Page 1

SERVICE MANUAL

BLU-RAY DISC HOME THEATER

HTS3106/F7 C

Page 2

IMPORTANT SAFETY NOTICE

Proper service and repair is important to the safe, reliable operation of all

P&F Equipment. The service procedures recommended by P&F and

described in this service manual are effective methods of performing

service operations. Some of these service special tools should be used

when and as recommended.

It is important to note that this service manual contains various CAUTIONS

and NOTICES which should be carefully read in order to minimize the risk

of personal injury to service personnel. The possibility exists that improper

service methods may damage the equipment. It also is important to

understand that these CAUTIONS and NOTICES ARE NOT EXHAUSTIVE.

P&F could not possibly know, evaluate and advice the service trade of all

conceivable ways in which service might be done or of the possible

hazardous consequences of each way. Consequently, P&F has not

undertaken any such broad evaluation. Accordingly, a servicer who uses a

service procedure or tool which is not recommended by P&F must first use

all precautions thoroughly so that neither his safety nor the safe operation

of the equipment will be jeopardized by the service method selected.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-1-1

Laser Beam Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-2-1

Important Safety Precautions . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-3-1

Standard Notes for Servicing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-4-1

Cabinet Disassembly Instructions. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-5-1

How to Initialize the Blu-ray Disc Home Theater. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-6-1

Firmware Renewal Mode . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-7-1

Adjustment Instructions for BD Main CBA or BD Mechanism Assembly Replacement . . . . . . . . . . . . . . . . . . 1-8-1

Troubleshooting. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-9-1

Error Message. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-10-1

Block Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-11-1

Schematic Diagrams and CBA . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-12-1

Waveforms . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-13-1

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-14-1

Exploded Views. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-15-1

Mechanical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .1-16-1

Electrical Parts List . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1-17-1

Manufactured under license from Dolby Laboratories.

Dolby and the double-D symbol are trademarks of Dolby Laboratories.

Page 3

SPECIFICATIONS

General

Signal system NTSC Color

Power requirements 120 V AC, 60 Hz

Power consumption 70 W (standby: 0.6 W)

Total output power (Amplifier) Home theater mode: 1000 W

Dimensions (width x height x depth) 17.2 x 2.4 x 11.7 inches (435 x 59 x 295.6 mm)

Weight Total weight: 24.03 lbs. (10.9 kg)

Operating temperature 41°F (5°C) to 104°F (40°C)

Operating humidity Less than 80 % (no condensation)

SD card slot

slot x 1

MP3 LINK jack

mini jack x 1 500 mVp-p (75:)

Analog audio output

(SPEAKERS (4:))

Front and rear speakers System: Full range satellite

Center speaker System: Full range satellite

Subwoofer Impedance: 4:

Video output

RCA jack x 1 1 Vp-p (75:)

Analog audio input (AUX)

RCA jacks(L / R) x 1 L/R: 2 Vrms (47k:)

Digital audio input (COAXIAL)

RCA jack x 1 500 mVp-p (75:)

HDMI output

HDMI jack x 1 Video: 480p, 720p, 1080i, 1080p, 1080p24/Audio

LAN terminal

Wireless LAN (Internal)

FTC* output power: 700 W

* (Main Ch @ 1 kHz within 10 % THD, Sub Ch 60 Hz within 2.5 % THD)

Main unit: 8.05 lbs. (3.65 kg)

Terminals

Impedance: 4:

Frequency response: 180 Hz ~ 20 kHz

Dimensions: 3.9 x 5.1 x 4.0 inches (100 x 130 x 100.5 mm)

Speaker cable length: front - 9.8 feet (3 m)

rear - 30 feet (9.15 m)

Weight: front - 1.19 lbs. (0.54 kg)

rear - 1.13 lbs. (0.51 kg)

Impedance: 4:

Frequency response: 180 Hz ~ 20 kHz

Dimensions: 3.9 x 5.1 x 4.0 inches (100 x 130 x 100.5 mm)

Speaker cable length: 9.8 feet (3 m)

Weight: 1.61 lbs. (0.73 kg)

Speaker drivers: 5.25 inches (130 mm) woofer

Frequency response: 60 Hz ~ 150 Hz

Dimensions: 6.1 x 11.8 x 7.8 inches (154 x 300.5 x 198 mm)

Speaker cable length: 14.1 feet (4.3 m)

Weight: 6.02 lbs. (2.73 kg)

10BASE-T / 100BASE-TX

IEEE 802.11 b/g/n

D Note

• The specifications and design of this product are subject to change without notice.

1-1-1 EDA02SP

Page 4

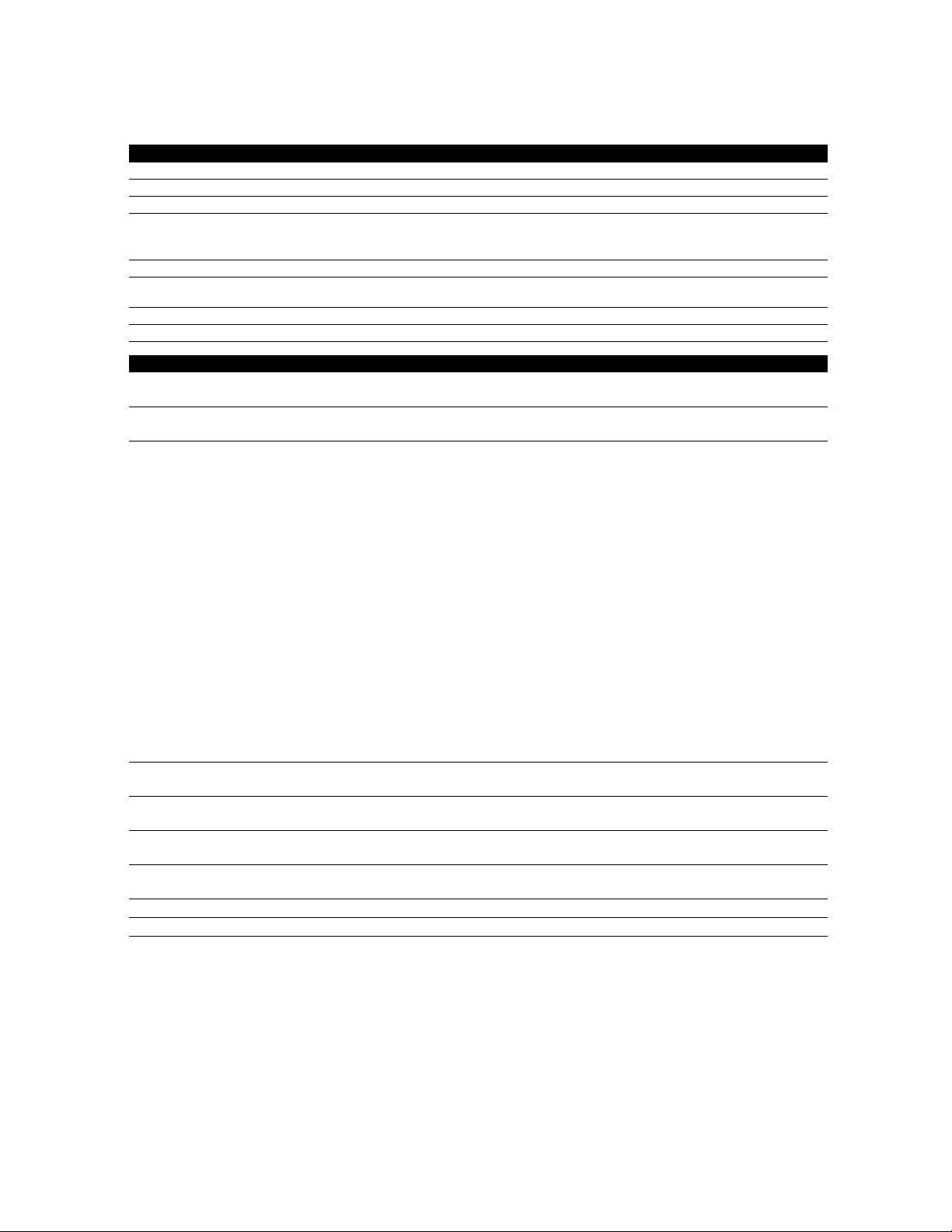

LASER BEAM SAFETY PRECAUTIONS

This BD player uses a pickup that emits a laser beam.

Do not look directly at the laser beam coming

from the pickup or allow it to strike against your

skin.

The laser beam is emitted from the location shown in the figure. When checking the laser diode, be sure to keep

your eyes at least 11.8 inches (30 cm) away from the pickup lens when the diode is turned on. Do not look directly

at the laser beam.

CAUTION: Use of controls and adjustments, or doing procedures other than those specified herein, may result in

hazardous radiation exposure.

Drive Mechanism Assembly

Laser Beam Radiation

Laser Pickup

Turntable

Location: Inside Top of BD mechanism.

1-2-1 HT3.5N_LBSP

Page 5

IMPORTANT SAFETY PRECAUTIONS

Product Safety Notice

Some electrical and mechanical parts have special

safety-related characteristics which are often not

evident from visual inspection, nor can the protection

they give necessarily be obtained by replacing them

with components rated for higher voltage, wattage,

etc. Parts that have special safety characteristics are

identified by a # on schematics and in parts lists. Use

of a substitute replacement that does not have the

same safety characteristics as the recommended

replacement part might create shock, fire, and/or other

hazards. The Product’s Safety is under review

continuously and new instructions are issued

whenever appropriate. Prior to shipment from the

factory, our products are carefully inspected to confirm

with the recognized product safety and electrical

codes of the countries in which they are to be sold.

However, in order to maintain such compliance, it is

equally important to implement the following

precautions when a set is being serviced.

Precautions during Servicing

A. Parts identified by the # symbol are critical for

safety. Replace only with part number specified.

B. In addition to safety, other parts and assemblies

are specified for conformance with regulations

applying to spurious radiation. These must also be

replaced only with specified replacements.

Examples: RF converters, RF cables, noise

blocking capacitors, and noise blocking filters, etc.

C. Use specified internal wiring. Note especially:

1) Wires covered with PVC tubing

2) Double insulated wires

3) High voltage leads

D. Use specified insulating materials for hazardous

live parts. Note especially:

1) Insulation tape

2) PVC tubing

3) Spacers

4) Insulators for transistors

E. When replacing AC primary side components

(transformers, power cord, etc.), wrap ends of

wires securely about the terminals before

soldering.

F. Observe that the wires do not contact heat

producing parts (heat sinks, oxide metal film

resistors, fusible resistors, etc.).

G. Check that replaced wires do not contact sharp

edges or pointed parts.

H. When a power cord has been replaced, check that

11~13 lb (5~6 kg) of force in any direction will not

loosen it.

I. Also check areas surrounding repaired locations.

J. Be careful that foreign objects (screws, solder

droplets, etc.) do not remain inside the set.

K. When connecting or disconnecting the internal

connectors, first, disconnect the AC plug from the

AC outlet.

L. When reassembling, be sure to use the original

screws or specified screws listed in the parts list.

M. This unit is classified as a CLASS 1 LASER

PRODUCT.

1-3-1 EDA02_ISP

Page 6

Safety Check after Servicing

Examine the area surrounding the repaired location for damage or deterioration. Observe that screws, parts, and

wires have been returned to their original positions. Afterwards, do the following tests and confirm the specified

values to verify compliance with safety standards.

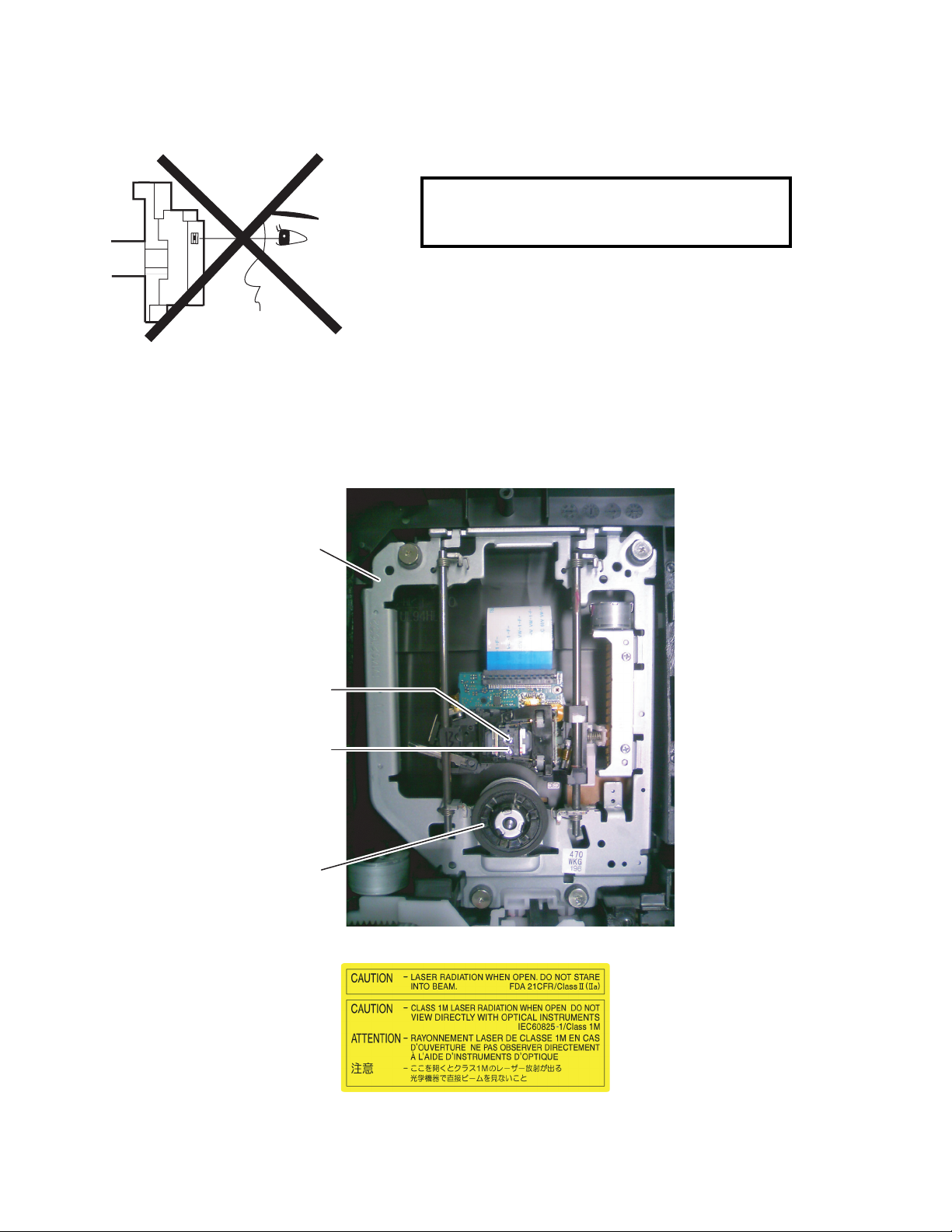

1. Clearance Distance

When replacing primary circuit components, confirm

specified clearance distance (d) and (d’) between

soldered terminals, and between terminals and

surrounding metallic parts. (See Fig. 1)

Table 1: Ratings for selected area

Chassis or Secondary Conductor

Primary Circuit

AC Line Voltage Clearance Distance (d), (d’)

120 V

Note: This table is unofficial and for reference only. Be

sure to confirm the precise values.

≥ 3mm(d)

≥ 5.8mm(d’)

2. Leakage Current Test

Confirm the specified (or lower) leakage current

between B (earth ground, power cord plug prongs) and

externally exposed accessible parts (RF terminals,

antenna terminals, video and audio input and output

terminals, microphone jacks, earphone jacks, etc.) is

lower than or equal to the specified value in the table

below.

Measuring Method (Power ON):

Insert load Z between B (earth ground, power cord plug

prongs) and exposed accessible parts. Use an AC

voltmeter to measure across the terminals of load Z.

See Fig. 2 and the following table.

d' d

Exposed Accessible Part

Z

One side of

B

Power Cord Plug Prongs

Fig. 1

AC Voltmeter

(High Impedance)

Table 2: Leakage current ratings for selected areas

AC Line Voltage Load Z Leakage Current (i)

2kΩ RES.

Connected in

parallel

120 V

50kΩ RES.

Connected in

parallel

Note:This table is unofficial and for reference only. Be sure to confirm the precise values.

i≤0.7mA AC Peak

i≤2mA DC

i≤0.7mA AC Peak

i≤2mA DC

1-3-2 EDA02_ISP

One side of power cord plug

prongs (B) to:

RF or

Antenna terminals

A/V Input, Output

Fig. 2

Page 7

STANDARD NOTES FOR SERVICING

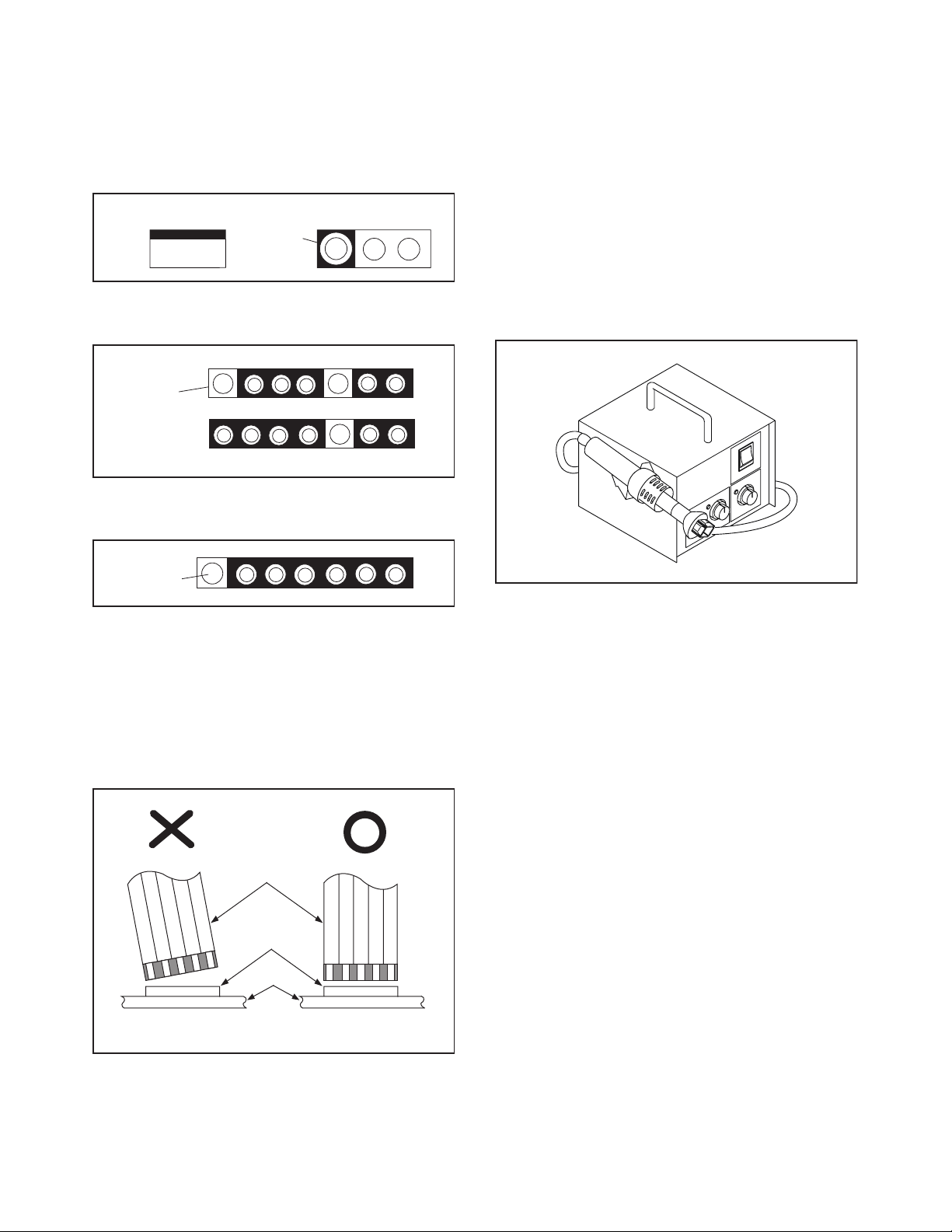

Circuit Board Indications

1. The output pin of the 3 pin Regulator ICs is

indicated as shown.

To p Vi ew

Out

2. For other ICs, pin 1 and every fifth pin are

indicated as shown.

Pin 1

3. The 1st pin of every male connector is indicated as

shown.

Pin 1

Input

In

Bottom View

5

10

Pb (Lead) Free Solder

When soldering, be sure to use the Pb free solder.

How to Remove / Install Flat Pack-IC

1. Removal

With Hot-Air Flat Pack-IC Desoldering Machine:

1. Prepare the hot-air flat pack-IC desoldering

machine, then apply hot air to the Flat Pack-IC

(about 5 to 6 seconds). (Fig. S-1-1)

Fig. S-1-1

Instructions for Connectors

1. When you connect or disconnect the FFC (Flexible

Foil Connector) cable, be sure to first disconnect

the AC cord.

2. FFC (Flexible Foil Connector) cable should be

inserted parallel into the connector, not at an

angle.

FFC Cable

Connector

CBA

* Be careful to avoid a short circuit.

2. Remove the flat pack-IC with tweezers while

applying the hot air.

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

CAUTION:

1. The Flat Pack-IC shape may differ by models. Use

an appropriate hot-air flat pack-IC desoldering

machine, whose shape matches that of the Flat

Pack-IC.

2. Do not supply hot air to the chip parts around the

flat pack-IC for over 6 seconds because damage

to the chip parts may occur. Put masking tape

around the flat pack-IC to protect other parts from

damage. (Fig. S-1-2)

1-4-1 BDN_SN

Page 8

3. The flat pack-IC on the CBA is affixed with glue, so

be careful not to break or damage the foil of each

pin or the solder lands under the IC when

removing it.

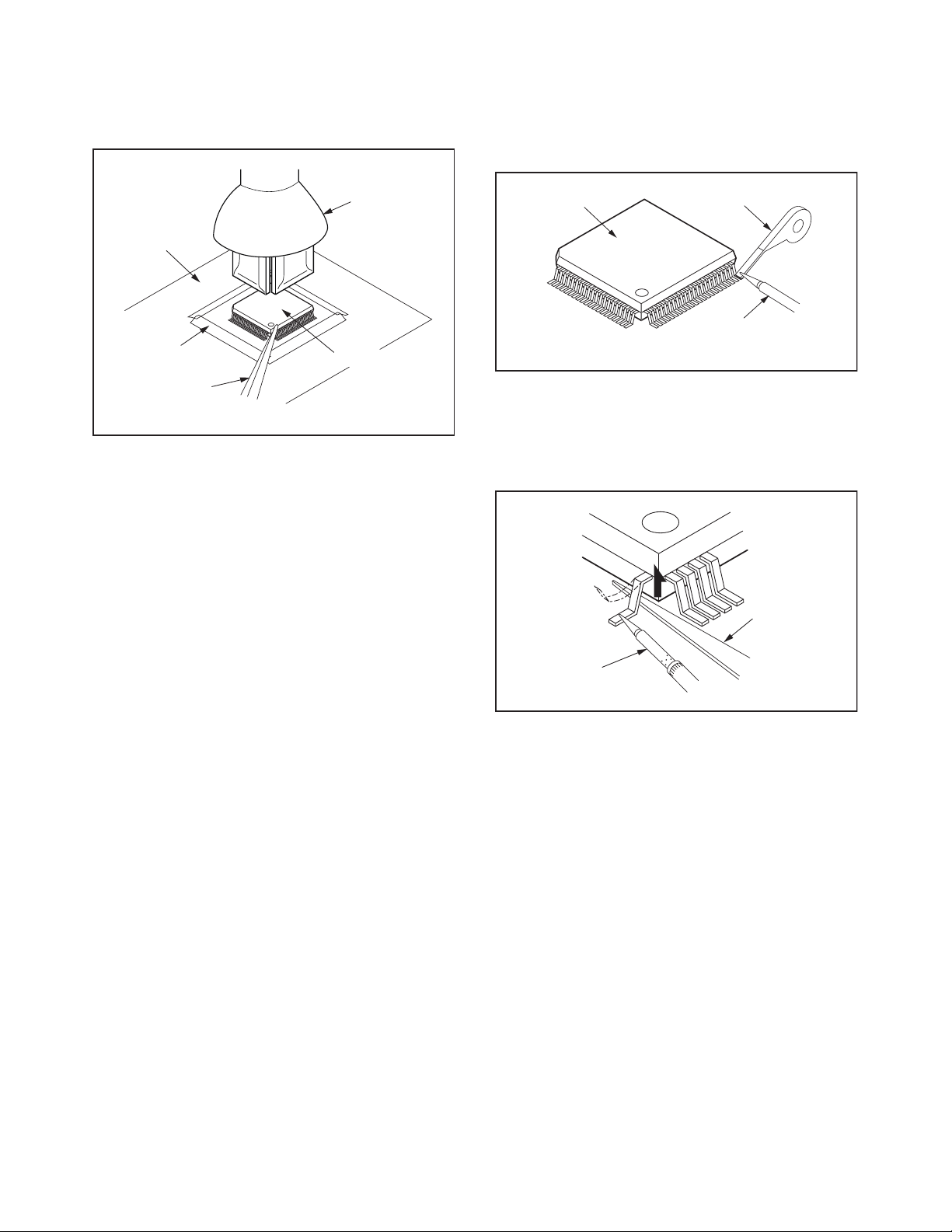

With Soldering Iron:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

CBA

Masking

Ta pe

Tweezers

Hot-air

Flat Pack-IC

Desoldering

Machine

Flat Pack-IC

Fig. S-1-2

Flat Pack-IC

Desoldering Braid

Soldering Iron

Fig. S-1-3

2. Lift each lead of the flat pack-IC upward one by

one, using a sharp pin or wire to which solder will

not adhere (iron wire). When heating the pins, use

a fine tip soldering iron or a hot air desoldering

machine. (Fig. S-1-4)

Sharp

Pin

Fine Tip

Soldering Iron

3. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

4. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Fig. S-1-4

1-4-2 BDN_SN

Page 9

With Iron Wire:

1. Using desoldering braid, remove the solder from

all pins of the flat pack-IC. When you use solder

flux which is applied to all pins of the flat pack-IC,

you can remove it easily. (Fig. S-1-3)

2. Affix the wire to a workbench or solid mounting

point, as shown in Fig. S-1-5.

3. While heating the pins using a fine tip soldering

iron or hot air blower, pull up the wire as the solder

melts so as to lift the IC leads from the CBA

contact pads as shown in Fig. S-1-5.

4. Bottom of the flat pack-IC is fixed with glue to the

CBA; when removing entire flat pack-IC, first apply

soldering iron to center of the flat pack-IC and heat

up. Then remove (glue will be melted). (Fig. S-1-6)

5. Release the flat pack-IC from the CBA using

tweezers. (Fig. S-1-6)

Note: When using a soldering iron, care must be

taken to ensure that the flat pack-IC is not

being held by glue. When the flat pack-IC is

removed from the CBA, handle it gently

because it may be damaged if force is applied.

Hot Air Blower

2. Installation

1. Using desoldering braid, remove the solder from

the foil of each pin of the flat pack-IC on the CBA

so you can install a replacement flat pack-IC more

easily.

2. The “ I ” mark on the flat pack-IC indicates pin 1.

(See Fig. S-1-7.) Be sure this mark matches the

pin 1 on the PCB when positioning for installation.

Then presolder the four corners of the flat pack-IC.

(See Fig. S-1-8.)

3. Solder all pins of the flat pack-IC. Be sure that

none of the pins have solder bridges.

Example :

Pin 1 of the Flat Pack-IC

is indicated by a " " mark.

Fig. S-1-7

To Solid

Mounting Point

CBA

Tweezers

Iron Wire

Soldering Iron

Fig. S-1-5

Fine Tip

Soldering Iron

Flat Pack-IC

or

Presolder

Flat Pack-IC

CBA

Fig. S-1-8

Fig. S-1-6

1-4-3 BDN_SN

Page 10

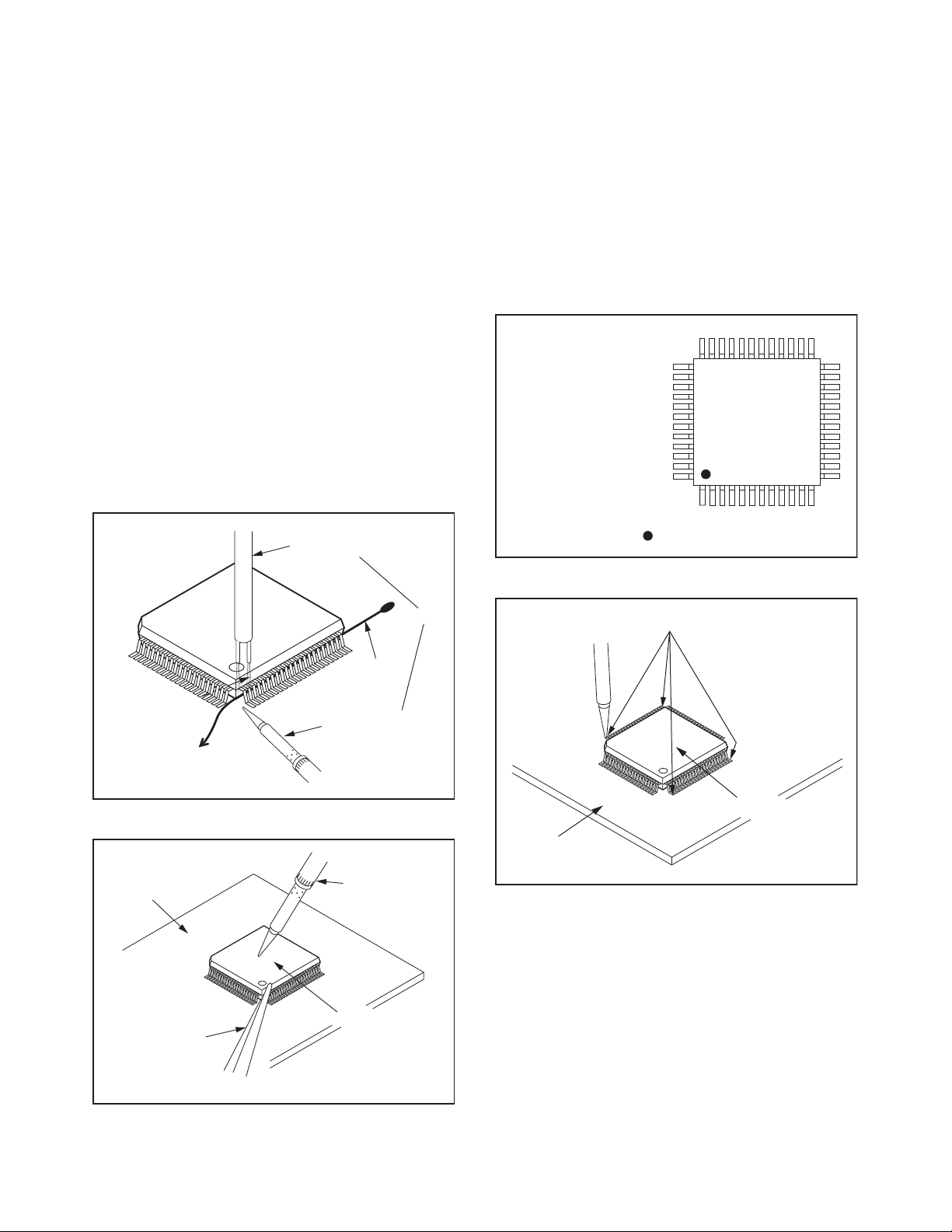

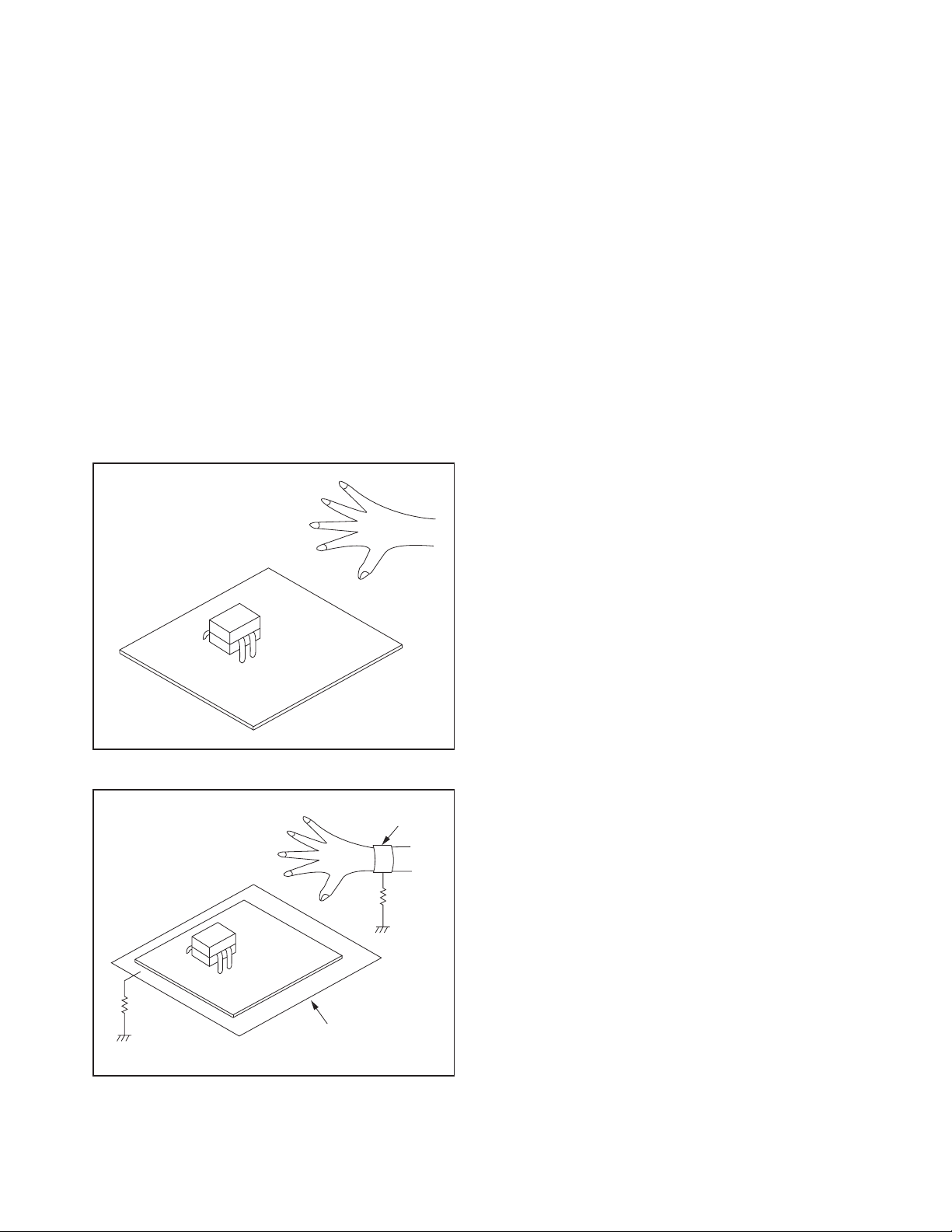

Instructions for Handling Semiconductors

Electrostatic breakdown of the semi-conductors may

occur due to a potential difference caused by

electrostatic charge during unpacking or repair work.

1. Ground for Human Body

Be sure to wear a grounding band (1 MΩ) that is

properly grounded to remove any static electricity that

may be charged on the body.

2. Ground for Workbench

Be sure to place a conductive sheet or copper plate

with proper grounding (1 MΩ) on the workbench or

other surface, where the semi-conductors are to be

placed. Because the static electricity charge on

clothing will not escape through the body grounding

band, be careful to avoid contacting semi-conductors

with your clothing.

<Incorrect>

<Correct>

1MΩ

CBA

Grounding Band

1MΩ

CBA

Conductive Sheet or

Copper Plate

1-4-4 BDN_SN

Page 11

CABINET DISASSEMBLY INSTRUCTIONS

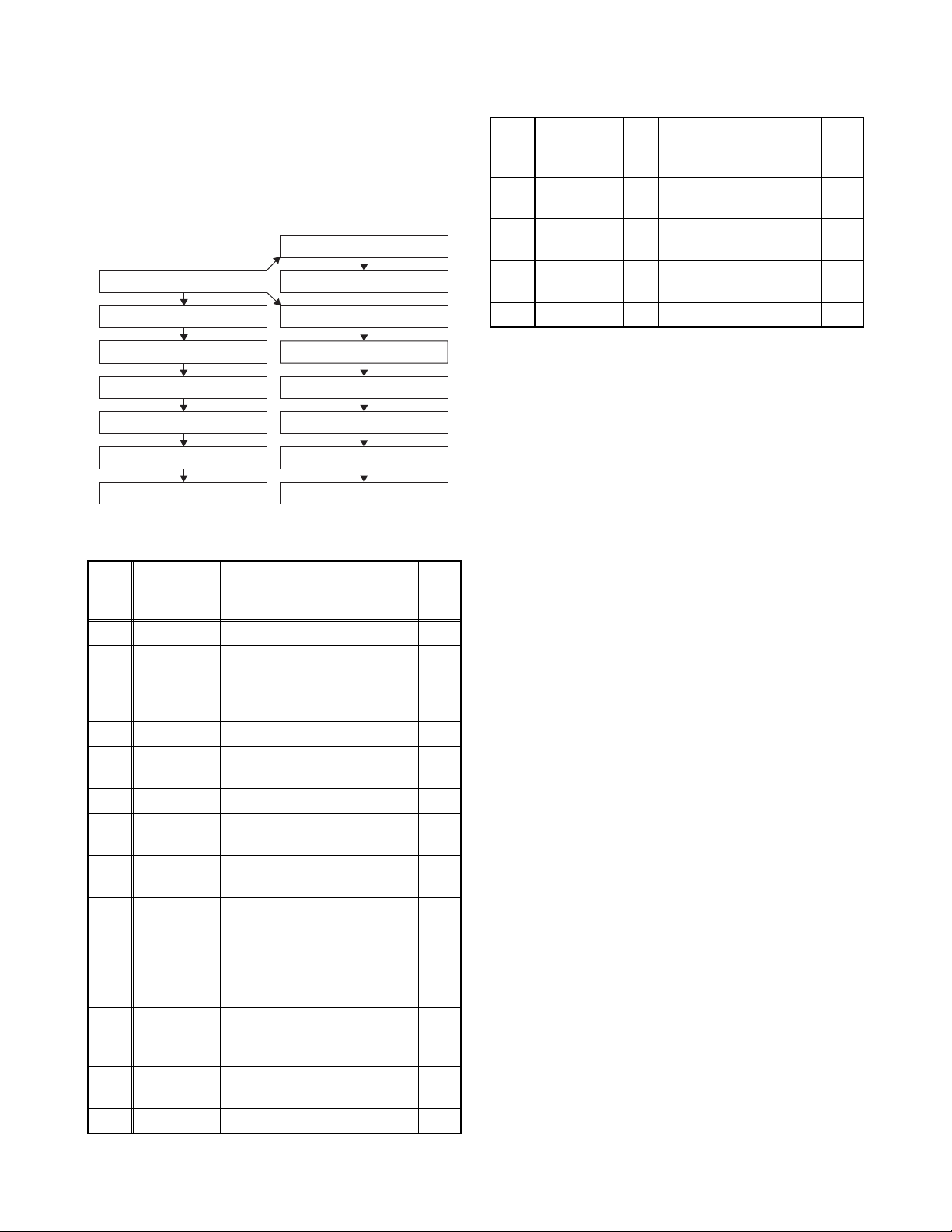

1. Disassembly Flowchart

This flowchart indicates the disassembly steps to gain

access to items to be serviced. When reassembling,

follow the steps in reverse order. Bend, route, and

dress the cables as they were originally.

[10] Fan Cover

[1] Top Cover

[8] BD Main CBA

[9] BD Mechanism Assembly

[12] AV CBA

[13] AMP/PSU CBA

[14] SD Card CBA

[15] MP3 CBA

[11] Rear Panel

[2] Front Unit

[3] Front CBA

[4] Power SW CBA

[5] WiFi CBA

[6] Rotary CBA

[7] Front Assembly

2. Disassembly Method

ID/

Loc.

No.

[1] Top Cover D1 8(S-1) ---

[2] Front Unit D2

[3] Front CBA D2 --------------- ---

[4]

[5] WiFi CBA D3 --------------- ---

[6]

[7]

[8]

[9]

[10] Fan Cover D6

[11] Rear Panel D6 3(S-8), (S-9), 2(S-10) 3

Part

Power SW

CBA

Rotary

CBA

Front

Assembly

BD Main

CBA

BD

Mechanism

Assembly

Fig.

No.

D3 2(S-3) ---

D4

D4 --------------- ---

D5

D5 4(S-6) 2

Removal

5(L-1), 3(L-2), 3(L-3),

4(S-2), CN2005,

CN2006, CN2007,

CN7601

Volume Knob, Nut,

Washer

(S-4), 2(S-5), CN101,

CN301, CN302,

CN6101, CN7001,

CN7101, M-PCB Plate

Earth, Locking Card

Spacer

(S-7), CN5001,

Fan Earth Plate

Note

1

---

2

---

ID/

Loc.

No.

[12] AV CBA D7

[13]

[14]

[15] MP3 CBA D8 (S-14) ---

↓

(1)

Note:

(1) Identification (location) No. of parts in the figures

(2) Name of the part

(3) Figure Number for reference

(4) Identification of parts to be removed, unhooked,

unlocked, released, unplugged, unclamped, or

desoldered.

P = Spring, L = Locking Tab, S = Screw,

CN = Connector

e.g. 2(S-2) = two Screws of (S-2),

2(L-2) = two Locking Tabs of (L-2)

(5) Refer to “Reference Notes.”

Part

AMP/PSU

CBA

SD Card

CBA

↓

(2)

Fig.

No.

D7

D8 2(S-13) ---

↓

(3)

Removal

2(S-11), CN402,

CN403

5(S-12), CN9002,

PCB Bracket Front

↓

(4)

Note

---

---

↓

(5)

Reference Notes

1. CAUTION 1: Locking Tabs (L-1), (L-2) and (L-3)

are fragile. Be careful not to break them.

2. When replacing the BD Mechanism Assembly

or BD Main CBA, refer to "ADJUSTMENT

INSTRUCTIONS FOR BD MAIN CBA OR BD

MECHANISM ASSEMBLY REPLACEMENT."

3. When reassembling, be sure to use the original

screws or specified screws listed in the parts

list.

1-5-1 EDA02DC

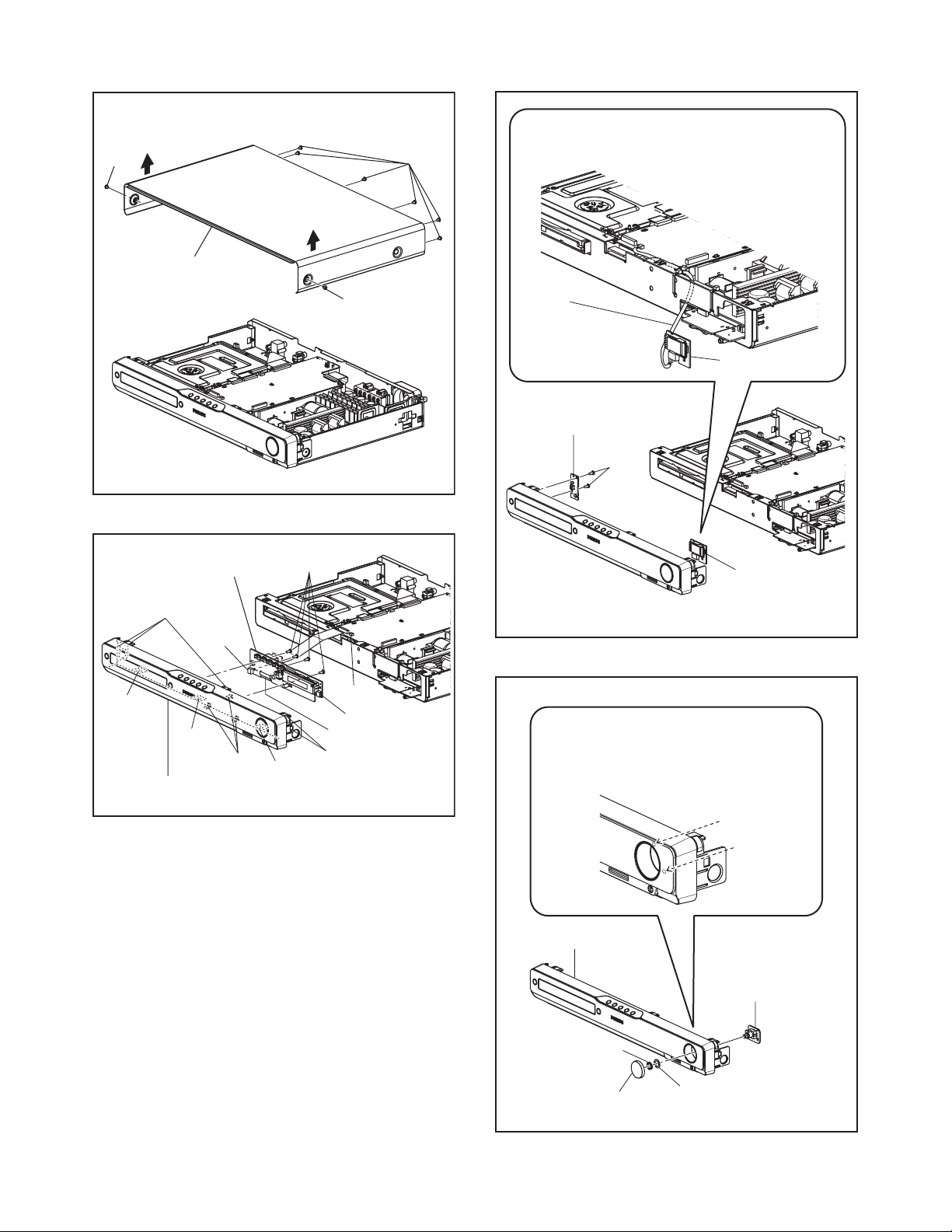

Page 12

(S-1)

[1] Top Cover

(S-1)

The cable (connected to the WiFi

CBA) should be placed as shown.

[3] Front CBA

(L-1)

(L-2)

(L-2)

[2] Front Unit

CN2006

(L-3)

(L-2)

(S-2)

(S-1)

CN7601

CN2007

CN2005

(L-1)

Cable

(connected to

the WiFi CBA)

WiFi CBA

[4] Power SW CBA

(S-3)

Fig. D1

[5] WiFi CBA

Fig. D3

From behind the front panel,

push the two holes with a driver

or hexagonal wrench to remove

the volume knob.

Fig. D2

[7] Front Assembly

[6] Rotary CBA

Nut

Volume Knob

Washer

Fig. D4

1-5-2 EDA02DC

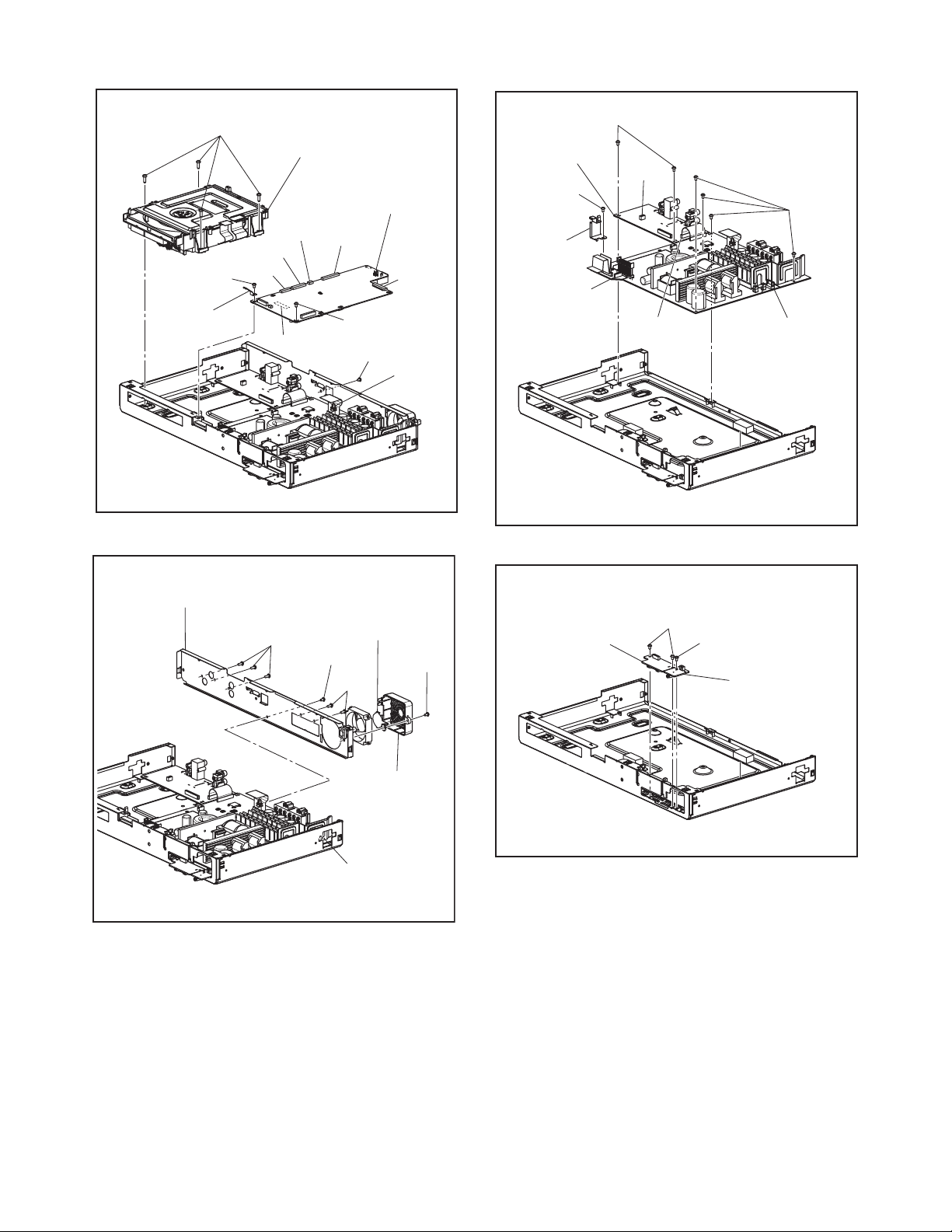

Page 13

(S-6)

[9] *BD Mechanism

Assembly

[8] *BD Main CBA

[12] AV CBA

(S-12)

(S-11)

CN402

(S-12)

CN101

CN302

(S-5)

M-PCB

Plate

Earth

CN6101

* See Reference Note 2.

[11] *Rear Panel

(S-8)

CN301

CN7101

(S-5)

(S-4)

Fan Earth Plate

(S-9)

(S-10)

CN7001

Locking

Card

Spacer

Fig. D5

(S-7)

PCB Bracket

Front

CN9002

[14] SD Card CBA

CN403

(S-13)

[13] AMP/PSU

CBA

Fig. D7

(S-14)

[15] MP3 CBA

* See Reference Note 3.

[10] Fan Cover

Fig. D8

CN5001

Fig. D6

1-5-3 EDA02DC

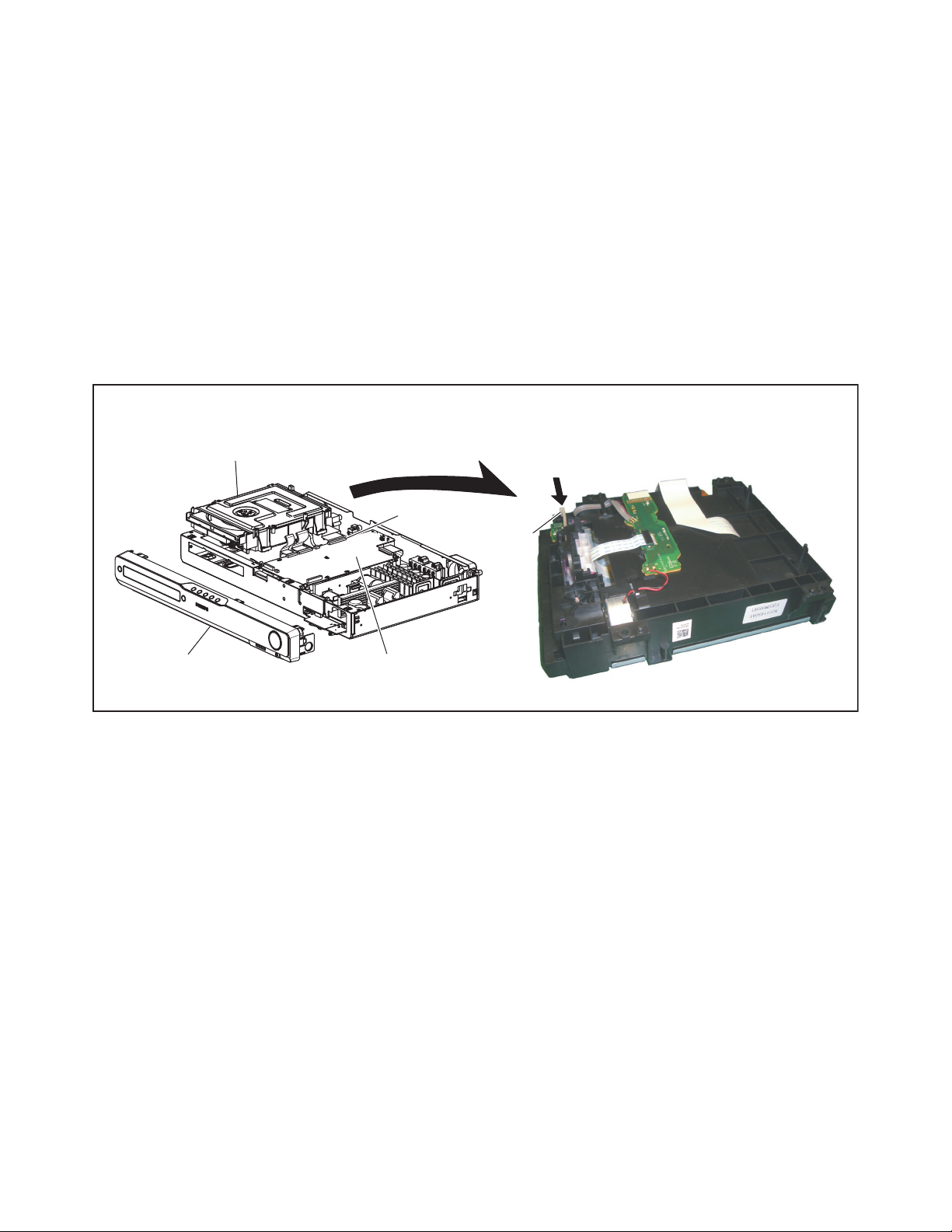

Page 14

3. How to Eject a Disc

When a disc cannot be removed due to malfunction or when an unplayable disc is inserted, follow the

procedure below to remove the disc.

Procedure A

1. Unplug the AC power cord and then plug it in.

2. Turn the power on by pressing the [ A] button and the disc tray will open automatically.

Procedure B

1. Remove the Top Cover and Front Unit.

2. Disconnect connector (CN7101) on the BD Main CBA.

3. Remove the BD Mechanism Assembly.

4. Slide the portion A in the direction of the arrow from bottom side of the BD Mechanism Assembly.

5. Pull the tray out manually and remove the disc.

BD Mechanism Assembly

Front Unit

Bottom of BD Mechanism Assembly

CN7101

Portion A

BD Main CBA

1-5-4 EDA02DC

Page 15

HOW TO INITIALIZE THE BLU-RAY DISC HOME THEATER

To put the program back at the factory-default,

initialize the BD player as the following procedure.

Note:

• By initializing, network is reset to disconnected state

and “Network Service Disclaimer” appears on the

screen.

• Once the unit is initialized, the unit starts in Virgin

Mode the next time it is turned on. The Virgin Mode

allows quick set up of language and network settings.

To exit this mode, select “Cancel” on the screen.

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [ ] (skip up), [1], [2], and [3] buttons on the

remote control unit in this order.

Fig. a appears on the screen. All VFD lights.

"*" differ depending on the models.

Version Display

F/W Name

Version

Region

Pickup

ESN

DRM

: *******

: *.**.**

: *-*

: **

: ********************************

: OK

Default Setting : --

Default Setting : STOP End : STANDBY-ON

VFD/LED Check : OK

Fig. a

4. Press [ C ] button on the remote control unit.

Fig. b appears on the screen and Fig. c appears

on the VFD.

"*" differ depending on the models.

Version Display

F/W Name

Version

Region

Pickup

ESN

DRM

Default Setting : SUCCESS

Default Setting : STOP End : STANDBY-ON

VFD/LED Check : OK

: *******

: *.**.**

: *-*

: **

: ********************************

: OK

Fig. b

Fig. c

5. After initializing, the power will turn off

automatically.

1-6-1 E1U21INT

Page 16

FIRMWARE RENEWAL MODE

Note:

The file extension of the available firmware is “b41”.

1. Turn the power on and remove the disc on the tray

and close the tray.

2. Press [ ] (skip up), [6], [5], and [4] buttons on the

remote control unit in this order.

Fig. a appears on the screen.

"*" differ depending on the models.

F/W Version Mode

Please select software update mode.

Disc

USB

SD Card

The available software update mode will

differ depending on the model type.

F/W Name : ******* Ver *.**.**

Fig. a Version Up Mode Screen (Example)

3. Select “Disc” or “USB” or “SD Card” and press

[OK] button on the remote control unit. The tray

will open automatically, if “Disc” is selected.

4. Insert the disc or USB Memory Stick or SD Card

for version up.

5. The BD player enters the F/W version up mode

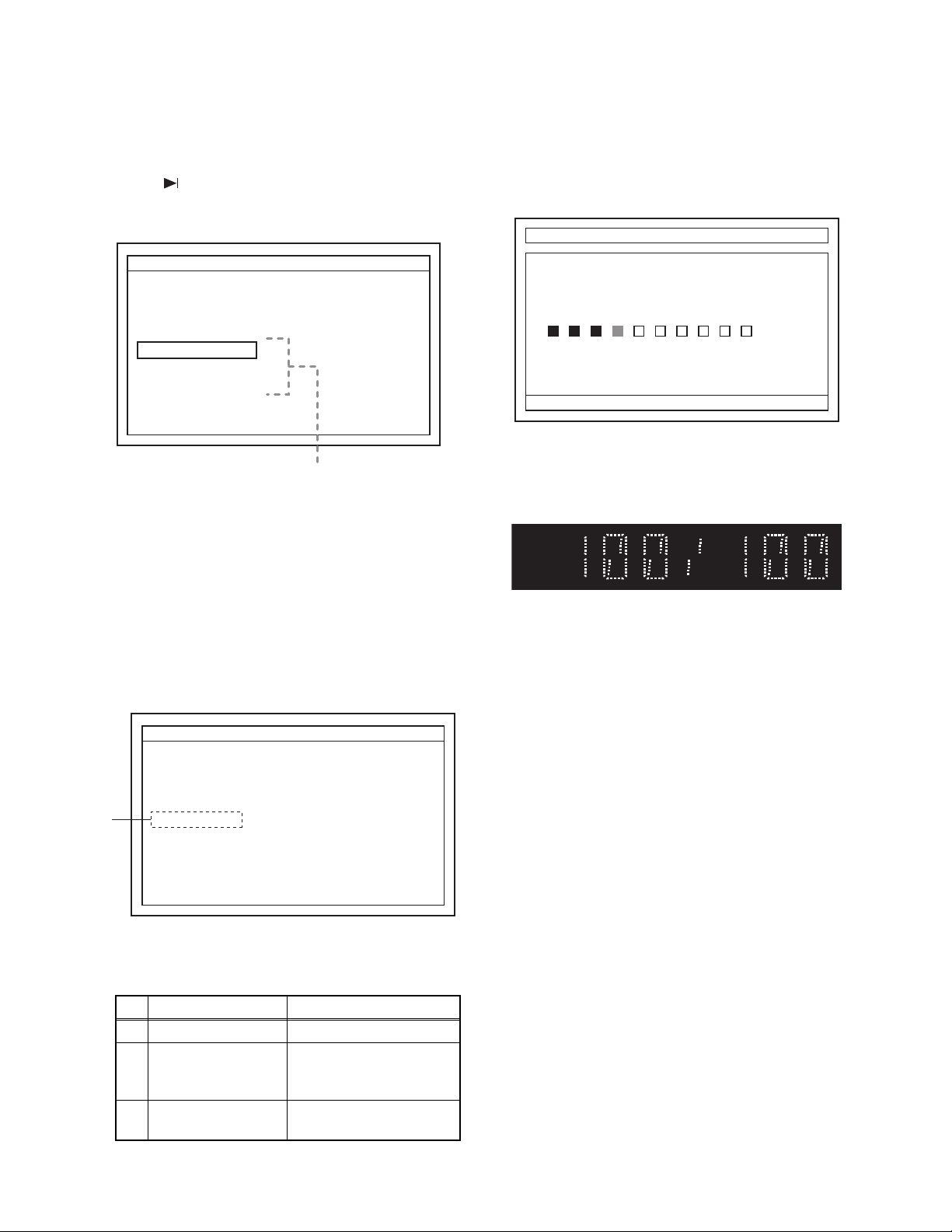

automatically. Fig. b will appear on the screen.

Make sure to insert the proper F/W for the state of

this model.

"*" differ depending on the models.

F/W Version Mode

F/W Name : ******* Ver *.**.**

6. After reading the new firmware, the power will turn

off automatically.

7. The power turns on and updating starts

automatically.

Fig. c will appear on the screen.

Software Update

Please wait for a few minutes. Do not unplug the AC cord or interrupt the

updating process. When update is completed unit will automatically turn off,

and unit will automatically turn back on.

Updating Software....

******* Ver *.**.**

CHECK SUM : - - - -

"*" differ depending on the models.

Fig. c Version Up Mode

8. After the update, Fig. d will appear on the VFD and

the power will turn off automatically.

Fig. d

VFD upon Finishing the Programming Mode (Example)

9. The power turns back on automatically. If disc

mode was selected, the tray will open

automatically. Remove the disc or USB Memory

Stick or SD Card from the unit.

Notes:

• All the settings will be put back to factory-default.

• Do not unplug the AC cord and do not remove the

disc or USB Memory Stick or SD Card while this

procedure.

(*1)

Loading Disc...

Fig. b Programming Mode Screen (Example)

The appearance shown in (*1) of Fig. b is

described as follows:

No. Appearance State

1 Loading Disc... Loading the disc

Checking the new

2 Reading...

firmware and preparing

the update system

Updating

3

Software...

Downloading and

writing the new firmware

The following USB Memory Stick/SD Card can be

used for software update. Make sure to use a device

that has enough space.

• USB Memory Stick (FAT16/FAT32 file system)

•

SD/Mini SD/Micro SD Card (FAT12/FAT16 file system)

•

SDHC/Mini SDHC/Micro SDHC Card (FAT32 file system)

1-7-1 HT3.5(P&F)_(VFD)FW

Page 17

How to Verify the Firmware Version

1. Turn the power on.

2. Remove the disc on the tray and close the tray.

3. Press [ ] (skip up), [1], [2], and [3] buttons on the

remote control unit in this order.

Fig. e appears on the screen. All VFD lights.

"*" differ depending on the models.

Version Display

F/W Name

Version

Region

Pickup

ESN

DRM

: *******

: *.**.**

: *-*

: **

: ********************************

: OK

When update is interrupted during

the Software Update

In a case where software update is interrupted due to

unplugging of AC cord, removal of SD card or power

outage, the unit will start from the software update

mode the next time it is turned on. (Unless the update

is completed, the unit starts from software update

mode and not from the Home Menu.)

Fig. f appears on the screen when software update is

interrupted.

Software Update

Default Setting : --

Default Setting : STOP End : STANDBY-ON

VFD/LED Check : OK

Fig. e

4. To exit this mode, press [ ] button.

The software update failed. For the state that the remote control key does not

work, press the [STANDBY/ON] key of this unit for 10 seconds. As this unit will

turn off, press the [STANDBY/ON] key again. After this unit turns back on, the

software update will start again.

If the software update failed with above procedure, please do the following.

1. Write the software downloaded on our website in SD Memory Card.

2. Press the [STANDBY/ON] key of this unit for 10 seconds.

3. As this unit will turn off, press the [STANDBY/ON] key.

Fig. f

Follow the procedures below to enter the software

update mode again.

1. Press the [STANDBY/ON] button of this unit for 10

seconds.

2. As this unit will turn off, press the [STANDBY/ON]

button again.

3. After this unit turns back on, the software update

will start again. Fig. g will appear.

Software Update

Please wait for a few minutes. Do not unplug the AC cord or interrupt the

updating process. When update is completed unit will automatically turn off,

and unit will automatically turn back on.

Updating Software....

******* Ver *.**.**

CHECK SUM : - - - -

"*" differ depending on the models.

Fig. g

Note:

If the software update fails following the above

procedure, please perform the following.

1. Write the software downloaded on our website in

SD Memory Card.

2. Insert the SD Memory Card into the SD card slot.

3. Press the [STANDBY/ON] button of this unit for 10

seconds.

4. As this unit will turn off, press the [STANDBY/ON]

button.

1-7-2 HT3.5(P&F)_(VFD)FW

Page 18

FIRMWARE RENEWAL MODE (for User)

Disc/USB Memory Stick/SD Card Update

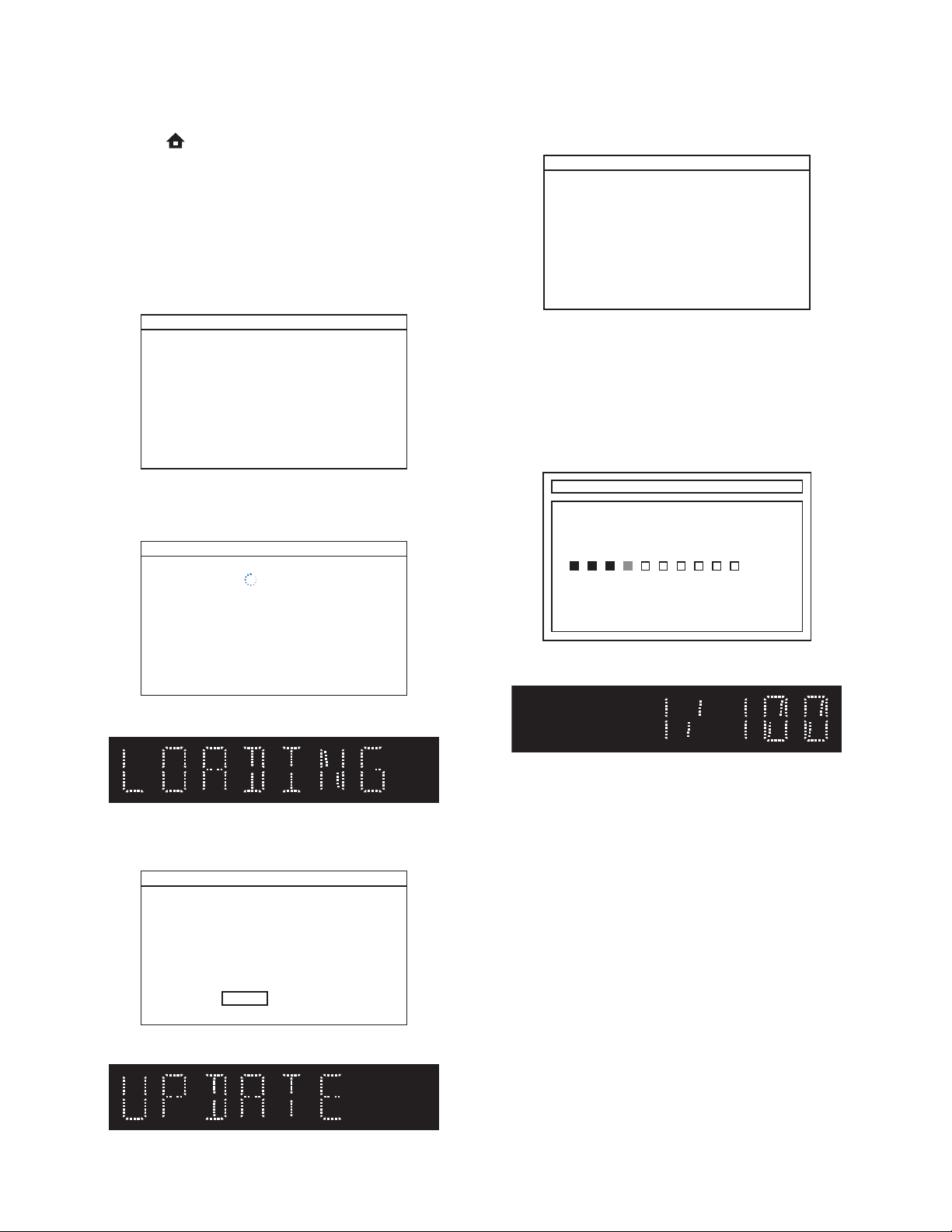

1. Press [ ] button to display Setup menu.

2. Select Setup - Advanced Setup - Software Update.

3. Select the software update mode from "Disc" or

“USB” or “SD Card.” The available software update

mode will differ depending on the model type.

4. The screen appears in Fig. h when “Yes” is

chosen. If disc mode was selected, the tray will

open automatically.

Insert the disc or USB Memory Stick or SD Card for

software update.

Please insert a disc for software update. If you want to exit update,

press [BACK].

Software Update

7. Fig. m will appear on the screen.

8. After a few minutes, the power will turn off

9. The power turns on and updating starts

Software Update

Please wait for a few minutes. During the updated process the player

will automatically turn off and turn back on.

Fig. m

automatically.

automatically.

Fig. n will appear on the screen and update

progress will be displayed as shown in Fig. o on

the VFD.

Fig. h (Example of Disc mode)

5. Disc loading starts. Fig. i will appear on the screen

and Fig. j will appear on the VFD.

Software Update

Loading Disc....

Fig. i (Example of Disc mode)

Fig. j VFD in Update Mode

6. Fig. k will appear on the screen, then select “Yes”.

Fig. l will appear on the VFD.

Software Update

Current Version : X.XX.XX

: X.XX.XXInsert Version

Software Update

Please wait for a few minutes. Do not unplug the AC cord or interrupt the

updating process. When update is completed unit will automatically turn off,

and unit will automatically turn back on.

Updating Software....

Fig. n

Fig. o VFD in Update Mode

10. After the update, the power turns off and then

turns back on automatically. If disc mode was

selected, the tray will open automatically. Remove

the disc or USB Memory Stick or SD Card from the

unit.

Note: The setup setting configured before the update

will be kept.

Select 'Yes' and press [OK] button start updating. Press 'No' to exit

software update.

No Yes

Fig. k

Fig. l VFD in Update Mode

The following USB Memory Stick/SD Card can be

used for software update. Make sure to use a device

that has enough space.

• USB Memory Stick (FAT16/FAT32 file system)

• SD/Mini SD/Micro SD Card (FAT12/FAT16 file

system)

• SDHC/Mini SDHC/Micro SDHC Card (FAT32 file

system)

1-7-3 HT3.5(P&F)_(VFD)FW

Page 19

Network Update

1. Press [ ] button to display Setup menu.

2. Select Setup - Advanced Setup - Software Update

- Network.

3.

When “Yes” is chosen, the screen appears in Fig. p

and the unit starts connecting to the network.

Software Update

Network Connecting...

7. The power turns on and updating starts

automatically.

Fig. s will appear on the screen and Fig. t will

appear on the VFD.

Software Update

Please wait for a few minutes. Do not unplug the AC cord or interrupt the

updating process. When update is completed unit will automatically turn off,

and unit will automatically turn back on.

Updating Software....

Fig. p

4. The firmware version confirmation screen (Fig. q)

will appear on the screen. Select “Yes” and press

[OK] button.

Software Update

Current Version : X.XX.XX

The latest software can be download. Do you want to download?

: X.XX.XXInsert Version

No Yes

Fig. q

5. Fig. r will appear on the screen.

Software Update

Please wait for a few minutes. During the updated process the player

will automatically turn off and turn back on.

Fig. s

Fig. t

8. After the update, the power turns off and then

turns back on automatically.

Note: The setup setting configured before the update

will be kept.

Network Error Message

No. Error Message

The cable is not connected.

1

Please confirm the connection of the cable.

DHCP cannot be acquired.

2

Please confirm connection or set it with the

manual operation.

Internet Protocol address is not set.

3

Please confirm the set content.

Fig. r

6. After a few minutes, the power will turn off

automatically.

The equipment with same Internet Protocol

4

address already exists.

Please set another Internet Protocol address.

There is no response from Default gateway.

5

Please confirm the address of Default

gateway.

It is not possible to connect to the DNS server.

6

Please confirm the Internet connection or the

DNS address setting.

It is not possible to connect to the server.

7

Please contact our support center.

It is not possible to confirm the software

8

version.

Please contact our support center.

Cannot connect to the wireless network.

9

Please confirm the wireless network setting.

1-7-4 HT3.5(P&F)_(VFD)FW

Page 20

ADJUSTMENT INSTRUCTIONS FOR BD MAIN CBA OR

BD MECHANISM ASSEMBLY REPLACEMENT

When replacing either BD Main CBA or BD Mechanism Assembly, the unique OPU DATA of the BD Mechanism

needs to be written into the BD Main CBA. Follow the procedure below for OPU DATA write operation.

Equipments:

• PC (OS: Windows XP strongly recommended)

• Barcode reader

• COMTOOL jig relay board + 6PIN FFC cable

• USB cable Type AB

• Device driver for COMTOOL jig (CDM 2.06.00 WHQL Certified)

• Specialized application (OpuDataWriter)

Caution:

Always turn the unit power off before connecting the FFC cable or removing the FFC cable from the BD Main CBA

•

1. Preparation Of Work Environment

1-1.

For the OPU DATA write operation, refer to the connection diagram and connect each device as shown below.

Connection Diagram

Note: The unit configuration may differ depending on model types.

.

Unit (Completed product)

BD Mechanism

Assembly

BD Main CBA

Connect to 6-pin connector

of BD Main CBA

6-pin FFC cable

6-pin

connector

USB cable Type AB

(To USB Port)

COMTOOL Jig Relay Board

PC

Barcode Reader

(To USB Port)

Location of Pin 1 on COMTOOL Jig Relay Board

Lower side of Ref. No CN06 is pin 1 (printed 1 by silk)

1-8-1 HT3.5(2D)_HT_AIR

Page 21

Caution:

• Make sure the FFC cable is inserted in the proper direction so the Pin 1 of COMTOOL jig relay board and Pin 1

of BD MAIN CBA connector is connected.

Location of Pin 1 on BD Main CBA

1pin

Pin 1 is located on the left side

• If the device driver (CDM 2.06.00 WHQL Certified) of COMTOOL jig relay board is not installed in the PC, install

this before connecting COMTOOL jig relay board to the PC.

<How to install the device driver for COMTOOL jig relay board>

1) Save the device driver for COMTOOL jig relay board in the C: drive.

2) Connect COMTOOL jig relay board to the PC.

3) The driver installation screen opens. Select [Install from a list or specific location (Advanced)] then click

[Next].

4) Select [Search for the best driver in these locations.] then check the box for [Include this location in the

search:].

5) Click on Browse button then select the device driver (CDM 2.06.00 WHQL Certified) folder in the C: drive.

Click [Next].

6) Confirm that installation of [USB Serial Converter] device driver has completed and click on [Finish].

2. How To Check Which Port Is Used For COMTOOL Jig Relay Board

2-1. Click on the Windows [Start] button on the PC.

2-2. Right click on [My Computer].

2-3. Click on [Properties].

2-4. Click on [Hardware] tab in System Properties window.

2-5. Click on [Device Manager].

2-6. Click on [Ports (COM&LPT)].

2-7. Check which connection port is assigned for [USB Serial Port] (e.g. COM1).

The connection port number assigned here will be used later during setup of application.

3. Application Setup

3-1. Save the application folder (OpuDataWriter) directly under the C: drive.

3-2. Create a shortcut for [OpuDataWriter.exe] which is located inside the folder on the desktop.

1-8-2 HT3.5(2D)_HT_AIR

Page 22

4. OPU DATA WRITE

4-1. Connect the unit’s AC power cord. Wait for about 30 seconds until the unit is in standby mode.

4-2. Double click on the [OpuDataWriter.exe] shortcut on the desktop to start the application.

4-3. Application start screen appears.

Select the assigned connection port of [USB Serial Port] for the [COM PORT] field located at the right corner

of the screen.

Check that [Please input OPU DATA] message is displayed in the Status Display.

Set the cursor position at the blank box next to the [OPU DATA].

Cursor position

Status Display

Select the assigned COM PORT

4-4. Using the Barcode reader, scan the QR code attached on the side of the BD Mechanism Assembly.

QR Code

4-5. Check that [FE CONNECTION CHECK] message appears on the Status Display then turn the unit power on.

Status Display

If error occurs:

If an error occurs, the screen changes to a red display. In such case, close the window and then unplug the

unit AC power cord. Check if each device is properly connected then repeat from step 1.

1-8-3 HT3.5(2D)_HT_AIR

Page 23

4-6. Data write begins. While writing data, the Status Display message will change.

SEND LD PAR

Status Display

4-7. [OK] appears in the Status Display if data write has been completed successfully.

If error occurs:

• If an error occurs, the screen changes to a red display. In such case, close the window and then unplug the

unit AC power cord. Check if each device is properly connected then repeat from step 1.

• If an error other than connection error occurs for more than 3 times, the BD MAIN CBA or BD Mechanism

Assembly may be defected. Replace with a new one before performing the OPU DATA write.

4-8. After data write has been completed successfully, unplug the AC power cord.

4-9. Remove the FFC Cable of COMTOOL jig relay board connected to the BD Main CBA.

Then disconnect all devices connected to the unit.

1-8-4 HT3.5(2D)_HT_AIR

Page 24

Error Code

Error Code Error Description

10 Start word error The first letter entered for [LOADER S/N] does not match.

101 [ReadBackup]Drive Mount error Cannot mount the drive set for [ReadBackup] folder.

102 [Transfer]Drive Mount error Cannot mount the drive set for [Transfer] folder.

103 [OpuData]Drive Mount error Cannot mount the drive set for [OpuData] folder.

104 [Log]Drive Mount error Cannot mount the drive set for [Log] folder.

210 Start word error The first letter entered for [OPU DATA] does not match.

300 CheckSum NG

301 QRCheckSum NG [Process1]CheckSum Test error.

310 CreateHeader NG [Process2]Error creating Header region.

320 CreateLDD NG [Process3]Error creating LDD region.

330 CreateFBIAS NG [Process4]Error creating FBIAS region.

340 CreateExp NG [Process5]Error creating EXP region.

350 CreateLcd NG [Process6]Error creating LCD region.

360 CreateCrc NG [Process7]Error creating CRC region.

370 CreateDDD NG [Process8]Error creating DDD file.

380 CreateLog NG [Process9]Error creating LOG file.

390 CreateOpuData NG [Process10]Error creating OPU DATA file.

1010 Start word error The first letter entered for [LOADER S/N] does not match.

1130 DDDFile not found

1140 DDDFile search error Error occurred while searching DDD file in [WriteBackup] folder.

1151 [WriteBackup]Drive Mount error Cannot mount the drive set for [WriteBackup] folder.

1152 [Transfer]Drive Mount error Cannot mount the drive set for [Transfer] folder.

1153 [OpuData]Drive Mount error Cannot mount the drive set for [OpuData] folder.

1154 [Log]Drive Mount error Cannot mount the drive set for [Log] folder.

1210 ComConnection TIME OUT

1211 Tray Close error Cannot close tray.

1220 TestUnitReady ERROR0 [ERROR0] returned for TestUnitReady command issued.

1221 TestUnitReady ERROR1 [ERROR1] returned for TestUnitReady command issued.

1222 TestUnitReady TIME OUT No reply received for TestUnitReady command issued.

1230 ReadVirRAM32 NG

1240 WriteReg16 NG

1250 WriteReg1 NG

1260 FlashWrite ERROR0 [ERROR] returned for FlashWrite command issued.

1261 FlashWrite ERROR1 [ERROR] returned for FlashWrite command issued.

1262 FlashWrite TIME OUT No reply received for FlashWrite command issued.

1310 MoveDDDFile NG [Move DDD file to written folder]Process Error

1320 CreateLog NG [Create LOG file]Process Error

1330 CreateComLOG NG [COM PORT connection LOG file create]Process Error

1400 TIME OUT System Time Out

2031 LdParamSend NG LD Parameter Send Error

The checksum of the entered OPU DATA(QR code) does not

match.

As a result of searching DDD file in the [WriteBackup] folder, the

entered DDD file for [LOADER S/N] could not be found.

No reply received for NOP commmand (20 times at 500mSec

interval).

[Acquire DRAM head address of DDD data forwarding

region]Process Error

[Send ddd data to DRAM head address region(16BYTE unit)]

Process Error

[Send ddd data to DRAM head address region(1BYTE

unit)]Process Error

1-8-5 HT3.5(2D)_HT_AIR

Page 25

Error Code Error Description

2042 LdParamClear ERROR0 Cannot initialize LD Parameter.

2043 LdParamClear ERROR1 Cannot initialize LD Parameter.

2044 LdParamClear TIME OUT Cannot initialize LD Parameter (TimeOut).

2051 IopSet NG Iop Set Error

2052 IopSet ERROR0 Iop Set Error

2053 IopSet ERROR1 Iop Set Error

2054 IopSet TIME OUT lop Set Error (TimeOut)

2055 IopSet ERROR0 Iop Set Error

2056 IopSet ERROR1 Iop Set Error

2057 IopSet TIME OUT lop Set Error (TimeOut)

2058 CD Iop LIMIT NG CD Iop exceeds limit value.

2059 DVD Iop LIMIT NG DVD Iop exceeds limit value.

2060 BD Iop LIMIT NG BD Iop exceeds limit value.

2081 LdParamVerify NG LD Parameter Verify Error

2091 AtapiComCheck NG BE start Error.

2101 ID4 OFF NG Cannot set ID4 OFF.

2111 SET BOR RATE NG Failed to change Serial Connection Rate.

2200 Genaration NG Generation detect failure.

6001 Factory Info save Error Failed to create FactoryInfo file.

6002 Factory Info save Error Failed to create FactoryInfo file.

6100 Factory Info save Error Failed to create FactoryInfo file.

5. Saving The Pre-Operation OPU DATA

OPU DATA before performing the OPU DATA write is saved in a folder automatically.

5-1. When the OPU DATA write operation has been completed successfully, a folder named [FactoryInfo] is

created in the application folder (OpuDataWriter).

5-2. In the [FactoryInfo] folder, a folder is created monthly in which text file data are saved.

This text file is created with a file name of the OPU serial number and contains the pre-operation OPU DATA.

Pre-operation OPU DATA text file

Year(2010)Month(12)

5-3. The text file is necessary for analyzing the defective BD Mechanism. Submit this text file with the defective

BD Mechanism as necessary to the appropriate managing Department.

1-8-6 HT3.5(2D)_HT_AIR

Page 26

FLOW CHART NO.1

The power cannot be turned on.

TROUBLESHOOTING

Is the fuse normal?

Ye s

Is normal state restored when once unplugged

power cord is plugged again after several seconds.

Ye s

Is 3.5V voltage outputted to the cathode of D9024?

Ye s

Are the voltage of each pin of CN9001 become

as shown below?

CN9001

CN9001

CN9001

CN9001

CN9001

CN9001

Check each rectifying circuit of secondary circuit

and replace BD Main CBA if defective.

FLOW CHART NO.2

The fuse blows out.

1-3PIN

4,6PIN

9,11,13PIN

10PIN

19,20PIN

22PIN

+1.8V

+5V

+1.2V

+10.5V

+3.3V

+5V

Ye s

1V8

5V-1, U5V

1V2

10V5

3V3

5V-2

No

No

No

No

See FLOW CHART No.2 <The fuse blows out.>

Check for leak or short-circuiting of primary

circuit component and replace AMP/PSU CBA

if defective.

Replace AMP/PSU CBA.

Check the presence that the primary component

is leaking or shorted and replace AMP/PSU CBA

if defective.

After servicing, replace the fuse (F9000).

FLOW CHART NO.3

Picture does not appear normally.

Set the disc on the disc tray, and playback.

(Composite output)(HDMI output)

Are the video signals outputted to Pin(23) of

CN404?

Ye s

Replace AV CBA.

Replace BD Main CBA or BD MECHANISM

ASSEMBLY.

Check the presence that the rectifying diode or circuit

is shorted in each rectifying circuit of secondary side

and replace AMP/PSU CBA if defective.

No

Replace BD Main CBA or BD MECHANISM

ASSEMBLY.

1-9-1 E1U00TR

Page 27

FLOW CHART NO.4

Audio does not appear normally.

Set the disc on the disc tray, and playback.

Ye s

Are the audio signals(serial data) outputted to

Pin(3, 4, 5, 6) of CN201?

Ye s

Replace AMP/PSU CBA.

No

Replace BD Main CBA or BD MECHANISM

ASSEMBLY.

1-9-2 E1U00TR

Page 28

ERROR MESSAGE

Note: Only error messages for the unit’s corresponding media will appear.

Playback feature may not be available on this Disc.

Error Message

Disc Error

Loader Error

Parental Lock Error

Region Error

The device connected for HDMI

connection does not support HDCP.

- - Please eject the disc. - -

Disc Error

Disc Error

- - Please eject the disc. - Playback feature may not be available on this Disc.

Loader Error

The unit stopped automatically due to loader error.

Please open the disc tray once and then close it.

Parental Lock On

The current selected parental level prohibits playback.

Region Error

Playback is not authorized in your region.

Region code of this disc :

(There is no message.)

The following error will appear on the VFD.

USB/SD Card Error

BD-Live Network Connecting Error

LAN Cable Not Connected

Cannot Acquire DHCP Server

Cannot Acquire IP Address

Already Existing IP Address

No Response From Default

Gateway

Cannot Connect To DNS Server

Memory Device Error

- - Please check the Memory Device. - There is no playback file on the Memory Device or Device has incorrect/

no format.

BD-Live Setting Error

Network connection is interrupted. Please confirm “BD-Live Setting”.

The cable is not connected.

Please confirm the connection of the cable.

DHCP cannot be acquired.

Please confirm connection or set it with the manual operation.

Internet Protocol address is not set.

Please confirm the set content.

The equipment with same Internet Protocol address already exists.

Please set another Internet Protocol address.

There is no response from Default gateway.

Please confirm the address of Default gateway.

It is not possible to connect to the DNS server.

Please confirm the Internet connection or the DNS address setting.

1-10-1 E1U00ER

Page 29

Error Message

Cannot Connect To Server

Cannot Confirm Firmware Version

Firmware Update Error

(Update File Error)

Cannot Connect To Download

Server

Cannot connect to wireless

network.

USB Error

It is not possible to connect to the server.

Please contact our support center.

It is not possible to confirm the software version.

Please contact our support center.

Error detected.

File may be corrupted.

Please download software again.

Error detected.

Please confirm whether it is SD Memory Card that corresponds to

software update.

Error detected.

Please confirm whether it is USB device that corresponds to software

update.

It is not possible to connect to the server.

Please contact our support center.

Cannot connect to the wireless network.

Please confirm the wireless network setting.

Error in the USB Connection. USB operation has been stopped

automatically. Please remove the USB device and restart the unit.

1-10-2 E1U00ER

Page 30

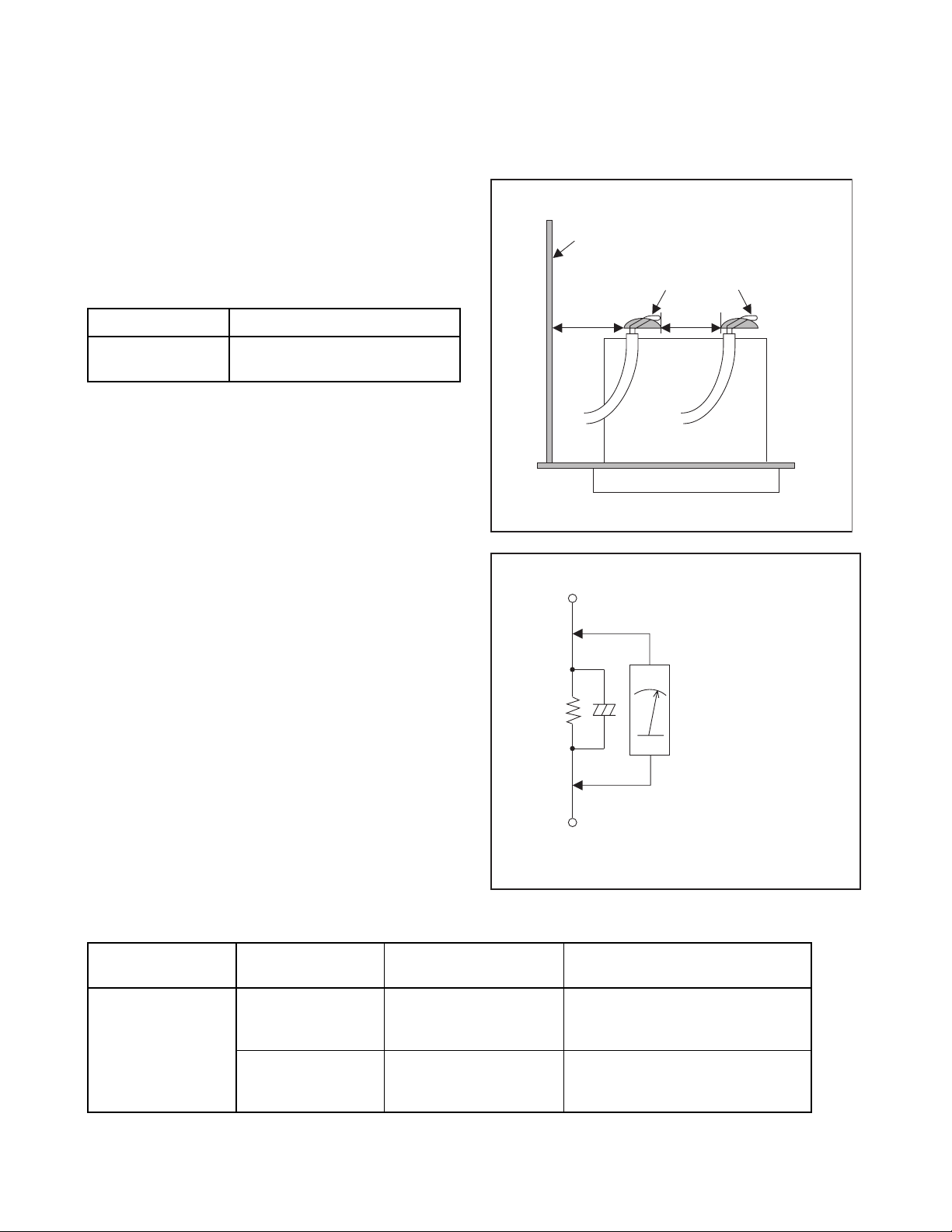

OVERALL BLOCK Diagram

JK405

VIDEO

CVBS, Composit Y /Cr/Cb OUT

IC301

VIDEO

Driver

CVBSOUT, CompOUT(Y/Cr/Cb)

JK7501

HDMI 19pin

CEC

HDMI

HotPlug

I2C(DDC)

IC7501

HDMI

Transmitter

IRQ

I2S 4, S PDIF

/RST,MCLK,SCLK,LRCLK

Video CLK(4 80i:27MHz,480p: 54MHz:720p,1 080i:74MHz)

IC6601, 2

DDR2 SDRAM

(Nom:512Mbit X 2)

(FullHD,OSD:1Gbit X 2)

IC6501, 2

DDR2 SDRAM

(1Gbit X 2)

IC6901

NAND FLASH

(Nom:512Mbit,)

(w/NetUpdate,Failsafe:1Gbit)

(w/Netflix:2Gbit)

IC6002

8kBit EEPROM

(NO CONNECTION)

CN7902

50pin

CN7901

40pin

CN804

6pin

CN7903

4pin

CN801,2,3

10pin

SW

/VMute, SD/HD LPF1

PON+5V-BE

PON+3V3-BE,

PON+1V2

SCL, SDA

PON+1V8

SCL, SDA

JK403B

COAX

COAX SPDIF

IC405

IC306,

IC307

AV+5V_1

/VMute, SD/HD LPF

AV CBA

74HCU04

PON+1V8

PON+3V3_BE

D3.3V,

PON+10V5

,

D3.3V

A5V

Buffer AMP

Single SW

IC301

SPM Driver

BD Loader unit

2

ARC SPDI F

SPDIF IN

ARC-SPDI FOUT

PON+5V-BE

VHALF

Spindle

+3.3V

CN404

CN7101 30pin

CN101 45pinCN302 16pin

A8V,

D3.3V,

SW

AV+5V_1

30pin

Ipod-TX, Ipod-RX

/VMute,SDHD

SPDIFIN

CompOUT (Y/Cr/Cb),CVBSOUT

IC6001

BP1A

VREFH

IC302

Motor Driver

CN301 4pin

Pick Up

AVCC

BD OPU

Analog

Audio ADC

MCLK

I2S 4

FM_L

IC402

AMP

Audio

L/R IN

IC7201

LRCLK

SCLK

PON+10V5,

A8V, A5V

CN402A

AUX1

AUX1_L

AUX1_R

IC303, IC304

Multi Plexer

Analog

L/R IN

FM_R

AV+12V, AV-12V

Analog

Audio

L/R IN

CN402

BD MAIN CBA

PON+5V-BE

PON+3V3-BE,

PON+5V-BE

/PDN

SCL, SDA

I2S_DATA0-3

/A-Mute, MCLK, LRCLK, SCLK, RST 2, IRQ

SUB-TX, SUB-RX, MD,MC,MS

SYSRST,RDY

PON+3V3-BE,

PON+1V8, PON+1V 2

MII

/RST

LAN Transceiver

SCL,

SDA

74.25/74.1758MHz (Vpix)

33.864

33.33MHz(PC I)

27MHz (V)

PON+3V3_FE( D3.3V)

A8V

Clock Generator

/33.8688/2 4.576MHz (A)

SD-DAT0-3, SD-WP, SD-CD,

SD-CLK, SD-CMD

USBDP,USBDN

PON+3V3_BE

10V5(PON+10V5)

5V-2(PON+5V_ 2,

PON+5V-BE)

8V Reg.

CN6101 30pin

MP3_L

MP3_R

IC404 AMP

MP3-R

MP3-L

2pin(3pin)

IC6401

25MHz

IC6702

Inductor

3V3(PON+3V3)

U5V(USB+5V)

AV+12V,

InputSel1-3

SingleSW1,2

+3.3V

AV+12V, AV-12V

AV+5V_2AV+5V_2

/VMute, SD/HD LPF

SCL, SDA

CEC

PON+3V3-BE

PON+3V3_BE

27MHz

1V8(PON+1V8)

1V2(PON+1V2)

AV-12V

MII

CN7601 5pin

A5V, AVCC

Inductor

5V-1(PON+5V_ 1

PON+5V-FE)

BLOCK DIAGRAM

JK201 16pin

30pin

CN403

CN7001 27pin

LAN JK6401

,

+3.3V

AV+5V_2

AV-12V

W_SDA,W_SCL

AV+12V

+3.3V

30pin

CN202

Input Sel1-3, SingleSW1-2, SD/HD_LPFSW1, /VMute

AMP/uCOM Block

MCLK

LRCLK

W_SCLK

W_TSD1,3

W_RST , W_IRQ

W_SCLK

W_TSD1,3

SW

CEC

EV+3V3

SAFETY

AV-12V

AV+12V

A+5V

34V

FL+

FL+

IC501

D-AMP

IC204

Buffer

AMP

CEC

IC201

EEPROM

EV+3V3

+3V3

JK5001

FL-

FR+

FR+

FL-

SDOUT2,4

+3.3V

WIRELESS_RST,

W_SDA,W_SCL

CEC IN

CEC OUT

FAN+

CN203

WIRELESS_INT

Speaker OUT X 6ch

FR-

SL+

SL-

SL-

SL+

FR-

IC5001

D-AMP

PWM3,4

PWM1,2

MCLK

LRCLK

5086_RST

LRCLK

5086_RST

SCLK

LRCLK

MCLK

CN201

/SYSRST

RDY

/RST, INT

EV+3V3

EV+3V3

SAFETY

VOL_UP,VOL_DOWN,LED( Play),LED(DiscIn),LED( PowerON),Remote(IRQ),

VFD_DAT,VFD_CLK,VFD_STB,AD(PWM_OP/CL),AD(FT P_KEY)

22pin

C+

C-

SR-

SR+

SR-C+C-

SR+

SCLKOUT2

SUB+

SUB+

IC5002

D-AMP

PWM5,6

IC5004

PWM Processer

SDOUT1-4

SUB-

SUB-

P+12V, 34V

5352_OTW

5352_SD

VALID2

IC5003

Audio DS P

SCLK

SDIN0-3

SW

PWMDSP _RST

I2S_DATA0-3

CN27pin

SUB_TX,

SUB_RX

IC203

COM

/HP_MUTE

/A_MUTE

SW

POWER_C

SAFETY

IPOD_SDA, IPOD_SCL, iPod R eset

XL201

12MHz

debug1-5

UART5_TX,UART5_RX,upgate_SW

H_DETECT, /H_MUTE

FAN Control, AD(FAN_LOCK)

PW_ON, PW_SW1, PW _SW2, PW_SW 3, PW_SW4, PW _SW5

5352_OTW, 5352_SD, 5086_BK_ERR

10V5

5V-2

CN9001

VFD+5V

AMP Power

Over Detect

+12V

IC5005A

Comparator

5086_BK_ERR

/5086_MUTE

5086_SDA,5086_SCL

SDOUT

5086_SDA, 5 086_SCL

12.288MHz

SCL, SDA

MD,MC,MS

/RST

SCL, SDA

/5086_MUTE

+3V3

(NO CONNECTION)

(NO CONNECTION)

5V-1

1V8

3V3

U5V

30pin

F2

F1EV+3V3

FAN

FAN+

IC5006

Xtal

DV33

FAN Fast/Slow

+12V

FAN Control

AMP pow er

over

POWER_C

EEPROM

XL5001

SW

IC202

IPOD

Certification

5pin

CN204

CN205

7pin

1V2

SD-DAT0-3, SD-WP, SD-CD, SD-CLK, SD-CMD

-FL

AMP/PSU CBA

AD(FAN_LOCK)

EV+3V3

+3.3V

PSU Block

PW_ON

Inductor

SW

-12V

AV-12V

Inductor

P+12V

Inductor

AV+12V

A+5V

Inductor

/HP_MUTE

BK3V3

-FL

Inductor

VFD+5V

HP Block

DV33

PWM

IC1

PC

PW_SW5

BK3V3

EV+3V3

CN9002

F1

F2

IC205

MUTE_L,MUTE_R

MUTE

Phone-L

3V3

LDO

Phone-R

11pin

T9000

Trans

Filter

SW

DV33

+12V

PW_SW5

+12V

+5V

+12V

Inductor

Inductor

+12V, -12V

H_DETECT

/H_MUTE

A+5V

T9001

Trans

PWM

A+5V

Phone-R

Phone-L

IC2

CN9000

+5V

+5V

+5V

+5V

A+5V

A+5V_2

(TO AC CORD)

2pin

Fuse

EMI

Filter

Bridge

BD9000

AMP

Driver

T9002

Trans

Gene.

VCC

Inductor

34V

Inductor

Safety

5V-1

U5V

5V-2

Reg.

Safety

3V3

Reg.

1V2

Reg.

1V8

Reg.

Safety

10V5

Inductor

IPOD+5V

SDOUT

MCLK

SCLKOUT2

MD,MC,MS

HP DAC

VOUT_L

VOUT_R

AMP

Phone_L

Phone_R

MUTE

Phone-Det

4pin

CN501

(NO CONNECTION)

EV+3V3

SAFETY

PW_SW2

EV+3V3

SAFETY

PW_SW3

PW_SW4

EV+3V3

SAFETY

LRCLK

CN2002

WIRELESS

LAN MODULE

CN2001

22pin

SW2007

5pin

SW

Solder

Directly

POWER SW CBAWiFi CBA

SW

3pin

CN2006

FRONT CBA

(PWM_OP/CL)

SW2001-6

AD

SW X 6

AD

(FTP_KEY)

EV+3V3

Remote

(IRQ)

RS2001

CN2005

F1

F2

IR

IC2001

VFD

GR1-8

SG1-18

IC2002

VFD

Driver

3Wire

-FL

VFD+5V

Vol_UP,Down

CN2007

Solder

3pin

Directly

VOL801

Rotary

Encoder

ROTARY CBA

1-11-1

CN807 12pin

3V3

SD Slot

SD801

SD CARD CBA

3pin

CN406

MP3R

MP3L

JK406 Pin Jack

MP3 CBA

EDA02BLOA

Page 31

SCHEMATIC DIAGRAMS AND CBA

Standard Notes

WARNING

Many electrical and mechanical parts in this chassis

have special characteristics. These characteristics

often pass unnoticed and the protection afforded by

them cannot necessarily be obtained by using

replacement components rated for higher voltage,

wattage, etc. Replacement parts that have these

special safety characteristics are identified in this

manual and its supplements; electrical components

having such features are identified by the mark “#” in

the schematic diagram and the parts list. Before

replacing any of these components, read the parts list

in this manual carefully. The use of substitute

replacement parts that do not have the same safety

characteristics as specified in the parts list may create

shock, fire, or other hazards.

Notes:

1. Do not use the part number shown on these

drawings for ordering. The correct part number is

shown in the parts list, and may be slightly

different or amended since these drawings were

prepared.

2. All resistance values are indicated in ohms

(K = 10

3. Resistor wattages are 1/4W or 1/6W unless

otherwise specified.

4. All capacitance values are indicated in µF

(P = 10

5. All voltages are DC voltages unless otherwise

specified.

6. Electrical parts such as capacitors, connectors,

diodes, IC’s, transistors, resistors, switches, and

fuses are identified by four digits. The first two

digits are not shown for each component. In each

block of the diagram, there is a note such as

shown below to indicate these abbreviated two

digits.

3

, M = 106).

-6

µF).

1-12-1 HTN_SC

Page 32

LIST OF CAUTION, NOTES, AND SYMBOLS USED IN THE SCHEMATIC DIAGRAMS ON

THE FOLLOWING PAGES:

1. CAUTION:

FOR CONTINUED PROTECTION AGAINST FIRE HAZARD, REPLACE ONLY WITH THE

F

A V

SAME TYPE FUSE.

ATTENTION: POUR UNE PROTECTION CONTINUE LES RISQES D'INCELE N'UTILISER

QUE DES FUSIBLE DE MÊME TYPE.

RISK OF FIRE-REPLACE FUSE AS MARKED.

This symbol means fast operating fuse.

Ce symbole represente un fusible a fusion rapide.

2. CAUTION:

Fixed Voltage (or Auto voltage selectable) power supply circuit is used in this unit.

If Main Fuse (F9000) is blown, first check to see that all components in the power supply circuit are not

defective before you connect the AC plug to the AC power supply. Otherwise it may cause some components

in the power supply circuit to fail.

3. Note:

1. Do not use the part number shown on the drawings for ordering. The correct part number is shown in the

parts list, and may be slightly different or amended since the drawings were prepared.

2. To maintain original function and reliability of repaired units, use only original replacement parts which are

listed with their part numbers in the parts list section of the service manual.

4. Voltage indications for PLAY and STOP mode on the schematics are as shown below:

2

1

(Unit: Volt)

The same voltage for

both PLAY & STOP modes

5.0

3

5.0

(2.5)

Indicates that the voltage

is not consistent here.

PLAY mode

STOP mode

1-12-2 HTN_SC

Page 33

AMP/PSU 1 Schematic Diagram

( TO AV CBA CN403 )

CN202

1

GND

0

TU_GPIO

2

0

3

TU_/RST

3.3

TU_/SEN

4

3.3

5

GND

0

6

TUPOD_SDA

3.3

GND

7

0

TUPOD_SCL

8

3.3

9

GND

0

10

Input_Sel3

0

11

Input_Sel2

0

12

Input_Sel1

0

13

SingleSW2

3.3

14

AV+5V

5.2

15

SingleSW1

3.3

16

AV-12V

-11.7

17

GND

0

18

AV+12V

13.0

19

GND

0

20

+3.3V

3.3

21

SD/HD_LPFSW1

0

22

V_Mute

0

23

GND

0

24

IPOD_TX

0

25

GND

0

26

IPOD_RX

3.3

27

GND

0

28

IPOD+5V AV+5V_2

0

29

0

30

IPOD_Det

0

( TO BD MAIN CBA CN7001 )

CN201

1

FB237 600

1.6

2

FB238 600

1.7

3

FB239 600

1.3

4

FB240 600

0.1

5

FB241 600

0

6

FB242 600

0

7

GND

0

8

1.3

9

GND

0

10

FB252 600

3.3

11

WIRELESS/RST

3.3

12

WIRELESS/IN T

0

13

SCL2

3.2

14

SDA2

15

16

17

18

19

20

21

22

23

24

25

26

27

33

GND

FB251 600

SYSTEM_RST

FB243 600

FB244 600

GND

FB245 600

FB246 600

GND

FB247 600

FB248 600

FB249 600

FB250 600

3.2

0

3.2

3.3

3.3

1.9

0

2.8

2.7

0

0

0

0

0

CN27/P1.0FFCDIP

--->> TESET P OINT symbol

( TO FRONT CBA CN2005 )

CN203

22

VFD+5V

5.2

21

0

20

FB234 600

3.4

19

0

FB232 600

18

3.4

17

0

FB233 600

16

3.4

15

0

14

-20.7

13

-15.1

12

-18.2

11

FB231 600

3.3

10

3.4

9

FB236 600

3.3

8

FB235 600

3.4

7

0

6

FB230 600

0

5

FB210 OPEN

3.3

FB224 OPEN

4

0

3

FB228 OPEN

3.2

FB229 OPEN

2

0

1

0

15

14

GND16GND

13

R219 33

12

R220 33

11

R221 33

10

R222 33

9

R223 33

8

7

R2036 33

6

R224 33

5

R225 33

4

R226 33

3

R2025 OPEN

2

1

JK201

C219

WIRELESS JACK

CE201

Wireless use olny

PW_SW6

SAFETY

PW_SW5

PW_SW4

PW_SW3

PW_SW2

PW_ON

VCC

VCC

+5V

+5V

-12V

-12V

BK3V3

BK3V3

+12V

+12V

3V3

3V3

-FL

-FL

F1

F1

F2

F2

FB211

BK3V3

-FL

FB209 600

PW_SW6

SAFETY

PW_SW5

PW_SW4

PW_SW3

PW_SW2

PW_ON

FB214 600

FB212 600

FB225

600

AV+5V_2

FB253

FB227

SCLKI

LRCKI

I2S_DAT0

I2S_DAT1

I2S_DAT2

I2S_DAT3

MCLKI

R203833

PWM.DSP/RST

R204

0

R205open W_IRQ

5086_SCL

R20233

5086_SDA

R203

CEC

A_MUTE

RDY

SUB_TXD

SUB_RXD

HP_MUTE

1782_MD

1782_MC

1782_MS

600

A+5V

GND

VFD_STB

GND

VFD_DAT

GND

VFD_CLK

GND

-FL

F1

F2

Remote(IRQ)

BK3V3

AD(FTP KE Y)

AD(PWM OP/CL)

GND

LED(PowerON)

VOL_UP

VOL_DOW N

LED(Play)

LED(Disc ln)

Reserve

C240

C241

W_TSD1

option pin

W_SCLK

LRCK

W_TSD3

W_SDA

W_SCL

W_RST

W_IRQ

MCLK

+3.3V

470U/10V

104

FB_100MHZ

FB222

FB223 FB_100MH Z

FB213 600

AV-12V

EV+3V3

47U/10V

C212 104

C211 104

C222

GND TO GND PART EMC US E

C5001 104

C5002 104

FE5001 OPEN

SCLK

LRCK

MCLK

W_RST

B3V3

W_SCL

TUPOD_SCL

W_SDA

TUPOD_SDA

I2C Jumper Option

104

104

W_TSD1

W_TSD3

W_SCLK

+3.3V

34V

A+5V

C223220U/25V

C216

C213 104

C224 220U/10V

R201

C5003 104

C5005 104

C5007 104

C5009 104

C5011 104

C5013 104

C5004 104

C5006 104

C5008 104

C5010 104

C5012 104

C5014 104

FE5007 OPEN

FE5006 OPEN

FE5005 OPEN

FE5004 OPEN

FE5003 OPEN

FE5002 OPEN

OPEN

R2039

IC206C

IC206G

EV+3V3

R2040

R2041

10

74HC04

5086_SCL

IC206E

1

74HC04

OPEN

IC206F

12

OPEN

8

IC206D

714

VCC

74HC04

C239

104

5086_SDA

EV+3V3

LED(Pla y)

LED(Dis c ln)

TU_GPIO

SYSTEM_RST

Panasonic POWER Control

R293

XL201

C220

10P

R284

C203

R2045 33

12MHz

100K

C221

10P

IC206A

2

74HC04

IC206B

43

74HC04

65

74HC04

R2013 open

R2023 open

R2024 open

R2037 open

EV+3V3

CEC

R2047

3M3

RCI341216-0002 Support Iphone

RCI341216-0003 Support Ipod

11

12

TUPOD_SCL

13

TUPOD_SDA

14

15

R294

4k7

open

R274

IC204A

IC204E

1

10 11

74HC04

74HC04

open

R275

IC204F

IC204B

3

12

74HC04

74HC04

OPEN

R276

IC204C

65

8

74HC04

IC204D

B3V3

14

GND

7

VCC

IC204G

74HC04

C238

47U/16V

+12V

AV+12V

FB215 600

C227

C228

104

EV+3V3

VFD+5V

220U/25V

C225

C226

PW_SW6

104

104

FB226 600

103

3.3

2

4

C201104

C5015 104

C5016 104

FE5008 OPEN

11

13

9

74HC04

GND

IC201 AT24C16

1

S0

2

S1

3

S2

4

GND

R258 4.7K

R259 4.7K

TP289

TP290

10K

104

AD(PWM OP/ CL)

D201 IN4148

10

VSS

I2C SCLK

I2C DA

READY

NC

NC16NC17NC18NC19NC

MFI341S2164

13

9

74HC04

R2049

R2051

1K

GND

JK401A

GND

JK5001

SUB-

SUB+

SL-

SL+

SR-

SR+

C-

C+

FL-

FL+

FR-

FR+

SCLKI

LRCKI

MCLKI

VCC

WC

SCL

SDA

NRST

AD(FAN-LO CK)

SAFETY

AD(FTP KEY)

NRSTupgate_sw

Q201

KTC3875

DSP_SL/SR

DSP_SBL/SBR

SCLKOUT2

R2048

Q202 DMP3120L

S

47K

14

13

12

11

10

9

8

7

6

5

4

3

2

1

8

7

6

SCL

5

SDA

R2046 33

R206 33

R2032

FB201 600

R207 33

R227 open

EV+3V3

SD/HD_LPFSW1

D202 1N4148

R290 10K

IC202

NC6NC7NC8NC9NC

5

VCC

4

RES

3

NC

2

Mode

1

NC

20

1/2W 1R(OPEN)

G

R2050

1k

Q203

2SC1623

SUB-

SUB+

SR-

SR+

SL-

SL+

FR-

FR+

FL+

R208

33

C202

R260 33

R261 33

C217

C218

R2031

R295 30K

R296

R287

W_RST

R5167 4K7

D

220U/25V

C232

TO POWER IC

C-

C+

FL-

104

100P

100P

5086_RST

0

R228 33

R229 33

R230 33

R231 33

R232 33

FB202 600

R285 10K

R272 0

R273

CEC_IN

CEC_OUT

+3.3V

33

0

+3.3V

Remote(IRQ)

PW_SW6

R297 4K7

R300 4K7

EV+3V3

FB216 600

FB217 600

104

C214

34V

FR-

R5014

3.3

3.3

C5075

C5087

P+12V

C5031 104

34V_1

C5105 103 R5020

L5001

10UH/10A

R5001 10

C5065 333

42

43

44

NC

BST_A

GVDD_A

C5100 103 R 5015 3.3

IC501

OTW

NC3NC

GVDD_B

1

2

C5037 104

R5007 10

R5063 0

5352_OTW

P+12V

EV+3V3

TU_GPIO1

0

0

iPod Reset

AD(FTP KEY)

R288 4K7

W_IRQ

EV+3V3

EE_SCL

EE_SDA

R209 33

99

98

100

VSS_3

VDD_3

1

PE2

2

PE3

3

PE4

4

PE5

5

PE6

6

VBAT

7

PC13-TAMPER-RTC

8

PC14-OSC32_IN

9

PC15-OSC32_OUT

10

VSS_5

11

VDD_5

12

OSC_IN

13

OSC_OUT

14

NRST

15

PC0

16

PC1

17

PC2

18

PC3

19

VSSA

20

VREF-

21

VREF+

22

VDDA

23

PA0-WKUP

24

PA1

25

PA2

PA326VSS_427VDD_428PA429PA530PA631PA732PC433PC534PB035PB136PB2/BOOT1

IR

EV+3V3

FB203 600

EV+3V3

Remote(IRQ)

PULL_UP

TU_GPIO

VOL_UP

VOL_DOWN

VFD_STB

AD(PWM OP/CL)

R299 4K7

R2001 4K7

R2002 4K7

R289 4K7

R298 4K7

P+12V

A+5V

FB218

600

104

220U/25V

C215

C233

220U/16V

SPDIF SW&ATS5086&TAS3108 Power Supply

C5101

C5017

41

PVDD_A

4

TU_/SEN

R277 33

R281 10K

96

PE097PE1

C5099

103

102

104

FB5001 100MHZ

C5212 470U/50V

C5216

104

40

PVDD_A

SD

5

R5029 33

R5074 0

5352_SD

W_RSTR278 33

10K

R282

BOOT0

94

PB895PB9

BOOT0

103

C5114

824/63V

104

C5018 104

37

39

38

OUT_A

GND_B

GND_A

PWM_A6RESET_AB7PWM_B8OC_ADJ

33

R5030

VALID2

PWM_FR

W_SCL

W_SDA

debug4

debug5

upgate_sw

33

R279 33

R210 33

R211 33

R280 OPEN

R202633R2027

88

93

PB389PB490PB591PB692PB7

C5076

102

C5088

104

34V

36

9

R5077 27K

SingleSW2

R262 33

87

PD7

R5016

3.3

OUT_B

IC203

STM32F100VCT6

256 K

PE738PE839PE940PE1041PE1142PE1243PE1344PE1445PE1546PB1047PB11

37

VOL+

VOL-

10K

R235 33

R234 33

R233 33

LED(PowerON)

R2034 33

R266 33

R267 33

R268 33

R265 33

Input_Sel1

VFD_CLK

R2003 4K7

C229

Input_Sel2

VFD_DAT

R2004 4K7

Input_Sel3

FB219

600

AV+5V_2

R286

FB204 33R

FB205 33R

V_Mute

H_MUTE

H_ DETECT

TU_/RST

VOL_UP

VOL_DOWN

SUB_RXD

SUB_TXD

RDY

IPOD_Det

IPOD_TX

R2005 4K7

R2006 4K7

R2007 4K7

R2008 4K7

R2009 4K7

IC205

OPEN

2

3

3V3 LDO

1

104

C234

34V_1

SingleSW1

R263 33

V_STB

FB206 600

VFD_STB

EE_SCL

R2010 4K7

TP291

35

PVDD_B

GND

10

iPod Reset

IPOD_Det

R264 33

R212 33

V_CLK

V_DAT

FB207 600

FB208 600

VFD_CLK

VFD_DAT

EE_SDA

R2011 4K7

+3.3V

C230 220U/16V

C5066 333

FR+