Philips BDH4222V, BDH4222V-22, BDH4223V-27 Service Manual

CONFIDENTIAL

Issue: 8. Apr .05

Version: 1.0

42“ PDP

SERVICE MANUAL

MODEL:BDH4222V/00,BDH4222V/22

BDH4223V/27

PANEL:VVFPF42C128UC51

Collation: Andy Lai

CONTENTS

1. IMPORTANT SAFETY PRECAUTIONS ……..1-2

2. BLOCK DIAGRAM ……………………………..2-5

3. FACTORY & ELECTRONIC ADJUSTMENT ..3-1

4. TROUBLE SHOOTING GUIDES ……………..4-7

5. SPECIFICATION ……………………………….5-8

6. P.C. BOARD TOP VIEW ………………………6-7

7. ELECTRONIC MODULES LIST ……………...7-1

8. EXPLODED VIEW ……………………………..8-1

9. PACKING OF THE LIST ……………………....9-1

If having any changes, do not do advanced advice.

SAFETY PRECAUTIONS VER1.0

A

1. Before returning an instrument to the customer, always make a safety check of the entire instrument,

including, but not limited to, the following items.

a. Be sure that no built-in protective devices are defective and/or have been defeated during servicing. (1)

Protective shields are provided on this chassis to protect both the technician and the customer. Correctly

replace all missing protective shields, including any removed for servicing convenience. (2) When

reinstalling the chassis and/or other assembly in the cabinet, be sure to put back in place all protective

devices, including, but not limited to, nonmetallic control knobs, insulating fishpapers, adjustment and

compartment covers/shields, and isolation resistor/capacitor networks. Do not operate this instrument

or permit it to be operated without all protective devices correctly installed and functioning.

b. Be sure that there are no cabinet openings through which an adult or child might be able to insert their

fingers and contact a hazardous voltage, Such opening include, but are not limited to, (1) spacing

between the picture tube and the cabinet mask, (2) excessively wide cabinet ventilation slots, and (3) an

improperly fitted and/or incorrectly secured cabinet back cover.

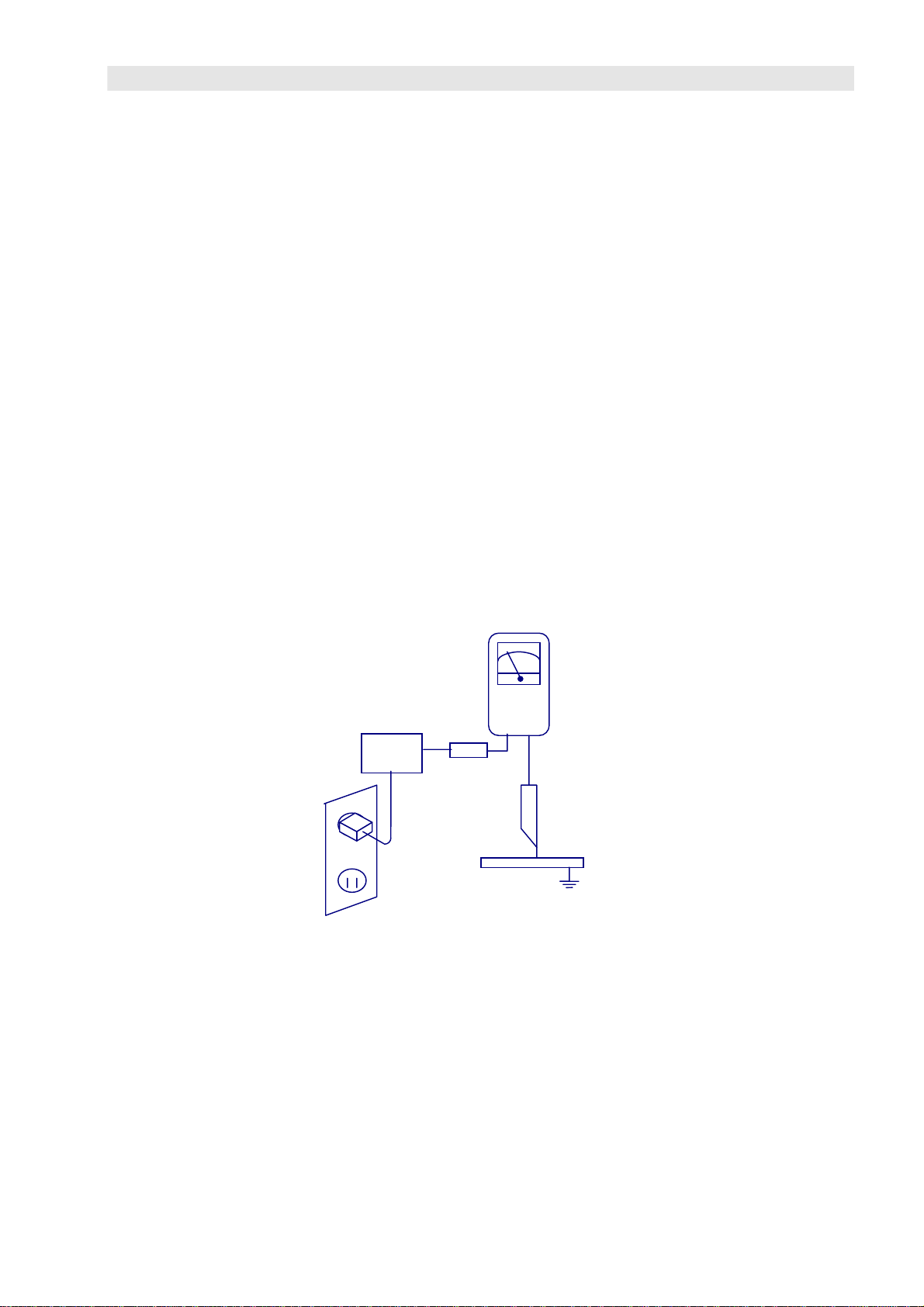

c. Leakage Current Hot Check—With the instrument completely reassembled, plug the AC line cord directly

into a 120V AC outlet. (Do not use an isolation transformer during this test.) Use a leakage current tester

or a metering system that complies with American National Standards Institutes (ANSI) C101.1 Leakage

Current for Appliances and Underwriters Laboratories (UL) 478. With the instrument AC switch first in the

ON position and then in the OFF position, measure from a known earth ground (metal waterpipe, conduit,

etc.) to all exposed metal parts of the instrument (antennas, handle bracket, metal cabinet, screwheads,

metallic overlays, control shafts, etc.), especially any exposed metal parts that offer an electrical return

path to the chassis. Any current measured must not exceed 3.5 milliamp. Reverse the instrument power

cord plug in the outlet and repeat test. ANY MEASUREMENTS NOT WITHIN THE LIMITS SPECIFIED

HEREIN INDICATE A POTENTIAL SHOCK HAZARD THAT MUST BE ELIMINATED BEFORE

RETURNING THE INSTRUMENT TO THE CUSTOMER.

AC Leakage Test

DEVICE

UNDER

TEST

TEST ALL

EXPOSED METAL

SURFACES

3. WIRE CORD

LSO TEST WITH

PLUG REVERSED

(USING AC ADAPTER

PLUG AS REQUIRED)

2. Read and comply with all caution and safety-related notes on or inside the Monitor cabinet, on the

Projection Monitor chassis, or on the picture tube.

LEAKAGE

CURRENT

TESTER

+-

(READING

SHOULD NOR

BE ABOVE

3.5mA)

EARTH

GROUND

3. Design Alteration Warning—Do not alter or add to the mechanical or electrical design of this unit. Design

alterations and additions, including, but not limited to, circuit modifications and the addition of the items

such as auxiliary audio and/or video output connections might alter the safety characteristics of this

Projection Monitor and create a hazard to the user. Any design alterations or additions will void the

manufacturer’s warranty and will make you, the service, responsible for personal injury or property

damage resulting therefrom.

1-1

SAFETY PRECAUTIONS VER1.0

4. Hot Chassis Warning—a. Some Monitor chassis are electrically connected directly to one conductor of

the AC power cord and may be safely serviced without an isolation transformer only if the AC power plug

is inserted so that the chassis is connected to the ground side of the AC power source. To confirm that the

AC power plug is inserted correctly, with an AC voltmeter measure between the chassis and a known

earth ground. If a voltage reading in excess of 1.0V is obtained, remove and reinsert the AC power plug in

opposite polarity and again measure the voltage potential between the chassis and a known earth ground.

b. Some Monitor chassis normally have 85V AC (RMS.), between chassis and earth ground regardless of

the AC plug polarity. These chassis can be safely serviced only with an isolation transformer inserted in

the power line between the receiver and the AC power source, for both personnel and test equipment

protection. c. Some Projection Monitor chassis have a secondary ground systems in addition to the main

chassis ground. This secondary ground system is not isolated from the AC power line. The two ground

system are electrically separated by insulating material that must not be defeated or altered.

5. Observe original lead dress. Take extra care to assure correct lead dress in the following areas: a. near

sharp edges, b. near thermally hot parts—be sure that leads and components do not touch thermally hot

parts, c. the AC supply, d. high voltage, e. antenna wiring. Always inspect in all areas for pinched,

out-of-place, or frayed wiring. Do not change spacing between components, and between components

and the printed-circuit board. Check AC power cord for damage.

6. Components, parts, and/or wiring that appear to have overheated or are otherwise damaged should be

replaced with components, parts, or wireing that meet original specifications. Additionally, determine the

cause of overheating and/or damage and, if necessary, take corrective action to remove any potential

safety hazard.

7. PRODUCT SAFETY NOTICE—Many Monitor electrical and mechanical parts have special safety-related

characteristics some of which are often not evident from visual inspection, nor can the protection they give

necessarily be obtained by replacing them with components rated for higher voltage, wattage, etc. Parts

that have special safety characteristics are identified in this service data by shading with a mark on

schematics and by shading or a * mark in the parts list. Use of a substitute replacement part that does

not have the same safety characteristics as the recommended replacement part in this service data parts

list might create shock, fire, and/or other hazards.

1-2

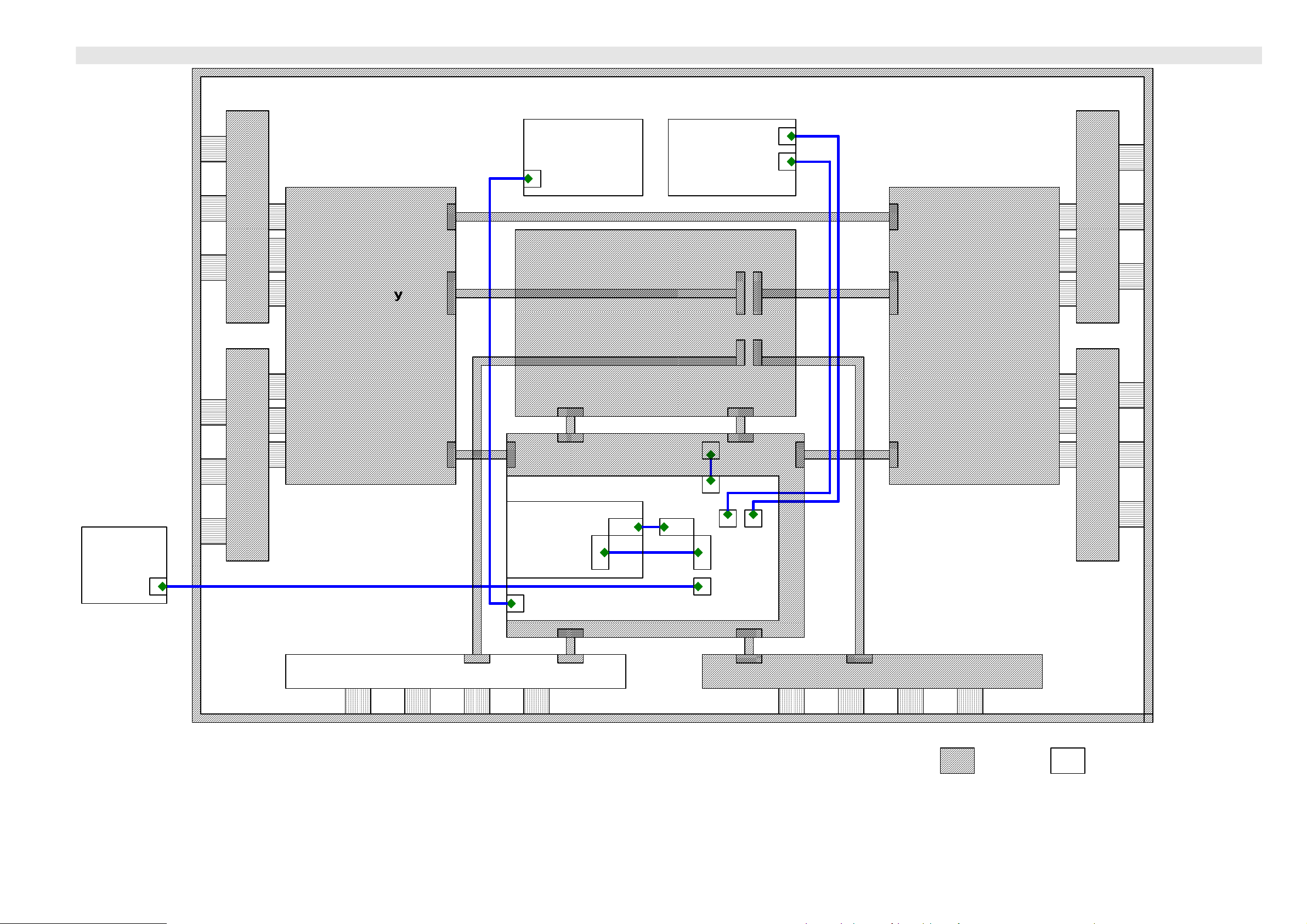

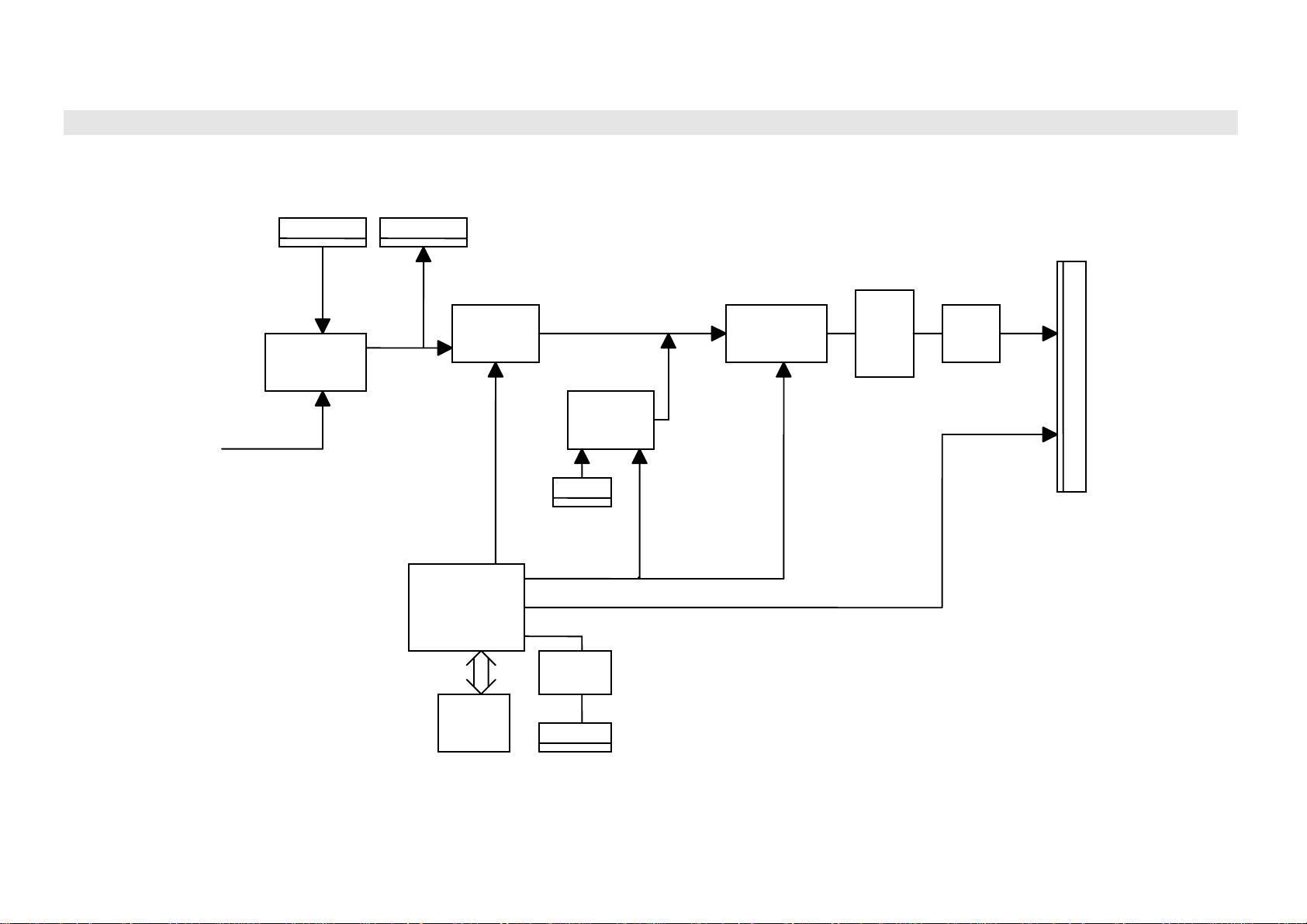

BLOCK DIAGRAM VER1.0

PDP Panel Module

Front Button

Control

Board Ass'y

JA3

JA1

SUB-Power

Boar d Ass'y

J10

Audio

Amplifier

Boar d Ass'y

JA2

PANEL Power Supply

Ass'y

Interface

Y Amp Board- Upper Ass'y

Boar d- Y Ass'y

Logic Board Ass'y

CN2

CN8

Interface

Boar d- X Ass'y

X Amp Board-U pper Ass'y

Image Boar d Ass'y

AV Modu l e

Y Amp Board- Lower Ass'y

Board

Ass'y

CN13

CN4

CN5

CN15

CN6

CN14

J5

CN7

X Amp Board-Low er Ass'y

Address BUS -L Ass'y

Address BUS-R Ass'y

Pan e l's Bo a r d A ssem bly

SAMPO Board Assembly

2-1

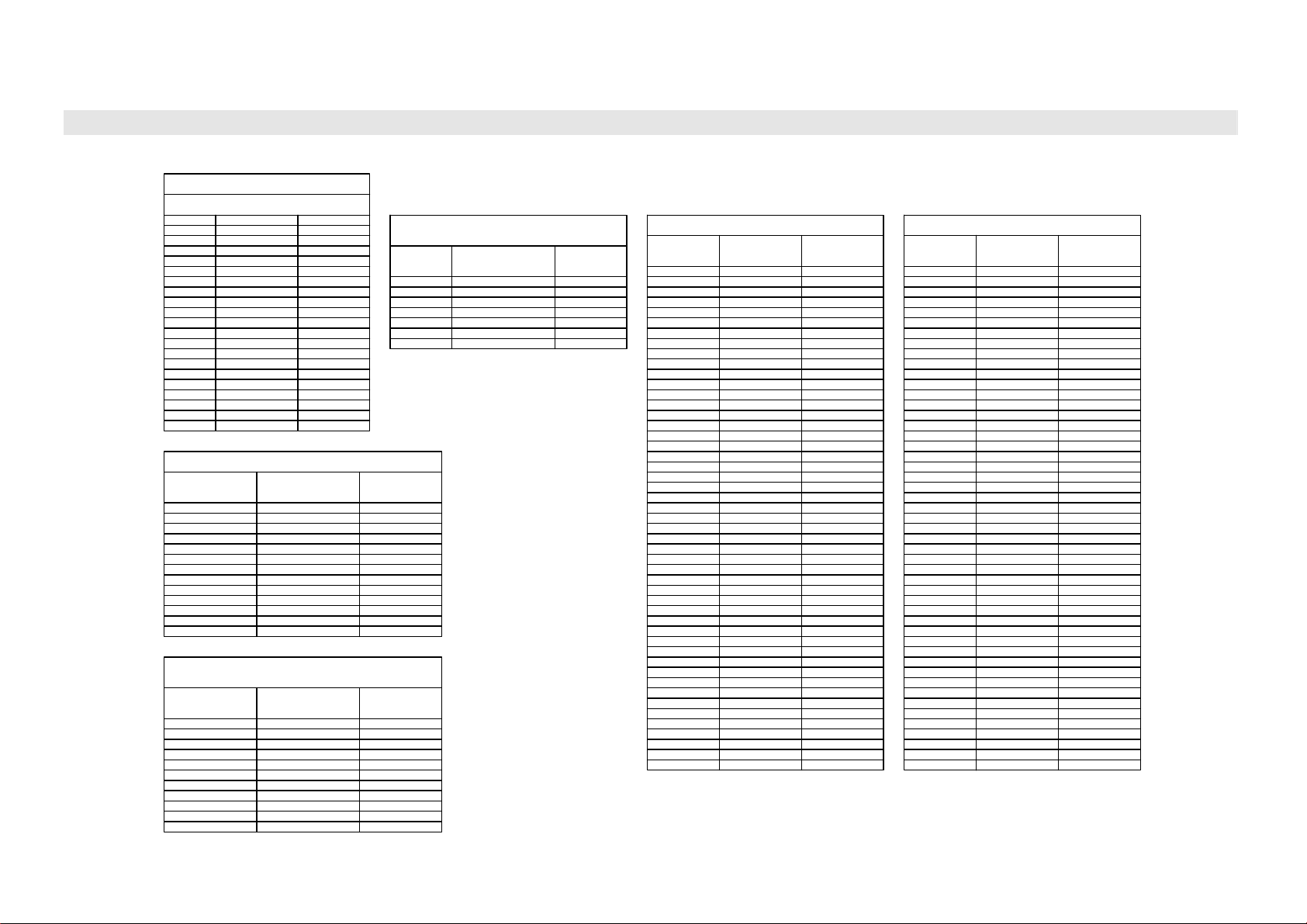

BLOCK DIAGRAM VER1.0

Image Board ¡ö¡÷ Panel

Image Board Ass'y

CN8 (20 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Pin 13

Pin 14

Pin 15

Pin 16

Pin 17

Pin 18

Pin 19

Pin 20 GND

RXIN3 +

GND

RXIN3 SCL0_33

RXCLK IN+

GND

RXCLK INSDA0_33

RXIN2 +

GND

RXIN2 ALISCPUGO

RXIN1 +

ALISPDPGO

RXIN1 ALIS_IRQ

RXIN0 +

ALISPDWN

RXIN0 GND

CN2 (5 Pin)

+5VSB

NC

V33SB

NC

GND

Image Board ¡ö¡÷

Image

Board

J5 (6 Pi n )

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Fr ont Button

Contr ol B oard

JA3 (6 P i n )

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6 GND

Front Button Control

Board

Image Board ¡ö¡÷ Audio Amplif i er Board

Image Board

J11 (12 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

A udio Amplifier

Board

JA1 (12 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7 B14

Pin 8

Pin 9

Pin 10

Pin 11

Pin 12

Content

P18V

P18V

DGND

SB5V

DGND

AO_SEL

SDA2

SCL2

A_MUTEn

SURR1

SURR2

NC

Image Board ¡ö¡÷ Audio Amplif i er Board

Image Board

J12 (10 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

A udio Amplifier

Board

JA2 (10 Pin)

Pin 1

Pin 2

Pin 3

Pin 4

Pin 5

Pin 6

Pin 7

Pin 8

Pin 9

Pin 10

Content

L_IN

R_IN

AGND

L_OUT

R_O UT

AGND

SUB_WFR

SPK_CTL

PWR_CTL

NC

Image Board Socket Data

Image Board ¡ö¡÷ AV Module Boar d

Image

Content

RC_O UT

SW_OUT

ON_LED

SB_LED

DGND

SB5V

Board

CN4 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

Image Board ¡ö¡÷ AV Module Boar d

AV Module

Board

CN14 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14 A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

Content

YPBPR_R

YPBPR_G

YPBPR_B

YPBPR_HS

YPBPR_VS

P7

P5

GND

P3

P1

ALE_DPTV

RDn_ DP TV

INT_DPTV_S

RST_DP TV

12VT

5V1

GND

GND

GND

SB5V

GND

P6

P4

GND

P2

P0

WRn_DPTV

INT_DPTV

GND

PS_DPTV

GND

P12V

SB5V

TDO

TDI

GND

GND

TMS

GND

TCK

GND

GND

GND

GND

GND

NC

GND

NC

Image

Board

CN5 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A14

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16

AV Module

Board

CN15 (48 Pin)

A1

A2

A3

A4

A5

A6

A7

A8

A9

A10

A11

A12

A13

A15

A16

B1

B2

B3

B4

B5

B6

B7

B8

B9

B10

B11

B12

B13

B14

B15

B16

C1

C2

C3

C4

C5

C6

C7

C8

C9

C10

C11

C12

C13

C14

C15

C16C16

Content

L_OUT

L_IN

GND

YUV_SPSW

HSYNC_SP

15Kn_SP

AVB_DETn

T UN_ DE Tn

GND

GND

GND

GND

GND

GND

R_OUT

R_IN

GND

YUV_SW

HSYNC_MP

15Kn_MP

GND

SDA2

SCL2

5V1

GND

GND

GND

GND

GND

GND

SUB_WFR

PWR_ CTL

AFT_TUN

NC

NC

GND

GND

SDA2

SCL2

5V1

GND

SSO

PCS_CLK

PCSI

PCS_CS

PCn_MPU

2-2

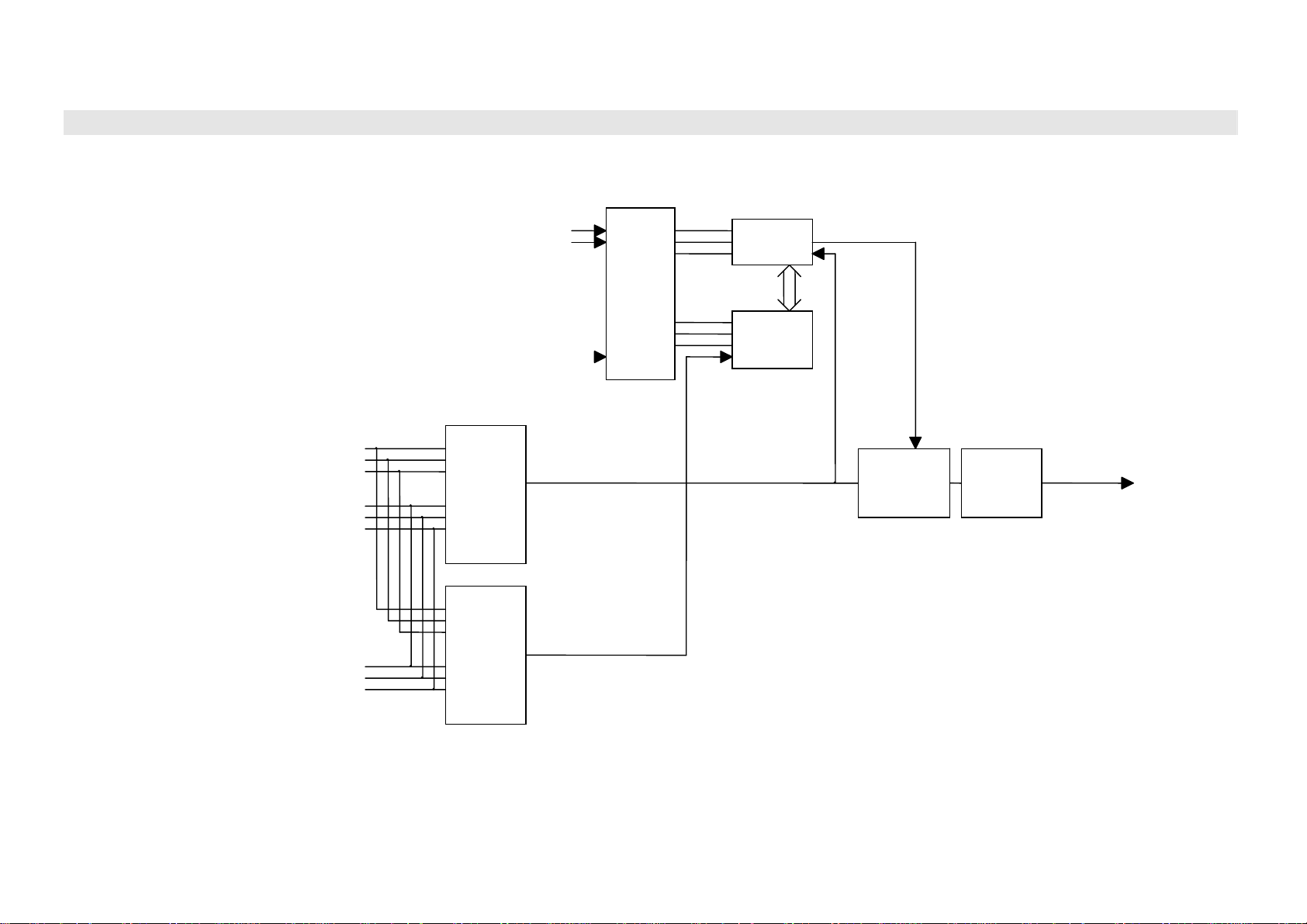

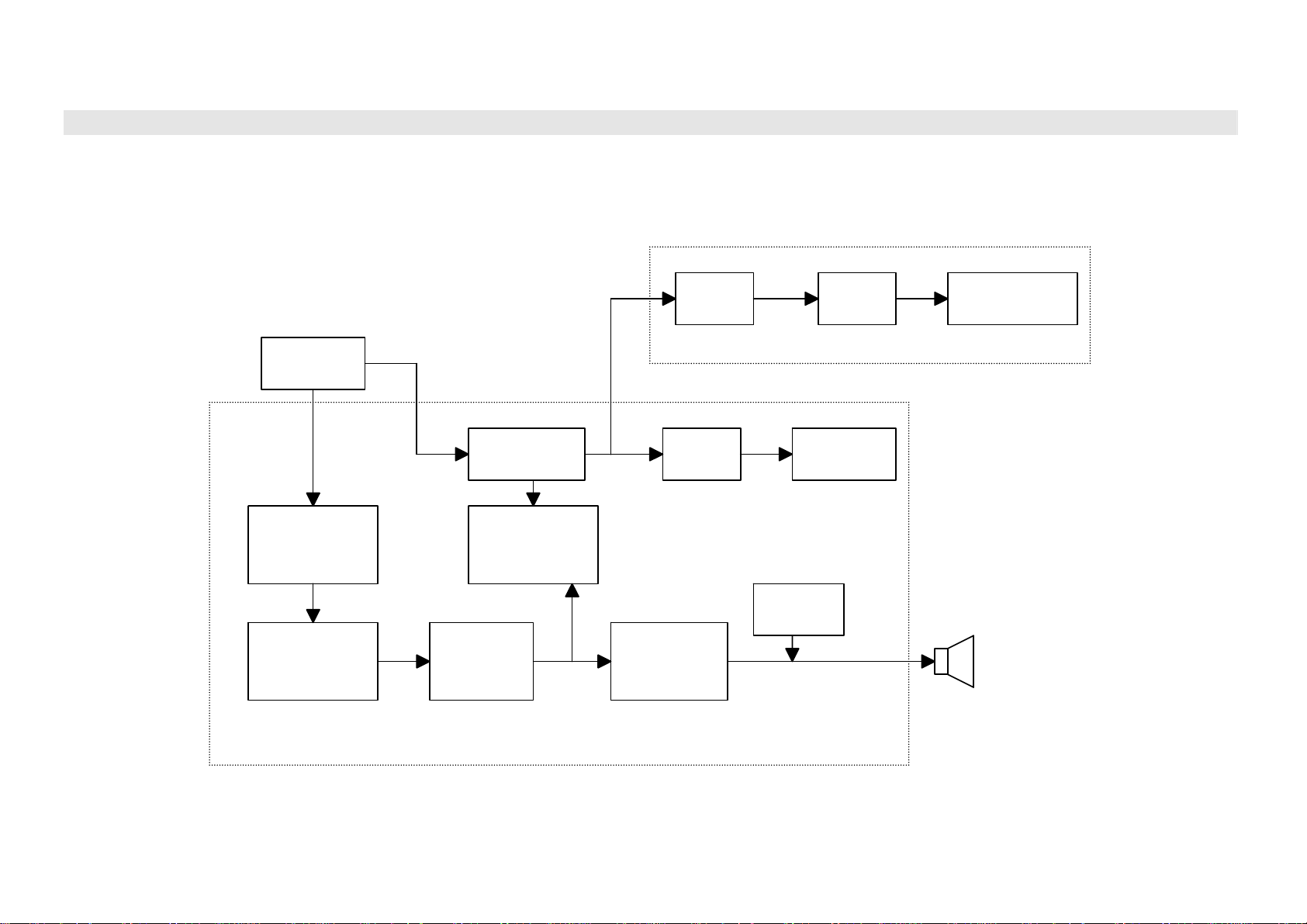

BLOCK DIAGRAM VER1.0

AV Signal Block Diagram

S-VIDEO

AV

TA8551

AV

SWITCH

IC101

VIDEO

Y

C

VIDEO

Y

C

6630/6730

MAIN

IC116

6630/6730

SUB

IC117

YCBCR

YUV

Y1/Y1

CB1/CB1

CR1/CR1

MULTIPLEX

SWITCH

IC103

YCBCR

MULTIPLEX

YCBCR

SWITCH

IC106

TA1276

COLOR

SDACE

IC110

YPBPR RGB OUT

Y1/Y1

CB1/CB1

CR1/CR1

MULTIPLEX

SWITCH

IC105

2-3

BLOCK DIAGRAM VER1.0

am

Digital Signal Block Diagr

RGB IN

RGB OUT

MULTIPLEX

SWITCH

IC29

YPBPR_RGB IN

AD9884

A/D

IC23

SIL169

DVI

IC27

C711/C713

IC17

PICO

IC14

LVDS

IC15

P

A

N

E

L

DVI IN

CPU

IC1

E ROM

IC2

RS232

IC10

RS232 IN

2-4

BLOCK DIAGRAM VER1.0

PDP Sound Block Diagram

ICS1

LPF

FROM AV

SELECTOR

ICS2

MUTE

PAGE2

SUB_WOOFER

OUTPUT

Q1/Q2

INPUT BUFFER

ICA1 /I CA 2

MUTE

AV_ OUTPUT

ICR1

SRS SURROUND

PROCESSOR

ICA3

FIXE D/ V A RIB LE

OUTPUT

SELECTOR

IC1

BBE & SOUND

PROCESSOR

U1

BUFFER

AMPLIFIER

IC2

M A IN P O WE R

AMPLIFIER

Q8/Q9/Q11

MUTE

INSIDE

SPEAKER

PAGE1

DPWB11372-1G-SX

2-5

FACTORY ADJUSTED METHOD VER1.0

1. Color temperature adjustment

Push the factory service key to into the adjustment mode. The picture will appear as

follow

DVI

7180ºk

X=308 Y=298

GAIN Bias

RGB RGB

XXX XXX

Use the AV key to select the color to adjust andorkey to adjust the level.

The required equipments are CA-100,Vp300.

a. Adjust Bias first to let the Y be 0.4 on CA-100. Adjust R or B to let the value

of X,Y on CA-100 be the same as the value showing screen, The value of Y

should be Maintained 0.55 during the adjusting.

b. Move the cursor to adjust Gain. The value of Y should be adjusted to 35.

Then adjust R or B to let the value of X,Y on CA-100 be the same as the

value showing on screen. The value of Y should be maintain 20 during the

adjustment.

c. Repeat to check the Bias and Gain. The value of Y,X and Y should be the

same as the previous adjusted value. Then the DVI 7180ºk mode is adjusted

completely.

d. Push the factory service key again to next picture. Then repeat the steps a.

b. c. to adjust.

e. If the adjustment is completed, repeat d. a. b. and c steps to adjust again.

f. When the last mode AV 10180ºk is adjusted completely, push the factory

service key again to leave the adjustment mode,

Note: 1. There are 9 adjusted modes(DVIx3.RGBx3 Avx3)

2. The adjusted sequence is DVI´RGB´AV.

3. DVI: Bias Y=0.55

Gain Y=36

RGB: Bias Y=0.70

Gain Y=36

YPbPr : Bias Y=1.2

Gain Y=41

3-1

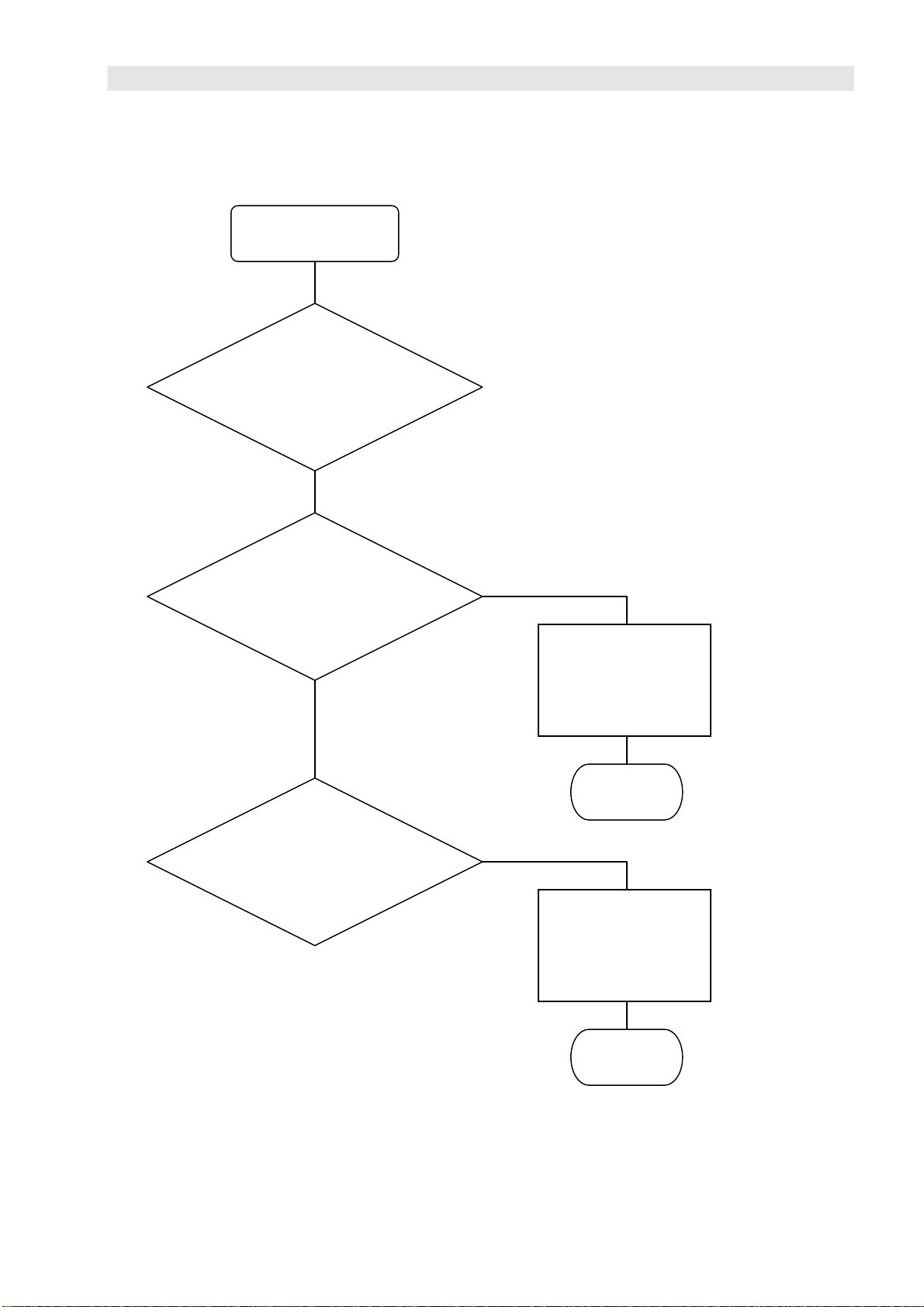

TROUBLE SHOOTING GUIDES VER1.0

NO POWER

SET POWER ON

AC Master Power

Switch Board

DPWB11405-1G---

Panel Power Supply

ND61100-0003

SUB POWER

RUNTP1005-1----

Y

Y

N

Replace Panel

Power Supply

ND61100-0003

OK

N

Replace Power

Input Module

RUNTP1005-1----

OK

4-1

Loading...

Loading...