Page 1

CM-150 CA

Control module for large scale architectural and media applications using

Flex nodes

Page 2

CM-150 CA

Control module for large scale architectural and media

applications using Flex nodes

CM-150 CA delivers integrated data and power to Flex LED luminaires from Philips Color Kinetics. With

multiple mounting options, CM-150 CA is the single solution for all large scale installations using Flex nodes,

whether color or white. An integrated test button instantly confirms proper functioning of your devices,

eliminating costly and time-consuming reinstallation.

• Supports up to 150 W of power output—

CM-150 CA accommodates input and output

voltages of 7.5, 12, and 24 volts, so it’s compatible

with all current and discontinued Flex family

products from Philips Color Kinetics. CM-150 CA

supports up to two strands of Flex, with up to 75

nodes per strand.

• Modular and versatile—CM-150 CA is available

in a surface mount or DIN rail mount form

factor, allowing placement in indoor and outdoor

environments, or in your own custom housing.

CM-150 CA is compatible with third-party power

supplies, so you can purchase the power supplies

that work best for your installation.

• Available with 3-wire or 4-wire output—3-wire

output is a cost-effective option for shorter runs

of up to 7.6 m (25 ft) from the CM-150 CA to

your Flex strands. 4-wire output offers more

flexibility of placement and can be used in runs

of up to 30.5 m (100 ft) from the CM-150 CA

to your Flex strands. Longer leader cables are

available for custom configurations.

• Integrated test button— CM-150 CA features an

onboard button for testing LED nodes that are

attached to the control module, even before fully

installing your control system. Press this button

to instantly show a color wash on attached Flex

nodes, confirming that your devices are working

just as you expect them to. Press the button

again, and your Flex nodes will resume normal

operation. On-board indicator LEDs provide

visual feedback for normal operation, DMX and

Ethernet connection detection, and Ethernet

data transmission.

• Compatible with ActiveSite—CM-150 CA is

designed to work with ActiveSite from Philips

Color Kinetics. With ActiveSite, you can check

the devices on your lighting network right from

your web browser. And because ActiveSite

knows the status of your control module, you can

instantly pinpoint a problematic CM-150 CA or

attached LED nodes from anywhere in the world.

CM-150 CA Product Guide2

DMX and Ethernet input

and output

CM-150 CA can accept DMX or

Ethernet data. DMX and Ethernet

output ports allow for daisychaining of control modules.

Page 3

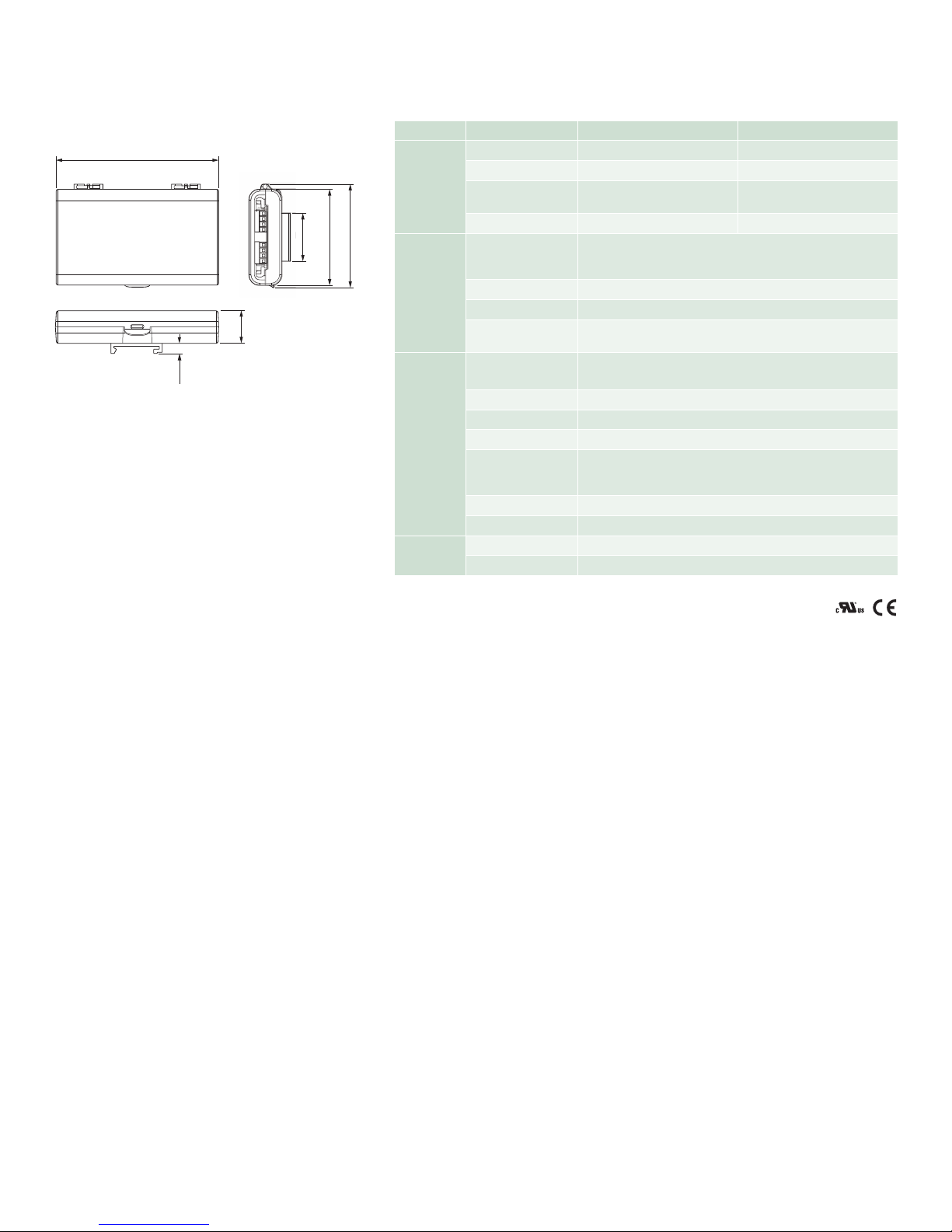

CM-150 CA, DIN Rail Mount Specications

8.7 mm

153 mm (6.02 in)

Due to continuous improvements and innovations, specifications may change without notice.

Item Specication 7.5/12V 24V

Input Voltage 7.5 VDC or 12 VDC 24 VDC

Power Consumption 3 W 3 W

Electrical

Power Output

Fuse (2) 5 A, fast-blow fuses (2) 4 A, fast-blow fuses

45 mm

(1.77 in)

97 mm (3.82 in)

90 mm (3.54 in)

Connections

Data Input Source

Power Input V+ and GND terminal block

Data Input/Output Double-pair, double-entry IDC connectors

31 mm

(1.2 in)

Power/Data Output

(To luminaire)

Dimensions

(.34 in)

(Heig ht x Width x Depth)

Weight 0.2 kg (0.4 lb)

Housing Material Plastic housing

Physical

Mounting DIN rail mountable

Temperature Ranges

Humidity 0 to 95%, non-condensing

Cooling Convection

Certification

and Safety

Certification UL/cUL Recognized, CE

Environment Dry location, IP 00

60 W maximum at 7.5 VDC, or

96 W maximum at 12 VDC

150 W maximum at 24 VDC

Philips Color Kinetics full range of controllers, including Light

System Manager, Video System Manager Pro, iPlayer 3, Antumbra

iColor Keypad, and ColorDial Pro, or third-party controllers.

†

‡

(2) V+, GND, Dat a+, and Dat a- terminal blocks†, or

(2) V+, GND, and Data terminal blocks

†

153 x 97 x 31 mm (6 x 3.8 x 1.2 in)

-20 to 50 °C (- 4 to 122 °F) Startup

-30 to 50 °C (-22 to 122 °F ) Operating

-40 to 70 °C (-40 to 158 °F) Storage

2

† Terminal block connectors accept wire sizes from 0.5 to 2 .1 mm

(14 to 20 AWG).

‡ IDC connectors accept wire sizes from 0. 326 to 0.129 mm2 (22 to 26 AWG).

CM-150 CA Product Guide 3

Page 4

CM-150 CA, Surface Mount Specications

38.5 mm

(1.52 in

208 mm (8.19 in)

90 mm (3.54 in)

Due to continuous improvements and innovations, specifications may change without notice.

Item Specication 7.5/12V 24V

Input Voltage 7.5 VDC or 12 VDC 24 VDC

Power Consumption 3 W at 7.5 VDC or 12 VDC 3 W at 24 VDC

Electrical

Connections

Physical

Certification

and Safety

Power Output

Fuse (2) 5 A, fast-blow fuses (2) 4 A, fast-blow fuses

Data Input Source

Power Input V+ and GND terminal block

Data Input/Output Double-pair, double-entry IDC connectors

Power/Data Output

(To luminaire)

Dimensions

(Heig ht x Width x Depth)

Weight 0.7 kg (1.6 lb)

Housing Material Die-cast aluminium, powder-coated finish

Mounting Surface mountable

Temperature Ranges

Humidity 0 to 95%, non-condensing

Cooling Convection

Certification UL/cUL, CE

Environment Dry/Damp/Wet Location, IP66

60 W maximum at 7.5 VDC, or

96 W maximum at 12 VDC

150 W maximum at 24 VDC

Philips Color Kinetics full range of controllers, including Light

System Manager, Video System Manager Pro, iPlayer 3, Antumbra

iColor Keypad, and ColorDial Pro, or third-party controllers.

†

‡

(2) three-pin panel mount connectors, or

(2) four-pin panel mount connectors

208 x 90 x 39 mm (8. 2 x 3.5 x 1.5 in)

-20 to 50 °C (- 4 to 122 °F) Startup

-30 to 50 °C (-22 to 122 °F ) Operating

-40 to 80 °C (- 40 to 176 °F) Storage

184 mm (7.24 in)

198 mm (7.8 in)

78 mm

8 mm

(0.31 in)

)

(3.07 in)

2

† Terminal block connectors accept wire sizes from 0.5 to 2 .1 mm

(14 to 20 AWG).

‡ IDC connectors accept wire sizes from 0. 326 to 0.129 mm2 (22 to 26 AWG).

CM-150 CA Product Guide4

Page 5

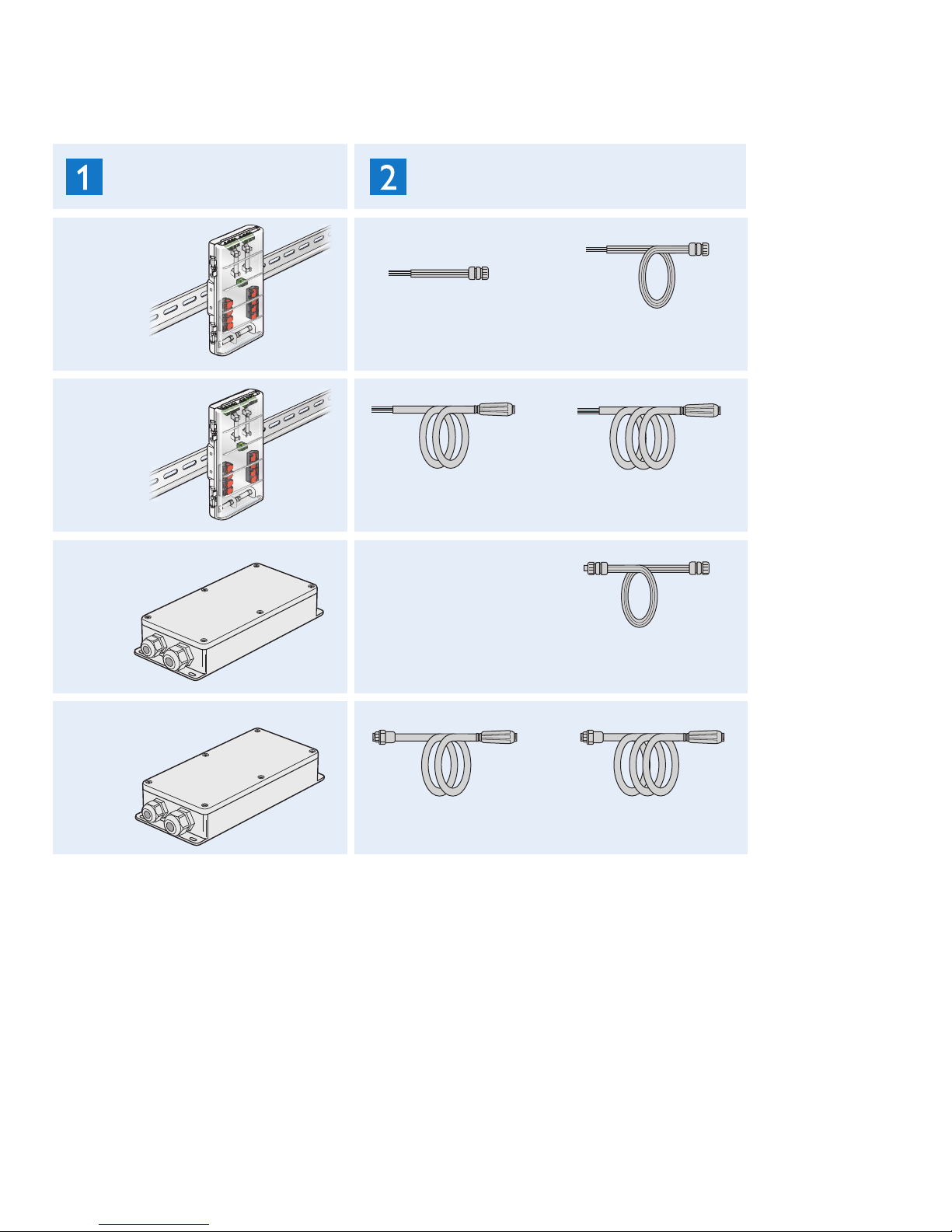

Product Selection

To order a complete CM-150 CA, choose a mounting type (DIN Rail Mount or Surface Mount), 3-wire or 4-wire output, a voltage that matches

your Flex nodes (7.5/12 V or 24 V), any necessary accessories (such as leader cables).

Choose

Mounting

DIN Rail Mount

7.5/12 or 24 VDC

3-wire

DIN Rail Mount

7.5/12 or 24 VDC

4-wire

Surface Mount

7.5/12 or 24 VDC

3-wire

Choose

Leader Cables

3-wire cable

0.3 m (1 ft)

4-wire cable

15.2 m (50 ft)

3-wire

Direct connection

without leader cable

3-wire cable

7.6 m (25 ft)

4-wire cable

30.4 m (100 ft)

3-wire cable

7.6 m (25 ft)

Surface Mount

7.5/12 or 24 VDC

4-wire

4-wire cable

15.2 m (50 ft)

4-wire cable

30.4 m (100 ft)

CM-150 CA Product Guide 5

Page 6

Control Module and Leader Cables

CM-150 CA is part of a complete system which includes the control module and:

• One or more third-party power supplies

• One leader cable to attach each Flex strand to a control module port

• A Philips Color Kinetics controller, including Light System Manager, Video System

Manager Pro, iPlayer 3, Antumbra iColor Keypad, and ColorDial Pro, or a thirdparty controller.

Control Modules

Item Typ e Item Number Philips 12NC

CM -150 C A

DIN Rail Mount

CM -150 C A

Surface Mount

3-Wire

4-Wire

3-Wire

4-Wire

Leader Cables for CM-150 CA, DIN Rail Mount

Item Typ e Item Number Philips 12NC

Flex SLX Adapter, 3-Wire 305 mm (1 ft) 108-000084-00 9 124001359 13

Leader Cable, 3-Wire

Leader Cable, 4-Wire

305 mm (1 ft) 108-000081-01 912400136051

7.6 m (25 ft) 108-000081-00 912400 1359 09

15.2 m (50 f t) 108-000080-01 91240 013 5907

30.5 m (100 ft) 108-000080-02 9 124001359 0 8

7.5/ 12V 109-000033-03 9124 00135769

24V 109-000033-02 912400135768

7.5/ 12V 109-000033-01 91240 0135767

24V 109-000033-00 912400135766

7.5/ 12V 109-000034-03 9124 00135773

24V 109-000034-02 9124 0 013577 2

7.5/ 12V 109-000034-01 9124 00135771

24V 109-000034-00 9124 0 013577 0

Use Item Number when ordering in North America.

Use Item Number when ordering in North America.

Leader Cables for CM-150 CA, Surface Mount

Item Typ e Item Number Philips 12NC

Leader Cable, 3-Wire 7.6 m (25 f t) 108-000083-00 912400135912

Leader Cable, 4-Wire

15.2 m (50 f t) 108-000082-01 912400135910

30.5 m (100 ft) 108-000082-02 912400135911

Use Item Number when ordering in North America.

Power Supplies

24 V power supply must be ordered separately from Philips or a third party

manufacturer. 7.5 V or 12 V power supply must be ordered separately from a third

party manufacturer.

Item Item Number Philips 12NC

Power Supply, 320W 24V, 100-277V, IP67, UL, CE, PSE 309-000014-01 9124 00130539

Power Supply, 320W 24V, 100-277V, IP67, CCC 309-000014-03 9124 00133 656

Power Supply, 320W 24V, 100-277V, IP67, RCM 309-000014-07 91240 01336 60

Use Item Number when ordering in North America.

CM-150 CA Product Guide6

Page 7

CM-150 CA

E Refer to the CM-150 CA Installation

Instructions for specic warning and caution

statements at www.colorkinetics.com/ls/pds/

cm150ca/.

Installation

CM-150 CA integrates data and power transmission for the Flex family of luminaires.

Installation specics will vary depending on luminaire types, controller, environment

(dry or damp/wet).

Owner/User Responsibilities

It is the responsibility of the contractor, installer, purchaser, owner, and user to install,

maintain, and operate CM-150 CA in such a manner as to comply with all applicable

codes, state and local laws, ordinances, and regulations. Consult with the appropriate

electrical inspector to ensure compliance.

Installing in Damp or Wet Locations

When installing in damp or wet locations, seal all junction boxes, power supplies, and

other devices with electronics-grade RTV silicone sealant so that water or moisture

cannot enter or accumulate in any wiring compartments, cables, luminaires, or other

electrical parts. You must use suitable outdoor-rated junction boxes when installing

in wet or damp locations. Additionally, you must use gaskets, clamps, and other parts

required for installation to comply with all applicable local and national codes.

Plan the Installation

To streamline installation and ensure accurate configuration, start with a layout or a

lighting design plan that shows the physical layout of the installation and identifies the

locations of all luminaires, CM-150 CA devices, controllers, switches, and cables.

DMX or Ethernet Conguration

CM-150 CA can be used in either DMX or Ethernet networks. DMX is appropriate

for relatively simple installations, or for installations in which groups of lights operate

in unison—for example, for accent lighting.

Typical DMX installations with intelligent LED luminaires from Philips Color Kinetics

use a controller such as iPlayer 3, a Controller Keypad for turning the lighting system

on and off and for triggering light shows, and one or more CM-150 CA devices.

CM-150 CA devices can be connected in series to deliver DMX data from a single

controller to all connected lights.

iColor Flex LMX gen2

iPlayer 3

Controller

Because it is not subject to the DMX addressing limitations, Ethernet is the preferred

environment for large-scale, color-changing light shows and video displays, both of

which require large numbers of unique addresses.

Typical Ethernet installations with Philips Color Kinetics LED luminaires use an

Ethernet switch, an Ethernet controller such as Light System Manager or Video

System Manager Pro, Antumbra Ethernet Keypads for push-button light show

CM-150 CA Product Guide 7

Page 8

triggering, and one or more CM-150 CA devices. While your specific lighting

CM-150 CA

network configuration may allow for additional devices, we recommend that you limit

individual Ethernet runs to 15 or fewer CM-150 CA, DIN Rail Mount devices. For

additional CM-150 CA devices in a network, use additional Ethernet switch ports.

Light

System

Manager

Ethernet

Switch

PC

iColor Flex LMX gen2

Electrical Conguration Guidelines

The maximum number of nodes each CM-150 CA can support depends on the

luminaire type, as well as on additional configuration details such as node spacing

and leader cable length. The table in the margin lists the maximum number of Flex

nodes each CM-150 CA can support, assuming a suitable power supply is used. Keep

in mind that these figures, provided as a guideline, are accurate for the specified

configuration only, and that changing the configuration can affect the number of

nodes per CM-150 CA.

CM-150 CA must be installed in a location that allows air to move freely around the

device. Startup and operating temperatures are rated to 50 °C (122 °F). Exceeding

this temperature limit may cause device damage or failure.

Maximum nodes per CM-150 CA

Luminaire

eW Flex Compact 75 nodes 150 nodes

eW Flex Micro 75 nodes 150 nodes

iColor Flex LMX gen2 75 nodes 150 nodes

iColor Flex MX gen2 75 nodes 150 nodes

iW Flex Compac t 75 nodes 150 nodes

Nodes per

port

Nodes per

CM -150 C A

Data Conguration Guidelines

In addition to maximum run lengths determined by the electrical configuration, each

CM-150 CA imposes maximum run lengths based on data integrity.

When selecting mounting locations for the CM-150 CA devices in your installation,

keep cable length maximums in mind:

iColor Flex LMX gen2

CM-150 CA

• In Ethernet networks, maximum data cable lengths are 100 m (328 ft) between

Ethernet devices without a repeater (for example, controller to switch, or switch

to CM-150 CA).

100 m (328 ft) Max100 m (328 ft) Max

Ethernet maximum data cable length

CM-150 CA Product Guide8

Page 9

Power supply requirements for

Flex strands

Luminaire Power supply

eW Flex Compact 24 to 24.5 VDC

eW Flex Micro 24 to 24.5 VDC

iColor Flex LMX gen2 24 to 24.5 VDC

iColor Flex MX gen2 7.5 to 7.7 VDC

iColor Flex SLX 12 to 12.3 VDC

iW Flex Compac t 24 to 24.5 VDC

Select the Right Components

To work with your Flex luminaires, you will need to select the right form factor,

leader cable, and third party power supply, as detailed in this section.

Surface Mount or DIN Rail Mount?

CM-150 CA is available in either a Surface Mount or a DIN Rail Mount form factor.

The DIN Rail Mount form factor is suitable for dry locations only. It can be used

indoors, or it can be mounted in a suitable outdoor enclosure. On the other hand,

the Surface Mount form factor features an IP66 housing, and can be installed in dry,

damp, and wet locations without needing a separate enclosure, allowing greater

flexibility of placement.

Third Party Power Supply

Select a third-party power supply that matches the physical and electrical

requirements of your lighting installation. Because CM-150 CA passes voltage from

the power supply to the attached Flex nodes, it is important that you use a power

supply the has the right input voltage, output voltage, and wattage. Refer to the table

in the margin to find the correct output voltage for your Flex nodes.

Some power supplies can be shared between multiple control modules. Refer to the

specification sheets for your specific control module, Flex strands, and power supply

to determine whether this can be done in your lighting installation.

Leader Cables

The type of leader cable you select depends on the distance from the control

module to the first Flex node, the form factor of your CM-150 CA, and whether

your CM-150 CA has three-wire or four-wire output. The following table shows the

available leader cable options for your configuration:

Mounting option Dist ance to Flex Output to Flex Leader cable options

≤7.6 m (25 ft) 3-Wire

DIN Rail Mount

>7.6 m (25 f t) 4-Wire

≤7.6 m (25 ft) 3-Wire

Surface Mount

>7.6 m (25 f t) 4-Wire

305 mm (1 ft)

7.6 m (25 ft)

15.2 m (50 f t)

30.5 m (100 ft)

Direct connection without leader cable

7.6 m (25 ft)

15.2 m (50 f t)

30.5 m (100 ft)

Assemble Additional Items

The following additional items are required to mount and connect CM-150 CA.

• For installations using the Surface Mount housing, four mounting screws suitable

for the mounting surface

• Cat. 5e or better data cable, as required

• Associated cables as listed in Leader Cable Part Numbers table

• Electronics-grade RTV silicone for installations in damp and wet locations

• Screwdrivers, wire strippers, and other tools as needed

• Top hat DIN rail EN 50022, if needed.

CM-150 CA Product Guide 9

Page 10

Inspect CM-150 CA and Accessories

Included in the box, Surface Mount

38.5 mm

(1.52 in

208 mm (8.19 in)

90 mm (3.54 in)

153 mm (6.02 in)

97 mm (3.82 in)

Carefully inspect the box containing CM-150 CA and the contents for any damage that

may have occurred in transit.

We recommend that you ensure your CM-150 CA devices are running the latest

version of the firmware, and update the firmware if necessary, before positioning and

mounting the devices. See www.colorkinetics.com/support/downloads/rmware/ for

complete information.

Position and Mount CM-150 CA

Make sure the power is OFF before mounting and connecting CM-150 CA.

CM-150 CA, Surface Mount

2.5 mm (0.25 in) hex wrench

DMX termination pin jumper

(2) Spare fuses

(2) Connector caps

1. Each CM-150 CA is identied by a unique serial number and IP address. The

serial number and default IP addresses are located on a label on the CM-150 CA

housing. If your installation requires multiple CM-150 CA devices, record the

IP addresses (Ethernet) in a layout grid (typically a spreadsheet or list) for

easy reference.

2. Assign each device to a position in the lighting design plan.

3. Position each CM-150 CA in its designated mounting location, as detailed below.

Surface Mount Installation

Make sure the mounting surface is flat, suitable for the mounting hardware, and clear

of debris and other obstructions.

The overall dimensions of each CM-150 CA, Surface Mount device are 208 mm

(8.2 in) wide x 90 mm (3.5 in) deep x 39 mm (1.5 in) high. Make sure the mounting

location allows enough space for air to move freely around the device. Be careful not

to obstruct or submerge the vent on the CM-150 CA housing.

Use four suitable mounting screws to secure CM-150 CA to the mounting location.

Included in the box, DIN Rail Mount

CM-150 CA, DIN Rail Mount

DMX termination pin jumper

(2) Spare fuses, attached inside housing

184 mm (7.24 in)

78 mm

(3.07 in)

198 mm (7.8 in)

8 mm

(0.31 in)

)

DIN Rail Mount Installation

The overall dimensions of each CM-150 CA, DIN Rail Mount device are 153 mm

(6 in) wide x 97 mm (3.8 in) deep x 31 mm (1.2 in) high. Make sure the mounting

location allows enough space for air to move freely around the device.

CM-150 CA Product Guide10

(.34 in)

8.7 mm

31 mm

(1.2 in)

45 mm

(1.77 in)

90 mm (3.54 in)

Page 11

Prepare for Cable Connections

2.5 mm he x or

DMX input Ethernet input

Surface Mount Installation

1. Using the included 2.5 mm (1/4 in) hex wrench, loosen the housing cover’s six

captive screws to open the CM-150 CA housing.

1/4 in hex

2. Loosen the cable glands.

Make Data Input Connections

E IDC connectors accept wire sizes from

0.326 to 0.129 mm2 (22 to 26 AWG).

Instead of RJ45 connectors, CM-150 CA uses double-pair, double-entry IDC

connectors, which accept unstripped cable wire strands.

Surface Mount Installation

1. Run Cat. 5e or better cable from the data output port of a Philips Color Kinetics

Ethernet controller, such as Light System Manager or Video System Manager Pro.

2. If necessary, cut the cable jacket to expose the wire pairs. Do not strip the wire

pairs. The Brown, Brown/White, Blue, and Blue/White wires are not used and

should be capped and turned back.

3. Locate the pivot connectors inside the CM-150 CA housing. If installing in a

DMX environment, open the DMX input connectors. If installing in an Ethernet

environment, open the Ethernet input connectors.

4. Feed the data cable through the smaller cable gland. Following the wire color

codes printed on the data board, insert the Orange/White, Orange, Green/White,

and Green wires into the pivot connector’s wire entry holes.

5. While holding the wires rmly in place, push down on the pivot connectors until

they click shut.

3. If installing CM-150 CA in a DMX installation, terminate the DMX run.

CM-150 CA Product Guide 11

Page 12

DIN Rail Mount Installation

(optional)

DMX output

(optional)

Not terminated Terminated

1. Run Cat. 5e or better cable from the data output port of a Philips Color Kinetics

Ethernet controller, such as Light System Manager or Video System Manager Pro.

2. If necessary, cut the cable jacket to expose the wire pairs. Do not strip the wire

pairs. The Brown, Brown/White, Blue, and Blue/White wires are not used and

should be capped and turned back.

3. Locate the pivot connectors inside the CM-150 CA housing. If installing in a DMX

environment, open both DMX connectors. If installing in an Ethernet environment,

open both Ethernet connectors.

4. Following the wire color codes printed on the data board, insert the Orange/

White, Orange, Green/White, and Green wires into the pivot connector’s wire

entry holes.

Ethernet input

Ethernet output

DMX input

5. While holding the wires rmly in place, push down on the pivot connectors until

they click shut.

6. If installing the last CM-150 CA control module in a DMX run, terminate the end

of the DMX run using the supplied pin jumper.

Connect CM-150 CA Devices in Series

(Optional, DIN Rail Mount only)

Installations with large numbers of luminaires may require multiple CM-150

CA devices.

Series Connection Using Ethernet

We recommend that you limit individual Ethernet runs to 15 or fewer CM-150 CA,

DIN Rail Mount devices. Use additional Ethernet switch ports to connect additional

CM-150 CA devices to your network.

In Ethernet networks, maximum run lengths for data cables are 100 m (328 ft)

between Ethernet devices without a repeater.

1. Cut a sufcient length of Cat. 5e or better cable to connect the rst CM-150 CA

device in a series with the next.

2. If necessary, cut both ends of the cable jacket to expose the wire pairs. Do not

strip the wire pairs. The Brown, Brown/White, Blue, and Blue/White wires are

not used and should be capped and turned back.

CM-150 CA Product Guide12

100 m (328 ft) Max100 m (328 ft) Max

Ethernet maximum data cable length

Page 13

4. Locate the Ethernet output pivot connectors inside the CM-150 CA housing.

Ethernet output

(optional)

DMX output

(optional)

Not terminated Terminated

Open both pivot connectors.

Ethernet input

5. Following the wire color codes printed on the data board, insert the Orange/

White, Orange, Green/White, and Green wires into the pivot connector’s wire

entry holes.

6. While holding the wires rmly in place, push down on the pivot connectors until

they click shut.

7. Run the free end of the cable to the next CM-150 CA device in the series, and

make Ethernet data input connections as described in the previous section.

8. Repeat for each CM-150 CA device in the series.

Series Connection Using DMX

1. Cut a sufcient length of Cat. 5e cable to connect the rst CM-150 CA device in a

series with the next.

2. If necessary, cut both ends of the cable jacket to expose the wire pairs. Do not

strip the wire pairs. The Brown, Brown/White, Blue, and Blue/White wires are

not used and should be capped and turned back.

4. Locate the DMX output pivot connectors inside the CM-150 CA housing. Open

both pivot connectors.

DMX input

5. Following the wire color codes printed on the data board, insert the Orange/

White, Orange, Green/White, and Green wires into the pivot connector’s wire

entry holes.

6. While holding the wires rmly in place, push down on the pivot connectors until

they click shut.

7. Run the free end of the cable to the next CM-150 CA device in the series, and

make DMX data input connections as described in the previous section.

8. Repeat for each CM-150 CA device in the series.

9. If installing the last CM-150 CA control module in a DMX run, terminate the end

of the DMX run using the supplied pin jumper.

CM-150 CA Product Guide 13

Page 14

Make DC Power Connections

5 mm (0.2 in)

Surface Mount Installation

1. Run the power cable through the larger cable gland of the CM-150 CA housing.

Pull at least 127 mm (5 in) of wire into the housing.

2. Strip 5 mm (0.2 in) of insulation from the wires. If using stranded wire, twist each

wire tight to secure the wire threads.

E The terminal block connectors

accept wire sizes from 0.5 to 2.1 mm

(14 to 20 AWG).

2

3. Locate the DC power 2-wire terminal block connector inside the CM-150

CA housing.

4. Insert the appropriate wire (V+ and ground) in each terminal. Tighten the

retaining screws by hand with a screwdriver.

5. Tighten the cable gland around the power cable.

6. Connect the power cable to the power supply.

-V

+V

DIN Rail Mount Installation

1. Strip 5 mm (0.2 in) of insulation from the wires. If using stranded wire, twist each

wire tight to secure the wire threads.

2. Run the DC power cable through the bottom of the CM-150 CA housing. Pull at

least 127 mm (5 in) of wire into the housing.

B Power supply must be isolated type.

For 7.5 V Flex, power supply must not

exceed 7.7 VDC. For 12 V Flex, power

supply must not exceed 12.3 VDC.

For 24 V Flex, power supply must not

exceed 24.5 VDC.

3. Locate the DC power 2-wire terminal block connector inside the CM-150

CA housing.

4. Insert the appropriate wire (V+ and ground) in each terminal. Tighten the

retaining screws by hand with a screwdriver.

6. Connect the power cable to the power supply.

-V

+V

CM-150 CA Product Guide14

Page 15

Make Luminaire Cable Connections

3-wire output4-wire output

4-wire output

V+

V-

Data Data +

3-wire output

V+

GND

Data

GND

V+

Flex strands from Philips Color Kinetics can use a detachable leader cable, or the

strands can be connected directly to a CM-150 CA, Surface Mount, 3-Wire control

module. Leader cables range from 305 mm (1 ft) to 30.5 m (100 ft), while Flex

strands range from 152 mm (6 in) to 3.7 m (12 ft) distance from the connector to the

first node.

Surface Mount Installation

1. Remove the end caps.

2. Plug leader cable or the Flex strand into the CM-150 CA, and secure

the connection.

DIN Rail Mount Installation

1. Strip 5 mm (0.2 in) of insulation from the wires. If using stranded wire, twist each

wire tight to secure the wire threads.

2. Run a leader cable to the top of the CM-150 CA housing.

3. Locate the luminaire three-wire or four-wire terminal block connectors inside the

CM-150 CA housing.

4. Securely install each wire in the appropriate terminal. Tighten the retaining screws

by hand with a screwdriver.

CM-150 CA Product Guide 15

Page 16

Secure Cover (Surface Mount only)

Once you have finished connecting all data and power inputs and outputs, secure the

CM-150 CA cover.

1. Seat the cover on the CM-150 CA housing.

2. Using the included 3 mm hex wrench, tighten the housing cover’s six captured

screws, as indicated in the diagram to the left. Torque each screw to

approximately 1.8 Nm (16 in-lb).

3. Tighten the cable glands around all cables. Do not overtighten.

4. For wet or damp locations, seal all points of entry to prevent water inltration.

Use RTV silicone to seal screw holes and cable glands.

Conguring CM-150 CA with QuickPlay Pro

(Optional)

You can configure CM-150 CA devices using QuickPlay Pro addressing and

configuration software. In Ethernet installations, you can automatically discover

all CM-150 CA devices using QuickPlay Pro with a computer connected to your

lighting network.

RTV Silicone

E You can download QuickPlay Pro from

www.colorkinetics.com/support/addressing/.

When a CM-150 CA device is connected to your lighting network, the CM-150 CA

tab under PDS Conguration becomes active.

E For details on standard QuickPlay

Pro options for CM-150 CA, refer to the

Addressing and Conguration Guide,

which you can view or download at www.

colorkinetics.com/support/addressing/.

CM-150 CA Product Guide16

Page 17

Updating CM-150 CA Firmware

The CM-150 CA firmware image is periodically updated to improve system

performance and functionality. To maximize system performance, make sure your

CM-150 CA devices are running the most recent version of the firmware. We

recommend that you confirm that your CM-150 CA devices have the most recent

version of the firmware before installing them in your lighting network.

Determine CM-150 CA Firmware Version

1. You can determine the rmware version that your CM-150 CA devices are

running with a computer and QuickPlay Pro:

In Ethernet installations, connect a computer to the lighting network and run

QuickPlay Pro. QuickPlay Pro automatically discovers all connected CM-150

CA devices. Select a device from the Controllers list.

2. If necessary, select a CM-150 CA device from the Controllers list.

The rmware version for the selected CM-150 CA device appears at the top of

the QuickPlay Pro window, on the right.

Download CM-150 CA Firmware

If a more recent version of the CM-150 CA firmware is available, download the

firmware file (.hex extension):

1. Visit the Firmware Updater page at www.colorkinetics.com/support/downloads/

rmware/ to check for the latest rmware version.

E You can nd more information on

Firmware Updater at www.colorkinetics.

com/support/downloads/rmware/

2. If a newer rmware image is available, click the link on the Firmware Updater page

to download the rmware le to an accessible location on your computer.

Download CK Firmware Updater

To update the firmware image on a CM-150 CA device, you must download and

install the CK Firmware Updater application on your computer.

1. Visit the Firmware Updater page at www.colorkinetics.com/support/downloads/

rmware/

2. Download the CK Firmware Updater installer.

3. Decompress the le to an accessible location on your computer and open it.

4. Run the installer, and follow the on-screen instructions.

Running a CM-150 CA Firmware Update (Ethernet network)

1. Connect a computer to the lighting network, and run CK Firmware Updater.

2. From the Interface Select list, select Ethernet Controllers.

3. From Device Select list, select CM-150 CA.

4. Click File Select, navigate to the folder to which you downloaded the rmware le

(.hex extension), and click Open.

CM-150 CA Product Guide 17

Page 18

5. Click Discover. CK Firmware Updater automatically discovers all CM-150 CA

devices connected to your lighting network.

6. Select a CM-150 CA device and click PROGRAM.

7. Repeat step 6 for each CM-150 CA device that you want to update.

Recovering from Firmware Update Errors

In rare instances, you may experience power or data loss or interruption during

the firmware update process. In such cases, a CM-150 CA device may receive an

incomplete or corrupt firmware image. You must successfully re-install the firmware

image to restore normal CM-150 CA operations.

• In the case of power loss or interruption, the CM-150 CA device retains its

assigned IP address, but you are temporarily unable to communicate with the

device using that address.

If this happens, enter the reserved IP address 10.1.250.250 in CK Firmware

Updater, and re-install the rmware image.

Once the rmware image is successfully installed, you can again communicate with

the CM-150 CA device using its assigned IP address.

• In the case of data loss or interruption, you must manually enter the device IP

address in CK Firmware Updater to re-install the rmware image.

If you don’t know the assigned IP address, you can cycle power, then use the

reserved IP address 10.1.250.250, as described above.

CM-150 CA Product Guide18

Page 19

Replacement fuses

CM-150 CA fuse types

Control module Fuse type

CM-150 CA, 24V 4 A, 250 V

CM-150 CA, 7.5/12V 5 A, 250 V

E Two replacement fuses are included

in the box with the CM-150 CA,

Surface Mount.

Replacing Fuses

CM-150 CA has two fuses, each of which protects a Flex strand from

excessive current. Two extra fuses are included in with all DIN rail mountable

CM-150 CA devices.

Surface Mount Fuse Replacement

1. Make sure that the device power is OFF.

2. Using a Phillips screwdriver, unscrew the six screws holding the cover in place.

Remove the device cover.

3. Pull the protective cover from the fuse you wish to replace.

4. Remove the fuse from its metal clips.

5.

Replace with a new fuse of the same type, as noted in the margin.

6. Replace the protective cover over the fuse and clips.

7. Replace the device cover and secure it with the six cover screws.

E Two replacement fuses are located

inside the housing of the CM-150 CA,

DIN Rail Mount.

DIN Rail Mount Fuse Replacement

1. Make sure that the device power is OFF.

2. Open the device cover.

3. Remove the fuse from its metal clips.

4.

Replace with a new fuse of the same type, as noted in the margin.

5. Close the device cover.

CM-150 CA Product Guide 19

Page 20

Copyright © 2017 Philips Lighting Holding B.V. All rights reserved.

Chromacore, Chromasic , CK, t he CK logo, Col or Kinetics, the Color

Kinetics logo, ColorBlast, ColorBlaze, ColorBurst , ColorGraze, ColorPlay,

ColorReach , iW Reach, eW Reach, DI Mand , EssentialWhite, EvenB alance,

eW, iColor, iColor Cove, I ntel liWhite, i W, iPlayer, Optibi n, and Powercore

are either registe red tr adem arks or trademarks of Philips Lighting Holding

B.V. in the United St ates and/or ot her countries. All othe r brand or product

names are tradema rks or registered trademarks of their respective owners.

Due to continuous improvements and innovations, sp ecif ications m ay change

without notice.

PUB-000163-00 R00 06 Jul 2017

Philips Color Kinetics

www.philips.com/colorkinetics

Loading...

Loading...