Page 1

Philips Medical Systems

INTRODUCTION AND

TECHNICAL DATA

INSTALLATION

1

2

BuckyDiagnost TH2 / TF

(MSB)

9890 010 06503

LEVEL 1

DOCUMENTATION

FAULT FINDING

REPLACEMENTS

PROGRAMMINGS

ADJUSTMENTS

ACCEPTANCE

3

4

5

6

7

This document and the information contained in it is strictly reserved for

current Philips Medical Systems (”Philips”) personnel, Philips licensed

representatives and Philips customers who have purchased a valid

service agreement for use by the customer’s designated in-house

service employee on equipment located at the customer’s designated

site. Use of this document by unauthorized persons is strictly prohibited.

This document must be returned to Philips when the user is no longer

licensed and in any event upon Philips’ first written request.

Printed in Hamburg, Germany

© 2005 Koni nklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

4512 984 29612 Vers. 00 1

regist er12_L1

SERVICE INFORMATION

DRAWINGS

SCHEMATIC DIAGRAMS

WIRING DIAGRAMS

8

Z1

Z2

Z3

Page 2

Proprietary Notice:

This document and the information contained in it is proprietary and

confidential information of Philips Medical Systems (”Philips”) and

may not be reproduced, copied in whole or in part, adapted, modified, disclosed to others, or disseminated without the prior written

permission of the Philips Legal Department. Use of this document

and the information contained in it is strictly reserved for current

Philips personnel and Philips customers who have a current and

valid license from Philips for use by the customer’s designated in-house service employee on equipment located at the customer’s

designated site. Use of this document by unauthorized persons is

strictly prohibited. Report violation of these requirements to the Philips Legal Department. This document must be returned to Philips

when the user is no longer licensed and in any event upon Philips’

first written request.

Warranty Disclaimer Language:

Philips provides this DOCUMENT without warranty of any kind, implied or expressed, including, but not limited to, the implied warranties of merchantability and fitness for a particular purpose.

Limitations of Liability Language:

Philips has taken care to ensure the accuracy of this document.

However, Philips assumes no liability for errors or omissions and reserves the right to make changes without further notice to any products herein to improve reliability, function, or design. Philips may

make improvements or changes in the product(s) or program(s) described in this document at any time.

CSIP Level 1

© 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

4512 984 29612 Vers. 002

regist er12_L1

Page 3

BuckyDiagnost TH2 / TF (MSB)

SERVICE MANUAL -- SUBSYSTEM

BuckyDiagnost TH2 / TF (MSB) Author: M. Bierstedt

Type No : 9890 010 06503

In case there are any questions concerning this manual,

please send this LOPAD via fax to 49/(0)40/5078 2481

File: BD_TH2_TF_MSB 29612Vers00

List of pages and drawings (LOPAD) Manual Order No: 4512 984 29612

released: 06/2005

1 ... 4

_________________________________

1--0.1 (05.0)

1--1...5 (05.0)

_________________________________

2--0.1 (05.0)

2--1...9 (05.0)

_________________________________

3--0.1 (05.0)

3--1...8 (05.0)

_________________________________

4--0.1 (05.0)

4--1...2 (05.0)

_________________________________

6--0.1 (05.0)

6--1...2 (05.0)

_________________________________

Z--0.1 (05.0)

Z--1.1 (04.0) A3 4512 982 0096.

Z--1.2 (04.0) A3 4512 982 0096.

2Z--10 (e/04.0) A3 4512 983 05451

________________________________

Z--0.2 (05.0)

Z1--1 (a/05.0) A3 DigiDiagn. TH

Z1--1.2 (05.0) A3

Z1--1.3 (05.0) A3

Z1--1.4 (05.0) A3

Z1--2 (05.0) A3

Z1--3 (d/05.0) A3 DigiDiagn. TH

Z1--5 (05.0) A3 DigiDiagn. TH

________________________________

Z2--1 (05.0) A3

Z2--3 (05.0) A3

Z2--4 (a/05.0) A3 DigiDiagn. TH

________________________________

Z3--1.1 (04.1) A4 DigiDiagn. TH

Z3--1.2 (05.0) A3 DigiDiagn. TH

Z3--2.1 (04.1) A4 DigiDiagn. TH

Z3--2.2 (04.1) A4 DigiDiagn. TH

Z3--3.1 (05.2) A3 DigiDiagn. VM

Z3--3.2 (05.0) A3 DigiDiagn. VM

Z3--4.1 (05.0) A3 BuckyDiag TH2

4512 984 29612 Vers. 00 3

BD_th2_TF_MSB_lopad

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 4

Blank page

BuckyDiagnost TH2 / TF (MSB)

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

4512 984 29612 Vers. 00CSIP Level 1 (05.0)4

BD_th2_TF_MSB_lopad

Page 5

BuckyDiagnost TH2 / TF (MSB)

INTRODUCTION AND TECHNICAL DATA

Contents 1--0.1.......................................................

1. Purpose of the manual 1--1.............................................

2. Items supplied 1--1....................................................

3. Compatibility 1--2.....................................................

4. Technical data 1--3....................................................

4.1. Mechanical data 1--3....................................................

4.2. Environmental data 1--3.................................................

4.3. Electrical data 1--3......................................................

4.4. Tools / Material required 1--4.............................................

4.5. Network data 1--4......................................................

4.6. Remote service data 1--4................................................

4.7. Transport data 1--4.....................................................

4.8. Pre--installation requirements 1--4........................................

4.9. Movements 1--4........................................................

4.10. Pre--installation data 1--4................................................

INTRODUCTION AND TECHNICAL DATA

5. Saftey information 1--4.................................................

6. Compliance information 1--5...........................................

7. Equipment identification and labelling 1--5..............................

8. Abbreviations and definitions 1--5......................................

9. Manual history 1--5....................................................

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 1--0.1

BD_th2_TF_MSB_1_inh

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 6

BuckyDiagnost TH2 / TF (MSB)

INTRODUCTION AND TECHNICAL DATA

1. Purpose of the manual

This documentation is valid for BuckyDiagnost TH2 / TF.

The table BuckyDiagnost TH2 / TF is part of the BuckyDiagnost family and can be installed together with the ceiling

suspension BuckyDiagnost CS, respectively the floor stand BuckyDiagnost FS and the X-ray generator OPTIMUS

RAD / OPTIMUS 30 single phase.

The table BuckyDiagnost TH2 is characterized by:

-- height-adjustable tablebase

-- floating tabletop

The table BuckyDiagnost TF characterized by:

-- fixed height tablebase

-- floating tabletop

2. Items supplied

BuckyDiagnost TH2

-- Table with floating tabletop, 750 mm x 2400 mm, Kevlar

-- Height sensor

-- Manual bucky unit, non-sensing

-- Grid for bucky unit

-- AMPLIMAT chamber

Options:

-- Manual bucky unit with format sensing

-- Automatic cassette loader (ACL4)

-- Tomo 2 device

-- Footswitch locking device

-- Second table control

-- Wider table top 850 mm x 2400 mm

-- Shorter table top 750 mm x 2000 mm

BuckyDiagnost TF

-- Table with floating tabletop, 750 mm x 2400 mm, Kevlar

-- Manual bucky unit, non-sensing

-- Grid for bucky unit

-- AMPLIMAT chamber

Options:

-- Manual bucky unit with format sensing

-- Automatic cassette loader (ACL4)

-- Tomo 2 device

-- Wider tabletop 850 mm x 2400 mm

-- Shorter tabletop 750 mm x 2000 mm

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 1--1

BD_th2_TF_MSB_1_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 7

BuckyDiagnost TH2 / TF MSB)

3. Compatibility

-- Bucky unit non format sensing 9848 500 2030x

-- Bucky unit with format sensing 9804 609 6030x

-- Bucky unit with format sensing 9848 500 2040x

-- Automatic cassette loader (ACL4) 9848 600 0202x

-- Tabletop standard 9890 010 0219x

-- Tabletop Aramid 9890 010 0220x

-- Tomo 2 device BuckyDiagnost TH 9848 600 0256x

-- System control BuckyDiagnost 9848 500 2270x

-- Height sensor for BuckyDiagnost TH 9848 500 2260x

-- Grid 36/8 FO 100 9860 834 9010x

-- Grid 36/8 FO 110 9896 010 2608x

-- Grid 36/8 FO 140 9896 010 2609x

-- Grid 36/12 FO 100 9860 836 9010x

-- Grid 36/12 FO 110 9896 010 2600x

-- Grid 36/12 FO 140 9896 010 2607x

-- Grid 36/12 FO 180 9896 010 2604x

-- Grid 40/12 FO 100 9860 846 9010x

-- Grid 40/12 FO 110 9860 846 901 1x

-- Amplimat chamber 9890 000 0161x

-- BuckyDiagnost CS 9890 xxx xxxxx

-- BuckyDiagnost FS 9890 xxx xxxxx

INTRODUCTION AND TECHNICAL DATA

Options:

-- Footswitch locking device 9890 010 02712

-- Second table control 9890 010 02731

Accessories:

-- Adjustable head clamp 9804 662 33009

-- Pair of handgrips 9804 662 43009

-- Ratchet compressor 9804 666 22009

-- Symm. ratchet compressor 9804 666 22109

-- Lateral cassette holder 9804 666 32009

-- Cassette holder, hor. beam 9804 668 10009

-- Pair of leg supports 9804 668 50009

-- Infusion bottle holder 9804 669 10009

-- Pair adj. positioners 9804 669 20009

-- Parking frame for accessories 9804 669 30009

Upgrades:

-- Upgrade f. bucky brake TH 9890 010 02881

-- Upgrade sec. table contr. TH 9890 010 02901

-- Upgrade footswitch look 9890 010 02912

-- Upgrade kit tracking 9890 010 80191

-- Upgrade kit high load 9890 010 81251

-- Upgrade kit key switch for bucky TH 4512 130 82901

CSIP Level 1 (05.0)1--2

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_1_BW

Page 8

BuckyDiagnost TH2 / TF (MSB)

INTRODUCTION AND TECHNICAL DATA

4. Technical data

4.1. Mechanical data

-- Mechanical dimensions BuckyDiagnost TH2 / TF see 2Z--1.1 and 2Z--1.2

4.2. Environmental data

Operation Stock / Transport

Temperature in °Celcius 10 / + 40 -- 25 / + 70

Temperature in °Celcius / Hour N/A N/A

Humidity in % (non-- condensing) 20 / 80 5/95

Gradient in % / hour N/A N/A

Vibrations / Shock range in Hz 5 -- 500 5 -- 500

Vibrations / Shock amplitude in mm N/A N/A

Vibrations / Shock acceleration in g 0.25 peak 1.0 peak

Shock acceleration in g 5 peak 30 peak

Shock pulse duration in msec 11 11

Air pressure in Hecto--pascal 700 / 1100 700 / 1100

Acoustic noise level : N / A

Air cooling : N / A

EMC : IEC 950

4.3. Electrical data

Equipment related:

Power required : max. 900 VA

Nominal voltages : 230 VAC

Supply configurations : 230 VAC

Voltage variation : N/A

Voltage impulse : N/A

Voltage surge : N/A

Voltage sag : N/A

Static frequency variation : 50 or 60 Hz ± 1Hz

Dynamic frequeny variation : N/A

Harmonic voltage distortion (single, total) : N/A

Neutral to ground voltage variation : N/A

Neutral to ground volate impulse : N/A

Nominal current : 6.0 A / 0.6 A (TH2 / TF)

Nominal frequency : 50 Hz / 60 Hz

Heat emission

standby : N/A

in operation : N/A

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 1--3

BD_th2_TF_MSB_1_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 9

BuckyDiagnost TH2 / TF MSB)

4.4. To o ls / Material required

Pre--installation

Delivered : N/A

To be ordered : N/A

To be arranged locally : -- TC 129, Tool kit, standard

-- Power tools (hammer drill with 12 mm carbide drill bits)

Installation

Delivered : Set of standard fixing material

Wooden table transport bars

To be ordered : N/A

To be arranged locally : -- TC 129, Tool kit, standard

-- Spirit level

-- TC 092, Notebook, service PC

-- TC 003, Service PC cable kit

-- TC 091, Multimeter

-- Service software X--Scope 1.4.2 or higher

-- Power tools (hammer drill with 12 mm carbid drill bits)

-- Measuring tape, 10 m

4.5. Network data

INTRODUCTION AND TECHNICAL DATA

N/A

4.6. Remote service data

N/A

4.7. Transport data

For information about transport data refer to the corresponding PRD.

4.8. Pre --installation requirements

-- Room layout (floor fixing) (Refer to PRD)

The preliminary planning work is restricted to the selection of a suitable room. The outfit of the room has to be

equipped with the conduits and pipes required and, in cases where the loading capacity of the bearing area

(380 kg on 2 x ≅ 500 cm

Where DIN specification are not applicable the minimum wall clearances should be determined in compliance with

the concerning national regulations.

2

) is insufficient, the floor preparation for the table.

4.9. Movements

-- Table height (see 2Z--1.1 and 2Z--1.2)

-- Tabletop (see 2Z--1.1 and 2Z--1.2)

4.10. Pre-installation data

For information about the pre--installation data refer to PRD ’Product planning’ BuckyDiagnost TH2 / TF.

5. Safety information

N/A

CSIP Level 1 (05.0)1--4

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_1_BW

Page 10

BuckyDiagnost TH2 / TF (MSB)

6. Compliance information

N/A

7. Equipment id entification an d labellin g

N/A

8. Abbreviations an d definitio n s

Abbreviation Explanation

CS Ceiling Suspension

FS Floor Stand

MSB Mini System Bus

PMS Philips Medical Systems

POST Power-On Self Test

PRD Product Reference Data

SID Source Image Distance

INTRODUCTION AND TECHNICAL DATA

TC Tool Code

TF Table Fix

TH Table Height adjustable

VE Vertical

VR Vertical Radiography

VT Vertical Tiltable

9. Manual history

Date Ve rsion Name Reason of changes

01.02.2005 V1 REV AA M. Bierstedt Introduction of TH2 (MSB)

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 1--5

BD_th2_TF_MSB_1_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 11

BuckyDiagnost TH2 / TF (MSB)

Contents 2--0.1............................................................

1. Unpack, transport, mount 2--1.............................................

1.1. Box dimensions 2--1.......................................................

1.2. Unpack 2--2..............................................................

2. Floor fixation of BuckyDiagnost TH2/TF 2--3...............................

3. Height adjustment for installation (TH2) 2--3................................

4. Alignment for BuckyDiagnost TH2 /TF 2 --3.................................

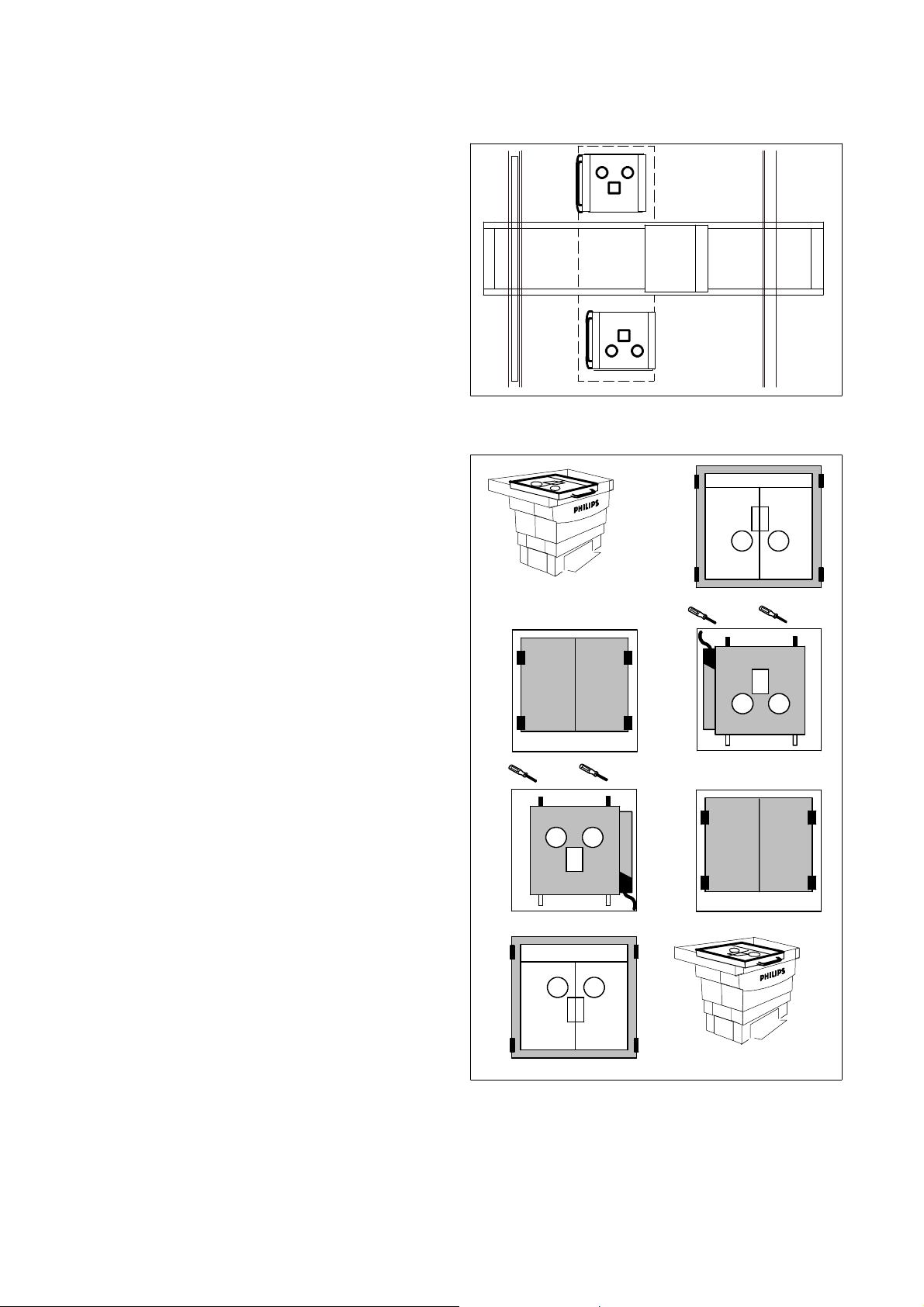

5. Change position of the AMPLIMAT chamber from left to right side 2--4.......

6. Electrical connection 2--5.................................................

6.1. Connection location at the BuckyDiagnost TH2 / TF 2--5........................

7. Installation of the table covers 2--6........................................

INSTALLATION

Installation

8. Installation of the tabletop for BuckyDiagnost TH2/TF 2--7..................

9. Installation of the table end covers 2--8....................................

10. Final work 2--8...........................................................

10.1. Final work for BuckyDiagnost TH2 2--8.......................................

10.2. Final work for BuckyDiagnost TF 2--9........................................

11. Labels 2--9...............................................................

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--0.1

BD_th2_TF_MSB_2_INH

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 12

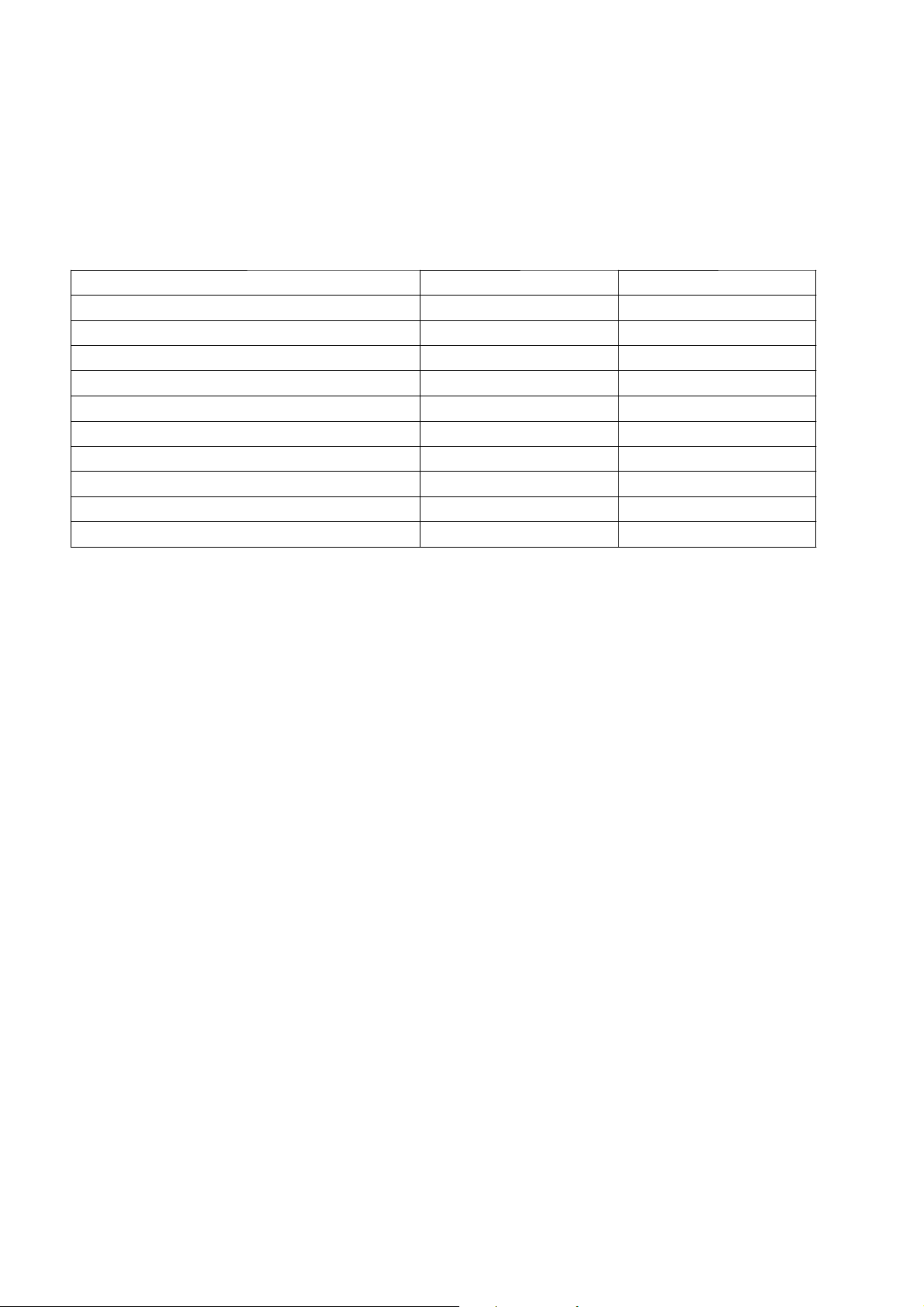

BuckyDiagnost TH2 / TF (MSB)

1. Unpack, transport, mount

1.1. Box dimensions

INSTALLATION

Crate / Box

Tablebase

TH2

Dimension (mm)

Weight (Newton)

(10 N = 1 kg)

Length Width Height

Packed 1350 950 1000 2500

Installed Refer to mechanical dimension drawings 2040

Crate / Box

Tablebase

TH2 incl. tomo

Dimension (mm)

Weight (Newton)

(10 N = 1 kg)

Length Width Height

Packed 1350 950 1000 2620

Installed Refer to mechanical dimension drawings 2160

Crate / Box

Tablebase

TF

Dimension (mm)

Weight (Newton)

(10 N = 1 kg)

Length Width Height

Packed 1360 980 1120 max.1740

Installed Refer to mechanical dimension drawings max. 1300

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--1

BD_th2_TF_MSB_2_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 13

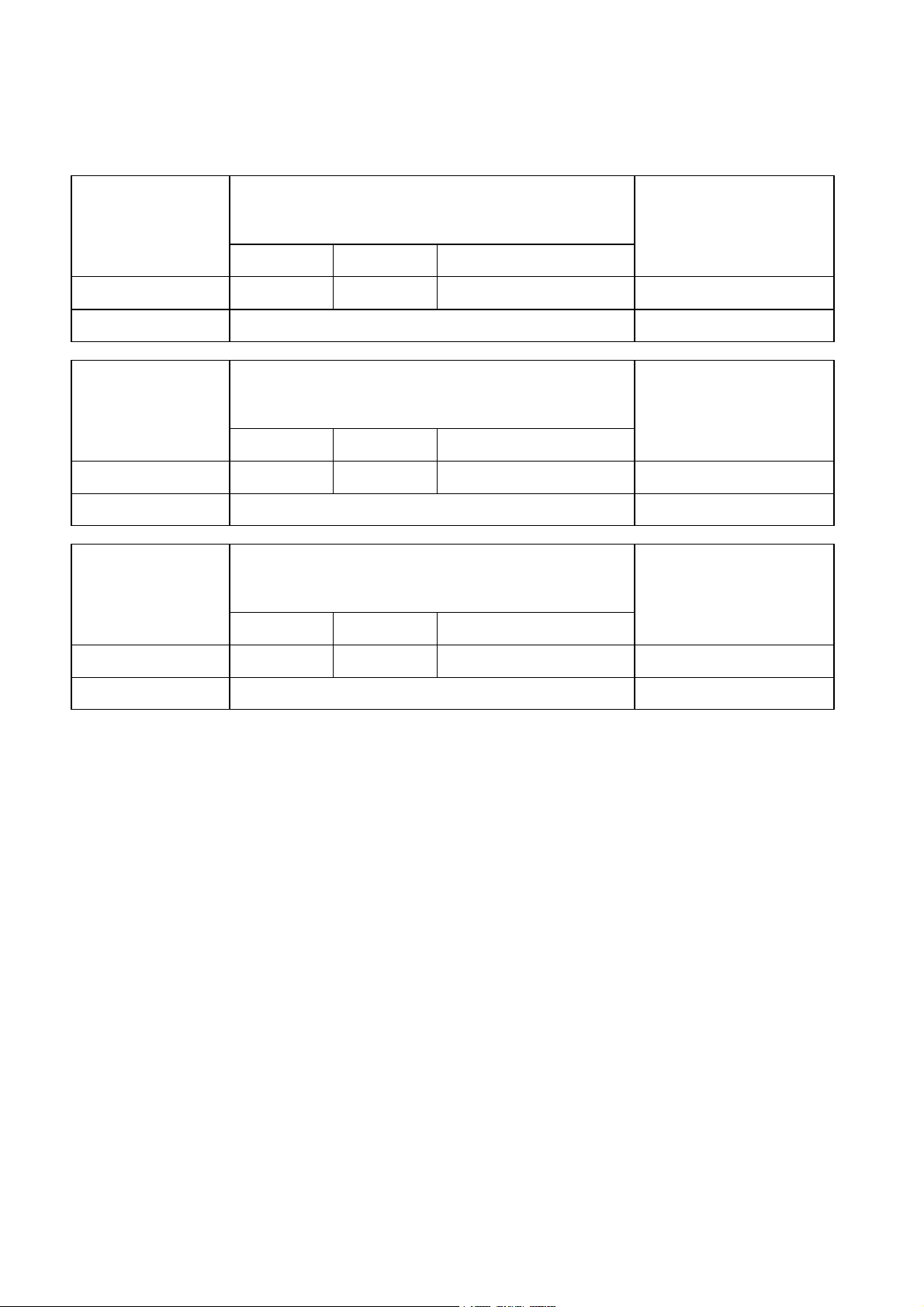

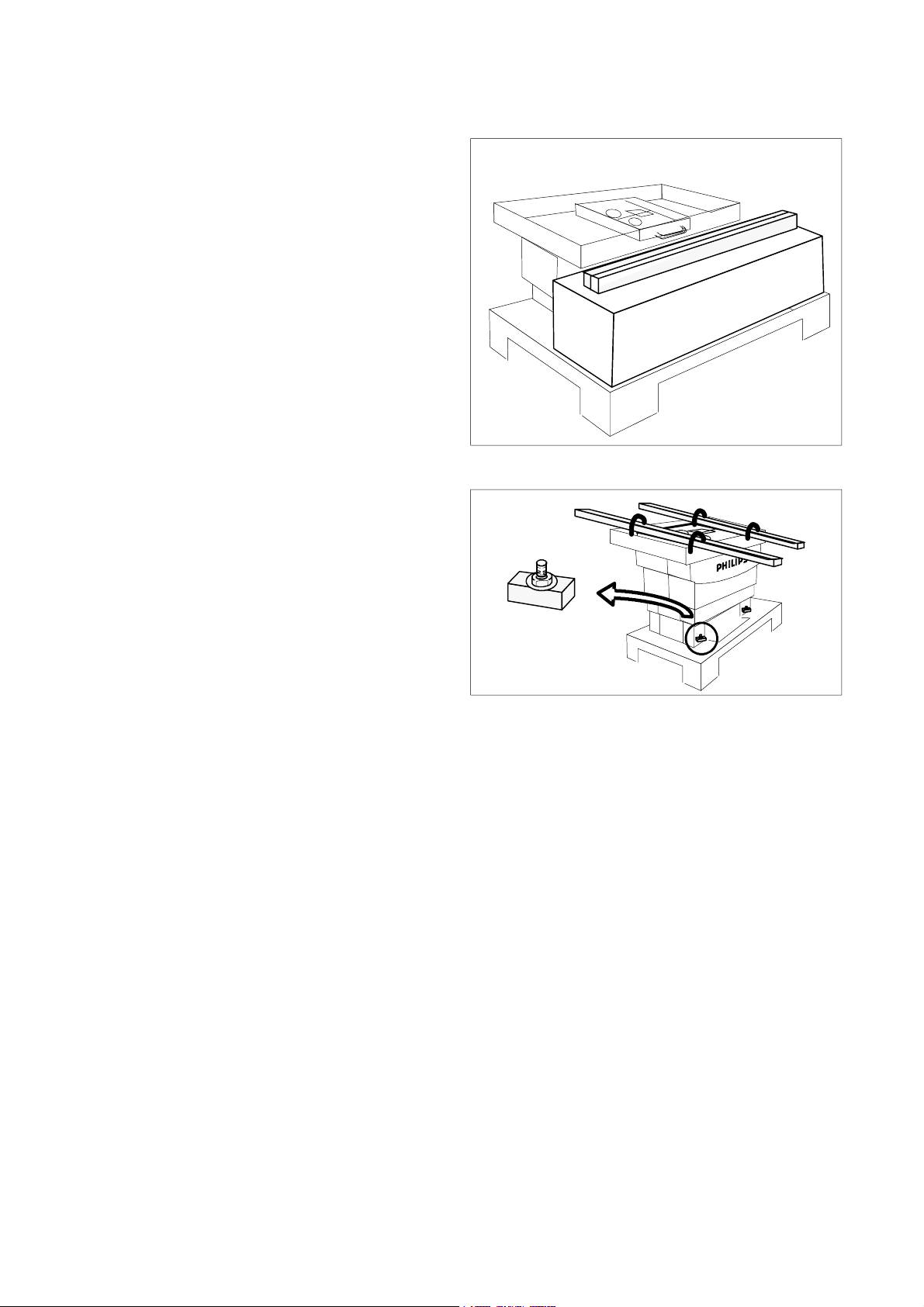

1.2. Unpack

S Remove the boxes and the wooden bars from the

pallet. The boxes include the table covers.

BuckyDiagnost TH2 / TF (MSB)INSTALLATION

S Loosen the nuts 4x of the screwings at the front

and rear side.

-- Remove the nuts.

-- Remove the washers.

-- Remove the fixing blocks.

S Insert the wooden bars into the loops.

S Lift up the table base with four persons and remove

it from the pallet.

4x

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)CSIP Level 1 (05.0)2--2

BD_th2_TF_MSB_2_BW

Page 14

BuckyDiagnost TH2 / TF (MSB)

2. Floor fixation of BuckyDiagnost TH2/TF

Determine the working position of the table.

Note

Refer to PRD room layout or local planning data and use

the drilling template from the System Manual

Installation.

S Mark the four fixing points at the floor.

S Drill ∅12 mm holes in the middle of the marked

area about 100 mm deep.

S Insert the four anchor dowels in the holes.

S Fix the anchor dowels.

S Lift the table and place it in its working position.

3. Height adjustment for installation (TH2)

INSTALLATION

S Connect cable MEX from table to the mains of

220 VAC to move the table upwards into a better

working position.

Also connect the protection lead (green/yellow).

S Press foot switch to move the table upwards.

S Press foot switch to move the table

downwards.

Warning!

If the table does not move downwards,

press on the tabletop with 20kp. Do not

adjust the collision switch! The table

automatically stops at the middle

position.

S Disconnect MEX from mains.

4. Alignment for BuckyDiagnost TH2 /TF

S Level the table in both directions by using a spirit

level or by using the laser alignment tool, use the

spacer, if necessary (1).

4x

S Insert the fixing block (2, 4x), the special washer

and fasten the nut with a spanner.

2

1

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--3

BD_th2_TF_MSB_2_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 15

BuckyDiagnost TH2 / TF (MSB)INSTALLATION

5. Change position of the AMPLIMAT chamber from left to right side

A manipulation of the connector at the AMPLIMAT

chamber is necessary, if the position of the

BuckyDiagnost TH2 / TF must be changed from left

(1) to right (2) side.

S Remove the tabletop by removing the four

screws (1).

S Mark the center line of the tabletop to the frame

(both sides).

S Remove the tabletop.

1

2

Left hand

version

Right hand

version

1

Left hand

version

1.5mm

S Dismantle the anti--scatter grid by unscrewing the

four metal holders (2).

S Remove the anti--scatter grid.

S Dismantle the AMPLIMAT chamber by loosening

the two grub screws (3).

S The wire assignment on the connector PH X1 must

be interchanged, the violett wire on X1:1 with the

black wire on X1:3.

S Place the measuring chamber at the new

position (4).

S Tighten the measuring chamber with the two grub

screws.

S Re--install the anti--scatter grid (5).

S Tighten the anti--scatter grid.

PH X1

2

4

3

5

6

Right hand

version

S Re--install the table cover at the new position (6).

S Tighten the table cover.

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)CSIP Level 1 (05.0)2--4

BD_th2_TF_MSB_2_BW

Page 16

BuckyDiagnost TH2 / TF (MSB)

6. Electrical connection

The BuckyDiagnost TH2/TF is supplied with sets of

cables including plugs connected at one side.

S Install the cables and connect them as specified in

the corresponding SMI, Section 8, ’Cabling and

earthing’, connection diagrams.

6.1. Connection location at the

BuckyDiagnost TH2 / TF (MSB)

Power supply 230 VAC SX50 ... SX56

Power supply 24 ... 30 VDC SX40 ... SX45

Power supply TH SN1

Power supply ACL4 SN3

Bucky controller SZ1

CAN bus SZ1X2

Signal bus SZ1X1

Connection to PC ( X-Scope ) X20

Amplimat to generator SX60

Tomo CAN bus SX90

Second table control, option SAX10

Bucky brake, option SAX100

Motor amplifier board SZ2

Tomo drive and control SAN1

INSTALLATION

X2

X1

SZ1

bucky controller

X20

to service PC

Rear side

SAX10

SX50 ... SX56

SF1

SL1

SN1

SN2

VA

ACL4

4

SX40

...

SX45

SZ1

SAX100

SAN1

SX90

SX60

Front side

SZ2

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--5

BD_th2_TF_MSB_2_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 17

7. Installation of the tab le covers

S Raise the table to its uppermost position (only

TH2). Press foot switch to move the table

upwards.

S Lift up the foot switch assembly (1).

S Fit the lower front cover (2) into pins and screw it

on.

S Connect the earth wire SX72, SX73 to the lower

front cover.

S Fit the lower rear cover in the pins and screw it on.

S Connect the earth wire SX74 to the lower rear

cover.

BuckyDiagnost TH2 / TF (MSB)INSTALLATION

2

1

S Insert the middle side covers at both sides of the

table.

S Install both middle covers at the front and rear side.

The covers are identical.

S Insert the screws. Do not fasten the screws

completely.

S Install the upper covers at the front and the rear

side. The covers are identical. Do not fasten the

screws completely .

S Adjust the covers.

S Fasten all screws.

S Move the table up and down and check whether the

covers slide without any abrasion and noise

(only TH2).

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)CSIP Level 1 (05.0)2--6

BD_th2_TF_MSB_2_BW

Page 18

BuckyDiagnost TH2 / TF (MSB)

8. Installation of the tabletop for BuckyDiagnost TH2/TF

S Remove the tabletop from the transport box.

S Check whether the ball bearings are adjusted

correctly to the tabletop. If not, remove the tabletop

and adjust the eccentric bearings.

Installation of the end stops:

S Remove the parabolic buffer from the stop angle to

install the stop assembly.

S Screw the stop angle to the table rail (respect the

“right direction”).

S Screw the parabolic buffer to the stop angle.

INSTALLATION

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--7

BD_th2_TF_MSB_2_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 19

9. Installation of the tab le end covers

The cover profile prevents injury by sharp edges.

S Install (4x) new end covers to the four tabletop

edges.

S Check the level of the table in both directions with a

spirit level.

-- If necessary, use linings.

10. Final work

10.1. Final work for BuckyDiagnost TH2

S Check all table functions:

-- table movement upwards and downwards

switched by the foot switches

-- table movement upwards and downwards

switched by the second table control

(optional)

-- function of longitudinal and transverse

brakes.

BuckyDiagnost TH2 / TF (MSB)INSTALLATION

200 N

S Check the collision switch.

S Move the tabletop downwards.

Press foot switch to move the table

downwards.

If the table does not move downwards

press on the tabletop with 200 N.

Do not adjust the collision switch

(SS10)!

This switch is factory adjusted.

S Seal the base of the table with silicon.

S Clean all covers with a mild cleaner like soapsuds.

S Move the table to the ”preferred table height

position” (about 750 mm), the table stops

automatically.

S Place the labels so that the dotted line is in line with

lower edge of the mid cover.

Seal

750 mm

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)CSIP Level 1 (05.0)2--8

BD_th2_TF_MSB_2_BW

Page 20

BuckyDiagnost TH2 / TF (MSB)

10.2. Final work for BuckyDiagnost TF

S Check the function of longitudinal and transverse

brakes.

S Seal the base of the table with silicon.

S Clean all covers with a mild cleaner like soapsuds.

11. Labels

S Check the labeling (see 2Z--10).

INSTALLATION

J

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 2--9

BD_th2_TF_MSB_2_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 21

BuckyDiagnost TH2 / TF (MSB)

Contents 3--0.1.......................................................

1. Faultfinding guide 3--1.................................................

2. Power supply of BuckyDiagnost TH2 / TF with ACL4 and tomo 3--2.......

2.1. Location of electrical Components 3--2....................................

3. Power-ON sequence and stand --by 3--3.................................

3.1. BuckyDiagnost TH2/TF selftest 3--3.......................................

3.2. Tomo unit (option) selftest 3--4...........................................

4. Table movement of BuckyDiagnost TH2 3--5.............................

4.1. Table switches 3--5.....................................................

4.3. Collision switch 3--6.....................................................

5. Tabletop movement 3--7...............................................

5.1. Floating table 3--7......................................................

5.2. Table carriage brakes 3--7...............................................

6. Height sensing 3--8....................................................

6.1. Table height sensor 3--8.................................................

FAULTFINDING

FAULTFINDING

TEXT

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0)

BD_th2_TF_MSB_3_inh

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

3--0.1

Page 22

FAULTFINDING

1. Faultfinding guide

BuckyDiagnost TH2 / TF (MSB)

Convention

Switch is closed = ON

Switch is open = OFF

LED / lamp illuminated = ON

LED / lamp not illuminated = OFF

YES

Switching--ON possible ?

See

Power Supply

See

Power--ON Sequence and Stand--by

Table movements possible ?

YES

See

Table Movement

Tabletop movements possible ?

YES

See

Tabletop Movement

NO

NO

NO

Bucky carriage movement possible ?

YES

See

Tomo Unit (option) Selftest

Table Height Sensing possible ?

YES

See

Height Sensing

Tomography Run possible ?

YES

See manual

System Faultfinding Guide

Tomography Run

NO

NO

NO

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 3--1

BD_th2_TF_MSB_3_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 23

BuckyDiagnost TH2 / TF (MSB)FAULTFINDING

2. Power supply of BuckyDiagnost TH2 / TF with ACL4 and tomo

Mains power of 220 VAC for

table via F1, L1 to X50 ...X56

table lift motor SNV

PCB power supply SN1 for

table control SZ2

bucky carriage, magnetic brake VAC

bucky controller SZ1

table tomo drive & control SAN1

ACL4

PCB power supply for SN2 for

automatic cassette loader ACL4

Power supply

230 VAC

F1/L1

X56

table lift motor

X50

X51

X52

X53

X54

X55

S

230 VAC

for

230 VAC

230 VAC

SZ2

X6

X14:2 X14:1

GND

SN1

26 VDC

GND(--)

26VDC(+)

VAC

GND 26 VDC

X6:2 X6:1

SZ1

SAN1

SN2

X1

X2:2 X2:1

GND

(--)

24 VDC

(+)

X3:2 X3:1

ACL4

X5

X1M X2

X100

M

SNV

X43

X42

X44

X41

X40

2.1. Location of electrical components

ACL4

SAX10

VA

4

SN1

SX50 ... SX56

Rear side

SF1

SL1

SN2

SX40

...

SX45

SZ1

SAX100

SAN1

SX60

Front side

SZ2

CSIP Level 1 (05.0)3--2

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_3_BW

Page 24

FAULTFINDING

3. Power-ON sequence and stand-by

The BuckyDiagnost system runs through a selftest after

power--ON.

S Switch ON the system.

3.1. BuckyDiagnost TH2/TF selftest

S Raise the table to its uppermost position.

Press foot switch to move the table

upwards. The table stops automatically

(only TH2).

S Unscrew the service cover at the rear side, open it

for inspection.

BuckyDiagnost TH2 / TF (MSB)

S Press reset switch (1) to re-start the bucky

controller.

The red LED (2) (= bucky controller is not ready) is

illuminated until the selftest is ended successful.

The yellow LED (3) (= CAN bus is working) flashes after

successful selftest.

The green LED (4) (= bucky controller is ready) is

illuminated after successful selftest.

-- If the board SZ1 fails, replace it. Configure the

new board via program X-Scope.

SZ1 bucky

controller

2

34

1

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 3--3

BD_th2_TF_MSB_3_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 25

3.2. Tomo unit ( o p tio n) selftest

During the initialization phase the bucky carriage moves

to its tomo center position. Afterwards the bucky

carriage moves to one side then to the other side and

stops in the middle position.

If the tomo unit selftest fails:

S Check brake release switch (1) and magnetic

brake (2) on the bucky carriage.

The brake release switch is currently closed and is

mechanically opened via the grip (3).

brake

release

SACS

BuckyDiagnost TH2 / TF (MSB)FAULTFINDING

1

2

3

X8

carriage

brake

SA

VAC

SA X100

X10

SAN1

CSIP Level 1 (05.0)3--4

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_3_BW

Page 26

FAULTFINDING

4. Table movement of BuckyDiagnost TH2

4.1. Table switches

S Check the function of the footswitch lock SAE.

Pressed switch = footswitches without function.

S Move the tabletop into the working position via

footswitches SC S6, S5 or via the optional second

table control SCH.

BuckyDiagnost TH2 / TF (MSB)

CH

AE

If the tabletop does not move

upwards

S Check closed 900 mm switch SNVS1 at

SZ2 X5:6/7 (24VDC) via 750 mm switch

SNVS3 at SZ2 X5:3/4.

S Check footswitch S5 for upwards movement at

SZ2 X4.

S Check optional handswitch SCH for upwards

movement at

SZ2 X9.

If the tabletop does not move

downwards

S Check closed safety switch SS10 at

SZ2 X7:2/1 (24 VDC) via closed 500 mm switch

SNVS2 at SZ2 X5:8/9 via 750 mm switch

SNVS3 at SZ2 X5:3/4.

S Check footswitch S6 for downwards movement at

SZ2 X4.

S Check optional handswitch SCH for downwards

movement at SZ2 X9.

S10

S

NVS1

NVS3

Z2

C

S

S6 S5

C

NVS2

NV

S3

Front side

S2 S1

CH

1

1

X9

1

1

X7

Z2

X4

X5

S10

If the tabletop does not move upwards or

S Check the relay K1 or K2 on board SZ2. One of the

two relays must be activated by pressing either the

footswitch or the optional handswitch.

The relay contact supplies the voltage of 230 VAC to the

motor SNV via SZ2 X3:1/:2/:3.

downwards

K7 K2

M

X3

1

K1

K3

3

Z2

X6

S

3

1

X50

230 VAC

K1 Table upwards relay

K2 Table downwards relay

K3 Start-up relay for starting capacitor.

Relay is activated over 1 s only in the upwards

starting phase.

1

230 VAC

3

SZ2X6 SNV

K1

K2

K7

K3

X3

M

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 3--5

BD_th2_TF_MSB_3_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 27

BuckyDiagnost TH2 / TF (MSB)FAULTFINDING

During movement the tabletop stops in the middle

position of the table height via the 750 mm

switch SNV S3 on the table lift motor.

S Seealsodrawing4Z--2.

4.2. Collision switch

S Check the force of the table movement.

-- Pull up the tabletop with a spring balance.

The safety switch SS10 must open if a force

of 160 ... 240 N is reached. Otherwise:

-- Adjust the spring tension at the tension screw

with a 13 mm spanner

clockwise = force of collision

decreases

counterclockwise = force of collision

increases

S

C

Z2

S6

X4

0VDC

1 ... 2 mm

Clearence of retainer

W1

+24 VDC

K2

K1

K3

K7

160 ... 240 N

K4 X5

S10

X7

X5

S3

750 mm

S2

500 mm

S1

900 mm

NV

CSIP Level 1 (05.0)3--6

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_3_BW

Page 28

FAULTFINDING

5. Tabletop movement

5.1. Floating table

S Press the footswitch SC S3. The tabletop must be

floatable. If not, check items:

-- footswitch lock SAE

(must not be active = pressed)

-- brakes for longitudinal and transverse direction

-- footswitch for tabletop floating

S Use the second table control to check functions as

described above, if possible.

5.2. Table carriage brakes

S Check the function of the brakes.

BuckyDiagnost TH2 / TF (MSB)

AE

S

Z2

C

S3S3

Front side

S Check the connection to SZ2 X10. Voltage of +24 V

is delivered via the footswitch S3 or via the optional

second table control switch.

If the footswitches are locked via the footswitch

lock, functions of tabletop movements via the

optional second table control are always possible.

SD

S

SA

C

S3

CH

X9

X8

1

1

X10

SA SD SAE

SA

SD

S4

1

Z2

X4

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 3--7

BD_th2_TF_MSB_3_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 29

6. Height sensing

6.1. Table height sensor

S SeealsodrawingZ1-3.

The height sensor operates as a current source.

The range of the current value is 5 mA (table is in lowest

position) up to 18 mA (table is in uppermost position).

BuckyDiagnost TH2 / TF (MSB)FAULTFINDING

S

U

The current value can be shown :

S Connect a service PC to SZ1 X20.

S Call up program VT100 for monitoring.

S Type in:↵

-- superuser↵

-- set service output_errors_to_vt100

1↵

Every action is shown on the PC screen, also the current

depending on the topical table height.

-- show analogue↵

The analogue inputs is displayed on the PC screen.

-- show service sid↵

The SID parameters are displayed on the PC screen.

S Check the height sensor SU at SZ1 X4, measure

the current.

S

U

24 VDC

1

6

A

I = 5 ... 18 mA

U

X4

Rear

side

Z1

D1

X4

Z1

24 VDC

1

6

analog

S

-- I f I = 0 m A ,

check the voltage at X4:1 or find the reason

in the cable.

-- I f I = 2 0 m A ,

check the cable or replace the height sensor.

X20

24 V

GND

5V

Z1

J

CSIP Level 1 (05.0)3--8

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_3_BW

Page 30

BuckyDiagnost TH2 / TF (MSB)

Contents 4--0.1............................................................

1. Replacement of the table lift motor at BuckyDiagnost TH2 4--1..............

1.1. Manpower 4--1............................................................

1.2. Replacement 4--1.........................................................

1.3. Final work 4--1............................................................

2. Replacement of the height sensor 4--2.....................................

REPLACEMENTS

REPLACEMENTS

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 4--0.1

BD_th2_TF_4_050_inh

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 31

REPLACEMENTS

BuckyDiagnost TH2 / TF (MSB)

1. Replacement of the table lift motor at BuckyDiagnost TH2

1.1. Manpower

1 service engineer, approximately 2 hours.

A second person must be present on request

(e.g. to insert the safety rod).

1.2. Replacement

S Switch OFF the system.

S Remove the table covers.

S Disconnect the motor unit from the table controller

board SZ2 on X3 and X5.

If the table is in the lowest position:

S Screw the bolt (1) against the frame and lift the

frame about 1 cm so that access to the cylindrical

pin (2) is possible.

S Remove the retaining ring on the pin (2).

S Remove the cylindrical pin.

S Lift up the table assembly to insert the safety rod

through the holes (3) at the rear side and the front

side.

(The safety rod is placed near the safety label on

the frame.)

2h

Rear side

Replacement of the

table lift motor

Handing over

Z2

S

2

1

on request

X5

X3

3

S Remove the retaining ring on the cylindrical pin (4).

S Remove the cylindrical pin.

S Replace the table lift motor.

S Re-assemble the table.

S Park the safety rod.

1.3. Final work

S Test all movements of the table.

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0)

BD_th2_TF_MSB_4

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Front side

4

SZ2

4--1

Page 32

2. Replacement of the height sensor

S Raise the bucky tabletop to its uppermost position.

S Loosen the two screws on the housing.

S Replace the height sensor unit.

S Assemble in reverse order.

BuckyDiagnost TH2 / TF (MSB)Replacements

U

J

CSIP Level 1 (05.0)4--2

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

BuckyDiagnost TH2 / TF (MSB)

BD_th2_TF_MSB_4

Page 33

BuckyDiagnost TH2 / TF (MSB)

Contents 6--0.1............................................................

1. Delay time check by test exposures 6--1...................................

1.1. Cassette loader INALFA 6--1................................................

1.2. Cassette loader ACL4 6--1..................................................

2. Tomography (option) 6--2.................................................

2.1. Adjustment of tomo force 6--2...............................................

2.2. Tomo exposure 6--2........................................................

ADJUSTMENTS

ADJUSTMENTS

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0)

BD_th2_TF_MSB_6_inh

© 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

6--0.1

Page 34

BuckyDiagnost TH2 / TF (MSB)

1. Delay time check by test exposu res

To adjust the exposure delay time preparatory work is

necessary.

S Remove the tabletop to have free access to the

anti-scatter grid of the bucky table .

S Check the delay time with a test exposure.

-- Lay the lead plate (1) on the grid (2), fix it with a

piece of adhesive tape.

-- Make two exposures (see table) on the same

film.

The exposure shows a spot and a bar (3).

ADJUSTMENTS

2

1

anti-scatter grid motion

after exposure release

Exposure Exposure

time

[sec]

1 0.5 60 15 0.6

2 0.02 125 25 0.6

[kV] [mA] Focus

S Measure the distance as shown in (3).

1.1. Cassette loader INALFA

S See manual of INALFA.

1.2. Cassette loader ACL4

S See manual of ACL4.

[mm]

3

8 ... 10 mm

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) 6--1

BD_th2_TF_MSB_6_BW

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 35

2. Tomography (option)

2.1. Adjustment of tomo force

S Move the tabletop to its height center position.

If the tomography function is established, the

bucky unit centers itself after power--ON.

BuckyDiagnost TH2 / TF (MSB)ADJUSTMENTS

1

S Switch OFF the system.

S Insert a spring scale in the handle (1).

-- Pull with the spring balance.

The value of force is <10 N.

S Switch ON the system.

S Insert a spring scale in the handle (1).

-- Pull with the spring balance.

The value of force is <5 N for a system with

servo.

As necessary, loosen or tighten the belt via both

screws (2) by loosening the nut (3) after removing the

tabletop.

S Check the tomo force as described above.

If the belt oscillates it must be tensioned.

The tray servo assistance can be defined, see

documentation of program X-Scope, Tomography

configuration, ’Tray servo assistance’.

<5 N = System without belt

<10 N = System with belt

<5 N = System ON & Servo

3

2

2.2. Tomo exposure

For programming tomo run direction see manual

X-Scope.

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

J

BuckyDiagnost TH2 / TF (MSB)CSIP Level 1 (05.0)6--2

BD_th2_TF_MSB_6_BW

Page 36

Drawings

BuckyDiagnost TH2, Mechanical dimensions Z--1.1

BuckyDiagnost TF, Mechanical dimensions Z--1.2

Labelling 2Z--10

Section ZBuckyDiagnost TH2 / TF (MSB)

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) Z--0.1

BD_z01

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 37

Page 38

Page 39

Bucky unit 2 digital

Y

Table height adjustable

W

X

Logo

Table top

Address

Barcode

UL/CSA

Type No.

Logo

Bucky unit 2 digital

Z

Logo

Type No.

UL/CSA

Barcode

Table top

Logo

Type No.

IEC 60601-1

UL / CSA

CE

Address

Electr. data

IEC 60601-2-32

Type No.

FDA

Y

X

Z

PHILIPS

A1/A3 04-10-05 Schr.

W+Z

BuckyDiagnost TH (BUF)

Labelling

4512 983 05451

C Philips Medical Systems

(e/04.0)

2Z-10

Page 40

Schematic diagrams

Wiring diagrams

BuckyDiagnost TH2/TF MSB Survey of components Z1--1

BuckyDiagnost TH2/TF (MSB) with Inalfa sensing Internal connection diagram Z1--1.2

BuckyDiagnost TH2/TF (MSB) with ACL4 Internal connection diagram Z1--1.3

BuckyDiagnost TH2/TF (MSB) with Inalfa non sensing Internal connection diagram Z1--1.4

BuckyDiagnost TH2/TF (MSB) Power supply Z1--2

BuckyDiagnost TH2/TF (MSB) Safety circuit and brakes Z1--3

BuckyDiagnost TH2/TF (MSB) CAN and MSB bus Z1--5

BuckyDiagnost TH2/TF (MSB) Wiring diagram Z2--1

BuckyDiagnost TH2/TF (MSB) Earthing diagram Z2--3

Tomo drive control survey of components Z2--4

Section ZBuckyDiagnost TH2 / TF (MSB)

IIFmainTH Z3--1.1

IIFmainTH Z3--1.2

AI IF carriage Z3--2.1

AI IF carriage Z3--2.2

Z1 Bucky controller (4512 108 07508) Z3--3.1

Z1 Bucky controller (4512 108 07508) Z3--3.2

SZ1 Table control Z3--4.1

BuckyDiagnost TH2 / TF (MSB) CSIP Level 1 (05.0) Z--0.2

BD_z02

E 2005 Koninklijke Philips Electronics N.V.

ALL RIGHTS RESERVED

Page 41

Top view

A - B

A

C

SAE

SA SAVA

PHILIPS

SC

SNVS1..3

SNVM

B

D

SAPCB

SACH

SA

SACH

SAE

SAI

SAN

SAS1

SAVA

SAY1+2

SAY20+21

SAY31

SC

SF1

SI

SL1

SNVM

SNVS1...3

SN1

SN3

SU

SZ1

SZ2

A3 05-01-25 Schr.

=

Transverse carriage

=

Second table control (option)

=

Footswitch lock

=

IF Carriage board

=

Tomo control (option)

=

Switch Bucky frame brake

=

Bucky unit

=

Logitudinal brakes

=

Transversal brakes

=

Bucky frame brake

=

Footswitch

=

Motor protection switch

=

IF Main board TH

=

Mains filter 1

=

Table height motor

=

Motor control switches

=

Power supply 20,4VAC

=

Power supply 24VAC (ACL4 only)

=

Height Poti

=

Bucky controller

=

Table control

for DigitalDiagnost TH (BUF) only

SAPCB

SL2

SN2

STSN1

STSN2

=

Pixium control board

=

Mains filter 2

=

Power supply 24VDC

=

Power supply 9.26 V AC

=

Power supply 9.26 V AC

STSN1

SU

SAY1

SAY21

SZ1 SI

STSN2

SN3

SZ2

SAI

SN2

SAS1

Top view

SN1

Front

Front

C - D

SL2

SAN

SAY31

SF1

DigitalDiagnost TH (BUF)

BuckyDiagnost TH2 (MSB)

SL1

SC

Survey of components

SAY20

SNVM

SNVS1..3

SAY2

DigitalDiagnost TH

C Philips Medical Systems

Z1-1(a/05.0)

Page 42

EZX21

Generator

X60

Intermediate

Connector

Transversal Carriage

A

S1

Switch

Y31

Brake f. Bucky

Frame

E

Encoder

X5

Motor

X2

M

X1

Power

N1

(Option)

CAN in

X3

Tomo

X8

X10

X1

Amplimat Chamber

PH

Long. Brake

left

Transv. Brake

left

Long. Brake

right

Y20Y2Y21Y1

Transv. Brake

right

CH Handswitch

(Option)

E

(Option)

Footswitch

Lock

VA

Bucky Unit (Inalfa)

Signal-Bus

CAN out

EZX23

EZX43

I

230 VAC in

20,4 VAC out

N1 Power Supply

20,4VAC

X1X6

IF Carriage

X51

X39

YX21

Connector

X3

X2

X52

X7

X5

X4

X1

MSB / Power

I IF Main TH

X4

X54

X41

X50

X300

X55

X40

X3

X2

X90

X5

only for BuckyDiagnost VS

Release

X1

Signal-Bus

X1

CAN in

X2

Grid Control

X13

CAN out

X3

26Vdc in

X6

sensing BWS

release BWS/

grid control

X12 X10 X11 X5

Sensing

position BWS

X100

X2

gender

changer

X9

Sensing

Z1 Bucky Controller

remoteX8safety Tomo

tracking BWS

X7

X4

X20

YX20

Connector

MEXT1/T2/N

Generator

BuckyDiagnost VS

BuckyDiagnost VS

BuckyDiagnost

VE/VT

VPIX10

VPIX7

VPX1

VP1X2

VP1X3

VP1X5

A1/A3 05-01-26 Schr.

BuckyDiagnost TH2 TF

C Philips Medical Systems

Power Supply Unit

F1

L

Mains Switch

T

AE

Line

L1

Load

Mains Filter

F

X6

X14

26VDC in

230VAC in

Safety Circle

X7 X4 X1

S10

Safety Switch

Footswitch

C Footswitch

Z2Table Control

C1/C2

Start-/Operation-

Capacitor

Safety Tomo out

X11

X3

X5

M

Motor

S1 (Height switch upper position)

X13

X12

Remote

light tr.

Safety

Brakes

X10

Handswitch

X9

Footswitch Lock

X8

NV Table Drive

Z1X20.1

UBN2X3 / UAX1 / UADX3

Ceiling Suspension

UL1

Ceiling Suspension

U

Tomo in

SID-Poti

Service

Interface

Ceiling Suspension

UBN1X4

BuckyDiagnost TH2 (MSB)

with Inalfa sensing

Internal connection diagram

S2 (Height switch lower position)

Table

S

S3 (Height switch middle position)

Z1-1.2(05.0)

Page 43

EZX21

Generator

X60

Intermediate

Connector

Transversal Carriage

A

S1

Switch

Y31

Brake f. Bucky

Frame

E

Encoder

X5

Motor

X2

M

X1

Power

N1

(Option)

CAN in

X3

Tomo

X8

X10

VA

X1

Amplimat Chamber

PH

ACL4

Long. Brake

left

Transv. Brake

left

Long. Brake

right

Y20Y2Y21Y1

Transv. Brake

right

CH Handswitch

(Option)

E

(Option)

Footswitch

Lock

Signal-Bus

CAN out

EZX23

EZX43

I

N3 Power Supply

24VAC (ACL 4)

230 VAC in

24 VAC out

230 VAC in

20,4 VAC out

N1 Power Supply

20,4VAC

X1X6

IF Carriage

X53

X38

X51

X39

Intermediate

X50

Connector

X300

Intermediate

Connector

X200

X55

X40

X3

X2

X90

Release

X5

only for BuckyDiagnost VS

X3

X2

X7

X4

X5

X101

Intermediate

Connector

X1

X37

MSB / Power

I IF Main TH

X4

X41

X52

X54

X2

Release

X3

Power

Signal-Bus

X1

CAN in

X2

Grid Control

X13

CAN out

X3

26VDC in

X6

position BWS

sensing BWS

release BWS/

grid control

X12 X10 X11 X5

X100

remoteX8safety Tomo

tracking BWS

X7

YX21

Connector

X9

sensing

Z1 Bucky Controller

X4

X20

YX20

Connector

MEXT1/T2/N

Generator

BuckyDiagnost VS

BuckyDiagnost VS

BuckyDiagnost

VE/VT

VPIX10

VPIX7

VPX1

VP1X2

VP1X3

VP1X5

A1/A3 05-01-26 Schr.

BuckyDiagnost TH2 TF

C Philips Medical Systems

Power Supply Unit

F1

L

Mains Switch

T

AE

Line

L1

Load

Mains Filter

F

X6

X14

26VDC in

230VAC in

Safety Circle

X7 X4 X1

S10

Safety Switch

Footswitch

C Footswitch

Z2Table Control

C1/C2

Start-/Operation-

Capacitor

Safety Tomo out

X11

X3

X5

M

Motor

S1 (Height switch upper position)

X13

X12

Remote

light tr.

Safety

Brakes

X10

Handswitch

X9

Footswitch Lock

X8

NV Table Drive

D 25p.

Z1X20.1

Ceiling Suspension

UBN2X3

Ceiling Suspension

UL1

U

Tomo in

SID-Poti

Service

Interface

UBN1X4

Ceiling Suspension

BuckyDiagnost TH2 (MSB)

with ACL 4

Internal connection diagram

S2 (Height switch lower position)

Table

S

S3 (Height switch middle position)

Z1-1.3(05.0)

Page 44

EZX21

Generator

X60

Intermediate

Connector

Transversal Carriage

A

S1

Switch

Y31

Brake f. Bucky

Frame

X6

Intermediate

connector

Amplimat Chamber

PH

X1

VA

Bucky Unit (Inalfa)

Long. Brake

left

Transv. Brake

left

Long. Brake

right

Y20Y2Y21Y1

Transv. Brake

right

CH Handswitch

(Option)

E

(Option)

Footswitch

Lock

WAX1

Generator

I

230 VAC in

20,4 VAC out

N1 Power Supply

20,4VAC

X1X6 X2

IF Carriage

X51

X39

YX21

Connector

X3

X52

X7

X5

X4

X1

MSB / Power

I IF Main TH

X4

X54

X41

Intermediate

connector

X50

X300

X55

X40

X3

X2

X90

Release

X1

X5

YX20

Connector

MEXT1/T2/N

Generator

A1/A3 05-01-26 Schr.

BuckyDiagnost TH2 TF

C Philips Medical Systems

Power Supply Unit

F1

L

Mains Switch

T

AE

Line

L1

Load

Mains Filter

F

X6

X14

26VDC in

230VAC in

Safety Circle

X7 X4 X1

S10

Safety Switch

Footswitch

C Footswitch

Z2Table Control

C1/C2

Start-/Operation-

Capacitor

Safety Tomo out

X11

X3

X5

M

Motor

S1 (Height switch upper position)

X13

X12

Remote

light tr.

Safety

Brakes

X10

Handswitch

X9

Footswitch Lock

X8

NV Table Drive

UBN2X3 / UAX1 / UADX3

Ceiling Suspension

UL1

Tomo in

UBN1X4

Ceiling Suspension

Ceiling Suspension

BuckyDiagnost TH2 (MSB)

with Inalfa non sensing

Internal connection diagram

S2 (Height switch lower position)

Table

S

S3 (Height switch middle position)

Z1-1.4(05.0)

Page 45

S

Table

SA

Transverse

carriage

SAVA

Bucky unit

SF1

L1

N

230VAC Generator

SL1

Mains

filter

L1

N

X52:1

X52:3

X53:1

X53:3

X51:1

X51:3

Main interface

SI

X50:1

X50:3

X54:1

X54:3

L1

L1

N

N

L1

N

L1

N

in

SN3

24V AC

(ACL4)

230V AC

0V AC

SN1

230V AC

20,4V AC

0V AC

VPX7 BuckyDiagnost VS

in

out

out

24V AC

0V AC

20,4V AC

0V AC

X38:1

X38:3

X39:1

X39:2

SX101

X37:1

X37:4

X40:1

X40:2

X1:4 X5:4

X1:15

X1:8

X41:1

X41:2

24V AC

24V GND

26V DC

26V GND

26V DC

26V GND

26V DC

26V GND

L1

N

1

2

X6:1

X6:2

X14:1

X14:2

X6:1

X6:3

SZ1

Bucky

controller

SZ2

Table

control

SA X200

X5:15

X5:8

8

9

SAI

Interface

carriage

X4:15

X4:8

SA

X300

15 8

or

or

X3

1

2

X1

X1

1

5

X1

15

2

ACL4

1

5

Inalfa

Bucky

unit 2

A3 05-01-26 Schr.

BuckyDiagnost TH2 TF

C Philips Medical Systems

(05.0)

X55:1

X55:3

L1

N

UZX9 Ceiling suspension

BuckyDiagnost TH2 (MSB)

Power supply

Z1-2

Page 46

Transverse carriage

SIX1:4

X8:3

X8:4

X8:5

X4:3

X4:4

X9:3

X9:4

X20:19

K8

K8

161

K81

161

brakes

2

S3

1

4

SACH

Handswitch

SAE

Footswitch

lock

(option)

lock

S1

H1

S3

2

1

brakes

S4

2

1

SC

Footswitch

(option)

X9:5

X4:5

S6

2

S6

S5

S5

down

1

4

2

up

1

4

SIX41:1

26V

SIX41:2

0V

SIX50:1

L

230V~

SIX50:3

N

2

down

1

4

2

up

1

4

X4:7

X9:7

X4:6

X9:6

X4:8

X9:8

X14:1

X14:2

X6:1

X6:3

X20:17

0V

X20:3

X20:4

X20:1

X20:2

lock

K81

0V

64

+26V

0V

A1/A3 05-01-26 Schr.

bucky controller

SZ1X8

X12:1

X12:2

lock

X20:16

X20:15

+26V

0V

+26V

0V

0V

0V

0V

0V

SZ2

Table control

control/

delay

B2

B1

X20:05

U1

X20:06

H5

+15V+26V

test

B4

B3

D1A

D1B

K4

safety tomo

48

X20

collimator light

0V

0V

+26V

16

1

safety servo

100R

R2

X20:12

+15V

+15V

H2

H1

start-up

16

down

2K21

R32

up

2K21

R31

K2

K1

K3

1

12

12

12

H3

K7

ED

12

H4

4

up

K1

4

5

3

down

K2

R100

collimator light

X20:22 X20:21

X20:08X20:07

K5

K6

X20:11

470µ

C2

K4

safety tomo

X20:10

X20:13

X20:09

ED

K7

3

K3

start-up

R1

4K7

K5

64

K4

43

5

1

16

+26V

+26V

X10:1

X10:2

X5:3

9

13

X5:4

X5:5

X7:1

+24V

0V

X7:2

X5:8

X5:9

X5:6

X5:7

X3:4

X3:5

X3:3

X1:1

3

X1:3

4

1M

X1:4

X1:2

X3:1

X3:2

X13:1

X13:2

X11:1

X11:2

collimator

Tomo safety circuit CS

+26V

SX120:15

SX120:4

SIX1:15

SIX1:8

0V

only if DigitalDiagnost VM

X5:4

X5:15

X5:8

YX20:1

YX20:2

A1

Collisions

A2

switch VM

C1C2

SA

X6:1

IF Carriage

I

W1

transverse brakes longitudinal brakes

++

SK1

1

2

11

14

2

SS10

safety switch

1

X6:3

X7:1

X7:3

X1:1

X1:2

YX21:1

YX21:2

2

S1

1

+

Y31

-

+

--

+

750mm

1

S3

24

500mm

21

S2

900mm

21

S1

X8:1

X10:1

-

N1

+26V

Y2 Y1Y20 Y21

right leftright left

Tomo control

0V

in

out

out

-

SNV

Motor

control

switches

P2

P1

L2

K3

M

L1

N

DigitalDiagnost TH (BUF)

BuckyDiagnost TH2 (MSB)

Safety circuit and brakes

DigitalDiagnost TH

C 1999 Philips Medical Systems

ALL RIGHTS RESERVED

(d/05.0)

Z1-3

Page 47

CAN

bus

SZ1

Bucky controller IF Main TH

X2

1

2

3

4

5

X3

1

6

7

8

9

6

2

7

3

8

4

9

5

CAN out

X2

1

2

3

4

5

6

7

8

9

SI

X90

1

6

2

7

3

8

4

9

5

CAN to CS

SAI

IF Carriage

X3 X3

6

7

8

9

male

1

2

3

4

5

CAN

1

2

3

4

5

female

6

7

8

9

SZN1

Motor control

Tomo

r

o

t

a

r

e

n

e

G

m

o

r

f

Signal

bus

female

X1

1

14

2

15

3

16

4

17

5

18

6

19

7

20

8

21

9

22

10

23

11

24

12

25

13

male

A

Driver

SZ1 SI

male female

X13

1

6

2

7

3

8

4

9

5

female

X12 X5

1

6

2

7

3

8

4

9

5

female

SAVA

PHILIPS

Top view

A - B

Grid control

BUF table

Grid control

BWS

X3

6

7

8

9

male

6

7

8

9

male

male

X1

1

9

2

1

2

3

4

5

10

3

11

4

12

5

13

6

14

7

15

8

male

MSB MSB

X5

9

10

11

12

13

14

15

male

X4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

male

1

2

3

4

5

6

7

8

X1

9

10

11

12

13

14

15

male

1

2

3

4

5

6

7

8

X16

1

3

5

7

9

11

13

15

2

4

6

8

10

12

14

16

CAN control

Release

circuit

control

X4

1

9

2

10

1

2

3

4

5

3

11

4

12

5

13

6

14

7

15

8

MSB to BWS

SAVA

male

B

MSB Signal Pin connector

CAN GND

CAN L in

CAN L out

not used

not used

sync grid GND

sync grid

26V DC GND

CAN 15V

CAN H in

CAN H out

not used

start grid

start grid GND

26V DC

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

1

9

2

10

3

11

4

12

5

13

6

14

7

15

8

CAN Signal Pin connector

not used

CAN L

CAN GND

not used

not used

CAN GND

CAN H

SW reset CAN

CAN 15V

BUF

1

2

3

4

5

6

7

8

9

1

6

2

7

3

8

4

9

5

A3 05-01-26 Schr.

DigitalDiagnost TH

C Philips Medical Systems

SZ1

SI

SAI

SZN1

DigitalDiagnost TH (BUF)

BuckyDiagnost TH2 (MSB)

CAN + MSB bus

Front

Z1-5(05.0)

Page 48

SZ2X8:4

+

SAYX21:1

SIX41:1

SIX41:2

SZ1X7:1

SZ1X7:2

SZ1X8:1

SZ1X8:2

UBN1X4:5

UBN1X4:6

SAYX20:1

SAYX20:2

SAYX21:2

SAE1 (option)

3

1

ba

2

4

SZ2X8:3

SZ2X8:5

12

12

3 124

3 124

12

X10

X14

X13

SAY21SAY1

SAIX1:2

SAIX6:1

SAY31

SAIX6:3

2 1

1

4

2

SACH handswitch

SAIX1:1

SAS1

VA

Bucky unit

+--

SAYX21:1

SAYX21:2

SAYX21 SAYX20

SAY1:+

SAY1:-

01

02

SAY21:+

SAYX20:1

SAY21:SAYX20:2

35 4

9 8127 6

(option)

35 4

9 8127 6

X8

SAE footswitch lock

(option)

SA

Transverse carriage

AMPLIMAT

X20 TEST

1

PHX1

SNVS2:1

SNVS3:2

SCS5:4

SCS6:4

SCS3:1

SCS5:1

SCS4:2

SCS6:2

DOWNUP

H2H1

35 4

9 8127 6

SNVS2:2

SNVS3:4

9 8127 6

SX60

SNVS1:1

SNVS1:2

SNVS3:1

35 4

X5X4X9

X12

START UPED

SN1VM1:L1

SNV1M1:N

SNV1M1:L2

X3

1254

3 6

SNV1F1:P2

SNV1F1:P1

X1

3 124

C1

C1

C2

C2

X11

X6

X7

3 12

12

SS10:2

SS10:1

SIX50:1

SIX50:3

H5 H3H4

15V

SZ2

Table control

SZ2X10:1

SAYX21:1

SZ2X10:2

SAYX21:2

SS10

SAY2SAY20

SZ2X9:4

-

+

SAYX20:1

SAYX20:2

+-

SAYX20:1

SAYX20:2

SZ2X9:3

S3

1

4

2

SACH

SAY20:+

01

SAY2:+

SAY20:-

02

SAY2:-

SZ2X5:6

1

S1

4

SZ2X5:7

2

SZ2X7:2

1

4

SZ2X7:1

2

SZ2X5:4

2

SZ2X5:5

4

SZ2X5:3

S3

1

SZ2X9:5

S5:2

S6:1

SZ2X9:8

(option)

S6

2

4

1

S5

2

4

1

F1:6/T3

SX70

F1:2/T1

L1:1

SIX52:2

L1:2

NO NC

2/T1

4/T2

6/T3

2

5 LINE

1

S4:1

SZ2X3:3

1

4

2

SZ2X4:7

SZ2X4:5

1

4

2

SC

SZ2X4:6

S6:1

SZ2X4:8S5:2

1

4

2

SZ2X4:4

S3:2

1

4

2

Foot switch

SZ2X5:9

2

4

SZ2X5:8

S2

1

SZ2X1:3

SZ2X1:4

SZ2X1:1

SZ2X1:2

C2

C1

SF1

2214

01

SL1

21 13

NC NO

LOAD

1/L1

3/L2

5/L3

MEX (L1)

SNV

MEX (N)

SZ2X3:4

P2

SZ2X3:5

P1

SZ2X3:3

L2

SZ2X3:1

SZ2X3:2

F1

SN3

Power

supply

for ACL4

1.0A slow 250V

3,15A slow

250V

F2

24VAC

SIX38:1

0V

SIX38:2

SN1

Power

F1

supply

5,0A slow 250V

1.0A slow 250V

switched

SIX52:3

4

SIX52:1

3

SIX51:1

SIX51:3

230V AC

L

N

F2

0V

20,4VAC

SIX39:1

SIX39:2

SIX53:1

SIX53:3

230V AC

L

N

M1/F1

L1

N

Motor

A1/A3 05-01-26 Schr.

BuckyDiagnost TH2 TF

C Philips Medical Systems

ALL RIGHTS RESERVED

BuckyDiagnost TH2 (MSB)

Wiring diagram

Z2-1(05.0)

Page 49

Potential

X80

A

Balance

Transversal

Carriage

YX14

YX13

(SAY)X11

Y31

Brake f.

Bucky Frame

(SAVAX11

Bucky Unit)

X12

X11

(SAY)X12

CH

Handswitch

E

Footswitch Lock

Y1

Long.

Brake

right

X2

screw

Powe supply

20,4 Vac

F1

N1

Mains Switch

screw

X1

screw

L1

Mains Filter

IF Main TH

I

Sheet Power Supply Unit

Y21

Transv.

Brake left

Sheet Bucky Carriage

X80

X71

I

IF Carriage

Release Bar

S1

Switch

YX12

Y20

Transv.

Brake right

Transversal Carriage

screw

Y2

Long.

Brake

right

X1

S

X2

Table

X72

X73

X11

X11

X12

X13

BuckyDiagnost TH2 (MSB)

S10

Safety switch

Sheet Table Control

Z2

C

Table control

screw

X11

Footswitch

A1/A3 05-01-26 Schr.

C1 / C2

Start- /Operationcapacitor

Lower Cover Front

Lower Cover Rear

Service Cover

Motor

M

S1

S2

S3

NV

(Height switch upper position)

(Height switch lower position)

(Height switch middle position)

X74

Table drive

Earthing diagram

BuckyDiagnost TH2 TF

C Philips Medical Systems

Z2-3(05.0)

Page 50

SAN1

Tomo drive control

rd FAILURE

yw INK_B

yw INK_A

gn RUN

gn REF

LEDs on

soldering side

yw P_1.1

gn P_1.2

LEDs on

soldering side

P_1.0

U1

M1

X5

X2

SAI X2

U1

+24VDC

0VDC

+24VMOT

0VMOT

X5X6

Encoder

X7

Jumper

GAL 66.952

GAL 66.953

IC2

IC4

EPROM

Motorcontroller

IC9

EPROM

CAN program

IC13

GAL 66.954

IC16

LEDs on

soldering side

ST8

1

X8

switchbrake

SAI X7

IC18

insolation plate

X6 X5

ST4

gn REF

gn RUN

yw INK_A

X7

yw INK_B

1

rd FAILURE

LEDs on

soldering side

IC3

ST4

ST6

1

ST7

1

X10 X9 X8

ST5

ST5

1

X9X10

reference switch

SAI X7

SW1

X1X2

X1

CAN INCAN OUT

SAI X3

ST3

A1/A3 05-01-26 Schr.

DigitalDiagnost TH

C Philips Medical Systems

ALL RIGHTS RESERVED

M1

Motor Power supply

X2

X4 X3

X4 X3

Tomo drive control

Survey of components

Z2-4(a/05.0)

Page 51

X53

2

1

3

R4 R5

W1

W11

21

21

X2

1

6

5

CAN

9

in

Power in

X50

1

X51

1

X52

1

X54

1

X55

1

230V

X1

21

21

1

9

5

9

2

3

D1

2

3

D2

W44

W4

X3

8

15

MSB

Bucky unit table

1

Grid control

Bucky unit table

6

X41

1

2

3

X40

1

8

15 9

X38

2

3

1

X4

1

MSB wallstand

X5

5

9

1

6

Grid control

wallstand

X37

2

3

31

6

4

X39

1

2

X90

5

9

CAN

1

out

6

D1 = +26 VDC

D2 = +26 MSB

R4 +R5 = Multi fuses (1,85A)

A4 04-11-23 Schr.

DigitalDiagnost TH

C Philips Medical Systems

Jumper:

W1 + W11 present if connector SIX1 is not used

not present if connector SIX1 is used

W4 + W44 present if connector SIX4 is not used

not present if connector SIX4 is used

I

IF Main TH

4512 131 3864.

Z3-1.1(04.1)

Page 52

Jumper: W1 + W11

Present if connector SIX1 is not used

X2 X1

1

1

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

CAN in

not present if connector SIX1 is used

CAN L

CAN GND

CAN GND

CAN H

SW reset CAN

CAN 15V

W1

2

1

W11

2

1

CAN L in

CAN H in

10

11

12

13

14

15

1

CAN GND

2

3

CAN L out

4

26V DC

5

free exp. 1

6

sync grid GND

7

sync grid

8

26V DC GND

CAN 15V

9

CAN H out

free exp. 2

start grid

start grid GND

26V DC

X3

1

1

2

3

3

start grid GND

4

4

5

5

start grid

6

6

7

7

8

8

9

9

Grid control

Bucky unit table

X4

1

CAN GND

2

CAN L in

3

CAN L out

4

free exp.BWS 1

5

6

sync grid GND

7

sync grid

8

9

10

CAN H in

11

CAN H out

12

free exp.BWS 2

13

start grid

start grid GND

14

15

Jumper: W4 + W44

present if connector SIX4 is not used

not present if connector SIX4 is used

W4

1

2

W44

1

2

X5 X90

1

1

2

2

3

3

4

4

start grid GND

5

5

6

6

start grid

7

7

8

8

9

9

Grid control

Wallstand

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

CAN out

CAN L

CAN GND

CAN GND

CAN H

SW reset CAN

CAN 15VCAN 15V

X39

2

1

VACP

VACN

C1

B1

B2

R1

C2

MSB

Bucky unit table

C3

C4

R4

2

1,85A

Multi fuse

R5

2

1,85A

Multi fuse

+26V

1

1

26V MSB

R2

R3

D1

D2

GND

MSB

Wallstand

C5

X6

X7

screen

VACP

VACN

X40

2

1

X38

1

2

3

+26V

GND

X37

1

2

3

4

5

6

X41

2

1

24V

screen

GND 24V

screen