Page 1

CHAPTER 7

PACKING METHODS

page

Introduction 7-2

Glossary of terms 7 - 2

Drypack for moisture sensitive SMDs 7 - 3

Survey of IC packing methods 7 - 5

Packing methods in exploded view 7 - 6

Packing quantities, box dimensions and carrier shapes 7 - 13

Page 2

Philips Semiconductors IC packages

Packing methods Chapter 7

INTRODUCTION

The chapter contains a survey of the packing methods

most frequently used by Philips Semiconductors. It

includes information that may be important to customers

when making their purchasing decisions, for example the

main dimensions, shapes, and packing quantities.

Standardization

For semiconductors, packing serves two important

functions. The firstand most obvious function isprotection

duringstorageand transport to customers. This, ofcourse,

applies to all products, not just semiconductors.

The second is to act as a delivery medium for automatic

placement machines during equipment manufacture.

To do this effectively, the reels, trays and tubes that

components are packed in must meet recognized

standards.In this respect, PhilipsSemiconductors actively

cooperateswith standardization authorities throughout the

world.

In addition, its packing methods meet all major

international standards, including those of IEC

(International Electrotechnical Commission), JEDEC

(Joint Electron Device Engineering Council, USA) and

NEDA (National Electronic Distributor Association, USA).

Environmental care

Nowadays, an important issue is environmental impact.

Component and equipment manufacturers are

continuously working to improve the environment

friendliness of their products and packing, and have

devoted much effort to eliminating the use of toxic

materials and to looking at ways in which materials can be

recycled.

In these respects, Philips Semiconductors has taken

several important steps on the packing front. These

include:

• Reducingtheamountofpacking material by switching to

‘onepiece’boxes(insteadofboxeswithupperandlower

parts)

• Changing to ‘mono material’ to aid recycling.

For example, from aluminium-lined boxes to

carbon-coated boxes.

• Changing from white boxes to natural brown boxes to

eliminate the use of bleach (chlorine) in their

manufacture.

The aim is minimum waste and minimum environmental

impact. We have already gone a long way towards this in

the development of our packing methods. And future

developments will take us even further along this route.

For more information relating to environmental issues,

refer to Chapter 8 - Environmental data on ICs.

GLOSSARY OF TERMS

Through-hole mounted onto a PCB by insertion of leads into holes

Surface mount mounted on the surface of a PCB

Package container with terminals for an IC chip (also known as an envelope or outline)

Carrier plastic tube, tray or tape with cavities, which can contain semiconductor products

Packing method combination of a carrier and a box to protect products during transport and storage

Pin rigid plastic pin that closes a tube for DIPs by insertion through holes in its end

Plug flexible plastic plug that closes a tube for PLCCs or SILs by insertion into its end

Turnlock rigid plastic pin that closes a tube for SOs by insertion into its end and turning to lock in place

SPQ Smallest Packing Quantity, in one carrier

PQ Packing Quantity, in a box containing one or more SPQs

For a full definition ofIC package abbreviations and their suffixes, refer to

2000 May 11 7 - 2

Chapter 2 - IC Package range and dimensions

.

Page 3

Philips Semiconductors IC packages

Packing methods Chapter 7

DRYPACK FOR MOISTURE SENSITIVE SMDs

If packed or stored incorrectly, moisture-sensitive plastic

SMDs can easily be damaged after a prolonged exposure

to the high temperatures associated with certain soldering

methods. If any moisture is present in the plastic package

during soldering, it may turn into steam and expand

rapidly. Under certain circumstances, the force exerted by

this expansion can cause internal delamination or, in the

most severe cases, may result in internal or external

package cracks (the popcorn effect). This effect is more

prominentwithinfrared and vapour-phase reflow soldering

methods when soldering temperatures can reach severe

levels.

To avoid this problem, and ensure trouble-free soldering,

we deliver moisture-sensitive ICs in a resealable

moisture-resistant plastic packing called a DRYPACK.

Moisture sensitivity level

Not all plastic packages are equally sensitive to moisture.

To differentiate between types, we assign each IC

package a moisturesensitivity level (MSL). The MSLof an

IC’s package is influenced by:

• chip area and size of the die-pad

• package body size

• package material properties

• moisture content of the package

• temperature and duration of the soldering process.

Determining MSL

We determine moisture sensitivity levels by testing

batches of each package according to a detailed

specification, which includes moisturizing and

infrared-reflowsoldering.Thissoldering method is used as

infrared radiation is readily absorbed by the black IC

packages and therefore is the most critical soldering

process when testing for the popcorn effect.

After moisturizing to predetermined levels, the packages

pass through an oven where they are first preheated, then

heated to a soldering temperature, and finally cooled. The

convection solder reflow requirements are given in

Table 1.

Although the profile has a low maximum temperature, the

packagesare exposed to 183 °Candabove for a relatively

long time. If this maximum temperature is higher than that

givenin Table 1, the effect ofsolderingwill be more severe

compared with the test on which the MSL ofthe specific IC

package is based. If, however, the package is soldered

well within its specified floor life limit (see Table 2), a

higher soldering temperature can be used as the

package’s moisture content will be much less.

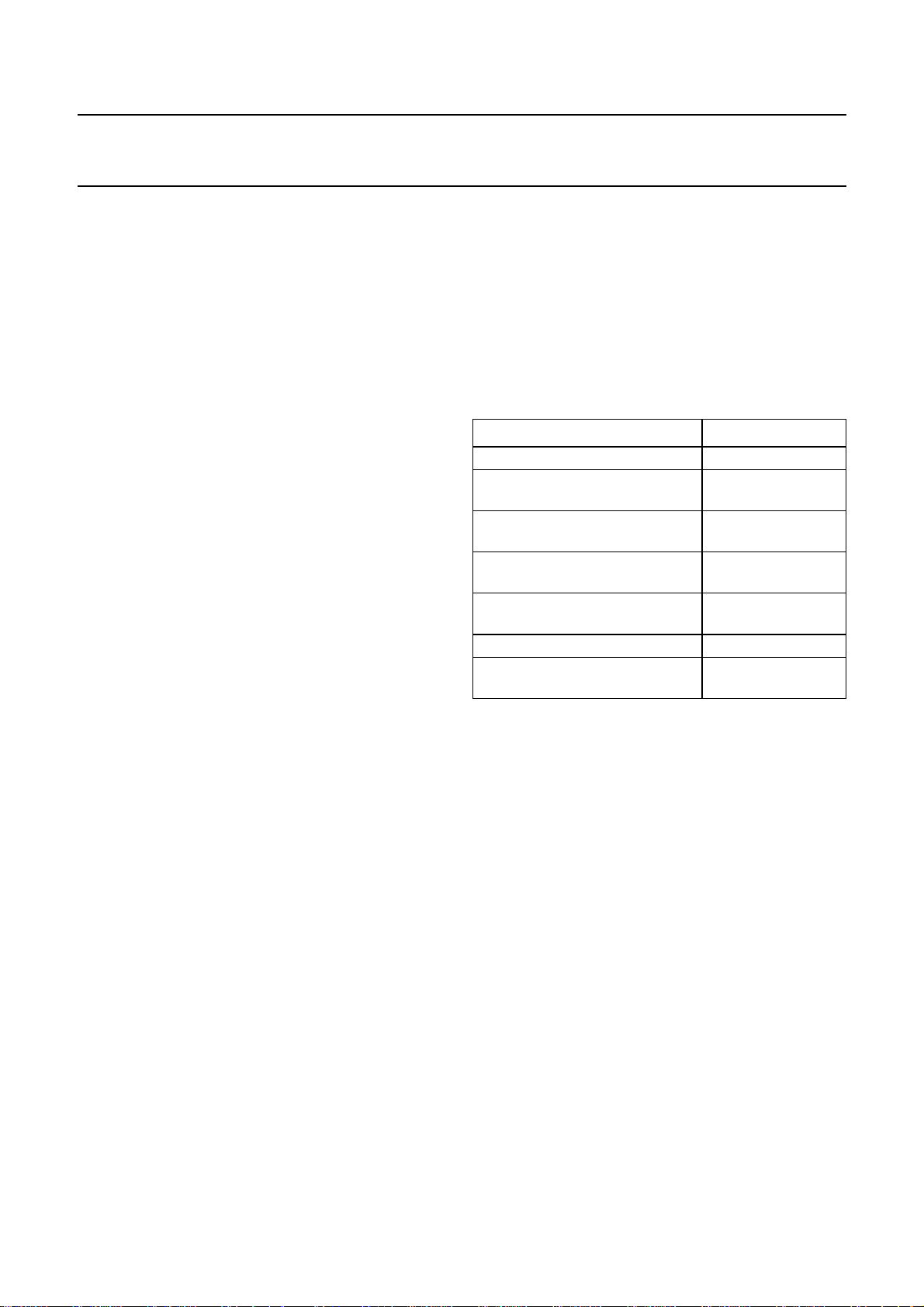

Table 1 Convection solder reflow requirements

PROFILE PARAMETER REQUIREMENTS

Ramp-up rate (183 °C to peak) 3 K/s max.

Preheat temperature

(125 °C ± 25 °C)

Temperature maintained above

183 °C

Time within 5 °C of actual peak

temperature

Peak temperature range

Ramp down rate 6 K/s max.

Time from 25 °C to peak

temperature

Notes

1. Alltemperaturesrefertothe top side of thepackageas

measured on the centre of the plastic body surface.

2. Peak temperature requirements:

a) Packages with a thickness ≥ 2.5 mm and all BGA

packages: peak temp. 220 °C +5/ −0 °C.

b) Packages with a thickness < 2.5 mm and all with a

package volume ≥ 350mm3: peak temp. 220 °C

+5 /−0 °C.

c) Packages with a thickness < 2.5 mm and all with a

package volume < 350mm3: 235 °C +5/−0 °C.

(Packagevolume is defined asbody-height× width

× length, but excludes external leads and

non-integral heatsinks).

(2)

120 s max.

60 to 150 s

10 to 20 s

220 °C +5/−0 °C or

235 °C +5/−0 °C

6 minutes. max.

(1)

To reduce any moisture-related stresses within the

packages, they are first preheated to around 125 °C to

allow them to dry before they reach their maximum

temperature. The longer this preheating time, therefore,

thesmallerthe chance of packages being damagedduring

the high temperatures associated with soldering.

2000 May 11 7 - 3

Page 4

Philips Semiconductors IC packages

Packing methods Chapter 7

Table 2 Floor life versus moisture sensitivity levels

MSL CONDITIONS FLOOR LIFE

130°C / 90% RH unlimited

230°C / 60% RH 1 year

2a 30 °C / 60% RH 4 weeks

330°C / 60% RH 168 hours

430°C / 60% RH 72 hours

530°C / 60% RH 48 hours

5a 30 °C / 60% RH 24 hours

(2)

6

Notes

1. Packages that are not sensitive to moisture do not

require DRYPACK.

2. MSL 6 packages must be baked before use, after

which they have a 6-hour floor life.

No problems are associated with wave soldering as the

components are only exposed to high temperatures for a

short time.

AllPhilipstestcentresperform these MSL investigations to

the same rigorous specification, and classify the moisture

sensitivity of packages into levels ranging from 1 (not

sensitive to moisture) to 6 (very sensitive to moisture).

In addition, and as part of our Reliability Monitoring

Program,we conduct regular stress testsonourSMDs. As

part of these tests, the packages are exposed to a

simulated moisturizing and soldering run to reproduce a

typical production process, then they are checked both

visuallyand electronically for anysignsof deterioration. As

a result, we guarantee that if the packages are stored

correctly, IC reliability will not be affected after soldering.

Philips DRYPACK

The Philips DRYPACK is a laminated plastic packing that

prevents the moisture content of the IC plastic packages

rising above 0.1% by weight for up to one year. The

DRYPACK must be stored at normal room temperature

(between 10 °C and 30 °C), and in an atmosphere of less

than 60% relative humidity (RH).

30 °C / 60% RH 6 hours

(1)

The DRYPACK contains a desiccant and a humidity

indicator, used to monitor the moisture content when the

bag is opened.

Using ICs from a DRYPACK

Before using ICs from a DRYPACK, it's essential that the

humidity indicator is checked. If it shows that the RH has

remained below 20% (the colour of the 20% dot is blue),

the ICs are ready for use.

As soon as the ICs are removed for the DRYPACK,

however, they are immediately exposed to moisture in the

atmosphere. To prevent them absorbing excessive

moisture, they must be soldered onto the PCB within the

specified floor life period given in Table 2. These times are

related to the MSL of the package.

If the humidity indicator in a DRYPACK shows an RH of

more than 20% (the colour of the 20% dot has changed

from blue to pink), the DRYPACK has been damaged,

opened, or stored incorrectly. To prevent the popcorn

effect in such a situation, the ICs that were in the

DRYPACK must first be dried before soldering.

For example, the minimum drying time to reduce the

moisture content of an IC package from an initial level of

0.3% by weight to around 0.05% by weight, is given by:

Drying time (hours) = 5 × package thickness (mm) at a

drying temperature of 125 °C ± 5 °C.

Note:Hightemperaturesmaydeterioratesolderability.Itis

strongly recommended to dry at a maximum 125 °C ±

5 °C, and not to dry longer than required.

Resealing a DRYPACK

If some ICs from an opened DRYPACK are not used, the

desiccant and the humidity indicator should be reinserted

intotheDRYPACK and the DRYPACK resealed withinhalf

an hour after opening using commercially available

heat-sealing equipment

The time aresealed DRYPACK can be storeddepends on

thetime since it wasoriginally packed, and howlong it was

open before being resealed.

2000 May 11 7 - 4

Page 5

Philips Semiconductors IC packages

Packing methods Chapter 7

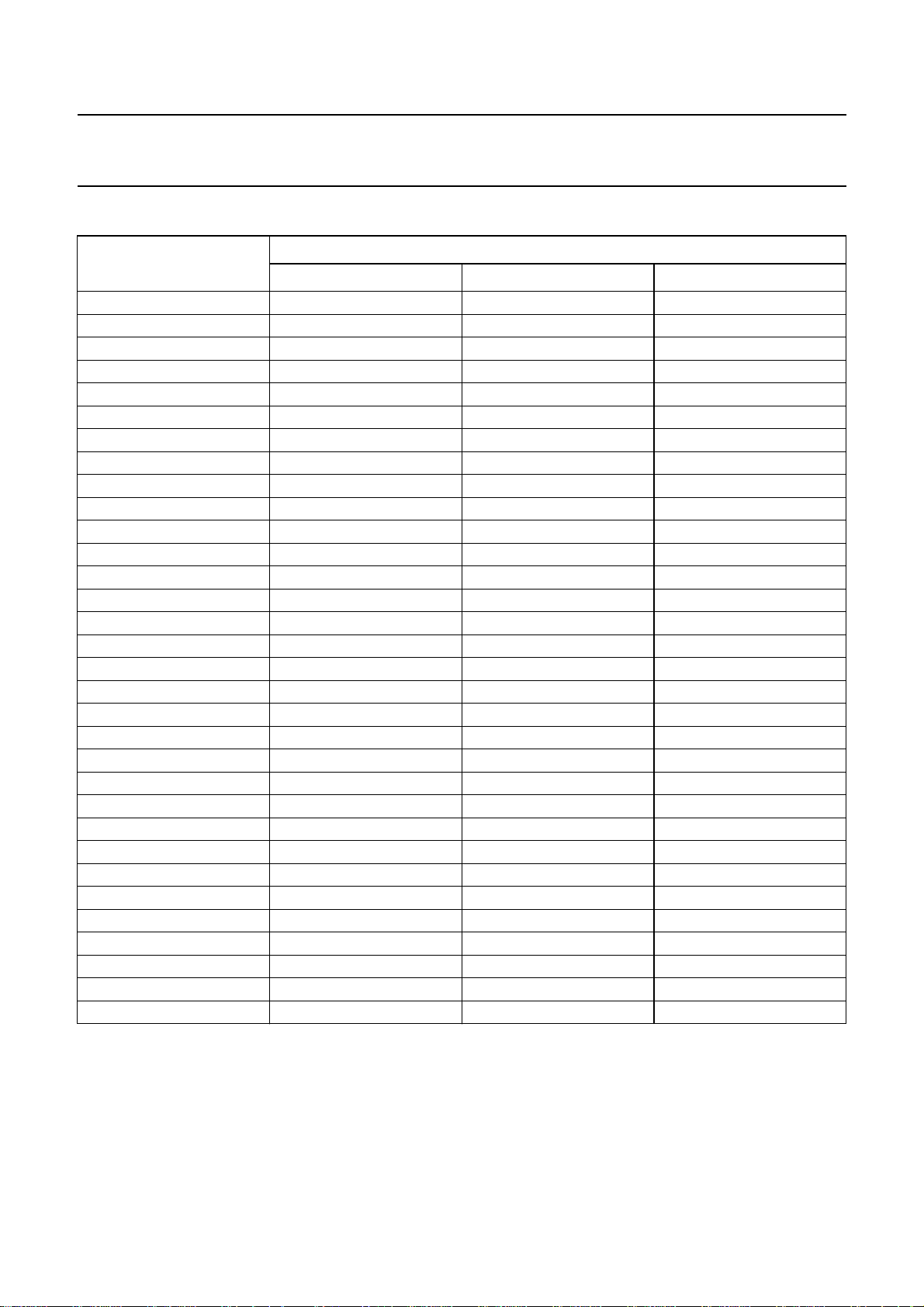

SURVEY OF IC PACKING METHODS

PACKAGE NAME

TUBE TAPE/REEL TRAY

BGA − XX

DBS X −−

DIP X −−

HBCC − XX

HBGA − XX

HDIP X −−

HLQFP − XX

HQFP − XX

HSOP X X −

HSQFP −−X

HTQFP − XX

HTSSOP X X −

LFBGA − XX

LQFP − XX

MSQFP −−X

PLCC X X −

PMFP − X −

QFP − XX

RBS X −−

SDIP X −−

SIL X −−

SMS X X −

SO X X −

SOJ X X −

SQFP −−X

SSOP X X −

TBS X −−

TFBGA − XX

TO − X −

TQFP − XX

TSSOP X X −

VSO X X −

CARRIER TYPE

2000 May 11 7 - 5

Page 6

Philips Semiconductors IC packages

Packing methods Chapter 7

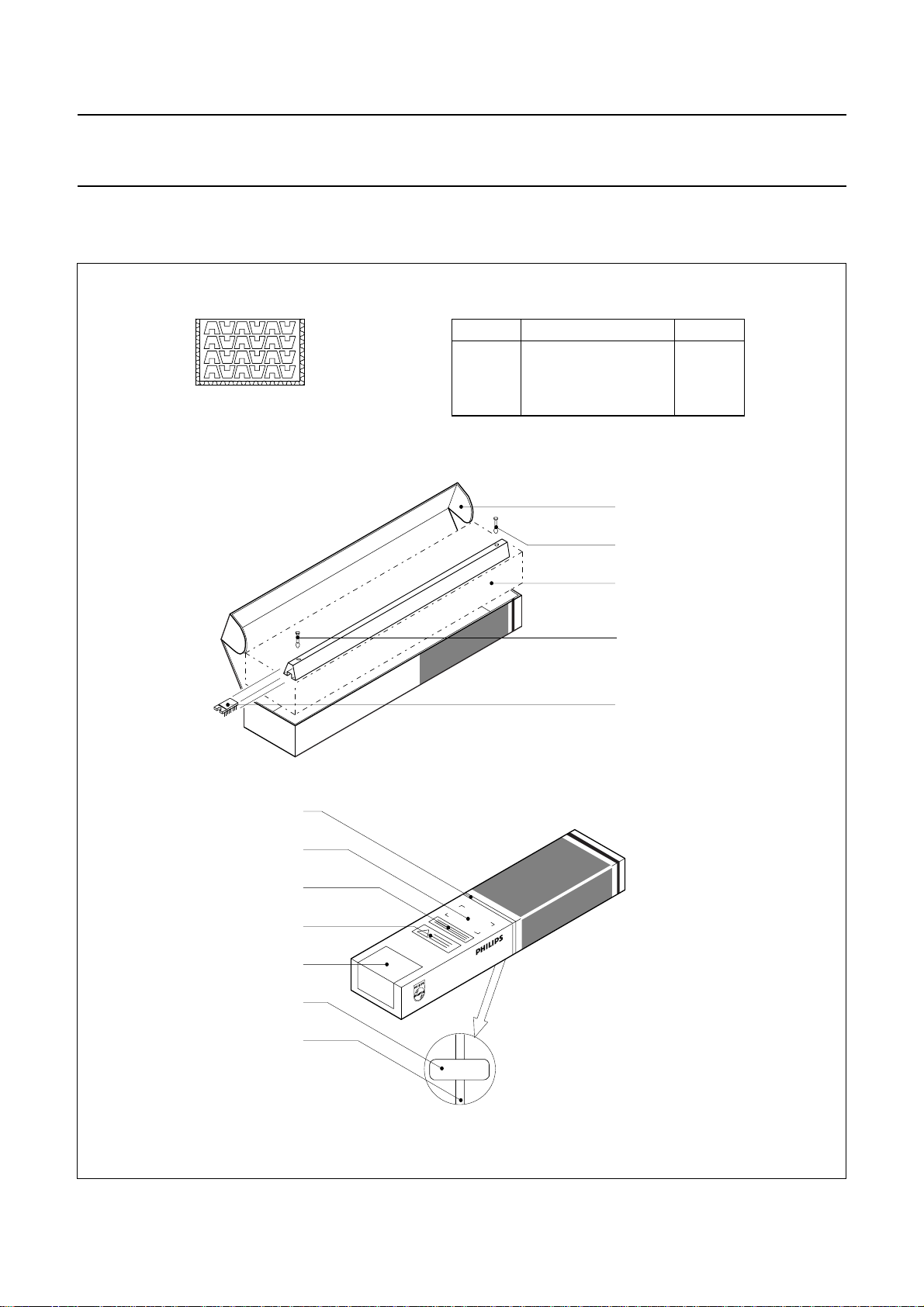

PACKING METHODS IN EXPLODED VIEW

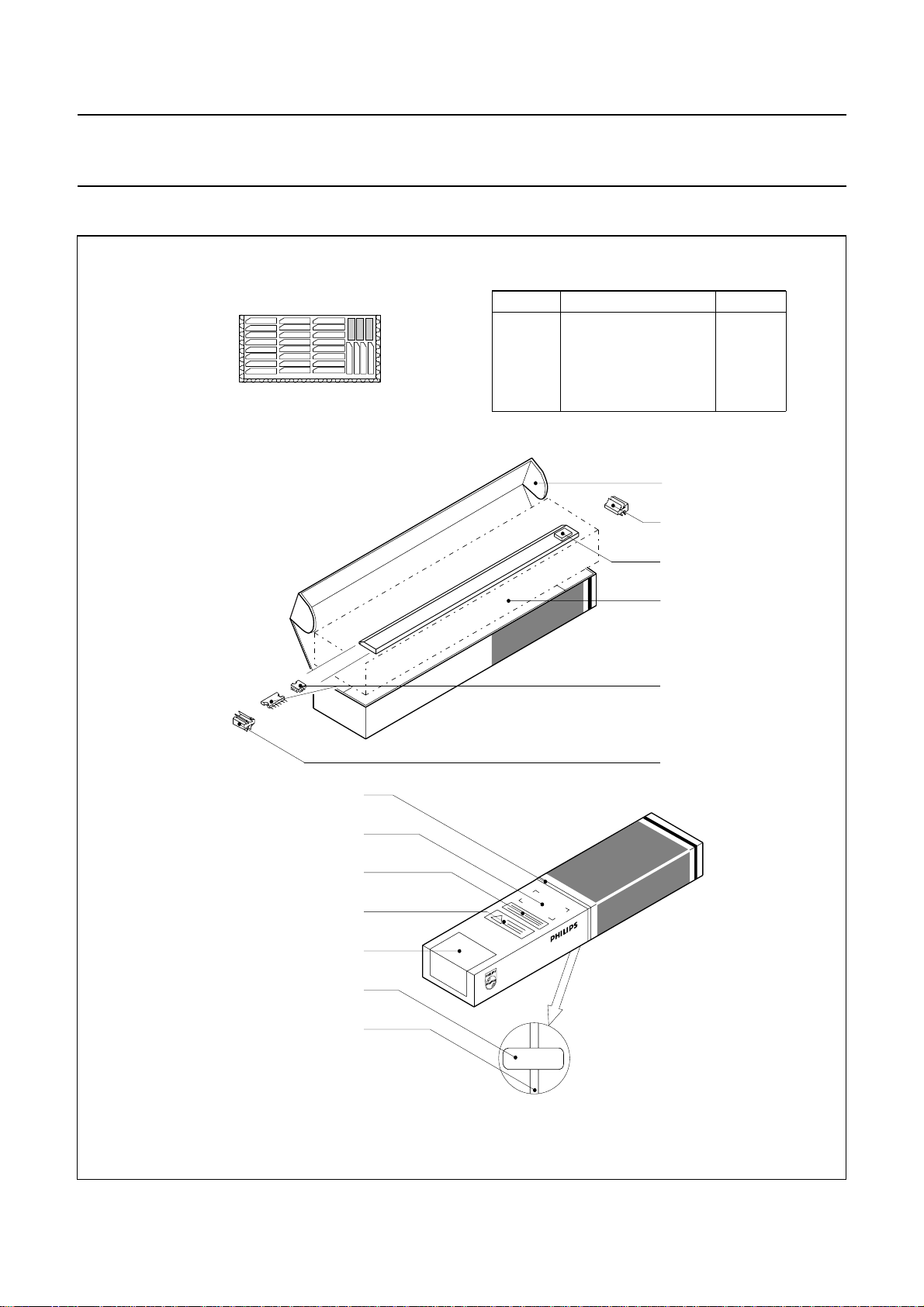

Packing for DIP (tube/pin)

handbook, full pagewidth

Stacking method

Item

Box

Seal

Labels

Endstops

Tubes

Strap

Material

Cardboard carbon coated

Acrylate

Paper

Polyvinylchloride

Polyvinylchloride

Polypropylene

(1)

For DIP,row pitch 0.6"

Printed plano box

Endplug (white)

Stacked tubes

Endplug (green)

Product orientation in tube

(pin 1 towards this side,

this is label side of box)

Weight

145

0.2

1.65

5.6

840

0.7

(1)

(g)

Strap

Space for additional label

Preprinted Hyatt patent

Preprinted ESD warning

Barcode label

QA seal

Strap

Fig.1 Packing for DIP (tube/pin).

2000 May 11 7 - 6

MSC042

Page 7

Philips Semiconductors IC packages

Packing methods Chapter 7

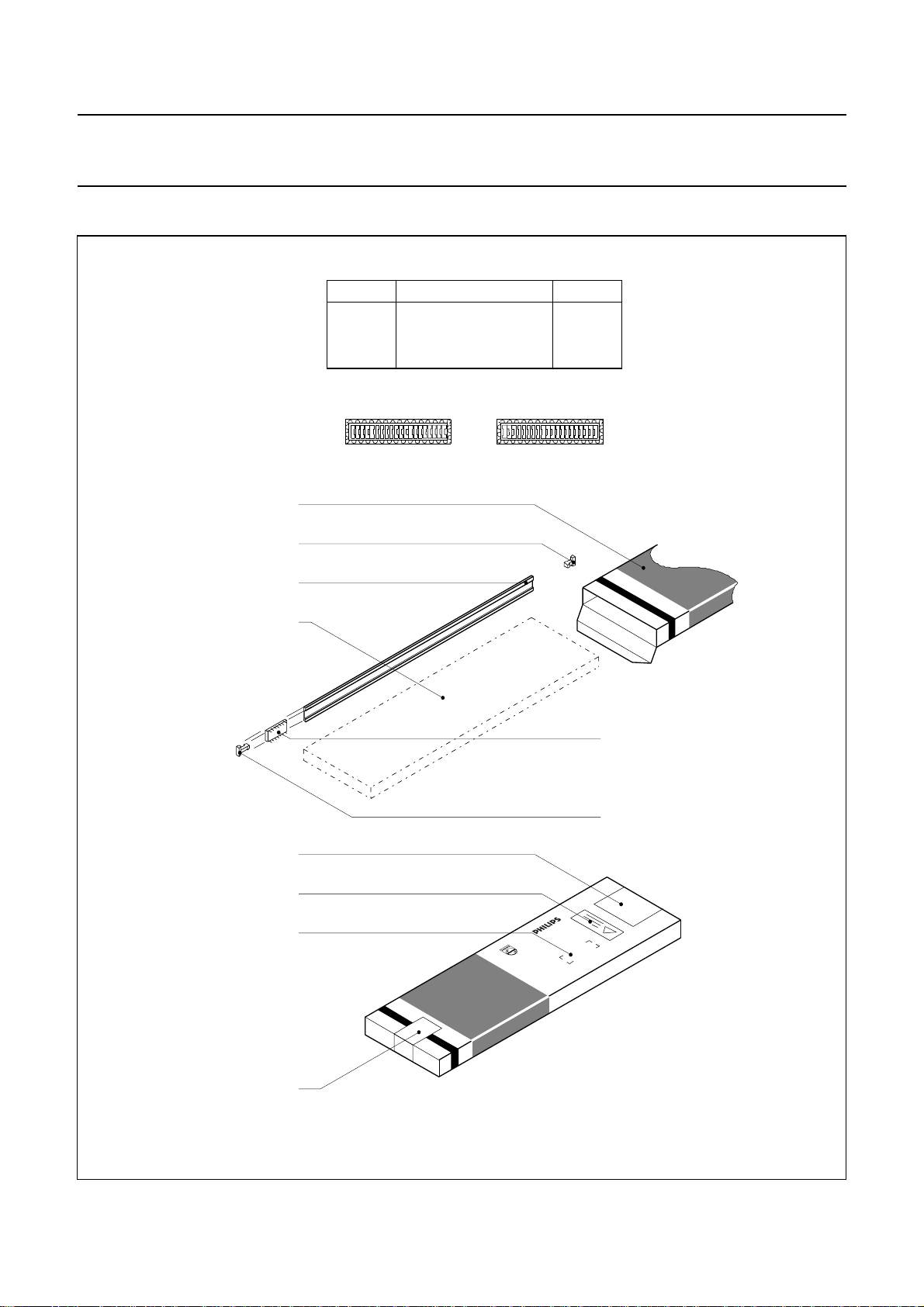

Packing for PLCC/SIL (tube/plug)

handbook, full pagewidth

Stacking method

Item

Box

Seal

Labels

Endstops

Tubes

Strap

Foam

Foam

Material

Cardboard carbon coated

Acrylate

Paper

Polyvinylchloride soft

Polyvinylchloride

Polypropylene

Polyethylene

Ethylenevinylacetate

Printed plano box

Endplug (white)

Foam (optional)

Stacked tubes

Product orientation in tube

(Pin 1 towards this side,

this is label side of box)

Weight

145

0.2

1.65

115

1190

0.7

9

1

(1)

For PLCC84

(1)

(g)

Strap

Space for additional label

Preprinted Hyatt patent

Preprinted ESD warning

Barcode label

QA seal

Strap

Fig.2 Packing for PLCC/SIL (tube/plug).

2000 May 11 7 - 7

Endplug (green)

MSC043

Page 8

Philips Semiconductors IC packages

Packing methods Chapter 7

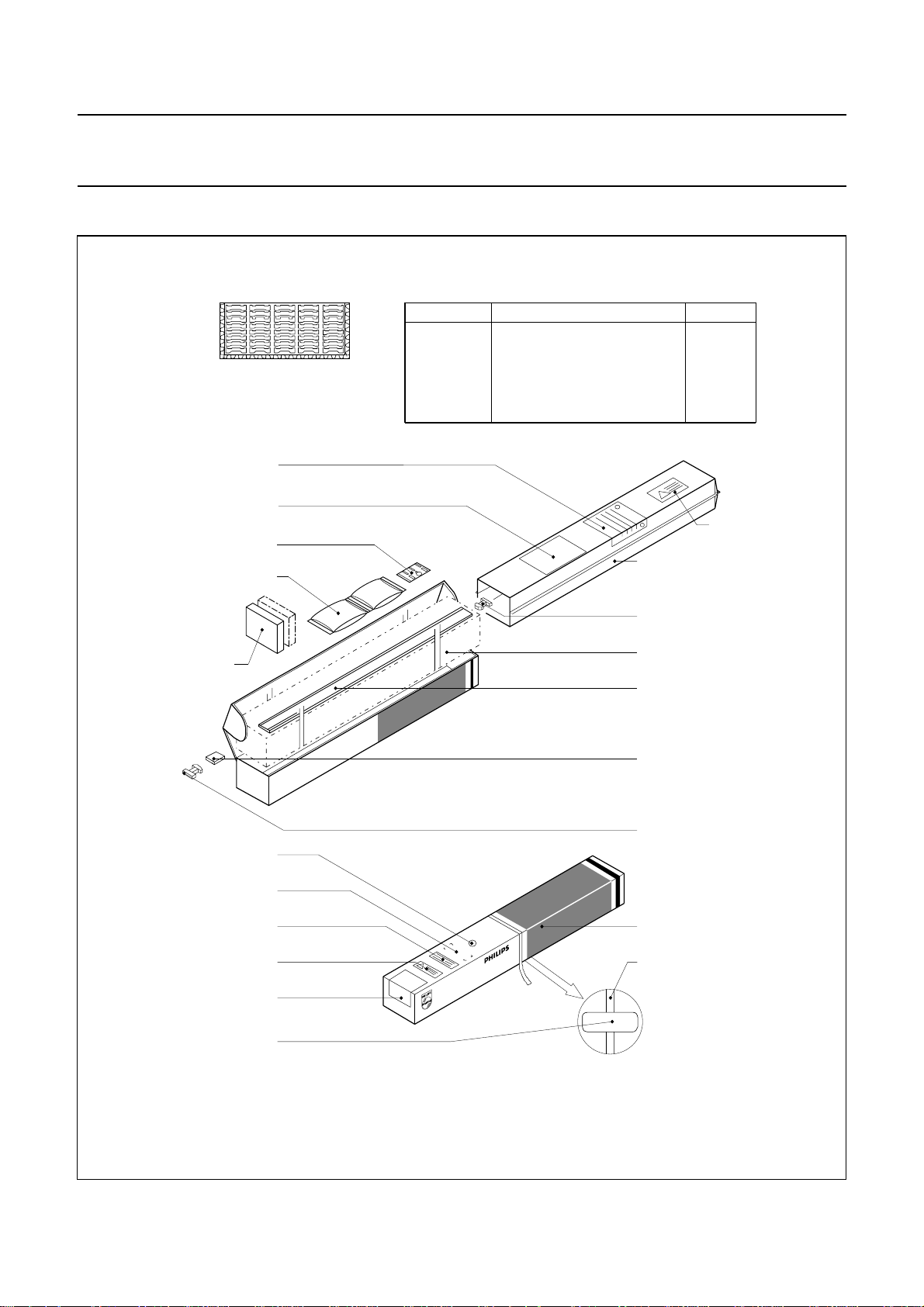

Packing for SO (tube/turnlock)

handbook, full pagewidth

Printed plano box

Turnlock (white)

Tube

Stacked tubes

Item

Box

Seal

Labels

Endstops

Tubes

Material

Cardboard carbon coated

Acrylate

Paper

Polyvinylchloride

Polyvinylchloride

(1)

For SO, row pitch 0.15"

or

Stacking method

Weight

61

0.2

1.65

4

164

(1)

(g)

Barcode label

Preprinted ESD warning

Space for additional label

QA seal

MSC044

Fig.3 Packing for SO (tube/turnlock).

Product orientation in tube

(pin 1 towards this side).

Turnlock (green)

2000 May 11 7 - 8

Page 9

Philips Semiconductors IC packages

Packing methods Chapter 7

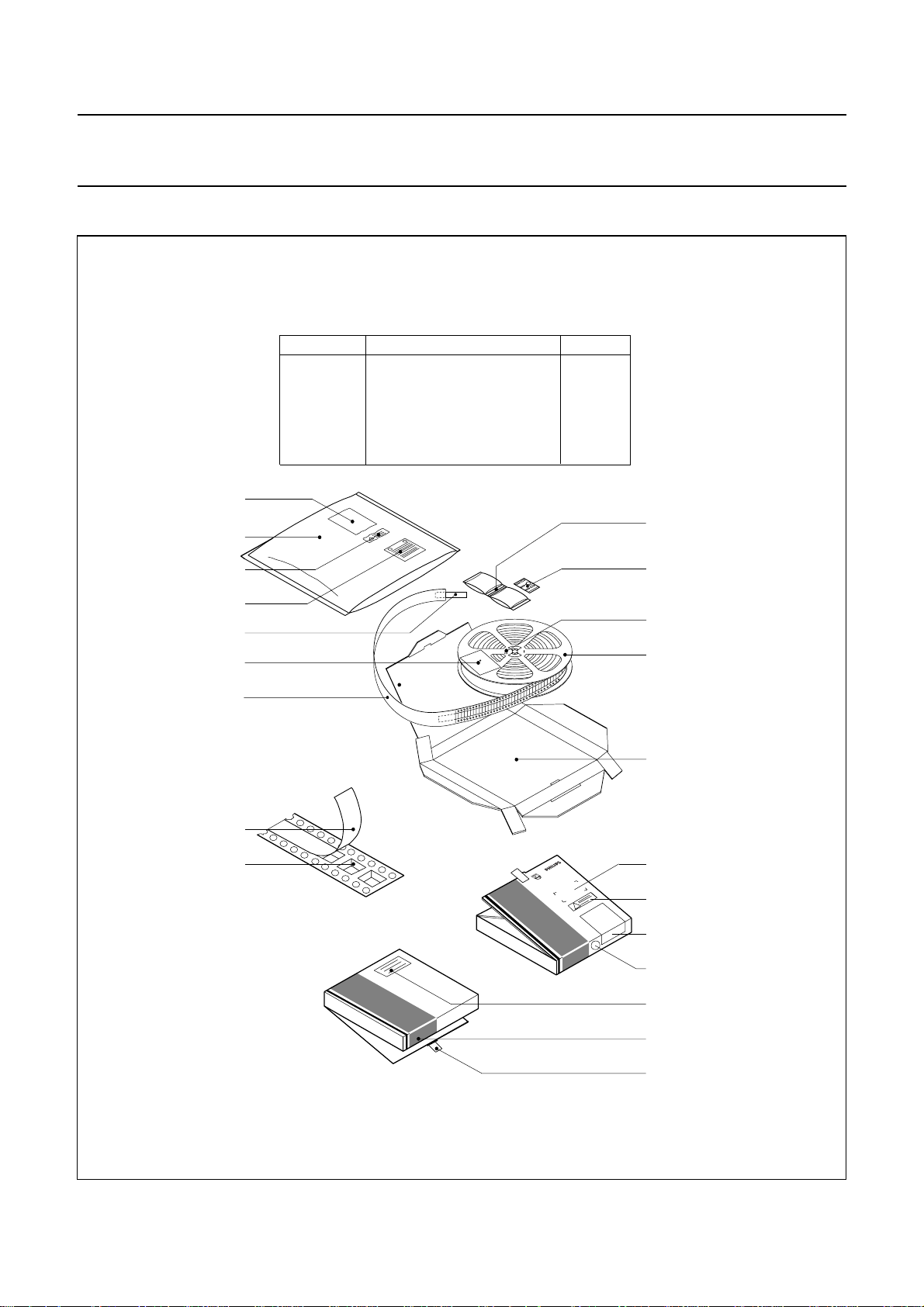

Packing for SO/PLCC/QFP (tape/reel)

handbook, full pagewidth

Cover tape

Carrier tape

Tape

Barcode label

Guard band

Item

Box

Reel

Cover tape

Carrier tape

Seals

Tape

Labels

Material

Cardboard carbon coated

Polystyrene

Polyester

Polystyrene

Acrylate

Paper

(1)

For SO large 8/16 pins

Weight

165

310

10

73

0.2

0.15

1.77Paper

(1)

(g)

Reel assembly

Printed plano box

Space for additional label

Preprinted ESD warning

Barcode label

MSC046

Fig.4 Packing for SO/PLCC/QFP (tape/reel).

2000 May 11 7 - 9

Preprinted Hyatt patent

Printed plano box

QA seal

Page 10

Philips Semiconductors IC packages

Packing methods Chapter 7

Drypack for tube-packing

handbook, full pagewidth

Moisture caution print

Relative humidity indicator

Barcode label

Fill up plate

material

Stacking method

Dry-agent

Item

Box

Tubes

Endstops

Bag

Strap

Foam

Labels

Dry-Agent

Rel. Hum. Ind.

Material

Cardboard

Polyvinylchloride

Polyvinylchloride

Aluminium/Polyethylene/Polyolefine

Polypropylene

Polyethylene

Paper

Amorphous Silicic Acid

Paper+CoCl

2

(1)

For SO large, row pitch 0.3"

Bag

Turnlock (white)

Stacked tubes

Tube

Weight

112

724

10

38

0.6

2

2.8

88

1.15

(1)

(g)

ESD print

Drypack ID sticker

Space for additional label

Preprinted Hyatt patent

Preprinted ESD warning

Barcode label

QA seal

Fig.5 Drypack for tube-packing.

2000 May 11 7 - 10

Product orientation in tube

(Pin 1 towards this side,

this is label side of box)

Turnlock (green)

Printed plano box

Strap

MSC045

Page 11

Philips Semiconductors IC packages

Packing methods Chapter 7

Drypack for tape/reel-packing

handbook, full pagewidth

Barcode label

Moisture caution

Barcode label

Bag

ESD print

print

Tape

Guard band

Item

Box

Reel

Cover tape

Carrier tape

Seals

Tape

Labels

Bag

Dry-Agent

Rel. Hum. Ind.

Material

Cardboard

Polystyrene

Polyester

Polystyrene

Acrylate

Paper

Paper

Aluminium/Polyethylene/Polyolefine

Amorphous Silicic Acid

Paper+CoCl

2

(1)

For TSSOP24, for example

Weight

203

288

16

177

0.2

0.15

3.66

94

88

1.15

(1)

(g)

Dry-agent

Relative humidity

indicator

ESD embossed

Reel assembly

Printed plano box

Cover tape

Carrier tape

MSC047

Fig.6 Drypack for tape/reel-packing.

2000 May 11 7 - 11

Space for additional

label

Preprinted ESD

warning

Barcode label

Drypack ID sticker

Preprinted Hyatt patent

Printed plano box

QA seal

Page 12

Philips Semiconductors IC packages

Packing methods Chapter 7

Drypack for tray-packing

handbook, full pagewidth

Moisture caution

ESD warning

print

Bag

Chamfer

Pin 1

Item

Box

Tray Bakeable

Seal

Strap

Labels

Bag

Dry-Agent

Rel. Hum. Ind.

Material

Cardboard

Polyethersulfone (PES)

Acrylate

Polypropylene

Paper

Aluminium/Polyether/Polyolefine

Amorphous Silicic Acid

Paper + CoCl

2

(1)

For QFP 14 × 20 mm body

Weight

113

654

0.15

2.2

2.55

47

88

1.15

(1)

(g)

Barcode label

Strap

Dry-agent

Relative humidity

indicator

Tray

Printed plano box

Product orientation

in tray

Chamfer

Pin 1

Preprinted ESD

warning

QA seal

Preprinted Hyatt

Patent

Fig.7 Drypack for tray-packing.

2000 May 11 7 - 12

Printed plano box

Space for additional

label

Barcode label

Drypack ID sticker

MSC048

Page 13

2000 May 11 7 - 13

PACKING QUANTITIES, BOX DIMENSIONS AND CARRIER SHAPES

Tube - through hole devices

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

OUTER BOX

DIMENSIONS

L × W × H

(mm)

DBS9MPF SOT111 501 turnlock 22 34 748 530 × 136 × 65

SIL9MP SOT142 501 turnlock 22 34 748 530 × 136 × 65

SIL9MPF SOT110 501 turnlock 22 34 748 530 × 136 × 65

RBS9MPF SOT352 501 turnlock 22 42 924 530 × 136 × 65

DBS7P SOT524 501 turnlock 36 24 864 530 × 136 × 65

DBS9P SOT523 501 turnlock 36 24 864 530 × 136 × 65

CARRIER PROFILE

7.25

11.6

22

32.2

MBL176

5.2

15.4

± 0.2

MSC054

5.4

MSC055

5.1

11.7

28

Page 14

2000 May 11 7 - 14

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

OUTER BOX

DIMENSIONS

DBS9P SOT157 575 plug 23 24 552 595 × 137 × 68

SMS9P SOT354 575 plug 23 24 552 595 × 137 × 68

RDBS13P SOT462 575 plug 23 24 552 595 × 137 × 68

RDBS13P SOT528 575 plug 23 24 552 595 × 137 × 68

DBS13P SOT141 575 plug 23 24 552 595 × 137 × 68

TBS13 SOT578 575 plug 23 24 552 595 × 137 × 68

DBS17P SOT243 575 plug 23 24 552 595 × 137 × 68

DBS17P SOT475 575 plug 23 24 552 595 × 137 × 68

RDBS17P SOT577 575 plug 23 24 552 595 × 137 × 68

DBS23P SOT411 575 plug 18 24 432 595 × 137 × 68

DBS27P SOT521 575 plug 18 24 432 595 × 137 × 68

SIL9P SOT131 575 plug 23 24 552 595 × 137 × 68

SIL13P SOT193 575 plug 23 24 552 595 × 137 × 68

L × W × H

(mm)

CARRIER PROFILE

MSC064

8.5

33.2

14.6

6.7

Philips Semiconductors IC packages

Packing methods Chapter 7

12.2

DIP8 SOT97 501 pin 50 40 2000 532 × 142 × 63

12.25

36

8.4

15.25

MSC052

MSC051

Page 15

2000 May 11 7 - 15

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

OUTER BOX

DIMENSIONS

DIP14 SOT27 501 pin 25 40 1000 532 × 142 × 63

DIP16 SOT38-1 501 pin 22 40 880 532 × 142 × 63

DIP16 SOT38-4 501 pin 25 40 1000 532 × 142 × 63

DIP18 SOT102-1 501 pin 22 40 880 532 × 142 × 63

DIP18 SOT102-2 501 pin 20 40 800 532 × 142 × 63

DIP18 SOT102-4 501 pin 20 40 800 532 × 142 × 63

HDIP18 SOT398 501 pin 22 40 880 532 × 142 × 63

DIP20 SOT146 501 pin 18 40 720 532 × 142 × 63

DIP22 SOT116 501 pin 17 32 544 530 × 136 × 65

SDIP24 SOT234 501 pin 21 32 672 532 × 142 × 63

SDIP32 SOT232 501 pin 16 32 512 532 × 142 × 63

L × W × H

(mm)

Philips Semiconductors IC packages

Packing methods Chapter 7

CARRIER PROFILE

8.8

13.45

MSC058

15.25

11.0

13.5

DIP24 SOT101 501 pin 15 24 360 532 × 142 × 63

DIP24 SOT222 501 pin 15 40 600 532 × 142 × 63

DIP24 SOT248 501 pin 15 32 480 530 × 136 × 65

DIP28 SOT117 501 pin 13 24 312 532 × 142 × 63

DIP32 SOT201 501 pin 11 24 264 532 × 142 × 63

DIP40 SOT129 501 pin 9 24 216 532 × 142 × 63

SDIP42 SOT270 501 pin 12 24 288 532 × 142 × 63

DIP48 SOT240 501 pin 7 24 168 532 × 142 × 63

SDIP52 SOT247 501 pin 10 24 240 532 × 142 × 63

SDIP56 SOT400 501 pin 9 24 216 532 × 142 × 63

13.5

18.5

19.3

22.8

MSD502

MSC059

Page 16

2000 May 11 7 - 16

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

OUTER BOX

DIMENSIONS

SDIP64 SOT274 501 pin 8 20 160 532 × 142 × 63

L × W × H

(mm)

Philips Semiconductors IC packages

Packing methods Chapter 7

CARRIER PROFILE

22

12.8

DIP14 SOT27 575 pin 28 40 1120 595 × 137 × 68

DIP16 SOT38-1 575 pin 25 40 1000 595 × 137 × 68

DIP16 SOT38-4 575 pin 28 40 1120 595 × 137 × 68

DIP18 SOT102-1 575 pin 25 40 1000 595 × 137 × 68

HDIP18 SOT398 575 pin 25 40 1000 595 × 137 × 68

DIP20 SOT146 575 pin 20 40 800 595 × 137 × 68

DIP22 SOT116 575 pin 21 40 840 595 × 137 × 68

SDIP24 SOT234 575 pin 25 40 1000 595 × 137 × 68

DIP24 SOT101 575 pin 17 30 510 595 × 137 × 68

DIP28 SOT117 575 pin 15 30 450 595 × 137 × 68

DIP32 SOT201 575 pin 13 30 390 595 × 137 × 68

SDIP32 SOT232 575 pin 19 40 760 595 × 137 × 68

DIP40 SOT129 575 pin 10 30 300 595 × 137 × 68

SDIP42 SOT270 575 pin 14 30 420 595 × 137 × 68

SDIP52 SOT247 575 pin 11 30 330 595 × 137 × 68

13.5

13.5

13.45

26.8

8.8

15.25

11.0

18.5

19.3

22.8

MBL177

MSC058

MSD502

MSC059

Note

1. If only a package type code is given, the data supplied is applicable to all its outline versions.

Page 17

2000 May 11 7 - 17

M

Tube - surface mount devices

OUTER BOX DIMENSIONS

L × W × H

NON-DRYPACK

(mm)

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

SMS13P SOT517 575 plug 23 24 552 − 595 × 137 × 68

SO8 SOT96 515 turnlock 100 20 2000 525 × 83 × 15 528 × 101 × 23

SO14 SOT108 515 turnlock 57 20 1140 525 × 83 × 15 528 × 101 × 23

SO16 SOT109 515 turnlock 50 20 1000 525 × 83 × 15 528 × 101 × 23

SO8 SOT176 515 turnlock 64 40 2560 551 × 90 × 46 572 × 94 × 54

SO16 SOT162 515 turnlock 48 40 1920 551 × 90 × 46 572 × 94 × 54

SO20 SOT163 515 turnlock 38 40 1520 551 × 90 × 46 572 × 94 × 54

SO24 SOT137 515 turnlock 30 40 1200 551 × 90 × 46 572 × 94 × 54

SO28 SOT136 515 turnlock 27 40 1080 551 × 90 × 46 572 × 94 × 54

SO32 SOT287 515 turnlock 24 40 960 551 × 90 × 46 572 × 94 × 54

VSO40 SOT158 515 turnlock 31 40 1240 551 × 90 × 46 572 × 94 × 54

HSOP20 SOT397 515 turnlock 30 24 720 551 × 90 × 46 572 × 94 × 54

HSOP20 SOT418 515 turnlock 30 24 720 551 × 90 × 46 572 × 94 × 54

DRYPACK

(mm)

CARRIER PROFILE

(mm)

8.5

36

3.8

7.9

5.1

15.4

6.4

Philips Semiconductors IC packages

Packing methods Chapter 7

MSC056

MSC053

VSO56 SOT190 495 turnlock 22 28 616 551 × 90 × 46 572 × 94 × 54

5.55

19.5

21.5

MBL178

MSC060

Page 18

2000 May 11 7 - 18

OUTER BOX DIMENSIONS

L × W × H

NON-DRYPACK

(mm)

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

SSOP16 SOT369 511 turnlock 93 18 1674 525 × 83 × 20 530 × 103 × 29

SSOP20 SOT266 511 turnlock 75 18 1350 525 × 83 × 20 530 × 103 × 29

SSOP14 SOT337 508 turnlock 78 14 1092 525 × 83 × 20 530 × 103 × 29

SSOP16 SOT338 508 turnlock 78 14 1092 525 × 83 × 20 530 × 103 × 29

SSOP20 SOT339 508 turnlock 66 14 924 525 × 83 × 20 530 × 103 × 29

SSOP24 SOT340 508 turnlock 59 14 826 525 × 83 × 20 530 × 103 × 29

SSOP28 SOT341 508 turnlock 47 14 658 525 × 83 × 20 530 × 103 × 29

SSOP16 SOT519 515 turnlock 100 20 2000 525 × 83 × 15 530 × 101 × 23

SSOP24 SOT556 515 turnlock 57 20 1140 525 × 83 × 15 530 × 101 × 23

SSOP48 SOT370 515 turnlock 31 51 1581 551 × 90 × 46 572 × 94 × 54

SSOP56 SOT371 515 turnlock 26 51 1326 551 × 90 × 46 572 × 94 × 54

DRYPACK

(mm)

CARRIER PROFILE

(mm)

3.45

8.8

MSC049

4.0

MSD504

10.6

3.8

MSC056

7.9

5.0

MSC562

13.7

Philips Semiconductors IC packages

Packing methods Chapter 7

TSSOP14 SOT402 510 plug 96 25 2400 525 × 83 × 15 528 × 101 × 23

TSSOP16 SOT403 510 plug 96 25 2400 525 × 83 × 15 528 × 101 × 23

TSSOP20 SOT360 510 plug 75 25 1875 525 × 83 × 15 528 × 101 × 23

HTSSOP20 SOT527 510 plug 75 25 1875 525 × 83 × 15 528 × 101 × 23

TSSOP24 SOT355 510 plug 63 25 1575 525 × 83 × 15 528 × 101 × 23

TSSOP28 SOT361 510 plug 51 25 1275 525 × 83 × 15 528 × 101 × 23

TSSOP30 SOT607 510 plug 63 25 1575 525 × 83 × 15 528 × 101 × 23

TSSOP38 SOT510 510 plug 51 25 1275 525 × 83 × 15 528 × 101 × 23

3.05

7.83

MSC563

Page 19

2000 May 11 7 - 19

C

OUTER BOX DIMENSIONS

L × W × H

NON-DRYPACK

(mm)

PACKAGE

NAME

PHILIPS

PACKAGE

TYPE/OUTLINE

(1)

CODE

CARRIER

LENGTH

(mm)

END

STOP

SPQ

CARRIERS

PER BOX

PQ

TSSOP32 SOT487 510 plug 44 25 1100 525 × 83 × 15 528 × 101 × 23

HTSSOP32 SOT549 510 plug 44 25 1100 525 × 83 × 15 528 × 101 × 23

TSSOP48 SOT362 510 plug 39 25 975 525 × 83 × 15 528 × 101 × 23

TSSOP56 SOT364 510 plug 35 25 875 525 × 83 × 15 528 × 101 × 23

PLCC28 SOT261 491 plug 34 64 2176 530 × 136 × 65 554 × 136 × 81

PLCC44 SOT187 491 plug 26 50 1300 530 × 136 × 65 554 × 136 × 81

PLCC44 SOT187 491 plug 26 48 1248 530 × 136 × 65 554 × 136 × 81

DRYPACK

(mm)

CARRIER PROFILE

(mm)

3.05

9.58

MSC564

7.1

MSC062

15

7.1

Philips Semiconductors IC packages

Packing methods Chapter 7

PLCC52 SOT238 491 plug 23 44 1012 − 554 × 136 × 81

PLCC68 SOT188 491 plug 18 36 648 530 × 136 × 65 554 × 136 × 81

PLCC84 SOT189 491 plug 15 28 420 530 × 136 × 65 554 × 136 × 81

Note

1. If only a package type code is given, the data supplied is applicable to all its outline versions.

7.1

7.1

20.1

22.6

7.1

27.7

32.8

MSD503

MBL175

MSC057

MS

Page 20

Philips Semiconductors IC packages

Packing methods Chapter 7

Tape and reel - surface mount devices

PACKAGE

NAME

PHILIPS PACKAGE

TYPE/OUTLINE CODE

)

DIMENSIONS

(1

CARRIER

D × W

(mm)

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

HBCC

HBCC24 SOT564 330 × 12 3500 341 × 338 × 30 341 × 338 × 39

HBCC32 SOT560 330 × 12 3500 341 × 338 × 30 341 × 338 × 39

LFBGA

LFBGA56 SOT516 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

LFBGA64 SOT534 330 × 16 t.b.d. 341 × 338 × 30 341 × 338 × 39

LFBGA84 SOT518 330 × 16 t.b.d. 341 × 338 × 30 341 × 338 × 39

LFBGA96 SOT536 330 × 24 3500 341 × 338 × 39 341 × 338 × 49

LFBGA114 SOT537 330 × 24 3500 341 × 338 × 39 341 × 338 × 49

LFBGA156 SOT472 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

TFBGA

TFBGA56 SOT542 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TFBGA64 SOT543 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TFBGA80 SOT557 330 × 16 t.b.d. 341 × 338 × 30 341 × 338 × 39

PLCC

PLCC28 SOT261 180 × 24 300 191 × 188 × 39 209 × 206 × 48

PLCC28 SOT261 330 × 24 750 341 × 338 × 39 341 × 338 × 49

PLCC44 SOT187 330 × 32 500 341 × 338 × 49 341 × 338 × 68

PLCC52 SOT238 330 × 32 500 341 × 338 × 49 341 × 338 × 61

PLCC68 SOT188 330 × 44 250 341 × 338 × 61 341 × 338 × 68

PLCC84 SOT189 330 × 44 250 341 × 338 × 61 341 × 338 × 68

PMFP

PMFP8 SOT144 180 × 8 (2 reels) 10000 185 × 185 × 32 −

QFP

QFP44 SOT307 330 × 24 1500 341 × 338 × 39 341 × 338 × 49

QFP44 SOT205 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

QFP52 SOT379 330 × 24 600 n.a. 341 × 338 × 49

QFP64 SOT319 330 × 44 500 341 × 338 × 61 341 × 338 × 68

QFP64 SOT393 330 × 32 600 341 × 338 × 49 341 × 338 × 61

QFP80 SOT310 330 × 44 500 341 × 338 × 61 341 × 338 × 68

QFP80 SOT318 330 × 44 500 341 × 338 × 61 341 × 338 × 68

QFP80 SOT496 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

QFP100 SOT317 330 × 44 500 341 × 338 × 61 341 × 338 × 68

QFP100 SOT382 330 × 44 500 341 × 338 × 61 341 × 338 × 68

2000 May 11 7 - 20

Page 21

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

PHILIPS PACKAGE

TYPE/OUTLINE CODE

)

DIMENSIONS

(1

CARRIER

D × W

(mm)

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

LQFP

LQFP32 SOT358 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

LQFP32 SOT401 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

LQFP44 SOT389 330 × 24 1500 341 × 338 × 39 341 × 338 × 49

LQFP48 SOT313 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

LQFP64 SOT314 330 × 24 1500 341 × 338 × 39 341 × 338 × 49

LQFP64 SOT414 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

LQFP80 SOT315 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

LQFP100 SOT407 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

LQFP128 SOT420 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

LQFP144 SOT486 330 × 44 1750 341 × 338 × 61 341 × 338 × 68

HLQFP

HLQFP100 SOT470 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

TQFP

TQFP44 SOT376 330 × 24 1500 341 × 338 × 39 341 × 338 × 49

TQFP80 SOT375 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

HTQFP

HTQFP32 SOT547 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

HTQFP48 SOT545 330 × 16 2500 341 × 338 × 39 341 × 338 × 49

HTQFP80 SOT513 330 × 24 t.b.d. 341 × 338 × 39 341 × 338 × 49

SMS (SIL power)

SMS13P SOT517 330 × 44 500 − 341 × 338 × 68

SO

SO4 SOT223 330 × 12 4000 341 × 338 × 26 341 × 338 × 39

SO8 SOT96 180 × 12 1000 191 × 188 × 26 209 × 206 × 36

SO8 SOT96 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

SO8 SOT176 180 × 16 500 191 × 188 × 30 209 × 206 × 40

SO8 SOT176 330 × 16 1000 341 × 338 × 30 341 × 338 × 39

SO14 SOT108 180 × 16 1000 191 × 188 × 30 209 × 206 × 40

SO14 SOT108 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

SO16 SOT109 180 × 16 1000 191 × 188 × 30 209 × 206 × 40

SO16 SOT109 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

SO16 SOT162 180 × 16 500 191 × 188 × 30 209 × 206 × 40

SO16 SOT162 330 × 16 1000 341 × 338 × 30 341 × 338 × 39

SO20 SOT163 180 × 24 500 191 × 188 × 39 209 × 206 × 48

SO20 SOT163 330 × 24 2000 341 × 338 × 39 341 × 338 × 49

SO24 SOT137 180 × 24 500 191 × 188 × 39 209 × 206 × 48

2000 May 11 7 - 21

Page 22

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

PHILIPS PACKAGE

TYPE/OUTLINE CODE

)

DIMENSIONS

(1

CARRIER

D × W

(mm)

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

SO24 SOT137 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

SO28 SOT136 180 × 24 500 191 × 188 × 39 209 × 206 × 48

SO28 SOT136 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

SO32 SOT287 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

SOJ

SOJ40 SOT449 330 × 44 750 − 341 × 338 × 68

VSO

VSO40 SOT158 180 × 24 300 191 × 188 × 39 209 × 206 × 48

VSO40 SOT158 330 × 24 500 341 × 338 × 39 341 × 338 × 49

VSO56 SOT190 330 × 32 500 341 × 338 × 49 341 × 338 × 61

SSOP

SSOP14 SOT337 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

SSOP16 SOT338 330 × 16 2000 341 × 338 × 30 341 × 338 × 39

SSOP16 SOT369/SOT519 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

SSOP20 SOT266 180 × 16 1000 191 × 188 × 30 209 × 206 × 40

SSOP20 SOT266 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

SSOP20 SOT339 330 × 16 1000 341 × 338 × 30 341 × 338 × 39

SSOP24 SOT340 330 × 16 1000 341 × 338 × 30 341 × 338 × 39

SSOP24 SOT556 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

SSOP28 SOT341 330 × 24 1000 341 × 338 × 39 341 × 338 × 49

SSOP36 SOT378 330 × 24 1000 − 341 × 338 × 49

SSOP48 SOT370 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

SSOP56 SOT371 330 × 32 1000 341 × 338 × 49 341 × 338 × 61

HSSOP

HSSOP20 SOT397/SOT418 330 × 24 500 341 × 338 × 39 341 × 338 × 49

TSSOP

TSSOP8 SOT505 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TSSOP10 SOT552 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TSSOP14 SOT402 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TSSOP16 SOT403 330 × 12 2500 341 × 338 × 26 341 × 338 × 39

TSSOP20 SOT360 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

TSSOP24 SOT355 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

TSSOP28 SOT361 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

TSSOP30 SOT607 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

TSSOP32 SOT487 330 × 24 2000 341 × 338 × 39 341 × 338 × 49

TSSOP48 SOT362 330 × 24 2000 341 × 338 × 39 341 × 338 × 49

TSSOP56 SOT364 330 × 24 2000 341 × 338 × 39 341 × 338 × 49

2000 May 11 7 - 22

Page 23

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

HTSSOP

HTSSOP20 SOT527 330 × 16 2500 341 × 338 × 30 341 × 338 × 39

HTSSOP32 SOT549 330 × 24 2000 341 × 338 × 39 341 × 338 × 49

TO

TO-92 SOT465 Ammo pack 2000 341 × 260 × 30 −

Note

1. If only a package type code is given, the data supplied is applicable to all its outline versions.

PHILIPS PACKAGE

TYPE/OUTLINE CODE

)

(1

CARRIER

DIMENSIONS

D × W

(mm)

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

2000 May 11 7 - 23

Page 24

Philips Semiconductors IC packages

Packing methods Chapter 7

Carrier tape dimensions - surface mount devices

PACKAGE

NAME

HBCC

HBCC24 SOT564 4.4 4.4 1.1 8 12 A

HBCC32 SOT560 5.4 5.4 1.1 8 12 A

BGA

BGA156 SOT472 15.3 15.3 2.2 20 24 A

LFBGA

LFBGA56 SOT516 6.5 6.5 1.7 8 12 A

LFBGA64 SOT534 t.b.d. t.b.d. t.b.d. 12 16 A

LFBGA84 SOT518 7.3 7.3 2.3 12 16 A

LFBGA96 SOT536 5.9 13.9 2.2 8 24 A

LFBGA114 SOT537 5.9 16.4 2.2 8 24 A

TFBGA

TFBGA56 SOT542 6.5 6.5 1.7 8 12 A

TFBGA64 SOT543 6.5 6.5 1.7 8 12 A

TFBGA80 SOT557 7.3 7.3 2.3 12 16 A

PLCC

PLCC28 SOT261 13.0 13.0 4.9 16 24 A

PLCC44 SOT187 18.0 18.0 5.7 24 32 B

PLCC52 SOT238 20.5 20.5 5.3 24 32 B

PLCC68 SOT188 25.6 25.6 5.8 32 44 B

PLCC84 SOT189 30.7 30.7 5.8 36 44 B

PMFP

PMFP8 SOT144 specific taping

QFP

QFP44 SOT307 13.1 13.1 2.8 24 24 A

QFP52 SOT379 14.2 14.2 2.8 24 24 A

QFP44 SOT205 19.2 19.2 3.0 24 32 B

QFP64 SOT319 19.0 25.0 3.7 32 44 B

QFP64 SOT393 18.0 18.0 3.6 24 32 B

QFP80 SOT310 19.0 25.0 3.7 32 44 B

QFP80 SOT318 19.0 25.0 3.7 32 44 B

QFP80 SOT496 19.2 19.2 3.0 24 32 B

QFP100 SOT317 19.0 25.0 3.7 32 44 B

QFP100 SOT382 19.0 25.0 3.7 32 44 B

LQFP

LQFP32 SOT358 9.6 9.6 2.2 12 16 A

LQFP32 SOT401 7.4 7.4 1.75 12 16 A

PHILIPS PACKAGE

TYPE/OUTLINE CODE

(1)

A0 B0 K0 P1 W TYPE

CARRIER TAPE DIMENSIONS IN mm (see Fig.8)

2000 May 11 7 - 24

Page 25

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

LQFP44 SOT389 12.35 12.35 2.2 16 24 A

LQFP48 SOT313 9.6 9.6 2.2 12 16 A

LQFP64 SOT314 12.35 12.35 2.2 16 24 A

LQFP64 SOT414 9.6 9.6 2.2 12 16 A

LQFP80 SOT315 14.4 14.4 2.1 20 24 A

LQFP100 SOT407 16.5 16.5 1.9 20 24 A

LQFP128 SOT420 16.5 16.5 1.9 20 24 A

LQFP144 SOT486 22.6 22.6 2.15 32 44 B

HLQFP

HLQFP100 SOT470 16.5 16.5 1.9 20 24 A

TQFP

TQFP44 SOT376 12.35 12.35 1.85 16 24 A

TQFP48 SOT545 9.3 9.3 1.8 12 26 A

TQFP80 SOT375 14.4 14.4 2.1 20 24 A

SMS (SIL power)

SMS13P SOT517 20.0 24.5 5.2 24 44 B

SO

SO4 SOT223 7.0 7.4 1.9 8 12 A

SO8 SOT96 6.65 5.4 1.8 8 12 A

SO8 SOT176 10.5 8.0 3.0 12 16 A

SO14 SOT108 6.65 9.65 1.8 8 16 A

SO16 SOT109 6.65 10.45 1.8 8 16 A

SO16 SOT162 11.1 10.95 2.7 12 16 A

SO20 SOT163 11.1 13.5 2.7 12 24 A

SO24 SOT137 11.1 16.1 2.7 12 24 A

SO28 SOT136 11.1 18.5 2.7 12 24 A

SO32 SOT287 10.9 21.2 3.1 16 32 B

SOJ

SOJ40 SOT449 11.6 26.55 4.4 16 44 B

VSO

VSO40 SOT158 12.8 16.3 3.0 16 24 A

VSO56 SOT190 16.0 22.3 3.15 20 32 B

SSOP

SSOP14 SOT337 8.2 6.6 2.5 12 16 A

SSOP16 SOT338 8.2 6.6 2.5 12 16 A

SSOP16 SOT369 6.9 5.4 2.0 8 12 A

SSOP20 SOT266 7.1 7.2 2.0 12 16 A

SSOP20 SOT339 8.2 7.5 2.5 12 16 A

PHILIPS PACKAGE

TYPE/OUTLINE CODE

(1)

A0 B0 K0 P1 W TYPE

CARRIER TAPE DIMENSIONS IN mm (see Fig.8)

2000 May 11 7 - 25

Page 26

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

SSOP24 SOT340 8.2 8.8 2.5 12 16 A

SSOP24 SOT556 6.65 9.65 1.8 8 16 A

SSOP28 SOT341 8.4 10.9 2.4 12 24 A

SSOP36 SOT378 11.1 16.1 2.7 12 24 A

SSOP48 SOT370 12.0 16.2 3.2 16 32 B

SSOP56 SOT371 12.0 18.7 3.2 16 32 B

HSSOP

HSSOP20 SOT397 14.7 16.4 4.0 20 32 B

HSSOP20 SOT418 14.7 16.4 4.0 20 32 B

TSSOP

TSSOP8 SOT505 5.2 3.3 1.6 8 12 A

TSSOP10 SOT552 5.2 3.3 1.6 8 12 A

TSSOP14 SOT402 6.95 5.6 1.6 8 12 A

TSSOP16 SOT403 6.95 5.6 1.6 8 12 A

TSSOP20 SOT360 6.95 7.1 1.6 8 16 A

TSSOP24 SOT355 6.95 8.3 1.6 8 16 A

TSSOP28 SOT361 6.8 10.2 1.6 8 16 A

TSSOP30 SOT607 6.95 8.3 1.6 8 16 A

TSSOP32 SOT487 8.6 11.5 1.5 12 24 A

TSSOP48 SOT362 8.35 13.0 1.6 16 24 A

TSSOP56 SOT364 8.6 14.5 1.8 12 24 A

HTSSOP

HTSSOP20 SOT527 6.95 7.1 1.6 8 16 A

HTSSOP32 SOT549 8.6 11.5 1.5 12 24 A

PHILIPS PACKAGE

TYPE/OUTLINE CODE

(1)

A0 B0 K0 P1 W TYPE

CARRIER TAPE DIMENSIONS IN mm (see Fig.8)

Note

1. If only a package type code is given, the data supplied is applicable to all its outline versions.

2000 May 11 7 - 26

Page 27

Philips Semiconductors IC packages

Packing methods Chapter 7

handbook, full pagewidth

W

B0

W

elongated

sprocked hole

4

B0

P1

Type A

4

Type B

A0

direction of feed

A0

P1

direction of feed

K0

Fig.8 Carrier tape (dimensions in mm).

K0

MLC338

handbook, full pagewidth

pin 1

SO4

pin 1

pin 1

1

SO SOPLCC QFP QFP

3

enlongated

BGA

bare die

pin 1 in quadrant 1circular

pin 1

2

4

direction of feed

Fig.9 Product orientation in tape.

2000 May 11 7 - 27

product orientation ONLY for turned

products with 12NC ending 128

pin 1

pin 1

MBL180

Page 28

Philips Semiconductors IC packages

Packing methods Chapter 7

JEDEC tray dimensions - surface mount devices (see Fig.10)

BODY SIZE

(mm)

POCKETS COLUMNS ROWS

COLUMN DIMENSIONS (mm) ROW DIMENSIONS (mm)

C

m

C

s

R

m

R

s

QFP trays

40 × 40 12 2 6 77.46 29.22 50.56 31.10

32 × 32 24 3 8 41.38 26.57 37.82 25.13

28 × 28 24 3 8 37.02 30.93 37.02 27.93

24 × 24 40 4 10 31.50 20.70 30.40 20.70

20 × 20 60 5 12 25.20 17.55 25.40 17.80

14 × 20 66 6 11 21.00 15.45 27.00 22.50

14 × 20 72 6 12 21.00 15.45 25.40 17.80

14 × 14 84 6 14 21.00 15.45 21.50 17.75

14 × 14 90 6 15 21.00 15.45 20.30 15.40

12 × 12 119 7 17 18.00 13.95 17.90 14.30

10 × 10 96 6 16 19.86 18.30 18.70 17.25

10 × 10 160 8 20 15.70 13.00 15.20 13.10

7 × 7 250 10 25 12.60 11.25 12.60 11.10

5 × 5 360 12 30 10.50 10.20 10.10 11.05

BGA trays

35 × 35 24 3 8 38.00 29.95 38.00 29.95

27 × 27 40 4 10 29.20 24.15 29.20 26.10

16 × 16 84 6 14 21.40 14.45 22.00 14.50

15 × 15 126 7 18 17.20 16.35 17.20 11.30

10 × 10 184 8 23 13.15 21.92 12.40 21.10

5.5 × 16 240 15 16 t.b.d. t.b.d. t.b.d. t.b.d.

5.5 × 13.5 285 15 19 t.b.d. t.b.d. t.b.d. t.b.d.

8 × 8 348 12 29 t.b.d. t.b.d. t.b.d. t.b.d.

7 × 7 416 13 32 9.40 11.55 9.40 11.80

6 × 6 429 13 33 8.75 15.45 8.85 15.90

5.5 × 5.5 570 15 38 t.b.d. t.b.d. t.b.d. t.b.d.

5 × 5 640 16 40 t.b.d. t.b.d. t.b.d. t.b.d.

4 × 4 810 18 45 6.50 12.70 6.50 14.50

2000 May 11 7 - 28

Page 29

Philips Semiconductors IC packages

Packing methods Chapter 7

handbook, full pagewidth

C

C

6.35

322.6

315

m

s

R

s

R

m

135.9

MLC339

Fig.10 Tray (dimensions in mm).

2000 May 11 7 - 29

Page 30

Philips Semiconductors IC packages

Packing methods Chapter 7

Trays - surface mount devices

PACKAGE

NAME

BGA156 SOT472 15 × 15 mm 1 126 325 × 145 × 22 352 × 183 × 27

BGA256 SOT466 27 × 27 mm 1 40 325 × 145 × 22 352 × 183 × 27

BGA256 SOT471 27 × 27 mm 1 40 325 × 145 × 22 352 × 183 × 27

BGA292 SOT489 27 × 27 mm 1 40 325 × 145 × 22 352 × 183 × 27

BGA304 SOT550 35 × 35 mm 1 24 325 × 145 × 22 352 × 183 × 27

BGA316 SOT531 35 × 35 mm 1 24 325 × 145 × 22 352 × 183 × 27

BGA388 SOT532 35 × 35 mm 1 24 325 × 145 × 22 352 × 183 × 27

BGA492 SOT514 35 × 35 mm 1 24 325 × 145 × 22 352 × 183 × 27

HBCC24 SOT564 4 × 4 mm 1 810 325 × 145 × 22 352 × 183 × 27

HBCC32 SOT560 5 × 5 mm 1 640 325 × 145 × 22 352 × 183 × 27

HBCC292 SOT553 27 × 27 mm 1 40 325 × 145 × 22 352 × 183 × 27

HBCC352 SOT546 35 × 35 mm 1 24 325 × 145 × 22 352 × 183 × 27

HLQFP100 SOT470 14 × 14 mm 1 90 325 × 145 × 22 352 × 183 × 27

HSQFP208 SOT431 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

HSQFP240 SOT464 32 × 32 mm 1 24 325 × 145 × 22 352 × 183 × 27

HTQFP32 SOT547 5 × 5 mm 1 360 325 × 145 × 22 352 × 183 × 27

HTQFP48 SOT545 7 × 7 mm 1 250 325 × 145 × 22 352 × 183 × 27

HTQFP80 SOT513 14 × 14 mm 1 90 325 × 145 × 22 352 × 183 × 27

LFBGA56 SOT516 6 × 6 mm 1 429 325 × 145 × 22 352 × 183 × 27

PHILIPSPACKAGE

TYPE/OUTLINE

CODE

(1)

PACKAGE

BODY

CARRIERS

PER BOX

5 630 348 × 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 4050 348× 148 × 47 356 × 161 × 56

5 3200 348× 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 450 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 1800 348× 148 × 47 356 × 161 × 56

5 1250 348× 148 × 47 356 × 161 × 56

5 450 348 × 148 × 47 356 × 161 × 56

5 2145 348× 148 × 47 356 × 161 × 56

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

2000 May 11 7 - 30

Page 31

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

LFBGA64 SOT534 8 × 8 mm 1 348 325 × 145 × 22 352 × 183 × 27

LFBGA84 SOT518 7 × 7 mm 1 416 325 × 145 × 22 352 × 183 × 27

LFBGA96 SOT536 5.5 × 13.5 mm 1 285 325 × 145 × 22 352 × 183 × 27

LFBGA114 SOT537 5.5 × 16 mm 1 240 325 × 145 × 22 352 × 183 × 27

LFBGA324 SOT571 16 × 16 mm 1 84 325 × 145 × 22 352 × 183 × 27

LQFP32 SOT358 7 × 7 mm 1 250 325 × 145 × 22 352 × 183 × 27

LQFP32 SOT401 5 × 5 mm 1 360 325 × 145 × 22 352 × 183 × 27

LQFP44 SOT389 10 × 10 mm 1 160 325 × 145 × 22 352 × 183 × 27

LQFP48 SOT313 7 × 7 mm 1 250 325 × 145 × 22 352 × 183 × 27

LQFP64 SOT314 10 × 10 mm 1 160 325 × 145 × 22 352 × 183 × 27

LQFP64 SOT414 7 × 7 mm 1 250 325 × 145 × 22 352 × 183 × 27

LQFP80 SOT315 12 × 12 mm 1 119 325 × 145 × 22 352 × 183 × 27

LQFP100 SOT407 14 × 14 mm 1 90 325 × 145 × 22 352 × 183 × 27

LQFP128 SOT420 14 × 14 mm 1 90 325 × 145 × 22 352 × 183 × 27

LQFP128 SOT425 14 × 20 mm 1 72 325 × 145 × 22 352 × 183 × 27

LQFP144 SOT486 20 × 20 mm 1 60 325 × 145 × 22 352 × 183 × 27

LQFP160 SOT435 24 × 24 mm 1 40 325 × 145 × 22 352 × 183 × 27

LQFP176 SOT506 24 × 24 mm 1 40 325 × 145 × 22 352 × 183 × 27

LQFP208 SOT459 28 × 28 mm 1 36 325 × 145 × 22 352 × 183 × 27

PHILIPSPACKAGE

TYPE/OUTLINE

CODE

(1)

PACKAGE

BODY

CARRIERS

PER BOX

5 1740 348× 148 × 47 356 × 161 × 56

5 2080 348× 148 × 47 356 × 161 × 56

5 1425 348× 148 × 47 356 × 161 × 56

5 1200 348× 148 × 47 356 × 161 × 56

5 420 348 × 148 × 47 356 × 161 × 56

5 1250 348× 148 × 47 356 × 161 × 56

5 1800 348× 148 × 47 356 × 161 × 56

5 800 348 × 148 × 47 356 × 161 × 56

5 1250 348× 148 × 47 356 × 161 × 56

5 800 348 × 148 × 47 356 × 161 × 56

5 1250 348× 148 × 47 356 × 161 × 56

5 595 348 × 148 × 47 356 × 161 × 56

5 450 348 × 148 × 47 356 × 161 × 56

5 450 348 × 148 × 47 356 × 161 × 56

5 360 348 × 148 × 47 356 × 161 × 56

5 300 348 × 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 200 348 × 148 × 47 356 × 161 × 56

5 180 348 × 148 × 47 356 × 161 × 56

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

2000 May 11 7 - 31

Page 32

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

MSQFP240 SOT474 32 × 32 mm 1 24 325 × 145 × 22 352 × 183 × 27

QFP44 SOT205 14 × 14 mm 1 84 325 × 145 × 22 352 × 183 × 27

QFP44 SOT307 10 × 10 mm 1 96 325 × 145 × 22 352 × 183 × 27

QFP52 SOT379 10 × 10 mm 5 480 348 × 148 × 47 356 × 161 × 56

QFP64 SOT319 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

QFP64 SOT393 14 × 14 mm 1 84 325 × 145 × 22 352 × 183 × 27

QFP80 SOT310 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

QFP80 SOT318 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

QFP80 SOT496 14 × 14 mm 1 84 325 × 145 × 22 352 × 183 × 27

QFP100 SOT317 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

QFP100 SOT382 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

QFP120 SOT349 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

QFP128 SOT320 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

QFP144 SOT573 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

QFP160 SOT322 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

SQFP128 SOT387 14 × 20 mm 1 66 325 × 145 × 22 352 × 183 × 27

SQFP208 SOT316 28 × 28 mm 1 24 325 × 145 × 22 352 × 183 × 27

SQFP240 SOT334 32 × 32 mm 1 24 325 × 145 × 22 352 × 183 × 27

SQFP304 SOT575 40 × 40 mm 1 12 325 × 145 × 22 352 × 183 × 27

TFBGA56 SOT542 6 × 6 mm 1 429 325 × 145 × 22 352 × 183 × 27

PHILIPSPACKAGE

TYPE/OUTLINE

CODE

(1)

PACKAGE

BODY

CARRIERS

PER BOX

5 120 348 × 148 × 47 356 × 161 × 56

5 420 348 × 148 × 47 356 × 161 × 56

5 480 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 420 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 420 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 330 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 120 348 × 148 × 47 356 × 161 × 56

5 60 348 × 148 × 47 356 × 161 × 56

5 2145 348× 148 × 47 356 × 161 × 56

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

2000 May 11 7 - 32

Page 33

Philips Semiconductors IC packages

Packing methods Chapter 7

PACKAGE

NAME

TFBGA64 SOT543 6 × 6 mm 1 429 325 × 145 × 22 352 × 183 × 27

TFBGA80 SOT557 7 × 7 mm 1 416 325 × 145 × 22 352 × 183 × 27

TQFP44 SOT376 10 × 10 mm 1 160 325 × 145 × 22 352 × 183 × 27

TQFP64 SOT357 10 × 10 mm 1 160 325 × 145 × 22 352 × 183 × 27

TQFP80 SOT375 12 × 12 mm 1 119 325 × 145 × 22 352 × 183 × 27

TQFP100 SOT386 14 × 14 mm 1 90 325 × 145 × 22 352 × 183 × 27

Note

1. If only a package type code is given, the data supplied is applicable to all its outline versions.

PHILIPSPACKAGE

TYPE/OUTLINE

CODE

(1)

PACKAGE

BODY

CARRIERS

PER BOX

5 2145 348× 148 × 47 356 × 161 × 56

5 2580 348× 148 × 47 356 × 161 × 56

5 800 348 × 148 × 47 356 × 161 × 56

5 800 348 × 148 × 47 356 × 161 × 56

5 595 348 × 148 × 47 356 × 161 × 56

5 450 348 × 148 × 47 356 × 161 × 56

SPQ

AND

PQ

OUTER BOX DIMENSIONS L × W × H

NON-DRYPACK

(mm)

DRYPACK

(mm)

2000 May 11 7 - 33

Page 34

Philips Semiconductors IC packages

Packing methods Chapter 7

2000 May 11 7 - 34

Loading...

Loading...