Philips G22K511, G25K512 Service Information

COLOUR

TELEVISION

S E R V I C E I N F O R M A T I O N F O R T H E

PHILIPS

G22K511

AND

G 2 2 K 5 1 1

G6 SINGLE STANDARD'

COLOUR TELEVISION

RECEIVERS

. •

c-es

C O M M B I N E D E L E C T R O N I C S E R V I C E S L I M I T E D

604 P UR LE Y WAY • W ADDON • CROYDON • CR9 4D R

TE LEPHON ES :

Spare part orders : 01-686 3831 General service enquiries : 01-688 7722

After business hours: Recorded messages on both lines Telex 262308

AUGUST, 19 69 (Please quote CES 739 when ordering further copies) CES 739

CONTENTS

TEXT

Section

Page No.

UNIT LOCATION

Unit

Page No.

A — INTRODUCTIO N

3

A — CONVERGENCE ASSEMBLY LAYOUT

17

B — SPECIFICATION

3

B — L.O.P.T. ASSEMBLIES—UPPER

18

C — RECEIVER NOTES

4

C — L.O.P.T. ASSEMBLIES—LOWER

18

D — 625-LINE V.H.F. RELAY OPERATION

5

D — T.B. PANEL—PRINT SIDE

20

E — SPECIALLY MOUNTED COMPONENTS

5

E — C.R.T. BASE PANEL—COMPONENT SIDE

21

F — MAIN TENANCE NO TES

6

F — CHROMA. PANEL—PRINT SIDE

22

G — L.O.P.T. ASSEMBLY

6-7

G — CENTRE CHASSIS WIRING

25

H —PRESET ADJUSTMENTS

9-10

H — TOP LEFT CHASSIS WIRING

25

- CONVERG EN CE

10-11

J — SUB-ASSEMBLIES WIRING

26

J — GREY SCALE TRACKING

12

K — LOWER CHASSIS WIRING

26

K — COLOUR DIFFERENCE OUTPUT

L — I.F. PANEL—COMPONENT SIDE

27

ADJUSTMENTS

12

L — I.F . ALIGNM ENT

12-14

EXPLANATION OF WIRING CODING

M — DECODER ALIGNMENT

14-15

N — INTEGRATED TUNER ASSEMBLY

32-35

On unit J, lead marked is connected to unit K

0 — SPARE PARTS LIST

37-43

and there marked . Similarly, on unit D, lead marked

is connected to unit E and there marked

ILLUSTRATIONS

Fig. No.

RECEIVER IDENTIFICATION

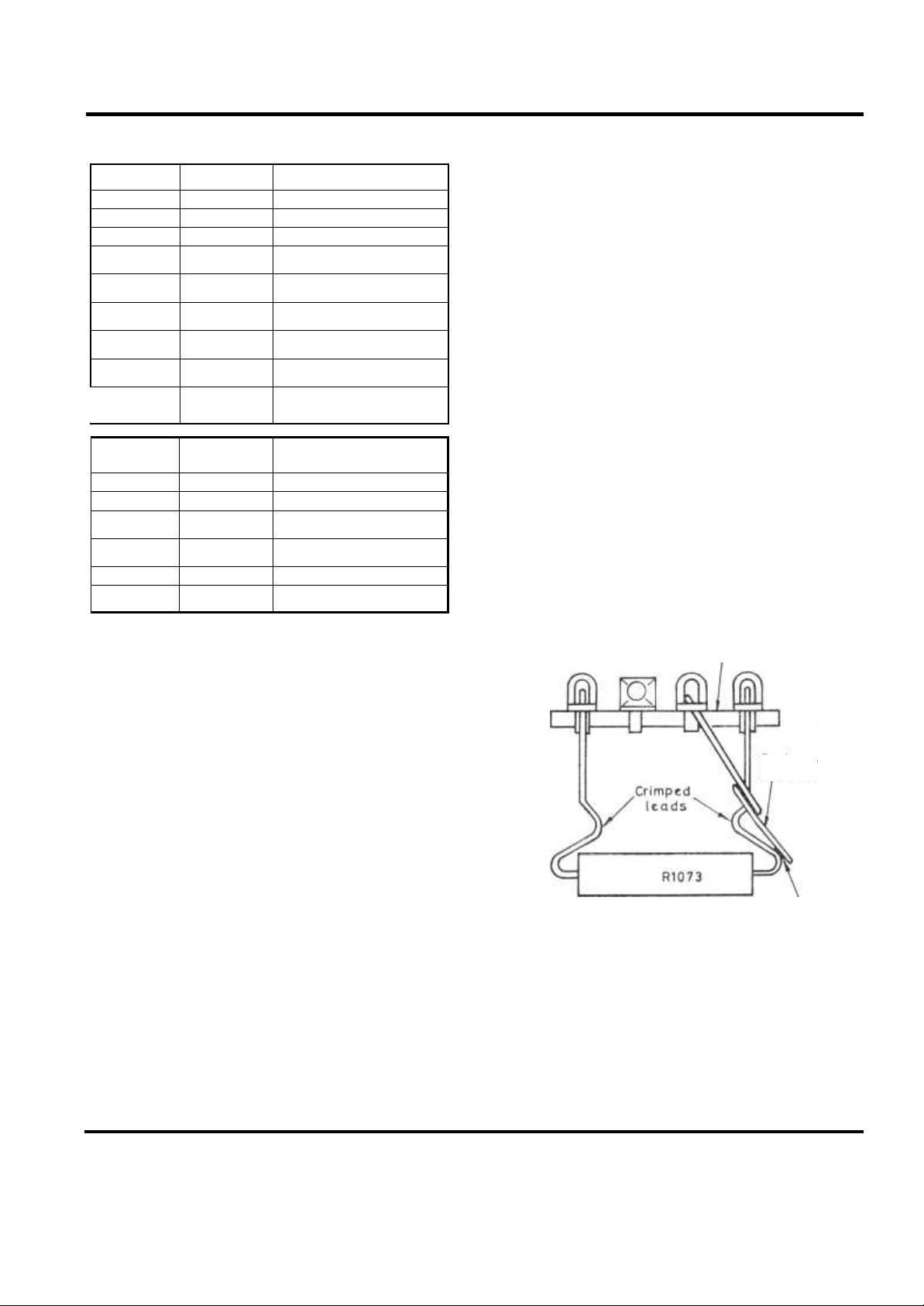

1 — SPRING RESISTOR R1073

If

2 — C ONVERG E N C E COVER 3 —

ASSEMBLY OF C.R.T. AND SHIELD 4 —

C. R.T. SHIEL D 5 — TR IM P LAN

6 — THI RD HARMONIC TUNI NG

7 — DEFLECTION ASSEMBLY

8 — CONVERGENCE PANEL

9 — TER MINATING PAD

10 — DAMPER/DETECTOR UNIT

11 — DETECTOR UNIT

12-15 RESPONSE CURVES

16 — BIAS NETWORK

17 — X-Y DISPLAYS

18 — BLOCK DIAGRAM

19 — CONVERGENCE ASSEMBLY WIRING

20 — L.O.P.T. ASSEMBLY—UPPER

21 — L.O.P.T. ASSEMBLY—LOWER

22 — L.O.P.T. PANEL

23 — TIME BASE PANEL—PRINT SIDE

Page No.

2

5

6

6

7

8

9

10

11

12

12

12

14

14

15

16

17

18

18

19

Fig. No.

24 — TIME BASE PANEL—COMPONENT SIDE

25 — C.R.T. BASE PANEL—COMPONENT SIDE

26 — C.R.T. BASE PANEL—PRIPANEL-PRINT

27 — CHROMA. PANEL—PRINT SIDE

28 — CHROMA. PANEL—COMPONENT SIDE

29 — CAN ASSEMBLIES—A TO F

30 — CHASSIS WIRING—CENTRE AND

TOP LEFT

31 — CHASSIS WIRING—LOWER, AND

SUB-ASSEMBLIES

32 — I.F. PANEL—COMPONENT SIDE

33 — I.F. PANEL—PRINT SIDE

34-36 VOLTAGE WAVEFORMS

37 — TUNER MECHANISM—EXPLODED

VIEW

38 — DRIVE GEAR SETTING

39 — TUNER—COMPONENT LAYOUT

40 — TUNER—CIRCUIT DIAGRAM

41 — CIRCUIT DIAGRAM—I.F., etc.

42 — CIRCUIT DIAGRAM—T.B., etc.

Page No.

21

21

21

22

23

24

25

26

27

28

29-31

32

33

34

35

In

pocket

Page One

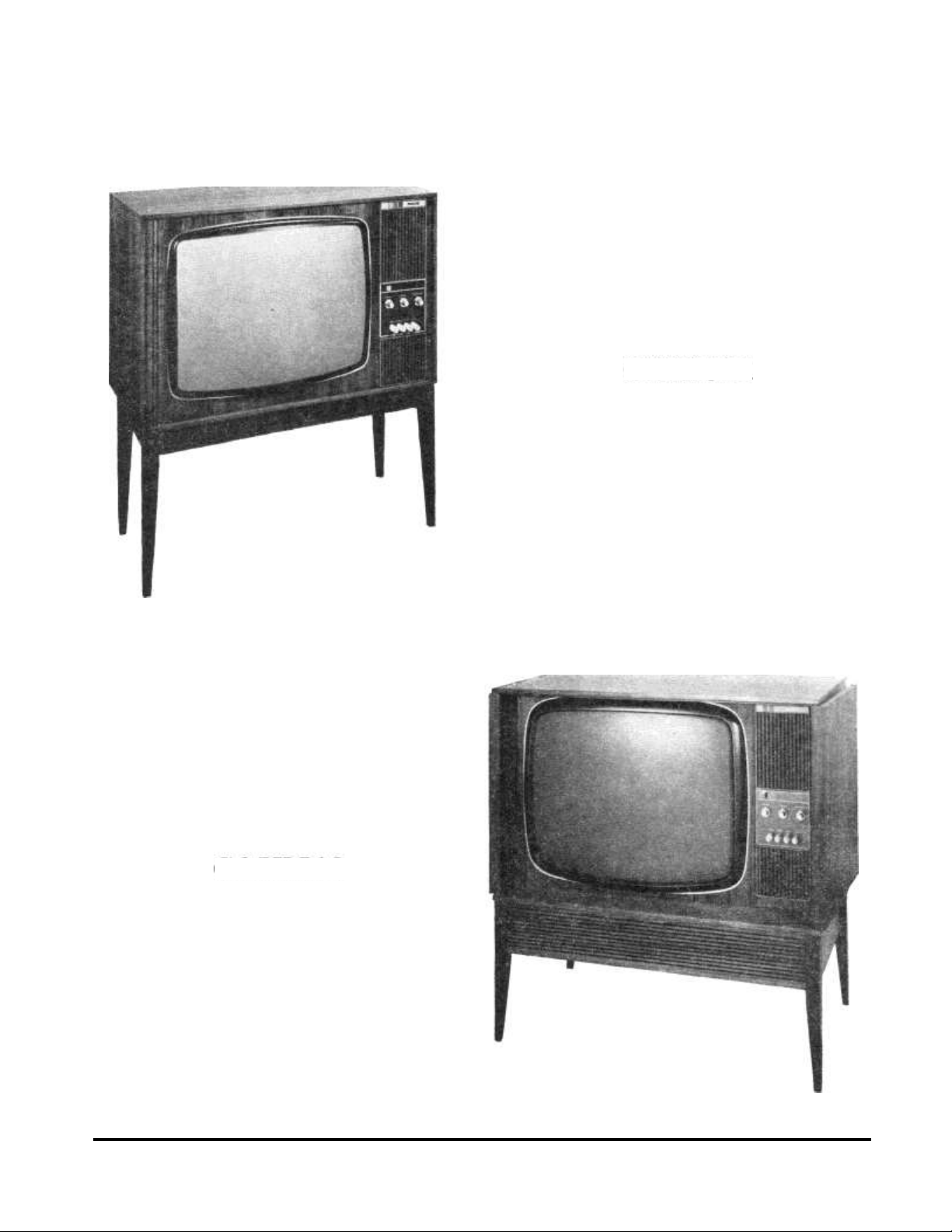

G22K511

G25K512

Page Two

A — INTRODUCTION

The G22K511 television receiver is designed for reception of both

colour and monochrome pictures on 625 lines. A 22" rectangular

shadow mask cathode ray tube is employed around which are

fitted a pair of degaussing coils. These automatically degauss the

tube each time the receiver is switched on. The main chassis is

mounted vertically at the rear of the receiver, and when servicing

is necessary, it can either be hinged backwards or removed completely. The tuner is a UHF/VHF integrated type, operated by

four push-buttons which can be set to receive any 625-line channel

on UHF or relay channel on VHF. By removing one screw, a part

of the front escutcheon comes away, revealing easy access to the

grey scale and dynamic convergence controls. This enables the

more difficult setting up to be done from the front of the receiver.

Special features include a fully pluggable I.F. panel to facilitate easy

servicing, and a new black level clamp circuit to ensure faithful

reproduction of low key scenes.

The G25K512 is a 'Deluxe' version of the above receiver employng a 25" push through cathode ray tube. Housed in a consolette

tyle cabinet and finished in teak veneers, it has two single doors

which are secured by ball catches when closed.

B — SPECIFICATION

Mains supply 240 volts a.c. only

Valves Type Function

V1706 A56-120X 22" Shadow-mask C.R.T.

or V1706 A63-120X 25" Shadow-mask C.R.T.

V2001 PFL200 Luminance output and sync. separator

V2002 EF80 Line sync. amplifier

V4001 PCF802 Line reactance and oscillator

V4002 ECC81 Field oscillator

V4003 PCC85 Field buffer/fly-back suppression

V4004 PL508 Field output

V5001 PL509 Line output

V5002 PY500 Boost diode

V5003 PD500 Shunt stabiliser

V5004 GY501 E.H.T. rectifier

V5005 EY51 Focus diode

V7001 EF183 1st chroma. amplifier

V7002 EF184 2nd chroma. amplifier

V7003 PCC85 Chroma. A.G.C./colour killer

V7005 PCF200 R-Y amplifier/clamp

V7006 PCF200 G-Y amplifier/clamp

V7007 PCF200 B-Y amplifier/clamp

V7008 EF184 Burst amplifier

V7009 PCF802 Reactance/reference oscillator

VA V7010 PCL86 A.F. amplifier/output

Semi- Type Function

conductors

T1321 AC128

T2140 BF194

T2141 BF194

T2142 BF196

T2143 BF196

T2144 BC148

T2145 BC148

T2146 BC148

T2147 BC148

T2624 BF197

T2755 BF173

T3401 BF180

T3402 BF182

T3403 BF183

T3495 BC108

T7011 BF195

T7012 BF195

T7013 BF194

T7014 BF194

T7015 BC107

X1101 BY127

X1102 BY127

X1103 BA148

X1104 BA148

X1105 BYX10

X1106 BA148

X1292 BA148

X1293 BA148

X1294 BA148

X2151 0A91

X2152 BA154

X2153 0A91

X2530 AA119

X2531 AA119

X2625 0A90

X2756 0A90

X3496 BZY88

X4140 BA148

X4141 BA148

X4142 BYX10

X7315 0A90

X7316 0A85

X7317 0A202

X7318 0A95

X7319 BA100

X7320 AA119

X7321 AA119

X7322 0A91

X7323 BA148

X7324

X7325 BA154

X7568 0A95

X7569 0A95

X7570 0A95

X7571 0A95

X7628 BAY38

X7629 BAY38

X7630 BAY38

X7631 BAY38

X7632 BAY38

X7655 0A95

X7656 0A95

Circuit protectors

Fuses Type

FS1107 3A

FS1108 Thermal

FS1109 250mA

FS1110 Thermal

FS1114 Thermal

Drop-off resistors

R2111 1.5K52

R4135 12052

Safety resistors

R4083 3.3K52

R7148 1052

R7151 1052

R7263 1ic52

R7293 18052

Spark gaps

SG10981

SG1099 f

E.H.T.

Loudspeaker

Sound output

Dimensions

G22K511

G25K512

Weight

G22K511

G25K512

li

Convergence clamp

1st sound I.F.

2nd sound I.F.

1st vision I.F.

2nd vision I.F.

Luminance phase splitter

Luminance A.G.C. amplifier

Black level clamp

Chroma. pre-amplifier

3rd vision I.F.

Chrominance amplifier

R.F. amplifier

Mixer

Oscillator

A.G.C. amplifier

B-Y pre-amplifier

R-Y pre-amplifier

}Bistable oscillator

Identification signal amplifier

Mains rectifier

Mains rectifier

L.T. supply rectifier L.T.

supply rectifier –ve supply

rectifier Supply for black

level clamp

}Auxiliary d.c. supply to C.R.T.

1

A.G.C. delay

Black level clamp

A.G.C. rectifier

1 F.M. ratio detector

Luminance demodulator

Chrominance demodulator

Tuner supply stabilisation

} Line discriminator

Fly-back pulse clipper

Chroma. noise clipper

}Burst keying

Burst blanking

Bias clamp

}PAL switch (180°)

Identification signal gate

Stabilised H.T. supply

4.43 MHz crystal

Beam current limiter

B-Y demodulator

R-Y demodulator

Anti-lock-out

Chroma. A.G.C. demodulator

Burst demodulator

Ref. oscillator A.G.C.

Ref. oscillator grid clamp

Location

Mains supply

Main H.T. supply

Field output

Main H.T. supply

Mains transformer

Luminance output

Field output stage

Line reactance stage 1st

chroma. amp. stage

2nd chroma. amp. stage

Burst amp. stage

A.F. output stage

C.R.T. base panel

25kV

6" x 4" elliptical, 5ohm

impedance 2.5 watts

Height Width Depth

(Inc. backplate)

28" 2W

31-i" 23"

861bs.

1291bs.

181'

33f"

(Inc. legs)

Page Three

C — RECEIVER NOTES

1. Mains supply voltage

This colour receiver has been designed to be used with a nominal

mains voltage of 240v. a.c. Engineers are advised that operating a

receiver on a mains supply which provides poor voltage regulation

(i.e., an isolation transformer rated at less than 500 watts) may

present difficulties in obtaining optimum convergence.

Note.—Once the receiver controls have been set-up, slight re-adjust-

ment may be necessary if the set is operated from a supply voltage

different from the initial setting-up voltage.

2. X-ray radiation warning

The voltages and currents on the cathode ray tube are higher in a

colour receiver than in a monochrome type, and as a result, the

X-rays produced will have a greater penetrating power and will

be present in larger quantities. In practice, this means that suitable

protection has to be built into a receiver in order to reduce the radiation hazard to an acceptable level. It is important that personnel

involved in installation and servicing should be well aware of any

possible dangers.

The radiation problems are confined to X-rays generated by two

sou r ces:

(a) The cathode ray tube

(b) The extra high tension generator

During the development of the `G6' colour television chassis,

special attention has been given to these points. With the backplate

removed no significant radiation is present, and therefore the maximum dose rate is much less than the accepted danger level. This low

level of radiation is due to :—

(i) The absorbing power of the glass in the cathode ray tube.

(ii) The C.R.T. metal cone shield provided for magnetic screening.

(iii) The metal screening enclosing the E.H.T. generator (L.O.P.T.

assembly).

Provision is made on the E.H.T. generator so that the unit is inoperative when the side cover of the screening can is removed. This

takes the form of an inter-lock switch disconnecting the H.T.

supply. On no account must this inter-lock be tampered with.

Line stabilisation control (R5040)

It is most important that this control is adjusted to the correct boost

voltage setting (see Adjustments). Any increase above this setting

will cause the E.H.T. voltage to rise, resulting in possible forward

X-ray radiation from the C.R.T. face.

3. Colour coding of H.T. supply leads

In order to assist service engineers in identifying the various H.T.

supply leads to different parts of the receiver, a system of colour

coding these leads is used which is shown below.

Supply

Lead colour

Voltage

H.T.2

Red

+285v.

H.T.2 (fused)

Red/Brown

+285v.

H.T.3

Red/Orange

+250v.

H.T.4

Red/Yellow

+230v.

H.T.5

Red/Green

+220v.

H.T.6

Red/Blue

+220v.

H.T.7

Red/Grey

—120v. stab.

H.T.8

Black/Orange

+12v. stab.

H.T.9

Black/White

+18v.

4. Special trimming tool

A special star-shaped trimming tool is necessary for the alignment

of the tuner I.F. coil, and also for adjustment of certain other

cores. This trimming tool is available as part of the Philips

trimming tool kit 800/TX, and engineers are advised that any attempt

to adjust these cores with a non-standard tool may damage them.

5. Use of the circuit diagram

(a) The complete circuit of the `G6' single-standard colour tele-

vision receiver (less integrated tuner) has been drawn out on two

separate sheets accompanying this manual. The connecting leads

have been so arranged that the two halves of the circuit may be

permanently joined together with transparent adhesive tape if

required. H.T. points from the power supply circuits are shown

set in boxes, and an equivalent symbol is indicated at the particular

part of the circuit to which it is connected (see also note in colour

coding of H.T. leads—para. 3 above).

(b) For component identification on the circuit, a grid refe

system is used. This has been arranged so that each sheet may be

used either separately or joined together, the letters at the top of the

circuit running from A to S and the numbers at the side of each

diagram running down from 1 to 7. The grid location for all components has been included in the Spare Parts List.

Where it has been found impracticable to show direct connections

between various parts of the circuit, e.g. the line pulse feeds

from L5505 and L5524, a grid reference has been included to assist

in locating the appropriate circuit connections.

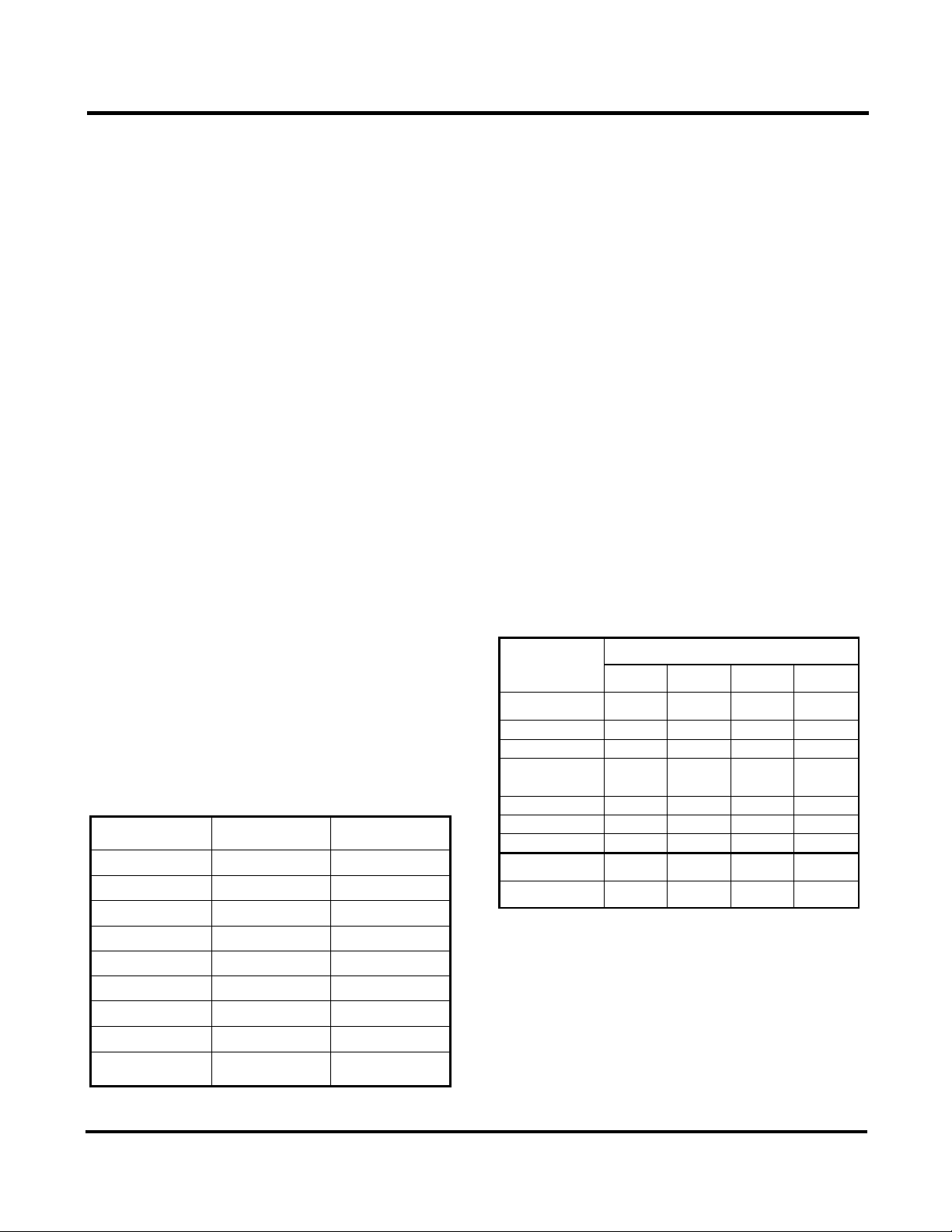

(c) In order to identify a particular component on the circuit

with its position in the receiver, a coding system for component

numbers is used. For instance, any component with a 2000 number

is located on the I.F. panel, and a component with a 5000 number

will be found in the line transformer assembly. The complete

coding system is as follows:

LOCA TIO N

Number

Val ves &

Sem icon .

Re sis tors

Ca paci tor s

Coils

Main chassis and sub.

ass embl ies

1100

1000-1100

1000-1100

1500

C.R .T. base panel

1700

1000

1000

1500

Co nv erg enc e u ni t

1200-1300

1200-1300

1200-1300

1600

Deflec tion, con vergence and degaussing

yokes

—

1700

1700

1700

I.F. Panel

2000

2000

2000

2000

In tegr ate d tu ner

3000

3000

3000

3000

Ti me B ase

4000

4000

4000

4000

Line t ran sfo rme r

ass embly

5000

5000

5000

5000

Ch roma . p anel

7000

7000

7000

7000

6. Connecting plugs and sockets

The plugs and sockets used for interconnecting assemblies are

colour coded to enable service engineers to identify where each is

fitted to the main chassis. This takes the form of a coloured ring

around the plug on the appropriate connection panel, and a

similarly coloured sleeve marker around the leads into the respective socket.

Note.—Sockets should never be removed from the plugs by pulling

on the leads, since this practice may lead to the pins within the

sockets being damaged.

Page Four

P lu g an d so ck et l oc ati on t able s

P lu g so ck et N o.

C ol ou r co di ng

Location

I

—

I. F. i npu t o n I. F. pane l

2

—

I.F . pa nel ( 5 le ads)

3

—

I.F . pa nel ( 6 le ads)

4

Red

Con verg ence plug on c entr e

cha ssis (up per)

5

Ye ll ow

Con verg ence plug on centr e

ch assi s ( lowe r)

6

—

Def lectio n coi l plu g on c entre

chas sis

7

—

Upp er p lug o n si de of L.O .P.T.

ass embl the

8

—

Low er p lug o n si de of L.O .P.T.

ass embl y

9

—

Deg auss ing c oil plug on l ower

chassis

P lu gg ed

c on ne ct io ns

L ea d co lo ur

L oc at io n

Pc!

Ri lll ack

Tu ner sup ply lea d

Pc2

Grey

Tu ne r A .G. C. le ad

Pc3

Black

Ea rth link bet ween ch roma . an d

I.F. panels

Pc4

Grey

Chr ominan ce si gnal f eed to

ch roma . p anel

Pc5

Sc reen ed

A. F. o utp ut o n I .F. pan el

Pc6

Brown

Lu mina nce out put on I .F. pan el

D — 625-LINE V.H.F. RELAY OPERATION

Ten channels have been allocated inside the V.H.F. T.V. bands

(I and III) for use on wired relay systems.

Conversion instructions

1. Tuner

With all the push buttons in the unlatched position, depress the

appropriate plastic knob at the rear of the tuner and rotate until

-

Nao indication on the end of the knob lines up with the required

,and and system. A label which is attached to the rear of the tuner

wvill assist in this setting-up procedure.

2. Operation

Depress the appropriate push-button and apply the 625-line relay

signal to the V.H.F. aerial socket. Using the receiver in the normal

way, tune for best picture definition, consistent with maximum

sound.

E — SPECIALLY MOUNTED COMPONENTS

The following information relates to the replacement of certain

components; it is very important that the methods described below

are carried out.

1. Drop-off resistors

122111 and R4135 are spaced from their printed panels on stand-

off solder tags. Should one of these resistors overheat for any reason,

such as an inter-electrode short-circuit occurring in a valve, the

solder on the tags will melt, allowing the component to fall away.

This provides a degree of protection to the panels and other

circuitry. Replacements should be made with Dubilier type

BTA 1 watt resistors, using ordinary '60/40' resin-cored solder.

The resistor must be mounted on the underside of the solder tags,

with the connecting wires placed straight under the tags and not

wrapped around them.

2. Ballast resistors

During manufacture, a high melting point solder is employed on

all connections to the supply ballast resistors R1052/R1053. It is

most essential that this grade of solder (e.g. Ersin Comsol

Alloy) is used with a high temperature soldering iron if this

component is replaced.

3. Thermal fuses FS1108 and FS1110

Two thermal fuses (FS1108 and FS1110) in the form of wire

springs, are soldered on R1052/R1053. Excessive heat dissipation

causes the solder to melt and the fuses to spring free. The fuses

must be refitted using '60/40' solder.

4. Thermal fuse FS1114

A thermal fuse FS1114 is fitted inside the mains transformer bobbin.

When this fuse blows, tin splashes may be deposited on its surrounding plastic shield. The faulty fuse, as well as the plastic

shield, should be withdrawn from the bobbin, and the tin splashes

removed from the shield. The shield should then be reinserted in the bobbin together with a new fuse.

5. 'Spring resistor' R1073 (See Fig. 1)

A resistor R1073 and spring-off, mounted on a tag strip near the

mains transformer, are included to protect the line output stage

valves against certain fault conditions. The assembly forms a

thermal fuse with properties dependent upon the melting point of

the solder used to fix the spring-off to the resistor. When necessary

the spring-off wire must be soldered to the outside of the bend in

R1073 lead-out wire using ordinary '60/40' resin-cored solder.

Note.—If it is necessary to replace R1073 and/or spring-off, the

resistor should be carefully fitted across the two end tags of the

strip. The b1/4nt end of the spring-off should be fitted through the

second tag from one end of the strip, then turned approx. 45° to

the strip before being soldered to the outside of the crimped part

of R1073 lead-out wire.

(Top view) Ta g strip

Soldered

joint

SD3880

Fi g.

I. "S pri ng resisto r" assemb ly

6. Safety resistors R4083, R7148, R7151, R7263 and R7293

The safety resistors listed above are designed to act as fuses when

their rated dissipation is exceeded. In the event of a fault causing

any one of these components to become open-circuit, it is most

important that they are replaced with a similar type (see Spare

Parts List) and that they are spaced approximately i" from the

printed panel by crimping the connecting leads.

s

Spring off wire

Page Five

Loading...

Loading...