Page 1

Coffee Maker Senseo “Latte Select”

HD7850/60

Philips Consumer Lifestyle

Service Manual

PRODUCT INFORMATION

- This product meets the requirements regarding

interference suppression on radio and TV.

- After the product has been repaired, it should function

properly and has to meet the safety requirements as

officially laid down at this moment.

TECHNICAL INFORMATION

- Voltage : 220 - 240 V

- Frequency : 50 - 60 Hz

- Power consumption : 2650 W

Boiler : 1450 W

Steam heater : 1200 W

- Standby power (switched off) : < 1 W

- Standby power : ± 30 W

(switched on 30 min) (room temperature)

- Pressure Coffee system : < 1.6Bar

- Pressure Steam system : < 1 Bar

- Contents water reservoir : 1200 cc/mL

- Contents milk reservoir : 120 cc/mL

- Auto shut off : 30 min

- Variable Coffee volume : Min, Normal and Max

Coffee volume overview

Min cc/mL Normal cc/mL Max cc/mL

France version 80 100 140

General version 80 122 145

Indication temperature for

Coffee/Milk receipe volume

all versions cc/mL

Cappuccino 160 ± 16 ≥ 69

Latte Macchiato 220 ± 24 ≥ 63

Café Latte 190 ± 20 ≥ 67

- Colour setting : Deep Black

- Sap coding : HD7850/60

chosen Coffee/Milk receipe,

very depended from milk inlet

temperature. (°C)

Published by Philips Consumer Lifestyle Printed in the Netherlands © Copyright reserved Subject to modification

08/09

Page 2

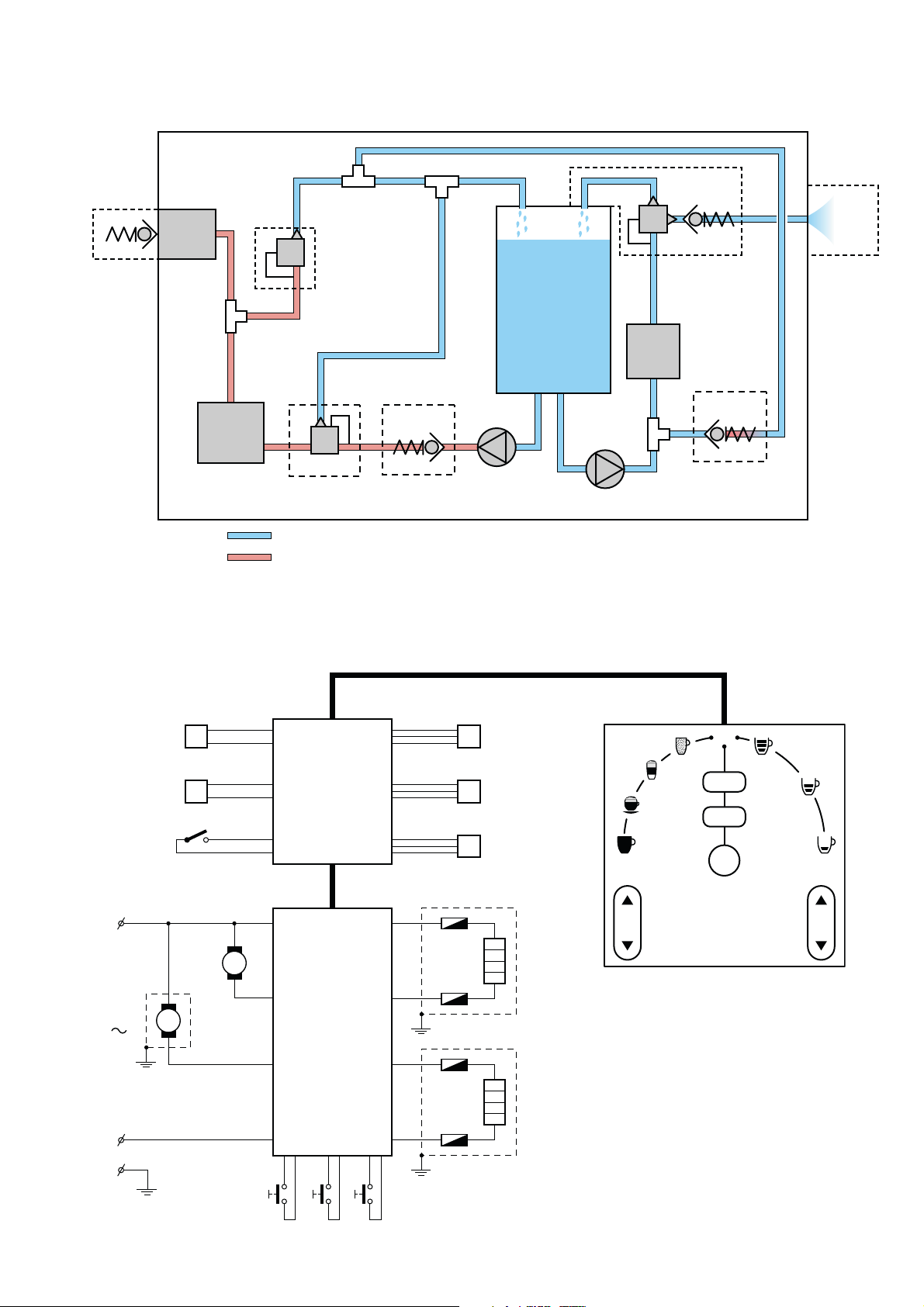

Build up: Steam circuit

Steam

ll

seal

Reflux

valve in

jj

milk

container

hh

gg

Thermo

block

Legend: Low pressure tube

ii

a - w

aa - ll

u

w

Venting

valve

kk

p

Check valve

ff

ddee

Overpressure

valve

High pressure tube

Low pressure connections

High pressure connections

rstv

q

bbcc

aa o

Steam

pump

x

Water

Container

na

b

Water pump

k

Three-way

valve with

Check valve

j

Boiler

i

e

c

Pressure

release

valve

gh

f

d

Inside the appliance

HD7850/60

lm

Brew

Chamber

Electrical circuit

Temp. sensor

boiler

Temp. sensor

Thermo block

Lid close

detection

switch

L

M

Pump

Steam

pump

Boiler

Water level

sensor

Milk tank

detection

sensor

Descale tool

detector

CALC

CLEAN

CLEAN

USER INTERFACE

PCB

W

X

U

M

Z

CONNECTION

PCB

Y

CONTROL

PCB

S

V

T

Fuse

Fuse

Thermo block

Fuse

N

Push buttons

Fuse

2-11

Page 3

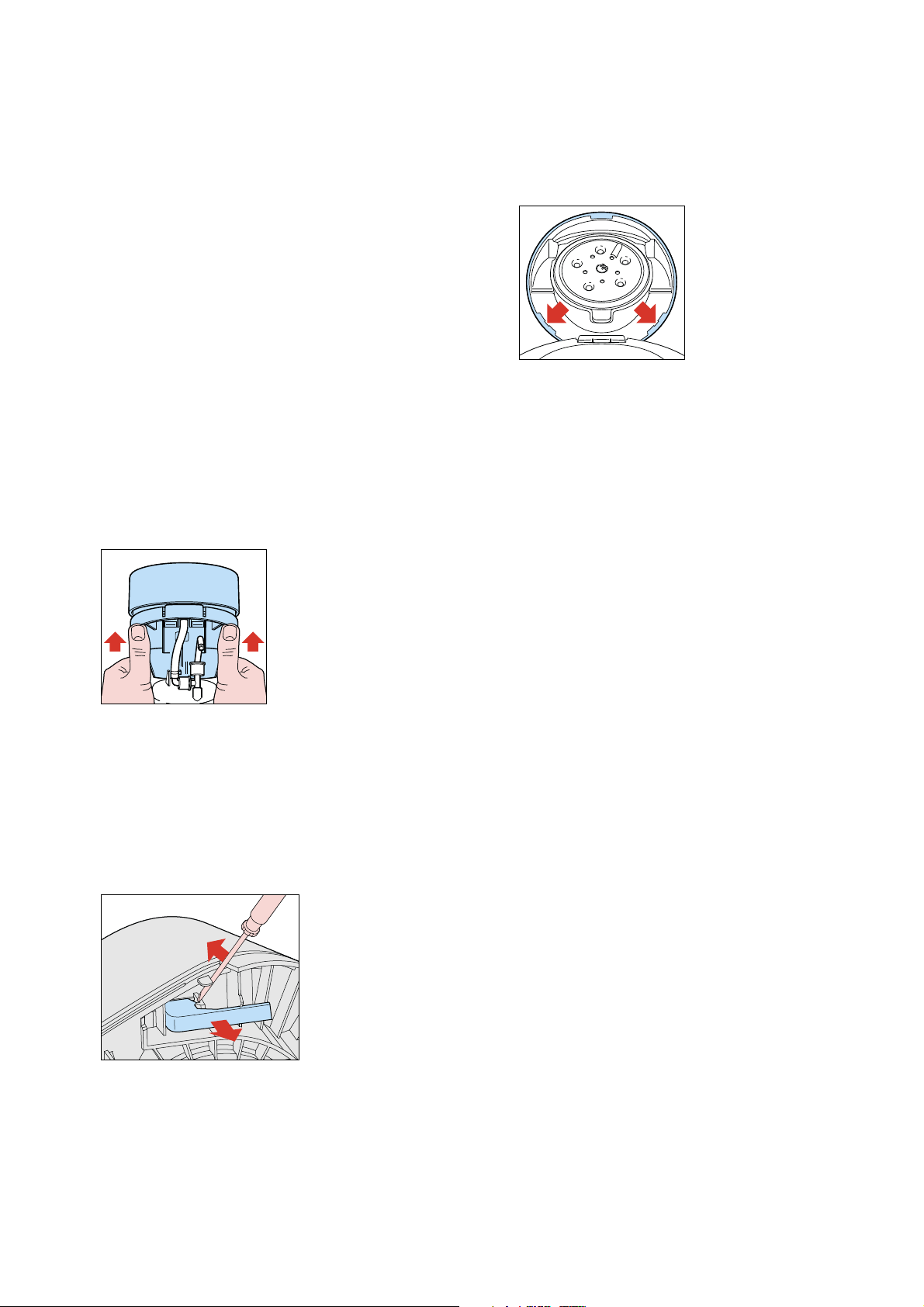

DISASSEMBLY- AND RE-ASSEMBLY ADVISE

HD7850/60

Remove back cover.

- Remove screws (T15) from the back cover.

- Remove valve outlet.

- Start at the upper side of the back cover and stick a

screwdriver between the back cover and lid cover and gently

pull the back cover from the appliance so that a little chink

between back cover and lid becomes visible.

- Put the screwdriver into the 2 rectangular holes (snap locks)

at the back and gently pull the screwdriver such away that

the lips of the snap locks are bent outwards.

- If both clicks positions are loose, it is possible to remove the

back cover.

- Reassemble follow steps backwards.

Remove brew chamber:

Removing Brew chamber head handle as follows:

- Remove boiler from the snap lock position of the brew

chamber.

- Gently lift the backside (see picture) of the brew chamber

up and unhook the two snap locks on front with help of a

screw driver.

Remove brew chamber cover to reach user interface PCB.

- To remove the brew chamber lid cover place the screwdriver

on the positions (see picture) and lift the cover over the

snap locks on both positions.

- The cover lid can now be lifted a little.

- Remove the complete cover by unlocking the pushrod from

the brew chamber.

- The user interface PCB can be removed by unscrewing

3 screws (T8)

- Reassemble follow steps backwards.

Removing the “de-scaling Hall sensor” detector / steam

connection

- To be able to remove the Hall sensor, first unhook the spout

out of the housing.

- Hall sensor assy can be taken out.

- To disconnect the steam connector rotate it clockwise and

pull out of the spout.

- Remove connection PCB + PCB cover.

- Remove 3 way valve and electronic connectors (U & Z)

from the connection PCB.

- Reassemble follow above steps backwards.

Remove the “lid closed” detection micro switch.

Disassemble brewing head.

- Unlock the snap lock which is holding the micro switch

assembly. (see picture for detail)

- Gently pull out the switch assembly.

- Reassemble follow above steps backwards.

To reach the components like pump, PCB, steam heater

placed on the base.

- First remove back cover, brew chamber, 3-way valve, steam

pump and boiler.

- Remove the 4 Torx T15 screws (two at the base and two at

the housing part.

- Bend the 2 click snap locks with a screwdriver (see base),

the housing can now be removed.

- To remove the rest of the housing unlock the 4 snap locks at

the base and gently pull of the front cover.

- To reassemble follow above steps backwards.

OPTIONAL (accessories)

- HD7010 Latte Select Milk Container.

- 4222 259 43670 Senseo Descaler kit

3-11

Page 4

REPAIR INSTRUCTION

HD7850/60

Descaling

Regular descaling will prolong the life of your appliance and

will guarantee optimal brewing results for a long time.

• Follow the steps in the section headed “Preparing the

appliance for use” see DFU (Direction for Use manual)

• Instead of only water use a mix of water and Lemon sour.

• For the best result leave the mix of water and Lemon sour

for about 30 Minutes in the appliance, before you start with

flushing the appliance.

• To get the best results repeat above-mentioned step once or

twice.

• When finished, flush the appliance twice by repeating the

above-mentioned steps only use water instead.

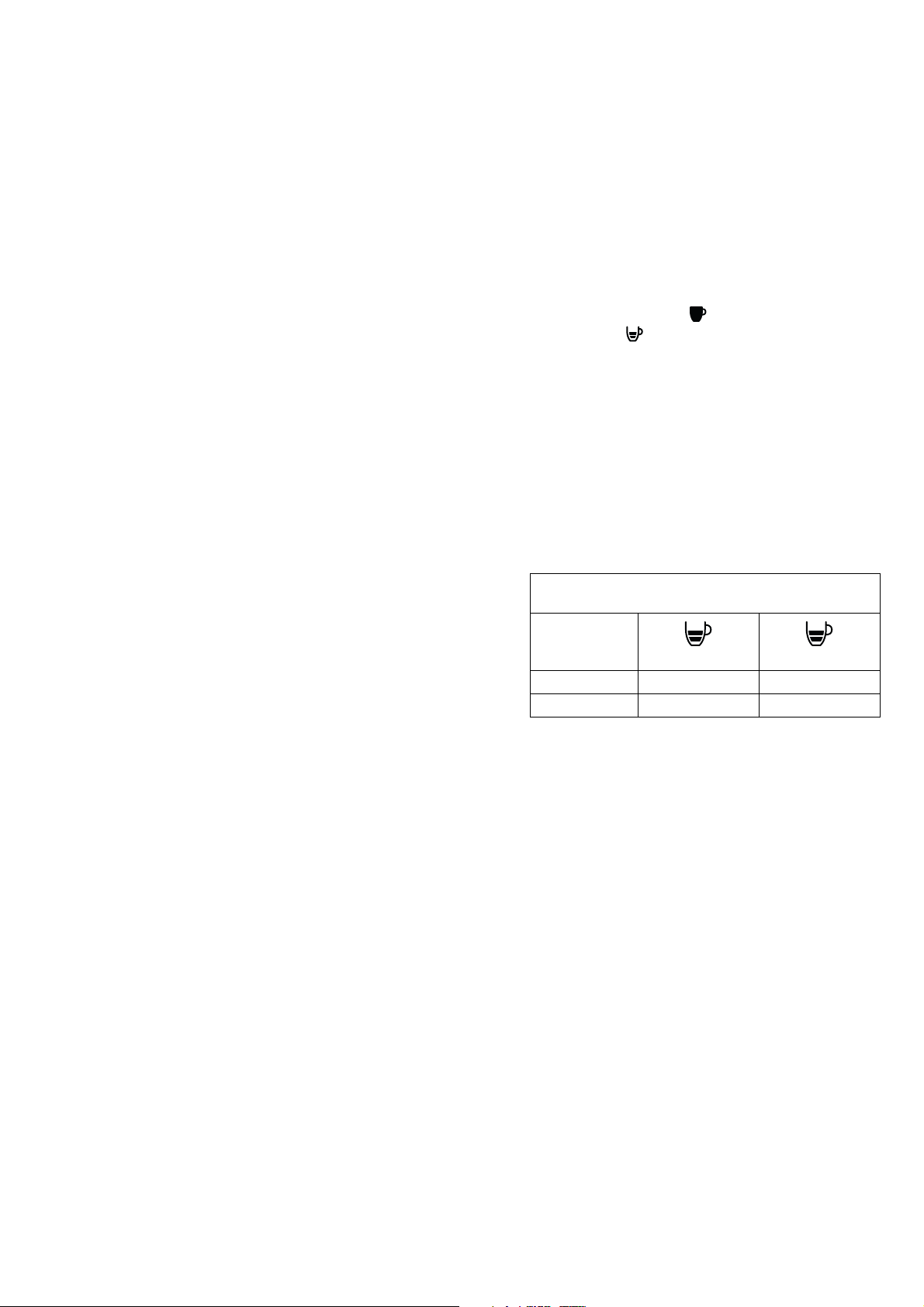

Volume adjustment

The PCB circuit board makes it possible to adjust the volume

output by means of pushing the one-cup and two-cup user

controls.

How to adjust the volume output:

1. Be sure the boiler is fi lled properly, other wise perform fi ll

procedure see DFU for instructions.

2. Switch appliance on and wait until the unit is ready to

brew.

3. Select the Coffee function

normal volume

4. Be sure a pod holder is placed, but without a Coffee

POD. (Only adjusting with plain water)

5. Place a cup on the drip tray cover and push the one-cup

button.

6. When the appliance has fi nished it is stabilized to perform

the volume adjustment.

7. Empty the cup, podholder and push again for one cup

setting, measure the volume output with a graduated

beaker. In the table you can fi nd the requirements for

the minimum / maximum volume output cc/mL values

depending from the country version:

and select

One-cup setting, normal volume,

Including Pod holder, water spec. (Without Coffee pod)

Min. water cc/mL Max. water cc/mL

France version 104 120

General version 125 141

8. Unplug the appliance from the mains.

9. Press the one and two cup button simultaneously and

plug the mains on.

10. When above steps succeeded the main on/off switch- ,

one cup- and two cup button led will be on.

11. Depending if the volume has to de- or increase you have

to push the one- or two cup button.

Every time you push the 1- or 2 cup button the LED will

turn off for 0.5 second (feedback to user) and the pump

time will be shortened or lengthened for 0.5 seconds

depending which button was pushed.

Pushing 1 cup button pump, time will be shorten with

0.5 sec is approximately − 3.5 cc/mL (less coffee)

Pushing 2 cup button pump, time will be lengthen with

0.5 sec is approximately + 3.5 cc/mL (more coffee)

When the volume has to increase with 10 cc for example,

push the 2 cup button 3 times.

The new value will only be stored when you switch the

appliance off by pushing the main switch.

(LED will turn off)

12. Turn appliance on again and brew one cup, measure the

volume. In case the volume is not within specifi cation

repeat steps 7 – 11.

13. End.

4-11

Page 5

REPAIR INSTRUCTION

HD7850/60

Service test routines.

Sensors and buttons check mode.

The Senseo is equipped with a lot of sensor and push buttons.

To be able to check the function of those components a

special service routine has been applied.

1. Unplug the appliance from the mains.

2. Press the on/off- and two cup button simultaneously

and plug the mains on.

3. When above steps succeeded the main on/off switch- ,

one cup- and two cup button led will be on.

In below table you can fi nd which sensors or buttons

correspondent with the indication of the user panel.

For example push the one cup button and the light will be

on.

Selected function User panel reaction

One cup button

On/off button

CLEAN

Two cup button

Calc-clean button

Coffee select button

Volume select button

Close lid detection switch

Automatic fi lling procedure:

The Senseo PCB contains an automatic fi lling procedure

software routine.

This fi ll routine is only meant for back-up.

Normally the consumer has to follow the guidelines stated in

the DFU.

The fi lling procedure functions as follows:

The consumer has to fi ll the water container and has to plug

the appliance on the mains.

When the Senseo main switch has been pushed the main

switch led, one- and two cup led will light continuously.

This is only the case when the Senseo has not fi nished the

fi lling procedure completely! (First use)

This can be checked by reconnect the power cord a second

time to the net and check if the main switch LED will blink

very rapidly for approximately 1 second.

When the consumer pushes the one or two-cup button, the

Senseo will start automatically the pump to fi ll the boiler and

after that the Steam heater will also be fi lled.

When the boiler is fi lled the pump stops pumping. (Pump

time approximately 22 seconds)

When the fi lling procedure has been successful the software

will clear a Boiler_empty_fl ag in the Eeprom.

By means of this Boiler_empty_fl ag the system knows the

boiler is fi lled or not!

When the Senseo is switched off or disconnected from the

mains, the value of the Boiler_empty_fl ag is stored in the

Eeprom chip.

Hall sensor milk container

Hall sensor descale tool

Hall sensor Tank low volume

Hall sensor Tank high volume

CALC

CLEAN

Restoring the Boiler_empty_fl ag to production default:

Some times it is needed that the boiler of the Senseo have to

be emptied.

This for instance in wintertime were the possibility exists that

the boiler becomes frozen during transport e.g.

For those occasions it is handy to restore the Boiler_empty_

fl ag again to production default in the Eeprom.

Bringing the Senseo back into production status, has the

benefi t the fl ush routine will be activated automatically

when installed by the consumer, see topic Automatic fi lling

procedure.

To SET the Boiler_empty_fl ag can be done by:

Keep the 1-cup button pressed while plugging in the power

cord of the appliance.

The main switch LED will blink very rapidly for

approximately 1 second.

To check if the Boiler_empty_fl ag is really set, you should

reconnect the power cord a second time to the net and

check if the main switch LED will blink very rapidly for

approximately 1 second.

5-11

Page 6

PARTS LIST

Pos Service code Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

4222 259 41540

4222 259 41550

4222 259 41730

4222 240 00320

4222 259 42320

4222 259 41510

4222 259 42310

4222 259 41710

4222 247 58300

4222 247 58270

4222 240 01410

4222 259 42420

4222 247 06810

4222 240 05990

4222 247 41920

4222 247 58910

4222 247 58940

4222 247 58950

4222 247 58930

4222 259 41660

4222 259 42440

4222 247 58920

4222 259 42160

4222 259 41610

4222 259 41180

4222 259 42680

4213 247 05250

4222 259 42430

4222 259 41230

4222 259 41210

4222 247 58780

4222 259 41470

4222 259 41500

4222 247 05510

4222 259 41870

4222 259 37240

4222 259 41750

4222 259 35440

4222 247 05130

4222 259 41620

4222 247 60010

4222 259 41200

4222 259 43650

4222 247 60260

4222 247 56920

Padholder assy 1-cup Dark Grey

Padholder assy 2-cup Dark Grey

Milk container assy Translucent Bright White

Driptray cover

Driptray assy Deep Black

Water container assy Translucent Dark Grey

Decalcifi cation dummy assy

Lasered/printed lid panel Deep Black

Lever Dark Grey

Push rod

Slider spring

User interface PCB assy Red

Brew chamber seal

Ejector pin

Distribution disk

Collector

Spout housing cover Dark Grey

Spout lever Translucent Bright White

Spout

Sensor decalcifi cation assy

Steam connecting assy

Spouthousing Dark Grey

Venting valve assy

Sensor milk container

Safety valve assy

One way valve

Foot

Lid switch lid close detection assy

Steam pump CEME E151

Sensor water level + PCB housing

Valve outlet Deep Black

Valve assy zebra

Backcover assy Deep Black

Corrugated tube

Fuse assy welded

Pump ULKA HF 230 V ~50 Hz

Thermo block assy

Boiler assy V7.0 - 230 V

NTC O-ring

NTC boiler assy

Driptray shaft support

PCB assy base Red

Pressure release valve

T-piece

Milk Tube

HD7850/60

6-11

Page 7

EXPLODED VIEW

1

HD7850/60

4

2

45

3

5

6

7

7-11

Page 8

EXPLODED VIEW

8

HD7850/60

10

11

9

m

l

12

Z

13

14

15

8-11

Page 9

EXPLODED VIEW

HD7850/60

16

17

18

19

aa

x

28

l

U

k

j

29

o

n

31

32

20

21

22

T

24

ll

V

c

gg

30

S

n

a

b

X

ff

33

34

35

36

37

27

9-11

Page 10

EXPLODED VIEW

HD7850/60

j

43

38

39

40

e

W

W

X

V

U

T

S

Y

Z

30

44

i

d

h

f

c

g

41

42

y

10-11

Page 11

EXPLODED VIEW

HD7850/60

44

ll

gg

jj

hh

ii

wv

kk

4423

u

h

ee

ff

44

rst

x

q

p

25

dd

cc

26

bb

aa

11-11

Loading...

Loading...