Philips EJ3.0UPA Service Manual

Color Television Chassis

EJ3.0U

PA

G_16480_000.eps

060207

Contents Page Contents Page

1. Technical Specifications, Connections, and Chassis

Overview 2

2. Safety Instructions, Warnings, and Notes 5

3. Directions for Use 6

4. Mechanical Instructions 7

5. Service Modes, Error Codes, and Fault Finding 12

6. Block Diagrams, Test Point Overviews, and

Waveforms

Wiring Diagram 42” & 50” 31

Block Diagram Video 32

Block Diagram Audio 33

Block Diagram Control & Clock Signals 34

Test Point Overview SSB 35-40

Test Point Overview AL Inter Conn. Panel 41

I2C IC’s Overview 42

Supply Lines Overview 43

7. Circuit Diagrams and PWB Layouts Diagram PWB

SSB: DC/DC (B01A) 44 76-81

SSB: Supply & RS232 (B01B) 45 76-81

SSB: Channel Decoder (B02A) 46 76-81

SSB: Main Tuner (B02B) 47 76-81

SSB: MPIF Main: Video Source Selection(B03A)48 76-81

SSB: MPIF Main: Supply (B03B) 49 76-81

SSB: MPIF Main: IF & SAW Filter (B03C) 50 76-81

SSB: MPIF Main: Audio Source Selection(B03D)51 76-81

SSB: MPIF Main: Audio Amplifier (B03E) 52 76-81

SSB: PNX2015: Audio / Video (B04A) 53 76-81

SSB: PNX2015: DV I/O Interface (B04B) 54 76-81

SSB: PNX2015: Tunnelbus (B04C) 55 76-81

SSB: PNX2015: DDR Interface (B04D) 56 76-81

SSB: PNX2015: Standby & Control (B04E) 57 76-81

SSB: PNX2015: Supply (B04F) 58 76-81

SSB: VIPER/PNX2015: Display Interface(B04G)59 76-81

SSB: VIPER: Control (B05A) 60 76-81

©

Copyright 2007 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

SSB: VIPER: Main Memory (B05B) 61 76-81

SSB: VIPER: A/V & Tunnelbus (B05C) 62 76-81

SSB: VIPER: Supply (B05D) 63 76-81

SSB: VIPER: EEPROM (B05E) 64 76-81

SSB: VIPER: Miscellaneous (B05F) 65 76-81

SSB: Display Interface: MOP (B06) 66 76-81

SSB: HDMI & Supply (B07A) 67 76-81

SSB: HDMI I/O & Control (B07B) 68 76-81

SSB: Analog I/O (B07C) 69 76-81

SSB: Uart (B07D) 70 76-81

SSB: HDMI (B07E) 71 76-81

SSB: Audio: Amplifier (B08A) 72 76-81

SSB: Audio: Connectors (B08B) 73 76-81

SSB: SRP List 73-75

Side I/O Panel (D) 82 83

Keyboard Control Panel (E) 84 85

Front IR / LED Panel (J) 86 87

AL Inter Connect Panel: DC/DC Converter (M1) 88 93-94

AL Inter Connect Panel: Pacific 3 (M2) 89

AL Inter Connect Panel: Display Interface (M3) 90 93-94

AL Inter Connect Panel: Inter Connection (M4) 91 93-94

AL Inter Connect Panel: DC/DC Ambi (M5) 92 93-94

8. Alignments 95

9. Circuit Descriptions, Abbreviation List, and IC Data

Sheets 101

Abbreviation List 104

IC Data Sheets 106

10. Spare Parts List 117

11. Revision List 125

93-94

Published by WS 0763 BG CD Customer Service Printed in the Netherlands Subject to modification EN 3122 785 17000

EN 2 EJ3.0U PA1.

Technical Specifications, Connections, and Chassis Overview

1. Technical Specifications, Connections, and Chassis Overview

Index of this chapter:

1.1 Technical Specifications

1.2 Connection Overview

1.3 Chassis Overview

Notes:

• Some models in this chassis range have a different

mechanical construction. The information given here is

therefore model specific.

• Figures below can deviate slightly from the actual situation,

due to the different set executions.

• Specifications are indicative (subject to change).

1.1 Technical Specifications

1.1.1 Vision

Display type : PDP

Aspect ratio : 16: 9

Screen size(s) : 32” (82 cm)

: 42” (107 cm)

Resolution : 1024(*3) x 768p (42”)

Typical contrast ratio : 10,000: 1

Minimum light output (cd/m

Viewing angle (HxV degrees) : 160 x 160

Tuning system : PLL

TV Color systems : ATSC, NTSC

Video playback : NTSC

Cable : Unscrambled digital

Tuner bands : VHF, UHF, S, H

Supported video formats : 480i @ 60Hz

2

) : 1200

: 50” (127 cm)

: 1366(*3) x 768 (50”)

cable - QAM

: 480p @ 60Hz

: 720p @ 60Hz

: 1080i @ 60Hz

1.1.2 Sound

Sound systems : AV Stereo

Maximum power (W

1.1.3 Multimedia

Supported file formats : JPEG

USB input : USB1.1

1.1.4 Miscellaneous

Power supply:

- Mains voltage (V

Ambient conditions:

- Temperature range (°C) : +5 to +35

- Maximum humidity : 90% R.H.

Power consumption:

- Normal operation (W) : 400 (42”)

- Stand-by (W) : < 1

Dimensions (WxHxD in inch) : 41.1x27.6x4.37 (42”)

Weight, stand included (lbs) : 70.4 (42”)

) : 2 x 15

RMS

) : 110 - 240

AC

:BTSC

: Dolby Digital (AC3)

:MP3

: Slideshow (.alb)

: 500 (50”)

: 49.2x32.2x4.23 (50”)

: 124.3 (47”)

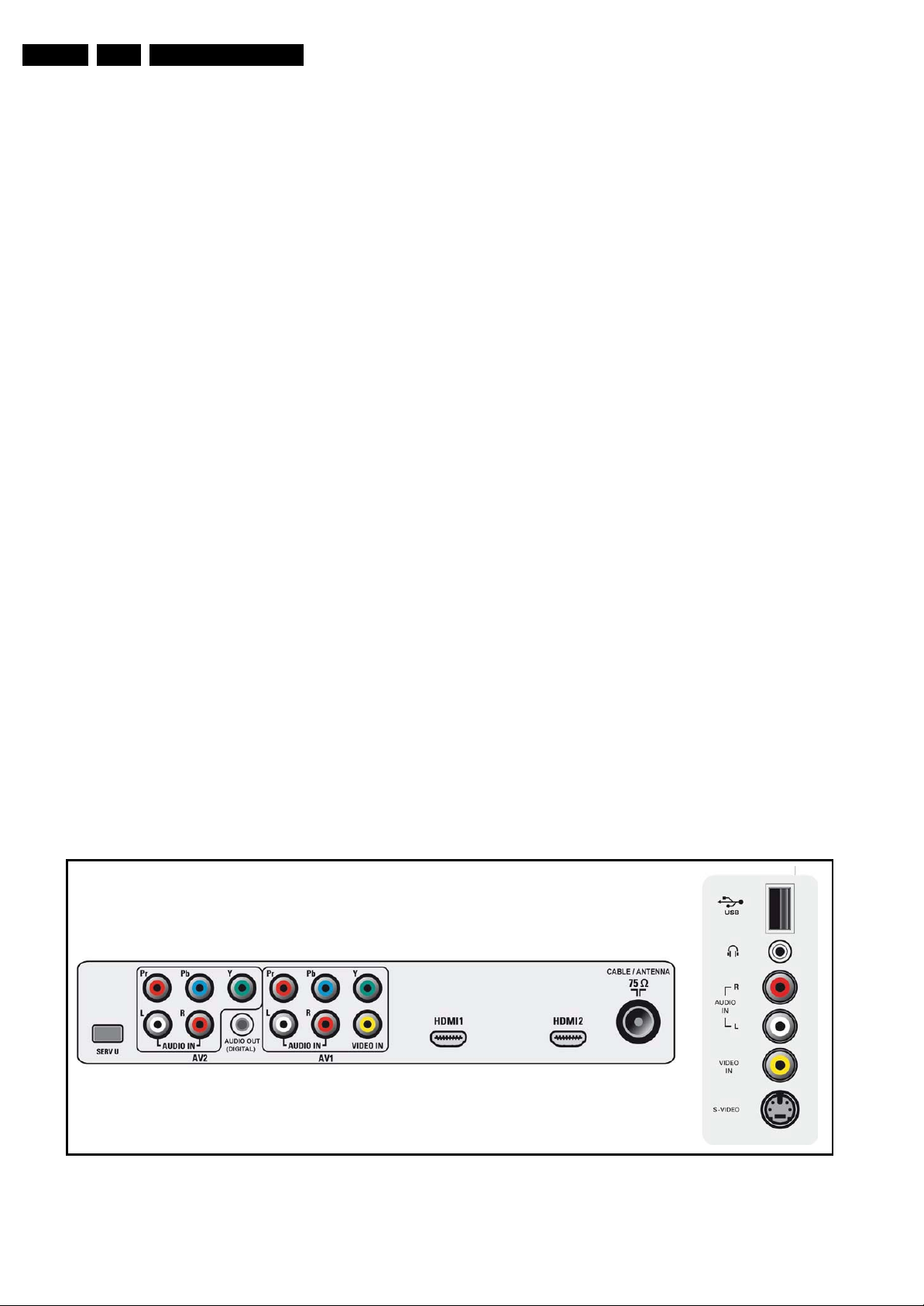

1.2 Connection Overview

Note: The following connector color abbreviations are used

(acc. to DIN/IEC 757): Bk= Black, Bu= Blue, Gn= Green, Gy=

Grey, Rd= Red, Wh= White, and Ye= Yellow.

REAR CONNECTIONS

SIDE A/V

G_16840_093.eps

060207

Figure 1-1 Rear and side A/V connections

Technical Specifications, Connections, and Chassis Overview

1.2.1 Side Connections

EN 3EJ3.0U PA 1.

USB1.1

1234

E_06532_022.eps

300904

Figure 1-2 USB (type A)

1-+5V k

2 -Data (-) jk

3 -Data (+) jk

4 -Ground Gnd H

Mini Jack: Audio Headphone - Out

Bk - Headphone 32 - 600 ohm / 10 mW ot

Cinch: Video CVBS - In, Audio - In

Ye - Video CVBS 1 V

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 75 ohm jq

PP

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

S-Video (Hosiden): Video Y/C - In

1 -Ground Y Gnd H

2 -Ground C Gnd H

3 -Video Y 1 V

4 -Video C 0.3 V

/ 75 ohm j

PP

P / 75 ohm j

PP

HDMI 1 & HDMI 2: Digital Video, Digital Audio - In

19

18 2

1

E_06532_017.eps

250505

Figure 1-3 HDMI (type A) connector

1 -D2+ Data channel j

2 -Shield Gnd H

3 -D2- Data channel j

4 -D1+ Data channel j

5 -Shield Gnd H

6 -D1- Data channel j

7 -D0+ Data channel j

8 -Shield Gnd H

9 -D0- Data channel j

10 - CLK+ Data channel j

11 - Shield Gnd H

12 - CLK- Data channel j

13 - n.c.

14 - n.c.

15 - DDC_SCL DDC clock j

16 - DDC_SDA DDC data jk

17 - Ground Gnd H

18 - +5V j

19 - HPD Hot Plug Detect j

20 - Ground Gnd H

1.2.2 Rear Connections

Service Connector (UART)

1 -UART_TX Transmit k

2 -Ground Gnd H

3 -UART_RX Receive j

AV2 Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

AV2 Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Cinch: S/PDIF - Out

Bk - Coaxial 0.4 - 0.6V

/ 75 ohm kq

PP

AV1 Cinch: Video YPbPr - In

Gn - Video Y 1 V

Bu - Video Pb 0.7 V

Rd - Video Pr 0.7 V

/ 75 ohm jq

PP

/ 75 ohm jq

PP

/ 75 ohm jq

PP

AV1 Cinch: Video CVBS - In

Ye - Video CVBS 1 V

/ 75 ohm jq

PP

AV1 Cinch: Audio - In

Wh - Audio L 0.5 V

Rd - Audio R 0.5 V

/ 10 kohm jq

RMS

/ 10 kohm jq

RMS

Aerial - In

- - F-type (US) Coax, 75 ohm D

EN 4 EJ3.0U PA1.

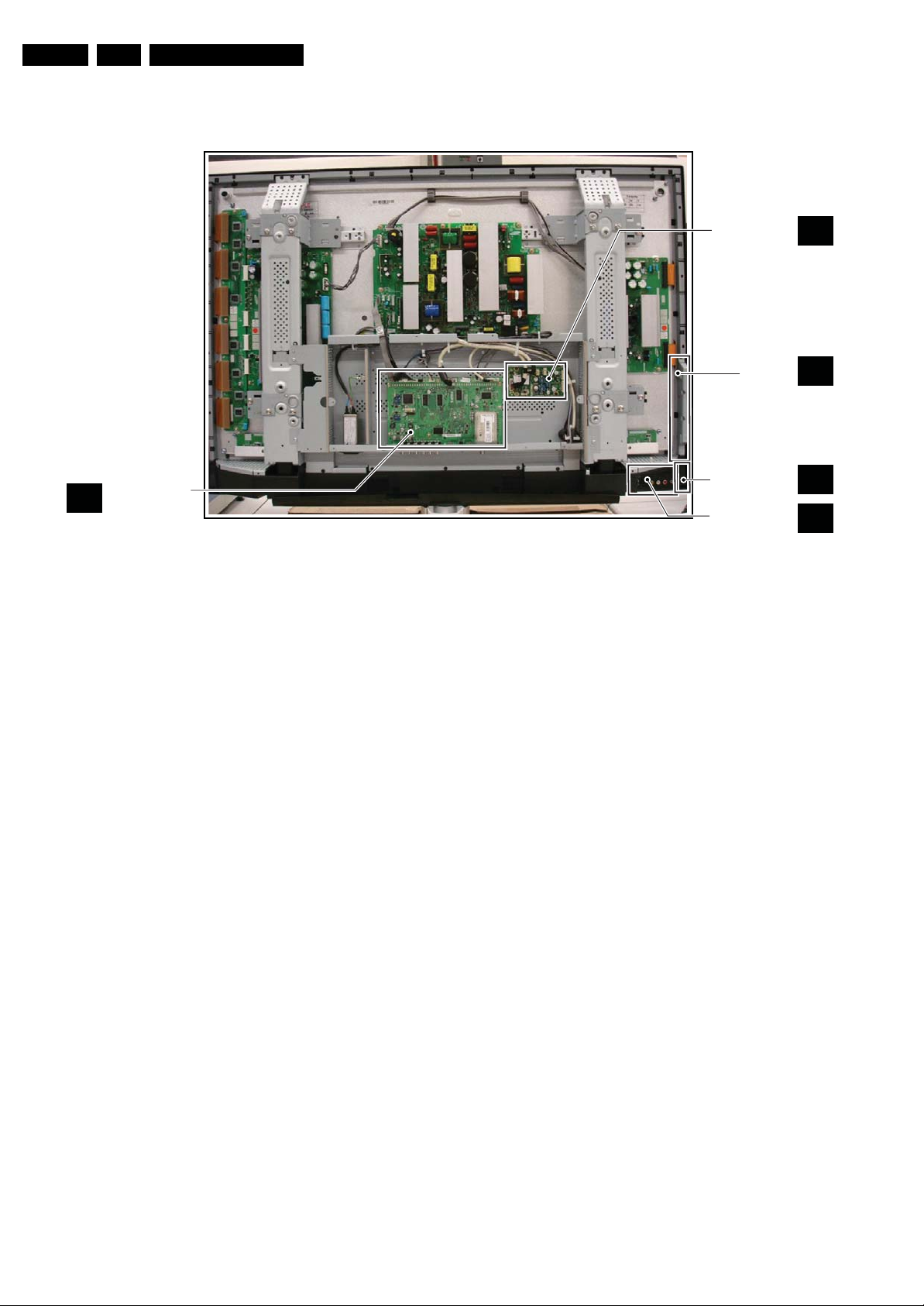

1.3 Chassis Overview

Technical Specifications, Connections, and Chassis Overview

AMBILIGHT INTER-

CONNECTION

PA NE L

M

SMALL SIGNAL

B

BOARD

Figure 1-4 PWB/CBA locations

H_17000_017.eps

270207

CONTROL

PA NE L

IR / LED PANEL

SIDE I/O PANEL

E

J

D

Safety Instructions, Warnings, and Notes

2. Safety Instructions, Warnings, and Notes

EN 5EJ3.0U PA 2.

Index of this chapter:

2.1 Safety Instructions

2.2 Warnings

2.3 Notes

2.1 Safety Instructions

Safety regulations require the following during a repair:

• Connect the set to the Mains/AC Power via an isolation

transformer (> 800 VA).

• Replace safety components, indicated by the symbol h,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, the set must be

returned in its original condition. Pay in particular attention to

the following points:

• Route the wire trees correctly and fix them with the

mounted cable clamps.

• Check the insulation of the Mains/AC Power lead for

external damage.

• Check the strain relief of the Mains/AC Power cord for

proper function.

• Check the electrical DC resistance between the Mains/AC

Power plug and the secondary side (only for sets that have

a Mains/AC Power isolated power supply):

1. Unplug the Mains/AC Power cord and connect a wire

between the two pins of the Mains/AC Power plug.

2. Set the Mains/AC Power switch to the "on" position

(keep the Mains/AC Power cord unplugged!).

3. Measure the resistance value between the pins of the

Mains/AC Power plug and the metal shielding of the

tuner or the aerial connection on the set. The reading

should be between 4.5 Mohm and 12 Mohm.

4. Switch "off" the set, and remove the wire between the

two pins of the Mains/AC Power plug.

• Check the cabinet for defects, to prevent touching of any

inner parts by the customer.

Service Default Mode (see chapter 5) with a color bar

signal and stereo sound (L: 3 kHz, R: 1 kHz unless stated

otherwise) and picture carrier at 475.25 MHz for PAL, or

61.25 MHz for NTSC (channel 3).

• Where necessary, measure the waveforms and voltages

with (D) and without (E) aerial signal. Measure the

voltages in the power supply section both in normal

operation (G) and in stand-by (F). These values are

indicated by means of the appropriate symbols.

• Manufactured under license from Dolby Laboratories.

“Dolby”, “Pro Logic” and the “double-D symbol”, are

trademarks of Dolby Laboratories.

2.3.2 Schematic Notes

• All resistor values are in ohms, and the value multiplier is

often used to indicate the decimal point location (e.g. 2K2

indicates 2.2 kohm).

• Resistor values with no multiplier may be indicated with

either an "E" or an "R" (e.g. 220E or 220R indicates 220

ohm).

• All capacitor values are given in micro-farads (μ= x10

nano-farads (n= x10

• Capacitor values may also use the value multiplier as the

decimal point indication (e.g. 2p2 indicates 2.2 pF).

• An "asterisk" (*) indicates component usage varies. Refer

to the diversity tables for the correct values.

• The correct component values are listed in the Spare Parts

List. Therefore, always check this list when there is any

doubt.

2.3.3 BGA (Ball Grid Array) ICs

Introduction

For more information on how to handle BGA devices, visit this

URL: www.atyourservice.ce.philips.com (needs subscription,

not available for all regions). After login, select “Magazine”,

then go to “Repair downloads”. Here you will find Information

on how to deal with BGA-ICs.

-9

), or pico-farads (p= x10

-12

-6

),

).

2.2 Warnings

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD w). Careless handling

during repair can reduce life drastically. Make sure that,

during repair, you are connected with the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools also at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the high voltage

section.

• Never replace modules or other components while the unit

is switched "on".

• When you align the set, use plastic rather than metal tools.

This will prevent any short circuits and the danger of a

circuit becoming unstable.

2.3 Notes

2.3.1 General

• Measure the voltages and waveforms with regard to the

chassis (= tuner) ground (H), or hot ground (I), depending

on the tested area of circuitry. The voltages and waveforms

shown in the diagrams are indicative. Measure them in the

BGA Temperature Profiles

For BGA-ICs, you must use the correct temperature-profile,

which is coupled to the 12NC. For an overview of these profiles,

visit the website www.atyourservice.ce.philips.com (needs

subscription, but is not available for all regions)

You will find this and more technical information within the

"Magazine", chapter "Repair downloads".

For additional questions please contact your local repair help

desk.

2.3.4 Lead-free Soldering

Due to lead-free technology some rules have to be respected

by the workshop during a repair:

• Use only lead-free soldering tin Philips SAC305 with order

code 0622 149 00106. If lead-free solder paste is required,

please contact the manufacturer of your soldering

equipment. In general, use of solder paste within

workshops should be avoided because paste is not easy to

store and to handle.

• Use only adequate solder tools applicable for lead-free

soldering tin. The solder tool must be able:

– To reach a solder-tip temperature of at least 400°C.

– To stabilize the adjusted temperature at the solder-tip.

– To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature of around

360°C - 380°C is reached and stabilized at the solder joint.

Heating time of the solder-joint should not exceed ~ 4 sec.

Avoid temperatures above 400°C, otherwise wear-out of

tips will increase drastically and flux-fluid will be destroyed.

EN 6 EJ3.0U PA3.

Directions for Use

To avoid wear-out of tips, switch “off” unused equipment or

reduce heat.

• Mix of lead-free soldering tin/parts with leaded soldering

tin/parts is possible but PHILIPS recommends strongly to

avoid mixed regimes. If this cannot be avoided, carefully

clear the solder-joint from old tin and re-solder with new tin.

2.3.5 Alternative BOM identification

The third digit in the serial number (example:

AG2B0335000001) indicates the number of the alternative

B.O.M. (Bill Of Materials) that has been used for producing the

specific TV set. In general, it is possible that the same TV

model on the market is produced with e.g. two different types

of displays, coming from two different suppliers. This will then

result in sets which have the same CTN (Commercial Type

Number; e.g. 28PW9515/12) but which have a different B.O.M.

number.

By looking at the third digit of the serial number, one can

identify which B.O.M. is used for the TV set he is working with.

If the third digit of the serial number contains the number “1”

(example: AG1B033500001), then the TV set has been

manufactured according to B.O.M. number 1. If the third digit is

a “2” (example: AG2B0335000001), then the set has been

produced according to B.O.M. no. 2. This is important for

ordering the correct spare parts!

For the third digit, the numbers 1...9 and the characters A...Z

can be used, so in total: 9 plus 26= 35 different B.O.M.s can be

indicated by the third digit of the serial number.

2.3.6 Exchanging a Defective PDP

If a PDP has defective or "dead" pixels, do the following:

1. Locate the defective pixels.

2. Indicate their positions by means of a marker (with

erasable ink!).

3. Indicate the positions of the defective pixels in the Defects

Description Form (DDF), which is published in the PDP

manuals.

4. After this, remove the PDP and return it to your Service

organization.

If a PDP has to be removed from the TV set, always keep in

mind that the PDP parts can easily be damaged by ESD, so

take the following protective measures:

• Do not damage the flex foils (they are located on the left,

right, upper and lower sides of the PDP).

• Do not scratch the glass plate.

• Avoid fingerprints.

2.3.7 Board Level Repair (BLR) or Component Level Repair

(CLR)

If a board is defective, consult your repair procedure to decide

if the board has to be exchanged or if it should be repaired on

component level.

If your repair procedure says the board should be exchanged

completely, do not solder on the defective board. Otherwise, it

cannot be returned to the O.E.M. supplier for back charging!

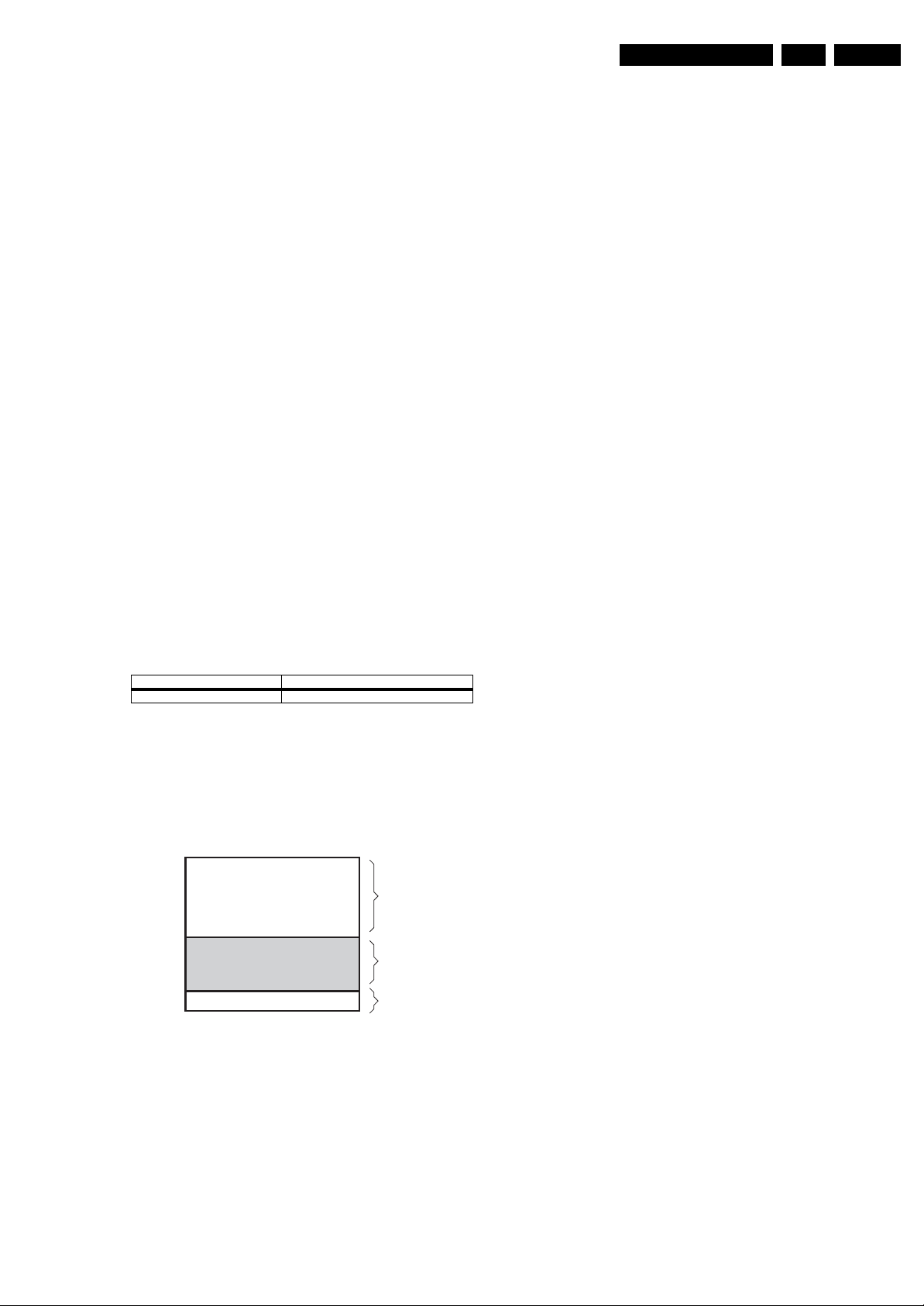

Identification: The bottom line of a type plate gives a 14-digit

serial number. Digits 1 and 2 refer to the production center (e.g.

AG is Bruges), digit 3 refers to the B.O.M. code, digit 4 refers

to the Service version change code, digits 5 and 6 refer to the

production year, and digits 7 and 8 refer to production week (in

example below it is 2006 week 17). The 6 last digits contain the

serial number.

MODEL :

PROD.NO:

32PF9968/10

AG 1A0617 000001

220-240V 50/60Hz

VHF+S+H+UHF

S

Figure 2-1 Serial number (example)

3. Directions for Use

You can download this information from the following websites:

http://www.philips.com/support

http://www.p4c.philips.com

MADE IN BELGIUM

~

128W

BJ3.0E LA

E_06532_024.eps

130606

2.3.8 Practical Service Precautions

• It makes sense to avoid exposure to electrical shock.

While some sources are expected to have a possible

dangerous impact, others of quite high potential are of

limited current and are sometimes held in less regard.

• Always respect voltages. While some may not be

dangerous in themselves, they can cause unexpected

reactions that are best avoided. Before reaching into a

powered TV set, it is best to test the high voltage insulation.

It is easy to do, and is a good service precaution.

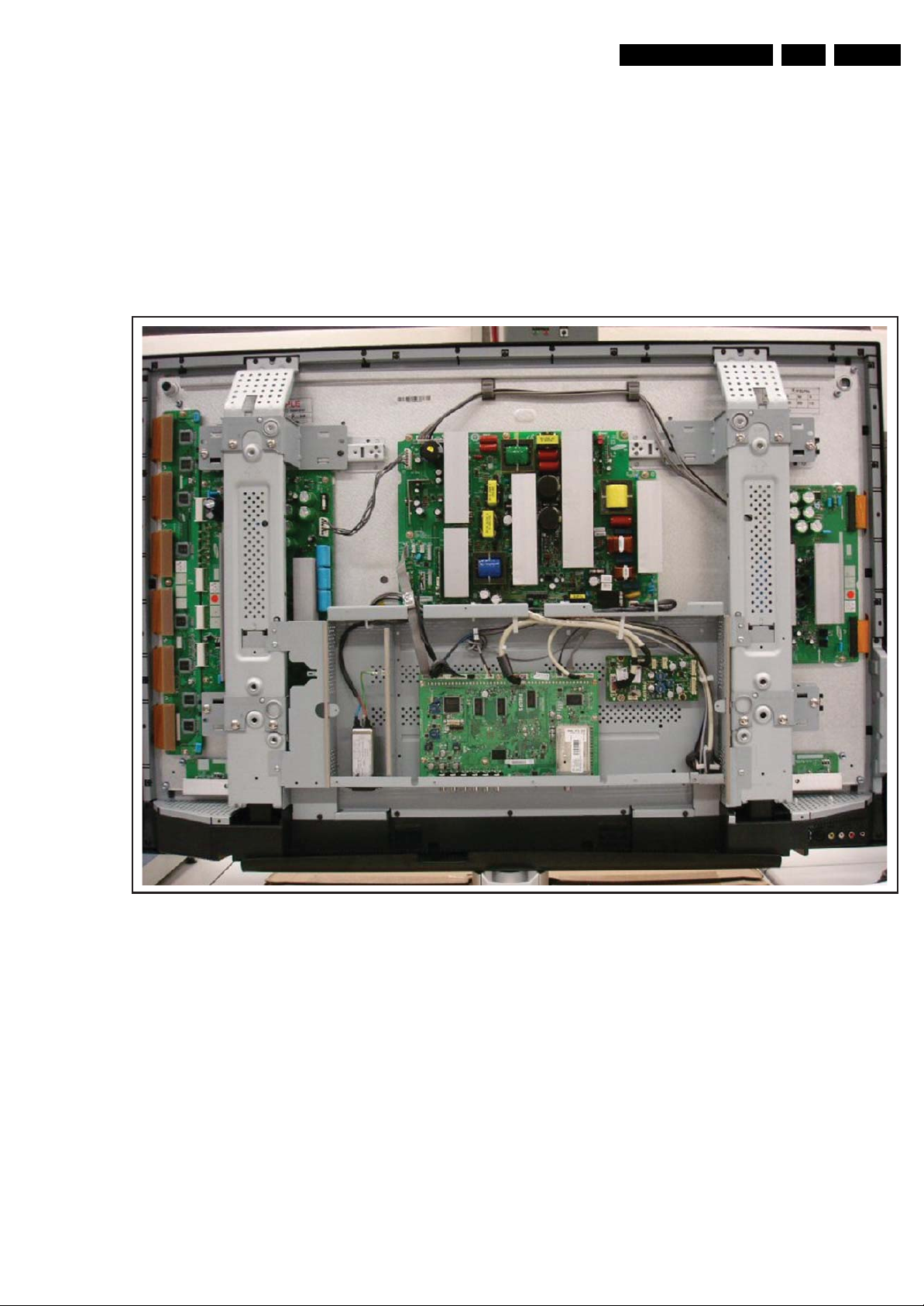

4. Mechanical Instructions

Mechanical Instructions

EN 7EJ3.0U PA 4.

Index of this chapter:

4.1 Cable Dressing

4.2 Service Positions

4.3 Assy/Panel Removal

4.4 Set Re-assembly

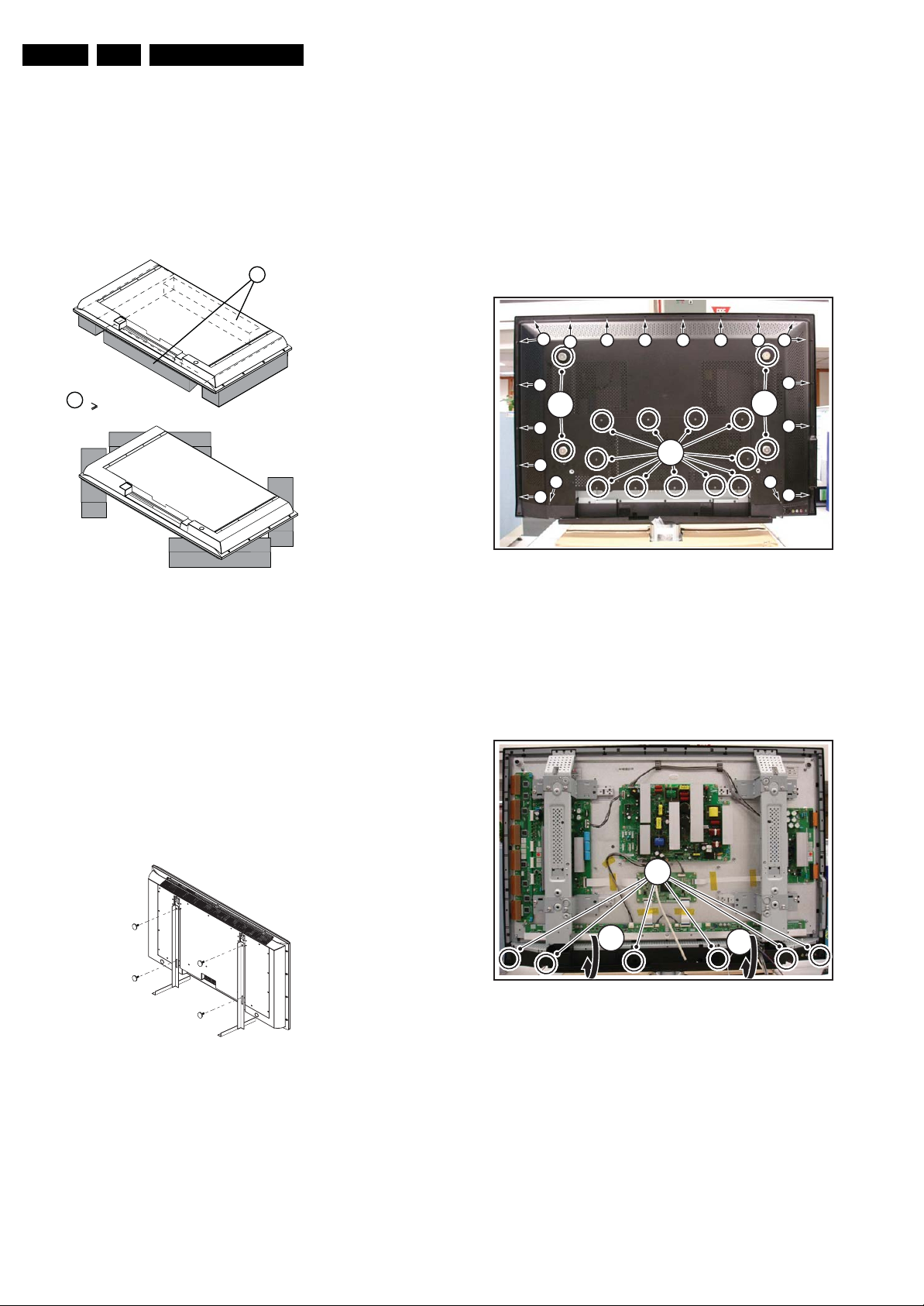

4.1 Cable Dressing

Notes:

• Several models in this chassis range have a different

mechanical construction, the instructions given in this

chapter are therefore very model specific.

• Follow the disassembly instructions in described order.

Figure 4-1 Cable dressing

H_17000_005.eps

260207

EN 8 EJ3.0U PA4.

Mechanical Instructions

4.2 Service Positions

For easy servicing of this set, there are a few possibilities

created:

• The buffers from the packaging.

• Foam bars (created for Service).

• Aluminium service stands (created for Service).

4.2.1 Foam Bars

1

Required for sets

1

42”

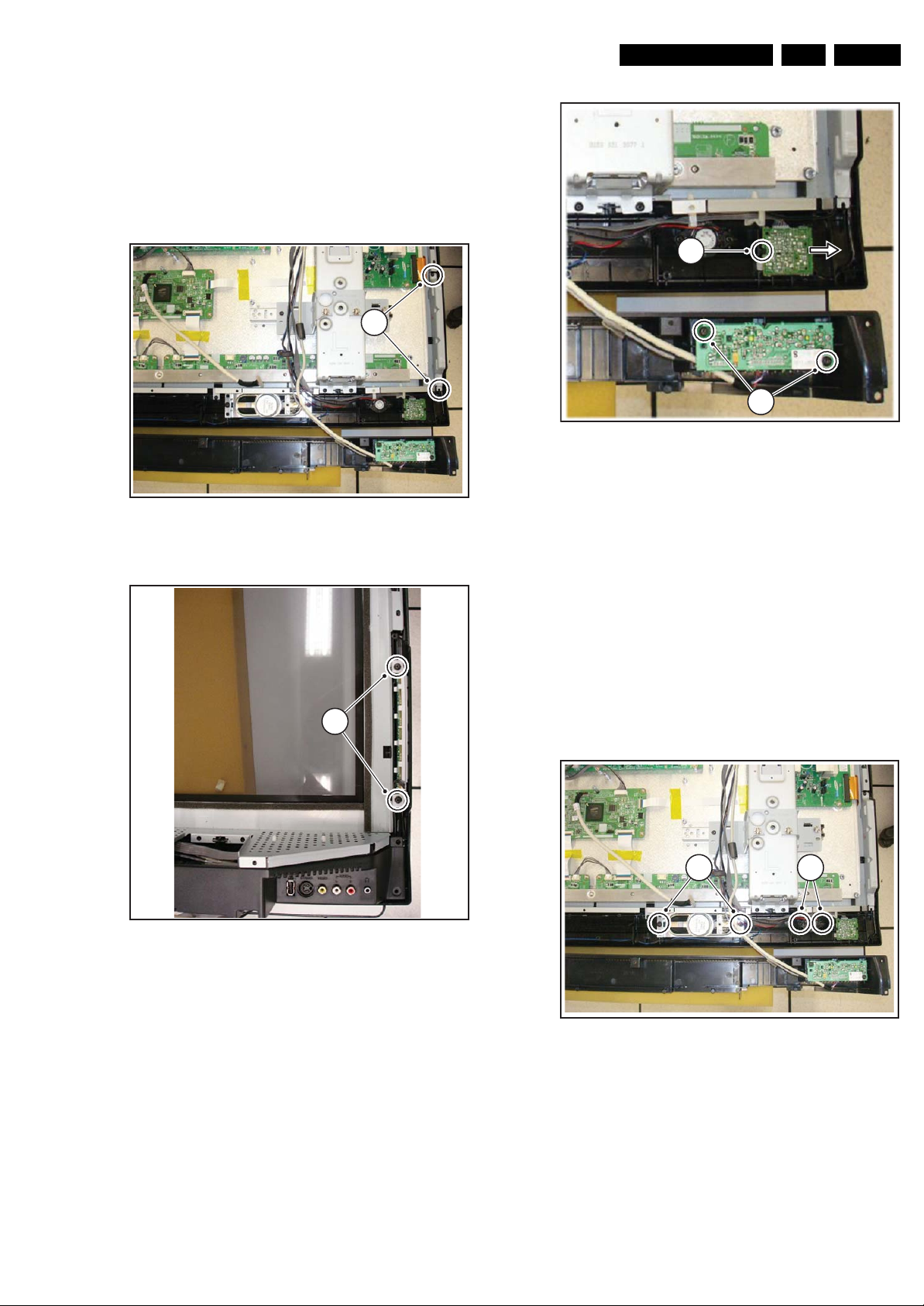

4.3 Assy/Panel Removal

4.3.1 Rear Cover

Warning: Disconnect the mains power cord before you remove

the rear cover.

1. Place the TV set upside down on a table top, using the

foam bars (see part “Service Positions”).

2. Remove the stand (if present).

3. Remove T10 Parker screws [1].

4. Remove T10 Tapping screws [2].

5. Remove “mushrooms” [3] and lift the rear cover.

1

1

3

1

1

1 1

1

1 1 1 1 1 1

1

2

1

3

1

1

E_06532_018.eps

171106

Figure 4-2 Foam bars

The foam bars (order code 3122 785 90580 for two pieces) can

be used for all types and sizes of Flat TVs. See figure “Foam

bars” for details. Sets with a display of 42” and larger, require

four foam bars [1]. Ensure that the foam bars are always

supporting the cabinet and never only the display.

Caution: Failure to follow these guidelines can seriously

damage the display!

By laying the TV face down on the (ESD protective) foam bars,

a stable situation is created to perform measurements and

alignments. By placing a mirror under the TV, you can monitor

the screen.

4.2.2 Aluminium Stands

Figure 4-4 Rear cover removal

4.3.2 Speaker Cover

1. Remove T10 Parker screws [1].

2. Twist [2] and lift the speaker cover as shown.

3. Now you have access to the speakers, Side I/O panel, IR/

LED panel.

1

2

H_17000_004.eps

2

H_17000_012.eps

260207

260207

E_06532_019.eps

170504

Figure 4-3 Aluminium stands (drawing of MkI)

The new MkII aluminium stands (not on drawing) with order

code 3122 785 90690, can also be used to do measurements,

alignments, and duration tests. The stands can be

(dis)mounted quick and easy by means of sliding them in/out

the "mushrooms" (not valid for all models!). The new stands are

backwards compatible with the earlier models.

Important: For (older) FTV sets without these "mushrooms", it

is obligatory to use the provided screws, otherwise it is possible

to damage the monitor inside!

Figure 4-5 Speaker cover removal

4.3.3 Keyboard Control Panel [E]

s

7

1. Refer to next fig. “Keyboard control panel“.

2. Remove the T10 Parker screws [1] from the shielding.

3. Remove the shielding.

4. Remove the T10 Parker screws [2] from the bracket.

5. Remove the unit.

6. Unplug connector(s).

When defective, replace the whole unit.

Mechanical Instructions

EN 9EJ3.0U PA 4.

2

1

1

H_17000_014.ep

28020

Figure 4-8 Side I/O and IR/LED panel

Figure 4-6 Keyboard control panel [1/2]

2

H_17000_010.eps

260207

H_17000_011.eps

260207

4.3.5 IR/LED Panel [J]

1. Remove the bottom “speaker cover”, as described earlier.

2. Refer to earlier fig. “Side I/O and IR/LED panel“.

3. Release clip [2] and remove the board.

4. Unplug connector(s).

When defective, replace the whole unit.

4.3.6 Speakers

1. Remove the bottom “speaker cover”, as described earlier.

2. Refer to fig. “Speakers“ below.

3. Unplug connectors.

4. Remove T10 Parker screws [1] and [2].

5. Take out the speaker(s).

1 2

Figure 4-7 Keyboard control panel [2/2]

4.3.4 Side I/O Panel [D]

1. Remove the bottom “speaker cover”, as described earlier.

2. Refer to next fig. “Side I/O and IR/LED panel“.

3. Remove T10 Parker screws [1] and take out the panel.

When defective, replace the whole unit.

Figure 4-9 Speakers

H_17000_013.eps

260207

EN 10 EJ3.0U PA4.

s

7

Mechanical Instructions

4.3.7 Power Supply Board

The PSU belongs to the PDP panel. Please refer to the PDP

repair manual for more info.

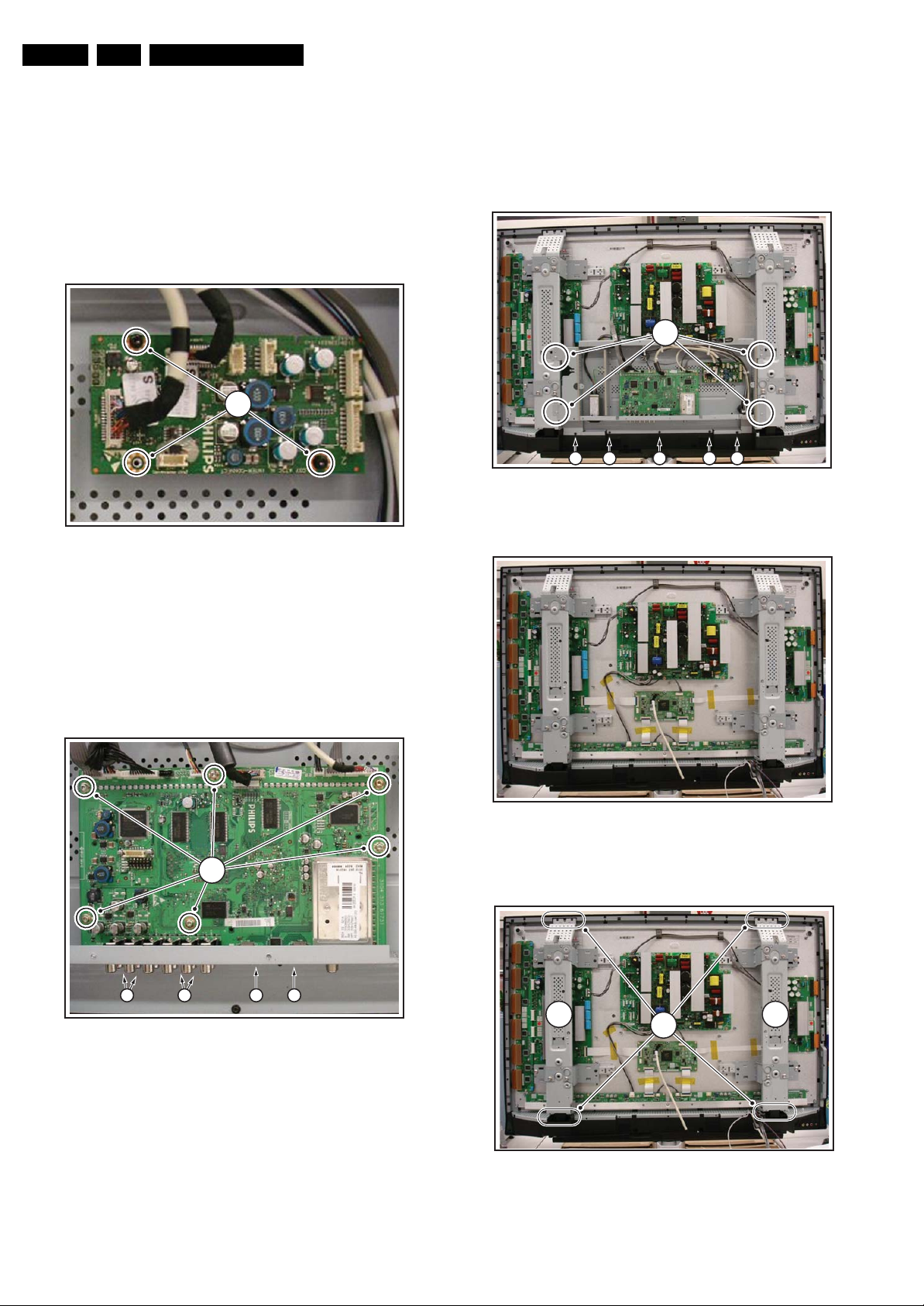

4.3.8 Interconnection Board [M]

1. Unplug all connectors. Carefully unplug the LVDS

connector as it is very fragile.

2. Remove the fixation screws [1].

3. Take out the panel.

1

H_17000_007.eps

260207

4. You now view the PDP boards, as shown in fig. “PDP panel

[2/3]“ below.

5. Remove fixation screws [3] and lift the complete PDP (incl.

the boards and wiring) by means of the mounting brackets

[4] from the set. Note: Remove these brackets [4] before

returning the defective PDP.

2

1 1 1 1 1

H_17000_008.eps

260207

Figure 4-12 PDP panel [1/3]

Figure 4-10 Interconnection board

4.3.9 Small Signal Board [B]

1. Unplug all connectors. Carefully unplug the LVDS

connector as it is very fragile.

2. Remove the fixation screws [1] from the connector plate.

3. Remove the fixation screws [2].

4. Take out the panel.

2

1 1

1 1

H_17000_006.eps

260207

Figure 4-13 PDP panel [2/3]

3

H_17000_009.eps

260207

44

Figure 4-11 Small Signal Board

4.3.10 PDP Panel

1. Refer to figures “PDP panel“ below.

2. Unplug all connectors to/from the panels inside the “SSB

tray”.

3. Remove T10 Tapping screws [1] and T10 Parker screws

[2], and remove the metal “SSB tray” (incl. panels) from the

set.

H_17000_015.ep

28020

Figure 4-14 PDP panel [3/3]

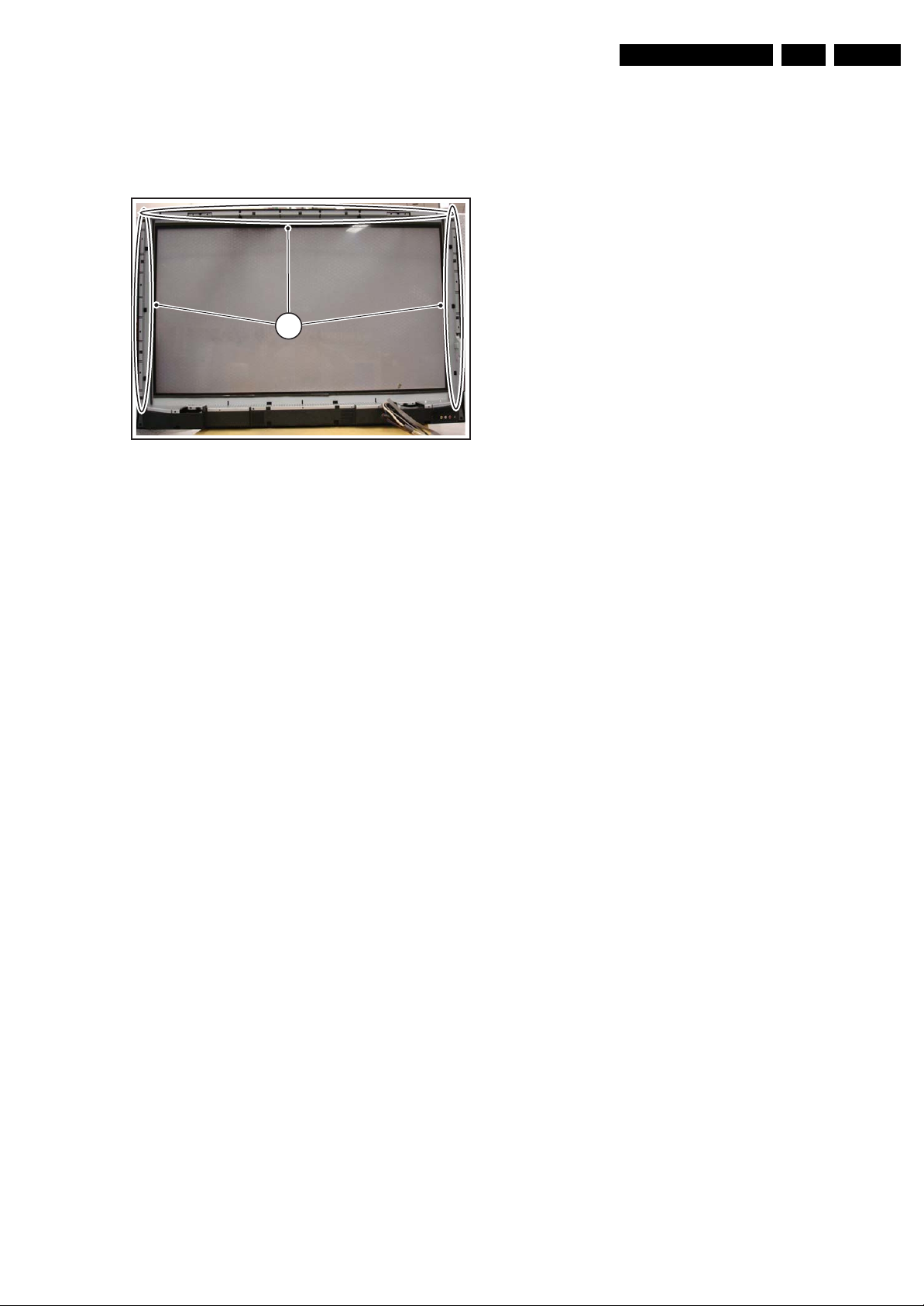

4.3.11 Glass Plate

1. Refer to figures “Glass plate“ below.

2. Remove T10 Parker screws [1] along the side of the glass

plate, and remove the metal fixation brackets.

3. Lift the glass plate form the set.

1

Figure 4-15 Glass plate

Mechanical Instructions

H_17000_016.eps

280207

EN 11EJ3.0U PA 4.

4.4 Set Re-assembly

To re-assemble the whole set, execute all processes in reverse

order.

Notes:

• While re-assembling, make sure that all cables are placed

and connected in their original position. See figure "Cable

dressing".

• Pay special attention not to damage the EMC foams.

Ensure that EMC foams are mounted correctly.

EN 12 EJ3.0U PA5.

Service Modes, Error Codes, and Fault Finding

5. Service Modes, Error Codes, and Fault Finding

Index of this chapter:

5.1 Test Points

5.2 Service Modes

5.3 Stepwise Start-up

5.4 Service Tools

5.5 Error Codes

5.6 The Blinking LED Procedure

5.7 Protections

5.8 Fault Finding and Repair Tips

5.9 Software Upgrading

5.1 Test Points

As most signals are digital, it will be almost impossible to

measure waveforms with a standard oscilloscope. Therefore,

waveforms are not given in this manual. Several key ICs are

capable of generating test patterns, which can be controlled via

ComPair. In this way it is possible to determine which part is

defective.

Perform measurements under the following conditions:

• Service Default Mode.

• Video: Color bar signal.

• Audio: 3 kHz left, 1 kHz right.

5.2 Service Modes

Service Default Mode (SDM) and Service Alignment Mode

(SAM) offer several features for the service technician, while

the Customer Service Mode (CSM) is used for communication

between a Customer Helpdesk and a customer.

There is also the option of using ComPair, a hardware interface

between a computer (see requirements below) and the TV

chassis. It offers the ability of structured troubleshooting, test

pattern generation, error code reading, software version

readout, and software upgrading.

Minimum requirements for ComPair: a Pentium processor,

Windows 95/98, and a CD-ROM drive (see also paragraph

“ComPair”).

Remark: as the Hotel Mode is a User Mode, rather than a

Service Mode, we have put the description in Chapter 3,

Directions for Use.

• Tuning frequency 61.25 MHz for NTSC: The TV shall tune

to physical channel 3 only if channel 3 is an analog channel

or if there is no channel 3 installed in the channel map. If

there is a digital channel installed in channel 3, then the

frequency to which the set will tune, would be as specified

in the channel map and could be different from the one

corresponding to the physical channel 3.

• All picture settings at 50% (brightness, color, contrast).

• All sound settings at 50%, except volume at 25%.

• All service-unfriendly modes (if present) are disabled, like:

– (Sleep) timer.

– Child/parental lock.

– Picture mute (blue mute or black mute).

– Automatic volume levelling (AVL).

– Auto switch "OFF" (when no video signal was received

for 10 minutes).

– Skip/blank of non-favorite pre-sets.

– Smart modes.

– Auto store of personal presets.

– Auto user menu time-out.

How to Activate SDM

Use one of the following methods:

• Use the standard RC-transmitter and key in the code

“062596”, directly followed by the “MENU” button.

Note: It is possible that, together with the SDM, the main

menu will appear. To switch it "OFF", push the “MENU”

button again.

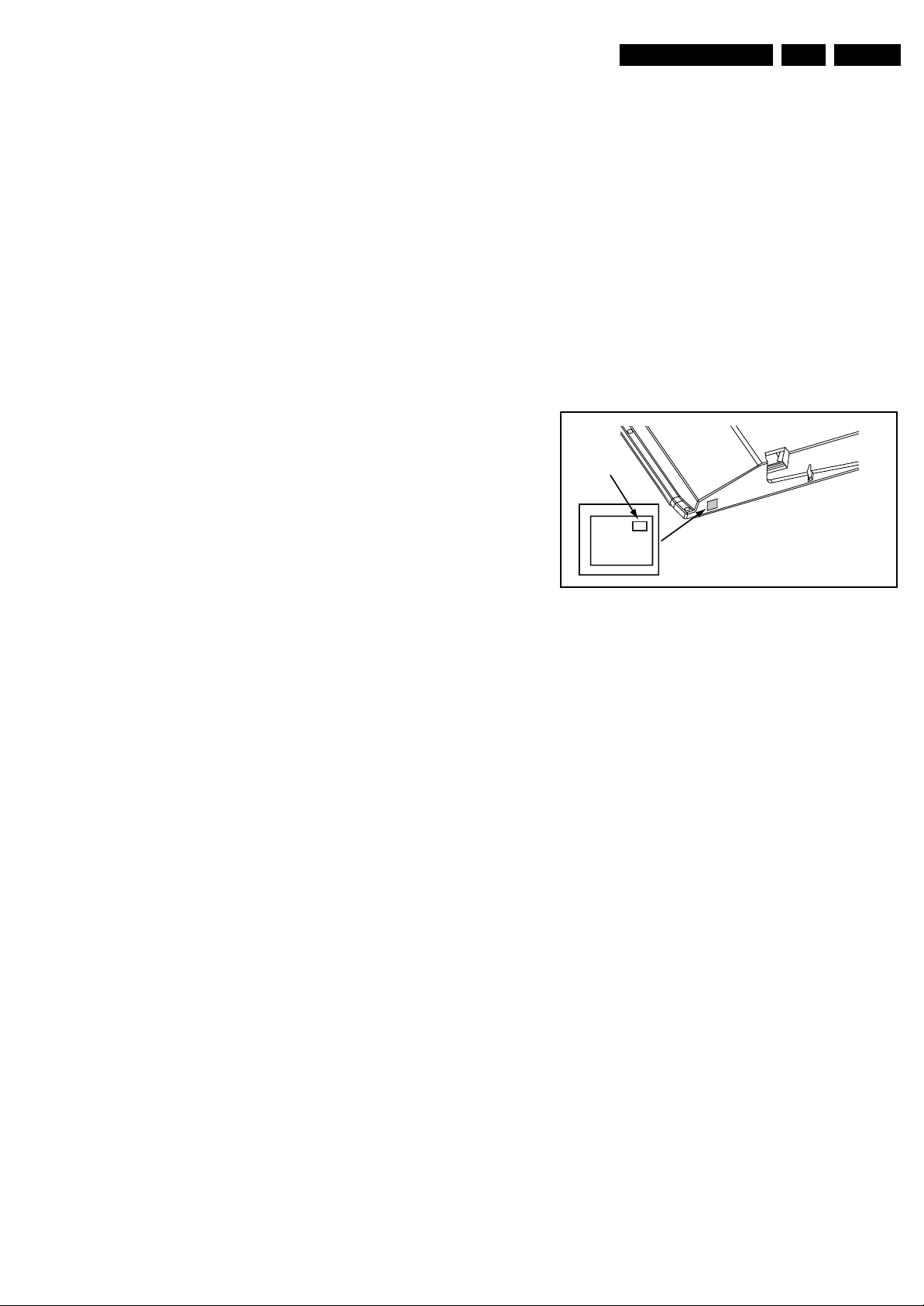

• Short for a moment the two solder pads [1] on the SSB,

with the indication “SDM”. They are located on top of the

SSB. Activation can be performed in all modes, except

when the set has a problem with the Stand-by Processor.

See figure “SDM and SPI service pads”.

12

SDMSPI

5.2.1 Service Default Mode (SDM)

Purpose

• To create a pre-defined setting, to get the same

measurement results as given in this manual.

• To override SW protections (only applicable for protections

detected by stand-by processor) and make the TV start up

to the step just before protection (a sort of automatic

stepwise start up). See paragraph “Stepwise Start Up”.

• To start the blinking LED procedure (not valid in protection

mode).

Specifications

Table 5-1 SDM default settings

Region Freq. (MHz)

Europe, AP-PAL/Multi 475.25 PAL B/G

NAFTA, AP-NTSC, LATAM 61.25 (ch. 3) NTSC M

Default

system

G_16840_014.eps

030107

Figure 5-1 SDM and SPI service pads

After activating this mode, “SDM” will appear in the upper right

corner of the screen (if you have picture).

How to Navigate

When you press the “MENU” button on the RC transmitter, the

set will toggle between the SDM and the normal user menu

(with the SDM mode still active in the background).

How to Exit SDM

Use one of the following methods:

• Switch the set to STAND-BY via the RC transmitter.

• Via a standard customer RC transmitter: key in “00”sequence.

Service Modes, Error Codes, and Fault Finding

EN 13EJ3.0U PA 5.

5.2.2 Service Alignment Mode (SAM)

Purpose

• To perform (software) alignments.

• To change option settings.

• To easily identify the used software version.

• To view operation hours.

• To display (or clear) the error code buffer.

How to Activate SAM

Via a standard RC transmitter: key in the code “062596”

directly followed by the “INFO” button. After activating SAM

with this method a service warning will appear on the screen,

you can continue by pressing the red button on the RC.

Contents of SAM:

• Hardware Info.

– A. VIPER SW Version. Displays the software version

of the VIPER software (main software) (example:

EJ30U_0.77.0.0 = AAAAB_X.Y.W.Z_NNNNN).

• AAAA= the chassis name.

• B= the region: A= AP, E= EU, L= Latam, U = US.

• X.Y.W.Z= the software version, where X is the

main version number (different numbers are not

compatible with one another) and Y is the sub

version number (a higher number is always

compatible with a lower number). The last two

digits are used for development reasons only, so

they will always be zero in official releases.

• NNNNN= last five digits of 12nc code of the

software.

– B. SBY PROC Version. Displays the software version

of the stand-by processor.

– C. Production Code. Displays the production code of

the TV, this is the serial number as printed on the back

of the TV set. Note that if an NVM is replaced or is

initialized after corruption, this production code has to

be re-written to NVM. ComPair will foresee in a

possibility to do this.

• Operation Hours. Displays the accumulated total of

operation hours (not the stand-by hours). Every time the

TV is switched "ON/OFF", 0.5 hours is added to this

number.

• Errors. (Followed by maximal 10 errors). The most recent

error is displayed at the upper left (for an error explanation

see paragraph “Error Codes”).

• Defective Module. Here the module that generates the

error is displayed. If there are multiple errors in the buffer,

which are not all generated by a single module, there is

probably another defect. It will then display the message

“UNKNOWN” here.

• Reset Error Buffer. When you press “cursor right” and

then the “OK” button, the error buffer is reset.

• Alignments. This will activate the “ALIGNMENTS” submenu.

• Dealer Options. Extra features for the dealers.

• Options. Extra features for Service.

• Initialize NVM. When an NVM was corrupted (or replaced)

in the former EMG based chassis, the microprocessor

replaces the content with default data (to assure that the

set can operate). However, all preferences and alignment

values are gone now, and option numbers are not correct.

Therefore, this was a very drastic way. In this chassis, the

procedure is implemented in another way: The moment the

processor recognizes a corrupted NVM, the “initialize

NVM” line will be highlighted. Now, you can do two things

(dependent of the service instructions at that moment):

– Save the content of the NVM via ComPair for

development analysis, before initializing. This will give

the Service department an extra possibility for

diagnosis (e.g. when Development asks for this).

– Initialize the NVM (same as in the past, however now it

happens conscious).

Note: When you have a corrupted NVM, or you have replaced

the NVM, there is a high possibility that you will not have picture

any more because your display option is not correct. So, before

you can initialize your NVM via the SAM, you need to have

picture and therefore you need the correct display option. To

adapt this option, you can use ComPair (the correct HEX

values for the options can be found in the table below) or a

method via a standard RC (described below).

Changing the display option via a standard RC:

Key in the code “062598” directly followed by the “MENU”

button and by “XXX” (where XXX is the 3 digit decimal display

option code as mentioned in the first column of the next table).

Make sure to key in all three digits, also the leading zero’s. If

the above action is successful, the front LED will go out as an

indication that the RC sequence was correct. After the display

option is changed in the NVM, the TV will go to the Stand-by

mode. If the NVM was corrupted or empty before this action, it

will be initialized first (loaded with default values). This

initializing can take up to 20 seconds.

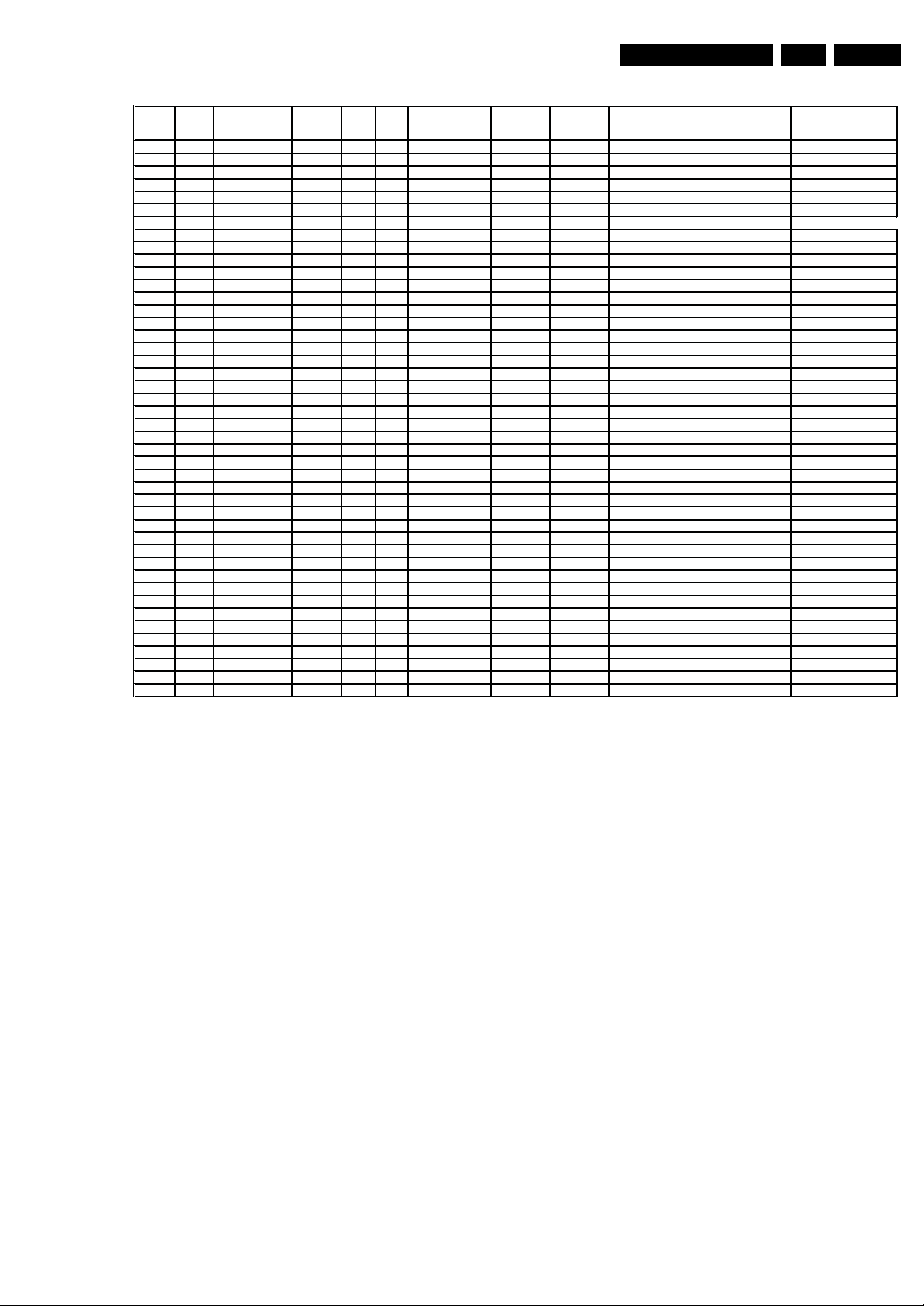

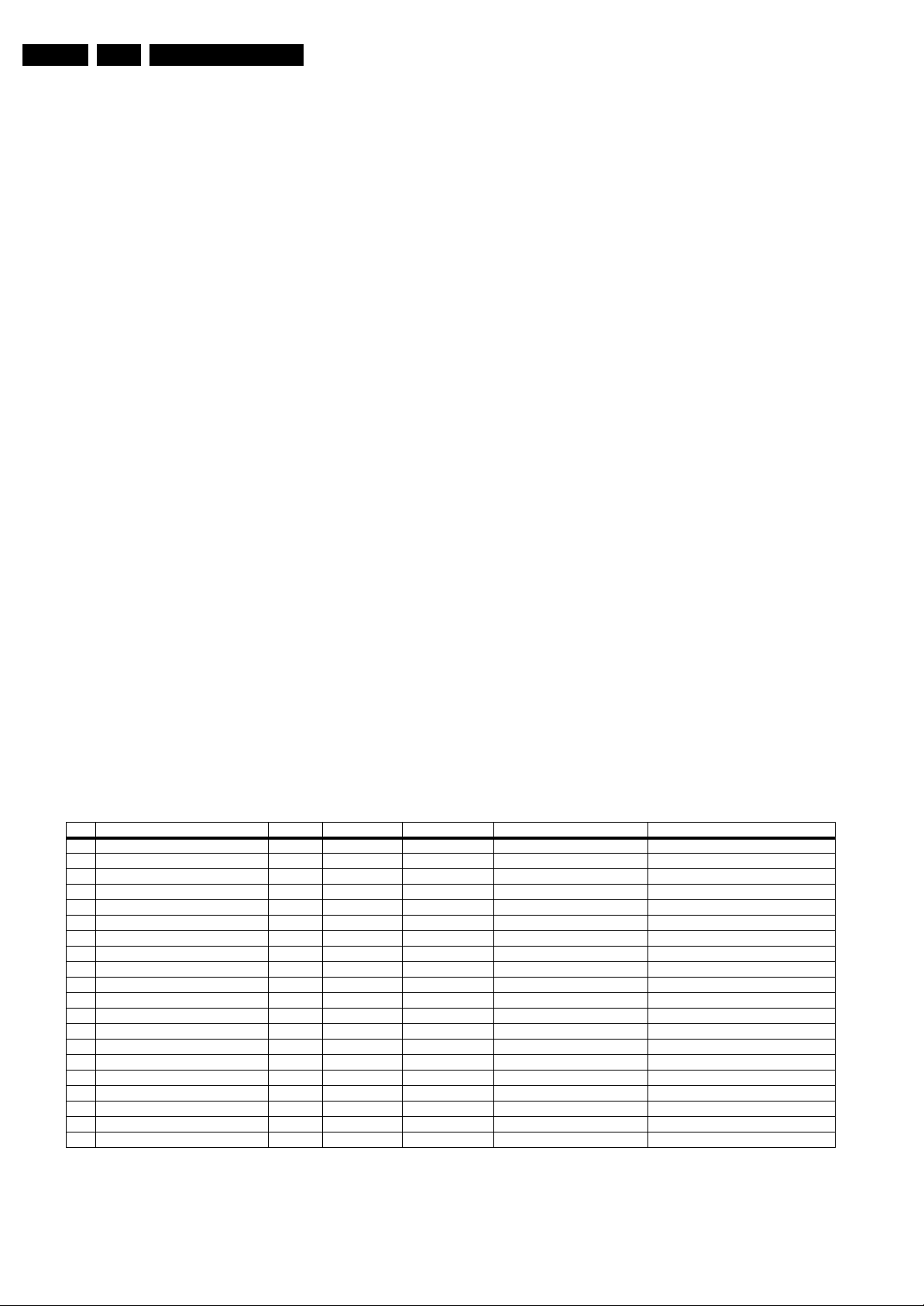

Display Option

Code

39mm

040

PHILIPS

MODEL:

32PF9968/10

27mm

PROD.SERIAL NO:

AG 1A0620 000001

(CTN Sticker)

E_06532_038.eps

290107

Figure 5-2 Location of Display Option Code sticker

EN 14 EJ3.0U PA5.

Display

option

000 00 PDP SDI 42 768p 1024

001 01 PDP SDI 50 768p 1366

002 02 PDP FHP 42 1024i 1024

003 03 LCD LPL 30 768p 1280 LC300W 01-A3P7 9322 198 00682

004 04 LCD LPL 37 768p 1366 LC370W01-A6 9322 220 87682

005 05 LCD LPL 42 768p 1366 LC420W02-A6 9322 226 39682

006 06 LCD Sharp 32 768p 1366 LQ315T3LZ13 (ASV1)

007 07 PDP SDI 42 480p 852

008 08 PDP FHP 37 1024i 1024

009 09 LCOS XION 720p 1280 n.a. n.a.

010 0A LCD AUO 30 768p 1280

011 0B LCD LPL 32 768p 1366 LC320W01-A6K1 9322 217 44682

012 0C LCD AUO 32 768p 1366 T315XW 01V5 9322 231 69682

013 0D LCD Sharp 37 768p 1366 LQ370T3LZ21 (ASV2)

014 0E LCD LPL 42 X 1080p 1920 LC420WU1-SL01 9322 228 99682

015 0F PDP SDI 37 480p 852

016 10 PDP FHP 37 1080i 1024

017 11 PDP FHP 42 1080i 1024

018 12 PDP FHP 55 768p 1366

019 13 LCOS VENUS 720p 1280 n.a. n.a.

020 14 LCOS VENUS X 1080p 1920 n.a. n.a.

021 15 LCD LPL 26 768p 1366 LC260WX2-SL01 9322 221 01682

022 16 LCD LPL 32 SC BL 768p 1366 LC320WX2-SL01

023 17 PDP LGE 42 480p 852

024 18 PDP SDI 42 480p 852

025 19 PDP SDI 42 768p 1024

026 1A PDP FHP 42 1024i 1024

027 1B PDP SDI 50 768p 1366

028 1C LCD Sharp 37 X 1080p 1920 LQ370D3LZ13 (ASV2.2) 9322 228 48682

029 1D LCD AUO 32 768p 1366 T315XW01-V3 not used

030 1E LCD Sharp 37 X BDI 1080p 1920 LW370D3LZ1x (ASV 3 first samples) not used

031 1F LCD Sharp 37 X BDI 1080p 1920 LK370D3LZ33 (ASV 3)

032 20 LCD LPL 20 768p 1366 LC200WX1-SL01 9322 222 90682

033 21 LCD QDI 23 768p 1366

034 22 ECO PTV 51 1080i 1366 ?

035 23 ECO PTV 55 1080i 1366 ?

036 24 ECO PTV 61 1080i 1366 ?

037 25 PDP FHP 42 1024I 1024

038 26 DLP 50 720p 1280 ?

039 27 DLP 60 720p 1280 ?

040 28 LCD Sharp 32 768p 1366 LK315T3LZ43 (ASV 2.3) 9322 235 32682

041 29 LCD LPL 42 SC BL 768p 1366 LC420WX2-SLA1 9322 240 80682

042 2A PDP SDI 63 768p 1366

043 2B LCD Sharp 37 BDI 768p 1366 LK370T3LZ63 (ASV 3)

044 2C LCD Sharp 37 768p 1366 LK370T3LZ53 (ASV 2.3)

045 2D LCD LPL 26 768p 1366 LC260W X2-SLB2 9322 234 13682

046 2E LCD LPL 32 768p 1366 LC320W01-SL06 9322 230 03682

047 2F LCD LPL 42 768p 1366 LC420W 02-SLB1 9322 234 12682

048 30 LCD QDI 26 768p 1366 QD26HL02-REV01

049 31 LCD AUO 26 768p 1366 T260XW02V4 9322 231 90682

050 32 LCD AUO 32 768p 1366 T315XW01V9 9322 231 89682

051 33 LCD AUO 37 768p 1366 T370XW01V1 9322 233 78682

052 34 LCD AUO 32 768p 1366 T315XW02V5 not used

053 35 LCD LPL 37 768p 1366 LC370WX1-SL04 9322 233 19682

054 36 PDP LGE 42 768p 1024

055 37 LCD LPL 42 X 1080p 1920

056 38 LCD LPL 47 X 1080p 1920

057 39 LCD LPL 42 768p 1366

058 3A LCD LPL 42 X SC BL 1080p 1920

059 3B

060 3C LCD Sharp 37 X DFI 1080p 1920

061 3D LCD LPL 42 DFI 768p 1366

062 3E LCD LPL 32 DFI 768p 1366

063 3F LCD LPL 47 X DFI 1080p 1920

Service Modes, Error Codes, and Fault Finding

HEX Display type Brand SIZE Full HDClear LCD Resolution

vertical

Resolution

horizontal

Type number 12 NC

S42AX-YD01(PP42AX-007A) 9322 225 38682

S50HW-XD03 9322 215 26682

FPF42C128128UC-52 (A1) 9322 212 78682

LQ315T3LZ23 (ASV2.2)(5Vtcon)

LQ315T3LZ23 (ASV2.2)(12Vtcon)

S42SD-YD05 (V3) 9322 215 27682

FPF37C128128UB-72 9322 217 56682

T296XW01

T296XW01V2

T296XW01V3

LQ370T3LZ44 (ASV2.2)

S37SD-YD02 9322 217 39682

not used not used

FPF42C128135UA-52 9322 235 43682

not used not used

not used not used

S42SD-YD07(PP42SD-015A) (V4)

S42SD-YD07(PP42SD-015B) (V4)

S42SD-YD07(PP42SD-015F) (V4)

S42AX-YD01(PP42AX-007A) (V4)

S42AX-YD01(PP42AX-008A) (V4)

S42AX-YD01(PP42AX-008B) (V4)

S42AX-YD02(PP42AX-009A) (W1)

S42AX-YD02 (PS-425-PHN) (W1)

FPF42C128128UD-51 (A2) not used

S50HW-XD04(PP50HW-005A) (V4)

S50HW-XD04(PP50HW-005B) (V4)

S50HW-XD04(PP50HW-005E) (V4)

S50HW-YD01(PP50HW -010A) (W1)

QD23HL02 REV01

QD23HL02 REV01(03)

FPF42C128135UA-52 (A3) 9322 235 43682

S63HW-XD05(1H341W) 9322 246 18682

QD26HL02-REV02

PDP42X3S000

PDP42X3V000

LC420WU2-SLA1 9322 246 84682

LC470WU1-SLC2 9322 248 50682

LC420WX3-SLA2

LC420WU5-SLA1

LK370D3LZXX

FMB reserved

WX5 SLB1

WCG

9322 209 35682

9322 226 58682

9322 226 16682

9322 206 49682

9322 219 45682

9322 213 33682

?

9322 241 46682

9322 226 37682

9322 226 96682

9322 233 81682

9322 225 38682

9322 226 95682

9322 233 80682

9322 240 08682

9322 242 85682

9322 226 54682

9322 226 97682

9322 233 79682

9322 240 25682

9322 242 22682

9322 223 91682

9322 232 69682

9322 247 94682

9322 235 83682

9322 227 29682

9322 235 05682

9322 245 29682

9322 246 93682

under development

under development

reserved

under development

under development

under development

E_06532_030a.eps

080207

Figure 5-3 Display option code overview [1/2] (for all Philips FTV chassis)

Service Modes, Error Codes, and Fault Finding

Display

HEX Display type Brand SIZE Full HDClear LCD Resolution

option

064 40

065 41

066 42 PDP SDI 63 x 1080p 1920

067 43 LCD AUO 26 768p 1366

068 44 LCD CMO 26 768p 1366

069 45 LCD CMO 32 768p 1366

070 46 LCD CPT 32 768p 1366

071 47 LCD LPL 37 768p 1366

072 48 LCD AUO 37 768p 1366

073 49 LCD LPL 42 768p 1366

074 4A LCD LPL 42 DFI 768p 1366

075 4B LCD Sharp 52 X DFI 1080p 1920

076 4C LCD AUO 42 768p 1366

077 4D LCD AUO 42 BDI 768p 1366

078 4E LCD AUO 42 X 1080P 1920

079 4F LCD CMO 42 BDI 768p 1366

080 50 LCD CMO 42 X 1080P 1920

081 51 LCD LPL 47 X 1080P 1920

082 52 LCD AUO 47 X 1080P 1920

083 53 PDP SDI 42 768p 1024

084 54 PDP LGE 42 768p 1024

085 55 PDP SDI 50 768p 1366

086 56 PDP LGE 50 768p 1366

087 57 LCD Sharp 37 X BDI 1080p 1920

088 58 LCD Sharp 37 BDI 768P 1366

089 59 LCD AUO 42 768p 1366

090 5A LCD AUO 26 768p 1366

091 5B LCD AUO 32 768P 1366

092 5C LCD LPL 42 768p 1366 LC420WX2-SLA1 9322 240 80682

093 5D LCD LPL 42 X 1080p 1920

094 5E PDP SDI 63 x 1080p 1920

095 5F LCD Sharp 37 X 1080p 1920

096 60 LCD LPL 42 X SC BL DFI 1080p 1920

097 61 LCD LPL 47 X SC BL 1080p 1920

098 62 LCD Sharp 52 X 1080p 1920

099 63

100 64 LCD 42 X 1080p 1920

101 65

102 66 LCD Sharp 32 DFI 768p 1366

103 67 LCD LPL 20 480p 640

104 68 LCD AUO 20 600p 800

105 69 LCD CMO 19 900p 1440

106 6A LCD AUO 23 768p 1366

107 6B LCD LPL 42 768P 1366

vertical

Resolution

horizontal

Type number 12 NC

reserved

reserved

S63HW-YD02 (W2)

T260XW03V1

V260B1-L03 9322 249 37682

V315B1 L05 9322 248 65682

CLLAA320WB02P

LC370WX1-SLB1 9322 246 96682

T370XW02V5 9322 249 77682

LC420WX3-SLA1 9322 246 97682

LC420WX4-SLA1

LK520D3LZ1X under development

T420XW01V8 9322 249 10682

T420XW

T420HW01 V0

V420B1

V420H1

LC470WU4-SLA2

T470HW01 V0

S42AX-YD04(PS-426-PH) 9322 246 76682

HD X4

S50HW-YD05(PS-506-PH) 9322 246 81682

HD X4

LK370D3LZ43 (ASV3.0) 9322 248 28682

(ASV2,3 VE1)

T420XW01V5

T260XW03V1

T315XW02VD 9322 249 06682

LC420WU2-SLA1 9322 246 84682

S63HW-YD02 (W2) used with JIP panel

LK370D3LZ23 9322 249 96682

TBD

LC470WU6 - SLA1 under development

LK520D3LZ1X

3D

LK315T3LZ53 under developm ent

LC201V02-SDB1

A201SN02 V5

TPM190A1-L02 9965 000 43654

T230XW01V3

LC420WX5-SLD1

under development

under development

9322 245 31682

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

under development

reserved

under development

reserved

9322 242 65682

not in ECM2

9322 249 79682

9322 249 09682

E_06532_030b.eps

EN 15EJ3.0U PA 5.

080207

Figure 5-4 Display option code overview [2/2] (for all Philips FTV chassis)

• Store. All options and alignments are stored when

pressing “cursor right” and then the “OK” button

• SW Maintenance.

– SW Events. Not useful for service purposes. In case of

specific software problems, the development

department can ask for this info.

– HW Events. Not functional at the moment this manual

is released, description will be published in an update

manual if the function becomes available.

• Upload to USB. Write the channel list and the settings to

a USB device.

• Download from USB. Retrieve the channel list and the

settings from a USB device.

How to Navigate

• In SAM, you can select the menu items with the “CURSOR

UP/DOWN” key on the RC transmitter. The selected item

will be highlighted. When not all menu items fit on the

screen, move the “CURSOR UP/DOWN” key to display the

next/previous menu items.

• With the “CURSOR LEFT/RIGHT” keys, it is possible to:

– (De)activate the selected menu item.

– (De)activate the selected submenu.

How to Exit SAM

Use one of the following methods:

• Press the “MENU” button on the RC transmitter.

• Switch the set to STAND-BY via the RC transmitter.

Note: As long as SAM is activated, it is not possible to change

a channel. This could hamper the White Point alignments

because you cannot choose your channel/frequency any more.

Workaround: after you have sent the RC code “062596 INFO”

you will see the service-warning screen, and in this stage it is

still possible to change the channel (so before pressing the

“OK” button).

EN 16 EJ3.0U PA5.

Service Modes, Error Codes, and Fault Finding

5.2.3 Customer Service Mode (CSM)

Purpose

When a customer is having problems with his TV-set, he can

call his dealer or the Customer Helpdesk. The service

technician can then ask the customer to activate the CSM, in

order to identify the status of the set. Now, the service

technician can judge the severity of the complaint. In many

cases, he can advise the customer how to solve the problem,

or he can decide if it is necessary to visit the customer.

The CSM is a read only mode; therefore, modifications in this

mode are not possible.

How to Activate CSM

Key in the code “123654” via the standard RC transmitter.

Note: Activation of the CSM is only possible if there is no (user)

menu on the screen!

How to Navigate

By means of the “CURSOR-DOWN/UP” knob on the RC

transmitter, you can navigate through the menus.

Contents of CSM

• CSM 1

– 1.3. Set type: Model number of the set. This

information is very helpful for a helpdesk/workshop as

reference for further diagnosis. In this way, it is not

necessary for the customer to look at the rear of the

TV-set. (*)

– 1.4. Production Code: Displays the production code

(the serial number) of the TV. (*)

– 1.5. Code 1: Gives the latest five errors of the error

buffer. As soon as the built-in diagnose software has

detected an error, the buffer is adapted. The last

occurred error is displayed on the leftmost position.

Each error code is displayed as a 2-digit number.

When less than 10 errors occur, the rest of the buffer is

empty (00). See also paragraph Error Codes for a

description.

– 1.6. Code 2: Displays the 2nd part of the error buffer.

See also paragraph Error Codes for a description.

– 1.7. Options 1: Gives the option codes of option group

1 as set in SAM (Service Alignment Mode).

– 1.8. Options 2: Gives the option codes of option group

2 as set in SAM (Service Alignment Mode).

– 1.13. 12NC SSB: Indication of the SSB order code. (*)

– 1.13. Install date: This shall be filled in after time

extraction (triggered by disabling of virgin mode, so

first time customer does channel installation). Time

extraction is done via, teletext for Europe, PBS Public

Broadcast Channels for US. This, to determine exactly

the guaranty period for call centers.

• CSM 2:

– 2.2. Pixel Plus: Gives an indication if PixelPlus is set

“ON” or “OFF”.

– 2.4. DNR. Gives the selected DNR setting (Dynamic

Noise Reduction), “OFF”, “MINIMUM”, “MEDIUM”, or

“MAXIMUM”. Change via “MENU”, “TV”, “PICTURE”,

“DNR”

– 2.5. Noise Figure. Gives the noise ratio for the

selected transmitter. This value can vary from 0 (good

signal) to 127 (average signal) and to 255 (bad signal).

For some software versions, the noise figure will only

be valid when “Active Control” is set to “medium” or

“maximum” before activating CSM.

• CSM 3:

– 3.1. Headphone Volume: Gives the last status of the

headphone volume, as set by the customer. The value

can vary from 0 (volume is minimum) to 100 (volume is

maximum). Change via ”MENU”, “TV”, “SOUND”,

“HEADPHONE VOLUME”.

– 3.2. Dolby: Indicates whether the received transmitter

transmits Dolby sound (“ON”) or not (“OFF”). Attention:

The presence of Dolby can only be tested by the

software on the Dolby Signaling bit. If a Dolby

transmission is received without a Dolby Signaling bit,

this indicator will show “OFF” even though a Dolby

transmission is received.

– 3.3. Surround Mode: Indicates the by the customer

selected sound mode (or automatically chosen mode).

Possible values are “STEREO” and “VIRTUAL DOLBY

SURROUND”. Change via “MENU”, “TV”, “SOUND”,

“SOUND MODE”. It can also have been selected

automatically by signaling bits (internal software).

– 3.4. Center Input: Not applicable.

– 3.5. Audio System: Gives information about the

audible audio system. Possible values are “Stereo”,

”Mono”, “Mono selected”, “Analog In: No Dig. Audio”,

“Dolby Digital 1+1”, “Dolby Digital 1/0”, “Dolby Digital 2/

0”, “Dolby Digital 2/1”, “Dolby Digital 2/2”, “Dolby Digital

3/0”, “Dolby Digital 3/1”, “Dolby Digital 3/2”, “Dolby

Digital Dual I”, “Dolby Digital Dual II”, “MPEG 1+1”,

“MPEG 1/0”, “MPEG 2/0”. This is the same info as you

will see when pressing the “INFO” button in normal

user mode (item “signal”). In case of ATSC receiving

there will be no info displayed.

– 3.6. AVL: Indicates the last status of AVL (Automatic

Volume Level): “ON” or “OFF”. Change via “MENU”,

“TV”, “SOUND”, “AVL”. AVL can not be set in case of

digital audio reception (e.g. Dolby Digital or AC3)

– 3.7. Delta Volume: Indicates the last status of the

delta volume for the selected preset as set by the

customer: from “-12” to “+12”. Change via “MENU”,

“TV”, “SOUND”, “DELTA VOLUME”.

• CSM 4:

– 4.1. Preset Lock. Indicates if the selected preset has

a child lock: “LOCKED” or “UNLOCKED”. Change via

“MENU”, “TV”, “CHANNELS”, “CHANNEL LOCK”.

– 4.3. Lock After: Indicates at what time the channel

lock is set: “OFF” or e.g. “18:45” (lock time). Change

“MENU”, “TV”, “CHANNELS”, “LOCK AFTER”.

– 4.6. TV Ratings Lock: Indicates the “TV ratings lock”

as set by the customer. Change via “MENU”, “TV”,

“CHANNELS”, “TV RATINGS LOCK”. Possible values

are: “ALL”, “NONE”, “TV-Y”, “TV-Y7”, “TV-G”, “TV-PG”,

“TV-14” and “TV-MA”.

– 4.7. Movie Ratings Lock: Indicates the “Movie ratings

lock” as set by the customer. Change via “MENU”,

“TV”, “CHANNELS”, “MOVIE RATINGS LOCK”.

Possible values are: “ALL”, “NR”, “G”, “PG”, “PG-13”,

“R”, “NC-17” and “X”.

– 4.8. V-Chip TV Status: Indicates the setting of the V-

chip as applied by the selected TV channel. Same

values can be shown as for “TV RATINGS LOCK”.

– 4.9. V-Chip Movie Status: Indicates the setting of the

V-chip as applied by the selected TV channel. Same

values can be shown as for “MOVIE RATINGS LOCK”.

– 4.10. Region rating Status (RRT): OFF.

• CSM 5:

– 5.1. On timer: “OFF” or “ON”.

– 5.2. Location: Gives the last status of the location

setting as set via the installation menu. Possible values

are “Shop” and “Home”. If the location is set to “Shop”,

several settings are fixed. So for a customer, location

must be set to “Home”. Can be changed via the

installation menu (see also DFU).

• CSM 6:

– 6.1. HDMI key validity: Indicates the key’s validity.

– 6.2. IEEE key validity: Indicates the key’s validity (if

applicable).

– 6.3. POD key validity: Indicates the key’s validity (if

applicable).

Service Modes, Error Codes, and Fault Finding

EN 17EJ3.0U PA 5.

• CSM 7:

– 7.2. TV System: Gives information about the video

system of the selected transmitter.

a. M: NTSC M signal received.

b. ATSC: ATSC signal received.

– 7.3. Source: Indicates which source is used and the

video/audio signal quality of the selected source.

(Example: Tuner, Video/NICAM) Source: “TUNER”,

“AV1”, “AV2”, “AV3”, “HDMI 1”, “SIDE”. Video signal

quality: “VIDEO”, “S-VIDEO”, “RGB 1FH”, “YPBPR

1FH 480P”, “YPBPR 1FH 576P”, “YPBPR 1FH 1080I”,

“YPBPR 2FH 480P”, “YPBPR 2FH 576P”, “YPBPR

2FH 1080I”, “RGB 2FH 480P”, “RGB 2FH 576P” or

“RGB 2FH 1080I”. Audio signal quality: “STEREO”,

“SPDIF 1”, “SPDIF 2”, or “SPDIF”.

– 7.4. Tuned Bit: Indicates if the selected preset is

automatically tuned (via “Automatic Installation” in the

setup menu) or via the automatic tuning system of the

TV. In this case “Tuned bit” will show “YES”. If the TV

was not able to auto-tune to the correct frequency, this

item will show “NO”. So if “NO” is displayed, it could

indicate that the customer has manually tuned to a

frequency which was too far from a correct frequency,

that the TV was not able to auto-tune any more.

– 7.6. Digital Signal Modulation: Indicates quality of

the received digital signal (0 = low).

• CSM 8:

– 8.1. 12NC one zip SW: Displays the 12NC number of

the one-zip file as it is used for programming software

in production. In this one-zip file all below software

version can be found.

– 8.2. Initial Main SW: Displays the main software

version which was initially loaded by the factory.

– 8.3. Current Main SW: Displays the built-in main

software version. In case of field problems related to

software, software can be upgraded. As this software

is consumer upgradeable, it will also be published on

the Internet. E.g. EJ30U_0.77.0.0.

– 8.5. Flash Utils SW: Displays the software version of

the software which contains all necessary components

of the download application. To program this software,

EJTAG tooling is needed.E.g. EJ30U_0.77.0.0.

– 8.6. Standby SW: Displays the built-in stand-by

processor software version. Upgrading this software

will be possible via ComPair or via USB.(see chapter

Software upgrade). E.g. STDBY_3.0.1.37.

– 8.7. MOP SW: Displays the MOP software version.

E.g. RXS3E_2.3.0.0.

– 8.8. Pacific 3 Flash SW: Displays the Pacific 3

software version. E.g. P3FW0_1.6.2.0

– 8.11. NVM version: Displays the NVM version as

programmed by factory. E.g. EJ30U_0.0.0.4

How to Exit CSM

Press any key on the RC transmitter (with exception of the

“CHANNEL +/-”, “VOLUME”, “MUTE” and digit (0-9) keys).

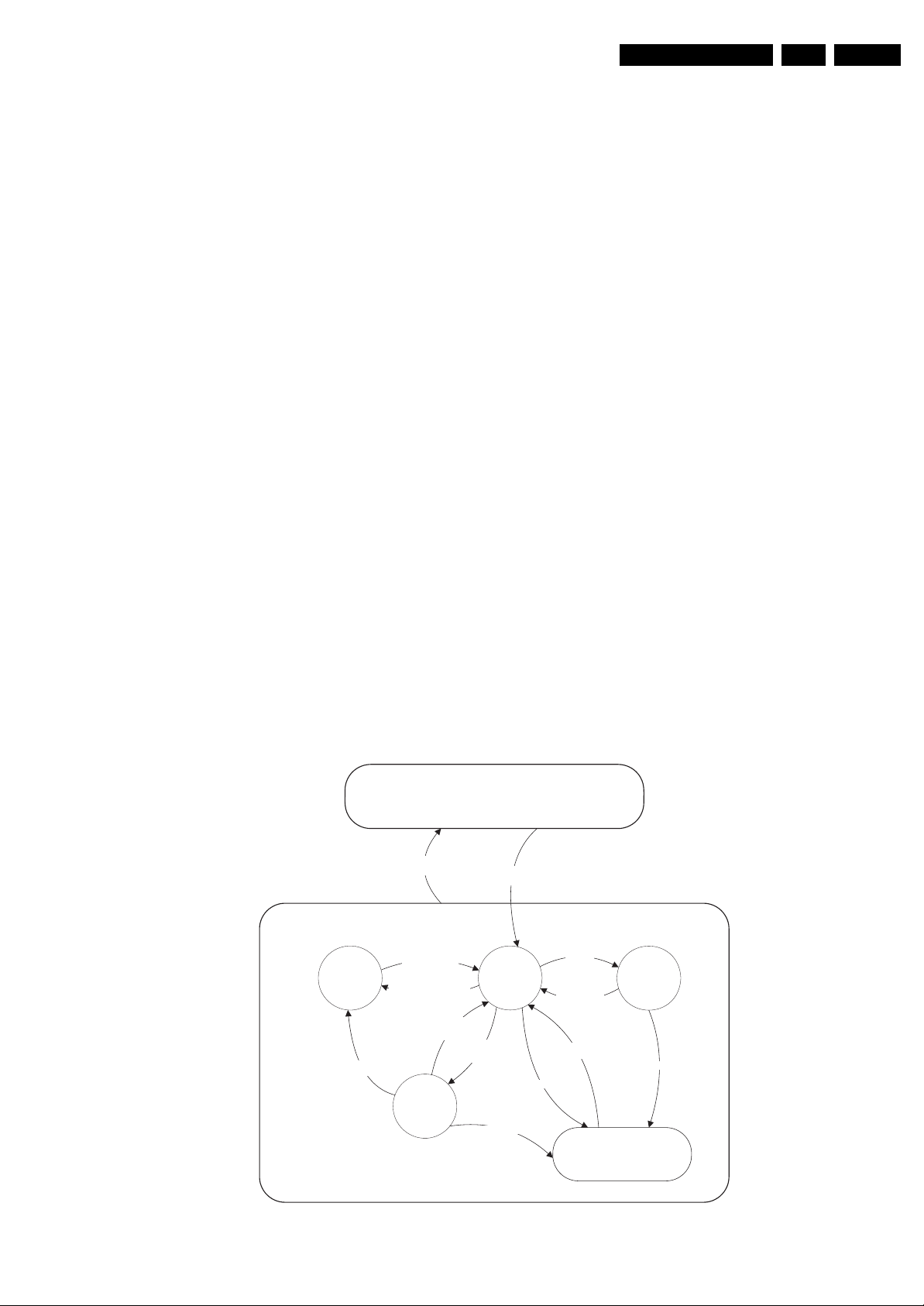

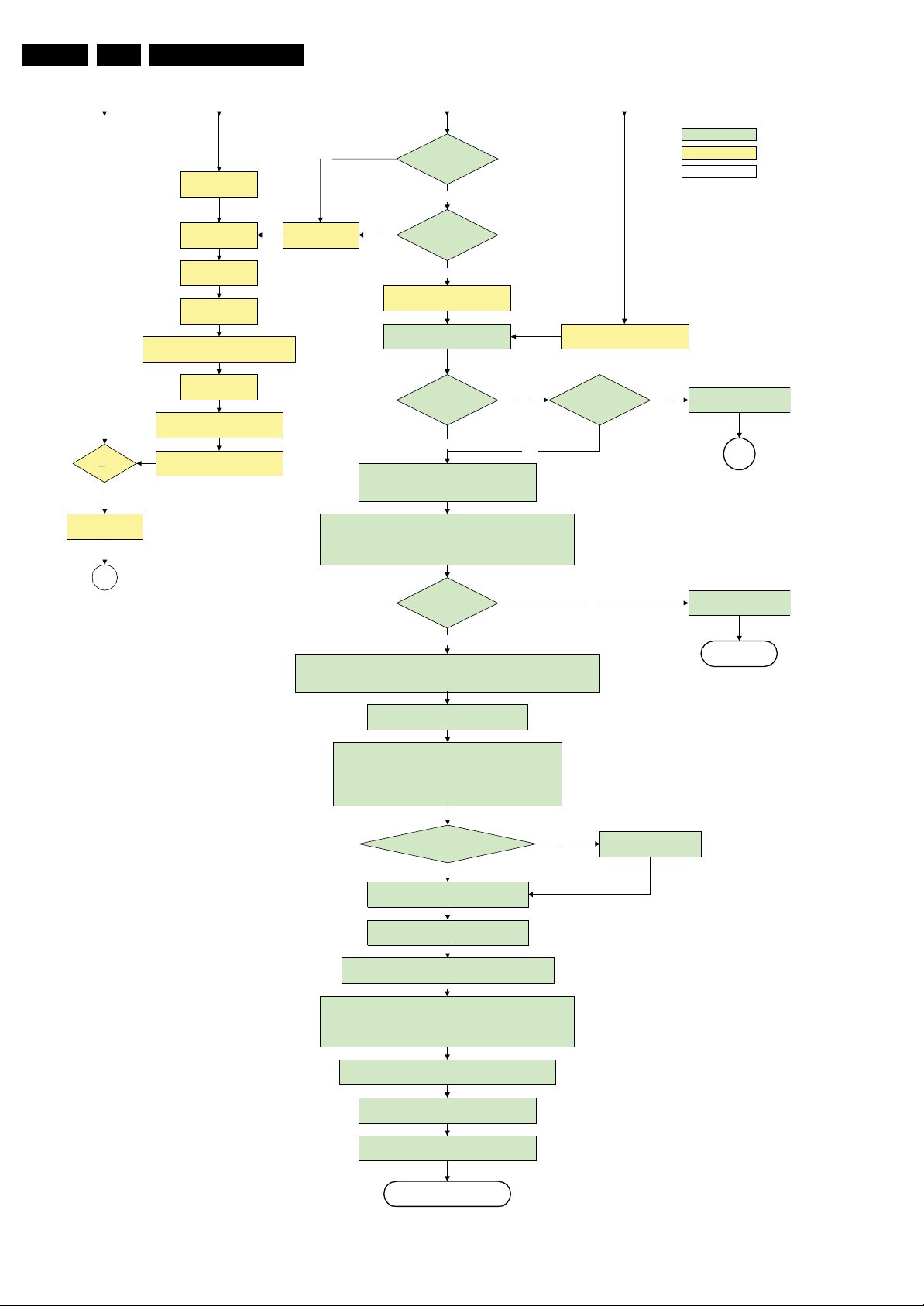

5.3 Stepwise Start-up

When the TV is in a protection state detected via the Stand-by

Processor (and thus blinking an error) and SDM is activated via

short cutting the pins on the SSB, the TV starts up until it

reaches the situation just before protection. So, this is a kind of

automatic stepwise start-up. In combination with the start-up

diagrams below, you can see which supplies are present at a

certain moment.

Important to know here is, that if e.g. the 3V3 detection fails

(and thus error 11 is blinking) and the TV is restarted via SDM,

the Stand-by Processor will enable the 3V3, but will not go to

Stand-by

(Off St-by)

- POD Card remove

- Tact SW pushed

Mains

“off”

- WakeUp requested

- Acquisition needed

- No data Acquisition required

and no POD present

- Tact SW pushed

- WakeUp requested

- Acquisition needed

d

POD

*

Stand-by

Off

Semi

Stand-by

No data Acquisition

required and

POD present

GoToProtec

Mains

“on”

protection now. The TV will stay in this situation until it is reset

(Mains/AC Power supply interrupted).

The abbreviations “SP” and “MP” in the figures stand for:

• SP: protection or error detected by the Stand-by

Processor.

• MP: protection or error detected by the VIPER Main

Processor.

WakeUp

requested

Active

- St-by requested

- Tact SW pushed

WakeUp

requested

GoToProtection

tion

GoToProtection

On

Only applicable for sets with CableCARDTM slot (POD)

*

Figure 5-5 Transition diagram

Protection

F_15400_095.eps

020206

EN 18 EJ3.0U PA5.

Service Modes, Error Codes, and Fault Finding

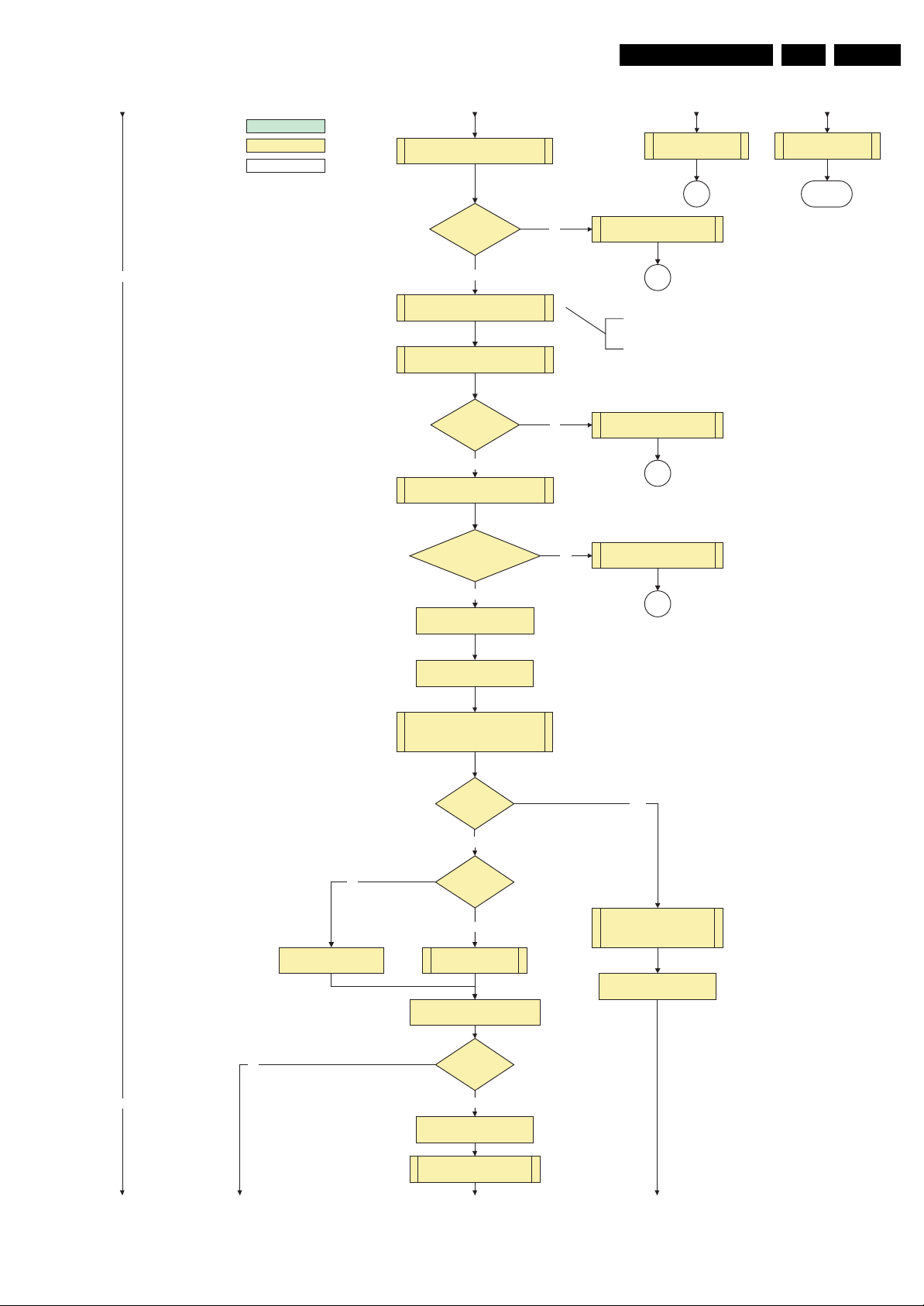

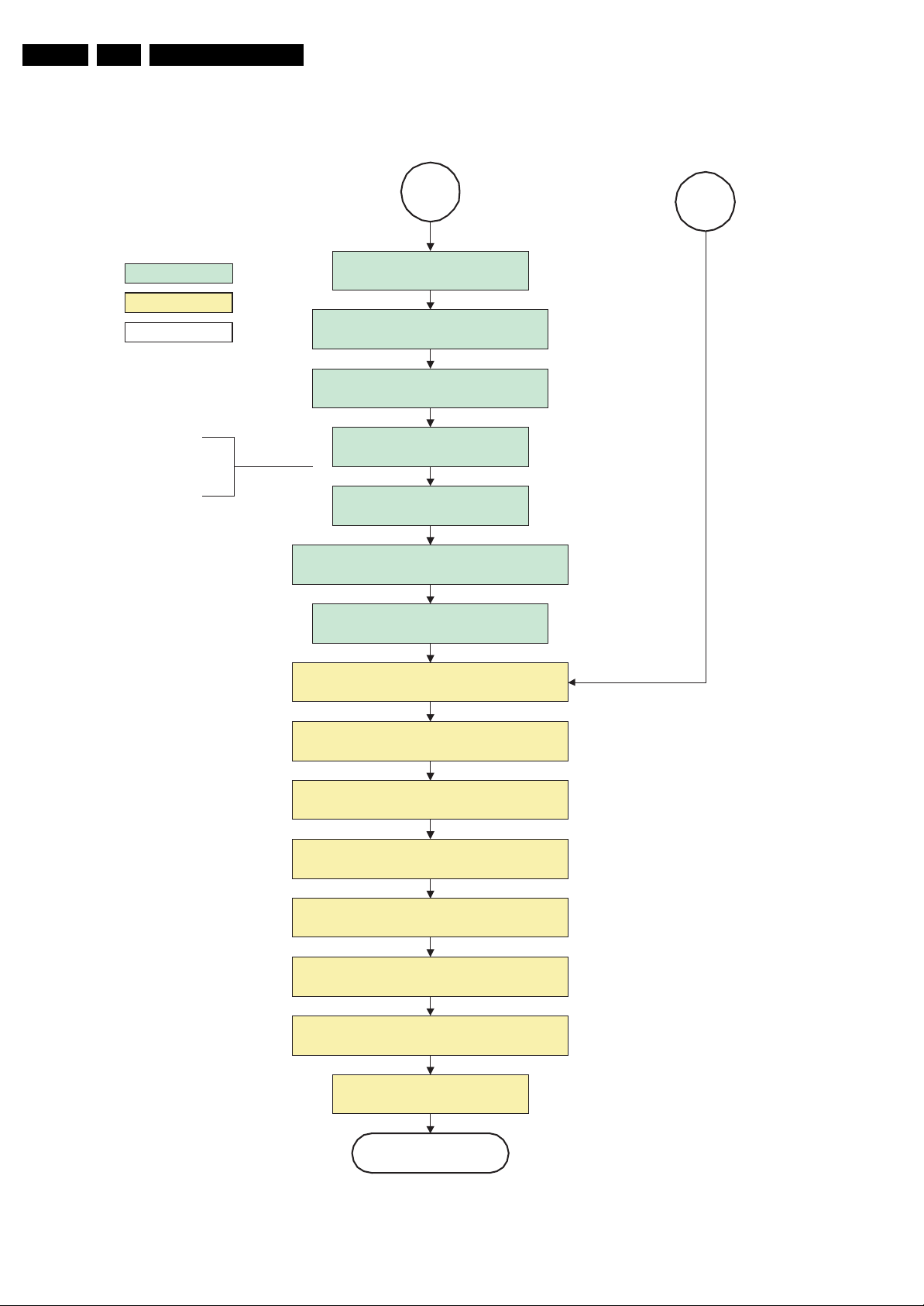

action holder: MIPS

action holder: St-by

autonomous action

The audio protection circuit shuts down the supply

autonomously. This triggers a set restart and during that restart

(so at this check here), it will be observed that the audio

protection line is high and the audio protection mode is entered.

This condition is not valid for an SDI PDP. In this PDP set, the

audio protection latch is not present and hence the HIGH

condition here will never be observed. As a result, when an

audio protection occurs, the set will restart and will enter a

supply protection mode because of a missing power supply.

Switching on the power supply in an LPL scanning

backlight set, also switches on the backlight supply.

The display should not be used the first 5 seconds

the backlight supply is running due to a pre-heat time

of 4s and a 100% light output (not adjustable) the next

second. This 5 second delay does not delay the startup

of the display as this time is absorbed in the startup time

of the rest of the system.

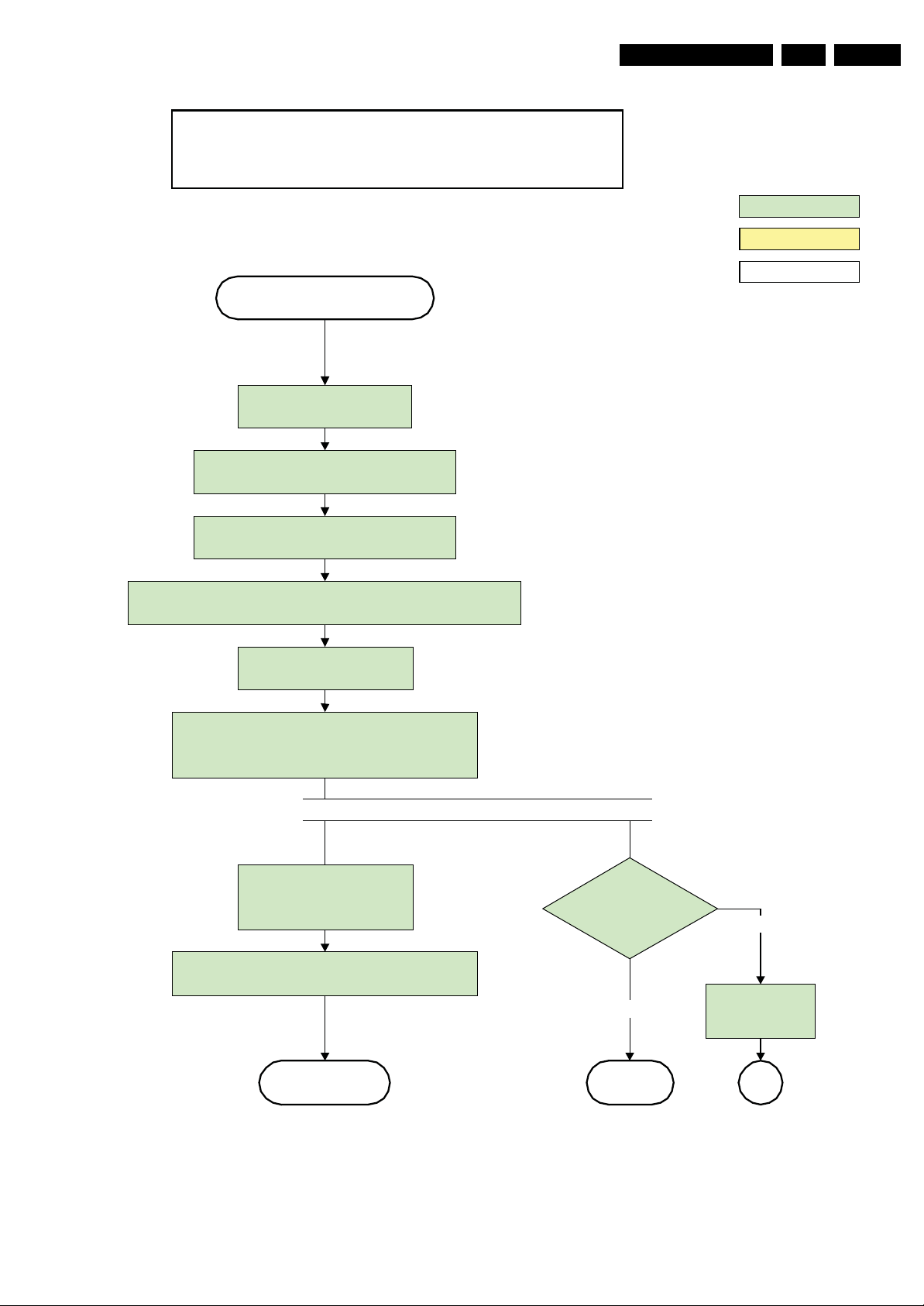

Off

Mains is applied

Standby Supply starts running.

+5V2, 1V2Stb, 3V3Stb and +2V5D become present.

In case of PDP 3V3 Vpr to CPU PDP becomes present.

st-by µP resets

All I/O lines have a High default state:

- Sound-Enable and Reset-Audio should remain high.

- NVM power line is high, no NVM communication possible.

Initialise I/O pins of the st-by µP, start keyboard scanning, RC

PDPGO line is high (either HW wise in a non FHP set or

because of the stby µP reset in a FHP set) which is the good

Switch LOW the NVM power reset line. Add a 2ms delay

before trying to address the NVM to allow correct NVM

Switch ON all supplies by switching LOW the POD-MODE

+5V, +8V6, +12VS, +12VSW and Vsound are switched on

- Assert the Viper reset.

detection, P50 decoding. Wake up reasons are off.

state at cold boot to be able to start the FHP.

Audio Protection Line

HIGH?

No

initialization.

and the ON-MODE I/O lines.

Wait 50ms and then start polling the detect-

5V, detect-8V6 and detect-12V every 40ms.

Stand by or

Protection

If the protection state was left by short circuiting the

SDM pins, detection of a protection condition during

startup will stall the startup. Protection conditions in a

playing set will be ignored. The protection mode will

- Switch Sound-Enable and Reset-Audio high.

not be entered.

They are low in the standby mode if the

standby mode lasted longer than 10s.

Yes

Audio Er ror

SP

Switching the POD-MODE

low in an FHP PDP set

makes the CPUGO go high

and starts the PDP CPU.

The availability of the supplies is checked through detect signals (delivered by

dedicated detect-IC's) going to the st-by µP. These signals are available for

+12V, +8V6, +5V, +1V2 and +2V5. A low to high transition of the signals should

occur within a certain time after toggling the standby line. If an observers is

detected before the time-out elapses, of course, the process should continue in

order to minimize start up time.

Switching the POD-MODE and the

ON-mode low in an SDI PDP set

makes the PDP supplies go to th e

ON mode.

No

- Only when the PDPGO is low, a retry should be

considered (the PDP could have reset internally). If

the PDPGO is already high, there is no use in trying

to restart.

- PDPGO line is pulled high in all non FHP sets so

this extra startup delay in case of a fault condition

is not valid.

- Switching the PDPGO high will give a visual

artefact and should only be done if really

necessary.

detect-5V

received within 2900 ms after

POD-MODE I/O line

toggle?

Yes

activate +5V supply detection algorithm

No

Yes

PDPGO

=

Hig h?

No

Switch PDPGO high:

PDP should start: 5V, 8V6 and

12V are activated

detect-5V

received within

2900 ms after PDPGO

toggle?

Yes

No

+5V erro r

SP

detect-12VSW received within

2900 ms after POD-mode I/O

line toggle?

Yes

activate +12VSW supply

detection algorithm

No need to wait for the 8V6 detection at this point.

Enable the +1V2 supply (ENABLE-1V2)

To part BTo part B To part B To part B

No

+12V error

SP

detect-8V6 rece ived

within 6300 ms after POD-mode I/O line

toggle? Startup shall not wait for this

detection and continue startup.

No

Yes

G_15960_118a.eps

200406

Figure 5-6 “OFF” to “Semi Stand-by” flowchart (part 1)

Service Modes, Error Codes, and Fault Finding

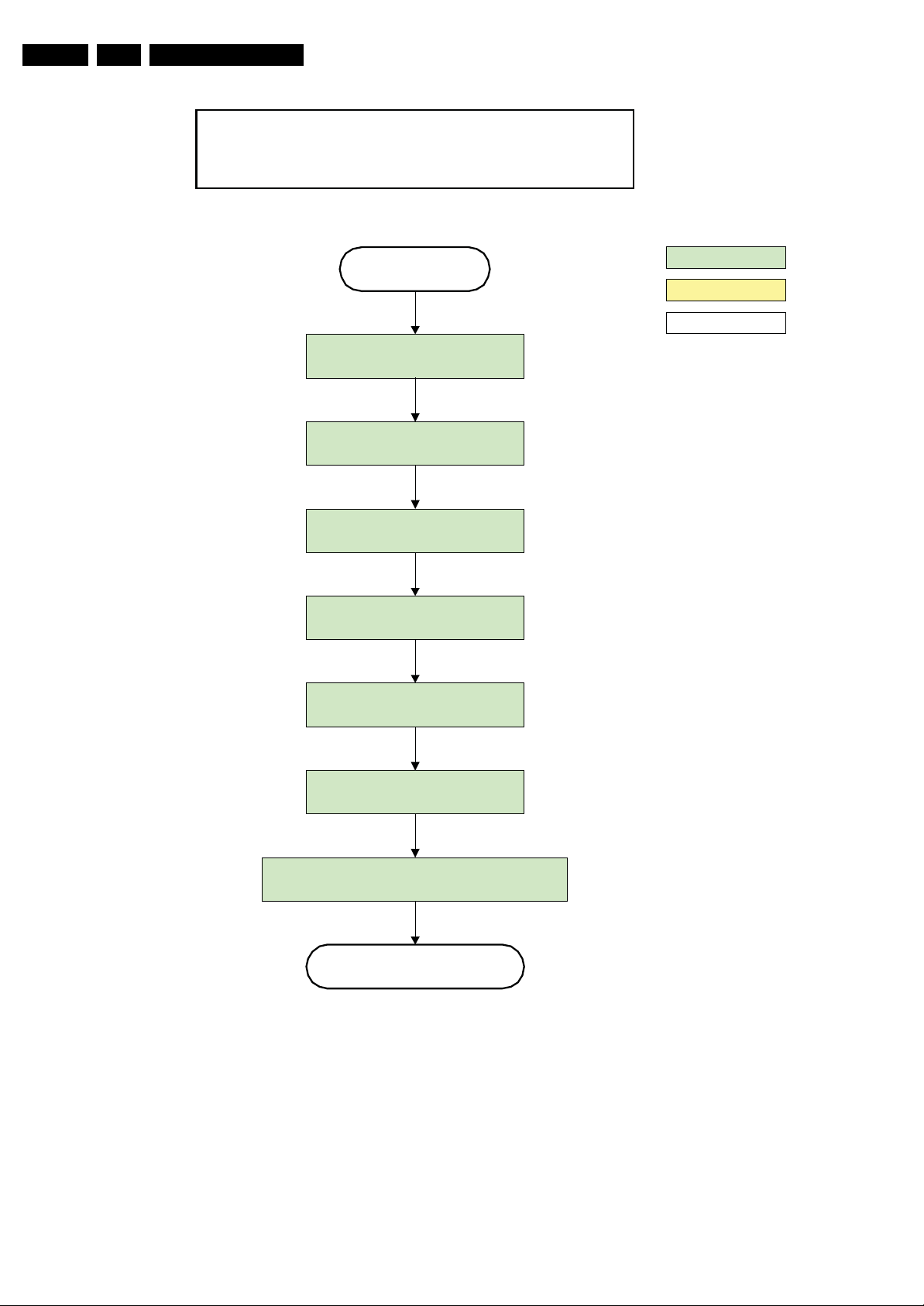

From part AFrom part A From part A From part A

action holder: MIPS

action holder: St-by

autonomous action

Start polling the detect-1V2 every 40ms

+8V6 erro r

EN 19EJ3.0U PA 5.

activate +8V6 supply

detection algorithm

SP

detect-1V2

received within

250ms?

No

+2.5V and +3.3V (ENABLE-3V3)

Start polling the detect-3V3 every 40ms

Activate supply detection algorithms for

Enable the supply fault detection

Yes

Enable the supply for

detect-3V3

received within

250 ms?

Yes

+1V2 and +3V3

SUPPLY-FAULT I/O line

is High?

Yes

interrupt

No

+1.2V error

SP

No separate enable and

detect is present for the +2V5

supply in the Baby Jaguar.

+3.3V errorNo

SP

Supply fault errorNo

SP

return

Set I²C slave address

of Standby µP to (A0h)

Detect EJTAG debug probe

(pulling pin of the probe interface to

ground by inserting EJTAG probe)

EJTAG pro be

connected ?

No

No

Release viper reset

Feed warm boot script(2)

No

No

Cold boot?

Yes

Release viper reset

Feed cold boot script(1)

Release PNX2015 reset 100ms after

Viper reset is released

Bootscript ready

in 1250 ms?

Yes

Set I²C slave address

of Standby µP to (64h)

Yes

Release vipe r reset

Feed initializing boot script (3)

disable alive mechanism

Release PNX2015 reset 100ms

after Viper reset is released

RPC start (comm. protocol)

To part C To part C To part C To part C

Figure 5-7 “OFF” to “Semi Stand-by” flowchart (part 2)

G_15960_118b.eps

030806

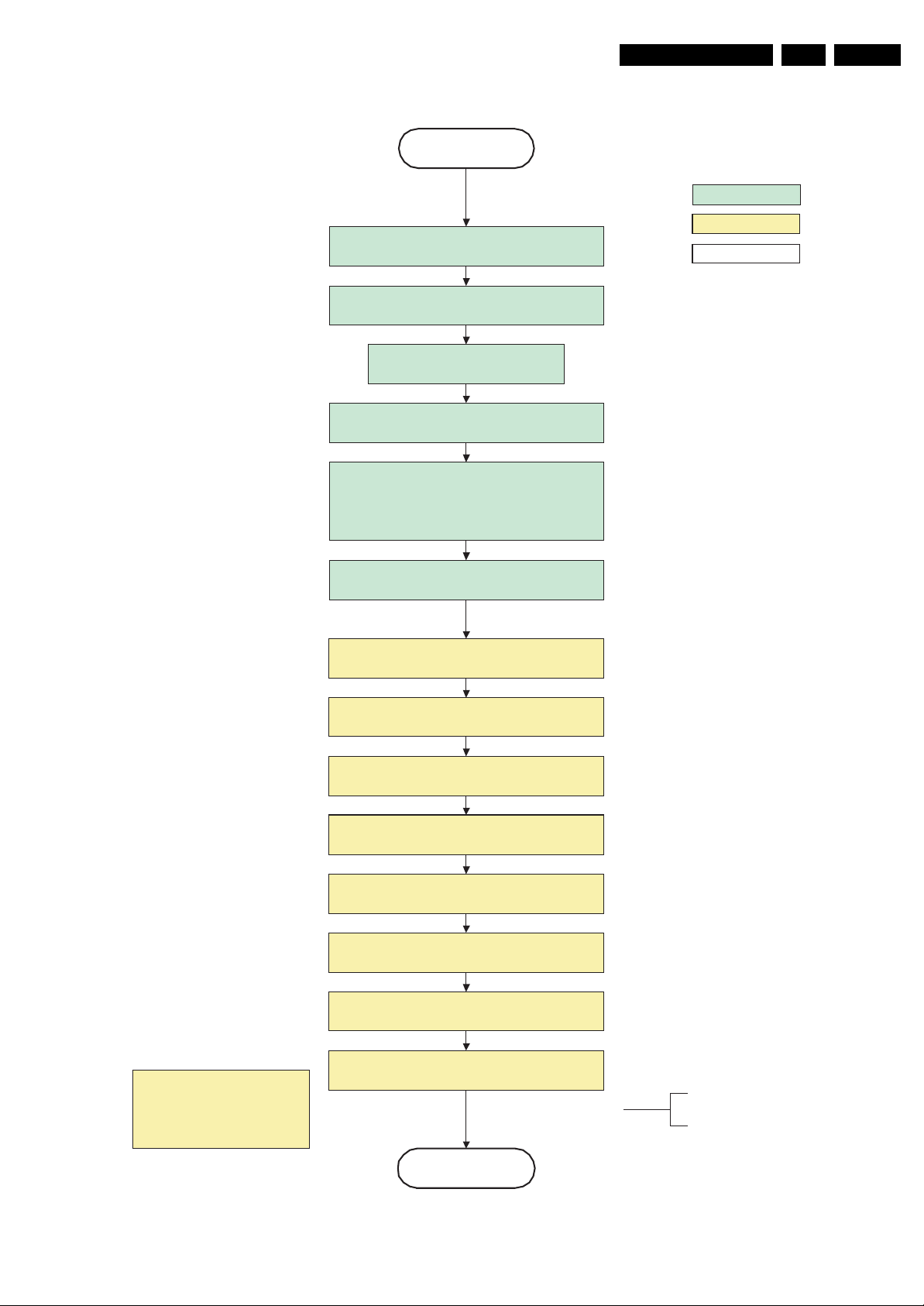

EN 20 EJ3.0U PA5.

F

F

F

F

Service Modes, Error Codes, and Fault Finding

rom part A

Yes

Disable all supply related protections and

switch off the +2V5, +3V3 DC/DC converter.

3- th try?

Log Code as

error code

rom part B

Code = 5

Switch Viper in reset

Wait 10ms

Switch the NVM reset

line HIGH.

Wait 5ms

switch off the remaining DC/DC

converters

Switch POD-MODE and ON-MODE

I/O line high.

No

Code = 53

No

Wait for the +8V6 to be detected if not yet present. (if

it does not come, the standby µP will enter a

protection mode, this is not a dead end here)

- Register PIIConfig of the Pacific3: LVDS function should be set to 0

(CMOS input) in the Baby Jaguar platform.

- POIConfig: lvds function should be set to 0 (CMOS out on Baby)

- PanelConfig register: PanelOff = 0, PanelOn = 1. P3 can always be

on, switching of lvds is done through PNX.

rom part B

Flash to Ram image

transfer succeeded

wit hi n 3 0s ?

Yes

Viper SW initialization

succeeded

wit hi n 2 0s ?

Yes

Enable Alive check mechanism

MIPS reads the wake up reason

from standby µP.

Set is

SDI PDP or

FHP PDP?

Yes

No

Power OK-display is

Yes

rom part B

Wait until Viper starts to

communicate

High?

action holder: MIPS

action holder: St-by

autonomous action

Log display error No

MP

SP

Was Pacific responding

to I²C?

No

Log Pacific error and

Go to Standby

yes

(AVIP's need to be started before the MPIF's in order to have a good clock distribution).

AVIP default power-up mode is Standby. The Viper instructs AVIP via I²C to enable all the

PLL's and clocks and hence enter to Full Power mode. See FMS AVIP for further details

and the rest of the initialization.

initialize PNX2015 HD subsystem according

FMS information

MPIF's should be initialized according the FMS information.

MPIF should deliver 2 observers:

POR= 0; normal operation

ROK = 1; reference frequency is present (coming from AVIP)

All observers present with correct state?

Yes

Initialize tuners and Hirate

Initialize source selectio n

Initialize video processing IC's

- Spider

Initialize Columbus

Initialize 3D Combfilter

Initialize AutoTV

Do not enter semi-standby state in case of an LPL

scanning backlight LCD set before 4s preheating timer has

elapsed.

Initialize Pacific related Ambilight settin gs

(if applicable)

No

Log appropriate

Observer error

Standby

Initialize Ambilight with Lights off.

Semi-Standby

Figure 5-8 “OFF” to “Semi Stand-by” flowchart (part 3)

G_15960_118c.eps

301106

Service Modes, Error Codes, and Fault Finding

PDP SDI

[42"/50" V5, W1 & W2, or 63" V4]

Semi Standby

Assert RGB video blanking

and audio mute

Ini tialize audio and video processing IC's and

functions according needed use case.

EN 21EJ3.0U PA 5.

action holder: MIPS

action holder: St-by

autonomous action

Wait until QVCP generates a valid LVDS

output clock.

Switch off RGB blanking after valid, stable video, corresponding to

the requested output is delivered by the Viper

Switch on LVDS transmitter

(PNX2015) (if not already on)

Switch the SDI Picture Flag “low ” to enable picture 1.5

seconds later, the display will unblank automatically

and show the LVDS content.

Enable anti-aging

Swit ch Audio-Reset and sound enable “low”

and demute

PWR-OK-PDP

received within 10s

after Picture flag toggle

?

Yes

No

Log error and

enter protection

mode

Active

Figure 5-9 “Semi Stand-by” to “Active” flowchart

SP return

G_15960_125.eps

020307

EN 22 EJ3.0U PA5.

Service Modes, Error Codes, and Fault Finding

PDP SDI

[42"/50" V5, W1 & W2, or 63" V4]

Active

Mute all sound outputs.

Swit ch reset-audio and sound-enable

lines “high”

Blank PDP display

Mute all video outputs

Wait 600ms to prevent image

retention

(display error)

action holder: MIPS

action holder: St-by

autonomous action

Swit ch “off” LVDS signal

(PNX2015)

Switch the SDI Picture flag “high” to prevent

testpattern display in semi-standby mode

Semi Standby

Figure 5-10 “Active” to “Semi Stand-by” flowchart

G_15960_132.eps

020307

Service Modes, Error Codes, and Fault Finding

Semi Stand by

Delay transition until ramping down of ambient light is

finished. *)

EN 23EJ3.0U PA 5.

action holder: MIPS

action holder: St-by

autonomous action

Switch ambient light to passive mode with RGB

values on zero. *)

transfer Wake up reasons to the

Stand by µP.

Images are re-transferred to DDR-RAM from

Flash RAM (verification through checksum)

MIPS image completes the application reload,

stops DDR-RAM access, puts itself in a

sleepmode and signals the standby µP when the

standby mode can be entered.

DDR-RAM is put in self refresh mode and the images

are kept in the hibernating DDR-RAM.

Wait 5ms

Switch Viper in reset state

*) If this is not performed and the set is

switched to standby when the ramping of

the EPLD is still ongoing, the lights will

remain lit in standby.

Important remark:

release reset audio and sound-

enable 10 sec after entering

standby to save power

Wait 10ms

Switch the NVM reset line HIGH.

Disable all supply related protections and switch off

the +2V5, +3V3 DC/DC converter.

Wait 5ms

switch off the remaining DC/DC converters

Switch OFF all supplies by switching HIGH the POD-

MODE and the ON-MODE I/O lines.

Stand by

For PDP this means CPUGO

becomes low.

G_15960_133.eps

100306

Figure 5-11 “Semi Stand-by” to “Stand-by” flowchart

EN 24 EJ3.0U PA5.

Service Modes, Error Codes, and Fault Finding

action holder: MIPS

action holder: St-by

autonomous action

If needed to speed up this transition,

this block could be omitted. This is

depending on the outcome of the

safety investigations.

MP

Log the appropriate error and

set stand-by flag in NVM

Redefine wake up reasons for protection

state and transfer to stand-by µP.

Switch off LCD lamp supply

Wait 250ms (min. = 200ms)

Switch off LVDS signal

Switch off 12V LCD supply within a time frame

of min. 0.5ms to max. 50ms after LVDS switch

off.

Ask stand-by µP to enter protection state

SP

Switch Viper in reset state

Wait 10ms

Switch the NVM reset line HIGH.

Disable all supply related protections and switch off

the +2V5, +3V3 DC/DC converter.

Wait 5ms

switch off the remaining DC/DC converters

Switch OFF all supplies by switching HIGH the POD-

MODE and the ON-MODE I/O lines.

Flash LED in order to indicate

protection state*. (see FRS) (*): This can be the standby LED or the ON LED

depending on the availability in the set under

discussion.

Protection

Figure 5-12 “Protection” flowchart

G_15960_137.eps

100306

Service Modes, Error Codes, and Fault Finding

EN 25EJ3.0U PA 5.

5.4 Service Tools

5.4.1 ComPair

Introduction

ComPair (Computer Aided Repair) is a Service tool for Philips

Consumer Electronics products. and offers the following:

1. ComPair helps you to quickly get an understanding on how

to repair the chassis in a short and effective way.

2. ComPair allows very detailed diagnostics and is therefore

capable of accurately indicating problem areas. You do not

have to know anything about I2C or UART commands

yourself, because ComPair takes care of this.

3. ComPair speeds up the repair time since it can

automatically communicate with the chassis (when the uP

is working) and all repair information is directly available.

4. ComPair features TV software up possibilities.

Specifications

ComPair consists of a Windows based fault finding program

and an interface box between PC and the (defective) product.

The (new) ComPair II interface box is connected to the PC via

an USB cable. For the TV chassis, the ComPair interface box

and the TV communicate via a bi-directional cable via the

service connector(s).

The ComPair fault finding program is able to determine the

problem of the defective television, by a combination of

automatic diagnostics and an interactive question/answer

procedure.

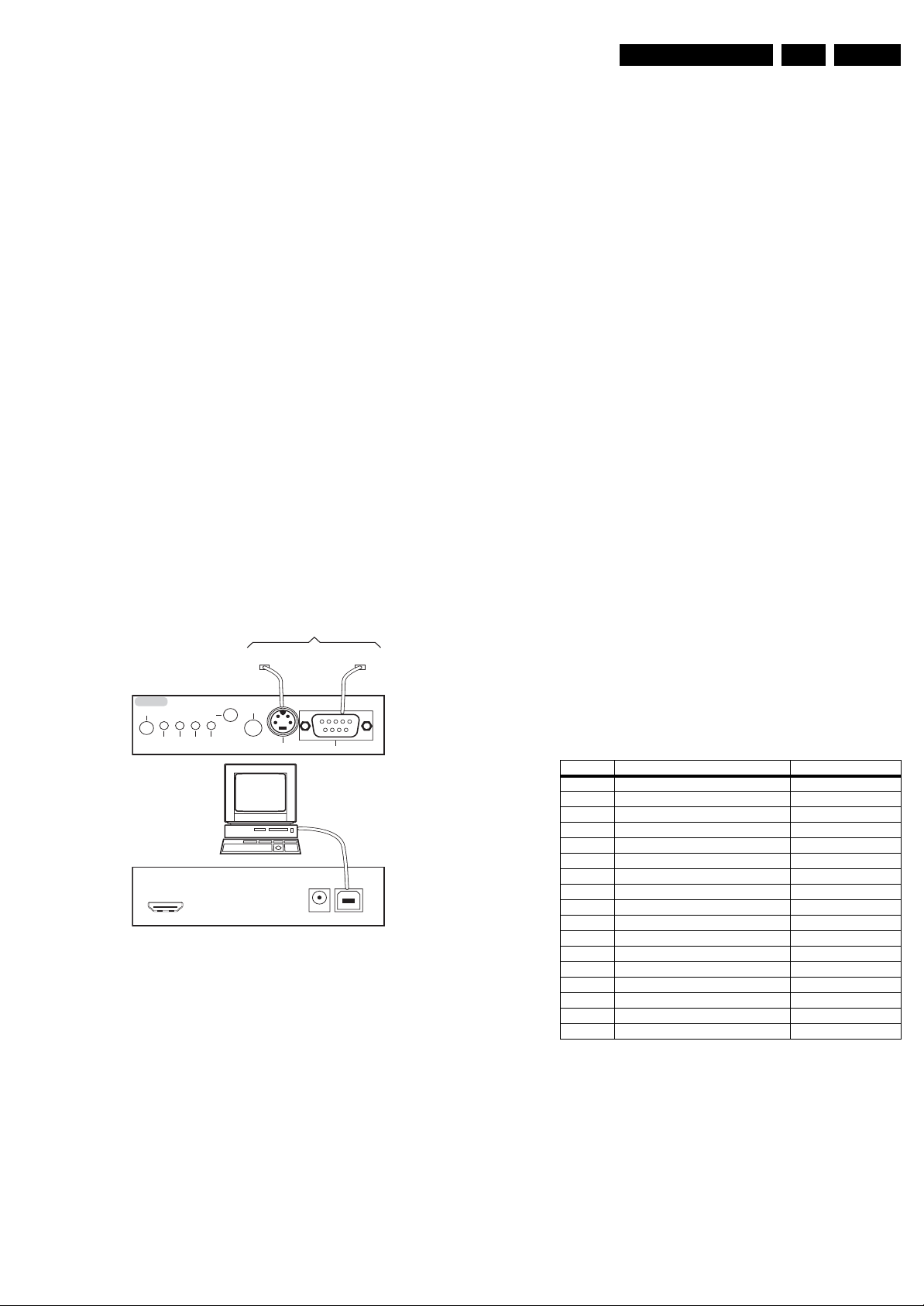

How to Connect

This is described in the chassis fault finding database in

ComPair.

TO TV

RS232 /UART

G_06532_036.eps

TO

UART SERVICE

CONNECTOR

260107

TO

ComPair II

RC in

Optional

Switch

Power ModeLink/

Activity

HDMI

2

I

C only

RC out

I2C SERVICE

CONNECTOR

Multi

function

PC

OR

2

C

I

ComPair II Developed by Philips Brugge

Optional power

5V DC

Figure 5-13 ComPair II interface connection

Caution: It is compulsory to connect the TV to the PC as

shown in the picture above (with the ComPair interface in

between), as the ComPair interface acts as a level shifter. If

one connects the TV directly to the PC (via UART), ICs will be

blown!

How to Order

ComPair II order codes:

• ComPair II interface: 3122 785 91020.

• ComPair32 CD (update): 3122 785 60160.

• ComPair interface cable: 3122 785 90004.

• ComPair interface extension cable: 3139 131 03791.

• ComPair UART interface cable: 3122 785 90630.

Note: If you encounter any problems, contact your local

support desk

5.4.2 LVDS Tool

Introduction

This Service tool (also called “ComPair Assistant 1“) may help

you to identify, in case the TV does not show any picture,

whether the Small Signal Board (SSB) or the display of a Flat

TV is defective. Thus to determine if LVDS, RGB, and sync

signals are okay.

When operating, the tool will show a small (scaled) picture on

a VGA monitor. Due to a limited memory capacity, it is not

possible to increase the size when processing high-resolution

LVDS signals (> 1280x960). Below this resolution, or when a

DVI monitor is used, the displayed picture will be full size.

How to Connect

Connections are explained in the user manual, which is packed

with the tool. The LVDS cables included in the package cover

most chassis. For some chassis, a separate cable must be

ordered.

Note: To use the LVDS tool, you must have ComPair release

2004-1 (or later) on your PC (engine version >= 2.2.05).

For every TV type number and screen size, one must choose

the proper settings via ComPair. The ComPair file will be

updated regularly with new introduced chassis information.

How to Order

• LVDS tool (incl. two LVDS cables: 31p and 20p, covering

chassis BJx, EJx, FJx and LC4.1): 3122 785 90671.

• LVDS tool Service Manual: 3122 785 00810.

• LVDS cable 20p/DF -> 20p/DF (standard with tool):

3122 785 90731.

• LVDS cable 31p/FI -> 31p/FI (standard with tool):

3122 785 90662.

For other chassis, a separate LVDS cable must be ordered.

Refer to table “LVDS cable order number” for an overview of all

available cables.

Table 5-2 LVDS cable order number

Chassis LVDS cable order number Remarks

BJ2.4 3122 785 90662

BJ2.5 3122 785 90662

BJ3.0 3122 785 90662

BJ3.1 3122 785 90662

EJ2.0 3122 785 90662

EJ3.0 3122 785 90662

EL1.1 3122 785 90662 1 / 3122 785 90821

FJ3.0 3122 785 90662

FTL2.4 3122 785 90662

LC4.1 3122 785 90731 1 / 3122 785 90851

LC4.3 3122 785 90821

LC4.31 3122 785 90821

LC4.41 3122 785 90662

LC4.8 3122 785 90662

LC4.9 3122 785 90662

LC7.2 t.b.d.

JL2.1 3122 785 90861

1

1

1

1

1

1

1

1, 2

1, 2

/ 3122 785 90851 Only for 26 & 32” sets.

1, 2

/ 3122 785 90851