Philips DVP-3350 Service Manual

VCR+DVD PLAYER

DVP3350V

DVP3350V/01/02/05/19

Service

Service

Service

Service Manual

SECTION 1 SUMMARY 1-1

PRODUCT SAFETY SERVICING GUIDELINES FOR

VCR+DVD PRODUCTS 1-3

SERVICING PRECAUTIONS 1-4

INFORMATION ABOUT LEAD-FREE SOLDERING 1-5

SERVICE INFORMATION FOR EEPROM IC SETTING(VCR) 1-6

SERVICE INFORMATION FOR EEPROM (DVD) 1-7

SPECIFICATIONS 1-8

SECTION 2 CABINET & MAIN CHASSIS 2-1

1. CABINET AND MAIN FRAME SECTION 2-2

2. DECK MECHANISM SECTION [ DVD MD (DP-10C) ] 2-3

3. DECK MECHANISM SECTION [ VCR DECK D37(N) ] 2-4

1) FRONT LOADING MECHANISM SECTION 2-4

2) MOVING MECHANISM SECTION (1) 2-5

3) MOVING MECHANISM SECTION (2) 2-6

4. PACKING ACCESSORY SECTION 2-7

SECTION 3 ELECTRICAL 3-1

VCR PART

VCR ELECTRICAL ADJUSTMENT PROCEDURES 3-2

1. SERVO ADJUSTMENT 3-2

VCR ELECTRICAL TROUBLESHOOTING GUIDE 3-3

1. POWER(SMPS) CIRCUIT 3-3

2. SYSTEM/KEY CIRCUIT 3-6

3. SERVO CIRCUIT 3-7

4. Y/C CIRCUIT 3-10

5. HI-FI CIRCUIT 3-14

6. TUNER/IF CIRCUIT 3-17

BLOCK DIAGRAMS 3-19

1. POWER(SMPS) BLOCK DIAGRAM 3-19

2. SYSTEM BLOCK DIAGRAM 3-21

3. AVCP BLOCK DIAGRAM 3-23

4. HI-FI BLOCK DIAGRAM 3-25

5. TUNER BLOCK DIAGRAM 3-27

CIRCUIT DIAGRAMS 3-29

1. POWER(SMPS) CIRCUIT DIAGRAM 3-29

2. SYSTEM CIRCUIT DIAGRAM 3-31

3. AVCP CIRCUIT DIAGRAM 3-33

4. HI-FI CIRCUIT DIAGRAM 3-35

5. TUNER CIRCUIT DIAGRAM 3-37

WAVEFORMS 3-39

CIRCUIT VOLTAGE CHART 3-41

IC BLOCK DIAGRAMS 3-47

PRINTED CIRCUIT BOARD DIAGRAMS 3-51

1. MAIN P.C.BOARD (TOP SIDE) 3-51

2. MAIN P.C.BOARD (BOTTOM SIDE) 3-53

3. POWER P.C.BOARD 3-55

4. KEY P.C.BOARD 3-57

DVD PART

DVD ELECTRICAL TROUBLESHOOTING GUIDE 3-59

1. POWER CHECK FLOW 3-59

2. SYSTEM OPERATION FLOW 3-60

3. TEST & DEBUG FLOW 3-61

DETAILS AND WAVEFORMS ON SYSTEM TEST AND DEBUGGING 3-67

1. SYSTEM 27MHZ CLOCK, RESET SIGNAL 3-67

2. SDRAM CLOCK 3-68

3. TRAY OPEN/CLOSE SIGNAL 3-68

4. SLED CONTROL RELATED SIGNAL(NO DISC CONDITION) 3-70

5. LENS CONTROL RELATED SIGNAL (NO DISC CONDITION) 3-70

6. LASER POWER CONTROL RELATED SIGNAL

(NO DISC CONDITION) 3-71

7. FOCUS ON WAVEFORM 3-71

8. SPINDLE CONTROL WAVEFORM (NO DISC CONDITION) 3-72

9. TRACKING CONTROL RELATED SIGNAL

(SYSTEM CHECKING) 3-73

10. RF WAVEFORM 3-74

11. ZR36966 AUDIO OPTICAL AND COAXIAL OUTPUT (SPDIF) 3-74

12. ZR36966 VIDEO OUTPUT WAVEFORM 3-75

13. AUDIO OUTPUT FROM AUDIO PREAMP 3-76

BLOCK DIAGRAMS 3-77

1. SYSTEM BLOCK DIAGRAM 3-77

2. SERVO BLOCK DIAGRAM 3-78

3. AUDIO & VIDEO IN/OUT BLOCK DIAGRAM 3-79

CIRCUIT DIAGRAMS 3-81

1. MPEG CIRCUIT DIAGRAM 3-81

2. SERVO CIRCUIT DIAGRAM 3-83

3. JACK CIRCUIT DIAGRAM 3-85

IC BLOCK DIAGRAMS 3-87

SECTION 4 MECHANISM (D-37) OF VCR PART 4-1

SECTION 5 MECHANISM (DP-10C) OF DVD PART 5-1

This Service Manual is for DVP3350v Second Generation models,

For Second Generation Service models, The serial number begins with DE2Axxxxxxxxxx

Published by LG-LM 0805 AV System Printed in the Netherlands Subject to modification GB 3139 785 33440

CONTENTS

SECTION 1 .........SUMMARY

SECTION 2 .........CABINET & MAIN CHASSIS

SECTION 3 .........ELECTRICAL

SECTION 4 .........MECHANISM OF VCR PART

SECTION 5 .........MECHANISM OF DVD PART

SECTION 6 .........REPLACEMENT PARTS LIST

SECTION 1

SUMMARY

CONTENTS

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD+VCR PRODUCTS ......................1-3

SERVICING PRECAUTIONS ....................................................................................................................1-4

• General Servicing Precautions

• Insulation Checking Prodedure

• Electrostatically Sensitive Devices

INFORMATION ABOUT LEAD-FREE SOLDERING.........................................................................1-5

SERVICE INFORMATION FOR EEPROM IC SETTING (VCR) ....................................................1-6

SERVICE INFORMATION FOR EEPROM (DVD)..............................................................................1-7

SPECIFICATIONS ........................................................................................................................................1-8

1-2

PRODUCT SAFETY SERVICING GUIDELINES FOR DVD+VCR PRODUCTS

CAUTION : DO NOTATTEMPTTO MODIFY THIS PRODUCT IN ANYWA Y, NEVER PERFORM

CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER’S APPROVAL. UNAUTHORIZED

MODIFICATIONS WILLNOT ONLYVOID THE WARRANTY, BUT MAY LEAD TO YOUR BEING

LIABLE FOR ANYRESUL TING PROPERTYDAMAGE OR USER INJURY.

SERVICE WORK SHOULD BE PERFORMED ONL YAFTER YOU ARE THOROUGHLYF AMILIAR

WITH ALL OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO

OTHERWISE, INCREASES THE RISK OF POTENTIALHAZARDS AND INJUR YTO THE USER.

WHILE SERVICING, USE AN ISOLA TION TRANSFORMER FOR PROTECTION FROM A.C. LINE

SHOCK.

SAFETY CHECKS

AFTER THE ORIGINALSERVICE PROBLEM HAS BEEN CORRCTED. ACHECK SHOULD BE

MADE OF THE FOLLOWING.

SUBJECT : FIRE & SHOCK HAZARD

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH AWAY AS TO AVOID

POSSIBILITYOF ADJACENTCOMPONENTSHORTS. THIS IS ESPECIALL YIMPORTANT ON

THOSE MODULES WHICH ARE TRANSPORTED TO AND FROM THE REPAIR SHOP.

2. NEVER RELEASE AREPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULAT ORS,

BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER SUPPLYCORDS, AND OTHER

HARDWARE HAVE BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE

SAFETY PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS,

SOLDER SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE OF DAMAGE OR DETERIORATION TO PARTS AND

COMPONENTS. FOR FRAYED LEADS, DAMAGED INSULATION (INCLUDING A.C. CORD).

AND REPLACE IF NECESSARYFOLLOW ORIGINALLAYOUT, LEAD LENGTH AND DRESS.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECIVING TUBE OR ARESISTOR RATED

AT 1 WATTOR MORE. LEAD TENSION AROUND PROTRUNING METAL SURFACES MUST

BE AVOIDED.

6. ALLCRITICALCOMPONENTS SUCH AS FUSES, FLAMEPROOF RESISTORS, CAP ACITORS,

ETC. MUST BE REPLACED WITH EXACT FACTORYTYPES, DO NOT USE REPLACEMENT

COMPONENTS OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT

MODIFICATIONS.

7. AFTER RE-ASSEMBLY OF THE SET ALWAYS PERFORM AN A.C. LEAKAGE TESTON ALL

EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB,

ANTENNA TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO

OPERATE WITHOUTDANGER OF ELECTRICAL SHOCK. DO NOT USE ALINE ISOLATION

TRANSFORMER DURING THIS TESTUSE AN A.C. VOLTMETER, HAVING 5000 OHMS PER

VOLT OR MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A 1500 OHM 10

WATT RESISTOR, PARALLELED BYA .15 MFD. 150.V A.C TYPE CAPACITOR BETWEEN A

KNOWN GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED

METALLIC PARTS, ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE

COMBINATION OF 1500 OHM RESISTOR AND .15 MFD CAPACITOR. REVERSE THE A.C.

PLUG AND REPEAT A.C. VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC

PART.

VOLT AGE MEASURED MUSTNOTEXCEED 75 VOL TS R.M.S. THIS CORRESPONDS TO 0.5

MILLIAMP A.C ANY VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK

HAZARD AND MUSTBE CORRECTED IMMEDIA TELY .

SUBJECT : GRAPHIC SYMBOLS

THE LIGHTNING FLASH WITH APROWHEAD SYMBOL. WITHIN AN

EQUILATERAL TRIANGLE, IS INTENDED TO ALERT THE SERVICE

PERSONNEL TO THE PRESENCE OF UNINSULATED “DANGEROUS

VOLTAGE” THAT MAY BE OF SUFFICIENT MAGNITUDE TO CONSTITUTE A

RISK OF ELECTRIC SHOCK.

THE EXCLAMATION POINT WITHIN AN EQUILATERAL TRIANGLE IS

INTENDED TO ALERT THE SERVICE PERSONNEL TO THE PRESENCE OF

IMPORTANTSAFETYINFORMA TION IN SERVICE LITERATURE.

SUBJECT : X-RADIATION

1. BE SURE PROCEDURES AND INSTRUCTIONS TO ALLSER VICE PERSONNELCOVER THE

SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENTT .V.

RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RAYS

WHEN THE HIGH VOLTAGE IS AT THE FACTORYSPECIFIED LEVEL. THE PROPER VALUE

IS GIVEN IN THE APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY

CAUSE A FAILURE OF THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER

CERTAIN CIRCUMSTANCES, MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE

LEVELS.

2. ONLYFACTOR YSPECIFIED C.R.T. ANODE CONNECTORS MUSTBE USED. DEGAUSSING

SHIELDS ALSO SERVE AS X-RAY SHIELD IN COLOR SETS, AL W AYS RE-INSTALLTHEM.

3. IT IS ESSNTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND

RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE

CHECKED PERIODICALLY AGAINST A REFERENCE STANDARD, SUCH AS THE ONE

AVAILABLE ATYOUR DISTRIBUTOR.

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY THERE IS NO

POSSIBILITY OF AN X-RADIATION PROBLEM. EVERY TIME A COLOR CHASSIS IS

SERVICED. THE BRIGHTNESS SHOULD BE RUN UPAND DOWN WHILE MONITORING THE

HIGH VOLTAGE WITH A METER TO BE CERTAIN THAT THE HIGH VOLTAGE DOES NOT

EXCEED THE SPECIFIED VALUE AND THA TITIS REGULA TING CORRECTLY , WE SUGGEST

THATYOU AND YOUR SERVICE ORGANIZATION REVIEW TEST PROCEDURES SO THAT

VOLT AGE REGULA TION IS AL W A YS CHECKED AS ASTANDARD SERVICING PROCEDURE.

AND THAT THE HIGH VOLTAGE READING BE RECORDER ON EACH CUSTOMER’S

INVOICE.

5. WHEN TROUBLESHOOTING AND MAKING TESTMEASUREMENTS IN APRODUCTWITH A

PROBLEM OF EXCESSIVE HIGH VOLTAGE, AVOID BEING UNNECESSARILY CLOSE TO

THE PICTURE TUBE AND THE HIGH VOLTAGE SUPPL Y. DO NOTOPERA TE THE PRODUCT

LONGER THAN IS NECESSARYTO LOCA TE THE CAUSE OF EXCES SIVE VOLTAGE.

6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES DESCRIBED IN THE

APPROPRIATE SCHEMATIC AND DIAGRAMS (WHERE USED).

SUBJECT : IMPLOSION

1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTE GRALIMPLOSION

PROTECTION SYSTEM, BUT CARE SHOULD BE TAKEN TO AVOID DAMAGE DURING

INSTALLATION, A VOID SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

2. USE ONLYRECOMMENDED FACTOR YREPLACEMENTTUBES.

SUBJECT : TIPS ON PROPER INSTALLATION

1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS, CUBBYHOLE OR CLOSELY

FITTING SHELF SPACE. OVER OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED

AIR FLOW.

2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO INSTALLATIONS

WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A

FACTOR, ETC.

3. AVOID PALCEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING. THE

CUSTOMER SHOULD ALSO AVOID THE USE OF DECORATIVE SCARVES OR OTHER

COVERINGS WHICH MIGHT OBSTRUCT VENTILATION.

4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT.

MUST FOLLOW THE FACTORY APPROVED MOUNTING INSTRUCTIONS A PRODUCT

MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE

EQUIVALENTTHICKNESS IN SPACERS) TO PROVIDE ADEQUA TE AIR FLOW ACROSS THE

BOTTOM, BOLTS OR SCREWS USED FOR F ASTENERS MUSTNOT TOUCH ANYP ARTS OR

WIRING. PERFORM LEAKAGE TESTON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON SLOPING SHELF

OR ATILTED POSITION, UNLESS THE PRODUCTIS PROPERLYSECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO THE

CART. CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLLA CART WITH

SMALLCASTERS ACROSS THRESHOLDS OR DEEPPILE CARPETS.

7. CAUTION CUSTOMERS AGAINSTTHE USE OF ACART OR STAND WHICH HAS NOTBEEN

LISTED BY UNDERWRITERS LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC

MODEL OF TELEVISION RECEIVER OR GENERICALLYAPPROVED FOR USE WITH T.V.’S

OF THE SAME OR LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS, EXPLAIN THAT A

FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO

DISASTROUS CONSEQUENCES TO HOME AND FAMILY.

1-3

SERVICING PRECAUTIONS

CAUTION: Before servicing the VCR+DVD covered by this

service data and its supplements and addends, read and

follow the SAFETY PRECAUTIONS. NOTE: if unforeseen

circumstances create conflict between the following servicing

precautions and any of the safety precautions in this

publications, always follow the safety precautions.

Remember Safety First :

General Servicing Precautions

1. Always unplug the VCR+DVD AC power cord from the AC

power source before:

(1) Removing or reinstalling any component, circuit board,

module, or any other assembly.

(2) Disconnecting or reconnecting any internal electrical

plug or other electrical connection.

(3) Connecting a test substitute in parallel with an

electrolytic capacitor.

Caution : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an

explosion hazard.

2.Do not spray chemicals on or near this VCR+DVD or any of

its assemblies.

3.Unless specified otherwise in this service data, clean

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner, cottontipped swab, or comparable soft applicator.

Unless specified otherwise in this service data, lubrication of

contacts is not required.

4. Do not defeat any plug/socket B+ voltage interlocks with

which instruments covered by this service manual might be

equipped.

5.Do not apply AC power to this VCR+DVD and/or any of its

electrical assemblies unless all solid state device heat sinks

are correctly installed.

6.Always connect the test instrument ground lead to an

appropriate ground before connecting the test instrument

positive lead. Always remove the test instrument ground

lead last.

Insulation Checking Procedure

Disconnect the attachment plug from the AC outlet and turn

the power on. Connect an insulation resistance meter (500V)

to the blades of the attachment plug. The insulation resistance

between each blade of the attachment plug and accessible

conductive parts (Note 1) should be more than 1Mohm.

Note 1: Accessible Conductive Parts include Metal panels,

Input terminals, Earphone jacks,etc.

Electrostatically Sensitive (ES) Devices

Some semiconductor (solid state) devices can be damaged

easily by static electricity. Such components commonly are

called Electrostatically Sensitive (ES) Devices. Examples of

typical ES devices are integrated circuits and some field effect

transistors and semiconductor chip components.

The following techniques should be used to help reduce the

incidence of component damage caused by static electricity.

1.Immediately before handling any semiconductor component

or semiconductor-equipped assembly, drain off any

electrostatic charge on your body by touching a known earth

ground. Alternatively, obtain and wear a commercially

available discharging wrist strap device, which should be

removed for potential shock reasons prior to applying power

to the unit under test.

2.After removing an electrical assembly equipped with ES

devices, place the assembly on a conductive surface such

as aluminum foil, to prevent electrostatic charge buildup or

exposure of the assembly.

3.Use only a grounded-tip soldering iron to solder or unsolder

ES devices.

4.Use only an anti-static solder removal device. Some solder

removal devices not classified as “anti-static” can generate

electrical charges sufficient to damage ES devices.

5.Do not use freon-propelled chemicals. These can generate

an electrical charge sufficient to damage ES devices.

6.Do not remove a replacement ES device from its protective

package until immediately before you are ready to install it.

(Most replacement ES devices are packaged with leads

electrically shorted together by conductive foam, aluminum

foil,or comparable conductive material).

7. Immediately before removing the protective material from

the leads of a replacement ES device, touch the protective

material to the chassis or circuit assembly into which the

device will be installed.

Caution: Be sure no power is applied to the chassis or

circuit, and observe all other safety precautions.

8.Minimize bodily motions when handling unpackaged

replacement ES devices. (Normally harmless motion such

as the brushing together of your clothes fabric or the lifting

of your foot from a carpeted floor can generate static

electricity sufficient to damage an ES device.)

1-4

INFORMATION ABOUT LEAD-FREE SOLDERING

Philips CE is producing lead-free sets from 1.1.2005 onwards.

INDENTIFICATION:

Regardless of special logo (not always indicated)

one must treat all sets from 1 Jan 2005 onwards, according next rules:

Example S/N:

Bottom line of typeplate gives a 14-digit S/N. Digit 5&6 is the year, digit 7&8 is the

week number, so in this case 1991 wk 18

So from 0501 onwards = from 1 Jan 2005 onwards

Important note: In fact also products of year 2004 must be treated in this way as long as you avoid mixing solder-alloys

(leaded/ lead-free). So best to always use SAC305 and the higher temperatures belong to this.

Due to lead-free technology some rules have to be respected by the workshop during a repair:

• Use only lead-free solder alloy Philips SAC305 with order code 0622 149 00106. If lead-free solder-paste is required,

please contact the manufacturer of your solder-equipment. In general use of solder-paste within workshops should be

avoided because paste is not easy to store and to handle.

• Use only adequate solder tools applicable for lead-free solder alloy. The solder tool must be able

* To reach at least a solder-temperature of 400°C,

* To stabilize the adjusted temperature at the solder-tip

* To exchange solder-tips for different applications.

• Adjust your solder tool so that a temperature around 360°C - 380°C is reached and stabilized at the solder joint.

Heating-time of the solder-joint should not exceed ~ 4 sec. Avoid temperatures above 400°C otherwise wear-out of tips

will rise drastically and flux-fluid will be destroyed. To avoid wear-out of tips switch off un-used equipment, or reduce heat.

• Mix of lead-free solder alloy / parts with leaded solder alloy / parts is possible but PHILIPS recommends strongly to avoid

mixed solder alloy types (leaded and lead-free).

If one cannot avoid or does not know whether product is lead-free, clean carefully the solder-joint from old solder alloy

and re-solder with new solder alloy (SAC305).

• Use only original spare-parts listed in the Service-Manuals. Not listed standard-material (commodities) has to be

purchased at external companies.

• Special information for BGA-ICs:

- always use the 12nc-recognizable soldering temperature profile of the specific BGA (for de-soldering always use the

lead-free temperature profile, in case of doubt)

- lead free BGA-ICs will be delivered in so-called ‘dry-packaging’ (sealed pack including a silica gel pack) to protect the

IC against moisture. After opening, dependent of MSL-level seen on indicator-label in the bag, the BGA-IC possibly still

has to be baked dry. (MSL=Moisture Sensitivity Level). This will be communicated via AYS-website.

Do not re-use BGAs at all.

• For sets produced before 1.1.2005 (except products of 2004), containing leaded solder-alloy and components, all

needed spare-parts will be available till the end of the service-period. For repair of such sets nothing changes.

• On our website www.atyourservice.ce.Philips.com you find more information to:

* BGA-de-/soldering (+ baking instructions)

* Heating-profiles of BGAs and other ICs used in Philips-sets

You will find this and more technical information within the “magazine”, chapter “workshop news”.

For additional questions please contact your local repair-helpdesk.comparable conductive material).

1-5

SERVICE INFORMATION FOR EEPROM IC SETTING(VCR)

◀▶

EEPROM option code No. setting

NAME HEX BINARY

OPT0 00 00000000

OPT1 00 00000000

OPT2 00 00000000

OPT3 00 00000000

OPT4 00 00000000

OPT5 00 00000000

12/26 - 00 V00 <--- µ-COM Ver.

ID : LG

VERSION : 05 ROM

DATE : 02.17.05 Correction Ver.

MODEL NAME HEX BINARY

DVP3350V/01 OPT0 90 00000000

OPT1 F4 00000000

OPT2 60 00000000

OPT3 40 00000000

OPT4 03 00000000

OPT5 4B 00000000

DVP3350V/02 OPT0 90 00000000

OPT1 D4 00000000

OPT2 6B 00000000

OPT3 40 00000000

OPT4 0D 00000000

OPT5 4B 00000000

DVP3350V/05 OPT0 90 00000000

OPT1 F4 00000000

OPT2 21 00000000

OPT3 80 00000000

OPT4 0D 00000000

OPT5 4B 00000000

EEPROM option code No. setting procedure

1. DETECT NEW EEPROM (OPTION EDIT

SCREEN)

- Eeprom EDIT screen automatically

appears if replacing Eeprom.

- Setup option data using the cursor

Up/Down key of a remote control.

(Setup upon BOM depending on

OPT0~OPT5 model)

• Since an initial remote control is set to LG

for LG model, appropriately set optiona

data using the cursor Up/Down key.

2. EEPROM WRITED AND EEPROM INITIAL

- Writes data on EEPROM by using

REMOCON "OK" + FRONT PLAY KEY

FOR MORE THAN 5 SECONDS.

3. PG ADJUST

1) Payback the SP standard tape

2) Press the “OK” key on the Remote

controller and the “PLAY” key on the

Front Panel the same time, then it goes

in to Tracking initial mode.

3) Repeat the above step(No.2), then it

finishes the PG adjusting automatically.

4) Stop the playback, then it goes out to

PG adjusting mode after mony the PG

data.

DVP3350V/19 OPT0 90 00000000

OPT1 FC 00000000

OPT2 E8 00000000

OPT3 40 00000000

OPT4 06 00000000

OPT5 4B 00000000

WR : OK I : EXIT MOVE :

EDIT :

1-6

SERVICE INFORMATION FOR EEPROM (DVD)

POWER ON

DVD LOGO Status (NO Disk status)

Remotecontrol

Pause key-->1-->4-->7-->2 in order.

Press number 0~9, Press charater

A~F (1~6 for a while)

Use arrow key ( ) to move

to approprite position and make

changes

DETECT NEW EEPROM (OPTION EDIT SCREEN)

MODEL DVP3350V/01 DVP3350V/02 DVP3350V/05 DVP3350V/19

NAME HEX HEX HEX HEX

OPT1 44 48 47 46

OPT2 45 55 42 52

OPT3 00 00 00 00

OPT4 D3 D3 D3 D3

OPT5 07 07 07 07

OPT6 0F 0F 0F 0F

OPT7 F4 F4 F4 F4

OPT8 00 00 00 00

OPT9 00 00 00 00

OPTA 00 00 00 00

OPTB 80 80 80 80

OPTC 00 00 00 00

OPTD 00 00 00 00

OPTE 00 00 00 00

OPTF 00 00 00 00

OPTG 00 00 00 00

Press pause key once

Change will be applied when power

OFF-->ON.

* OPTION

• NTSC model doesn’t have VCR option and use DVD option B~F as VCR option. (only DVD exist)

• PAL model has another separate VCR option. (Both VCR and DVD exist)

1-7

SPECIFICATIONS

• GENERAL

Power requirements AC 220 ~ 230V, 50Hz

Power consumption 17W

Dimensions (approx.) 430 x 78.5 x 265mm (W x H x D)

Mass (approx.) 4.06kg

Operating temperature 5°C to 35°C (41°F to 95°F)

Operating humidity 5% to 90%

Timer 24 hours display type

RF Modulator UHF 22 ~ 68 (Adjustable)

• SYSTEM

Laser Semiconductor laser, wavelength 650nm

Video Head system Double azimuth 6 heads, helical scanning.

Signal system PAL

Frequency response DVD (PCM 96kHz): 8Hz to 44kHz

DVD (PCM 48kHz): 8Hz to 22kHz

CD: 8Hz to 20kHz

Signal-to-noise ratio More than 100dB (ANALOG OUT connectors only)

Harmonic distortion Less than 0.008%

Dynamic range More than 100dB (DVD)

More than 95dB (CD)

• INPUTS (VCR)

Audio -6.0dBm, more than 10kohms (SCART)

-6.0dBm, more than 47kohms (RCA)

Video 1.0Vp-p, 75ohms, unbalanced (SCART/RCA)

• OUTPUTS (DVD)

VIDEO OUT 1Vp-p 75ohms, sync negative

COMPONENT VIDEO OUT (Y) 1.0V (p-p), 75Ω, negative sync, RCA jack x 1

(Progressive Scan) (Pb)/(Pr) 0.7V (p-p), 75Ω, RCA jack x 2

RGB output 0.7Vp-p, 75ohms

Audio output (coaxial audio) 0.5V (p-p), 75Ω, RCA jack x 1

Audio output (analog audio) 2.0Vrms (1kHz, 0dB), 600Ω,

RCA jack (L, R)x2/SCART (TO TV)

• OUTPUTS (VCR)

Audio -6.0dBm, less than 1kohms (SCART)

Video 1.0Vp-p, 75ohms, unbalanced (SCART)

RGB output 0.7Vp-p, 75ohms

*Design and specifications are subject to change without notice.

1-8

SECTION 2

CABINET & MAIN CHASSIS

CONTENTS

EXPLODED VIEWS.....................................................................................................................................2-2

1. CABINET AND MAIN FRAME SECTION..................................................................................................2-2

2. DECK MECHANISM SECTION [ DVD MD (DP-10C) ].............................................................................2-3

3. DECK MECHANISM SECTION [ VCR DECK D37(N) ]............................................................................2-4

1) FRONT LOADING MECHANISM SECTION.........................................................................................2-4

2) MOVING MECHANISM SECTION (1)...................................................................................................2-5

3) MOVING MECHANISM SECTION (2)...................................................................................................2-6

4. PACKING ACCESSORY SECTION...........................................................................................................2-7

2-1

EXPLODED VIEWS

1. CABINET AND MAIN FRAME SECTION

463

463

THE EXCLAMATION POINT WITHIN AN

NOTES)

EQUILATERAL TRIANGLE IS INTENDED

TO ALERT THE SERVICE PERSONNEL

TO THE PRESENCE OF IMPORTANT

SAFETY INFORMATION IN SERVICE

LITERATURE.

463

250

463

272

300

273

457

470

471

469

A26

A47

271

A00

469

A50

288

324

A46

465

323

CN501

322

469

274

463

330

261

452

285

283

280

286

284

A43

2-2

A44

260

452

261

452

2. DECK MECHANISM SECTION [ DVD MD (DP-10C) ]

A26

012

A02

017

013

015

019

439

435

018

015B

015A

014

440

001

A01

002

003

020

016

012A

432

026

A03

012

2-3

036

030

024

025

439

010

431

435

012A

021

430

3.DECK MECHANISM SECTION [ VCR DECK D37(N) ]

1) FRONT LOADING MECHANISM SECTION

A22

054A

054

100

A21

106

105

107

102

A23

114

032

113

112

109

103

A24

110

116

115

2-4

2) MOVING MECHANISM SECTION (1)

008

026

A03

006

007

015

004

027

014

013

029

009

409

021

031

028

405

406

016

A01

003

022

2-5

012

024

017

011

031

079

032

3) MOVING MECHANISM SECTION (2)

A12

068

069

066

070

023

065

078

076

032

051

052

067

A11

064

061

517

056

077

410

052A

058

080

518

2-6

055

060

4. PACKING ACCESSORY SECTION

808

BATTERY

806

RF CABLE

REMOTE CONTROLLER

900

ASSEMBL

803

PACKING, CASING

802

BOX

Y

INSTRUCTION ASSEMBLY

801

P

ACKING, CASING

803

804

BAG

2-7

MEMO

2-8

SECTION 3

ELECTRICAL

CONTENTS

VCR PART

VCR ELECTRICAL ADJUSTMENT

PROCEDURES

1. SERVO ADJUSTMENT................................3-2

VCR ELECTRICAL

TROUBLESHOOTING GUIDE

1. POWER(SMPS) CIRCUIT ............................3-3

2. SYSTEM/KEY CIRCUIT...............................3-6

3. SERVO CIRCUIT .........................................3-7

4. Y/C CIRCUIT..............................................3-10

5. HI-FI CIRCUIT............................................3-14

6. TUNER/IF CIRCUIT ...................................3-17

BLOCK DIAGRAMS.....................................3-19

1. POWER(SMPS) BLOCK DIAGRAM..........3-19

2. SYSTEM BLOCK DIAGRAM......................3-21

3. A VCP BLOCK DIAGRAM...........................3-23

4. HI-FI BLOCK DIAGRAM ............................3-25

5. TUNER BLOCK DIAGRAM........................3-27

CIRCUIT DIAGRAMS ..................................3-29

1. POWER(SMPS) CIRCUIT DIAGRAM........3-29

2. SYSTEM CIRCUIT DIAGRAM ...................3-31

3. A VCP CIRCUIT DIAGRAM.........................3-33

4. HI-FI CIRCUIT DIAGRAM..........................3-35

5. TUNER CIRCUIT DIAGRAM......................3-37

WAVEFORMS ................................................3-39

CIRCUIT VOLTAGE CHART .........................3-41

IC BLOCK DIAGRAMS..................................3-47

................................................3-2

....................3-3

DVD PART

DVD ELECTRICAL

TROUBLESHOOTING GUIDE

1. POWER CHECK FLOW .............................3-59

2. SYSTEM OPERATION FLOW ...................3-60

3. TEST & DEBUG FLOW .............................3-61

DETAILS AND WAVEFORMS ON

SYSTEM TEST AND DEBUGGING

1. SYSTEM 27MHZ CLOCK,

RESET SIGNAL .........................................3-67

2. SDRAM CLOCK ........................................3-68

3. TRAY OPEN/CLOSE SIGNAL....................3-68

4. SLED CONTROL RELATED SIGNAL

(NO DISC CONDITION) .............................3-70

5. LENS CONTROL RELATED SIGNAL

(NO DISC CONDITION) ............................3-70

6. LASER POWER CONTROL RELATED

SIGNAL (NO DISC CONDITION)...............3-71

7. FOCUS ON WAVEFORM...........................3-71

8. SPINDLE CONTROL WAVEFORM

(NO DISC CONDITION) .............................3-72

9. TRACKING CONTROL RELATED

SIGNAL (SYSTEM CHECKING)................3-73

10. RF WAVEFORM.........................................3-74

11. ZR36966 AUDIO OPTICALAND

COAXIAL OUTPUT (SPDIF).......................3-74

12. ZR36966 VIDEO OUTPUT WAVEFORM...3-75

13. AUDIO OUTPUT FROM

AUDIO PREAMP........................................3-76

..................3-59

........3-67

PRINTED CIRCUIT BOARD

DIAGRAMS

1. MAIN P.C.BOARD (TOP SIDE)..................3-51

2. MAIN P.C.BOARD (BOTTOM SIDE) ..........3-53

3. POWER P.C.BOARD..................................3-55

4. KEY P.C.BOARD........................................3-57

.....................................................3-51

BLOCK DIAGRAMS.....................................3-77

1. SYSTEM BLOCK DIAGRAM......................3-77

2. SERVO BLOCK DIAGRAM ........................3-78

3. AUDIO & VIDEO IN/OUT

BLOCK DIAGRAM .....................................3-79

CIRCUIT DIAGRAMS ..................................3-81

1. MPEG CIRCUIT DIAGRAM........................3-81

2. SERVO CIRCUIT DIAGRAM......................3-83

3. JACK CIRCUIT DIAGRAM.........................3-85

IC BLOCK DIAGRAMS..................................3-87

3-1

VCR PART

VCR ELECTRICAL ADJUSTMENT PROCEDURES

1. SERVO ADJUSTMENT

1) PG Adjustment

• Test Equipment

a) OSCILLOSCOPE C) PAL MODEL : PAL SP TEST TAPE

b) NTSC MODEL : NTSC SP TEST TAPE

• Adjustment And Specification

MODE MEASUREMENT POINT ADJUSTMENT POINT SPECIFICATION

PLAY

H/SW(TP)

R/C TRK JIG KEY 6.5 ±0.5H

• Adjustment Procedure

V.Out

a) Insert the SP Test Tape and play.

Note - Adjust the distance of X, pressing the Tracking(+) or Tracking(-) when the “ATR” is blink after the

SP Test Tape is inserted.

b) Connect the CH1 of the oscilloscope to the H/SW(TP) and CH2 to the Video Out for the VCR.

c) Trigger the mixed Combo Video Signal of CH2 to the CH1 H/SW(TP) and then check the distance (time

difference), which is from the selected A(B) Head point of the H/SW(TP) signal to the starting point of

the vertical synchronized signal, to 6.5H ± 0.5H (412µs, 1H=63µs).

• PG Adjustment Method

a-1) Playback the SP standard tape

b-2) Press the “OK” key on the Remote control and the “REC” key on the Front Panel at the same time for

more than 5seconds, then it goes in to Tracking initial mode.

c-3) Repeat the above step(No.b-2), then it finishes the PG adjusting automatically.

d-4) Stop the playback, then it goes out to PG adjusting mode after mony the PG data.

• CONNECTION

V.Out

OSCILLOSCOPE

•WAVEFORM

H/SW(TP)

H/SW

Composite

VIDEO

6.5H(416us)

3-2

R/C KEY

CH1 CH2

H/SW

(TP)

V.out

VCR ELECTRICAL TROUBLESHOOTING GUIDE

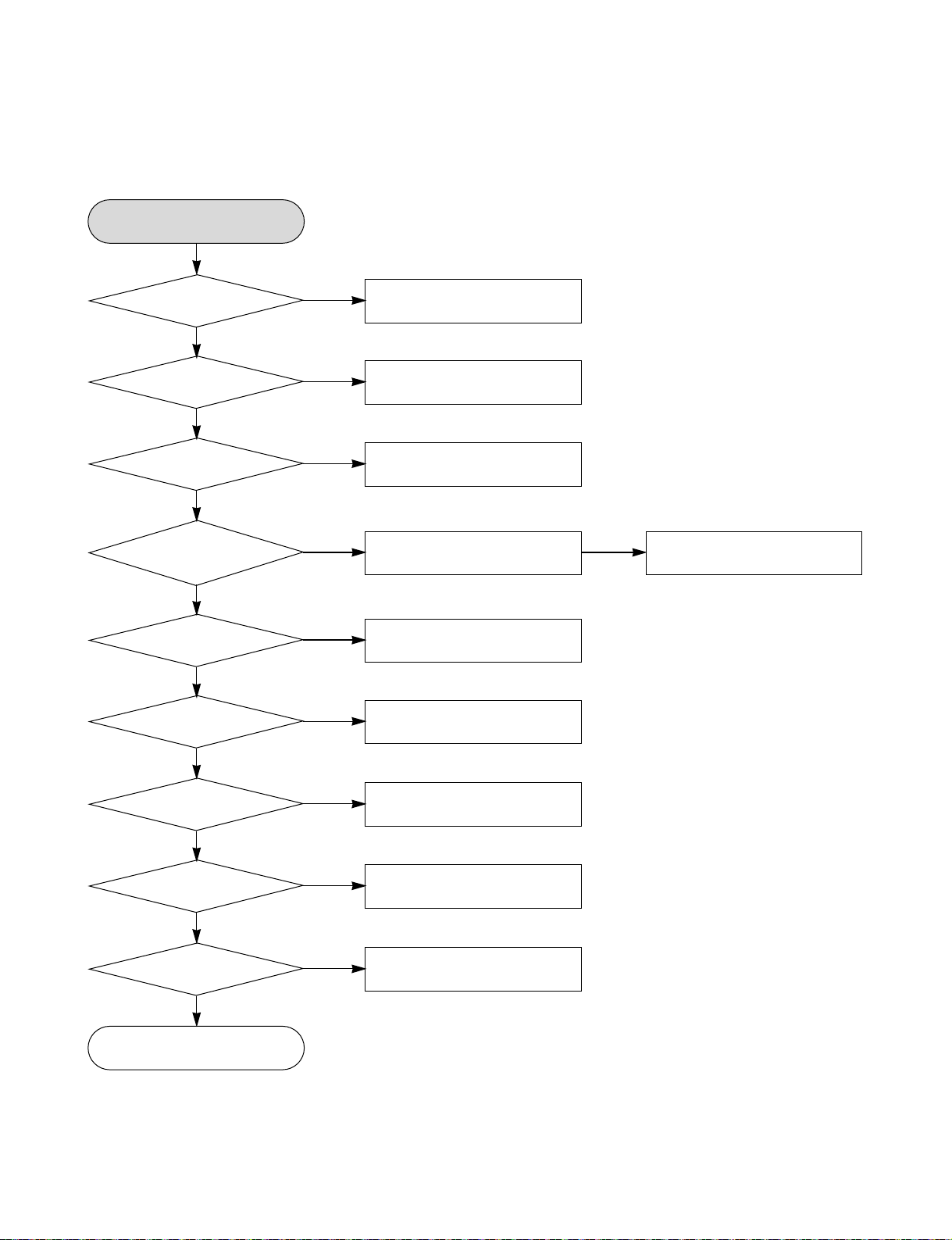

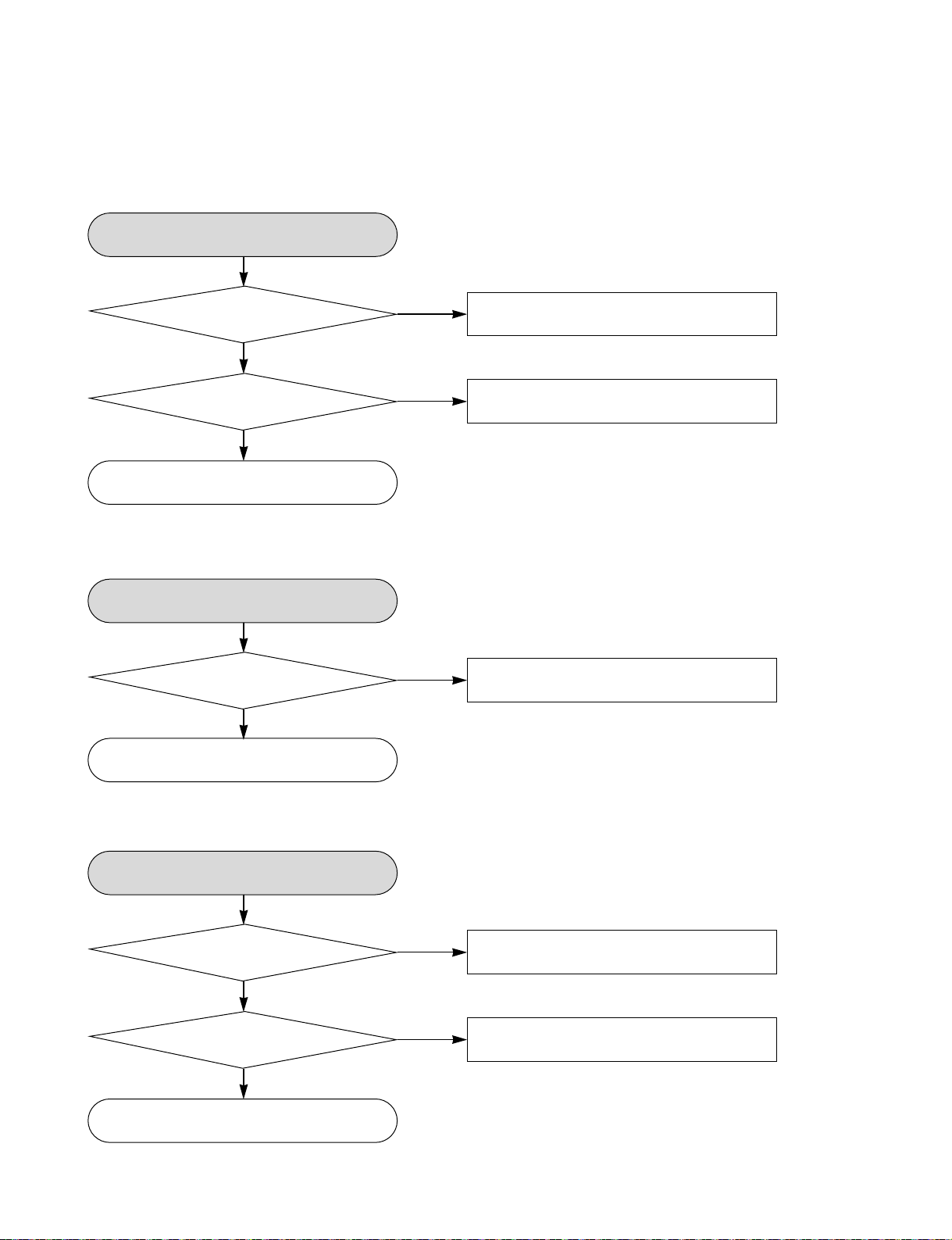

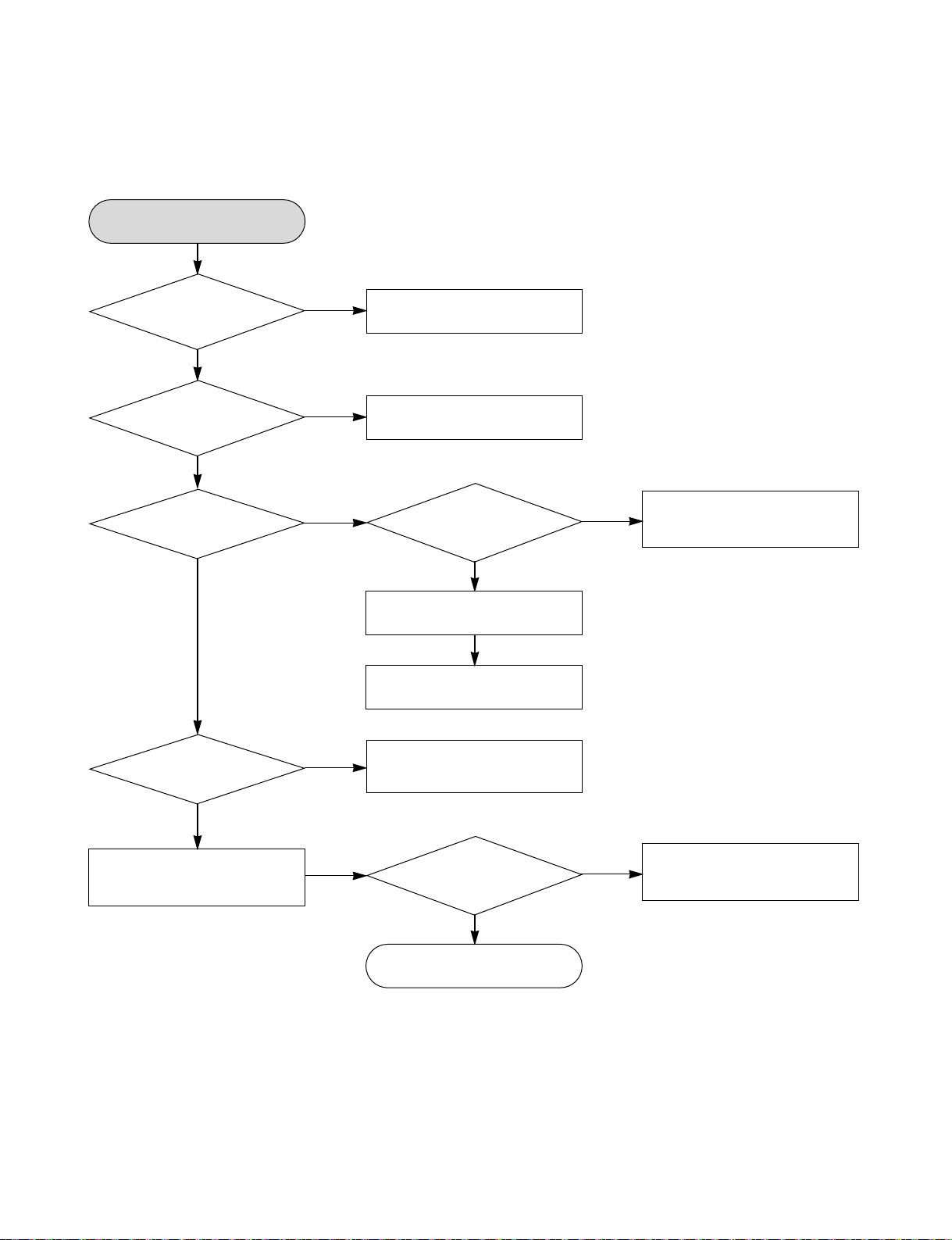

1. POWER(SMPS) CIRCUIT

1-1. No 5.3VA

No 5.3VA

YES

Is the FR101

Normal?

YES

Is the BD101

Normal?

YES

Is the R101

Normal?

YES

Is Vcc

(9V ~ 18V) supplied

to IC101 Pin2?

YES

Are the D125

normal?

YES

Is there

about 2.5V at the

IC103 Pin1?

YES

NO

NO

NO

NO

NO

NO

Replace FR101

(Use the same ICW)

Replace the BD101

Replace the R101

Is the D102 normal?

Replace the D125

Replace the IC103

NO

Check or Replace the D102

Is the D123

normal?

YES

Is the D124

Normal?

YES

Is the D121

Normal?

YES

Power Line of Main

PCB is short

NO

NO

NO

Replace the D123

Replace the D124

Replace the D121

3-3

VCR ELECTRICAL TROUBLESHOOTING GUIDE

1-2. No 5.0V_D

No 5.0V_TNo 9V

YES

Vcc(5.3V) supplied to

Q165 Emittor?

Q162 Base “H”?

Check or Replace

1-3. No 5.0V_T

Vcc(5.3V) supplied to

Q163 Emittor?

Is the

YES

Is the

YES

the Q165

No 5.0V_T

YES

Is the

YES

NO

NO

NO

Check or Replace the D125

Check the PWR CTL

“H” signal from µ-com

Check or Replace the D125

Check or Replace the Q163

1-4. No 3.8V

Is the

Q162 Base “H”?

YES

No 3.8V

YES

Is the D123

normal?

YES

Power line of Main

PCB is short

NO

NO

Check the PWR CTL

“H” signal from µ-com

Check or Replace the D123

3-4

VCR ELECTRICAL TROUBLESHOOTING GUIDE

1-5. No 33V

No 33V

YES

Vcc(33V) supplied to

Is the

Q161 Emittor?

YES

Is the Q162 Base

“H”?

YES

Check or Replace the Q161

1-6. No Motor_Vcc (To Cap, Drum Motor)

No Motor_Vcc

YES

Is the Vcc(14V)

supplied to C134?

YES

NO

NO

NO

Check or Replace the D121

Check the PWR CTL

“H” signal from µ-com

Check or Replace the D124

Check or Replace the Cap / Drum

1-7. No REG 12V

No REG 12V

YES

Is the

Vcc(14V) supplied to

Q165 Collector?

YES

Is the

Vcc(14V) supplied to

Q165 Base?

YES

Check or Replace the Q165

NO

NO

Check or Replace D124

Check the PWR CTL

“H” signal from µ-com

3-5

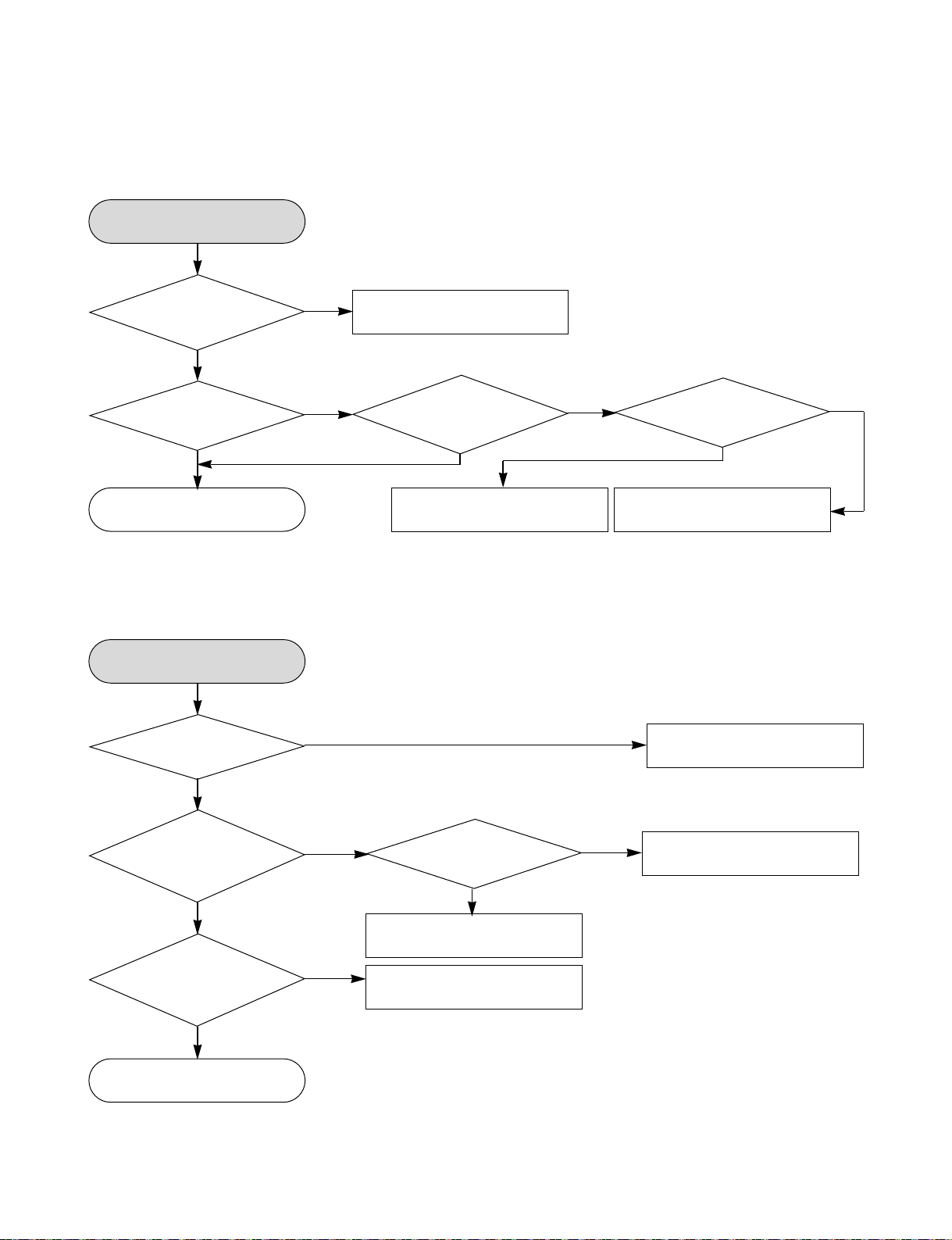

VCR ELECTRICAL TROUBLESHOOTING GUIDE

2. SYSTEM/KEY CIRCUIT

2-1. AUTO STOP

Auto Stop

YES

Does the

SW25 waveform

appear at the IC501

NO

Check the Drum Motor

signal.

Pin23?

YES

Do the

T-UP Reel Pulses

appear at the IC501

Pin3?

YES

Replace the IC501.

NO

YES

Do T/UP

Reel Pulses appear

at the Q514 Base

terminal?

Replace the T/UP Reel

2-2. The unstable loading of a Cassette tape

The unstable loading

of a Cassette tape

YES

applied to the PMC01

Is 12V

Pin8?

NO

Sensor (RS501).

NO

Does 5.0V

appear at the

RS501?

YES

Check the Power Circuit.

Check the Power.

NO

YES

Does the

“H” signal appear

at the IC501 Pin32

during inserting

NO

Is 5.0V

applied to the

R544 ?

the CST?

YES

YES

Check the CST SW and

Does the

“L” signal appear

at the IC501 Pin19

during inserting

NO

the peripheral circuitry.

Check the IC501

Pins 86, 87, 88, 89.

the CST?

YES

Check the Deck

Mechanism.

Caution : Auto stop can occur because Grease or Oil is dried up

3-6

NO

Refer to SMPS 5.3VA

troubleshooting.

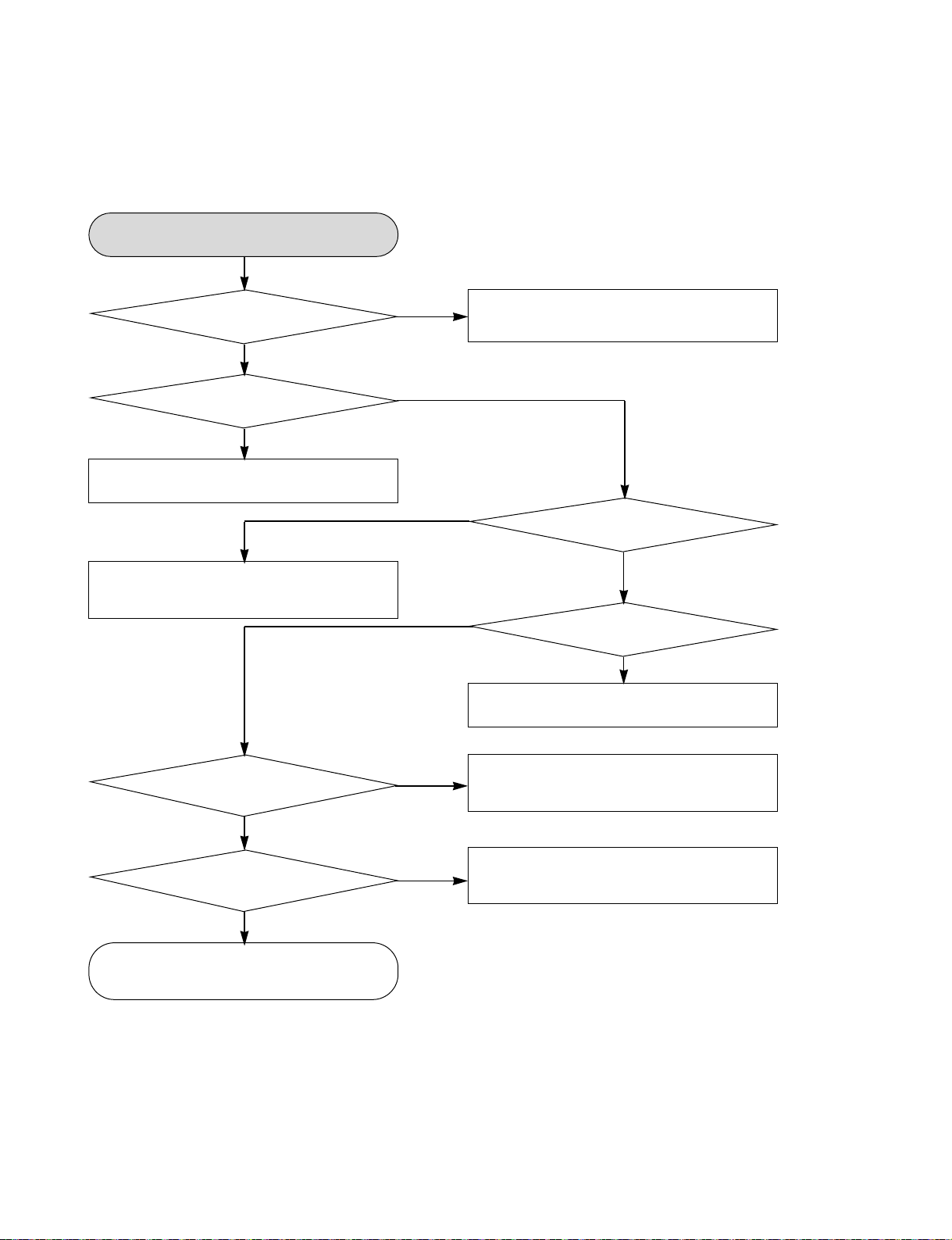

VCR ELECTRICAL TROUBLESHOOTING GUIDE

3. SERVO CIRCUIT

3-1. Unstable Video in PB MODE

Unstable Video in

PB Mode.

YES

Does the Noise level of the

screen change periodically?

YES

Does the CFG waveform

appear at the IC501 Pin67?

YES

On tracking

do the CTL pulses

move?

YES

Does the

Video Envelope waveform

appear at the IC501

Pin82?

YES

Replace the IC501.

3-2. When the Drum Motor

doesn’t run.

When the Drum Motor

doesn’t run,

YES

Does 12V

appear at PMC01

Pin8?

YES

Does 2.8V

appear at PMC01

Pin12?

YES

Check the connector

(PMC01) and the Drum

Motor Ass’y .

NO

NO

NO

NO

Replace the IC501.

Refer to “When the Y

signal doesn’t appear on

the screen in PB Mode”.

Refer to “(2)

No 12VA of Power section”

Do the

Drum PWM Pulses

appear at the IC501

Pin34?

YES

Aren’t the foil patterns and

the Components between

IC501 Pin34 and PMC01

Pin12 short?

Do the DFG

Pulses appear at the

IC501 Pin104?

YES

Do the

Drum PWM Pulses

appear at IC501

Pin34?

YES

NO

NO

NO

YES

Do the

DFG Pulses appear

at the PMC01

Pin11?

Replace the Cap M.

Aren’t the foil patterns and

the Components between

IC501 Pin 104 and PMC01

Pin11 short?

Replace the IC501.

NO

Aren’t the connecting patterns and the Components

between IC501 Pin34 and PMC01 Pin12 short?

3-7

VCR ELECTRICAL TROUBLESHOOTING GUIDE

3-3. When the Capstan Motor doesn’t run,

When the Capstan Motor doesn’t run,

Does

12VA appear at the

PMC01?

YES

Does

2.8V appear at the

PMC01?

YES

Check the PMC01 and the

Capstan Motor Ass’y.

YES

Aren’t the foil patterns and Components

between IC501 Pin33 and PMC01

Pin9 short?

YES

NO

Refer to “SMPS(CAPSTAN/12Volt)

Trouble Shooting”.

NO

Does the

PWM signal appear at the

IC501 Pin33?

NO

Does the

CFG signal appear at the

PMC01 Pin1?

NO

Check the Capstan Motor Ass’y.

Does the

CFG signal come into the

IC501 Pin67?

YES

Does the

Capstan PWM signal appear at

the IC501 Pin33?

YES

Aren’t the foil patterns and Components

between IC501 Pin33 and PMC01

Pin9 short?

NO

NO

Aren’t the foil patterns and component

between IC501 Pin67 and PMC01

Pin1 short?

Replace IC501.

3-8

VCR ELECTRICAL TROUBLESHOOTING GUIDE

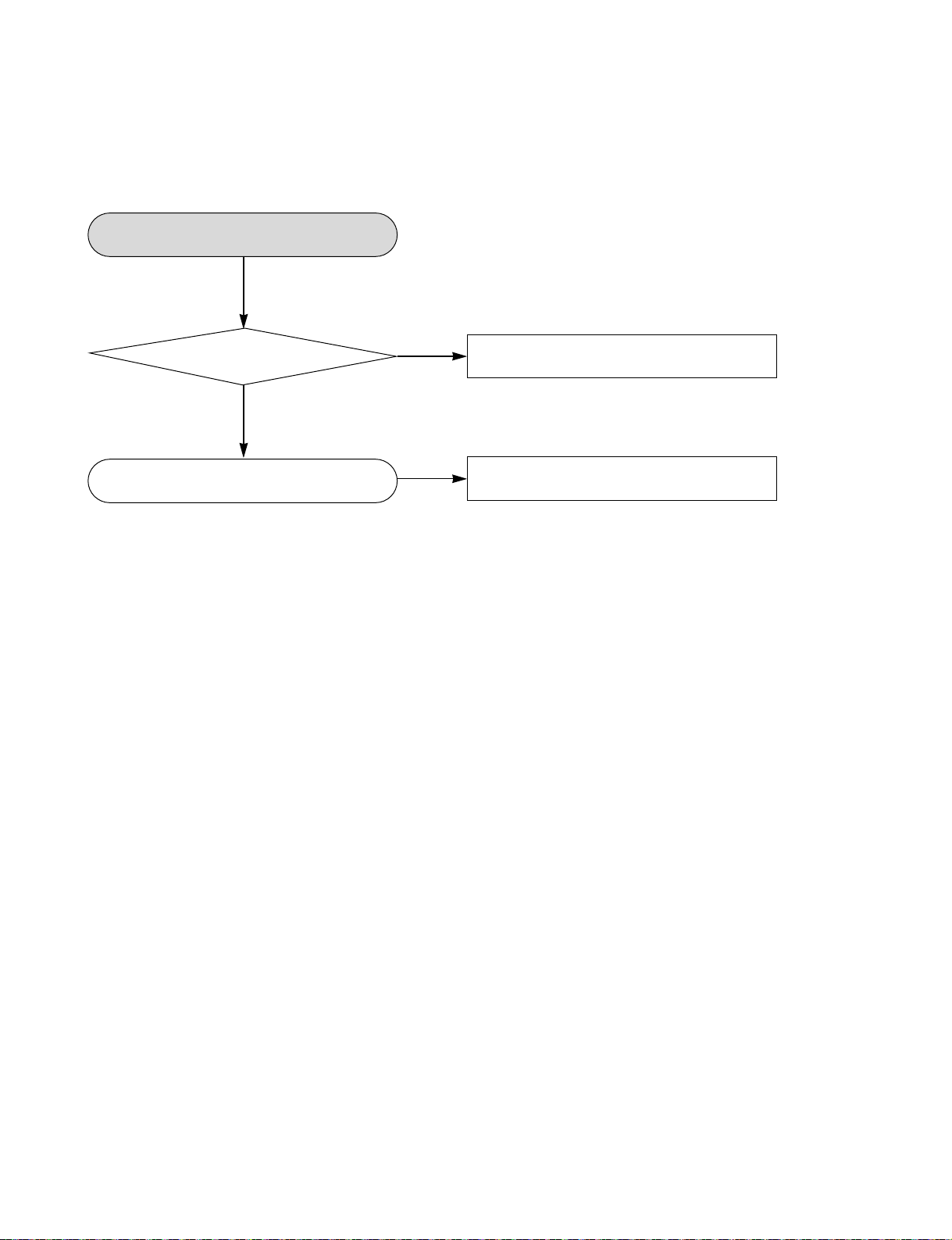

3-4. KEY doesn’t working

KEY doesn’t working.

YES

Is 5V

applied to the IC501

Pin36?

YES

Does LED or FLD change

when a function button is pressed?

NO

NO

Refer to “SMPS 5.3VA Trouble Shooting”.

Replace the defective switches.

3-9

VCR ELECTRICAL TROUBLESHOOTING GUIDE

4. Y/C CIRCUIT

4-1. No Video in EE Mode,

No Video in EE Mode

YES

Does the

Video signal appear

at the IC301

Pin48?

YES

Is 5V

applied to the IC301

Pins18, 24, 42, 55,

72, 91?

YES

Does the Video

signal appear at the

IC301 Pin65?

YES

NO

NO

NO

Check the 19Pin of Tuner.

Check the 5.0VT, 5.3VA

Line. (Power Circuit)

Is I2C BUS

signal applied to the

IC301 Pins68,

69?

YES

Check C316. (AGC)

YES

Replace the IC301.

NO

Check the System Circuit.

(Refer to “SYSTEM I2C BUS

Check Trouble Shooting”)

Does the Video

signal appear at the

IC501 Pin47?

YES

Does the Video signal

appear at the Emitter

terminal of the Q309?

NO

NO

Chck the path of the signal

between the IC301 Pin65

and IC501 Pin49.

Does the

12VT, 5.3VA appear

at the Emitter terminal

of the Q309.

YES

Replace the Q309.

3-10

NO

Check the 12VT, 5.4VA

Line. (Power Circuit)

VCR ELECTRICAL TROUBLESHOOTING GUIDE

4-2. When the Y(Luminance) signal doesn’t appear on the screen in PB Mode,

When the Y(Luminance)

signal doesn’t appear on

the screen in PB Mode,

YES

Is 5.0VT,

5.3VA applied to the

IC301 Pins24, 42, 55,

72, 91?

YES

Is the I2C

Bus siganl applied

IC301 to the Pins68,

69?

YES

Does the

normal RF signal

appear at the IC301

Pin78?

YES

NO

NO

NO

Check the line of the 5.0VT,

5.3VA Line. (Power Circuit)

Refer to “SYSTEM I2C BUS

Check Trouble Shooting”.

Is the

V.H.S/W signal

applied to the IC301

Pin70?

YES

Is V.H.S/W “H”

about 3.4V at the

IC301 Pin70?

YES

Clean the Drum.

NO

NO

NO

Check the System Circuit.

(IC501 Pin23)

Check the V.H.S/W level.

(Check R303, R304)

Replace the IC301.

Does the

Y(Luminance) RF

signal appear at the

IC301 Pin79?

YES

Is the

Y(Luminance) Video

waveform showed up

at the IC301

Pin43?

YES

Replace the IC301.

NO

NO

Check the path of the

Y(Luminance) RF signal.

(Check the C312)

Check the path of the

Y(Luminance) RF signal.

(Check C327)

3-11

YES

YES

VCR ELECTRICAL TROUBLESHOOTING GUIDE

4-3. When the C(Color) signal doesn’t appear on the screen in PB Mode,

When the C(Color) signal

doesn’t appear on the

screen in PB Mode,

YES

Is 5.0VT/

5.3VA applied to the

IC301 Pins24, 42,

55, 72, 91.

YES

Is the Color

Rotary signal

applied to the IC301

Pin70?

YES

Is Color Rotary “H”

about 3.4V?

YES

Does the

Color signal

appear at the IC301

Pin25 ?

YES

NO

NO

NO

NO

Check the line of the 5.0VT/

5.3VA Line. (Power Circuit)

Check the Color Rotary

Circuit. (IC501 Pin98 )

Check the Color Rotary

level. (Check the R303)

Does the

X301(4.43MHZ)

oscillate?

YES

Does the

Color signal

appear at the IC301

Pin21?

NO

NO

Replace the X301.

Check the Color Pass.

Replace the IC301.

YES

Replace the IC301.

3-12

VCR ELECTRICAL TROUBLESHOOTING GUIDE

4-4. When the Video signal doesn’t appear on the screen in REC Mode,

When the Video

signal doesn’t appear on

the screen in REC Mode,

YES

Is the EE

signal normal?

YES

Is 5.0VT/

5.3VA applied to the

IC301 Pins24,42,55,

72,91?

YES

Does PB

Mdoe operate

normally?

YES

Does the RF

signal appear at the

IC301 Pin78?

YES

NO

NO

NO

NO

Check EE Mode.

Check the line of the 5.0VT/

5.3VA Line.(Power Circuit)

Check PB Mode.

Is the REC

“H” signal (about 4V)

applied to the IC301

Pin80?

YES

Check REC Luminance

Pass & Color Pass.

NO

YES

Check the System

of REC “H”.

(the IC501 Pin27 / the D301)

Replace the IC301.

Does the

REC RF signal appear

at the IC301 Pins88,

89,94,95?

YES

Check the Drum &

Drum Connector

NO YES

Check the circuit of the

IC301 Pins85, 86.

3-13

Loading...

Loading...