Page 1

Colour Television Module

FHP PDP Repair Manual

FPF42C128135UA-52 (42” A4)

Contents Page

1. Technical Specifications 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 6

5. Service Modes, Error Codes, and Fault Finding 10

6. Block Diagrams, Test point Overview, and Wave

Forms 27

7. Circuit Diagrams and PWB Layouts 29

8. Alignments 29

9. Circuit Descriptions and Abbreviation List 30

10. Spare Parts List 33

11. Revision List 34

©

Copyright 2006 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by MW 0667 BG CD Customer Service Printed in The Netherlands Subject to modification EN 3122 785 16400

Page 2

EN 2 FHP PDP1.

Technical Specifications

1. Technical Specifications

Index of this chapter:

1.1 Specifications

1.2 Serial Numbers

1.3 Chassis overview

FPF42C128128UC -52 䊶 䊶䊶䊶䊶䊶䊶 42A1 ( covered )

FPF42C128128UD -52 䊶 䊶䊶䊶䊶䊶䊶 42A2 ( by manual )

FPF42C128128UE -52 䊶䊶䊶 䊶䊶䊶䊶 42A3 ( 3122 785 14580)

1.1 Specifications

1.1.1 42” A4

No Item Spec. FPF42C128135UA-52

1 Resolution 1024 (H) x 1080 (V) pixels

(1 pixel = 1 R,G,B cells)

2 Number of Cells 3072 (H) x 1080 (V)

3 Pixel Pitch 0.90 mm (H) x 0.485 mm (V)

4 Cell Pitch 0.30 mm (H) x 0.485 mm (V)

5 Display size 921.60 (H) x 523.8 mm (V)

6 Screen size Diagonal 42"

7 Screen aspect 16:9

8 Dimensions 994 (W) x 587 (H) x 66 (D) mm

9 Weight About 16 kg

10 H sync, V sync, data 50 kHz (H), 50/60/70 Hz (V),

LVDS

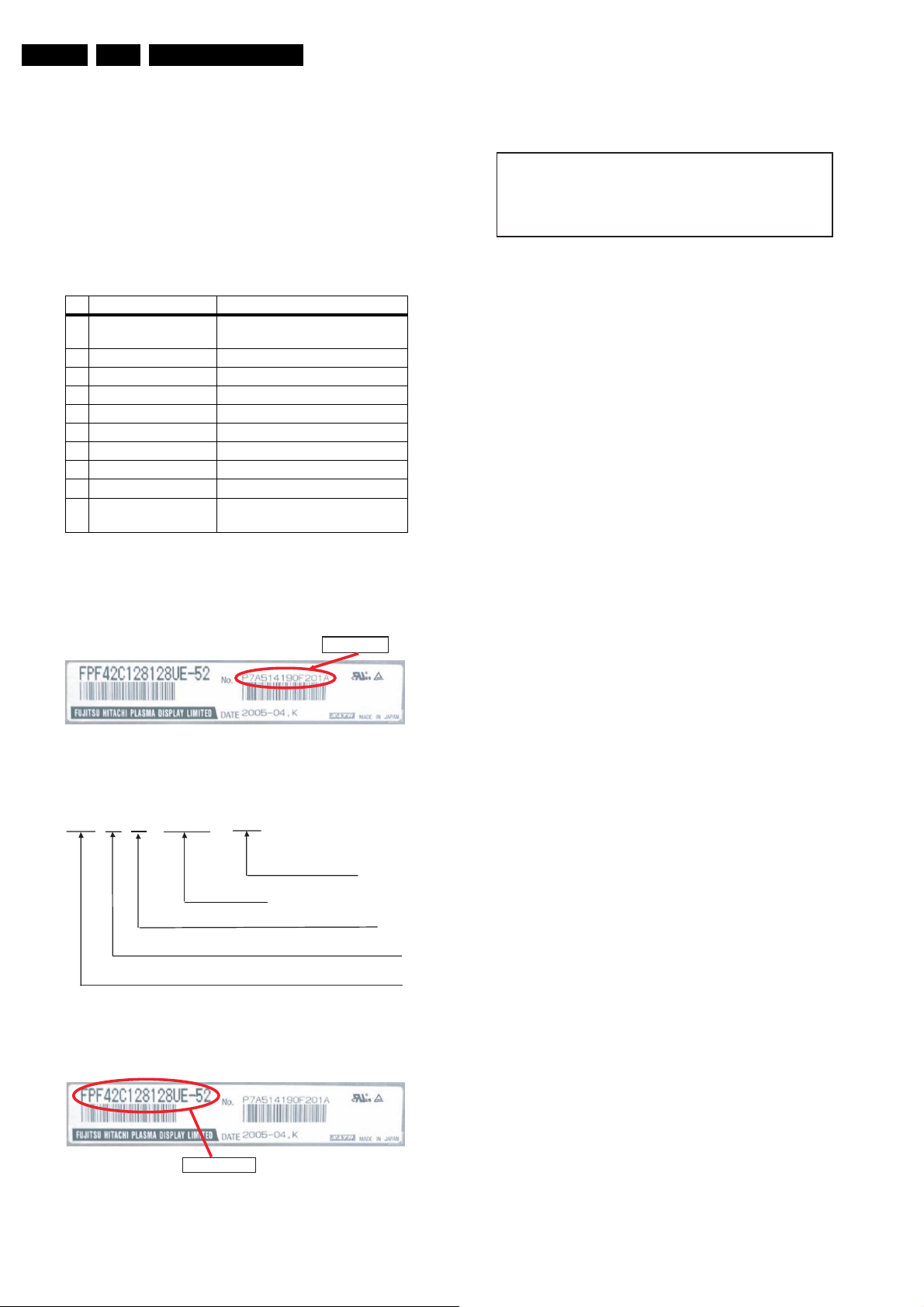

1.2 Serial Numbers

Check the serial ID number of the product requested for repair,

before starting the problem analysis and repair.

Serial Number

FPF42C128135UA -52 䊶䊶䊶 䊶䊶䊶䊶 42A4 (in this manual)

G_16400_004.eps

270706

Figure 1-4 List of model numbers

Note: The PDP serial number and the serial number of the

completed chassis (product requested for repair) are usually

the same when the product is brought in for repair the first time.

G_16400_001.eps

Figure 1-1 PDP Serial number

P7A 6 01 001A1 01A

Version Number

Lot Number

Week code, 1 – 53, from Jan. to Dec.

Last digit of ye ar of production: 6 means 2006

Product code: N7A, P7A, S7A are 42 inch type PDP

G_16400_002.eps

Figure 1-2 PDP Serial number explanation

Model Number

G_16400_003.eps

280706

180706

280706

Figure 1-3 PDP Model number

Page 3

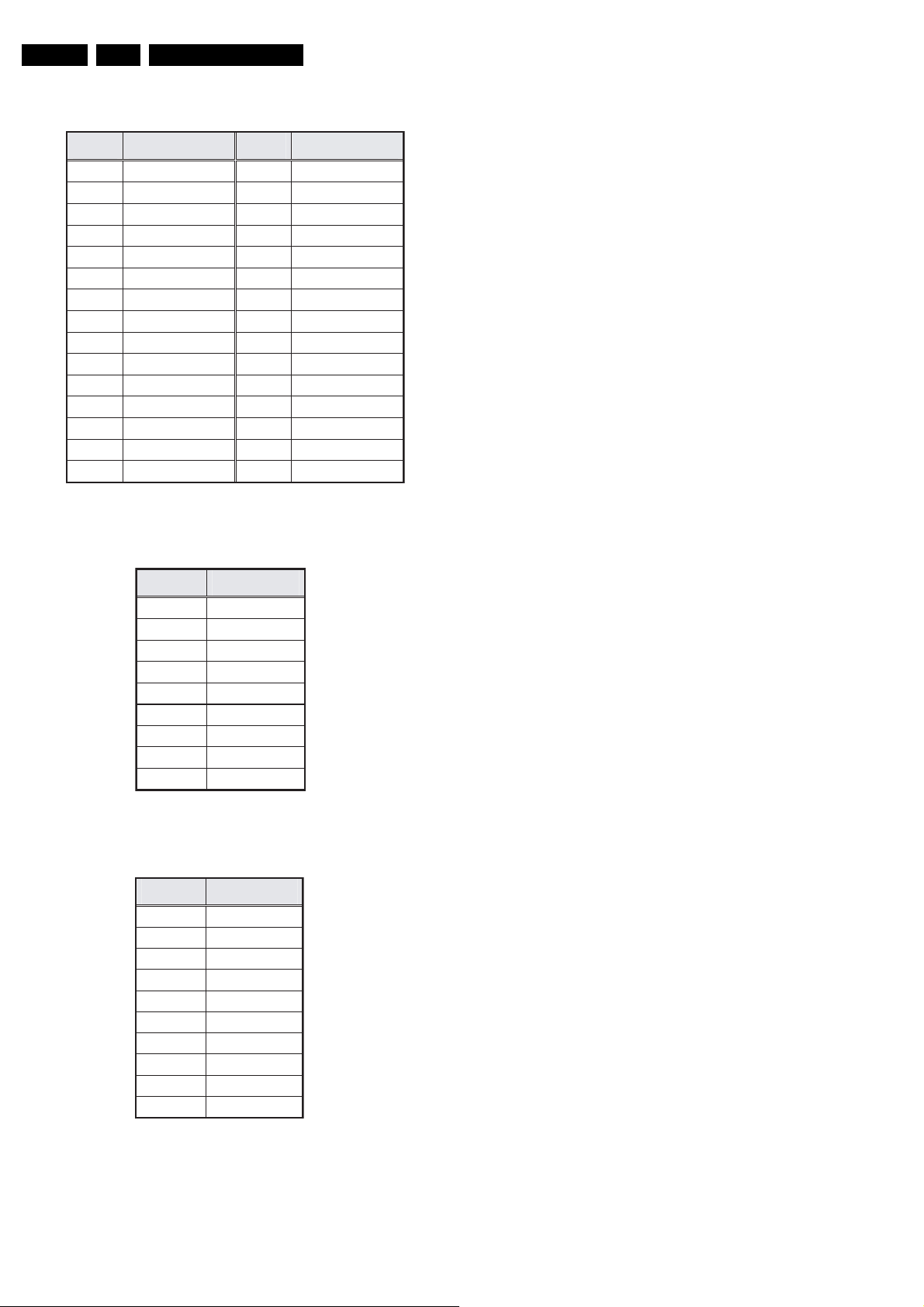

1.3 Chassis overview

㪯㪄㪪㪬㪪

㪯㪄㪙㪬㪪㩷㩿㪯㪙㪙㪀

Technical Specifications

EN 3FHP PDP 1.

㪰㪄㪪㪬㪪

㪧㪪㪬

㪪㪛㪤㪄㪬

㪪㪛㪤㪄㪛

㪣㪦㪞㪠㪚

㪘㪙㪬㪪㪄㪣

㪘㪙㪬㪪㪄㪩

㪘㪛㪤㪈 㪘㪛㪤㪉 㪘㪛㪤㪊 㪘㪛㪤㪋 㪘㪛㪤㪌 㪘㪛㪤㪍 㪘㪛㪤㪎 㪘㪛㪤㪏

Figure 1-5 PWB locations

G_16400_005.eps

180706

㪯㪝㪧㪚 㪯㪝㪧㪚 㪯㪝㪧㪚㪯㪝㪧㪚

Figure 1-6 Connector positions

G_16400_006.eps

270706

Page 4

EN 4 FHP PDP1.

1.4 Some connector layouts

Pin No. Signal name Pin No. Signal name

1 RA- 2 GND (LVDS)

3 RA+ 4 SCL

5 RB- 6 GND

7 RB+ 8 SDA

9 RC- 10 GND (LVDS)

11 RC+ 12 CPUGO

13 RXCLKIN- 14 PDPGO

15 RXCLKIN+ 16 IRQ

17 RD- 18 PDWN

19 RD+ 20 GND (LVDS)

21 RE- 22 GND

23 RE+ 24 GND

25 GND 26 GND

27 GND 28 GND

29 GND 30 GND

Technical Specifications

G_16400_035.eps

280706

Figure 1-7 LVDS connector CN1 Logic Board

Pin No. Symbol

1 Vcc

2 GND

3 Vpr2

4 GND

5 Vra

6 Vrs

7 VCEGO

8 VSAGO

9 PFCGO

G_16400_036.eps

270706

Figure 1-8 Power supply connector CN6 Logic Board

Pin No. Symbol

1 Va

2 N.C.

3 Vcc

4 GND

5 GND

6 GND

7 N.C.

8 Vs

9 Vs

10 Vs

G_16400_037.eps

270706

Figure 1-9 Power supply connector CN23 X-SUS Board

Page 5

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5FHP PDP 2.

2.1 Safety Instructions h

It is not allowed to operate the FTV-set without glass plate. One

function of this glass plate is to absorb Infrared Radiation.

Without this glass plate the level of Infrared Radiation produced

by the plasma display could damage your eyes.

1. Safety regulations require that during a repair:

– the set should be connected to the mains via an

isolating transformer (in this particular case a

transformer of ≥ 800 VA).

– safety components, indicated by the symbol h,

should be replaced by components identical to the

original ones.

2. Safety regulations require that after a repair the set must

be returned in its original condition. In particular attention

should be paid to the following points.

– Note: The wire trees should be routed correctly and

fixed with the mounted cable clamps.

– The insulation of the mains lead should be checked for

external damage.

– The electrical DC resistance between the mains plug

and the secondary side should be checked (only for

sets that have a mains isolated power supply). This

check can be done as follows:

• unplug the mains cord and connect a wire between

the two pins of the mains plug;

• set the mains switch to the on position (keep the

mains cord unplugged!);

• measure the resistance value between the pins of

the mains plug and the metal shielding of the tuner

or the aerial connection on the set. The reading

should be between 4.5 MΩ and 12 MΩ;

• switch off the TV and remove the wire between the

two pins of the mains plug.

– The cabinet should be checked for defects to avoid

touching of any inner parts by the customer.

2.2 Warnings

ESD w

All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling during

repair can reduce life drastically. When repairing, make sure

that you are connected with the same potential as the mass of

the set by a wristband with resistance. Keep components and

tools also at this same potential.

1. Available ESD protection equipment:

– complete kit ESD3 (combining all 6 prior products -

small table mat) 4822 310 10671

– wristband tester 4822 344 13999

2. Never replace modules or other components while the unit

is switched on.

3. When making settings, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

1. A glass plate is positioned before the plasma display. This

glass plate can be cleaned with a slightly humid cloth. If

due to circumstances there is some dirt between the glass

plate and the plasma display panel it is recommended to do

some maintenance by a qualified service employee only.

2. Never disconnect the power display cable when the set is

operating

3. With DST no failures (error-codes) can be red, when the

set is in Service-mode.

4. If DST reacts with "error 2", there is no communication

between the TV and the DST. Note that the IR-transmitter

LED is positioned at the right side of IR-receiver eye of the

E-box. Take into account that receiver-LED on DST is

positioned not in the middle but at the left side. Point

corresponding LEDs to each other. In case the amount of

Infrared produced by the screen pollutes the

communication, the set can be set in Stand-by-mode. Then

still the error-messages can be retrieved.

2.3.1 Notes on Safe Handling of the Plasma Display

Notes to Follow During Service

• The work procedures shown with the Note indication are

important for ensuring the safety of the product and the

servicing work. Be sure to follow these instructions.

• Before starting the work, secure a sufficient working space.

• At all times other than when adjusting and checking the

product, be sure to turn OFF the main POWER switch and

disconnect the power cable from the power supply of the

display during servicing.

• To prevent electric shock and breakage of PC board, start

the servicing work at least 30 seconds after the main power

has been turned off. Especially when installing and

removing the power supply PC board and the SUS PC

board in which high voltages are applied, start servicing at

least 2 minutes after the main power has been turned off.

• While the main power is on, do not touch any parts or

circuits other than the ones specified. The high voltage

power supply block within the PDP module has a floating

ground. If any connection other than the one specified is

made between the measuring equipment and the high

voltage power supply block, it can result in electric shock or

activation of the leakage-detection circuit breaker.

• When installing the PDP module in, and removing it from

the packing carton, be sure to have at least two persons

perform the work white being careful to ensure that the

flexible printed-circuit cable of the PDP module does not

get caught by the packing carton.

• When the surface of the panel comes into contact with the

cushioning materials, be sure to confirm that there is no

foreign matter on top of the cushioning materials before the

surface of the panel comes into contact with the cushioning

materials. Failure to observe this precaution may result in,

the surface of the panel being scratched by foreign matter.

• When handling the circuit PC board, be sure to remove

static electricity from your body before handling the circuit

PC board.

• Be sure to handle the circuit PC board by holding the large

parts as the heat sink or transformer. Failure to observe

this precaution may result in the occurrence of an

abnormality in the soldered areas.

• Do not stack the circuit PC boards. Failure to observe this

precaution may result in problems resulting from scratches

on the parts, the deformation of parts, and short-circuits

due to residual electric charge.

• Routing of the wires and fixing them in position must be

done in accordance with the original routing and fixing

configuration when servicing is completed. All the wires are

routed far away from the areas that become hot (such as

the heat sink). These wires are fixed in position with the

wire clamps so that the wires do not move, thereby

ensuring that they are not damaged and their materials do

not deteriorate over long periods of time. Therefore, route

the cables and fix the cables to the original position and

states using the wire clamps.

• Perform a safety check when servicing is completed. Verify

that the peripherals of the serviced points have not

undergone any deterioration during servicing. Also verify

that the screws, parts and cables removed for servicing

purposes have all been returned to their proper locations in

accordance with the original setup

Page 6

EN 6 FHP PDP3.

Directions for Use

3. Directions for Use

Not applicable.

4. Mechanical Instructions

Notes:

• Figures below can deviate from the actual situation, due to

different set executions.

• For more detailed instructions regarding the (dis)assembly

of the TV chassis that hold these PDPs, read the

corresponding TV Service Manual.

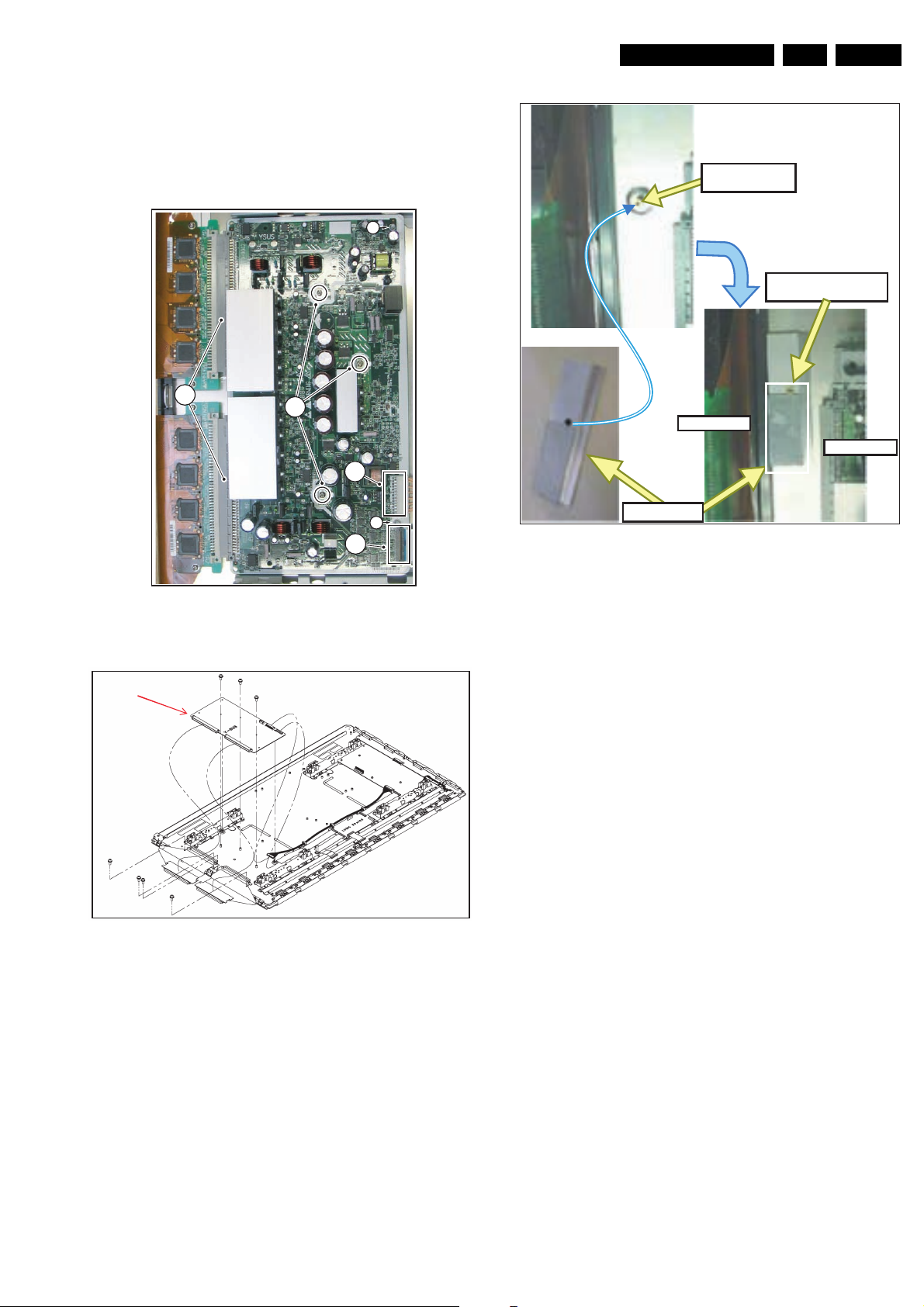

4.1 Board Swap Instructions

4.1.1 General

Before dismounting panels read notes below!

Caution when removing circuit board!

When removing the circuit board after the main power is turned

on/off, wait for at least one minute before starting to remove the

circuit board.

If the circuit board removal is started immediately after turning

off the main power, it can result in electric shock or damage to

the circuit due to residual electric charge.

Caution on handling the FPC connector!

To release the black lock lever of the connector, flip it up gently

in the middle with the nail of the thumb or forefinger, from the

side with the cable.

Never pinch the lock lever with fingers or tools. Doing so might

damage the lock lever.

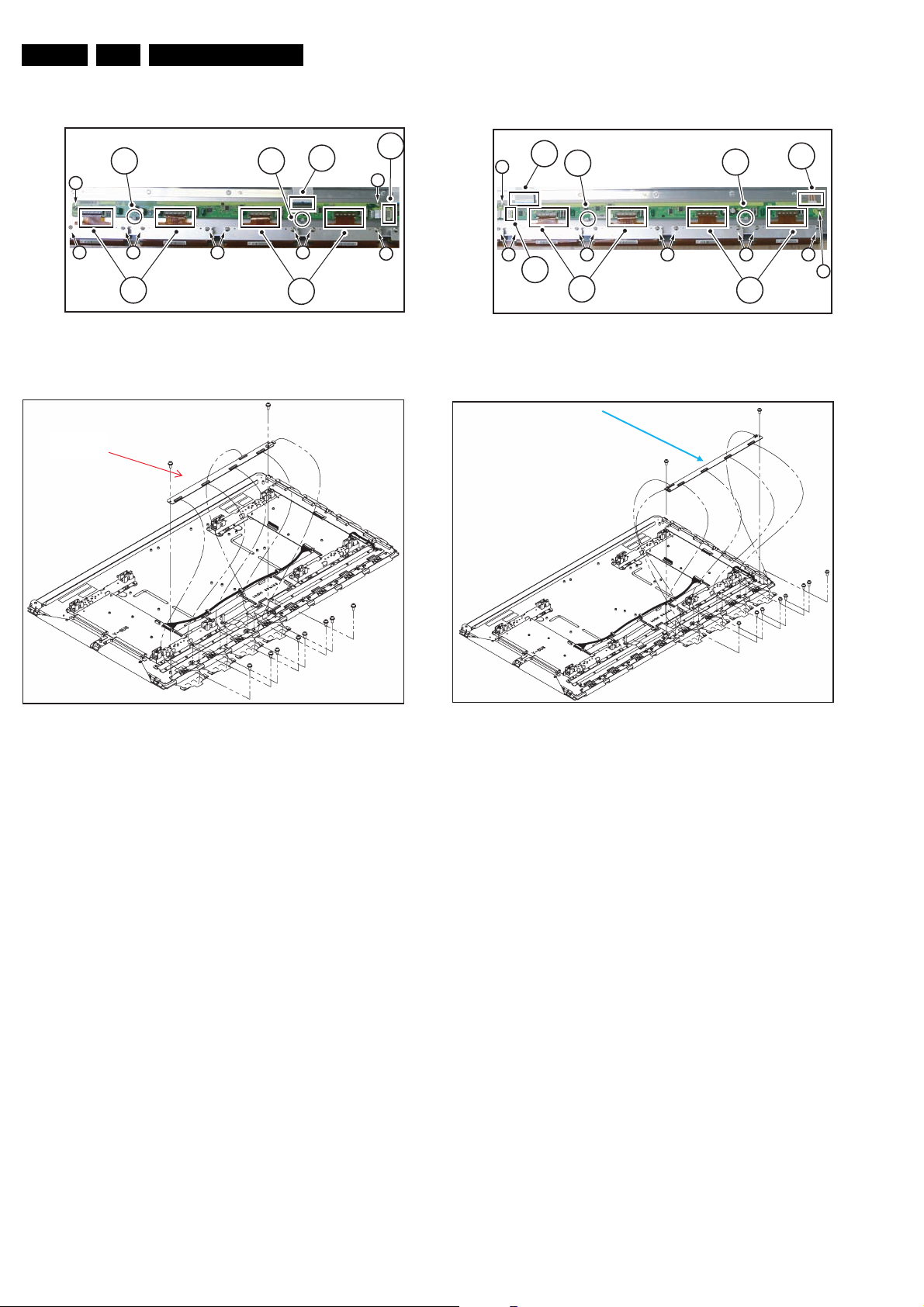

4.1.2 X-SUS and X-BUS Circuit Boards

5

2

2

5

1

3

4

4

2

5

3

5

G_16400_007.eps

300706

Figure 4-2 X-BUS and X-SUS board removal (1/2)

X-BUS

X-SUS

E_14580_025.eps

071005

Figure 4-1 Handling the FPC connector

Figure 4-3 X-BUS and X-SUS board removal (2/2)

Remove the circuit boards by following the steps below. To

install the circuit boards, reverse the removal procedure.

1. Release the lock of the FPC connector [1] and unplug the

signal cable.

2. Unplug the connectors [2].

3. Unplug the 4 XFPC’s [3] on the X-BUS board.

4. Remove the fixing screws [4].

5. Release the white stand-offs [5] from the X-SUS board, and from the top and bottom of the X-BUS board.

G_16400_008.eps

180706

Page 7

Mechanical Instructions

6. Remove the X-BUS board and the X-SUS board together.

Make sure that you do not touch the heat sink when removing

the Y-SUS board.

EN 7FHP PDP 4.

4.1.3 Y-SUS Circuit Board

5

Threaded bush for

SDM-U board

4

Adhesive side should be

against the IC of SDM-U

3

SDM-U board

Y-SUS board

2

4

1

Radiation Plate

G_16400_010.eps

310706

Figure 4-6 Radiation plate position

G_16400_009.eps

300706

Figure 4-4 Y-SUS board removal (1/2)

Y-SUS

Figure 4-5 Y-SUS board removal (2/2)

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Release the lock of the FPC connector [1] and unplug the

signal cable.

2. Unplug the connector [2].

3. Remove the fixing screws [3].

4. Release the white stand-offs [4] from the Y-SUS board.

5. Pull out the Y-SUS board horizontally, in this way

unplugging the connectors [5].

6. Remove the Y-SUS board.

G_16400_011.eps

180706

Make sure that you do not touch the heat sink when removing

the Y-SUS board.

Note: Make sure the radiation plate is positioned correctly. It is

located underneath the upper SDM, and the threaded bush

should sit in the hole of the radiation plate.

Page 8

EN 8 FHP PDP4.

Mechanical Instructions

4.1.4 ABUS-L Circuit Board

6 6

5

22 2 2

3

Figure 4-7 ABUS-L board removal (1/2)

ABUS-L

4

3

G_16400_012.eps

1

5

2

310706

4.1.5 ABUS-R Circuit Board

4

6

7

2 2 2 22

1

3

Figure 4-9 ABUS-R board removal (1/2)

ABUS-R

7

3

G_16400_014.eps

5

6

310706

G_16400_013.eps

180706

Figure 4-8 ABUS-L board removal (2/2)

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Unplug the connector [1].

2. Remove the screws [2] fixing the ADMs.

3. Release the lock of the FPC connectors [3], and remove

the ADM flexible board.

4. Release the lock of the FPC connector [4] and unplug the

signal cable.

5. Remove the screws [5] fixing the ABUS-L board.

6. Remove the ABUS-L board.

7. When installing the ABUS-L board, put the board in such a

position that it is locked by the tabs [6] before fixing it with

the screws.

G_16400_015.eps

180706

Figure 4-10 ABUS-R board removal (2/2)

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Unplug the connector [1].

2. Remove the screws [2] fixing the ADMs.

3. Release the lock of the FPC connectors [3], and remove

the ADM flexible board.

4. Release the lock of the FPC connector [4] and unplug the

signal cable.

5. Unplug the connector [5].

6. Remove the screws [6] fixing the ABUS-R board.

7. Remove the ABUS-R board.

8. When installing the ABUS-R board, put the board in such a

position that it is locked by the tabs [7] before fixing it with

the screws.

Page 9

Mechanical Instructions

EN 9FHP PDP 4.

4.1.6 LOGIC Board

3

4

Figure 4-11 LOGIC board removal (1/2)

Logic

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Unplug connectors [1].

2. Remove screws [2].

3. Remove the PSU.

3

1

2

4

G_16400_016.eps

310706

Figure 4-12 LOGIC board removal (2/2)

Remove the circuit board by following the steps below. To

install the circuit board, reverse the removal procedure.

1. Unplug connectors [1].

2. Release the lock of the FPC connectors [2] and unplug the

signal cables.

3. Remove the screws [3] fixing the LOGIC board.

4. Remove the LOGIC board.

5. When installing the LOGIC board, put the board in such a

position that it is locked by the tabs [4] before fixing it with

the screws.

4.1.7 PSU Board

Not yet available

G_16400_017.eps

180706

Figure 4-13 PSU board removal

E_06532_032.eps

270706

Page 10

EN 10 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Repair Tools

5.3 Process Flow

5.4 Repair Instructions

5.5 Defect Description Form

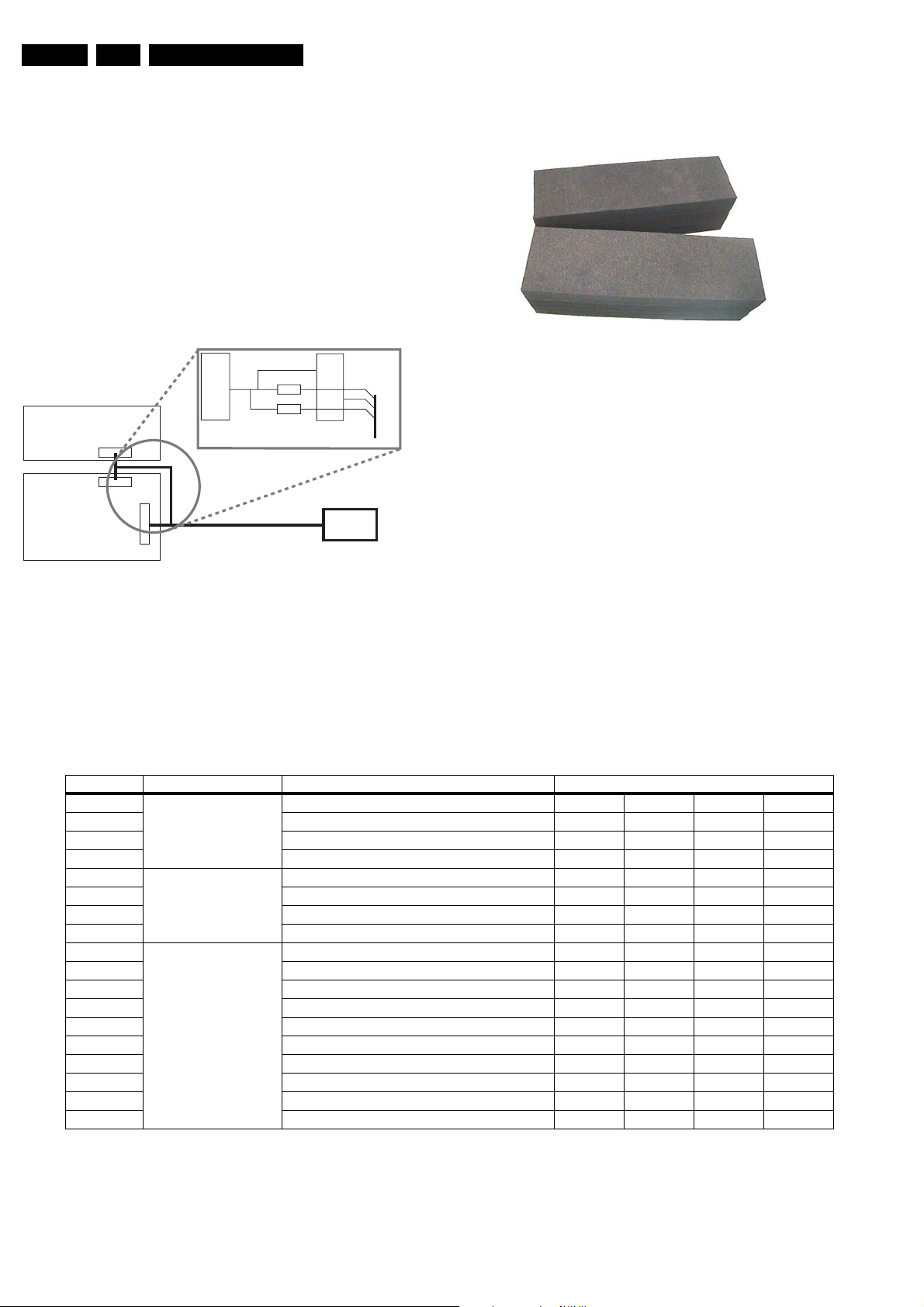

5.1 Repair Tools

To be able to repair the Plasma Display Panels on board level,

the following repair tools are available:

• Special LVDS cable: T.B.D.

• Foam buffers: 3122 785 90581.

Power Supply

CN06

Logic Board

CN06

Vpr

3

CN01

Figure 5-1 Extension cable kit ALiS PDP

CN01

14

3k3

3k3

8

6

4

SDA

GND

SCL

2

I

Compair

C

5.2 Error codes

Figure 5-2 Foam buffers for FTV

When an error causes the PDP to switch “OFF”, an error code

is put into an EEPROM on the Logic Board. You can read out

the contents of the error code memory with the ComPair tool.

2

C

I

Compair

G_16400_018.eps

270706

5.2.1 How to Connect the ComPair Tool

• Carefully disconnect the LVDS cable from CN01 on the

Logic Board.

• If necessary connect a PSU with a voltage of 3.3V to drive

the LOGIC board.

• Connect the cable from the ComPair tool to connector

CN01 of the LOGIC board.

• Turn on the ComPair tool.

• Launch the ComPair software.

• Read out the error buffer.

E_14580_024.eps

250304

5.2.2 Error Code Overview

Table 5-1 Error code table

Error code Detected by board Error description Suspected board(s)

21 X-SUS Vxx power voltage is too high X-SUS LOGIC

24 Vxx power voltage is too low X-SUS LOGIC

25 Vex power voltage is too high X-SUS

26 Vex power startup is faulty X-SUS LOGIC

44 Y-SUS Vey power voltage is too low Y-SUS LOGIC

45 Vey power voltage is too high Y-SUS

46 Vey power startup is faulty Y-SUS LOGIC

4C Temperature too high Y-SUS LOGIC

61 X-SUS

62 Vs power startup is faulty X-SUS Y-SUS PSU LOGIC

Y-SUS

64 Ve power voltage is too low LOGIC X-SUS Y-SUS

65 Ve power voltage is too high Y-SUS Y-SUS

66 Ve power startup is faulty LOGIC X-SUS Y-SUS

68 Vw power voltage is too low Y-SUS LOGIC

69 Vw power voltage is too high LOGIC Y-SUS

6A Vw power startup is faulty Y-SUS LOGIC

79 Vw power current is too high (during operation) Y-SUS X-SUS LOGIC

7B Vs power voltage is too high (during startup) Y-SUS X-SUS LOGIC

Vs power voltage is too high Y-SUS X-SUS LOGIC PSU

Page 11

Service Modes, Error Codes, and Fault Finding

EN 11FHP PDP 5.

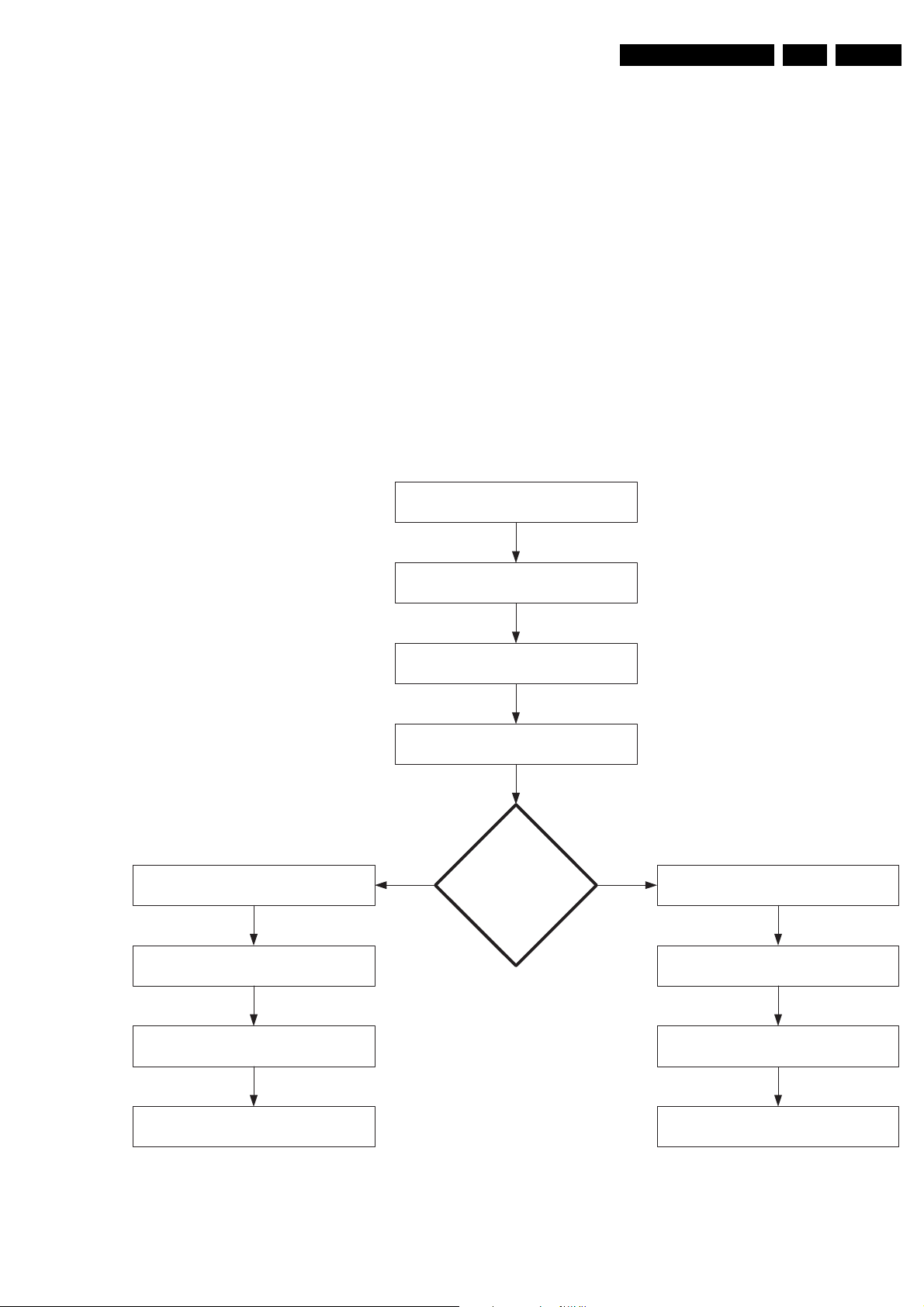

5.3 Process Flow

The selected workshop receives the defect TV set and

investigates the PDP. Two possible solutions follow:

5.3.1 Advanced PDP Exchange (Actual Way-of-Working)

In case of:

• Glass broken,

• Flex foil damaged,

• Y-COM IC on flex foil is damaged, or

• NVM on logic board defect: no communication with

ComPair

the procedure for repair is as follows:

A new PDP will be ordered at EuroService. They issue an RMA

number and ship a refurbished PDP from its swap pool in a

flight case to the workshop. After receipt, the workshop sends

the defective PDP, accompanied by a completely filled in

Defect Description Form (see figure “Defect Description Form

(DDF)“), in this flight case to EuroService. EuroService makes

sure the defect PDP is repaired and afterwards added to its

swap pool. The workshop makes the TV set complete by

building in the refurbished PDP. Afterwards the TV set is

returned to the customer.

5.3.2 Customized Repair

If the defect is not mentioned in 5.2.1, the workshop orders the

necessary spare parts, being boards, at EuroService. After

receipt the workshop swaps the concerning board and makes

the TV set complete by building in the PDP. Afterwards the TV

set is returned to the customer.

PDP flow chart

(from 1st May 2003 onw ard s)

End user contacts dealer because his

plasma TV set is defective

VIP workshop orders refurbished PDP

at EuroService

EuroService ships refurbished PDP from its

swap pool to VIP workshop in a flight case

Dealer requests VIP workshop

to contact end user

VIP workshop pays home visit to end user

and swaps defective TV set with a loan set

VIP workshop analyses the PDP

of the defective plasma TV set

PDP:

YES

gl ass rep air

or

fl ex c abl e mach ine

need ed

??

NO

VIP workshop orders spare part(s)

being boards at EuroService

EuroService ships spare part(s) with

next-day-delivery to VIP workshop

VIP workshop swaps PDP's

and makes plasma TV set complete

VIP workshop brings plasma TV set to

end user and swaps with loan set

Figure 5-3 PDP flow chart

VIP workshop repairs PDP on board level

and makes plasma TV set complete

VIP workshop brings plasma TV set to

end user and swaps with loan set

E_14580_027.eps

280706

Page 12

EN 12 FHP PDP5.

5.4 Repair Instructions

5.4.1 General

In case of:

• a broken glass panel,

• a defective flex foil, or

• a defective Y-COM IC on the flex foil

the PDPs need to be send back via the central repair procedure

of EuroService.

In other cases the Plasma Display Panels must be repaired on

board level.

5.4.2 42” A4 ALiS Plasma Display Panel

The involved Plasma Display Panel is:

Display type Service code number

FPF42C128135UA-52 9322 235 43682

The available modules for these Plasma Display Panels are:

Module description

X-SUS board FPF33R-XSS0041 9965 000 35647

Y-SUS board FPF33R-YSS0042 9965 000 35648

Logic board FPF33R-LGC0061 9965 000 35646

A-BUS Left FPF33R-ABL0038 9965 000 35649

A-BUS Right FPF33R-ABR0039 9965 000 35650

X-BUS board FPF33R-XBU0035 9965 000 35651

Signal Cable LOGIC-X-SUS FPF29R-CBL001411 9965 000 32669

Signal Cable LOGIC-Y-SUS FPF29R-CBL001412 9965 000 32670

Signal Cable LOGIC-ABUS-L FPF29R-CBL001401 9965 000 32668

Signal Cable LOGIC-ABUS-R FPF29R-CBL001421 9965 000 32671

Power Cable X-SUS-Y-SUS FPF29R-CBL003601 9965 000 32672

Power Cable X-SUS-ABUS-R FPF29R-CBL003701 9965 000 32673

FHP code number Service code number

Service Modes, Error Codes, and Fault Finding

Remark:

1. If the LOGIC board is defective, the procedure mentioned

in figures "Logic Board Exchange (1 and 2)" must be used.

Page 13

Service Modes, Error Codes, and Fault Finding

5.4.3 Fault Finding Flowcharts

Problem analysis procedure: PDP repair / board swap

PDP Repair procedure Board Swap

EN 13FHP PDP 5.

The entire Screen does not light.

The set is going into protection.

(PSU is OK)

Go to Step 1 in the procedure

Check the 3.3V Vpr2 on the PSU

and the Logic board

Go to Step 2 in the procedure

Check if there is a short circuit

on boardsY-SUS, X-SUS, SDMs,

X-BUS, or XFPCs

Go to Step 3 in the procedure

Check if there is a short circuit on

boards ABUS-L, ABUS-R, or ADMs

Vertical Line / Vertical Bar?

Go to the

"Vertical line/Vertical bar"

problem analysis procedure

Restore data into the new

Horizontal bar?

Go to the

"Horizontal bar"

problem analysis procedure

Logic Board Exchange

procedure.

Use of ComPair

Copy data from the

defective Logic board

board

Go to Step 4 in the procedure

Check if Vcc (5V), Vs (85V) and

Va (63V) are present

on PSU and boards

Figure 5-4 Problem analysis procedure: PDP repair / board swap

Ship Out

Auto alignment procedure

G_16400_025.eps

310706

Page 14

EN 14 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

Problem Analysis Procedure: The entire screen does not light

1

The entire screen does not light

Caution 1: never disconnect connectors or

remove boards when the mains plug is connected.

Remove CN06

(on LOGIC Board,

PSU-LOGIC cable)

All the boards are connected

Connect the set to mains.

Allow discharge of power supplies before

disconnecting connectors!

Caution 2: do not interchange boards between

different PDPs, this might damage your PDP

Switch “ON” the set

via the mains switch

Vpr2 (3.3 V) on

the PSU board is present?

Y

Turn “OFF” AC power

Connect CN 6 (LOGIC)

Turn on AC power

Vpr2 (3.3 V) on

the PSU board is present?

Y

N

N

PSU board is

defective

Replace the

Power Supply

LOGIC board is

defective

Disconnect the mains plug.

Remove the following power connections:

on X-SUS: CN23 (PSU -> X-SUS)

on X-SUS: CN26 (X-SUS -> ABUS-R)

on X-SUS: CN32 (X-SUS -> Y-SUS)

on ABUS-R: CN47 (ABUS-R -> ABUS-L)

2

Figure 5-5 Problem analysis procedure: the entire screen does not light

Replace Logic Board

Follow the

“Logic Board Exchange” procedure

G_16400_026.eps

310706

Page 15

Service Modes, Error Codes, and Fault Finding

(

)

areshorted

Short-circuit check on Boards and Power Supply Lines

2

Check with an ohmmeter if following

pins are shorted

EN 15FHP PDP 5.

CN23

[X-SU S - PS U]

Vs

Vs

Vs

NC

GND

GND

GND

Vcc

NC

Va

X-SUS

10

9

8

7

6

5

4

3

2

1

Y-SUS

CN32

[Y-SUS - X-SUS]

Vs

Vs

NC

GND

NC

Vcc

NC

Vx

NC

GND

NC

-Vs

-Vs

CN22

[X-SUS - Y-SUS]

-Vs

-Vs

NC

GND

NC

Vu

NC

Vcc

NC

GND

NC

Vs

Vs

13

12

11

10

9

8

7

6

5

4

3

2

1

X-SUS Board:

CN23 pins 3 - 4

13

12

11

10

9

8

7

6

5

4

3

2

1

CN23 pins 6 - 8

CN22 pins 10 - 13

are shorted?

N

Y-SUS Board:

On Y-SUS board,

CN32 pins 1 - 4

CN32 pins 8 - 10

Y

(Switching circuit (power

supply) has a short-circuit)

Y

CN32 pins 10 - 13

are shorted?

(Switching circuit (power

X-SUS board is

defective

Y-SUS board is

defective

supply) has a short-circuit)

N

Remove SDM from the following

two connectors of Y-SUS:

CN34 and CN35

On SDM board,

A1-A2, B1-B2,

C1-C2, D1-D2,

?

Y

SDM is defective

(PDP is defective)

A1 B1 B2

A2

C1

C2 D1 D2

N

On X-BUS board,

CN61 pins 1 - 9

are shorted?

N

3

Y

disconnect CN63, CN64, CN65, CN66

On X-BUS board,

CN61 pins 1 - 9

are shorted?

Remove the 4 XFPCs

Y

N

X-BUS board is

defective

PDP

is defective

End of analysis

G_16400_027.eps

310706

Figure 5-6 Short circuit check on boards and power supply lines (1/3)

Page 16

EN 16 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

3

ABUS-L board:

CN52 pins 1 - 3 or

CN52 pins 4 - 7

are shorted?

ABUS-L

Y

Remove ADM from the

N

following connectors.

CN 53, CN 54,

CN 55, CN 56

ABUS-L board:

CN52 pins 1 - 3 or

CN52 pins 4 - 7

are shorted?

N

ADM is defective

(PDP is defective)

Y

ABUS-L board is defective.

ABUS-R board

CN42 pins 1 - 3 or

CN42 pins 3 - 5

are shorted?

ABUS-R

N

Remove ADM from the

following connectors:

Y

CN 43, CN 44,

CN 45, CN 46

ABUS-R board

CN42 pins 1 - 3 or

CN42 pins 3 - 5

are shorted?

N

ADM is defective

(PDP is defective)

Y

ABUS-R board is defective.

Replace the defective part

4

G_16400_028.eps

310706

Figure 5-7 Short circuit check on boards and power supply lines (2/3)

Page 17

Service Modes, Error Codes, and Fault Finding

4

EN 17FHP PDP 5.

Connect CN23 (X-SUS) and

CN32 (Y-SUS), and

give the “PDP-go” signal (*1)

Are Vcc (5V), Vs (85V),

and Va (63V) present on

the PSU board?

Y

Turn “OFF” AC power

Connect SDM (with CN34 and CN35)

Give the “PDP-go” signal (*1)

On PSU board

Vcc (5V), Vs (85V)

exist ?

Y

Turn “OFF” AC power.

Connect CN 26 (X-SUS)

Give the “PDP-go” signal (*1)

*1 When turning “ON” the PDP with PDP-go, refer to following procedure:

1. Connect the special LVDS cable (see paragraph “Repair Tools”)

between CN01 and CN06

2. Supply power to the PSU

N

Logic board, or X-SUS board, or

Y-SUS board is defective

In case that Vs Power system or Va Power

system of X-SUS or Y-SUS is defective, Vcc

starts but goes down in a few seconds.

N

SDM or PDP is defective

PSU board

Va (63V) exists ?

Y

Turn “OFF” the AC power.

Connect CN 47 (ABUS-R)

Give the “PDP-go” signal (*1)

PSU board

Va (63V) exists ?

Y

End of analysis

N

Va (63V) exists ?

N

And remove ADMs from following connectors

Turn “OFF” AC power.

CN43, CN44, CD45, CN46

Afterwards give the “PDP-go” signal (*1)

PSU board

Y

N

ABUS-R board is defective

ADM is defective

(PDP is defective)

Turn “OFF” AC power.

And remove ADMs from following connectors

CN53, CN54, CD55, CN56

Afterwards give the “PDP-go” signal (*1)

PSU board

Va (63V) exists ?

Y

N

ABUS-L board is defective

ADM is defective

(PDP is defective)

Replace defective boards

(In case of Logic Board replacement:

Follow the “Logic Board Exchange”

procedure!)

G_16400_029.eps

310706

Figure 5-8 Short circuit check on boards and power supply lines (3/3)

Page 18

EN 18 FHP PDP5.

–

Service Modes, Error Codes, and Fault Finding

"Vertical line/Vertical bar" problem analysis procedure

Vertical line / Vertical bar

LOGIC board ABUS-R/L

board signal cable has

abnormal appearance?

N

ADM flexible cable has

abnormal appearance?

N

Give the “PDP-go” signal (*1)

One vertical line?

N

Y

Signal cable is

defective

Y

ADM is defective

(PDP is defective)

*1 When turning “ON” the PDP with PDP-go, refer to following procedure:

1. Connect the special LVDS cable (see paragraph “Repair Tools”)

between CN01 and CN06

2. Supply power to the PSU

Y

Tap lightly heat seal portion on

ADM flexible cable

Any

changes?

N

Y

Heat-melted junction is defective

(PDP is defective)

Panel address has open circuit or

ADM IC chip is defective

(PDP is defective)

Left half of the

panel does

not light?

N

Right half of the

panel does

not light?

N

(1)

Y

Y

Va (63V) exists on

RL41(resistor) on

ABUS-L board?

N

Logic board is defective,

or ABUS-R board is defective,

or Signal cable is defective,

or loose contact of

CN02 (LOGIC) or CN41(ABUS-R)

Logic board is defective,

Y

or ABUS-L board is defective,

or Signal cable is defective,

or loose contact of

CN03 (LOGIC) or CN51 (ABUS-L)

Power cable (CN52 to CN47) is defective

or loose contact of CN47 (ABUS-R)

Replace defective parts

G_16400_030.eps

310706

Figure 5-9 Vertical line / vertical bar problem analysis procedure (1/3)

Page 19

(1)

Is vertical bar

monochromatic?

Service Modes, Error Codes, and Fault Finding

*1 When turning “ON” the PDP with PDP-go, refer to following procedure:

1. Connect the special LVDS cable (see paragraph “Repair Tools”)

N

between CN01 and CN06

2. Supply power to the PSU

EN 19FHP PDP 5.

Y

Does the vertical bar

Y

appear in left

half of panel?

N

Turn “OFF” the AC power

Replace ABUS-L board

Give the “PDP-go” signal (*1)

Normal?

Y

ABUS-L board is defective

N

Turn “OFF” AC power

Replace LOGIC board

Give the “PDP-go” signal (*1)

Normal?

Y

LOGIC board is defective

N

(2)

Turn “OFF” AC power

Replace LOGIC - ABUS-L signal cable

Give the “PDP-go” signal (*1)

Normal?

Y

Signal cable is defective

N

ADM is defective

(PDP is defective)

(3)

Figure 5-10 Vertical line / vertical bar problem analysis procedure (2/3)

Replace the defective parts

G_16400_031.eps

310706

Page 20

EN 20 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

(2)

(3)

*1 When turning “ON” the PDP with PDP-go, refer to following procedure:

1. Connect the special LVDS cable (see paragraph “Repair Tools”)

between CN01 and CN06

2. Supply power to the PSU

Turn “OFF” the main power

Replace ABUS-R board

Give the “PDP-go” signal (*1)

Normal?

N

Turn “OFF” the main power

Replace LOGIC board

Give the “PDP-go” signal (*1)

Normal?

N

Y

ABUS-R board is defective

Y

LOGIC board is defective

Panel is defective

(PDP is defective)

Turn “OFF” the main power

Replace signal cables LOGIC - ABUS-R

Give the “PDP-go” signal (*1)

Y

Normal?

Signal cable is defective

N

ADM is defective

(PDP is defective)

Figure 5-11 Vertical line / vertical bar problem analysis procedure (3/3)

Replace the defective parts

G_16400_032.eps

310706

Page 21

Service Modes, Error Codes, and Fault Finding

"Horizontal bar" problem analysis procedure

Horizontal bar

EN 21FHP PDP 5.

Turn “OFF” the main power

Replace the X-SUS board

Give the “PDP-go” signal (*1)

Normal?

Y

N

Turn “OFF” the main power

Remove the X-SUS board

Put back the initial X-SUS board

Replace Y-SUS board

Give the “PDP-go” signal (*1)

Normal?

Y

*1 When turning “ON” the PDP with PDP-go, refer to following procedure:

1. Connect the special LVDS cable (see paragraph “Repair Tools”)

between CN01 and CN06

2. Supply power to the PSU

X-SUS board is defective

Y-SUS board is defective

N

Figure 5-12 Horizontal line problem analysis procedure

Remark: Do not interchange boards between different PDPs,

this might damage your PDP

PDP is defective

Replace the defective parts

G_16400_033.eps

310706

Page 22

EN 22 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

Logic Board Exchange (1)

1. Copy NVM Data from defective Logic Board

1.

2.

3.

Connect the FHP A4 Service cable to CN01

and CN06 of the Logic Board. Reconnect the power

cable from the PSU to the FHP A4 Service cable on the

CN06 side of the Logic Board. Connect the ComPair

cable to the CN01 side of the FHP A4 Service cable.

4.

5.

6.

Click the link in ComPair to open the Logic Board

Remove the Small Signal Board

Disconnect the LVDS cable from CN01 and

the power cable from CN06 of the Logic Board

Plug in the Mains cable to the Mains filter and the

screen will start up in Stand alone mode.

Set will go into protection or into stand-by

exchange window

7.

In the title bar the module type will appear

8.

9.

Use the "Save" button to save the information to a file

10.

11.

Remove the Mains cable from the Mains filter.

Click the "On" button.

Click button "copy from original"

Click the "Off" button

Figure 5-13 Logic Board Exchange (1/2)

1. Remove the SSB. Now you can reach the cable going to

connector CN01 on the Logic Board.

2. Unplug the LVDS cable from the SSB at connector CN01.

Also unplug the power cable at CN06.

3. Connect the FHP A4 service cable to CN01 and CN06.

Connect the ComPair I2C cable to the CN01 side of the

service cable, and the power cable to the CN06 side of it.

4. Plug in the mains cable. The display starts up in standalone mode.

G_16400_019.eps

010806

5. Click the link in ComPair to open the Logic Board exchange

window.

6. Click the 'On' button. In the title bar the module type will

appear: 42A4, or something similar.

7. Click button 'Copy from original'

8. The data is read from the EEPROM on the logic board and

displayed in the list.

9. Use the 'Save' button to save the information to a file. This

is optional, but better safe than sorry!

Note: If you close the window without saving, all settings

Page 23

Service Modes, Error Codes, and Fault Finding

EN 23FHP PDP 5.

will be lost. If you intend to close this window before

replacing the board, you should save the settings so you

can load them later.

10. Click the 'Off' button.

Logic Board Exchange (2)

2. Write NVM Data to the new Logic Board

1.

2.

3.

Remove the Mains cable from the Mains filter.

Connect the FHP A4 Service cable to CN01

and CN06 of the Logic Board. Connect the power

cable from the PSU to the FHP A4 Service cable on the

CN06 side of the Logic Board. Connect the ComPair

cable to the CN01 side of the FHP A4 Service cable.

Click the "On" button

11. Switch off the set and replace the Logic Board with another

one.

4.

5.

6.

7.

Disconnect the ComPair cable and Power cable from the

Load the saved values

Click button “paste to replacement”

Click button "Ship Out" (1)

FHP A4 Service cable on the CN01 and CN06 sides of the

Logic Board. Disconnect the FHP A4 Service cable. Reconnect

the Power cable from the PSU to CN06 and the LVDS cable

to CN01 on the Logic Board.

Figure 5-14 Logic Board Exchange (2/2)

1. Switch off the set and replace the Logic Board by another

one. Now connect the service cable to connectors CN01

and CN06. Connect the power cable to the CN06 side of

the service cable, and the ComPair cable to the CN01 side.

2. Restart the display with the new board.

3. Click the 'On' button.

4. The module type will again appear in the title bar. This may

be different now from step 6 on the previous page, because

now another Logic Board is used. If you closed the window

after step 9 and did save the settings you should load them

now. Use the ‘Load’ button to do so.

5. Click button 'Paste to replacement'. The settings previously

copied from the old board are now written to the new board.

If successful the button 'Ship out' will be enabled.

6. Click button 'Ship out'.

7. Now a process of voltage feedback initialization and selfadjustment starts. This will take a few seconds. When

ready you can switch off the display.

(1) The PDP screen will be blanked for about 15s,

then 15s later, the 'Ship out' process will end

G_16400_020.eps

010806

8. Disconnect ComPair and remove the service cable, plug in

the power cable at CN06 and the original LVDS cable at

CN01.

Page 24

EN 24 FHP PDP5.

Service Modes, Error Codes, and Fault Finding

NO Fault

Fault status Suspected

contents

1 After momentarily going on, the

Entire screen

does not

light.

screen becomes black

immediately or after a few

seconds (main power is turned

off.)

2

Screen lights dimly even on the

back screen.

3 Single vertical line (of different

Vertical line

color)

4

Vertical line from the middle of

effective scan area (vertical line

of different color)

Analysis procedure

fault location

X-SUS

Y-SUS

PSU

and measure

Refer to

“Entire screen

does not light”

Panel chassis

LOGIC

ABUSL

ABUSR

LOGIC Replace the LOGIC

board, following the

“Logic Board

Exchange” procedure

Panel chassis

LOGIC

Refer to

“Vertical line/bar”

Panel chassis Replace panel

chassis

5 Bar width of 1/7 of horizontal size

Vertical bar

or in multiples of 1/7, is displayed.

Abnormal display

6

Bar width of 3/7 or 4/7 of the

screen width, is displayed.

Abnormal display (vertical line of

different color)

Horizontal

7 Single horizontal line (no light) or

line

single horizontal line does not

light among the effective scanning

area.

Single horizontal line does not

light.

8

Every other line (no light) in entire

X-SUS

screen

Panel chassis

ABUS-L

ABUS-R

LOGIC

Above boards

are connected

.

ABUS-L

ABUS-R

LOGIC

Above boards

are connected.

Panel chassis

X-SUS

Y-SUS

ABUS-L

ABUS-R

Y-SUS

ABUS-L

ABUS-R

Refer to

“Vertical line/bar”

Replace panel

chassis

Replace

X-SUS, Y-SUS

Figure 5-15 Fault symptom overview (1/2)

G_16400_023.eps

280706

Page 25

Service Modes, Error Codes, and Fault Finding

#$%&'(

NO

Fault contents Fault status Suspected

fault

location

EN 25FHP PDP 5.

Analysis procedure

and measure

9 Bar width of 1/8 or multiples of

Horizontal bar

1/8 of the screen height, is

displayed.

Abnormal (screen does not

light)

10

Bar width of 1/2 of the screen

height.

Abnormal display

(screen does not light)

11 Image sticking

(Image

Fixed display contents are

always displayed.

retention)

12 Twinkle The entire screen momentarily

becomes brighter or darker.

13 Flicker The entire screen flickers

continuously.

Panel chassis Replace panel

chassis

Panel chassis

Y-SUS

Refer to

“Horizontal bar”

X-SUS

Above boards

are connected.

Panel chassis Perform all white heat

#$%&'(

run. After judgement,

replace panel chassis

Poor connector

contact

Poor connector

contact

(CN2,3,21,31)

Connector / cable

re-connection or

cable exchange

14 Luminance is

abnormal

15 Chrominance

is abnormal

Screen is too dark or too bright.

(Out of specifications)

Colors cannot be displayed

correctly.

16 Sync is

disturbed

17 Picture

distorted

18 Steps of

Luminance linearity is poor.

gradation are

skipped

19

Abnormal

sound

LOGIC board

Replace Logic

board, following the

“Logic Board

Exchange” procedure

PSU

X-SUS

Y-SUS

(Core is broken,

or transformer

Locate cause of

abnormality from

listening and viewing.

Replace the cause of

problem.

is abnormal.)

20 Control on

external

communication

is abnormal

Contrast, color temperature

adjustment and ϒ cannot be

changed.

Figure 5-16 Fault symptom overview (2/2)

LOGIC board

Replace Logic

board, following the

“Logic Board

Exchange” procedure

G_16400_024.eps

190706

Page 26

EN 26 FHP PDP5.

5.5 Defect Description Form

This form must be used by the workshops for warranty claims:

DDF FLAT TV (panels & boards) version 1.1 Date last modified: 08/03/2005

To be filled in by WORKSHOP / WORK CENTER

Service Modes, Error Codes, and Fault Finding

Country:

Customer Account nr.:

Job sheet nr.:

ATAD RIAPER LARENEG

Condition

Symptom(s)

Philips

Type nr./Model nr. set

LCD & Plasma

DEFECT DESCRIPTION

FORM

Return number

❐ Constantly

❐ Intermittently

❐ After a while

❐ No backlight

❐ No picture

❐ Picture too bright

❐ Shading / smearing on

picture

❐ Only partial picture

❐ Unstabel picture

❐ In a hot environment

❐ In a cold environment

❐ Other : …………………………………

❐ Flickering / flashing picture

❐ Lines across/down image

❐ Inactive row(s)

❐ Inactive column(s)

❐ Missing colour(s)

❐ Other: ………………………………………………

……………………………………………….

Serial nr. display

Part nr display (12nc)

Serial nr. set

Type nr. display

0170 _ _ _ _ _ _

Qty of dots :

RIAPER LENAP

Pixel

Defect(s):

Symptoms

Out of

warranty

R

IA

P

For Plasma

ER DR

TV repair

only

A

OB

To be filled in by EUROSERVICE

Note 1: The defective LCD-panel / PDP needs to be returned in the same packaging as the new part was send. If not

Note 2: Please fill out this form completely

Owner: PHILIPS CE EUROSERVICE DE10WEG

the warranty claim will be rejected.

❐ Dark dots

❐ Bright dots

Following defect symptoms are out of warranty:

• Broken glass

• Scratch(es) on display

Spare Part Nr. New Board Barcode Nr. Defect Board Barcode Nr. Replaced Board

1.

2.

3.

4.

RMA number: Date of receipt:

……..

……..

• Number of dark/bright pixels within spec.

• Burn in (only for Plasma TV)

and correctly, otherwise Euroservice is unable to fulfil the repair request!

Mark

Defect(s)

---------- Picture ----------

Insert picture or mark defect !

These

symptoms

are not

claimable.

Figure 5-17 Defect Description Form (DDF)

F_15590_115.eps

110705

Page 27

Block Diagrams, Test point Overview, and Wave Forms

EVEN SW

6. Block Diagrams, Test point Overview, and Wave Forms

6.1 Block Diagrams

EN 27FHP PDP 6.

CN31

Y-SUS

Y-SUS

EVEN SW

Y-SCAN

EVEN SW

Y-SUS

ODD SW

Y-SCAN

ODD SW

POS /NEG

S

D

M

U

S

D

M

X

B

U

S

X-SUS

X-SUS

X-SCAN

EVEN SW

X-SUS

D

ADM1 ADM4 ADM8ADM7ADM6ADM5ADM3ADM2

ABUS-L

ABUS-R

CN41CN51

X-SCAN

POS

RESET SW

CN21

SIGNAL

INPUT

CN3

24MHz

CN1

Analog Sw

10MHz

OSC

LVDS

OSC

I2C

DATA PROCESSOR

γ comp.

V-SYNC cont

Failure DET.

RGB

GAIN

.

SCI.

FLASH

TIMING ROM

SCAN CONTROLLER

DITHER

MPU

OSC

40MH

EEPROM

APC cont

.

I/O

CN7

D/A

CN69

LOGIC Board

DATA CONVERTER

SUB FIELD

PRC.

OSC

80MH

Vrs

Vra

Vrw

Vrx

PFCgo

Vsago

Vcego

MEMORY

CONTROLLER

FRAME

MEMORY

PSU

CN2

CN5

CN4

Figure 6-1 Signal block diagram

G_16400_021.eps

190706

Page 28

EN 28 FHP PDP6.

g

Block Diagrams, Test point Overview, and Wave Forms

Y-SUS

Y-SUS

EVEN SW

Y-SCAN

EVEN SW

Y-SUS

ODD SW

Y-SCAN

ODD SW

POS/NEG

RESET SW

Vcc 5V

Vs 85V

Va 63V

Vw 190V

Vu 55V

YFVE Vy VE

18V 18V 17V

DC/DC

CONVERTER

S

D

M

U

S

D

M

D

ADM2 ADM4

ADM1

CN52

CN36

CN32 CN22

Va 63V

Vcc 5V

ADM3

ABUS-L

D/A

CPUgo

PDPgo

ADM5

ABUS-R

Vra

Vrs

Vrw

ADM6

ADM7

Va 63V

Vcc 5V

ADM8

CN42

Vxwgo

MPU

Vpr2 3.3V

Vcc

Vrst

LOGIC

CN6

board

RST

X

B

U

S

CN26

XFVE Vxx VE

18V 20V 17V

X-SUS

X-SUS

EVEN SW

X-SCAN

EVEN SW

X-SUS

ODD SW

X-SCAN

ODD SW

POS/NEG

RESET SW

Vcc 5V

Vs 85V

Va 63V

DC/DC

CONVERTER

Vs 85V

DC/DC

CONVERTER

Vcc

5V

Vs

85V

AC100

~240V

PFCgo

Vsago

Vcego

10A

CN61

5/3.3V

Control

Servce

PFC

SW

PFC

o

380V

Vpr2 3.3V

Vpr1 5V

PSU

Figure 6-2 Power block diagram

Vsago

Vce

Vs

V

CN23

63V

5V

go

85V

ra

CN68

CN64

G_16400_022.eps

190706

6.2 Test Points

Not available.

6.3 Wave Forms

Not available.

Page 29

Circuit Diagrams and PWB Layouts

7. Circuit Diagrams and PWB Layouts

Not applicable.

8. Alignments

8.1 Voltage Setting Procedure

On the back of the PDP, in the top right hand corner, you find the Voltage Setting label:

EN 29FHP PDP 7.

G_16400_034.eps

270706

Figure 8-1 Voltage setting label

This Voltage Setting label shows the following messages:

Table 8-1

Item Adjustment items Measurement point Adjustment value (conditions)

1 Vs voltage adjustment Pins 8-9-10 of CN23 on the X-SUS board Voltage setting label indication value* ± 1%

2 Va voltage adjustment Pin 1 of CN23 on the X-SUS board Voltage setting label indication value* ± 1%

If the voltage adjustments Vs and Va on the Power Supply Unit must be performed, depends on the version of the Power Supply Unit.

Page 30

EN 30 FHP PDP9.

Circuit Descriptions and Abbreviation List

9. Circuit Descriptions and Abbreviation List

9.1 Board Function Description

9.1.1 Logic Board Function

Data Processor

• Gamma adjustment (1 / 2.2 / 2.4 / 2.6 / 2.8).

• NTSC/EBU format (Colour matrix) Switch.

• RGB gain Control (White balance adjustment, amplitude

limitation).

• Error diffusion technology (grey scale adjustment).

• Dither (grey scale adjustment).

• Burn-in pattern generation.

Data Converter

• Quasi out-line adjustment (luminous pattern control).

Scan Controller

• Address driver control signal generator (ADM).

• Scan driver control signal generator (SDM).

• X/Y sustain control signal generator.

Waveform ROM

• Waveform pattern for drive / timing memory.

MPU

• Synchronous detection.

• System control.

• Driving voltage (Va, Vs, Vr, Vw) adjustment.

• Abnormal watch (breakdown detection) / abnormal

processing.

• I_s (sustain) current control (sustain pulse control).

• I_a (address) current control (sub-field control).

• External communication control.

• Flash memory (firmware).

EEPROM

• Control parameter memory.

• Counts operating time (number of hours).

• Abnormal status memory (16 places).

9.1.3 Function of Y-SUS Board

DC/DC Power Supply Block

• Vcc (+5V) -> Ve (+17V) / YFve (+ 18V, floating)

• Vs (+85V) -> Vw (+185V)

Switching Block

• Switching during address period.

• Switching during sustain period.

• Switching during reset period.

Current Detector Block

• I_sy (sustain) current detection.

• I_sp (SDM) current detection.

9.1.4 Function of ADM Board

Address Driver Module

• Supplies voltage Va to the glass plate.

9.1.5 Function of SDM Board

Scan Driver Module

• Supplies voltage Vs to the glass plate.

9.1.6 Function of PSU Board

Stand-by Power Supply Block

• AC100-240: +5V & +3V3 Stand-by.

PFC Block (AD/DC Power Supply Block)

• AC100-240: +390V.

AD/DC Power Supply Block

• +380V, Vcc (+5V), Vs (+80V), Va (+60V).

Current Detection Block

• l_a (address) current detection.

9.1.2 Function of X-SUS Board

DC/DC power supply block

• Vcc (+5V) -> Ve (+17V) / XFve (+18V, floating).

X Switching Block

• Switching during address period.

• Switching during sustain period.

• Switching during reset period.

Current Detector Block

• I_sx (sustain) current detection.

• I_ax (address) current detection.

Abnormal Voltage Monitoring

• Vs excess voltage monitoring.

• Va excess voltage monitoring.

Page 31

Circuit Descriptions and Abbreviation List

C

C

9.2 Differences between the Versions A1, A2, A3, and A4

9.2.1 Specifications

Table 9-1 Specifications

EN 31FHP PDP 9.

Item

Dimensions (mm) 994 x 585 x 66 994 x 585 x 66 994 x 587 x 66 994 x 587 x 66

Weight (kg) 16 16 16 16

Resolution (h x v) 1024 x 1024 1024 x 1024 1024 x 1024 1024 x 1080

Brightness (cd/m

(display load 1%,

standard)

Contrast (dark room) 1000 : 1 1000 : 1 3000 : 1 3000 : 1

9.2.2 Layouts

42A1 42A2 42A3 42A4

2

)

SDM-U

SDM-D

1,100 1,200 1,400 1,400

Y-SUS

PSU

X-SUS

XBB-UXBB-D

LOGI

ABUS-L

ABUS-R

ADM1 ADM2 ADM3ADM4 ADM5 ADM6ADM7 ADM8

Figure 9-1 Layout 42A1

PSU

Y-SUS

SDM-USDM-D

X-SUS

LOGI

ABUS-L ABUS-R

ADM2ADM1 ADM3 AD M4

ADM6ADM5 ADM7 ADM8

G_16400_038.eps

310706

XBB-UXBB-D

G_16400_039.eps

310706

Figure 9-2 Layout 42A2

Differences with respect to 42A1:

• The signal cable arrangement has changed.

• The power cable arrangement has changed.

• An 80-pin FPC cable is used between Logic Board and

ABUS-L and ABUS-R.

• The signal cable from the PSU to the Logic Board is

standardised.

• The power cable from the PSU to the Logic Board is

standardised.

Page 32

EN 32 FHP PDP9.

C

C

Circuit Descriptions and Abbreviation List

Y-SUS

PSU

SDM-U

SDM-D

ABUS-L

ADM1 ADM2 ADM3ADM4 ADM5 ADM6ADM7 ADM8

Figure 9-3 Layout 42A3

Differences with respect to 42A2:

• The signal cable arrangement has changed (now similar to

42A1).

• The power cable arrangement has changed (now similar to

42A1).

• The XBB has been replaced by XFPC and X-BUS.

• A new connector type is used on ABUS-L, ABUS-R, and XBUS.

LOGI

ABUS-R

X-SUS

X-BUS (XBB)

G_16400_040.eps

310706

XFPC XFPC XFPCXFPC

Y-SUS

SDM-U

SDM-D

ABUS-L

ADM1 ADM2 ADM3ADM4 ADM5 ADM6ADM7 ADM8

Figure 9-4 Layout 42A4

Differences with respect to 42A3:

• There are no differences in cable arrangements with

respect to 42A3.

PSU

LOGI

ABUS-R

X-SUS

X-BUS (XBB)

G_16400_041.eps

310706

XFPC XFPC XFPCXFPC

Page 33

Spare Parts List

EN 33FHP PDP 10.

9.3 List of abbreviations

ADM Address driver module

Burn-in rack Test equipment of the shelf test in

which the PDP unit is left to stand in

drive condition

CPU The unit for controlling the circuit

operation

DOXE The control voltage for even-

numbered lines in the X direction

DOXO The control voltage for odd-numbered

lines in the X direction

DOYSD Used in the drive voltage in the Y

direction (down)

DOYSU Used in the drive voltage in the Y

direction (up)

External power ON Running the external powers (Vcc, Va,

Vs) on the designated voltage. Unless

otherwise specified

External power OFF Making the external powers (Vcc, Va,

Vs) to stop their operation completely.

Unless otherwise specified

Flexible cable The cable to connect the electric

circuit to the panel

Flicker Continuous switching between bright

and dark views by the PDP itself

Gradation Shading of the display colour

OPUMP The name of a circuit where the

current from X/Y-SUS is returned

Oscilloscope A device that allows the flow and

strength of the running current to be

visually checked and measured

Panel The indication part of the plasma

display panel (PDP)

Panel voltage The voltage required operating the

PDP normally

Parts Each PC board and parts mounted in

the PC boards

PDP Plasma display panel abbreviated

Probe A cable with contact finger that can

transfer the status of the electric circuit

to be measured to an oscilloscope

Protection cover A cover made of aluminium to protect

the PDP entirely during test

ROM Memory that stores the drive

sequence and other data

SCAVIO Scaler Control Audio Video Output &

Input

SDM Scan driver module

SUS X-SUS or Y-SUS

Tapping Light impact

Unit of COM The unit of circuits connected to the

panel with flexible cable (YCOM UP/

DOWN, X-BUS UP/DOWN, address

sections, the unit of PC boards in

ACOM 1 to 5).

Va The power supply at 60 V, which is

used to write data on the panel

Vcc The power supply at 5 V, which is used

to operate the logic section mainly

Vs The power supply ranging from 127 V

to 180 V, which is used to maintain

display data. In addition, this can serve

as the primary side for the secondary

voltage (Vw, -Vy, Vsc)

Solid white A condition when the screen display is

entirely white

X-SUS The name of the circuit that controls

the panel operation in the X direction

YCOM The circuit used to output a panel Y

line selection signal and the voltage of

a display data keep signal

YCOMDV The name of the panel drives voltage

signal output from YCOM UP/DOWN

section

Y-SUS The name of the circuit that controls

the panel operation in the Y direction

10. Spare Parts List

For spare parts list see chapter 5

Page 34

EN 34 FHP PDP11.

11. Revision List

This manual is a supplement to the following service manuals:

Table 11-1 Overview of chassis and manuals, covered by

this manual

Display type Model CTN Chassis 12NC Manual

42" A4 42PF5331/10 LC4.41E AA 3122 785 16240

42PF5411/10 LC4.41E AA 3122 785 16240

42PF9531/79 BJ3.0A PA 3122 785 15980

42PF9531/93 BJ3.0A PA 3122 785 15980

42PF9531/98 BJ3.0A PA 3122 785 15980

42PF9631D/10 BJ3.0E PA 3122 785 15960

11.1 Service Manual xxxx xxx xxxx.0

First release.

Revision List

Loading...

Loading...