Page 1

12.18.07

Philips Medical Systems

www.medical.philips.com/us

Note for Architects and/or Contractors: "If revisions are listed, these drawings must be thoroughly reviewed so that all changes can be incorporated into your project"

Rev.

Level

Date Revision Descriptions By

Revisions

Table of Contents

Section A - Equipment Plan

General Notes -------------------------------------- AN

Equipment Plan ------------------------------------- A1

Equipment Details ----------------------- AD1 - AD2

Transport Details --------------------------------- AD3

Section S - Support Plan

Support Notes --------------------------------------- SN

Support Plan - Floor and Wall ------------------- S1

Support Plan - Ceiling------------------------------ S2

Support Details --------------------------- SD1 - SD2

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

Section E - Electrical Plan

Electrical Notes ------------------------------------ EN

Electrical Plan -------------------------------- E1 - E2

Electrical Details --------------------------------- ED1

Section N - Network Plan

Network Diagram ---------------------------------- N1

Check List ----------------------------------------- CHK

N-SRD040005

Project Number

C1

Sheet 1 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 2

HVAC Requirement for General Equipment Locations

Heating, ventilation, air conditioning requirement for general equipment locations must

maintain temperature at 75° +/- 11° fahrenheit (24° +/- 6° celsius) and non-condensing

relative humidity at 47%, +/- 28%.

Electrical Requirements

Optimus 65/80/C

Supply Configuration: 3 phase, 3 wire power and ground. Delta or wye

Nominal Line Voltage: 400, 440, 460 or 480 VAC, 60 Hz

Branch Power Requirement: 150 KVA

Circuit Breaker: 3 pole, 100 Amps (@ 480V)

(03.0)

(06.0)

Minimum Site Preparation Requirements

A smooth efficient installation is vital to Philips and its' customers. Understanding what the

minimum site preparation requirements are will help achieve this goal. The following list clearly

defines the requirements which must be fulfilled before the installation can begin.

1. Walls to be painted or covered, baseboards installed, floors to be tiled and/or covered,

ceiling shall have grid tiles and lighting fixtures installed.

2. Doors and windows, especially radiation protection barriers, installed and finished with

locksets operational.

3. All electrical convenience, conduit, raceway and junction boxes installed.

4. Incoming mains power operational and connected to room x-ray breaker.

5. 115v convenience outlets operational.

6. All support structures correctly installed. All channels, pipes, beams and/or other supporting

devices should be level, parallel, and free of lateral or longitudinal movements.

7. All contractor supplied cables pulled and terminated.

8. A dust-free environment in and around the procedure room.

9. All HVAC (heating, ventilating and air conditioning) installed and operational as per

specifications.

10. Architectural features such as computer floor, wood floor, casework, bulkheads, installed

and finished. When technical cabinets are installed in a closet with doors, it is suggested that

the customer install a temperature alarm in the event of an air conditioning failure.

11. All plumbing installed and finished.

12. Philips does not install or connect developing tanks, automatic processors or associated

equipment, built in illuminators, cassette pass boxes, loading benches and cabinets, lead

protective screens, panels or lead glass window and frame. This is to be done by the

customer/contractor.

13. Clear door openings for moving equipment into the building must be 42" (1067mm) w x 82"

(2083mm) h min. 48" (1219mm) w x 82" (2083mm) h rec., or larger contingent on an 8'-0"

(2438mm) corridor width.

Note

Once Philips has moved equipment into the suite and started the installation, the contractor

shall schedule his work around the Philips installation team on site. It is suggested that a

telephone be provided in the room to receive telephone calls. This would alleviate facility staff

from answering calls for Philips personnel.

Remote Service Diagnostics

Medical imaging equipment to be installed by Philips Medical is equipped with a service

diagnostic feature which allows for remote and on site service diagnostics. To establish this

feature, a dedicated direct-distance - dialing, voice-grade line must be installed as shown on

plan. All costs with this feature are the responsibility of the customer.

(00.1)

General Specifications

1. Responsibility

The customer shall be solely responsible, at its expense for preparation of site, including any

required structural alterations. The site preparation shall be in accordance with plans and

specifications provided by Philips. Compliance with all safety, electrical, and building codes

relevant to the equipment and its installation is the customer's responsibility. Sufficiency of

such plans and specifications, specifically including, but not limited to the accuracy of the

dimensions described therein, shall be the sole responsibility of customer. The customer shall

advise Philips of conditions at or near the site which could adversely affect the carrying out of

the installation work and shall ensure that such conditions are corrected and that the site is fully

prepared and available to Philips before the installation work is due to begin. The customer

shall provide all necessary plumbing, carpentry work, or conduit wiring required to attach and

install products ready for use.

2. Permits

Customer shall obtain all permits and licenses required by federal, state/provincial or local

authorities in connection with the construction, installation and operation of the products and

shall bear any expense in obtaining same or in complying with any related rules, regulations,

ordinances and statutes.

3. Radiation Protection

The customer or his contractor, at his own expense, shall obtain the service of a licensed

radiation physicist to specify radiation protection. For the purpose of the radiation protection

design for the suite, the physicist should assume a maximum kVp x-ray tube output of 150.

4. Asbestos and Other Toxic Substances

Philips assumes no hazardous waste (i.e., pcb's in existing transformers) exists at the site. If

any hazardous materials are found, it shall be the sole responsibility of the customer to properly

remove and dispose of this material at its expense. Any delays caused in the project for this

special handling shall result in Philips time period for completion being extended by like period

of time. Philips assumes that no asbestos material is involved in this project in any ceilings,

walls or floors. If any asbestos material is found anywhere on the site, it shall be the

customer's sole responsibility to properly remove and/or make safe this condition, at the

customer's sole expense.

5. Labor

In the event local labor conditions make it impossible or undesirable to use Philips' regular

employees for such installation and connection, such work shall be performed by laborers

supplied by the customer, or by an independent contractor chosen by the customer at the

customer's expense, and in such case, Philips agrees to furnish adequate engineering

supervision for proper completion of the installation.

6. Schedule

The general contractor should provide Philips with a schedule of work to assist in the

coordination of delivery of Philips supplied products which are to be installed by the contractor

and delivery of the primary equipment.

7. Extended Installation or Turnkey Work by Philips.

Any room preparation requirements for Philips equipment indicated on these drawings is the

responsibility of the customer. If an extended installation or turnkey contract exists between

Philips and the customer for room preparation, then additional work required for the equipment

will not be represented on these drawings. Some of the responsibilities of the customer as

depicted in these drawings may be assumed by Philips. In the event of a conflict between the

work described in the turnkey contract workscope and these drawings, the turnkey contract

workscope shall govern.

(00.0)

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AN

Sheet 2 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 3

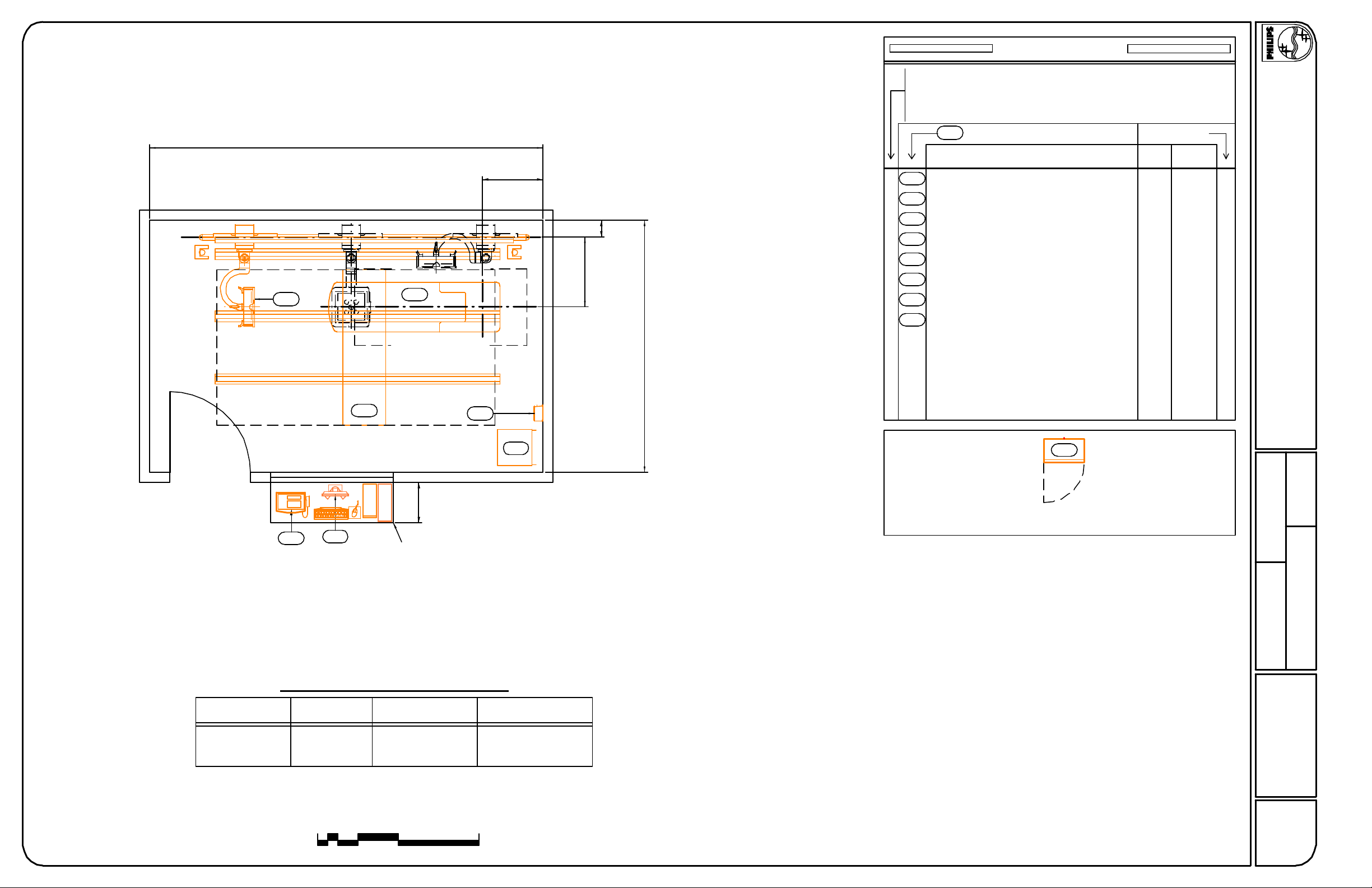

19'-6"

Table Floorplate Centerline

3'-0"

Equipment Legend

A

Furnished and installed by Philips

B

Furnished by customer/contractor and installed by customer/contractor

C

Installed by customer/contractor

Furnished by Philips and installed by contractor

D

E

Existing

F

Future

G

Option

Equipment Designation

Description

A

Detail Sheet

Weight

Heat Load

(btu/hr)(lbs)

1707462Optimus 80 Control Cabinet (40E Rack)ME

12.18.07

AD1

4' Wide Patient Entry

(Recommended)

DVM

PBC

DDW

MU

MS

2'-0"

Counter provided and

installed by customer

SCU

ME

10"

Floor Rail

Centerline

3'-5 1/2"

Table Longitudinal Centerline

12'-6"

A

A

A

A

A

A

A

MSC

Final location to be coordinated with the customer and architect of record.

AD1

1379Optimus Control PanelPBC

AD1

1297810CS 2 Tube Crane w/ Cable Carrier RailMU

AD1

060Manual Storage CabinetMSC

AD1

11914Segment Control UnitSCU

AD2

444753Digital Diagnost VM (Left)DVM

AD2

2083176Digital Diagnost WorkstationDDW

AD2

341472Single Sided Table TH-SMS

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Equipment Layout

Wall Stand Tube Position

Digital

Diagnost VM

Reported Existing Ceiling Height : None

Ceiling heights (from finished floor to bottom of Unistrut) other than

recommended may impact equipment functionality; consult with Philips.

0 8'1'

Minimum/Preferred

Ceiling Height

2'

4'

9' - 10 1/8" (3000mm)8' - 8 3/8" (2650mm)Upper Position

11' - 1 3/4" (3400mm)9' - 11 3/4" (3040mm)Lower Position

Maximum

Ceiling Height

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

A1

Sheet 3 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

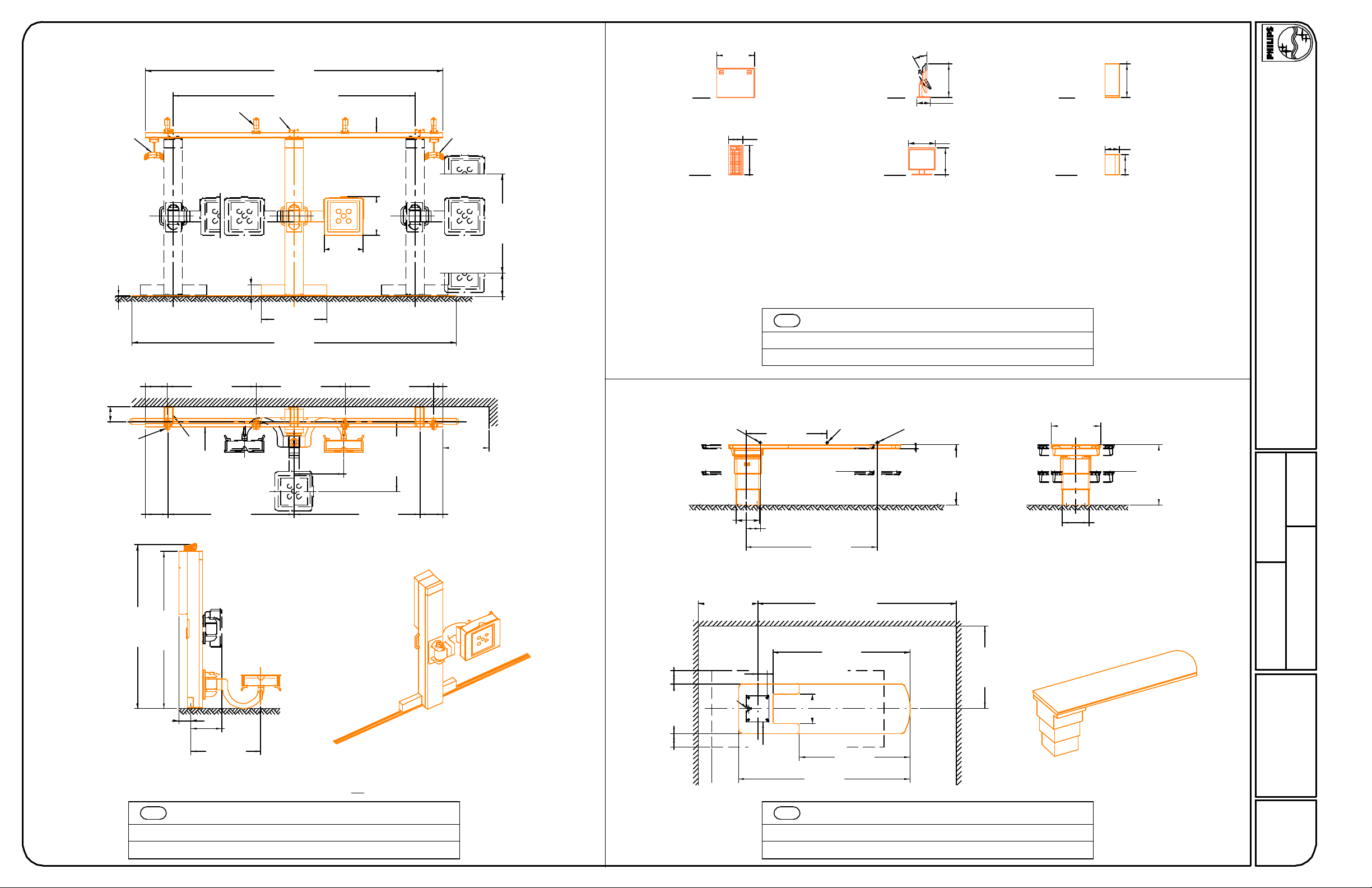

Page 4

Optional Wall Mounting Bracket

12.18.07

max.

107.47"

2730mm

25.59"

650mm

8.27"

210mm

min.

49.22"

1250mm

90°

90°

Option:

Tomo

Option:

Tomo

92.13"

9.57"

243mm

max.

2340mm

33.86"

min.

860mm

14.96"

380mm

92.76"

2356mm

34.41"

874mm

Option:

Tomo

57.87"

1470mm

9.49"

241mm

*

Option:

Tomo

25.59"

36.00"

914mm

9.49"

241mm

650mm

Option:

Rail for

Cable Carrier

4.49"

114mm

3.07"

78mm

6.00"

152mm

PBC

Weight

Heat Dissipation

15.75"

400mm

16.93"

430mm

Optimus Control Panel

9 lbs (4 kg)

137 Btu/hr (35 kcal/hr)

11.03"

13.19"

335mm

280mm

.79"

20mm

(07.0)

24.02"

610mm

30.00"

762mm

Max. weight of cabinet with manuals = 260 lbs. (118 kg)

MSC

Weight

Heat Dissipation

Manual Storage Cabinet

14.02"

356mm

60 lbs (27 kg)

0 Btu/hr ( 0 kcal/hr)

2.56"

65mm

(03.0)

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

8x45º

11.81"

300mm

Option:

Tomo

Supporting Arm UpSupporting Arm Down

* Column movement range = 1260mm (49.61");

standard range of 1470mm reduced by 210mm

(8.28") to allow optional cable carrier to be

mounted on transverse carriage.

* Optional cable carrier can be mounted on

longitudinal rail, causing 210mm (8.28") of

tube crane coverage loss (foot or head-end).

MU

Weight

Heat Dissipation

* Extension Rails are an additional 113lbs (51kg).

CS 2 Tube Crane

8x45º

Longitudinal

Rail

(368 kg)810 lbs

(326 kcal/hr)1297 Btu/hr

Transverse

Carriage

Option:

Cable Carrier

(07.1)

5.47"

139mm

8.94"

227mm

Cable

Openings

SCU

Weight

Heat Dissipation

21.06"

535mm

1.97"

50mm

42.50"

1080mm

±

Segment Control Unit

14 lbs (6 kg)

119 Btu/hr (30 kcal/hr)

(07.0)

2.76"

70mm

Clear Area

Around Cabinet

ME

Weight

Heat Dissipation

20.48"

520mm

21.66"

550mm

Optimus 50/65/80 Control Cabinet

2.76"

70mm

7.88"

200mm

76.98"

1955mm

462 lbs (210 kg)

1707 Btu/hr (430 kcal/hr)

Filler Panel

(07.0)

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AD1

Sheet 4 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 5

22.44"

177.17"

4500mm

143.70"

A

3650mm

B

max.

guide rail

570mm

Side

Side

30°

max

19.92"

506mm

8.07"

205mm

Top

20.32"

516mm

12.18.07

cable carrier

for CS 2/4

.63"

13.27"

337mm

min.

max.

9.06"

230mm

13.38"

340mm

13.78"

350mm

16mm

A

52.83"

1342mm

B

guide rail

74.80"

1900mm

User side left User side right (default)

22.64"

575mm

23.46"

596mm

6.89"

175mm

39.37"

1000mm

192.91"

4900mm

52.83"

1342mm

52.83"

1342mm

29.53"

750mm

74.80"

1900mm

41.54"

1055mm

cable carrier

for wall stand

min.

5.39"

137mm

27.56"

700mm

13.78"

350mm

59.06"

1500mm

13.78"

350mm

Required for insertion

of column

8.07"

205mm

Front

17.52"

445mm

CPU (Sun Ultra 25)

Weight: 60 lbs (27 kg)

Heat Dissipation: 1707 btu/hr (430 kCal/hr)

DDW

Weight

Heat Dissipation

center of gravity

table

13.80"

350mm

48.31"

1227mm

8.66"

220mm

center of gravity

table & patient

78.27"

1988mm

15.91"

404mm

Front

15.98"

406mm

19 " LCD Color Monitor

Weight: 16 lbs (8 kg)

Heat Dissipation: 171 btu/hr (43 kCal/hr)

Digital Diagnost Workstation

center of gravity

patient

2.13"

54mm

max.

min.

20.08"

510mm

35.83"

910mm

8.31"

211mm

Front

12.01"

305mm

UPS

Weight: 100 lbs (46 kg)

Heat Dissipation: 205 btu/hr (93 kCal/hr)

(07.0)

(81 kg)176 lbs

(566 kCal/hr)2083 Btu/hr

29.53"

750mm

35.83"

910mm

max.

20.08"

510mm

15.87"

403mm

min.

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

97.64"

2480mm

93.70"

2380mm

7.22"

183mm

Guide rail to be supported using ceiling holders (A) OR wall holders (B)

DVM

Weight

Heat Dissipation

18.10"

460mm

41.54"

1055mm

Digital Diagnost VM

(342 kg)753 lbs

(112 kcal/hr)444 Btu/hr

(06.0)

wall clearance required for

installation and service of table base

7.87"

200mm

29.53"

750mm

7.87"

200mm

min.

cable

outlet

15.75"

400mm

35.43"

900mm

5.55"

141mm

floor plate

Weight

Heat Dissipation

wall clearance required for insertion of tabletop

118.11"

min.

3000mm

81.89"

2080mm

17.72"

450mm

66.14"

1680mm

102.36"

2600mm

MS

Single Sided Table TH-S

472 lbs (214 kg)

341 Btu/hr (86 kcal/hr)

49.21"

1250mm

wall clearance required for

installation and service of table base

(06.0

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

AD2

Sheet 5 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

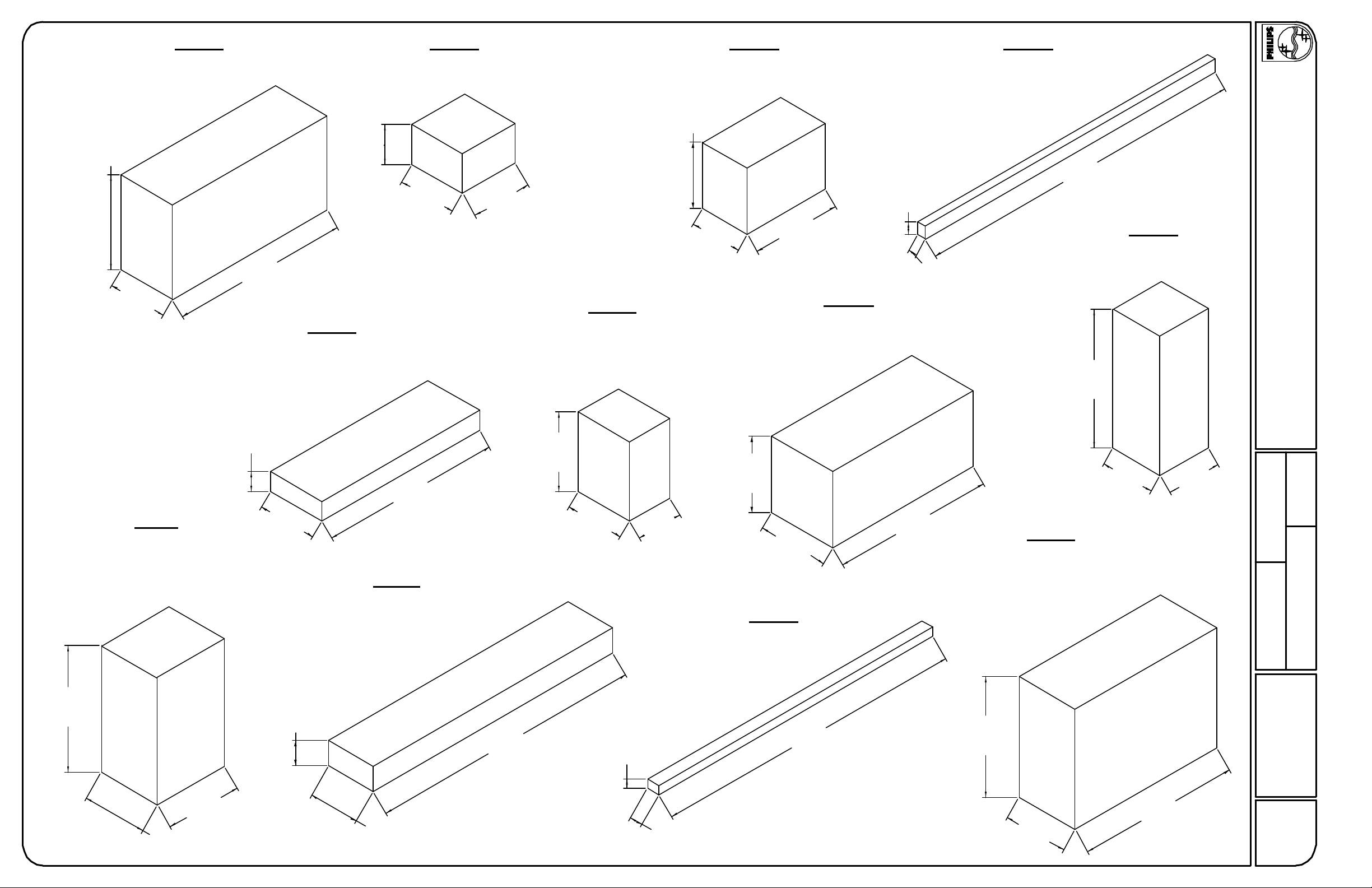

Page 6

4'-8.30"

1430mm

2'-11.43"

900mm

Crate A

Moveable Column

Weight: 629 lbs.

8'-10.30"

2700mm

1'-11.62"

600mm

Crate E

Single Sided Table TH-S

Table Top

Weight: 270 lbs.

Crate B

Flat Detector

Weight: 99 lbs.

2'-10.65"

880mm

3'-.22"

920mm

Digital Bucky Unit with Swivelling Arm

Crate F

Single Sided Table TH-S

Table Base

Weight: 450 lbs.

Crate C

Weight: 281 lbs.

3'-3.37"

1000mm

2'-6.71"

780mm

7.87"

200mm

4'-5.54"

1360mm

5.12"

130mm

Crate G

Single Sided Trolley TF-M

Weight: 584 lbs.

Crate D

Floor Rail and Guide Rail

Weight: 135 lbs.

16'-6.82"

5050mm

Generator Cabinet

6'-10.68"

12.18.07

Crate H

Weight: 508 lbs.

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

2100mm

Crate I

CS4 Transverse Carriage

Weight: 562 lbs.

Tomography (option)

Additional Weight: 67 lbs.

6'-3.59"

1920mm

11.81"

300mm

2'-11.43"

900mm

9'-.27"

2750mm

Crate J

CS4 Longitudinal Carriage

Weight: 429 lbs.

1'-2.97"

380mm

13'-8.56"

4180mm

3'-11.24"

1200mm

2'-11.43"

900mm

5.50"

140mm

2'-3.56"

700mm

3'-9.28"

1150mm

3'-6.13"

1070mm

Crate K

CS Base Rails 4.3 m

Weight: 198 lbs.

15'-8.19"

4780mm

8'-.46"

2450mm

2'-8.28"

820mm

Crate L

CS2 Complete

Weight: 931 lbs.

Tomography (option)

Additional Weight: 67 lbs.

5'-11.65"

1820mm

2'-9.07"

840mm

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

3'-2.58"

980mm

3'-10.06"

1170mm

2'-6.72"

780mm

7.88"

200mm

3'-2.59"

980mm

8'-1.25"

2470mm

(06.0)

AD3

Sheet 6 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 7

Equipment Support Information

1. General

The customer shall be solely responsible, at its expense, for preparation of the site, including

any required structural alterations. The site preparation shall be in accordance with this plan

and specifications, the architectural/construction drawings and in compliance with all safety and

building codes. The customer shall be solely responsible for obtaining all construction permits

from jurisdictional authority.

2. Equipment Anchorage

Philips provides, with this plan and specifications, information relative to equipment size,

weight, shape, anchoring hole locations and forces which may be exerted on anchoring

fasteners. The customer shall be solely responsible, through the engineer of record for the

building, to provide on the architectural/construction drawings, information regarding the

approved method of equipment anchoring to floors, wall and/or ceiling of the building. Any

anchorage test required by local authority shall be the customer's responsibility. Stud type

anchor bolts should not be specified as they hinder equipment removal for service. Consult

with Philips service prior to specifying anchor methods.

3. Floor Loading and Surface

Philips provides, with this plan and specifications, information relative to size, weight and shape

of floor mounted equipment. The customer shall be solely responsible, through the engineer of

record for the building, to provide on the architectural/construction drawings confirmation of the

structural adequacy of the floor upon which the equipment will be placed. Any load test

required by local authority, shall be the customer's responsibility.

The floor surface upon which Philips equipment is to be placed/anchored shall be flat and level

to within plus or minus 1/16 inch (2mm) over a length of 39" (1m).

4. Ceiling Support Apparatus

Philips provides, with this plan and specifications, information relative to size, weight and shape

of ceiling supported equipment. The customer shall be solely responsible, through the

engineer of record for the building, to provide on the architectural/construction drawings,

information regarding the approved method of structural support apparatus, fasteners and

anchorage to which Philips will attach equipment. Any anchorage and/or load test required by

local authority shall be the customer's responsibility.

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Contractor to clearly mark Philips equipment longitudinal centerline on bottom of each structural

support.

The structural support apparatus surface to which Philips equipment is to be attached, shall

have horizontal equipment attachment surfaces parallel, square and level to within plus or

minus 1/16 inch (2mm).

Any drilling and/or tapping of holes required to attach Philips equipment to the structural

support apparatus shall be the responsibility of the customer.

Fasteners/anchors (i.e., bolts, spring nuts, lock and flat washers) and strip closures shall be

provided by the customer.

5. Lighting

Lighting fixtures shall be placed in such a position that they are not obscured by equipment or

its movement, nor shall they interfere with Philips ceiling rails and equipment movement or

otherwise adversely affect the equipment. Such lighting fixture locations shall be the sole

responsibility of the customer.

6. Ceiling Obstructions

There shall be no obstructions that project below the finished ceiling in the area covered by

ceiling suspended equipment travel.

7. Seismic Anchorage (For Seismic Zones Only)

All seismic anchorage hardware, including brackets, backing plates, bolts, etc., shall be

supplied and installed by the customer/contractor unless otherwise specified within the support

legend on this sheet. Installation of electronic cabinets to meet seismic anchorage

requirements must be accomplished using flush mounted expansion type anchor/bolt systems

to facilitate the removal of a cabinet for maintenance. Do not use threaded rod/adhesive

anchor systems. Consult with Philips regarding any anchor system issues.

8. Floor Obstructions/ Floor Coverings

There shall be no obstructions on the floor (sliding door tracks, etc.) in front of the Philips

technical cabinets. Floor must be clear to allow cabinets to be pulled away from the wall for

service.

Date

Quote Number O.A. Number

Drawn By

Contractor to verify with Philips the preferred floor covering installation method.

(05.0)

N-SRD040005

Project Number

SN

Sheet 7 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 8

F2

F4

Table Floorplate Centerline

3'-0"

2'-2"

10"

3'-5 1/2"

Floor Rail

Centerline

Floor Support Legend

Furnished and installed by Philips

A

Furnished by customer/contractor and installed by customer/contractor

B

Installed by customer/contractor

C

Furnished by Philips and installed by contractor

D

Existing

E

Future

F

G

Item Number

Description

F1

D Single Sided Table TH-S Flush Mounted Floorplate SD2

F2

B Digital Diagnost VM Floor Rail Anchorage SD1

F3

Manual Storage Cabinet Anchorage SD2B

Floor must be level within this area - See note "3. Floor Loading and Surface" on

F4

sheet SN

F5

Segment Control Unit Anchorage (not shown) SD1B

Detail Sheet

SNB

12.18.07

Not Site Specific

Digital Diagnost VM

F1

F4

Table Longitudinal Centerline

CUSTOMER / CONTRACTOR SHALL RECOMMEND

AND / OR PROVIDE EQUIPMENT ANCHORING SYSTEMS

(I.E. "HILTI", "REDHEAD", ETC) BASED UPON SPECIFIED

"PULL" FORCES AND WALL / CEILING / FLOOR COMPOSITIONS.

F3

Final location to be coordinated with the customer and architect of record.

All dimensions must be off the final finished wall.

If a wall is furred out to hide electrical duct or boxes, the dimensions included in this plan

must come off the finished furred wall.

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

Floor Support Layout

Wall Stand Tube Position

Digital

Diagnost VM

Upper Position 8' - 8 3/8" (2650mm) 9' - 10 1/8" (3000mm)

Lower Position 9' - 11 3/4" (3040mm) 11' - 1 3/4" (3400mm)

Ceiling heights (from finished floor to bottom of Unistrut) other than

recommended may impact equipment functionality; consult with Philips.

0

Minimum/Preferred

Ceiling Height

4'2'1'

8'

Maximum

Ceiling Height

N-SRD040005

Project Number

S1

Sheet 8 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 9

10'-0"

11 1/2"

4'-1/2"

2'-10 7/16"

C2

13'-3"

12'-5"

C3

C1

Table Floorplate Centerline

C1

C2

3'-0"

10"

Floor Rail

Centerline

3'-5 1/2"

Table Longitudinal Centerline

Ceiling Support Legend

Furnished and installed by Philips

A

Furnished by customer/contractor and installed by customer/contractor

B

Installed by customer/contractor

C

Furnished by Philips and installed by contractor

D

Existing

E

Future

F

G

Item Number

Description

C1

Philips Equipment Rails SD2A

C2

Unistrut (P1001 or equal) mounted flush with finished ceiling SD2B

C3

A

Philips Equipment Guide Rail SD1

CUSTOMER / CONTRACTOR SHALL RECOMMEND

AND / OR PROVIDE EQUIPMENT ANCHORING SYSTEMS

(I.E. "HILTI", "REDHEAD", ETC) BASED UPON SPECIFIED

"PULL" FORCES AND WALL / CEILING / FLOOR COMPOSITIONS.

12.18.07

Detail Sheet

/SD2

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

4'-1 3/4" 4'-1 3/4" 4'-1 3/4"

No obstructions below the

finished ceiling within this

area (i.e. sprinklers, lights,

etc.). See sheet SN for more

details.

Ceiling Support Layout

Tube PositionWall Stand

Minimum/Preferred

Ceiling Height

Maximum

Ceiling Height

All dimensions must be off the final finished wall.

If a wall is furred out to hide electrical duct or boxes, the dimensions included in this plan

must come off the finished furred wall.

Date

Quote Number O.A. Number

Drawn By

Digital

Diagnost VM

9' - 10 1/8" (3000mm)8' - 8 3/8" (2650mm)Upper Position

11' - 1 3/4" (3400mm)9' - 11 3/4" (3040mm)Lower Position

Ceiling heights (from finished floor to bottom of Unistrut) other than

recommended may impact equipment functionality; consult with Philips.

08'1' 2' 4'

N-SRD040005

Project Number

S2

Sheet 9 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 10

177.17"

4500mm

Ceiling mounting device for the top guide rail

3.15"

80mm

3.15"

80mm

.39"

.79"

160mm

10mm

20mm

6.30"

.28"

7mm

cover

12.18.07

97.64"

2480mm

192.91"

4900mm

Ceiling Height

104.33" (2650mm) - 105.55" (2681mm)

105.51" (2680mm) - 113.94" (2894mm)

113.70" (2888mm) - 137.40" (3490mm)

guide rail

floor rail

Required Ceiling Holder

Short

Medium

Long

Part Number

4512 201 0218x

4512 201 0219x

4512 201 0220x

F5

Floor rail detail (side view)

3.54"

90mm

2.87"

73mm

A

cable outlet

.79"

.79"

20mm

** Not to scale

Weight of Segment Control box:

14 lbs. (10 kg.)

4.72"

120mm

20mm

1.97"

50mm

±

46.18"

1173mm

Recommended fixation:

4 mm x 8 mm dowel

4 mm x 6 mm screws, length >50 mm

Digital Diagnost VS Segment Control Unit

Wall Mounting Detail

The customer's architect/engineer of record shall specify

a wall backing plate sufficient for the bolt forces shown.

1.97"

50mm

±

59.57"

1513mm

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

(04.0)

Date

200mm

7.87"

500mm

19.69"

500mm

19.69"

500mm

19.69"

500mm

19.69"

Floor rail detail

4900mm

192.91"

500mm

19.69"

*Drawing not to scale

500mm

19.69"

500mm

19.69"

500mm

19.69"

500mm

19.69"

200mm

7.87"

Detail - Digital Diagnost VM Floor Rail & Guide Rail Support (w/ ceiling holders)

Bolt Forces:

T max (Tension)(ceiling) = 870 lbs/bolt

V max (Shear)(ceiling) = 174 lbs/bolt

V max (Shear)(floor) = 180 lbs/bolt

F2

C3

(07.0)

0.63"

16mm

1.44"

36.5mm

min. 9.06"

A - Phillips screw 5 x 60 + 8 mm (or equivalent) dowels for concrete floors

230mm

CUSTOMER / CONTRACTOR SHALL RECOMMEND

AND / OR PROVIDE EQUIPMENT ANCHORING SYSTEMS

(I.E. "HILTI", "REDHEAD", ETC) BASED UPON SPECIFIED

"PULL" FORCES AND WALL / CEILING / FLOOR COMPOSITIONS.

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

SD1

Sheet 10 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 11

Self-locking

Bolt, M10x40

Clip Rail

Detail - Clip Rail Cross-section

Finished Ceiling

6.25"

159mm

5.93"

150.7mm

3.98"

101mm

2.85"

72.5mm

P1001 (or equal) Unistrut

Fixing Block

Fixing Block

Clip

Cover

3.94"

* Philips does not specify the overhead equipment support structure.

Unistrut (or equal) may or may not be used. If Unistrut are used, it is

up to Unistrut and the structural engineer for the project to

determine which of it's products are appropriate for each project.

P1001 Unistrut may not be appropriate given the equipment

weight on a specific project.

* Finished ceiling must NOT be lower than the bottom of

the Unistrut in order to prevent damage to the finished ceiling

during the installation of clip rails.

* Nothing shall be attached to the Unistrut with any fastener that

protrudes into the unistrut which would interfere with positioning of

the fixing block.

1.30"

1.26"

32mm

0.55"

14mm

100mm

Floor Plate

(side view)

Mount tablebase to floorplate: Mount floorplate to floor:

Bolt Forces:

T max (Tension) = 3377 lbs/bolt

V max (Shear) = 735 lbs/bolt

* NOTE: Floorplate must be mounted flush with the finished floor

F1

(07.0)

12.99"

330mm

15.59"

396mm

Floor Plate*

(top view)

33mm

Bolt Forces:

T max (Tension)(floor) = 2040 lbs/bolt

V max (Shear)(floor) = 506 lbs/bolt

Detail - Single Sided TH-S Table Base and Floor Plate

0.53"

14mm

11.02"

280mm

13.54"

344mm

Drawings Not to Scale

Base Transverse

Centerline

0.43"

11mm

7.87"

200mm

0.75"

19mm

Table cover

0.59"

15mm

15.87"

403mm

Table Base

(top view)

8.27"

210mm

cable

outlet

7.09"

180mm

750mm

1.97"

50mm

29.53"

Base Longitudinal

Centerline

floor plate

Table base

Table top

Table base

mounting holes

Floor plate

mounting holes

6.69"

170mm

13.80"

4.29"

109mm

1.38"

35mm

4.65"

351mm

118mm

102.36"

2600mm

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

1.25"

32mm

Tube Crane

Support Forces

CS2

CS4

C2C1 C3

5.88"

150mm

Detail - Fixing Block for Philips Ceiling Rails (Clip Rails)

(Tension) Tmax = 794 lbs/support

(Shear) Vmax = 134 lbs/support

(Tension) Tmax = 686 lbs/support

(Shear) Vmax = 160 lbs/support

(07.2)

(Tension) Tmax = 891 lbs/support

(Shear) Vmax = 149 lbs/support

(Tension) Tmax = 756 lbs/support

(Shear) Vmax = 175 lbs/support

0.63"

16mm

With Trauma AttachmentWith Tomo OptionWithout Tomo Option

(Tension) Tmax = 1106 lbs/support

(Shear) Vmax = 158 lbs/support

(Tension) Tmax = 887 lbs/support

(Shear) Vmax = 184 lbs/support

20.00"

508mm

Backing

Plates

Bolt Forces:

(Tension) Tmax = 107 lbs/bolt

(Shear) Vmax = 146 lbs/bolt

26.00"

660mm

Manual Storage Cabinet Mounting Detail

The customer's architect/engineer of record shall

specify a wall backing plate sufficient for the bolt

forces shown.

F3

(07.0)

Date

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

SD2

Sheet 11 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 12

General Electrical Information

1. General

The customer shall be solely responsible, at its expense, for preparation of the site, including any required electrical alterations. The site preparation

shall be in accordance with this plan and specifications, the architectural/construction drawings and in compliance with all safety and electrical codes, the

customer shall be solely responsible for obtaining all electrical permits from jurisdictional authority.

2. Materials and Labor

The customer shall be solely responsible, at its expense, to provide and install all electrical ducts, boxes, conduit, cables, wires, fittings, bushing, etc., as

separately specified herein.

3. Electrical Ducts and Boxes

Electrical ducts and boxes shall be accessible and have removable covers. Floor ducts and boxes shall have watertight covers. Ducts shall be divided

into as many as three separate channels by metal dividers, separately specified herein, to separate wiring and/or cables into groups as follows: Group a,

power wiring and/or cables. Group b: signal and/or data and protective ground wiring and/or cables. Group c: x-ray high voltage cables, the use of 90

deg. ells is not acceptable. On ceiling duct and wall duct use 45 deg. bends at all corners. All intersecting points in duct to have cross over tunnels

supplied and installed by contractor to maintain separation of cables.

4. Conduit

Conduit point - to - point runs shall be as direct as possible. Empty conduit runs used for cables may require pull boxes located along the run. Consult

with Philips. A pull wire or cord shall be installed in each conduit run. All conduits which enter duct prior to their termination point must maintain

separation from other cables via use of dividers, cross over tunnels, or flex conduit supplied and installed by contractor from entrance into duct to exit

from duct.

5. Conductors

All conductors, separately specified, shall be 75° c stranded copper, rung out and marked.

6. Disconnecting Means

A disconnecting means shall be provided as separately specified.

7. Warning Lights and Door Switches

"X-Ray On" warning lights and x-ray termination door switches should be provided at all entrances to x-ray rooms as required by code.

8. Dimmer Switches

X-ray room lights should be provided with dimmer switches.

(02.0)

Electrical Legend

Furnished and installed by Philips

A

Furnished by customer/contractor and installed by customer/contractor

B

Installed by customer/contractor

C

Furnished by Philips and installed by contractor

D

Existing

E

Future

F

G

Item Number

Description

CB

ST

ME

PBC

SCU

MS

DVM

480V, 3 phase 100 AMP circuit breaker with shunt trip and load side pressure lugs for #2 A.W.G. extra-flexible

cable (T+B type 31009 "locktight" or similar). Run power from breaker to wall box "ME" leaving an 8' tail. See

sheet "ED1" for power quantity requirements. Location per local code or owner requirements. Coordinate with

local Philips service.

Shunt trip (emergency off) - large mushroom-head button on remote control station with contacts to operate

feature of "CB." (if required by local code or owner, and mandatory for VA and D.O.D. installations). Its location

must be within easy reach but not subject to an accidental bump. Exact location to be determined by customer or

coordinated with local Philips Service. (Not shown on plan)

19 1/4"W x 67"H x 4"D flanged-edge terminal wall box with removable screw-type cover plate, surface mounted

75" A.F.F. to top of box. Conduits to terminate on top & sides of the box as required.

6"W x 6"L x 4"D pull box with removable screw-type cover plate, surface mounted 22" A.F.F. to bottom of box.

Location shown is recommended and may be changed - verify relocation with local Philips Service.

Grommetted opening on "WR1". Exact size to be determined in field. Modify cover of Segment Control Unit as

needed.

8"W x 8"L x 6"D floor box with removable gasketted screw-type cover plate. Top of box to be mounted 1.26"

below finished floor to accommodate flush mounted TH-S floor plate .

8"W x 8"L x 6"D ceiling box flush mounted with removable screw-type cover plate.

6"W x 6"L x 4"D pull box with removable screw-type cover plate, surface mounted 22" A.F.F. to bottom of box.

Location shown is recommended and may be changed - verify relocation with local Philips Service.

B

B

D

B

B

B

MU

B

B

DDW

Detail Sheet

ED1

ED1

Not Site Specific

- Standard Reference Drawing -

12.18.07

Digital Diagnost VM

Electrical Notes

1. The contractor will supply & install all breakers, shunt trip and incoming power to the breakers. The exact location of the breakers and shunt trips will

be determined by the architect or contractor.

2. The contractor shall supply & install all pull boxes, raceways, conduit runs, stainless steel covers, etc. Conduit/raceways must be free from burrs and

sharp edges over its entire length. A Greenlee pull string/measuring tape (part no. 435, or equivalent) shall be provided with conduit runs.

3. All pre - terminated, cut to length cables, will be supplied and installed by Philips Medical Systems. All cables to the breakers, will be supplied and

installed by the contractor, subject to local arrangements.

4. Provide and install 4 - 2" (50 mm) dia. Chase nipples between adjacent wall boxes where applicable.

5. Electrical raceway shall be installed with removable covers. The raceway should be accessible for the entire length. In case of non - accessible floors,

walls and ceilings, an adequate number of access hatches should be supplied to enable installation of cabling. Approved conduits may be substituted.

All raceways will be designed in a manner that will not allow cables to fall out of the raceway when the covers are removed. In most cases, this will

require above - ceiling raceway to be installed with the covers removable from the top. Raceway system as illustrated on this drawing are based upon

length of furnished cables. Any changes in routing of raceway system could exceed maximum allowable length of furnished cables. Conduit or raceway

above - ceiling must be kept as near to finished ceiling as possible.

6. Conduit sizes shall be verified by the architect, electrical engineer or contractor, in accordance with local or National Electrical Codes, whichever

govern.

7. Convenience outlets are not illustrated. Their number and location are to be specified by the customer/architect.

8. All sections of raceway and conduit shall be grounded with an independent #6 a.w.g.green wire that is to be attached using solderless lugs. All ceiling

mounted structural support members and ceiling plates shall also be grounded. All grounding connections, terminals, etc. Shall be installed in a manner

to provide accessibility for inspection, maintenance, repair, etc.

(99.0)

B

B

Warning light - provide an incandescent surface or flush mounted light fixture above door to indicate when X-Ray

WL

is on. Provide a 115V, 15A normally open relay in this fixture. (Not shown on plan)

Door switch - 120V, 5A switch limited to open when door is open. Mount in upper corner on strike side of main

DS

entry door(s) (Cooper no. 1665 or equivalent), if required by local code or physicist of record. (Not shown on plan)

ED1

ED1

Date

B

B

WR1

B

120 V / 20 A dedicated duplex outlet. Coordinate exact location with local Philips Service. (For Digital Diagnost

Workstation "DDW")

6"W x 3 1/2"D wall raceway with removable screw-type cover plate, surface mounted 63.5" A.F.F. to bottom of

raceway from side of "ME" to Segment Control Unit.

RJ45 type ethernet 10/100/1000 Mbit network connector. Access through customer's network to VPN device

N

capable of connecting to the Philips Remote Service Network (RSN) Datacenter is needed. Refer to page N1 for

RSN connectivity options. Locate within 10' of network card. Network Fiber optic and ethernet cabling,

connectors, wall boxes, patch panels, etc, are the responsibility of the purchaser. Philips assumes no

responsibility for procurement, installation, or maintenance of the components.

N1

E2

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

EN

Sheet 12 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 13

Refer to electrical legend - Sheet EN

9"

MU

Table Floorplate Centerline

13'-11" 1'-7"

9"

2 1/2"

3'-0"

DVM

10"

3'-5 1/2"

Floor Rail

Centerline

Conduit Required

General Notes

1. All conduit runs must take most direct route point to point.

2. All conduit runs must have a pull string.

Conduit supplied/installed by contractor - Philips cables installed by Philips

A

B

Conduit supplied/installed by contractor - Philips cables installed by contractor

Conduit and cables supplied and installed by contractor

C

Conduit existing - cables supplied and installed by Philips

D

Conduit existing - cables supplied by Philips, installed by contractor

E

Conduit existing - cables supplied and installed by contractor

F

Conduit

Run No. From

1

2

3

4

C

C 50'1/2"1 (P)WLME

Power

Panel

Conduit

Quantity

(* Cable

To

Type)

Minimum

Conduit

Size

per NEC per NEC1 (P)C CB

Default

Conduit

Length

50'2"1 (P)MECBB

50'3/4"1 (P)STCBC

*

Requirements

12.18.07

Power / Ground CablesP

Signal CablesS

Video CablesV

High Tension Power CablesH

Fiber OpticF

Special

2'-0"

PBC

2'-4"

N

DDW

MS

SCU

ME

1'-8"

1'-3"

WR1

Table Longitudinal Centerline

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

2"1 (S)DVMMEA 65'

2"1 (P)DVMMEA 65'

2"1 (P)DVMMEA 65'

2"1 (S)DVMMEA 65'

50'1/2"1 (P)DSMEC

65' 2"1 (P)PBCMEA

65' 2"1 (S)PBCMEA

52'1/2"1 (P)MSMEA

32'2 1/2"1 (S)MUMEA

32'2 1/2"1 (H)MUMEA

65'1 1/2"1 (S)DDWMEA

78'1 1/2"1 (S)DDWDVMA

78'1/2"1 (F)DDWDVMA

32'2"1 (S)MSMEA

32'2"1 (P)MSMEA

65'1 1/2"1 (S)DDWMEA

52'1 1/2"1 (S)MUMEA

52'1 1/2"1 (P)MUMEA

Grounding

Max. conduit length = 59' (each conduit) if

DVM2.

Grounding

Max. conduit length = 72' if DVM2.

Max. conduit length = 59' (each conduit) if

DVM2.

Runs #16 - #22 are for cables to/from SCU.

(Routed via ME and WR.)

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

Electrical Layout

Tube PositionWall Stand

Digital

Diagnost VM

Ceiling heights (from finished floor to bottom of Unistrut) other than

recommended may impact equipment functionality; consult with Philips.

1' 2'

0 8'

Minimum/Preferred

Ceiling Height

9' - 10 1/8" (3000mm)8' - 8 3/8" (2650mm)Upper Position

11' - 1 3/4" (3400mm)9' - 11 3/4" (3040mm)Lower Position

4'

Maximum

Ceiling Height

All dimensions must be off the final finished wall.

If a wall is furred out to hide electrical duct or boxes, the dimensions

included in this plan must come off the finished furred wall.

N-SRD040005

Project Number

E1

Sheet 13 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 14

Cable Trough Divisions

Troughs or ducts must be separated by metal barriers into three sections:

1. High voltage (H.T.) cables to be run separately from all other cables.

2. Power cables and ground cables can be run together.

3. Signal cables and data cables can be run together but must be separated

from power cables.

4. Video cables to be run separately from all other cables.

12.18.07

Power &

Grounds

5. It is important that all cables are placed in the appropriate trough and

at no given point do any cables from one division cross with cables

from another. Trough separation must be continuous from the beginning

to the end of the run. Utilize crossover tunnels as appropriate please see example below

6. Trough or ducts: steel with steel dividers grounded to building ground.

7. Contractor to provide cable restraints in all troughs.

8. No cables, except cables to & from the generator rack (ME) and transfomer,

must pass through the 20" (500mm) exclusion zone around the generator rack.

(For interventional procedures only)

Signal &

Data

Video

(if not in conduit)

High Tension

(if separate conduit

not used)

Crossover Example

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

WR1

(03.2)

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

E2

Sheet 14 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 15

CB

Line Voltage Variation:

Frequency Variation:

Voltage Surges:

Voltage Sags:

Line Impulses:

Neutral-ground Impulses:

High Frequency noise:

Ground and Neutral

Conductor Impedance:

Power Quality Requirements

Optimus 80 / Optimus C

80 KWPower Output:

3 phase, 3 wire power and ground, Delta or wyeSupply Configuration:

400, 440, 460, or 480 VAC, 60 HzNominal Line Voltage:

± 8% steady-state

2% maximum of nominal voltage between phasesLine Voltage Balance:

± 1% (± 0.6 Hz)

To 110% of steady-state voltage 100 msecs.

Maximum duration, 6 per hour maximum

To 90% of steady-state voltage 100 msecs.

Maximum duration, 6 per hour maximum

1000 VPK above phase-neutral RMS absolute

maximum. No more than 1 impulse per hour to exceed

500 VPK.

2.0 volts maximum RMS valueNeutral-ground Voltage:

No more than 1 per hour that exceeds 25 volts and 1

Mjoule

3.0 volts steady-state maximum. Over 3.0 volts

permitted for 100 msec. maximum, 1 per hour

maximum.

0.1 Ohms @ 60 Hz maximum

Branch Circuit and Wire Gauge Requirements

Optimus 80 / Optimus C

150 KVABranch Power:

3 pole, 100 amperes (@ 480V)Circuit Breaker:

158 KVA (800 MA @ 100 KV) (Short-term)Maximum Instantaneous Power:

<8 Amps (Stand-by/Long-term)

Recommended conductor sizes for 1% impedance of branch conductors.

Based on 20°C copper conductors:

66.9 ft.#1 AWG

84.3 ft.1/0 AWG

106 ft.2/0 AWG

133 ft.3/0 AWG

169 ft.4/0 AWG

199 ft.250 MCM

239 ft.300 MCM

399 ft.400 MCM

359 ft.500 MCM

79 ft.

100 ft.

126 ft.

159 ft.

201 ft.

230 ft.

285 ft.

380 ft.

476 ft.

87 ft.

110 ft.

139 ft.

175 ft.

221 ft.

261 ft.

313 ft.

418 ft.

522 ft.

480 VAC460 VAC440 VAC400 VAC

96 ft.

121 ft.

152 ft.

192 ft.

242 ft.

287 ft.

344 ft.

459 ft.

574 ft.

CB

Electrical power distribution at the facility shall comply with:

Utilization voltages per ANSI C84.1 - 1982 range A.

Voltage to be supplied is 3 phase, 3 wire power and ground (delta or wye) unless otherwise noted

in equipment specifications.

Phase conductors to be sized for instantaneous voltage drop per NEC 517 - 73 and Philips

recommendations.

Neutral and ground conductors to be sized equivalently to phase conductors, unless

otherwise noted.

Metal conduit shall not be used as the equipment ground conductor.

Clamping type surge suppressors are highly recommended in addition to standing facility lighting

arrestors. Equipment to be protected from ANSI/IEEE C62.41-1980 location category B impulses.

ANSI / NFPA 70 - National Electrical Code

Article 250 - grounding

Article 517 - health care facilities

ANSI / NFPA 99 - health care facilities

NEMA standard XR0 - power supply guideline for x-ray machines

Eletrical Requirement Notes

Power Quality Guidelines

1. Power supplied to medical imaging equipment must be separate from power feeds to air

conditioning, elevators, outdoor lighting, and other frequently switched or motorized loads.

Such loads can cause waveform distortion and voltage fluctuations that can hinder high quality

imaging.

2. Equipment that utilizes the facility power system to transmit control signals (especially clock

systems) may interfere with medical imaging equipment, thus requiring special filtering.

3. The following devices provide a high impedance, nonlinear voltage source, which may affect

image quality:

Static UPS systems, Series filters, Power conditioners, and Voltage regulators.

Do not install such devices at the mains supply to medical imaging equipment without

consulting Philips installation or service personnel.

4. Line impedance is the combined resistance and inductance of the electrical system and

includes the impedence of the power source, the facility distribution system, and all phase

conductors between the source and the imaging equipment. Philips publishes recommended

conductor sizes based on equipment power requirements, acceptable voltage drops, and

assumptions about the facility source impedance. The minimum conductor size is based on

the total line impedance and NEC requirements. Unless impedance calculations are performed

by an electrical engineer, the recommended values must be used.

WL DS

ME

EZX1

Wall Box

"ME"

SW UN EX 4

PO26V

CMSW

RM DR CT

RM DR 0V

5

6

8

9

10

Relay Supplied by Philips

Detail for Connection of

X-Ray On Light and Door Switch

(Optimus Rad/RF Generator Only)

19.25"

489mm

Terminal Box

Finished Floor

Wall Box Mounting Detail

1/2" Conduit

Hospital

Supplied

110 VAC

Door Switch

67.00"

Radiation

Indication

1702mm

75.00"

1905mm

(01.0)

(99.1)

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Impedance

Drop

Maximum Load

Minimum copper wire size, circuit breaker to equipment: #2

190 A200 A210 A228 AInst. Current

0.2 Ω0.2 Ω0.2 Ω0.2 ΩMax. Phase-phase

38.0 V40.0 V42.0 V45.6 VMax. Load Voltage

7.9 %8.7 %9.5 %11.4 %Percent Regulation at

(06.0)

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

ED1

Sheet 15 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 16

Philips Medical Systems Remote Services Network (RSN)

Secure broadband connection required for Philips remote technical support, diagnostics, and applications assistance

12.18.07

Broadband Site-to-Site Connectivity (Preferred)

This connectivity method is designed for customers who prefer a

connection from the RSN Data Center to the Health Care Facility (HCF)

utilizing their existing VPN equipment.

Connectivity Details:

- A Site-to-Site connection from the RSN data center's Cisco router will be established to the

HCF's VPN concentrator

- The VPN Tunnel will be an IPSEC, 3DES encrypted Tunnel using IKE as standard, but

alternative standards are also available, such as AES, MD5, SHA, Security Association

lifetime and Encryption Mode

- Every system that we will be servicing remotely will have a static NAT IP that we configure

on the RSN Data center side.

HCF VPN

Concentrator

General Network

Router

Overview

(not site specific)

c

Internet

Shared VPN

Action Required by Hospital:

- Review and approve connection details

- Complete appropriate Site Checklist

- Configure and allow Site-to-Site access prior to setting up connectivity depending on the

access criteria that the HCF decides to implement (ex: Source IP filtering, destination IP

filtering, NAT assignment, etc.)

- Route traffic from within the hospital network with destination addresses 192.68.48.0/22 to

the designed IP provided by Philips

Health Care Facility

Philips

PACS

Ultrasound

Philips

Nuc Med

Hospital

Network

Patient

Monitoring

Philips

MR

Philips

X-Ray

Philips

CT

Broadband Router Installed at Health Care Facility

This connectivity method is designed for customers who have a dedicated high speed

connection for Philips equipment.

Connectivity Details:

- An RSN Cisco 1711 or 1712 router will be preconfigured and installed at the HCF by Philips

in conjunction with the HCF IT representative.

- The VPN Tunnel will be an IPSEC, 3DES encrypted Tunnel using IKE and will be

established from the RSN-DC and terminated at the RSN Router on-site

- One to One NAT is used to limit access to Philips eqiupment only

- Router Config and IP auditing is enabled for Customer IT to view via website 24/7

- Dedicated DSL connections are also supported

Option 1: Parallel to HCF Firewall Connectivity Method

This connectivity method is designed for customers who prefer a Philips RSN Router installed

on site utilizing all the security features provided and managed by Philips.

Philips

General Network

Router

Overview

(not site specific)

Firewalls

Internet

Philips VPN or

Site-to-Site VPN

Action Required by Hospital:

- Assign a fixed public IP Address from the ISP to be configured on the Philips router. This is

the DOTTED link on the picture connected to the firewall.

- Assign a Back end IP for the Philips router on the Hospital Network

- Complete appropriate Site Checklist

- Route traffic from within the hospital network with destination addresses 192.68.48.0/22 to

internal Philips router Ethernet interface. This is the DASHED line connected to the firewall.

Health Care Facility

Philips

PACS

Ultrasound

Philips

Nuc Med

Hospital

Network

Patient

Monitoring

Philips

MR

Philips

X-Ray

Philips

CT

Option 3: Router Installed Inside the HCF's DZM

This connectivity method is designed for customers who prefer the RSN Router installed inside

and existing, or new DMZ, allowing access to Philips equipment.

General Network

Overview

(not site specific)

Internet

Philips VPN or

Site-to-Site VPN

Philips

Router

Health Care Facility

Philips

Philips

PACS

Ultrasound

Nuc Med

Hospital

Network

Patient

Monitoring

Philips

MR

Philips

X-Ray

Philips

CT

Action Required by Hospital:

- Assign a fixed public IP Address from the ISP to be configured on the Philips router. This is

the DOTTED link on the picture connected to the firewall.

- Assign a Back end IP for the Philips router on the Hospital Network

- Complete appropriate Site Checklist

- Route traffic from within the hospital network with destination addresses 192.68.48.0/22 to

internal Philips router Ethernet interface. This is the DASHED line connected to the firewall.

- Configure and allow on the firewall on the DASHED line interface IPSec protocol

communication by opening protocol 500, 50, 51, 47 and port 23 + TACACS. Traffic should

be between external IP Address located on the Philips router and the RSN Data center IP

address 192.68.48/24 and IP address AOSN TACAS

- Configure and allow on the firewall on the DASHED line interface access between the IP

address allocated by the hospital to the Philips internal Ethernet router interface and the

target modality IP address

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Option 2: Back End Connected to the HCF Firewall Connectivity Method

This connectivity method is designed for customers who prefer a Philips RSN Router installed

on site by setting up an IP-Based policy allowing access thru existing HCF Firewall to Philips

equipment.

Health Care Facility

Philips

General Network

Overview

(not site specific)

Router

Philips

PACS

Internet

Philips VPN or

Site-to-Site VPN

Ultrasound

Action Required by Hospital:

- Assign a fixed public IP Address from the ISP to be configured on the Philips router. This is

the DOTTED link on the picture connected to the firewall.

- Assign a Back end IP for the Philips router on the Hospital Network

- Complete appropriate Site Checklist

- Route traffic from within the hospital network with destination addresses 192.68.48.0/22 to

internal Philips router Ethernet interface. This is the DASHED line connected to the firewall.

- Configure and allow on the firewall on the DASHED line interface access between the IP

address allocated by the hospital to the Philips internal Ethernet router interface and the target

modality IP address.

Philips

Nuc Med

Hospital

Network

Patient

Monitoring

Philips

MR

Philips

X-Ray

Philips

CT

Quote Number O.A. Number

Drawn By

N-SRD040005

Project Number

N1

Sheet 16 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Page 17

Instructions

Questionnaire for DigitalDiagnost VM

Order No. :

Customer :

Project leader :

Phone No. :

mail :

Signature :

This form is to be used by Project Manager, Contractor and Service Engineer.

Information is used to develop and determine site ready date.

Items listed are go/no go items for delivery unless noted as delay only items.

Items identified with *** as delayed items must be completed after hours or on weekend. These itmes cannot be accomplished while installation is

in progress. Also, these items must be completed within two days of installation start or they may stop installation.

Site Readiness Checklist

Customer site preparation verified in general against the Philips final planning drawings.

Walls finished including painting.

Doors installed.

Floor leveled according to Philips drawings and specifications.

Floors are tiled/covered finished. Flooring is covered with protective covering (scratch protection).

Ceiling lights installed.

Cable conduit and ductwork installed and clean. Position checked. Duct covers in place but not finally closed. Cable opening are clear,

without sharp edges. Pull strings in conduit. Installation per Philips specifications.

HVAC environmental equipment installed and working according to Philips specifications.

Ceiling installation completed.

Electrical preparation according to Philips specifications.

All network cabling, drops installed according to Philips specifications (including hardcopy cameras).

All pre-cabling identified on Philips drawings has been installed.

Pre-move survey completed - Delivery route identified.

Lead glass installed ***.

X-ray warning lights installed ***.

Dedicated phone line for modem use***.

Room has been cleaned ***.

Cabinets and casework installed***.

Modality Checklist

Unistrut installed and level according to Philips specifications

Blocking support for wall stand

Conduit lenghts measured according to Philips specifications. NOTE: Specifications are from source box to destination box (not just conduit

run length)

Wall support for wall stand

Cataloque section 712-55 Direct Radiography)

This questionnaire must be used with your order.

Mark all items with a cross.

Fill in your special requests with help of the drawing Z-5.1 and forward it to your SSD order desk.

Bold * marked items = default.

Country :

e-

Siebel

catalogue

FRQ 3101 704-Q01

FRQ 3123 704-Q23 Generator → Workstation 20*

FDQ 5505 712-Q05 SCU2 → Workstation

FRQ 3121 704-Q21

Single Sided Table TH-S CAN → SCU2/Generator (PE)

General

FMS 0001 704-Q99 Country of delivery USA*

FMS 0002 712_Q98 Operator Manual Language ENG*

Generator

FMS 0003 Mains voltage (50/60Hz) 415-480V NMSA 604 / MRD 5781

Control desk version Desk version*

BuckyDiagnost CS

FRQ 3110 704-Q10 Ceiling height

NRDN 223 MRD 1821

NRDN 223 MRD 1821

NRDN 223 MRD 1821

NRDN 223 MRD 1821

NRDN 229 MDD 1521

NRDN 222 MRD 5581

NRDN 223 MRD 1821 E → Rail length (total) 4300 mm mm

Date :

PMS

catalogue

Cable lengths (m) from outlet to outlet

Generator → Generator control desk

Generator

Generator control desk → SCU2

Workstation

Generator → Segment control unit 2 (SCU2 )

Generator → BuckyDiagnost CS

SCU2 → BuckyDiagnost CS

Additional remarks:

< 3.0 m*

Tube support upper pos.

Length of ceiling rails

A → For longitudinal carriage rear side CS2 mm max. 100 mm

B → For longitudinal carriage front side CS2

A → For longitudinal carriage rear side CS4

B → For longitudinal carriage front side CS4

C → Option: Rail extension (CS2/4 + VM)

D → Rail separation (rail connection parts incl.)

Standard Reduction

2356 mm

4076 mm

2700 mm mm

0 mm mm

20*

20

20

24

6

20*

10*

16

10/16

>3.0 m

Tube support lower pos.

mm max. 500 mm

mm max. 500 mm

mm max. 900 mm

12.18.07

Not Site Specific

Digital Diagnost VM

- Standard Reference Drawing -

Date

Quote Number O.A. Number

Drawn By

Approved for Delivery

Project Manager Date

Service Engineer Date

DigitalDiagnost VM

FDQ 5523 712-Q23 Operation side DigitalDiagnost VM userside right*

FDQ 5038 704-Q38

Wall holder for min. room height 2650mm no

Ceiling holder for guide rail room height 2680-2894 (middle version)*

N-SRD040005

Project Number

CHK

Sheet 17 of 17

THE INFORMATION IN THIS PACKAGE IS PROVIDED AS A CUSTOMER CONVENIENCE, AND IS NOT TO BE CONSTRUED AS ARCHITECTURAL DRAWINGS OR CONSTRUCTION DOCUMENTS.

Philips assumes no liability nor offers any warranty for the fitness or adequacy of the premises or the utilities available at the premises in which the equipment is to be installed, used, or stored.

Loading...

Loading...