden

sind mit dem gleichen Potential wie die Masse

des Gerätes.

Bauteile und Hilfsmittel auch auf dieses gleiche

Potential halten.

ESD PROTECTION EQUIPMENT:

NL

Alle IC’s en vele andere halfgeleiders zijn

gevoelig voor electrostatische ontladingen (ESD).

Onzorgvuldig behandelen tijdens reparatie kan

de levensduur drastisch doen verminderen.

Zorg ervoor dat u tijdens reparatie via een

polsband met weerstand verbonden bent met

hetzelfde potentiaal als de massa van het

apparaat.

Houd componenten en hulpmiddelen ook op

ditzelfde potentiaal.

Tutti IC e parecchi semi-conduttori sono

sensibili alle scariche statiche (ESD).

La loro longevità potrebbe essere fortemente

ridatta in caso di non osservazione della più

grande cauzione alla loro manipolazione.

Durante le riparazioni occorre quindi essere

collegato allo stesso potenziale che quello della

massa dell’apparecchio tramite un braccialetto

a resistenza.

Assicurarsi che i componenti e anche gli utensili

con quali si lavora siano anche a questo

potenziale.

WAARSCHUWING

I

AVVERTIMENTO

GB

Safety regulations require that the set be restored to its original

condition and that parts which are identical with those specified,

be used

Safety components are marked by the symbol

!

.

NL

Veiligheidsbepalingen vereisen, dat het apparaat bij reparatie in

zijn oorspronkelijke toestand wordt teruggebracht en dat onderdelen,

identiek aan de gespecificeerde, worden toegepast.

De Veiligheidsonderdelen zijn aangeduid met het symbool

!

F

Les normes de sécurité exigent que l’appareil soit remis à l’état

d’origine et que soient utiliséés les piéces de rechange identiques

à celles spécifiées.

Less composants de sécurité sont marqués

!

D

Bei jeder Reparatur sind die geltenden Sicherheitsvorschriften zu

beachten. Der Original zustand des Geräts darf nicht verändert werden;

für Reparaturen sind Original-Ersatzteile zu verwenden.

Sicherheitsbauteile sind durch das Symbol

!

markiert.

I

Le norme di sicurezza esigono che l’apparecchio venga rimesso

nelle condizioni originali e che siano utilizzati i pezzi di ricambio

identici a quelli specificati.

Componenty di sicurezza sono marcati con

!

CLASS 1

LASER PRODUCT

GB

Invisible laser radiation when open.

Avoid direct exposure to beam.

Osynlig laserstrålning när apparaten är öppnad och spärren

är urkopplad. Betrakta ej strålen.

SF

Avatussa laitteessa ja suojalukituksen ohitettaessa olet alttiina

näkymättömälle laserisäteilylle. Älä katso säteeseen!

DK

Usynlig laserstråling ved åbning når sikkerhedsafbrydere er

ude af funktion. Undgå udsaettelse for stråling.

S

Warning !

Varning !

Varoitus !

Advarse !

GB

After servicing and before returning set to customer perform a leakage

current measurement test from all exposed metal parts to earth ground to

assure no shock hazard exist. The leakage current must not exceed

0.5mA.

F

"Pour votre sécurité, ces documents doivent être utilisés par

des spécialistes agréés, seuls habilités à réparer votre

appareil en panne".

Page 7

Measurements Setup, Service Aid & Lead Free Requirements

2.1 Lead Free Requirements

3139 785 31550

2.

EN 7

Pb(Lead) Free Solder

When soldering , be sure to use the pb free solder.

INDENTIFICATION:

Regardless of special logo (not always indicated)

one must treat all sets from 1 Jan 2005 onwards, according next

rules:

Important note: In fact also products of year 2004 must be treated in

this way as long as you avoid mixing solder-alloys (leaded/ lead-free).

So best to always use SAC305 and the higher temperatures belong

to this.

Due to lead-free technology some rules have to be respected by the

workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order

code 0622 149 00106. If lead-free solder-paste is required,

please contact the manufacturer of your solder-equipment.

In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

• Use only adequate solder tools applicable for lead-free solder

alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the solder-tip

o To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C

– 380°C is reached and stabilized at the solder joint. Heatingtime of the solder-joint should not exceed ~ 4 sec. Avoid

temperatures above 400°C otherwise wear-out of tips will rise

drastically and fl ux-fl uid will be destroyed. To avoid wear-out

of tips switch off un-used equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder alloy /

parts is possible but PHILIPS recommends strongly to avoid

mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is leadfree, clean carefully the solder-joint from old solder alloy and

re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the Service-Manuals.

Not listed standard-material (commodities) has to be

purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature

profi le of the specifi c BGA (for de-soldering always use the

lead-free temperature profi le, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘drypackaging’ (sealed pack including a silica gel pack) to protect

the IC against moisture. After opening, dependent of MSLlevel seen on indicator-label in the bag, the BGA-IC possibly

still has to be baked dry. (MSL=Moisture Sensitivity Level).

This will be communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of 2004),

containing leaded solder-alloy and components, all needed

spare-parts will be available till the end of the service-period.

For repair of such sets nothing changes.

• On our website www.atyourservice.ce.Philips.com you fi nd

more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profi les of BGAs and other ICs used in

Philips-sets

You will fi nd this and more technical information within the

“magazine”, chapter “workshop news”.

For additional questions please contact your local repair-helpdesk.

Page 8

EN 8

3139 785 315502.

Measurements Setup, Service Aid & Lead Free Requirements

2.2 Service Hints

CAUTION

CHARGED CAPACITORS ON THE SERVO BOARD MAY DAMAGE THE DRIVE

ELECTRONICS WHEN CONNECTING A NEW DRIVE.THAT’S WHY, BESIDES THE SAFETY

MEASURES LIKE

• SWITCH OFF POWER SUPPLY

• ESD PROTECTION

ADDITIONAL ACTIONS MUST BE TAKEN BY THE REPAIR TECHNICIAN.

The following steps have to be done when replacing the defective loader :

1. Dismantling of the loader to access the ESD protection point if necessary.

2. Solder the ESD protection point*.

3. Disconnect fl exfoil cable from the defective loader.

4. Put a paper clip on the fl exfoil to short-circuit the contacts (fi g.1)

5. Replace the defective loader with a new loader.

6. Remove paperclip from the fl exfoil and connect it to the new loader.

7. Remove solder joint on the ESD protection point.

ATTENTION: The laser diode of this loader is protected against ESD by a solder joint which shortcircuits the laserdiode to ground.

Type 1 Type 2

(ESD protection point is accessible from top of loader) (ESD protection point is accessible from bottom of the loader)

*Only applicable for defective loader needed to be sent back to supplier for failure analysis and to support backcharging

evidence.

This is also applicable for all partnership workshops.

For proper functionality of the loader this solder joint must be remove after connection loader to the set.

Page 9

Measurements Setup, Service Aid & Lead Free Requirements

IMPORTANT: For HTS3300MKII /55, /98 only, please select the correct voltage before switching on.

3139 785 31550

2.

EN 9

Figure 2-1

Page 10

EN 10

3139 785 315503.

3. Mechanical Instructions

Dismantling Instructions & Service Positions

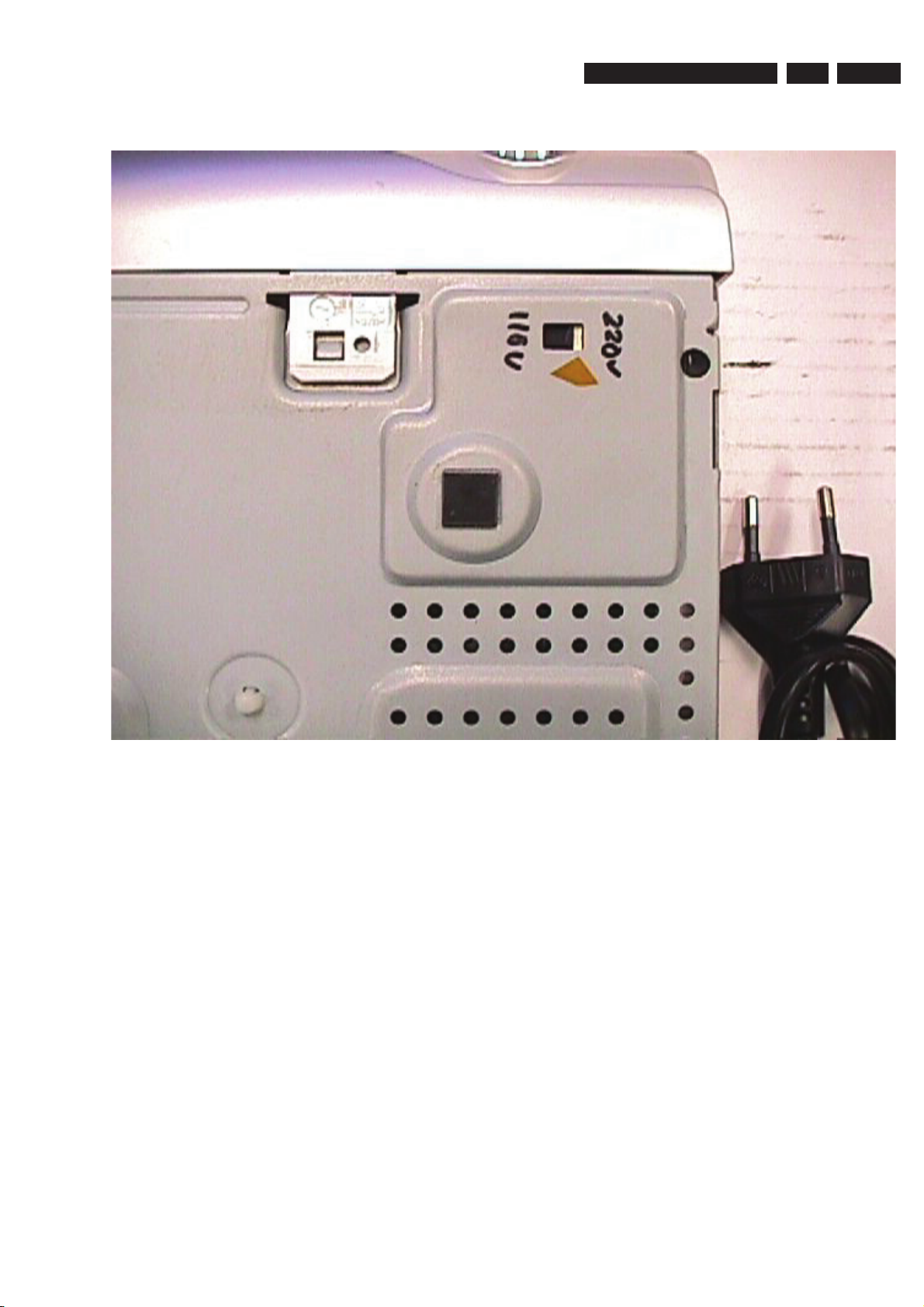

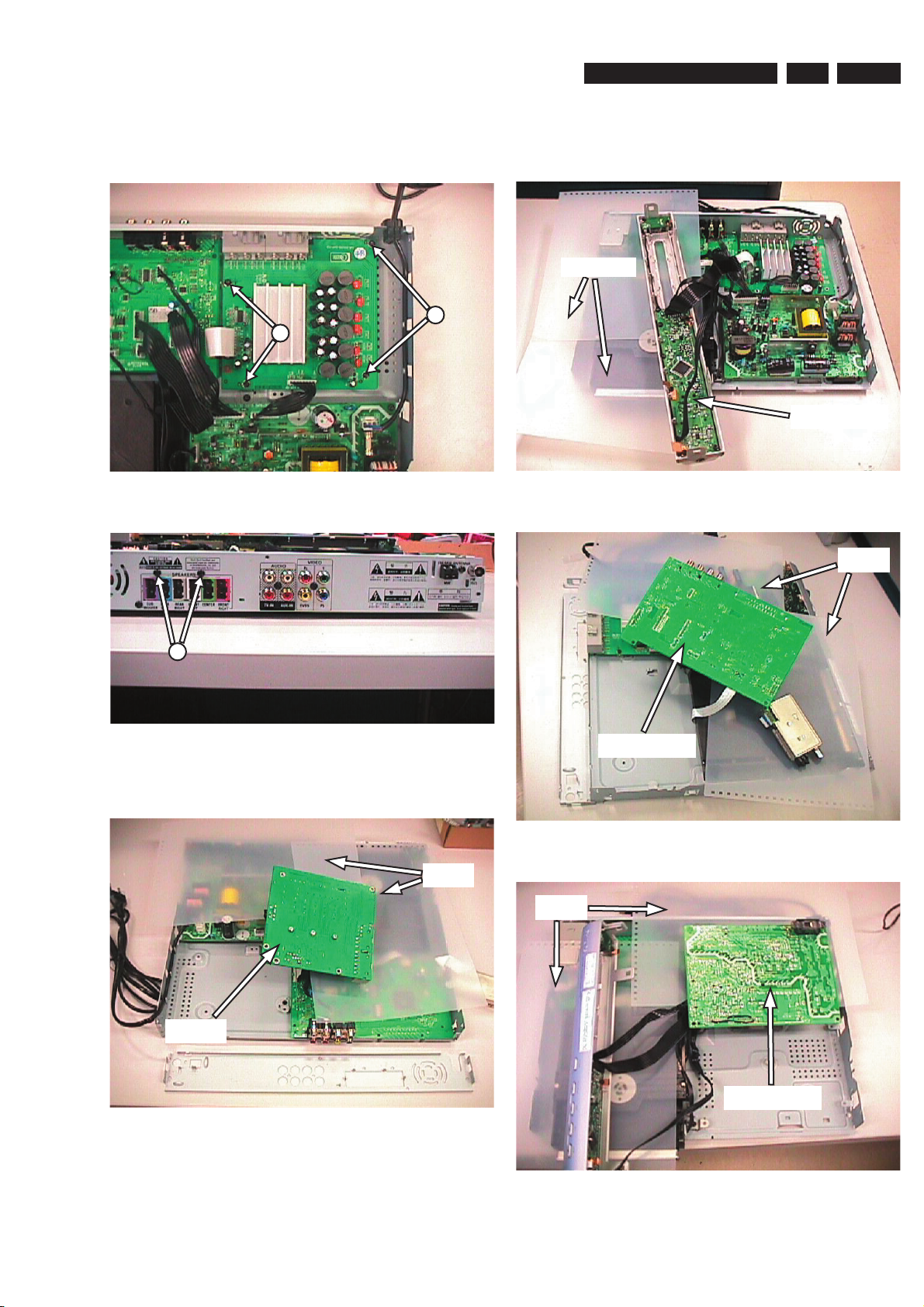

3.1 Dismantling of the Front Board, PSU Module

& DVD Loader.

1) Release 4 snap hooks to remove the Front Board.

- 1 snap hook each on the left & right side

- 2 snap hooks on the bottom side

2) Loosen 4 screws A (See Figure 3-1) to remove the PSU

Module.

A

Figure 3-1

A

3.2 Dismantling of the Tuner Module & Mono

Board.

1) Loosen 1 screw C (See Figure 3-3) to remove the Tuner

Module.

C

Figure 3-3

2) Loosen 2 screws D and E (See Figure 3-4 & Figure 3-5)

to remove the Mono Board.

3) Loosen 4 screws B (See Figure 3-2) to remove the DVD

Loader.

B

Figure 3-2

B

D

E

Figure 3-4(AP) Figure 3-4(Europe)

F

Figure 3-5

Page 11

Dismantling Instructions & Service Positions

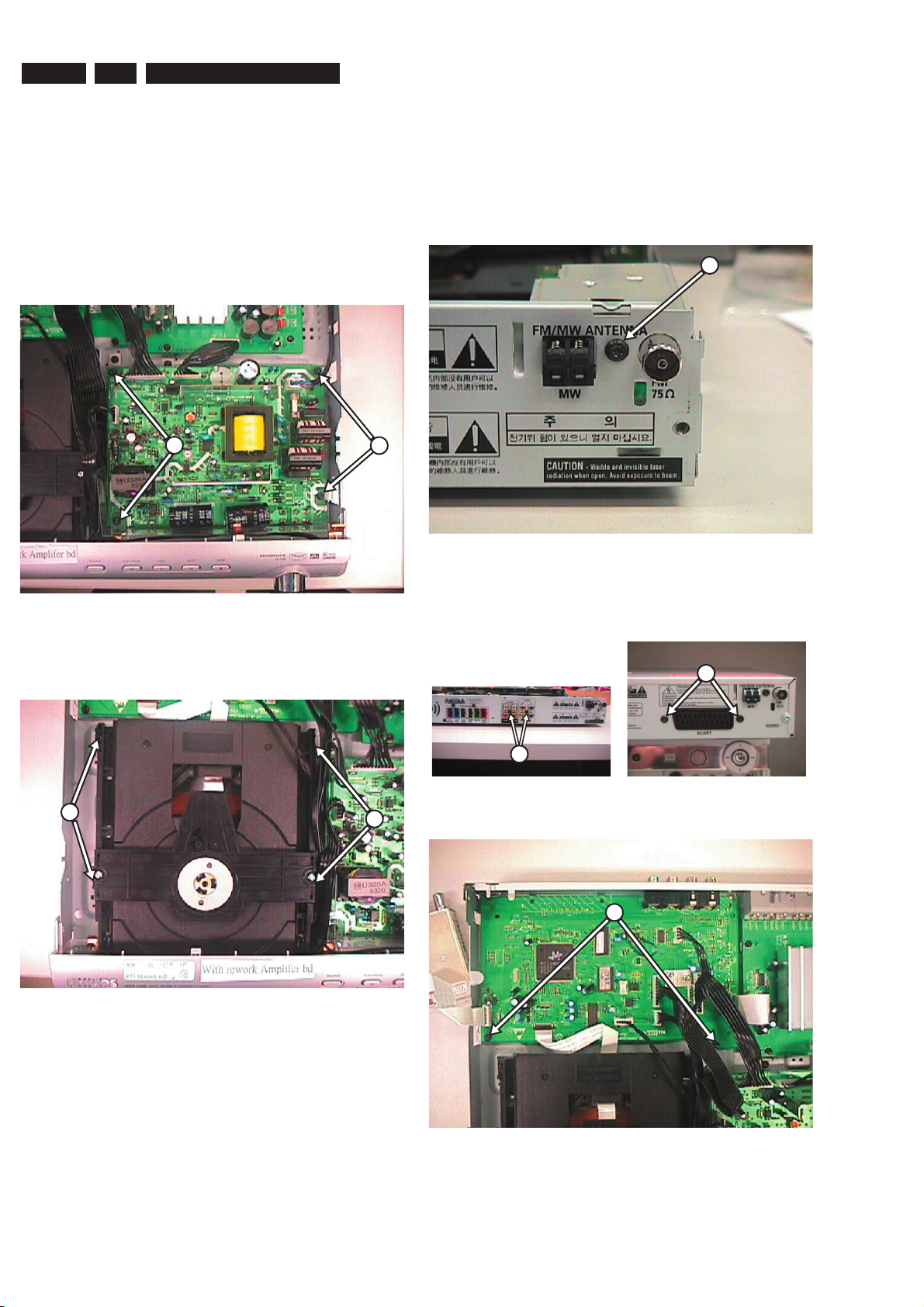

3.3 Dismantling of the Amp-module Board

1) Loosen 4 screws F and 2 screws G (See Figure 3-6 &

Figure 3-7) to remove Amp-Module Board

G

EN 11

3139 785 31550

Insulation Sheet

3.

G

Front Panel Board

H

3.4 Service Positions

Figure 3-6

Figure 3-7

Insulation

Sheet

Insulation

Sheet

Service Position - Front Panel

Mono Board

Service Position - Mono Board

Insulation

Sheet

Amp Module

Bd

Service Position - Amp Module Bd

PSU Module

Service Position - PSU Module

Page 12

EN 12

A

A

3139 785 315504.

4. Service Test Program

Service Test Program

To start service test program

open the tray with remote control

or front panel key, while plugging

in the mains cord press 2, 5 8 on

remote control, the tray will close

by itself and the set will display

shown “S-Vxx-yy”

Display shows

“SERVICE”

followed by ROM version

“S-Vxx-yy”

Main Menu

Display Test

key

"DisplayTest"

triggered?

y

ctivate and display

"Pattern1"

n

S refers to Service Mode

V refers to Version

xx refers to Software version number of BEA

(counting up from 01 to 99)

yy refers to Software version number of Front uP

(counting up from 01 to 99)

4.1 Display Test

Purpose:

This test is used to check the driving circuits, the display and whether there are

any short-circuits, open-circuits or any other defects.

Player:

Following display patterns are used to test the display and its connections to μP.

Pattern 1:

- to check the open-circuits

Pattern 2: Alternate display control pins are on (Test Pattern: 0x55)

- to check the short-circuits on Data port

Default: All display control pins are ON

key

"DisplayTest"

triggered?

y

ctivate and display

"Pattern2"

key

" "

triggered?

y

n

Receiver:

Following display patterns are used to test the display and its connections to μP.

Pattern 1:

Default: All display control pins are ON

- to check the open-circuits

Pattern 2: Alternate display control pins are on (Test Pattern: 0x55)

n

- to check the short-circuits on Data port

TEST Activated with ACTION

EEPROM FORMAT

TEST

to Exit

Load default data. Display shows “NEW”.

Caution!

All presets from the customer will be lost!!

ROTARY

ENCODER TEST

Volume

Knob

Display shows value for 2 seconds.

Volume values increases or decreases in

steps of 1

until 0 (VOL MIN) or 40 (VOL MAX) is

reached.

LEAVE SERVICE

TEST PROGRAM

Disconnect

mains cord

Page 13

Service Test Program

3139 785 31550

4.

EN 13

4.1.1 Reprogramming of DVD version Matrix

After repair, the customer setting and region code may be lost.

Reprogramming will put the set back in the state in which it has left

the factory, ie. with the default setting and the allowed region code.

Model Region Region Code TV Type

HTS 3300MK2/05 UK, Ireland 2 PAL

HTS 3300MK2/12 Europe 2 PAL

HTS 3300MK2/51 Russia 5 PAL

HTS 3300MK2/55 Latam 4 NTSL

HTS 3500MK2/98 AP 3 PAL

To reprogram do as follows:

1) Power up the set and select DISC source.

2) Open tray by press “OPEN/CLOSE” button on the set or press

and hold “STOP” button on the RC.

3) Press the following buttons on the Remote Control:

<9> <9> <9> <9> <AUDIO> <0> ...........for HTS 3300MK2/12

<9> <9> <9> <9> <AUDIO> <1> ...........for HTS 3300MK2/51

<9> <9> <9> <9> <AUDIO> <2> ...........for HTS 3300MK2/05

<9> <9> <9> <9> <AUDIO> <3> ...........for HTS 3300MK2/98

<9> <9> <9> <9> <AUDIO> <6> ...........for HTS 3300MK2/55

4) The display shows ‘YYYY-ZZ’ and the tray will close.

YYYY = model number (eg. 8300, 8500, etc.)

ZZ = slash stroke version (eg. 01, 69, etc.)

4.1.2 Procedure for check Software version

1) Power up the set and select DISC source.

2) Open tray by press “OPEN/CLOSE” button on the set or press

and hold “STOP” button on the RC.

3) Press “DISPLAY” button on the Remote control.

4) The TV screen will shows:

PPPP-Vxx YYYYY-ZZ

SERVO: GGGGGGGG REG:DD

PPPP = HTS 3300MKII

xx = version number

YYYYY = model # - 3300D

ZZ = stroke version (12, 51, 05, 98, 55, 51K)

GGGGGGGG = version for servo code

4.1.4 Procedure to upgrade the fi rmware

1. Power up the set and open tray.

2. Insert the prepared Upgrade CDROM and close the tray.

3. The set will display:

LOAD -> MULTICH ->…………. ->UPG END.

The whole process takes less than 2 minutes.

Note: Do not press any button or interrupt the main supply upgrading

process,Otherwise the set may become defective.

4. When the upgrade is completed, the tray will close automatic.

5. The tray will close and the set will go to Standby mode

automatically when the upgrade process is completed.

4.1.5 Procedure to check the fi rmware version to confi rm

upgrading

1. Power up the set and open tray.

2. Press the <Menu Display> button on the Remote Control.

3. The fi rmware version will be displayed on the top left hand corner

of the OSD.

4.1.6 Trade Mode

Trade mode is a feature that will block all set keys when enabled. It is

for dealers to prevent customers fromremoving disc, changing source

etc using the set keys.Rotary and Remote Control (RC) keys are still

allowed inTrade mode.

To activate Trade Mode:

1) Power up the set and select DISC source.

2) Open tray by press “OPEN/CLOSE” button on the set

or press and hold “STOP” button on the RC.

3) Then press buttons <2> <5> <9> on the RC.

4) The display shows ‘TRA ON’ and the tray will close.

Trade Mode is now enabled.

To deactivate Trade Mode:

1) Power up the set and select DISC source.

2) Open tray by press and hold “STOP”button on the RC.

3) Then press buttons <2> <5> <9> on the RC.

4) The display shows ‘TRA OFF’ and the tray will close.

Trade Mode is now disabled.

4.1.7 Procedure to change Tuner Grid (/98, /55 only)

4.1.3 Burning of fi rmware

1. Unzip the zip-archive attached with this service information.

2. Start the CD burning software and create a new CD Project

(Data disc) with the following settings:

a. File System: ISO9660

b. Format: MODE 2/XA

c. Recording format: Single Session (Track at once),

Finalized CD

3. Place the content of the zip-archive into the root directory of the

new CD project.

4. Burn the data onto a blank CDR or CDRW.

Note: ISO9660 is mandatory, UDF discs are not supported!

The fi nal CDROM must not contain any other data except

the fi le from the zip-archive.

1 Press SOURCE to select “FM” or “MW”.

2 Press STANDBY ON to switch the

DVD system to standby mode.

3 Press STANDBY ON again to turn on

the DVD system and hold down S

button on the front panel.

➜ The display will show "GRID 9" or

"GRID 10".

Helpful Hint:

– GRID 9 and GRID 10 indicate that the

tuning grid is in step of 9 kHz and 10 kHz

respectively.

Note: Repeating the same action will toggle back to its previous

tuning grid setting.

Page 14

EN 14

3139 785 315505.

FTD Display Pin Connection

5. FTD Display Pin Connection

Page 15

EN 15

3139 785 31550

6

Block Diagram, Wiring Diagram

AUX

IN

FTD DISPLAY

1702

VSTB 1

VSTA 2

VSCK 3

GND_MTK 4

40KHZ 5

IR 6

ioSTBY 7

8

9

VGL-1

-24V

+12VL

FRONT BOARD

3139 11335761

7400

TDA8922

7401

TDA8920

7402

TDA8922

Clock Generator

Curcuit

7301

HEF4013BT

CLOCK

OUT_1 OUT_2 OUT_3

OUT_4

OUT_5

OUT_6

Vdd Vdd Vdd

VGL-2

7701

IR

-V-FI L

(-17.8V)

+Vcc 1

+Vcc 2

+Vcc 3

AMP_GND 4

AMP_GND 5

AMP_GND 6

-Vcc 7

-Vcc 8

-Vcc 9

NC 10

CN2

CN1

SMPS04-01

Mitsumi

3139 117 11 061

IC101

+5VL

T101

T102

IC151

VCC

D101 - D04

L100

LINE

OUT

CN3

SURR

RIGHT

1505

7708

V63111

Controller / Dr iver

1711

Filament

DRIVER

40KHZ

1 +5VL

2 +12VL

3 GND_D

4 +5VEV

5 -24V

Drain

FB

GND

IC301

STBY ON/OFF

CN100

FUSE

STBY ON/OFF

POWER DOWN

Vss

Vss

Vss

1 +3V3

2

GND_D

3 +3V3

4 +5

VL

5 GND _D

6 +12VA

7 GND _A

8 -12VA

9 STBY ON/OFF

10 POWER DOWN

11 +12VL

12 GND

+5VD

STBY

1705

VOLB

VOLA

7900

1 +Vcc

2 +Vcc

3 +Vcc

4 AMP_GND

5 AMP_GND

6 AMP_GND

7 -Vcc

8 -Vcc

9 -Vcc

10 NC

VSS

Control

Circuit

C

S VIDEO

OUT

Y

1802A

SCART

RED

1800

CVBS

1802B

21

20

19

18

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

7201

IS42S16400A

DRAM

7109

MT1389B

DVD/SACD PLAYER SYSTEM CHIP

DVD LOADER

WXD-8136 ASA

3139 247 11121

SL+ 6

SL- 5

GND 4

LIMIT 3

SP+ 2

SP- 1

24P FLEX

1 GND_LD

2 DVD-LD

3 NC

4 HFM

5 MD

6 CD_LD

7 VD_DVD

8 VD_CD9

9 NC

10 E

11 VCC

12 VREF

13 GND

14 F

15 B

16 A

17 RF

18 CD_DVD SW

19 C

20 D

21 TRAC K+

22 TRACK-

23 FOC+

24 FOC-

1101

GND_LD 1

DVD-LD 2

NC 3

HFM 4

MD 5

CD_LD 6

VD_DVD 7

VD_CD 8

NC 9

E 10

VCC 11

VREF 12

GND 13

F 14

B 15

A 16

RF 17

CD_DVD SW 18

C 19

D 20

TRACK+ 21

TRACK- 22

FOC+ 23

FOC- 24

7203

M29W160ET70

FLASH

+5M

+L_V33

+L_V33

7110

MM1646XH

Motor Drivers

LOAD+ 1

LOAD- 2

TROUT 3

GND 4

TRIN 5

1105

7200

IM24C16-RDW6

NVRAM

1109

1401

5130

27MHZ

7202

CS8415A

Digital Audio Interface

receiver

1502

SP- 1

SP+ 2

LIMIT 3

GND 4

SL+ 5

SL- 6

LOAD- 1

LOAD+ 2

TROUT 3

GND 4

TRIN 5

1102

AM / FM

Tuner TM10

2422 542 0001 4

AM

FM

GND 1

NC 2

SD 3

+9.1V 4

RDS_Mux

5

Rch 6

CE 7

Lch 8

Data_IN 9

DO/Stereo

10

CL 11

1 GND

2 NC

3 TU_SD

4 +9V

5 TU_RDS_IN

6 TU_RIGHT

7 TU_CE

8 TU_LEFT

9 TU_DAT_IN

10 TU_DO_STEREO

11

TU_CLK

1 +3V3_D

2

RXD

3 TXD

4 GND

1108

1 VSTB

2 VSDA

3 VSCK

4 GND

5 PCM_LRCK

6 RC6

7 IO

STBY

8

9

1501

AUX IN

Logic Switch

LO_Left

LO_Right

SCART_TV_L_IN

Left_in

Right_in

7503

74HC4052

Input Switch

7615

CS42406

CODEC

Left_in

Right_in

TV IN

MIC IN

Tuner IN

SEL-B

SEL-A

LPF Circuit

7613/7616/

7621

RDS_DA

RDS_CLK

6 channel audio data

Mode 12

Mode 34

Mode 56

STANDBY

BOARD

Standb

y

Button

1 stby

2

1 +5VAM

2 MIC

3 MGND

4 -12VAM

1 +5VAM

2 MIC

3 MGND

4 -12VAM

Mute

Circuit

RDS_CK

RDS_DA

Video

FRONT

LEFT

FRONT

RIGHT

CENTER

SUB_

WOOFER

SURR

LEFT

+3V3 1

GND_D 2

+3V3 3

+5VL 4

GND_D 5

+12VL 6

GND_A 7

+12VA 8

POW_ON 9

POWER_DN 10

+12VL 11

GND 12

TV IN

CVBS

7662

SAA6581T

RDS IC

1500

Component

Video

Digital In

1806

+5VL 1

+12VL 2

GND_D 3

+5VSTBY 4

-24V 5

1703

1707

1708

1900

1900

1302

VDD

Mono BOARD

MPEG+AV+AMP

3139 11331 471

6. Block Diagram

HTS 3500 block diagram.pdf_051305

Page 16

EN 16

3139 785 31550

6.

Block Diagram, Wiring Diagram

10

TUNER

TM10 1

10

151 6 9

1

Digital Datas (I2S & I2C &Control )

1

1

18

151 6

12

1

5

191415

2P-stand-by switch

AMPLIFIER BOARD

(3139 247 11781)

SP-

Sp+

LIMIT

GND

SL+

SL-

Port_S

TU_SCL

TU_SDA

TU_SD

TU_L

TU_Stereo

TU-R

NC/RDS

VCC

GND

+Vcc

+Vcc

+Vcc

GND_AGND_AGND_

A

+12VL

+5VL

+5VL

GNDD

+5VL

+5VL

GNDD

+12VA

GNDA

-12VA

STBY

POW_DN

+12VL

GNDM

+5VL

+12VL

GND

+5V EV

-24V

LOAD-

LOAD+

TROUT

GND

TRIN

DVD LOADER

(

3139 247 12211

)

+5VL 1

+12VL

GND

+5V EV

-24V 5

FRONT BOARD(V63111)

9P EH TO FRONT

10P FFC TO TUNER

10 Port_S

I2S-CLK

I2S-DATA

TU_SD

TU_L

TU_Stereo

TU-R

NC/RDS

VCC

1 GND

1303

L-out

SCART

1501

1502YPb

PrCVBS

1302

A

UX_IN

TV_IN

8001 313911103781(FFC FOIL 10P/120/10P

AD FOLD)

MONO BOARD

(3139 243 32765)

24P/220mm FFC

1 LOAD-

LOAD+

TROUT

GND

5 TRIN

5P/220mm PH

6P/180mm PH

1 SP-

Sp+

LIMIT

GND

SL-

6 SL+

4P PH BOARD-IN TO FRONT(MIC)

3139 248 87361 FR1 2-layer

3139 248 87371

5P EH TO Front

HTS 3300MKII WIRING V0.1

+12VA 1

MIC

GND

-12VA 4

1 +5VL

GND

+5VL

+5VL

GND-D

+12VA

GNDA

-12VA

STBY

POW_DN

+12VL

12 GND-M

12P EH TO PSU

Power Supply

(3139 247 12171

3139 247 12161)

1 GNDD

SCLK

GNDD

LRCLK

GNDD

MCLK

GNDD

SDIN1

GNDD

SDIN2

GNDD

SDIN3

GNDD

SDA

SCL

GNDD

/RESET

/SD

/TD

/PDN

20 GND

20Pin FFC Cable

Video Circuit

MT1389

Analog SW

ADC

DAC

2422 542 00015

2422 542 00031

1300

1101 1103 1102

1105

1301

1 +12AM

MIC

GND_A

4 -12AM

1400

1201

+5VL

+12VL

GND-A

GND-A

GND-A

+Vcc

+Vcc

+Vcc

FR C FL SR SL SW

1702

NC 9NCSTBYRCLR-CLK

GND

VSCK

VSDA

VSTB 1

1707

1 NC

NC

STBY

RC

LR-CLK

GND

VSCK

VSDA

9 VSTB

1703

1708

1 STBY

2 GND

STBY BD

(3139 248 87401)

1900

Wiring Diagram

3300MKII wiring diagram.pdf _010506

Page 17

EN 17

3139 785 31550

7

5

DIN

DOUT

STB

CLK

OSC

1

2

KEY

SWI

LED

SEG<1:20>

KS

GRID

4

6

8

7

VSS

5

4

3

2

1

3

4

1

2

3

4

IC

1

2

3

4

5

VEE

2

VDD

3

1

11

10

9

8

7

6

12

13

14

15

16

12

11

10

9

6708 G12

6709 G12

7701 H1

F732 F9

F712 G2

F728 I4

F729 D8

6710 G12

6711 G12

3738 I13

6720 I8

FROM 0202 OF PSU

A

1708 G7

1709 B1

10

2708 B5

1712 H7

1713 H7

1714 H5

1715 H6

1716 H7

3703 B4

3704 C4

3705 B5

3706 C5

2706 C5

7703 C3

TO/FROM 1105 OF

7702-2 B6

VSDA

3730 I6

3731 I7

3701 B2

2701 B3

1710 H5

612 5

3739 C7

3741 G4

F727 I2

2704 B5

2705 C4

3

F704 E2

F701 E2

7708 E10

F702 E2

7707 I12

4

7705 I12

7706 I12

VOLB

ioSTBY

F703 E2

7704 E5

6719 H8

6712 G12

F726 H3

6707 G11

3734 I11

1717 G8

11 12

2707 C5

9

F724 D1

F725 E5

6706 G11

3733 I10

6714 G13

6718 H8

6717 G6

F713 G2

F733 G9

F709 F2

F710 F2

F708 F2

3746 D8

4700 G9

4701 G9

4702 G9

3722 E5

4703 G4

F711 F2

40kHZ

F735 D1

+12VL

3740 D3

6704 E10

6705 G11

3732 F8

3702 B2

2702 B4

2703 B4

2719 G8

F

F723 D1

-24V

F718 B2

F719 B2

F715 D9

F720 B2

F721 D1

F716 C8

F717 C11

F714 G2

2729 I8

3700 C2

2700 B3

IR

3712 C8

1

3735 I12

3736 I12

3737 I13

3707 C6

F730 E10

VSCK

6716 G6

6713 G13

6715 G13

3708 B6

78

3711 C11

3713 C11

3710 C8

3709 D4

3742 G5

3743 H9

3716 E6

2715 I13

B

C

D

E

1711 H6

6700 E5

4704 G4

6703 C4

6701 D9

5700 B3

7702-1 B4

F734 C3

F705 E2

F706 F2

3744 H9

3717 E7

2716 E2

2717 E2

2718 H2

FROM 1500 OF MONOBOARD

GND_MTK

+5VL

VOLA

2712 E8

2713 E8

13

2709 C6

2710 E8

2711 D10

12 13

A

B

C

D

E

F

G

H

I

1705 G3

2345678910

3714 D8

3715 D9

2714 E8

+5V_Ever

11

3725 H3

3728 I5

MONOBOARD

3727 I4

G

H

I

1701 B8

1702 F2

1703 E1

3723 E4

3729 I6

3724 H2

3726 I4

DISPLAY BOARD

F731 D10

F707 F2

3745 E4

3718 E7

3719 E5

3720 E5

3721 E4

2720 G8

F705

VSTB

1707 D1

2726 D10

2725 E4

2723 H11

2722 I11

2724 E10

GND_D

2721 I10

SKQNAB

1713

F728

MGND

MGND

F727

F726

2714

10p

4702

3745

4K7

3K3

3718

BAS316

6703

3732

1M0

MGNDMGND

BAS316

6716

F718

F719

4701

3720

4K7

6715 BAS316

6713 BAS316

3736

330R

3701

1K2

2716

100n

100p

2700

6711 BAS316

F701

F720

2726 100n

1710

SKQNAB

MGND

F723

F721

4K7

3742

BAS3166712

3714

22K

MGND

3707

6K8

4704

4703

MGND

47p

2704

3733

2K2

3708

1K0

3K3

3717

455K

1717

1

2

3

4

5

F707

1703

WH05D-1

3704

1K0

2720

100p

2706

1u0

F714

3719

470R

4K7

3721

2717

100n

4700

F708

1K2

3727

1714

SKQNAB

1

2

F734

1708

WH02D-1

F730

F731

F732

4

3715

10K

1

2

3

MGND

MGND

WH04D-1

1707

3K3

F716

3716

BAS316

6720

2722

10u 35V

F713

5

6

7

84

4K7

3729

84

LM833D

7702-2

7702-1

LM833D

3

2

1

1u0

2725

F725

BAS316

6718

5700

F703

22u

3728

4K7

2710

F710

2u2

3737

4K7

BAS3166708

10u2724

F729

28

P2

P327P426P525P624P723P822P921P1020P11

19

18

P12

P13

17

16

P1415P1514P16

P17

13

7

4G

5G86G97G108G

11

F1

1

F232P1

29

DSP

1G42G53G

6

1701

HUV-08SS57T

PDZ6.2-B

6701

F717

470R

3722

4

5

1709

MSJ-035-11C B AG SR

1

2

33R

3712

GND

2

4

5

OUT

1

VS

3

7701

TSOP4836ZC1

2718

100n

7707

BC847B

F712

1715

SKQNAB

1711

SKQNAB

10K

3738

2

3

4

5

6

7

8

9

1702

WH09D-1

1

3730

4K7

470n

2703

2701

100p

F715

1716

SKQNAB

F702

3702

3703

68K

2K2

2707

1u0

3726

1K0

100R

3724

F733

BAS3166714

F704

10u

2721

35V

F706

3741

4K7

1u0

2705

6707 BAS316

BAS3166706

6705 BAS316

F724

3713

33R

3744

4K7

2702

470n

10p

2713

2K7

3705

4K7

3731

6700

LTL-816EELC

7706

BC857B

2729

100p

F735

6704

BAS316

3706

3K9

100p

2719

F711

1712

SKQNAB

22p

2715

1705

EVEMC

A

1B3

C

245

100p

2708

47p

2709

MGND

3740

150R

100n

2711

33n

2723

3725

10K

1

2

3

4

143345

34

51

36

16

17

18

19

20

21

22

23

9

24

25

26

27

28

29

30

31

32

35

15

10

11

12

13

50

49

48

47

46

52

6

5

44

43

42

41

40

39

38

37

7

7708

UPD16311GC-AB6

Φ

FIP

CONTROLLER/

DRIVER

8

6717

BAS316

6719

BAS316

4K7

3743

4K7

3723

3709

8K2

3735

2712

10p

330R

MGND

6709 BAS316

MGND

MGND

2K2

3746

BC847B

7704

F709

3734

BC817-25

7705

2K2

1K0

3739

10K

3700

BAS3166710

3710

33R

BC847B

7703

33R

3711

P(15)

P(14)

P(13)

P(12)

P(11)

P(10)

P(1)

G(8)

G(7)

G(6)

G(5)

G(4)

G(3)

G(2)

G(1)

RESET

-12VAM

+5VAM

VOLA

-24V

+5VL

+5VDSTBY

stdby_2

+5VDSTBY

stdby_1

VOLB

P(9)

P(8)

P(7)

P(6)

P(5)

P(4)

P(3)

P(2)

P(17)

P(16)

G(7) G(6)

G(5) G(4) G(3)

P(1)

MISCB

MISCA

MISCB

+5VDSTBY

P(3)

P(3) P(2)

P(2)

VOLA

VOLB

+5VDSTBY

REMOTE

P(1)

P(1)

+12VL

-12VAM

+5VAM

MIC_DET

-V_FIL

VGL+1

+12VL

VGL+1

40kHZ

+5VDSTBY

REMOTE

VGL-1

+5VDSTBY

+5VDSTBY

P(10)

P(11)

P(12)

P(13)

P(14)

MGND

+5VAM

MIC

+5VAM

-12VAM

MIC

MIC_DET

MISCA

stdby_1

+5VDSTBY

40kHZ

stdby_2

-24V

VGL-1

RESET

-V_FIL

G(1)

G(2)

G(8)

P(15)

P(16)

P(17)

P(2)

P(3)

P(4)

P(5)

P(6)

P(7)

P(8)

P(9)

3139_243_33711_sh130_sh1.pdf_010406

7. Front: Display

Circuit Diagram and PWB Layout

Page 18

EN 18

3139 785 31550

7.

Topview_DisplayBd_33711.pdf_010406

Front: Display (topview)

Circuit Diagram and PWB Layout

Page 19

EN 19

3139 785 31550

Front: Display (Bottom view)

7

Circuit Diagram and PWB Layout

Bottom view_DisplayBd_33711.pdf_010406

Page 20

EN 20

3139 785 31550

Mono Board: Circuit Diagram (Part 1)

VIN3

VIN4

VINLOp

VINLOn

PREGND

PWRVCC

PREVCC

PS

VBIAS

SB

VIN1

VIN2p

VIN2n

PWRGND

HS_GND

OUTLn

OUTLp

OUT4n

OUT4p

OUT3n

OUT3p

OUT2n

OUT2p

OUT1n

OUT1p

VO2

COM

OUT

IN

T195 I10

T182 B4

T183 B4

T184 D4

T185 D5

T189 A5

T190 A6

T191 I11

T192 D4

T193 D3

T194 I11

T135 I1

T136 E6

T137 E6

T138 B9

T148 I9

T149 I9

T150 I9

T151 I9

T152 I9

T153 I10

T154 I10

T155 I10

T156 I10

T157 I10

T158 I10

T160 G4

T161 G4

T162 G4

T163 G4

T164 G4

T165 H4

T166 H5

T167 H5

T171 A2

T172 A3

T173 A4

T174 B2

T175 B3

T176 B5

T177 B5

T179 B2

T181 B4

T125 G1

T126 G1

T127 G1

T128 G1

T129 G1

T130 G1

T131 H1

T132 H1

T133 I1

T134 I1

T104 D1

T105 D1

T106 D1

T107 D1

T109 E1

T110 E1

T111 E1

T112 E1

T113 E1

T114 E1

T115 E1

T116 E1

T117 E1

T118 E1

T119 E1

T120 E1

T121 E1

T122 E1

T123 F1

T124 F1

5122 B2

5123 D2

5124 D4

5125 D3

5126 E5

6100 I10

7102 A2

7104 D4

7105 D3

7106 E2

7107 E3

7108 E3

7109 E9

7110 F3

7112 I12

F125 F12

F126 F12

F141 C6

F155 E6

F156 E6

T101 D1

T102 D1

T103 D1

3188 B10

3189 B10

3190 B10

4102 C6

4103 C6

4104 C6

4105 C6

4106 D6

4108 F6

4109 H10

5101 A8

5104 A1

5105 A2

5106 A3

5107 A4

5108 A6

5113 B7

5114 B8

5115 B9

5116 B9

5117 B1

5118 B3

5119 B4

5120 B5

3162 I2

3164 I9

3165 I9

3168 I2

3169 I2

3170 I11

3171 I10

3172 I11

3173 D2

3174 D2

3175 A11

3176 A10

3177 A12

3178 A13

3181 I9

3182 I9

3183 I9

3184 I9

3186 D12

3187 B10

3136 E5

3137 E5

3140 F4

3141 G5

3142 G5

3143 G2

3144 G5

3145 G1

3146 G5

3147 H1

3148 H2

3149 H2

3150 H5

3151 H9

3152 H9

3153 H10

3154 H10

3155 H10

3156 H10

3157 H10

3158 H5

3159 H5

3160 I2

3161 I12

3105 A13

3106 A9

3107 B10

3108 A7

3109 A11

3111 A12

3113 A10

3115 A11

3116 B11

3117 B11

3118 B9

3119 B7

3120 B11

3121 C12

3122 B11

3123 B12

3124 D12

3125 D13

3126 D4

3128 D3

3129 D2

3131 D12

3132 E3

3133 E2

3134 E3

3135 E2

2215 E5

2216 H5

2217 E5

NB

2218 I2

2219 I2

2220 E6

2221 E5

2223 F4

2241 I8

2242 I8

2243 I8

2245 I9

2246 I9

2249 I11

2250 I10

2251 I11

3101 A13

3102 A13

3103 A5

3104 A12

2186 H2

2187 I8

2188 I9

2194 G5

2195 G5

2196 G5

2197 G6

2198 H5

2199 H2

2200 C12

2201 C6

2202 C6

2203 C12

2204 C6

2205 C6

2206 C6

2207 C6

2208 D2

2209 D2

2210 D5

2211 D3

2212 E2

2213 E5

2214 E2

2165 H5

2166 H5

2167 C2

3121 = 1K8 for high Z mode

2168 C3

2169 C4

2170 C4

2171 C4

2172 C4

2173 C4

2174 C5

2175 B10

2179 F5

2180 E3

2181 G2

2182 G2

2183 G2

2184 H1

2185 H2

2143 B3

2144 B3

2145 B3

NB :

2146 B3

2147 B4

2148 B4

2149 B5

2151 B5

2152 B6

2153 B6

2154 B6

2155 B6

2156 B6

2157 B6

2158 B9

2159 B7

2160 B7

2161 B8

2162 B8

2163 B8

2164 B8

F

G

H

2116 H7

2117 A8

2118 A8

2119 A5

2120 A6

2121 A8

2122 A11

2123 A12

2126 D13

2127 B7

2128 B7

2129 B8

2130 B8

2131 B8

2132 B9

2133 B9

2134 A10

2135 A11

2138 B1

2139 B2

2140 B2

2141 B3

2142 B3

678910111213

A

B

C

D

E

F

G

H

I

A

B

C

D

E

123

4 5 6 7 8 9 10 11 12 13

12345

2105 A13

2106 A13

2107 A7

2108 A8

2109 A9

2111 A3

2112 A4

2114 H7

2115 A4

I

1101 D1

1102 G1

1103 H1

1105 I9

1108 I10

2100 A3

2101 A3

2102 A8

2103 A13

2104 A12

F125

2251

220p

100K

3172

3102150R

1n5

2197

3120

22R

560R

3121

T135

600R

5106

T165

T166

T164

T163

2118 1n0

T156

T155

T126

7107

BSH103

2170100n

T174

2101100n

100n 2100

T181

F155

T179 T182

150n

T161

2196

T160

T189

2132

2181

220p

10u

100R

3182

3183 100R

3117 150R

150R3116

T176

7112

BC847B

47R3189

3188 47R

2168100n

10p2243

2207 120p

2194

470p

T115

47u 2167

T158

5123

2214

100n

600R

1K0

2115100n

T167

3157

3107 100R

10n2126

3108

1n02117

100K

2204 1u0

T125

3140 10K

3173 100R

T162

2245 100p

2162

3118

1u0

22R

T133

T134

600R5126

2203

100n

1u02206

8K23146

T191

2105

47p

T131

T124

3119 15K

100n2102

5120

60R

47R3187

10K

3171

2242 10p

2179 10n

47p 2122

1u0

2201 1u0

5116

600R

2202

3144 56K

T132

60R

5104

2241 10p

27M

5108

T106

2138100n

2211

47u

10K3158

T157

100R3184

10n2166

2188220p

3133 100K

4109

10K3135

T130

31641K2

23

24

26

27

6

22

1

10

21

8

9

28

2

3

5

4

11

12

18

17

16

15

20

19

25

7

7110

29

30

13

14

2160

MM1646XH

Φ

100n

2174100n

390p

6

2109

B6B-PH-K

1102

1

2

3

4

5

2106

789

47p

B9B-EH-A

12345

6

1105

5115

600R

2154100n

2172

100n

T152

4R73176

2111220u

330K

3147

1K0 3153

31651K0

2129 100n

2SB1132

7104

2148

512410u

10u

T110

315510R

4104

600R

5114

2208 220u

F156

T101

4105

T104

T192

T103

22K3150

2212 100n

T114

3178

F126

4R7

2114

D

22u

D

T148

BSH103

7106

100n2159

2130 100n

470n

330K 3148

2158

3124

22R

T190

600R

5119

2121

100n

100n 2149

1K03160

T193

2183220p

T129

T127

T128

315410R

4R73126

F141

T149

2123

33R 3156

47p

3109150R

3134 10K

3104

150R

T184

316810K

3151100R

10n2175

100R3174

100n2223

2127

100n

T153

3136 680K

3129 390R

T113

600R

5122

T112

2112100n

47u 2171

10K3159

150R

T194

3111

1R03145

2133 100n

215110u

2157100n

T109

47n2164

T105

2180

10n

3161

4K7

T150

T151

100n 2140

100n 2145

470p 2219

3

4

5

47p

2135

B5B-PH-K

1

2

1103

10V

T185

D

1u0

2250

BAS316

6100

100n

T117

2220

5107

600R

3125

470R

2163 47n

680K

3106

2141

T138

100n

2147

314910K

3152

100n

2173

100R

47u

100n2198

D

T121

D

47p

2103

2184

220p

T136

22R

3131

220p 2187

60R

5105

3175 4R7

3181 100R

100n 2213

47p

D

D

2104

2146100n

100n

2144

2218

2139100n

470p

600R

5101

150R

2108

3101

100n

220p2185

123

4

T177

1108

B4B-PH-K

470p 2199

T183

T118

22p2107

3177 4R7

512510u

3162 1K0

4106

T122

213447p

4R73128

100K

2SB1132

7105

T137

3103

220p

2182

27K3141

T173

100n 2155

216947u

2221992n2

AD792A1793IOA094DVSS_395UWR#96URD#

DVDD18_297UP1_298UP1_3

AD385DVSS_286AD487AD588AD689IOA21

9

MB

90

ALE

91

77

IOA1

78

79

IOOE#

MA

8

80

DVDD3_281AD082AD183AD2

84

7

HIGHA570HIGHA471HIGHA372DVDD3_1

73

74

HIGHA275HIGHA1

IOA2076IOCS#

APLLCAP

63

64

APLLVSS

APLLVDD365IOWR#

66

67

A1668HIGHA7

HIGHA6

69

DVDRFIN

IOA5

56

IOA6

57

IOA7

58

HIGHA0

59

DVDRFIP

6

IOA18

60

IOA19

61

DVSS_1

62

49

TMS

DVDD

5

50

TCK

TDO

51

52

DVDD18_1

IOA2

53

IOA3

54

IOA4

55

41

TRO

42

FOO

43

USB_VSS

USBP

44

45

USBM

USB_VDD3

46

47

FG

48

TDI

34

OP_OUT

35

OP_INN

36

OP_INP

DMO

37

38

FMO

TROPENPWM

39

DVDC

4

40

PWMOUT1

27

SGND

28

V2REFO

29

V20

DVDB

3

30

VREFO

FEO

31

32

TEO

33

TEZISLV

250

CEQP

251

CEQN

252

OSP

OSN

253

RFGC

254

255

IREF

AVDD3

256

26

RFLVL

243

244

RFVDD3

245

RFRPDC

RFRPAC

246

HRFZC

247

CRTPLP

248

RFGND

249

25

CSO

236

LPFIP

237

LPFIN

LPFOP

238

ADCVDD3

239

24

SVDD3

240

S_VCM

ADCVSS

241

S_VREFP

242

S_VREFN

229

XTALI

23

LDO1

JITFO

230

JITFN

231

PLLVSS

232

IDACEXLP

233

PLLVDD3

234

235

LPFON

221

DVDD18_6

222

ASDATA4

DVSS_13

223

MC_DATA

224

SPDIF

225

226

RFGND18

RFVDD18

227

228

XTALO

214

ABCK

ACLK

215

DVSS_12

216

ASDATA0

217

218

ASDATA1

ASDATA2

219

LDO2

22

220

ASDATA3

207

SPMCLK

208

SPDATA

209

MDI2

21

210

SPLRCK

SPBCK

211

DVDD3_10

212

213

ALRCK

20

MDI1

200

YUV4

201

DACVSSA

YUV5

202

203

YUV6

DVDD3_9

204

VSYN

205

YUV7

206

HSYN

DACVSSC

194

YUV1

DACVDDB

195

YUV2

196

DACVSSB

197

198

YUV3

DACVDDA

199

DVDA

2

RD17

187

RD16

188

DACVDDC

189

19

TPI

VREF

190

191

FS

YUV0

192

193

DQM2

18

TNI

180

RD23

RD22

181

182

DVDD3_8

RD21

183

RD20

184

RD19

185

RD18

186

RD28

172

RD27

173

DVDD18_5

174

RD26

175

DVSS_11

176

RD25

177

RD24

178

DQM3

179

165

RA5

166

RA4

DVDD3_7

167

168

RD31

169

RD30

17

CDFOP

170

RD29

171

CKE

RA11

158

RA9

159

CDFON

16

RA8

160

161

DVSS_9

162

RA7

163

DVSS_10

RA6

164

RA2

150

RA3

151

DVDD18_4

152

RVREF

153

154

RCLKB

DVDD3_6

155

RCLK

156

157

RCS#

BA0

143

144

DVSS_7

BA1

145

146

RA10

147

RA0

DVSS_8

148

149

RA1

SD

15

RD8

136

DQS1

137

DQM1

RWE#

138

139

CAS#

14

SC

140

RAS#

141

DVDD3_5

142

129

RD13

SB

13

130

RD12

RD11

131

RD10

132

RD9

133

DVSS_6

134

135

121

122

DVDD18_3

RD2

123

124

RD1

RD0

125

RD15

126

DVDD3_4

127

128

RD14

DQS0

115

RD7

DVSS_4

116

RD6

117

RD5

118

DVSS_5

119

SA

12

RD4

120

RD3

107

108

DVDD3_3

109

ICE

11

MD

PRST#

110IR111

112

INT0#

113

DQM0

114

MC

10

UP1_4

100

101

UP1_5

102

UP1_6

UP1_7

103

UP3_0

104

UP3_1

105

UP3_4

106

UP3_5

MT1389

7109

AGND

1

600R

5117

2119

27p

T195

2186 220p

T175

3105

150R

100n

2200

1

32

7102

LD1117DT33

221047u

2165 10n

3186

22R

100n 2142

2215

100n 2152

100n

T171

2128 100n

680K3137

2153100n

2143

100n

100n

2131

T154

T123

T116

3122 150R

150R

3115

2116100n

2n22217

100p2246

BC817-25W

7108

100K

3132

2216 470p

27p

2120

3143 1K0

T120

T119

3142

15K

4108

T172

2249

100p

3113

150R

T102

100n

D

2156

8

9

25

26

20

21

22

23

24

3

4

5

6

7

10

11

12

13

14

15

16

17

18

19

2

1101

SFV24R-1ST

1

4103

4102

D

T111

1u02205

600R

5113

150R3123

1K0

3170

5118

600R

1K0

3190

2161 33n

316910K

2209 100n

T107

2195 100n

XO

XTALI

PCM_LRCK

PCM_SCLK

PCM_MCLK

P16

TU_SD

+5VL

+3V3_D

+3V3_D

VSTB

PCM_MIC_IN

+5M

VO2

V1P4

ADIN

LIMIT

+3V3_D

PCM_MIC_IN

MUTE_TV_

AMP_RST

+3V3_D

+L_V33

V1P4

+3V3_D

+3V3_D

+3V3_D

+S_V33

+5VL

+5D

+5M

+5M

+3V3_D

+V_V33

+DV33B

+S_V33

+DV33B

+3V3_D

+DV33A

+DV33A

+3V3_D

+V18

+V18

+3V3_D

+S_V33

+S_V33 +S_V33

+V18

+3V3_D

+1V8

PCM_LRCK

VSDA

VSCK

STBY

RC6

+5VL

VSDA

VSCK

VSTB

Source_sel_A1

SCL_DAC

SDA_DAC

S0_L3_0

PCM_LTRT

Erro_Det

VO2

V1P4

V1P4

FOO

TROUT

TRIN

OP+

OP-

DMO

V1P4

FMO

TROPEN

TRCLOSE

V1P4

TRO

V1P4

+5M

+5D

A_

Mot_stb

IOA

V20

V20

V1P4

C_

+S_V33

V20

V2P8

V2P8

E

F

B_

D_

IOA

+L_V33

+L_V33

B_

C_

D_

A_

CVBS

G_Y

V1P4

TxD

R_Cr

B_Cb

DQ(0:15)

MA(0:11)

A(0:21)

AD(0:7)

AD(4)

AD(5)

AD(6)

A(21)

AD(7)

A(17)

A(0)

+V18

A(10)

A(9)

A(20)

PCE

A(1)

PRD

AD(0)

AD(1)

AD(2)

AD(3)

+3V3_D

PWR

A(16)

A(15)

A(14)

A(13)

A(12)

A(11)

+DV33A

A(4)

A(5)

A(6)

A(7)

A(8)

A(18)

A(19)

TRO

FOO

TROUT

TRIN

Mot_stb

TRCLOSE

+V18

A(2)

A(3)

ADIN

OPOP+

DMO

FMO

TROPEN

V1P4

XO

XTALI

SPLRCK

SPBCK

+DV33B

PCM_LR

PCM_LsRs

PCM_CLfe

+DV33B

SPMCLK

SPDATA

S1_L3_1

E

+V_V33

F

+V_V33

+V_V33

MA(8)

MA(7)

MA(6)

MA(5)

MA(4)

+DV33B

+V18

MA(2)

MA(3)

+V18

+DV33B

DCLK

DCKE

MA(11)

MA(9)

WE

CAS

RAS

+DV33B

CS

BA0

BA1

MA(10)

MA(0)

MA(1)

DQ(15)

+DV33B

DQ(14)

DQ(13)

DQ(12)

DQ(11)

DQ(10)

DQ(9)

DQ(8)

LIMIT

DQM1

DQM0

DQ(7)

DQ(6)

DQ(5)

DQ(4)

DQ(3)

+V18

DQ(2)

DQ(1)

DQ(0)

Source_sel_A0

RxD

+DV33A

RC6

3139_243_32765_a2_sh130_a1.pdf_010406

7

Circuit Diagram and PWB Layout

Page 21

EN 21

3139 785 31550

Mono Board: Circuit Diagram (Part 2)

11

1

0

13

12

9

8

9

10

VSS

VDDQ

1M-1

DQM

VDD

VSSQ

0

A

BA

1

6

H

0

WE

L

NC

CAS

RAS

7

5

4

3

2

15

14

11

10

CS

CKE

CLK

D

0

1

2

3

4

5

6

7

8

SCL

ADR

0

1

2SDA

WC

19

0

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

VSS

VDD

0

A

D

5

2

4

RB

OE

CE

7

6

WE

3

1

RP

0

BYTE

2M-1 / 1M-1

NC

A-1

8

9

10

11

12

13

14

15

*

(SHEET1)

T211 C12

T212 C12

T213 C12

T214 C12

T215 C12

T216 D12

T217 D12

T218 D12

T219 D12

T220 D12

T221 D12

T222 D12

T231 F5

T232 F5

T236 A3

T237 B2

T238 F3

T240 D6

7200 A2

7201 D3

7202 E6

7203 F2

T200 E8

T201 G6

T202 B3

T203 B3

T204 E8

T205 E8

T210 C12

3214-4 E1

3227 E8

3229 E8

3231 E8

3233 F3

3234 F5

3235 F6

3236 G5

3237 G5

3238 G6

3240 H2

3241 H3

3244 C11

3245 C11

4201 G2

4202 C10

4203 C10

4204 C10

5200 B3

5201 D6

5202 D7

3210-1 B1

3210-2 D1

3210-3 D1

3210-4 D1

3211-1 D1

3211-2 C1

3211-3 C1

3211-4 C1

3212-1 C1

3212-2 C1

3212-3 C1

3212-4 C1

3213-1 D1

3213-2 D1

3213-3 D1

3213-4 E1

3214-1 E1

3214-2 E1

3214-3 E1

2267 F3

2268 F3

2269 F5

2271 E9

2272 H6

2273 H7

2274 E9

2275 G11

2276 F5

3203 A3

3204 G10

3209 B3

2255 C3

2256 C3

2257 C3

2258 C3

2259 E10

2260 E10

2261 E10

2262 E10

2263 E10

2264 D6

2265 D7

2266 F5

(SHEET1)

# SPDIF

6789101112

A

B

C

D

E

F

G

H

A

* OPTIONAL

123456789101112

12

345

# Refer to Table

B

C

D

E

F

G

H

1201 B12

2110 E10

2252 A3

2253 B3

2254 C3

10R

18

*

(SHEET1)

(SHEET1)

(SHEET1)

3210-1

T238

10R3233

3213-3

10R

36

2265

100n

100n2264

6

DD

10R

3210-3

3

10R

45

3210-2

27

3210-4

10R

D

3K33203

3212-2

10R

27

2263

22p

600R

5201

600R

D

D

5200

16

3238 1K2

94349

2841546124652

44

39

15

36

40

18

11427

3

50

51

53

5

7

8

10

11

13

42

20

21

17

37

38

19

2

4

45

47

48

24

22

35

25

26

29

30

31

32

33

34

7201

1M X 16 X 4

DRAM

F

IS42S16400A-7TLI

23

100n

D

18

2268

3213-1

10R

22p

2274

100n

D

2272

3234

75R

47n2273

2275

45

22p

10R

3214-4

22p

2110

22R

3227

3229

22R

D

22R3231

27

3213-2

10R

100n2253

2254 100n

2255 100n

T211

4201

10K

3240

100n2269

D

100n2266

D

D

D

10K3236

5202

600R

4

7

T200

1

2

3

6

5

8

36

(2Kx8)

F

EEPROM

7200

M24C16-RDW6

27

10R

3211-3

8

10R

3211-2

3212-1

10R

1

T205

T204

T202

T203

T210

8

9

T231

D

19

2

20

21

3

4

5

6

7

1

10

11

12

13

14

15

16

17

18

T237

1201

21FMN-BTRK-A

6

3214-3

10R

3

16V

18

2258 47u

3211-1

10R

323522R

2262

22p

2252

D

100n

4203

45

4202

8

10R

3213-4

3214-1

10R

1

10R

3214-2

27

3212-3

36

10R

45

10R

T222

3212-4

T221

T219

D

T217

T218

T215

T216

T213

T214

T212

3245 10K

2271

22p

10K3204

47u

16V

2276

2267

T201

100p

3211-4

45

D

10R

T232

2260

22p

T240

10

28

15

12

37

27

46

11

33

35

38

40

42

44

30

32

13

14

7

47

26

29

31

34

36

39

41

43

45

17

16

9

23

22

21

20

19

18

8

25

24

6

5

4

3

2

1

48

6

VD+

23

[FLASH]

2Mx8/1Mx16

7203

M29W160ET70

15

RXP5

25

RXP6

26

SCL|CCLK

28

SDA|CDOUT

1

SDOUT

18

U

20

VA+

RMCK

10

RST_

9

RXN0

5

RXP0

4

RXP1

12

RXP2

13

RXP3

14

RXP4

3

EMPH_

FILT

8

H|S_

24

INT

19

OLRCK

17

OMCK

21

OSCLK

16

RERR

11

7202

CS8415A

AD0|CS_

2

AD1|CDIN

27

AGND

7

DGND

22

T236

T220

3209 3K3

10K3237

3241 33R

4204

2259

22p

22p

2261

D

10K3244

2256

100n

100n

SCL_DAC

D

2257

PCM_SCLK

PCM_LRCK

PCM_MCLK

PCM_LR

PCM_LsRs

+3V3_D

AMP_RST

Erro_Det

+3V3_D

PW_DN_

TD

SPDIF_IN

+5D

+5D

+3V3_FL

+5D

+3V3_D

+3V3_D

+3V3_D

SPDATA

SPLRCK

SPBCK

SPMCLK

+3V3_D

SCL_DAC

SDA_DAC

DQ(0:15)

MA(6)

RAS

CS

DCKE

DCLK

BA1

BA0

WE

CAS

MA(0:11)

MA(4)

MA(3)

MA(2)

MA(1)

MA(0)

MA(11)

MA(10)

MA(9)

MA(8)

MA(7)

MA(5)

DQ(9)

DQM1

DQM0

DQ(12)

DQ(13)

DQ(14)

DQ(15)

DQ(2)

DQ(3)

DQ(4)

DQ(5)

DQ(6)

DQ(7)

DQ(8)

DQ(0)

DQ(1)

DQ(10)

DQ(11)

A(21)

+3V3_FL

PWR

A(0:21)

A(20)

AD(0:7)

AD(5)

AD(6)

AD(7)

PRD

+3V3_FL

+3V3_FL

PCE

AD(0)

AD(1)

A(0)

AD(2)

AD(3)

AD(4)

A(19)

A(3)

A(4)

A(5)

A(6)

A(7)

A(8)

A(9)

A(10)

A(1)

A(2)

A(11)

A(12)

A(13)

A(14)

A(15)

A(16)

A(17)

A(18)

SCL_DAC

SDA_DAC

+5VS

SP_RST

SDA_DAC

PCM_MIC_IN

PCM_MIC_IN

+5VS

PCM_CLfe

TU_SD

TU_SD

+5D

SPDIF_IN

SPDIF_IN

3139_243_32765_a2_sh130_a2.pdf_010406

7.

Circuit Diagram and PWB Layout

Page 22

EN 22

3139 785 31550

Mono Board: Circuit Diagram (Part 3)

M

AINL

MCLK

RST

1

0

AINR

GND REF_GND

VQ

LRCK

SCLK

FILT+

SDOUT

VLVD

VA

G4

0

3

2

VDD

VEE VSS

1

0

3

2

1

4X

030

1

SDIN

SCLK

GND

VQ

FILT+

AOUTL

AOUTR

DEM

LRCK

MCLK

VA

F324 G2

T300 B6

T301 D6

T302 D6

T303 E7

T304 E7

T305 E14

T314 I5

T315 H13

T316 I13

T317 H10

T318 I10

T319 E9

T320 E9

T321 A9

F302 A2

F303 A2

F304 A1

F305 A2

F306 A2

F307 A2

F308 A2

F309 B2

F310 B2

F311 C2

F312 D2

F313 D2

F314 D2

F316 F3

F317 G3

F318 H2

F320 D2

F321 E2

F322 H2

F323 H2

7302 C7

7303 E11

7304-1 H8

7304-2 I8

7305-1 H3

7305-2 I3

7306 H12

7307 I5

7308-1 A6

7308-2 A8

F301 A2

3371 A6

3372 H10

3373 I10

4300 C3

4301 D3

4302 D10

4303 E14

4304 H2

4305 H2

4306 H2

4307 I2

5302 I13

5303 D9

6300 C3

6301 C3

6302 D10

6303 A6

6304 A7

6305 B8

6306 B8

6307 H4

7301 B3

3347 H9

3348 H9

3349 H10

3350 H4

3351 H3

3352 H4

3353 H7

3354 I13

3355 I3

3356 I4

3357 I8

3358 I9

3359 I9

3360 I10

3361 I4

3362 I4

3363 I5

3364 I5

3366 A6

3367 A7

3368 A7

3370 B9

3329 E4

3330 E13

3331 E13

3332 E3

3333 E4

3334 E4

3335 E7

3336 F4

3337 F7

3338 F4

3339 F5

3340 F5

3341 G4

3342 G4

3343 G5

3344 G7

3345 G5

3346 H8

2363 A7

2364 B7

3300 A3

3301 A3

3304 A3

3305 A4

3307 B2

3308 B3

3310 B3

3311 B6

3313 C6

3314 C7

3315 C7

3316 C4

3317 D8

3318 D8

3320 D4

3321 D9

3322 D8

3323 D11

3324 D11

3325 D3

3326 D4

3327 E8

2340 H10

2341 H7

2342 H11

2343 H11

2344 I11

2345 I7

2346 I13

2347 I10

2348 I9

2349 I9

2350 I10

2351 F11

2352 F12

2353 F12

2354 I13

2355 I13

2356 I13

2362 D12

2326 E3

2327 E3

2328 F7

2329 F6

2330 F4

2331 F5

2332 G6

2333 G4

2334 G5

2335 G7

2336 H7

2337 H10

2338 H8

2339 H9

2311 D8

2312 D9

2313 D12

2314 D8

2315 D10

2316 D10

2317 D4

2318 E9

2319 E10

2320 E13

2321 E13

2322 E12

2323 E3

2324 E3

2325 E4

10 11 12 13 14

A

B

C

D

E

F

G

H

I

A

B

C

D

E

1234567891011121314

1234

5

678

9

F

G

H

I

1300 A1

1301 C1

1302 F1

1303 G1

1304 H1

2306 A2

2307 C2

2308 C6

2310 E13

2337

4u7

35V

2K2

3371

F301

560R

3341

2333

68p

4R7

3308

3343

5K6

5K6

3339

470R

3356

3352

470R

4306

4305

3327

100K

100p

2324

100p

2348

1

3

2

GND_A

GND_A

8

9

7307

BC857B

1

10

2

3

4

5

6

7

10FE-BT-VK-N

1300

3350

680R

F305

5K1

3347

F311

F310

F313

GND_A

GND_A

GND_A

3329

22K

35V4u7

2347

2334

100p

T301

3354

2K2

2329

1u0

2331

100p

2363

220u 16V

BC857BS

7308-1

2

6

1

6303

BAS316

3366

3K3

GND_A

2314

1u0

2318

4n7

3K3

3359

22p

2356

2320

GND_tu

2u2

GND_A

2354

22p

6K8

3337

F314

GND_A

GND_tu

2317

2351

22p

1u0

2327

100p

10K

3307

3326

5K6

220p

2350

2349

220p

GND_A

56p

2345

GND_A