Philips DVD-963-SA Service manual

DVD-Video Player DVD963SA

DVD963SA /001 /171 /691

CL 26532105_000.eps

Contents Page Contents Page

1 Technical Specs and Connection Facilities 2

2 Safety Instructions, Warnings, and Notes 3

3 Directions for Use 4

4 Mechanical-, Dismantling Instructions, and Ser vice

Hints 18

5 Diagnostic Software, Trouble Shooting and Test

Instructions 21

6 Block-, Wiring Diagram and Testpoint Overview

Block Diagram 41

Wiring Diagram 42

Testpoint Overviews 43

7 Electrical Diagrams and Print-Layouts Diagram PWB

Power Supply Unit 46

AV Board: SYS Clk & Control (Diagram A1) 47 53-56

AV Board: Upsampling DAC (Diagram A2) 48 53-56

AV Board: Audio DAC (Diagram A3) 49 53-56

AV Board: Curr to Volt. Converter(Diagram A4) 50 53-56

AV Board: Audio (Diagram A5) 51 53-56

AV Board: Video & SCART (Diagram A6) 52 53-56

Front Board: Display (Diagram D) 57 58-61

P-Scan Board: Line Doubler (Diagram P1) 62 65-70

P-Scan Board: Encoder (Diagram P2) 63 65-70

P-Scan Board: Video Output (Diagram P3) 64 65-70

Standby Board (Diagram S) 71 71

8 Alignments(Not Applicable) 73

9 Circuit Descriptions 73

List of Abbreviations 82

IC Data 83

10 Spare Parts List 87

280802

©

Copyright 2002 Philips Consumer Electronics B.V. Eindhoven, The Netherlands.

All rights reserved. No part of this publication may be reproduced, stored in a

retrieval system or transmitted, in any form or by any means, electronic,

mechanical, photocopying, or otherwise without the prior permission of Philips.

Published by MW 0268 Service PaCE Printed in the Netherlands Subject to modification EN 3122 785 12330

EN 2 DVD963SA1.

Technical Specifications and Connection Facilities

1. Technical Specifications and Connection Facilities

Specifications

PLAYBACK SYSTEM

DVD Video

SACD multi channel and SACD stereo

Video CD & SVCD

CD (CD-Recordable and CD-Rewritable)

MP3 CD

TV STANDARD (PAL/50Hz) (NTSC/60Hz)

Number of lines 625 525

Playback Multistandard (PAL/NTSC)

VIDEO PERFORMANCE

RGB output 0.7 Vpp into 75 ohm

YUV output Y: 1Vpp into 75 ohm

Pr/Cr Pb/Cb: 0.7Vpp into 75 ohm

S-Video output Y: 1Vpp into 75 ohm

C: 0.3Vpp into 75 ohm

Video output 1 Vpp into 75 ohm

Black Level Shift On/Off

Video Shift Left/Right

AUDIO FORMAT

DSD Multichannel and Stereo

MPEG/ Compressed Digital

Dolby Digital 16, 20, 24 bits

DTS/PCM fs, 44.1, 48, 96 kHz

MP3 96, 112, 128, 256 kbps and

(ISO 9660) variable bit rate fs 32, 44.1, 48kHz

Full decoding of Dolby Digital and DTS multi channel sound

Analogue Stereo Sound

Dolby Surround-compatible downmix from Dolby Digital

multi-channel sound

3D Sound for virtual 5.1 channel sound on 2 speakers

SACD AUDIO PERFORMANCE

D/A Converter DSD

SACD fs 2.8224MHz DC - 100kHz

Max. output voltage (0dB) 2V rms

Channel unbalance <0.5 dB

Cut-off frequency 50kHz (Front)

40kHz (Surround, Centre,

Subwoofer)

Signal-Noise (1kHz) -125 dB

Dynamic Range (1kHz) -105 dB

Crosstalk (1kHz) -120 dB

Total Harmonic Distortion (1kHz) -100 dB

AUDIO PERFORMANCE (Without upsampling)

DA Converter 24 bits

DVD fs 96 kHz 4 Hz - 44 kHz

CD/Video CD fs 44.1 kHz 4 Hz - 20 kHz

S-Video CD fs 48 kHz 4 Hz - 22 kHz

fs 44.1 kHz 4 Hz - 20 kHz

Signal-Noise (1kHz) < -120 dB

Dynamic Range (1kHz) < -95 dB

Crosstalk (1kHz) < -110 dB

Total Harmonic Distortion (1kHz) < -95 dB

MPEG MP3 MPEG Audio L3

CONNECTIONS

SCART 2x Euroconnector

Y Pb/Cb Pr/Cr (480i/p) Cinch 3x (green, blue, red)

S-Video Output Mini DIN, 4 pins

Video Output Cinch (yellow) 2x

Audio L+R output Cinch (white/red)

Digital Output 1 coaxial, 1 optical

IEC958 for CDDA / LPCM

IEC1937 for MPEG1/2, Dolby

Digital, DTS

6 channel analogue output

Audio Front L/R Cinch (white/red)

Audio Surround L/R Cinch (white/red)

Audio Centre Cinch (blue)

Audio Subwoofer Cinch (black)

CABINET

Dimensions (w x h x d) 435 x 101 x 315 mm

Weight Approximately 4.6 Kg

POWER SUPPLY

Power inlet 110-240V, 50/60Hz

Power usage Approx. 30W

Power usage standby < 1W

* typical playing time for movie with 2 spoken languages and

3 subtitle languages

Specifications subject to change without prior notice

CL 26532105_050.pdf

280802

Safety Instructions, Warnings and Notes

2. Safety Instructions, Warnings and Notes

EN 3DVD963SA 2.

2.1 Safety Instructions

2.1.1 General Safety

Safety regulations require that during a repair:

• Connect the unit to the mains via an isolation transformer.

• Replace safety components, indicated by the symbol ,

only by components identical to the original ones. Any

other component substitution (other than original type) may

increase risk of fire or electrical shock hazard.

Safety regulations require that after a repair, you must return

the unit in its original condition. Pay, in particular, attention to

the following points:

• Route the wires/cables correctly, and fix them with the

mounted cable clamps.

• Check the insulation of the mains lead for external

damage.

• Check the electrical DC resistance between the mains plug

and the secondary side:

1. Unplug the mains cord, and connect a wire between

the two pins of the mains plug.

2. Set the mains switch to the 'on' position (keep the

mains cord unplugged!).

3. Measure the resistance value between the mains plug

and the front panel, controls, and chassis bottom.

4. Repair or correct unit when the resistance

measurement is less than 1 MΩ.

5. Verify this, before you return the unit to the customer/

user (ref. UL-standard no. 1492).

6. Switch the unit ‘off’, and remove the wire between the

two pins of the mains plug.

2.1.2 Laser Safety

This unit employs a laser. Only qualified service personnel may

remove the cover, or attempt to service this device (due to

possible eye injury).

2.2 Warnings

2.2.1 General

• All ICs and many other semiconductors are susceptible to

electrostatic discharges (ESD, symbol "). Careless

handling during repair can reduce life drastically. Make

sure that, during repair, you are at the same potential as

the mass of the set by a wristband with resistance. Keep

components and tools at this same potential. Available

ESD protection equipment:

– Complete kit ESD3 (small tablemat, wristband,

connection box, extension cable and earth cable) 4822

310 10671.

– Wristband tester 4822 344 13999.

• Be careful during measurements in the live voltage section.

The primary side of the power supply (pos. 1005), including

the heatsink, carries live mains voltage when you connect

the player to the mains (even when the player is 'off'!). It is

possible to touch copper tracks and/or components in this

unshielded primary area, when you service the player.

Service personnel must take precautions to prevent

touching this area or components in this area. A 'lightning

stroke' and a stripe-marked printing on the printed wiring

board, indicate the primary side of the power supply.

• Never replace modules, or components, while the unit is

‘on’.

2.2.2 Laser

• The use of optical instruments with this product, will

increase eye hazard.

• Only qualified service personnel may remove the cover or

attempt to service this device, due to possible eye injury.

• Repair handling should take place as much as possible

with a disc loaded inside the player.

• Text below is placed inside the unit, on the laser cover

shield:

Laser Device Unit

Type : Semiconductor laser

GaAlAs

Wavelength : 650 nm (DVD)

: 780 nm (VCD/CD)

Output Power : 20 mW (DVD+RW

writing)

: 0.8 mW (DVD

reading)

: 0.3 mW (VCD/CD

reading)

Beam divergence : 60 degree

Figure 2-1 Class 1 Laser Product

Note: Use of controls or adjustments or performance of

procedure other than those specified herein, may result in

hazardous radiation exposure. Avoid direct exposure to beam.

CAUTION VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID EXPOSURE TO BEAM

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING VED ÅBNING UNDGÅ UDSÆTTELSE FOR STRÅLING

ADVARSEL SYNLIG OG USYNLIG LASERSTRÅLING NÅR DEKSEL ÅPNES UNNGÅ EKSPONERING FOR STRÅLEN

VARNING SYNLIG OCH OSYNLIG LASERSTRÅLNING NÄR DENNA DEL ÄR ÖPPNAD BETRAKTA EJ STRÅLEN

VARO! AVATT AESSA OLET ALTTIINA NÄKYVÄLLE JA NÄKYMÄTTÖMÄLLE LASER SÄTEILYLLE. ÄLÄ KATSO SÄTEESEEN

VORSICHT SICHTBARE UND UNSICHTBARE LASERSTRAHLUNG WENN ABDECKUNG GEÖFFNET NICHT DEM STRAHL AUSSETSEN

DANGER VISIBLE AND INVISIBLE LASER RADIATION WHEN OPEN AVOID DIRECT EXPOSURE TO BEAM

ATTENTION RAYO NNEMENT LASER VISIBLE ET INVISIBLE EN CAS D'OUVERTURE EXPOSITION DANGEREUSE AU FAISCEAU

!

Figure 2-2 Warning text

2.2.3 Notes

Dolby

Manufactered under licence from Dolby Laboratories. “Dolby”,

“Pro Logic” and the double-D symbol are trademarks of Dolby

Laboratories. Confidential Unpublished Works. ©1992-1997

Dolby Laboratories, Inc. All rights reserved.

Figure 2-3

Trusurround

TRUSURROUND, SRS and symbol (fig 2-4) are trademarks of

SRS Labs, Inc. TRUSURROUND technology is manufactured

under licence frm SRS labs, Inc.

Figure 2-4

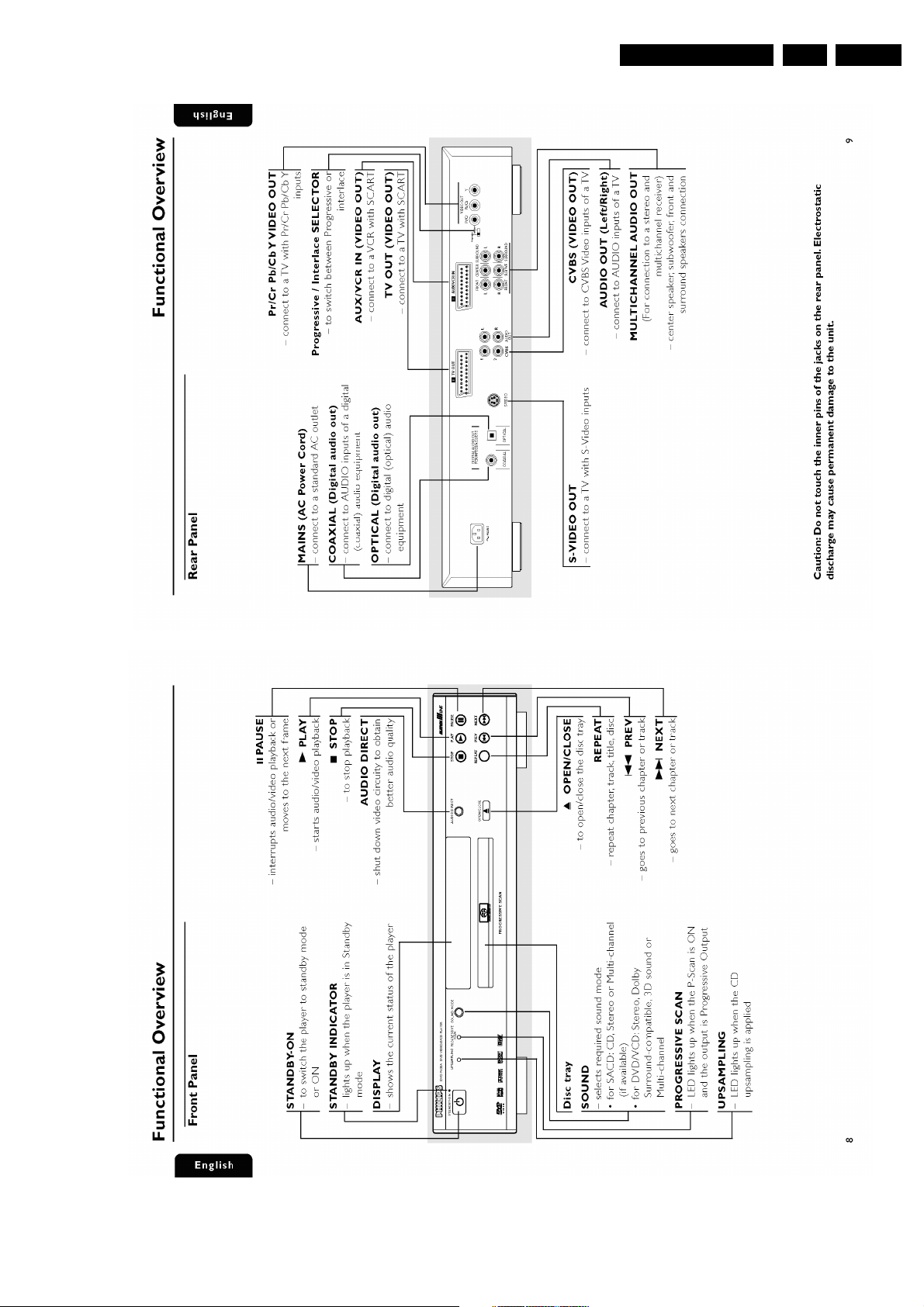

EN 4 DVD963SA3.

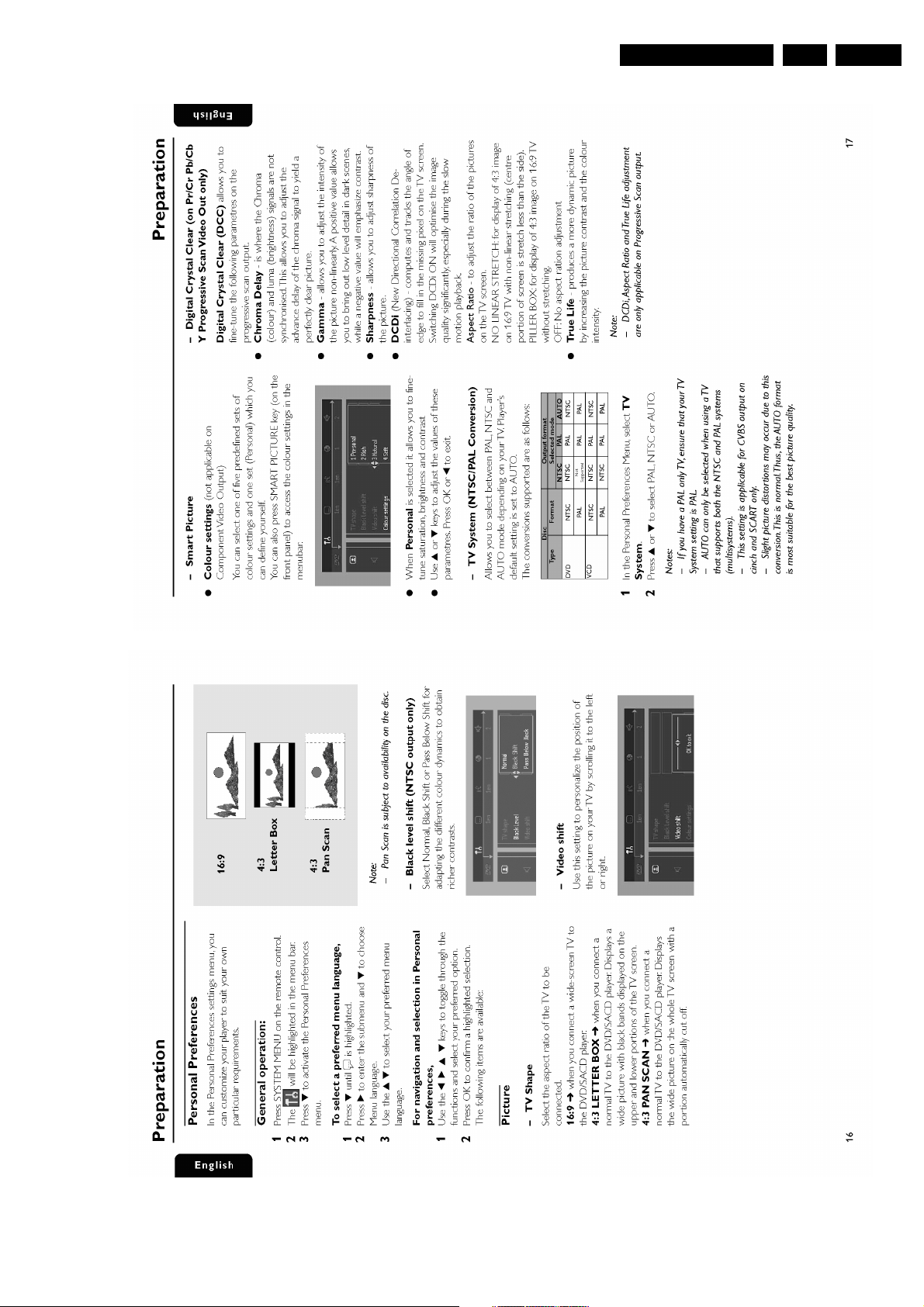

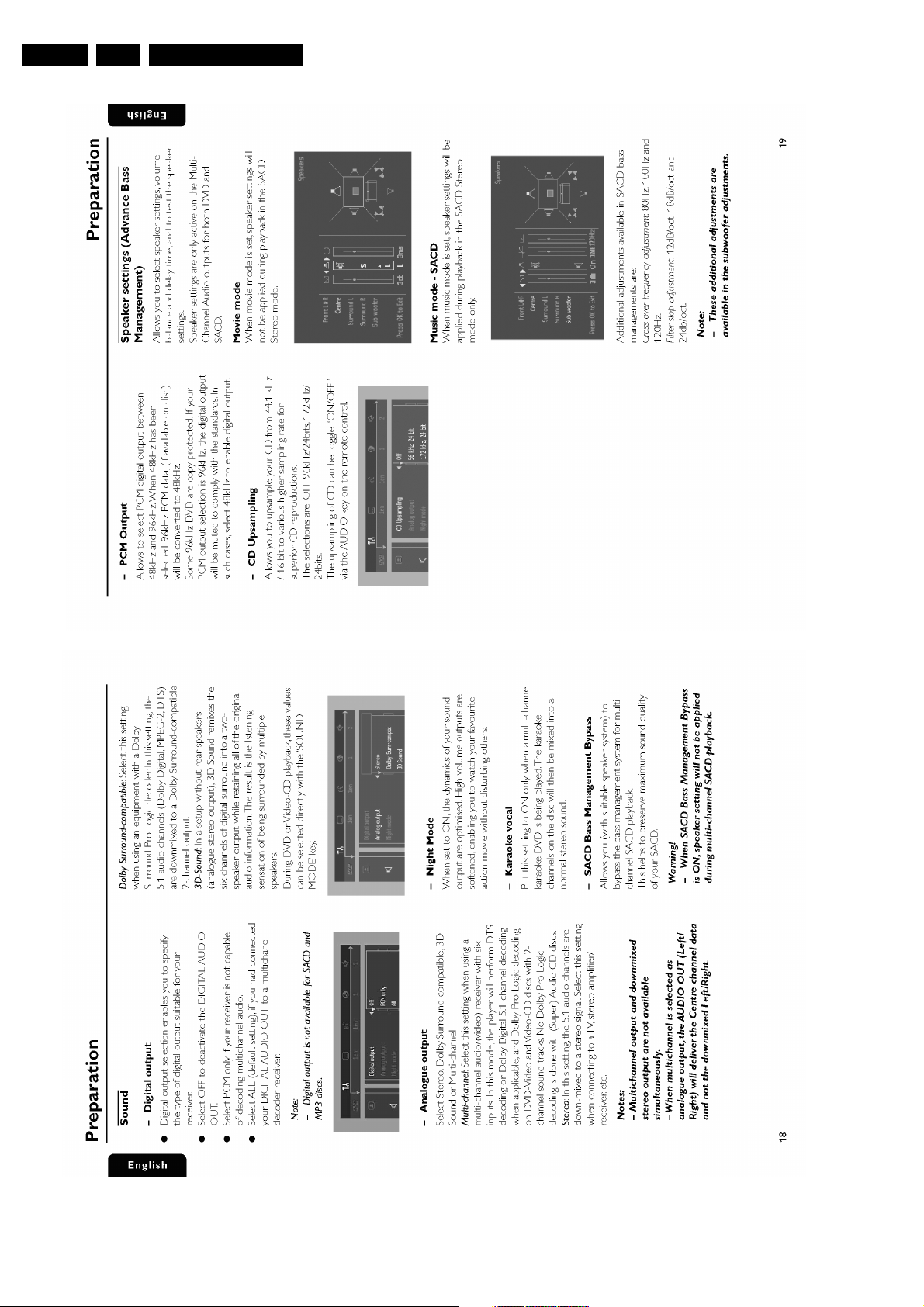

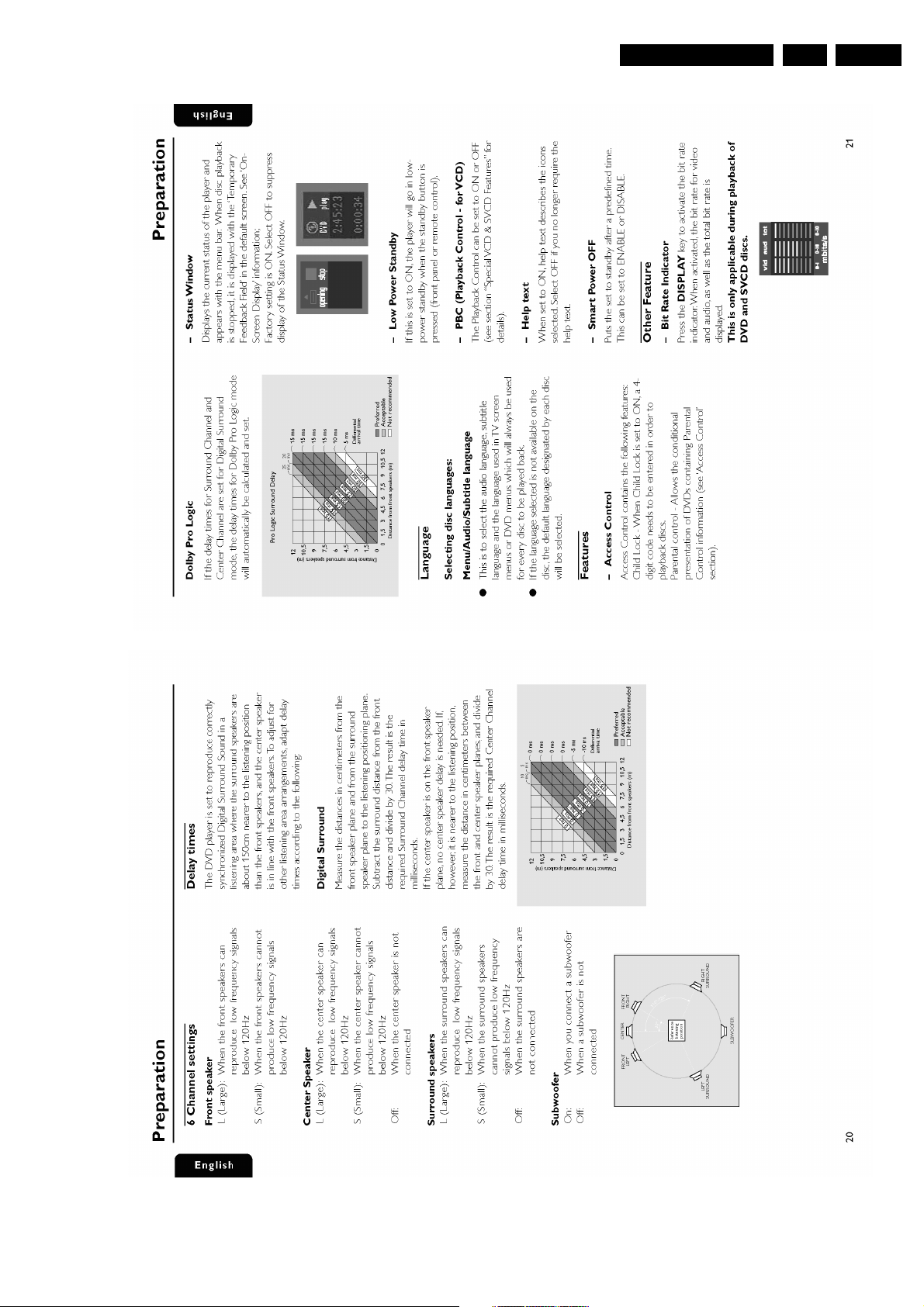

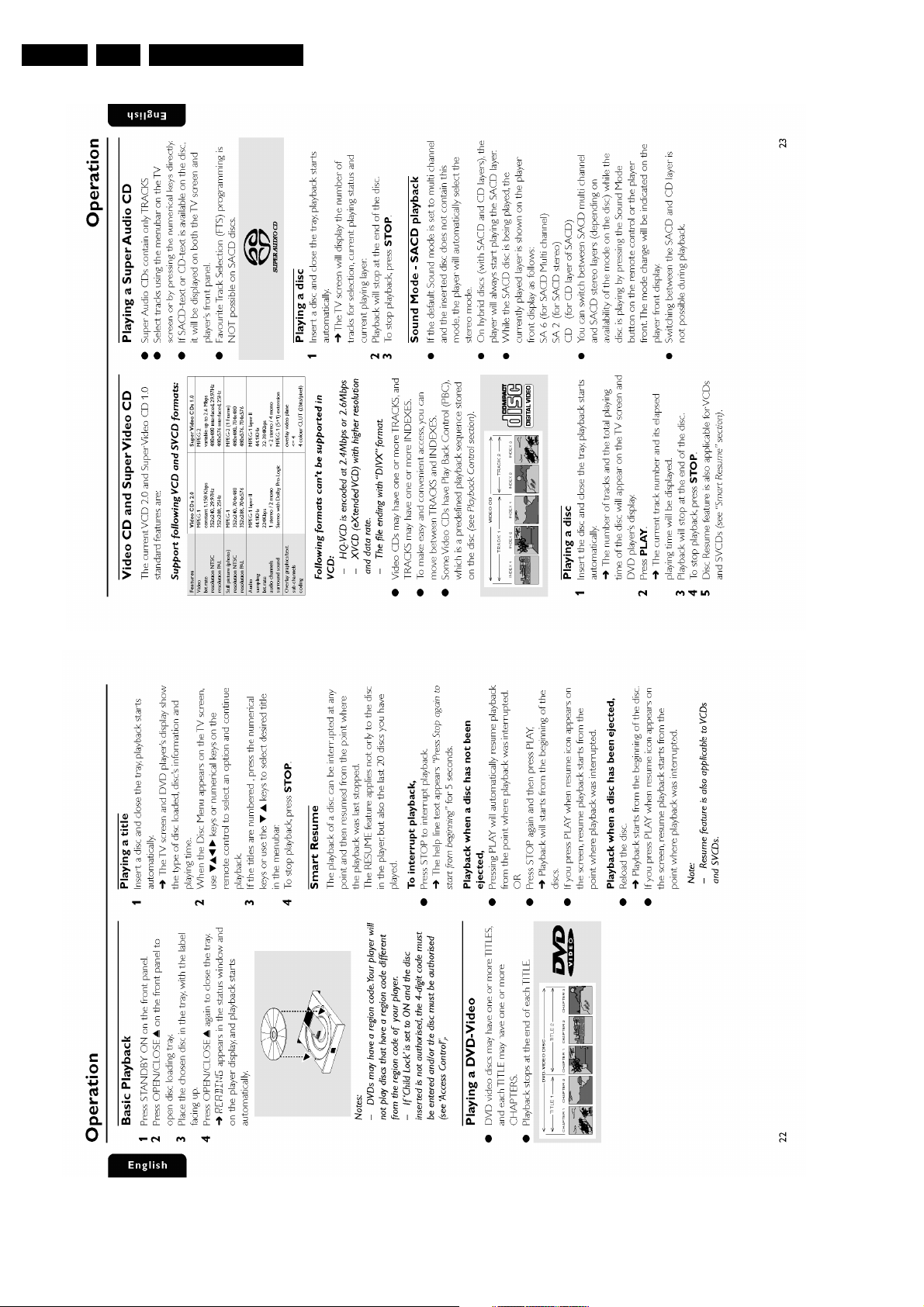

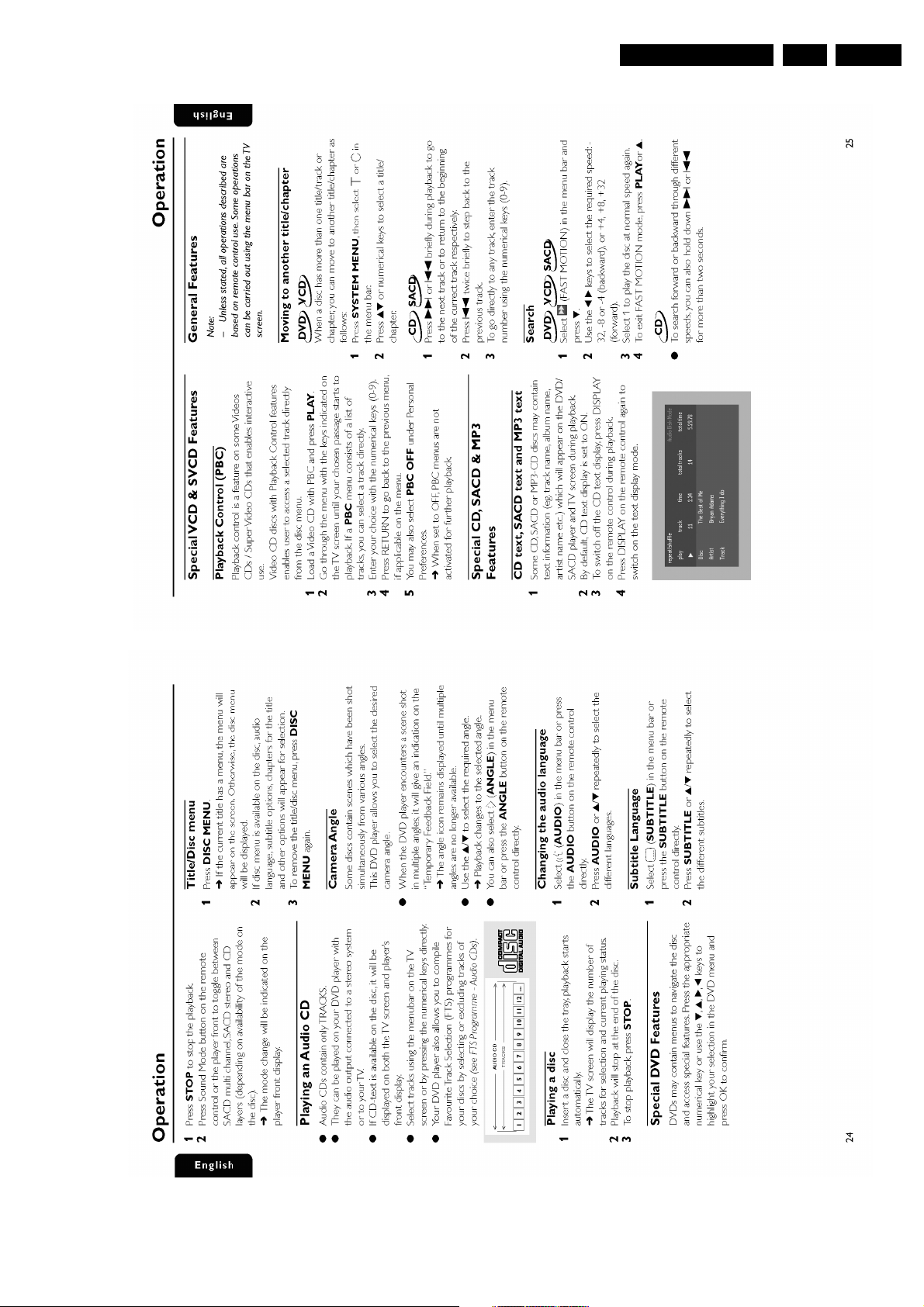

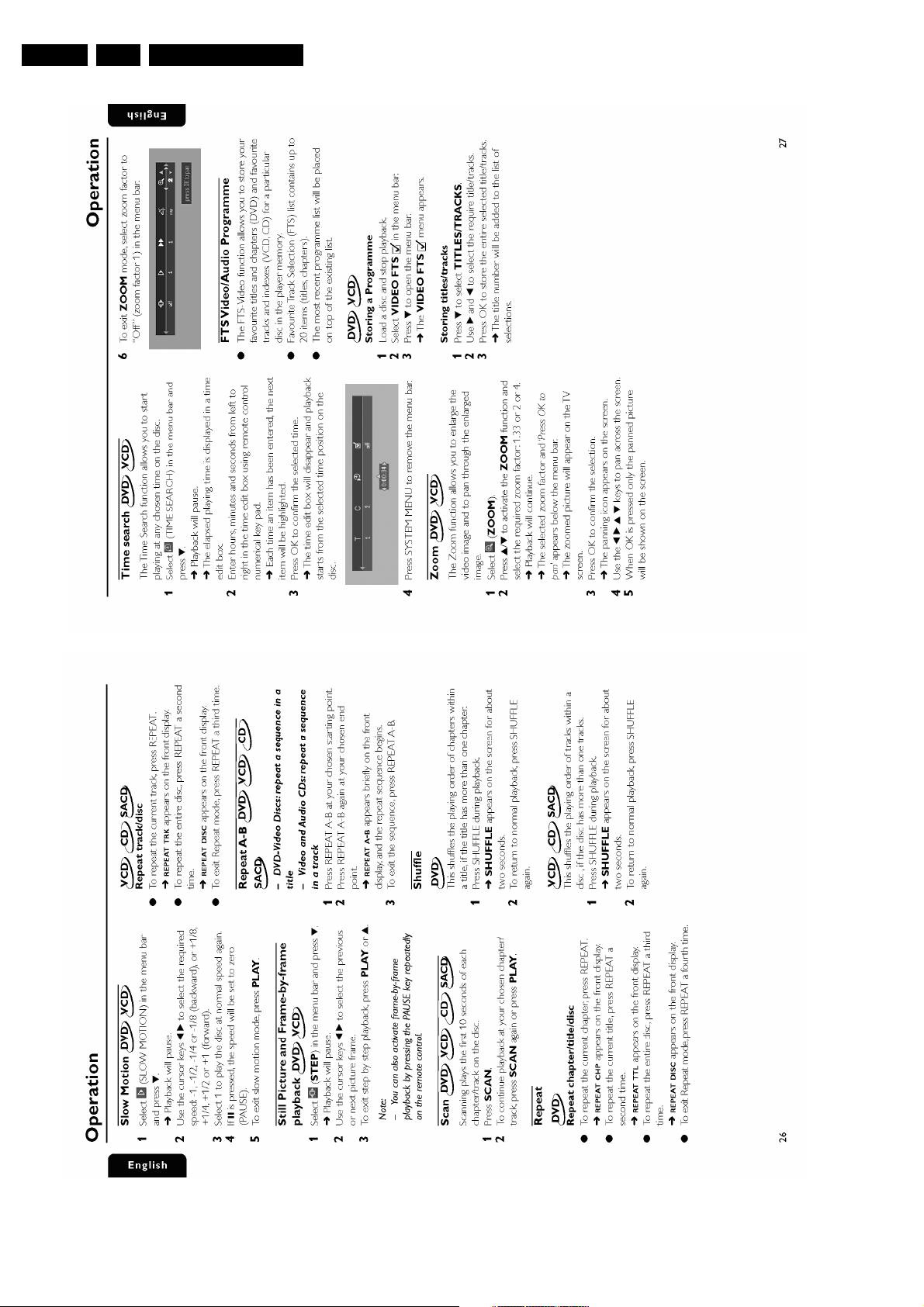

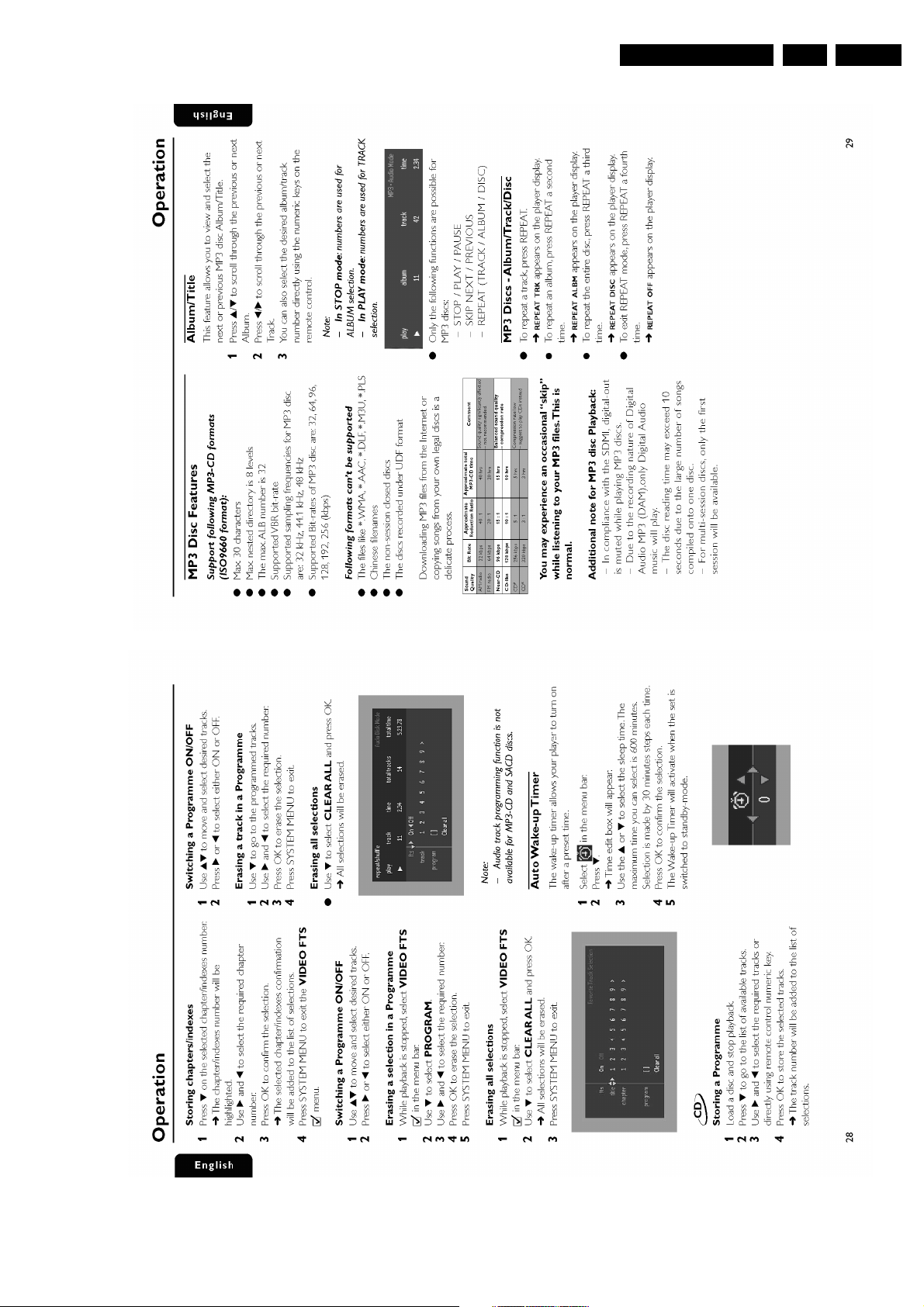

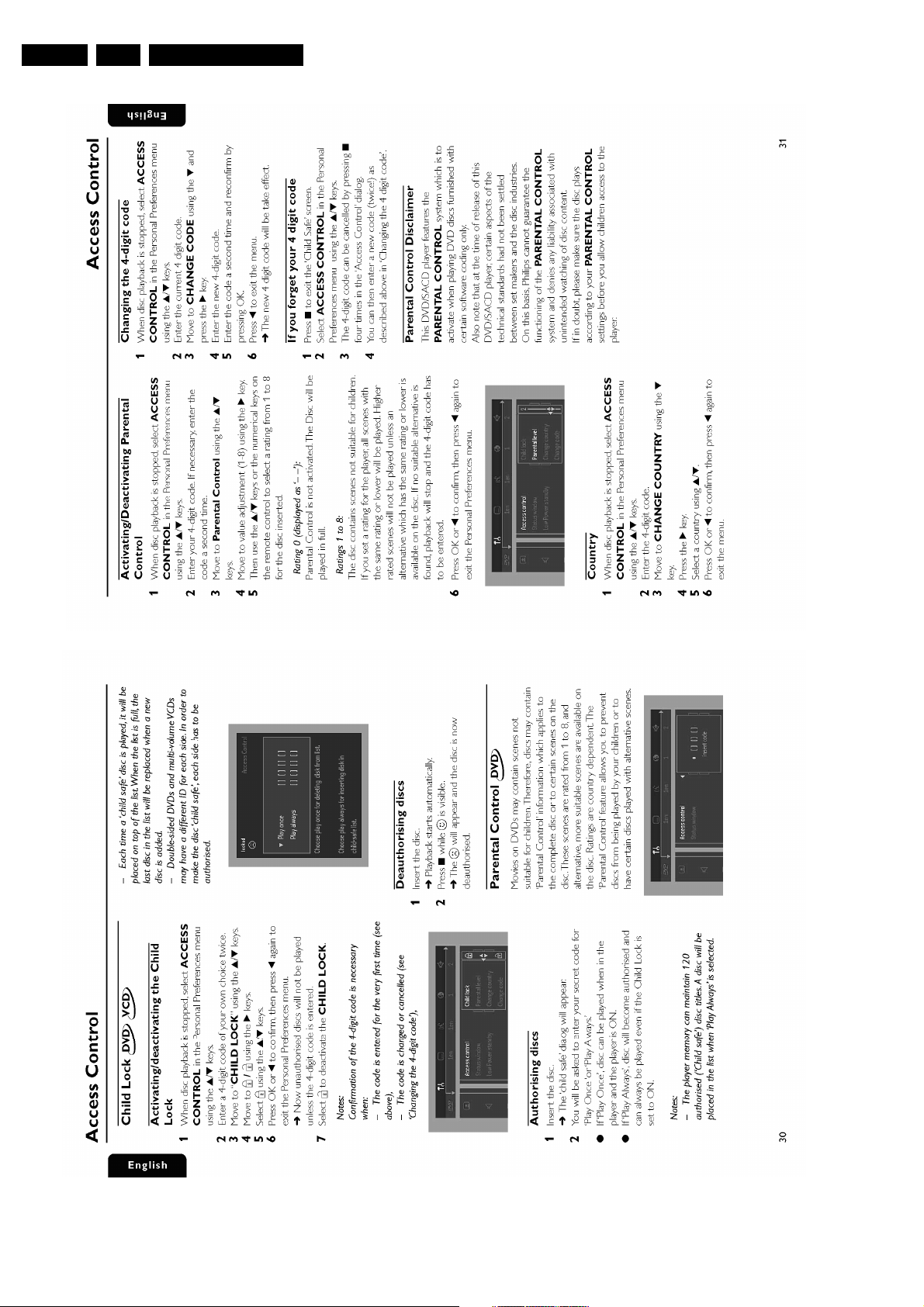

3. Directions for Use

Directions for Use

Directions for Use

EN 5DVD963SA 3.

EN 6 DVD963SA3.

Directions for Use

Directions for Use

EN 7DVD963SA 3.

EN 8 DVD963SA3.

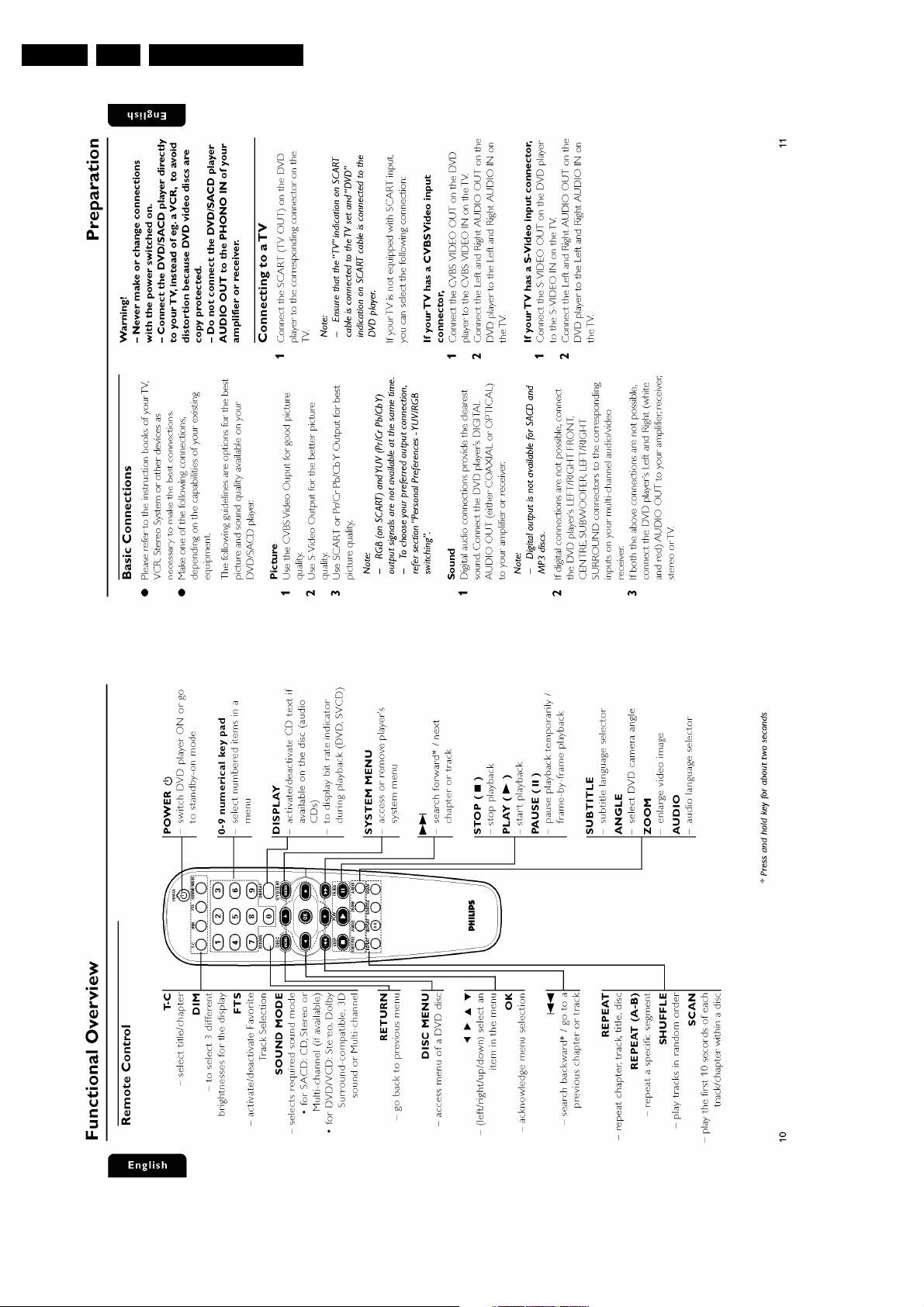

Directions for Use

Directions for Use

EN 9DVD963SA 3.

EN 10 DVD963SA3.

Directions for Use

Directions for Use

EN 11DVD963SA 3.

EN 12 DVD963SA3.

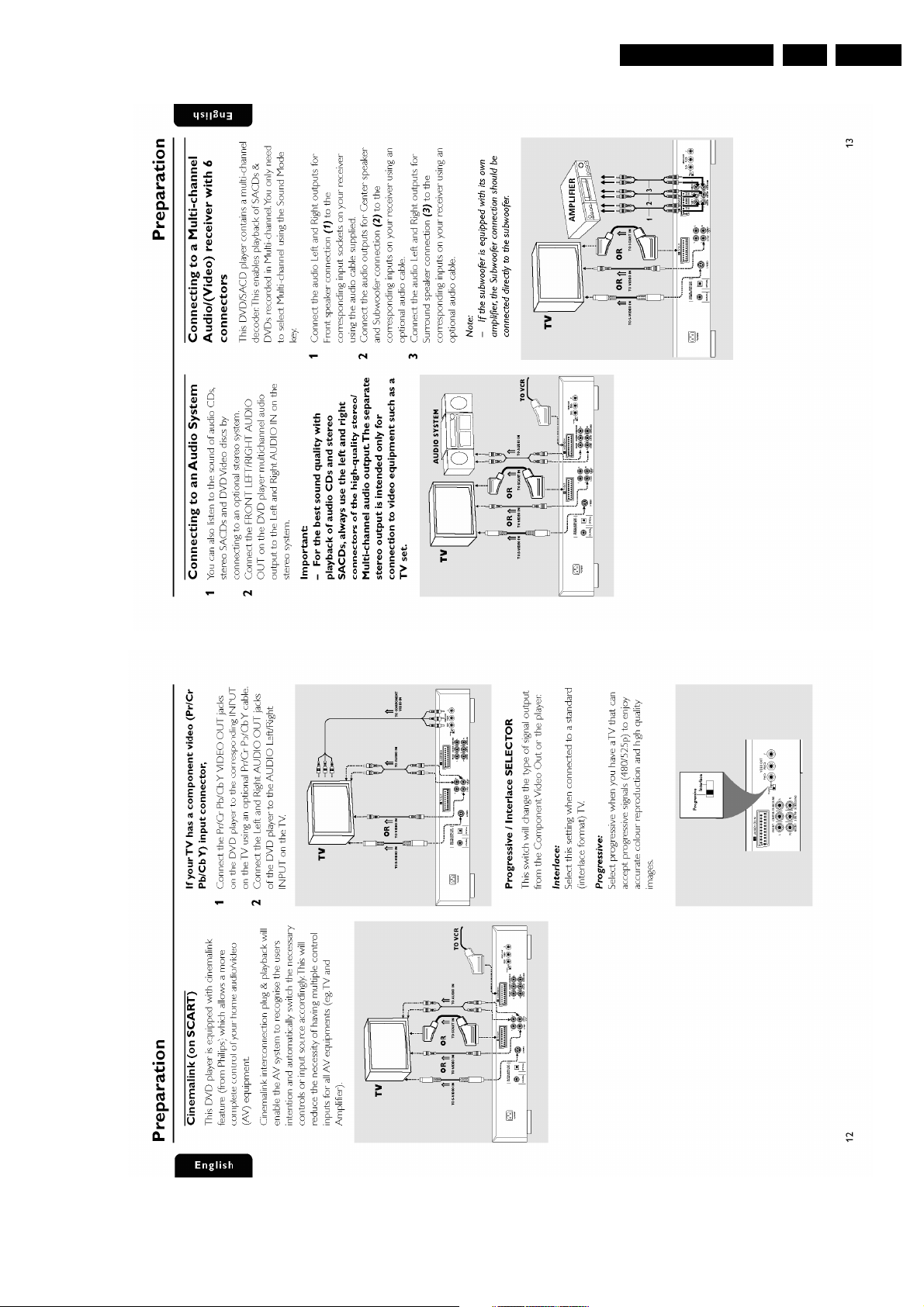

Directions for Use

Directions for Use

EN 13DVD963SA 3.

EN 14 DVD963SA3.

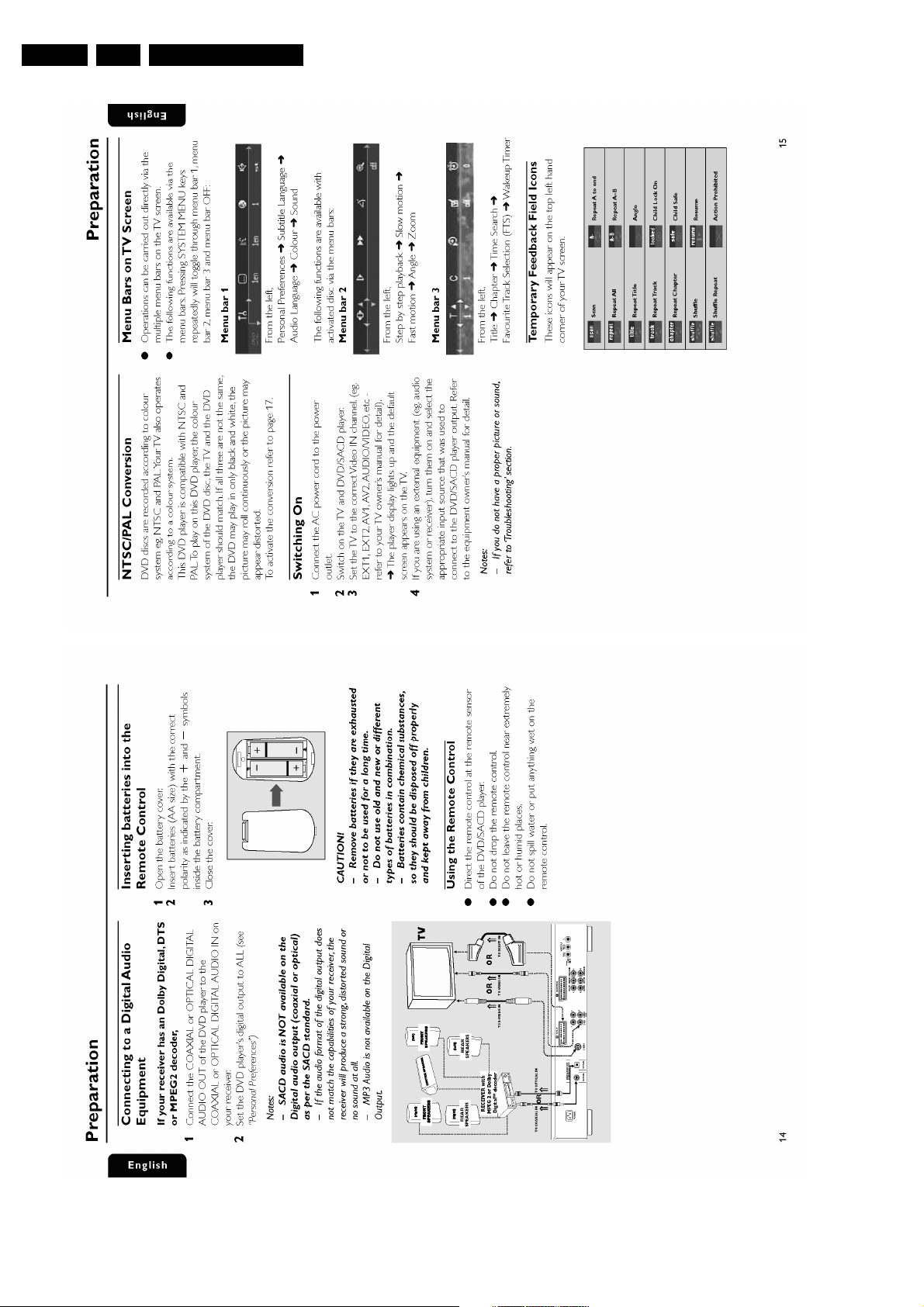

Directions for Use

Directions for Use

EN 15DVD963SA 3.

EN 16 DVD963SA3.

Directions for Use

Directions for Use

EN 17DVD963SA 3.

EN 18 DVD963SA4.

Mechanical-, Dismantling Instructions, and Service Hints

4. Mechanical-, Dismantling Instructions, and Service Hints

4.1 Dismantling Instructions

290802

CL 26532105_002.eps

Power supply unit 1010

Remove cable connections.

Remove 2 screws 190.

Release spacer locking.

è

Dismount board.

è

è

è

(Board to bottom frame)

(Board to bottom frame)

Mounting

Dismounting

TopCover 300

Remove 7 screws 305.

Lift cover from rear side to

remove.

è

è

P-scan board 1004

Removes flex connection.

Remove 2 screws 275

è

Double Scart board 1003

(Only for DVD963SA /EU)

DVD Module 146

Removes flex connections

è

Dismount board

è

è

(skt cinch to back-plate) and

screw 261 (board to Pscan

bracket)

Removes flex connection to

Remove 4 screws 290.

Dismount board.

conn 1300 on scart board.

è

è

è

(scart to back-plate)

Open tray (see instruction below).

Unlock Tray cover 025.

Remove 4 screws 185.

to A/V board.

Close tray.è Lift module up slightly and move

(Loader to bottom frame)

è

è

backward to remove.

è

è

A/V board 1001

Remove Double Scart board

Remove flex and cable

Remove 4 screws 275

è

è

è

(Only for DVD963SA /EU)

connections.

(skt cinch ,optical to back-

plate) and screw 280.

(S-video to back-plate)

DVD Monoboard

Remove flex and cable

Remove 4 screws 10 to 13.

connections from DVD

Loader to Monoboard.

(Monoboard to Loader,VAL6011/14)

è

è

Remove 4 screws to remove loader.

Release 2 spacers locking.

Dismount board.

è

è

Dismount Monoboard.

è

Front cabinet 002

Remove cable connection.

è

DISMANTLING INSTRUCTIONS

See exploded view of DVD963SA for item numbers

Open Tray (see instruction below).

Unlock Tray cover 025 and

Remove 2 screws 120

Unlock Front panel from frame by

è

è

è

close tray.

(Front cabinet to frame)

Place Front panel in front of

è

è

releasing successively 6 snaps.

(2 on the side and 2 each on the top

and bottom)

the set ( service position ).

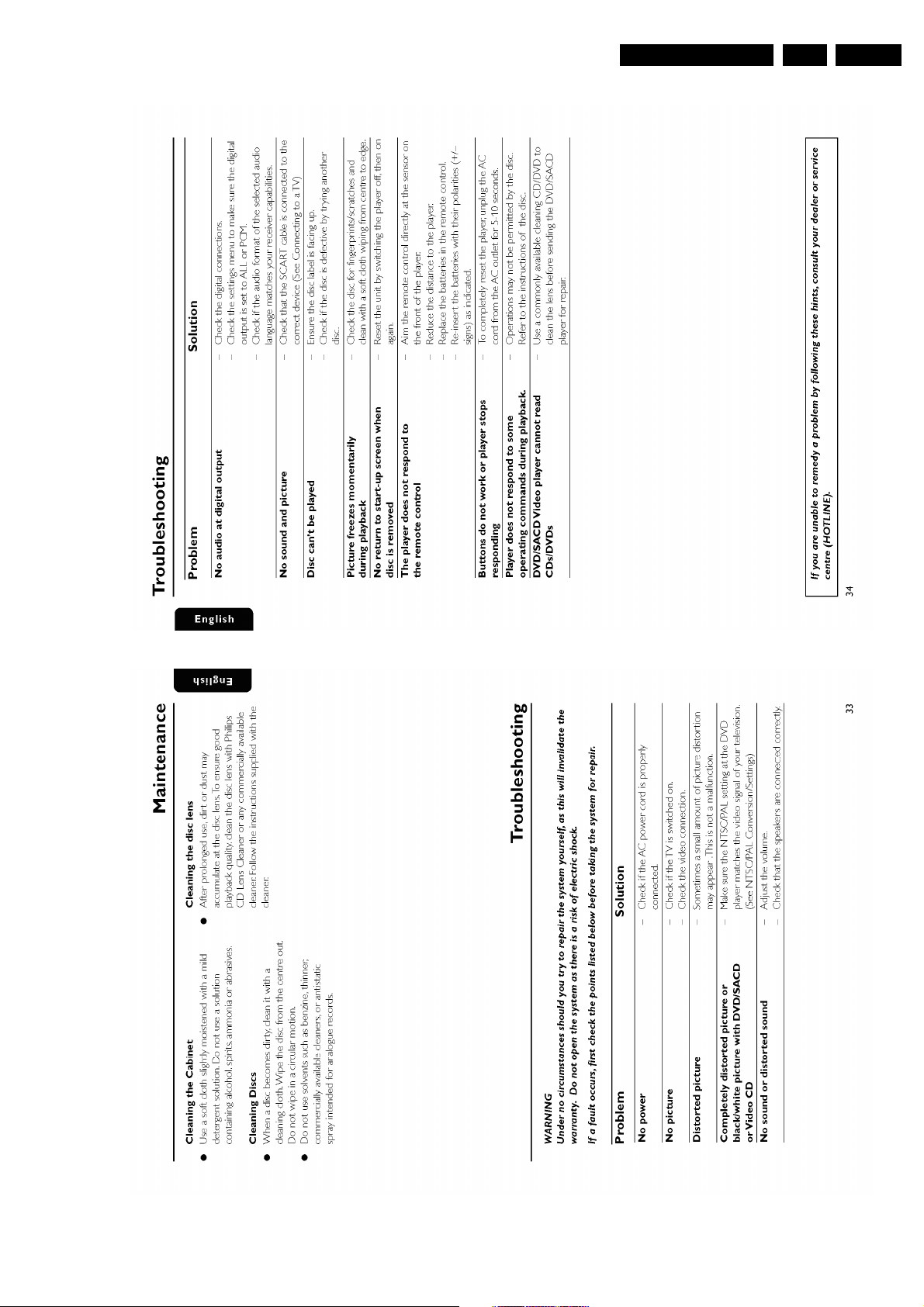

Figure 4-1 Dismantling Instructions

Front Standby board

Remove cable connection.

Remove 2 screws 105.

Dismount board.

è

è

è

(Board to Front cabinet)

Front Display board 1002

Remove cable connections.

Remove 8 screws 100.

Dismount board.

è

è

è

(Board to Front cabinet)

When it is not possible to open the tray with the EJECT button,

the tray can be manually opened.

Manually opening of tray

When a disc is loaded, unlock the tray by pushing the slide inwards with

a screwdriver and pull tray outwards.

When no disc is loaded, unlock the tray by moving the slide from left

to right and pull tray outwards.

Mechanical-, Dismantling Instructions, and Service Hints

270802

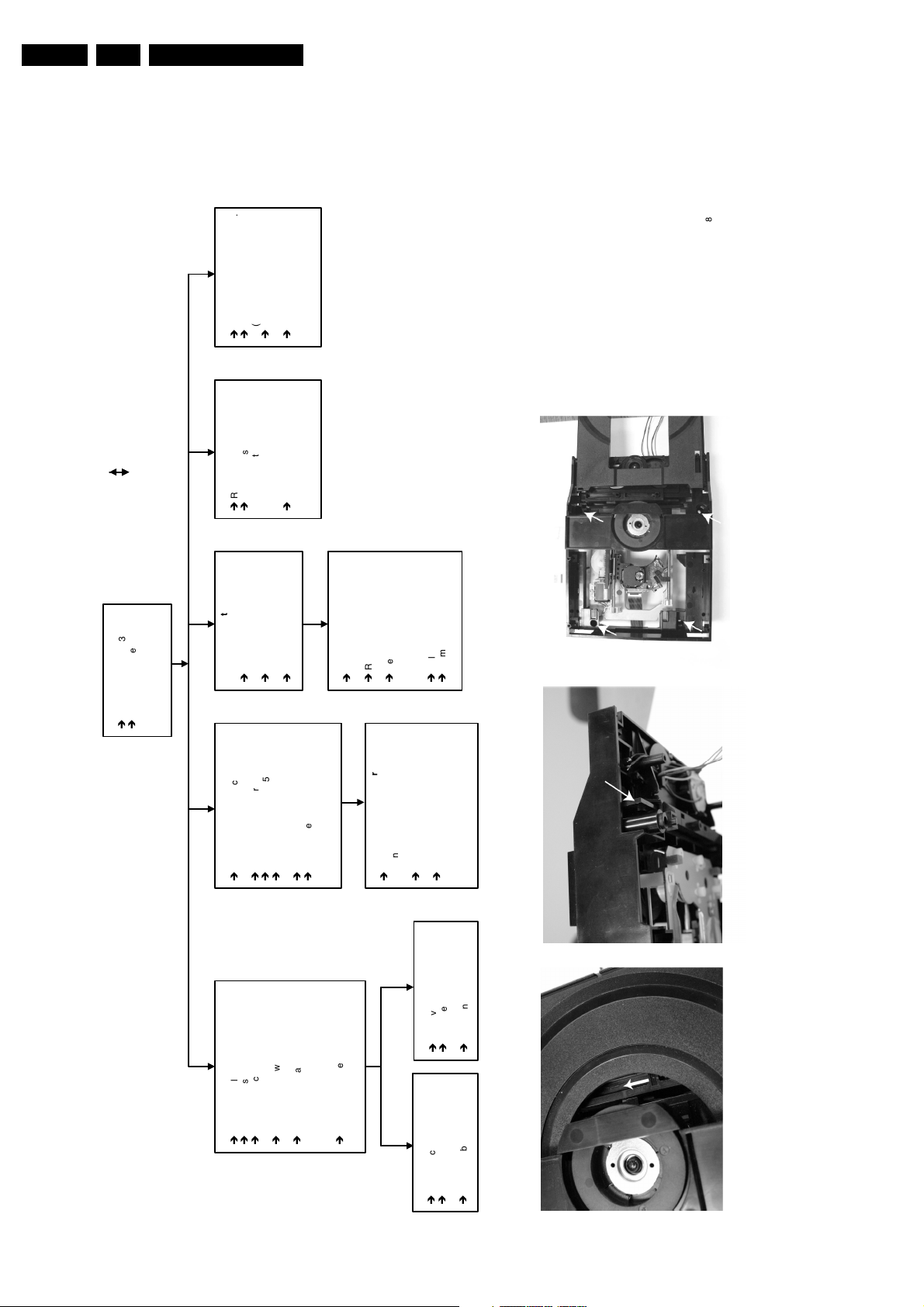

4.2 Exploded View

EN 19DVD963SA 4.

CL 26532105_003.eps

Figure 4-2 Exploded View

EN 20 DVD963SA4.

Mechanical-, Dismantling Instructions, and Service Hints

4.3 Service Hints

4.3.1 Switched Mode Power Supply

The power supply unit has to be replaced in case of failure. The

schematic provided in the manual is only for information and no

service parts will be available.

4.3.2 DVD Module

This module can be repaired as follows:

1. The VAL6011/14 is a combination of loading mechanism

and DVD-mechanism. Both are not repairable units and in

case of failure, it has to be replaced with a new loader

VAL6011/14.

Note: When replacing with a new VAL6011/14, two solder

joints have to be removed after connecting the OPU flex foil

to the mono board.

The solder joints, which shortcircuits the laser diodes to

ground, are for protection against ESD. Refer to figures 25 and 2-6 for location of solder joints.

2. The mono board has to be repaired down to component

level. Repair handling of the monoboard requires a

workshop with sophisticated desoldering tools.

4.3.3 ComPair

For assistance with the repair process of the monoboard an

electronic fault finding guidance has been developed. This

program is called ComPair.

This ComPair program is available on CDROM.

The version of the CDROM for repair of the monoboard is V1.3

or higher and can be ordered with codenumber 4822 727

21637. This is an update CDROM, so when the ComPair

CDROM is used for the first time, one has to install the ComPair

Engine CDROM V1.2 first.

The V1.2 CDROM can be ordered with code number 4822 727

21634 and has to registered after instalation. The procedure for

registration is explained in the help file of the program and in

the CDROM booklet.

The cable to connect the monoboard with a PC can be ordered

with codenumber: 3122 785 90017.

All the hardware and software requirements of the systems,

necessary for working with ComPair, are described on the

CDROM.

4.3.4 Service Positions

Refer to dismantling instructions for dismounting of the board.

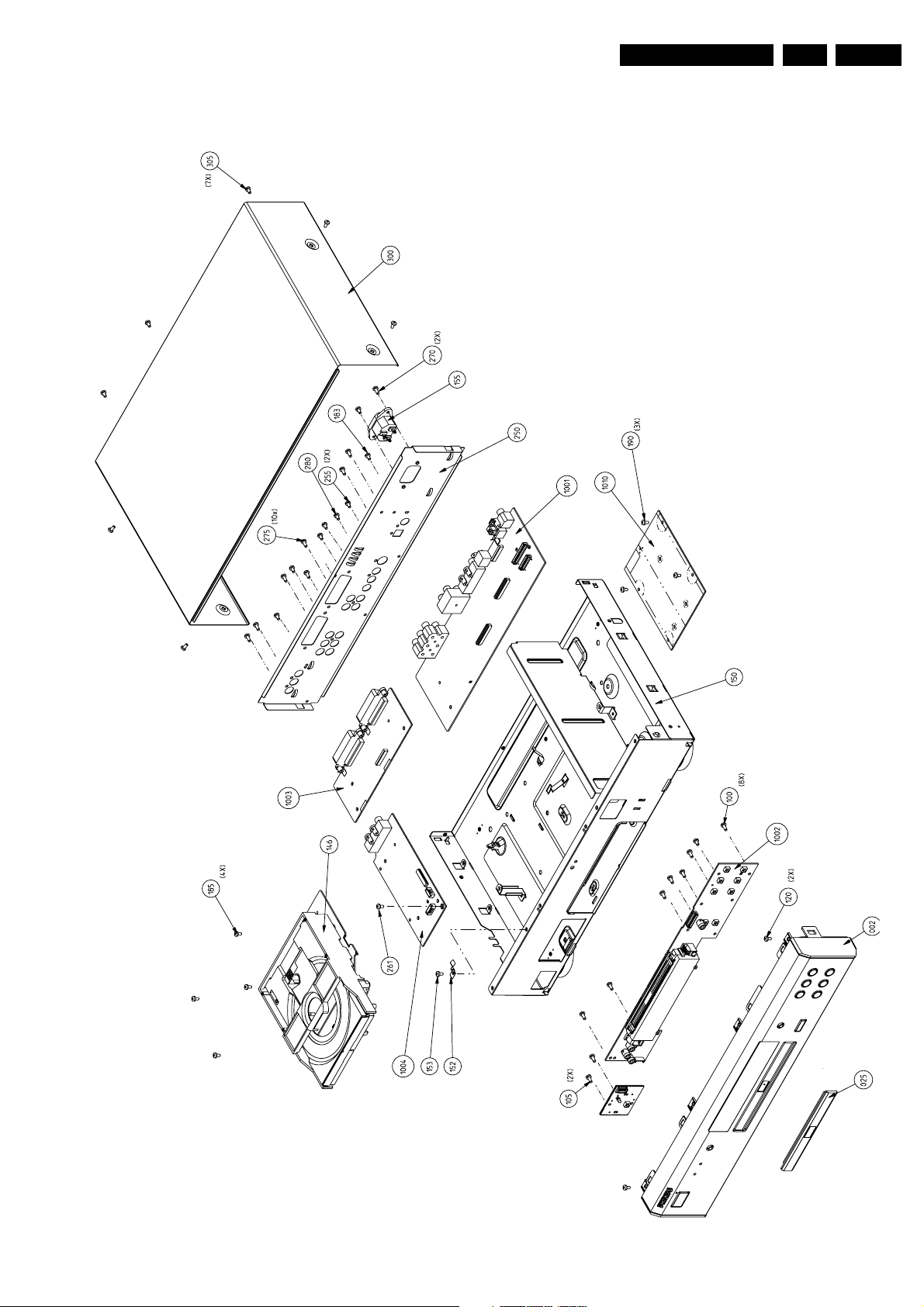

Figures 2-7 to 2-8 shows the service position that are

recommended during repair of the boards.

Figure 4-3 Solder joints

Figure 4-4 Solder joints

Figure 4-5 DVD963SA Layout

Figure 4-6 DVD963SA service manual

Diagnostic Software, Trouble Shooting and Test Instructions

5. Diagnostic Software, Trouble Shooting and Test Instructions

EN 21DVD963SA 5.

5.1 Dealerscript

5.1.1 Purpose of Dealer Script

The dealer script can give a diagnosis on a standalone DVD

player, no other equipment is needed to perform a number of

hardware tests to check if the DVD player is faulty. The

diagnosis is simply a "error" or "pass" message. No indication

is given of faulty hardware modules. Only tests within the scope

of the diagnostic software will be executed hence only faults

within this scope can be detected.

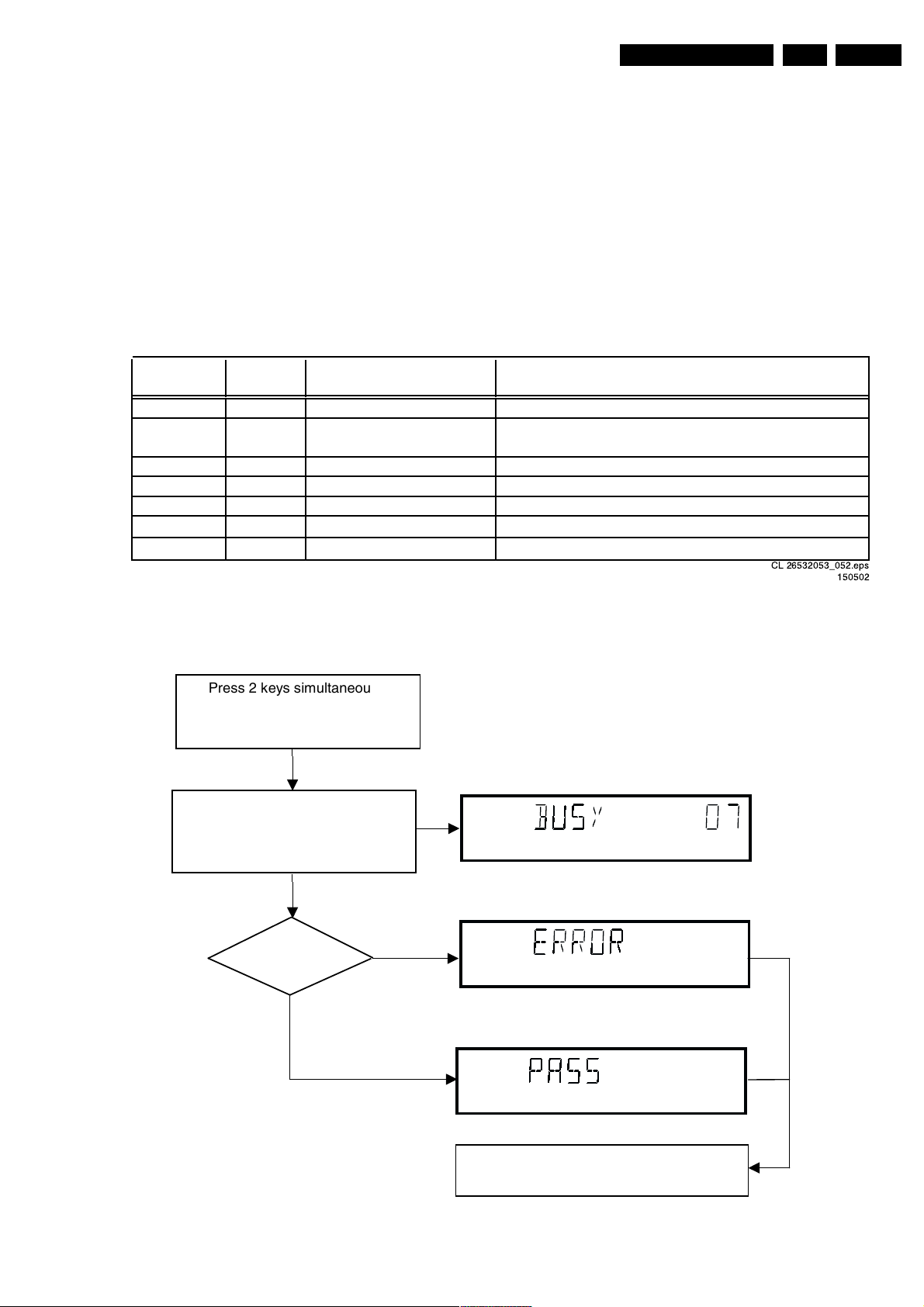

Nucleus

Display Nucleus Nucleus Description

Countdown Number Name

7 6 PapChksFl Calculate and verify checksum of FLASH memory

6 12 PapI2cDisp

5 13 PapS2bEcho Checks the I2C interface to the basic engine

4 11 PapI2cNvram Checks the I2C interface with the NVRAM

3 15 PapNvramWrR Pattern test of all locations in the NVRAM

2 16 CompSdramWrR Pattern test of all locations in the SDRAM(s)

1 63 FURORERSdramWrRLow Pattern test of all locations in the SDRAM(s)

5.1.2 Contents of Dealer Script

The dealer script executes all diagnostic nuclei that do not

need any user interaction and are meaningful on a standalone

DVD player.

The nuclei called in the dealer script are the following (the

number after each nucleus name corresponds with the number

being on the local display when the nucleus is executed during

the dealer script):

Checks the I2C interface with the slave processor on

the display board

CL 26532053_052.eps

150502

Press 2 keys simultaneously

<OPEN/CLOSE> + <PLAY>

Connect to mains.

During the test, the following display

is shown: the counter counts down

from the number of nuclei to be run

before the test finishes. Example:

SET O.K.?

NO

YES

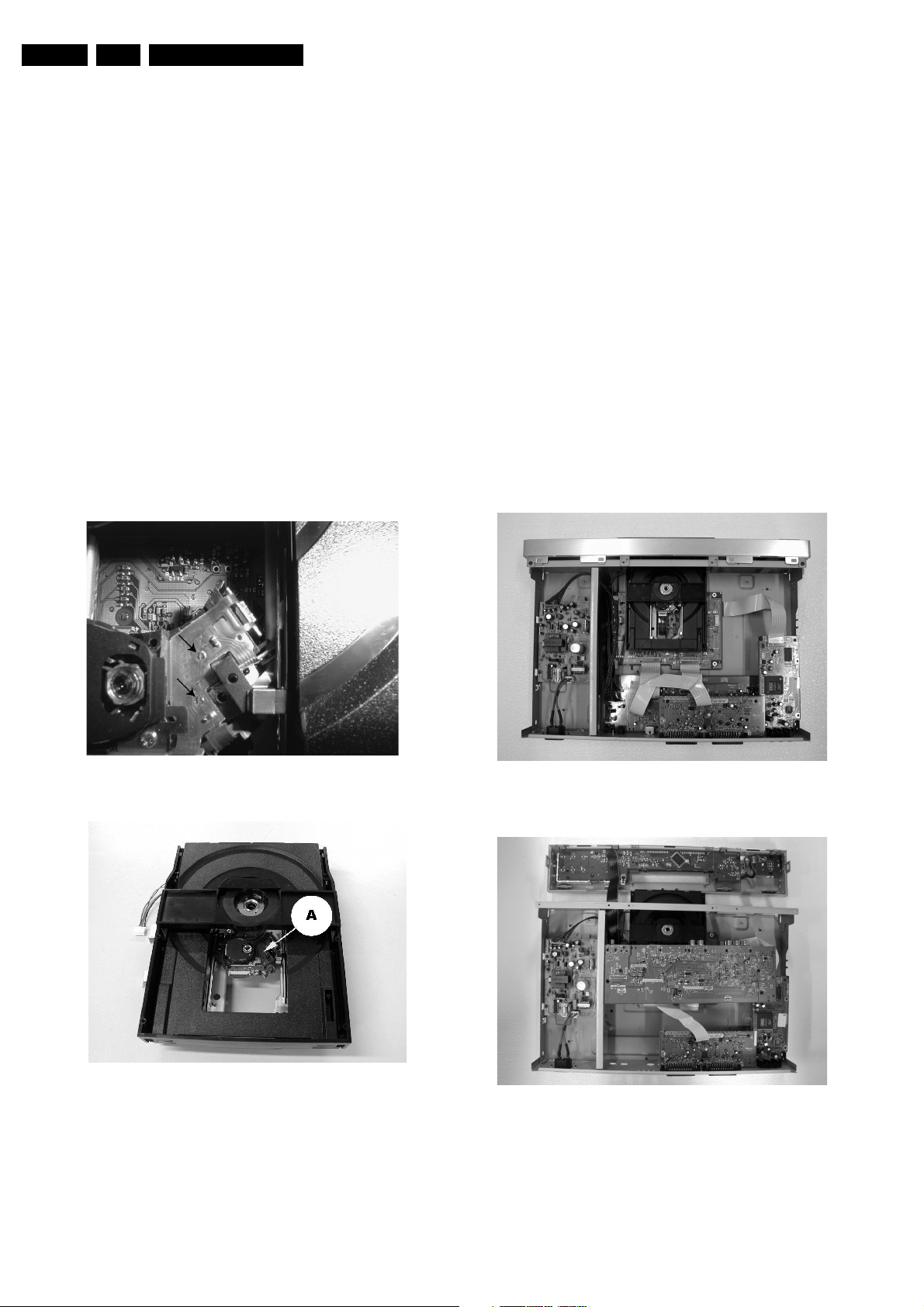

Figure 5-1 Dealer script nuclei

To exit DEALER SCRIPT, disconnect from mains

Figure 5-2 Dealer Script

CL 26532053_053.eps

150502

EN 22 DVD963SA5.

s

Diagnostic Software, Trouble Shooting and Test Instructions

5.2 Player Script

5.2.1 Purpose of Player Script

The Player script will give the opportunity to perform a test that

will determine which of the DVD player's modules are faulty, to

read the error log and error bits and to perform an endurance

loop test. To successfully perform the tests, the DVD player

must be connected to a TV set to check the output of a number

of nuclei. For DVDv2b a multi-channel amplifier, a set of 6

speakers and an external video source are necessary to test.

To be able to check results of certain nuclei, the player script

expects some interaction of the user (i.e. to approve a test

picture or a test sound). Some nuclei (e.g. nuclei that test

functionality of the Basic Engine module) require that the DVD

player itself is opened, to enable the user to observe moving

parts and approve their movement visually. Only tests within

the scope of the diagnostic software will be executed hence

only faults within this scope can be detected.

5.2.2 Contents of Player Script

The player script contains all nuclei that are useful on a DVD

player that is connected to a TV set and help to determine

which module of the DVD player is faulty, as well as to read out

the contents of the error logs.

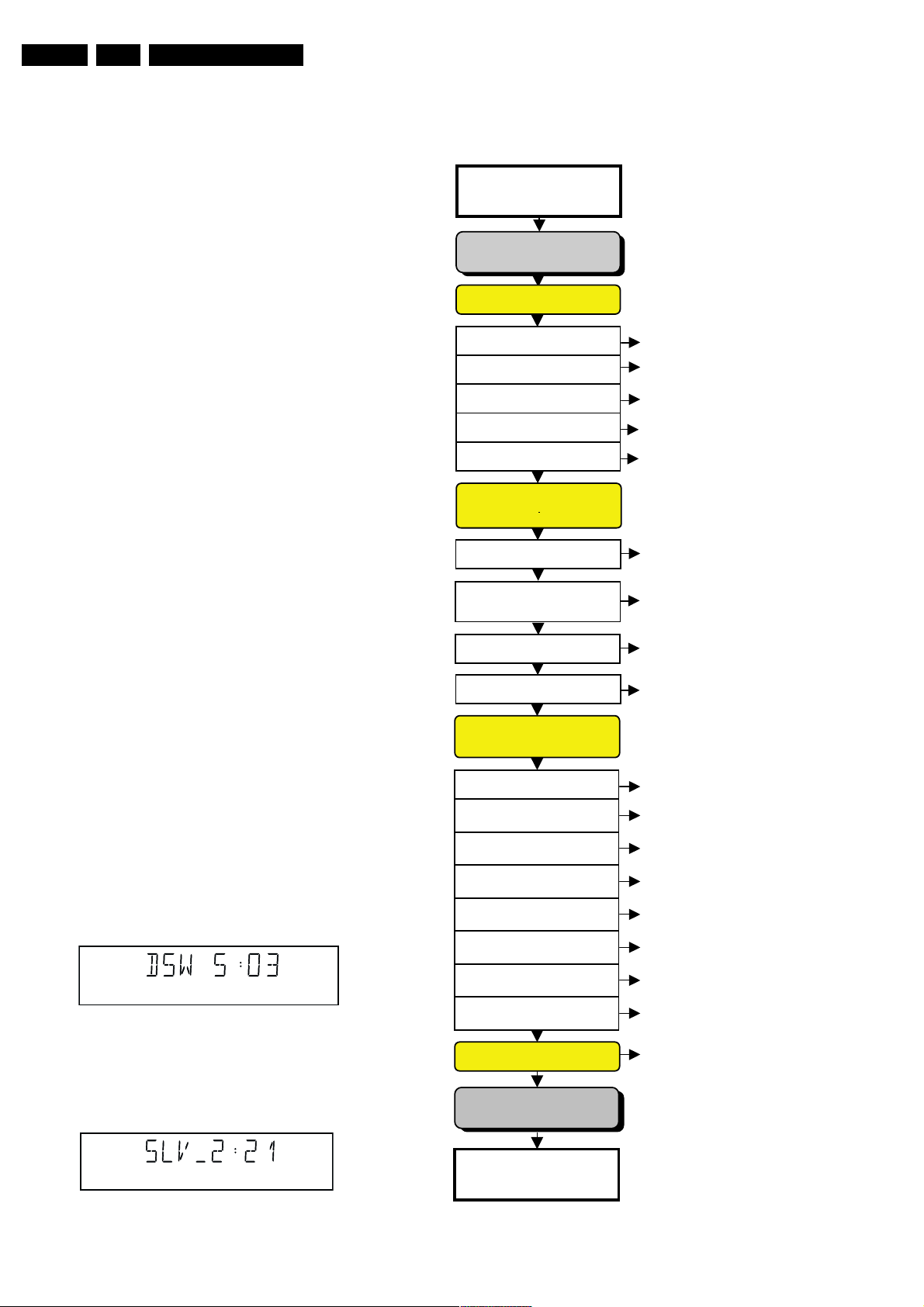

5.2.3 Structure of Player Script

The player script consists of a set of nuclei testing the three

hardware modules in the DVD player: the Display PWB, the

Digital PWB, and the Basic Engine.

Nuclei run by the player test need some user interaction. In the

next paragraph this interaction is described. The player test is

done in two phases:

1. Interactive tests: this part of the player test depends

strongly on user interaction and input to determine nucleus

results and to progress through the full test. Reading the

error log and error bits information can be useful to

determine any errors that occurred recently during normal

operation of the DVD player.

2. The loop test: this part of the player test will loop through

the list of nuclei indefinitely, till the player is reset. The list

of nuclei is as follows:

• PapChksFlash

• PapI2cNvram

• CompSdramWrR

• PapS2bEcho

• PapI2cDisp

At the beginning of the tests, the DSW version number will be

indicated on the local display of the DVD.

The display will look like the following:

Press the OPEN/CLOSE key to proceed to the next test.

5.2.4 Survey

Press 2 keys simultaneously

<OPEN/CLOSE> + <STOP>

Connect to main

INTERACTIVE TESTS

DISPLAY PCB

DISPLAY TEST

LED TEST

KEYBOARD TEST

REMOTE CONTROL

P50 LOOP BACK TEST

DispDisplay (30a)

DispLed (29)

DispKeyb (27)

DispRc (28)

DispP50 (60)

MONO PCB

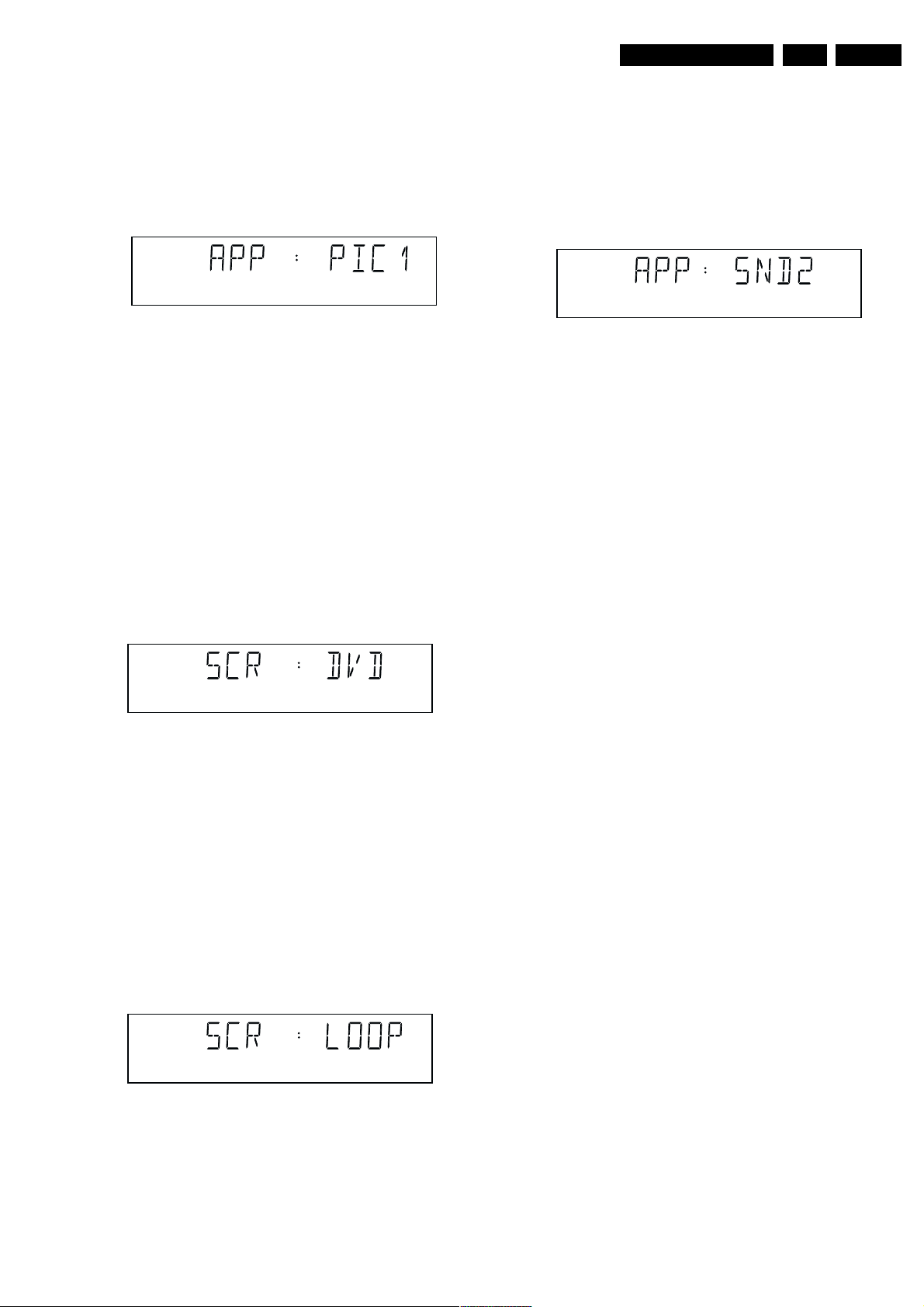

DIGITAL PART

PICTURE TEST

SOUND 1 TEST

SCART DVD TEST

SCART LOOP TEST

SOUND 2 TEST

VideoColDencOn (23a)

AudioPinkNoiseOn (20a)

VideoScartSwDvd (55a)

VideoScartSwPass (55b)

AudioSineOn (21a)

MONO PCB(SERVO)

& BASIC ENGINE

VERSION NUMBER

TRAY TEST

SLEDGE TEST

DISC MOTOR TEST

FOCUS TEST

RADIAL TEST

BeVer (37)

BeTrayOut/In (43a/b)

BeSledgeOut/In (41a/b)

BeDiscMotorOn (39a/b)

BeFocusOn (38a/b)

BeRadialOn (40a/b)

CL 26532053_054.eps

150502

Figure 5-3

Pressing the PLAY key will proceed to the slave S/W version

display, which is shown on the local display of the DVD player.

The display will look like the following:

CL 26532053_055.eps

150502

Figure 5-4

JUMP TEST

TRAY TEST

ERROR LOG & BITS

LOOP TEST

To exit player test,

disconnect from mains

BeGroovesIn/Mid/Out (42a/b/c)

BeTrayOut/In (43a/b)

LogReadErr (31)

LogReadbits (32)

= Dealer script exclusive of test2

CL 16532162_030.eps

Figure 5-5

090102

Diagnostic Software, Trouble Shooting and Test Instructions

Y

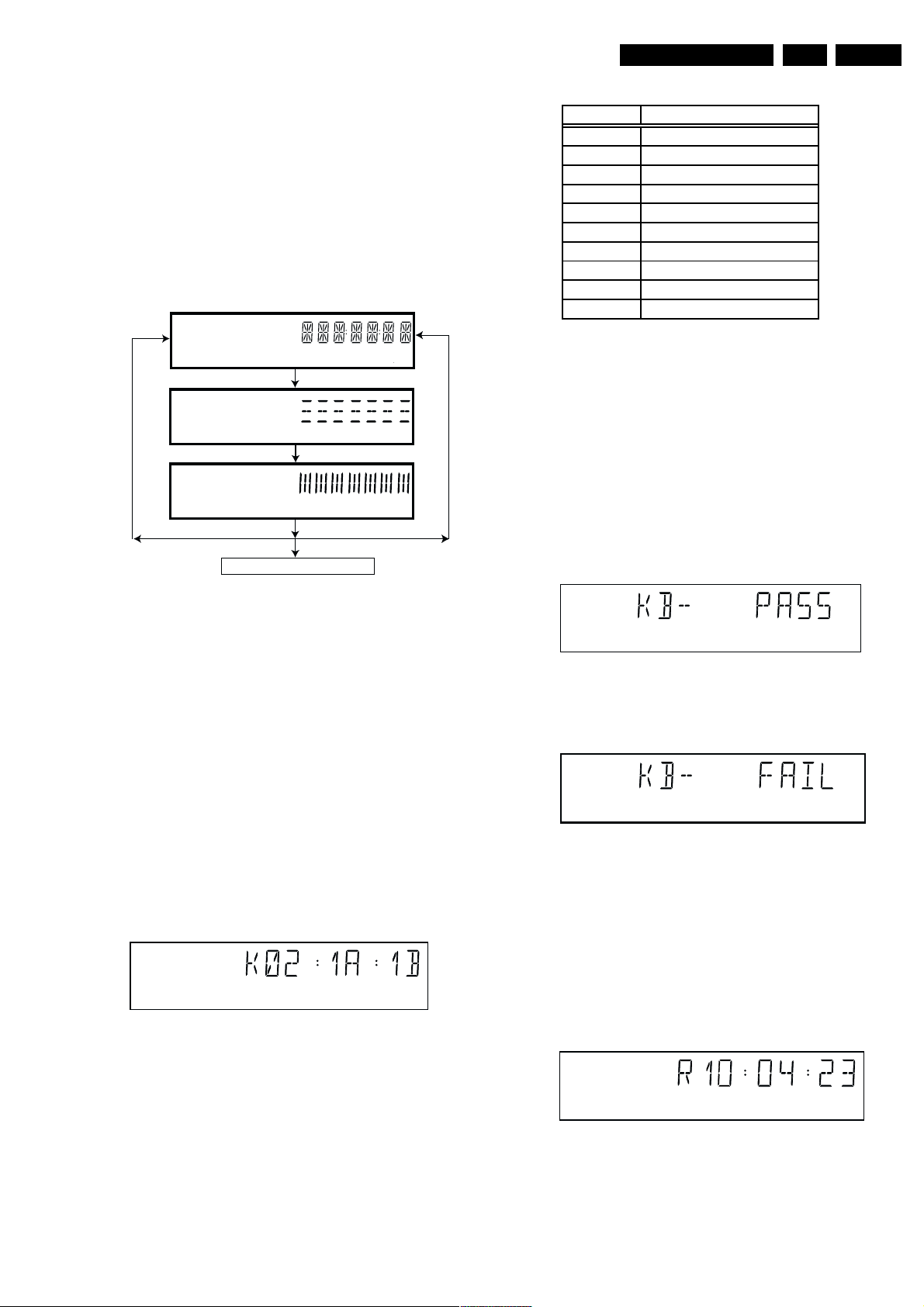

5.3 Display PCB

5.3.1 Display Test

The display test is performed by nucleus DispDisplay. By

putting a serie of test patterns on the local display, the local

display is tested. To step through all different patterns, the user

must either press OPEN/CLOSE (pattern is ok) or STOP

(pattern was incorrect) to proceed to the next pattern. The

display of patterns is continued in a cyclic manner, shown in

Fig. 5-6, until the user presses PLAY. If the user presses PLAY

before all display patterns are tested, the DispDisplay nucleus

will return FALSE (display test unsuccessful).

KEY ID KE

0 PLAY

1STOP

2 OPEN/CLOSE

3 STANDBY

4 NEXT

5 PREVIOUS

6 PAUSE

7 AUDIO DIRECT

E SOUND MODE

F REPEAT

CL 26532105_057.eps

300802

EN 23DVD963SA 5.

If OK, press OPEN/CLOSE

If OK, press OPEN/CLOSE

If OK, press OPEN/CLOSE

press PLAY to continue

If NOK, press STOP

If NOK, press STOP

If NOK, press STOP

CL 16532162_031.eps

Figure 5-6

5.3.2 LED Test

The LED(s) on the DVD player is (are) tested by nucleus

DispLed. The user must check if the LED(s) is (are) lighted; if it

is, press OPEN/CLOSE, if it is not, press STOP. By pressing

PLAY the script will proceed to the next test. If the user presses

PLAY before OPEN/CLOSE or STOP, the DispLed nucleus will

return TRUE (LED test successful).

5.3.3 Keyboard Test

The keyboard of the DVD player is tested by nucleus

DispKeyb. The user is expected to press all keys on the local

keyboard once. The code of the key pressed is shown on the

local display (1 hexadecimal digit) immediately followed by a

(hexadecimal) number indicating how many times that key has

been pressed. Example of the local display during this test:

080102

Figure 5-8

If any keys are detected more than once (due to hardware

error), the key-code is displayed twice (or more), with the

second digit increased by 1.

If the user does not press all keys minimally once (in any order),

the DispKeys nucleus will return FALSE and cause an error in

the overall result of the player script.

The user can leave the keyboard test by pressing the PLAY key

on the local display of the DVD player for at least one full

second.

The result of the keyboard test is shown on local display as

follows:

CL 16532162_033.eps

080102

Figure 5-9

Or

CL 16532162_034.eps

080102

Figure 5-10

Pressing PLAY on the local keyboard again will proceed to the

next text.

5.3.4 Remote Control Test

The remote control of the DVD player is tested by nucleus

DispRc. The user must press any key on the remote control just

CL 196532162_032.eps

080102

once. The codes of the key pressed will be shown on the local

display in hexadecimal format. Example:

Figure 5-7

The key-codes displayed on the local display will scroll from

right to left when the display gets full, the text "K" will remain

on display.

CL 16532162_035.eps

140102

Figure 5-11

In this example 23 is the hexidecimal code of the pressed RC

key. The user can leave the remote-control test by pressing

PLAY on the local keyboard of the DVD player. The remote

control test is successful if a code was received before the user

EN 24 DVD963SA5.

pressed the PLAY key. Pressing the PLAY key, before

pressing a key on the remote control, gives an error in the

remote control test (note that the remote control test will also

fail if a key on the remote control was pressed but no code was

received). The remote control test does not check upon the

contents of the received code, that is it will not be checked if the

received code matches the key pressed. If desired, the user

can manually check this code by using a code-table for the

remote control key-codes.

Diagnostic Software, Trouble Shooting and Test Instructions

Figure 5-13

CL 96532065_013.eps

120799

RC Key id Hexadecimal code

Or

STANDBY 0C

11

22

33

44

55

66

77

Pressing PLAY on the local keyboard again will proceed to the

next test.

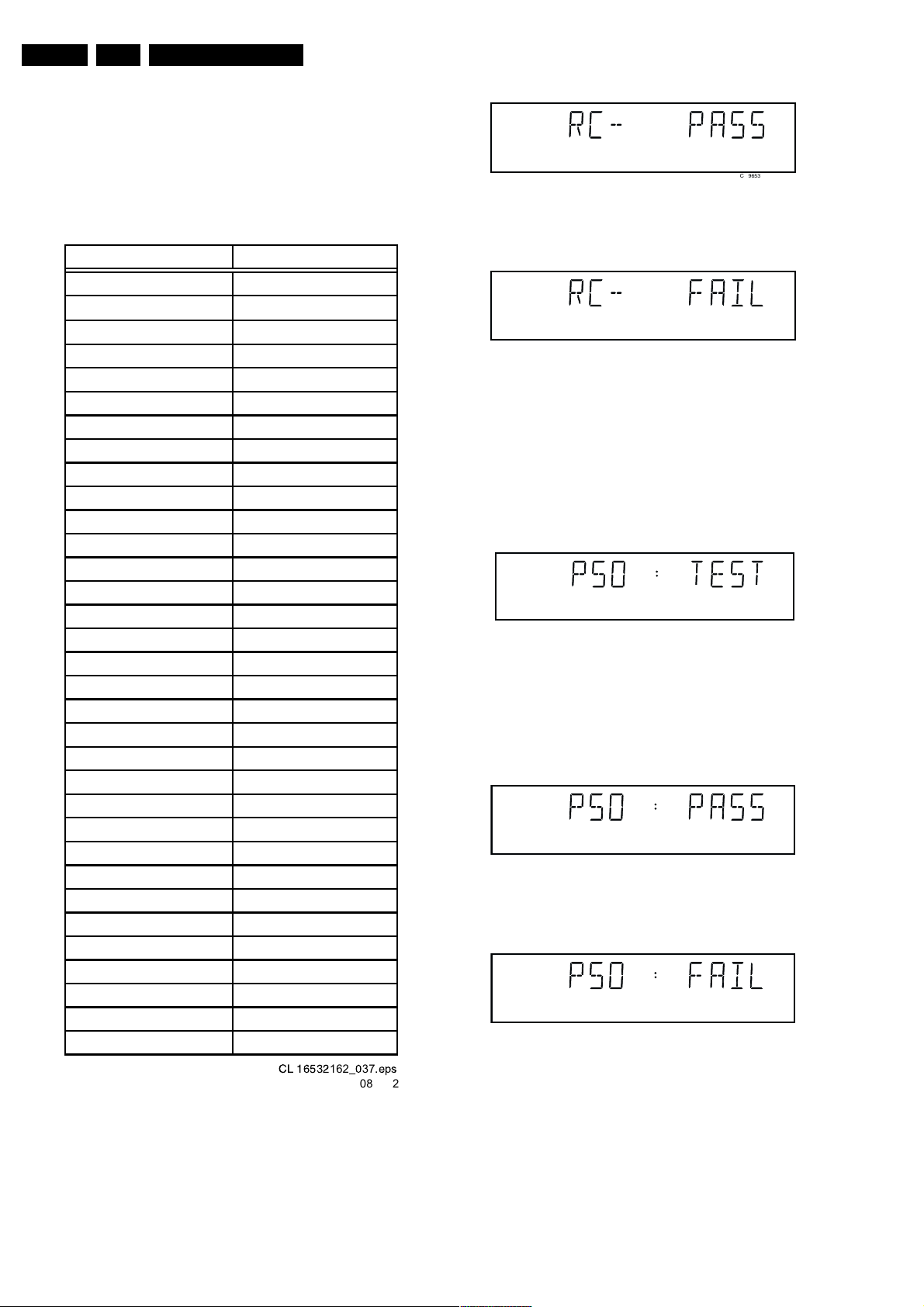

5.3.5 P50 Loop-Back Test

88

99

00

For the P50 loop-back test, the user must first press a key to

decide if the test is to be performed.

The display will show the following message:

RETURN 83

DISPLAY EF

DISC MENU 54

SYSTEM MENU 82

CURSOR UP 58

CURSOR DOWN 59

CURSOR LEFT 5A

CURSOR RIGHT 5B

OK 5C

PREVIOUS 21

If the user presses STOP, the P50 test will be skipped.

If the user presses OPEN/CLOSE, the P50 test is performed

and the result is displayed as follows:

Test successful:

NEXT 20

STOP 31

PLAY 2C

PAUSE 30

SUBTITLE 4B

ANGLE 85

ZOOM F7

Test fails:

AUDIO 4E

REPEAT 1D

REPEAT A-B 3B

SHUFFLE 1C

SCAN 2A

CL 16532

Figure 5-12

162_037

080102

.eps

Press the PLAY key to continue to the next text

Figure 5-14

Figure 5-15

Figure 5-16

Figure 5-17

CL 96532065_014.eps

120799

CL 16532007_004.eps

090102

CL 16532007_005.eps

090102

CL 16532007_006.eps

090102

After pressing PLAY, the result of the remote control test is

displayed on the local display of the DVD player as follows:

Diagnostic Software, Trouble Shooting and Test Instructions

EN 25DVD963SA 5.

5.4 Mono PCB Digital Part

5.4.1 Picture Test

The picture test is performed by putting a predefined picture

(colour bar) on the display (nucleus VideoColDencOn), and

asking the user for confirmation.

The display will show the following message:

Figure 5-18

By pressing OPEN/CLOSE the user confirms the test, pressing

STOP will indicate the picture was invisible or incorrect.

Pressing PLAY will proceed to the next test. If the user presses

PLAY without pressing OPEN/CLOSE or STOP first, the result

of this test will be TRUE (picture ok).

Note: The colour bar must be simultaneously available on the

CVBS, YC, and RGB (or YUV) outputs available. On the

SCART only the CVBS and RGB signals will be available.

5.4.2 Sound 1 & SCART DVD Test

CL 96532065_015.eps

100102

The test can be left by pressing the PLAY key for more than

one second.

5.4.3 Sound 2 Test

The second soundtest is performed by producing a sine sound

(nucleus AudioSineOn). The signal can be stopped by pressing

the STOP key.

The display will show the following message:

Figure 5-21

After the audio signal has been stopped, by pressing OPEN/

CLOSE, the user confirms the test. Pressing STOP will indicate

that something went wrong. Pressing PLAY will proceed to the

next. If the user presses PLAY without pressing OPEN/CLOSE

or STOP first, the result of this test will be TRUE (sound ok).

CL 96532065_019.eps

100102

The first soundtest is performed by starting a pink noise sound

that needs confirmation from the user (nucleus

AudioPinkNoiseOn).

The display will show the following message:

CL 16532162_038.eps

080102

Figure 5-19

On the TV screen a colour bar (generated by nucleus

VideoColDencOn) is visible and the internally generated

pinknoise is audible.

By pressing the PLAY key, the user confirms the test. Pressing

the STOP key will indicate the sound was inaudible or

incorrect.

Note: Only for double scart models, SCART loop-through will

be simultaneously active during this test. SCART loop-through

will be measured with the aid of an external video source.

By pressing the PLAY key, there will be switched over to the

external source. This must become now visible on the TV

srcreen (using the SCART).

The local display will show the following message:

CL 16532162_039.eps

080102

Figure 5-20

The internally generated colour bar is still available on the

CVBS and Y/C outputs. And the pinknoise-signal is still

available on the cinch audio outputs. By pressing the OPEN/

CLOSE button, the internal generated colour bar becomes

visual again.

EN 26 DVD963SA5.

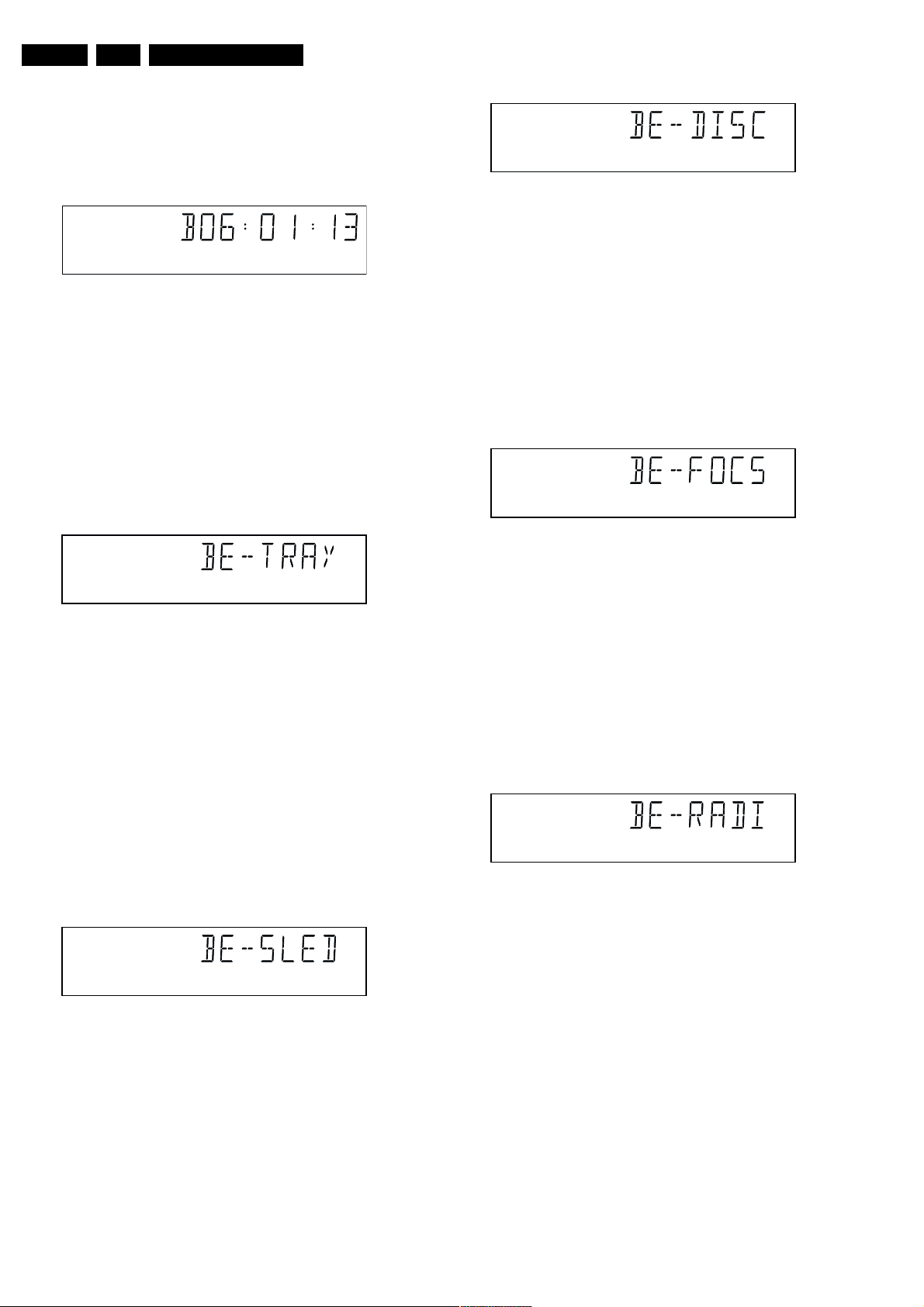

5.5 Basic Engine

5.5.1 Version Number

Diagnostic Software, Trouble Shooting and Test Instructions

In the basic engine tests, the version number of the Basic

Engine will be shown first, as the following example:

Figure 5-22

By pressing the PLAY key, the Basic Engine tests are started.

5.5.2 Tray Test

First, the tray is tested. The purpose of this test is also to give

the user the opportunity to put a disc in the tray of the DVD

player. Some tests on the Basic Engine require that a disc (e.g.

DVD MPTD test disc) is present in the player. At the end of the

Basic Engine tests this tray test will be repeated solely to

enable the user to remove the disc in the tray.

The local display will look as follows:

Figure 5-23

By pressing OPEN/CLOSE the user can toggle the position of

the tray. Note that this test will not contribute to the test result

of the Basic Engine. Pressing PLAY will proceed to the next

test. At this point, the tray will be closed automatically by the

software if it was open.

5.5.3 Sledge Test (Visual Test)

CL 16532162_040.eps

080102

CL 16532162_041.eps

080102

Figure 5-25

By pressing OPEN/CLOSE the user confirms that the disc

motor is running. Pressing STOP indicates the disc motor does

not work. Pressing PLAY proceeds to the next test, after a reset

of the disc motor (nucleus BeDiscMotorOff). If the user presses

PLAY before pressing OPEN/CLOSE or STOP, the result of

this test will be TRUE (disc motor is running).

5.5.5 Focus Test (Visual Test)

The fourth Basic Engine test tests the focussing. First

focussing is turned on by calling nucleus BeFocusOn.

The display will look as follows:

Figure 5-26

By pressing OPEN/CLOSE the user confirms that the

focussing was succesful. Pressing STOP indicates a focussing

failure. Pressing PLAY proceeds to the next test after a reset of

the focussing (nucleus BeFocusOff). If PLAY is pressed before

OPEN/CLOSE or STOP, the result of this test will be TRUE

(focus successful).

5.5.6 Radial Test (Visual & Listening Test)

The fifth Basic Engine test tests the radial functionality (nucleus

BeRadialOn).

The local display looks as follows:

CL 16532162_043.eps

080102

CL 16532162_044.eps

080102

The second Basic Engine test tests the sledge. The user can

move the sledge as many times as desired by using OPEN/

CLOSE (nucleus BeSledgeOut) and STOP (nucleus

BeSledgeIn). Pressing PLAY on the local keyboard proceeds

to the next test. Note that this test will not contribute to the test

result of the Basic Engine.

The local display will look as follows during the sledge test:

Figure 5-24

5.5.4 Disc Motor Test (Visual Test)

The third Basic Engine test tests the disc motor (nucleus

BeDiscMotorOn).

The local display looks as follows:

CL 165321625_042.eps

080102

Figure 5-27

By pressing OPEN/CLOSE the user confirms that the radial

function works.Pressing STOP indicates the function does not

work. Pressing PLAY proceeds to the next test, after a reset of

the radial (nucleus BeRadialOff). If the user presses PLAY

before pressing OPEN/CLOSE or STOP, the result of this test

will be TRUE (radial successful).

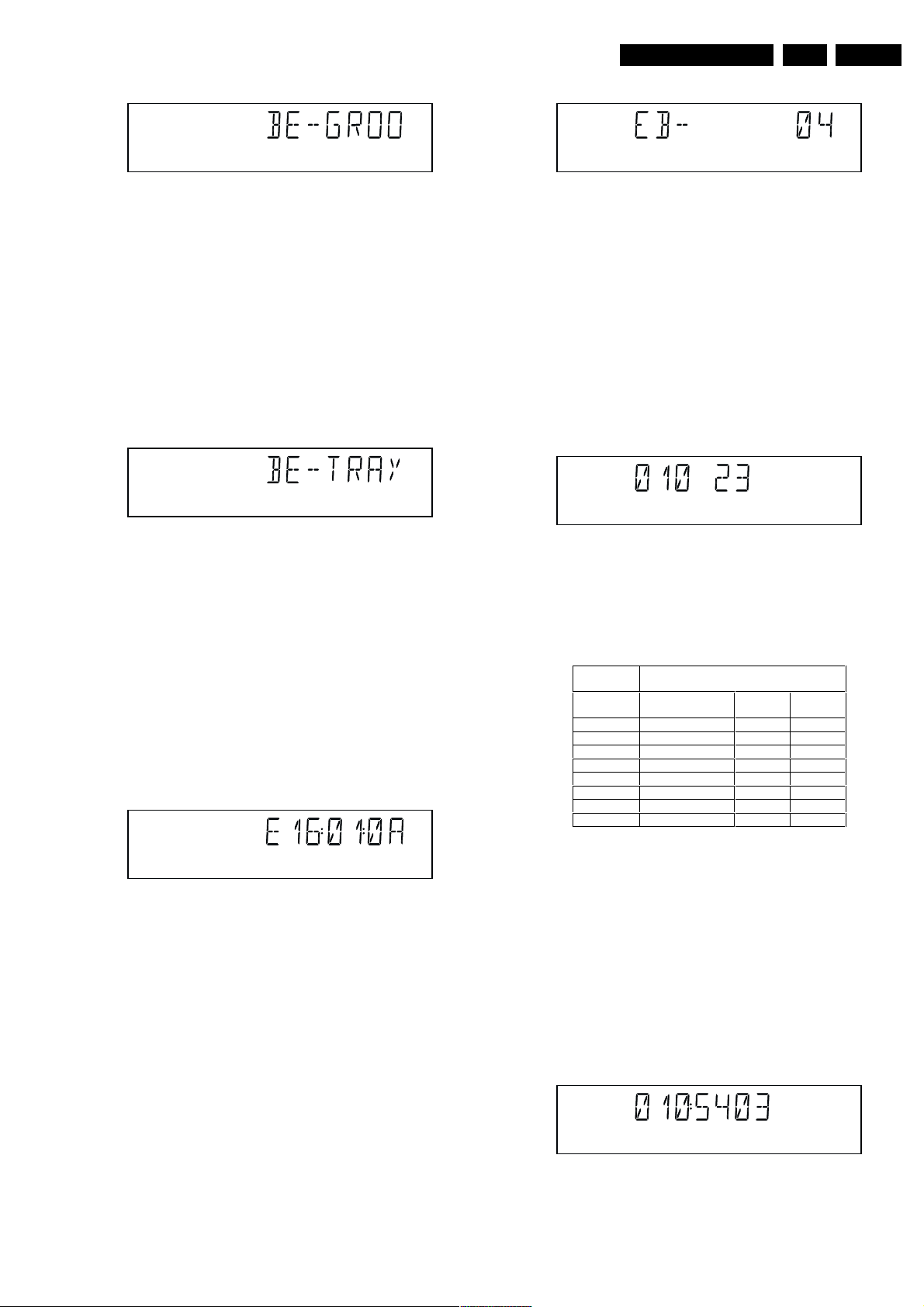

5.5.7 Jump Test (Listening Test)

The sixth and last Basic Engine test tests the jumping by calling

nuclei BeGroovesIn, BeGroovesMid and BeGroovesOut.

During this test, the local display looks as follows:

CL 16532162_045.eps

080102

Diagnostic Software, Trouble Shooting and Test Instructions

EN 27DVD963SA 5.

Figure 5-28

The user can switch between the three different types of

groove settings by pressing OPEN/CLOSE (forward to next

nucleus in the list In-Mid-Out), or STOP (backward in the list InMid-Out). This is done in a cyclic manner; note that this test will

not contribute to the test result of the Basic Engine. Pressing

PLAY proceeds to the next test, after the disc motor has been

shut off with a call to nucleus BeDiscMotorOff.

5.5.8 Tray Test

As a last action for the Basic Engine tests, the tray test is

repeated. The local display will look as follows:

Figure 5-29

This test is meant to give the user the opportunity to remove the

disc in the tray. The tray position can be toggled using the

OPEN/CLOSE key. The tray will be closed (by the software, if

it is open) before proceeding to the next test when the user

presses the PLAY key.

5.5.9 Error Log (See Table on Page 25)

Reading the error log and error bits information can be useful

to determine any errors that occurred recently during normal

operation of the DVD player. Reading the error log is done by

nucleus LogReadErr.

The display during the errorlog readout looks as follows :

CL 16532162_046.eps

080102

CL 16532162_041.eps

080102

Figure 5-31

Only the identification number (decimal) representing set

errorbits will be shown. By pressing OPEN/CLOSE or STOP,

the user can move forward or backward (respectively) through

the logged errorcodes. If the display only shows "EB-0", no

error bits were set. By pressing PLAY the user can continue to

the next test.

5.6 Loop Test (See Table Below)

At the start of the loop test, the local display of the DVD player

will show the interactive player test result readout in the

following display:

Figure 5-32

The left side of the display contains a 3-digit code, which can

have a value between 000 and 111. These values indicate the

faulty modules and are to be interpreted as follows:

Displayed

Value

000 ok ok ok

001 ok ok faulty

010 ok faulty ok

011 ok faulty faulty

100 faulty ok ok

101 faulty ok faulty

110 faulty faulty ok

111 faulty faulty faulty

Indication for each module

Basic Engine Mono

PCB

Display

PCB

CL 96532065_031.eps

CL 16532162_048.eps

080102

CL 16532162_049.eps

080102

120799

Figure 5-30

Note: Previous versions of the diagnostic software showed a 8-

digit error code.

Due to limitations in the number of digits that can be displayed

by some front panel displays, the most significant digits will not

be shown. This can be done since all the error codes used by

this player has set these 2 digits to “00”

By pressing OPEN/CLOSE or STOP the user can move

forward or backward (respectively) through the logged error

codes. If "0000" is displayed at all positions, the error log is

empty. Display of the logged errors is done in a cyclic manner.

By pressing PLAY on the local keyboard, the user can proceed

to the next test.

5.5.10 Error Bits

Reading the error bits is done by nucleus LogReadBits. The

display during the errorbits readout looks as follows:

CL 16532162_047.eps

080102

Figure 5-33

The loop test will perform the same nuclei as the dealer test,

but it will loop through the list of nuclei indefinitely. The display

of the DVD player will display not only the three digits indicating

correct/faulty modules and the last found error code (as

mentioned, faults are detected as far as they can be within the

scope of the diagnostic software), but also a loop counter

indicating how many times the loop has been gone through. If

an error was detected, the display will remain as in figure 5-34

until the user presses the PLAY key and then it will continue to

the next loop.

Example:

CL 16532162_050.eps

080102

Figure 5-34

The 2-digit number (23) on the right of figure 5-32 indicates the

number of times the loop test has been performed.

EN 28 DVD963SA5.

Diagnostic Software, Trouble Shooting and Test Instructions

After one loop cycle: Display the 3-digit module bits together

with the last error code which occured in the loop test. The 4

digits at the right side of the display (fig. 5-34) show the last

error that was found during the loop test. The leftmost two digits

(54) of this code indicates which nucleus resulted in a fault. The

rightmost two digits (03) refer to the faultcode within that

nucleus. For further explanation of this error code, refer to

chapter 5.8 (Nuclei Error Codes).

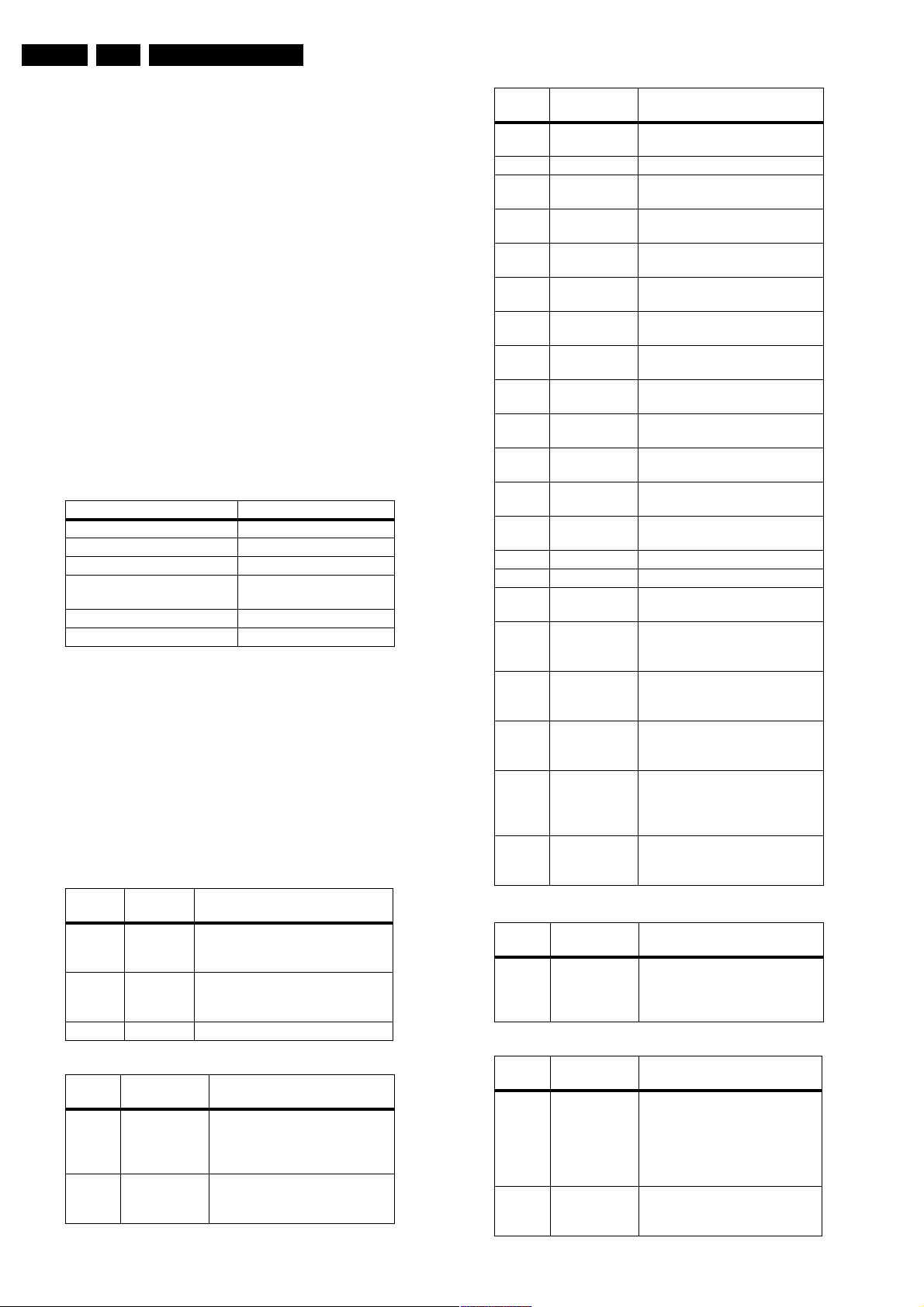

5.6.1 Errorlog

Explanation:

The application errors will be logged in the NVRAM. The

maximum number of error bytes that will be visible is 16. The

first word (4 digits) of the byte is the component identification,

the last word is the error code.

The diagnostics software will present a combination of this

component identification plus an error code on the local display

(and on the attached terminal). The last reported error is shown

as < 00000000, the oldest visible error as 00000000 > and the

errors in between as < 00000000 >.

The devices that may report errors are the serial controller

(UART), the basic engine (BE), the slave processor (SLPH),

the SACD Stream Manager (SSM) and the SACD Media

Access (SMA). The identification of these components is as

follows:

Component name Component identification

Serial controller (UART) 000A

Engine (BE) 0016

Slave Processor (SLPH) 001A

SACD Stream Manager

(SSM)

SACD Media Access (SMA) 002E

Diagnostic software (DS) Dxxx

The tables in the next chapters list the error code and

corresponding problem. The column ‘Explanation’ holds a

more elaborate description and the most likely reason for the

error.

Some Examples:

002E0000 (SMA reported a timeout error)

0016010A (Engine could not fully close or open the tray)

D0010001 (Flash checksum failed).

For further explanation of DS errors, see description of nucleui

error codes in paragraph 5.8.

UART Error Codes

Error

Number

0000 BUF_OVE

0001 COMMUNI

0002 TIME OUT

BE Errors

Error

Number Error name Explanation

0101 S2B_ILL_CO

0102 S2B_ILL_PARAMCommand not allowed in this

Error

name Explanation

RFLOW

CATION

MMAND

001C

To many characters were offered in

too little time. Reason: system was

too busy doing other jobs.

Usually a protocol error. Reason:

bad connection between engine

and processor.

Parameter(s) not valid for this

command. Reason: some

communication problem

between UART and engine.

state or unknown. Reason: see

S2B_ILL_COMMAND error

Error

Number Error name Explanation

0103 S2B_SLEDGE Sledge could not be moved to

home position.

0104 S2B_FOCUS Focus failure

0105 S2B_MOTOR Motor could not reach speed

0106 S2B_RADIAL Servo didn't get on track after

0107 S2B_PLL_LOCKPLL could not lock in Accessing

0108 SBC_HEADE

R_TO

0109 S2B_SBC_NO

T_FOUND

010A S2B_TRAY Tray could not be opened or

010B S2B_TOC_READTOC could not be read within

010C S2B_JUMP Requested seek could not be

010D S2B_NON_EX

IST_SES

010E S2B_NON_EX

IST_BCA

010F Speed setting A wrong or inappropraiate speed

0116 NO_DISC No disc selected

011A TRAY_INIT After reset, initialized tray

011B NO TOC INFO No TOC information in lead-in

01F0 S2B_OVERRUNToo many bytes received over

01F1 S2B_COMM_TONot enough bytes are received

01F2 S2B_PARITY Byte received with parity error.

01F3 S2B_ILL_PHASECMD IDC is not valid,

01F4 S2B_ILL_NR_

OF_BYTES

SLPH Error Codes

Error

Number Error name Explanation

0000 COMMUNICA

TION

SSM Error Codes

Error

Code Error name Explanation

0006 SP_SYNCER

ROR

0007 SP_EDCERRORData coming from disc is

within timeout

several retries.

or Tracking state

Header timeout

Requested subcode item could

not be found.

closed completely.

timeout period.

performed.

Attempt to access a non-existing

session.

Caller tries to acces a non-

existing BCA area

value has been set

area or erase TOC found

S2B Reason: see

S2B_ILL_COMMAND error

over S2B Reason: see

S2B_ILL_COMMAND error

Reason: see

S2B_ILL_COMMAND error

transmission out of sync.

Reason: see

S2B_ILL_COMMAND error

Byte count has an illegal value.

Reason: see

S2B_ILL_COMMAND error

Error in I2C communication.

Reason: bad connection

between slave processor and

main processor.

System cannot get synchronised

with sectors coming from disc.

Reason: Usually a damaged

disc or the player was dropped/

pushed during operation. If not,

the engine is malfunctioning.

damaged. Reason: see

SP_SYNCERROR

Loading...

Loading...