PHILIPS DVP3980KX-77 Service Manual

DVP3980K

DVP3980KX/77

Service Manual

TABLE OF CONTENTS

Technical Specifications……………………………………..............1-2

. Safety Instruction, Warning & Notes….……………………....….....1-3

. Region Code, Software Version & Upgrade…………....................2-1

. Trouble Shooting Chart................................……………...............

. Wiring Diagram................………………………………………………

. Electrical Diagrams and Print-layouts..……………..………..….….5-1

.Set Mechanical Exploded view & Part list.…………………....….…6-1

. Revision List.............................................…………………..….….7-1

©Copyright 2008 Philips Consumer Electronics B.V. Eindhoven, The Netherlands

All rights reserved. No part of this publication may be reproduced, stored in aretrieval system or

transmitted, in any form or by any means, electronic, mechanical, photocopying, or otherwise

without the prior permission of Philips.

Page

.

3-1

4-1

.

CLASS 1

LASER PRODUCT

Published by KC-ET0846 Service Audio Printed in The Netherlands Subject to modification

Version 1.1

GB

3139 785 34291

PHILIPS

Technical Specifications

TV standard (PAL/50Hz) (NTSC/60Hz)

Number of lines 625 525

Playback Multi standard (PAL/NTSC)

Video performance

Video DAC 12 bit, 108MHz

YPbPr: 0.7Vpp ---- 75 ohm

Video output 1Vpp ----- 75 ohm

Video format

Digital Compression MPEG 2 for DVD,SVCD

MPEG 1 for VCD

DVD 50Hz 60Hz

Horiz resolution 720 pixels 720 pixels

1920pixels 1920 pixels

Vertical resolution 576lines 480 lines

1080 lines 1080 lines

1-2

Audio performance

DA converter 24 bits, 192KHz

DVD fs 96 kHz 4 Hz----44 kHz

fs 48kHz 4 Hz----22 kHz

SVCD fs 48kHz 4 Hz----22 kHz

fs 44.1kHz 4 Hz----20 kHz

CD/ VCD fs 44.1kHz 4 Hz----20 kHz

Signal-Noise (1kHz) >90 dB

Dynamic Range (1kHz) >80 dB

Cross talk (1kHz) >70 dB

Distortion/Noise (1kHz) >65 dB

MPEG MP3 MPEG Audio L3

Connections

YpbPr output Cinch 3x

Video output Cinch ( yellow)

Audio output (L+R ) Cinch (white/red)

Digital output 1 coaxial

IEC60958 for CDDA/ LPCM

IEC61937 for MPEG1/2,

Dolby Digital

HDMI Out

VCD 50Hz 60Hz

Horiz. resolution 352 pixels 352 pixels

Vertical resolution 288lines 240 lines

Audio format

Digital MPEG/AC-3/ Compressed Digital

PCM 16, 20, 24 bits

fs, 44.1, 48, 96KHz

MP3 (ISO 9660) 96,112,128,256kbps

& variable bit rate fs,32,

44.1,48 kHz

Analogue Sound Stereo

Dolby surround compatible downmix from Dolby Digital multi-channel

sound

Cabinet

Dimensions (w X h X d) 360 x 37 x 209 mm

Weight Approximately 1.3 kg

Power consumption

Power supply Rating 120V; 60HZ

Power consumption <10W

Power consumption in standby mode <1W

Specifications subject to change without prior notice.

1-3

Safety instruction, Warning & Notes

Safety instruction

1. General safety

Safety regulations require that during a repair:

. Connect the unit to the mains via an isolation transformer.

. Replace safety components indicated by the symbol

only by components identical to the original ones. Any

other component substitution (other than original type)

may increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must

return the unit in its original condition. Pay, in particular,

attention to the following points:

. Route the wires/cables correctly, and fix them with the

mounted cable clamps.

. Check the insulation of the mains lead for external

damage.

. Check the electrical DC resistance between the mains

plug and the secondary side:

1) Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2) Set the mains switch the “on” position (keep the

mains cord unplug).

3) Measure the resistance value between the mains

plug and the front panel, controls, and chassis

bottom.

4) Repair or correct unit when the resistance

measurement is less than 1M

5) Verify this, before you return the unit to the

customer/user (ref. UL-standard no. 1492).

6) Switch the unit “off”, and remove the wire between

the two pins of the mains plug.

¡

.

2.Laser safety

This unit employs a laser. Only qualified service personnel

,

may remove the cover, or attempt to service this device

(due to possible eye injury).

Laser device unit

Type : Semiconductor laser GaAlAs

Wavelength : 650nm (DVD)

: 780nm (VCD/CD)

Output power : 7mW (DVD)

: 10mW (DVD /CD)

Beam divergence: 60 degree

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to

beam.

Warning

1-4

1.General

. All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD). Careless handing during

repair can reduce life drastically. Make sure that, during

repair, you are at the same potential as the mass of the

set by a wristband with resistance. Keep components and

tools at this same potential. Available ESD protection

equipment:

1) Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable)

4822 310 10671.

2) Wristband tester 4822 344 13999.

. Be careful during measurements in the live voltage

section. The primary side of the power supply , including

the heat sink, carries live mains voltage when you

connect the player to the mains (even when the player is

“off”!). It is possible to touch copper tracks and/or

components in this unshielded primary area, when you

service the player. Service personnel must take

precautions to prevent touching this area or components

in this area. A “lighting stroke” and a stripe-marked

printing on the printed wiring board, indicate the primary

side of the power supply.

. Never replace modules, or components, while the unit is

“on”.

2. Laser

. The use of optical instruments with this product, will

increase eye hazard.

. Only qualified service personnel may remove the cover

or attempt to service this device, due to possible eye

injury.

. Repair handing should take place as much as possible

with a disc loaded inside the player.

. Text below is placed inside the unit, on the laser cover

shield:

CAUTION: VISIBLE AND INVISIBLE LASER

RADIATION WHEN OPEN, AVOID EXPOSURE

TO BEAM.

Notes: Manufactured under licence from Dolby

Laboratories. The double-D symbol is trademarks of Dolby

Laboratories, Inc. All rights reserved.

Notes

Lead-Free requirement for service

1-5

INDENTIFICATION:

Regardless of special logo (not always indicated)

One must treat all sets from 1.1.2005 onwards, according

next rules.

Important note

be treated in this way as long as you avoid mixing

solder-alloys (leaded/ lead-free). So best to always use

SAC305 and the higher temperatures belong to this.

Due to lead-free technology some rules have to be

respected by the workshop during a repair:

x Use only lead-free solder alloy Philips SAC305 with

order code 0622 149 00106. If lead-free solder-paste is

required, please contact the manufacturer of your

solder-equipment. In general use of solder-paste within

workshops should be avoided because paste is not easy

to store and to handle.

x Use only adequate solder tools applicable for lead-free

solder alloy. The solder tool must be able

o To reach at least a solder-temperature of 400°C,

o To stabilize the adjusted temperature at the

o To exchange solder-tips for different applications.

x Adjust your solder tool so that a temperature around

360°C

joint. Heating-time of the solder-joint should not exceed

~ 4 sec. Avoid temperatures above 400°C otherwise

wear-out of tips will rise drastically and flux-fluid will be

destroyed. To avoid wear-out of tips switch off un-used

equipment, or reduce heat.

x Mix of lead-free solder alloy / parts with leaded solder

alloy / parts is possible but PHILIPS recommends

strongly to avoid mixed

solder alloy types (leaded and lead-free). If one cannot

avoid, clean carefully the

solder-joint from old solder alloy and re-solder with new

solder alloy (SAC305).

: In fact also products a little older can also

solder-tip

– 380°C is reached and stabilized at the solder

x Use only original spare-parts listed in the

Service-Manuals. Not listed standard-material

(commodities) has to be purchased at external

companies.

x Special information for BGA-ICs:

- always use the 12nc-recognizable soldering

temperature profile of the specific BGA (for

de-soldering always use highest lead-free

temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called

‘dry-packaging’ (sealed pack including a silica gel

pack) to protect the IC against moisture. After

opening, dependent of MSL-level seen on

indicator-label in the bag, the BGA-IC possibly

still has to be baked dry. This will be

communicated via AYS-website.

Do not re-use BGAs at all.

x For sets produced before 1.1.2005, containing

leaded soldering-tin and components, all needed

spare-parts will be available till the end of the

service-period. For repair of such sets nothing

changes.

x On our website:

www.atyourservice.ce.Philips.com

You find more information to:

BGA-de-/soldering (+ baking instructions)

Heating-profiles of BGAs and other ICs used in

Philips-sets

You will find this and more technical information

within the “magazine”, chapter “workshop news”.

For additional questions please contact your local

repair-helpdesk.

2-1

Software upgrade

Preparation to upgrade software

1) Start the CD Burning software and create a new CD

project (Data Disc) with the following setting:

Label: DVP3XXX (No need the label name)

File Name: DVPXXXX_XX.BIN

Power on the set and open the tray, then press <5><5>

to check the File Name.

Note: It is required capital letter for the File System

name.

2) Burn the data onto a blank CDR

A. Procedure for software upgrade:

1) Power on the set and insert the prepared Upgrade

CDR.

2) The set will starts reading disc & response with the

following display TV screen:

Upgrade File DETECTED

Upgrade?

Press Play TO START.

3) Press <OK> button to confirm, then screen will display :

Files coping…

UPGRADING…

4) The upgraded tray will automatically open when files

coping complete, then take out the disc.

5) About 1 minute later, the trace will automatically close

when upgrading complete.

B. Read out the software versions to confirm upgrading

1) Power on the set and press <Setup> button on the

remote control.

2) Press <1><3><7><9> button.

The software version and other information are display

on the TV screen as follows:

Version XX.XX.XX.XX (Main version)

SUB-VER XX.XX.XX.XX (software version of

application software)

8032 XX.XX.XX.XX

Servo XX.XX.XX.XX (software version of

Servo)

RISC XX.XX.XX.XX

DSP XX.XX.XX.XX

Region Code X

Caution: The set must not be power off during

upgrading, Otherwise the Main board will be

damaged entirely.

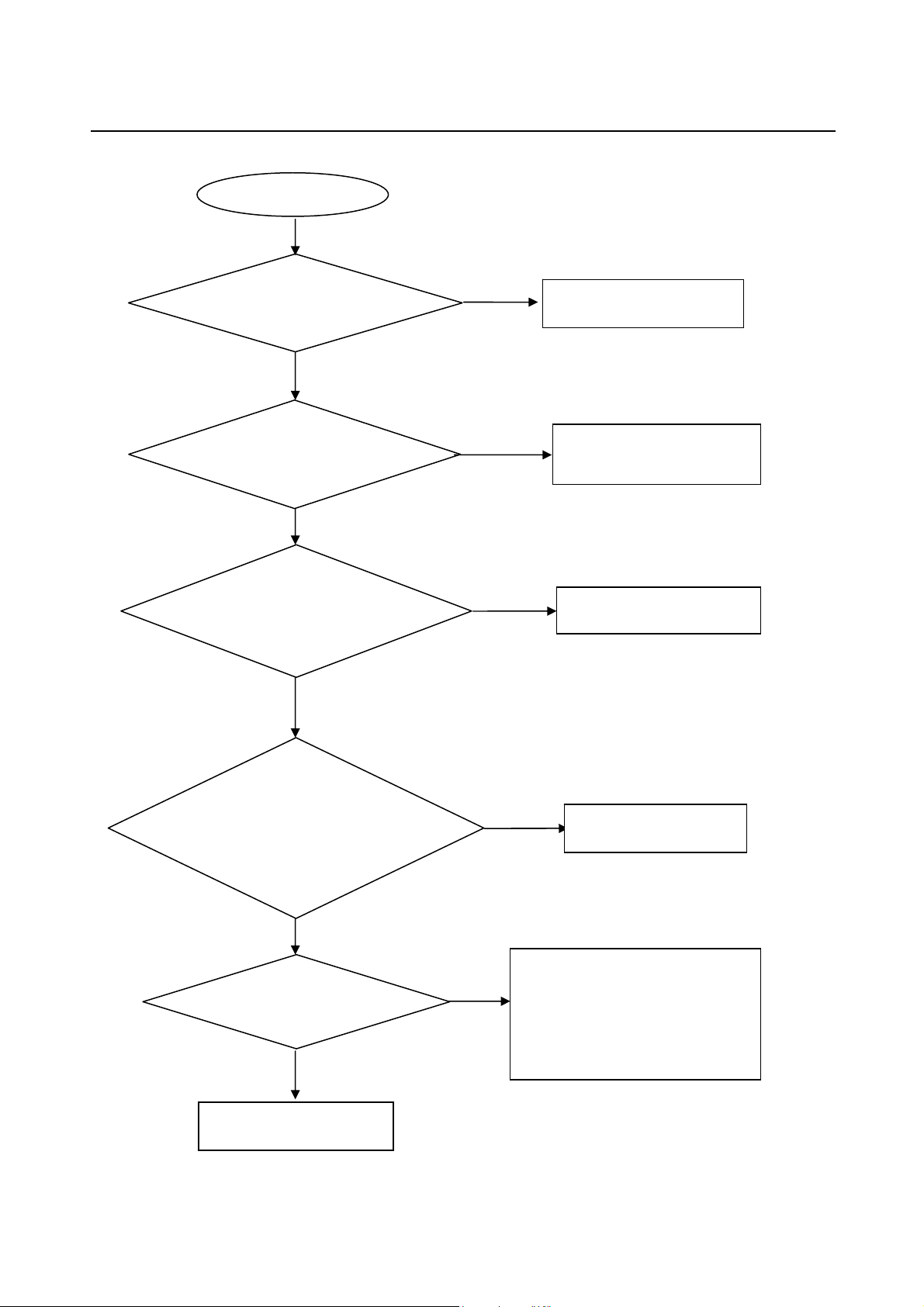

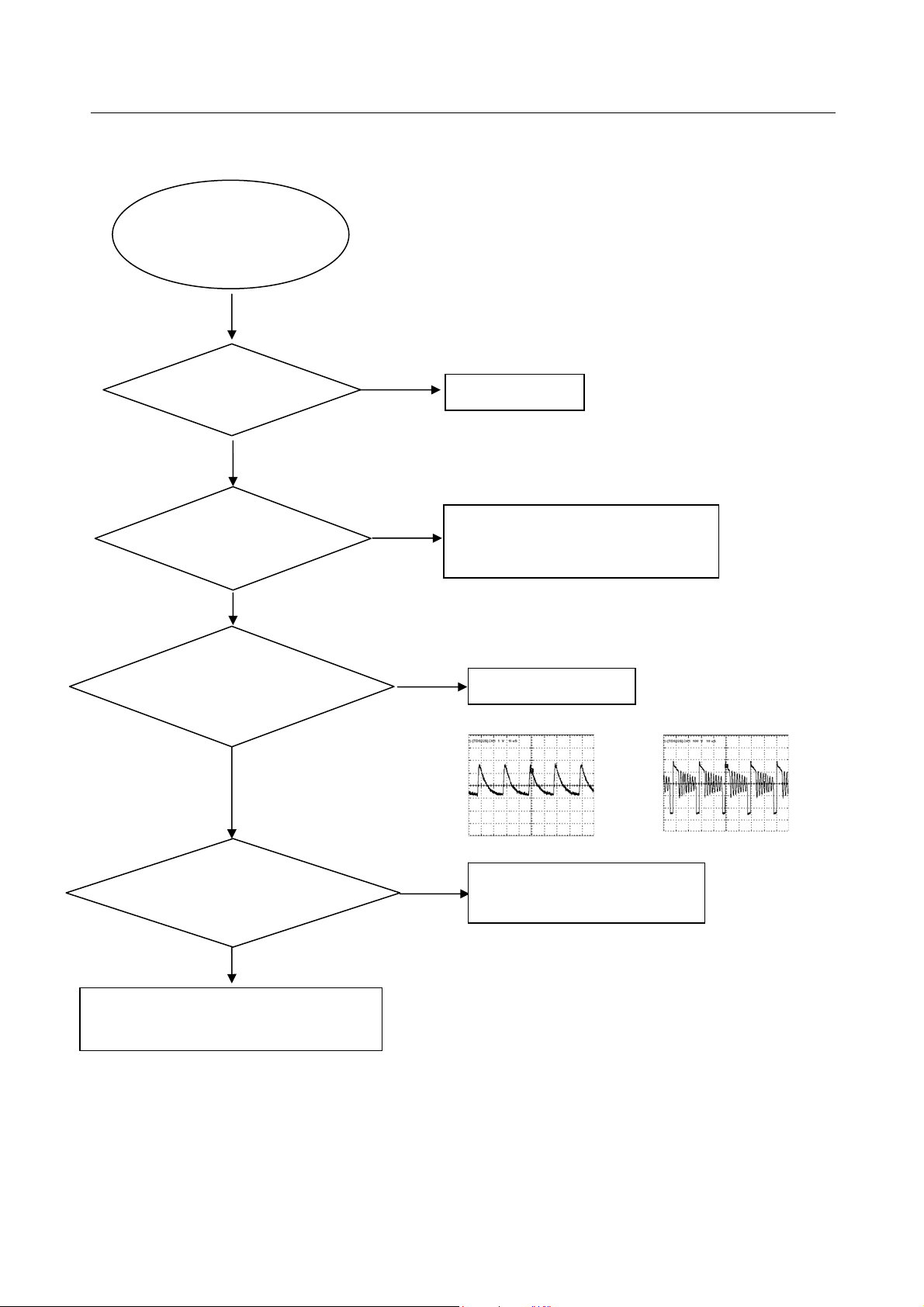

Spindle motor does not move

Motor no move

Go

3-1

Trouble shooting chart

Check the FFC connection

No

Correct connection

between 24P and the loader.

Yes

Check whether “VCC”

No

Check the VCC power supply

(+5V) voltage is normal.

Yes

Check whether laser voltage

(2V for VCD & 2.2V for DVD)

on Collector of Q13 and Q14

No

Check/Replace Q13ǃQ14

Yes

I

1.Whether voltage on pin 54 of

U1varies between 0 and 3.3V (3.3V

for VCD and 0V for DVD),

2.Whether peripheral components

are eroded or badly soldered.

Yes

Have no to focus

Yes

Check/Replace the loader

No

No

Check/ Replace U1

1. Check U1 FOO signals

2.If there are F+, F-, T+ and T-

signals output from U2.

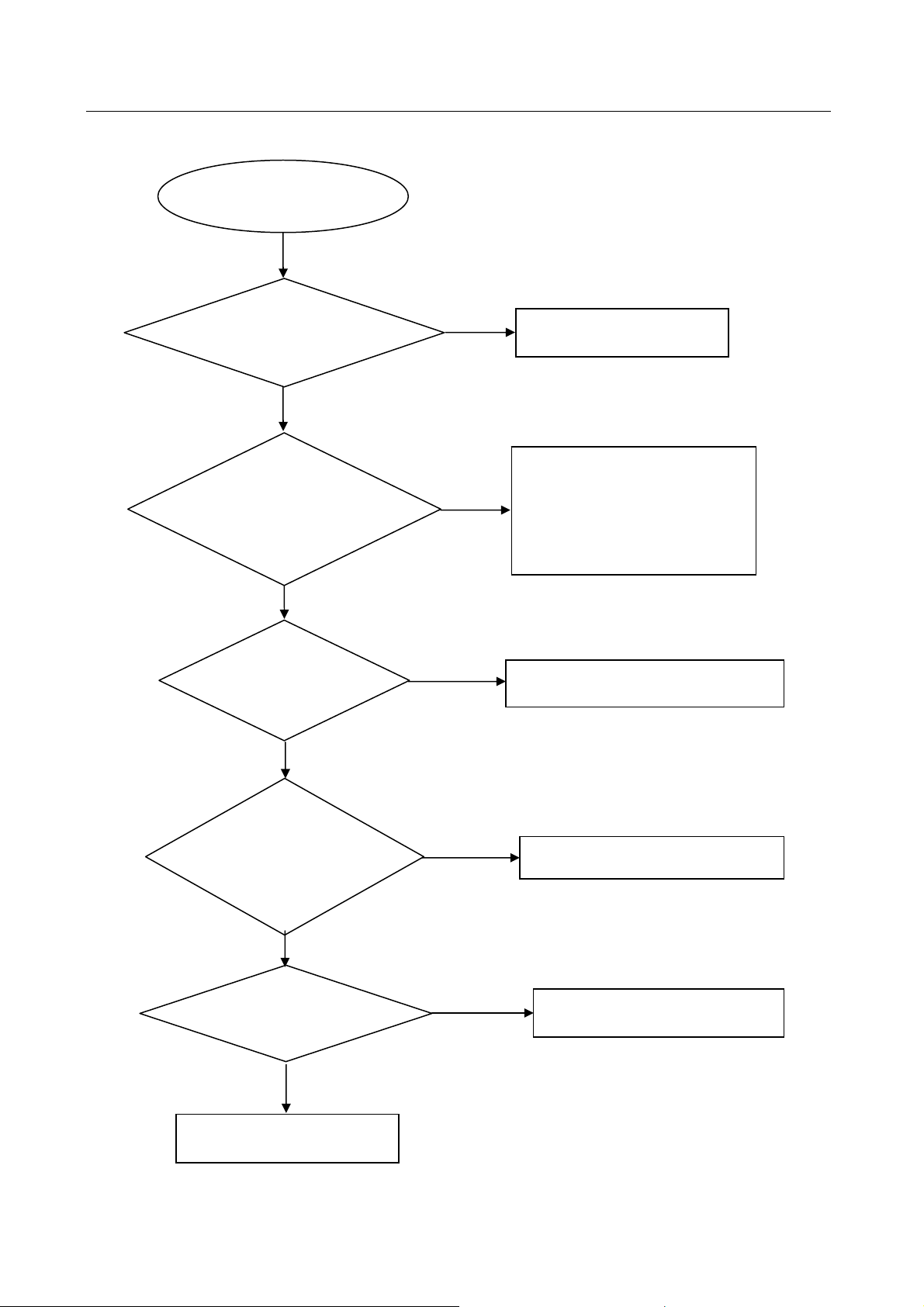

The power can not be on or off

The power can’t be

on or off

Go

3-2

Trouble shooting chart

Check the power supply

on the power board is

normal.

Yes

Check if the XS301on the

front board to XP2 on the

decoder board is in good

contact.

Yes

Whether the connection

to K301 is broken.

Ye s

No

No

No

Repair the power board

Check/Correct

connection

Correct the connection

Yes

Whether there is 0V and

3.3V voltage difference on

Pin 203 PCON

Yes

of U1.

No

Replace U1

3-3

All output voltages on the power board is 0V or deviated.

All output voltages on

the power board is 0V or

deviated

Yes

Trouble shooting chart

Check whether

F1 is blown

No

Check whether there is

300V on C1,C2

Yes

Check whether 100KHz

oscillating signal on

Pin6 of U1

Yes

Yes

No

No

Replace F1

Replace C1,C2 if D1, D2, D3, D4 are

normal.

Check/ replace U1.

U1(PIN 3 - RC waveform)

U1(PIN 8 - Drain waveform)

Check if +5V, +3.3v, +12V,

-12V are short.

Yes

Check whether the components in the

short-circuit voltage are defected or eroded.

No

Check whether U2 are eroded.

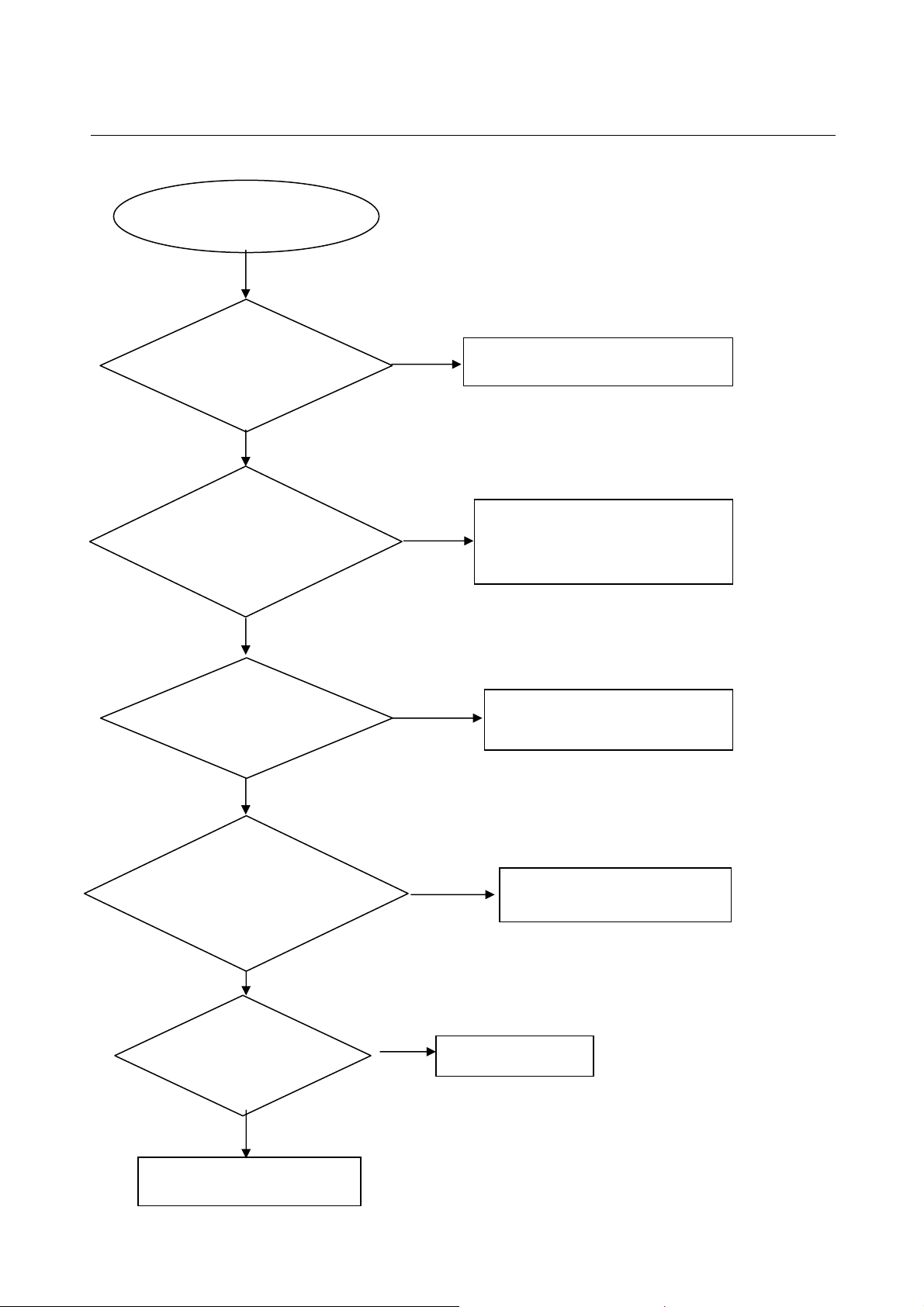

Disc cannot be read.

Disc cannot be read.

Yes

3-4

Trouble shooting chart

Check the FFC connection

between 24P and the loader.

Yes

Check whether there is laser

voltage (2V for VCD and 2.2V for

DVD) on Collector of

Q13ǃQ14.

Yes

CheckU1,U2,and peripheral

components are eroded or

badly soldered.

Yes

No

No

No

Check the loaded circuit

1.Check voltage on pin 54 of U1 varies

between 0 and 3.3V:

Æ3.3V for VCD

Æ0V for DVD

2.Check whether peripheral components

are eroded or defect

Re-solder or replace the defective parts

Check if there is RFO signal on

pin8 of XP5. (The normal RFO

signal is a clear reticulated wave)

Yes

Check the connection

between U1

Yes

Replace U1 or loader.

No

No

Check U1 and peripheral components

Correct connection

3-5

p

p

g

Only DVD disc or only disc except DVD can be played

Only DVD disc, or only disc

t DVD can be Played.

exce

Go

Trouble shooting chart

Check the FFC

connection between

24pin and the loader.

Yes

Check laser voltage (2V) output

on Collector of Q14 if pin 22 of U1

is at low level.

Yes

Check whether there

is voltage variance on

in 22 of U1.

No

No

No

Check the loaded circuit

Check the solder status on U1 and

peripheral components

check if bad solder exist on U1 and

peripheral components

Yes

Check whether pin 1 to pin38

of U1 and peripheral

components are badly

soldered, defected

Yes

Check Q10, Q11,

Q12 whether in

ood condition

Yes

Change U1 or the loader.

No

Replace the bad spare parts

No

Correct connection

Loading...

Loading...